Self-drilling type spiral anchor rod and construction process using self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing

A construction technique and screw anchor technology, which is applied in the installation of bolts, earthwork drilling, foundation structure engineering, etc., can solve the problems of insufficient tensile force and poor grouting effect of bolts, etc., and achieve good grouting effect and ensure The surrounding environment is safe and the effect of ensuring the quality of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

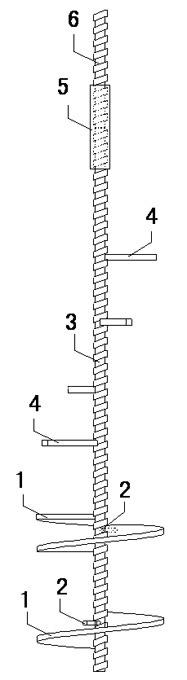

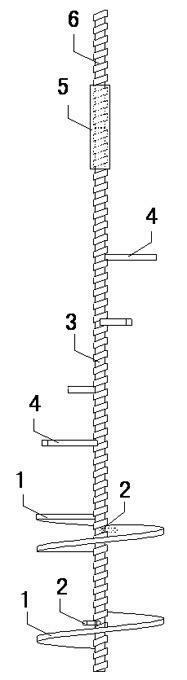

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings. Referring to the accompanying drawings, a self-drilling screw anchor includes an anchor rod body 3, which is provided with a grout hole 2, and the front end of the anchor rod body 3 is closed. The blade 1 is welded on the front end of the anchor rod body 3 , and the stirring piece 4 is welded on the anchor rod body 3 behind the helical blade 1 . In one embodiment, the slurry outlet hole 2 is set on the anchor rod body 3 on the rear side of the helical blade 1, and its hole diameter is 4mm-8mm, such as 5mm, 7mm, 8mm and so on. When the grout hole 2 is directly arranged on the anchor rod body 3, its aperture will be smaller, which can increase its spraying capacity and prevent the soil body from blocking the grout hole 2. The slurry outlet hole 2 of another embodiment is a slurry outlet pipe welded on the anchor rod body 3, and is arranged on the rear side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com