Patents

Literature

390results about How to "Improve grouting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

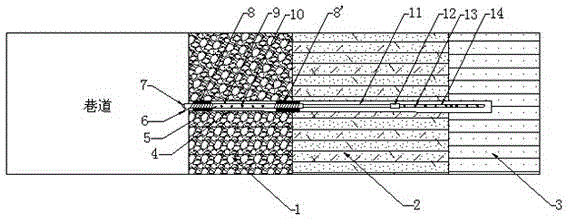

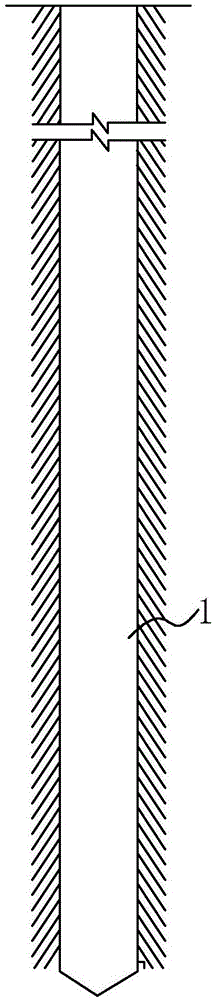

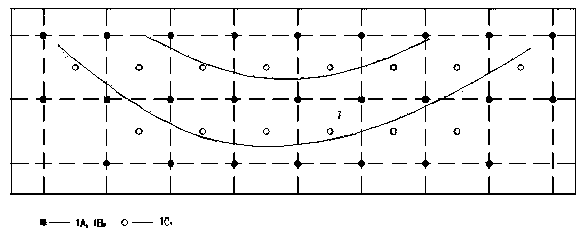

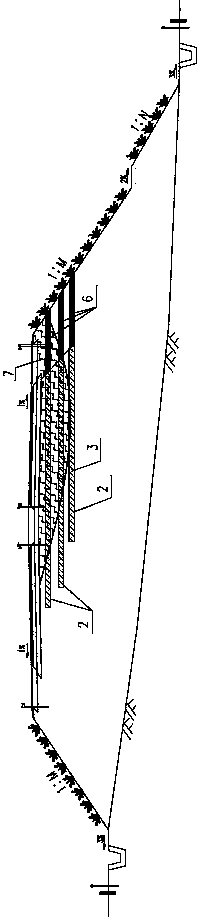

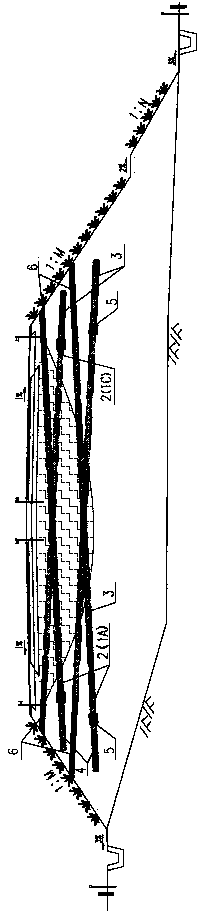

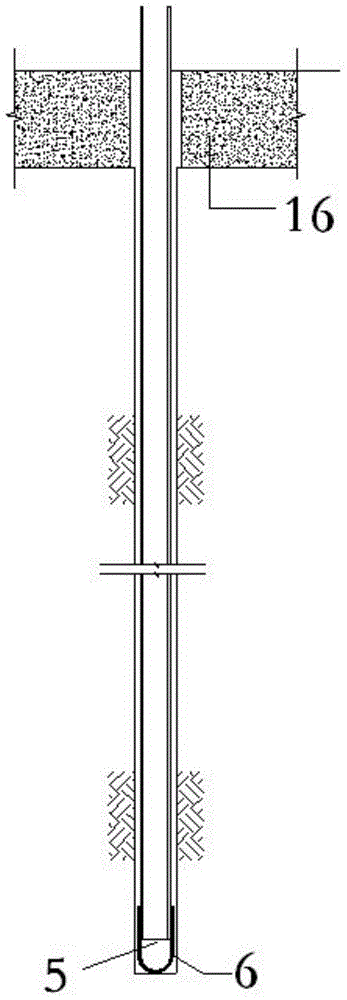

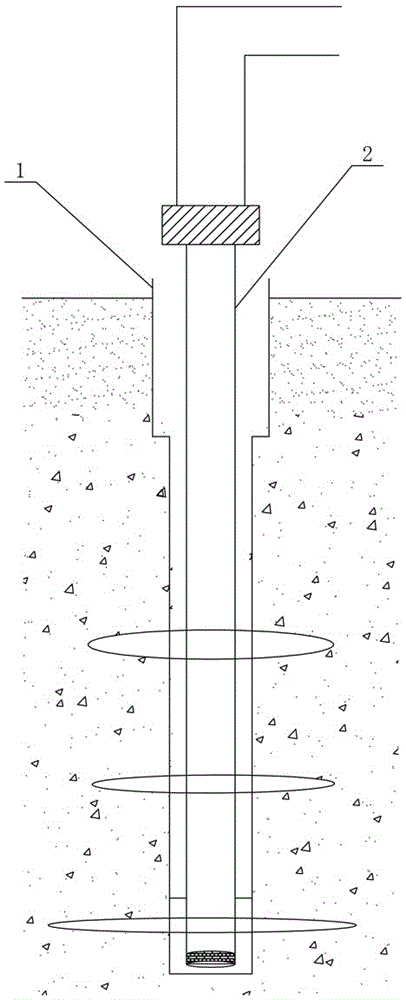

Method for extracting gas from separation layer below overlying strata, draining water and grouting through combined drill hole

ActiveCN104863629AHigh extraction rateImprove grouting effectMaterial fill-upDrainageDrill siteCement paste

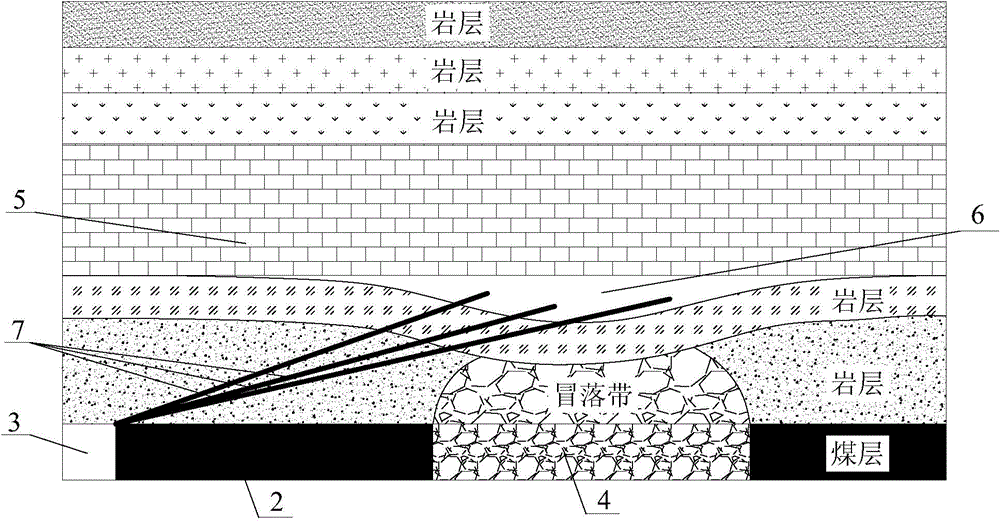

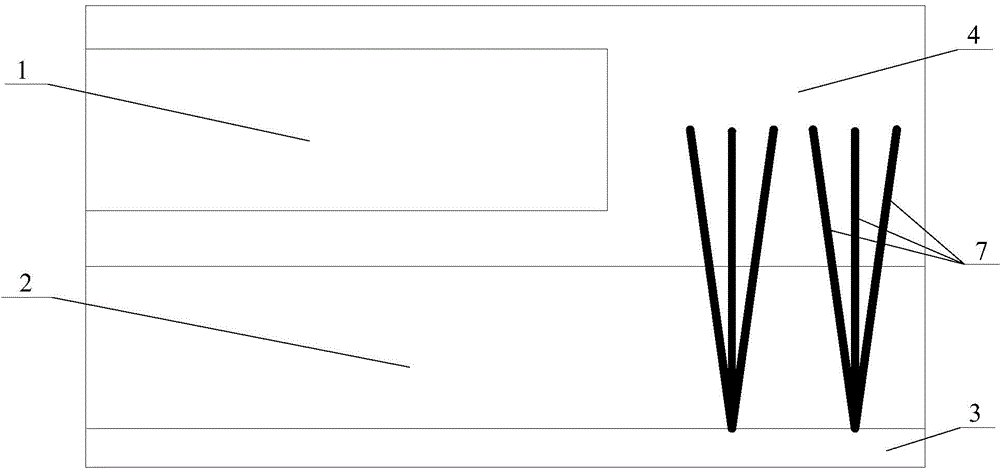

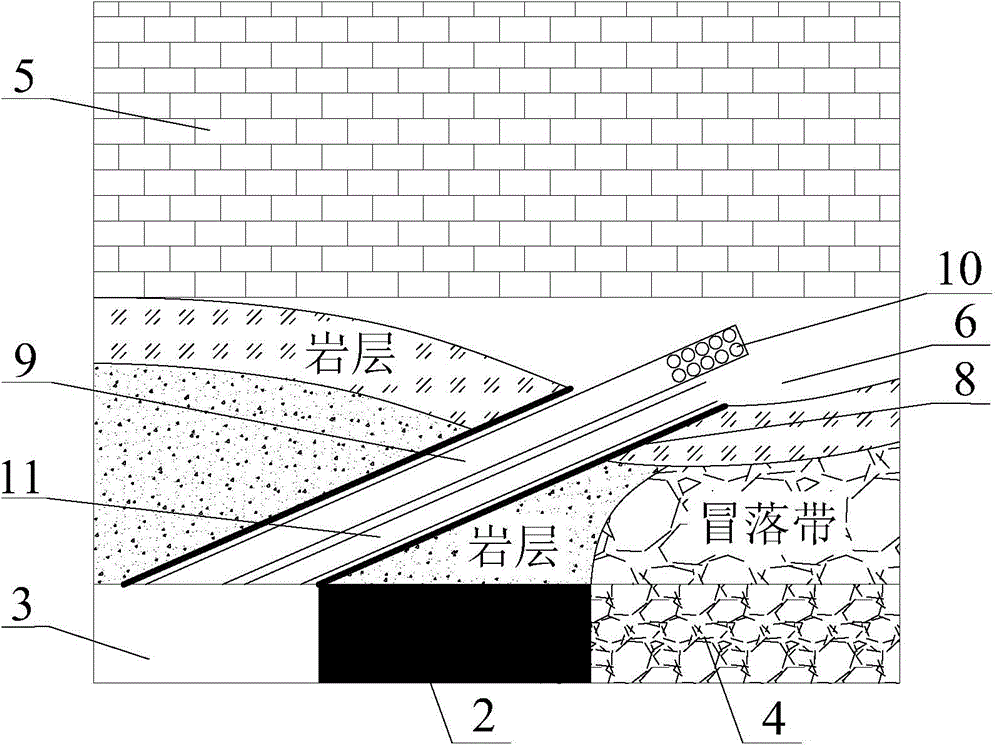

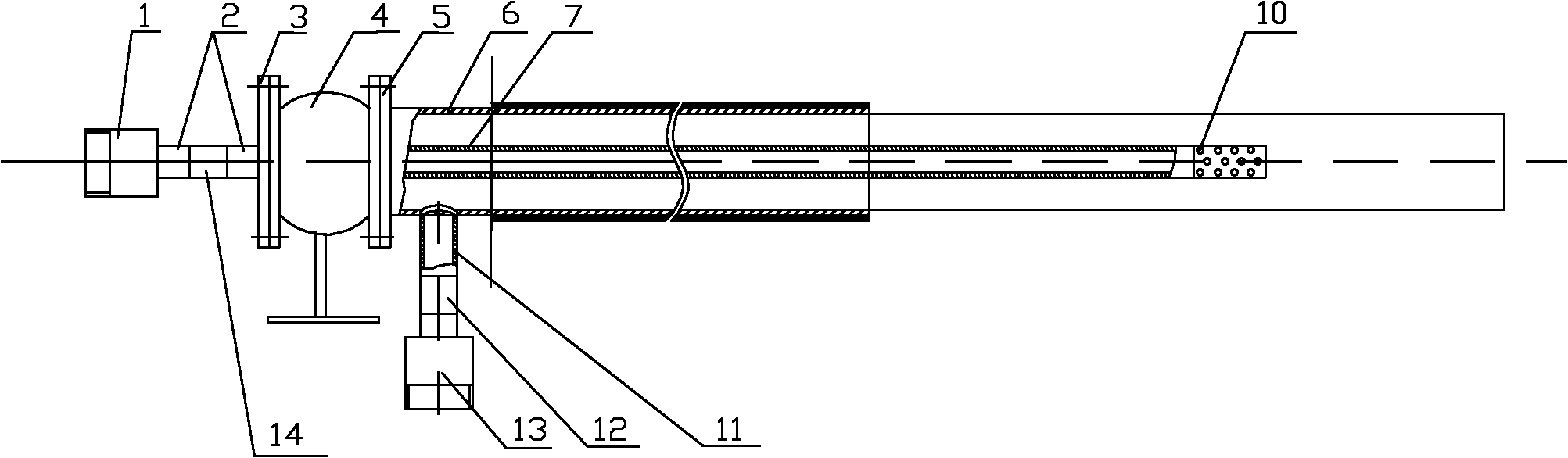

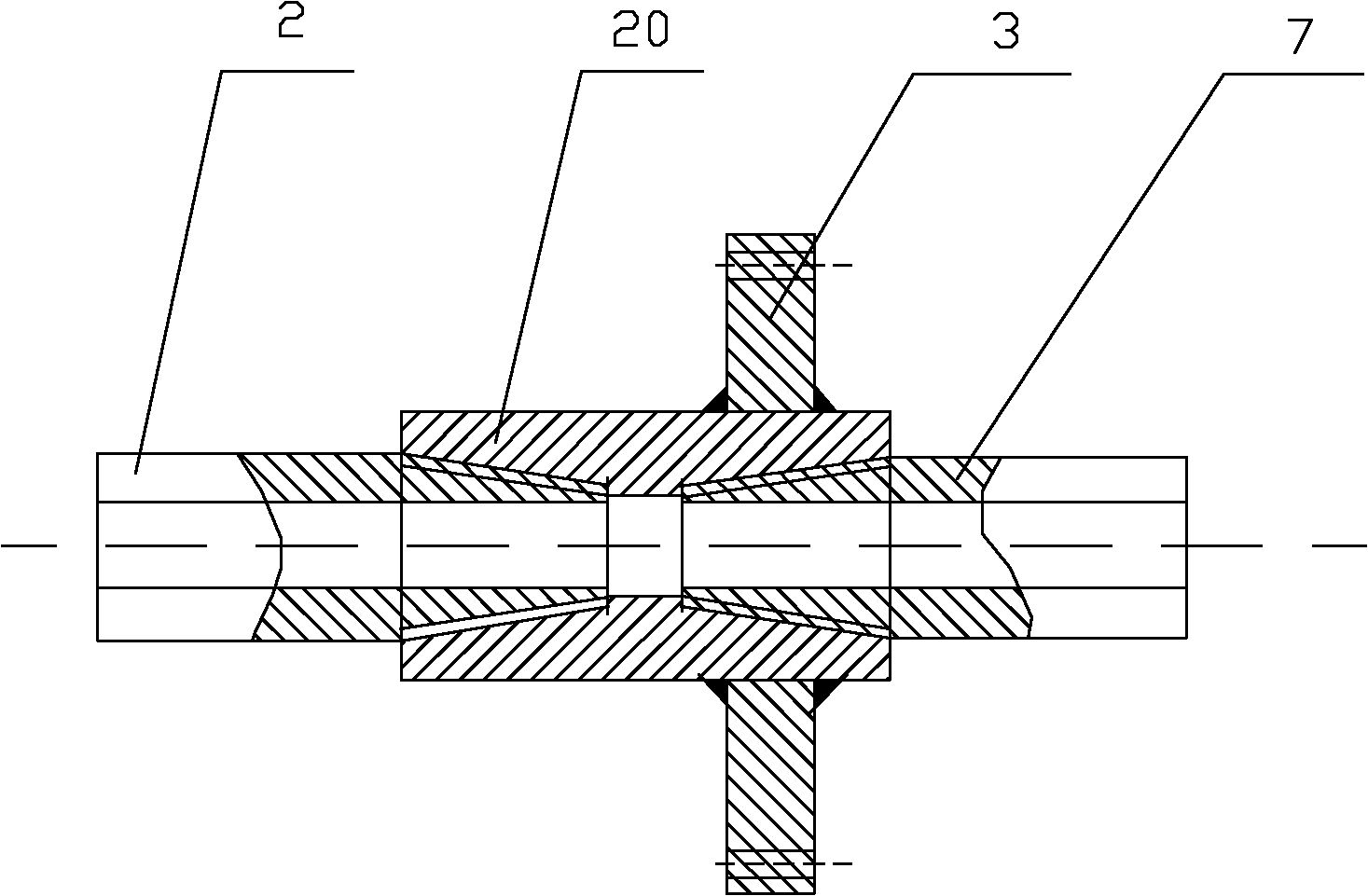

The invention discloses a method for extracting gas from a separation layer below an overlying strata, draining water and grouting through a combined drill hole and belongs to a mine disaster prevention method. The method for extracting gas from the separation layer below the overlying strata, draining water and grouting through the combined drill hole includes that installing a drill site at a transportation roadway of a preparatory work face adjacent to a coalface, constructing the combined drill hole in the part about to generate the separation layer below the overlying strata above the gob of the coalface in a mode of keeping away from a caving zone, wherein the combined drill hole is composed of an inside gas extraction pipe and a water draining-grouting pipe; after the separation layer is generated, preventing the mine disaster according to the stages that firstly, draining water from the separation layer through the combined drill hole; secondly, after the gas is gathered in the separation layer after the water in the separation layer is emptied, using the primary combined drill hole to extract the gas from the separation layer; finally, after the water and gas are completely drained and extracted from the separation layer, filling cement paste to the separation layer through the primary combined drill hole. The method for extracting gas from the separation layer below the overlying strata, draining water and grouting through the combined drill hole is capable of solving the mine disasters of water bursting in mine, gas outburst (gas emission), rock burst, surface subsidence and the like through the combined drill hole, the separation layer water and gas extraction rate is high, and the grouting effect is good.

Owner:CHINA UNIV OF MINING & TECH

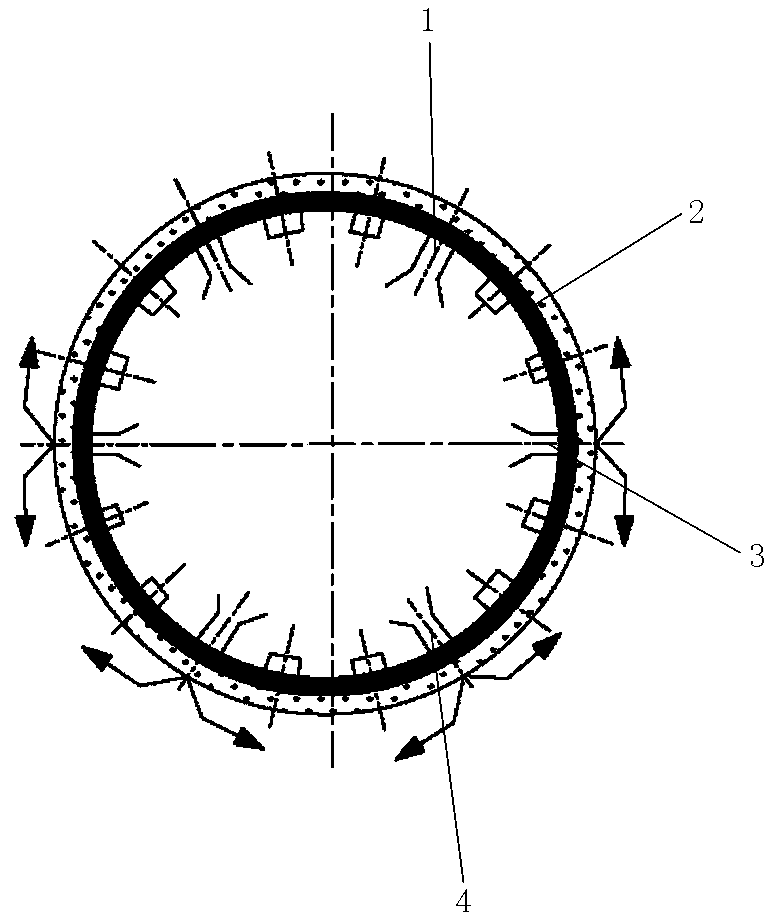

Process for grouting on back of shield segment

The invention discloses a process for grouting on the back of a shield segment to control stratum settlement in shield tunnel construction. The process comprises steps of synchronous grouting, secondary grouting and a special treatment process; during synchronous grouting, when a shield advances and a shield tail is formed, a grouting pump of a shield tunneling machine is used for symmetrical grouting through a synchronous grouting system of the shield tunneling machine; during secondary grouting, double grout is injected to the back of the segment through a shield segment secondary grouting hole, and a gap on the back of the segment is subjected to secondary filling and compression; and the special treatment process comprises steps of adding a triallyl cyanurate (TAC) high-molecular polymer material solution and pressing and injecting epoxy resin seal reinforcing rings. By the process, particularly the TAC high-molecular polymer is added to improve a soil layer and the epoxy resin reinforcing rings are pressed and injected to reinforce the stratum in the special treatment process, the grouting effect is good in a safe and convenient way, the flow and loss of the grout are prevented, the grouting plumpness is ensured, the soil body can be well improved, the stratum is reinforced, the settlement amount is effectively controlled, and the shield tunneling construction is safely and smoothly carried out.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

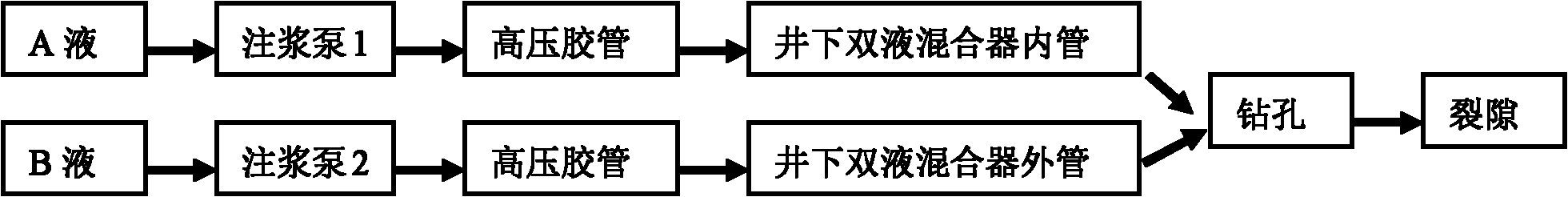

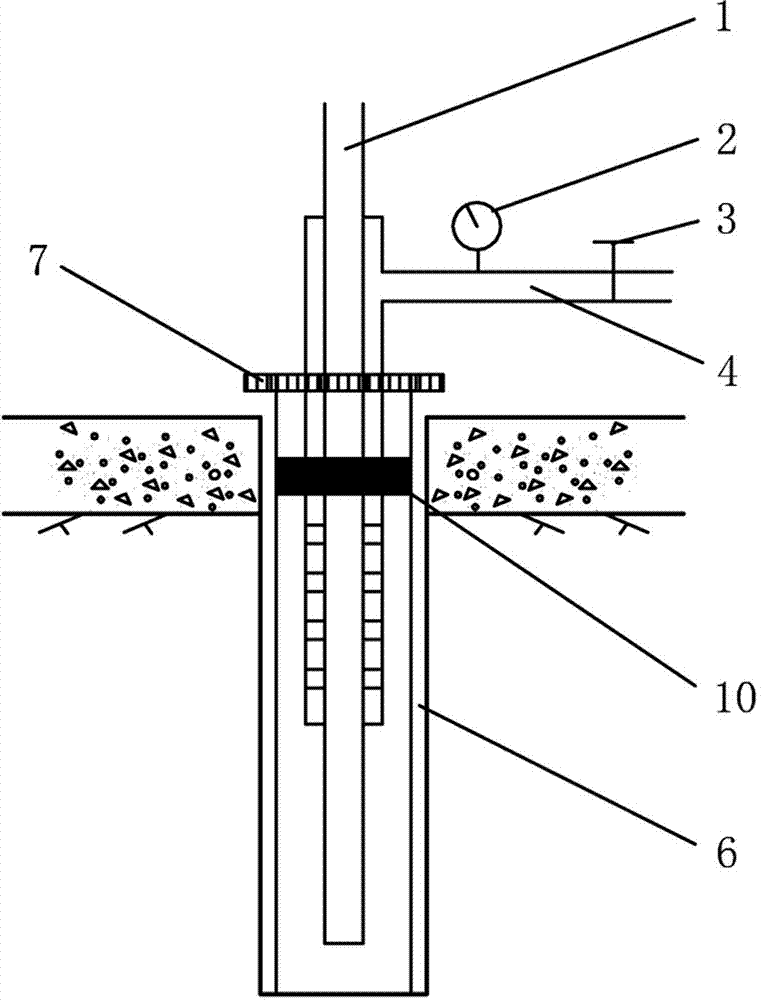

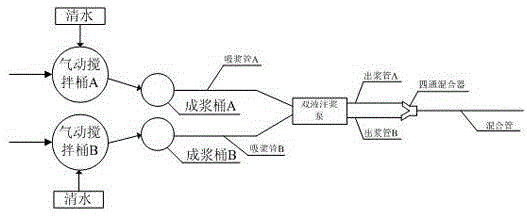

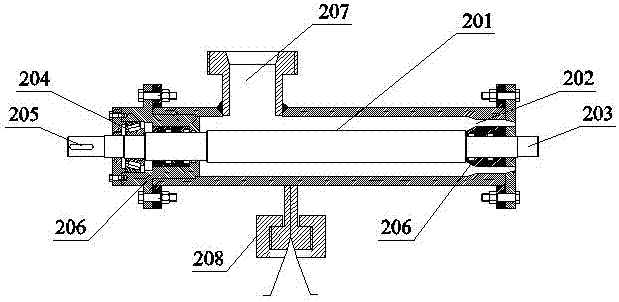

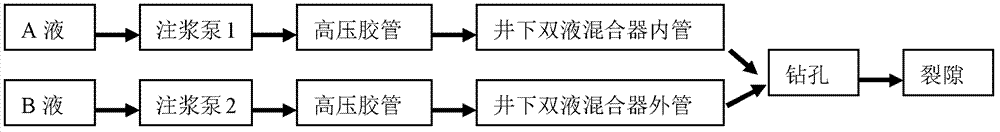

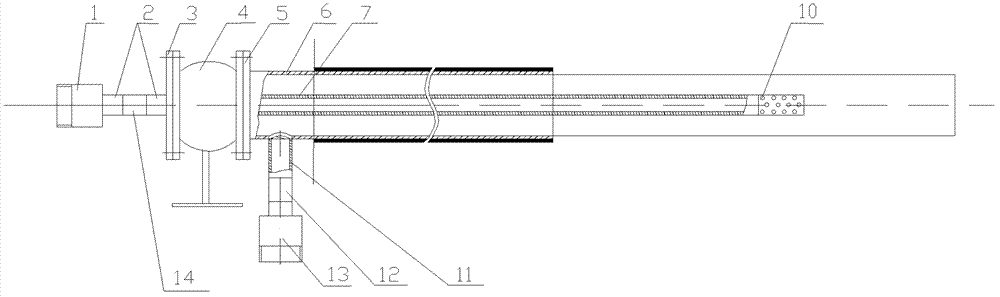

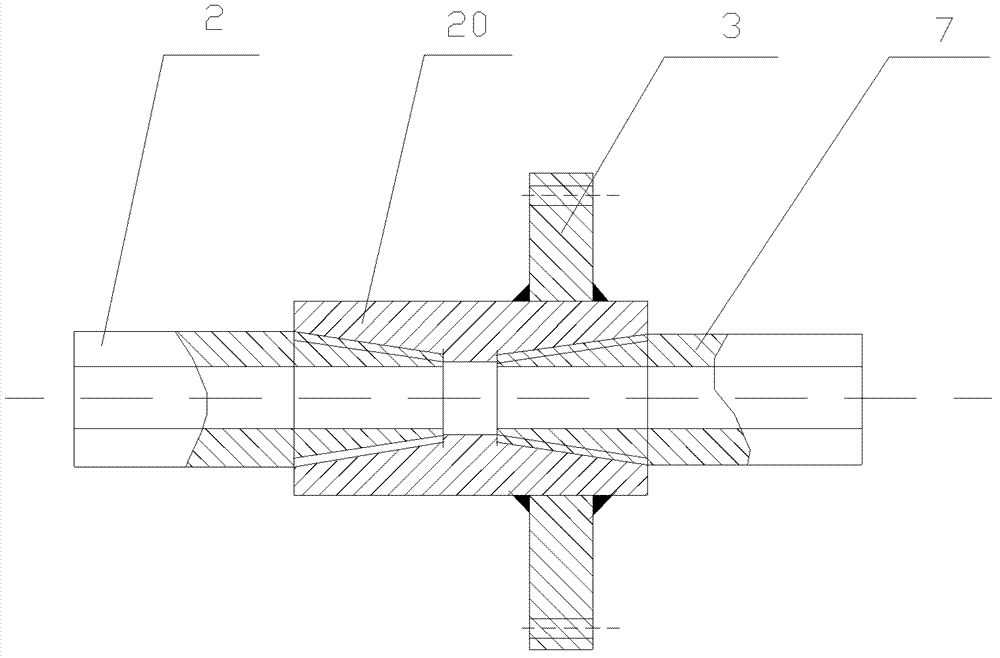

Underground double liquid grouting process and underground double liquid grouting machine thereof

ActiveCN102080552AEliminate the evil effect of cloggingAdjustable setting timeUnderground chambersTunnel liningSlurryPulp and paper industry

The invention relates to an underground double liquid grouting process, which comprises the following steps: (1) making preparations for implementing the double liquid grouting process and judging whether the grouting conditions are met; and (2) implementing the double liquid grouting process. The invention also discloses an underground double liquid grouting machine. An underground double liquidgrouting machine comprises an inner grouting tube and an outer grouting tube which are nested together, wherein the inner and outer grouting tubes are two independent airtight tubes. According to theinvention, a drill rod and a drill hole water-stopping casing pipe are respectively used as a grout conveying pipeline, the double pipeline grouting is realized, and the position for mixing two grouts and the running time of the grouts in the drill hole after the grouts are mixed are both adjusted by changing the depth of the grouting tubes in the drill hole, thus achieving the purpose of adjusting the coagulation time of the double grouts in the deeper drill hole and eliminating the disastrous effect of blocking the drill hole with the grouts, thereby ensuring a better grouting effect.

Owner:SHANDONG UNIV

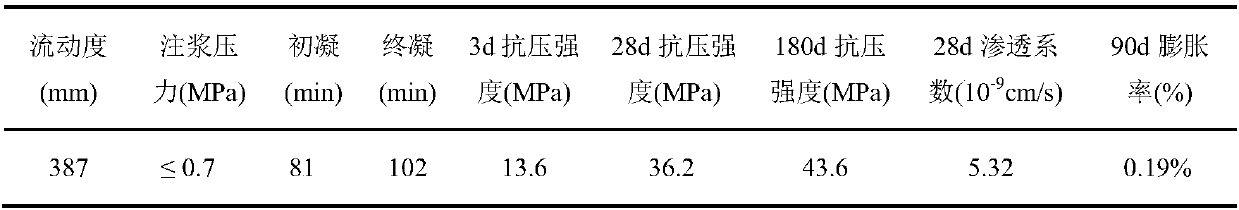

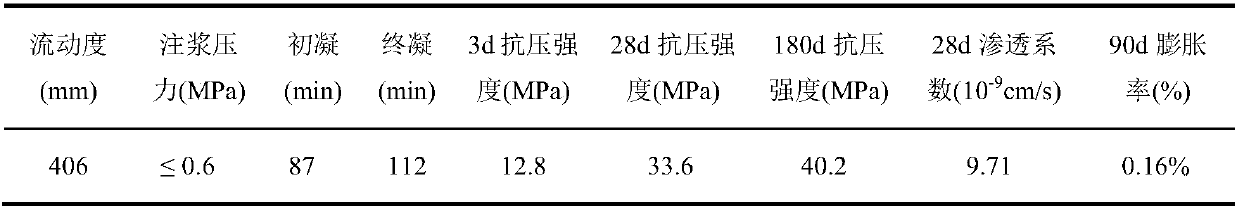

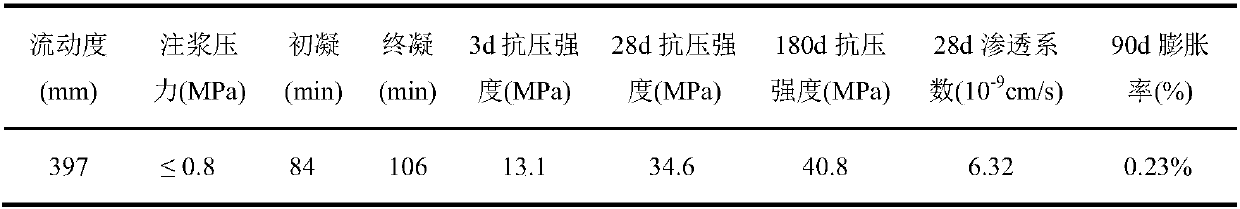

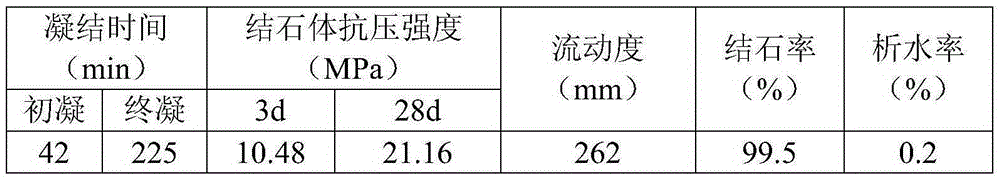

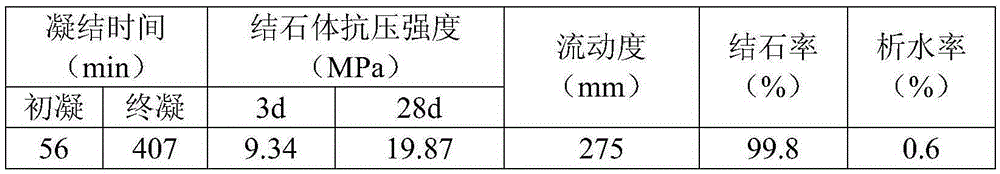

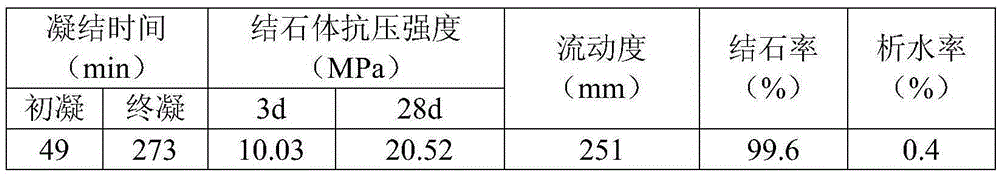

High-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment and application of grouting material

The invention discloses a high-performance superfine cement based grouting material for microfissuring and silty fine sand soil grouting treatment, and application of the grouting material. The grouting material comprises the following ingredients in parts by weight: 50-79 parts of Portland cement clinker, 19-48 parts of an auxiliary cementing material and 2-7 parts of desulfurized gypsum, whereinthe auxiliary cementing material comprises the following ingredients in parts by weight: 25-57 parts of mineral slag, 8-21 parts of steel slag, 18-36 parts of pulverized fuel ash, 6-12 parts of limestone flour, 1-8 parts of silica fume and 2.5-12.8 parts of a high-performance composite regulator; the high-performance composite regulator comprises the following ingredients in parts by weight: 5-16parts of sodium hydroxide, 4-12 parts of sodium silicate, 4-14 parts of potassium metaaluminate, 12-21 parts of calcium chloride, 11-18 parts of lithium chloride, 4-12 parts of triethanolamine, 21-27parts of alum, 18-29 parts of aluminum sulfate, 0.2-1.5 parts of hydroxypropyl methyl cellulose, 0.1-3.0 parts of viscous polymer, 0-0.8 parts of polypropylene fiber and 0.5-3.0 parts of a superplasticizer; and the viscous polymer is an acrylic ester polymer or an ethylene-vinyl acetate copolymer.

Owner:SHANDONG UNIV

Construction method for covering layer closed porthole high-pressure curtain grouting

InactiveCN103485345ASolve the difficulty of forming holesIncrease drilling speedFoundation engineeringHigh pressureInjection rate

The invention relates to a construction method for covering layer closed porthole high-pressure curtain grouting. The method includes following steps: (1), non-grouting section construction; (2), grouting section hole-creating; (3), grouting section long division; (4), grouting pressure determination; and (5), grouting way determination. A casing pipe is used for following up to the non-grouting section, and mud fixes walls and creates holes, so drilling speed and hole-forming rate can be greatly improved, and the problem of difficulty in hole-forming of a ground layer of a deep covering layer is solved. On the deep covering layer, higher grouting pressure is adopted, grouting injection rate increases obviously, diffusion radius enlarges, and grouting effect is fine. On the covering layer, the closed porthole curtain grouting construction method is adopted, grouting quality is guaranteed, frequent 'pipe hugging'drilling accidents during grouting are basically avoided, and construction efficiency is improved.

Owner:GEZHOUBA GROUP FOUND ENG

Coal mine tunnel broken surrounding rock layering grouting technology and method

InactiveCN104594914AReduce grouting costsGood grouting effectUnderground chambersTunnel liningViscosityCoal

The invention discloses a coal mine tunnel broken surrounding rock layering grouting technology and method. Novel double-fluid inorganic grouting materials are adopted, and the method is matched with a novel grouting hole sealing device to achieve drilling layering grouting. The method comprises the steps that grouting drilling is constructed at first, the dual-layer grouting hole sealing device is adopted for hole sealing, then, grouting materials with the low water cement ratio, high viscosity and high condensation speed are adopted to be used in cooperation with the low-pressure and low-flow grouting technology, an outer layer grouting pipe is utilized for conducting grouting on a surrounding rock shallow layer broken zone to form an effective grouting stopping layer, then, the water cement ratio of the grouting materials is improved gradually, the material permeability characteristics are improved, the material curing time is prolonged, the grouting pressure is gradually improved, and an inner layer grouting pipe is utilized for completing surrounding rock deep layer grouting. The method adapts to surrounding rock failure and permeability characteristic zoned characteristics, the grout leakage problem is effectively solved, and layering grouting in the same drilled hole is achieved.

Owner:HENAN POLYTECHNIC UNIV +1

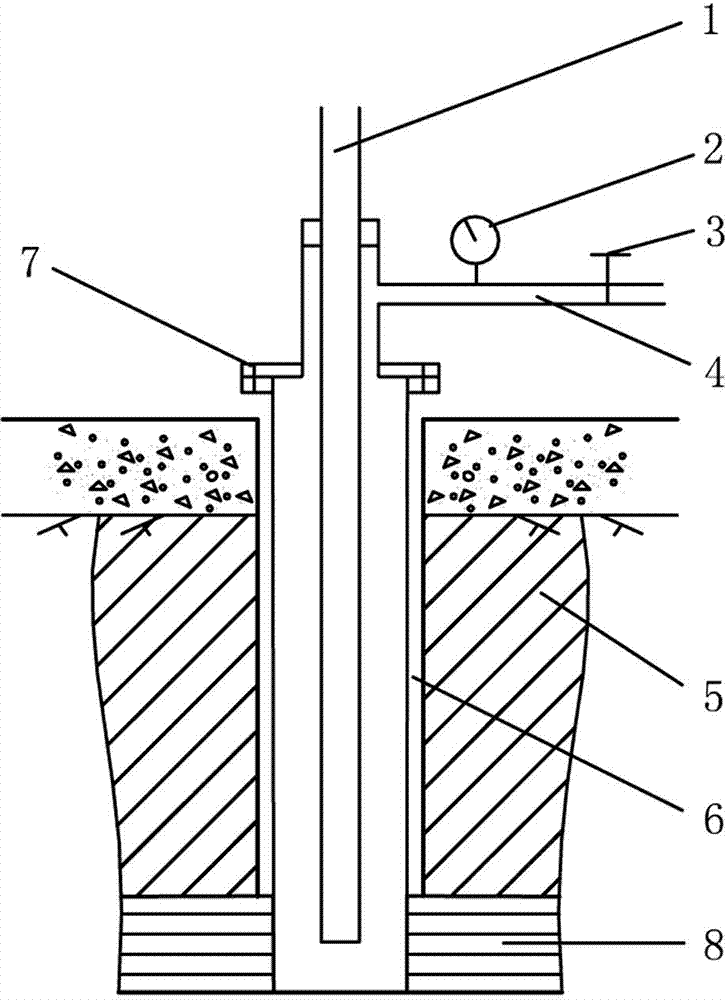

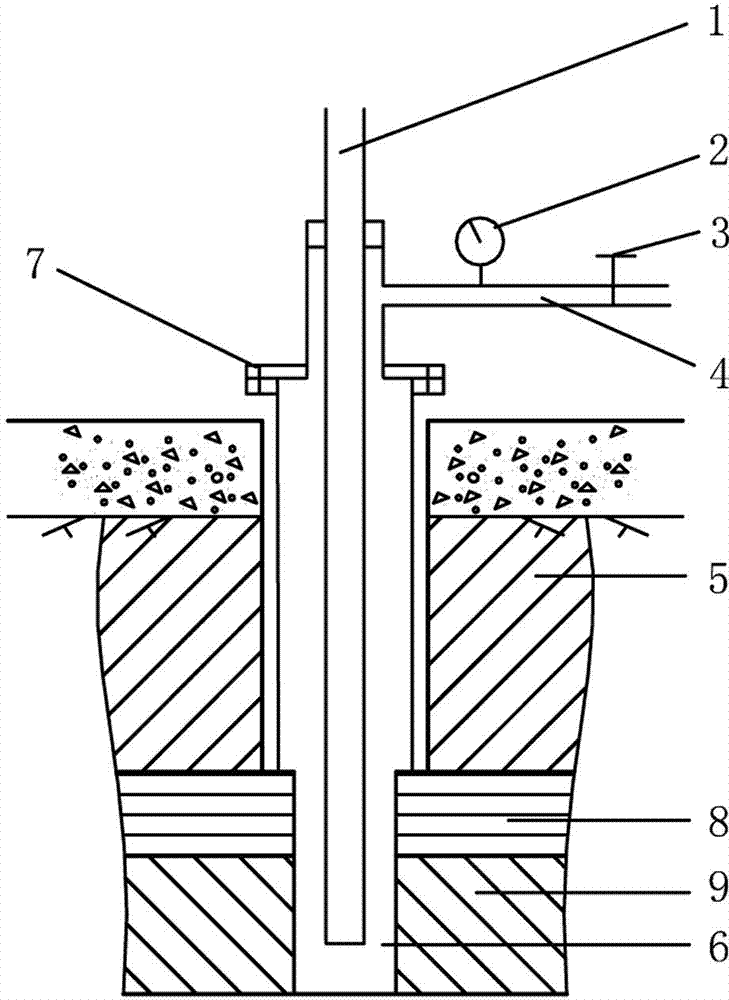

Grouting structure and grouting method for ground surface ultra-deep hole double liquid slurry grouting

The invention discloses a grouting structure and grouting method for ground surface ultra-deep hole double liquid slurry grouting. The structure is characterized by comprising a drill hole opened in the ground surface. A sleeve valve pipe is arranged in the drill hole. A blocking device is arranged in the sleeve valve pipe. A sealed mixing cavity is formed between the blocking device and the sleeve valve pipe bottom. A first grouting pipe and a second grouting pipe are arranged in the drill hole, and communicated with the mixing cavity. The inner wall of the mixing cavity is provided with grouting holes. The parts of the sleeve valve pipe, which correspond to the grouting hole, is bound by a leather sheath which blocks the grouting hole. The blocking device is used for sealing, and an enclosed mixing cavity is formed, thus cement slurry and sodium silicate paste are injected into the mixing cavity through the first grouting pipe and the second grouting pipe respectively to be mixed. Because the cement slurry and the sodium silicate paste are mixed at the bottom of the sleeve valve pipe, the time for mixing used in the re-transportation process is saved. Therefore, with the technical scheme, in a deeper drill hole, mixed slurry has more sufficient time to overflow from the grouting hole, and the requirement of deeper grouting can be met.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP 2ND ENG CO LTD

Fracture rock no-slurry-blocking wall compound grouting construction method

ActiveCN101666234ASave on concrete costsReduce further damageUnderground chambersTunnel liningCement slurryMaterials science

The invention discloses a fracture rock no-slurry-blocking wall compound grouting construction method. The method comprises the following steps: when carrying out grounting, firstly, pressing and injecting pure water cement slurry in an inner hole, closing water glass slurry inlet gate valve, opening the water glass slurry inlet gate valve after the heading face leaks cement slurry and simultaneously pressing and injecting double liquid slurry of cement and water glass; after the heading face does not leak the slurry or the heading face leaks double liquid slurry which is solidified and basically blocks fracturing crack, firstly stopping water-injecting glass, then stopping water-injecting slurry, and opening a pressure-relief gate valve in time. The fracture rock no-slurry-blocking wall compound grouting construction method has the beneficial effects that by normal grouting hole channels and pipelines, the double liquid slurry is pressed to carrying out consolidation to rock bodies near the heading face, simultaneously the double liquid slurry does not block the normal grouting hole channels either, thus achieving the purposes of consolidating the rock bodies near the heading face, then normally grouting single liquid slurry and forming water curtain.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

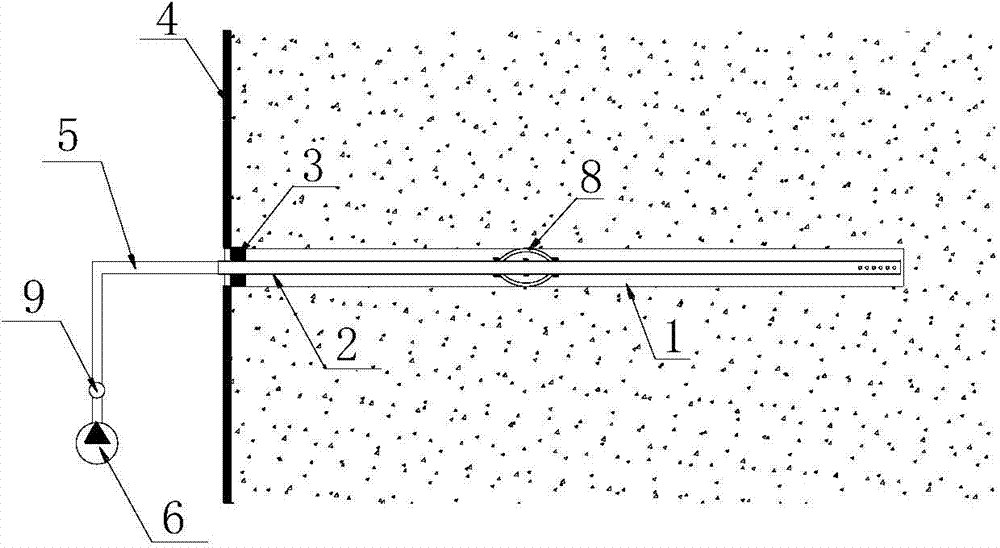

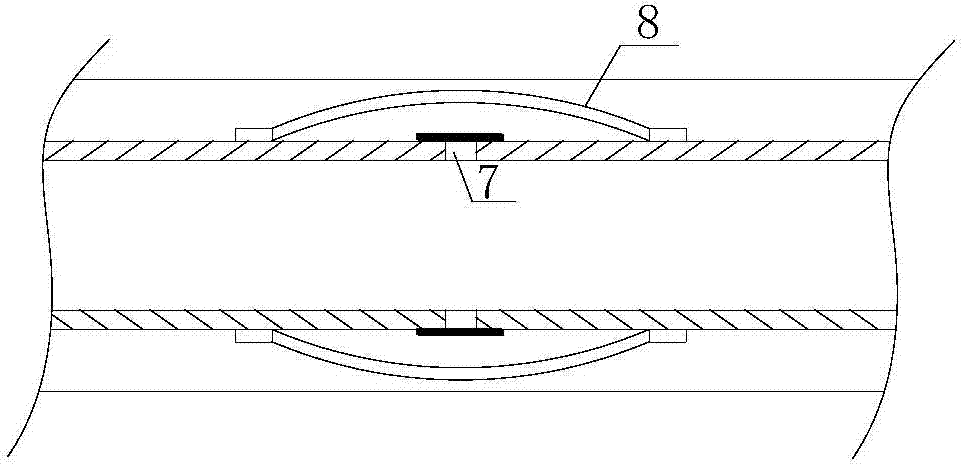

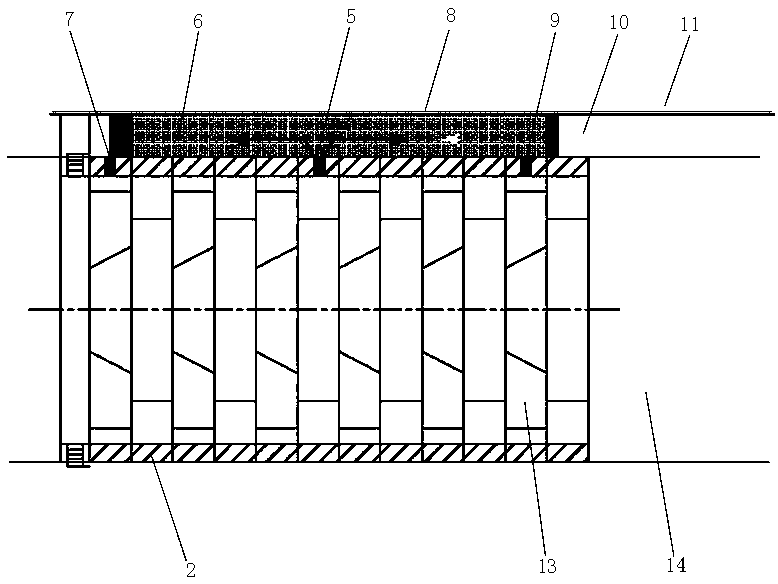

Method and structure for reinforcing flat hole grouting roadbed without damaging road surface

ActiveCN103981782AGuaranteed integrityAvoid damageRoadwaysSoil preservationStructural engineeringCement grout

The invention discloses a method and a structure for reinforcing flat hole grouting roadbed without damaging road surface. The method comprises the following steps of A. determining the positions of grouting holes; B. drilling horizontal or slant grouting holes to ensure that the drilling angle is orthogonal to the main damaging direction of the roadbed; C. striking the grouting holes in an interlaced mode; D. drilling and grouting from the periphery of the damaged roadbed to the inside; E. arranging grouting floral pipes; F. arranging seamless grouting outer pipes at the front ends of the grouting holes which penetrate through the cross section of the roadbed and are dimensionally and crossly distributed; G. uniformly filling cement grouts and determining grouting pressure through tests and areas; and H. performing sedimentation, inclination, deformation and displacement observation on the roadbed surfaces, structures and surrounding buildings during grouting. Horizontal or inclined drilling is carried out on roadbed slopes in the affected area for forming the grouting holes, the grouting floral pipes and the seamless grouting outer pipes are arranged, and the grouting floral pipes are connected with the seamless grouting outer pipes by virtue of joint by screws. The method is feasible and convenient to carry out; because of no-damage road surface structure, the bearing capacity and the stability of the roadbed structure in the affected area are obviously improved, and the reinforcement effect is high.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

Geopolymer composite grouting material, and preparation method and use method thereof

The invention discloses a geopolymer composite grouting material, and a preparation method and a use method thereof. The preparation method comprises the following steps: uniformly mixing cement clinker, metakaolin, silica fume, blast furnace slag, fly ash, metal mine tailing, quicklime, a water reducer and dispersible latex powder according to a certain ratio, and grinding to prepare fine powder until the sieving residue ratio of a square hole sieve with the fineness of 45[mu]m is not greater than 30%. Solid wastes comprising the blast furnace slag, the fly ash and the metal mine tailings are adopted in the invention, so the cost of the material is reduced, the fluidity of the material is improved, and the compressive strength of the geopolymer composite grouting material is also improved without increasing the cost.

Owner:SHANDONG UNIV OF SCI & TECH

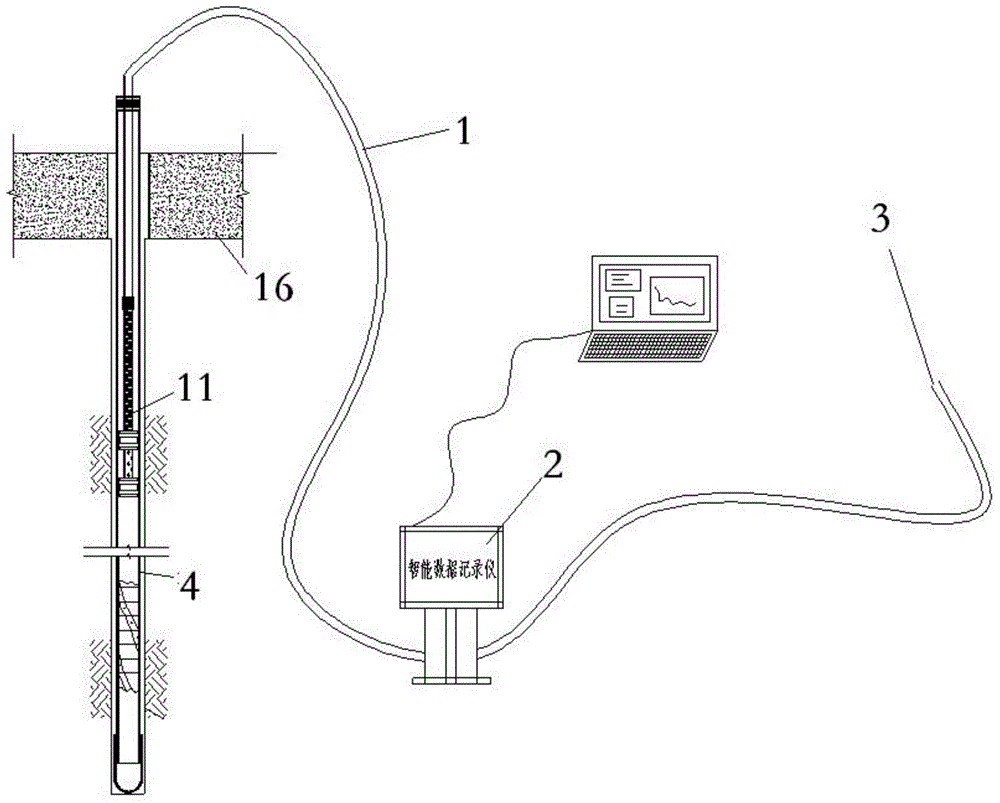

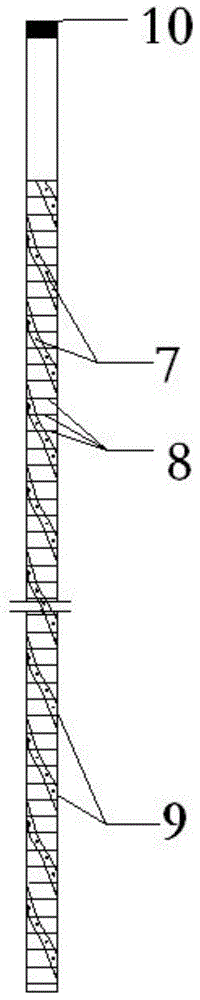

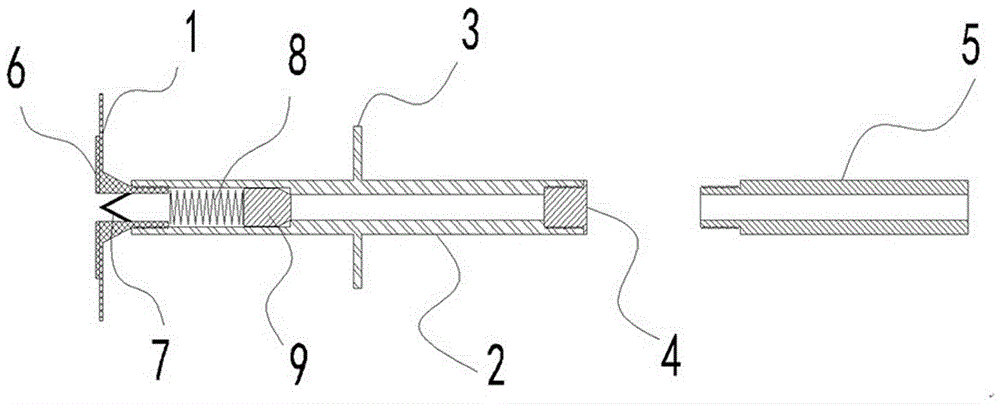

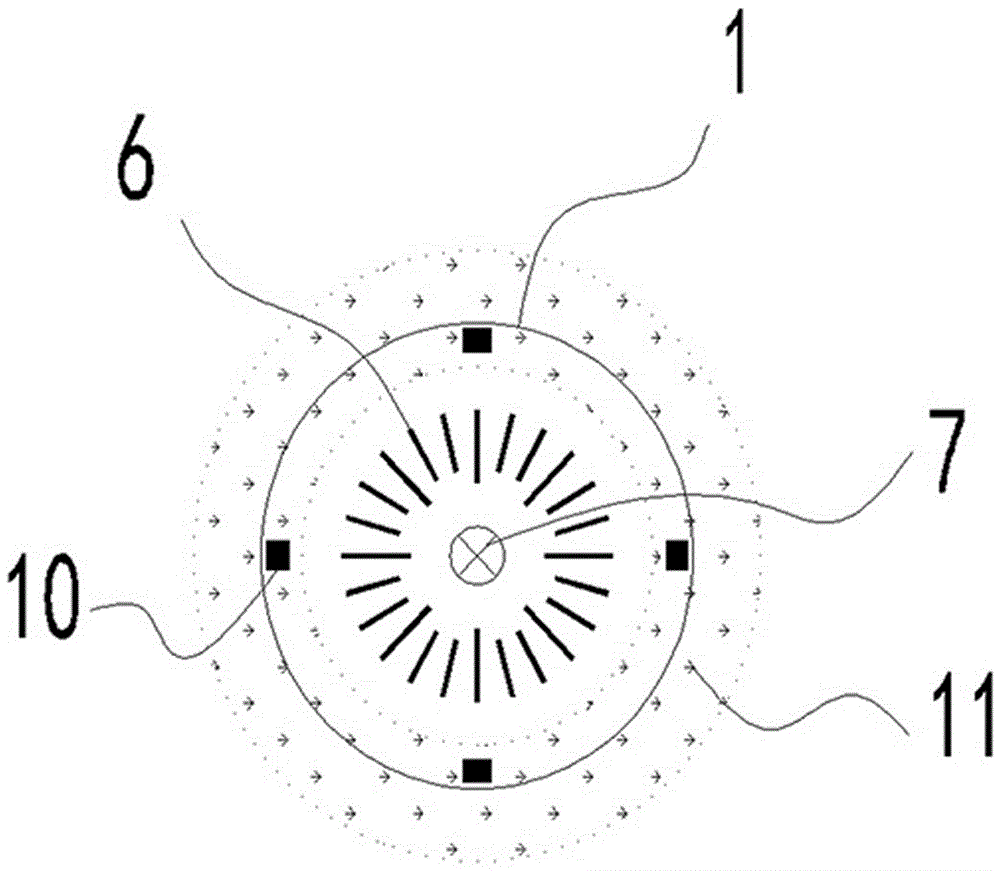

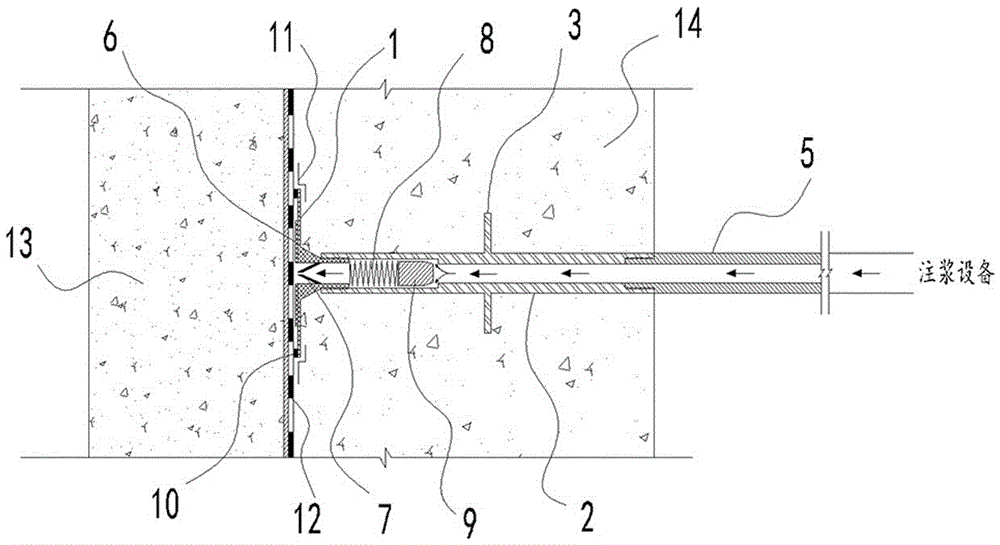

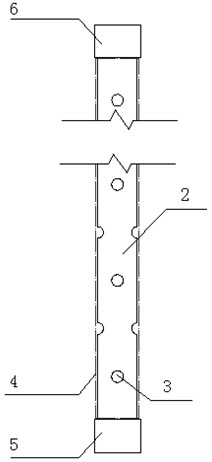

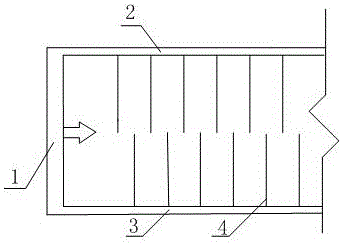

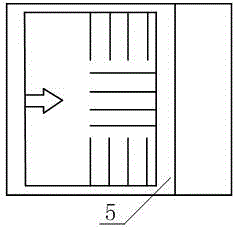

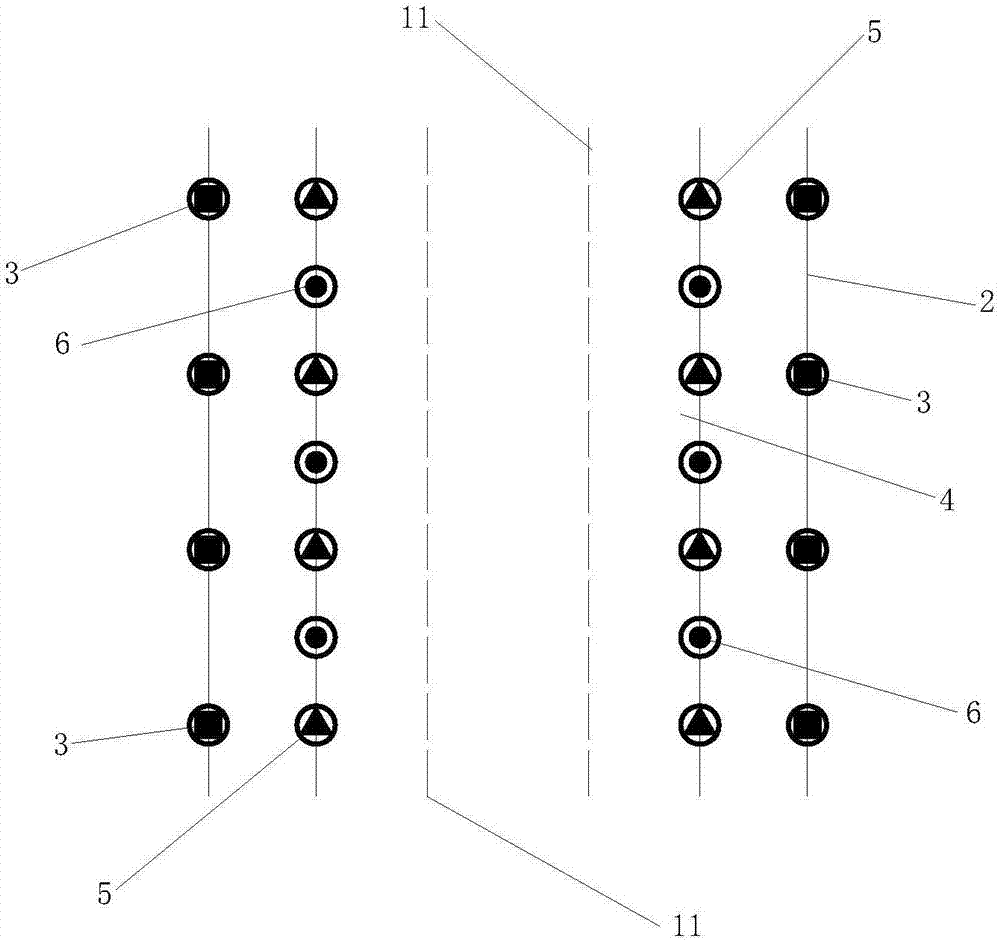

Steel flower pipe segmented grouting system and construction method thereof

ActiveCN104805842AImprove grouting effectSimple structureBulkheads/pilesSoil preservationArchitectural engineeringSlurry

The invention discloses a steel flower pipe segmented grouting system, which comprises a spiral rubber sleeve steel flower pipe and a matched telescopic grouting gun head, wherein the telescopic grouting gun head is connected with an intelligent data recording instrument through a grouting pipe, the other end of the intelligent data recording instrument is connected with a grouting slurry inlet opening, the spiral rubber sleeve steel flower pipe comprises a steel flower pipe, the bottom of the steel flower pipe is sequentially provided with a steel flower pipe sealing bottom plate and a U-shaped support frame which are mutually matched, a plurality of spirally distributed grouting holes are formed in the pipe body of the steel flower pipe, and a spiral rubber sleeve in spiral matching is fixedly arranged on the grouting hole through a plurality of steel wires, the telescopic grouting gun head comprises a grouting gun head shaft rod, one end of the grouting gun head shaft rod is movably connected with an upper slurry stop plug, and meanwhile, the other end of the grouting gun head shaft rod is fixedly connected with a lower slurry stop plug.

Owner:CHINA RAILWAY CONSTR GROUP +1

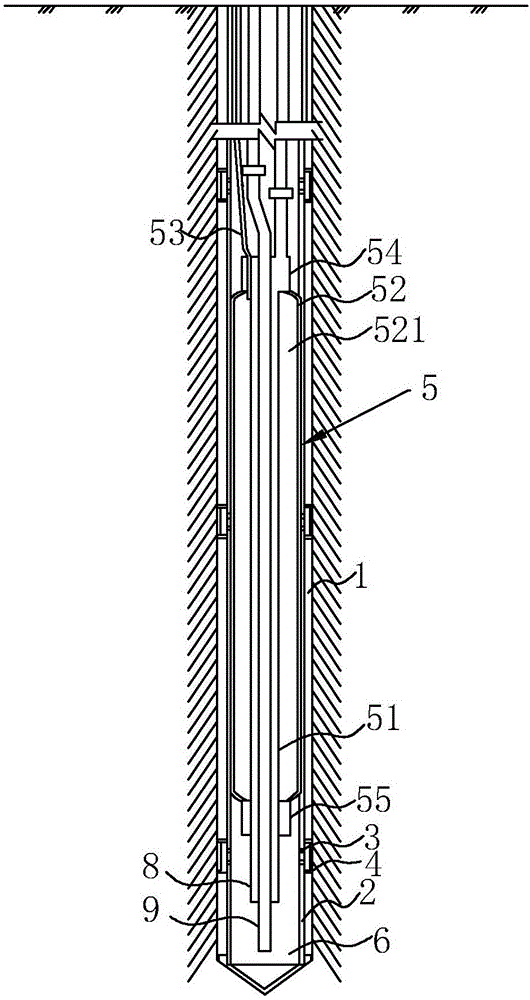

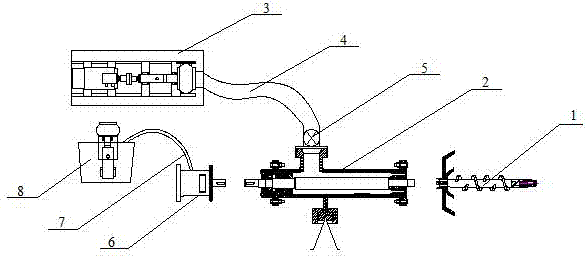

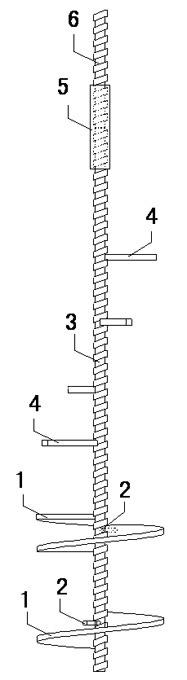

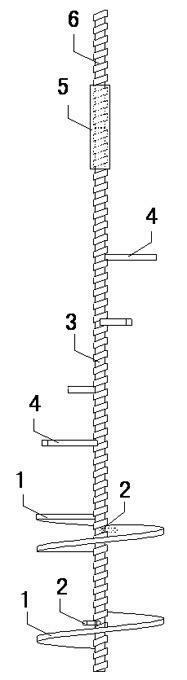

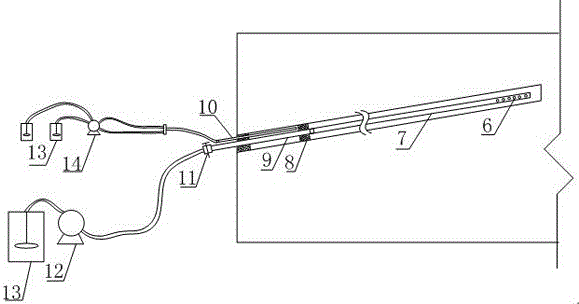

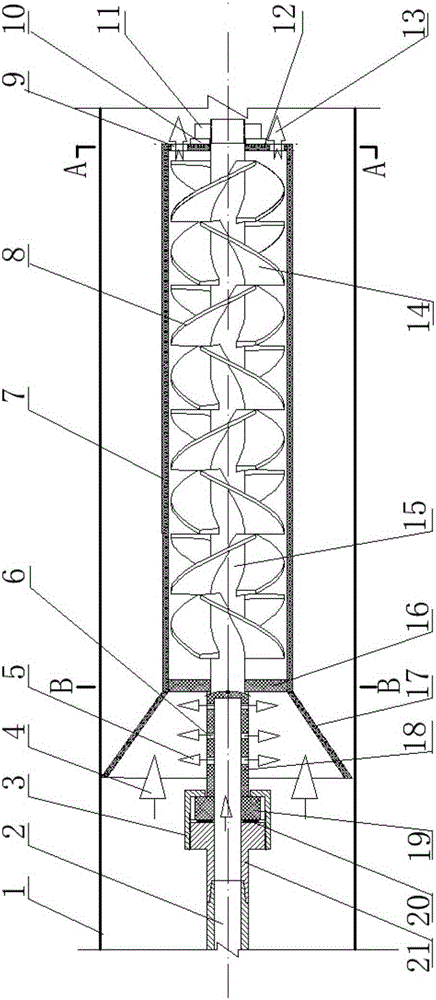

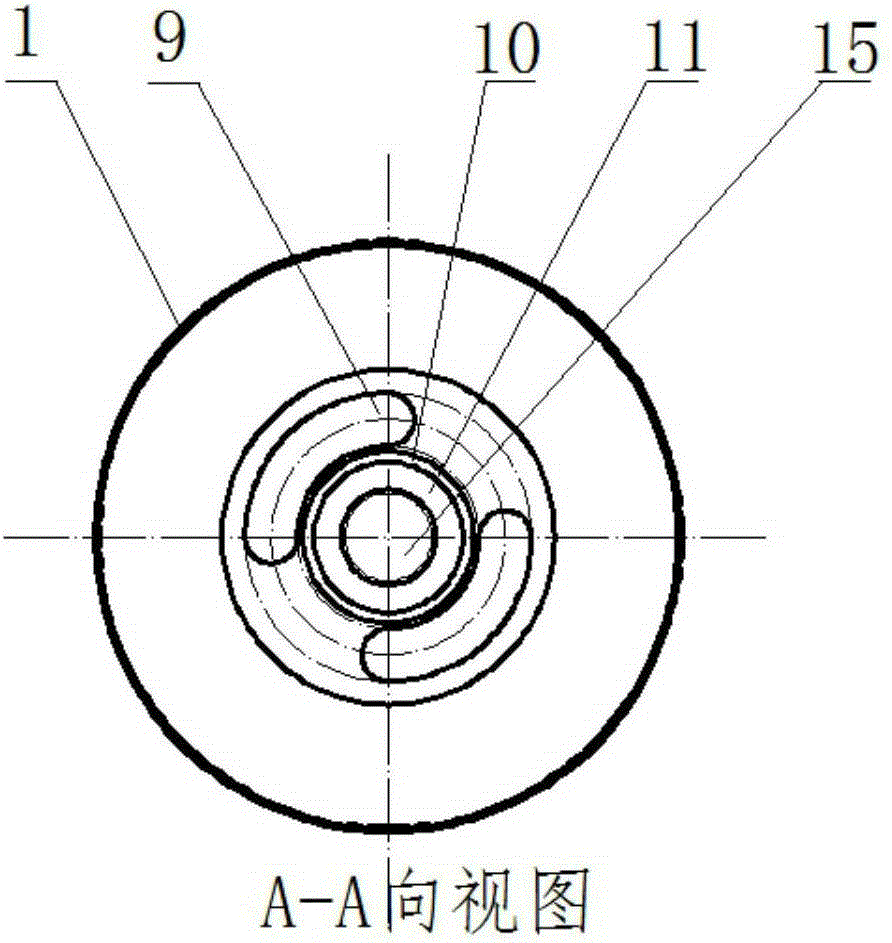

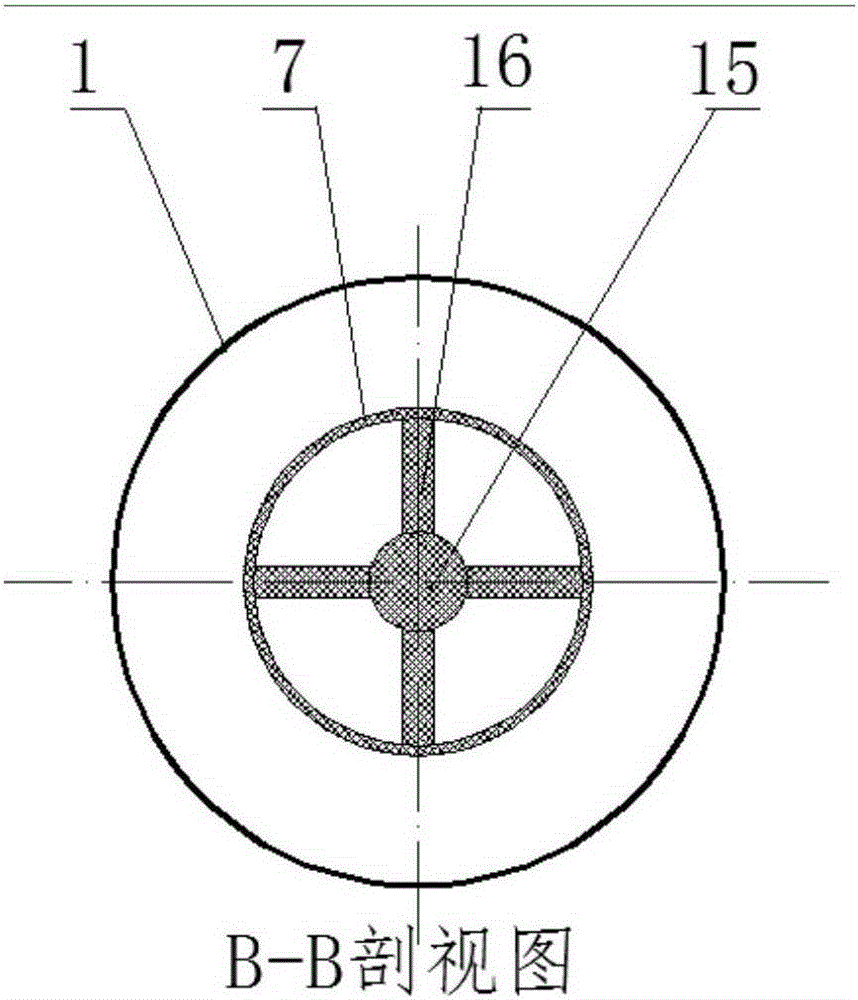

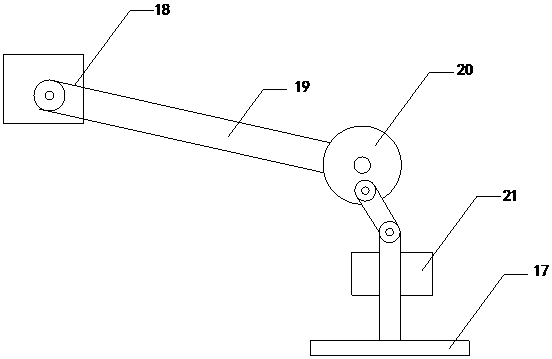

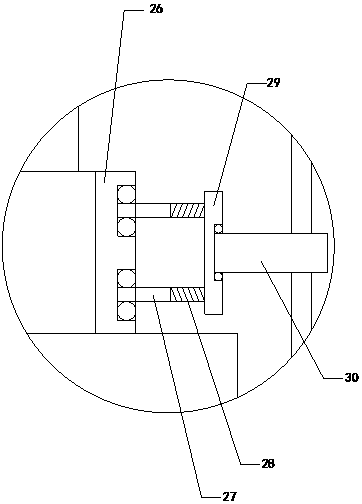

Self-vibrating flow-jetting and grouting anchor rod integrated construction equipment and method

PendingCN107476814AImprove rock drilling or rock breaking efficiencyDrilling speed is fastAnchoring boltsDrill bitHigh pressure

The invention discloses self-vibrating flow-jetting and grouting anchor rod integrated construction equipment and method. The equipment is composed of a self-vibrating flow-jetting and grouting anchor rod, a high-pressure rotary slurry mixing device, a grouting device and a hydraulic driving device. The self-vibrating flow-jetting and grouting anchor rod is a hollow rod body with a screw-edge stirring piece, and the front end of the anchor rod is provided with a vibration generator which is connected with a drill bit; the upper portion of the high-pressure rotary slurry mixing device is provided with a feed hole, the bottom of the high-pressure rotary slurry mixing device is provided with a rotary supporting leg which can freely lift and rotate, the front portion of the high-pressure rotary slurry mixing device is provided with a flow-jetting spray pipe, an inner cavity is provided with a rotating shaft, the front end of the rotating shaft is provided with a connection plug, the connection plug is cooperated and connected with a connection inserted groove of the self-vibrating flow-jetting and grouting anchor rod, the rear end of the rotating shaft is provided with a bearing, and the two ends of the rotating shaft are provided with high-pressure sealing boxes. The grouting device adjusts the grouting amount and the grouting pressure at any time, and the hydraulic driving device provides rotating power. The equipment and the method is widely used in support and reinforcement engineering in mines, transportation, water conservancy and other engineering fields, the application prospect is broad and the economic benefit is remarkable.

Owner:BINZHOU UNIV

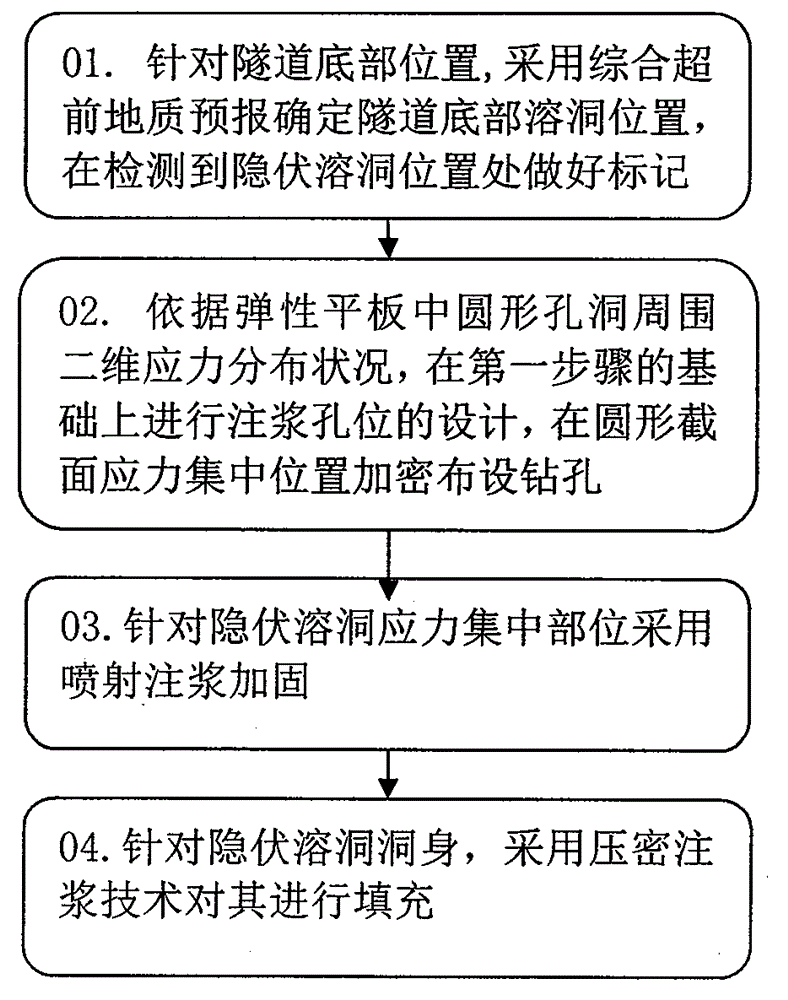

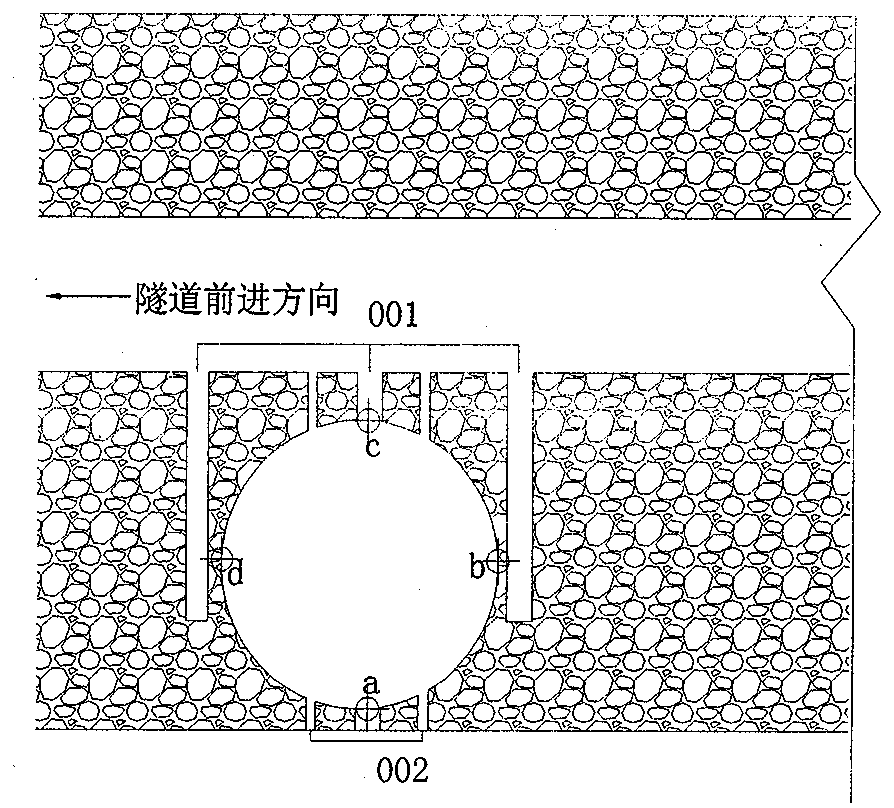

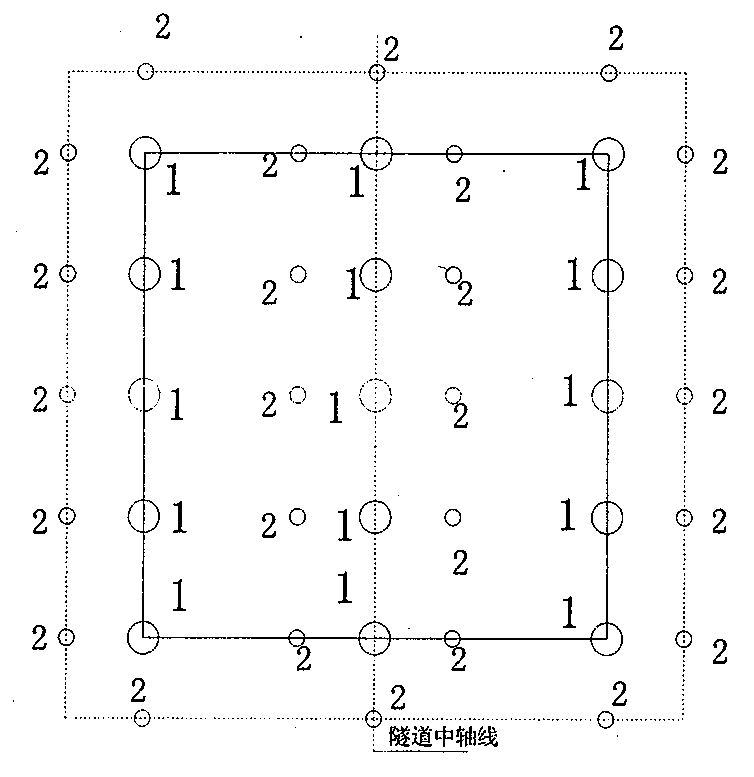

Method for processing grouting position of hidden cave at bottom of tunnel

ActiveCN104612130AReduce the impactImprove self-stabilitySoil preservationStress concentrationStress distribution

The invention relates to the technical field of tunnel engineering and discloses a method for processing a grouting position of a hidden cave at the bottom of a tunnel. The processing method includes the steps that firstly, cave detection is conducted, wherein an advance geological forecast method is comprehensively used for determining the position of the cave at the bottom of the tunnel according to the position of the bottom of the tunnel, and the position where the hidden cave is detected is marked; secondly, a second hole site is designed, the position of a grouting hole is designed based on the first step according to the two-dimensional stress distribution condition around a round hole in an elastic flat plate; thirdly, grouting is conducted, jet grouting is conducted on the stress concentrated part of the hidden cave for strengthening; fourthly, grouting is conducted, a compaction grouting technology is used for filling a hidden cave body. According to the method for processing the grouting position of the hidden cave at the bottom of the tunnel, the two-dimensional stress distribution state around the round hole in the elastic flat plate serve as the theoretical basis, the defect that construction is conducted by mainly relying on experience in the past is overcome, the stability of tunnel surrounding rock on the upper portion of the hidden cave is ensured, and the normal operation of the rear stage of the tunnel is ensured.

Owner:SHANDONG UNIV OF SCI & TECH

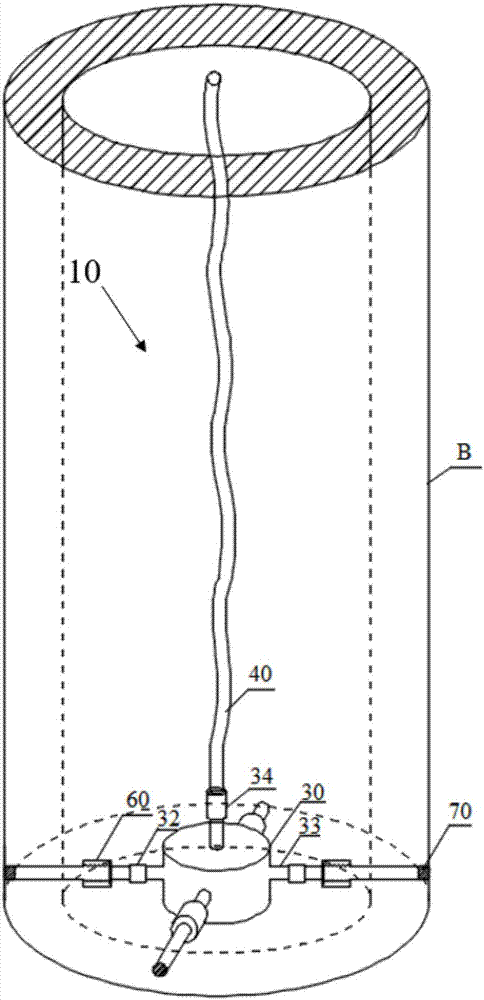

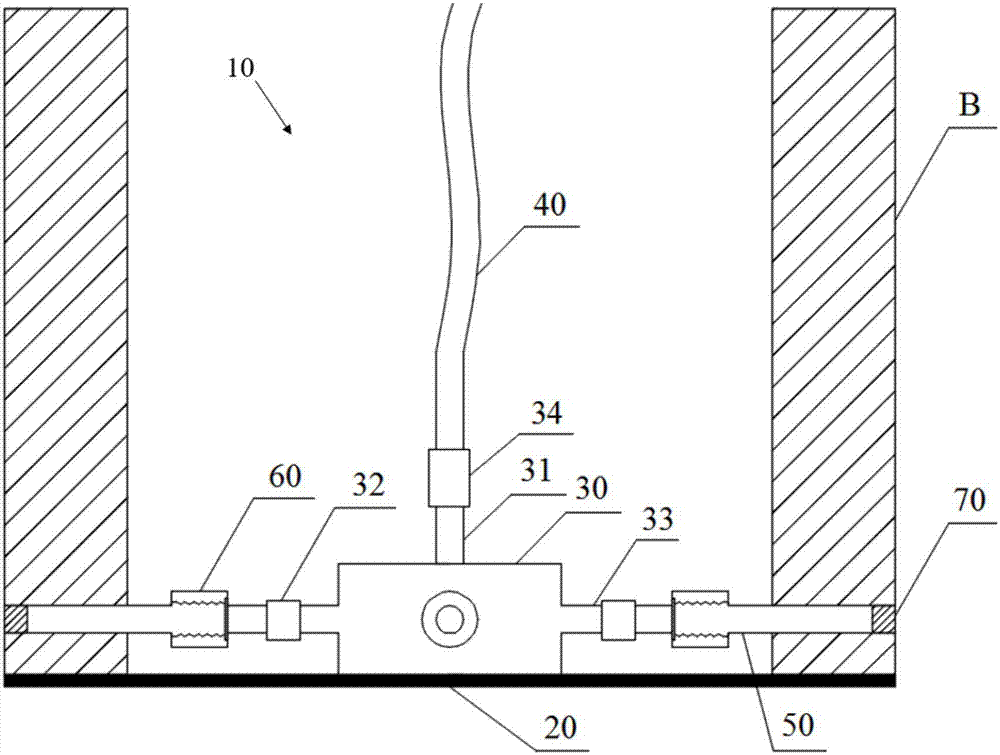

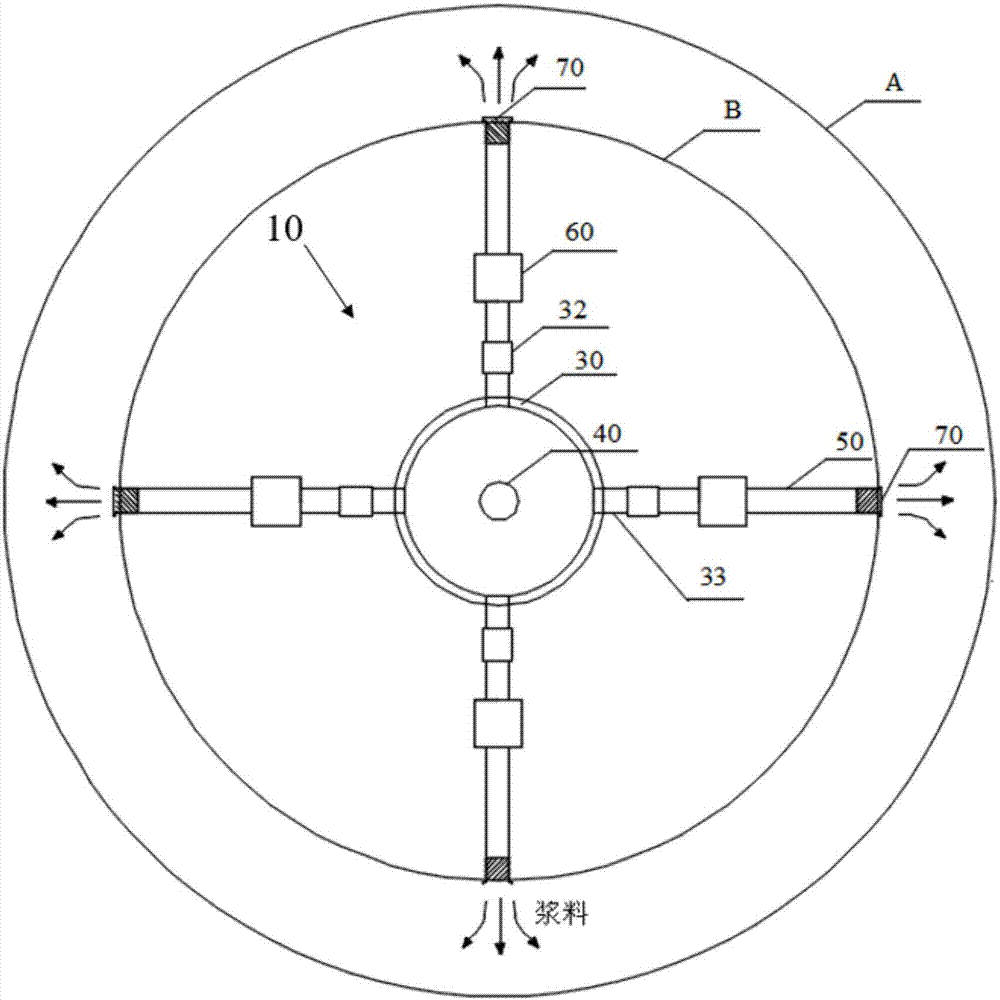

Grouting device and grouting method

ActiveCN107237329ASolve post-grouting construction problemsIncrease frictionBulkheads/pilesPipeGrout

The invention provides a grouting device which is high in construction speed, simple in structure, convenient to operate, high in efficiency and economical and a corresponding grouting method. The grouting device is characterized by being matched with a prefabricated pipe pile, and the grouting device carries out grouting after the prefabricated pipe pile is put into a pile hole with a larger diameter; the grouting device comprises an end plate which is used for sealing the bottom end of the prefabricated pipe pile, a grouting cushion chamber which is arranged in the end plate and is hollow inside, a grouting pipe, a plurality of grout outlet pipes, a plurality of reversing grout stopping valves and a plurality of end caps, wherein a grouting opening is formed in the upper end of the grouting pipe, and the lower end of the grouting pipe communicates with the grouting cushion chamber; the multiple grout outlet pipes are evenly arranged on the periphery of the grouting cushion chamber, a grout inlet of each grout outlet pipe communicates with the grouting cushion chamber, grout outlets can penetrate reserved holes in the side wall of the prefabricated pipe pile and face the space to be grouted on the outer side of the prefabricated pipe pile; the multiple reversing grout stopping valves are arranged on the grout outlet pipes correspondingly and stop grout from reversely flowing in the direction from the grout outlets to the grout inlets; and the multiple end caps block the grout outlets.

Owner:WUHAN UNIV

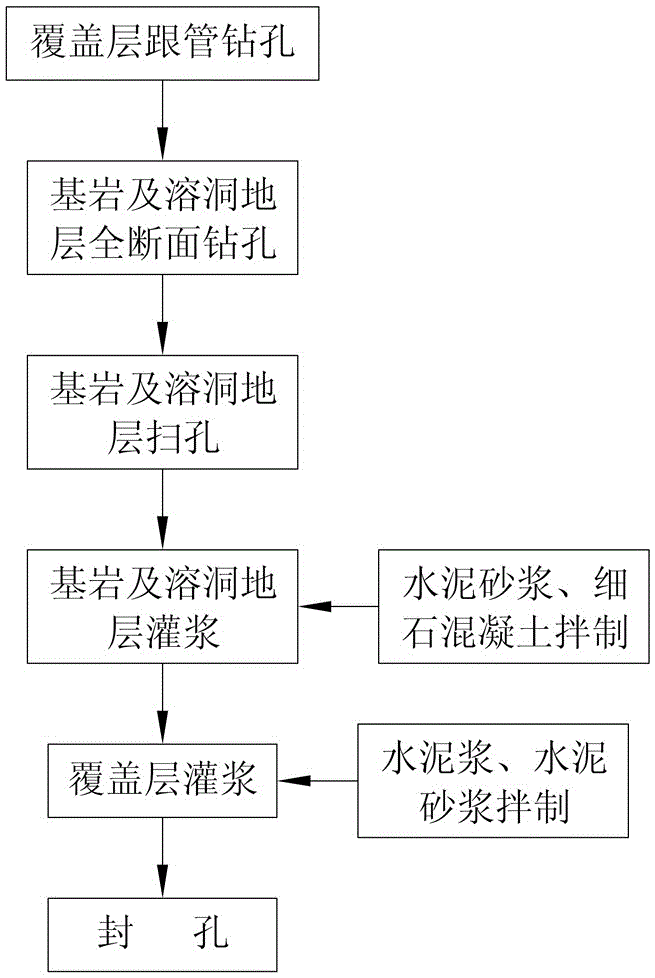

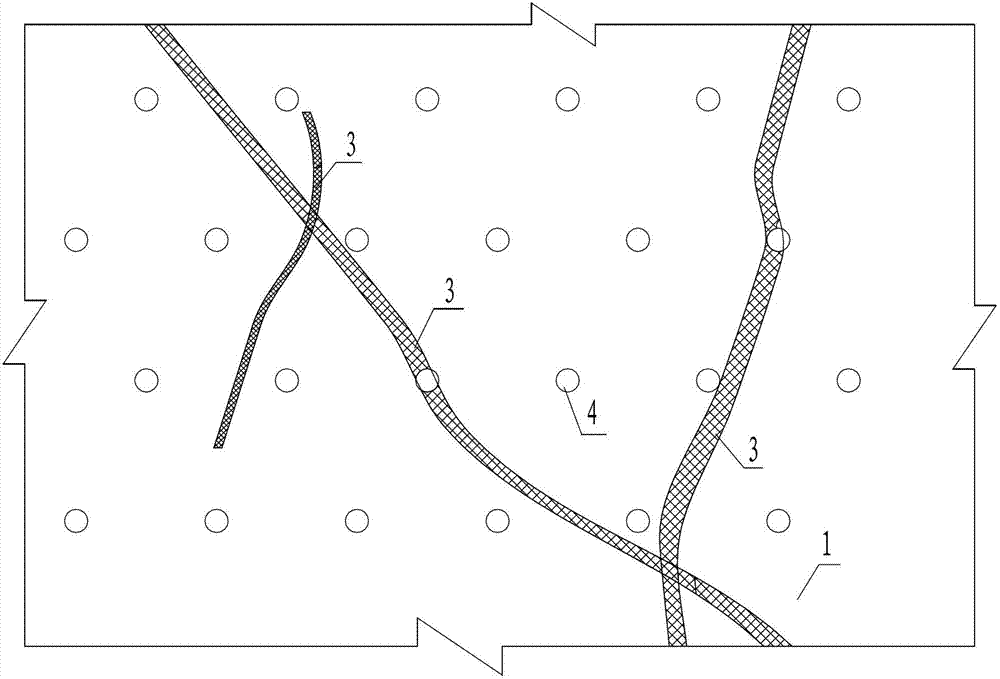

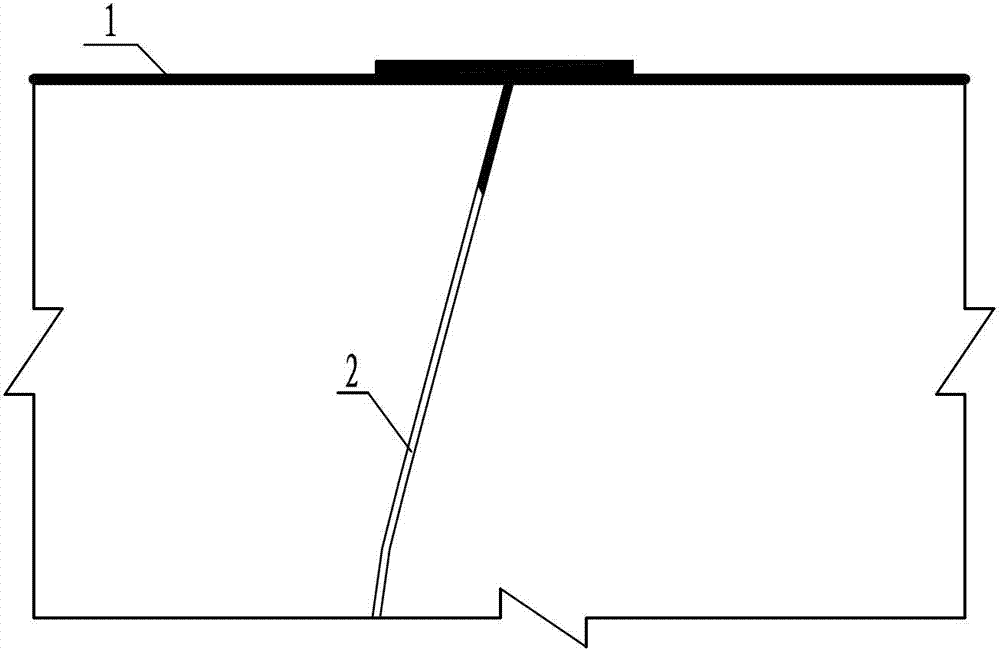

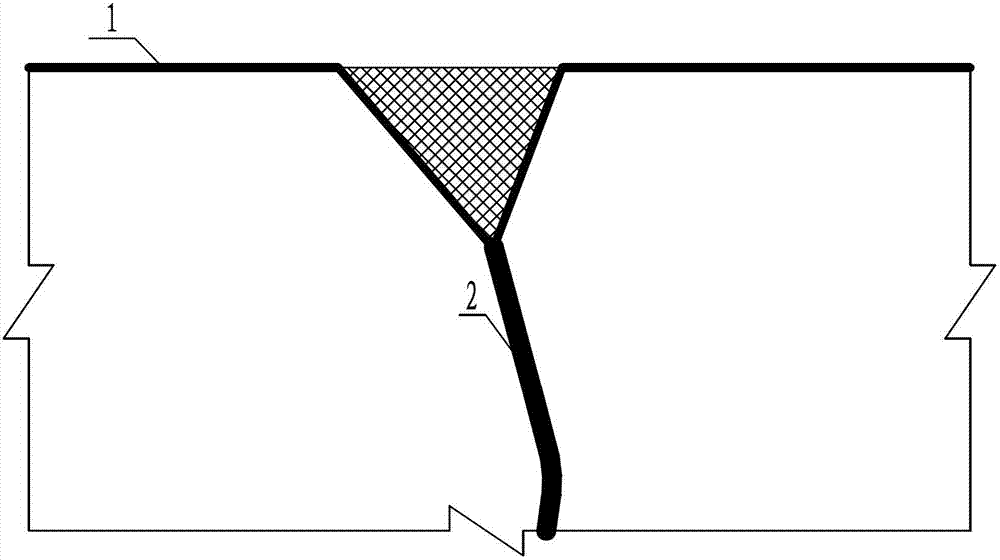

Anti-seepage construction method for karst cave development stratum under overburden

ActiveCN106320354AImprove bearing capacityImprove deformation resistanceFoundation engineeringBasementOverburden

The invention discloses an anti-seepage construction method for karst cave development stratum under overburden. The anti-seepage construction method comprises the following steps: S1, overburden drilling with a casing; S2, full-section drilling of basement and karst cave stratum; S3, drill-hole cleaning of basement and karst cave stratum; S4, grouting of basement and karst cave stratum; S5, grouting of overburden; and S6, hole sealing. The anti-seepage construction method has the advantages of simplicity in construction, favorable quality, controllable cost and high efficiency.

Owner:SINOHYDRO BUREAU 8 CO LTD

Method for coating and sealing fracture of bed rock in uncovered heavy consolidation grouting

InactiveCN103046513ASmall amount of workReduce distractionsMarine site engineeringWater leakageChisel

The invention discloses a method for coating and sealing a fracture of a bed rock in uncovered heavy consolidation grouting. The method comprises the steps of: firstly cleaning to remove impurities in the fracture of a rock body after the evenness of a base rock body to be grouted reaches to a design requirement; then coating a cement base waterproof material on the fracture of the rock body after keeping the surface of the rock body wet for 1-2 hours; checking an appearance effect of the coating layer after the final setting time of the cement base waterproof material arrives and coating the cement base waterproof material again on the places with empty holes or fractures; and then performing pressurized-water check, marking the fractures of the rock body with water seepage and water emission, and coating the cement base waterproof material again on the fractures of the rock body until the pressurized-water check shows that the fractures of the rock body have no water leakage. The method for coating and sealing the fracture of the bed rock in the uncovered heavy consolidation grouting, disclosed by the invention, not only overcomes the disadvantages of convenient fracture processing ways such as concrete sealing, spraying thin layer structure sealing, chisel groove and caulking sealing, and bare rock without sealing, and realizes a relative good consolidation grouting effect, but also has the characteristics of being convenient and rapid in construction, low in interference, economic, safe and reliable.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

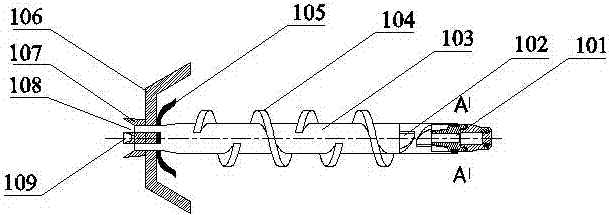

Self-drilling type spiral anchor rod and construction process using self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing

InactiveCN102587366AGood effectImprove construction safetyExcavationsBulkheads/pilesHelical bladeEngineering

The invention discloses a self-drilling type spiral anchor rod and a construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing, which are suitable for support engineering of anchor-pulling slopes in weak soil regions. A paste outlet is arranged on a rod body of the spiral anchor rod, the front end of the rod body of the anchor rod is enclosed, a spiral vane is welded at the front end of the rod body of the anchor rod, and a stirring slice is welded behind the spiral vane on the rod body of the anchor rod. The construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing comprises the following steps of: injecting cement paste while drilling by rod body of the anchor rod, so that a paste body of the cement paste is ejected out of the paste outlet of the rod body of the anchor rod, mixing the paste body and a soil body cut by using the spiral vane on the front end, uniformly stirring the soil body and the cement paste by using the stirring slice arranged behind the spiral vane, forming an irregular anchor body after curing so that the anchoring force of the anchor rod is increased. Because the drilling and the grouting are integrated, the pressure influence of subsequent grouting on the side wall of a foundation pit is avoided; and meanwhile, the grouting pressure can be effectively controlled so that the grouting quality can be ensured.

Owner:中石化胜利建设工程有限公司

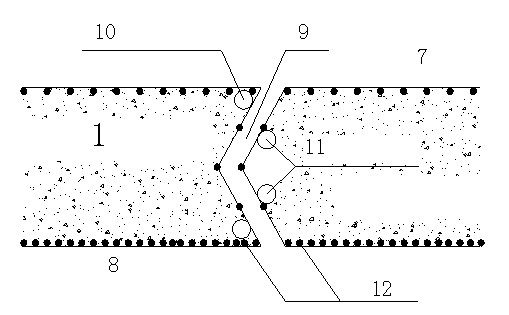

High-low pressure integrated roadway grouting reinforcement method

ActiveCN103758533AFully pulpedOvercoming high and low pressure grouting and drilling twiceUnderground chambersTunnel liningSlurryHigh pressure

A high-low pressure integrated roadway grouting reinforcement method is applicable to coal mine roadway support projects. Aiming at deformation and fracture of surrounding rocks of a roadway and fracture distribution rules, injected holes of the surrounding rocks of the roadway are subjected to grouting in sequence by means of low-pressure grouting and high-pressure grouting. The method includes: drilling a rock mass to a designed depth, installing a grouting pipe, and sealing holes with cement; subjecting the roadway surface to guniting to form a surface guniting layer; connecting pipelines, starting a grouting pump, subjecting the superficial rock mass to low-pressure grouting, increasing the grouting pressure after the diffusion range meets design requirements, and opening an expansion pipe under the action of high grouting pressure. The expansion pipe is expanded to stop grout flowing to the superficial surrounding rocks along the grouting holes, so that diffusion of the grout to the superficial rock mass is prevented. The deep rock mass is grouted by high-pressure grout through the grouting pipe to realize high-pressure grouting of the deep surrounding rocks.

Owner:CHINA UNIV OF MINING & TECH

Underground two-fluid grouting device

ActiveCN102852535AEliminate the evil effect of cloggingAdjustable setting timeUnderground chambersTunnel liningDouble tubeEngineering

The invention relates to an underground two-fluid grouting device comprising a grouting inner tube and a grouting outer tube which are nested together, wherein the grouting inner tube and the grouting outer tube are two independent closed pipelines. The grouting inner tube comprises a high-pressure rubber hose joint I, a short tube I, a seal joint, a drill rod and an injector which are sequentially connected, wherein the components are connected to form a closed grouting pipeline, and the short tube I is provided with a check valve I. According to the invention, the drill rod and a drill hole water stopping sleeve are used for being respectively taken as a fluid conveying pipeline, double-tube grouting is realized, depth of a grouting tube in a drill hole is changed for adjusting a position at which two fluids are mixed and the operation time of the mixed fluid in the drill hole, and the aims of adjusting two-fluid solidification time in a deeper drill hole and eliminating a bad result that the drill hole is blocked by the fluid are achieved, so that a better grouting effect is guaranteed.

Owner:SHANDONG UNIV

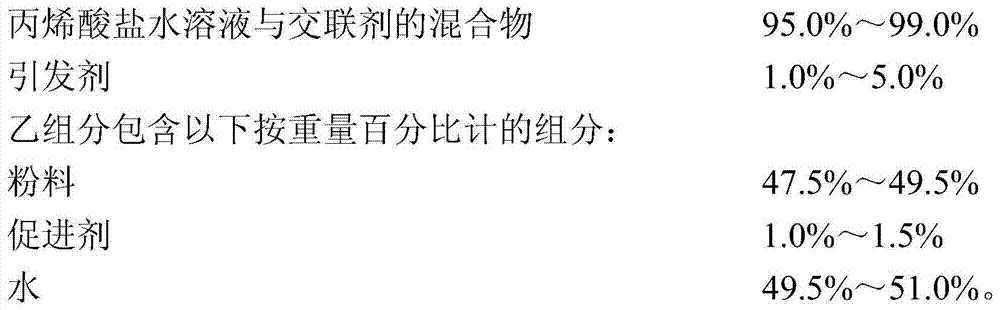

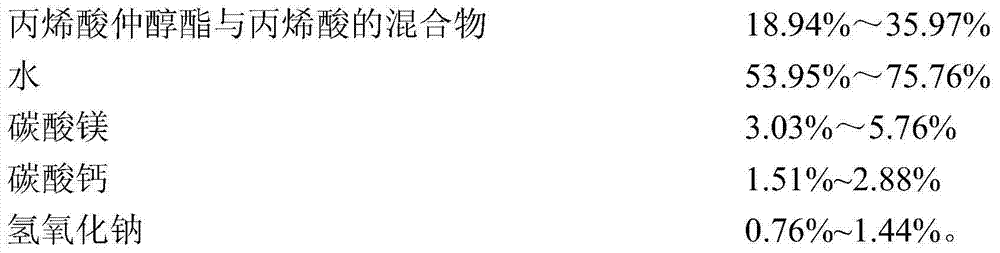

Powder-acrylate composite grouting material and preparation method and application thereof

ActiveCN103772868AHigh strengthIncrease elasticityUnderground chambersProtective foundationCross-linkCompressive strength

The invention discloses a preparation method and application of a powder-acrylate composite grouting material. The material is prepared from a component A and a component B according to weight ratio of (1:1)-(1:4), wherein the component A comprises the following raw materials by weight percent: 95.0%-99.0% of mixture of acrylate water solution and cross-linking agent and 1.0%-5.0% of initiator, the component B comprises the following raw materials by weight percent: 47.5%-49.5% of powder, 1.0%-1.5% of accelerator, and 49.5%-51.0% of water, the compressive strength of concretion body 28d is 12-18MPa, and the bonding strength is 0.5-1.3MPa. In the preparation process, no cross-linking agent is needed, so that the production technology is simplified; the powder is added for compound grouting, so that the adhesive property of the acrylate concretion body and the interface of concrete can be improved. The material can be used in the engineering parts with water.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Grouting system and grouting method used for composite lining structure backfill and grouting

ActiveCN105697034ASolve the problem that grouting cannot be repeatedRealize repeated groutingUnderground chambersTunnel liningScrew threadGrout

The invention discloses a grouting system and a grouting method used for composite lining structure backfill and grouting.The grouting system comprises a one-way non-return suction cup, a one-way non-return grouting pipe, a water-stopping ring, a sealing plug and a connection pipe, wherein the one-way non-return suction cup is composed of a grouting disc and a non-return hole; the one-way non-return grouting pipe comprises a grouting pipe first end and a grouting pipe second end, a one-way valve is arranged at the grouting pipe first end, and the grouting pipe first end is communicated with a grout inlet of the grouting disc through a screw thread; the water-stopping ring is located on the outer wall of the middle of the one-way non-return grouting pipe; the sealing plug is connected with the grouting pipe second end through a screw thread; the connection pipe comprises a first end and a second end; the first end of the connection pipe is connected with the grouting pipe second end are connected through a screw thread, and the second end of the connection pipe is used for being connected with grouting equipment.The water-stopping ring is additionally arranged on the middle of the grouting pipe, and the water-stopping effect of a contact face between the outer wall of the pipe and a secondary lining structure can be effectively improved.The one-way non-return suction cup is arranged at the tail end of the one-way non-return grouting pipe, repeated grouting can be achieved, and the defect that a traditional grouting system cannot achieve repeated grouting is overcome.

Owner:BCEG CIVIL ENG

Liquid division slip casting reinforcing method for subsurface structure construction joints

InactiveCN102002950APrevent leakageImprove compactnessArtificial islandsUnderwater structuresWater leakageStructural engineering

The invention discloses a liquid division slip casting reinforcing method for subsurface structure construction joints, mainly aiming at the problems that as the subsurface structure construction is severely influenced by ground water, the peripheral structure leaks water, the material strength is reduced, the structure integrity is poor and the like. A purpose-made grouting pipe is arranged at the construction joint of a structure connector with weak stress in the process of subsurface structure peripheral construction, and the liquid division slip casting reinforcing operation is performed based on a designated method, thus making up for the defects of poor rigidity and poor waterproof effect at the construction joint of the subsurface structure preferably. The method in the invention has good grouting effect and high grouting success rate, can effectively improve the strength and the integrality of the subsurface structure, and reduce the leakage of the construction joint of the subsurface structure.

Owner:SOUTHEAST UNIV +1

Strong karst development stratum curtain grouting construction method

ActiveCN105887886ASolve the technical problems of hole formationGuarantee smooth implementationFoundation engineeringChemical treatmentInjection volume

The invention belongs to the field of water and hydropower construction projects and particularly relates to a strong karst development stratum curtain grouting construction method. According to the construction method, the high pressure washing replacement technological innovation technology is adopted in the construction process, the technical problem of pore-forming of deep-layer karst development stratum curtain grouting is solved, and the project can be implemented smoothly; according to different geological conditions, various blending agents and chemical treatment agents are blended into cement grout so that the viscosity, shear force and plastic molding parameters of the grout can be adjusted, certain pouring measures and means are taken, and thus the injection volume and diffusance of the grout are controlled; the optimal grouting effect can be achieved, and unnecessary losses of the grout can be reduced.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD

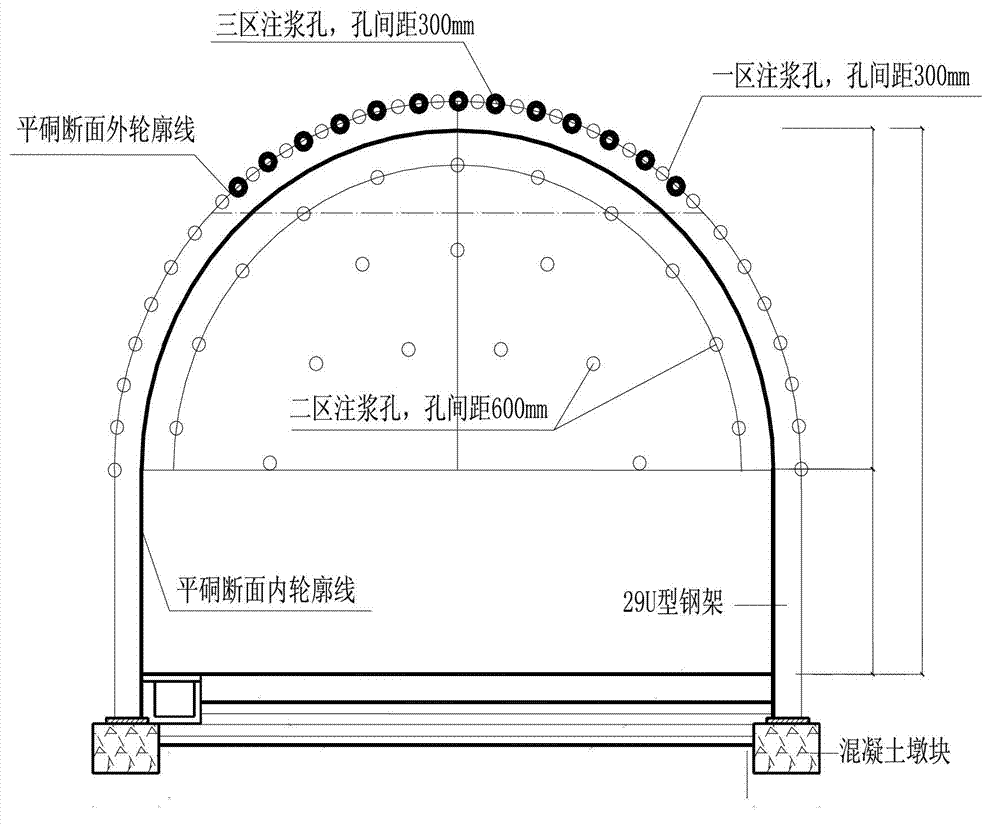

Space reinforcing construction technology of sand layer roadway

InactiveCN103089277AEnrich and develop construction technologySmall settlement deformationUnderground chambersTunnel liningSlurryEngineering

The invention relates to space reinforcing construction technology of a sand layer roadway. The technology comprises the following steps of (1), determining a grouting reinforcing range; (2), distributing holes in the determined grouting reinforcing range; (3), constructing and drilling the holes in the positions distributed with the holes; and (4), inserting grouting guide tubes in the holes drilled and filling reinforcing grout. The space reinforcing construction technology of the sand layer roadway is capable of effectively control development of a surrounding rock plastic zone, reduces surrounding rock pressure acted on a supporting structure and settlement deformation of the ground surface and guarantees stability of a roadway operation face and safety of ground constructions.

Owner:SHAANXI COAL & CHEM CONSTR GRP CO LTD

Deep hole grouting technology and method at advanced abutment pressure region for comprehensive mining work surface of coal mine

ActiveCN105909287AImprove mechanical propertiesAvoid coal wall flakingAnchoring boltsCoal miningEngineering

The invention provides a deep hole grouting technology and method at an advanced abutment pressure region for a comprehensive mining work surface of a coal mine. According to the method disclosed by the invention, early strength deep hole grouting materials are matched with a high-pressure mass-flow grouting pump, and an advanced hole forming technology, a pipe inserting technology, a hole sealing technology and a grouting technology for the advanced abutment pressure region are adopted, so that the problem that high-yield high-efficiency coal mining work surfaces with large mining height, top coal caving and the like can are often subjected to rib spalling can be solved; the method does not influence the production of the work surface, the mechanical properties of coal bodies are essentially improved, the completeness of the coal bodies is re-molded, and the method has a favorable popularization property.

Owner:HENAN POLYTECHNIC UNIV +1

Shield tunnel segment backfill grouting construction method

InactiveCN108331597ASolve the problem of excessive settlementReduce construction riskUnderground chambersTunnel liningSlurryShield tunneling

The invention belongs to a shield tunnel segment backfill grouting construction method. The method includes: a grout blocking net used for encapsulating grout injected from the reserved grouting holesin segments is arranged between each segment and a tunnel soil layer; compressively injecting mortar into the grout blocking nets below the middles of tunnel rings formed by the segments, and compressively injecting mortar into the grout blocking nets below the middles of tunnel rings formed by the segments at the shield tail through shield tail grouting holes during shield tunneling; injecting double-grout for sealing into gaps between 10 segment rings and the grout blocking nets through reserved annular sealing grouting holes in the segments above the middle of the 10th ring every other 10segment rings to form front sealing rings, and then injecting supplementary mortar into gaps between the segments between two sealing rings and the tunnel soil layer through reserved grouting holes inthe top of the fifth segment ring. By the method which is low in construction risk, low in cost, capable of shortening construction period and good in use effect, the problems of large filling coefficient, incompactness and excessively large ground surface settlement can be solved effectively.

Owner:CHINA CONSTR MUNICIPAL ENG +2

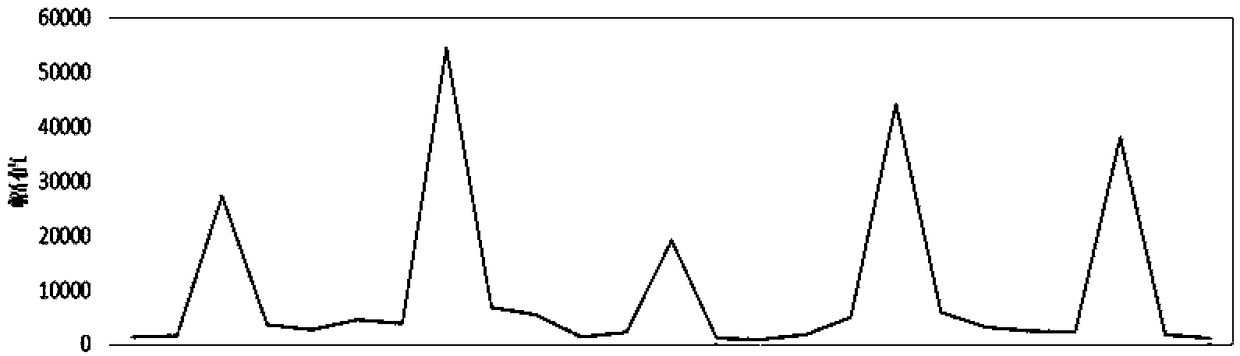

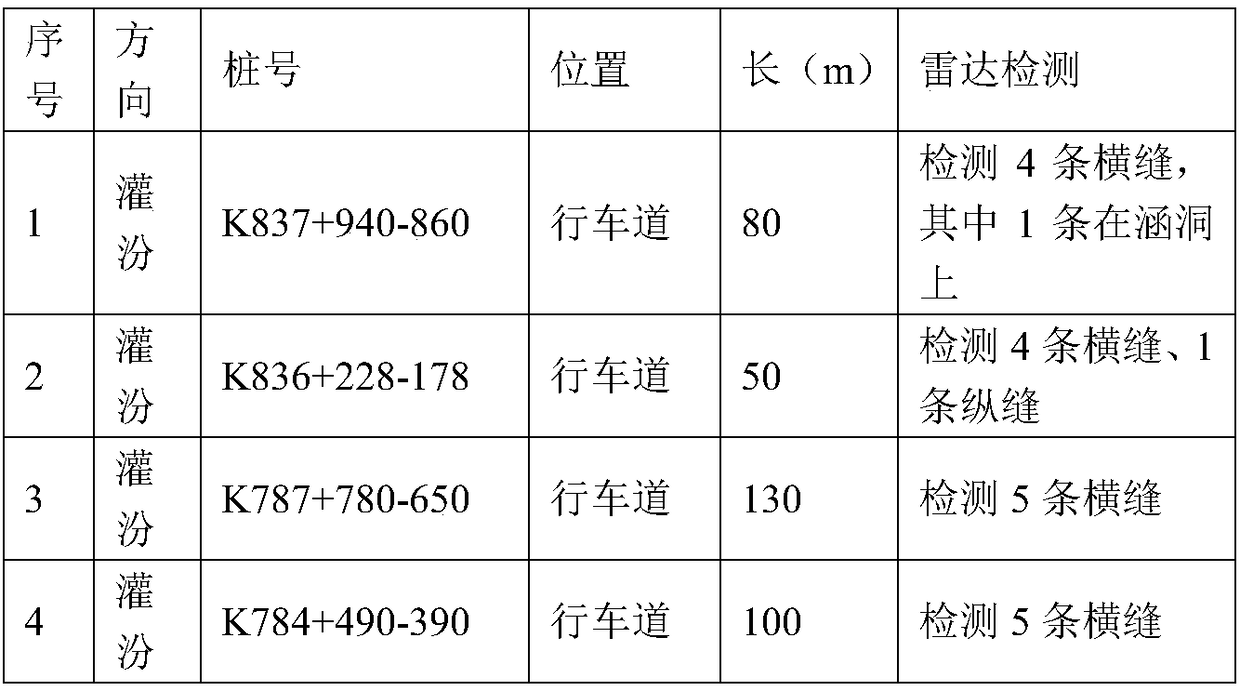

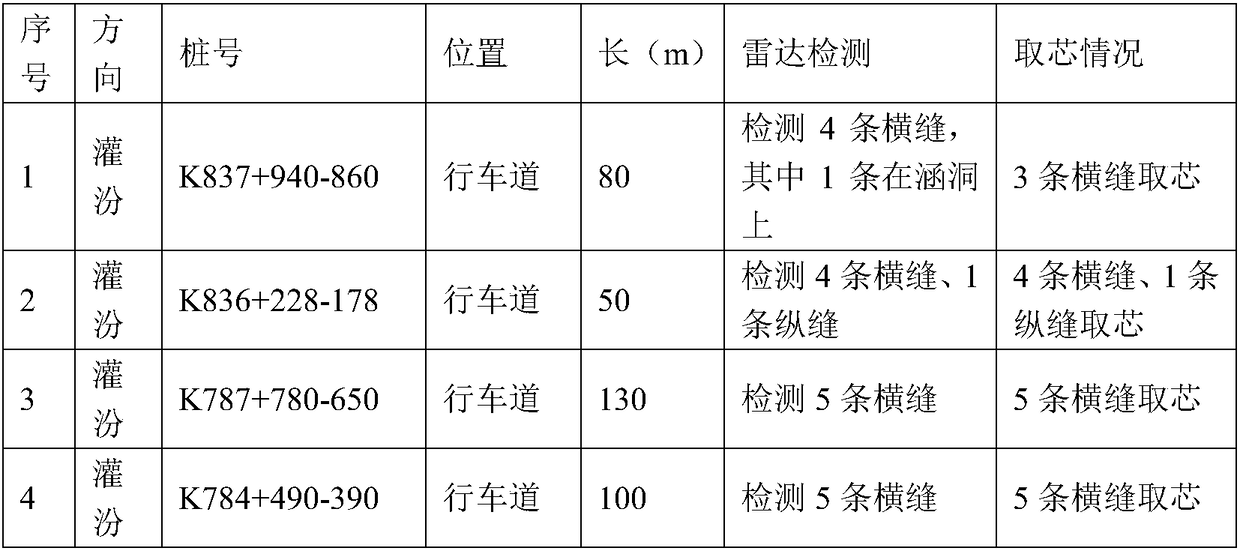

Determination method for width and depth of pavement crack based on ground penetrating radar and rapid maintenance method

InactiveCN109440610AWidth losslessImprove applicabilityIn situ pavingsRoads maintainenceRadar waveformsAbnormal positions

The invention discloses a determination method for the width and the depth of a pavement crack based on a ground penetrating radar and a rapid maintenance technology, and belongs to the technical field of roadbed and pavement detection and maintenance. According to the key points of the technical scheme, the determination method for the width and the depth of the pavement crack based on the groundpenetrating radar comprises the following steps that S1, the ground penetrating radar is adopted to detect the pavement crack so as to obtain a radar waveform image, and the radar waveform image is converted into a gray level image; S2, the width of the pavement crack is judged according to the analyzed magnitude of the amplitude value of the gray level image, and the larger the amplitude value of the gray level image is, the larger the width of the crack is; and S3, a reflected signal of the gray level image is analyzed, the abnormal position of the reflected signal is judged, and the development level and the depth of the crack are determined. The determination method and the rapid maintenance technology have the advantage that rapid, nondestructive and continuous detection of the widthand the depth of the pavement crack is realized, so that maintenance personnel can conveniently take reasonable and scientific maintenance measures in time .

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD +1

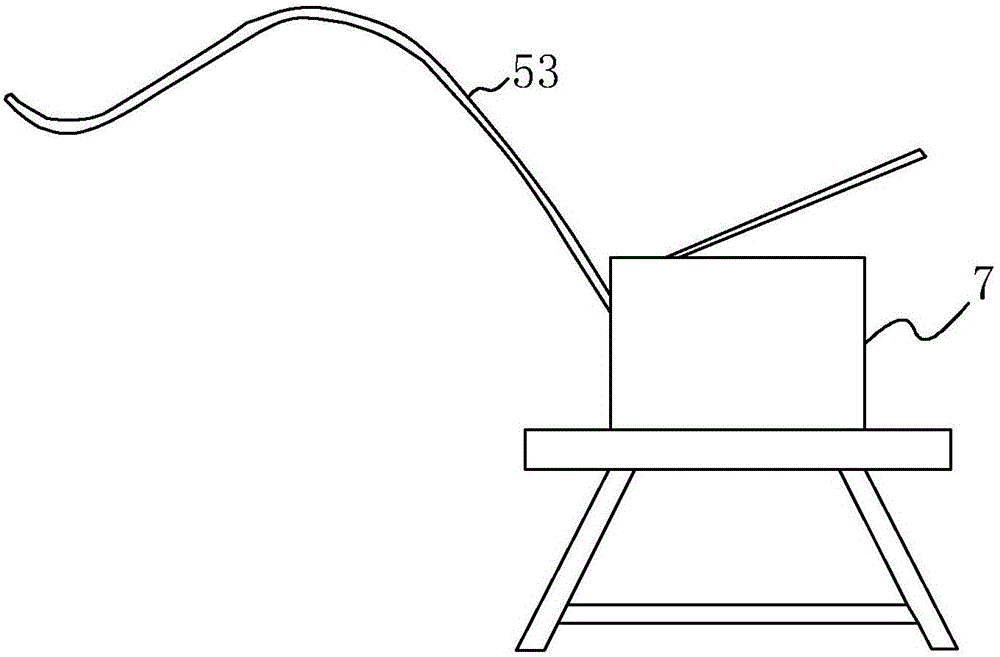

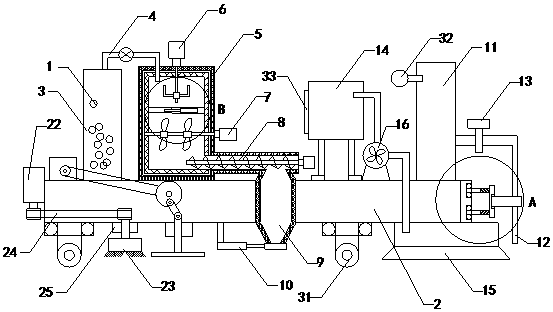

Mixing device for grout in inlet well at ground and application method thereof

ActiveCN105317396ASolve the technical problems of serious in-hole accidentsAvoid security risksSealing/packingChemical reactionEngineering

The invention discloses a mixing device for grout in an inlet well at the ground and an application method thereof. The mixing device comprises a mandril, a protecting bush and a grout collector, wherein the mandril is arranged in the protecting bush, and two ends of the mandril move through the protecting bush; the bottom end of the mandril is fixed to the protecting bush, and the upper end of the mandril is connected to a drilling rod through a short tube; the upper end of the protecting bush is connected to the grout collector; rightward rotating blades and leftward rotating blades are correspondingly arranged on the mandril in a staggering manner; the rightward rotating blade and the leftward rotating blade are arranged from the middle positions of the corresponding previous blades. The mixing device has the beneficial effects that the three purposes of injection mixing, swirling and agitating mixing, and slitting mixing can be essentially achieved in theory; the grout of two types can be fully mixed and completely chemically reacted, and the grouting effect is obvious.

Owner:SHANDONG UNIV

Pavement crack sealing device for road construction

InactiveCN108301299AReduce heat lossImprove grouting effectRoads maintainenceElectric machineryScrew conveyor

The invention relates to the technical field of auxiliary devices for road construction and pavement maintenance, in particular to a pavement crack sealing device for road construction. The pavement crack sealing device is capable of mixing and melting asphalt materials by self so as to reduce heat loss and to improve filling effect, and is also capable of automatically clearing litter from an expansion joint. The pavement crack sealing device comprises the asphalt materials, a bottom plate, a material placement tank, a material suction pipe, a hot melt kettle, a first mixing motor, a second mixing motor, a screw conveyor, a material discharging gun and a second hydraulic cylinder, wherein a partition plate is arranged inside the hot melt kettle; the partition plate divides the hot melt kettle into a material storage chamber and a material mixing chamber; a first transmission shaft is arranged at the bottom output end of the first mixing motor; the first transmission shaft is providedwith first mixing blades; a second transmission shaft is arranged at the left output end of the second mixing motor; and the second transmission shaft is provided with second mixing blades. The pavement crack sealing device also comprises an air compressor and a nozzle, wherein the bottom end of the air compressor is connected to the top end of the bottom plate; the air compressor is connected tothe nozzle through an air pipe; and a pressure reducing valve is arranged on the air pipe.

Owner:山西云度知识产权服务有限公司

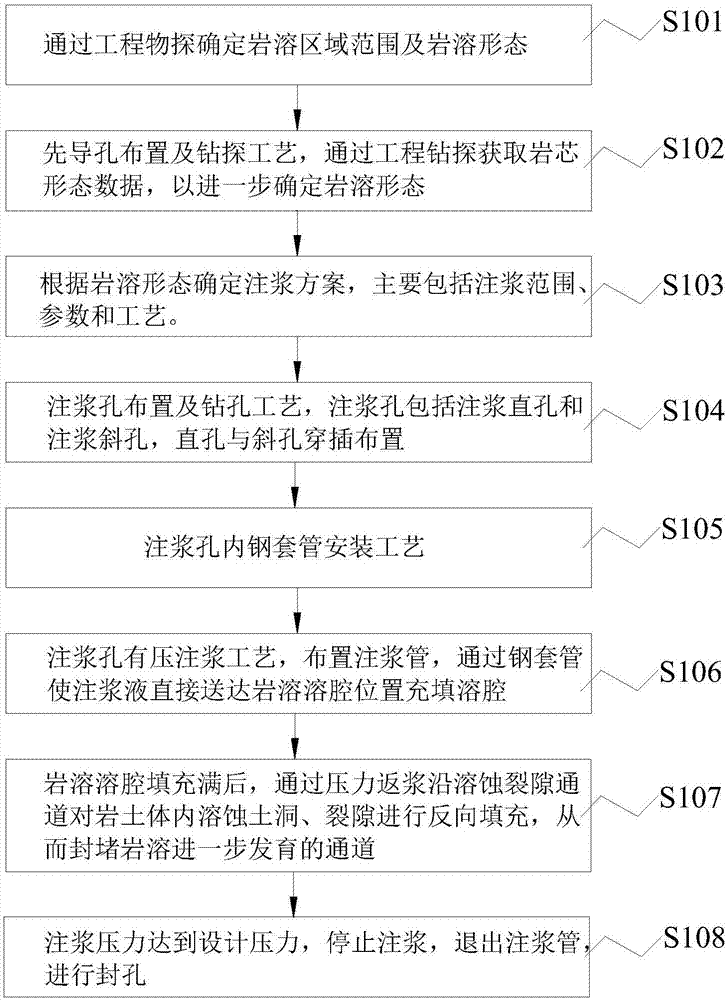

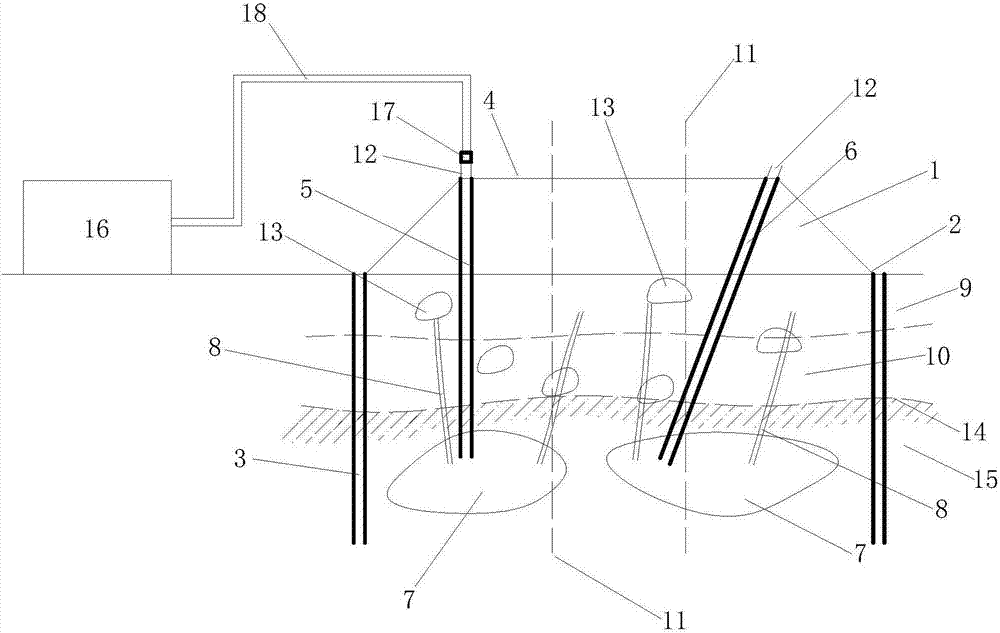

Pressurized returned grout reinforced covered karst embankment grouting method

PendingCN107151956AAvoid developmentSecure the foundationRoadwaysSoil preservationGeomorphologyPilot hole

The invention discloses a pressurized returned grout reinforced covered karst embankment grouting method. The method includes steps: determining a karst area range, depth and karst morphology through engineering geophysical exploration; determining a pilot hole arrangement range, spacing and depth according to the determined karst area range, depth and karst morphology; carrying on a hole forming process on each pilot hole according to reconnaissance standards, and acquiring stratum rock core morphological data in a pilot hole implementation process; determining a grouting scheme according to the karst area range, depth and karst morphology determined according to the acquired rock core morphological data. Aiming at existing railway lines with roadbeds in covered karst development areas, the pressurized returned grout reinforced covered karst embankment grouting method is provided for solving the problem of geological disasters such as roadbed differential settlement, instability and collapse caused by karst dissolution to provide a safety environment for normal operation of the existing railway lines.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com