Method for coating and sealing fracture of bed rock in uncovered heavy consolidation grouting

A technology of consolidated grouting and no cover weight, which is applied in water conservancy projects, sea area projects, construction, etc., can solve the problems of large engineering volume, cumbersome processing process, and poor results, and achieve high work efficiency, simple construction procedures, and grouting effects good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] For the foundation rock mass of the high arch dam of the Goupitan Hydropower Station, the method of brushing and sealing the foundation rock fissures in heavy consolidation grouting without cover is adopted, and the steps are as follows:

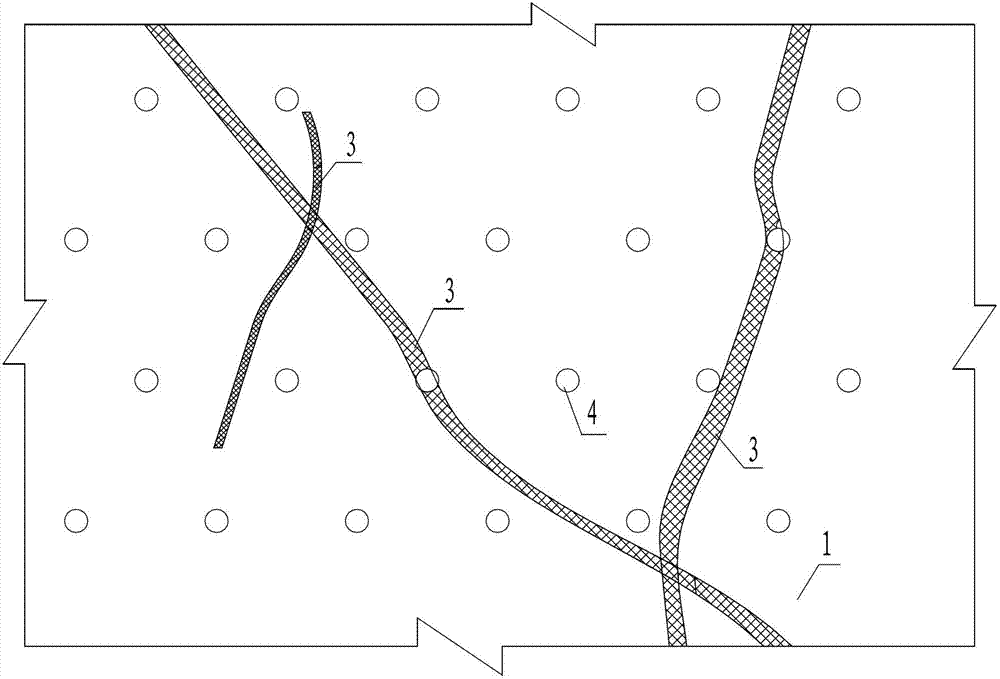

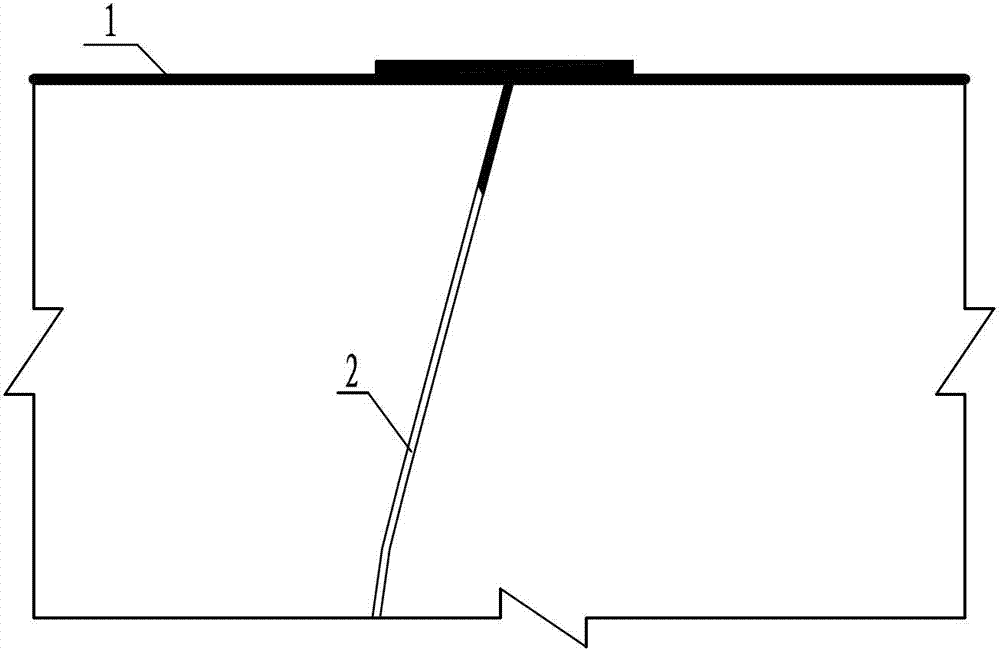

[0030] (1) Preliminary acceptance of the bedrock surface 1 of the dam excavation is carried out, and the rock mass properties and flatness of the bedrock surface 1 are required to meet the predetermined requirements. Wash the bedrock surface 1 with high-pressure water or wind, and use a steel brush to clean and remove impurities such as mud, grease, and dirt on the surface of the rock mass fissure 2 .

[0031] (2) 1h to 2h before formal painting, wet the bedrock surface 1 with spray water to ensure it is in a wet state.

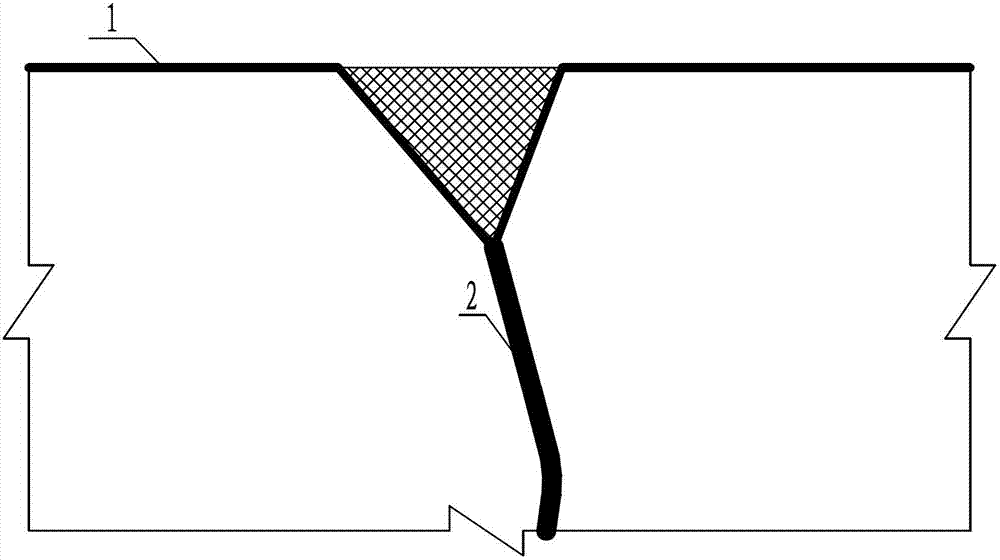

[0032] Use a soft brush of architectural paint to paint cement-based p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com