Patents

Literature

3622results about How to "Easy to pour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

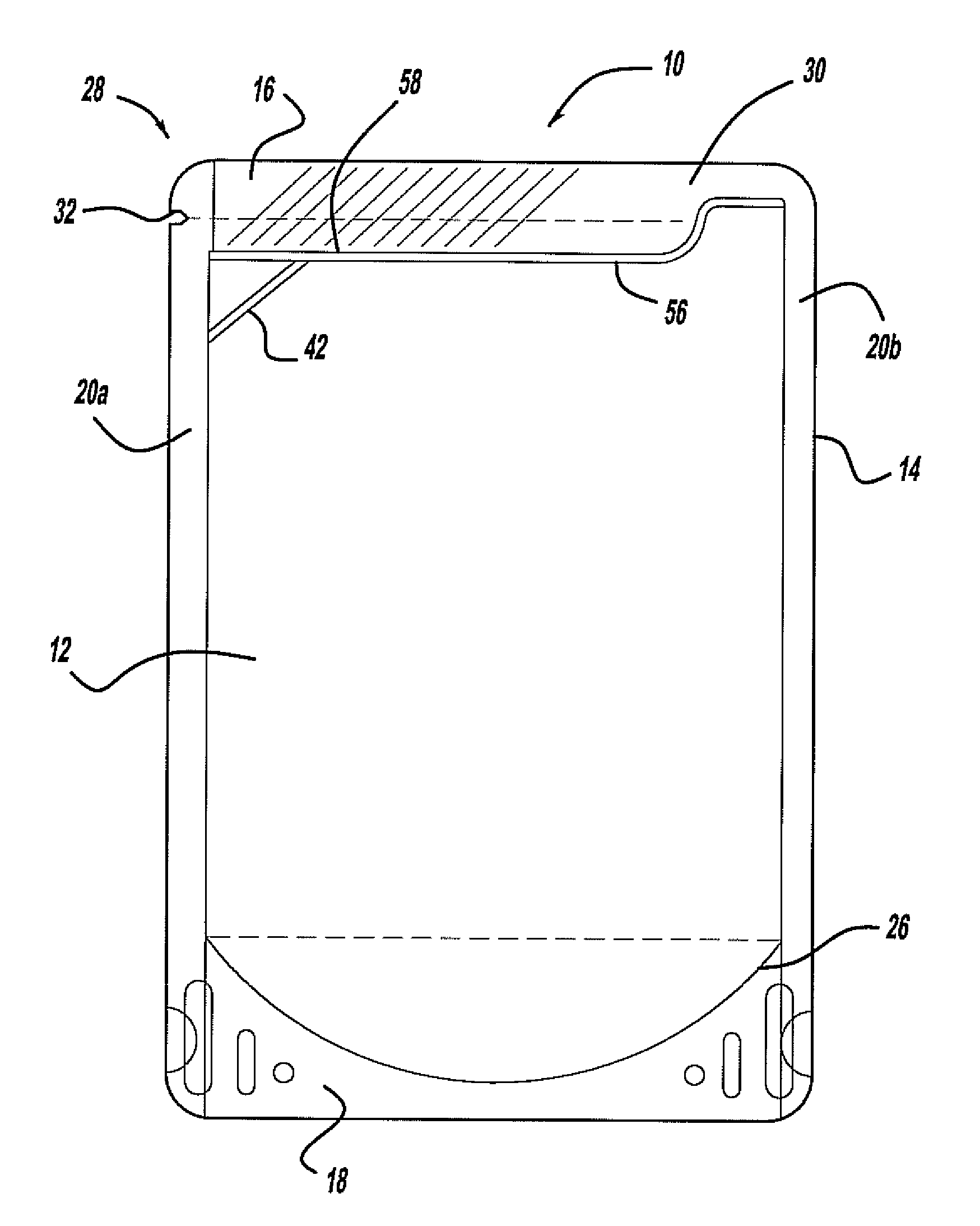

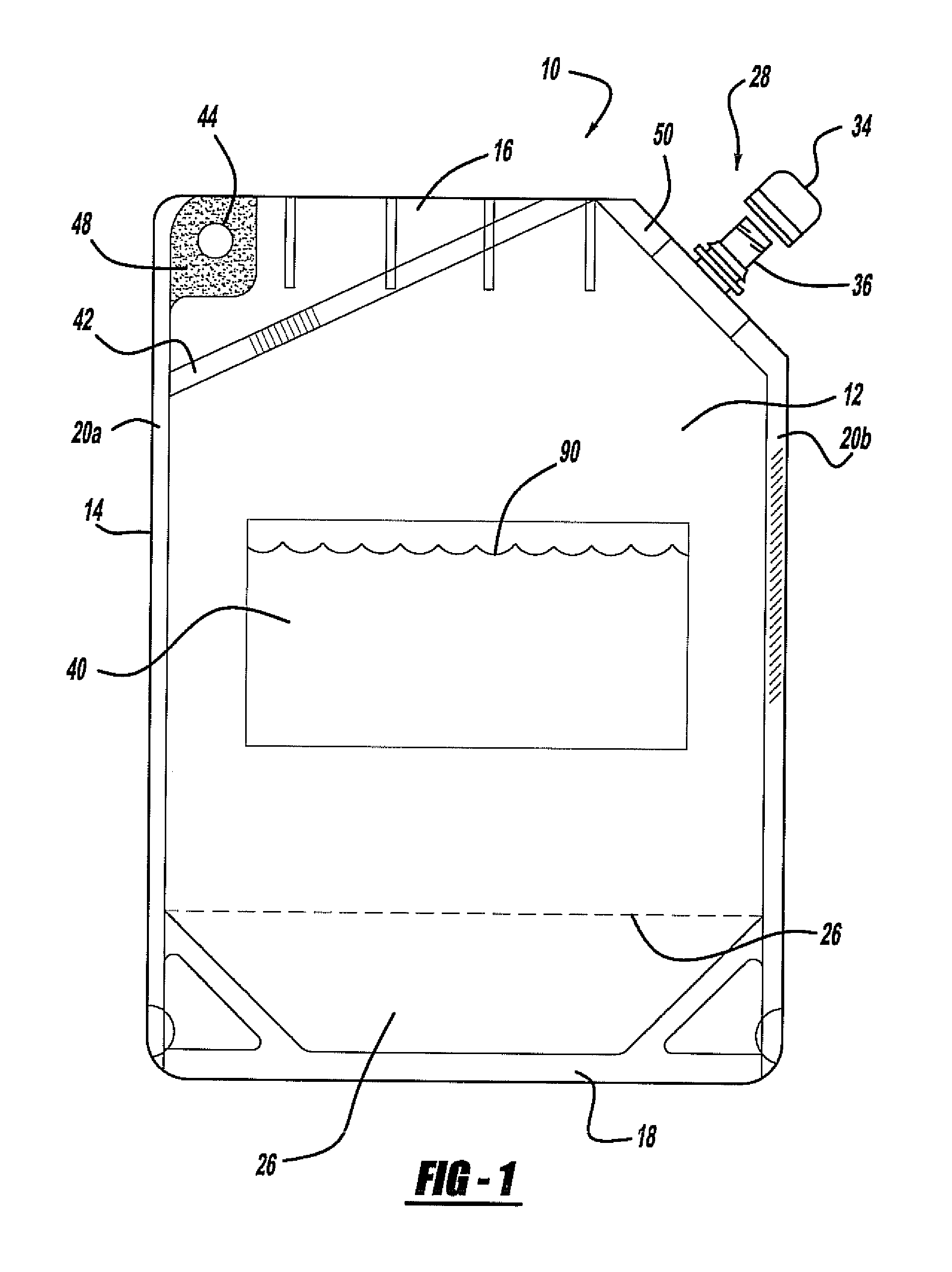

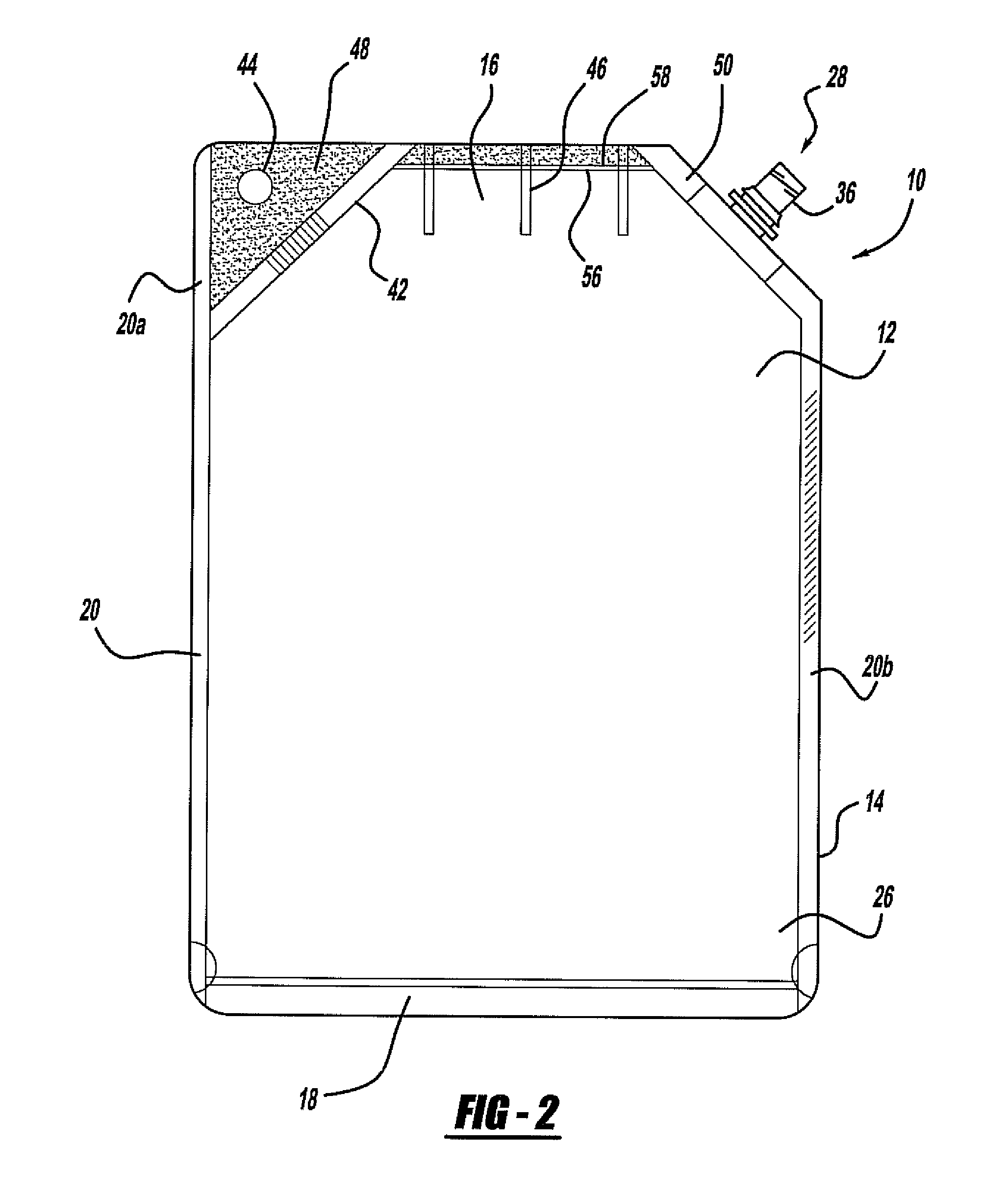

Flexible pouch for an alcoholic beverage and method of forming

InactiveUS20070211967A1Easy to pourCost-effective manufacturingContainer decorationsFlexible coversEngineeringFace sheet

Owner:POUCH PAC INNOVATIONS

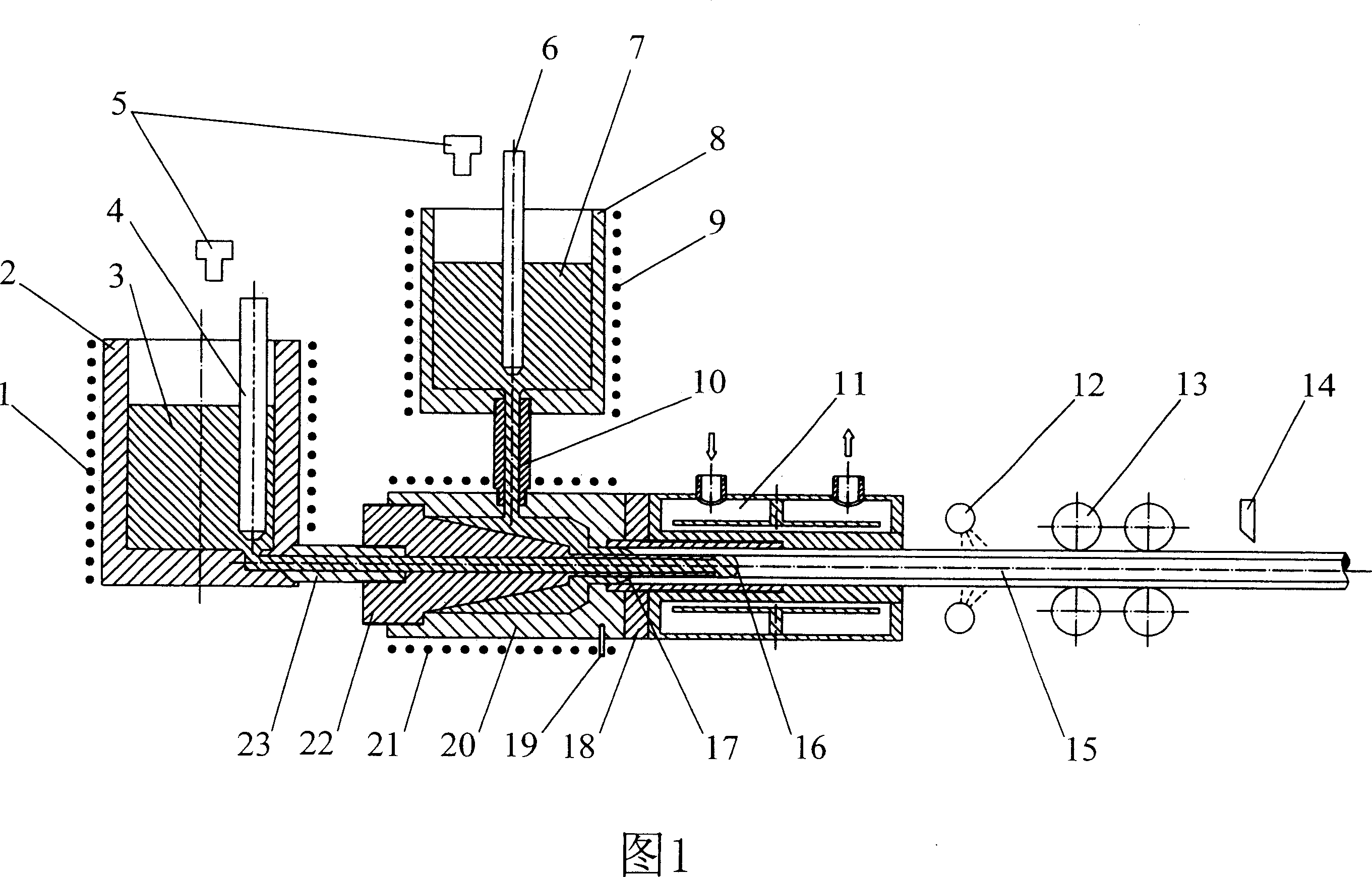

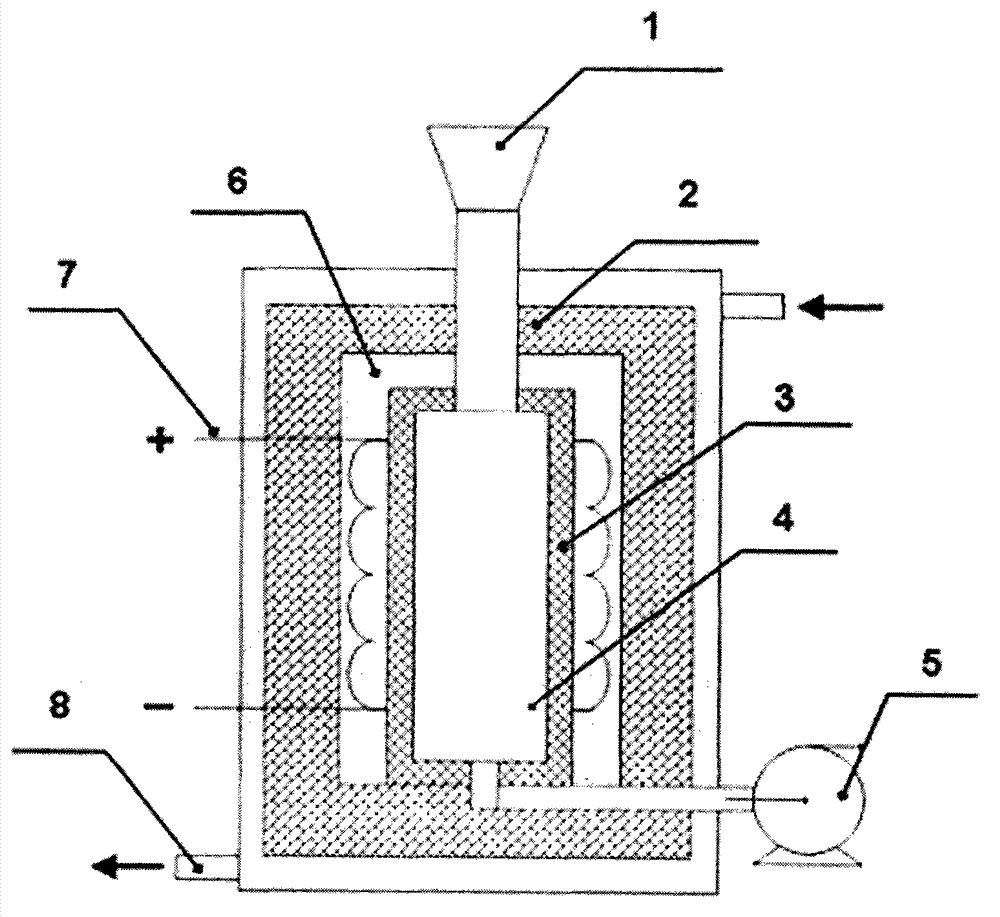

Coating material horizontal continuous casting direct recombination forming apparatus and technology

ActiveCN1927504AAchieve energy saving and consumption reductionContinuous pullHeating elementCrucible

The invention relates to a package material horizontal casting shaping device. Wherein, it comprises core metal temperature-control pot, package metal temperature-control pot, core metal liquid irrigate tube, package metal crystallizer, drawing device, temperature tester, heating element and secondary cooler; and the producing method comprises the temperature of package metal is kept by the package metal temperature-control pot, passing through the package metal thermal-insulated chamber, irrigates into the casting mould formed by crystallizer and irrigate tube to be solidified into package metal tube; the core metal is solidified in the solidified package metal tube, with he package metal tube to form composite cast ingot; the cast ingot via second cooler is cooled and drawn by the drawing device, to be cut by cutter at certain length. The invention has simple process and lower cost, while the interface between package metal and core metal has non oxidization and non pollution.

Owner:UNIV OF SCI & TECH BEIJING

Beverage can lid with articulated neck

InactiveUS7059490B2Easy to manufactureAvoid spillage and splashClosuresLiquid flow controllersEngineering

Owner:SON

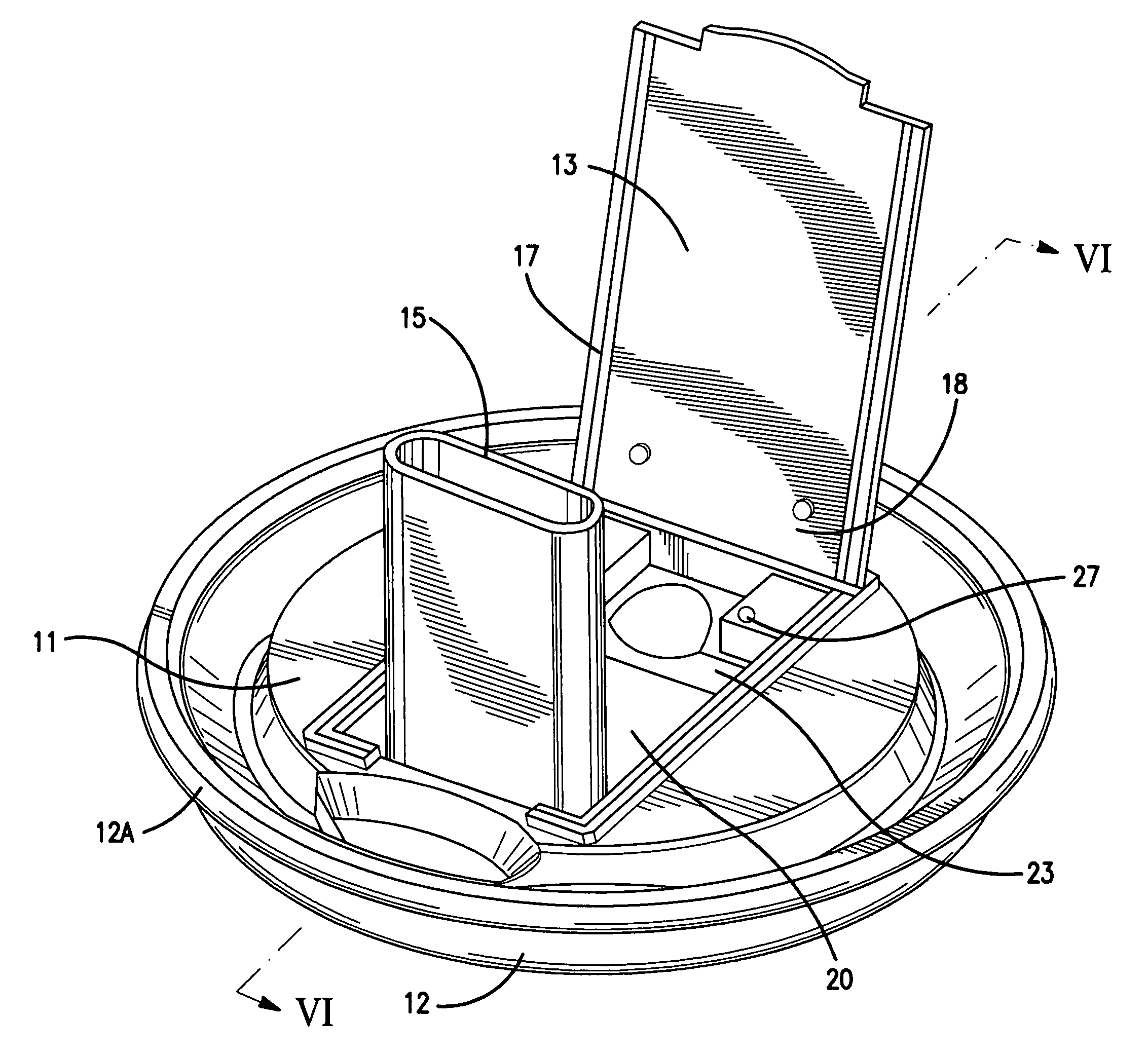

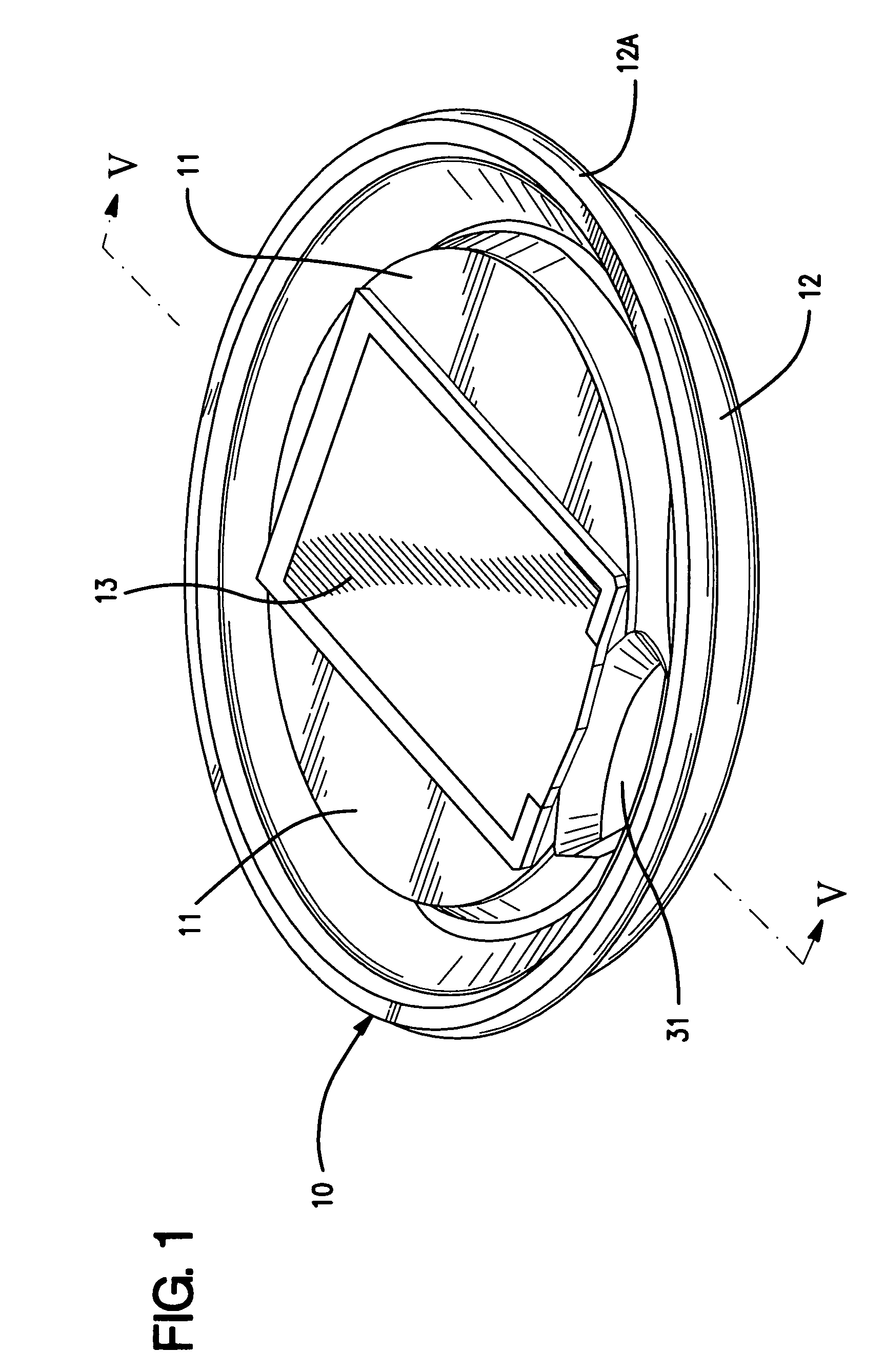

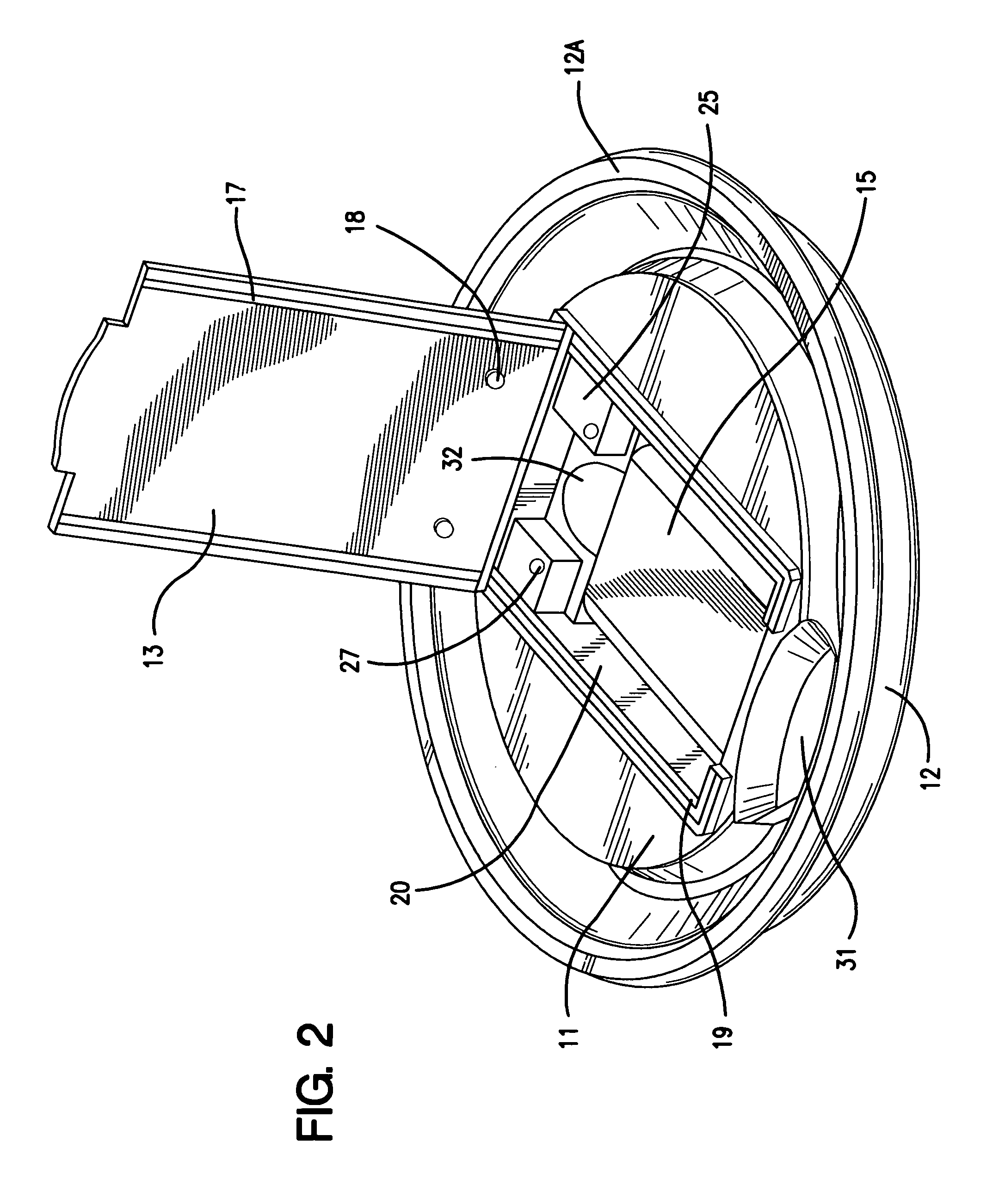

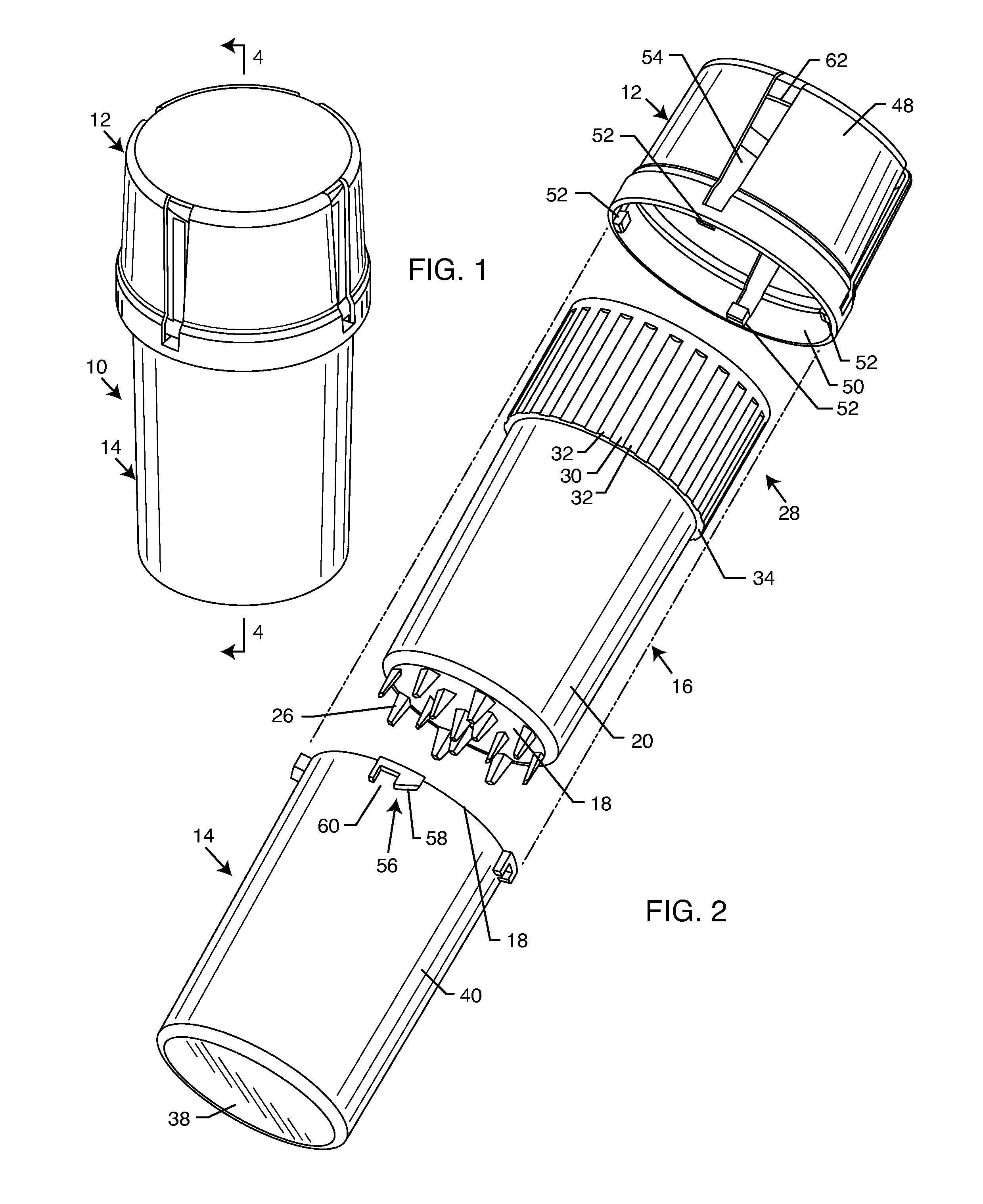

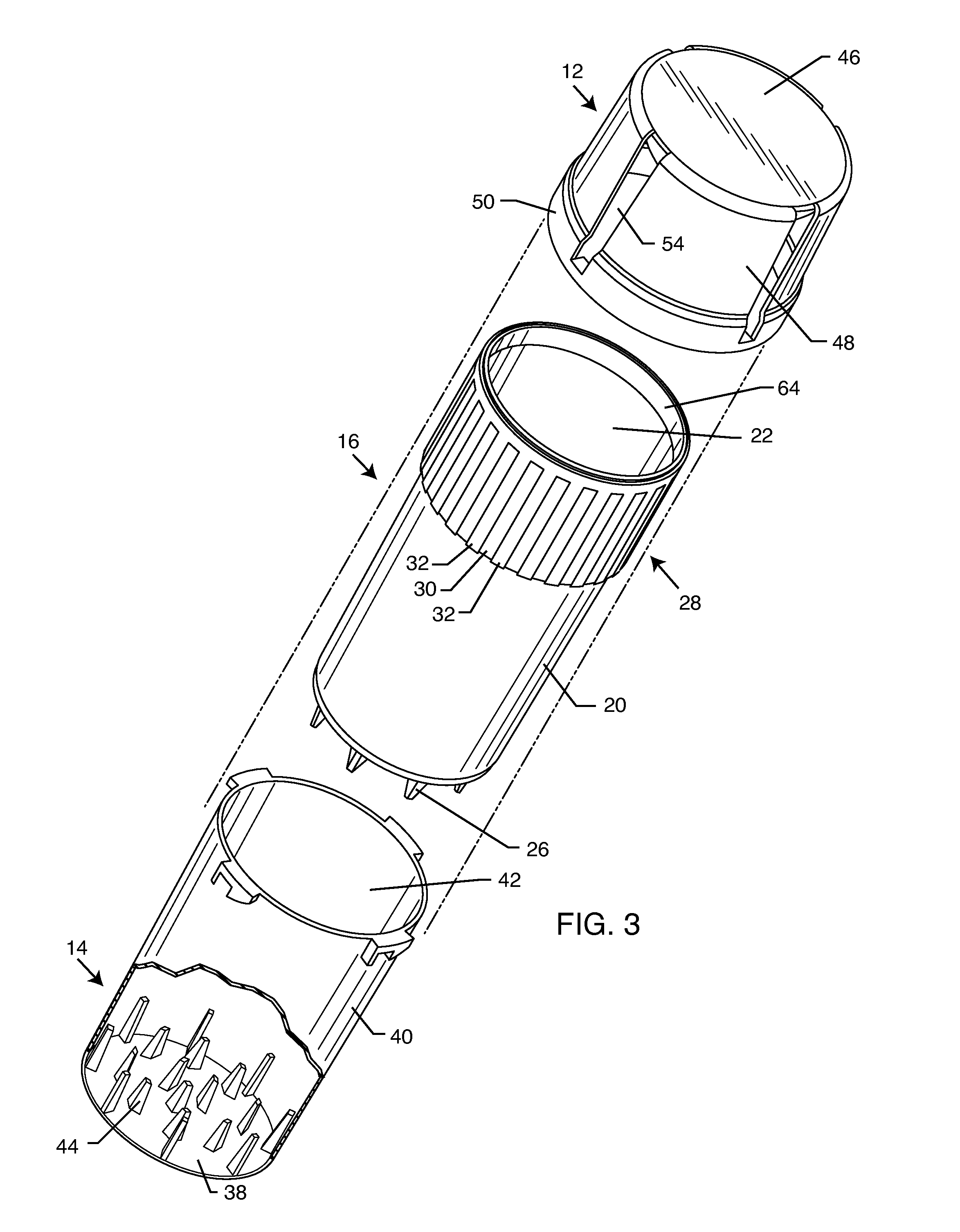

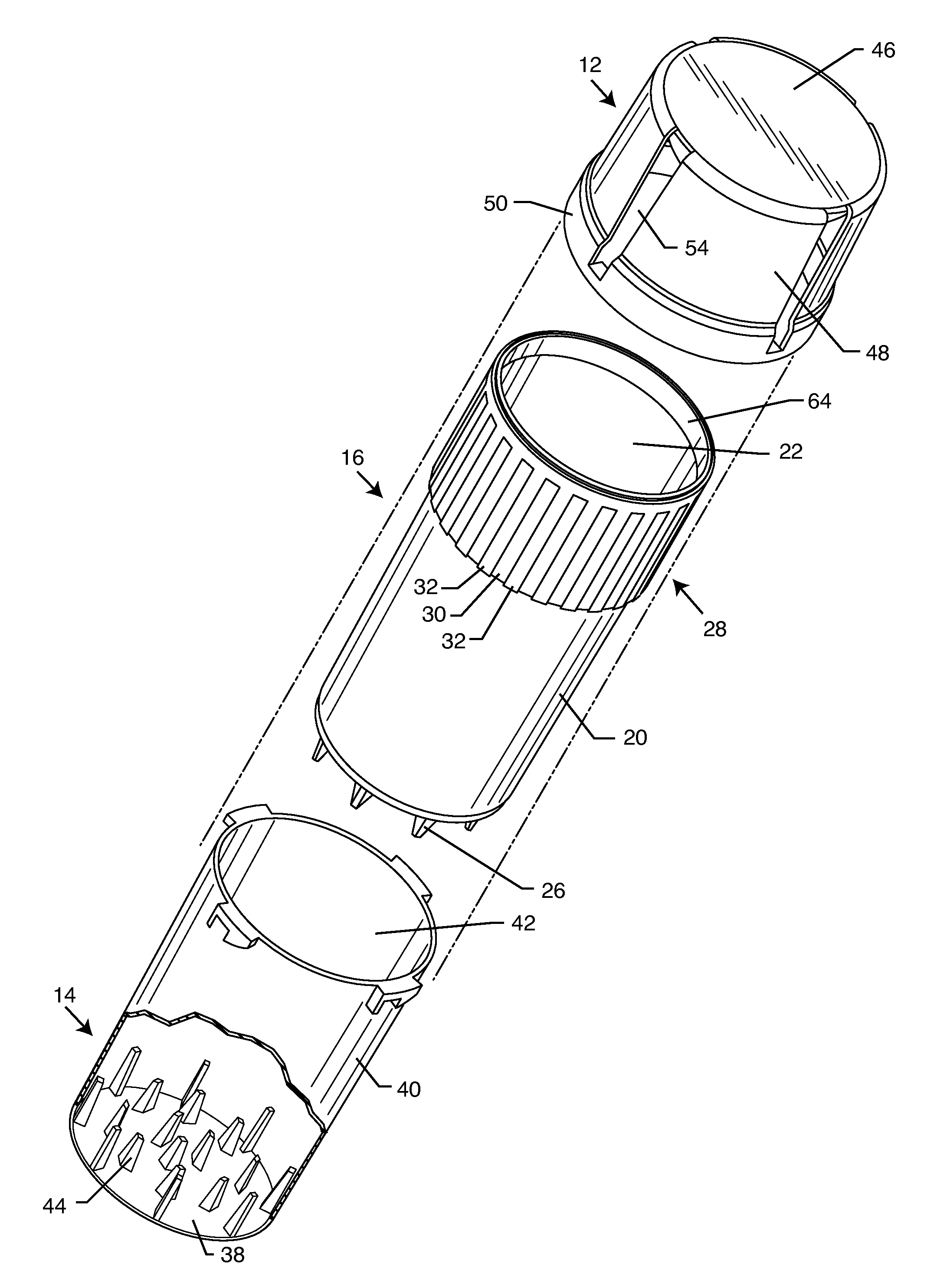

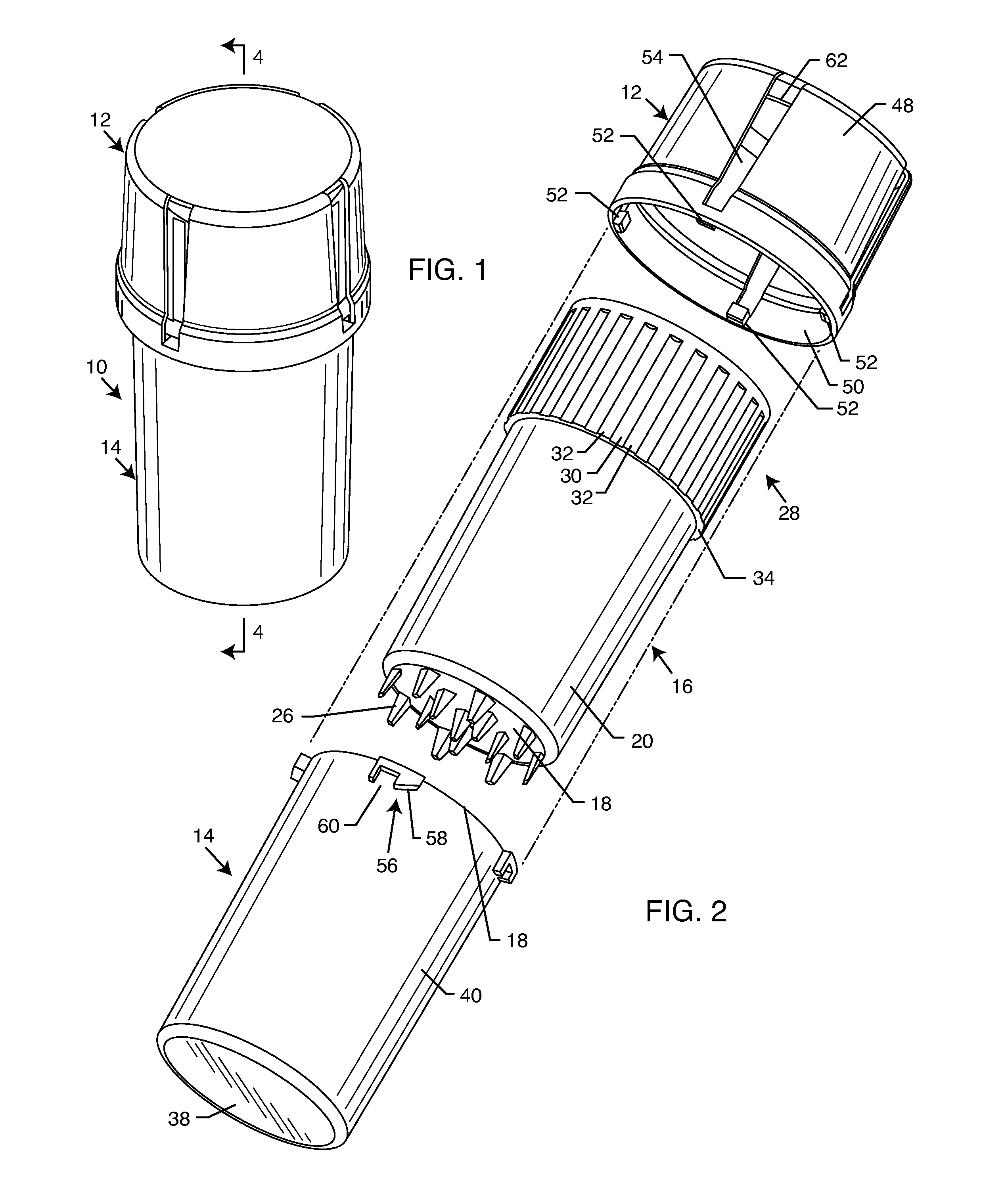

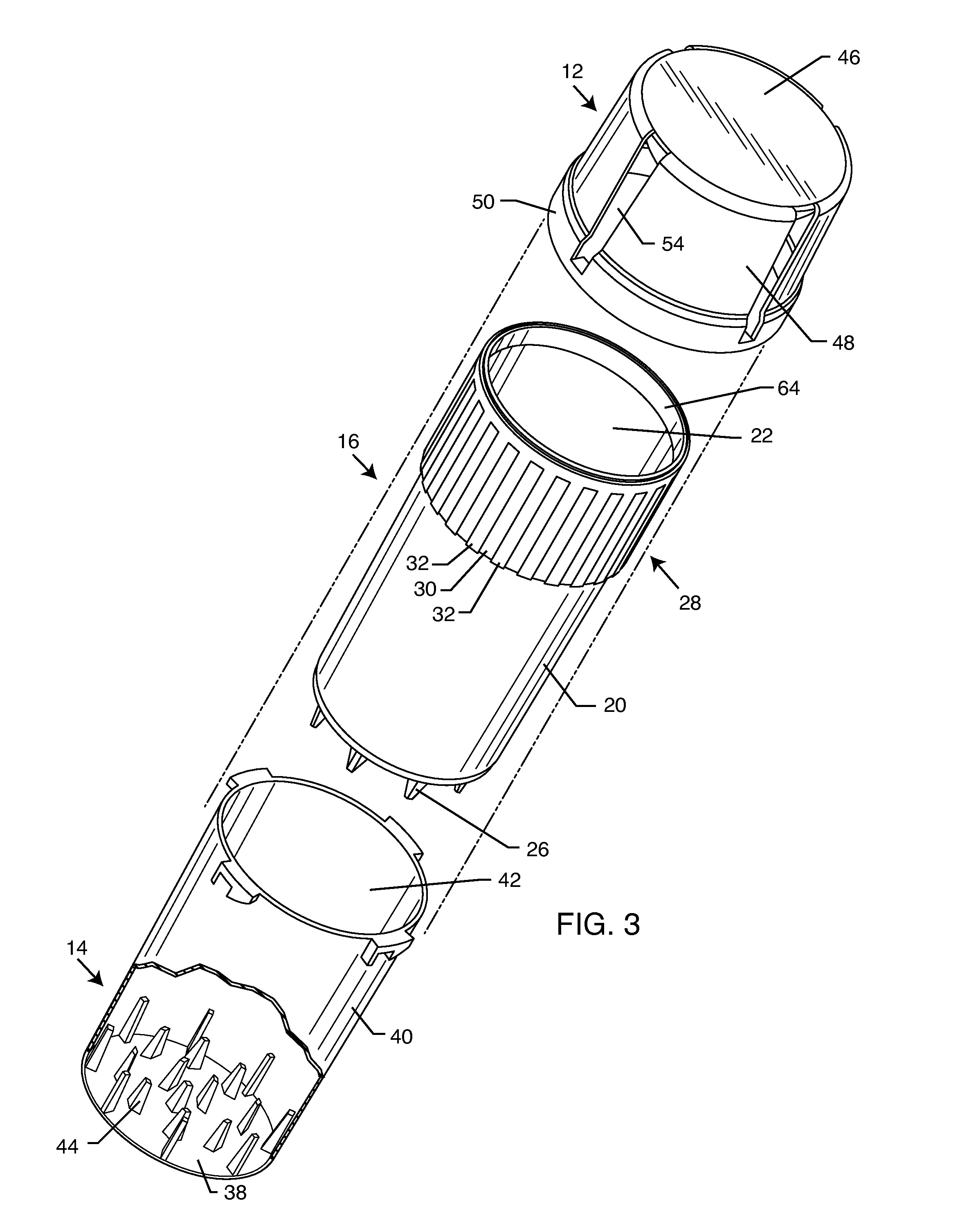

Combination herb storage, grinder and pouring container

A combination herb storage, grinder and pouring container includes a grinding and pouring cup having grinding elements. A cap is removably attached to the grinding and pouring cup. An herb storage receptacle is nested within the cup and cap. The receptacle defines an herb storage compartment having grinding elements extending therefrom so as to be disposed adjacent to the grinding elements of the cup, so as to selectively grind herbs placed between the storage receptacle and the cup. Preferably, the cup and cap are removably locked to one another, and an airtight and watertight seal formed between the cap, cup and storage receptacle.

Owner:HAINBACH MARK

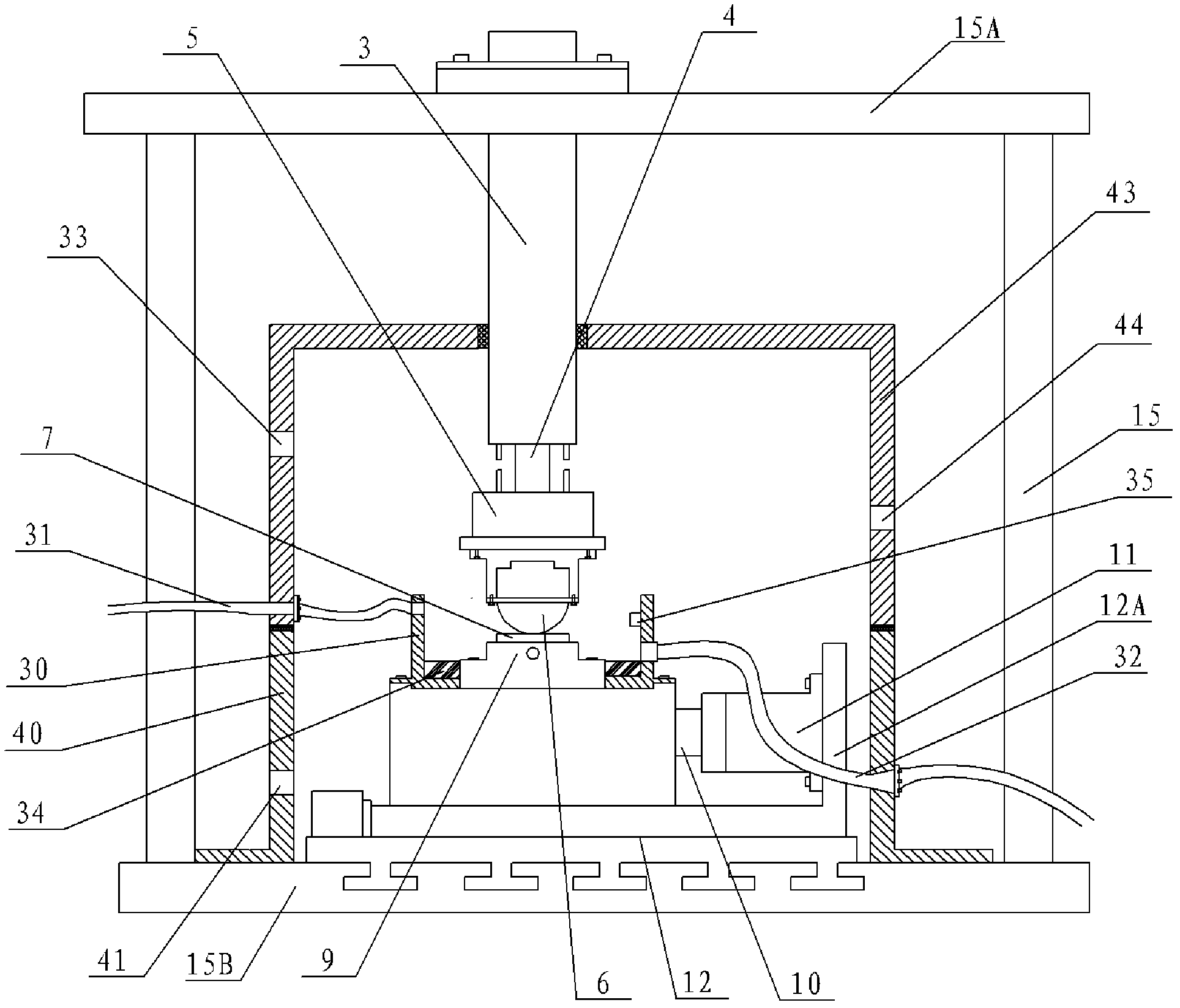

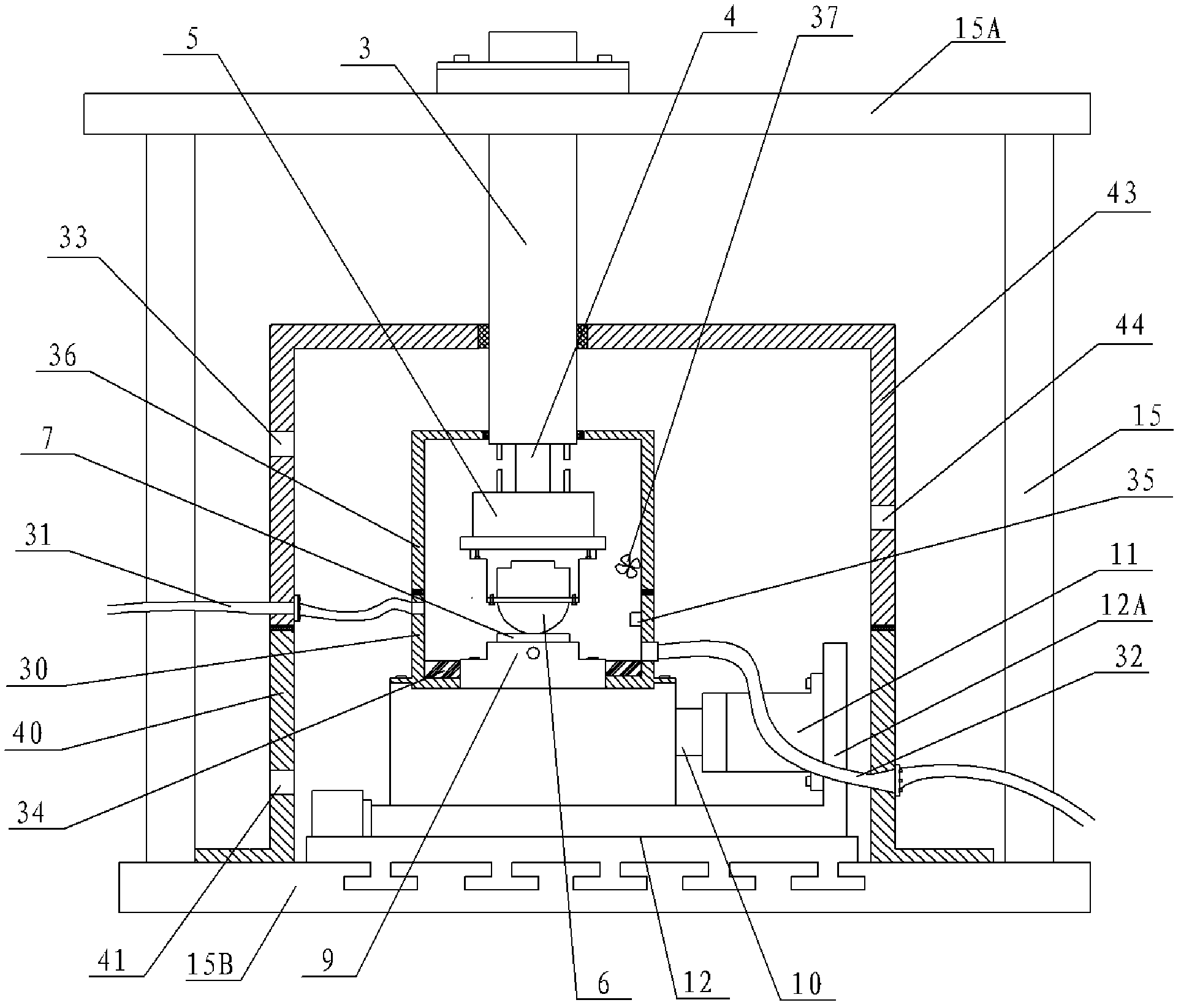

Tester and method for testing test environment controllable multi-directional fine motion fatigue

InactiveCN102607976AAccurate use and maintenanceImprove performance and longevityMaterial strength using tensile/compressive forcesInvestigating abrasion/wear resistanceEngineeringEnvironment controlled

The invention discloses a tester and a method for testing test environment controllable multi-directional fine motion fatigue. The tester comprises a vertical fine motion mechanism and a transverse fine motion mechanism, wherein the vertical fine motion mechanism consists of an electromagnetic excitation actuator, a force transducer I, an upper clamp for clamping a spherical upper test piece and the like; the transverse fine motion mechanism consists of a lower clamp for clamping a planar lower test piece, a force transducer II, a piezoelectric ceramic actuator, a longitudinal and transverse two-dimensional moving platform and the like; the vertical fine motion mechanism and the transverse fine motion mechanism are covered by a lower atmosphere cover and an upper atmosphere cover to form an atmosphere control space; and the periphery of the lower clamp is provided with a liquid medium groove higher than the planar test piece. Through the tester, a tightly matched friction pair can carry out multi-directional fine motion in a specific atmosphere and / or a liquid environment controlled artificially, thus the multi-directional fine motion frictional wear performance of a material under the specific environment condition is tested really and accurately, an accurate and reliable proof is provided for related design, use and maintenance of machinery and bioengineering, the properties of equipment and apparatuses are improved, and the service lives of the equipment and the apparatuses are prolonged.

Owner:SOUTHWEST JIAOTONG UNIV

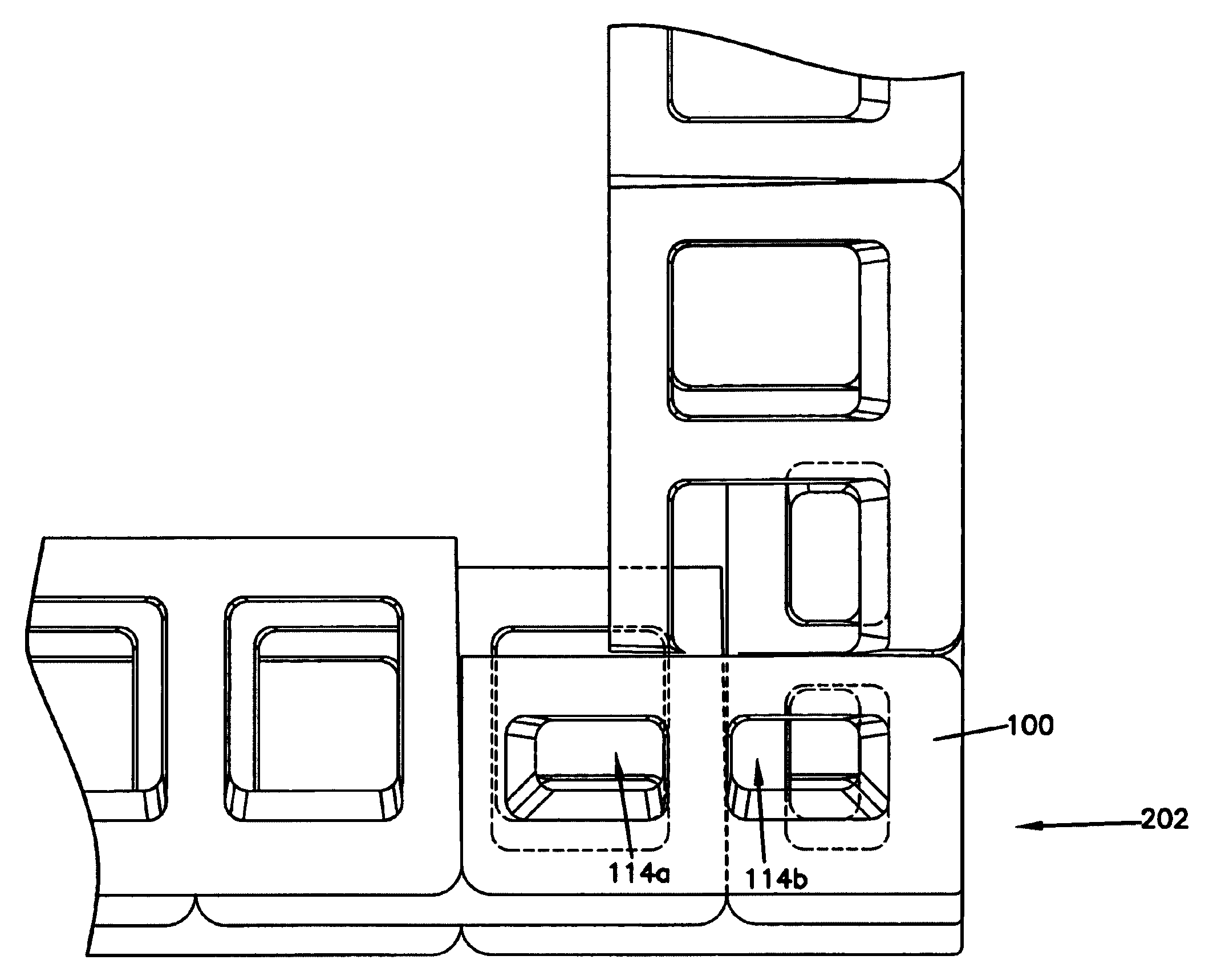

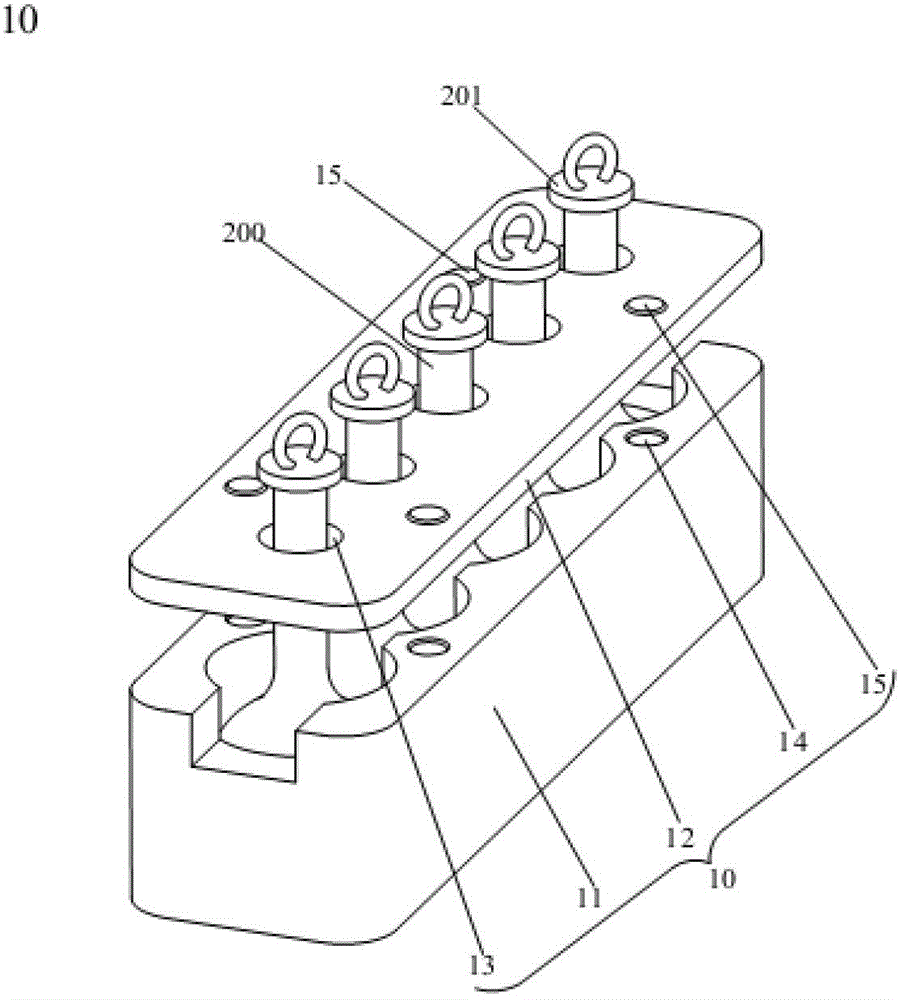

Retaining wall block system

Concrete blocks configured for use in forming retaining walls that require the use of rebar and grout to structurally anchor a retaining wall to a foundation. The blocks include first and second core openings extending through the blocks. The core openings are configured so that when the blocks are stacked into courses with other blocks, the core openings of the blocks line up in a manner that allow rebar to extend through the core openings from the foundation to the top of the retaining wall. Further, the core openings facilitate pouring of the grout down through the aligned core openings. In addition, the core openings are configured so that the core openings do not overhang joints between blocks or overhang block edges that would allow grout to leak out as grout is being poured down the core openings.

Owner:ANCHOR WALL SYST

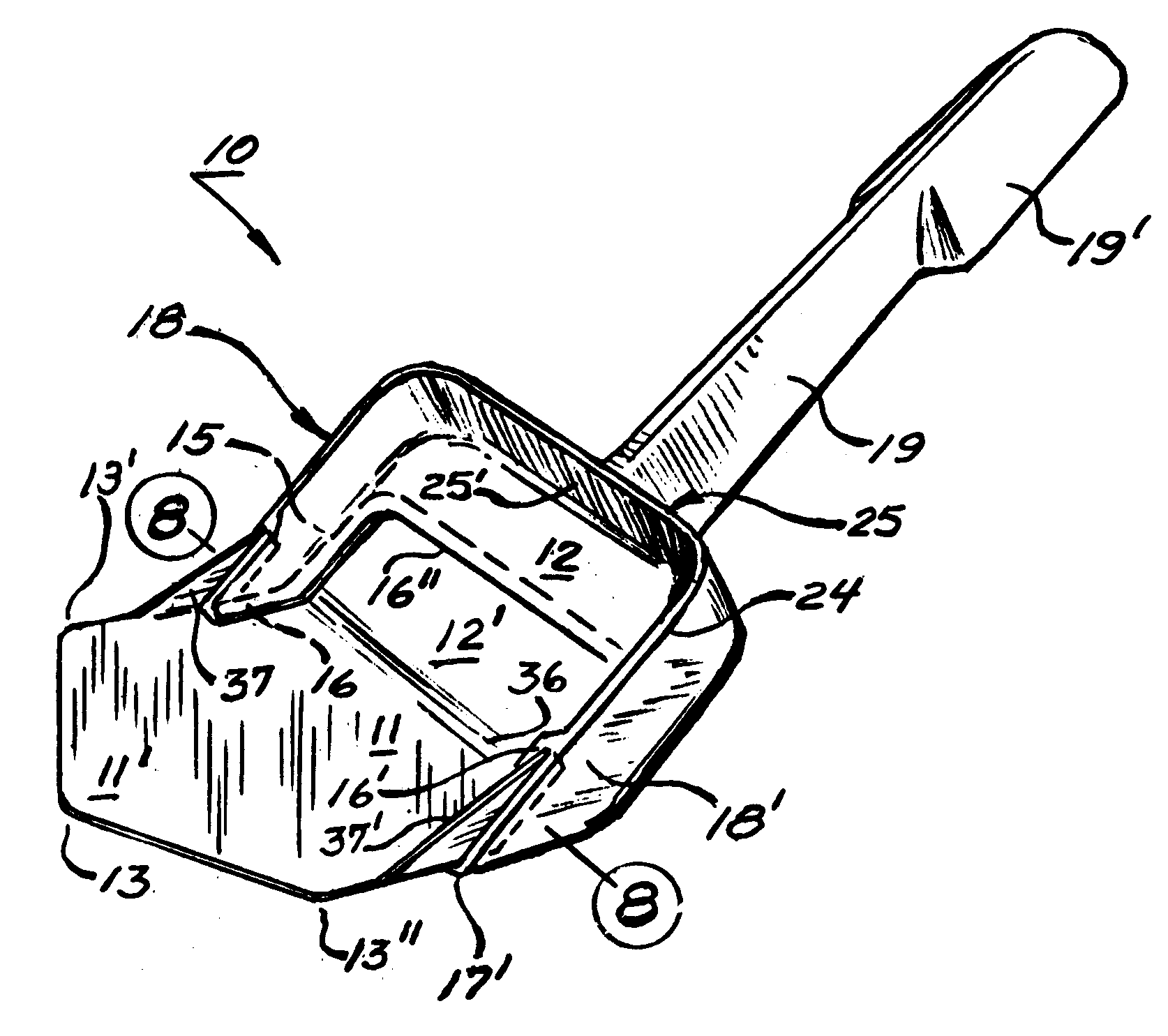

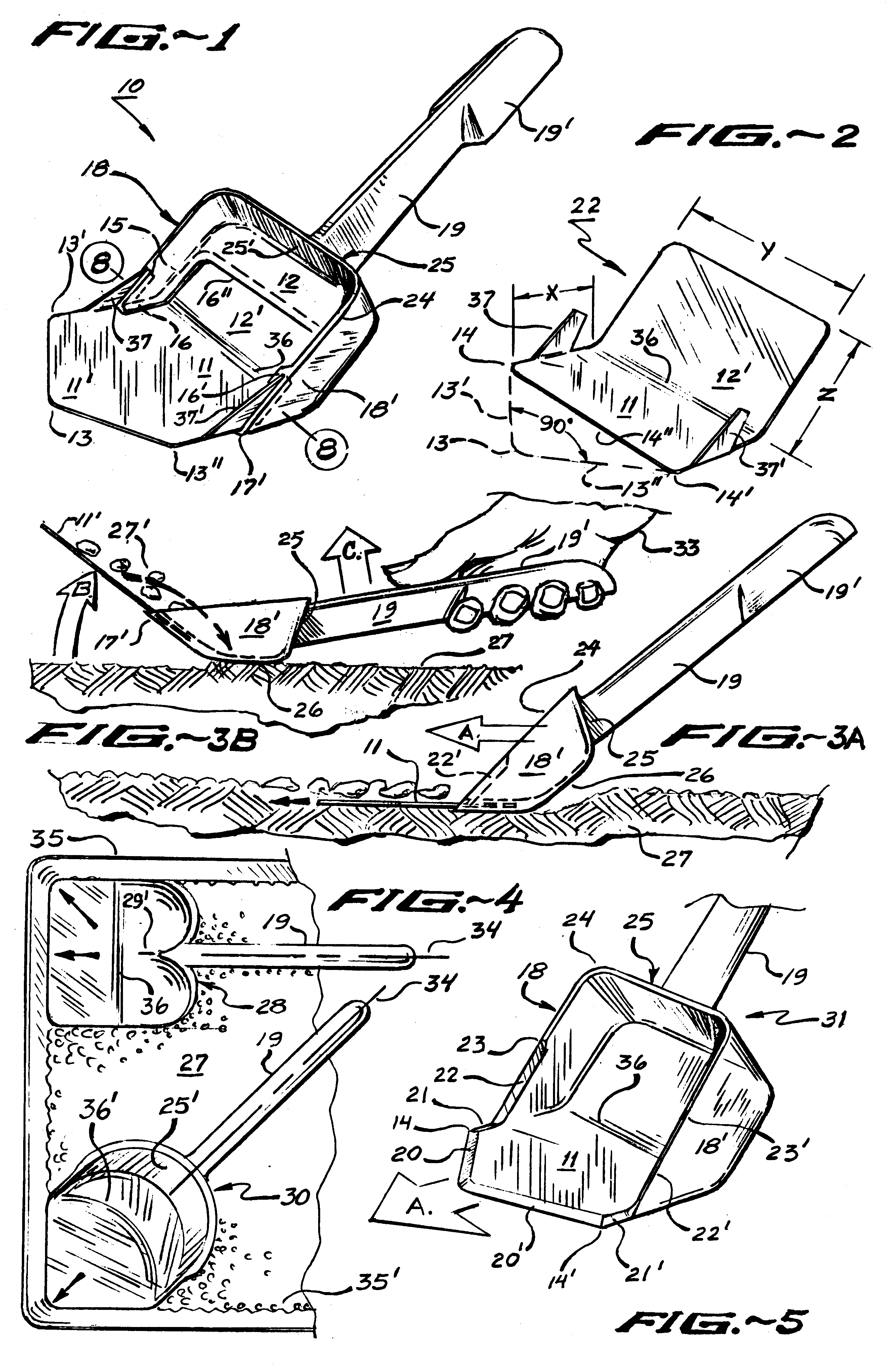

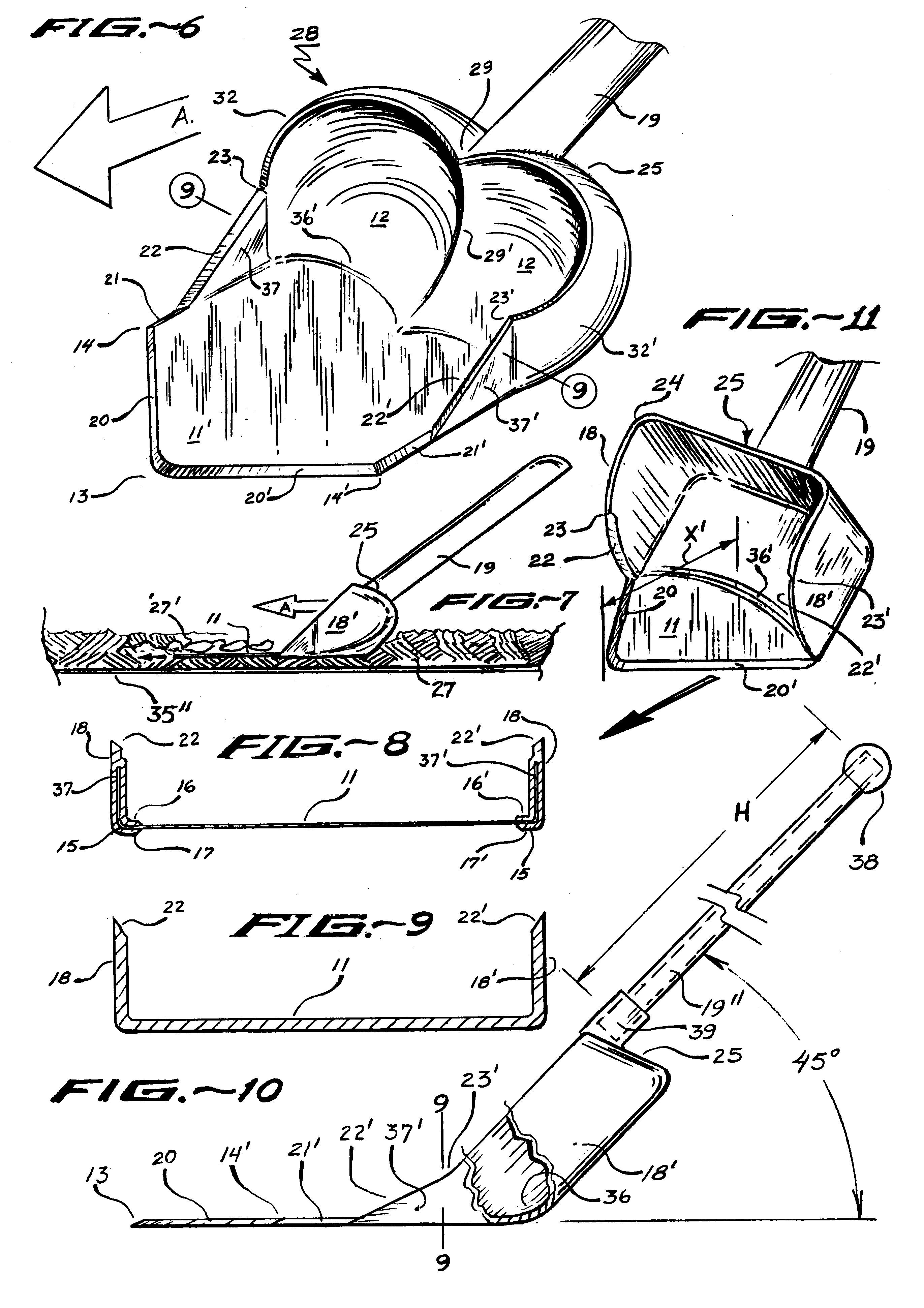

Dual Action Scooper for clumping and non-clumping cat litter

InactiveUS6234549B1Effectively segregateEfficient removalAnimal housingShop accessoriesLeading edgeDual action

An improved hand-held two-stage cat-litter scooper tool critically configured to more effectively segregate and lift-away wet cat-litter, without causing migration into, or disturbing clean dry areas. The planar leading-edge of the scooping-blade portion, is formed to either a 90-degree triangular, or transversely-square, plan-view shape; either shape thus able to project closely into the corners of a conventional cat-litter box. The rear portion of either scooping-blade includes an approximate 40-degree transverse-bend, creating an aftward containment-bowl area, effectively holding wet cat-litter when the rearward projecting handle is tilted down (the scooping-blade thus tilting upward) after a horizontal forward scooping motion. The handle is arranged along the medial longitudinal-axis of the tool, angling upward at approximately 45-degrees relative to the plane of the scooping-blade, facilitating the special "tilt-loading action" without dragging of one's hand into the cat-litter. A further aid to performance of the tool being shoved through soiled cat-litter, includes acutely up-turned blade sides; both set slightly back from the actual frontal-sides of the scooping-blade. This particular formation being discovered to function most effectively, providing minimal disturbance to surrounding cat-litter, while very precisely shaving away waste cat-litter. Generic-variations include a preferred 2-piece construction, embodying a stainless-steel blade portion, permanently locking into a retention-groove formed into the aftward injection-molded plastic-body forming the side-walls of the essential containment-bowl; including an integral handle member thereto.

Owner:SPENCER LOUIS E

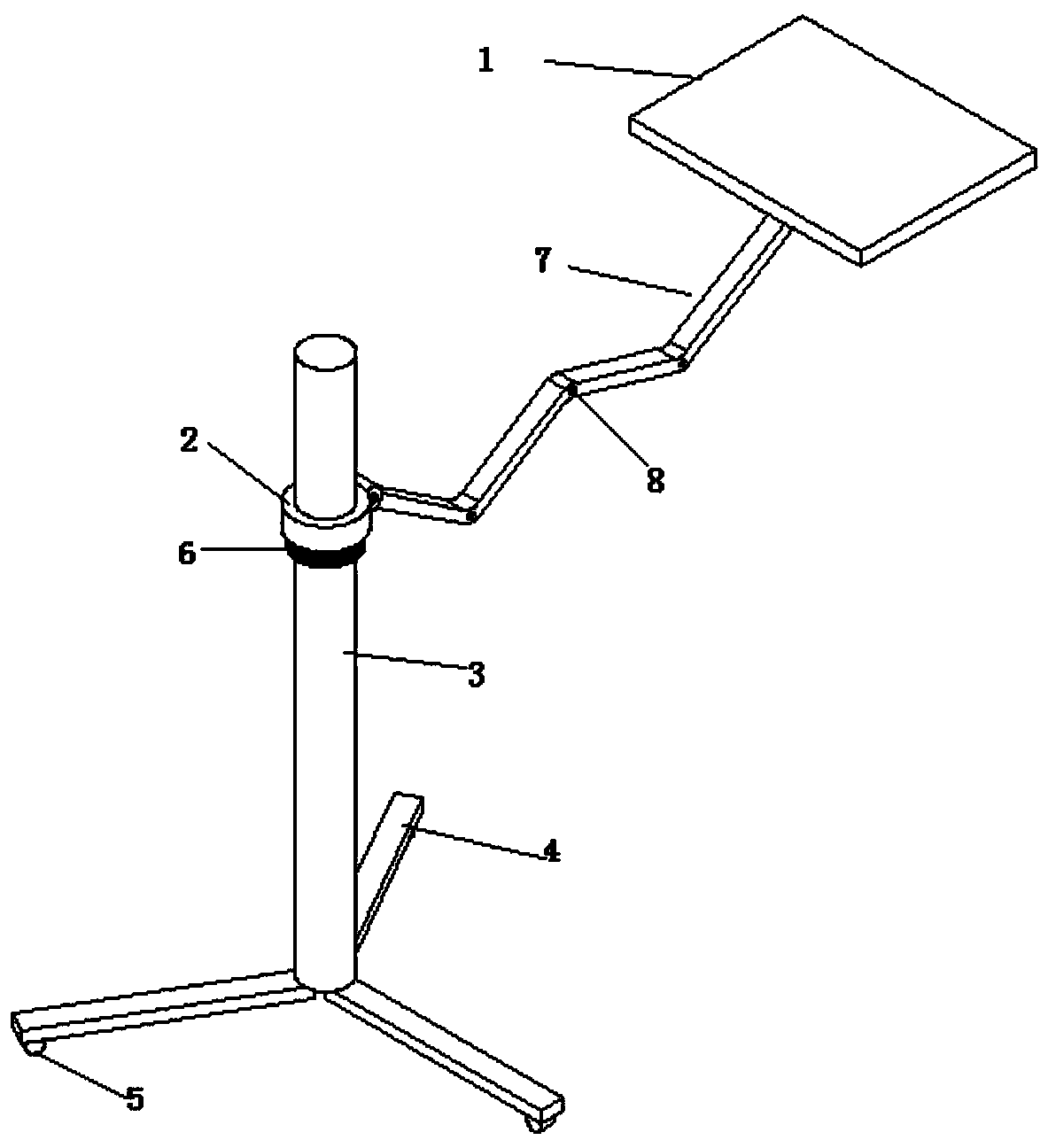

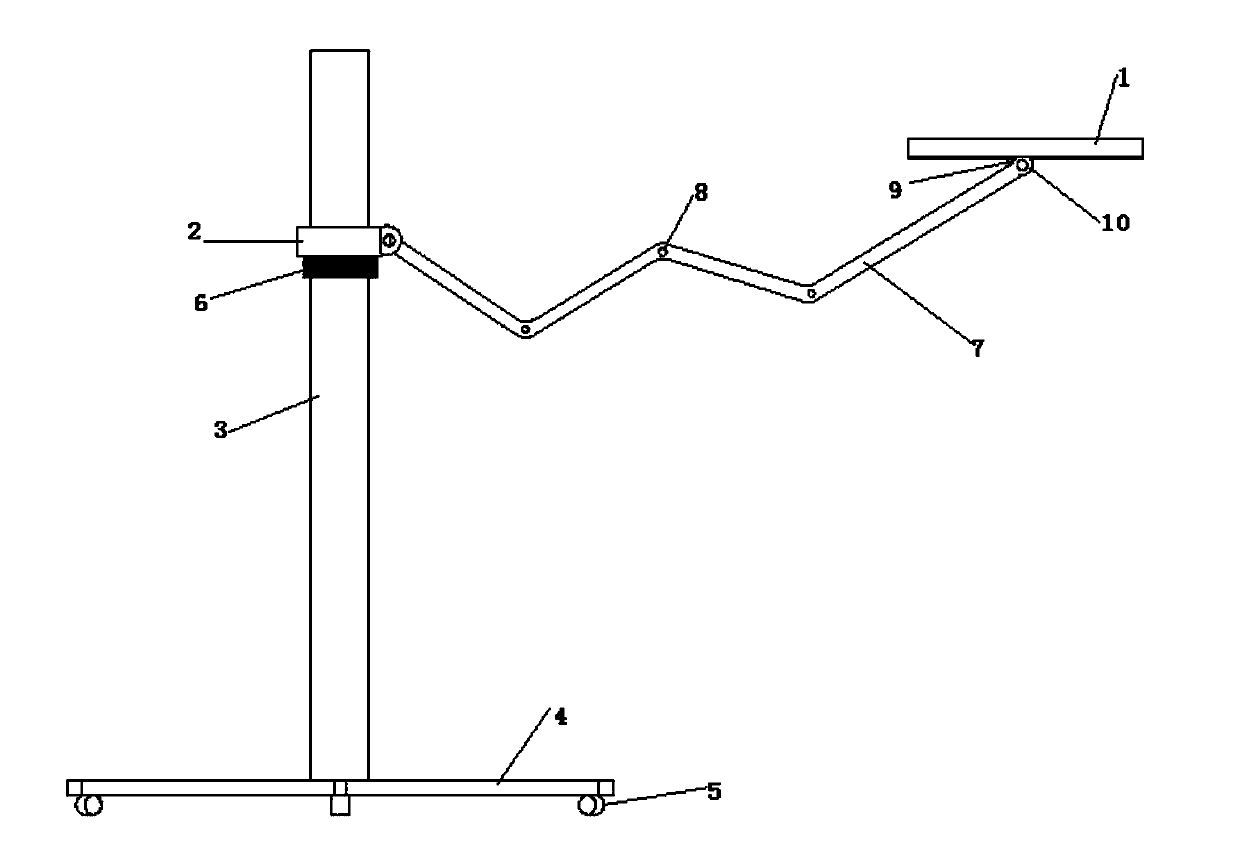

Foldable nut collection support system

InactiveCN104191423ANot limited by workspaceFlexible adjustment of horizontal working rangeWork tools storageOther workshop equipmentSupporting systemPush and pull

The invention provides a foldable nut collection support system. The system comprises a workpiece tray, a supporting portion and a telescopic support portion, and a supporting base, a supporting frame, a bottom frame and universal rotating wheels are arranged in the supporting portion. A positioning sleeve, a plurality of telescopic arms and self-locking rotating joints are arranged in the telescopic support portion. The bottom of the workpiece tray is provided with and connected with a bolt and a nut for the self-locking rotating joints through a locking fixing device. According to the needs, through the telescopic support portion, a single person only needs to transversely push and pull the workpiece tray by the hand, the working range of the workpiece tray can be freely adjusted by slightly exerting external force, the workpiece tray is pulled to the distance which is considered to be suitable by a user, the working comfort of a worker is improved, a tool trolley can be moved, and the working field requirement is met. The workpiece tray can be turned over, collected nuts can be conveniently toppled over, and the whole moving or adjusting process is quite convenient.

Owner:TIANJIN DARENSHE METAL PROD

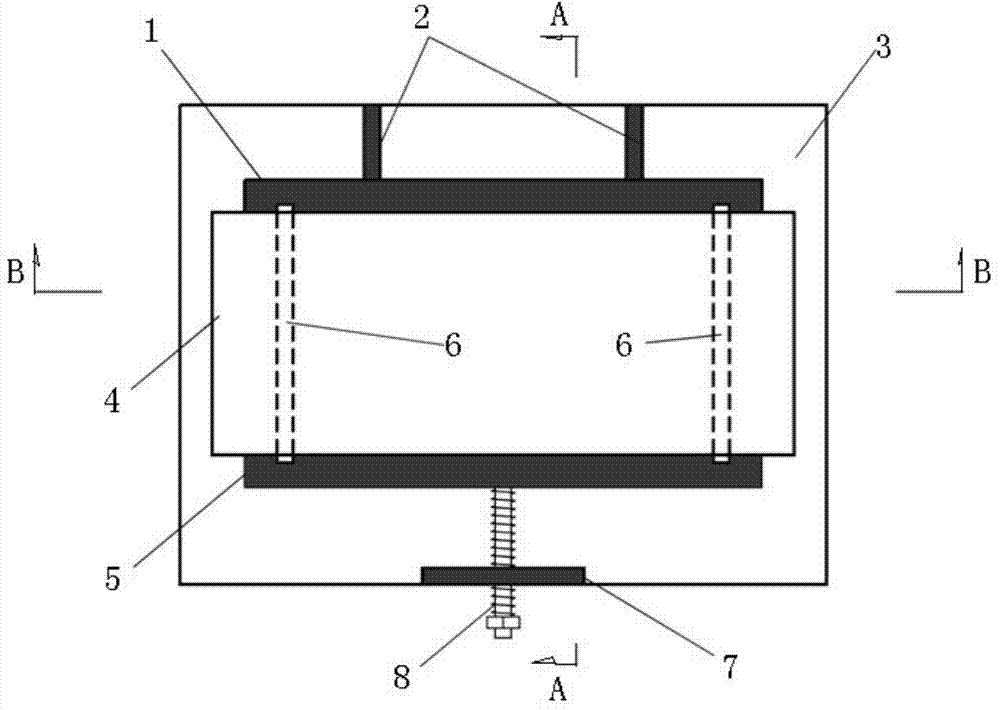

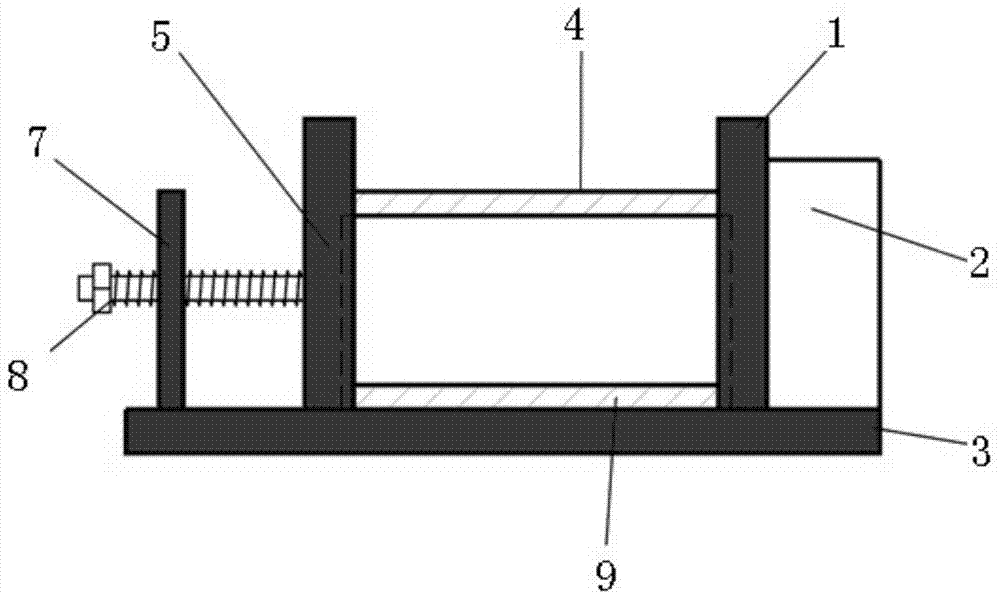

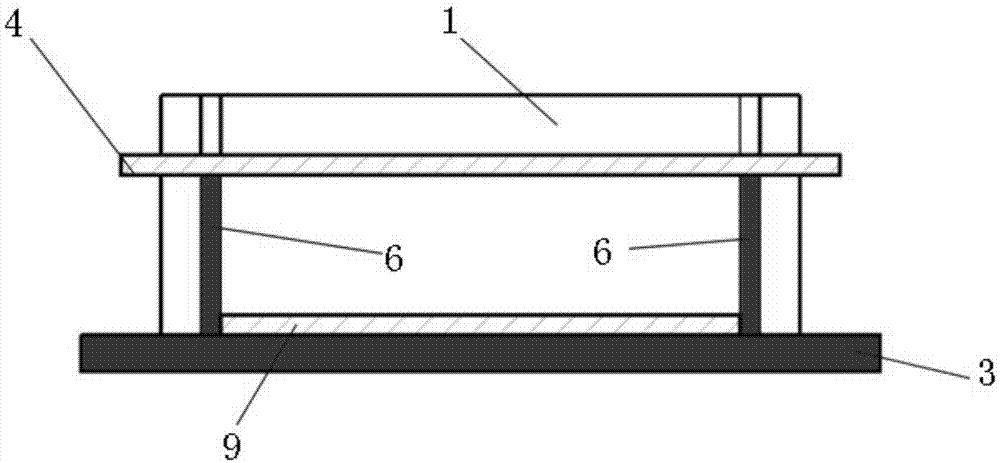

Mold and method for manufacturing intermittent-fissure rock mass simulating test piece

The invention discloses a mold and a method for manufacturing an intermittent-fissure rock mass simulating test piece. The mold comprises a bottom plate on which a fixed long side plate, a movable long side plate, movable short side plates, a grooved bottom base plate and a grooved top cover plate are arranged, wherein reinforcing ribs are arranged between the outer side of the fixed long side plate and the bottom plate; a bolt end plate is arranged at the outer side of the movable long side plate and on the bottom plate and is provided with a side edge bolt; the inner end of the side edge bolt pushes against the outer side of the movable long side plate; grooves are formed in the grooved top cover plate and the grooved bottom base plate. The mold can be used for manufacturing simulating test pieces of rock masses under the combination of geometrical parameters of various fissures, and has the advantages that fissures can be accurately positioned, the pouring of the test piece is easy, air bubbles can be easily discharged, de-molding is convenient, and the mold can be used repeatedly; besides, the pouring and curing processes of the test piece can be strictly controlled.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

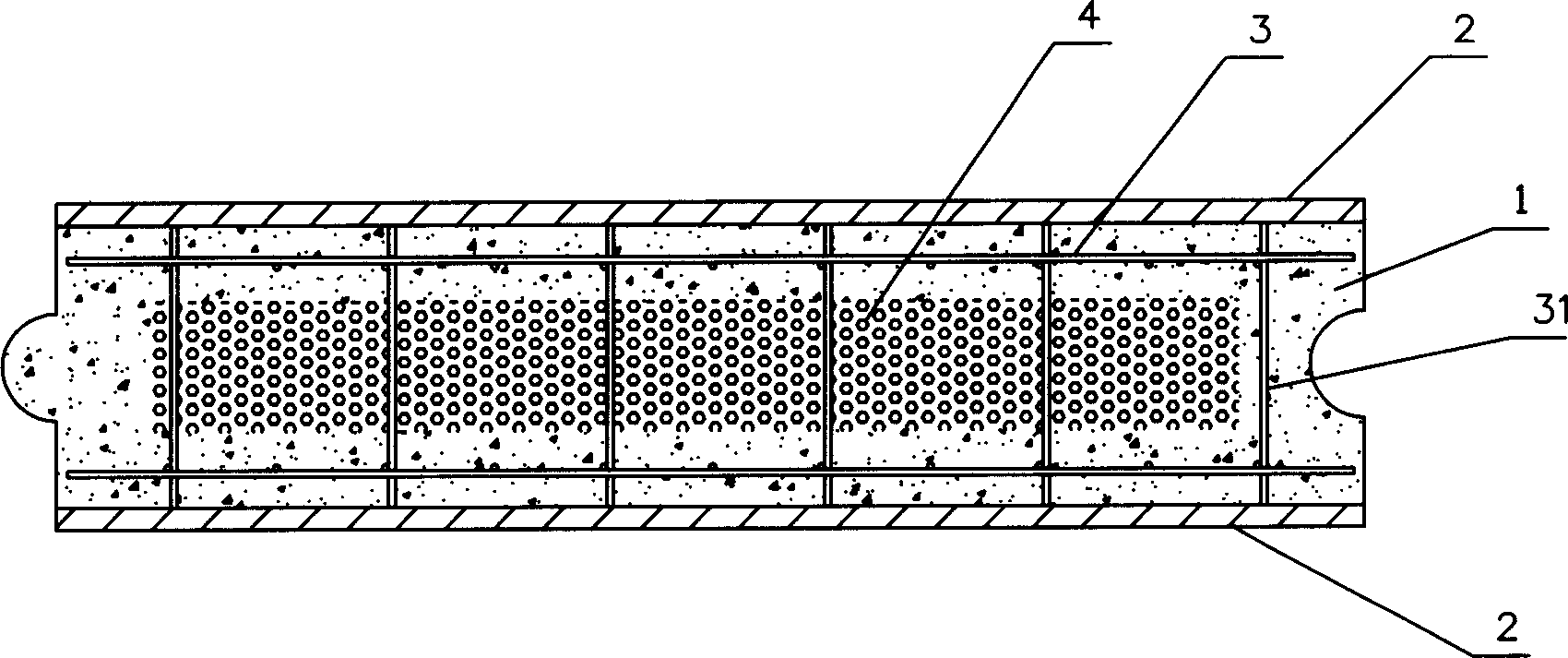

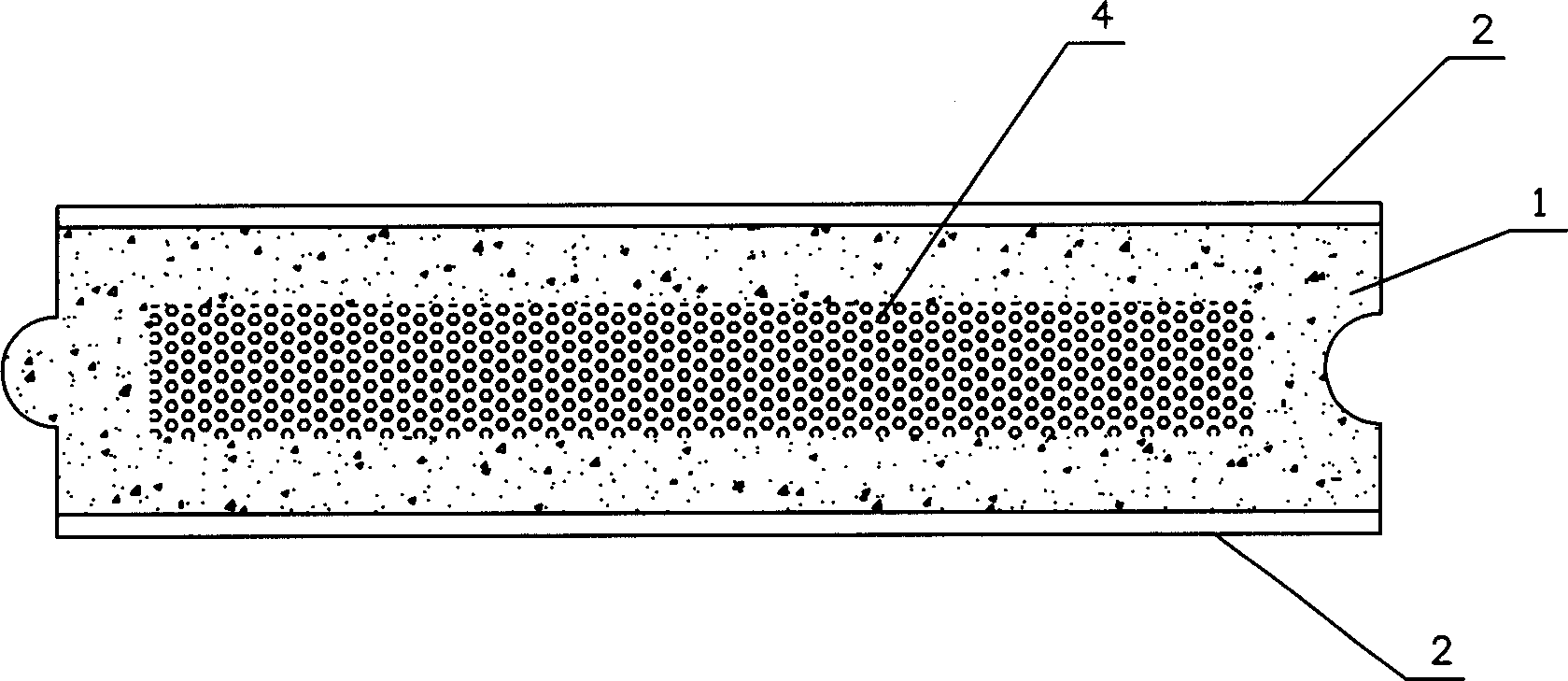

Light compound side fascia and its manufacturing method

ActiveCN1831270AReasonable structureSuperior performanceConstruction materialMouldsRebarHigh intensity

The invention relates to a lightweight compounded outer wallboard and the manufacturing method thereof. And it is compounded of fiber or wire fabric reinforced cement slab and bearing layer, where the bearing layer is made of reinforcing fabric reinforced light aggregate concrete, one or two sides of the bearing layer are combined with cement slabs and a cavity in the bearing layer is enveloped by light aggregate concrete and full of heat insulator. And its manufacturing method comprises a process as follows: A. placing cement slabs on one or two sides in a die space; B. placing reinforcing fabric provided with heat insulator in the middle by the cement slabs in the die space; C. pouring light aggregate concrete in the die space to bury the reinforcing fabric; and D. staying, curing and hardening and then demoulding to make it. And the method is simple, practical, high-efficiency and it has advantages of lightweight, high intensity, strong bearing capacity, good heat insulating property, seismic resistance, seepage prevention, etc.

Owner:广州益群板业有限公司

Geo-polymer recycled concrete and preparation method thereof

InactiveCN101570426ADelayed activationImprove liquiditySolid waste managementCement productionRoad engineeringSlag

The invention belongs to the fields of civil engineering and environmental material engineering, and in particular relates to geo-polymer recycled concrete and a preparation method thereof. The geo-polymer recycled concrete is prepared from raw materials of recycled coarse aggregate, recycled fine aggregate, fly ash, slag powder, water, sodium silicate, sodium hydrate, naphthalene sulfonate formaldehyde condensation compound and calcium saccharate according to certain mixing proportion by adopting a special stirring process. The product of the geo-polymer recycled concrete not only has simple preparation process, but also has good working performance, mechanical property, durability and heat-insulating property. Simultaneously, the geo-polymer recycled concrete and the preparation method can efficiently use a great deal of waste concrete and two industrial byproducts of the fly ash and blast furnace slag, are significant in saving resources, saving energy sources and protecting the environment, and accord with the sustainable development strategy of the building industry. The product of the geo-polymer recycled concrete can be widely applicable to road engineering, structural engineering and other various civil engineering constructions.

Owner:TONGJI UNIV

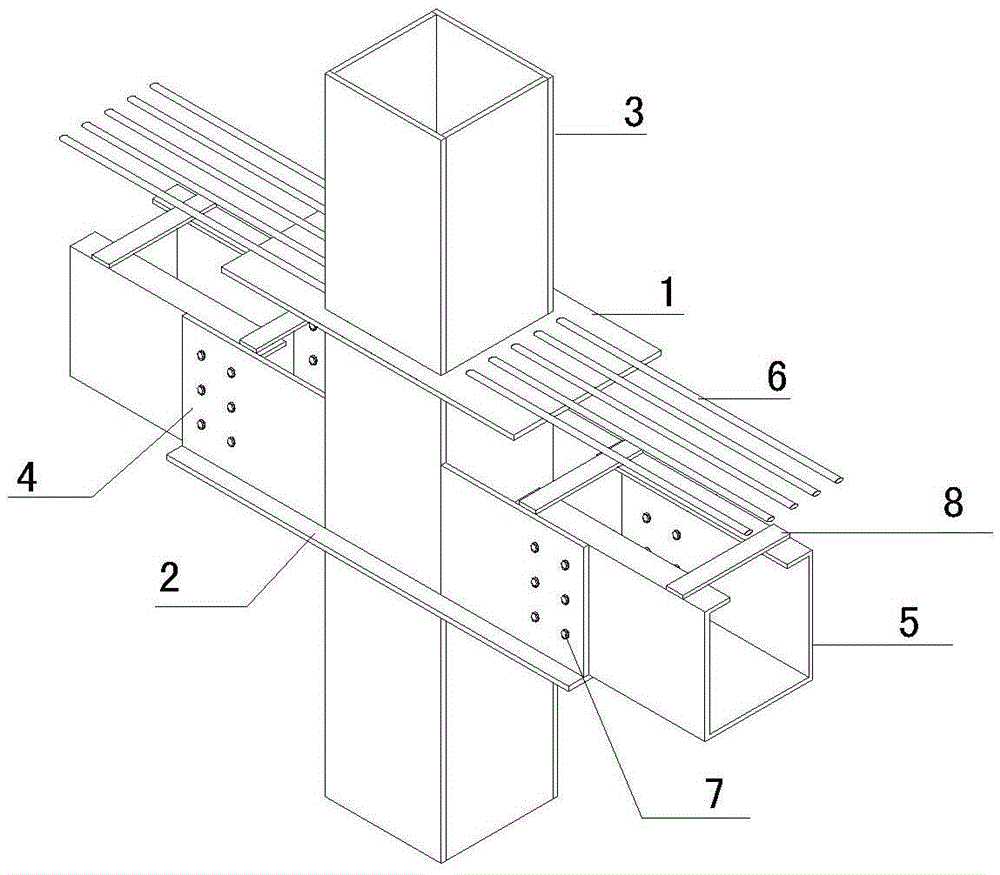

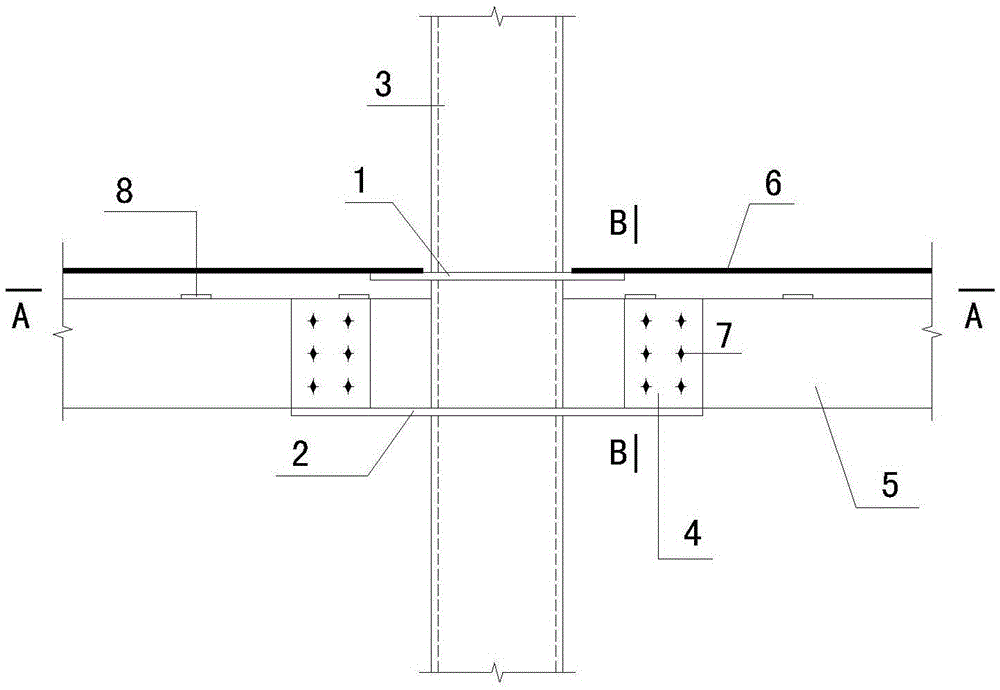

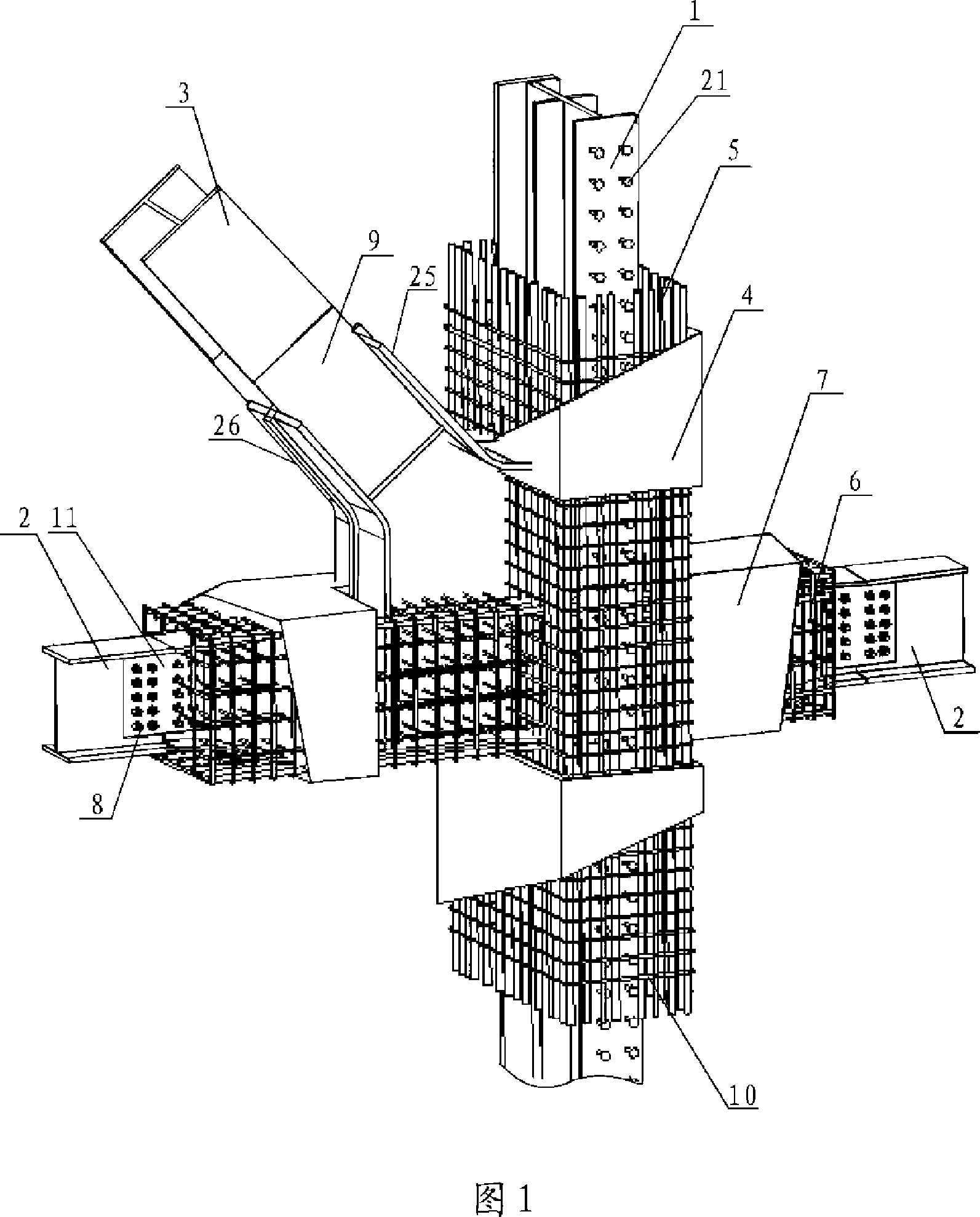

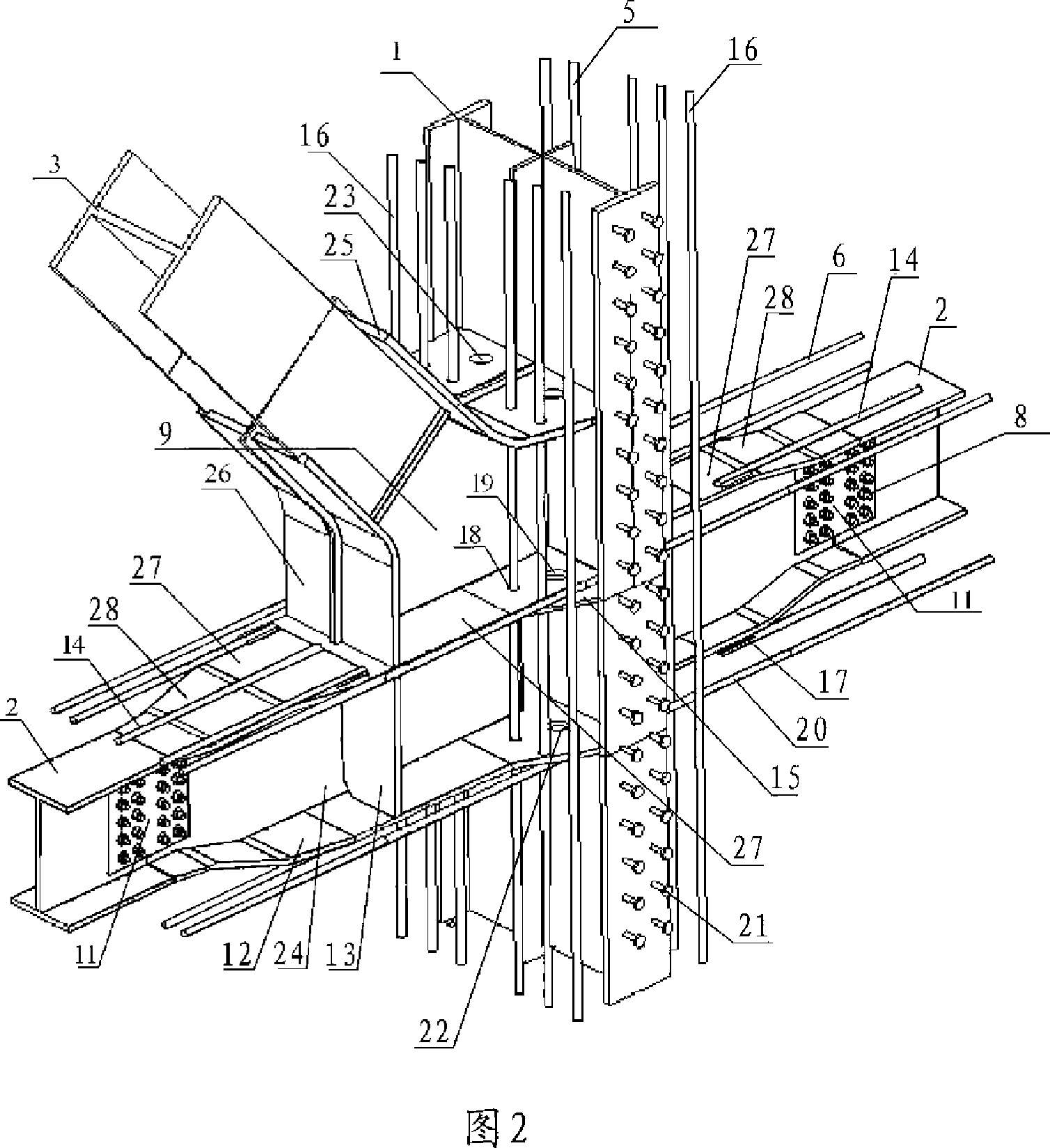

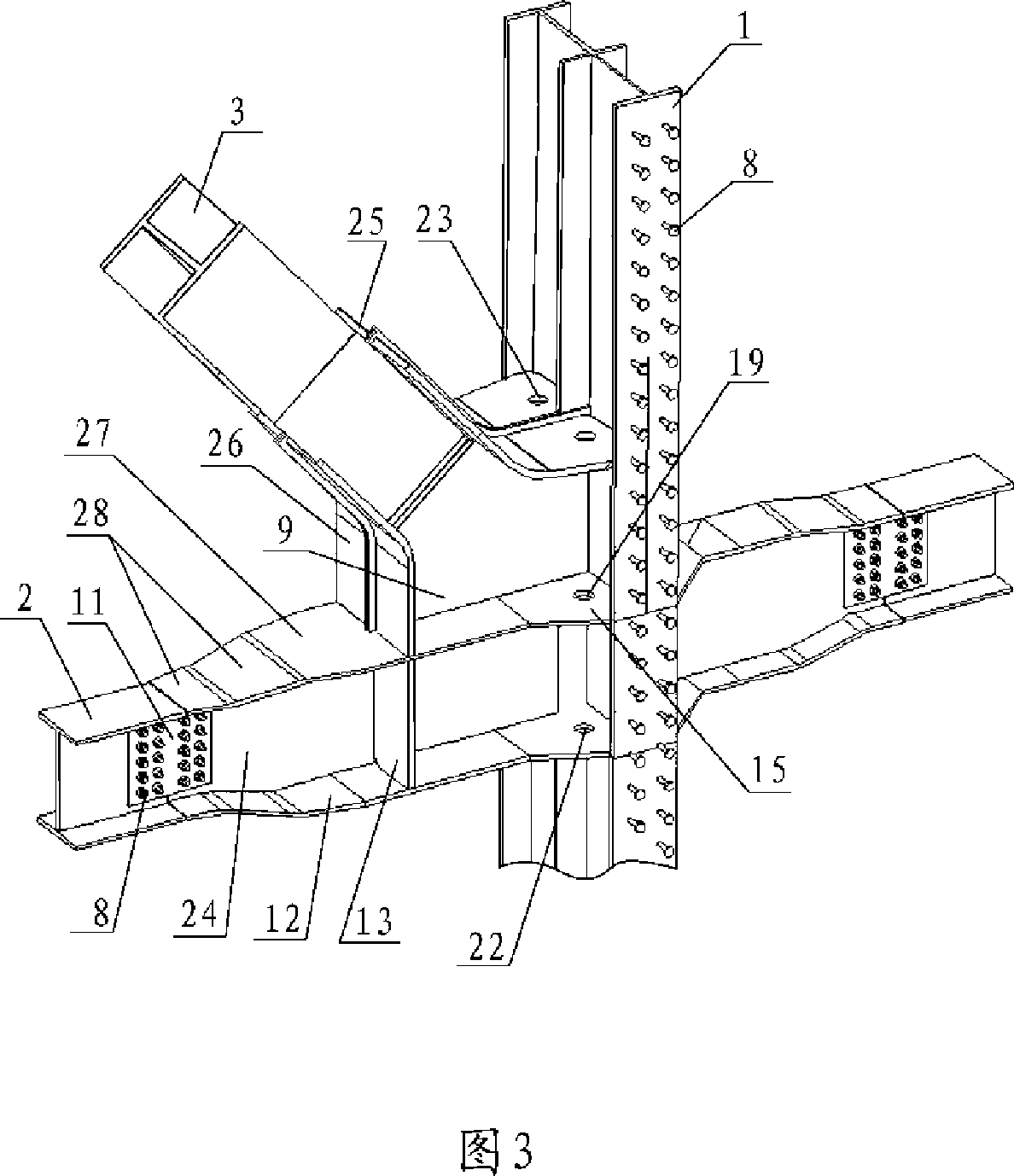

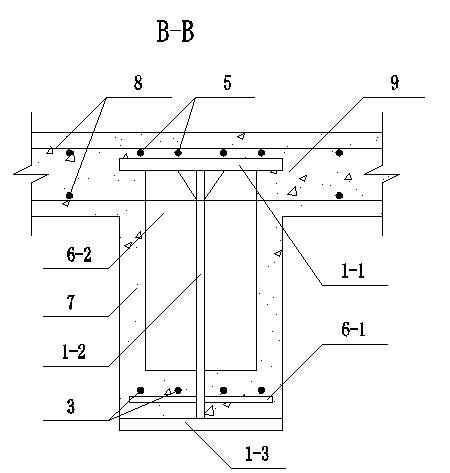

Steel-encased concrete composite beam-steel pipe column connection joint

InactiveCN105569191AReduce welding workloadEasy constructionBuilding constructionsSteel tubeBending moment

The invention discloses a steel-encased concrete composite beam-steel pipe column connection joint and a manufacturing method thereof. The joint comprises a steel pipe column, an upper through partition plate, a lower through partition plate, a lateral connection plate and the like; the upper through partition plate and the lower through partition plate are arranged on the steel pipe column in a transverse penetrating mode; hogging moment reinforcing steel bars are welded to the two ends of the end face of the upper through partition plate, the lower through partition plate and the lateral connection plate form a U-shaped device on the column side, and the U-shaped device can be made into a uniform cross-section or a variable cross-section form according to beam-column cross section size; a steel-encased girder is directly placed in the U-shaped device and connected with the U-shaped device through high-strength bolts. The steel-encased concrete composite beam-steel pipe column connection joint has the advantages that the welding work of the whole U-shaped device can be completed in a factory, a steel-encased girder bottom plate and a lateral plate are connected with the joint through high-strength bolts, the site welding work amount is greatly reduced, and construction and assembling are facilitated; the hogging moment reinforcing steel bars are directly welded to the upper through partition plate, the situation that steel pipe bearing capacity is weakened due to trepanning in the side wall of a steel pipe can be reduced, and force transfer is definite.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD +1

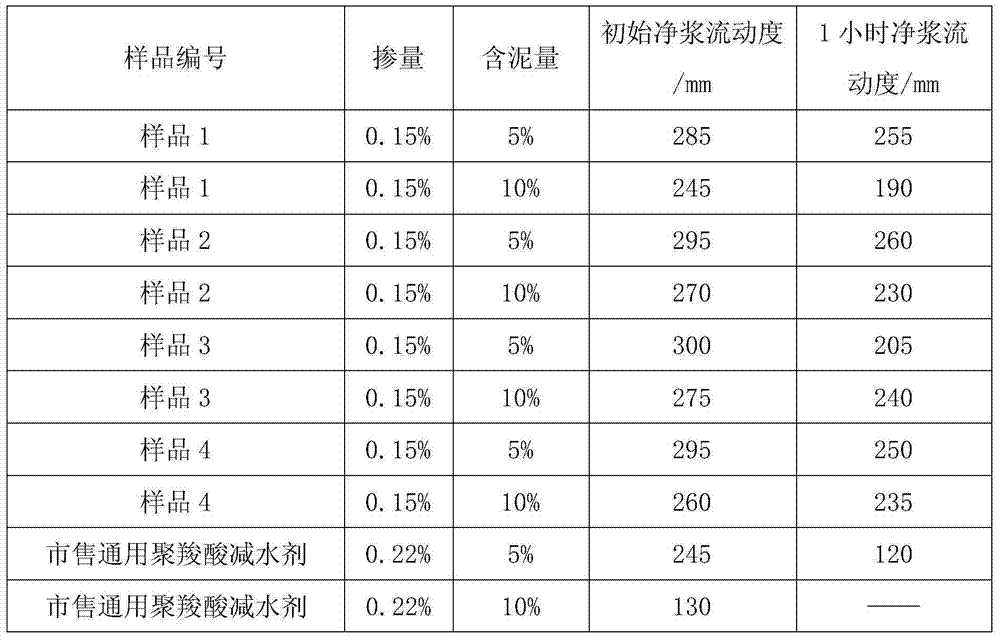

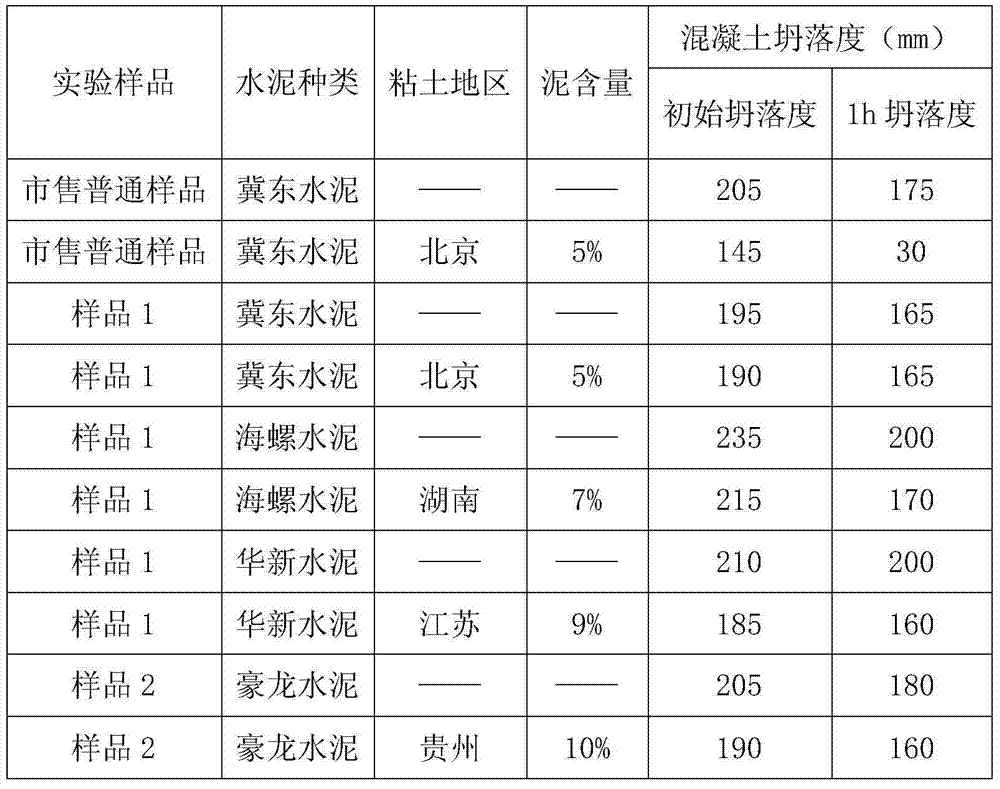

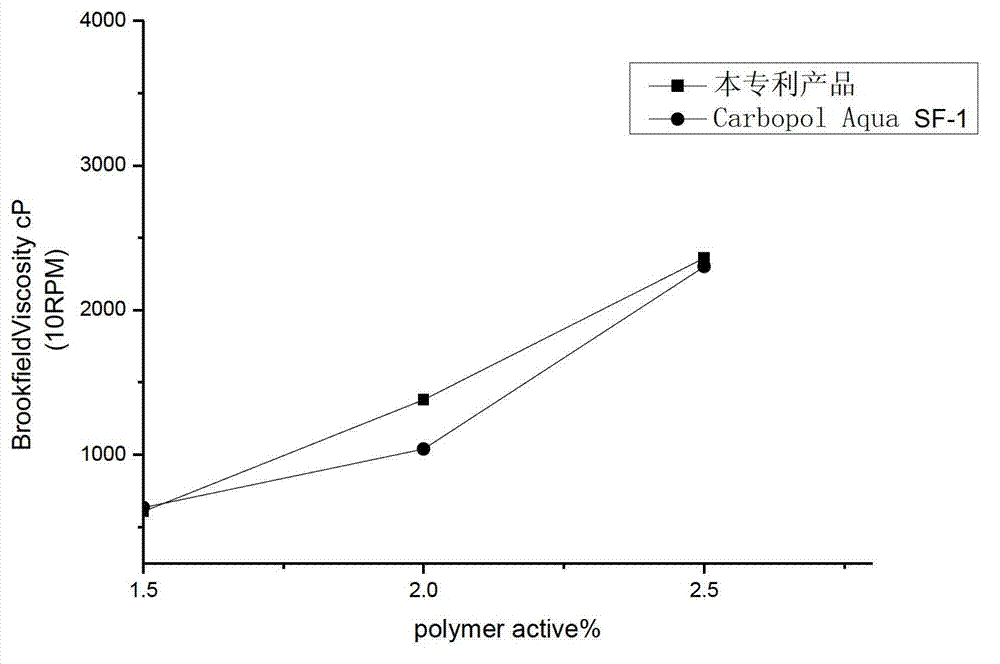

Mud-resistant polycarboxylic acid water reducer and preparation method thereof

The invention discloses a mud-resistant polycarboxylic acid water reducer. The mud-resistant polycarboxylic acid water reducer is prepared from the following components: vinyl polyoxyethylene ether, sodium p-styrenesulfonate, an acrylic acid and acrylamide compounds as monomers as well as an alkaline neutralizer, an initiator and a molecule modulator as auxiliary materials through copolymerization. The mud-resistant polycarboxylic acid water reducer disclosed by the invention is high in water-reducing rate, small in slump loss, good in mud-resistant effect, free of formaldehyde pollution in a production process, and especially adapts to sand concrete with relatively high mud content.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

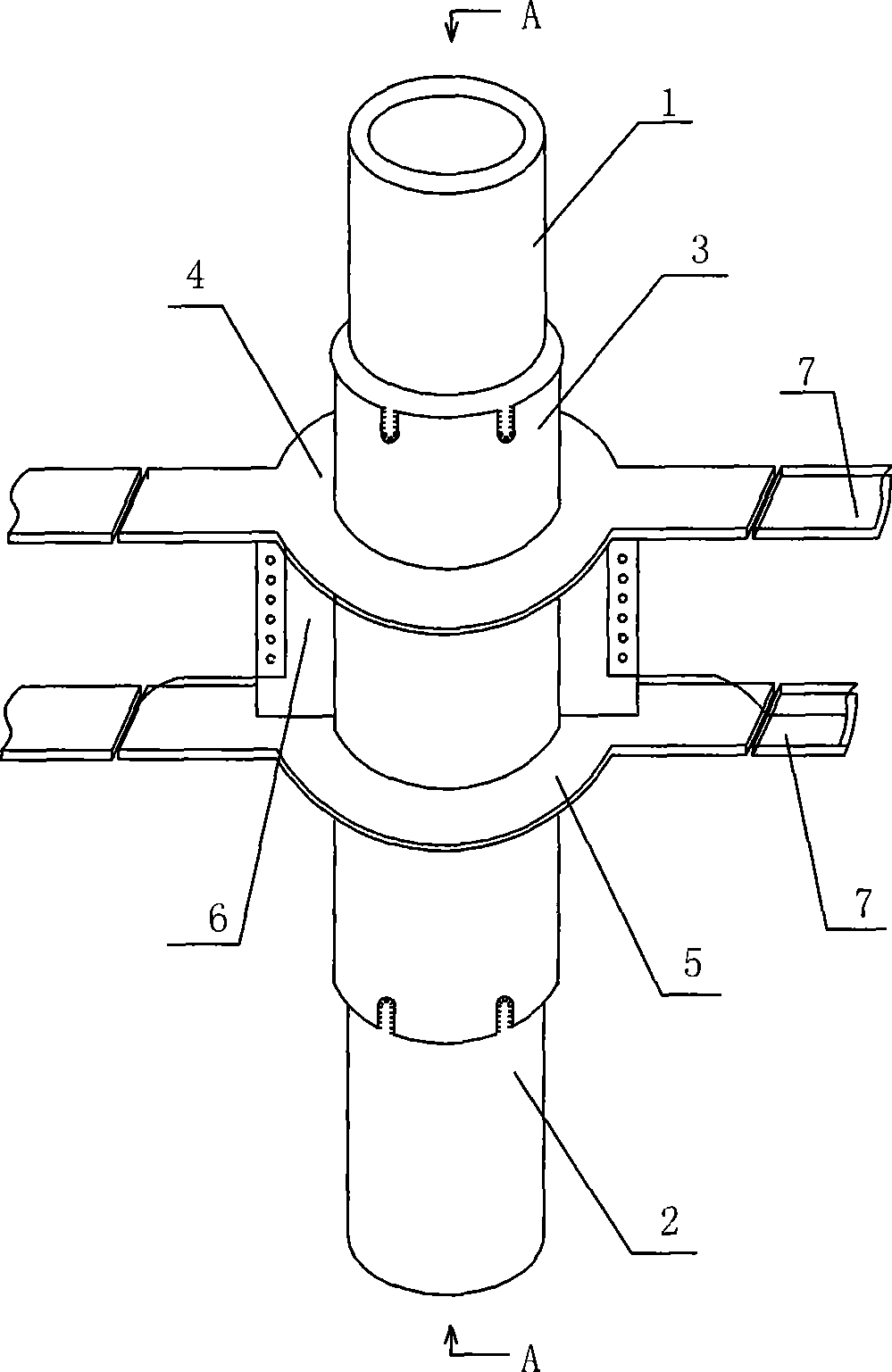

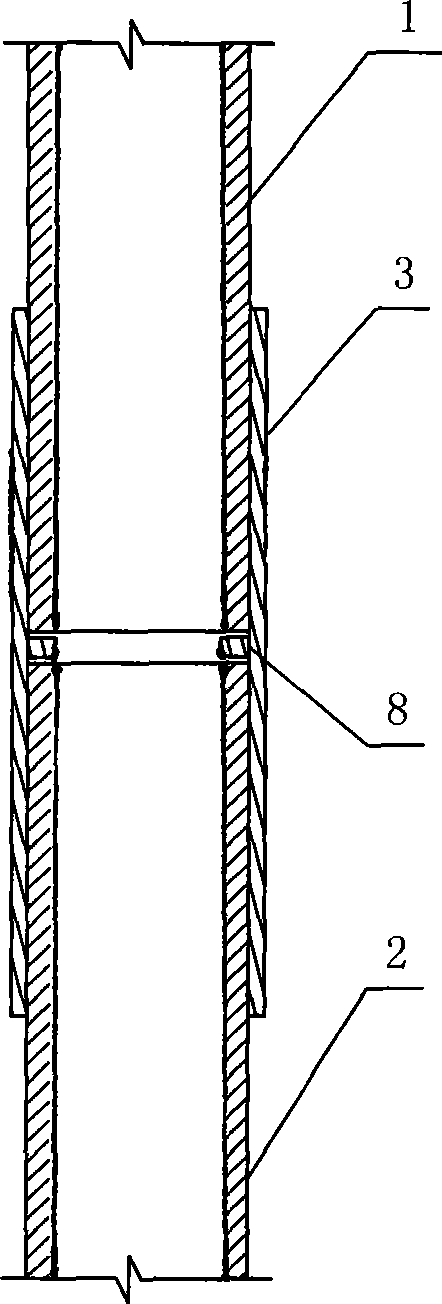

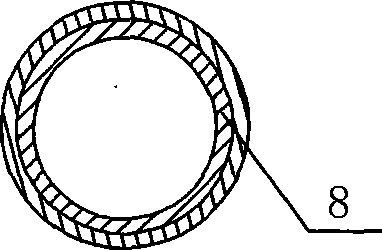

Steel pipe concrete segment type coat node and its construction method

InactiveCN101476348AMeet the needs of strong nodes and weak membersIncrease stiffnessBuilding constructionsUltimate tensile strengthMechanical property

The invention relates to a concrete-filled steel tube sectional type sleeve gusset and a construction method thereof, which relate to a connecting gusset for connecting a concrete-filled steel tube column and a girder in civil engineering and a construction method thereof. The concrete-filled steel tube sectional type sleeve gusset comprises the concrete-filled steel tube column and the steel girder which is connected with the column, wherein the concrete-filled steel tube column is formed by filling concrete into a steel tube; the steel tube is formed by connecting an upper column steel tube and a lower column steel tube through a connecting sleeve; the connecting sleeve and the lower column steel tube are in split type; an upper reinforcement ring plate and a lower reinforcement ring plate are arranged outside the connecting sleeve; and a vertical connecting plate is arranged between the upper reinforcement ring plate and the lower reinforcement ring plate. The connecting sleeve and the lower column steel tube in the concrete-filled steel tube sectional type sleeve gusset are in split type, so that the concrete casting strength of the lower column steel tube and the upper column steel tube can be different under the condition of construction, thereby the requirement of strong gussets and weak members can be met. Moreover, the concrete-filled steel tube sectional type sleeve gusset has the advantages of concise and definite force transferring path, large gusset rigidity, high bearing capacity, superior mechanical property, good anti-seismic performance and simple and convenient processing and manufacture.

Owner:DAQING GASOLINEEUM INST

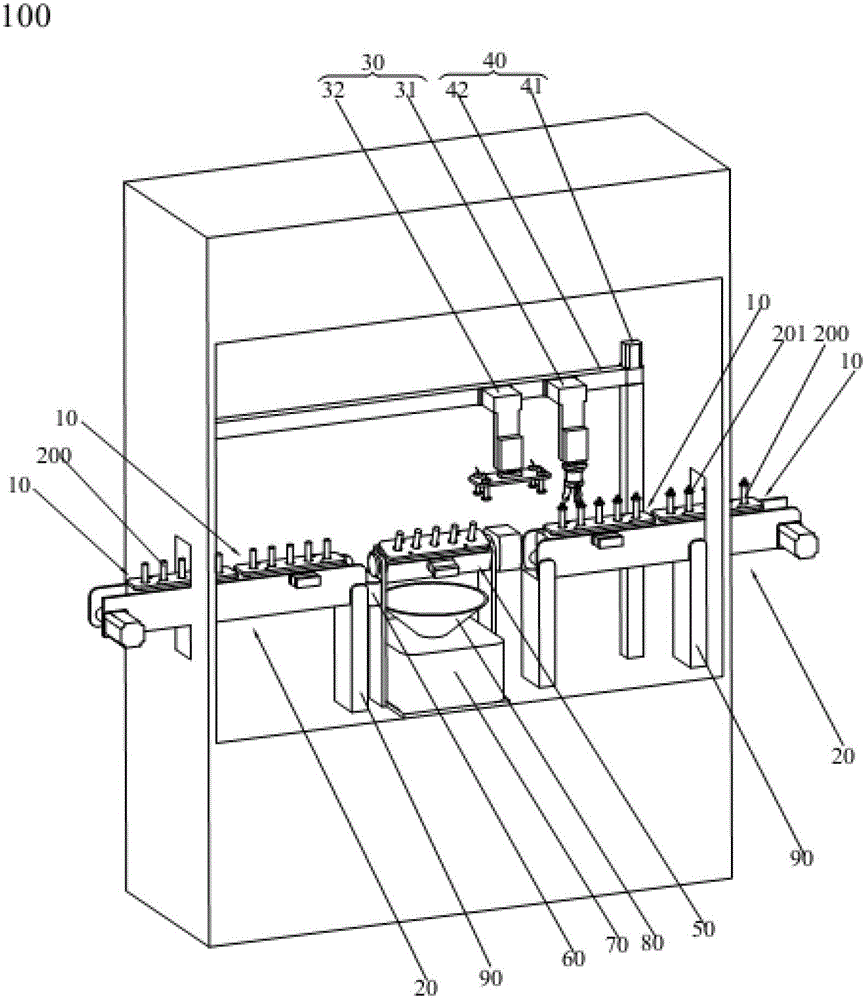

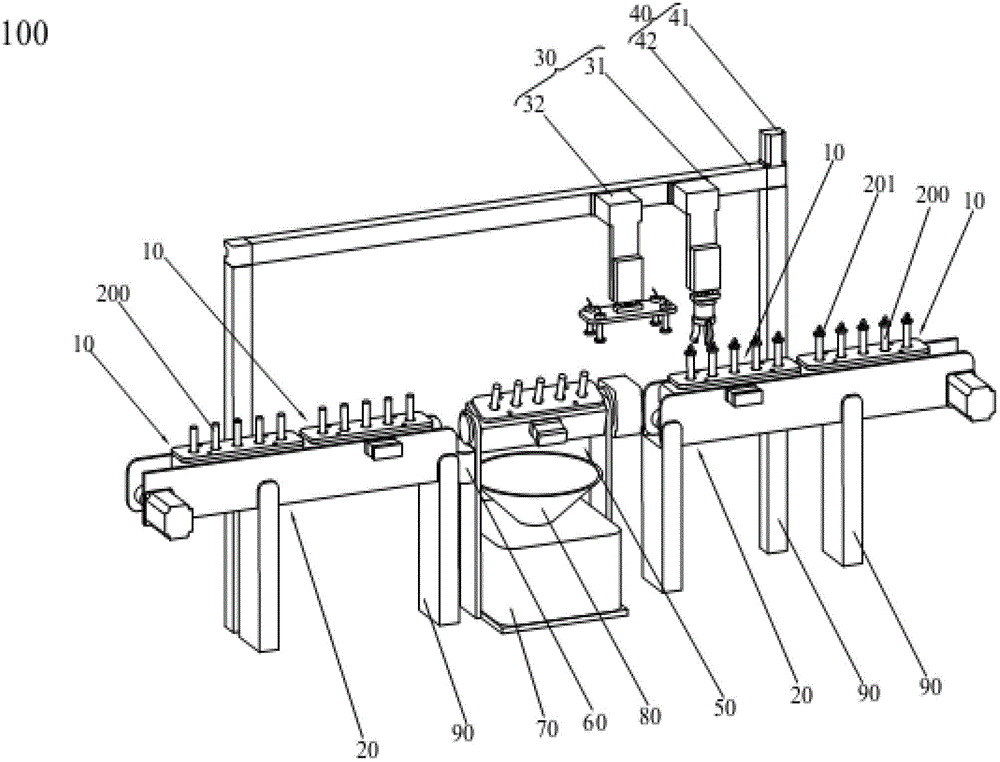

Facility for automatically collecting waste liquid in volumetric flasks

InactiveCN102745636AEasy to operateSimple structureTight-fitting lid removalThreaded caps removalLiquid wasteMaterial resources

The invention discloses facility for automatically collecting waste liquid in volumetric flasks. The technical scheme of the facility includes that the facility for automatically collecting waste liquid comprises a fixing device, a power transmission device, a single-shaft robot, a transportation device and a rotary fixture. A container containing waste liquid is arranged on the fixing device, the fixing device on a conveyor is driven by a motor to be conveyed to an operation table, a cover of the container is unscrewed and placed in a cover collecting disc by a manipulator, the fixing device is transported to the rotary fixture above a waste liquid collecting barrel by a sucker, is fixed in a fixed sleeve, is turned and shaken by a rotating cylinder so that the waste liquid can be poured out, and finally is transported to the conveyor to be moved out of the operation table. The facility for automatically collecting waste liquid is simple in structure, convenient to operate, labor-saving, material-resource-saving, time-saving, safe, quick, high-efficient and automatic. Frequent working procedures are avoided.

Owner:CENT TESTING INT GRP CO LTD

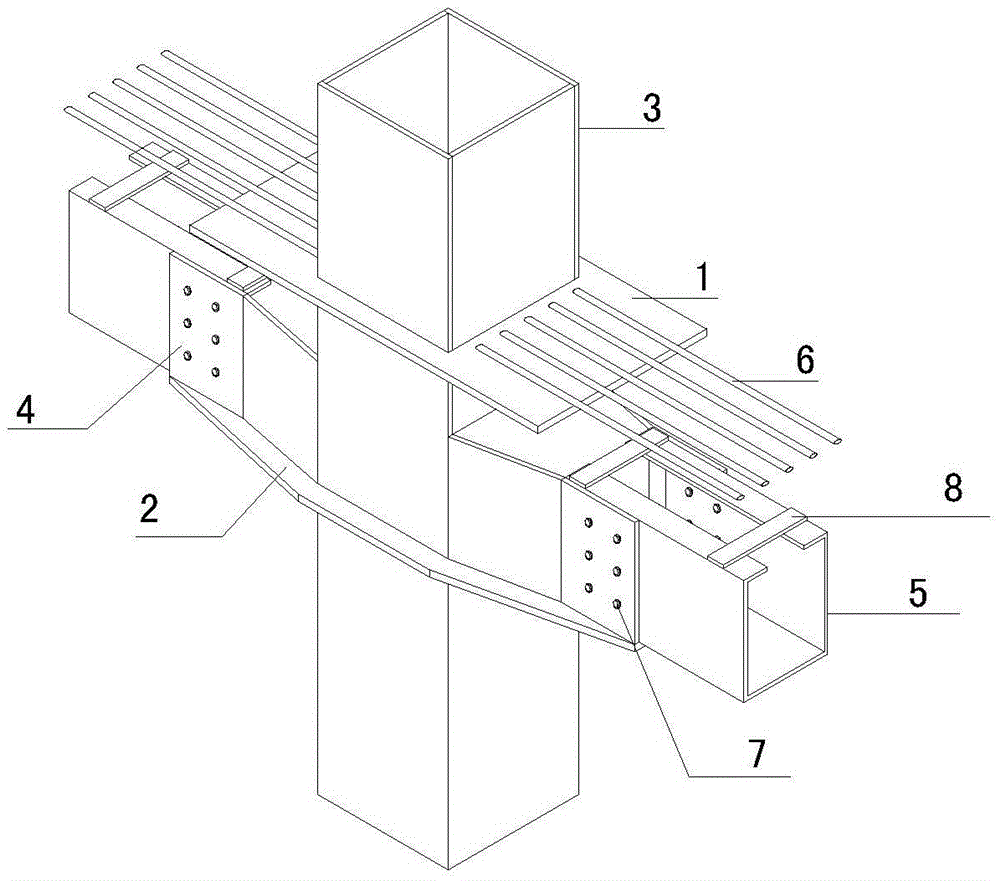

Shaped-steel concrete frame-steel supporting structure section-changeable conversion node

ActiveCN101024975AImprove seismic performanceImprove synergyBuilding constructionsReinforced concreteInto-structure

The invention is a variable section conversion node for profiled steel concrete framework-steel support structure, interconnecting in-pillar profiled steel, in-beam profiled steel, steel support, in-pillar reinforced concrete and in-beam reinforced concrete and pouring then into an organic whole, where the steel support is orthogonally connected with in-pillar an in-beam profiled steel flange plates by section conversion, the web of the in-beam profiled steel in the node connection position is converted into heightening variable section web and the top surface of the heightening variable section web is welded with widening variable section upper wing plate, the bottom surface of the heightening variable section web is welded with widening variable section lower wing plate; the shape of the steel support in the node connecting position is converted into structure of variable section node conversion region and two flange plates of the steel support in variable section conversion region are orthogonally connected with the in-pillar and in-beam profiled steel respectively. And the invention intensifies fore bearing performance of node regions of the profiled steel concrete framework-steel support structure and ability of cooperating of profiled steel and reinforced concrete.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

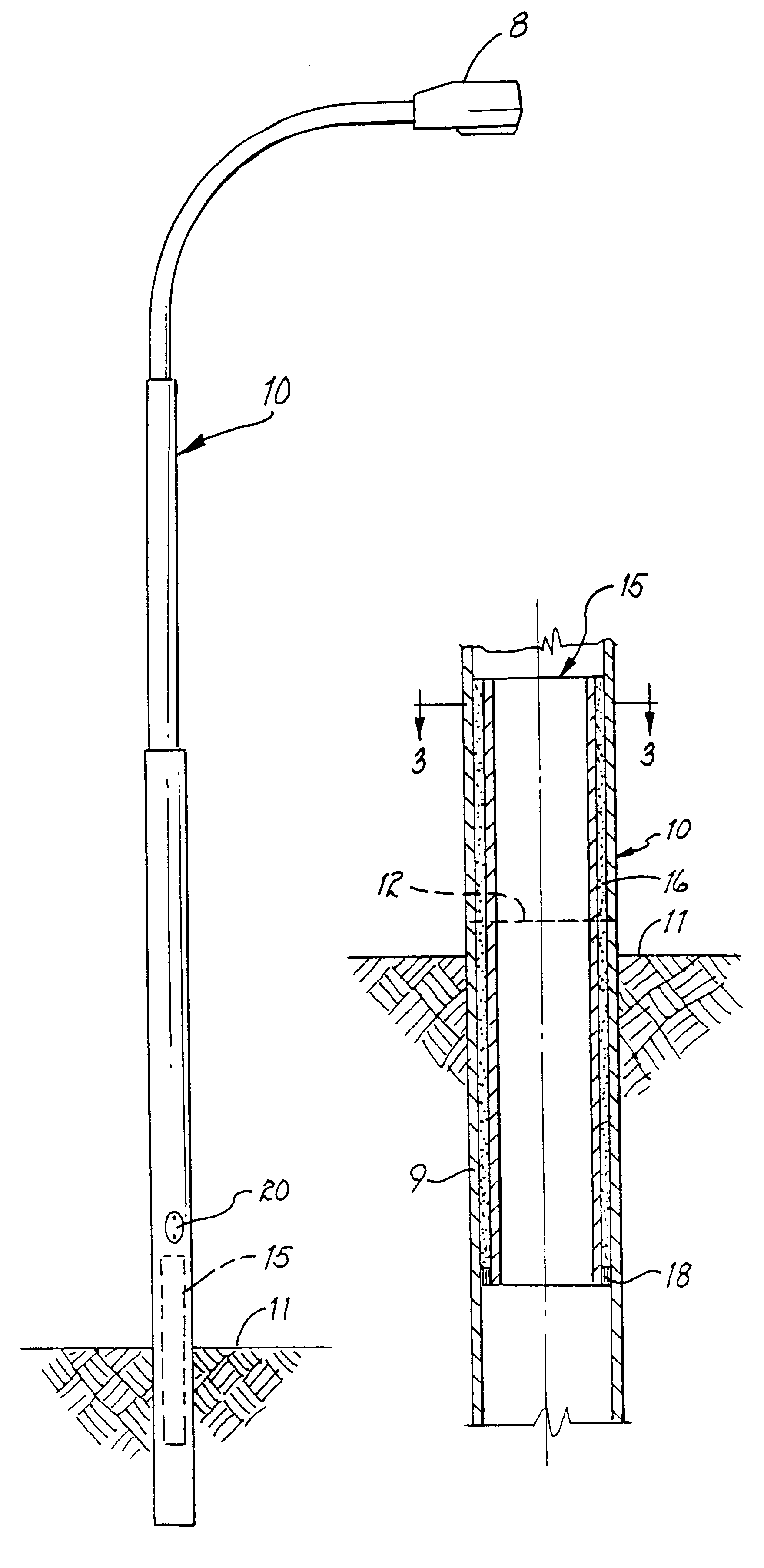

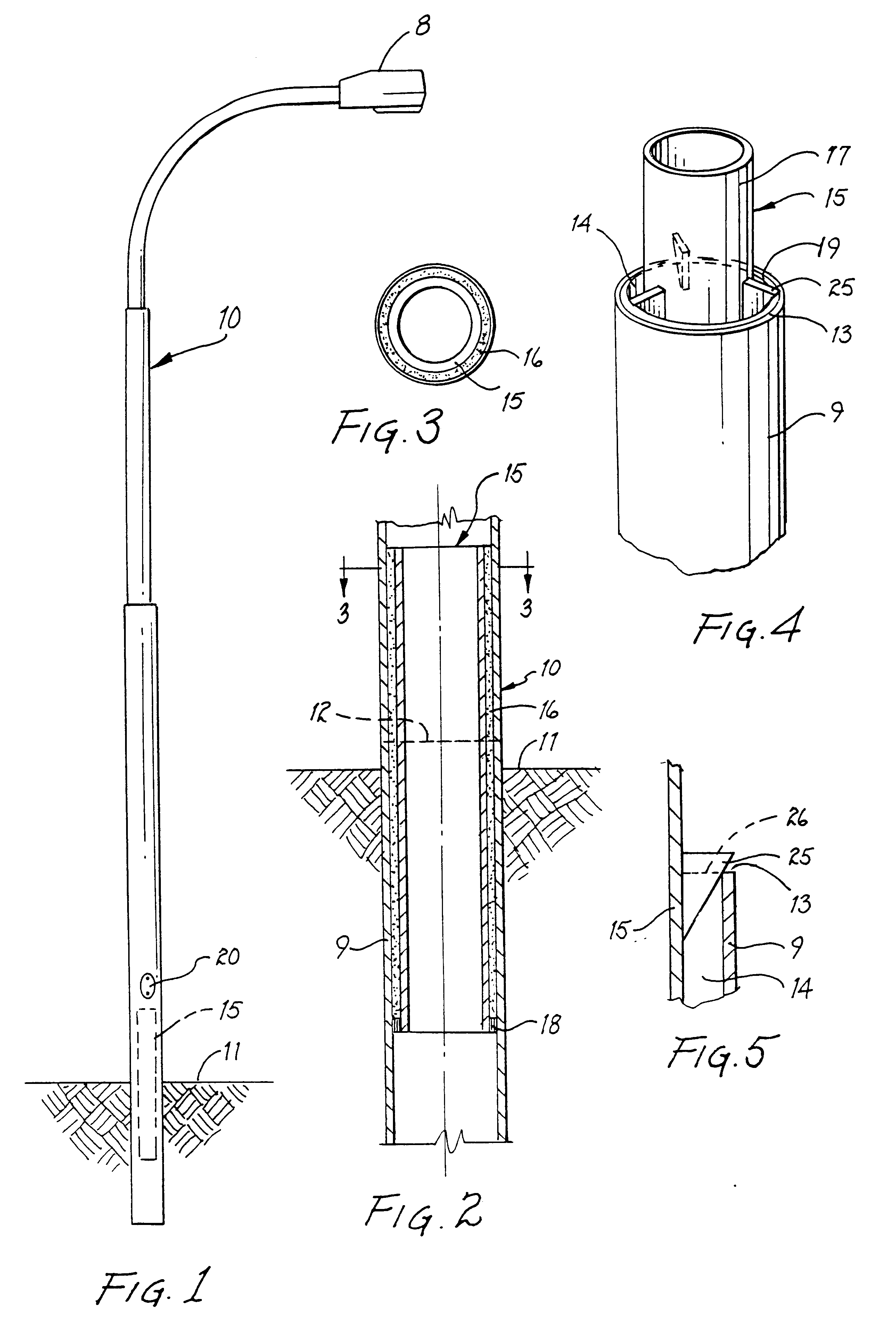

Working poles and method of repair

InactiveUS6742314B2Improve the immunityLow viscosityStrutsBuilding repairsAbove groundMechanical engineering

A hollow working pole such as a luminaire pole is repaired by cutting the pole above ground level and inserting a sleeve. The sleeve is maintained in position while grout is poured to fill the space between the sleeve and the inner surfaces of the pole base. The top portion of the pole, previously removed, are replaced and grout is poured into the circumferential space between the insert and the inner surfaces of the upper portion of the pole.

Owner:YOUNG ROBERT A

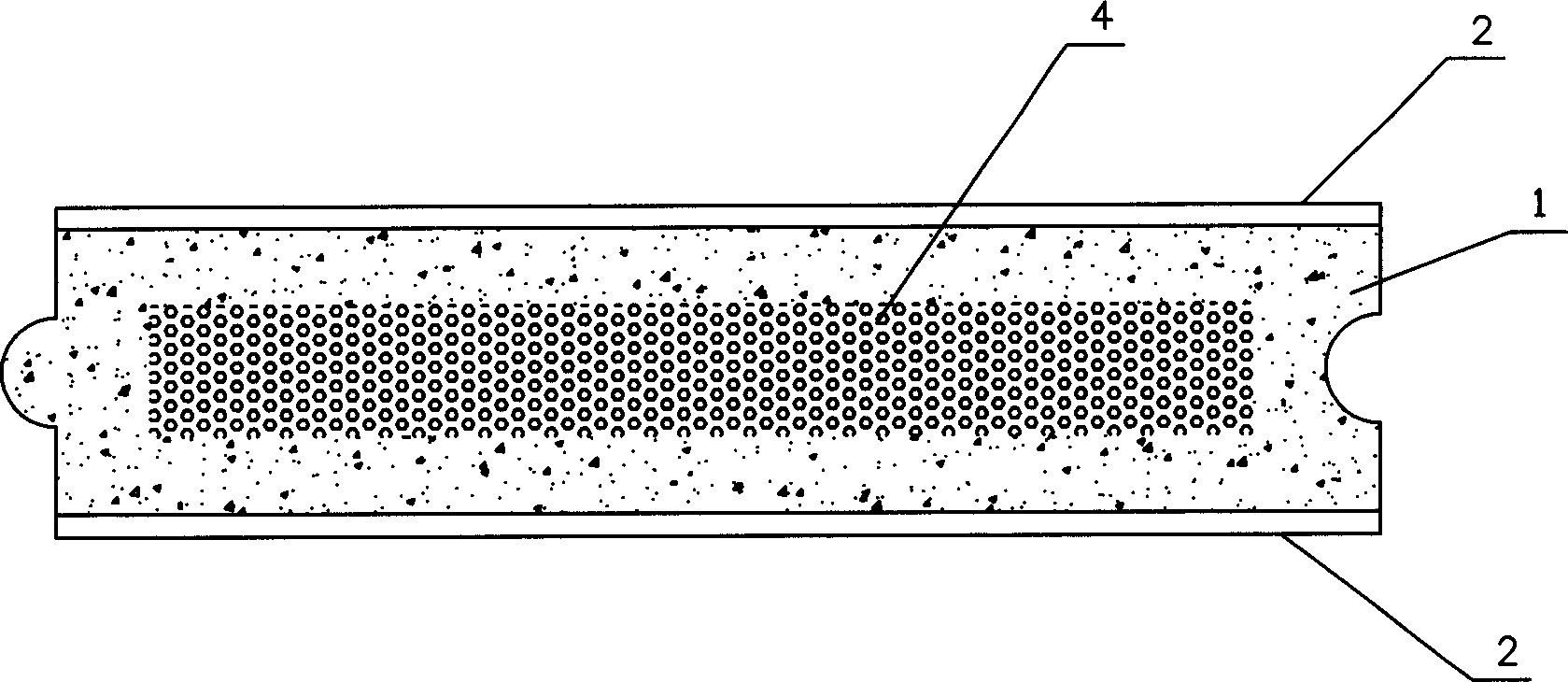

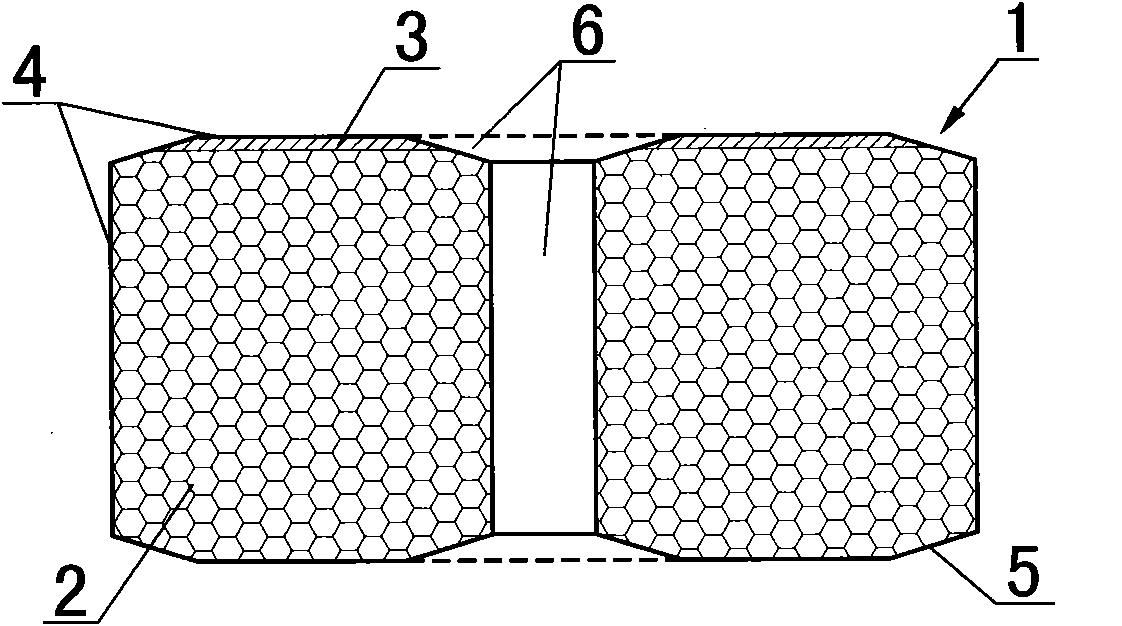

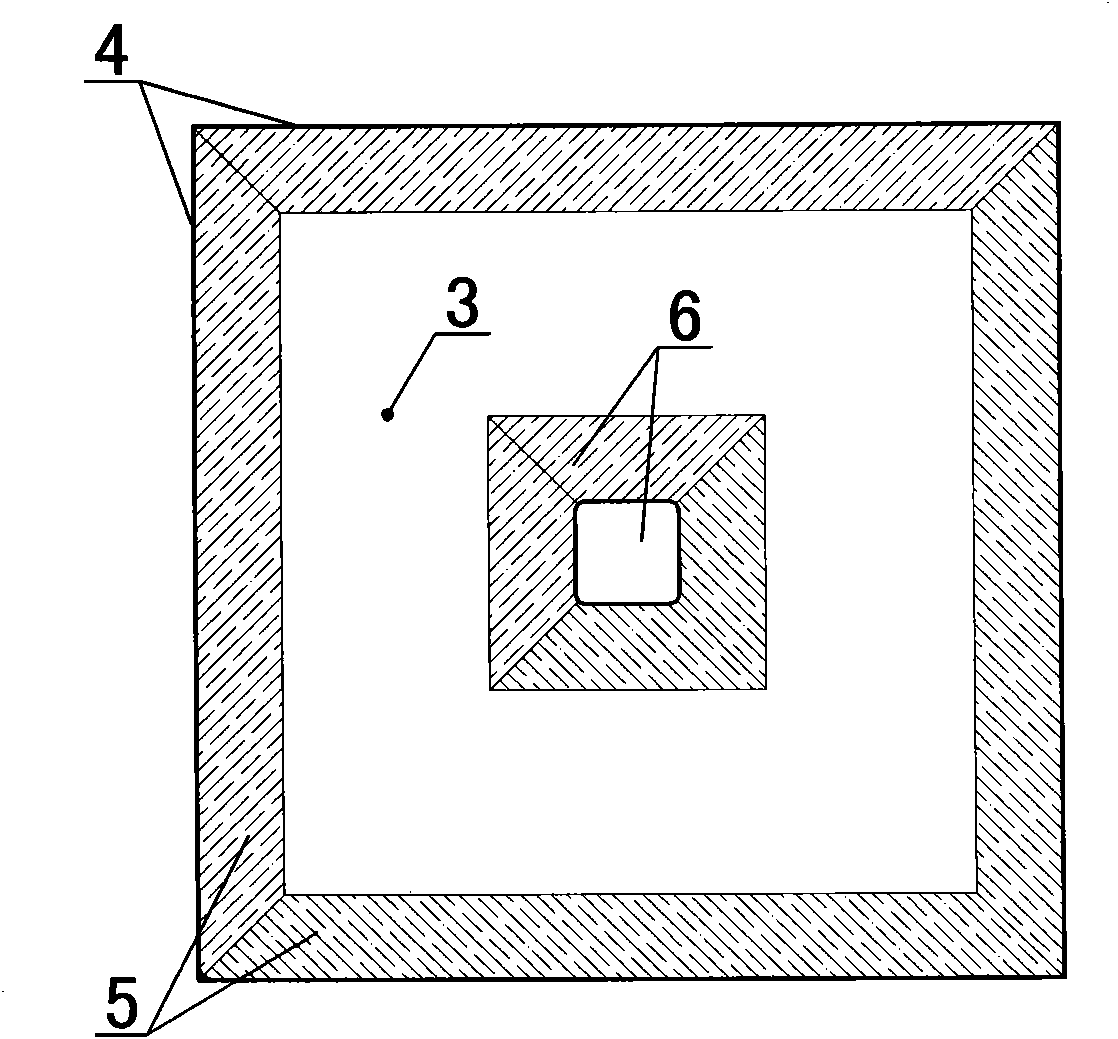

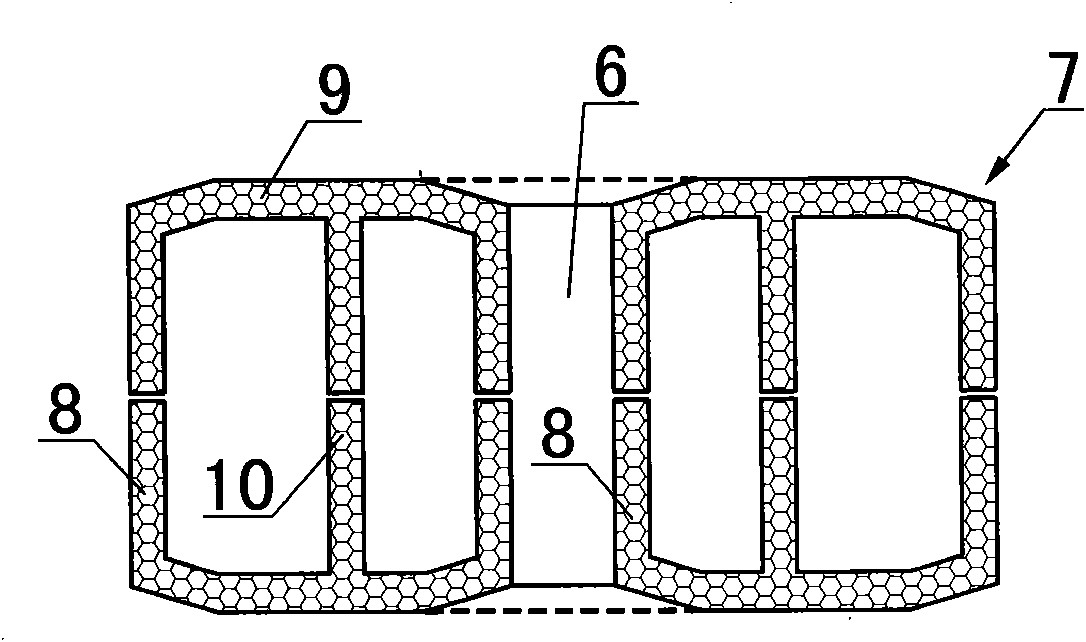

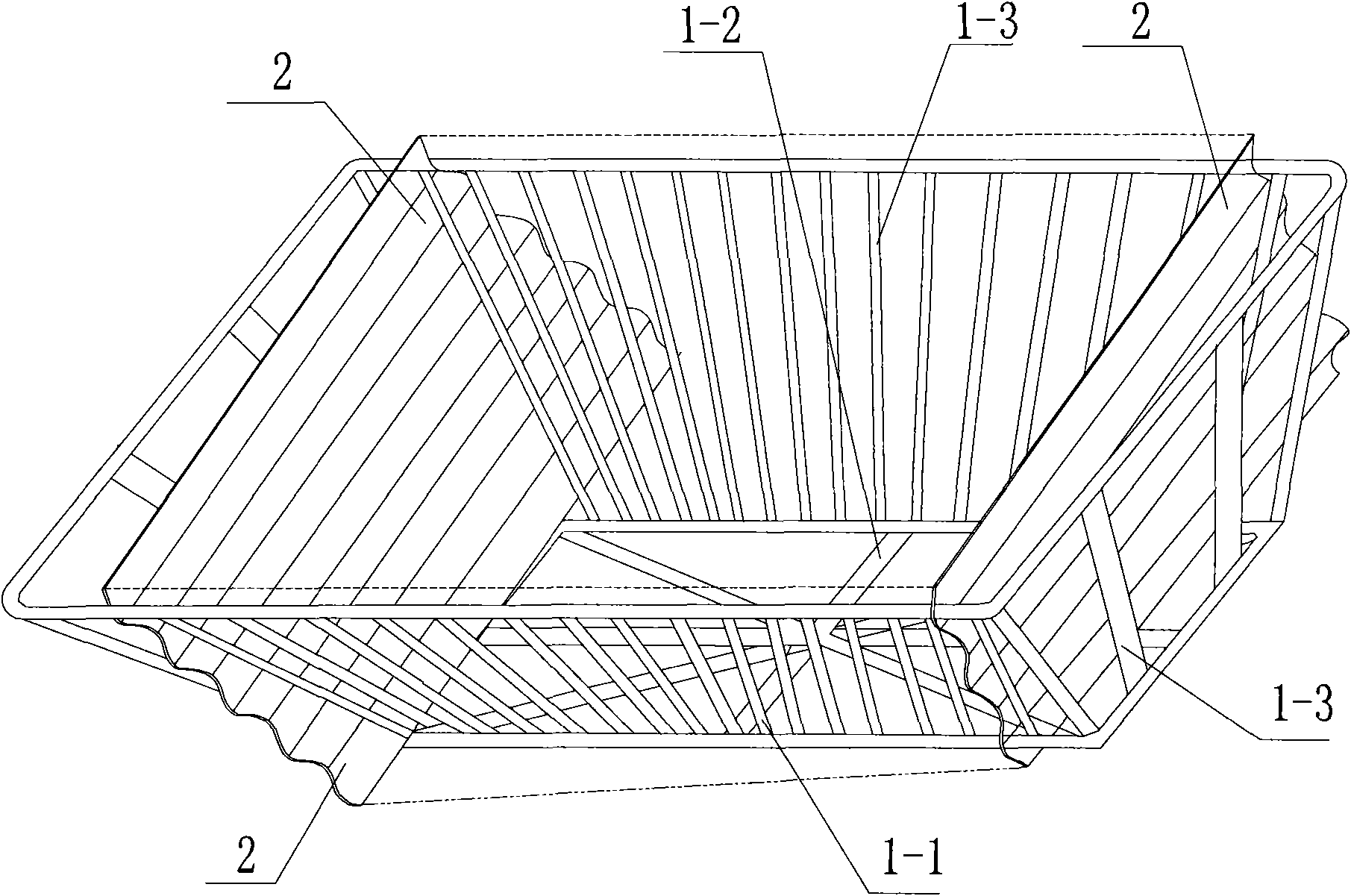

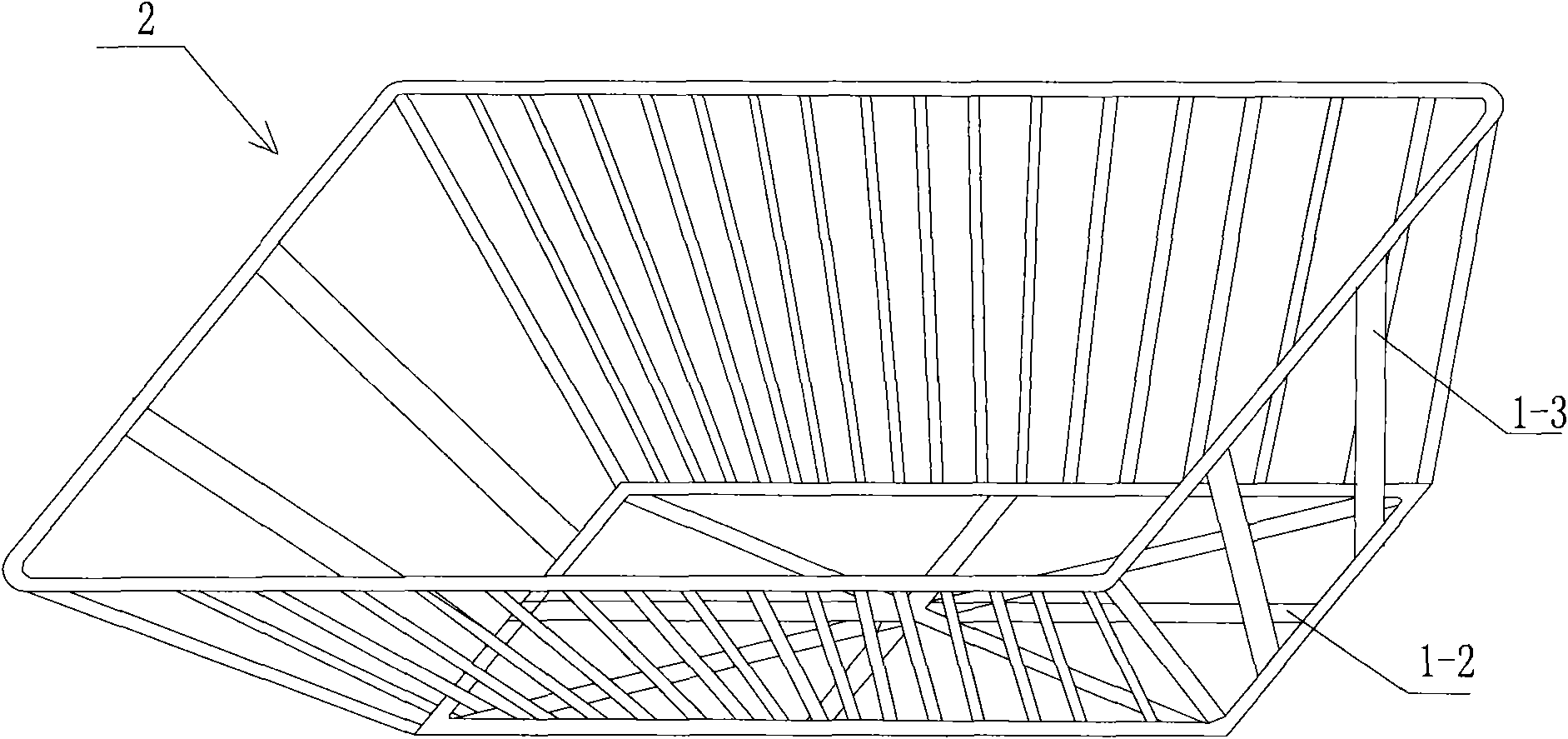

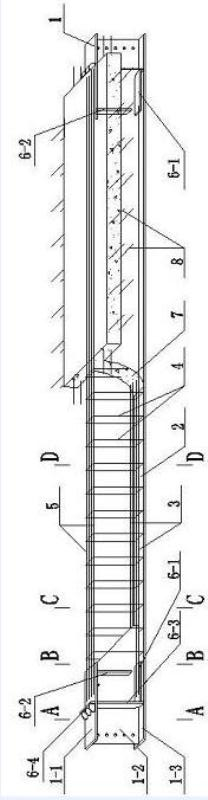

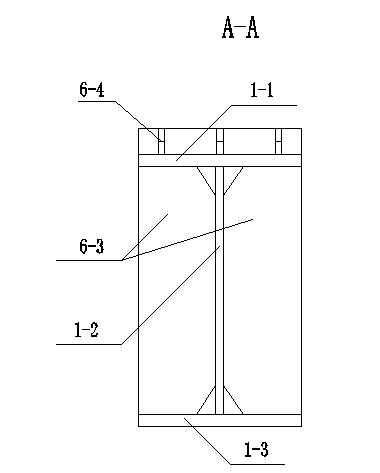

Foaming material filling box with reinforced layer and slurry leakage hole

ActiveCN102031870AEasy to pourEnsure safetyFloorsForms/shuttering/falseworksEngineeringShock resistance

The invention relates to a foaming material filling box with a reinforced layer and a slurry leakage hole and a manufacturing method thereof, belonging to the field of building construction. A main material of a body (2) of the filling box (1) is a light weight foaming material, the plane shape of the filling box (1) is rectangular, and the ratio of a long side to a short side is not more than 2;the upper surface of the body (2) is provided with the hard reinforced layer (3), the outer surface of the body is provided with an isolation layer (4); the hard reinforced layer (3) is located between the body (2) and the isolation layer (4); tangential angles or arc chamfers (5) are arranged at the peripheries of the upper surface and the lower surface of the filling box (1); and the middle part of the filling box (1) is provided with the vertical slurry leakage hole (6), the upper end of the slurry leakage hole (6) is in a big end up funnel shape, and the lower end of the slurry leakage hole (6) is in a big end down inverse funnel shape. In the invention, the sectional shape of the filling box meets the mechanical requirement, and the filling box is very convenient for production, transportation and installation, and has better structural reliability, shock resistance and crack resistance and favorable economical efficiency and applicability.

Owner:徐焱

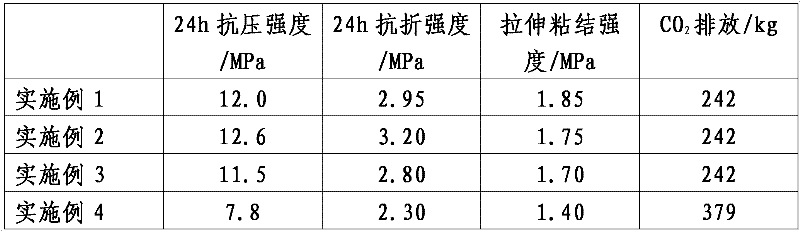

Desulfurization alpha semi-hydrated gypsum self-leveling mortar

The invention belongs to a construction mortar material, and particularly relates to desulfurization alpha semi-hydrated gypsum self-leveling mortar. The conventional cement-based self-leveling motor has the defects of low construction efficiency, low strength, massive cement consumption in mortar and disadvantage to energy conservation and environmental protection. The desulfurization alpha semi-hydrated gypsum self-leveling mortar is prepared by uniformly mixing and stirring the following materials in parts by weight: 40 to 60 parts of desulfurization alpha gypsum, 4 to 6 parts of cement, 20-30 parts of quartz sands of between 40 and 80 meshes, 20 to 30 parts of quartz sands of between 80 and 120 meshes, 0.06 to 0.10 part of retarder, 0.06 to 0.08 part of a water reducing agent, 0.08 to 0.10 part of a water-retaining agent, 0.05 to 0.08 part of a defoaming agent, 2 to 3 parts of re-dispersible gelatin powder, and 22 to 24 parts of water. The desulfurization alpha semi-hydrated gypsum self-leveling mortar has the advantages of high early-stage strength, strong adhesive force with a substrate, no radiation, low emission of CO2, high construction efficiency, and resource utilization of desulfurization gypsum.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

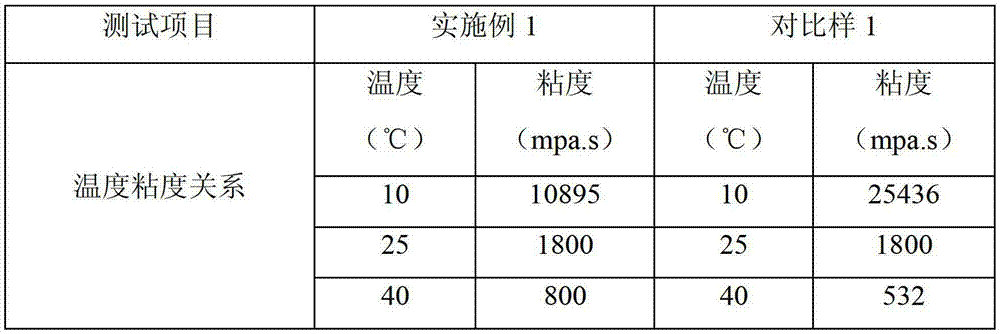

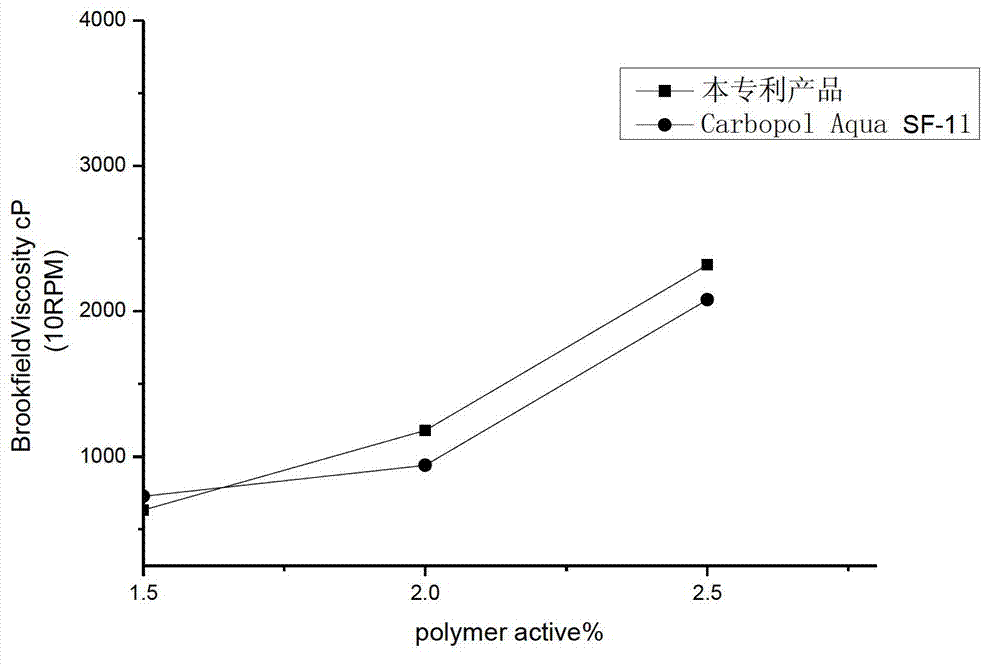

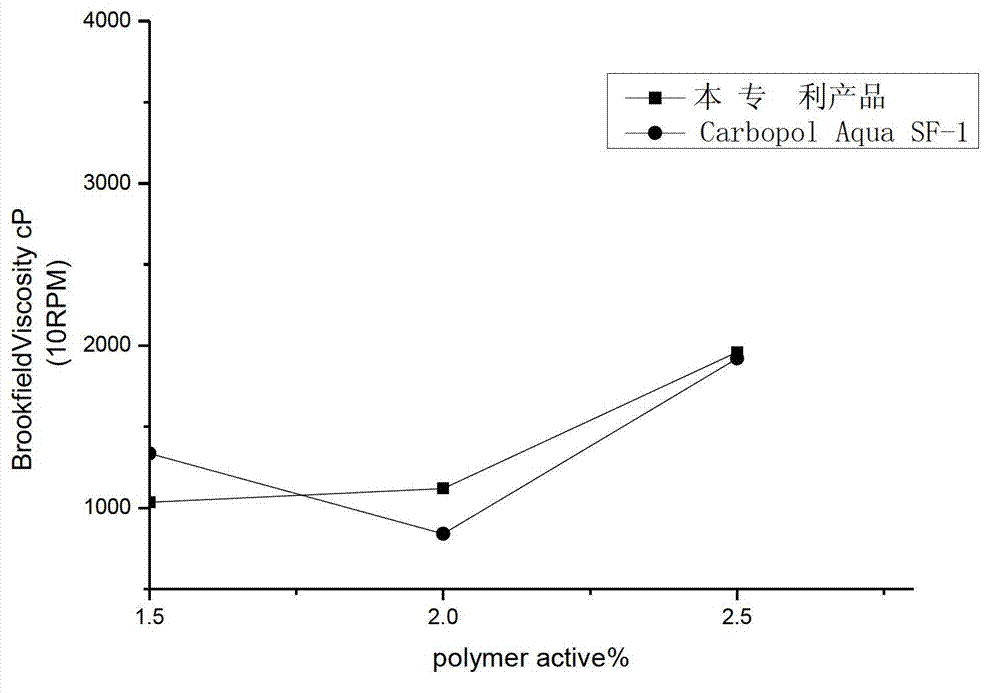

Fruit, vegetable and tableware detergent with good rheological property

ActiveCN103242974AEasy to useGood high and low temperature fluidityOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsNonionic surfactantViscosity modifier

The invention discloses a fruit, vegetable and tableware detergent with a good rheological property. The detergent comprises the following raw material components in percentage by weight: 0.01-5.0% of a fluidity modifier, 5.0-40.0% of an anionic surfactant, 0.5-15.0% of a nonionic surfactant, 1.0-8.0% of an amphoteric surfactant, 0.1-8.0% of a viscosity modifier, 0.01-0.2% of an antiseptic agent, 0.01-0.5% of a chelating agent, 0.01-10% of other components, and the balance of deionized water. The invention relates to the detergent with viscosity characteristics, and the fluidity modifier is added into the detergent, so that the rheological property is improved, and the needs of consumers can be well satisfied.

Owner:GUANGZHOU LIBY

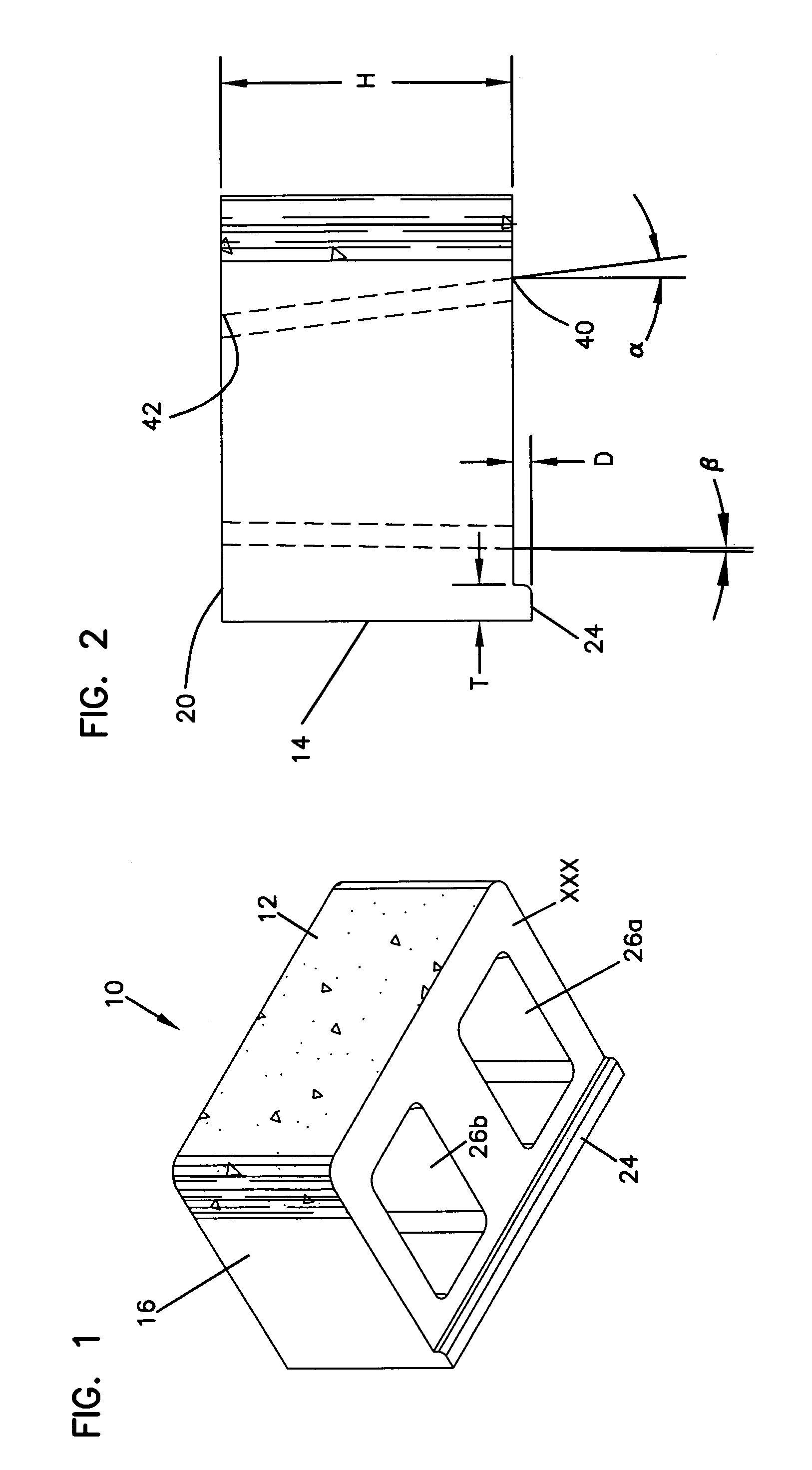

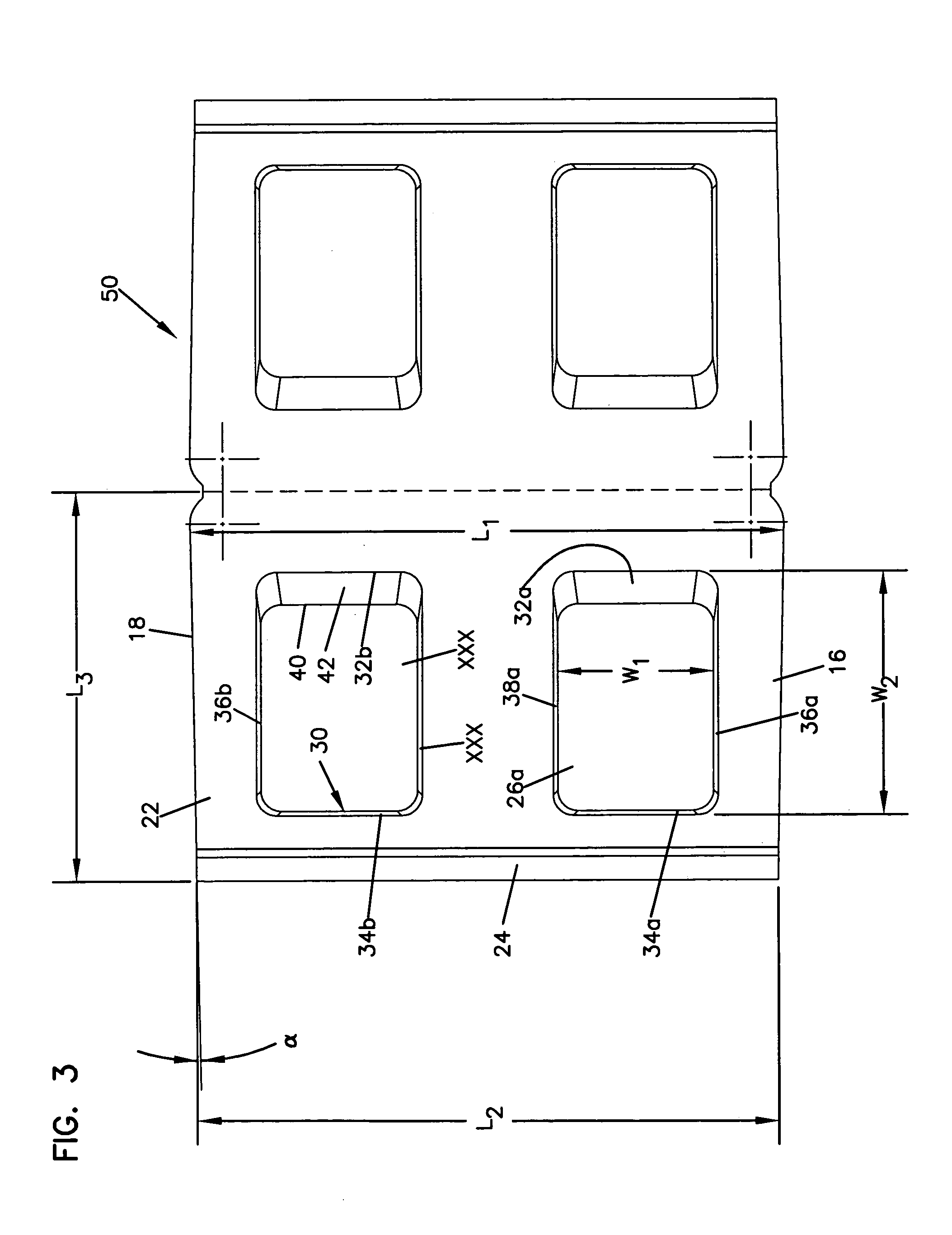

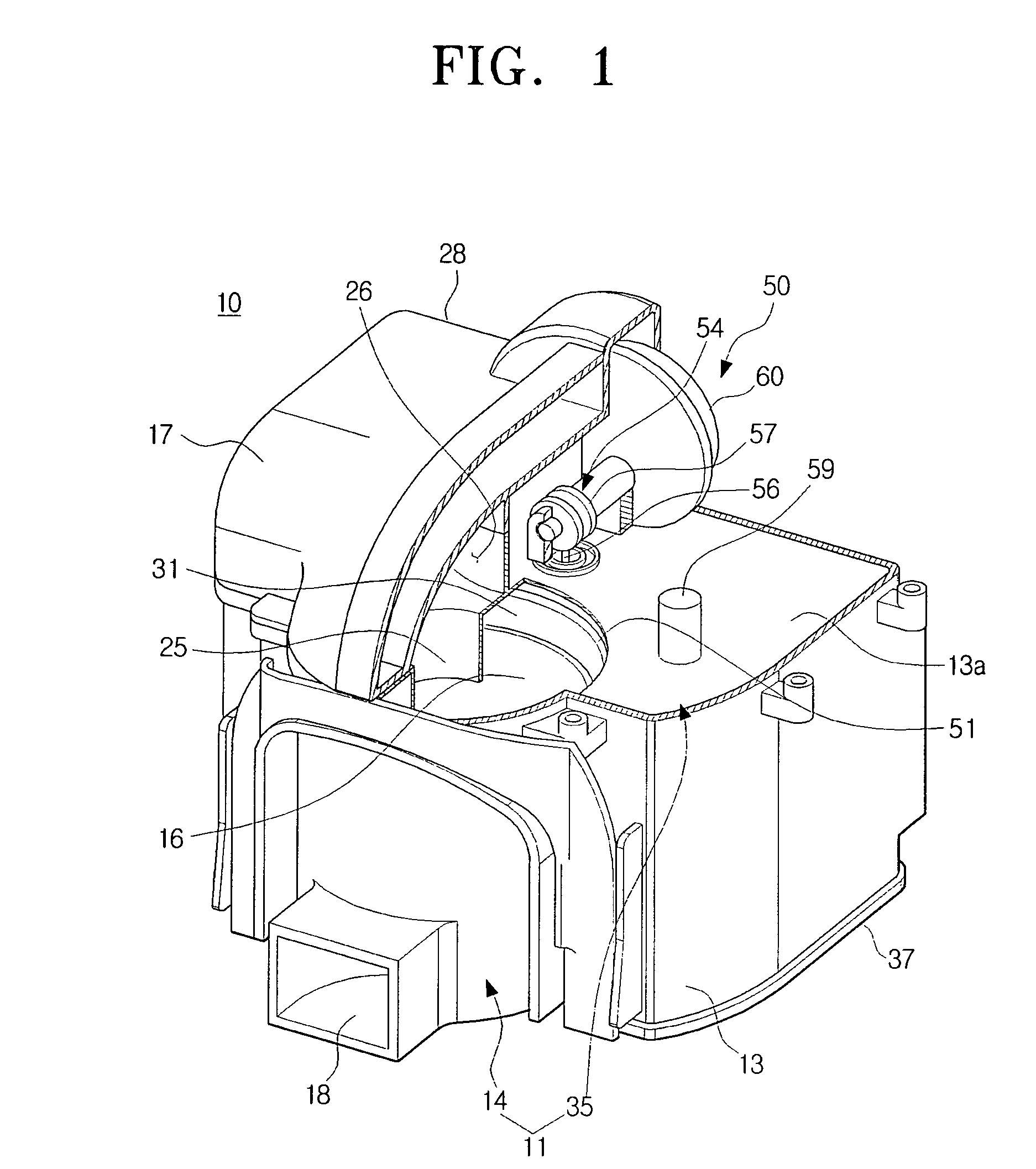

Combination herb storage, grinder and pouring container

ActiveUS8695906B2Easy to pourMinimizes and eliminates odorCoffee millsSpice millsMechanical engineering

A combination herb storage, grinder and pouring container includes a grinding and pouring cup having grinding elements. A cap is removably attached to the grinding and pouring cup. An herb storage receptacle is nested within the cup and cap. The receptacle defines an herb storage compartment having grinding elements extending therefrom so as to be disposed adjacent to the grinding elements of the cup, so as to selectively grind herbs placed between the storage receptacle and the cup. Preferably, the cup and cap are removably locked to one another, and an airtight and watertight seal formed between the cap, cup and storage receptacle.

Owner:HAINBACH MARK

Polymer latex and application thereof

InactiveCN102863594AOmit demulsificationEasy to pumpTransportation and packagingSurface-active non-soap compounds and soap mixture detergentsPolymer sciencePhosphoric acid

The invention discloses a polymer latex which can be obtained by the reaction among alpha, beta-vinyl unsaturated carboxylic acid monomer (I) and or acid monomer with sulfonic acid, phosphoric acid or hypophosphorous acid, alpha, beta-vinyl unsaturated monomer (II), hydrophilic unsaturated crosslinking monomer or bifunctional and multifunctional vinyl unsaturated crosslinking monomer (III-VI), nonionic vinyl or acryl surface active agent (VII), anionic emulsifier, initiator, and chain transfer agent, wherein the polymer latex can be used for forming into a binary system in a surface active agent composition. Due to the unique crosslinking nodes in the polymer latex, the polymer latex can be used in various fields even under the low-pH and high-salt content severe environment such as the cosmetics, the medicines, the emulsion paint, and the effective and high-efficiency thickening agent and suspending agent in cleaning composition.

Owner:JIANGSU FEIXIANG CHEM

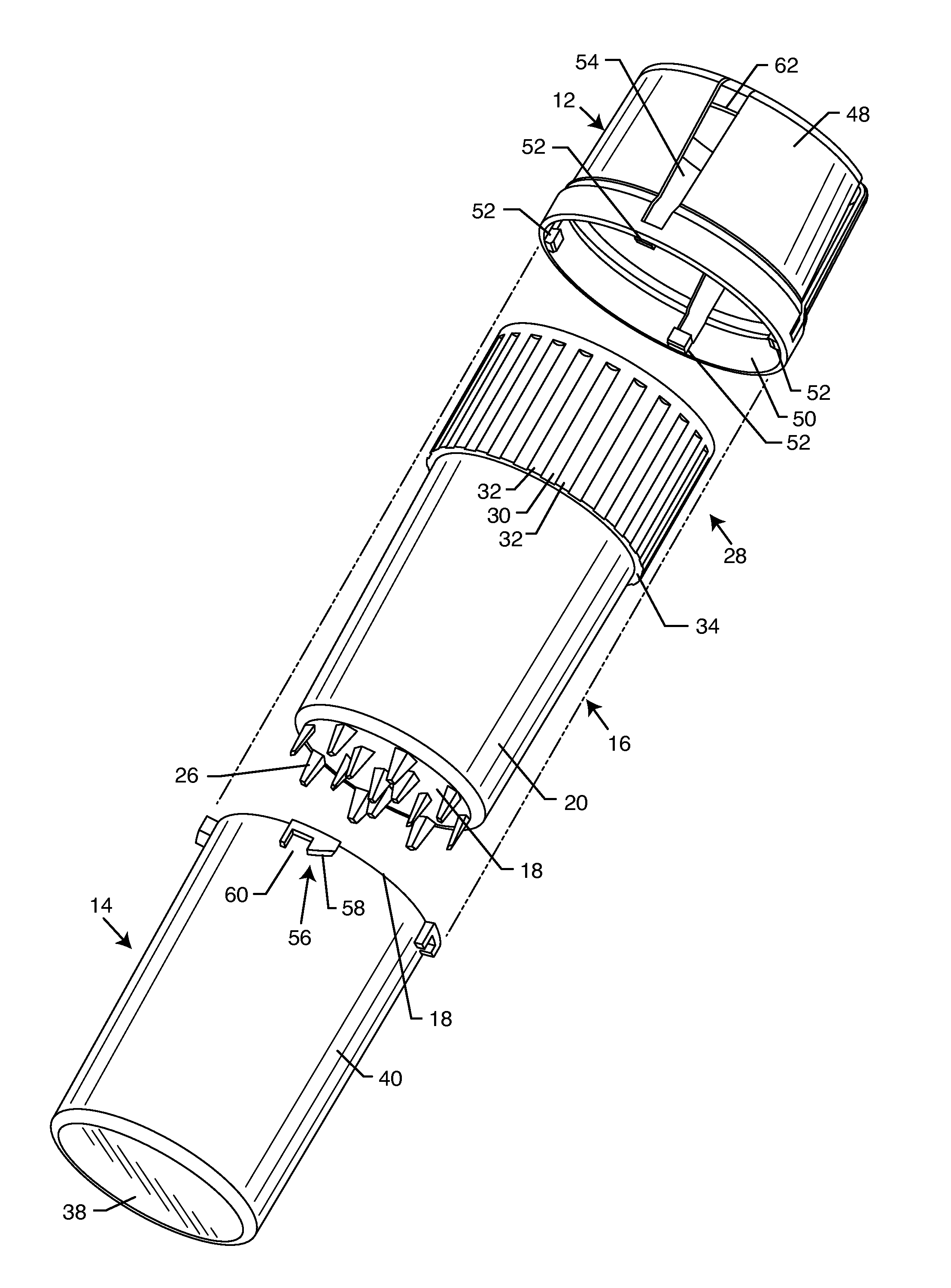

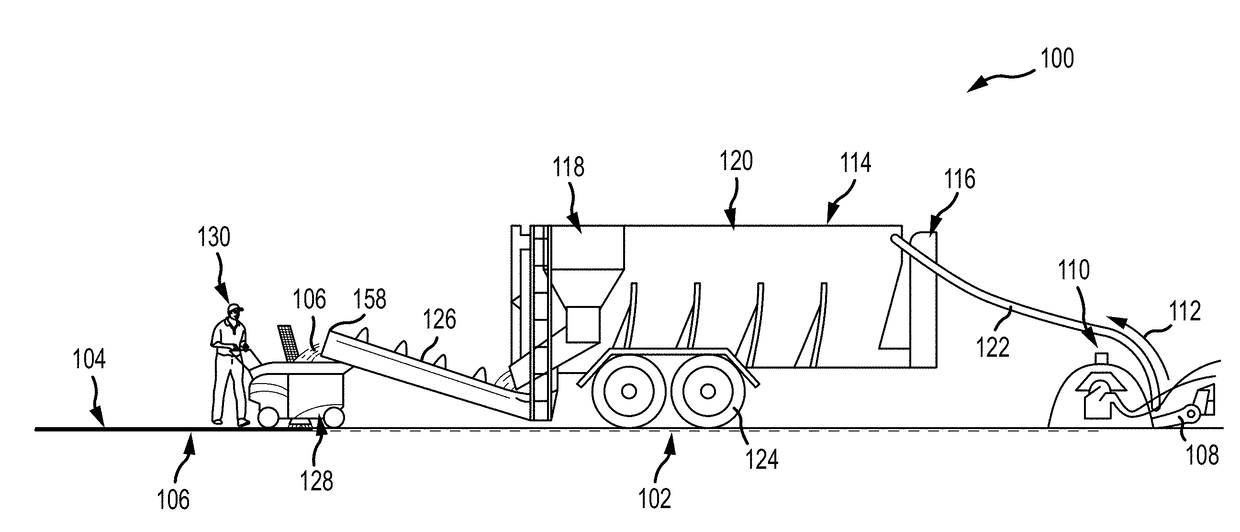

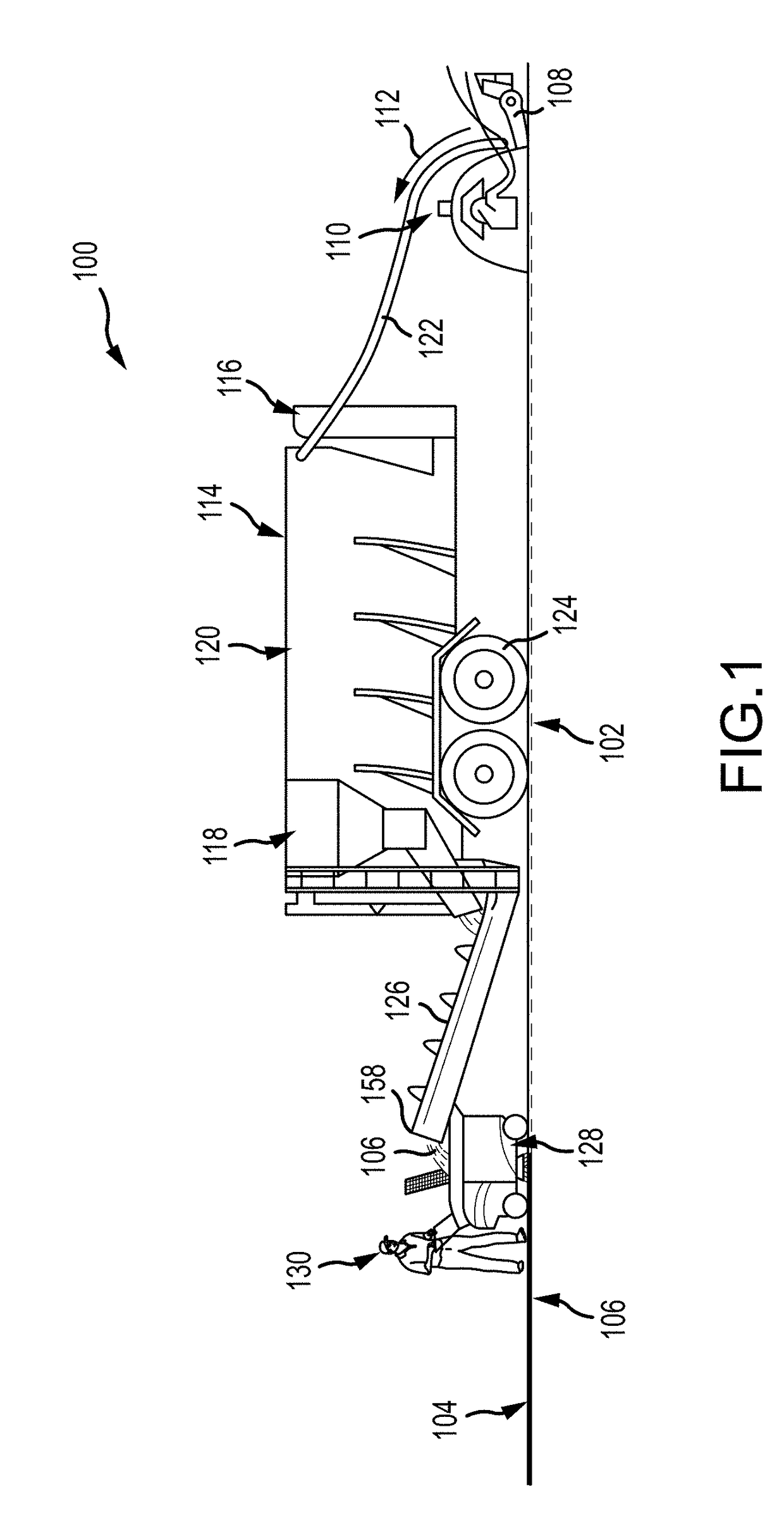

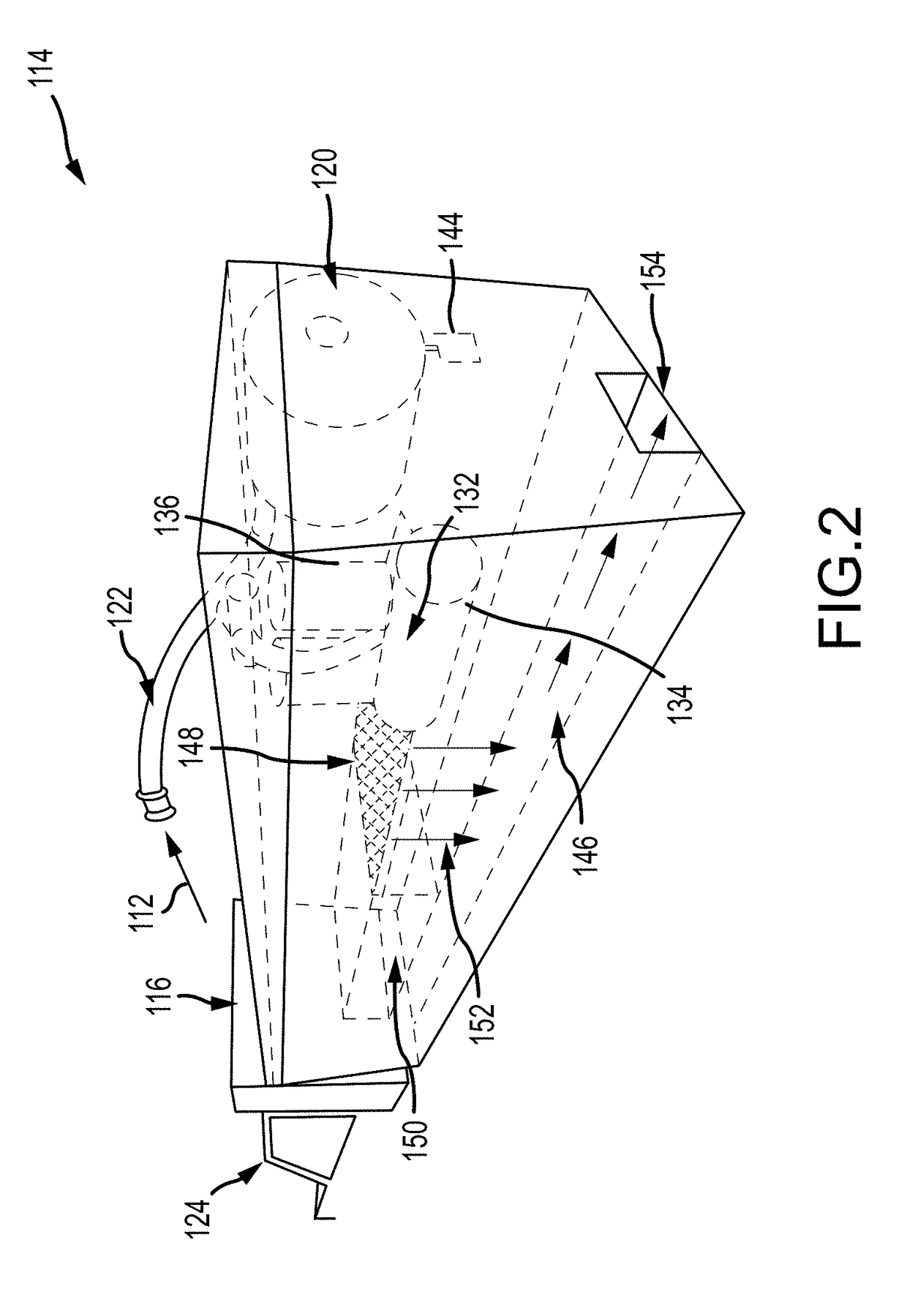

Volumetric concrete mixing system, equipment, and method

ActiveUS20180126592A1Easy to pourRotary stirring mixersTransportation and packagingWaste managementCement

A mobile volumetric concrete mixing system includes a suction system that vacuums up trench spoils while a trench is being cut. These trench spoils are then screened on-site for particle size to be reused and mixed with water, cement, and / or other admixtures at an auger mixer to form a backfill mixture. This backfill mixture may then be loaded into a hopper that continuously agitates the mixture so that the mixture does not harden before pouring. The agitating hopper is coupled to a discharge chute of the auger mixer and includes one or more augers disposed at various orientations that the backfill mixture is channeled through. From the agitating hopper, the backfill mixture is channeled to an applicator that moves along the trench and that enables the mixture to be quickly poured into the trench with little clean-up required.

Owner:J&P INVESCO LLC

Compositions and articles containing a cross-linked polymer matrix and an immobilized active liquid, as well as methods of making and using the same

ActiveUS20080070025A1Suitable for useEasy to pourLayered productsDeodrantsCross-linkCrosslinked polymers

The invention relates to compositions and articles containing a cross-linked polymer matrix and an immobilized active liquid, as well as methods of making and using the same.

Owner:CRODA INT PLC

Preparation method of aluminum oxide metal ceramic reinforced iron-based composite

The invention relates to a preparation method of aluminum oxide metal ceramic reinforced iron-based composite, namely, aluminum-oxide-based metal ceramic is used as a structural framework and one of effective components to prepare metal ceramic iron-based composite, which is consistent in structure, even in metal phase distribution, high in mechanical performance, and high in wear resistance, under certain pressure by melt casting and further processing. The preparation method includes the steps of firstly, preparing aluminum oxide metal ceramic framework base pretreated by activated Si into surface-modified prefabricated ceramic part with a silk-screen-shaped pore structure by high-temperature sintering; secondly, preparing a pouring sand module; thirdly, placing the pouring sand module into a casting sand box for pretreating, pouring, vacuumizing, and allowing iron-based molten metal to fully permeate into pores of the prefabricated ceramic part to form a rigid integrity; and fourthly, performing heat treatment and air cooling to obtain the iron-based composite with closely combined aluminum oxide metal ceramic and iron base.

Owner:北京康盛宏达科技有限公司

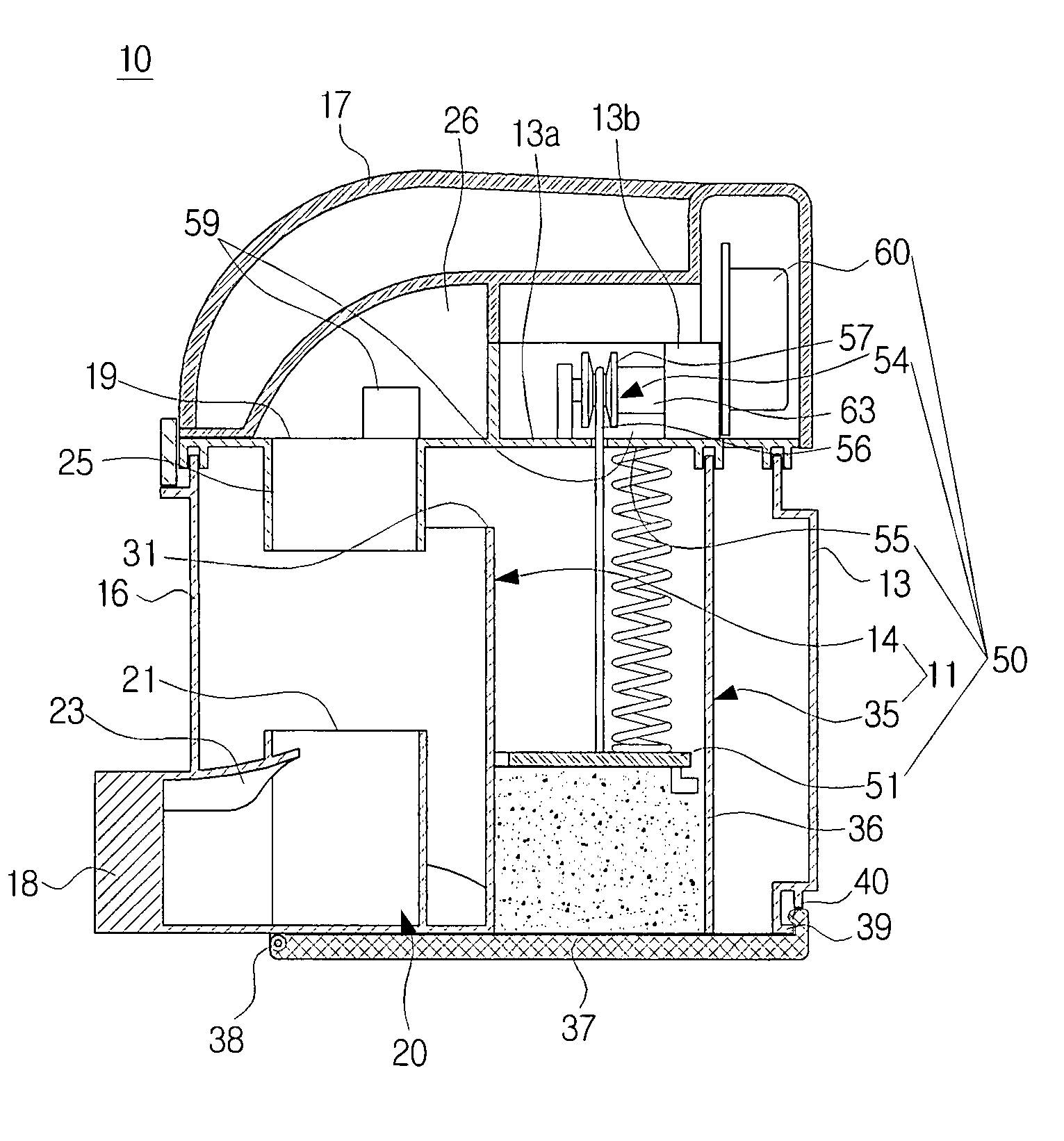

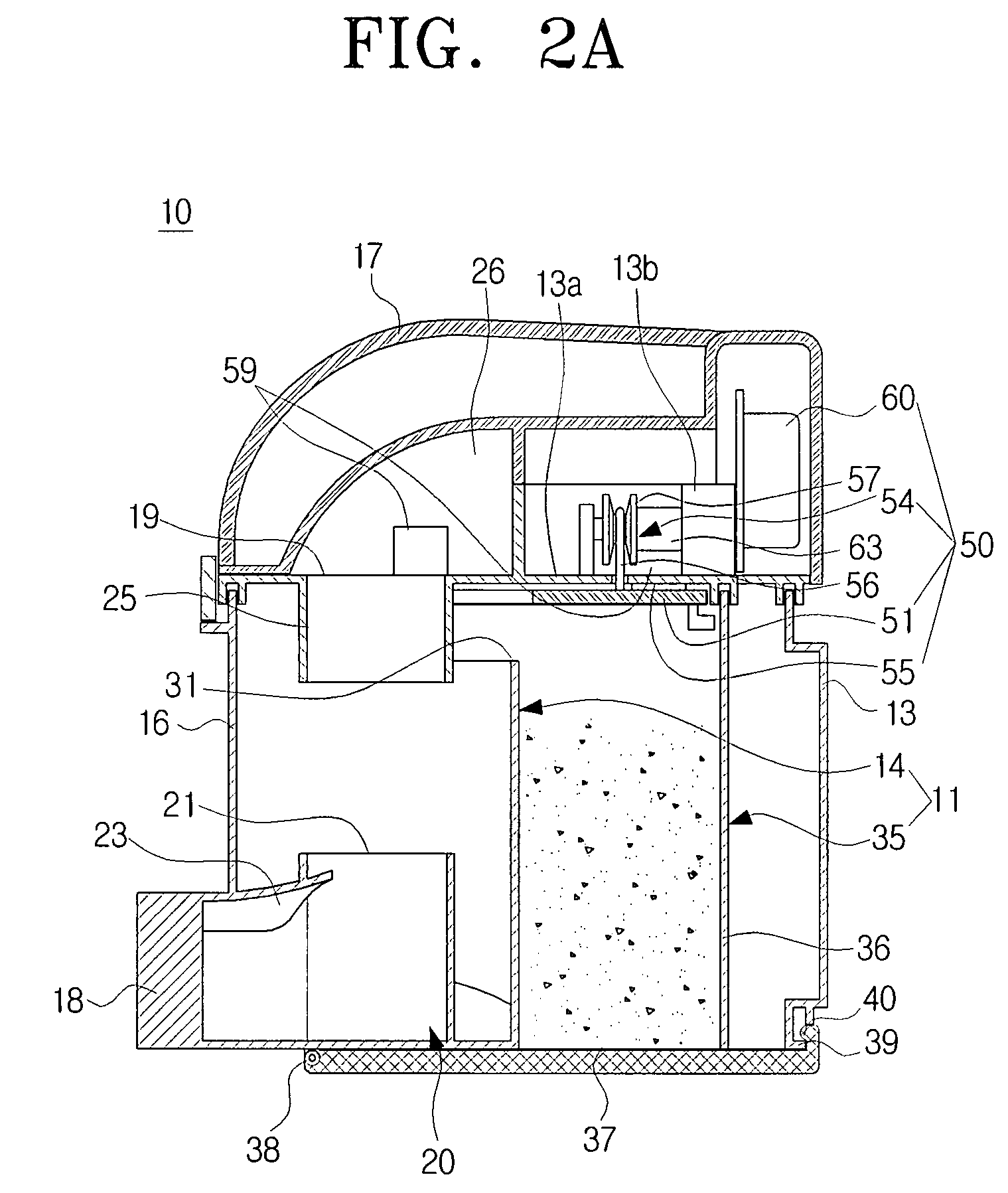

Dust compressing apparatus of vacuum cleaner

A dust compressing apparatus of a vacuum cleaner capable of automatically compressing dust or dirt collected in a dust separating unit is disclosed. The dust compressing apparatus includes a compressing plate to compress the dust or dirt collected in the dust separating unit, a moving unit connected to the compressing plate on one side of the dust separating unit to move the compressing plate, an elastic unit to elastically urge the compressing plate to a compressing position where the compressing plate compresses the dust or dirt, and a driving motor to drive the moving unit thus to move the compressing plate.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

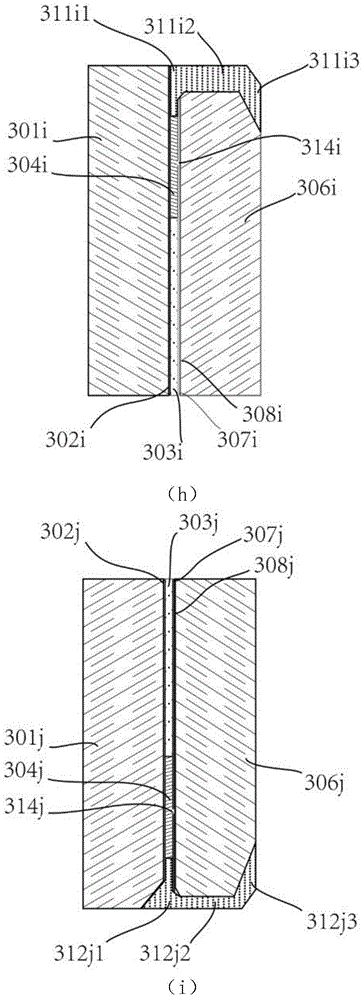

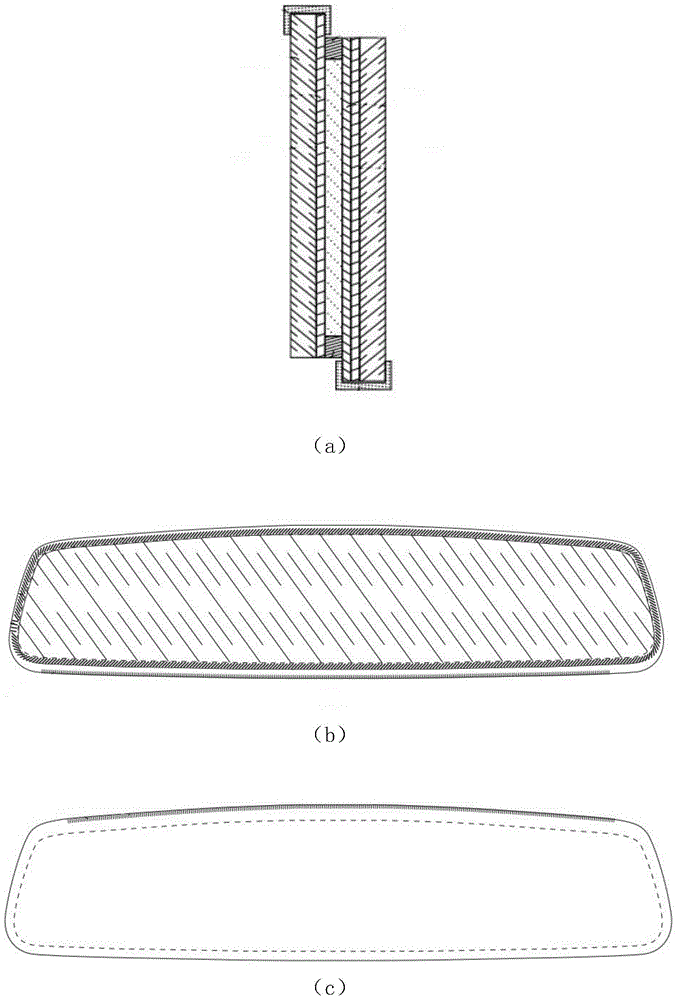

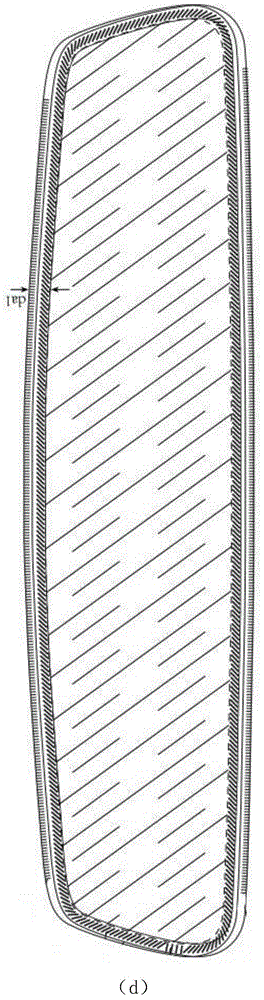

Manufacturing packaging method of electrochromic anti-dazzle device for vehicle

The invention relates to a packaging method of an electrochromic anti-dazzle device, and in particular relates to a packaging manufacturing method for edging and chamfering in a conduction region, where an electrode needs to be imported, of the conductive layer of the glass substrate of the electrochromic anti-dazzle device so as to increase the sectional area of a conductive silver adhesive; according to the requirements of reduce the package and the electrode leading-out region of the electrochromic anti-dazzle device and increasing the thermochromic device structure of a visible range, the packaging of the electrochromic anti-dazzle device is completed by use of the techniques of etching, vacuum electrochromic material pouring, sealant box hot pressing, silver adhesive pouring, heat treatment and the like. Compared with the traditional packaging of the electrochromic anti-dazzle device, the electrical conductivity of the silver adhesive after heat treatment is improved, the width of the conductive sealant is reduced and the production process and the equipment are simplified; the packaging method has obvious advantages; the height of the visual range of the electrochromic anti-dazzle device package is increased by 2-3mm.

Owner:CHANGZHOU YAPU NEW MATERIALS CO LTD

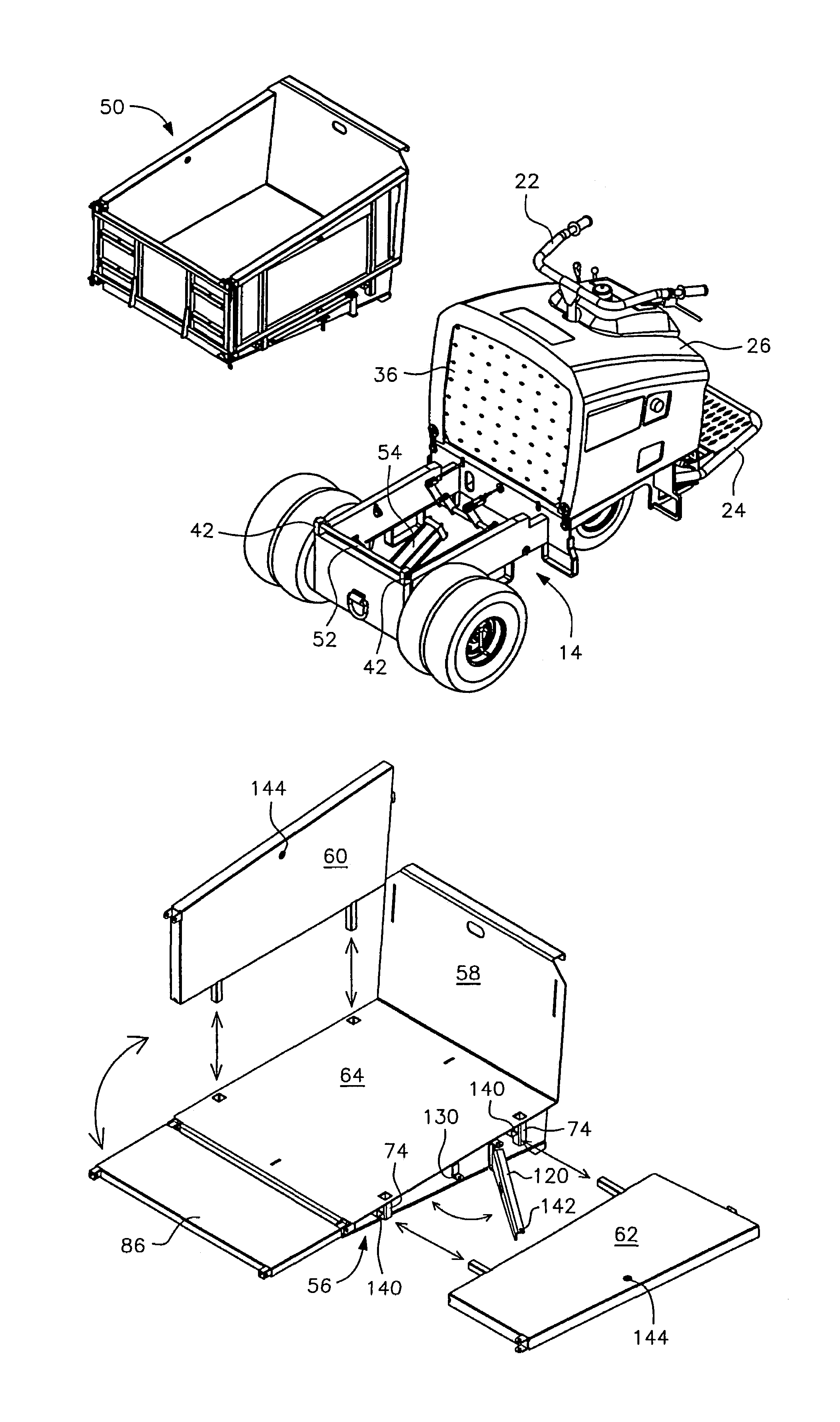

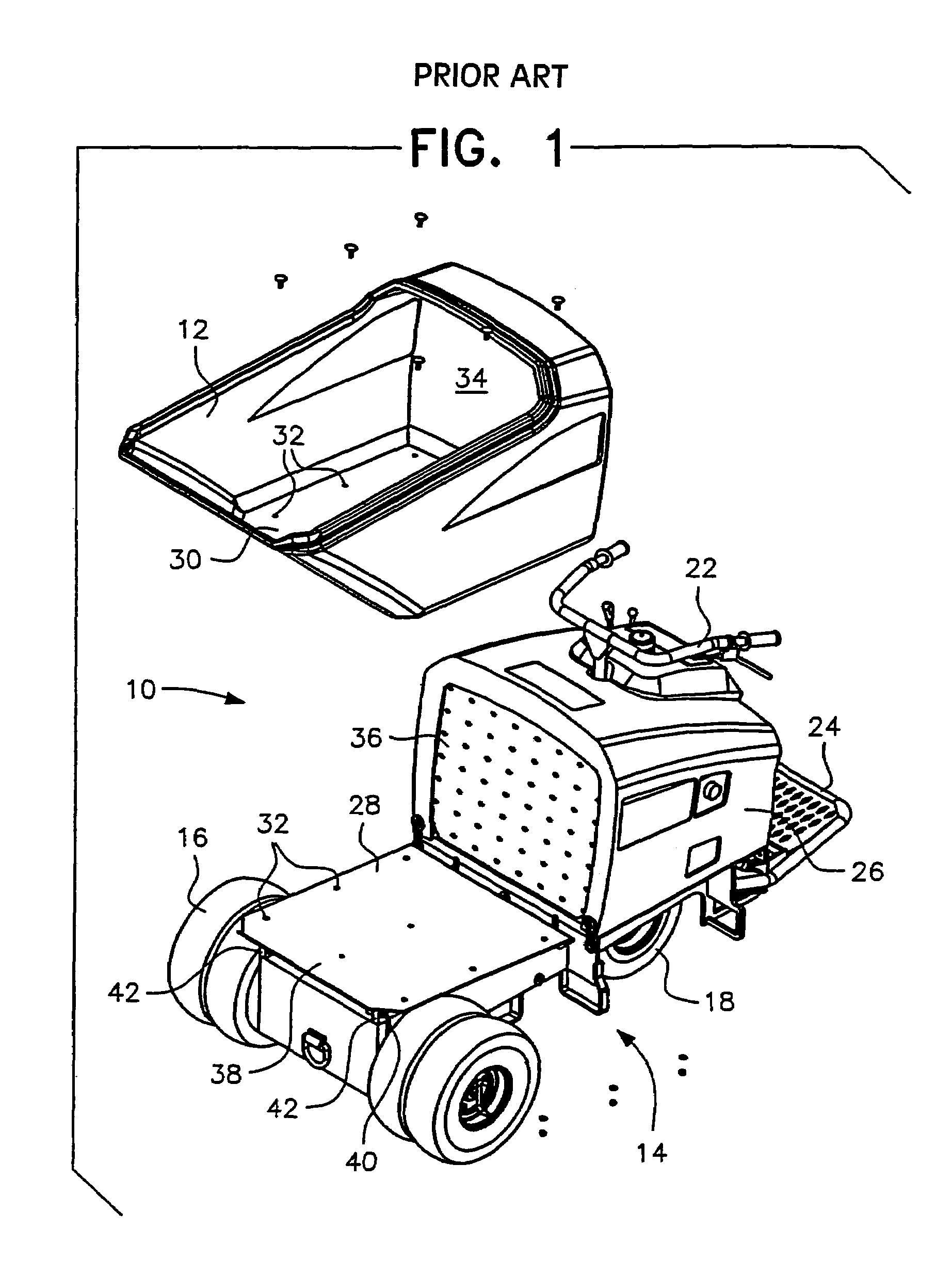

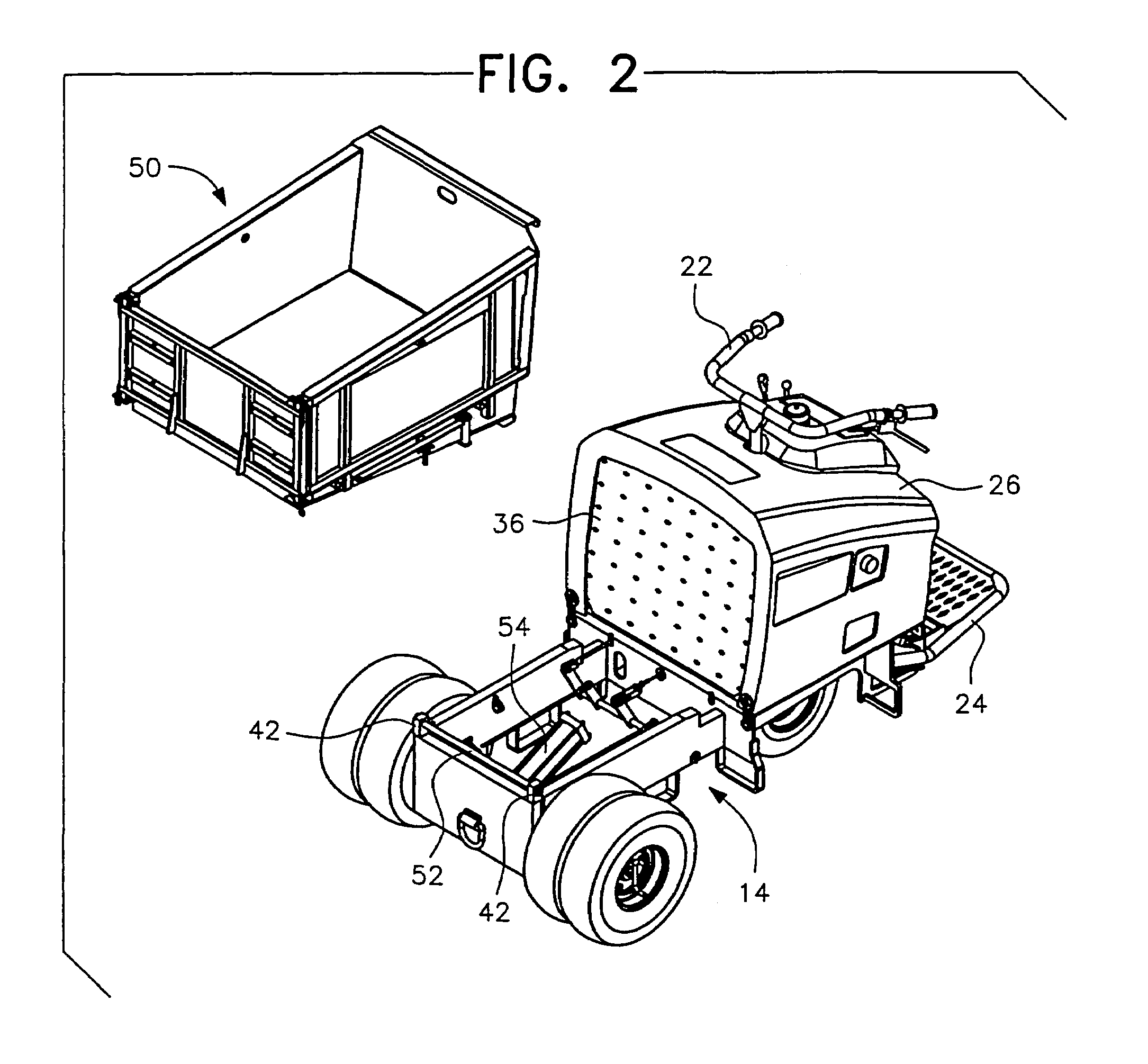

Mortar buggy with stake bed assembly

ActiveUS7201453B2Easy to pourReadily and easily convertedVehicle with living accommodationSuperstructure subunitsAlloyEngineering

Owner:TORO CO THE

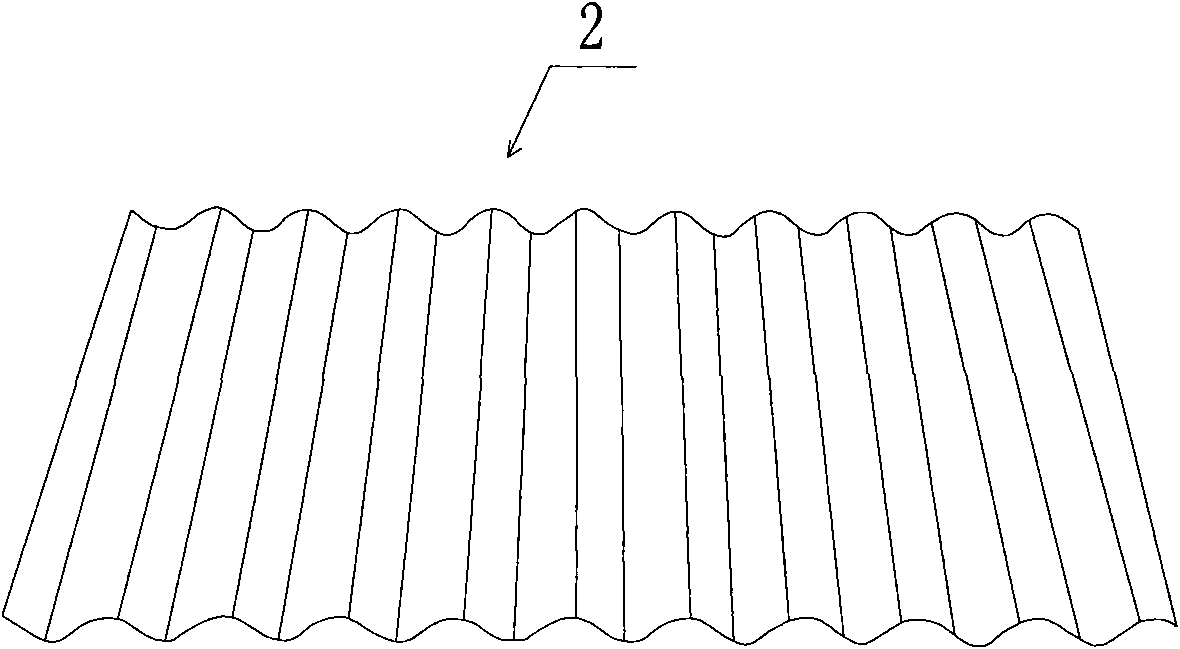

Method for culturing monomeric oyster seeds and seed collector

InactiveCN101773079AEasy to useExcellent adhesionClimate change adaptationPisciculture and aquariaOysterMonomer

The invention provides a method for culturing monomeric oyster seeds and a seed collector. The problems such as poor seed fixation effect, difficult substrate removal and the like in the prior art can be solved. By using a plastic corrugated plate as the fixation substrate of the monomeric oyster seeds in the invention, the problems such as unsatisfactory seed collection effect, difficult substrate removal, easy breakage of the oyster seeds, mutual conglomeration and attachment of oysters and the like in the prior art are solved.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

Cast-in-place steel-concrete composite beam

ActiveCN101845871AFast constructionFast integrityLoad-supporting elementsFloor slabReinforced concrete

The invention discloses a cast-in-place steel-concrete composite beam, which relates to a composite beam. The cast-in-place steel-concrete composite beam solves the problems that a reinforced concrete beam and a column connection node in the existing steel structure and the existing steel-concrete composite structure have complex structures and are difficult to construct, the problems that a common composite beam has a large steel consumption and a high structure manufacturing cost, and the problems that a composite beam of which the publication number is CN101215855 is complex in operation and is inconvenient to construct when connected with a reinforced concrete wall column, and has low bearing capacity, small rigidity, weak spanning capacity, large fracture width for tensile region concrete and small application range. Bottom flanges of two I-shaped steel beam sections of the cast-in-place steel-concrete composite beam and a tensile region steel plate are made into an integral body; a longitudinal steel plate ribbed stiffener is connected through a fire-resisting longitudinal bar; top flanges of the two I-shaped steel beam sections are connected through a tensile region longitudinal bar; stirrups are uniformly arranged along the longitudinal direction of the fire-resisting longitudinal bar; floor steel bars are paved on a stiffening framework of the composite beam; and concrete is poured on the floor steel bars and the stiffening framework of the composite beam. The cast-in-place steel-concrete composite beam is applied to civil engineering constructions.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com