Patents

Literature

808results about How to "Facilitate continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

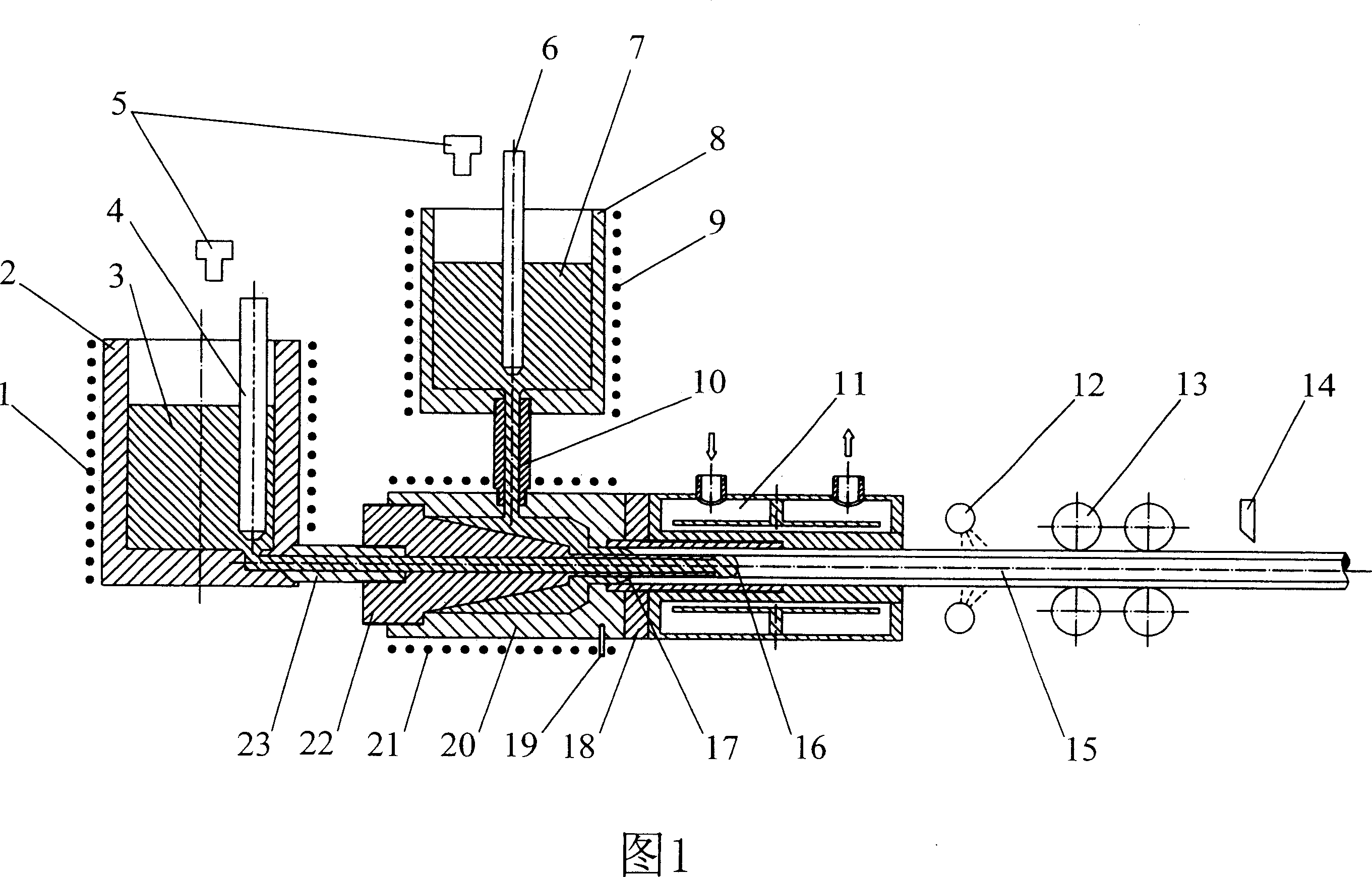

Coating material horizontal continuous casting direct recombination forming apparatus and technology

ActiveCN1927504AAchieve energy saving and consumption reductionContinuous pullHeating elementCrucible

The invention relates to a package material horizontal casting shaping device. Wherein, it comprises core metal temperature-control pot, package metal temperature-control pot, core metal liquid irrigate tube, package metal crystallizer, drawing device, temperature tester, heating element and secondary cooler; and the producing method comprises the temperature of package metal is kept by the package metal temperature-control pot, passing through the package metal thermal-insulated chamber, irrigates into the casting mould formed by crystallizer and irrigate tube to be solidified into package metal tube; the core metal is solidified in the solidified package metal tube, with he package metal tube to form composite cast ingot; the cast ingot via second cooler is cooled and drawn by the drawing device, to be cut by cutter at certain length. The invention has simple process and lower cost, while the interface between package metal and core metal has non oxidization and non pollution.

Owner:UNIV OF SCI & TECH BEIJING

Adsorption method for preparing hydroxyapatite pesticide and slow-release fertilizer compound

InactiveCN101589709AHas biodegradable propertiesQuality improvementBiocideAnimal repellantsBurst effectPhosphate

The invention discloses an adsorption method for preparing hydroxyapatite pesticide and slow-release fertilizer compound, which comprises the following steps: soaking a nano hydroxyapatite carrier in phosphate buffer solution, then adding a starting material into the buffer solution and continuously stirring the mixture to form compound solution, finally centrifuging the compound solution to obtain sediment, and drying the sediment to obtain the compound. By using a porous structure of the nano hydroxyapatite self to embed medicaments into an internal grid of the carrier, the burst effect of the medicaments is avoided, the medicinal effect is long, the medicament residue is greatly reduced, and the medicaments are safer. A product obtained by using the nano hydroxyapatite as a pesticide and fertilizer carrier has the advantages of reliable quality, strong stability, safe use and low cost, greatly improves the medicament loading amount and adsorption amount, is easy for continuous production, and has good application prospect.

Owner:JILIN UNIV

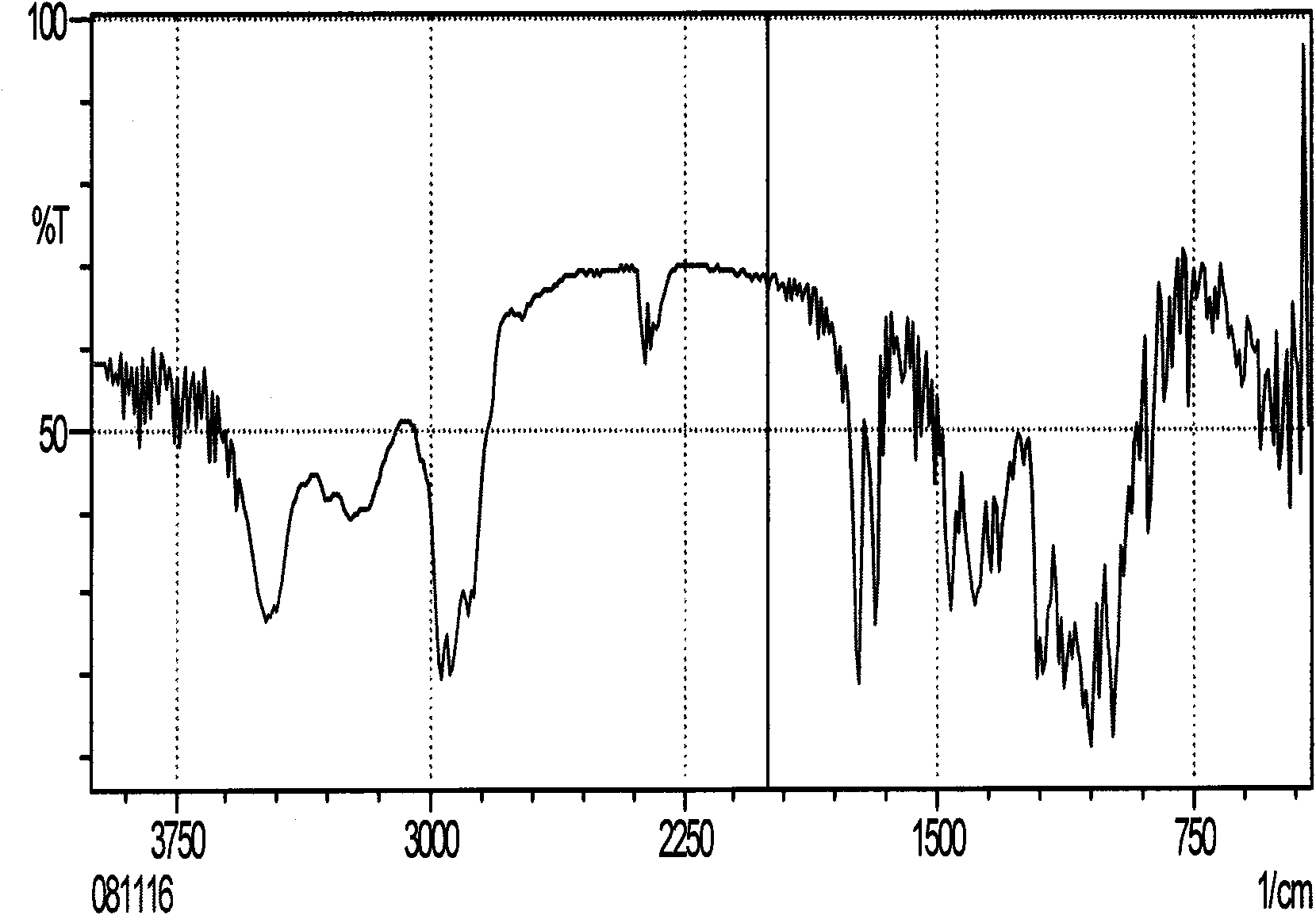

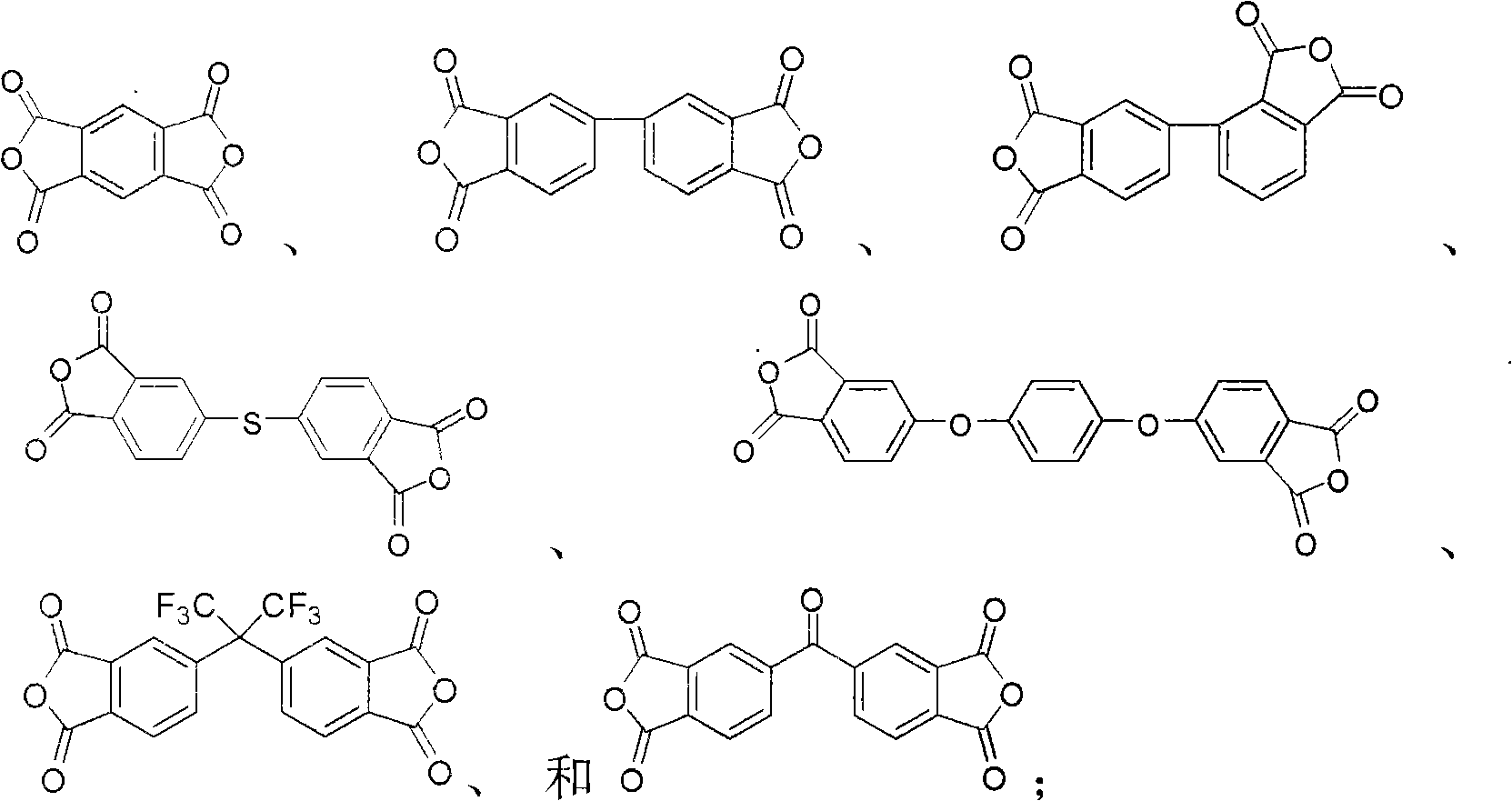

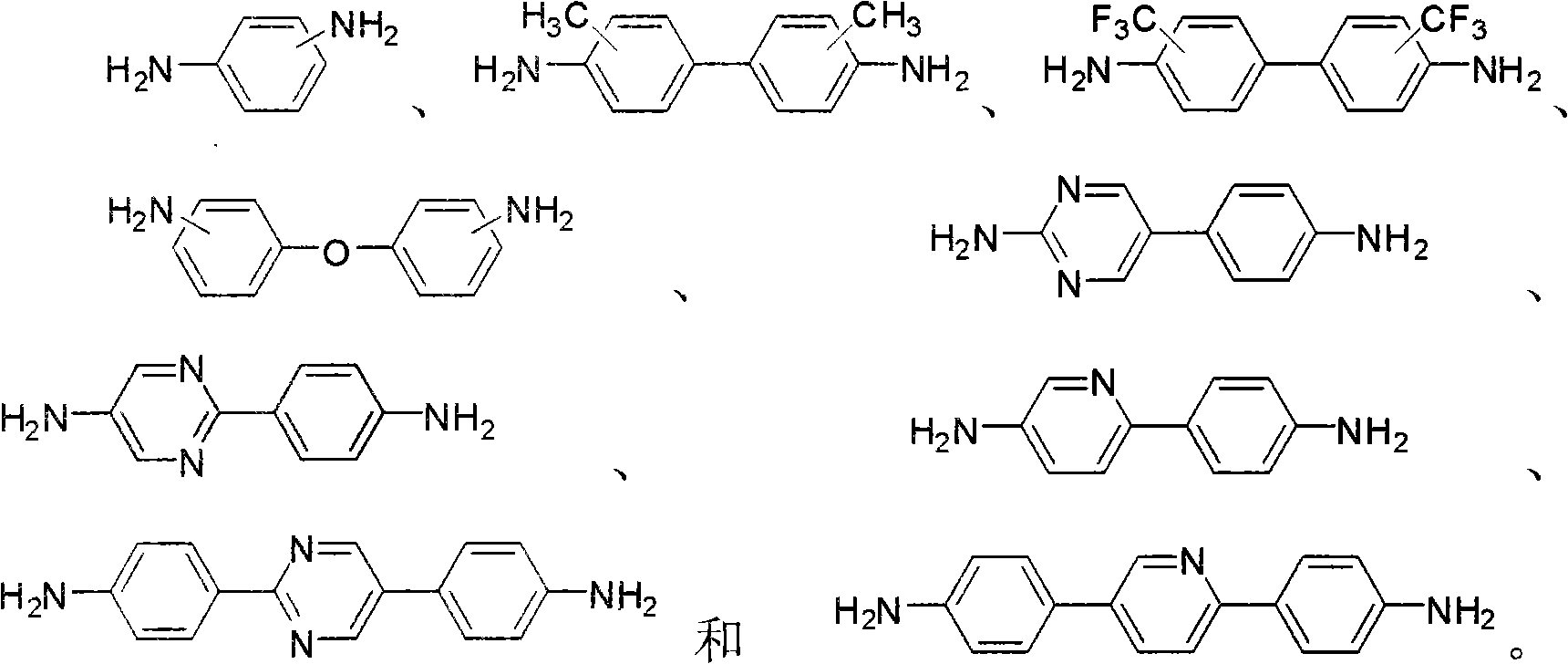

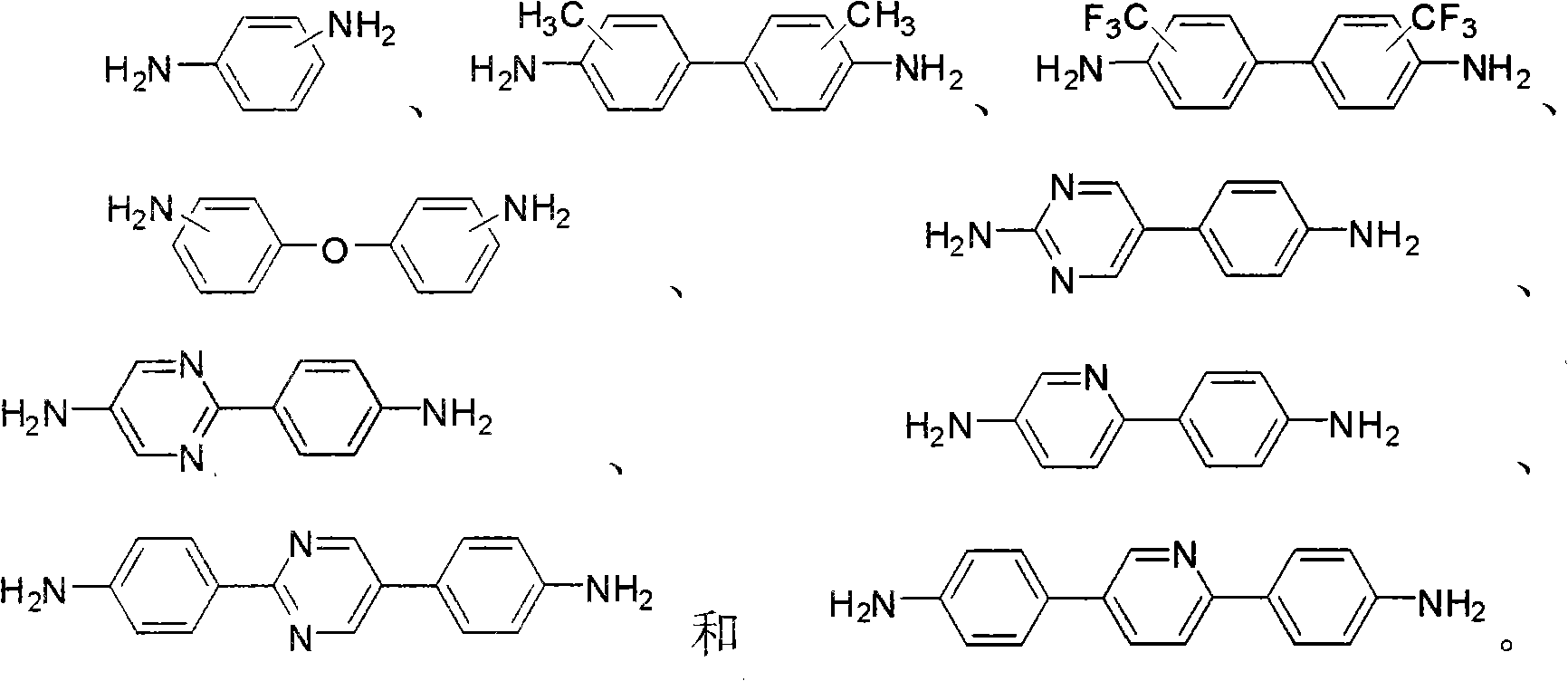

Method for preparing polyimide fiber

ActiveCN101338462AHigh strengthHigh modulusSynthetic polymer filament chemical after-treatmentMonocomponent polyamides artificial filamentFiberTemperature control

The invention relates to a preparation method of polyimide fiber. The procedures and conditions of the preparation method are as follows: (1) precursor acid polyamine solution used for spinning is made by fasculating diamine and dianhydride monomer; (2) the preparation of the polyimide fiber adopts dry-wet spinning process; (3) the polyimide fiber is imidized; and (4) the polyimide fiber undergoes the heat drawing under the temperature of 300 to 500 DEG C, and the drawing multiple of the fiber is 1 to 7 times. Imide process adopts a gradient heating-up thermal treatment furnace so as to overcome the defects of the inaccurate temperature control and the non-feasibility of the prior double thermal furnace process. The preparation method has simple process and is easy for continuous production. The prepared polyimide fiber has stronger strength and high modulus and can be used under the temperature of over 300 DEG C. In addition, the polyimide fiber has UV irradiating resistance property, a higher limited oxygen index and corrosion resistance, so the polyimide fiber can be widely applicable for the reinforced fiber of composite materials, a cable sheath, a cable reinforcing core, the mooring rope of vehicle and vessel and the filtering materials of high temperature or radioactive substance, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Fluororesin mixture, copper-clad plate prepared therefrom and manufacturing method thereof

ActiveCN101838431AImprove dipping qualityUniform glue contentGlass/slag layered productsMetal layered productsVinyl etherGlass fiber

The invention relates to a fluororesin mixture, a copper-clad plate prepared therefrom and a manufacturing method thereof. The fluororesin mixture contains the following two substances as necessary components in 100 parts by weight of an organic solid substance: 90-99 parts of polytetrafluoroethylene (PTFE) emulsions and 1-10 parts of polytetrafluoroethylene perfluoroalkyl vinyl ether (PFA) emulsions. The copper-clad plate prepared from the fluororesin mixture comprises a plurality of superimposed varnished cloths and copper foil coating one or two surfaces of the varnished cloths, and each varnished cloth comprises a glass fiber cloth and the fluororesin mixture attached to the dipped and dried glass fiber cloth. The fluororesin mixture is prepared by using the PTFE emulsions as main resins and can dip the glass fiber cloths many times under the condition that the PTFE sintering temperature is330 DEG C to prepare the vanished cloths, and the vanished cloths prepared from the fluororesin mixture has the advantages of good gum dipping quality, level surface, flexibility and easy operation; and besides, the copper-clad plate made from the fluororesin mixture has excellent dielectric performance which meets the dielectric performance requirement of the high-frequency communication field for a base plate material, and has simple making method and process and is beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

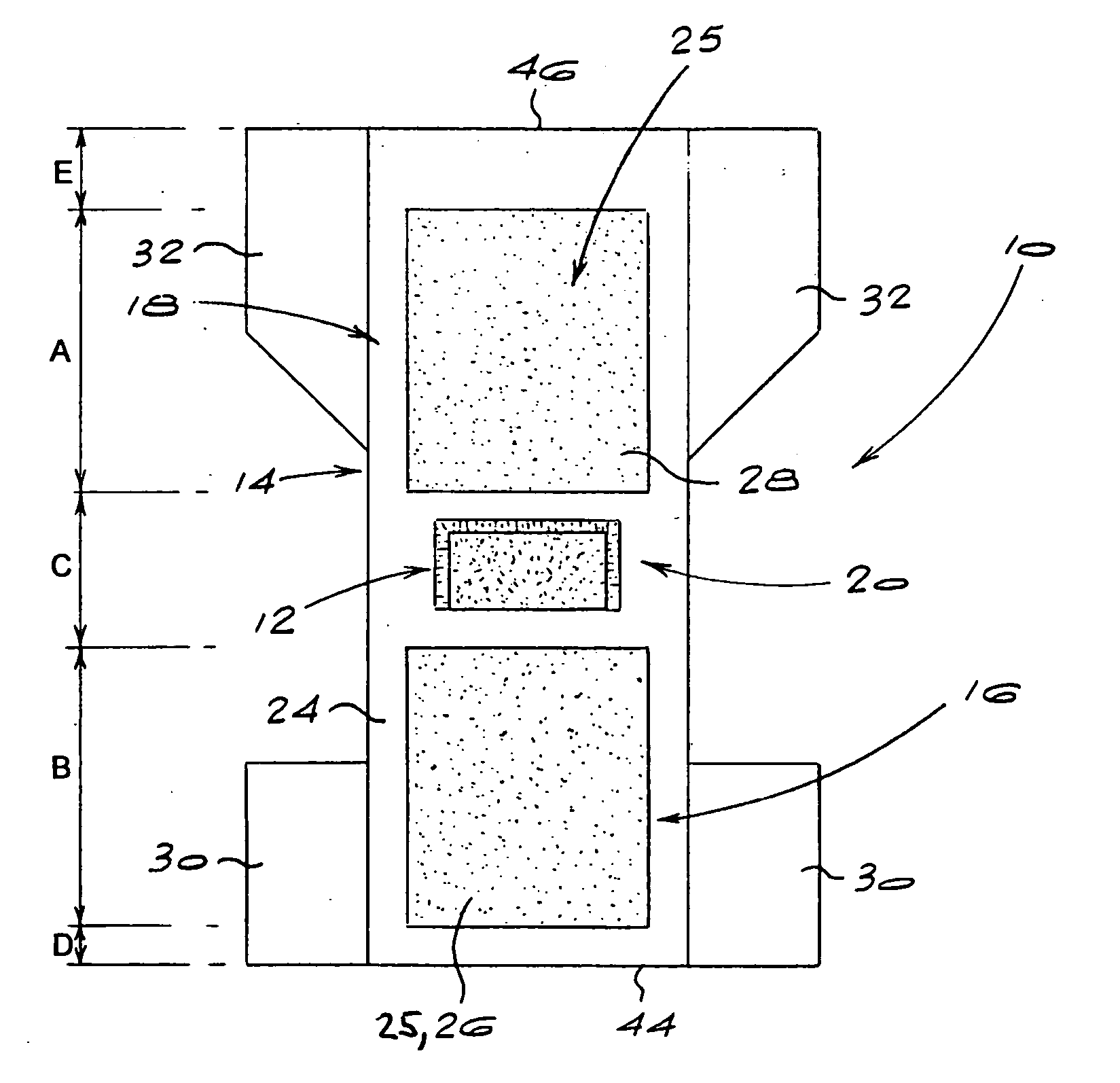

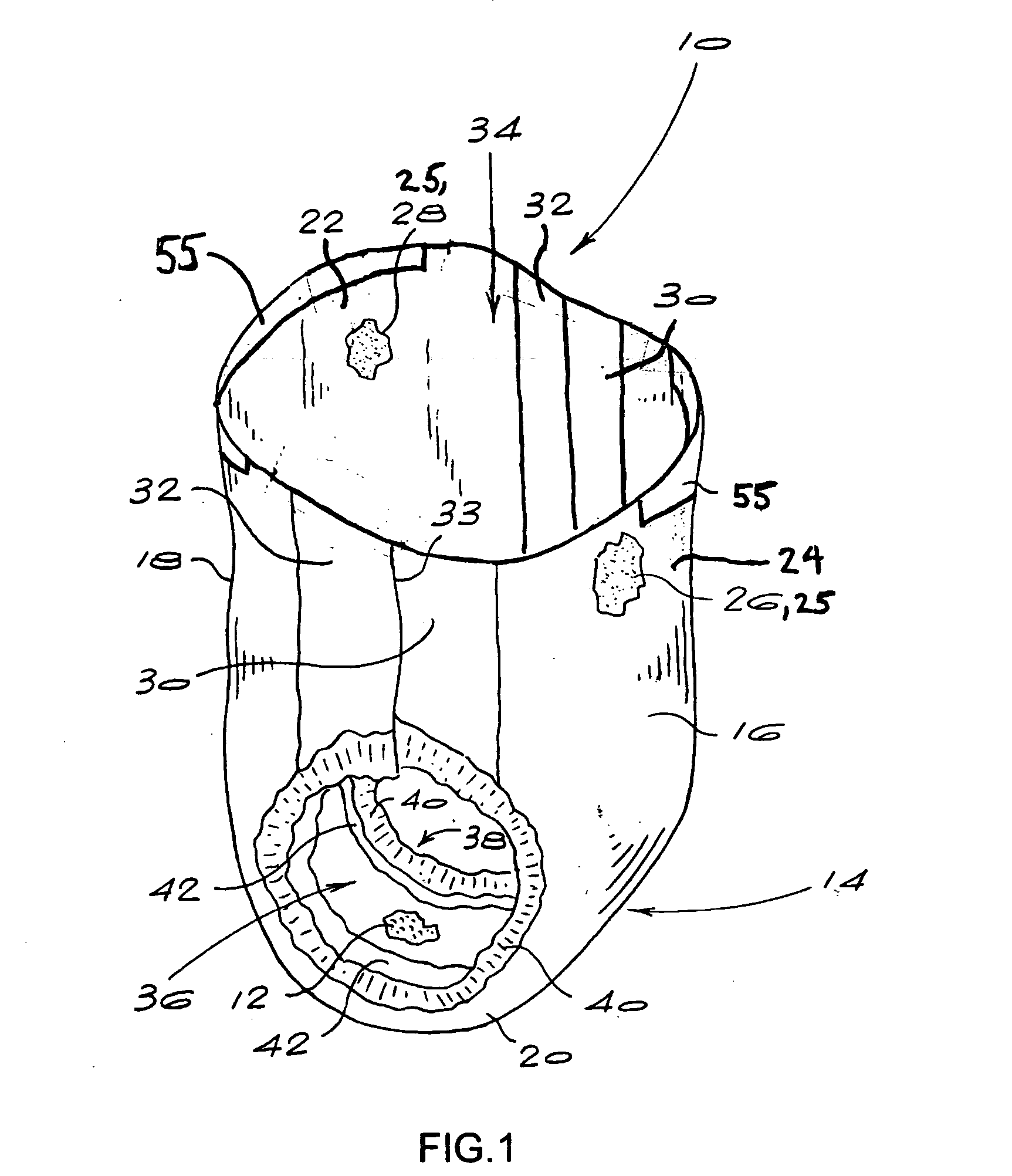

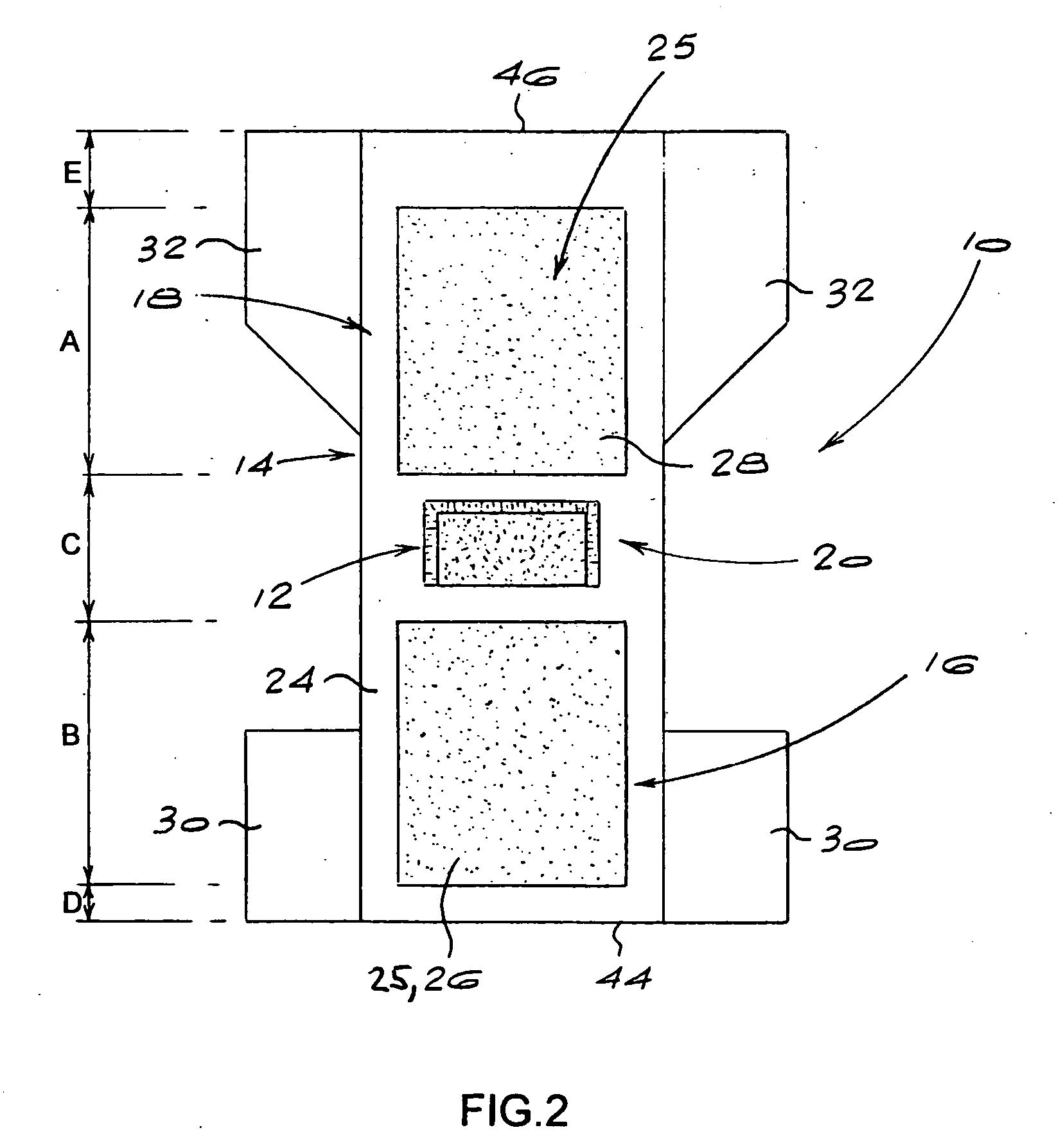

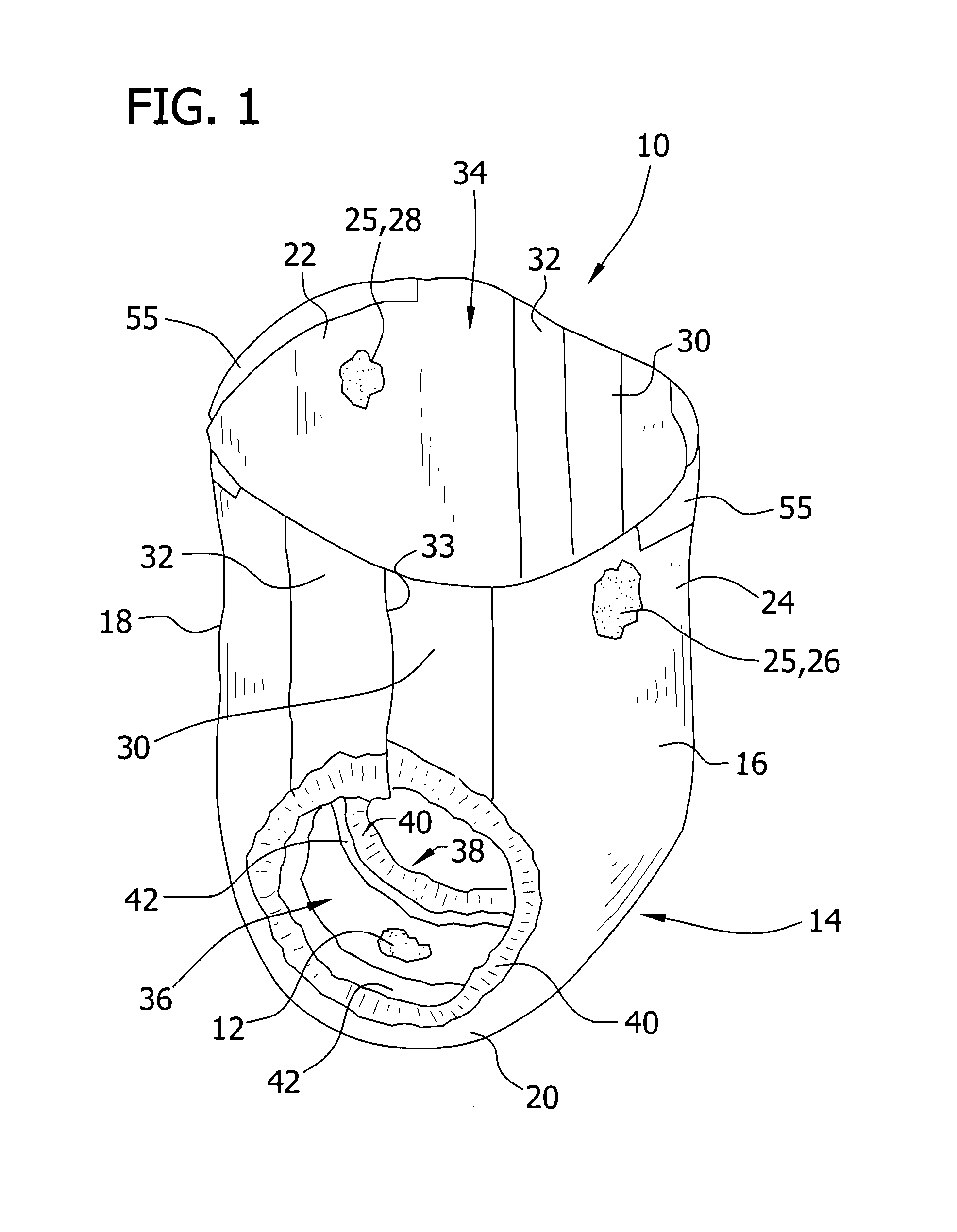

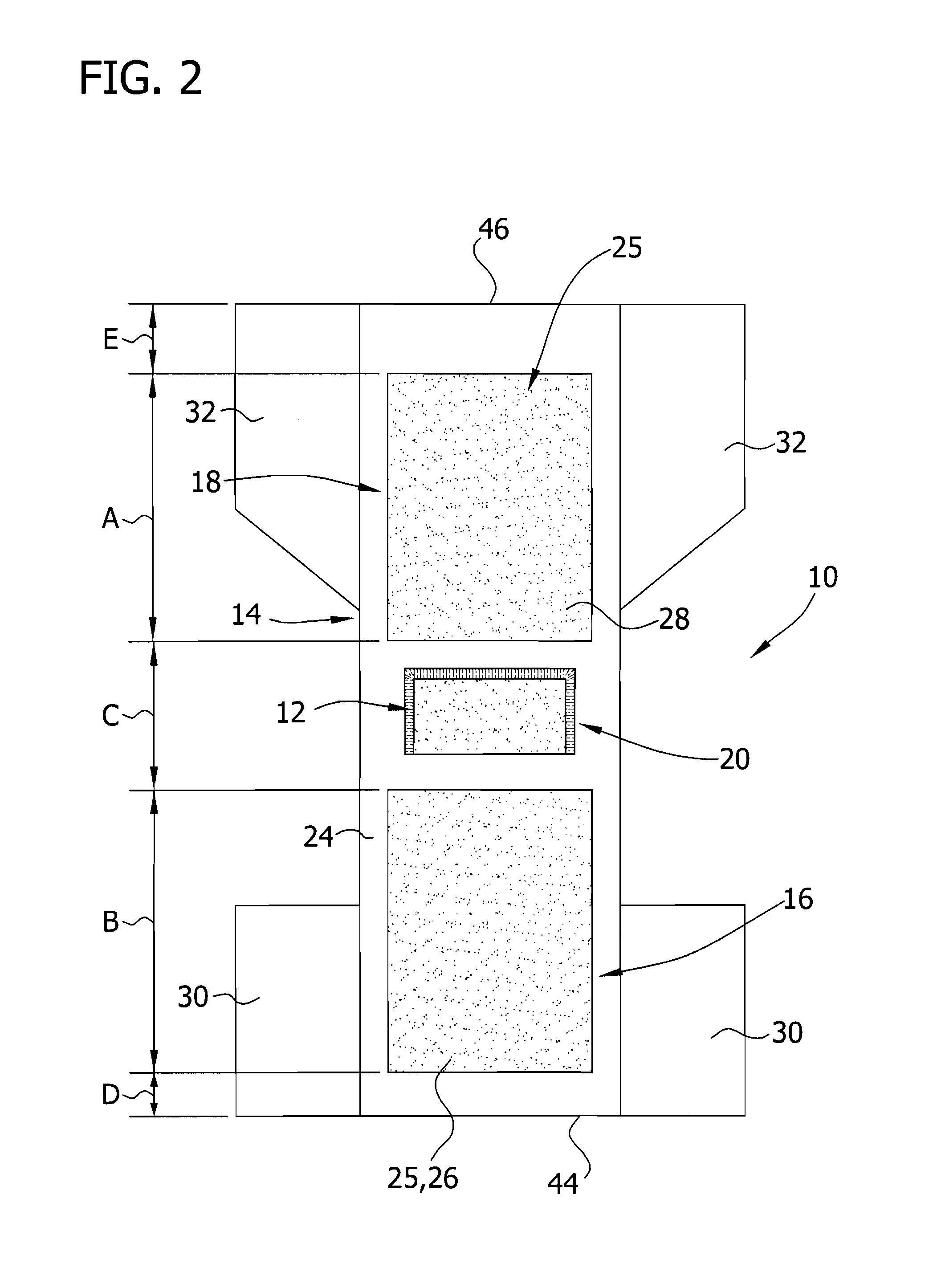

Absorbent article including a temperature change member

InactiveUS20060069363A1Facilitate continuous productionBaby linensTamponsMechanical engineeringCrotch

An absorbent article including a temperature change member is disclosed. The absorbent article may define a front region, a rear region, a crotch region intermediate the front and rear regions. The article may include an outercover, an absorbent assembly front portion disposed intermediate the outercover and the liner in the front region. The article may also include an absorbent assembly rear portion disposed intermediate the outercover and the liner in the rear region and at least partially spaced from the absorbent assembly front portion to provide a first gap. The article further includes a temperature change member disposed in the first gap.

Owner:KIMBERLY-CLARK WORLDWIDE INC

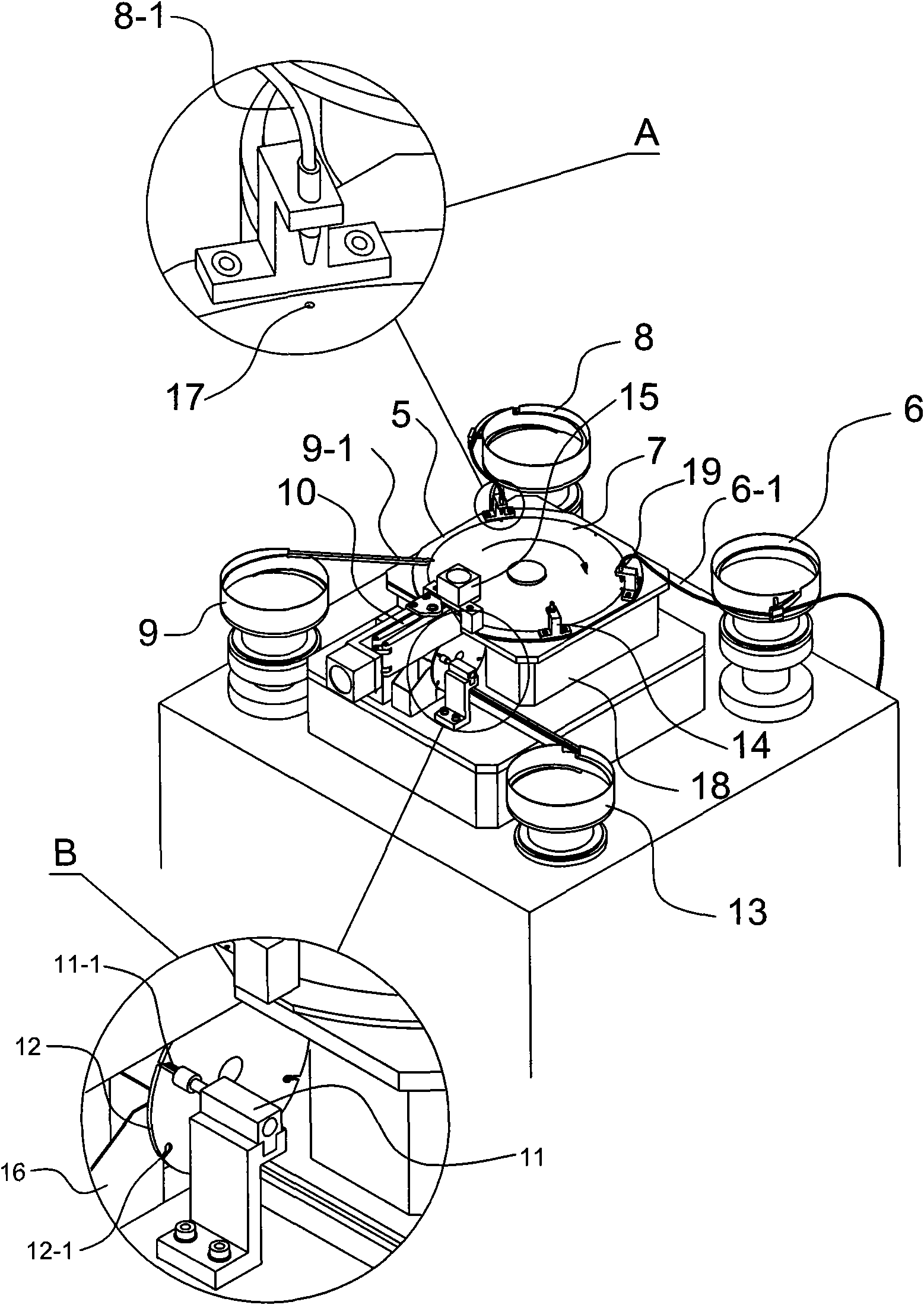

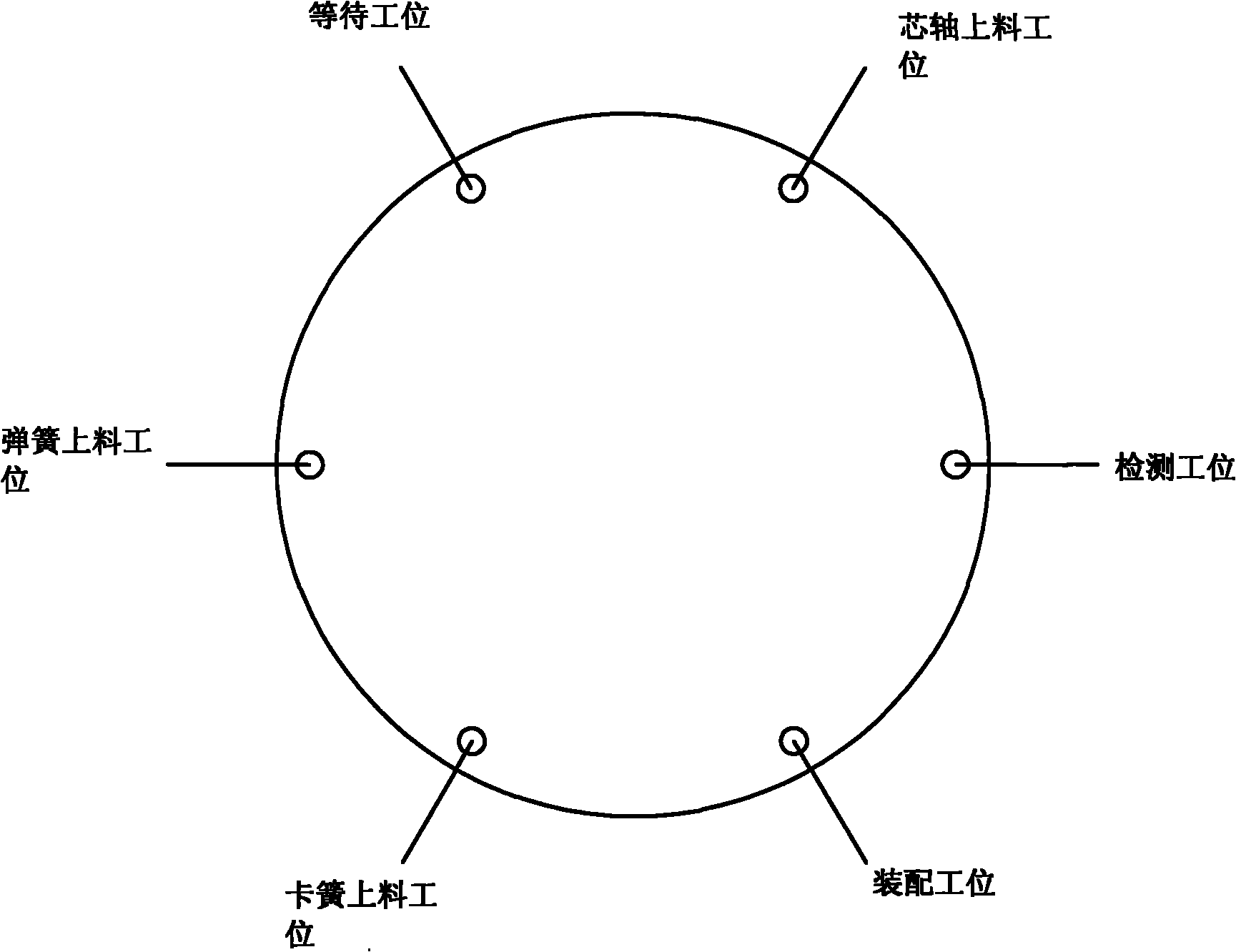

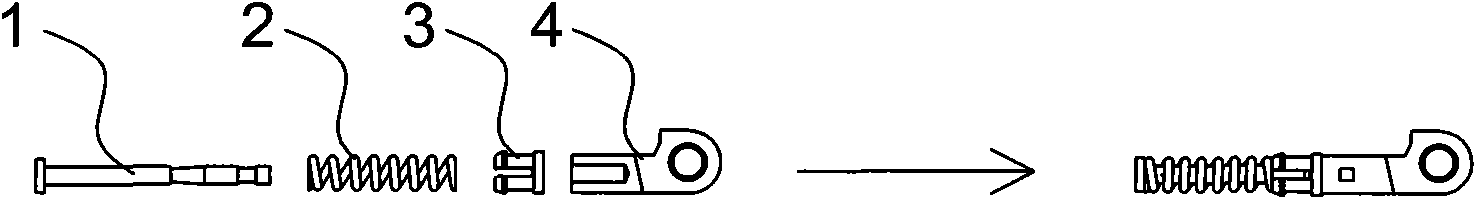

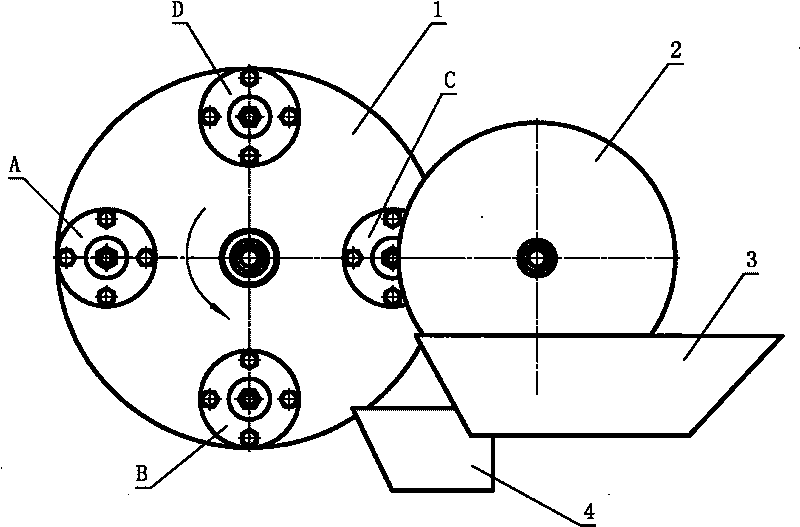

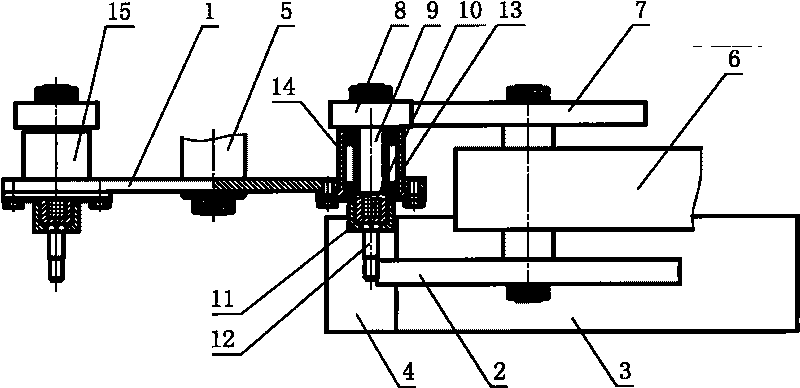

Automatic assembling machine of hinge spring shafts

InactiveCN101875167AReduce the differenceUnified specificationsAssembly machinesNon-optical partsEngineeringAssembly machine

The invention belongs to an assembling machine for manufacturing spectacle frames, in particular to an automatic assembling machine of hinge spring shafts, which can continuously and automatically complete the integral assembly of spectacle hinge spring shafts. The traditional assembly of the spectacle hinge spring shafts completely depends on manual operation of workers and has the defects of low assembly speed, long period and low production efficiency due to one-by-one serial connection, and the assembled spectacle hinge spring shafts have great difference and unstable quality due to the limitations of the technical level of the workers, which greatly influences the later actual use of the spectacle frames. Aiming at the defects, the invention provides an automatic assembling machine of hinge spring shafts, which has the technical characteristic that one large rotary table and one small rotary table which are mutually perpendicular are arranged, the rotary tables are provided with a plurality of corresponding through holes and card slots for installing corresponding parts, and the two rotary tables rotate and are mutually matched according to a set beat so as to continuously and automatically assemble the hinge spring shafts. Compared with the traditional manual operation, the invention has high speed and high efficiency, and the finished hinge spring shafts assembled by the machine have uniform specifications, small difference and stable quality.

Owner:浙江康华眼镜有限公司 +1

Preparation method of thermotropic liquid crystal polyarylester fiber

InactiveCN104389045AEasy to operateReaction condition controlArtificial filament heat treatmentMonocomponent polyesters artificial filamentFiberAcetic anhydride

The invention discloses a preparation method of a thermotropic liquid crystal polyarylester fiber, relates to a preparation method of thermotropic liquid crystal polyarylester, and aims to solve the problems that the existing method for preparing the thermotropic liquid crystal polyarylester is complex and the polyarylester fiber is low in tensile strength. The preparation method of the thermotropic liquid crystal polyarylester fiber comprises the following steps: step one, adding p-hydroxybenzonic acid, 2-(4-hydroxyphenyl)-5-carboxylbenzimidazole, acetic anhydride, 4-diethylaminopyridine and an antioxidant into a polymerization kettle for carrying out melt condensation polymerization to prepare a pre-polymer of thermotropic liquid crystal polyarylester; step two, putting the pre-polymer in a rotary kiln under the condition with nitrogen protection for carrying out solid phase polycondensation reaction to obtain high-molecular-weight polymer powder; step three, mixing the high-molecular-weight polymer powder, then cooling and drawing to prepare primary polyarylester fiber; and step four, carrying out heat treatment on the primary polyarylester fiber. The preparation method of the thermotropic liquid crystal polyarylester fiber is simple to operate; the tensile strength of the polyarylester fiber which is finally obtained can reach 4.0-4.5GPa.

Owner:HEILONGJIANG JUXIANG TECH DEV CO LTD

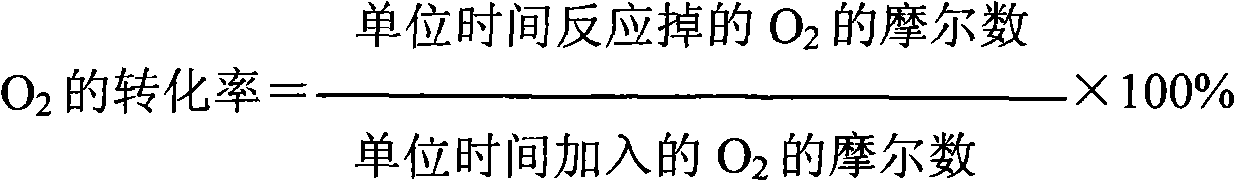

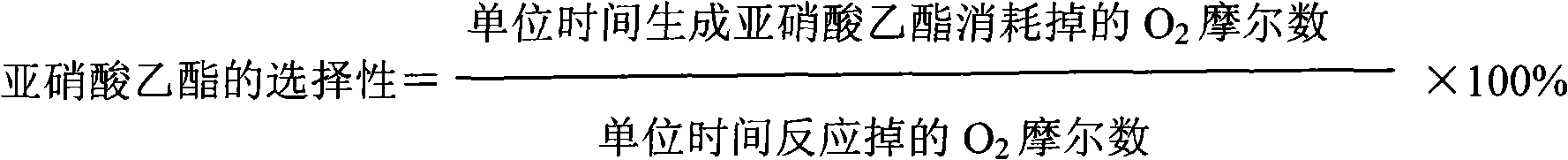

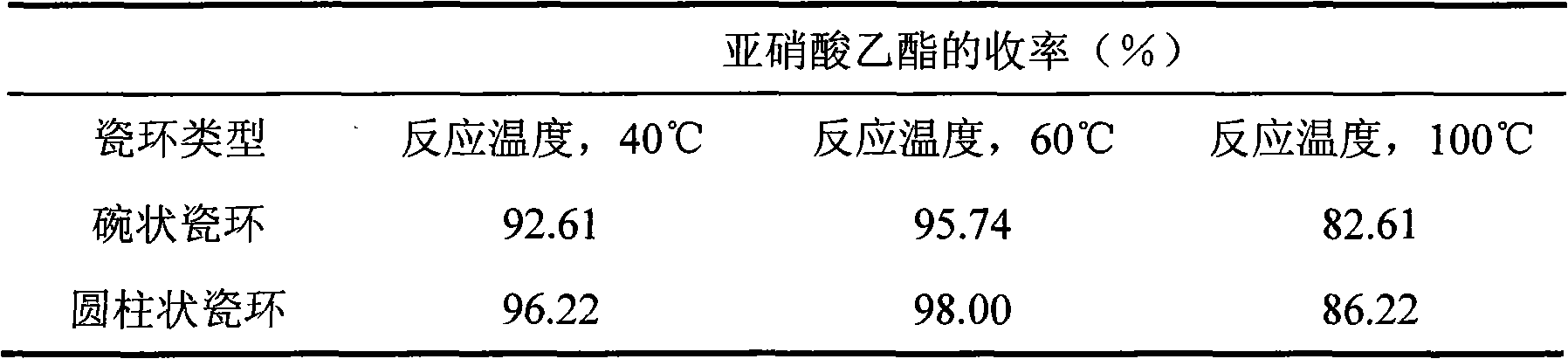

Reaction system and preparation method for nitrous alkyl ester

InactiveCN101314569AHigh yieldImprove efficiencyLiquid-gas reaction processesNitrous acid preparation ester preparationRetention timeGas phase

The invention relates to a reaction system for alkyl nitrite and a preparation method for the alkyl nitrite. The preparation method comprises the following steps that: a trickle-bed reactor is adopted and porcelain ring filler is filled into the trickle-bed reactor; liquid added into the reactor forms liquid membranes on the filler; alkyl alcohol is taken as a liquid-phase raw material and nitric monoxide, oxygen and nitrogen are taken as gas-phase raw materials; and gas and liquid phases are reacted in the trickle-bed reactor by means of co-current flow or countercurrent flow under the condition of nitrogen protection so as to generate the alkyl nitrite. The mol ratio of the alkyl alcohol to NO is between 2 to 1 and 7 to 1, and the mol ratio of the NO to O2 is between 4 to 1 and 8 to 1; the reaction temperature is between 40 and 100 DEG C, and the reaction pressure is between 0.1 and 1.0 MPa; and the retention time of continuous feeding of liquid-phase alkyl alcohol in the trickle-bed reactor is between 10 and 500 minutes, and the retention time of continuous feeding of gas phase in the trickle-bed reactor is between 0.02 and 1 minute. The reaction system and the preparation method have the advantages that: the operating condition is mild; the reaction time is short; the conversion rate of the raw materials, and the selectivity and the yield of products are high; and the whole reaction system is convenient for realizing continuous production, etc.

Owner:TIANJIN UNIV

Preparation method of PTFE (polytetrafluoroethylene) copper-clad plate with high elastic modulus

InactiveCN102166852ALow dielectric constantLow elastic modulusGlass/slag layered productsMetal layered productsGlass fiberPolymer science

The invention provides a preparation method of a PTFE (polytetrafluoroethylene) copper-clad plate with a high elastic modulus, which comprises the following steps of: preparing copper foil and glass fiber cloth with a low dielectric constant, and preparing a fluororesin mixture; soaking the glass fiber cloth with the prepared fluororesin mixture, transferring the soaked glass fiber cloth into a baking oven for baking and drying, and repeating the steps to enable the glass fiber cloth to be soaked, baked and dried many times, thereby obtaining soaking pieces the resin content of which is about 60-70%; and superposing the soaking pieces, coating the copper foil on two sides, and laminating to obtain the PTFE copper-clad plate. The baking and drying process comprises three stages, wherein the temperature of the baking oven in the first stage is 50-100 DEG C, the temperature of the baking oven in the second stage is 200-320 DEG C, and the temperature of the baking oven in the third stage is 380-400 DEG C. The plate prepared by the method provided by the invention not only has a lower dielectric constant but also has a higher elastic modulus, and the plate has the advantages of consistent internal structure and good dimensional stability.

Owner:GUANGDONG SHENGYI SCI TECH

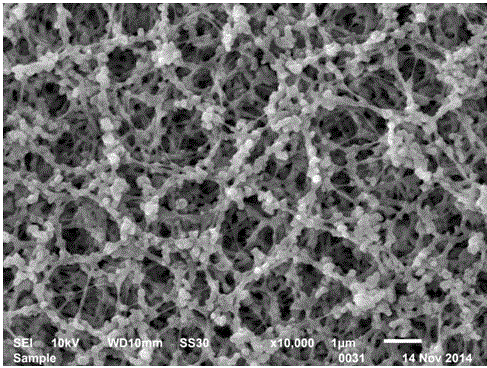

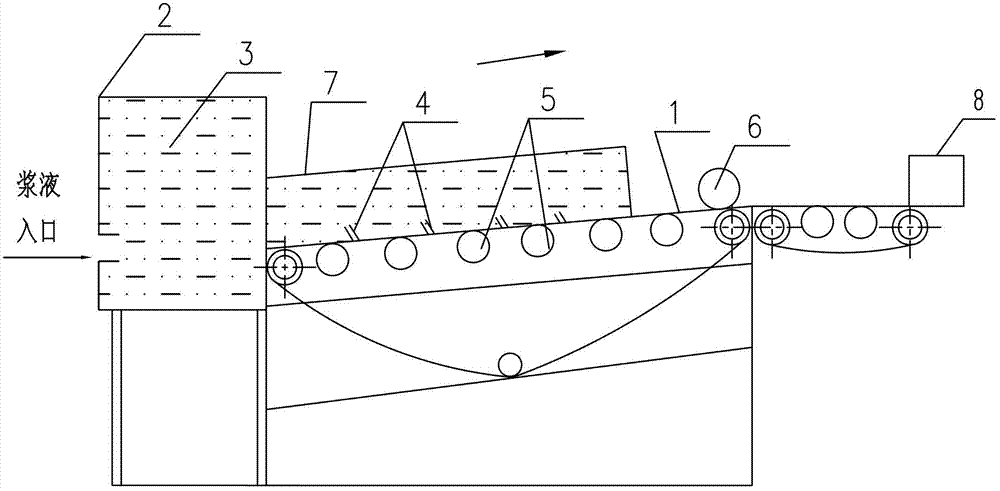

Aramid fiber polymer coated lithium ion battery membrane and preparation method thereof

ActiveCN104979515AAvoid decompositionReduce adverse effectsSecondary cellsCell component detailsPhysical chemistrySlurry

The invention discloses an aramid fiber polymer coated lithium ion battery membrane and a preparation method thereof. The membrane comprises a lithium ion battery base membrane and a coating, wherein the single side or the two sides of the base membrane are coated with the coating, the coating thickness is 0.5-4 microns, an aramid fiber polymer is used in aramid fiber slurry, and the aramid fiber slurry is solidified in advance at the environment in which the relative humidity is more than 90% to obtain the membrane which has good mechanical performance and high temperature resistance. Meanwhile, the membrane has an opening structure, so that the wettability of electrolyte is greatly promoted, in addition, the preparation method has the characteristics of good environmentally friendly effect, low cost, simple process and the like, and is convenient for continuous production.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

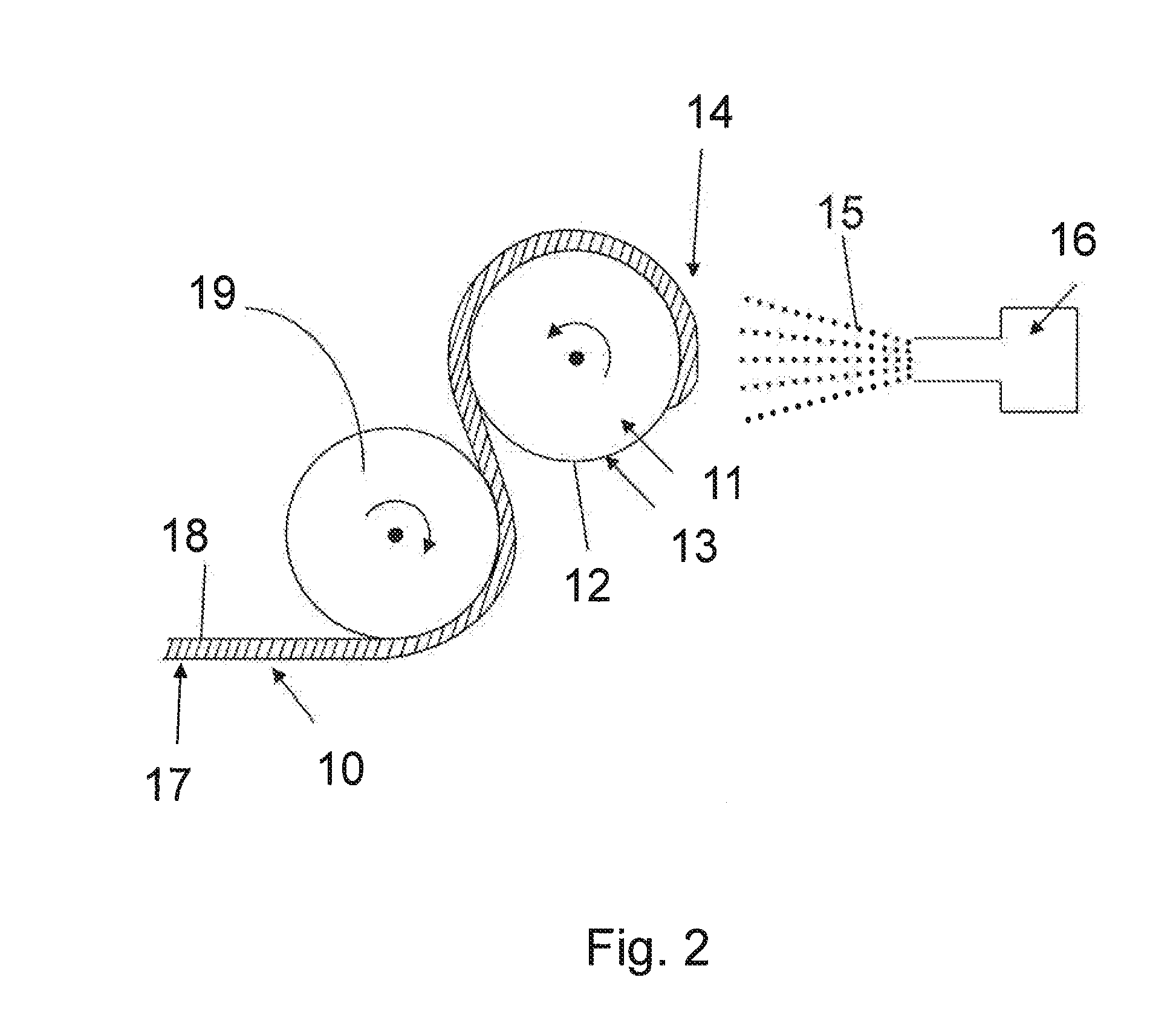

A high-performance cooper-coated aluminum rectangle section compound conductive bus bar and its making technology

ActiveCN101241778AMeet the requirements of multiple specificationsGreat widthSingle bars/rods/wires/strips conductorsMeasuring devicesCopperAluminum composites

The present invention provides a high-performance copper-clad aluminum cross section composite conductive bus-bar and the preparing technique thereof, and the invention relates to a rectangle-cross section bimetal composite material and the preparation thereof. The copper-clad aluminum rectangular cross section composite conductive bus-bar is compounded by the core-part aluminum and the coating layer copper. The area proportion of the coating copper layer is 15to 50 The technique comprises the following procedures: Adopting horizontal continuous casting for directly compounding and forming the copper-clad aluminum composite blank. Commonly flat-roller rolling and finish drawing-pulling the copper-clad aluminum blank according to requirement or rolling with the flat roller provided with a vertical roller, the range of the rolling speed is 3-50m / min, and the single-pass relative reduction is between 15and 40 The speed range of finish drawing-pulling is 1-20m / min and the single-pass cross section scalage is 10%. When the multiple-pass relative reduction is up to 70%, the low-temperature intermediate annealing is executed to the copper-clad aluminum composite conductive bus-bar. The annealing temperature is between 250 and 450 DEG C and the annealing time is between 0.5 and 3h. The annealed composite conductive bus-bar is executed with hole-form rolling or drawing. The invention not only can produce the high-performance copper-clad aluminum cross section composite conductive bus-bar, but also has the advantages of short process flow and high efficiency of the producing method.

Owner:UNIV OF SCI & TECH BEIJING

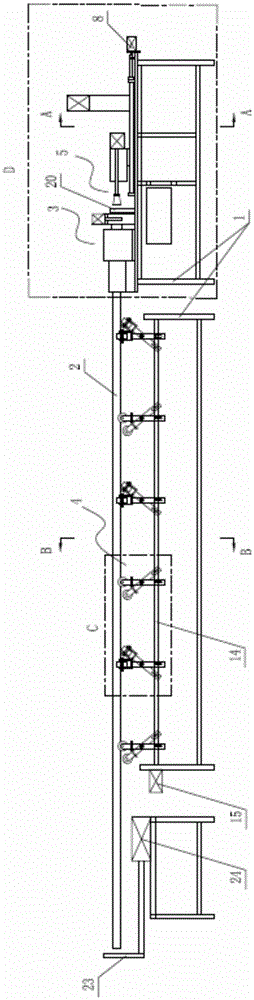

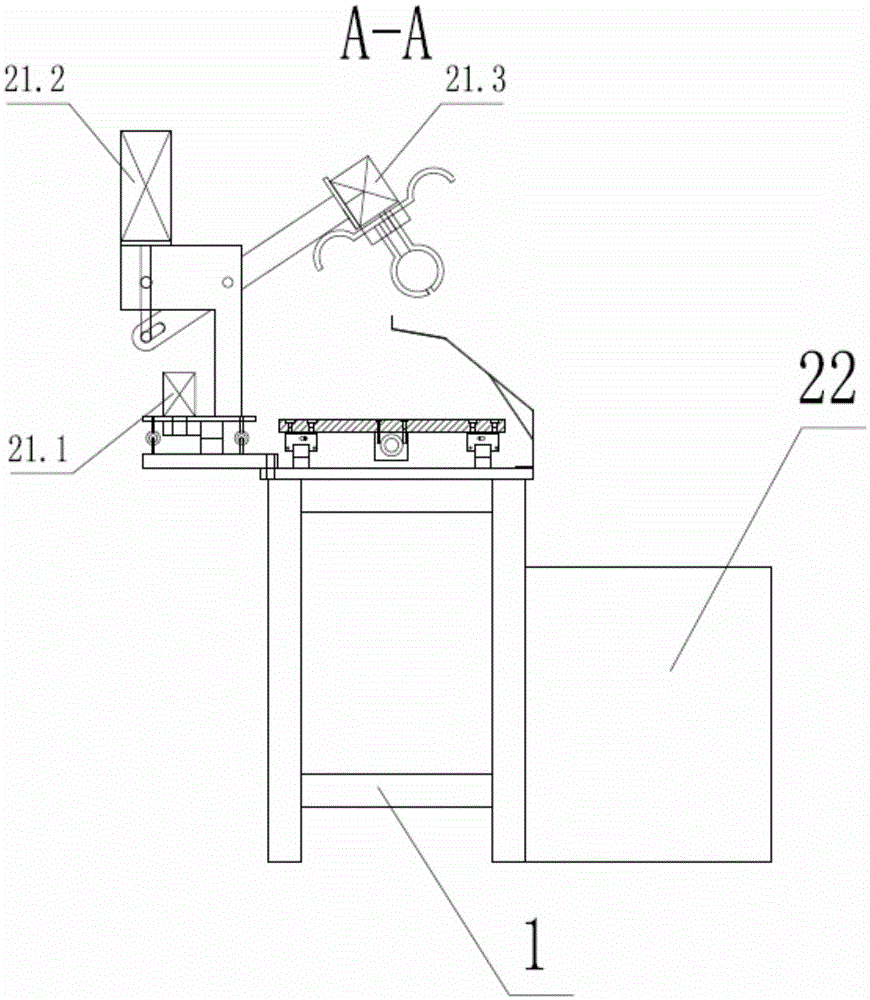

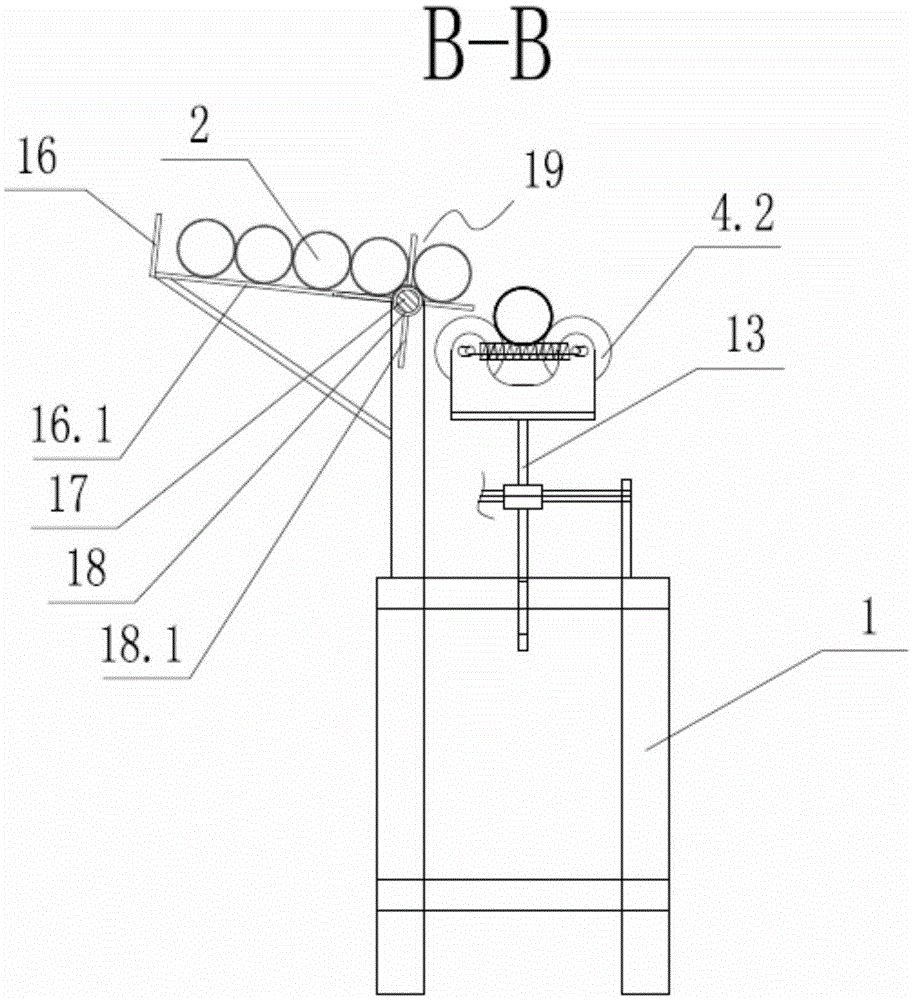

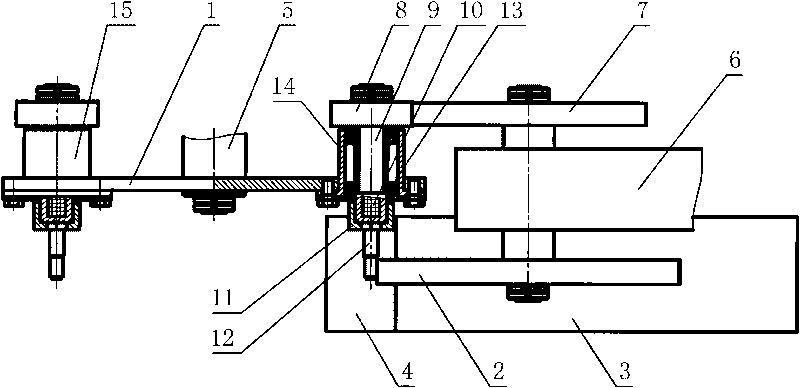

Automatic pipe cutter

ActiveCN105345128ARealize multiple continuous cuttingFacilitate continuous productionTube shearing machinesMetal working apparatusPipe fittingEngineering

The invention discloses an automatic pipe cutter. The automatic pipe cutter comprises a machine frame (1), wherein a cutting device (3) for cutting off pipe fittings (2) is arranged on the machine frame (1). The automatic pipe cutter disclosed by the invention is characterized in that a guiding mechanism (4) for lifting the pipe fittings (2) is arranged at the feeding end, which is close to the machine frame (1), of the machine frame (1), and a feeding mechanism (5) which pulls the ends to be cut of the pipe fittings (2) to move in the axial direction to a position to be processed when the cutting device (3) resets is arranged at the discharging end, which is close to the cutting device (3), of the machine frame (1). The automatic pipe cutter provided by the invention can automatically feed the pipe fittings after the pipe fittings are cut off in a disposable manner, so that the automatic continuous cutting-off processing of the pipe fittings is realized.

Owner:PINGXIANG WEIDA IND CO LTD

Fluoro-resin mixture, copper-clad plate made of same and making method thereof

ActiveCN101857708AImprove dipping qualityUniform glue contentFibre treatmentLaminationGlass fiberPolymer science

The invention relates to a fluoro-resin mixture, a copper-clad plate made of the same and a making method thereof. The fluoro-resin mixture comprises the following two substances as necessary components: 90-99 parts by weight of polytetrafluoroethylene (PTFE) emulsion and 1-10 parts by weight of fluorinated ethylene propylene (FEP) based on 100 parts by weight of an organic solid matter. The copper-clad plate made of the fluoro-resin mixture comprises a plurality of pieces of superimposed varnished cloth and copper foils covering one side or two sides of the varnished cloth, wherein each piece of varnished cloth comprises glass fiber cloth and a fluoro-resin mixture adhered thereon through dipping drying. The fluoro-resin mixture is prepared by taking the PEFE emulsion as base resins, the glass fiber cloth can be dipped for many times in the mixture under the condition of below PTFE sintering temperature (330 DEG C) to obtain the varnished cloth. The varnished cloth made from the fluoro-resin mixture has favorable gum dipping quality, uniform gum content, smooth surface, softness and easy operation. The copper-clad plate made from the fluoro-resin mixture has favorable comprehensive properties, excellent dielectric properties, simple making method and process, satisfies the dielectric property requirements on substrate materials in the field of high frequency communication and is beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

Preparation method for waterborne polyurethane synthetic leather Bass

ActiveCN102797165AGood breathability and moisture permeabilityFine foamTextiles and paperPolymer sciencePolypropylene

The invention discloses a preparation method for a waterborne polyurethane synthetic leather Bass. The method comprises the following steps of: adding a dispersing agent, a polypropylene powder and a talcum powder to waterborne polyurethane under a stirring condition; after sufficiently dispersing these materials, adding a thickening agent to these materials to stir the materials, so as to obtain a waterborne polyurethane synthetic leather paste; before coating, adding a foam stabilizer to the waterborne polyurethane synthetic leather paste under a stirring condition; bubbling the paste by using compressed air, wherein the bubbling speed is 0.2-0.8 m3 / h; and stirring and bubbling the paste for 5-10 minutes at a speed of 600-1000 rpm; and then coating a waterborne polyurethane synthetic leather foaming paste to a base fabric, which is treated by a base fabric treating liquid and ironed by an ironing roller, wherein the coating quantity is 300-600 g / m2; and finally, drying the waterborne polyurethane synthetic leather foaming paste, so as to obtain the waterborne polyurethane synthetic leather Bass. According to the invention, a foaming material has the advantages of rapidness in foaming and good foam stabilizing property; and the preparation method disclosed by the invention has the advantages of simplicity, easiness and easiness for continuous production and is very suitable for large-scale industrial production.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

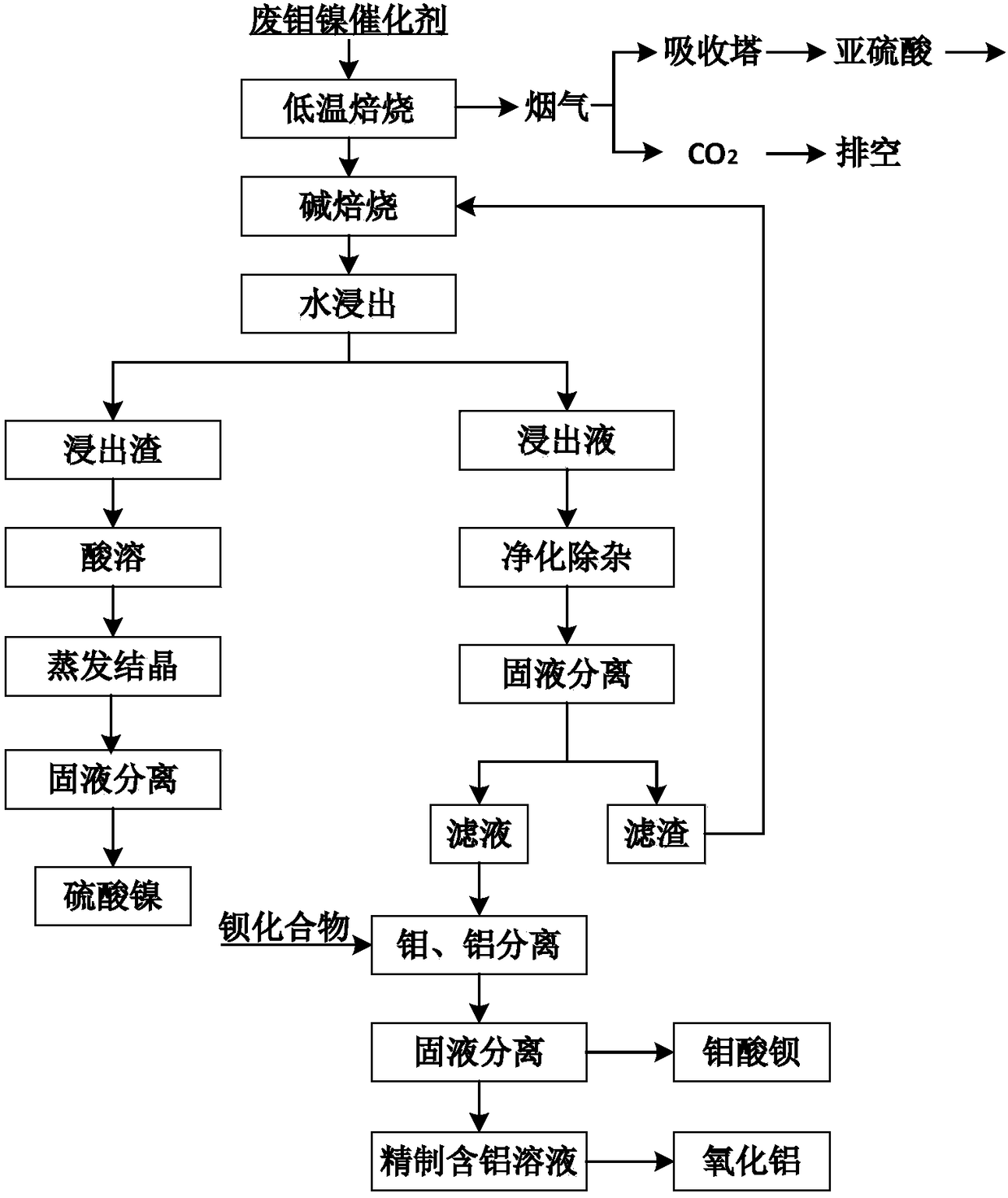

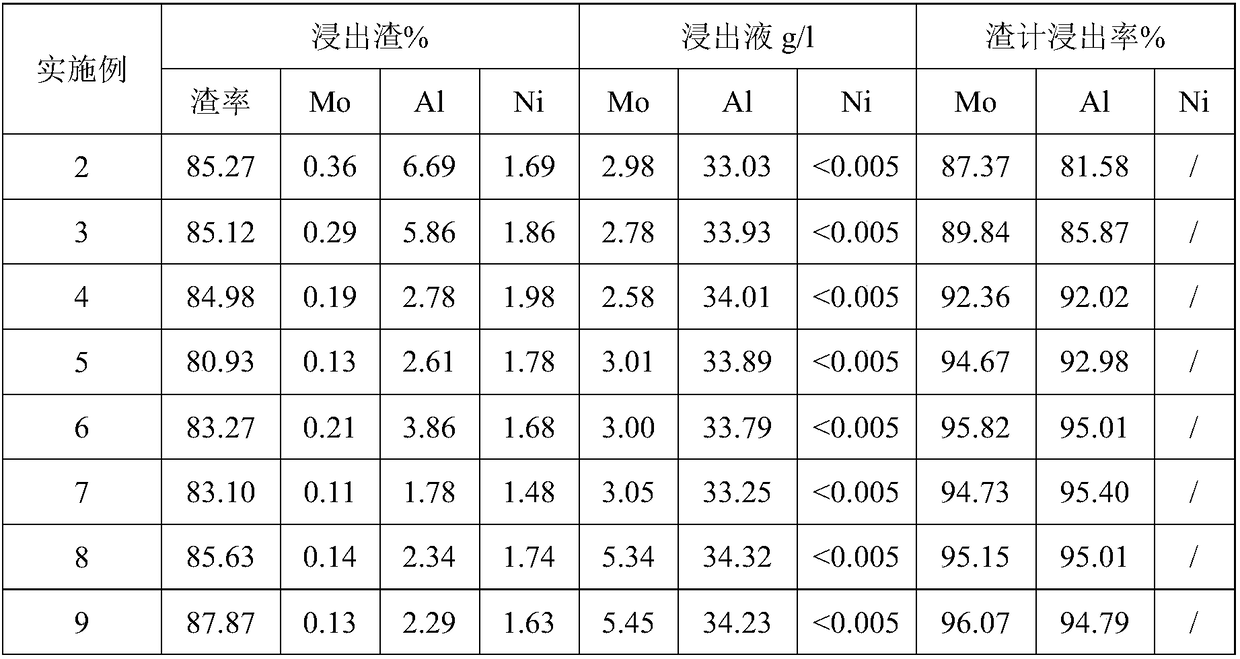

Method for recovering nickel and molybdenum from waste nickel-molybdenum catalyst

The invention discloses a method for recovering nickel and molybdenum from a waste nickel-molybdenum catalyst. The method comprises the concrete steps of firstly carrying out primary low-temperature roasting, then carrying out secondary high-temperature alkali roasting, and transforming molybdenum and aluminum components in the waste catalyst into water-soluble sodium molybdate and sodium metaaluminate; then carrying out water leaching and solid-liquid separation to obtain a nickel slag and an alkaline filter liquor containing molybdenum and aluminum; carrying out acid leaching, evaporative crystallization and solid-liquid separation on the nickel slag to obtain a nickel sulfate product; and adding a barium salt precipitant into the filter liquor to separate the aluminum and the molybdenum, obtaining a refined aluminum-containing solution, adopting a chemical precipitation method to obtain an aluminum hydroxide precipitate, and calcining to obtain an aluminum oxide product. According to the method for recovering the nickel and the molybdenum from the waste nickel-molybdenum catalyst provided by the invention, valuable metals in the catalyst is comprehensively recycled, three products such as nickel sulfate, barium molybdate and aluminum oxide are obtained, the valuable metal recovery rate is high, the product added value is high, and the method has a certain application value.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST +1

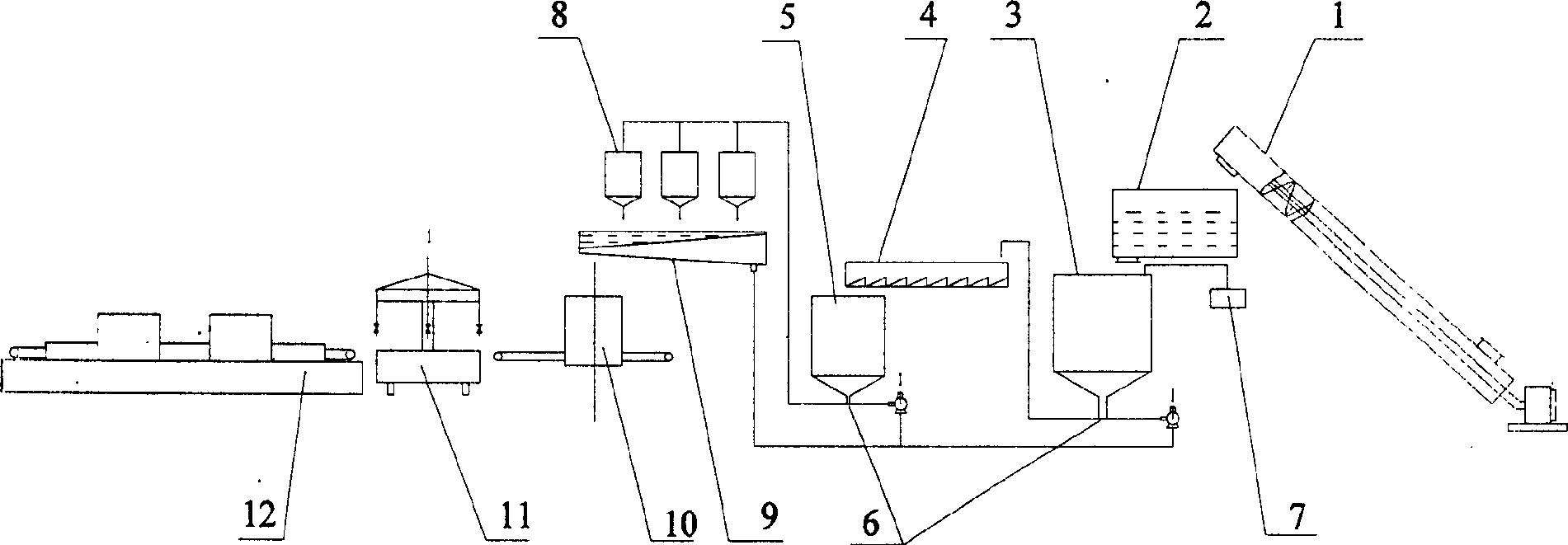

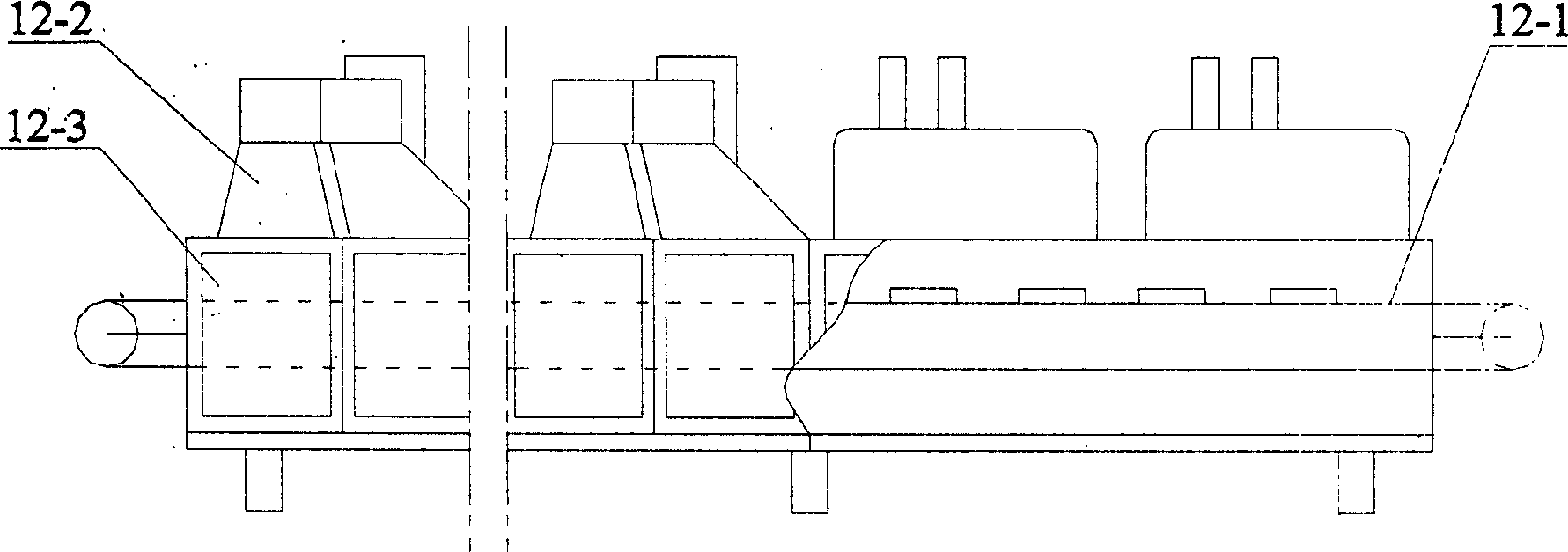

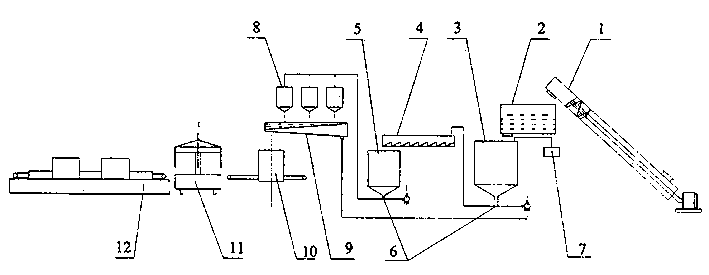

Method and device for continuously cooking rice

A technology for continuously cooking rice includes such steps as washing rice, immersing, quantitatively loading in boxes, microwave cooking and outputting rice in boxes. Its apparatus is composed of screw conveyer, high-position rice tank, rice washer, redox washer, jet-type sprayer, step impurities remover, rice immersing container, oblique rich dropper, quantitative loaders of rice and water, and continuous microwave cooker. Its advantages are high speed, high utilization rate of heat energy, and high productivity.

Owner:SOUTH CHINA UNIV OF TECH

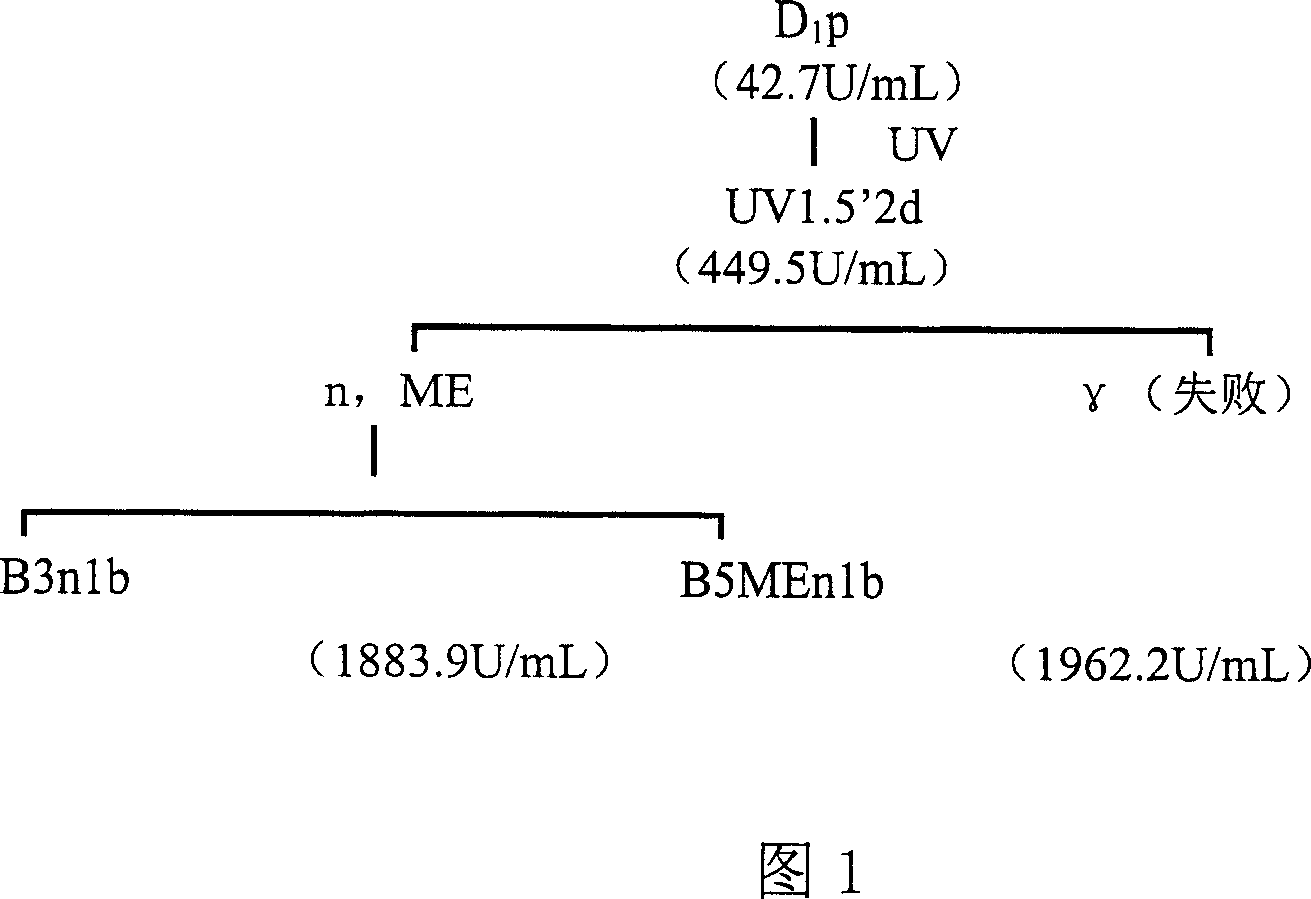

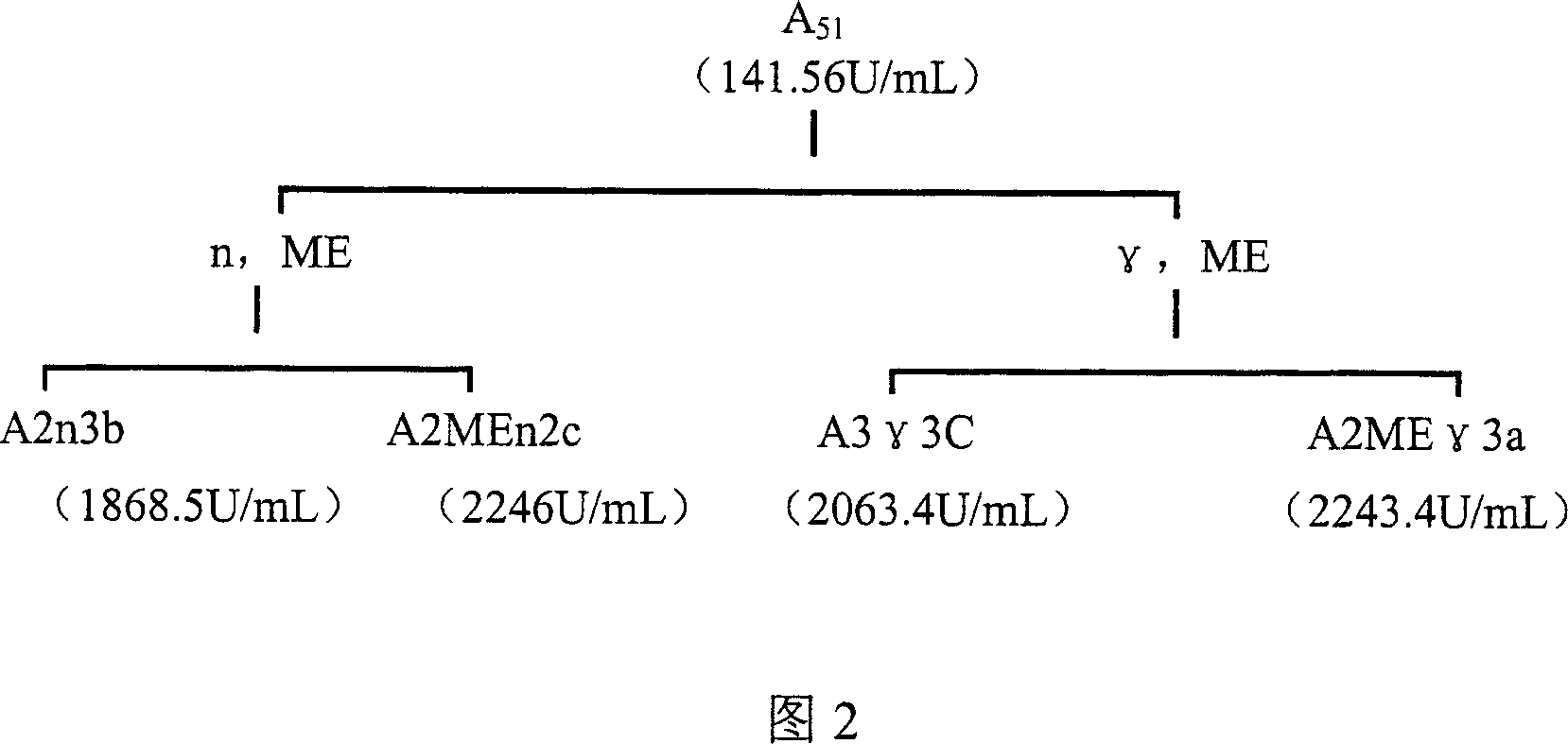

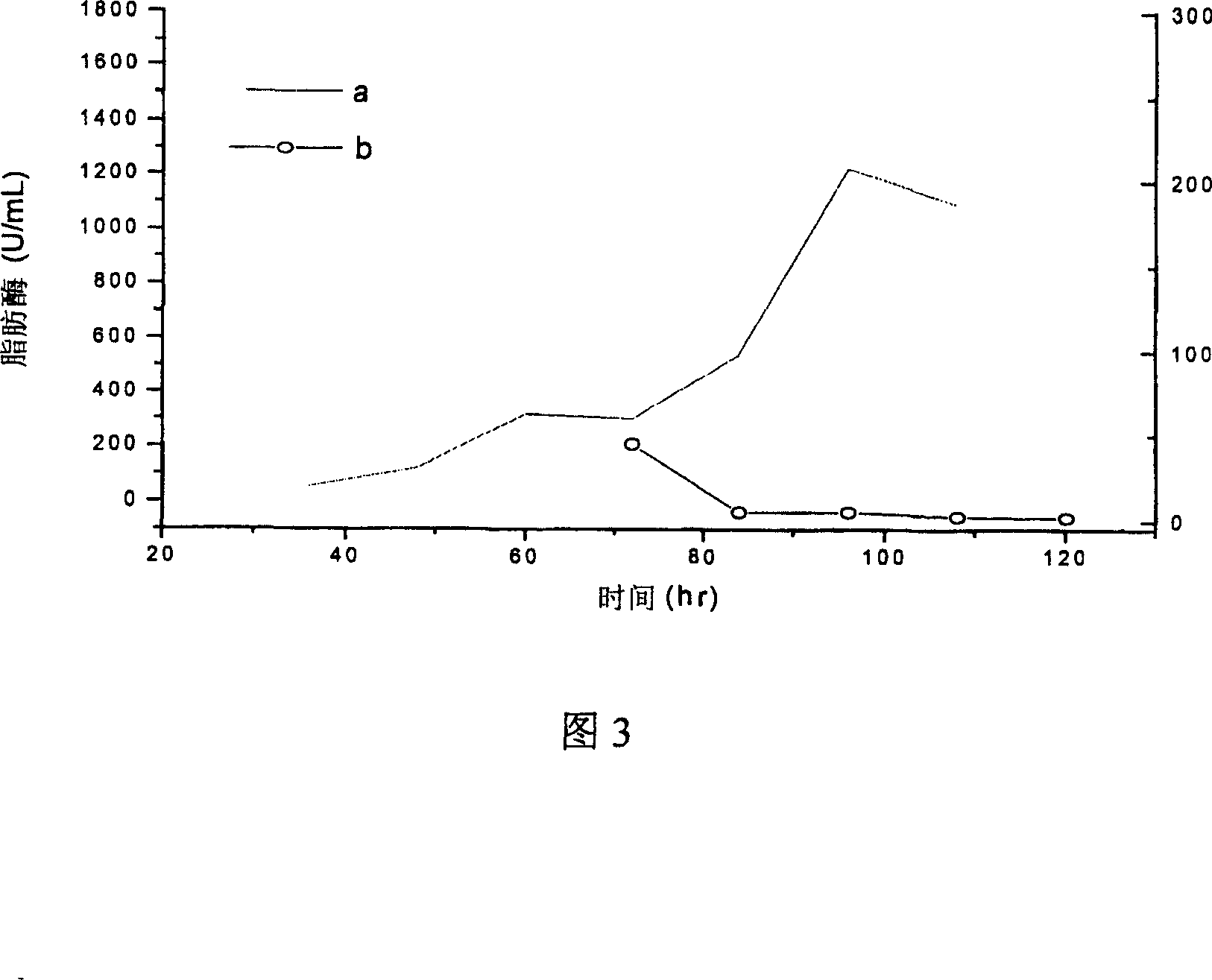

Lipase, its gene, yalulipolytic geast for producing said enzyme and its application

ActiveCN1948470AWide substrate adaptabilityImprove stabilityImmobilised enzymesFungiConservative mutationAmino acid

This invention relates to a preparation of a kind of lipase and the method of using the lipase to compound ester. Exactly is that amino acid sequence is SEQ ID NO:1 or its lipase of conservative mutation sequence, it also relates to the gene coding this lipase, Yarrowia lipolytica generating this lipase.

Owner:BEIJING UNIV OF CHEM TECH

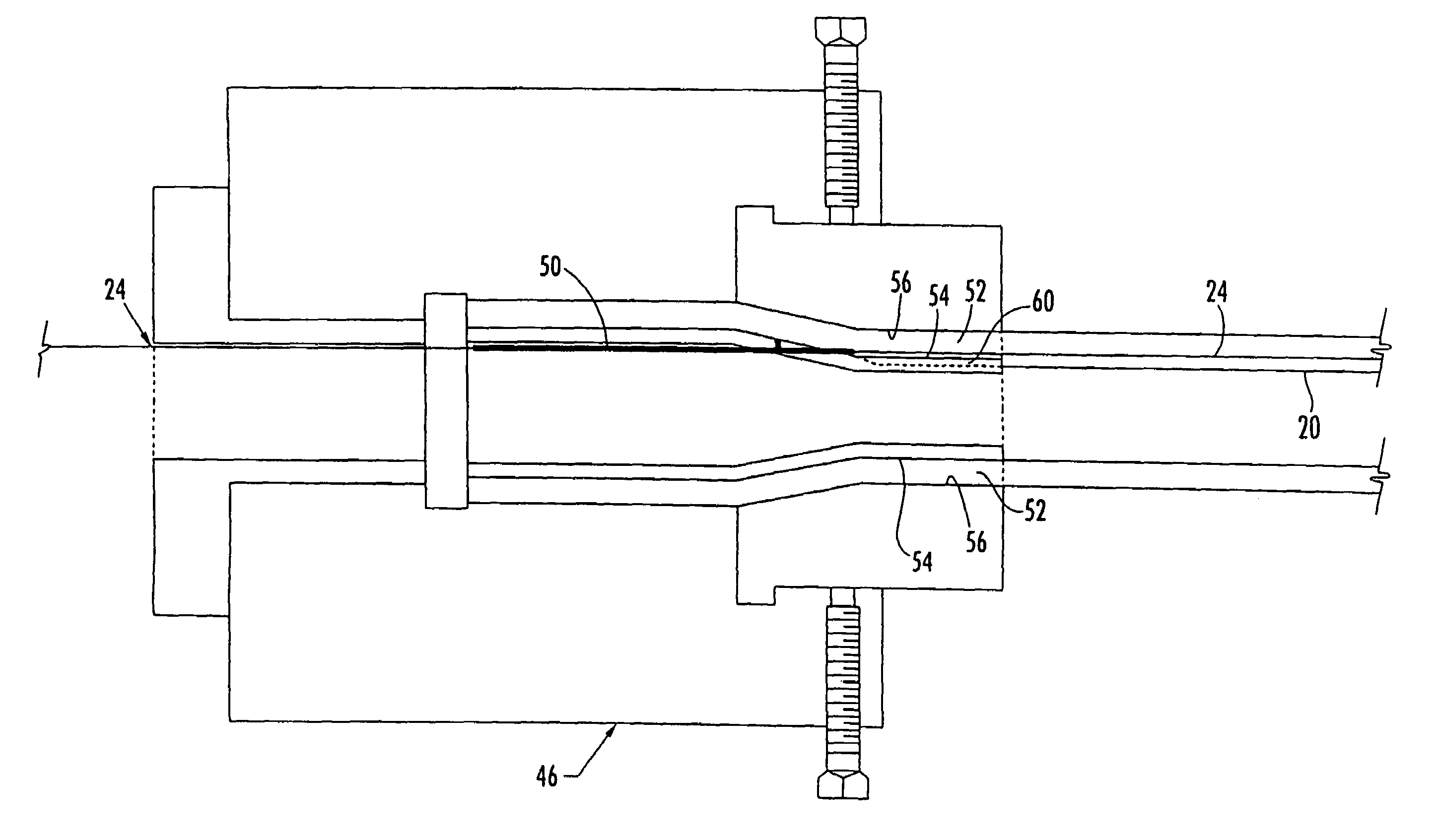

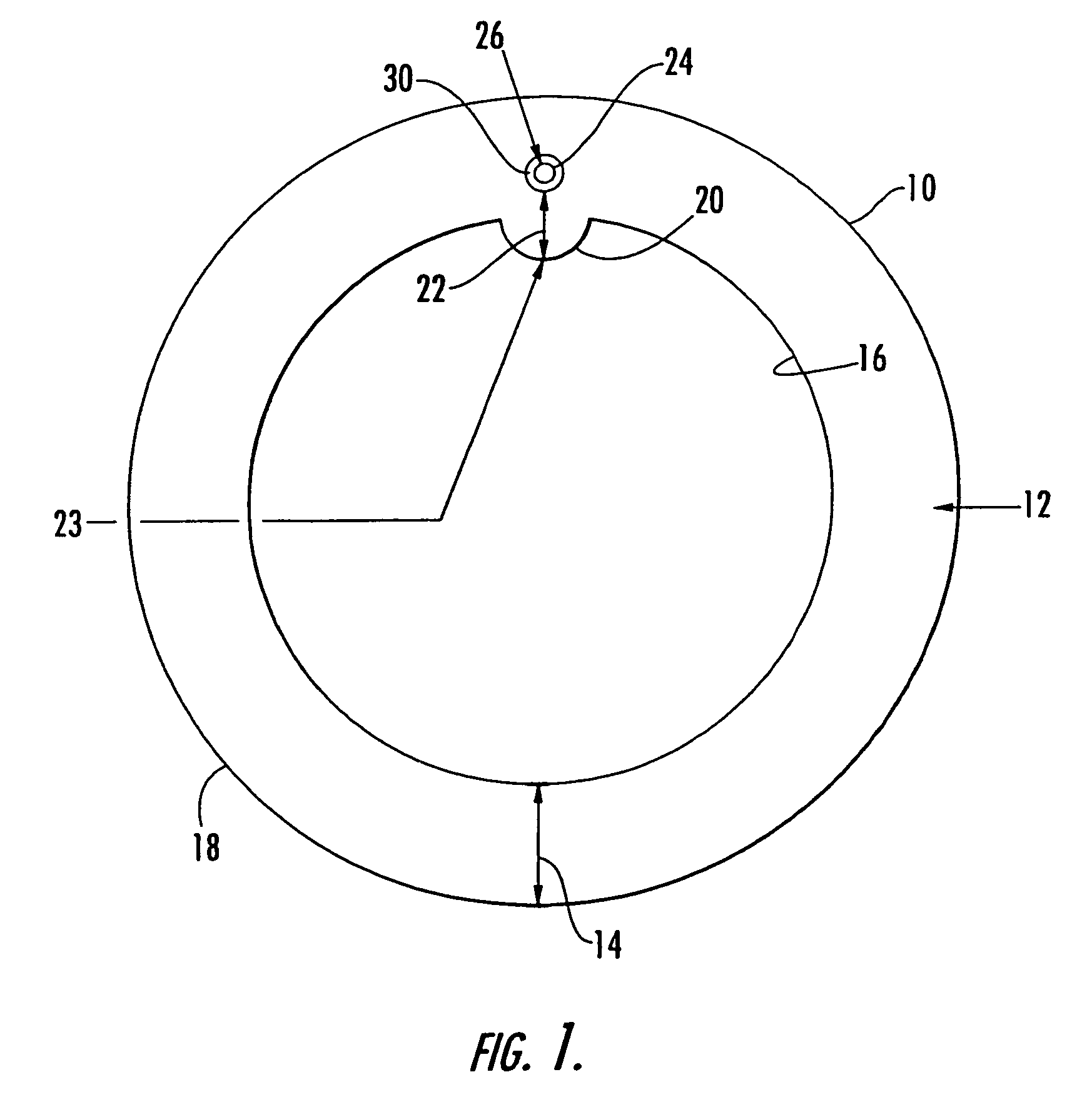

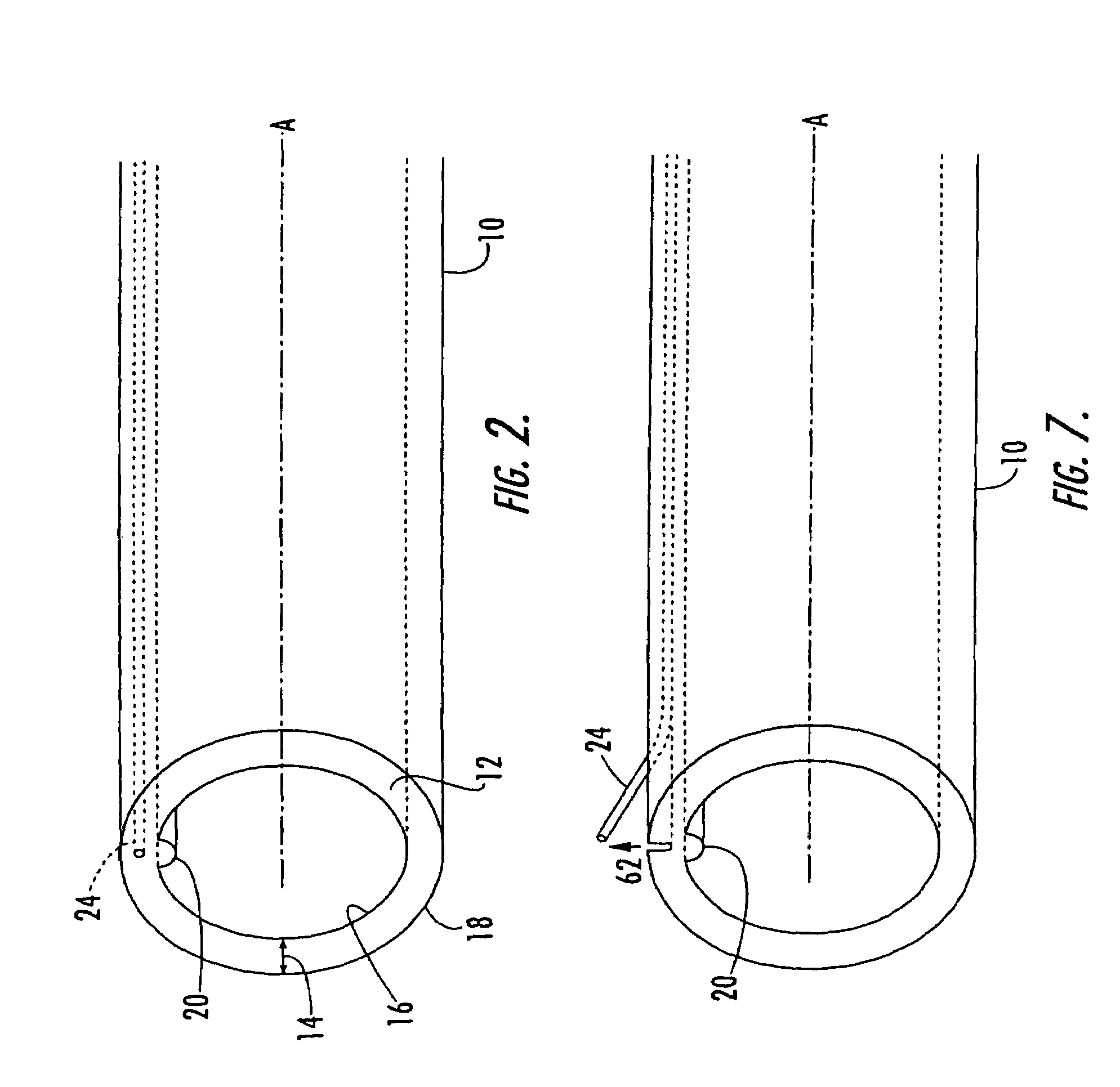

Toneable conduit and method of preparing same

InactiveUS7279643B2Easy to detectAvoid moisture leakagePipe laying and repairPipe elementsCatheterEngineering

The invention is a toneable conduit that can transmit a signal and be readily detected by toning equipment. The conduit can be coupled with other conduit to provide extended lengths of conduit. The toneable conduit includes an elongate polymeric tube having a wall with an interior surface, an exterior surface, and a predetermined wall thickness. A channel preferably extends longitudinally within the wall of the elongate polymeric tube; a stabilizing rib extends longitudinally along the interior surface of the wall of the elongate polymeric tube and is located radially inward from the channel. A continuous wire is coincident with the channel in the elongate polymeric tube and preferably coated with a composition that prevents it from adhering to the polymer melt that forms the elongate polymeric tube. The present invention includes methods of making the toneable conduit and methods of coupling a first toneable conduit with a second toneable conduit.

Owner:DURA LINE CORP A CORP OF KY

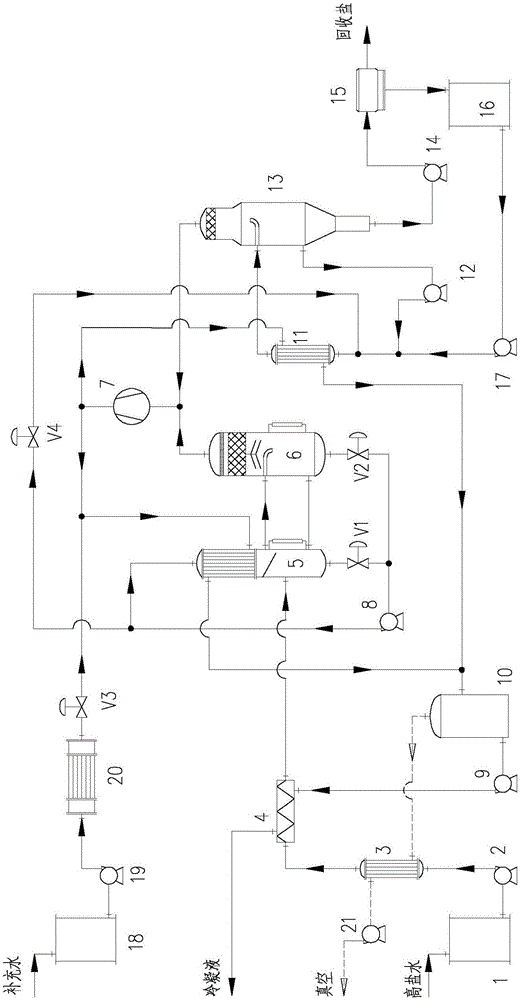

MVR (mechanical vapor recompression) evaporation crystallization system and method for high-salinity wastewater

PendingCN106669207ATake advantage ofAchieve recyclingEvaporator accessoriesEvaporators with forced circulationVapor–liquid separatorEvaporation

The invention discloses an MVR (mechanical vapor recompression) evaporation crystallization system and method for high-salinity wastewater[0]. The system comprises a raw material tank, a first preheater, a second preheater, an MVR evaporator, a gas-liquid separator, a compressor, a first circulating pump, a condensate tank, a forced circulation evaporator, a second circulating pump, a crystallizer, a centrifuge and a vapor generator. The full utilization of secondary vapor is realized after high-salinity wastewater is treated with the system, and the system has the advantages that the cost is low, the continuity and the energy saving effect are good, and the crystal salt quality is high.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Vacuum insulated panel core material and manufacturing method thereof

ActiveCN103196007ALow costStable and controllable qualityFibreboardThermal insulationGlass fiberFiber

The invention relates to a vacuum insulated panel core material and a manufacturing method thereof. the core material is small in heat conductivity coefficient and low in cost and comprises 70wt% to 100wt% of short chopped glass fiber strands with diameters in a range of 6 microns to 13 microns and lengths in a range of 4 millimeters to 20 millimeters and 0wt% to 30wt% of glass fiber cotton with diameters in a range of 1.0 microns to 4 microns and lengths in a range of 1 millimeters to 5 millimeters, wherein the short chopped glass fiber strands are produced through a strand drawing method, and the glass fiber cotton is produced through a flame method flame method. According to the manufacturing method for core panels, multi-layer liquid adding and multi-layer vacuum dewatering are used, the heat conductivity coefficient of the vacuum insulated panel core material is below 0.03W / m.k, and the heat conductivity coefficient of the vacuum insulated panel is below 0.0025 W / m.k, the heat conductivity coefficient is lower than that of a glass fiber cotton core material 100% produced through the flame method, the insulating effect is good, the manufacture cost of the vacuum insulated panel core material is saved greatly simultaneously, and the quality is stable and controllable.

Owner:CHANGZHOU SANYOU DIOR INSULATION MATERIALS MFG

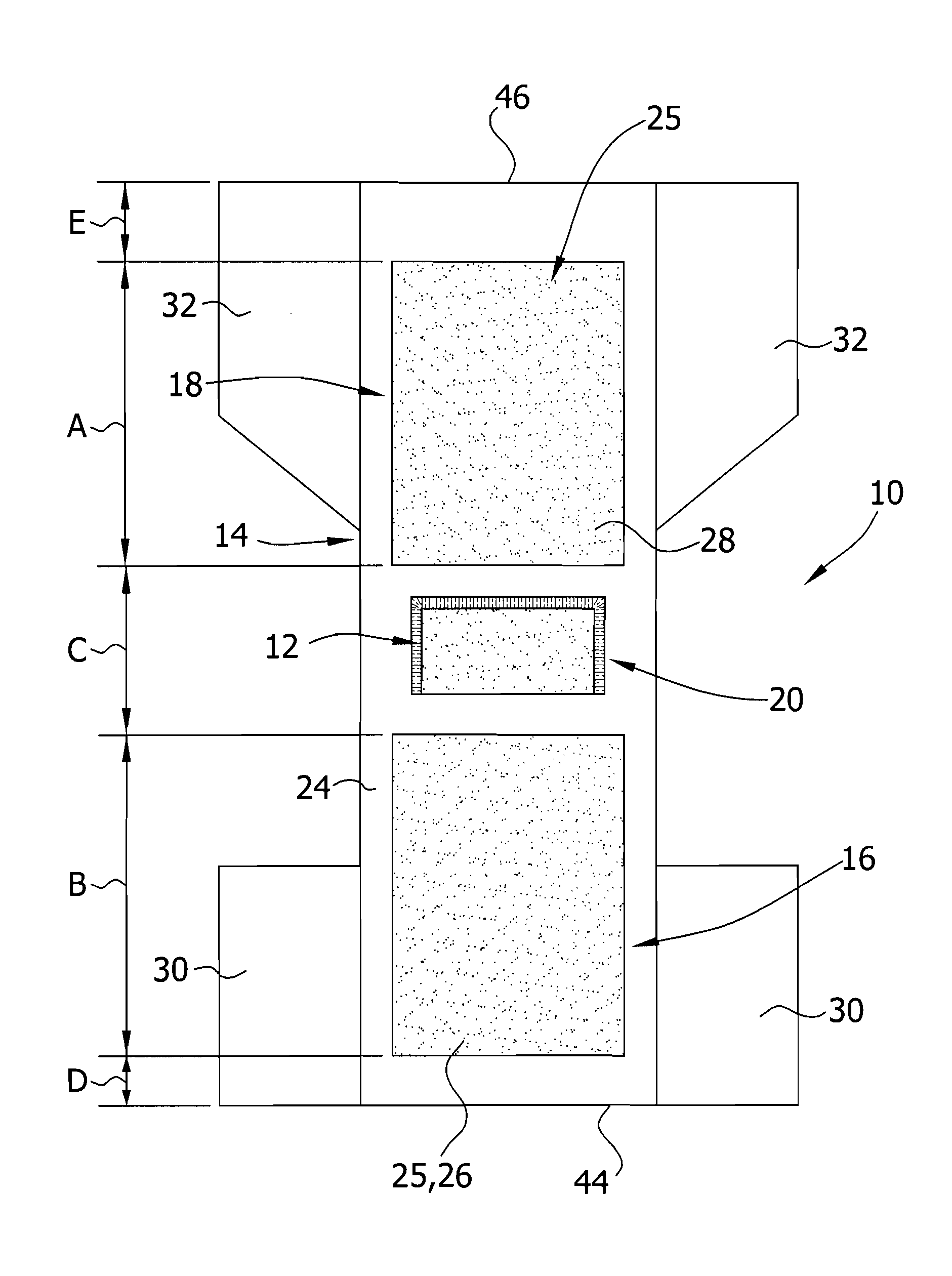

Absorbent article with temperature change member disposed on the outer cover and between absorbent assembly portions

InactiveUS7250548B2Facilitate continuous productionBaby linensTamponsEngineeringMechanical engineering

An absorbent article may define a front region, a rear region, and a crotch region intermediate the front and rear regions. The article may include an outercover, a liner and an absorbent assembly front portion disposed intermediate the outercover and the liner in the front region. The article may also include an absorbent assembly rear portion disposed intermediate the outercover and the liner in the rear region and at least partially spaced from the absorbent assembly front portion to provide a first gap. The article further includes a temperature change member disposed in the first gap.

Owner:KIMBERLY-CLARK WORLDWIDE INC

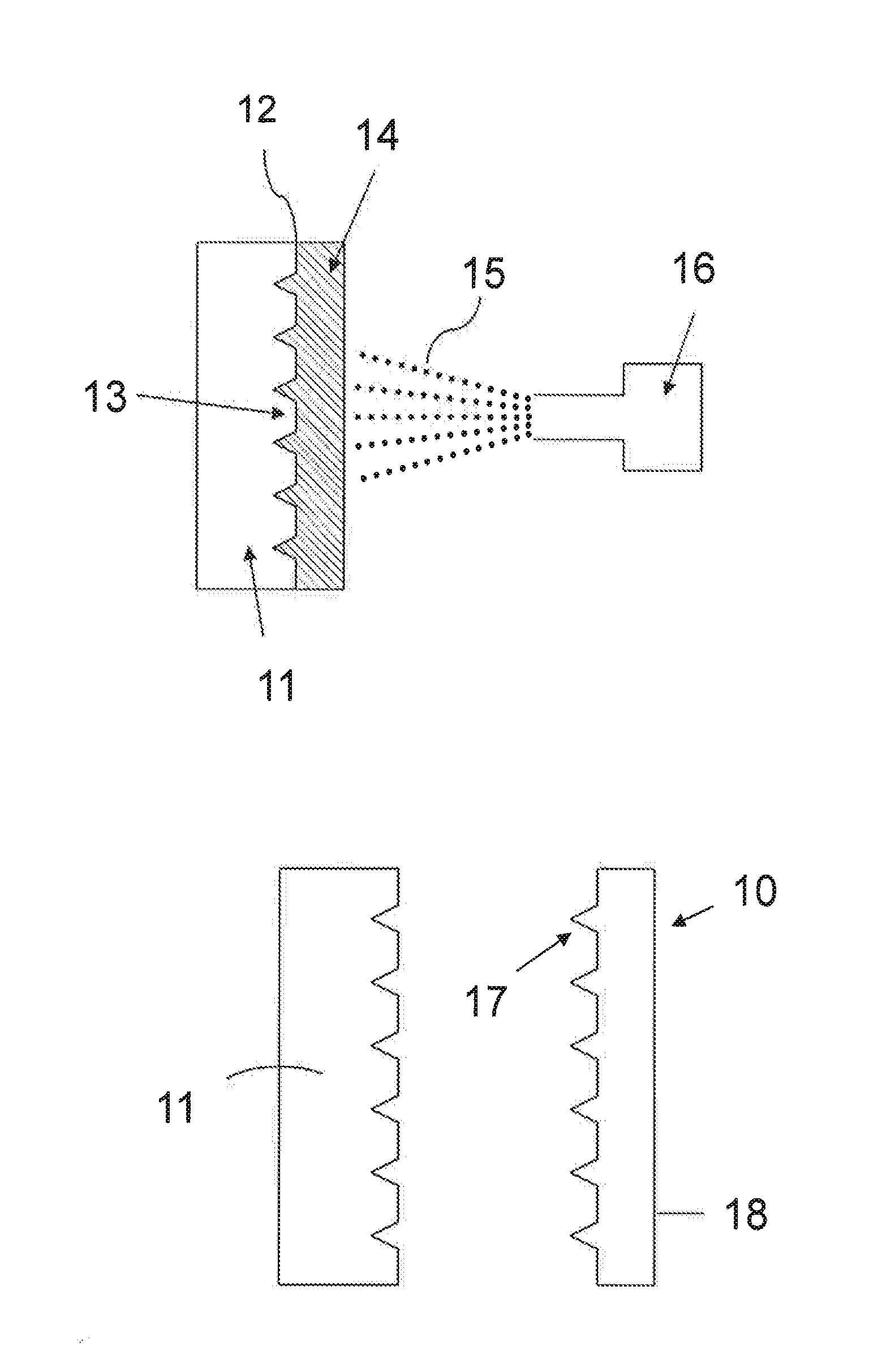

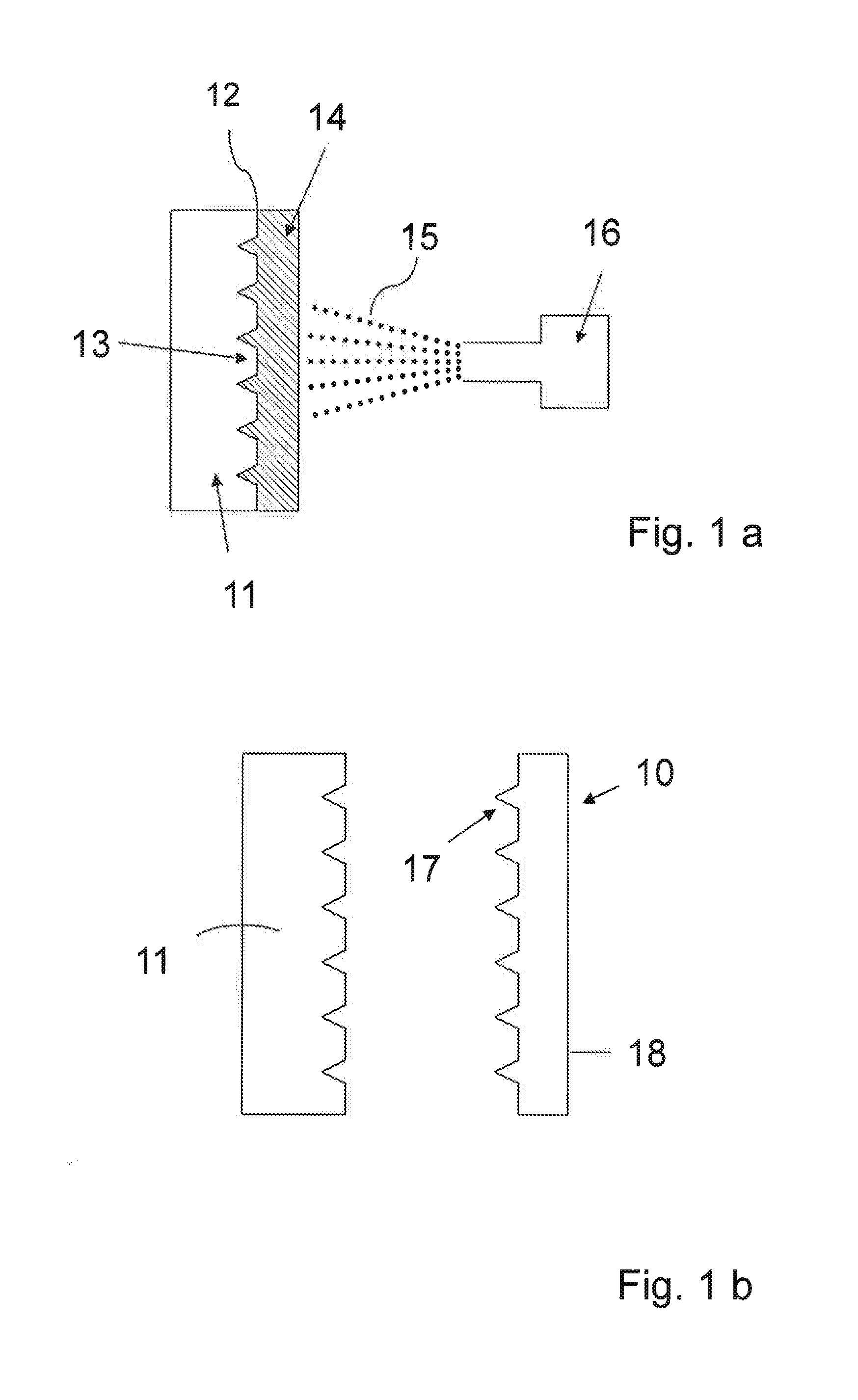

Riblet Foil and Method for Producing Same

InactiveUS20140356219A1Facilitate continuous productionIncrease rotational speedMetallic materialsMetal powder

A method for producing a layer-type buildup of riblet foil involves applying a metal powder is to a reference mold, which has a female mold of a riblet structure, in such a manner that a metallic material is formed. The layered portion applied in this manner is then detached, thereby forming a riblet foil having a riblet structure.

Owner:EADS DEUT GMBH

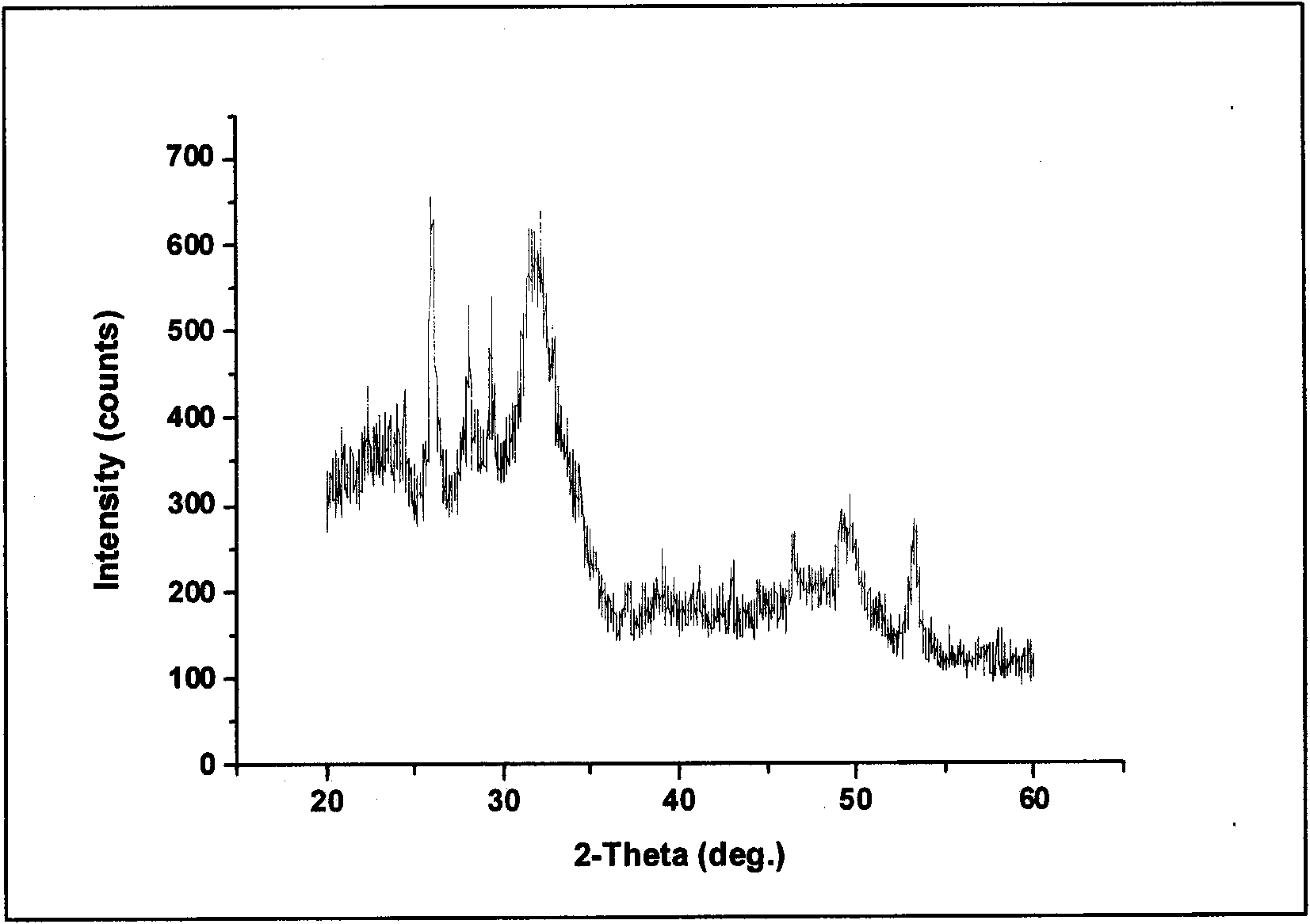

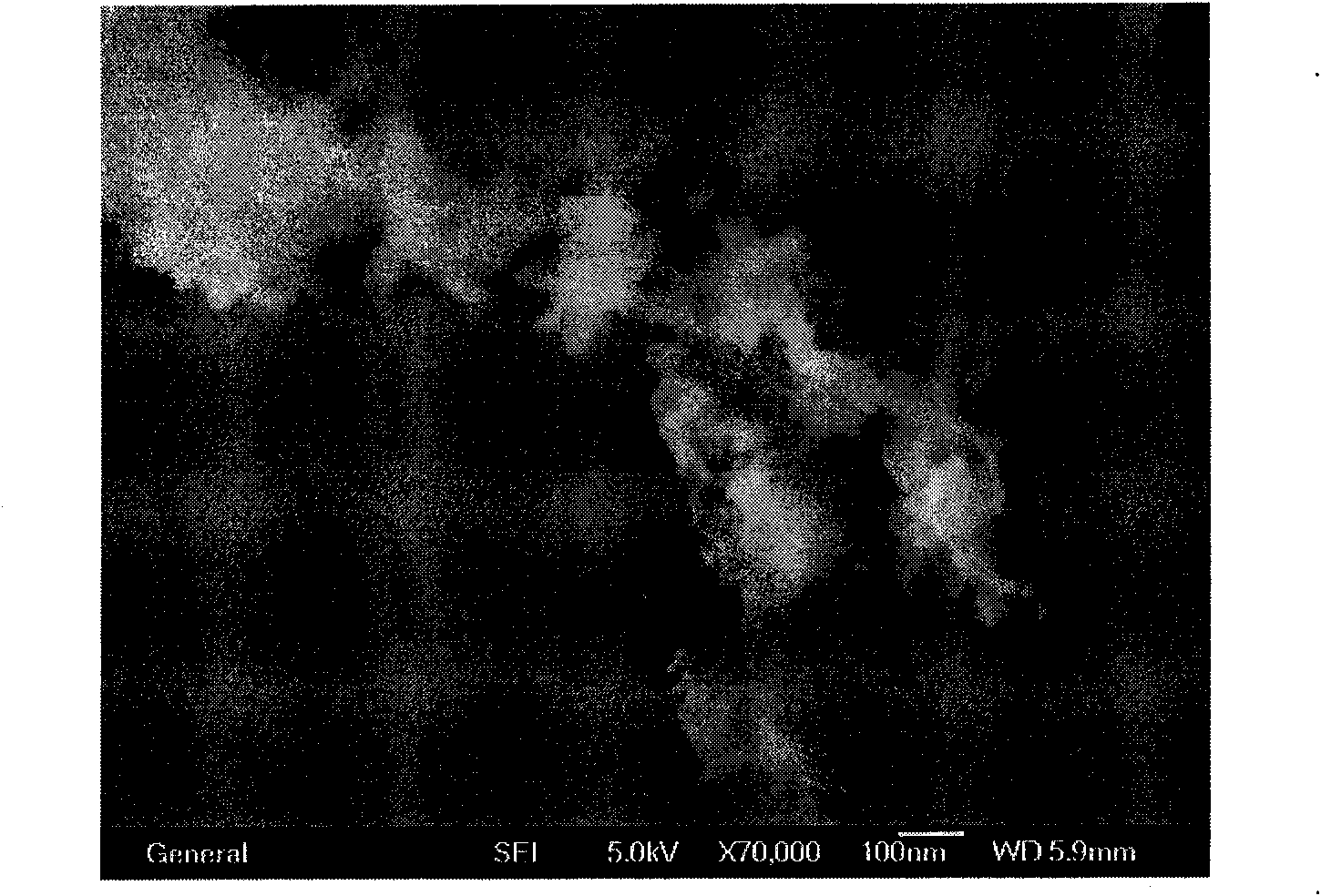

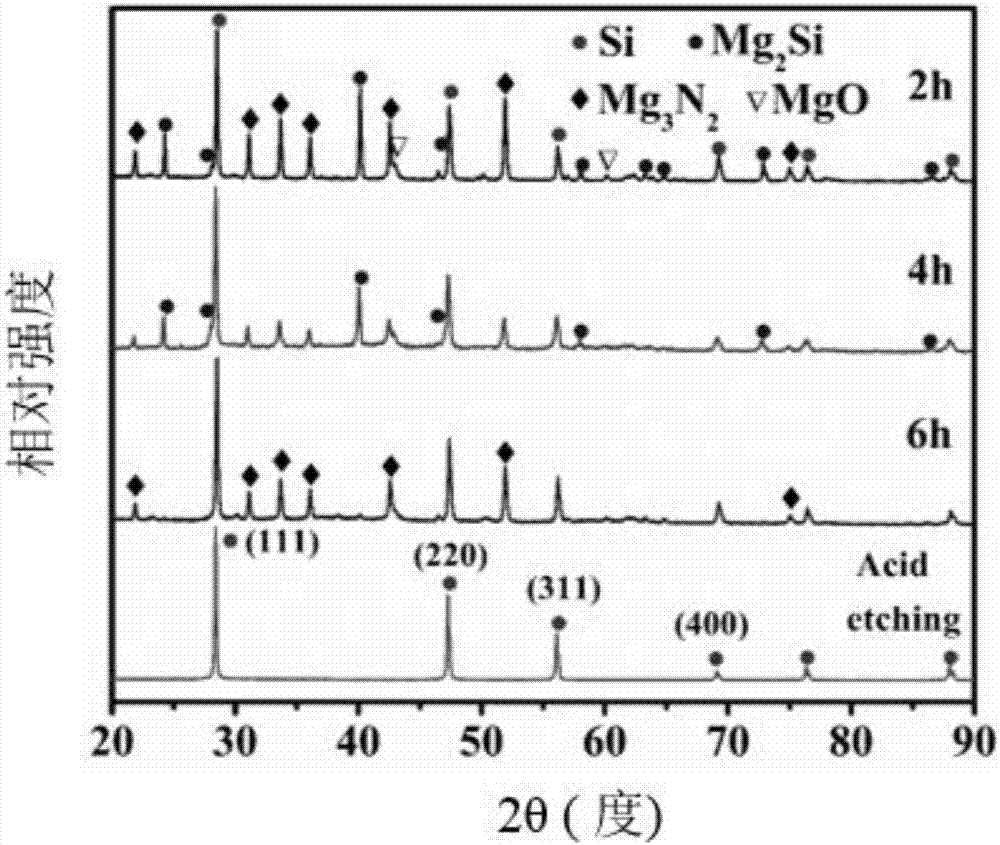

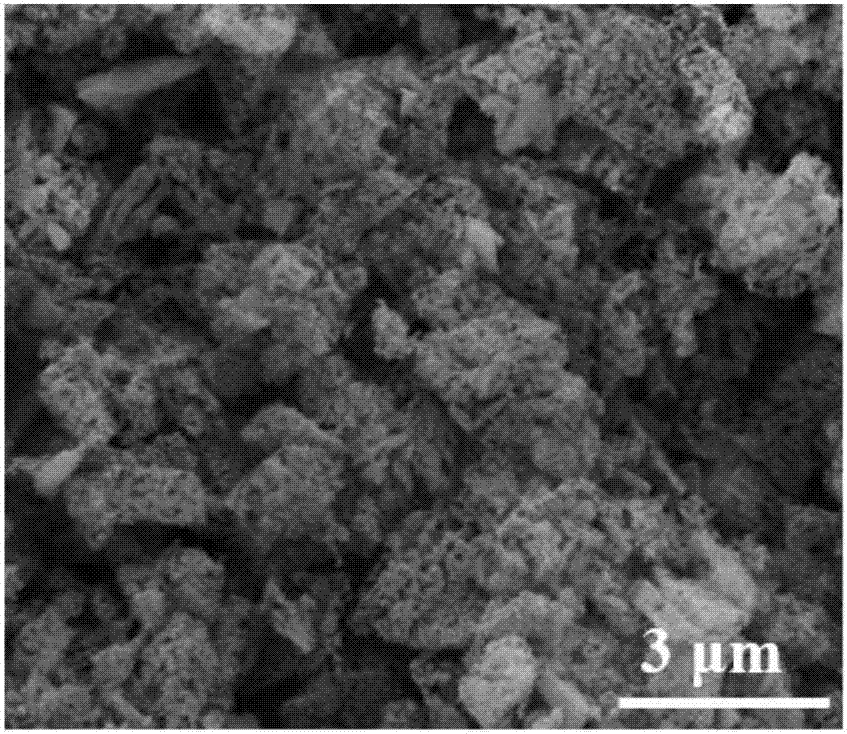

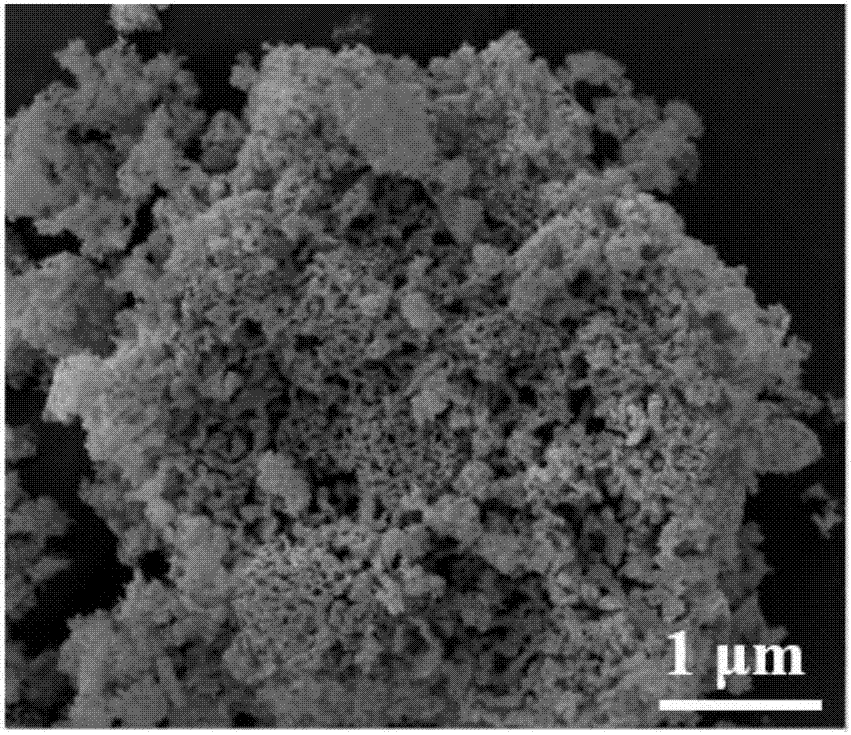

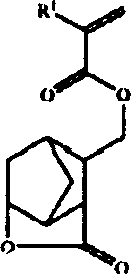

Preparation method of formicary-shaped porous silicon for lithium ion battery

ActiveCN107215874ASave raw materialsThe synthesis method is simpleCell electrodesSecondary cellsLithium-ion batteryReaction step

The invention discloses a preparation method of formicary-shaped porous silicon for a lithium ion battery. The preparation method comprises the following steps: (1) enabling a magnesium silicide raw material to react for 2 to 24h in an ammonia gas atmosphere at a temperature of 600 to 900 DEG C, and obtaining a crude product containing porous silicon (3Mg2Si+4NH3 to 3Si+2Mg3N2+6H2), wherein a particle size of the magnesium silicide raw material is 0.2 to 10 micrometers; and (2) acid pickling the crude product containing the porous silicon to obtain the formicary-shaped porous silicon for the lithium ion battery. By improving an overall process flow of the porous silicon key preparation method and parameters and conditions of various reaction steps, compared with the prior art, the preparation method has the advantage of simplicity and easiness, a great number of porous micrometer silicon can be obtained by directly heating the obtained magnesium silicide in ammonia gas (or mixed gas of the ammonia gas and inert gas), and the yield is high.

Owner:WUHAN UNIV OF SCI & TECH

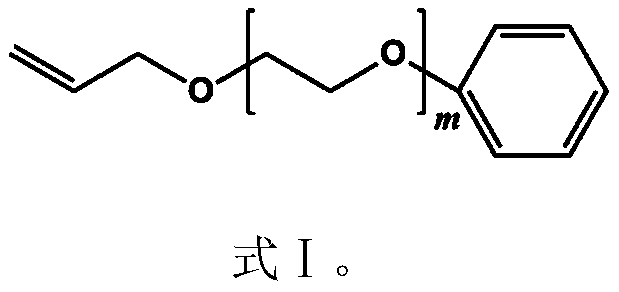

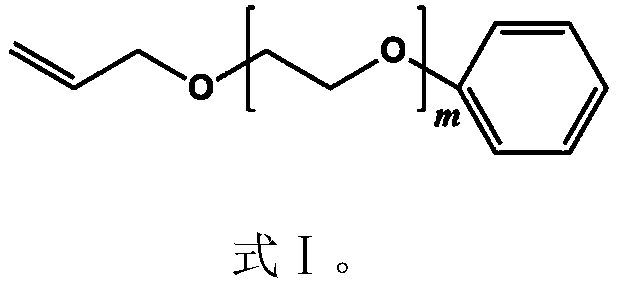

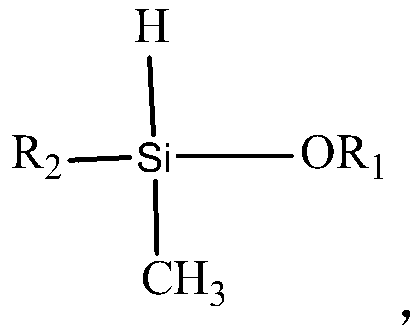

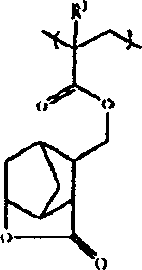

Preparation method of high-polymer viscosity reducer for heavy oil production

ActiveCN110372816ARaw materials are easy to getThe production process is simple and safeDrilling compositionCysteamineFunctional monomer

The invention relates to a preparation method of a high-polymer viscosity reducer for heavy oil production. According to the preparation method, by utilizing cysteamine as a chain transfer agent, a macromolecule functional monomer containing various functional groups such as nitrogen heterocyclic rings, benzene rings and ethylene oxide chain segments is prepared, then the macromolecule functionalmonomer, acrylamide, vinyl pyrrolidone, acrylic acid and a 2-acrylamide-2-methylpropanesulfonic acid water-soluble monomer are taken as raw materials, and a water-soluble polymer with a comb-shaped functional structure is prepared through aqueous solution polymerization. The product has the good dissolving property in an aqueous solution, and the viscosity of heavy oil can be lowered significantly. In addition, oil-water separation is easy under still standing of a heavy oil viscosity-reducing sample, and produced liquid is convenient to treat.

Owner:CHINA NAT OFFSHORE OIL CORP +2

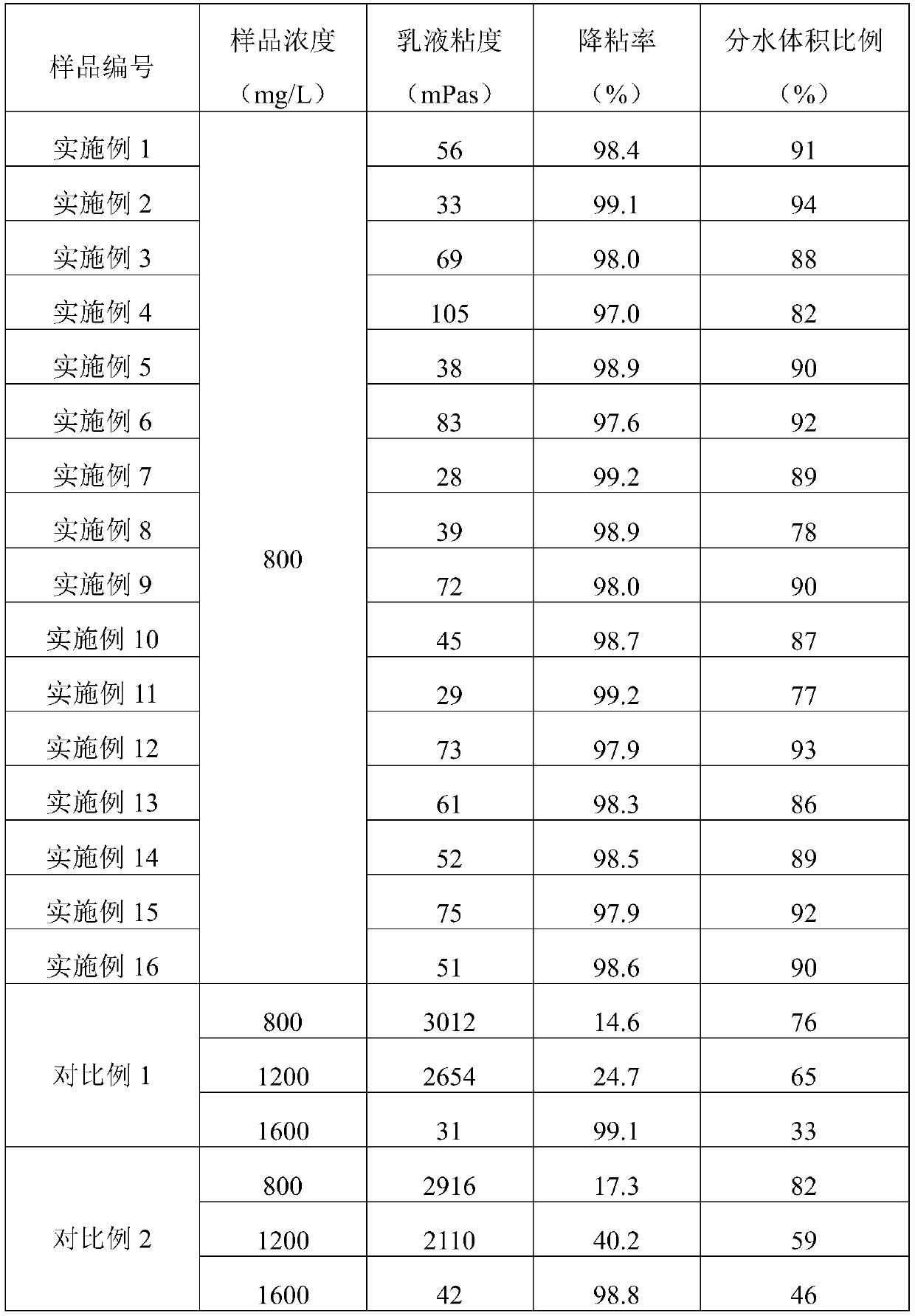

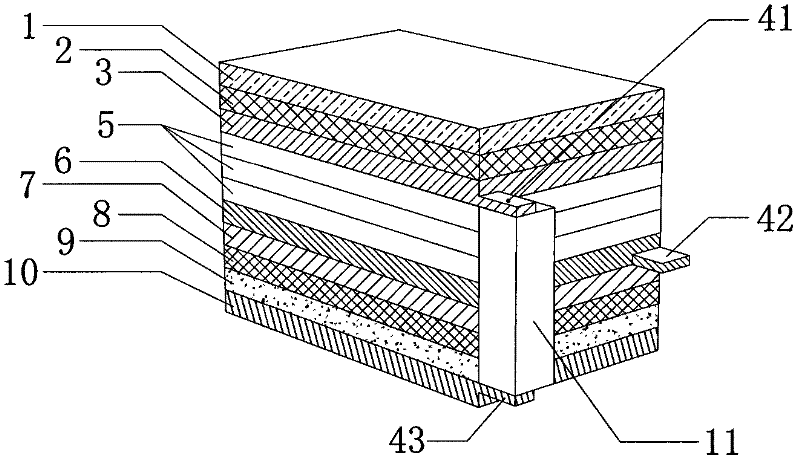

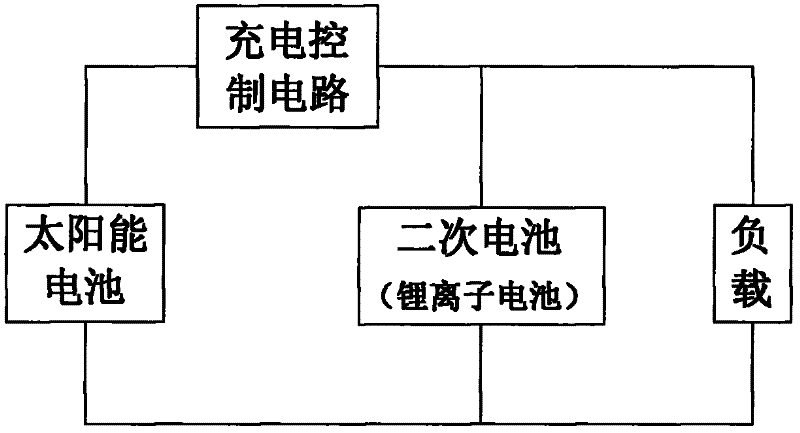

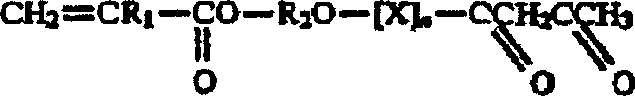

Lamination type energy-storable solar battery and preparation method thereof

ActiveCN102394321AImprove connection reliabilityImprove conductivitySecondary cellsElectrical batteryMoisture resistance

The invention discloses a lamination type energy-storable solar battery, which is characterized in that: a secondary battery is laminated on a lamination type solar battery; the secondary battery is a lithium ion battery and is provided with a charge control circuit; and all the components are packaged through flexible plastic. The prepared lamination type energy-storable solar battery integrates the solar battery and the lithium ion battery so as to reduce external circuits, improve the compactness, reduce the volume, reduce wire jumper and also ensure high conductivity; and through application of a gel electrode and a plastic packaging process, the moisture resistance is improved, and foldability is achieved. During preparation, a back electrode layer of the solar battery also bears an anode current collector of the lithium ion battery, so that materials can be saved, and the conductivity can be improved at the same time; and an anode active layer, a diaphragm and a cathode active layer of the lithium ion battery can be prepared into sheets in advance to facilitate compounding during the preparation and realize continuous production.

Owner:FUJIAN REIDA PRECISION

Automatic bolt spreading machine

InactiveCN101757999AEasy accessIncrease productivityLiquid surface applicatorsCoatingsDrive wheelStructural engineering

The invention relates to an automatic bolt spreading machine, which comprises a frame, a gluing wheel and a transmission device, wherein the gluing wheel and the transmission device are arranged on the frame; an output shaft of the transmission device is jointed with the gluing wheel; the lower part of the gluing wheel stretches into a glue-storing plate; an automatic outer-bolt spreading machine also comprises a rotating plate, wherein the periphery of the rotating plate is distributed with at least two electromagnetic chucks for clamping an outer bolt to be processed; driven wheels are fixedly arranged at the upper ends of the electromagnetic chucks; the driven wheels and driving wheels are ganged; the driving wheels are connected with the tail end of the output shaft of the transmission device; and the position to be glued of the outer bolt is contacted with the gluing wheel. The invention provides an automatic outer-bolt spreading machine which has high production efficiency and uniform glued glue line.

Owner:ZHEJIANG ZHAPU IND

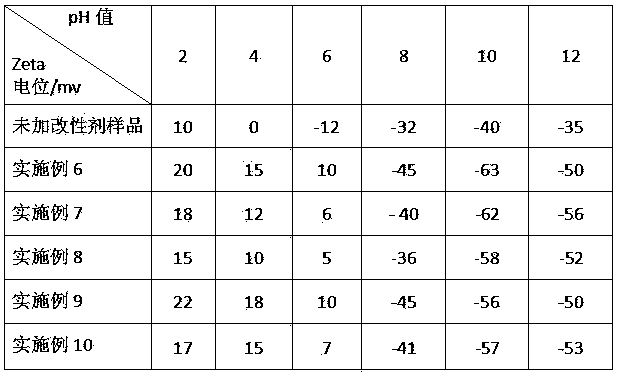

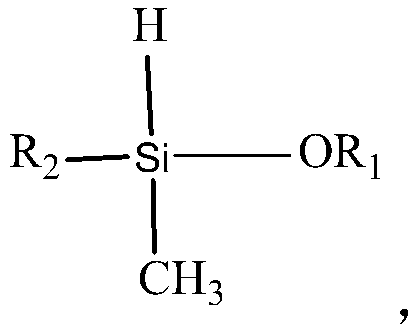

Surface modification method of silicon carbide micropowder

The invention relates to a surface modification method of silicon carbide micropowder. Two modifying agents are adopted to perform two-step dry modification of the silicon carbide micropowder. The surface modification method comprises steps of: preparing an ethanol solution of a silane coupling agent and an aqueous solution of water-soluble polymer, preheating the silicon carbide micropowder at 30-70 DEG C for 20-60 min, spraying the ethanol solution of the silane coupling agent in a form of mist into the silicon carbide micropowder stirred at a high speed, stirring and drying at 110-150 DEG C for 0.5-3 h, spraying the aqueous solution of the water-soluble polymer preheated to 30-80 DEG C in a form of mist into the silicon carbide micropowder stirred at a high speed, and stirring and drying at 110-150 DEG C for 0.5-3 h to obtain surface modified silicon carbide micropowder. The surface modification method aims at dry-method modification of the silicon carbide micropowder, and is capable of effectively solving the dispersibility problem of the dispersibility, and improving the uniformity and increasing the powder yield of granulation of the silicon carbide micropowder.

Owner:连云港海蓝研磨材料有限公司 +1

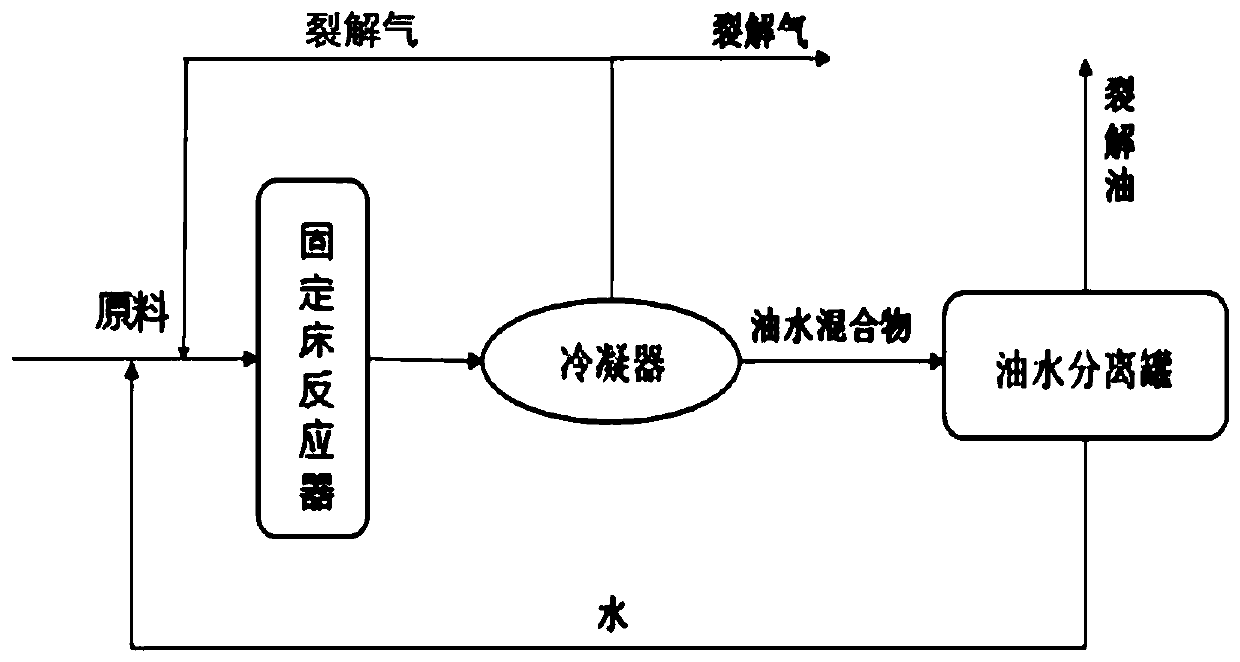

Olefin cracking catalyst, preparation method thereof and olefin cracking method

PendingCN111482199AApplicable to a wide range of feedstock oilsImprove conversion rateMolecular sieve catalystsBulk chemical productionMolecular sievePtru catalyst

The invention provides an olefin cracking catalyst, a preparation method thereof and an olefin cracking method. The preparation method of the catalyst comprises the following steps: mixing at least two of the pretreated SAPO-34 molecular sieves, ZSM-5 molecular sieves, beta molecular sieves and USY molecular sieves according to a mass ratio of (0-30): (50-80): (0-30): (0-50) to obtain composite molecular sieves, respectively performing alkali treatment on the ZSM-5 molecular sieves, the beta molecular sieves and the USY molecular sieves, and performing acid treatment on the SAPO-34 molecular sieves; performing steps of silanization treatment and nonmetal and metal modification treatment on the composite molecular sieve, and finally obtaining the olefin cracking catalyst by mixing a matrixand a binder. The invention also provides an olefin cracking method using the catalyst. The catalyst provided by the invention has a porous structure and suitable acid distribution, has high olefin conversion rate and high ethylene and propylene yield in the reaction, and has long service life.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Completely biodegradable hydrophobic material and its prepn

The present invention discloses one kind of completely biodegradable hydrophobic material and its preparation process. The starch-base biodegradable material is prepared through reaction and extrusion in extruder of the following material: starch, PVA, lactone polymer capable of reacting with hydroxy group, biodegradable polymer, initiator and other assistant. The present invention has the advantages of low cost, high hydrophobicity of the product, simple operation, complete biodegradation of the material to eliminate 'white pollution', etc. The present invention is suitable for continuous production.

Owner:EAST CHINA UNIV OF SCI & TECH

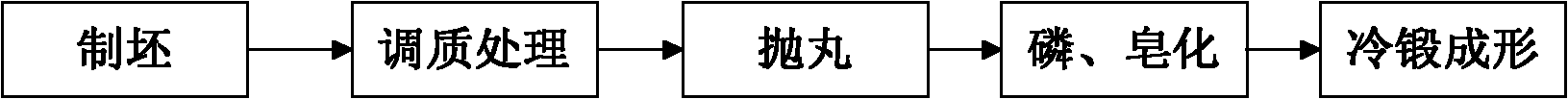

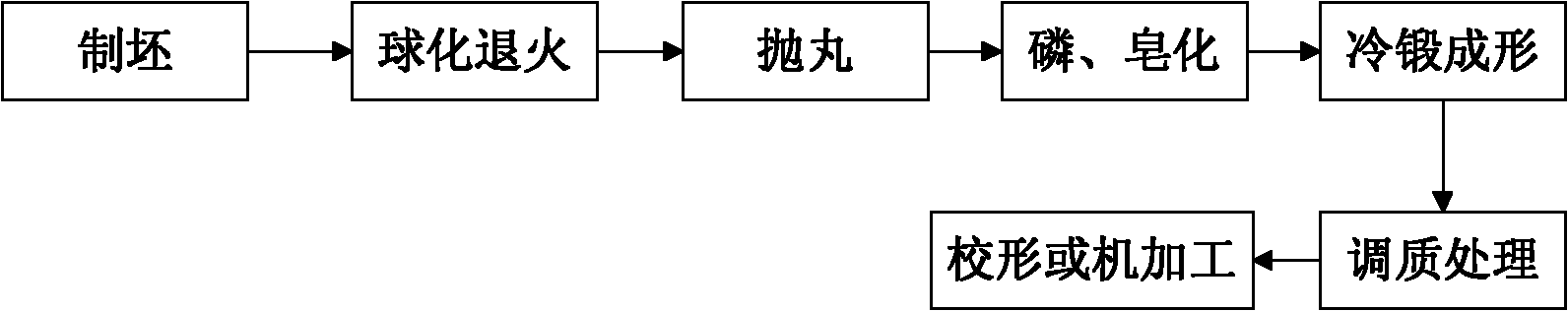

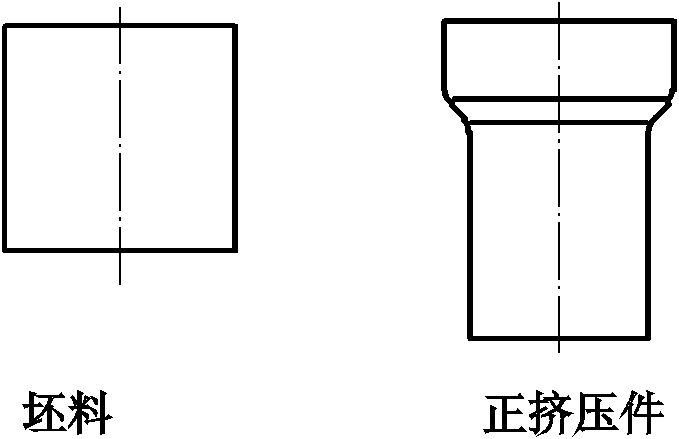

Cold forging processing method of hardened and tempered structural steel

InactiveCN102019335ASmall cutting allowanceSave raw materials and energyForging/hammering/pressing machinesQuenchingThermal treatment

The invention discloses a cold forging processing method of hardened and tempered structural steel, which belongs to the technical field of steel cold forging. The method comprises the following steps of: firstly, performing corresponding blank forming treatment on different blanks and performing quenching treatment and high-temperature tempering treatment so as to obtain a structural steel hardened and tempered blank; secondly, blowing steel shots out of a barrel-type shot blasting machine by using compressed air, continuously impacting the steel shots onto the hardened and tempered structural steel blank and phosphating and saponifying the structural steel blank; and lastly, deforming the structural steel blank by using a cold forging mold in a cold extruding or cold heading way so as to obtain a precision forming part. The classical cold forging process is changed completely, softening treatment is not performed before cold forging of a steel material, a mechanical part with high size accuracy and high comprehensive mechanical property is processed by material hardening and tempering treatment and cold forging deformation and reinforcement, and subsequent thermal treatment is not needed after cold forging forming.

Owner:SHANGHAI JIAO TONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com