Lamination type energy-storable solar battery and preparation method thereof

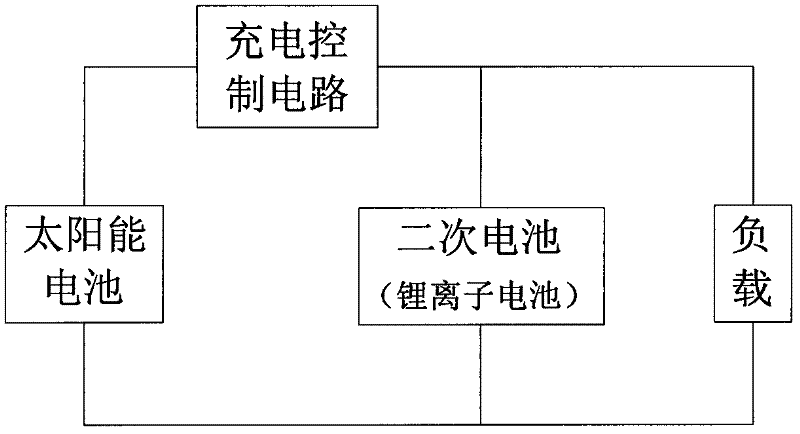

A solar cell and stacking technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of changing the appearance and shape of secondary batteries, large power supply system, and increased jumper wires, etc., to reduce the appearance and volume , material saving and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

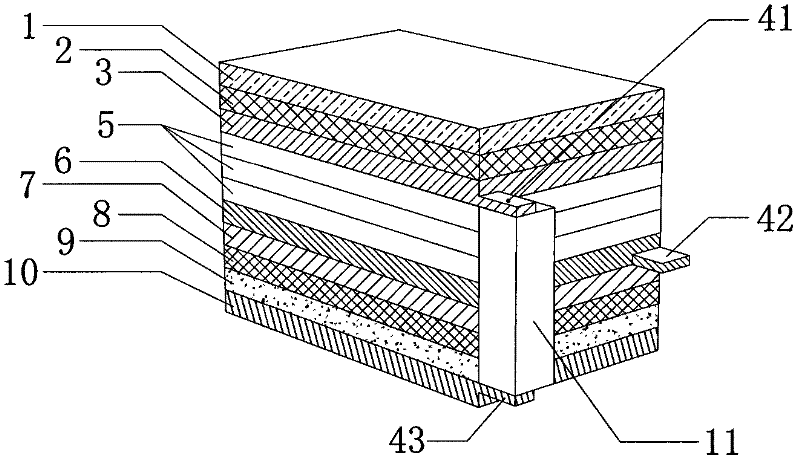

[0062] Embodiment 1, the preparation method of the laminated energy-storage solar cell using quartz as the solar cell substrate material:

[0063] Step 1: Use 0.3mm-0.5mm quartz glass sheet as the solar cell substrate material, and prepare the solar cell substrate according to the set size.

[0064] Step 2: Coating a transparent insulating film on the surface of the solar cell substrate as a topcoat layer 2 . After the solar cell substrate formed in step 1 is ultrasonically cleaned and dried, an insulating surface paint layer is coated by electrophoresis. The surface paint layer used is polyester material, and the thickness of the film layer is 10 μm to 100 μm.

[0065] Step 3: Prepare the front electrode layer 3, and deposit a transparent composite conductive film on the surface paint layer by deposition method, and the distance between the front electrode layer and the edge of the solar cell substrate is not less than 0.5mm.

[0066] Step 4: Press in the connection terminal...

Embodiment 2

[0080] Embodiment 2, the preparation method of the laminated energy-storage solar cell using polyamide plastic as the solar cell substrate material:

[0081] Step 1: Use polyamide plastic with a thickness of 1mm as the solar cell substrate material, and prepare the solar cell substrate according to the set size.

[0082] Step 2: Coating a transparent insulating film on the surface of the solar cell substrate as a topcoat layer 2 . After the solar cell substrate formed in step 1 is ultrasonically cleaned and dried, an insulating surface paint layer is coated by electrophoresis. The surface paint layer used is polyester material, and the thickness of the film layer is 10 μm to 100 μm.

[0083]Step 3: Prepare the front electrode layer 3, and deposit a ZnO transparent conductive film on the surface paint layer by a deposition method, and the distance between the front electrode layer and the edge of the solar cell substrate is not less than 0.5 mm.

[0084] Step 4: Press in the c...

Embodiment 3

[0098] Example 3, the preparation method of the laminated energy-storage solar cell using modified polystyrene as the solar cell substrate material:

[0099] Step 1: Use modified polystyrene with a thickness of 1mm as the solar cell substrate material, and prepare the solar cell substrate according to the set size.

[0100] Step 2: Coating a transparent insulating film on the surface of the solar cell substrate as a topcoat layer 2 . After the solar cell substrate formed in step 1 is ultrasonically cleaned and dried, an insulating surface paint layer is applied, and the surface paint layer used is SiO 2 material, the thickness of the film layer is 10 μm to 100 μm.

[0101] Step 3: Prepare the front electrode layer 3, and deposit SnO on the surface paint layer by deposition method 2 Transparent conductive film, the distance between the front electrode layer and the edge of the solar cell substrate is not less than 0.5mm.

[0102] Step 4: Press in the connection terminal 41 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com