Surface modification method of silicon carbide micropowder

A silicon carbide micropowder and surface modification technology, which is applied in the field of silicon carbide micropowder processing, can solve the problems of poor particle dispersion, poor product stability, and long production cycle, and achieve uniform coating, improved dispersion performance, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

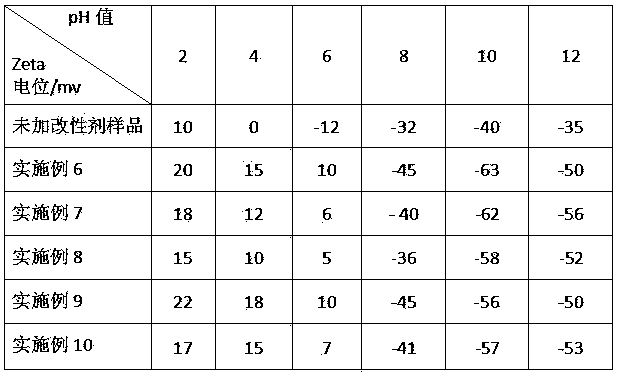

Examples

Embodiment 1

[0022] Embodiment 1, a kind of surface modification method of silicon carbide micropowder, its steps are as follows:

[0023] (1) Configure two modifier solutions: one is a silane coupling agent ethanol solution with a mass concentration of 5-30% obtained by mixing a silane coupling agent with ethanol;

[0024] Among them, the silane coupling agent is methyltriethoxysilane, vinyltriethoxysilane, N-(β-aminoethyl)-γ-aminopropyltrimethyl(ethyl)oxysilane, γ-(2, One or more of 3-glycidyloxy)propyltrimethoxysilane, 3-aminopropyltriethoxysilane, and γ-(methacryloyloxy)propyltrimethoxysilane;

[0025] The other is a water-soluble polymer aqueous solution with a mass concentration of 5-30% obtained by mixing a water-soluble polymer with water;

[0026] Wherein the water-soluble polymer is one or more of polyethylene glycol, polyacrylamide, polyacrylate, polyethyleneimine, carboxymethyl cellulose;

[0027] (2) Dry modification of silicon carbide micropowder: first preheat the silicon ...

Embodiment 2

[0028] Embodiment 2, in the surface modification method of the silicon carbide micropowder described in embodiment 1, the silane coupling agent described in step (1) is by the methyl triethyl ethyl that mass ratio is 1~3:1~3:1 Oxysilane, vinyltriethoxysilane and 3-aminopropyltriethoxysilane, preferably methyltriethoxysilane, vinyltriethoxysilane and 3-aminopropyltriethoxysilane The mass ratio of oxysilane is 2:2:1.

Embodiment 3

[0029] Example 3, in the surface modification method of silicon carbide micropowder described in Example 1, the silane coupling agent described in step (1) is composed of N-(β-aminoethyl with a mass ratio of 1:2~4 )-γ-aminopropyltrimethyl(ethyl)oxysilane and γ-(2,3-glycidoxy)propyltrimethoxysilane are mixed, preferably with a mass ratio of 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com