Patents

Literature

1096results about How to "Solve reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

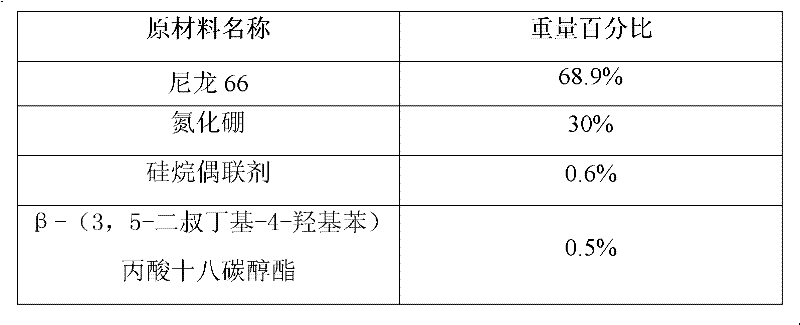

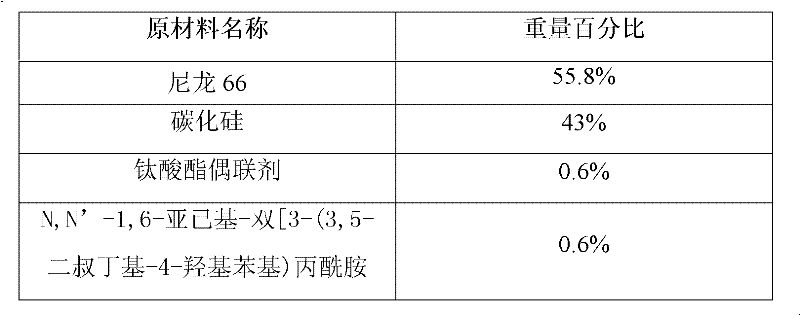

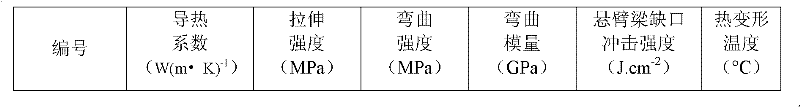

Nylon 66 composite material with high heat conductivity and preparation method thereof

ActiveCN102408710AGood dispersionEvenly dispersedHeat-exchange elementsStrength of materialsNylon 66

The invention discloses a nylon 66 composite material with high heat conductivity, comprising the following substances based on weight percentages: 70-42% of nylon 66, 27-55% of heat conduction filler, 0.5-1.5% of coupling agent and 0.5-1.5% of anti-oxidant. In addition, the invention also discloses a preparation method for the nylon 66 composite material with high heat conductivity, wherein the method adds a processing step on the heat conduction filler based on the conventional method. The nylon 66 composite materials with high heat conductivity prepared by the invention can better keep themechanical property of the nylon 66 composite material and largely raise the heat conductivity at the same time. In comparison with the heat conductivity of the nylon 66 composite material prepared from the heat conduction filler without processing, the heat conductivity of the nylon 66 composite material prepared from the processed heat conduction filler is raised by about 30-50%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

High-strength and high-conductivity dispersion-strengthened alloy and preparation method thereof

InactiveCN101956094AImprove conductivityImprove interface structureElectro conductivityHigh conductivity

The invention relates to a high-strength and high-conductivity dispersion-strengthened alloy, which comprises a copper base, a ceramic dispersion-strengthening phase and a doping element, wherein the ceramic dispersion-strengthening phase may be one or several of ZrO2, Y2O3, MgO, Al2O3 and TiB2 which accounts for 0.1 to 2 mass percent of the copper alloy; and the doping element may be one or several of Ni, Y, Ag, Ti, Zr and Hf which accounts for 0.1 to 1 percent of the copper alloy. In the invention, the problems of ceramic particle agglomeration caused by low bonding performance of the copper and ceramic interface, the roughening of the ceramic particles in sintering and material conductivity reduction caused by the scattering of electrons at the copper and ceramic interface are solved, and the dispersion-strengthened alloy with higher hardness and higher conductivity is obtained. The invention also relates to a preparation method of the high-strength and high-conductivity dispersion-strengthened alloy.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Ultra-fine highly effective anion powder material and its preparation method

The invention relates to an ultrafine high-effect negative ion powder material, which comprises: 60~95% natural negative ion releasing material, 2~30% activated material, and 3~25% energy transfer material. Wherein, using dry way and wet way to ultrafine break the material and obtain the product. This material increases the ion releasing ability more than twenty times to pure natural tourmalin and three times to the material theoretic value, and has high far-infrared radiation function without toxin.

Owner:深圳市金士吉康复用品科技有限公司

Negative-ion, far-infrared, antibacterial and anti-mite compound polyester fibers and manufacturing method thereof

InactiveCN107083579AWith far infrared heating performanceAntibacterial and anti-mite effectMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to negative-ion, far-infrared, antibacterial and anti-mite compound polyester fibers and a manufacturing method thereof. The compound polyester fibers are added with a negative-ion additive, a far-infrared additive and an antibacterial and anti-mite additive, wherein the negative-ion additive, the far-infrared additive and the antibacterial and anti-mite additive respectively account for 2%, 5% and 6% by mass in the compound polyester fibers; the negative-ion additive comprises an additive carrier and tourmaline negative-ion powder; the far-infrared additive comprises an additive carrier, Tai Chi stone powder, ZrO2 nano-powder, nano-silicon dioxide, nano-aluminum oxide, nano-manganese oxide and nano-calcium oxide; the antibacterial and anti-mite additive comprises an additive carrier, nano-Cu-ZnO compound particles, nano-titanium dioxide, nano-zinc oxide and nano-silicon dioxide; and the additive carrier is TiO2 hollow spheres.

Owner:GUANGZHOU ZHONGCHENG NEW MATERIALS TECH

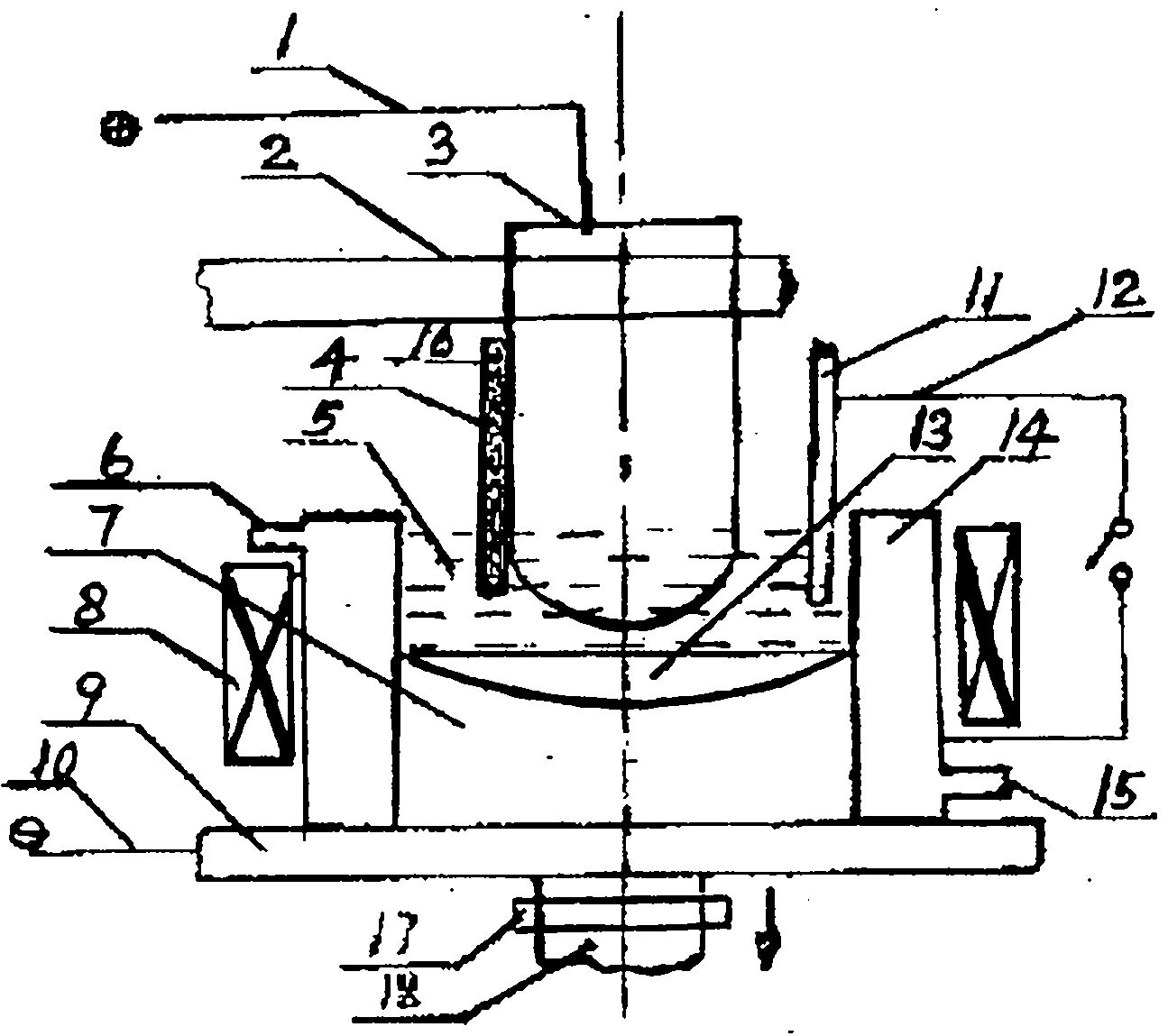

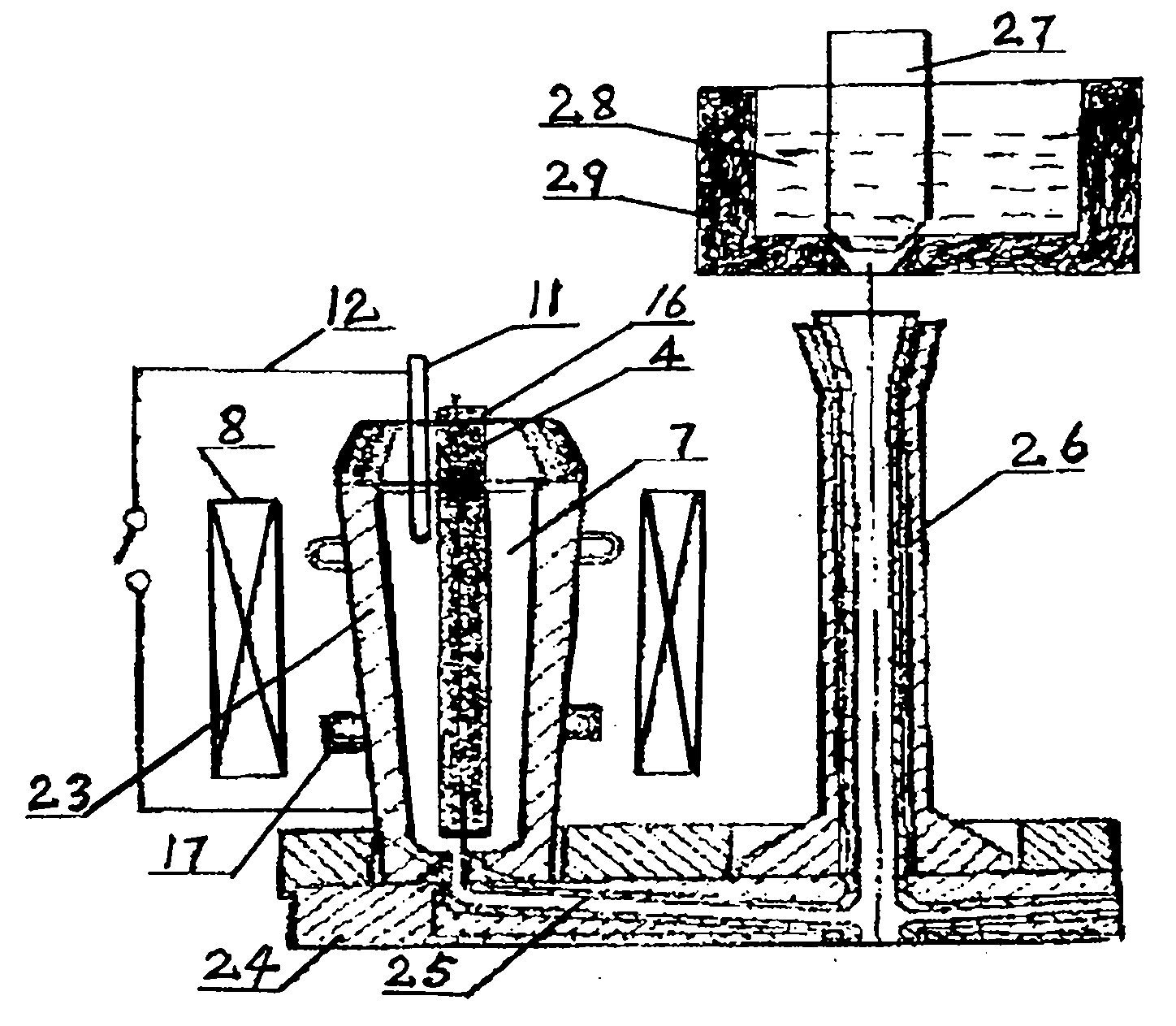

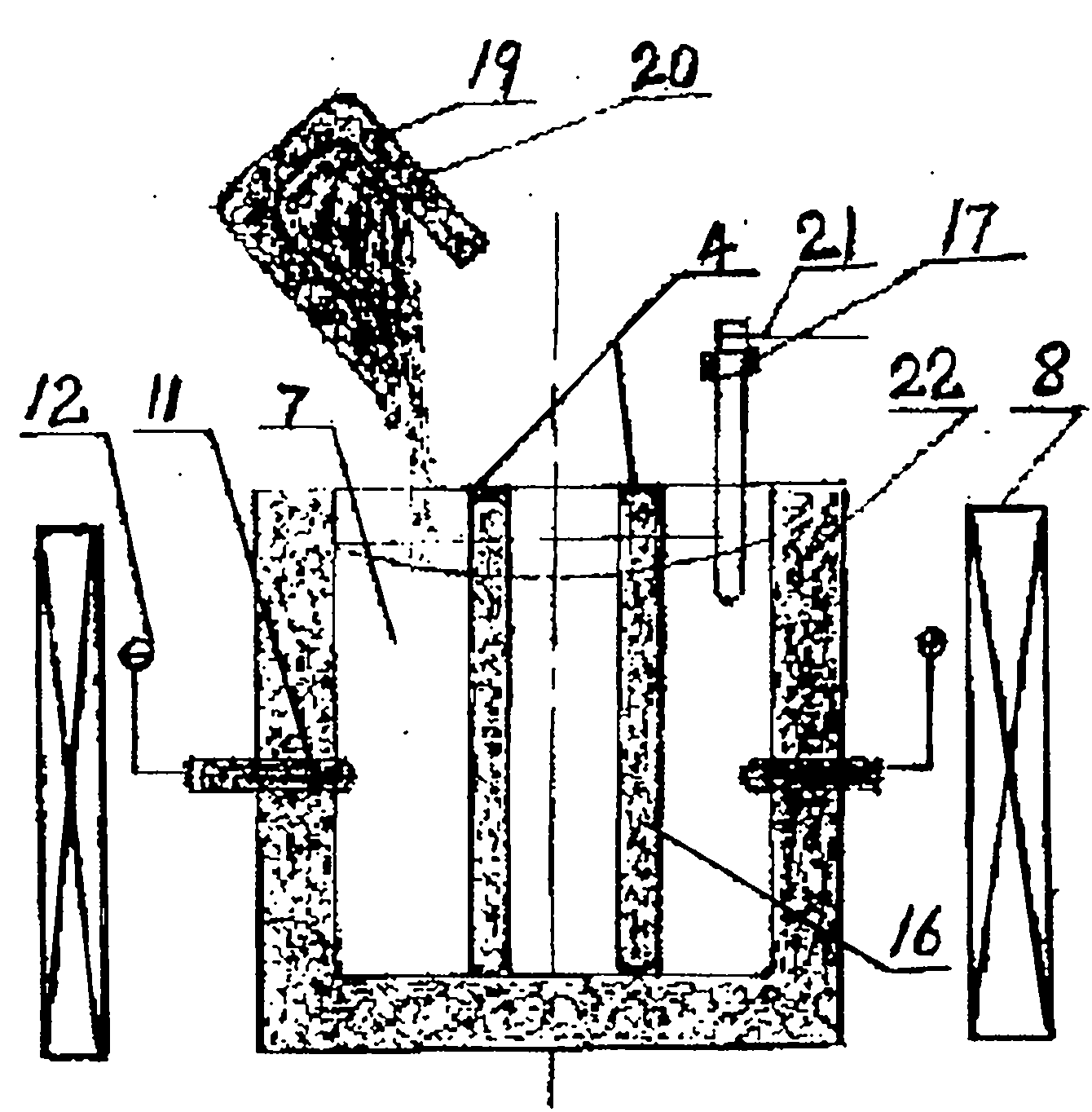

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

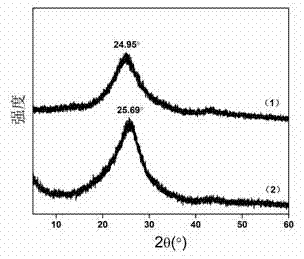

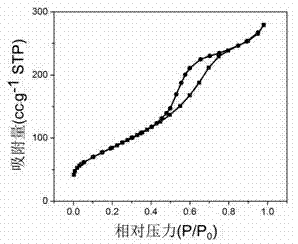

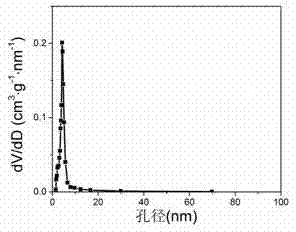

Preparation method for graphene with three-dimensional porous structure

ActiveCN104261403ASimple stepsAvoid toxic chemical reagents and graphene agglomeration problemsGraphitePolystyrene spheresGraphite oxide

The invention provides a preparation method for graphene with a three-dimensional porous structure. An even dispersion liquid is formed under the electrostatic interaction of a polystyrene template and graphene oxide, then the polystyrene template is removed through high-temperature calcination, and graphene with the three-dimensional porous structure is obtained after thermal reduction. According to the method, polystyrene spheres are taken as the template, and the pore size in graphene can be effectively controlled through controlling the particle size of the polystyrene spheres; and graphene is prepared through a calcination reduction method, so that problems of poisonous chemical reagent application and graphene agglomeration in a chemical reduction process can be avoided, and meanwhile the poriform structure of graphene after calcination is firmer.

Owner:FUZHOU UNIVERSITY

Heat-conductive silicone grease composition being high in heat conductivity and low in viscosity, and preparation method of the silicone grease composition

ActiveCN107603224ALiquidity is not affectedLiquidity impactHeat-exchange elementsNetwork structureSilicone grease

The invention discloses a heat-conductive silicone grease composition being high in heat conductivity and low in viscosity and freeness degree, and a preparation method of the silicone grease composition. The heat-conductive silicone grease composition includes organo-polysiloxane, heat conductive filler and other additives. By selecting the heat conductive fillers in multiple dimensions (one-dimension, two-dimension and three-dimension) and multiple scales (micron, submicron and nanometer) and in special ranges, synergistic effect among the multi-dimension and multi-scale fillers is achieved,thus achieving compact stack of the fillers in a local network structure. The heat-conductive silicone grease not only is improved in heat-conductivity but also has good flowability, low viscosity and low freeness degree.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

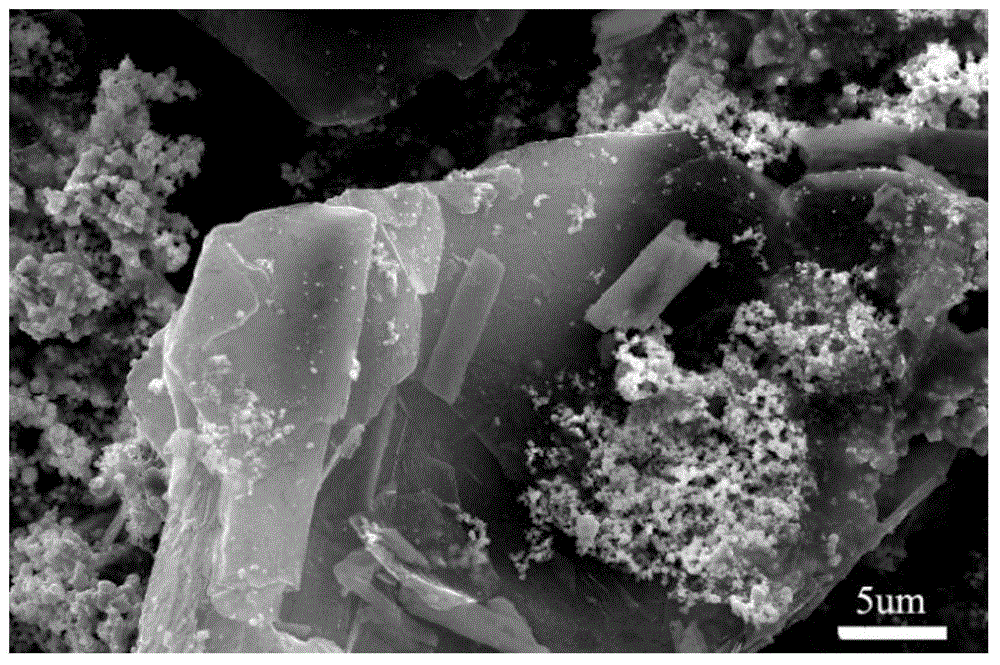

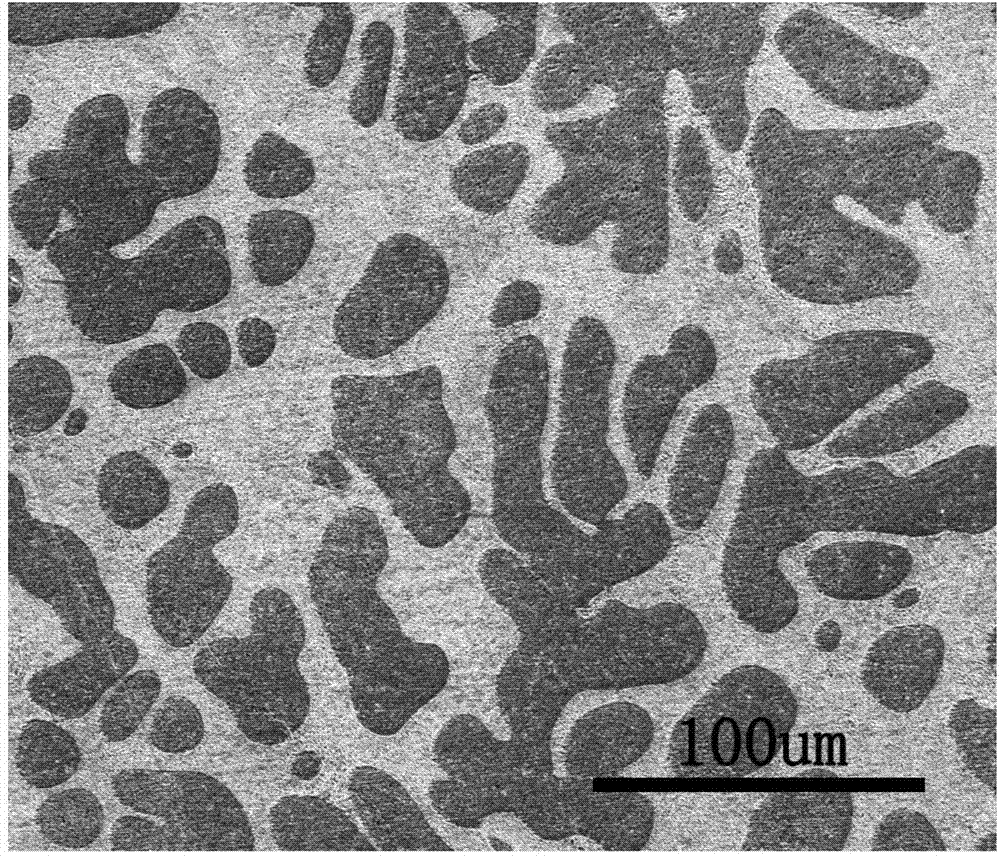

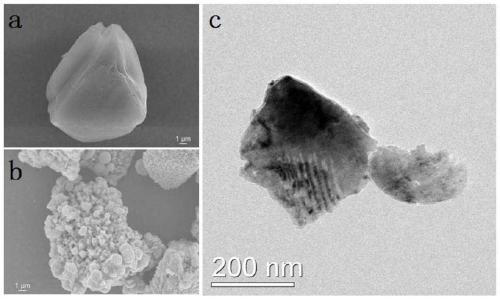

Preparation method of high-thermal conductivity graphene-Sn-Ag composite brazing filler metal

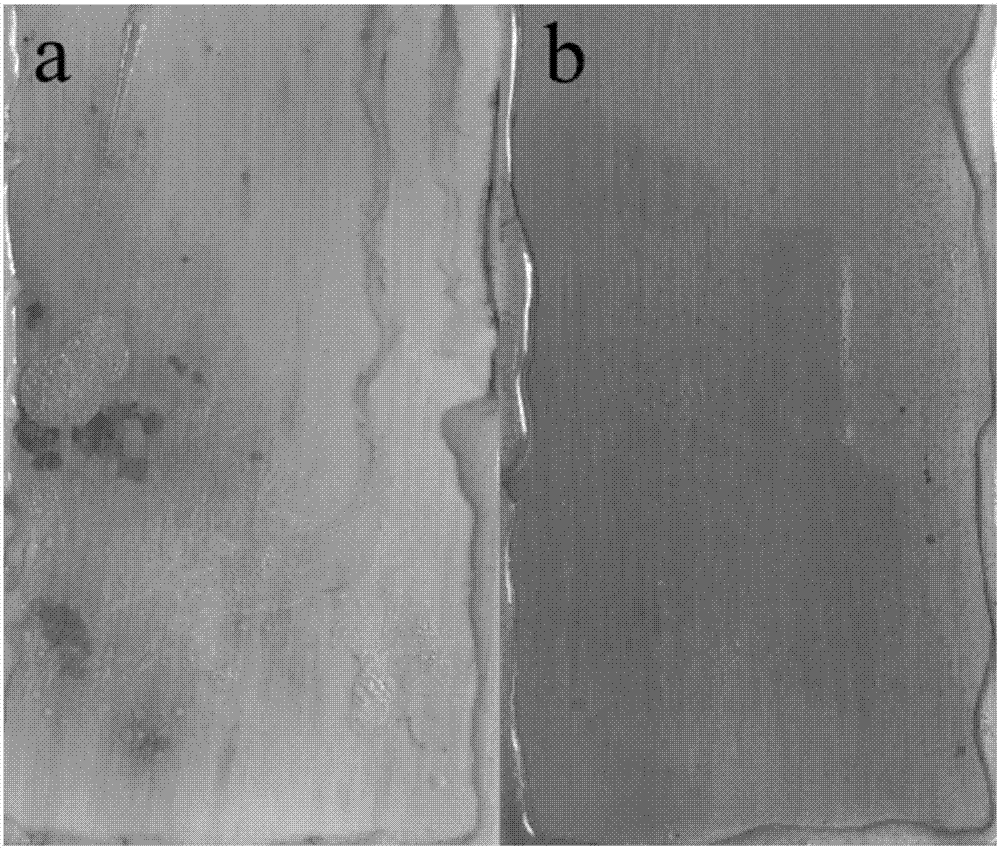

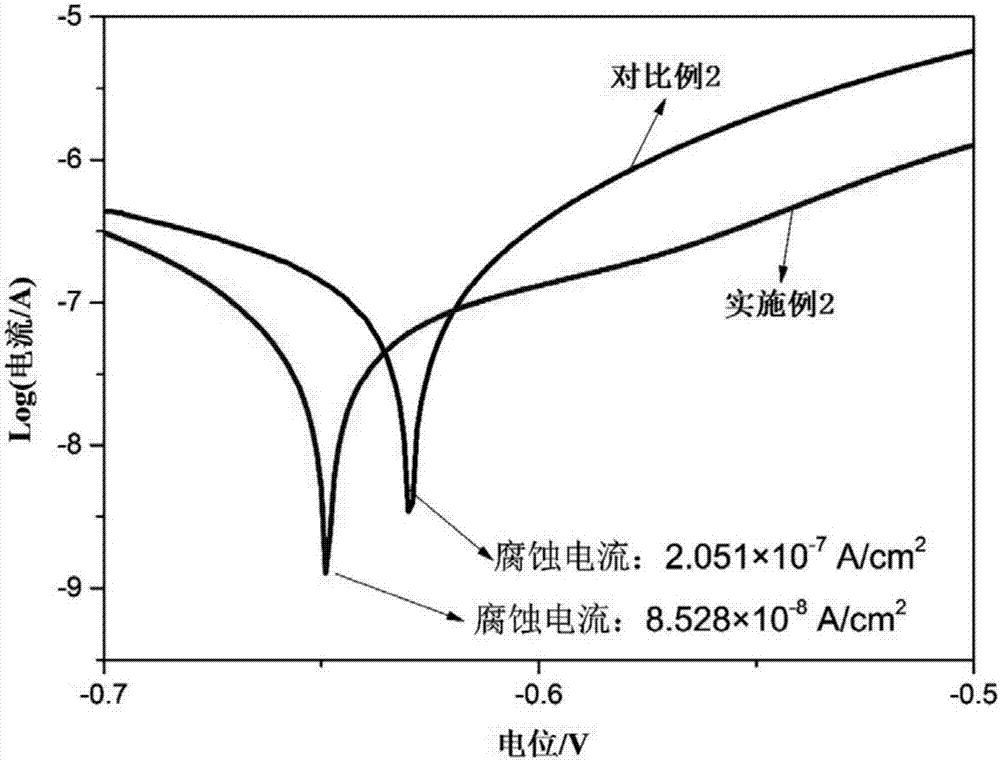

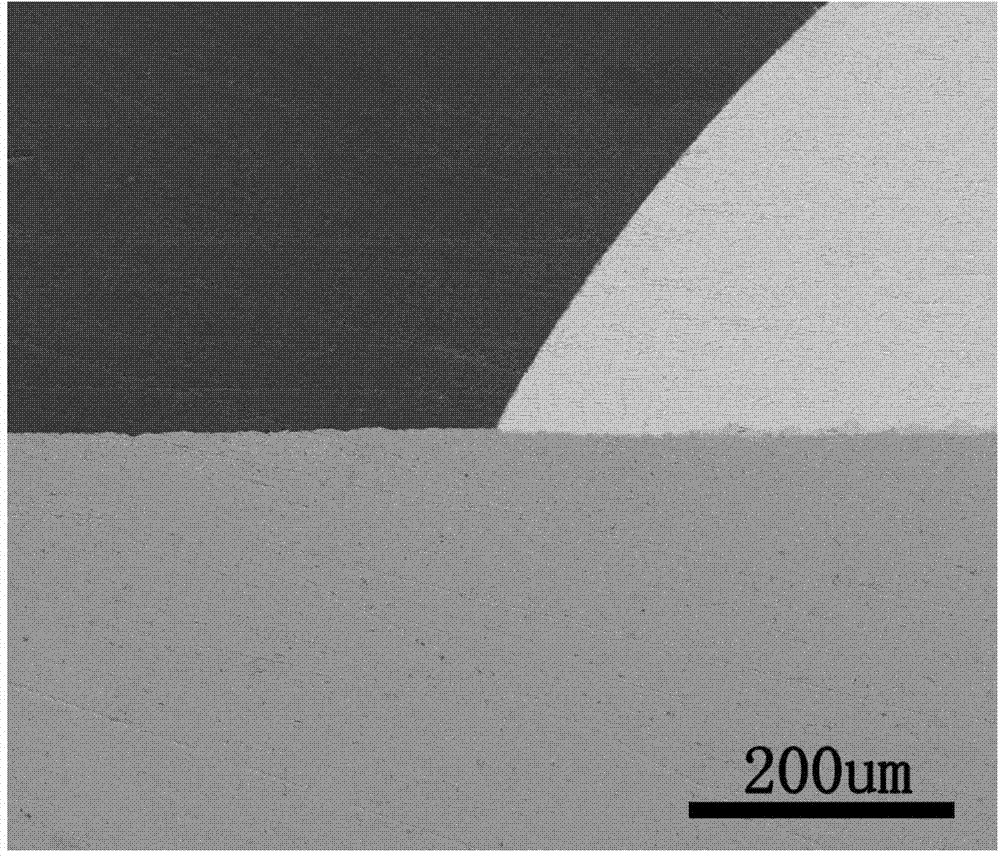

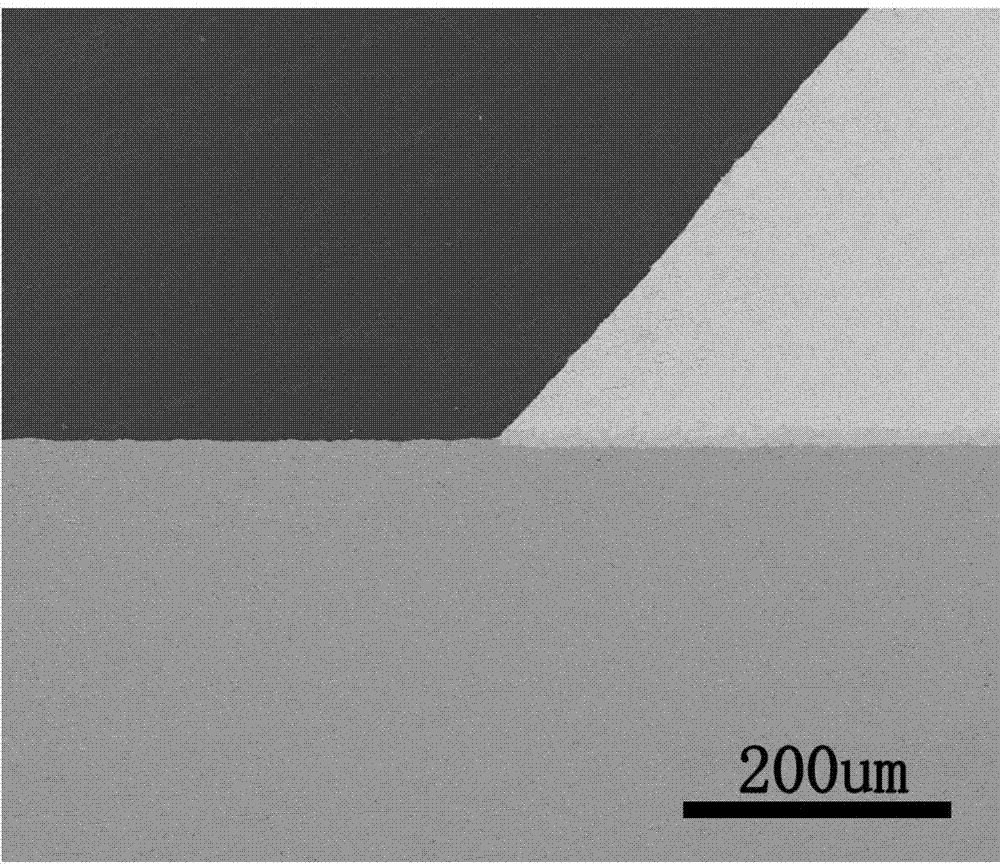

ActiveCN104400247AImprove performanceSolve reunionWelding/cutting media/materialsSoldering mediaDensity differenceCvd graphene

The invention discloses a preparation method of a high-thermal conductivity graphene-Sn-Ag composite brazing filler metal, ad relates to a preparation method of a high-thermal conductivity composite brazing filler metal. The preparation method has the following purposes: the problem of graphene floating and agglomeration in the preparation and application process of the composite brazing filler metal is solved by reducing a greater density difference between graphene and an Sn-Ag brazing filler metal matrix through plating a metal on the graphene; meanwhile, the graphene is dispersed more uniformly in the brazing filler metal matrix; and the reliability of sealing and brazing is improved by improving the heat conductivity of the composite brazing filler metal through adding the graphene. The method comprises the following steps: (1) the metal is plated on the graphene; and (2) the ball milling, the mixing and the medium-temperature smelting are performed for the metal-plated graphene and the Sn-Ag brazing filler metal to obtain the high-thermal conductivity composite brazing filler metal. The prepared composite brazing filler metal is high in thermal conductivity, has a higher wettability compared with a traditional Sn-Ag brazing filler metal, and is a composite brazing filler metal accordant with the present development tendency of an electronic industry as a connecting material of traditional large-scale integrated circuits.

Owner:HARBIN INST OF TECH

Functionalized polypropylene fibre and its preparation method

InactiveCN1766184AWith deodorizing functionSolve reunionMonocomponent polyolefin artificial filamentArtifical filament manufactureNatural substanceSilicon dioxide

The invention discloses a functional polypropylene fibre contained and fused a plurality of natural inorganic materials and polypropylene, which comprises: tourmaline, alumina, zirconium phosphate carried-Ag antibacterial agent, silicon dioxde, and titania. The preparation method comprises: breaking and mixing the materials, fusing and mixing said materials with polypropylene slice to obtain mother grain; then, using common fusion spinning method to treat said grain and slice. This product has well spinnability, high strength, and deodorization function.

Owner:上海依福瑞实业有限公司

Preparation method of high dispersion metal-organic framework (MOF)/organic hybrid priority alcohol through composite membrane

The invention relates to a preparation method of a high dispersion metal-organic framework (MOF) / organic hybrid priority alcohol through composite membrane, belonging to the technical field of membrane separation. The method comprises the steps of cleaning MOF crystal particles, and dispersing the cleaned crystal particles into a polar solvent without drying to form stable MOF emulsion; dissolving 0.5-5wt% of high-molecular polymer into a solvent, feeding the MOF emulsion, and then feeding a cross-linking agent and a catalyst to prepare membrane liquid A; dissolving 8-20wt% of high-molecular polymer into the solvent, and feeding the cross-linking agent and the catalyst to prepare membrane liquid B; dipping a base membrane into the membrane liquid A, taking out the base membrane and drying; dipping the surface of the base membrane for a plurality of times to obtain a nascent state MOF / high-molecular polymer hybrid separation layer; after that, dipping the base membrane into the membrane liquid B, taking out the base membrane and drying; putting into a vacuum oven to enable the high-molecular polymer to be completely cross-linked on the surface of the base membrane. The prepared hybrid composite membrane has excellent alcohol through performance and potential application value.

Owner:BEIJING UNIV OF TECH

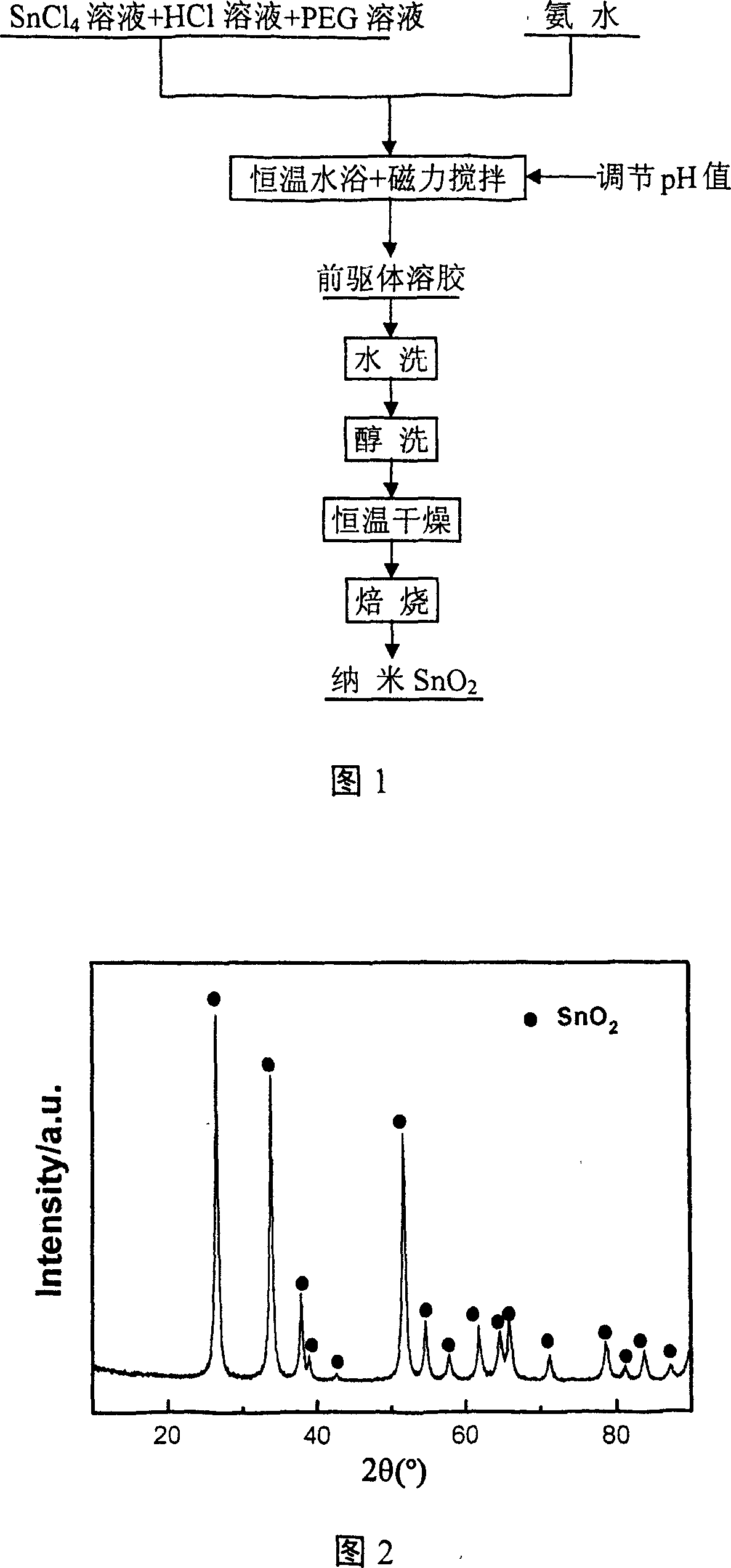

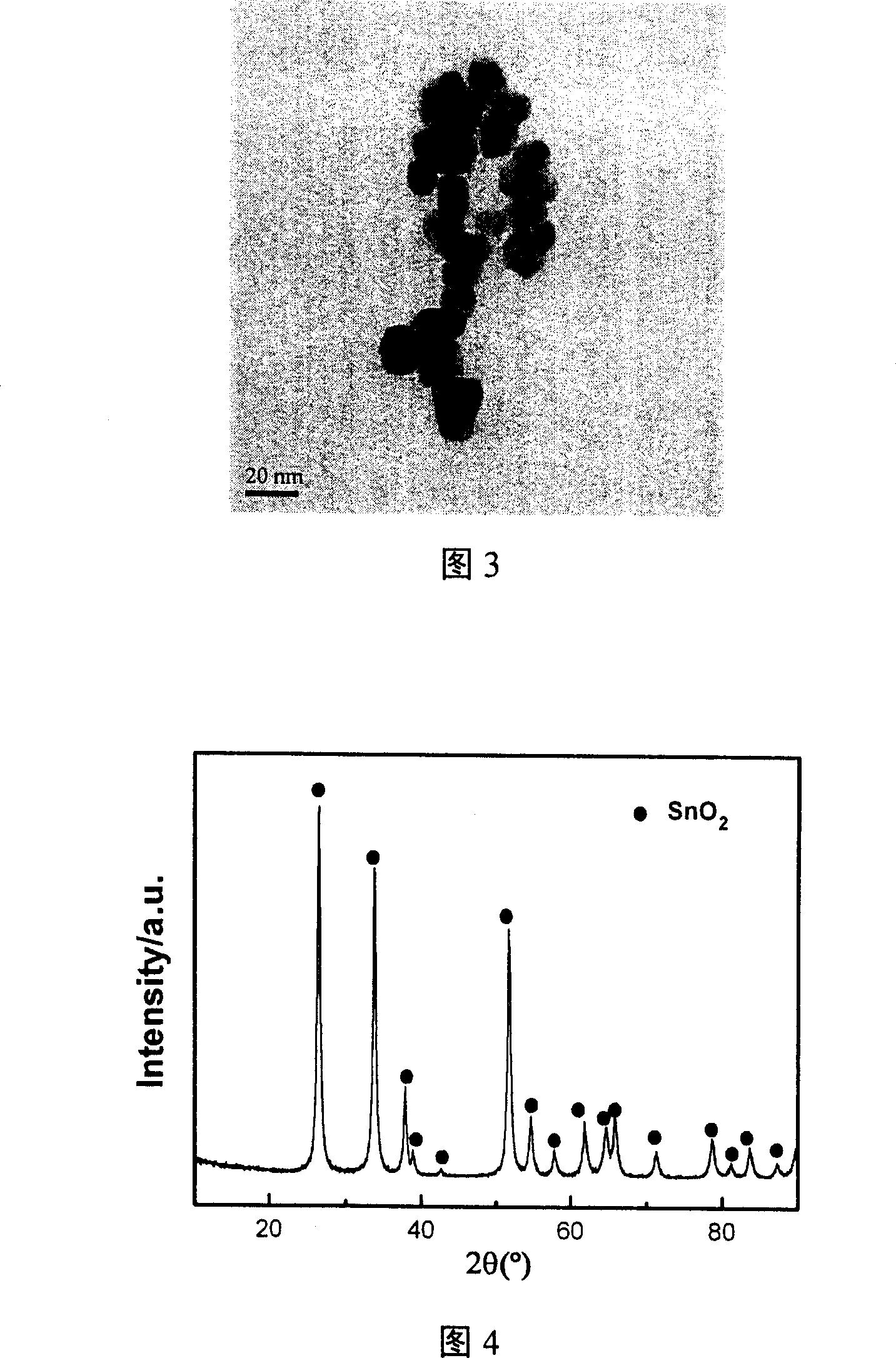

Method for manufacturing nano tin dioxide

A method for preparing the nano SnO2 powder is provided. The soluble pink salt as the tin source is made into the pink salt solution with concentration of 0.1mol / L to 0.5mol / L. The diluted acid solution is added, and then 0g / L to 10g / L surfactant is added, the precipitant agent is added in drops and the pH value is adjusted to 2.5 to 10, reaction is carried out through magnetic stirring and under the constant temperature of 20 DEG C. to 80 DEG C. to produce the precursor. The nano SnO2 finished product is gained after filtering, washing by deionized water, ultrasonic washing by absolute ethyl alcohol, drying and roasting the gained product. The invention adopts the soluble pink salt as the raw material with low price and cost, which do not need to grind and sieve the precursor with high ratio of product output and simpler process. The nano SnO2 grain size is evener.

Owner:CENT SOUTH UNIV

Polishing film and method for making same

ActiveCN101225281AUniform performanceReduce manufacturing costOther chemical processesPolishing compositionsOrganic solventRoller Coating Method

The invention discloses a polishing film and the preparation method, which adopts the ultrafine micro mist as the grinding material and prepares in flow-casting coating method, namely the powdered or granular resin is dissolved into the organic solvent and then added in functional additive to make the resin adhesive, then the abrasive of surface-modified ultrafine micro mist is added into the resin adhesive and the spread coating liquid can be obtained after fully mixing, finally the paint is painted on the surface of soft base in flow-casting coating method and the polishing film can be obtained after drying and curing. The preparation method of the polishing film has the advantages of small equipment investment, simple operation, high productivity and automation level, steady craft, even film performance and low manufacturing cost. The polishing film can adjust the craft parameters of the flow-casting craft conveniently according to the different quality requirement and standards of the products, and can achieve production in multi-specification and small lot production and overcomes the problems that the rapid transformation of the product specification is difficult due to the limit of the equipment structure in roller coating method.

Owner:HENAN UNION ABRASIVES

Preparation method of halogen-free flame-retardant polyurethane (PU) sealant

ActiveCN102181260AGuaranteed physical propertiesGood adhesionNon-macromolecular adhesive additivesOther chemical processesScavengerAntioxidant

The invention relates to a preparation method of a halogen-free flame-retardant polyurethane (PU) sealant. The preparation method comprises the following steps: dewatering and drying the following materials, namely a filler, a thixotropic agent, a halogen-free flame retardant, a flame-retardant synergist, a plasticizer, a light stabilizer and an antioxidant in vacuum; stirring a PU prepolymer and the materials for dispersion in a double planet mixer with a high-speed dispersion disk or a tri-roller grinder at the temperature of 30-50 DEG C for 2-5 hours under the condition that the vacuum degree is not less than 0.092Mpa; under normal pressure and protection of high-purity nitrogen, adding a catalyst A, a silane adhesion promoter and a water scavenger, and stirring for 0.1-1 hour for dispersion; and removing small molecules and stirring for 0.3-1 hour under the condition that the vacuum degree is not less than 0.092Mpa to finally obtain the halogen-free flame-retardant PU sealant. The halogen-free flame-retardant PU sealant effectively overcomes the disadvantages of the PU sealant such as big flame, fast burning speed, severe drippage and the like in the prior art on the premise of ensuring the original physical properties of the PU sealant, thus the PU sealant has the advantages of flame retardance, no drippage during the burning process, good adhesive property and the like.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

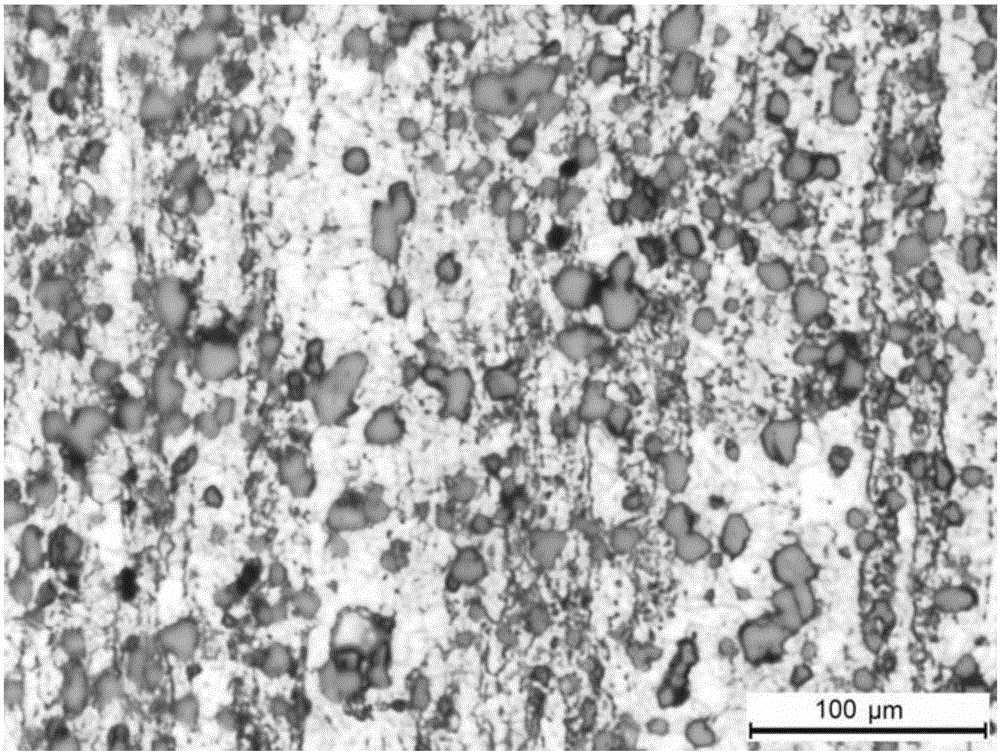

Silicon carbide particle reinforcement aluminum-based composite for train brake disc and preparation method

Disclosed are a silicon carbide particle reinforcement aluminum-based composite for a train brake disc and a preparation method. The composite includes the following components of, by mass percentage, 15-25% of SiC particles, 18-24% of Si, 0.6-3.5% of Mg, 0.15-0.35% of Zr, 0.12-0.45% of Sc, and the balance Al and unavoidable impurities. According to the preparation method, SiC, Mg, Si, Zr and Sc with the particle size being 10-15 [mu]m are added into molten aluminum in the form of intermediate alloy, SiC with the particle size being 15-25 [mu]m is added into the molten aluminum in the form of particles, and thus the silicon carbide particle reinforcement aluminum-based composite is obtained. The SiC thin particles are added in the form of Mg-SiC, so that the problems of uniform dispersing difficulty of silicon carbide particles in a matrix and poor interface bonding are effectively solved, the particle reinforcement effect is fully played, and the toughness of alloy is improved. Meanwhile, transitional element zirconium and rare earth element scandium are added to replace titanium fine grains, the roughness and heat resistance of the aluminum-based composite are remarkably improved, and occurrence of heat fatigue cracks is restrained. In addition, the added rare earth scandium has a good modification effect on the interfacial compatibility of the silicon carbide particles and aluminum alloy.

Owner:湖南中南智造新材料协同创新有限公司

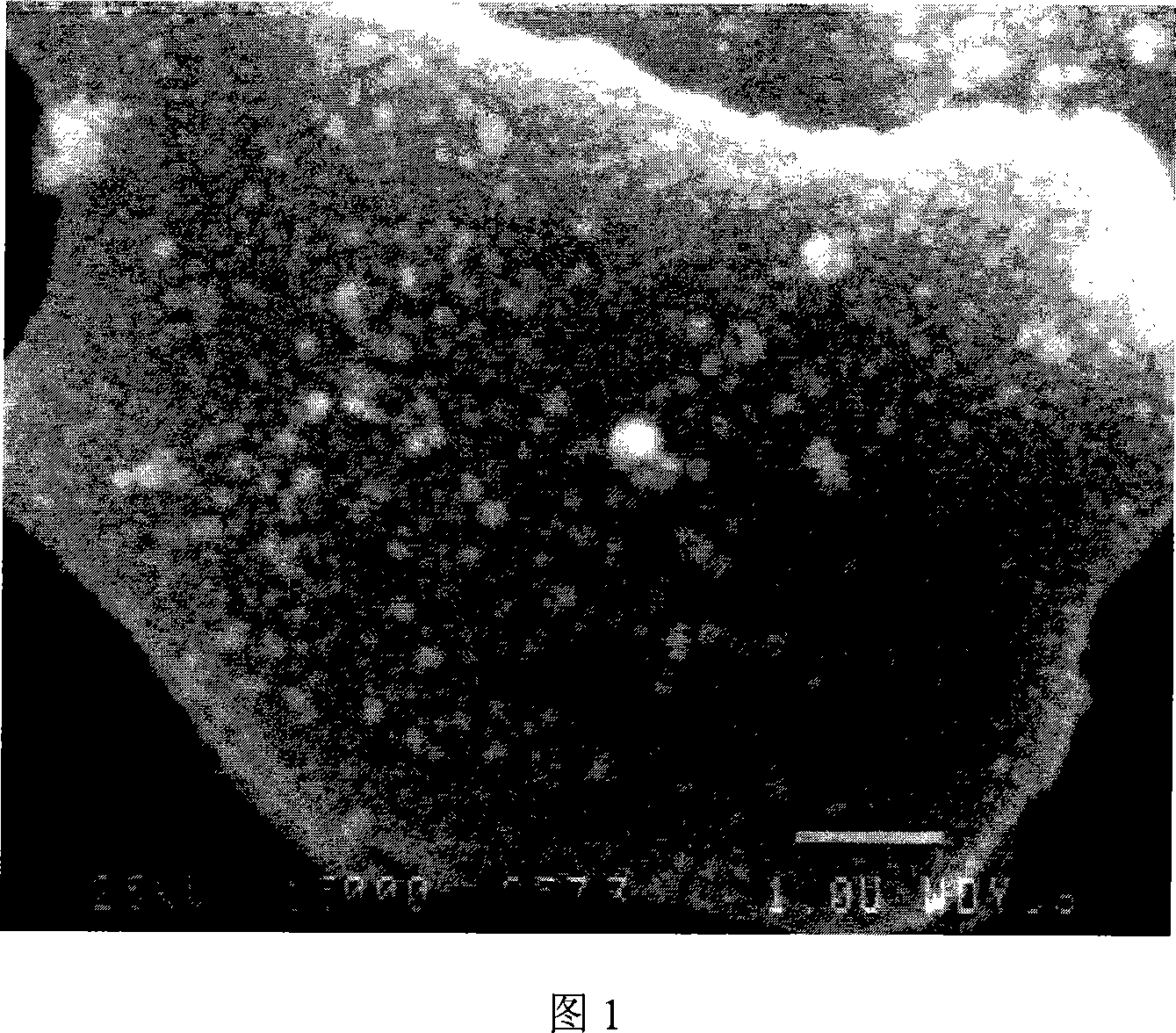

Load type nano selenium and preparation method

InactiveCN1686789ASolve reunionFix stability issuesAnimal feeding stuffAccessory food factorsNanoreactorAquatic product

The present invention discloses a load-type nano selenium and its preparation method. It is a nano-elementary selenium loaded no the porous mineral material, the average particle size of said elementary selenium is less than 100 nano. By weight percentage, selenium content in the porous mineral material is 0.1-1%. It is made up by using porous mineral material as miniature nano reactor and adding reductant into selenium salt to make reduction reaction to obtain the nano elementary selenium, drying-grinding or spray-drying so as to obtain the invented product.

Owner:BEIJING BOAI XIKANG NITRITION TECH

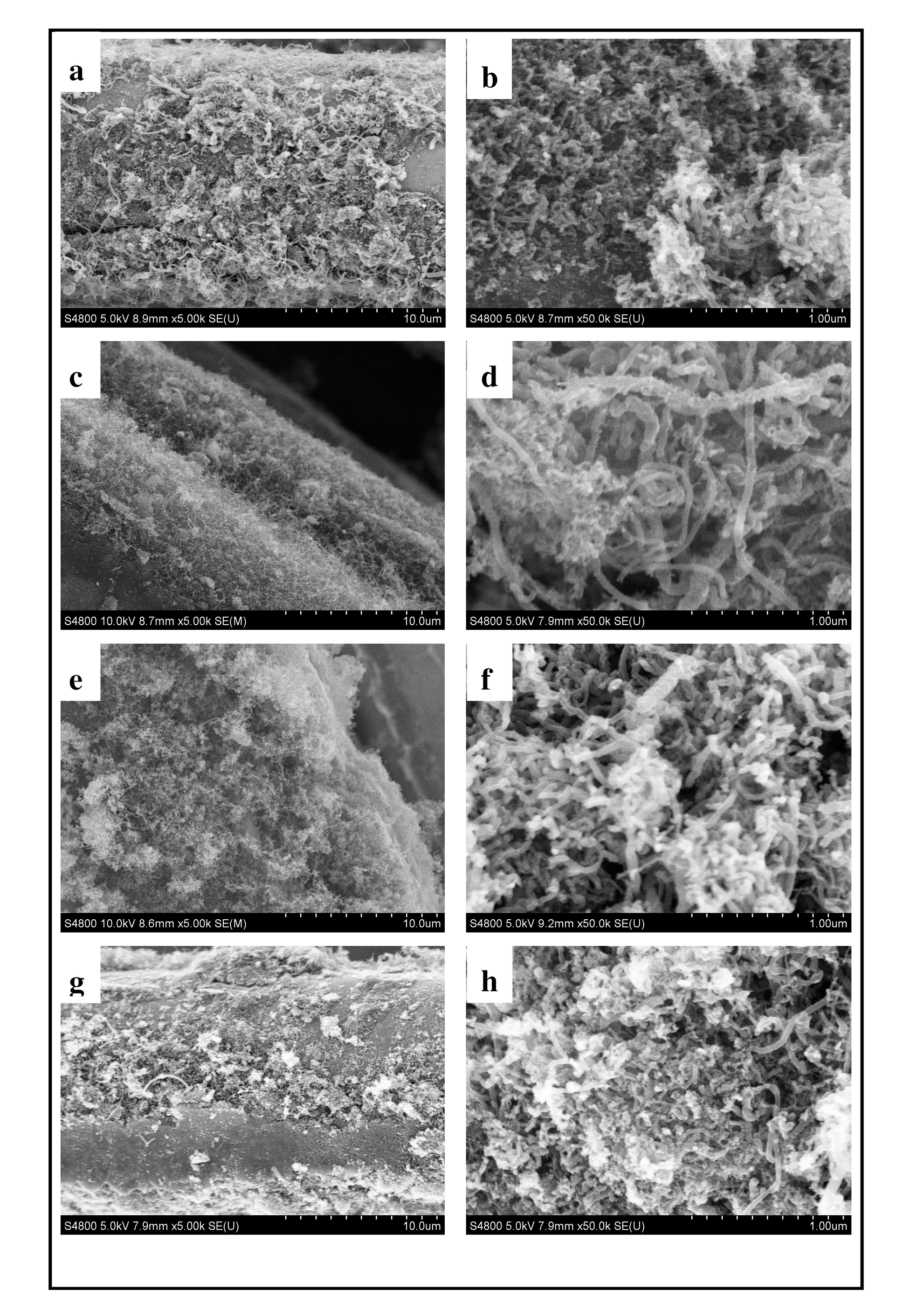

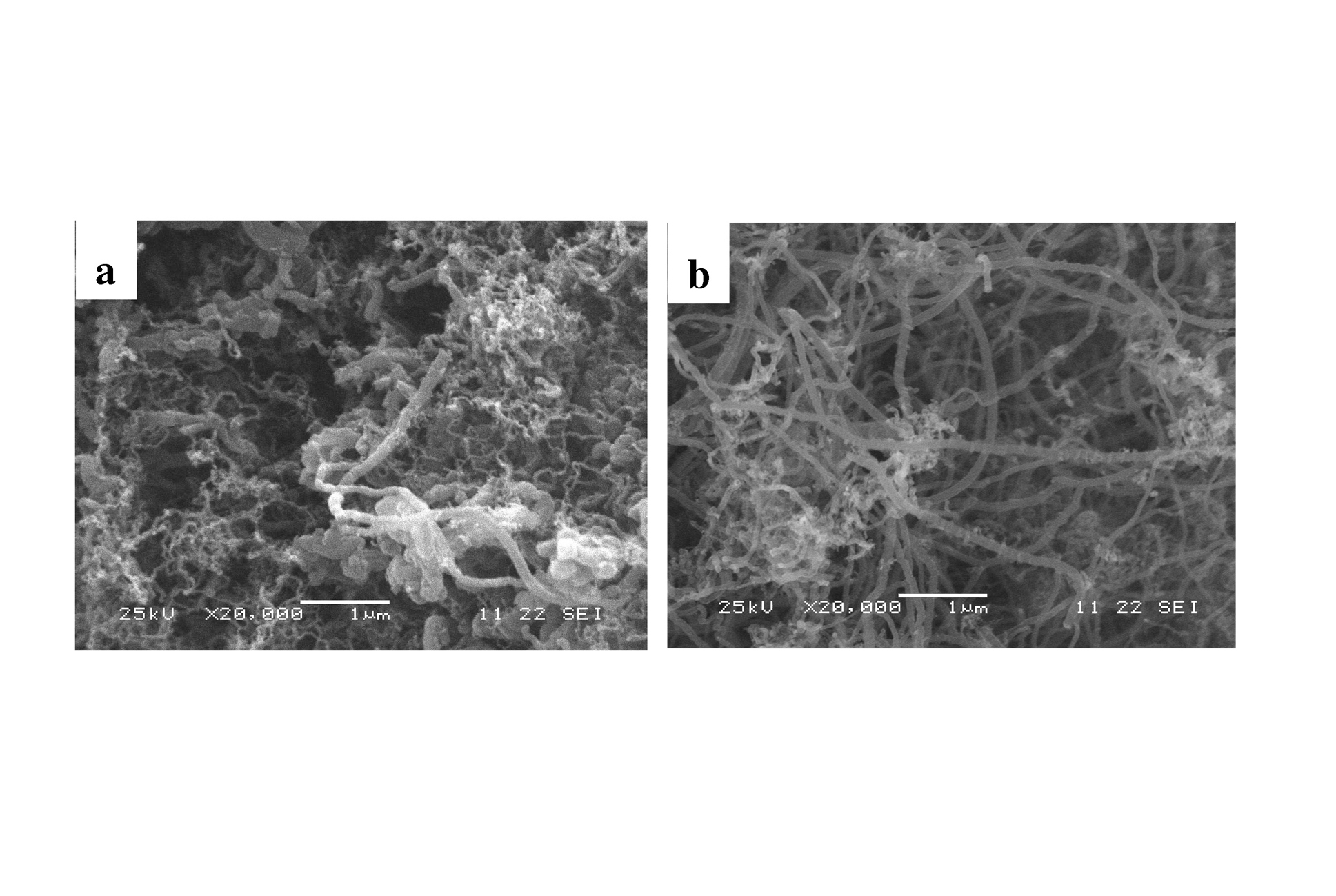

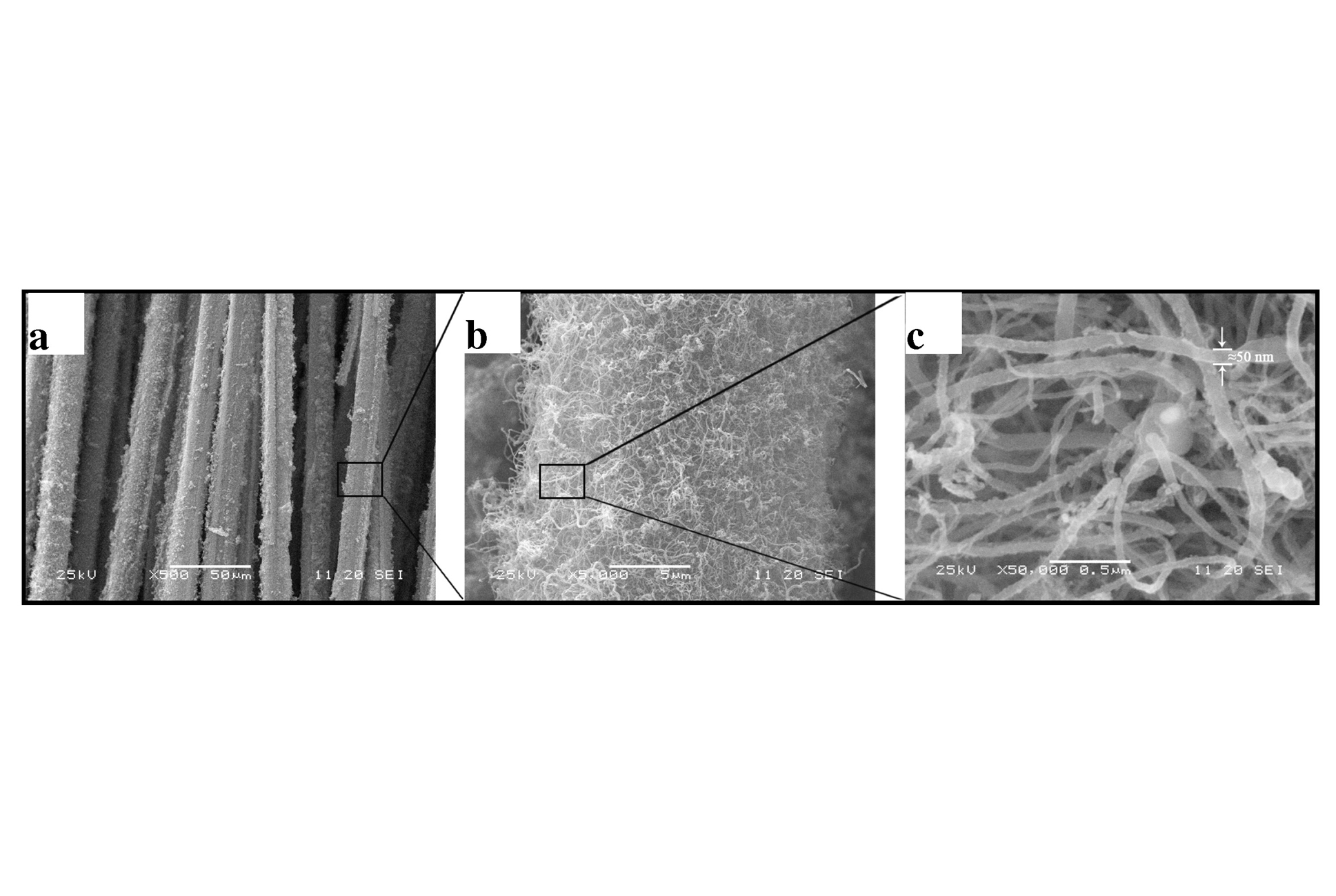

Silicon carbide fiber solid fabric for in-situ growing carbon nano tubes, composite material and preparation method thereof

The invention discloses a silicon carbide fiber solid fabric for in-situ growing carbon nano tubes, which is formed by mainly weaving silicon carbide fibers. In the invention, in-situ grown carbon nano tubes are uniformly distributed on the surfaces of the silicon carbide fibers and mutually wound to form a reticular structure. The preparation method comprises the following steps of: pretreating the silicon carbide fiber solid fabric; loading a Ni-La-Al composite catalyst by adopting a catalyst precursor vacuum impregnation-reduction method; and finally, carrying out chemical gas-phase deposition to ensure that the carbon nano tubes are in-situ grown on the silicon carbide fiber solid fabric. The invention also discloses a carbon nano tube-silicon carbide fiber mixed enhanced composite material which is prepared by using silicon carbide as a substrate and the silicon carbide fiber solid fabric as a reinforcement body by adopting a traditional precursor impregnation-conversion method. The silicon carbide fiber solid fabric has the advantages of uniform carbon nano tube dispersion, higher and controllable carbon nano tube content, good combination with fibers, and the like.

Owner:NAT UNIV OF DEFENSE TECH

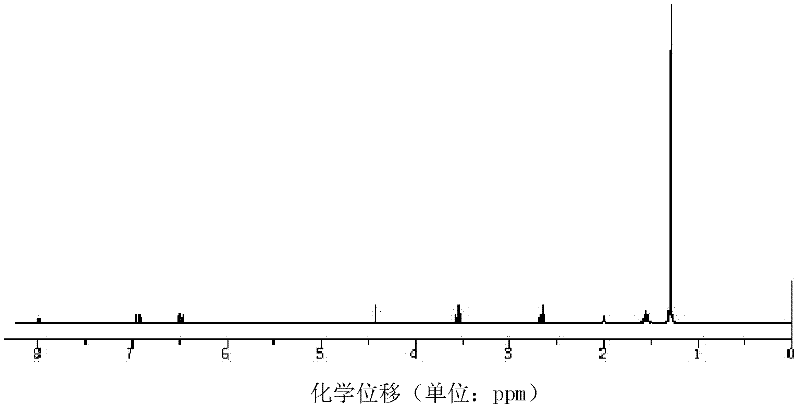

Preparation method of graphene/nano silver epoxy conductive adhesive

ActiveCN102153976AImprove electrical performanceEvenly dispersedEpoxy resin adhesivesElectrically-conducting adhesivesOrganic solventEpoxy matrix

The invention discloses a preparation method of a graphene / nano silver epoxy conductive adhesive, which comprises the following steps: (1) mixing graphite, promoter and organic solvent, then carrying out ultrasonic treatment at 20-50 DEG C for 3-6 hours, standing for 12 hours, centrifuging, and distilling; (2) dissolving epoxy resin and precursor in organic solvent, stirring at 20-50 DEG C for 5-30 minutes, adding a graphene solution to continue reacting for 10-40 minutes, distilling, and carrying out ultrasonic treatment for 5-20 minutes; and (3) adding silver sheets into the graphene-nano silver epoxy resin compound, and carrying out ultrasonic treatment to react at 20-60 DEG C for 30-120 minutes so as to obtain the graphene / nano silver epoxy conductive adhesive. The graphene / nano silver epoxy conductive adhesive disclosed by the invention ensures that the graphene-nano silver compound can be uniformly dispersed in the epoxy matrix, and avoids the problem that the prepared graphene conglobates when the epoxy resin is added, thereby being beneficial to realizing the low-temperature sintering of the nano silver and improving the conductivity and adhesive strength of the conductiveadhesive.

Owner:SOUTH CHINA UNIV OF TECH

Diaphragm and preparation method thereof, and lithium ion battery

ActiveCN102623658AThe absolute value of the surface potential is largeEvenly distributedSecondary cellsCell component detailsHexafluoropropyleneLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an inorganic and organic composite multihole diaphragm. The diaphragm comprises a multihole diaphragm base material and an active coating layer attached to at least one surface of the multihole diaphragm base material, wherein the active coating layer comprises inorganic particles, vinylidene fluoride and hexafluoropropylene copolymer, cellulose based polymer with the molecular weight of 100,000 to 1,000,000 and at least one of polyacrylic acid and polyacrylate. Compared with the prior art, the diaphragm keeps relatively high air permeability and lithium ion transmission capacity; the active coating layer and the multihole diaphragm base material are well bonded; and the overheating contraction performance and the puncture strength of a diaphragm base can be improved remarkably. Furthermore, the invention also discloses a preparation method for the diaphragm and a lithium ion battery with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

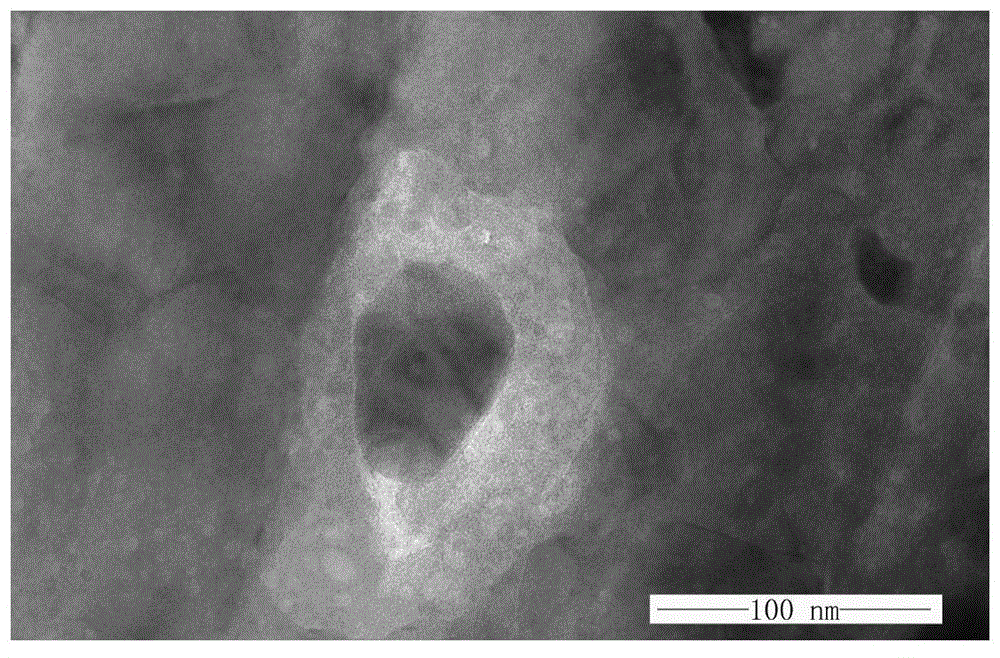

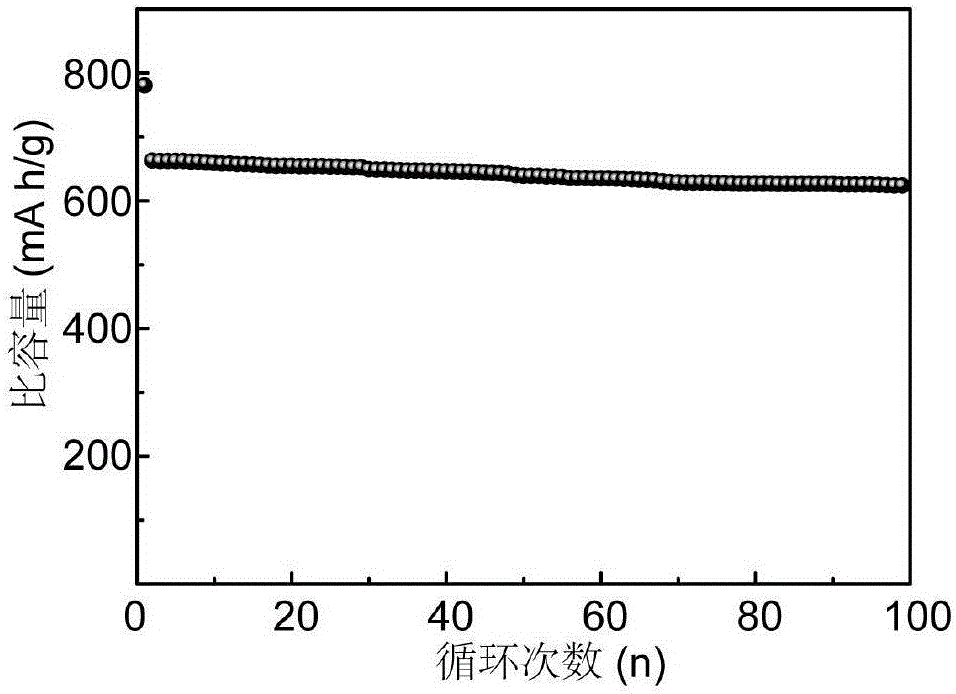

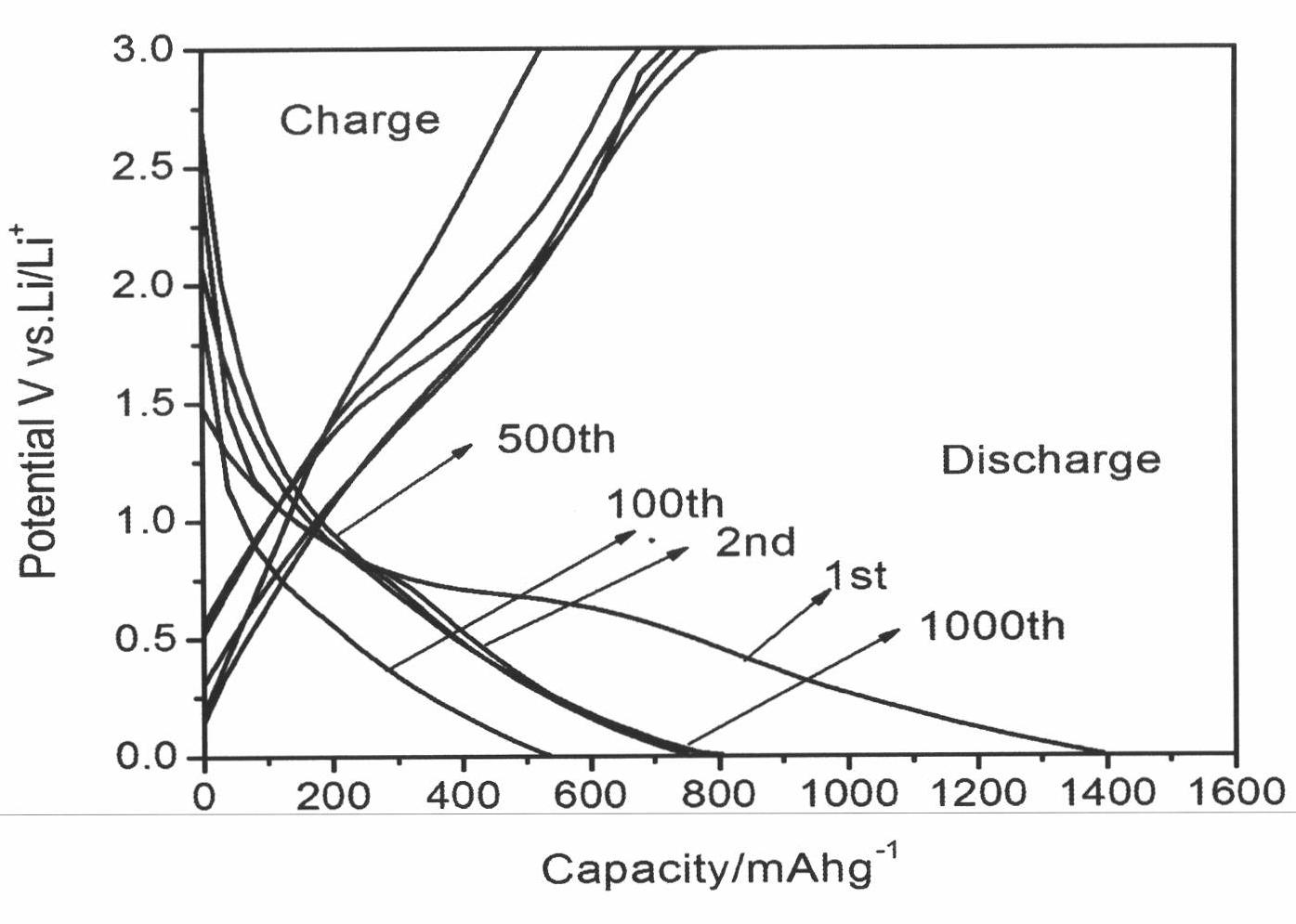

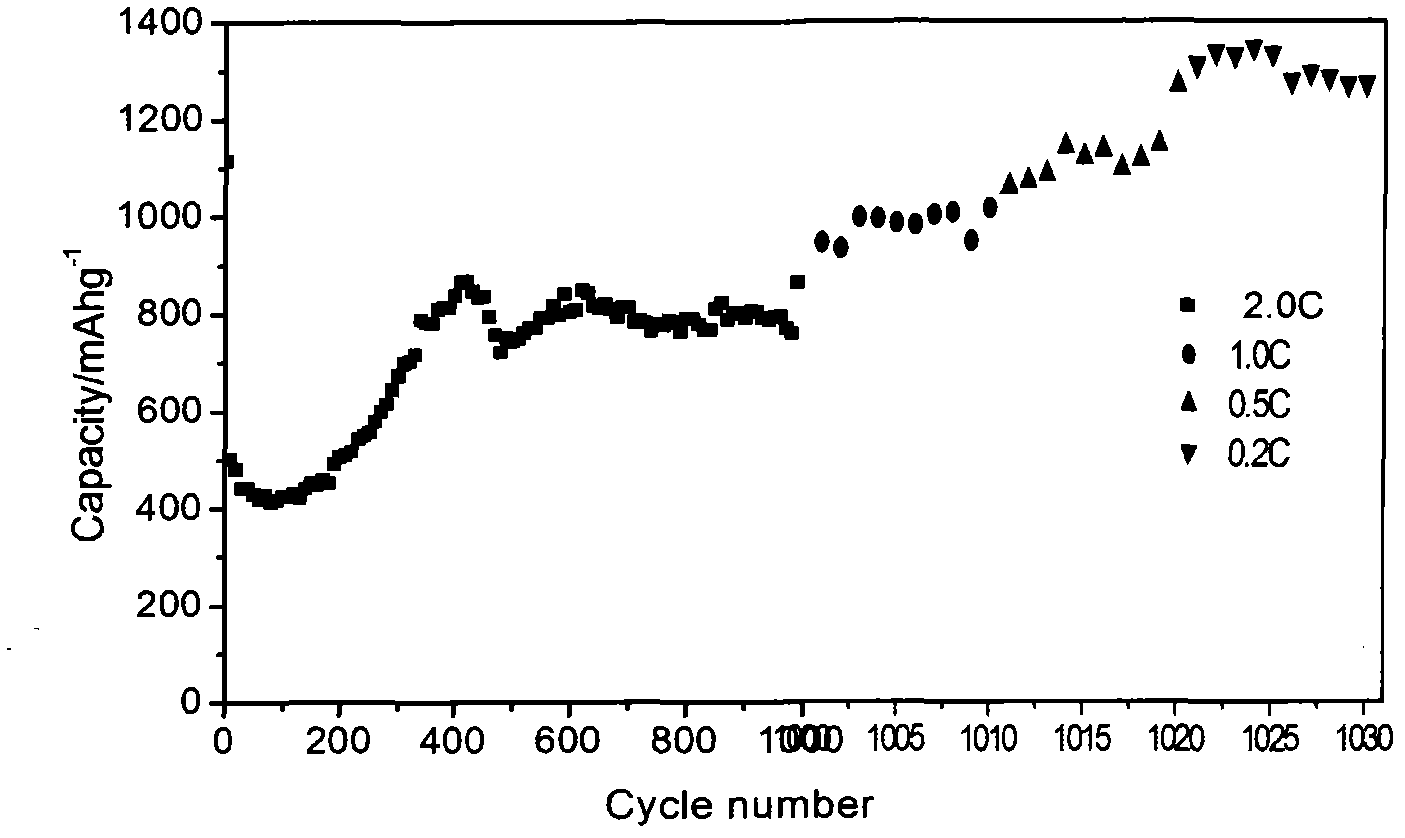

Silicon/silicic oxide/carbon composite material as well as preparation method and application thereof

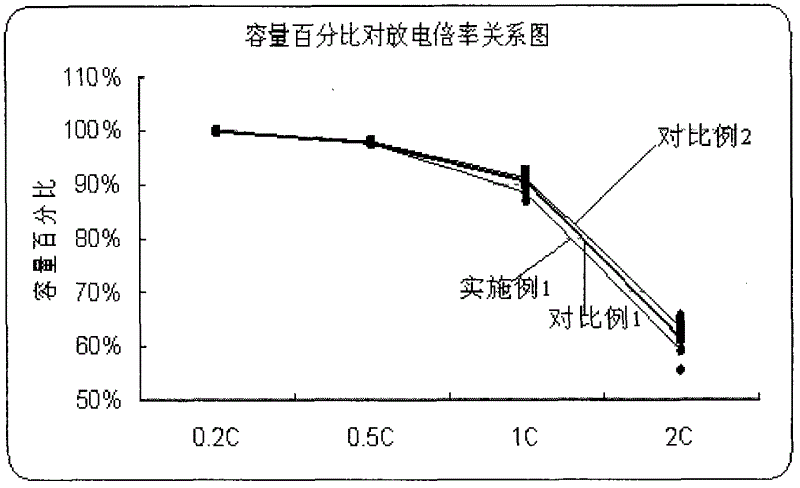

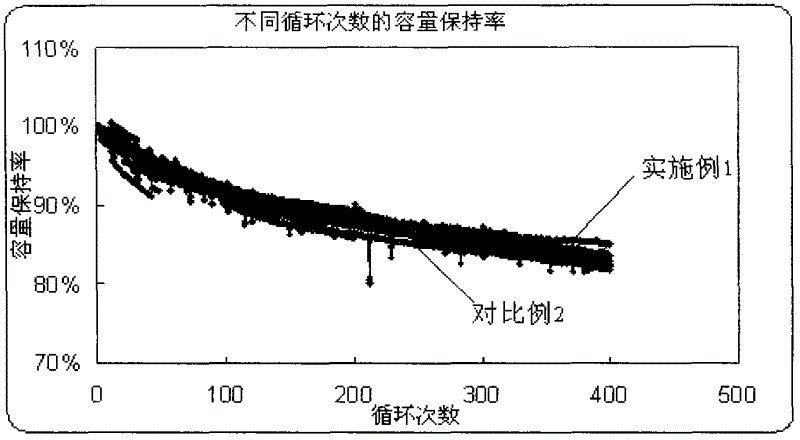

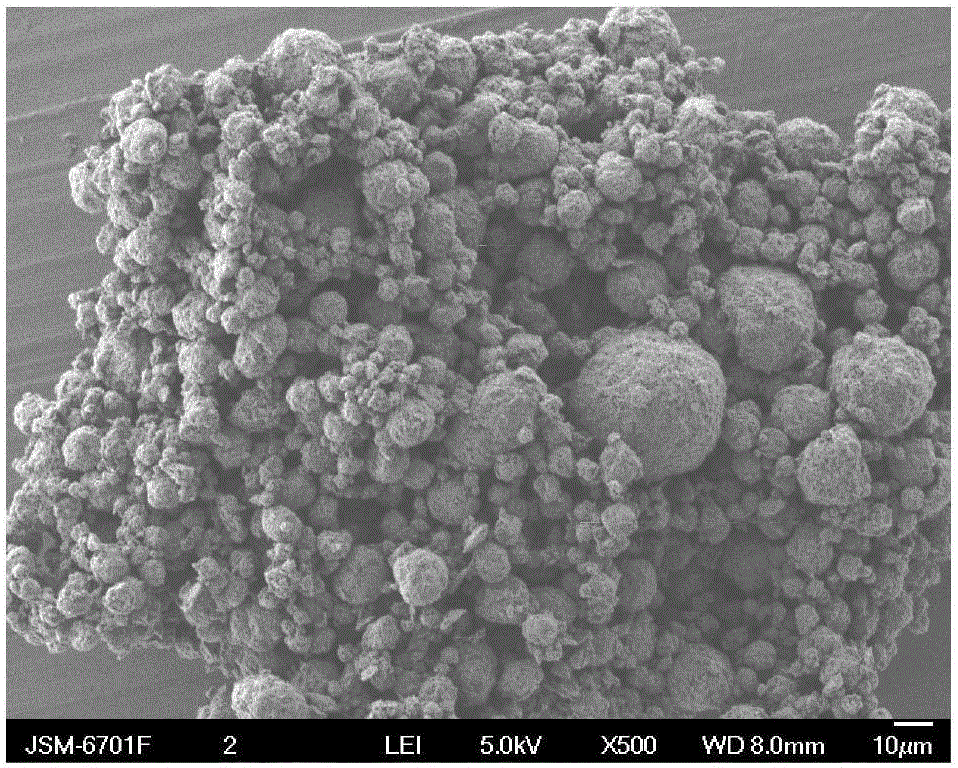

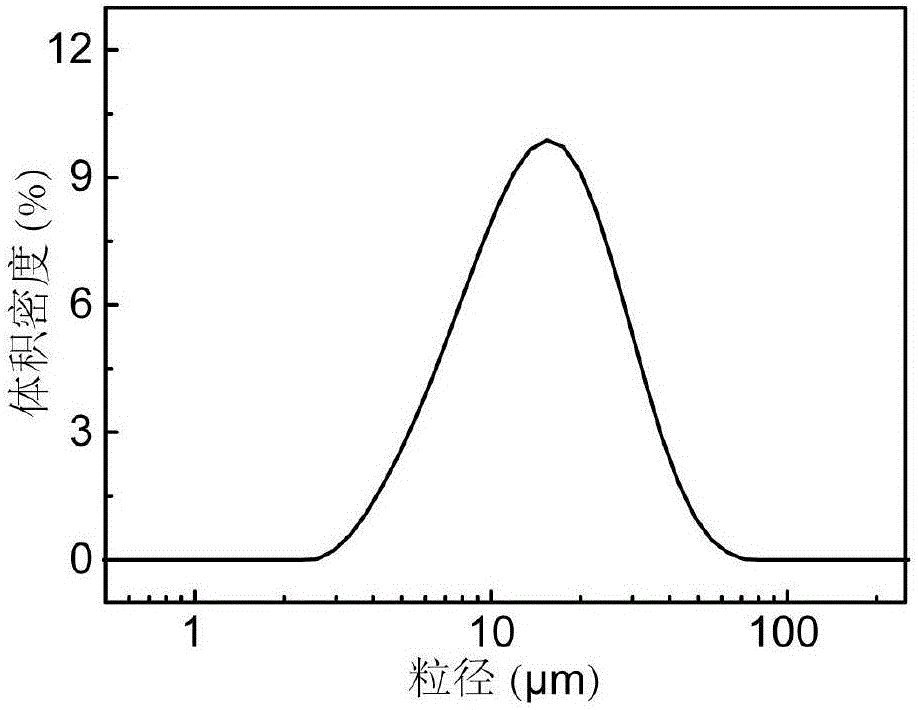

ActiveCN105789594AEasy to prepareLow costNegative electrodesSecondary cellsCyclic stabilityHigh energy

The invention provides a preparation method and application of a Si / SiOx / C composite material. By using the Si / SiOx / C composite material, the advantages that a Si-based negative electrode material is high in capacity, a SiOx-based negative electrode material is stable in circulation and a carbon material is good in electric conductivity are combined; the defects that a high-capacity negative electrode material is low in first coulombic efficiency and poor in cyclical stability are overcome; a Si / SiOx / C negative electrode material shows excellent electrochemical properties; meanwhile, the defects that a technique is complicated and the cost is high in the processing procedure of a nano-material are overcome; a technical route which is simple in production technique and available for commercialized large-scale production is researched and developed; the Si / SiOx / C composite material has a wide application prospect in the field of high-energy-density lithium ion batteries.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

Nano-silver sol antibacterial agent and preparation method thereof

The invention discloses a nano-silver sol antibacterial agent and a preparation method thereof. The preparation method includes the steps: dissolving silver nitrate in water, adding ammonia water, adjusting pH (potential of hydrogen) to be 10+ / -0.5 and adjusting the concentration of Ag+ to range from 0.006mol / l to 0.1mol / l to prepare silver ammonium solution; dissolving a reducing agent and a protective agent in the water to obtain reducing agent and protective agent solution; and slowly adding the reducing agent and protective agent solution into the silver ammonium solution according to the volume ratio of 1:1-5 of the reducing agent and protective agent solution to the silver ammonium solution when the silver ammonium solution is at 20-40 DEG C and 100-200rpm, performing ultrasonic operation for mixed solution for 5-20min under the condition of ice-bath after mixed reaction, and finally filtering the mixed solution to obtain colorless and transparent nano-silver sol antibacterial agent. In the silver ammonium solution, the quantity relative ratio of n (the reducing agent) to n (Ag+) is 1-5:1, the mass ratio of the n (the reducing agent to m (the protective agent) is 1-2:1, and output power is 150-200w. The nano-silver sol antibacterial agent can avoid agglomeration of nano-silver particles in long-term storage and use process.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

6000 mesh inorganic powder filling-modified pe agglomerate and its preparation method

The invention discloses a 6000-order inorganic powder fill modified PE mother particle and preparing method, which comprises the following parts: PE, surface disposer, polyethylene wax, paraffine, 6000-order inorganic material powder, manufacturing adjuvant. The preparing method comprises the following steps: placing 6000-order inorganic material powder in the high-blender to stir and dehumidify; adding surface disposer in the cooling machine to cool; placing PE, polyethylene wax, paraffine and manufacturing adjuvant in the high-blender with modified 6000-order inorganic powder to cool; discharging; graining through squeezer.

Owner:TIANJIN DEHAO NEW MATERIALS

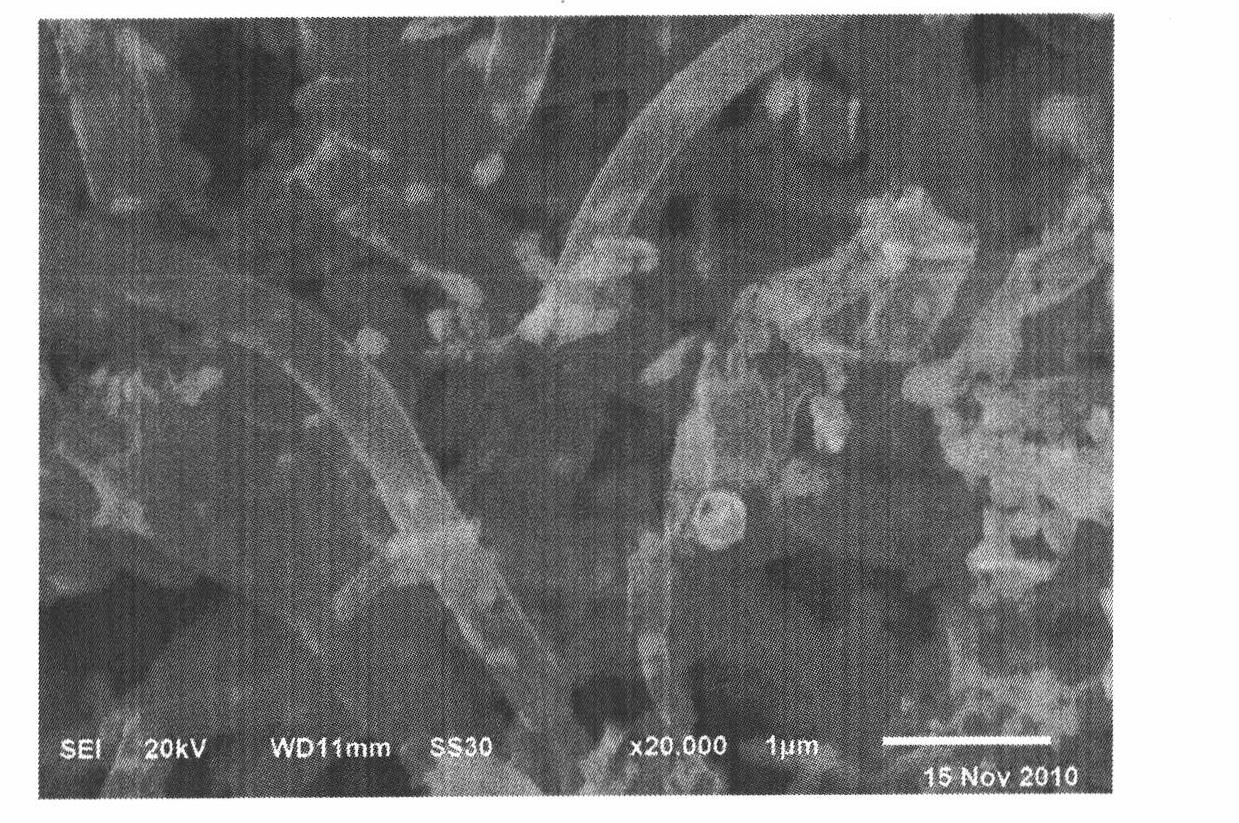

Method for preparing lithium ion battery cathode material ZnFe2O4/C nano fibers

InactiveCN102154739AControl diameterSolve reunionCell electrodesFilament/thread formingFiberCyclic process

The invention discloses a method for preparing lithium ion battery cathode material ZnFe2O4 / C nano fibers. The method has the advantages that: 1, the preparation process flow is short, the diameter of the nano fibers can be controlled more effectively, nano fiber precursors with regular structure are obtained, and the lithium ion battery cathode material ZnFe2O4 / C nano fibers with uniform structure are prepared by combining different change of two polymers in the calcining process; and 2, the prepared lithium ion battery cathode material ZnFe2O4 / C nano fibers are apparently nano fibers, the diameter of the nano fibers is about 200 to 400 nanometers, ZnFe2O4 nano granules are distributed in the continuous phase of carbon in the internal structure, and meanwhile, because of the carbon, the volume change in the electrode circulating process is greatly relieved, the problem of granule agglomeration in the circulating process is solved and the electrochemical circulating stability is improved.

Owner:XIANGTAN UNIV

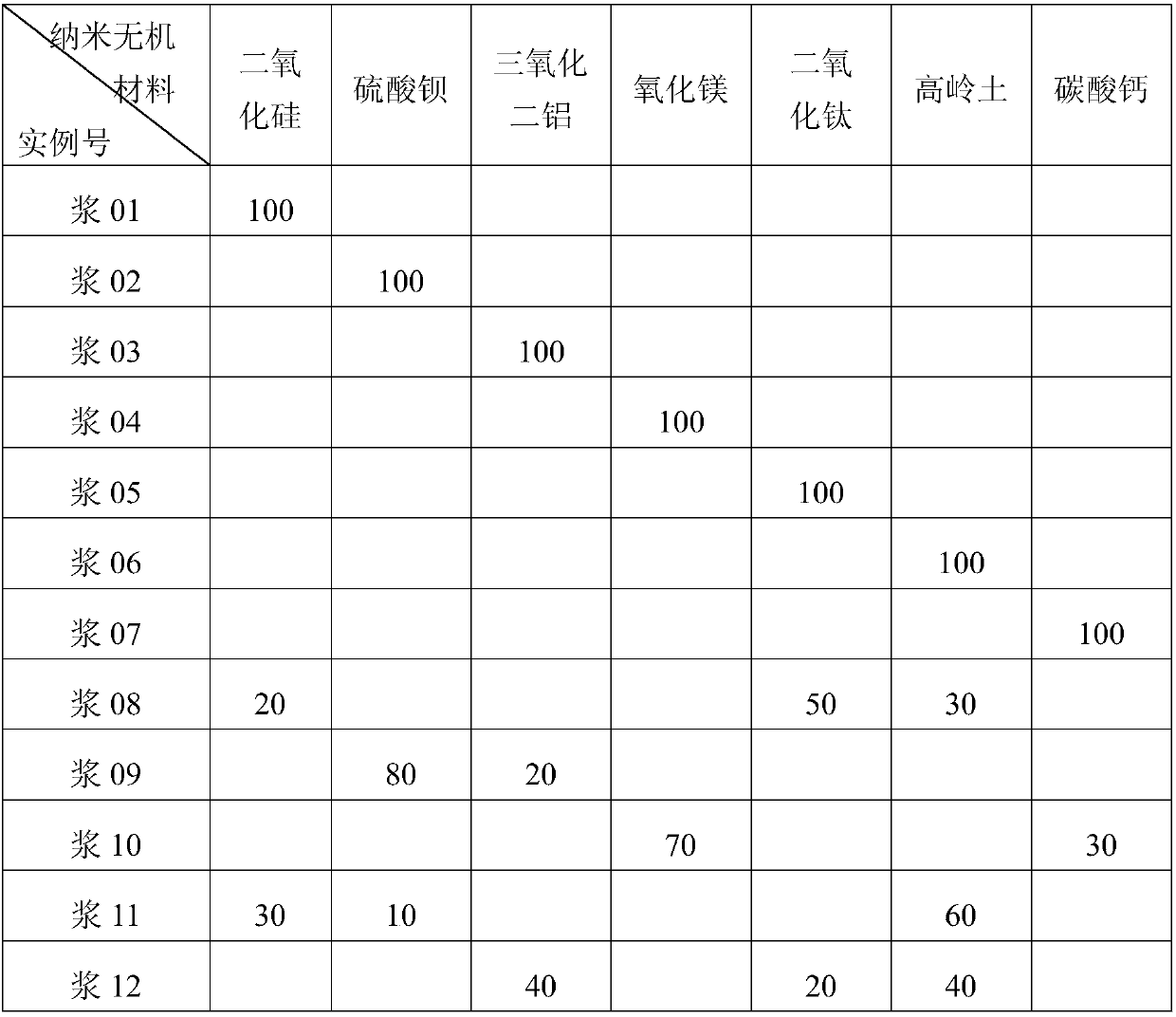

Ultra-low surface roughness polyester base film/composite base film and preparation method thereof

ActiveCN107915960ASolve reunionSolving Dispersion ProblemsSynthetic resin layered productsElectrical equipmentPolyesterTectorial membrane

The invention discloses an ultra-low surface roughness polyester base film / composite base film and a preparation method thereof. The ultra-low surface roughness polyester base film / composite base filmis characterized in that an ultra-low surface roughness polyester base film (a film A layer) is a single-layer film with the thickness of 20-250 microns and the surface roughness Ra of 15-35nm, prepared by performing melt mixing on a mixture of 40-80 mass percent of polyester and 20-60 mass percent of a surface modifier, extruding, casting, performing longitudinal and transverse biaxial stretching and performing heat setting; a composite base film (three-layer film A / B / A) is prepared by co-extrusion compounding of a film A, a film B and a film A and has the thickness of 20-250 microns and surface roughness of 15-35nm; and the film B is prepared by performing melt extrusion on polyester, casting, performing longitudinal and transverse biaxial stretching and performing heat setting. The ultra-low surface roughness polyester base film / composite base film disclosed by the invention is applicable to production-manufacturing of optical separation films, chip-type multilayer ceramic capacitor release films and high-end protective films of various display devices.

Owner:江苏东材新材料有限责任公司

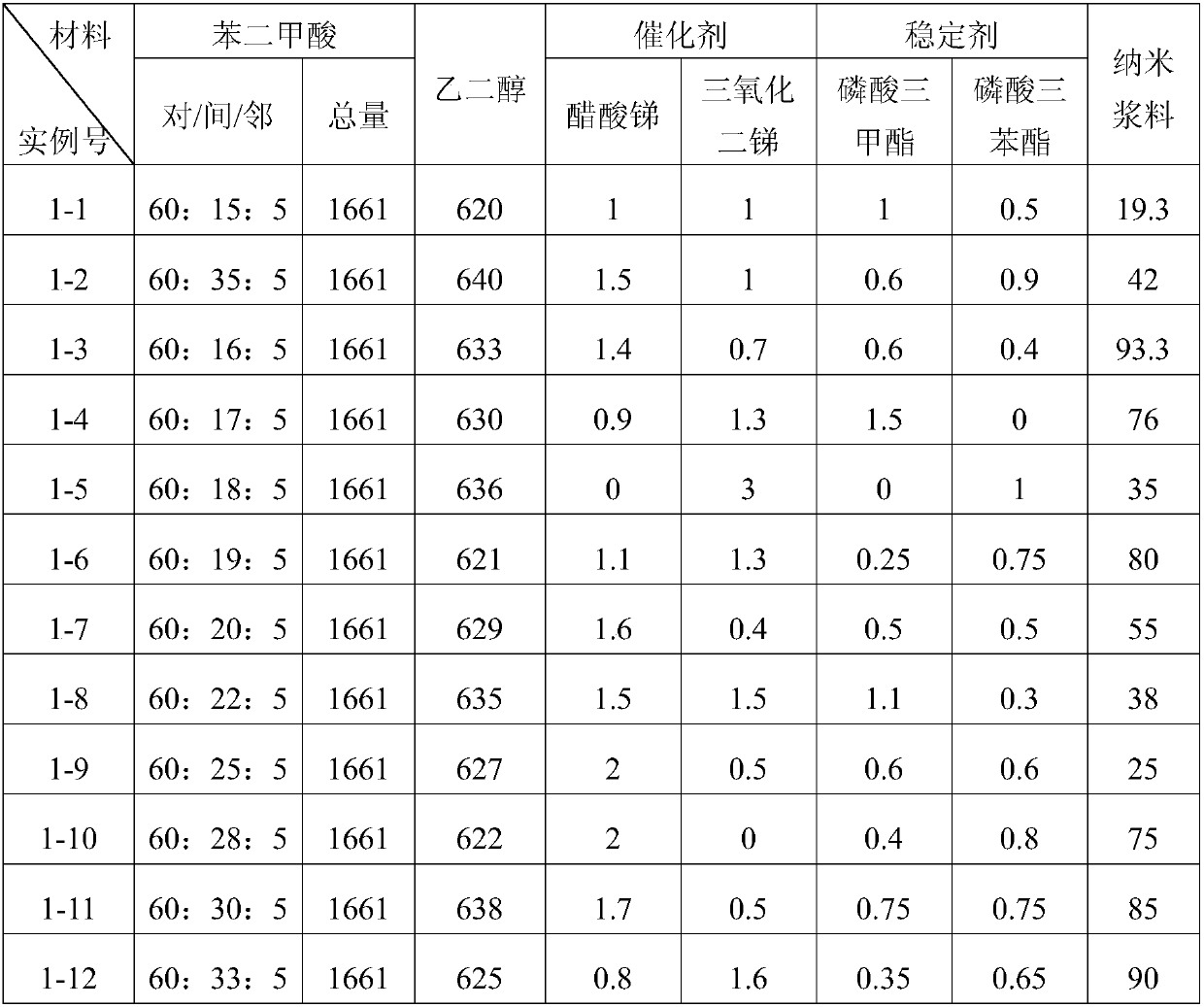

Process for in-situ quiclely preparing crystalline polyester using nano silicon dioxide

The present invention relates to composite material preparing technology. The production process of nano composite silica / polyester material includes the following steps: coating nano silica as crystallizing nucleartor with organic matter for surface modification to make it capable of distribute well in ethylene glycol as one monomer for polyester; high temperature pre-treating compounded nano silica / ethylene glycol slurry to make nano silica possess average size smaller than 100 nm; and polymerization or copolymerization between nano silica / ethylene glycol slurry and other monomer for polyester inside reactor to obtain in-situ nano composite silica / polyester material. The composite material with 1 wt% of nanometer silica contained has non-isothermal crystallization melting peak temperature raised to 213.4 deg.c and 4-8 times raised isothermal crystallization rate at 185-200 deg.c.

Owner:SHANGHAI JIAO TONG UNIV

Water-based coating containing graphene/zinc-aluminum hydrotalcite nano composition and preparation method thereof

InactiveCN106995643AImprove compatibilitySolve reunionFireproof paintsAnti-corrosive paintsWater basedDefoaming Agents

The invention discloses water-based coating containing a graphene / zinc-aluminum hydrotalcite nano composition and a preparation method thereof. The water-based coating is prepared from the following components in parts by weight: 30 to 50 parts of water-based resin, 25 to 40 parts of water, 0.1 to 0.5 part of dispersing agent, 0.1 to 0.5 part of wetting agent, 0.1 to 0.5 part of defoaming agent, 0.1 to 0.5 part of thickening agent, 0.1 to 0.5 part of film forming aids, 0 to 10 parts of curing agent, 0 to 25 parts of titanium dioxide, 0 to 20 parts of calcium carbonate, and 0.1 to 2.5 parts of graphene / zinc-aluminum hydrotalcite nano composition. The graphene / zinc-aluminum hydrotalcite nano composition is added into the water-based coating, so that the high temperature resistance, the corrosion resistance, the flame retardant property, the weather resistance, the impact resistance, the abrasion resistance, the hardness and the obstruction property of the water-based coating are significantly improved, and the multiple functions of the water-based coating are improved.

Owner:东营聚强新材料有限责任公司

Composite high-strength lead-free brazing filler metal for electronic packaging and preparation method thereof

ActiveCN104842089AHigh strengthEvenly dispersedWelding/cutting media/materialsMetal working apparatusVacuum furnaceFiller metal

The invention discloses composite high-strength lead-free brazing filler metal for electronic packaging and a preparation method thereof. The composite high-strength lead-free brazing filler metal comprises graphene and lead-free brazing filler metal. The preparation method includes the steps of firstly, dispersing the graphene and lead-free brazing filler metal powder in ethyl alcohol under the ultrasonic action, and subjecting the ethyl alcohol solution with the graphene and the lead-free brazing filler metal powder to ball milling mixing; secondly, performing vacuum drying to obtain mixed powder of the graphene and the lead-free brazing filler metal powder; thirdly, placing the mixed powder of the graphene and the lead-free brazing filler metal powder into a mould to be squeezed to form a precast block, placing the precast block along with the mould in a vacuum furnace to sinter for 3 hours at the temperature of 180 DEG C, and demoulding to obtain the composite high-strength lead-free brazing filler metal. The composite high-strength lead-free brazing filler metal for electronic packaging and the preparation method thereof have the advantage that the problem that a lead-free brazing filler metal welding spot of an existing electronic product needs to bear high strength under working is solved.

Owner:HARBIN INST OF TECH

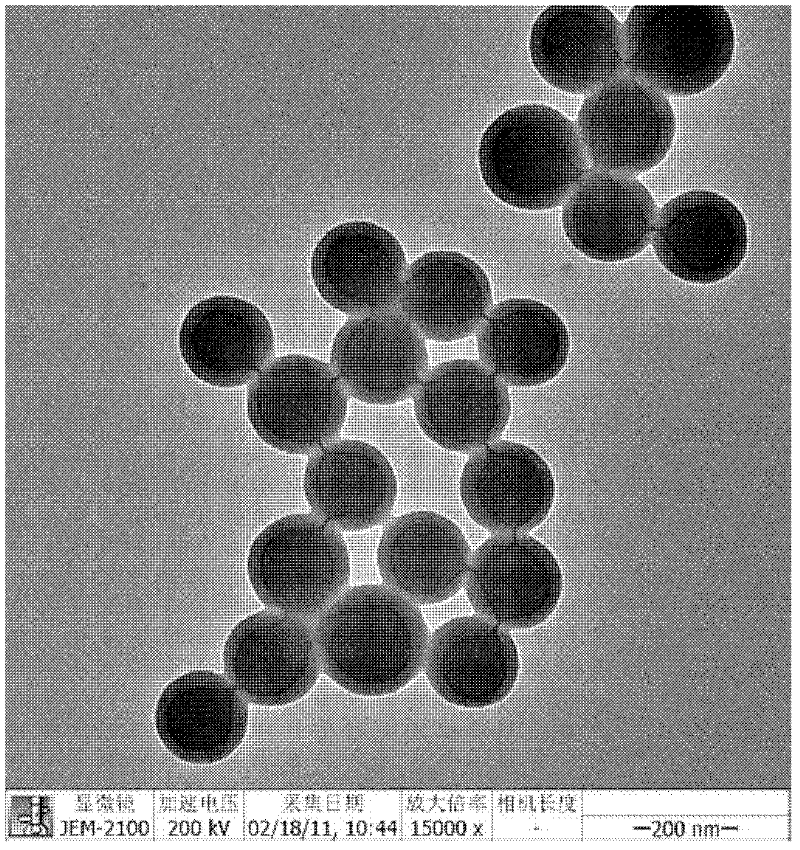

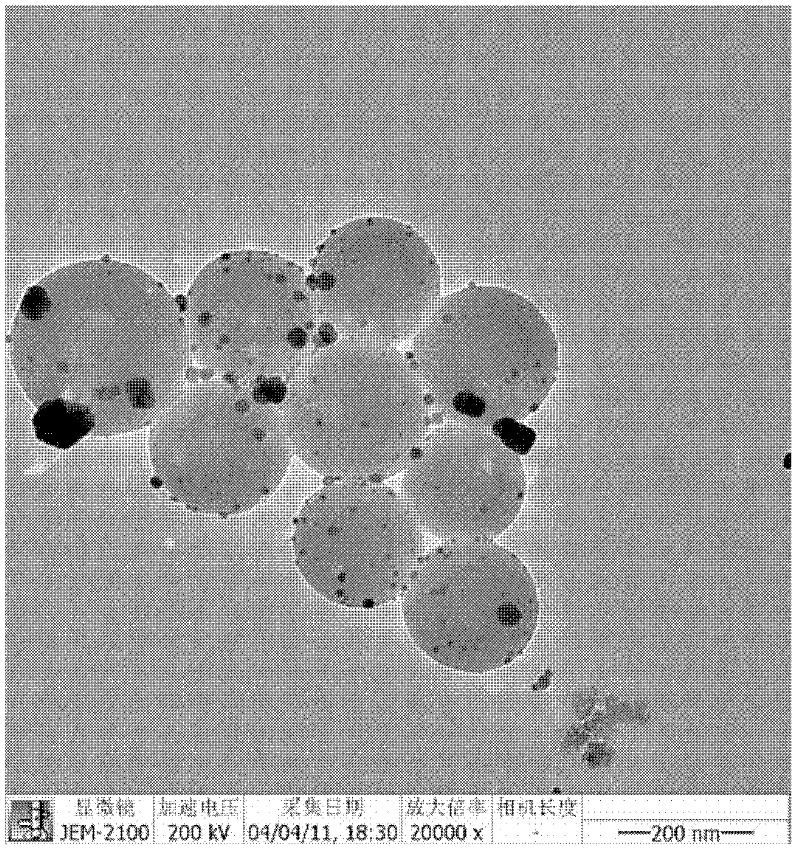

Antimicrobial fabric supported with nano silver core-shell polymer microsphere and preparation method thereof

InactiveCN102444027ASolve reunionImprove biocompatibilityVegetal fibresMaleic anhydrideWeather resistance

The invention discloses an antimicrobial fabric supported with nano silver core-shell polymer microspheres and a preparation method thereof. According to the preparation method, amphipathic polyethylene glycol-maleic anhydride-octadecylamine (PEG-Ma-OC) is synthesized at first, and the polymerized styrene is emulsified and dispersed by utilizing the hydrophily and lipophilicity of PEG-Ma-OC, so as to obtain core-shell polymer microspheres; and silver is supported on the surface of the core-shell polymer microspheres, thereby achieving the dispersion uniformity of nano silver particles and well solving the agglomeration problem of the nano particles; by utilizing the high surface activity of the antimicrobial fabric on the surface of which the nano silver core-shell polymer microspheres are supported, the nano silver core-shell polymer microspheres are added in the fabric, thereby improving the biocompatibility of the antimicrobial fabric; polystyrene in the inner core is used, so thatthe strength of the fabric is improved, and the washing fastness and weather resistance of the antimicrobial fabric are enhanced; and the preparation process of the antimicrobial fabric is suitable for batch production and is easy to industrialize.

Owner:翔瑞(泉州)纳米科技有限公司

Method of preparing sericite ultraviolet radiation screening agent

InactiveCN101058679AGood coating effectGood dispersionOther chemical processesInorganic pigment treatmentChlorideVolumetric Mass Density

The invention discloses a making method of ultraviolet masking agent of sericite mica, which comprises the following steps: 1) preparing fined sericite mica; 2) activating the sericite mica powder; 3) adding water in the sericite mica to form the suspension with density at 2. 5-5%; adjusting the pH value to 2. 0-2. 5 through alcaine as system C; 4) allocating titanic chloride solution with density at 10-15%; adding zinc chloride in the titanic chloride solution; making the molar rate of Zn and Ti at 1: 2; obtaining the solution D; 5) dripping the solution D into the system D; controlling the pH value to 7. 0; 6) filtering the sediment; washing; drying at 95 deg. c; 7) grinding the drier; placing the drier in the electric furnace at 600 deg. c for 2-3h; 8) grinding the sintered material; beating to 10-15um; obtaining the product.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

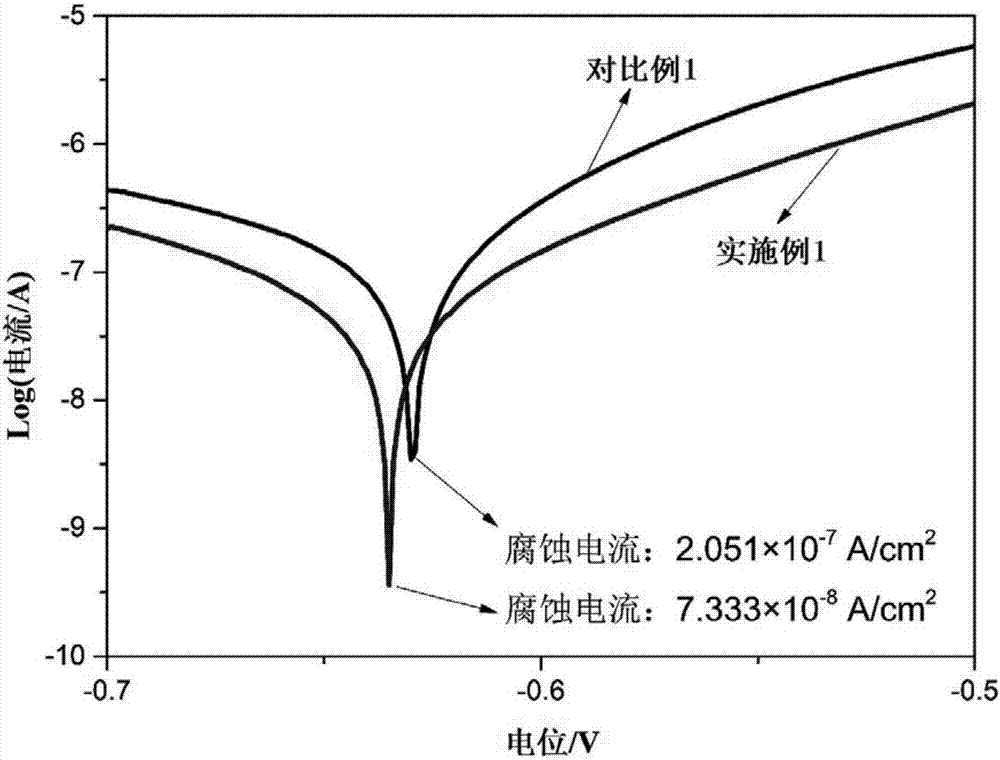

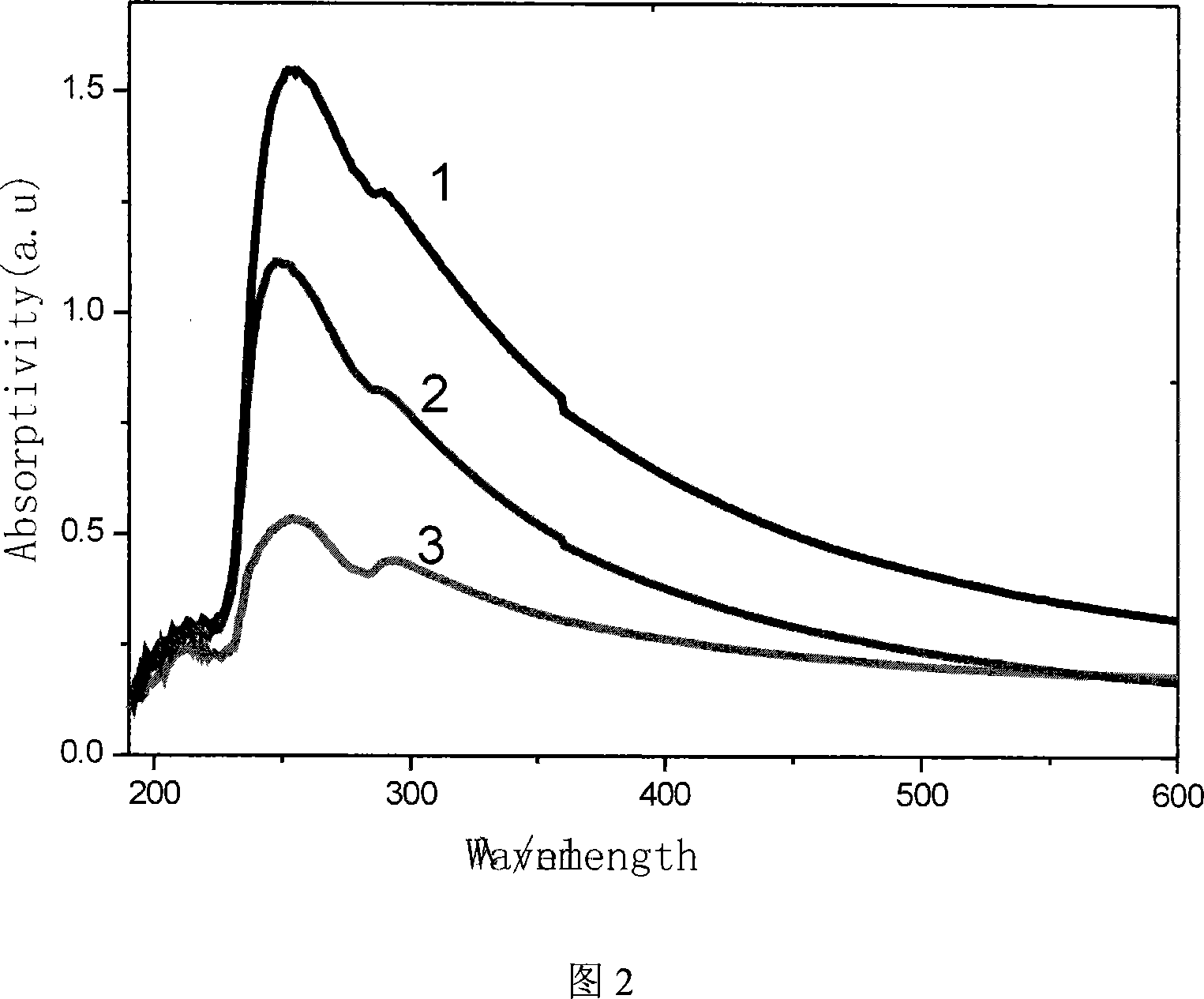

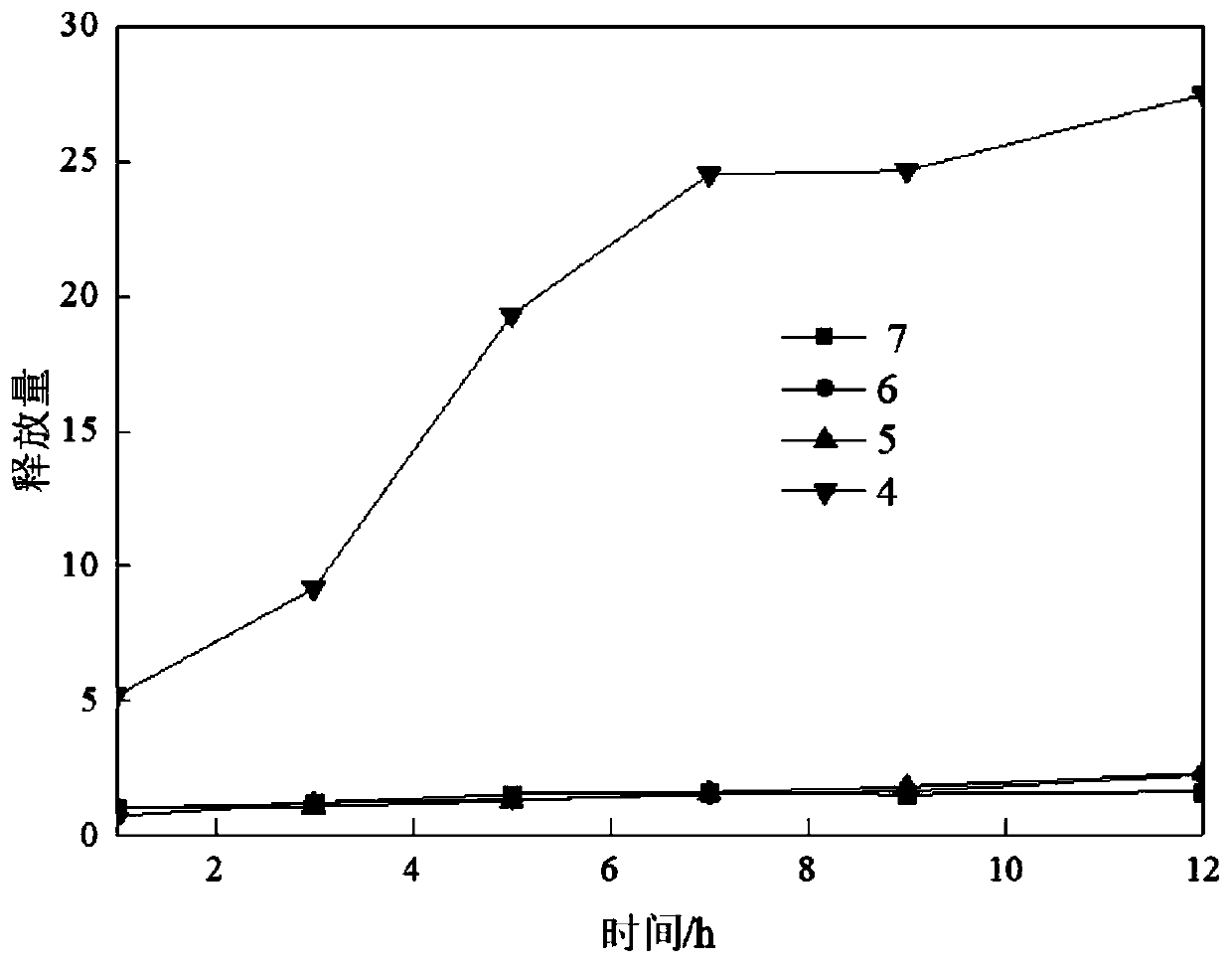

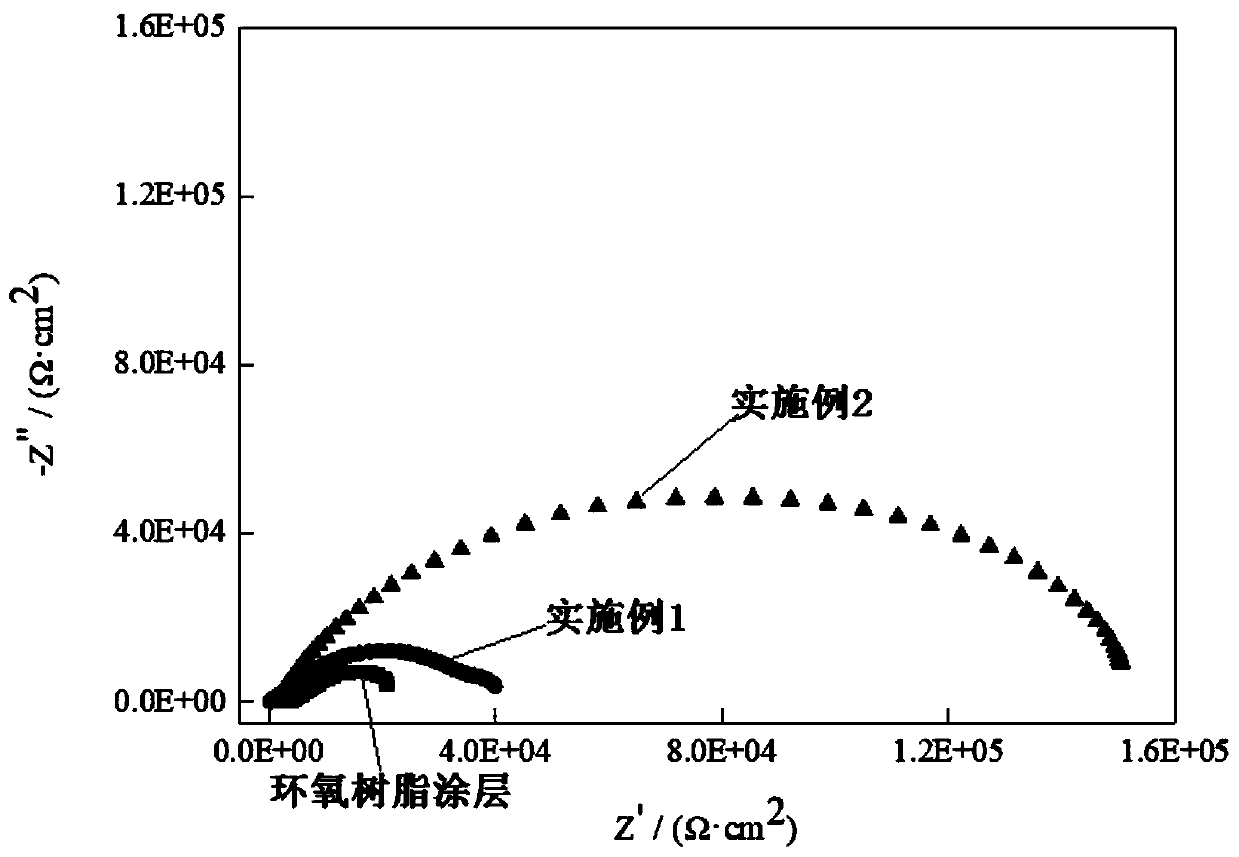

Stimulus-responsive self-repair anticorrosive coating material and preparation method

ActiveCN110105843AImprove anti-corrosion performanceIncrease load rateAnti-corrosive paintsEpoxy resin coatingsCationic polyelectrolytesLayer by layer self assembly

The invention discloses a stimulus-responsive self-repair anticorrosive coating material and a preparation method. The coating material comprises a CuO microcapsule and a coating matrix. The CuO microcapsule comprises a capsule core and a capsule core carrier, the capsule core is a corrosion inhibitor, and the capsule core carrier is porous CuO; and the surface of the CuO microcapsule is coated byan anionic polyelectrolyte layer and a cationic polyelectrolyte layer alternately. The invention successfully constructs the anticorrosive coating material with ph responsiveness and self-repair dualefficacy. The porous CuO can improve the loading rate and encapsulation rate of the capsule core substance; at the same time, the anionic polyelectrolyte can be adsorbed on the surface by means of layer-by-layer self-assembly, under the action of Coulomb force, then cationic polyelectrolyte can be adsorbed on the surface, thus improving the dispersibility of the microcapsule in the coating, solving the agglomeration problem of the porous substance CuO, and at the same time improving the bonding performance of the capsule core carrier and the coating matrix, and the anticorrosion performance of the coating material can be further improved.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com