Antimicrobial fabric supported with nano silver core-shell polymer microsphere and preparation method thereof

A technology of polymer microspheres and antibacterial fabrics, applied in the directions of plant fibers, textiles and papermaking, fiber types, etc., to achieve the effect of solving agglomeration, improving strength, and being easy to industrialize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1. Dissolve 1g of maleic anhydride and 2.04g of polyethylene glycol 200 in 5-20mL of toluene, reflux the reaction for 4h, and then remove the toluene in the reaction solution by evaporation with a rotary evaporator to obtain polyethylene glycol maleic anhydride .

[0025]Step 2. Dissolve 3g of polyethylene glycol maleic anhydride, 2.7g of octadecylamine, and 0.057g of p-toluenesulfonic acid in 20-80mL of toluene, then add 0.07mL of pyridine, and reflux for 6 hours; then evaporate through a rotary evaporator Toluene and pyridine in the reaction solution were removed, finally dissolved in water, and filtered through a dialysis bag to obtain polyethylene glycol-maleic anhydride-octadecylamine.

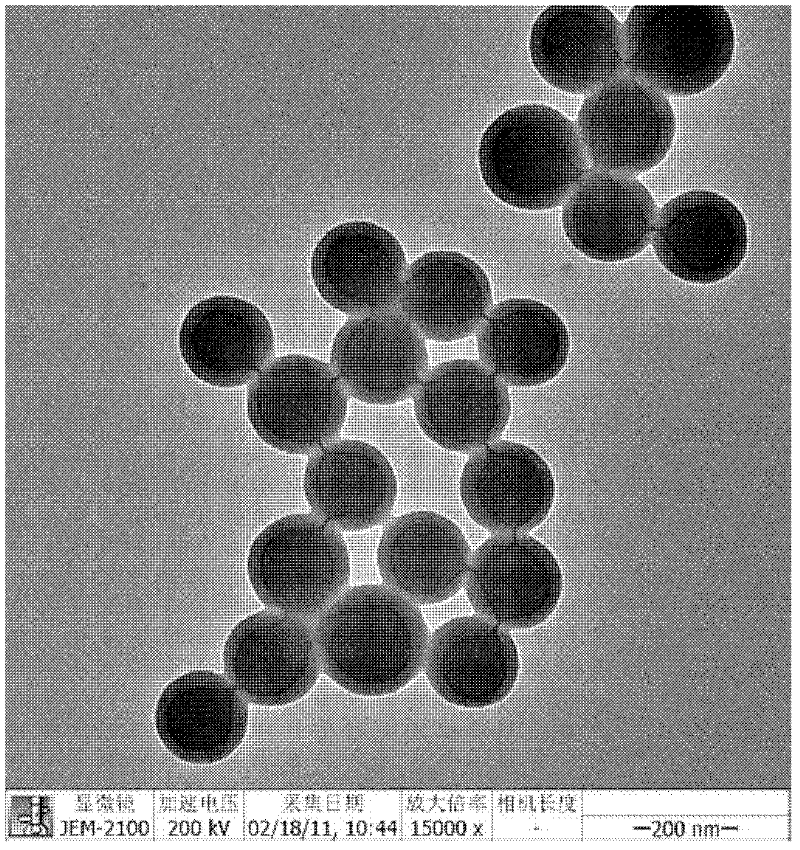

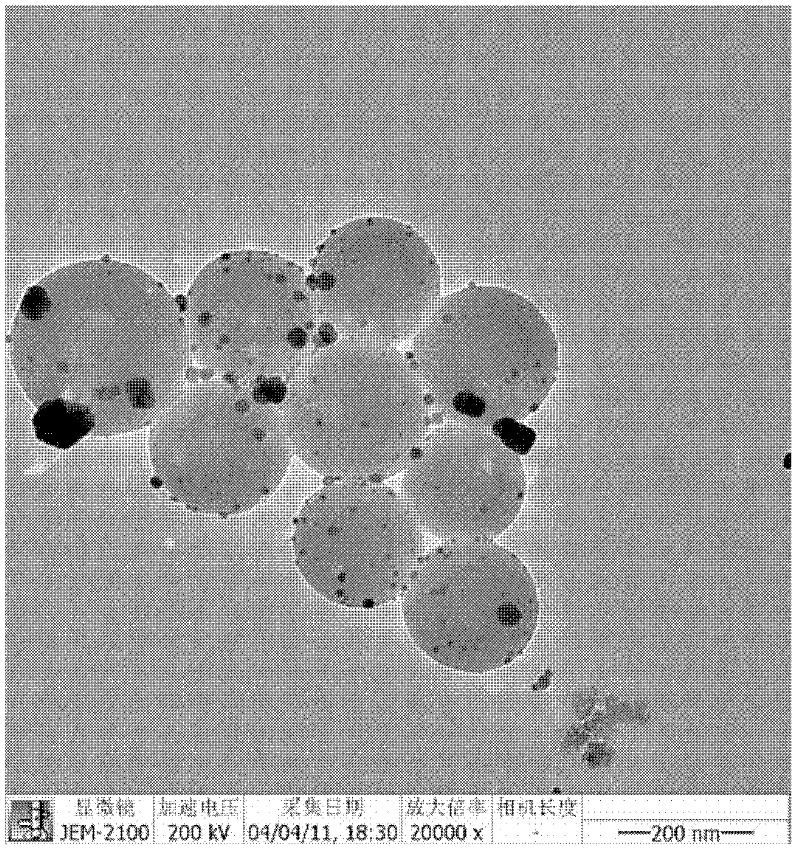

[0026] Step 3. Dissolve 4.33g of polyethylene glycol-maleic anhydride-octadecylamine, 3.12g of styrene, 0.0537g of azobisisobutyronitrile, and 0.0185g of N,N-methylenebisacrylamide in 50mL of distilled water, Mix evenly, react for 6 hours, then add 3.39g of silver nitrate wit...

Embodiment 2

[0029] Step 1. Dissolve 1 g of maleic anhydride and 5.732 g of polyethylene glycol 400 in 8 mL of toluene, reflux the reaction for 6 h, and then remove the toluene in the reaction solution by evaporation with a rotary evaporator to obtain polyethylene glycol maleic anhydride.

[0030] Step 2. Dissolve 6.8g of polyethylene glycol maleic anhydride, 2.92g of octadecylamine, and 0.217g of p-toluenesulfonic acid in 35mL of toluene, then add 0.09mL of pyridine, and reflux for 10 hours; then remove by evaporation with a rotary evaporator The toluene and pyridine in the reaction solution are finally dissolved in water and filtered through a dialysis bag to obtain polyethylene glycol-maleic anhydride-octadecylamine.

[0031] Step 3. Dissolve 7.92g of polyethylene glycol-maleic anhydride-octadecylamine, 8.2g of styrene, 0.195g of ammonium persulfate, and 0.122g of polyethylene glycol (400) diacrylate in 60mL of distilled water, and mix well , reacted for 10h, then added 9.57g of 1.2% si...

Embodiment 3

[0034] Step 1. Dissolve 1 g of maleic anhydride and 11.27 g of polyethylene glycol 800 in 10 mL of toluene, reflux the reaction for 8 hours, and then remove the toluene in the reaction solution by evaporation with a rotary evaporator to obtain polyethylene glycol maleic anhydride.

[0035] Step 2. Dissolve 12g of polyethylene glycol maleic anhydride, 3.1g of octadecylamine, and 0.07125g of p-toluenesulfonic acid in 50mL of toluene, then add 0.1mL of pyridine, and reflux the reaction for 16h; The toluene and pyridine in the solution are finally dissolved in water and filtered with a dialysis bag to obtain polyethylene glycol-maleic anhydride-octadecylamine.

[0036] Step 3. Dissolve 13.31g of polyethylene glycol-maleic anhydride-octadecylamine, 15.81g of styrene, 0.4069g of potassium persulfate, and 0.279g of N,N-methylenebisacrylamide in 75mL of distilled water, and mix well. React for 18 hours, then add 18.8g of silver nitrate solution with a mass fraction of 2.7% and stir fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com