Patents

Literature

433results about How to "Improve wash resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of antibacterial composition and its application

InactiveCN102258064AExtended cleaning cycleTo achieve the effect of saving waterBiocideAntifouling/underwater paintsSodium PyrithioneNonwoven fabric

The invention relates to an antibacterial composition, comprising an organic antibacterial component containing at least one pyrithione salt, a pyrithione complex or an adduct thereof, an aqueous solution containing one or more metal ions or its The inorganic antibacterial component of the complex aqueous solution or its nanometer metal hydrosol or its nanometer metal oxide hydrosol and its composition, and the mass ratio of the organic antibacterial component to the inorganic antibacterial component is 1:100-50:1, It also includes other auxiliary agents, and its mass percentage in the antibacterial composition described in the patent is 0.001-20%. The antibacterial composition of the present invention can form a nanoparticle film on the surface of base materials such as natural fabrics, non-woven fabrics, clothing, bedding, toiletries, household items, medical care supplies, and filter screens, and realize its antibacterial properties through the nanoparticle film. Antibacterial, anti-mite, deodorizing and self-cleaning functions. The antibacterial composition of the invention is safe to use and can be used in medical treatment and life to protect people's health.

Owner:赵正坤

Manufacturing technique of wash-resistant and flame-retardant blended fabric

ActiveCN102392356AImprove flame retardant performanceImprove wash resistanceHeating/cooling textile fabricsYarnGlass fiberPolyester

The invention provides a manufacturing technique of a wash-resistant and flame-retardant blended fabric. The technique comprises the following steps of: 1) preparing a cotton fiber flame-retardant coating adhesive; 2) coating the coating adhesive obtained in the step 1) on the cotton fiber and carrying out heat setting to the cotton fiber so as to obtain a flame-retardant cotton fiber; 3) preparing a glass fiber flame-retardant coating adhesive; 4) directly coating the coating adhesive obtained in the step 3) on the glass fiber and carrying heat setting on the coating adhesive so as to obtaina flame-retardant glass fiber; and 5) blending one of the flame-retardant cotton fiber obtained in the step 2) and a carbon fiber or the flame-retardant glass fiber obtained in the step 4) and one ofa flame-retardant polyester fiber or a flame-retardant nylon fiber so as to obtain the product of the invention. The manufacturing technique of the wash-resistant and flame-retardant blended fabric, provided by the invention, has the advantages of simple process, low cost, good product permeability, softness as well as good wash resistance and flame retardation. The manufacturing technique of thewash-resistant and flame-retardant blended fabric, provided by the invention, is mainly used for manufacturing products like smoke screens, fire-proof insulated curtains, bedspreads, flame-retardant furniture and the like.

Owner:应急管理部四川消防研究所

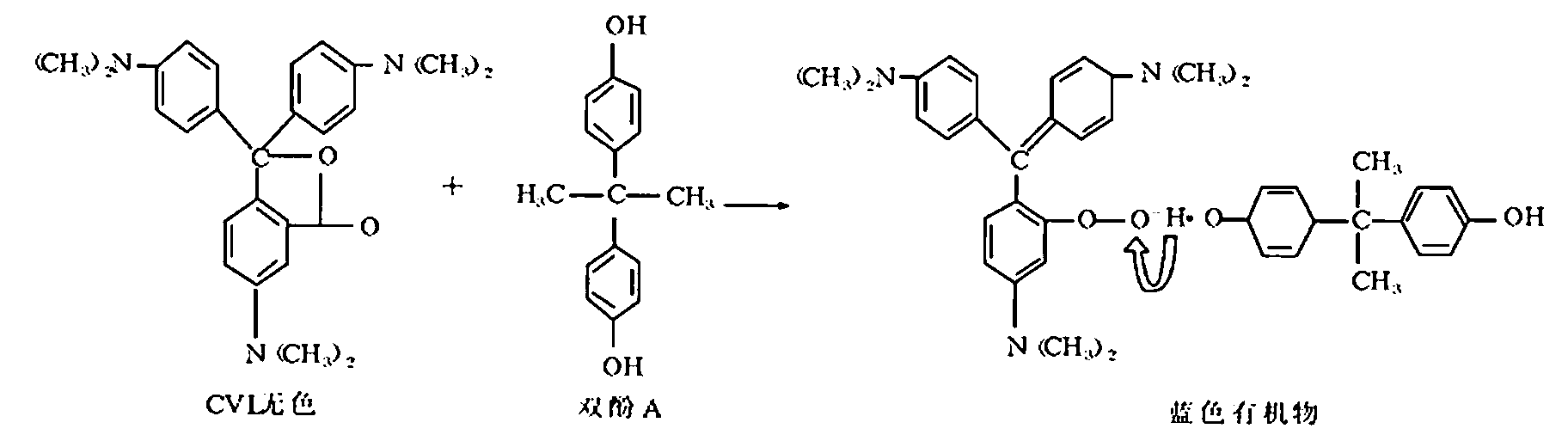

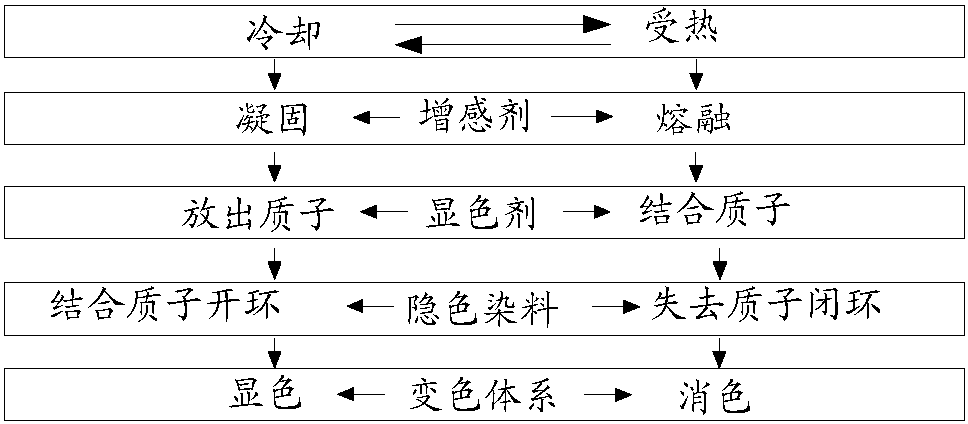

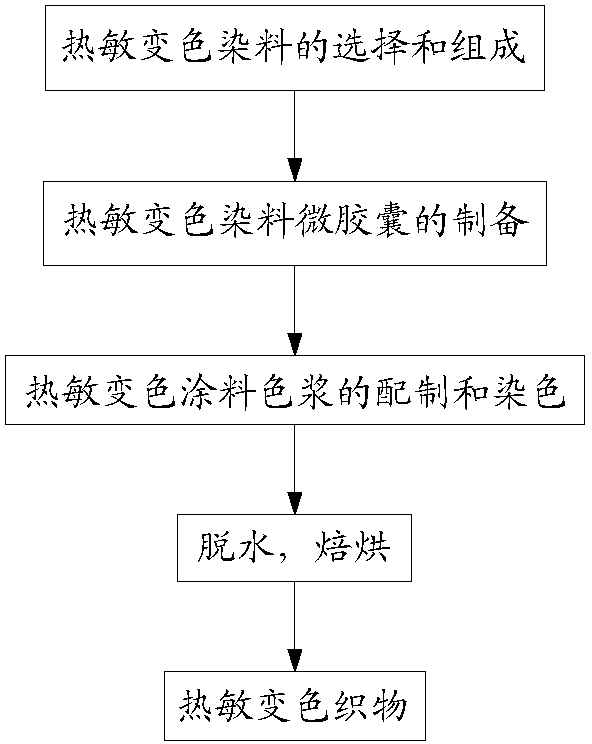

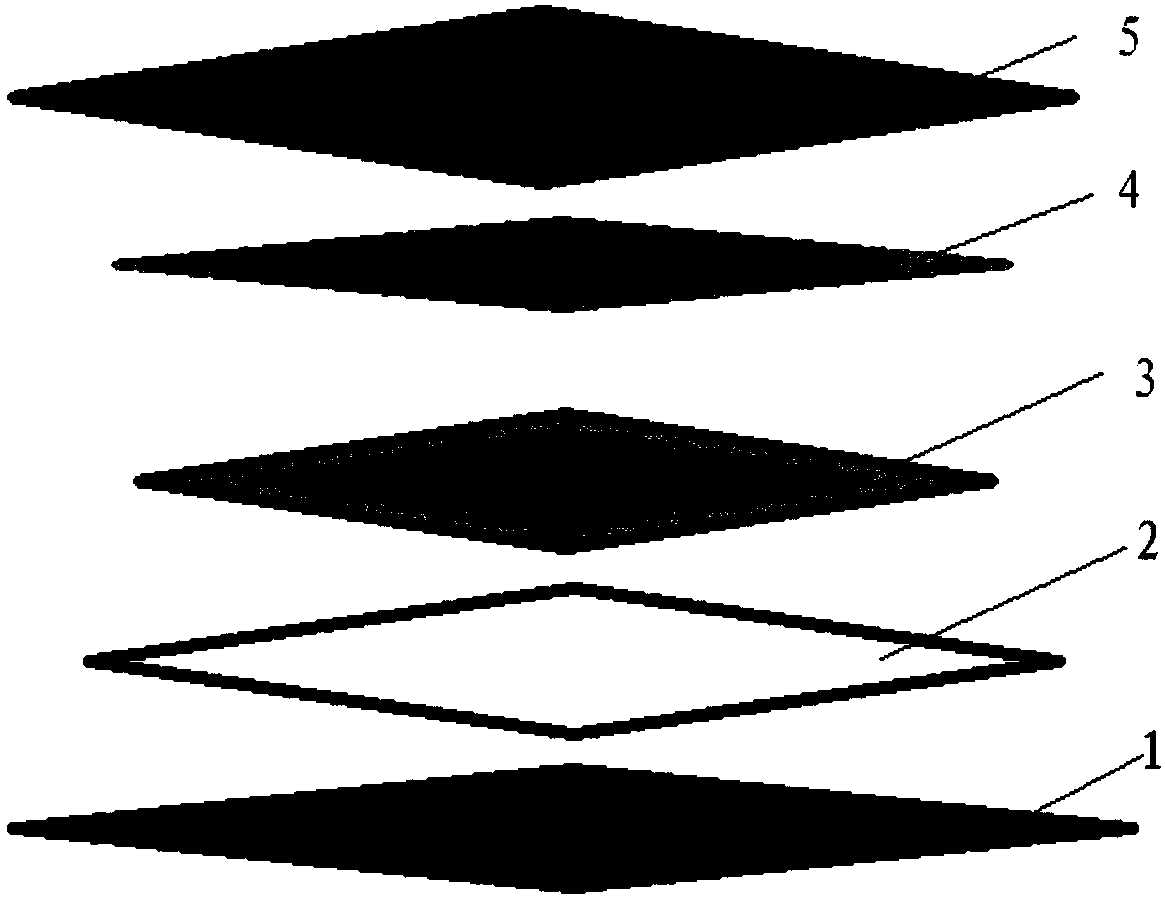

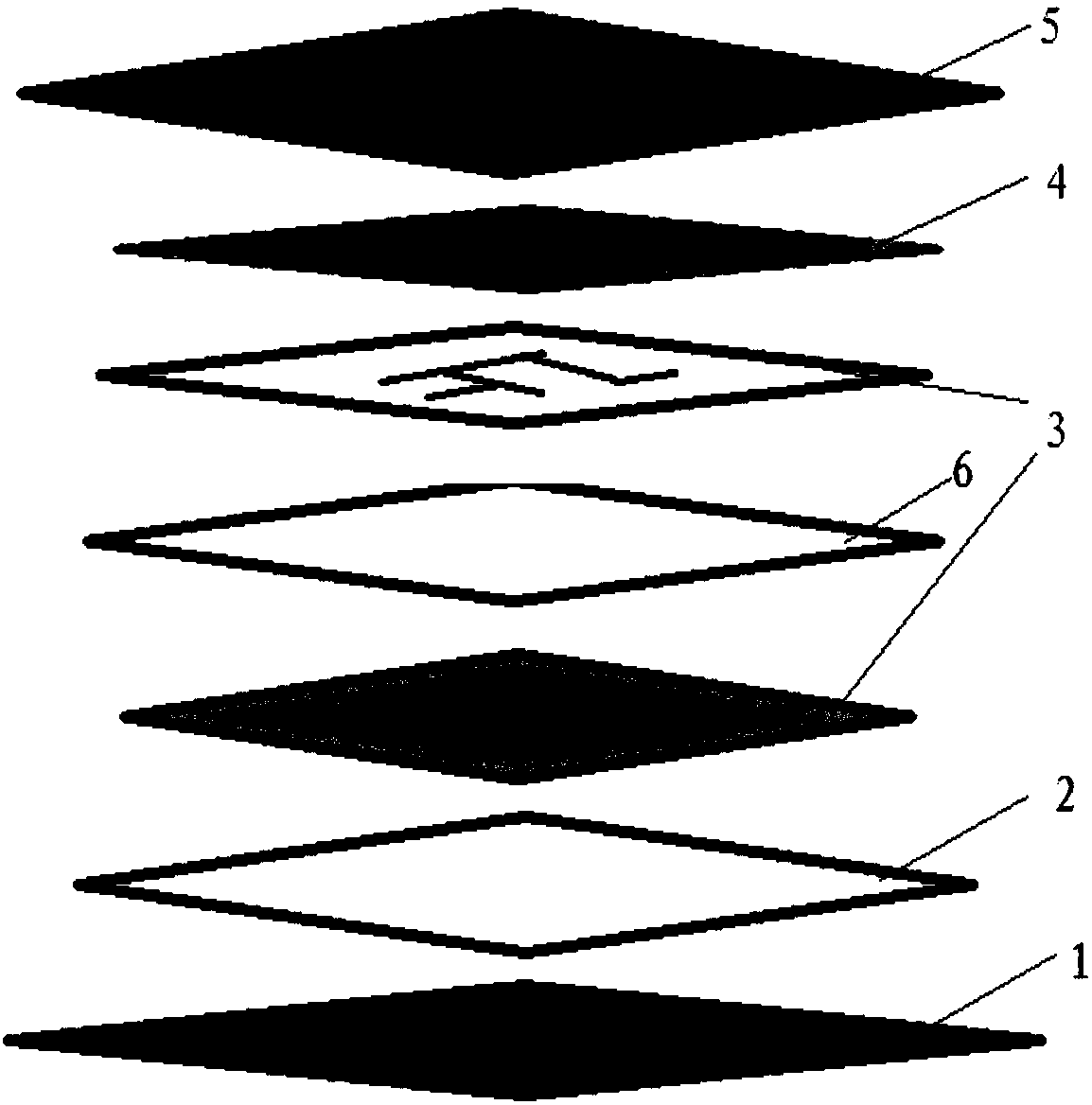

Temperature-sensitive color-changing paint dyeing technology of textile fabrics

InactiveCN103225212AObvious color differenceImprove qualityDyeing processMicroballoon preparationPolyesterFiber

Owner:FUJIAN ZHONGHE

Preparation of nanometer graphene oxide modified cotton fibers and antibiosis product thereof

InactiveCN103205890AImprove securityBroad-spectrum high-efficiency antibacterial propertiesCarbon compoundsVegetal fibresAntibiosisFiber

The invention relates to preparation of nanometer graphene oxide modified cotton fibers and an antibiosis product thereof, wherein the preparation comprises that: (1) graphite oxide is prepared; (2) the graphite oxide and a cross-linking agent are put in a beaker, deionized water is added, and ultrasonic processing is performed to obtain a uniformly dispersed graphene oxide solution; and (3) preparation of an antibiosis product adopts a two dipping and two rolling technology. The nanometer graphene oxide modified cotton fibers and the antibiosis product thereof have characteristics of simple preparation, low cost, good security, broad-spectrum and high efficiency antibacterial property, excellent launderability and excellent permeability.

Owner:SUZHOU ZHENGYECHANG INTELLIGENT TECH

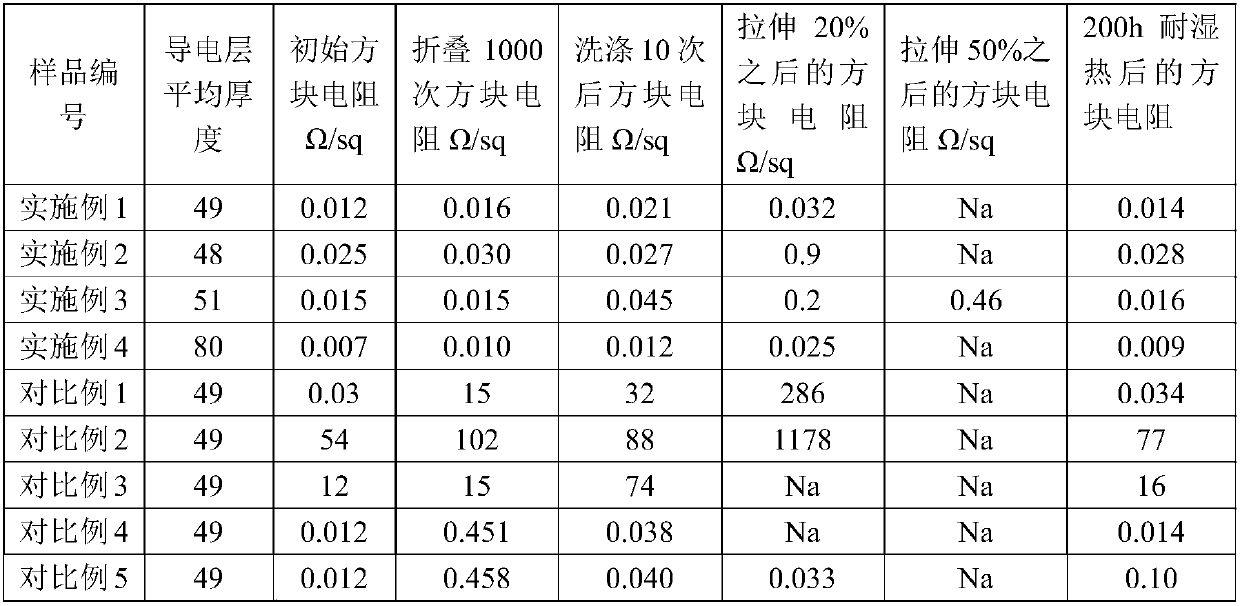

Conductive fabric and preparation method thereof

ActiveCN107938369AImprove wash resistanceImprove tensile propertiesTextiles and paperSurface layerLiquid metal

The invention provides a conductive fabric and a preparation method thereof. The conductive fabric comprises, from inside to outside, an adhesive force improving layer attached to the surface layer ofa fabric substrate, a liquid metal layer, an oxygen isolation protective layer and a packaging protective layer. The preparation method comprises: applying the adhesive force improving layer to the surface layer of a fabric substrate, coating the adhesive force improving layer with the liquid metal layer, coating the liquid metal layer with the oxygen isolation protective layer, and coating the oxygen isolation protective layer with the packaging protective layer. The coating manner includes spraying, brush coating, flow coating or printing. Compared with a conductive fabric in the prior art,the conductive fabric is excellent in conductivity, fold resistance, laundering durability and tensile property. The preparation method is simple and reliable.

Owner:BEIJING DREAM INK TECH CO LTD

Antibacterial viscose rayon and production thereof

InactiveCN1779004AEvenly dispersedHigh antibacterial rateMonocomponent cellulose artificial filamentCelluloseAntiseptic Agent

The invention provides an antiseptic viscose fiber. It is spinned by the silver antiseptic agent and the cellulose sulphonic acid ester. The silver antiseptic agent is 0.5-5% weight of the cellulose. The product has the good antisepsis and the detergent resistance.

Owner:XINXIANG CHEM FIBER

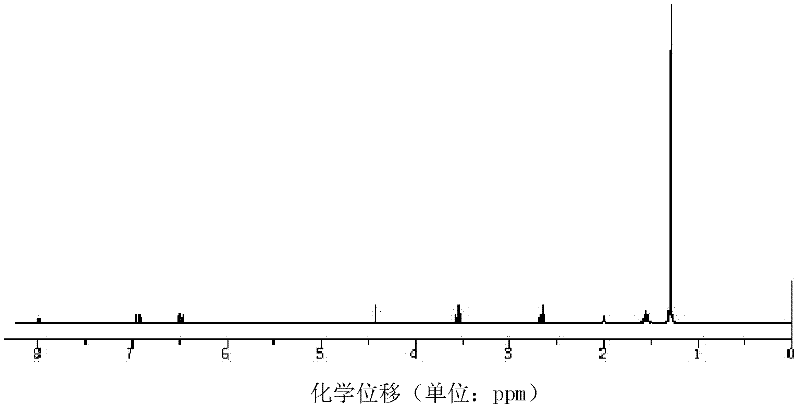

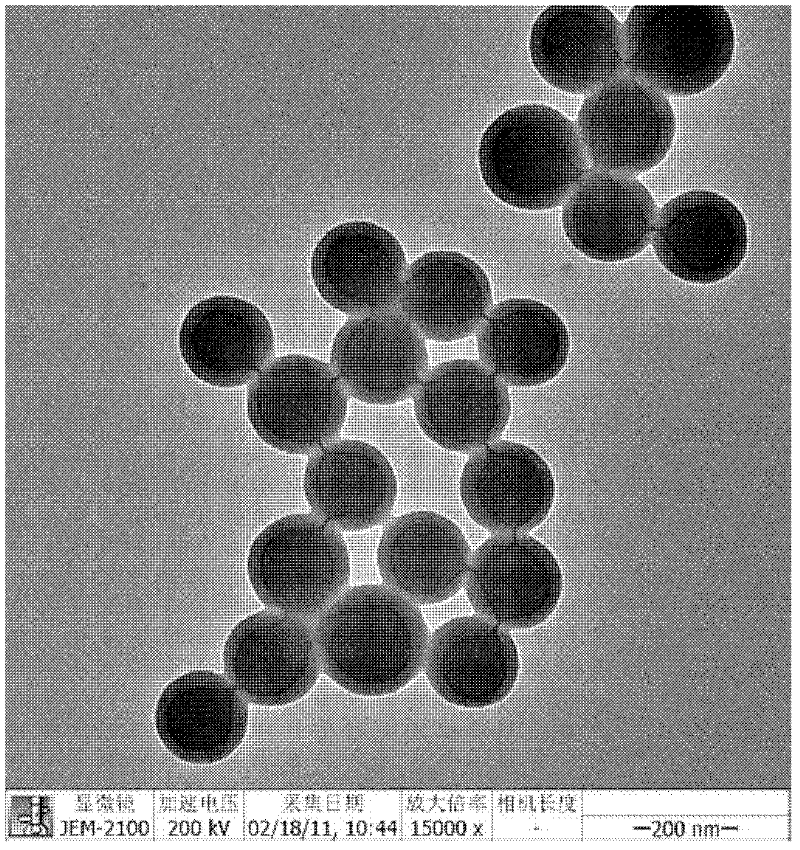

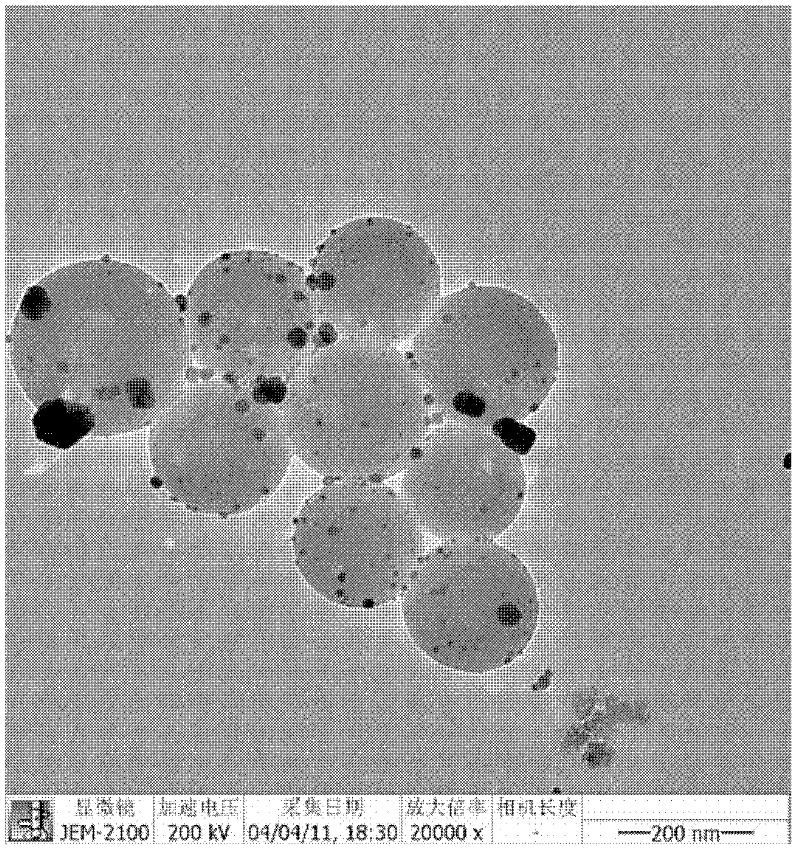

Antimicrobial fabric supported with nano silver core-shell polymer microsphere and preparation method thereof

InactiveCN102444027ASolve reunionImprove biocompatibilityVegetal fibresMaleic anhydrideWeather resistance

The invention discloses an antimicrobial fabric supported with nano silver core-shell polymer microspheres and a preparation method thereof. According to the preparation method, amphipathic polyethylene glycol-maleic anhydride-octadecylamine (PEG-Ma-OC) is synthesized at first, and the polymerized styrene is emulsified and dispersed by utilizing the hydrophily and lipophilicity of PEG-Ma-OC, so as to obtain core-shell polymer microspheres; and silver is supported on the surface of the core-shell polymer microspheres, thereby achieving the dispersion uniformity of nano silver particles and well solving the agglomeration problem of the nano particles; by utilizing the high surface activity of the antimicrobial fabric on the surface of which the nano silver core-shell polymer microspheres are supported, the nano silver core-shell polymer microspheres are added in the fabric, thereby improving the biocompatibility of the antimicrobial fabric; polystyrene in the inner core is used, so thatthe strength of the fabric is improved, and the washing fastness and weather resistance of the antimicrobial fabric are enhanced; and the preparation process of the antimicrobial fabric is suitable for batch production and is easy to industrialize.

Owner:翔瑞(泉州)纳米科技有限公司

Natural hair dye prepared by using phytochrome curcumin and hair dyeing method of natural hair dye

InactiveCN102423286AImprove dyeing effectEasy to floatCosmetic preparationsHair cosmeticsPolyolHair dyes

The invention relates to a hair dye, in particular to a natural hair dye prepared by using phytochrome curcumin and a hair dyeing method of the natural hair dye. The hair dye comprises an agent A and an agent B, and is characterized in that: the agent A contains 0.1 to 10 weight percent of curcumin, 20 to 50 weight percent of polyol, 1 to 5 weight percent of thickening agent, 1 to 10 weight percent of surfactant and the balance of water, and the pH value is regulated to be 3 to 7; and the agent B contains 1 to 10 weight percent of metal ion mordant, 1 to 5 weight percent of thickening agent, 1 to 10 weight percent of surfactant, 0.1 to 0.3 weight percent of natural essence and the balance of water, and the pH value is regulated to be 3 to 7. The hair dyeing method comprises the following steps of: uniformly spreading the agent A on the hair when the hair is dyed, and dyeing the hair for 10 to 40min at the temperature of between normal temperature and 60 DEG C; and uniformly spreading the agent B on the hair, mordanting for 10 to 20min, cleaning the hair and blow-drying. The curcumin has a good dyeing effect and also has the effects of resisting bacteria and protecting skin. Reagents which are toxic to human bodies are not used in the hair dye, and substances which are toxic to the human bodies are also not generated in the hair dyeing process, so the hair dye is high in safety. The adopted curcumin is insoluble in water and cannot fall off easily in the washing process, so the hair dye has a good dyeing effect, and the color of the dyed hair can be kept for a long time.

Owner:JIANGNAN UNIV

Compound photocatalysis antimicrobial air filter material and preparation method thereof

InactiveCN101745271AImprove wash resistanceImprove crosslink strengthFibre treatmentFiltration separationAir filtrationPolyurethane adhesive

The invention discloses a compound photocatalysis antimicrobial coating air filter material and a preparation method thereof. The method is as follows: respectively preparing nano titanium oxide collosol, nano zinc oxide collosol and nano copper-nickel compound metallic collosol; preparing compound photocatalysis antimicrobial finishing agent; in cationic waterborne polyurethane adhesive emulsion, firstly, adding nano copper-nickel compound metallic collosol, nano titanium oxide collosol and nano zinc oxide collosol, stirring, and then adding deionized water; at room temperature, stirring and dispersing to form stable emulsion compound photocatalysis antimicrobial finishing agent; preparing finishing agent accounting for 5-15 wt% of air filter material to be treated; adding deionized water until reaching 100%; adopting a continuous padding technology to perform dip coating classification to the filter material to be treated; and drying and backing. The invention solves the problems of unfavorable nano photocatalysis antimicrobial effect, single effect and poor laundering durability, and improves the laundering durability of compound coating.

Owner:JIANGSU FILTERTEX FILTER MATERIAL +1

Method for processing knitted composite fabric

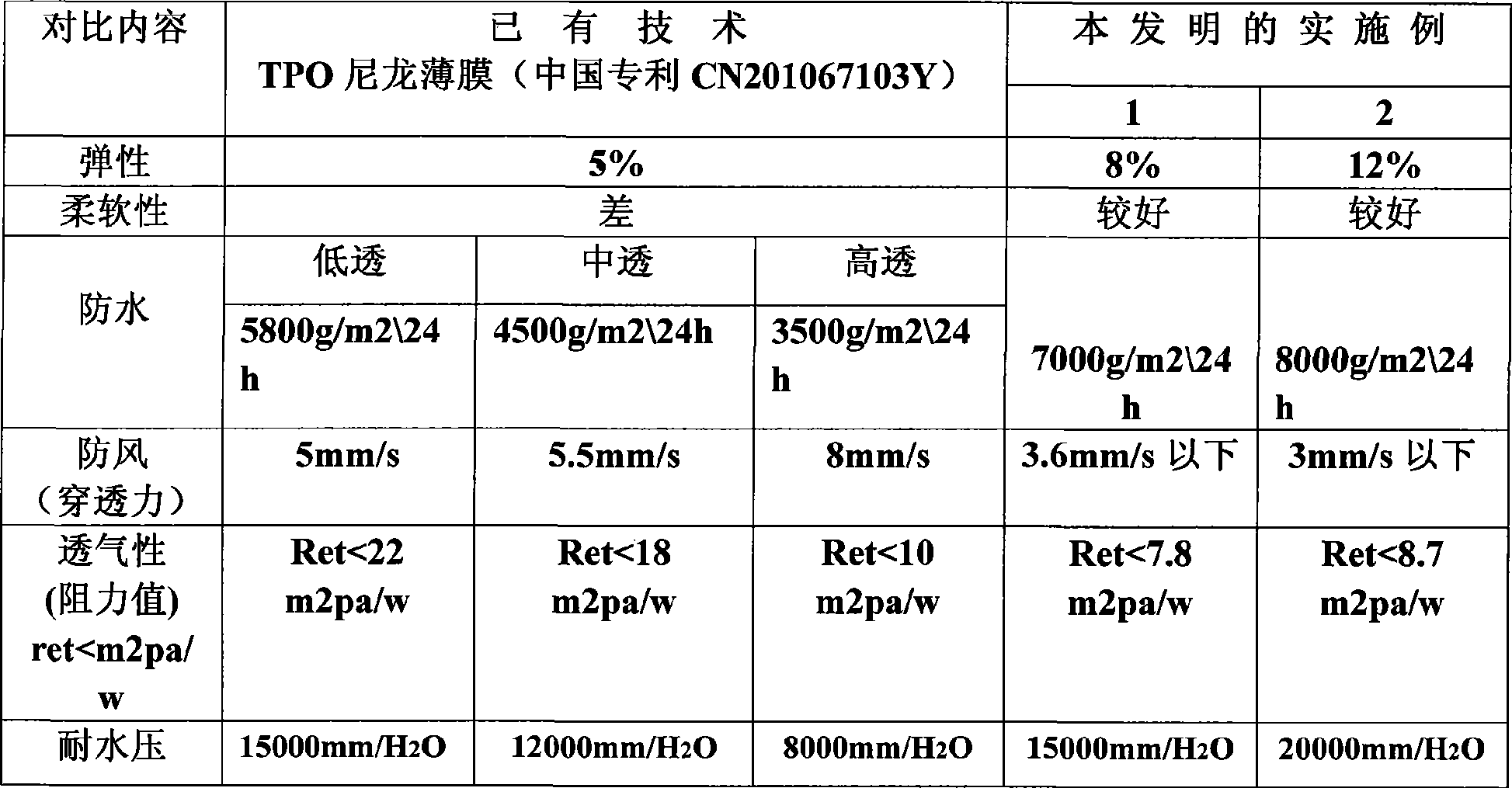

InactiveCN101532252AGood windproofImprove waterproof performanceWeft knittingFibre treatmentEngineeringMoisture absorption

A method for processing a knitted composite fabric belongs to the technical field of knitted fabric processing. The method comprises the steps of fabric raw material selection, lining raw material selection, weft knitting, presetting, dyeing and post treatment, coating and combination. The method has the advantages of requiring less processing steps and allowing the obtained knitted composite fabric to achieve ideal windproof and waterproof performance, moisture absorption, ventilation property, flexibility, elasticity and laundering durability.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

Water-and-oil repellant composition

InactiveCN1461334AImprove friction resistanceImprove wash resistanceOther chemical processesCoatingsSide chainMelting point

A water and oil repellent composition which can impart an excellent water and oil repellency to an object, even if it is processed at a low temperature, and which can achieve a water and oil repellent treatment providing a soft hand. The water and oil repellent composition which has as an essential component a copolymer consisting essentially of polymerized units of the following monomer (a) and polymerized units of the following monomer (b). monomer (a) : an R<f> monomer wherein the melting point of fine crystals derived from the R<f> groups of the homopolymer does not exist or is at most 50 DEG C. monomer (b) : a monomer having no R<f> group, wherein the melting point of fine crystals derived from the side chains of the homopolymer is at least 30 DEG C.

Owner:ASAHI GLASS CO LTD

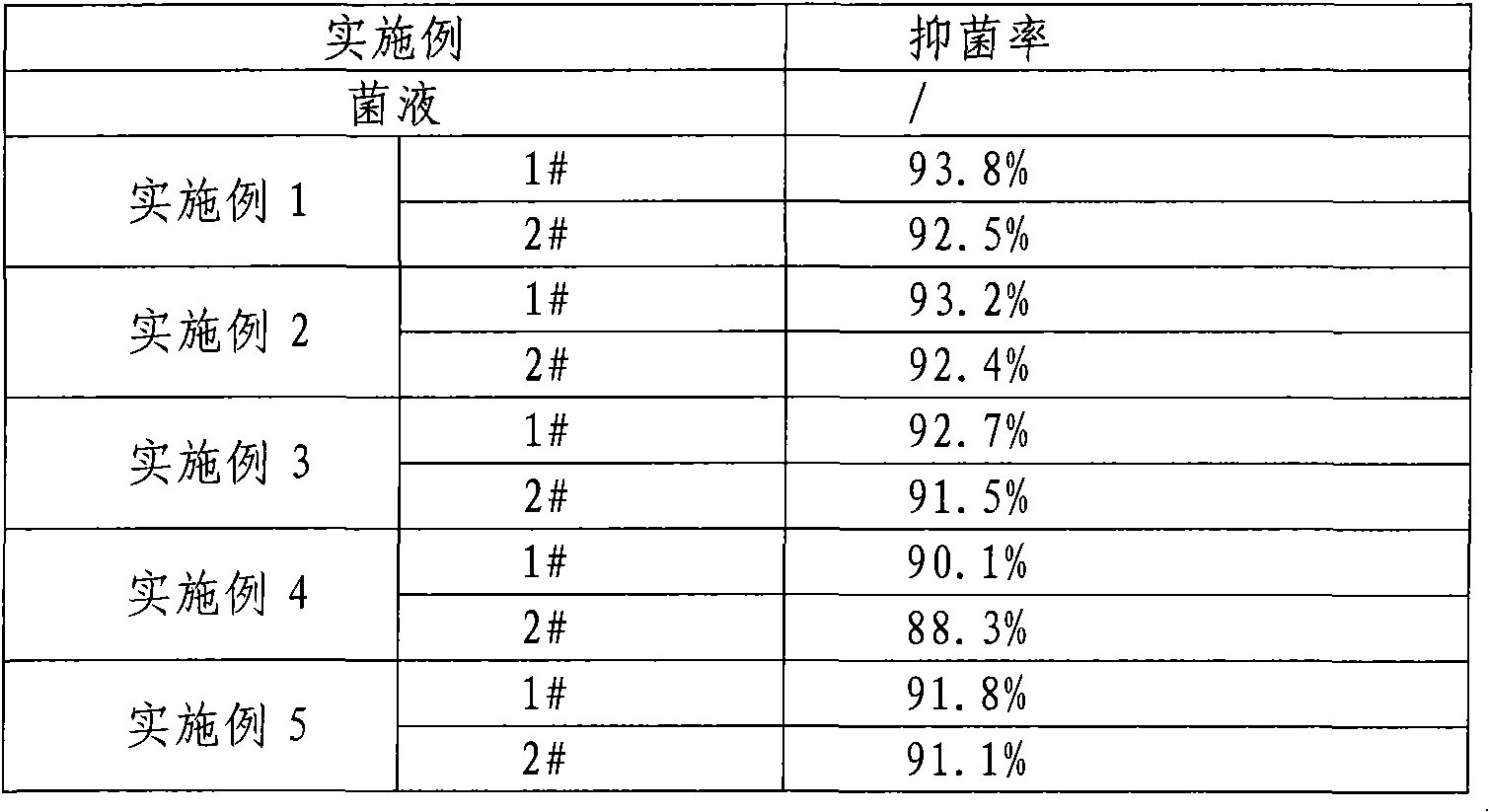

Preparation method of antibacterial antivirus cotton fabric, cotton fabric and applications thereof

ActiveCN105177985AImprove antibacterial propertiesImprove hydrophilicityUltrasonic/sonic fibre treatmentVegetal fibresUltraviolet lightsBiocompatibility Testing

The invention discloses a preparation method of an antibacterial antivirus cotton fabric, a cotton fabric and applications thereof. The preparation method comprises the following steps: preprocessing cotton fabrics to generate free radicals that can react; and soaking the preprocessed cotton fabrics in a finishing solution to carry out a finishing treatment to introduce at least two different kinds of antibacterial antivirus groups into the cotton fabrics so as to obtain the antibacterial antivirus cotton fabric. According to the preparation method, the cotton fabric is preprocessed by ultraviolet lights or plasma so as to generate reactive free radicals, and then at least two different kinds of functional groups with antibacterial antivirus functions are introduced into the cotton fabric. The provided cotton fabric has the advantages of chitosan such as moisture absorption function, breathability, good biocompatibility, and the like, and at the same time has a broad-spectrum antibacterial function and hydrophilicity. Moreover, the cotton fabric is connected to the functional groups with antibacterial antivirus functions through chemical bonds, the washing resistant function of functional cotton fabric is prominently enhanced, the broad-spectrum antibacterial function of the functional cotton fabric is also improved, and the application range of the cotton fabric is enlarged.

Owner:SHENZHEN QIANHAI GUANGDA TECH INFORMATION SERVICE

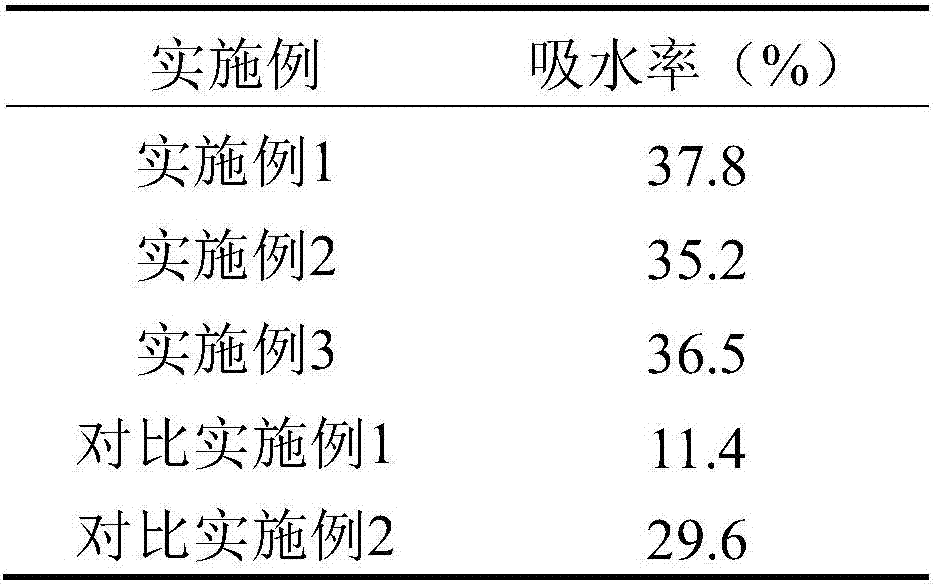

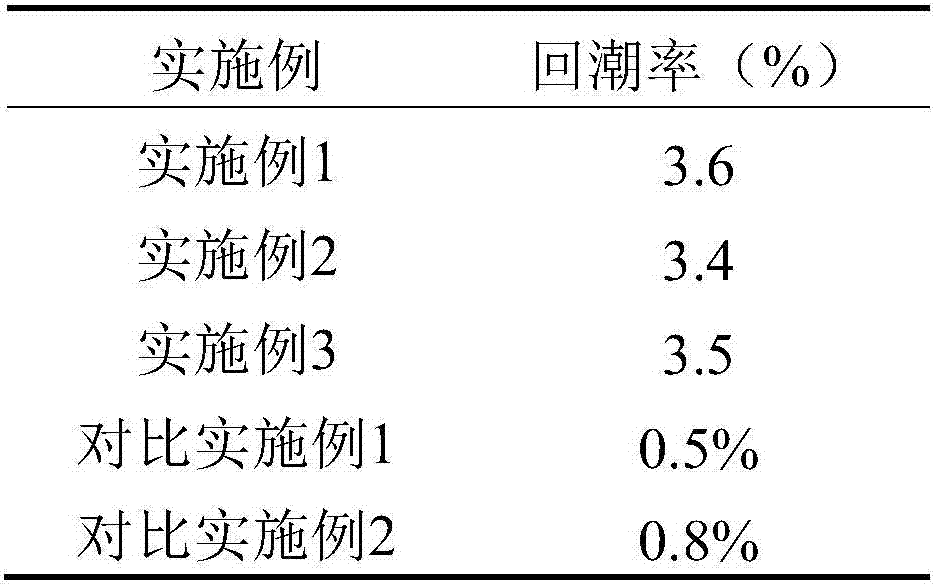

Moisture-absorbing anti-static and anti-bacterial polyester fiber, moisture-absorbing anti-static and anti-bacterial fabric and preparation and application

InactiveCN107475801AImprove water absorptionGood hygroscopicityElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPolyesterPolyethylene terephthalate glycol

The invention belongs to the field of clothes textiles, and particularly relates to a moisture-absorbing anti-static and anti-bacterial polyester fiber, a moisture-absorbing anti-static and anti-bacterial fabric and preparation and application. A preparation method of the moisture-absorbing anti-static and anti-bacterial polyester fiber comprises the following steps of mixing and spinning polyethylene terephthalate, polyvinyl alcohol, nanosilver and polyethylene glycol, so as to obtain mixed fiber; respectively treating the mixed fiber by a lipase water solution and a quaternary ammonium salt chitosan / glyoxal solution, and washing by water; stretching the mixed fiber after water washing, coiling, and thermally shaping, so as to obtain the moisture-absorbing anti-static and anti-bacterial polyester fiber. The moisture-absorbing anti-static and anti-bacterial fabric comprises the moisture-absorbing anti-static and anti-bacterial polyester fiber. The prepared moisture-absorbing anti-static and anti-bacterial polyester fiber has the advantages that the defects of poor moisture absorbing property, low moisture regain rate, easiness in electrostatic charge forming and the like in the unmodified polyester fiber are overcome; the water absorbing property, moisture absorbing property, anti-static property and antibacterial property are good.

Owner:广州弘雅服装科技有限公司

Fabric nano post-treatment reagent with durable antibiotic fragrance effect and mfg. technique thereof

A method for preparing post finishing nanoreagent of fabric product with persistant aromatic and antibiotic effect includes using high adhesion material as wall material and mixture of aromatics and germicide as core material of microcapsule, forming 25% core material solution by mixing aromatics and germicide with volume ratio as 4:1-2:1 and then diluting it by pure water, forming A solution by mixing oily emulsifier with high adhesion material and toluene solution in volume ratio as 5:12:20, forming B solution by mixing liquid phase curing agent with core solution in volume ratio as 1.5:6 and forming said nanoreagent by mixing A solution with B solution in volume ratio as 1:1.

Owner:GUANGDONG PENGYUN IND

Semen Cassiae Composite Antibacterial Finishing Agent, Preparation Method, Fiber Treatment Method and Application

The invention discloses a cassia seed composite antibacterial finishing agent which is prepared from a cassia seed extract or nano-cassia seed, a finishing agent and TW-80 (Tween-80). The cassia seed composite antibacterial finishing agent is convenient to use and stable; by adopting the technology of applying the cassia seed composite antibacterial finishing agent on fiber, a product has high-efficient, lasting and safe antibacterial performance; the natural cassia seed is introduced into the traditional home textile industry, thereby avoiding the safety problem during the application of an organic antibacterial agent; and the problems of dispersion, uniformity, firm combination and the like between the antibacterial agent and the fiber can be solved, and the high-efficient lasting antibacterial effect can be achieved in the real sense. The invention further discloses a preparation method of the cassia seed composite antibacterial finishing agent, a method for processing the fiber byutilizing the cassia seed composite antibacterial finishing agent and an application of the cassia seed composite antibacterial finishing agent in home textile products.

Owner:SHANGHAI SHUIXING HOME TEXTILE

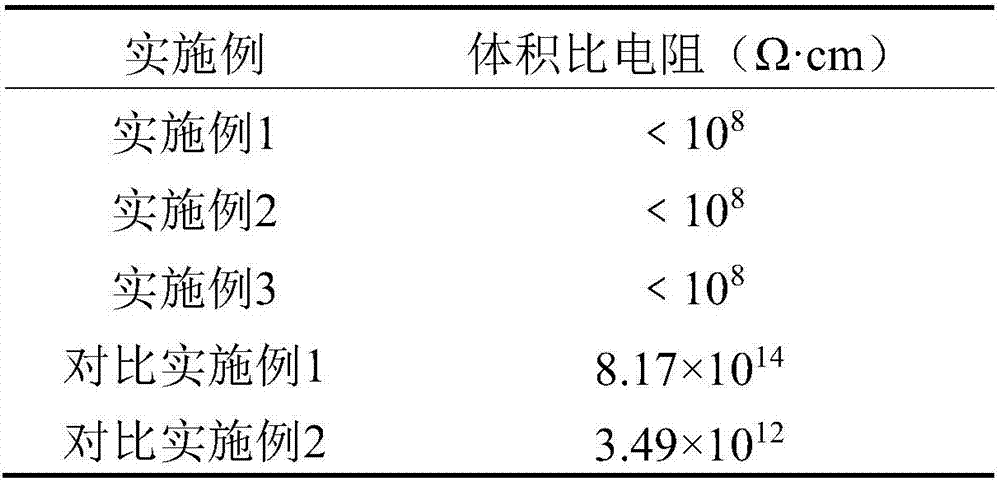

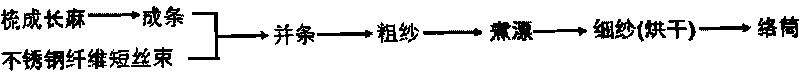

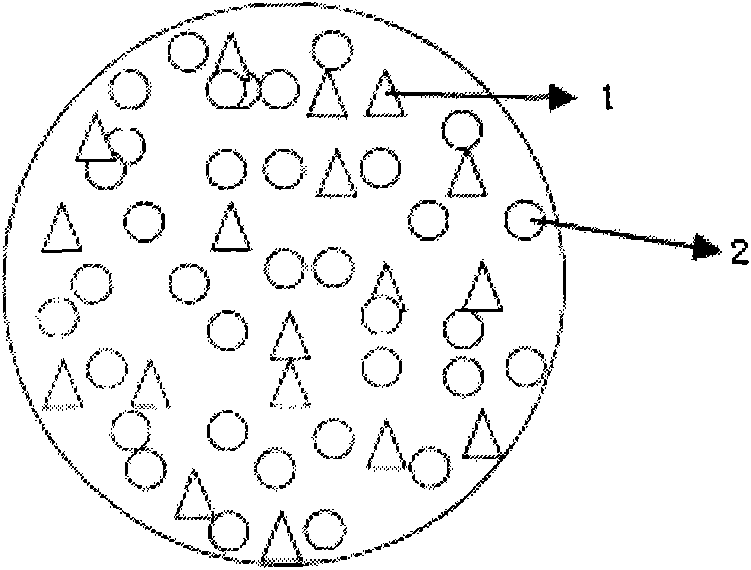

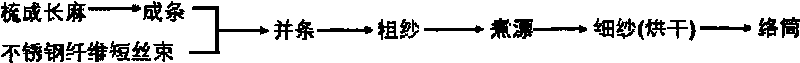

Anti-microwave radiation flax yarn and production process thereof

The invention relates to an anti-microwave radiation flax blended yarn and a production process thereof, and the yarn is formed by blending stainless steel fibers and flax filaments, wherein the stainless steel fibers account for 5%-40% of the blended yarn, and the flax filaments account for 60%-95% of the blended yarn. The production process comprises the steps of producing the flax filaments into ramie stripes, mixing with the stainless steel fibers in the flax long ramie strips during the drawing process, further carrying out three or more drawing procedures after mixing with the stainless steel fibers, leading the stainless steel fibers to account for 5%-40% of the blended yarn, doubling the two, drafting, then producing a coarse yarn, boiling and bleaching the coarse yarn, spinning for producing a spun yarn, drying, winding and shaping. The flax blended yarn has excellent magnetic radiation protection function and lasting fabric shielding effectiveness, and can be washed repeatedly without basically affecting the shielding effectiveness; and the production process has the advantages of convenience, rapidness, simpleness and low cost.

Owner:ZHEJIANG JINYUAN FLAX

Flame-retardant jean fabric

ActiveCN103233360ABreathable and moisture-permeableImprove wash resistanceBiochemical fibre treatmentDry-cleaning apparatus for textilesCelluloseTetrakis(hydroxymethyl)phosphonium chloride

The invention relates to a flame-retardant jean fabric. The flame-retardant jean fabric is prepared by comprising the following steps: (1) placing jean fabric in a jig dyeing machine, adding water and desizing enzyme for processing, then discharging liquid and washing with water; (2) enzyme washing: adding the desized jean fabric, water and neutral cellulose enzyme into the jig dyeing machine, performing temperature rise, discharging liquid and cleaning with water; (3) flame retardant padding-batching: mixing tetrakis hydroxymethyl phosphonium chloride, urea, etherified hexamethylol melamine resin and penetrating agent JFC to obtain flame-retardant finishing liquid, padding and batching the jean enzyme-washed fabric into the flame-retardant finishing liquid, performing twice padding and twice batching; (4) ammonia fumigation: performing ammonia fumigation to the flame retardant-padded-and-batched jean fabric in an ammonia fumigation flame-retardant machine; and (5) later-stage arrangement: performing once padding and once batching to the ammonia-fumigated jean fabric in hydrogen peroxide, and storing after padding and batching; and drying after being washed. According to the flame-retardant jean fabric, the excellent flame-retardant property of the jean fabric is endowed, and the added value of the product can be improved.

Owner:邦威防护科技股份有限公司

Antibacterial blended yarn and application thereof

InactiveCN101560711AImprove antibacterial propertiesLow costFibre treatmentFlat-bed knitting machinesPolyesterYarn

The invention provides antibacterial blended yarn, which is obtained by blending 30 to 40 weight percent of hemp fiber, 15 to 25 weight percent of modal fiber, 15 to 25 weight percent of high-elastic polyester fiber and 15 to 25 weight percent of viscose fiber. The yarn blended by multiple fibers mainly comprising natural hemp fiber is taken as a wool fabric so as to greatly improve the antibacterial property, the launderability is good, and a processing process has no pollution and meets requirements of health and environmental protection. A wool fabric woven by the yarn as a raw material has enduring antibacterial effect, is healthy and environment-friendly, and reduces the cost.

Owner:JIANGNAN UNIV +1

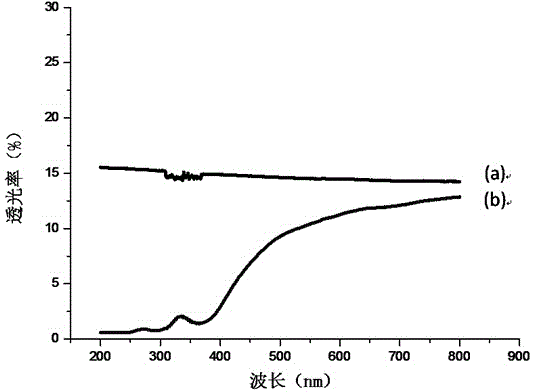

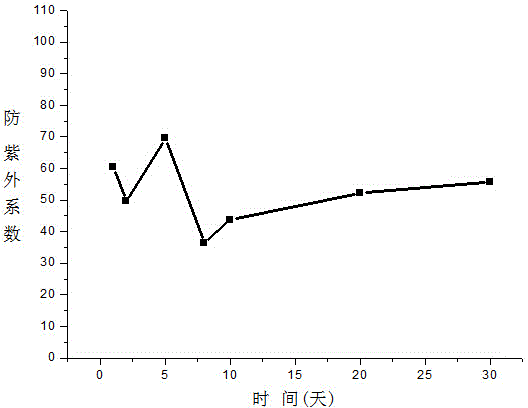

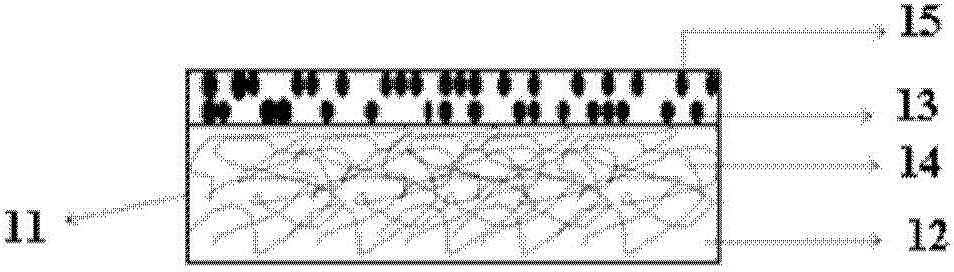

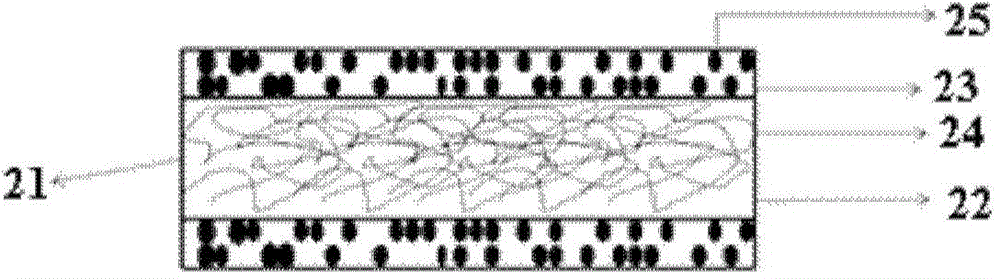

Wash-wear nonwoven fabric capable of selectively blocking ultraviolet rays

ActiveCN104562682AImprove wash resistanceGood solvent resistanceFibre typesUltraviolet absorptionNonwoven fabric

The invention discloses a wash-wear nonwoven fabric capable of selectively blocking ultraviolet rays, and belongs to the field of a functional textile, and particularly relates to a nonwoven fabric with an ultraviolet-proof function. The nonwoven fabric is prepared through the following steps: by adopting a large piece of graphene oxide as ultraviolet absorption padding, uniformly mixing the graphene oxide and water-based polymer resin in water to obtain a mixture, coating two sides of the nonwoven fabric with the mixture, and drying and molding the nonwoven fabric. The average transmittance of the nonwoven fabric in the long-wavelength ultraviolet area is less than 4 percent, and the ultraviolet-proof factor is more than 30, the transmittance of the nonwoven fabric in a visible light area is reduced by 30 to 50 percent compared with that of the pure nonwoven fabric, and the performance still can be maintained after the nonwoven fabric is severely stirred in water for 30 days. The wash-wear nonwoven fabric is simple, low in cost, environmentally friendly, suitable for industrialized mass production, high in selectivity, good in ultraviolet-proof performance, wash-wearable and good in flexibility, and a coating has small possibility of falling off, and can resist acid and alkali. The wash-wear nonwoven fabric can preserve the heat and can be used in fields such as ultraviolet protection clothing, ultraviolet protection screen windows and ultraviolet protection paulin.

Owner:杭州德烯科技集团有限公司

Method for preparing pearlesent color coated fabric

InactiveCN101440576ASimple manufacturing methodRich in elasticityTextile decorationWear resistanceChemistry

The invention discloses a method for producing fabric with pearly luster magic color coating. The method comprises the following steps: firstly, base cloth is coated with base coating pulp and dried to form a base coating; secondly, the base coating is coated with leather membrane coating pulp and dried to form a leather membrane coating; thirdly, the leather membrane coating is coated with pearly luster coating pulp and dried to form a pearly luster coating; and the pearly luster coating pulp contains mica pearl powder. By the method, the fabric with magically colorful pearly luster can be produced, and is beautiful and fashionable; and, the fabric has the advantages of good covering power, good fastness, fully elastic hand-touch and excellent wearing resistance and washing resistance and can be widely applied to fashionable dress, jackets, winter proofing clothes, decorative cloth and the like.

Owner:SHENGHONG GRP CO LTD

Method for enhancing washing resistance of nano-silver antibacterial cotton fabric by surface modification of cotton fabric

The invention discloses a method for enhancing washing resistance of nano-silver antibacterial cotton fabric by surface modification of cotton fabric. The method comprises the following steps: Step 1, impregnating cotton fabric into a cysteine hydrochloride solution, heating to carry out an esterification reaction between carboxyl group of cysteine hydrochloride and hydroxyl group of cellulose, cleaning, and drying; and Step 2, impregnating the above modified cotton fabric into nano-silver sol, fixing nano-silver by complexation of mercapto group, drying, and cleaning to finally obtain the antibacterial cotton fabric. Particle size of nano-silver particles obtained is 20-60 nm. Sterilizing rates of escherichia coli and staphylococcus aureus both reach 100%. After 20 times of standard washing, sterilizing rate of escherichia coli and staphylococcus aureus is still maintained at 100%. The method of the invention has high safety to human body and is pollution-free to the environment. By the method, excellent performance of the cotton fabric is maintained. The method has practical application potential in antibacterial modification of cotton fabric.

Owner:ZHEJIANG SCI-TECH UNIV

Water repellent finishing agent and method for manufacturing moisture absorbing and sweat releasing jean fabric by using same

The invention relates to a water repellent finishing agent, which comprises the following components in percentage by mass: 50 to 80 percent of fluorine-containing emulsion, 10 to 30 percent of resin finishing agent, 5 to 20 percent of softening agent and 0.3 to 2 percent of thickening agent; and pH value buffer solution is added to adjust the pH value of the water repellent finishing agent to between 4 and 7. The invention also relates to a method for manufacturing moisture absorbing and sweat releasing jean fabric by using the water repellent finishing agent, which comprises the following steps: performing water repellent coating finishment on the inner side of the jean fabric by using the water repellent finishing agent; and not treating the outer side of the jean fabric to keep the hydrophilicity of cotton, wherein the water repellent coating finishment process comprises the steps of coating the inner side of the jean fabric, pre-drying, baking, and cooling and cloth falling; the pre-drying temperature is between 80 and 135DEG C, and the time is 1 to 150 minutes; and the baking temperature is between 110 and 170DEG C and the time is 2 to 10 minutes. By adopting the water repellent finishing agent and the method for manufacturing the moisture absorbing and sweat releasing jean fabric, common jean fibers can be manufactured into the moisture absorbing and sweat releasing jean fabric with good washing fastness and strong processability.

Owner:GUANGDONG JUNAN JEANS RES INST

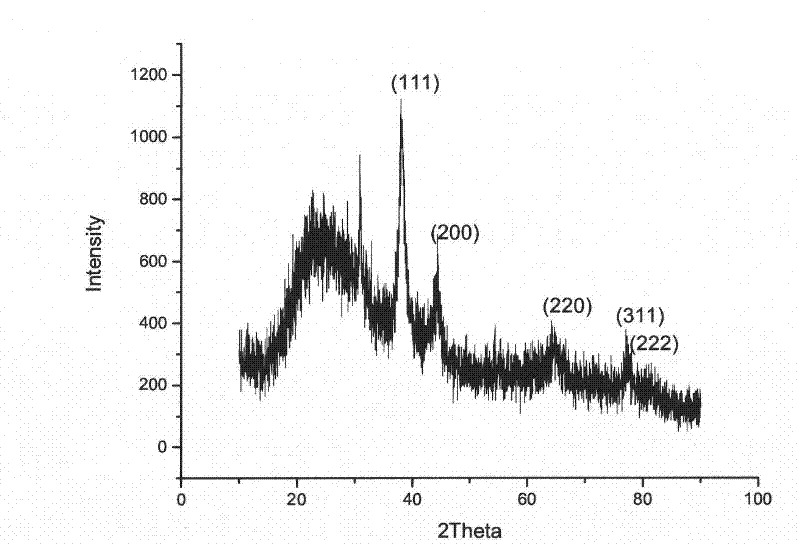

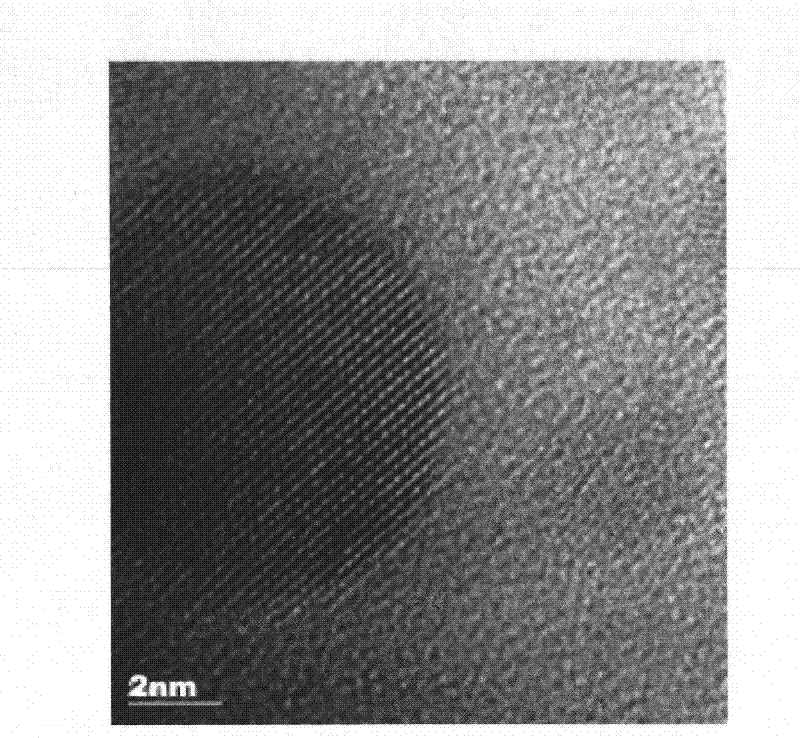

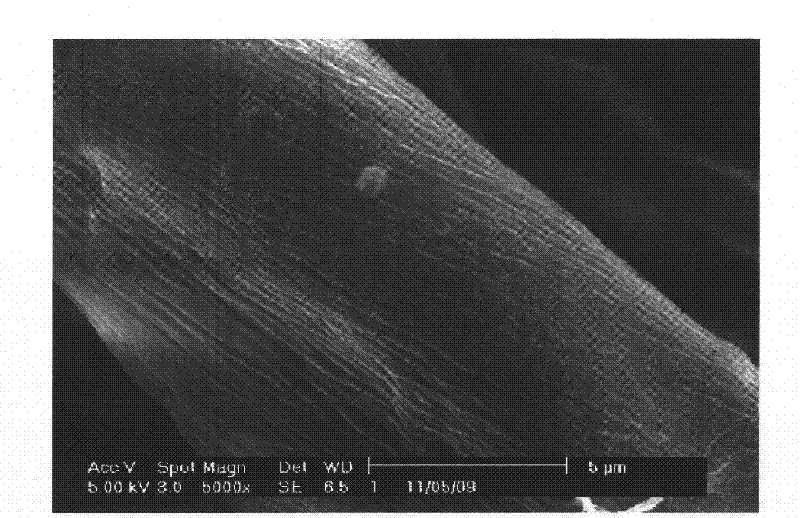

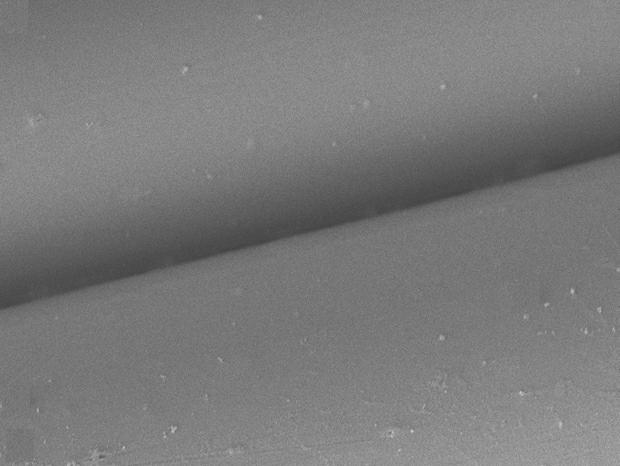

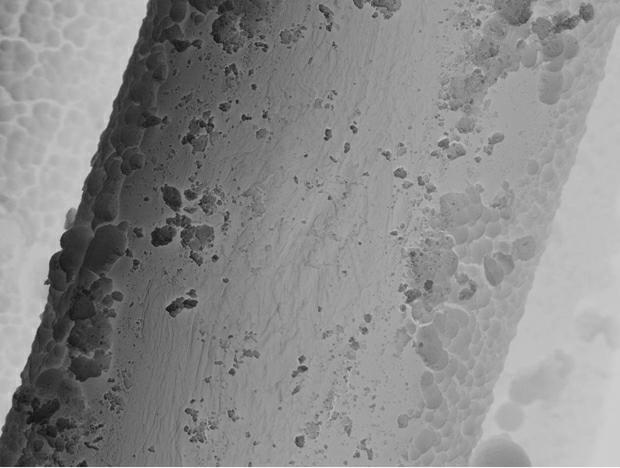

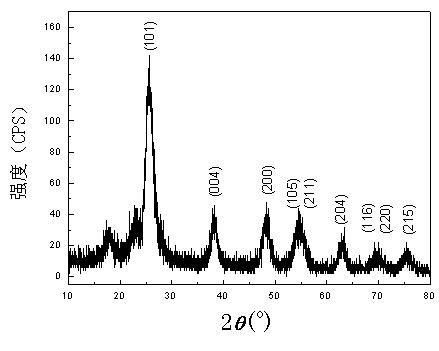

A kind of method that prepares nano titanium dioxide film on the surface of polyester fabric

InactiveCN102277723AImprove wash resistanceImproves UV resistancePhysical treatmentFibre typesPolyesterTitanium sulfate

The invention discloses a method for preparing a nano titanium dioxide thin film on the surface of a dacron. The method provided by the invention comprises the following steps of: firstly, ultrasonically vibrating and washing the dacron to be treated for 10-30 min at a temperature in a range of 60-90 DEG C by utilizing treating fluid under the conditions that the frequency is 28 kHz and the poweris 100 w; then drying the dacron for future use; secondly, utilizing titanium sulfate solution and urea solution to subject the dacron to a hydro-thermal reaction; finally, washing the dacron by utilizing the washing solution in the bath ratio of 1 to 30-50 for 15-30 min at a temperature of 100 DEG C; repeatedly washing the dacron by hot water and cold water and then drying to prepare the nano titanium dioxide thin film on the surface of the dacron. The method for preparing the nano titanium dioxide thin film on the surface of the dacron provided by the invention saves raw materials, is convenient for operating and has a good use effect; and the washing resistance of the modified dacron is obviously improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

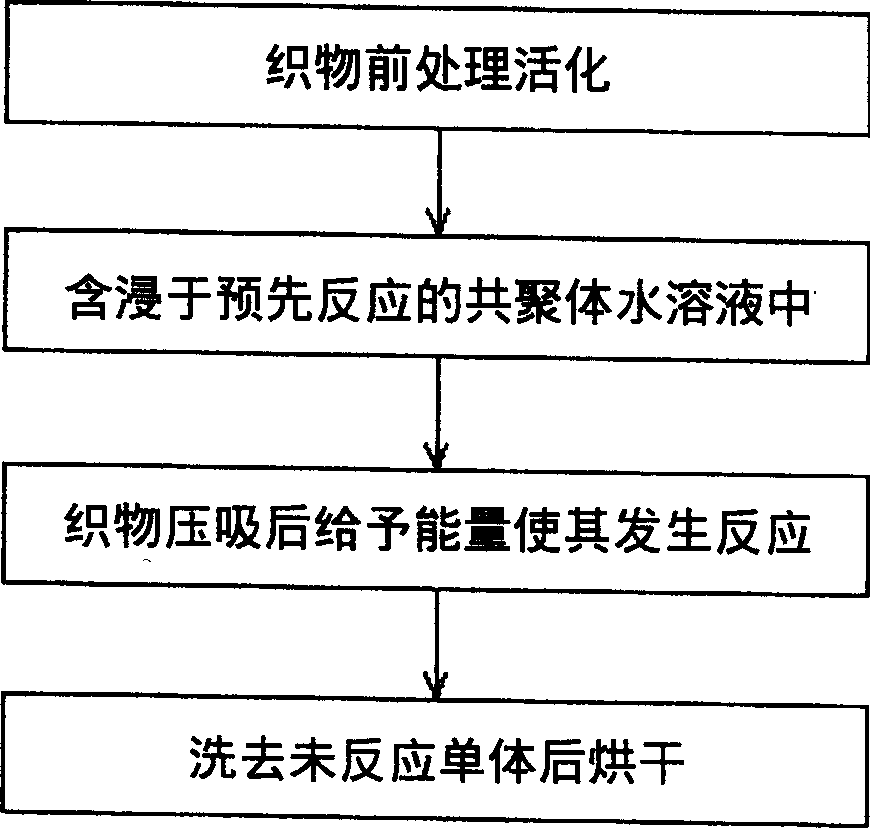

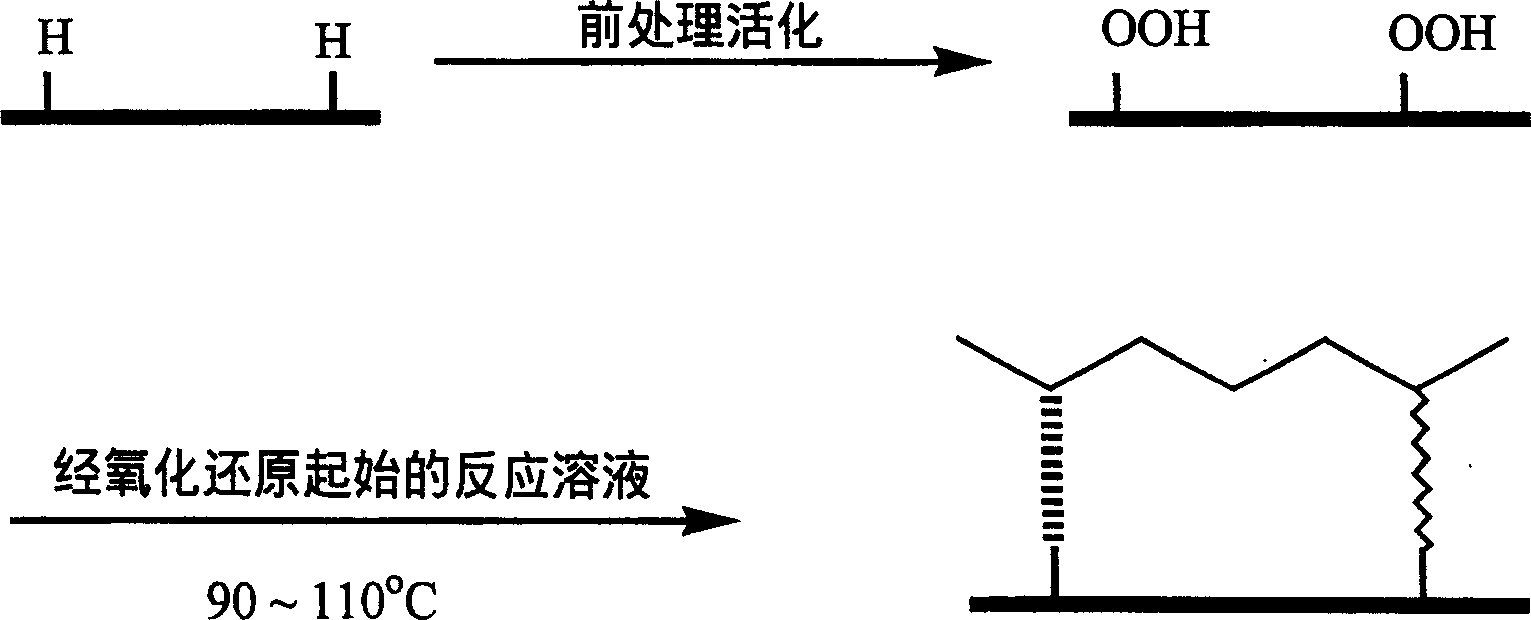

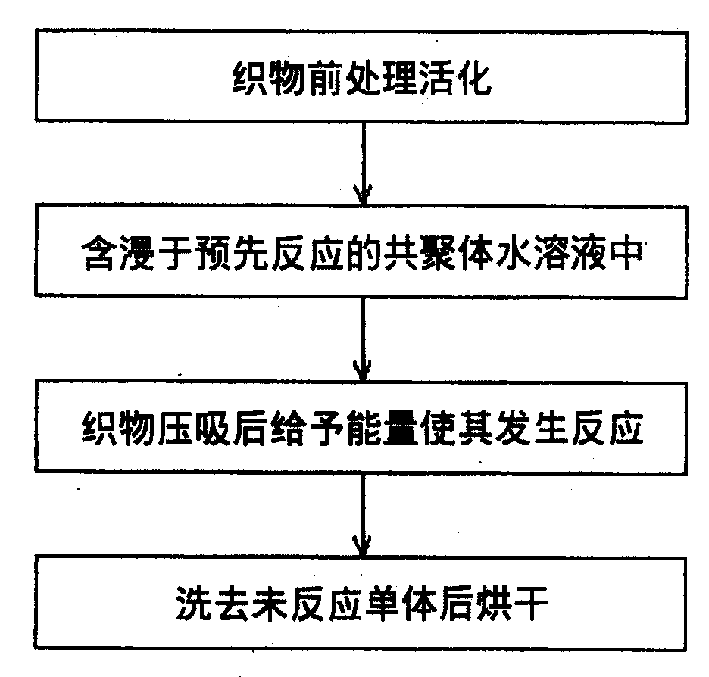

Method for manufacturing fabric with moisture absorption and sweat discharge performance

The invention relates to a method for making fabric having moisture absorbing and sweating property, which includes: pre-activating on the surface of the hydrophobic fabric; then taking grafting reactions with polyalcohol, natural polysaccharide and copolymer formed by unsaturated carboxylic acid with double bond and a covalent bond is formed.

Owner:IND TECH RES INST

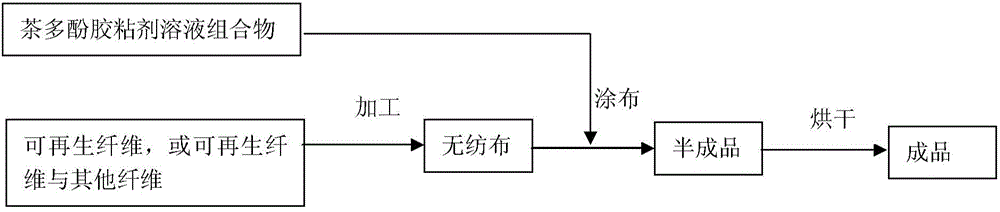

Antibacterial adhesive composition, antibacterial non-woven fabric, cleaning product and manufacturing method of antibacterial non-woven fabric

ActiveCN105331304AGood broad-spectrum antibacterial effectGood long-acting antibacterialNon-macromolecular adhesive additivesFibre treatmentGreen environmentAdhesive

The present invention provides an antibacterial adhesive composition, an antibacterial non-woven fabric, a cleaning product and a manufacturing method of the antibacterial non-woven fabric. The composition includes 10-40 wt% of a hydrophilic adhesive and 1-10% of tea polyphenol particles and water, calculated by the total weight of the composition. The invention provides a green environment-friendly antibacterial non-woven product with excellent broad-spectrum antibacterial and long-acting antibacterial properties and good durability.

Owner:3M INNOVATIVE PROPERTIES CO

Preparation method for shape thermo-sensitive hydro-gel material

The invention relates to a preparation method for a shape thermo-sensitive hydro-gel material. The method comprises the following steps: (1) carrying out vacuum drying on polyether glycol or polyester glycol, reducing temperature to 80-90 DEG C and then reacting with maleic anhydride MA for 4-6h, thereby obtaining a macromolecular diene compound; (2) by taking the macromolecular diene compound as a cross-linking agent, isopropyl acrylamide NIPAM as a functional monomer and an alkenyl compound containing hydroxyl or amido as a cross-linking reaction monomer, mixing the materials with an emulgator and an initiator and reacting for 6-8h at 70-80 DEG C, thereby obtaining the shape thermo-sensitive hydro-gel material. After the shape thermo-sensitive hydro-gel material provided by the invention is settled on a textile fabric, the autonomic regulation for the air permeability and water vapor permeability of the textile fabric under different temperature conditions can be realized, and then the initiative regulation for the moisture permeability, air permeability and heat insulating property of the textile fabric can be realized.

Owner:DONGHUA UNIV +1

Energy and water saving dyeing method for seamless underwear

ActiveCN102561070AReduce residual rateHigh whitenessBiochemical fibre treatmentBleaching apparatusWater savingOxygen

The invention relates to an energy and water saving dyeing method for a seamless underwear. A seamless weft knitting weaving technology is used for achieving one-off weaving forming of the seamless underwear. The dyeing and finishing process of the seamless underwear after being woven includes oxygen bleaching by the liquor ratio of 1: 8-10, dyeing by the liquor ratio of 1: 12-15 and soaping by the liquor ratio of 1: 8-10. By means of the energy-saving dyeing and finishing technology of non-caustic-soda oxygen bleaching process, one-bath one-step dyeing process and biological enzyme soaping process, one-time accurate dyeing is achieved, one-bath one-step completion is achieved, processing time is shortened, and sewage discharge and treatment are reduced.

Owner:GUANGDONG RUIYUAN TECH

Method for preparing photochromic fiber and photochromic fabric

The invention discloses a method for preparing photochromic fabric. The photochromic fabric is formed by interweaving of warps and wefts. The warps are photochromic fiber and polyester fiber blended yarn which comprises 45-65 wt% of photochromic fiber, the wefts are polyester fiber and cotton fiber blended yarn which comprises 45-65 wt% of polyester fiber, and the specification of the warps and the wefts is 100-135 dtex / 40F. The color of the photochromic fabric changes along with the change of the light condition, so that the fabric has more colors; besides, through pattern arrangement and color design during weaving, the situation that the style of a traditional set of printed home textiles is changeless is changed, and the aesthetic fatigue of consumers on the product is reduced.

Owner:LUOLAI LIFESTYLE TECH CO LTD +2

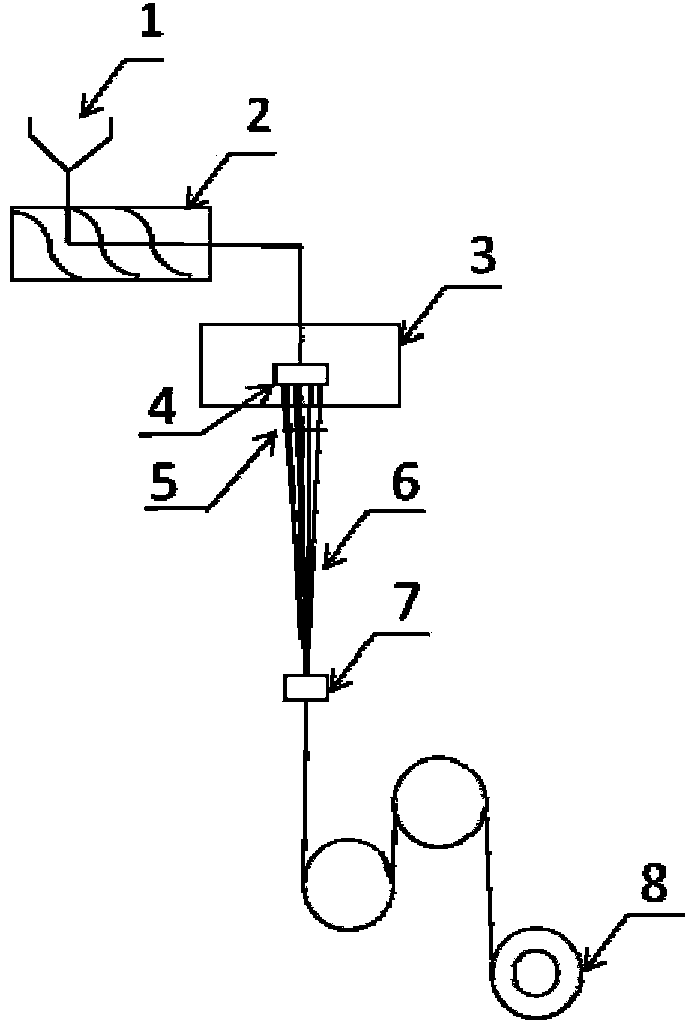

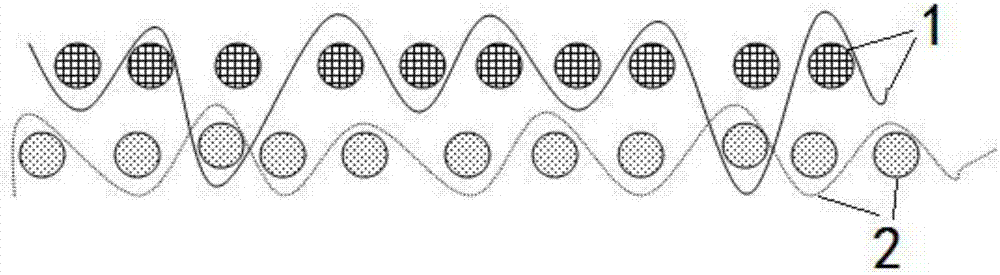

Antistatic and flame retardant copolyester fiber and preparation method thereof

ActiveCN104278349AExcellent overall performanceBroaden the field of applicationElectroconductive/antistatic filament manufactureFlame-proof filament manufactureFire retardantPolybutylene terephthalate

The invention belongs to the technical field of polymer materials, and relates to an antistatic and flame retardant copolyester fiber and a preparation method thereof. The copolyester fiber comprises the following components by weight: 100 parts of polybutylene terephthalate / polybutylene adipate, 1-5 parts of polyethylene glycol, 0.2-1.3 parts of an antistatic agent, 2-10 parts of a phosphorus based flame retardant and 0.1-4 parts of inorganic nano powder. The antistatic and flame retardant copolyester fiber has the strength no less than 2.58cN / dtex and the elongation at about 30%, is soft in hand feeling and good in antistatic property, flame retardant properties and mechanical properties, and has the widespread application prospect.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Double-layer flame-retardant fabric with water-repellent surface layer and hydrophil inner layer, and preparation technology thereof

InactiveCN106995965AHigh flame retardant and high temperature resistanceEasy to handleSynthetic resin layered productsHeating/cooling textile fabricsYarnSurface layer

The invention discloses double-layer flame-retardant fabric with a water-repellent surface layer and a hydrophil inner layer, and a preparation technology thereof. The double-layer flame-retardant fabric comprises the surface layer and the inner layer, wherein the surface layer is composed of at least one of aramid fibers, polyimide fibers, polysulfonamide fibers, flame-retardant viscose and ; the inner layer is formed by mixing flame-retardant modacrylic fibers with chloride, Tencel fibers and partner fibers, and the partner fiber is one selected from flame-retardant nylon fibers, aramid fibers and polysulfonamide fibers; water-repellency of the surface layer is implemented by the technology comprising the steps of preparing three proofing auxiliary size, soaking surface layer yarn into the three proofing auxiliary size, drying with high temperature, weaving and hot rolling with rollers; and water absorption of the inner layer is implemented by the technology comprising the steps of preparing hydrophil and sweat-releasing auxiliary size, soaking inner layer yarn into the size, drying, weaving and decating. The double-layer flame-retardant fabric with the water-repellent surface layer and the hydrophil inner layer has the characteristics of being soft, comfortable, air and moisture permeable and skin-friendly, has multifunctional protection performance, and meanwhile is high in comfort, so as to be applicable to special protection clothing in industries of firefighting, military police, electric power and smelting.

Owner:SHANGHAI IBENA TEXTILE PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com