A kind of method that prepares nano titanium dioxide film on the surface of polyester fabric

A technology of nano-titanium dioxide and polyester fabrics, which is applied to the surface treatment of polyester fabrics. In the field of preparing nano-titanium dioxide films on the surface of polyester fabrics, it can solve the problems of fabric hand feeling and poor washing resistance, and achieve excellent UV resistance and washing resistance. Improved performance and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

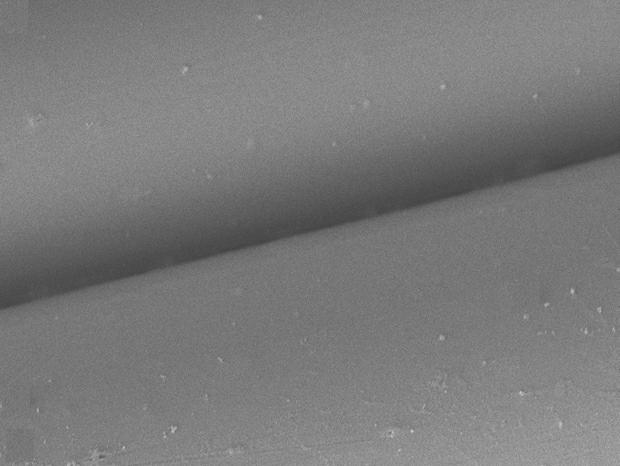

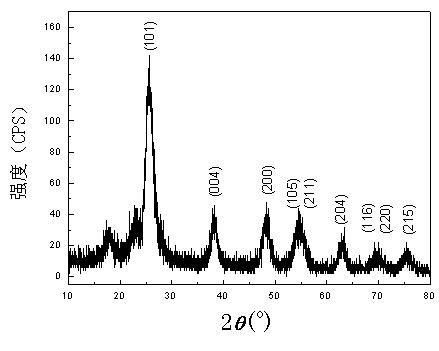

[0032] Weigh 4.8g of polyester fabric, 4.8g of titanium sulfate and 12g of urea respectively. The polyester fabric was washed with a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1 at a temperature of 60°C for 10 minutes under ultrasonic vibration at 28KHz and a power of 100W, and dried at 80°C. Weigh the silane coupling agent KH-560 according to 0.5% of the fabric mass, dissolve it in absolute ethanol and deionized aqueous solution with a volume ratio of 1:3, add polyester fabric and stir at 60°C for 1 hour, then Place it under a 25W ultraviolet lamp for 10 minutes, pre-bake at 80°C for 10 minutes, bake at 110°C for 20 minutes, and rinse once with deionized boiling water. Dissolve titanium sulfate and urea in 50ml of deionized water respectively, add the urea solution into the titanium sulfate solution and stir vigorously, then add the polyester fabric and soak for 5 minutes; put the polyester fabric together with the solution into a 200ml hi...

Embodiment 2

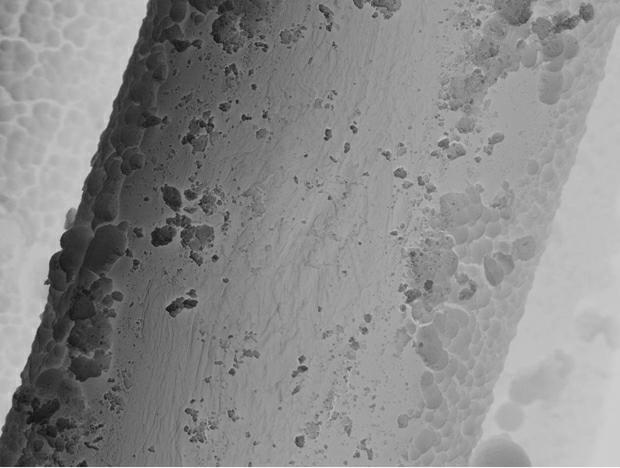

[0035] Weigh 4.8g of polyester fabric, 24g of titanium sulfate and 12g of urea respectively. The polyester fabric was washed with a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1 at a temperature of 80°C for 30 minutes under ultrasonic vibration at 28KHz and a power of 100W, and dried at 80°C. Weigh the silane coupling agent KH-560 according to 1.5% of the fabric mass, dissolve it in absolute ethanol and deionized aqueous solution with a volume ratio of 1:3, add polyester fabric and stir at 60°C for 3 hours, then Place it under a 25W ultraviolet lamp for 30 minutes, pre-bake at 80°C for 10 minutes, bake at 110°C for 20 minutes, and rinse with deionized boiling water for 3 times. Dissolve titanium sulfate and urea in 100ml and 50ml of deionized water respectively, add the urea solution into the titanium sulfate solution and stir vigorously, then add the polyester fabric to soak for 30min; put the polyester fabric together with the solution int...

Embodiment 3

[0038] Weigh 4.8g of polyester fabric, 15g of titanium sulfate and 12g of urea respectively. Polyester fabrics were washed with a mixed solution of deionized water and absolute ethanol with a volume ratio of 1:1 at a temperature of 70 ° C for 20 min under ultrasonic vibration at 28 KHz and a power of 100 W, and dried at 80 ° C. Weigh the silane coupling agent KH-560 according to 1.0% of the fabric mass, dissolve it in absolute ethanol and deionized aqueous solution with a volume ratio of 1:3, add polyester fabric and stir at 60°C for 2 hours, then Place it under a 25W ultraviolet lamp for 15 minutes, pre-bake at 80°C for 10 minutes, bake at 110°C for 20 minutes, and rinse twice with deionized boiling water. Dissolve urea and titanium sulfate in 50ml and 80ml of deionized water respectively, add the urea solution into the titanium sulfate solution and stir vigorously, then add the polyester fabric to soak for 20min; put the polyester fabric together with the solution into a hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com