Double-layer flame-retardant fabric with water-repellent surface layer and hydrophil inner layer, and preparation technology thereof

A technology for preparing flame-retardant fabrics, which is applied in the field of textile fabrics, can solve the problems of long production cycle, high processing cost, and high energy consumption, and achieve high flame-retardant and high-temperature resistance, permanent flame-retardant performance, and improved washing resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

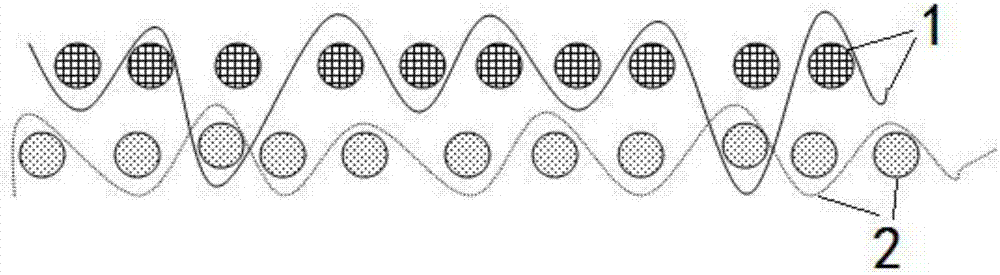

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of a double-layer flame-retardant fabric with water-repellent surface and water-absorbing inner layer

[0034]The surface layer of the double-layer fabric adopts 100% (wt) aramid fiber, and the inner layer adopts 30% (wt) flame-retardant acrylic fiber, 30% (wt) Tencel fiber, and 40% (wt) flame-retardant nylon fiber.

[0035] Water-repellent treatment and water-absorption treatment are respectively performed on the surface layer yarn and the inner layer yarn of the above-mentioned double-layer fabric. The finishing steps of surface yarn water-repellent treatment include: three-proof auxiliary agent preparation-surface layer yarn soaking-high temperature drying-reel, specifically, the following components are used for the three-proof auxiliary agent preparation: Fluorine-free water-repellent agent 60g / L, cross-linking agent 20g / L, glacial acetic acid 1.0g / L; yarn soaking time 3s; yarn baking time 2min, baking temperature 200°C. The finishing steps o...

Embodiment 2

[0037] Example 2 Preparation of a double-layer flame-retardant fabric with water-repellent surface and water-absorbing inner layer

[0038] The surface layer of the double-layer fabric adopts 50% (wt) aramid fiber and 50% (wt) polyimide fiber, and the inner layer adopts 30% (wt) flame-retardant acrylic fiber, 30% (wt) Tencel fiber, 40% (wt) aramid fiber.

[0039] Water-repellent treatment and water-absorption treatment are respectively performed on the surface layer yarn and the inner layer yarn of the above-mentioned double-layer fabric. The finishing steps of surface yarn water-repellent treatment include: three-proof auxiliary agent preparation-surface layer yarn soaking-high temperature drying-reel, specifically, the following components are used for the three-proof auxiliary agent preparation: Fluorine-free water repellent agent 80g / L, crosslinking agent 30g / L, glacial acetic acid 0.5g / L; yarn soaking time 5s; yarn baking time 1min, baking temperature 210°C. The finishi...

Embodiment 3

[0041] Example 3 Preparation of a double-layer flame-retardant fabric with water-repellent surface and water-absorbing inner layer

[0042] The surface layer of the double-layer fabric adopts 70% (wt) flame-retardant viscose fiber and 30% (wt) polybenzimidazole fiber, and the inner layer adopts 50% (wt) flame-retardant acrylic fiber and 20% (wt) Tencel fiber , 40% (wt) sulfonamide fibers.

[0043] Water-repellent treatment and water-absorption treatment are respectively performed on the surface layer yarn and the inner layer yarn of the above-mentioned double-layer fabric. The finishing steps of surface yarn water-repellent treatment include: three-proof auxiliary agent preparation-surface layer yarn soaking-high temperature drying-reel, specifically, the following components are used for the three-proof auxiliary agent preparation: Fluorine-free water repellent agent 70g / L, crosslinking agent 25g / L, glacial acetic acid 0.8g / L; yarn soaking time 1s; yarn baking time 1.5min, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com