Patents

Literature

72results about How to "Permanent Flame Retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature resistant flame-retarding textile

The invention aims to provide high-temperature resistant flame-retarding textile. The high-temperature resistant flame-retarding textile is weaved by high-temperature resistant flame-retarding yarns, and the high-temperature resistant flame-retarding yarns are blended with preoxidized fibers, high tenacity flame-retarding fibers and common flame-retarding fibers; and conducting fibers can also be used to weave the high-temperature resistant flame-retarding textile when the high-temperature resistant flame-retarding textile is prepared. The high-temperature resistant flame-retarding textile overcomes the drawback that the preoxidized fiber is difficultly spun, low in tenacity and only has single color of blackness; and the high-temperature resistant flame-retarding textile also has the advantages of high high-temperature resistance, high tenacity, good wearing comfortability, rich color, proper price and safety and reliability for the human body and is reasonable high-temperature resistant flame-retarding textile.

Owner:汕头市奥山服饰有限公司

High-strength stretch-proof flame-retardant textile

InactiveCN101748549ASolve the difficulty of weavingSolve not easy to dyeWoven fabricsYarnCompound aEngineering

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

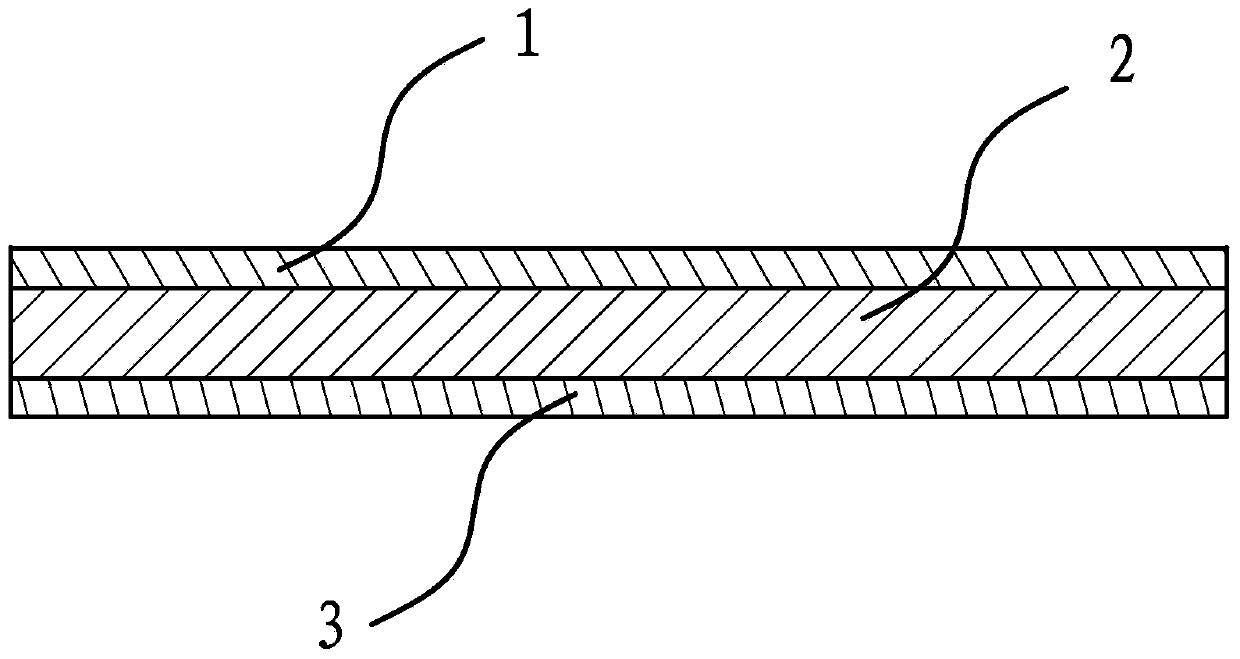

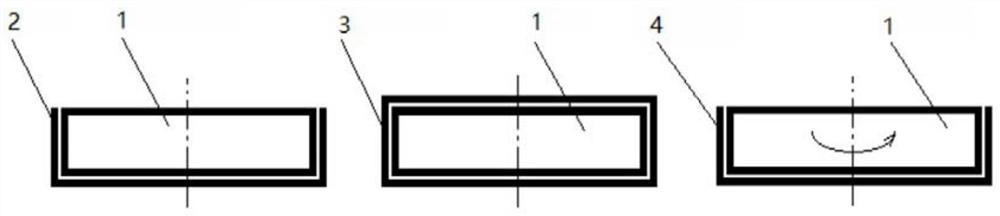

Preparation method of polyether material, polyether film and preparation method thereof

ActiveCN103627150AImprove stabilityEfficient responseSynthetic resin layered productsPhotovoltaic energy generationPolymer scienceHydrolysis

The invention relates to a preparation method of a polyether material, a polyether film and a preparation method thereof, belonging to the technical field of a polyether film for a backboard film of a solar battery. In order to solve the problem of bad flame retardance and humidity resistance of the existing polyether film, the invention provides a polyether film which comprises a surface layer I, a core layer and a surface layer II, wherein the core layer comprises a polyether chip and a master batch polyether chip, and the core layer also comprises a modified highly humidity-resistant flame-retardant polyether material which is prepared by the following steps: in the presence of a catalyst, performing an esterification reaction between pure terephthalic acid and dihydric alcohol; after the reaction, performing a pre-condensation polymerization reaction; when the intrinsic viscosity reaches 0.20-0.30g / dl, adding a reaction type phosphorus-based flame retardant, increasing the vacuum degree, and performing a condensation polymerization reaction; when the intrinsic viscosity reaches 0.50-0.65g / dl, adding a chain extender ADR and an anti-hydrolysis agent aromatic polycarbodiimide for a copolymerization reaction. Meanwhile, the polyether film has the advantages of high flame retardance and high humidity resistance.

Owner:浙江南洋科技有限公司

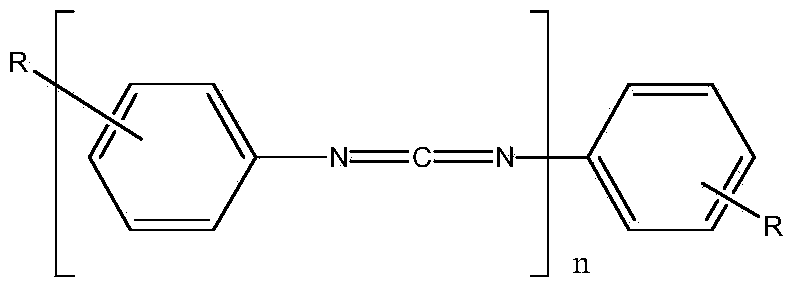

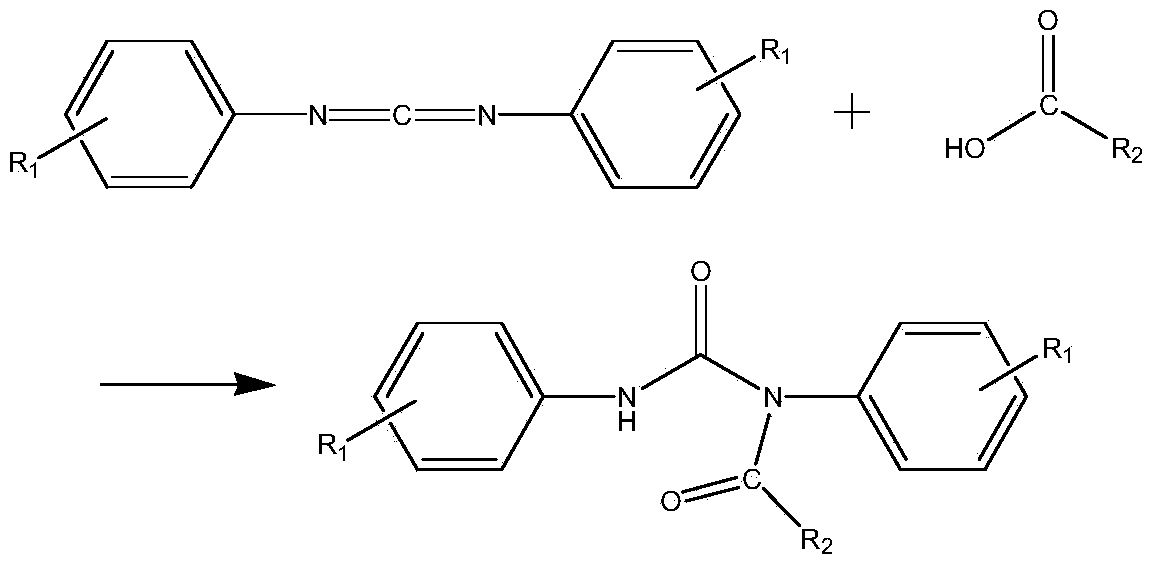

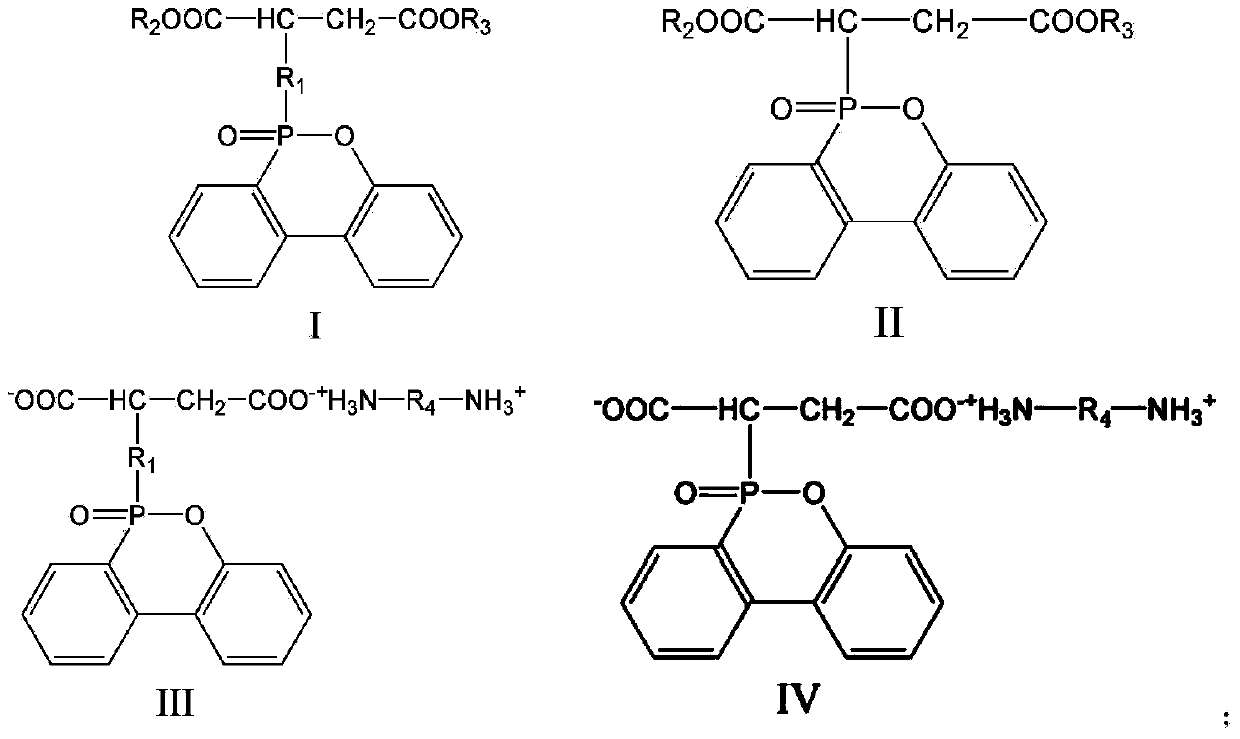

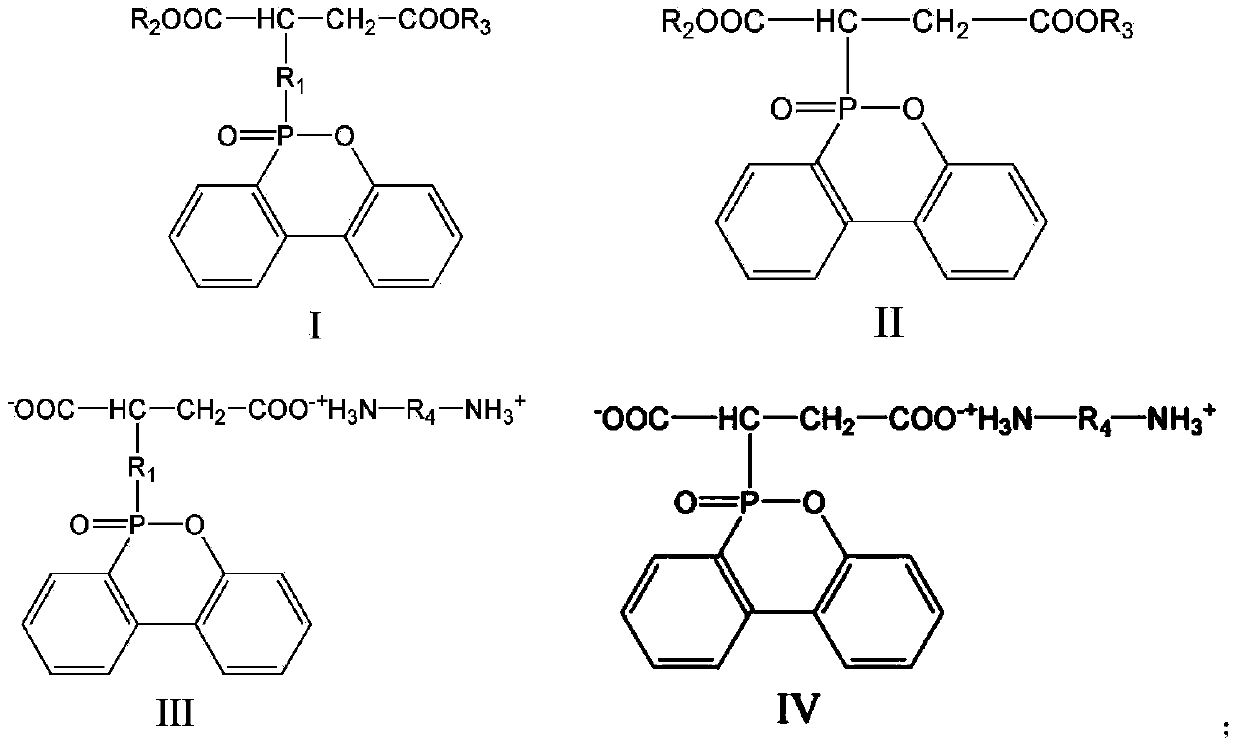

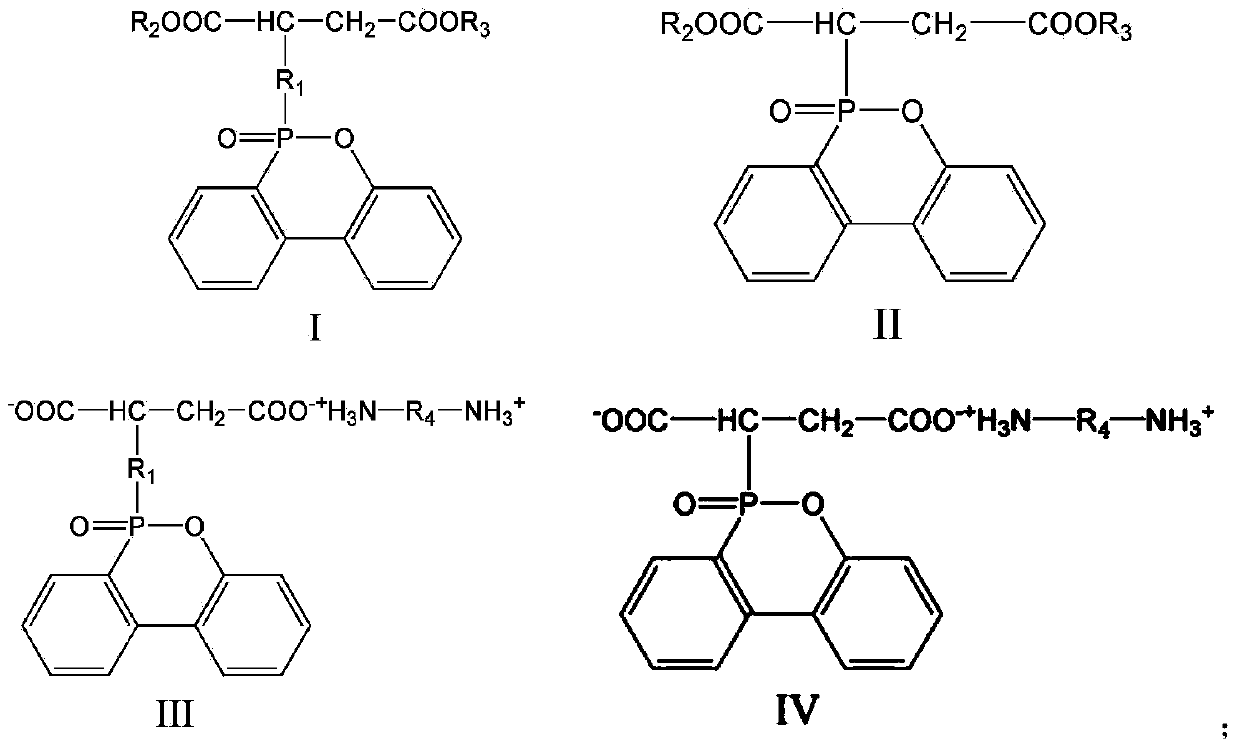

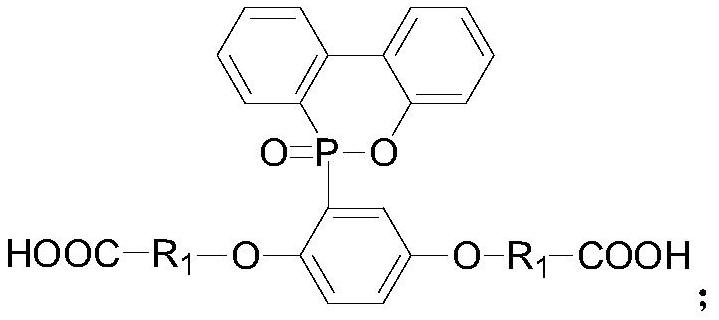

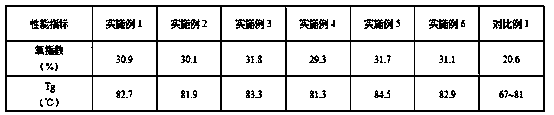

Nylon resin and preparation method thereof

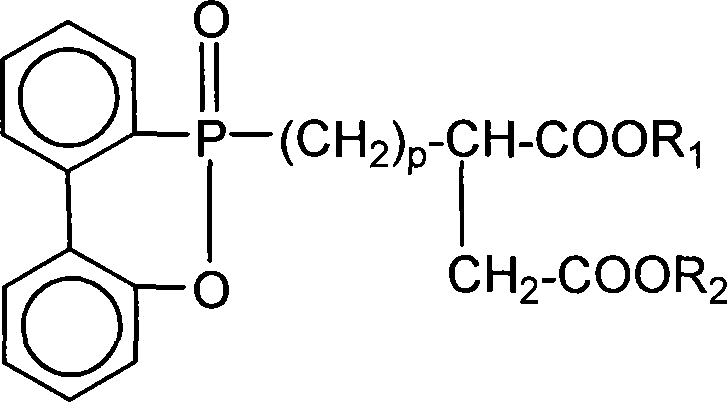

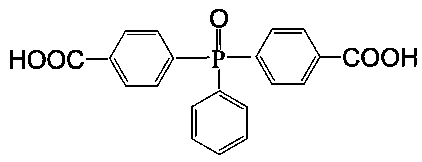

ActiveCN103694468ALittle effect of viscosityGood mechanical propertiesPolymer scienceCarboxyl radical

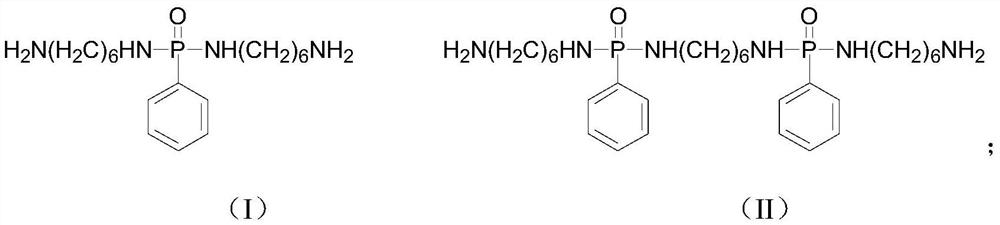

The invention provides a preparation method of nylon resin, which comprises the following steps of mixing a polymer monomer, a catalyst, a reaction type flame retardant and a charring agent, and performing a condensation polymerization reaction to obtain the nylon resin, wherein the polymer monomer is one or more of compounds containing amino and carboxyl and lactam, or the polymer monomer is diacid and diamine; the reaction type flame retardant is one or more of the compounds with the structures of formulas (I)-(IV). According to method provided by the invention, the reaction type flame retardant is a phosphorus-containing flame retardant; after being copolymerized with a monomer, the reaction type flame retardant is stably stored in the polymer without being transferred or lost and has a permanent flame retardant property. Moreover, the reaction type flame retardant is polymerized in a polymer, causes little influence on the viscosity of the nylon resin and has excellent mechanical properties.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Double-layer flame-retardant fabric with water-repellent surface layer and hydrophil inner layer, and preparation technology thereof

InactiveCN106995965AHigh flame retardant and high temperature resistanceEasy to handleSynthetic resin layered productsHeating/cooling textile fabricsYarnSurface layer

The invention discloses double-layer flame-retardant fabric with a water-repellent surface layer and a hydrophil inner layer, and a preparation technology thereof. The double-layer flame-retardant fabric comprises the surface layer and the inner layer, wherein the surface layer is composed of at least one of aramid fibers, polyimide fibers, polysulfonamide fibers, flame-retardant viscose and ; the inner layer is formed by mixing flame-retardant modacrylic fibers with chloride, Tencel fibers and partner fibers, and the partner fiber is one selected from flame-retardant nylon fibers, aramid fibers and polysulfonamide fibers; water-repellency of the surface layer is implemented by the technology comprising the steps of preparing three proofing auxiliary size, soaking surface layer yarn into the three proofing auxiliary size, drying with high temperature, weaving and hot rolling with rollers; and water absorption of the inner layer is implemented by the technology comprising the steps of preparing hydrophil and sweat-releasing auxiliary size, soaking inner layer yarn into the size, drying, weaving and decating. The double-layer flame-retardant fabric with the water-repellent surface layer and the hydrophil inner layer has the characteristics of being soft, comfortable, air and moisture permeable and skin-friendly, has multifunctional protection performance, and meanwhile is high in comfort, so as to be applicable to special protection clothing in industries of firefighting, military police, electric power and smelting.

Owner:SHANGHAI IBENA TEXTILE PROD

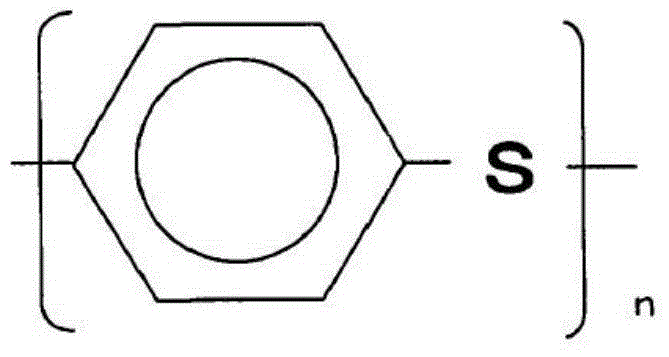

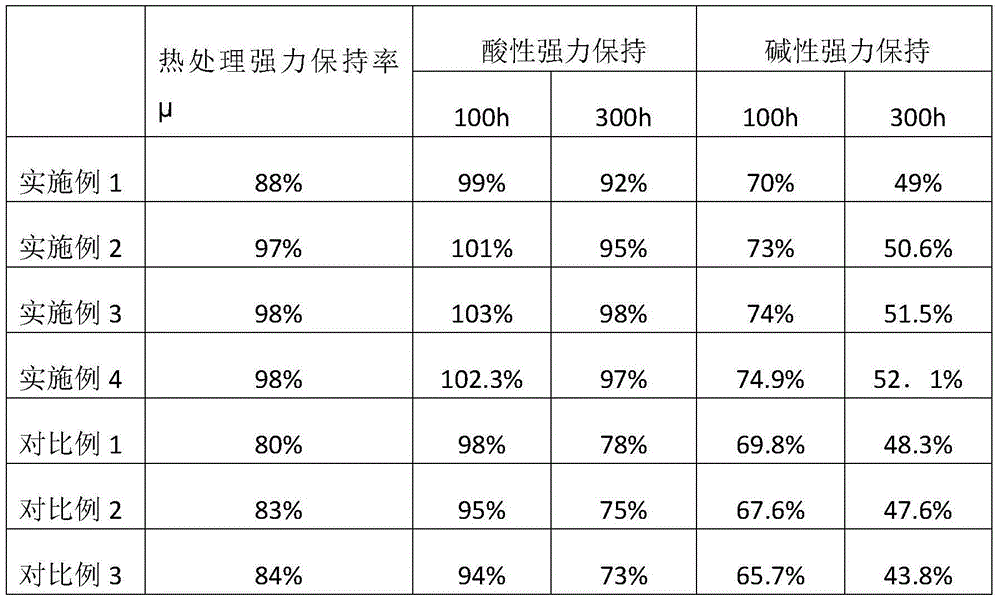

Material special for flame-retardant antistatic plastic flange and preparation method thereof

InactiveCN101817979AHigh temperature resistantCorrosion resistanceFlanged jointsFiberPolymer science

The invention relates to the field of organic plastic, in particular to a material special for a flame-retardant antistatic plastic flange and a preparation method thereof. The material consists of the following components in part by weight: 40 to 60 parts of polyphenylene sulfide resin, 10 to 40 parts of carbon fiber, 20 to 40 parts of glass fiber, 0.1 to 1 part of processing thermal stabilizer and 0.1 to 2 parts of processing lubricant. The preparation method thereof comprises the following steps of: uniformly mixing the polyphenylene sulfide resin, the processing thermal stabilizer and the processing lubricant; then adding the carbon fiber and the glass fiber into the mixture and melting and blending the mixture by using an extruder; and finally bracing, water-cooling, pelletizing and drying the obtained material so as to obtain the material special for the flame-retardant antistatic plastic flange. The plastic flange made of the material of the invention overcomes the defect of easy corrosion of a traditional metal flange, has permanent flame resistance, antistatic performance and high mechanical strength, and is suitable for connection of non-metal pipelines underground coal mine and in other combustible and explosive environments.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

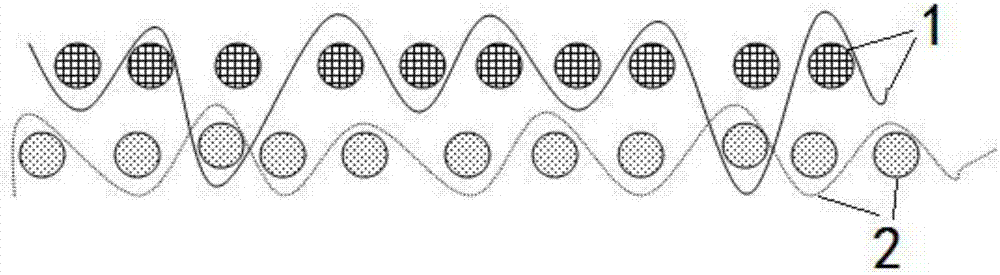

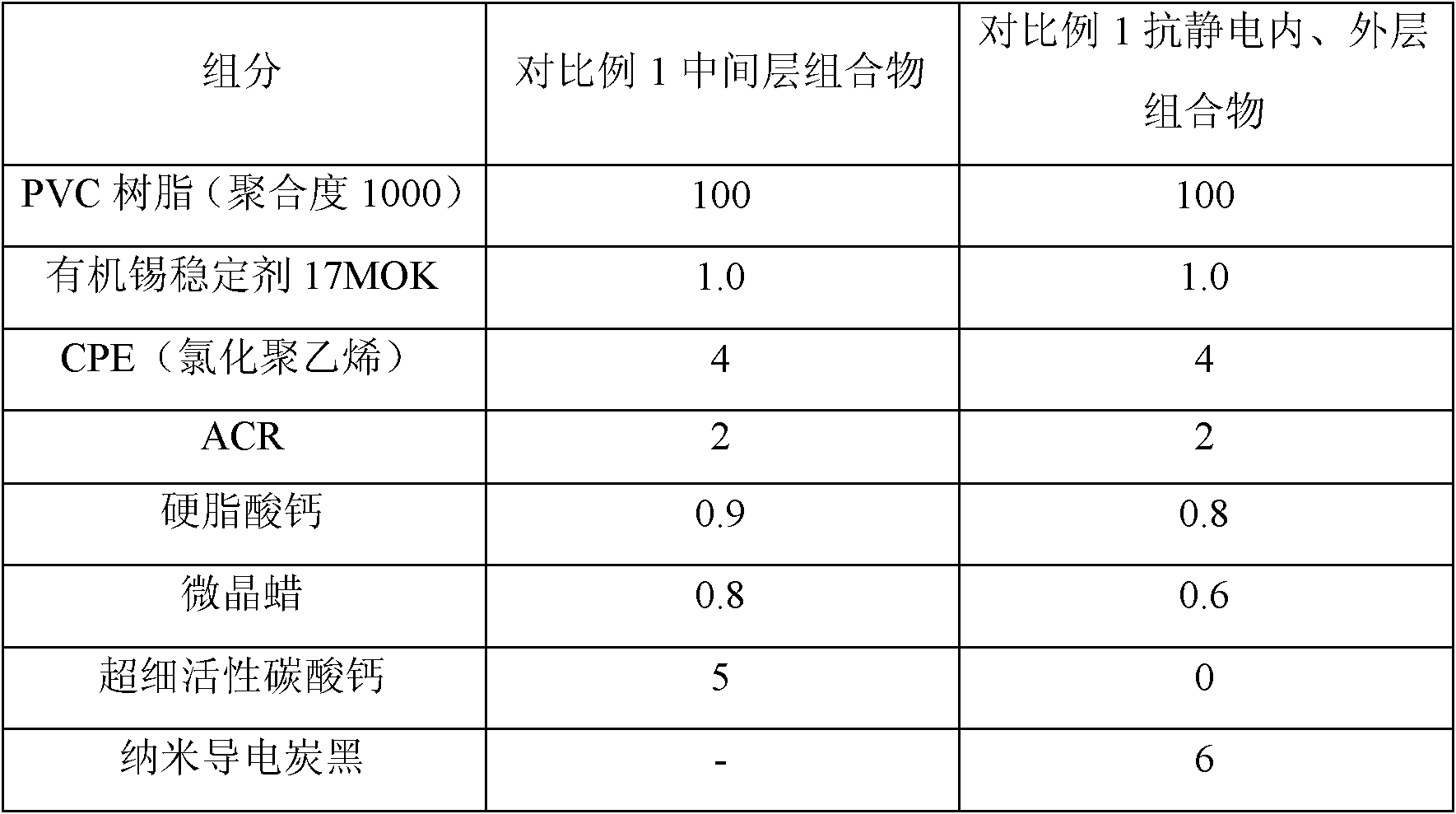

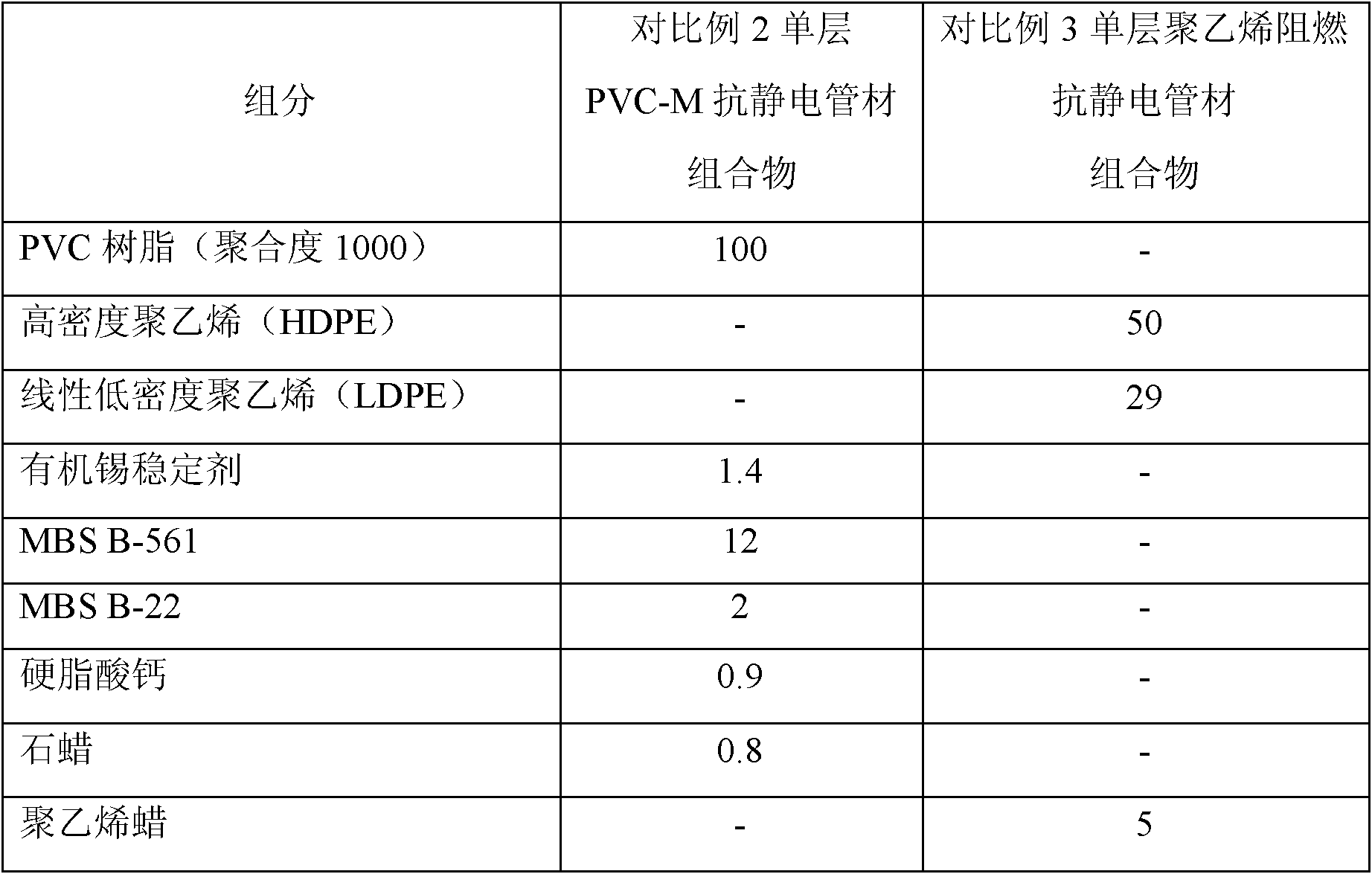

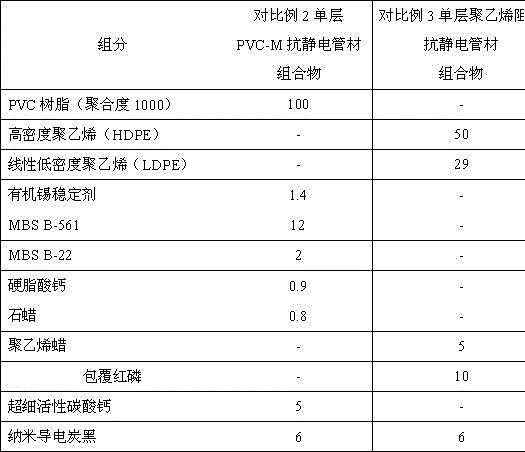

Three-layer co-extrusion PVC-M tubular product for coal mine

ActiveCN102863710AHigh strengthImprove the withstand voltage levelRigid pipesShock resistanceCo extrusion

The invention discloses a three-layer co-extrusion PVC-M tubular product for coal mine, characterized in that the tubular product comprises an antistatic inner layer, an antistatic outer layer and a PVC-M interlayer, wherein the antistatic inner and outer layer compositions comprise the following ingredients: 100 weight parts of PVC resin, 0.8-1.2 weight parts of heat stabilizer, 4-8 weight parts of toughening agent, 1.3-2.0 weight parts of lubricating agent, 5-10 weight parts of flow modifier, and 6 weight parts of nano conductive carbon black; the PVC-M interlayer composition comprises the following ingredients: 100 weight parts of PVC resin, 1.0-1.5 weight parts of heat stabilizer, 10-15 weight parts of toughening agent, 2.1-3.5 weight parts of lubricating agent, and 0-5 weight parts of filling agent. According to the invention, the composition of the tubular product has high strength, the shock resistance of the tubular product can be comparable to that of polyethylene antistatic tubular products for coal mine, the modulus reaches to 2231MPa, the tensile strength reaches to 46.3Mpa, the impact strength of the simple-supported beam reaches to 97.6Mpa, the mechanical property shows toughness and balance and permanent antistatic property, thus the requirements of the tubular product for coal mine are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP

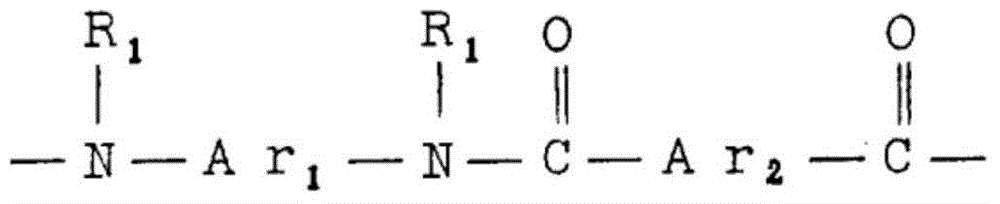

Yarn and fabric made of polyphenylene sulfide fibers and blended fibers based on aromatic polyamide and Astrel 360 and production method of yarn and fabric

ActiveCN104630957AImprove high temperature resistanceImprove heat resistanceWeft knittingSynthetic resin layered productsPolyamideYarn

The invention relates to flame-retardant yarn made of polyphenylene sulfide fibers and blended fibers based on aromatic polyamide and Astrel 360, fabric and garments made of the yarn, and production method of the yarn, the fabric and the garments. The yarn comprises the polyphenylene sulfide fibers (A) and blended fibers (B) based on aromatic polyamide and Astrel 360. The blended fibers comprises 40-98wt% of aromatic polyamide and 2-60wt% of Astrel 360, and the aromatic polyamide and the Astrel 360 are blended. The yarn is excellent in high temperature resistance and chemical resistance and widely applicable to high-temperature work environments with chemical corrosion.

Owner:中芳新材料有限公司

Flame-retardant anti-static two-faced plush cloth

ActiveCN105019119APermanent Flame RetardancyImprove thermal protection performanceWeft knittingYarnModacrylic

The invention discloses flame-retardant anti-static two-faced plush cloth which is formed by blending the following components in parts by weight: 50-60 parts of modacrylic, 30-40 parts of cotton, 5-15 parts of nylon and 1-3 parts of conductive wires. The two-faced plush cloth includes a first surface and a second surface, wherein both the first surface and the second surface are formed by blending and weaving modacrylic fibers and cotton fibers; the first surface and the second surface are connected with each other through polyamide yarns and the conductive wires; the polyamide yarns are arranged parallel to the conductive wires, the distance between adjacent polyamide yarns is 0.08-0.15 cm, and the distance between adjacent conductive wires is 0.8-1.2 cm. The two-faced plush cloth is knitted fabric and has the characteristics that the cloth is resistant to high temperature, non-combustible, free of molten drops, soft, comfortable and good in heat retention property, and does not lose plush.

Owner:上海俊首安防科技有限公司 +1

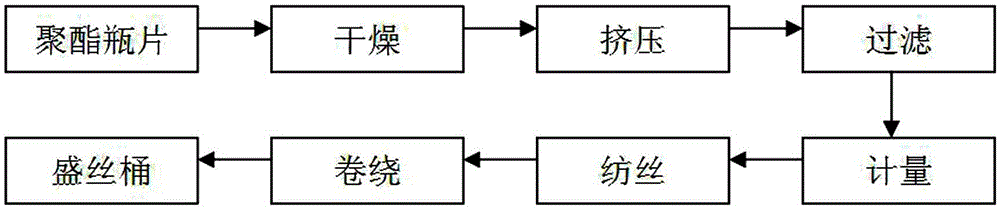

Dope dyed flame retardant polyester fibers, textle products therefrom and the method of manufacturing thereof

ActiveCN101084331APermanent Flame RetardancyIncreased durabilityFlame-proof filament manufactureFilament/thread formingFiberPolyester

The present invention relates to dope dyed flame retardant polyester fibers, textile products therefrom, and the method of manufacturing thereof. The polyester fiber comprises flame retardant polyester polymers containing 500 - 50,000ppm of phosphorus-based flame retardant agent based on phosphorus atom, and 500 5,000ppm of carbon black based on said polyester polymers. The polyester fibers can provide excellent fastness and flame retardant characteristic without occurring hazardous, materials such as a dioxin during an incineration, and can be applied for fiber products such as blackout curtain having an effective light shielding.

Owner:HYOSUNG CORP

Fire-resistant fiber fabric and preparation method thereof

The invention discloses a fire-resistant fiber fabric and a preparation method thereof. The fabric comprises broken filaments, central filaments and base filaments; the mass ratio of the broken filaments to the fabric is 50-80%, and the mass ratio of the central filaments and the base filaments to the fabric is 20-50%, wherein the broken filaments adopt polyester fibers of 120-150 D, the central filaments and the base filaments adopt fire-resistant fibers, and the fabric is woven by utilizing a two-needle-bar 288 / 292 warp knitting machine. According to the fire-resistant fiber fabric and the preparation method thereof, the fabric adopts the fire-resistant fibers and the polyester fibers, is woven by utilizing five guide bars, and has the permanent fire resistance, reduction of the fire resistance caused by the times of washing does not occur, and the fabric also has the characteristic of soft hand feeling.

Owner:CHANGSHU XINXIN WARP & KNITTING

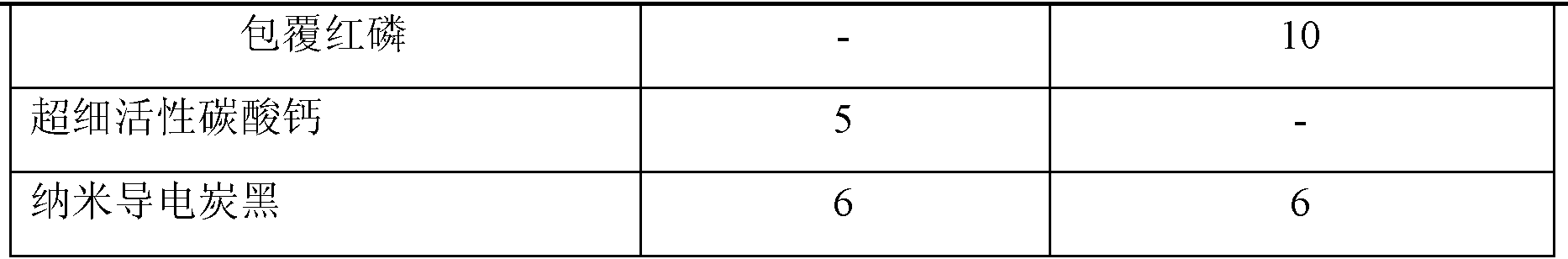

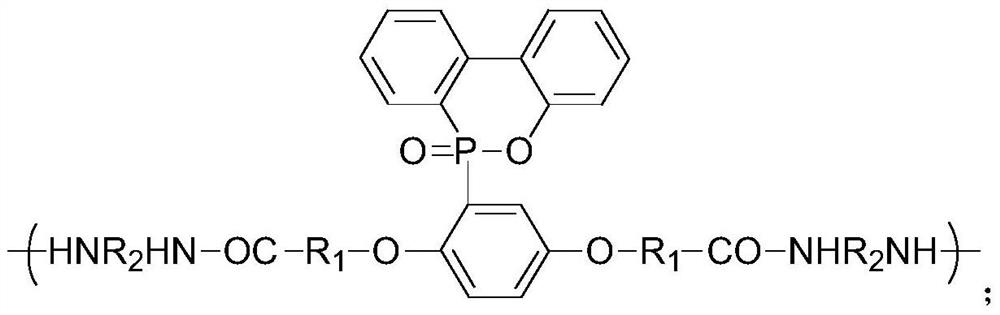

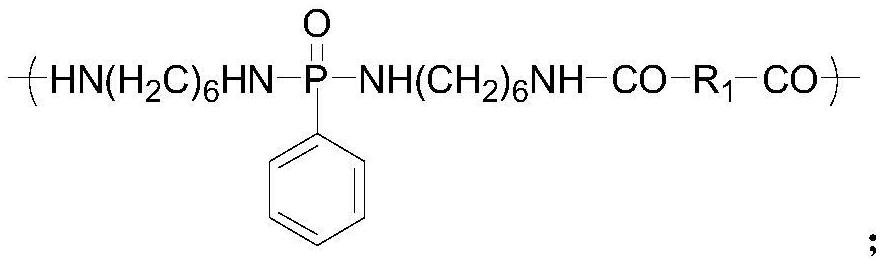

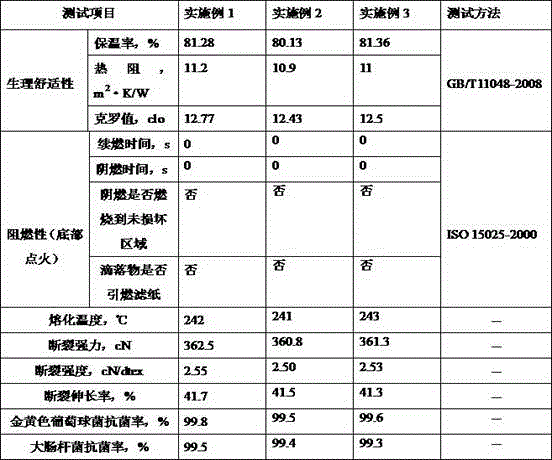

Copolymerized flame-retardant polyamide fiber and preparation method thereof

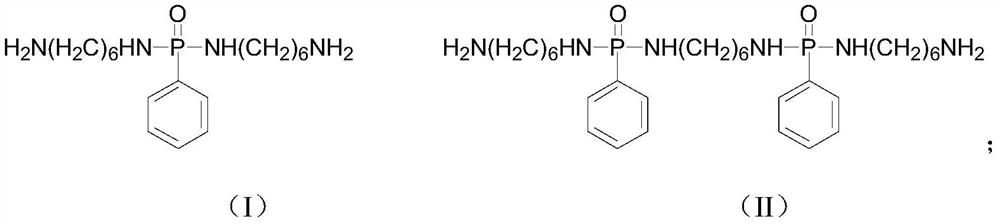

ActiveCN112048779APermanent Flame RetardancyHigh reactivityElectroconductive/antistatic filament manufactureMonocomponent copolyamides artificial filamentPolymer scienceSpinning

The invention relates to a copolymerized flame-retardant polyamide fiber and a preparation method thereof. The preparation method comprises the following steps that a flame-retardant polyamide copolymer serves as all or part of spinning raw materials for spinning to obtain the copolymerized flame-retardant polyamide fiber, wherein the flame-retardant polyamide copolymer is prepared by mixing a flame retardant salt with a polyamide 66 oligomer and / or a polyamide 6 oligomer and then carrying out condensation polymerization, the flame retardant salt is prepared from N,Ndi (6aminohexyl) phenyl phosphoramide and binary acid HOOCR1COOH through a high-temperature and high-pressure reaction, the temperature of the high temperature is 210-220 DEG C, and the pressure of the high pressure is 1.7-1.9MPa, and the main material of the finally prepared copolymerized flame-retardant polyamide fiber is the flame-retardant polyamide copolymer. The preparation method is simple to operate, the flame-retardant polyamide copolymer is excellent in flame retardance and good in spinnability, and the prepared copolymerized flame-retardant polyamide fiber is a functional fiber with flame retardance and canbetter meet the requirements of the fields of medical treatment and public health, professional clothing, clothing home textiles and the like in modern life on the flame-retardant polyamide fiber.

Owner:DONGHUA UNIV

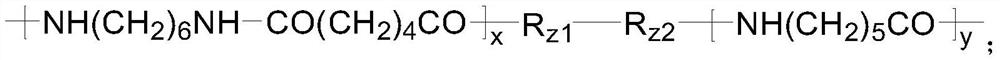

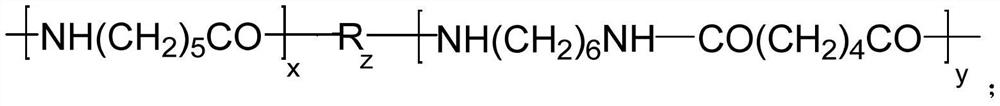

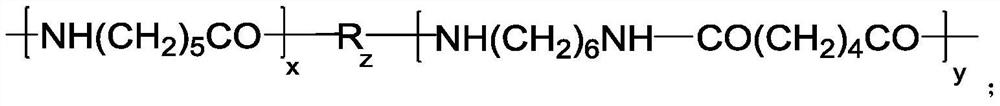

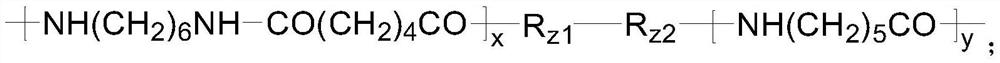

Copolymerized flame-retardant polyamide and preparation method thereof

The invention relates to copolymerized flame-retardant polyamide and a preparation method thereof. The preparation method comprises the following steps: mixing a flame retardant salt with a polyamide6 oligomer and / or a polyamide 66 oligomer, and carrying out condensation polymerization to obtain copolymerized flame-retardant polyamide. The flame retardant salt is prepared from a DOPO derivative and diamine NH2R2NH2 through a high-temperature and high-pressure reaction. The temperature of the high temperature is 200-250 DEG C, and the pressure of the high pressure is 1.2-1.8 MPa. The structural formula of the finally obtained copolymerized flame-retardant polyamide is as follows. In the structural formula, x is the polymerization degree of the polyamide 6 oligomer, y is the polymerizationdegree of the polyamide 66 oligomer, and the structural formula of Rz is as follows. The preparation method disclosed by the invention is simple to operate, and the prepared product has excellent flame retardance, good impact resistance and processability.

Owner:DONGHUA UNIV

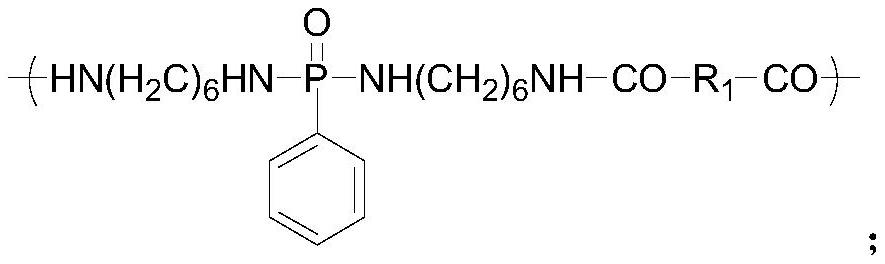

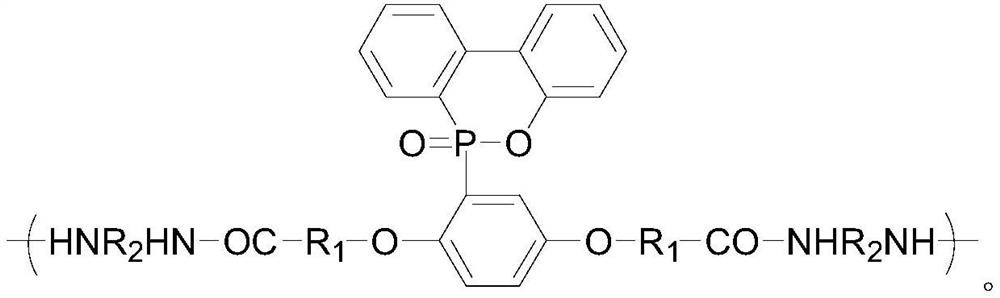

Copolymerized flame-retardant polyamide fiber and preparation method thereof

ActiveCN112144141APermanent Flame RetardancyHigh reactivityArtifical filament manufactureMonocomponent polyamides artificial filamentPolymer scienceSpinning

The invention relates to a copolymerized flame-retardant polyamide fiber and a preparation method thereof. The preparation method comprises the following steps of spinning by taking a flame-retardantpolyamide copolymer as all or parts of spinning raw materials to obtain the copolymerized flame-retardant polyamide fibers, wherein the flame-retardant polyamide copolymer is prepared by mixing a flame retardant salt with a polyamide 6 oligomer and / or a polyamide 66 oligomer and then carrying out a condensation polymerization reaction, the flame retardant salt is prepared from a DOPO derivative and diamine NH2R2NH2 through a high-temperature and high-pressure reaction, the temperature of the high temperature is 200-250 DEG C, the pressure of the high pressure is 1.2-1.8 MPa, and the main material of the finally prepared copolymerized flame-retardant polyamide fiber is the flame-retardant polyamide copolymer. The preparation method disclosed by the invention is simple to operate, the flame-retardant polyamide copolymer is excellent in flame retardance and good in spinnability, and the prepared copolymerized flame-retardant polyamide fiber is a functional fiber with flame retardance andcan better meet the requirements of the fields of medical treatment and public health, professional clothing, clothing home textiles and the like in modern life of the flame-retardant polyamide fiber.

Owner:DONGHUA UNIV

Permanent flame retardant anti-static light color fabric and preparation method thereof

The invention provides a permanent flame retardant anti-static light color fabric and a preparation method thereof. The fabric is prepared from, by mass, 97%-99% of raw materials and 1%-3% of electrically conductive filament; the raw materials comprise aramid fiber 1313 fiber accounting for 70%-80% by mass of the raw materials, aramid fiber 1414 fiber accounting for 5%-10% by mass of the raw materials and flame retardant polyester fiber accounting for 10%-20% by mass of the raw materials. Accordingly, the excellent anti-static property and permanent flame retardant property of the fabric are achieved, the appearance is improved, and wearing is comfortable.

Owner:CONCORDIA ADVANCED FABRICS SUZHOU

Antistatic PVC (Polyvinyl Chloride) pipe

InactiveCN106700318AImprove the withstand voltage levelHigh withstand voltage levelDrilling rodsSynthetic resin layered productsPolyvinyl chlorideEngineering

The invention discloses an antistatic PVC (Polyvinyl Chloride) pipe. The antistatic PVC pipe is characterized by comprising an antistatic inner layer, an antistatic outer layer and a PVC-M middle layer, wherein the composition of the antistatic inner layer and the antistatic outer layer comprises the following components in parts by weight: 100 parts of PVC resin, 0.8-1.2 parts of a heat stabilizer, 4-8 parts of an impact-resistant modifying agent, 1.3-2.0 parts of a lubricant, 5-10 parts of a processing aid and 6 parts of nano-conductive carbon black; and the composition of the PVC-M middle layer comprises the following components in parts by weight: 100 parts of PVC resin, 1.0-1.5 parts of a heat stabilizer, 10-15 parts of an impact-resistant modifying agent, 2.1-3.5 parts of a lubricant and 1.5 parts of filler. The composition of the antistatic PVC pipe disclosed by the invention has the advantages that the strength is higher, the impact resistance can be comparable with that of a polyethylene antistatic coal mine pipe, the modulus reaches 2231MPa, the tensile strength reaches 46.3MPa, the impact strength value of simply supported beams reaches 97.6MPa, the mechanical property is balanced in rigidity and toughness, the permanent antistatic property is achieved, and the requirements for pipes for coal mines are met.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

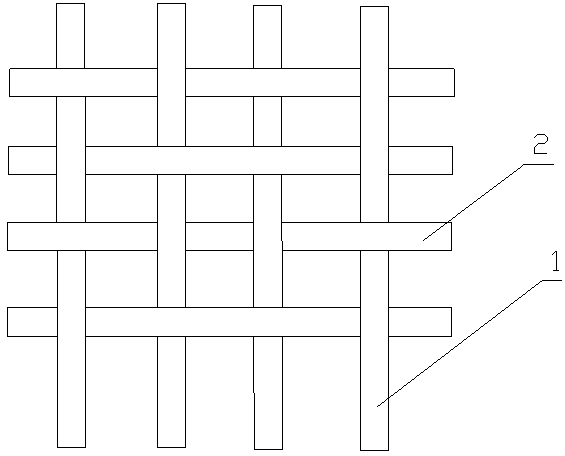

Flame retardant fabric

InactiveCN102851841ANo irritating smellPermanent Flame RetardancyWoven fabricsPolymer sciencePolymer chemistry

The invention discloses flame retardant fabric which is interwoven by warps and wefts according to a certain pattern. The warps are perpendicular to the wefts. The warps are made of cotton yarn. The wefts are made of flame retardant polyester filament yarn. The flame retardant fabric is soft, comfortable and breathable, and has permanent flame retardancy and no pungent smell.

Owner:NANTONG WULIAN BRAND PLANNING

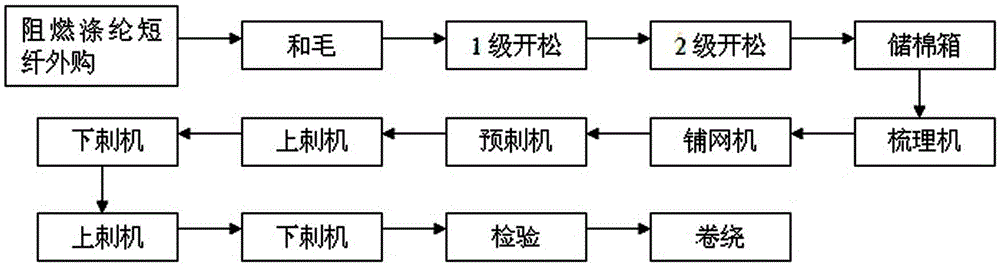

Flame retardant nonwoven needle-punched exhibition carpet

InactiveCN105401241APermanent Flame RetardancyHigh strengthFlame-proof filament manufactureArtificial filament physical treatmentPolyesterNeedle penetration

The invention provides a flame retardant nonwoven needle-punched exhibition carpet. The carpet uses colored polyester staple fibers which are environmentally friendly, have permanent flame retardation effects and are special for the carpet; the flame resistance meets the flame retardation requirement of a national floor paving material, the fineness is 2.2-13.2Dtex, and the length is 32-64mm; the fibers are woven into a piece of flame retardant grey cloth by a nonwoven needle-punching device, and a heat setting is carried out by using a baking oven. The flame retardant nonwoven needle-punched exhibition carpet has a permanent flame retardation effect, the high temperature fixing is carried out for the flame retardant nonwoven needle-punched prey cloth by the continuous tentering type high temperature baking oven, so that the prepared flame retardant nonwoven needle-punched exhibition carpet has the advantages of high-strength, high wear resistance and environmental protection.

Owner:诺奥(福建)环保家居用品有限公司

Insulation aramid fiber felt with high-temperature resistance and preparation method of insulation aramid fiber felt

ActiveCN106958078AGood securityGood physical and mechanical propertiesNon-woven fabricsLinear densityWoven fabric

The invention discloses insulation aramid fiber felt with high-temperature resistance and a preparation method of the insulation aramid fiber felt. The insulation aramid fiber felt with high-temperature resistance comprises at last two layers of aramid fiber 1313 non-woven fabric prepared from aramid fibers 1313, every two adjacent layers of the aramid fiber 1313 non-woven fabric are subjected to spunlace composition, and the linear density of the aramid fibers 1313 is 2D or 1.5D. Compared with the prior art, the insulation aramid fiber felt with high-temperature resistance has permanent flame retardance and is good in safety, physical and mechanical property and insulativity and aging-resistant.

Owner:X FIPER NEW MATERIAL CO LTD

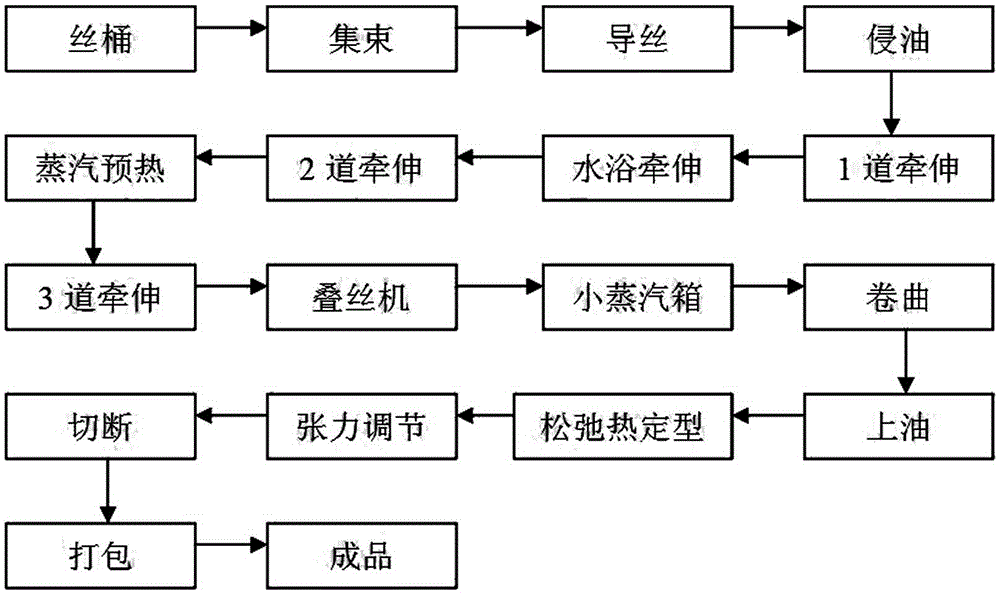

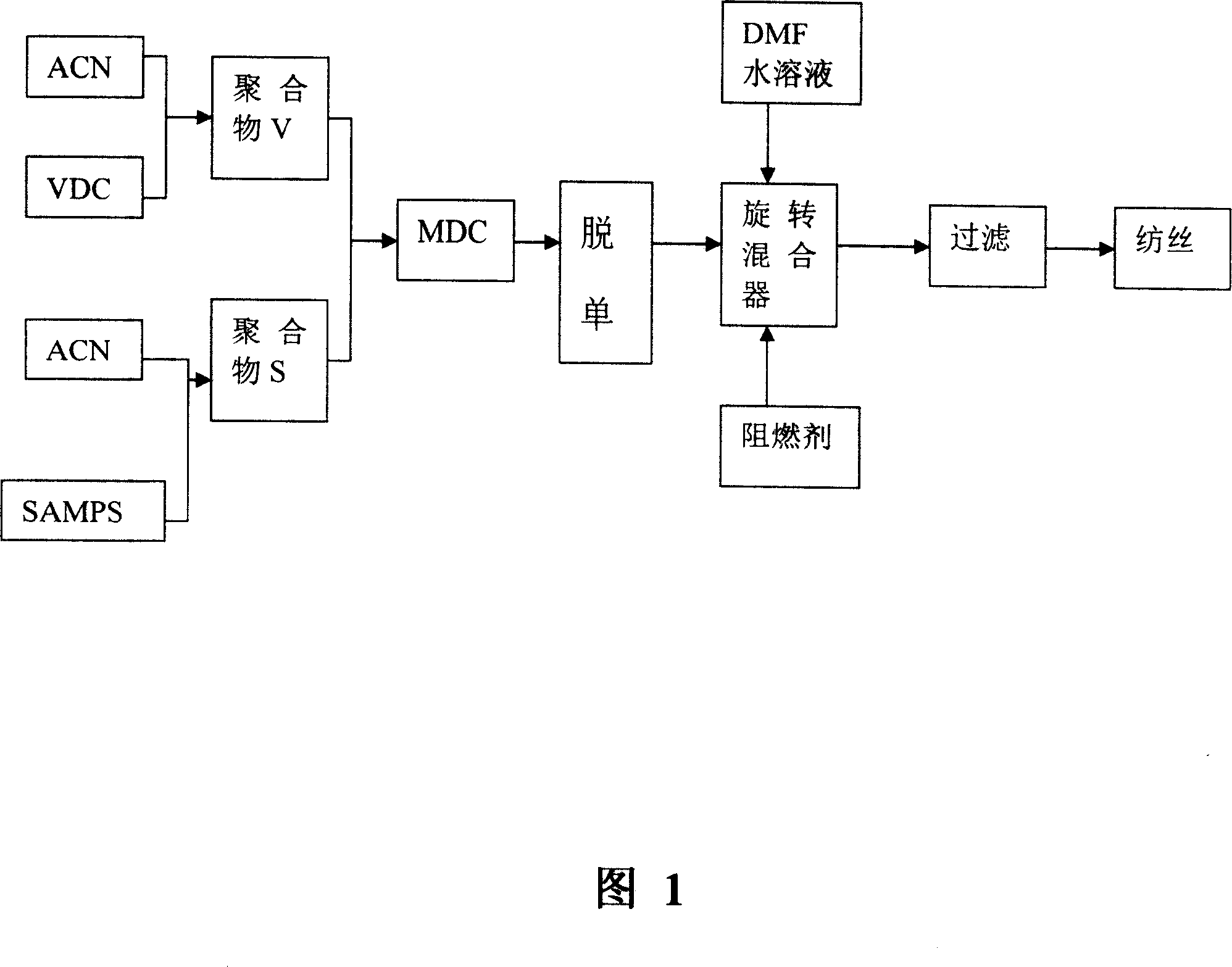

Flame retardant polyacrylic and polyester fiber and its production process

InactiveCN101021018AHigh whitenessImprove dyeing effectFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentFiberPolyester

The present invention discloses one kind of flame retardant polyacrylic and polyester fiber and its production process. The production process includes adding antimony pentoxide colloid solution and dimethyl formamide water solution into the polymerized solution, filtering and spinning to produce flame retardant polyacrylic and polyester fiber containing flame retardant antimony pentoxide. By means of the synergistic flame retarding effect of antimony and chlorine, the present invention has greatly raised flame retardant performance, limiting oxygen index up to 30-34 % and excellent comprehensive performance. The present invention may find its wide application in different fields, especially in flame retardant fabric.

Owner:抚顺惠抚阻燃纤维有限公司

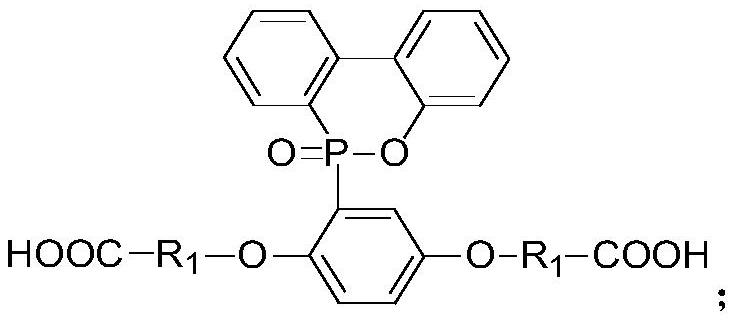

Copolymerized flame-retardant polyamide and preparation method thereof

The invention relates to copolymerized flame-retardant polyamide and a preparation method thereof. The preparation method comprises the following steps: mixing a flame retardant salt with a polyamide66 oligomer and / or a polyamide 6 oligomer, and carrying out condensation polymerization to obtain copolymerized flame-retardant polyamide; wherein the flame retardant salt is prepared from N, Ndi (6aminohexyl) phenyl phosphoramide and binary acid HOOCR1COOH through a high-temperature and high-pressure reaction; wherein the temperature of the high temperature is 210-220 DEG C, and the pressure of the high pressure is 1.7-1.9 MPa; wherein in the structural formula, x is the polymerization degree of the polyamide 66 oligomer, y is the polymerization degree of the polyamide 6 oligomer, and the structural formula of Rz1 is as follows: the structural formula of Rz2 is as follows: the preparation method disclosed by the invention is simple to operate, and the prepared product has excellent flameretardance, good impact resistance and processability.

Owner:DONGHUA UNIV

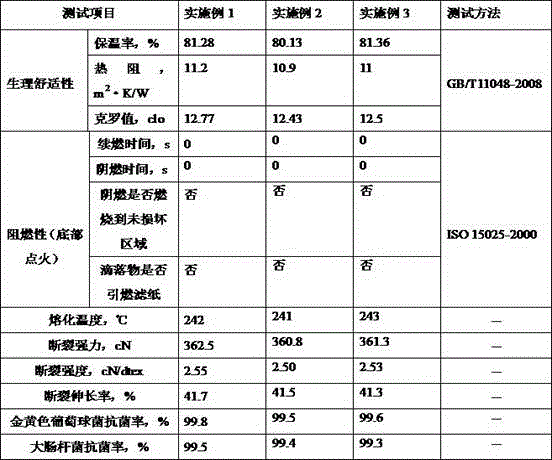

Flame-retardant and antibacterial polyester fiber for mattress filling and manufacturing method of fiber

ActiveCN105603560AExcellent Antimicrobial and ComfortGood warmth retention and mildew resistanceFlame-proof filament manufactureFibre typesPolyesterAnti bacterial

The invention relates to flame-retardant and antibacterial polyester fiber for mattress filling and a manufacturing method of the fiber, and belongs to the technical field of polyester fiber fillers. The manufacturing method of the flame-retardant and antibacterial polyester fiber for mattress filling comprises the steps of step I, raw material treatment; step II, PET resin modification; step III, polyester fiber modification; step IV, loosening. According to the flame-retardant and antibacterial polyester fiber for mattress filling and the manufacturing method of the fiber, blending modification of nano-montmorillonite, nano silica micro powder, HAPCP and PET resin is adopted, the polyester fiber with permanent flame retardant performance is prepared, and then the polyester fiber is endowed with excellent antibacterial property and comfort through immersion treatment of treating fluid. Besides, the flame-retardant and antibacterial polyester fiber for mattress filling has excellent heat retention property, mildew resistance and antibacterial activity, and at the same time, the mechanical property of the polyester fiber is improved greatly.

Owner:福建亿泰隆化纤股份有限公司

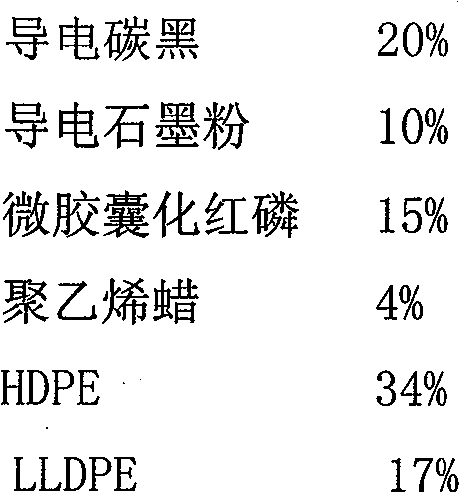

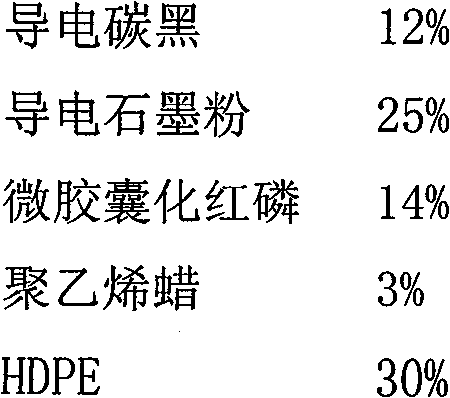

Flame-proof antistatic master material and production method thereof

The invention relates to a fire retarding antistatic masterbatch, comprising the following weight proportions of ingredients: 20 percent to 80 percent of carrier, 4 percent to 20 percent of fire retardant, 15 percent to 50 percent of antistatic agent and 3 percent to 20 percent of dispersant. The ingredients are prepared into the fire retarding antistatic master batch by pressurizing and kneadingor through a preparation method of double screw extrusion. The preparation method is characterized in that: 1. a convenient post processing of master batch and a good operation environment are available; 2. the dispersivity of the fire retardant and the antistatic agent are improved with good fire retardance and antistatic property of the products; 3. the product has permanent fire retardance andantistatic property; 4. the compound antistatic agent has certain synergy and low seepage threshold value; and 5. the adding quantity of the retarding agent is small, with little hazard smoke. The fire retarding antistatic masterbatch is prepared by pressurizing and kneading or by double screw granulation, and the products produced from the masterbatch has the advantages of permanent high conductivity, excellent retardance, little burning smoke, and comparatively low cost.

Owner:宁波市江北成达色母粒有限公司

Method for preparing melamine formaldehyde resin/polyvinyl alcohol flame-proof fiber

InactiveCN100516325CImprove spinnabilityIncrease productivityFlame-proof filament manufactureWet spinning methodsPolymer scienceMelamine formaldehyde resin

The invention discloses a manufacturing method of melamine-formaldehyde resin / polyvinyl alcohol flame-retardant fiber, which is characterized in that melamine-formaldehyde resin is synthesized at a temperature of 50-100° C. in an aqueous solution of melamine-formaldehyde resin at a molar ratio of 1:1.2 to 1:6. , mixed with polyvinyl alcohol aqueous solution according to the solid content ratio of 2:8 to 8:2 to obtain spinning stock solution, which is formed by conventional wet spinning, and the coagulation bath adopts acidic saturated sodium sulfate aqueous solution. The melamine-formaldehyde resin / polyvinyl alcohol flame-retardant fiber is obtained after the as-spun fiber is stretched, damp-heat-set, washed, crimped, oiled, dried, and dry-heat-set. The fineness of the flame-retardant fiber is 3-10dtex, the strength is 1-3cN / dtex, the elongation at break is 5%-15%, the moisture regain is 5-10%, and the limiting oxygen index is 30-45.

Owner:SICHUAN UNIV +1

Flame-retardant and antibacterial polyester fiber for mattress filling and production method thereof

ActiveCN105603560BPermanent Flame RetardancyImprove antibacterial propertiesFlame-proof filament manufactureFibre typesPolyesterFiber

The invention relates to flame-retardant and antibacterial polyester fiber for mattress filling and a manufacturing method of the fiber, and belongs to the technical field of polyester fiber fillers. The manufacturing method of the flame-retardant and antibacterial polyester fiber for mattress filling comprises the steps of step I, raw material treatment; step II, PET resin modification; step III, polyester fiber modification; step IV, loosening. According to the flame-retardant and antibacterial polyester fiber for mattress filling and the manufacturing method of the fiber, blending modification of nano-montmorillonite, nano silica micro powder, HAPCP and PET resin is adopted, the polyester fiber with permanent flame retardant performance is prepared, and then the polyester fiber is endowed with excellent antibacterial property and comfort through immersion treatment of treating fluid. Besides, the flame-retardant and antibacterial polyester fiber for mattress filling has excellent heat retention property, mildew resistance and antibacterial activity, and at the same time, the mechanical property of the polyester fiber is improved greatly.

Owner:福建亿泰隆化纤股份有限公司

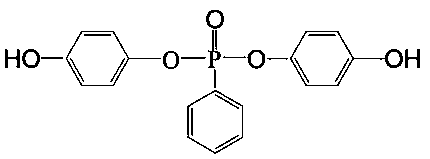

Flame-retardant copolyester material for automobile interior trim, and preparation method of flame-retardant copolyester material

ActiveCN109467687AGood effectPermanent Flame RetardancyPolymer sciencePolyethylene terephthalate glycol

The invention relates to the technical field of flame-retardant automobile interior trim materials, and provides a flame-retardant copolyester material for automobile interior trim, and a preparationmethod of the flame-retardant copolyester material. The method is characterized in that phosphorous flame retardants with rigid chains, namely bis(4-hydroxyphenyl)phenylphosphine oxide and bis(4-carboxyphenyl)phenylphosphine oxide, are prepared as flame-retardant monomers to copolymerize with an ethylene terephthalate prepolymer, terephthalic acid andethylene glycol, and thus the flame-retardant copolyester material is prepared. The prepared flame-retardant copolyester material provided by the invention has a good and lasting flame-retardant effect; and compared with a pure polyethylene terephthalate material, the glass transition temperature is increased, so that the flame-retardant copolyester material is suitable for being used as an automobile interior trim material.

Owner:银金达(上海)新材料有限公司

Batch processing method of flame-retardant cellulose staple fiber and obtained flame-retardant cellulose staple fiber

InactiveCN111005220BHigh strengthImprove flame retardant performanceHeat resistant fibresVegetal fibresPolymer scienceSpinning

Owner:山东芦氏阻燃纤维科技有限公司 +1

Yarn and fabric made of polyphenylene sulfide fibers and aromatic polymer fibers containing sulphone and production method of yarn and fabric

ActiveCN104630960AImprove high temperature resistanceImprove heat resistanceSynthetic resin layered productsMonocomponent copolyamides artificial filamentDicarboxylic acidPolymer science

The invention relates to flame-retardant yarn made of polyphenylene sulfide fibers and aromatic polymer fibers containing sulphone, fabric and garments made of the yarn, and a production method of the yarn, the fabric and the garments. The yarn comprises the polyphenylene sulfide fibers (B) and the aromatic polymer fibers (A) containing sulphone. The aromatic polymer fibers (A) containing sulphone is made of aromatic polymer containing sulphone. The aromatic polymer containing sulphone is polymerized by meta-position aromatic monomer (a) containing diamino, monomer (b) containing sulphone and amino and para-position aromatic monomer (c) containing dicarboxylic acid groups or yl halide (c) of the para-position aromatic monomer. The sulphone accounts for 4-10% in the aromatic polymer. The yarn is good in high temperature resistance and chemical resistance and widely applicable to high-temperature work environments with chemical corrosion.

Owner:中芳新材料有限公司

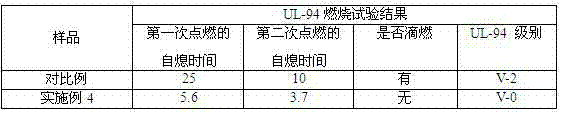

Antistatic flame-retardant PE plastic pipe

The invention provides an antistatic flame-retardant PE plastic pipe, which comprises the following raw materials (by mass): 90-110 parts of polyethylene, 5-10 parts of EVA resin, 5-15 parts of conductive graphite powder, 25-35 parts of a fire retardant, 1-5 parts of a flame retardant synergist, 0.1-1.5 parts of a coupling agent, 2-5 parts of an antioxidant, 1-2 parts of an assistant antioxidant,0.1-1.5 parts of an antistatic agent, 1-8 parts of a synergist, 0.1-1.5 parts of a dispersant, 1-6 parts of hollow glass beads, 2-4 parts of talcum powder and 2-6 parts of a stabilizing agent. The surface resistance of the conductive PE plastic pipe is stably controlled to be less than or equal to 1*105 omega, the flame retardant grade reaches V0 grade, and permanent antistatic and flame-retardanteffects are achieved.

Owner:江苏神达管阀件有限公司

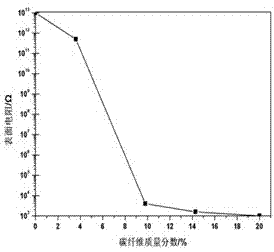

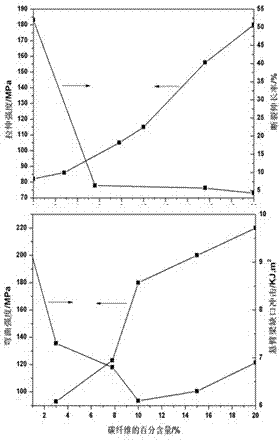

Environment-friendly and flame-proof nylon 66 with high conductivity and preparation method thereof

InactiveCN102766329AImprove mechanical propertiesImprove flame retardant performanceFiberPolymer science

An environment-friendly and flame-proof nylon 66 with high conductivity and a preparation method thereof. The environment-friendly and flame-proof nylon 66 with high conductivity is prepared by carrying out high-speed mixing on a nylon 66 resin, carbon fiber filament, a phosphorus nitrogen flame retardant, a coupling agents, an antioxidant and processing agent according to a proportion, and sending the mixture into an extruder for extrusion. The nylon 66 invention obtained by the invention has obviously improved mechanical properties as well as good flame retardance and permanent antistatic performance.

Owner:昆山聚威工程塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com