Three-layer co-extrusion PVC-M tubular product for coal mine

A co-extrusion, PVC resin technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as poor antistatic properties, and achieve good market application prospects, permanent antistatic properties and flame retardant properties , The effect of strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

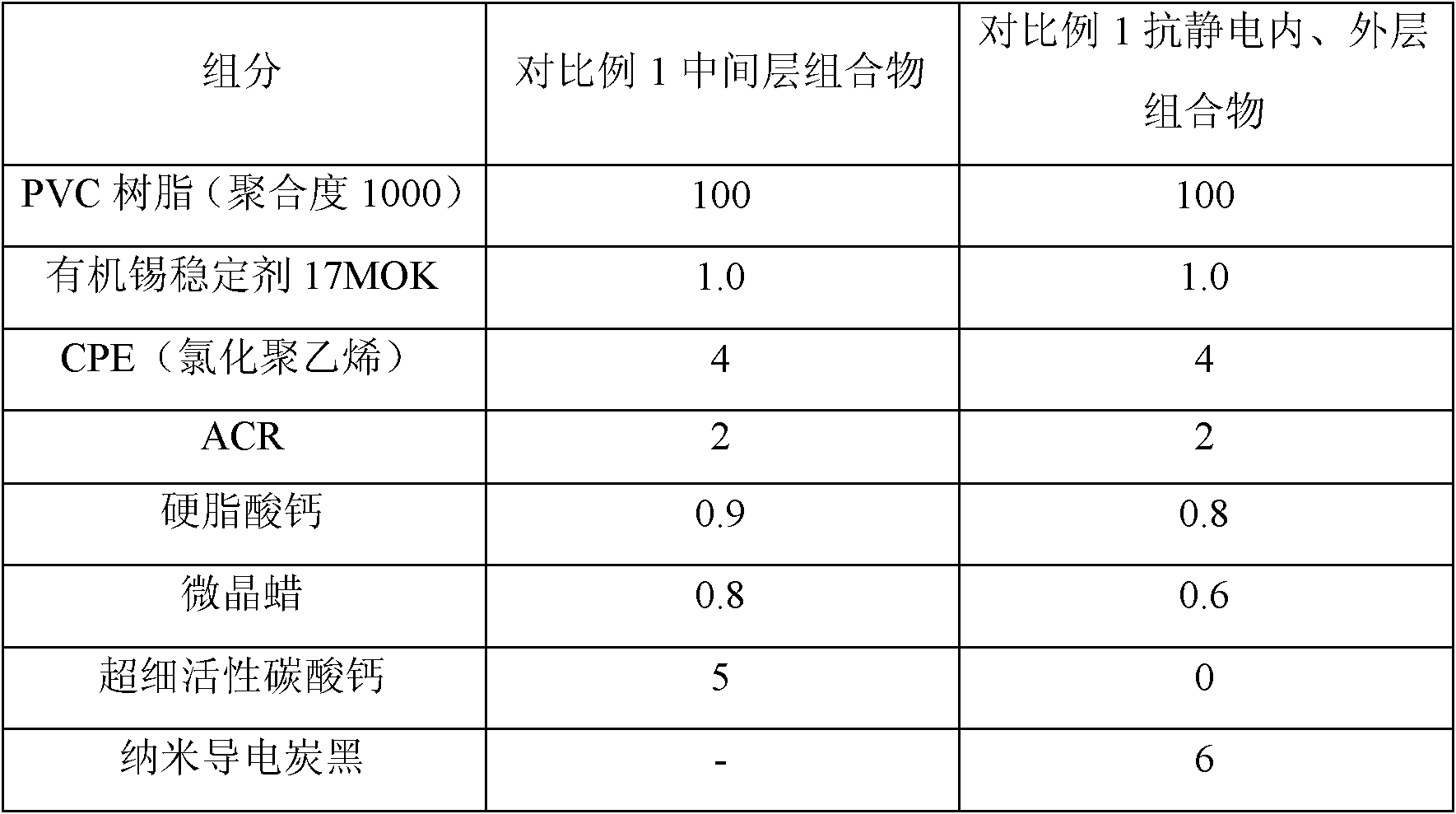

[0018] This coal mine uses three-layer co-extruded PVC-M pipe material antistatic interior, the proportioning composition of outer layer and PVC-M middle layer composition as shown in table 1:

[0019] Table 1 Example 1 three-layer co-extruded PVC-M pipe (by weight)

[0020] components

Embodiment 2

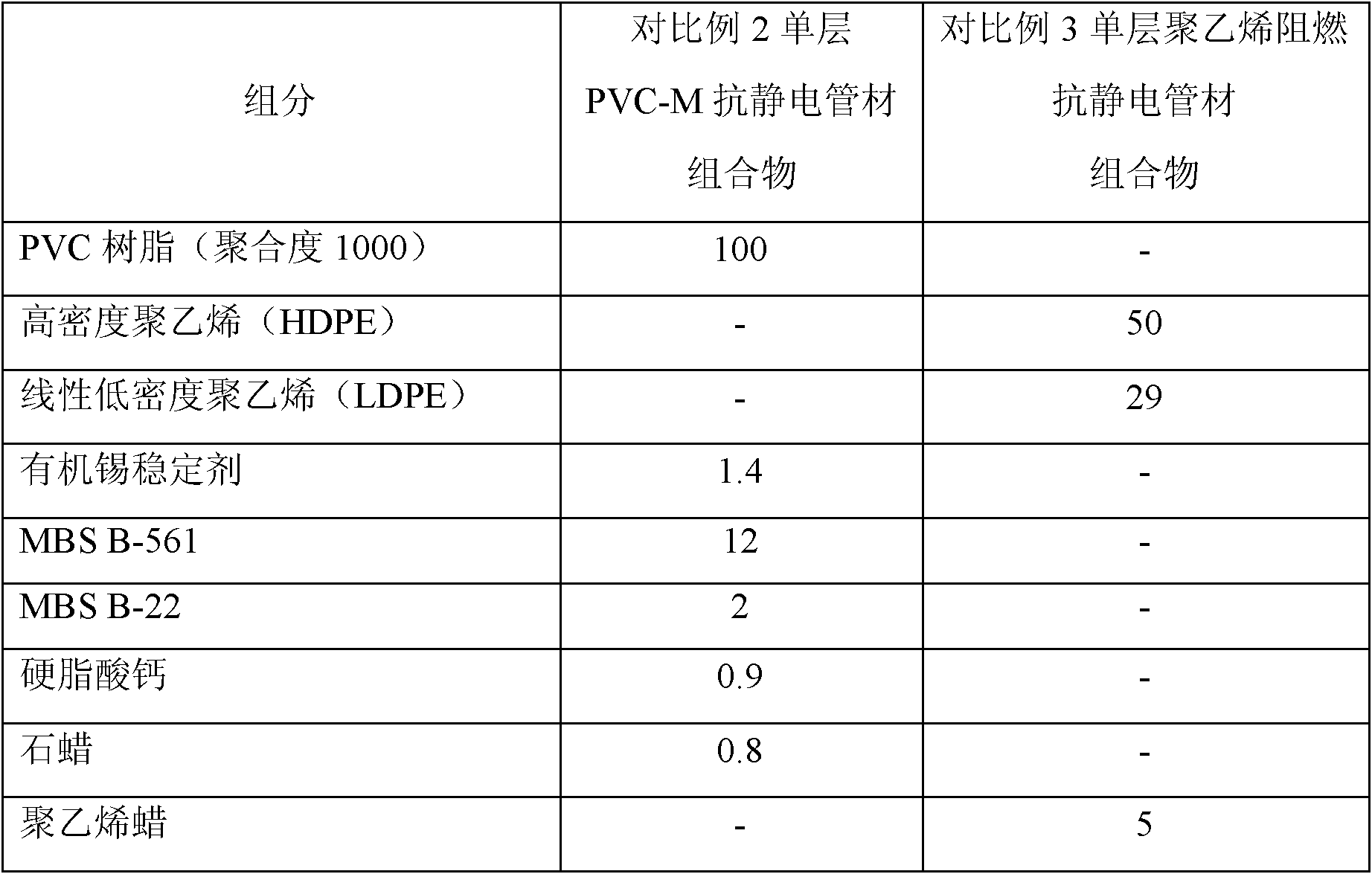

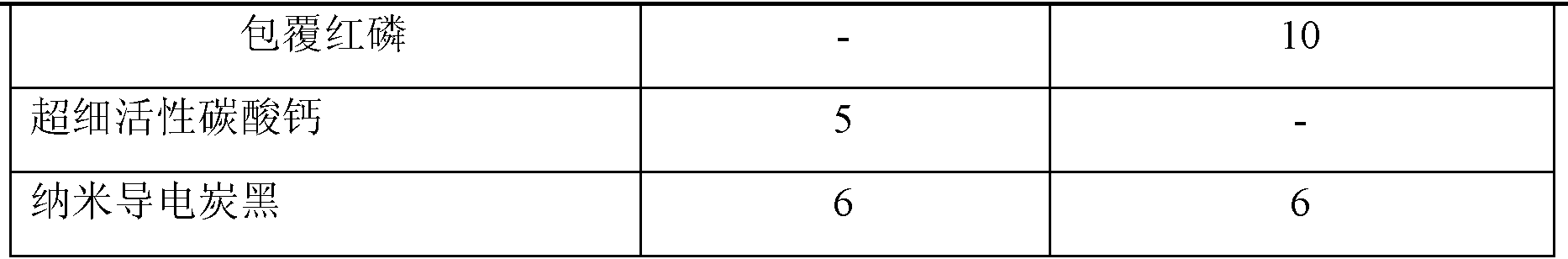

[0022] The proportioning composition of three-layer co-extrusion PVC-M pipe material antistatic interior, outer layer and PVC-M middle layer composition of this coal mine is as shown in table 2:

[0023] Table 2 Proportion (by weight) of the three-layer coextruded PVC-M pipe composition of Example 2

[0024] components

Embodiment 3

[0027] This coal mine uses three-layer co-extruded PVC-M pipe material antistatic inner, outer layer and the proportioning composition of PVC-M middle layer composition as shown in table 3:

[0028] Table 3 Proportion (by weight) of the three-layer coextruded PVC-M pipe composition of Example 3

[0029] components

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com