Patents

Literature

87results about How to "Permanent antistatic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antistatic, antibacterial and graphene-reinforced composite polyester fiber and preparation method thereof

InactiveCN103710790AGood spinnabilityGood electrical conductivityFilament/thread formingConjugated synthetic polymer artificial filamentsCvd grapheneChemistry

The invention provides an antistatic, antibacterial and graphene-reinforced composite polyester fiber, which is characterized in that the composite polyester fiber comprises a component A and a component B, wherein the component A is polyester excluding graphene, and the component B is polyester including 0.3-3.0wt% of graphene. The invention also provides a preparation method of the composite polyester fiber. The composite polyester fiber provided by the invention is low in cost, high in strength, and high in antistatic and antibacterial properties.

Owner:厦门翔鹭化纤股份有限公司

Carbon fiber reinforcement non-bittern flame-proof nylon 66 and preparation method thereof

The invention discloses a carbon-reinforced halogen-free fire-resistant nylon 66, which comprises by weight: nylon 66 resin 30-50 portions, long carbon fiber 10-50 portions, covering red phosphorus substrate 5-20 portions, fire resisting assistant 0-20 portions, flexibilizer 0-10 portions, antioxidant 0.1-1 portions, and processing assistant 0.1-15 portions. The carbon-reinforced halogen-free fire-resistant nylon 66 made by the invention is of high strength, high modulus, small creepage, and permanent anti-static performance, also good fire resistance, high mechanical strength, is resistant to high temperature, light, easy to process, with good fire resistance, and is also environmental friendly. The preparing method of the invention is simple to operate and applicable for industrialized production.

Owner:GUANGDONG HIGH & NEW ENG PLASTICS +1

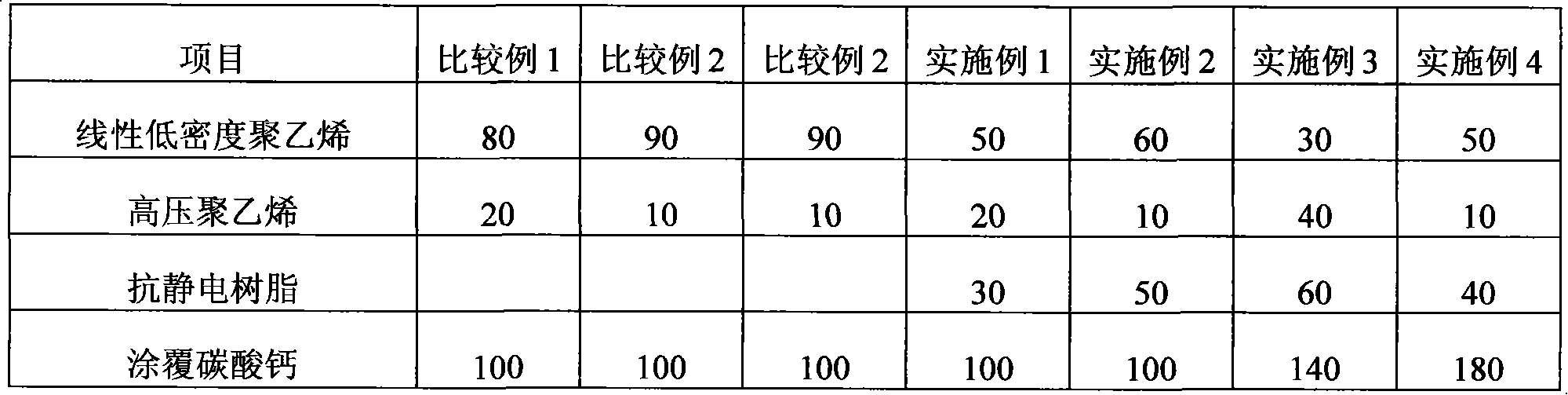

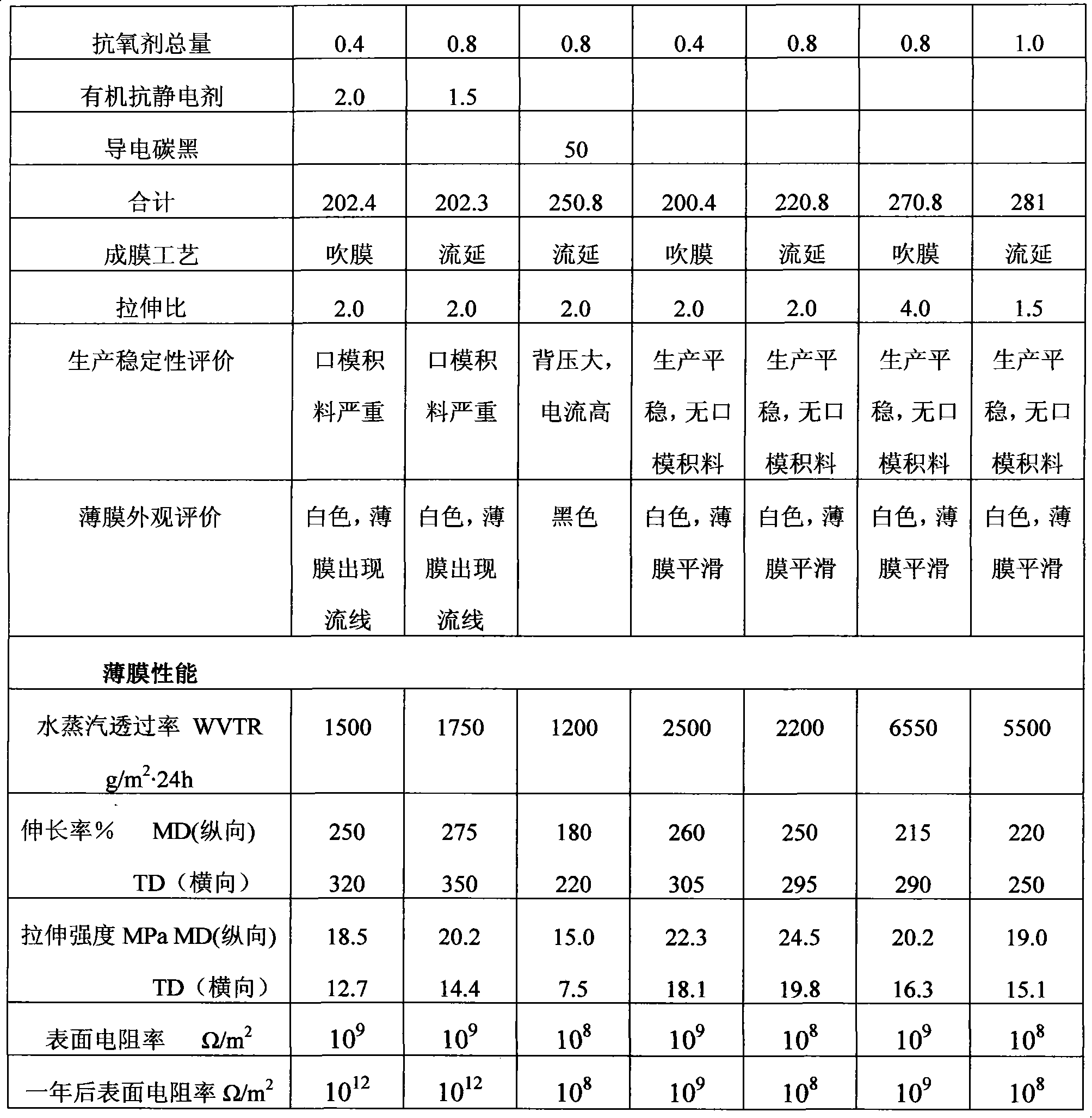

Anti-static polyolefin ventilated membrane composition and method for preparing the same

InactiveCN101250302APermanent antistaticGuaranteed antistatic effectCoatingsLinear low-density polyethylenePolyolefin

The invention discloses an antistatic polyolefin permeable film compound and a process for preparing the antistatic polyolefin permeable film. The compound comprises 30-60 parts by weight of linear low density polyethylene, 10-40 parts by weight of high-pressure polyethylene, 30-60 parts by weight of antistatic resin, 100-180 parts by weight of calcium carbonate and 0.4-1.0 parts by weight of anti-oxidant. The invention overcomes the weakness of traditional antistatic agent and antistatic filling, not only ensures the antistatic property of permeable film through adding antistatic resin, but also not affects the processing property, permeable property and the appearance of film. The processing flow-ability, the dispersing evenness of organic filling and processing stability of antistatic polyolefin permeable film compound in the invention can meet the production requirements of extrusion filmmaking. The water vapor permeable rate of the antistatic polyolefin permeable film which is prepared by the invention is not lower 2000g / m2 24h, and the surface electrical resistivity is no higher 10 9 omega / m2.

Owner:合诚技术股份有限公司

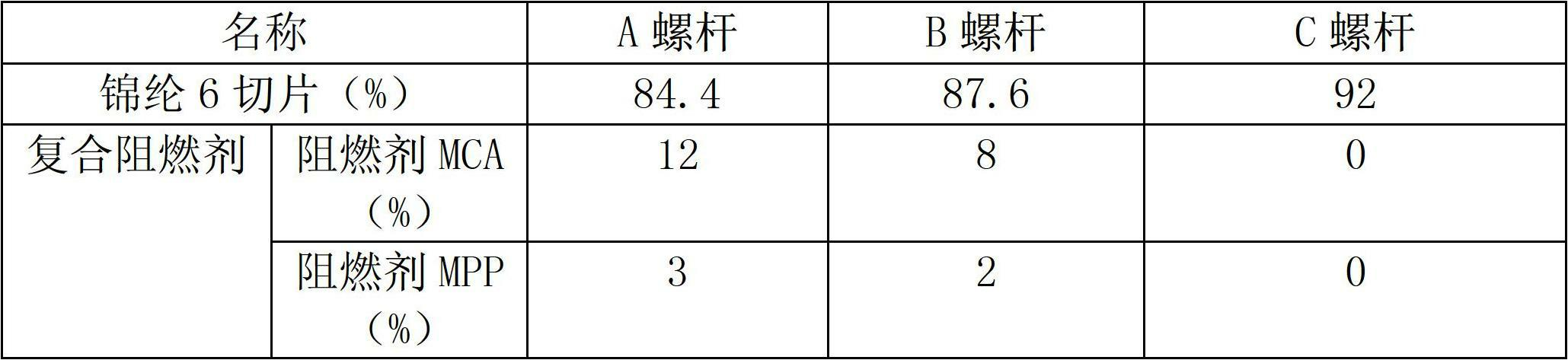

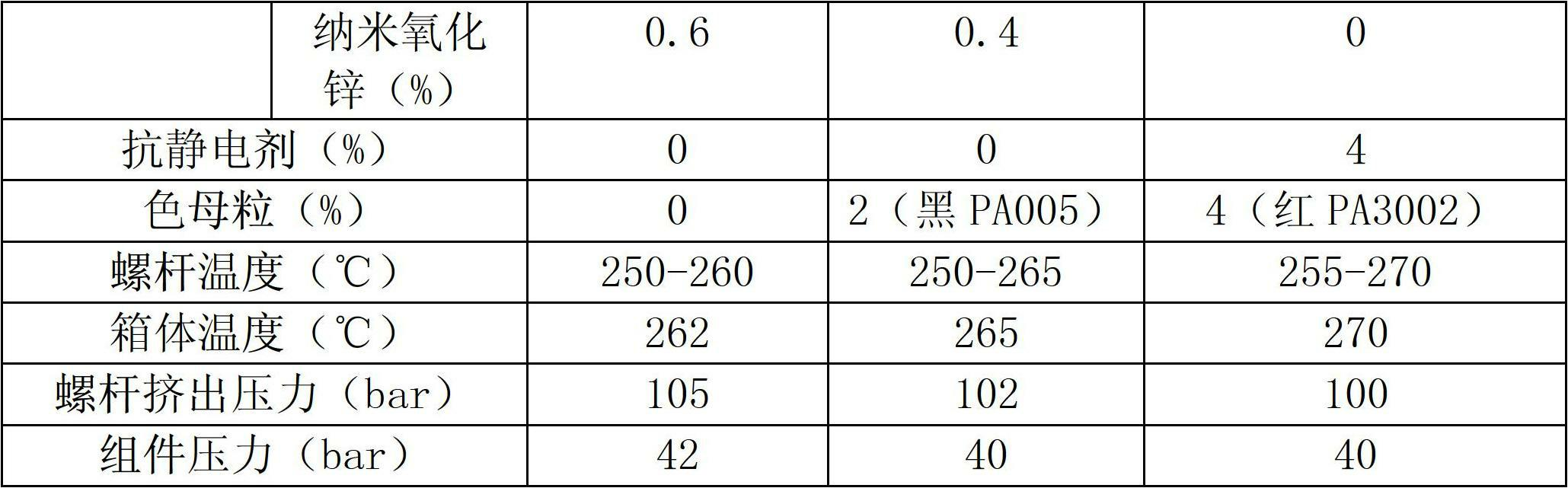

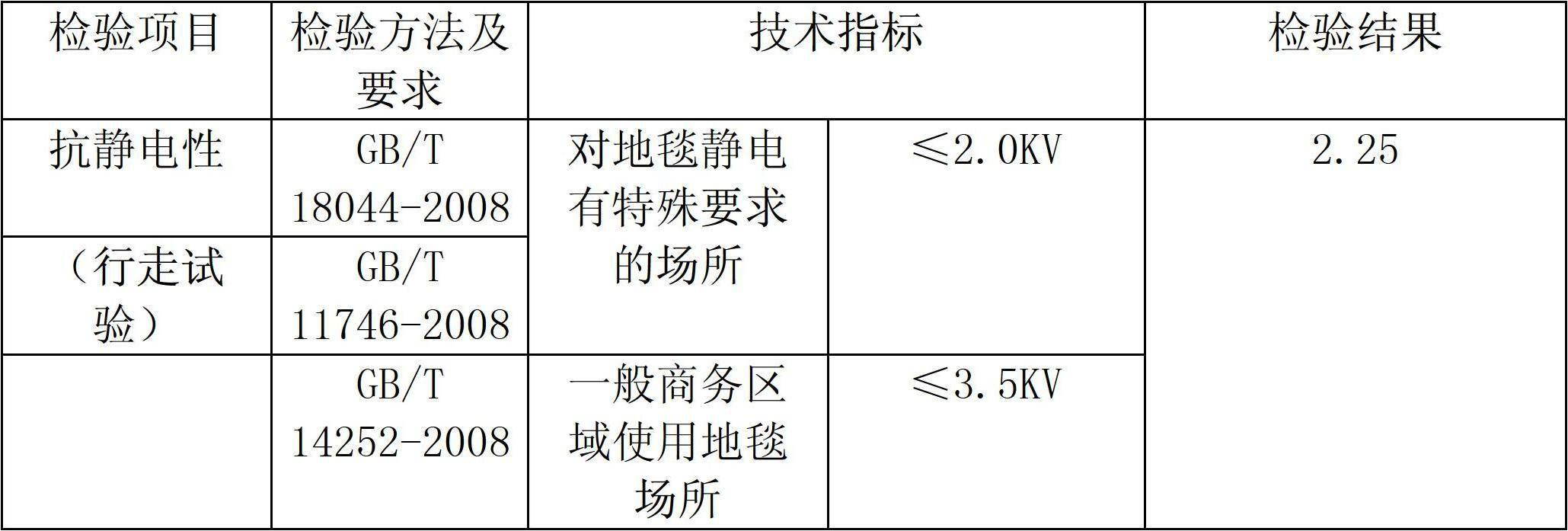

Permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and preparation method

ActiveCN102660819APermanent antistaticGuaranteed wear resistanceFlame-proof filament manufactureYarnComposite functionPolyamide

The invention relates to a permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn and a preparation method. The permanent antistatic flame-retardant polyamide-6 bulked continuous filament textured carpet yarn comprises a carpet yarn body, wherein the carpet yarn body consists of two tows of flame-retardant polyamide-6 bulked continuous filaments in different colors or the same color and a tow of antistatic polyamide-6 bulked continuous filaments; single fibers in the three tows of polyamide-6 bulked continuous filaments are random three-dimensional crimped fibers; different types of fibers are randomly mixed and intertwined; and periodical net knots are arranged on the surface of the carpet yarn body. The preparation method is implemented by one step through a tri-screw bulked continuous filament (BCF) spinning machine set. The product substantially maintains the characteristics of abrasion resistance, stain resistance, resilience and the like of polyamide-6, and also has a permanent antistatic function and a flame-retardant function. According to the preparation method, the characteristics of a production process of the tri-screw BCF spinning machine set are utilized, so that the aim of spinning the antistatic flame-retardant polyamide-6 textured carpet yarn by one step is fulfilled, and the production process is simple, practical and efficient.

Owner:CHANGZHOU LINGDA SPECIAL FIBER

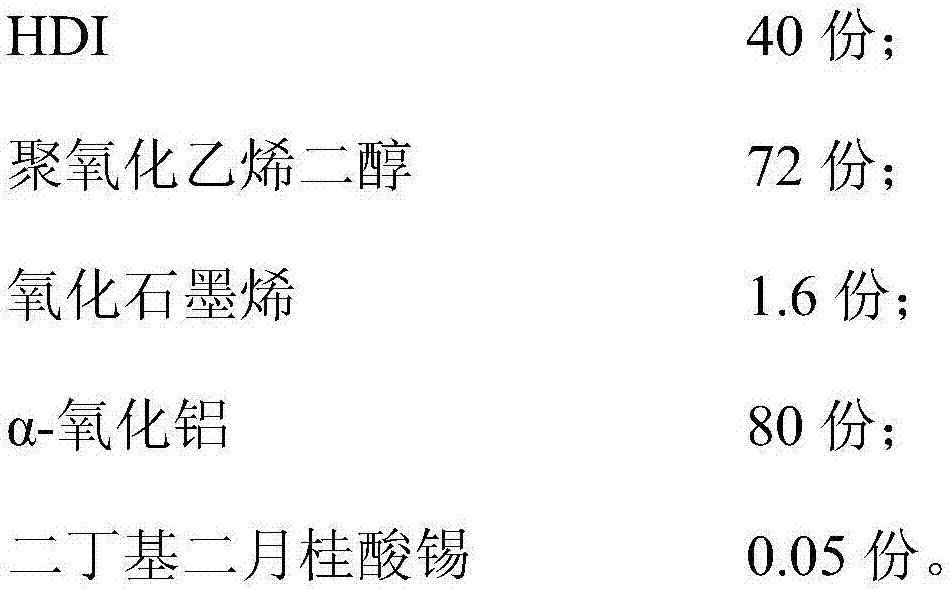

Preparation method of two-component waterborne polyurethane antistatic floor coating

InactiveCN105368292AWith antibacterial disinfectionPermanent antistaticPolyurea/polyurethane coatingsElectrically-conductive paintsChemistryAntistatic agent

The invention discloses a preparation method of a two-component waterborne polyurethane antistatic floor coating. The coating is composed of a base coat and a face coat. A base coat component A is composed of polyether polyols polyurethane, filler, silver-plated conductive materials, conductive mica powder, an additive and the like. A face coat component A is composed of polyester polyol or polycarbonate glycol polyurethane, titanium dioxide, filler, silver-plated conductive materials, a polymer antistatic agent, an additive and the like. A curing agent component B is composed of polyether polyol and diisocyanate. The ratio of A to B is 1:0.3-0.7 (W / W). The antistatic floor coating obtained through the preparation method meets the technical requirements of GB / T 22374-2008, HG / T 3829-2006 and SJ / T 11294-2003 standards, has the excellent waterproof, weatherproof, anti-aging, acid and alkali resisting and oil contamination resisting performance and the excellent impact resistance, friction resistance and skid resistance, and meets the antistatic requirements of top-grade plants, hospitals, ultra-clean plants and the like.

Owner:GUANGDONG HUALONG COATING IND

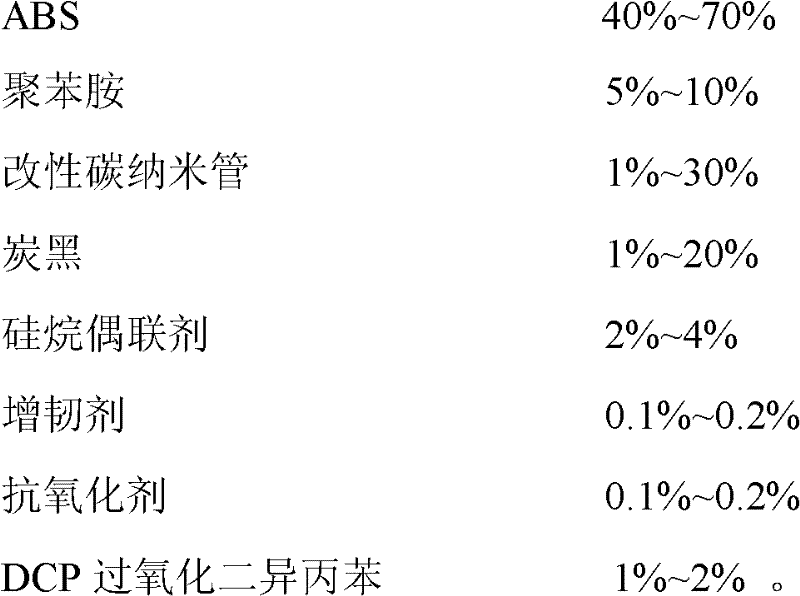

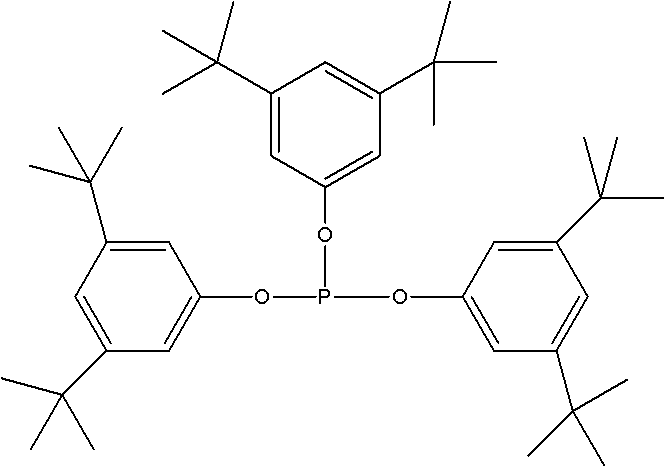

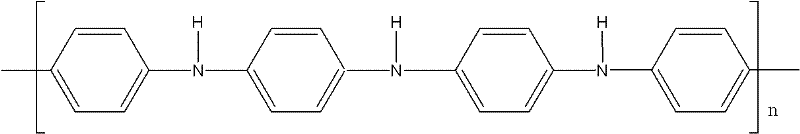

A new type of antistatic ABS resin material and preparation method thereof

ActiveCN102268171AImprove mechanical propertiesImprove chemical performanceOther chemical processesModified carbonOmega

The invention discloses a novel antistatic ABS (Acrylonitrile Butadiene Styrene) resin material and a preparation method thereof. The antistatic ABS resin material comprises the following components in percentage by weight: 40-70 percent of ABS, 5-10 percent of polyaniline, 1-30 percent of modified carbon nanotube, 1-20 percent of carbon black, 2-4 percent of silane coupling agent, 0.1-0.2 percent of toughener, 0.1-0.2 percent of anti-oxidant and 1-2 percent of DCP (Dicumyl Peroxide). The antistatic ABS resin material has the advantages of permanent antistatic property, good effect, high mechanical property, high processability, good application prospect and good comprehensive performance; the surface resistance of the ABS resin can be lowered to 105 omega.centimeter or lower; a permanentantistatic material can be obtained; the used raw materials do not have toxic or side effects; and the method is safe to operate, and has a simple and practical process.

Owner:5ELEM HI TECH CORP

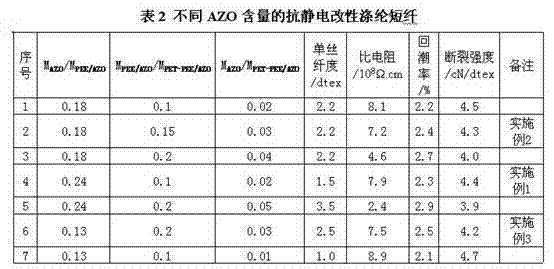

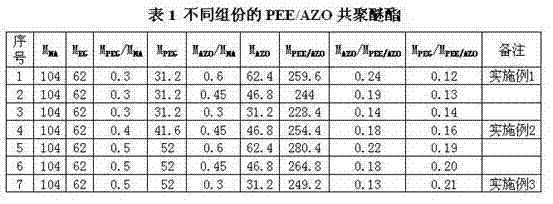

Anti-static modified polyester staple fiber and preparation method thereof

ActiveCN103361765AHas permanent antistatic propertiesImprove antistatic performanceElectroconductive/antistatic filament manufactureArtificial filament heat treatmentFiberPolymer science

The invention belongs to the field of processing of a high polymer material, and particularly relates to a different polyester staple fiber with an anti-static function, and a preparation method thereof. The method comprises the following steps of: a, preparing polyether ester fiber / aluminium-doped zinc oxide (PEE / AZO) composite polyether ester, namely adding the surface-modified aluminium-doped zinc oxide (AZO) to an ethylene glycol (EG) solution to carry out disperse treatment, esterifying together with malonic acid (MA) and polyether (PEG) to generate the PEE / AZO composite polyether ester; b, preparing PET-PEE / AZO copolyester, namely carrying out esterification on purified terephthalic acid (PTA) and EG, adding the PEE / AZO composite polyether ester to carry out copolycondensation after esterification is finished, and generating the PET-PEE / AZO copolyester with the anti-static property; and c, melting and spinning, namely preparing into the anti-static modified polyester staple fiber from the PET-PEE / AZO copolyester by melting and spinning. By adopting the preparation method, various problems caused by large static electricity in the processes of spinning, weaving and taking the polyester staple fiber are solved.

Owner:宿迁逸达新材料有限公司

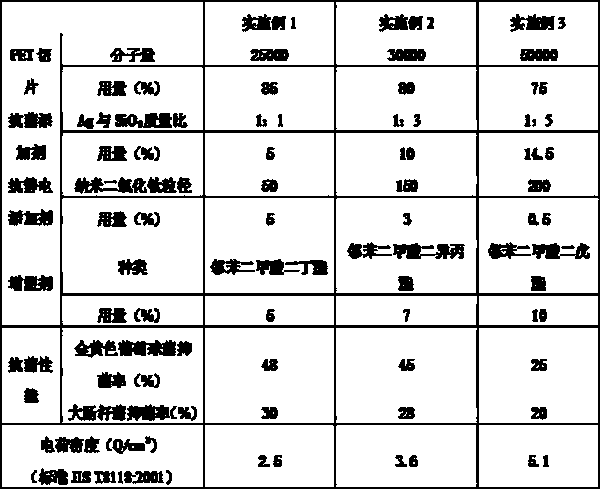

Antibacterial and antistatic polyester resin slice

ActiveCN103351585AHas antibacterial propertiesAntistaticElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPlasticizerPolyethylene glycol

The invention relates to an antibacterial and antistatic polyester resin slice which comprises the following raw materials in parts by weight: 75-85 parts of a PET (polyethylene glycol terephthalate) slice, 5-15 parts of an antibacterial additive, 0.5-5 parts of an antistatic additive and 5-10 parts of a plasticizer, wherein the molecular weight of the PET slice is 25,000-50,000 and the plasticizer is one of dibutyl-o-phthalate, diisopropyl-o-phthalate and diamyl-o-phthalate. Due to the application of the technical scheme, the antibacterial antistatic polyester resin slice has the following advantages: the antibacterial additive and the antistatic additive in the raw materials of the polyester resin slice are added at the same time, so that the polyester resin slice has antibacterial and antistatic performances at the same times; a textile prepared by the polyester resin slice is endowed with permanent antibacterial and antistatic performances; and the increasing requirement of people on the textile can be met.

Owner:CHANGSHU HULIAN PRINTING & DYEING

Anti-bacterial, anti-static and anti-corrosive rubber floor

InactiveCN104895297AExtended use timePermanent antistaticAnti-corrosive paintsFlooringFiberPolymer science

The invention discloses an anti-bacterial, anti-static and anti-corrosive rubber floor. The anti-bacterial, anti-static and anti-corrosive rubber floor is formed by raw material comprising, by weight, 20 to 30 parts of neoprene, 33 to 43 parts of chemigum, 25 to 30 parts of ethylene-propylene-diene monomer rubber, 2 to 4 parts of magnesium oxide, 0.5 to 1.5 parts of stearic acid, 15 to 28 parts of semi-reinforcing furnace black, 4 to 8 parts of zinc oxide, 0.3 to 0.8 parts of thiuram type accelerators, 4 to 8 parts of antioxidant RD, 1.5 to 1.8 parts of isothiazolinone, 0.5 to 0.8 parts of calcium hypochlorite and 3 to 5 parts of conductive fibers. The floor is coated with coating liquid. The anti-bacterial, anti-static and anti-corrosive rubber floor has following beneficial effects: an anti-bacterial effect is exerted upon bacteria on the surface; service lifetime of the rubber floor is prolonged; cost for cleaning and replacing the rubber floor at the later period is reduced; the rubber floor has permanent anti-static performance by adding the conductive fibers; the coating liquid of the rubber floor adopts acrylic resin, compound polybenzoxazine material and keto-aldehyde resin KR-80 F as film forming matter such that strength, adhesive force and corrosion-resistant performance are enhanced; the hydrophobic property of the rubber floor is improved so that the floor is prevented from foaming and falling by being soaked under water; and an anti-corrosion effect is obtained.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

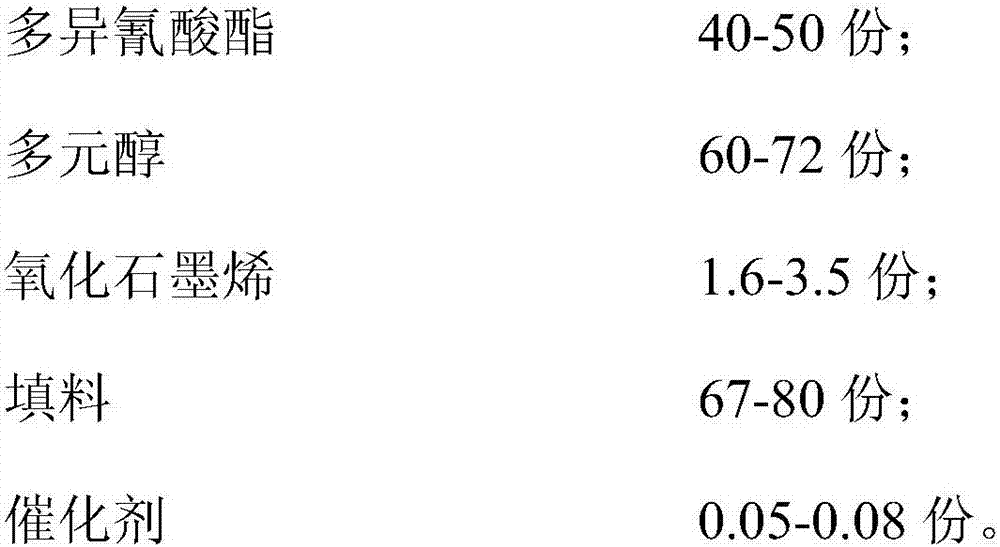

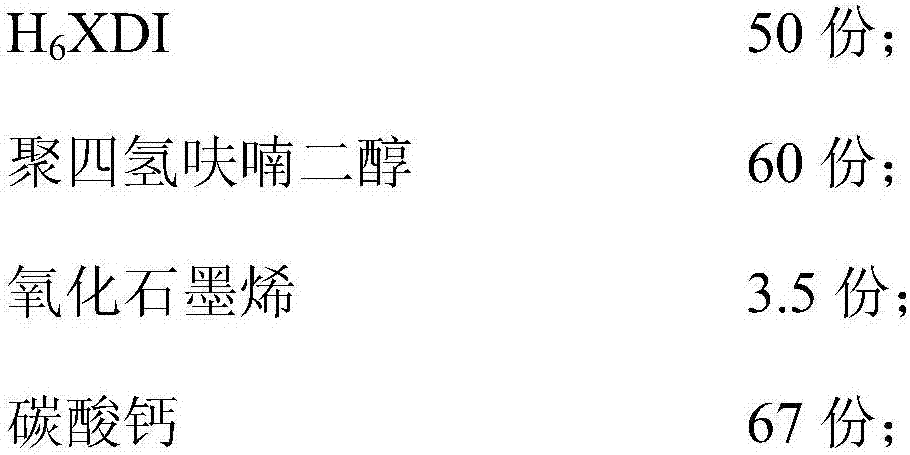

Anti-static polyurethane pouring sealant and using method thereof

ActiveCN107474782ALarge specific surface areaImprove adsorption capacityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAlcoholStatic performance

The invention provides an anti-static polyurethane pouring sealant and a using method thereof. The anti-static polyurethane pouring sealant comprises the following components in parts by weight: 40 to 50 parts of polyisocyanates, 60 to 72 parts of polyhydric alcohols, 2 to 2.4 parts of oxidized graphene, 67 to 80 parts of a filler and 0.05 to 0.08 part of a catalyst. The using method comprises the following steps: after all components of the anti-static polyurethane pouring sealant are mixed, pouring an object to be poured, and then curing the object to be poured at the temperature of 20 to 30 DEG C for 24 to 48 h to form a sealant block. The anti-static polyurethane pouring sealant provided by the invention has good mechanical performance after being cured, has relatively high insulation performance and anti-static performance, and is particularly applicable for pouring of electrical apparatus elements.

Owner:驻马店进化伙伴机器人有限公司

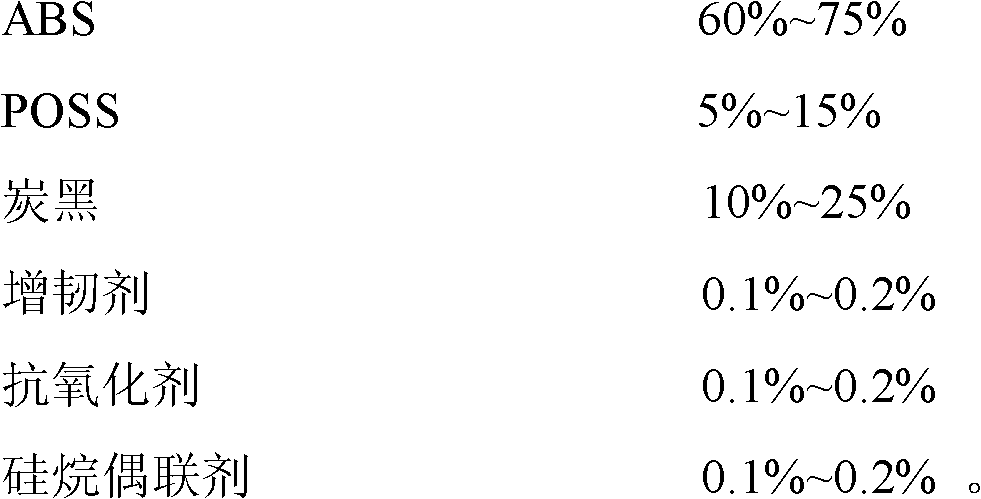

Antistatic flame-retardant acrylonitrile butadiene styrene (ABS) rubber material and preparation method thereof

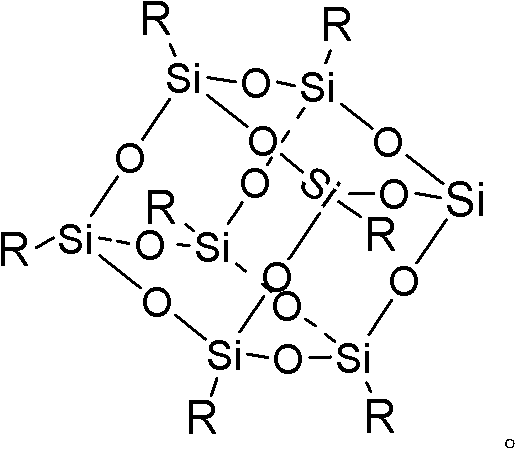

The invention discloses an antistatic flame-retardant acrylonitrile butadiene styrene (ABS) rubber material and a preparation method thereof. The rubber material contains the following components in percentage by mass: 60 to 75 percent of ABS, 5 to 15 percent of polyhedral oligomeric silsesquioxanes (POSS), 10 to 25 percent of carbon black, 0.1 to 0.2 percent of toughening agent, 0.1 to 0.2 percent of antioxidant, and 0.1 to 0.2 percent of silane coupling agent. The antistatic flame-retardant ABS material has good and lasting antistatic effect; the surface resistivity of the ABS resin can be reduced to 105 to 106omega per centimeter and even lower; the manufactured permanent antistatic material has good flame-retardant effect, the limited oxygen index of the antistatic material can be between 22 and 25 percent, and the antistatic material has the advantages of excellent mechanical property, good processing property and the like, and has good application prospect. The preparation method is environmentally-friendly, simple and feasible.

Owner:5ELEM HI TECH CORP

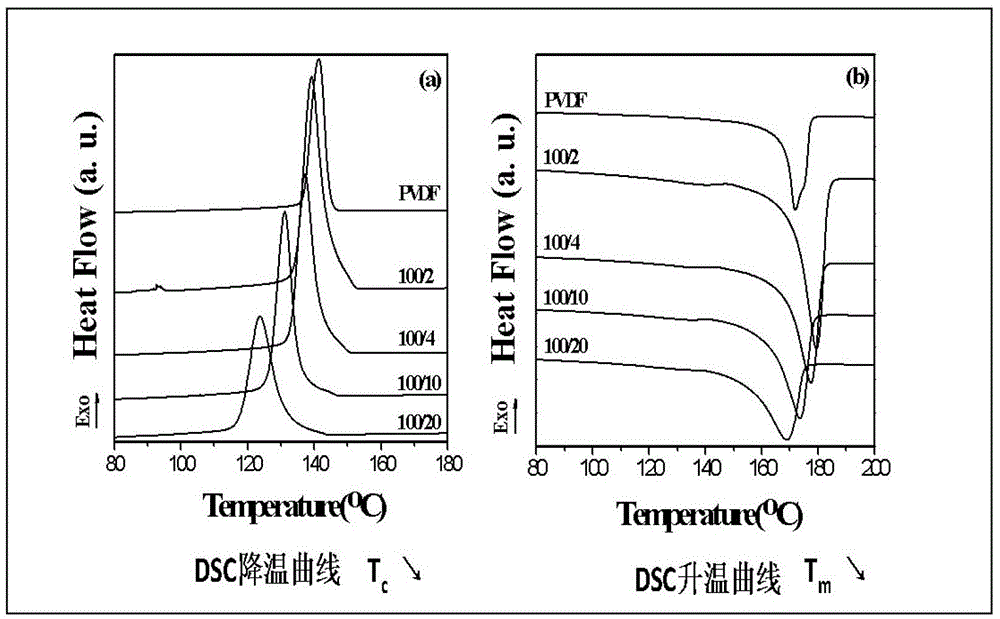

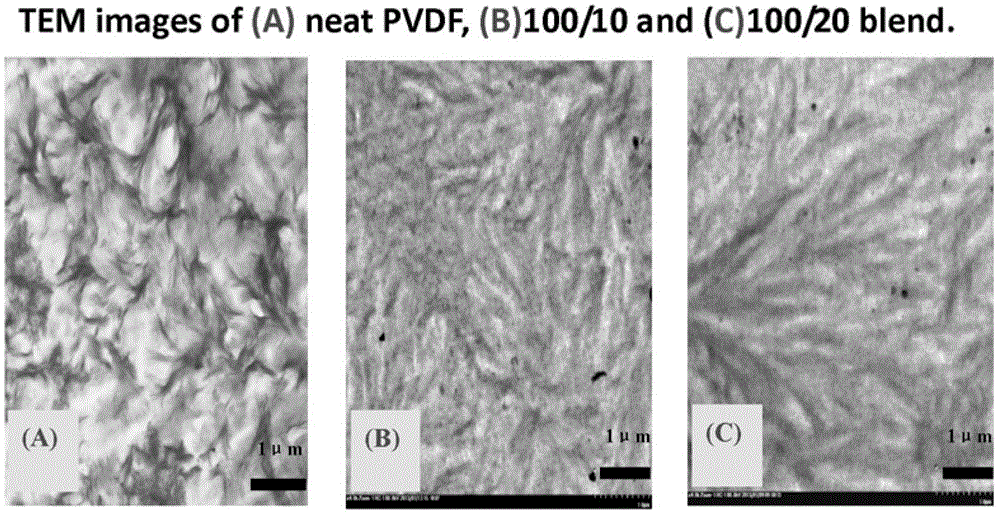

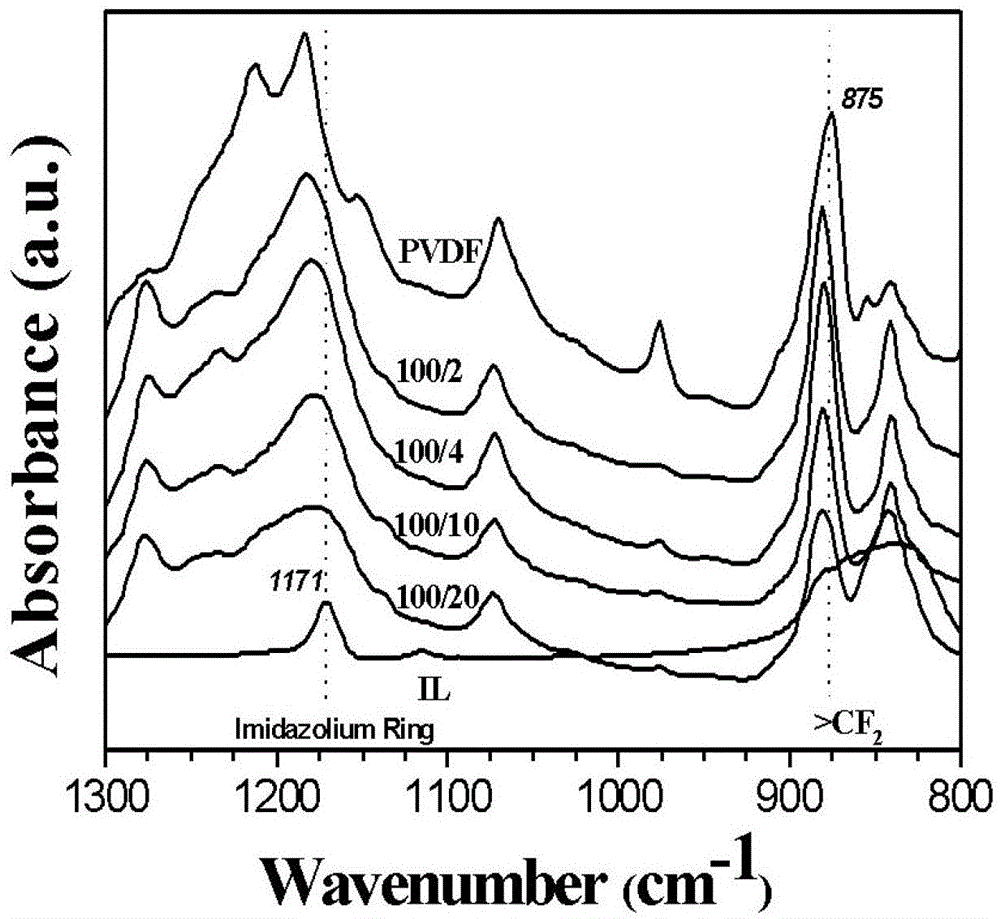

Transparent permanent antistatic transparent polyvinylidene fluoride composition and preparation method thereof

The present invention relates to a permanent antistatic polyvinylidene fluoride (PVDF) composition and a preparation method thereof. The composition comprises the following components, by weight, 68-99.4% of polyvinylidene fluoride, 0.5-30% of an ionic liquid antistatic agent, and 0.1-2% of other additives. During preparation, polycarbonate, a fluorine-substituted polyolefin additive and an ionic liquid are added to a banbury mixer to carry out melting blending at a temperature of 170-200 DEG C until mixing is uniform, the mixed material processed from the process is subjected to melting extrusion through a twin-screw extruder, and then granulation and drying are performed, wherein extrusion temperatures of various regions of the twin-screw extruder are maintained at a temperature of 160-190 DEG C. The composition has the following advantages that: 1, the product has good transparency and excellent antistatic property, and the antistatic property of the material is less affected by air humidity, and the resulting antistatic property is permanent, 2, the process is simple, processing is convenient, the use amounts of the ionic liquid antistatic agent and other additives are less, and the obtained PVDF composition has excellent mechanical properties, and 3, environmental protection requirements are met, the raw materials have characteristics of no toxicity and no harm, and no toxic element exists with chemical analysis.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

Carpet yarn manufacture method

The invention discloses a carpet yarn manufacture method, which comprises the following technical steps of: 1) carrying out hydrophobic processing on melamine cyanurate, melamine pyrophosphate and nano-zinc oxide by coupling agent; 2) carrying out high-speed dispersing and mixing and double-screw melt extrusion on modified fire retardant and polyamide-6 granula to obtain modified composite fire retardant master batch; 3) respectively metering and adding raw materials into the hoppers of three screw extruders; 4) ejecting two bundles of polyamide-6 fibers and one bundle of anti-static fiber; 5) gathering three bundles of fibers together to form a fiber bundle; after the fiber bundle is stretched via a stretching roller, causing the fiber bundle to enter a bulking device to form bulked yarn; cooling, forming and networking; generating a network node for lacing yarns periodically on the surface of the yarn; winding by a coiler to obtain a cheese; and obtaining the product. According to the carpet yarn manufacture method disclosed by the invention, the characteristics of abrasive resistance, resistance to soiling and rebound resilience of the polyamide-6 are almost kept for the carpet yarn. Meanwhile, the carpet yarn also has the composite function of permanent anti-static property and fire resistance.

Owner:CHANGSHU KAIXIN CARPET

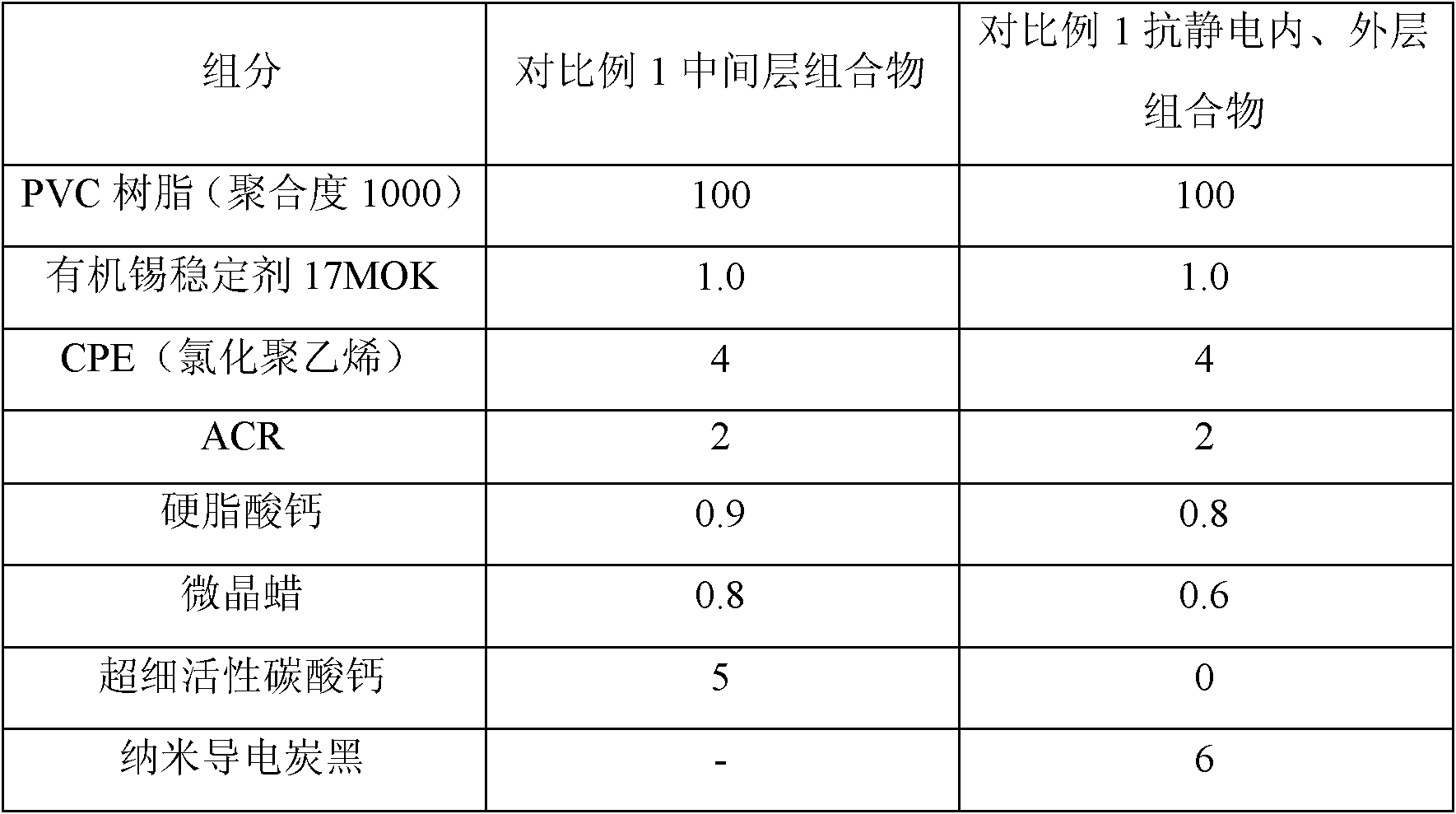

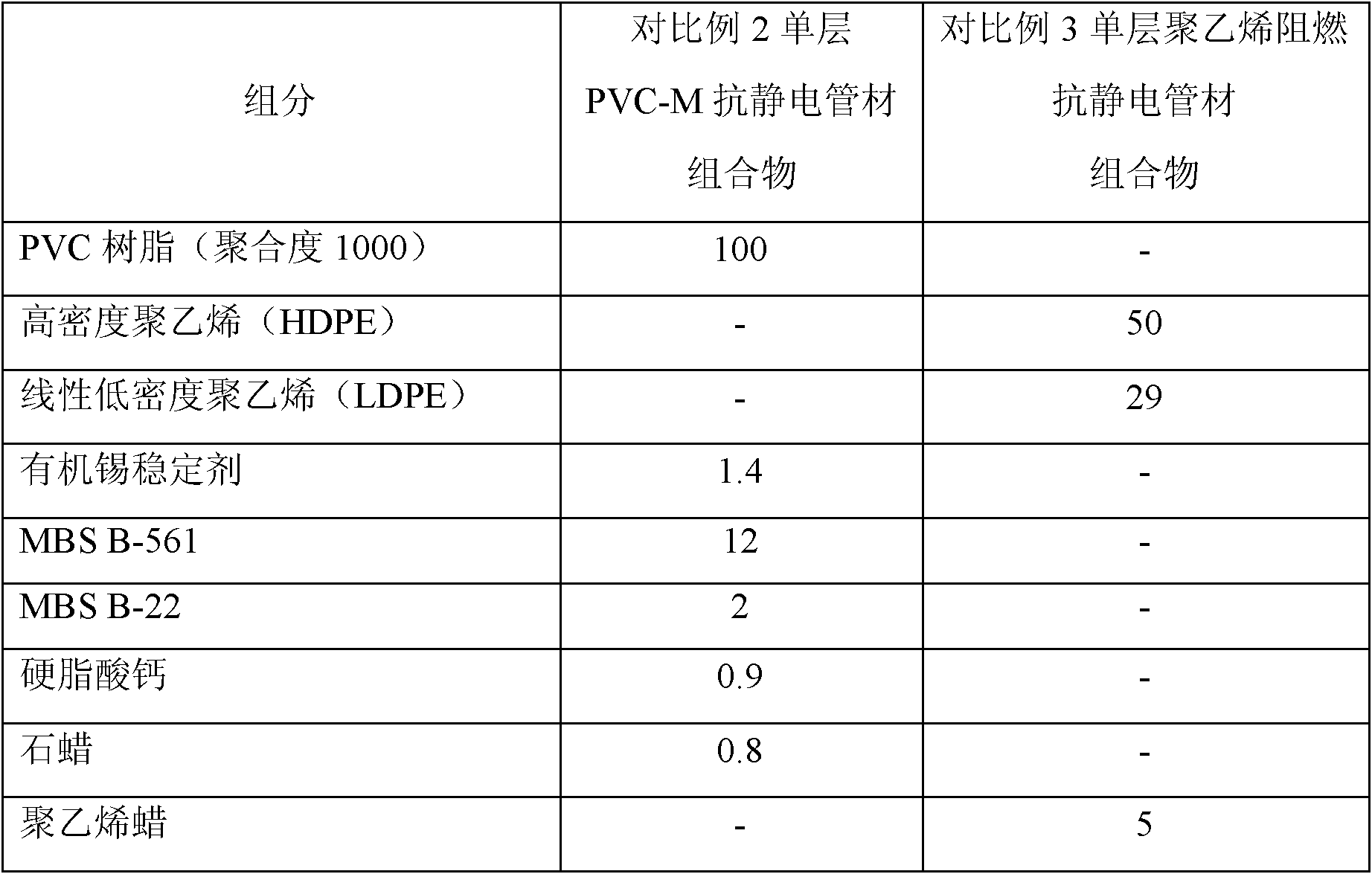

Three-layer co-extrusion PVC-M tubular product for coal mine

ActiveCN102863710AHigh strengthImprove the withstand voltage levelRigid pipesShock resistanceCo extrusion

The invention discloses a three-layer co-extrusion PVC-M tubular product for coal mine, characterized in that the tubular product comprises an antistatic inner layer, an antistatic outer layer and a PVC-M interlayer, wherein the antistatic inner and outer layer compositions comprise the following ingredients: 100 weight parts of PVC resin, 0.8-1.2 weight parts of heat stabilizer, 4-8 weight parts of toughening agent, 1.3-2.0 weight parts of lubricating agent, 5-10 weight parts of flow modifier, and 6 weight parts of nano conductive carbon black; the PVC-M interlayer composition comprises the following ingredients: 100 weight parts of PVC resin, 1.0-1.5 weight parts of heat stabilizer, 10-15 weight parts of toughening agent, 2.1-3.5 weight parts of lubricating agent, and 0-5 weight parts of filling agent. According to the invention, the composition of the tubular product has high strength, the shock resistance of the tubular product can be comparable to that of polyethylene antistatic tubular products for coal mine, the modulus reaches to 2231MPa, the tensile strength reaches to 46.3Mpa, the impact strength of the simple-supported beam reaches to 97.6Mpa, the mechanical property shows toughness and balance and permanent antistatic property, thus the requirements of the tubular product for coal mine are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP

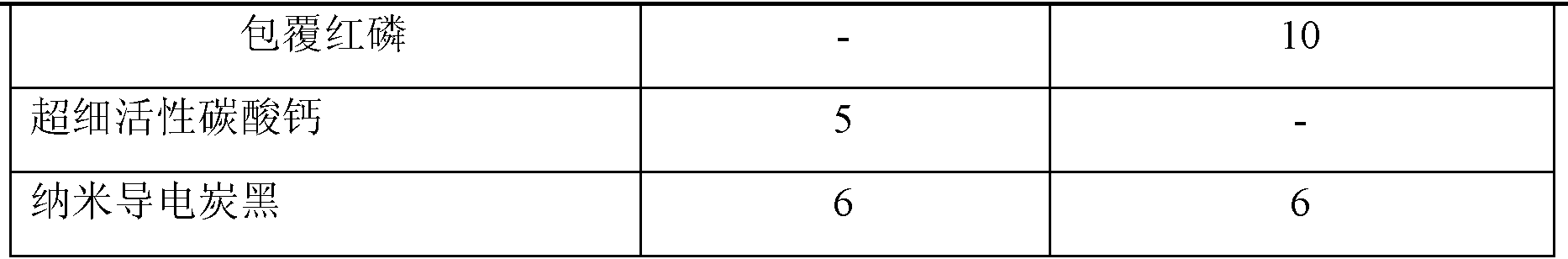

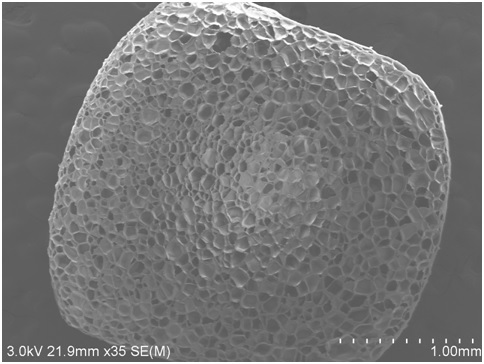

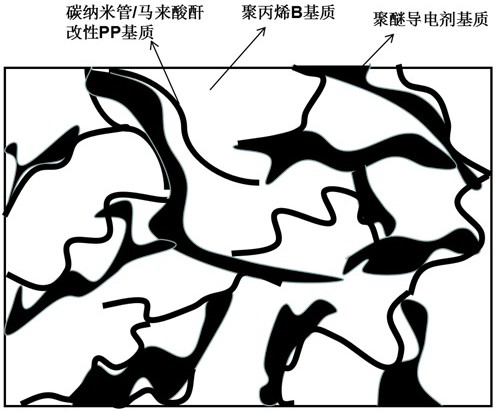

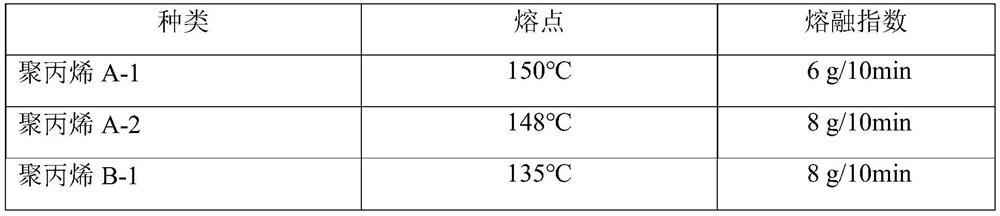

Gray antistatic polypropylene composite foamed beads with skin-core structure and molded product thereof

The invention discloses gray antistatic polypropylene composite foamed beads with a skin-core structure, which are composed of a foamed core layer and a non-foamed skin layer, and the foamed core layer is composed of polypropylene, a cell nucleating agent, an antioxidant, colored carbon black and a lubricant. The skin layer is prepared from polypropylene, a polyether block copolymer antistatic agent, maleic anhydride grafted modified polypropylene and multi-walled carbon nanotube; the composite foamed beads are obtained by extruding and granulating through a co-extrusion extruder and then foaming through a high-pressure foaming kettle. The skin layer contains the composite antistatic agent and the low-melting-point polypropylene, so that good fusion bonding, apparent quality and stable permanent antistatic property of the molded product are guaranteed; the foaming effect of the core layer is excellent, and the foaming ratio adjustability and the excellent mechanical property of a molded product are guaranteed. The molded product not only has permanent antistatic property, but also has good rigidity.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

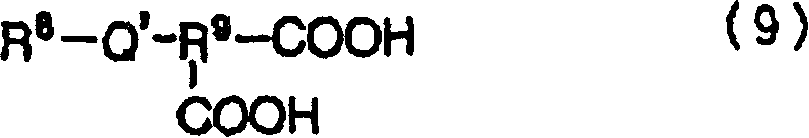

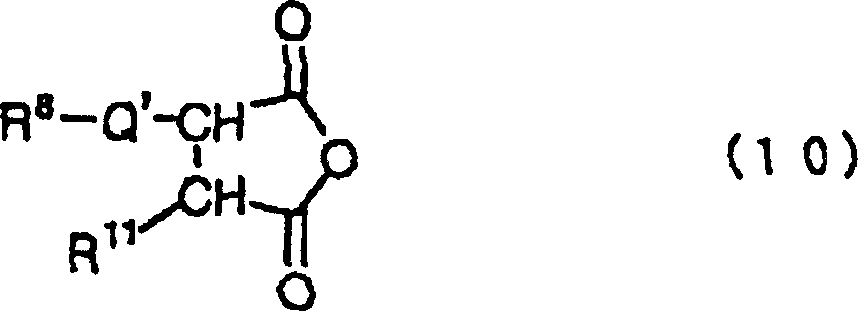

Block polymer and antistatic agent comprising the same

InactiveCN1827670AGood compatibilizerPermanent antistaticOther chemical processesPolymer scienceHydrophilic polymers

A thermoplastic resin which comprises a resin, especially a polyolefin, and a block polymer comprising polyolefin blocks and hydrophilic polymer blocks and finely dispersed therein without the need of a compatibilizing agent and gives a molding having permanent antistatic properties even when it is molded under shear-free conditions and even when the block polymer amount is small, and which does not foul the molds or rollers during molding because of satisfactory compatibility and has excellent mechanical strength. The block polymer is characterized by having a structure comprising blocks of a polyolefin (a) alternating with blocks of a hydrophilic polymer (b) having a volume resistivity of 10<5> to 10<11> OMEGA .cm. An antistatic agent comprising the block polymer is provided. The resin composition comprises the block polymer and a thermoplastic resin. A molded article obtained by coating or printing a molding of a resin composition containing the block polymer is further provided.

Owner:SANYO CHEM IND LTD

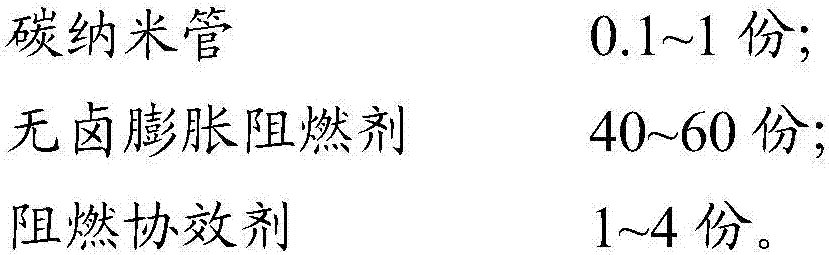

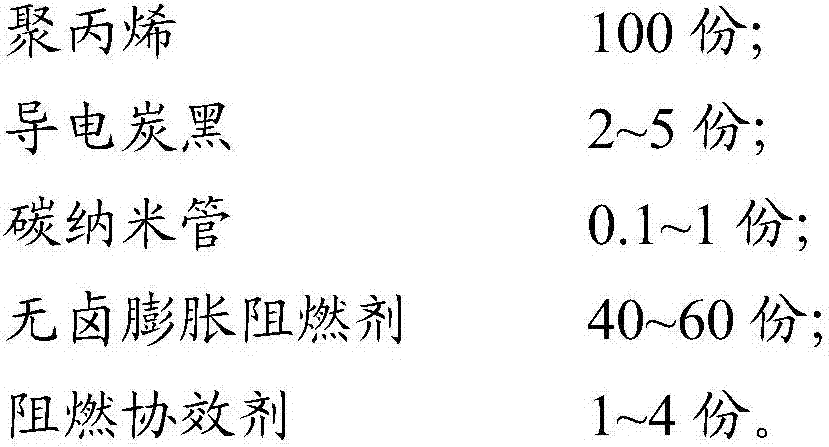

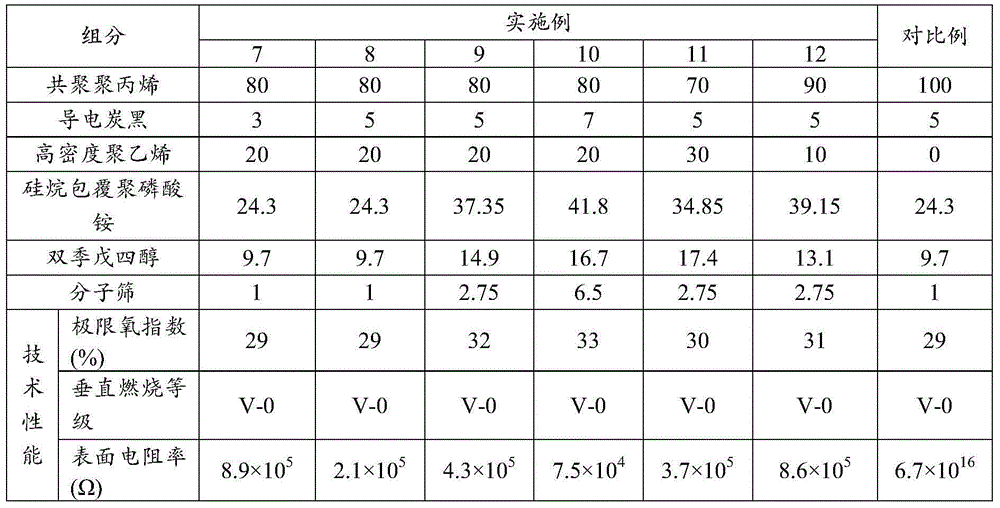

Polypropylene halogen-free flame-retardant anti-static material, and preparation method and applications thereof

The invention provides a polypropylene halogen-free flame-retardant anti-static material, and a preparation method and applications thereof. According to the preparation method, a halogen-free intumescent flame retardant is adopted for flame retardant treatment, the halogen-free intumescent flame retardant contains no halogen, is more safe, and is more friendly to the environment; reasonable adjustment of the formula of the halogen-free intumescent flame retardant is carried out, so that flame resistance is improved, material oxygen index is capable of reaching 32%, vertically burning is capable of reaching V0 grade; conductive carbon black and carbon nanotube are capable of providing the polypropylene halogen-free flame-retardant anti-static material with permanent antistatic performance, the antistatic performance is excellent, and cost is relatively low; adding of carbon nanotube is capable of increasing the electrical conduction efficiency of conductive carbon black, and improving the antistatic performance; and material surface resistance is capable of reaching 106omega at an extremely low conductive filling material content.

Owner:应急管理部四川消防研究所

Stone-plastic wallboard

InactiveCN107244868AHigh activityIncrease activationAnti-corrosive paintsElectrically-conductive paintsFiberCrack resistance

The invention provides a stone-plastic wallboard which comprises 50-80 parts of calcite powder, 40-60 parts of PVC (Polyvinyl Chloride) resin, 20-30 parts of chloroprene rubber, 33-43 parts of butadiene-acrylonitrile rubber, 3-5 parts of conductive fibers, 30-50 parts of marble powder, 4-8 parts of processing aids, 4-8 parts of a modifier, 1-3 parts of a stabilizer, 2-5 parts of a foaming agent, 1-5 parts of a lubricating agent, 90-100 parts of semi-hydrated gypsum, 1-3 parts of bamboo charcoal fibers, 2-5 parts of methyl cellulose, 3-7 parts of ethyl cellulose, 20-30 parts of a stone-like coating and 3-6 parts of polyvinyl alcohol. According to the stone-plastic wallboard disclosed by the invention, the calcite powder, the marble powder, the semi-hydrated gypsum, the PVC resin, chloroprene rubber and the butadiene-acrylonitrile rubber are mixed, so that the prepared stone-plastic wallboard has excellent mechanical strength, tensile strength and crack resistance, the activity of the semi-hydrated gypsum is improved, the content of soluble impurities in the semi-hydrated gypsum is reduced, a pulverization phenomenon on the surface of a gypsum base material is further avoided, and the strength and toughness of the semi-hydrated gypsum base material are improved, so that the gypsum is applied to the field of building materials in a wide range, the inventory of phosphogypsum in the natural world is reduced, and the environmental pollution is reduced.

Owner:合肥易美特建材有限公司

Halogen-free flame-retardance anti-static polypropylene composite material and preparation methods thereof

InactiveCN104140598AImprove flame retardant performancePermanent antistaticPolypropylene compositesHalogen

The invention provides a halogen-flame-retardance anti-static polypropylene composite material, belonging to the field of material chemistry. The composite material is prepared from the following raw materials in parts by mass: 70-90 parts of polypropylene, 3-7 parts of inorganic conductive filler, 10-30 parts of conductive promoter and 35-65 parts of halogen-free inrumescent flame retardant. The invention further provides two methods for preparing the composite material. Compared with a traditional flame-retardant anti-static polypropylene composite material, the material is prepared by a halogen-free flame-retardant technology and has permanent anti-static capability, excellent mechanical performance and excellent processing performance.

Owner:应急管理部四川消防研究所

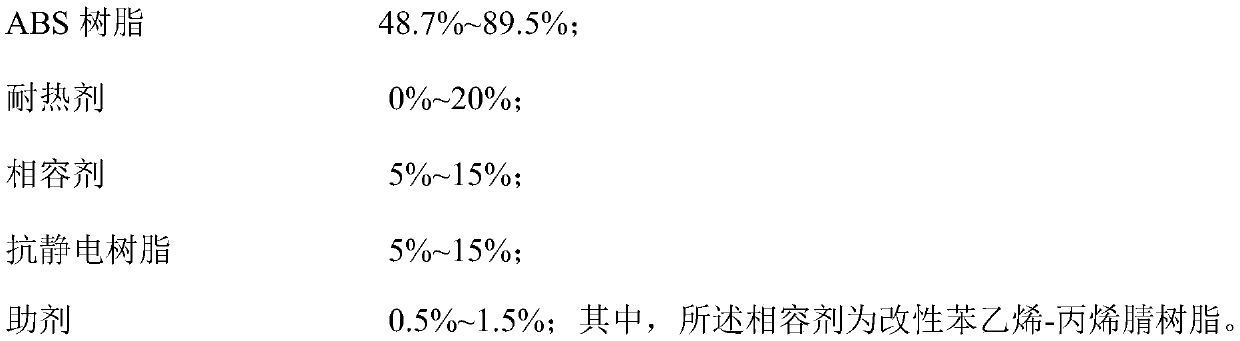

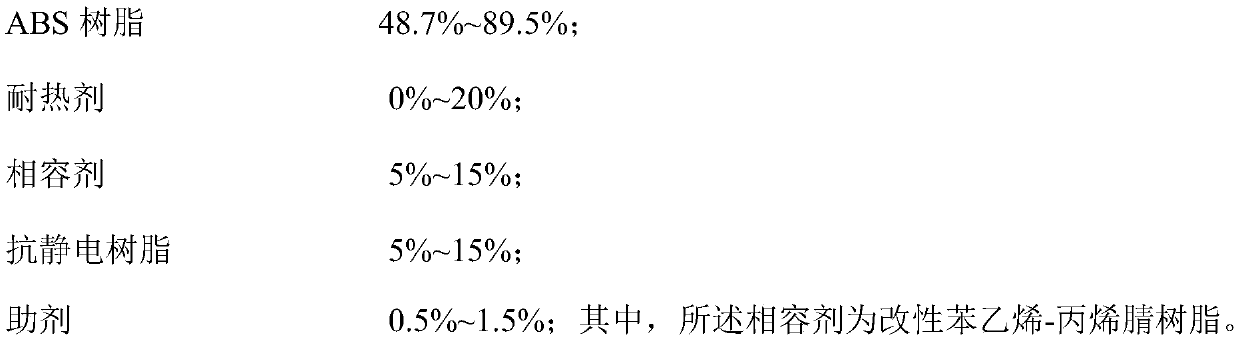

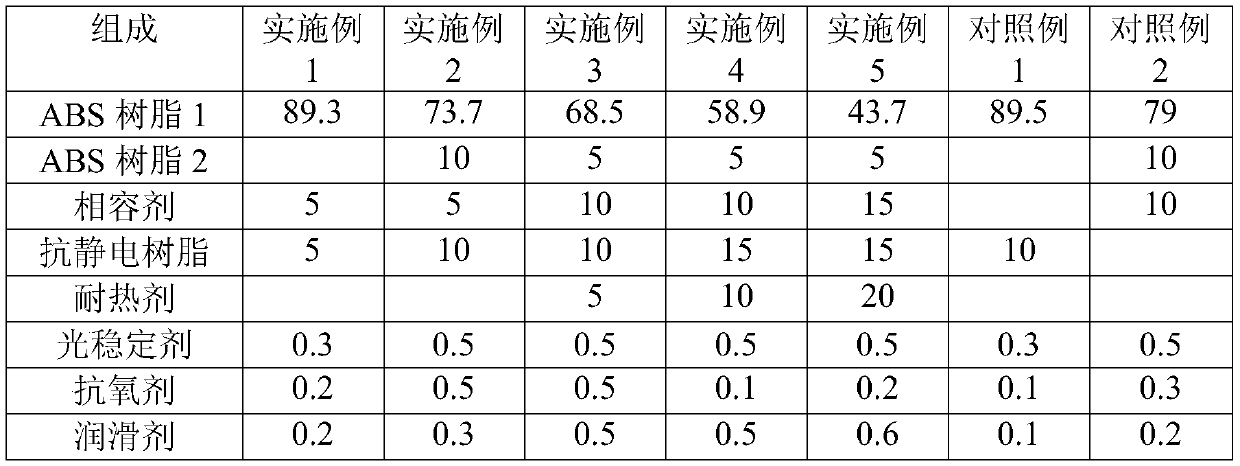

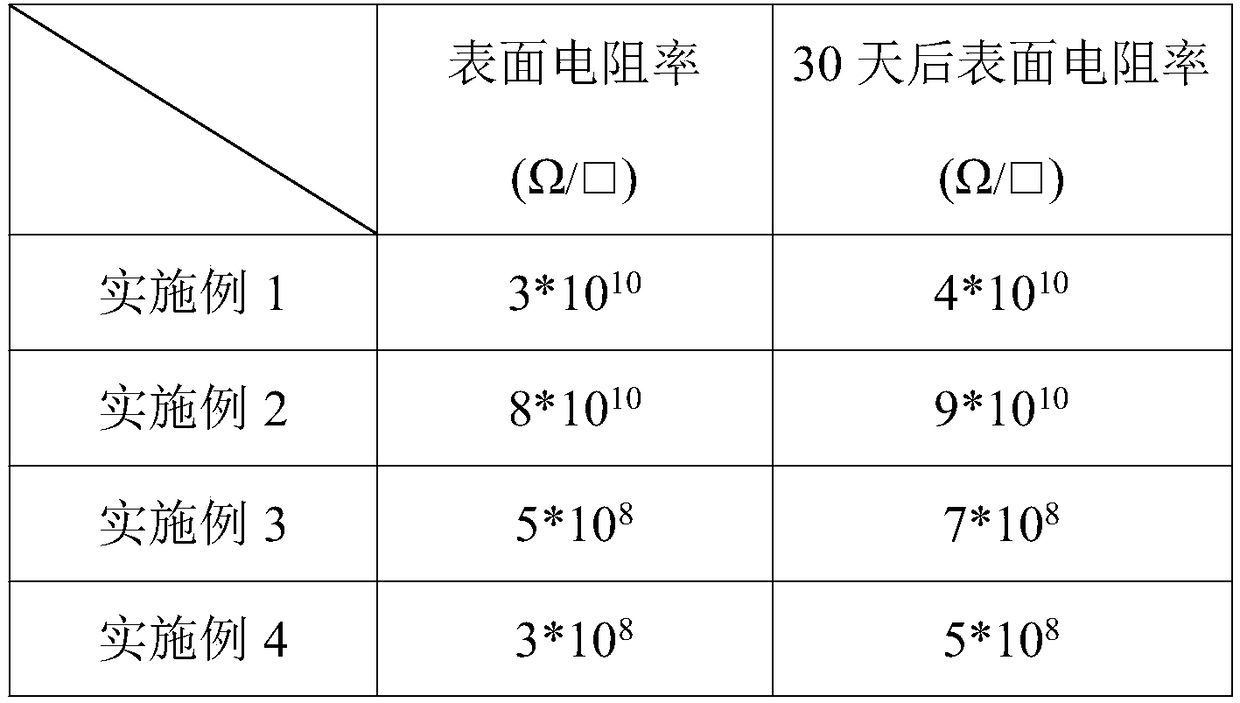

Permanent antistatic noise-reducing ABS resin composition and preparation method thereof

The invention relates to a permanent antistatic noise-reducing ABS resin composition and a preparation method thereof. The permanent antistatic noise-reducing ABS resin composition is composed of ABSresin, a heat-resistant agent, a compatilizer, antistatic resin and an auxiliary agent. By adding the compatilizer, on one hand, the compatibility between the ABS resin and the antistatic resin is improved; on the other hand, the antistatic resin can form a more stable interpenetrating network structure in a resin composition system, so that the ABS resin composition with antistatic and low-noisecharacteristics and excellent comprehensive performance is obtained, and the ABS resin composition is very suitable for being applied to the fields of automobiles, household appliances and the like.

Owner:SHANGHAI KINGFA SCI & TECH +1

Preparation method of antistatic silicone rubber

InactiveCN108929453ADoes not affect mechanical propertiesGood compatibilityElectrically-conductive paintsAntistatic agentPolymer science

The invention relates to a preparation method of an antistatic silicone rubber. The preparation method comprises following steps: a silicone rubber is prepared, and is subjected to surface treatment,so that the surface of the silicone rubber is provided with polar groups; the surface of the silicone rubber provided with the polar groups is coated with a multifunctional group compound so as to form a first coating layer, the multifunctional group is reacted with the polar groups to form chemical bonds; the surface of the first coating layer is coated with an antistatic agent and a binder so asto form a second coating layer, the binder is reacted with the multifunctional group for form chemical bonds, and curing is carried out so as to obtain the antistatic silicone rubber. According to the preparation method, silicone rubber is subjected to surface treatment firstly, and then the coating layer containing the antistatic agent is formed on the surface of the silicone rubber, so that permanent antistatic effect is achieved.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG

Production process of antistatic waterproof moisture-permeable fabric

InactiveCN109322038AGood water repellencyExpand the scope of applicationSolvent-treatmentLaminationPlasma treatmentAntistatic agent

The invention discloses a production process of an antistatic waterproof moisture-permeable fabric. The process includes the following steps of firstly, preparing warps and wefts, wherein the warps and wefts are chemical fibers mixed with an antistatic agent and conductive type high molecules, and the antistatic agent and conductive type high molecules are added through a mixing method in the melting step in the filament preparing process; secondly, weaving a gray fabric; thirdly, conducting plasma treatment on the gray fabric; fourthly, arranging water-repelling parts; fifthly, combining thefabric with a waterproof moisture-permeable film. According to the process, the antistatic agent and conductive type high molecules are added to the melting step of warp and weft preparing, and the warps and wefts have permanent antistatic performance. Water-repelling post-arrangement is conducted in the fabric subjected to the plasma treatment, so a water-repelling agent and the yarns in the fabric can be better combined, and the water-repelling performance and effect are better compared with traditional water-repelling arrangement. The fabric is combined with the waterproof moisture-permeable film, so the fabric has a waterproof moisture-permeable function.

Owner:沈玉芳

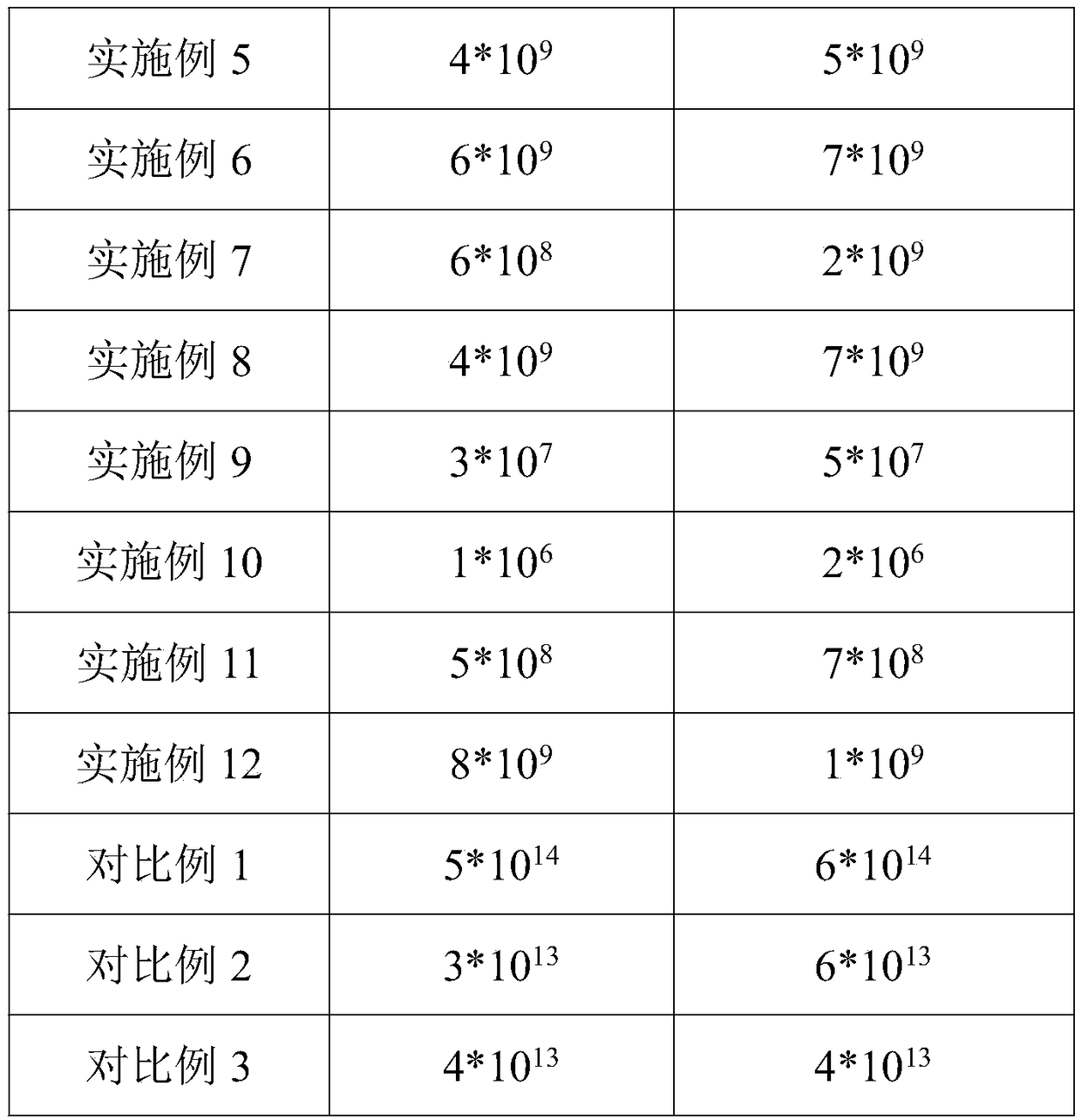

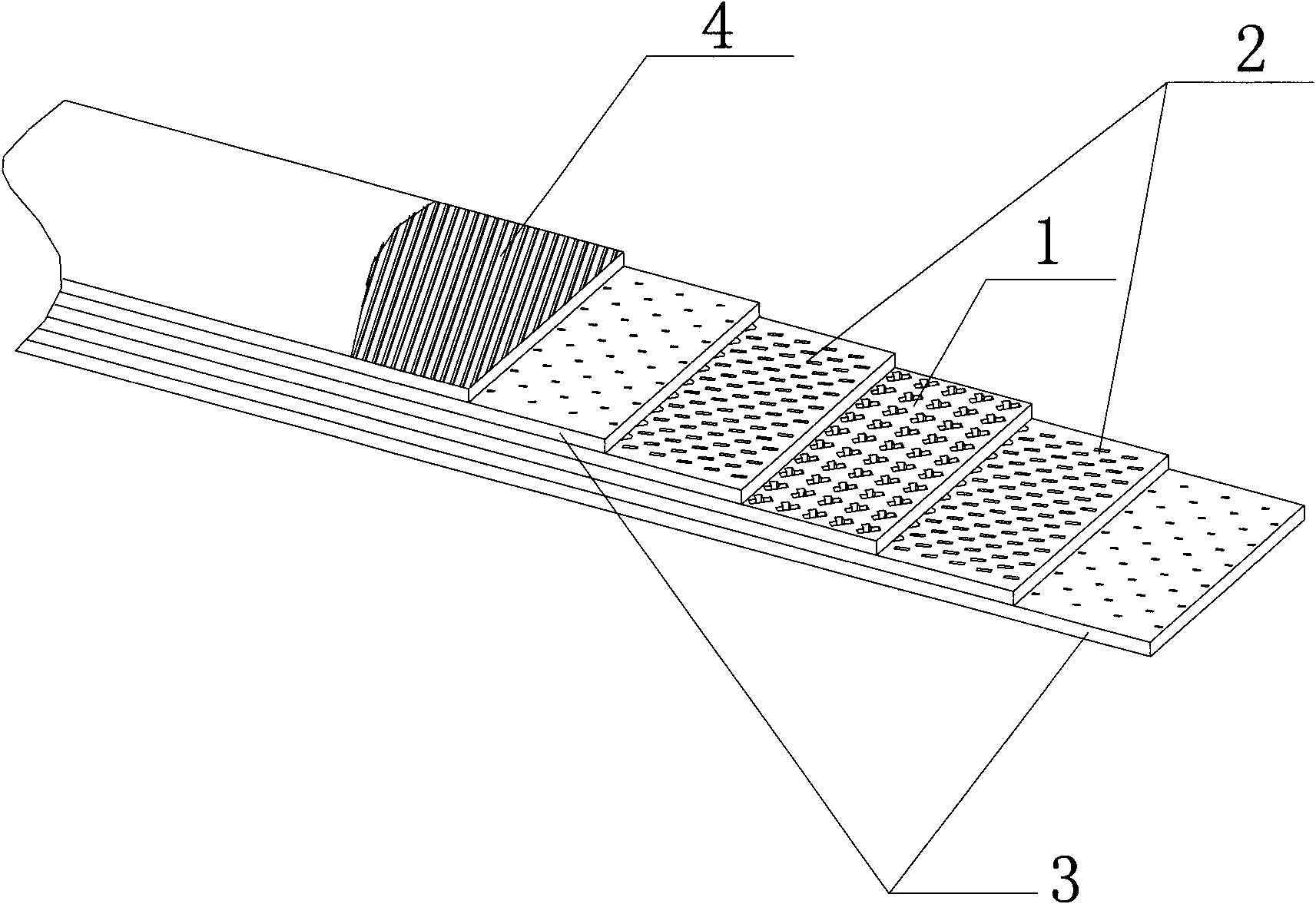

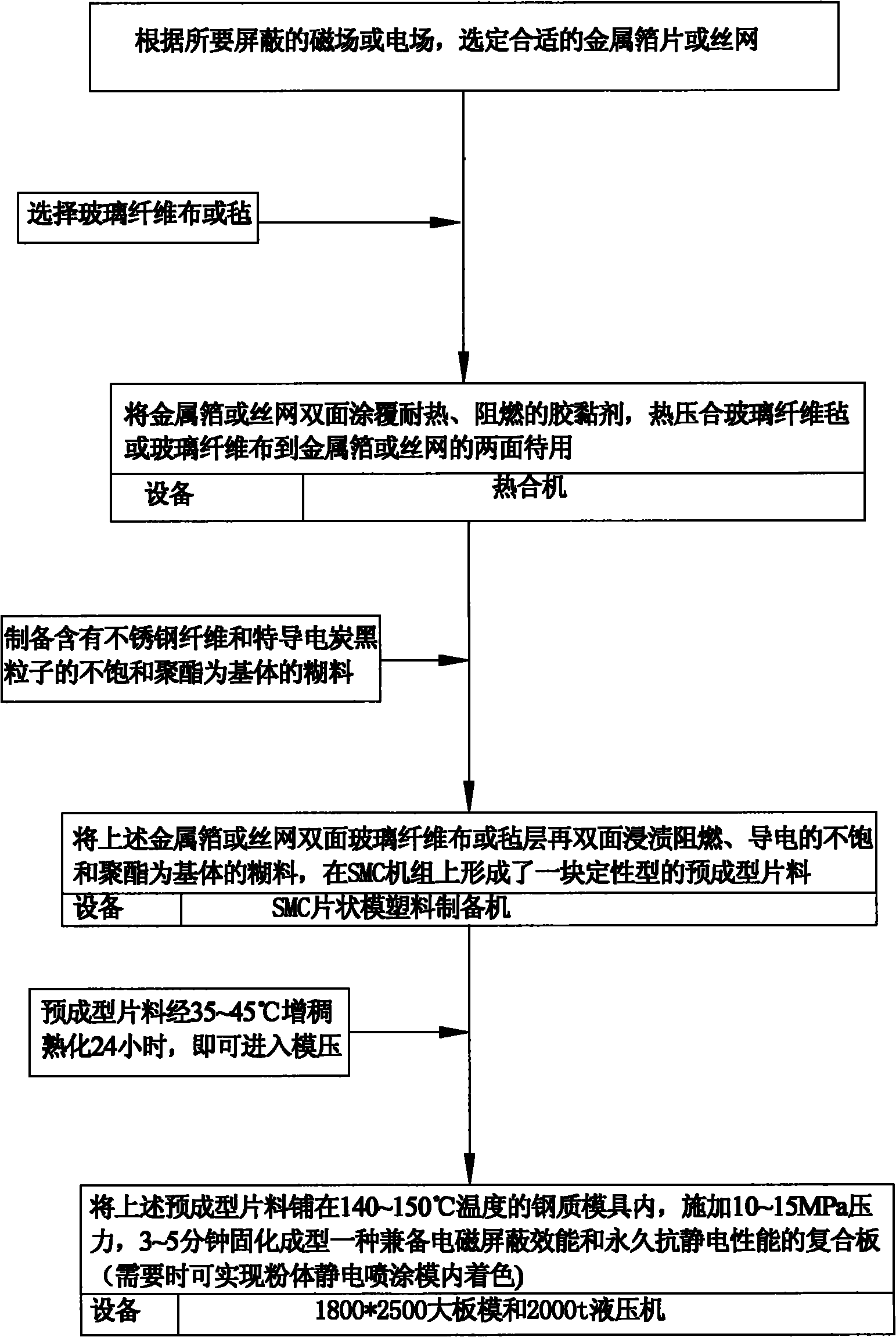

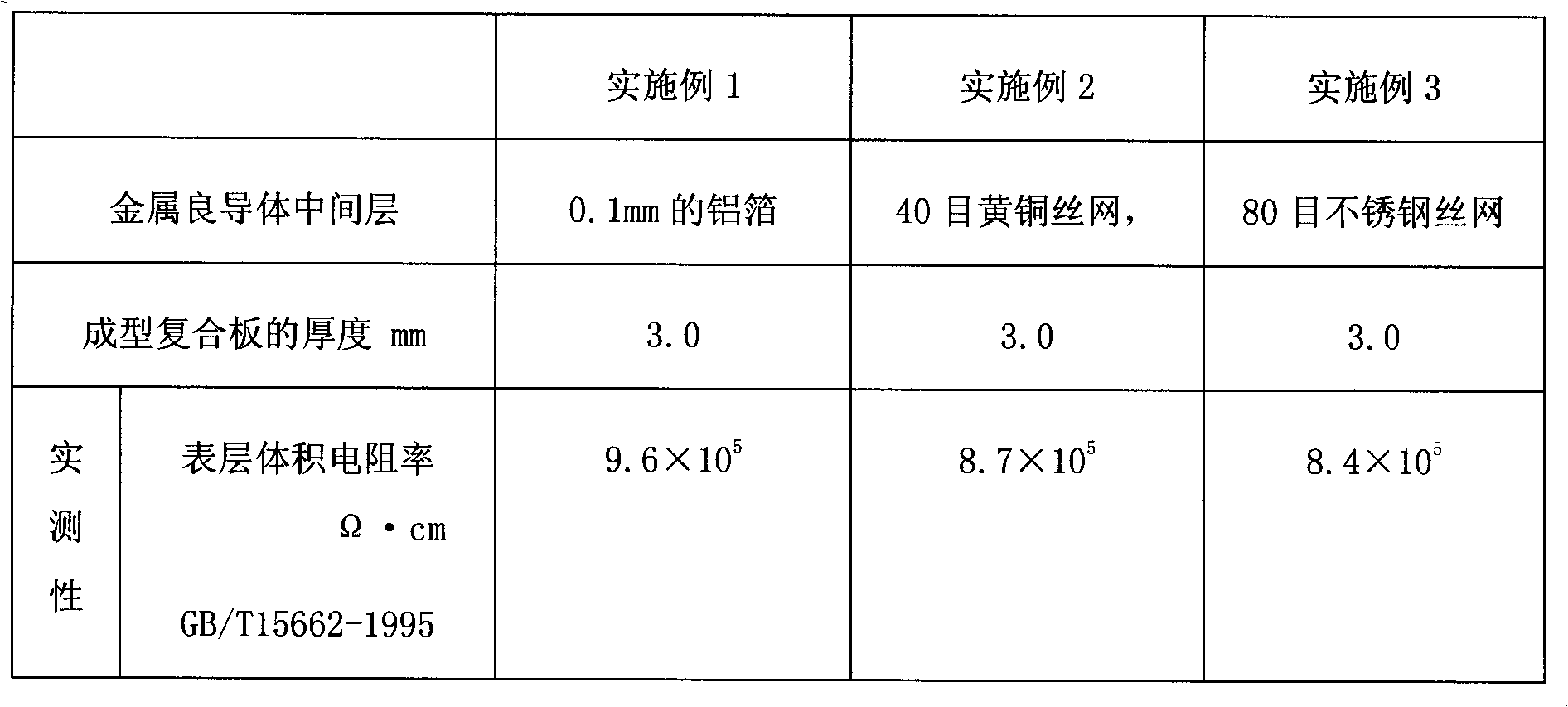

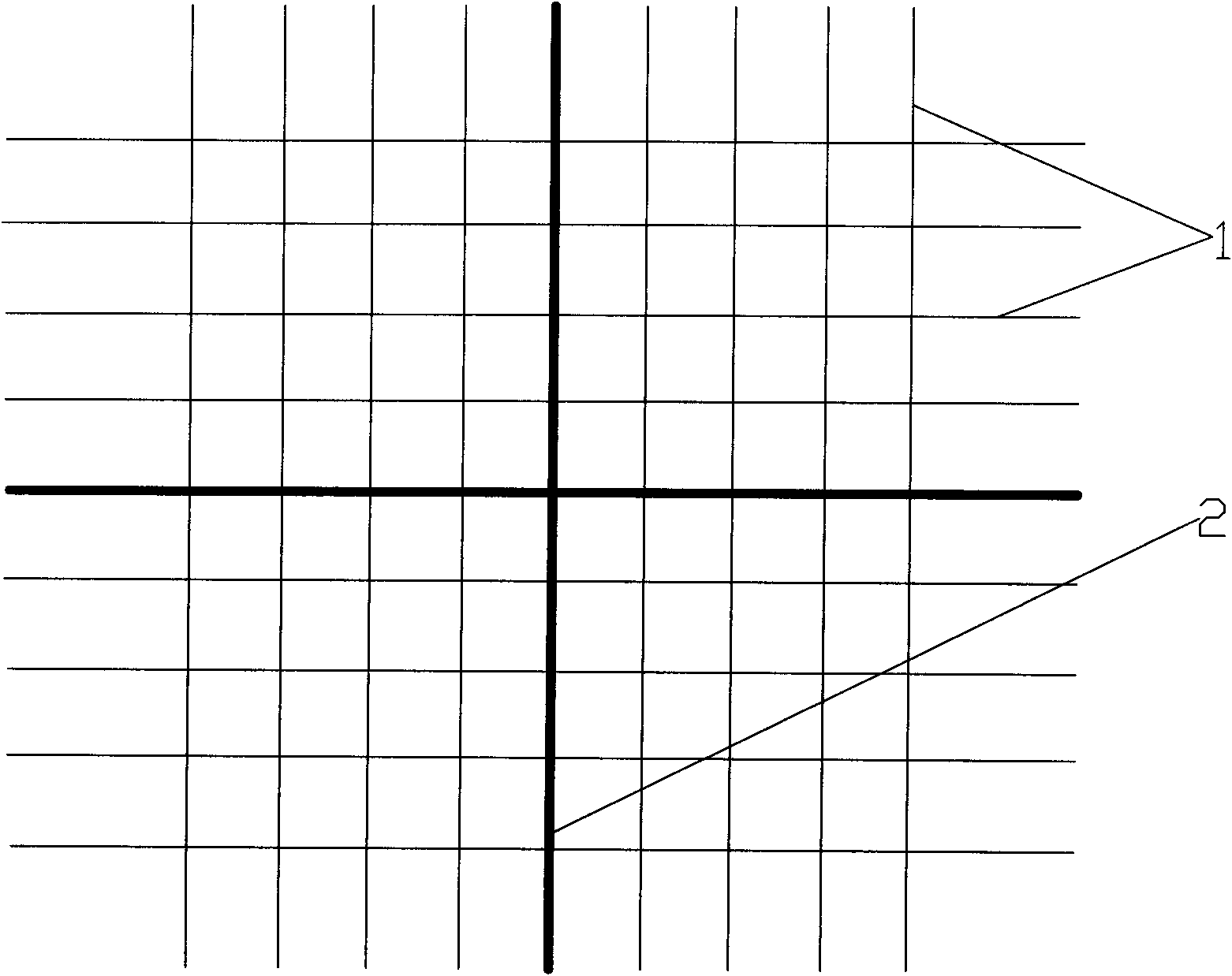

Composite plate with electromagnetic shielding efficiency and antistatic performance and preparation method thereof

InactiveCN102173107AImprove electromagnetic shielding performancePermanent antistaticSynthetic resin layered productsGlass/slag layered productsGlass fiberPolyester

The invention discloses a composite plate with electromagnetic shielding efficiency and antistatic performance, which is characterized by comprising a metal good conductor intermediate layer (1); glass fiber fabric composite layers (2) are thermally pressed on the front and the back surfaces of the metal good conductor intermediate layer (1); and flame-retardant conducting thickener layers (3) taking unsaturated polyester as matrixes are arranged on the outer surfaces of the glass fiber fabric composite layers (2). The invention also discloses a preparation method of the composite plate. The composite plate provided by the invention not only has electromagnetic shielding efficiency and antistatic performance, but also has the advantages of light weight, high strength, flame retardance and the like.

Owner:NINGBO HAIGE COMPOSITE MATERIAL

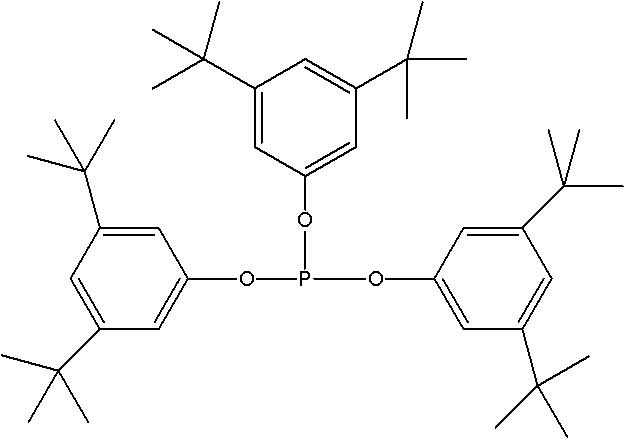

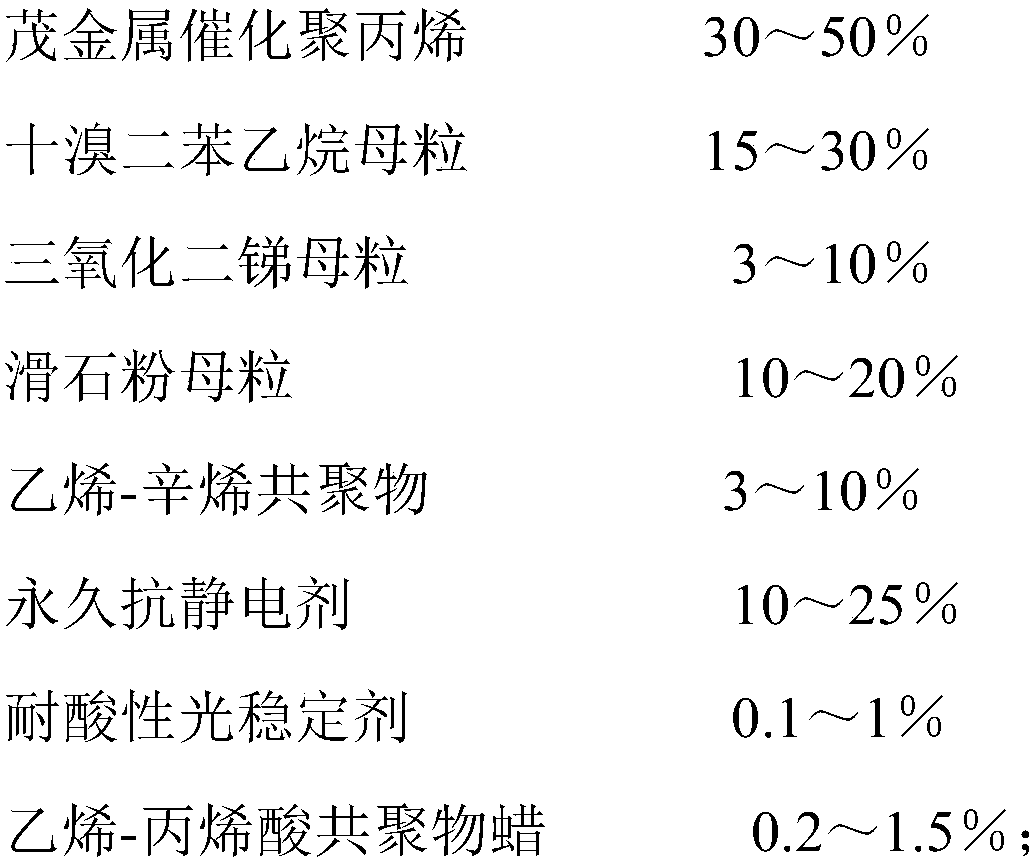

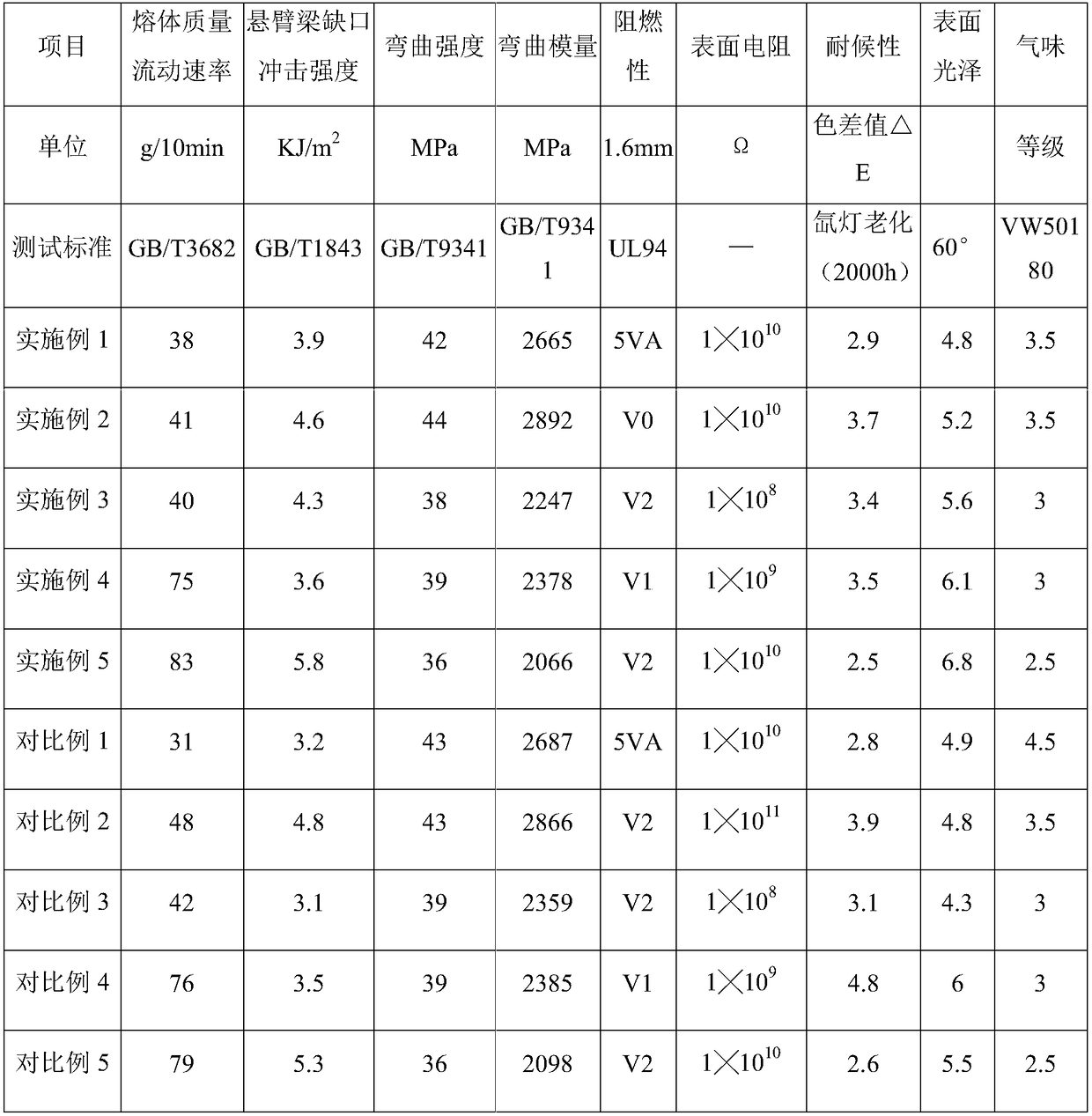

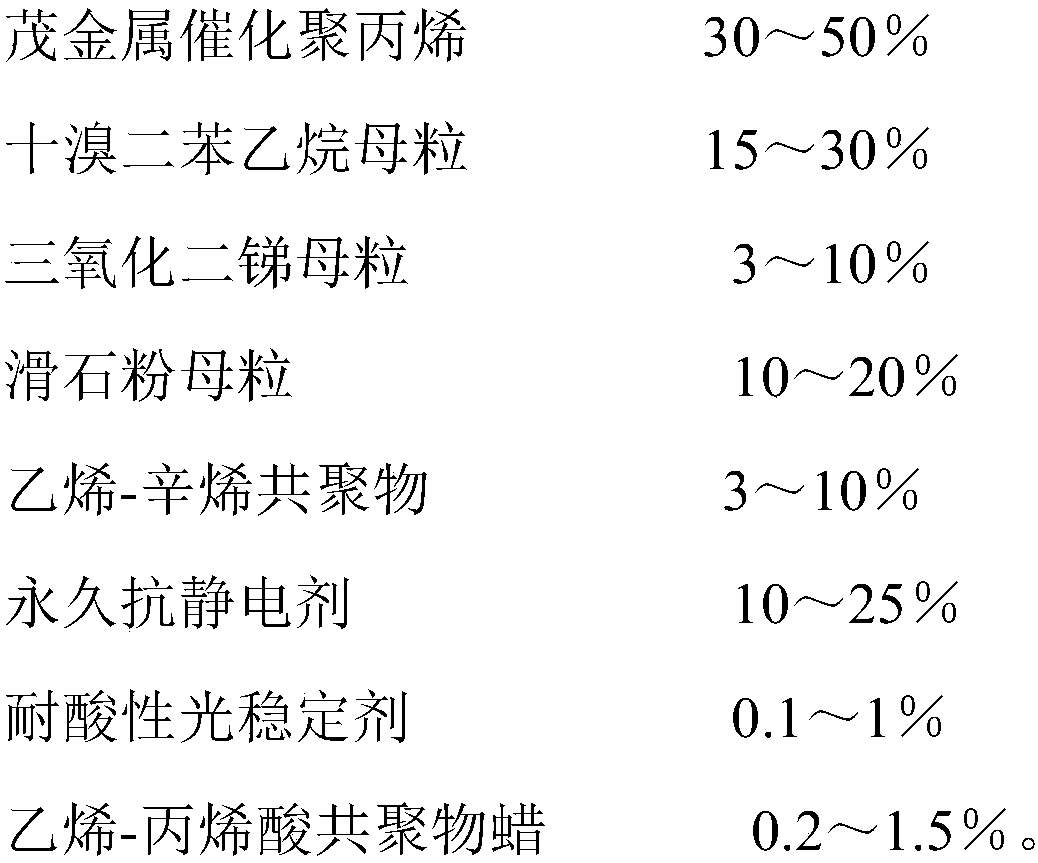

Highly weather-resistant permanent antistatic flame-retardant polypropylene material as well as preparation method and application thereof

The invention belongs to the technical field of improvement of high polymer composite materials and particularly relates to a highly weather-resistant permanent antistatic flame-retardant polypropylene material as well as a preparation method and application thereof. The highly weather-resistant permanent antistatic flame-retardant polypropylene material comprises the following components in percentage by mass: 30-50% of motallocene-catalyzed polypropylene, 15-30% of a decabrominated dipheny ethane master batch, 3-10% of an antimonous oxide master batch, 10-20% of a talcum powder master batch,3-10% of an ethylene-octylene copolymer, 10-25% of a permanent antistatic agent, 0.1-1% of an acid resistant light stabilizer and 0.2-1.5% of ethylene-acrylic acid copolymer wax. The polypropylene material provided by the invention has the characteristics of excellent weather resistance, permanent antistatic property, excellent flame-retardant property, low cost, forming simplicity, balanced physical and mechanical properties, and can be used for preparing a charging pile housing, an electric vehicle battery case, a heater shell or an extension socket shell.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

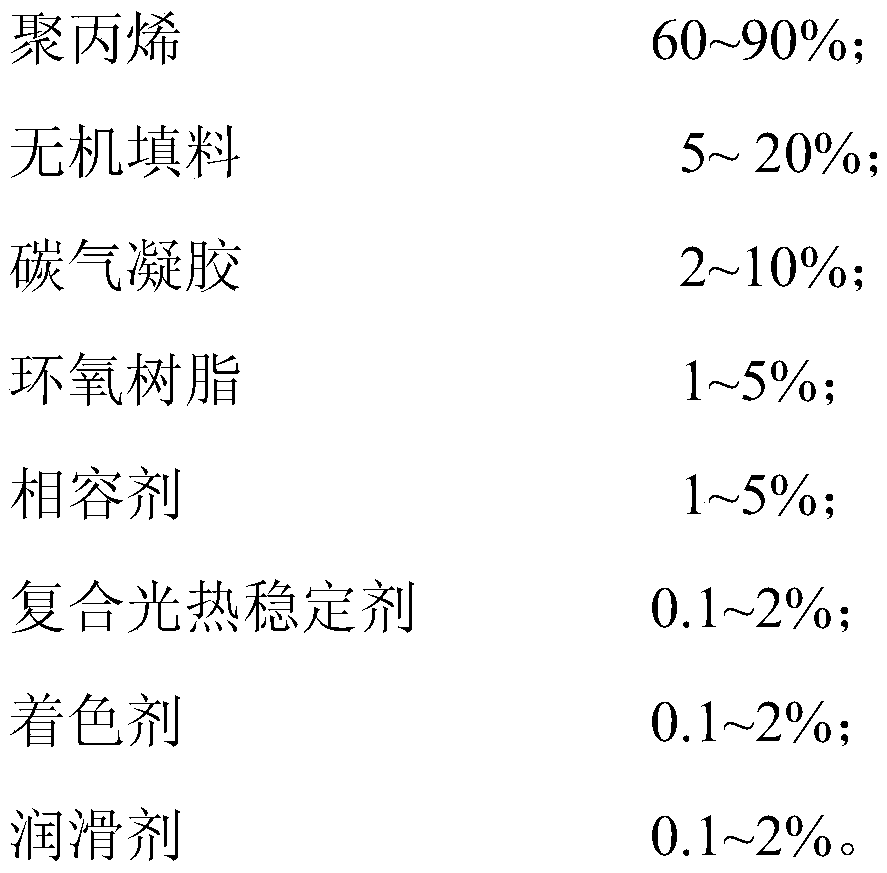

Low-VOC and antistatic polypropylene material as well as preparation method and application thereof

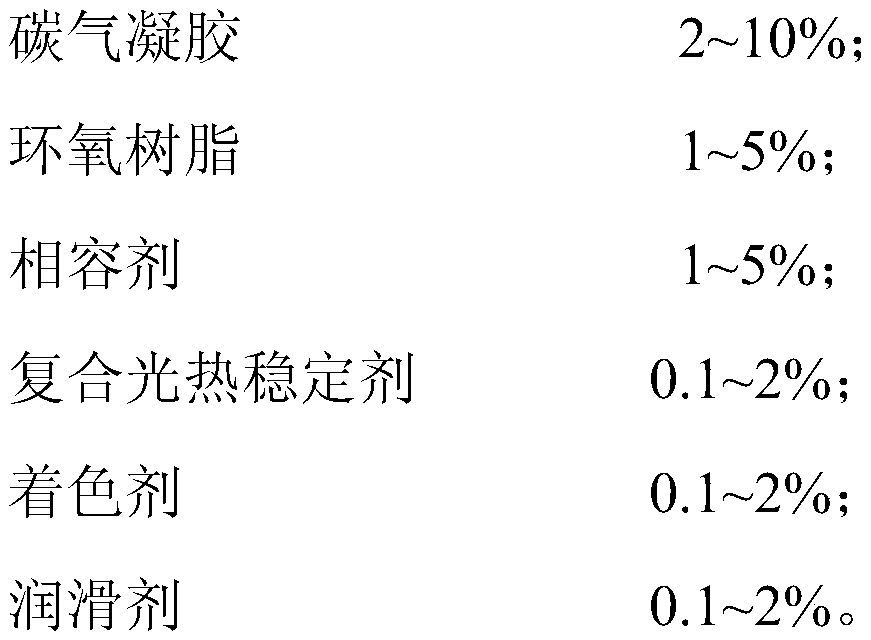

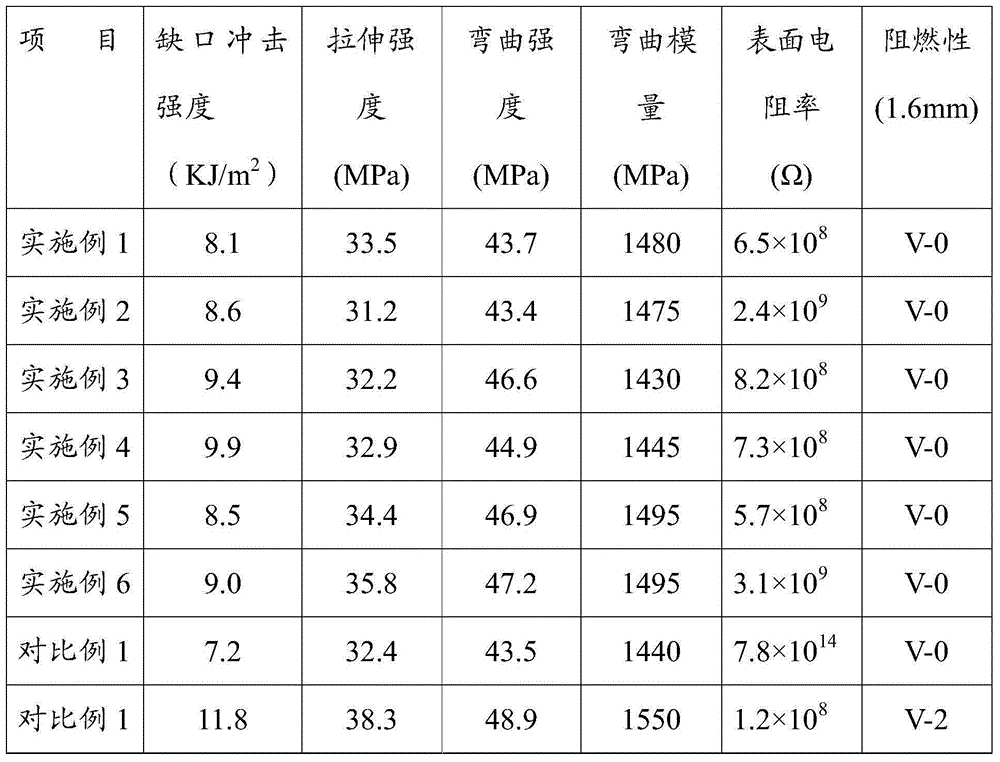

The invention relates to the technical field of high polymer materials, and discloses a low-VOC and antistatic polypropylene material as well as a preparation method and an application of the low-VOCand antistatic polypropylene material. 5-20% of an inorganic filler; 2 to 10 % of carbon aerogel; 1-5% of epoxy resin; 1-5% of a compatilizer; 0.1-2% of a composite photo-thermal stabilizer; 0.1-2% ofa colorant; 0.1-2% of a lubricant are melted and mixed to obtain the low-VOC and antistatic polypropylene material; the carbon aerogel is applied to plastic, the characteristics of the carbon aerogelare utilized, and the carbon aerogel, the epoxy resin and the compatilizer are reasonably proportioned to obtain the polypropylene composite material with excellent mechanical properties, VOC emission properties and antistatic properties, and the polypropylene composite material can be applied to parts of interior and exterior decorations of automobiles, and is excellent in touch and long-actingin dust prevention.

Owner:中广核俊尔(浙江)新材料有限公司 +1

Functional polyester and cotton conductive fabric

The invention discloses a functional polyester and cotton conductive fabric formed by vertically interweaving warp yarns and weft yarns, wherein the warp yarns are composed of polyester and cotton blended yarns and conductive fiber yarns, and the conductive fiber yarns are arranged at equal intervals. The functional polyester and cotton conductive fabric provided by the invention is reasonable in structure, has favorable antistatic property and abrasion resistance and can be widely applied to products such as clothing, carpets, packing materials, car seat cushions and the like.

Owner:NANTONG LVBAJIAO TEXTILE PROD

High-strength antistatic polyphenylene sulfide material and preparation method thereof

The invention relates to the technical field of polymer materials, and discloses a high-strength antistatic polyphenylene sulfide material and a preparation method thereof. The material is prepared from following components by weight: 45-55 parts of polyphenylene sulfide, 45-55 parts of glass fiber, 0.2-0.4 part of a lubricant, 0.2-0.4 part of an antioxidant, 0.6-1 part of a coupling agent and 0.5-1 part of an antistatic agent. The preparation method comprises steps of mixing uniformly the 45-55 parts of the polyphenylene sulfide, the 45-55 parts of the glass fiber, the 0.2-0.4 part of the lubricant, the 0.2-0.4 part of the antioxidant, the 0.6-1 part of the coupling agent and the 0.5-1 part of the antistatic agent at a high speed by a high-speed mixer, adding the mixture into a screw extruder, and stretching and pelletizing by the screw extruder to obtain a product. The material has permanent antistatic performance, and the cost of the material is largely reduced because of addition of the low-cost glass fiber, thus extending the application range of the material largely.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Stainless steel material for doors and windows

InactiveCN107058876AGood transverse yield strengthImprove plasticityAntifouling/underwater paintsPaints with biocidesRare-earth elementHigh intensity

The invention provides a stainless steel material for doors and windows. The material is prepared from a Fe element and modified chemical element impurities. The following modified chemical elements in percentage by mass are included: 0.05 to 0.11 percent of C, 0.5 to 1 percent of Mn, 0.21 to 0.24 percent of Si, 0.006 to 0.008 percent of P, 0.002 to 0.004 percent of S, 0.093 to 0.095 percent of Nb, 0.06 to 0.08 percent of V, 2.8 to 3.1 percent of Ti, 1.5 to 1.7 percent of Al, 0.001 to 0.006 percent of N, 0.0001 to 0.0002 percent of H, 0.05 to 0.07 percent of Cu, 7.4 to 15.2 percent of Cr, 8.1 to 11.3 percent of Ni, 0.23 to 0.25 percent of Mo, 0.21 to 0.23 percent of La, 0.04 to 0.08 percent of Sr, 0.05 to 0.1 percent of Th, 0.02 to 0.03 percent of Be, 0.05 to 0.08 percent of Zr, 0.0015 to 0.002 percent of B, and 0.06 to 0.09 percent of Re. According to the stainless steel material for doors and windows provided by the invention, the element contents in stainless steel are reasonably controlled, so that the obtained stainless steel is anti-corrosion and anti-erosion; and the rare earth element lanthanum is added, so that the high-strength anti-corrosion stainless steel for metal doors and windows are successfully obtained and has better transverse yield strength and high-ductility, the transverse tensile strength is larger than or equal to 450MPa, the transverse yield strength is larger than or equal to 240MPa, the transverse extension rate is larger than or equal to 30 percent, and the thickness-direction area reduction percentage is larger than or equal to 55 percent.

Owner:合肥市旺友门窗有限公司

Anti-static halogen-free flame-retardant polypropylene composition and preparation method

The invention discloses an anti-static halogen-free flame-retardant polypropylene composition. The anti-static halogen-free flame-retardant polypropylene composition is prepared from, by weight, 55-70 parts of polypropylene, 3-15 parts of an anti-static agent, 0.3-2.5 parts of a surface treating agent, 20-30 parts of a compound phosphorus-nitrogenous flame retardant, 1-5 parts of flame retardant synergist, 1-6 parts of char-forming synergist, 2-7 parts of polarity improver, 0.3-0.9 part of an antioxidant and 0.3-1.0 part of a processing additive. The anti-static halogen-free flame-retardant polypropylene composition is permanent in anti-static property, good in flame retardancy, harmless to the environment, good in operability and low in cost.

Owner:余姚市中发工程塑料有限公司

Antistatic polybutylece terephthalate (PBT)/acrylonitrile butadiene styrene (ABS) compound material and preparation method thereof

InactiveCN102108191AGood mechanical propertiesPermanent antistaticElectrical resistance and conductanceState of art

The invention relates to an antistatic polybutylece terephthalate (PBT) / acrylonitrile butadiene styrene (ABS) compound material and a preparation method thereof. The compound material comprises the following components by weight percent: 40-70% of PBT, 10-30% of ABS, 3-10% of compatilizer, 10-30% of antistat and 0.1-0.5% of lubricant. The preparation method comprises the following steps: putting all the raw materials in a high mixing machine, mixing for 2-5 minutes, and then discharging; and then putting the mixture in a screw machine, and carrying out extrusion and granulation so as to obtain the product, wherein the rotating speed of the screw machine is controlled at180-600 rpm (revolutions per minute) and the temperature is controlled at 210-240 DEG C. Compared with the compound material prepared by the prior art, the compound material prepared by the method in the invention has excellent mechanical property and permanent antistatic property, and the surface resistance of the compound material can reach 107-109 omega; and the material prepared by the method can be used for manufacturing production equipment with antistatic and no-dust requirements, and can be widely applied in the fields of electronics, automobiles, home appliances, sports goods and the like.

Owner:SHANGHAI SUNNY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com