Anti-static polyolefin ventilated membrane composition and method for preparing the same

A technology of polyolefin and breathable film, applied in the direction of coating, etc., can solve the problem of not being able to effectively balance the antistatic and mechanical properties of polyolefin breathable film, air permeability, product appearance and processability, poor mechanical properties of the film, and the addition of conductive fillers Large volume and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Preparation of antistatic resin:

[0037] 1. Preparation of antistatic resin 1

[0038] (1) 2,4-toluene diisocyanate (TDI) reacts with stearyl alcohol at a temperature of 60-70°C for 2-3 hours to obtain a pre-reactant, in which the isocyanate group (-NCO) in 2,4-toluene diisocyanate The ratio of the number of moles to the number of moles of hydroxyl groups in stearyl alcohol is 2. Then react the pre-reactant with the amino-terminated polyethylene glycol with a molecular weight of 2500 in a molar ratio of 1 at 150-160° C. for 5-10 minutes to prepare the antistatic agent AS.

[0039] (2) The antistatic agent (AS), glycidyl methacrylate and the third monomer styrene are melt-grafted to ethylene-propylene copolymer (EPR) by twin-screw under the action of dicumyl peroxide initiator The antistatic resin 1 is prepared on the macromolecular chain. Wherein the addition amount of antistatic agent AS is 30% of polyolefin weight, the addition amount of glycidyl methacrylate is 3...

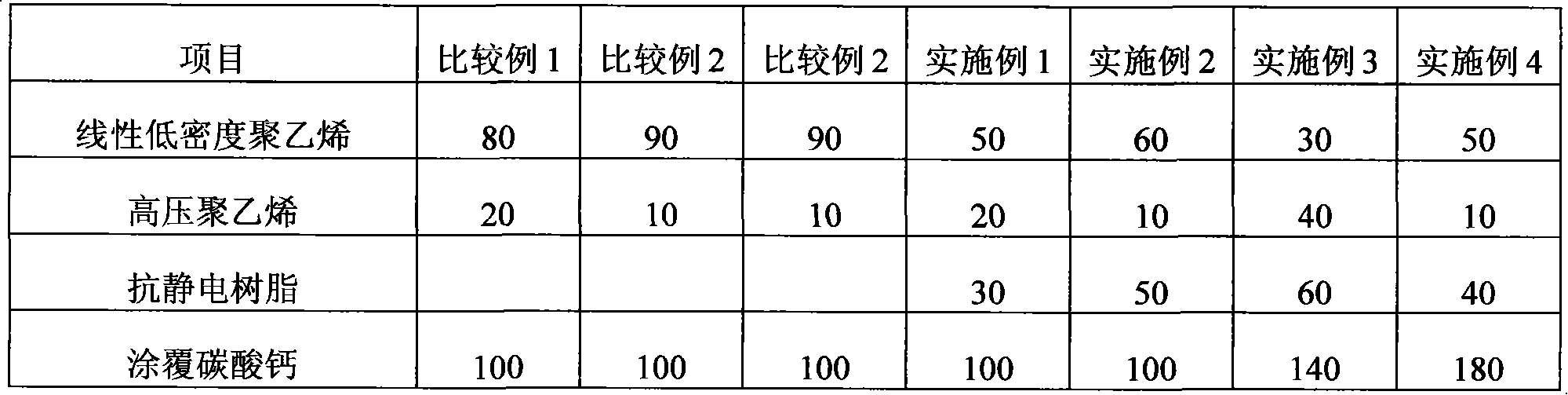

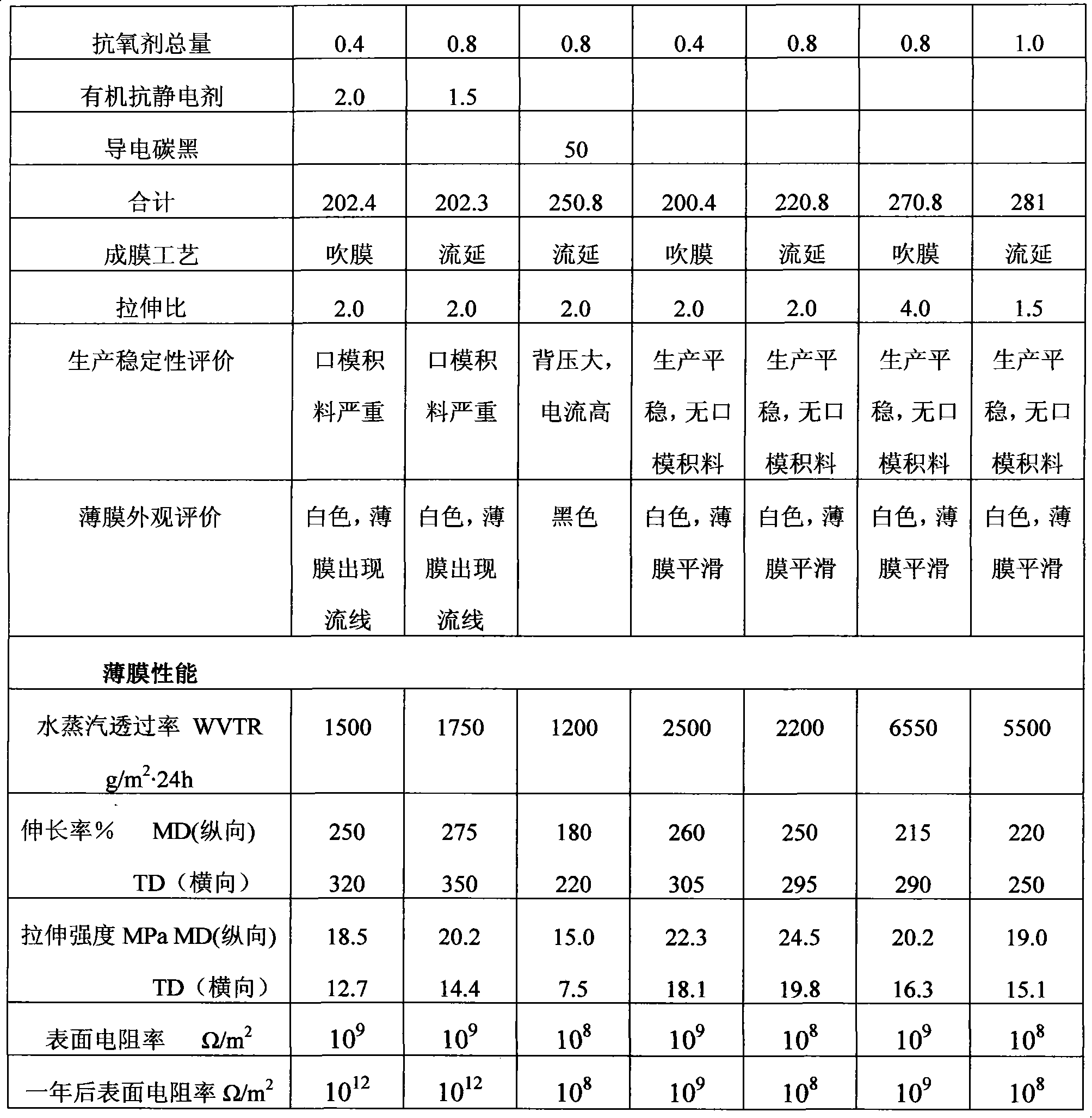

Embodiment 1

[0053] Example 1 Preparation of antistatic polyolefin gas permeable film

[0054] (1) Carry out surface coating treatment to calcium carbonate (particle diameter is 5.0 μ m) with surface modifier stearic acid in high-speed mixer and obtain coating calcium carbonate, the consumption of surface modifier is 2.0 of the total amount of calcium carbonate % (percentage by weight). The treatment process conditions are as follows: the rotation speed is 3000r / min, the treatment temperature is 100°C, and the treatment time is 45min.

[0055] (2) According to the weight ratio shown in Table 1, 50 parts by weight of linear low density polyethylene copolymerized with ethylene and hexene (C6) has a melt index of 1.0 g / 10 min and a density of 0.915 g / cm 3 , the molecular weight distribution is 3; 20 parts by weight of high-pressure polyethylene, the melt index is 2.0g / 10min, and the density is 0.920g / cm 3 30 parts by weight of antistatic resin 1; 100 parts by weight of calcium carbonate and...

Embodiment 2

[0058] (1) calcium carbonate (particle diameter is 0.5 μ m) is carried out surface coating treatment with surface modifier isopropyl tris (dioctyl phosphate acyloxy) titanate in high-speed mixer to obtain coated calcium carbonate, The amount of the surface modifier is 1.5% (percentage by weight) of the total amount of calcium carbonate. The treatment process conditions are as follows: the rotation speed is 3000r / min, the treatment temperature is 90°C, and the treatment time is 30min.

[0059] (2) According to the weight ratio shown in Table 1, 60 parts by weight of linear low-density polyethylene copolymerized with ethylene and butene (C4) has a melt index of 4.0 g / 10 min and a density of 0.940 g / cm 3 , the molecular weight distribution is 15; 10 parts by weight of high-pressure polyethylene, the melt index is 20.0g / 10min, and the density is 0.900g / cm 3 50 parts by weight of antistatic resin 2; 100 parts by weight of calcium carbonate coated with 0.8 parts by weight of antiox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com