Patents

Literature

76results about How to "Does not affect processing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

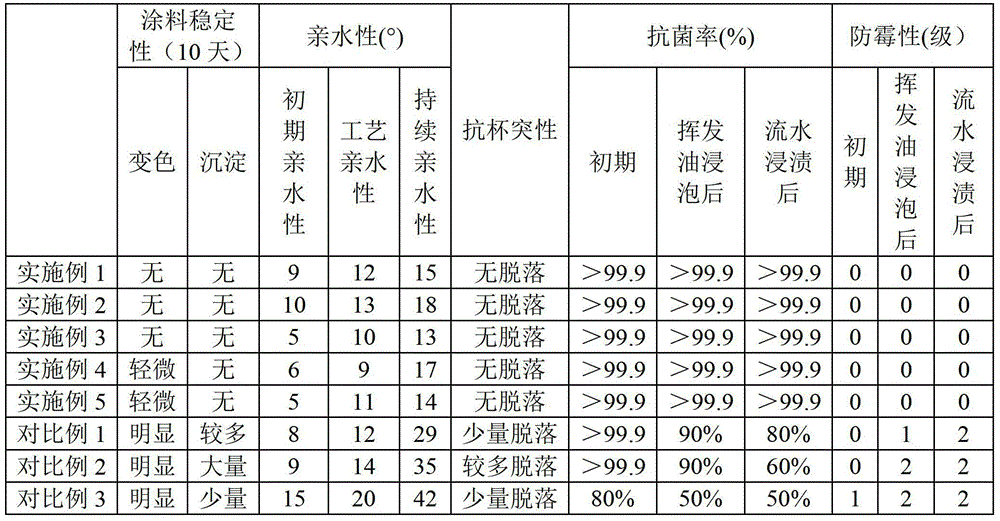

Water-based antimicrobial moldproof hydrophilic paint for heat exchanger fin surface treatment

ActiveCN103333571AImprove stabilityAdd lessAntifouling/underwater paintsPaints with biocidesWater basedReducer

The invention discloses a water-based antimicrobial moldproof hydrophilic paint for heat exchanger fin surface treatment. The paint comprises 3-30% of high molecular compound containing hydrophilic group, 0.05-1% of inorganic nano material with antibacterial action, 0.3-5% of curing agent, 0.02-0.2% of leveling agent and 2-10% of cosolvent. The inorganic nano material with antibacterial action is composed of 2-10% of nano oxide, 0.1-2% of silver salt or nano silver solution, 0.1-2% of reducer, 0.1-1% of stabilizer and the balance of water. Since the inorganic nano material with antibacterial action has high stability in the system, the antimicrobial and moldproof properties and hydrophilicity do not attenuate after the processing technique, and can last for a long time in the application process. The paint has the advantages of low addition amount and high cost performance, and does not influence the later working properties.

Owner:GUANGZHOU HUMAN CHEM

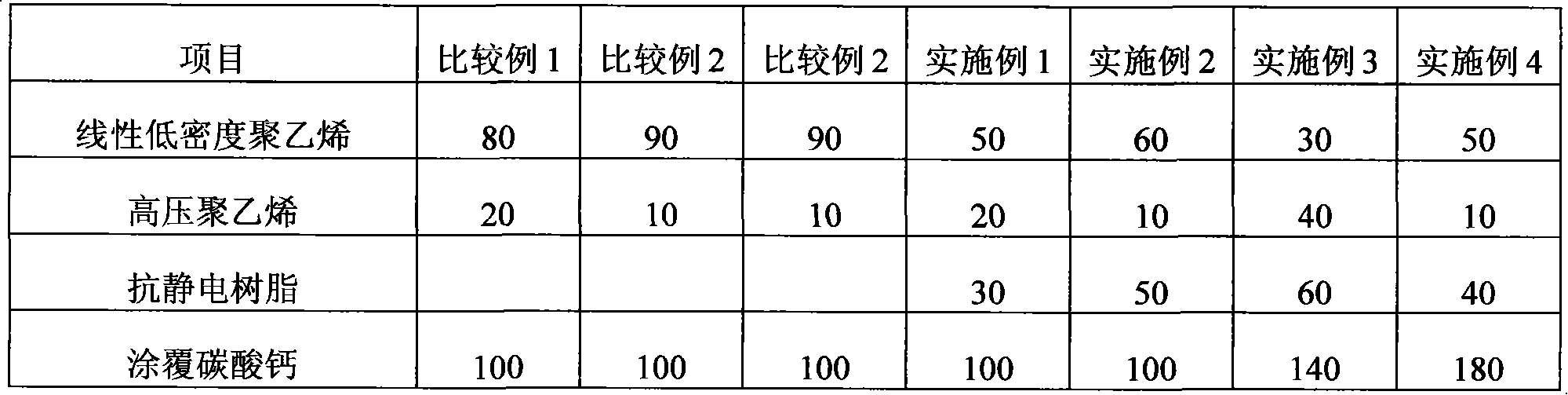

Anti-static polyolefin ventilated membrane composition and method for preparing the same

InactiveCN101250302APermanent antistaticGuaranteed antistatic effectCoatingsLinear low-density polyethylenePolyolefin

The invention discloses an antistatic polyolefin permeable film compound and a process for preparing the antistatic polyolefin permeable film. The compound comprises 30-60 parts by weight of linear low density polyethylene, 10-40 parts by weight of high-pressure polyethylene, 30-60 parts by weight of antistatic resin, 100-180 parts by weight of calcium carbonate and 0.4-1.0 parts by weight of anti-oxidant. The invention overcomes the weakness of traditional antistatic agent and antistatic filling, not only ensures the antistatic property of permeable film through adding antistatic resin, but also not affects the processing property, permeable property and the appearance of film. The processing flow-ability, the dispersing evenness of organic filling and processing stability of antistatic polyolefin permeable film compound in the invention can meet the production requirements of extrusion filmmaking. The water vapor permeable rate of the antistatic polyolefin permeable film which is prepared by the invention is not lower 2000g / m2 24h, and the surface electrical resistivity is no higher 10 9 omega / m2.

Owner:合诚技术股份有限公司

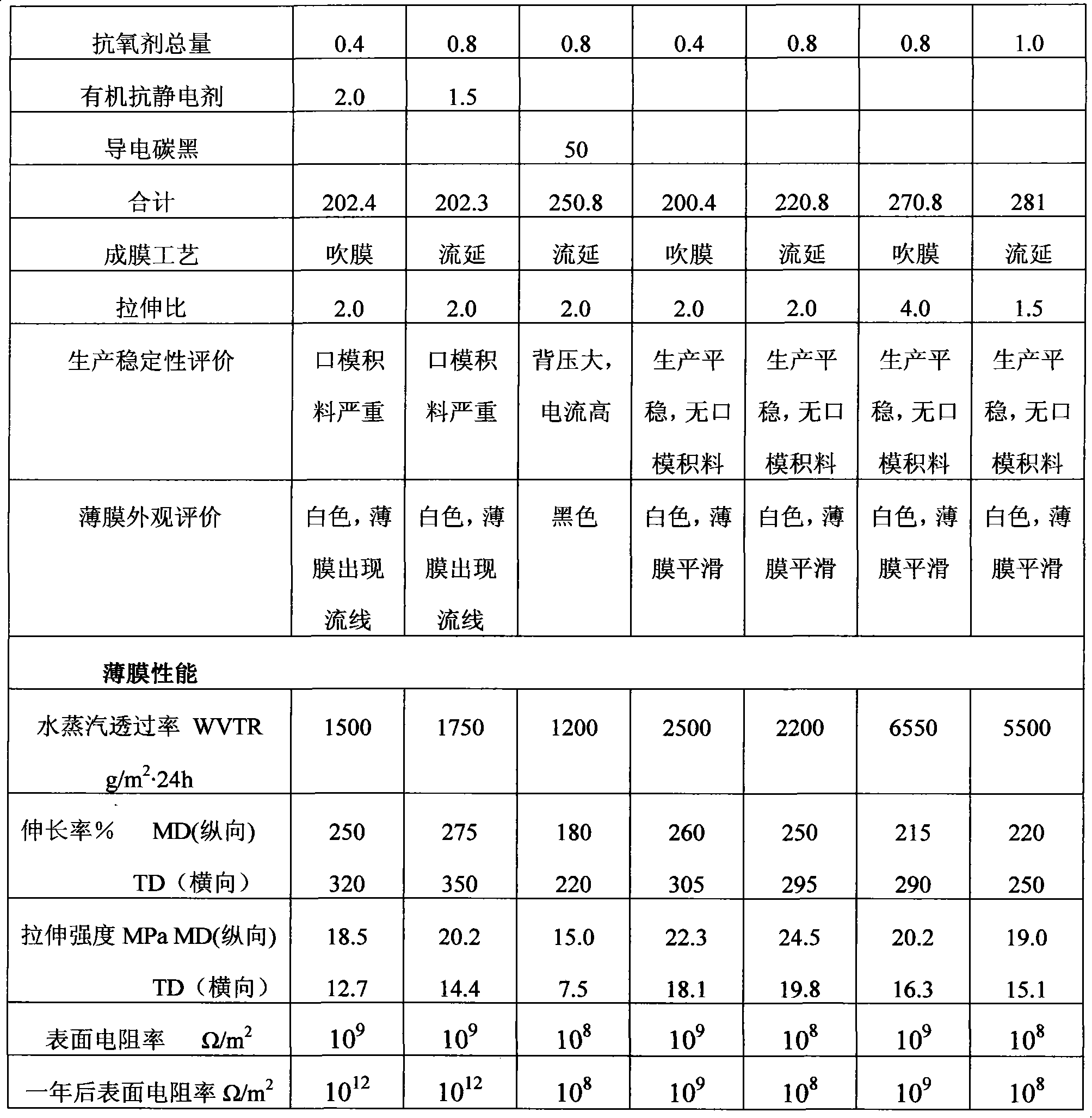

Polyolefin microporous air-permeable membrane and preparation method thereof

ActiveCN103739962AImprove process rangeDoes not affect processing performancePolymer sciencePolyolefin

The invention discloses a polyolefin microporous air-permeable membrane and a preparation method thereof. The microporous air-permeable membrane is prepared from a polyolefin substrate filled with a calcium carbonate filler with processed surface by means of casting extruding, stretching, and heat setting and film-forming. During the preparation, the polyolefin and the calcium carbonate filler with the processed surface are blended, extruded and pelletized, so as to prepare air-permeable particles; the air-permeable particles are extruded and molten by a casting extruder; the melt temperature is kept at 240-255 DEG C; the melt is continuously extruded to form a film through a die lip clearance of a T-shaped die head of a casting machine; the film is subjected to one-step or two-step stretching in a uniaxial manner; the draw ratio is controlled to be 1.5-2.5; the film obtained in the stretching manner is subjected to heat setting treatment at the heat setting temperature of 70-85 DEG C. The polyolefin microporous air-permeable membrane disclosed by the invention can ensure high air permeability and mechanical property of the microporous air-permeable membrane, meanwhile, the processing performance of the product is not affected, and the resistance to high temperature and high pressure of the film is also improved.

Owner:SHANGHAI ZIHUA FILM TECH CO LTD

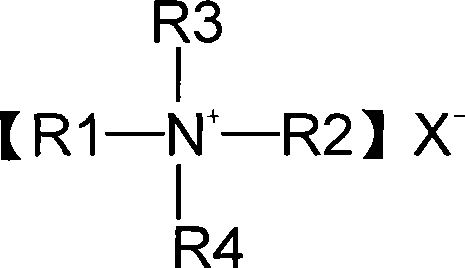

Novel low odor, low carbon emitting PC/ABS alloy material and preparation

ActiveCN101469122ADoes not affect processing performanceImprove adsorption capacityHigh concentrationAntioxidant

The invention discloses a novel low-odor low-volatilization PC / ABS (polycarbonate / acrylonitrile- butadiene-styrene copolymer) alloy material and a method for preparing the same. The PC / ABS alloy material comprises the following compositions by weight percentage: 50 to 80 percent of polycarbonate, 10 to 45 percent of ABS / PP graft, 1.0 to 5.0 percent of hydrophobic odor adsorption master particles. 0.1 to 1.0 percent of antioxidant and 0 to 0.5 percent of other additives. The preparation method comprises: firstly, 20 to 70 percent of ABS resin and 30 to 80 percent of attapulgite modified by quaternary ammonium salt type surfactant are mixed, extruded and pelletized to form high-concentration hydrophobic odor adsorption master particles; and secondly, the high-concentration hydrophobic odor adsorption master particles and the polycarbonate, the ABS / PP graft, the antioxidant and other additives are mixed, are placed in a double-screw extruder and are subjected to fusion, extrusion and pelletization. The obtained novel PC / ABS alloy material has the characteristics that the material is not influenced in molding processing at all and has excellent physical and chemical comprehensive performance and excellent odor property and the like.

Owner:CHONGQNG PRET NEW MATERIAL +2

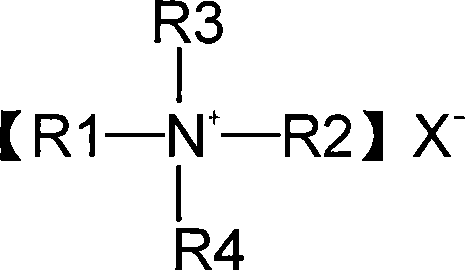

Environmental protection type HPVC door frame

InactiveCN101121802AComply with RoHS Directive requirementsDoes not affect processing performanceDomestic cooling apparatusLighting and heating apparatusAdditive ingredientStearic acid

The invention discloses an environment-friendly HPVC door frame, which is obtained by kneading and extruding. The main raw materials include PVC, a stabilizer, and a surface treatment agent, and are composed of the following substances by weight: PVC resin powder: 45-55, calcium Zinc composite stabilizer: 1-6, chlorinated polyethylene: 1-6, stearic acid: 0.1-1 part, polyethylene wax 0.1-1 part, ethylene bisstearamide: 0.1-0.8 part, acrylate copolymer Matter: 1-3, active calcium carbonate: 8-20, dioctyl phthalate: 0.1-1.5, epoxy soybean oil 0.3-1.2, triphenyl phosphite: 0.2-1.2, toner: 0.2-1 . The preparation method includes the steps of compounding, kneading, granulation and door frame extrusion. The performance index of the environment-friendly door frame prepared according to the invention meets the requirements of the RoHS directive, and the new formula does not affect the processing performance of the original equipment; the raw materials of the formula are easy to obtain and the price is low, and are suitable for industrial production.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

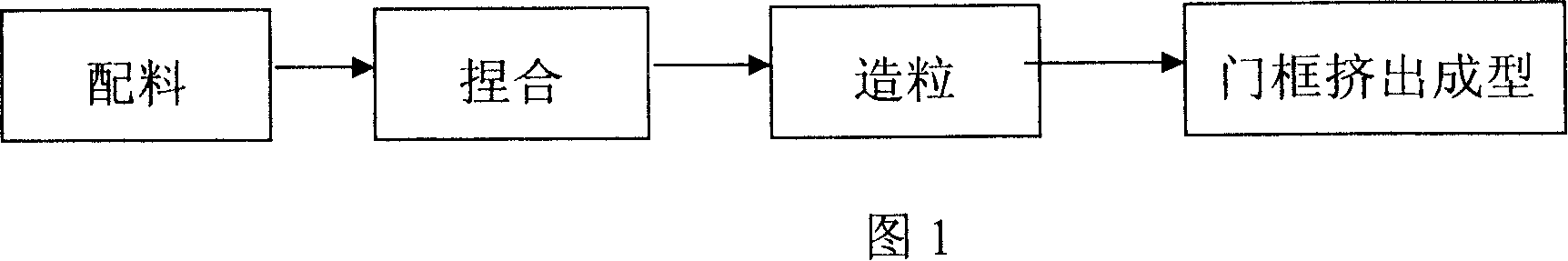

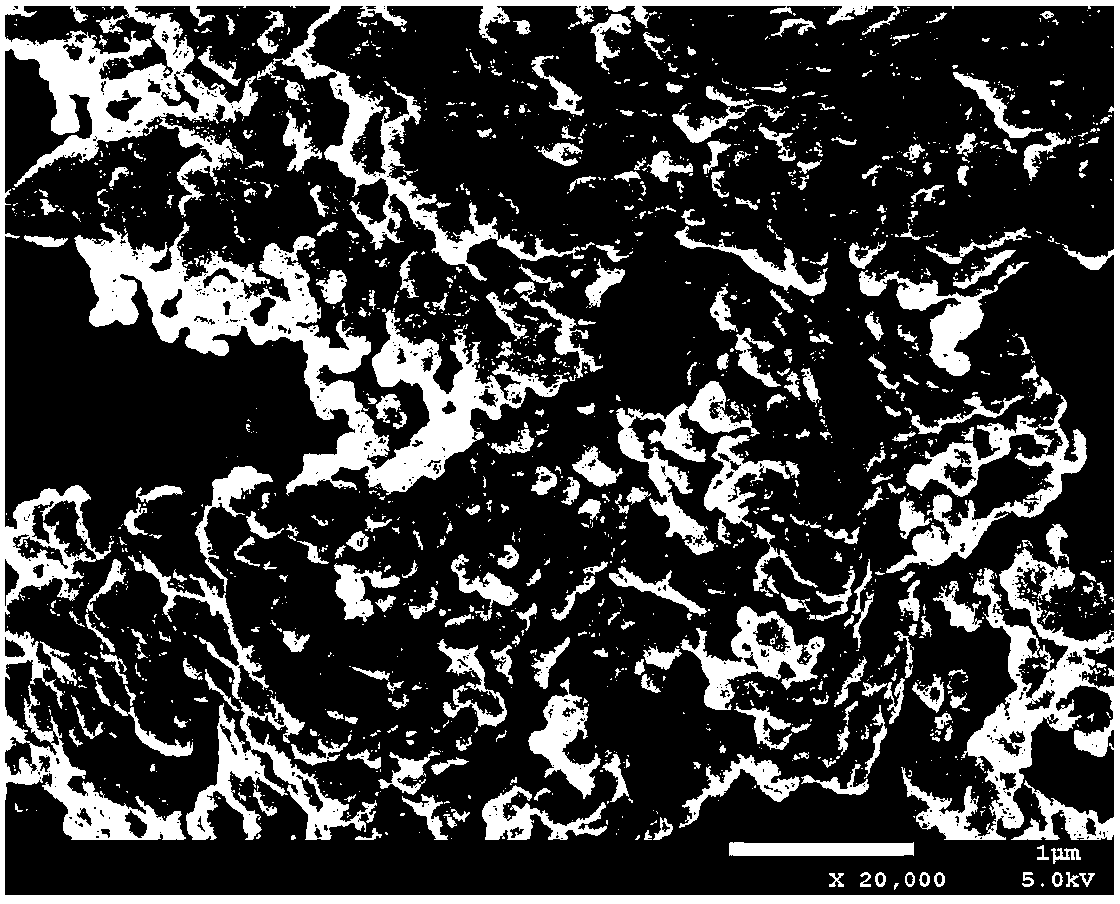

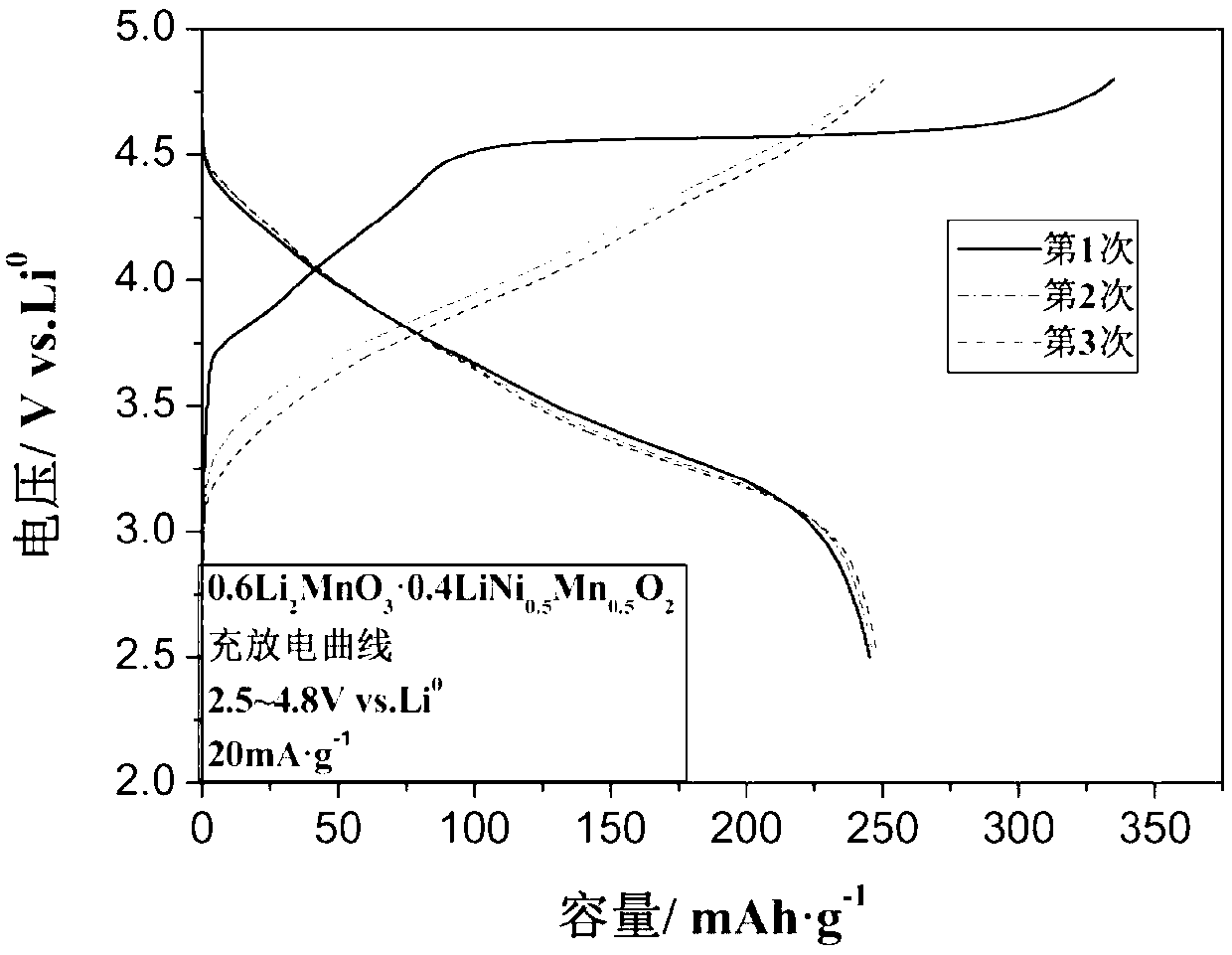

Lithium-rich manganese-based material and preparation method thereof

The invention relates to a lithium-rich manganese-based material and a preparation method thereof. The preparation method is a sol-spray pyrolysis method and comprises the steps of precursor sol preparation, spray drying, high-temperature calcining and the like. The preparation method disclosed by the invention has the advantages of simple process flow, less equipment input, high continuous degree and no exhaust of tail gas or discharge of waste liquid. The lithium-rich manganese-based anode material disclosed by the invention has excellent electrochemical performance, discharge capacity as high as 225-250A.h.g<-1> and favorable excellent performance; and under the multiplying power of 0.5C, the discharge capacity of the lithium-rich manganese-based material can be maintained over 150mA.h.g<-1>.

Owner:SICHUAN UNIV

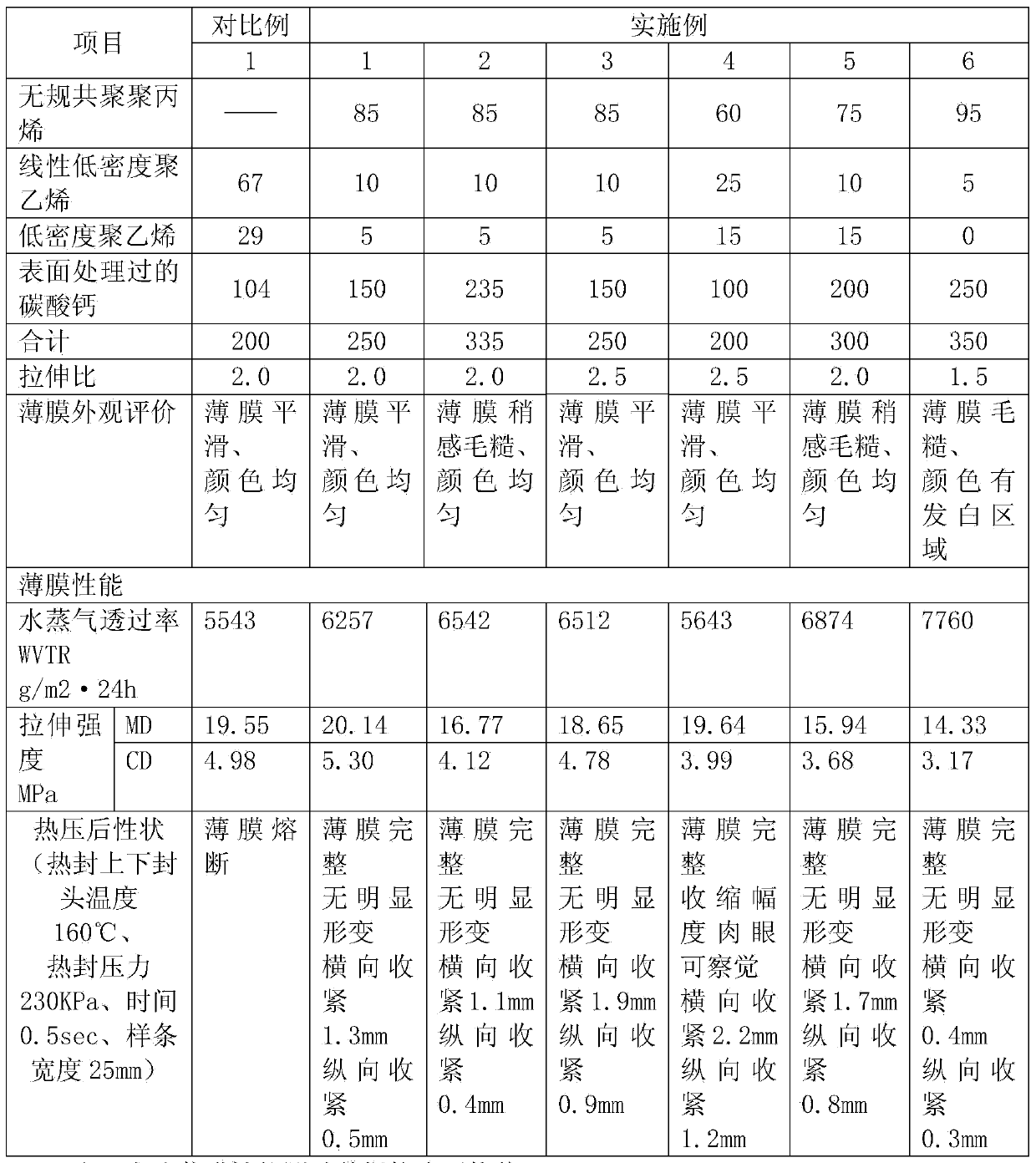

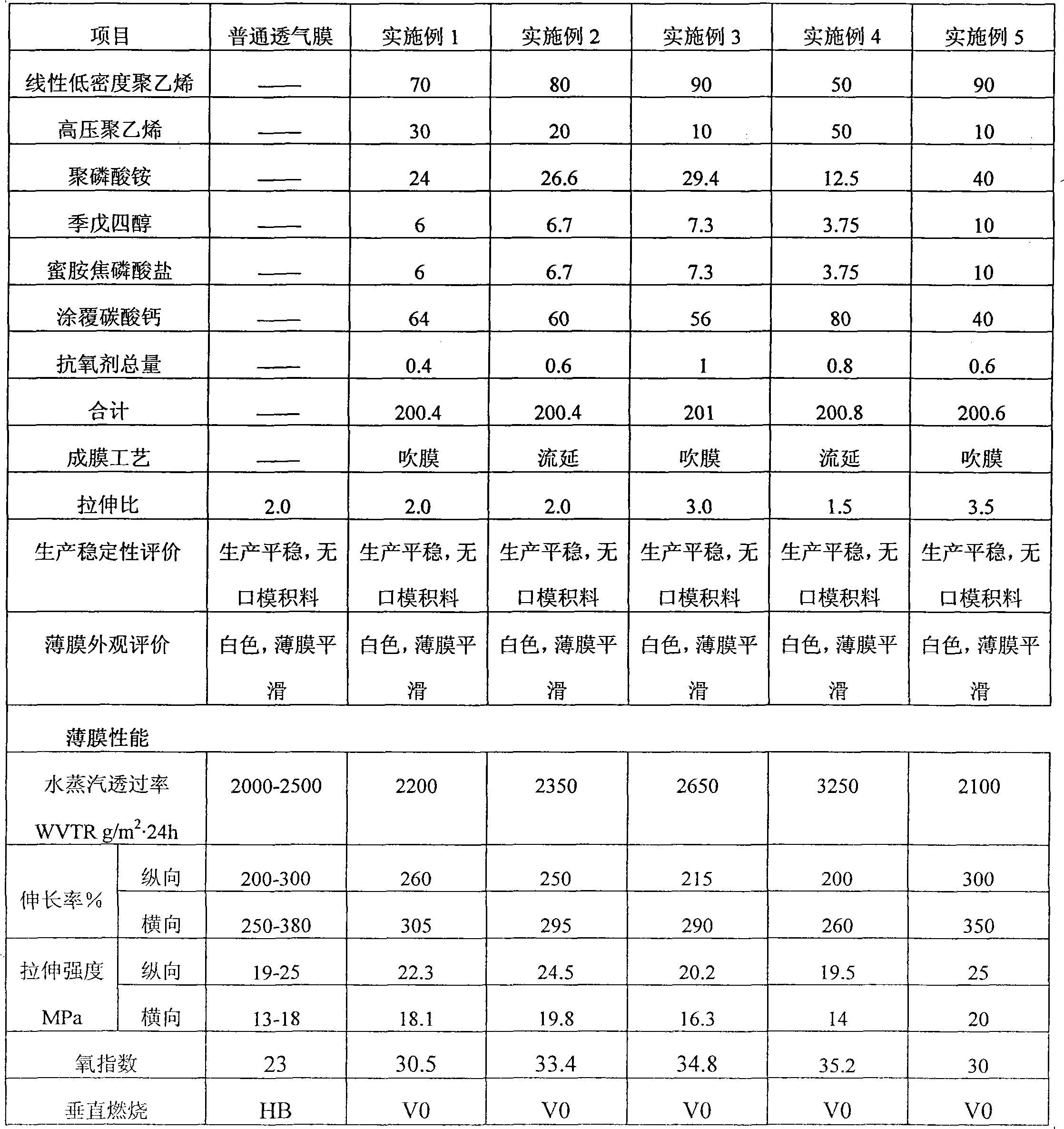

Zero halogen flame resistance polyethylene breathable film and preparation method and application thereof

ActiveCN101629006AGuaranteed flame retardant performanceDoes not affect processing performanceFlexible coversWrappersPolymer scienceHalogen

The invention discloses a zero halogen flame resistance polyethylene breathable film and a preparation method and an application thereof. The preparation method adopts surface modifier to treat calcium carbonate so as to promote the dispersion of calcium carbonate in a polyethylene resin system; then zero halogen fire retardant and polyethylene are treated by grafting treatment to have polar group and nonpolar macromolecular chain so that the dispersion of the zero halogen fire retardant in polyethylene is easier and the formed chemical bonds can effectively solve the problem that the mechanical properties of the breathable film are reduced; after the grafting treatment, the zero halogen fire retardant and the polyethylene both have the function of macromolecular coupling agent so as to further improve the dispersion of calcium carbonate in the polyethylene resin system and reduce the affect of calcium carbonate on the performance of the film. The zero halogen flame resistance polyethylene breathable film prepared by the invention not only ensures the gas permeability and mechanical properties of the polyethylene breathable film, but also improves the fire resistance of the film and does not affect the processing properties of the product. The product of the invention has both gas permeability and fire resistance, thus having wide application scope.

Owner:合诚技术股份有限公司

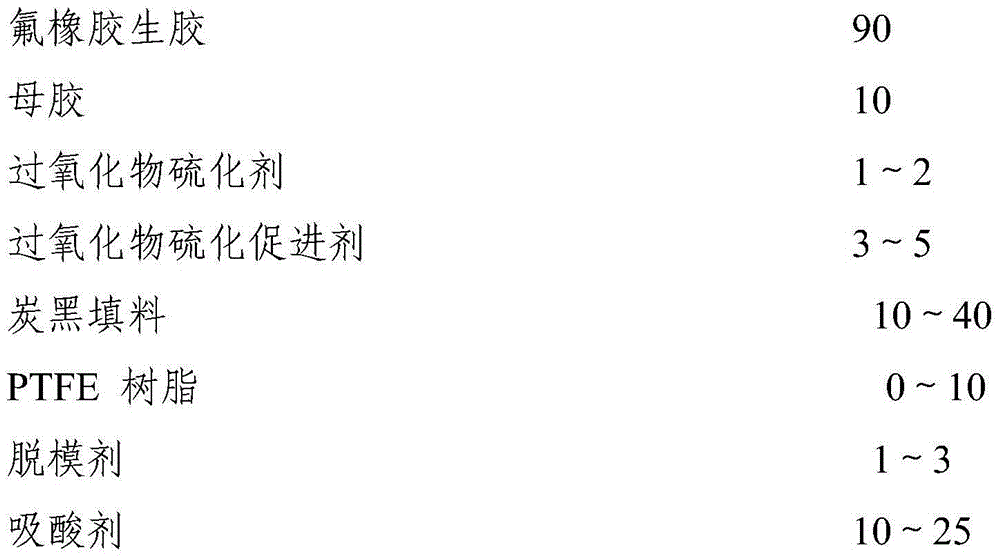

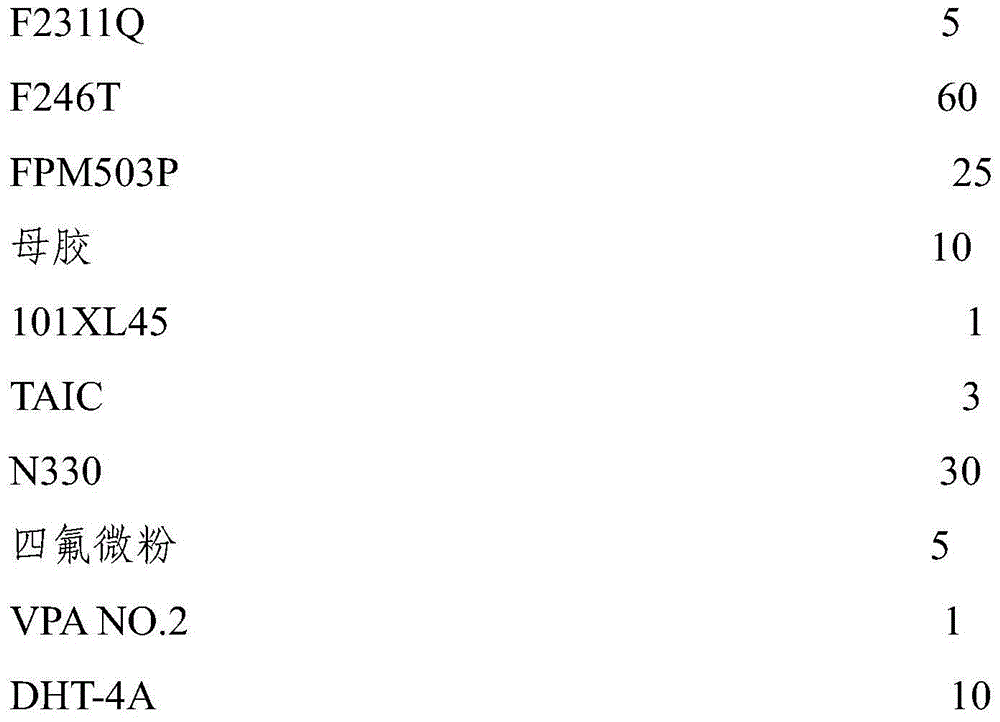

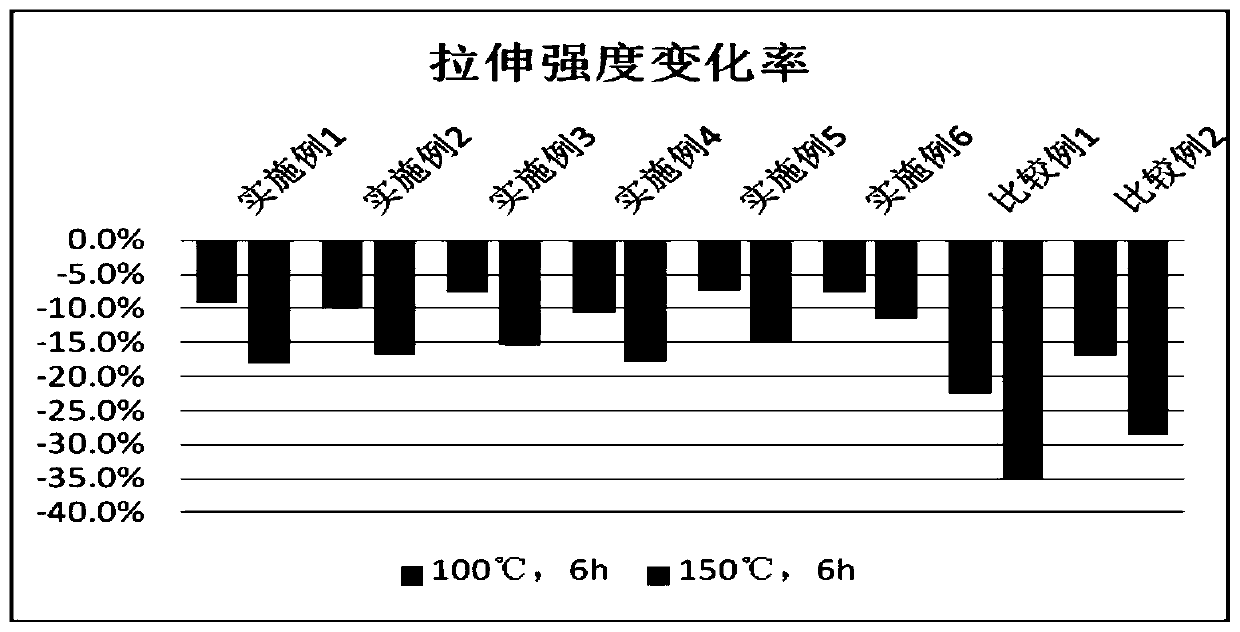

High-temperature/pressure-resistant vapor-resistant fluororubber compounded rubber

The invention relates to a high-temperature / pressure-resistant vapor-resistant fluororubber compounded rubber which is prepared by mixing the following raw materials in parts by weight: 90 parts of unvulcanized fluororubber, 10 parts of master batch, 1-2 parts of peroxide vulcanizing agent, 3-5 parts of peroxide vulcanization accelerator, 10-40 parts of carbon black filler, 0-10 parts of PTFE (polytetrafluoroethylene) resin, 1-3 parts of mold release agent and 10-25 parts of acid acceptor. By optimizing the proportioning of the basic unvulcanized rubbers and mixing proportioning of the novel assistants, the fluororubber compounded rubber prepared by the special preparation method has higher physical properties and improved vapor resistance, and satisfies the resistance to harsh chemical mediators. Therefore, the improved fluororubber compounded rubber has excellent tensile strength, percentage of elongation and high-temperature properties, also has improved vapor resistance as compared with the traditional fluororubber, and meanwhile, ensures excellent resistance to chemical mediators.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Flame-retardant polymer composite material

The invention discloses a flame retarding polymer composite material which is compounded by resin system, intumescent flame retardant and flame retardant synergist which are melted by a extruding machine or a mill mixer. The intumescent flame retardant comprises a triazine compound and polyphosphate. The flame retardant synergist is silicon magnetism containing inorganic substance. The triazine compound has good thermal stability and water resisting property, is used as carbon source and air source and compounded with ammonium polyphosphate to constitute the intumescent flame retardant which is applied in the flame-retardant polymer which has good flame retardant effect. The obtained coal bed reveals out compact and continuous structure. The silicon magnetism containing inorganic substance is added as the flame retardant synergist, thus promoting the formation of the coal bed, improving the quality of the coal bed, obtaining the flame retarding polymer materials with higher flame retardance in the condition of keeping the same addition of the flame retardant.

Owner:SOUTH CHINA UNIV OF TECH

Graphene protection method and graphene film containing protective layer

InactiveCN104692362ADoes not affect light transmissionDoes not affect processing performanceCarbon compoundsCarbon-silicon compound conductorsPolymethyl methacrylateSilicon dioxide

The invention relates to a method for protection of grapheme with a protective solution. The method comprises the steps of: 1) coating the graphene surface with the protective solution; and 2) curing the protective solution by heating or illumination to form a graphene film containing the protective layer. Specifically, the protective solution for forming the protective layer can be an acrylic acid based light curable glue, acrylic acid based heat curable glue, an epoxy light curable glue, an epoxy heat curable glue, a silicon based heat curable glue, a silicon based light curable glue, a silicon dioxide hardening liquid, a polyurethane based light curable glue, a polyurethane based heat curable glue, a polymethyl methacrylate heat curable glue or polymethyl methacrylate light curable glue. The invention also relates to the protective layer containing graphene film prepared according to the method.

Owner:2D CARBON CHANGZHOU TECH INC

Insulating and heat conducting polyamide composite material with high cost performance and preparation method thereof

ActiveCN102604371AExcellent insulation and thermal conductivityImprove mechanical propertiesHeat conductingPolyamide

The invention relates to a composite material, particularly to an insulating and heat conducting polyamide composite material with high cost performance and a preparation method of the composite material. The components are as follows by weight percentage: 40-95 of polyamide, 5-35 of common modified graphite, 1-10 of modified expanded graphite, 1-10 of a modified flake inorganic filler, 1-5 of a lubricant, and 0.1-1 of an antioxidant, and the sum of above components is 100%. The preparation method is as follows: adding the common modified graphite, the modified expanded graphite and the modified flake inorganic filler into a blending machine, blending for 5-10min at a temperature of 50-90 DEG C to obtain a modified heat conducting filler; adding polyamide, the modified heat conducting filler, the antioxidant and the lubricant into the blending machine, and blending for 5-10min; adding the uniformly mixed materials into a main feed hopper of a double screw extruder, and performing melt extrusion and granulation at a temperature of 230-260 DEG C. The composite material disclosed by the invention is good in insulating and heat conducting performance and good in comprehensive mechanical property.

Owner:NANJING JULONG SCI&TECH CO LTD

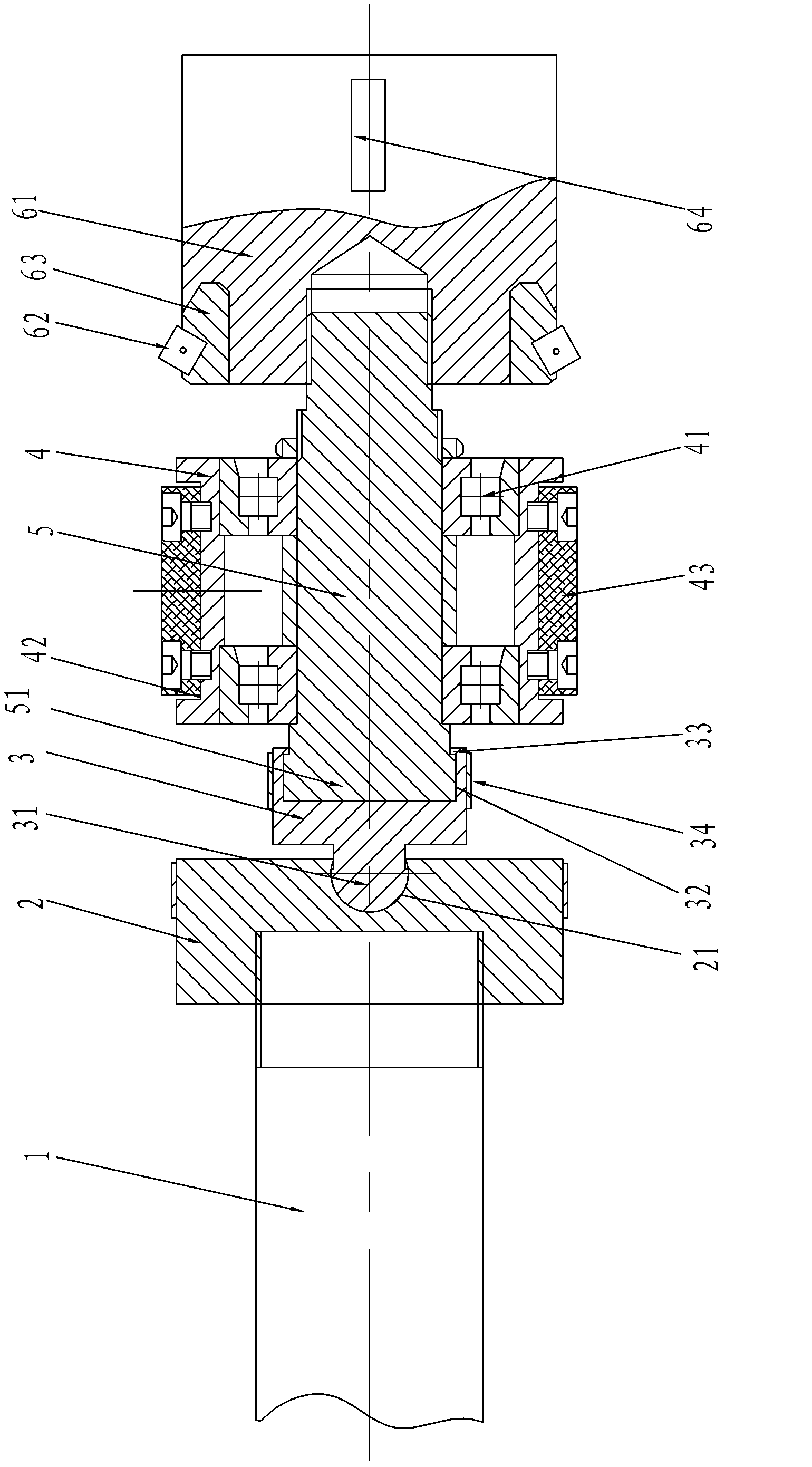

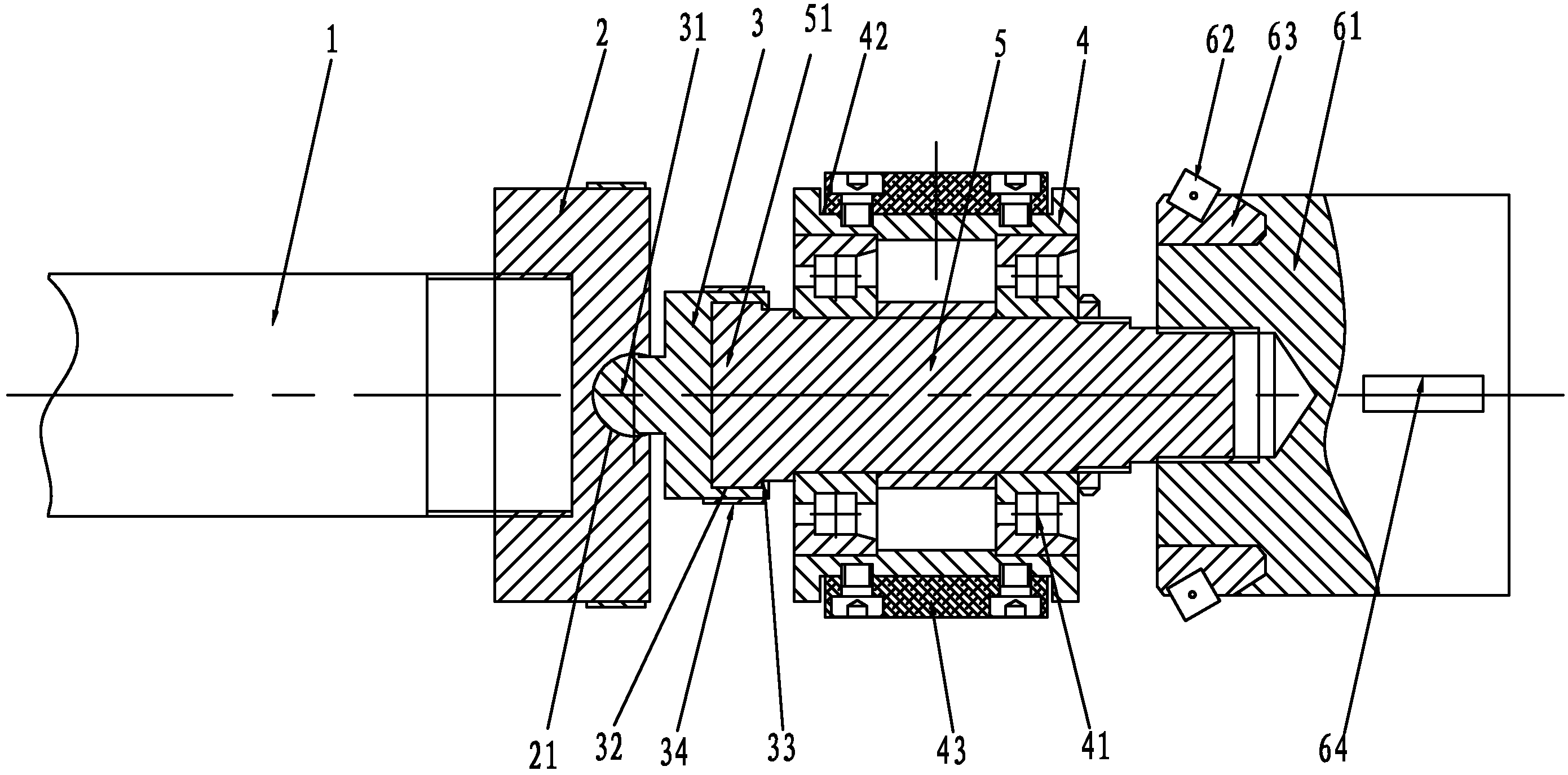

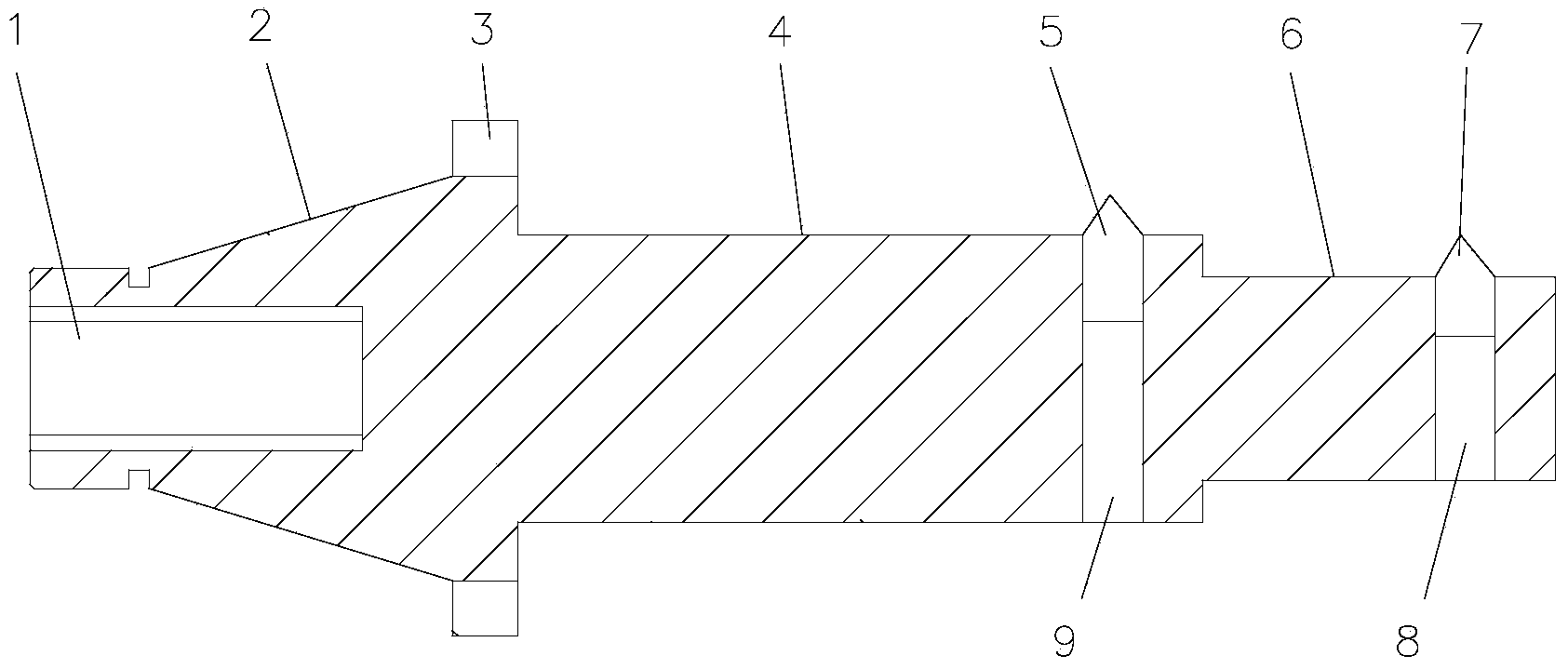

Floating boring head for processing inner surface of bent tube billets

InactiveCN102601402AAdaptive CurvatureGuaranteed Wall Thickness Error RangeBoring headsEngineeringMechanical engineering

The invention discloses a floating boring head for processing inner surface of bent tube billets, wherein one end of a boring bar connector is connected with a boring bar while the other end thereof is flexibly connected with a universal connection block; the other end of the universal connection block is connected with a support shaft; a guide mould is installed on the support shaft through a bearing; a boring cutter mechanism comprises a cutterhead and a boring cutter; the other end of the support shaft is fixedly connected with the cutterhead; and two boring cutters are symmetrically fixed by the central line on the cutterhead. In the floating boring head, as the other end of the boring rod connector is flexibly connected with the universal connection block, the guide mould can vertically and transversely move relative to the boring bar in the tube billet and adapts curvature of the tube billets effectively; moreover, the guide mould and the boring cutter mechanism are in a rigid connection manner; thus, the guide mould can transfer the curvature of the tube billets to the boring cutters well so as to ensure wall thickness uniformity of the processed tube billets, realize high processing efficiency, wide processing range, and small equipment upgrading investment and not influence the processing performance of the original boring lathe after transformations.

Owner:XINXING DUCTILE IRON PIPES CO LTD

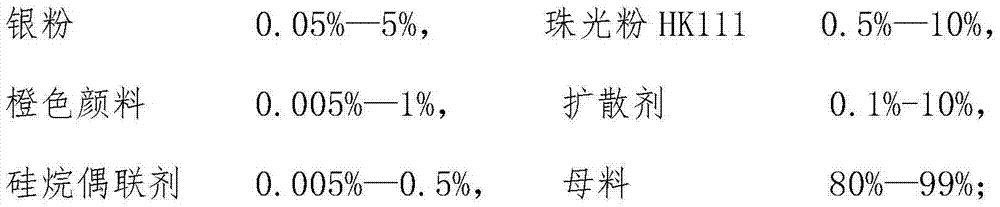

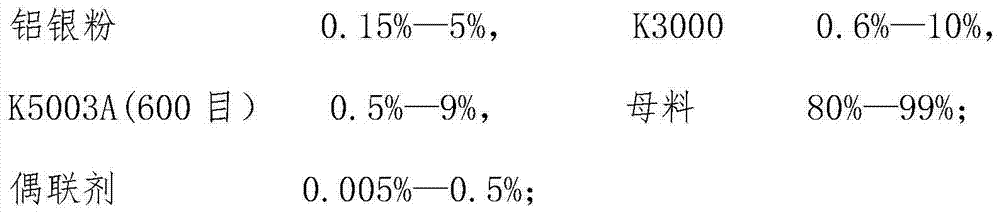

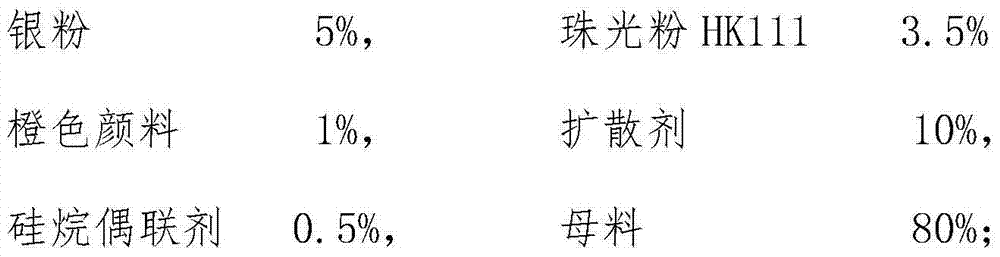

Spray-free metal-like color master batch

The invention relates to a spray-free metal-like color master batch which is composed of aluminum powder, pearl powder HK111, orange pigment, diffusant, silane coupling agent and master batch. The resin and gold / aluminum powder are organically combined and pretreated, so that the plastic product has the glossiness which is not less than metals. The spray-free metal-like color master batch has the advantages of excellent dispersity, excellent high temperature resistance, higher corrosion resistance and one-step forming, does not change the mechanical properties of the resin, does not influence the processability of the resin, greatly shortens the production cycle of the enterprise, lowers the production cost, and can substitute steel with plastics in deed.

Owner:LIANGCAI DYE ZHONGSHAN IND

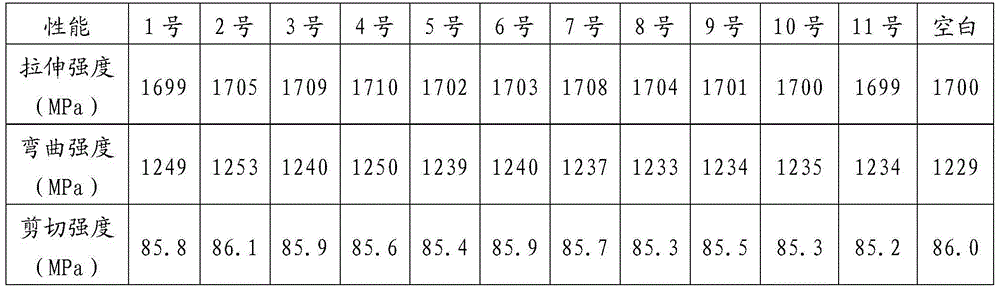

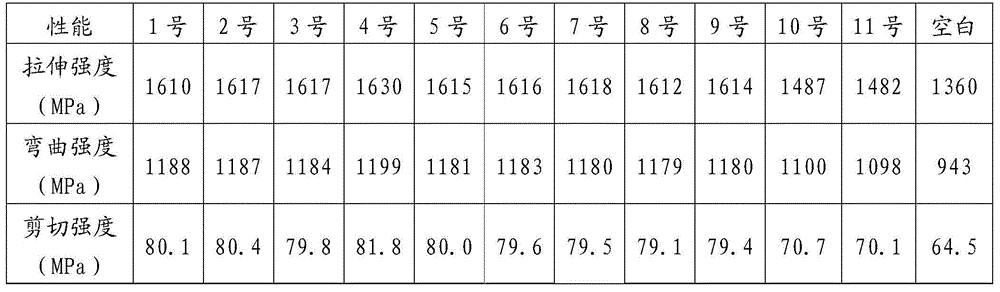

Fiber reinforced resin matrix composite weatherability improvement composition and application thereof

The present invention provides a fiber reinforced resin matrix composite weatherability improvement composition and application thereof, the composition comprises a complex antioxidant system and a light stabilizer system; and the weight ratio of the complex antioxidant system to the light stabilizer system is 1: 0.1-5. The composition can improve the fiber-reinforced resin matrix composite weatherability, can effectively inhibit the fiber reinforced resin matrix composite aging in processing and use processes, and can prolong the service life. Furthermore, the composition is a liquid composition, and when the composition is added into the fiber reinforced resin matrix composite, the product processing performance is not affected.

Owner:CHINA NAT BLUESTAR GRP CO LTD +1

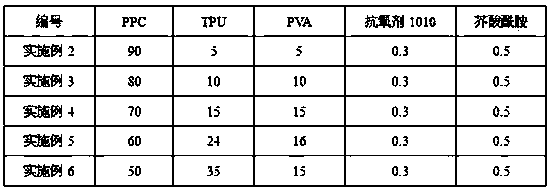

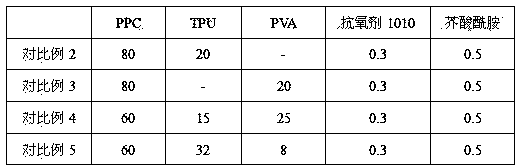

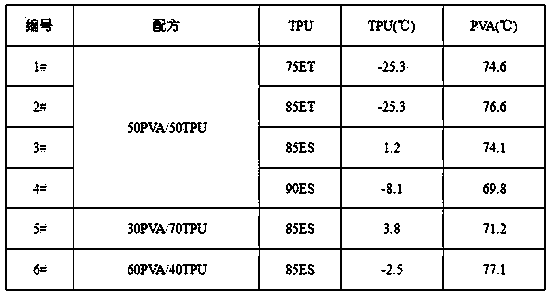

Poly-methyl ethylene carbonate composition and preparation method thereof

ActiveCN104371296AImprove film formationGood dimensional stabilityAdjuvantThermoplastic polyurethane

The invention relates to the technical field of modified materials, and discloses a poly-methyl ethylene carbonate composition and a preparation method thereof. The composition comprises the following raw materials: a poly-methyl ethylene carbonate matrix, a modified material and an adjuvant, wherein the modified material is composed of thermoplastic polyurethane and polyvinyl alcohol in melting and blending manners; the mass ratio of the modified material to the poly-methyl ethylene carbonate is (10-100) to 100; polyvinyl alcohol accounts for 30%-50% by mass of the modified material; the adjuvant accounts for 0.5%-2%. The preparation method comprises the following steps: melting and blending TPU with PVA; and then blending and pelletizing with PPC. The composition disclosed by the invention has the advantages of good film-forming property and dimensional stability, good tensile strength, breaking elongation, biodegradability and the like. The composition disclosed by the invention does not agglomerate or deform, and does not affect the processability after being placed for a long period of time when the matrix cost is lowered; the film is not bonded; the breaking elongation of the film disclosed by the invention after water absorption is increased; and meanwhile, good tensile strength is kept.

Owner:SUN YAT SEN UNIV +1

High-performance conductive engineering plastic

InactiveCN106118019AImprove mechanical propertiesImprove heat resistanceEngineering plasticElectromagnetic shielding

The invention discloses high-performance conductive engineering plastic. The method for preparing the high-performance conductive engineering plastic is different from the traditional method for increasing the conductivity of the engineering plastics, and comprises the following step: applying graphene to a polymer MPPO (polyphenyl ether / high impact polystyrene blend modified alloy) matrix to form the graphene / MPPO engineering plastic with high conductivity and high strength. The engineering plastic prepared by the method disclosed by the invention maintains the excellent characteristics of MPPO and has excellent conductivity, and the product has more technical characteristics in performance and can be widely applied to the fields of antistatic and electromagnetic shielding materials, electromagnetic shielding materials of electronic products and aerospace equipment, and the like.

Owner:东莞市友亮新材料科技有限公司

Abrasion-resistant flexible transparent conductive film and preparation method thereof

InactiveCN104464886AImprove conductivityImprove wear resistanceConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialFiberOrganic solvent

The invention discloses an abrasion-resistant flexible transparent conductive film and a preparation method of the film. The surface of PET is coated with coating, and then the film is prepared after being dried. According to the formula of a sizing material, the sizing material is composed of nanometer silver wires, oleoresin, additive powder, flatting agents and a proper quantity of organic solvents. The nanometer silver wires excellent in electrical conductivity are adopted and nanometer oxide and fiber-phase materials are mixed with the additive powder to serve as additives so that the electrical conductivity and the abrasion resistance of the film can be improved. The abrasion-resistant flexible transparent conductive film is suitable for reel-to-reel continuous production, production efficiency is improved, and transportation is facilitated. The abrasion-resistant flexible transparent conductive film is reasonable in design, simple and low in cost.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

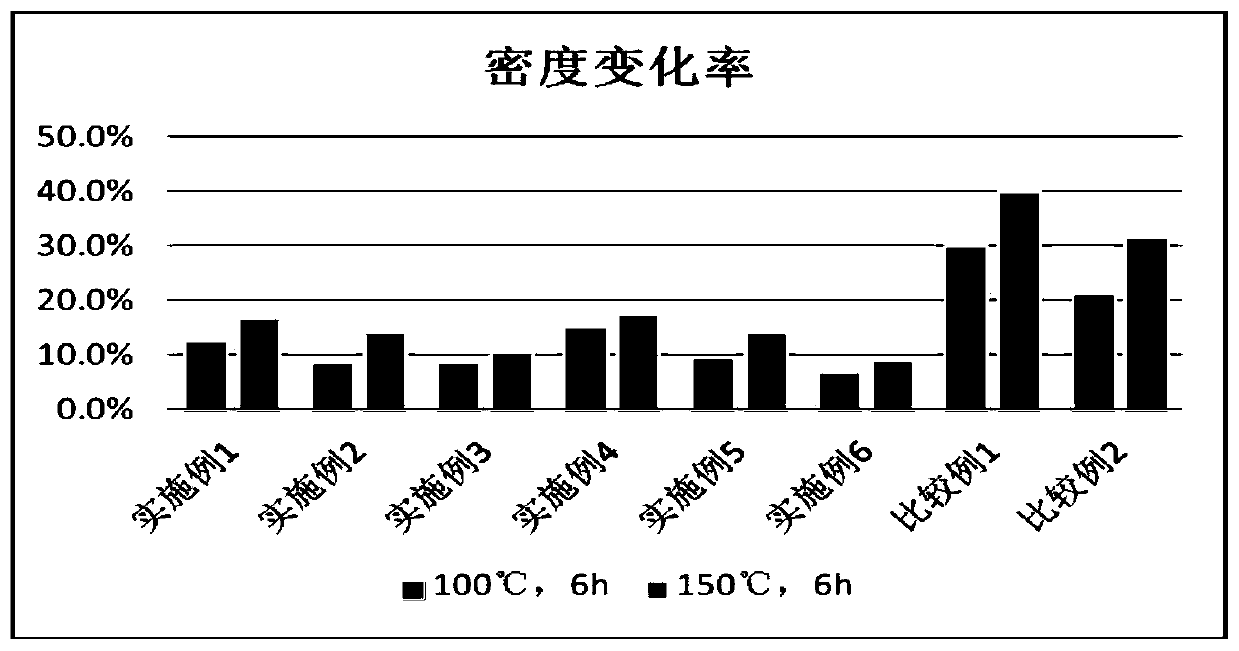

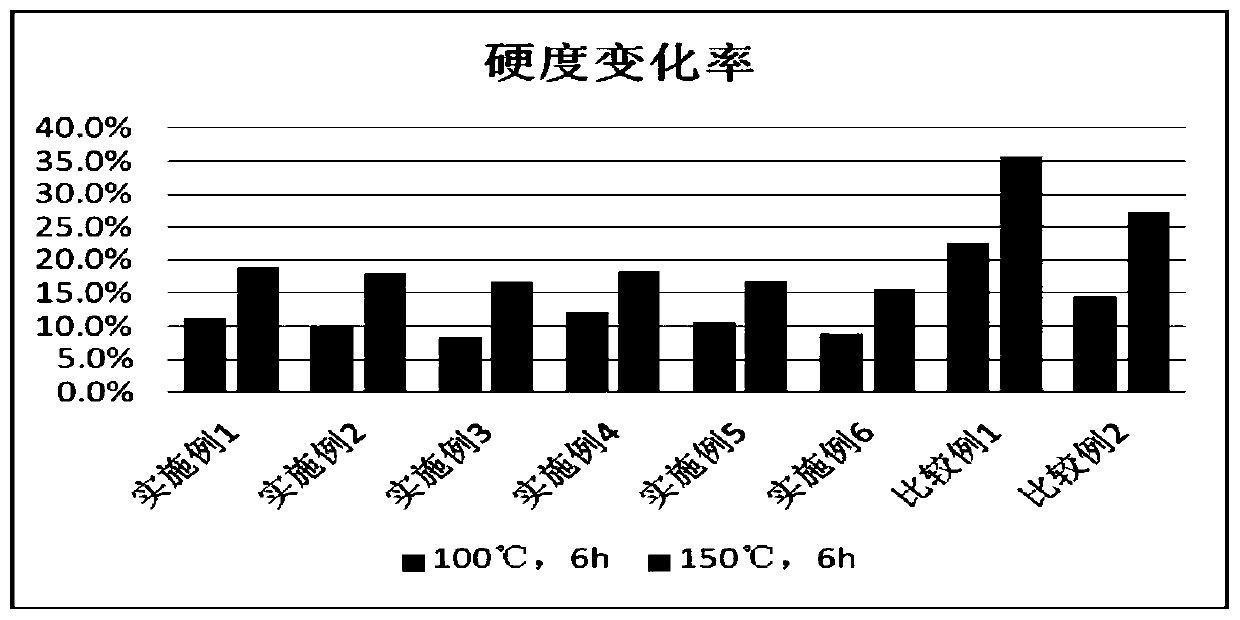

EVA foaming material with high-temperature resistance and aging resistance as well as preparation method and application of EVA foaming material

ActiveCN109912877ADoes not affect processing performanceKeep the original performanceSolesElastomerPolyolefin

The invention provides an EVA foaming material with high-temperature resistance and aging resistance as well as a preparation method and an application of the EVA foaming material. The foaming material is prepared from an EVA composite by foaming, wherein the EVA composite comprises 40-50 parts of EVA, 10-55 parts of AEM rubber, 10-20 parts of polyolefin elastomers, 10-20 parts of OBC, 0.5-0.8 parts of a peroxide crosslinking agent, 3-5 parts of a foaming agent, 1-4 parts of an active agent and 3-12 parts of a reinforcing agent. The thermal shrinkage rate of the foaming material in the embodiment is 0.6%-1%, which is lower than that of the traditional EVA foaming material. After the foaming material is aged under hot air, the permanent compression deformation change rate, the mechanical property change rate and the hardness change rate are all lower than 20%, original properties of the material are well maintained, and the foaming material has good high-temperature resistance and agingresistance. The processing temperature of the material is low, and thus, subsequent bonding is facilitated.

Owner:ANTA CHINA

Aluminum-carbon composite material used for tension-resisting joint fitting and preparing method of aluminum-carbon composite material

The invention provides an aluminum-carbon composite material used for a tension-resisting joint fitting and a preparing method of the aluminum-carbon composite material. Aluminum powder and carbon powder dispersed in an organic solvent are evenly mixed, dried, subjected to ball grinding and pressed into an aluminum-carbon powder block; and the above aluminum-carbon powder block and an aluminum block are used as raw materials to be subjected to smelting, ingot casting, cogging and rolling, and a joint fitting material high in strength and resistant to loosening is obtained. The electric conductivity of the joint fitting prepared through the aluminum-carbon composite material is equivalent to that of pure aluminum. Due to the adding of carbon particles, the hardness, strength and high-temperature loosening resisting performance of the joint fitting are greatly improved. Due to the fact that carbon has very good stability in the atmosphere and does not form an alloy or a compound with aluminum, the corrosion resistance of aluminum is not obviously changed. Preparing steps are simple, operation is convenient, and practicability is high.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

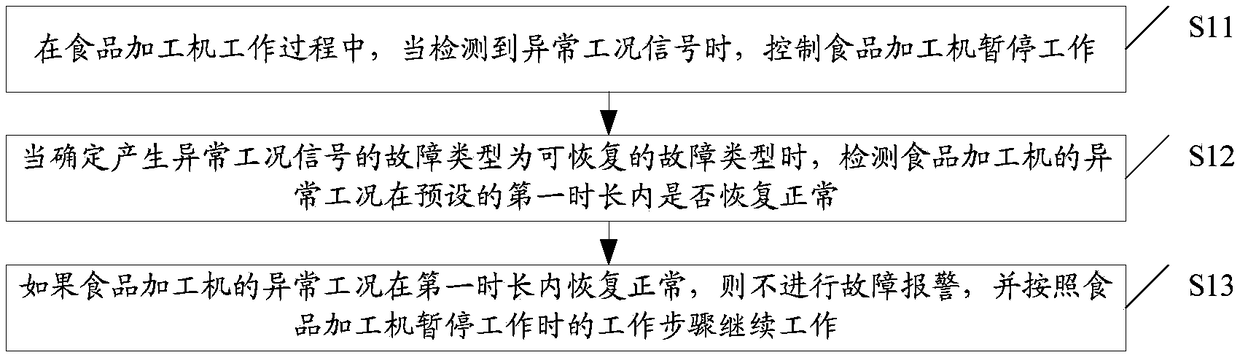

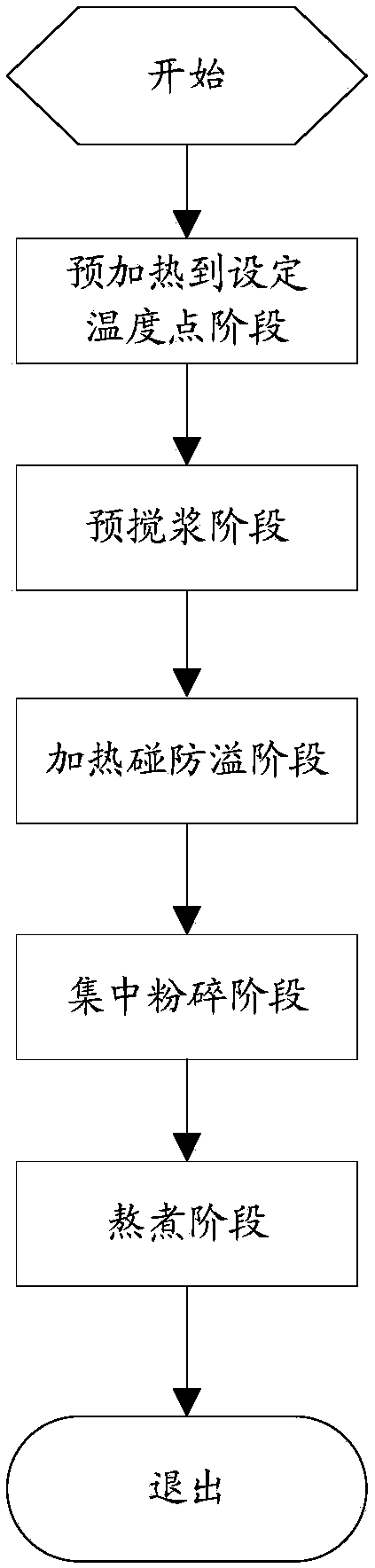

Fault handling method of food processor

ActiveCN108245049ADoes not affect processing performanceAvoid wastingKitchen equipmentTime durationFood processing

Owner:JOYOUNG CO LTD

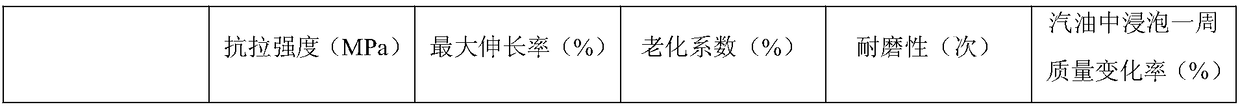

Organic silicon rubber

The invention provides organic silicon rubber which is prepared by the following steps: (1) mixing low-phenyl silicon rubber, saccharose polyester modified fluorinated silicone rubber, a structure controller and organic modified silicon micro powder by using a kneading machine so as to obtain a mixture; (2) putting a vulcanizing agent and a 2,4-pentadienoic acid zinc salt into the mixture, uniformly mixing, treating for 2-3 hours at 140-180 DEG C, heating for 25-40 minutes at a vacuum state, cooling to the room temperature, and discharging so as to obtain blended rubber; (3) cutting the blended rubber, carrying out mold pressing, carrying out hot pressing for 10-15 minutes by using a hot press at 200-220 DEG C at 15-20MPa so as to obtain a molded vulcanization product; (4) placing the molded vulcanization product into an oven for 10-12 hours at 250-300 DEG C, so as to obtain the organic silicon rubber. The organic silicon rubber provided by the invention has an excellent mechanical property, and is aging resistance, wearing resistance and oil resistance.

Owner:CHANGSHA XIAORU INFORMATION TECH CO LTD

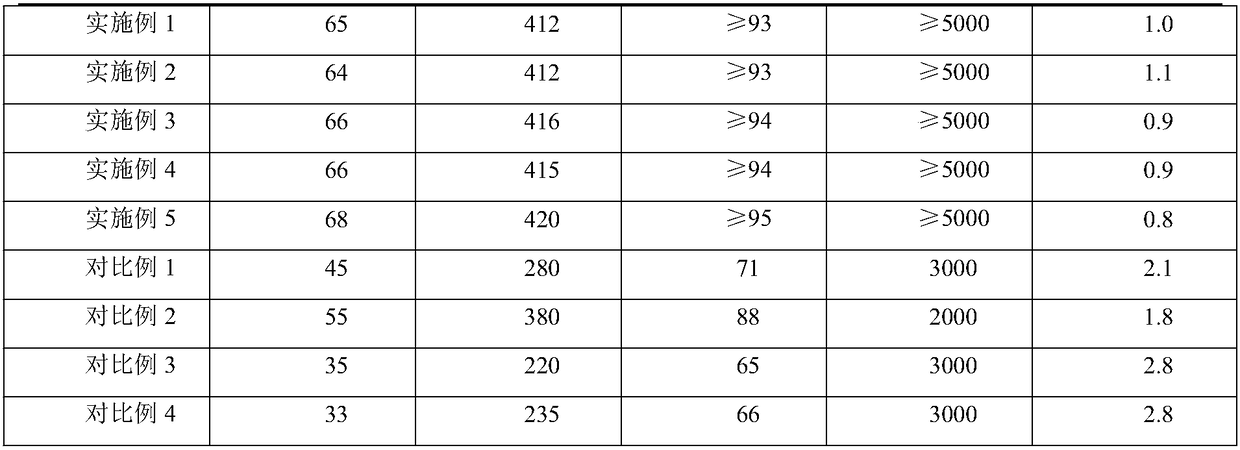

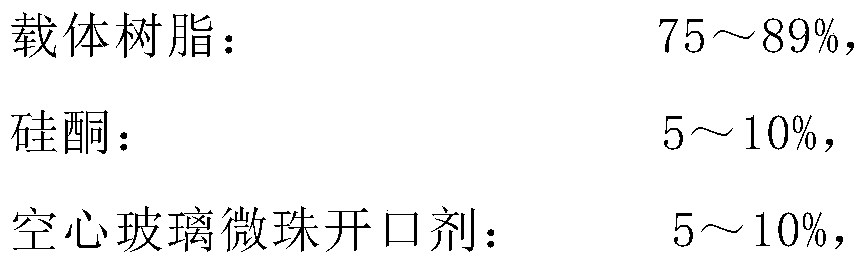

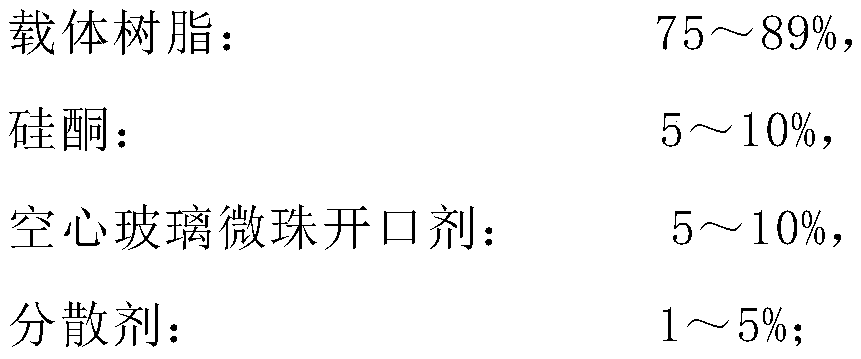

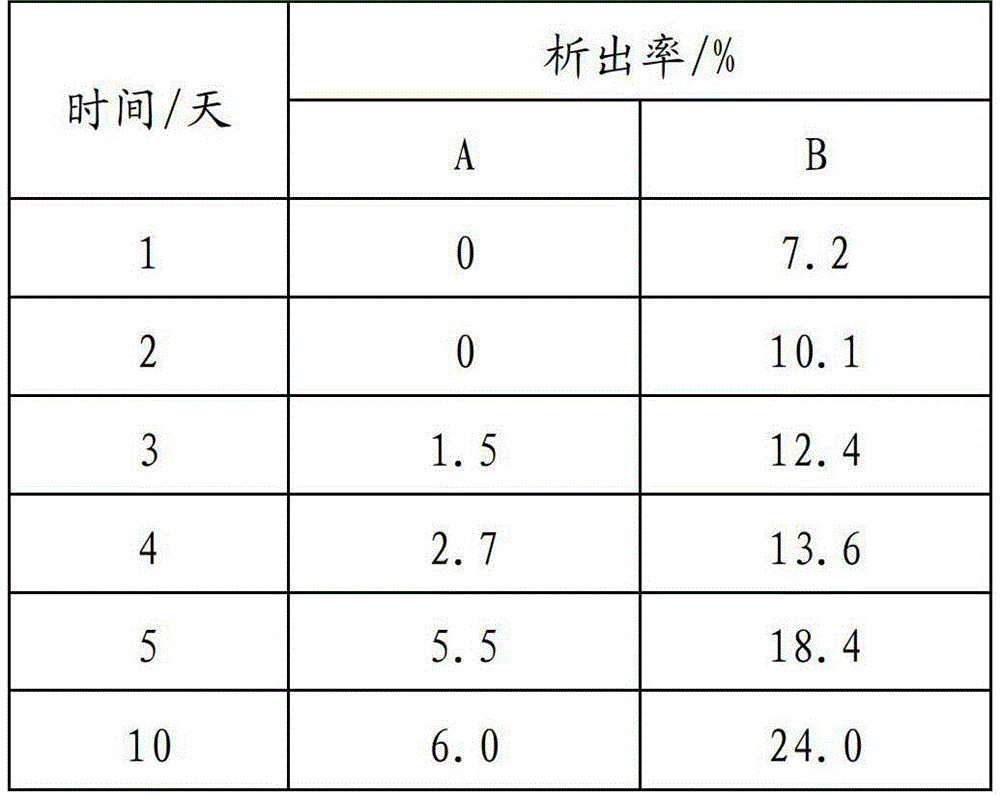

Silicone opening slipping agent master batch composition for plastic film and preparation method of silicone opening slipping agent master batch

The invention discloses a silicone opening slipping agent master batch composition for a plastic film and a preparation method of the silicone opening slipping agent master batch. The silicone openingslipping agent master batch comprises the following components in percentage by weight: 75%-89% of carrier resin, 5-10% of silicone, 5-10% of a hollow glass microsphere opening agent and 1-5% of a dispersing agent. The silicone cannot migrate to the surface in a film product, so that compared with a conventional amide slipping agent, silicone opening slipping agent master batch composition does not have the problem that a slipping agent is accumulated on the surface of a thin film, so that influence of processing performance of the thin film is effectively avoided. When the silicone opening slipping agent master batch composition is used in cooperation with a hollow glass microsphere opening agent, a good opening slipping effect can be achieved for the thin film, and transparency of the thin film is not influenced.

Owner:JIANGSU SHENGYING NEW MATERIAL +1

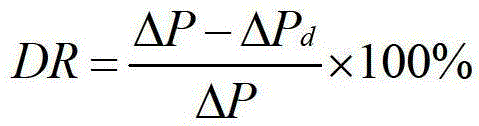

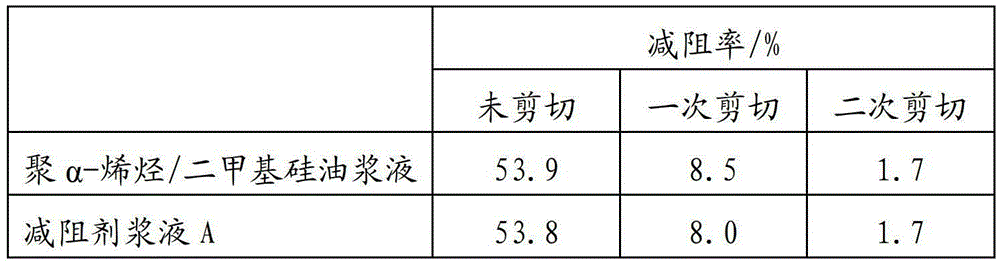

Drag reducer and preparation method thereof

ActiveCN103936900AAvoid sticking to each otherOmit cryogenic crushingPipeline systemsPolyesterCoordination polymerization

The invention provides a drag reducer and a preparation method thereof. The drag reducer is a suspension liquid containing poly(alpha-alkene), silicone oil, an isolating agent, and a surfactant, wherein the isolating agent is a solid polyester pour-point reducer. The preparation method comprises the following steps: (1) subjecting alpha-alkene to coordination polymerization in silicone oil; (2) mixing the system obtained in the step (1) with an isolating agent after the coordination polymerization, and then adding a surfactant so as to obtain the suspension liquid, wherein the isolating agent is a solid polyester pour-point reducer. The drag reducer has the advantages of good stability, low viscosity, good fluidity, and user-friendliness, and has the functions of reducing drag and pour-point. The preparation method is simple, and can be easily applied to the industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

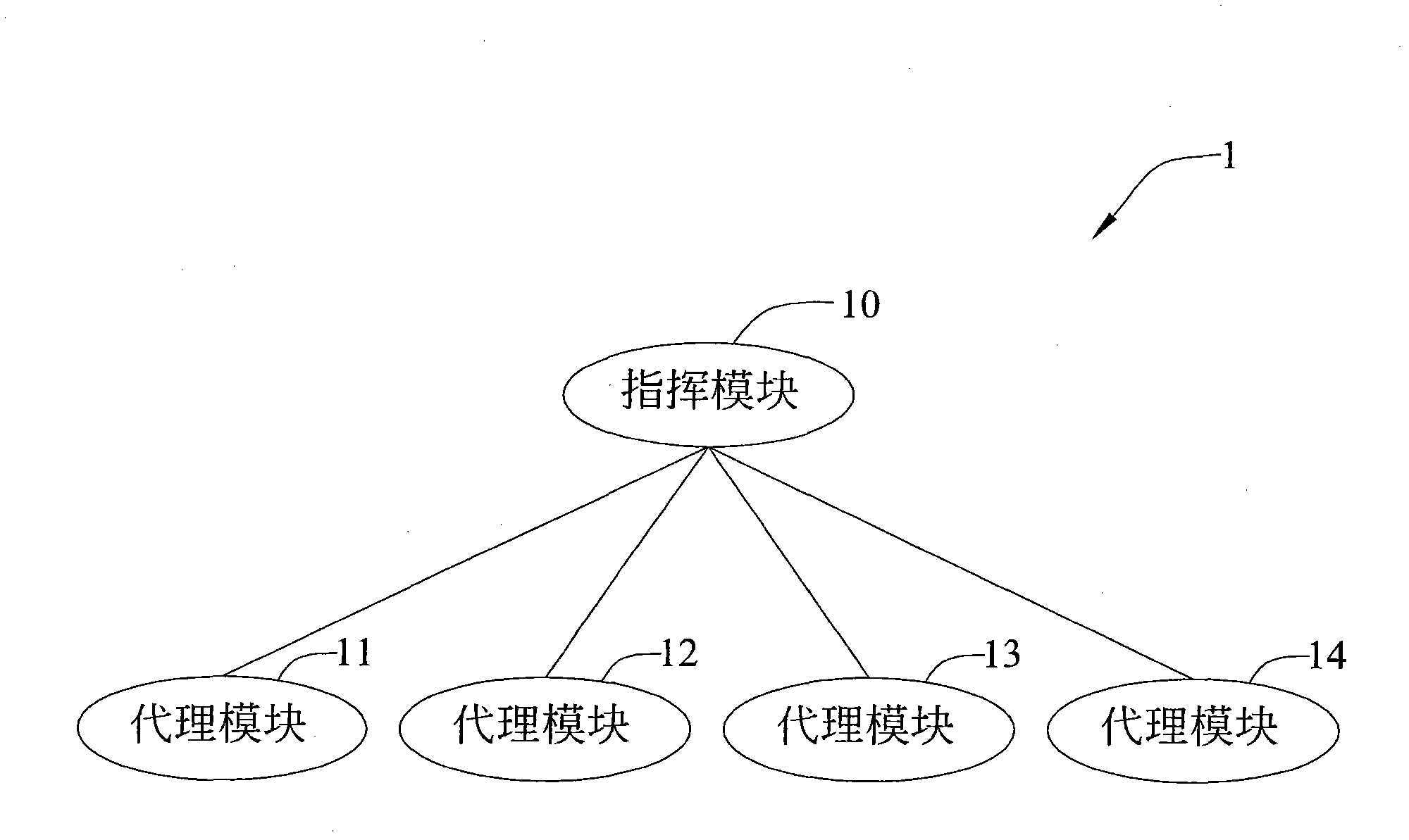

Distributed arithmetic system applied to video monitoring platform

InactiveCN102882910ADoes not affect processing performanceTransmissionVideo monitoringComputer module

A distributed arithmetic system applied to a video monitoring platform comprises a command module (Headquarter), and a plurality of agent modules connected with the command module. The command module is used to cut the video data received by the video monitoring platform into a plurality of video units, and send the plurality of video units to the agent modules respectively, so that the agent modules can carry out video identification and analysis on the received video units; after the agent modules identifies and analyzes the video, the identification and analysis results are transmitted back to the command module, so that the command module can carry out integration.

Owner:CHUNGHWA TELECOM CO LTD

Preparation method of low-temperature-resistant and scratch-resistant automobile zip-fastener sheath special material

The invention relates to a preparation method of a low-temperature-resistant and scratch-resistant automobile zip-fastener sheath special material, wherein the composite material comprises the following components in parts by weight: 65-80 parts of polypropylene; 1-5 parts of a scratch-resistant agent; 10-25 parts of an elastomer; and 0.5-2 parts of an antioxidant. The invention relates to the preparation method of the low-temperature-resistant and scratch-resistant automobile zip-fastener sheath special material. The low-temperature-resistant and scratch-resistant automobile zip-fastener sheath special material not only improves scratch resistance and low temperature resistance of polypropylene, but also has excellent mechanical properties, and besides, does not affect the processing properties of products.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

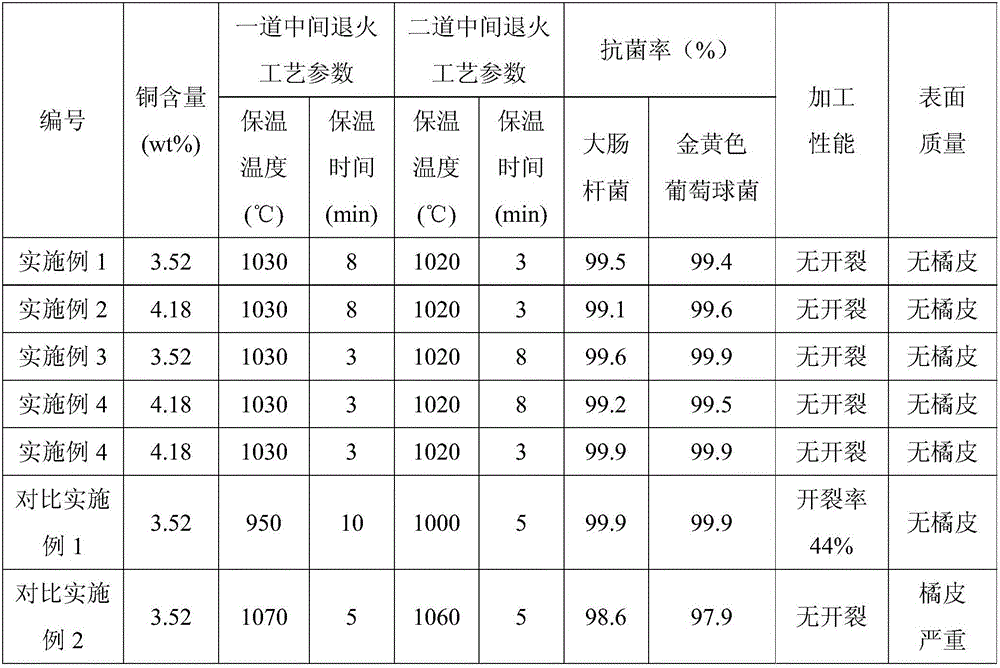

Production method of antibacterial stainless steel drainer drawn piece

ActiveCN105755392AFlat surfaceDoes not affect processing performanceDomestic plumbingAusteniteAmmonia gas

The invention discloses a production method of an antibacterial stainless steel drainer drawn piece. The method sequentially comprises primary drawing, primary intermediate annealing, secondary drawing, secondary intermediate annealing, edge curling, coarse wire drawing and fine wire drawing; austenite stainless steel is used as a raw material, Cu ranges from 3.5wt% to 4.5wt%, C is less than or equal to 0.08wt%, Si is less than or equal to 1.0wt%, Mn is less than or equal to 2.0wt%, P is less than or equal to 0.045wt%, S is less than or equal to 0.03wt%, Ni ranges from 8wt% to 10.5wt%, Cr ranges from 17wt% to 19wt%, and the balance is Fe; the primary intermediate annealing is bright annealing, the annealing atmosphere is ammonia gas, the annealing temperature is 1,000-1,060 DEG C, and the annealing holding time is 2-10 min; the secondary intermediate annealing is bright annealing, the annealing atmosphere is ammonia gas, the annealing temperature is 1,010-1,050 DEG C, and the annealing holding time is 2-10 min. The drainer drawn piece produced with the production method has the bright, clean and flat surface and is low in cost and stable in antibacterial performance, and mass production is easy to realize.

Owner:JOMOO KITCHEN & BATHROOM

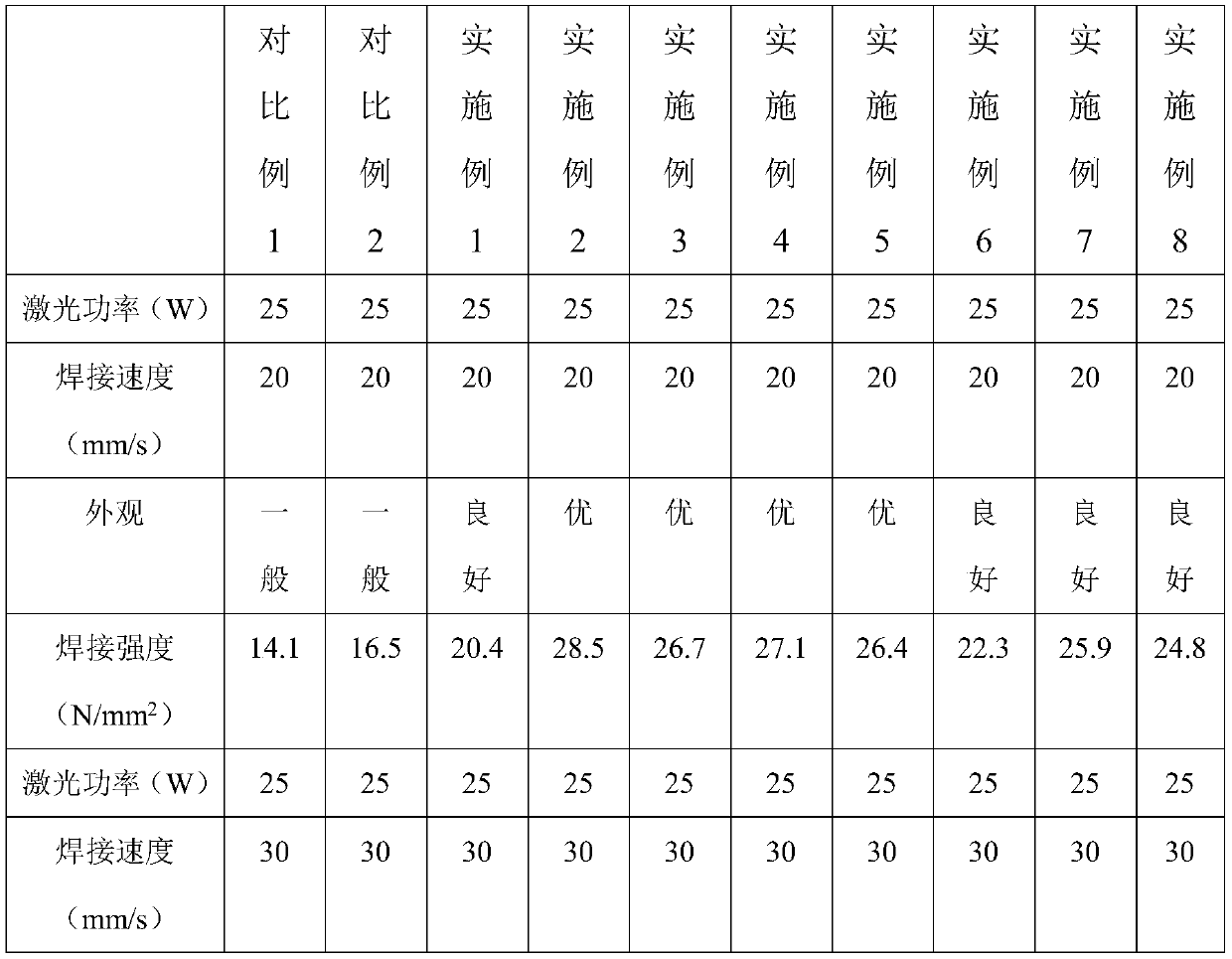

ABS composition easy to process in laser welding and preparation method thereof

InactiveCN111073211ADoes not affect processing performanceImprove the bonding strength of the interfacePolymer scienceIndium

The invention relates to an ABS composition easy to process in laser welding and a preparation method of the ABS composition. The composition comprises the following components in parts by weight: 80-99 parts of ABS resin, 1-20 parts of a reversible reaction cross-linking agent, 0.1-2 parts of nano indium tin oxide, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The reversible reaction cross-linking agent is composed of a copolymer A with a side group containing a furan functional group and a copolymer B with a side group containing maleimide. Compared with the prior art, after the reversible reaction cross-linking agent is added into the ABS composition provided by the invention, the welding strength of a product can be remarkably improved, and meanwhile, the welding efficiency is improved, so that the cost is reduced, and the ABS composition can be applied to interior and exterior ornaments of automobiles and the like.

Owner:CHONGQNG PRET NEW MATERIAL +3

New material for inner liner of fire hose and preparation method of material

The invention belongs to the technical field of fire-fighting equipment, and provides a new material for an inner liner of a fire hose and a preparation method of the material. The material comprises the following raw materials, by weight part, 20-39 parts of a phenolic resin, 16-31 parts of an acrylic resin, 2-7 parts of light calcium carbonate, 3-11 parts of nanometer carbon fiber, 2-6 parts of activated clay waste residue, 5-5 parts of silicon crystal whiskers, 2-5 parts of a fire retardant, 0.3-6 parts of a curing agent, 0.11-4 parts of an anti-aging agent, and 1-3.6 parts of a binder. The fire retardant, binder, and anti-aging agent are added in the formula, and inorganic and organic matters are added at the same time. The materials are prepared according to a reasonable ratio, and the inner liner has high temperature and pressure resistance, aging resistance, and long service life.

Owner:合肥轻风飏电气科技有限责任公司

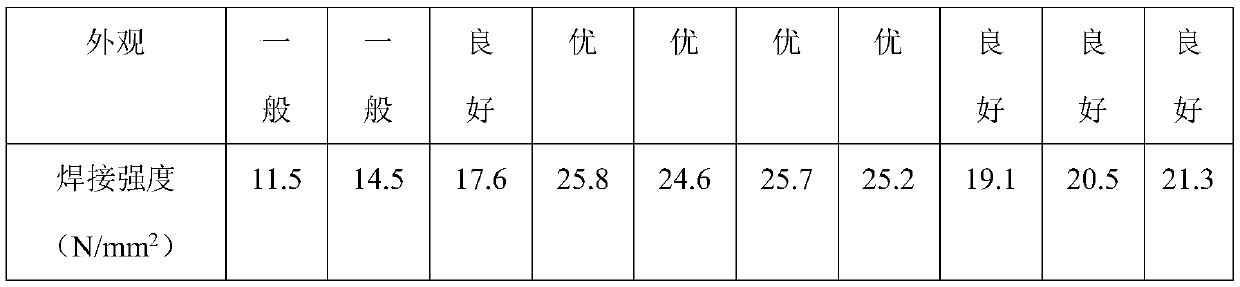

ABS composition for improving ultrasonic welding strength, and preparation method thereof

PendingCN111138797AImprove the bonding strength of the interfaceDoes not affect processing performancePolymer scienceUltrasonic welding

The invention discloses an ABS composition for improving the ultrasonic welding strength, and a preparation method thereof. The composition comprises, by weight, 80-99 parts of ABS resin, 1-20 parts of a reversible reaction cross-linking agent and 0.1-1 part of an antioxidant. The reversible reaction cross-linking agent is composed of a copolymer A with a side group containing a furan functional group and a copolymer B with a side group containing maleimide. The preparation method of the ABS composition comprises the following steps: (1) adding the ABS resin, the reversible reaction cross-linking agent and the antioxidant into a mixing stirrer, and performing premixing; and (2) carrying out melt blending, extrusion and granulation on a mixture obtained in step (1) by using a double-screw extruder, and performing granulation to obtain the ABS composition for improving the ultrasonic welding strength. Compared with like products in the prior art, the ABS composition of the invention hasthe following advantages: after the reversible reaction cross-linking agent is added, the effect of remarkably improving the welding strength with a PMMA product can be achieved, and the purpose of improving the welding efficiency can be achieved.

Owner:SHANGHAI PRET COMPOSITES +3

Boring cutter

InactiveCN103920896ADoes not affect processing performanceImprove processing efficiencyTurning toolsMechanical engineering

The invention relates to a boring cutter. The boring cutter comprises a cutter bar and a cutter body. A conical body is arranged at the left end of the cutter bar and is matched with another conical body of a main shaft hole of a boring machine, and an inner threaded hole is formed in the axis of the conical body. The conical body is connected with a connecting rod of a main shaft of the boring machine through a metric thread, so that the tensioning effect is achieved. Shoulder shafts are arranged at the right end of the cutter bar, a left radial cutter body fixing hole and a right radial cutter body fixing hole are formed in the right ends of the shoulder shafts respectively, and a left boring cutter and a right boring cutter are fixed in the left cutter body fixing hole and the right cutter body fixing hole respectively. The boring cutter is simple in structure, and can carry out hole diameter machining beyond the machining range of equipment.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com