Poly-methyl ethylene carbonate composition and preparation method thereof

A technology of polymethyl ethylene carbonate and composition is applied in the field of polymethyl ethylene carbonate composition and preparation thereof, and achieves the effects of improving flexibility, improving film-forming property and reducing processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] TPU: polyether type (ET), Shore hardness 75A, 85A (Tg=-18.9°C); polyester type (ES), Shore hardness 85A (Tg=-13.6°C), 90A.

[0037] PVA: Model 0588

[0038] TPU / PVA mixing process:

[0039] Twin-screw extruder, screw aspect ratio 40, feeding section 150-170°C, mixing section 175-190°C, screw speed 160rpm, feeding speed 2.5Kg / h.

[0040] The TPU / PVA pellets are hot-pressed by a flat vulcanizer, and the sample is cut for DMA testing. The loss peak at 1Hz frequency represents the glass transition temperature Tg.

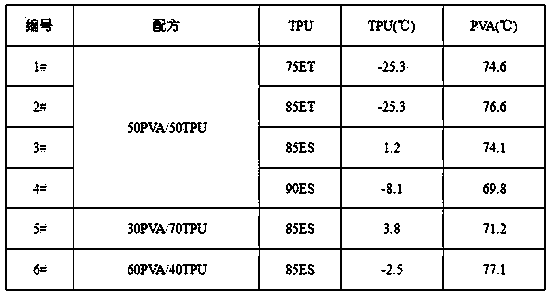

[0041] Table 1 Glass transition temperature test of different grades of TPU and PVA blends

[0042]

[0043] As shown in Table 1, when TPU and PVA are blended, the glass transition temperature of TPU and PVA changes, which shows that there is an interaction between TPU and PVA. The glass transition temperature of polyester TPU (85ES) increased from -13.6°C to 1.2°C of 50TPU / 50PVA, while the glass transition temperature of polyether TPU (85ET) decreased from...

Embodiment 2~6

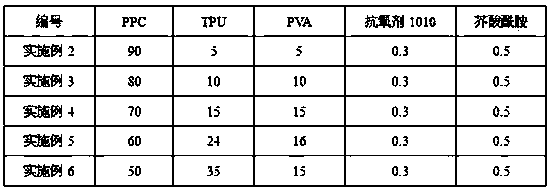

[0047] Table 2 Experimental formula Unit: parts by weight

[0048]

[0049] Experimental steps:

[0050]S1. Raw material pretreatment: Thermoplastic polyurethane TPU and polyvinyl alcohol PVA are dried at 100°C for 4 hours, and polymethylethylene carbonate PPC is dried at 80°C in a blast oven for 12 hours. According to the ratio in Table 4, together with additives Mix in a high-speed mixer for 2 minutes, mix well and pour into twin-screw for blending and granulation.

[0051] Twin-screw blending process for the first time: screw aspect ratio 40, feeding section 150-170°C, mixing section 175-190°C, screw speed 160rpm, feeding speed 2.5Kg / h.

[0052] S2. The TPU / PVA blend obtained by mixing is weighed by extrusion, granulation, mixed with a certain amount of PPC weighed in a high-speed mixer for 2 minutes, mixed evenly, poured into twin-screw blending and granulation.

[0053] The second twin-screw blending process: the feeding section is 100-140°C, the mixing section is 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com