Patents

Literature

30results about How to "Overcome shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

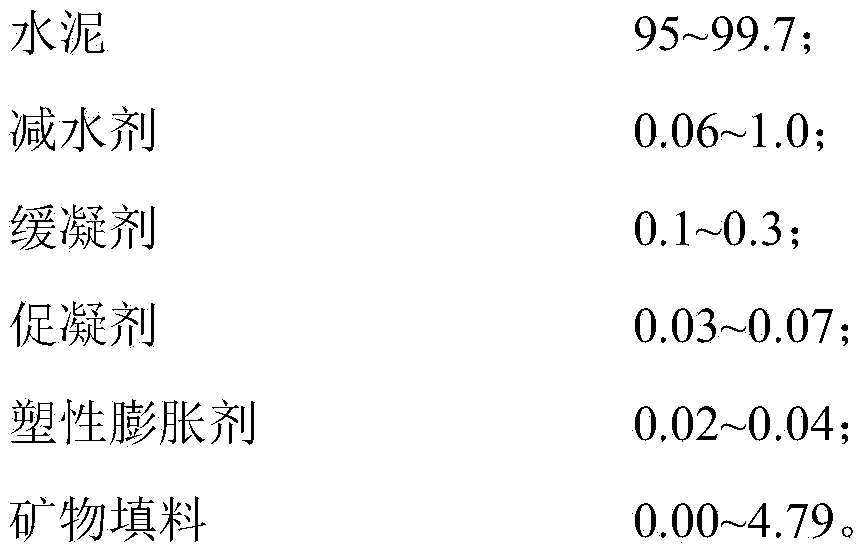

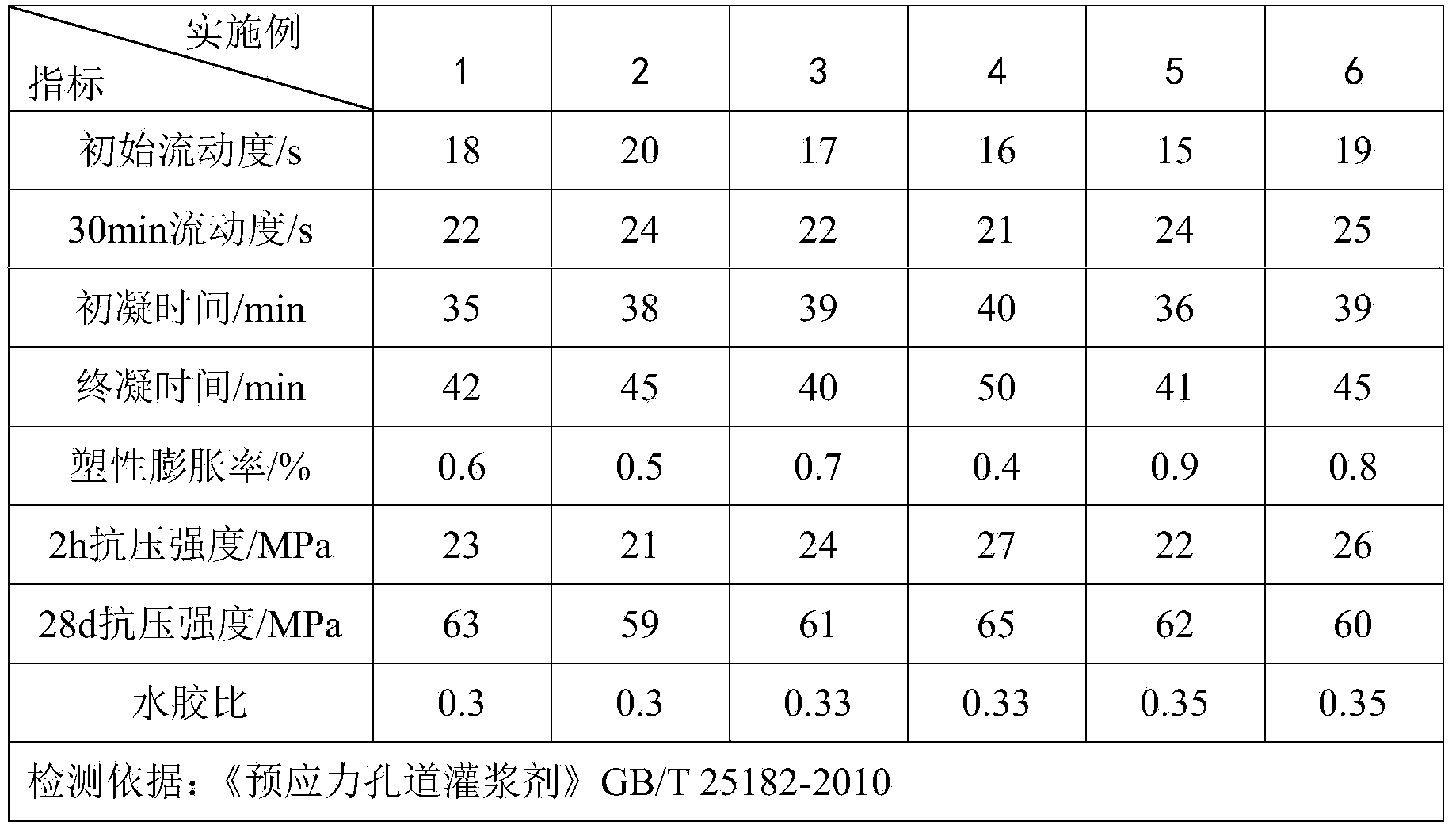

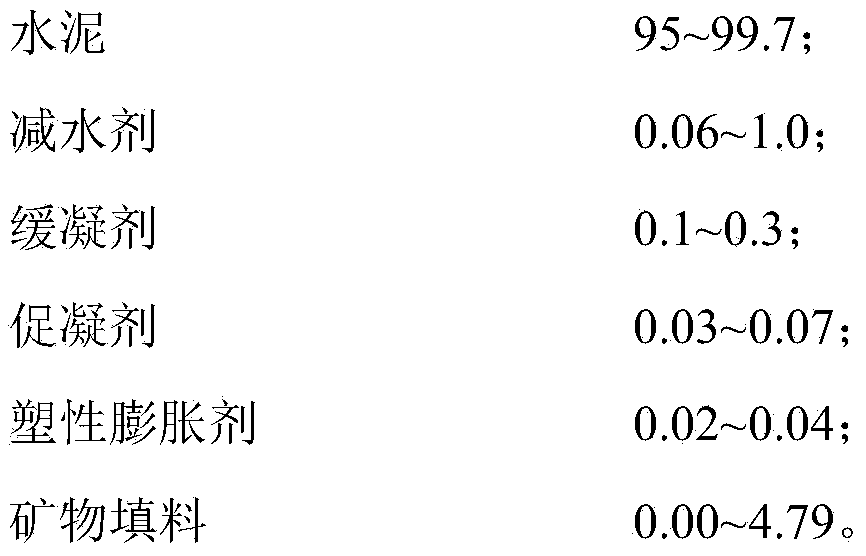

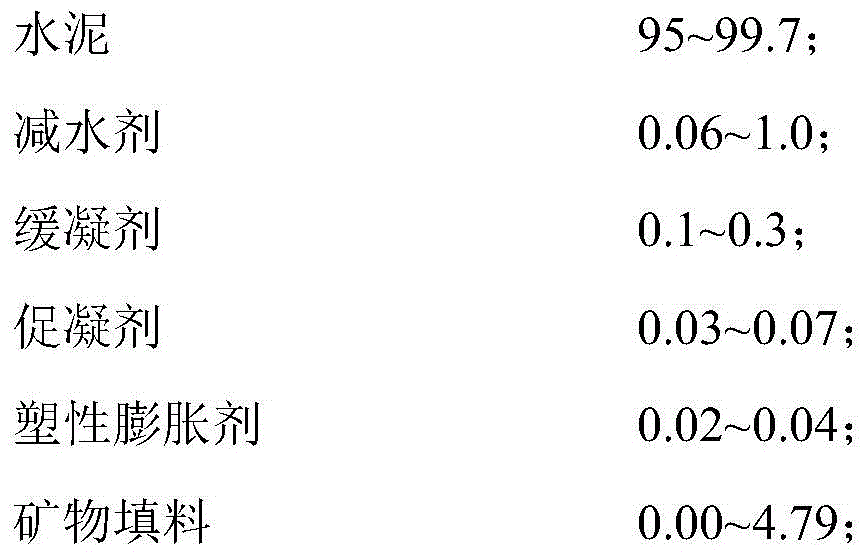

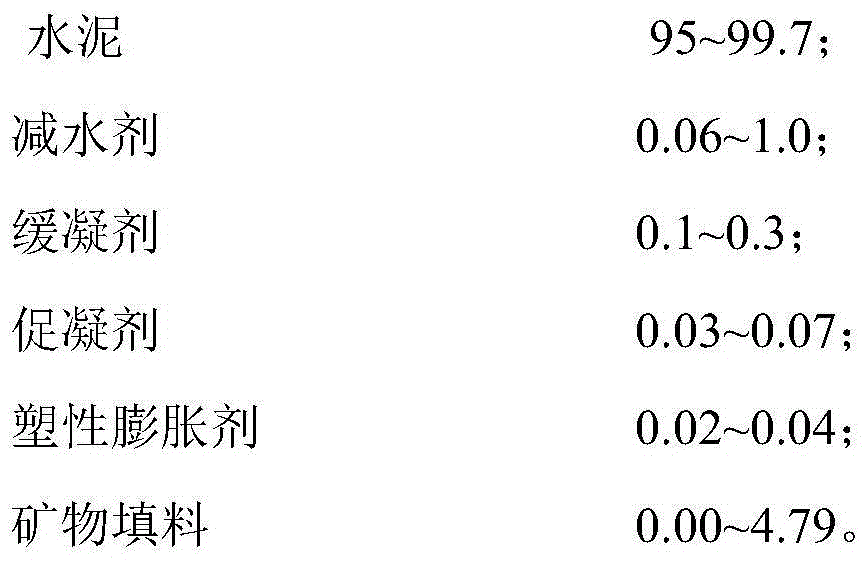

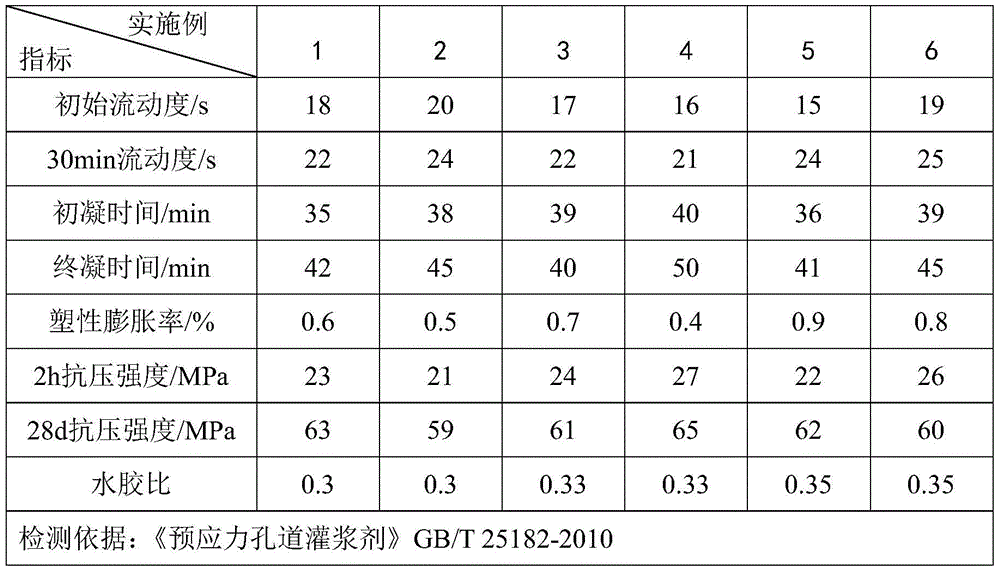

Reinforcing slurry for semi-rigid base and grouting method of reinforcing slurry

The invention relates to reinforcing slurry for a semi-rigid base and a grouting method of the reinforcing slurry. The reinforcing slurry comprises the raw materials by mass percent: 95-99.7% of cement, 0.06-1.0% of water reducer, 0.1-0.3% of retarder, 0.03-0.07% of coagulant, 0.02-0.04% of plastic expanding agent, and 0-4.79% of mineral filler, and the reinforcing slurry is prepared through stirring the raw materials. The grouting method comprises the steps of locating hole sites at 0.25-meter positions of the periphery of a crack in the pitch, and drilling down at the hole sites to the top of a roadbed, wherein the distance between every two holes is 0.75-1.0m; adding water into a stirrer, then adding the slurry, wherein the mass ratio of water to slurry is less than or equal to 0.35, the stirring speed is greater than or equal to 500r / min, and the stirring time is less than or equal to 5 minutes; grouting into a grouting pipe, wherein the grouting pressure is 0.5-1.0MPa, and the time for stirring and grouting is less than or equal to 30 minutes; and after grouting, sealing the grouting holes with sealant or pitch. The reinforcing slurry has the characteristics of low cost, good fluidity, fast speed in condensation and high strength, and the grouting method is simple.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

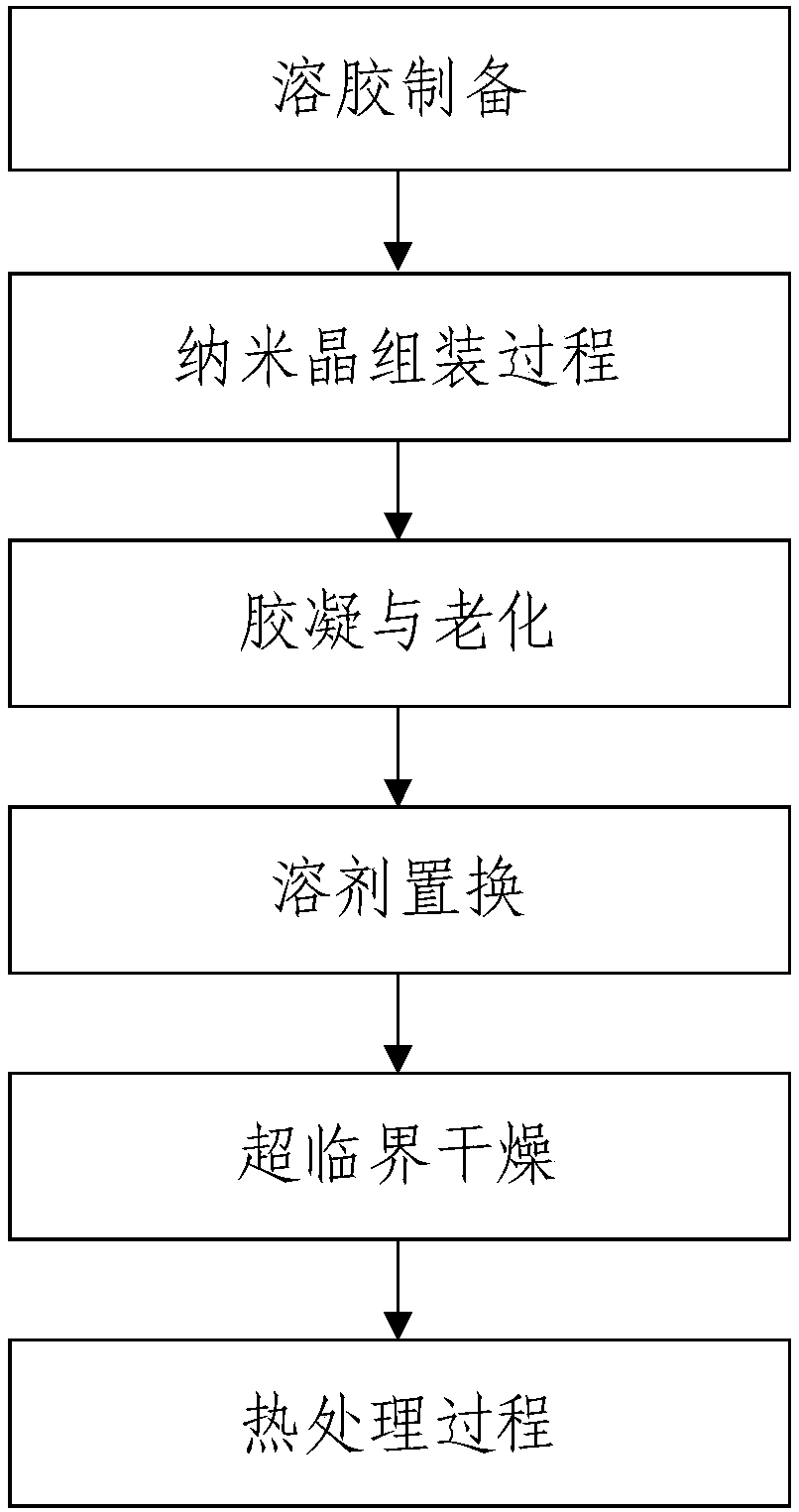

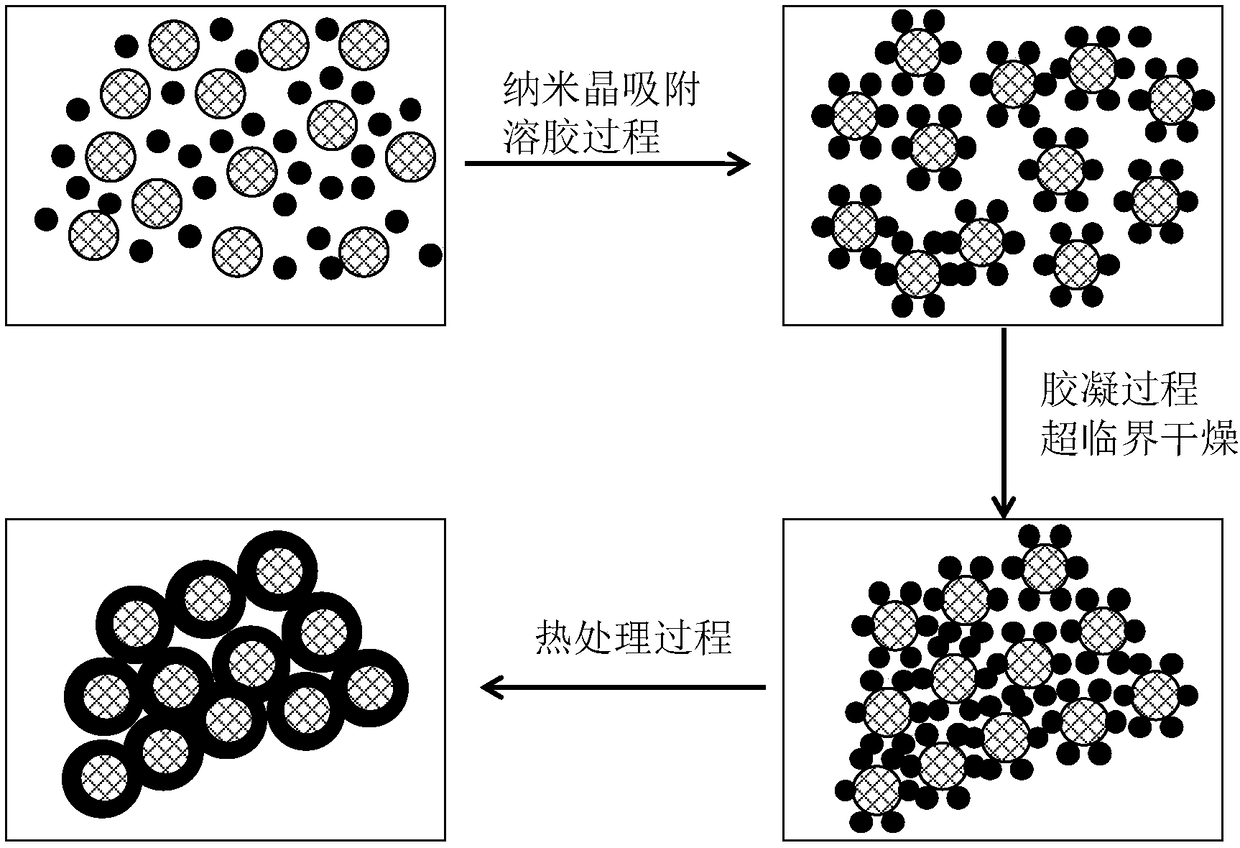

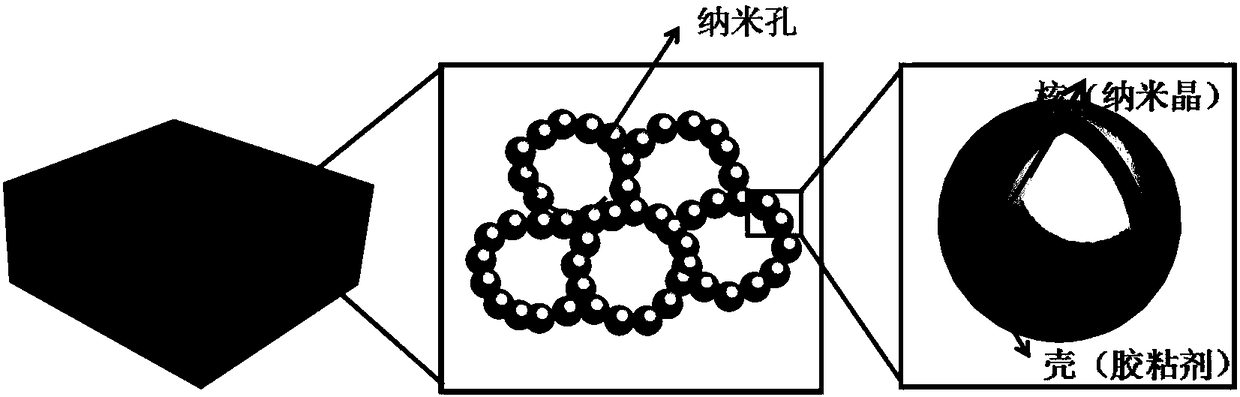

Preparation method of high-temperature-resisting aerogel material

The invention relates to a preparation method of a high-temperature-resisting aerogel material. The method comprises the following steps: (1) preparing sol; (2) carrying out a nano-crystal assemblingprocess to prepare aerogel wet gel which takes an oxide nano-crystal as a framework; (3) preparing an aerogel material; (4) carrying out a heat treatment process to prepare the high-temperature-resisting aerogel material. According to the preparation method provided by the invention, a nano-crystal assembling technology and heat treatment are combined to prepare the high-temperature-resisting aerogel material with a microcosmic core-shell structure; the core-shell structure forms a network framework under high temprature so that the growth of the oxide nano-crystal is inhibited and the shrinkage problem caused by the fact that the structure of oxide aerogel collapses in a high-temperature utilization process is effectively solved. The aerogel material prepared by the preparation method hasa good high-temperature-resisting property; the heat-resisting temperature is 1000 DEG C or more and the high-temperature-resisting aerogel material even can bear the high temperature of 1300 DEG C or more.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

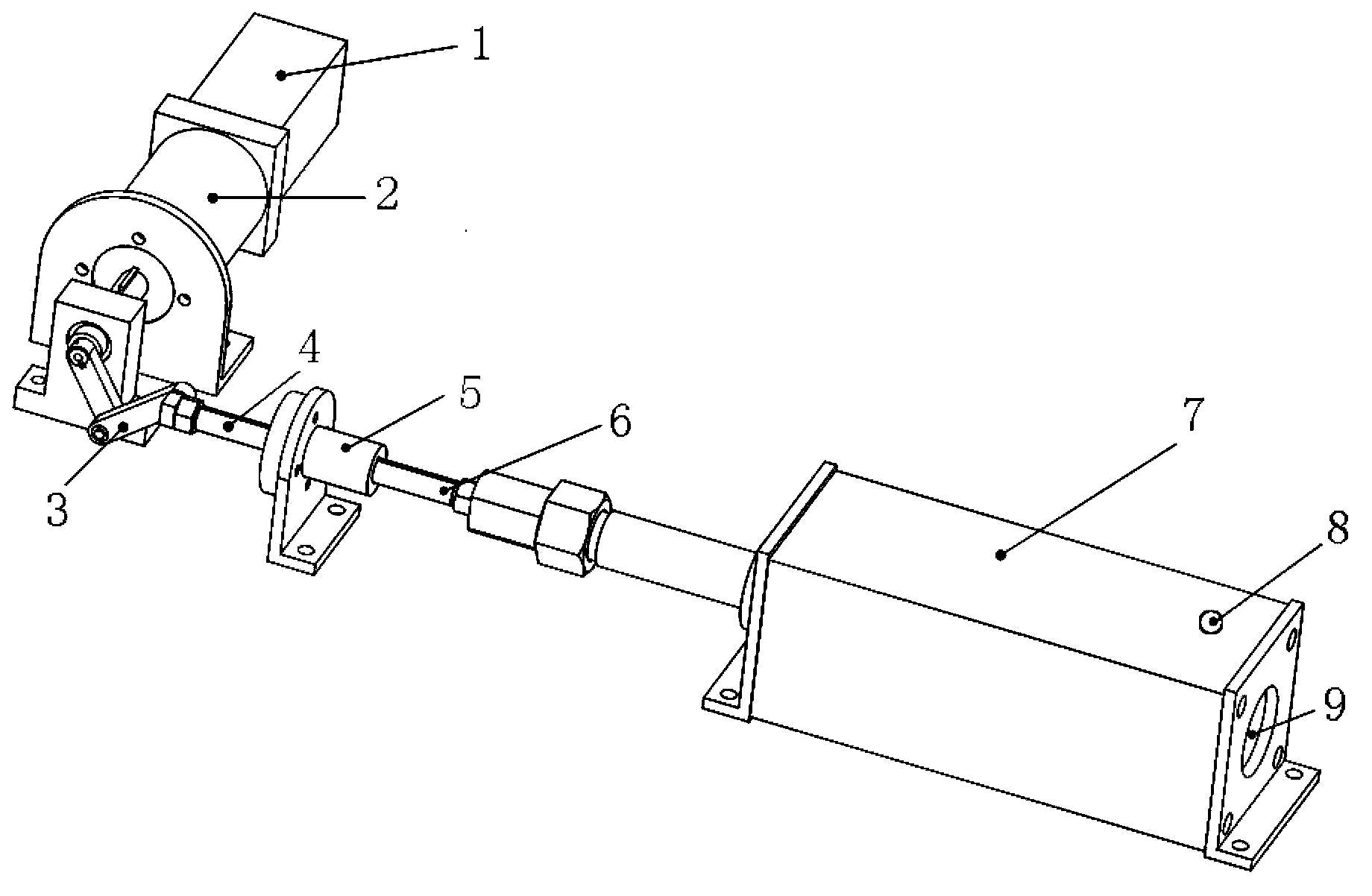

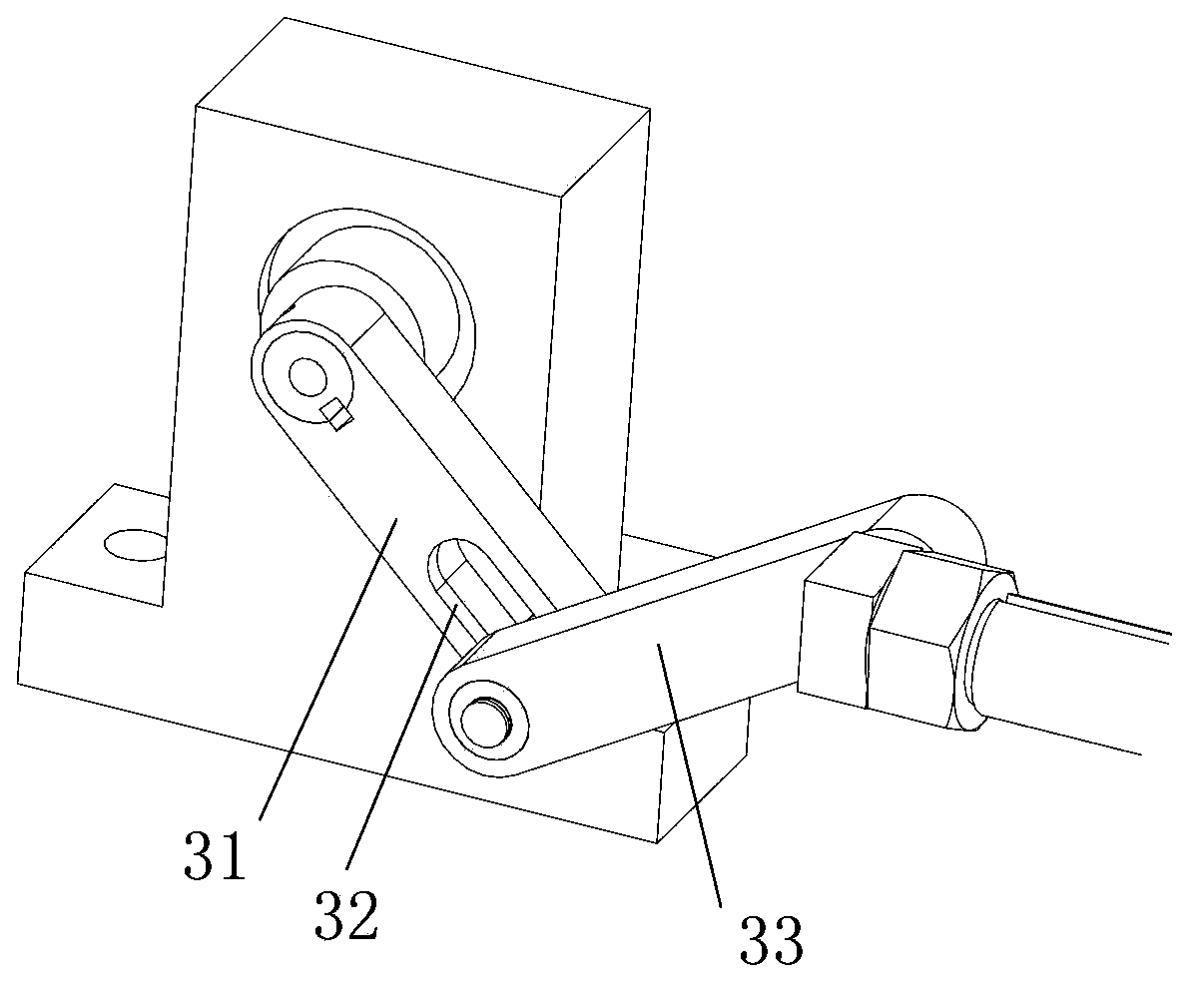

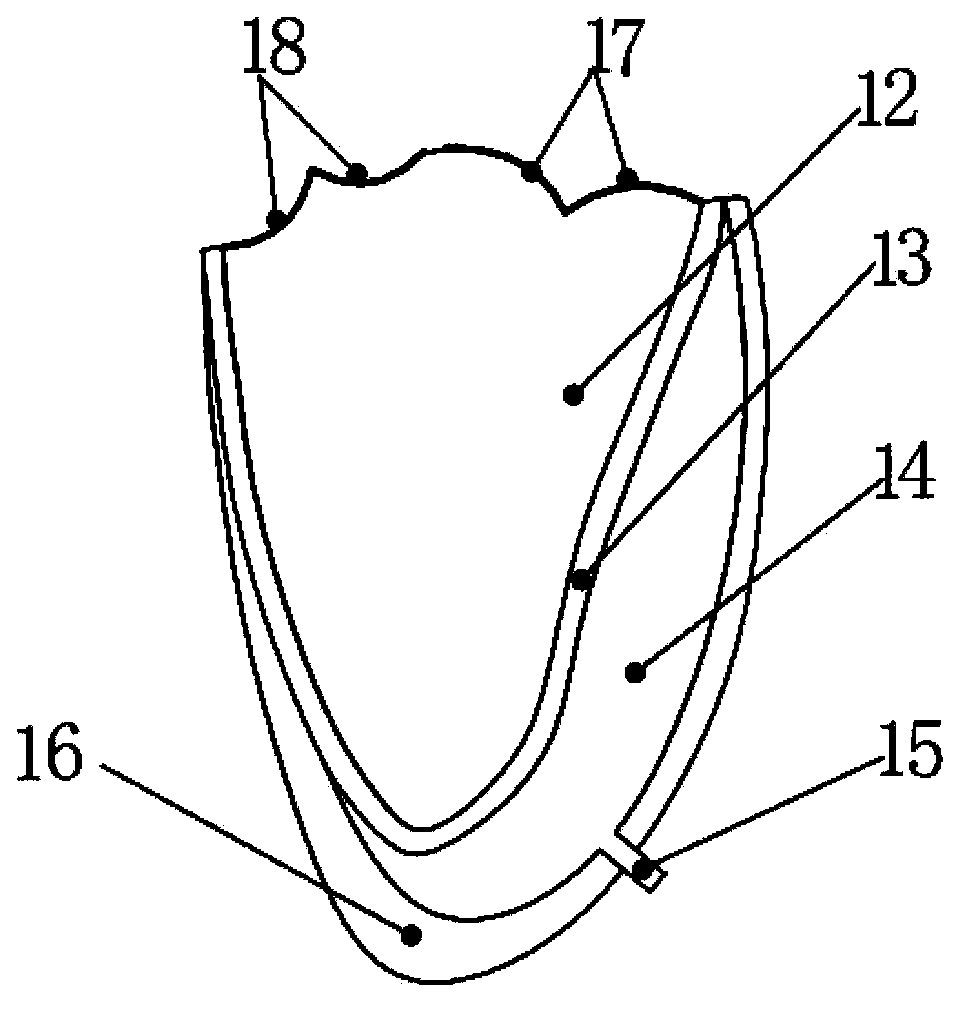

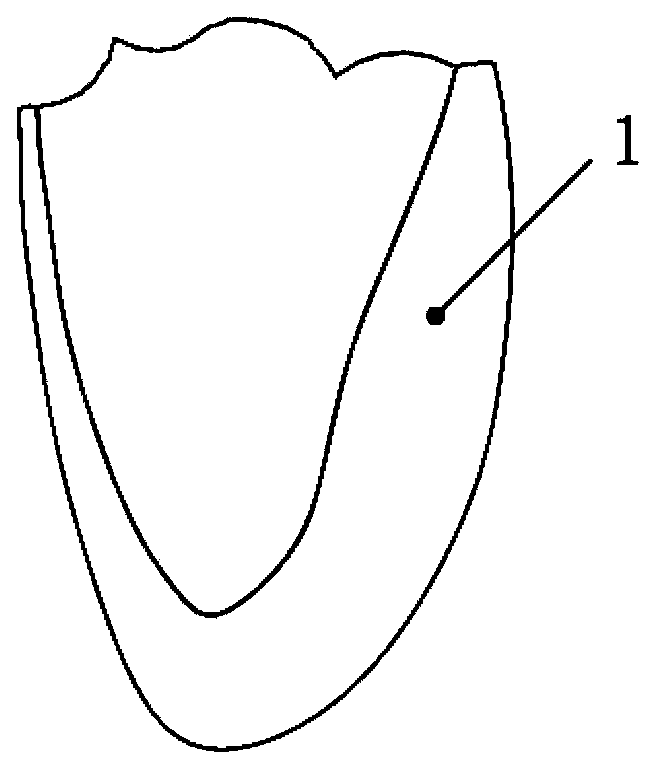

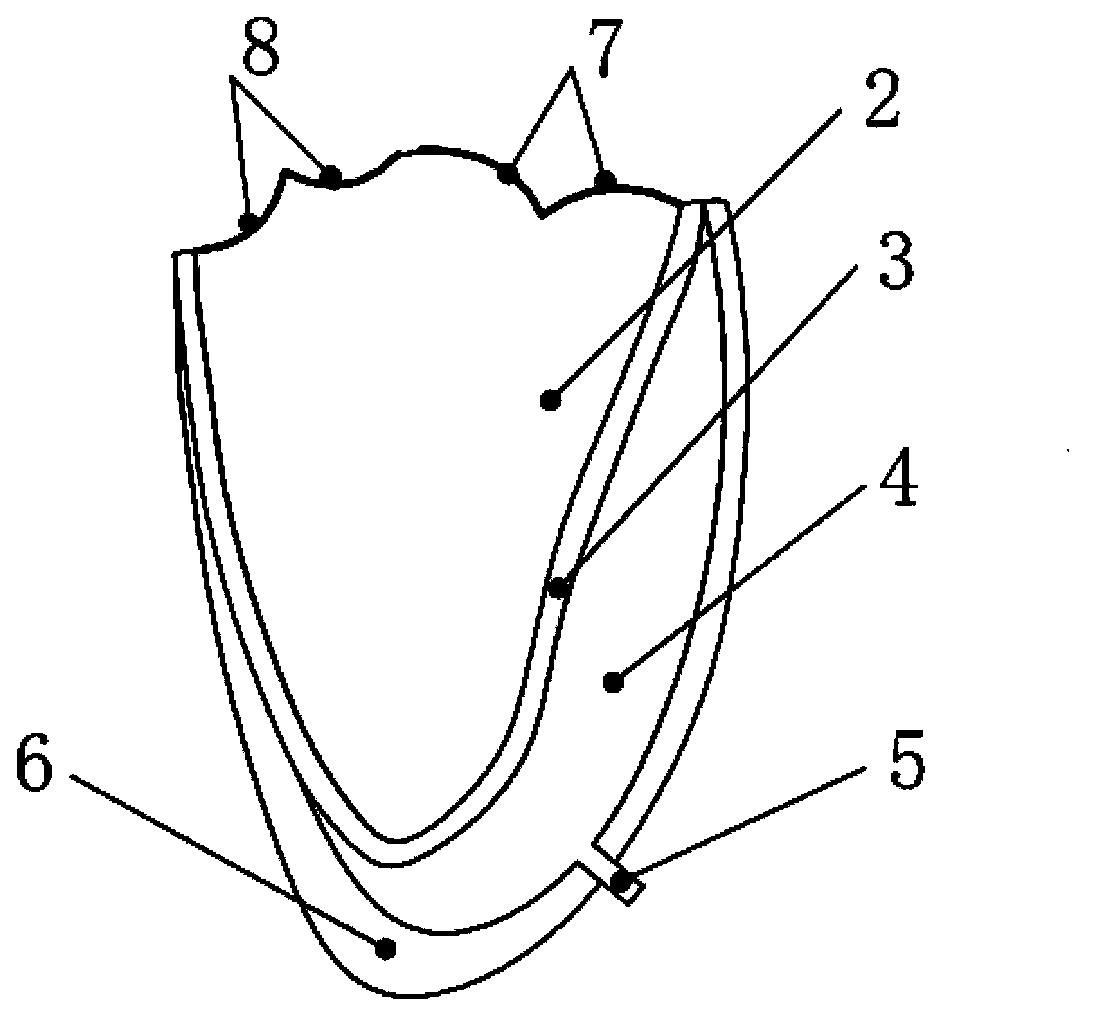

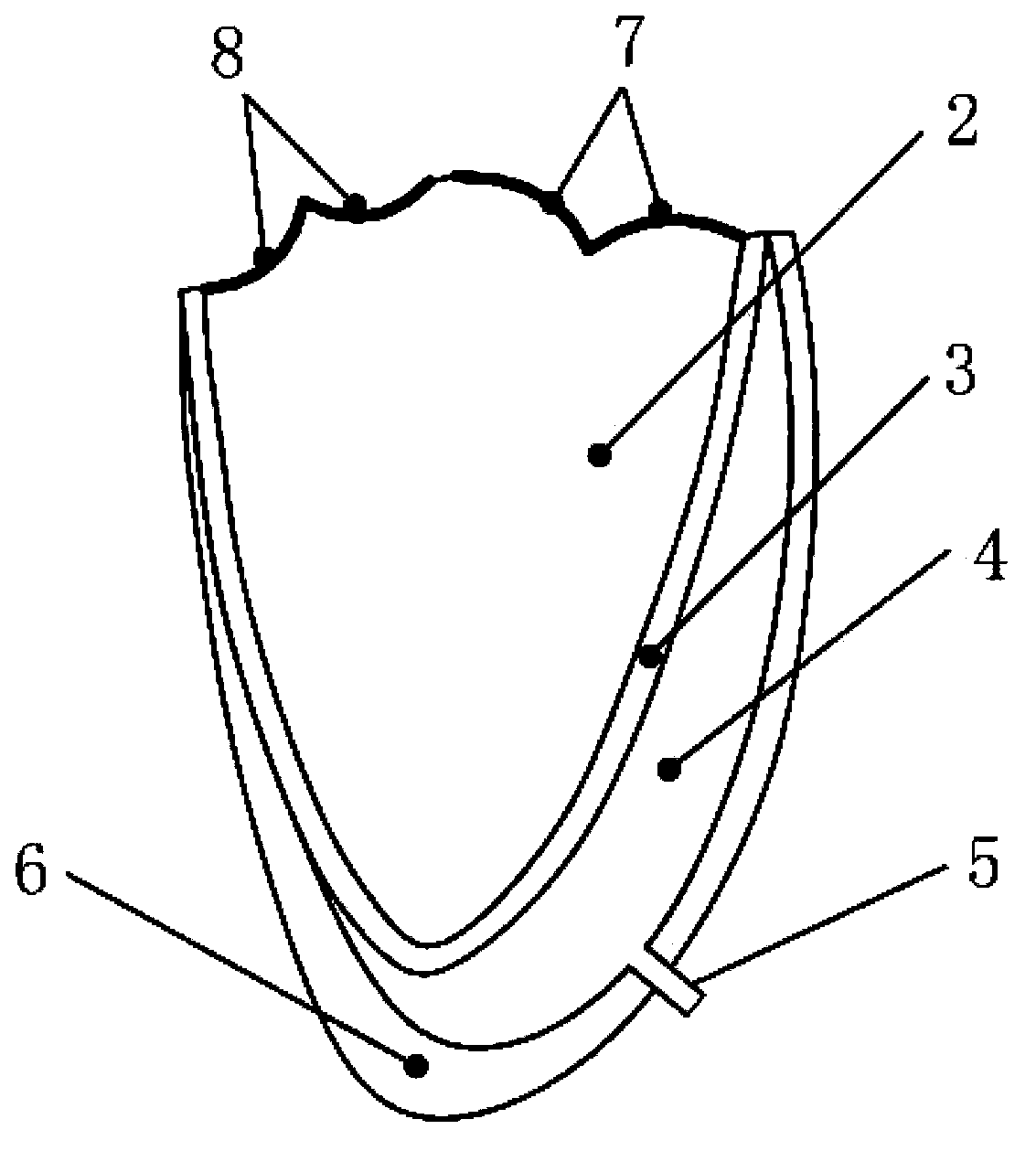

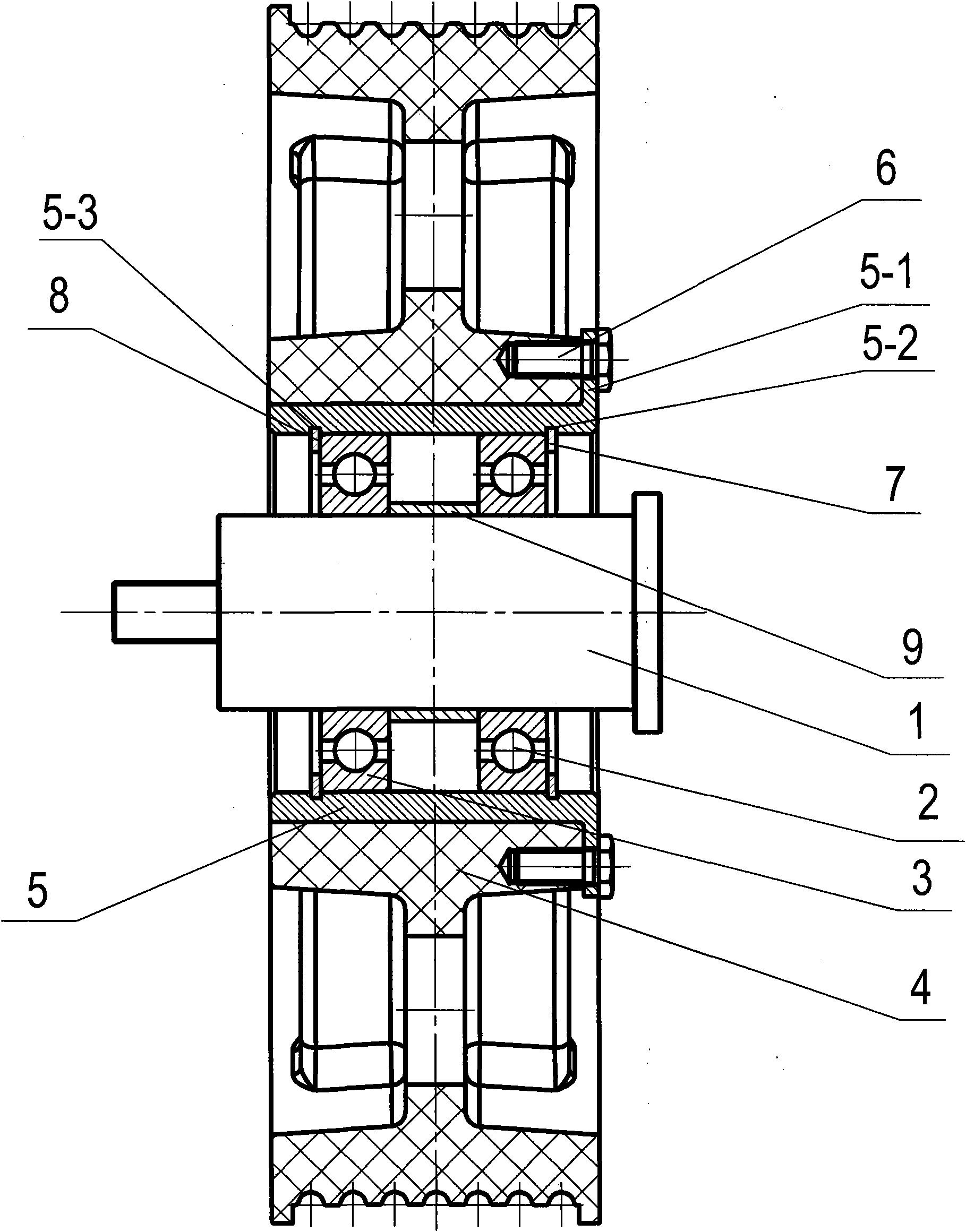

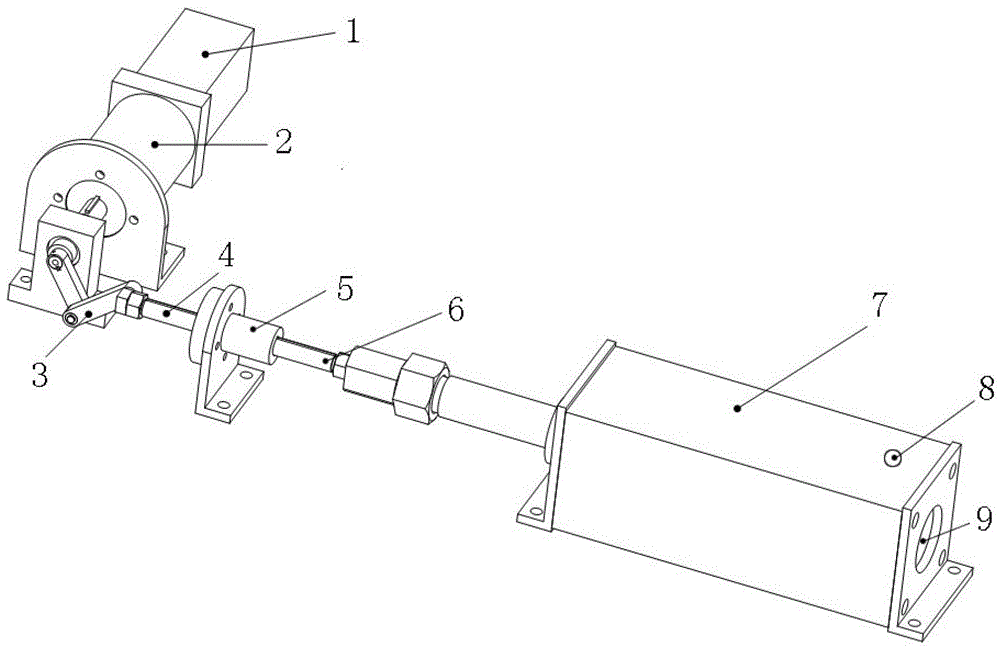

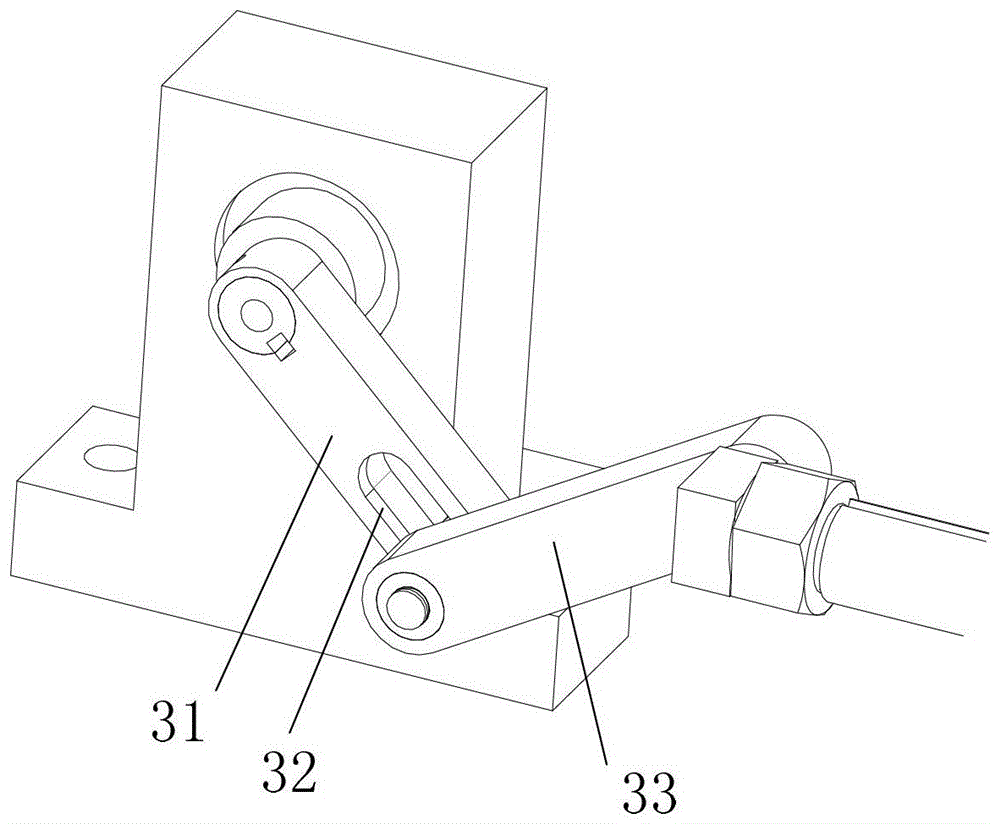

Heart chamber simulator driving mechanism

ActiveCN104346987ARegulate beat rateAdjustable beat rateEducational modelsHeart chamberHeart beating process

The invention discloses a heart chamber simulator driving mechanism, which comprises a motor, a speed reducer, a crank shaft connecting rod mechanism, a linear guide rail and a piston air cylinder, wherein an output end of the motor is connected with an input shaft of the speed reducer, an output shaft of the speed reducer is connected with one end of the linear guide rail through the crank shaft connecting rod mechanism, the other end of the linear guide rail is connected with the piston air cylinder through a shaft coupler, an air hole is formed in the side wall of the piston air cylinder, and the air hole is connected with a heart chamber simulator through a pipeline. The driving mechanism belongs to a driving mechanism capable of providing a pulsation type power source for the heart chamber simulator according to the set frequency and discharge capacity. The driving mechanism has the advantages that the pulsation feature of the beating of the heart chamber simulator can be realized, meanwhile, the beating frequency and the discharge capacity can be respectively regulated, and the human body heart beating process is more really simulated.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Automobile active steering system with cycloidal-pin wheel mechanism

ActiveUS20160031475A1Overcome shrinkageVariable transmission ratioHydraulic steering gearsElectrical steeringSteering wheelDrive shaft

The invention discloses an automobile active steering system with a cycloidal-pin wheel mechanism, and aims at overcoming the contraction between light steering effort and flexibility. The automobile active steering system comprises a steering hand wheel (47), a steering shaft (52), a steering transmission shaft (48), a cycloidal-pin wheel type transmission mechanism (49), a rotary hydraulic valve (50), and a steering box (51). The steering hand wheel (47) is connected with an upper end of the steering shaft (52) by use of a spline pair, a lower end of the steering shaft (52) is connected with an upper end of the steering transmission shaft (48) by use of a universal joint, a lower end of the steering transmission shaft (48) is connected with a right end of an input shaft (21) of the cycloidal-pin wheel type transmission mechanism (49) by use of a universal joint.

Owner:JILIN UNIV

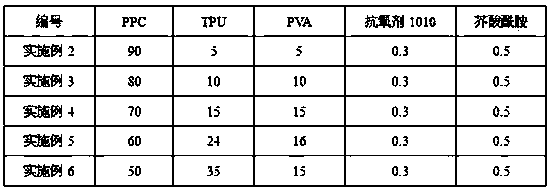

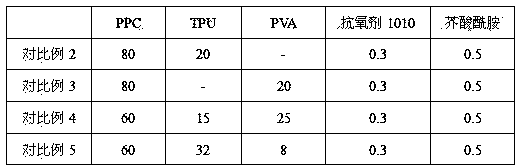

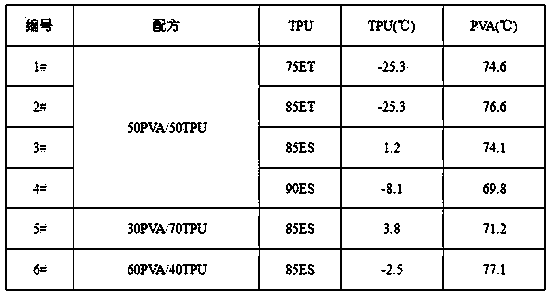

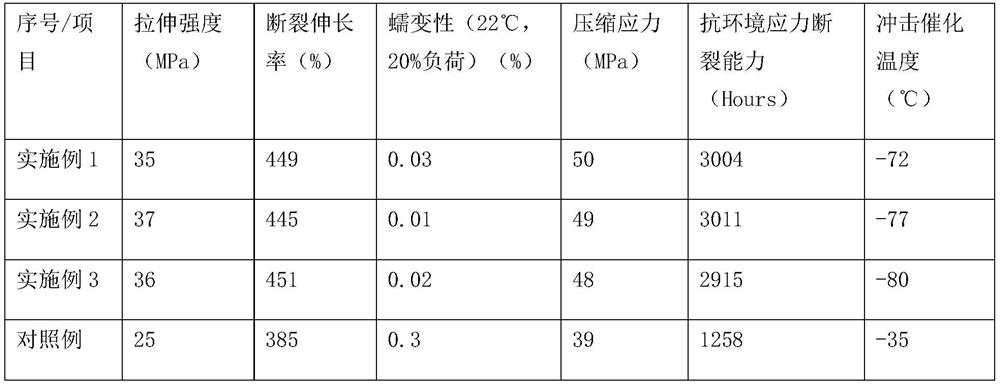

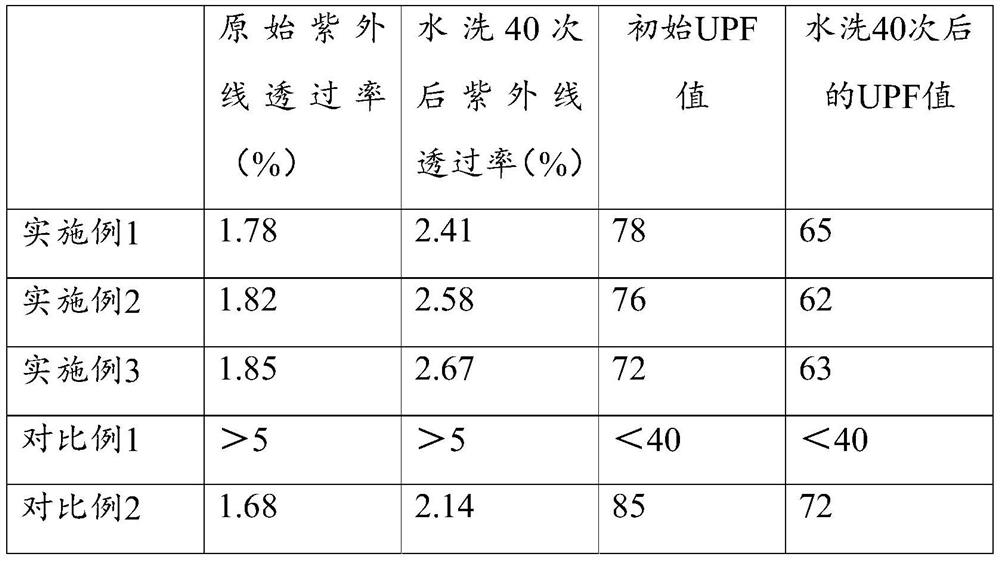

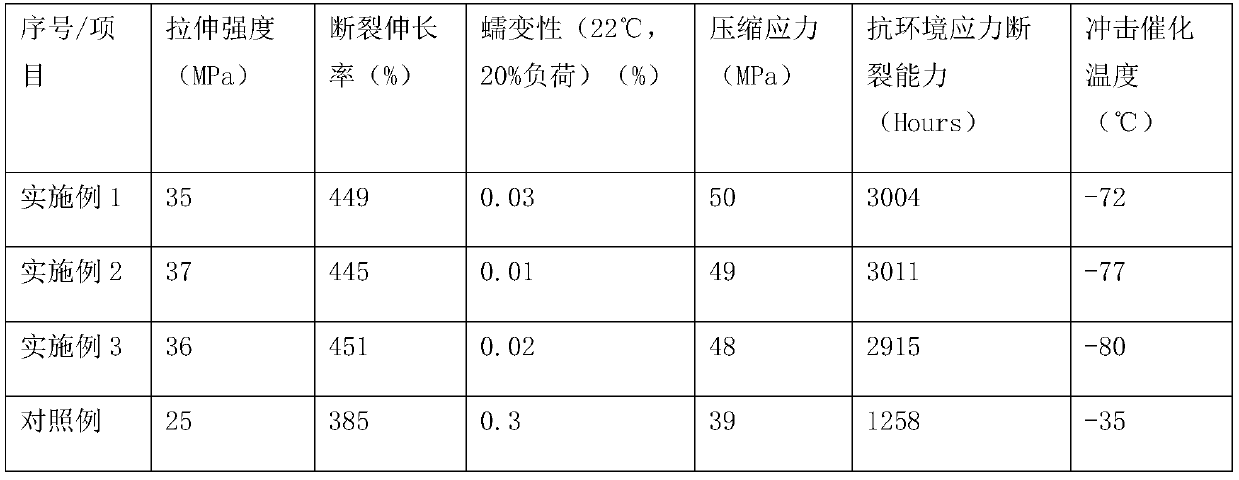

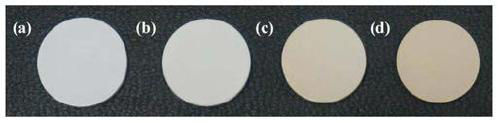

Poly-methyl ethylene carbonate composition and preparation method thereof

ActiveCN104371296AImprove film formationGood dimensional stabilityAdjuvantThermoplastic polyurethane

The invention relates to the technical field of modified materials, and discloses a poly-methyl ethylene carbonate composition and a preparation method thereof. The composition comprises the following raw materials: a poly-methyl ethylene carbonate matrix, a modified material and an adjuvant, wherein the modified material is composed of thermoplastic polyurethane and polyvinyl alcohol in melting and blending manners; the mass ratio of the modified material to the poly-methyl ethylene carbonate is (10-100) to 100; polyvinyl alcohol accounts for 30%-50% by mass of the modified material; the adjuvant accounts for 0.5%-2%. The preparation method comprises the following steps: melting and blending TPU with PVA; and then blending and pelletizing with PPC. The composition disclosed by the invention has the advantages of good film-forming property and dimensional stability, good tensile strength, breaking elongation, biodegradability and the like. The composition disclosed by the invention does not agglomerate or deform, and does not affect the processability after being placed for a long period of time when the matrix cost is lowered; the film is not bonded; the breaking elongation of the film disclosed by the invention after water absorption is increased; and meanwhile, good tensile strength is kept.

Owner:SUN YAT SEN UNIV +1

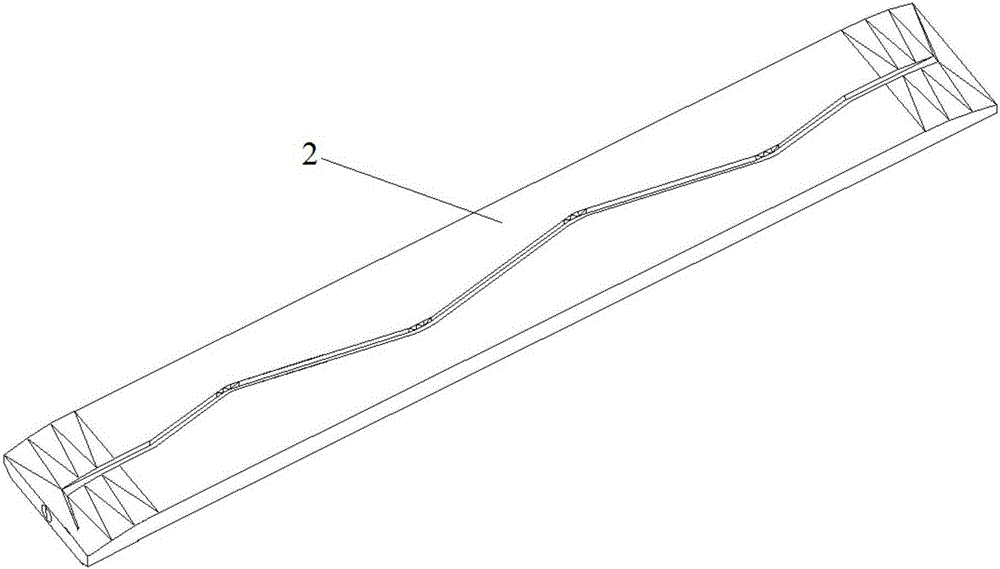

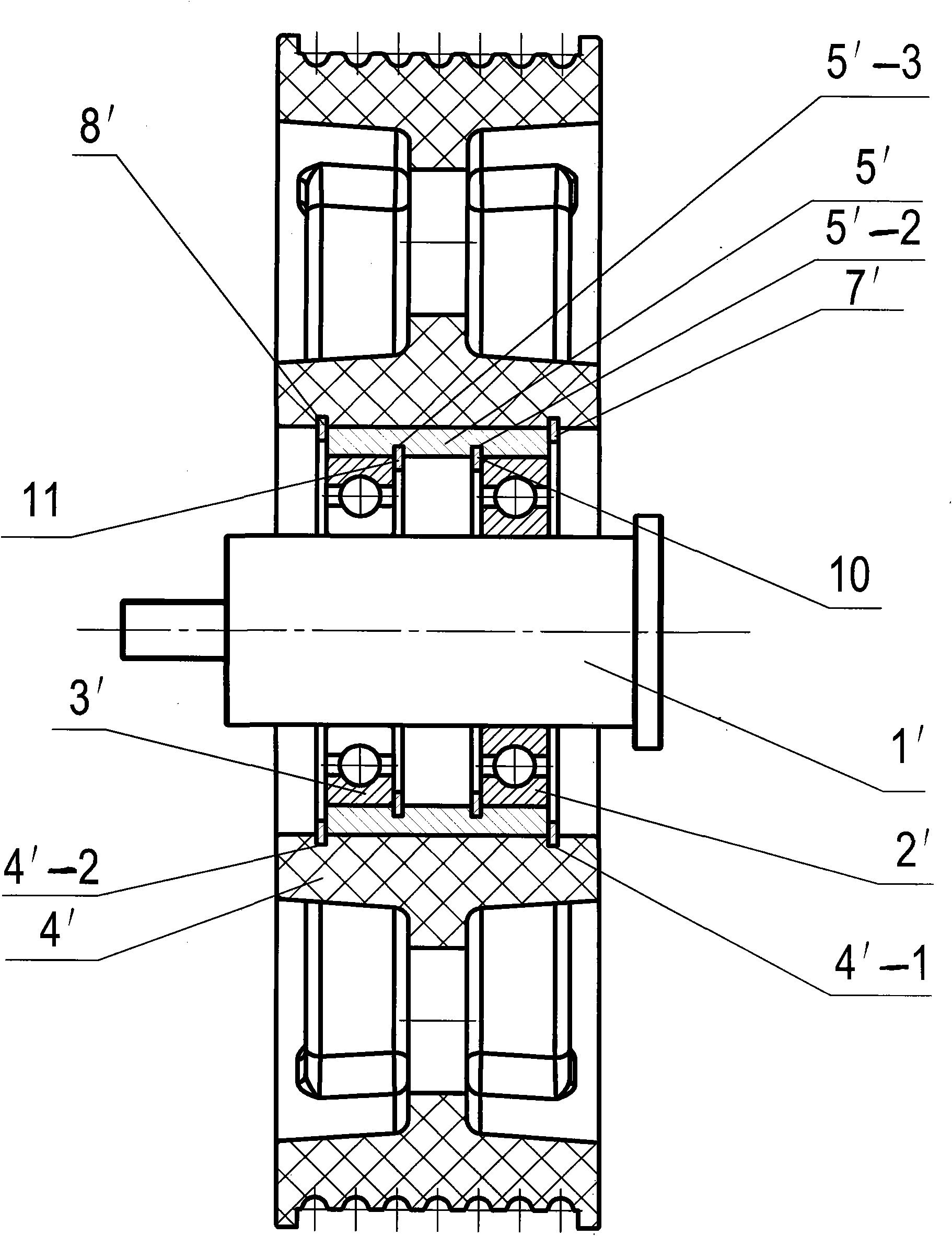

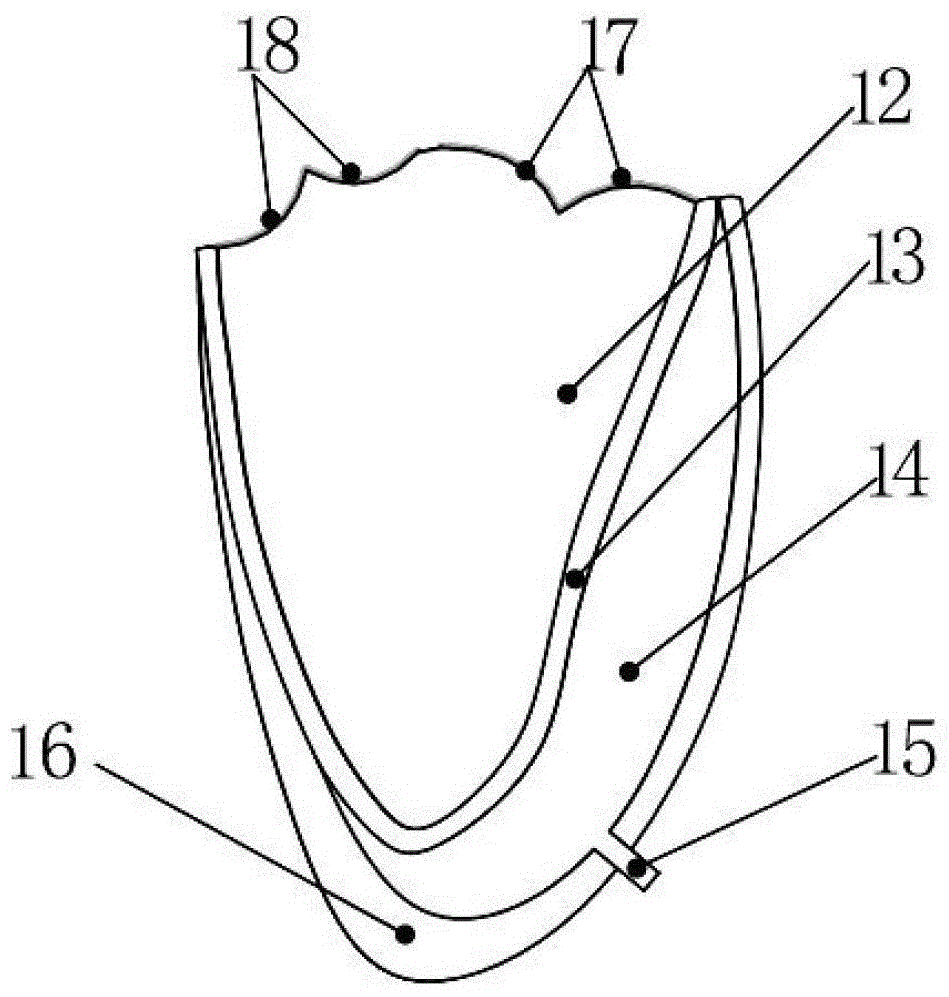

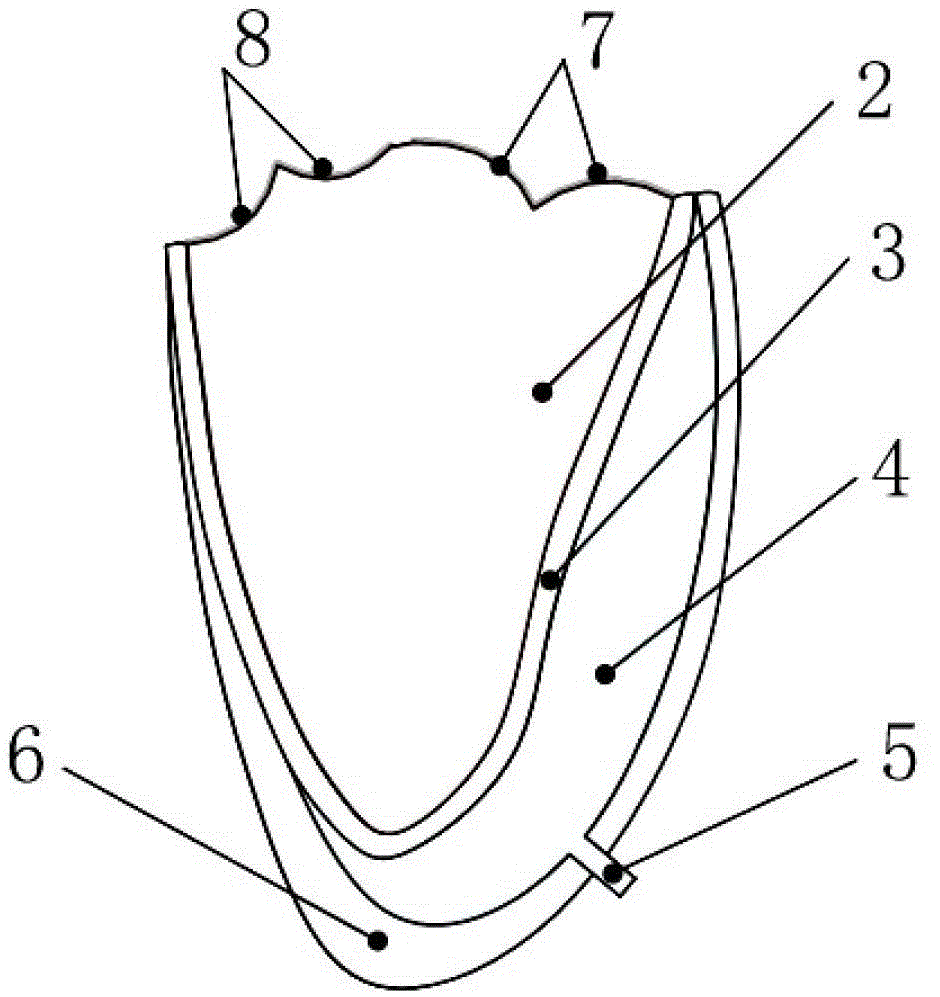

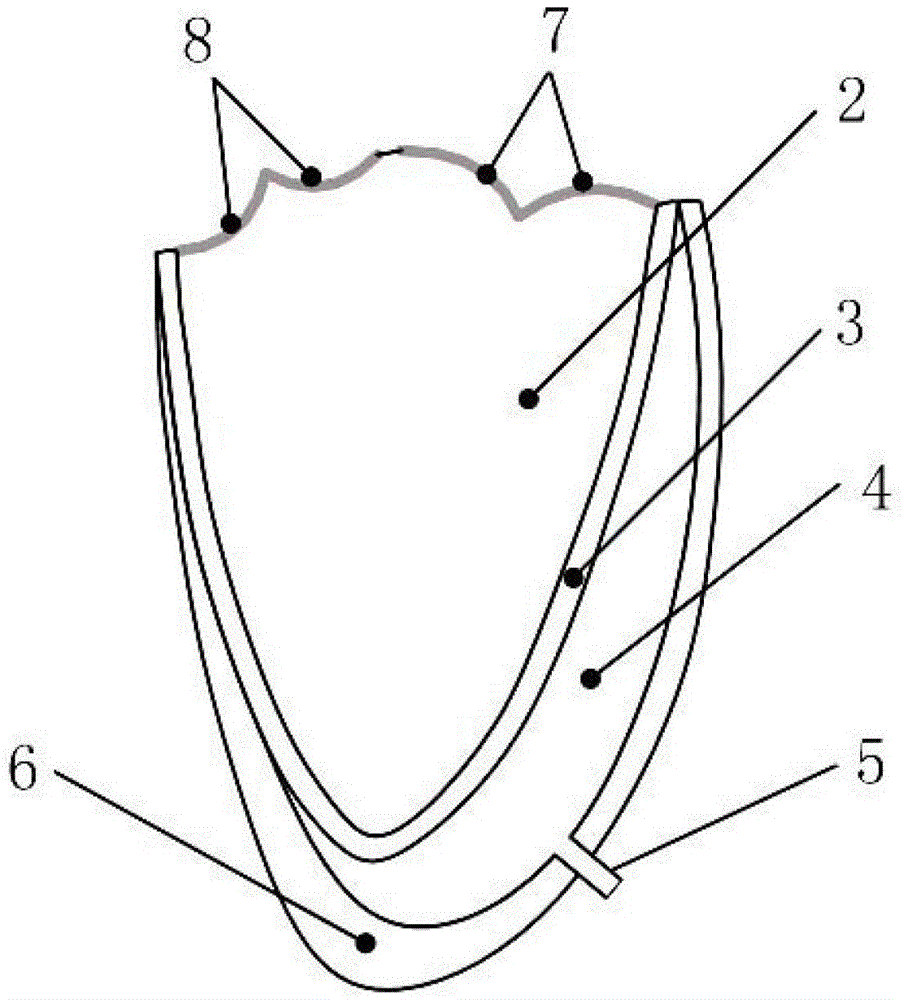

Heart chamber simulator driven by hydraulic or air-pressure artificial muscle

ActiveCN103854544AOvercoming systolic and diastolic pressure errorsOvercome shrinkageEducational modelsHeart chamberRelaxation process

The invention discloses a heart chamber simulator driven by a hydraulic or air-pressure artificial muscle. The heart chamber simulator can really reflect cardiac systolic and diastolic beating process pressure and chamber deformation. The simulator comprises an outer sheath layer, a myocardium layer, cardiac valves and a closed hollow cavity formed between the outer sheath layer and the myocardium layer. The wall surface of the outer sheath layer is provided with a through hole used for input or output of liquid (gas) in the hollow cavity. Contraction and relaxation of a heart model can be achieved by changing the pressure in the hollow cavity. The heart chamber simulator can overcome the defect that a contraction and relaxation pressure error is caused by a pump which is used in an external circulation pipeline and solve the problem that a difference between the heart chamber deformation caused by external mechanical loading and the actual myocardial contraction and relaxation process deformation is large, and really reflects the heart chamber beating process deformation and correct circulating pressure relationships.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +1

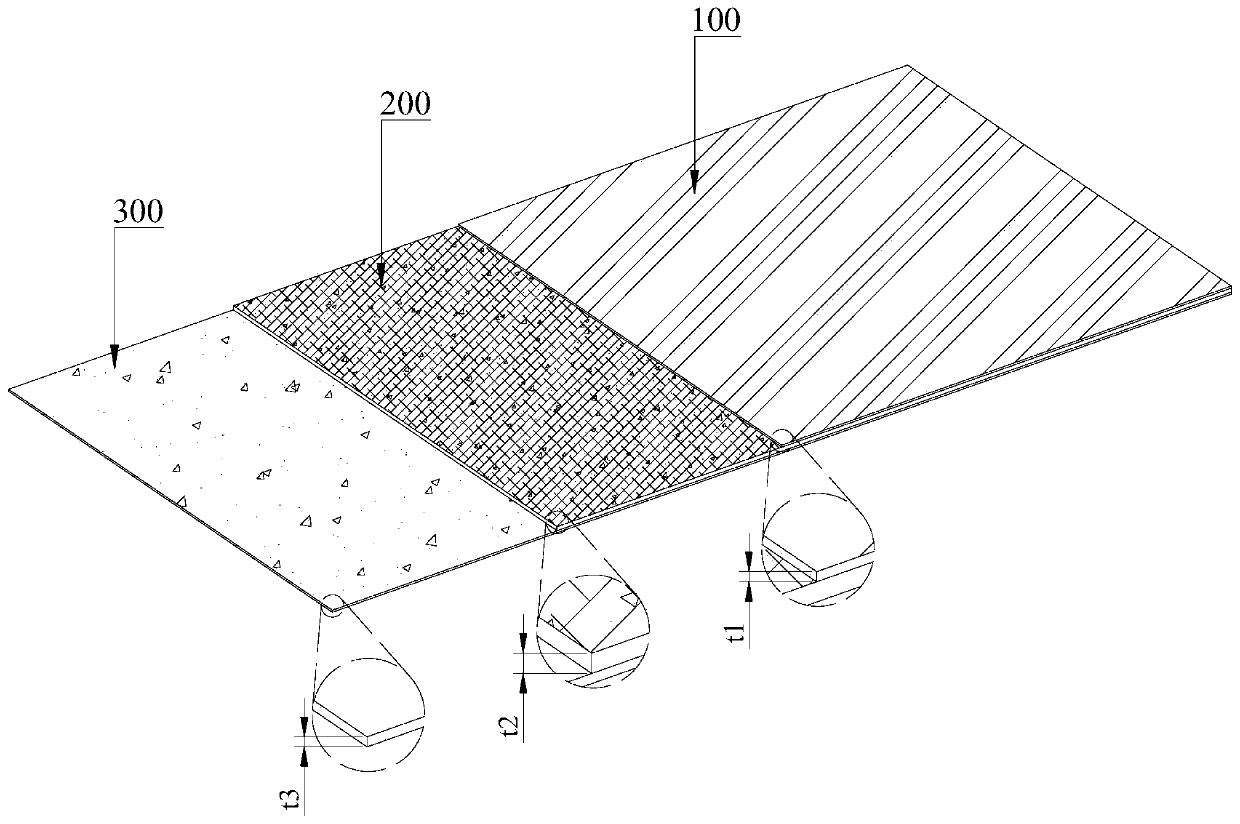

Organic fiber toughened inorganic composite artificial stone panel and preparation method thereof

InactiveCN110746152AImprove compactnessImprove production efficiencyCovering/liningsFeeding arrangmentsFiberArtificial stone

Owner:黄贺明 +1

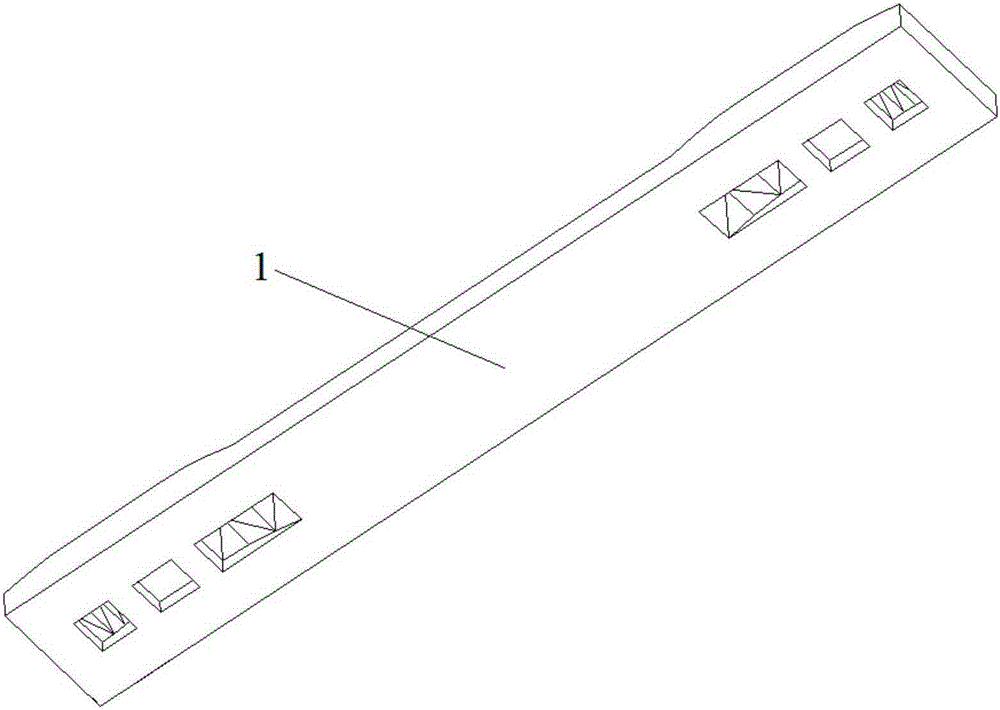

Elevator sliding guide shoe liner made of ultra-high molecular weight polyethylene and preparation method for elevator sliding guide shoe liner

The invention relates to an elevator sliding guide shoe liner made of ultra-high molecular weight polyethylene and a preparation method for the elevator sliding guide shoe liner. The shoe liner comprises a product B and two products A oppositely arranged on the product B in the length direction of the product B, and the product B and the two products A are combined to form a structure adaptive to an elevator sliding guide shoe in shape. The products A and the product B are prepared from ultra-high molecular weight polyethylene resin or composite materials with ultra-high molecular weight polyethylene resin as the base body through the injection molding process, the mass fraction of the ultra-high molecular weight polyethylene resin in the composite materials is 45%-75%, and the rest is low molecular weight polyolefine resin. Compared with the prior art, the elevator sliding guide shoe liner is made of the ultra-high molecular weight polyethylene composite materials for the first time, and the application of the ultra-high molecular weight polyethylene composite materials to special-shaped products is achieved through the characteristics of superior mechanical properties of high strength and wear resistance, superior chemical corrosion resistance and superior ageing resistance of the ultra-high molecular weight polyethylene.

Owner:SHANGHAI RES INST OF CHEM IND +1

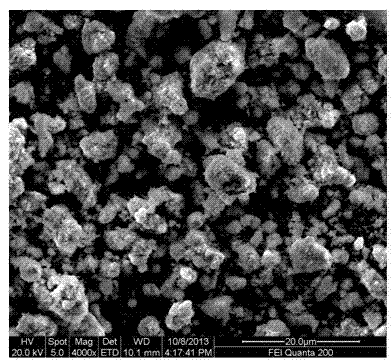

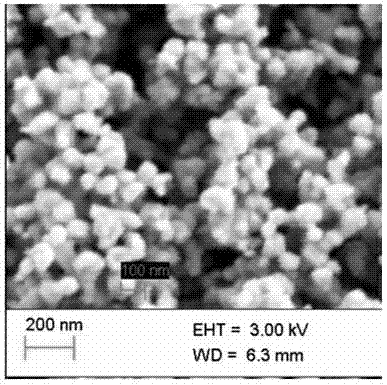

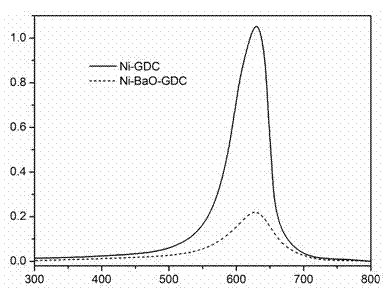

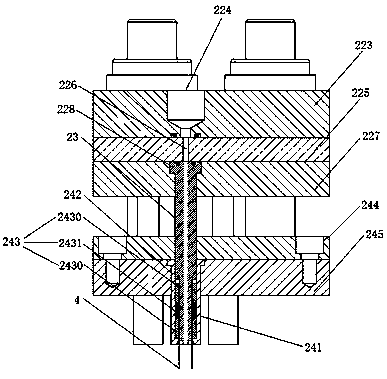

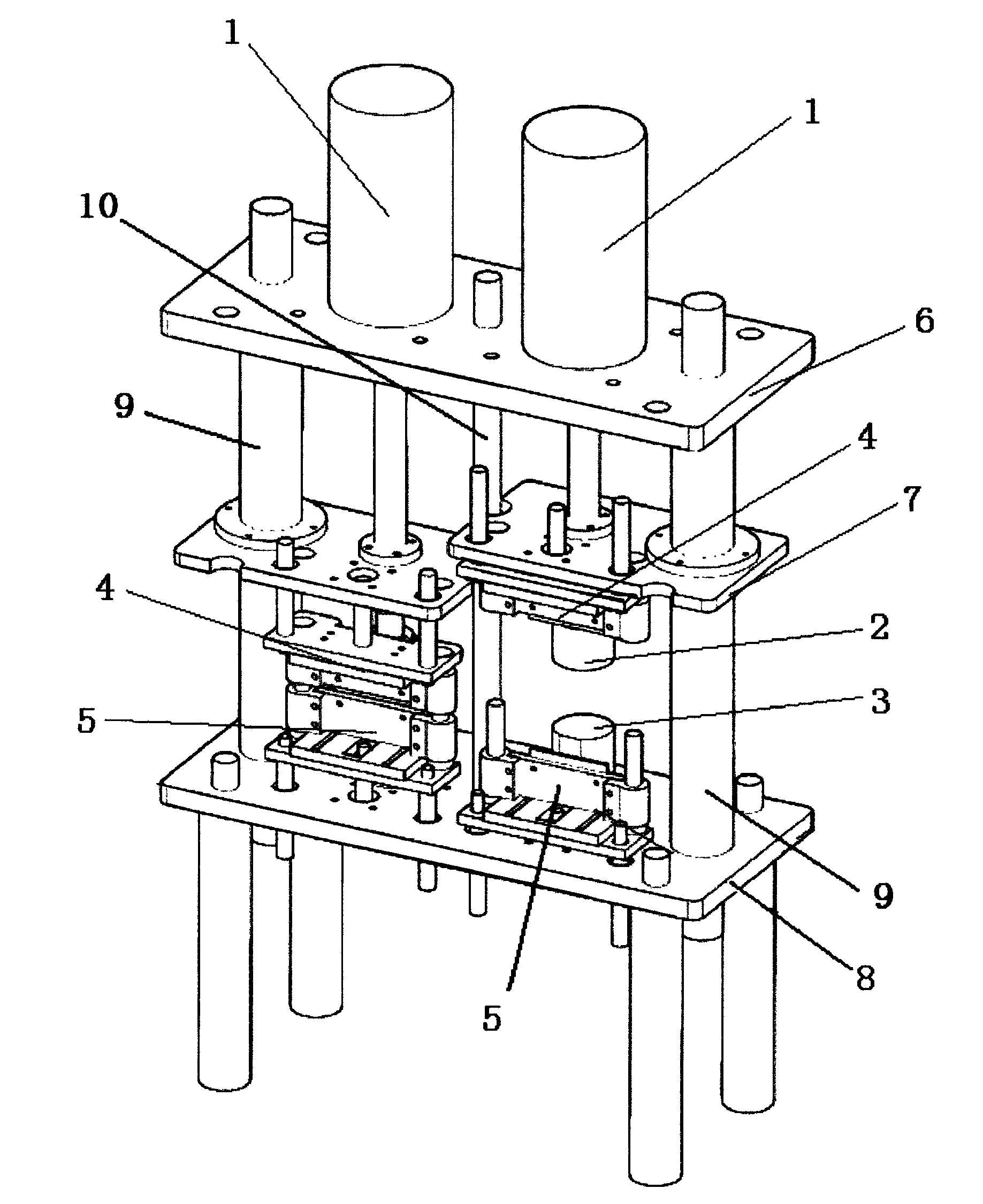

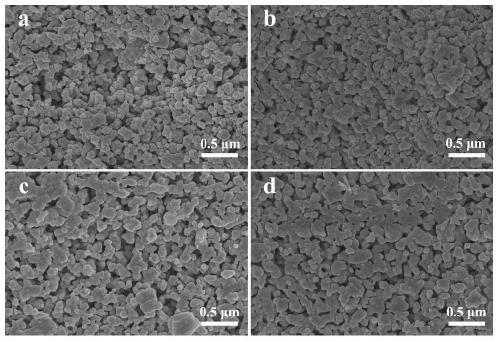

Method for preparing Ni-BaO-GDC nanometer SOFC anode by means of high-speed mixing-kernel blast

InactiveCN103567454APrevent sintering and agglomerationUniform particle sizeMaterial nanotechnologyCell electrodesHydrocotyle bowlesioidesMixed materials

The invention discloses a method for preparing a Ni-BaO-GDC nanometer SOFC anode by means of high-speed mixing-kernel blast. The method comprises the following steps: (1) mixing nanometer barium inorganic salt, nanometer GDC and micron metal Ni in a plain bumper at high speed to obtain a core-shell structure mixed material in which the micron Ni is coated with the nanometer particles; (2) sintering the materials mixed at high speed at the high temperature of 1100-1400 DEG C for 0.5-4 hours to obtain the Ni-BaO-GDC nanometer SOFC anode. The method disclosed by the invention has the following advantages: 1. The low-cost, continuous and batch production can be realized; (2) no wastewater and waste gas are discharged in the production process, and the raw materials are free from corrosivity, toxicity, inflammability and explosion hazard; 3. the product has higher dispersibility; 4, the prepared Ni-BaO-GDC anode is 50-100nm in grain size, uniform in particle size, good in dispersibility, excellent in carbon deposition resistance and electro-catalytic property, and applicable to the SOFC anode material with hydrocarbon as the fuel.

Owner:NANCHANG HANGKONG UNIVERSITY

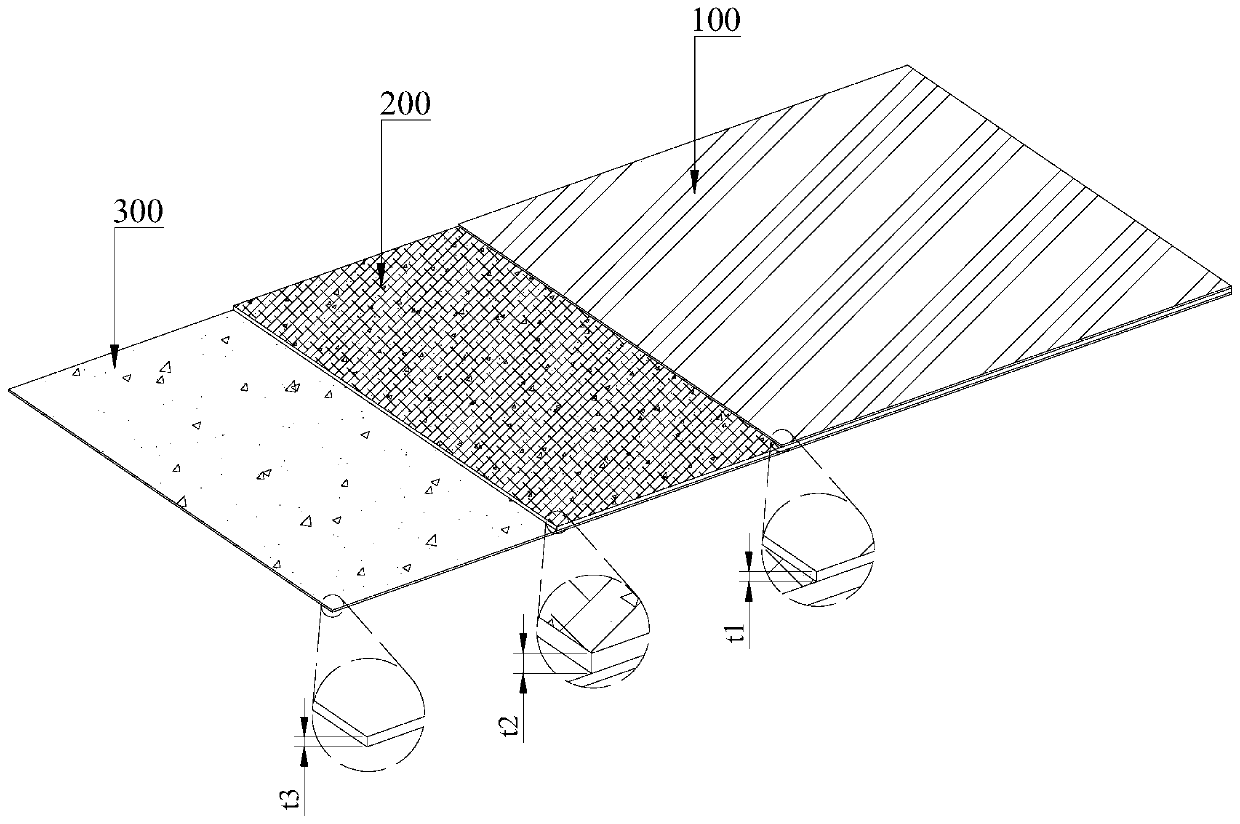

High toughness inorganic composite artificial stone panel and preparation method thereof

InactiveCN110423064AHigh strengthImprove bending resistanceLayered product treatmentLaminationMetal fibersWater reducer

A high toughness inorganic composite artificial stone panel and a preparation method thereof are disclosed. The panel comprises a surface layer, an intermediate metal fiber toughening layer and a substrate toughening layer. The surface layer comprises the following raw materials in parts by weight: 40 to 70 parts by weight of quartz sand, 10 to 30 parts by weight of quartz powder, 20 to 45 parts by weight of inorganic active powder, 0.5 to 4 parts by weight of pigment, 0.3 to 1 part by weight of water reducer and 3 to 10 parts by weight of water. The intermediate metal fiber toughening layer comprises the following raw material components in parts by weight: 40-60 parts of inorganic active powder, 45-65 parts of sand, 0.8-1.5 parts of water reducer, 6-14 parts of water and 4-8 parts of metal fiber. The substrate toughening layer comprises the following raw material components in parts by weight: 30-50 parts of inorganic active powder, 30-55 parts of quartz sand, 15-20 parts of quartz powder, 0.5-1.2 parts of water reducer, 4-8 parts of water and 0.8-2.5 parts of toughening agent. The panel has the advantages of good volume stability, low shrinkage, no warping deformation in use, extremely low water absorption, good durability, no aging and the like, strong bonding between layers, good ductility and no instant brittle fracture, and can be used as a bearing capacity structure with good surface pollution resistance, and is suitable for popularization and use.

Owner:黄贺明 +1

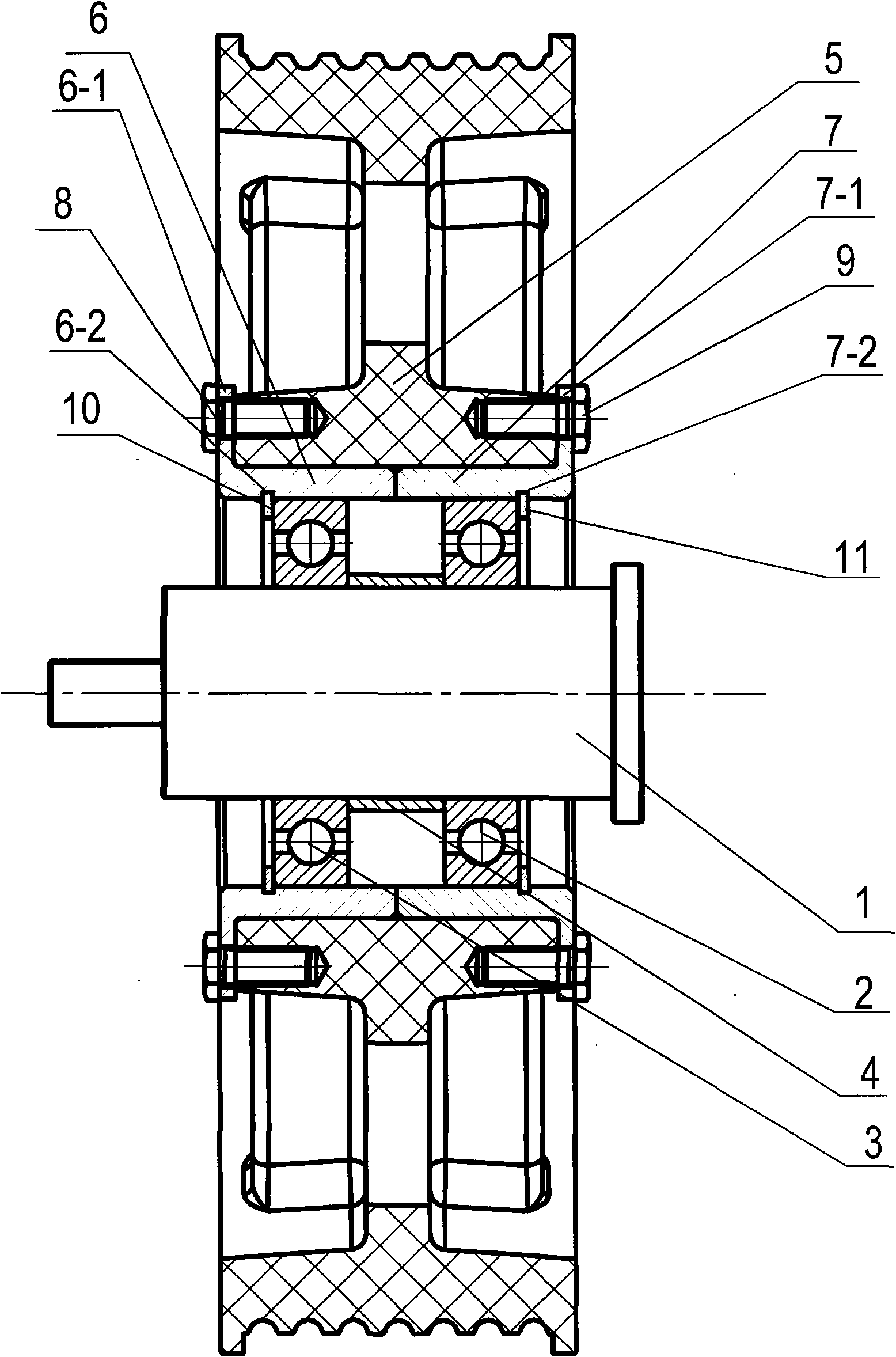

Composite bushing MC nylon wheel

InactiveCN101566862ASmooth vibrationIncreased operating lifeControlling membersEngineeringMechanical engineering

The invention relates to a composite bushing MC nylon wheel belonging to a wheel body structure technology used in the fields of elevator industry and hoisting machinery and other fields. The composite bushing MC nylon wheel comprises a wheel body made of MC nylon and a steel wheel axle concentric with the wheel body; a bearing is arranged between the wheel body and the wheel axle, two steel bushings are arranged on the inner surface of the wheel body and coaxially arranged along the length direction of the wheel body, and another bearing is arranged between one bushing and the wheel axle. The composite bushing MC nylon wheel has the advantages that abrasion and slipping phenomena generated by the direct contact between the MC nylon wheel and the bearing are avoided, the adverse influence of the self characteristics of the MC nylon, such as swelling or shrinking generated by temperature rise or drop, on the bearing and the whole mechanism, i.e. the bearing is loose or moves in a hole, is overcome, vibration generated by the shake of the bearing is stabilized, and the operation service life of the whole mechanism is prolonged.

Owner:张爱臣

Iron-zinc-tin alloy lithium ion battery cathode material

The invention provides a preparation method of an iron-zinc-tin alloy cathode material. The method comprises the following steps: 1. preparation of a tin electroplating solution; 2. the prepared tin electroplating solution is added into an electroplating bath, a platinum sheet is used as an anode, an iron sheet is used as a cathode, and electroplating is carried out; 3. preparation of an zinc electroplating solution; 4. the prepared zinc electroplating solution is added into the electroplating bath, the platinum sheet in the step 2 is used as an anode, the iron sheet with electroplated tin is used as a cathode, and electroplating is carried out; 5. after electroplating, the iron sheet is cleaned and dried, and the iron-zinc-tin alloy cathode material is obtained.

Owner:QINGDAO WINCHANCE TECH

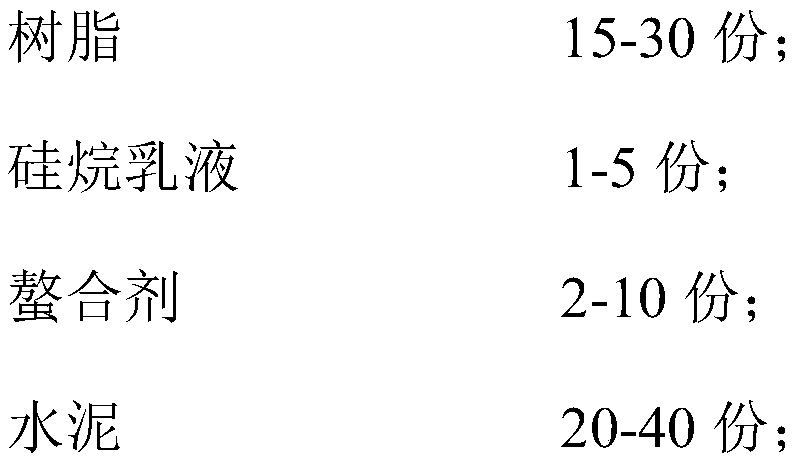

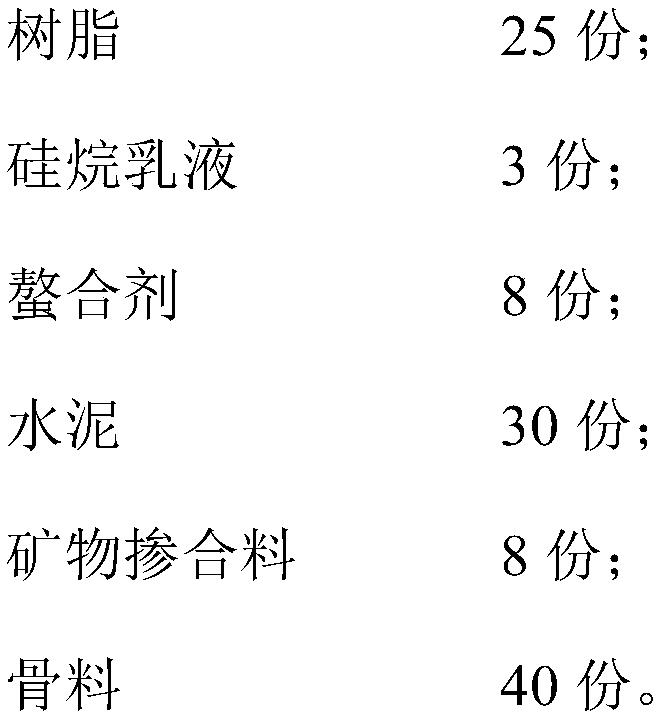

Single-component interfacial agent and preparation method thereof

InactiveCN108863188AImprove interfacial bond strengthThe rate of hydration reaction is stableEmulsionSilanes

The invention discloses a single-component interfacial agent and a preparation method thereof. The single-component interfacial agent is prepared from the following effective components in parts by weight: 15-30 parts of resin, 1-5 parts of silane emulsion, 2-10 parts of chelating agent, 20-40 parts of cement, 5-10 parts of mineral admixture and 30-50 parts of aggregate. The preparation method ofthe single-component interfacial agent comprises the following steps of: uniformly mixing powder of the effective components under a normal temperature according to a certain proportion, and obtainingthe single-component interfacial agent. The single-component interfacial agent and the preparation method disclosed by the invention have the beneficial effects that the reaction environment in the slurry of the single-component interfacial agent is adjusted by the chelating agent, by generation of more and dispersed small crystal and needle-shaped morphology, excellent interfacial bonding strength is formed.

Owner:杭州斯坦尼新材料有限公司

Single bushing-type MC nylon wheel

InactiveCN101566863ASmooth vibrationIncreased operating lifeControlling membersEngineeringBolt connection

The invention relates to a single bushing-type MC nylon wheel belonging to a wheel body structure technology used in the fields of elevator industry and hoisting machinery and other fields. The single bushing-type MC nylon comprises a wheel body made of MC nylon and a steel wheel axle concentric with the wheel body; two bearings are arranged between the wheel body and the wheel axle; a steel bushing is arranged among the bearings and the wheel body and provided with a flange edge which is connected with one side of the wheel body by bolts; the inner wall of the bushing is provided with two circular grooves, and two elastic collars are respectively supported inside the two circular grooves; the two bearings are arranged between the two elastic collars, and a lining is arranged between the two bearings and sleeved outside the wheel axle. The invention has the advantages of sliding, deformation and vibration resistance and long service life.

Owner:张爱臣

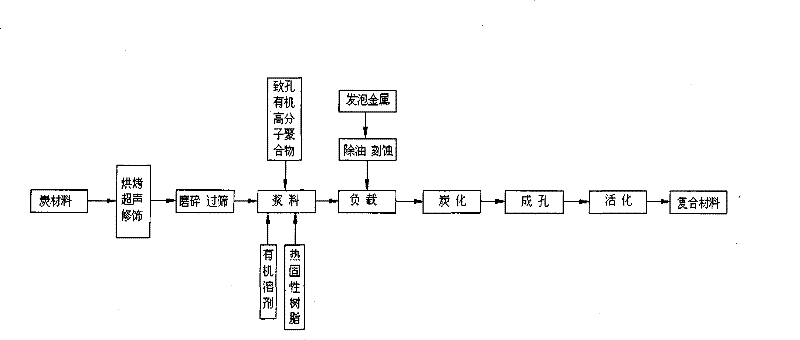

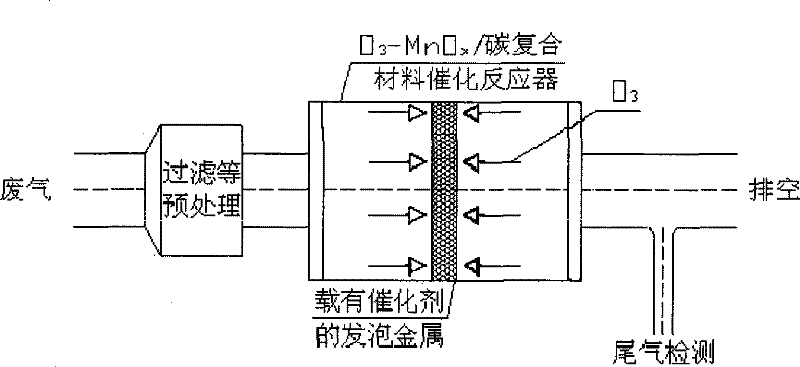

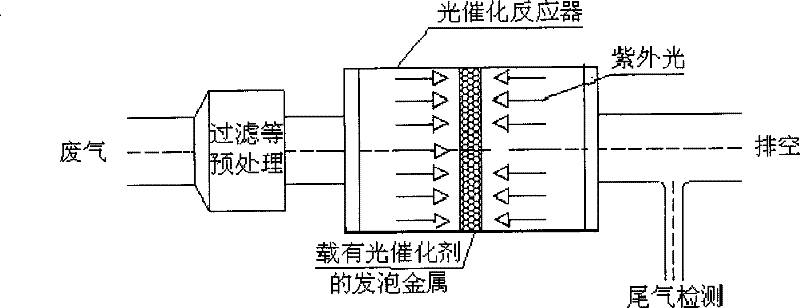

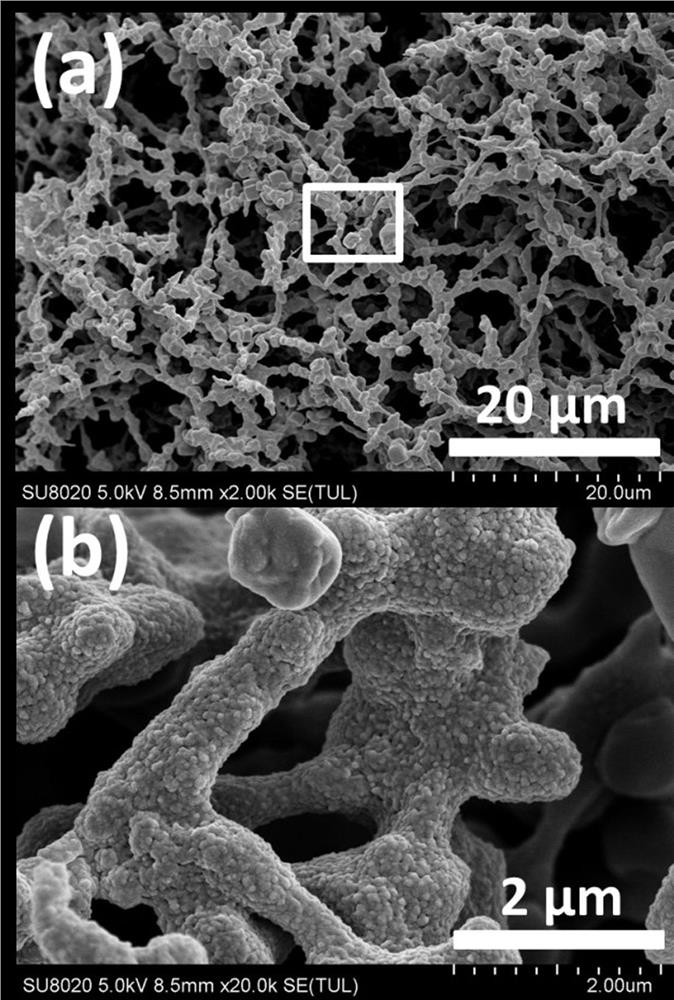

Carbon composite material based on foaming metal growth in situ and preparing method thereof

InactiveCN101293644BExcellent multi-dimensional space network structureOvercome shrinkageCarbon compositesAdhesive cement

The invention discloses a carbon composite material based on the in-situ growth of foamed metal and a preparation method thereof. The composite material is produced in situ on the foamed metal, the components of the precursor of the composite material are carbon material, thermosetting resin and Porogenic organic macromolecule polymer, and moreover, the mass proportion of the carbon material, thethermosetting resin and the Porogenic organic macromolecule polymer is 1:0.2-20:0.01-0.3. The preparation method is as the following: (1) the pretreatment of the foamed metal and the carbon material;(2) proportioning; (3) loading; (4) carbonizing and pore forming; and (5) activation of steam. The carbon composite material and the preparation method of the invention are based on the foamed metal,the composite material is provided with an excellent multidimensional spatial reticular structure, and at the same time, the thermosetting resin and the developing resin are adopted as the double efficiency of carbon resource and adhesive. Furthermore, the carbon composite material and the preparation method of the invention utilize the property that the powder of each carbon material have small shrinkage and take the powder of each carbon material as support architecture, thus overcoming the shortages of shrinkage and low porosity of the thermosetting resin in a carbonization process.

Owner:SOUTH CHINA UNIV OF TECH +1

A preparation method of polyaniline/manganese dioxide electrode material with three-dimensional network structure

ActiveCN109192528BOvercome bloatOvercome shrinkageHybrid capacitor electrodesPermanganate saltPolyvinyl alcohol

The invention discloses a preparation method of polyaniline / manganese dioxide electrode material with enhanced three-dimensional network structure. The preparation method reacts aniline hydrochloride, crosslinking agent and permanganate in polyvinyl alcohol aqueous solution to obtain polyaniline / manganese dioxide electrode material. In the preparation method of the invention, during the preparation of the electrode material, the polyaniline / manganese dioxide electrode material with a reinforced three-dimensional network structure is obtained due to the introduction of polyvinyl alcohol and a crosslinking agent. This enhanced three-dimensional network structure can not only overcome the expansion and contraction of polyaniline during charging and discharging, but also form a good protection for manganese dioxide, thereby improving the stability of electrode materials; and all raw materials only need to be added in sequence After the system is mixed evenly, it can be allowed to stand still for reaction. During the standing reaction, polyaniline is formed by oxidative polymerization while the oxidizing agent is reduced to manganese dioxide. The preparation method is simple and easy.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A semi-rigid base reinforcement grouting material and grouting method thereof

The invention relates to a semi-rigid base reinforcement grouting slurry and a grouting method thereof. The raw materials according to mass percentage are: cement 95-99.7, water reducing agent 0.06-1.0, retarder 0.1-0.3, accelerator 0.03-0.07, plastic Expansion agent 0.02~0.04, mineral filler 0~4.79, obtained by stirring. The grouting method is: firstly locate the hole position 0.25 meters around the grouting crack, the hole distance is 0.75-1.0 meters, and drill down from the hole to the top of the roadbed; first add water in the mixer and then add the slurry, the quality of the water and the grouting slurry Ratio ≤ 0.35, stirring speed ≥ 500r / min, stirring time ≤ 5min; lower grouting pipe, grouting pressure 0.5-1.0MPa, the time from slurry stirring to grouting is ≤ 30min; sealant or asphalt is used after grouting. Plug the grouting hole. The invention has the characteristics of low cost of grouting, good fluidity, fast setting and high strength, simple construction of grouting method and the like.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

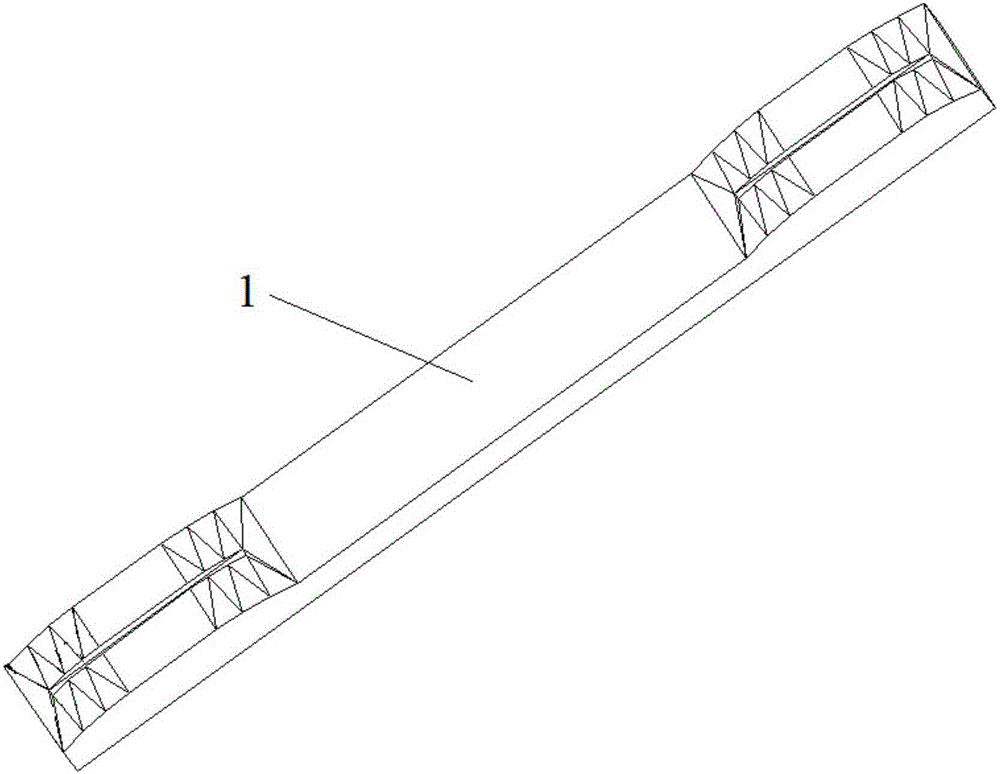

A kind of production method of bus duct bridge frame

The invention relates to a production method of a bus duct bridge, which uses high-density polyethylene and medium-density polyethylene as a combined modified matrix, and is cross-linked and modified with a cross-linking agent under the action of an initiator, and then melt-grafted and polymerized with maleic anhydride Form a multi-grafted modified polymer, and blend and modify with surface-treated inorganic rigid particles. The inorganic rigid particles are one or more of nano-calcium oxide, glass microspheres, nano-silica, and nano-magnesium carbonate. It is extruded with processing aids through a twin-screw extruder, melted and pre-plasticized and extruded into a mold on a shaping table to be shaped, and circulating water is added to the outside of the mold to cool and shape in a vacuum, and then pulled by a tractor, cut into shape, and anti-corrosion. On the basis of static electricity, the brittleness, creep resistance, yield strength and processing performance of extruded busway bridges are improved, and the service life is longer.

Owner:扬中市长龙管业有限公司

Hemp fabric and preparation method thereof

InactiveCN112695438AReduce hardnessOvercome wrinkleWoven fabricsVegetal fibresPolymer sciencePlant Gums

The invention relates to hemp fabric and a preparation method thereof. The hemp fabric is formed by blending cotton fibers serving as warp yarn and hemp cotton yarn serving as weft yarn, wherein the weight ratio of the cotton fibers to the hemp cotton yarn is (56-60):(40-44). The invention further provides a preparation method of the hemp fabric. The preparation method comprises the steps that the cotton fibers and the China-hemp cotton yarn serve as raw materials and are sequentially subjected to a warping process, a sizing process, a denting process and a weaving process to obtain the hemp fabric, wherein in the sizing process, a used sizing agent comprises the following components in parts by weight: 5.0-10.0 parts of vegetable gum, 70.0-80.0 parts of rubber powder and 20.0-30.0 parts of composite starch, and the solid content of the sizing agent is 13.0+ / -1%. The obtained hemp fabric is not prone to wrinkling and shrinking, and is resistant to ultraviolet rays and capable of inhibiting bacteria.

Owner:JIHUA 3509 TEXTILE

Production method for bus duct cable tray

The invention relates to a production method for a bus duct cable tray. The production method comprises the following steps: taking high-density polyethylene and medium-density polyethylene as a composite modified matrix; after carrying out cross-linking modification on the composite modified matrix and a cross-linking agent under the action of an initiator, fusing, grafting and polymerizing the product and maleic anhydride to obtain a multi-grafted modified polymer; blending the multi-grafted modified polymer and inorganic rigid particles subjected to surface treatment, and modifying, whereinthe inorganic rigid particles are selected from one or more of nano calcium oxide, glass microspheres, nano silicon dioxide and nano magnesium carbonate; extruding the blended product and a processing auxiliary agent through a double-screw extruder; fusing, pre-plasticizing and extruding into a mold of a sizing platform and sizing; adding circulating water outside the mold, and cooling and molding in vacuum; then pulling through a pulling machine, and cutting and molding. The fragility, creep resistance, yield strength and machinability of the extruded and molded bus duct cable tray are improved on the anticorrosion and antistatic basis, and the service life is longer.

Owner:扬中市长龙管业有限公司

Aluminum brass casting outlet terminal extruding casting technology

The invention discloses an extruding casting technology of an aluminum brass casting outlet terminal. The technology comprises the following steps of melting alloys; manually casting the aluminum brass casting outlet terminal through a fixed-quantity casting ladle with the casting period for each casting being one minute; using 125-MPa extrusion force of a main cylinder to shape and compact the aluminum brass casting outlet terminal and subsequently using 375-MPa extrusion force of a jacking cylinder to perform forging on the castings; making the extrusion speed of male dies for the aluminum brass casting outlet terminal 12 mm / s and the extrusion speed of a push rod 65 mm / s; controlling the dwelling time of the aluminum brass casting outlet terminal within a range between 15 seconds and 20 seconds; using a 2.5-kilowatt electrothermal ring to preheat an aluminum brass casting outlet terminal die for approximately three hours each time before a casting process and controlling a casting mold temperature between 250 degrees and 350 degrees; and spraying the working faces of female dies and male dies through a PQ-1 type spraying gun. The technology provided in the invention has the advantages of simple steps, high casting production efficiency and die service lifetime prolongation.

Owner:张年生

Horizontal type uniform-air-pressure pipe expansion device

The invention provides a horizontal type uniform-air-pressure pipe expansion device which includes a workbench, a pipe expansion unit and a flaring unit. The pipe expansion unit is arranged on the workbench, and the flaring unit is arranged at the position, on one side of the pipe expansion unit, of the workbench; the pipe expansion unit includes a first base, a first mounting base, a nozzle and acompacting base, the first base is arranged on a bearing surface and is driven by a first driving unit to move in the axial direction of a heat dissipation pipe, the first mounting base is arranged on the first base, the nozzle is carried on the side, opposite to a pipe opening of the heat dissipation pipe, of the first mounting base, and the nozzle is driven by the first mounting base to achieveinsertion and extraction of the heat dissipation pipe; an inlet of the nozzle communicates with an outlet of an ultra-high pressure gas generator through a pipe; the compacting base is arranged on the side, close to the heat dissipation pipe, of the first mounting base; the compacting base is driven by a second driving unit to do reciprocating linear motion; a plurality of positioning holes are formed in the compacting base, a compacting sleeve is arranged in each positioning hole, and the compacting sleeves penetrate through the positioning holes to protrude out; and the inner walls of the compacting sleeves are provided with sealing pieces.

Owner:珠海华星智能技术有限公司

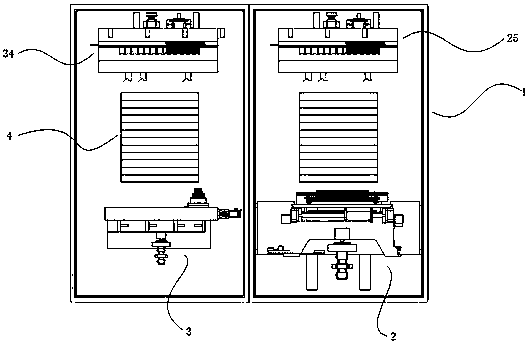

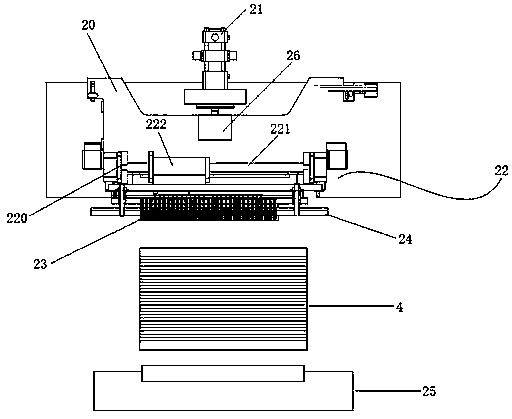

Double-station press machine for glasswork production

InactiveCN102795759AReduce adhesionReduce surface pittingGlass pressing apparatusGlass productionHydraulic cylinderEngineering

The invention relates to a double-station press machine which comprises an upper table top and a lower table top that are fixedly arranged vertically, wherein a pair of hydraulic cylinders is arranged on the upper table top; lower ends of piston rods of the hydraulic cylinders are connected with moving table tops respectively; an upper mould is arranged on the bottom surface of each of the moving table tops; a lower mould which is coaxial with and opposite to each of the upper moulds is arranged on the lower table top; an upper cutter saddle is arranged on one side of each of the moving table tops; a lower cutter saddle is arranged under each of the upper cutter saddles; and cutters suitable for matching vertically are arranged on the upper and lower cutter saddles. The double-station press machine solves the problems that the product surface has break marks, wrinkles, shrinkage and deformation, the yield is low, and the operation is complicated when glasswork with high requirements, such as an optical glass lens, is produced in the prior art. With the adoption of the double-station press machine, the product qualification rate and the yield are increased and the working load is reduced. The practical data shows that the product qualification rate is increased by about 30% and the yield is increased by about 25%.

Owner:刘继成

A kind of resin impregnated ceramic composite material and preparation method thereof

ActiveCN106007802BInhibition of volume changeImprove bending strengthImpression capsDentistry preparationsMethacrylateCeramic composite

The invention provides a resin-permeable ceramic composite which is formed by curing a ceramic body and mixed resin permeating in the porous network structure of the ceramic body, wherein the ceramic body has a porous network structure and comprises yttria-stabilized tetragonal phase zirconia; and the mixed resin comprises a mixture of methacrylate compounds and a thermal curing agent. The resin-permeable ceramic composite provided by the invention is composed of a porous ceramic network structure and resin permeating in the ceramic network structure; by adopting the ceramic as a matrix, the volume change of the composite in the curing process can be effectively avoided, and the defects that traditional particle reinforcing resin-based composite is easily cured and shrunk and consequently residual stress is introduced are overcome; and through the permeation way, the mixed resin can form a resin network structure penetrating through the ceramic network structure, and a ceramic-based composite with excellent mechanical properties is obtained.

Owner:TSINGHUA UNIV

Aluminum-cobalt-tin alloy lithium ion battery anode material

The invention relates to a preparation method of an aluminum-cobalt-tin alloy lithium ion battery anode material. The preparation method comprises the steps that 1, a tin electroplatingsolution is prepared; 2, the prepared tin electroplatingsolution is added to an electroplatingtank, and a platinum sheet serves as an anode and an aluminum sheetserves as acathode for electroplating; 3, a cobaltelectroplatingsolution is prepared; 4, the prepared cobaltelectroplatingsolution is added to the electroplatingtank, and the platinum sheetin the step 2 serves as theanode and the electroplatedaluminum sheetserves as thecathode for electroplating; 5, the electroplated aluminum sheet is cleaned and dried, and then the aluminum-cobalt-tin alloy lithium ion battery anode material is obtained.

Owner:QINGDAO WINCHANCE TECH

Process of making stone-imitating ceramic tile

The process of making stone-imitating ceramic tile includes the following steps: flow casting several ceramic color pastes in different colors in some carrier, pre-drying to obtain color paste adobe of certain water content, pressing inside a mold in a press, stoving, calcining and polishing. Pressing after pre-drying can ensure high density, fine and flat surface of product and the aesthetic sense similar to that of natural stone material.

Owner:杨晓东

Flame-retardant heat insulation material for solar water heater and preparation method of flame-retardant heat insulation material

InactiveCN109593177AIncreasing interlamellar spacingGood peeling effectSolar waterIsocyanate compound

The invention provides a flame-retardant heat insulation material for a solar water heater and a preparation method of the flame-retardant heat insulation material. The flame-retardant heat insulationmaterial comprises the following raw materials in parts by weight: 80-100 parts of polyether polyol, 110-130 parts of isocyanate, 1-5 parts of carbon nanofibers, 5-10 parts of modified expanded vermiculite, 2-5 parts of foaming agent, 0.1-0.5 part of foam stabilizer, 0.5-2 parts of catalyst, 0.5-1 part of crosslinking agent and 4-10 parts of water. The flame-retardant heat insulation material provided by the invention has favorable strength and heat insulation property, also overcomes the defect of high shrinkage after foam molding and has good flame retardance.

Owner:ANHUI MINGGUANG ZHONGXING SUNLIGHT NEW ENERGY TECH CO LTD

A heart chamber simulator driving mechanism

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Heart Chamber Simulators Actuated by Hydraulic or Pneumatic Artificial Muscles

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +1

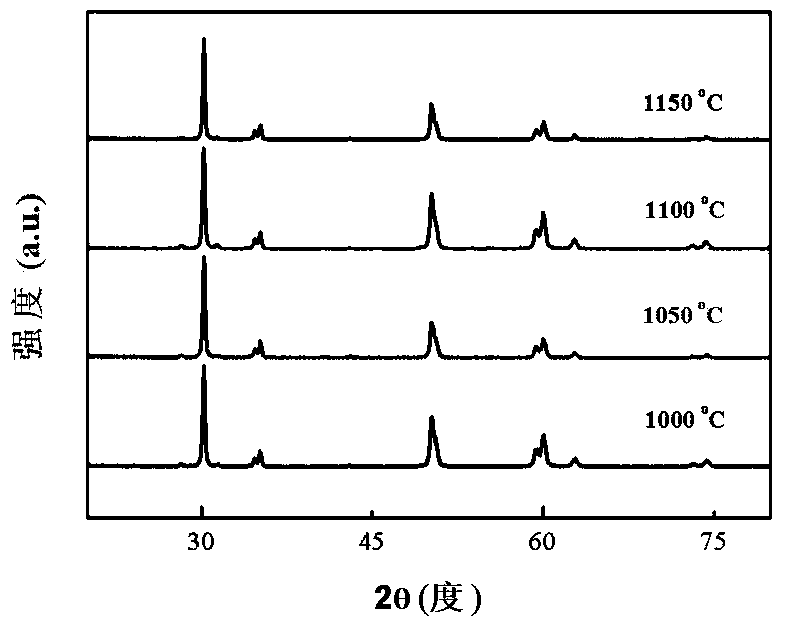

Lithium manganese oxide-bismuth titanate material of power lithium battery and preparation method of lithium manganese oxide-bismuth titanate material

ActiveCN107240689AOvercome volumeOvercome shrinkageCell electrodesSecondary cellsPower batteryLithium-ion battery

The invention provides a lithium manganese oxide-bismuth titanate material of a power lithium battery and a preparation method of the lithium manganese oxide-bismuth titanate material. The lithium manganese oxide-bismuth titanate material is of a layered sandwiched structure, wherein crystal grains of bismuth titanate are embedded among layered lithium manganese oxide. According to the preparation method, the lithium manganese oxide-bismuth titanate material with crystal grains embedded among layers is formed by crystal phase induction, cutting and high-electric field ion shaping of bismuth titanate and the layered lithium manganese oxide. In the lithium manganese oxide-bismuth titanate material, the bismuth titanate is grown among the layers of the lithium manganese oxide, the lithium manganese oxide is supported by a crystal framework of the bismuth titanate, a crystal lattice is prevented from being collapsed, the volume expansion and contraction is prevented, the high-temperature cycle property is substantially improved, and the lithium manganese oxide-bismuth titanate material is suitably used for the lithium power battery.

Owner:湖南盛利高新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com