Method for preparing Ni-BaO-GDC nanometer SOFC anode by means of high-speed mixing-kernel blast

A high-speed mixing, ni-bao-gdc technology for applications in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Ultrasonic dispersion of barium carbonate with a particle size of 50 nm, GDC with a particle size of 50 nm, and metallic Ni with a particle size of 1 μm was carried out for 30 min;

[0023] (2) Add barium carbonate, GDC and metal Ni after ultrasonic dispersion to the mixer in a mass ratio of 1: 1: 3 and stir for 30 min;

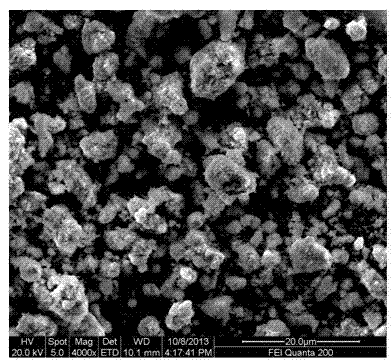

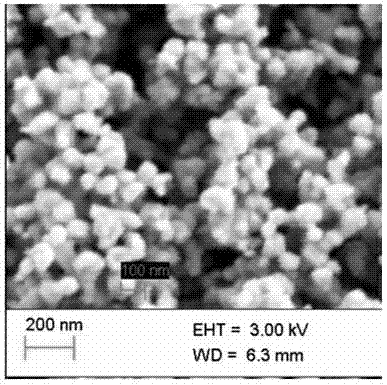

[0024] (3) Put the uniformly mixed barium carbonate, GDC and metallic Ni into a vibrator and mix for 30 min at a speed of 5000 rpm. Under the action of shear force and extrusion force, the small particles of barium carbonate, GDC coated onto the surface of large Ni metal to form core-shell BaCO 3 - GDCNi structure particles;

[0025] (4) The mixture was calcined at 1400 °C in air with a heating rate of 15 °C / min, and the holding time was 2 h. Using the difference in thermal expansion coefficient of the core and shell materials, the core was broken due to stress at high temperature, and the obtained Spherical grains with a grain size of 50-100 nm....

Embodiment 2

[0027] (1) Ultrasonic dispersion of barium carbonate with a particle size of 300 nm, GDC with a particle size of 200 nm, and metal Ni with a particle size of 4 μm was carried out for 20 min;

[0028] (2) Add barium carbonate, GDC and metal Ni after ultrasonic dispersion to the mixer in a mass ratio of 1: 1: 8 and stir for 20 min;

[0029] (3) Put the uniformly mixed barium carbonate, GDC and metal Ni into a vibrator and mix at a speed of 3000 rpm for 20 min;

[0030] (4) The mixture was calcined at 1250 °C in air at a heating rate of 13 °C / min, and the holding time was 1.5 h to obtain spherical grains with a grain size of 100-400 nm.

Embodiment 3

[0032] (1) Ultrasonic dispersion of barium carbonate with a particle size of 200 nm, GDC with a particle size of 100 nm, and metal Ni with a particle size of 3 μm was carried out for 25 min;

[0033] (2) Add barium carbonate, GDC and metal Ni after ultrasonic dispersion to the mixer at a mass ratio of 1.5: 1.5: 7 and stir for 20 min;

[0034] (3) Put the uniformly mixed barium carbonate, GDC and metal Ni into a vibrator and mix for 20 min at a speed of 4000 rpm;

[0035] (4) The mixture was calcined at 1350 °C in air at a heating rate of 10 °C / min, and the holding time was 1 h to obtain spherical grains with a grain size of 50-300 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com