Patents

Literature

2342 results about "Barium carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium carbonate (BaCO₃), also known as witherite, is a chemical compound used in rat poison, bricks, ceramic glazes and cement.

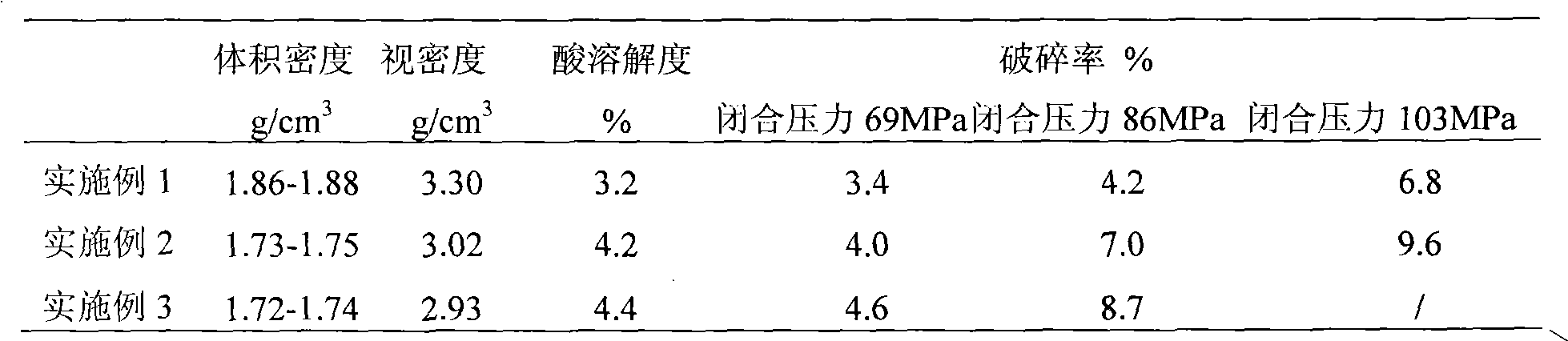

High-strength compress supporting agent for coarse oil and preparation method thereof

ActiveCN101575503AGood effectHas high strengthFluid removalDrilling compositionChemical compositionRed mud

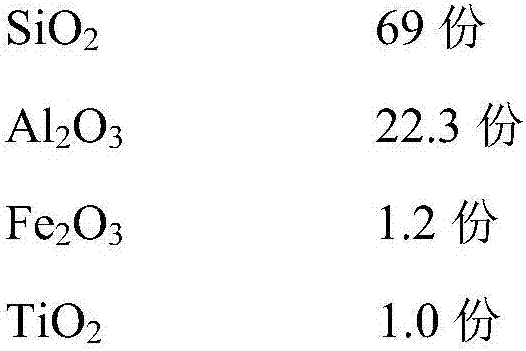

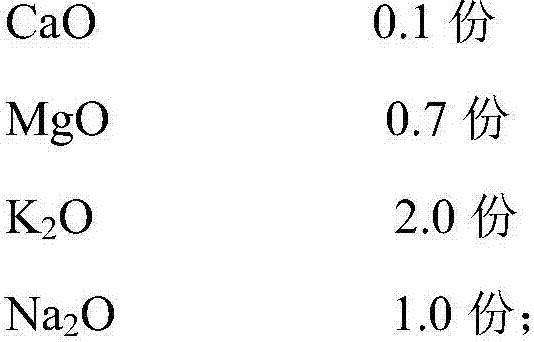

The invention relates to a high-strength compress supporting agent for coarse oil and a preparation method thereof. The high-strength compress supporting agent for the coarse oil is prepared from the following raw materials by mass portion: 60 to 85 portions of ceramic roller waste, 1 to 20 portions of red mud, 0 to 20 portions of fly ash, 0 to 5 portions of manganese oxide or barium carbonate, 0 to 3 portions of dolomite and 5 to 10 portions of ceramic clay. The ceramic roller waste refers to corner waste or / and damaged and broken ceramic roller waste in the processing process of ceramic roller manufactures, and Al2O3 content of chemical compositions of the ceramic roller waste is not less than 68 percent. The high-strength compress supporting agent for the coarse oil prepared from the ceramic roller waste with high alumina content has the characteristics of high strength and acid resistance, and is used for oil fracturing in medium-deep wells; and the preparation method is simple and feasible, and is suitable for batch production.

Owner:JINGANG NEW MATERIALS

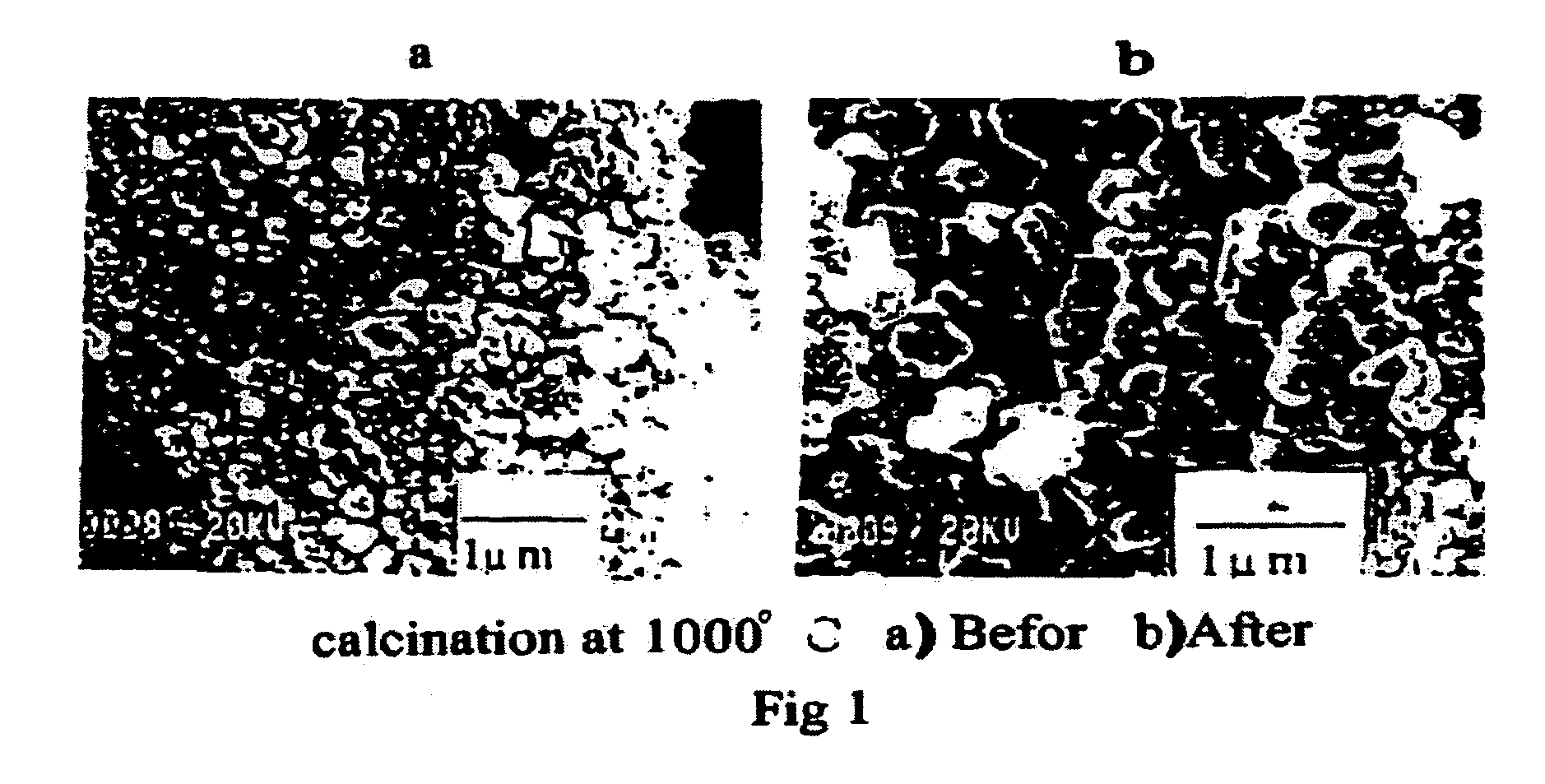

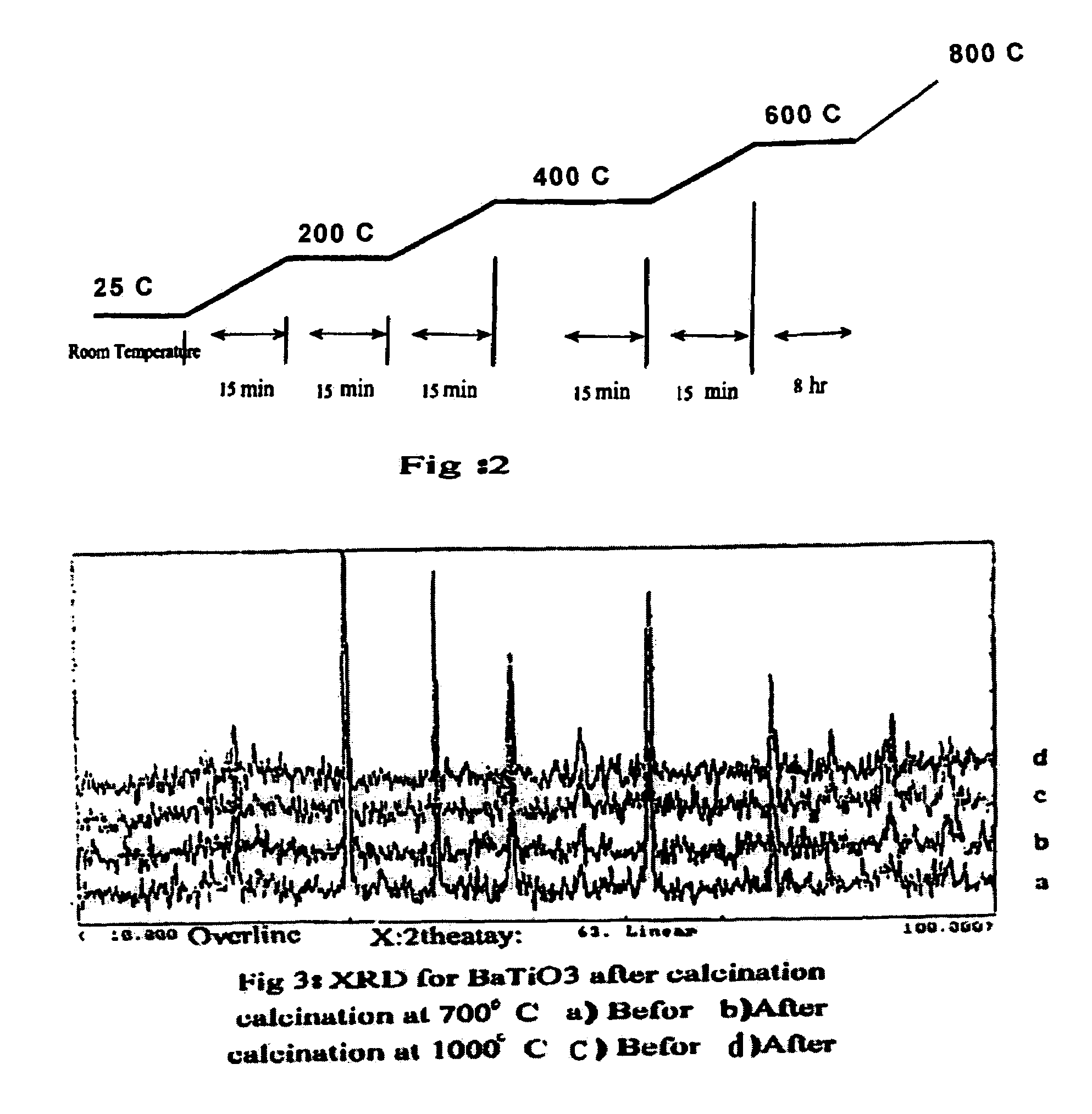

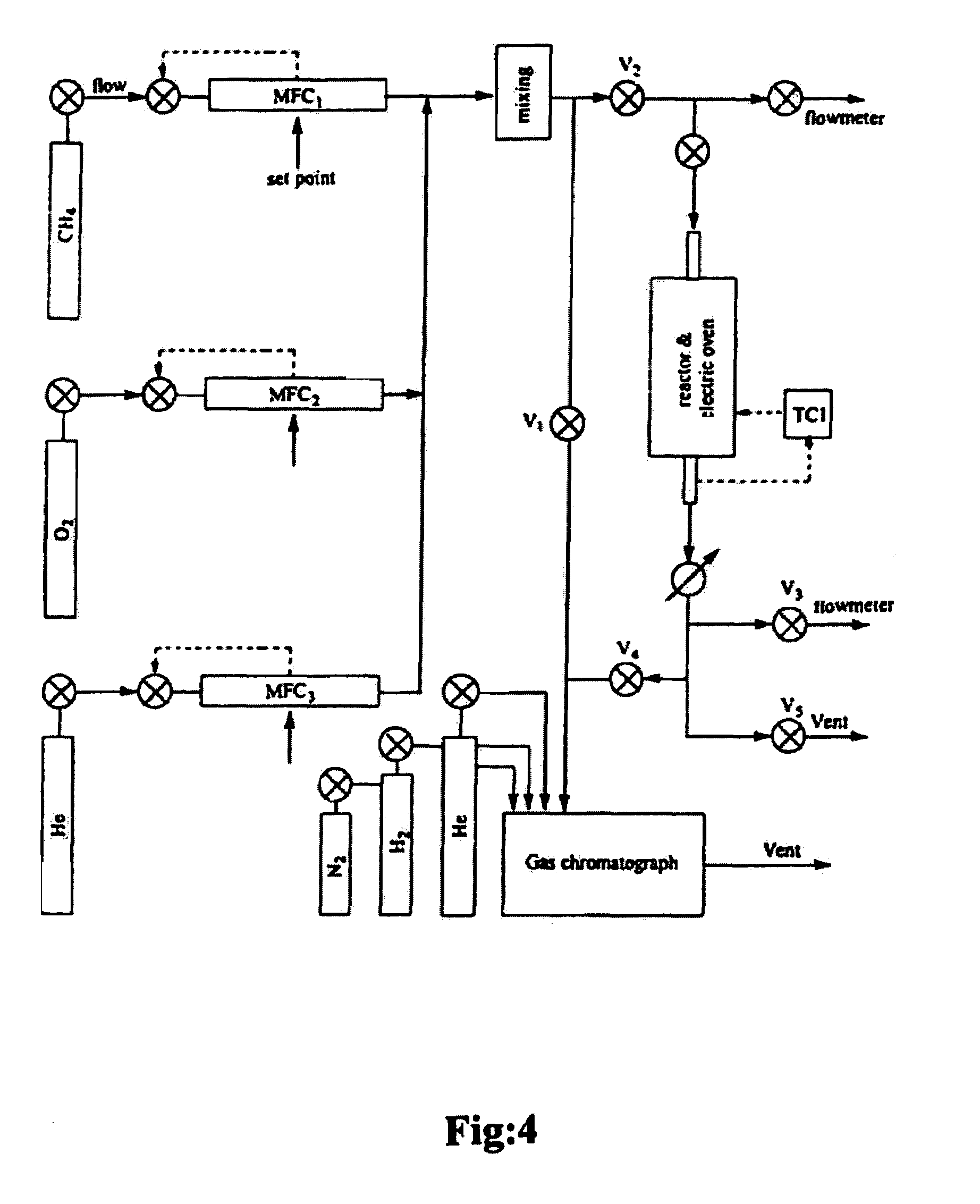

Preparation of catalyst and use for high yield conversion of methane to ethylene

InactiveUS7250543B2Maintain activityAlkaline earth titanatesHydrocarbon by hydrocarbon condensationAlkaline earth metalSlurry

A perovskite catalyst is prepared using a ceramic sol-sol methodology comprising preparing slurry in water of an alkaline earth metal salt, a powdered metal salt and a powdered transition metal oxide, adding a polymeric binder to form a paste, drying and comminuting the paste into a powder and heating the powder with a temperature profile to calcination temperatures. In one embodiment the slurry is formed of titanium oxide with barium carbonate and tin chloride in deionized water, and more specifically by a mixture according to Ba (1-0.05x)+TiO2+SnCl2(0.05x) where x is in moles. The perovskite catalyst is preferably used in a process for oxidative coupling of methane. Catalyst performance is enhanced through the addition of halides to the feed gas in the reaction.

Owner:HRD CORP

Production method of once-fired super-spar ceramic tile and ceramic tile

The invention relates to a production method of once-fired super-spar ceramic tile and the ceramic tile. The production method of the once-fired super-spar ceramic tile comprises the following steps: preparing green body powder; pressing a tile body; cleaning the green body; pouring ground glaze; printing; pouring overglaze; firing a glaze body at a high temperature; polishing; performing surface treatment; performing edge polishing; and packaging to obtain a finished product, wherein the overglaze comprises the following components in parts by weight: 5 to 13 parts of quartz powder, 3 to 20 parts of potassium feldspar, 20 to 28 parts of soda feldspar, 12 to 18 parts of dolomite, 3 to 6 parts of fired talc, 3 to 8 parts of kaolin, 14 to 22 parts of calcined kaolin, 3 to 8 parts of zinc oxide, 7 to 14 parts of barium carbonate and 3 to 6 parts of grammite. According to the invention, the problems that microlite has low wear resistance and is difficult to process in the prior art are solved, and the defect of water ripples caused by the situations that fully-polished glaze absorbs dirt, bottom is easy to expose and the tile surface is uneven is also solved. The super-spar product produced with the method has the advantages that the microlite is transparent, bright and smooth like a mirror and does not absorb dirt completely; and the fully-polished glaze is light, thin and wear-resistant.

Owner:周予

Method for preparing silicon-free or low-silicon acidproof ceramic fracturing propping agent

The invention discloses a method for preparing a silicon-free or low-silicon acidproof ceramic fracturing propping agent, which comprises the following steps of: (1) preparing the following raw materials in percentage by weight: 30 to 95 percent of alumina, 5 to 70 percent of barium carbonate and 0 to 10 percent of sintering aid, wherein the sintering aid is one or more of titanium dioxide, boric acid, calcium carbonate, magnesium oxide and dolomite; (2) performing ball milling on the raw materials in the step (1) in a ball mill for 24 to 48 hours; (3) preparing the raw materials obtained in the step (2) into semi-finished product particles; and (4) sintering the semi-finished product particles obtained in the step (3) at the temperature of between 1,500 and 1,800 DEG C for 1 to 3 hours, and cooling to the room temperature. The method has simple process; the barium carbonate is decomposed at high temperature to generate barium oxide, and the barium oxide is fully reacted with alumina to generate stable barium aluminate; and the barium aluminate has strong acidproof performance and protects other components in the finished product against corrosion of acid liquor, so the acidproof performance of the finished product is greatly improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Nickel-based welding electrode for welding nickel-chromium-molybdenum alloy

ActiveCN102430876AExcellent heat crack resistanceEasy to useWelding/cutting media/materialsSoldering mediaCrack resistanceNiobium

The invention relates to a nickel-based welding electrode which comprises the following component by weight percent (wt%): 50.0-68.0% of Ni, 18.0-23.0% of Cr, 6.0-11.0% of Mo, 3.0-6.0% of Nb, 2.50-9.00% of Fe, 0.01-0.1% of C, 0.10-1.00% of Mn, 0.010-0.10% of Si, 0.015% of S or less, 0.015% of P or less, 0.01-0.10% of Cu, 0.003-0.010% of Co and the balance of impurities. The coat of the nickel-based welding electrode comprises the following components by weight percent of the welding core: 12-18% of marble, 10-15% of fluorite, 12-18% of barium carbonate, 5.0-6.4% of rutile, 3.5-5.0% of ferroniobium, 3.3-4.5 of chromium metal powder, 0.45-0.65% of sodium carbonate, 0.45-0.65% of electrolytic manganese and 1.3-1.8% of zircon sand, and the adhesion agent is 10-20% of the total weight of the power. The nickel-based welding electrode is prepared by mixing, wrapping mixture on the welding core and baking at low and high temperature. The nickel-based welding electrode disclosed by the invention is used for nickel-chromium-molybdenum alloy steel welding, ensures that the excellent mechanical properties, the excellent corrosion resistance, the excellent thermal crack resistance and the hightensile strength of the welding seam match with those of the base material, has good welding process performance, guarantees attractive molding and can be used for the welding of the steel (with 9% of Ni) working at low temperature.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Wear-resistant transparent glaze and method for preparing glazed tile by utilizing same

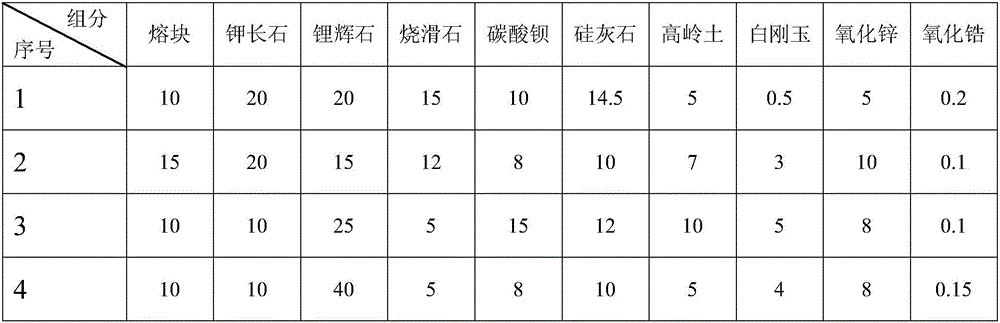

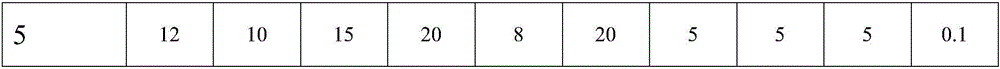

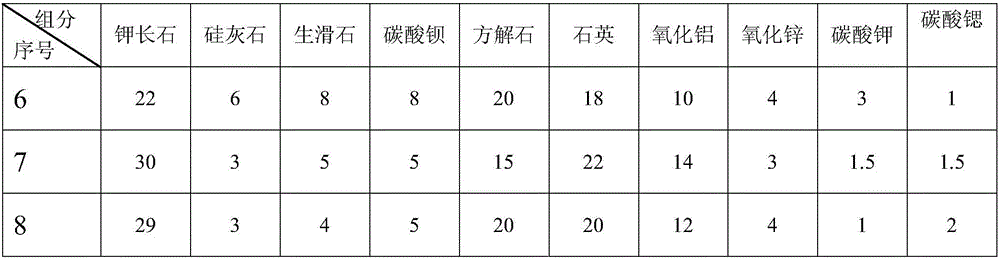

The invention provides a wear-resistant transparent glaze and a method for preparing a glazed tile by utilizing the same. According to the components of the wear-resistant transparent glaze, spodumene, frit, potash feldspar, calcinedtalc, barium carbonate and zinc oxide are adopted as a fluxing agent, and the Si / Al ratio is adopted by utilizing wollastonite and kaolin. Meanwhile, the wear-resistant performance of the glaze is improved by adopting white corundum and zirconium oxide as a wear-resistant agent. The weight percentage of zirconia relative to the total weight of the raw materials of the wear-resistant transparent glaze is smaller than or equal to 0.2%. The above wear-resistant transparent glaze is applied onto the surface of a green body, and then the green body is polished after being sintered in a furnace to obtain a glazed tile product. Compared with the prior art, the wear-resistant transparent glaze is excellent in wear resistance, and can be used for preparing ceramic tiles with thin glaze layers. The decorative properties and the anti-pollution characteristics of obtained products are greatly improved. Meanwhile, the manufacturing cost of products is lower.

Owner:FOSHAN DONGPENG CERAMIC +3

Formulation for medicinal neutral boron silicate glass

The present invention is one kind of neutral borosilicate glass for medicine production. The neutral borosilicate glass has recipe comprising quartz sand 168-178 Kg, feldspar powder 14.7-18.7 Kg, borax pentahydrate 49-51 Kg, sodium carbonate 8-12 Kg, barium carbonate 8.6-9.4 Kg, sodium nitrate 0.4-0.6 Kg, calcite 1-2 Kg, fluorite 0-4 Kg, potassium carbonate 8.5-9.5 Kg, salt 0.8-1.6 Kg, cerium oxide 0.5-0.9 Kg and cullet 120 Kg. It has high chemical stability, high hydrolysis stability, few alkali metal volatilizations, simple production process and low cost.

Owner:东营力诺玻璃制品有限责任公司

Process for preparing super-low expansion ceramic material

The invention provides a process for preparing a super-low expansion ceramic material, which is characterized in that lithium-contained mineral (such as spodumene, eucryptite, and the like), lithium carbonates, zinc oxide, barium carbonate, titanium dioxide, talcum, and the like. are mixed in advance, melted as a glass frit at the temperature of about 1450 DEG C and taken as material A; subsequently, raw materials such as kaolin, quartz, and the like are mixed and taken as material B; the material A, the material B and the calcined spodumene are mixed by a certain proportion; and the steps of ball-milling, forming and baking are carried out to prepare the super-low expansion ceramic material with the thermal expansion coefficient of 0.6-1.0*10[-6] / DEG C (at the normal temperature of about 800 DEG C). The ceramic material can be widely applied to kilns, high-temperature clamps, high-temperature radiation baffles, induction cooker panels, microwave oven liner, household heat-resistance dishware, thermocouple protection tubes, and the like.

Owner:JINGDEZHEN CERAMIC INSTITUTE

High-strength ceramic brick and preparation method thereof

The invention discloses a high-strength ceramic brick and a preparation method thereof. The ceramic brick is prepared from the following raw materials in parts by weight: 40-60 parts of yellow sand, 30-50 parts of barite, 15-25 parts of dolomite, 10-20 parts of volcanic rock, 20-30 parts of zirconite, 5-15 parts of mullite, 4-12 parts of blast furnace slag, 16-28 parts of modified clay, 7-14 parts of sea mud, 11-19 parts of a silica micro-powder, 8-16 parts of a waste brick powder, 3-9 parts of tricalcium phosphate, 4-8 parts of barium carbonate, 2-5 parts of nano silicon carbide, and 3-6 parts of nano alumina. The prepared ceramic brick has high strength, has the breaking strength of not less than 1050 N and the rupture modulus of not less than 30 MPa, is anti-knock, anti-cracking and non-friable, and enables the service life to be significantly improved.

Owner:安徽省亚欧陶瓷有限责任公司

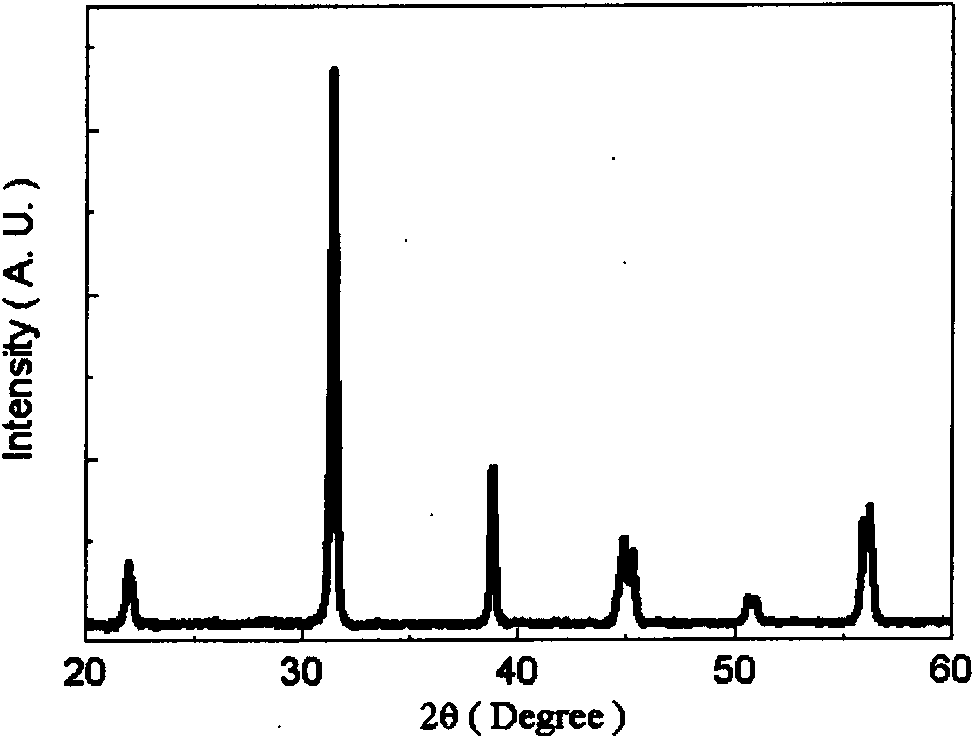

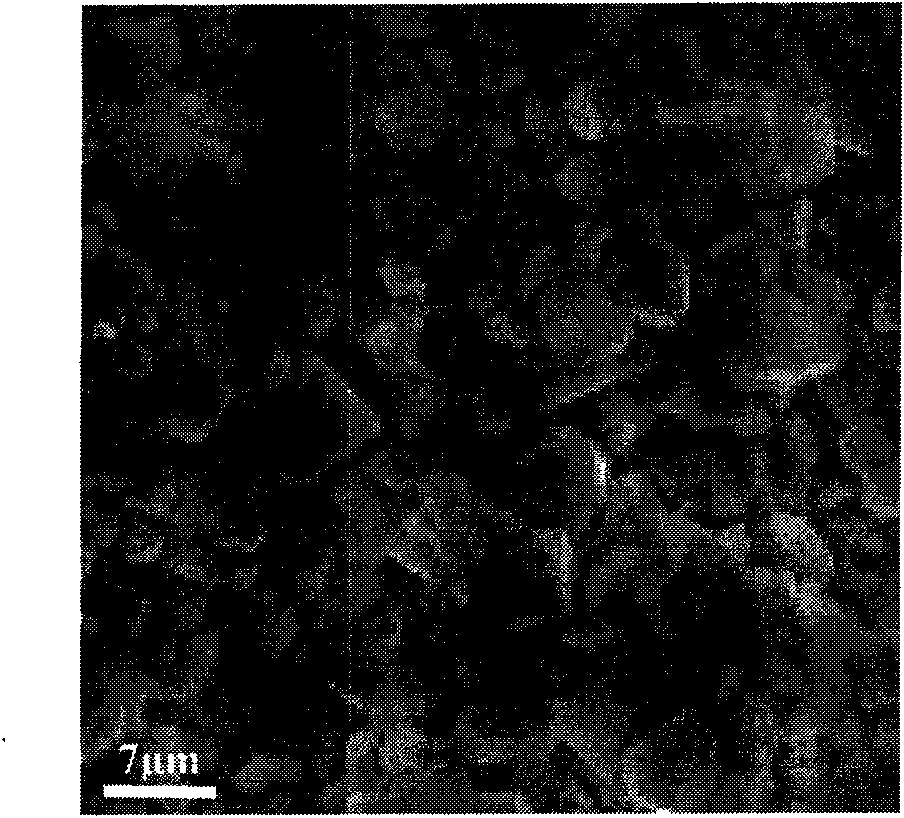

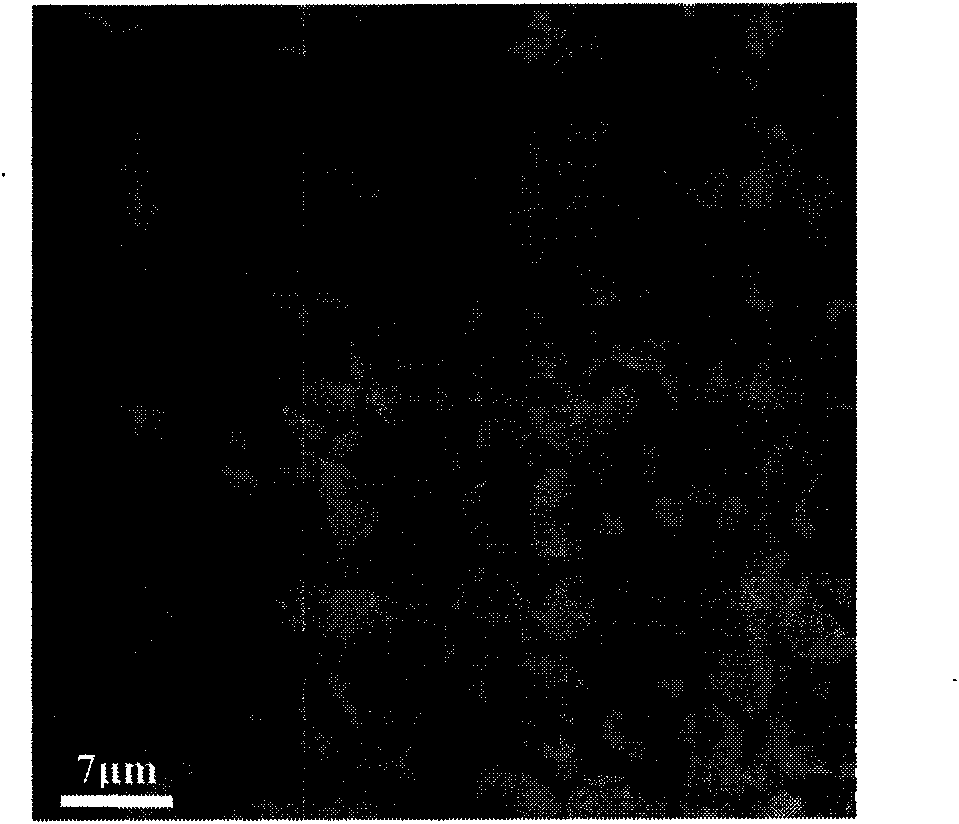

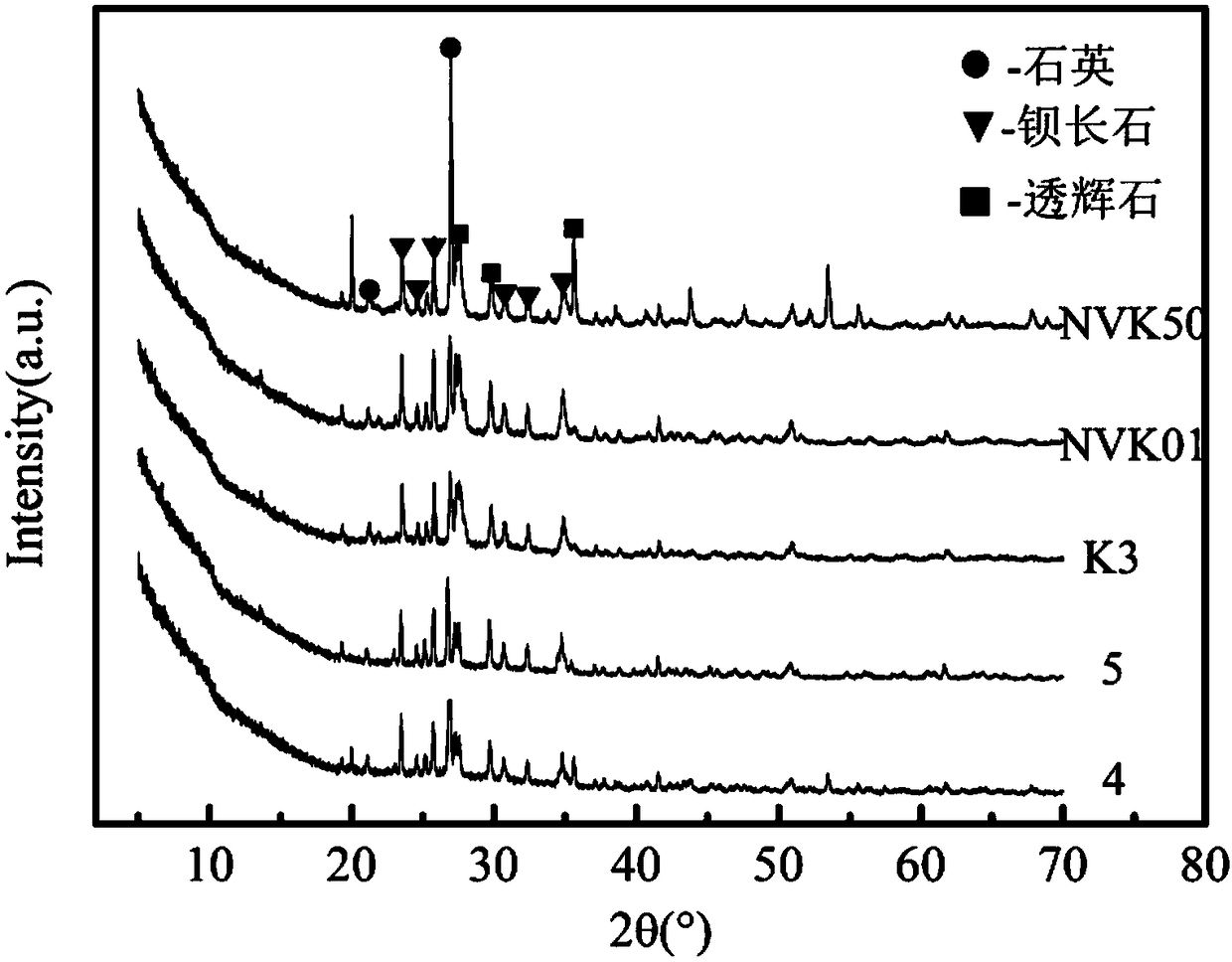

A kind of zirconia ceramic and its preparation method

The invention, belonging to the technical field of zirconia ceramic, discloses a zirconia ceramic and a preparation method thereof. The ceramic comprises matrix, sintering aid, neodymium oxide and additive, wherein, the matrix is yttria stabilized zirconia, the additive is selected from one or more of zinc oxide, barium carbonate and calcium fluoride, and the diffraction peak of the XRD appears when the 2 theta is 34.8-36.2 degrees. The zirconia ceramic has stable and beautiful purple. The preparation method comprises the following steps: adding neodymium oxide particles in a diethanolamine solution for soaking, then carrying out solid-liquid separation; carrying out ball mill mixing of the matrix, processed neodymium oxide particles, sintering aid and additive, then carrying out die forming and high temperature sintering. The preparation method provided by the present invention is simple and easy, and is suitable for large-scale industrial production.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Method for preparing sodium sulfhydrate from hydrogen sulfide tail gas

InactiveCN101186280AImprove protectionReduce pollutionSulfur compoundsSodium hydrosulfideAbsorption rate

A purpose of the invention is to provide a sodium hydrosulfide preparation method utilizing hydrogen sulfide exhaust. The invention not only can resolve the treatment problems of the three wastes of barium carbonate and strontium carbonate enterprises, but also can reuse calcium sulfate, the byproduct from the preparation of sodium hydrosulfide, as raw materials for other chemical production, which realizes the recycling of raw materials and products. The production ability of the traditional alkali solution absorbing method, the absorbing adaptability of mixed hydrogen sulfide exhaust and the sodium hydrosulfide preparation rate are enhanced; while the production cost is reduced and the exhaust can be discharged according to standards after being absorbed by alkali solution. The invention resolves the problems of low absorption rate of hydrogen sulfide gas, low production efficiency of preparation of sodium hydrosulfide, large investment of technical devices and difficulty of solid phase recycling existing in a method of 'one step for preparation of sodium hydrosulfide' using hydrogen sulfide gas, calcium hydroxide and sodium sulfide as raw materials.

Owner:QINGDAO AOHAIKE TRADE

Antibacterial ceramic tile capable of releasing negative oxygen ions and preparation method thereof

The invention belongs to the technical field of ceramic materials and in particular relates to an antibacterial ceramic tile capable of releasing negative oxygen ions and a preparation method thereof. The antibacterial ceramic tile capable of releasing the negative oxygen ions comprises a green body and a glaze layer, wherein the glaze layer is prepared from the following raw materials: potassium feldspar, potassium feldspar, calcite, calcined talc, zinc oxide, barium carbonate, alumina, a frit, calcined soil and kaolin; and the antibacterial ceramic tile also comprises antibacterial ceramic glaze additives capable of releasing the negative oxygen ions. The produced ceramic tile has the effects of permanently releasing the negative oxygen ions, emitting far-infrared rays, cleaning self, resisting to bacteria and purifying the air; and meanwhile, a ceramic glaze surface contains multiple mineral substances and trace elements, such as germanium and strontium, which are beneficial to human health.

Owner:山东统一陶瓷科技有限公司

Complete polishing glaze archaizing brick overglaze and preparation method thereof

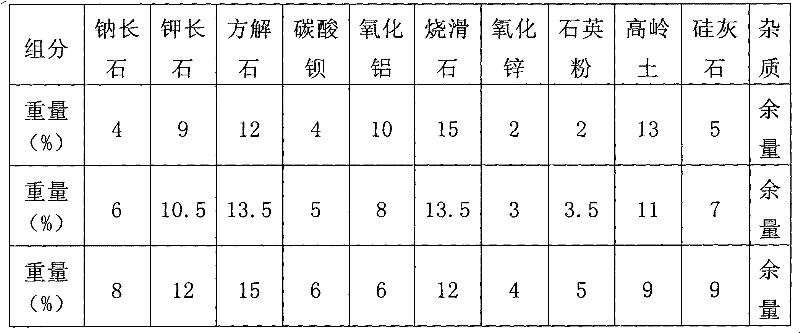

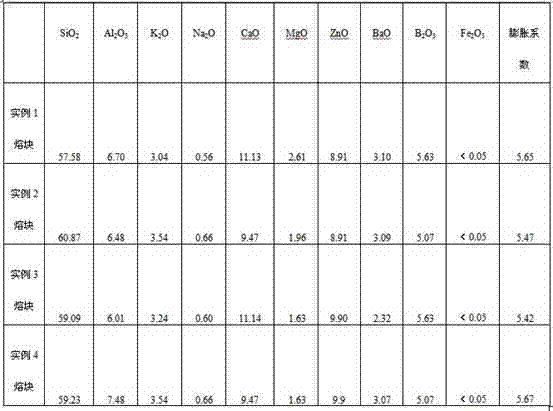

The invention relates to a complete polishing glaze archaizing brick overglaze and a preparation method thereof. The complete polishing glaze archaizing brick overglaze is prepared from the following raw materials by weight percent: 4-8% of albite, 9-12% of potassium feldspar, 12-15% of calcite, 4-6% of barium carbonate, 6-10% of alumina, 12-15% of burnt talcum, 2-4% of zinc oxide, 2-5% of quartz powder, 9-13% of kaolin, 5-9% of wollastonite and the balance of impurities. The preparation method comprises the following steps: carrying out ball milling in a ratio of weighed raw material to ballstone to ethylene glycol to squeegee oil of 1: (1.8-2): 0.25: 0.3, and simultaneously controlling the fineness degree as follows: the screenings of 325-mesh sieve is 0.3-0.4%; printing on ground glaze and fancy glaze layers through 100-mesh silk screen by using a continuous printing process; and finally, firing through a liquefied gas raceway kiln firing system. According to the invention, the purposes of improving the stability of the process and the quality of the product, reducing glaze material loss in production process, reducing cost and simultaneously avoiding the generation of a screen sticking problem in production are achieved.

Owner:霍镰泉

A kind of copper red glaze and its production method and the method for making ceramic product with it

The invention discloses copper red glaze and a production method thereof, and a method for preparing a ceramic product therefrom. The copper red glaze is prepared from parent glaze, a coloring agent and a stabilizing agent, wherein the parent glaze is prepared from the following components in parts by weight: 26 to 32 parts of quartz, 24 to 30 parts of feldspar, 10 to 14 parts of limestone, 12 to16 parts of barium carbonate, 4 to 8 parts of clay, 0 to 4 parts of zinc oxide and 0 to 4 parts of sodium borate; the coloring agent is one or a mixture of a plurality of copper oxide, cuprous oxide and copper carbonate, and the adding amount of the coloring agent is 1 to 4 parts by weight; the stabilizing agent is one or a mixture of a plurality of stannic oxide, ferric oxide, lead oxide and silicon carbide, and the adding amount of the stabilizing agent is 3 to 6 parts by weight. According to the invention, the copper red glaze is bright crimson red, the ceramic product produced from the copper red glaze has high yield and low cost, and can be used for producing domestic ceramic and display art ceramic products.

Owner:广东文化长城集团股份有限公司

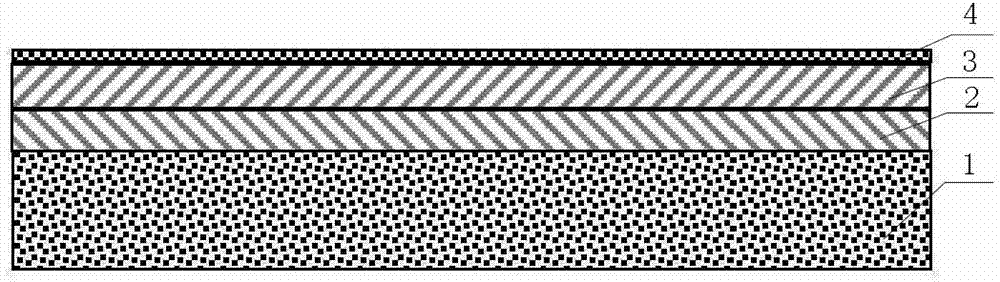

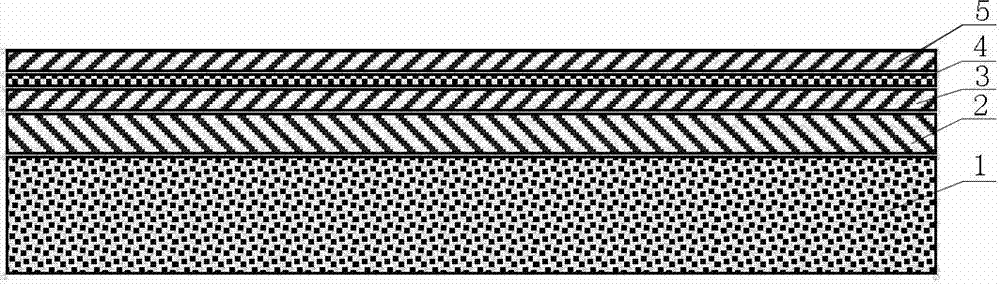

Fully glazed ceramic chip and preparation method thereof

The invention discloses a fully glazed ceramic chip and a preparation method of the fully glazed ceramic chip. The fully glazed ceramic chip comprises a green body layer, a ground coat layer, an overglazed layer and a fancy glaze layer. A fully glazed layer is arranged on the surface of the fancy glaze layer. The fully glazed layer comprises 64-71% of fully glazed smelted blocks, 0-7% of clinker, 25-32% of water, and 0.1-0.5% of auxiliary materials by weight percentage, wherein materials used by the fully glazed smelted blocks comprise potash feldspar, calcite, burned talc, zinc oxide, boronic acid, barium carbonate, aluminum oxide and quartz, and the clinker is qidao clay or kaolin. The fully glazed ceramic chip provided by the invention is used for ceramic chip decoration, and the glazing effect of the ceramic chip is good, the transparency of the enamel layer and the evenness are high, and the ceramic chip polished is bright so as to represent the clear texture level and rich texture of pictures under glazes, and the brick deformation is small, the thermal shock resistance is good, the mirror finish effect is good, and the transparent texture is excellent.

Owner:FOSHAN KEJIE GLAZE

Ceramic tile capable of releasing negative oxygen ions and preparation method thereof

The invention discloses a ceramic tile capable of releasing negative oxygen ions and a preparation method thereof. The ceramic tile is prepared from the following raw materials in parts by weight: 38-56 parts of river sand, 22-34 parts of fluorite, 18-26 parts of volcanic, 10-20 parts of dolomite, 24-36 parts of modified clay, 15-25 parts of magnesite ore, 12-18 parts of tourmaline, 10-15 parts of hexacyclic stone, 8-14 parts of medical stone, 5-10 parts of stove ash residue, 6-12 parts of talcum powder, 4-8 parts of shell powder, 3-6 parts of barium carbonate and 2-4 parts of zinc oxide. The tourmaline, the hexacyclic stone, the medical stone and the like are added into the ceramic tile, so that the ceramic tile can release negative oxygen ions beneficial to human health for a long time, can obviously enhance blood circulation, promote metabolism, improve immunity and soothe mind and body, has an effect of bacteriostat and sterilization and has an obvious deodorization function, the indoor air can be purified, and the indoor air quality is improved.

Owner:安徽省亚欧陶瓷有限责任公司

Nickel-based welding electrode matched with 9Ni steel

ActiveCN102500951AEasy to useExtend your lifeWelding/cutting media/materialsSoldering mediaNiobiumSlag

The invention belongs to a nickel-based welding electrode matched with 9Ni steel. A core wire comprises the following components in percentage by weight: more than or equal to 0.02 percent of C, 2.00 to 5.00 percent of Mn, 0.010 to 0.20 percent of Si, 55.0 to 70.0 percent of Ni, 2.50 to 10.00 percent of Fe, 0.05 to 0.30 percent of Cu, 14.00 to 19.00 percent of Cr, 7.00 to 10.00 percent of M, 1.00to 2.50 percent of Nb, 0.001 to 0.010 percent of Co, less than or equal to 0.010 percent of S, less than or equal to 0.020 percent of P and the balance of impurity; a coating comprises the following components 9.0 to 10.5 percent of marble, 7.0 to 8.5 percent of fluorite, 8.0 to 9.5 percent of barium carbonate, 8.0 to 8.5 percent of rutile, 4.0 to 5.0 percent of fluoride, 0.6 to 1.0 percent of ferroniobium powder, 1.2 to 1.5 percent of metal tungsten powder, 0.7 to 1.0 percent of soda ash, and 1.0 to 1.5 percent of electrolytic manganese based on the weight of the core wire; and binder is 20 percent based on the total weight of powder; the components are mixed, and wrapped on the core wire; and the coating and the core wire are baked at low and high temperature. The nickel-based welding electrode has the advantages that: during welding, an electric arc is stable, splashing is avoided basically, slag is detached well, the formed welding joint has an attractive appearance, and the nickel-based welding electrode is good in full-position welding performance; and the nickel-based welding electrode still has good comprehensive performance when used at the temperature of -196 DEG C.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

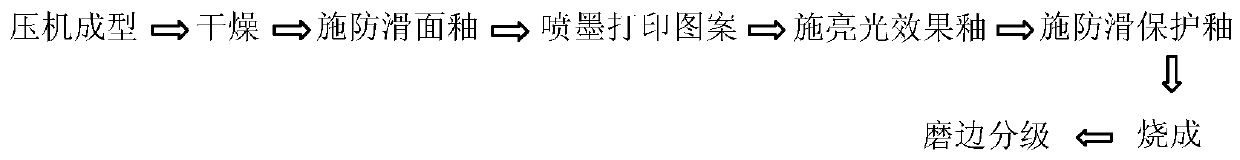

Wet water high anti-skid ink-jet ceramic tile with sunken glaze effect and preparation method of tile

The invention provides a wet water high anti-skid ink-jet ceramic tile with a sunken glaze effect and a preparation method of the tile. The preparation method includes sequentially applying anti-skidsurface glaze, decorative patterns, bright effect glaze and anti-skid protective glaze on a blank body, and then firing, wherein the mineral composition of the composition of the anti-skid surface glaze comprises 40-50% of potassium feldspar, 0-10% of albite, 7-10% of kaolin, 8-12% of quartz, 8-11% of calcined alumina, 0-5% of nepheline, 2-4% of zinc oxide, 7-10% of zirconium silicate and 6-10% ofbarium carbonate; and the mineral composition of the composition of the anti-skid protective glaze comprises 48-58% of potassium feldspar, 0-10% of albite, 10-20% of kaolin, 0-5% of quartz, 0-4% of nepheline, 2-5% of calcined alumina, 10-15% of barium carbonate and 5-8% of zinc oxide. The anti-skid ceramic tile can be used as a decorative material with a good decorative effect, excellent pollution resistance and anti-skid performance, and can be applied to the field of home decoration.

Owner:MONALISA GRP CO LTD

Calcium barium zirconate titanate base piezoceramics and preparation method thereof

InactiveCN101648807ALower coercive fieldLow equipment requirementsPiezoelectric/electrostrictive/magnetostrictive devicesBarium titanateZirconium dioxide

The invention discloses calcium barium zirconate titanate base piezoceramics and a preparation method thereof. The chemical formula of the calcium barium zirconate titanate base piezoceramics is (1-x-y)BaTiO3-xCaTiO3-yBaZrO3, wherein x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than 0.5, and both x and y are molar fractions. The preparation method comprises the following steps: mixing barium carbonate, calcium carbonate, titanium dioxide and zirconium dioxide according to the stoichiometric proportion (1-x-y)BaTiO3-xCaTiO3-yBaZrO3 (x is greater than 0 and smaller than 0.5, y is greater than 0 and smaller than 0.5, and both x and y are molar fractions), ball-milling, calcining, ball-milling for the second time, granulating, moulding, removing the binder, high-temperature sintering and the like so as to finally prepare the calcium barium zirconate titanate base piezoceramics with high piezoelectric performance. The method greatly enhances the piezoelectric performance of the lead-free piezoceramic system and the technical stability of the material, so that the lead-free piezoceramics in the barium titanate system achieve the practical level in the aspectsof components and technique.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation method of metal-imitation glaze

The invention provides a production method for a colorful, color-stable imitated metallic luster glaze which can meet the requirements of low-temperature rapid firing process. The method includes: (1) first making the following raw materials into a frit by weight percentage of 10-20 per cent quartz, 40-60 per cent lepidolite, 10-20 per cent boric acid, 2-6 per cent barium carbonate, 3-10 per cent limestone, 3-12 per cent metal oxide and then evenly mixing the raw materials after melting at 1200-1350 DEG C and obtaining a color frit by water quenching. (2) making the glaze with the following materials by weight of 75-90 per cent color frit, 0-20 per cent high boron frit and 5-10 per cent kaolinite. The metallic luster glaze products is colorful and low in sintering temperature and is suitable for the characteristics and style of interior wall glazed tiles of twice low-temperature rapid firing and the frit is produced by sintering metal oxides, therefore the color is very stable.

Owner:冼金源 +1

High-temperature domestic porcelain metallic bright glaze and product decorated by same

The invention relates to a high-temperature domestic porcelain metallic bright glaze and a product decorated by the same. The bright glaze produced by using natural mineral raw materials and industrial pure raw materials comprises the following materials by weight percent: 10-25 percent of potassium feldspar, 10-30 percent of albite, 0-35 percent of quartz, 0-10 percent of barium carbonate, 0-10 percent of wollastonite, 0-10 percent of kaolin, 0-5 percent of zinc oxide, 1-10 percent of aluminum oxide, 1-10 percent of bone ash, 1-5 percent of purple clay and 10-35 percent of ferric phosphate, and the glaze is obtained by mixing, ball-milling and screening the raw materials. The fabrication technology of the glaze is basically the same as the common porcelain glaze, the cost is low, not only can the pure color be guaranteed through redesigning of the formula of the glaze, but also the burning temperature of the glaze is increased to 1380 DGE C, so that the decoration effect of domestic porcelain is greatly enriched, and the high-temperature domestic porcelain metallic bright glaze has wide application prospect.

Owner:HUNAN KARPERY INDAL +1

Full polish ceramic product and preparation method thereof

The invention relates to a full polish ceramic product and a preparation method thereof. The full polish ceramic product comprises a ceramic green body and a full polish layer outside the ceramic green body, wherein the full polish layer mainly comprises powder which comprises following components by weight percent: 42-62% of albite, 2-7% of potash feldspar, 0-4% of dolomite, 4-8% of calcite, 0-2% of barium carbonate, 6-8% of aluminum oxide, 3-5% of fired talc, 2-4.6% of zinc oxide, 3-9% of quartz powder, 0.5-2.5% of soochow kaolin, 1-6% of calcined kaolin, 5-10% of aedelforsite, 0.1-3.0% of spodumene, and 0.1-2.8% of borocalcite. The full polish slurry is prepared by burdening and ball milling once. As the full polish slurry contains less wearproof materials like aluminum oxide, the ball milling time is short, and the production efficiency is higher; due to the addition of little amount of spodumene and borocalcite, the abrasion performance and hardness of the fired full polish ceramic product can be improved.

Owner:JIANGSU BAIFU TECH CO LTD +1

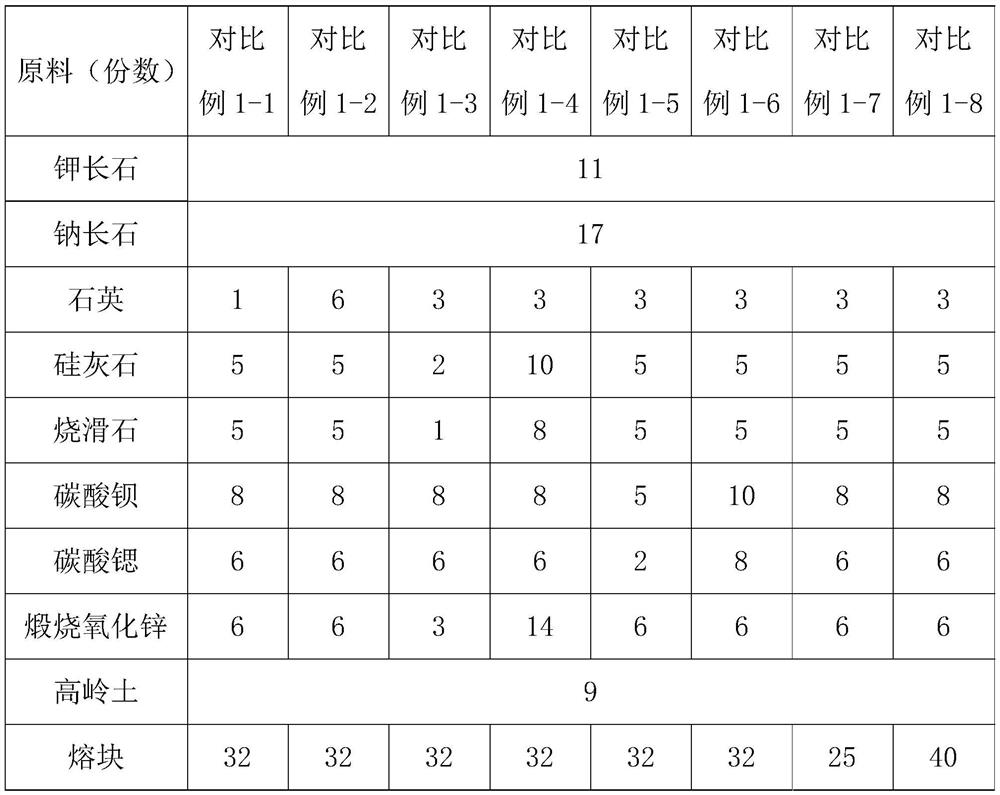

Low-gloss transparent glaze, ceramic tile using low-gloss transparent glaze and preparation method of ceramic tile

The invention discloses low-gloss translucent glaze, a ceramic tile using the low-gloss translucent glaze and a preparation method of the ceramic tile. The low-gloss transparent glaze is prepared from the following raw materials in parts by mass: 26-30 parts of feldspar, 2-4 parts of quartz, 4-6 parts of wollastonite, 4-6 parts of calcined talc, 7-9 parts of barium carbonate, 5-7 parts of strontium carbonate, 5-7 parts of calcined zinc oxide, 8-10 parts of kaolin and 30-33 parts of frit. According to the low-gloss transparent glaze provided by the technical scheme, the surface gloss of a fired glaze layer is low, the 3D layering sense is clear, the color development range of the glaze is wide, the production cost is low, and the defects in the prior art are overcome. The invention further provides a preparation method of the ceramic tile using the low-gloss transparent glaze, which has the advantages of simple steps and high operability, and is beneficial to ensuring the stable color development of the ceramic tile and enhancing the 3D stereoscopic effect of the ceramic tile. The technical scheme further provides the ceramic tile prepared by the preparation method of the ceramic tile, and the ceramic tile is stable in color development and strong in transparency.

Owner:肇庆乐华陶瓷洁具有限公司

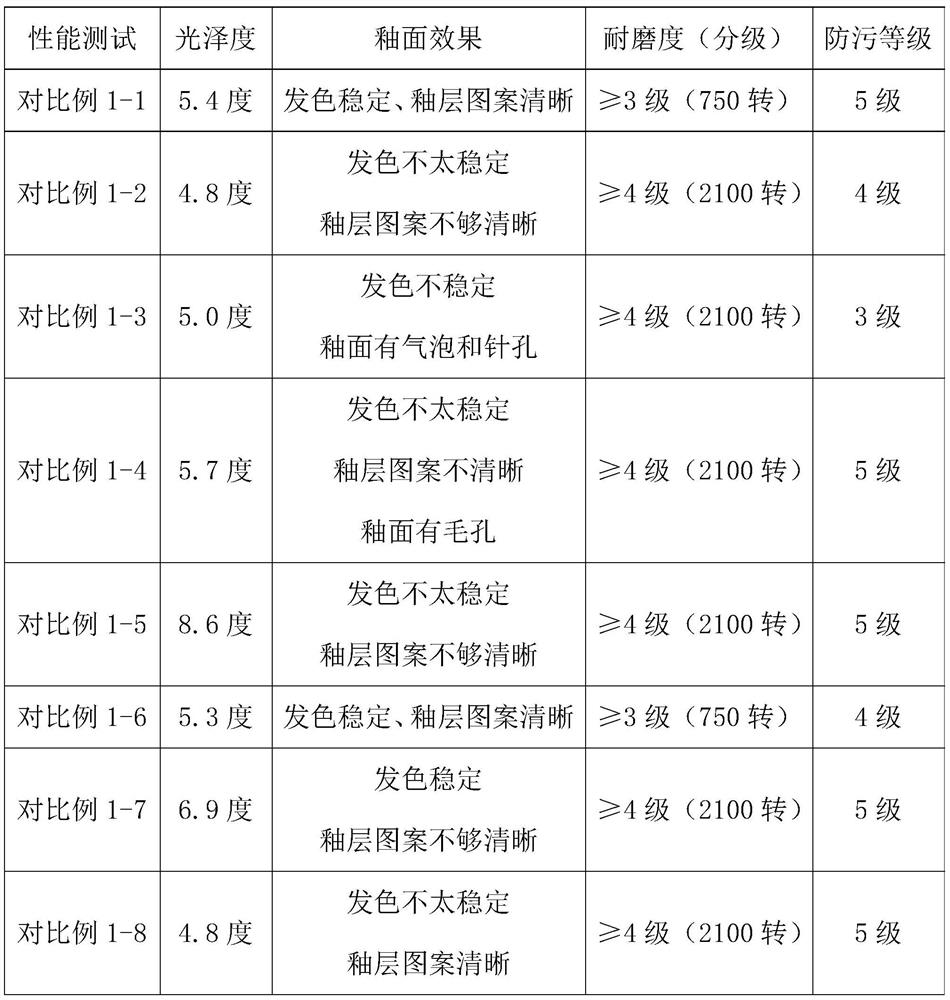

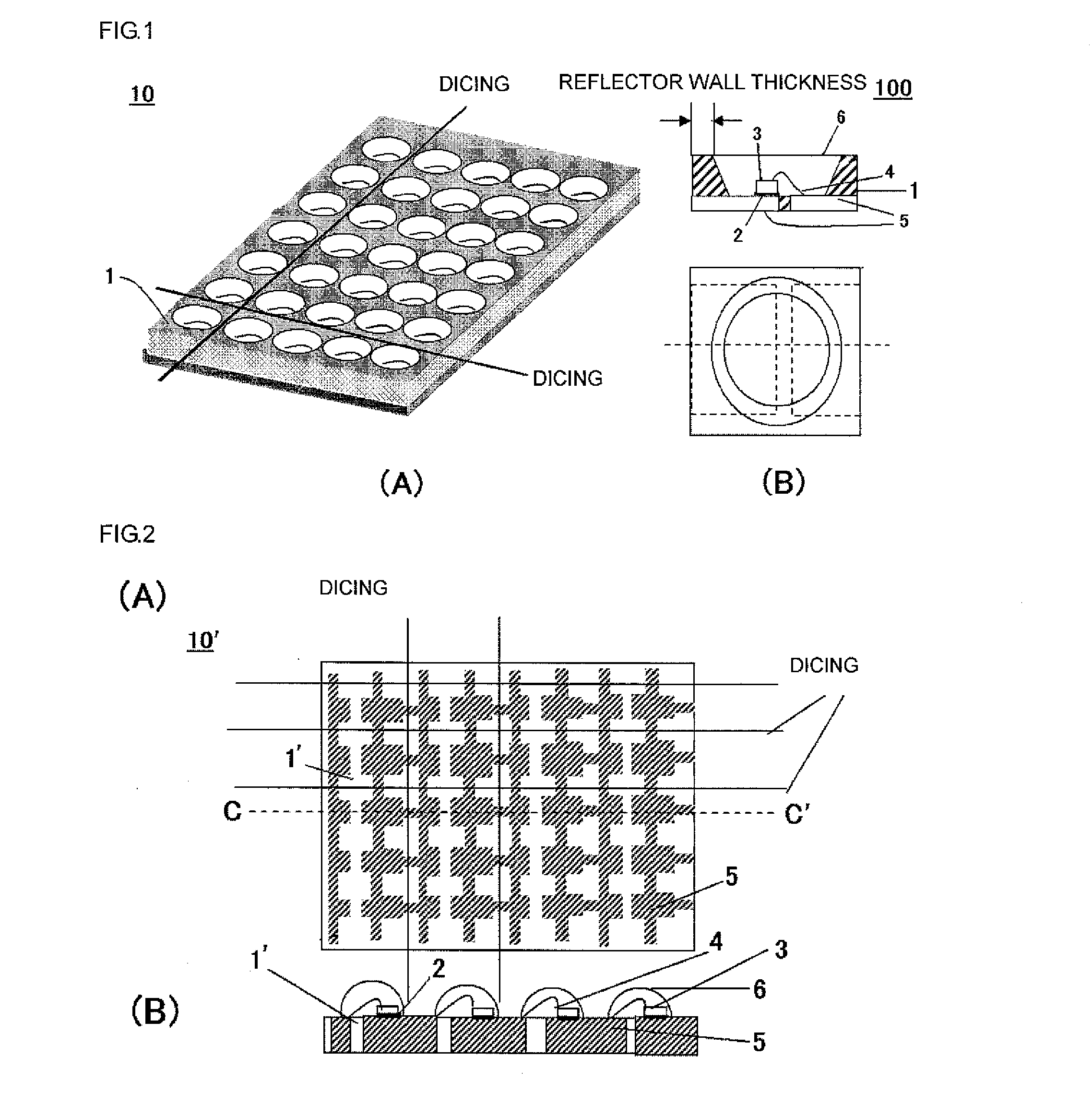

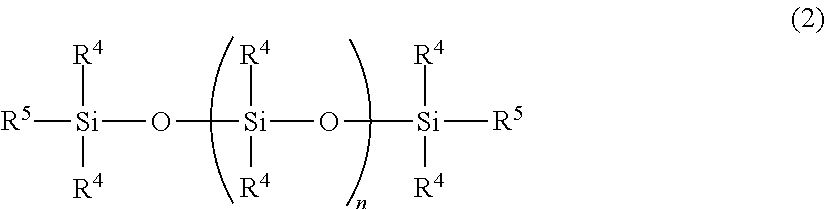

Thermosetting silicone resin composition for reflector of LED, reflector for LED using the same and optical semiconductor apparatus

ActiveUS20130274398A1Improve heat resistanceImprove light resistanceAlkaline-earth metal silicatesSolid-state devicesTitanium oxideBarium carbonate

A thermosetting silicone resin composition for reflector of LED has an organopolysiloxane represented by the following average compositional formula, and has at least two alkenyl groups in one molecule, a linear organohydrogen polysiloxane represented by the following formula and / or a branched organohydrogenpolysiloxane represented by the following formula, an addition reaction catalyst, a white pigment selected from titanium oxide, zinc oxide, magnesium oxide, barium carbonate, magnesium silicate, zinc sulfate and barium sulfate, and an inorganic filler other than Component,R1aR2bR3c(OR0)dSiO(4-a-b-c) / 2 (1)R7eR8fHgSiO(4-e-f-g) / 2 (3).There can be a thermosetting silicone resin composition which provides a cured product excellent in heat resistance and light resistance, less leakage of light to outside, and particularly suitable for a matrix array reflector.

Owner:SHIN ETSU CHEM IND CO LTD

Preparation method for smoky yellow crystal bead blanks

InactiveCN102503126AAchieve lead-freeHigh refractive indexGlass pressing apparatusPotassium carbonatePotassium permanganate

The invention discloses a preparation method for smoky yellow crystal bead blanks. The preparation method for smoky yellow crystal bead blanks aims to overcome shortcomings that existing preparation process for smoky yellow crystal bead blanks needs lead oxide as a raw material, coloring and optical properties of iron ions are poor, coloring property of manganese is unstable, and rhinestone bead blanks are poor in physical and chemical properties. Raw materials of the preparation method do not contain lead oxide, and the crystal bead blanks are good in physical and chemical properties, are proper in hardness and high in corrosion resistance. In the preparation method for the smoky yellow crystal bead blanks, raw materials of the smoky yellow crystal bead blanks include, by weight ratio, from 50 to 65 parts of quartz sand, from 2 to 20 parts of titanium dioxide, from 2 to 10 parts of sodium carbonate, from 7 to 20 parts of potassium carbonate, from 0.3 to 5 parts of potassium nitride, from 0.1 to 5 parts of cerium oxide, equal to or lower than 6 parts of boric acid, equal to or lower than 2 parts of aluminum hydroxide, equal to or lower than 8 parts of zinc oxide, equal to or lower than 10 parts of magnesium carbonate, equal to or lower than 15 parts of barium carbonate, equal to or lower than 2 parts of lithium carbonate, equal to or lower than 2 parts of potassium permanganate, equal to or lower than 4 parts of sodium nitrate and equal to or lower than 3 parts of iron oxide red.

Owner:ZHEJIANG WEIXING CRYSTAL

Applique antibacterial ceramic cutter

The invention relates to an applique antibacterial ceramic cutter, and belongs to the technical field of daily ceramics. The cutter comprises a cutter blank, and is characterized in that the outer surface of the cutter blank is covered with a layer of antibacterial self-cleaning ceramic glaze; the antibacterial self-cleaning ceramic glaze is prepared from the following raw materials in percentageby weight: 15 to 30 percent of quartz, 20 to 40 percent of feldspar, 10 to 20 percent of borax, 6 to 18 percent of boric acid, 3 to 7 percent of barium carbonate, 2 to 5 percent of sodium carbonate, 4to 9 percent of bentonite, 0 to 6 percent of phosphorus pentoxide, 10 to 20 percent of zinc oxide, 0 to 6 percent of titanium oxide, 1 to 5 percent of strontium carbonate, 0 to 4 percent of lithium carbonate, 1 to 4 percent of cooked steatite, 1 to 6 percent of alumina, and 1 to 4 percent of rare-earth; and the rare-earth is one or a mixture of arbitrary two of the cerium oxide, the cerium lanthanum chloride and the lanthanum nitrate. The cutter has the effect of antibacterial self-cleaning, has beautiful appearance, and is suitable for the occasion of high-grade application.

Owner:淄博博纳科技发展有限公司

Warm eye-protection matte glaze for building ceramic tiles, and preparation technology thereof

The invention discloses a warm eye-protection matte glaze for building ceramic tiles, and a preparation technology thereof. The preparation technology comprises the following steps: (1) weighing clay,feldspar, quartz, talcum, dolomite, limestone, borax, zirconium silicate, zinc oxide, alumina, barium carbonate and strontium carbonate according to the chemical composition range, crushing the weighed materials to form 180-350 mesh particles, mixing the particles, sintering the obtained mixture at 1480-1580 DEG C to form a glassy melt, and quenching the glassy melt with water to obtain a matte frit for the ceramic tile glaze; and (2) adding clay raw materials and a glaze slip performance regulator to the frit, and performing full wet ball-milling to obtain a matte glaze slip. The compositionof the formula is slightly changed, so the glaze obtained after sintering has the advantages of high strength, high wear resistance, high aging resistance and long service life; the glaze is flat, fine and smooth, is free of pinholes, and has silky or velvet gloss, and the glossiness of the glaze is 3-5 DEG less than that of existing products, so the glaze makes people have soft, quiet and comfortable eye-protection feeling; and the tile matte glaze has tender and soft hand feeling, and is warm.

Owner:FOSHAN UNIVERSITY +1

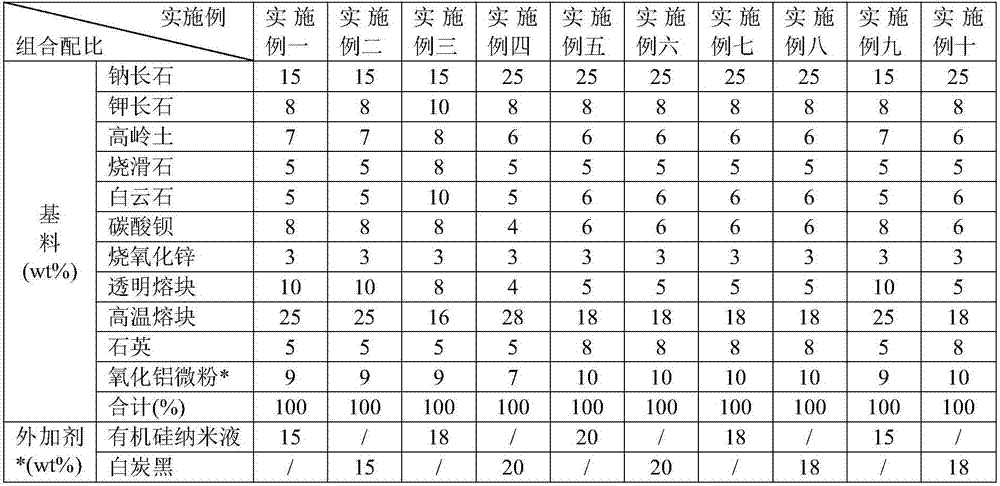

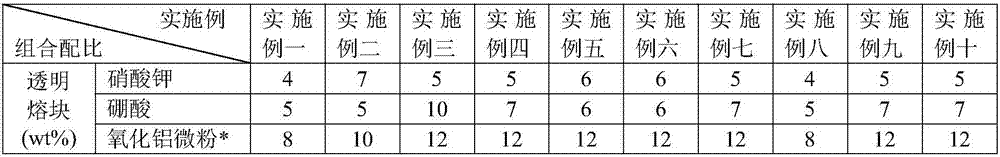

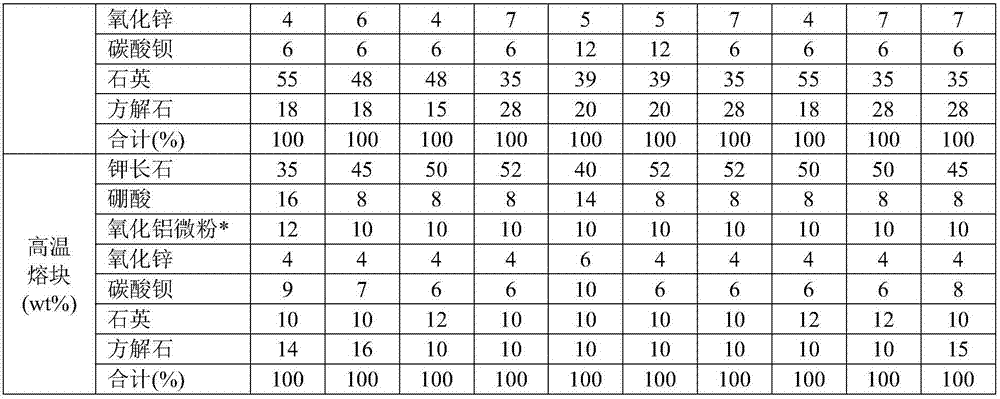

Low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and preparation method thereof

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Copper-red transmutation glaze, copper-red transmutation glaze ceramic product prepared from same and preparation method

The invention relates to a copper-red transmutation glaze, a copper-red transmutation glaze ceramic product prepared from the same and a preparation method and belongs to the technical field of ceramics. The copper-red transmutation glaze comprises components in parts by weight as follows: a glaze type basic material including 34-35 parts of nepheline syenite, 20-22 parts of calcium carbonate, 3-4 parts of barium carbonate, 2-3 parts of zinc oxide, 1-2 parts of magnesium carbonate, 26-27 parts of kaolin and 9.5-10.5 parts of nano silicon oxide, and a chromogenic reagent including 1.8-2.5 parts of lithium carbonate, 2-4 parts of bone ash and 2-4 parts of copper carbonate. The ceramic product prepared from the copper-red transmutation glaze through firing has brighter red color, the glaze color is uniformly distributed, and the yield is high.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

Preparation method of leadless glass powder for electronic slurry

A process for preparing lead-free glass powder used for electronic paste, which comprises: firstly uniformly mixing silicon dioxide or sodium silicate, barium oxide or barium carbonate, boron oxide or boric acid, bismuth oxide or bismuth sulfate, aluminum oxide, aluminum sulfate or aluminum silicate, zinc oxide or zinc carbonate, sodium oxide, sodium carbonate or sodium bicarbonate, potassium oxide or potassium carbonate and titanium dioxide, then heating the mixed raw materials to melt, cooling the melted mixture, then grinding into power by a ball grinder, sieving by a sieve of 100-400 eye and lastly drying glass powder to obtain the lead-free glass powder. Because the glass power of the invention does not contain lead oxide (PbO) or compounds of lead oxide (PbO), the invention is harmless in the manufacture process of paste, simultaneously is beneficial for environmental protection, and is convenient for recycling and reusing electronic product modules containing the electronic paste.

Owner:IRICO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com