Patents

Literature

623results about How to "Strong acid resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing silicon-free or low-silicon acidproof ceramic fracturing propping agent

The invention discloses a method for preparing a silicon-free or low-silicon acidproof ceramic fracturing propping agent, which comprises the following steps of: (1) preparing the following raw materials in percentage by weight: 30 to 95 percent of alumina, 5 to 70 percent of barium carbonate and 0 to 10 percent of sintering aid, wherein the sintering aid is one or more of titanium dioxide, boric acid, calcium carbonate, magnesium oxide and dolomite; (2) performing ball milling on the raw materials in the step (1) in a ball mill for 24 to 48 hours; (3) preparing the raw materials obtained in the step (2) into semi-finished product particles; and (4) sintering the semi-finished product particles obtained in the step (3) at the temperature of between 1,500 and 1,800 DEG C for 1 to 3 hours, and cooling to the room temperature. The method has simple process; the barium carbonate is decomposed at high temperature to generate barium oxide, and the barium oxide is fully reacted with alumina to generate stable barium aluminate; and the barium aluminate has strong acidproof performance and protects other components in the finished product against corrosion of acid liquor, so the acidproof performance of the finished product is greatly improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Sodium alginate-MOF (metal organic framework) composite spherule as well as preparation method and application thereof

InactiveCN105498695AStop erosionImprove acid resistanceOther chemical processesAlkali metal oxides/hydroxidesChemistryMaterial synthesis

The invention discloses a sodium alginate-MOF (metal organic framework) composite spherule as well as a preparation method and an application thereof, belongs to the field of material synthesis and overcomes the defect that a conventional MOF material has small grain size and poor acid resistance and is difficult to be separated from water. The co-precipitation technology is adopted, a sodium alginate-MOF mixed liquid is dropwise added to a precipitant solution containing calcium chloride, water and ethyl alcohol, a non-crosslinked composite spherule is obtained, then the composite spherule is added to a glutaraldehyde solution for cross-linking of a sodium alginate framework, the sodium alginate-MOF composite spherule is obtained, the grain size of the spherule is about 1 mm, and the composite spherule has the characteristics of high acid resistance, high separability from water, high water pollutant adsorption capacity, high mechanical strength, long service life, environment-friendliness and the like.

Owner:NANJING NORMAL UNIVERSITY

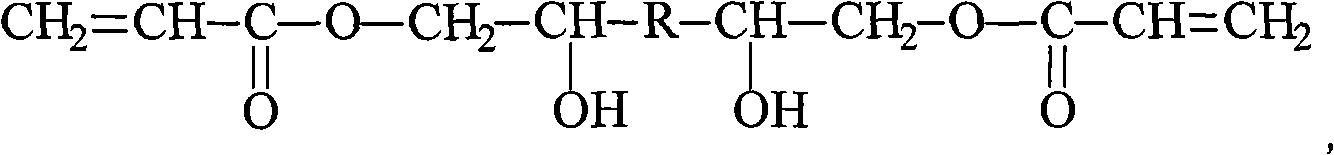

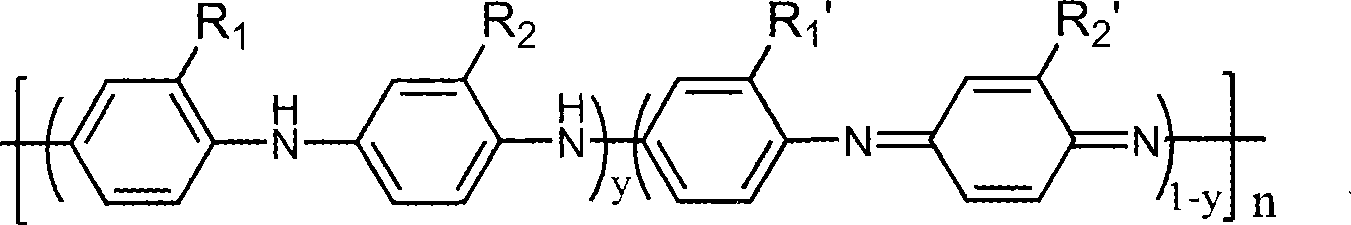

UV curing polyaniline anti-corrosive paint and preparation thereof

InactiveCN101407650AImprove anti-corrosion performanceTo achieve anti-corrosion effectAnti-corrosive paintsPhotoinitiatorChemistry

The invention provides an ultraviolet curing polyaniline anticorrosive coating and a preparation method thereof. The coating adopts polyaniline as a main anticorrosive material, an oligomer, a reactive diluent, the polyaniline, a filler, a photoinitiator and an auxiliary agent are mixed according to a formula, stirred, ground, filtered, and the like, thereby obtaining the ultraviolet curing polyaniline anticorrosive coating. The prepared anticorrosive coating has good anticorrosive effect on different metals, such as steel, copper, aluminum, etc. The coating has stronger corrosion resistance property of acid, base and other media, thereby being applicable to the use in extremely harsh environmental conditions and being particularly applicable to the corrosion resistance in marine environment. The coating does not contain Pb, Cr, Zn and other heavy metals, and the formula does not contain any organic solvents. Therefore, the coating does not have the environmental pollution problem during the production and the using processes and is a completely green environment-friendly coating.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

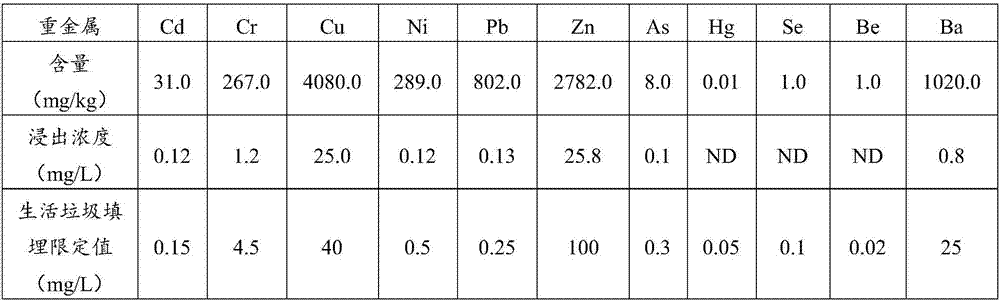

Heavy metal chelating agent for waste incineration fly ashes and preparation method for heavy metal chelating agent

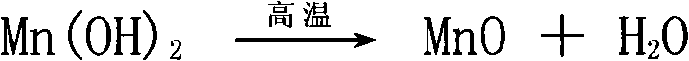

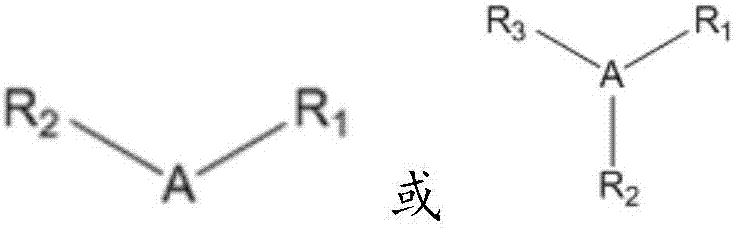

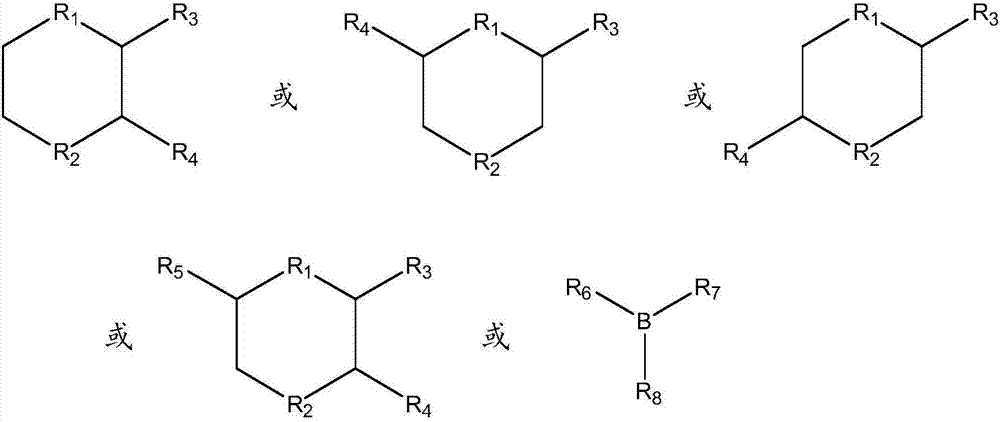

InactiveCN106955451AImprove stabilityReduce dosageChemical protectionHeavy metal chelationSodium phosphates

The invention discloses a heavy metal chelating agent for waste incineration fly ashes. The heavy metal chelating agent for the waste incineration fly ashes comprises a compound chelating agent and a sodium hydroxide solution mixed with a weight ratio being 1:2-3, wherein the compound chelating agent comprises, by weight percentage, 60-90% of an organic chelating agent, and 10-40% of an inorganic chelating agent, the organic chelating agent is dithiocarbamates and is one or more selected from zinc diethyl dithiocarbamate, zinc dimethyl dithiocarbamate, sodium dibutyl dithiocarbamate or sodium dibenzyl dithiocarbamate, and the inorganic chelating agent is one or two selected from sodium sulfide and sodium phosphate. The heavy metal chelating agent for the waste incineration fly ashes is capable of reducing the leaching concentration of heavy metals and ensuring that a fly ash solidification sample block can meet the limit value of the leaching concentration. The invention further provides a preparation method for the heavy metal chelating agent for the waste incineration fly ashes.

Owner:湖南云平环保科技有限公司

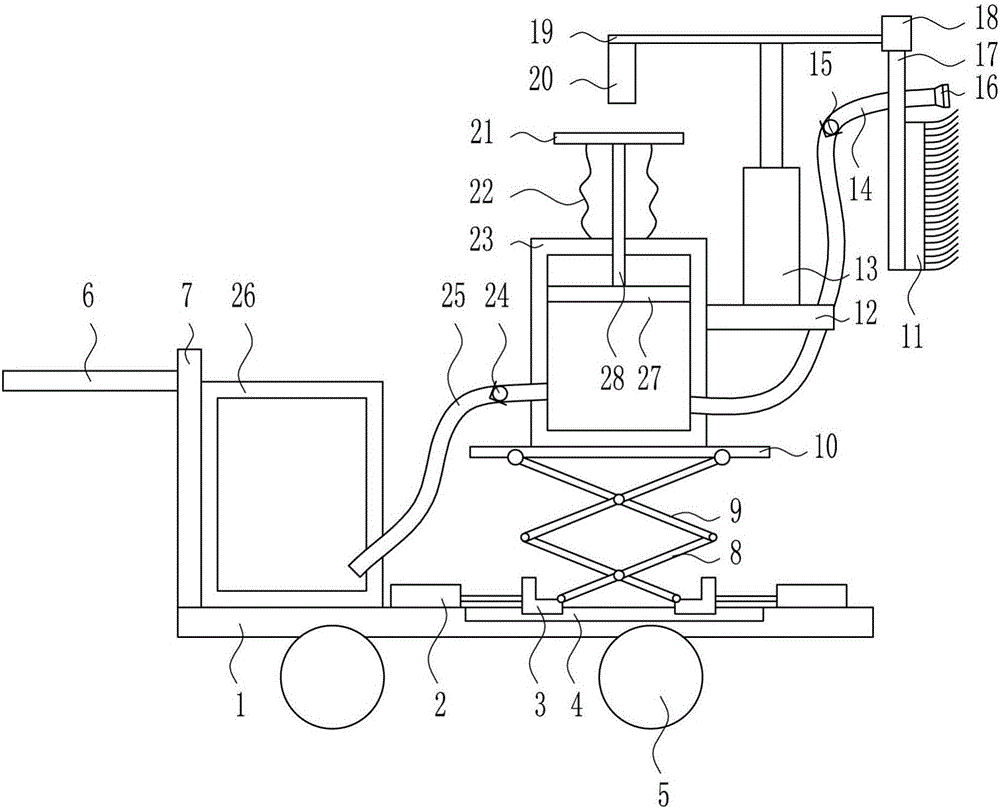

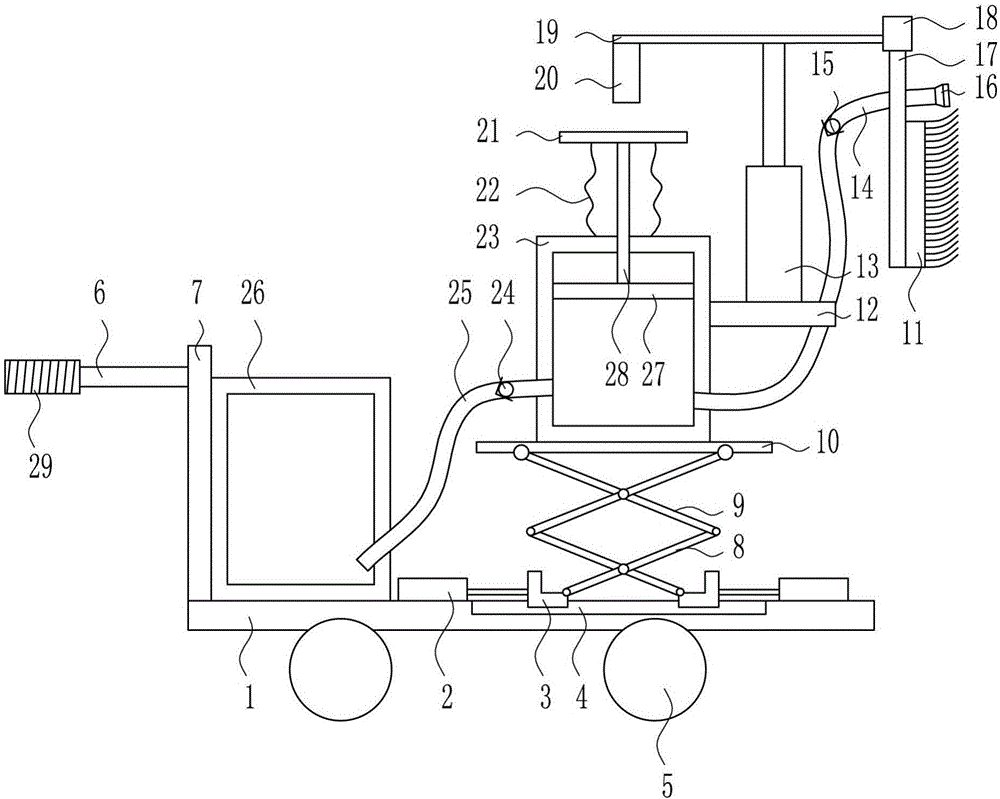

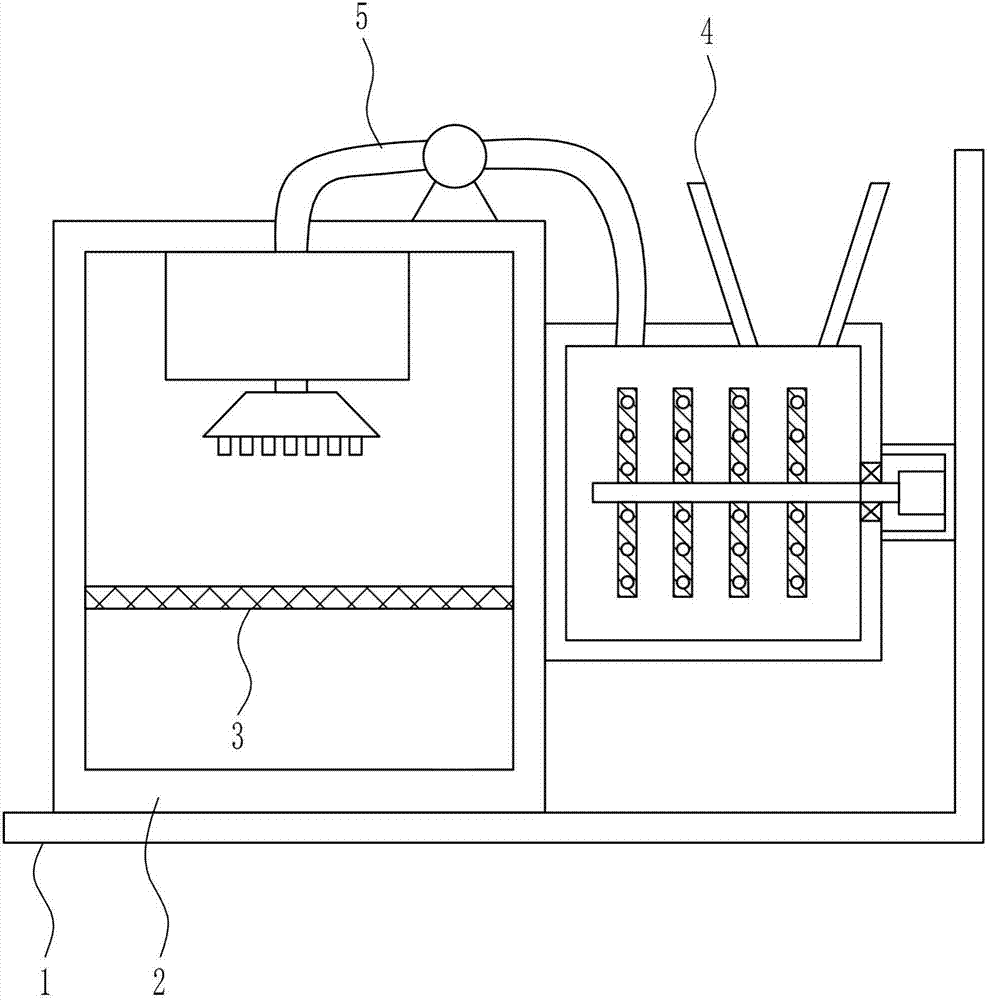

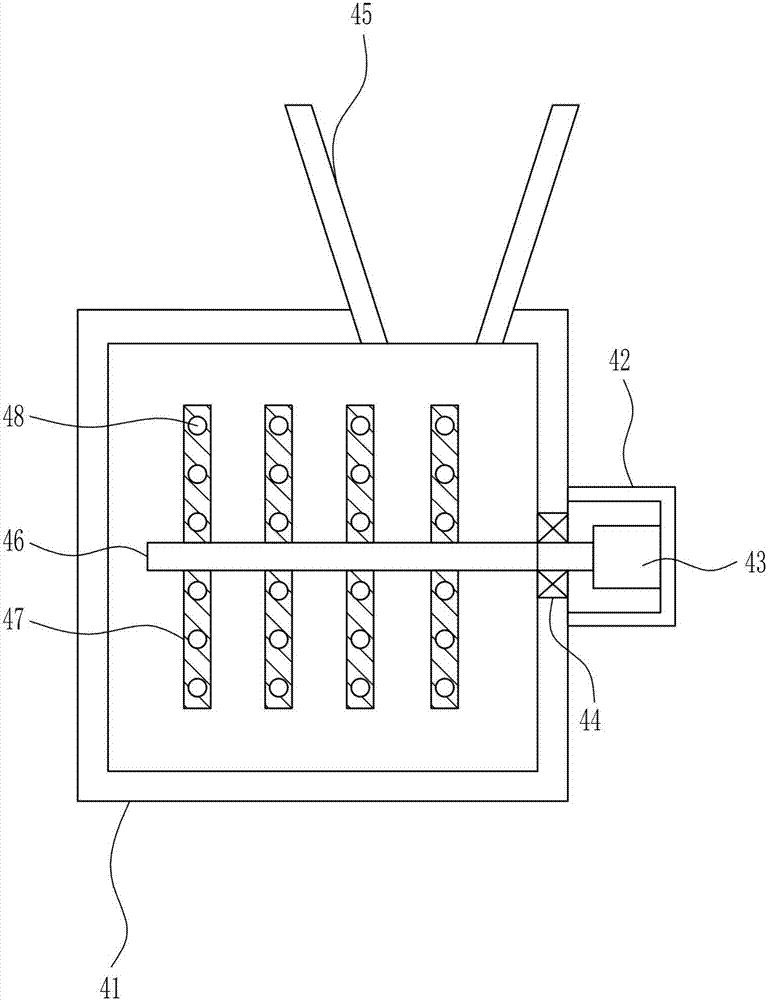

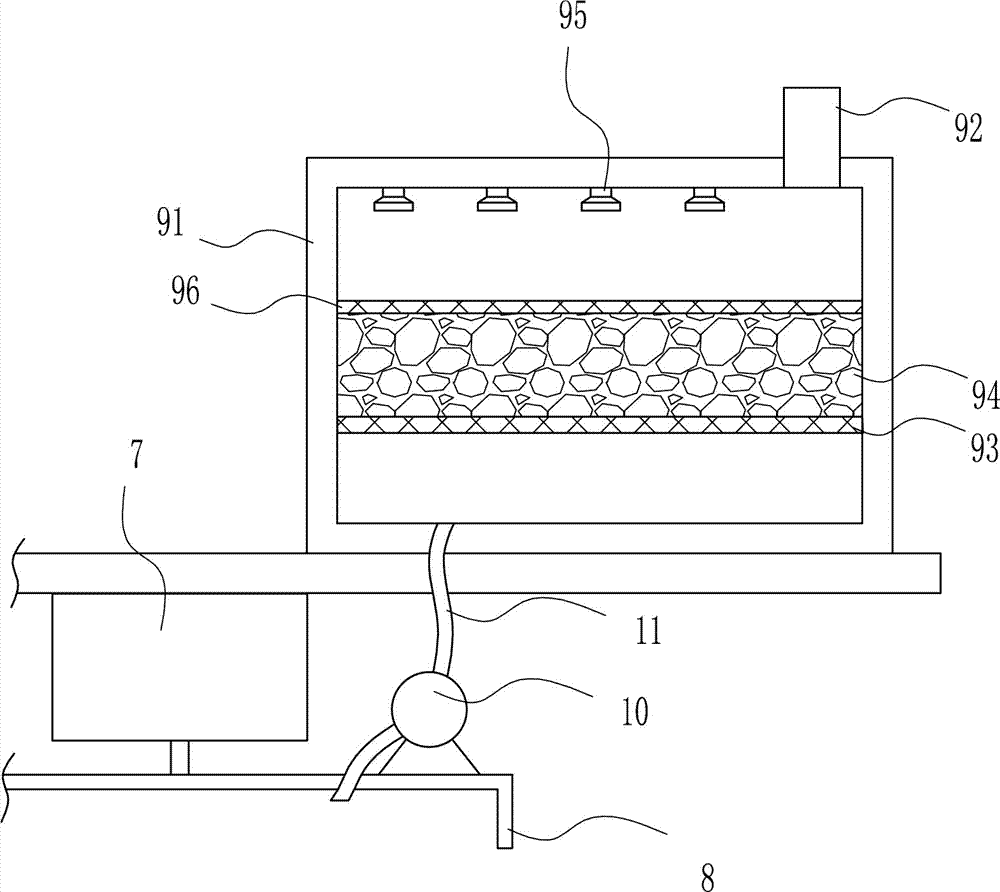

High-efficiency cleaning device for livestock shed for livestock farming

InactiveCN106180018AImprove corrosion resistanceStrong acid resistanceCleaning using toolsCleaning using liquidsSprayerEngineering

The invention relates to a cleaning device for a livestock shed for livestock farming, in particular to a high-efficiency cleaning device for the livestock shed for livestock farming. In order to achieve the technical purposes of thorough cleaning, high cleaning efficiency and convenient operation, the high-efficiency cleaning device for the livestock shed for livestock farming comprises a bottom board, a first electric push rod, an L-shaped sliding block, a sliding rail, wheels, a push handle, a left frame, a first connection rod, a second connection rod, a fixing board, a brush, a supporting board, a second electric push rod, a second hose, a second one-way valve, a sprayer, a fixing rod and the like, wherein the left frame and a water tank are arranged on the left side of the top of the bottom board; and the left frame is located on the left of the water tank. The high-efficiency cleaning device for the livestock shed for livestock farming achieves the effects of thorough cleaning, high cleaning efficiency and convenient operation. A livestock shed is closely linked with living of livestock, frequent cleaning of the livestock shed is beneficial for keeping the livestock shed clean, and the situation that the livestock get sick due to breeding of bacteria is avoided.

Owner:邵鹏程

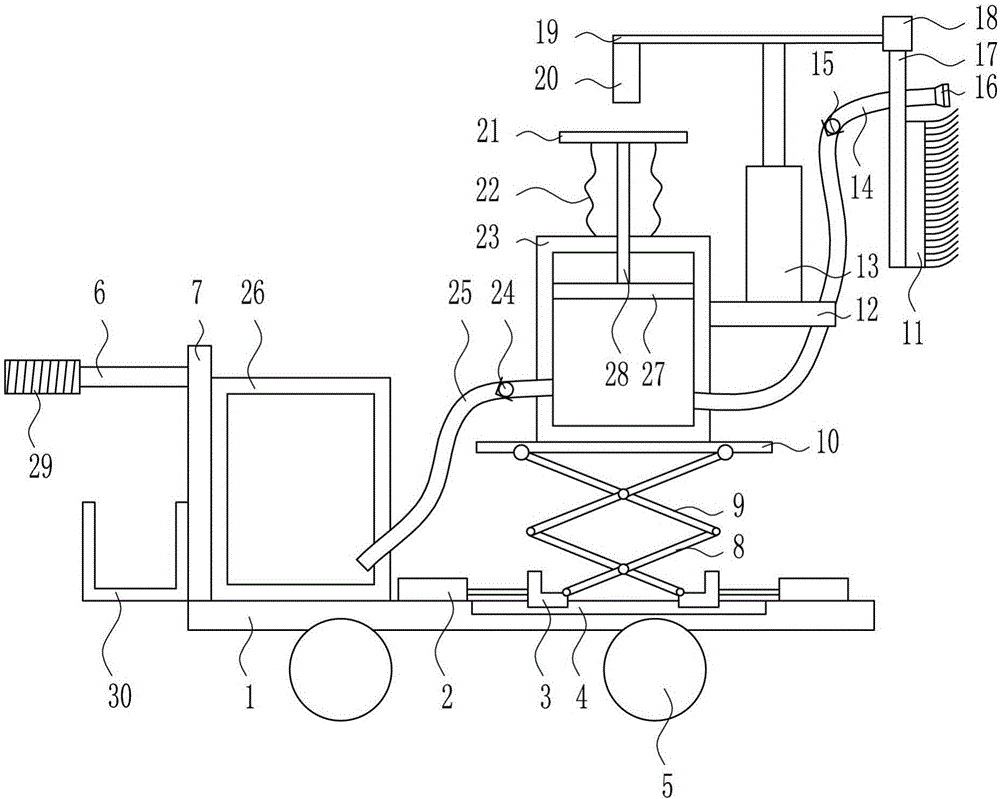

Method for preparing novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition

InactiveCN101736369ASolution to short lifeStrong acid resistancePhotography auxillary processesElectrolytic inorganic material coatingLead dioxideSand blasting

The invention discloses a method for preparing a novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition, which is characterized by sequentially plating conductive coating, an alpha-PbO2-CeO2-TiO2 layer and a beta-PbO2-MnO2-WC-ZrO2 layer outside an aluminum matrix of a composite lead dioxide-manganese dioxide anode from inside to outside. The method comprises the following steps of: carrying out quenching, oil removal and sand blasting processing on the aluminum matrix; spraying the conductive coating on a matrix material; then carrying out alkaline composite plating on the alpha-PbO2-CeO2-TiO2 layer and carrying out acidic composite plating on the beta-PbO2-MnO2-WC-ZrO2 layer to obtain the composite lead dioxide-manganese dioxide anode. The aluminum-based composite lead dioxide-manganese dioxide anode manufactured by the process and method of the invention can obviously reduce the voltage of an electrode bath and energy consumption; and meanwhile, a plating layer and a matrix have strong binding force and small internal stress, and the service life of an electrode is long.

Owner:KUNMING UNIV OF SCI & TECH

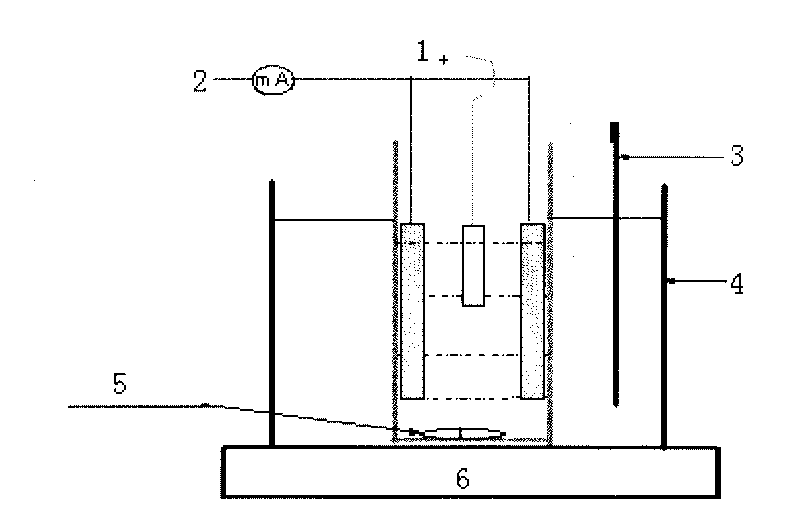

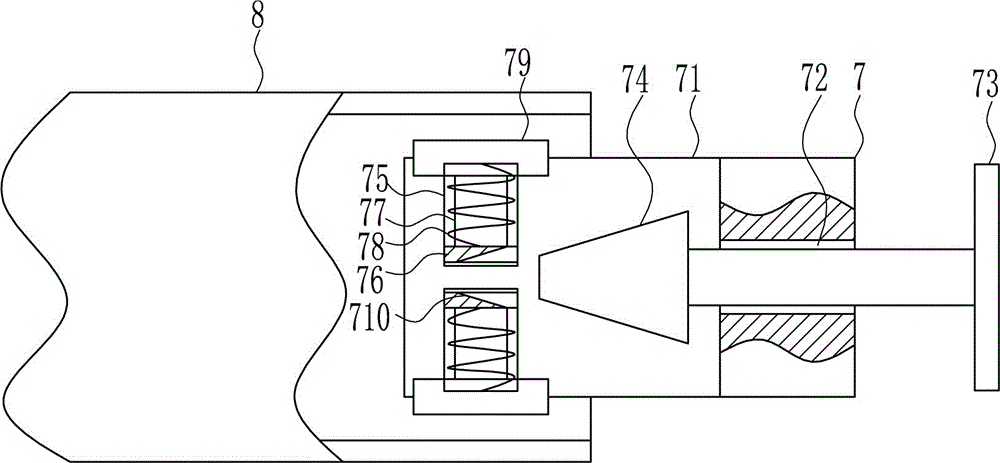

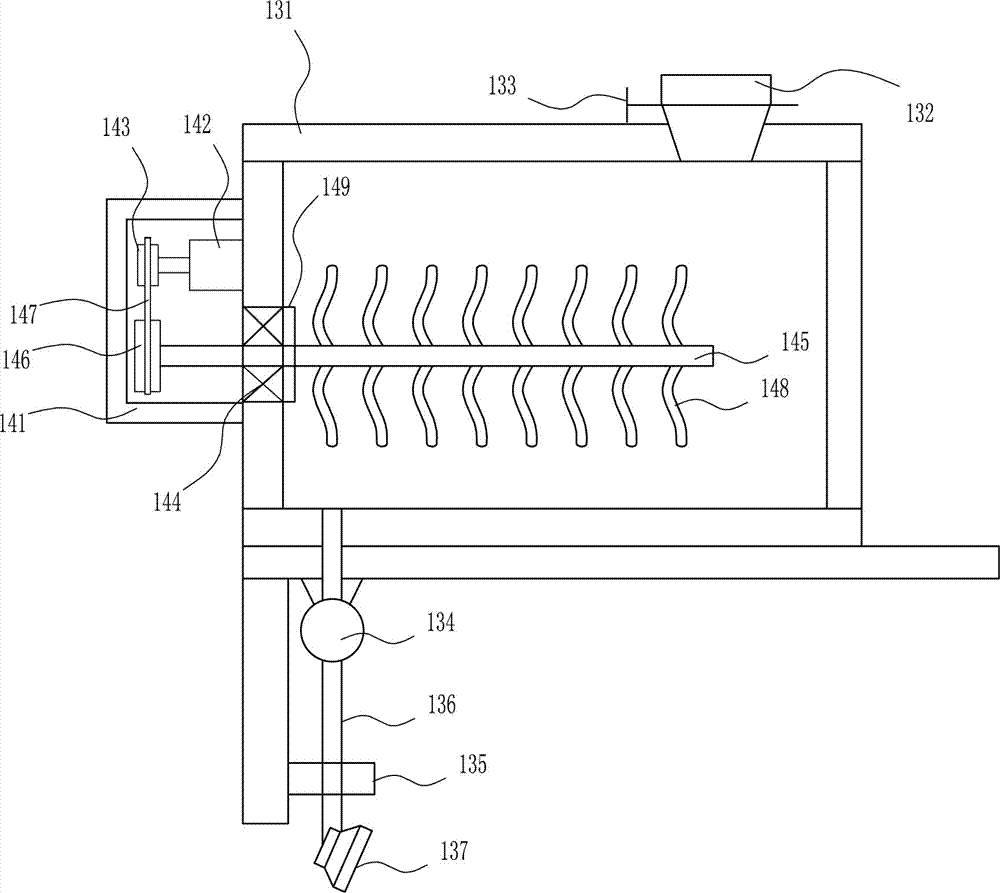

Coating spraying device for parts of agricultural machinery

InactiveCN107225065AStir wellImprove spraying effectLiquid surface applicatorsLiquid spraying apparatusAgricultural engineeringAgricultural machinery

The invention relates to a spraying device, in particular to a paint spraying device for parts and components of agricultural machinery. The technical problem to be solved by the present invention is to provide a paint spraying device for parts of agricultural machinery with high efficiency and good spraying effect. In order to solve the above-mentioned technical problems, the present invention provides such a paint spraying device for parts and components of agricultural machinery, including a bracket, etc.; The middle part of the side is connected with a stirring mechanism, the right side of the stirring mechanism is connected with the left wall of the bracket, the upper part of the spraying box is provided with a spraying mechanism, and the left side of the front part of the spraying box is connected with a box door through a hinge connection. The invention designs a paint spraying device for parts of agricultural machinery, which is provided with a stirring mechanism, which can stir the paint more fully, so that the spraying effect of the parts is better, and is provided with a spraying mechanism.

Owner:刘万忠

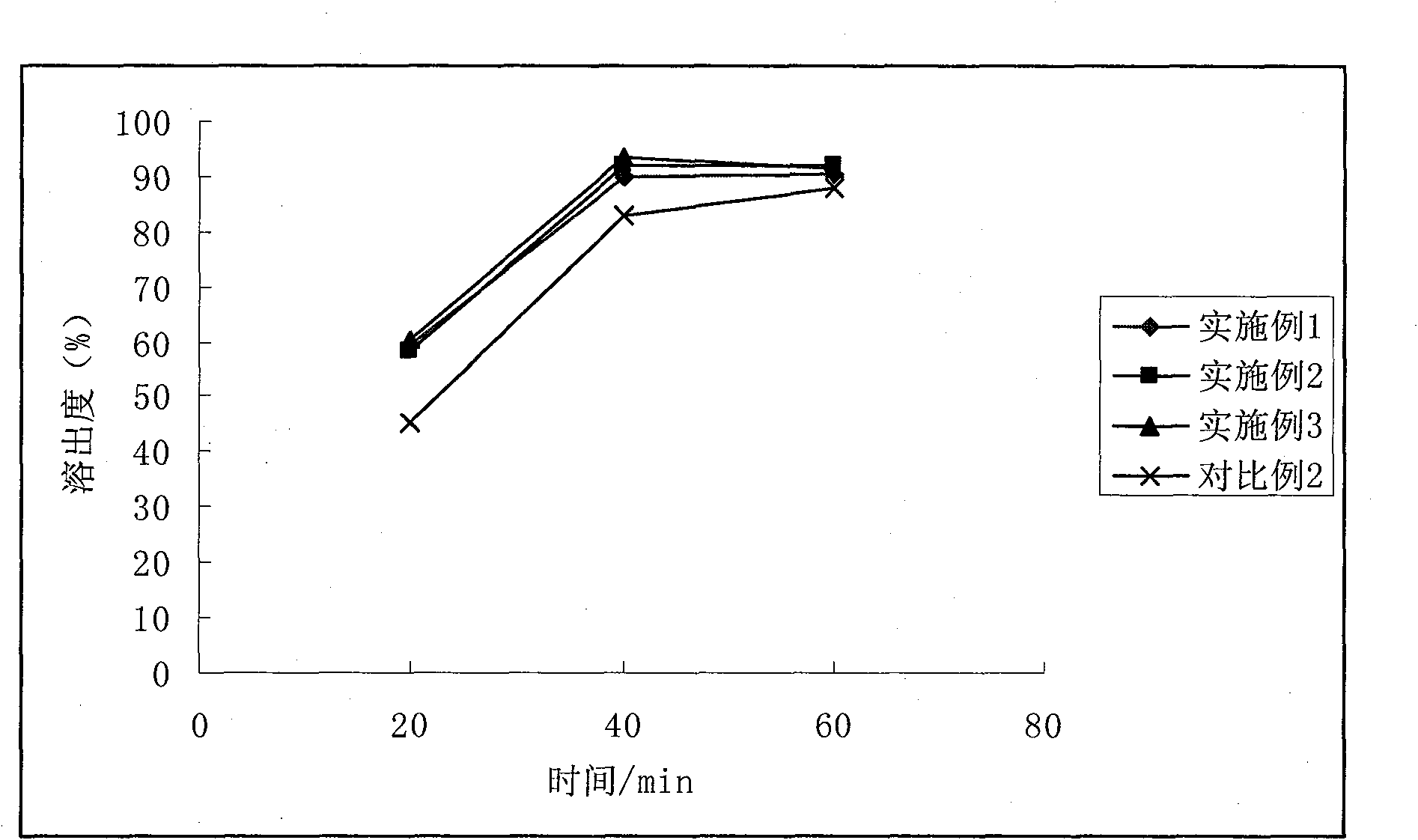

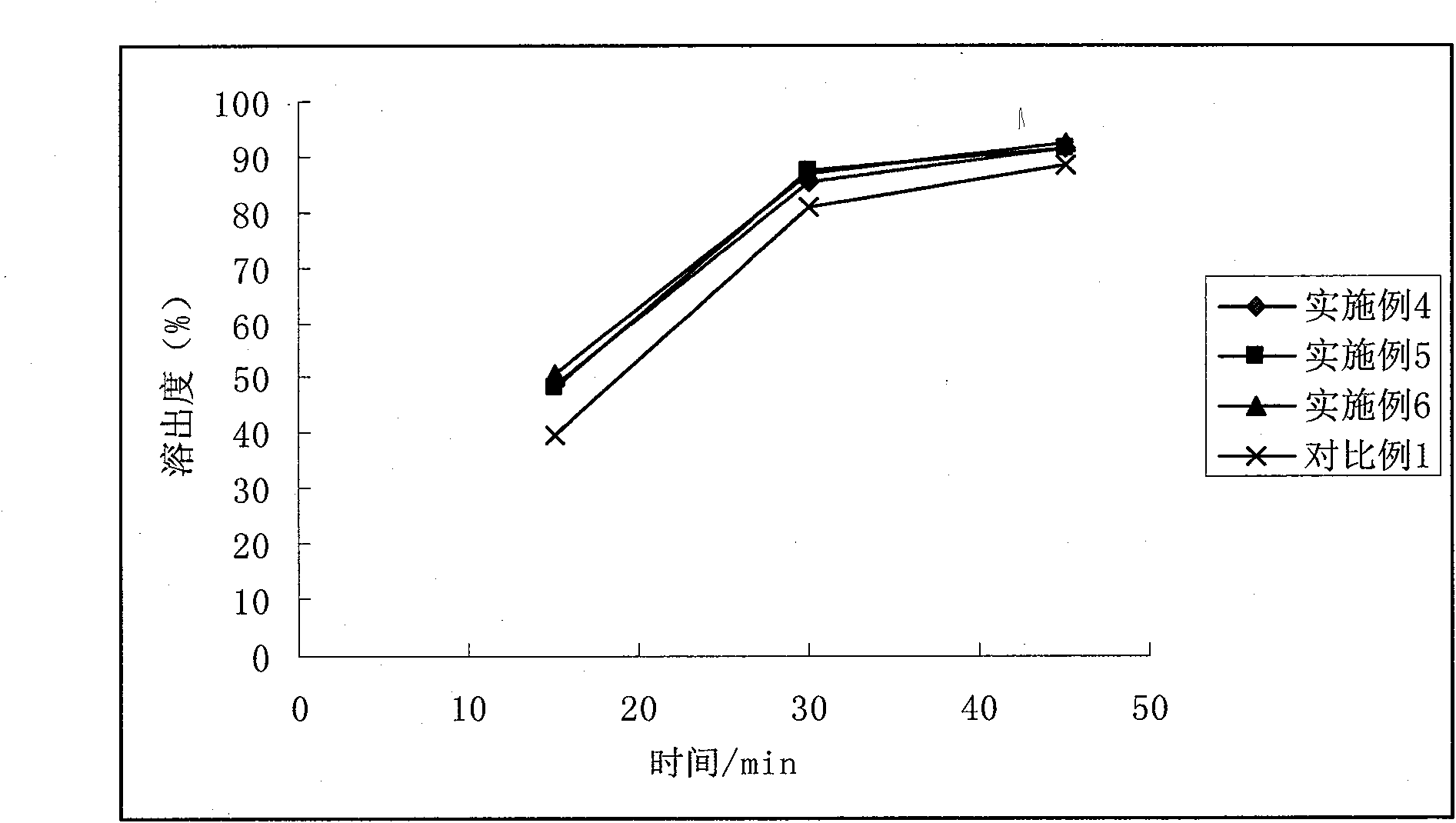

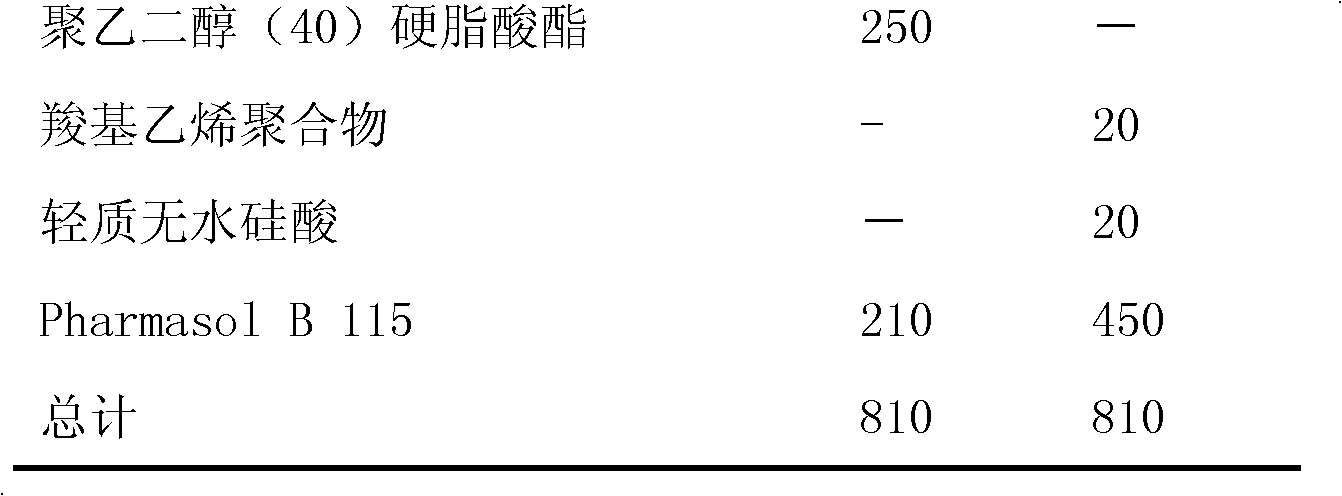

Enteric-coated pellet preparation of proton pump inhibitor and preparation method thereof

ActiveCN102119927AEvenly dispersedAvoid degradationOrganic active ingredientsDigestive systemWater solubleBioavailability

The invention relate to an enteric-coated pellet preparation of proton pump inhibitor and a preparation method thereof. The enteric-coated pellet preparation of proton pump inhibitor provided by the invention is composed of a blank pellet core, a drug-loaded layer, isolating layers (I) and (II) and an enteric-coated layer, wherein both the drug-loaded layer and the isolating layer (I) contain water soluble inorganic bases, and the base used in the drug-loaded layer contains sodium hydroxide and another water soluble inorganic base which can form buffer with sodium hydroxide in a water solution and the pH of which is in an alkaline environment of 11-12 (excluding 11). The enteric-coated pellet of proton pump inhibitor provided by the invention successfully solves the technical problems of the existing enteric-coated pellet preparation of proton pump inhibitor, and is a superior preparation with high drug loading efficiency, good anti-acid effect, high release rate, good repeatability, high bioavailability and good stability.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD

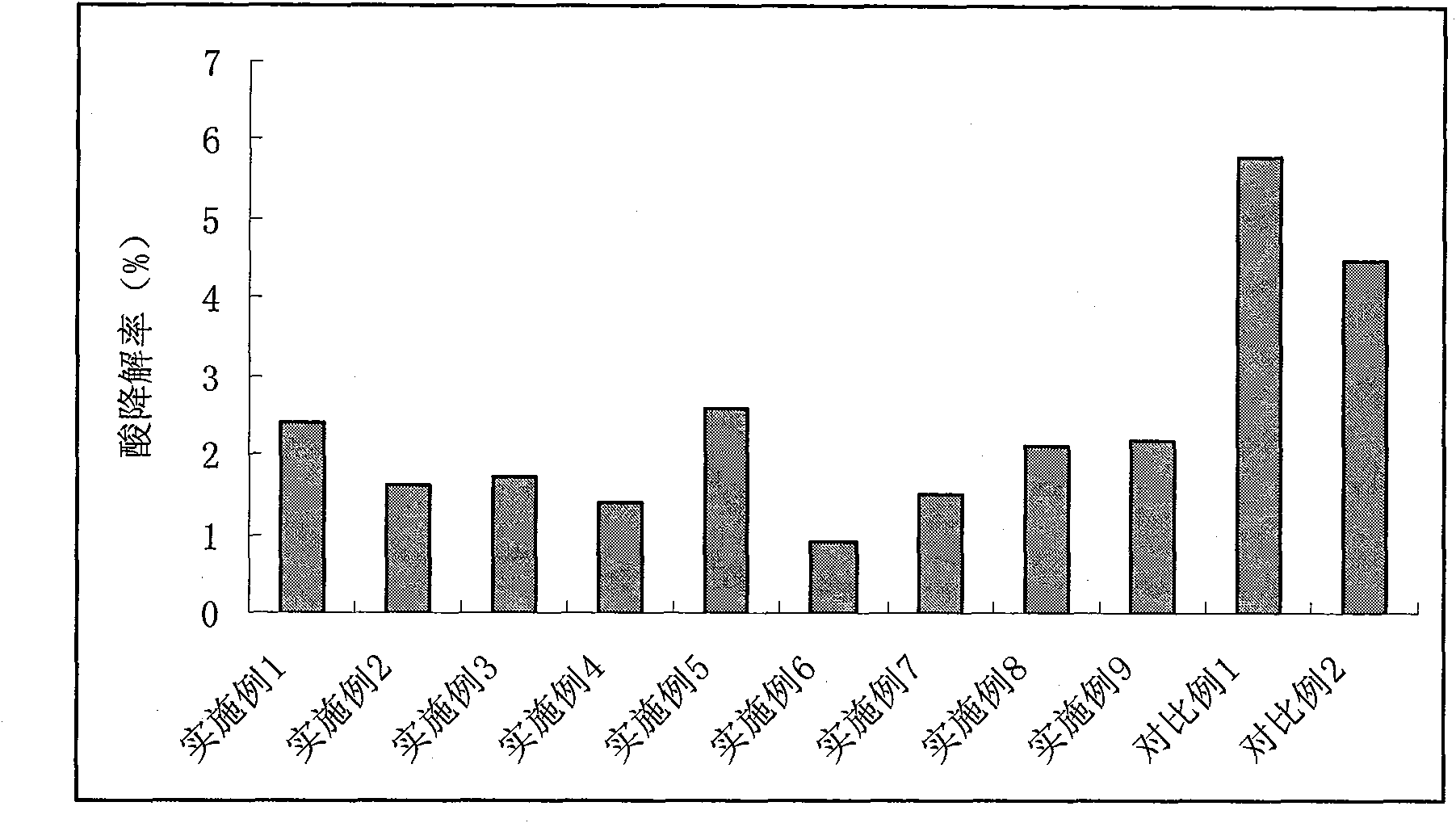

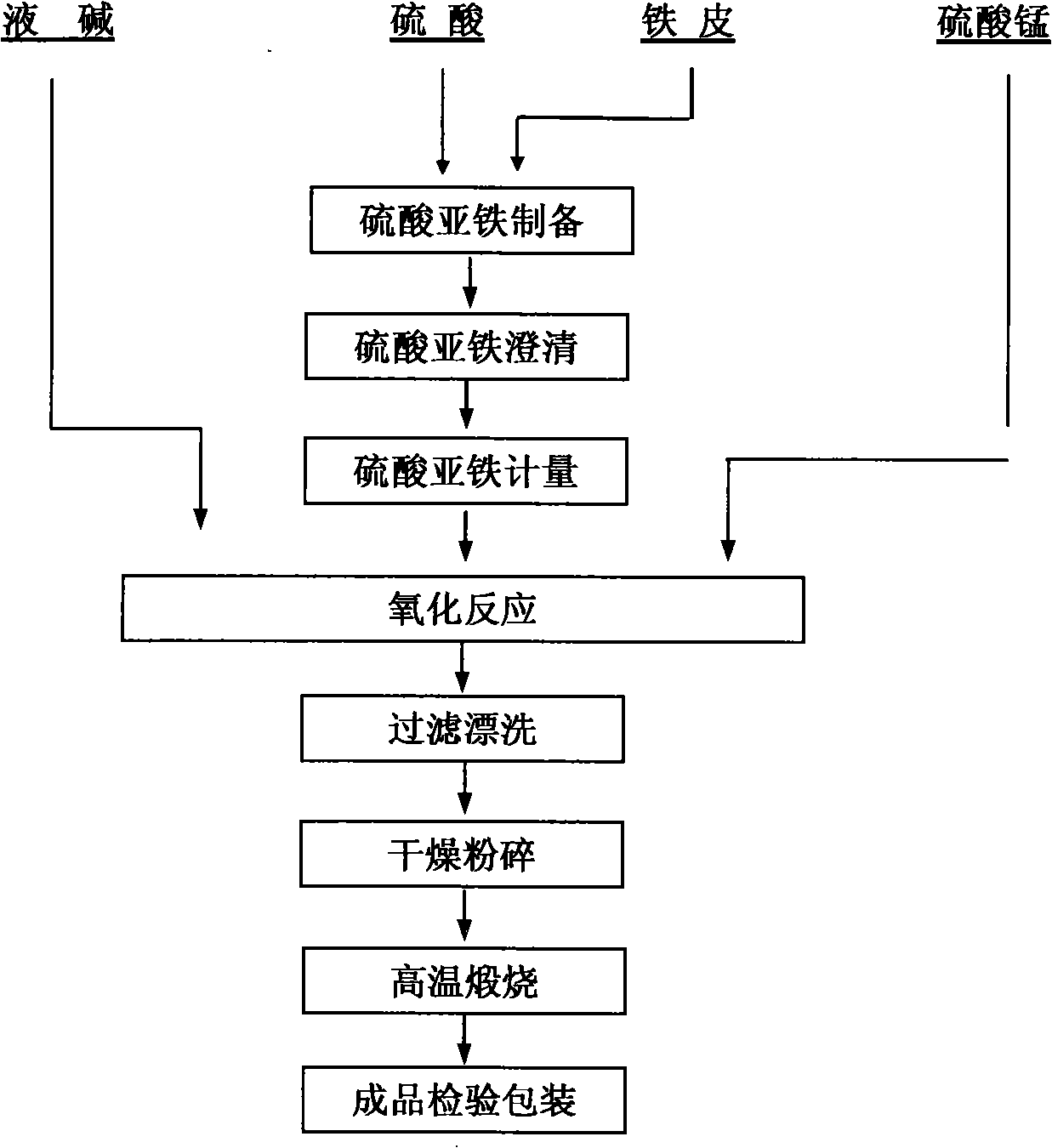

Fire resistant black iron oxide pigment and preparation method thereof

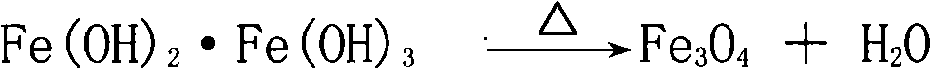

ActiveCN101314678AImprove acid resistanceGood alkali resistanceInorganic pigment treatmentFerric oxidesEngineering plasticManganese oxide

The invention relates to an inorganic iron oxide black pigment, in particular to a heat-resistant iron oxide black pigment (manganese ferrite black) and the preparation method thereof. The heat-resistant iron oxide black pigment comprises manganese ferrite black prepared from ferroferric oxide and manganese oxide by high-temperature lattice reaction, wherein the molar ratio of iron element to manganese pigment in the pigment is 1.5:1 to 5:1. The heat-resistant iron oxide black pigment has high heat resistance up to 700 DEG C or above, and can be widely used for ceramic, engineering plastic, color sand, etc., for products manufactured at high temperature, and for coloring agent for products. Meanwhile, the inorganic iron oxide black pigment has the advantages of high acid resistance, high alkali resistance and high light absorbability.

Owner:ZHEJIANG HUAYUAN PIGMENT CO LTD

Polysulfonamide nanofiltration or reverse-osmosis composite membrane, and preparation method thereof

InactiveCN107126850AHigh desalination rateImprove desalination propertiesMembranesGeneral water supply conservationSulfonyl chlorideReverse osmosis

The invention discloses a polysulfonamide nanofiltration or reverse-osmosis composite membrane, and a preparation method thereof. the preparation method for the polysulfonamide nanofiltration or reverse-osmosis composite membrane comprises the following steps: pretreatment of a porous supporting membrane; alternate layer-upon-layer assembling of a sulfonyl chloride organic-phase solution and a polyamine water-phase solution on the surface of the porous supporting membrane via reaction; heat treatment; etc.; wherein heat treatment can be carried out during or after layer-upon-layer assembling. Nanoparticles, a surfactant, a catalytic acid absorbent or catalyst, a pore forming agent and other additives are added into the sulfonyl chloride organic-phase solution and the polyamine water-phase solution. The polysulfonamide nanofiltration or reverse-osmosis composite membrane prepared by using the method has improved desalination performance and acid resistance, smoother surface and lower roughness compared with composite membranes prepared through traditional interfacial polymerization, and has good application prospects in the fields of nanofiltration and reverse osmosis.

Owner:青岛致用新材料科技有限公司

Method for preparing superfine calcium carbonate compound particles

ActiveCN102020878AUniform and stable dispersionCompact structureInorganic pigment treatmentCalcium hydroxideSlurry

The invention discloses a method for preparing superfine calcium carbonate compound particles, which comprises the following steps of: (1) introducing carbon dioxide gas or carbon dioxide-containing gas in suspension of calcium hydroxide, and reacting to obtain slurry containing superfine calcium carbonate particles; (2) when the pH value is reduced to be between 7.1 and 10.5, adding soluble aqueous solution of silicate, so that the pH value in a reaction system is between 7.5 to 9.5, after adding the silicate, stopping introducing the carbon dioxide-containing gas, aging at the temperature of between 40 and 90 DEG C for 0.5 to 3 hours, and introducing the carbon dioxide-containing gas until the pH value is between 6.5 to 7.0; and (3) filtering the obtained serous fluid, and washing by water to obtain the products. By the method, silicon dioxide can be subjected to film-forming cladding on the surface of calcium carbonate uniformly; and the method is simple in operating conditions, and the prepared calcium carbonate compound particles have the advantages of compact structures, high acid-resisting capacity, high dispersibility and low cost.

Owner:建德华明科技有限公司

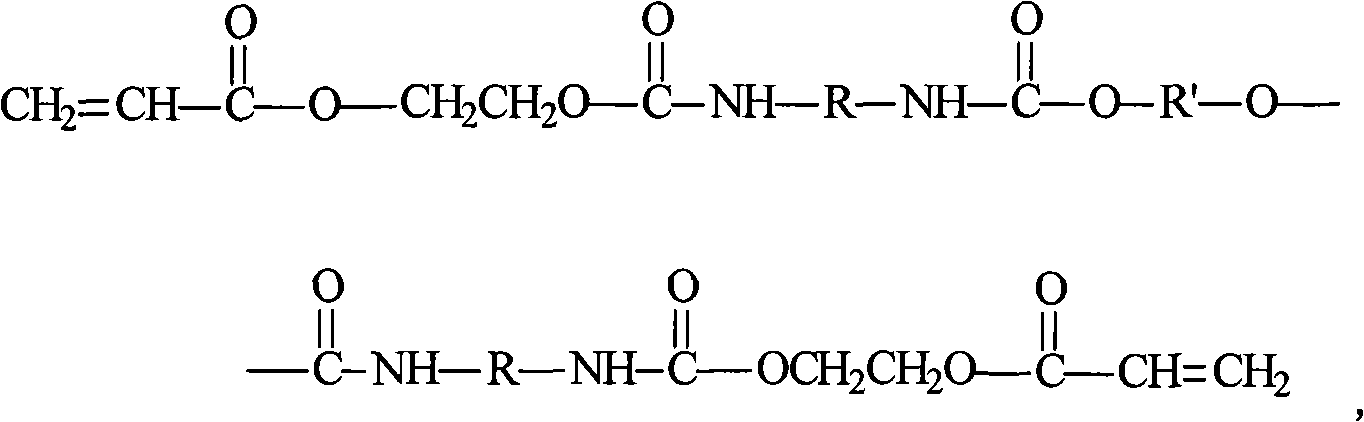

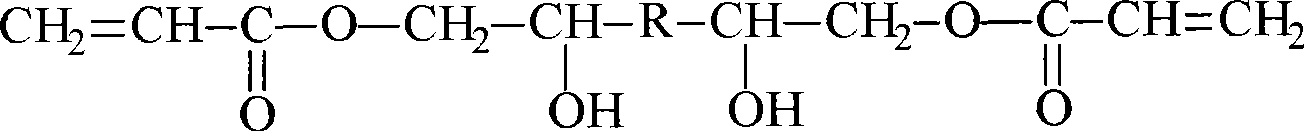

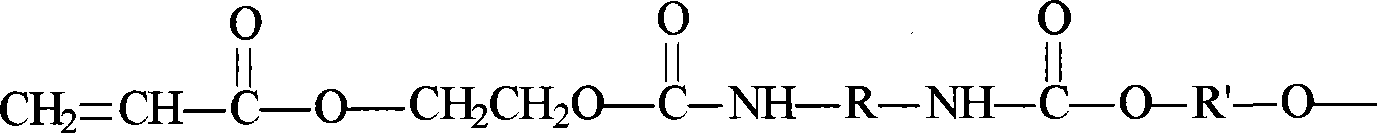

Ultraviolet-heat dual curing polyaniline anti-corrosive paint and preparation method thereof

ActiveCN101418146ANo emission issuesNo pollution problemAnti-corrosive paintsPolyurea/polyurethane coatingsUltravioletChromium

The invention provides an ultraviolet-thermal double curing polyaniline anti-corrosive coating and a preparation method thereof. In the coating, polyaniline is adopted as a main anti-corrosive material, and oligomer, a reactive diluent, polyurethane polylol, polyaniline, filler, light trigger and an auxiliary agent are used for preparing filtrate of the coating; and the filtrate and a polyurethane curing agent are stored respectively and uniformly mixed in proportion for use. The anti-corrosive paint has good anti-corrosive effect on different metals, not only can perform ultraviolet curing crosslinking but also can perform thermal curing crosslinking, well overcomes the defect of incomplete curing of an ultraviolet curing anti-corrosive paint, has the characteristics of resisting acid medium corrosion and alkali medium corrosion, is suitable to be used under the condition of a severe environment and particularly suitable for corrosion protection under the condition of a marine environment, does not contain heavy metals such as plumbum, chromium and zinc, and simultaneously does not contain any organic solvent in a formula. Therefore, the coating does not have the problem of environmental pollution during the production process and the use process, and is a completely environment-friendly coating.

Owner:中科应化(长春)科技有限公司

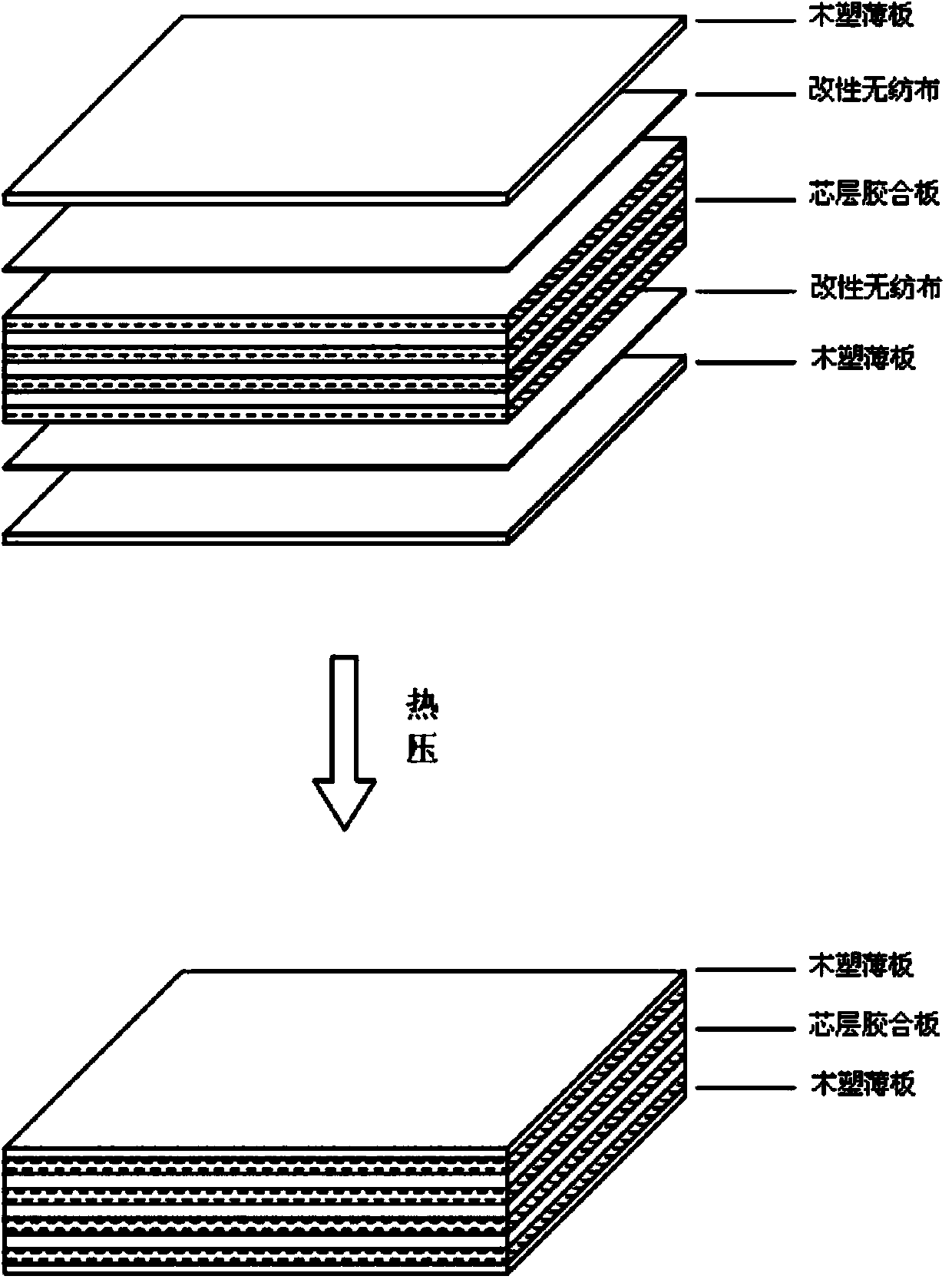

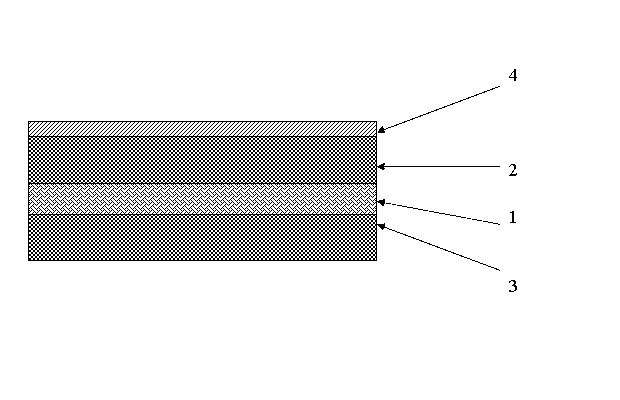

Wood plastic composite material cladding plywood formwork and manufacturing method thereof

ActiveCN103758340AReduced flatness errorGood dimensional stabilityFibre treatmentSynthetic resin layered productsPlastic filmToughness

The invention relates to a plywood formwork and a manufacturing method of the plywood formwork, in particular to a wood plastic composite material cladding plywood formwork and a manufacturing method of the wood plastic composite material cladding plywood formwork. The wood plastic composite material cladding plywood formwork aims to solves the problems that a wood plywood formwork manufactured in the prior art is low in intensity and poor in durability. The wood plastic composite material cladding plywood formwork is formed by a wood plastic sheet, an improved non-woven fabric and core-layer plywood in a manufactured mode. The manufacturing method comprises the steps that the wood plastic sheet is manufactured; the non-woven fabric is improved; the core-layer plywood is manufactured; pavement is carried out; the formwork is formed. The wood plastic composite material cladding plywood formwork is low in manufacturing cost, high in intensity, good in toughness, long in service life, resistant to moisture and corrosion, stainless, bright, clean and flat in surface, light in weight, and convenient to transport and construct, a die does not swell easily, and the die is released easily. The wood plastic composite material cladding plywood formwork is used as a building formwork.

Owner:NORTHEAST FORESTRY UNIVERSITY

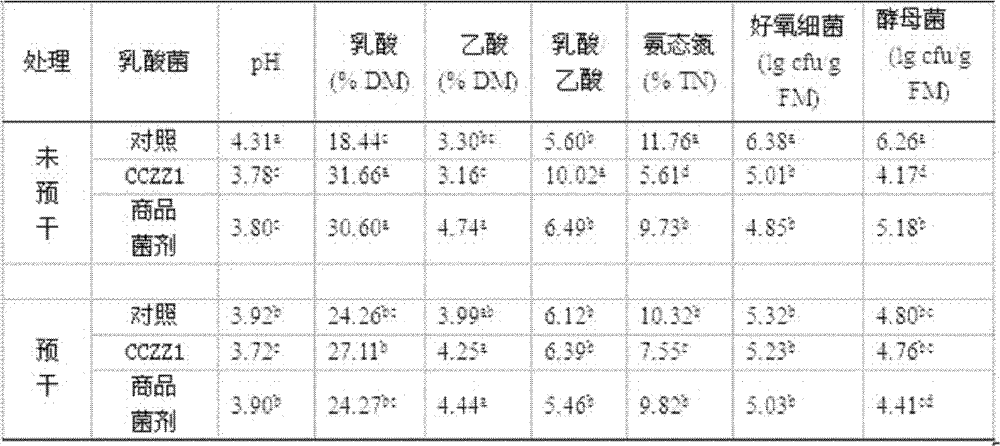

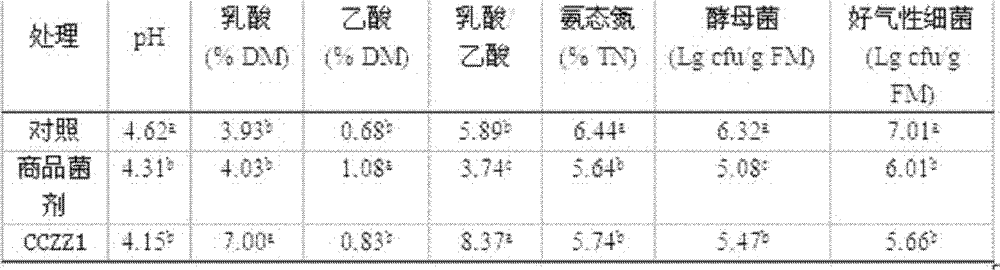

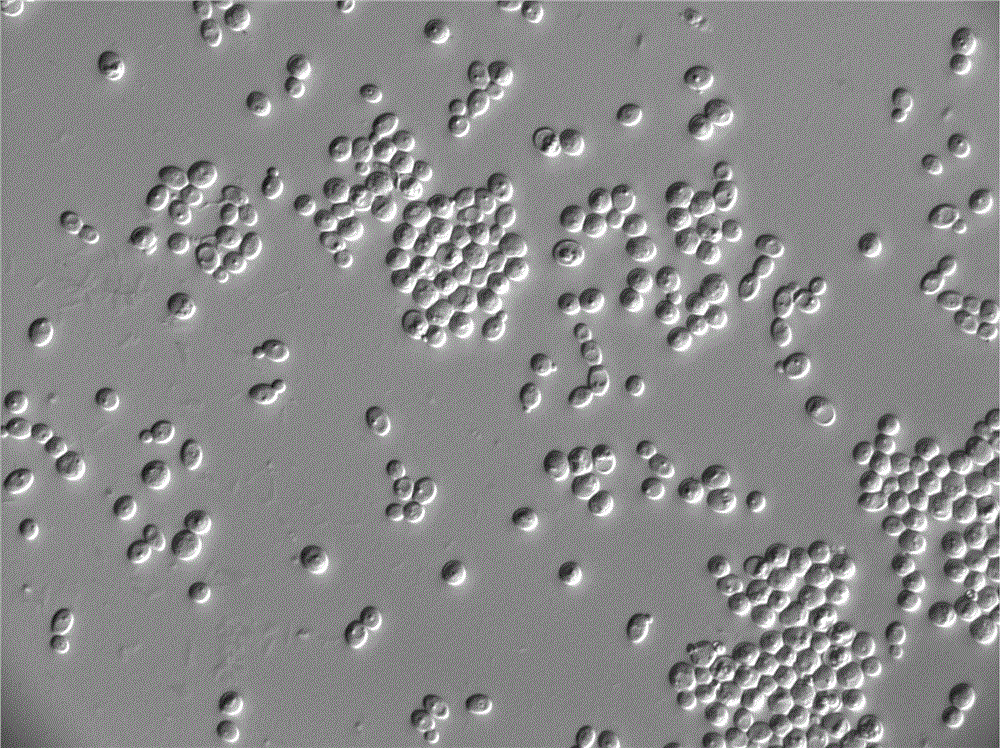

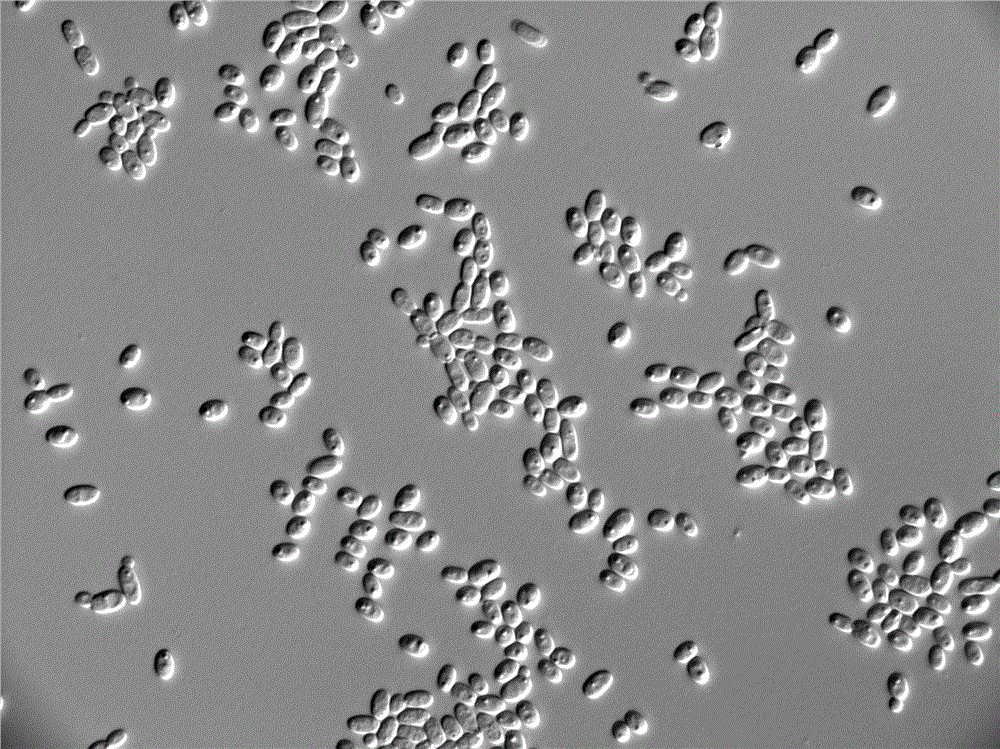

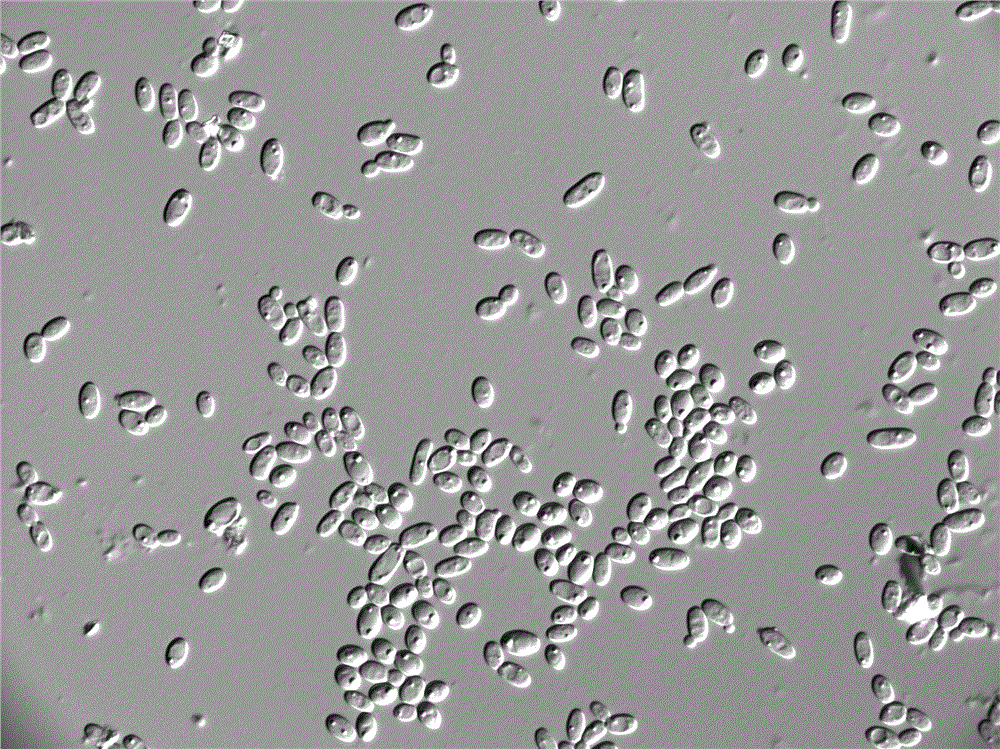

Low-temperature-resistant lactobacillus strain lactobacillus plantarum CCZZ1 and application thereof

ActiveCN102851233AStrong acid resistanceFast growthBacteriaAnimal feeding stuffMicrobiological cultureStain

The invention discloses a low-temperature-resistant lactobacillus strain which is lactobacillus plantarum CCZZ1, and an application thereof. The lactobacillus strain provided by the invention is collected at China General Microbiological Culture Collection Center with an address of Institute of Microbiology, Chinese Academy of Sciences, No.3, Court 1, West Beichen Road, Chaoyang District, Beijing. The strain has a collection number of CGMCC NO. 6078. A collection date is May 3rd, 2012. The lactobacillus strain provided by the invention is a Gram stain positive bacilli. The lactobacillus strain is glucose-homofermentative, and is acid-resisting. The strain has high growth speed and wide reproductive temperature range. With the strain, under a low-temperature or normal-temperature environment, silage fermentation quality can be substantially improved.

Owner:SOUTH CHINA AGRI UNIV

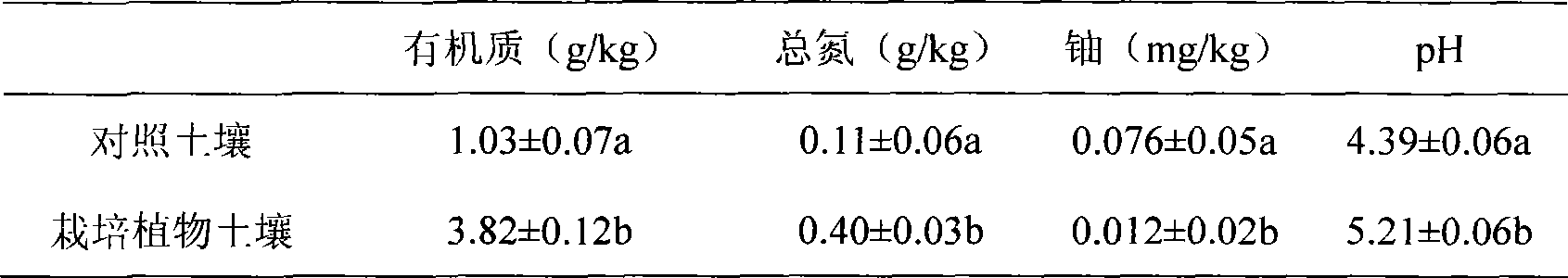

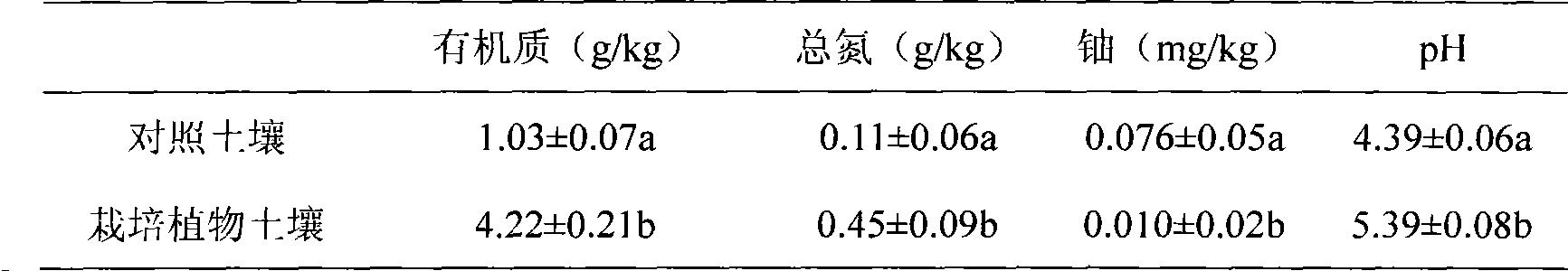

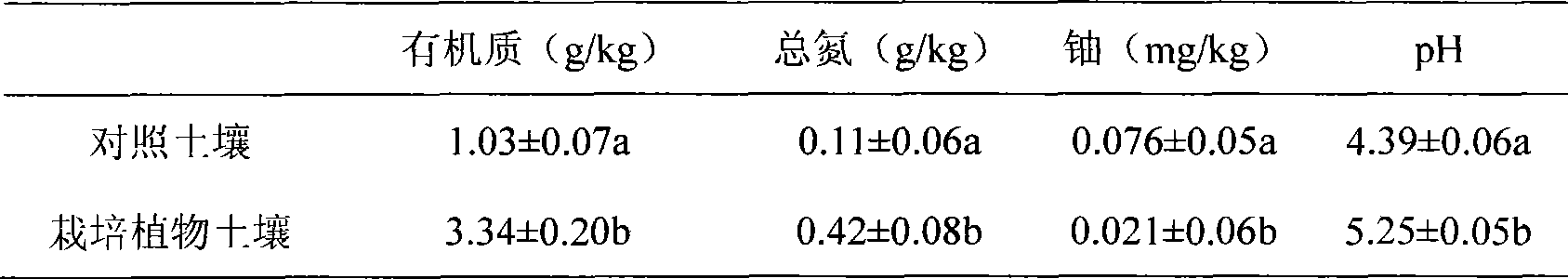

Method for repairing and improving soil polluted by uranium mine tailings

InactiveCN101502843AEnhanced efficiency of fixing uraniumInhibit migrationContaminated soil reclamationAeschynomene indicaVegetation

The invention discloses a method for restoring and improving uranium tailing residues-contaminated soil, the employed materials comprise Aeschynomene indica, Miscanthus floridulus and Imperatacylindrica, plant ash and cow dropping, the plant ash is made by burning the Miscanthus floridulus and the Imperatacylindrica. The plant ash and the cow dropping is formulated into a mixed fertilizer in accordance with a proportion to be fertilized in a plant ditch that is built in uranium tailing residues-contaminated region, the three plants of the Aeschynomene indica, the Miscanthus floridulus and the Imperatacylindrica are planted in groups in the plant ditch. By using the method, dense vegetation can be constructed in a very short time to prominently increase soil nitrogen, organic matters and pH value, and meanwhile, the soil root density is increased and the content of soil water-soluble uranium is reduced obviously. The method has the advantages of simple operation, low cost, good efficiency of preventing the uranium from transfer and diffusion, and beautifying the environment. The technique can be used in reconstructing vegetation in a degraded ecosystem of mines and greening expressways.

Owner:HUNAN UNIV OF SCI & TECH

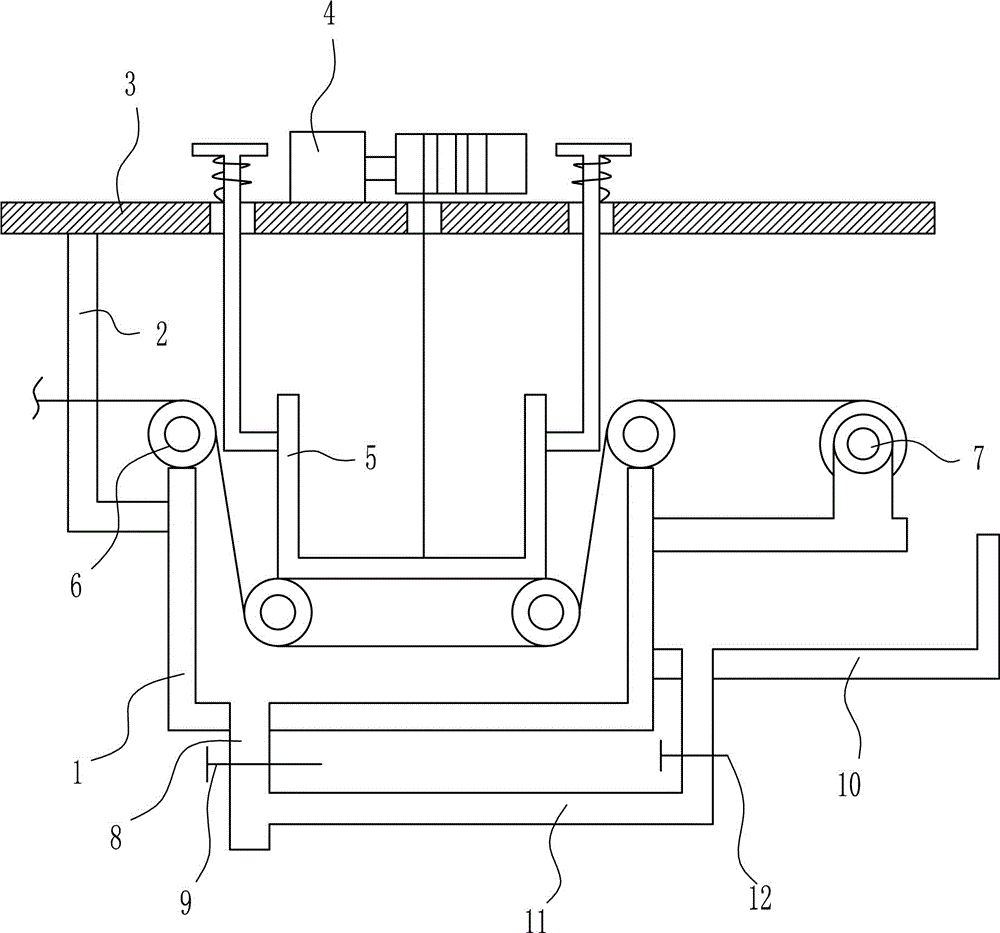

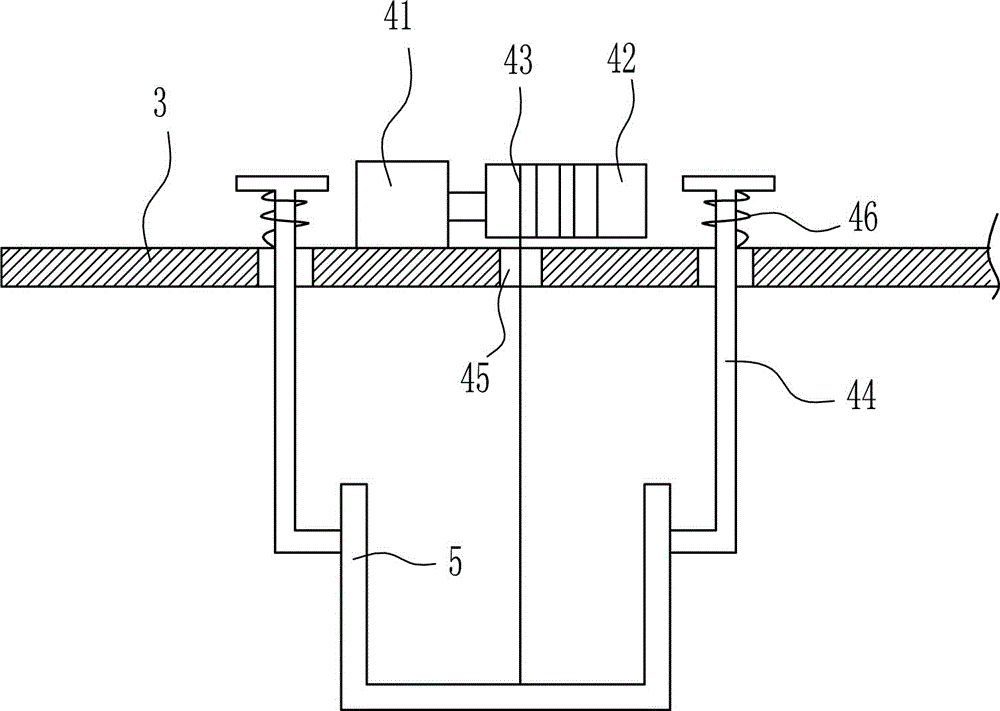

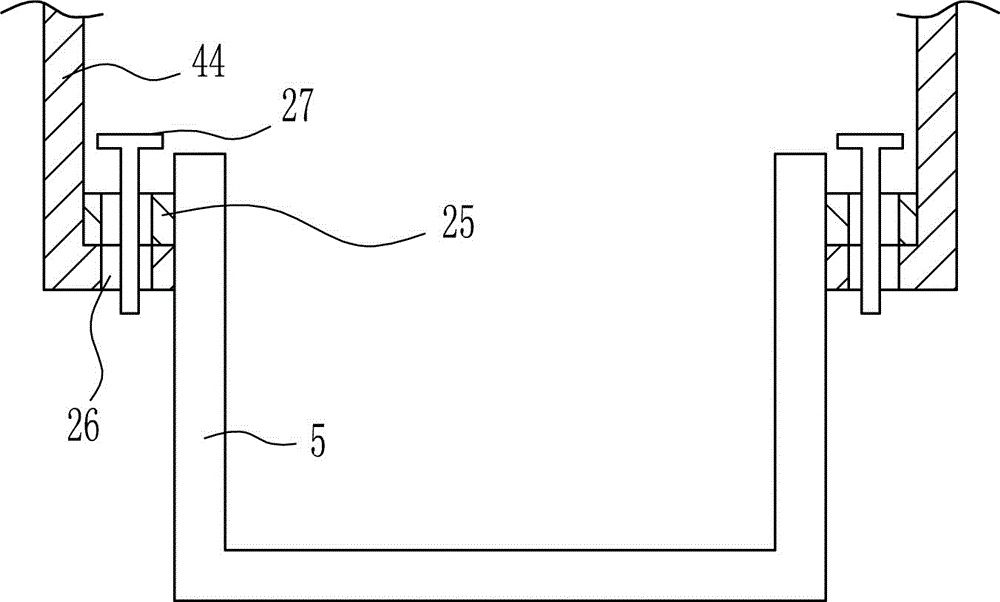

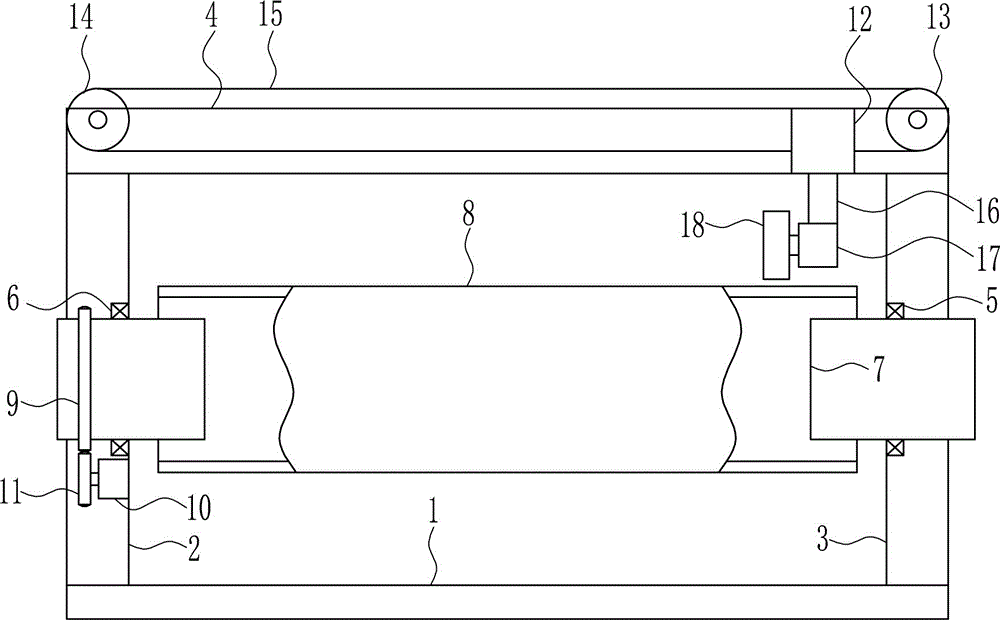

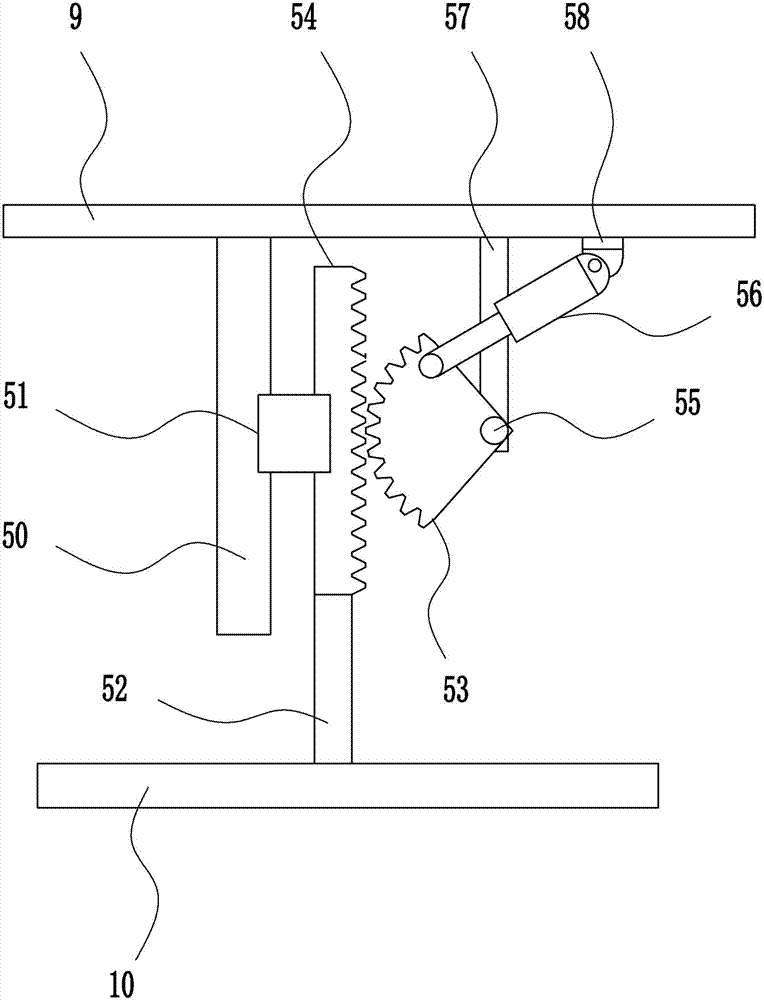

Non-woven lifting dye device for garment production

InactiveCN106835555AEasy to dyeEasy to rewindTextile treatment machine arrangementsTextile treatment carriersNonwoven fabricMechanical engineering

The invention relates to a dye device, particularly relates to a non-woven lifting dye device for garment production, and aims at solving the technical problem of providing a non-woven lifting dye device for garment production, which is capable of flatly putting non-woven into a dye for dyeing. In order to solve the technical problem, the invention provides the non-woven lifting dye device for garment production. The non-woven lifting dye device for garment production comprises a dye box, a connecting rod, a support rod, a lifting mechanism, a lifting frame, a guide roller and the like, wherein the upper part of the left side outside the dye tank is connected with the connecting rod; the top of the connecting rod is connected with the support rod; the support rod is connected with the lifting mechanism; and the lower side of the lifting mechanism is connected with the lifting frame. Through the lifting mechanism, the targets of driving the lifting frame to descend through the lifting mechanism, driving the guide roller at the inner side to descend through the lifting frame and flatly pressing the non-woven into the dye box for dip dyeing through the guide roller at the inner side are achieved.

Owner:绍兴金祥惠纺织印染有限公司

Metal bipolar plate for proton exchange membrane fuel cell and preparation method thereof

ActiveCN101800318AImprove conductivityImprove output performanceCell electrodesInternal resistanceProton exchange membrane fuel cell

The invention discloses a metal bipolar plate for a proton exchange membrane fuel cell. A modifying layer is arranged on the surface of the metal bipolar plate and comprises a metallic titanium intermediate layer contiguous to a metal substrate and a carbon-based film composite layer on the metallic titanium intermediate layer. The carbon-based film composite layer on the metallic titanium intermediate layer is a carbon-based film composite layer which is formed by mixing carbon, titanium carbide and metallic titanium. The invention has the advantages that a metal bipolar plate matrix is provided with multilayer protection; protective layers can be mutually compensated, so that the bipolar plate has extremely-strong corrosion resistant performance and thereby remarkably prolongs the service life of the bipolar plate; meanwhile, the bipolar plate has excellent conductive performance, can remarkably reduce the internal resistance of the proton exchange membrane fuel cell and improve the output performance of the cell; and the modifying layer has low cost, which is beneficial to reduce the cost of the whole fuel cell system, thereby improving the overall competitiveness.

Owner:SUNRISE POWER CO LTD

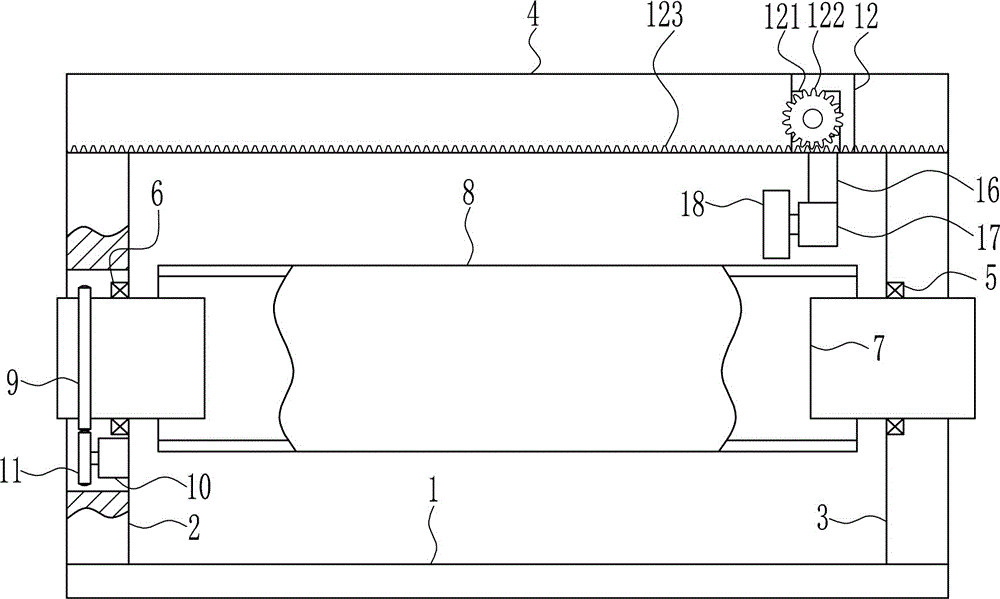

Polishing equipment for industrial steel pipe

InactiveCN106425818AHighly corrosiveStrong acid resistancePolishing machinesGrinding drivesIndustrial engineering

The invention relates to apolishingequipment, in particular to a polishing equipment for industrial steel pipes, and provides a polishing equipment for industrial steel pipes polishing uniformly, having less harm to people and saving both time and effort. In order to solve the technical problems, the invention provides the polishing equipment for industrial steel pipe. The polishing equipment for industrial steel pipes comprises a base plate, a first support plate, a second support plate, a first sliding rail, a first bearing pedestal, a second bearing pedestal, a positioning device, a steel pipe, a first gear and a first motor. The first support plate is welded at the left side of the base plate. The second support plate is welded at the right side of the base plate. The second support plate is arranged at the right of the first support plate. The polishing equipment for industrial steel pipes achieves the effect of uniform polishing, less harm to people and saving both time and labor during polishing through rotating steel pipes and moving polishing wheels.

Owner:南昌安润科技有限公司

Compound filter material for high-temperature flue gas bag-type dust removal system and preparation method of same

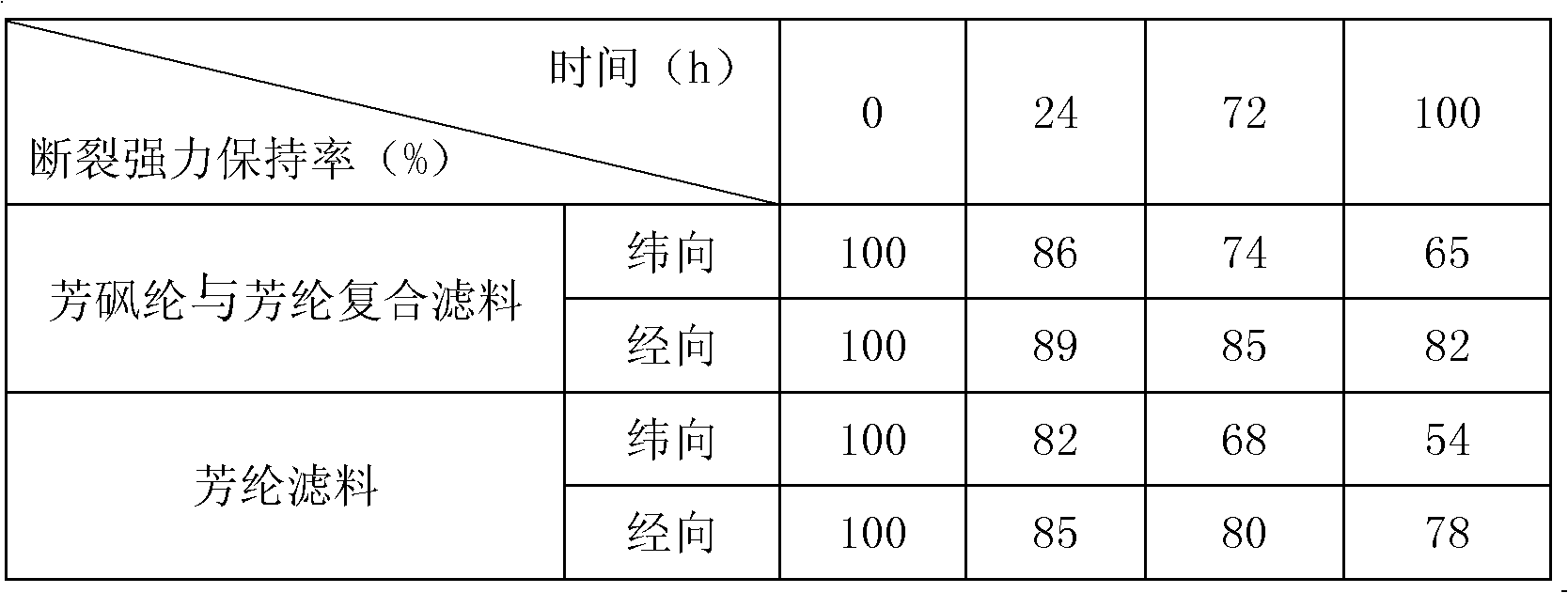

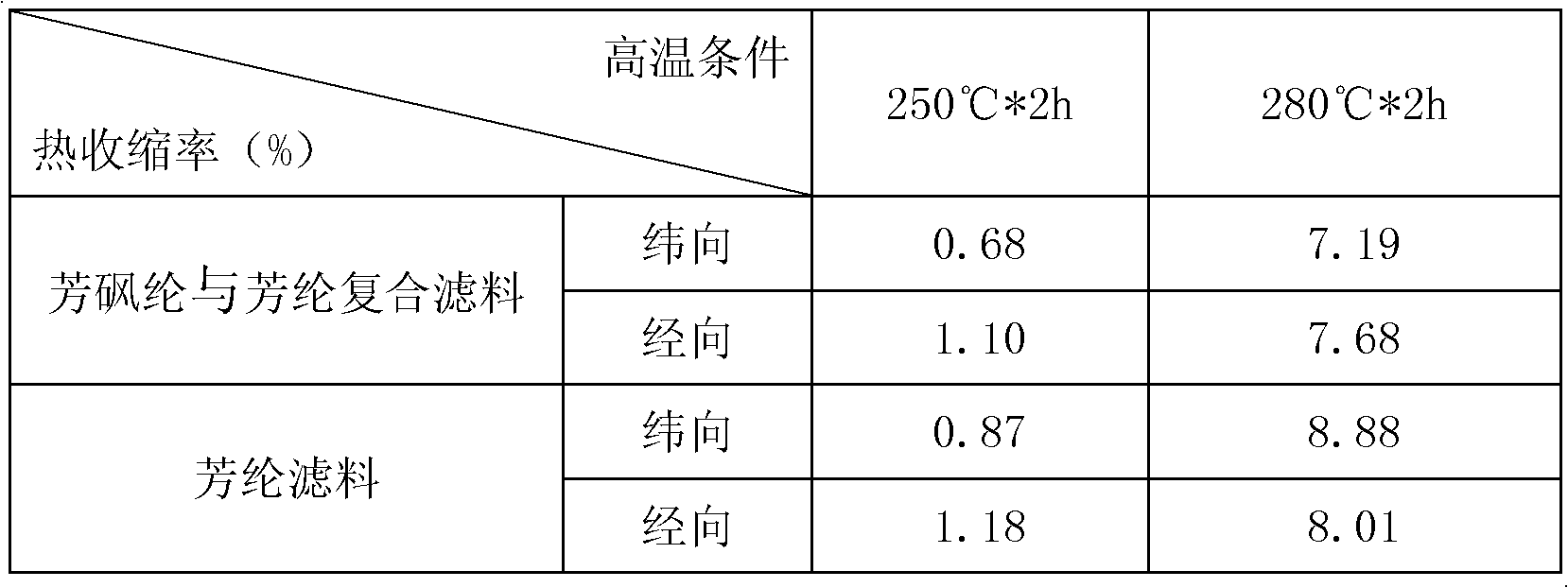

ActiveCN102872649AHigh strengthImprove stabilityLamination ancillary operationsDispersed particle filtrationYarnChemical industry

The invention provides a compound filter material for a high-temperature flue gas bag-type dust removal system and a preparation method of the compound filter material, belongs to the field of the chemical industry and solves the technical problems of high heat shrinkage, poor high temperature impact resistance, high system running resistance and short service life of a filter bag of a bag-type of a filtering material product of a bag-type dust collector. The compound filter material comprises a base fabric, wherein the base fabric is formed by weaving polysulfonamide and aramid blended yarns; a dust facing surface formed by polysulfonamide and aramid mixed fibers is arranged on the upper surface of the base fabric; a bottom layer formed by the polysulfonamide and aramid mixed fibers is arranged on the lower surface of the base fabric; and the dust facing surface, the base fabric layer and the bottom layer are connected by closing splinters. The preparation method disclosed by the invention comprises a process of compounding the air-laid and acupuncture / hydroentangle combination base fabric with the polysulfonamide and aramid mixed fibers. The filter material disclosed by the invention has high strength; the high temperature strength stability and the high temperature size stability of the filter material disclosed by the invention are obviously superior to those of an aramid filter material; and the compound filter material resists to the impact of 250 DEG C to 280 DEG C high temperature flue gas and the impact of high temperature particles.

Owner:AFCHINA CORP CO LTD

Flame-retardant fabric

The invention relates to a flame-retardant fabric, which is made of fiber materials, and specially comprises fiber materials in a weaving, knitting or non-woven form. The flame-retardant fabric is prepared by using a flame-retardant process, and the main ingredients of the flame-retardant fabric include a low molecular pre-shrinking body of tetrakis hydroxymethyl phosphonium sulfate (THPS) and amide, a surfactant, a flame-retardant finishing liquid of high-concentration polyethylene, so that the flame-retardant fabric has a durable flame retardant performance, and the flame retardant performance is not reduced with the increasing of the number of washing times; the flame-retardant finishing does not change the original features of the fabric fibers, so that the fabric is soft in handfeel, and small in strength loss, and the comfortableness and durability of the fabric are basically kept, therefore, the flame-retardant fabric has a characteristic that the fabric is carbonized after meeting fire and self-extinguished after leaving fire, and the spread of flames is effectively prevented; and the protective clothing prepared by using the fabric can prevent flames from causing harm to the human body.

Owner:魏延杰 +1

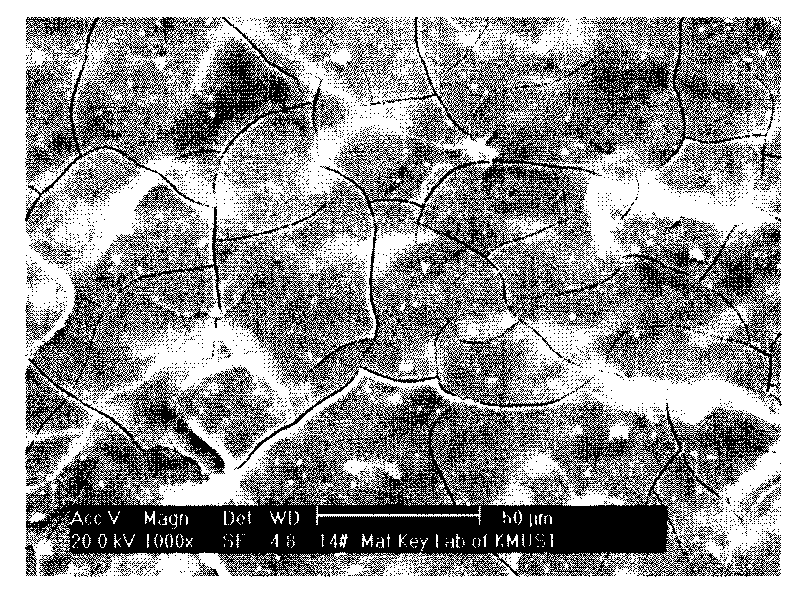

Titanium-based oxide acid resistant anode and preparation method thereof

InactiveCN102268689AStrong acid resistanceSolution to short lifeSurface reaction electrolytic coatingSolid state diffusion coatingFiberElectrolysis

The invention provides a titanium-based oxide acid resistant anode and a preparation method thereof, and specifically to an electrode catalyst used in the process of electrolysis and a preparation method thereof, belonging to the technical field of electrochemical engineering. The invention is characterized in that: the titanium-based oxide acid resistant anode is especially applicable to electrolysis with oxygen evolution and organic electrolysis and has a long life in a sulfuric acid solution; the anode comprises an electrode matrix, an intermediate transition layer and an active coating; the preparation method for the anode comprises the steps of preparing Ti / Tio2NT by electrochemical anodization in ionic liquid and forming Ti / TiO2NT / C+N+B by co-cementation of B, C and N under the catalytic cementation of rare earth at first or preparing Ti / C+N+B through surface alloying of titanium matrix and forming Ti / C+N+B / TiO2NT through anodization heat treatment at first, applying the graphite fiber loaded intermediate transition layer of Sn, Sb, rare earth and like next, and preparing the PbO2 or MnO2 active coating at last. The titanium-based oxide acid resistant anode prepared through the preparation method provided in the invention has a service life more than 160 hours.

Owner:TAIYUAN UNIV OF TECH

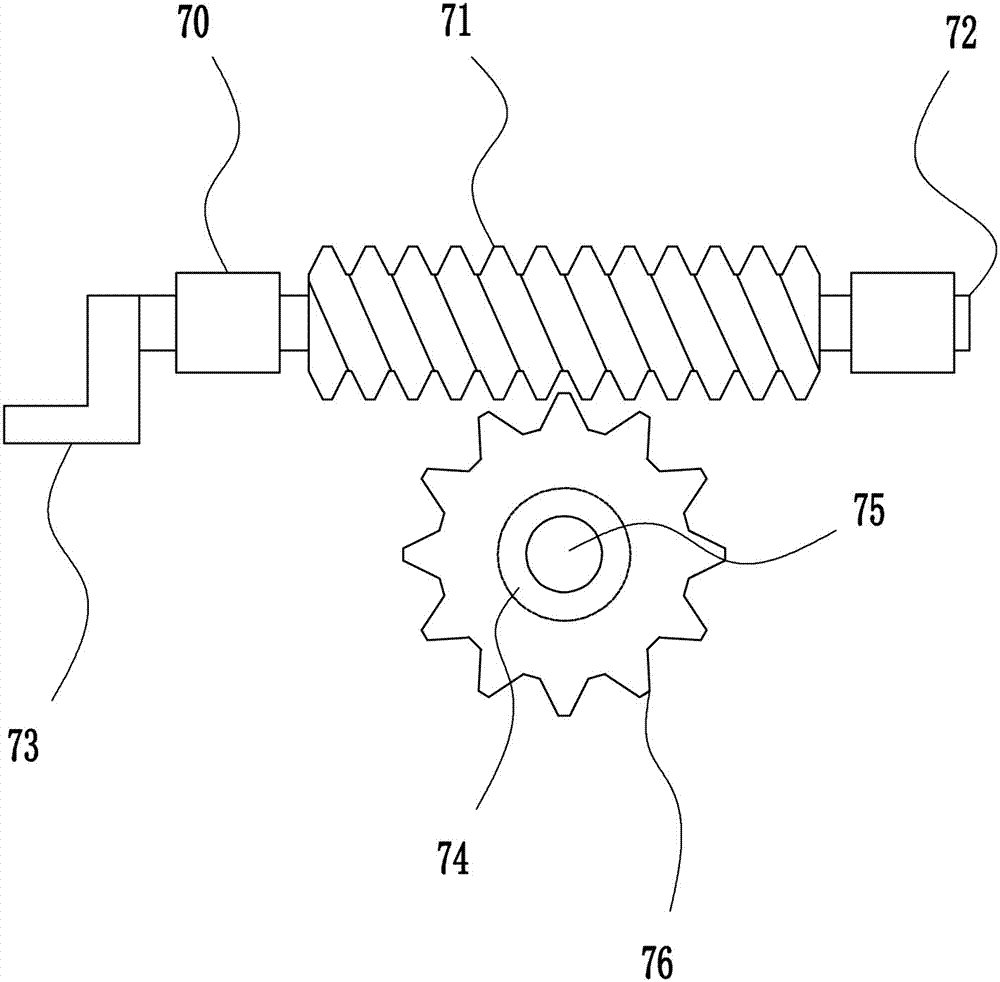

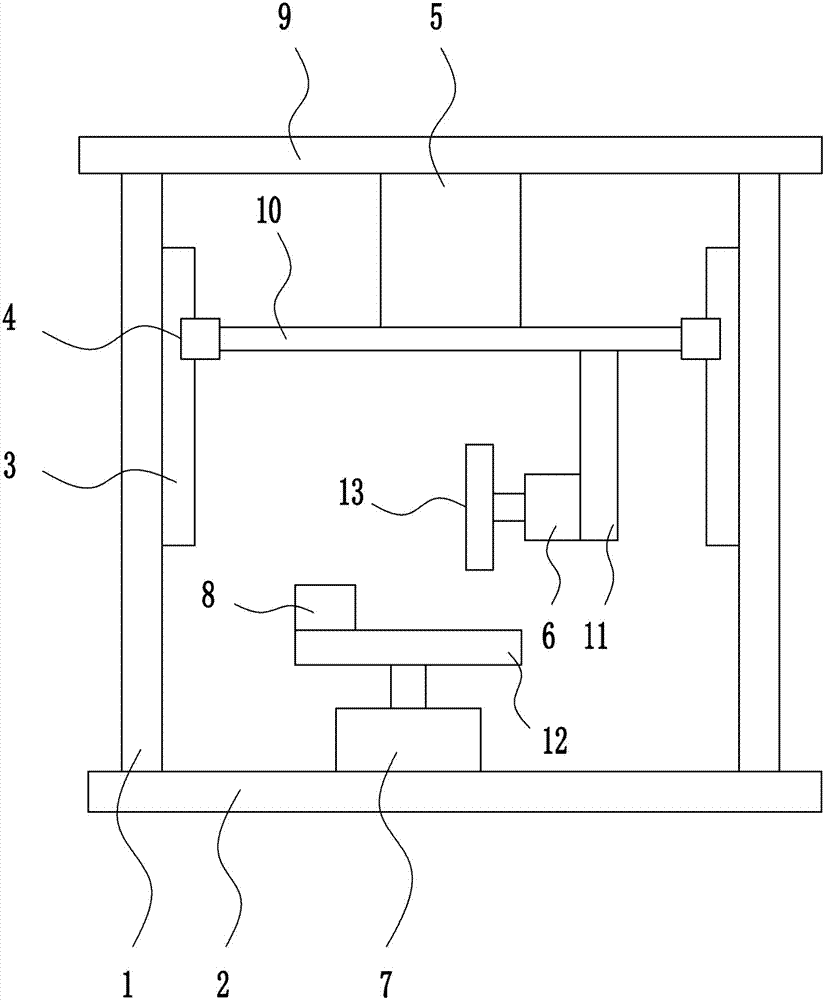

Rapid burring equipment for hardware parts

InactiveCN107042438ATo achieve the adjustment effectFlexible swingEdge grinding machinesGrinding work supportsEngineeringGrinding wheel

The invention relates to burring equipment, in particular to rapid burring equipment for hardware parts. The rapid burring equipment for the hardware parts aims at achieving the technical effects that operation is convenient, working efficiency is high, and burring is thorough. In order to achieve the technical effects, the rapid burring equipment for the hardware parts comprises supports, a bottom plate, first sliding rails, first sliding blocks, a lifting device, a first rotating device, a second rotating device, a fixing device, a top plate, a fixing plate and the like; the supports are welded to the left side and the right side of the top of the bottom plate, the first sliding rails are connected to the upper portions of the supports in a bolted connection mode, and the first sliding blocks are connected to the first sliding rails in a sliding mode. An electric push rod is controlled to stretch and retract, a fan-shaped gear is matched with a rack, the fixing plate can move up and down, the effect of adjusting the height of a grinding wheel is achieved, and a worm wheel is matched with a worm.

Owner:河北东海特钢集团有限公司

Acid-proof cathode electrophoretic paint as well as preparation method and application method

ActiveCN103865360AImprove acid resistanceGood adhesionElectrophoretic coatingsAnti-corrosive paintsEpoxyRutile

The invention discloses an acid-proof cathode electrophoretic paint as well as a preparation method and an application method. The electrophoretic paint comprises emulsion and color paste, wherein the emulsion is prepared by steps of mixing amine modified epoxy resin, a totally-closed isocyanate cross-linking agent and an emulsifying agent, uniformly stirring at the temperature of 43 DEG C to 47 DEG C, adding formic acid at the temperature of 45 DEG C to 49 DEG C to perform an acidification reaction for more than 70 minutes, subsequently adding deionized water, uniformly stirring and then filtering. The color paste is prepared by the steps of mixing quaternary ammonium dispersion resin, deionized water, dibutyl tin oxide, kaolin, carbon black, an emulsifying agent, rutile titanium dioxide and titanium-based nanometer paste, uniformly stirring at the temperature not higher than 30 DEG C, grinding the mixture at the temperature not higher than 35 DEG C by use of a grinder until the fineness is not larger than 15 microns, uniformly stirring and filtering. An application process comprises batching, preparation of a tank and an electrophoretic coating process; the preparation of the tank comprises steps of mixing 10-15 parts by weight of the color paste, 35-40 parts by weight of the emulsion and 50-75 parts by weight of the deionized water, and curing for 48-50 hours at the temperature of 28-30 DEG C; and the electrophoretic coating process comprises a step of performing electrophoresis to a to-be-coated element for 3-4 minutes under the voltage of 200V.

Owner:湖南伟邦汽车涂料有限公司

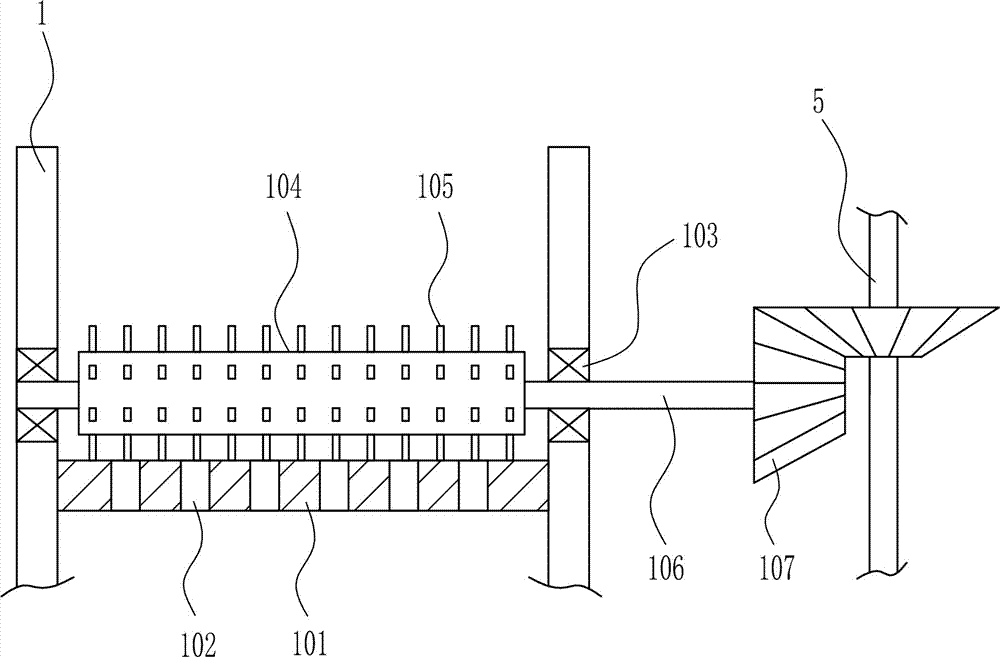

Graphite powder multi-stage grinding equipment for novel power battery production

InactiveCN107350057AFully brokenHighly corrosiveLighting applicationsMechanical apparatusPower batteryElectrical battery

The invention relates to a grinding device, in particular to a graphite powder multistage grinding device for new energy battery production. The technical problem to be solved by the present invention is to provide a graphite powder multistage grinding equipment for new energy battery production that can fully crush graphite and automatically add graphite for grinding. In order to solve the above technical problems, the present invention provides such a graphite powder multi-stage grinding equipment for new energy battery production, including a box, a filter screen, a mounting plate, a motor, a first rotating rod, a connecting rod, a storage box, etc.; The bottom wall of the box is connected with a filter screen, the lower side of the right wall of the box is connected with a mounting plate, the motor is installed on the right side of the top of the mounting plate, the output shaft of the motor is connected with the first rotating rod, and the upper side of the left wall of the box is connected with a connecting rod . The present invention designs a graphite powder multi-stage grinding equipment for new energy battery production. The first rotating rod drives the moving plate to move left and right so that the graphite is intermittently dropped from the storage box into the box.

Owner:叶世平

Method for increasing contents of total acid, total ester and reducing sugar in table vinegar by using Daqu intensified by high-ester-yield indigenous aroma-producing yeast

InactiveCN106701519AIncrease total acidIncreased reducing sugar contentMicroorganism based processesVinegar preparationYeastNitrogen

The invention belongs to the technical fields of biological materials and application thereof. In order to solve the problems that the effects of increasing yield and improving quality cannot be easily achieved by using Daqu intensified by exogenous non-indigenous yeasts, and on the contrary, the quality of vinegar is declined, the invention provides a method for increasing the contents of total acid, total ester and reducing sugar in table vinegar by using Daqu intensified by high-ester-yield indigenous aroma-producing yeast. The method comprises the steps of separating the high ester yield indigenous aroma-producing yeast, carrying out single strain activation, intensifying the Daqu, and carrying out acetic fermentation. The strain is separated out from traditional Shanxi mature vinegar Daqu, and is unique; the ester-producing ability of the strain is remarkably higher than that of commercialized angel aroma-producing yeast, so that the strain has very excellent high temperature resistance, acid resistance, ethanol tolerance and osmotolerance; after the Daqu is intensified by the strain, the problem of incompatibility of strains in a brewing process is solved; no matter the Daqu is intensified by double strains or a single strain according to the method provided by the invention in the actual production, the contents of the total acid, the total ester and the reducing sugar in the vinegar are obviously increased, and other two indexes, i.e., non-volatile acid and amino state nitrogen of the vinegar are not influenced.

Owner:SHANXI AGRI UNIV

Mulberry fruit cake

InactiveCN102125152ARetain nutrientsSmooth appearanceConfectionerySweetmeatsFruit cakeRich fruit cake

The invention provides a mulberry fruit cake which is characterized by being prepared from the following raw materials by weight percent: 20-30% of mulberry juice, 30-50% of white granulated sugar, 1-4% of pectin, 15-35% of starch syrup, 1-3% of citric acid, 0.1-0.3% of sodium citrate and 0.05-0.1% of sodium tripolyphosphate. The mulberry fruit cake is a mulberry food between jelly and soft sweet, is smooth in appearance, fine and smooth in mouth feeling and high in resilience, and effectively maintains the nutrient compositions of mulberry.

Owner:丽江得一食品有限责任公司

High-efficiency foaming agent for acidic CO2 foam fracturing system

ActiveCN103275693AHigh foaming height at room temperatureHigh foaming heightDrilling compositionFoaming agentActive agent

The invention discloses a high-efficiency foaming agent for an acidic CO2 foam fracturing system, which is applicable to a CO2 foam fracturing system of an Ordos Basin gas well. The high-efficiency foaming agent for the acidic CO2 foam fracturing system is characterized by being prepared from the following raw materials in percentage by mass: 38 to 42 percent of a zwitterionic surfactant A, 40 to 45 percent of a zwitterionic surfactant B, 5 to 8 percent of an amphoteric Gemini surfactant, 0.3 to 0.5 percent of a macromolecular polymer and the balance of a solvent. The high-efficiency foaming agent for the acidic CO2 foam fracturing system has excellent foaming performance, a good foam stabilizing effect, strong salt resistance, oil resistance, temperature resistance and acid resistance, and can meet the requirement of gas well CO2 foams on fracturing and foaming.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

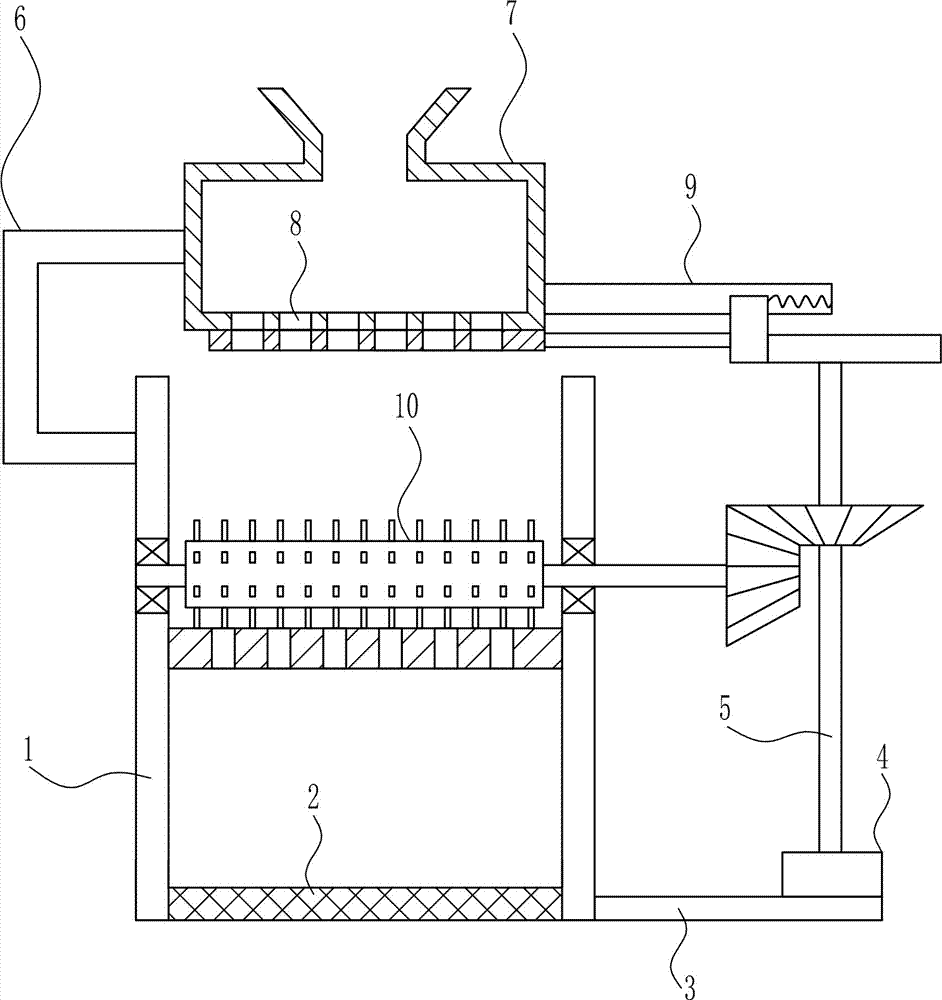

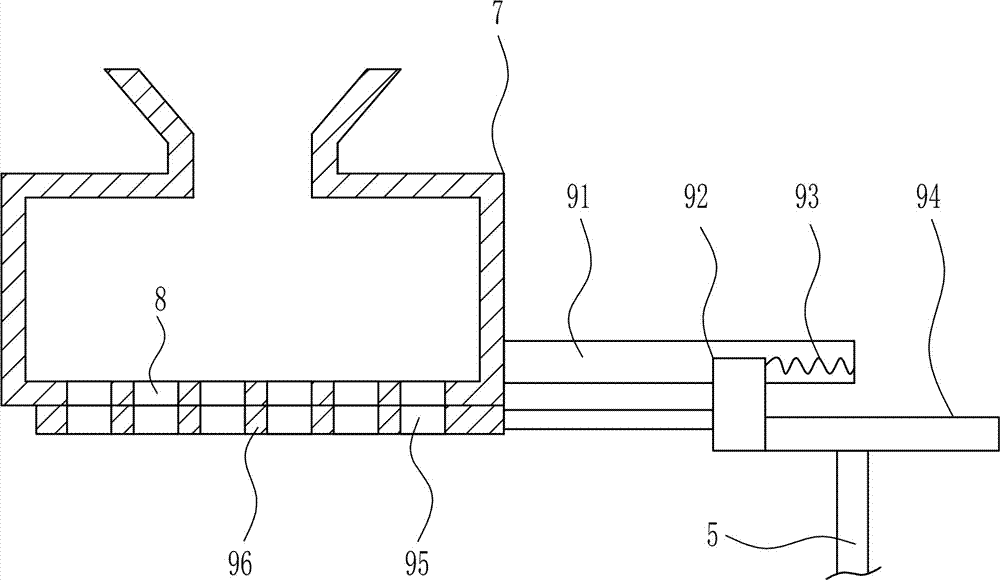

Environmental protection and deodorization equipment for household garbage transfer station

InactiveCN107010347AAchieve liftingSimple structureRefuse receptaclesRefuse cleaningEngineeringPre treatment

The invention belongs to the field of household garbage pre-treatment, and particularly relates to environmental protection and deodorization equipment for a household garbage transfer station. The environmental protection and deodorization equipment for the household garbage transfer station can purify odor, facilitate garbage disposal, and prevent microorganism from breeding, and comprises a base, a fixed plate, a top plate, rotating shafts, fixed links, a garbage can, a lifting device, a gas-collecting hood, an odor treatment device, an exhaust fan, and the like; and the fixed plate is arranged on the left side of the top of the base, a square groove is formed in the middle portion of the fixed plate, the fixed links are arranged on the front side and the back side of the middle portion of the right wall of the fixed plate correspondingly, and the rotating shafts are arranged on the middle portions of the two fixed links correspondingly. The environmental protection and deodorization equipment for the household garbage transfer station achieves the effects of purifying the odor, facilitating garbage disposal, and preventing the microorganism from breeding, and is novel in structure, environment-friendly, and beneficial to the construction of urban and rural garbage transfer stations.

Owner:江西太赫兹环保科技有限公司

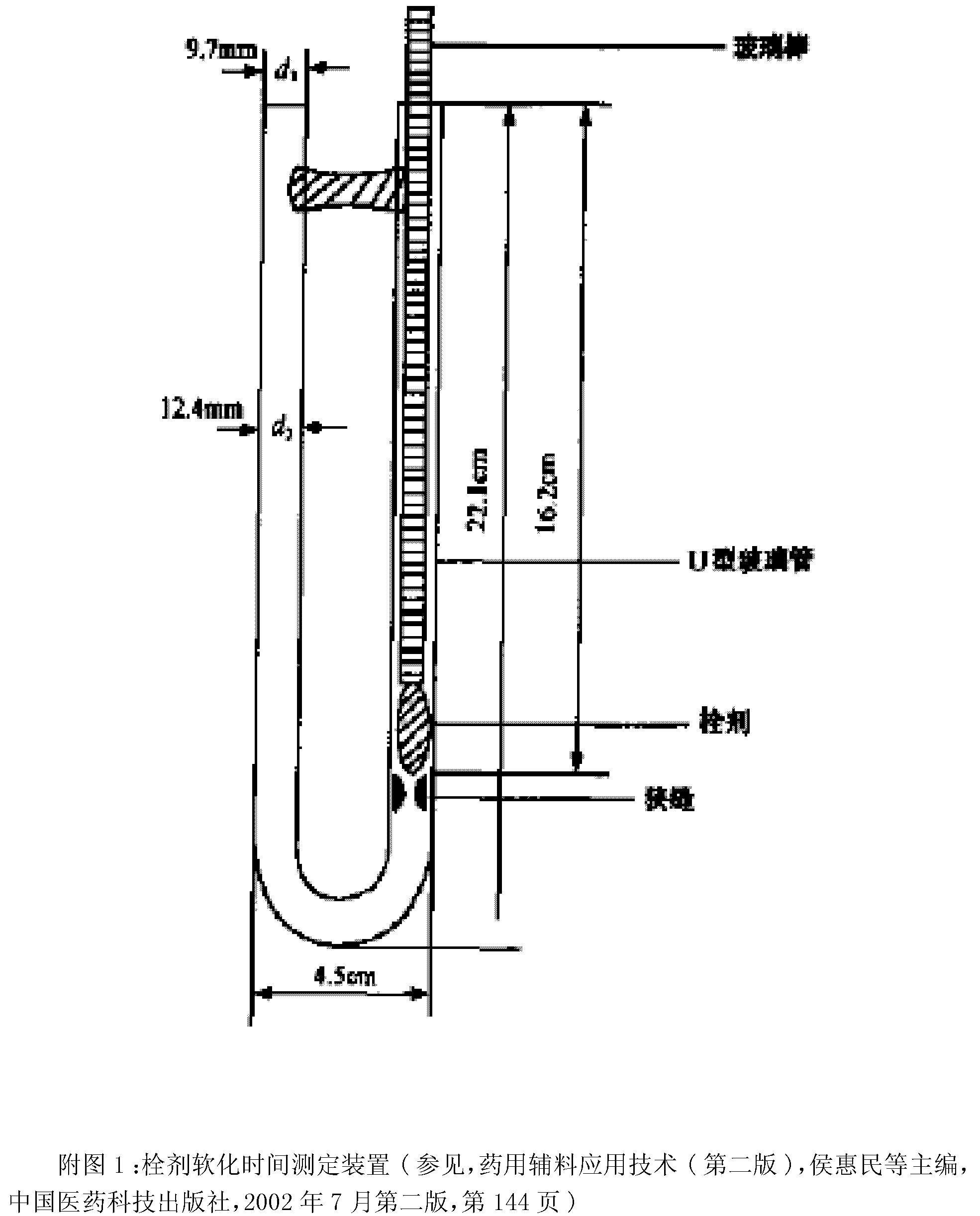

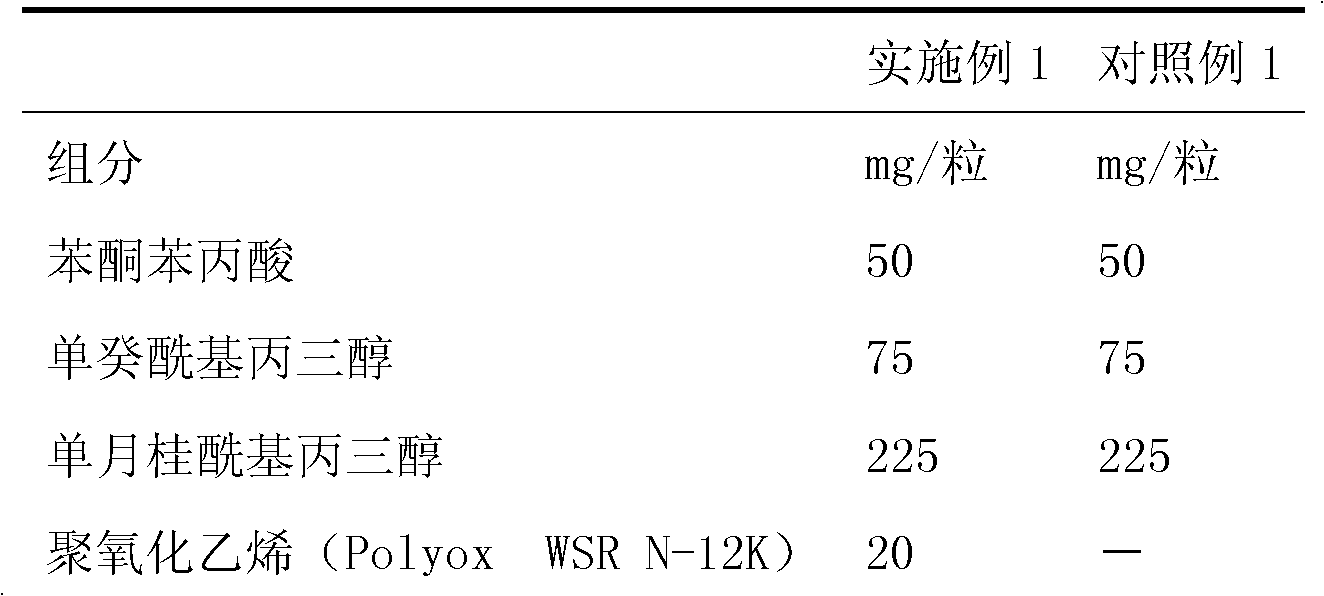

Suppository composition

InactiveCN101919807AStrong retention matrix”Low retention variabilitySuppositories deliveryPharmaceutical non-active ingredientsBiocompatibility TestingPolyethylene glycol

The invention discloses a suppository composition with improved performance. The suppository composition comprises an aliphatic suppository substrate, mono-capryl-based glycerin, mono-lauroyl-based glycerin, polyoxyethylene, a suppository substrate of which the molecular structure contains polyethylene glycol and alkyl having 8 to 24 carbon atoms and a suppository medicament. The suppository composition has the advantages of improving production repeatability and retention value otherness, enhancing the function of a cavity administration retention substrate, improving stability, namely, changing melting performance, decreasing medicament releasing rate and solving or relieving problems such as scumming and the like, improving medicament releasing performance, increasing liquefaction or gelling speed and achieving stronger salt resistance and acid resistance and higher biocompatibility and the like.

Owner:钟术光

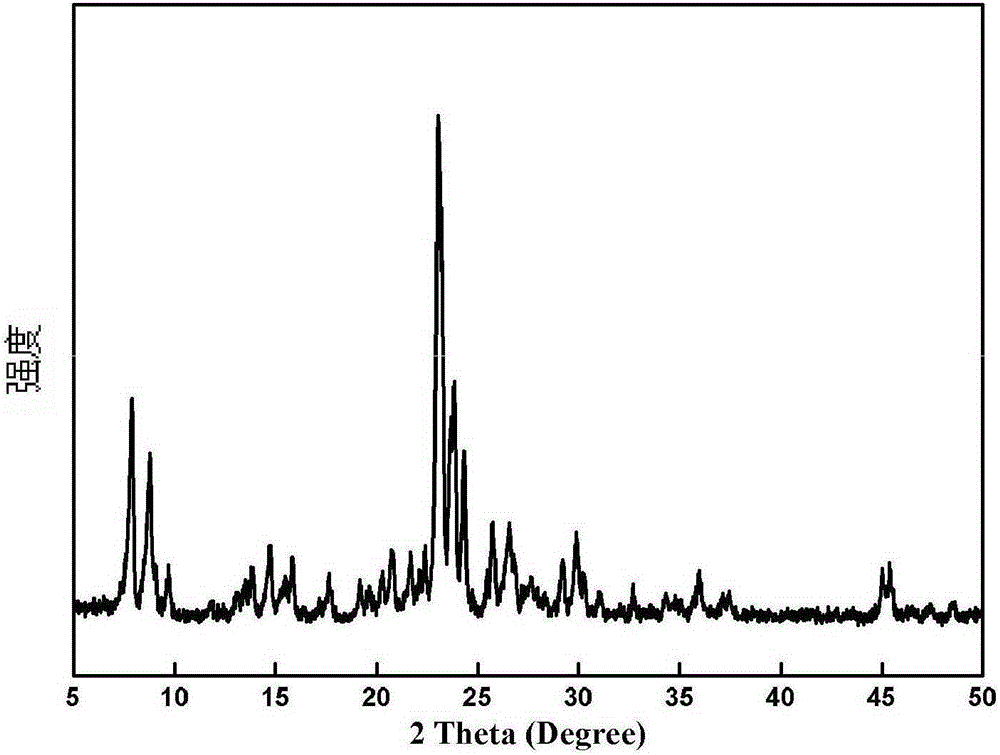

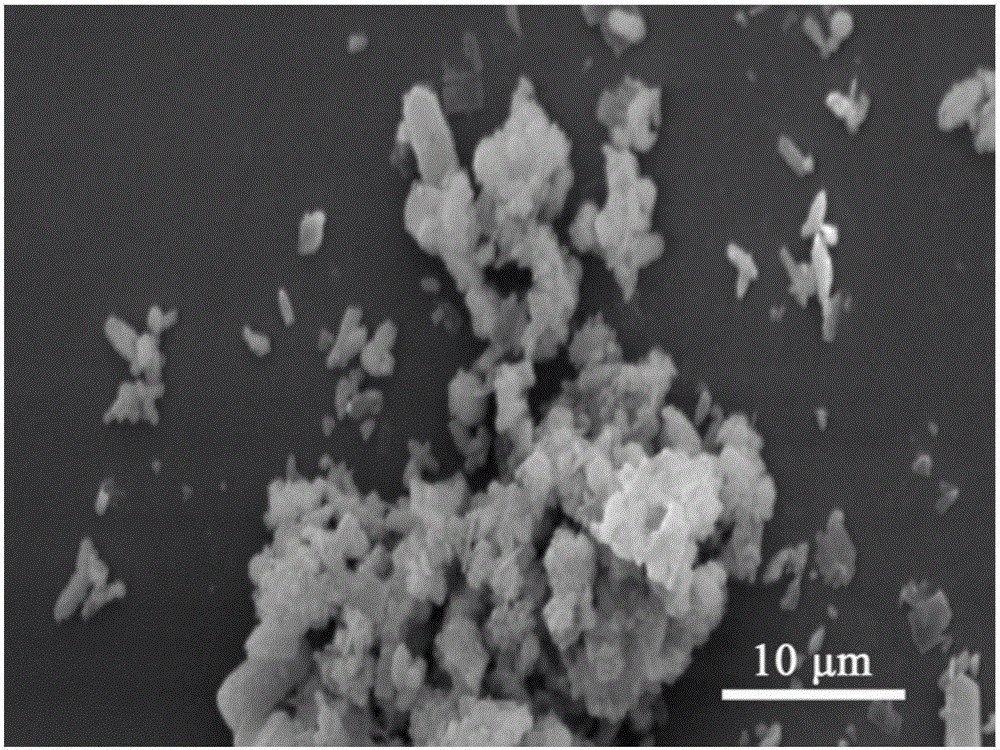

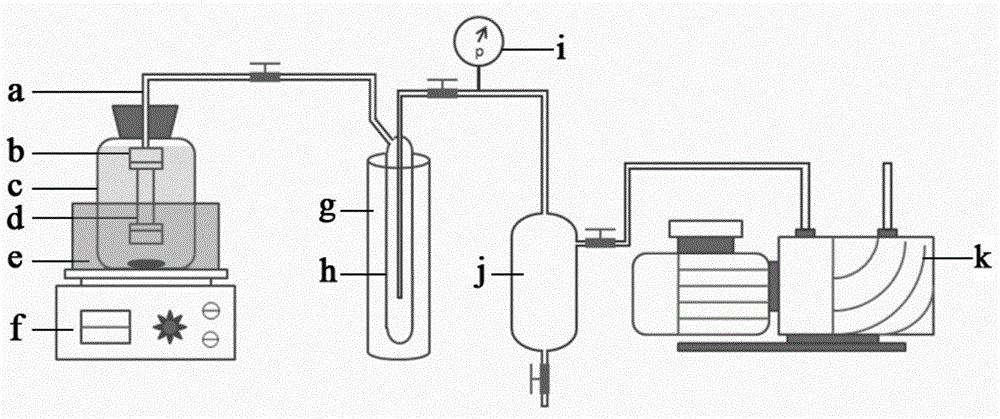

Method for synthesizing hydrophilic ZSM-5 zeolite molecular sieve membrane

InactiveCN105311972AShort synthesis timeImprove hydrophilic abilitySemi-permeable membranesOrganic acidMolecular sieve

The invention discloses a method for rapidly and efficiently synthesizing a hydrophilic ZSM-5 zeolite molecular sieve membrane. According to the invention, a microwave heating technology is adopted, so that the synthesis time of the ZSM-5 zeolite molecular sieve membrane is shortened greatly; a conventional hydrothermal synthesis mode is adopted, so that the prepared ZSM-5 zeolite molecular sieve membrane has extremely high hydrophilicity and acid resistance, has an excellent separating property for organic matter solution dehydration or acidic organic solution dehydration, can be widely applied to organic solvent dehydration, organic acid dehydration, organic matter dehydration under the acid environment and the like and has an important and wide application prospect.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com