Fire resistant black iron oxide pigment and preparation method thereof

A technology of iron oxide black and high temperature resistance, which is applied in the fields of iron oxide, chemical instruments and methods, iron oxide/iron hydroxide, etc., can solve the problems of poor high temperature resistance of iron oxide black, and achieve good acid resistance and strong light absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

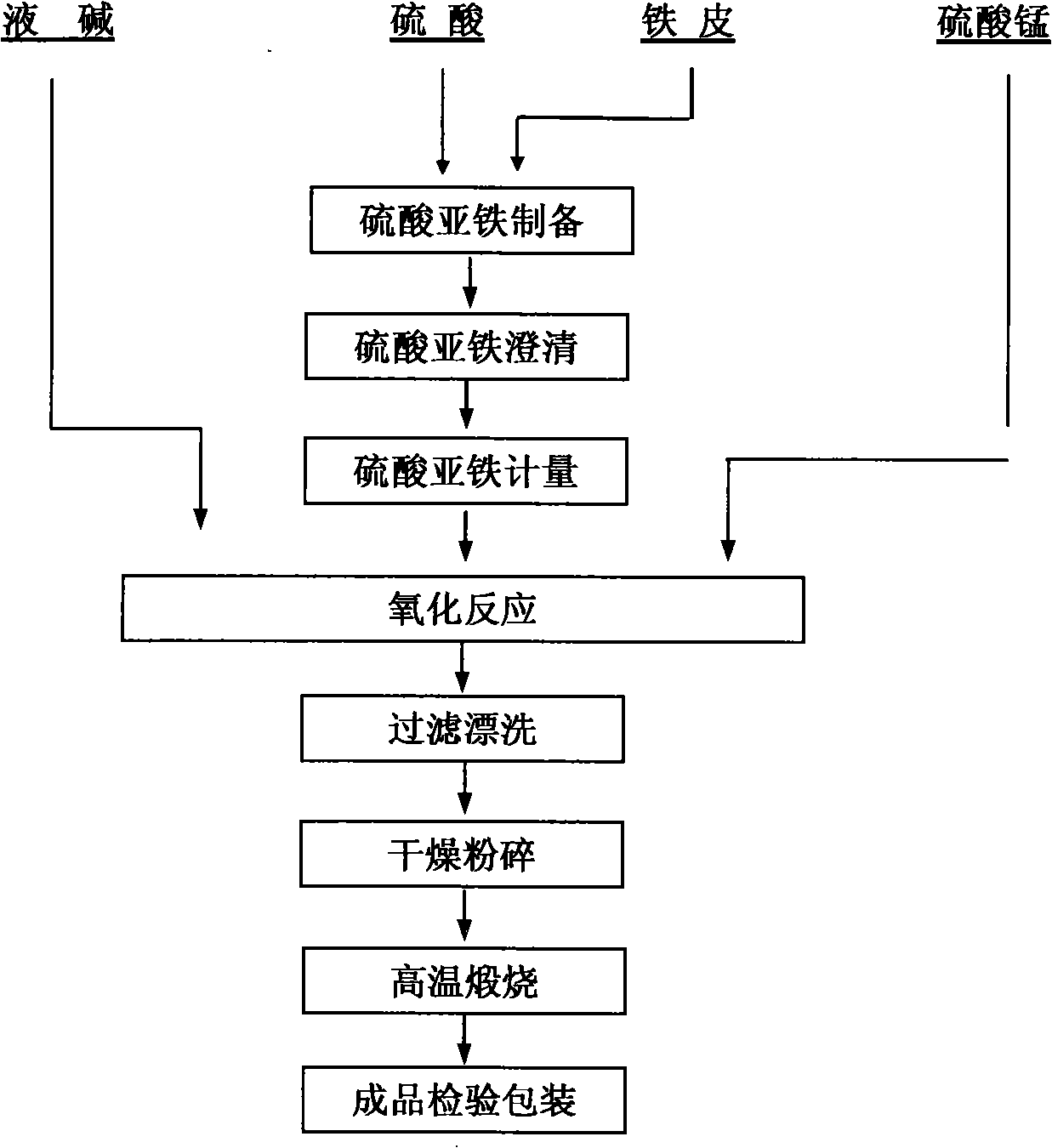

[0034] Such as figure 1 The preparation method of the high-temperature-resistant iron oxide black pigment shown, the preparation method includes two stages of oxidation reaction and high-temperature calcination, and the specific steps are as follows:

[0035] 1. Oxidation reaction part

[0036] 1. Mixing: Put the ferrous sulfate solution into the oxidation reaction barrel, start stirring, add manganese sulfate to dissolve and mix evenly, inject tap water to dilute. Start to heat up, intermittently in the middle, raise the temperature to 95°C, turn on the stirring, and keep the temperature stable.

[0037] The molar ratio of ferrous sulfate and manganese sulfate is 4:1, the amount of water added depends on the size of the reaction tank, and the concentration of ferrous sulfate is controlled at 5g / 100ml~10g / 100ml.

[0038] 2. Alkali adjustment: When the temperature of the feed liquid in the reaction tank reaches and stabilizes at 95°C, adjust the stirring speed to 400rpm, add ...

Embodiment 2

[0045] The preparation method of the high-temperature-resistant iron oxide black pigment has the same steps as in Example 1, except that the molar ratio of ferrous sulfate to manganese sulfate is 5:1.

Embodiment 3

[0047] The preparation method of the high-temperature-resistant iron oxide black pigment has the same steps as in Example 1, except that the raw materials are ferrous chloride and manganese chloride, and the molar ratio of ferrous chloride and manganese chloride is 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com