Patents

Literature

343results about How to "Strong alkali resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

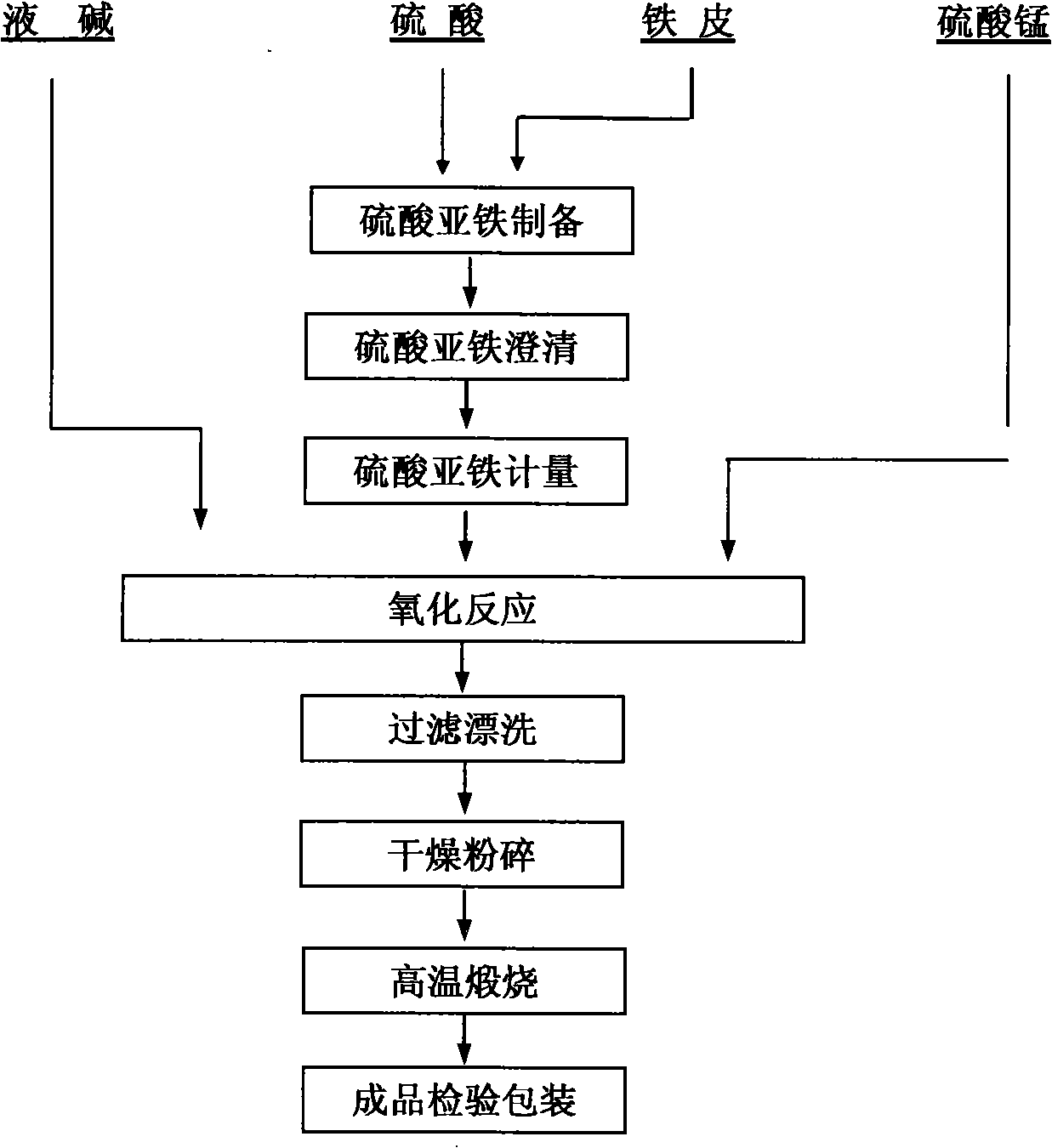

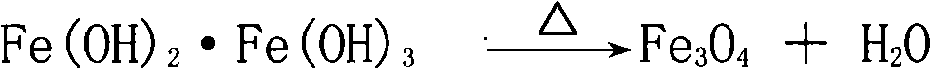

Fire resistant black iron oxide pigment and preparation method thereof

ActiveCN101314678AImprove acid resistanceGood alkali resistanceInorganic pigment treatmentFerric oxidesEngineering plasticManganese oxide

The invention relates to an inorganic iron oxide black pigment, in particular to a heat-resistant iron oxide black pigment (manganese ferrite black) and the preparation method thereof. The heat-resistant iron oxide black pigment comprises manganese ferrite black prepared from ferroferric oxide and manganese oxide by high-temperature lattice reaction, wherein the molar ratio of iron element to manganese pigment in the pigment is 1.5:1 to 5:1. The heat-resistant iron oxide black pigment has high heat resistance up to 700 DEG C or above, and can be widely used for ceramic, engineering plastic, color sand, etc., for products manufactured at high temperature, and for coloring agent for products. Meanwhile, the inorganic iron oxide black pigment has the advantages of high acid resistance, high alkali resistance and high light absorbability.

Owner:ZHEJIANG HUAYUAN PIGMENT CO LTD

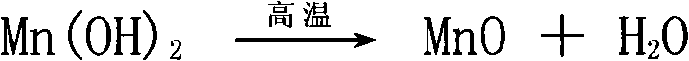

High fluidization micro expansive high-strength grouting material

ActiveCN104402345AReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

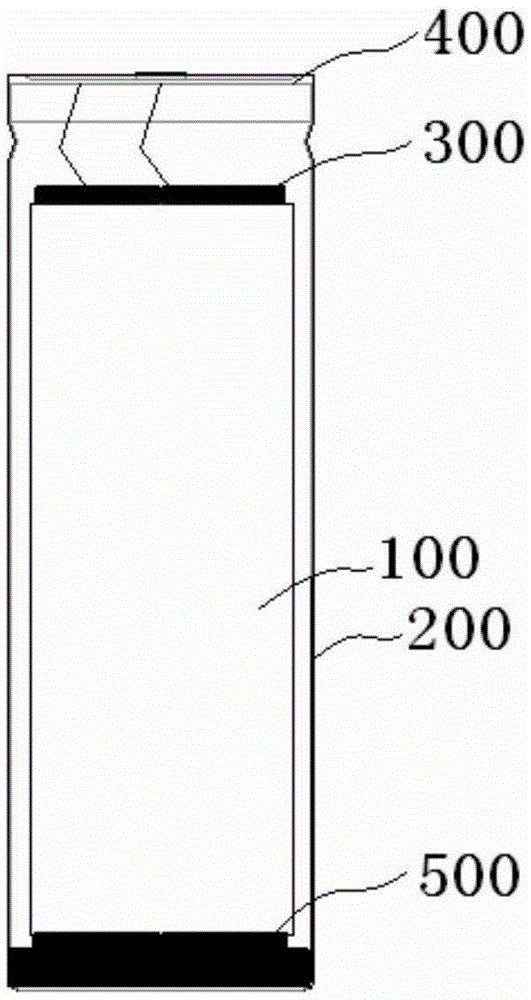

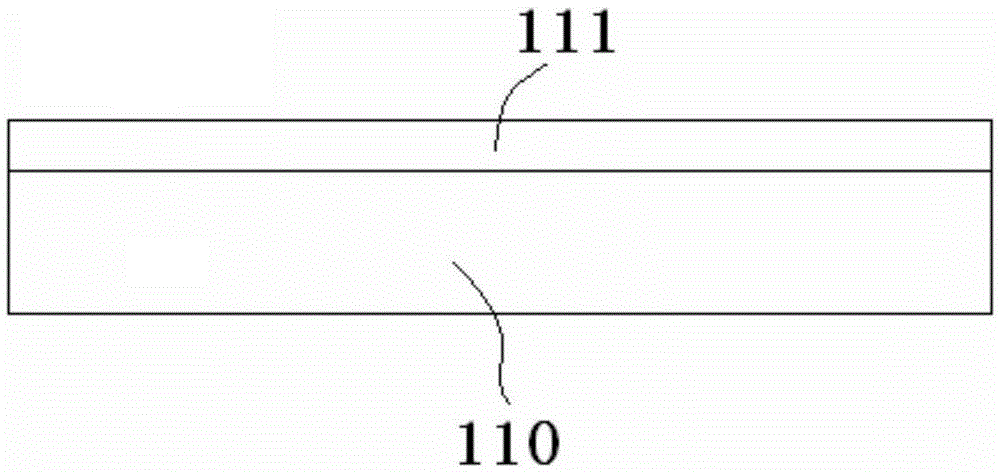

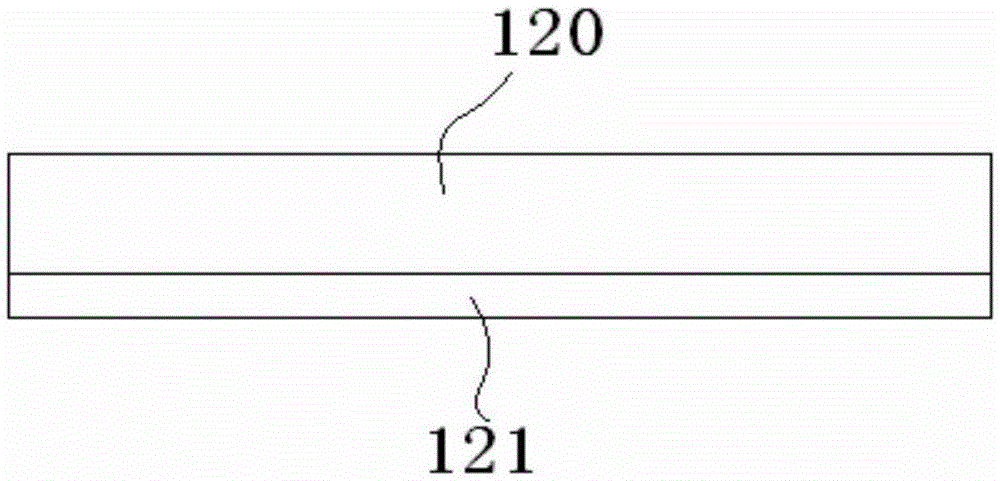

Super-wide-temperature-range nickel-hydrogen battery and manufacturing method therefor

ActiveCN105390755AImprove conductivityLower ohmic resistanceCell seperators/membranes/diaphragms/spacersFinal product manufacturePotassiumNickel electrode

The invention discloses a super-wide-temperature-range nickel-hydrogen battery. The battery comprises an iron shell as well as a nickel electrode, a hydrogen electrode, a diaphragm and an electrolyte solution mounted in the iron shell, wherein the nickel electrode takes foam nickel as a substrate material; the space in foam nickel is filled with a positive electrode active substance Ni(OH)2, a conductive agent, an additive and a binder; the hydrogen electrode takes a porous nickel-plated steel belt, a copper net or foam nickel as a substrate material; the porous nickel-plated steel belt, the copper net or foam nickel is coated with a negative electrode active substance, namely, hydrogen storage alloy powder, the conductive agent, the additive or the binder; and the electrolyte solution is a mixture of a potassium-rich alkaline aqueous solution and sodium tungstate or tungstic acid crystals. The invention furthermore discloses a manufacturing method for the super-wide-temperature-range nickel-hydrogen battery. According to the super-wide-temperature-range nickel-hydrogen battery disclosed by the invention, the ratio of 0.2C discharge capacity to normal-temperature capacity maximally can reach 70-80% in an environment with the temperature of -45 DEG C; and the ratio of 0.2C discharge capacity to normal-temperature capacity of the nickel hydrogen battery maximally can reach 85-95% in an environment with the temperature of 70 DEG C. Moreover, the manufacturing method is simple and suitable for large-scale production.

Owner:HENGYANG BST POWER

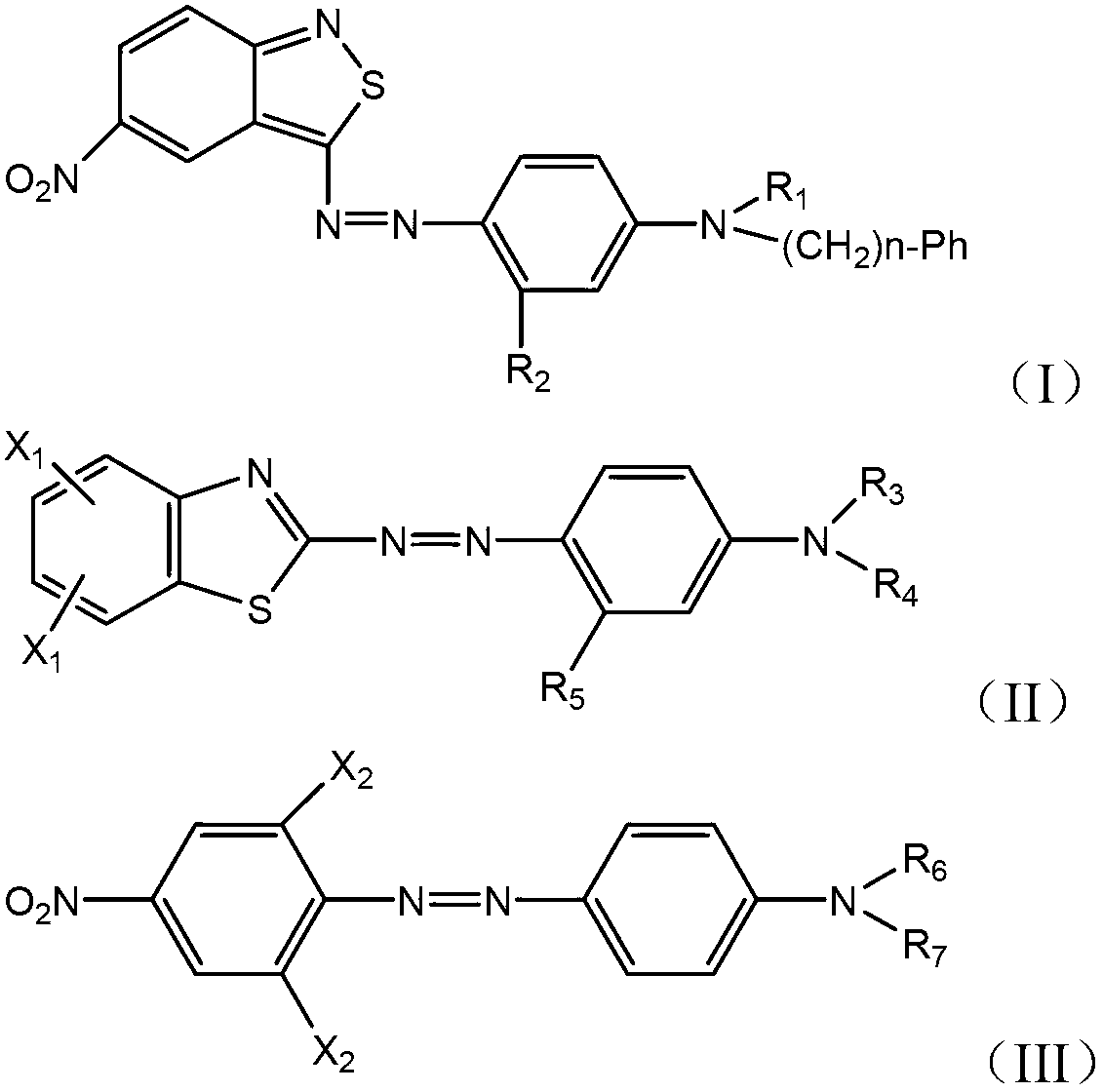

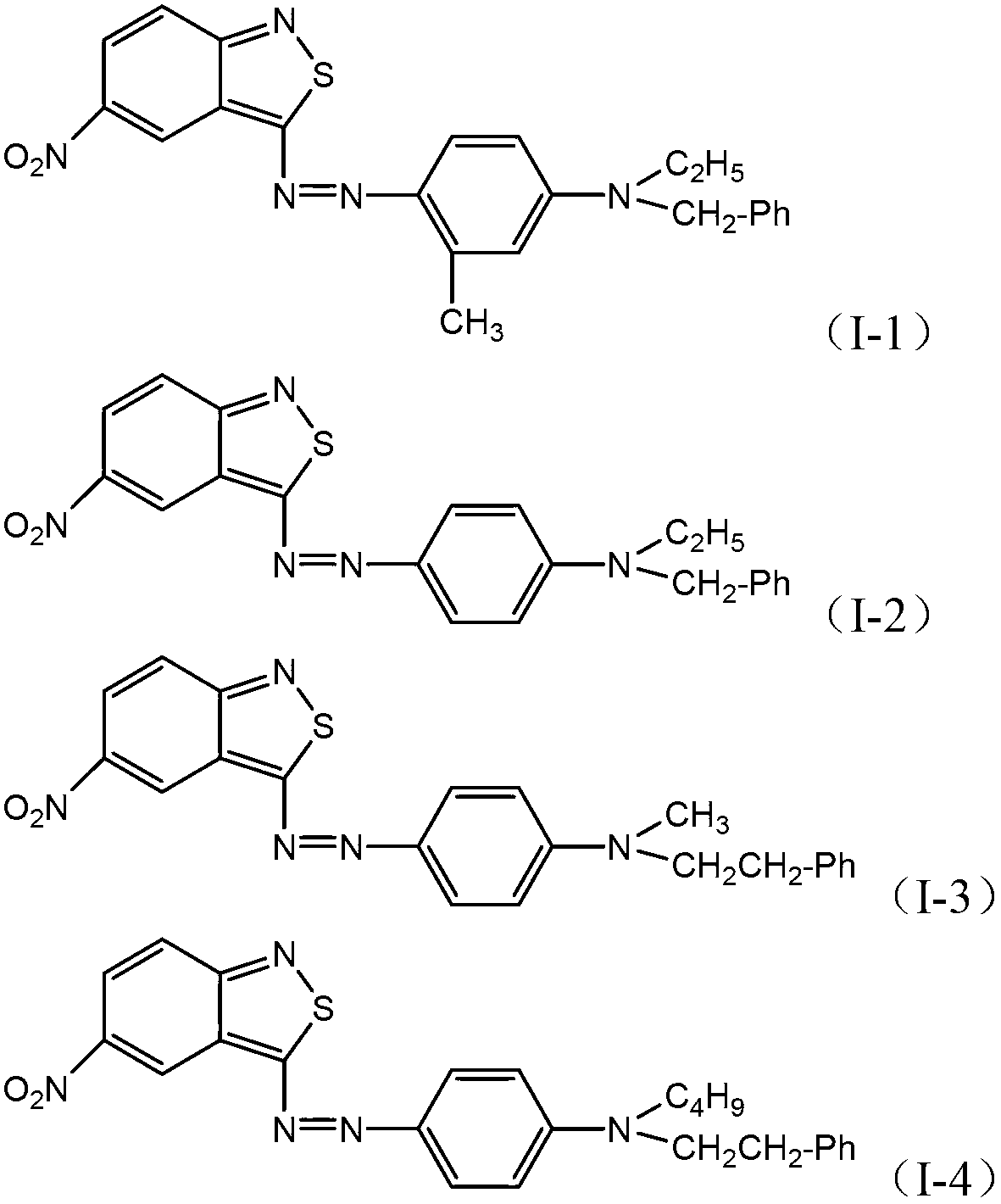

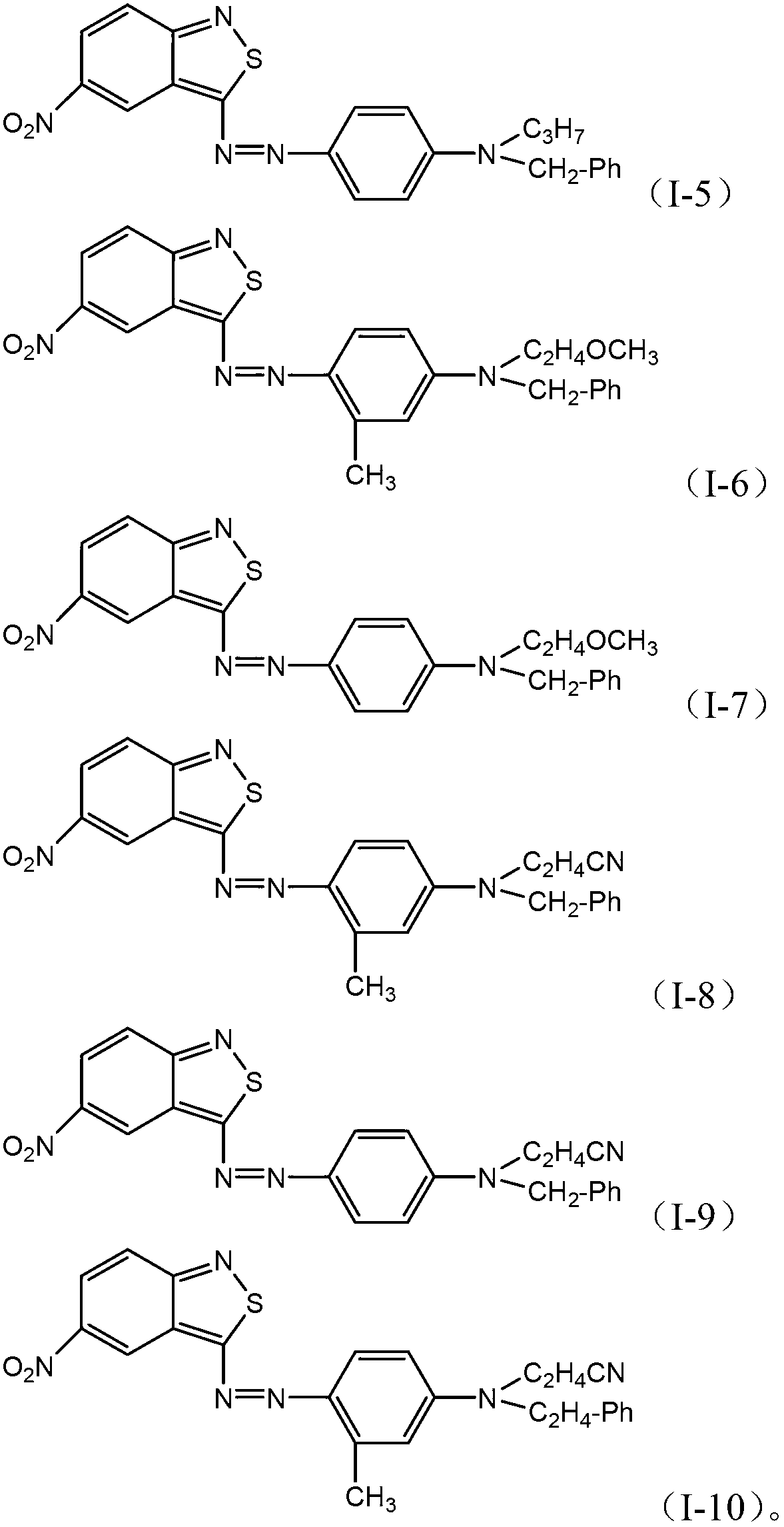

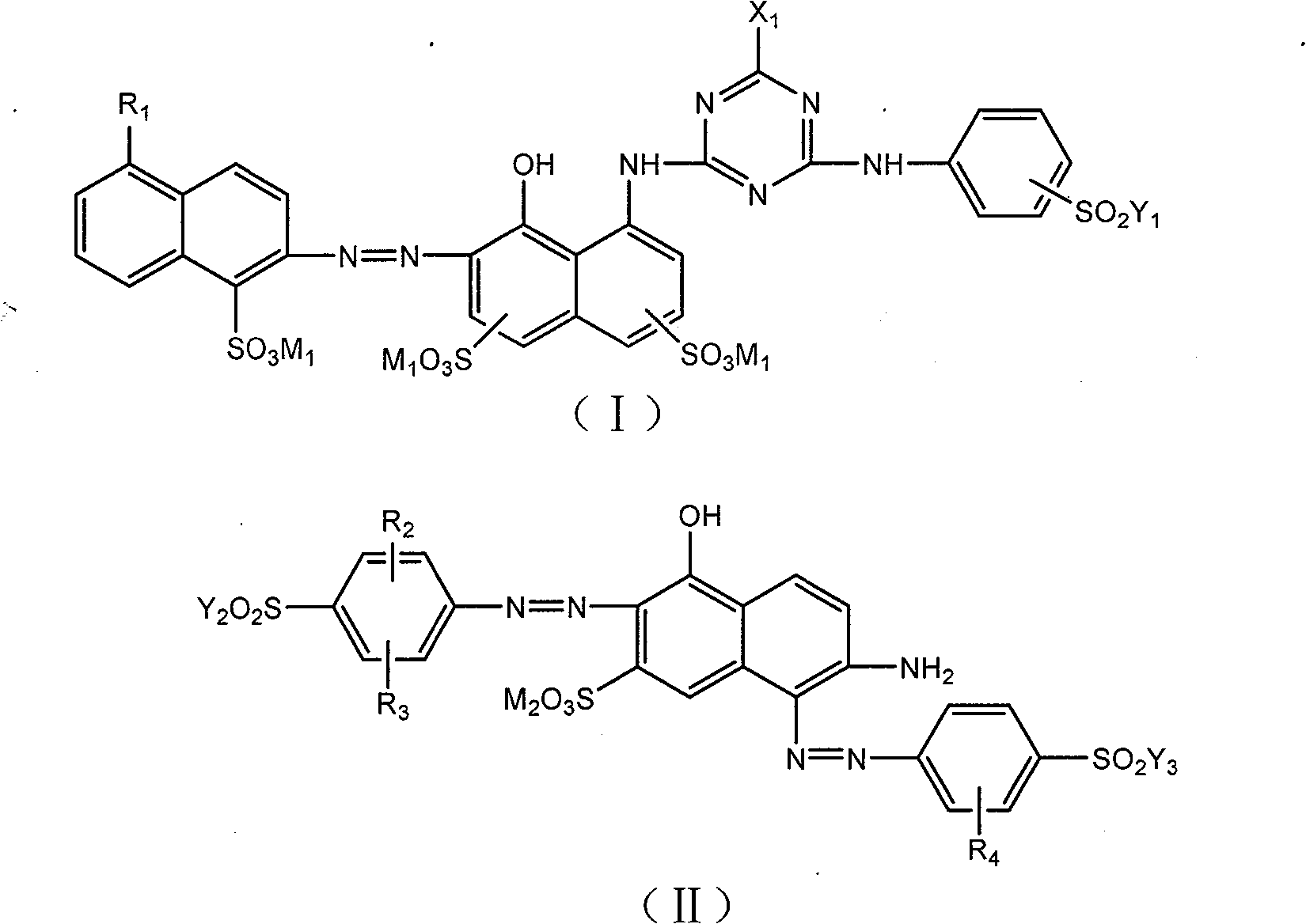

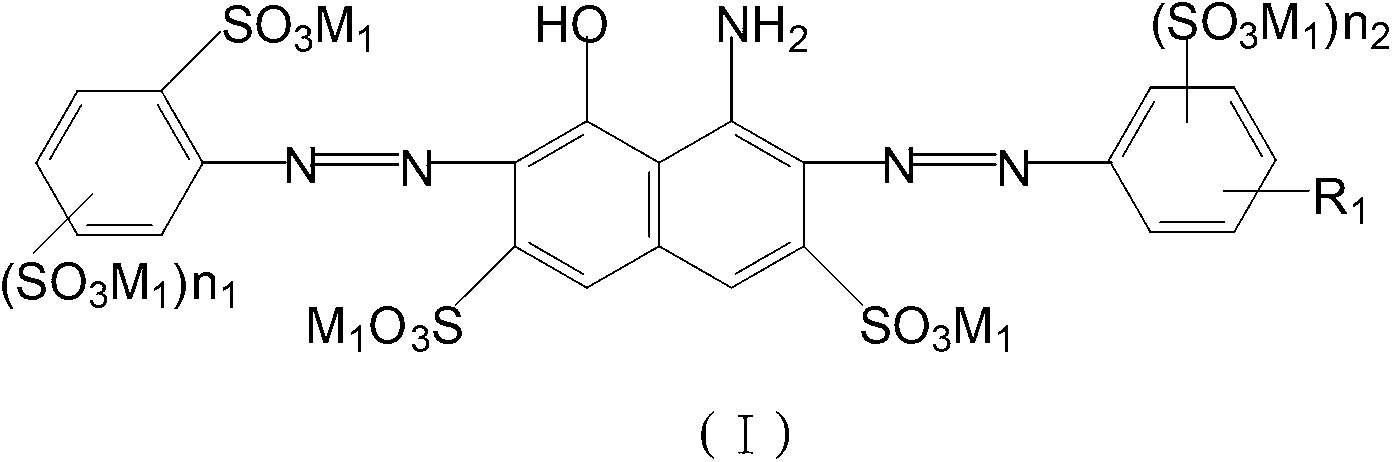

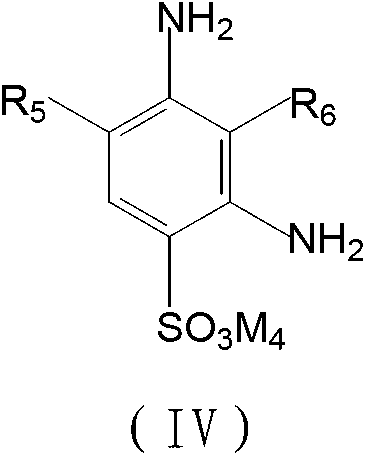

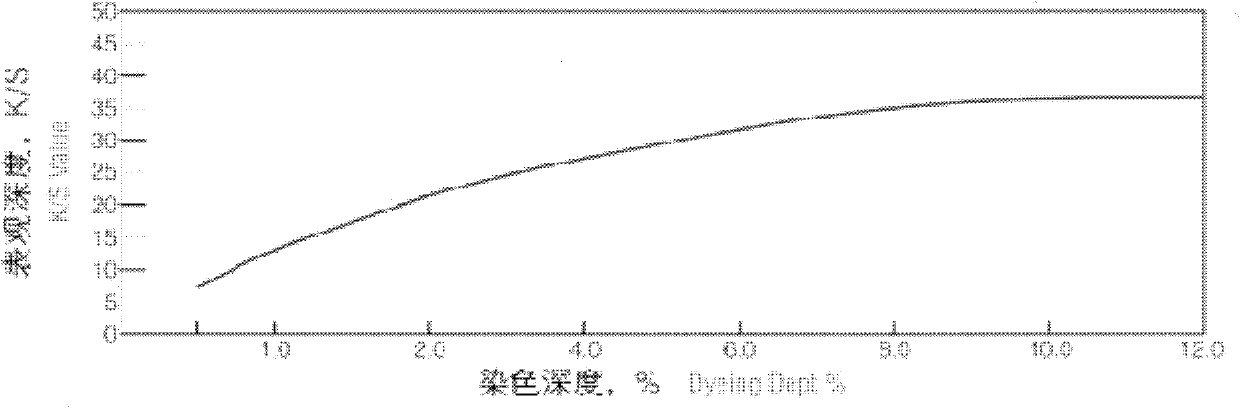

Blue-to-black disperse dye composition

ActiveCN102746713AStrong alkali resistanceAvoid problems such as contaminationOrganic dyesDisperse dyeAlkali burn

The invention provides a blue-to-black disperse dye composition, which mainly comprises one or multiple blue dye ingredients A shown as the structure formula (I), one or multiple red dye ingredients B shown as the structure formula (II) and one or multiple orange dye ingredients C shown as the structure formula (III). The disperse dye composition has the advantages that the dying bottleneck of the existing ordinary disperse dye under the alkaline condition is broken through, the problems of white powder, color points and dyeing defect generation caused by the dyeing under the acid condition, the contamination on the inner wall of dyeing equipment caused by low polymers, and the like are solved, the dyeing quality is effectively improved, the stability and the reproducibility of the process are ensured, and the once success rate of the dyeing is improved. In addition, the prepared disperse dye has higher alkali resistance capability and can be applied to an alkali burnt-out process, the defect of single acid burnt-out color is overcome, and the requirements of the society on the aesthetic perception and the variety on clothing and decorations are met.

Owner:ZHEJIANG LONGSHENG GROUP +1

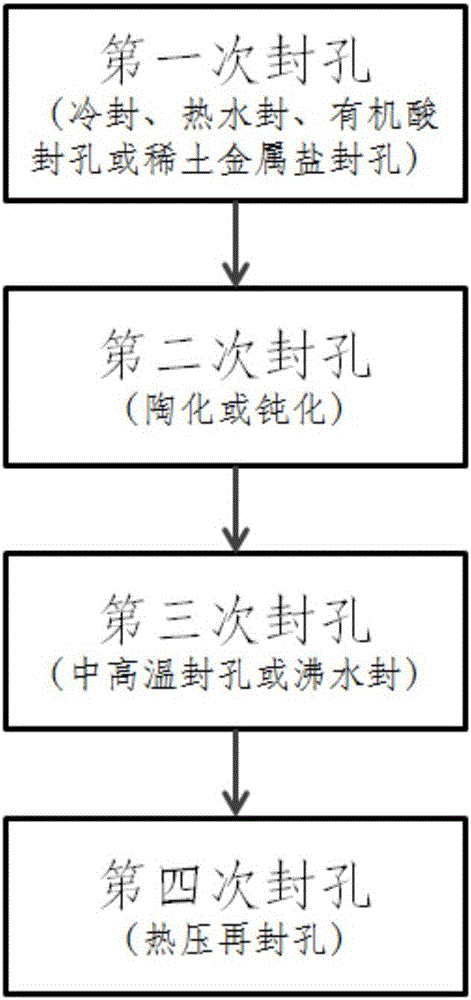

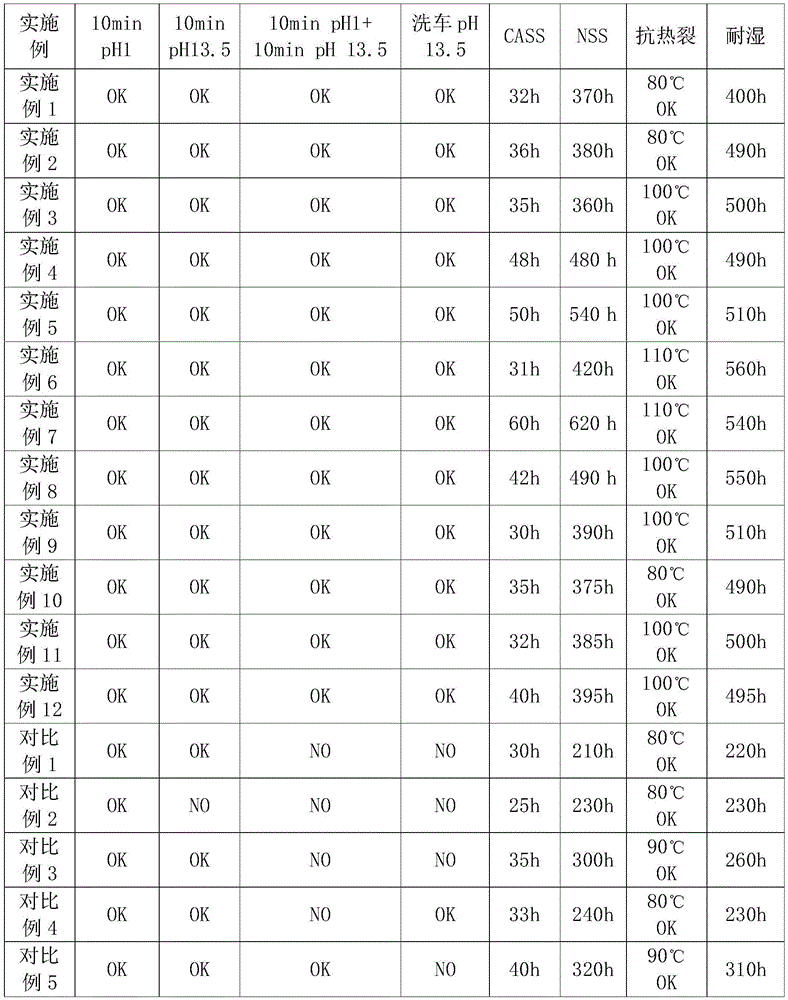

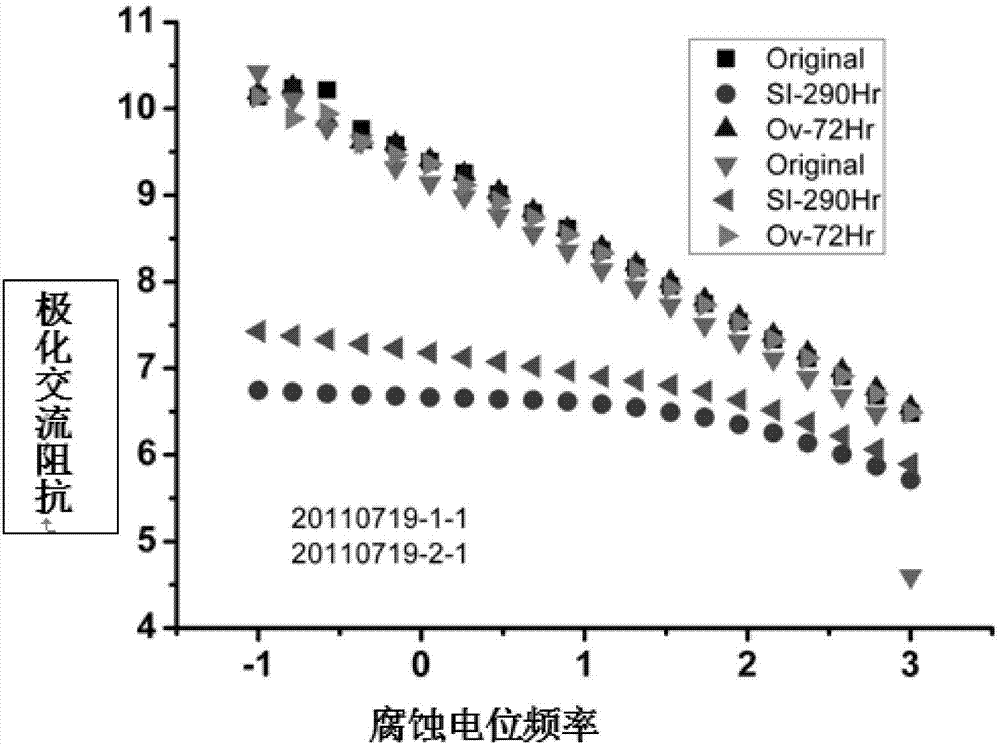

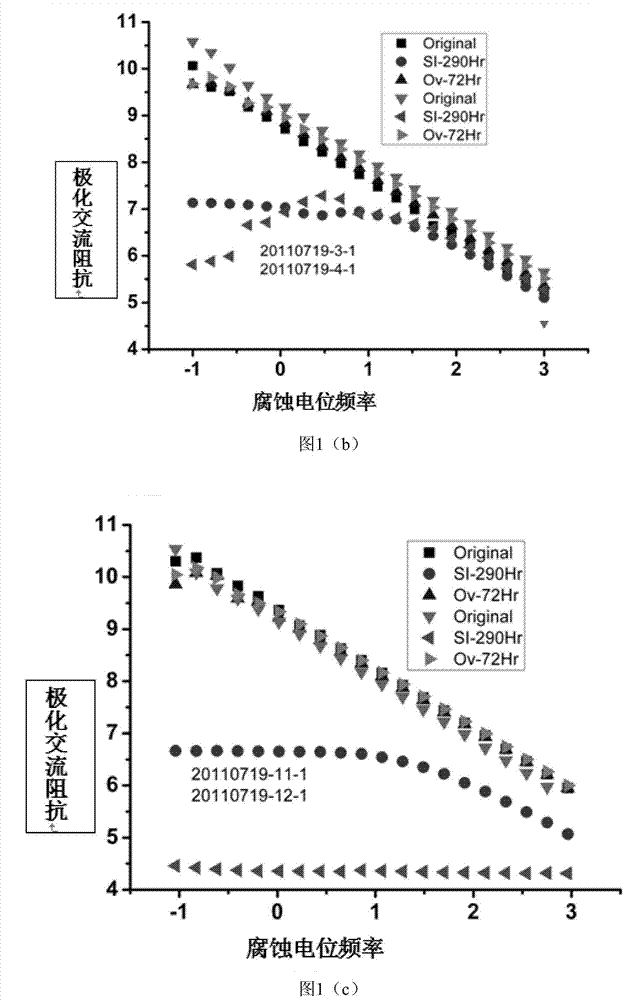

Hole sealing method capable of improving alkali resistance and corrosion resistance of anode oxide film of aluminum and aluminum alloy

ActiveCN106119924AImprove corrosion resistanceImprove continuous acid-base performanceSurface reaction electrolytic coatingRare earthMoisture resistance

The invention belongs to the technical field of surface treatment for anodic oxidation workpieces of the automobile industry, and particularly relates to a hole sealing method capable of improving the alkali resistance and corrosion resistance of an anode oxide film of aluminum and aluminum alloy. The hole sealing method comprises the step that hole sealing treatment is carried out on an aluminum and aluminum alloy workpiece subjected to anodic oxidation treatment three times sequentially, specifically, the first time of hole sealing adopts cold sealing, hot water sealing, organic acid hole sealing or rare earth metal salt hole sealing, the second time of hole sealing adopts passivation or ceramization, and the third time of hole sealing adopts intermediate and high-temperature heat hole sealing or boiling water sealing. The hole sealing method provided by the invention breaks through the bottleneck of an existing single-step or two-step hole sealing technology; a multi-step technology is utilized, the advantages of each step of hole sealing are taken into full play, and by introducing the passivation technology for intermediate hole sealing, the corrosion resistance and continuous acid-base resistance can be remarkably improved, and higher alkaline resistance is achieved; and the passivation hole sealing mode is adopted between cold sealing and heat sealing to form a barrier layer, so that the acid resistance, alkali resistance, the continuous acid and base resistance, moisture resistance and the like of the anode oxide film are comprehensively improved.

Owner:武汉风帆电化科技股份有限公司 +1

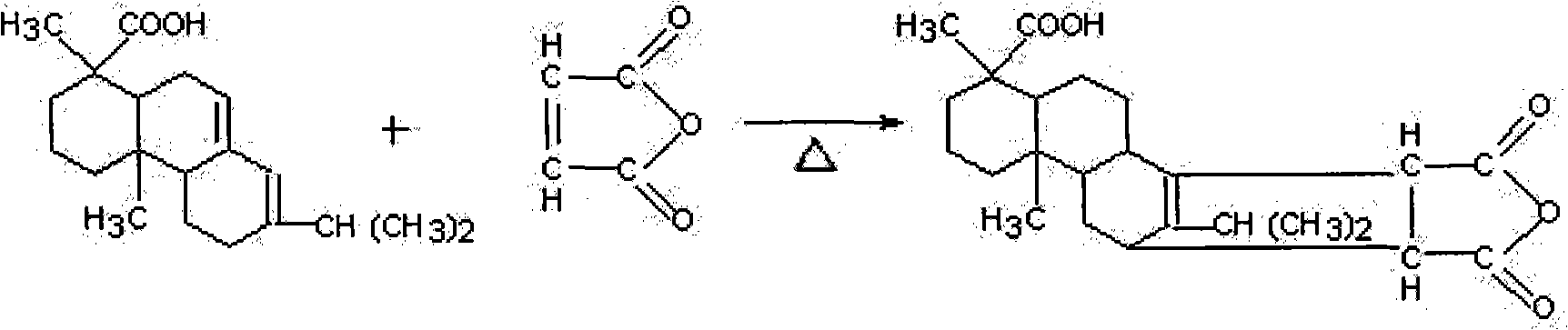

Production method of abietic maleic anhydride resin

InactiveCN102010503AExemption from releaseProtect physical and mental healthInksNatural resin chemical modificationSolubilityReaction temperature

The invention relates to a production method of abietic maleic anhydride resin, comprising the following two reaction steps of: 1, carrying out addition reaction on abietyl and maleic anhydride to generate an abietic maleic anhydride addition product; and 2, carrying out esterification reaction on the abietic maleic anhydride addition product and pentaerythritol to generate the abietic maleic anhydride resin. The production method is easy and convenient to operate, has the advantages of large temperature control range, high operability, small investment and stable product quality and is a method suitable for industrialized production; in the production method, appropriate process conditions including raw material proportion, reaction temperature, reaction time, catalysts, and the like, are adopted, thereby the acid value and the molecular weight range of a resin product can be effectively controlled; in addition, the resin product obtained with the production method has higher acid value of 150-170 mg KOH / g, reasonable softening point at 140-155 DEG C and good water solubility and is suitable for producing water-based ink, and a formed coating film has toughness and better after-tackiness resistance, water resistance and alkali resistance.

Owner:上海华谊精细化工有限公司上海南大化工厂

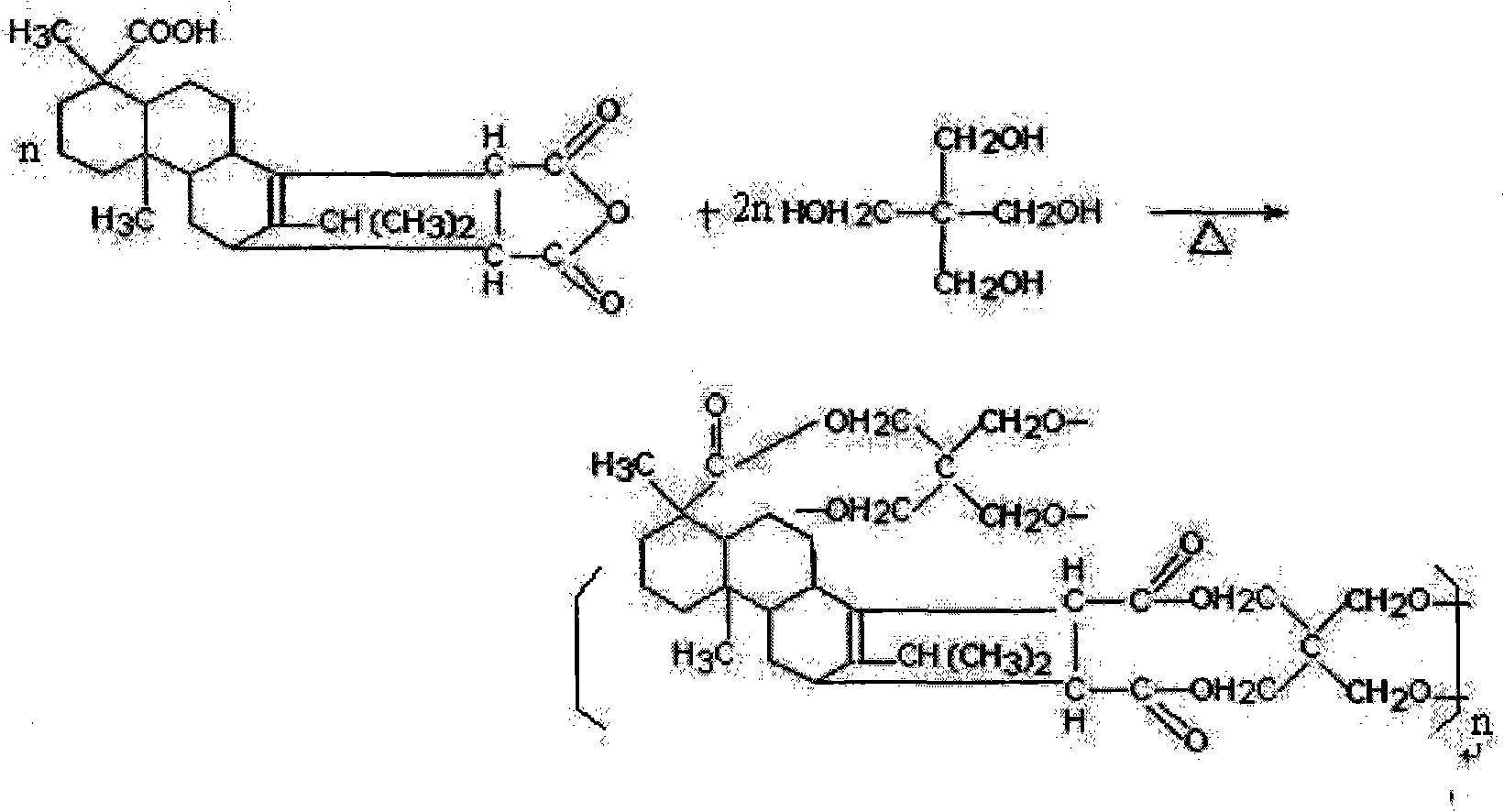

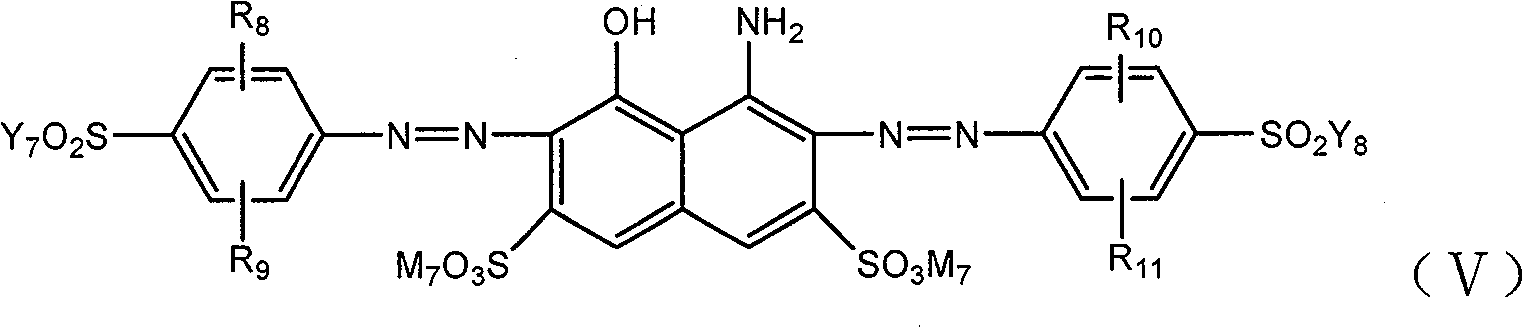

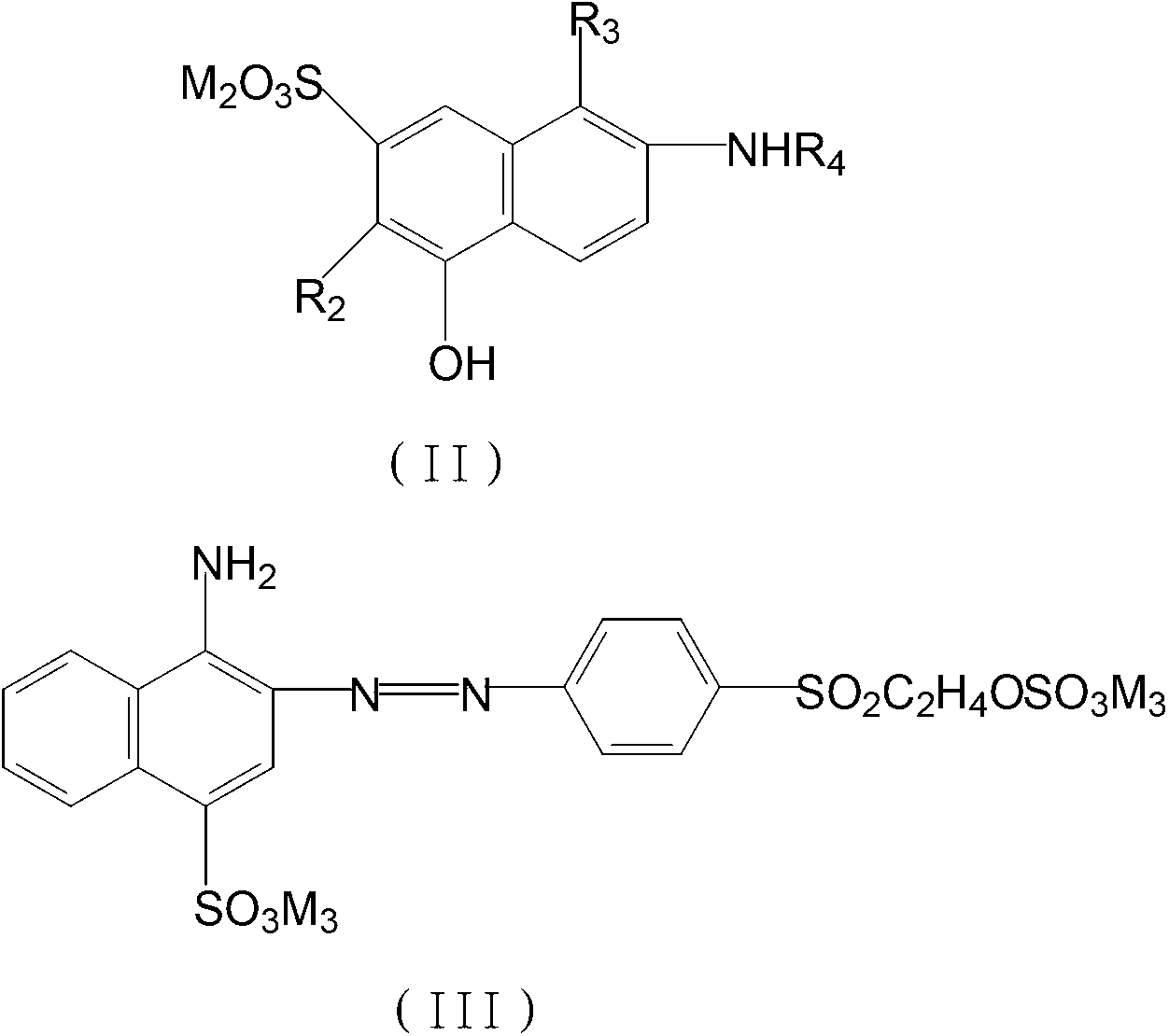

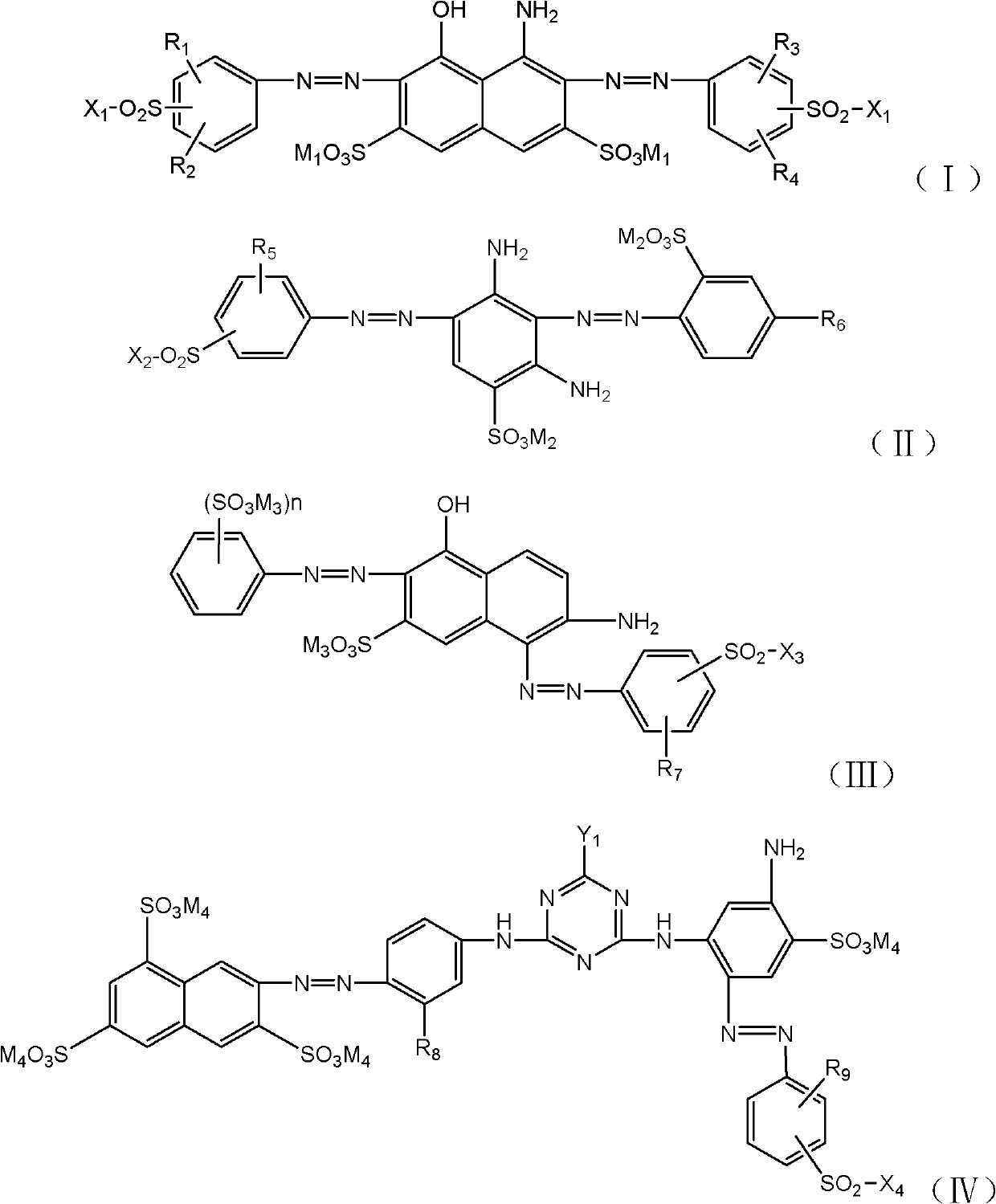

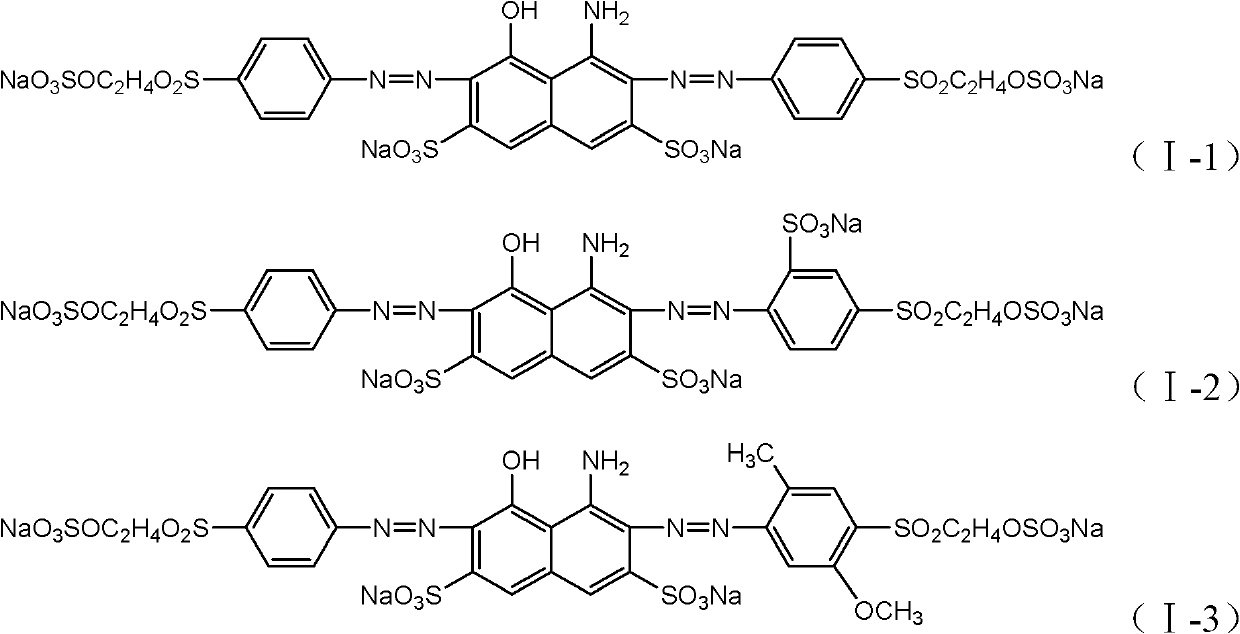

Active black dye

The invention relates to active black dye which essentially comprises fuchsine component A, orange yellow component B and navy component C, and is based on the component A, the component B and the component C; the weight percentage of the component A is 1 to 25 percent, the weight percentage of the component B is 1 to 25 percent, and the weight percentage of the component C is 50 to 95 percent; and the component A comprises at least a dye shown as formula (I) and a dye shown as formula (II), the component B comprises at least a dye shown as formula (III) and a dye shown as formula (IV), and the component C comprises at least a dye shown as formula (V). The active black dye has the advantages of high product solubility, strong salt and alkali resistance, high uptake date and color fixing rate, excellent dyeing fastness and environmental protection.

Owner:ZHEJIANG LONGSHENG GROUP +1

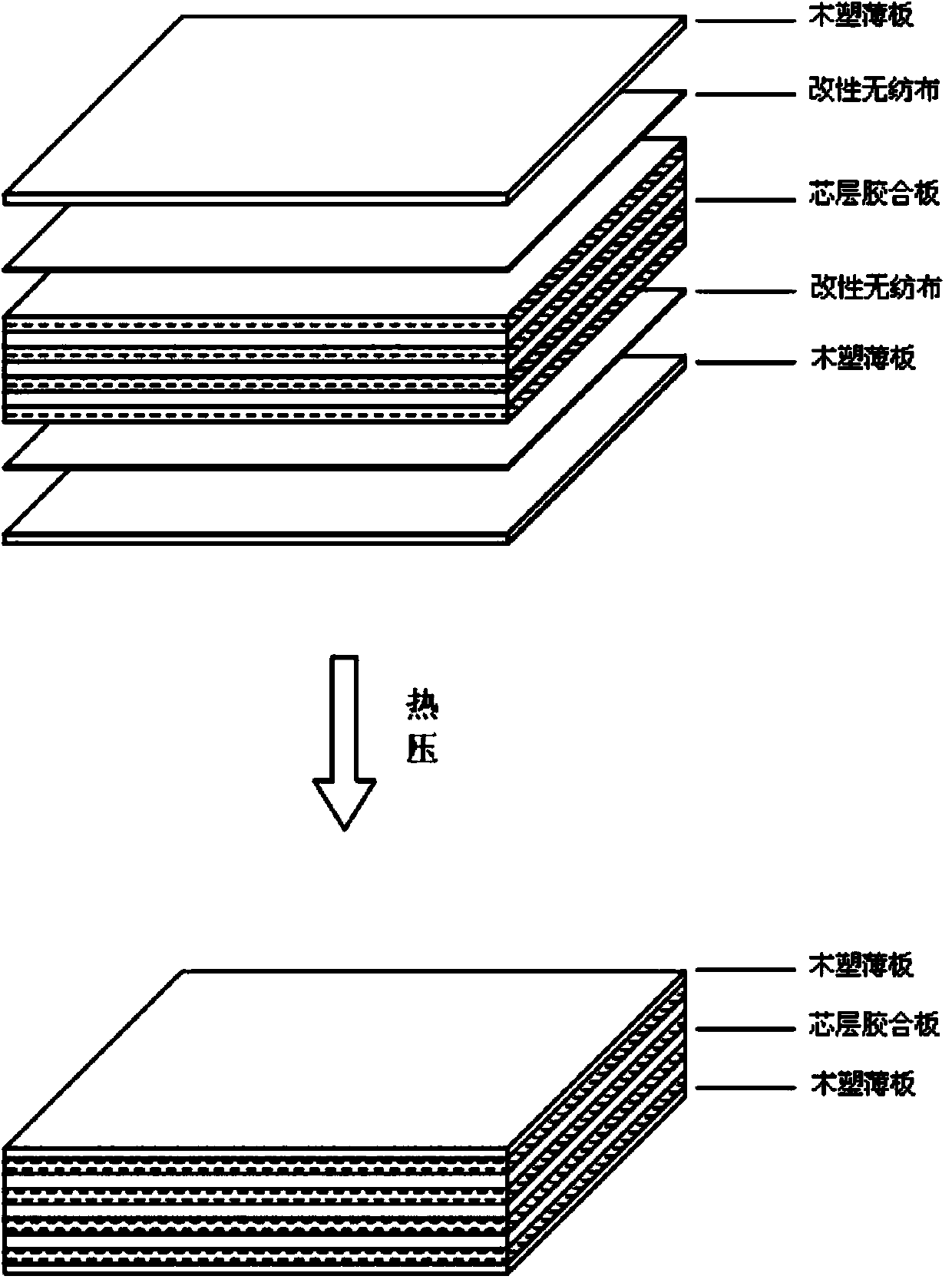

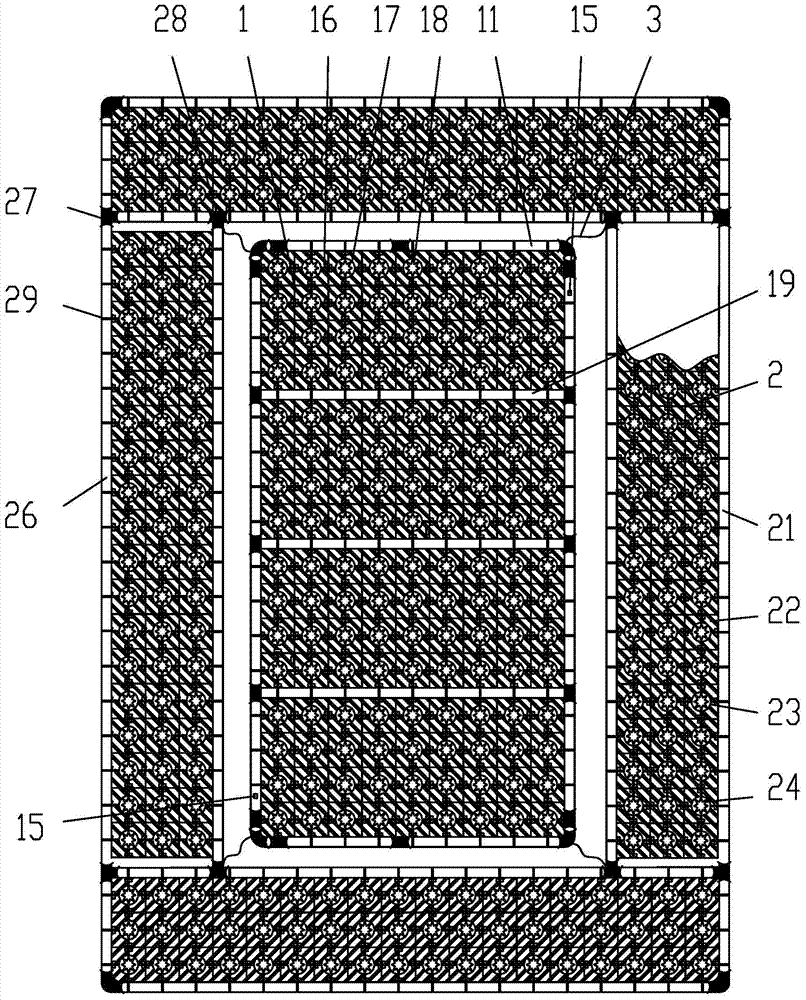

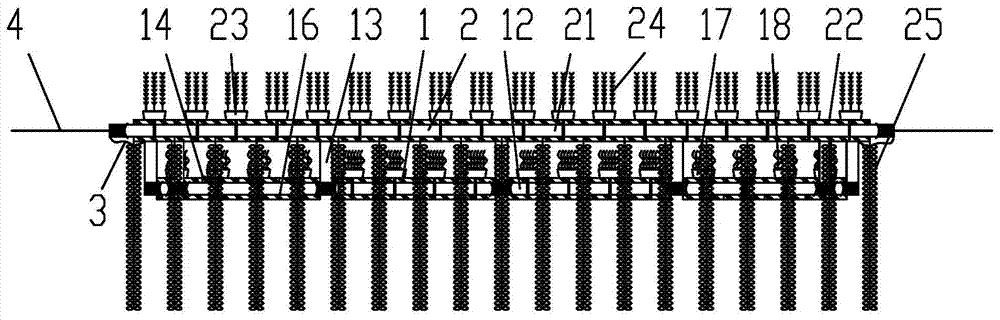

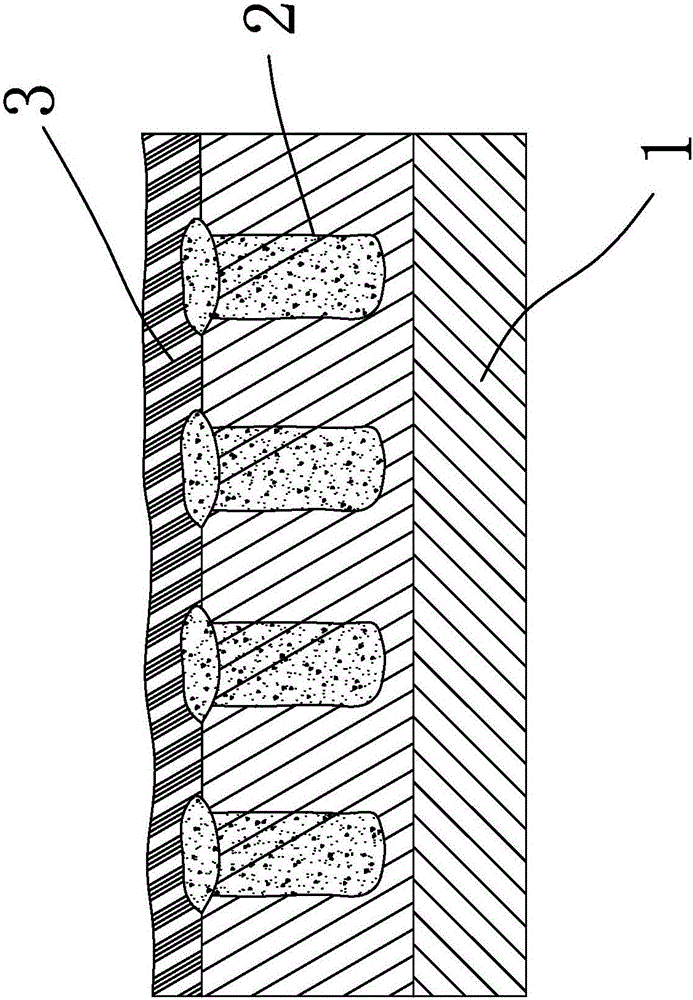

Wood plastic composite material cladding plywood formwork and manufacturing method thereof

ActiveCN103758340AReduced flatness errorGood dimensional stabilityFibre treatmentSynthetic resin layered productsPlastic filmToughness

The invention relates to a plywood formwork and a manufacturing method of the plywood formwork, in particular to a wood plastic composite material cladding plywood formwork and a manufacturing method of the wood plastic composite material cladding plywood formwork. The wood plastic composite material cladding plywood formwork aims to solves the problems that a wood plywood formwork manufactured in the prior art is low in intensity and poor in durability. The wood plastic composite material cladding plywood formwork is formed by a wood plastic sheet, an improved non-woven fabric and core-layer plywood in a manufactured mode. The manufacturing method comprises the steps that the wood plastic sheet is manufactured; the non-woven fabric is improved; the core-layer plywood is manufactured; pavement is carried out; the formwork is formed. The wood plastic composite material cladding plywood formwork is low in manufacturing cost, high in intensity, good in toughness, long in service life, resistant to moisture and corrosion, stainless, bright, clean and flat in surface, light in weight, and convenient to transport and construct, a die does not swell easily, and the die is released easily. The wood plastic composite material cladding plywood formwork is used as a building formwork.

Owner:NORTHEAST FORESTRY UNIVERSITY

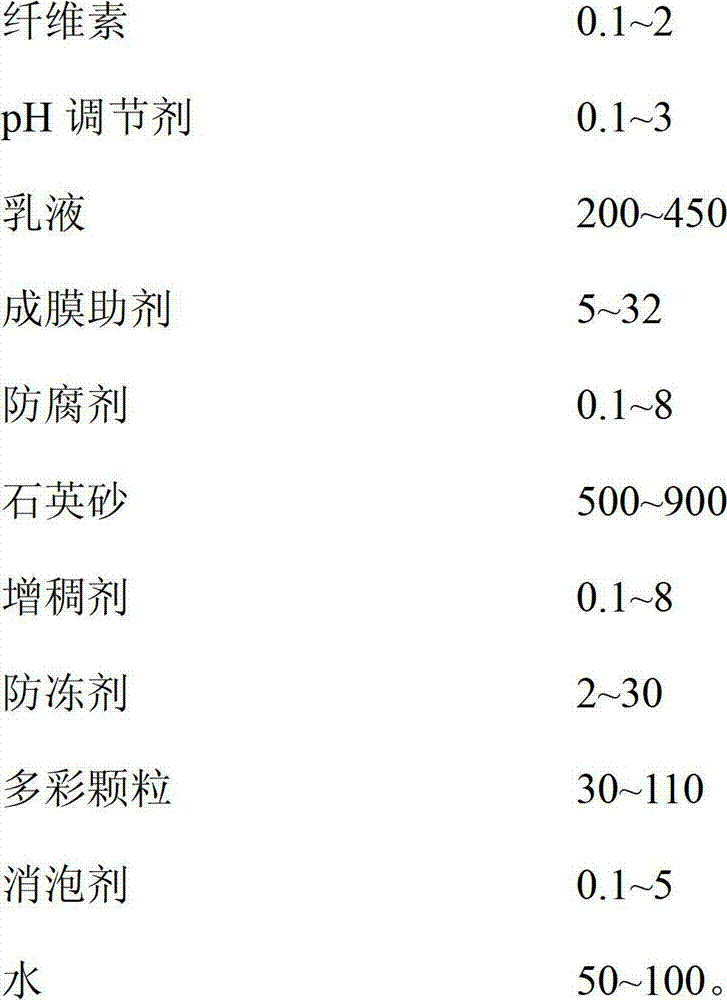

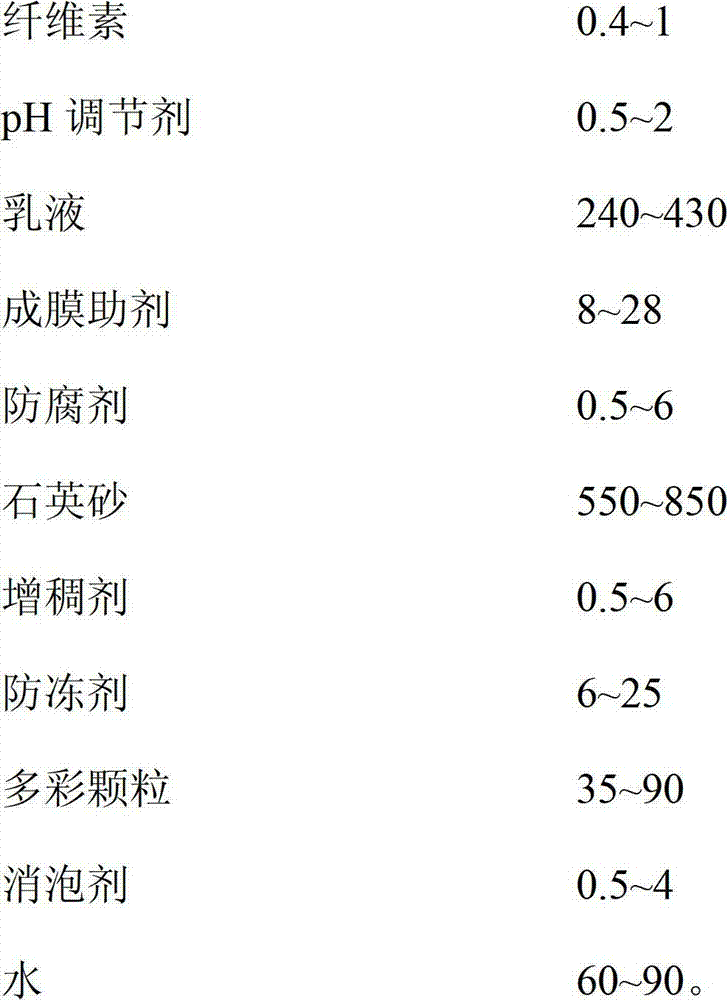

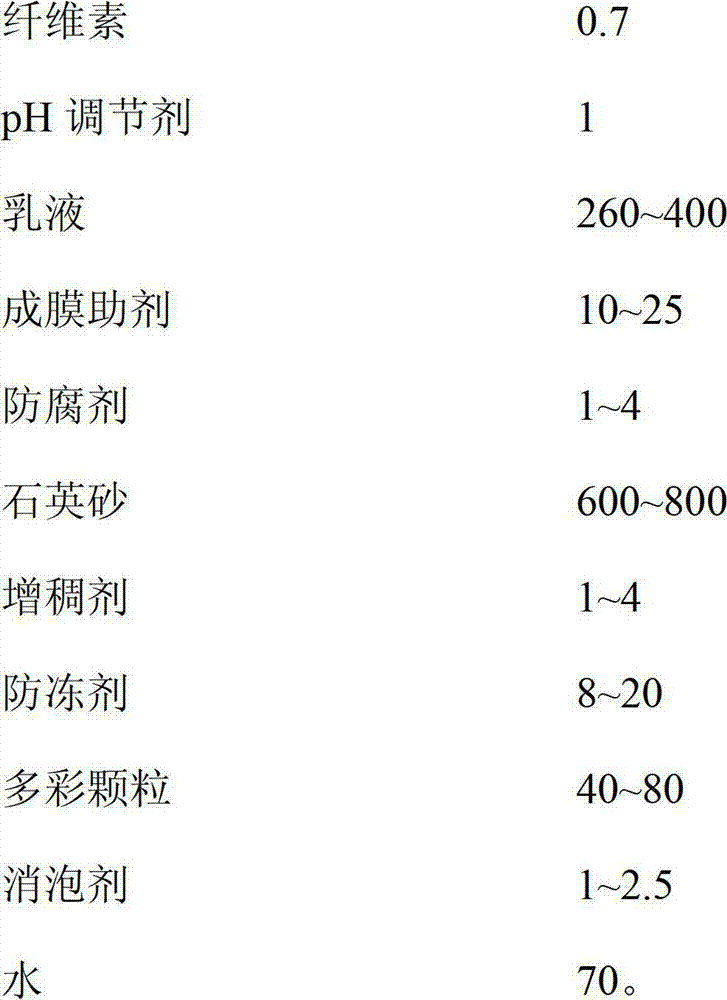

Marble paint and preparation method thereof

The invention discloses marble paint and a preparation method thereof. The marble paint comprises the following components in part by weight: 0.1 to 2 parts of cellulose, 0.1 to 3 parts of pH conditioning agent, 200 to 450 parts of emulsion, 5 to 32 parts of film forming aid, 0.1 to 8 parts of preservative, 500 to 900 parts of quartz sand, 0.1 to 8 parts of thickening agent, 2 to 30 parts of antifreezing agent, 30 to 110 parts of colorful particle, 0.1 to 5 parts of defoaming agent and 50 to 100 parts of water. According to the production process of the marble paint, the raw materials are uniformly mixed at the temperature of below 45 DEG C. The marble paint has high scrubbing resistance, water resistance, artificial aging resistance, stain resistance, alkali resistance and hydrophobic performance; simultaneously, the paint can be coated on the surface of a substrate through spraying, brushing or rolling; and a good decorative effect is achieved.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

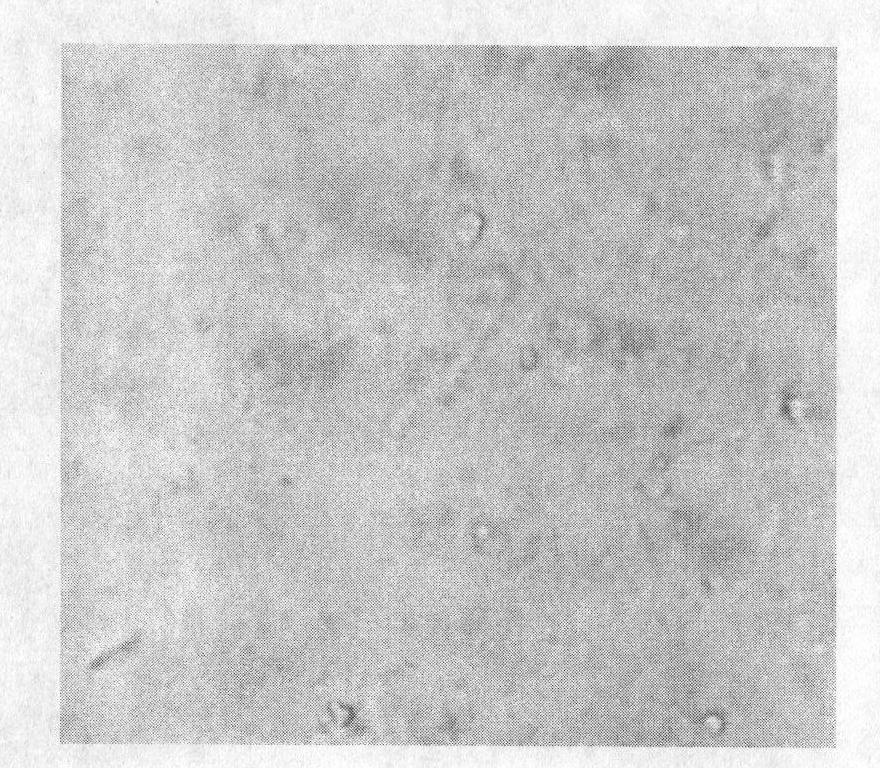

Venting, self-cleaning and degradable environmental-friendly preservative film and preparation method thereof

InactiveCN101817939AHigh tensile strengthImprove toughnessFlexible coversWrappersAntibiosisPolymer science

The invention discloses a venting, self-cleaning and degradable environmental-friendly preservative film and a preparation method thereof. Chitosan, nanometer titanium dioxide and beta-cyclodextrine serve as raw materials, and an ultrasonic wave blending compound technology and a freeze drying pore-forming technology are adopted to develop a novel bright and transparent degradable preservative film which has even thickness and totally satisfies the physical performance requirement of the preservative film. The method comprises the following steps: dispersing nanometer titanium dioxide, preparing mixed film liquid at a ratio, blending by ultrasonic wave, freezing, drying, baking and the like. Compared with the like product, the method of the invention is simple and easy to realize and has low preparation cost. The preservative film of the invention is degradable and has the functions of venting, antibiosis, self cleaning and the like, is a new-generation environmental-friendly preservative film for replacing the existing plastic preservative film, can be used for preserving fresh food and has wide application prospect and economic value in food field and the like.

Owner:徐紫宸

Chlorella sorokiniana CS-01 and culture method thereof for producing grease

InactiveCN101705190AWide adaptability to the environmentStrong alkali resistanceUnicellular algaeBiofuelsDry weightBiodiesel

The invention discloses chlorella sorokiniana CS-01 and a culture method thereof for producing grease. The preservation number of the chlorella is CCTCC M209220. The culture method for producing the grease comprises the following steps: inoculating index-cultured strains to BG11 sterilized culture solution, adding 0.3 to 1.5 g / L of sodium nitrate or urea and 1*10-5 mol / L to 1*10-3 mol / L of EDTA-Fe (III) into the culture solution, culturing the strains by ventilating or without ventilating at the temperature of between 25 and 35 DEG C, pH of 6 to 11, 6,600 to 10,000 Lx and lighting ratio of 14:10, and harvesting the grease, wherein the dry weight of the harvested cells is as high as 970 mg / L, and the content of the grease can reach 57 percent. The strain is fresh-water unicellular chlorella, has the advantages of strong environmental adaptation, high growing speed and higher grease yield, and has potential serving as a biodiesel preparation raw material to be cultured in a large scale in interior regions.

Owner:CENT SOUTH UNIV

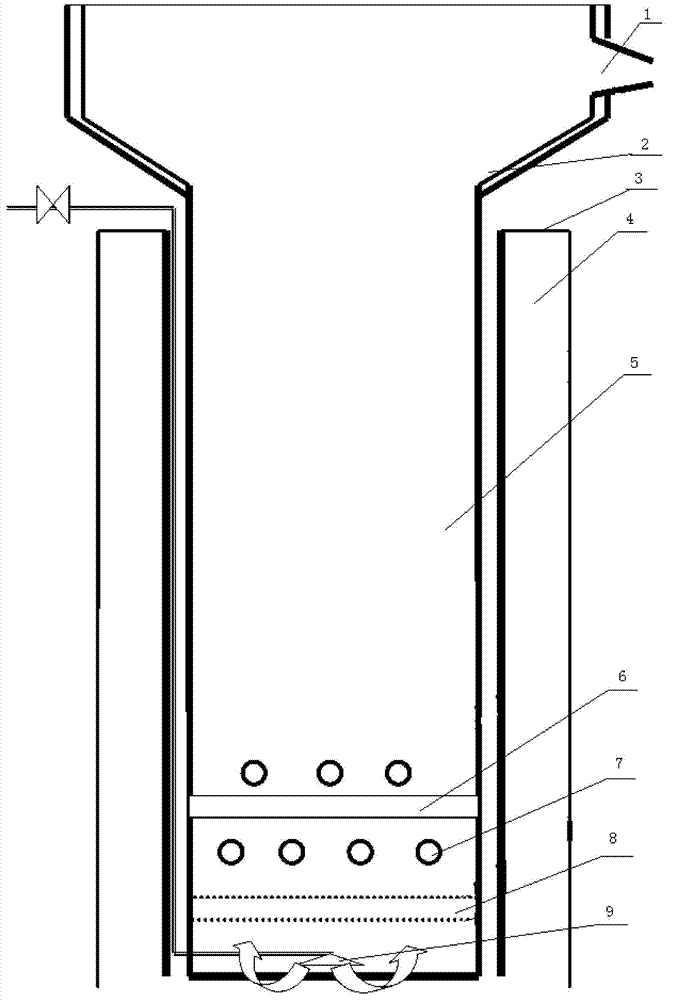

Special anticorrosion conductive powder coating for vertical shaft fluidized bed dip-coating as well as preparation method and application of coating

ActiveCN104710908AHigh glass transition temperatureLight weightAnti-corrosive paintsPolyurea/polyurethane coatingsNano al2o3Conductive materials

The invention relates to a special anticorrosion conductive powder coating for vertical shaft fluidized bed dip-coating. The special anticorrosion conductive powder coating is prepared from the following raw materials in parts by weight: 500-900 parts of film-forming resin and curing agent, 0-200 parts of glass flakes, 0-350 parts of filler, 15-50 parts of auxiliaries, 5-100 parts of conductive material and 1-5 parts of nanometer aluminum oxide or nano fumed silica. The powder coating has the characteristics of a high glass transition temperature, low specific gravity which is generally less than or equal to 1.1g / cm<3>, and easiness for fluidization; even though hundreds of tons of powder is added to a 20m deep well, the powder can be fluidized easily and uniformly; in case of too high specific gravity and difficult fluidization, the vertical shaft dip-coating method can not be utilized; the powder aims at a hot-dip coating construction process, and the film formed by the coating has surface conduction characteristics and high temperature water boiling resistance, and therefore, the coating is suitable for anti-corrosion coating of long linear workpieces such as mine mining anti-explosion gas pipelines, natural gas pipelines and liquefied gas pipelines; the coating is adaptive to the vertical shaft fluidized beds as deep as 20m, and still has good fluidity, which cannot be realized by common powders easily.

Owner:阜阳市诗雅涤新材料科技有限公司

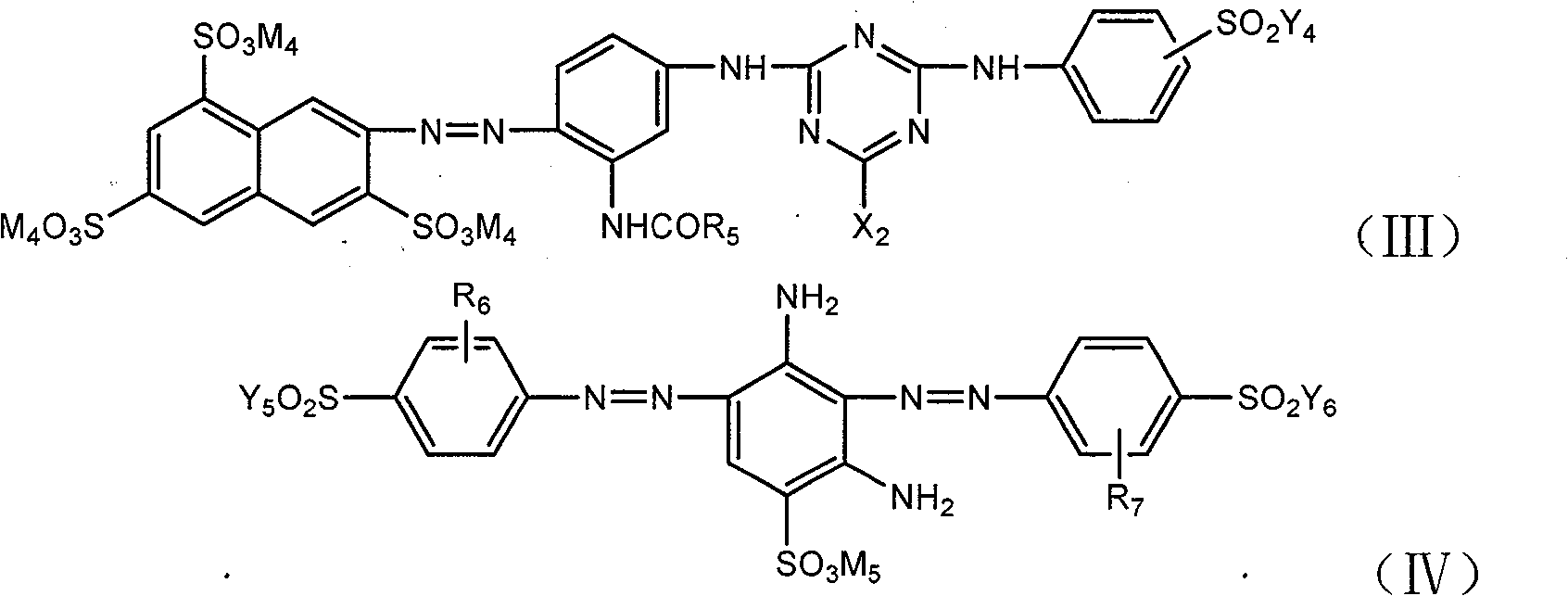

Black reactive dye composition

ActiveCN103073917AImprove washing fastnessImprove solubilityOrganic dyesDyeing processPerspirationCellulose fiber

A black reactive dye composition is characterized in that: based on the total weight, the black reactive dye composition comprises 30-90wt% of component A, 0-36wt% of component B, 0-30wt% of component C, 0-25wt% of component D and 0-45wt% of auxiliary agent, wherein the component A comprises at least one of compounds shown in formula (I), the component B comprises at least one of compounds shown in formula (II) or compounds shown in formula (III), the component C comprises at least one of compounds shown in formula (IV), and the component D comprises at least one of compounds shown in formula (V) or formula (VI). The black reactive dye composition is suitable for printing and dyeing of cotton, artificial cotton, hemp, regenerated fiber or textiles thereof, or printing and dyeing of polyamide fiber, cellulose fiber, protein fiber or textiles thereof, is particularly suitable for printing and embossing of the artificial cotton, has excellent wash fastness and perspiration fastness and can ensure a good hand feel of textiles.

Owner:ZHEJIANG RUIHUA CHEM

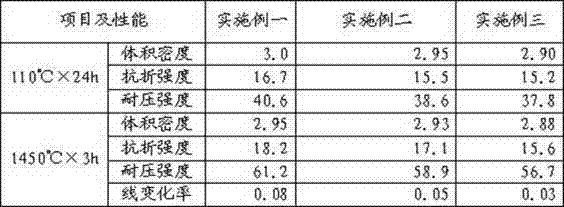

Castable for major iron runner of blast furnace larger than 2500m<3>

InactiveCN102746012AImproved thermal shock stabilityImprove insulation effectCarbon compositesSilicic acid

Owner:JIANGSU DAOJUE GRAND NEW ENERGY VEHICLE

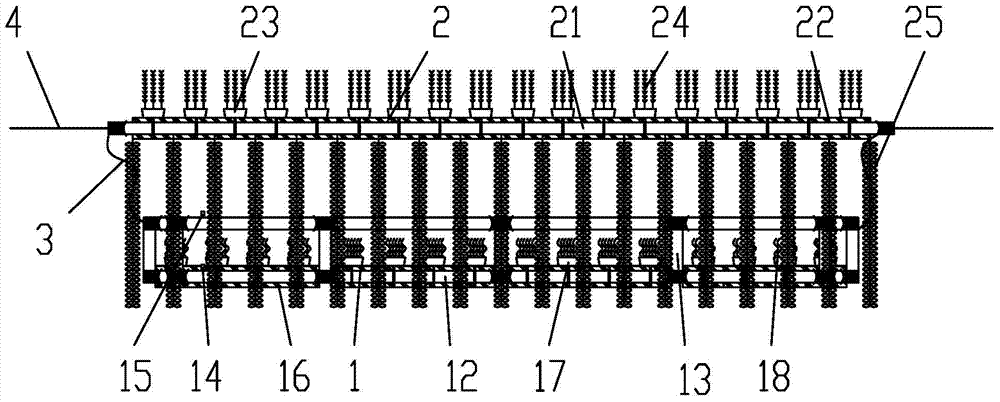

Submerging bed-floating bed coupled water purifying device

InactiveCN104743673AAvoid restrictionsDeep ecological nicheBiological treatment apparatusWater qualityPolyvinyl chloride

The invention discloses a submerging bed-floating bed coupled water purifying device. The submerging bed-floating bed coupled water purifying device comprises a submerging bed and a floating bed which are made of UPVC (hard polyvinyl chloride) tubes, wherein the submerging bed comprises upper and lower rectangular frames which are the same in shape; a plurality of perpendicular connecting tubes are arranged between the two rectangular frames; a plurality of horizontal connecting tubes are arranged in the lower rectangular frame; the frames are internally communicated; a floating block capable of being spliced is embedded into the lower rectangular frame, and a planting pot in which submerged plants are planted is arranged on the floating block; a floating block capable of being spliced is also embedded into the floating bed, a planting pot in which emergent aquatic plants are plants is arranged on the floating block, and artificial seaweeds are suspended between adjacent floating blocks of the floating bed; the submerging bed is placed on the center of the inner outline of the floating bed; a connecting rope is arranged between the submerging bed and the floating bed. According to the submerging bed-floating bed coupled water purifying device disclosed by the invention, positions, in water, of submerged plants are regulated by internally watering and pumping the submerging bed, so that the positions of the submerged plants are changed along with ecological niches of water level, transparency and the like, and a natural water environment is simulated to a greatest extent. The water plant planting amount is large, the varieties are rich, the survival rate is high, and the restoration of water body ecological community is facilitated.

Owner:TIANJIN UNIV

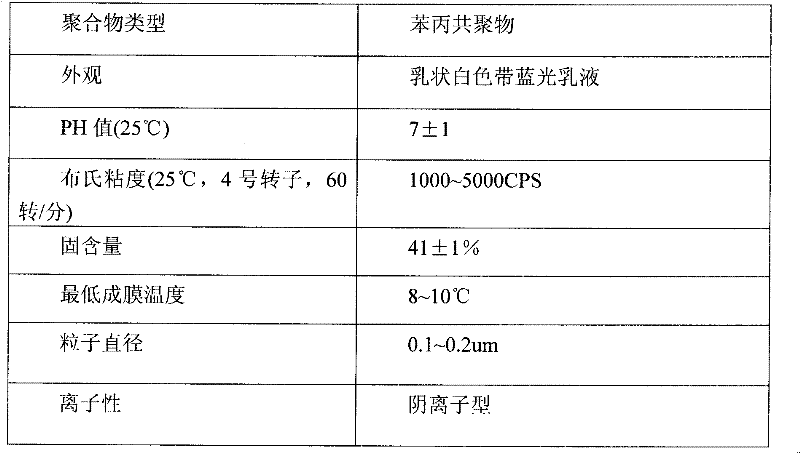

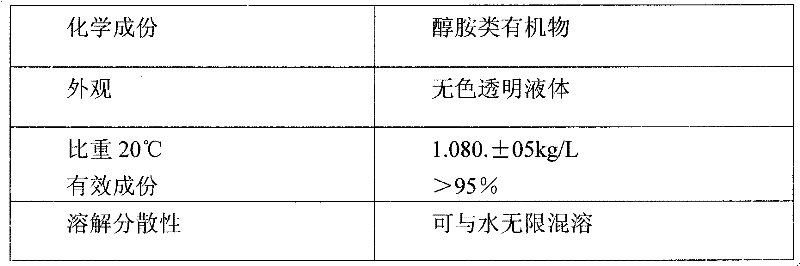

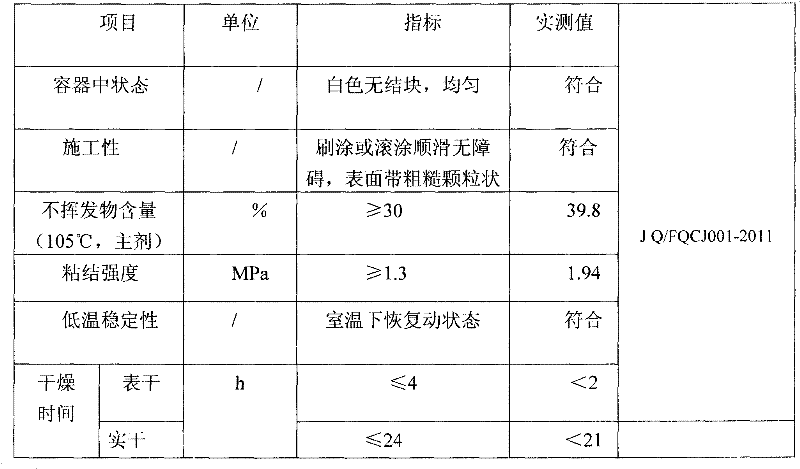

Polymer emulsion interface agent for base layer coating treatment and preparation method thereof

The invention discloses a polymer emulsion interface agent for base layer coating treatment and a preparation method thereof. The polymer emulsion interface agent for base layer coating treatment comprises a component A and a component B. In use, the component A and the component B are mixed according to a weight ratio of 1: 1. The mixture of the component A and the component B is white paint. The component A comprises 0.1 to 0.5% of hydroxyethylcellulose, 0.2 to 0.9% of a dispersing wetting agent, 12 to 19% of quartz powder, 48 to 65% of styrene-acrylic acid ester polymer emulsion, 0.05 to 0.35% of an antiseptic, 0.01 to 0.2% of a mildew inhibitor, 0.05 to 0.25% of a multifunctional auxiliary agent, 0.05 to 0.55% of a thickening agent, 0.1 to 0.5% of an antifoaming agent, 0.2 to 0.7% of a film forming auxiliary agent and 18 to 35% of water. The component B comprises 20 to 38% of wollastonite powder, 15 to 35% of quartz powder and 38 to 55% of quartz sand. Through combining the component A and the component B according to a ratio, the polymer emulsion interface agent for base layer coating treatment has the characteristics of good cohesion and adhesion, high bonding intensity, good closeness, rough surface layer and good adhesiveness with putty.

Owner:FUZHOU QICAIJU BUILDING MATERIAL

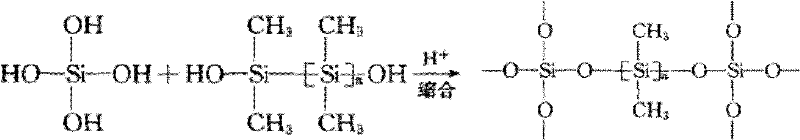

Preparation for organic/inorganic composite corrosion-resisting protective film coating layer for concrete and application thereof

InactiveCN102432336AImprove permeabilityHas a small molecular structureRoom temperatureDimethyl siloxane

The invention discloses a preparation method for an organic / inorganic composite corrosion-resisting protective film coating layer. The method is as follows: blending ethyl orthosilicate, deionized water and ethanol based on a mole ratio of 1: (3-4): (3-5) at room temperature, and adding an organic modifier HTPDMS (hydroxybutyl-terminated polydimethylsiloxane) under the action of catalyst dibutyltin dilaurate. The invention also discloses a neutral organic / inorganic composite corrosion-resisting thin film coating layer and a method for corrosion-resisting coating processing on concrete with the coating layer. The invention prepares the organic / inorganic composite corrosion-resisting thin film coating layer material by the sol-gel technology, wherein the prepared material has advantages of simple preparation method, economy, practicability, low production cost and so on. The production and construction are safe. The prepared material can be widely used for protecting the concrete.

Owner:ZHEJIANG UNIV

Quick screening method of alkali resistance rice breeding material

InactiveCN1413448AStrong alkali resistancePlant genotype modificationScreening methodFunctional genes

A method for quickly screening the alkali-resistance paddy rice includes such steps as choosing 2-4 standard refrerence varieties including at least one pair of sensitive and insensitive varieties, sterilizing, accelerating germination, sowing, pre-culturing, alkali stress treating, restorative growth and evaluating the alkali damage. It can be used for screening, genetic analysis and alkali-resistant functional gene mapping.

Owner:CHANGCHUN INST OF GEOGRAPHY CHINESE ACAD OF SCI

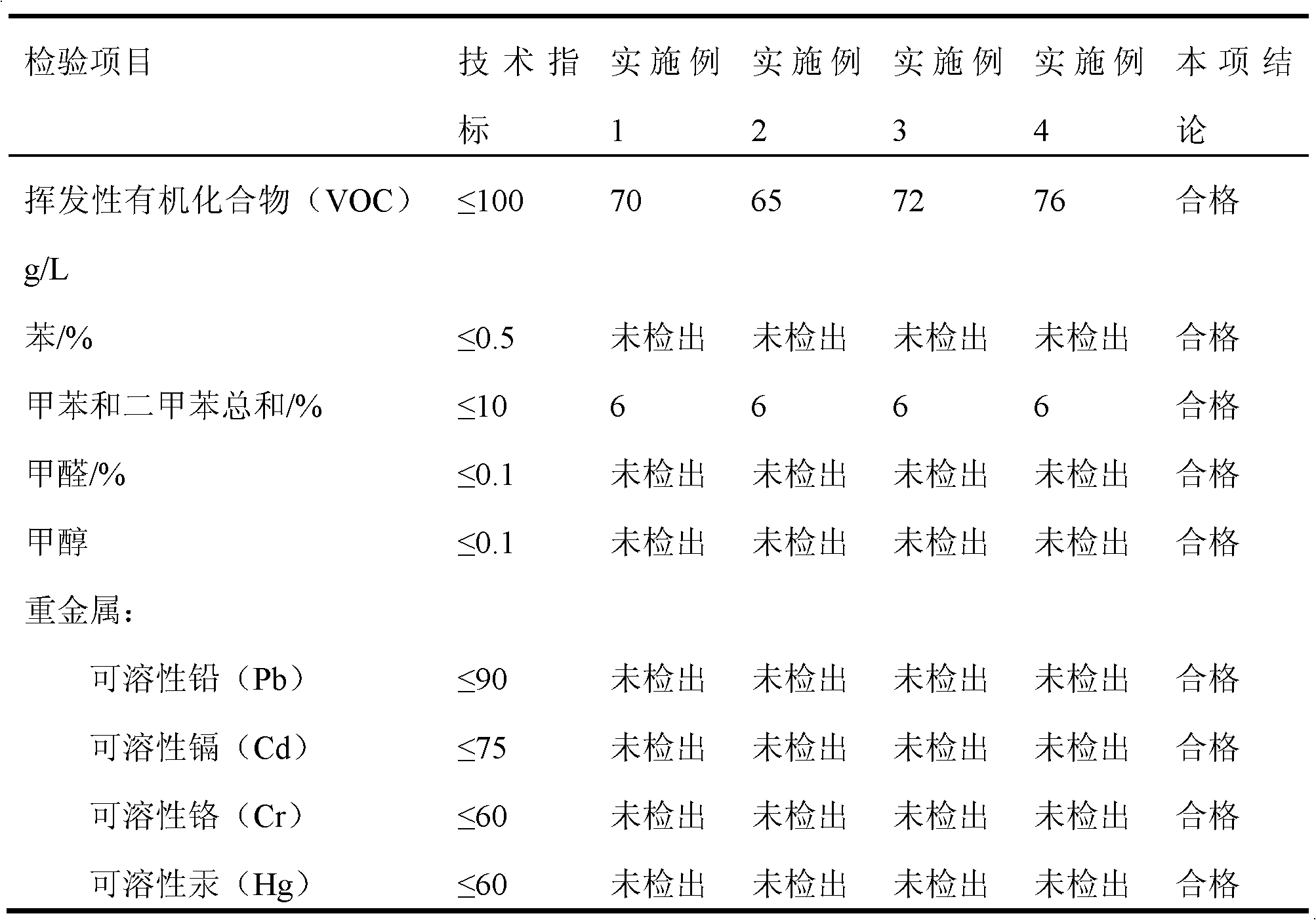

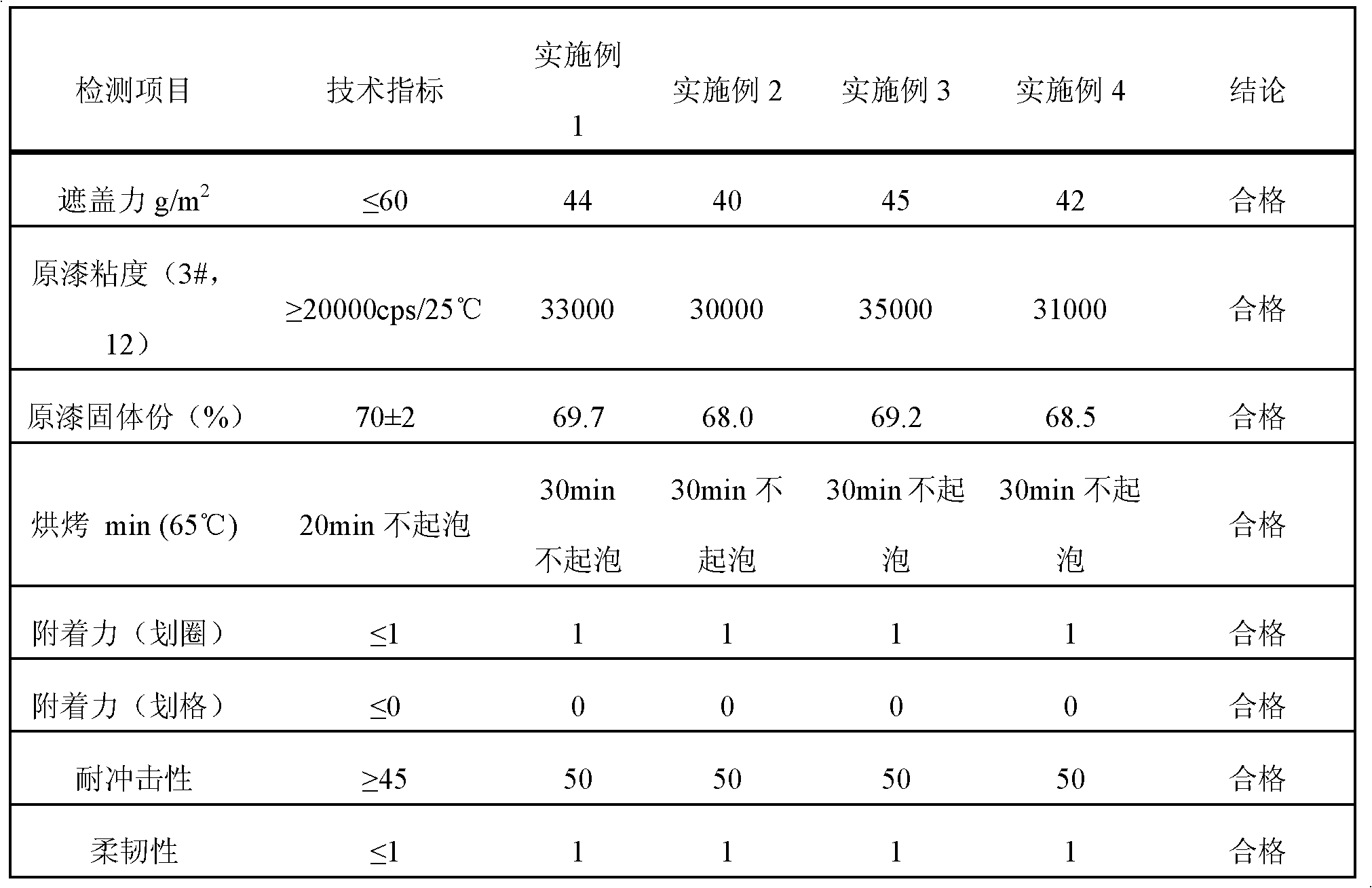

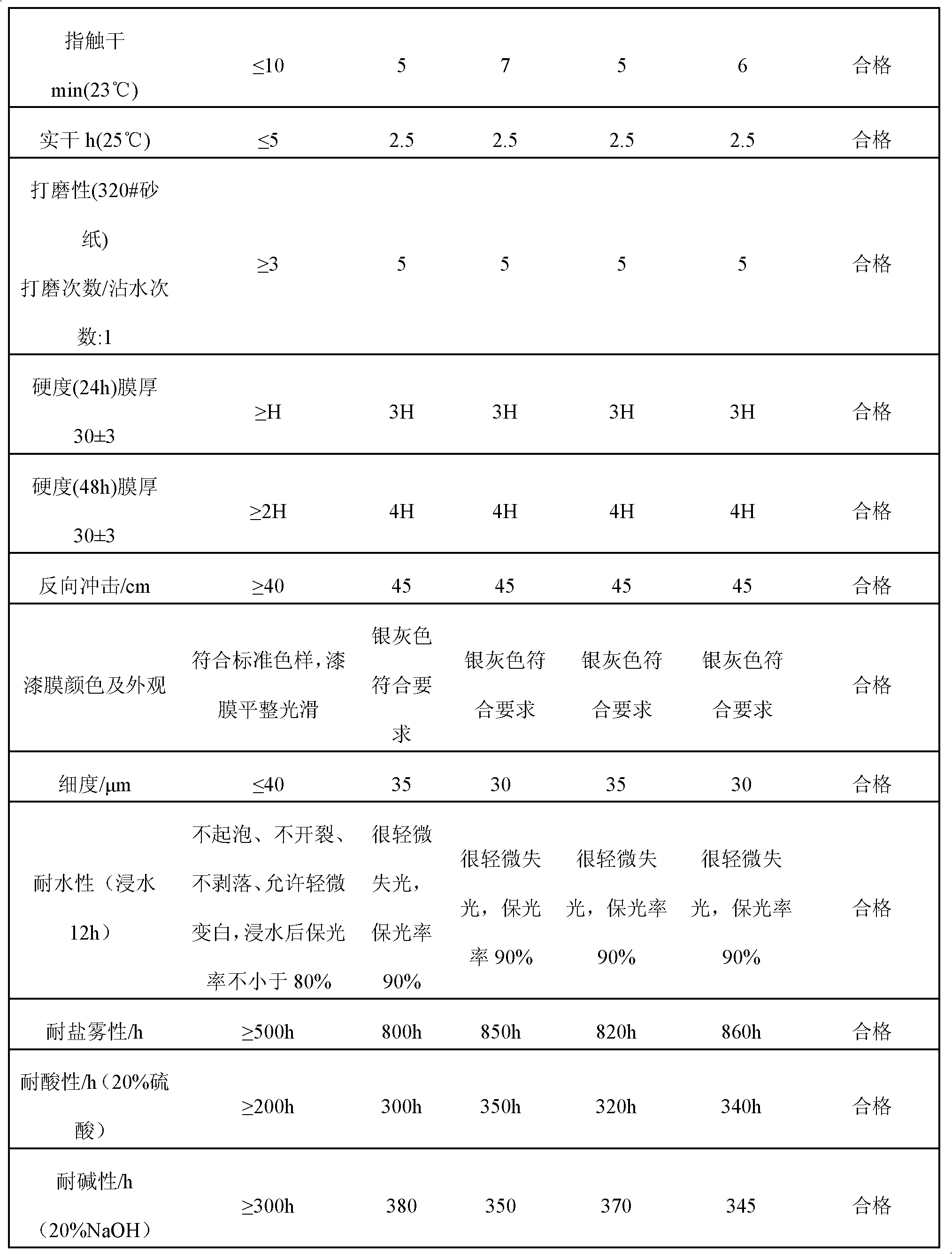

Special primer for heavy-duty machinery

InactiveCN102618144AAvoid interferenceEnsure quality stabilityAnti-corrosive paintsEpoxy resin coatingsEnvironmental resistanceEpoxy

The invention relates to a special primer for heavy-duty machinery, which consists of A components and B components, wherein the A components include, by weight percentage (amount to 100%), 40-50% of epoxy resin, 8-12% of diluents, 1-5% of auxiliary, 7-15% of paint and 28-37% of fillers, and the B components include modified polyamide curing agent. The primer made by resin with proper epoxy equivalent, functional paint and fillers and high-performance curing agent is stable in quality, dry, quick, excellent in corrosion resistance, applicable to various coating manners, excellent in construction compatibility, low in price, non-toxic and environment-friendly and can be applied to the heavy-duty machinery having high requirement for corrosion resistance.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Composite coating on surface of anti-alkali anti-corrosion aluminum alloy and technology

ActiveCN104962974APermeation barrierStrong alkali resistanceSynthetic resin layered productsSurface reaction electrolytic coatingEpoxyOrganosilicon

The invention belongs to the technical field of processing of metal surfaces, and provides a composite coating on the surface of an anti-alkali anti-corrosion aluminum alloy and a technology. The composite coating comprises aluminum or an aluminum alloy matrix and an anode oxide film layer coated on the aluminum or the aluminum alloy matrix, wherein an organosilicon coating is coated outside the anode oxide film layer, and the organosilicon coating is a composite layer consisting of epoxy modified organic silicon resin and methyl methacrylate. The organosilicon coating is firmly coated on the surface on which anodic oxidation is performed through construction of a mixing method and a spraying method, soaking, diffusion and closing on oxide film holes and solidification at 180 DEG C for 20-25min after flash drying of the surface layer of the organosilicon coating, infiltration of corrosive substances or alkaline substances on the inner-layer oxide film and the aluminum matrix is insulated, an aluminum alloy product processed by the technology disclosed by the invention has a good anti-alkali property and a good anti-corrosion property, the high temperature resistant property can be improved to 180 DEG C, so that cracks do not exist, and performance standard requirements can be satisfied under the condition that original appearance requirements are not changed.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

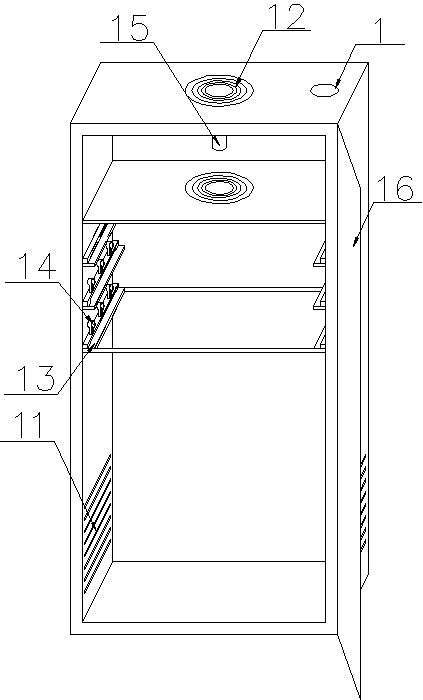

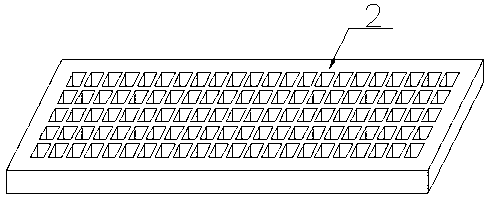

Photocatalysis sterilization deodorization device

InactiveCN103191457AIncrease contact surfaceExtension of timeDispersed particle separationDeodrantsControl systemEnvironmental engineering

The invention discloses a photocatalysis sterilization deodorization device which is used for eliminating bacteria and odor in the air, and comprises a chassis, a sterilization deodorization mechanism, an exhaust mechanism and a control system, wherein the sterilization deodorization mechanism comprises a photocatalysis plate and a catalysis light source, the catalysis light source is arranged on one side or two sides of the photocatalysis plate and illuminates a light catalyst layer; the exhaust mechanism is used for enabling the air to sequentially flow by an air inlet cavity, the photocatalysis plate and an air outlet cavity to reach an exhaust port from an air suction port; and the control system is respectively electrically connected with the catalysis light source and the exhaust mechanism. By adopting the advanced photocatalysis technology and utilizing the strong oxidation function of the photocatalysis, harmful substances including ammonia, sulfide and organic volatize gases in the air of a toilet can be high efficiently oxidized into harmless substances, the deodorization rate can reach more than 99 percent and all bacteria can be basically killed and cannot be recovered.

Owner:SUZHOU WU SHENG ENVIRONMENTAL SCI & TECH

1080 m<3> blast furnace main iron runner castable

InactiveCN102757252AImproved thermal shock stabilityImprove insulation effectCarbon compositesSilicic acid

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

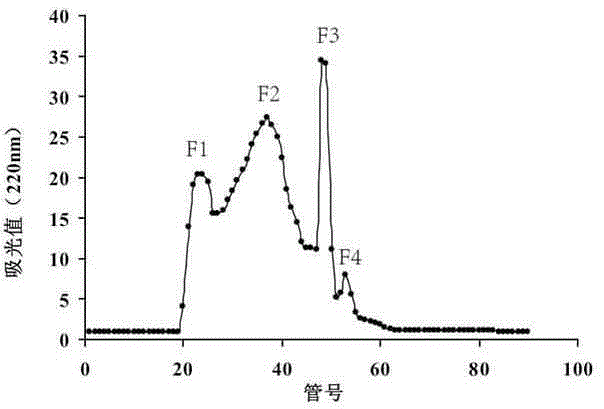

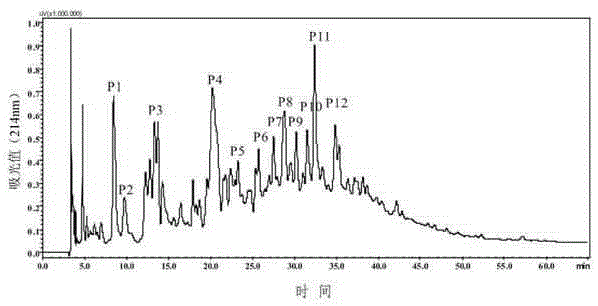

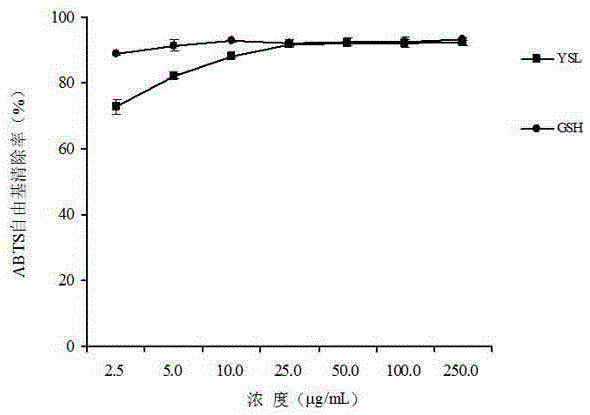

Carrot seed antioxidant tripeptide as well as preparation method and application thereof

InactiveCN105254708AImprove cleanlinessImprove stabilityPeptide preparation methodsFermentationDPPHBiochemistry

The invention discloses a carrot seed antioxidant tripeptide as well as a preparation method and an application thereof. The sequence of the carrot seed antioxidant tripeptide is Tyr-Ser-Leu (YSL). The in-vitro experiment shows that DPPH and ABTS free radicals can be effectively removed by the tripeptide, and meanwhile the tripeptide is relatively good in stability. The carrot seed antioxidant tripeptide disclosed by the invention has the characteristics of simple structure, high antioxidant activity, and the like, can be used as assistant and substitute of an artificially synthesized antioxidant, and has important values for development and application of novel antioxidant healthcare products.

Owner:FUZHOU UNIV

A high durability and high bearing capacity concrete pipe pile

The invention discloses a high-durability and high-bearing-capacity concrete pipe pile, which is characterized by comprising the following raw material in part by mass: 685 to 760 parts of common silicate cement, 170 to 200 parts of silicon powder with an average particle size of 0.30 mu m and a SiO2 content of more than or equal to 92 percent, 1,100 to 1,190 parts of quartz sand with a particle size between 0.16 to 1.25mm, 13 to 15 parts of superplasticizer, 165 to 190 parts of water, and 90 to 150 parts of copper-plated steel fibers with a diameter between 0.18 and 0.25mm and a length between 11 and 15mm. The preparation process of the pipe pile is to uniformly stir the steel fiber and fine quartz sand and the concrete, silicon powder, water and superplasticizer in turn to obtain a mixture, fill the mixture into a mold, form with vibrating, cure in a steam environment with a temperature between 75 and 95 DEG C and a humidity of not less than 95 percent for 36 to 48 hours and demold. The pipe pile has the advantages of high antifatigue performance and corrosion-resistance performance and small cross section thickness.

Owner:黄贺明

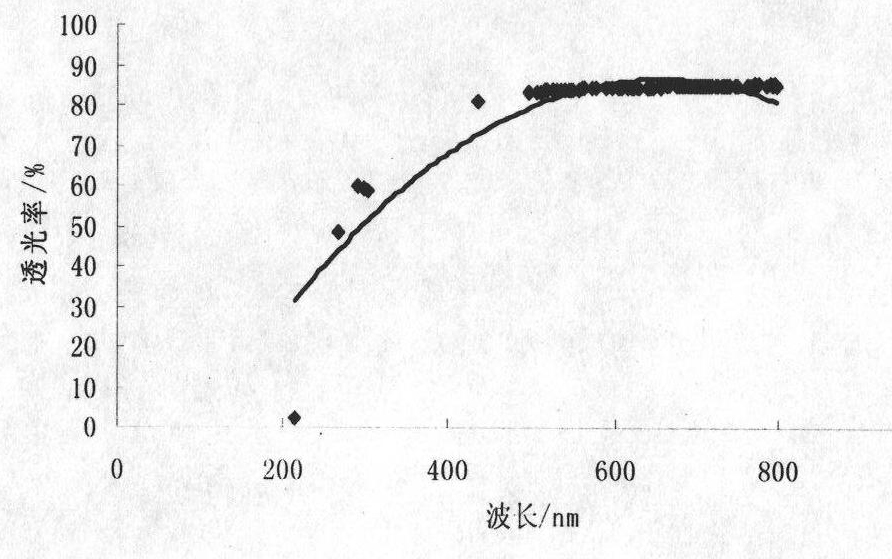

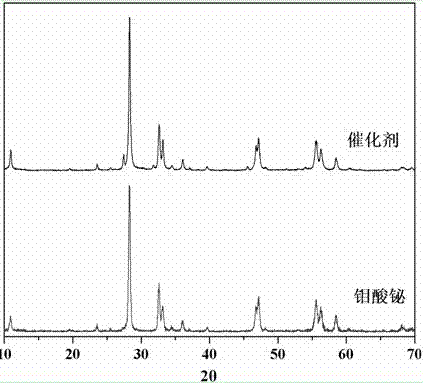

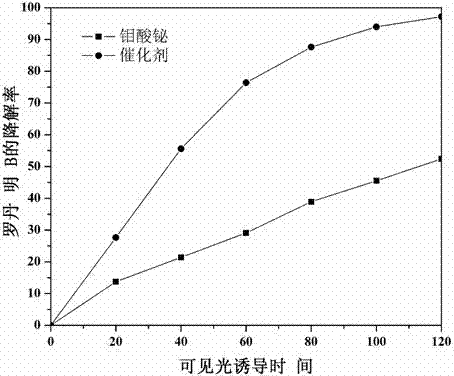

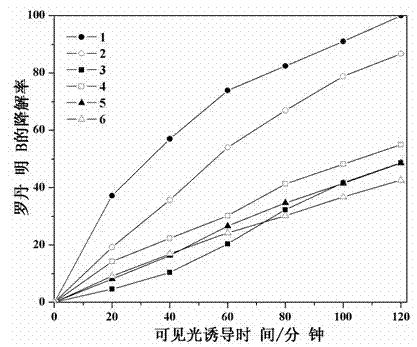

Catalyst for degrading rhodamine B by photocatalysis, and preparation method thereof

InactiveCN102357360AGood repeatabilityImprove thermal stabilityWater/sewage treatment by irradiationWater contaminantsStrong acidsThermal stability

The invention relates to a catalyst for degrading rhodamine B by photocatalysis, and a preparation method thereof. The catalyst is prepared from TiO2-supported Bi2MoO6, wherein a molar ratio of the TiO2 to the Bi2MoO6 is 10%. With the induction of visible light, 100 ml of the rhodamine B with the concentration of 10<-5> mol / L can be completely degraded in 2 hours with 0.1 g of the catalyst. According to the present invention: 1, the catalyst of the present invention is prepared by a hydrothermal method, the operation is simple, the production cost is low, the synthesis yield is high, the purity is high, the reproducibility is good, and the method is applicable for the requirements of expanded production; 2, the catalyst of the present invention has characteristics of good thermal stability, strong acid resistance and strong alkali resistance; 3, the catalyst of the present invention has a good effect of photocatalytic degradation of organic materials, and the catalytic efficiency of the catalyst of the present invention is improved by 2 times than the catalytic efficiency of the single Bi2MoO6.

Owner:NANCHANG HANGKONG UNIVERSITY

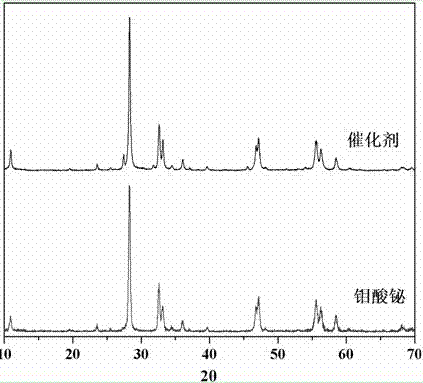

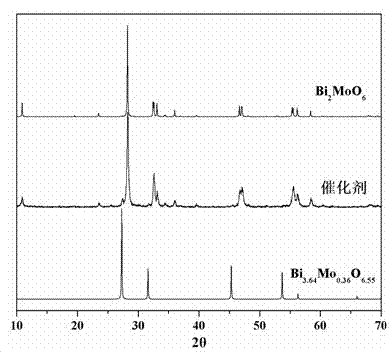

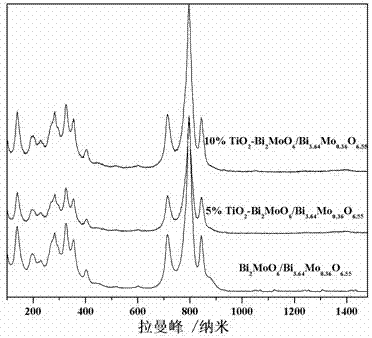

Ternary neterogeny structural light degradation organic matter catalyst TiO2-Bi2MoO6/Bi3.64Mo0.36O6.55 and preparation method thereof

ActiveCN102500361AGood repeatabilityImprove thermal stabilityWater/sewage treatment by irradiationCatalyst activation/preparationOrganic matterThermal stability

Disclosed is ternary neterogeny structural light degradation organic matter catalyst 5% TiO2-Bi2MoO6 / Bi3.64Mo0.36O6.55, which consists titanium dioxide (TiO2) and two types of dibismuth trimolybdenum dodecaoxide (Bi2MoO6 and Bi3.64Mo0.36O6.55) with different structures, wherein the titanium dioxide is 5% of total mole number of bismuth elements. The ternary neterogeny structural light degradationorganic matter catalyst 5% TiO2-Bi2MoO6 / Bi3.64Mo0.36O6.55 has the advantages that the catalyst is the ternary neterogeny structural light degradation organic matter catalyst reported for the first time; 2, the catalyst is directly synthesized by a one-step hydrothermal method, is simple in operation, low in production cost, high in synthesis yield and purity, fine in repeatability, and meets requirements of batch production; 3, the catalyst is fine in thermal stability and is high in acid resistance and alkali resistance; and 4, the catalyst has a good photocatalytic degradation organic effect, and has a higher catalysis effect as compared with single titanium dioxide, dibismuth trimolybdenum dodecaoxide (Bi2MoO6 and Bi3.64Mo0.36O6.55) and an optional combination (TiO2-Bi2MoO6, TiO2-Bi3.64Mo0.36O6.55 and Bi2MoO6 / Bi3.64Mo0.36O6.55) among the single titanium dioxide and the dibismuth trimolybdenum dodecaoxide (Bi2MoO6 and Bi3.64Mo0.36O6.55).

Owner:NANCHANG HANGKONG UNIVERSITY

Compound active black dye composition

ActiveCN102558907AImprove solubilityGood lifting effectOrganic dyesDyeing processTextile printerPhotochemistry

The invention provides a compound active black dye composition, mainly comprising one or more than one component A with a structure shown as a formula (I), one or more than one component B with a structure shown as a formula (II) and one or more than one component C with a structure shown as a formula (III) and / or a formula (IV), wherein on the basis of the component A, the component B and the component C, the percent by weight of the component A is 45-90%, the percent by weight of the component B is 1-30%, and the percent by weight of the component C is 5-40%. The compound active black dye composition provided by the invention has high dissolvability, good lifting performance, high alkali resistance, excellent wet-processing fastness and good drawing performance and is easy to wash when being used for textile printing and is a rare economical dark black dye.

Owner:ZHEJIANG KEYONG CHEM CO LTD

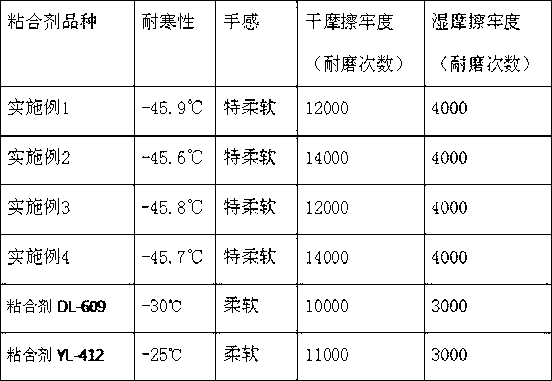

Acrylic ester electrostatic flocking binding agent and preparation method thereof

ActiveCN103214993AGood flexibilityImprove cold resistanceNon-macromolecular adhesive additivesEster polymer adhesivesIsooctyl acrylateSodium acetate

The invention relates to an acrylic ester electrostatic flocking binding agent and a preparation method thereof. The acrylic ester electrostatic flocking binding agent is a polymer emulsion which is prepared from the raw materials: polyoxyethylene dodecyl alcohol (50), sodium dodecyl sulfate, itaconic acid, N-hydroxymethyl acrylamide, acyclic acid, butyl acrylate, 2-ethylhexyl acrylate, styrene, gamma-methacryloxy propyl trimethoxyl silan, epoxy resin E-44, adipic acid dihydrazide, sodium acetate, ammonium persulfate and deionized water through seeded emulsion polymerization. The acrylic ester electrostatic flocking binding agent is an epoxy resin and organic silicon resin jointly-modified acrylic ester electrostatic flocking binding agent. The product has the advantages of flexibility, cold endurance, weather resistance and thermosetting stability and particularly has prominent water resistance and adhesive force.

Owner:LIAONING FIXED STAR FINE CHEM

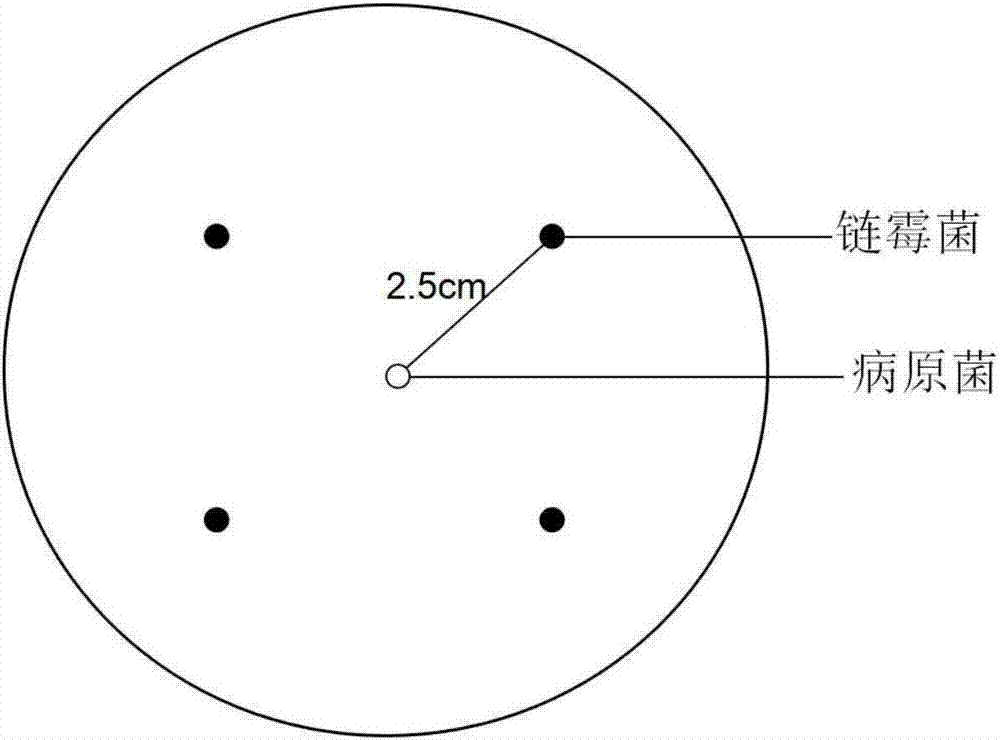

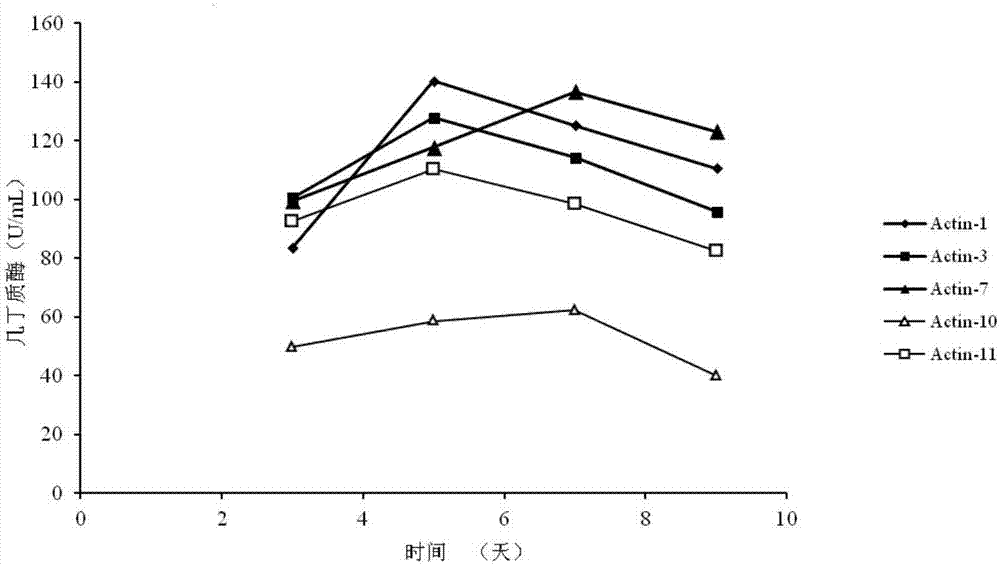

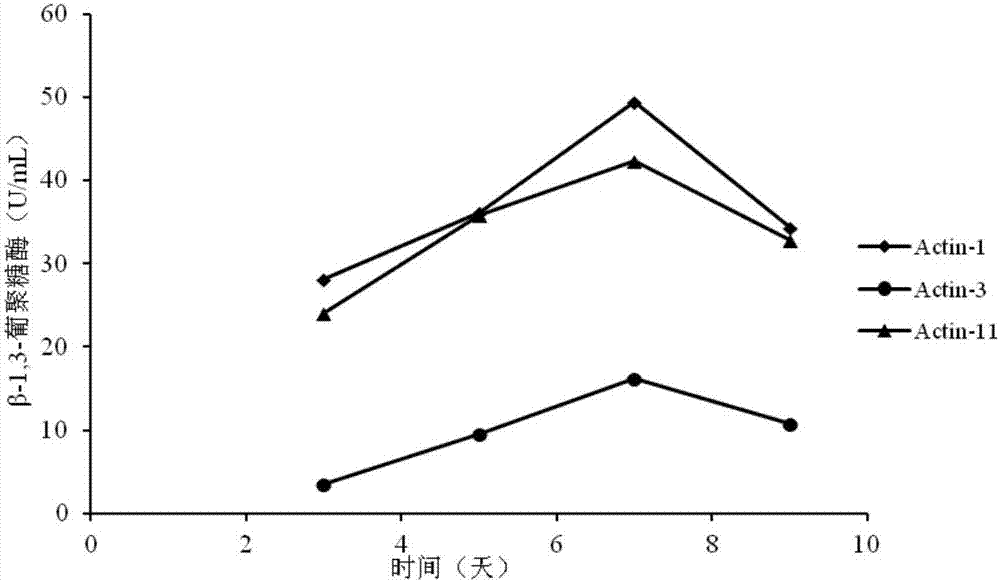

Streptomyces albidoflavus and application thereof in apple tree rot prevention and treatment

ActiveCN106906172AConducive to long-term colonizationStrong antibacterial active substanceBiocideBacteriaActive matterTherapeutic effect

The invention discloses streptomyces albidoflavus Actin-1. The streptomyces albidoflavus Actin-1 can grow and propagate with apple tree rot pathogenic bacterium mycelium as nutrition, long-term colonization of biocontrol bacteria on apple tree rot scabs is promoted, a long-term biological prevention and treatment function is achieved, meanwhile, the streptomyces albidoflavus Actin-1 is induced to generate multiple ectoenzyme cell wall hydrolytic enzymes, and pathogenic bacterium cells disintegrate in combination with the enzyme dissolving function; high antibacterial active matter can be generated, the bacteriostasis rate on the apple rot pathogenic bacteria is 89.82%, a good antibacterial effect is achieved on botryosphaeria berengeriana and other pathogenic bacteria, the bacteriostasis rate ranges from 76.08% to 87.10%, and broad spectrum bacteriostasis performance is achieved. The streptomyces albidoflavus Actin-1 is adopted as main biocontrol bacteria for preventing and treating the apple tree rot and other fruit and vegetable pathogenic bacteria, and the advantages of being good in prevention and treatment effect (100%), high in efficiency, low in recurrence rate (0), high in environment adaption capacity, high in stability, not likely to generate resistance to drugs and the like are achieved. Important significance is achieved on improving the prevention and treatment effect on the apple tree rot and other fruit and vegetable pathogenic bacteria, preventing pathogenic bacterium relapse and protecting the environment.

Owner:陕西枫丹百丽生物科技有限公司

Alkaline xylanase-containing dedicated enzyme for piglets and preparation method of alkaline xylanase-containing dedicated enzyme

ActiveCN103667221AIncrease vitalityHigh temperature resistanceAnimal feeding stuffAccessory food factorsBiotechnologyIntestinal structure

The invention discloses an alkaline xylanase-containing dedicated enzyme for piglets and a preparation method of the alkaline xylanase-containing dedicated enzyme, and belongs to the technical field of enzyme preparation. Thermophilic bacillus culture, acidic xylanase, beta-glucanase, acid protease, cellulose, amylase, beta-mannase, phytase, Chinese herb extracts, a protective agent and an activating agent are scientifically compounded to prepare the dedicated enzyme, wherein thermophilic bacillus cells in the thermophilic bacillus culture can improve animal body immunity, promote the development of immune organs, promote the maturity of animal intestinal structures and functions, and increase piglet daily gains and feed conversion rates. According to the invention, a safe digestive enzyme, namely the dedicated enzyme, is provided for piglets; the digestion burden is effectively reduced; the utilization rates of the raw materials and the growth rates of the piglets are increased; the environment is effectively protected; the effectiveness of the enzyme preparation can be brought into full play due to the addition of a proper amount of the activating agent; due to the scientific compound of the Chinese herb extracts, not only is the expiration date of the complex enzyme preparation prolonged, but also the immunity of the piglets is improved.

Owner:HUNAN HONGYING BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com