Active black dye

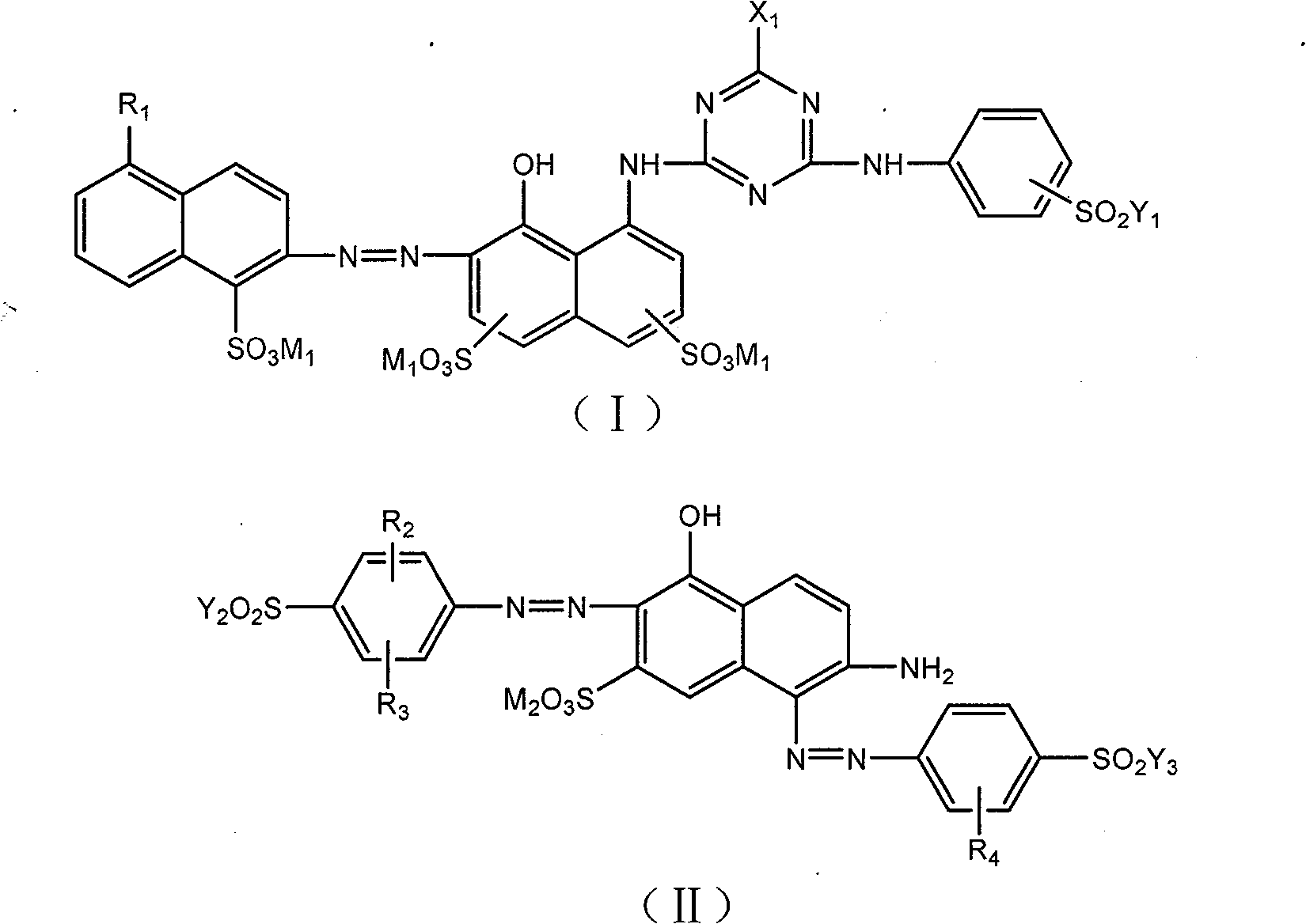

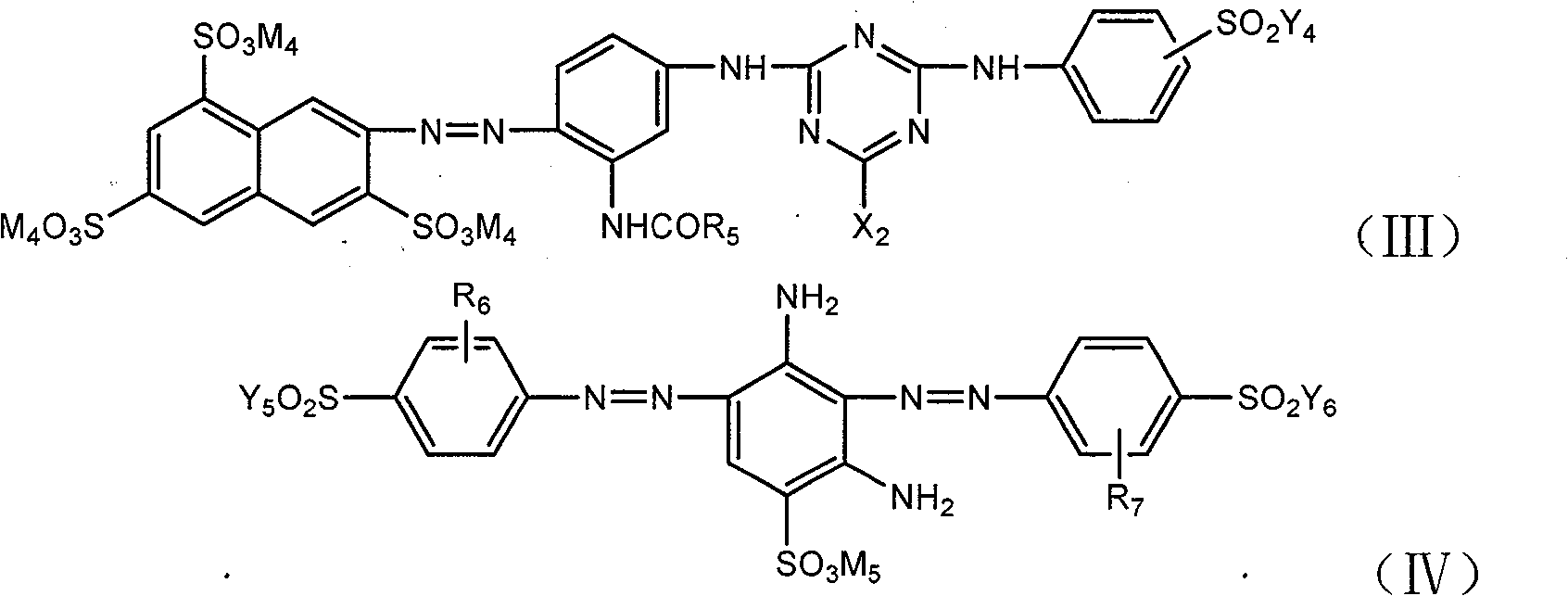

A reactive black and dye technology, applied in the field of reactive black dyes, can solve the problems of unsuitable large-scale popularization and application, unsatisfactory dyeing performance of compound dyes, and high product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The following dye compositions are provided:

[0051] Fuchsin dye component A15 grams, wherein weight percent, formula (I-1): formula (II-1): Yuanming powder (industrial sodium sulfate)=90: 10: 10;

[0052] Orange dye component B15 grams, wherein weight percentage, formula (III-1): formula (IV-1): Yuanming powder=92: 8: 15;

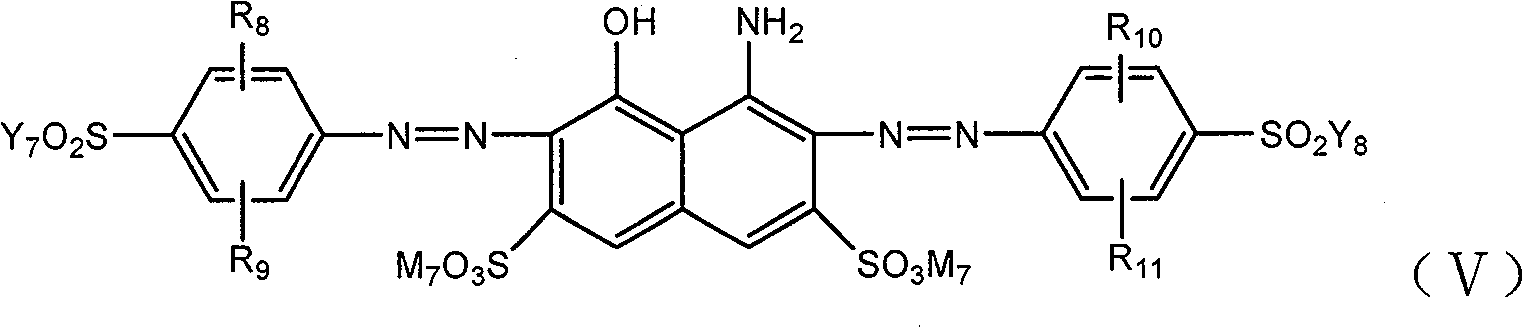

[0053] Navy blue dye component C70 grams, wherein weight percent, formula (V-1): Yuan Mingfen=85:15

[0054] Fully stir the dyes of each component according to the above ratio in the dry blending barrel, and mix the dry powder evenly. The black dye obtained is used for dyeing cotton fabrics, and has the properties of good blackness, level dyeing and color fastness.

Embodiment 2

[0056] The following dye compositions are provided:

[0057] Fuchsin dye component A10 grams, wherein weight percent, formula (I-1): formula (II-1): Yuan Mingfen=95: 5: 15;

[0058] Orange dye component B20 grams, wherein weight percent, formula (III-4): formula (IV-1): Yuanming powder=90: 10: 20;

[0059] Navy blue dye component C70 grams, wherein weight percent, formula (V-1): Yuan Mingfen=90:10;

[0060] With each component dyestuff of above-mentioned proportioning, 5 grams of diffusing agent naphthalenesulfonate formaldehyde condensate (NNO), add water to dissolve, stir evenly and dry, the black dyestuff that obtains is used for dyeing cotton fabric, has blackness good, uniform Good dyeing and color fastness properties.

Embodiment 3

[0062] The following dye compositions are provided:

[0063] Fuchsin dye component A10 grams, wherein weight percent, formula (I-1): formula (II-1)=95:5;

[0064] Orange dye component B15 grams, wherein weight percent, formula (III-1): formula (IV-1): Yuanming powder=90:10;

[0065] The navy blue dye component C75 gram of formula (V-4),

[0066] With the dyestuff of above-mentioned proportioning and 20 grams of sodium sulfate, 5 grams of dispersant MF (methylnaphthalenesulfonic acid formaldehyde condensate), after adding water to dissolve, stir evenly and dry, the black dyestuff that obtains is used for dyeing cotton fabric, has Good blackness, level dyeing and color fastness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com