Patents

Literature

393 results about "Naphthalenesulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

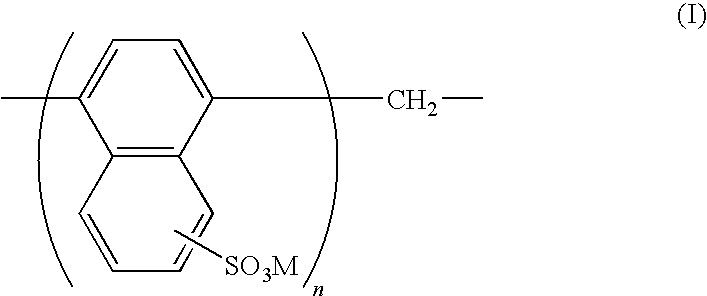

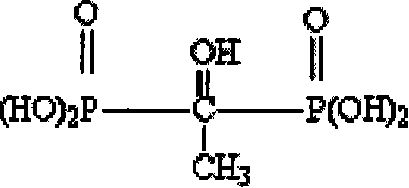

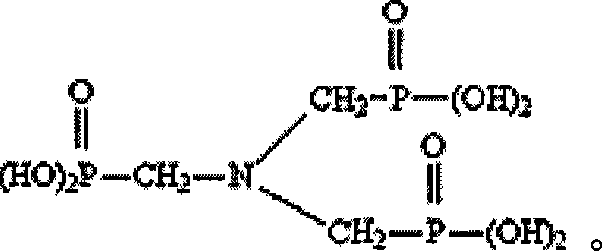

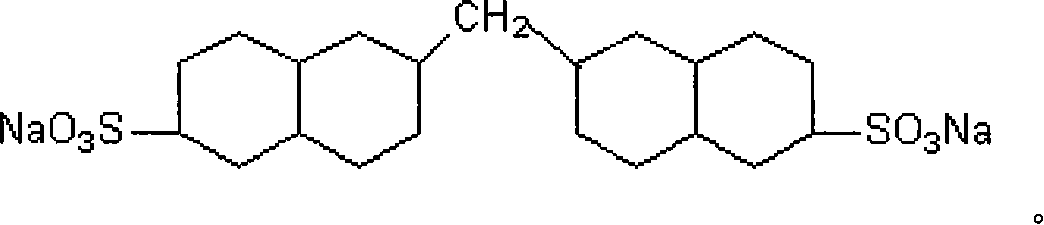

Naphthalenesulfonates are derivatives of sulfonic acid which contain a naphthalene functional unit. A related family of compounds are the aminonaphthalenesulfonic acids. Of commercial importance are the alkylnaphthalene sulfonates, which are used as superplasticizers in concrete. They are produced on a large scale by condensation of naphthalenesulfonate or alkylnaphthalenesulfonates with formaldehyde.

Low dust gypsum wallboard

ActiveUS20070048490A1High strengthReduce weightConstruction materialCovering/liningsDust controlSlurry

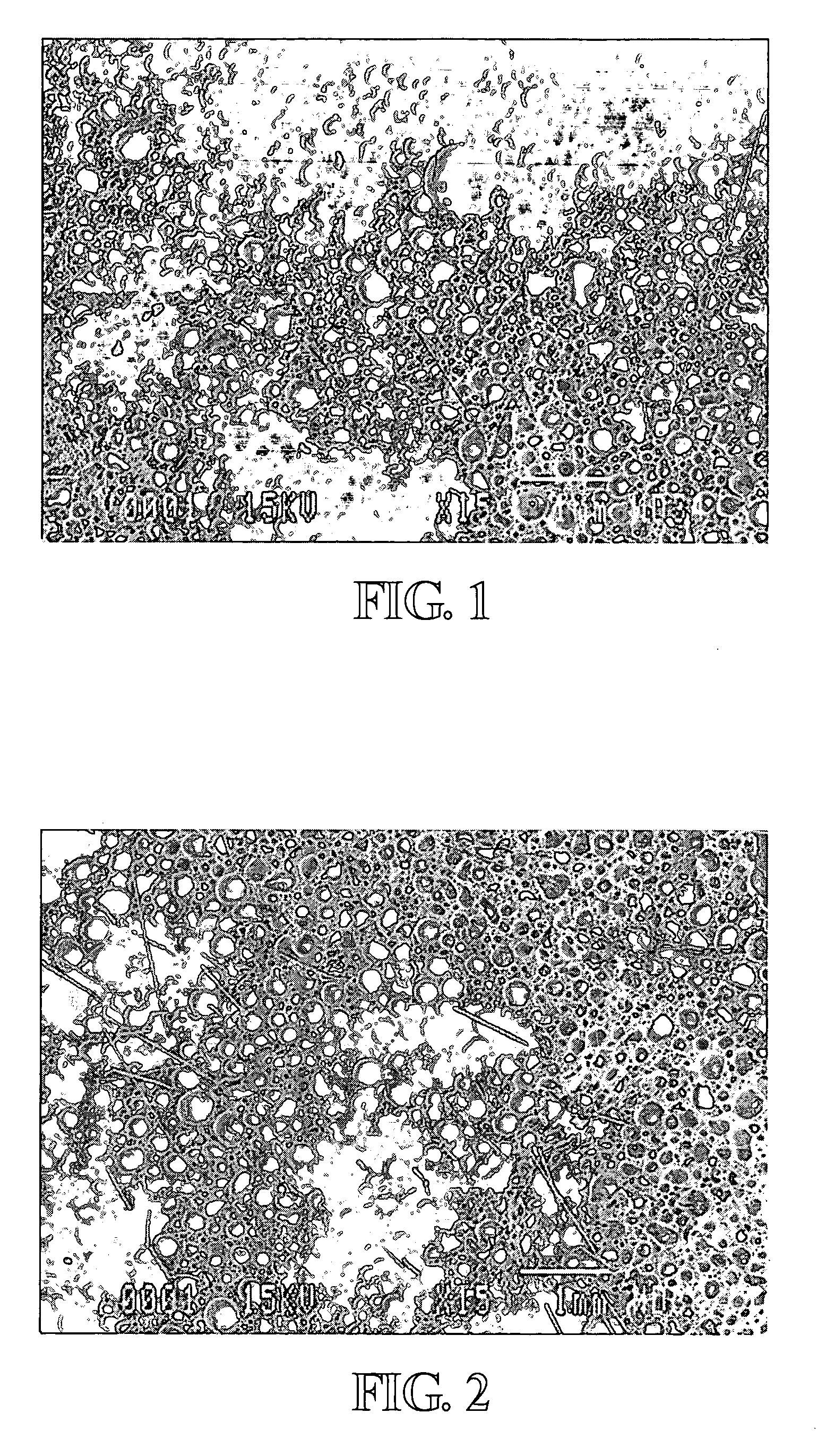

This invention provides low dust low density gypsum wallboard products having high total core void volumes, corresponding to low densities in the range of about 10 to 30 pcf. The wallboards have a set gypsum core formed between two substantially parallel cover sheets, the set gypsum core preferably having a total void volume from about 80% to about 92%, and made from a slurry including stucco, pregelatinized starch, and a naphthalenesulfonate dispersant. The combination of the pregelatinized starch and the naphthalenesulfonate dispersant also provides a glue-like effect in binding the set gypsum crystals together. The wallboard formulation, along with small air bubble voids (and water voids) provides dust control during cutting, sawing, routing, snapping, nailing or screwing down, or drilling of the gypsum-containing products. This invention also provides a method of making the low dust low density gypsum products including the introduction of soap foam in an amount sufficient to form a total void volume, including air voids, preferably from about 80% to about 92% in the set gypsum core, corresponding to a set gypsum core density from about 10 pcf to about 30 pcf. The wallboards produced by the method generate significantly less dust during working.

Owner:UNITED STATES GYPSUM CO

Composite light weight gypsum wallboard

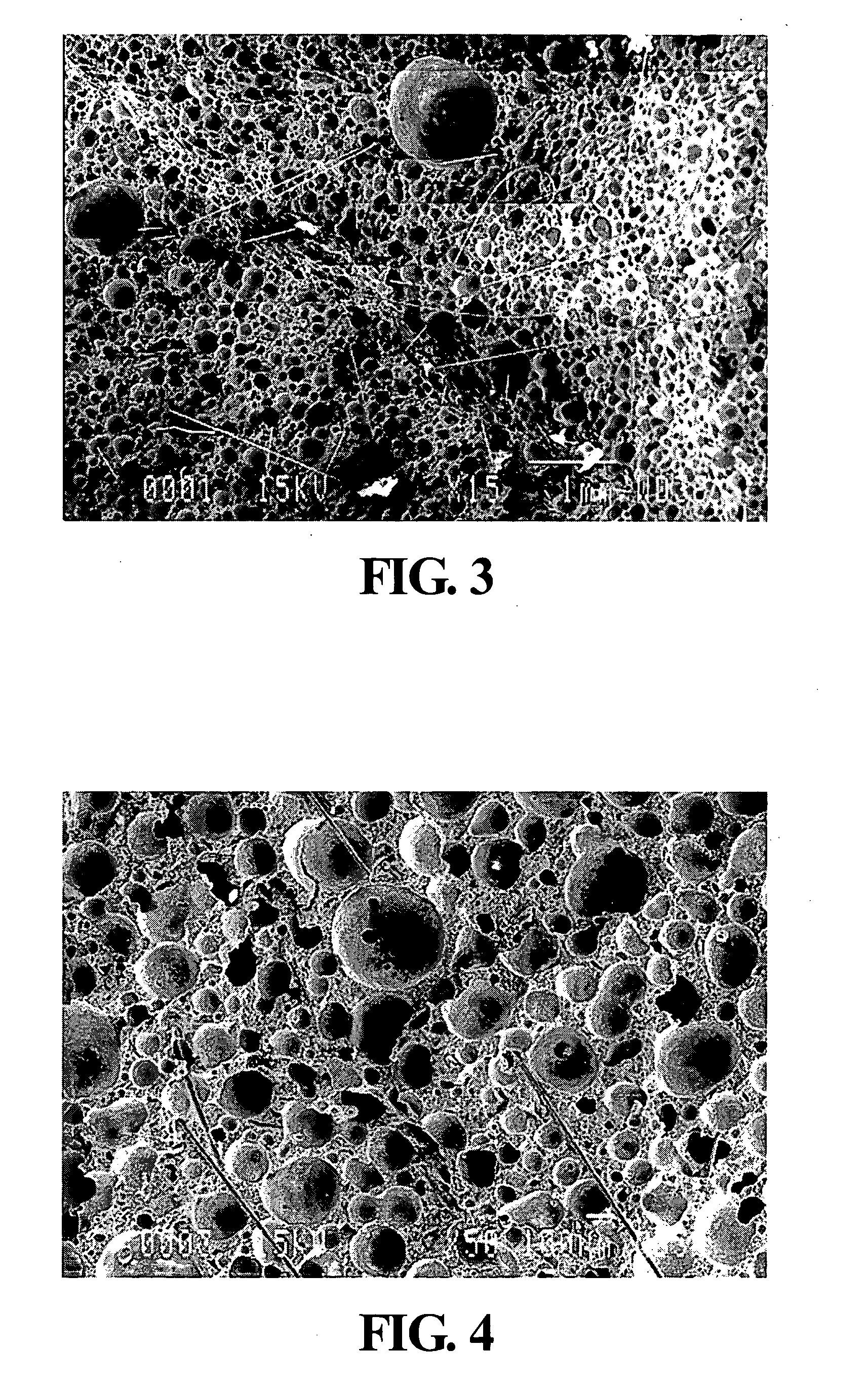

The invention generally provides a light weight composite gypsum board including a foamed low density set gypsum core, a top non-foamed (or reduced-foamed) bonding high density layer and a bottom non-foamed (or reduced-foamed) bonding high density layer, a top cover sheet bonded to the foamed low density set gypsum core by the top non-foamed (or reduced-foamed) bonding high density layer, and a bottom cover sheet bonded to the foamed low density set gypsum core by the bottom non-foamed (or reduced-foamed) bonding high density layer. The foamed low density set gypsum core and the non-foamed (or reduced-foamed) bonding high density layers are made from a gypsum slurry including stucco, pregelatinized starch present in an amount of about 0.5-10% by weight based on the weight of stucco, preferably a naphthalenesulfonate disperant present in an amount of about 0.1-3.0% by weight based on the weight of stucco, and preferably sodium trimetaphosphate present in an amount of about 0.12-0.4% by weight based on the weight of stucco. Other slurry additives can include accelerators, binders, paper fiber, glass fiber, and other known ingredients. The foamed low density set gypsum core is prepared having a density of less than about 30 pcf using soap foam in the gypsum-containing slurry. The combination of components provide a composite gypsum board having light weight and high strength. A method of making the composite gypsum board is also provided.

Owner:UNITED STATES GYPSUM CO

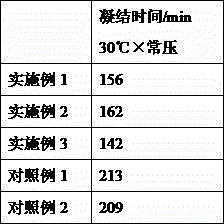

Dispersant and foaming agent combination

InactiveUS20040028956A1Low densityReduce weightConstruction materialOther chemical processesAlkaline earth metalAir entrainment

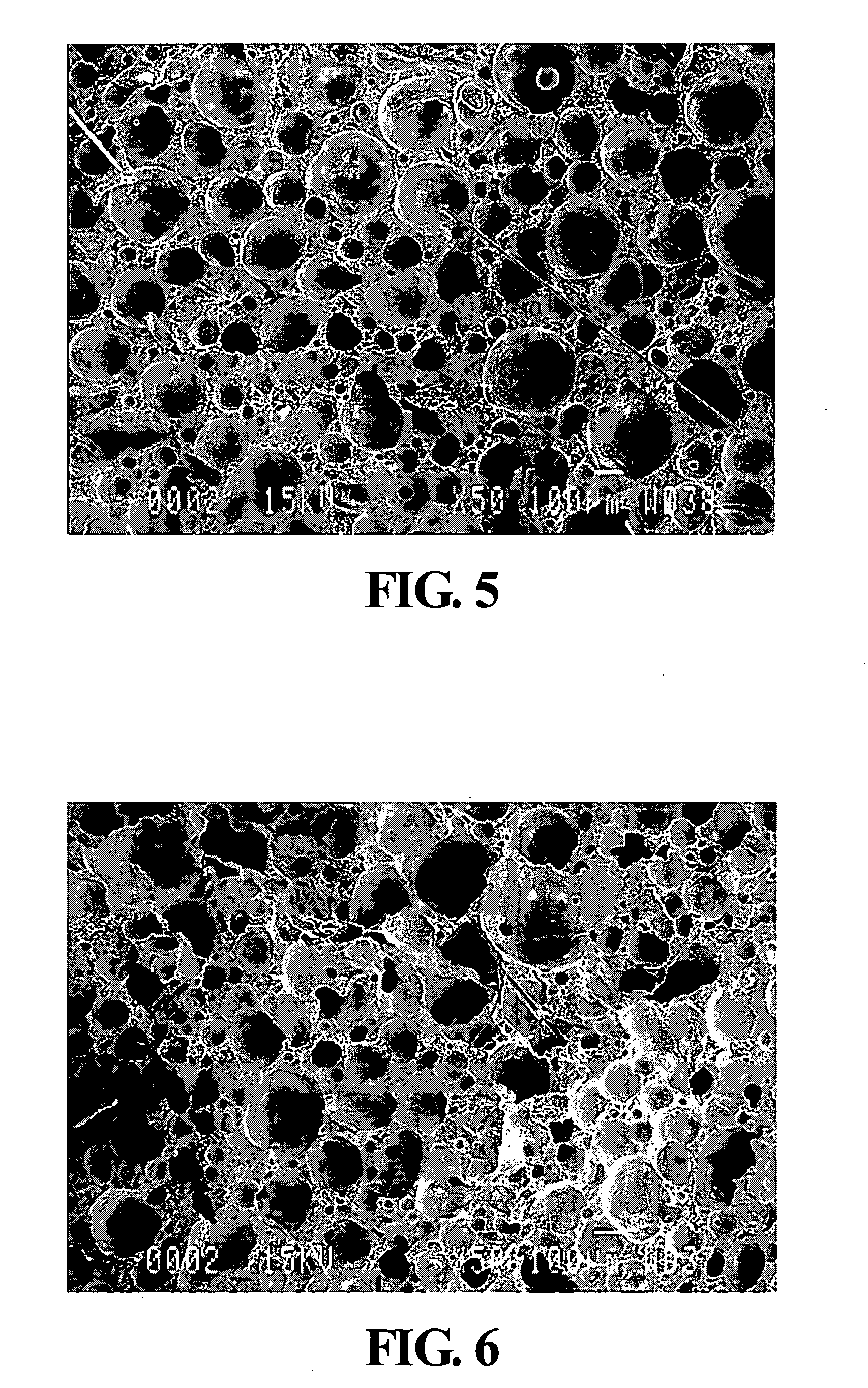

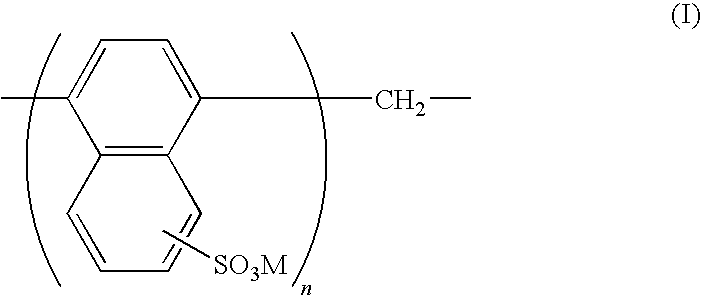

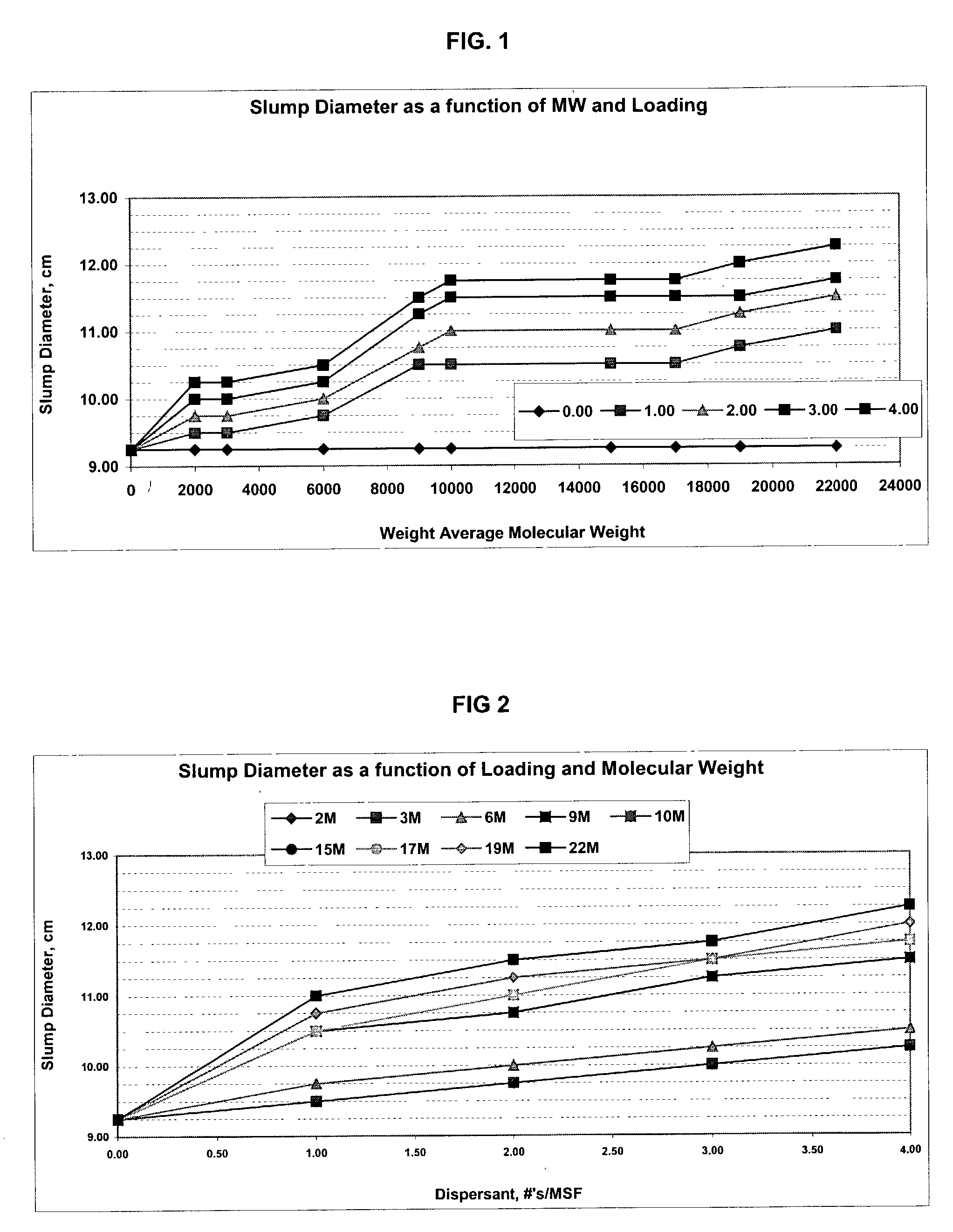

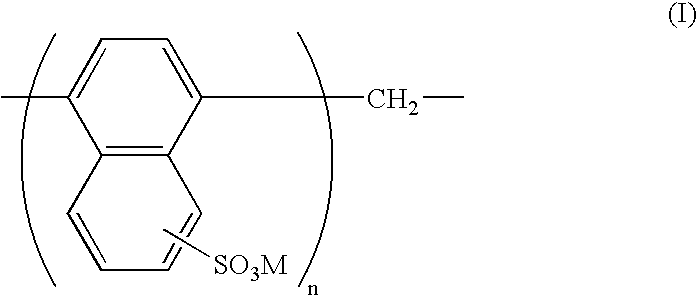

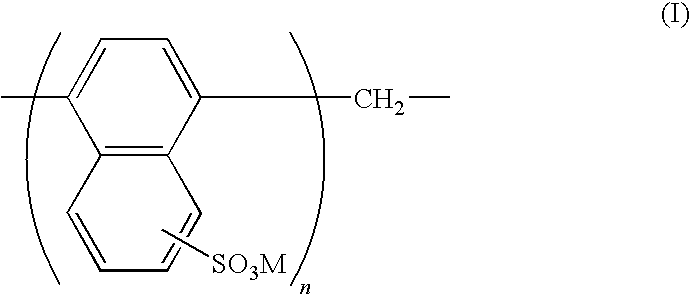

The present invention provides a dispersant and foaming agent combination that is useful in the production of gypsum wallboard and other aqueous cementitious products, a method of forming a gypsum wallboard and a gypsum wallboard. The dispersant in the combination according to the invention is a naphthalene sulfonate-aldehyde condensate alkali salt polymer having a weight average molecular weight of from about 17,000 to about 47,000. The alkali is preferably an alkali metal and / or an alkaline earth metal. The aldehyde is preferably formaldehyde. The foaming agent used in the combination according to the invention is a soap, preferably an alkali salt of an alkyl ether sulfate and / or an alkyl sulfate. The combination of a high molecular weight dispersant and a foaming agent produces a gypsum wallboard core effect that more efficiently entrains air (i.e., creates void space), thereby lowering overall board weight without detrimentally affecting strength. A gypsum wallboard formed using the dispersant and foaming agent combination according to the invention exhibits a higher nail pull value than gypsum wallboard formed using a conventional dispersant and a foaming agent at the same solids loading ratio.

Owner:GEO SPECIALTY CHEM

High hydroxyethylated starch and high dispersant levels in gypsum wallboard

InactiveUS20080070026A1High strengthReduce weightSynthetic resin layered productsPaper/cardboard layered productsGlass fiberFiber

The invention generally provides gypsum-containing slurries including stucco, a hydroxyethylated starch, naphthalenesulfonate dispersant, and sodium trimetaphosphate. The naphthalenesulfonate dispersant is present in an amount of about 0.1%-3.0% by weight based on the weight of dry stucco. The hydroxyethylated starch is present in an amount of from about 0.5% by weight to about 10% by weight based on the weight of dry stucco in the formulation. The sodium trimetaphosphate is present in an amount of about 0.1%-0.4% by weight based on the weight of dry stucco. Other slurry additives can include accelerators, binders, paper fiber, glass fiber, and other known ingredients. The invention also comprises the gypsum-containing products made with such slurries, for example, lightweight gypsum wallboard, and a method of making lightweight gypsum wallboard.

Owner:UNITED STATES GYPSUM CO

High starch light weight gypsum wallboard

The invention generally provides gypsum-containing slurries including stucco, naphthalenesulfonate dispersant, and pregelatinized starch. The naphthalenesulfonate dispersant is present in an amount of about 0.1%-3.0% by weight based on the weight of dry stucco. The pregelatinized starch is present in an amount of at least about 0.5% by weight up to about 10% by weight of pregelatinized starch by weight based on the weight of dry stucco in the formulation. Other slurry additives can include trimetaphosphate salts, accelerators, binders, paper fiber, glass fiber, and other known ingredients. The invention also comprises the gypsum-containing products made with such slurries, for example, gypsum wallboard, and a method of making gypsum wallboard.

Owner:UNITED STATES GYPSUM CO

High starch light weight gypsum wallboard

The invention generally provides gypsum-containing slurries including stucco, naphthalenesulfonate dispersant, and pregelatinized starch. The naphthalenesulfonate dispersant is present in an amount of about 0.1%-3.0% by weight based on the weight of dry stucco. The pregelatinized starch is present in an amount of at least about 0.5% by weight up to about 10% by weight of pregelatinized starch by weight based on the weight of dry stucco in the formulation. Other slurry additives can include trimetaphosphate salts, accelerators, binders, paper fiber, glass fiber, and other known ingredients. The invention also comprises the gypsum-containing products made with such slurries, for example, gypsum wallboard, and a method of making gypsum wallboard.

Owner:UNITED STATES GYPSUM CO

Low-foaming hydrogen peroxide cleaning solution for organic soils

InactiveUS6686324B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsParticulatesAlkane

A low-foaming cleaning solution and dry particulate formulation which can be diluted with water, deionized water, or mixtures thereof, to form the cleaning solution. The cleaning solution has an alkaline pH, which is preferably from about 8 to about 11.5 and consists essentially of at least one low foaming surfactant in a concentration of from about 0.005% to about 40% w / w of the total solution, at least one active oxygen releasing compound in an amount effective to produce a hydrogen peroxide concentration of from about 0.005% to about 50% w / w of the total solution, at least one builder in a concentration of from about 0.001% to about 50% w / w of the total solution, and at least one diluent selected from the group consisting of water, deionized water, and mixtures thereof. The at least one surfactant is selected from the group consisting of C3-C8 alkane sulfonates, C3-C8 alkyl sulfates, C1-C7 alkyl naphthalene sulfonates, polyoxyethylene / polyoxypropylene block copolymers having a polyoxypropylene molecular weight of from about 1500 to about 8500, of which less than about 30% of the total molecular weight is due to the polyoxyethylene portion, and mixtures thereof. The at least one active oxygen releasing compound is selected from the group consisting of hydrogen peroxide, at least one source of hydrogen peroxide, and mixtures thereof.

Owner:JOHNSONDIVERSEY INC

Additives for water-resistant gypsum products

ActiveUS20050250858A1Provides water resistanceFireproof paintsAntifouling/underwater paintsWater resistantChemistry

Emulsions are provided which are useful in imparting water-resistance to gypsum products. In one embodiment, the emulsions comprise at least one wax, an alkyl phenol, a salt of polynaphthalenesulfonic acid, and a complexed starch. Emulsions of this embodiment may be added to hot, even boiling, water without the emulsion separating or curdling. The emulsions of the present invention are stable for extended periods of time when stored at room temperature and do not require the addition of a bactericide. The emulsions of the present invention are pourable liquids at room temperature.

Owner:HEXION INC

Geo-polymer recycled concrete and preparation method thereof

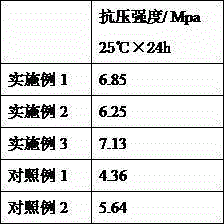

InactiveCN101570426ADelayed activationImprove liquiditySolid waste managementCement productionRoad engineeringSlag

The invention belongs to the fields of civil engineering and environmental material engineering, and in particular relates to geo-polymer recycled concrete and a preparation method thereof. The geo-polymer recycled concrete is prepared from raw materials of recycled coarse aggregate, recycled fine aggregate, fly ash, slag powder, water, sodium silicate, sodium hydrate, naphthalene sulfonate formaldehyde condensation compound and calcium saccharate according to certain mixing proportion by adopting a special stirring process. The product of the geo-polymer recycled concrete not only has simple preparation process, but also has good working performance, mechanical property, durability and heat-insulating property. Simultaneously, the geo-polymer recycled concrete and the preparation method can efficiently use a great deal of waste concrete and two industrial byproducts of the fly ash and blast furnace slag, are significant in saving resources, saving energy sources and protecting the environment, and accord with the sustainable development strategy of the building industry. The product of the geo-polymer recycled concrete can be widely applicable to road engineering, structural engineering and other various civil engineering constructions.

Owner:TONGJI UNIV

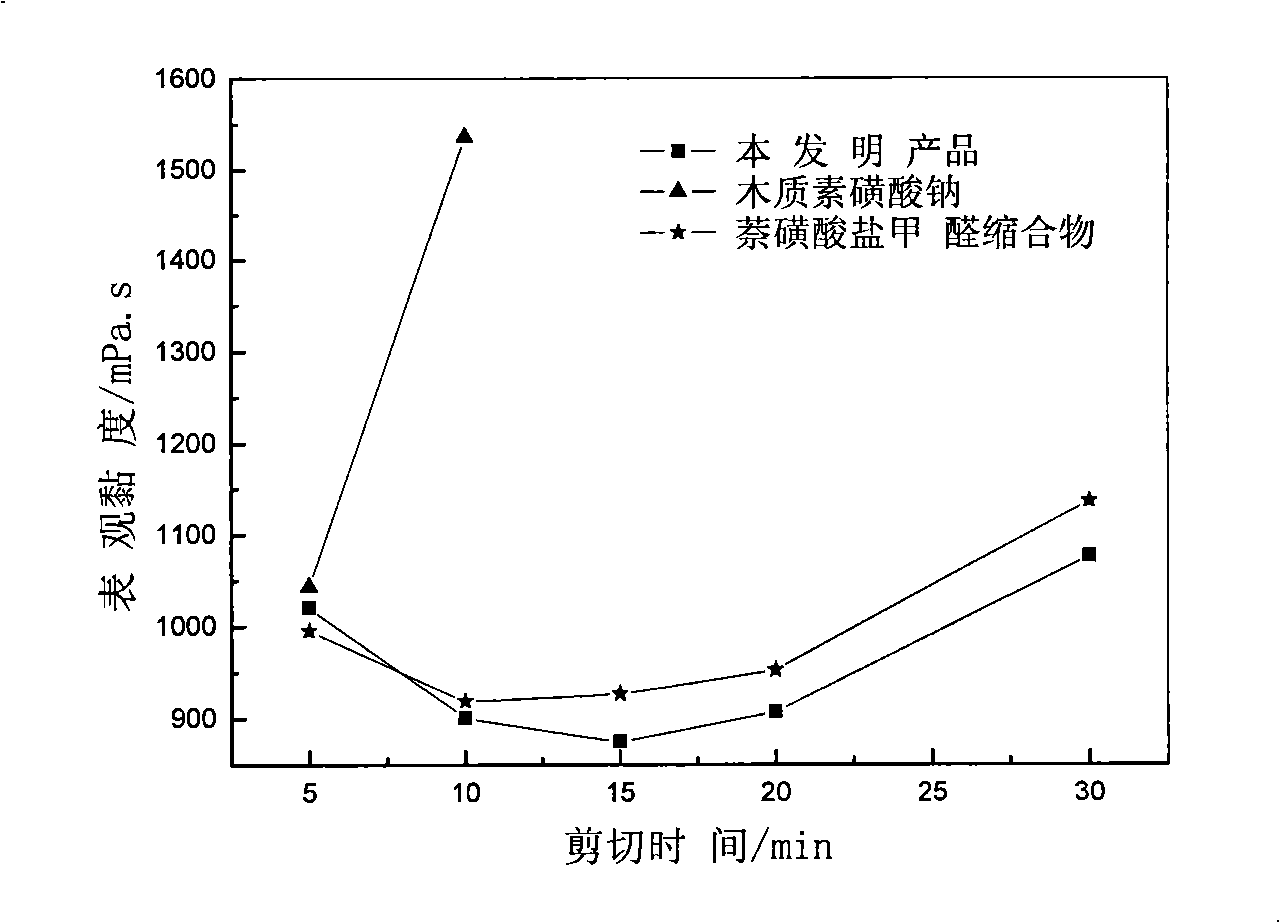

Coal water slurry additive and preparation method and application thereof

The invention discloses a coal water slurry additive and a preparation method and application thereof. The method is characterized in that the coal tar fraction wash oil is taken as the starting material, carries out sulfonation reaction with a sulfonating agent and then carries out polycondensation reaction with aminobenzene sulfonate, phenols and formaldehyde; and neutralization is carried out after reaction is completed. The method can greatly lower the production cost, and the obtained additive has the advantages of small mixing amount, excellent dispersibility, good slurry forming ability and stability and reduction of the stabilizing agent in the coal water slurry. The additive can not only be independently used for preparing the coal water slurry, but also be used by being compounded with other types of additives, such as naphthalene sulfonate-formaldehyde condensates, polycarboxylic acid additives or lignosulfonate and other anionic surfactants and synthesize the coal water slurry suitable for different types of coal by adjusting the production conditions. The coal water slurry prepared by the additive has the solid content between 63% and 70% and is easy to flow and clean. The viscosity of the coal water slurry is controlled below 1200mPa.s at the shearing rate of 100s<-1>.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD +1

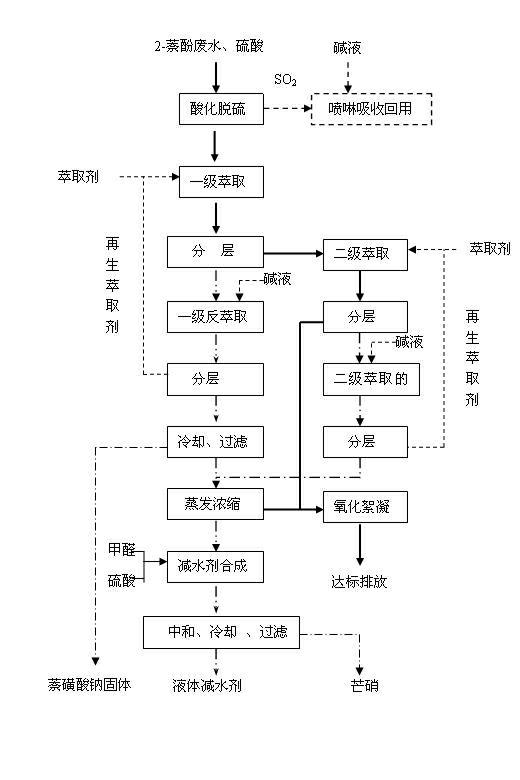

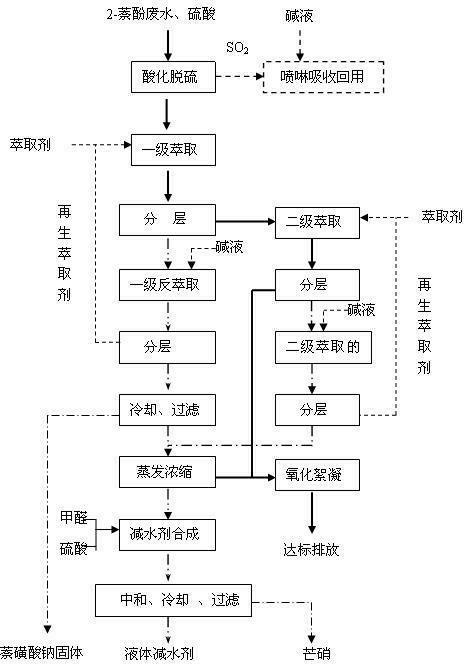

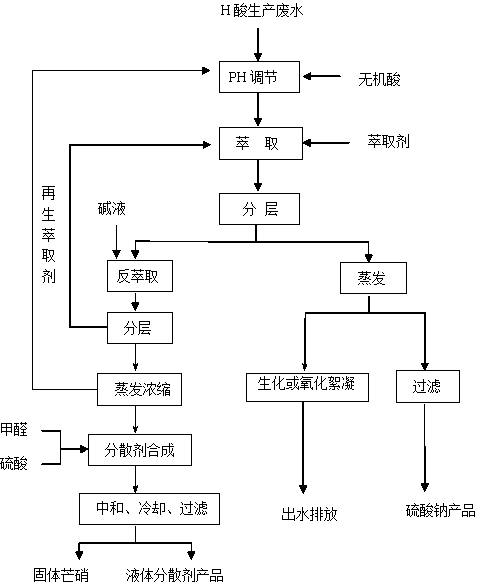

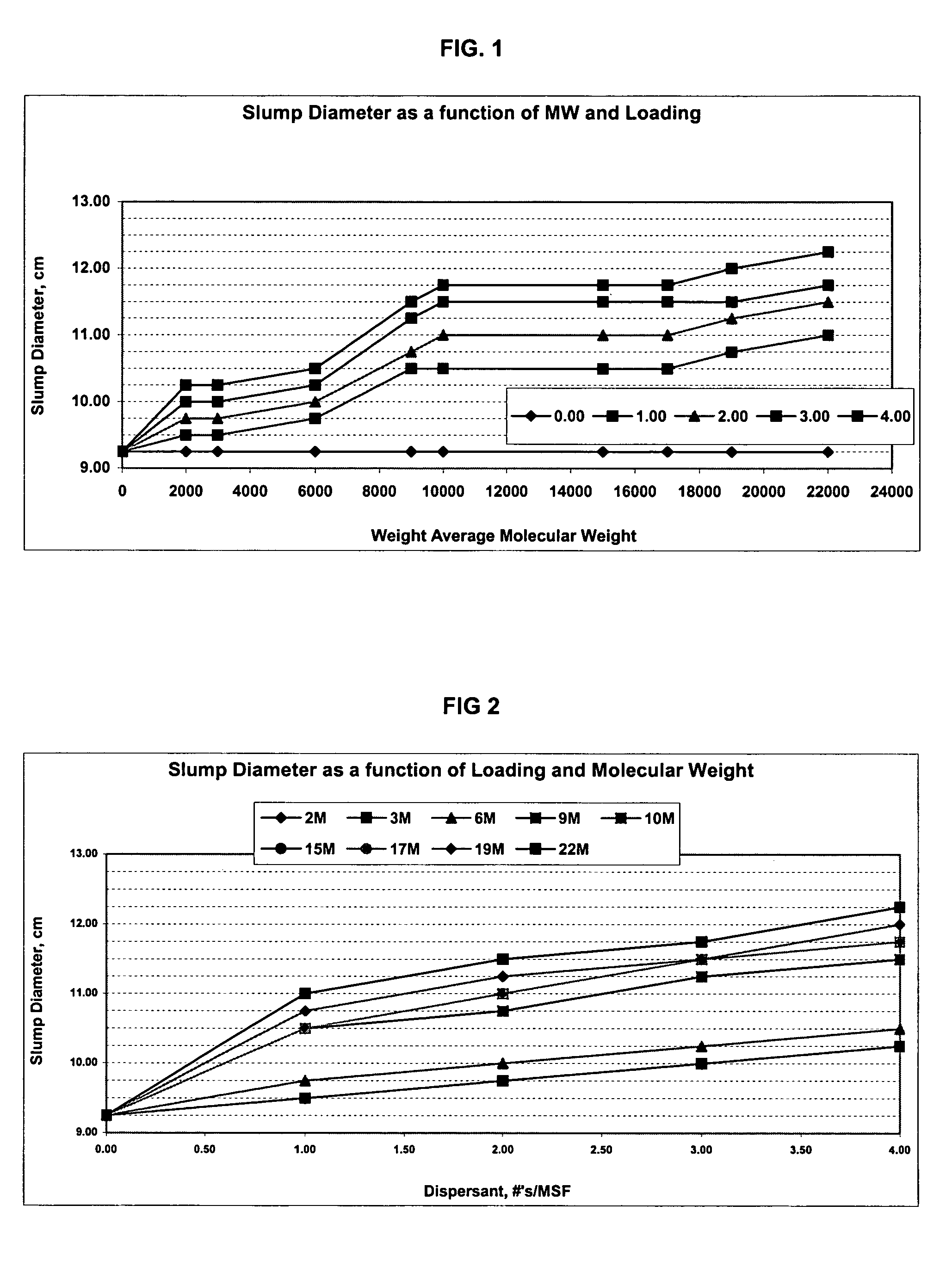

Comprehensive treatment and resource utilization technology of 2-naphthol production wastewater

ActiveCN102633399AAchieve governanceImplement resourcesMultistage water/sewage treatmentNature of treatment waterSulfonateAlpha-naphthol

The invention discloses a comprehensive treatment and resource utilization technology of 2-naphthol production wastewater. In the technology, the 2-naphthol production wastewater is directly acidified, and the discharged SO2 gas is absorbed and recycled by alkaline liquid; after the desulfurization wastewater is filtered to remove insoluble substance, two-level extraction is performed by use of acomplexing extracting agent; the extract phase is subjected to stripping by alkaline liquid, and the regenerated extracting agent is circularly utilized; the first-level strip liquor is cooled and filtered to obtain naphthalene sulfonate solid which is reused in a 2-naphthol hydrolysis naphthalene blowing process; the filtrate and the strip liquor of the second-level extraction are transferred toan evaporation system for evaporation concentration and then fed to a water reducing agent synthesis process; and the evaporation condensate water and the raffinate phase of the second-level extraction are subjected to oxidation flocculation treatment to reach the standard. The technology disclosed by the invention has reasonable design and treats the 2-naphthol production wastewater while realizing resource utilization of the wastewater.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

High Starch Light Weight Gypsum Wallboard

InactiveUS20100239886A1High strengthReduce weightLamination ancillary operationsSolid waste managementGlass fiberFiber

The invention generally provides gypsum-containing slurries including stucco, naphthalenesulfonate dispersant, and pregelatinized starch. The naphthalenesulfonate dispersant is present in an amount of about 0.1%-3.0% by weight based on the weight of dry stucco. The pregelatinized starch is present in an amount of at least about 0.5% by weight up to about 10% by weight of pregelatinized starch by weight based on the weight of dry stucco in the formulation. Other slurry additives can include trimetaphosphate salts, accelerators, binders, paper fiber, glass fiber, and other known ingredients. The invention also comprises the gypsum-containing products made with such slurries, for example, gypsum wallboard, and a method of making gypsum wallboard.

Owner:UNITED STATES GYPSUM CO

Urea-formaldehyde foam plant cultivation substrate and method for preparing the same

ActiveCN101134803ANo residueReasonable content of ingredientsAgriculture gas emission reductionCultivating equipmentsPhosphoric acidUrea formaldehyde foam

The present invention discloses one kind of urea-formaldehyde foam as plant cultivating matrix and its preparation process. The urea-formaldehyde foam as plant cultivating matrix is prepared through the following steps: 1. mixing formaldehyde and urea to produce polycondensation reaction to obtain urea-formaldehyde resin solution; 2. mixing sodium butyl naphthalenesulfonate to obtain foaming liquid; 3. foaming the urea-formaldehyde resin solution with the foaming liquid in a foaming machine to obtain liquid foam; 4. solidifying the liquid foam and drying to operate foamed matrix; and 5. eliminating aldehyde group from the matrix to obtain urea-formaldehyde foam as plant cultivating matrix. The preparation process is simple and low in cost, and the prepared urea-formaldehyde foam as plant cultivating matrix has penetrating porous structure, high hydroscopicity and high soil-less culturing character.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

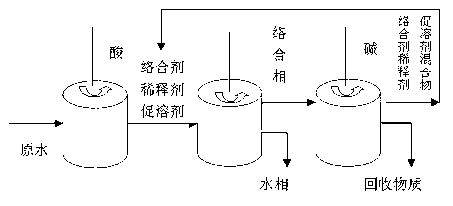

Comprehensive treatment method of H acid production wastewater

ActiveCN104326614AImprove extraction efficiencyHigh partition coefficientTransportation and packagingMixingLeather industryResource utilization

The invention discloses a comprehensive treatment method of H acid production wastewater. The method comprises the following steps: regulating the pH value of the H acid production wastewater, afterwards complexing and extracting a naphthalene sulfonic acid type substance in the wastewater, back-extracting an extract phase by using alkaline liquor, recycling an extracting agent after the extracting agent is regenerated, evaporating and concentrating back-extraction liquid to synthesize a liquid dispersant product; transferring a raffinate phase into an evaporation system, evaporating and separating to obtain a sodium sulfate byproduct, and discharging the desalted evaporation and condensation water after the water reaches the standards by means of biochemical or oxidization flocculation treatment. According to the method disclosed by the invention, the naphthalene sulfonic acid type substance in the wastewater is recycled by utilizing a complexation-extraction method, and the sodium sulfate salt product is recycled by utilizing an evaporation method. The liquid dispersant product (degree of polymerization is 1-3) synthesized by utilizing the recycled naphthalene sulfonate solution is used as a dispersing agent in textile dyeing and leather industries. The method disclosed by the invention is reasonable in process design and can be used for effectively realizing comprehensive treatment and resource utilization of the H acid production wastewater.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Gypsum compositions with naphthalene sulfonate and modifiers

An improved gypsum slurry that includes water, calcium sulfate hemihydrate, a naphthalene sulfonate dispersant and a modifier. The modifier is chemically configured to improve the efficacy of the naphthalene sulfonate dispersant. Preferred modifiers include cement, lime, slaked lime, soda ash, carbonates, silicates and phosphates.

Owner:UNITED STATES GYPSUM CO

Emulsions for lignocellulosic products, methods of their manufacture, improved lignocellulosic products and methods for their manufacuture

Emulsions are provided which are useful in imparting water-resistance to lignocellulosic products. In one embodiment, the emulsions contain a nonsaponifiable wax, a saponified wax, an alkyl phenol component, a dispersant / surfactant such as a salt of polynaphthalenesulfonic acid, and a carboxymethylcellulose. Such emulsions may be added to hot, even boiling, water without the emulsion separating or curdling. Various embodiments are stable for extended periods of time when stored at room temperature, do not require the addition of a preservative biocide to avoid contributing to biodegradation in a lignocellulosic product. The emulsions are pourable liquids at room temperature. Optionally, the emulsions may be added to lignocellulosic products with a preservative to inhibit the preservative from leaching out.

Owner:HEXION INC

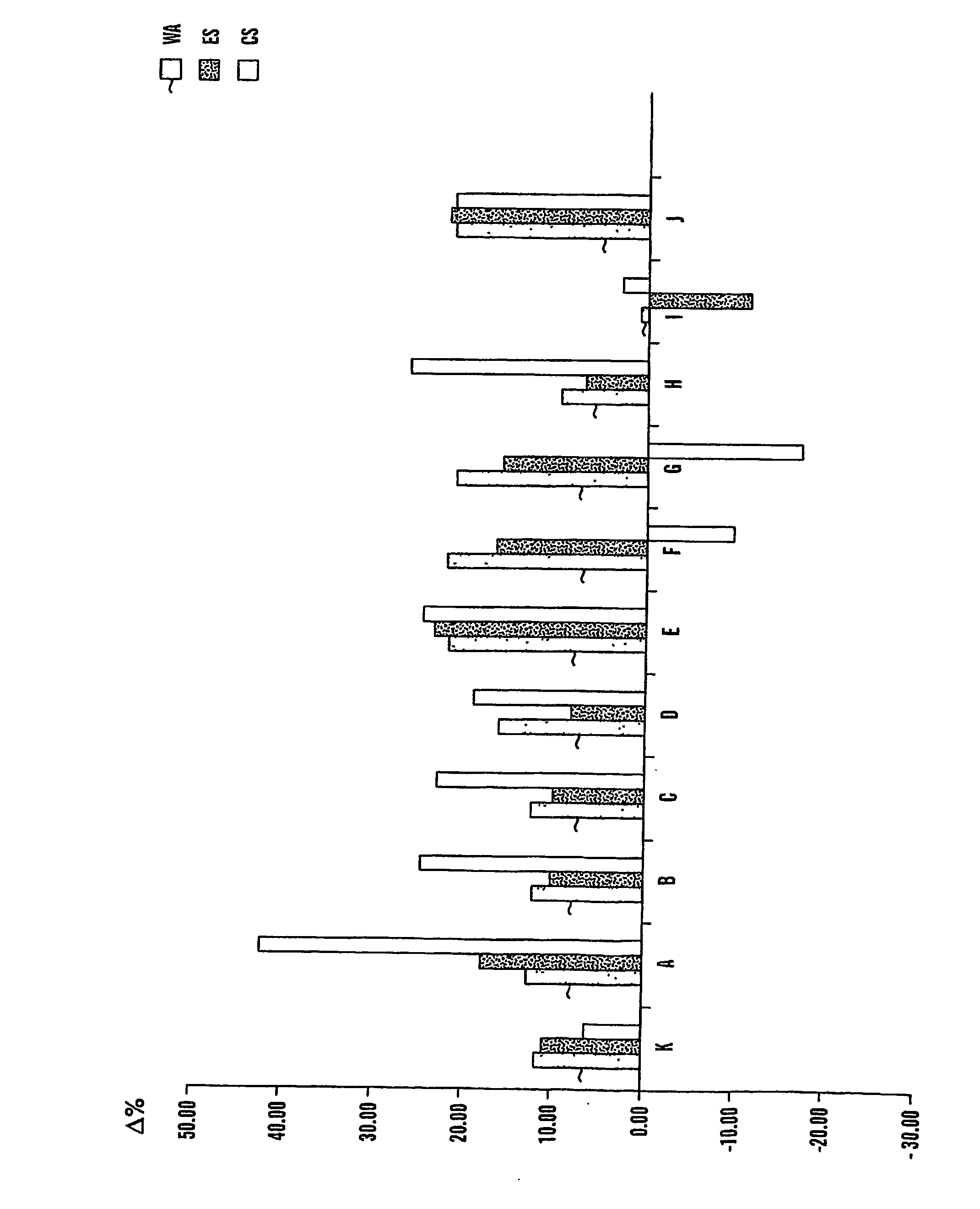

Coal water slurry dispersing agent made from black-liquor of straw pulping in paper-making and preparation thereof

InactiveCN101322927AReduce manufacturing costEasy to operate and controlTransportation and packagingMixingSolubilitySulfonate

The invention discloses a straw pulp papermaking black liquor water-coal slurry dispersant and a preparation method thereof. The prescription of the water-coal slurry dispersant is counted by mass portion and includes 20 portions of condensed straw pulp papermaking black liquor of 50 to 60 percent; 25 to 50 portions of aldehydes, 20 to 60 portions of carbonyl compounds and 25 to 50 portions of sulfonating agents. The preparation method thereof is to prepare the water-coal slurry dispersant by carrying out graft sulfonation and polycondensation on the condensed straw pulp papermaking black liquor, the aldehydes, the carbonyl compounds and a sulfonating agent. The materials of the invention have abundant sources and low cost; the production cost is low; the water-coal slurry dispersant prepared by the invention has excellent water solubility and surface activity as well as excellent slurry preparing performance to the water-coal slurry under a lower addition; the dispersing viscosity reduction performance of the water-coal slurry dispersant is far superior to lignin sulfonate; aiming at different coal varieties, the water-coal slurry dispersant achieves or exceeds the efficiency of naphthyl sulfonate formaldehyde condensate; besides, the anti-shearing performance of a slurry body is excellent; the application range to the coal varieties is broad; the water-coal slurry dispersant is novel, effective and environment-friendly.

Owner:SOUTH CHINA UNIV OF TECH

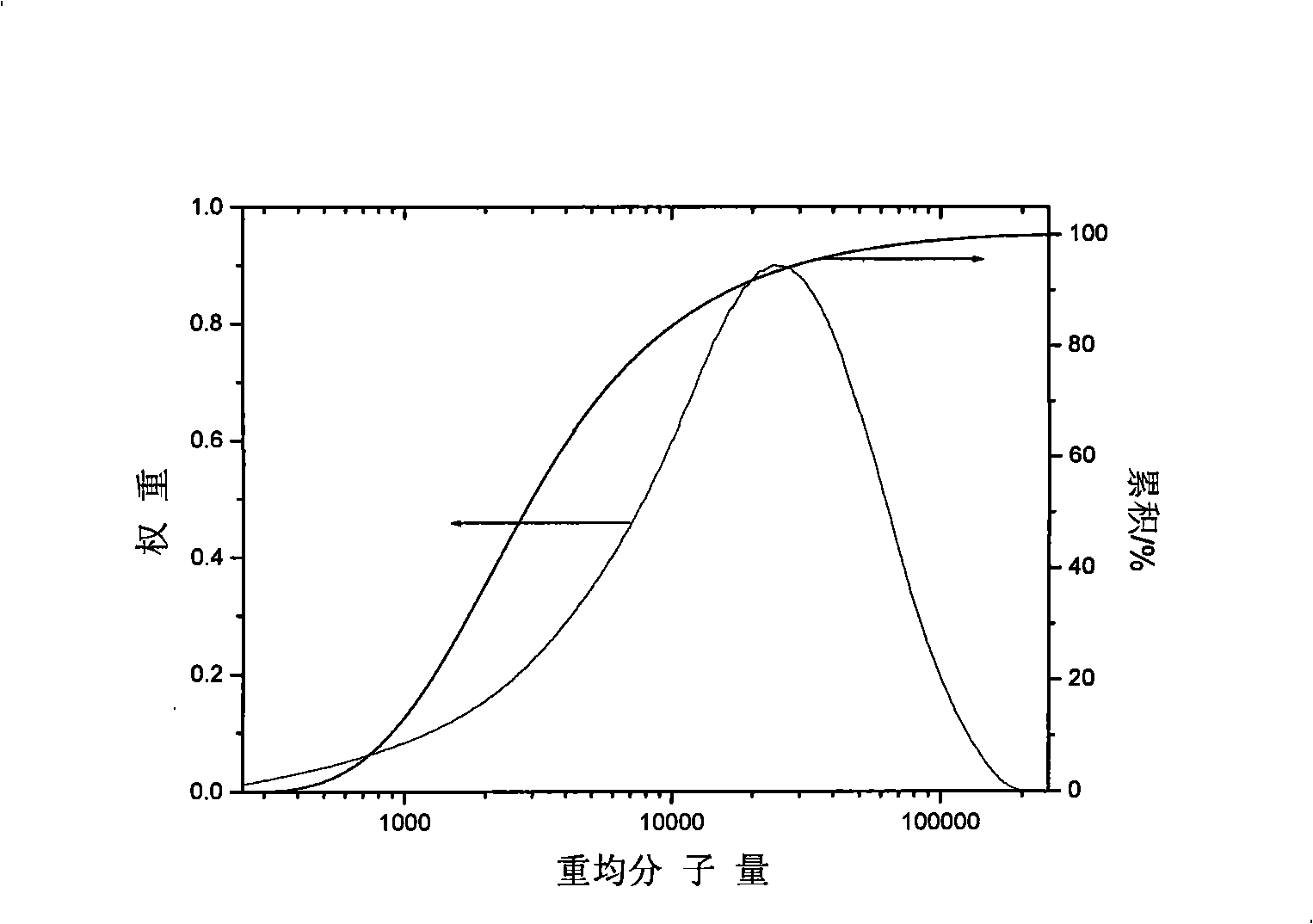

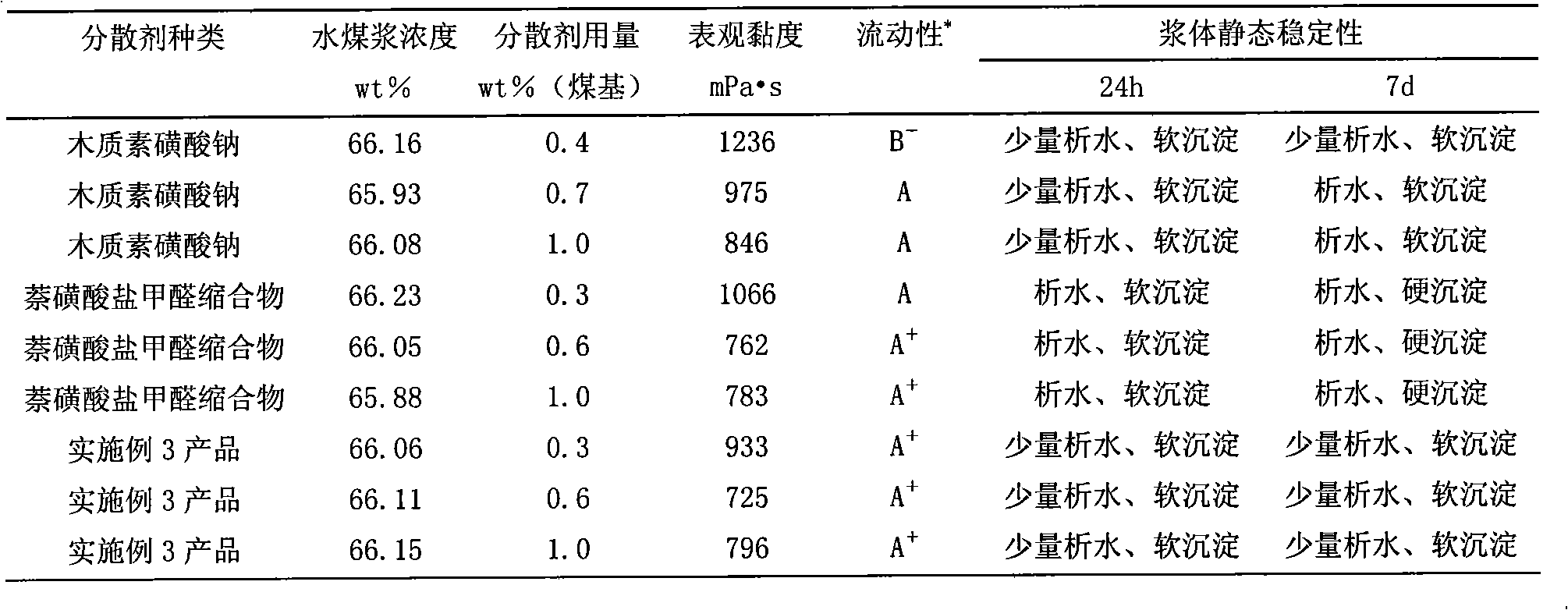

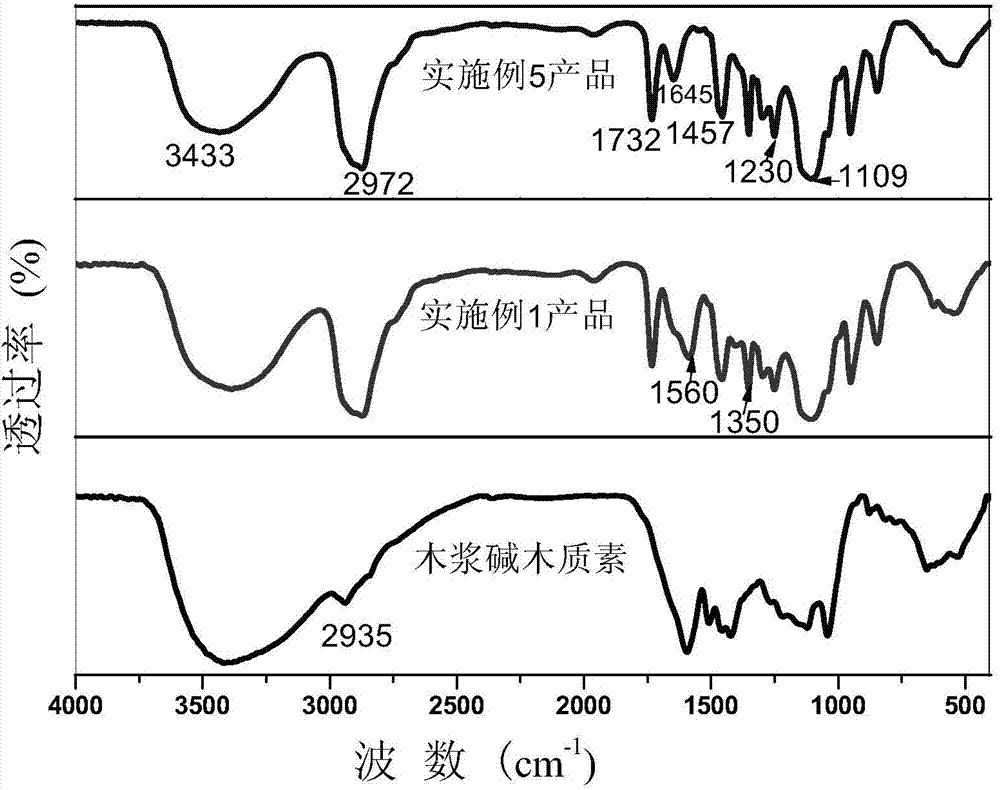

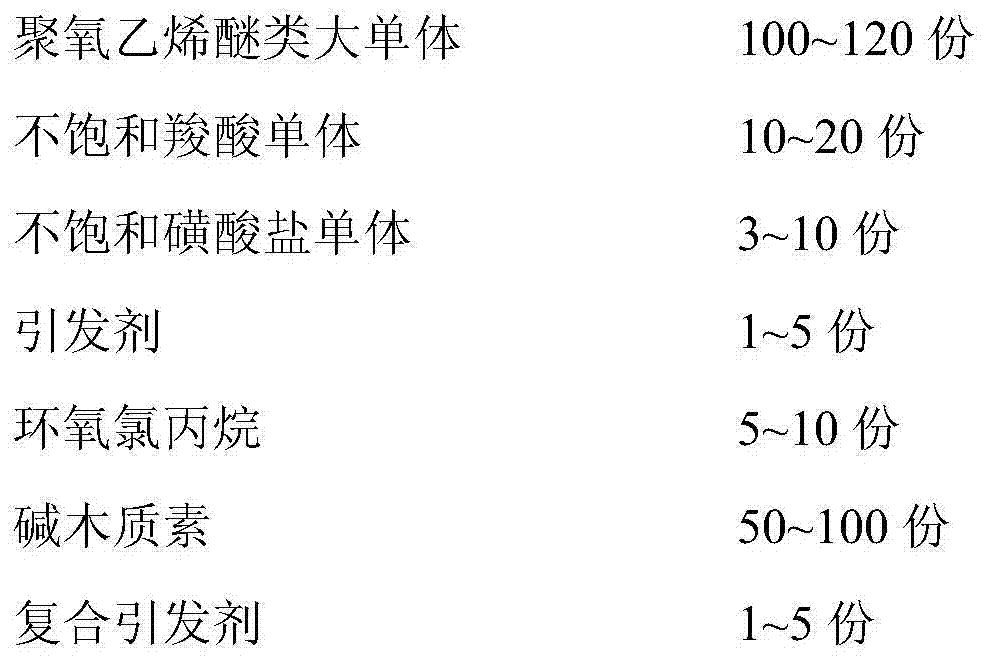

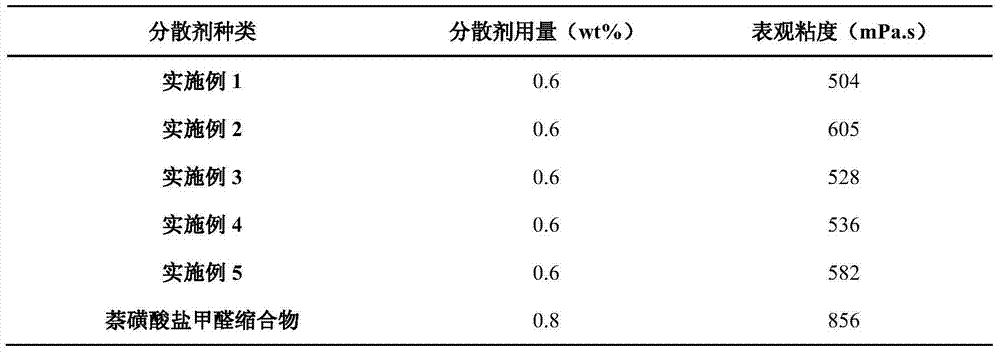

Preparation method of alkali lignin modified polycarboxylic acid-type coal water slurry dispersant

ActiveCN104327280AStay decentralizedReduce usageLiquid carbonaceous fuelsDispersion stabilityLiquid product

The invention relates to a preparation method of an alkali lignin modified polycarboxylic acid-type high-efficiency coal water slurry dispersant. The method comprises the steps: at the temperature of 50-80 DEG C, carrying out a copolymerization reaction of a polyoxyethylene ether macromonomer, an unsaturated carboxylic acid monomer, an unsaturated sulfonate monomer and an initiator for 2-3 h in an aqueous solution, adjusting the temperature to 30-50 DEG C, adding epoxy chloropropane, carrying out a reaction for 0.5-1 h, adding an alkaline regulator, adjusting the pH value to 10-12, adding an alkali lignin solution with the mass concentration of 20-50%, adjusting the reaction temperature to 60-80 DEG C, dropwise adding a composite initiator aqueous solution with the mass concentration of 2%, carrying out a reaction for 1-3 h, and thus obtaining a liquid product. The product has the dispersion viscosity reduction performance on coal water slurry superior to that of a naphthalenesulfonate formaldehyde condensation compound, and has good dispersion stability on coal slurry; and while original dispersive ability and other characteristics of the polycarboxylic acid-type dispersant are maintained, the production cost is reduced, and the usage amount of non-renewable resources and toxic materials is lowered.

Owner:SOUTH CHINA UNIV OF TECH

Low-foaming hydrogen peroxide cleaning solution for organic soils

InactiveUS20030078178A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsParticulatesAlkane

A low-foaming cleaning solution and dry particulate formulation which can be diluted with water, deionized water, or mixtures thereof, to form the cleaning solution. The cleaning solution has an alkaline pH, which is preferably from about 8 to about 11.5 and consists essentially of at least one low foaming surfactant in a concentration of from about 0.005% to about 40% w / w of the total solution, at least one active oxygen releasing compound in an amount effective to produce a hydrogen peroxide concentration of from about 0.005% to about 50% w / w of the total solution, at least one builder in a concentration of from about 0.001% to about 50% w / w of the total solution, and at least one diluent selected from the group consisting of water, deionized water, and mixtures thereof. The at least one surfactant is selected from the group consisting of C3-C8 alkane sulfonates, C3-C8 alkyl sulfates, C1-C7 alkyl naphthalene sulfonates, polyoxyethylene / polyoxypropylene block copolymers having a polyoxypropylene molecular weight of from about 1500 to about 8500, of which less than about 30% of the total molecular weight is due to the polyoxyethylene portion, and mixtures thereof. The at least one active oxygen releasing compound is selected from the group consisting of hydrogen peroxide, at least one source of hydrogen peroxide, and mixtures thereof.

Owner:JOHNSONDIVERSEY INC

Fourth generation alcohol-free additive not additionally added in suede preparation of monocrystalline silicon

InactiveCN103290484AReduce pollutionImprove photoelectric conversion rateAfter-treatment detailsAlcohol freeGlycerol

The invention relates to a fourth generation alcohol-free additive not additionally added in suede preparation of monocrystalline silicon. The fourth generation alcohol-free additive comprises the following main components: a dispersing agent, a humectant and deionized water, wherein the dispersing agent is one of or a combination of more of styrene sodium sulfonate, benzyl naphthalenesulfonate formaldehyde condensate, sodium polyaluminate, sodium hexametahposphate, sodium methylene dinaphthalenesulfonate, sodium polysilicate, sodium lignin sulfonate and sodium polyacrylate; and the humectant is one of or a combination of more of sodium hyaluronate, D5-panthenol, glycerol, propanediol, polyethylene glycol, polypropylene glycol, honey and collagen. When the suede preparation additive is added into a suede preparation solution, clean and uniform monocrystalline silicon suede can be quickly prepared, the photoelectric conversion rate is improved, the production cost is reduced, and the environmental pollution is reduced.

Owner:JINGJIANG JINGYI CHEM CO LTD

Auxiliary agent of formulation for dyeing Terylene

This invention discloses an aid used in terylene dyeing characterizing in including the following components in weight percentage: acid aid 10-20%, organic phosphonic acid 2-5%, organic carboxylic acid 3-7%, naphthalenesulfonate 10-18%, PEG 400 single oleic acid ester 5-8%, non-ion PAA 0-2%, polytrimethylene polyethenoxy aether 0-3% and water.

Owner:夏建明 +1

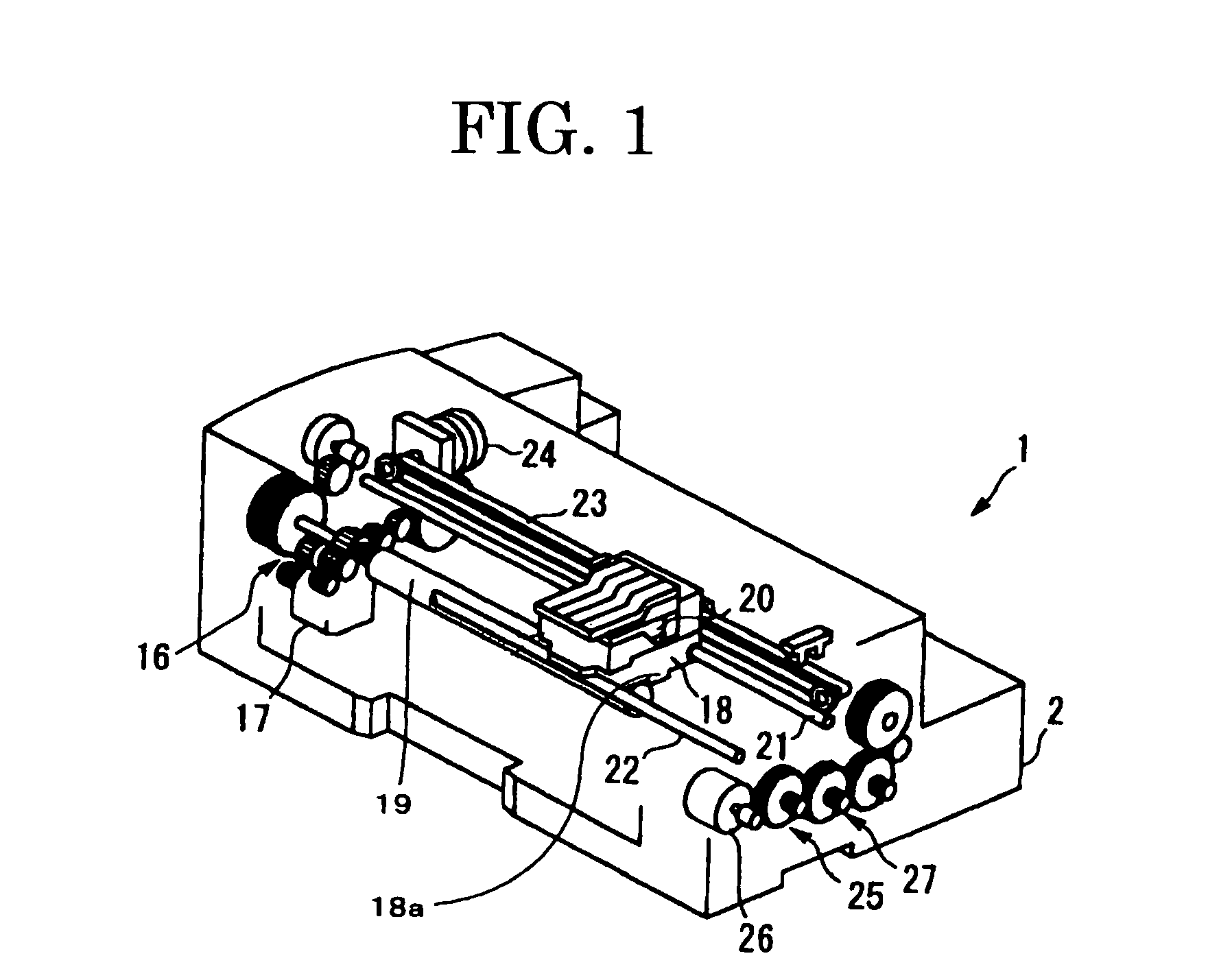

Pigment dispersion, inkjet-ink using the pigment dispersion, image forming process, and image forming apparatus

ActiveUS7798629B2High densityGood storage stabilityPigmenting treatmentMeasurement apparatus componentsPigment dispersionSODIUM NAPHTHALENESULFONATE

Owner:RICOH KK

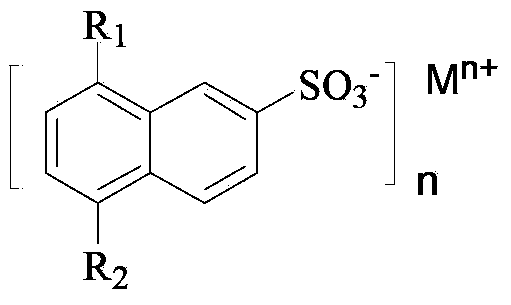

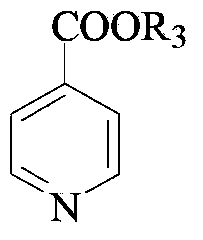

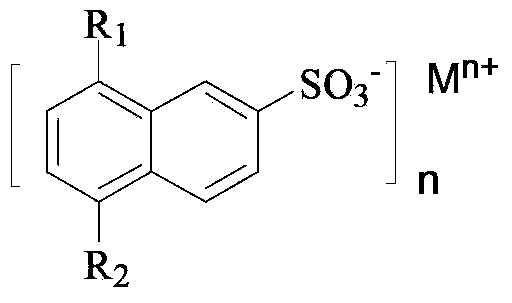

Synergic extraction agent and method for selectively extracting nickel in acidic nickeliferous solution through synergic extraction agent

The invention discloses a synergic solvent extraction and a method for selectively extracting nickel in an acidic nickeliferous solution through the synergic extraction agent. The synergic solvent extraction is the compound of naphthalene sulfonic acid or naphthalenesulfonate and pyridine carboxylic ester; the method comprises the following steps: adopting the synergic solvent extraction to selectively extract nickel ions from the acidic nickeliferous solution, adopting mineral acid to conduct back extraction on loaded organic phase to obtain highly purified nickeliferous solution to realize effective separation of nickel ions with impurity ions of iron ions, aluminium ions, manganese ions, magnesium ions, calcium ions, chromium ions and the like. Through adoption of the method, the recovery ratio of the nickel ions is high, the effect on separating the nickel ions from impurities is good, the process is short, and industrialization is easy to realize.

Owner:CENT SOUTH UNIV +1

Additives for water-resistant gypsum products

ActiveUS7473713B2Provides water resistanceFireproof paintsStarch dervative coatingsWater resistantPhenol

Emulsions are provided which are useful in imparting water-resistance to gypsum products. In one embodiment, the emulsions comprise at least one wax, an alkyl phenol, a salt of polynaphthalenesulfonic acid, and a complexed starch. Emulsions of this embodiment may be added to hot, even boiling, water without the emulsion separating or curdling. The emulsions of the present invention are stable for extended periods of time when stored at room temperature and do not require the addition of a bactericide. The emulsions of the present invention are pourable liquids at room temperature.

Owner:HEXION INC

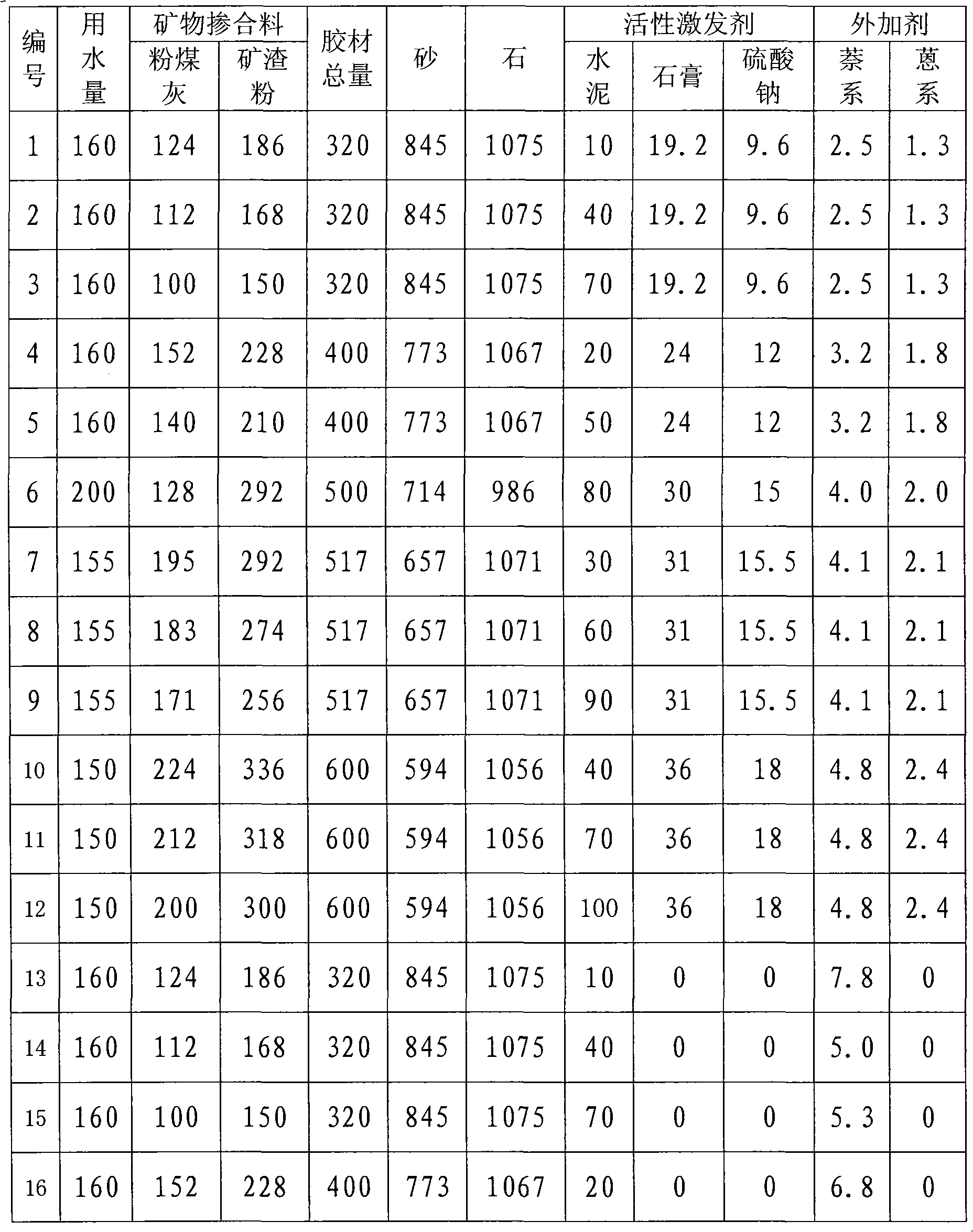

Mineral admixture concrete

The invention relates to a mineral admixture concrete. Mineral admixtures are used as concrete cementitous materials, common concrete and a complex of gypsum and sodium sulfate are added and used as activity excitants so as to coordinate the combined action of naphthalenesulfonate formaldehyde condensate and a crude anthracene sulfonate superplasticizer, and the high-efficiency concrete is prepared. Compared with the prior art, the excitants in the invention has the advantages that early excitation effect is good, mixing amount is less, the early or later strength and durance of the concrete can be greatly improved, the concrete dosage is reduced by 5-20% under the condition of maintaining the strength and workability of the concrete not to be changed, and the gypsum and sodium sylfate are both industrial byproducts with low costs. In the invention, concrete plaster is mixed in advance by using a secondary feeding method, residual materials are added in the mixed concrete plaster, and the strength of the concrete is improved while reducing the abrasion of coarse aggregates on equipment. The concrete has the advantages of good workability and less bleeding, is convenient for construction, and can be applied to large-volume concrete engineering, underground engineering, seaport engineering and the like.

Owner:北京元泰达环保科技有限公司

Concrete compound type chloride-free early strength agent and preparation method thereof

InactiveCN105198273AImprove cement strengthGood curing speed and strengthSodium silicateTriethanolamine

The invention relates to a concrete compound type chloride-free early strength agent and a preparation method thereof and belongs to the technical field of early strength agents. The early strength agent comprises components in parts by weight as follows: 20-40 parts of calcium carboxylate, 10-15 parts of alkali carbonate, 5-10 parts of triethanolamine, 5-10 parts of formamide, 3-6 parts of naphthalene sulfonate, 5-10 parts of sodium sulfate, 3-5 parts of sodium silicate, 3-5 parts of trisodium phosphate, 3-6 parts of alkanolamide, 2-4 parts of cellulose ether and 4-7 parts of aluminum dihydrogen phosphate. According to the provided compound water reducer, cement hydration can be accelerated by means of added calcium carboxylate; aluminum dihydrogen phosphate is added and used for controlling a space structure of components, and the cement strength is improved; after the water reducer is applied to cement, the water reducer has better curing speed and strength.

Owner:宋介珍

Method for preparing colorant used in producing color acrylic fibre by mass coloration method

The present invention relates to a preparation method of coloring material for producing colored acrylic fiber by adopting mass coloration process. Said method includes the following steps: mixing pigment, dispersing agent and NaSCN aqueous solution and grinding in ball-grinding machine, in the coloring material the pigment content is 5-25 wt%, the weight ratio of pigment and dispersing agent is 100:3-30, and the ginding time is 0.5-5.0, then the coloring material product can be obtained. The above-mentioned dispersing agent is one compound selected from naphthalenesulfonate formaldehyde condensate, methyl naphthalene sulfonate formaldehyde condensate or benzyl naphthalene sulfonate formaldehyde condensate or mixture of them, and the pigment is carbon black, phthalocyanine blue, iron oxide or ultrasmarine.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Dispersant and foaming agent combination

InactiveUS20040092676A1Reduce density and weightHigh strengthConstruction materialTransportation and packagingSulfonatePolymer science

Owner:GEO SPECIALTY CHEM

Process for treating dinaphthol wastewater by using complexation extraction method

InactiveCN102936051AImplement full automationCan run continuouslyMultistage water/sewage treatmentWater/sewage treatment by extractionKeroseneOil phase

The invention discloses a process for treating dinaphthol wastewater by using a complexation extraction method. A process core includes that trioctylamine or trialkyl tertiary amine serves as a complexing agent, sulfonated kerosene serves as a diluent, and chloric acid tributyl ester serves as a chaotropic agent to be mixed according to a certain ratio into an extraction agent, the extraction agent comprises, by volume, 20% to 30% of the complexing agent, 60% to 70% of the diluent and 5% to 15% of the chaotropic agent. Dinaphthol production wastewater is extracted when the temperature is in a range of 20 DEG C to 30 DEG C and the pH is 1, aqueous phase: oil phase is 1: 1 (volume ratio), the removal rate of first extraction CODcr can reach 97%, naphthalene sulfonate in wastewater can be extracted through multistage extraction, and simultaneously water is discharged up to standard. Water phases of back extraction can be recycled as production materials; and organic phases are mixtures of the extraction agent and the diluent and can be recycled.

Owner:SHANGHAI BIOFIT ENVIRONMENTAL TECH

Solid herbicidal composition

ActiveUS20090069346A1Suppression of decomposition of the compound ADisintegrability can be improvedBiocideOrganic chemistrySulfonateDecomposition

To provide a solid herbicidal composition in which decomposition of the herbicidal active ingredient is suppressed, and favorable herbicidal activity is stably exhibited. A solid herbicidal composition comprising (1) 1-(4,6-dimethoxypyrimidin-2-yl)-3-(3-trifluoromethyl-2-pyridylsulfonyl)urea or its salt and (2) at least one surfactant selected from the group consisting of a naphthalene sulfonate condensed with formaldehyde, an alkylnaphthalene sulfonate condensed with formaldehyde, a dialkylnaphthalene sulfonate condensed with formaldehyde and a polycarboxylate.

Owner:ISHIHARA SANGYO KAISHA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com