Patents

Literature

48results about How to "Can run continuously" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated converting and utilizing co-production method for agricultural waste

InactiveCN102476129AWidely used valueAvoid secondary pollutionSolid waste disposalBiofuelsBiofuelFuel oil

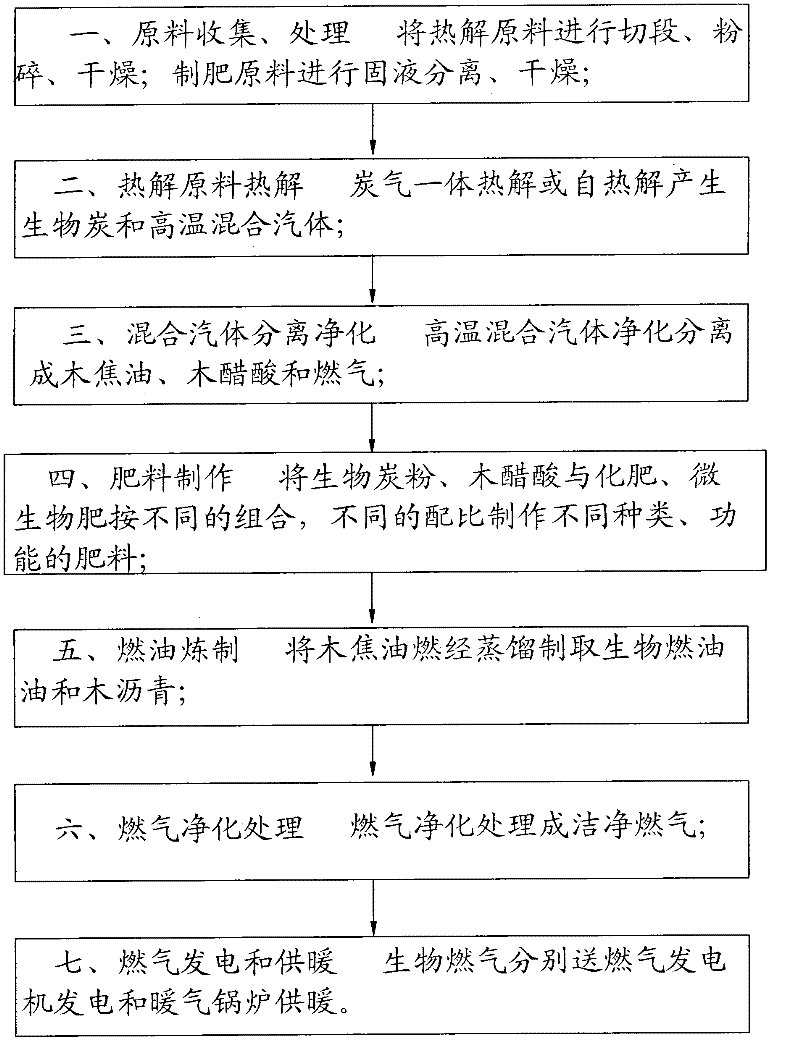

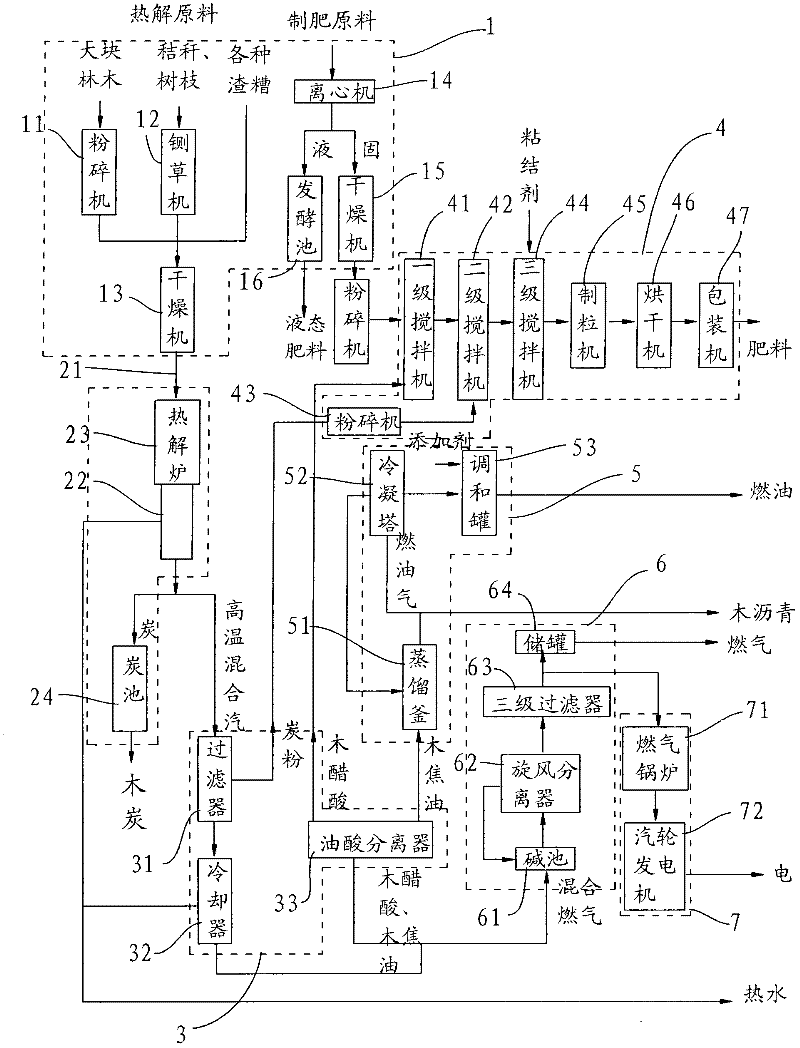

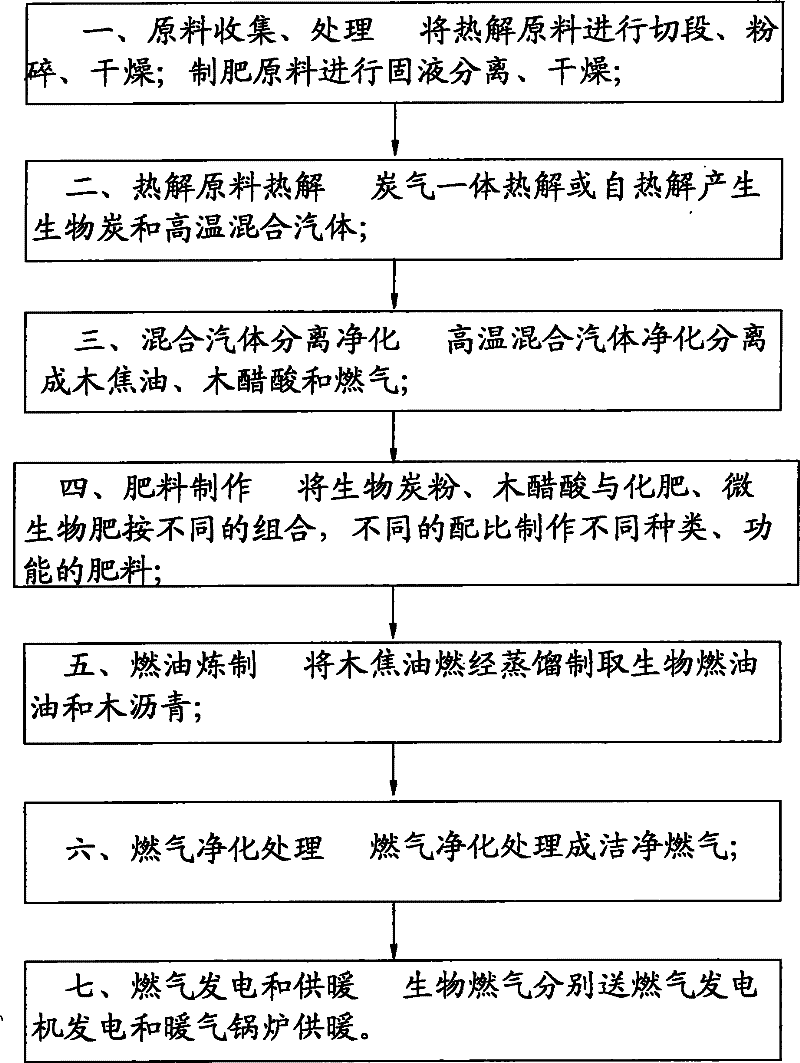

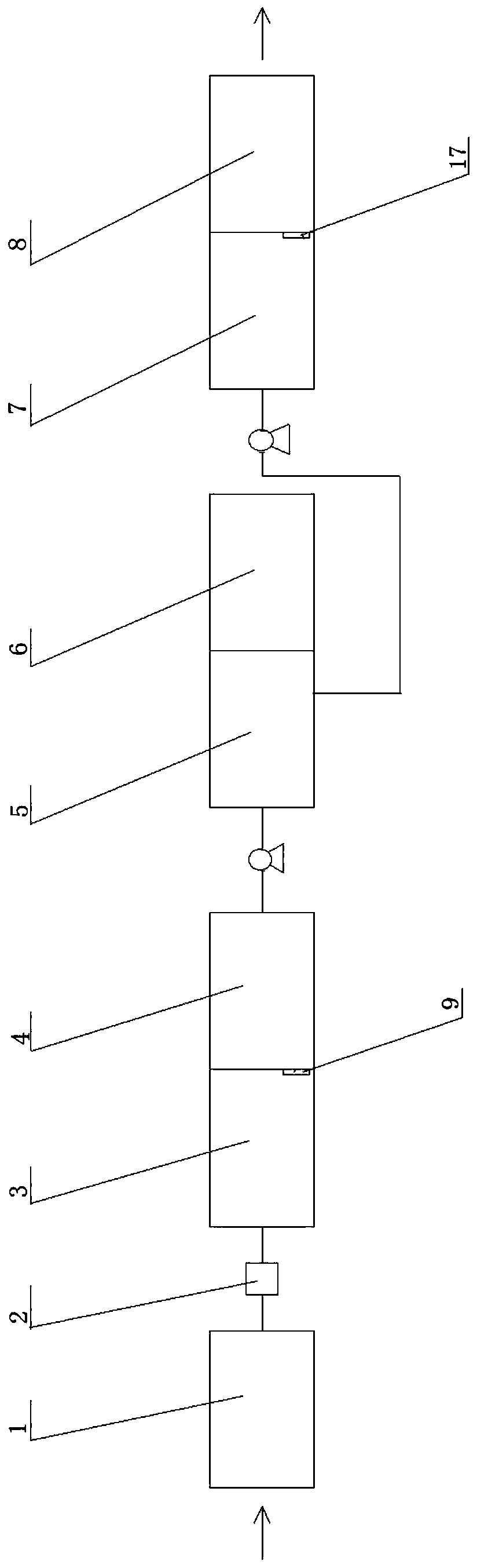

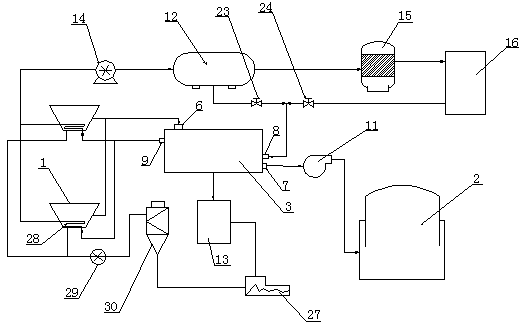

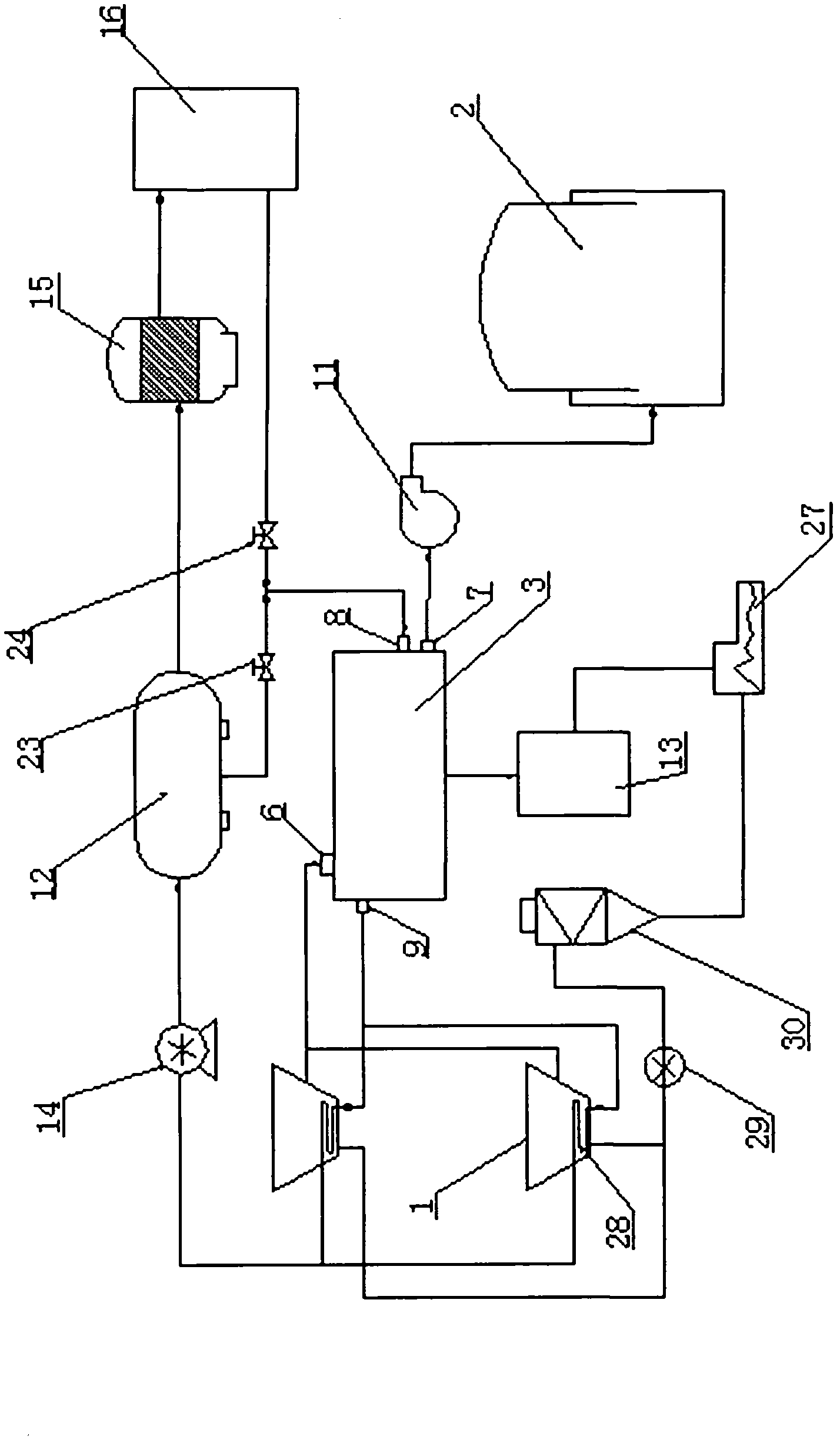

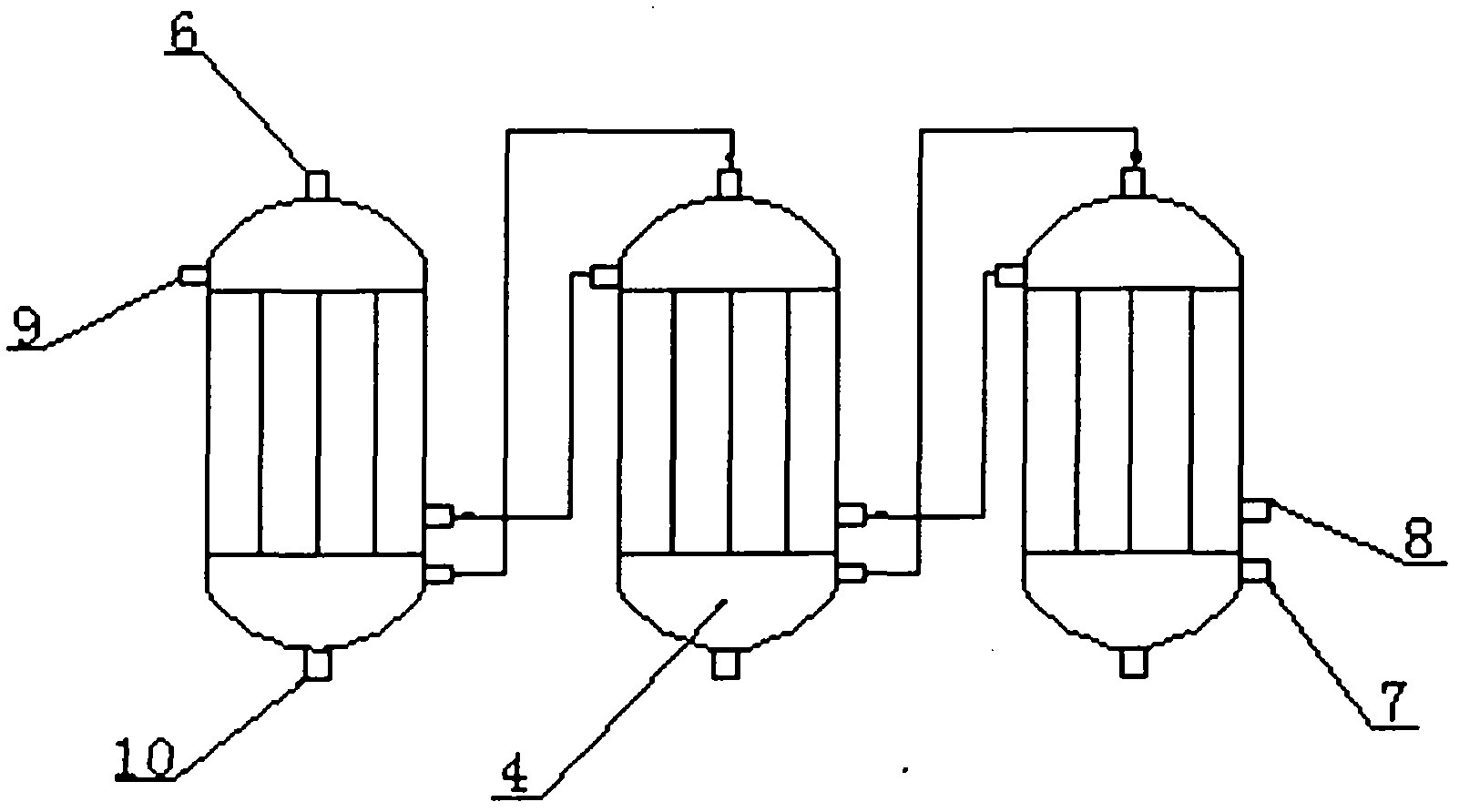

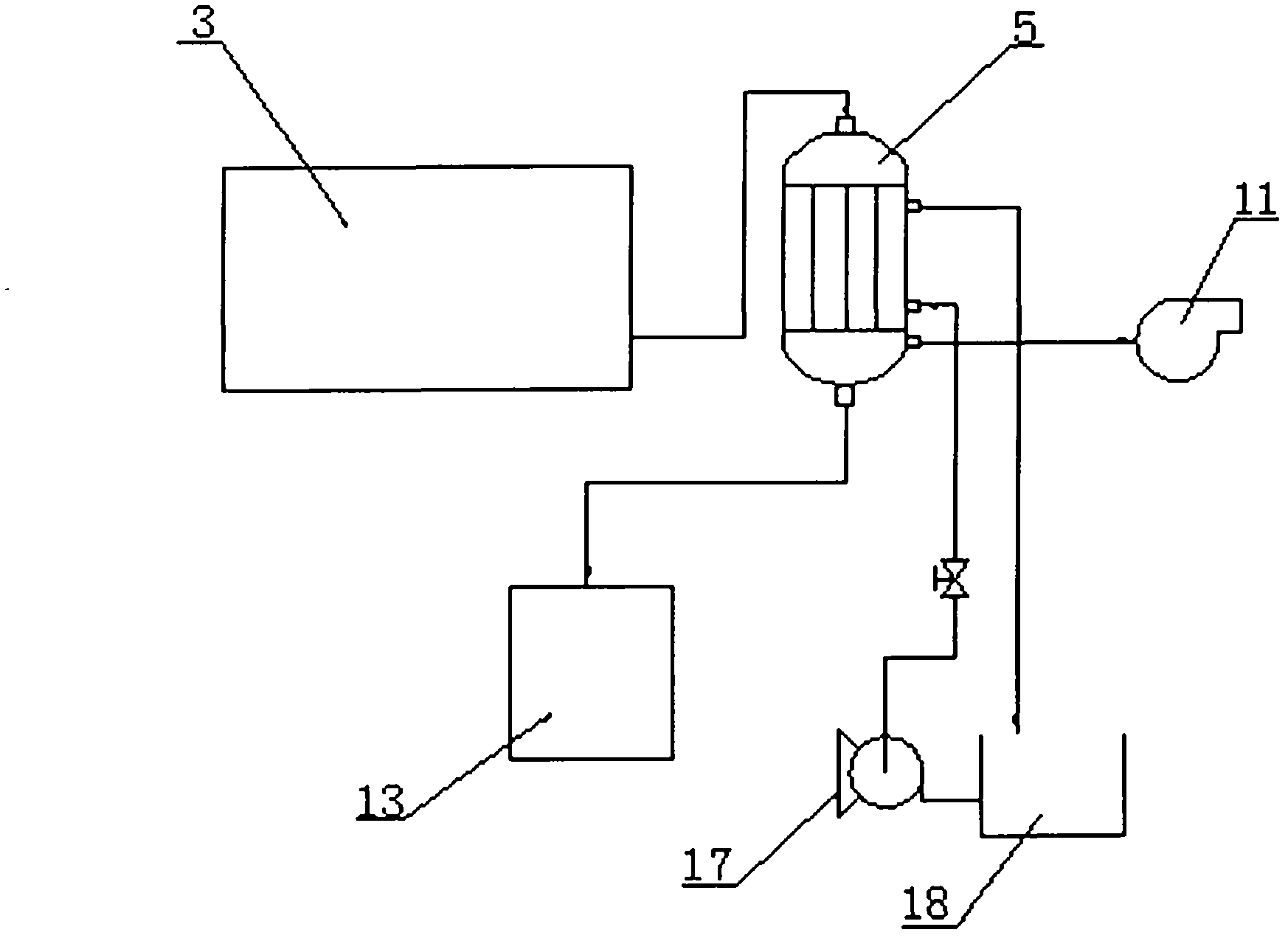

The invention relates to an integrated utilizing technology for agricultural waste and in particular relates to an integrated converting and utilizing co-production method for agricultural waste. The integrated converting and utilizing co-production method comprises the following steps: 1. collecting and processing raw materials; 2. carrying out pyrolysis on the raw materials: generating biochar and high-temperature mixed gas; 3. converting the high-temperature mixed gas: converting the high-temperature mixed gas into wood tar, wood vinegar and fuel gas; 4. manufacturing fertilizers; 5. refining fuel oil: converting the wood tar into biofuel oil and wood pitch; 6. purifying the fuel gas: purifying the fuel gas into clean fuel gas; and 7. converting the fuel gas: respectively sending the biofuel gas into a gas generator, a gas supply pipe network and a heat boiler to covert the biofuel gas into heat energy and electricity energy. The agricultural waste can be converted by multiple levels and are combined to be utilized to obtain straw carbon, fuel gas, heat energy, electricity energy, fertilizers, fuel gas and the like. The use ratio of the agricultural waste reaches 100%. The problem that the agricultural waste is stacked and burnt disorderly can be solved, the pollution problem caused by using chemical fertilizers and pesticides for a long time can be solved, and the problem of utilizing energy, fertilizer and oil in rural areas also can be solved.

Owner:周仁福 +2

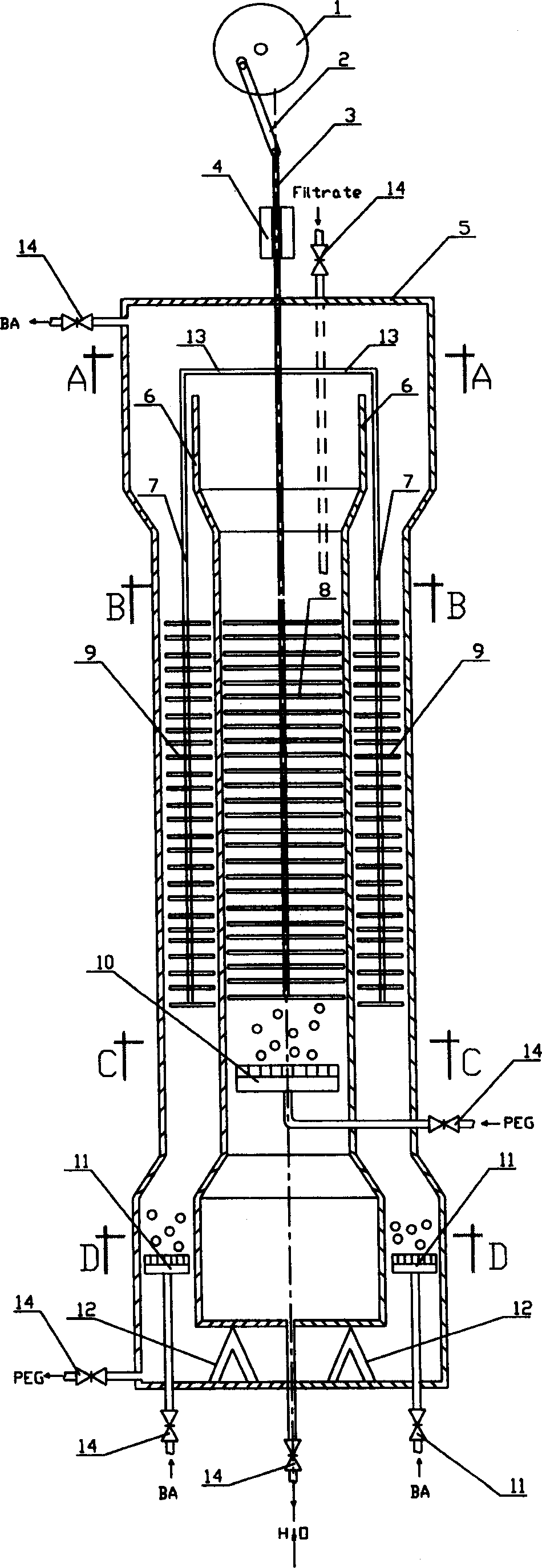

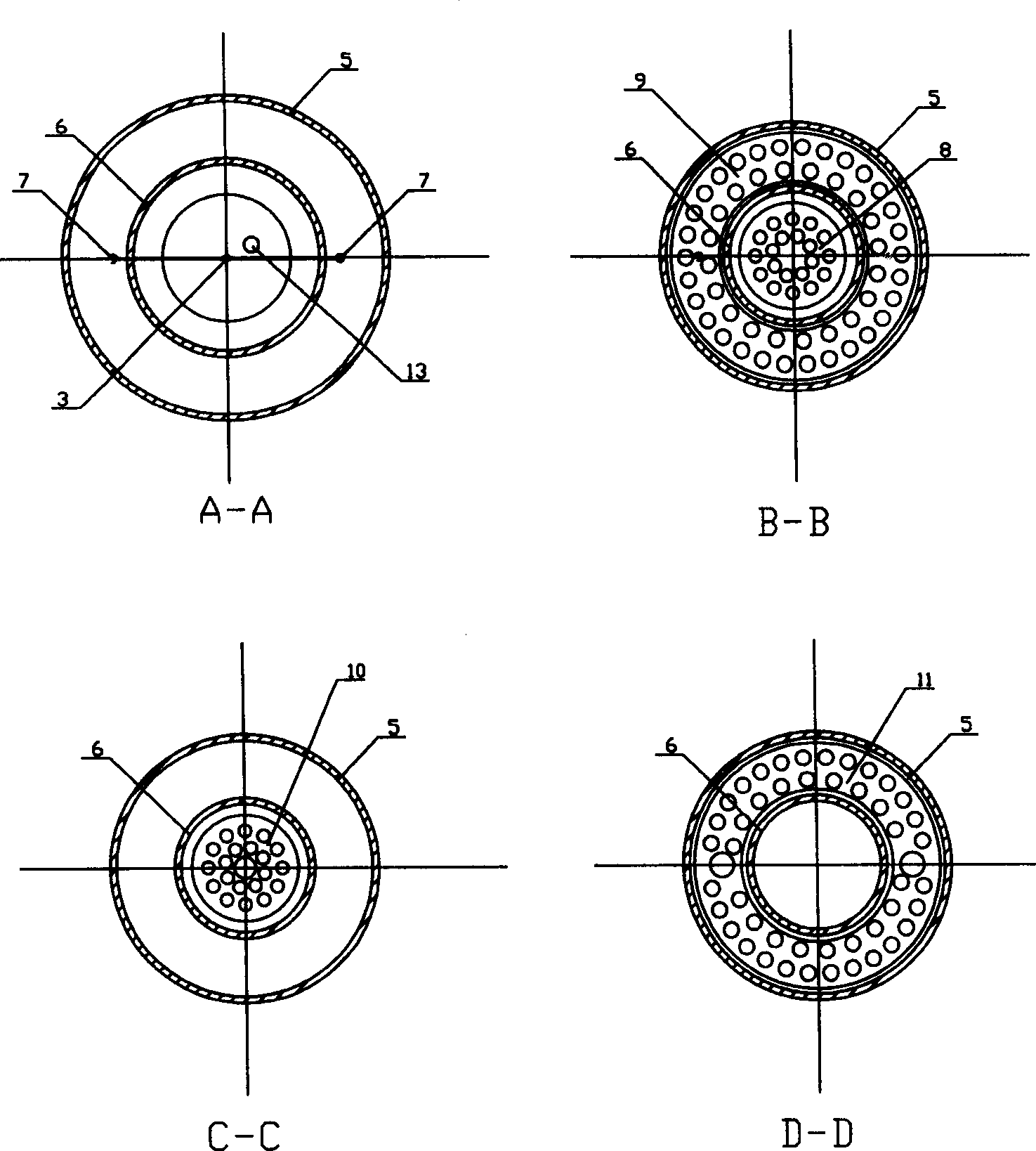

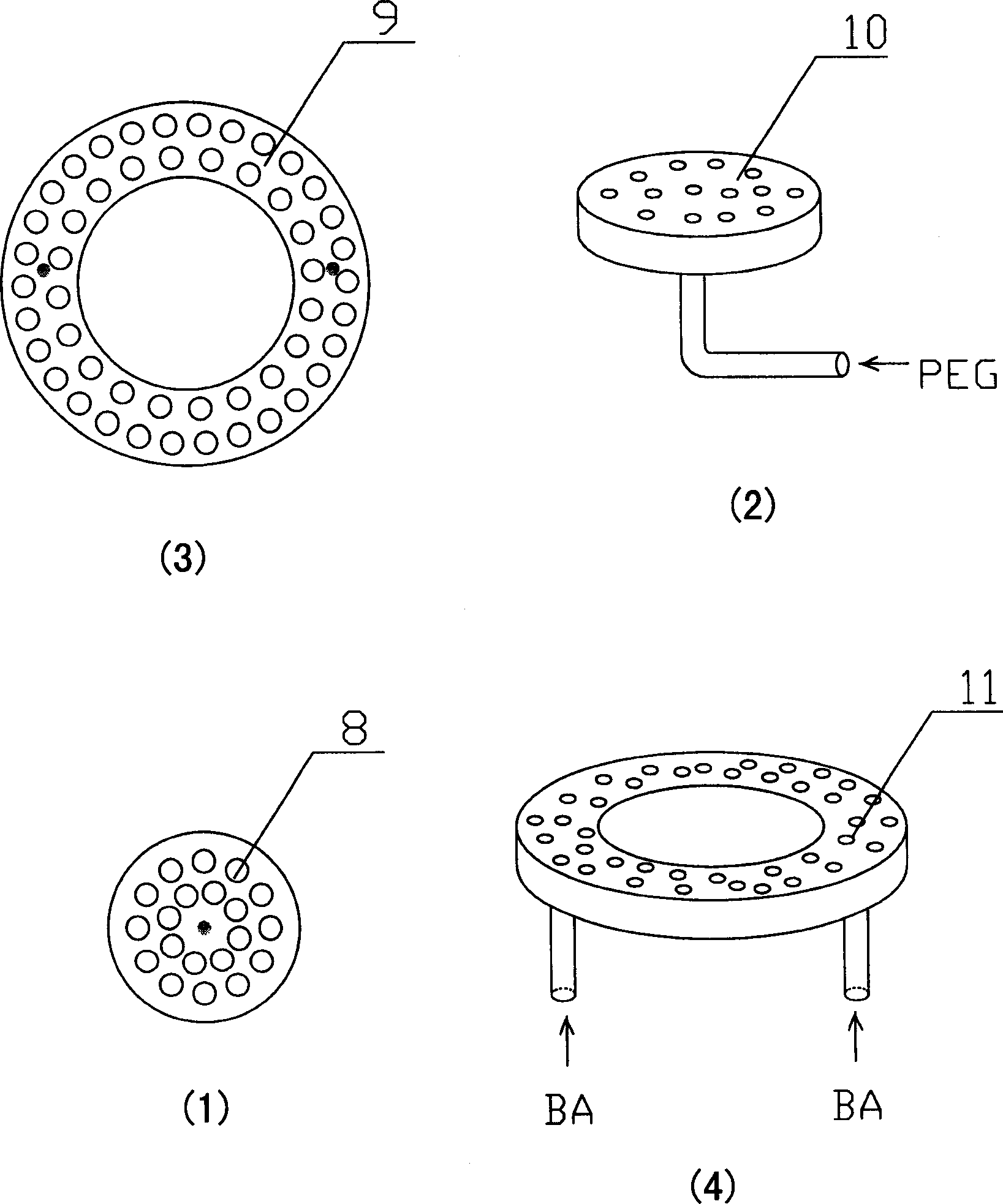

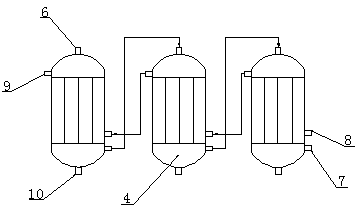

Liquid-liquid-liquid three phase continuous extraction vibrating sieve plate tower

InactiveCN1442223AImprove throughputImprove efficiencyLiquid solutions solvent extractionThree-phaseTower

A vibrating sieve-platte tower for three-phase (liquid-liquid-liquid) continuous extractions is suitable for a system containing solid and liquid easy to emulsify is composed of mechanical transmission unit, tower body, sieve plate, liquid-phase disperser and auxiliary unit. Its advantages are simple structure, flexible operation, easy regulation and low cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

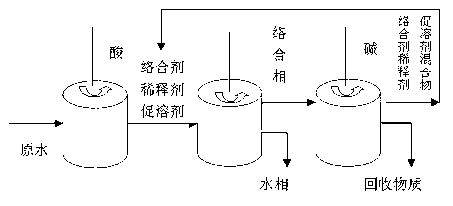

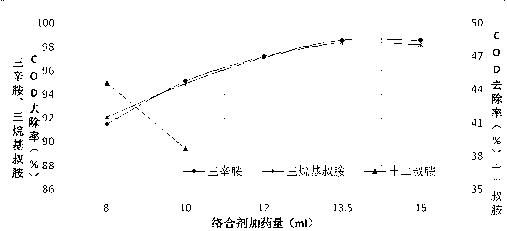

Process for treating dinaphthol wastewater by using complexation extraction method

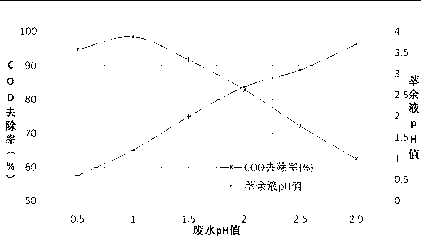

InactiveCN102936051AImplement full automationCan run continuouslyMultistage water/sewage treatmentWater/sewage treatment by extractionKeroseneOil phase

The invention discloses a process for treating dinaphthol wastewater by using a complexation extraction method. A process core includes that trioctylamine or trialkyl tertiary amine serves as a complexing agent, sulfonated kerosene serves as a diluent, and chloric acid tributyl ester serves as a chaotropic agent to be mixed according to a certain ratio into an extraction agent, the extraction agent comprises, by volume, 20% to 30% of the complexing agent, 60% to 70% of the diluent and 5% to 15% of the chaotropic agent. Dinaphthol production wastewater is extracted when the temperature is in a range of 20 DEG C to 30 DEG C and the pH is 1, aqueous phase: oil phase is 1: 1 (volume ratio), the removal rate of first extraction CODcr can reach 97%, naphthalene sulfonate in wastewater can be extracted through multistage extraction, and simultaneously water is discharged up to standard. Water phases of back extraction can be recycled as production materials; and organic phases are mixtures of the extraction agent and the diluent and can be recycled.

Owner:SHANGHAI BIOFIT ENVIRONMENTAL TECH

Treatment method and treatment system for wastewater produced during flue gas desulfurization adopting limestone/lime-gypsum method

ActiveCN105540960ARealize resourcesLow costCalcium/strontium/barium sulfatesTreatment involving filtrationSodium sulfateElectrodialysis

The invention provides a treatment method for wastewater produced during flue gas desulfurization adopting a limestone / lime-gypsum method. The treatment method comprises steps as follows: (1), lime, sodium sulfate, a heavy metal precipitant, a flocculating agent and a coagulant are added to to-be-treated desulfurization wastewater, precipitation is performed, and acid is added to effluent for neutralization; (2), the effluent in the step (1) is subjected to electrodialysis treatment through a homogeneous-phase monovalent ion exchange membrane, and contributing water containing NaCl and concentrated water containing CaSO4 are formed and are recycled respectively. The invention further provides a treatment system for the wastewater produced during flue gas desulfurization adopting the limestone / lime-gypsum method. According to the treatment method and the treatment system, zero emission is realized, the process is simple, the treatment efficiency is high, waste recycling is realized, an available industrial product can be directly obtained, the agent cost, the equipment cost and the energy consumption are lower, and accordingly, the overall operation and management cost is obviously lower than the cost of a conventional technology.

Owner:北京国泷环保科技有限公司

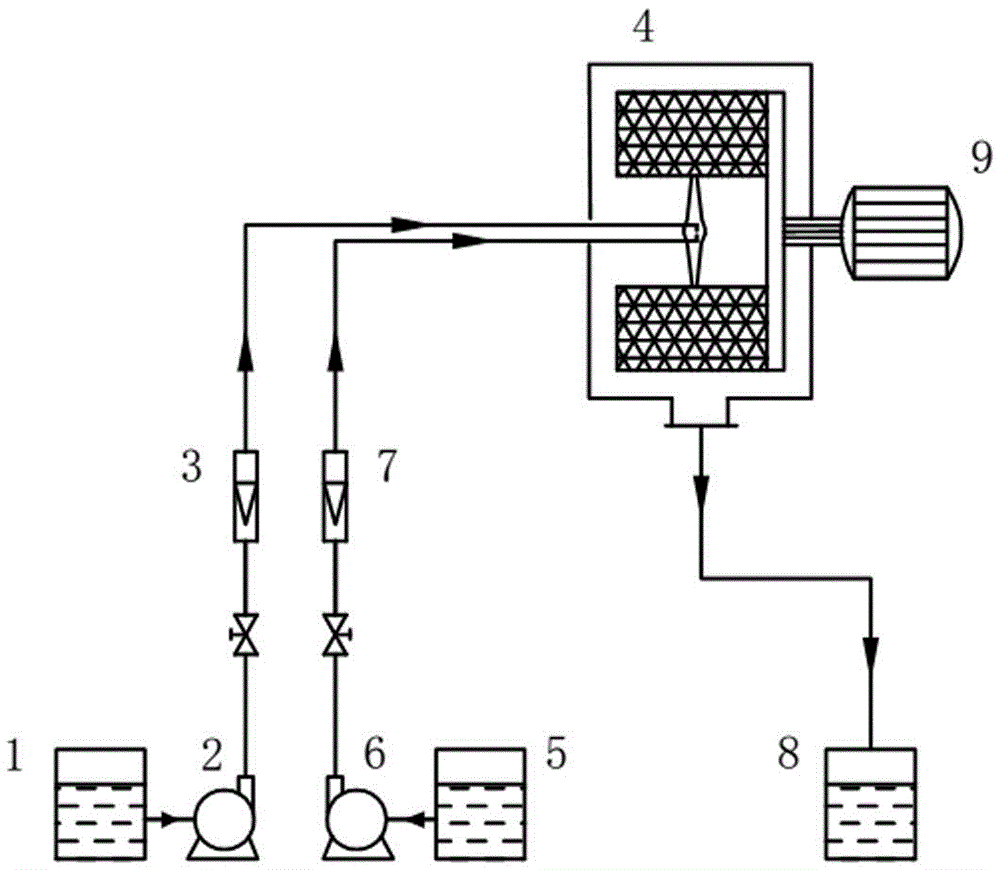

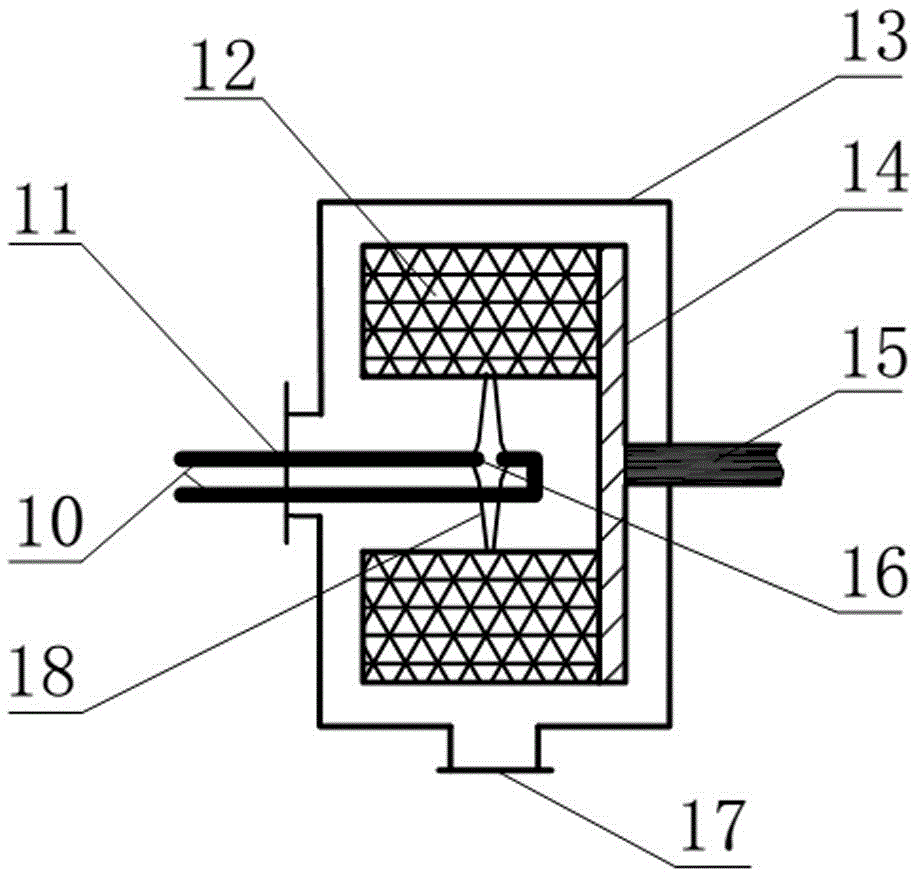

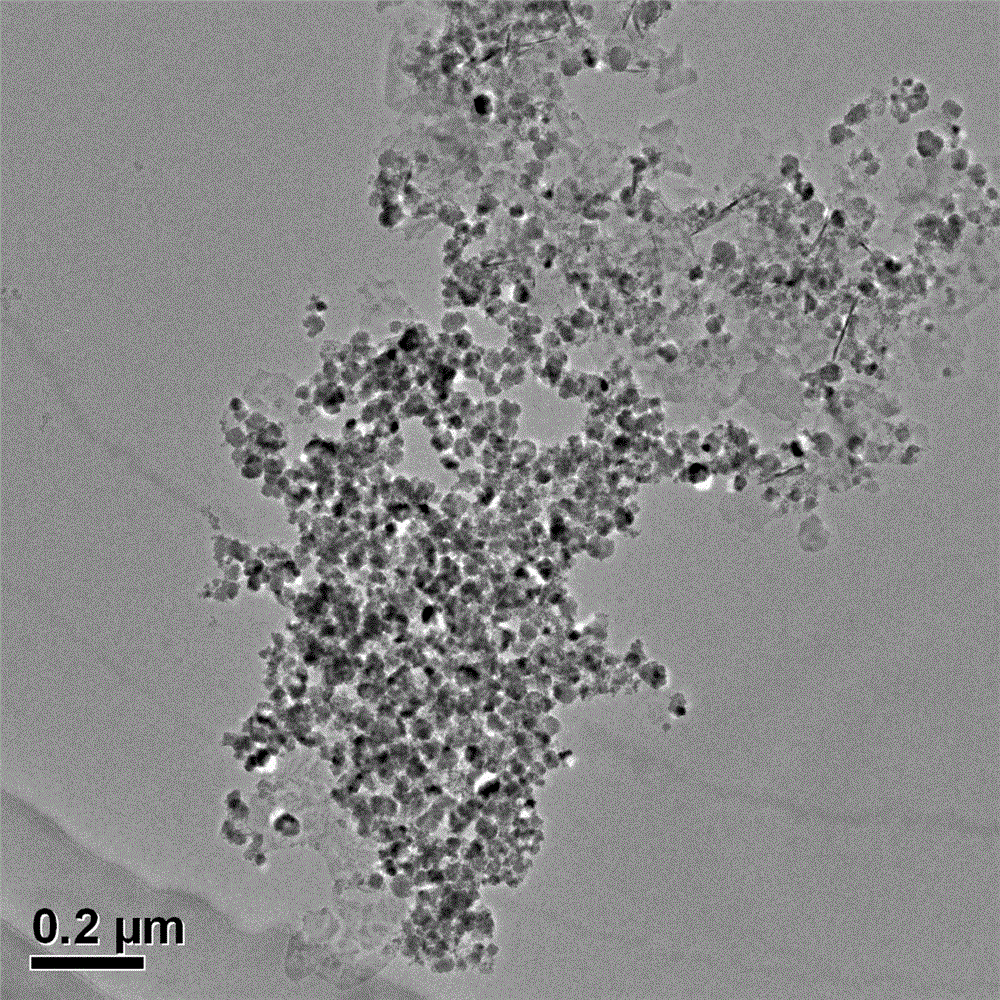

Method and device for supergravity on-line preparation of nano zero-valent iron and synchronous treatment on nitrobenzene wastewater

ActiveCN105858856AAvoid feedingEasy to prepareNanostructure manufactureWater contaminantsRetention timeFerrous salts

The invention belongs to the technical field of preparation of nano materials and nitrobenzene wastewater treatment, particularly relates to a method and a device for supergravity on-line preparation of nano zero-valent iron and synchronous treatment on nitrobenzene wastewater, and aims to solve the problems that conventional nano zero-valent iron is complex in preparation process, conditions are rigorous, the preparation process is not easy to amplify, nanoparticles are easy to agglomerate, oxidize and deactivate in the processes of drying, storage and use, and the like. The method comprises the following steps: enabling a ferrous salt containing nitrobenzene wastewater solution and a KBH4 or NaBH4 aqueous solution to react in an impinging stream device for collision, feeding into a rotating packed bed for mixing and reacting, and implementing preparation of nano zero-valent iron and treatment on the nitrobenzene wastewater by using the nano zero-valent iron simultaneously. The method and the device have the advantages that the situation that the nano zero-valent iron can be reacted with nitrobenzene only after being completely developed into large particles in a conventional method is avoided, the nano zero-valent iron can be relatively sufficiently utilized, the amount can be remarkably reduced, multiple steps of reaction is reduced to one step, the reaction can be implemented rapidly, the retention time is shortened, continuous operation can be achieved, and the method and the device are applicable to nitrobenzene wastewater treatment which is large in treatment volume and heavy in treatment task.

Owner:ZHONGBEI UNIV

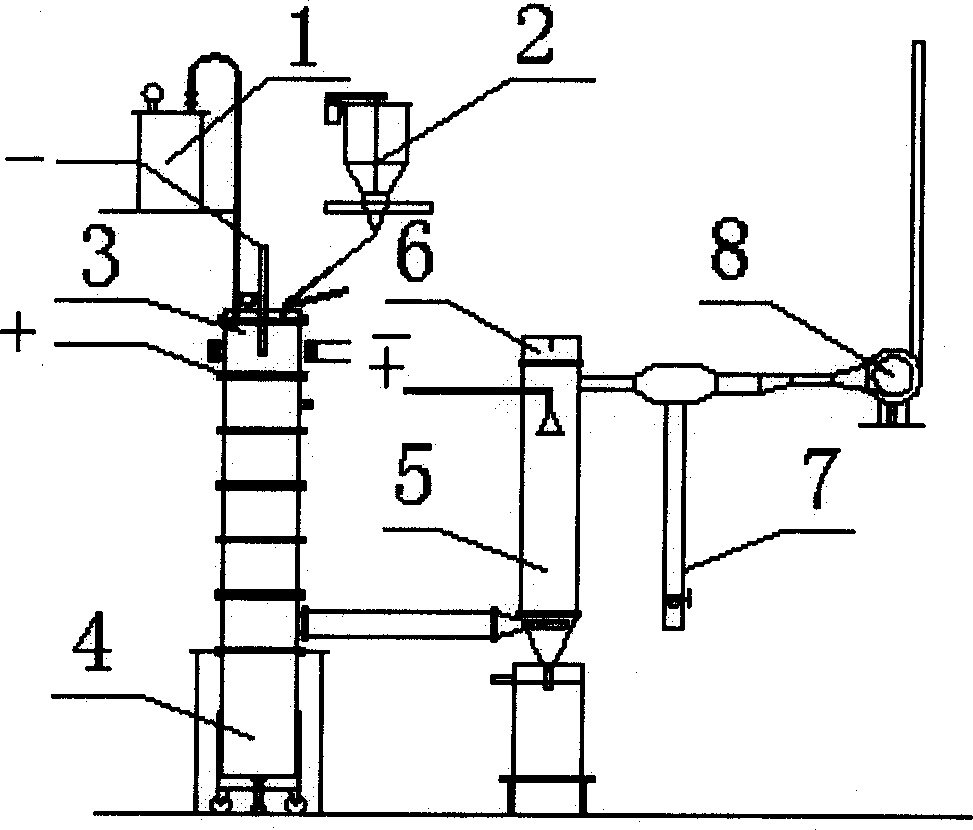

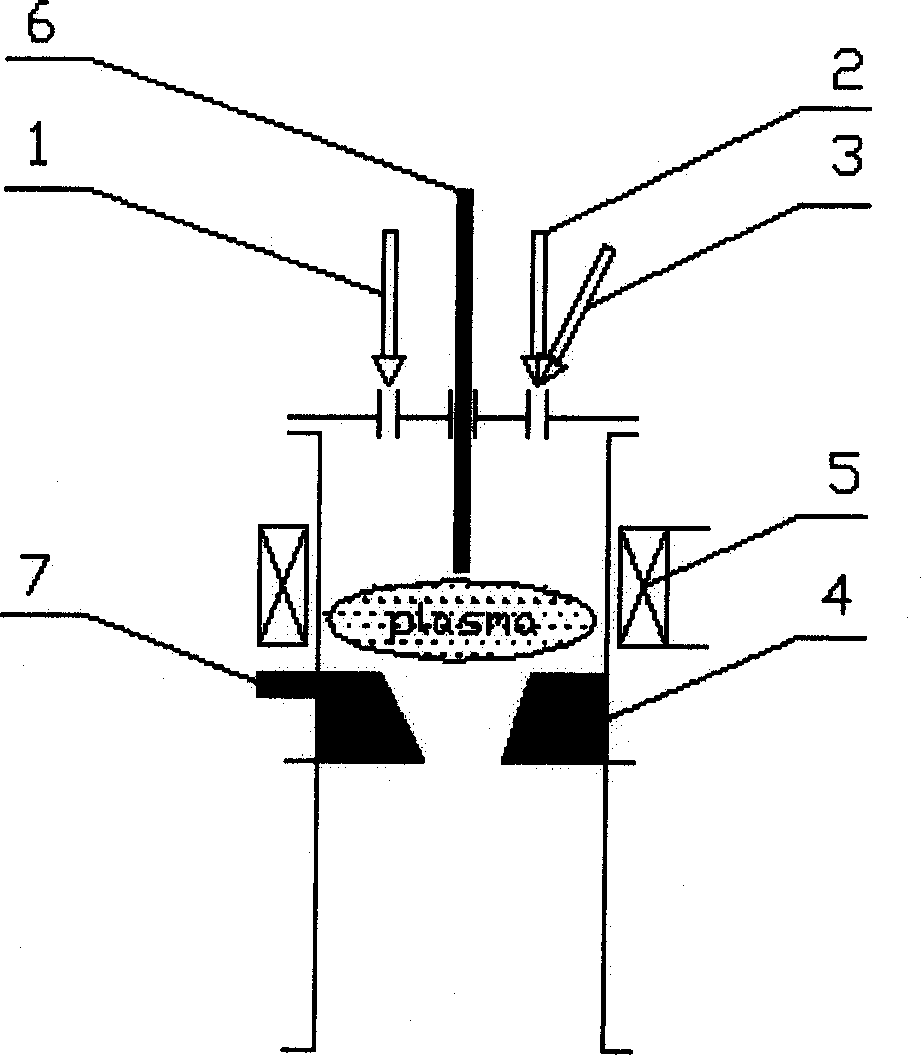

Method and apparatus for continuous preparation of carbon nanometer tube material from coal

InactiveCN1541938AReduce manufacturing costRealize continuous productionEnergy based chemical/physical/physico-chemical processesMetallurgyWater vapor

The present invention belongs to the field of coal chemical technology, plasma material science and carbon material technology. The present invention features that powdered coal and high temperature water vapor are sprayed directly into arc plasma to prepare carbon nanotube material continuously. That is, carbon nanotube material is prepared continuously by means of high temperature and arc plasma with high activity particle as medium. The arc plasma has work gas nitrogen and is rotated by means of outer magnetic field. The preparation apparatus consists of water vapor generating and supplying system, coal powder conveying system, plasma generator, product collector, gas cooling and purifying system, explosion-proof unit and pressure regulating system.

Owner:DALIAN UNIV OF TECH

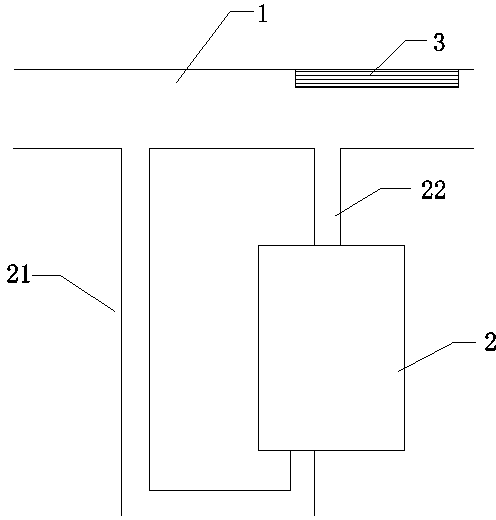

Water power spiral-flow type ballast water electrolysis disinfection device for ballast water monitoring system

InactiveCN101525172ALarge processing capacityWon't failWater/sewage treatmentParticulatesElectrolysis

The invention provides a water power spiral-flow type ballast water electrolysis disinfection device for a ballast water monitoring system. The water power spiral-flow type ballast water electrolysis disinfection device has the advantages of high treatment efficiency, large capacity, continuous operation, regardless density of entered particulates, no stoppage, simple and convenient flow control mode, simple and easy maintenance and low cost. The water power spiral-flow type ballast water electrolysis disinfection device comprises a shell, a ballast water inlet and a ballast outlet, and is characterized in that a vortex finder is arranged in the shell; an electrode configured for the vortex finder and an electrode arranged on the inner wall of the shell form an anode and a cathode; the lower end of the electrode configured for the vortex finder is provided with a through hole; and the electrode configured for the vortex finder is hollow, and is communicated with the ballast water outlet through a liquid outlet pipeline.

Owner:WUXI BRIGHTSKY ELECTRONICS

Method for breaking wall of chlorella by using compound enzyme

The invention provides a method for breaking the wall of chlorella by using a compound enzyme. The method comprises the steps: diluting a chlorella raw material so as to obtain a chlorella diluent, adding composite plant hydrolase and cellulase, adjusting the pH value, heating at a constant temperature for carrying out enzymatic hydrolysis, heating for enzyme deactivation, cooling so as to collect wall-broken chlorella and filling. The method has the advantages that the operation method is simple, the operating conditions are mild, the pollution is avoided, the requirements on equipment are low, the handling capacity is large, the continuous operation can be carried out, the method is suitable for industrial production, the composite plant hydrolase and the cellulase are mainly used for the specificity degradation of the cell wall polysaccharide of chlorella, do not contain protease, can effectively retain the functional components of the chlorella such as the proteins and amino acids and have high wall-breaking rate, and the obtained wall-broken chlorella is green and safe and can be directly applied to the fields such as medicines, food, household necessities, environments and the like.

Owner:BOHAI UNIV

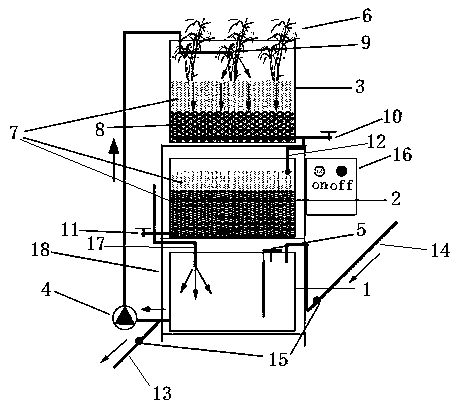

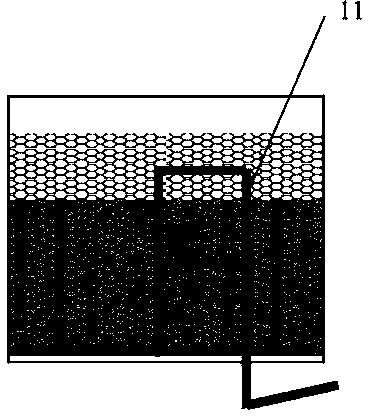

Backflow vertical wetland sewage treatment process and device, and application of process and device

ActiveCN104211182AGuarantee the effect of hanging filmAvoid cloggingSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater quality

The invention discloses a backflow vertical wetland sewage treatment process and device, and application of the process and the device. A vertical flow artificial wetland, a horizontal subsurface flow wet land and a reservoir are combined into a vertical structure from top to bottom. Circular treatment of sewage is achieved by laying a water level monitor to control the operation condition of a circulating pump, and each batch of sewage treatment capacity and treatment time are controlled and regulated by matching with a relay. Compared with a traditional artificial wetland, the backflow vertical wetland sewage treatment process has the advantages of being small in floor area, large in hydraulic loading, low in energy consumption, easy to operate and quick to remove pollutants; the conventional effluent water quality indicators CODCr, SS, TN and NH4<+>-N are much lower than the concentration threshold (GB18918-2002) defined by the first grade A standard of urban sewage treatment; the pesticide content in the effluent accords with the hygienic standard for drinking water (GB5749-2006); and the heavy metal content of the effluent reaches the surface water class II water standard (GB3838-2002). According to the backflow vertical wetland sewage treatment process, automatic treatment of the artificial wetland sewage is achieved, and the problem of poor single removal effect on organic matters and nitrogen pollutants in sewage through the artificial wetland is solved.

Owner:JINAN UNIVERSITY

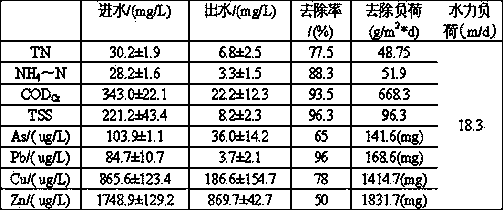

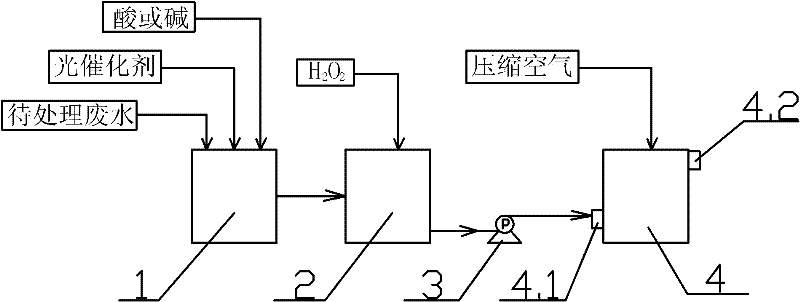

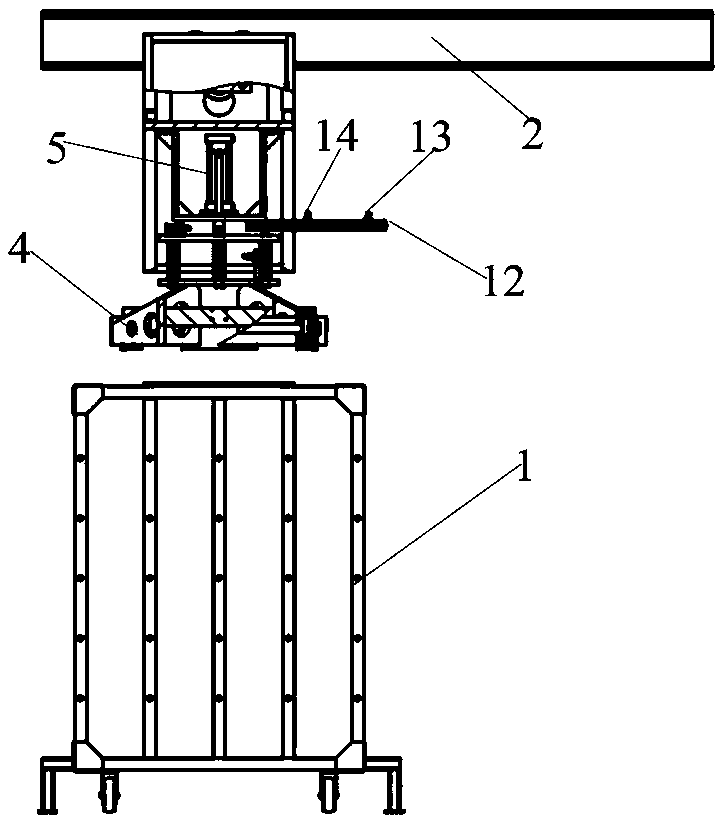

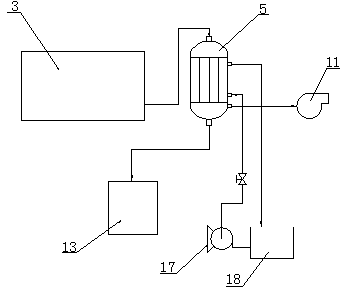

Homogeneous phase photo-oxidation device capable of degrading aromatic compound waste water continuously and processing method thereof

InactiveCN102229445AEasy to handleAdjustable and controllable handlingWater/sewage treatment by irradiationWater contaminantsSmall footprintWater processing

The invention provides a homogeneous phase photo-oxidation device capable of degrading aromatic compound waste water continuously and a processing method thereof. The method comprises the following steps: delivering waste water to be processed into a regulator, mixing the waster water to be processed with a photocatalyst which is added from the upper part of the regulator, and regulating the pH value to 3-4; delivering the mixture into a stirring mixer, and mixing the mixture with H2O2 which is added from the upper part of the stirring mixer; and entering a photoreactor through a constant flow pump after mixing, and carrying out continuous photo Fenton oxidation and degradation to finally obtain qualified clarified water. By the adoption of the processing method provided by the invention, problems of pollution and regeneration of the catalyst cannot be caused, the catalyst and an oxidizer have no secondary pollution, the reaction is carried out at normal temperature and pressure, the occupied area is small, the operation is simple and convenient, the waste water processing capability and processing effect are adjustable and controllable, and the aromatic compound waste water which is difficult to degrade can be processed continuously; and the aromatic compound waste water which is difficult to degrade is processed continuously by adopting the processing method, and the removal rate of a parent aromatic compound is more than 98%.

Owner:JIANGHAN UNIVERSITY

Remediation method for polluted soil

InactiveCN109622596ACompact processReduce kinetic energy consumptionContaminated soil reclamationIonPh balance

The invention discloses a remediation method for polluted soil. The remediation method comprises the following main steps of crushing, screening, spraying, heating sterilization and the like to remediate the polluted soil. Compared with a traditional remediation method for soil pollution, the remediation method for the polluted soil has the advantages that a treatment process is improved, and dustreduction and medicament addition in a soil treatment process are achieved through spraying; medicinal steam and pressure which are generated during heating sterilization are utilized to realize soilsterilization; by adding medicinal liquid and mixing the liquid uniformly, metal ion chelation and acid-base pH balance in the polluted soil are realized. The adopted treatment approaches of the method are hardly influenced by pollutant types and environmental conditions and have a wide application field. The method has the advantages of good effect, high operability and good social and environmental benefits.

Owner:王忠良

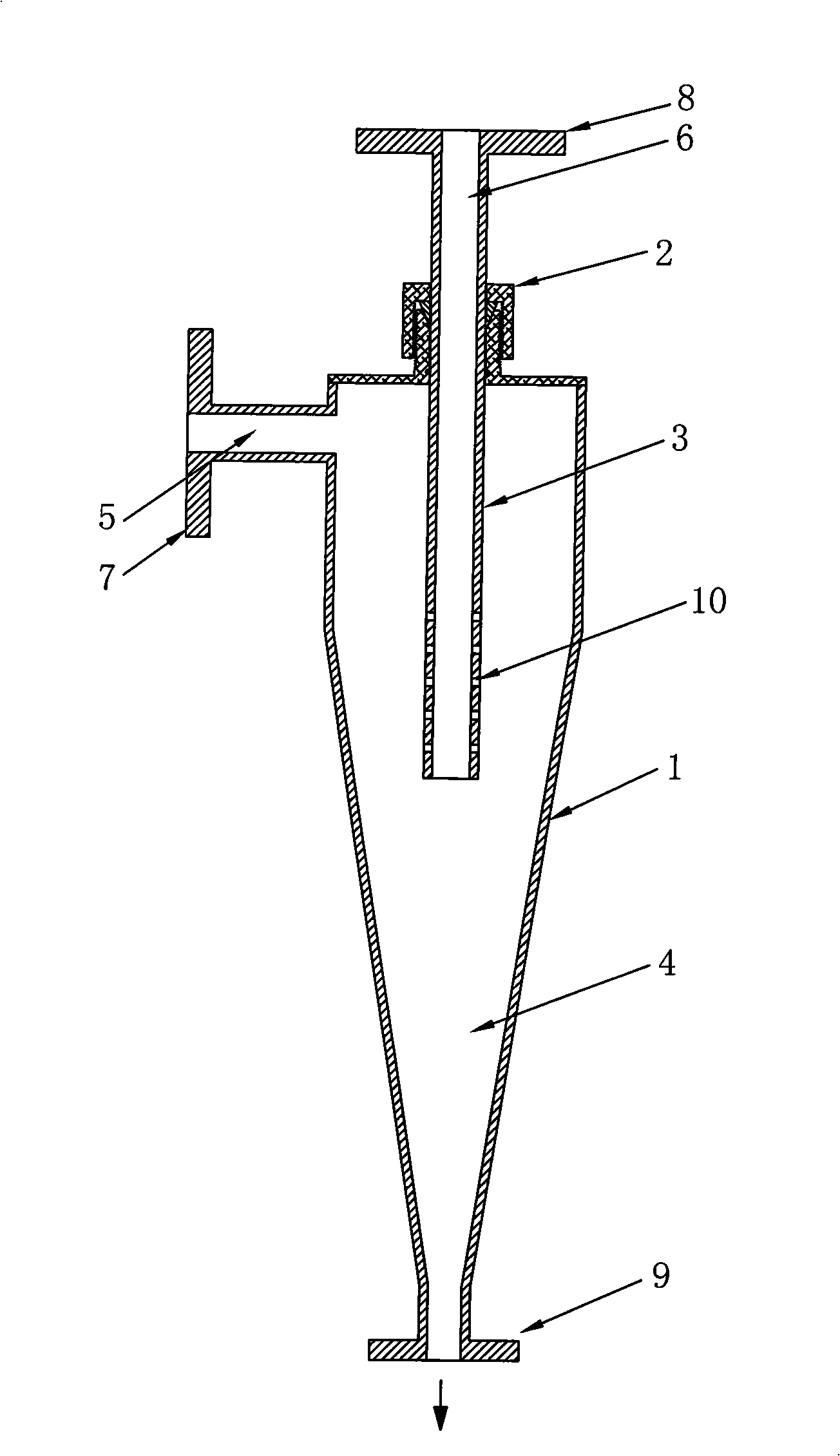

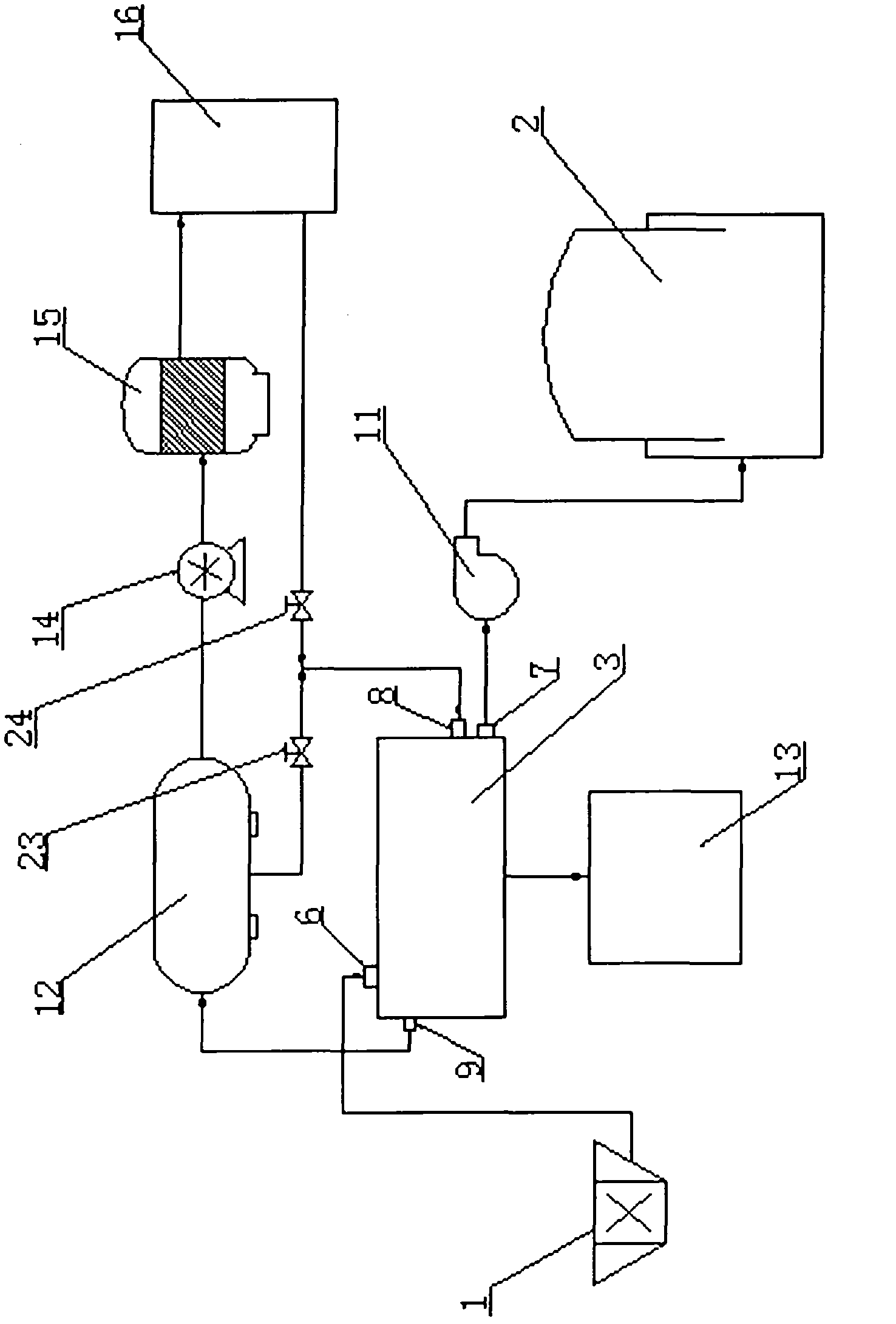

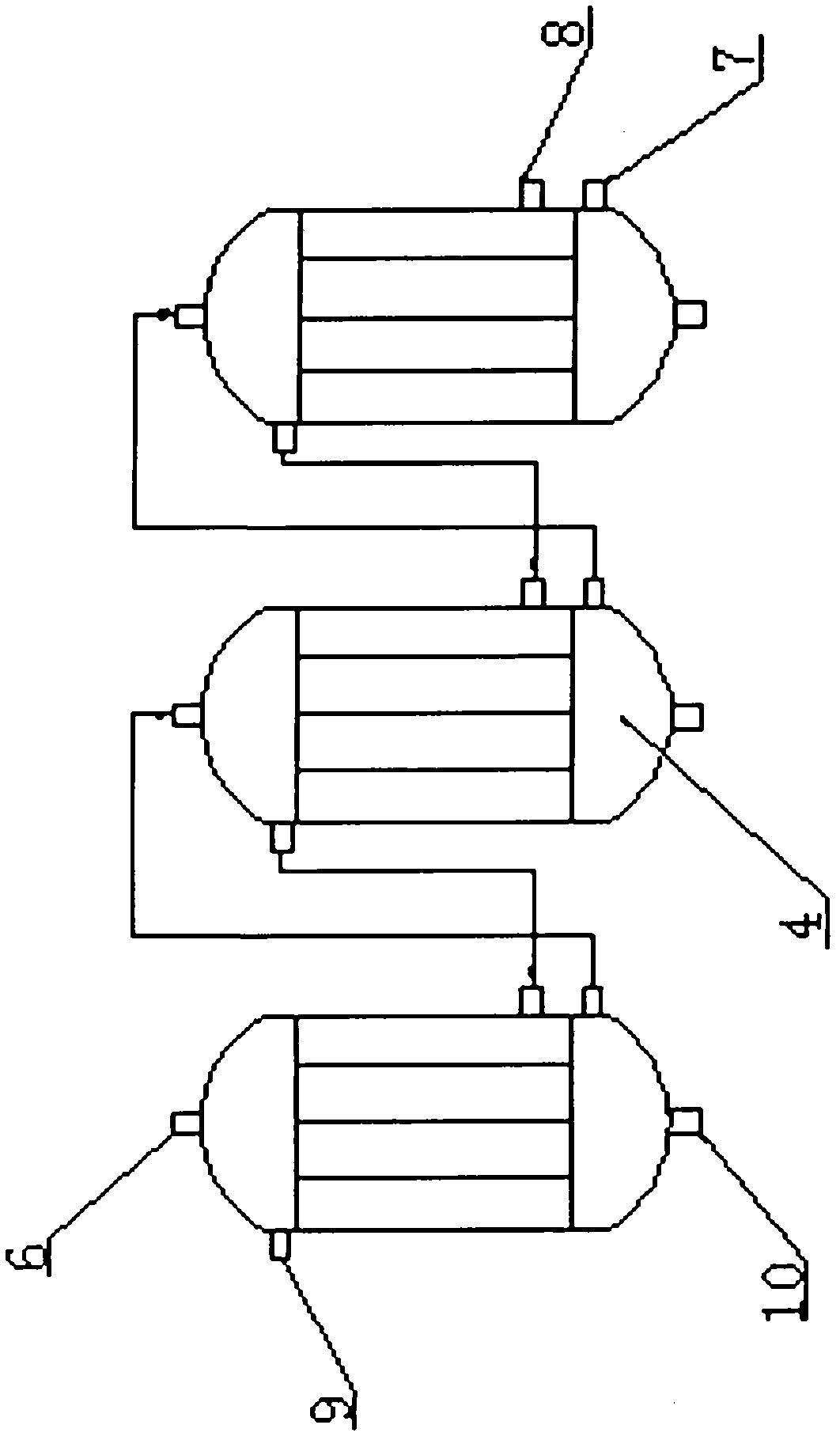

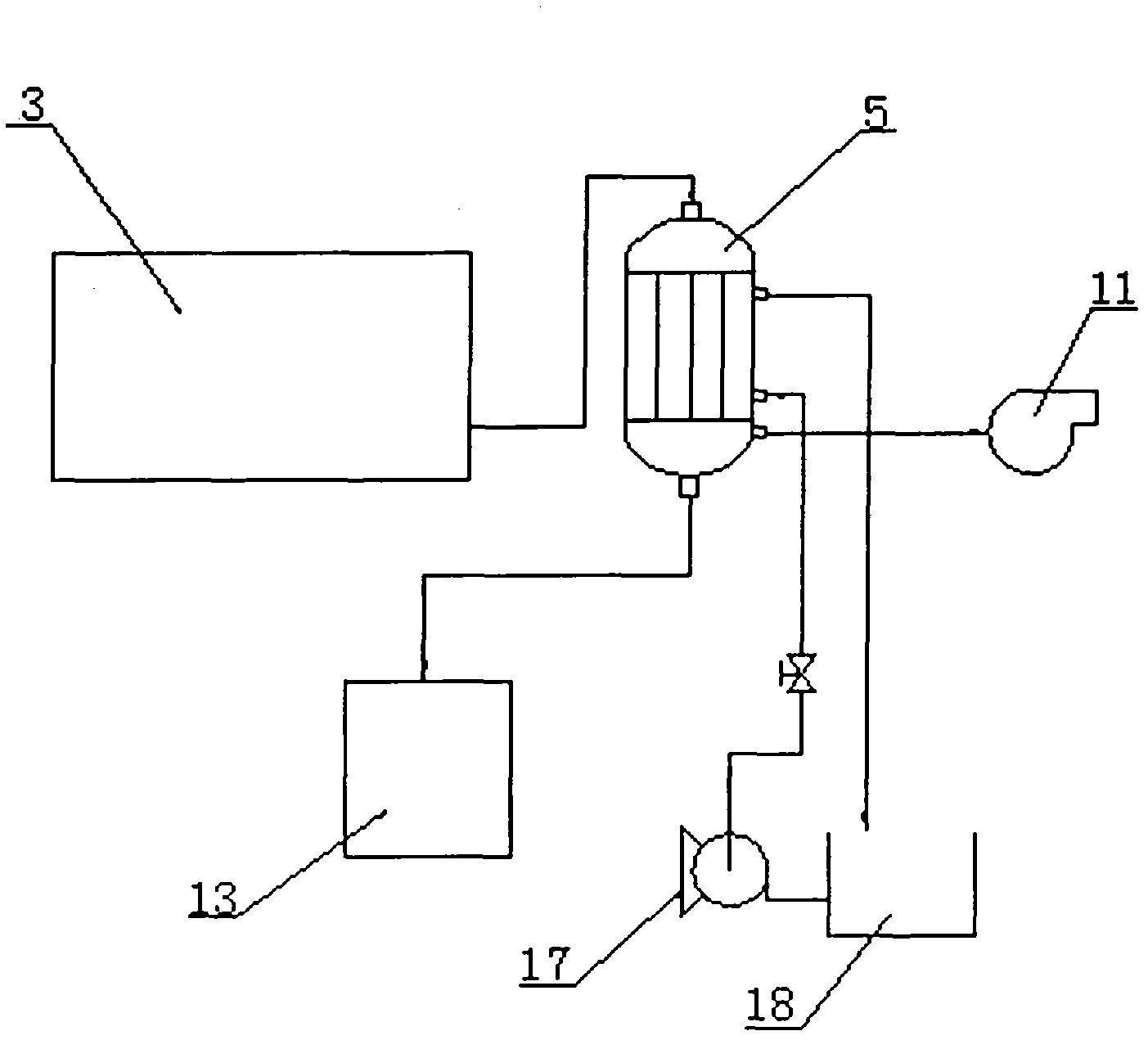

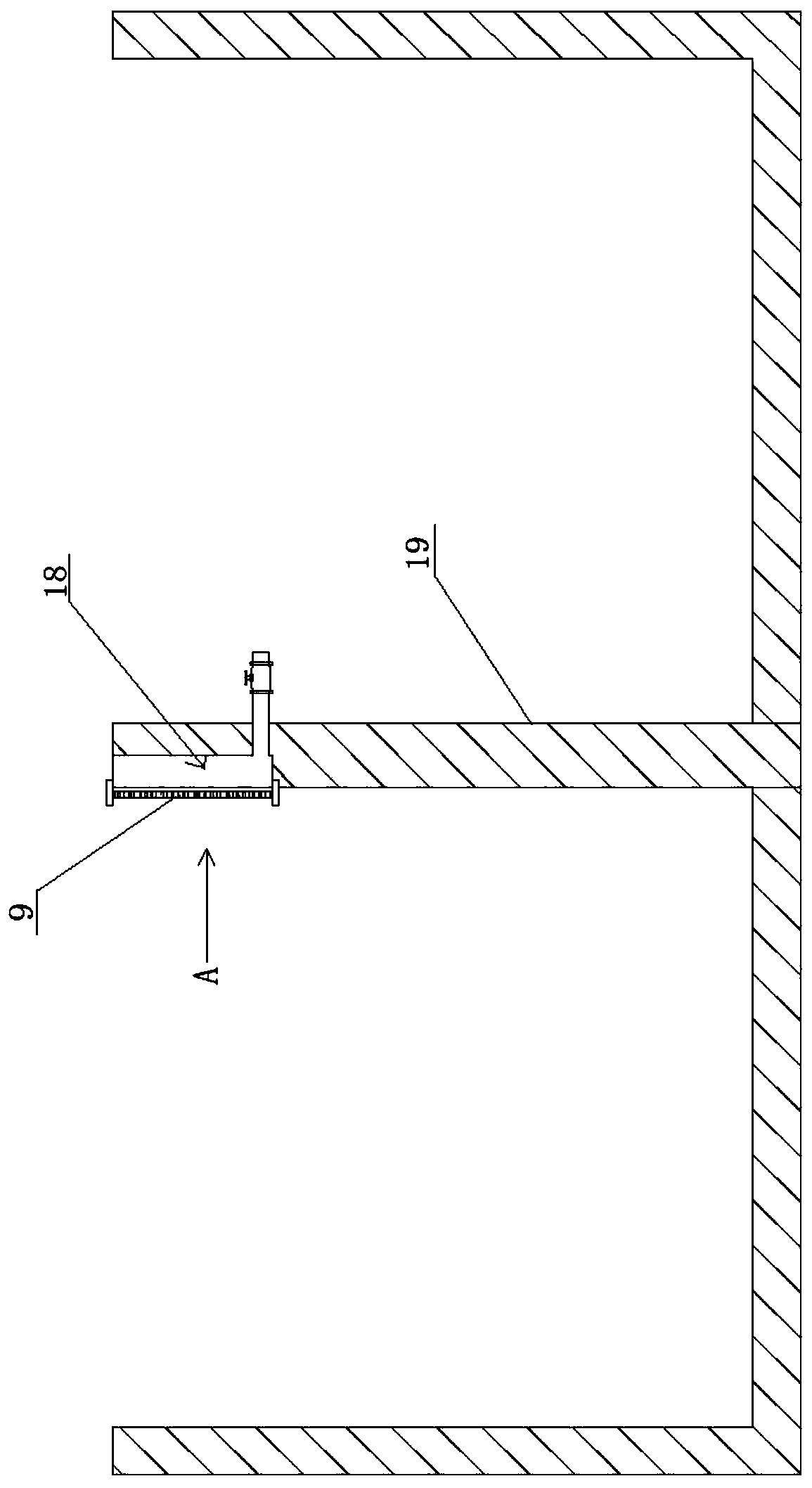

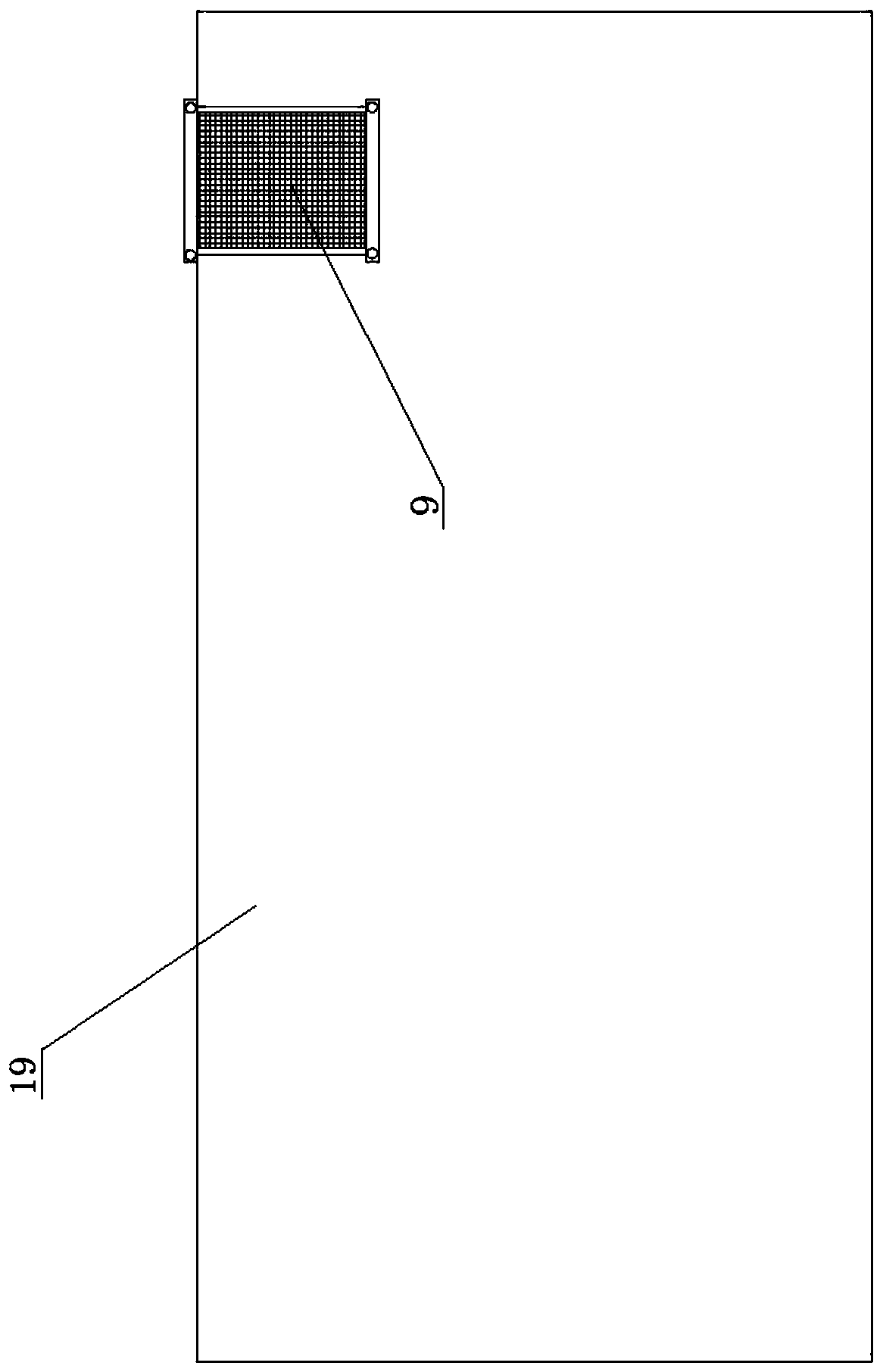

Pyrolysis-gasification integrated conversion and utilization system and method for waste biomass resources

InactiveCN103074119AImprove cooling effectGuaranteed puritySolid waste disposalBiofuelsWater vaporRaw material

The invention relates to a pyrolysis-gasification integrated conversion and utilization system for waste biomass resources and a method used by the same. The system comprises a pyrolysis device, a gas feeder, a multifunctional heat exchange device and a waste heat supply device, wherein a gas channel of the multifunctional heat exchange device is respectively connected with the pyrolysis device and the gas feeder, and a condensed water channel is connected with the waste heat supply device. The method comprises the following steps: delivering the raw material biomass waste into the pyrolysis device for high temperature pyrolysis to obtain mixed gas containing combustible gas, tar gas, acetic acid gas and water vapor; and introducing the mixed gas into the multifunctional heat exchange device for heat exchange and separating combustion gas from mixed liquor of tar and acetic acid after heat exchange, wherein hot water is obtained, hot water and combustion gas are respectively utilized by the waste heat supply device and the gas feeder to supply gas, heat and hot water for residents, acetic acid can be used as a biological foliar fertilizer, a biopesticide or a biological bactericide, and tar can be used as an industrial raw material. The integrated conversion, collection and utilization rate of the waste biomass resources approaches 100%.

Owner:LUOYANG JUNTENG ENERGY TECH

Low-carbon source two-stage MBR (Membrane-Bioreactor) enhanced nitrogen and phosphorus removal method for city sewage

InactiveCN106673371AAvoid easy cloggingEfficient separationTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesWater dischargeNitration

The invention discloses a low-carbon source two-stage MBR (Membrane-Bioreactor) enhanced nitrogen and phosphorus removal method for city sewage. The method is characterized by being a continuous flow nitrogen and phosphorus removal process with an adjusting tank, an anaerobic tank, a settling pond I, an aerobiotic MBR tank I, an anoxic pond, a settling pond II and an aerobiotic MBR tank II which are connected in series. The method comprises the following steps: firstly, feeding sewage into the anaerobic tank for anaerobic phosphorus release, further feeding the sewage into the settling pond I for sludge-water separation, feeding supernate obtained after settling into the aerobiotic MBR tank I for nitration and degradation of a part of organic matters, feeding settled sludge and a nitration liquid after aerobiotic nitration into the anoxic pond for denitrification phosphorus removal, feeding a part of a mixed liquid after anoxia into the settling pond II for settling sludge removal so as to remove phosphorus, feeding another part of the mixed liquid and the supernate of the settling pond II into the aerobiotic MBR tank II for further aerobiotic nitration and phosphorus removal, and finally filtering and discharging water by using an MBR membrane component. Due to two stages of aerobiotic MBRs, complete separation of nitration bacteria and phosphorus-accumulating bacteria can be achieved, the nitrogen and phosphorus removal effect can be improved, the process is simple in procedure and convenient to operate, and continuous water discharge can be achieved.

Owner:CHINA UNIV OF MINING & TECH

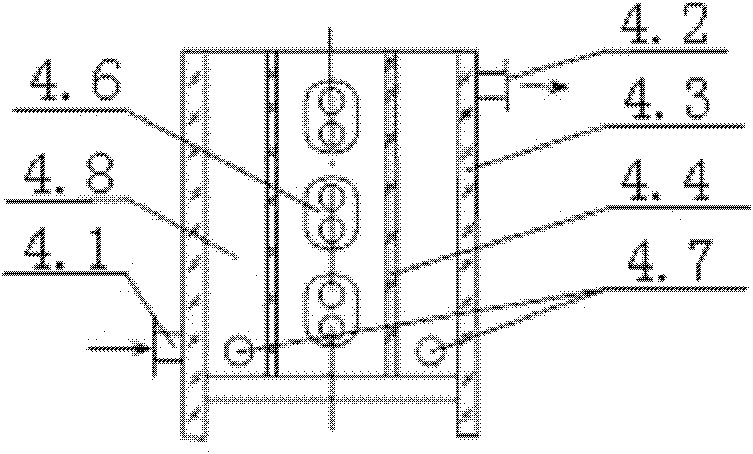

Special sealed feeding device for hazardous waste incinerator and feeding method of feeding device

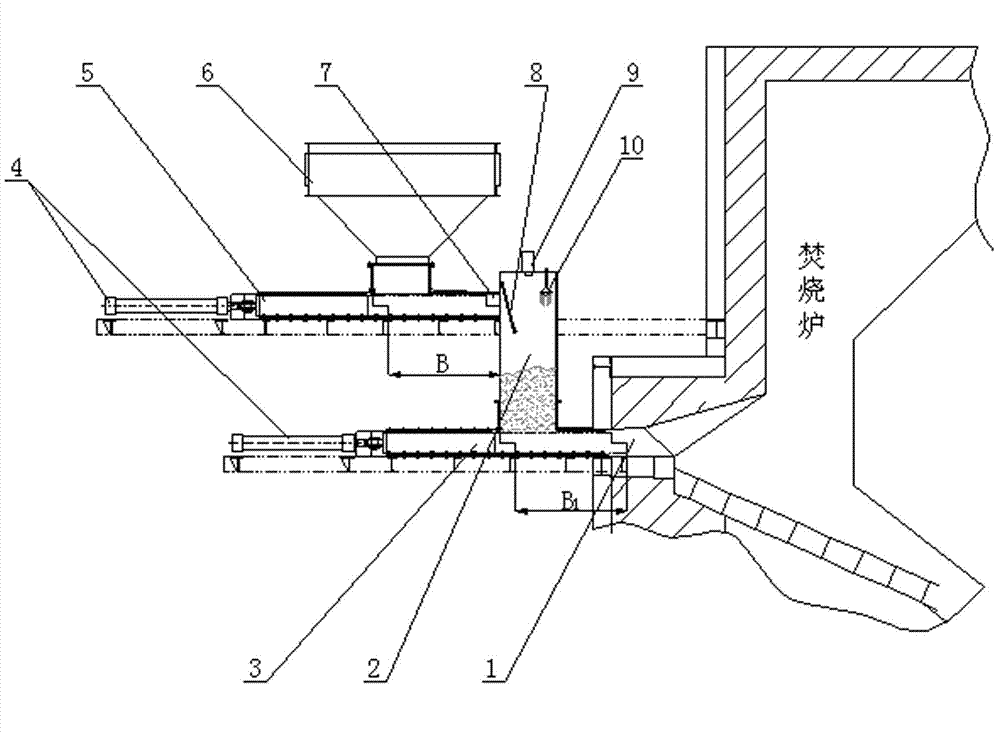

InactiveCN103196145AReasonable structureCan run continuouslyIncinerator apparatusEngineeringHazardous waste

The invention relates to a special sealed feeding device for a hazardous waste incinerator and a feeding method of the feeding device. The feeding device comprises a hopper, an oil cylinder, a first-stage push element, a feeding channel, a hook type flap gate, a sealed feed bin, a second-stage push element, a feeding port, a monitoring camera and a spray extinguishment unit. The hopper is disposed on the upper portion of the first-stage push element; the first-stage push element and the feeding channel are disposed on the left side of the sealed feed bin; the hook type flap gate and the feed channel are connected and mounted in the sealed feed bin; the second-stage push element and the feeding port are arranged at the bottom of the sealed feed bin; and the monitoring camera and the spray extinguishment unit are arranged at the top of the sealed feed bin. The feeding method comprises that hazardous waste in the hopper is sent to the sealed feed bin by the first-stage push element from the feeding channel, and when the first-stage push element pushes the waste forwards to move under the action of an oil cylinder, the waste in front of the push elements pushes the hook type flap gate open; and the hazardous waste sent into the sealed feed bin through the first-stage push element is sent to the incinerator through the second-stage push element.

Owner:丁剑

Magnetic ring liquid purification equipment

ActiveCN102795735AStrong resistance to shock loadsReduce energy consumptionMultistage water/sewage treatmentMagnetic separatorLoad resistance

The invention belongs to the technical field of magnetic separation liquid purification, and in particular relates to magnetic ring liquid purification equipment. The equipment comprises a magnetic separator, a residue scraping mechanism, a residue discharge mechanism, a power transmission mechanism and a water inlet and drainage mechanism, wherein the magnetic separator belongs to a flat ring type, and the flat ring type magnetic separator is positioned in parallel on the upper part of a settling tank and fixed on a frame; and the flat ring type magnetic separator consists of two or more magnetic rings with the same diameter, and the upper magnetic ring is connected with the lower magnetic ring through a fixing ring. The equipment greatly improves the residue absorbing capability of a magnet, and has high impact load resistance.

Owner:SCIMEE TECH & SCI CO LTD

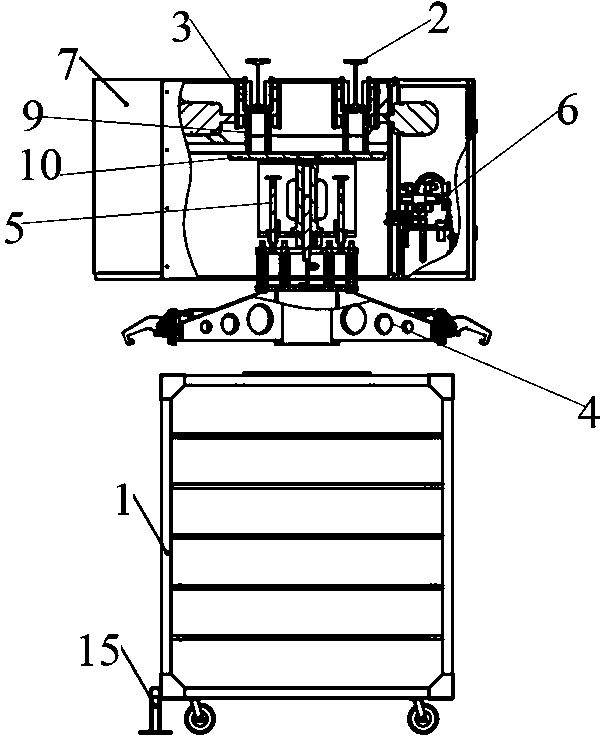

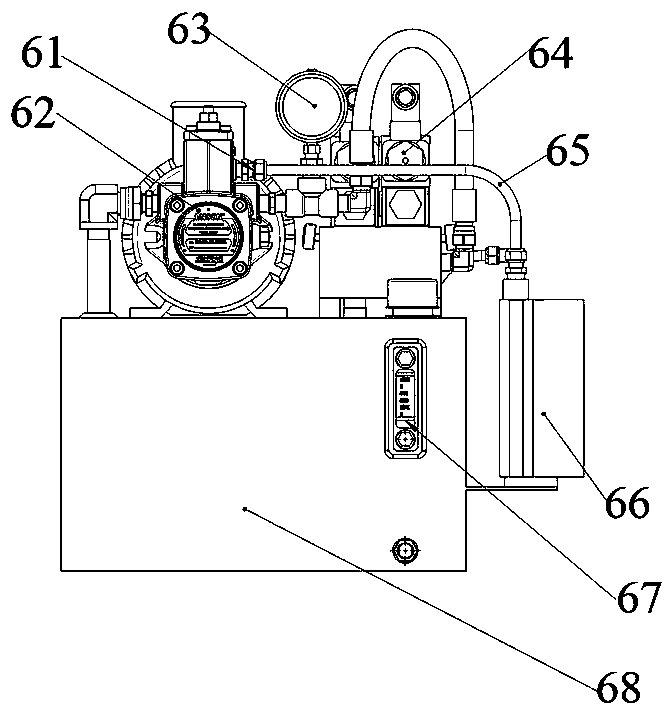

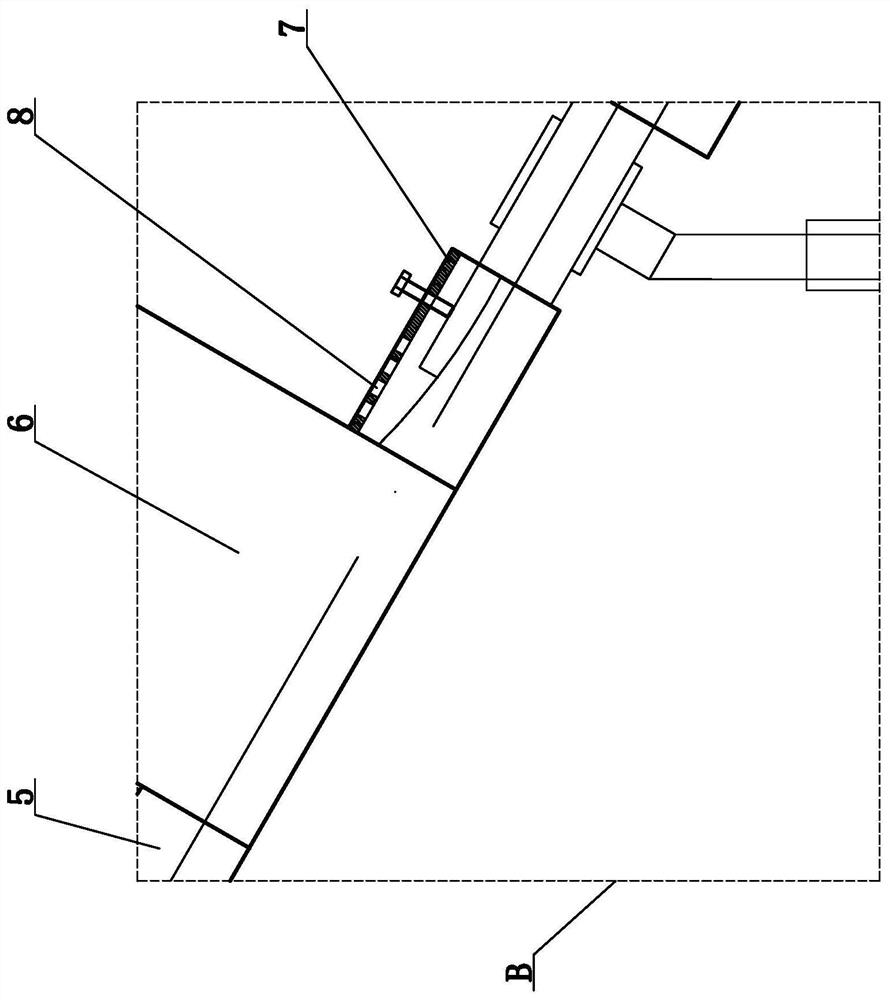

Handling system of dry trolley used for placing denitration catalyst

PendingCN110065528AGuaranteed uptimeCan run continuouslyDrying solid materialsHand carts with multiple axesProduction lineRemote control

The invention discloses a handling system of a dry trolley used for placing a denitration catalyst. The handling system comprises a trolley, a rail steel beam, and a power system, wherein the trolleyis used for handling the denitration catalyst, the rail steel beam is used for hanging handling tools, the power system is hung on the rail steel beam and used for grabbing the trolley, the power system comprises a hanging connection assembly, a clamping jaw assembly, a hydraulic guide lifting and lowering assembly, a hydraulic assembly, a control box, and a remote-control unit, wherein the hanging connection assembly is used for connecting with the rail steel beam in a hanging mode, the clamping jaw assembly is used for grabbing the trolley, the hydraulic guide lifting and lowering assembly is used for lifting or lowering the clamping jaw assembly, the hydraulic assembly is used for providing power for the hydraulic guide lifting and lowering assembly and the clamping jaw assembly, the control box is used for controlling the hydraulic assembly, and the remote-control unit is used for remotely controlling the handling system to grab and lower the trolley through the control box, and the hydraulic assembly, the hydraulic guide lifting and lowering assembly and the control box are successively fixed into a load bearing frame body from left to right. The handling system is stable andreliable, continuous operation can be realized, personnel fatigue caused by manually pushing trolley does not exist, and the handling time is greatly shortened than the original method; and the automation level of production line equipment is increased, and the site environment is improved.

Owner:JIANGSU LONGYUAN CATALYST CO LTD +1

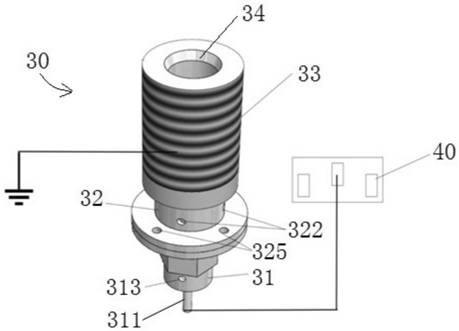

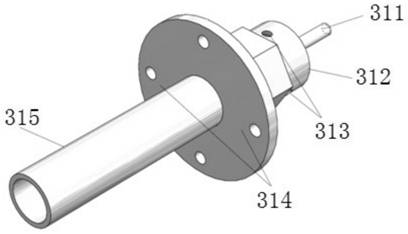

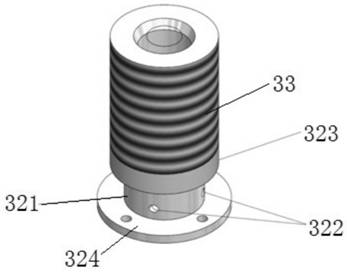

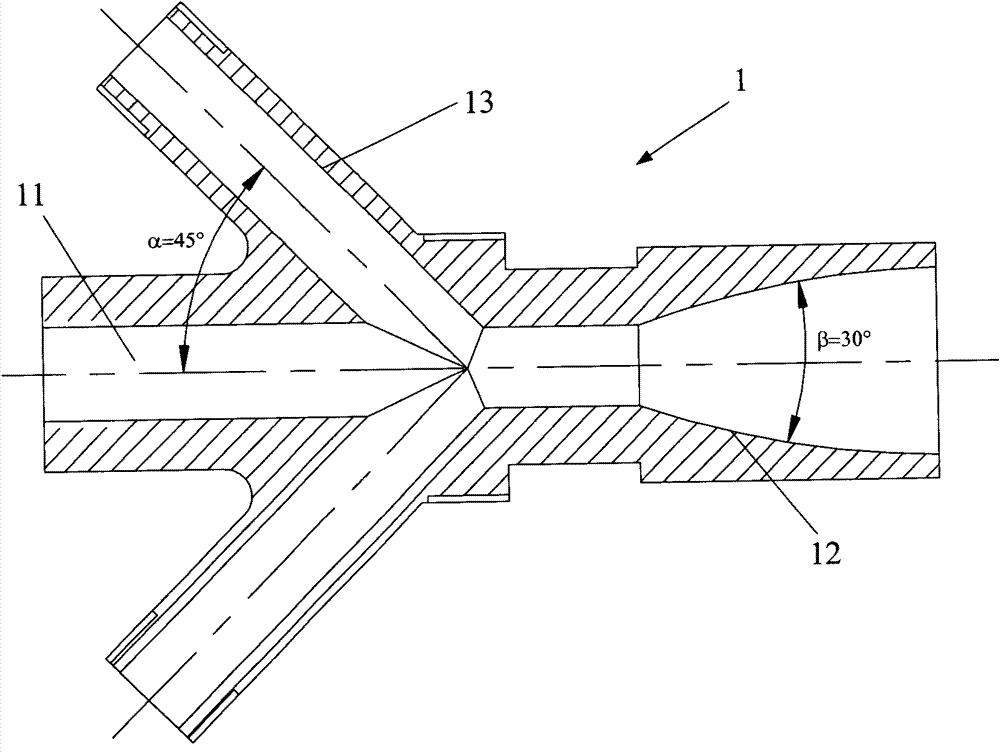

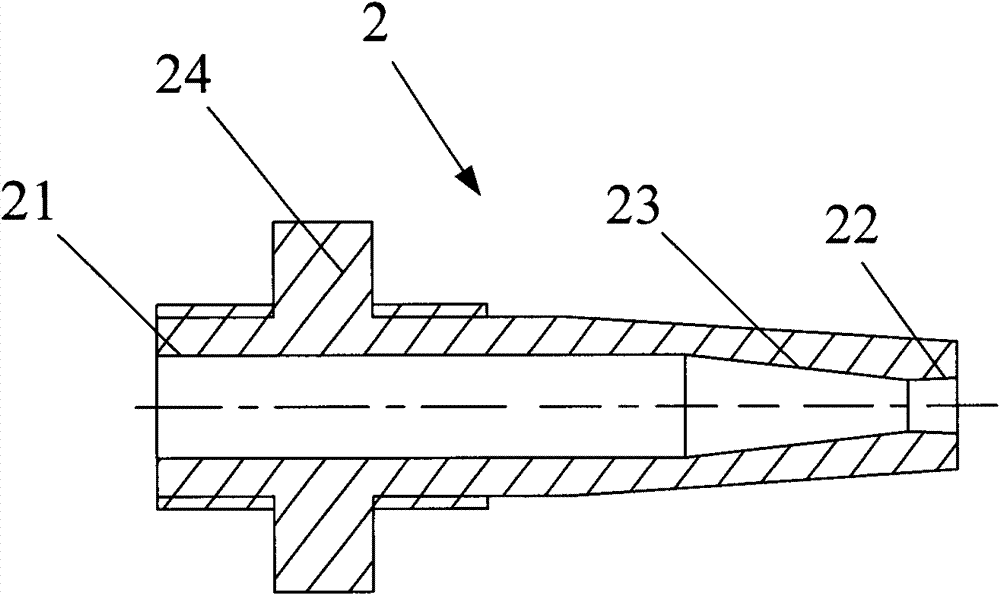

Efficient and stable combustion injector of medium and small thrust rocket engine

ActiveCN113446129ACan run continuouslyGuaranteed uptimeRocket engine plantsIndirect carbon-dioxide mitigationAutomotive engineeringInjector

The invention discloses an efficient and stable combustion injector for a medium and small thrust rocket engine. The efficient and stable combustion injector comprises an injection panel, centrifugal plasma nozzles and a high-voltage power supply, wherein the centrifugal plasma nozzles are uniformly distributed on the injection panel in a concentric circle mode, and the injection panel is an insulated single-layer injection panel or double-layer injection panel and can be well compatible with a plurality of plasma nozzles. The inner wall surface of the spraying end of an insulating outer nozzle is provided with a divergence angle alpha; an oxidant channel is arranged between an inner nozzle and the outer nozzle; the metal inner nozzle is grounded and has a retraction distance L; a metal ring sleeves the outer wall of the outer nozzle, is longer than L and is connected with a high-voltage power supply; and the atomization effect and the combustion efficiency can be adjusted by adjusting L and alpha. According to the efficient and stable combustion injector, the non-equilibrium plasma auxiliary combustion technology is combined with the design of the rocket engine injector, so that the effects of shortening the ignition delay of fuels such as methane, widening the ignition limit and rapidly diffusing flames to reach a stable state are achieved, and rapid ignition and efficient and stable combustion are realized.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Pig manure sewage treatment device and method

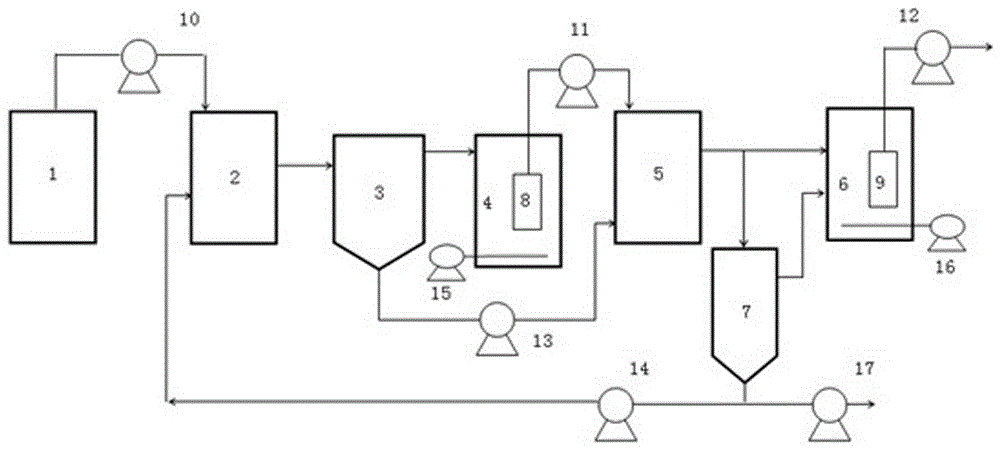

PendingCN109809646AImprove processing efficiencyLarge amount of processingWaste water treatment from animal husbandryMultistage water/sewage treatmentSewageSedimentation

The invention provides a pig manure sewage treatment device and relates to the technical field of sewage treatment. The pig manure sewage treatment device is mainly used for treating a lot of pig manure sewage which is continuously produced, and comprises a collection anaerobic tank, a primary filtering anaerobic tank, a secondary filtering anaerobic tank, an aerobic tank, a primary sedimentationtank and a secondary sedimentation tank, which are arranged in sequence; a dry and wet separator is arranged between the collection anaerobic tank and the primary filtering anaerobic tank; an aerationdevice is arranged in the aerobic tank. The invention further provides a pig manure sewage treatment method; the pig manure sewage treatment method comprises the following steps: (1) culturing decomposing bacteria; (2) collecting the pig manure sewage and carrying out primary anaerobic treatment; (3) filtering and precipitating and carrying out anaerobic treatment; (4) carrying out aerobic treatment; (5) carrying out precipitation and anaerobic treatment again; (6) carrying out disinfection and sterilization treatment. The sewage treatment device provided by the invention has the advantages of simple structure, low production cost, capability of being continuously operated, high treatment efficiency and great sewage treatment amount. The sewage treatment method provided by the invention adopts a method combining physical precipitation and filtering, and biodegradation to treat the sewage, and is green and environmentally friendly.

Owner:连云港市连威农牧科技有限公司

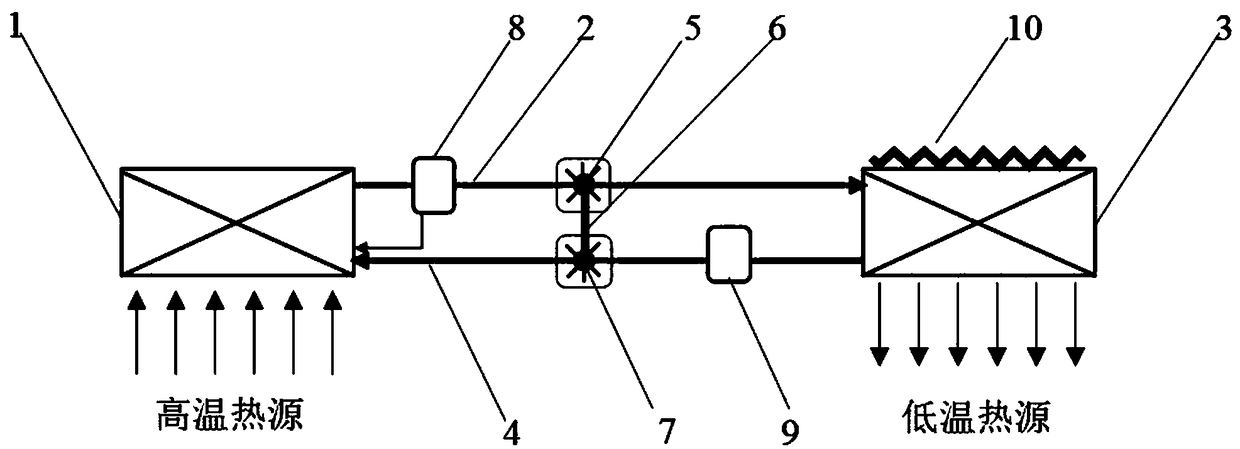

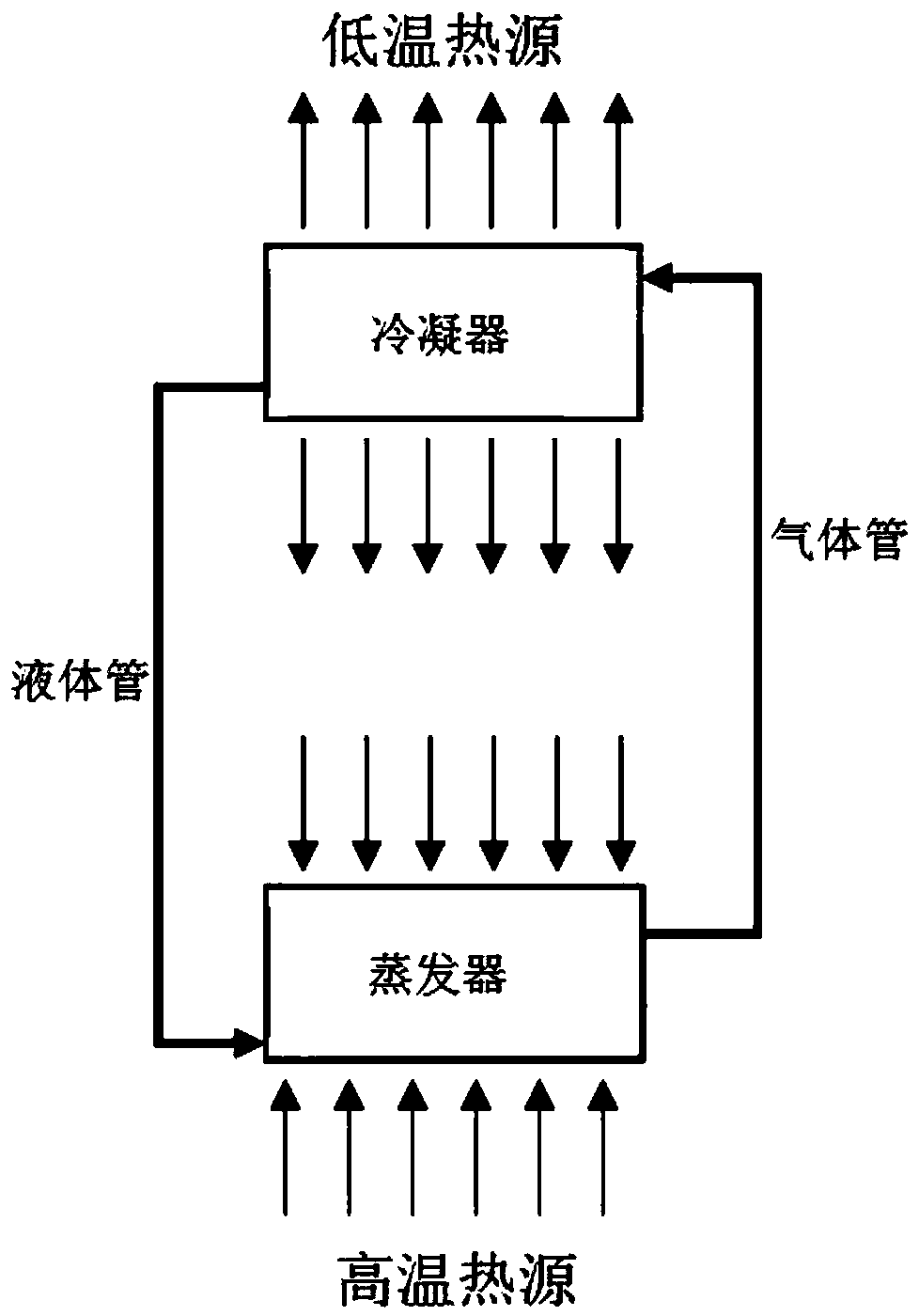

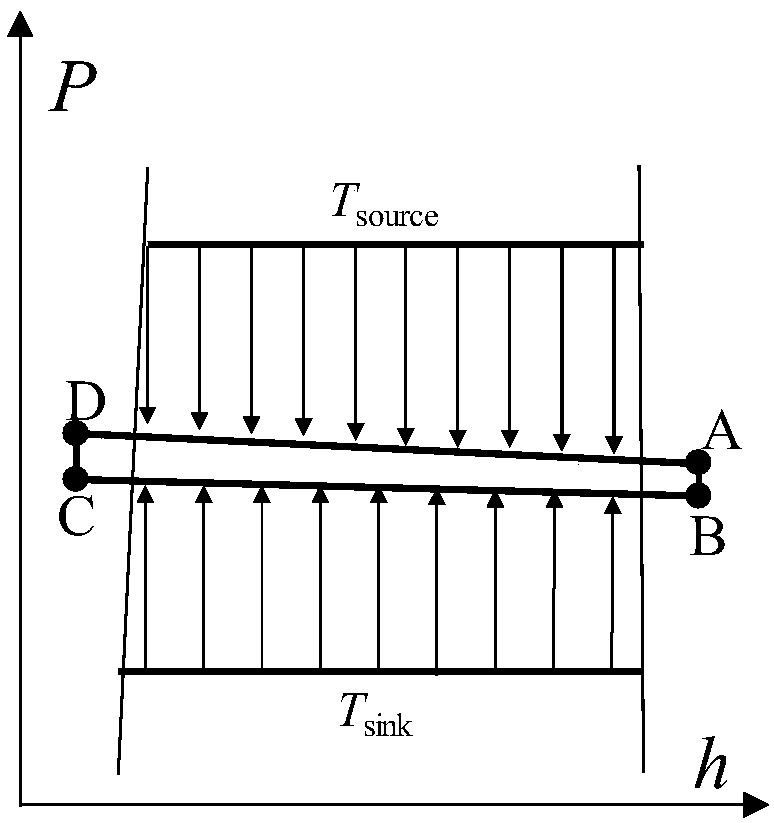

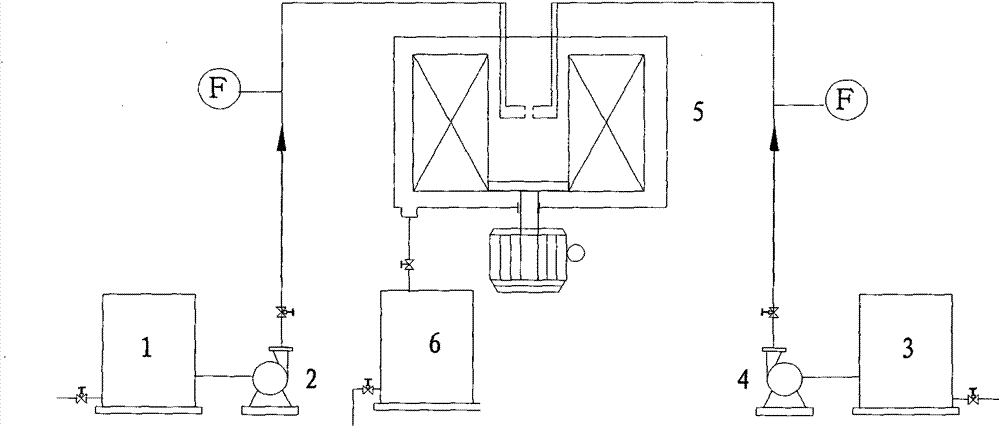

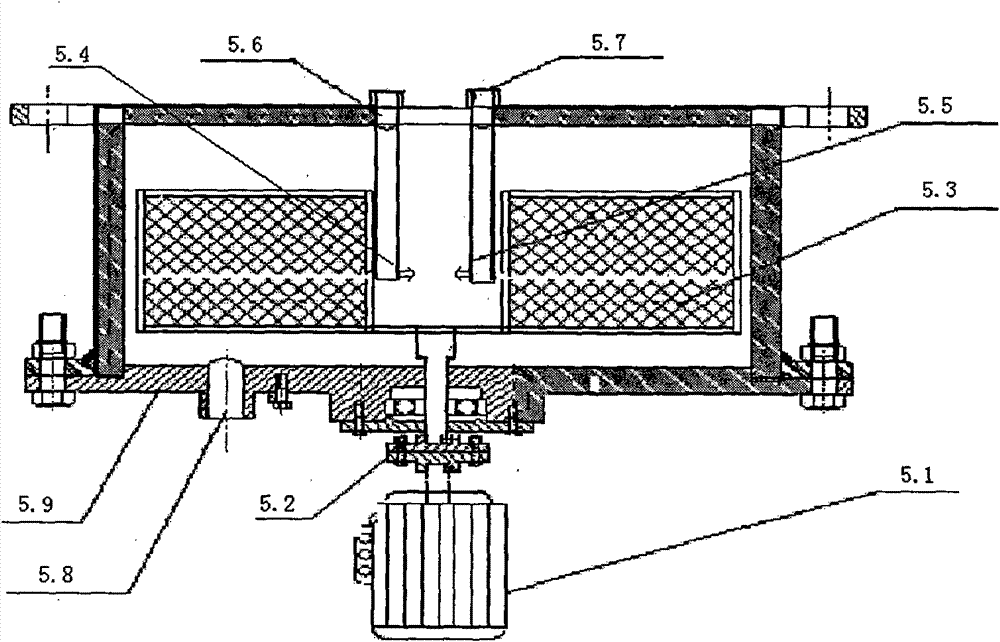

Self-driven heat pipe circulation heat exchanger

InactiveCN109029034AExpand the range of circular applicationsAvoid regulationIndirect heat exchangersDrive wheelMechanical energy

The invention discloses a self-driven heat pipe circulation heat exchanger, and relates to the field of heat energy transmission. The gravity cycle can be broken through, and working medium between acondenser and an evaporator can be automatically driven to circulate. The self-driven heat pipe circulation heat exchanger comprises the evaporator, a gas pipe, the condenser, a liquid pipe, a drivingwheel, a rotating shaft and a driven wheel. During the circulation working process of the heat pipe, gas-state working medium in the gas pipe drives the driving wheel to rotate, the driving wheel drives the driven wheel to rotate through the rotating shaft, and the driven wheel drives liquid working medium in the liquid pipe to return to the evaporator. The volume flow of the gas-state working medium in the gas pipe is much larger than the volume flow of the liquid working medium in the liquid pipe, coaxial rotation and the like, the pressure head obtained by the liquid working medium is farlarger than the lost pressure head of the gas working medium, and the pressure head can overcome the flowing resistance in the whole flowing process. A small amount of heat transfer temperature difference is sacrificed to generate mechanical energy, so that liquid working medium backflow is promoted, the gravity constraint is avoided, the circulating running range of the heat pipe is expanded, external driving is not needed, and the self-adaptive performance is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Method and device for continuously preparing methanol emulsified diesel

ActiveCN101665727BImprove stabilityUniform particle size distributionMixing methodsLiquid carbonaceous fuelsMomentumHypergravity

The invention belongs to the technical field of methanol emulsified diesel, in particular to a method and a device for continuously preparing methanol emulsified diesel, solving the problems of high equipment cost, intermittent production, poor stability of products and the like of the prior device for preparing the methanol emulsified diesel. The method comprises the following steps: adding hydrophilic emulsifier into methanol to form a water phase; adding lipophilic emulsifier into diesel to form an oil phase; carrying out preliminary emulsion on the oil phase and the water phase under the action of momentum; and then realizing precise emulsion under the action of hypergravity. The device comprises an emulsifier; the casing of the emulsifier is internally provided with annular filling which is made of silk screen and is capable of rotating at a high speed; and the hollow part of the annular filling is provided with a water-phase nozzle and an oil-phase nozzle the outlets of which are opposite to each other. The invention has the advantages of preparing high-quality emulsifiable solution with good stability and even distribution of particle size, realizing continuous operation for preparing methanol emulsified diesel according to the actual requirement, adjusting the use level of the emulsifier according to the requirement, saving the using amount of the emulsifier, and reducing the cost of methanol emulsified diesel. The device has simple structure and easy operation.

Owner:ZHONGBEI UNIV

Coal chemical industry black water treatment system and treatment method

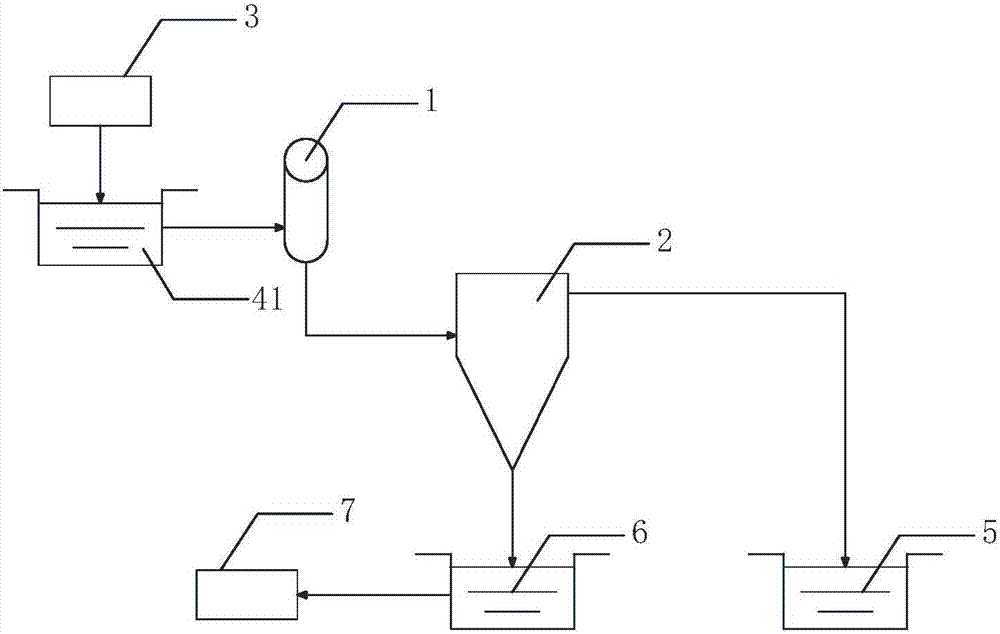

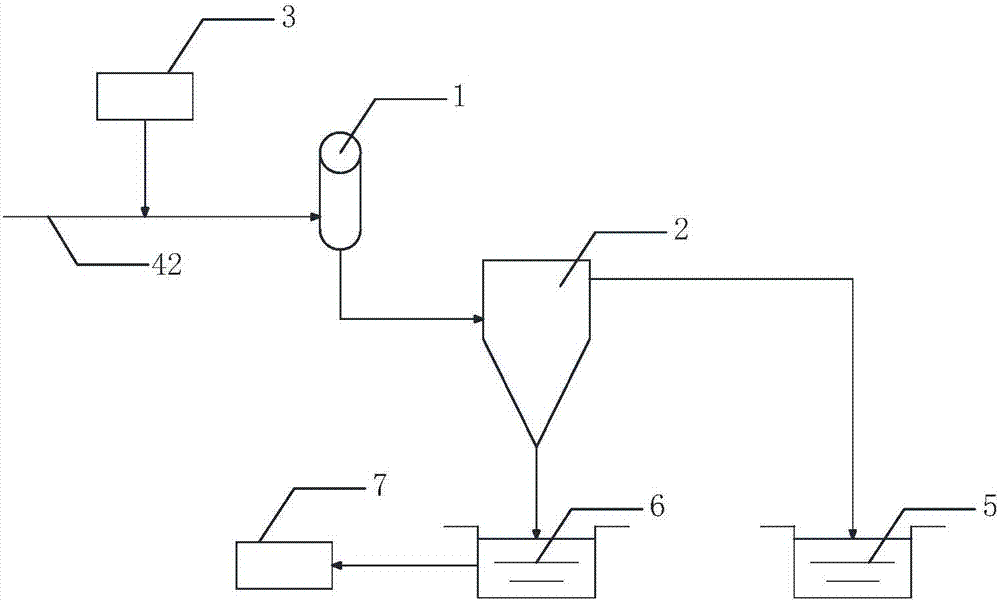

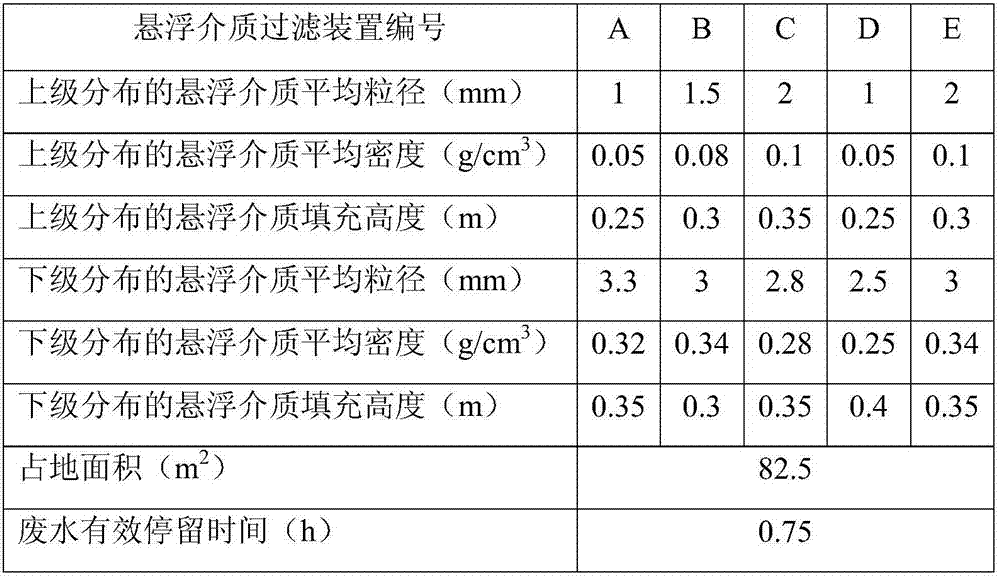

InactiveCN107050937AEasy to handleSmall footprintTreatment involving filtrationNature of treatment waterParticulatesWater treatment system

The invention relates to a coal chemical industry black water treatment system and treatment method. The treatment system comprises a gas-liquid separation device and a suspending medium filtering device, wherein the gas-liquid separation device is used for removing gas of coal chemical industry black water added with a flocculating agent to obtain first treatment water; the suspending medium filtering device is used for performing suspending medium interception, suspending medium electrostatic adsorption and gravity settling on the first treatment water; suspending media are filled in the suspending medium filtering device; clear liquid is obtained at the upper part of the suspending medium filtering device; coal ash particulate matter concentrated liquid is obtained at the bottom of the suspending medium filtering device. Compared with a traditional sedimentation method, the coal chemical industry black water treatment system and the coal chemical industry black water treatment method provided by the invention have the advantages that the treatment capability is improved; the occupied area is small; the treatment effect is improved; the continuous operation is realized; the operation energy consumption is low; the cost is low; suspending media replacing and chemical cleaning do not need.

Owner:池州西恩新材料科技有限公司 +1

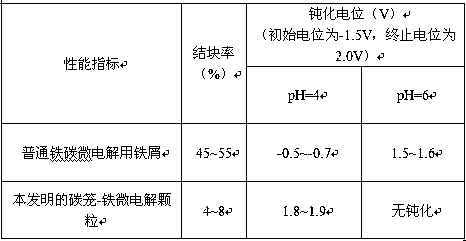

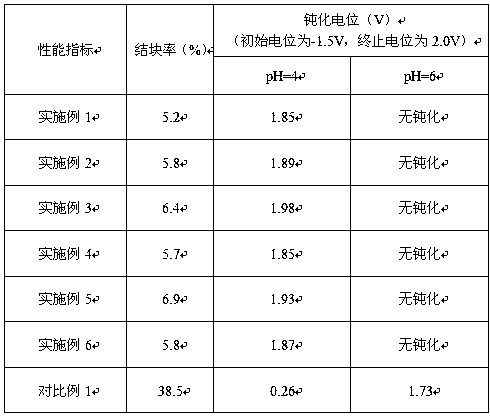

Carbon cage-iron microelectrolytic particles for acidic sewage treatment and preparation method

InactiveCN108191004AGood micro electrolytic performancePrevent compactionSpecific water treatment objectivesWater/sewage treatmentIron powderElectrolysis

The invention belongs to the technical field of sewage treatment and provides carbon cage-iron microelectrolytic particles for acidic sewage treatment and a preparation method. The method comprises steps as follows: an iron powder dispersion liquid is prepared for mist spray and condensation, iron powder agglomerated microspheres immobilized by stearic acid are prepared, then silica-chitosan composite gel is prepared, the microspheres are uniformly coated with the composite gel and then subjected to high-temperature carbonization, firm microporous cages are formed, iron powder is covered withthe cages, and the microelectrolytic particles with the iron powder covered with the carbon cages are obtained. Compared with a traditional method, the prepared carbon cage-iron microelectrolytic particles not only have good microelectrolysis performance, but also can effectively prevent the iron powder from hardening, the problem that an iron-carbon micro-electrolysis material is prone to hardening and passivating when applied to sewage treatment is solved thoroughly, the purposes of preventing scaling and blockage, realizing continuous operation and efficiently treating acidic sewage can beachieved effectively, meanwhile, the preparation process is simpler, the preparation cost is lower, and the carbon cage-iron microelectrolytic particles can be popularized for production and application.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

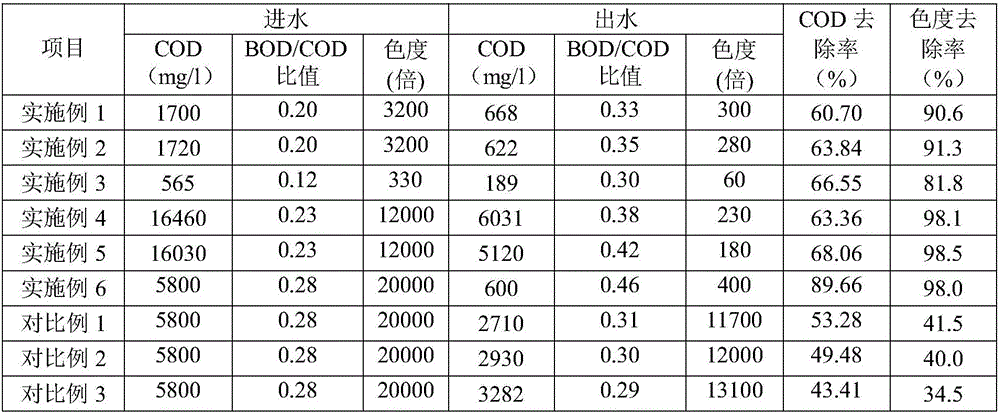

An electrochemical comprehensive treatment process for high-concentration and refractory organic wastewater

ActiveCN106186456BAvoid passivationHigh activityWater contaminantsMultistage water/sewage treatmentHigh concentrationPh regulation

The invention belongs to the field of wastewater treatment, and particularly relates to an electrochemical comprehensive treatment technology for high-concentration organic wastewater hard to degrade. The wastewater treatment technology comprises pH regulation, electric flocculation, electro-fenton comprehensive treatment, aeration oxidation and coagulating sedimentation. The technology can effectively degrade various benzene rings, phenols, macromolecular compounds to break bonds, the good treatment effect is achieved for organic matters and complexing state heavy metal hard to degrade, the wastewater COD and chroma removal effect is good, the BOD / COD ratio is increased, the wastewater biodegradability is remarkably improved, the treatment efficiency is high, power consumption is low, medicament consumption is low, mud consumption is low, and the good economic and social effect is achieved.

Owner:广东凯达环保科技有限公司

Central air-conditioning disinfection system

InactiveCN103644609AWith temperature adjustment functionImprove pollutionLighting and heating apparatusAir conditioning systemsUv disinfectionEnvironmental engineering

The invention discloses a central air-conditioning disinfection system which comprises an air supply pipeline, an ozone disinfection device and an ultraviolet disinfection device, wherein the ozone disinfection device and the ultraviolet disinfection device are arranged on the air supply pipeline. An ozone generator is arranged in the ozone disinfection device, the ultraviolet disinfection device is provided with a plurality of ultraviolet lamp tubes, the central air-conditioning disinfection system can effectively disinfect and continuously run through the ultraviolet disinfection device and the ozone disinfection device and is safe and free from secondary pollution, so that the central air-conditioning disinfection system not only has a temperature adjusting function, but also can effectively solve the problem of serious microorganism pollution in air-conditioning environments, infectious pathogenic bacteria cannot enter the central air-conditioning disinfection system to circulate through air, so that large-area spread and cross infection are avoided, and high-quality clean air is provided.

Owner:ZHONGSHAN LANSHUI ENERGY TECH DEV

Multi-batik method

InactiveCN104074017APrecise positioningImprove printing and dyeing qualitySucessive textile treatmentsTextile parts treatmentWaxEngineering

The invention discloses a multi-batik method which comprises the steps of cloth processing, cloth wax steaming, cloth dyeing, cloth dewaxing, cloth second wax steaming, cloth second dyeing, cloth dewaxing, cloth color fixing and cloth rolling. The multi-batik method has the advantages of being high in reliability, quick in production, convenient to use, good in printing effect, continuous in operation, good in adaptability, exquisite in pattern, low in price, and the like, patterns can be conveniently changed, and the dyeing market has wide market prospects.

Owner:TAICANG HONGYING PRINTING

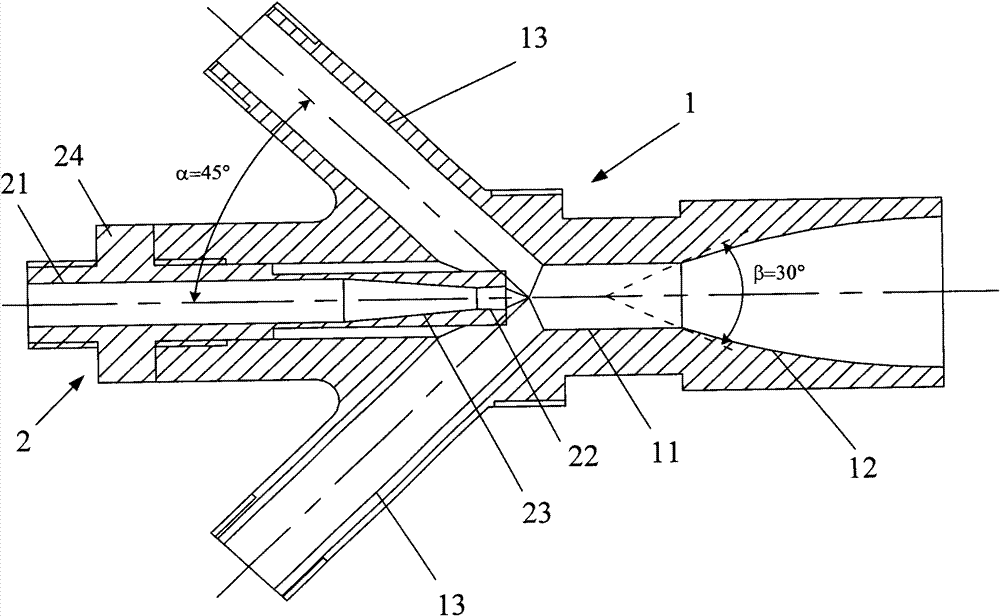

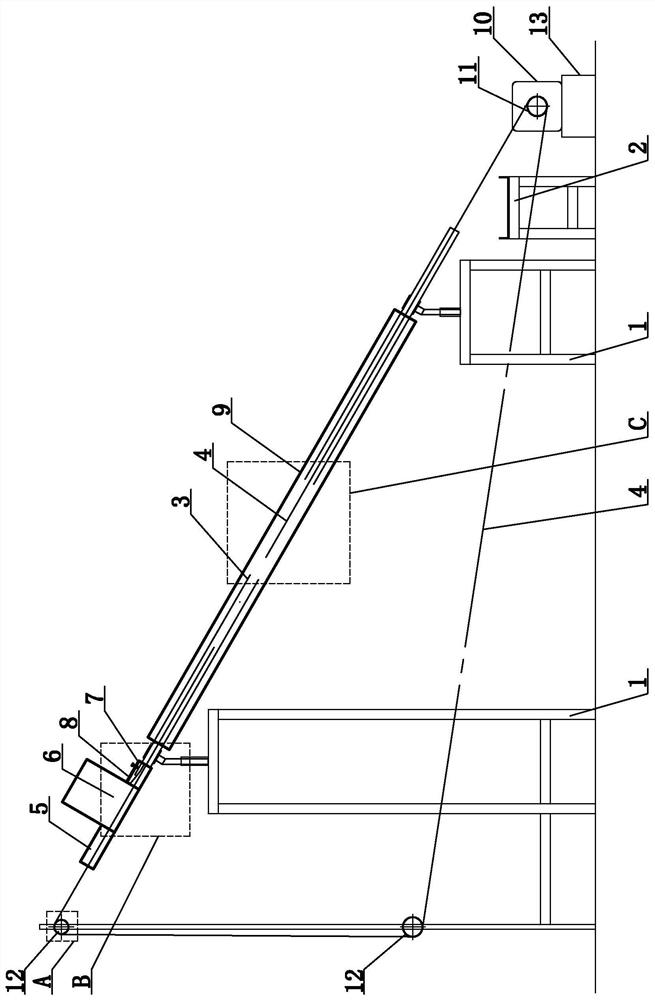

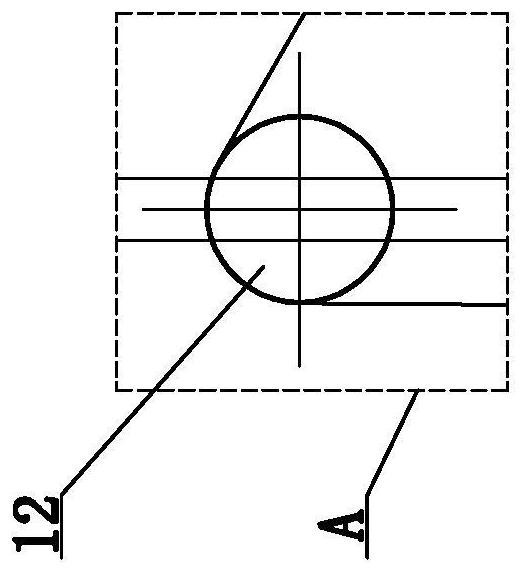

Jet nozzle for condensing and devolatilizing synthetic rubber

ActiveCN102179329BSmall particle sizeImprove condensation effectLiquid degasificationLiquid spraying apparatusGranularityWater flow

The invention discloses a jet nozzle for condensing and devolatilizing synthetic rubber, comprising a nozzle main body, wherein a straight throat pipe is formed in the nozzle main body, and an diffusion spray head is formed on the end of the straight throat pipe, pointing to a glue liquid jetting direction; at least one water inlet pipe communicated with the straight throat pipe is arranged on the side face of the nozzle main body; and the jet nozzle also comprises a glue liquid inlet joint inserted in the straight throat pipe. Glue liquid is sheared, dispersed, condensed and devolatilized inthe jet nozzle before entering a condensation pot, i.e., the aftertreatment process of the synthetic rubber, performed in the condensation pot in the industry, is finished in advance in the jet nozzle. Under the strong shearing action of high-speed flow, the granularity of grains of the synthetic rubber is greatly reduced, therefore, the condensing effect of the rubber grains is improved, and thevolatilizing yield of a solvent is increased. The jet nozzle has a simple structure and low equipment manufacturing cost and can continuously run, thereby having the advantages of small equipment investment and low running cost.

Owner:EAST CHINA UNIV OF SCI & TECH

A continuous heat storage system based on photothermal moving bed

InactiveCN110822743BCan run continuouslyImprove reliabilitySolar heating energySolar heat storageThermodynamicsHeat transmission

The invention relates to a continuous type heat storage system based on a photo-thermal moving bed and belongs to the field of solar heat storage. The discharging end of an automatic feeding device isconnected with the feeding end of an inner pipe of a photo-thermal reactor, the photo-thermal reactor is supported by a supporting frame and is arranged in an inclined mode, the discharging end of the photo-thermal reactor is lower than the feeding end of the photo-thermal reactor, a material collecting device is arranged below the discharging end of the photo-thermal reactor, a chain in a transmission system penetrates into the automatic feeding device and the photo-thermal reactor, and heat storage materials are put into the automatic feeding device and driven by the chain in the transmission system to enter the photo-thermal reactor and then fall into the material collecting device through a discharging port of the photo-thermal reactor. According to the continuous type heat storage system, complex heat transmission parts do not need to be arranged in the photo-thermal and heat storage process, sunlight is directly absorbed to carry out photo-thermal conversion, and the heat is stored in the adsorbing type heat storage materials. Moisture desorption and heat storage are achieved by erecting a moving bed system, the problems of clustering and wall sticking of high-water-contentadsorbents are effectively solved through transmission of the chain, and the system is capable of running continuously and good in reliability.

Owner:HARBIN INST OF TECH

Pyrolytic carbon gasification comprehensive transformation utilization system and method for biomass waste resources

Owner:LUOYANG JUNTENG ENERGY TECH +1

Biomass waste resource pyrolytic carbon gasification comprehensive conversion and utilization system and method

The invention relates to a biomass waste resource pyrolytic carbon gasification comprehensive conversion and utilization system and a method employing the system. In the system, a pyrolysis device is connected with a gas supply device through a gas channel of a multifunctional heat exchange device, and is connected with a carbon powder collection device through a pneumatic conveying device. A condensation water channel is connected with a residual warmth heat supplying device through a heat exchanger of the pyrolysis device. According to the method, mixed gas comprising combustible gas, tar gas, and acetic acid gas is produced by high-temperature pyrolysis of a biomass raw material in the pyrolysis device, and carbon is also produced; the mixed gas is absorbed into the multifunctional heat exchanging device and is subjected to heat exchange, and combustible gas and a mixed liquid of tar and acetic acid are separated; water absorbs heat, and enters the heat exchanger of the pyrolysis device, and heat exchange is continued, such that hot water is formed; hot water and combustible gas are respectively delivered through the gas supply device and the residual warmth heat supplying device, such that centralized gas supply, heating, and hot water for residents are realized; acetic acid can be used as a foliar fertilizer or a biocide, or can be mixed with carbon to form a bio-fertilizer; and tar is adopted as an industrial raw material. With the system and the method, a biomass waste resource conversion rate is approximately 100%.

Owner:LUOYANG JUNTENG ENERGY TECH

A kind of material and method for reducing the generation of foam in the recovery process of potato cell sap

InactiveCN104186941BLow equipment and operating costsThe processing method is simpleAnimal feeding stuffAnimal feedNutrient

The invention provides a material for reducing foam generated in the recovery process of potato cell fluid, and the material includes one or more of the following: (1) potato residue; (2) edible fungus residue; (3) cereals, beans (4) One or more of attapulgite and diatomaceous earth; (5) Food defoamer. The invention also provides a method for reducing foam generated during the recovery process of potato cell liquid. The method of the invention not only greatly reduces the foam produced in the recovery process, realizes the solid-liquid separation of the cell liquid by the centrifugal equipment, but also can operate continuously, and the recovery efficiency is greatly improved. The recovered material has high crude protein and starch content, which is equivalent to the main nutrients contained in corn after drying, and is suitable for use as animal feed or feed raw materials.

Owner:甘肃省农业科学院农产品贮藏加工研究所 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com