Coal chemical industry black water treatment system and treatment method

A treatment system and treatment method technology, applied in the field of coal chemical black water treatment system, can solve problems such as nozzle and pipeline blockage, and achieve the effects of low cost, strong impact resistance and improved treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 4800m of black water was discharged from a coal chemical production process in Jiangsu 3 / d, the main suspended solids are coal ash particles, the suspended solids concentration is 5000-12000mg / L, with an average of 8000mg / L.

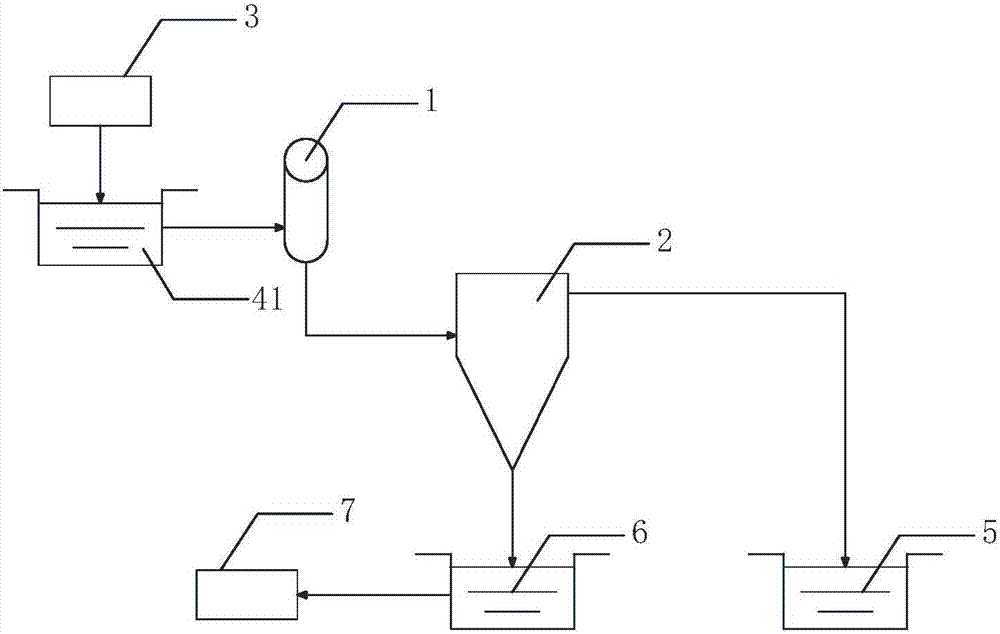

[0056] Processing systems such as figure 1 As shown, the treatment system includes a gas-liquid separation device 1, a suspension medium filter device 2, a flocculant dosing device 3, a coal chemical black water storage pool 41, a clear liquid pool 5, a concentrated liquid pool 6 and a solid-liquid separation device 7 , the lower part of the suspension medium filter device is conical, the black water discharged from the coal chemical production device flows into the gas-liquid separation device 1 by itself, and the intake liquid separation device 1 adds flocculant to the coal chemical black water storage pool 41, and then flows by itself Enter the gas-liquid separation device 1, the clear liquid overflows from the upper part of the gas-liquid se...

Embodiment 2

[0062] 1000m of black water was discharged during the coal chemical production process of a synthetic ammonia production plant in Henan 3 / d, the main suspended solids are coal ash particles, the suspended solids concentration is 400-800mg / L, with an average of 600mg / L.

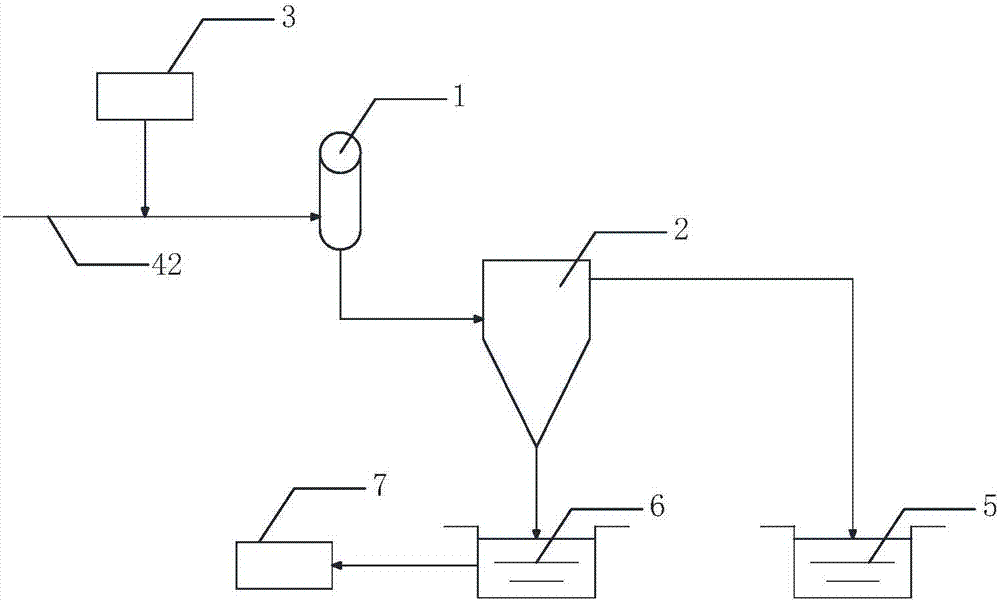

[0063] Processing systems such as figure 2 As shown, the treatment system includes a gas-liquid separation device 1, a suspension medium filter device 2, a flocculant dosing device 3, a coal chemical black water delivery pipeline 42, a clear liquid pool 5, a concentrated liquid pool 6 and a solid-liquid separation device 7 , the lower part of the suspension medium filter device is conical, and the black water discharged from the coal chemical production device flows into the gas-liquid separation device 1 by itself, and the flocculant is added to the coal chemical black water delivery pipeline 42 in front of the gas-liquid separation device 1, and then flows by itself Entering the gas-liquid separation devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com