Patents

Literature

13234results about "Treatment involving sedimentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

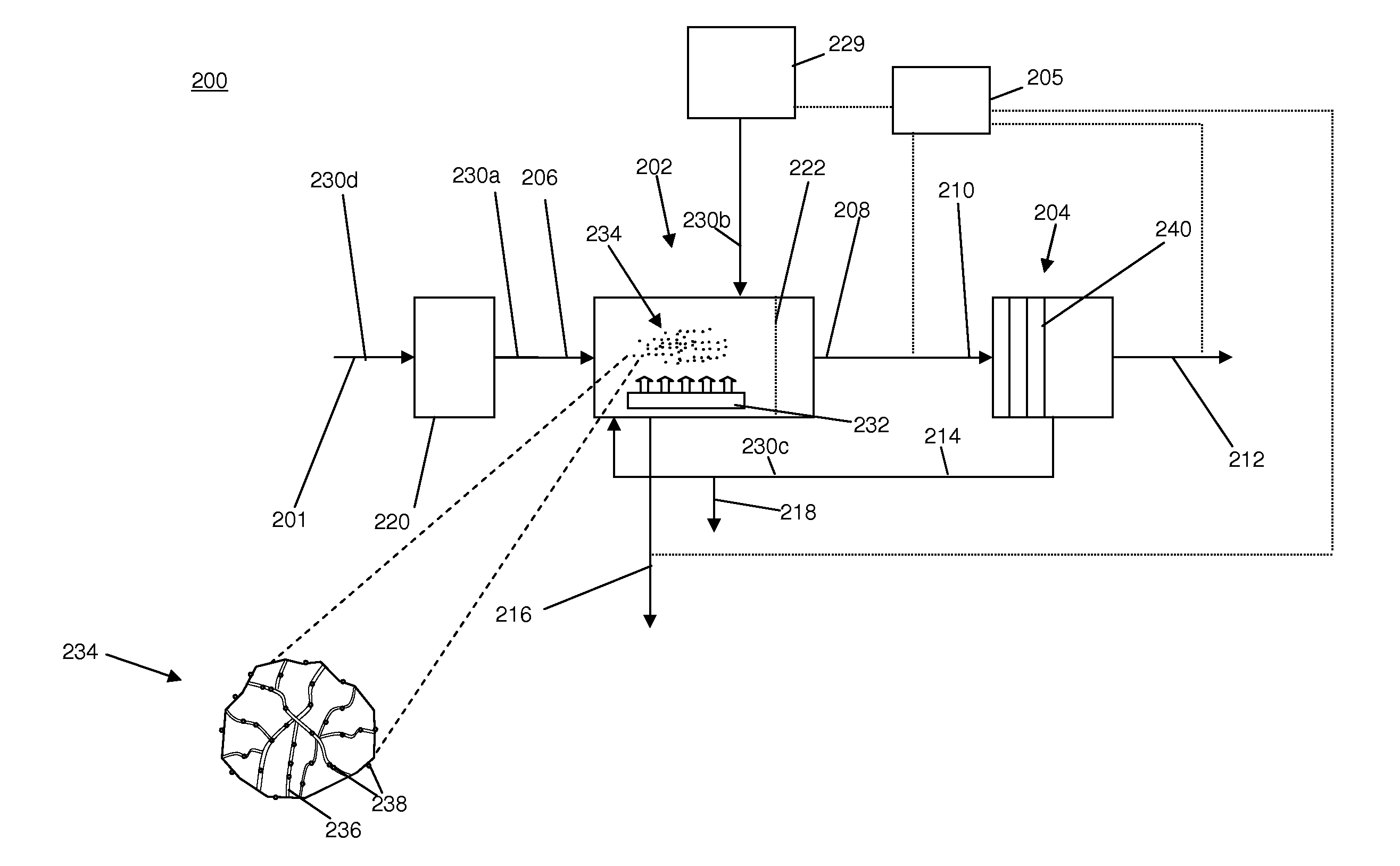

Mobile station and methods for diagnosing and modeling site specific full-scale effluent treatment facility requirements

InactiveUS20110257788A1Reduce financial riskHigh continuity of operationWater/sewage treatment by neutralisationSustainable biological treatmentInitial treatmentIon exchange

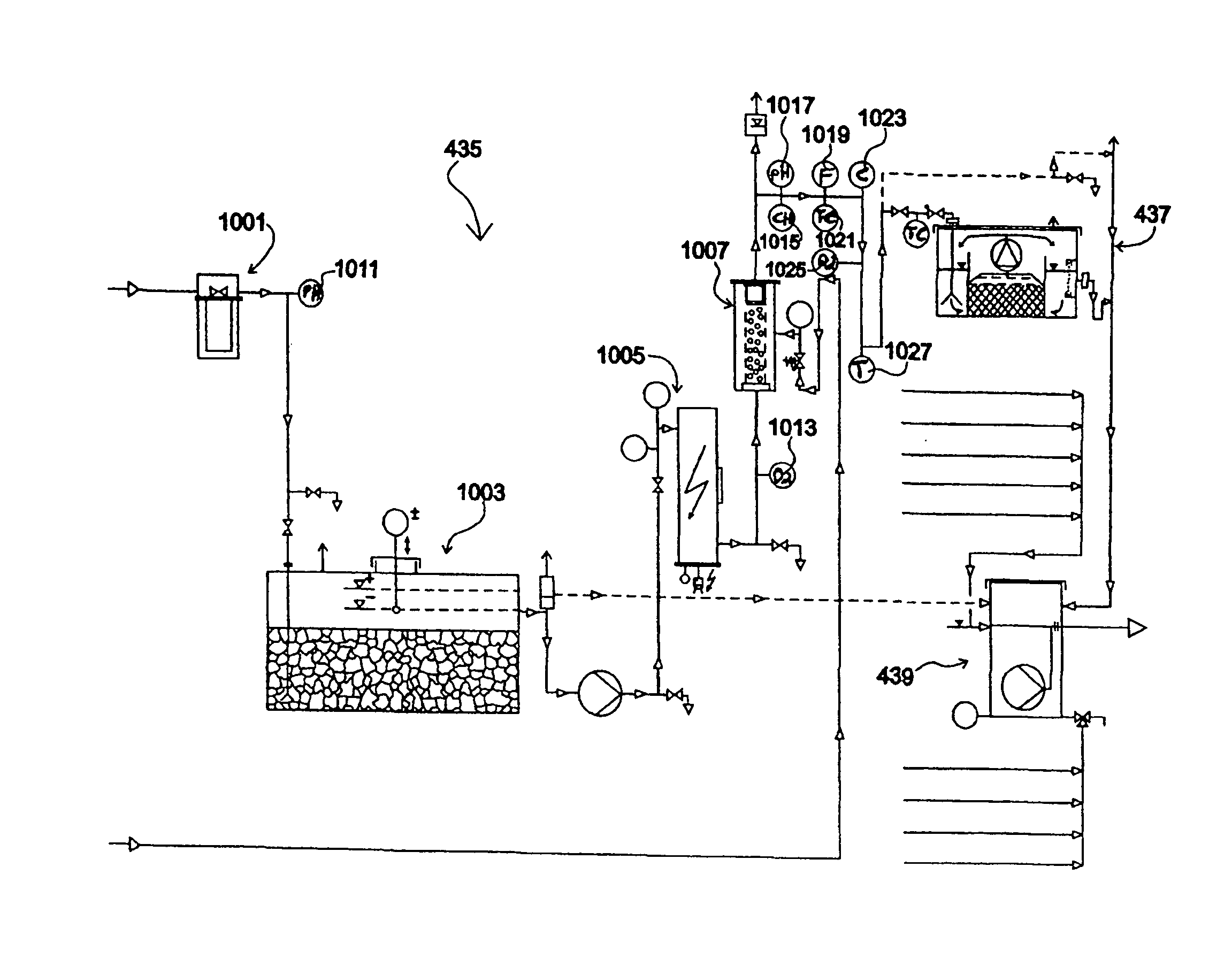

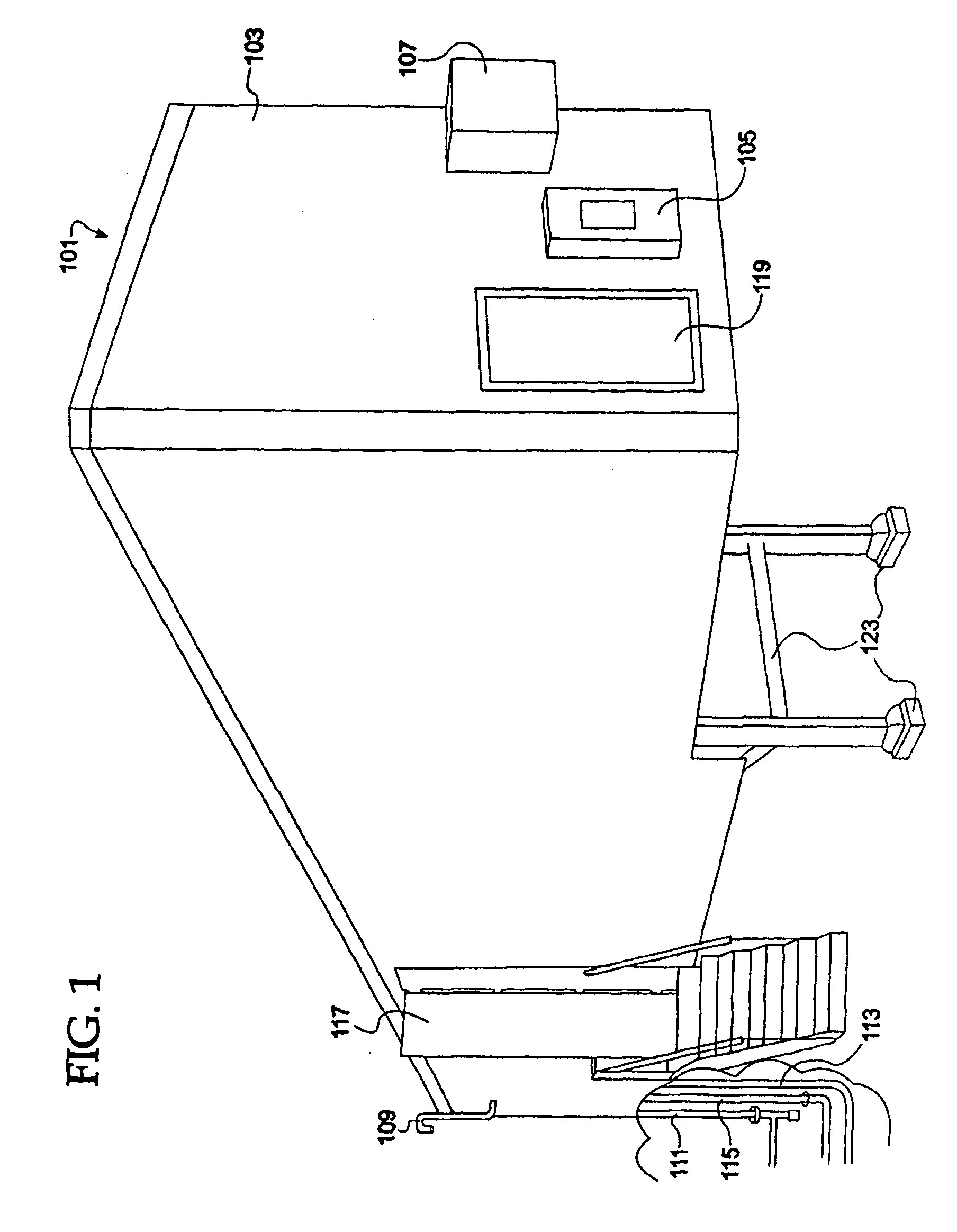

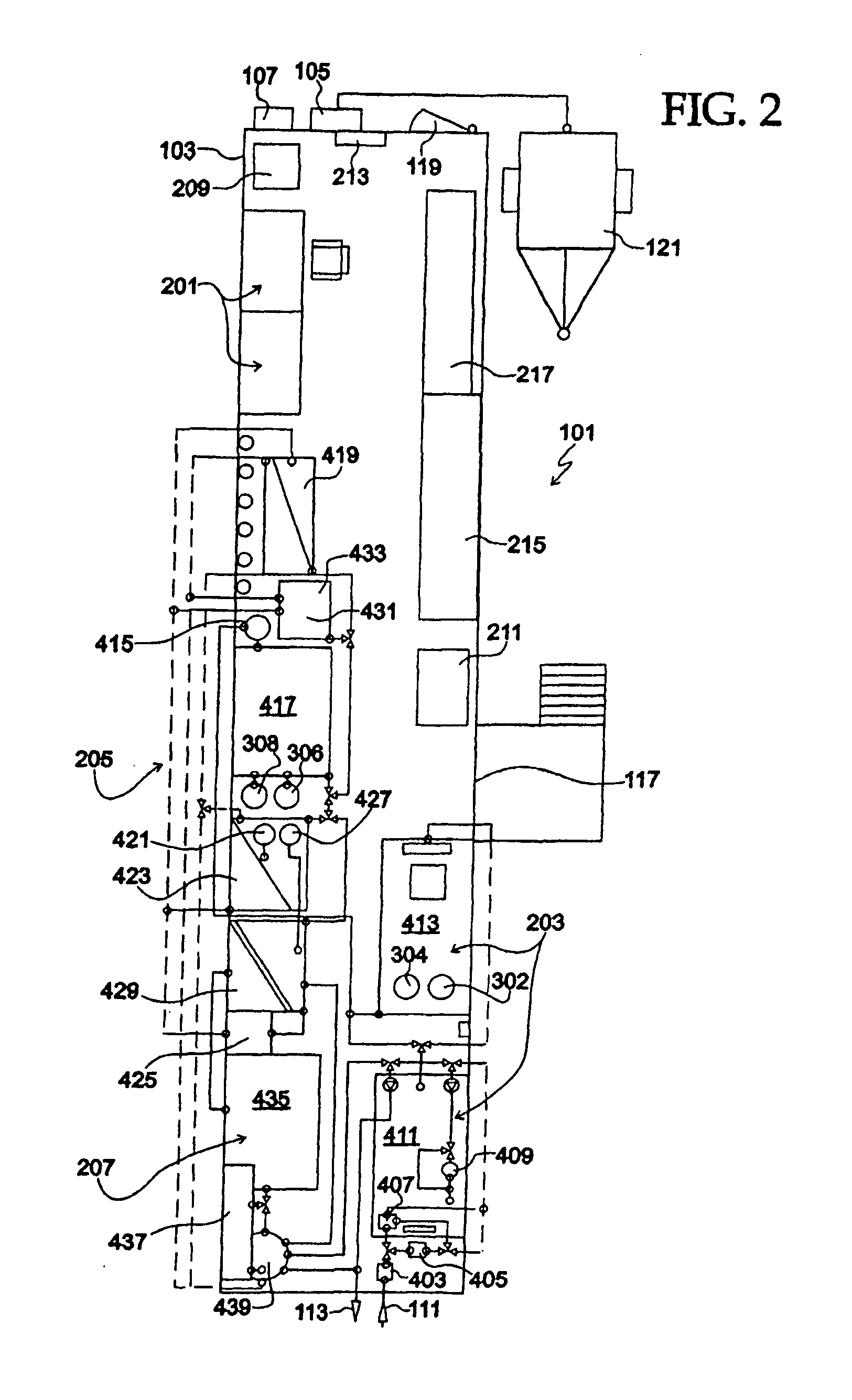

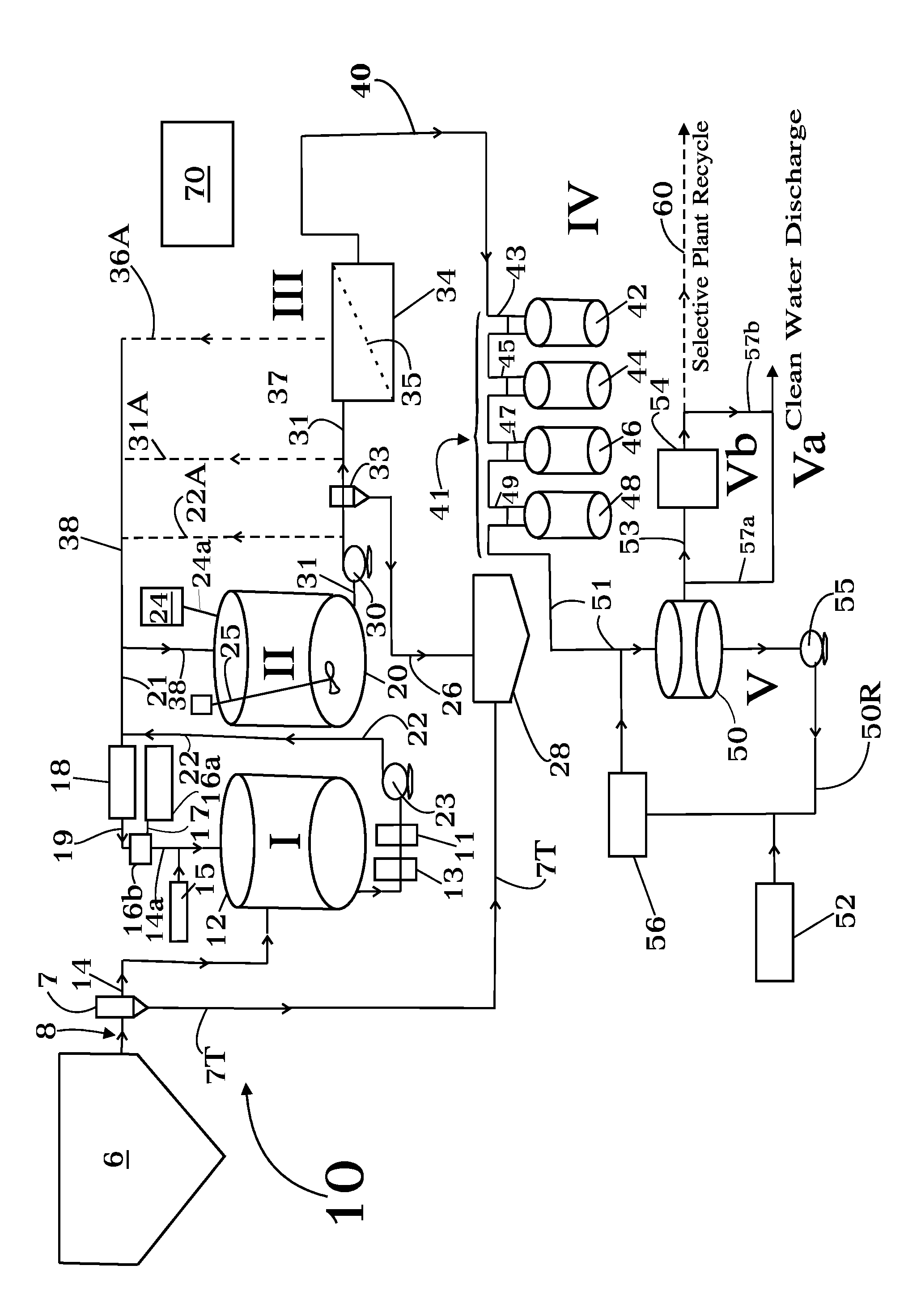

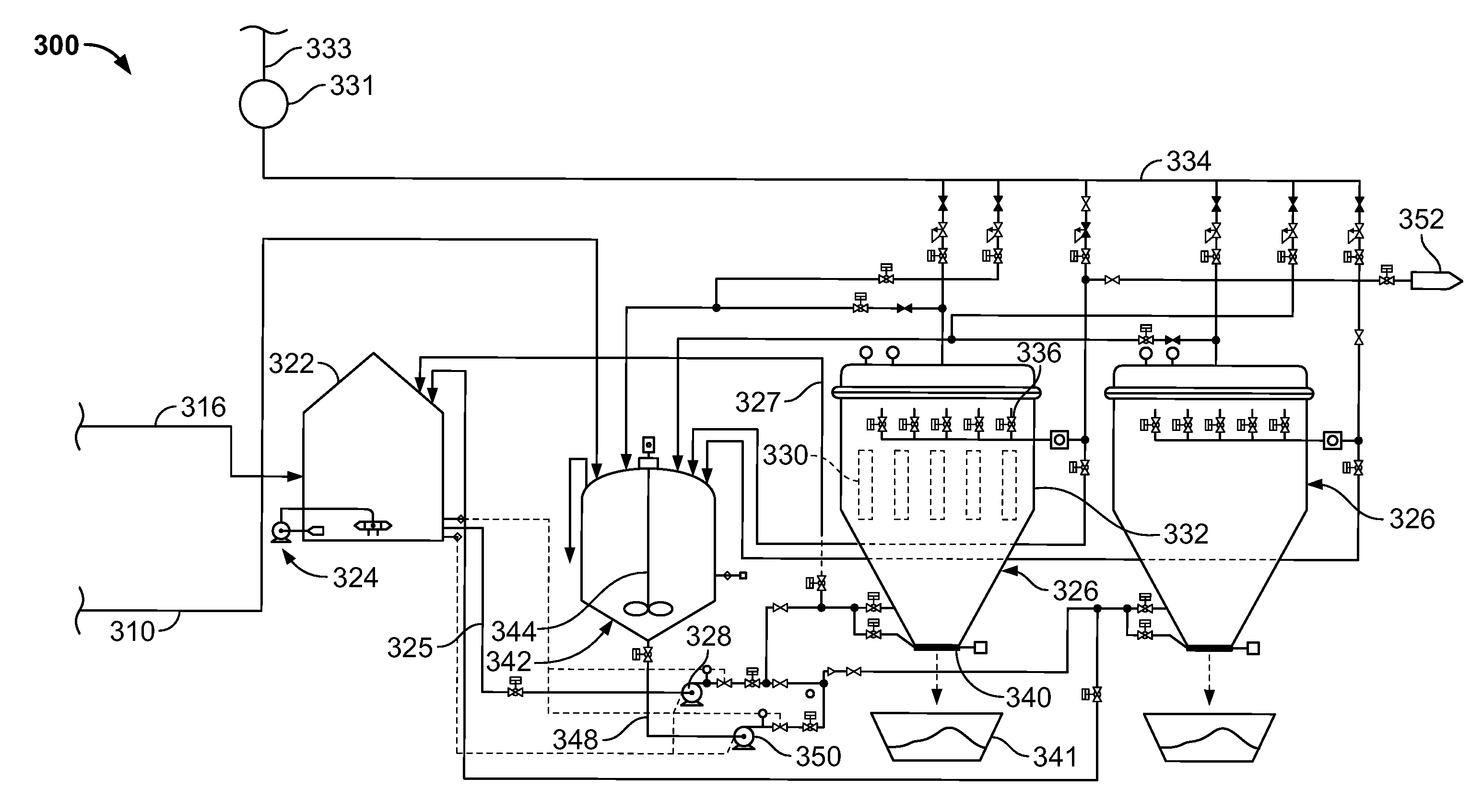

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus is housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies is also disclosed. The modeling methods include steps for analyzing raw effluent to be treated, providing a field of raw effluent condition entry values and a field of treated effluent condition goals entry values, and utilizing said fields to determine an initial treatment model including a selection of, and use parameters for, treatment technologies from the plurality of down-scaled treatment technologies at the facility, the model dynamically and continuously modifiable during treatment modeling.

Owner:ROCKWATER RESOURCE

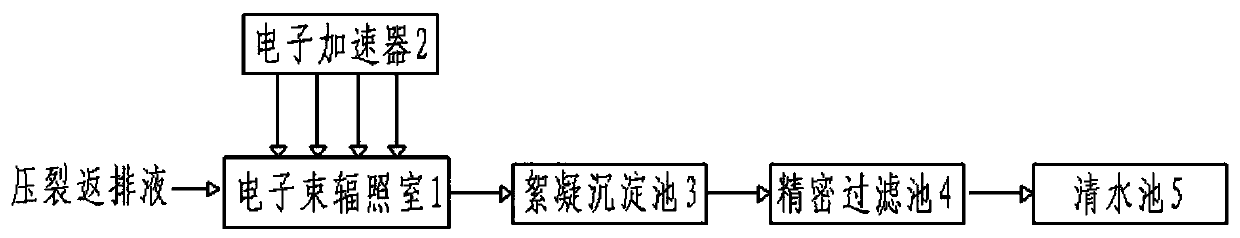

Rapid treatment method for fracturing flowback fluid

PendingCN110467298ARealize online processingLittle side effectsWaste water treatment from quariesTreatment involving filtrationFlocculationFiltration

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

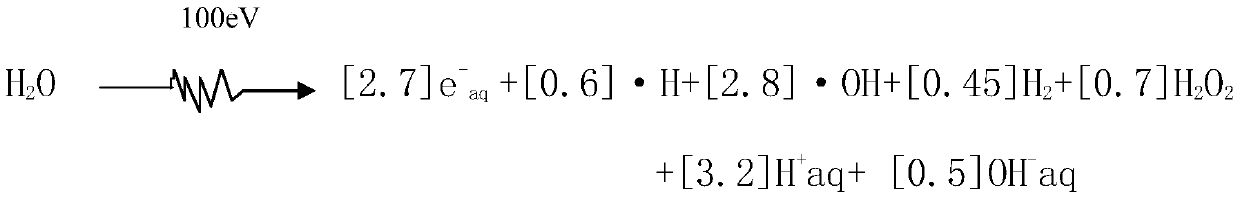

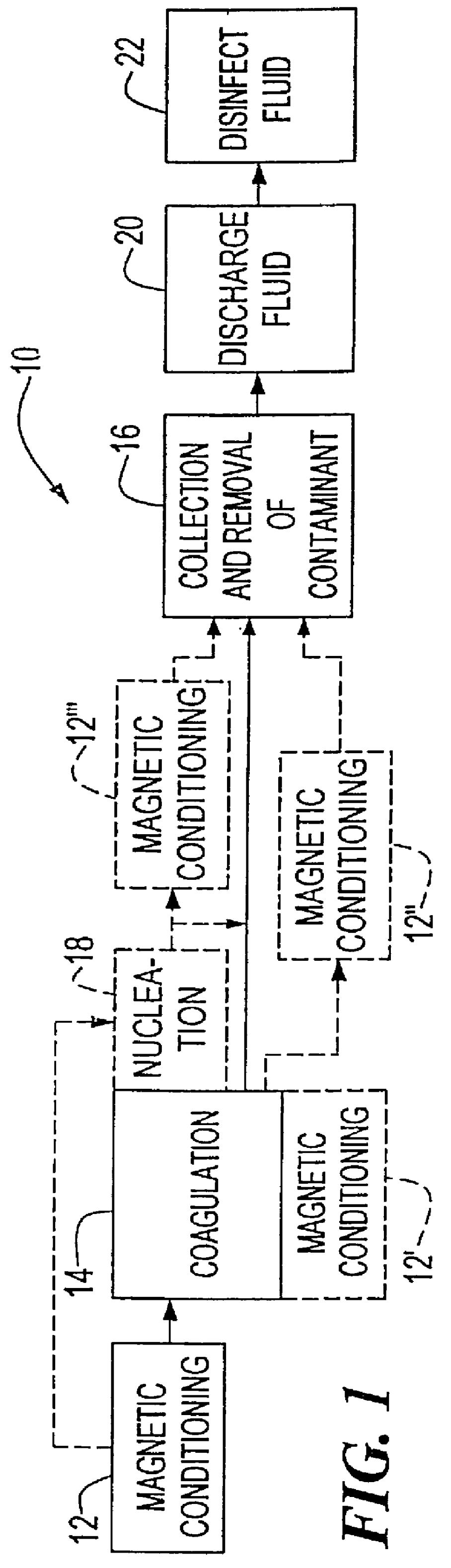

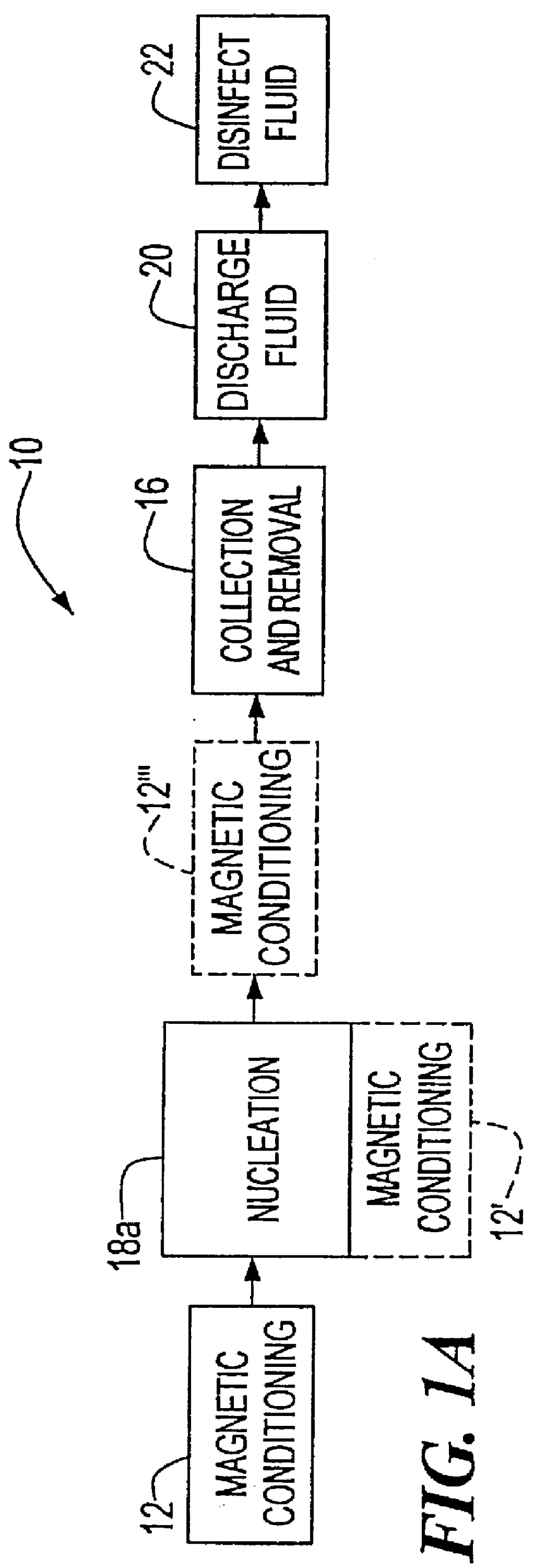

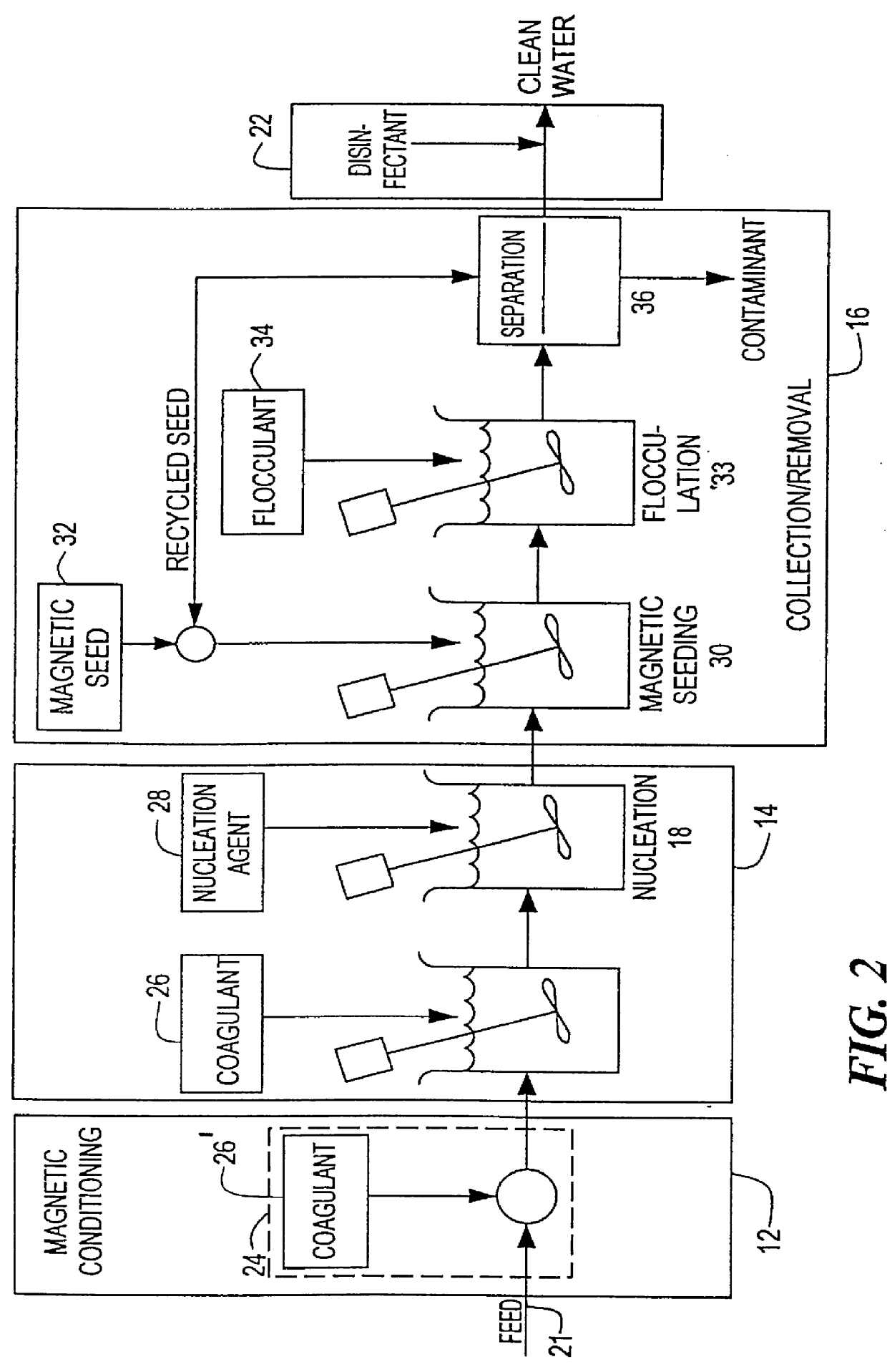

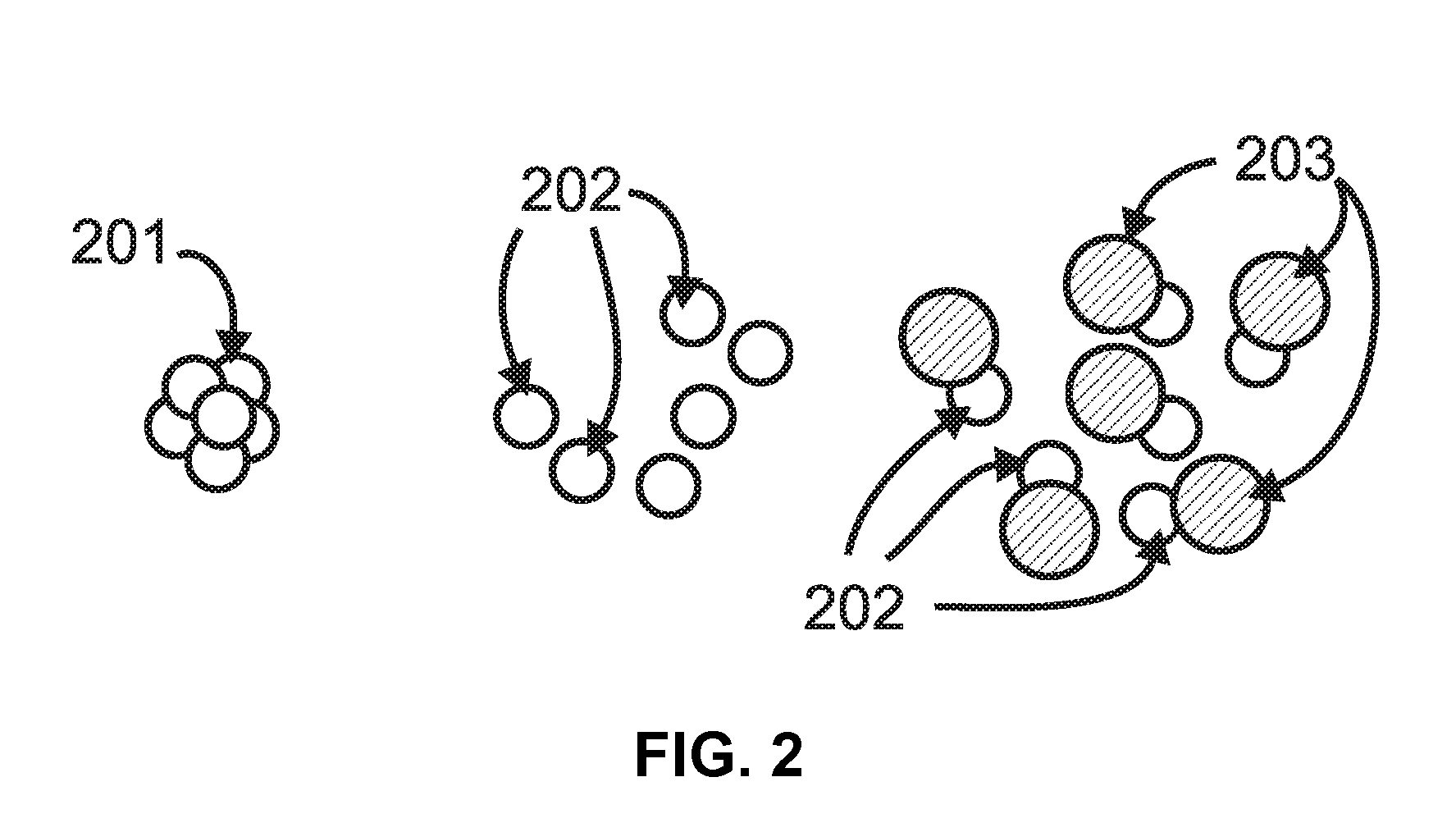

Method and system for removing solutes from a fluid using magnetically conditioned coagulation

InactiveUS6099738AImprove performanceEffective treatmentWater treatment compoundsWater contaminantsColloidEngineering

A method for removing a solute from a fluid using magnetically conditioned coagulation includes magnetically conditioning the fluid by applying a conditioning magnetic field to enhance the precipitation of solute particles for coagulation; adding a coagulant to the fluid before, during, or after application of the conditioning magnetic field to coagulate the increased available solute particles to form colloids; and collecting the colloids for removal from the fluid.

Owner:EVOQUA WATER TECH LLC

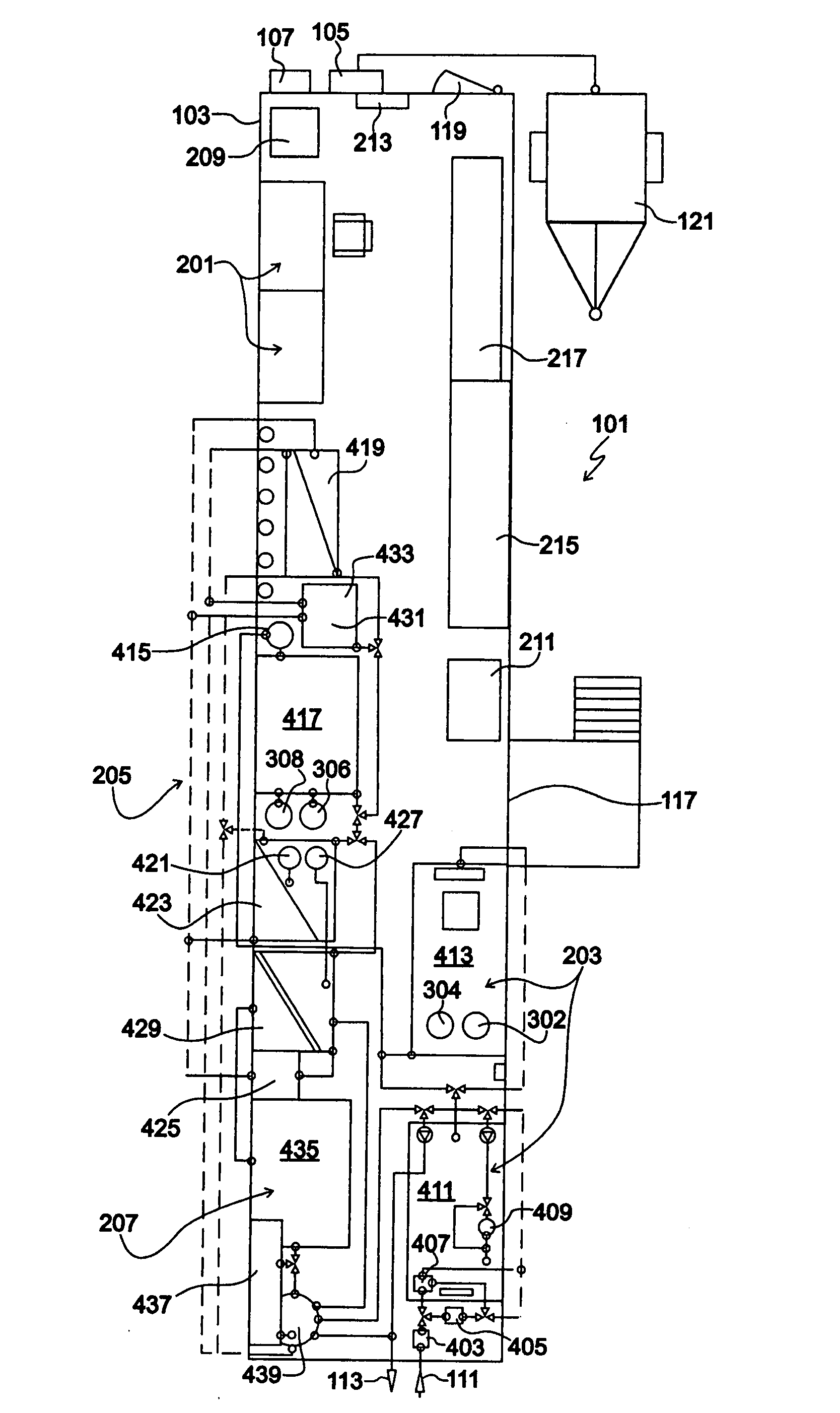

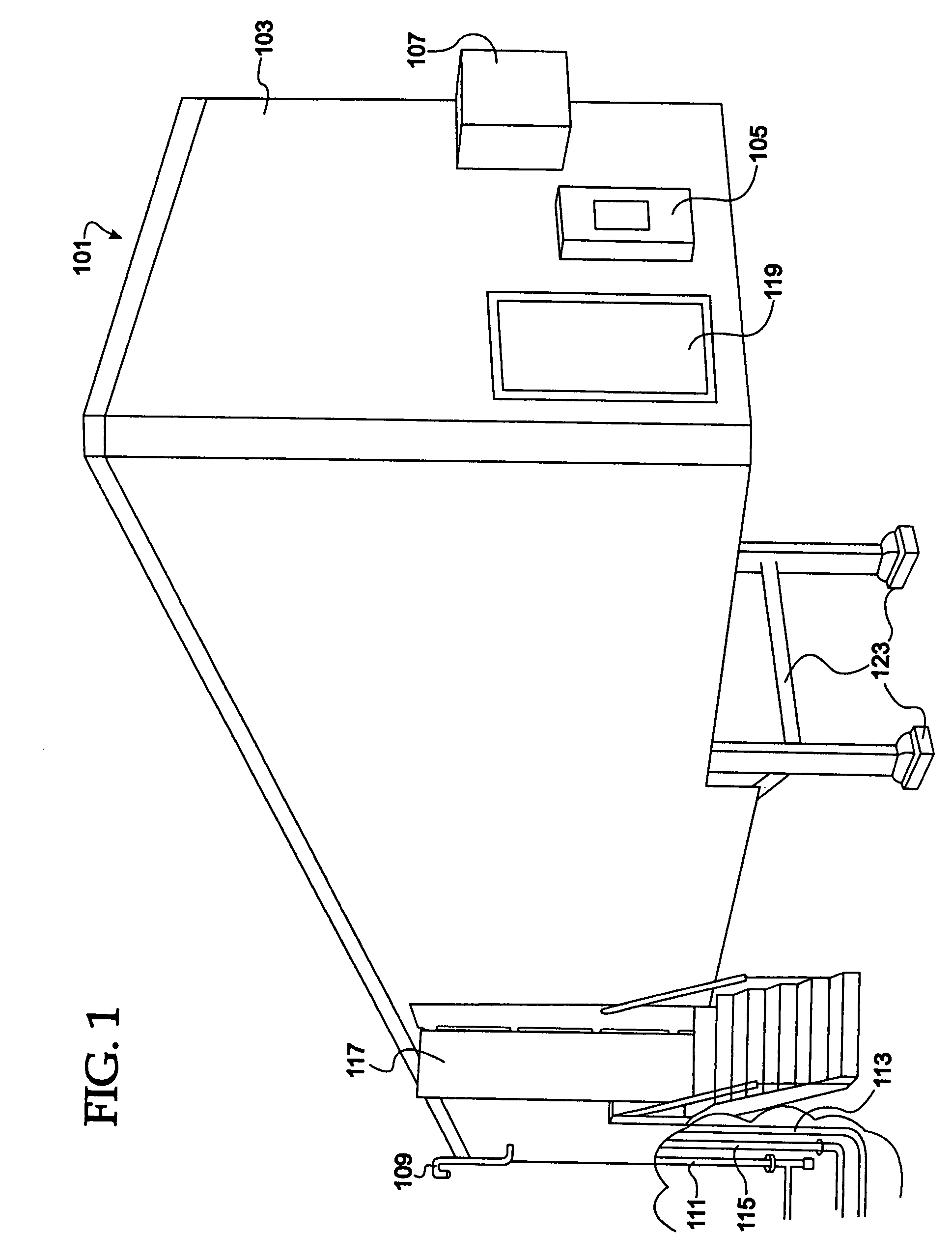

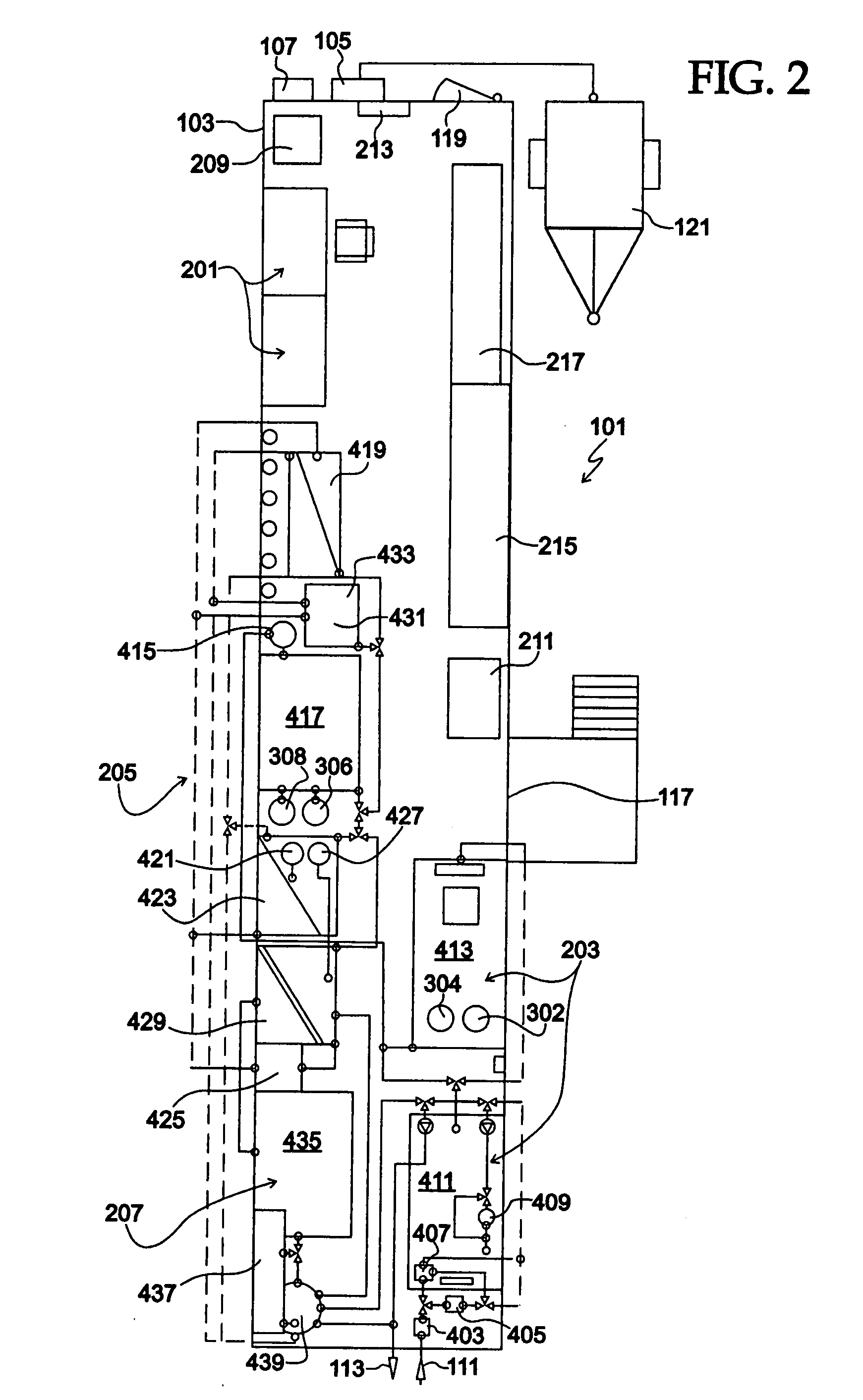

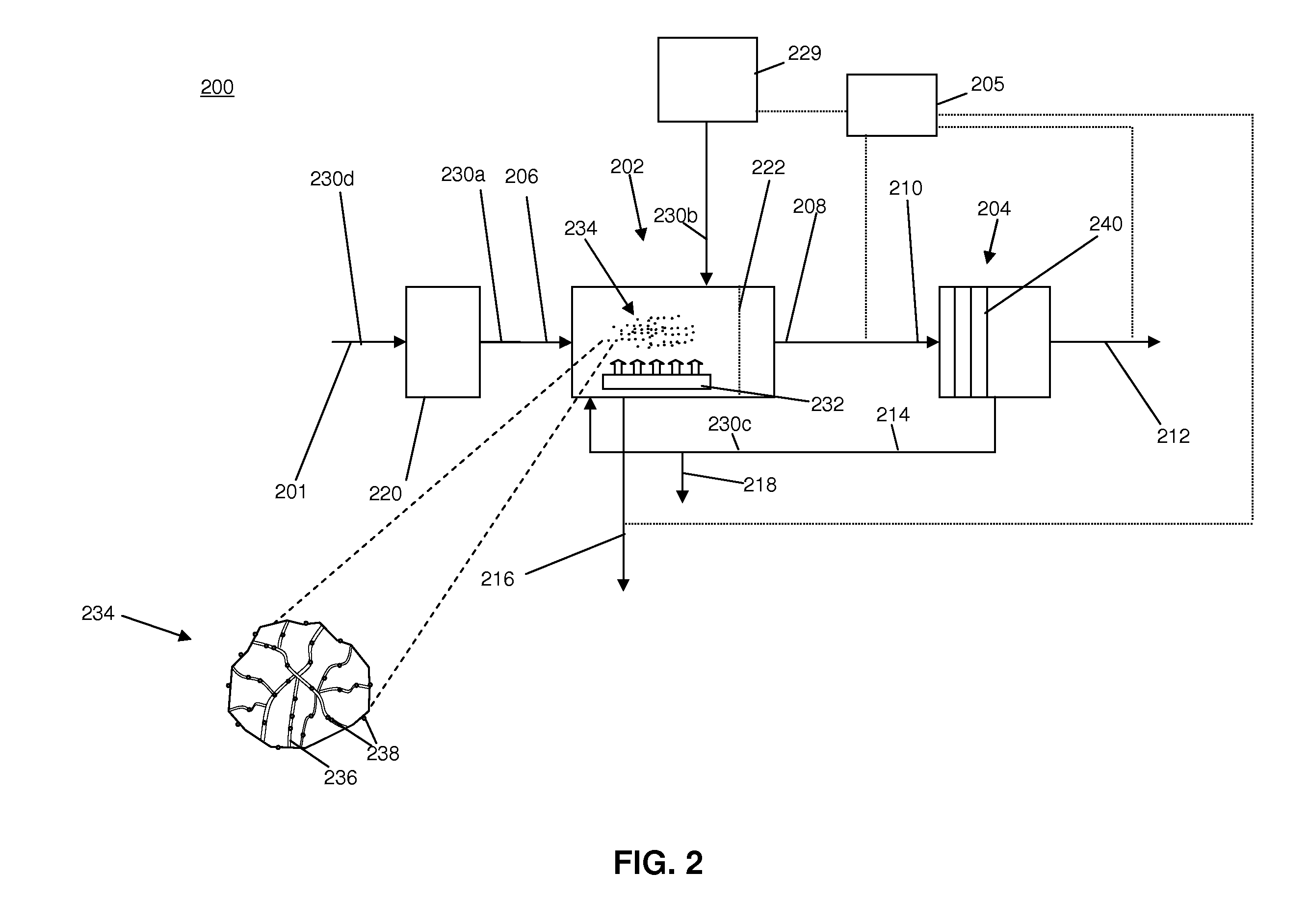

Mobile station and methods for diagnosing and modeling site specific effluent treatment facility requirements

InactiveUS20090032446A1Reduce financial riskHigh continuity of operationReverse osmosisFlash degasificationIon exchangeReverse osmosis

A mobile station and methods are disclosed for diagnosing and modeling site specific effluent treatment facility requirements to arrive at a treatment regimen and / or proposed commercial plant model idealized for the particular water / site requirements. The station includes a mobile platform having power intake, effluent intake and fluid outflow facilities and first and second suites of selectably actuatable effluent pre-treatment apparatus. An effluent polishing treatment array is housed at the station and includes at least one of nanofiltration, reverse osmosis and ion-exchange stages. A suite of selectively actuatable post-treatment apparatus are housed at the station. Controls are connected at the station for process control, monitoring and data accumulation. A plurality of improved water treatment technologies are also disclosed.

Owner:ROCKWATER RESOURCE

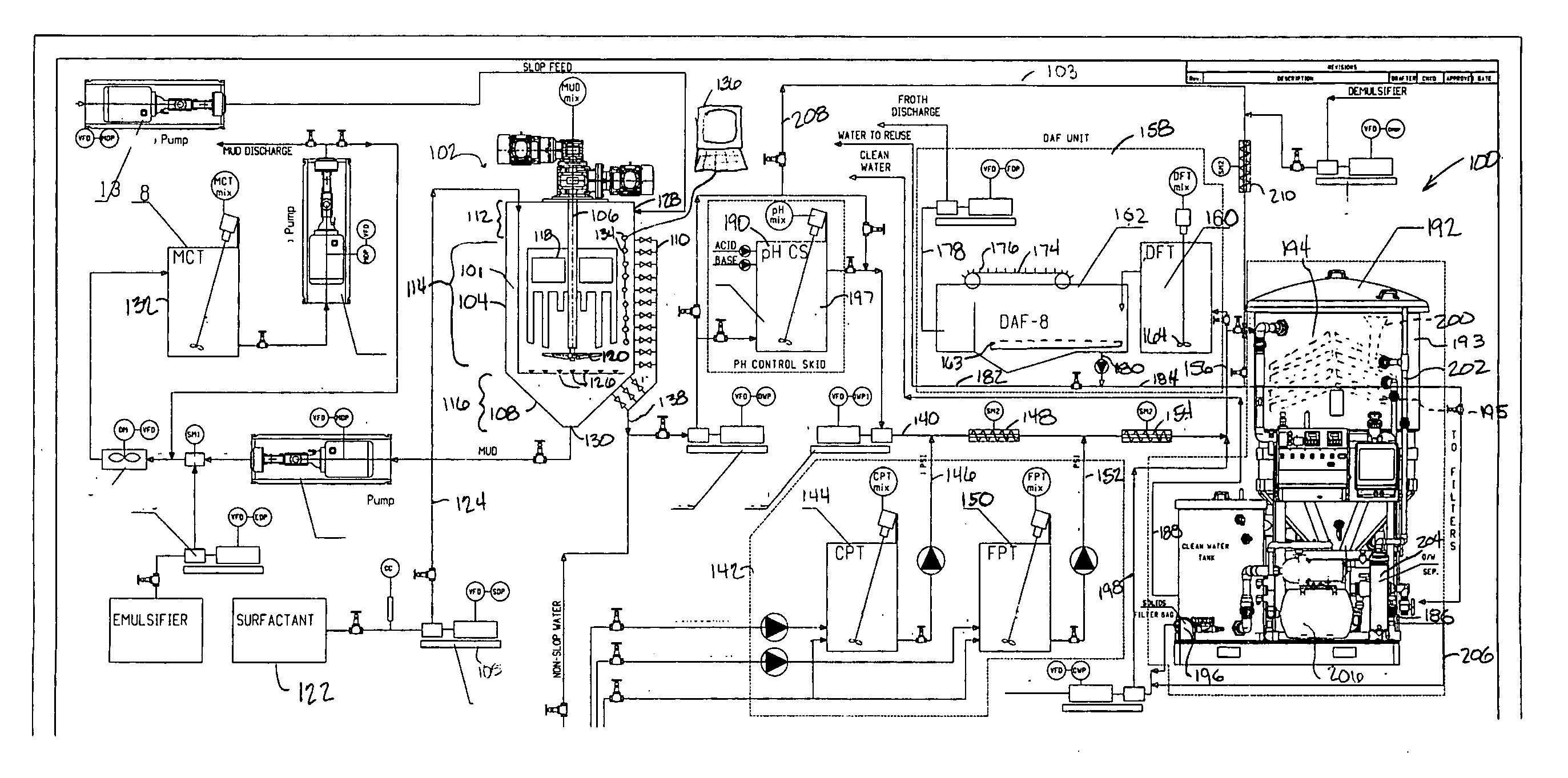

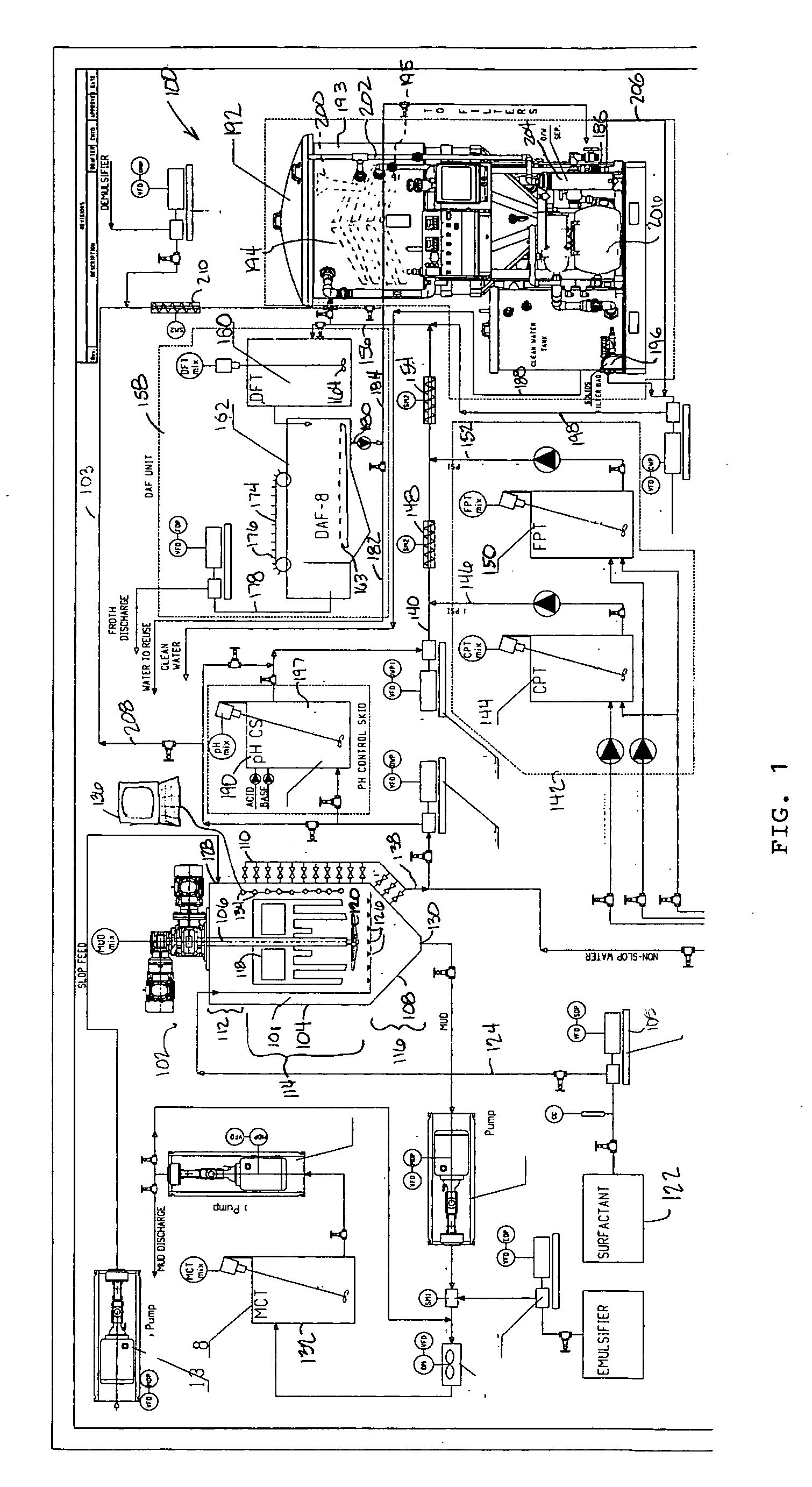

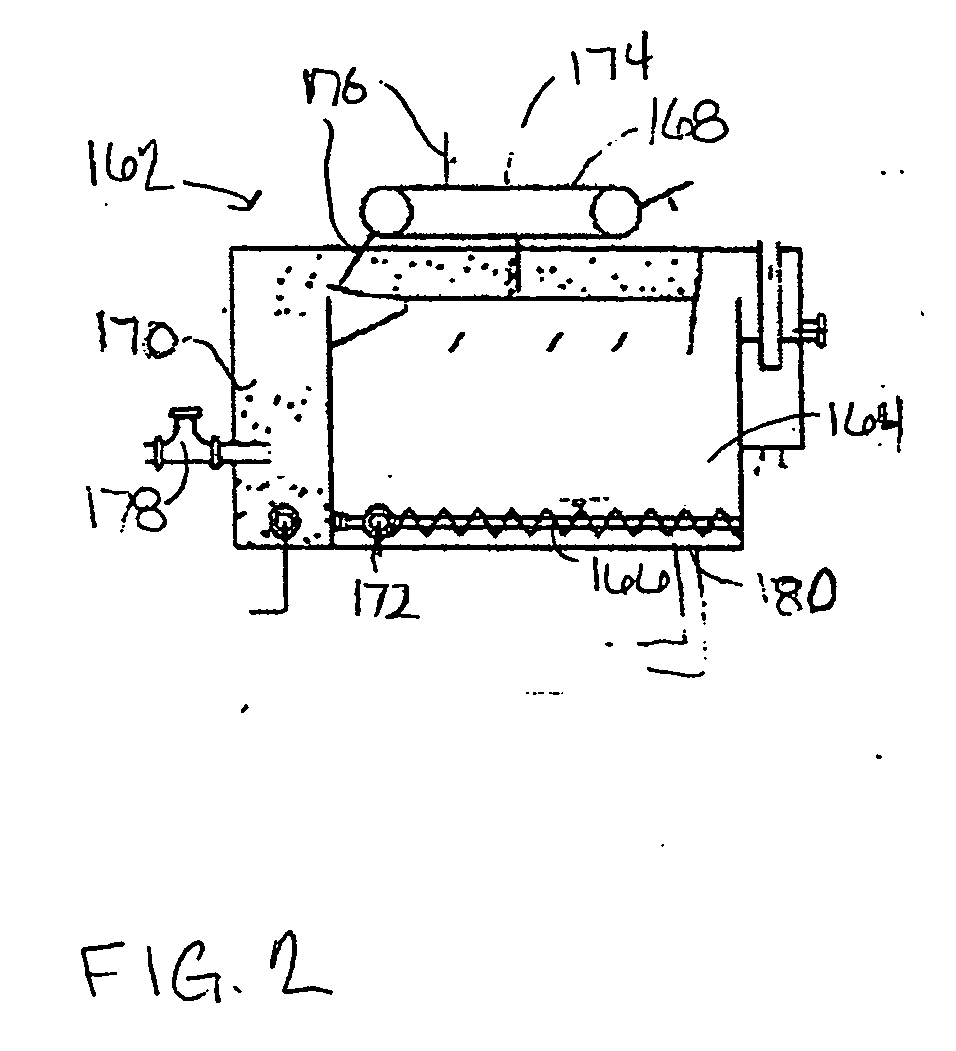

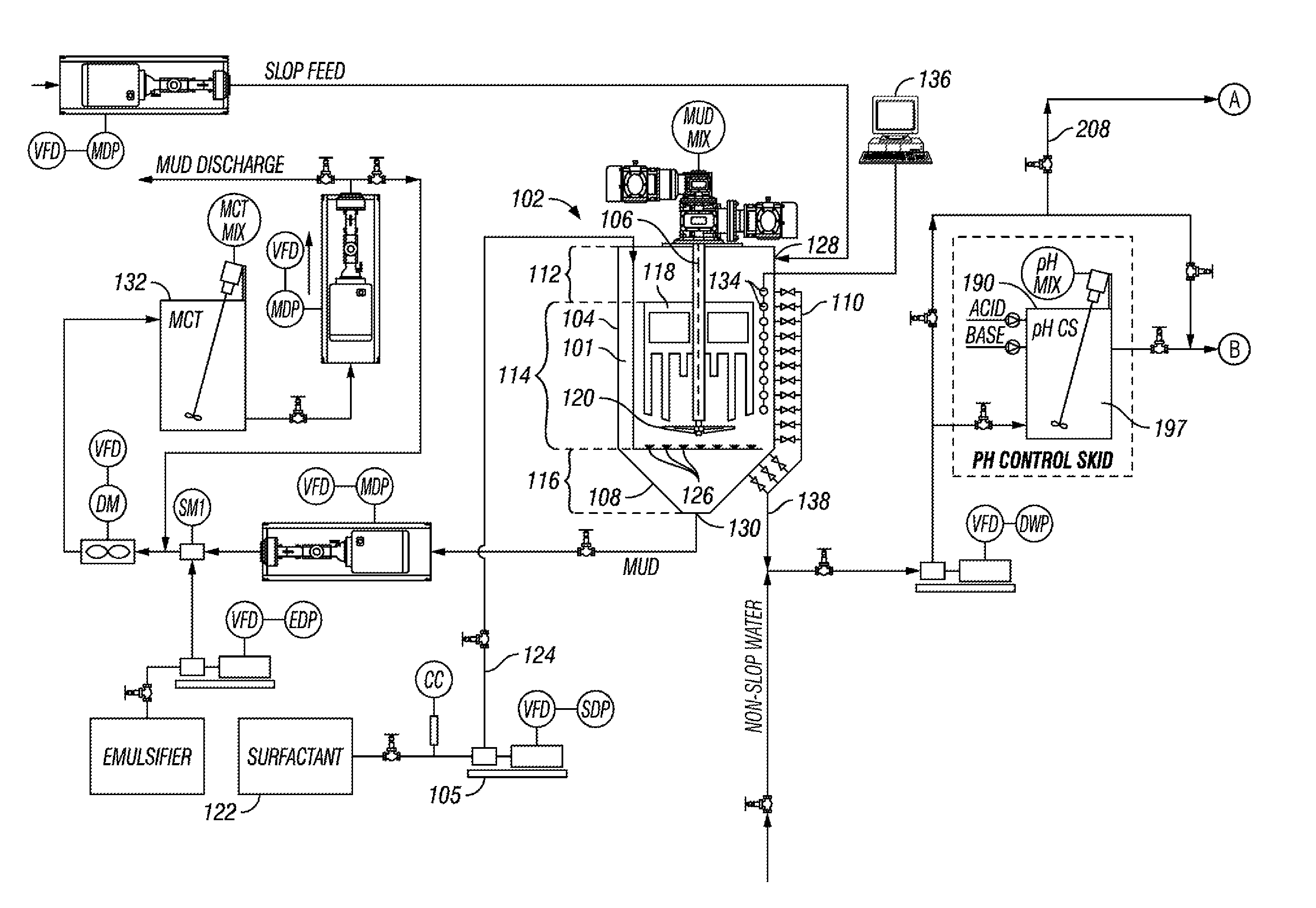

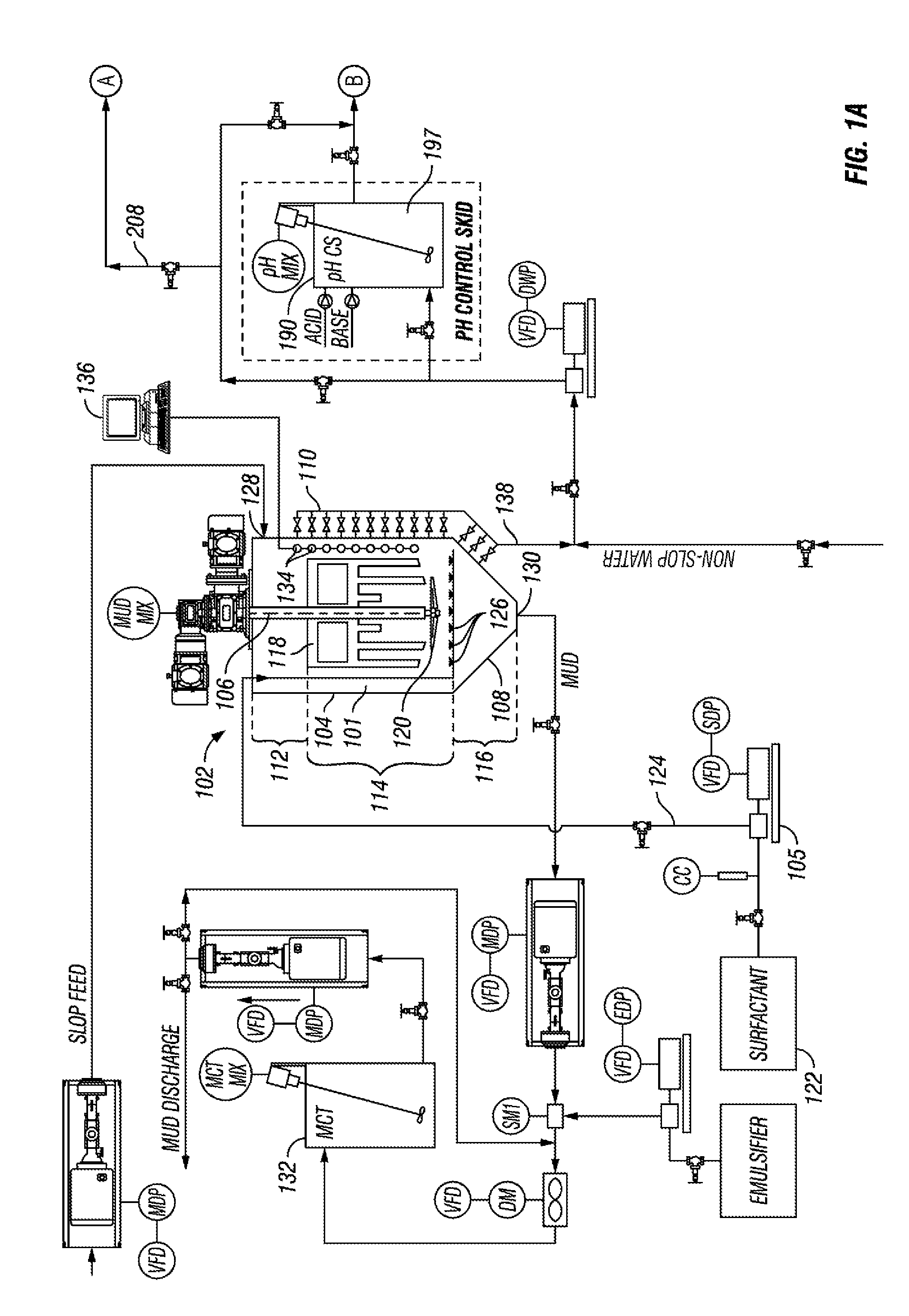

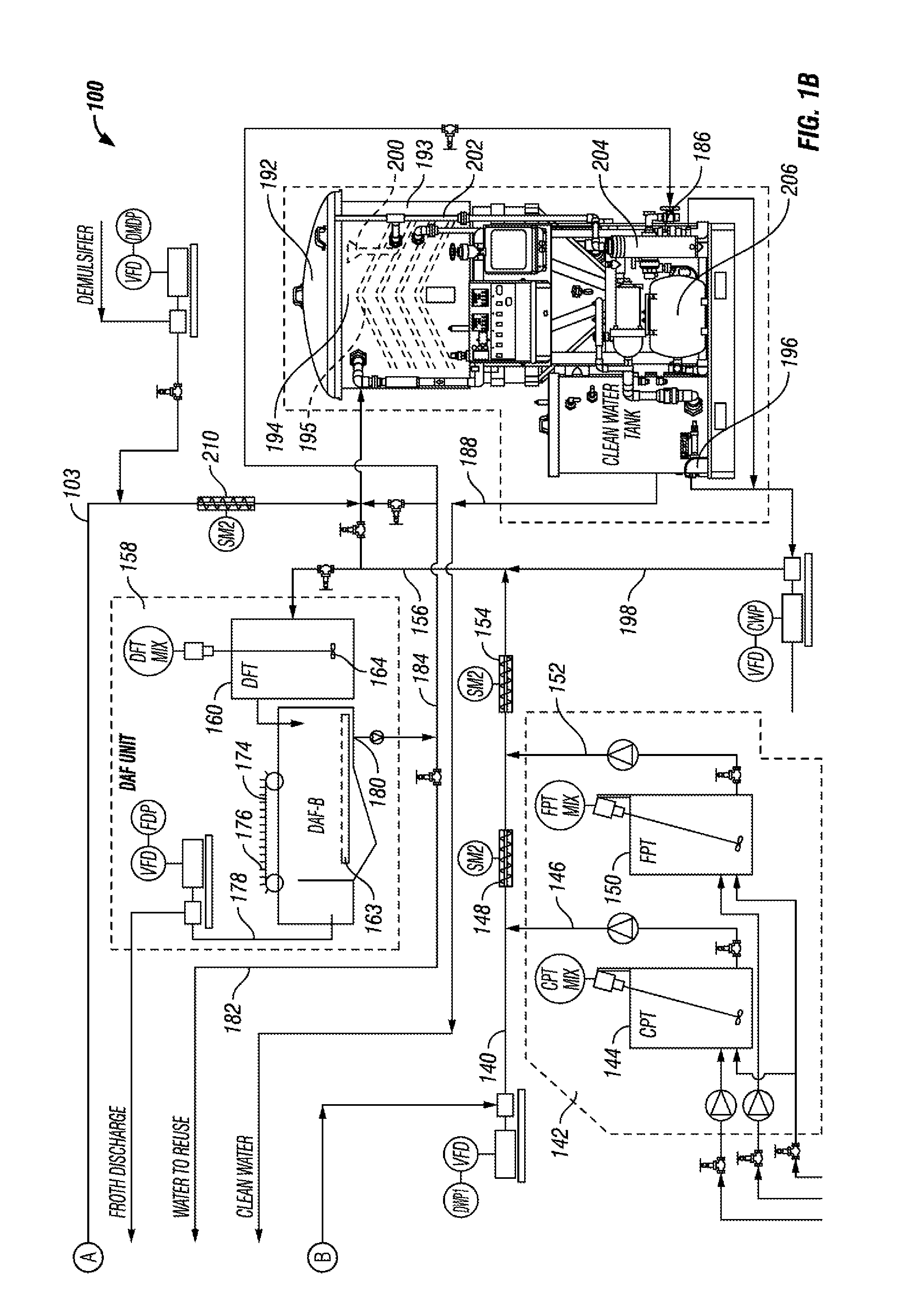

Apparatus for separation of water from oil-based drilling fluid and advanced water treatment

InactiveUS20060186056A1Shorten the timeIncrease the number ofWaste water treatment from quariesTreatment involving filtrationChemical treatmentFiltration

An apparatus for separating water from oil-based drilling fluid includes an separation tank, a chemical treatment apparatus having one or more de-oiling polymer preparation tanks, and a dissolved air flotation unit. Slop mud is directed into the separation tank where surfactant is added to separate the drilling fluid from oily water. The drilling fluid is drained for further processing. The oily water is removed by an outlet arrangement from the separation tank and directed to an initial treatment line. One or more de-oiling polymers are added to the oily water in the initial treatment line and mixed therewith. The mixture may then be directed to the dissolved air flotation unit where dissolved air is released into the bottom of the mixture. The dissolved air adheres to suspended solids in the mixture and lifts them to the top surface as a froth. The froth is skimmed from the top surface of the mixture and collected. The de-frothed water is reused or directed to a filtration system where it is prepared for discharge. A clarifying tank may be included after the de-oiling polymers are added to further separate the oil and water. The oil is removed from the top surface by a weir while the water is directed to the filtration system and discharged.

Owner:MI

System and method for removing deep sub-micron particles from water

InactiveUS20050045534A1Well mixedLiquid separation auxillary apparatusIon-exchanger regenerationFlocculationElectricity

The present invention discloses a process and an apparatus for removing deep sub-micron particles from water. The invented process includes adjusting pH value and conductivity, adding an oxidation agent, performing an electro coagulation reaction / an electro-oxidation reaction, and performing a flocculation sedimentation, etc. The invented apparatus includes a front adjustment tank for adjusting the properties of waste water, wherein the adjustment includes a pH adjustment, an electrolyte adjustment, or an oxidant addition, etc.; an electrocoagulation reaction tank receiving water from the front adjustment tank and having pairs of separated electrodes, one of the electrodes being made of iron; a rear adjustment tank for adjusting pH value of the effluent of the electrocoagulation reaction tank; and a sedimentation reservoir for providing the resulting pH-adjusted, sedimentary floccule-containing water from the rear adjustment tank with a sufficient residence time in said sedimentation reservoir, so that floccules and sedimentation are formed therein.

Owner:IND TECH RES INST

Water purification method

InactiveUS20140175015A1Conveniently and efficiently purifyingInexpensivelyWaste water treatment from quariesWaste water treatment from ceramic industriesPurification methodsSorbent

A water purification method comprising adding a purification agent to water having a contaminant concentration of 1 μg / L to 10 g / L, the purification agent containing an adsorbent having an average particle size of 100 nm to 500 μm, an iron-based flocculant, and an alkaline substance; causing the adsorbent to adsorb at least a part of the contaminants in water; settling the adsorbent with the adsorbed contaminants by the iron-based flocculant; and removing the sediment from water, wherein the purification agent is added in an amount of 0.01 g to 20 g per liter of water, can purify contaminated water conveniently and efficiently.

Owner:FUJIFILM CORP

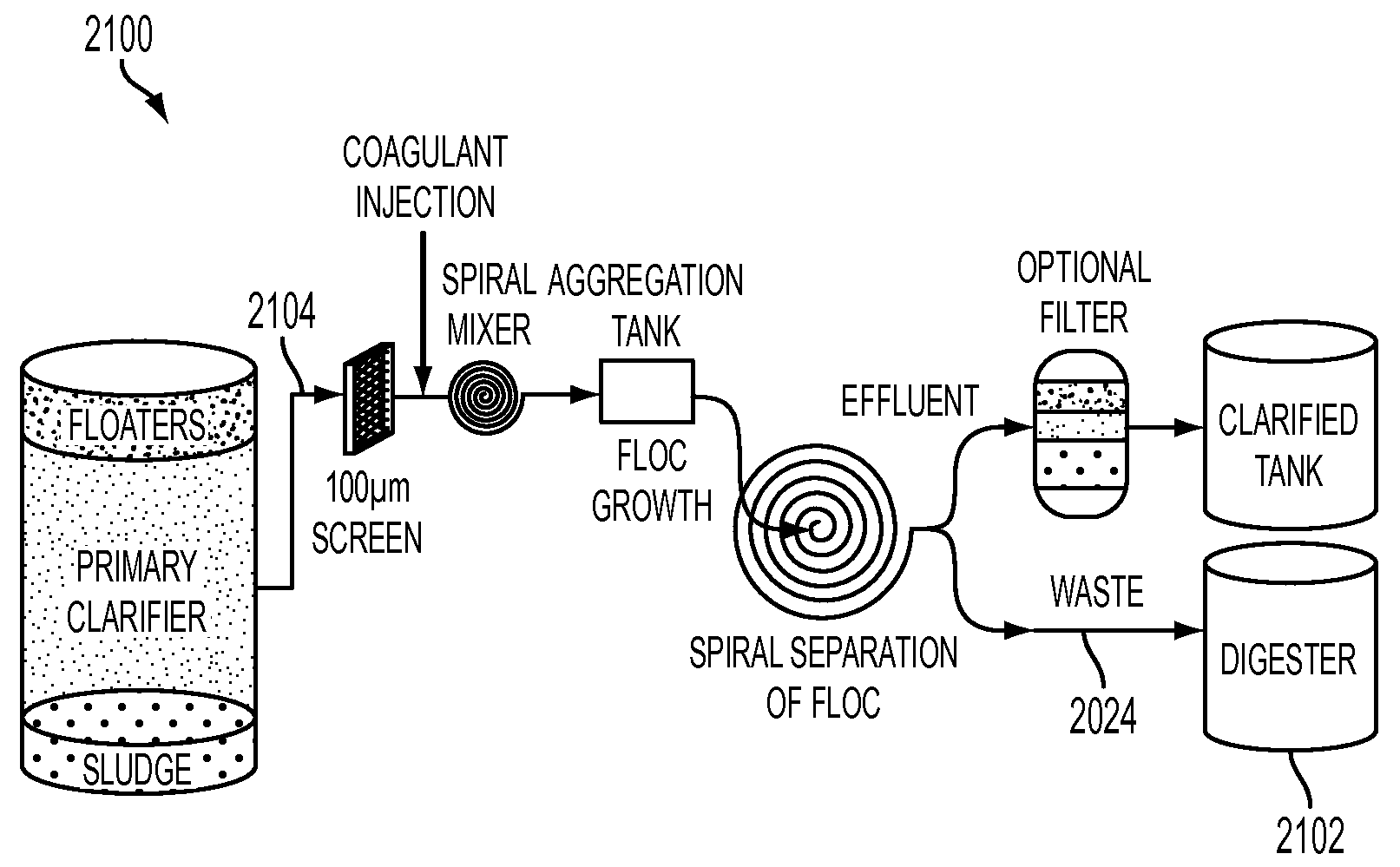

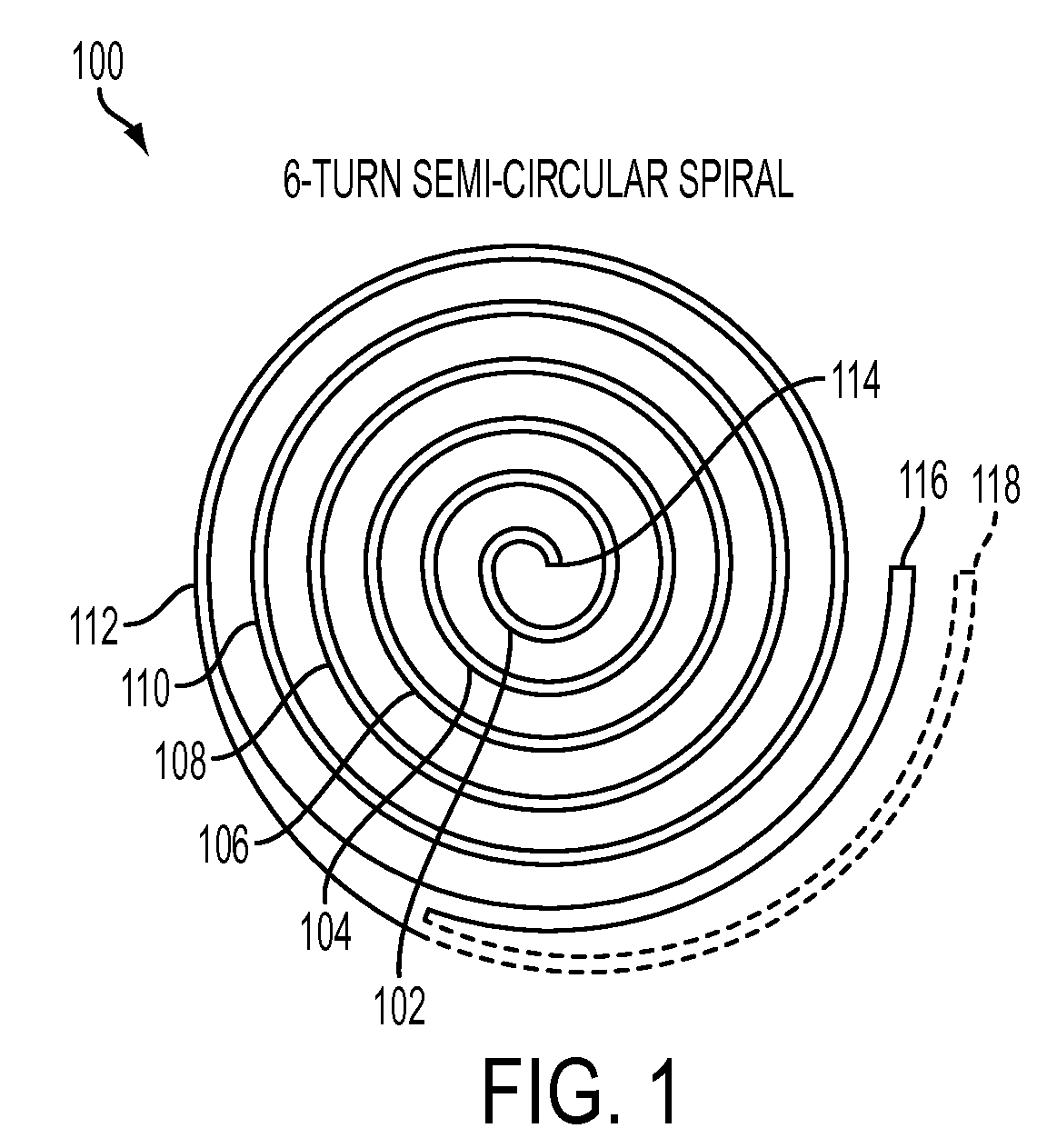

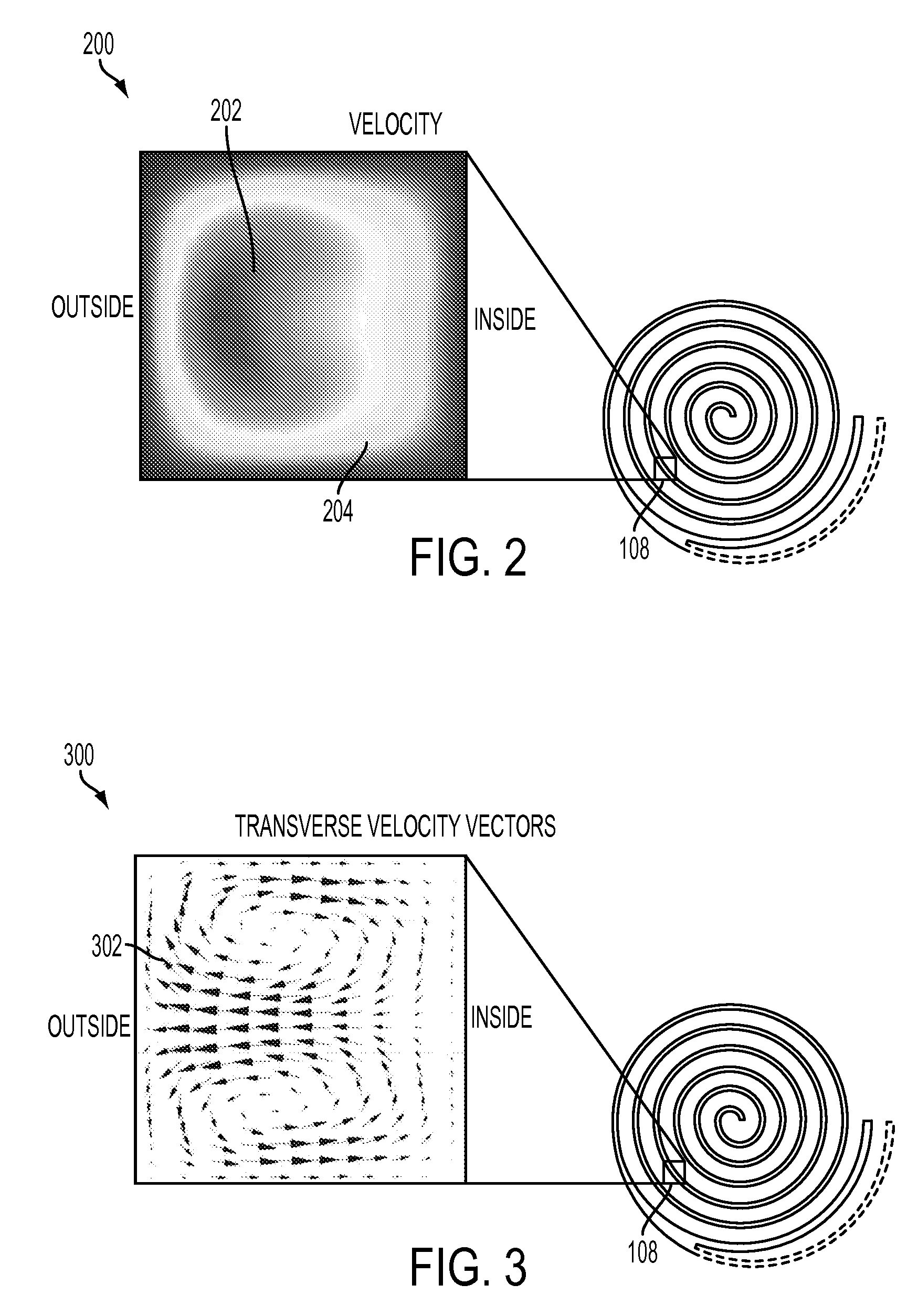

Platform technology for industrial separations

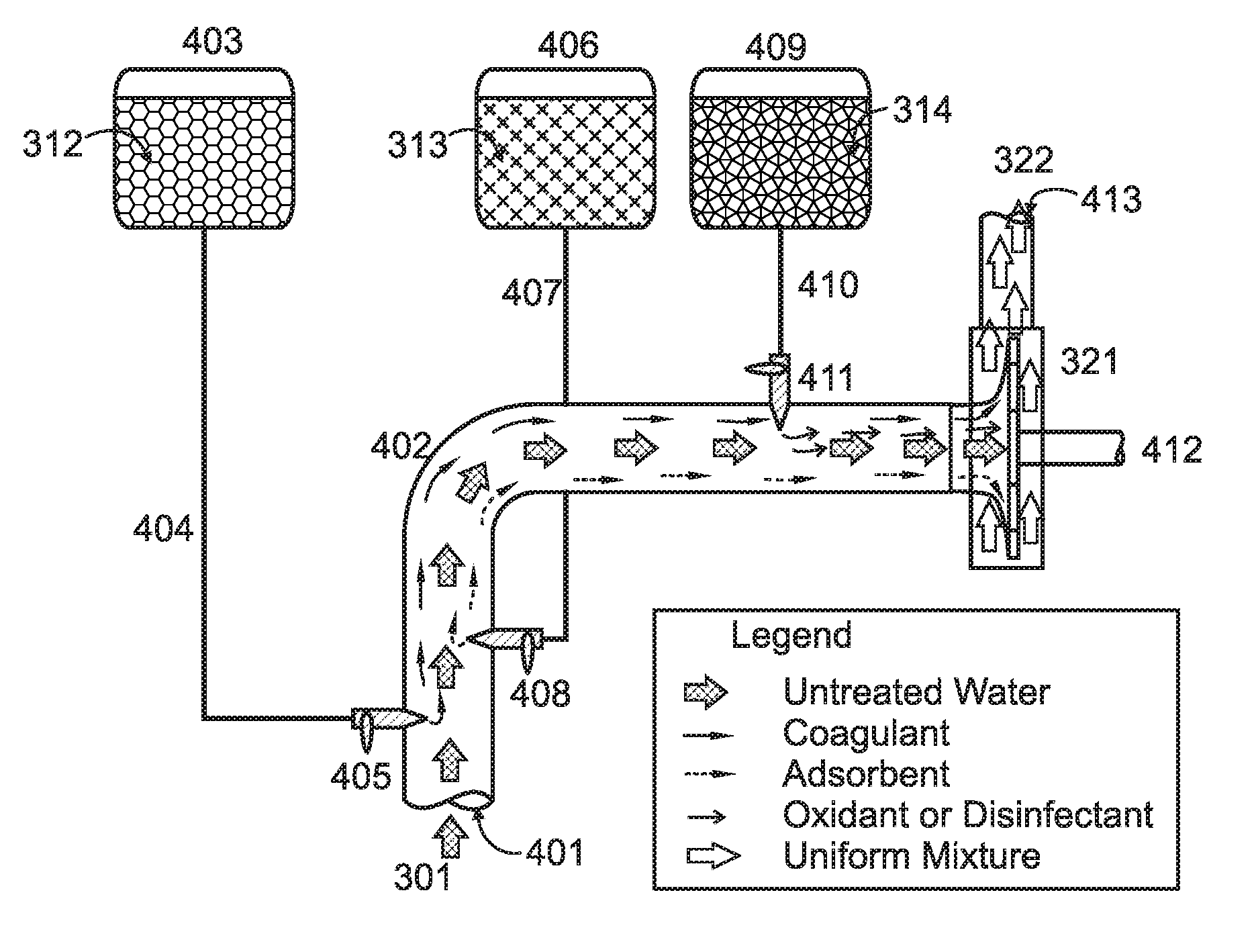

A method and system for treating a fluid stream includes inputting a fluid stream to an input section of the fluid treatment system and receiving the fluid stream via spiral mixer-conditioner. The spiral mixer-conditioner mixes and conditions the input stream. Thereafter the mixed and conditioned fluid stream is input to a spiral separator where the mixed and conditioned fluid stream is separated into at least two fluid streams, a first fluid stream having particulates in the input stream removed, and the second fluid stream having the particulates in the input fluid stream concentrated.

Owner:PALO ALTO RES CENT INC

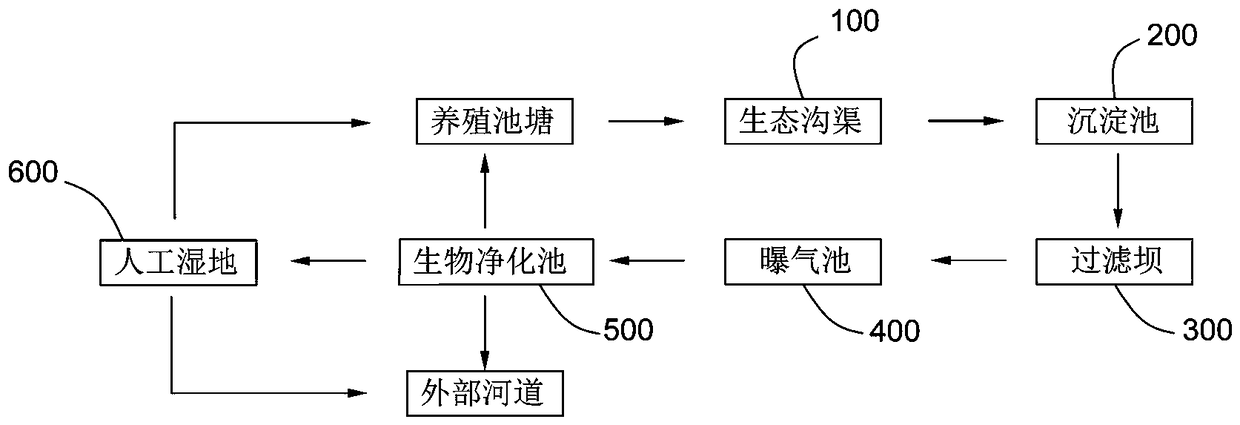

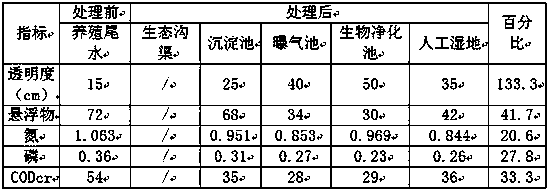

Freshwater shrimp culture tail water treatment system

InactiveCN108178447AAccelerated precipitationEfficient removalTreatment using aerobic processesTreatment involving filtrationConstructed wetlandWater discharge

The invention discloses a freshwater shrimp culture tail water treatment system for treatment of the tail water of a culture pond. The freshwater shrimp culture tail water treatment system comprises:a pair of ecological ditches for preliminary purification of culture tail water, a sedimentation tank for sedimentation to remove granular solids in the culture tail water subjected to preliminary purification in the ecological ditches, a filtration dam for filtering solid particles in the culture tail water subjected to sedimentation treatment in the sedimentation tank, an aeration tank for aeration treatment of the culture tail water subjected to filtration treatment by the filtration dam, a biological purification tank utilizing fungi and animals to remove harmful substances, algae and thelike in the culture tail water subjected to aeration treatment in the aeration tank, and a constructed wetland for effective degradation of pollutants and harmful substances in the culture tail watersubjected to purification in the biological purification tank. The freshwater shrimp culture tail water treatment system provided by the invention can effectively remove solid particle impurities in culture tail water, lower the dissolved nitrogen and phosphorus content, and degrade pollutants and harmful substances. The treated culture tail water can reach the culture tail water discharge standard, and can finally be discharged into external rivers or recycle to culture ponds.

Owner:ZHEJIANG INST OF FRESH WATER FISHERIES

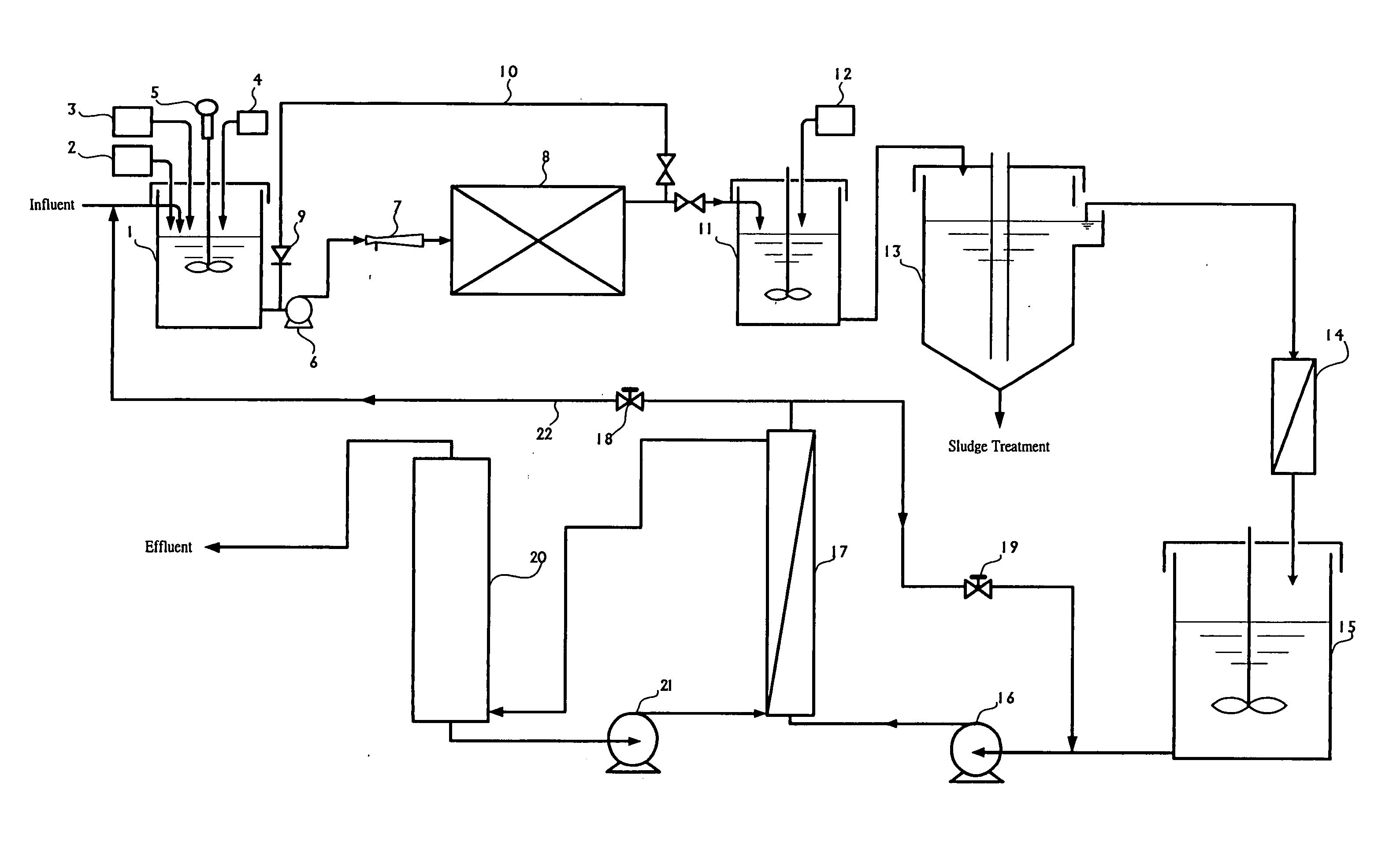

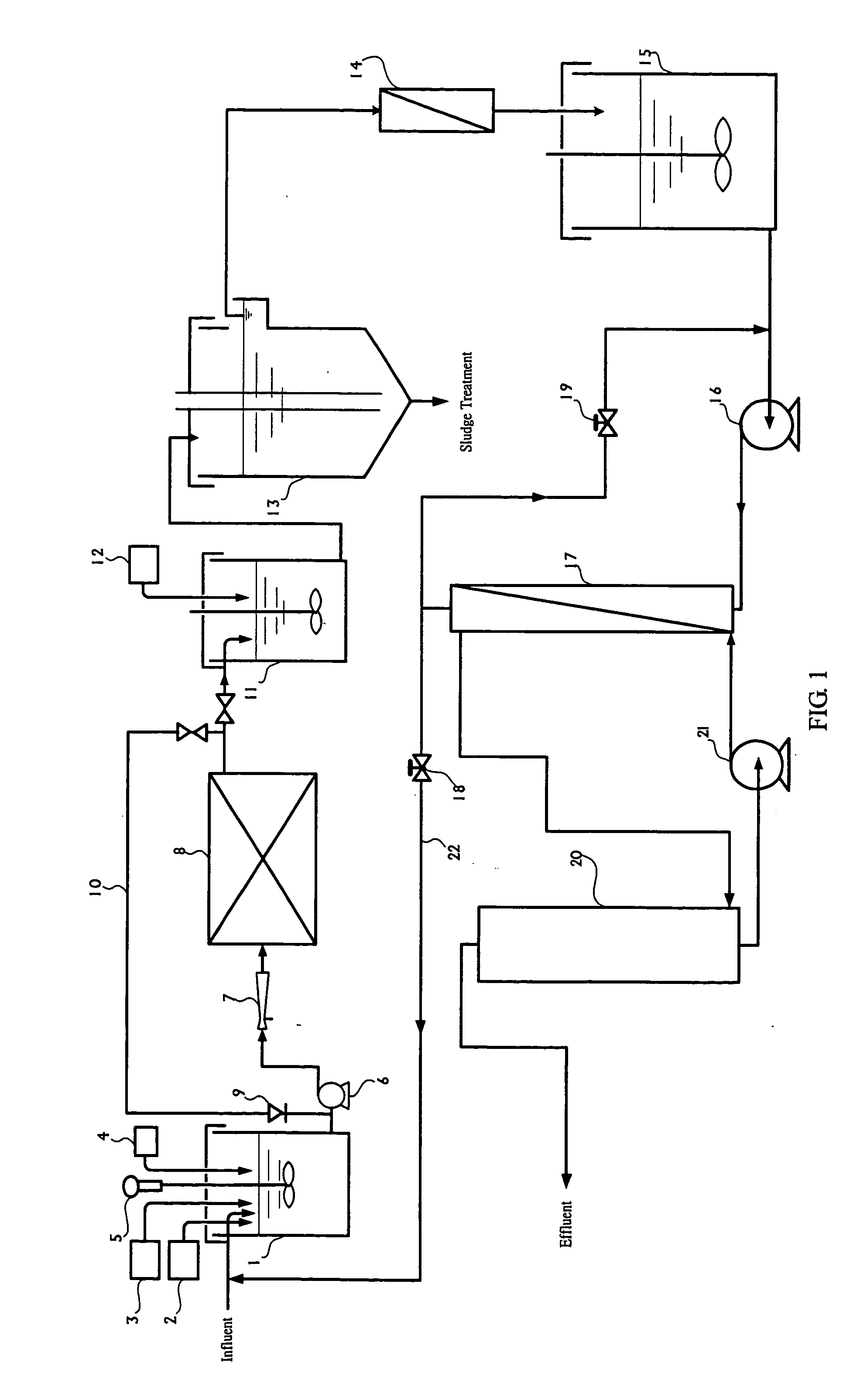

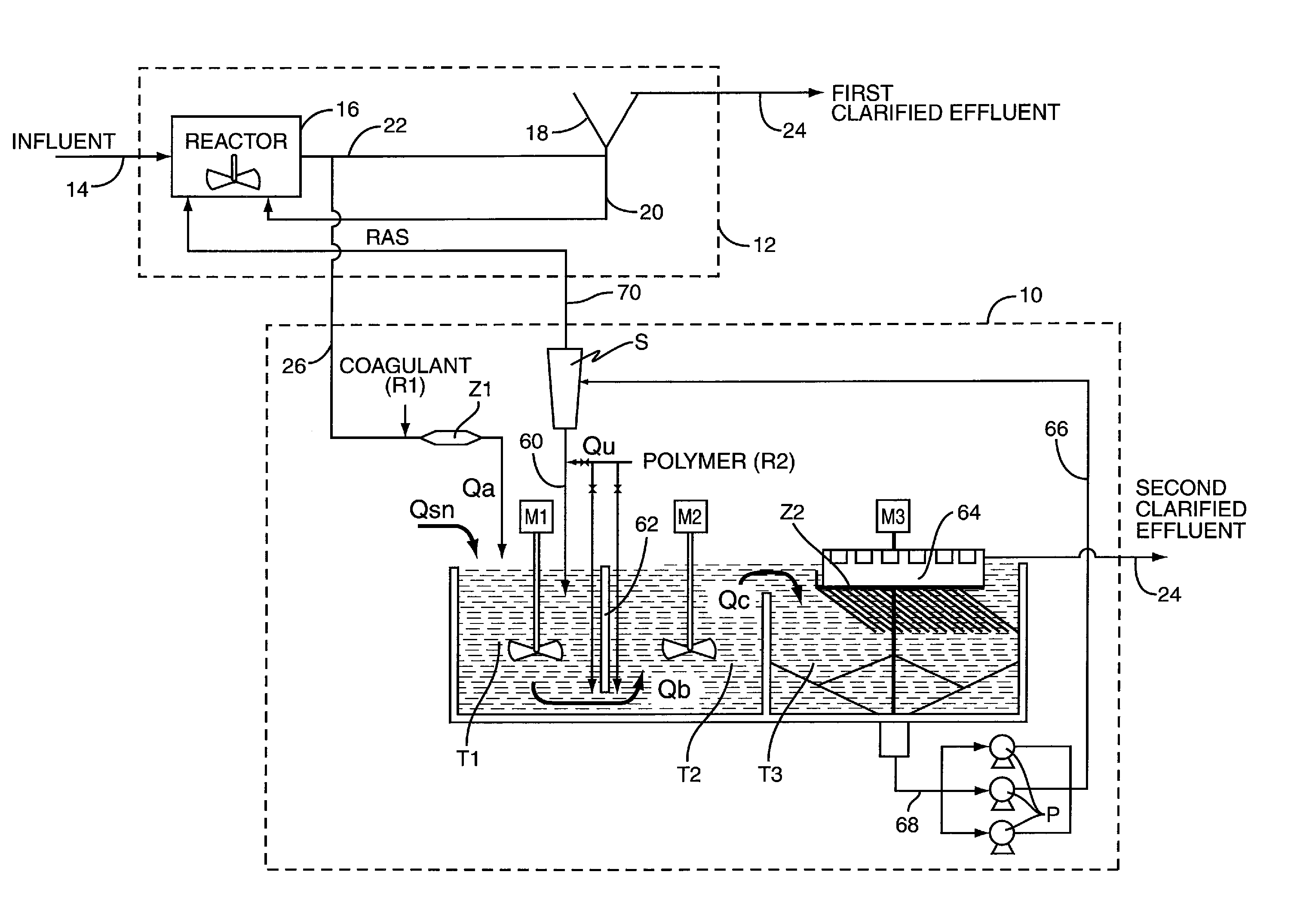

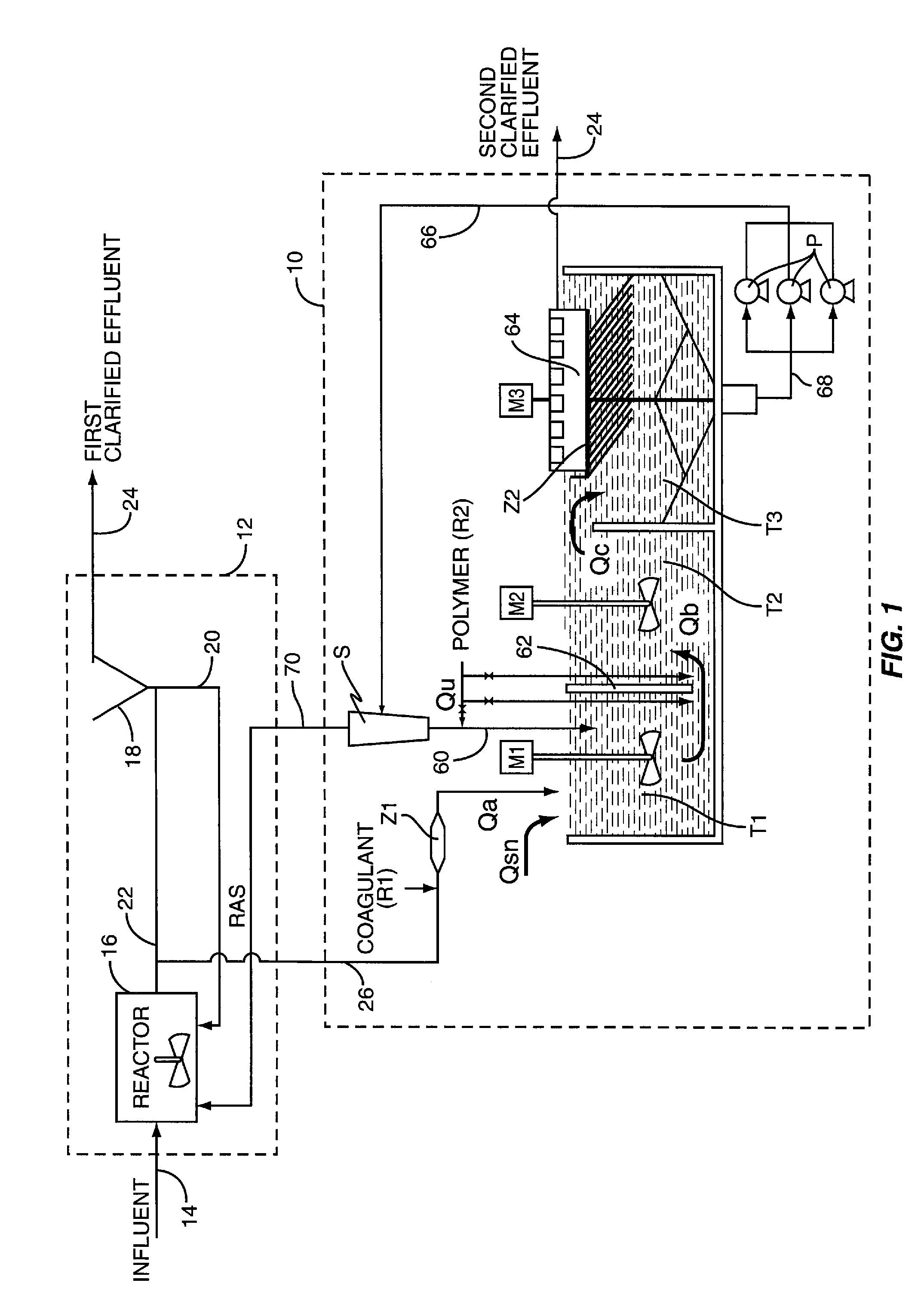

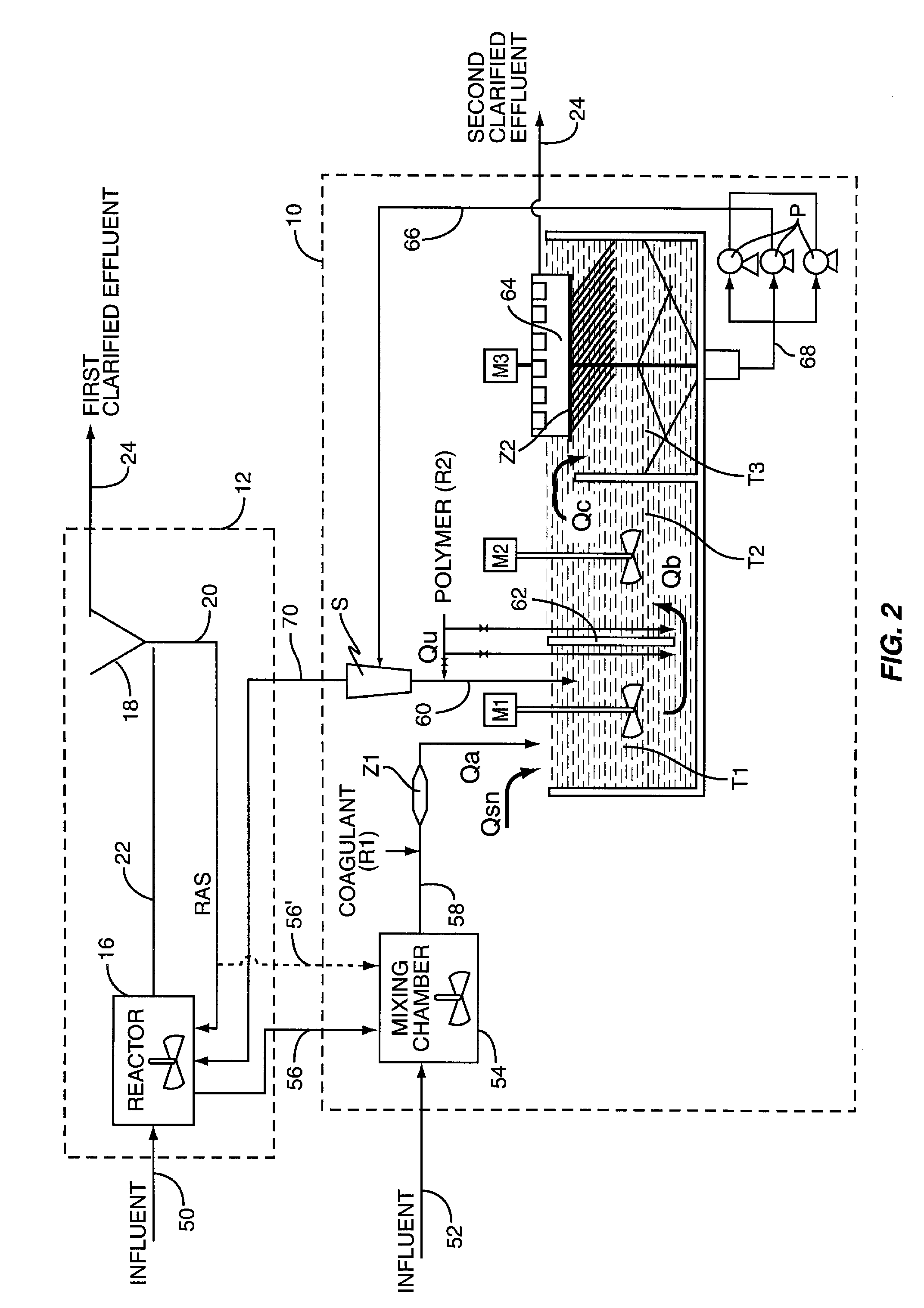

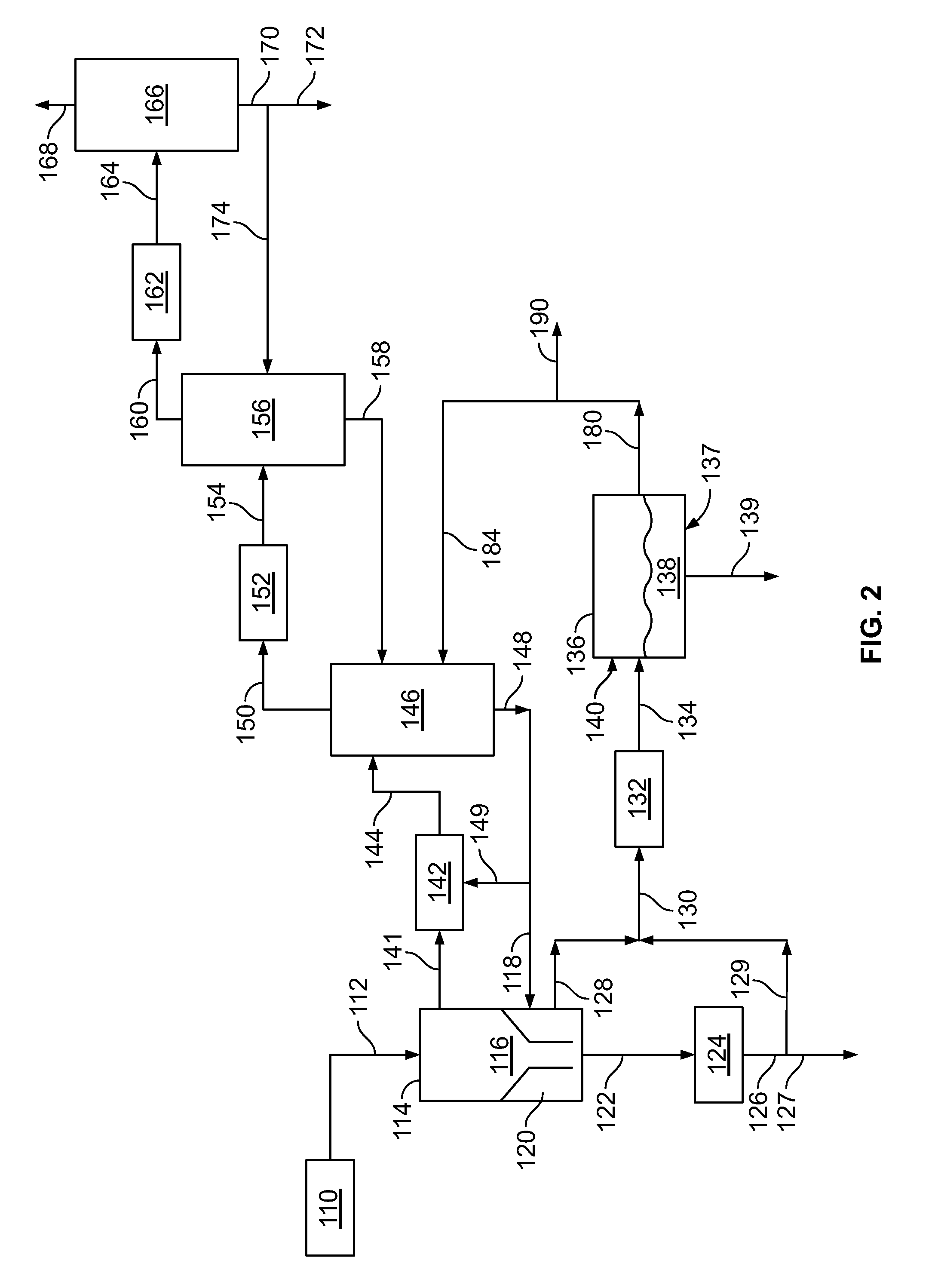

Combined biological and ballasted flocculation process for treating wastewater

InactiveUS7323108B1High recovery rateImprove concentrationWater treatment parameter controlTreatment using aerobic processesFlocculationMixed liquor suspended solids

A wastewater treatment process is provided that entails both a biological or activated sludge process and a ballasted flocculation process. A first stream of wastewater is directed to a biological system for biologically treating the wastewater. The biological treatment process produces a first effluent and a first sludge. In cases where the biological system is an activated sludge process, the first sludge is recycled. A second stream of wastewater is directed to a ballasted flocculation system. The second stream of wastewater can be a stream independent of the first stream of wastewater or can be derived from the wastewater passing through the biological system. Sludge in the form of activated sludge or mixed liquor from the biological system is mixed with a second stream of wastewater in the ballasted flocculation system for the purpose of biologically treating the second stream of wastewater. Forming a part of the ballasted flocculation system is a settling tank that produces a second effluent and a second sludge. The second sludge is routed to a separator where granular material that forms a ballast in the process is separated and recycled. To effectively remove suspended solids from the wastewater passing through the ballasted flocculation system, the second sludge recycle rate is controlled or maintained at a flow rate of about 15% and higher of the influent flow rate to the ballasted flocculation system. Furthermore, as the mixed liquor suspended solids (MLSS) concentration increases from, for example, 1000 mg / l to about 4000 mg / l, the recycle rate of the second sludge may be varied from about 15% to about 40% of the influent flow rate to the ballasted flocculation system.

Owner:KRUGER I INC

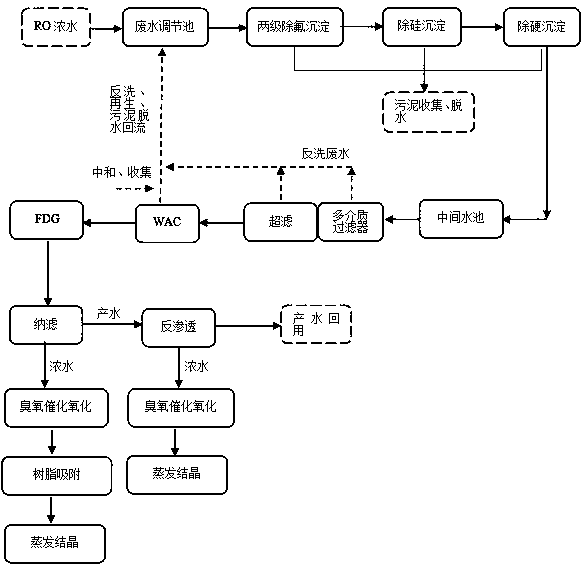

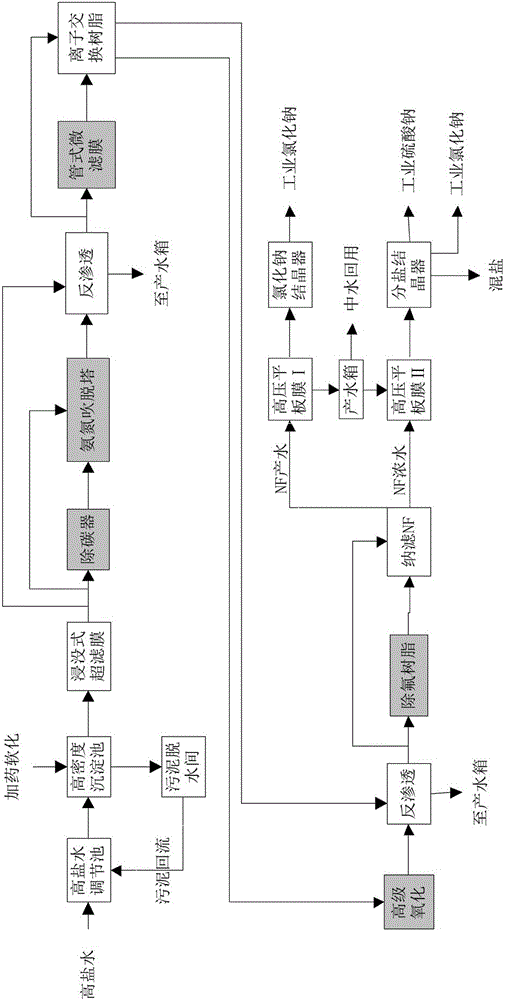

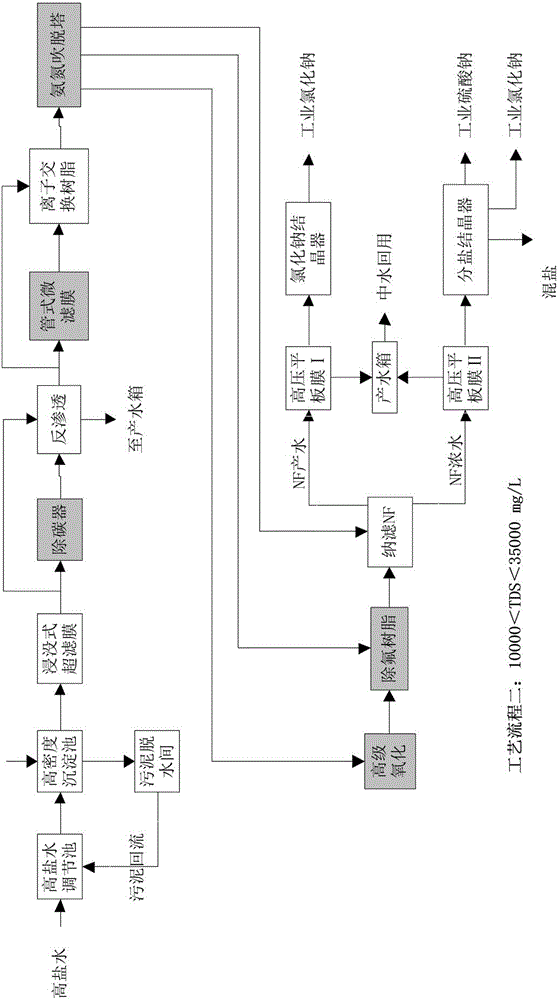

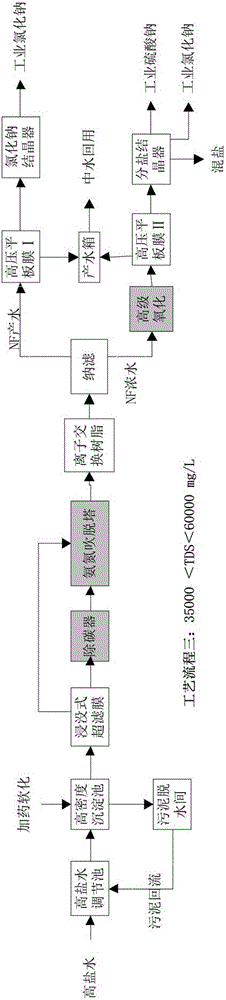

Recycling treatment process for coal coking high-salinity wastewater

PendingCN110606612AAchieving zero emissionsImplement resourcesWater contaminantsTreatment involving filtrationUltrafiltrationResource utilization

The invention relates to a recycling treatment process for coal coking high-salinity wastewater. The process comprises the following steps: (1) fluorine removing; (2) silicon removing; (3) softening;(4) treatment with a multi-medium filter; (5) ultrafiltration; (6) resin softening; (7) FDG; (8) nanofiltration and salt separation; (9) reverse osmosis concentration; (10) advanced oxidation; (11) resin adsorption; and (12) evaporative crystallization. The process has the advantages that the process of pretreatment, nanofiltration salt separation, reverse osmosis concentration, advanced oxidationand evaporative crystallization is adopted, so that zero emission and quality-divided resource utilization of the coal coking high-salinity wastewater are realized.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +2

Apparatus for separation of water from oil-based drilling fluid and advanced water treatment

InactiveUS7497954B2Shorten the timeIncrease the number ofWaste water treatment from quariesTreatment involving filtrationChemical treatmentFiltration

An apparatus for separating water from oil-based drilling fluid includes an separation tank, a chemical treatment apparatus having one or more de-oiling polymer preparation tanks, and a dissolved air flotation unit. Slop mud is directed into the separation tank where surfactant is added to separate the drilling fluid from oily water. The drilling fluid is drained for further processing. The oily water is removed by an outlet arrangement from the separation tank and directed to an initial treatment line. One or more de-oiling polymers are added to the oily water in the initial treatment line and mixed therewith. The mixture may then be directed to the dissolved air flotation unit where dissolved air is released into the bottom of the mixture. The dissolved air adheres to suspended solids in the mixture and lifts them to the top surface as a froth. The froth is skimmed from the top surface of the mixture and collected. The de-frothed water is reused or directed to a filtration system where it is prepared for discharge. A clarifying tank may be included after the de-oiling polymers are added to further separate the oil and water. The oil is removed from the top surface by a weir while the water is directed to the filtration system and discharged.

Owner:MI

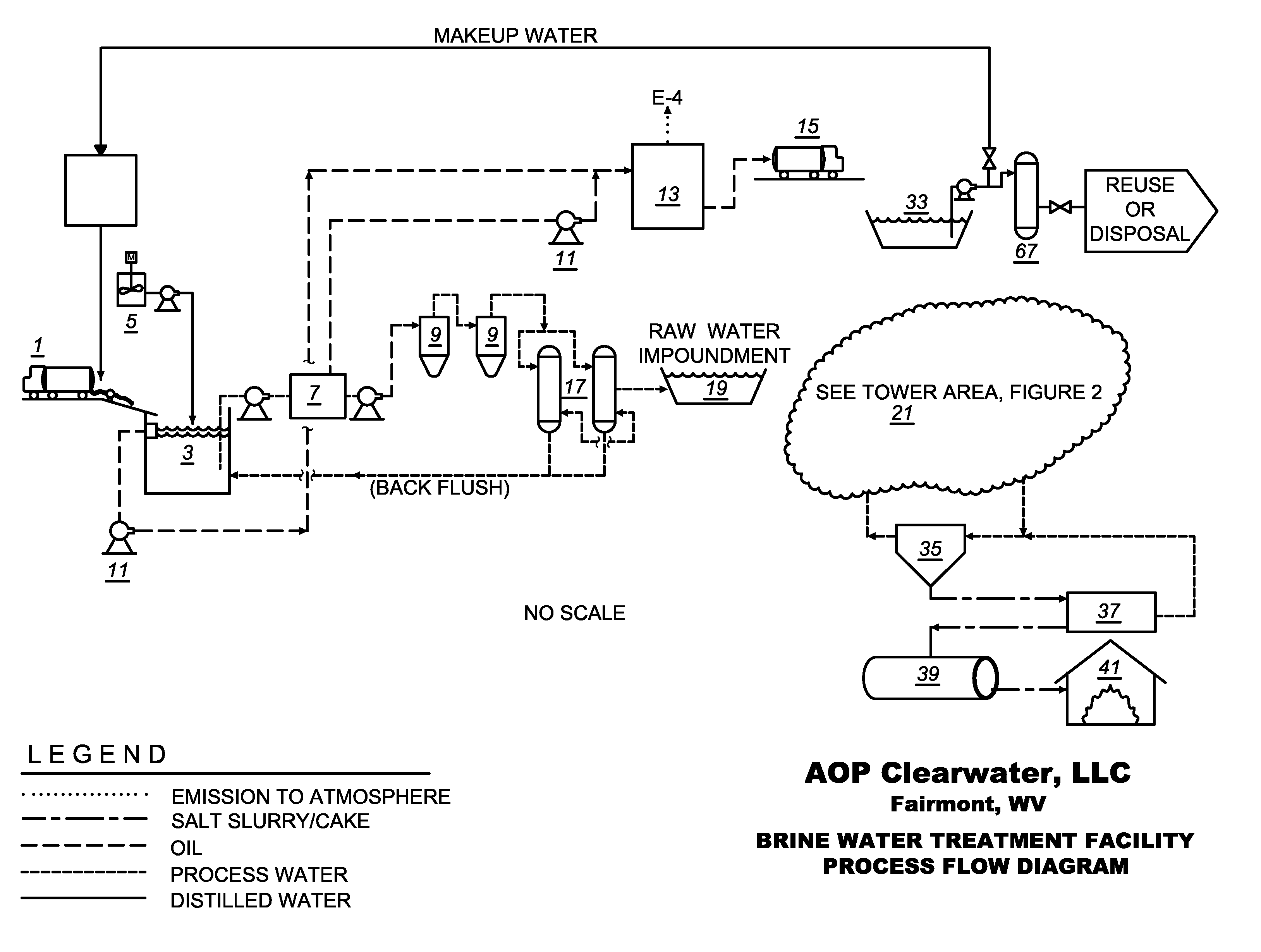

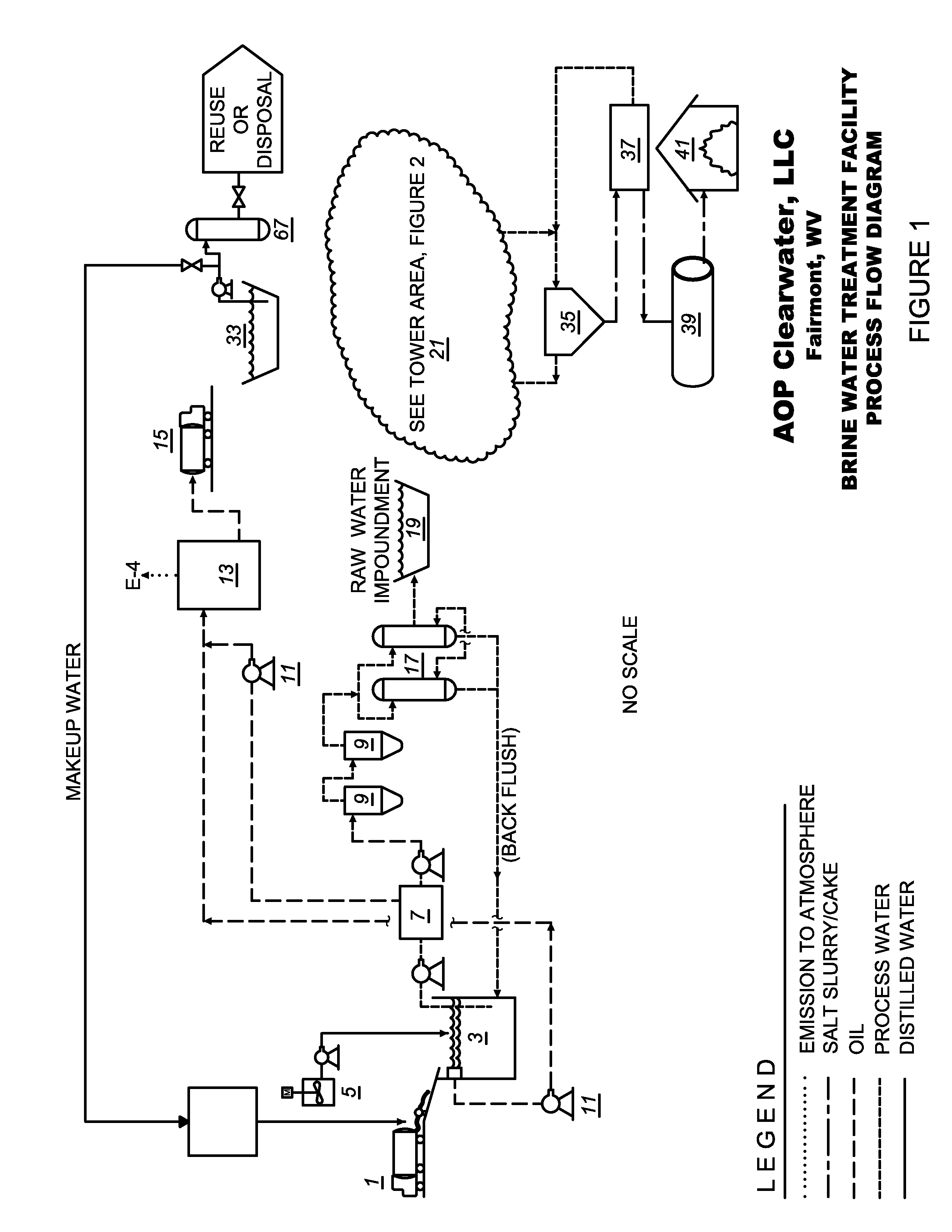

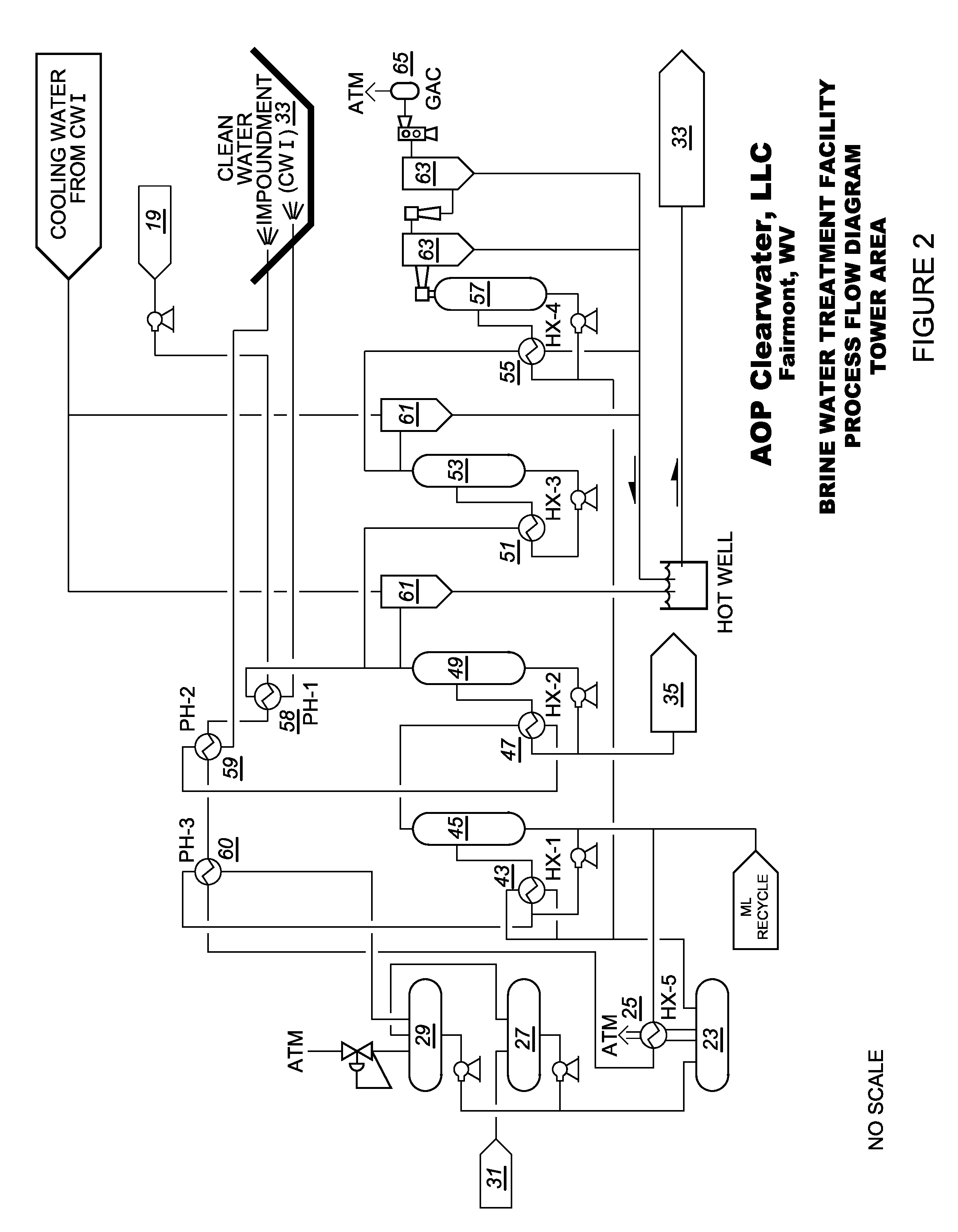

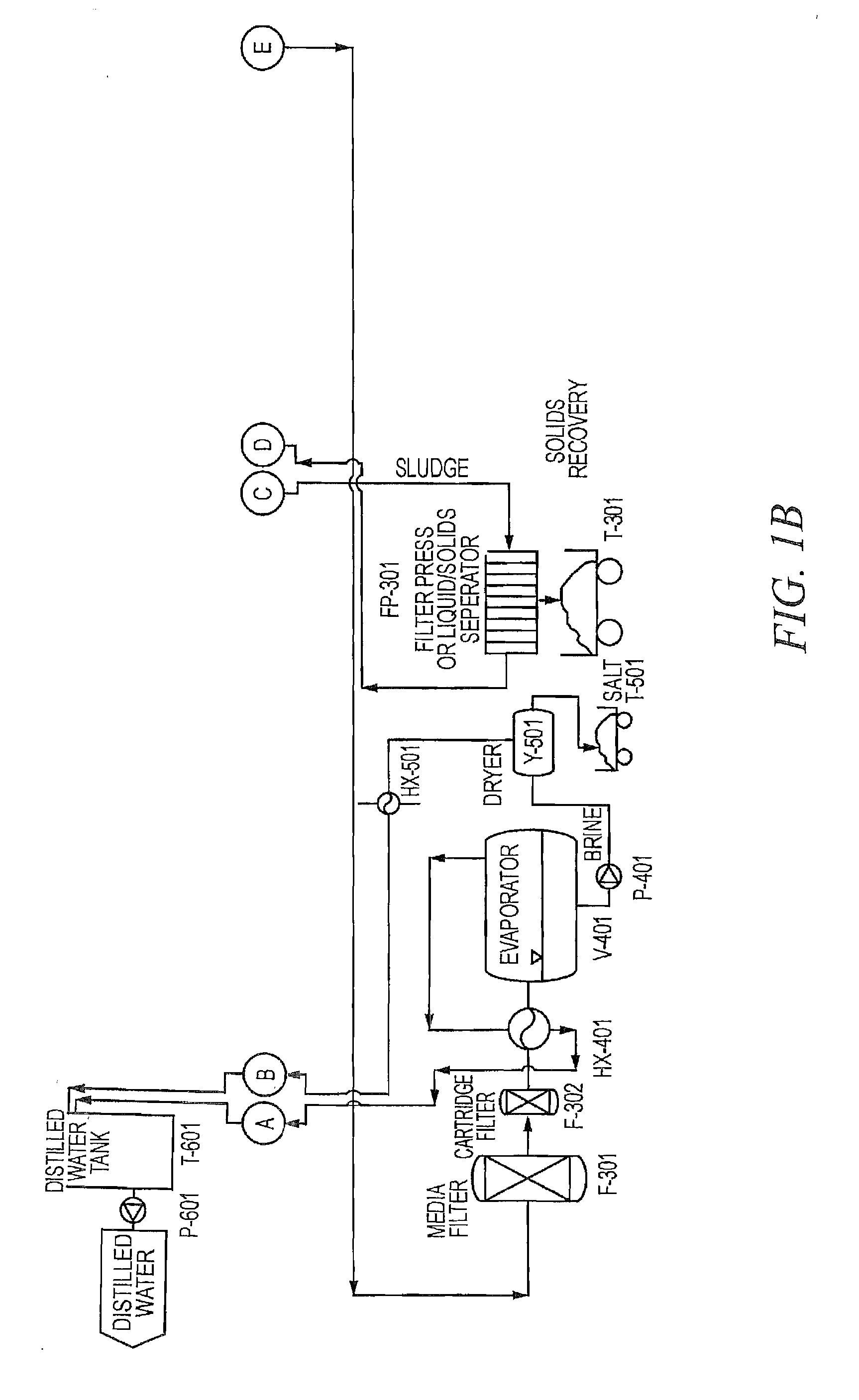

Brine water recycle process

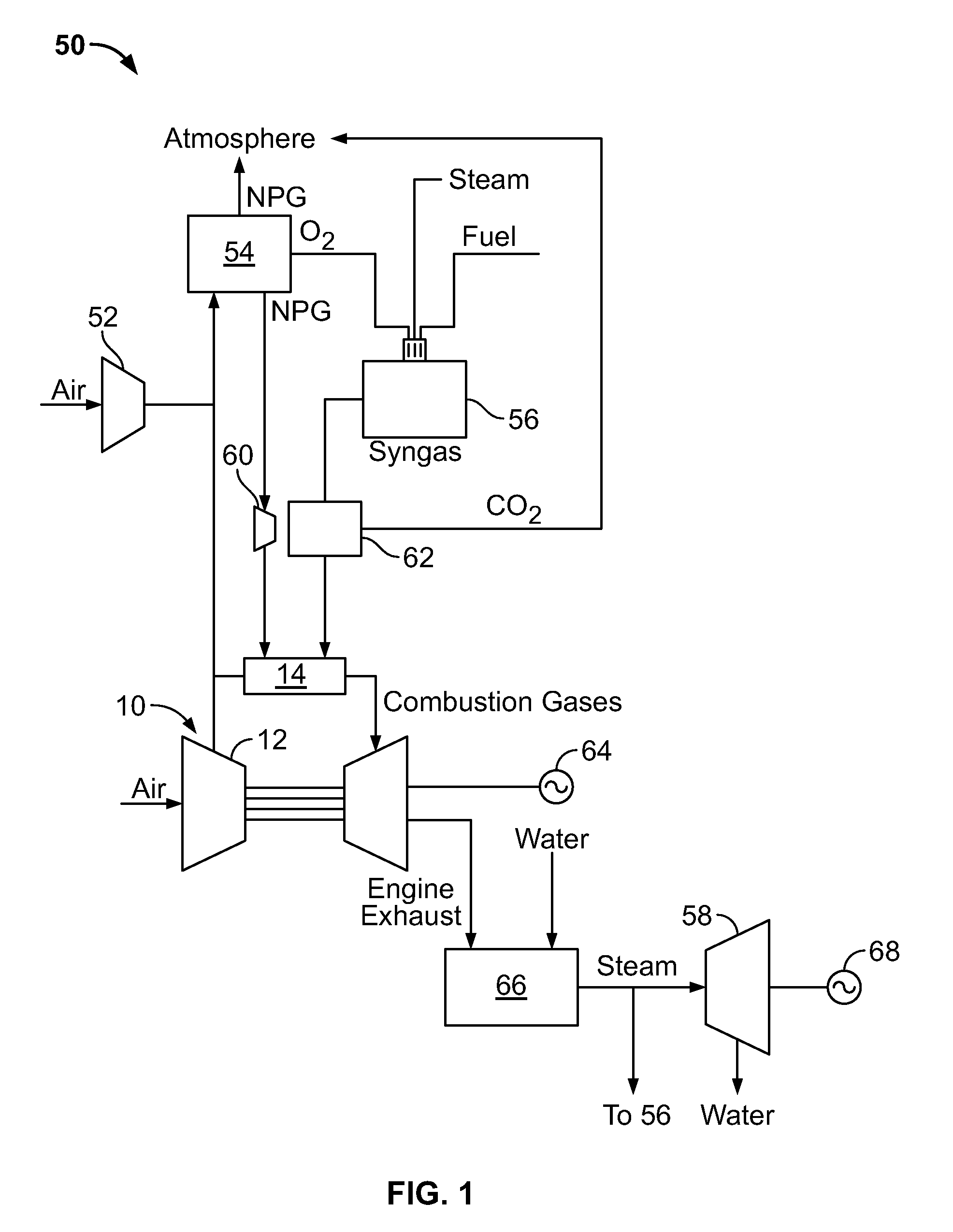

Embodiments provided herein include methods and apparatuses for purification and recycling of hydrofracture water used in natural gas drilling and production. Embodiments include removal of dissolved solids by precipitation with sodium sulfate and by evaporation using, for example, a multiple effect evaporator.

Owner:FAIRMONT BRINE PROCESSING

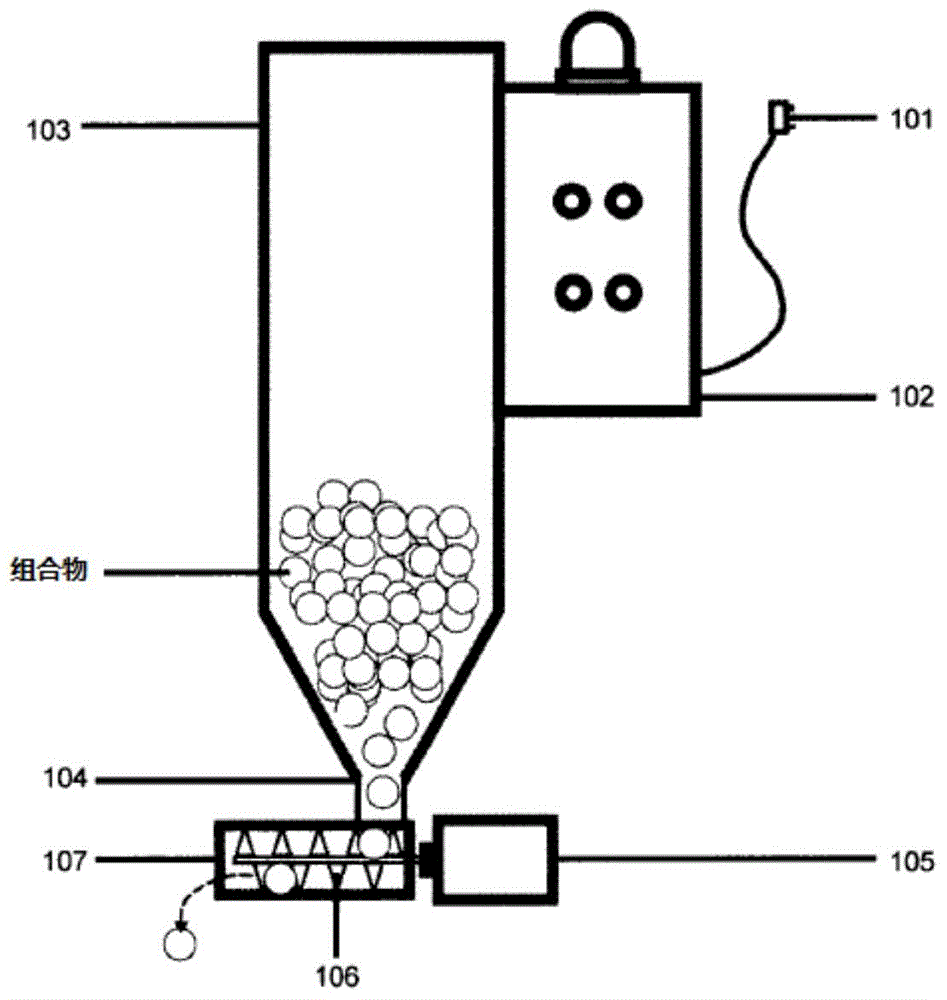

A composition for treating waste water

ActiveCN104903252AEasy to encapsulateEasy to separateSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesAluminium sulphateMaterials science

The present invention relates to a composition for treating waste water comprises, by weight percentage,: 43.7 - 46.2% bentonite; 24.1 - 25.9% aluminium sulphate (AI2(SO4)3), wherein the particle size of the AI2(SO4)3 is 18 - 74pm; 19.2 - 20.8% ceramic powder; 4.8 - 5.2% chitosan, wherein the particle size of the chitosan is 44μm; and 4.8 - 5.2% calcium carbonate (CaCO3). Further disclosed is a method of using the composition for treating waste water. In another further disclosure, there is introduced an apparatus for dispensing the composition into the waste water.

Owner:周朝晖

Wastewater treatment system and process including irradiation of primary solids

InactiveUS20110005284A1Lower Level RequirementsBio-organic fraction processingTreatment using aerobic processesOxygenCompost

The present invention provides a system and method for treating wastewater in which the majority of solids and biological oxygen demand compounds are separated from the wastewater feed using a primary separation process, to produce a solids phase and a water phase. The solids phase is irradiated to reduce the level of pathogens such that it is safe to use as a soil substitute and / or additive so that the solids can thus be disposed of in an environmentally-friendly manner. In additional embodiments, the solids that have been disinfected by radiation are mixed with a suitable inert filler material to produce a soil substitute, fertilizer, compost, or other soil additive. The liquid phase is treated in a substantially smaller system than would be required for treating the full-strength wastewater that can include a suspended media biological regeneration reactor system. The liquid treatment system can include a high flux adsorbent material treatment system integrated with a low flux adsorbent material biological regeneration reactor.

Owner:SIEMENS ENERGY INC +1

Device and method for treating industrial wastewater with high salt content

InactiveCN106396228AHigh recovery rateAchieving zero emissionsGeneral water supply conservationWater/sewage treatment by ion-exchangeFiltrationIon exchange

The invention provides a method for treating industrial wastewater with a high salt content. The method includes steps of pretreating the industrial wastewater with the high salt content, to be more specific, regulating and homogenizing the industrial wastewater with the high salt content by the aid of a high-salinity water regulating tank, then feeding the industrial wastewater into a high-density sedimentation tank, carrying out chemical softening treatment and flocculation sedimentation on the industrial wastewater, simultaneously removing most silicon dioxide and suspended matters, feeding water treated by the high-density sedimentation tank into an immersed ultra-filtration tank and further removing suspended matters and colloidal impurities in the water; carrying out separation and concentration, to be more specific, concentrating and separating the industrial wastewater with the high salt content after the industrial wastewater is pretreated at the pretreatment step, or carrying out ion exchange treatment on the industrial wastewater; recycling crystals, and to be more specific, separating the sodium chloride crystals and the sodium sulfate crystals from the water by the aid of crystallizers. The invention further provides a device for treating the industrial wastewater with the high salt content.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

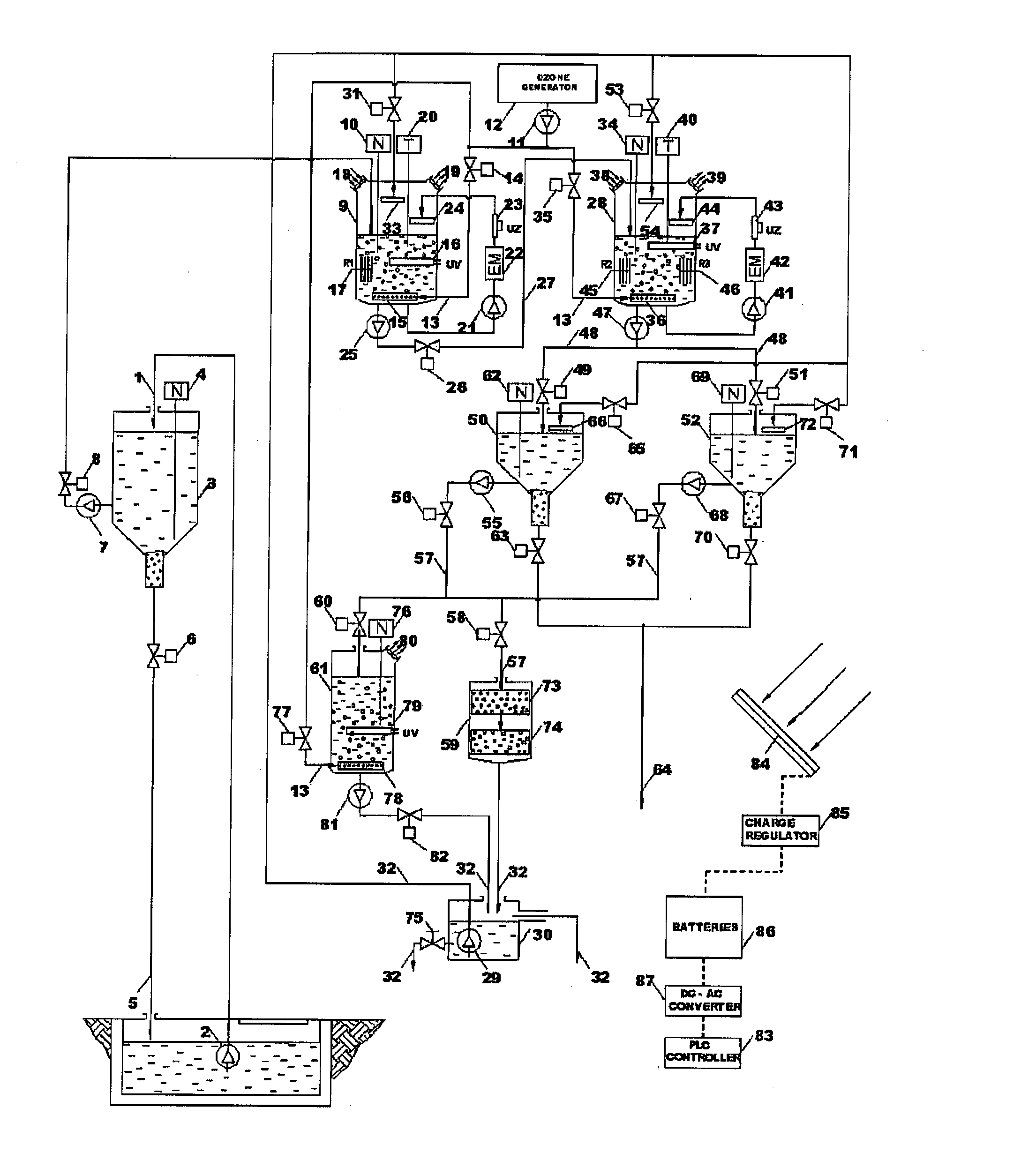

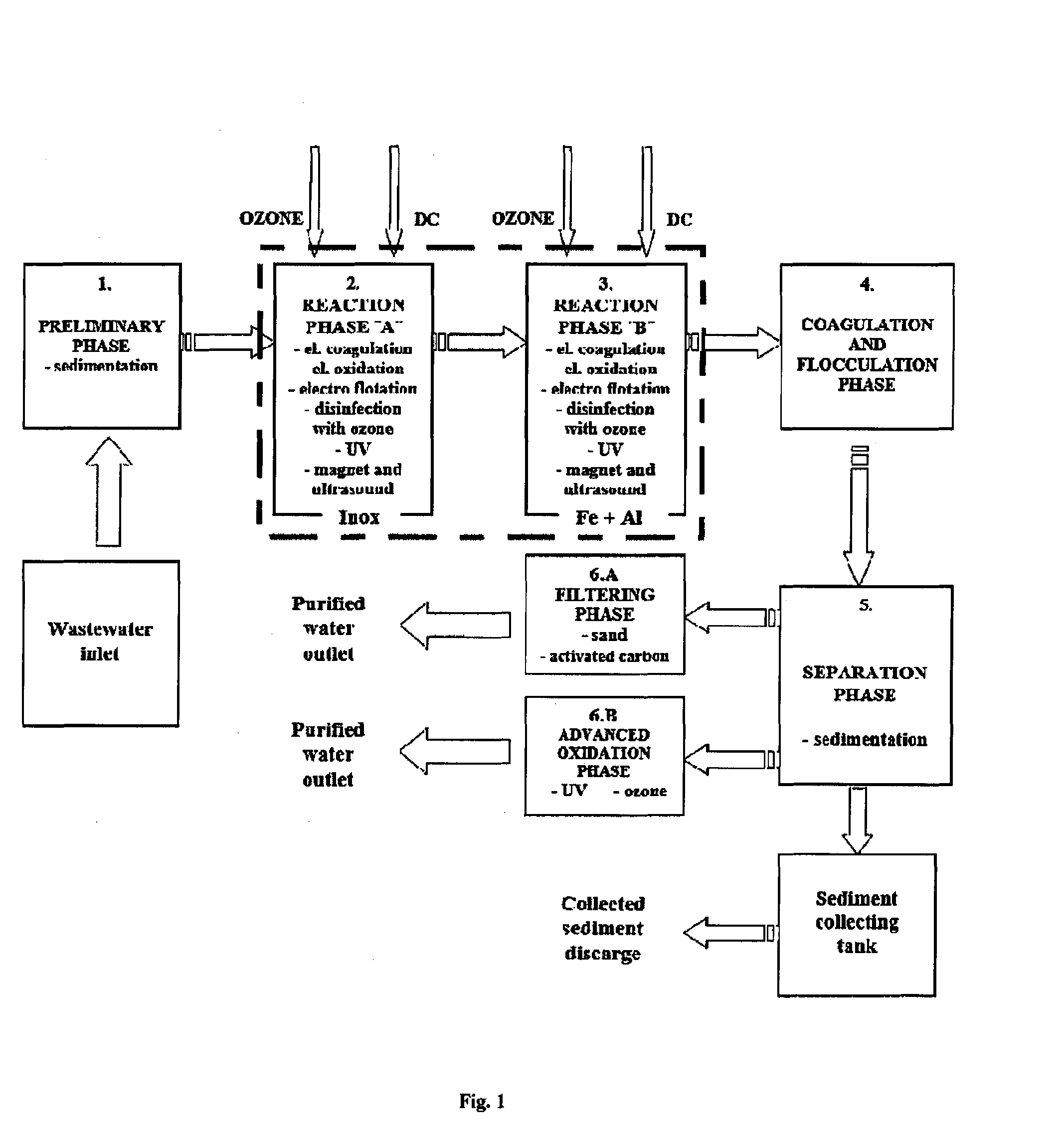

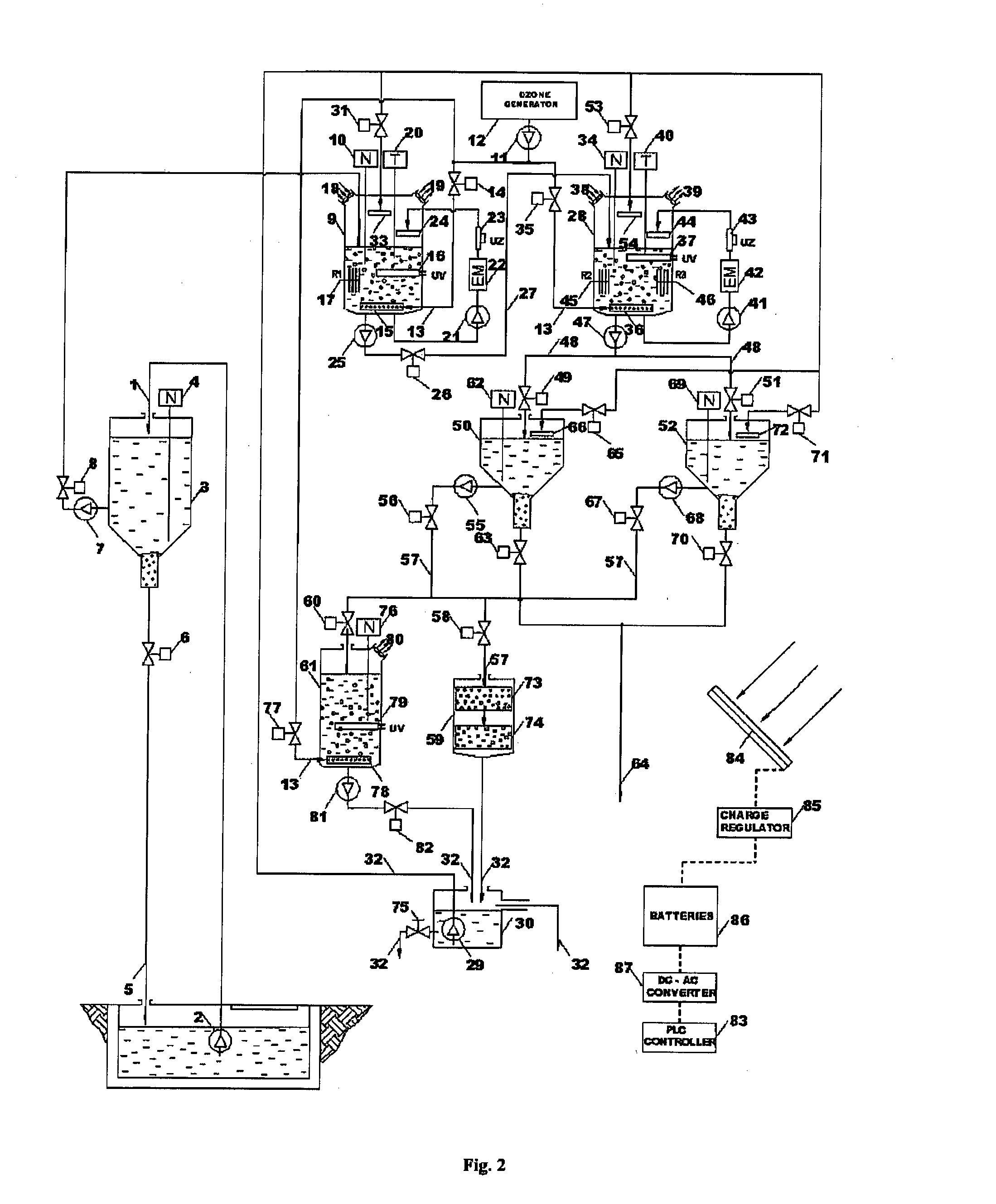

Process and device for electrochemical treatment of industrial wastewater and drinking water

InactiveUS20150166383A1Lower Level RequirementsTreatment involving filtrationSedimentation separationChemical treatmentIndustrial waste water

Subject matter of the invention is the procedure and plant for industrial wastewater and / or drinking water treatment by means of electrochemical methods and advanced oxidation processes. The preparatory phase of gravitational sedimentation is followed by main treatment consisting of electrocoagulation, electrooxidation and electroflotation through action of metal electrode sets made of inox, steel and aluminium respectively, with parallel disinfection / oxidation with ozone, UV irradiation and ultrasonic treatment, as well as recirculation in the electromagnetic field. At the end of the main treatment, the mixture of floccule and water is subject to coagulation / flocculation by electrochemically generated steel and aluminium floccule with slow infusion of ozone. The next phase is separation of sediment from clean water which is discharged through sand and activated charcoal filters for the purpose of removal of light floating floccule in the collection tank. If required, the water is subject to oxidation with simultaneous action of UV irradiation and ozone for the purpose of final destruction of organic matter and ammonia, and potential residues of microbiological contamination.

Owner:VISNJA ORESCANIN +2

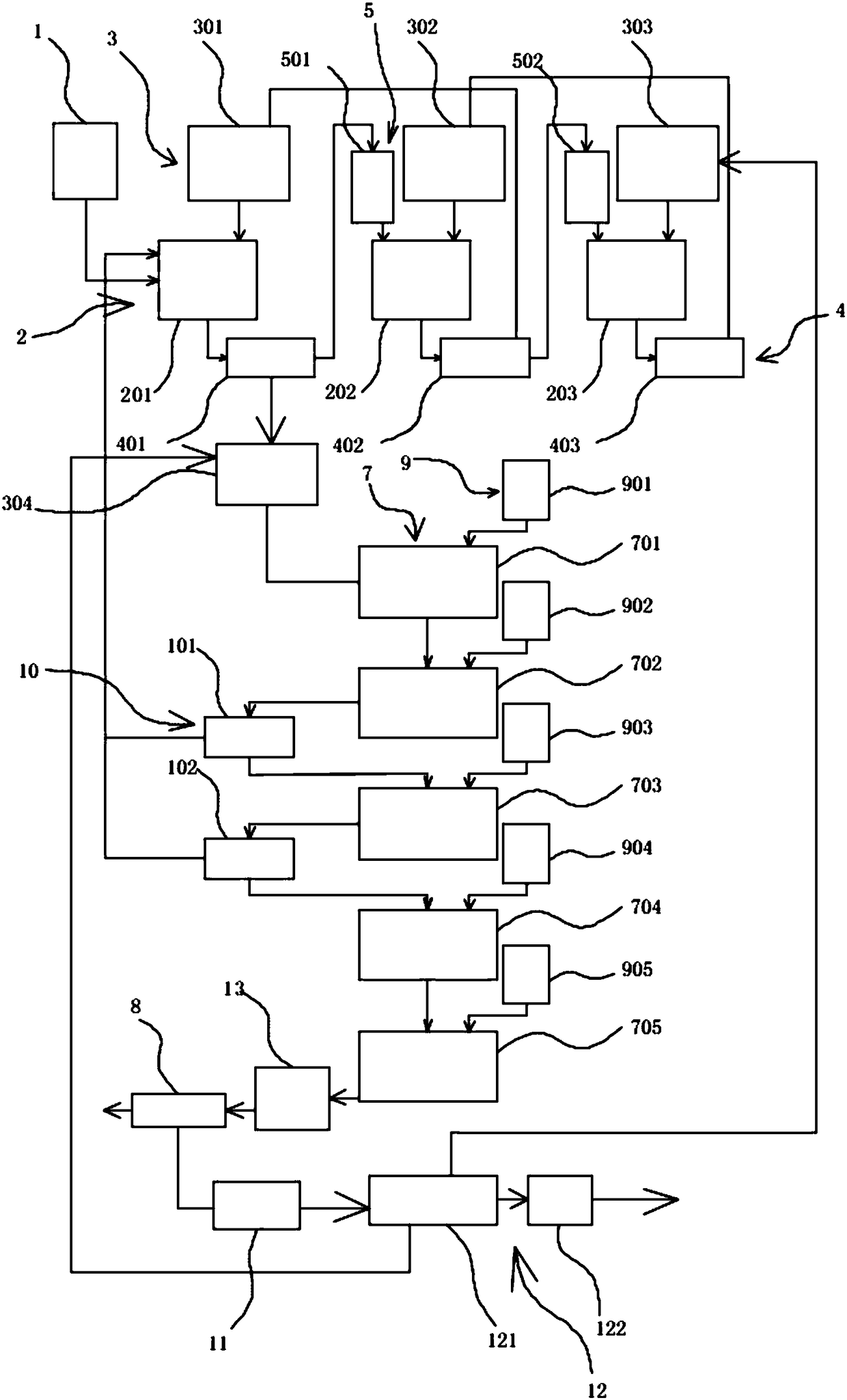

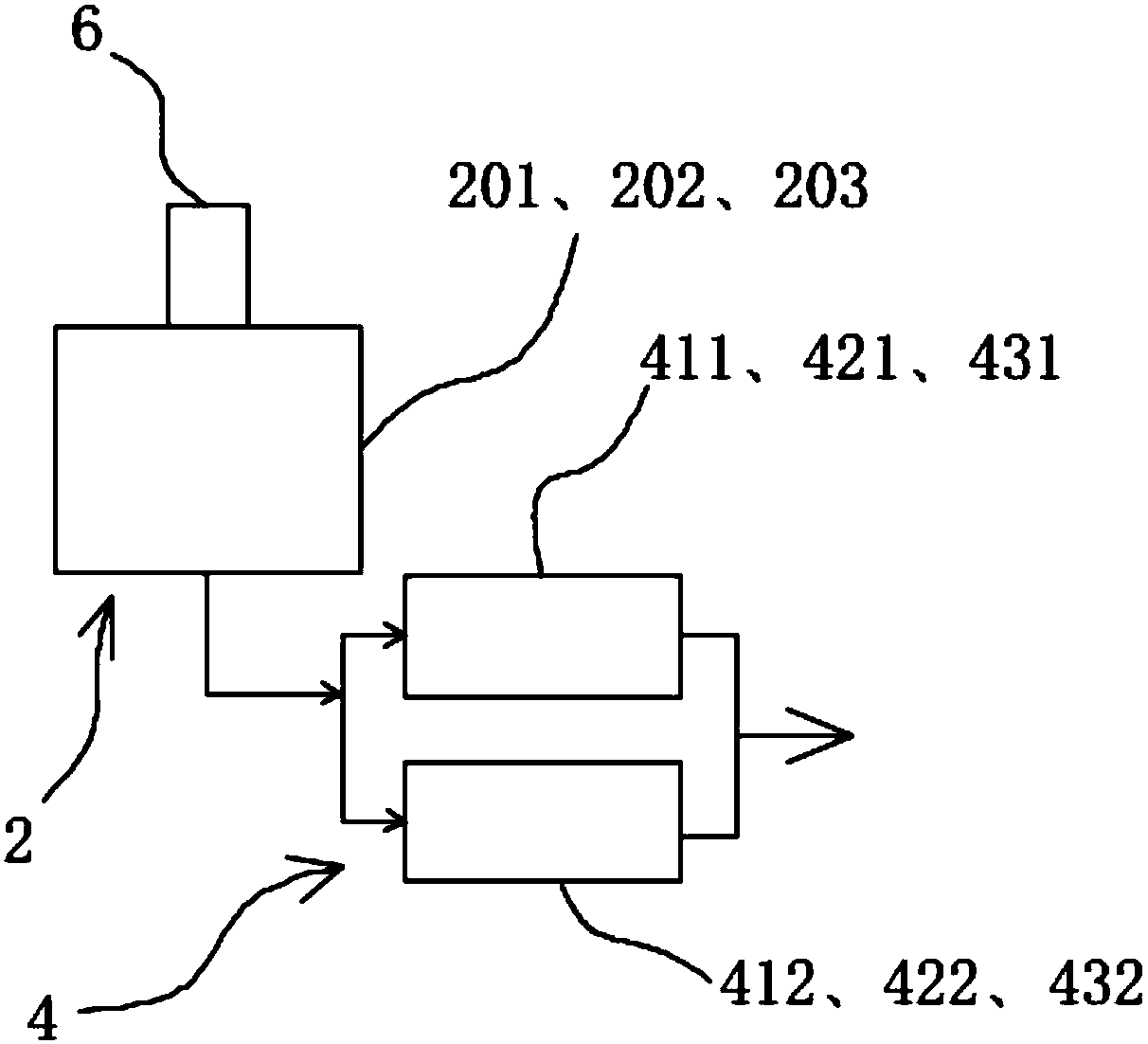

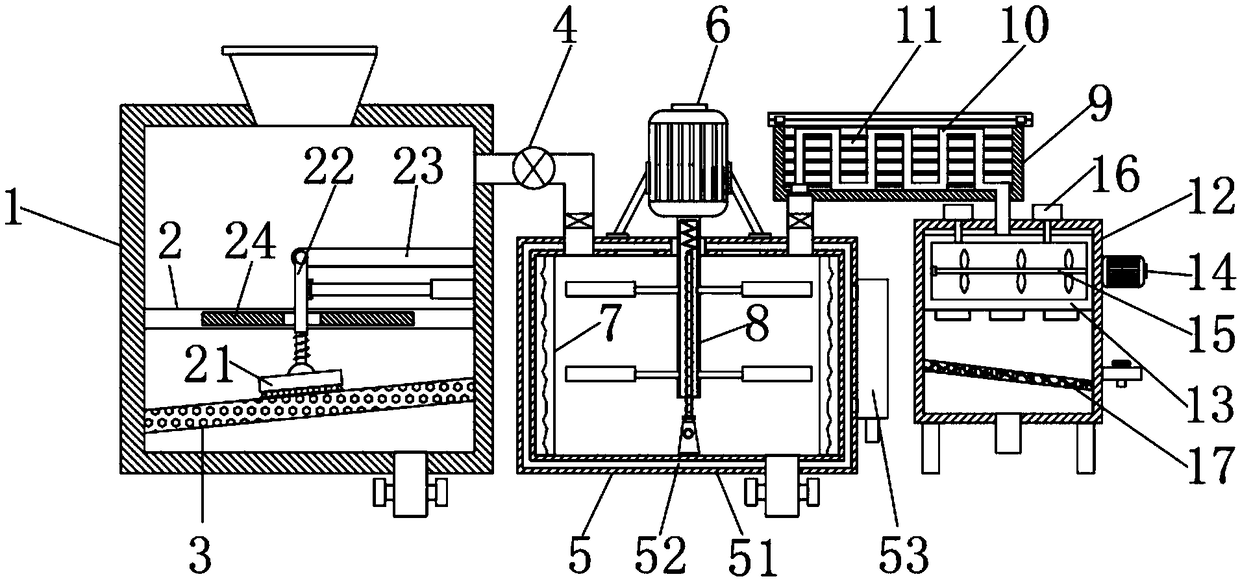

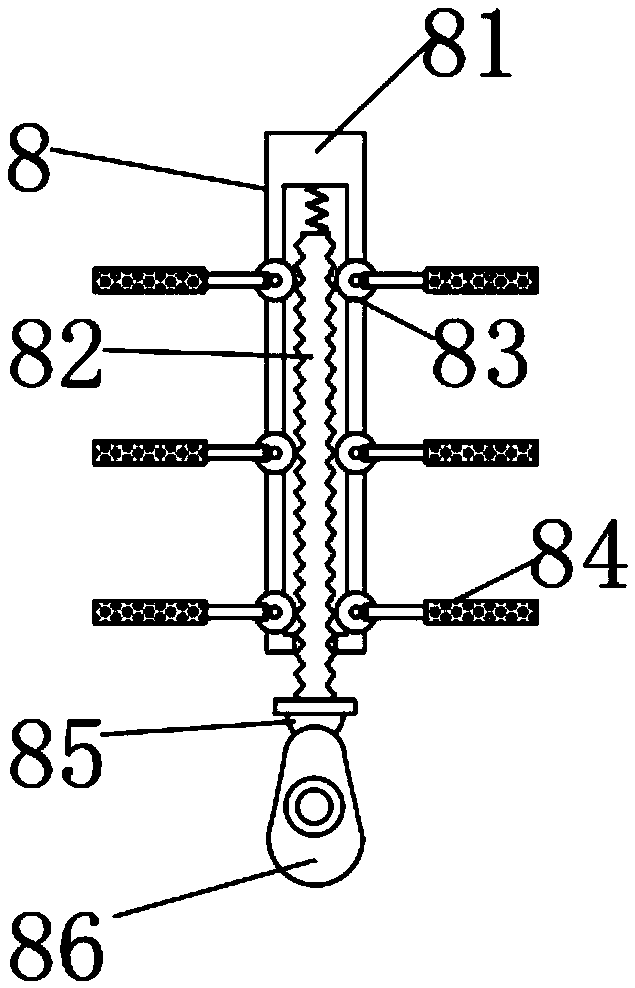

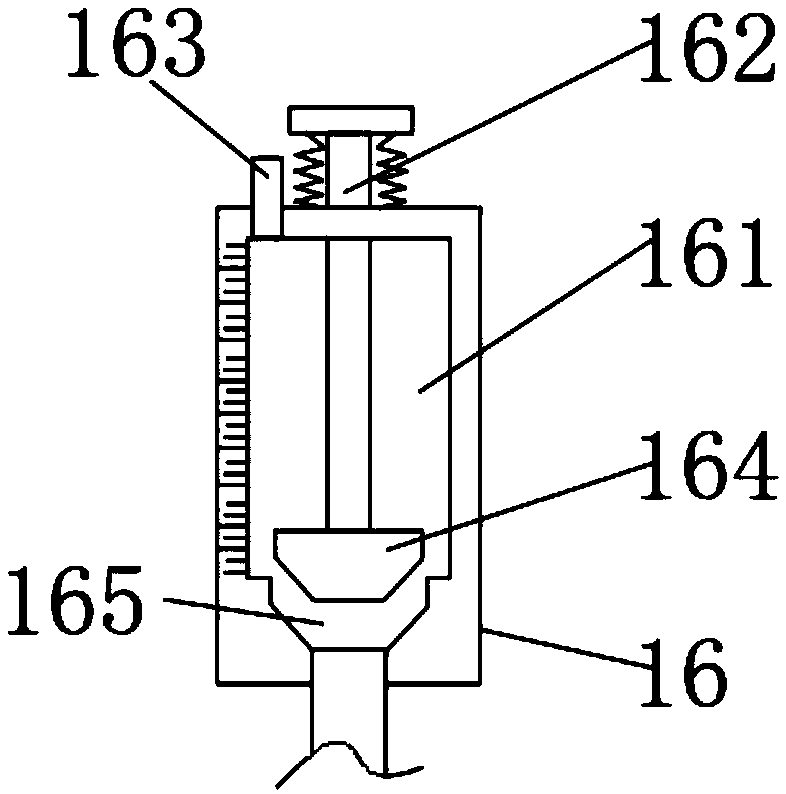

Waste fly ash treatment system and treatment process

ActiveCN108607870ASolve pollutionAvoid negative effectsTransportation and packagingSolid waste disposalFly ashCement kiln

The invention relates to the technical field of waste fly ash treatment, in particular to a waste fly ash treatment system and a treatment process. The waste fly ash treatment system comprises a fly ash water washing system and a wastewater treatment system; and the waste fly ash is subjected to distributed treatment through a two-step process, so that treated fly ash cannot achieve a negative effect on cooperative treatment of a cement kiln.

Owner:杭州秀澈环保科技有限公司

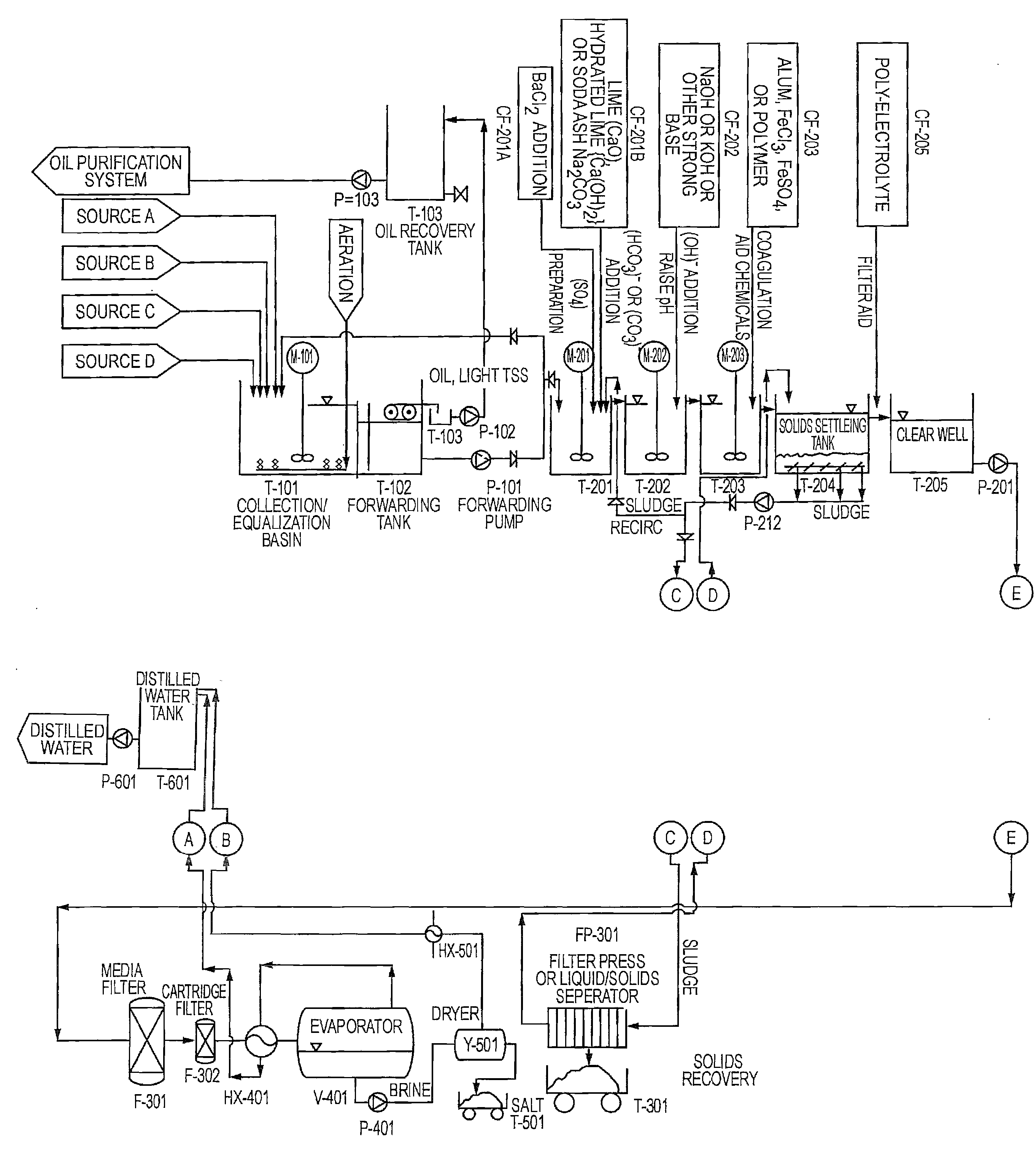

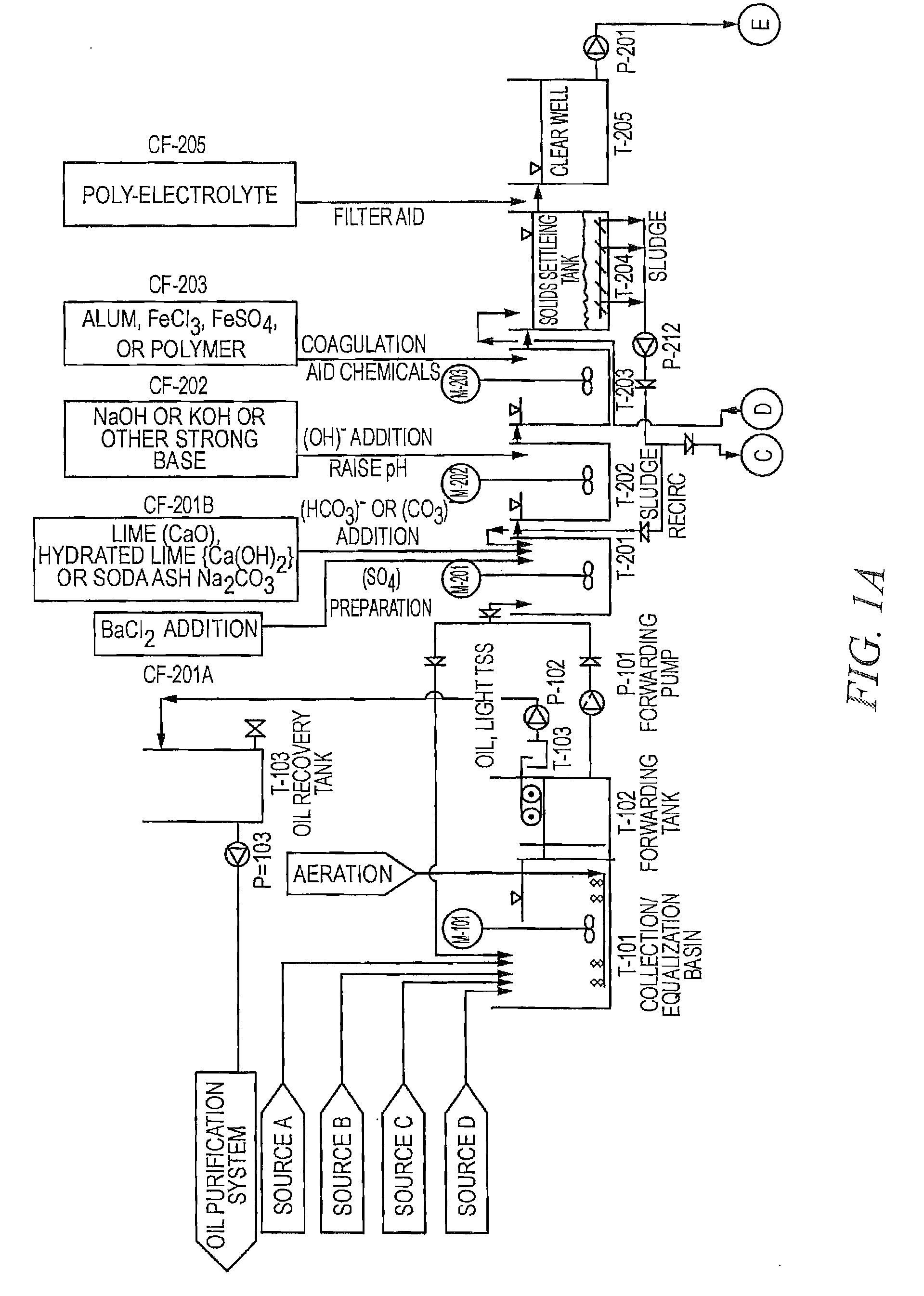

High Efficiency Water-Softening Process

ActiveUS20120145643A1Reduce pollutant contentSludge treatmentUltrafiltrationPolyelectrolyteWater softening

A high-efficiency water softening process is disclosed. The softening-process is particularly effective for the treatment of water process streams containing a broad array of contaminants, such as Ca, Mg, Ba, Sr, iron, aluminum, manganese, copper, zinc, silica, TOC, oil, and grease. The softening-process includes steps of: (a) adding carbonate ions and hydroxide ions to said water process stream until the process stream pH is raised to between at or about 10.5 and at or about 14.0; (b) optionally adding a coagulation aid so as to facilitate the creation of separated solids comprising a substantial portion of the contaminants; (c) optionally adding a polyelectrolyte so as to facilitate the creation of separated solids comprising a substantial portion of the contaminants; and (d) phase-separating the separated solids so as to remove the contaminants and produce a highly purified water process stream.

Owner:PANDYA KEN V

Salt-containing high concentrated organic wastewater treatment device and method

PendingCN108773960AEasy to handleImprove purification qualityWater contaminantsTreatment involving filtrationFiltrationActivated carbon filtration

The invention discloses a salt-containing high concentrated organic wastewater treatment device and method in technical field of wastewater treatment. The high concentrated organic wastewater treatment device comprises a separation precipitation tank, an inner cavity of the separation sedimentation tank is provided with a precipitation auxiliary component, the left and right inner walls of an evaporation tank component are symmetrically provided with heating radiant tubes, the other end of a condenser pipe penetrates through the right side at the bottom of the condensing tank and is connectedwith a central part of the top of a neutralization filtration tank, the top of the inner chamber of the neutralization filtration tank is provided with a mixing box, and the inner chamber of the neutralization filtration tank is provided with an activated carbon filter net obliquely; the treatment device has a good treatment effect and high purification quality; the wastewater is placed in the separation precipitation tank for precipitation, the precipitated wastewater enters the evaporation tank component and is heated at a high temperature by the heating radiant tubes to complete the sewageand salt separation, the water vapor passes through the condensing tank, the condenser pipe and the ice bag cooperate with each other, so that the steam is cooled to form water and then enters the mixing box, then the rotating rod is driven by the stirring motor to perform neutralization stirring, and finally the wastewater is filtered.

Owner:南京御楠枫技术转移有限公司

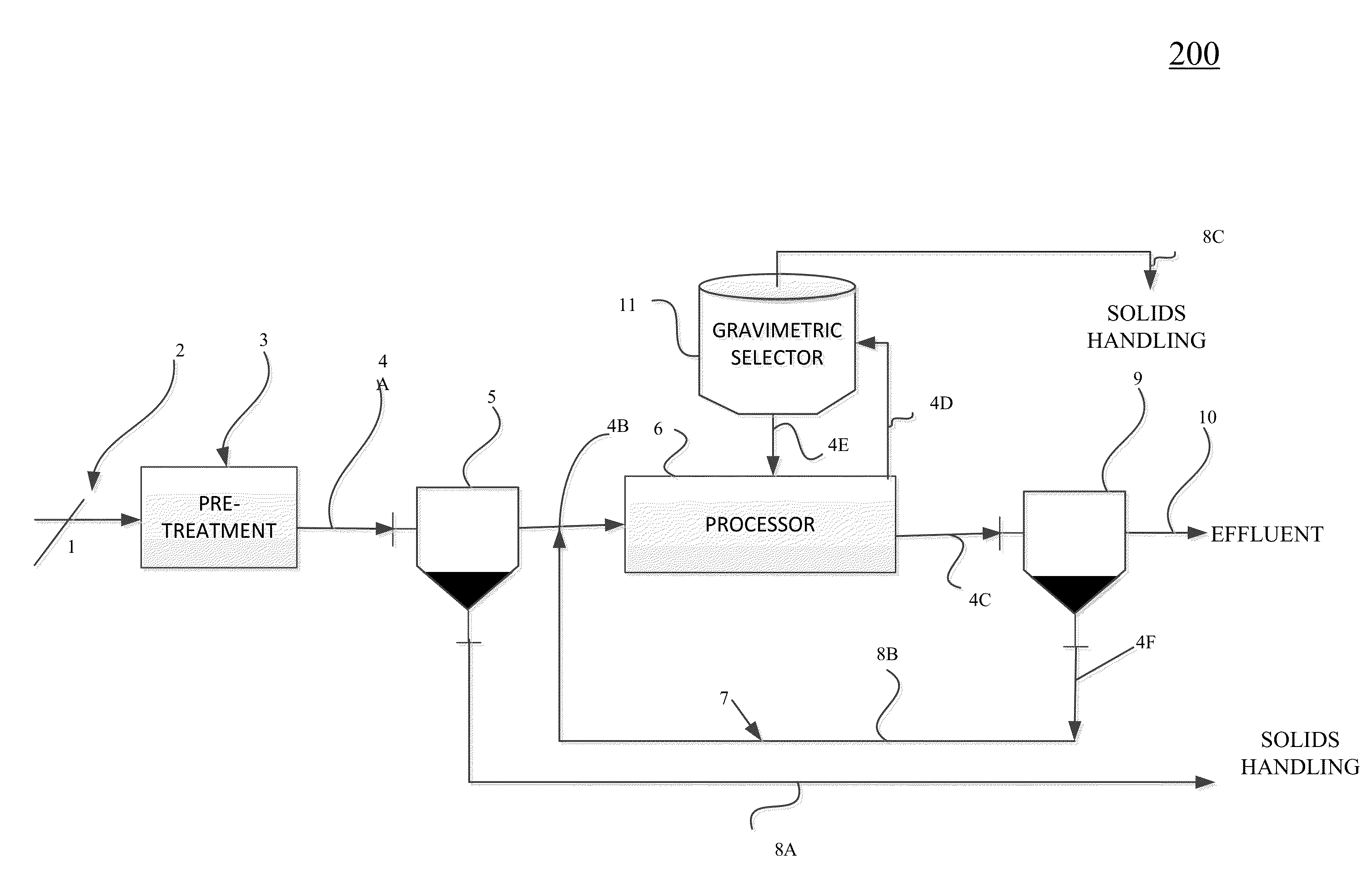

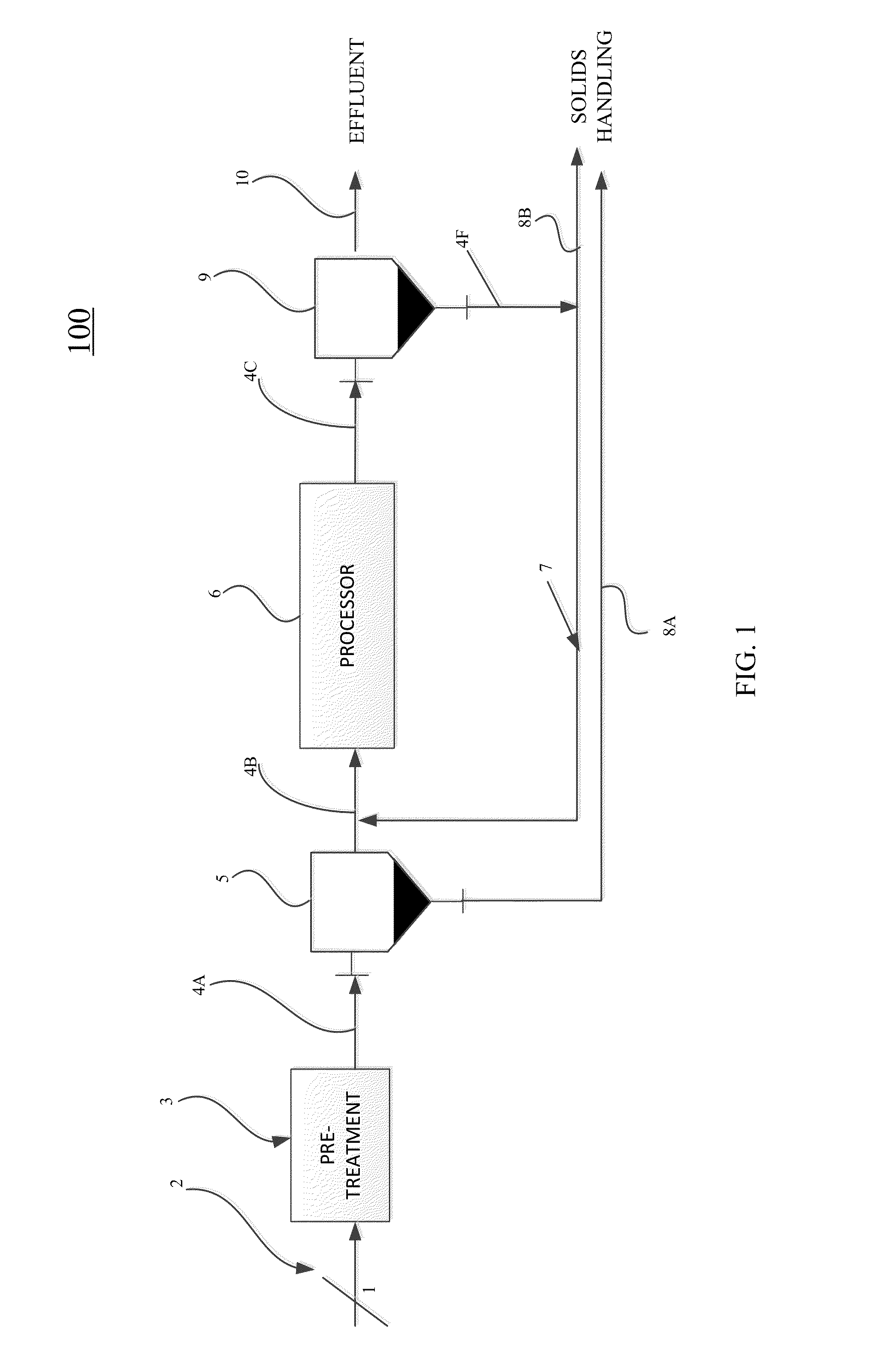

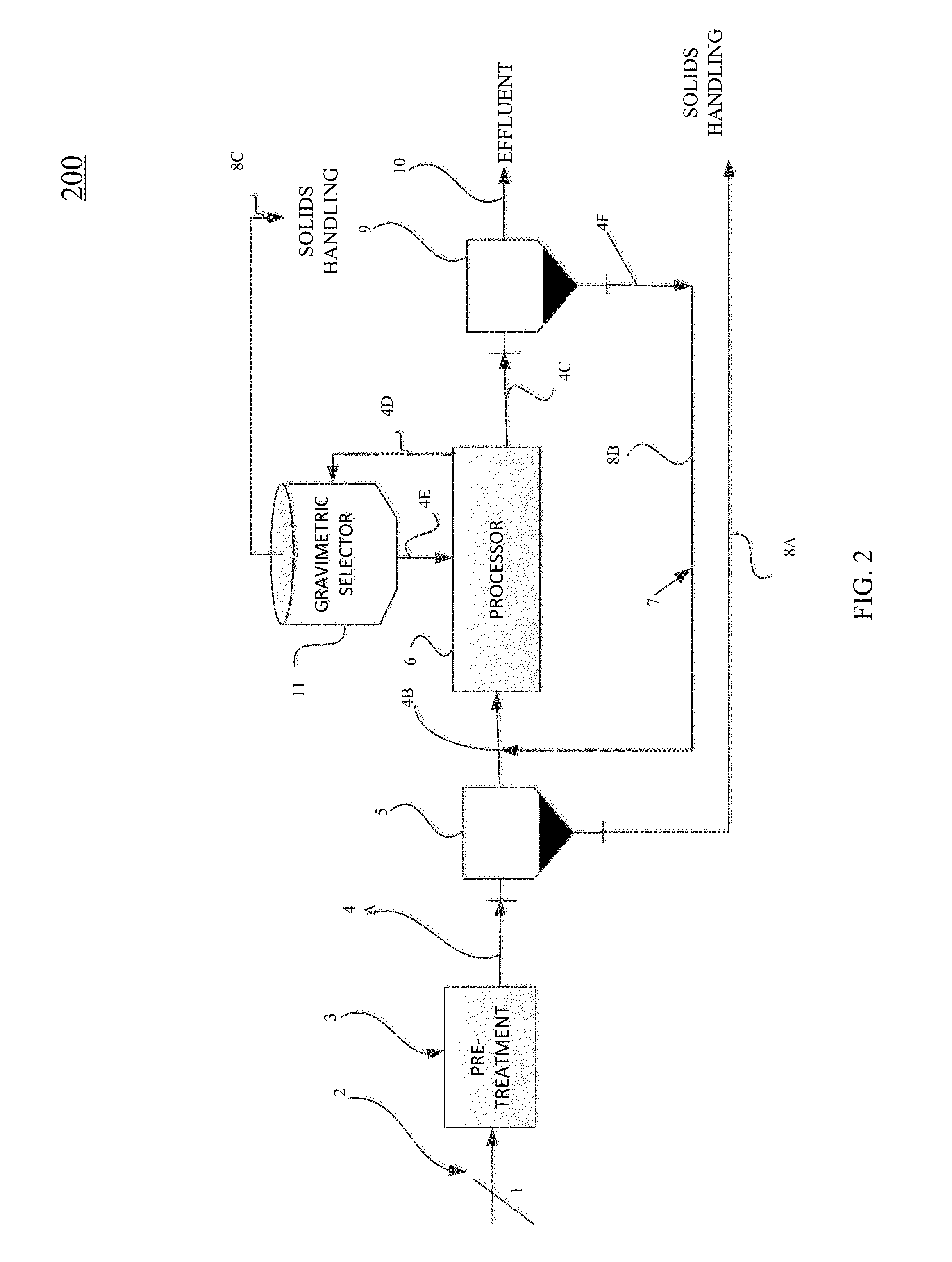

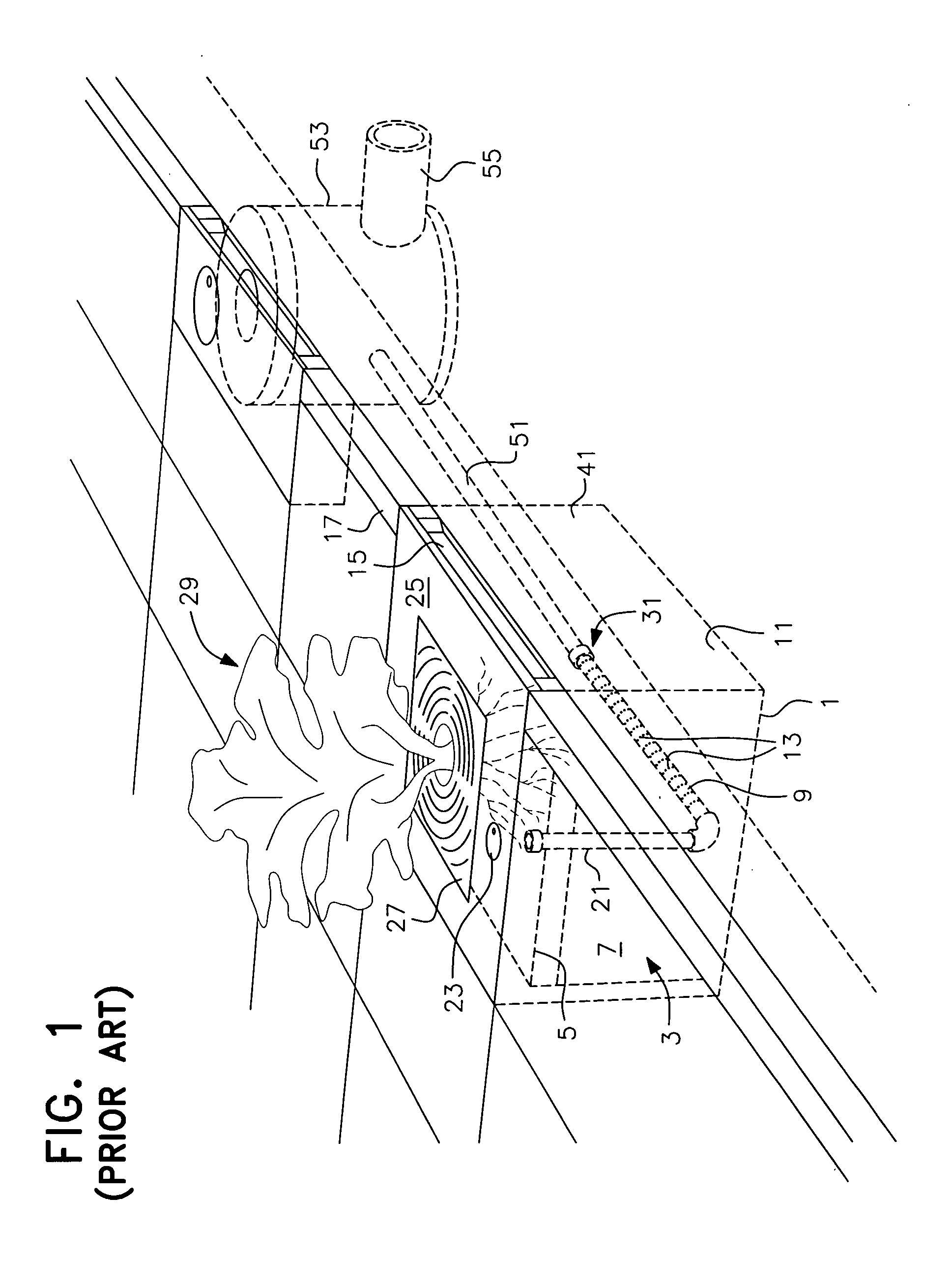

Method and apparatus for wastewater treatment using gravimetric selection

ActiveUS20140144836A1Extension of timeBiological treatment apparatusTreatment with aerobic and anaerobic processesWastewaterEngineering

A method and a system for selecting and retaining solids with superior settling characteristics, the method comprising feeding wastewater to an input of a processor that carries out a treatment process on the wastewater, outputting processed wastewater at an output of the processor, feeding the processed wastewater to an input of a gravimetric selector that selects solids with superior settling characteristics, and outputting a recycle stream at a first output of the gravimetric selector back to the processor.

Owner:HAMPTON ROADS SANITATION DISTRICT +1

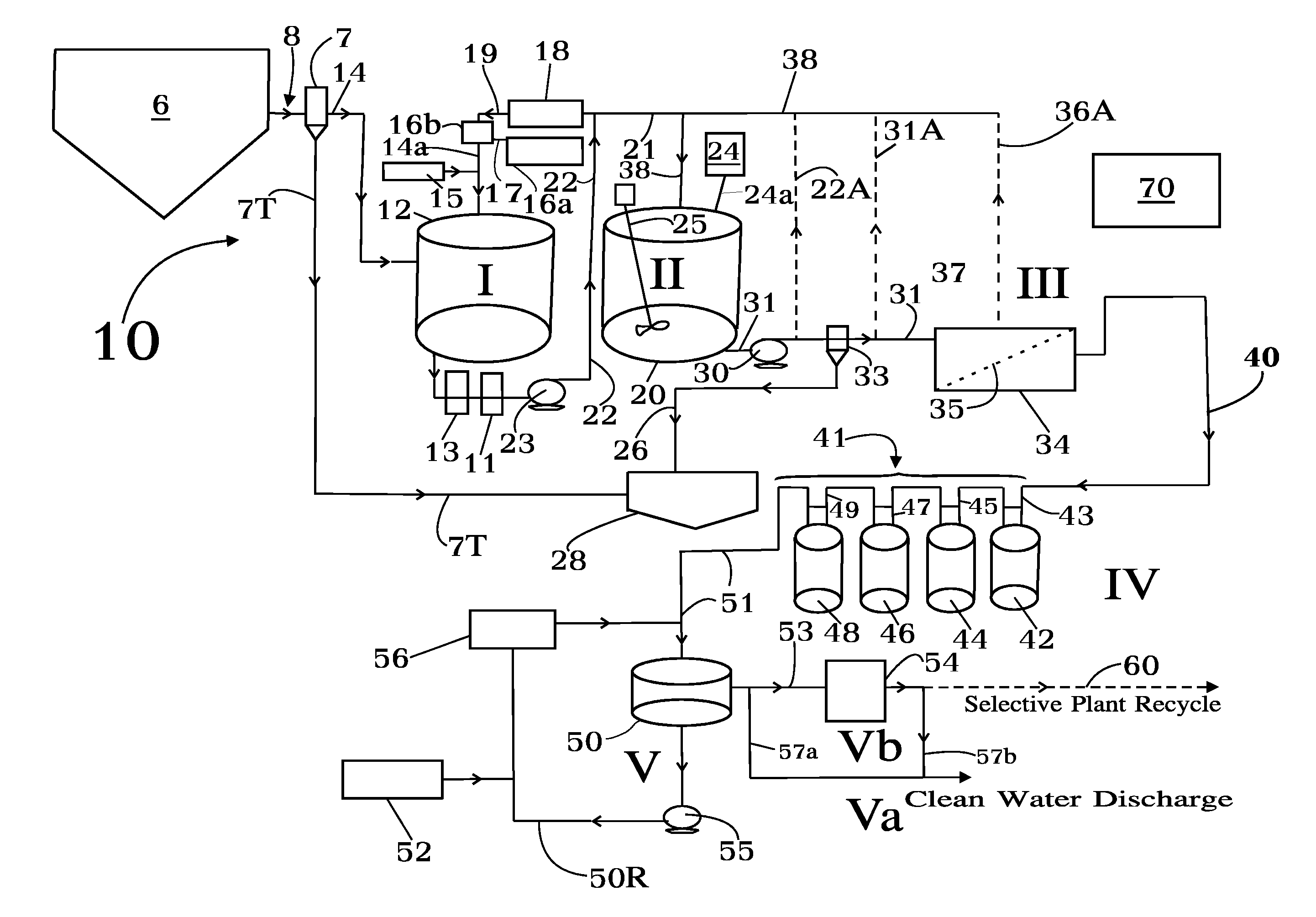

Concentrate treatment system

In one aspect the invention provides a system for treating a wastestream, particularly a radwaste, for safe disposal and, in final processing converting it into one or both forms including an aqueous form for safe discharge to the environment and a solidified form for safe disposal. In another aspect the invention provides the capacity to employ a step where a specific target element strategy can be set up synchronizing sorbent substance choices and multiple recycle options to remove target substances from wastestream as a part of its Sorption or Powder Sorbent Isotopic Reduction step (II). Other steps cooperate with Sorption step (II) including Oxidation (I), Solid-Liquid separation (III), and Selective Ion Exchange (IV) to deliver the wastestream to final processing.

Owner:AVANTECH LLC

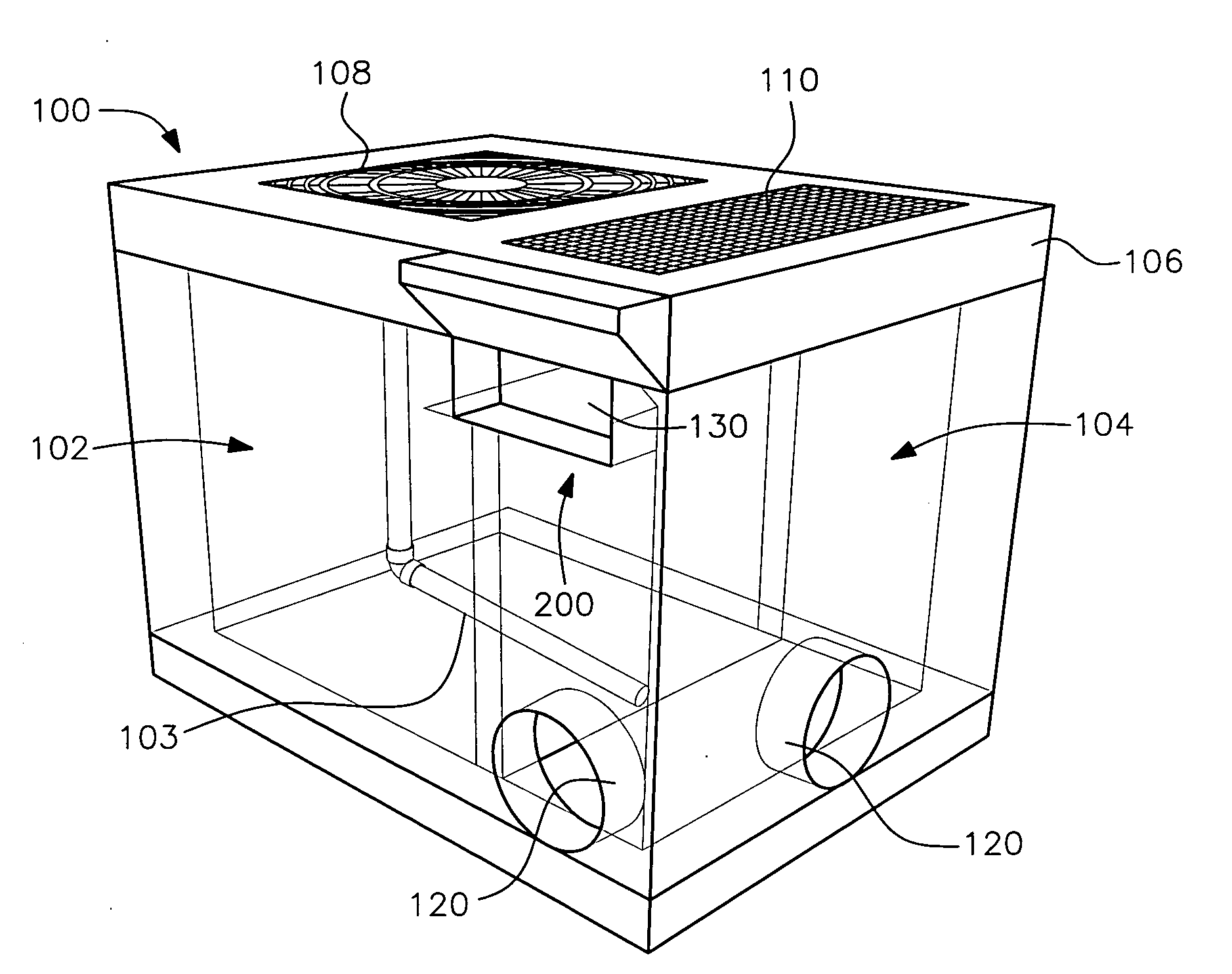

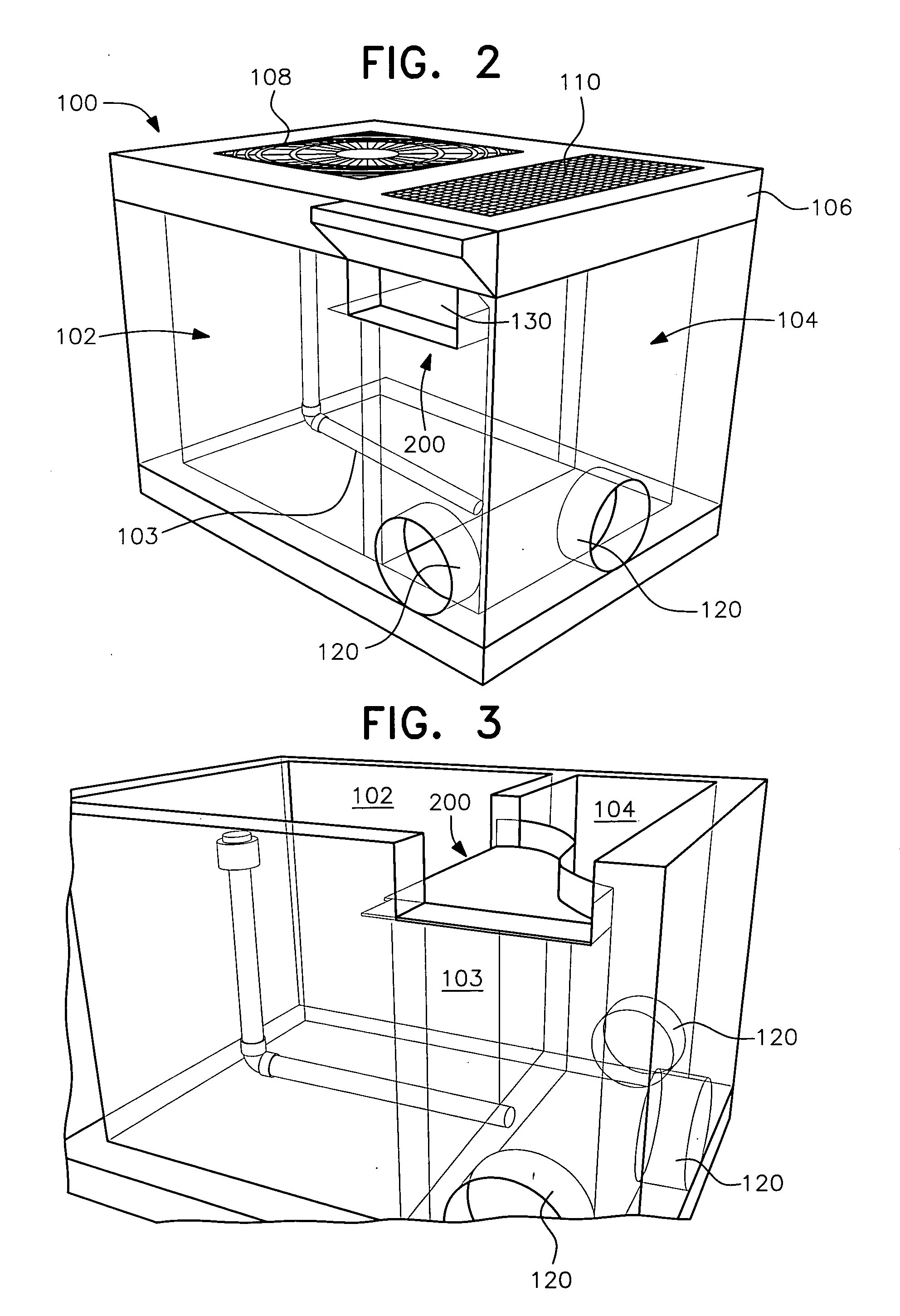

Stormwater treatment system with two chamber treatment container and overflow tray

InactiveUS20110186492A1Increase flow rateWater cleaningSeparation devicesFilter mediaEnvironmental engineering

A stormwater treatment system having a treatment container with two chambers, a treatment chamber and a bypass chamber. The bypass chamber includes an inlet for receiving stormwater. Disposed adjacent the inlet is an overflow tray secured to the walls of the bypass chamber. The tray includes an inlet opening for receiving the stormwater to be treated, and a discharge opening through the baffle wall that separates the two chambers for discharging stormwater that enters at low flow rates. The stormwater to be treated passes through the discharge opening into the treatment chamber where it is treated by the filter media. High flow rates will bypass the treatment chamber by overflowing a dam wall or weir defined by the overflow tray directly into the bypass chamber. Treated water from the treatment chamber passes through an underdrain pipe that enters into the bypass chamber. All water from the bypass chamber exits through pipe openings, preferably on each of three sides of the bypass chamber wall.

Owner:AMERICAST

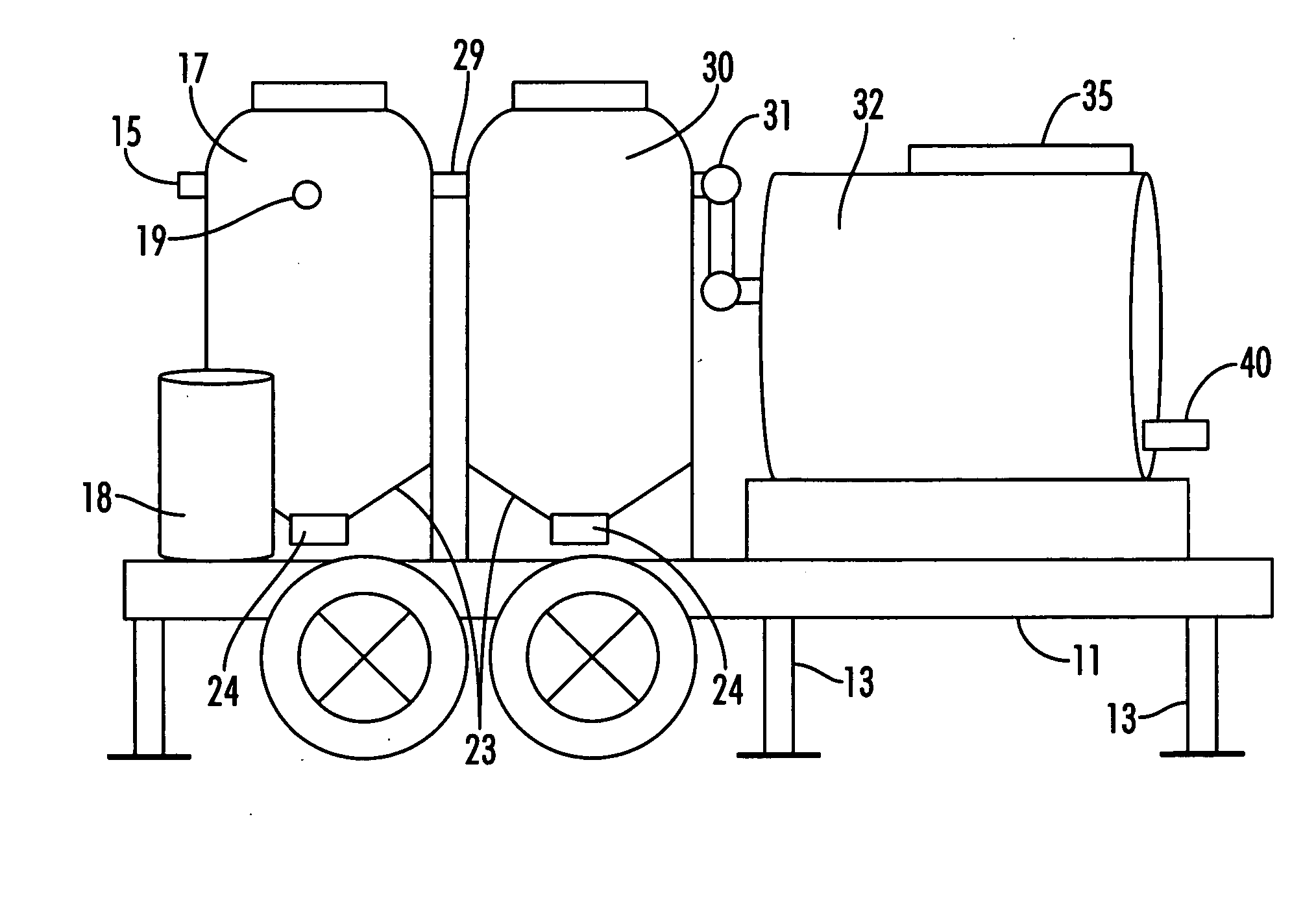

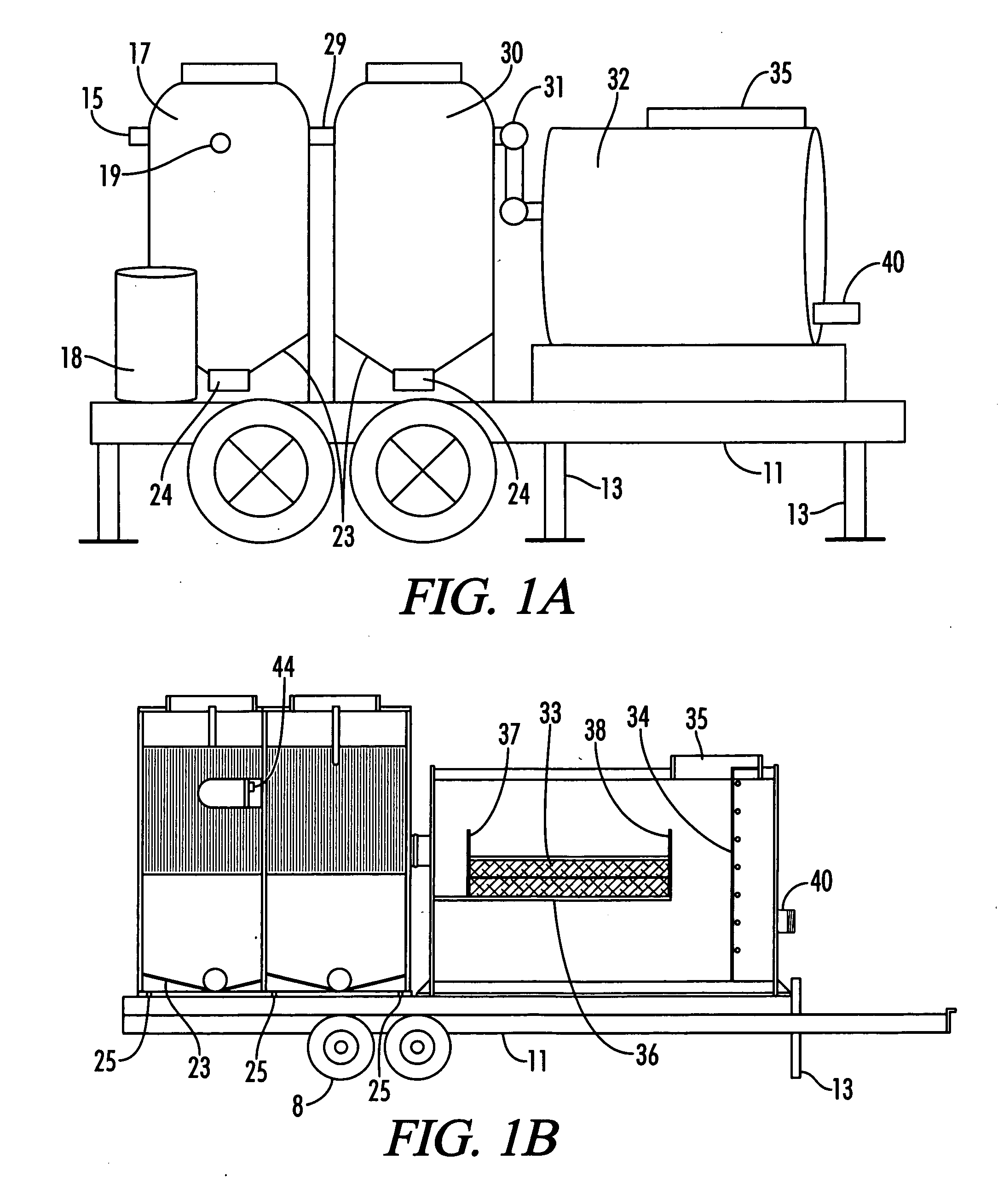

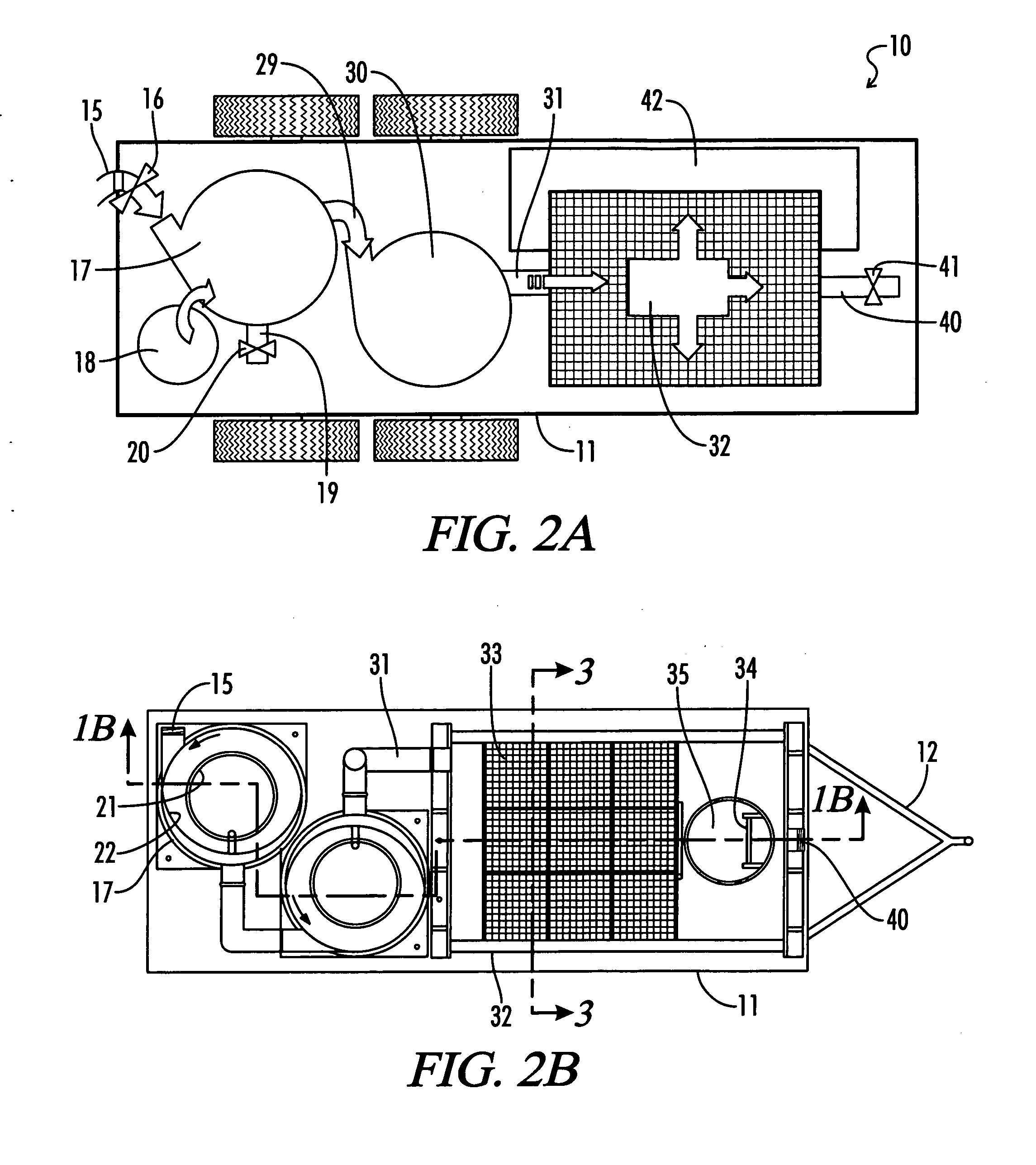

Mobile water treatment system

ActiveUS20070084808A1Increase flow rateEasy to separateTreatment involving filtrationSolid sorbent liquid separationWater treatment systemFiltration

A mobile water treatment unit is provided with separation and filtration components secured to a trailer.

Owner:AQUASHIELD

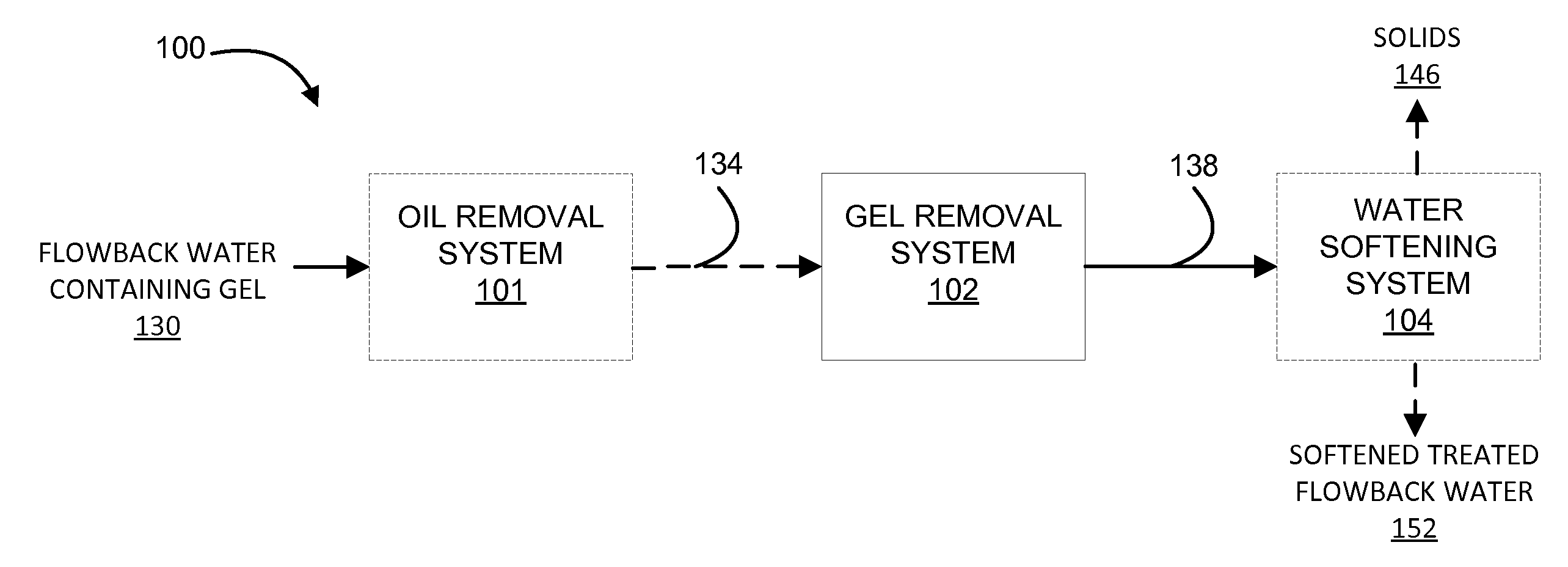

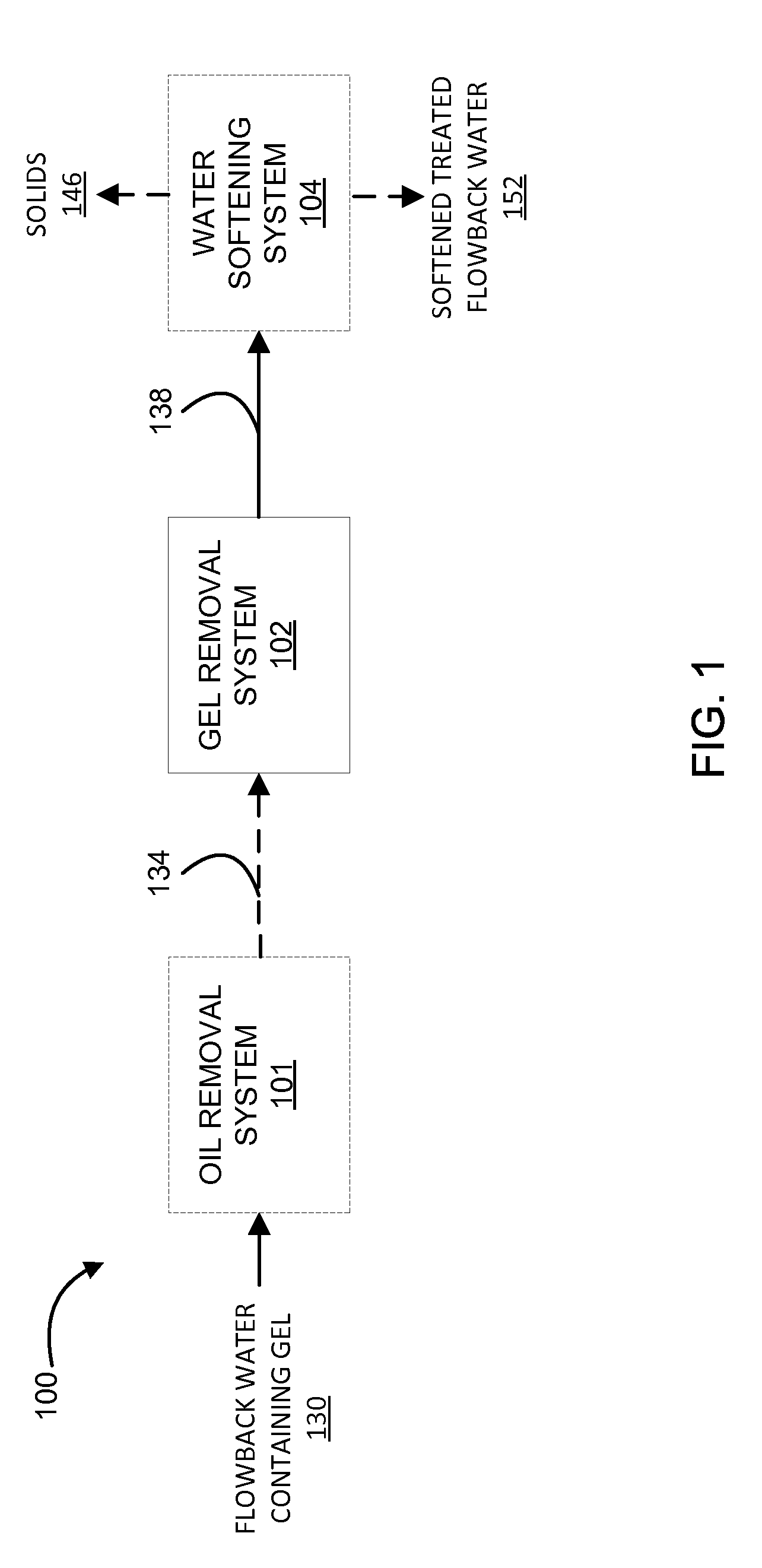

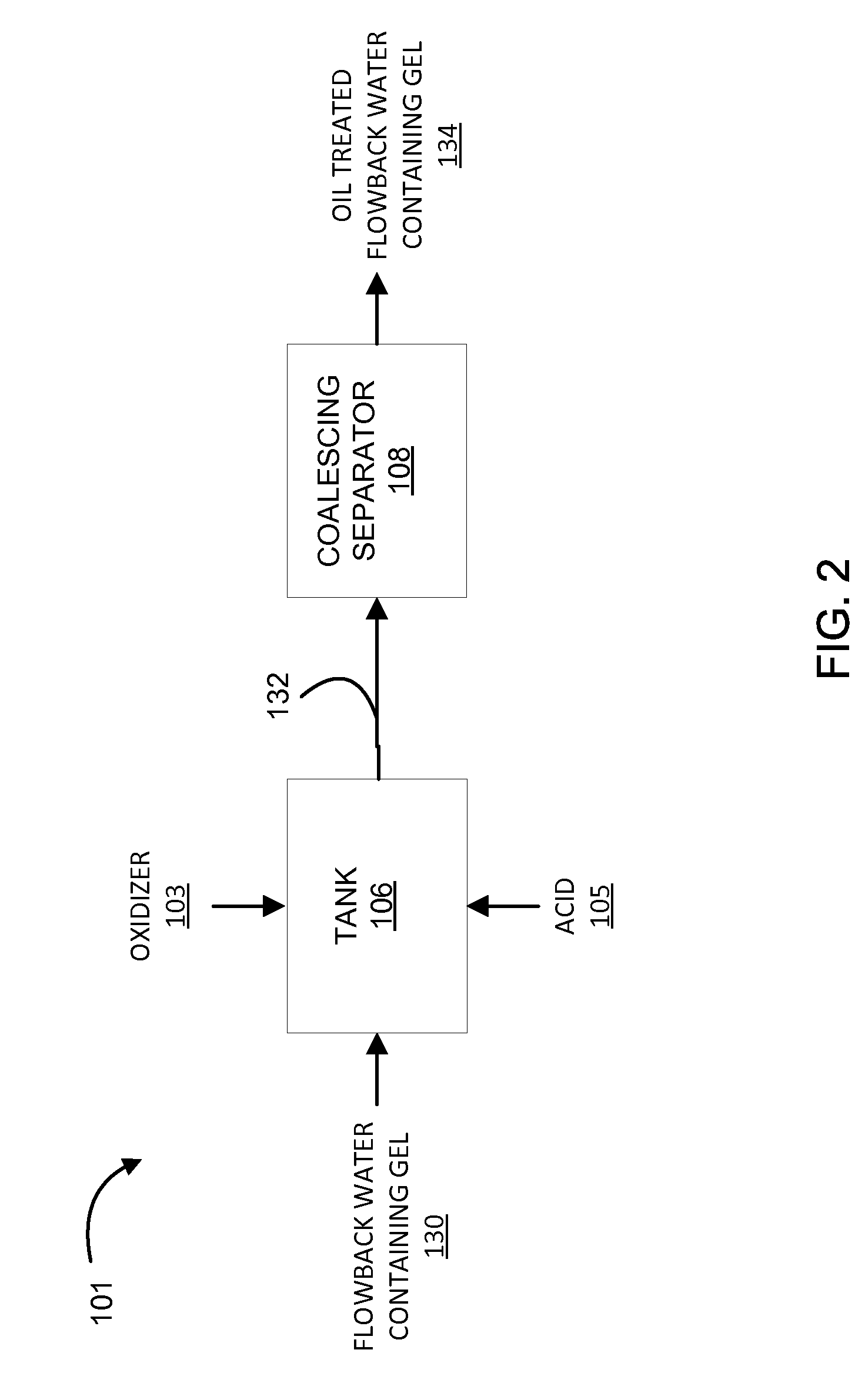

System and method for treatment of produced waters containing gel

This disclosure describes novel systems and methods for removing gel from flowback water. The methods and systems include treating acidified flowback water with aluminum chlorohydrate.

Owner:HIGH SIERRA ENERGY LP

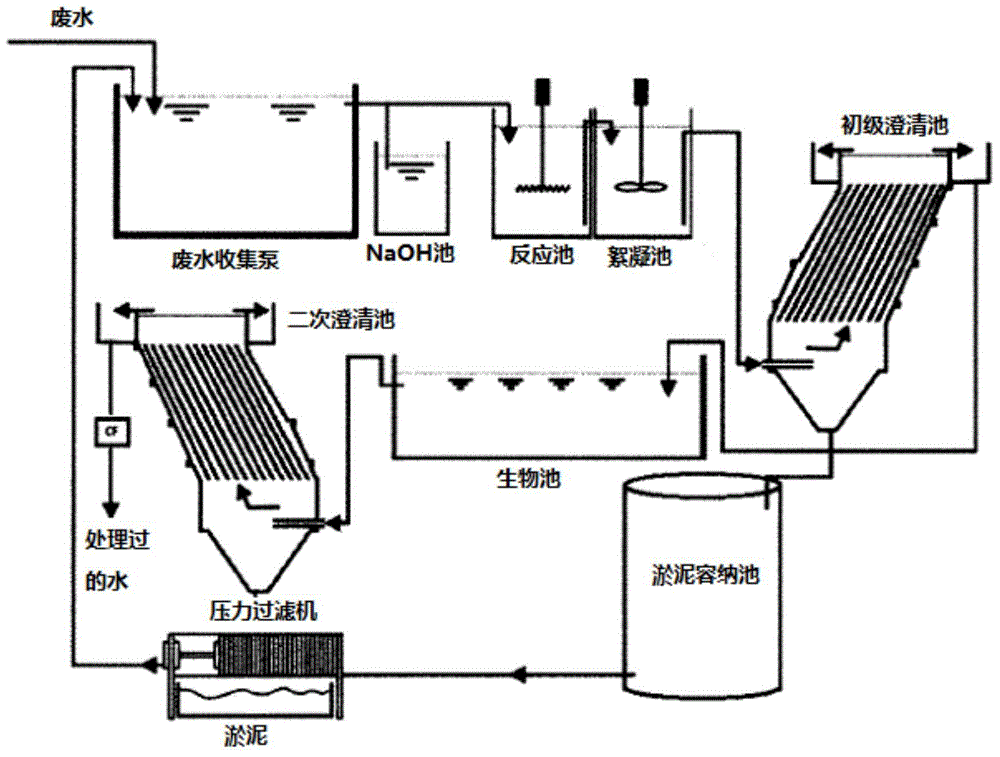

Recycle water treatment system for car wash

InactiveUS20090272681A1Reduce decreaseCompact structureOther chemical processesSolid sorbent liquid separationWater treatment systemBiological filter

The present invention relates to a recycle water treatment system for car wash comprising principally a flocculating sedimentation tank, a flotation tank, a tank of aerobic biofilter, a secondary sedimentation tank and a storage tank that are connected in sequence, wherein a flocculent feeder is equipped at the top of the flocculating sedimentation tank; a flotation aerator is equipped at the bottom and a float scraper is equipped at the top of the flotation tank; and an aerobic filter is equipped at the middle and an aerator is equipped at the bottom of the tank of aerobic biofilter, the inlet pipe of the flocculating sedimentation tank being the inlet pipe of the system of the invention, and the outlet pipe of the storage tank being the outlet pipe of the system of the invention. Such a system is particularly applicable for small- and medium-sized car washes, because it's effective in practical operation and convenient in installation and maintenance due to compactness.

Owner:BEIJING NENGTUO HI TECH

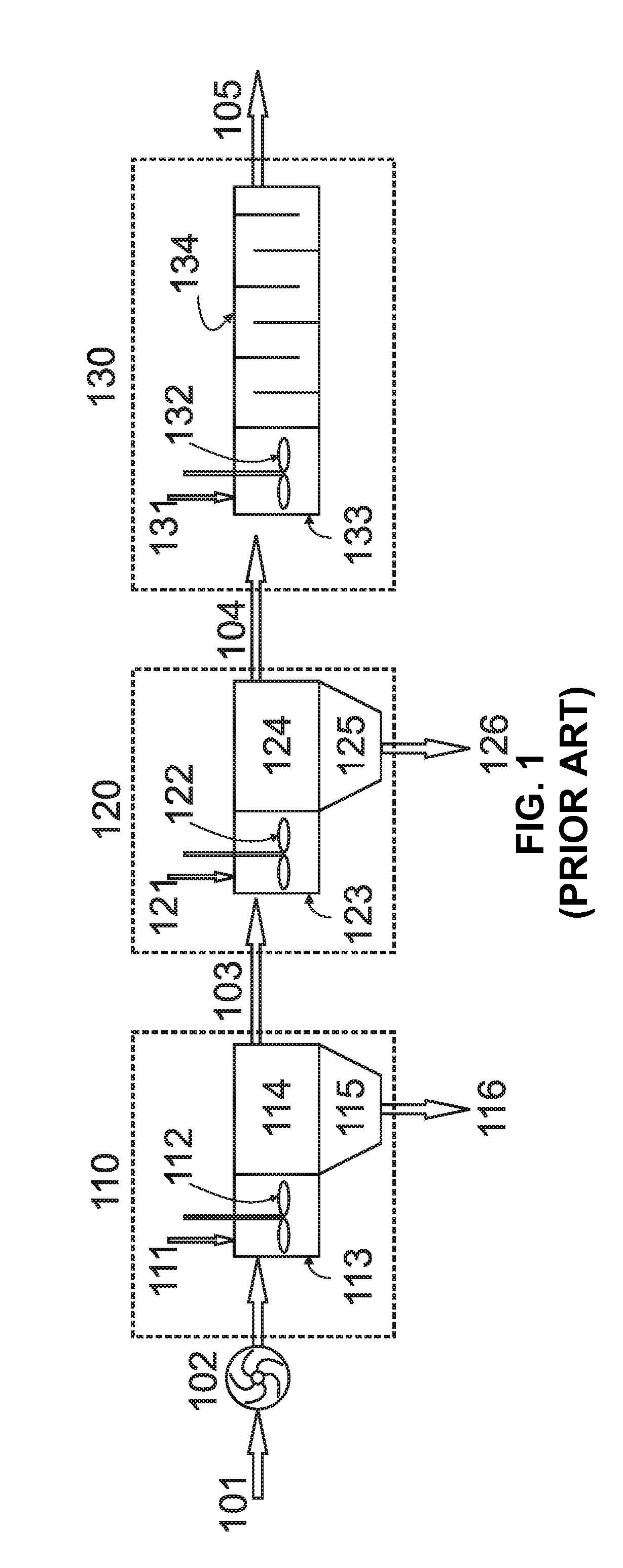

Method and system for treating a contaminated fluid

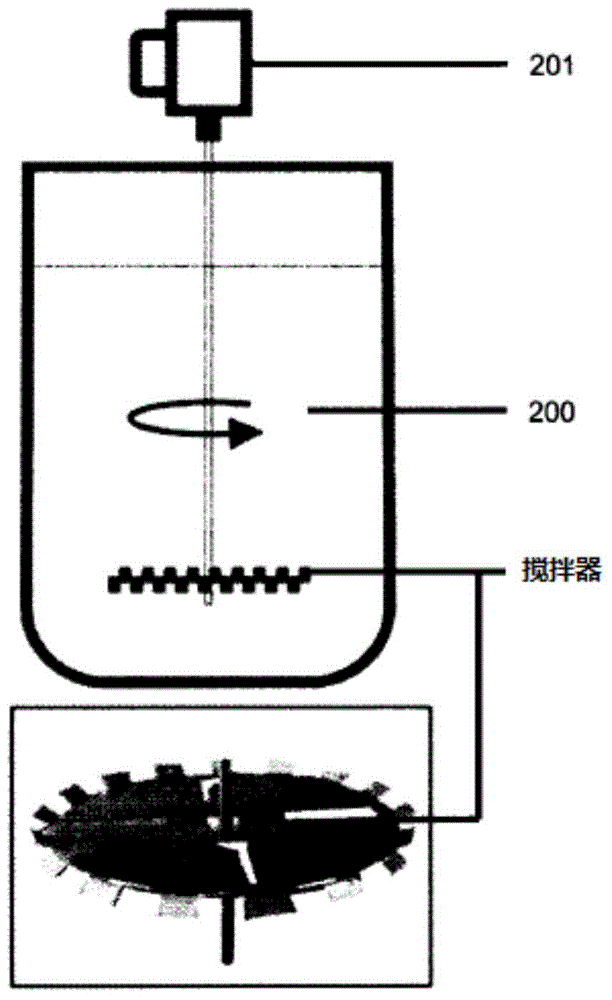

InactiveUS20120211426A1Improve processing efficiencyRapid responseFlow mixersTransportation and packagingSludgeSeparation system

The present invention provides an integrated method and system for treating a contaminated fluid. The integrated system and method is configured to simultaneously perform multiple functions, for example, transportation, mixing, treatment and separation. The contaminated fluid and treating agents are pumped simultaneously into a processing tank and vigorously mixed by at least one pump-mixer. The at least one pump-mixer is configured to simultaneously perform combined functions such as fluid transportation, rapid and vigorous mixing and treatment. The rapid and vigorous mixing by at least one pump-mixer enhances the processing rates considerably. The contaminants and the disaggregated particles undergo treatment as a result of their reactions with the treating agents. The process residuals, usually in the form of sludge, are separated from the treated fluid. The separation system is also configured to simultaneously perform multiple functions.

Owner:SANTORO ORONZO +5

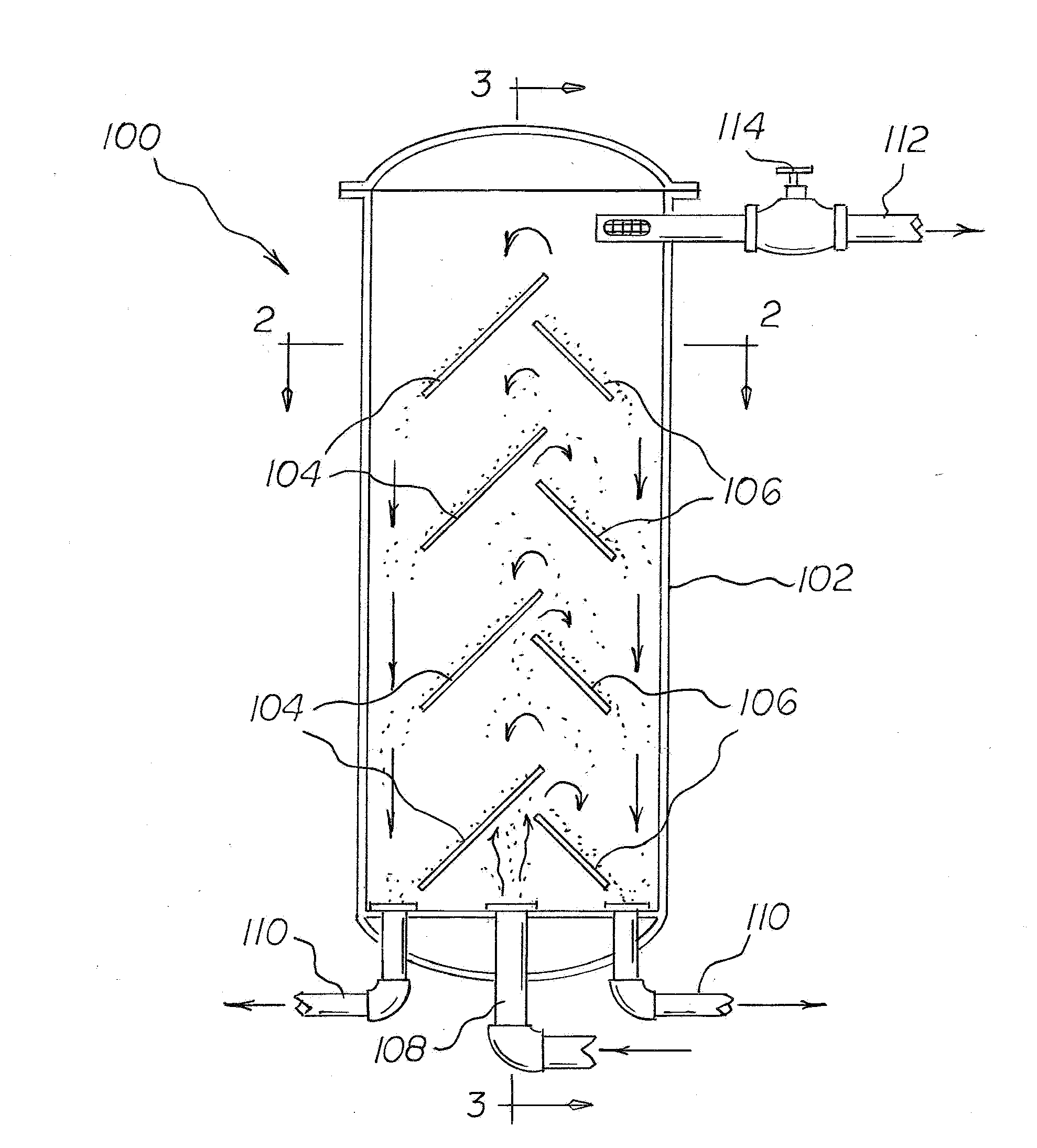

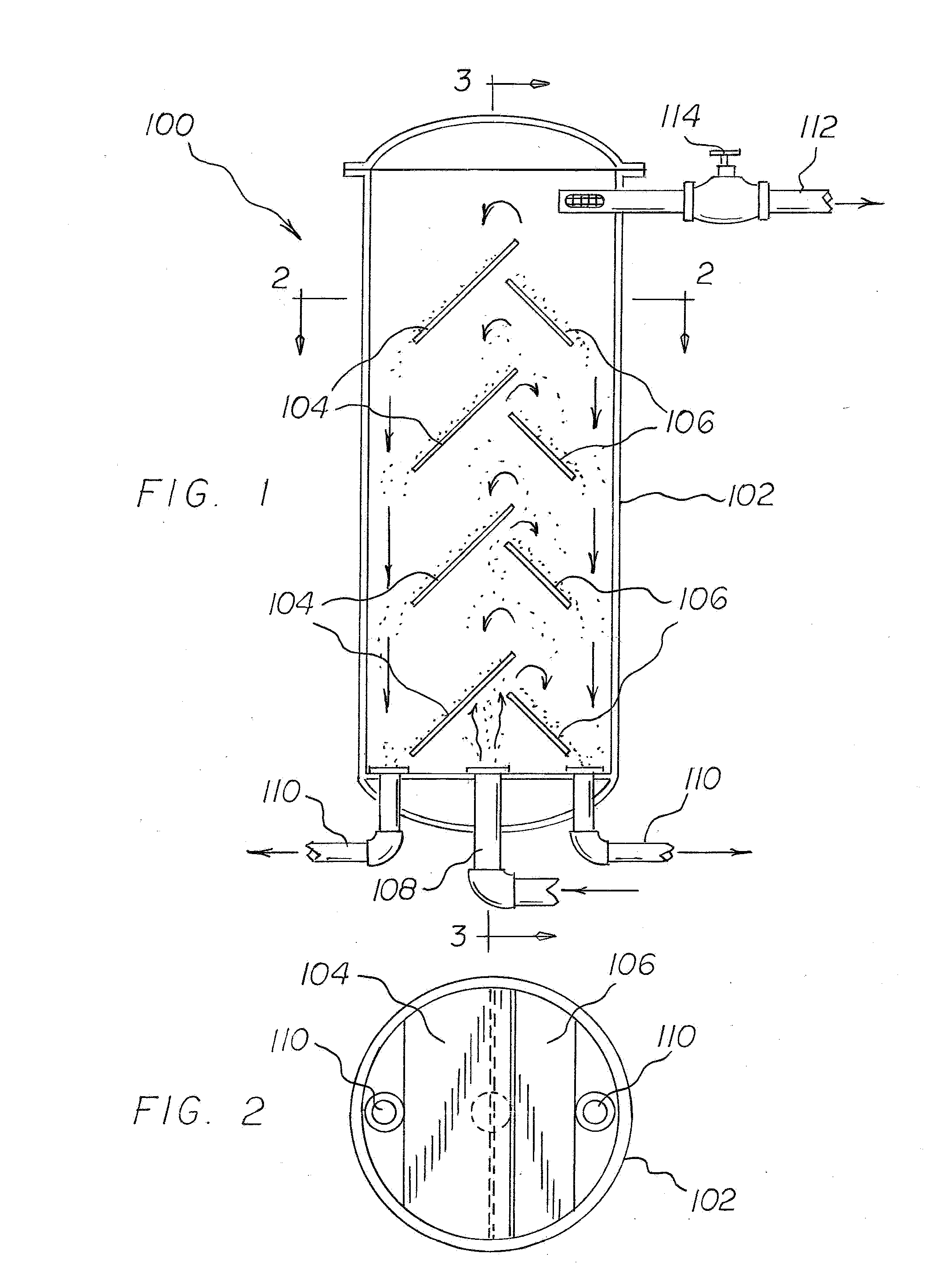

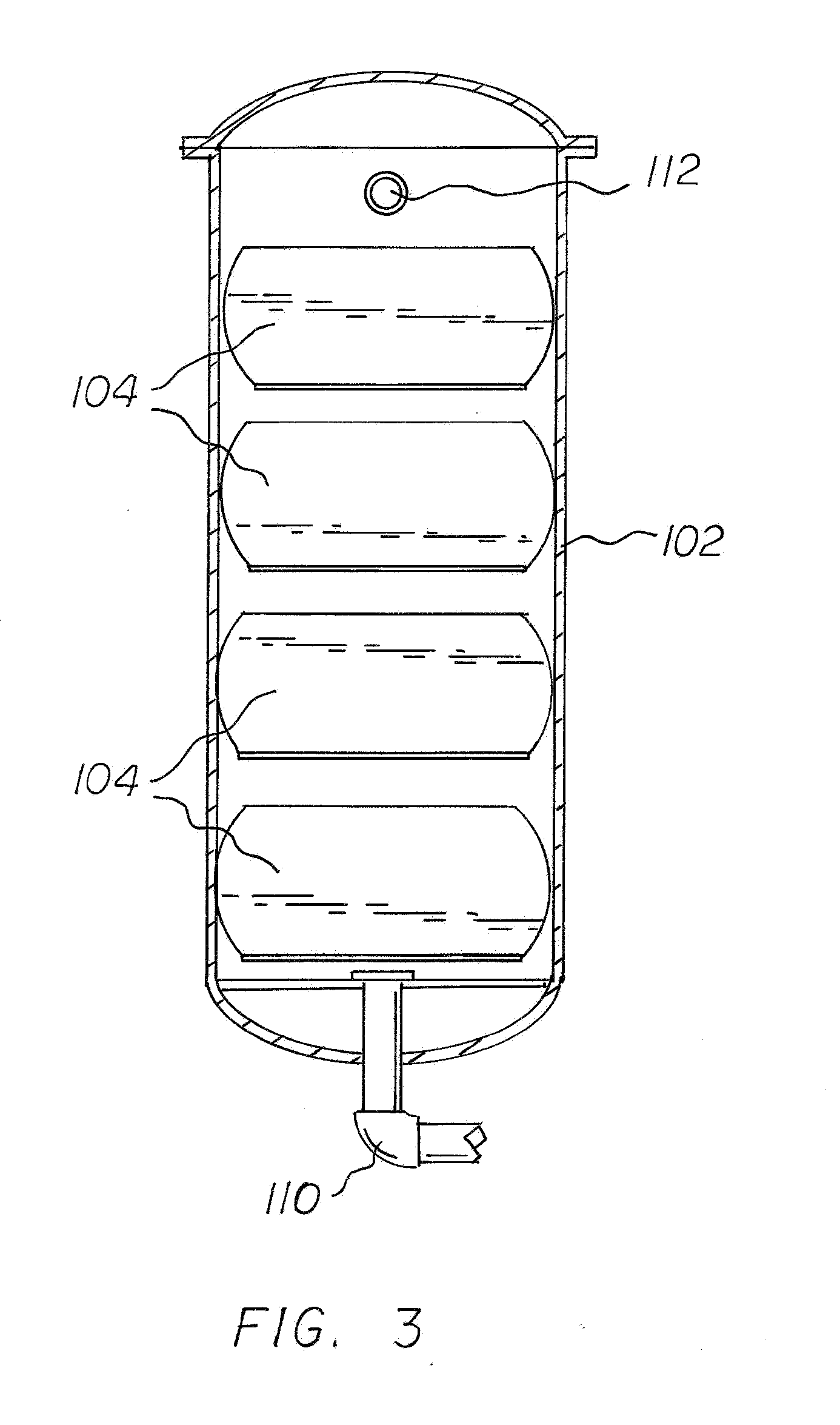

Method and system to separate solids from liquids

A system to separate solids from liquids is disclosed. In a particular embodiment, the system includes a series of alternating baffles disposed along a length of a tank, where the series of alternating baffles define a vertical tortuous flow path of the fluid from a first end of the tank to a second end of the tank to cause solids to settle out of the fluid. The alternating baffles each have a sloped planar surface disposed between a lower horizontal planar surface and an upper horizontal planar surface to cause at least one eddy in a vertical plane as the fluid flows through the tank. The system may also include a series of tanks in fluid communication with the at least one tank and secured side by side, where the solids progressively settle out from the fluid in stages as the fluid passes from one tank to another in series.

Owner:BUCKNER DON M

Methods for removing suspended solids from a gasification process stream

A method of removing suspended solids from a gasification process water stream includes, in an exemplary embodiment, providing a gasification process water stream containing process derived suspended solids, settling at least a portion of the suspended solids from the process water stream in a settling apparatus, providing a filter apparatus having a plurality of filter elements, and removing a portion of the settled solids from the settling apparatus. The method also includes precoating the filter elements with the settled solids removed from the settling apparatus, directing a portion of the process water stream from the settling apparatus to the filter apparatus, and filtering the portion of the process water stream directed from the settling apparatus through the precoated filter elements to remove suspended solids particles to form a filtrate.

Owner:AIR PROD & CHEM INC

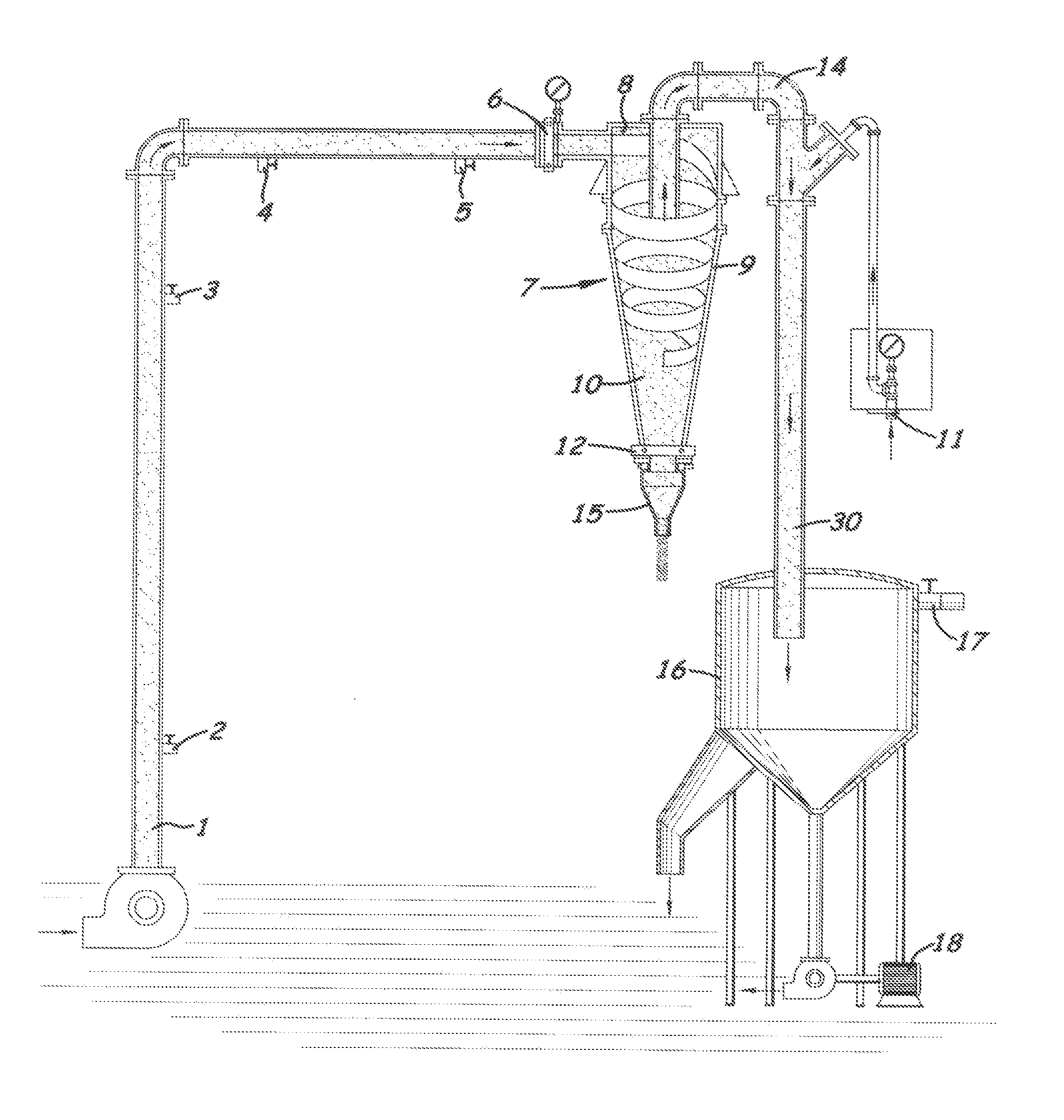

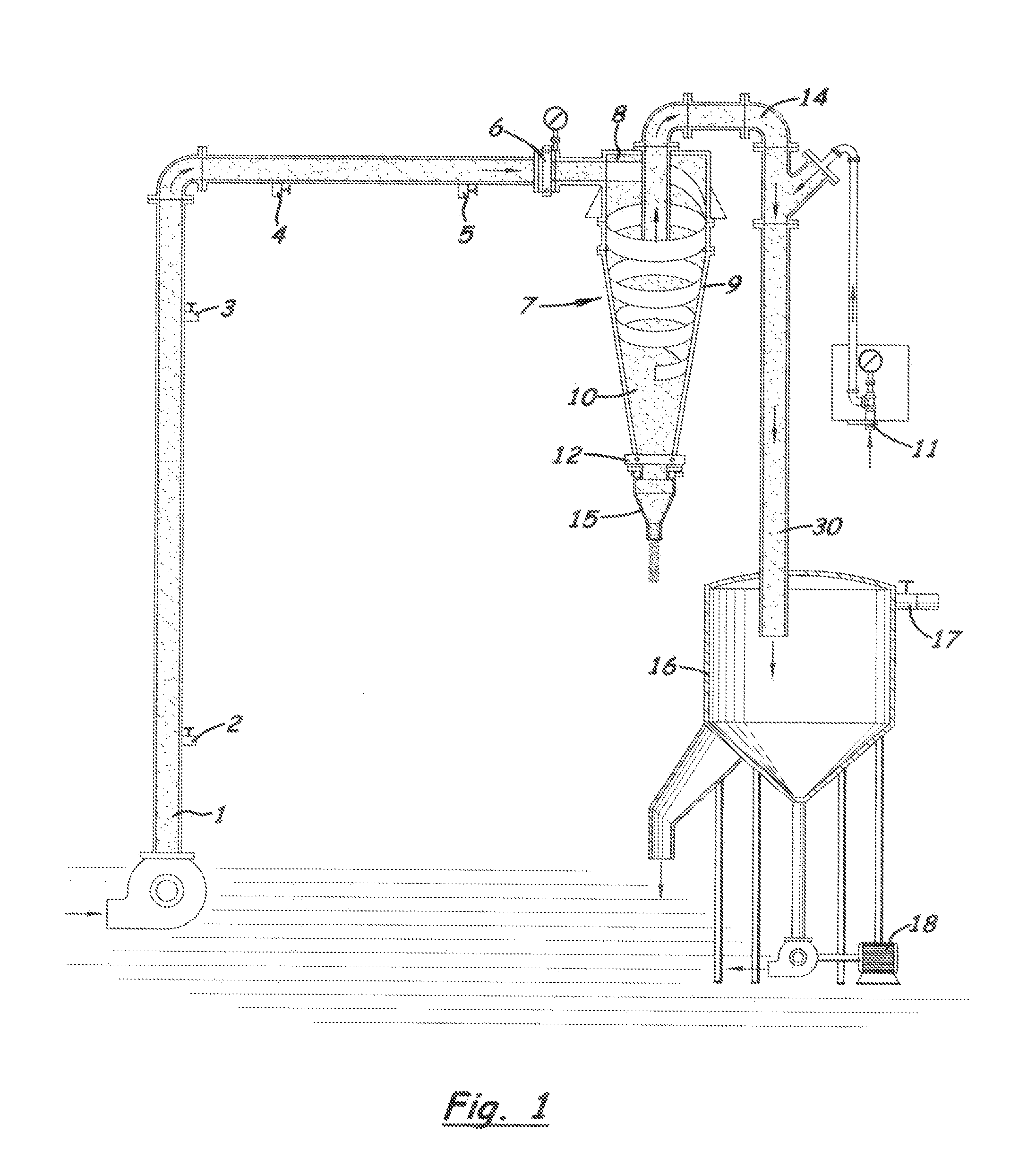

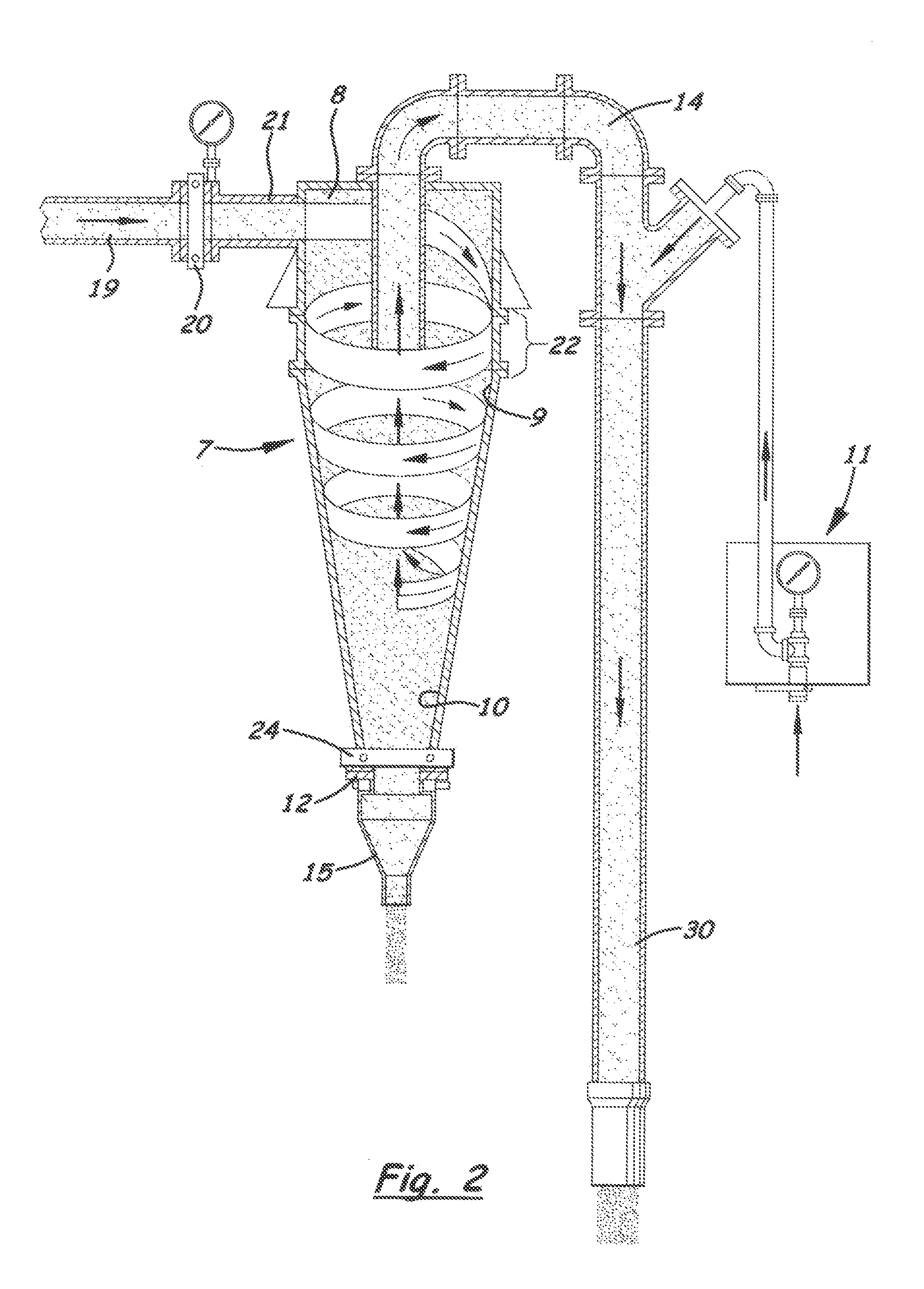

Method for enhancing cyclonic vessel efficiency with polymeric additives

InactiveUS7153436B2Increase contactReduce particle residueWater/sewage treatment by centrifugal separationSettling tank with pumpVolumetric Mass DensityEngineering

The present invention is directed to a novel method and system for enhancing the efficiency of hydraulic centrifugal separators (cyclones) in the removal of fine size particles from a liquid carrying medium. More particularly, it is concerned with improvements in the removal efficiency of any number of cyclonic devices that rely on the use of centrifugal force to separate fine size particles of differing density from the liquid carrying medium by addition of polymeric additives, both before, and, as necessary, inside the cyclone body.

Owner:BAIR PATRICK W +1

Popular searches

Water/sewage treatment by flocculation/precipitation Water/sewage treatment apparatus Biological water/sewage treatment Sampled-variable control systems Semi-permeable membranes Water/sewage treatment by irradiation Water/sewage treatment bu osmosis/dialysis Multistage water/sewage treatment Water/sewage treatment by degassing Treatment involving sedimentation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com