Patents

Literature

44 results about "Gravitational sedimentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

April 21, 2016. Gravitational sedimentation (originally the pipette method) measures the settling rate of particles in liquid medium and relates this rate to the particle mass by use of the Stokes law.

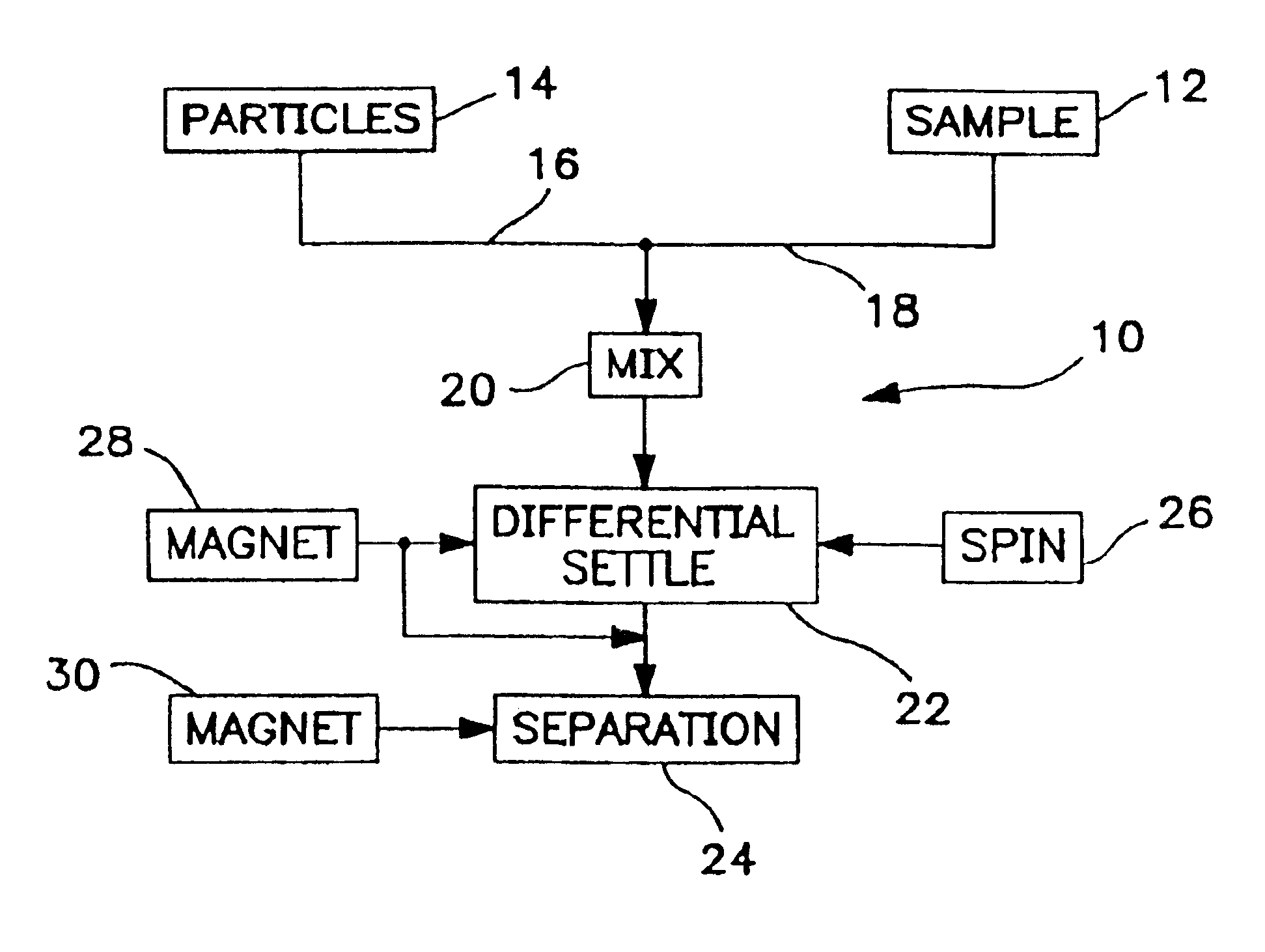

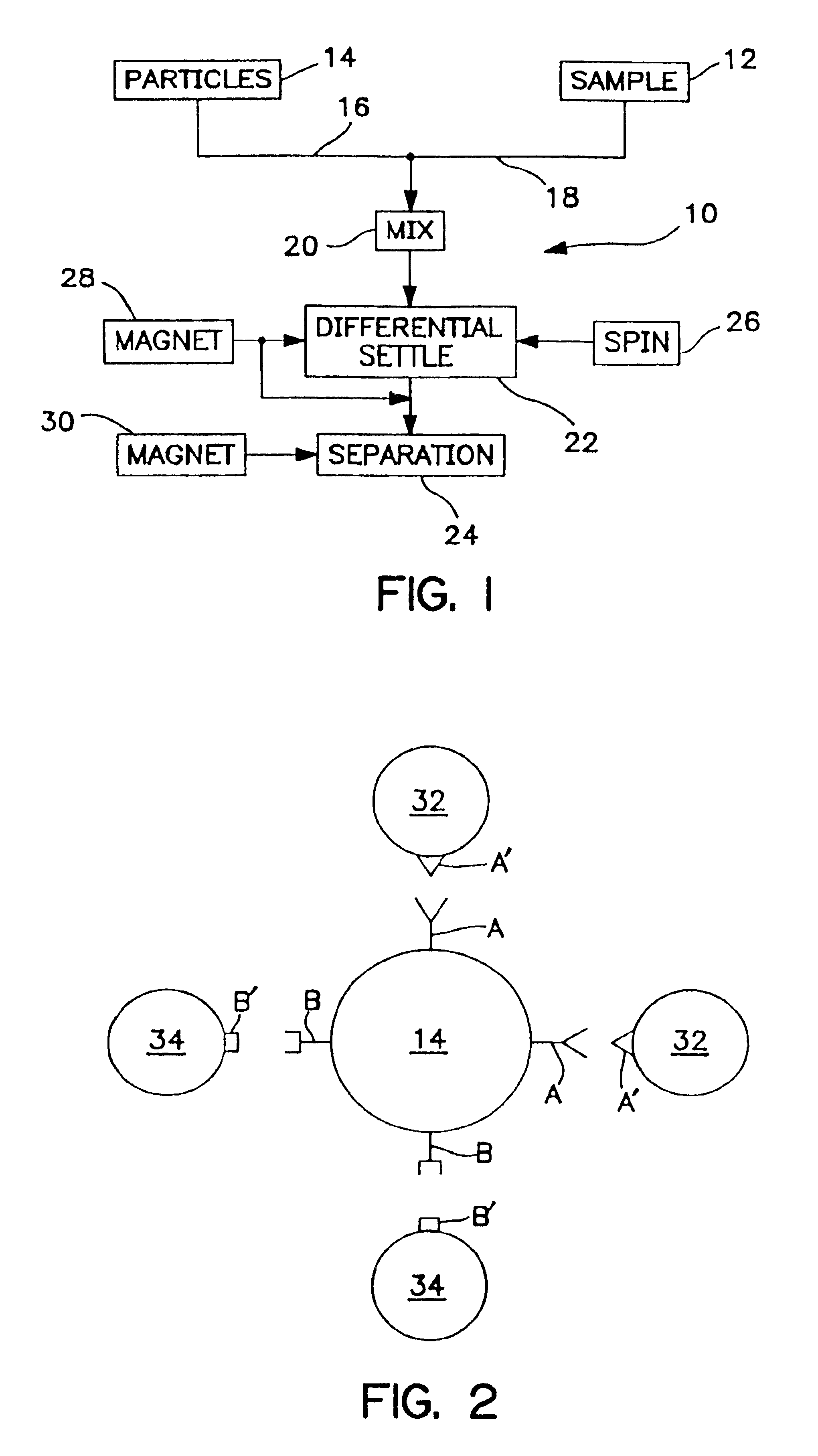

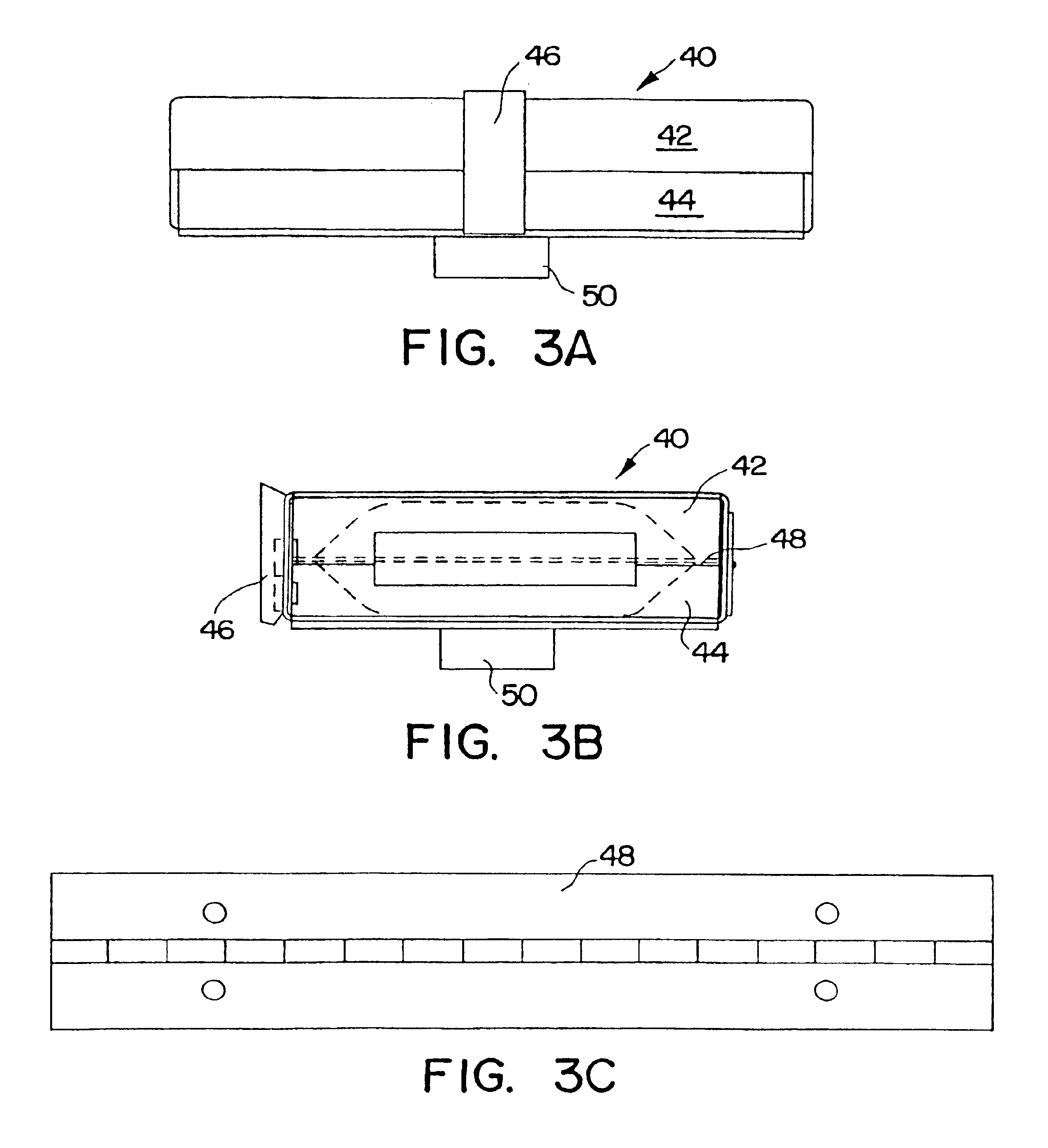

Method of selection of a population or subpopulation of a sample utilizing particles and gravity sedimentation

InactiveUS6900029B1Increase the number ofHigh yieldDead animal preservationSedimentation separationOrganismBiology

A separation procedure for separating a selected desired or undesired population from a biological sample utilizing relatively heavy, dense particles and gravity sedimentation. The particles have one or more reactants bound thereto which are specific to and will bind with the selected population. The particles preferably are mixed with the sample by repeatedly causing the particles to settle through a substantial portion of the sample to bind to the selected population. The particles with the bound selected population then are allowed to preferentially settle in the sample and the supernatant including an enriched population is separated from the particles with the selected population bound thereto. The enriched populations in the biological sample supernatant can be further enriched by multiple removal steps.

Owner:COULTER INTERNATIONAL CORPORATION

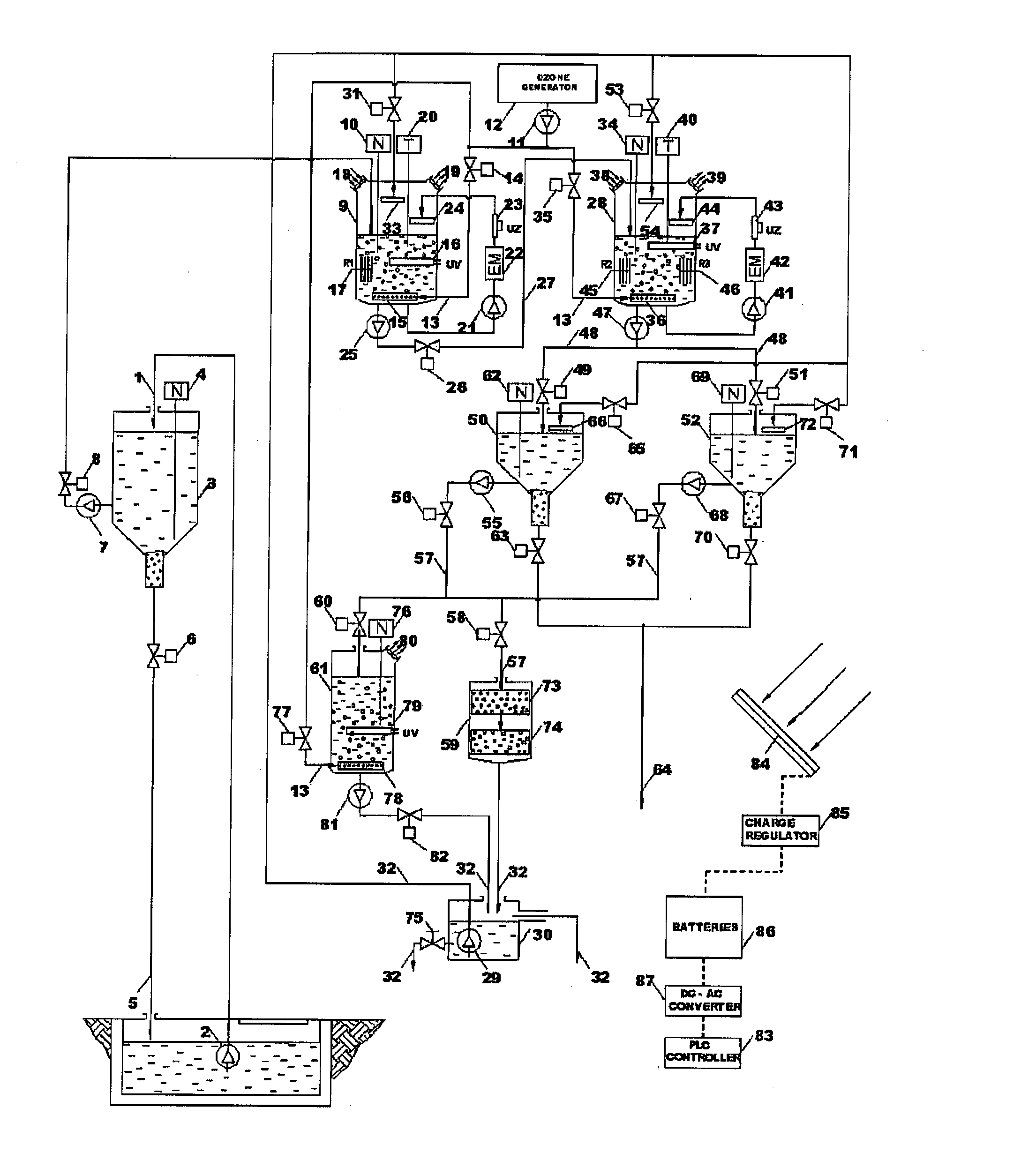

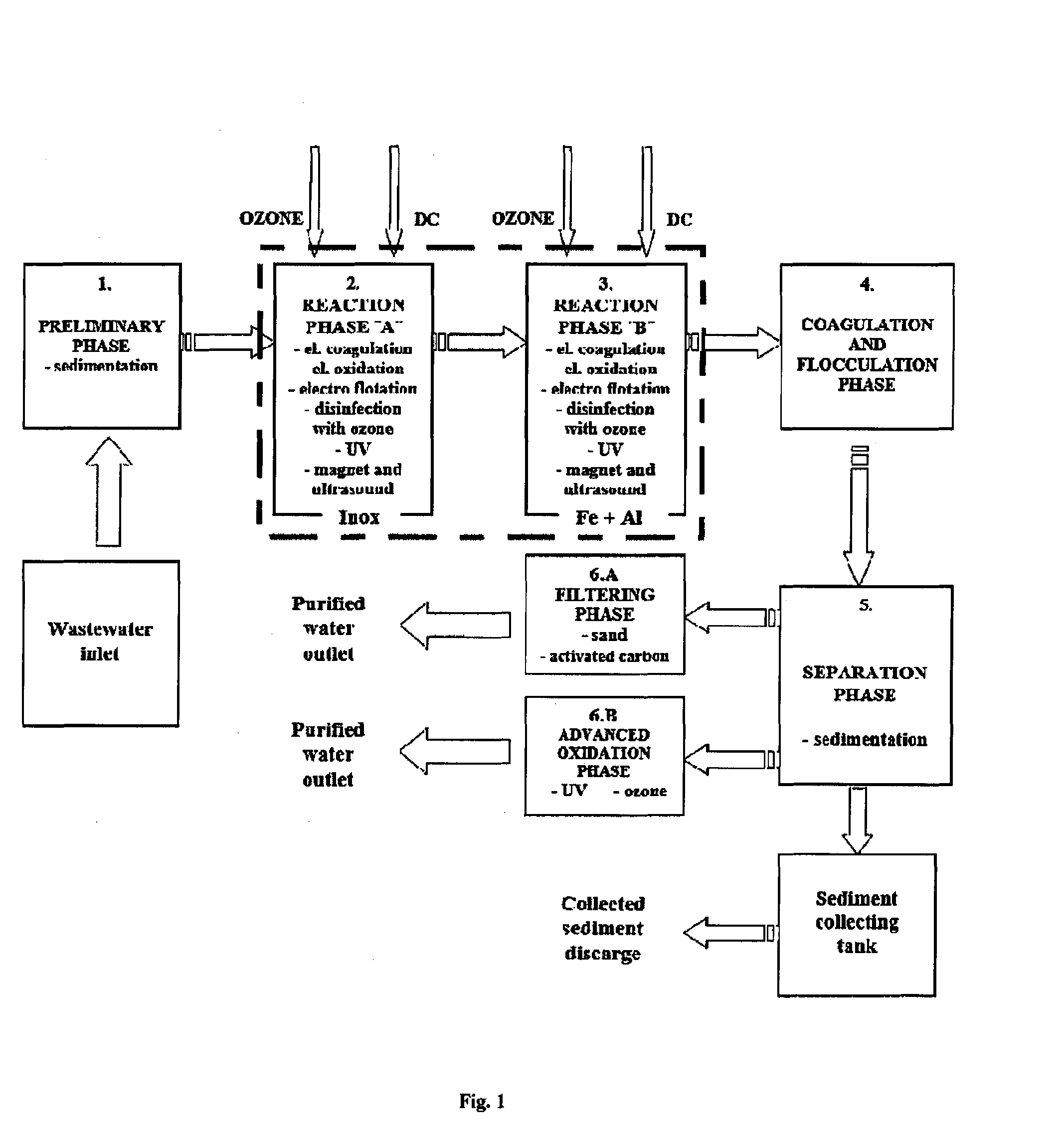

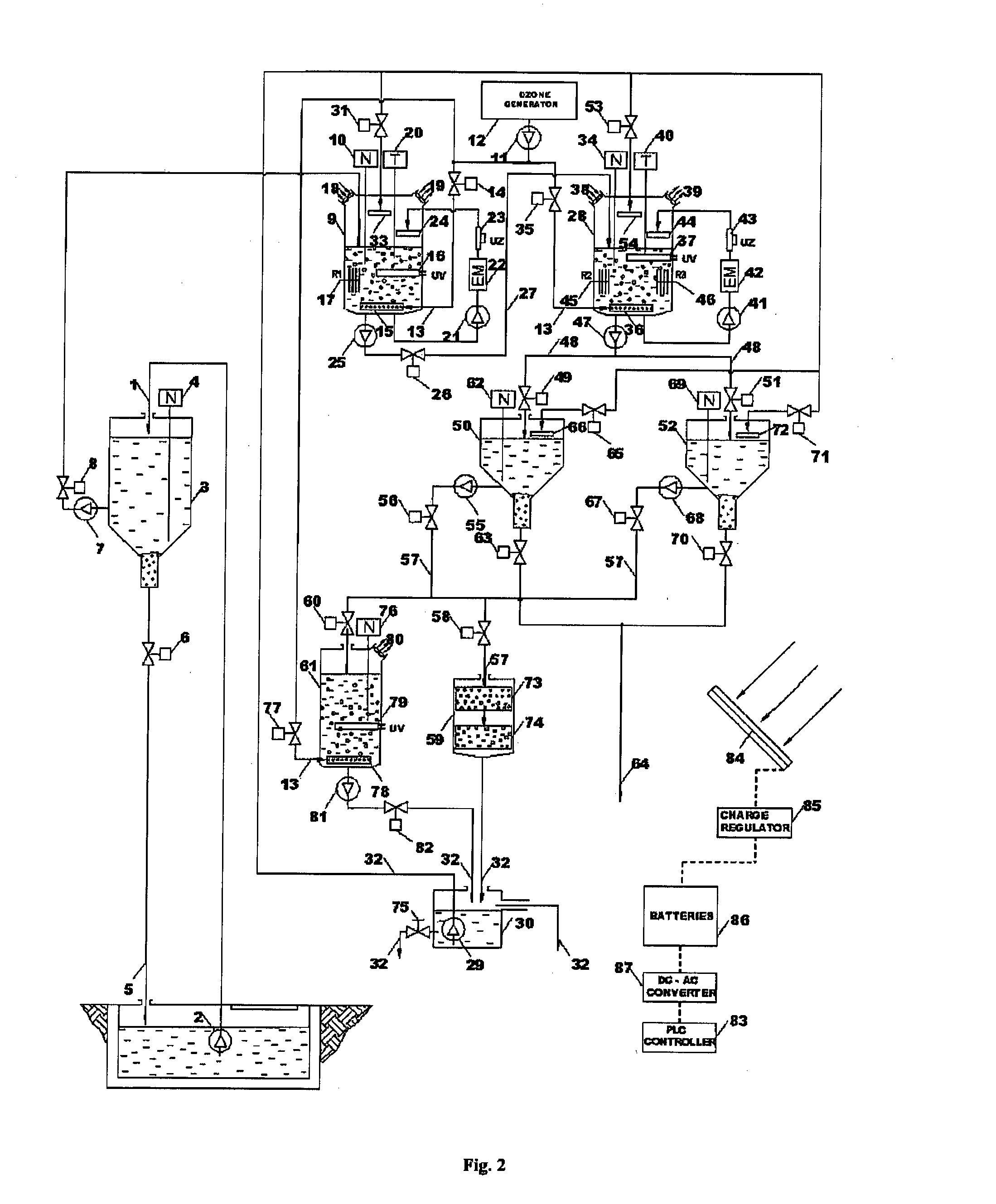

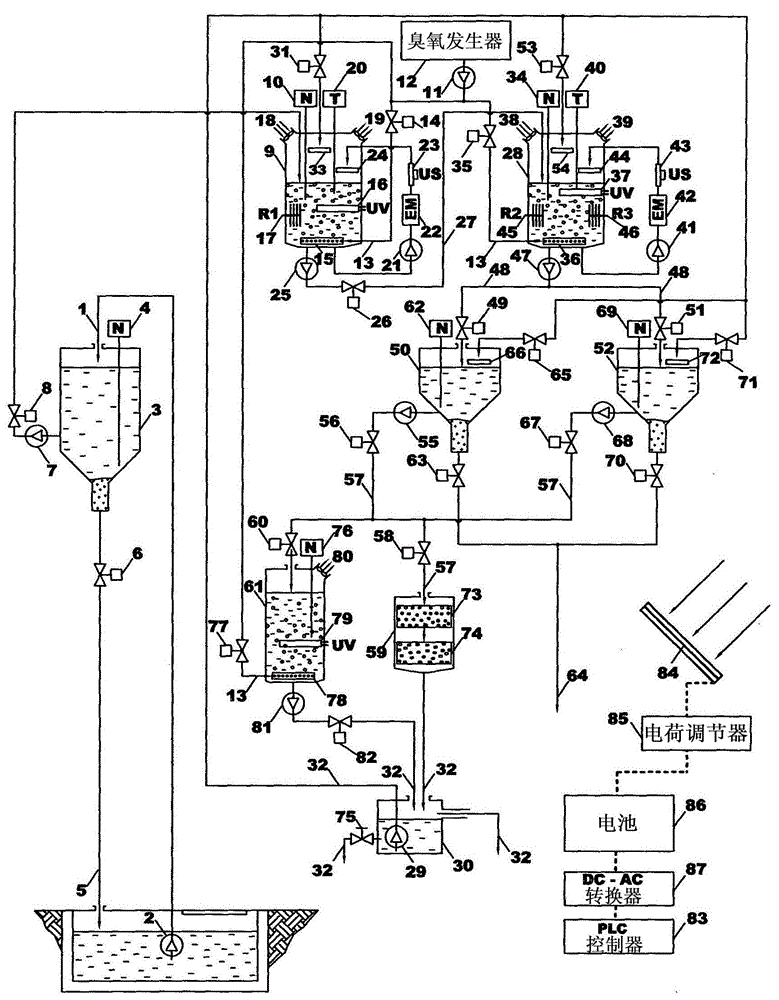

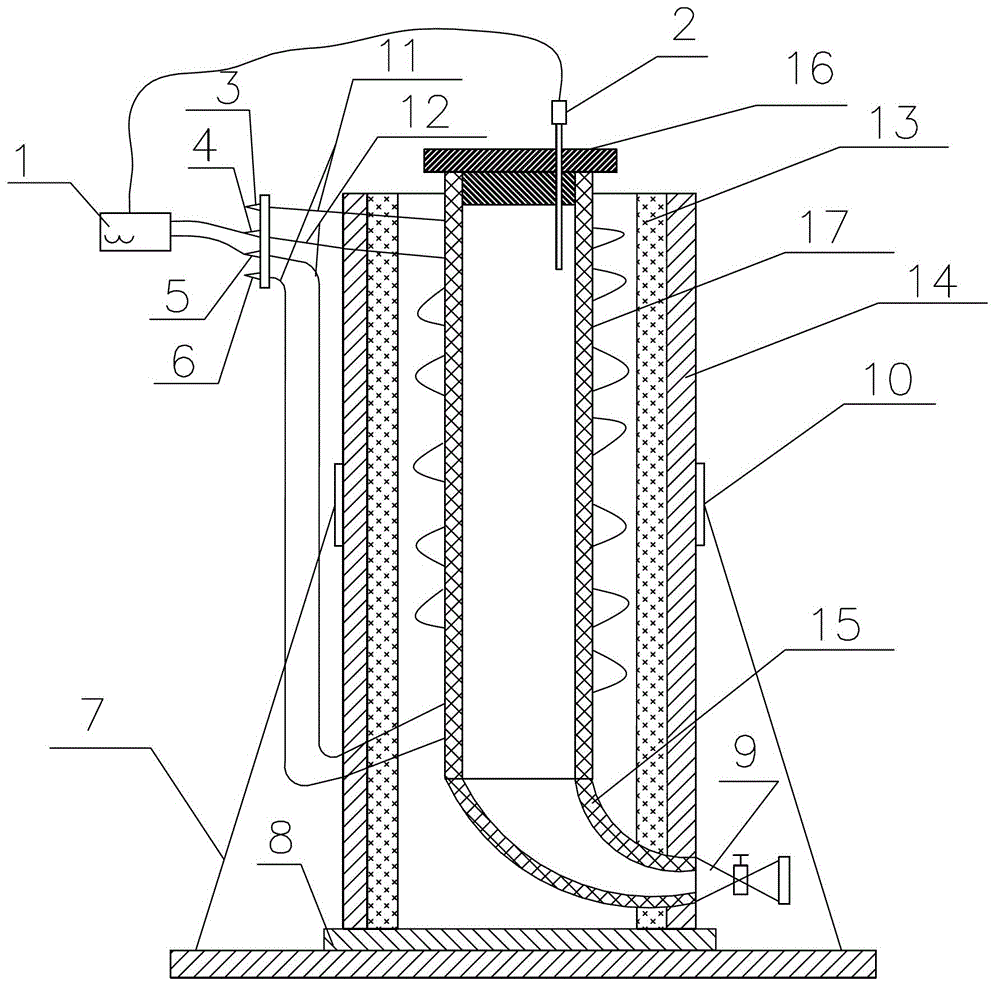

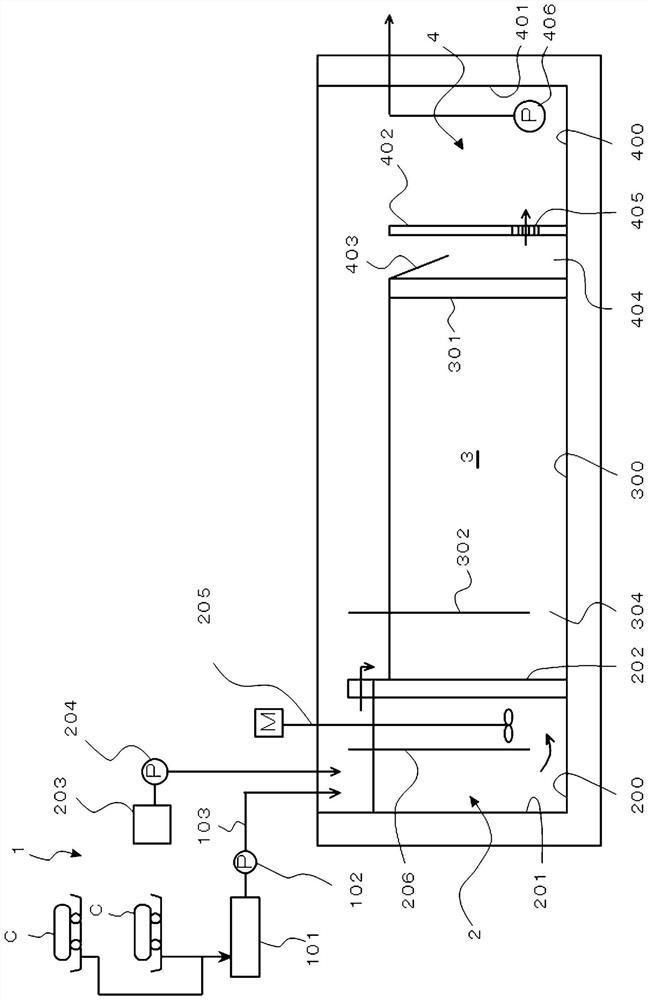

Process and device for electrochemical treatment of industrial wastewater and drinking water

InactiveUS20150166383A1Lower Level RequirementsTreatment involving filtrationSedimentation separationChemical treatmentIndustrial waste water

Subject matter of the invention is the procedure and plant for industrial wastewater and / or drinking water treatment by means of electrochemical methods and advanced oxidation processes. The preparatory phase of gravitational sedimentation is followed by main treatment consisting of electrocoagulation, electrooxidation and electroflotation through action of metal electrode sets made of inox, steel and aluminium respectively, with parallel disinfection / oxidation with ozone, UV irradiation and ultrasonic treatment, as well as recirculation in the electromagnetic field. At the end of the main treatment, the mixture of floccule and water is subject to coagulation / flocculation by electrochemically generated steel and aluminium floccule with slow infusion of ozone. The next phase is separation of sediment from clean water which is discharged through sand and activated charcoal filters for the purpose of removal of light floating floccule in the collection tank. If required, the water is subject to oxidation with simultaneous action of UV irradiation and ozone for the purpose of final destruction of organic matter and ammonia, and potential residues of microbiological contamination.

Owner:VISNJA ORESCANIN +2

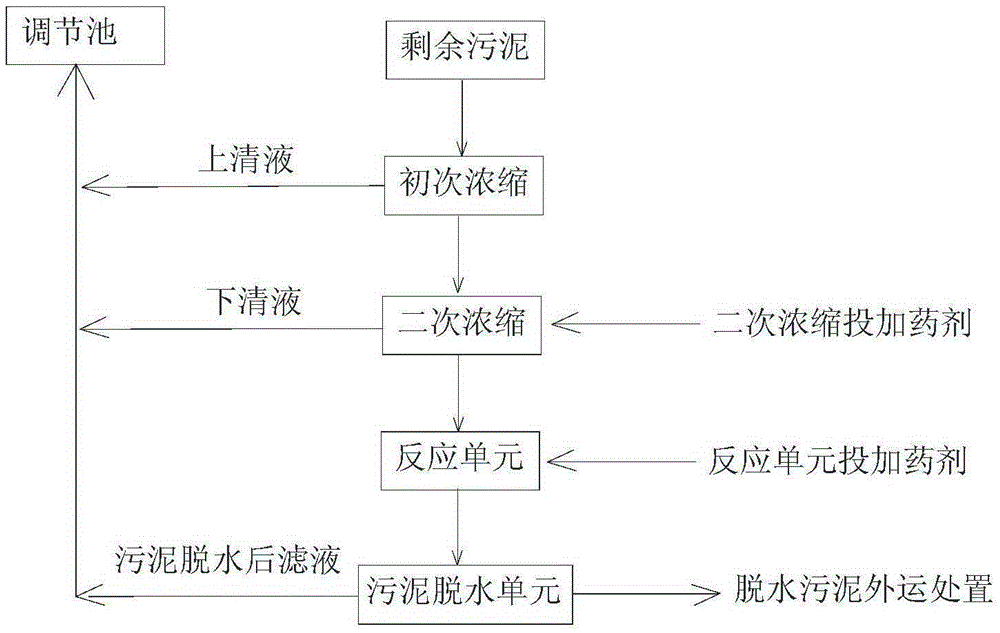

Treatment method for sludge reduction

InactiveCN105293845ADouble the concentrationHigh concentrationSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSewageGravitational sedimentation

The invention discloses a treatment method for sludge reduction. The method comprises the steps that residual sludge from a secondary sedimentation tank undergoes standing and gravitational sedimentation first, supernate obtained after sedimentation flows back to a regulating tank to complete initial concentration, then air floatation treatment is conducted on the sludge subjected to initial concentration to complete secondary concentration, supernate obtained after secondary concentration flows back to the regulating tank, the pH of the sludge after secondary concentration is regulated, a strong oxidizer is added after steam heating, the purposes of improving the concentration degree and dehydration performance and remarkably decreasing the amount are achieved after oxidation of the strong oxidizer, the reaction unit is completed after reaction is performed for a certain time, and then the final sludge-water mixture is delivered to a sludge dehydrator to be dehydrated, wherein the filtrate flows back to the regulating tank, and dry sludge is transported to the outside for disposal. By means of the method, the sludge concentration degree can be effectively improved, the sludge dehydrating performance can be improved, sludge can be remarkably decreased, and the energy consumption and operation cost are reduced. The treatment method has good development prospect.

Owner:GUANGZHOU LIBY

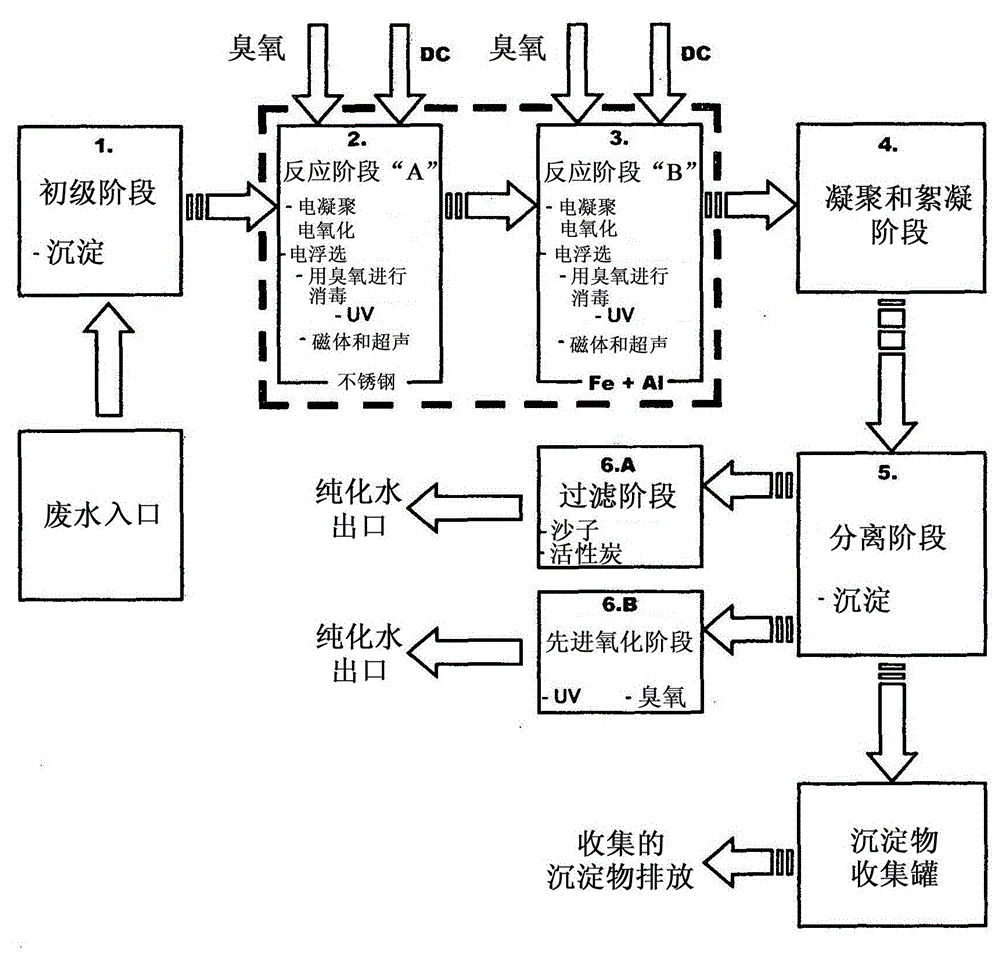

Process and device for electrochemical treatment of industrial wastewater and drinking water

InactiveCN104797535ATreatment involving filtrationSedimentation separationActivated carbon filtrationAdvanced oxidation process

Subject matter of the invention is the procedure and plant for industrial wastewater and / or drinking water treatment by means of electrochemical methods and advanced oxidation processes. The preparatory phase of gravitational sedimentation is followed by main treatment consisting of electrocoagulation, electrooxidation and electroflotation through action of metal electrode sets made of inox, steel and aluminium respectively, with parallel disinfection / oxidation with ozone, UV irradiation and ultrasonic treatment, as well as recirculation in the electromagnetic field. At the end of the main treatment, the mixture of floccule and water is subject to coagulation / flocculation by electrochemically generated steel and aluminium floccule with slow infusion of ozone. The next phase is separation of sediment from clean water which is discharged through sand and activated charcoal filters for the purpose of removal of light floating floccule in the collection tank. If required, the water is subject to oxidation with simultaneous action of UV irradiation and ozone for the purpose of final destruction of organic matter and ammonia, and potential residues of microbiological contamination.

Owner:奥雷斯卡宁·维斯贾 +2

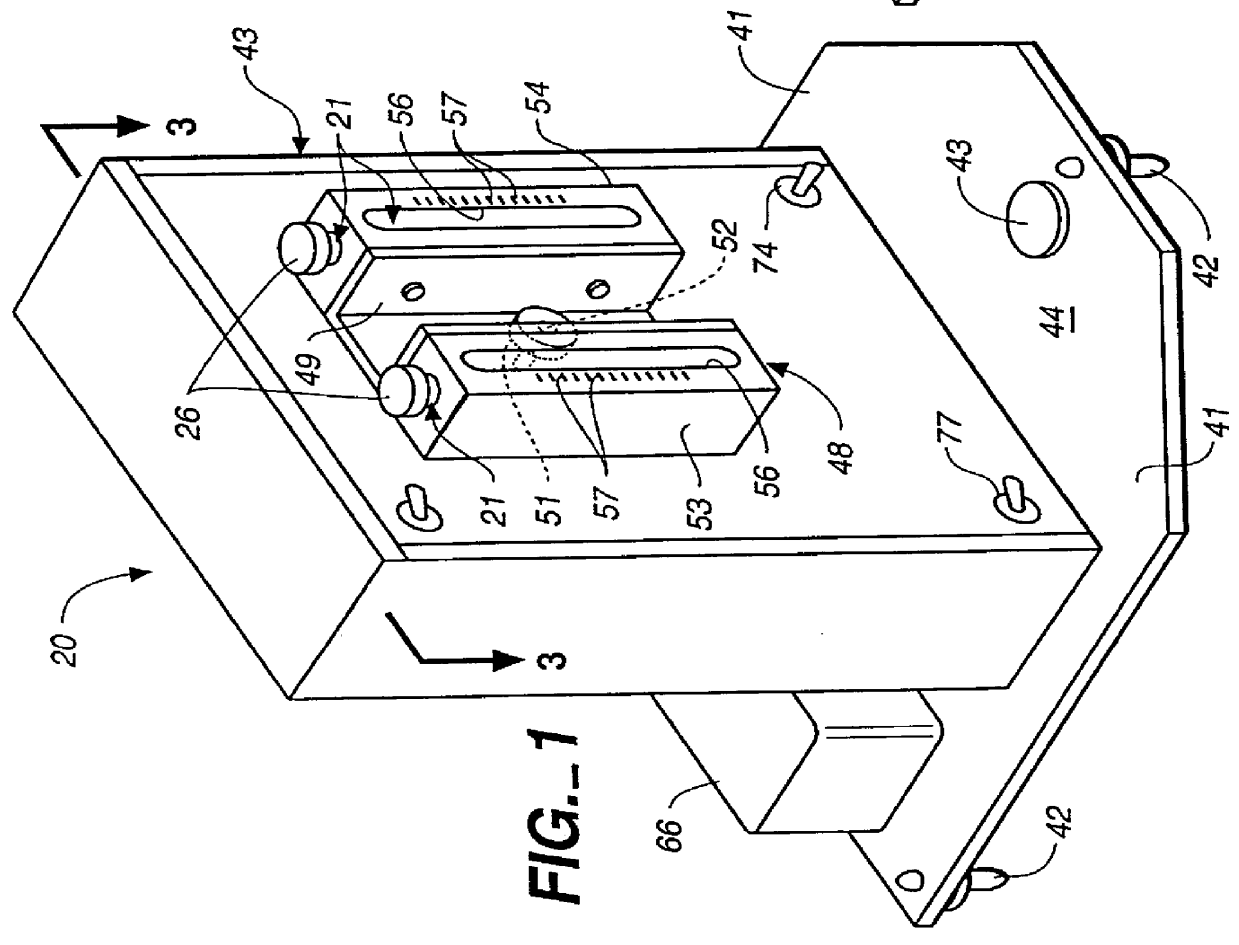

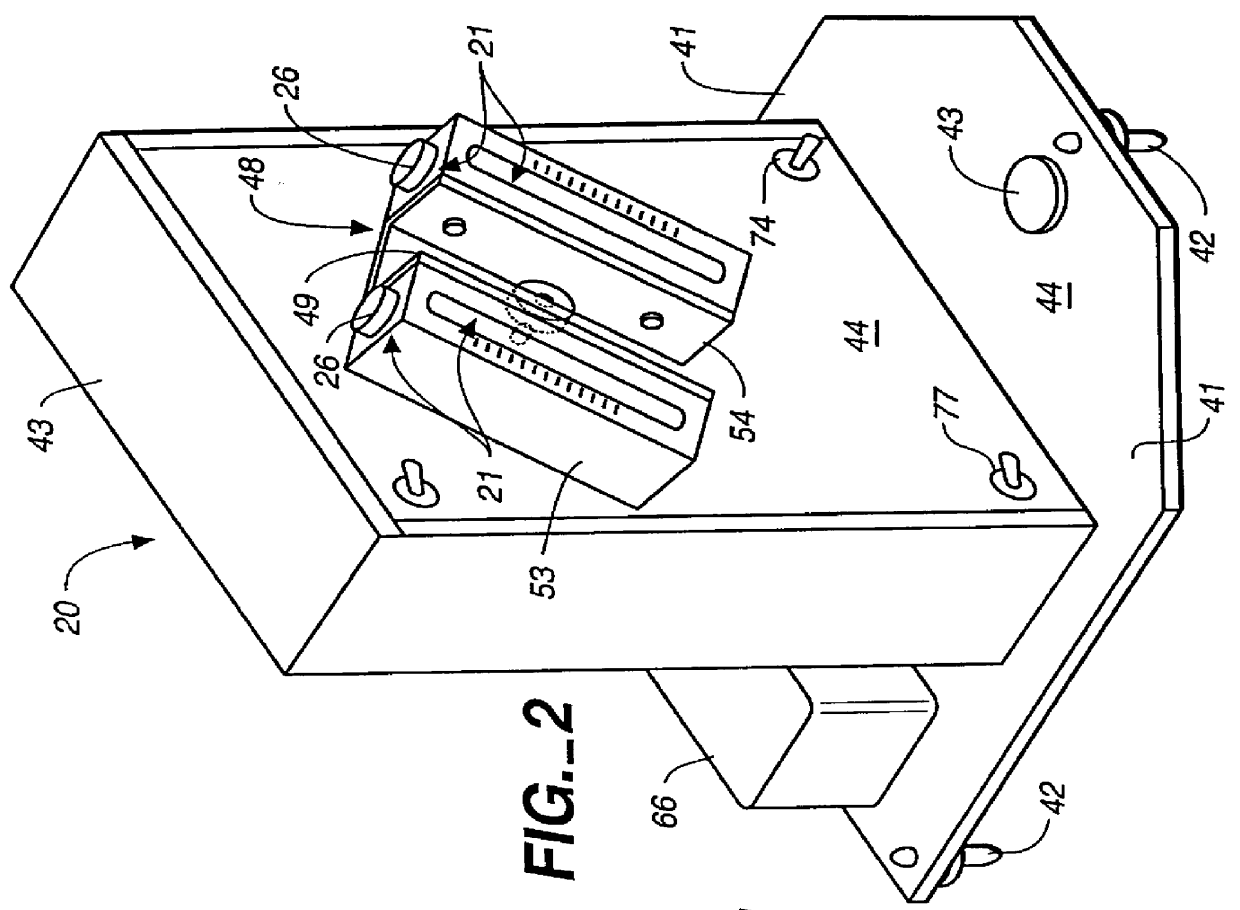

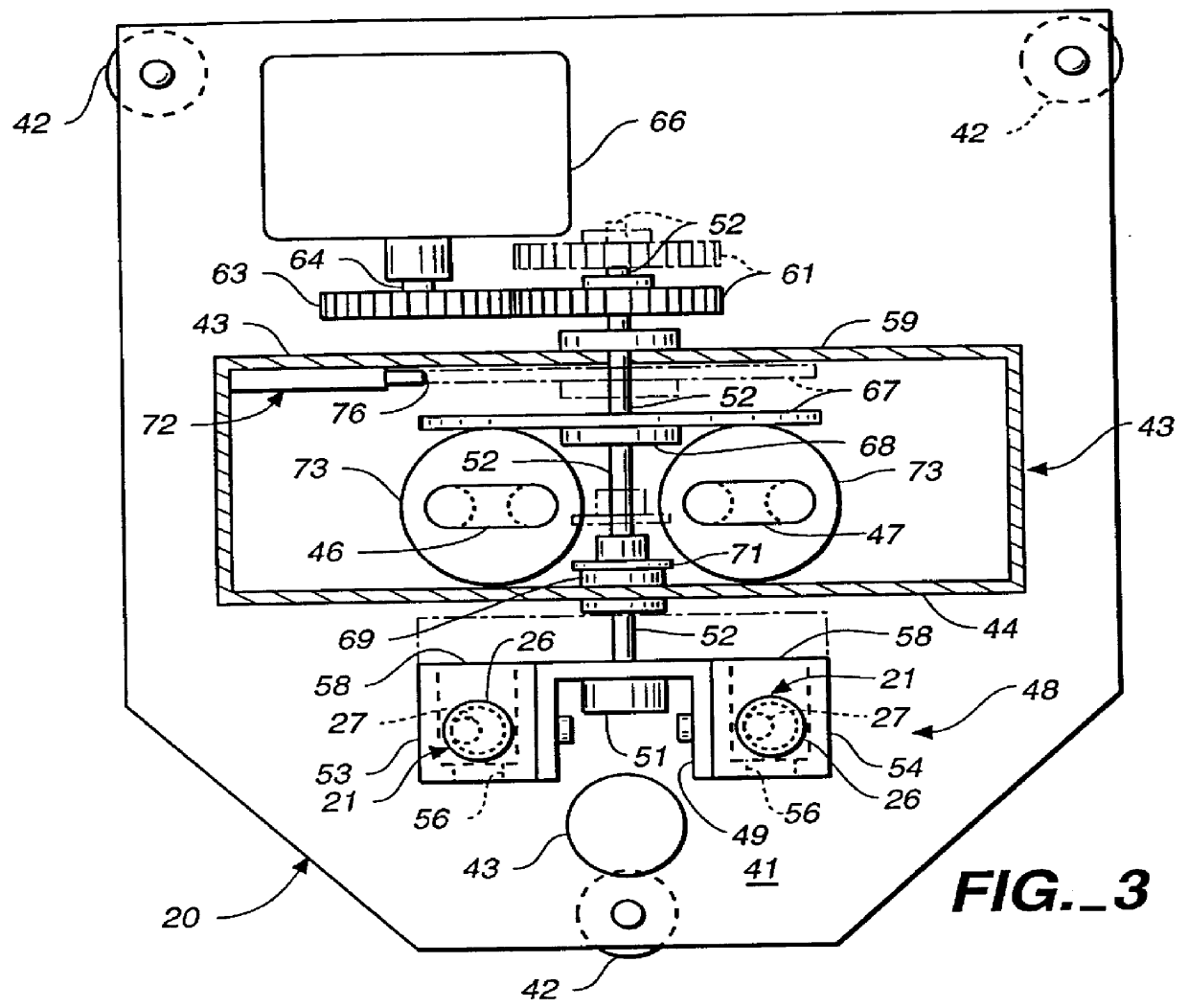

Method and apparatus for rapid determination of blood sedimentation rate

InactiveUS6098451AImprove trustAccelerates the lag phaseRead-only memoriesSedimentation analysisGravitational sedimentationBiology

An apparatus and method for rapid determination of erythrocyte sedimentation rates for a blood specimen (29) which can be linearly transposed to Westergren sedimentation rates. The method includes the steps of inducing accelerated rouleaux formation in the specimen (29) in an amount sufficient to begin settling at substantially the decantation rate for the specimen. In one embodiment a structure (27) which produces a very thin cross-sectional region (37) of the specimen (29) inside the lumen (23) of a specimen container (21) is provided to accelerate rouleaux formation. In an alternative embodiment (120), accelerated rouleaux formation is accomplished using a centrifuge (122). A third embodiment employs a movable rod (223) mounted inside the specimen tube (221) to induce accelerated rouleaux formation. All embodiments of the process next employ gravity settling the specimen in a near horizontal oriented container (21, 121, 221). Thereafter, the amount of settling occurring is determined. A sealed specimen container (21, 121, 221) which permits thorough mixing of blood in a very small diameter container for use in performing the method also is provided.

Owner:BULL BRIAN S

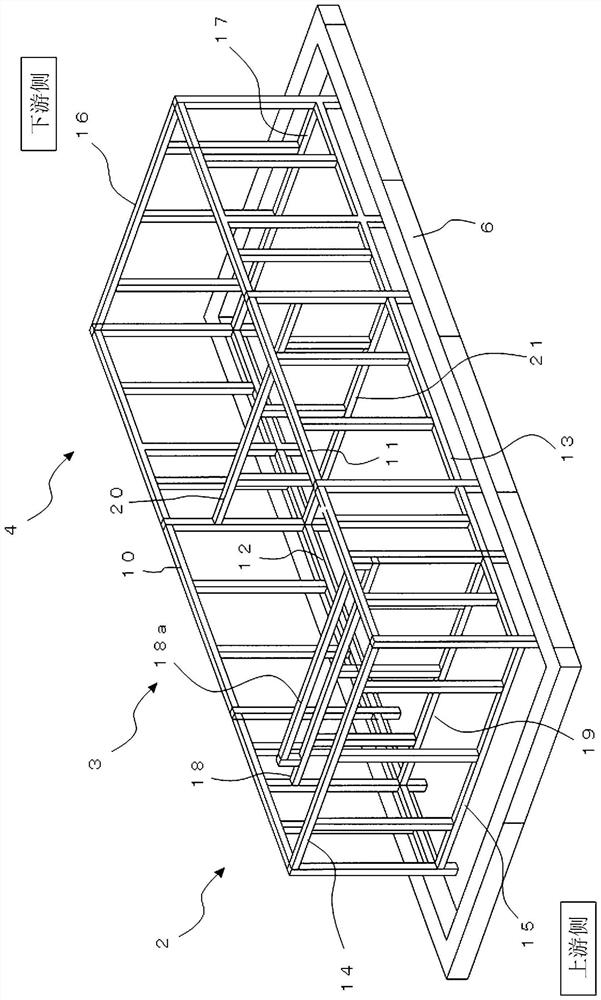

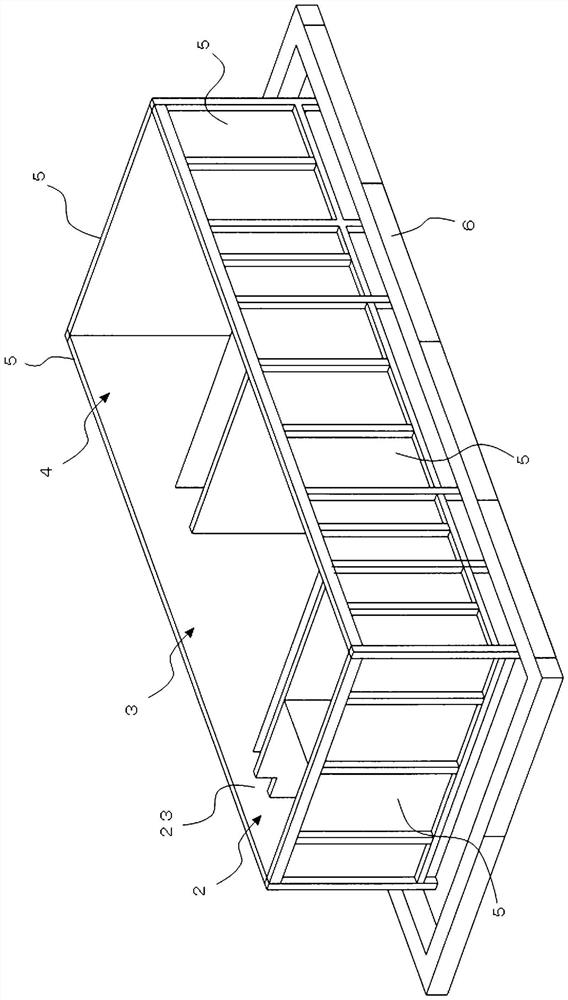

Method of washing solid grain

InactiveUS20060254622A1Low costReduce usageLiquid separation auxillary apparatusIon-exchanger regenerationHigh concentrationDispersed media

In the washing process of the invention, the solid particles in a high-concentration zone, which is formed in a washing tank by a gravitational sedimentation of solid particles, are continuously washed by a counter-current contact with upward flow of a washing liquid which is fed from the bottom portion of the washing tank. With this process, the impurities in the solid particles are sufficiently removed by a simple apparatus. Since the used washing liquid can be recycled as the disperse medium for feeding the solid particles and as the washing liquid, the amount of used washing liquid to be discharged as the waste from the system is reduced.

Owner:MITSUBISHI GAS CHEM CO INC

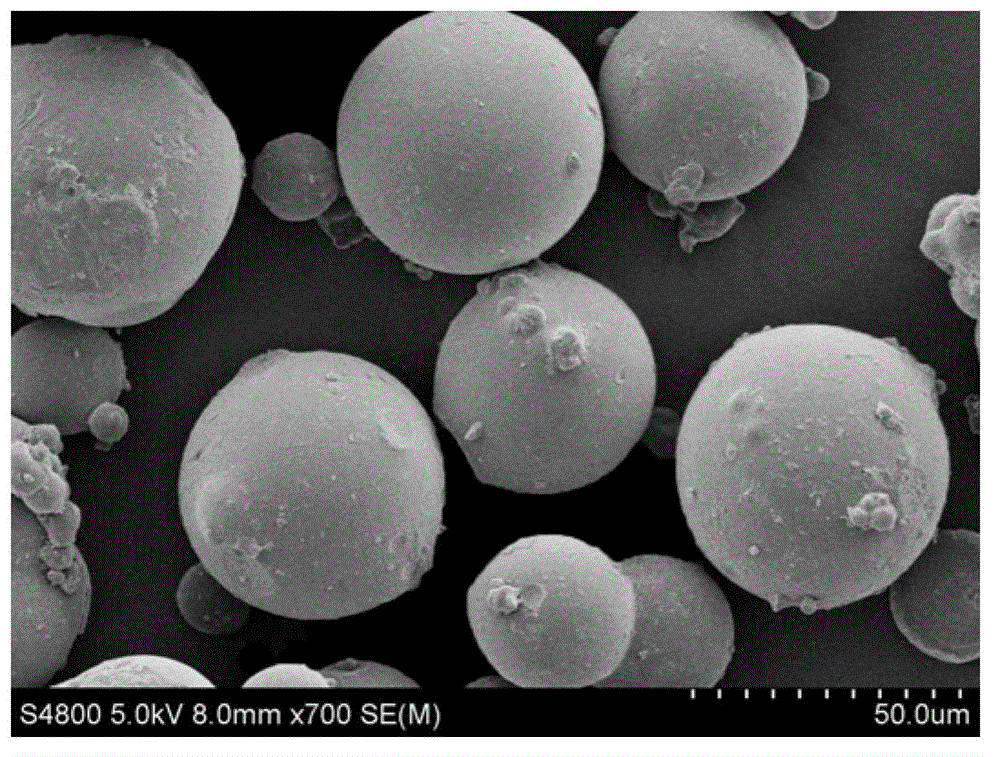

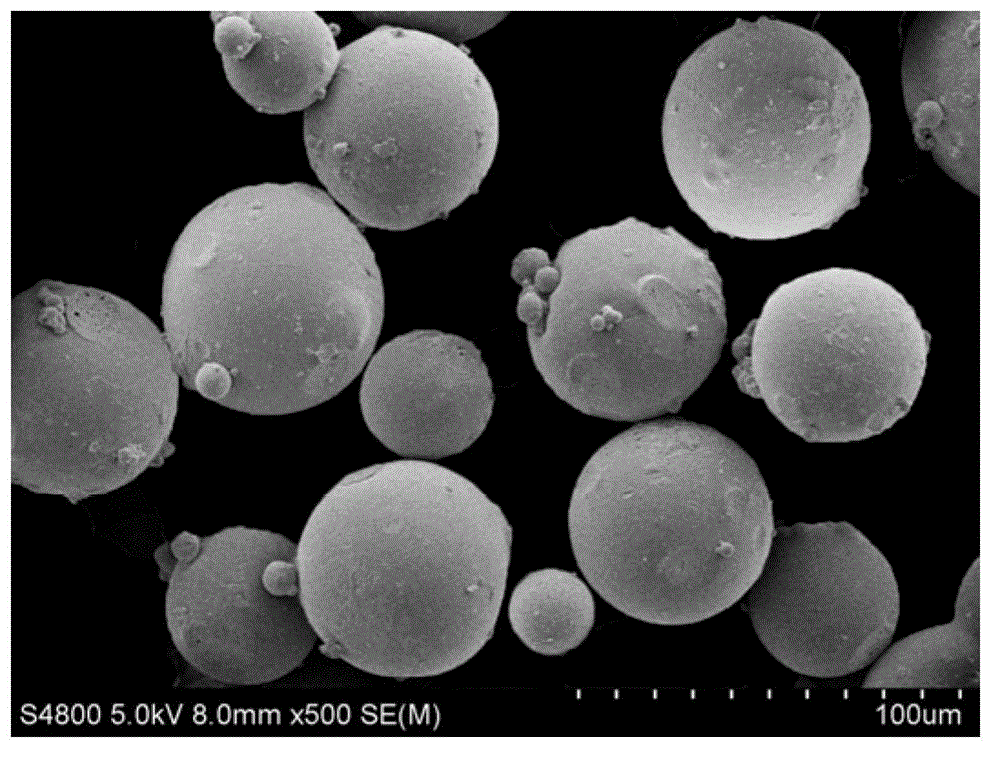

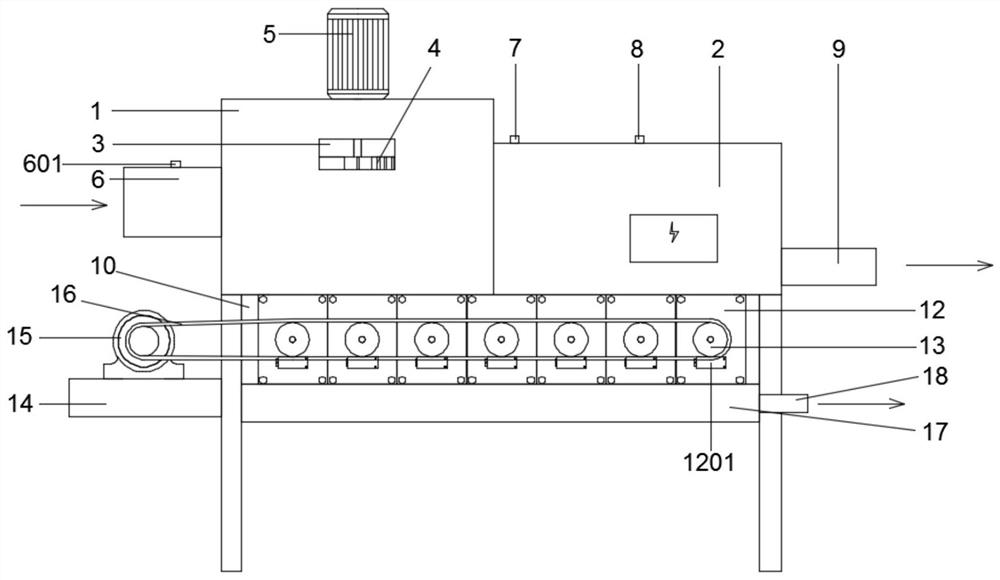

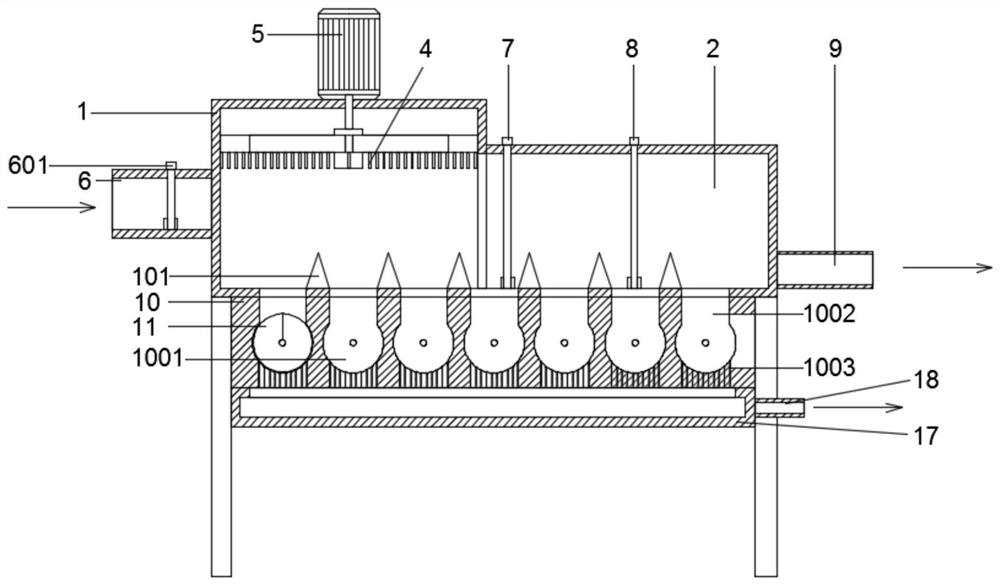

Method and device for preparing microballoons by bi-dispersible inverse suspension polymerization

The invention discloses a method and a device for preparing microballoons by bi-dispersible inverse suspension polymerization. The first dispersion is carried out in an agitating manner; the particle sizes of the microballoons are determined by the volume ratio of a water phase and an oil phase and the agitating speed; second dispersion is carried out by a gravity sedimentation method; adhesion generated by collision of the microballoons caused by agitation at middle and later periods of the reaction can be effectively avoided without adding a dispersing agent; and the instability of a reaction system is solved from the process and equipment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

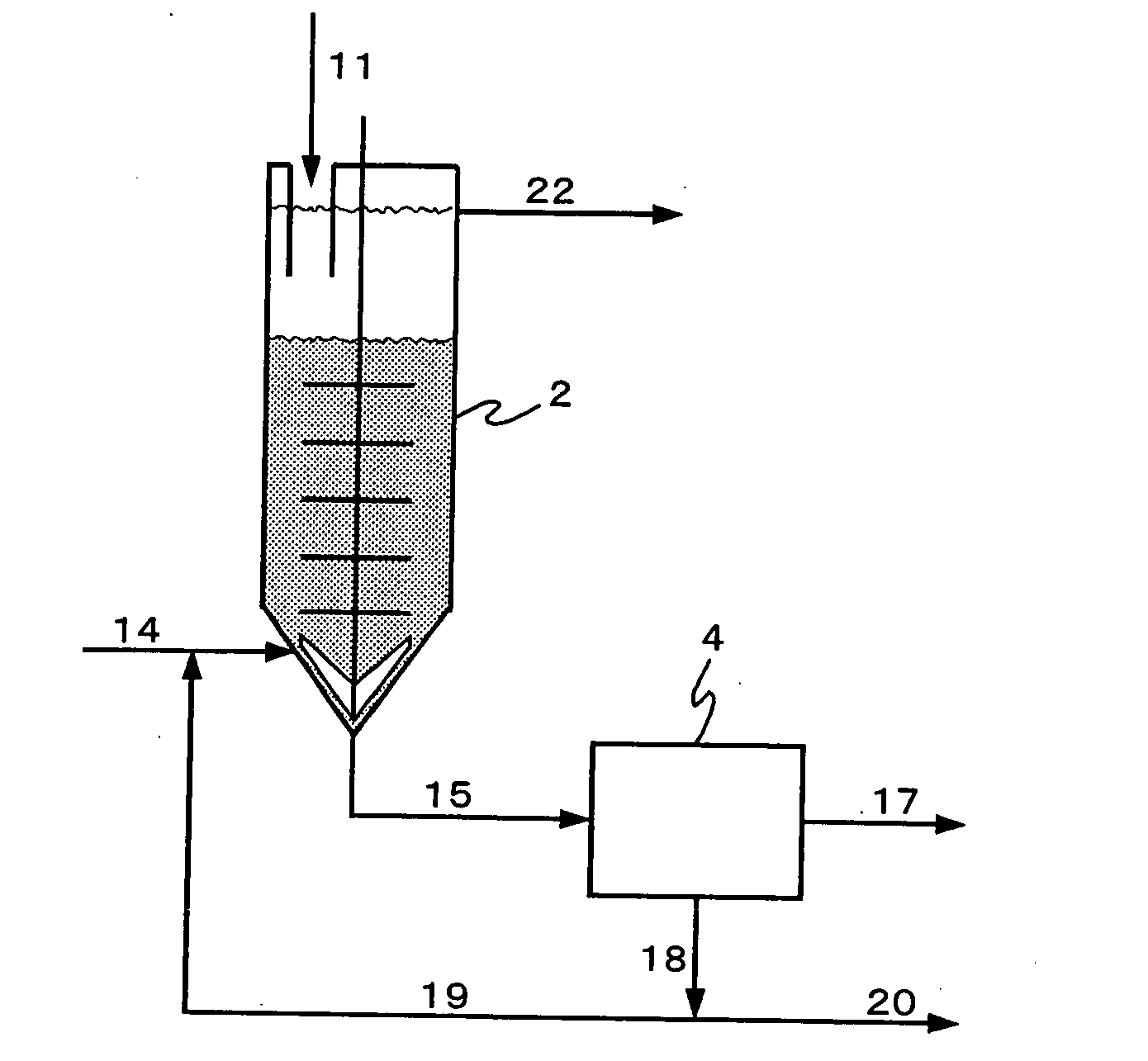

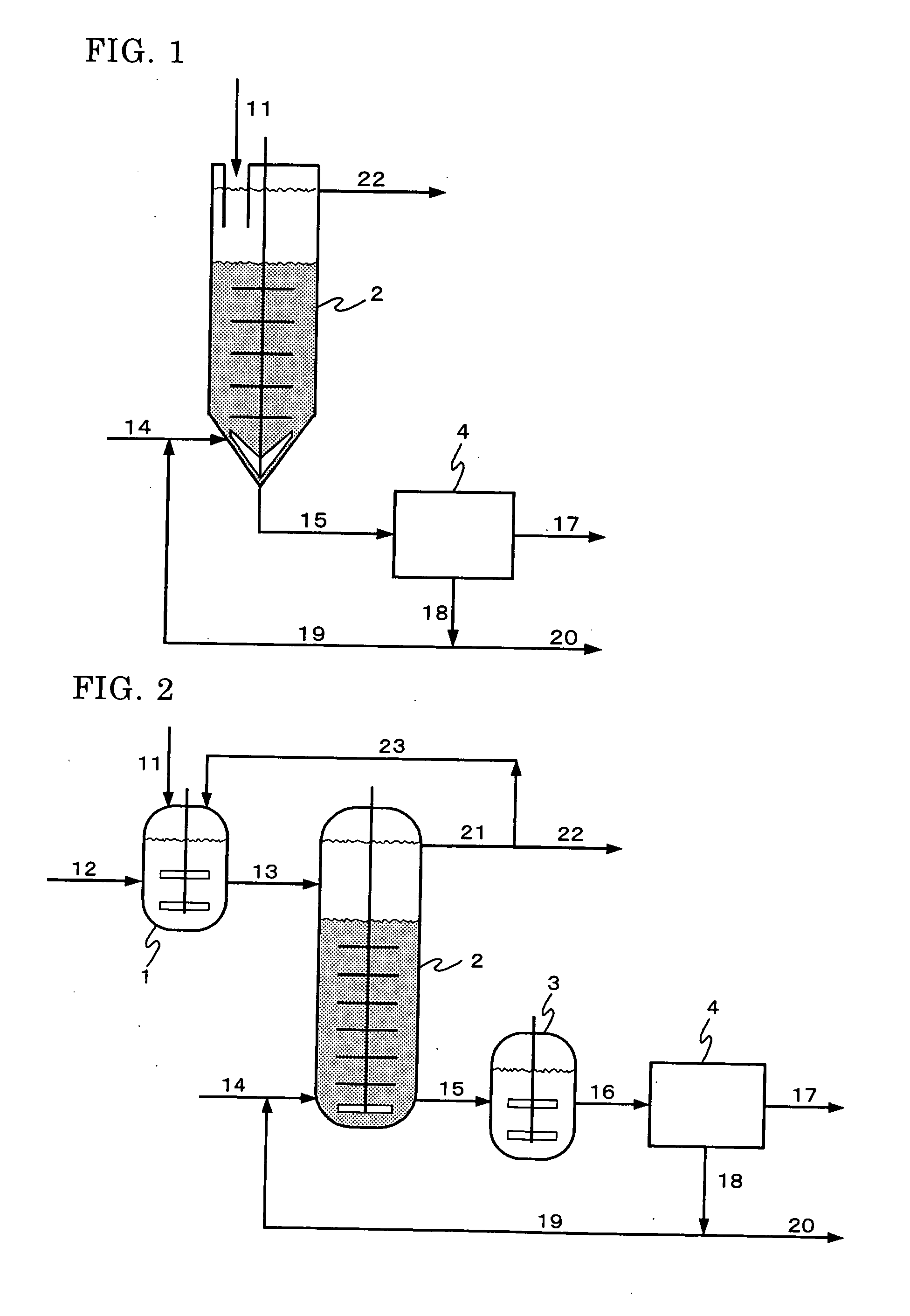

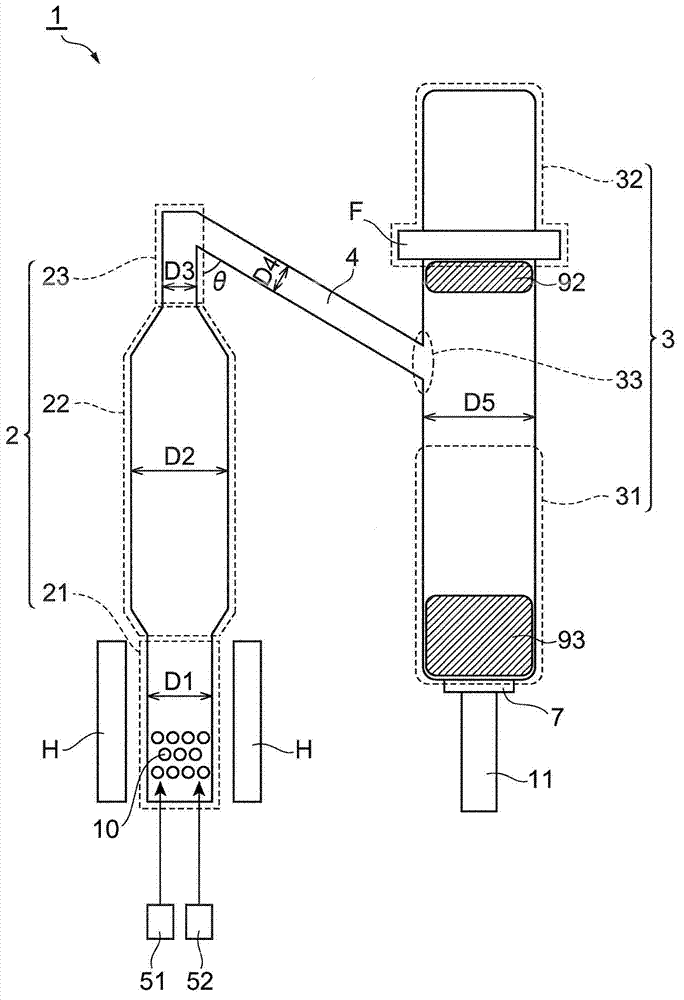

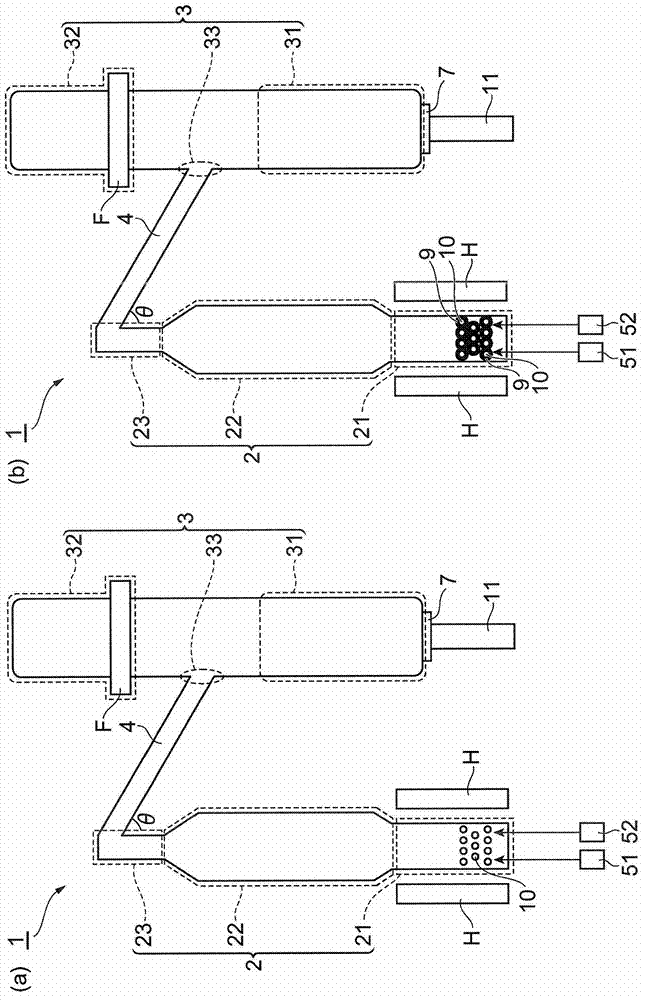

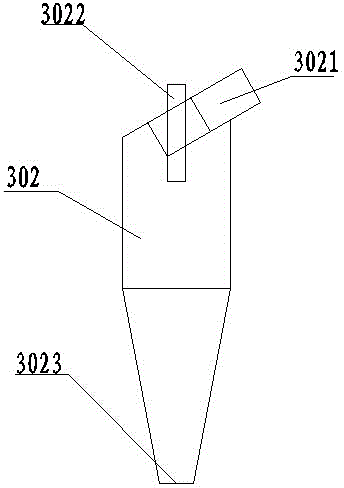

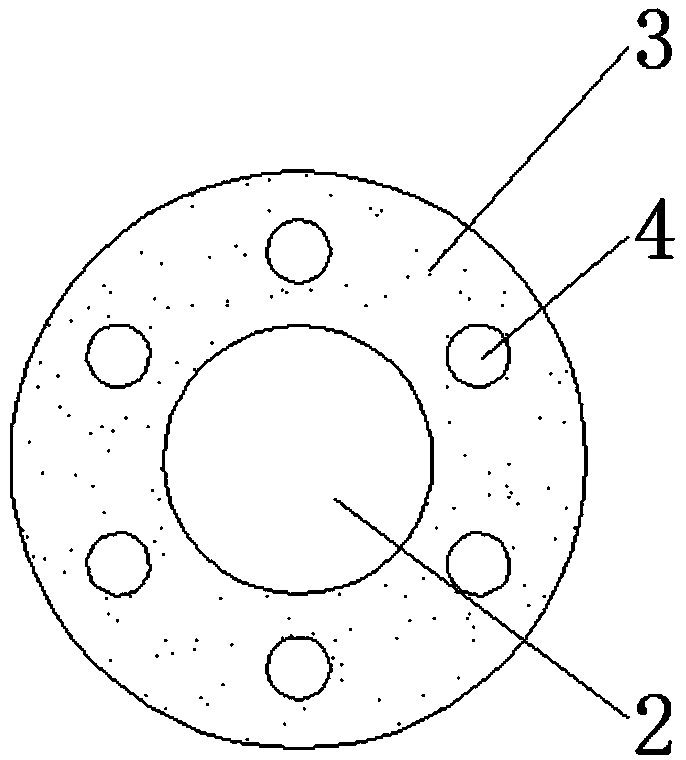

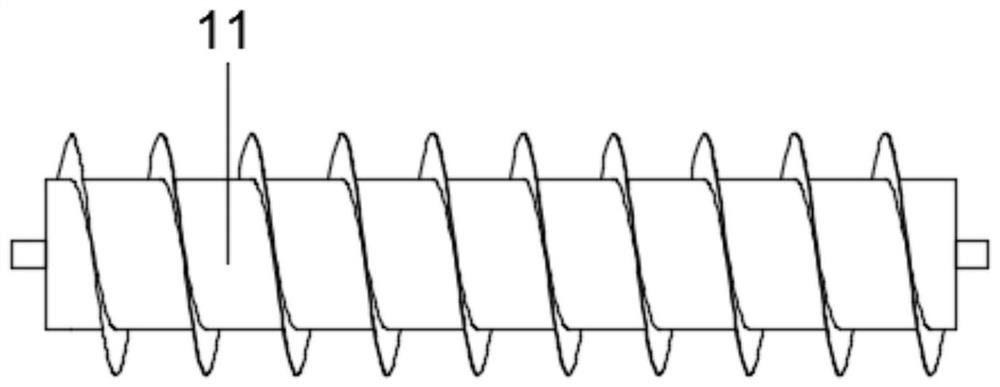

Apparatus for producing nanocarbon material and method for producing nanocarbon material

InactiveCN102741162AMaterial nanotechnologyIndividual molecule manipulationGravitational sedimentationReaction tube

Disclosed is an apparatus (1) for producing a nanocarbon material, which is characterized by comprising: a reaction tube (2) wherein a starting material gas and a carrier gas are supplied and a nanocarbon material is grown; a connection tube (4), which is connected to the reaction tube (2), and through which an aerosol-like mixture of the nanocarbon material and the carrier gas passes; and a collection tube (3), which is connected to the connection tube (4) and collects the nanocarbon material from the mixture. The apparatus (1) for producing a nanocarbon material is also characterized in that the collection tube (3) comprises a discharge section (32) that is located above a connection part (33), at which the collection tube (3) is connected to the connection tube (4), and discharges the carrier gas contained in the mixture to the outside, and a trapping section (31) that is located below the connection part (33), at which the collection tube (3) is connected to the connection tube (4), and traps the nanocarbon material that is separated from the mixture by means of gravitational sedimentation.

Owner:THE UNIV OF TOKYO +1

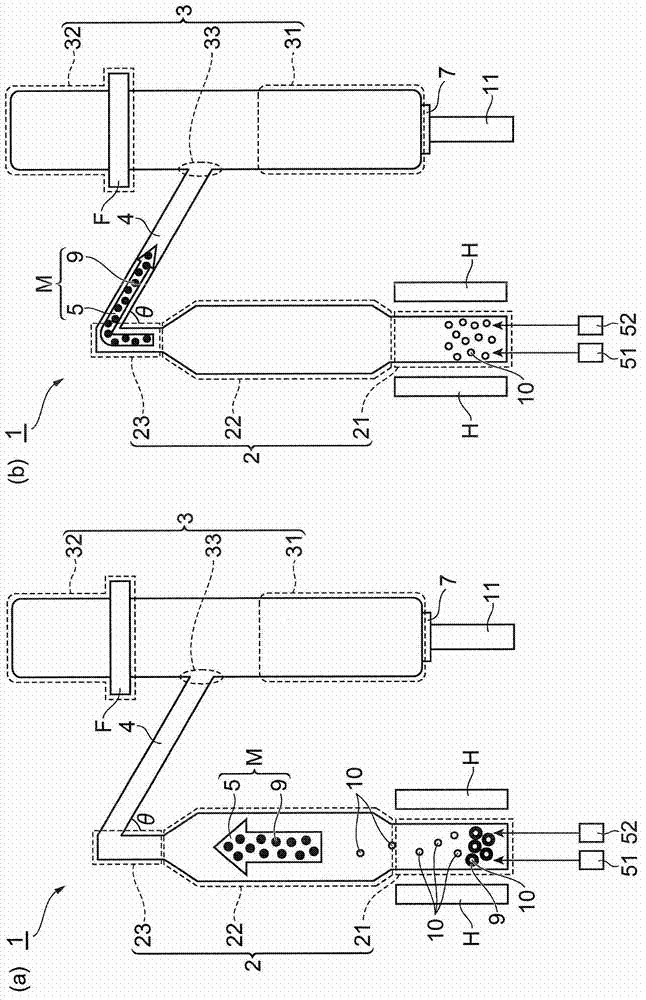

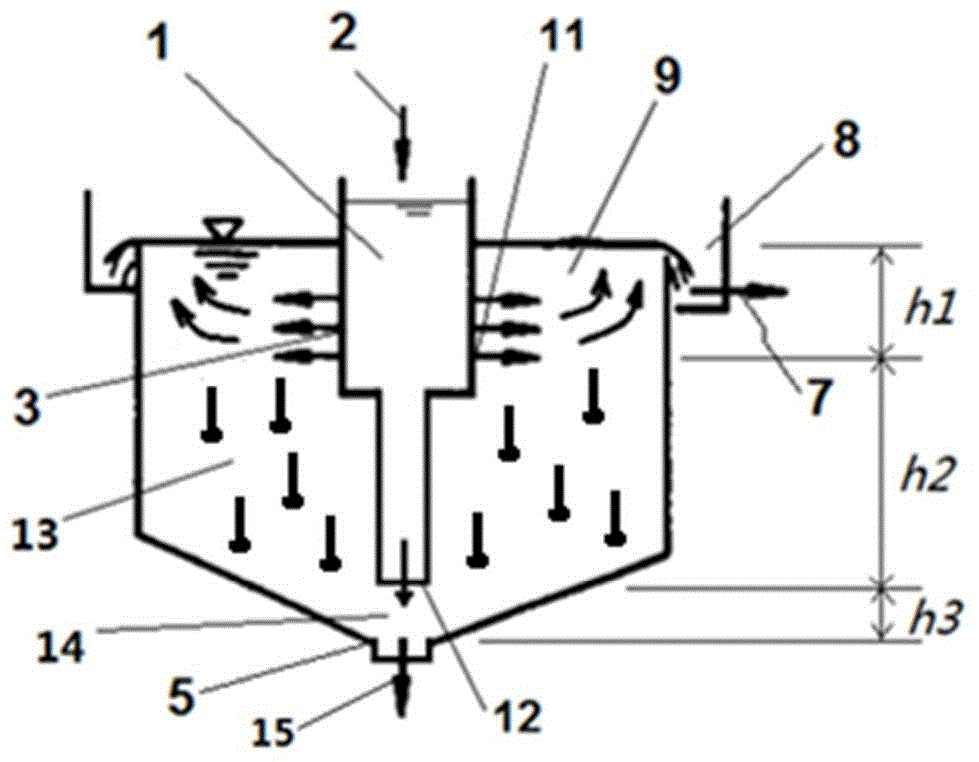

Gravity settling device used for solid-liquid separation

ActiveCN105800751AWater/sewage treatment by flocculation/precipitationSedimentation settling tanksSettling basinEngineering

The invention relates to a gravity settling device. The device comprises a settling pool, and a supernatant outlet, a first mixed solution inlet, a second mixed solution inlet and a concentrated mixed solution outlet which are successively arranged in the settling pool from top to bottom, wherein a rapid settling area arranged between the first mixed solution inlet and the second mixed solution inlet is not provided with a mixed solution inlet; meanwhile, the height of the rapid settling area accounts for 30% to 90% of the total height of a clarifying area, the rapid settling area and a washout area. The invention also relates to a sludge biological treatment device and a method using the gravity settling device. The gravity settling device provided by the invention has the following advantages: solid-liquid separation ability and efficiency are significantly improved; separation effect can be maintained; meanwhile, the yield of a supernatant is increased, or a desired yield of the supernatant is maintained during treatment of a mixed solution with an increased particle concentration.

Owner:金锣水务有限公司

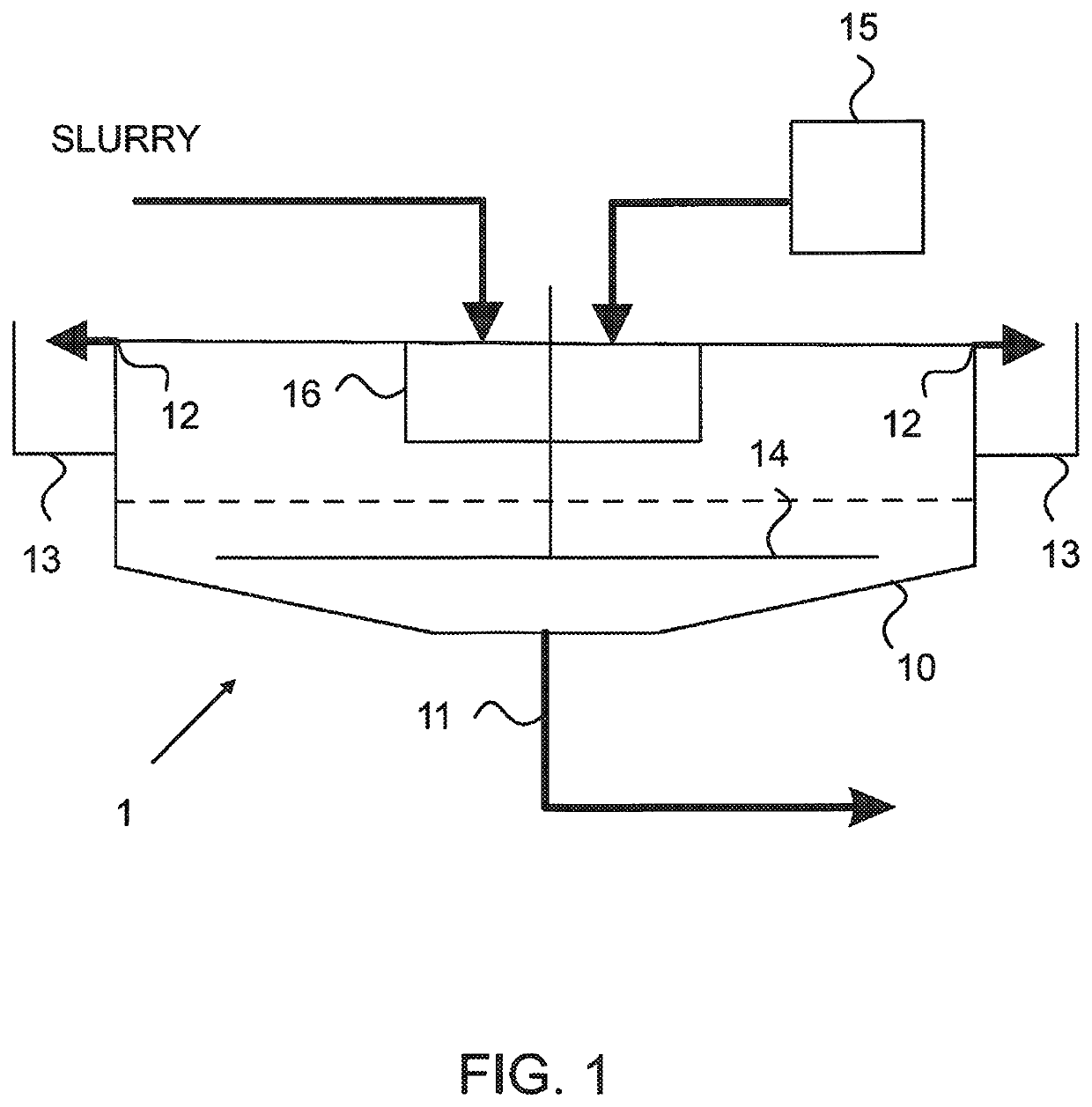

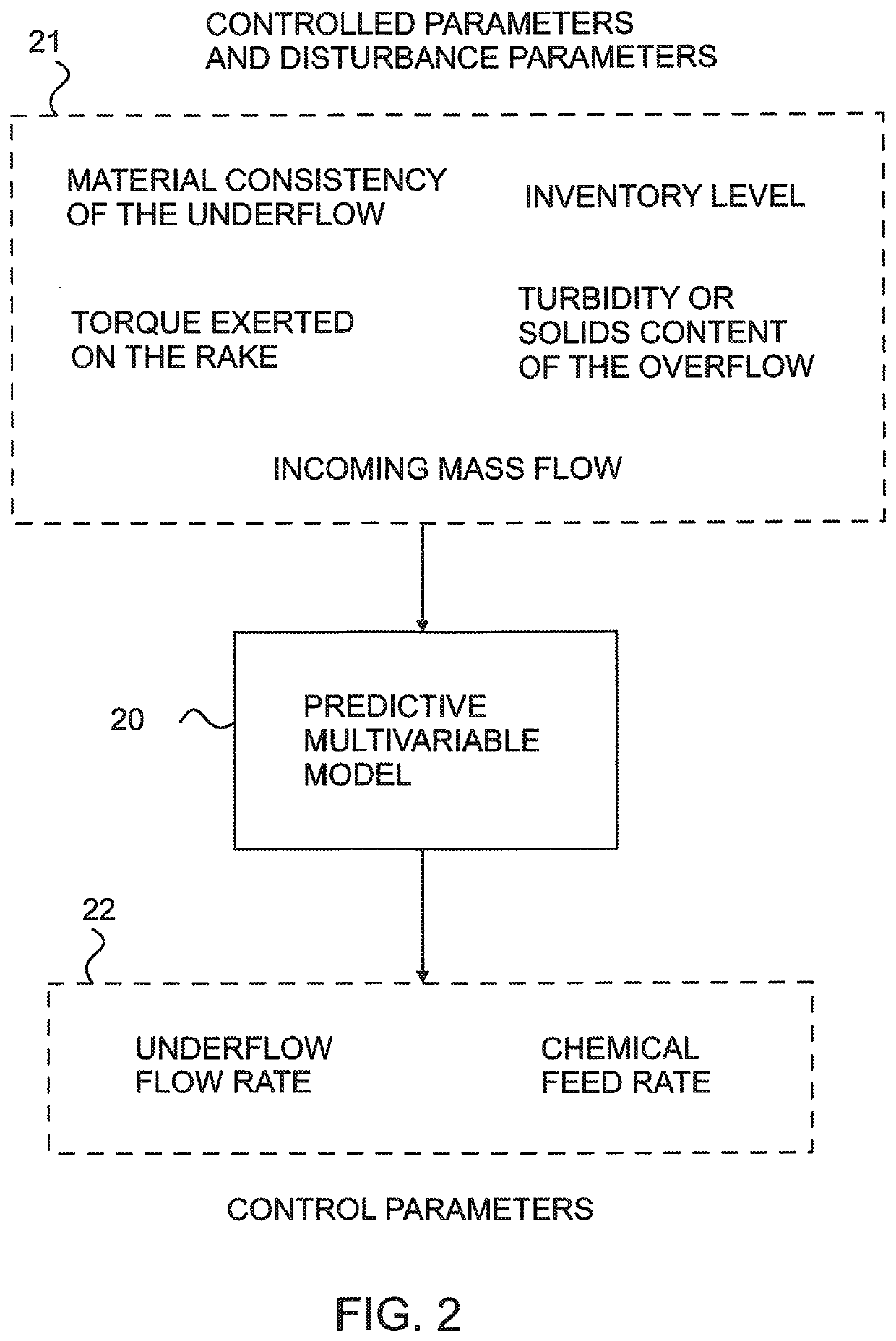

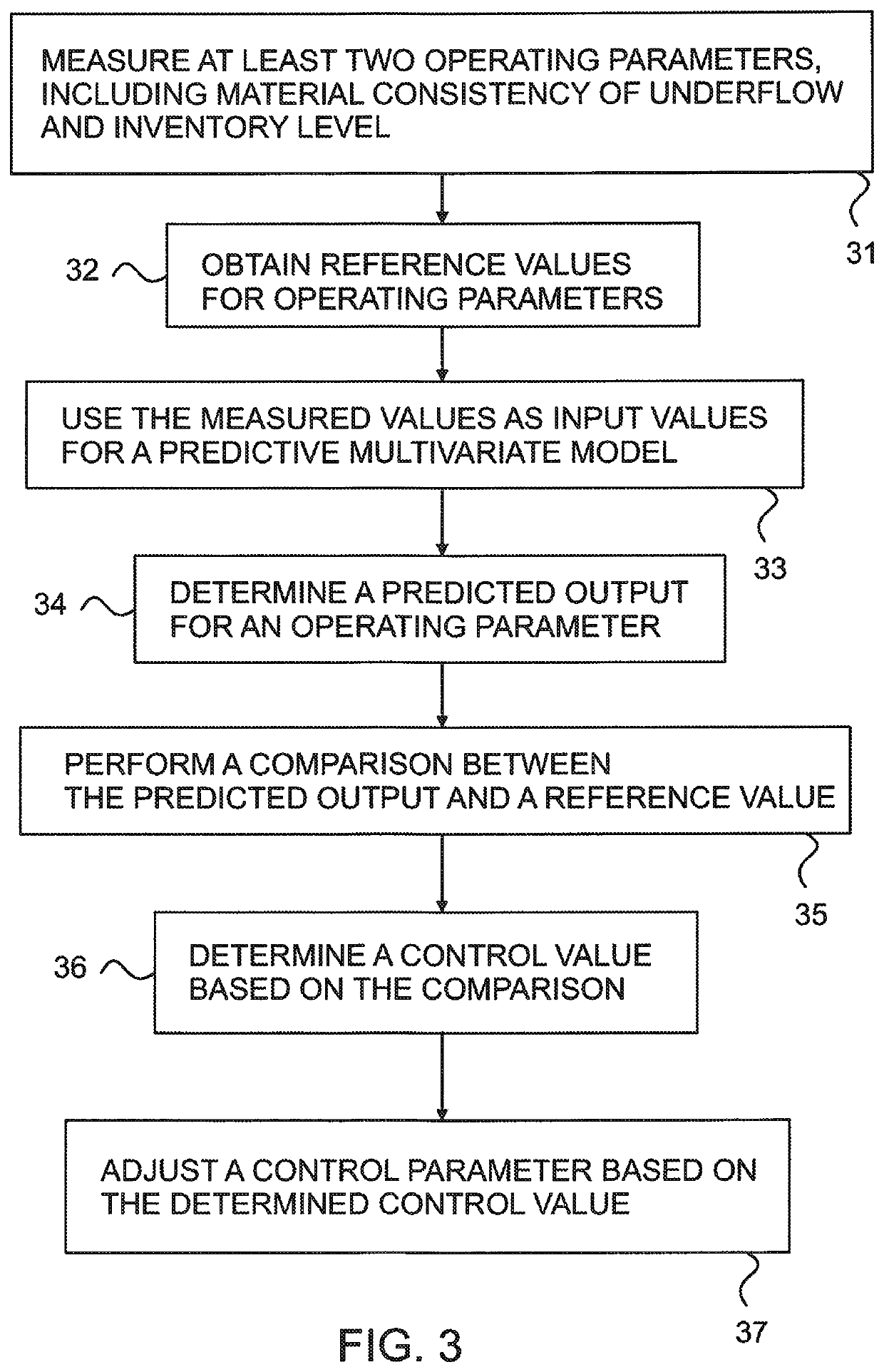

Method and arrangement for controlling a dewatering process

ActiveUS20200129887A1Reduce variationReduce usageWater treatment parameter controlComputer controlEngineeringGravitational sedimentation

An arrangement and a method for controlling a dewatering process including measuring values representing operating parameters of the gravitational sedimentation device and using the values as input values for a predictive multivariable model for predicting an operating state of the gravitational sedimentation device. The disclosure further relates to obtaining reference values for the operating parameters, determining at least one predicted output for an operating parameter of the gravitational sedimentation device, and comparing the predicted output to at the reference values to determine control values that will affect changes in operation of the gravitational sedimentation device.

Owner:METSO OUTOTEC (FINLAND) OY

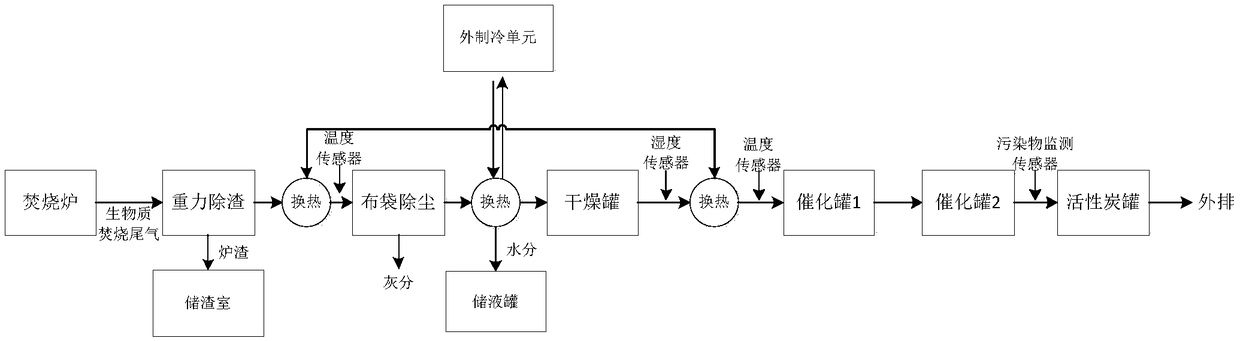

Tail gas treatment method of biomass incinerator

InactiveCN108379983AReduce usageSimple processing methodCombination devicesGas treatmentWater vaporLiquid storage tank

The invention provides a biomass incineration tail gas treatment method. The biomass incineration tail gas treatment method mainly comprises the following steps: enabling biomass incineration tail gasto pass through a high-temperature region and melting ash residues; then enabling the biomass incineration tail gas to pass through a low-temperature region and condensing into a block; then carryingout gravitational sedimentation to remove large-particle ash residues; then carrying out heat exchange and cooling the temperature of the tail gas to 130 to 170 DEG C; then removing dust through a ceramic filter and a cloth bag to remove micron dust; treating the tail gas through a heat exchanger and reducing the temperature, so as to condense water steam into liquid-state water; then recycling the liquid-state water into a liquid storage tank; after drying residual water steam through a drying tank, raising the temperature of the tail has to 110 to 140 DEG C through heat exchange of a hearthand directly introducing the tail gas into a catalysis tank 1; taking carbon monoxide in the tail gas as a reducing agent and removing nitrogen oxide; then enabling the tail gas to pass through a catalysis tank 2; removing the residual carbon monoxide and volatile organic pollutants by utilizing excessive oxygen in the tail gas; after an instrument monitors that the tail gas is qualified, discharging the tail gas through an activated carbon security tank. The biomass incineration tail gas treatment method provided by the invention has the advantages of simple and feasible procedure and relatively low energy consumption and material consumption; the biomass incineration tail gas treatment method is especially suitable for biomass incineration tail gas treatment in a controlled ecological life-support system.

Owner:YANSHAN UNIV

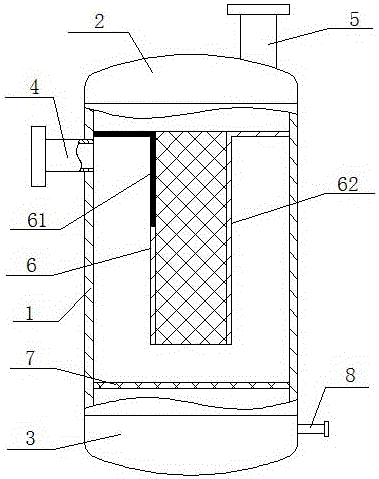

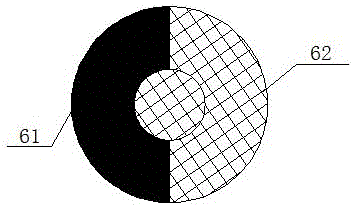

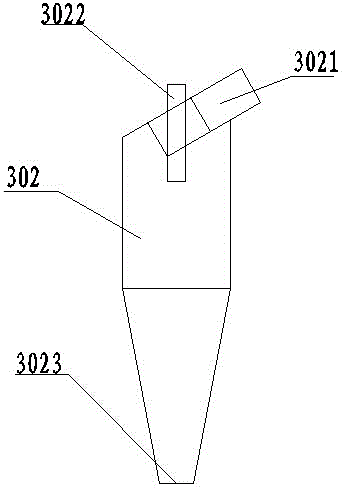

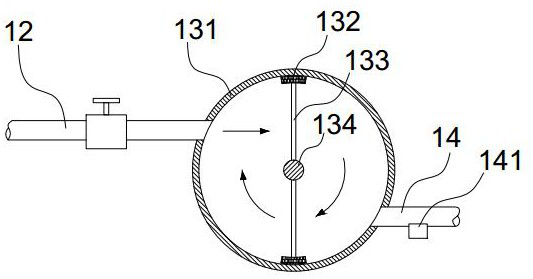

Gravitational settling type gas-liquid separation method

InactiveCN106318501AHigh speedImprove efficiencyCombination devicesGaseous fuelsFiltrationEngineering

The invention discloses a gravitational settling type gas-liquid separation method. The gravitational settling gas-liquid separation method comprises the following steps of: step (1) arranging an upper end cover at the upper end of a barrel, arranging a lower end cover at the lower end of the barrel, and arranging a gas inlet pipe on the barrel wall close to the upper end to cause a gas-liquid mixture to enter a separator from the barrel; step (2) arranging a filter element in the barrel, wherein the filter element comprises a diversion part and a filtration part, the diversion part is made from an airtight material and is located at one side, close to the air inlet pipe, of the filter element, and discharging gas through a gas outlet pipe arranged on the upper end cover after filtering the gas; and step (3) discharging liquid obtained after separation by arranging a liquid draining pipe at the lowest point of the bottom surface of the lower end cover.

Owner:CHENGDU ZHENGSHENG ENERGY TECH DEV CO LTD

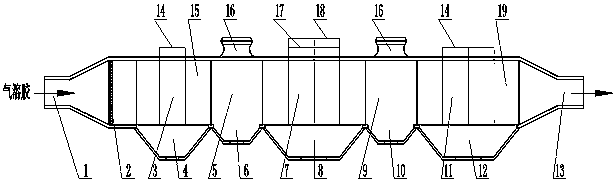

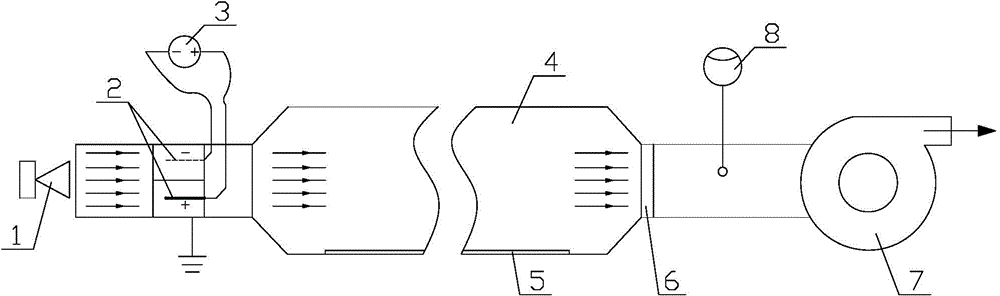

Device and method for efficiently removing fine particulate matters in a multi-field partition manner

ActiveCN111097251AGuarantee unimpededAvoid dust accumulationHuman health protectionCombination devicesElectrocoagulationDust control

The invention discloses a device and a method for efficiently removing fine particles in a multi-field partition manner. A box body structure with the same cross section structure size is adopted, andmain body channels are arranged in series in a manner that flow channel center lines coincide; the method comprises the steps of negative direct current pre-dedusting, primary acoustic agglomerationstrengthening, pulse charge coagulation and direct current bipolar coagulation, secondary acoustic agglomeration strengthening and negative direct current dedusting. Gravity settling, inertia separation and a virtual impactor effect are combined, the collision coagulation effect of fine particles is enhanced through multiple electric coagulation modes and the acoustoelectric synergistic effect, and efficient removal of the particles with the large particle size and the small particle size is achieved step by step in a regional mode. Through a parallel connection mode of pulse charge coagulation and direct-current bipolar coagulation, the partitioned electrocoagulation effect of particles with different particle sizes is achieved through the inertia effect and the virtual impactor effect, and meanwhile the trapping and removing effect of fine particles is enhanced through the ash removal and dust collection effect of the movable electrode plate. The fine particulate matter removal efficiency is high.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

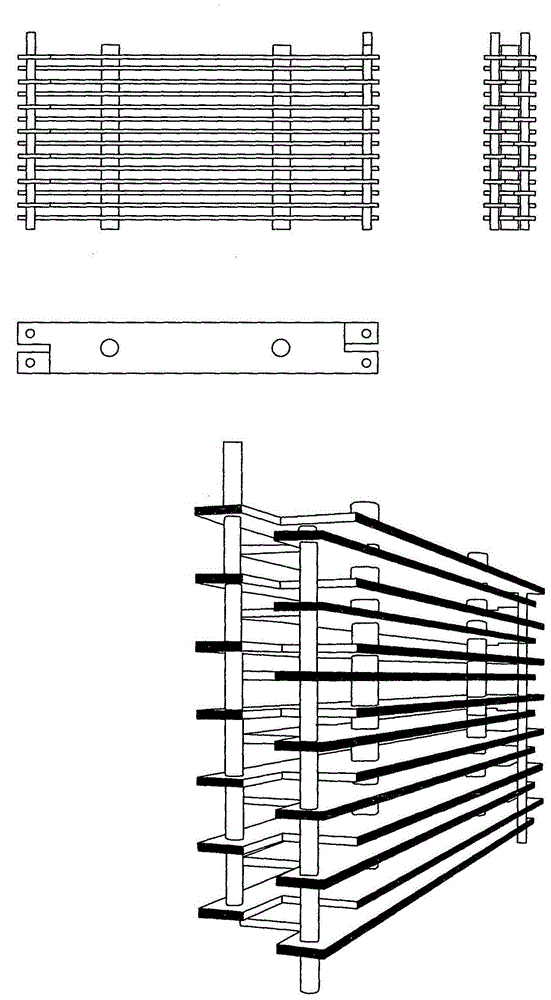

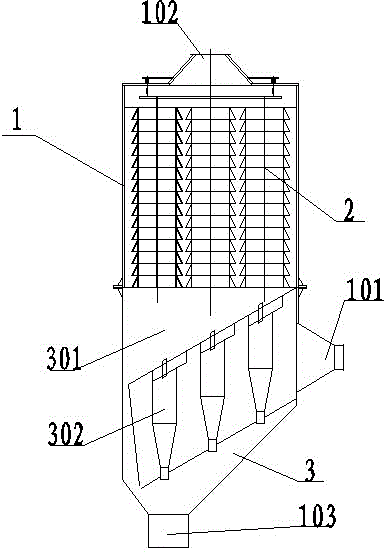

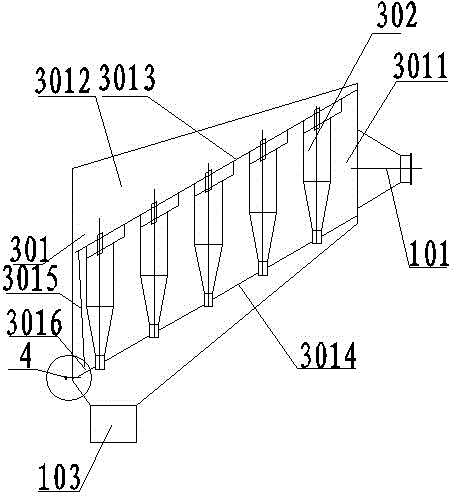

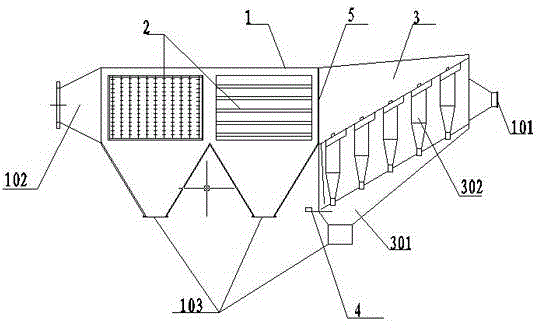

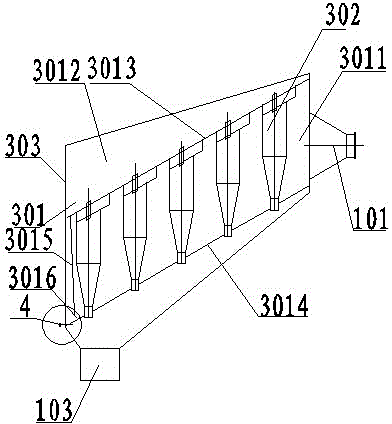

Vertical electrical dust collector integrating gravity and cyclone dust removal

A vertical electrical dust collector integrating gravity and cyclone dust removal is provided. Cyclones in the dust collector are arranged in a first-level gravity sedimentation chamber, and the central axis of each cyclone is in a vertical-state arrangement; a dust-containing gas inlet of each cyclone is located in the first-level gravity sedimentation chamber, and the center line of each dust-containing gas inlet is parallel to an upper tube sheet of the cyclones; the center line of a separated gas outlet of the upper end of each cyclone is coincident with the central axis of each cyclone; the separated gas outlet of the upper end of each cyclone and a dedusting port of the lower end of each cyclone are both communicated with a second-level gravity sedimentation chamber. By improving a structure of a gravity cyclone dust collector, the device described in the invention changes the structure of the cyclones and allows the dust-containing gas inlets of the cyclones to be parallel to the upper tube sheet of the cyclones, in the case, the center line and the central axis of the dust-containing gas inlet of each cyclone form an included angle which is an acute angle, a screw pitch of dust in the cyclones is small, the friction is mall, and the individual working efficiency of the mounted cyclones is improved with the connection way.

Owner:LUOYANG INST OF SCI & TECH

Method and device for detecting fine dust electrical agglomeration

InactiveCN104596899AIntuitivePracticalParticle size analysisExternal electric electrostatic seperatorElectrical field strengthGravitational sedimentation

The invention discloses a method and device for detecting fine dust electrical agglomeration. Through gravity settlement characteristics of aerosol particles, mass distribution and a particle size distribution rule of dust subjected to electrical agglomeration in a settling chamber of the device under the action of gravity and gas flows are tested. Several slide glasses arranged on a settlement plate is used as sampling units, when charged and agglomerate dust of dust-containing gas flows going through a charged electrode is blown into the settlement chamber, under the action of gravity, the dust is settled on the slide glasses arranged along a gas flow direction so that a sampling process is finished. The slide glasses are taken and weighed so that dust mass distribution of all settling sections is obtained. Through granularity analysis based on a biological microscope, particle size distribution of the settling sections is obtained. Based on charged performances of dust, through a contrast test after change of electric field intensity and frequency alternation, mass distribution and particle size distribution are tested and effects of electric field intensity and alternate frequency on dust electrical agglomeration are determined.

Owner:CHANGZHOU UNIV

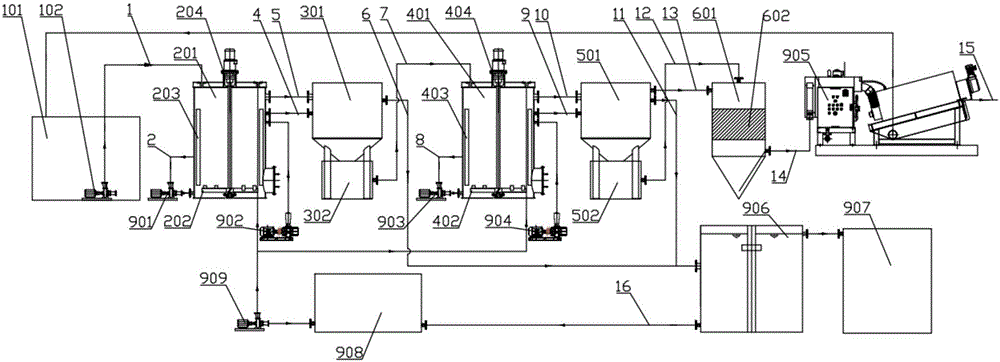

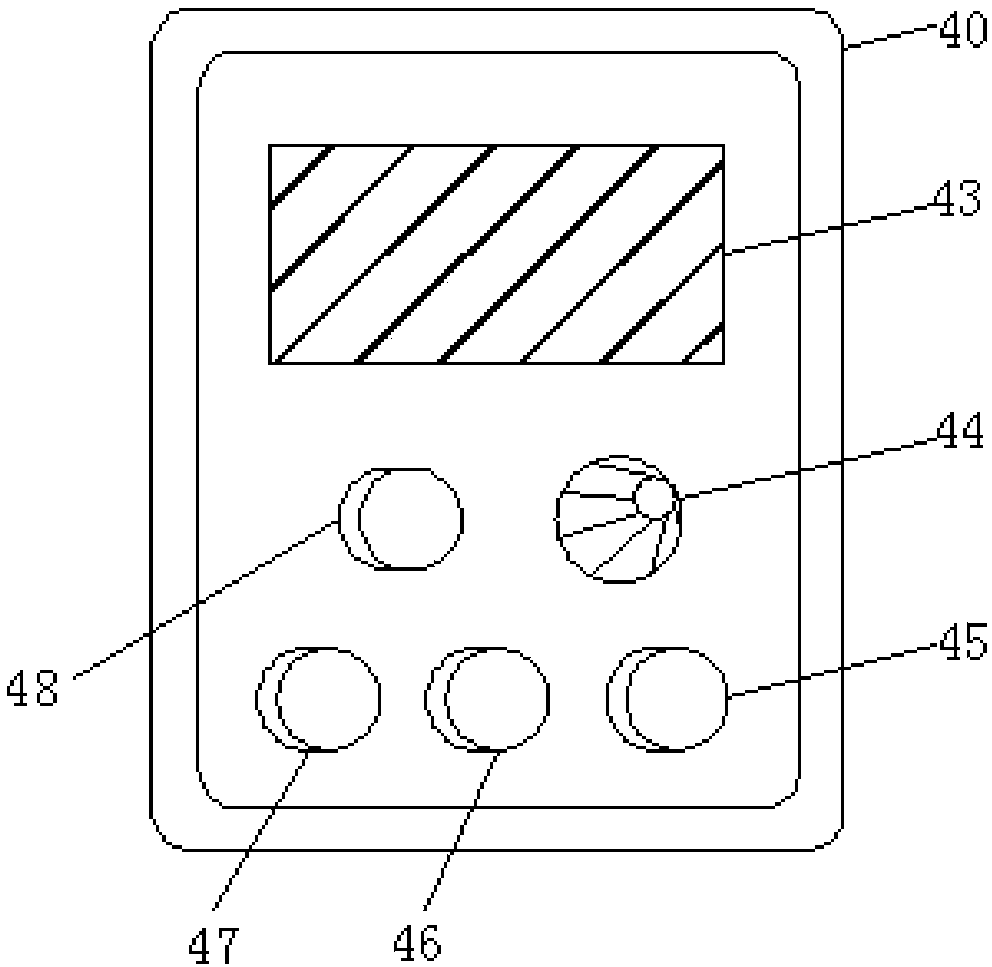

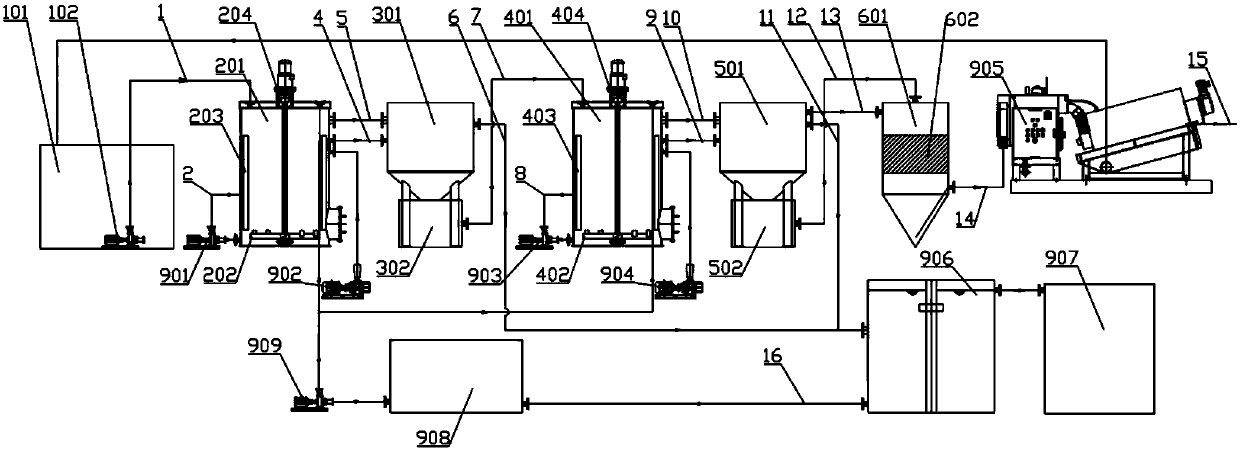

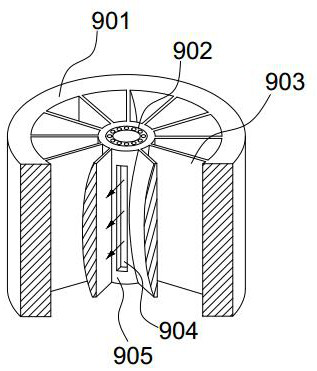

Short-process oily sludge treatment system

ActiveCN105668966AAvoid cloggingMeet the basic requirements for processingSludge treatmentFailure rateOil separation

The invention discloses a short-process oily sludge treatment system which comprises a first ultrasonic cleaning device, a first sedimentation device, a second ultrasonic cleaning device, a second sedimentation device, a third sedimentation device, an overlap dewatering machine, a gravitational sedimentation oil separation tank (906), an oil storage tank (907) and a high-temperature water tank. The short-process oily sludge treatment system is characterized in that a tank bottom oily sludge storage pool (101) is used for storing tank bottom oily sludge, to-be-treated materials only can be provided for the short-flow oily sludge treatment system when short-process oily sludge treatment system starting requirements are met by the oily sludge quantity of the tank bottom oily sludge, and double-cam pumps are arranged at the bottom of the tank bottom oily sludge storage pool (101). The short-process oily sludge treatment system has the advantages that the shortcoming of blockage due to oily sludge can be effectively overcome, and the oil and water separation efficiency further can be enhanced; the failure rate of water distribution pipelines can be greatly lowered while basic oily sludge treatment requirements are met.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

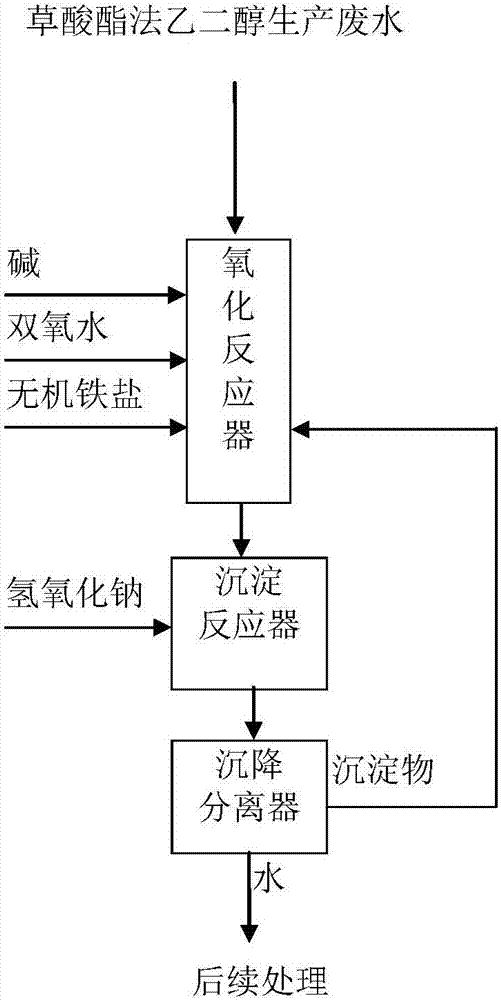

Ethylene glycol production wastewater treatment method

InactiveCN107311338ARaise the ratioReduce contentWater contaminantsMultistage water/sewage treatmentDecompositionWastewater

The invention relates to a method for treating ethylene glycol production wastewater from an oxalate method. The method comprises that 1, the pH value of ethylene glycol production wastewater is adjusted to 2.0-4.5; 2, the obtained ethylene glycol production wastewater is subjected to high temperature catalytic oxidation treatment; 3, the pH value of the treated effluent is adjusted to 6-9, and the precipitation reaction of dissolved iron and the decomposition reaction of residual H2O2 in the water are performed; and 4, the product obtained in the step 3 is subjected to gravitational sedimentation separation or centrifugal separation, wherein the separated iron precipitate can be recycled, and the separated water can be further treated. According to the present invention, with the treatment method, the COD content, the TOC content and the 1,4-dioxane content in the wastewater can be effectively reduced, and the biodegradability of the wastewater can be significantly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sediment water tank for filtering settling type pollutants

InactiveCN107601633ASlow down the flow of waterReduce processing costsSettling tanks feed/dischargeWater/sewage treatment by flocculation/precipitationWater storage tankWater flow

The invention discloses a sediment water tank for filtering settling type pollutants. The sediment water tank comprises a wastewater pipeline, a diffusion guide pipe, a reinforcing support frame, an overflow port and a draining port, wherein the wastewater pipeline is connected with a water inlet; a flange is arranged on the water inlet; a fixing hole is formed on the flange; the diffusion guide pipe is connected with the water inlet; a cofferdam is arranged at the top end of the water tank; the overflow port is connected with the water tank; the draining port is located at the bottom of the water tank; and a support base is connected with the water tank. The sediment water tank for filtering settling type pollutants is modified from a common PE water storage tank; a gravity settling principle is utilized to settle the pollutants heavier than water to the water bottom, so that water overflows from the overflow port at the upper end of the water tank; and the diffusion guide pipe is arranged in the water tank and the diameter of the diffusion guide pipe is more than the diameter of the wastewater pipeline, so that the flow speed of the wastewater is reduced when the wastewater flowsinto the diffusion guide pipe from the wastewater pipeline.

Owner:KUNSHAN YIMING WATER TREATMENT EQUIP CO LTD

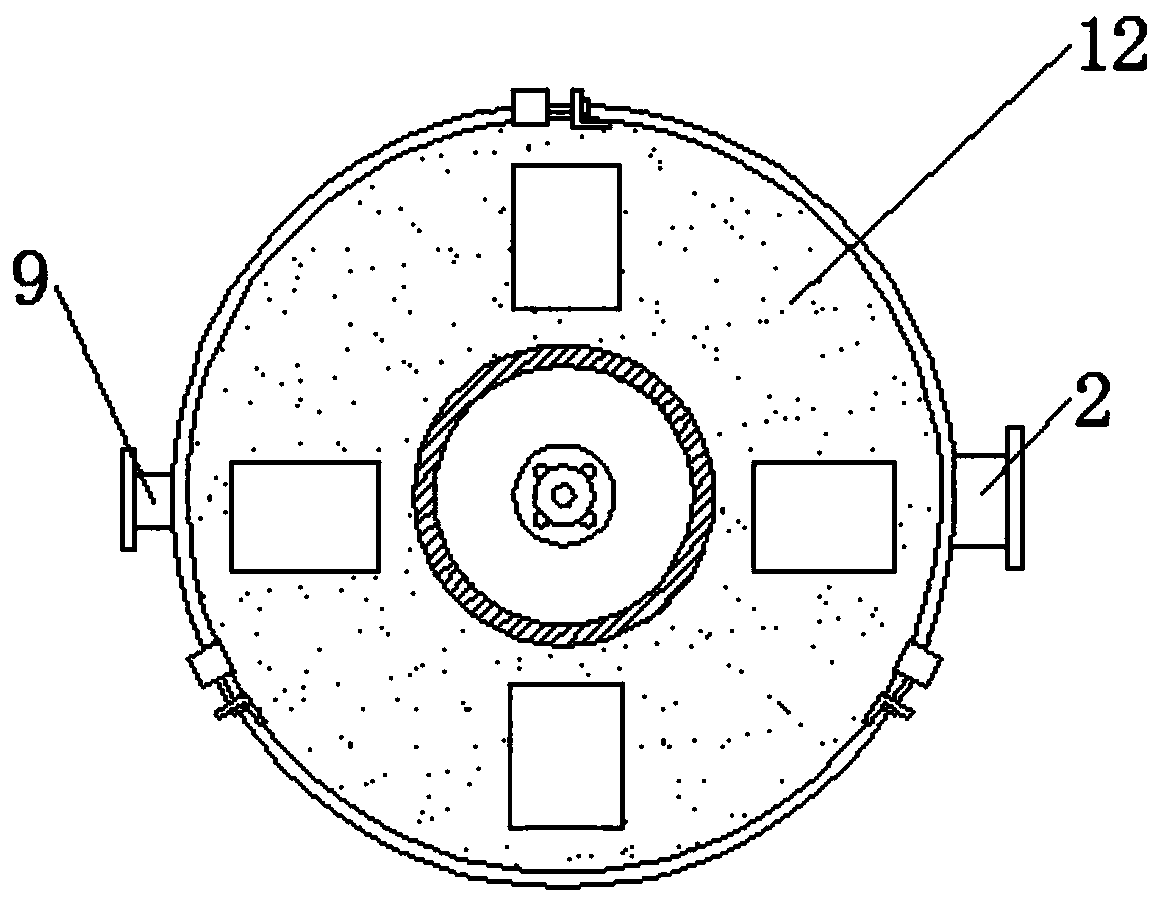

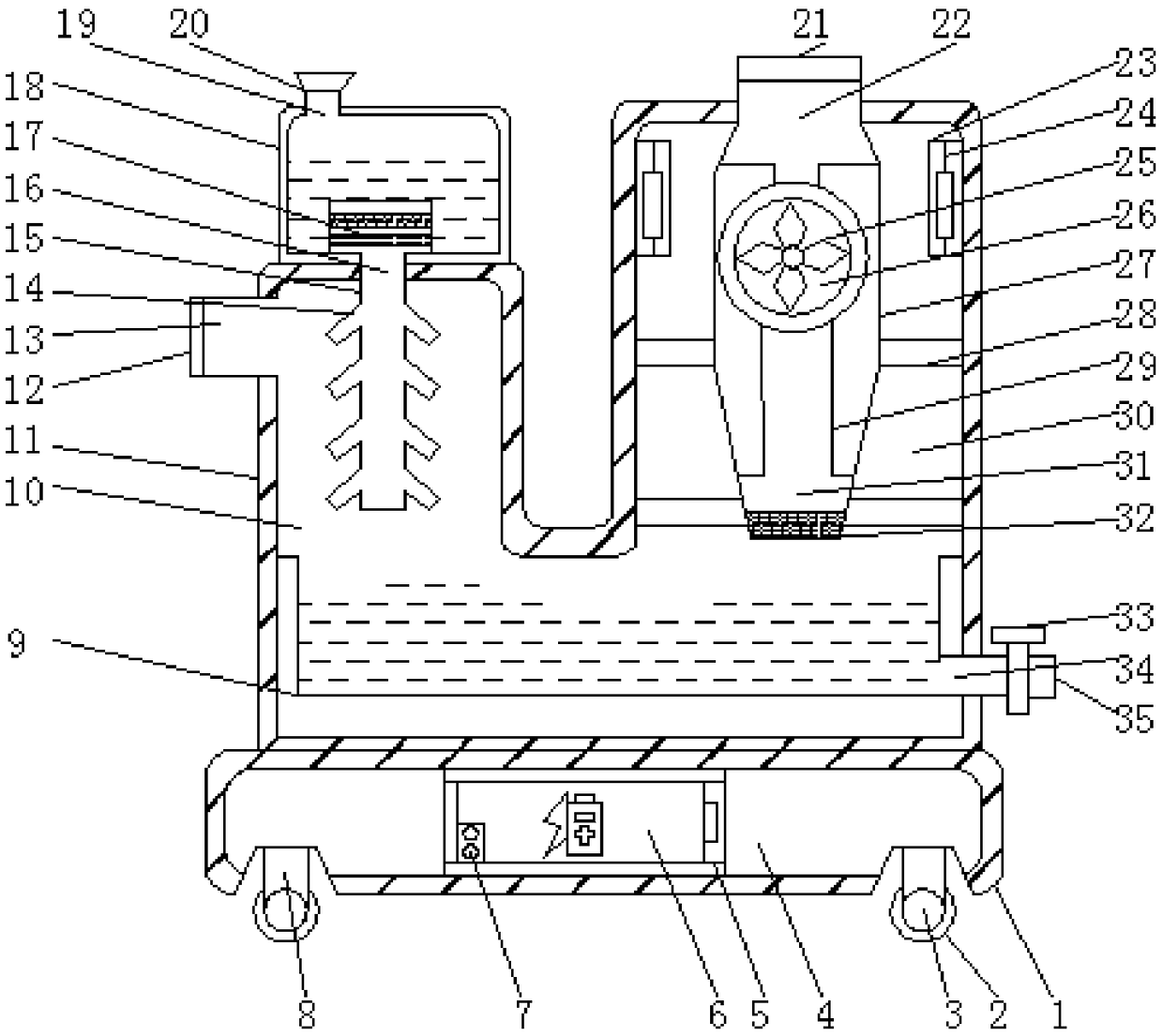

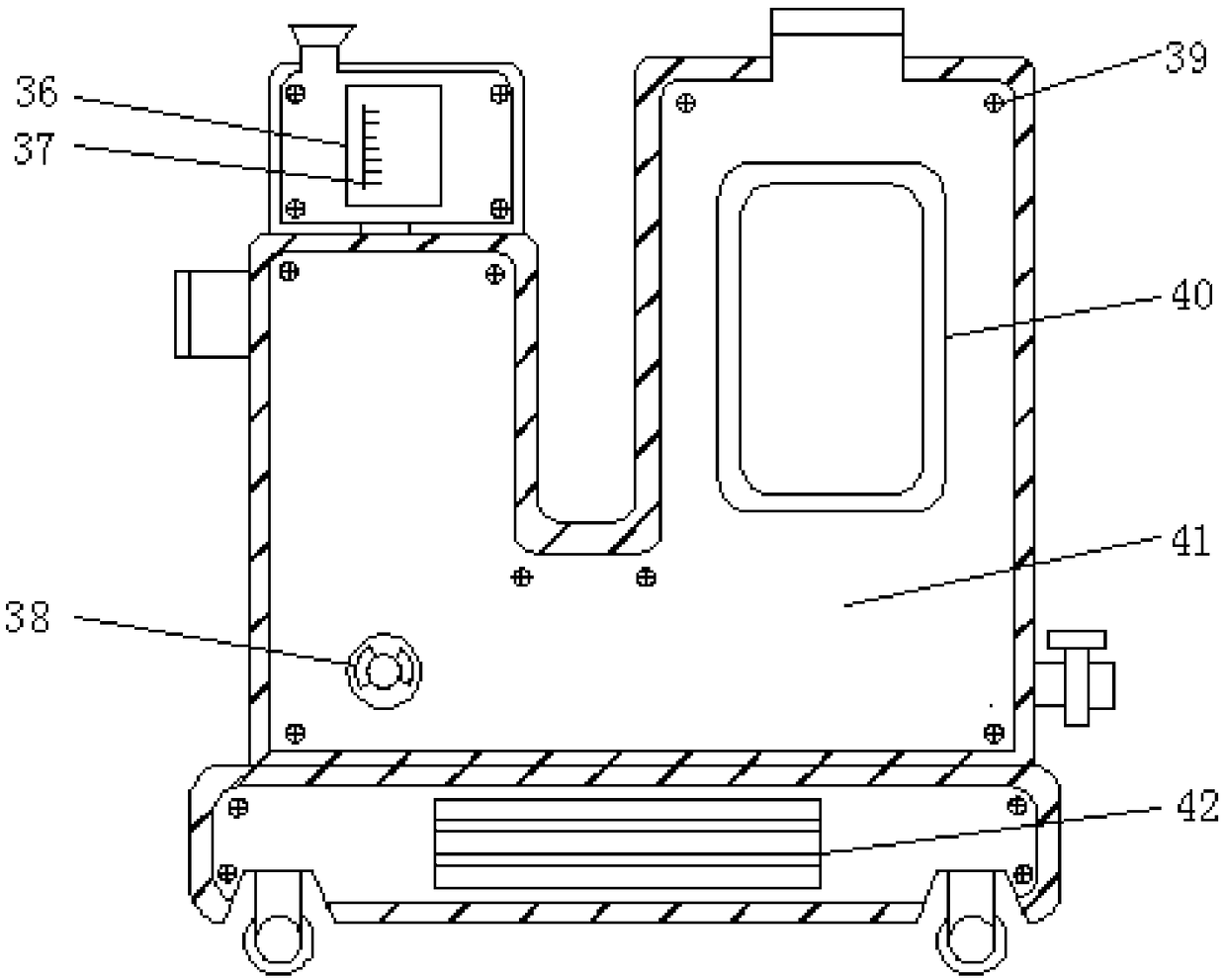

Gravitational sedimentation dust removal, spraying and acidic scent removal device

InactiveCN108854416AEffective secondary settlementHarm reductionCombination devicesEngineeringGravitational sedimentation

The invention discloses a gravitational sedimentation dust removal, spraying and acidic scent removal device. The gravitational sedimentation dust removal, spraying and acidic scent removal device comprises a main shell body, a spraying chamber, a rotary separation cavity and a base, wherein the main shell body is welded at the top of the base; the spraying chamber and the rotary separation cavityare arranged in the main shell body; an alkali-water mixed solution storage box is mounted at the top of the spraying chamber; a liquid charging opening is formed in one end of the top of the alkali-water mixed solution storage box; a liquid charging pipe is mounted at one end of the liquid charging opening; a pressurizing water cabin is mounted in the alkali-water mixed solution storage box; a liquid feeding opening is formed in the bottom of the pressurizing water cabin; an alkali liquid spraying pipe is mounted at one end of the liquid feeding opening; a rotary separation pipe is fixedly mounted in the rotary separation cavity through a rotary separation pipe fixing rod; the rotary separation pipe is internally provided with a fan. According to the gravitational sedimentation dust removal, spraying and acidic scent removal device, a series of structures are arranged so that the device has the characteristics of convenience for utilization, good dust sedimentation effect, good acidic scent removal effect and the like in a utilization process.

Owner:雷春红

A short-process oil sludge treatment system

ActiveCN105668966BAvoid cloggingMeet the basic requirements for processingSludge treatmentFailure rateSludge

The invention discloses a short-process oily sludge treatment system which comprises a first ultrasonic cleaning device, a first sedimentation device, a second ultrasonic cleaning device, a second sedimentation device, a third sedimentation device, an overlap dewatering machine, a gravitational sedimentation oil separation tank (906), an oil storage tank (907) and a high-temperature water tank. The short-process oily sludge treatment system is characterized in that a tank bottom oily sludge storage pool (101) is used for storing tank bottom oily sludge, to-be-treated materials only can be provided for the short-flow oily sludge treatment system when short-process oily sludge treatment system starting requirements are met by the oily sludge quantity of the tank bottom oily sludge, and double-cam pumps are arranged at the bottom of the tank bottom oily sludge storage pool (101). The short-process oily sludge treatment system has the advantages that the shortcoming of blockage due to oily sludge can be effectively overcome, and the oil and water separation efficiency further can be enhanced; the failure rate of water distribution pipelines can be greatly lowered while basic oily sludge treatment requirements are met.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

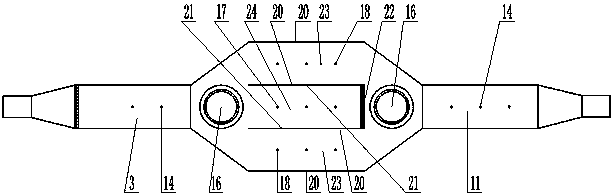

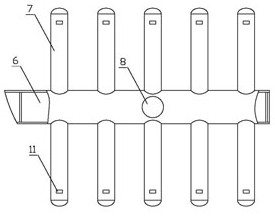

Horizontal electrical dust collector integrating gravity and cyclone dust removal

A horizontal electrical dust collector integrating gravity and cyclone dust removal is provided. Cyclones in the dust collector are arranged in a first-level gravity sedimentation chamber, and the central axis of each cyclone is in a vertical-state arrangement; a dust-containing gas inlet of each cyclone is located in the first-level gravity sedimentation chamber, and the center line of each dust-containing gas inlet is parallel to an upper tube sheet of the cyclones; the center line of a separated gas outlet of the upper end of each cyclone is coincident with the central axis of each cyclone; the separated gas outlet of the upper end of each cyclone and a dedusting port of the lower end of each cyclone are both communicated with a second-level gravity sedimentation chamber. By improving a structure of a gravity cyclone dust collector, the device described in the invention changes the structure of the cyclones and allows the dust-containing gas inlets of the cyclones to be parallel to the upper tube sheet of the cyclones, in the case, the center line and the central axis of the dust-containing gas inlet of each cyclone form an included angle which is an acute angle, a screw pitch of dust in the cyclones is small, the friction is mall, and the individual working efficiency of the mounted cyclones is improved with the connection way.

Owner:LUOYANG INST OF SCI & TECH

Composite efficient foam trap

The present invention relates to a compound high-effective foam-trapping device. It is characterized by simultaneously adopting three kinds of separationt echniques, namely, gravitational sedimentation, inertial collision and centrifugal separation on the equipment required for separating fog-foam from gas.

Owner:邰学林

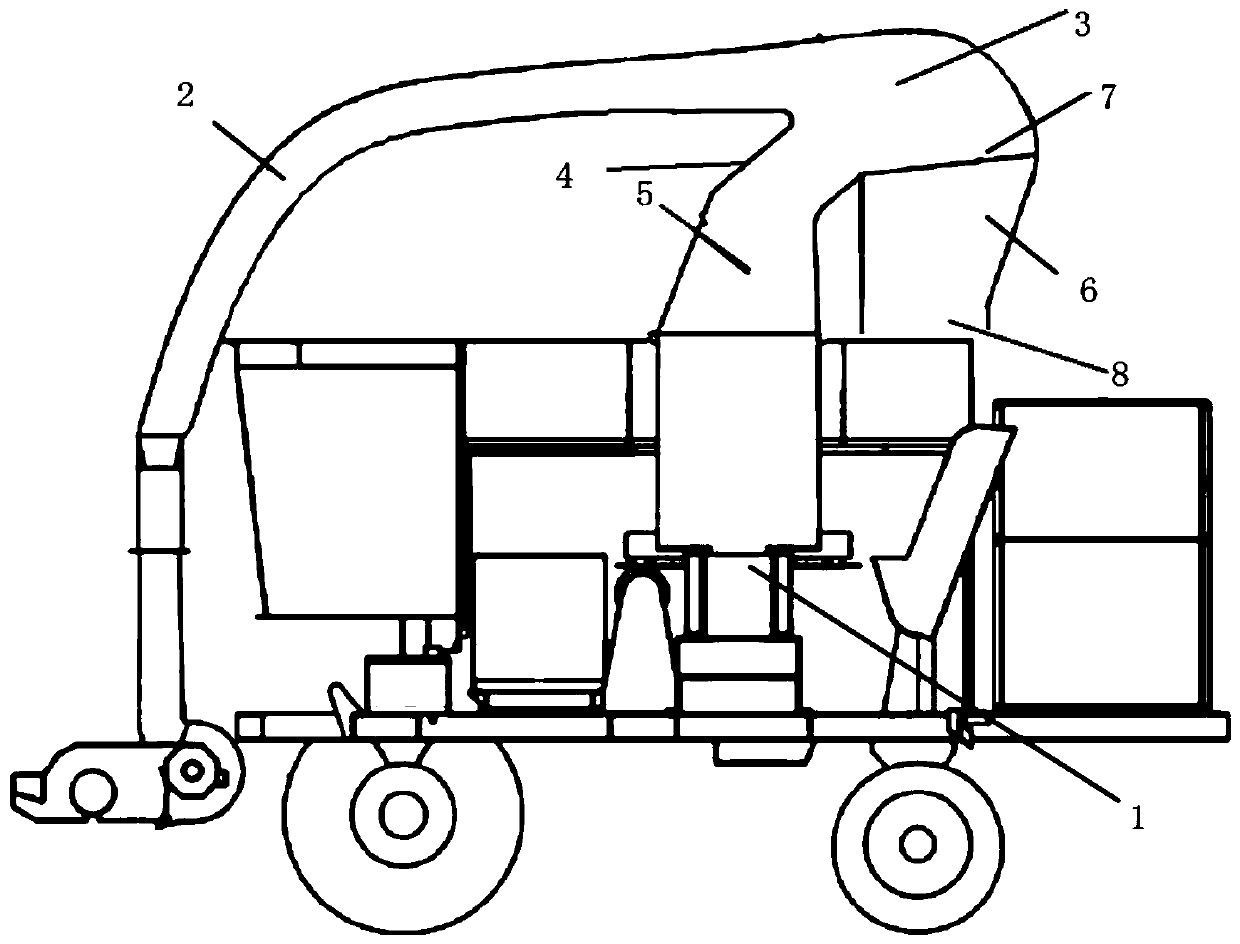

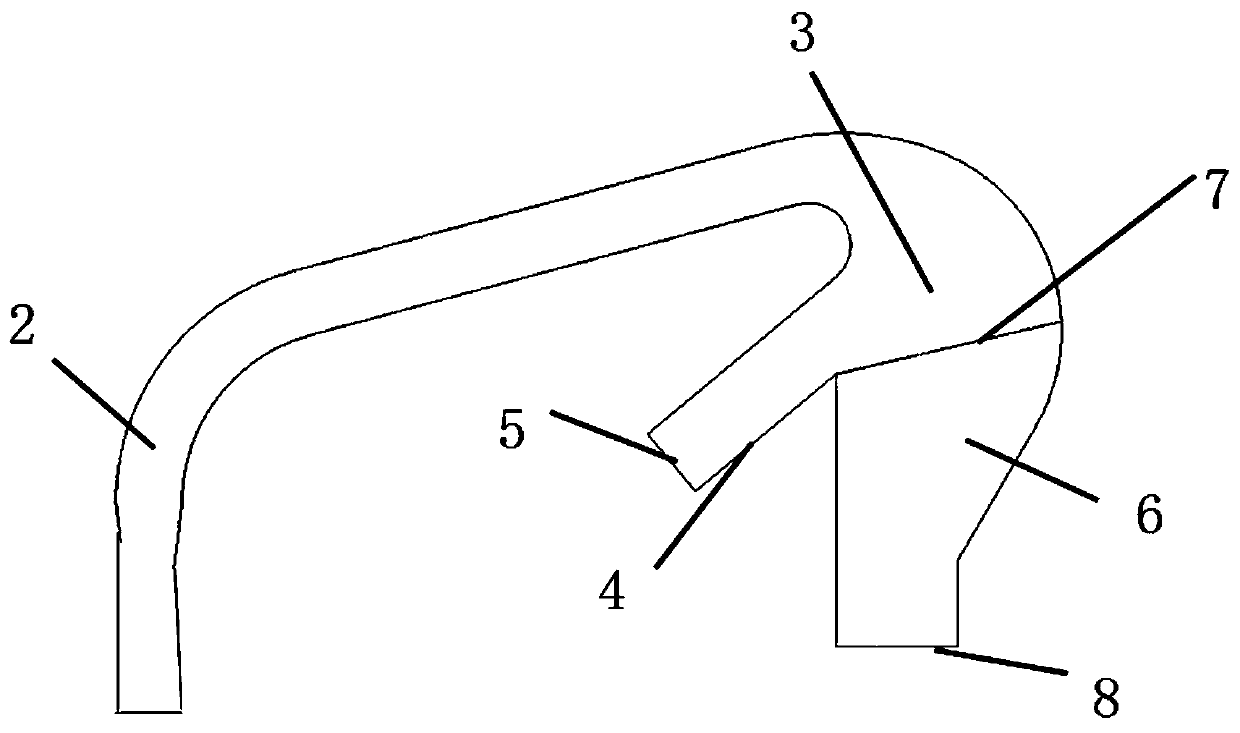

Dust removing device of protective self-propelled straw granulator

ActiveCN110976285AQuick releaseImprove the diffusion capacityGas current separationCuttersDust controlEnvironmental engineering

The invention discloses a dust removing device of a protective self-propelled straw granulator. The dust removing device comprises a straw channel, and the head end of the straw channel communicates with a cutting device of the protective self-propelled straw granulator. The tail end of the straw channel is inclined upwards and communicates with the inner wall of the top of a diffusion area. The bottom inner wall of the diffusion area communicates with one end of a gravity slope, and the other end of the gravity slope communicates with a straw granulator feeding port of the protective self-propelled straw granulator. The bottom of the diffusion area communicates with the top end of a deceleration area through a dust removing filtering screen, and the bottom end of the deceleration area communicates with a dust discharging channel. According to the dust removing device, based on the gravity sedimentation theory, the incoming speed of straw is reduced through the diffusion area, and thestraw passes through a gravity channel and slides into the feeding port through mass differences and the gravity action; and raising dust low in mass and small in particle passes through the dust removing filtering screen, enters the deceleration area, and is discharged to the ground.

Owner:SHENYANG AGRI UNIV +1

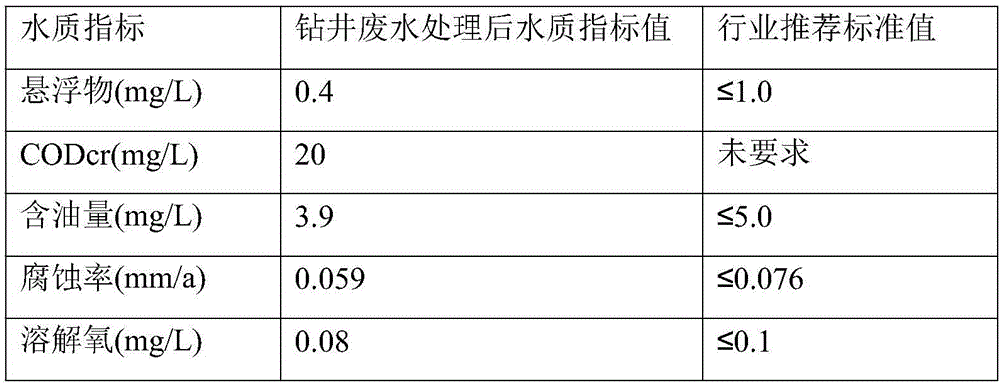

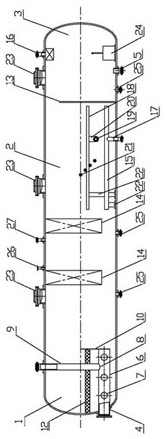

Oilfield drilling wastewater purifying and reusing treatment system and technology

ActiveCN105800823AProtect the safety of the working environmentAvoid secondary pollutionWaste water treatment from quariesWater contaminantsPipingCorrosion prevention

The invention relates to an oilfield drilling wastewater purifying and reusing treatment system and technology. The treatment system comprises a water inlet pipe, a coagulation filter, a gravity sedimentation chamber, an activated carbon filter and a water outlet pipe which are sequentially connected, wherein the water inlet pipe is provided with an expansion mixing section; a first dosing port and a second dosing port which are sequentially arranged are formed in the portion, in front of the expansion mixing section, of the water inlet pipe; the coagulation filter comprises a coagulation chamber communicated with the water inlet pipe, a filter screen and a water collection chamber communicated with the gravity sedimentation chamber, the water collection chamber is arranged outside the coagulation chamber, and the filter screen is located between the coagulation chamber and the water collection chamber; a connecting water pipe communicating the water collection chamber with the gravity sedimentation chamber is sequentially provided with a check valve and a third dosing port; the gravity sedimentation chamber is directly communicated with an inlet of the activated carbon filter, and an outlet of the activated carbon filter is communicated with the water outlet pipe. The chemical purifying process of drilling wastewater comprises the steps of efficient coagulation, disinfection and hydrogen sulfide removal, and the reusing treatment process comprises the steps of chemical deoxygenization, metal ion reduction and pipeline corrosion prevention. According to the treatment system, the structure is simple, the cost is low, the treatment technology is simple and convenient to operate, the technological steps are reasonable, integral treatment on the drilling wastewater is achieved, and the purified water can be directly drained and can be used as oilfield reinjection water after being conditioned.

Owner:SHANDONG UNIV OF SCI & TECH

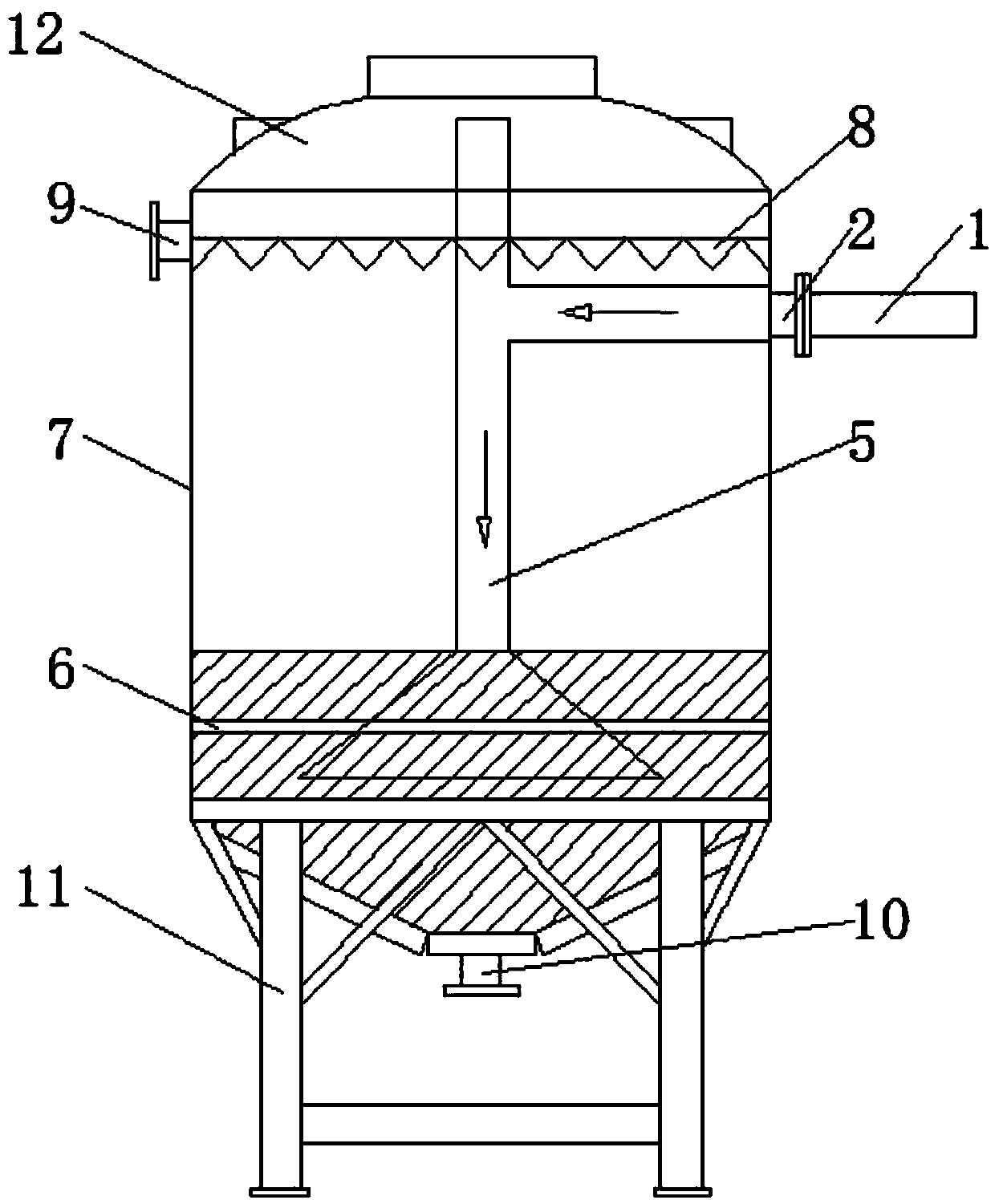

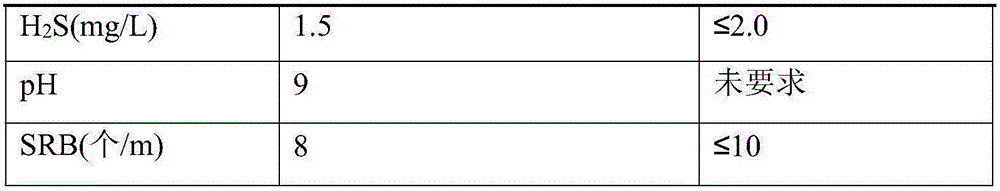

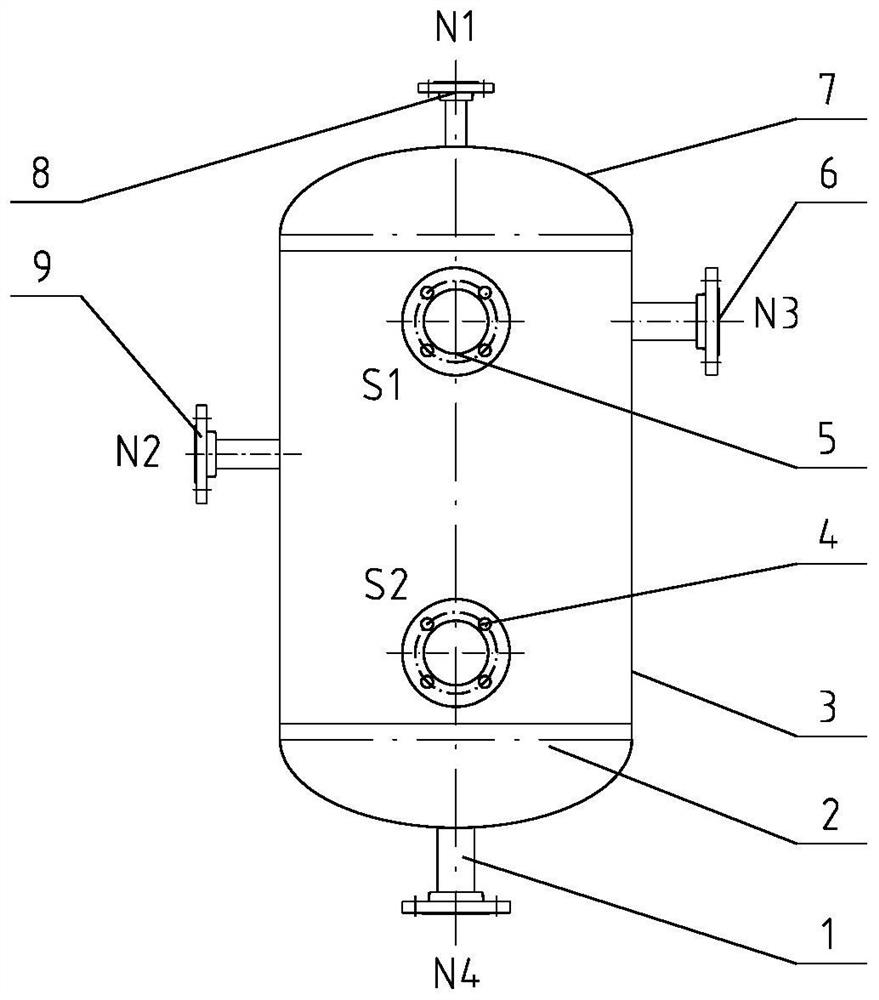

A vertical oil-water separation device

ActiveCN108658172BSimple structureReduce energy lossLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesPilot holeEngineering

A vertical oil-water separation device, comprising an upper head, a cylinder body, a lower head, a sight glass S1, a sight glass S2, an emptying port N1, a feed port N2, an oil outlet N3, a water outlet N4, and an upper seal The head, cylinder body and lower head enclose a closed container. It also includes an oil-water separation assembly, the oil-water separation assembly is located in the cylinder, including a bottom plate, a distance tube, a tie rod, a nut, a handle, a cap top plate, a cap, and a supporting rib plate, and a guide hole is opened in the center of the bottom plate , a number of round holes are evenly opened around the guide hole, a cap is arranged above the round hole, and a top plate of the cap is welded on the top of the cap; there are tie rod holes on the edge of the bottom plate, which run through the tie rod holes from the top bottom plate to the bottom bottom plate There is a pull rod, and the outside of the pull rod is covered with a distance tube. The vertical oil-water separation device is based on the principle of gravity sedimentation and adopts new coalescence components, which has the characteristics of low energy consumption and pressure loss, large processing capacity, high separation efficiency and long service life.

Owner:LINYI BAOLIJIA FOOD

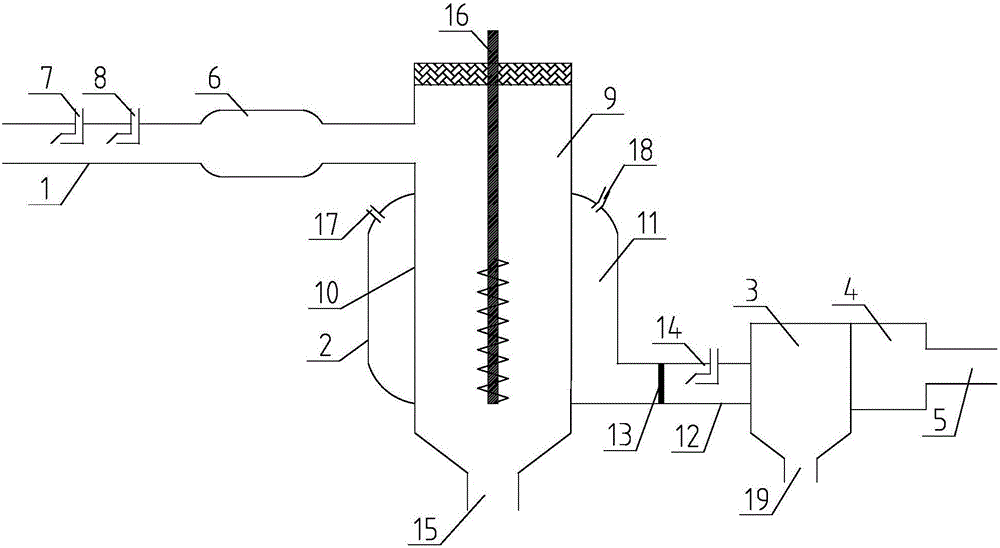

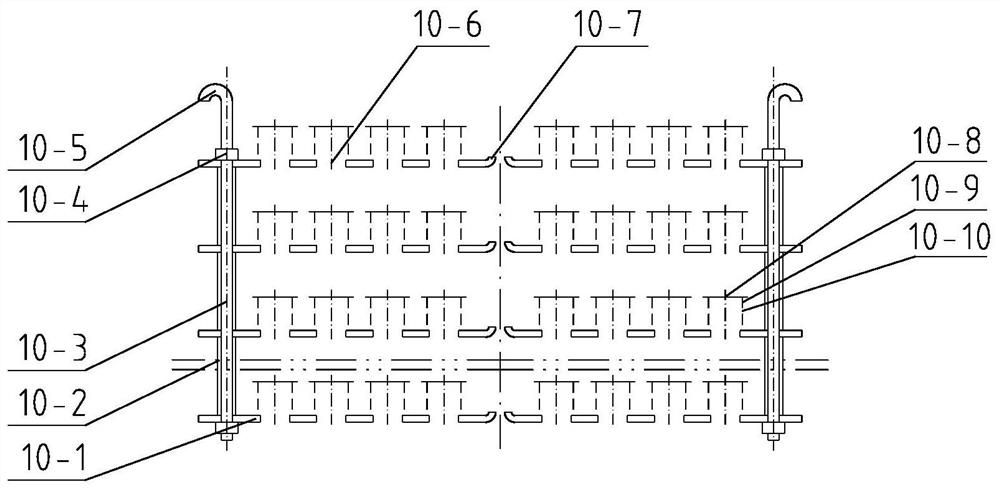

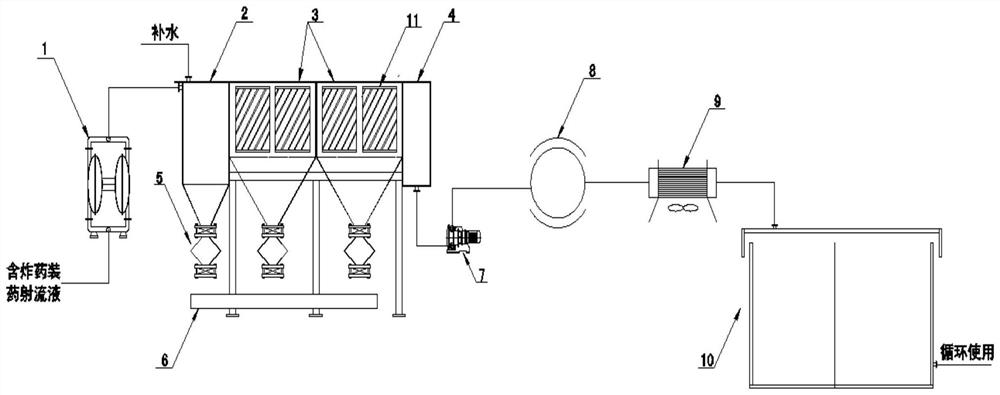

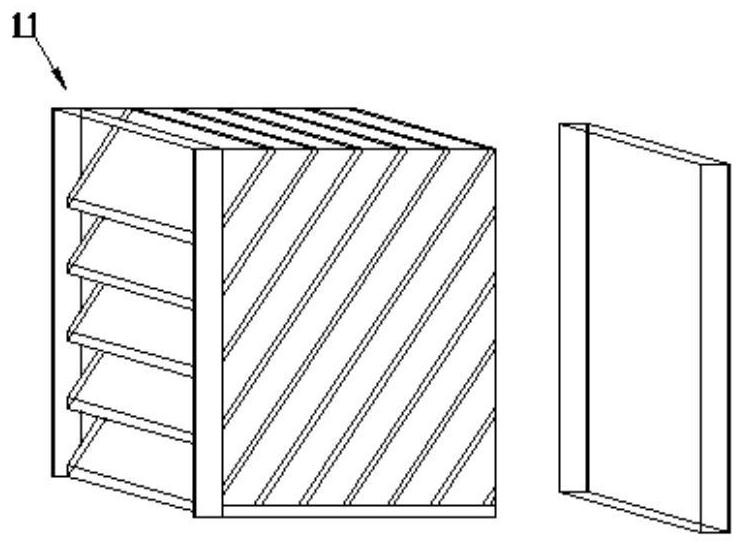

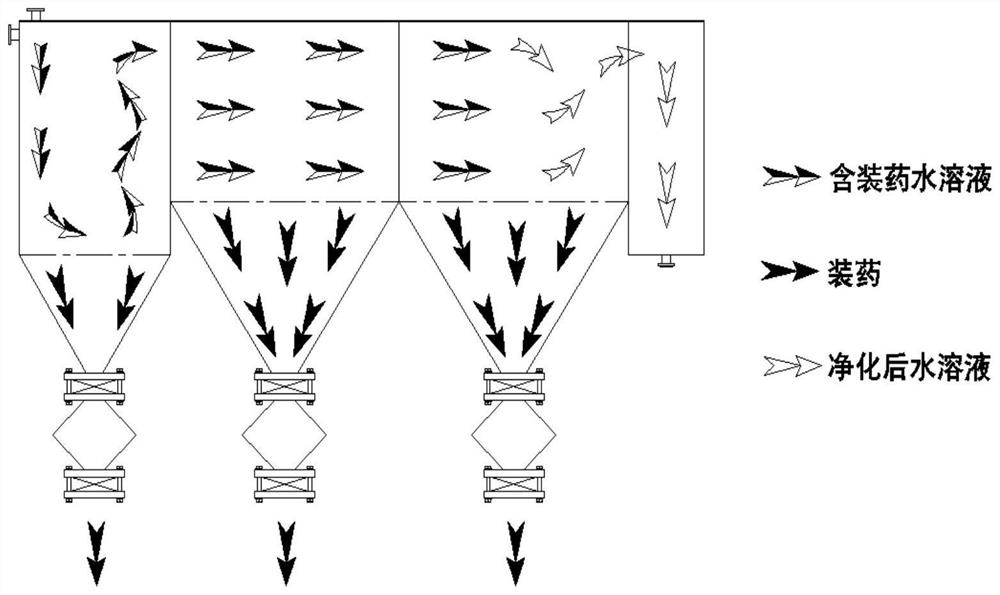

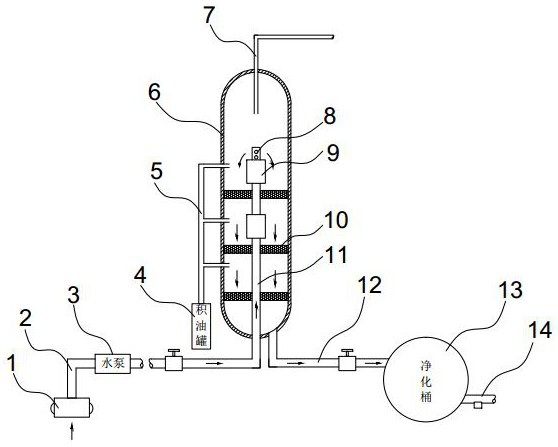

A Continuous Separation Process of Explosive Charge and Water Mixture

ActiveCN109761381BImprove securityThere are no hidden dangers that may cause dangerExplosive working-up apparatusMultistage water/sewage treatmentDiaphragm pumpExplosive Agents

The invention discloses a continuous separation process of explosive charge and water mixture. The process includes rough purification, gravity purification, fine filtration, etc., and the equipment used includes: a pneumatic double-diaphragm pump (1), a rough purification unit (2), Gravity purification unit (3), compensation tank (4), lock chamber (5), bottom tank (6), centrifugal pump (7), fine filter (8), cooling device (9), circulating water tank (10) and inclined Plate settler (11). The core process of this process is natural filtration through gravity sedimentation, there is no safety hazard such as mechanical friction and violent movement, and it can realize the safe, efficient and continuous separation of explosive charge and water mixture after decommissioning ammunition, and realize the recycling of aqueous solution .

Owner:XIAN MODERN CHEM RES INST

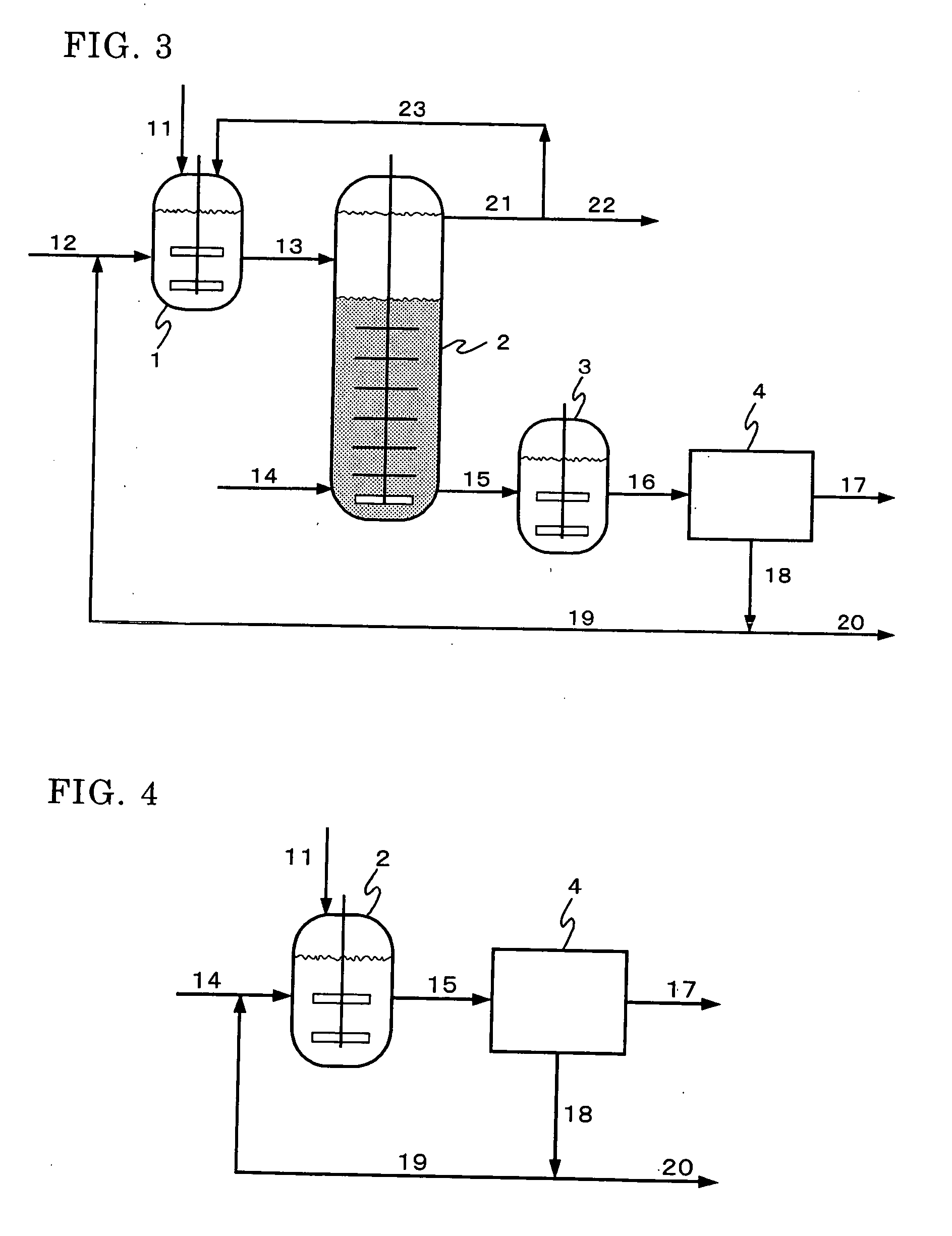

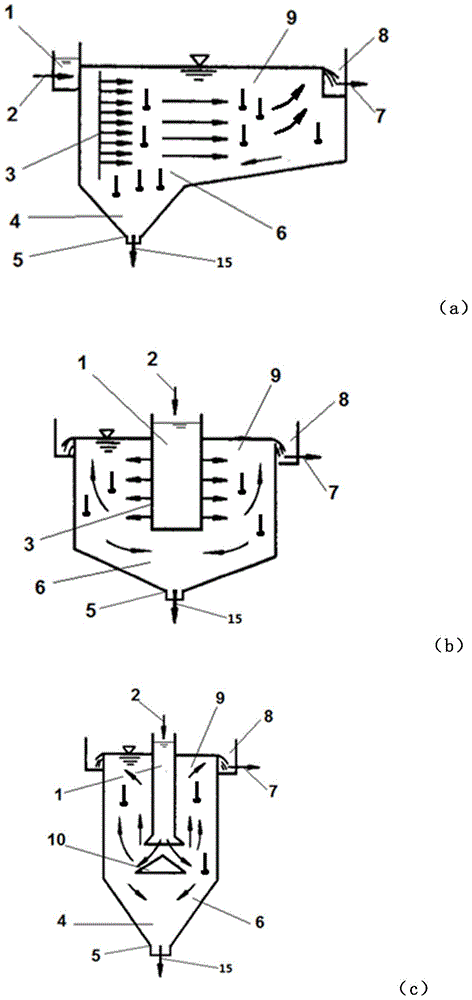

Flexible drainage treatment device

PendingCN114222718AEasy to assembleSettling tanks feed/dischargeTreatment involving filtrationSludgeWastewater

The present invention addresses the problem of providing a flexible wastewater treatment device that is easy to assemble. This problem is solved by a flexible waste water treatment device comprising: a reaction tank (2) into which waste water containing a turbid component is introduced, a chemical agent is added to cause a coagulation reaction, and a flocculate of a coagulated product containing the turbid component is formed; a precipitation tank (3) into which the flocculate-containing reaction liquid formed in the reaction tank (2) is introduced and which is subjected to solid-liquid separation into sludge and supernatant water by a gravitational sedimentation method; and a treatment water tank (4) in which the supernatant obtained in the precipitation tank (3) is stored as treatment water, a synthetic resin composite sheet (5) capable of forming the square reaction tank (2), the precipitation tank (3), and the treatment water tank (4) having the same width is prepared in advance, and the composite sheet (5) is attached to an assembly frame to form the reaction tank (2), the precipitation tank (3), and the treatment water tank (4).

Owner:HYDROLOGICAL ENG CO LTD

A device for recovering oil spilled from the seabed after a marine accident

ActiveCN109723045BReasonable designWater cleaningGeneral water supply conservationOutfallGravitational sedimentation

The invention discloses a device for recovering seabed oil leakage after a marine accident, belonging to the field of offshore oil recovery engineering. The device has a barrel-shaped separation tank with upper and lower seals, and the separation tank is divided into at least three chambers from top to bottom by hydrophilic fiber blocks. , there is a coaxial liquid inlet pipe in the separation tank, a throwing mechanism is provided on the liquid inlet pipe in each chamber of the separation tank, and a water outlet is opened at the connection with the throwing mechanism, and an oil suction pipe is provided in each chamber, and the bottom of the separation tank is The bottom of the end chamber is connected to the water outlet pipe; the throwing mechanism includes two coaxial inner and outer pipes, and the inner and outer pipes are uniformly distributed with arc-shaped rotating leaves, and the inner pipe between the two rotating leaves is provided with strips. The notch corresponds to the position of the water outlet, and the inner pipe is rotatably connected to the liquid inlet pipe through the bearing ring. The invention utilizes the gravity sedimentation method to recover leaked oil, effectively reduces the water content of the recovered oil, rapidly separates water, oil, and gas, and has high oil recovery rate and fast processing efficiency.

Owner:浙江舟环环境工程设计有限公司

Gravity sedimentation separation equipment for chemical mixed liquid

ActiveCN108970184BAct as decelerationAvoid residueSettling tanks feed/dischargeSedimentation settling tanksWater flowEngineering

The invention discloses gravity settling separation equipment for chemical mixed liquid. The equipment comprises a cylinder, a water outlet pipe B and conical protrusions; one collecting box is weldedto the bottom end surface of rectangular iron; and the water outlet pipe B is welded to the right end surface of the collecting box. According to the equipment, the six conical protrusions are weldedto the bottom end surfaces of the cylinder and a square barrel, so that on one hand, when the liquid flows in the cylinder and the square barrel, the conical protrusions can play a role in decelerating the liquid, on the other hand, blocky impurities can be prevented from staying on the conical protrusions in the settling process, and impurity residues in the equipment can be prevented; and a clearing structure is arranged, so that on one hand, floating objects in the chemical mixed liquid can be cleared, on the other hand, cylindrical rods on the clearing structure are arranged, so that thecontact area between the clearing structure and the liquid in the cylinder can be decreased, and therefore the influence on the water flow in the cylinder can be reduced in the rotary clearing processof the clearing structure.

Owner:江苏广域化学有限公司

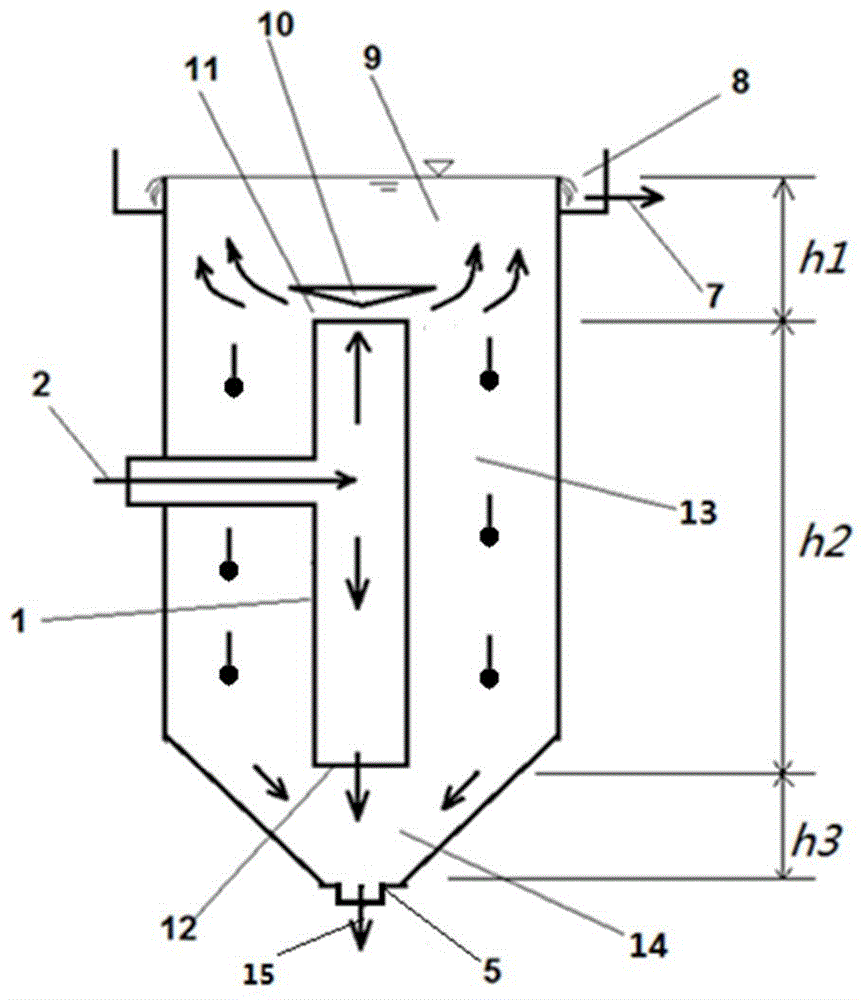

Oil-water pre-separation device and treatment method based on oilfield associated gas from air flotation

ActiveCN111778066BUniform escapeEscape validDewatering/demulsification with mechanical meansHydrocarbon oils treatmentThermodynamicsOil field

The invention relates to the technical field of oil-water separation of oil well production fluid, and is an oil-water pre-separation device and treatment method based on oilfield associated gas self-floating oil and water. chamber, the gravity sedimentation separation chamber and the crude oil buffer chamber, and a baffle plate 1 is arranged between the pretreatment chamber and the gravity sedimentation separation chamber to respectively connect the upper part and the lower part of the pretreatment chamber and the gravity sedimentation separation chamber. The invention fully utilizes the associated gas in the oil well production fluid as the air flotation gas source, accelerates the separation of crude oil and produced water, and then realizes the uniform escape of the associated gas in the liquid phase through the liquid distribution device, forming an effective air flotation Use this function to reduce the size of the equipment, reduce the investment cost, improve the efficiency of oil-water separation and achieve the expected separation effect without setting up external facilities. It has broad application prospects and great market potential.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com