Method and device for preparing microballoons by bi-dispersible inverse suspension polymerization

A reverse-phase suspension and double-dispersion technology, which is applied in the field of functional polymer microsphere preparation, can solve the problems of easy agglomeration and sticking to the kettle, and achieve the effect of avoiding adhesion and solving instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

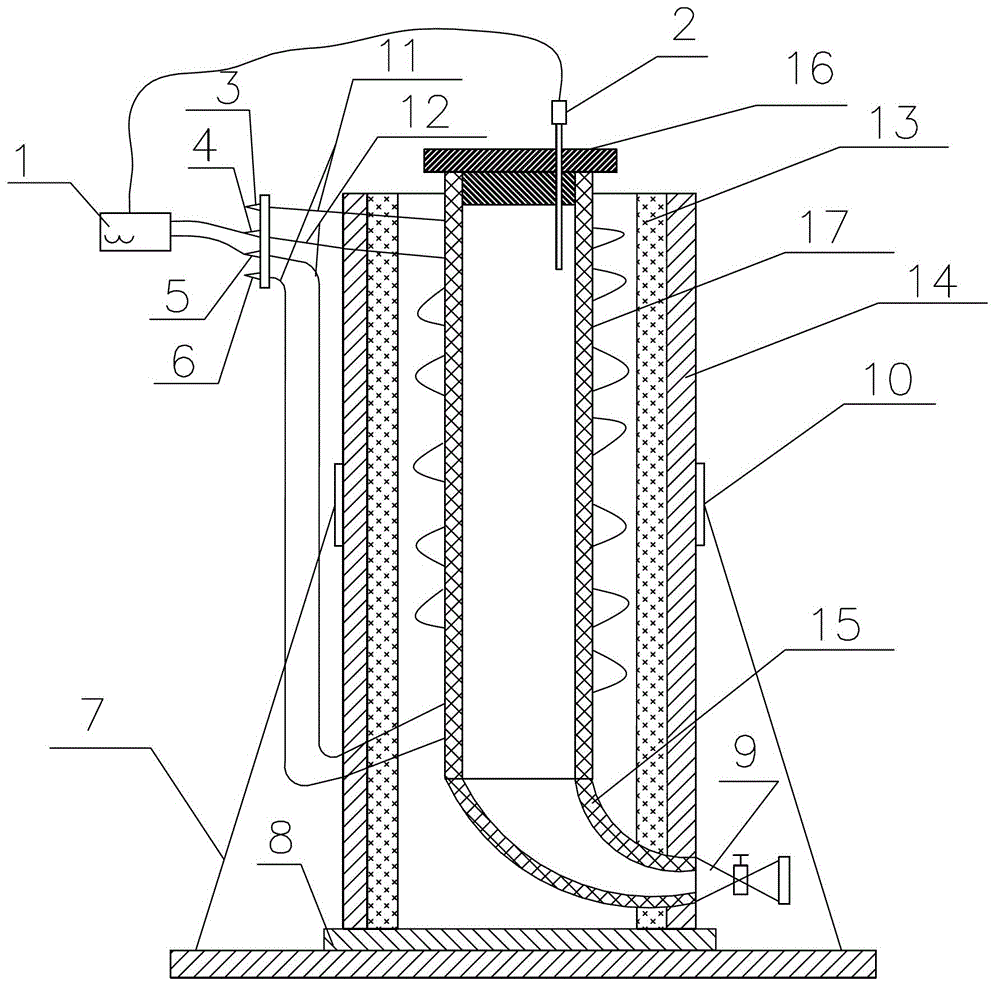

[0019] Dissolve 20g of acrylamide, 0.16g of potassium persulfate, 0.04g of sodium bisulfite (redox initiator), 0.04g of N,N-methylenebisacrylamide (crosslinking agent) in 120g of Distilled water, dubbed the reaction system (water phase). Take 1 part by volume of the reaction system, add it dropwise to 10 parts by volume of corn oil (oil phase), stir in a cold water bath at 10°C for 5 minutes, and the stirring speed is 200r / min, so that the reaction system can be dispersed into a certain particle size in the corn oil. Droplets form a dispersed system. After the stirring is finished, open the lid 16 of the kettle, inject the dispersion system into the reactor body 17 filled with 70 parts by volume of corn oil (used for sedimentation and dispersion) heated to 50°C in advance, the inner diameter of the reactor body 17 is 5cm, and the height is 2.5m. Sufficient settling distance can be provided for the microspheres to ensure the reaction time. The material of the reaction kettle b...

Embodiment 2

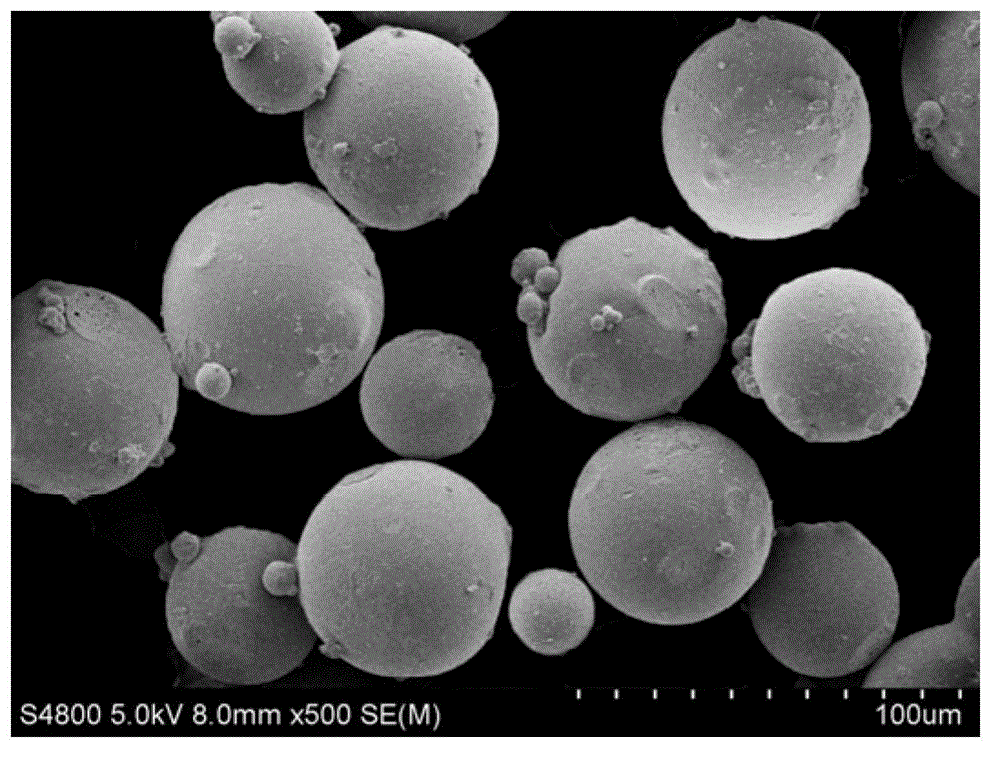

[0021] Dissolve 20g of acrylamide, 0.16g of potassium persulfate, 0.04g of sodium bisulfite (redox initiator), 0.04g of N,N-methylenebisacrylamide (crosslinking agent) in 120g of water in a cold water bath To form a reaction system, take 1.5 parts of the reaction system, add it to 10 parts of corn oil, and stir in a cold water bath for 5 minutes at a stirring speed of 250 r / min. After the stirring is completed, pour it into a reactor filled with 70 parts of corn oil, set the temperature at 50°C, and react for 3 hours. After the reaction is completed, open the valve, filter out the microspheres with a 400-mesh sieve, wash them, and dry them. The ball is denoted as sample 2, such as image 3 As can be seen from the figure, the microspheres have no adhesion, the particle size is relatively uniform, and the average particle size is 50 μm.

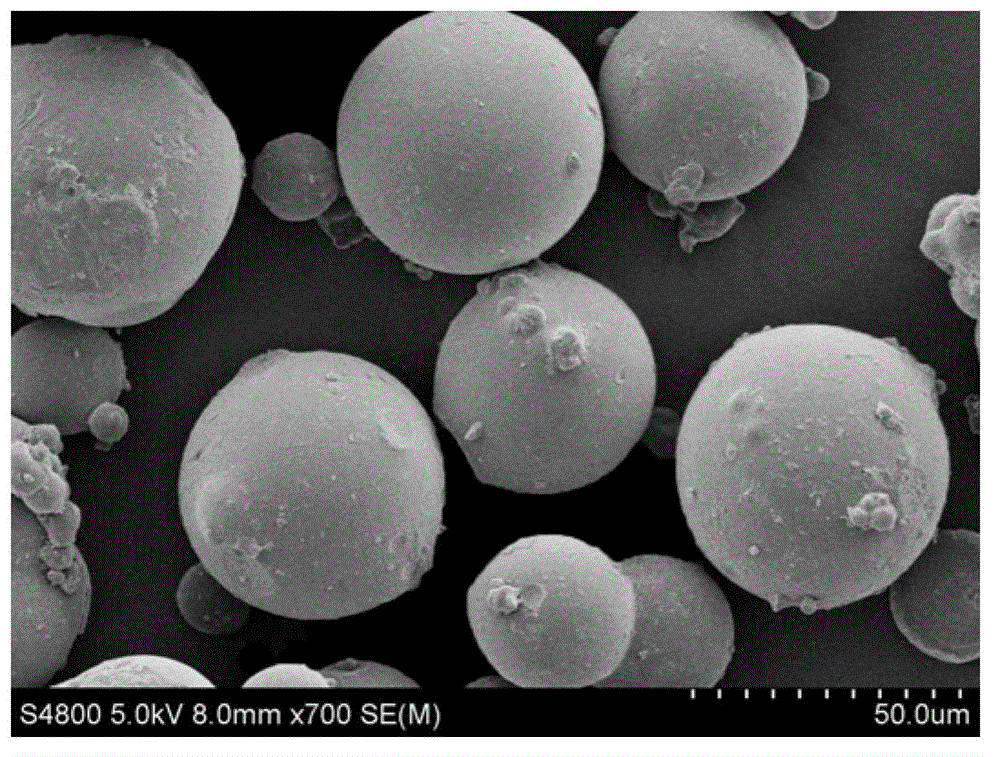

[0022] Compared figure 2 and image 3 It can be seen that when the volume ratio of the water phase to the oil phase and the stirring rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com