Patents

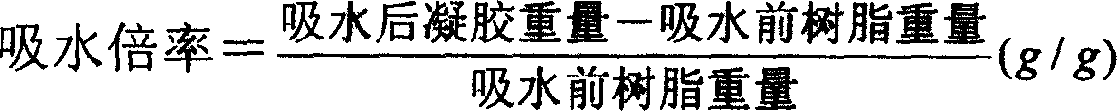

Literature

269 results about "Inverse suspension polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inverse suspension polymerization is one of the best methods to form polymer particle from water soluble monomer with high stability, narrow particle size distribution, fast process rate, and high conversion [15, 16]. It is reasonable to be adopted in preparation of new polymer beads catalyst with sulfonic containing monomer.

Water-absorbent resin and production prcess therefor

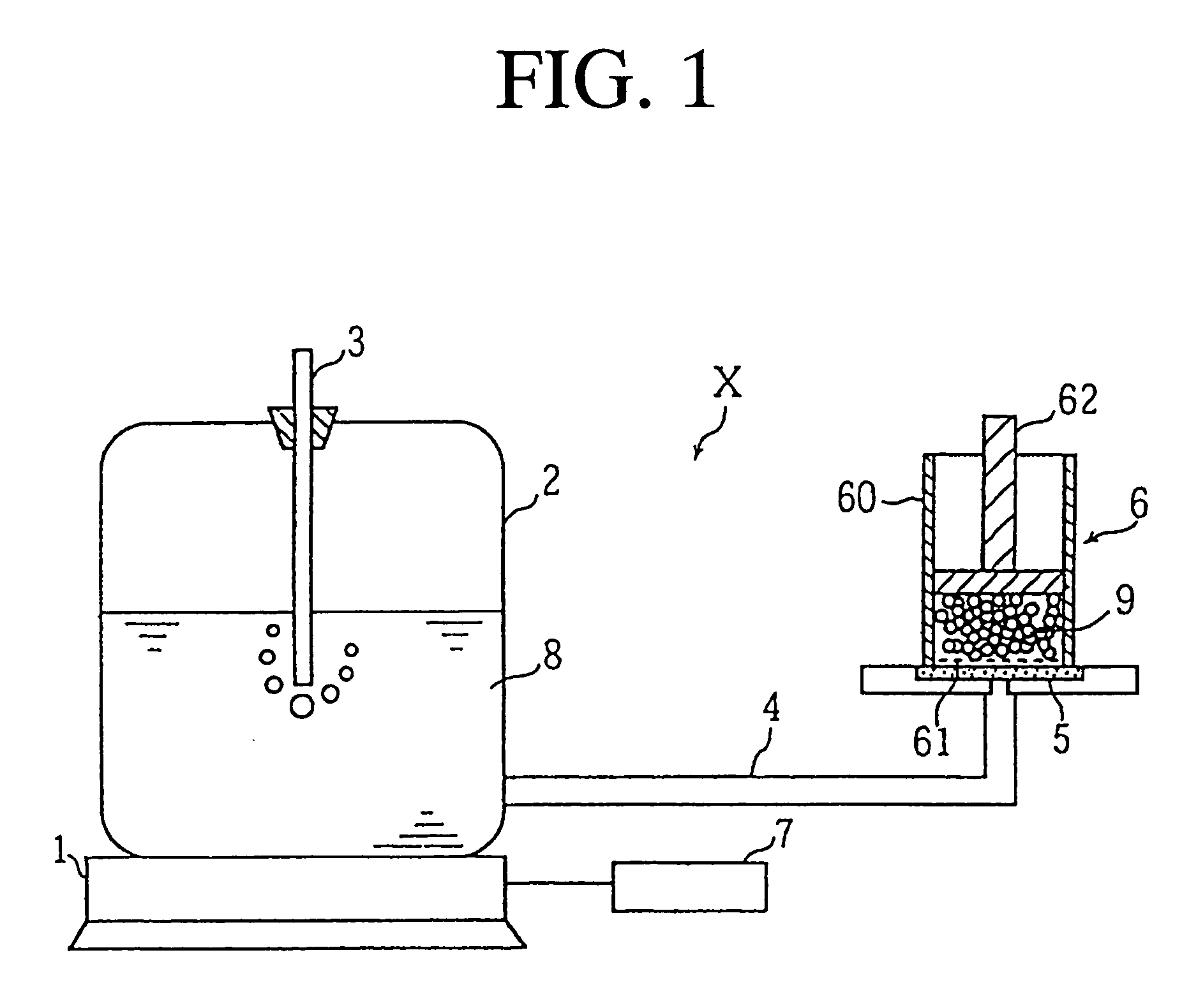

InactiveUS20040110913A1Solve problemsHigh propertyAbsorbent padsEmulsion paintsWater solubleAqueous solution

To provide: a process in which a coarse gel itself is made not to form in the case of applying the aqueous solution polymerization; and a process in which the polymerization is mildly controlled and the production is stably carried out in the case of applying the reversed-phase suspension polymerization or static polymerization, in a production of a water-absorbent resin. In a production process for a water-absorbent resin, which comprises a polymerization step that includes the steps of carrying out polymerization, involving crosslinking, of an aqueous solution of a water-soluble unsaturated monomer including acrylic acid(salt);and at the same time carrying out fine division of the resultant hydrogel, or in a production process for a water-absorbent resin, which comprises the steps of carrying out polymerization, involving crosslinking, of an aqueous solution of a water-soluble unsaturated monomer including acrylic acid(salt);and carrying out fine division of the resultant hydrogel, or in a production process for a water-absorbent resin, which comprises a polymerization step that includes the steps of carrying out polymerization, involving crosslinking, of an aqueous solution of a water-soluble unsaturated monomer including acrylic acid(salt); and at the same time obtaining a finely divided hydrogel, the water-soluble unsaturated monomer is adjusted in order to contain furfural in an amount of 11 to 1,000 weight ppm (relative to the monomer).

Owner:NIPPON SHOKUBAI CO LTD

Microsphere type embolic agent and preparation technology thereof

The invention provides a microsphere embolic agent, which is an elastic microsphere formed by the crosslink polymer of the functionalized macromolecules with the biocompatibility, and the particle size of the microsphere ranges from 1 Mum to 1500 Mum. The preparing technology includes the steps as follows: in a covalent link, linking a crosslinkable micromolecules with an acrylic acid structure on the polyvinyl alcohol, polyethylene glycol or polysaccharide macromolecules, forming the functionalized macromolecules; after that, the functionalized macromolecules and the monomer of the 2- acrylamide-2-methyl propanesulfonic acid undertakes opposite suspension polymerization, obtaining the crosslink polymeric microsphere embolic agent. The embolic agent has comparatively large retractility and elasticity, whose particle size is controllable and has perfect dispersiveness; moreover, the raw material is non-toxic and at the same time has good biocompatibility and stability. The preparing technology is a real chemosynthesis technology, whose material and preparing process does not produce any virus pollution, according with various requirements of the international embolic agent, which can replace various import and domestic expensive embolic agent products and is extensively applicable to various surgeries in the interventional radiology field.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

Moisture-retention sustained and controlled release fertilizer and method of preparing the same

InactiveCN101508616AThe synthesis process is simpleUniform thicknessFertilizer mixturesHigh absorptionDouble coating

The invention discloses a water holding slow-controlled releasing fertilizer and a preparation method thereof, belonging to the technical field of agricultural fertilizers and preparation thereof. Macromolecule coating fertilizer is taken as an inner core and a water holding layer is taken as an outside layer to form a double-coating water holding slow-controlled releasing fertilizer; an inner coating is macromolecule protective layer coating material with nutrition controlling and releasing property; an outside coating is the water holding layer with excellent water holding property. Water retention agent suspension liquid is sprayed to the surface of macromolecule coating fertilizer grains for outside coating; wherein the water retention agent is prepared by taking cyclohexane, emulsifier, acrylic acid, acrylamide, sodium hydroxide, cross linker and evocating agent and adopting the method of opposite phase suspension polymerization. The fertilizer has the function of controlled releasing, drought resistance, water saving, water holding and soil improving and the advantages of high absorption percentage, wear resistance, difficult falling and the like; utilization ratio of liquid manure is improved and the fertilizer can be widely used to desert control, lawn plant, soil improvement, gardening, agriculture and forestry and the like.

Owner:CHINA AGRI UNIV

Process for preparing high water absorption resin

The preparation process of high water absorption resin includes following steps: neutralizing acrylic acid monomer with alkali solution to 60-90 % neutralizing degree, adding functional monomer in 0.5-50 % of total monomer weight, water soluble initiator or oxidation-reduction system in 0.05-0.5 % and water soluble cross-linking agent in 0.005-0.2 %; feeding the said mixed liquid into reactor, adding non-polar organic solvent in 2-10 times the volume of the mixed liquid and containing non-ionic surfactant, stirring to form inverse suspended polymerizing system; heating to 35-80 deg.c for free radical cross-linking copolymerization while adding oil soluble cross-linking agent in 0.005-0.3 % total monomer weight; dewatering after finishing polymerization, separation and drying to obtain the high water absorption resin. The obtained polyacrylate resin has the advantages of powerful water absorption, high salt tolerance, high gel strength and fast water absorption speed.

Owner:ZHEJIANG UNIV

Anidoximated globular lignin macroporous chelate adsorption resin and preparation technique thereof

ActiveCN101357324ABroaden the development pathConducive to the mobilization of comprehensive utilizationOther chemical processesBlack liquorAcrylonitrile

The invention discloses an amidoxime spherical lignin chelate adsorbing resin and a preparation method thereof. A spherical lignin bead is prepared by adopting reversed-phase suspension polymerization techniques of programmed heating, crosslinking and solidification and taking concentrated pulping black liquor or concentrated pulping red liquor as a raw material. The spherical lignin bead is grafted with copolymerized acrylonitrile through further amidoxime to obtain the spherical lignin chelate adsorbing resin which has the grain-size average pore size of 5-150nm, the uniformity coefficient of not more than 1.30, the specific surface area of 30-480m<2> / g, the water content of 55-75%, the bulk density of 0.60-0.73g / ml, the bulk volume of 2.25-5.80ml / g, the amidoxime group content of 6.51-15.85mmol / g and the chelate adsorption capacity of 5-15 mmol / g. The method of the invention is simple for operation, has low production cost, is expected to be of value in the practical application to the enrichment recovery of noble metals and the extraction of uranium from seawater.

Owner:FUZHOU UNIV

Preparation method of super water absorbent resin

The invention provides a preparation method of super water absorbent resin. A free radical polymerization initator is used in a petroleum hydrocarbons solvent containing a surfactant and / or macromolecular protective colloid, a water-solubility olefinic unsaturated monomer is subjected to anti-phase suspension polymerization in water-in-oil system due to the existence of an inner cross-linking agent, and substances containing Si-OH and / or Si-O groups are added in the polymerization reaction and aftertreatment process, so that the performance of the super water absorbent resin is improved. The super water absorbent resin prepared by the method has the advantages that the water retention capability is high, the capability of absorbing saline in one minute is high, the water absorbing capability under compression is high, the liquid absorbing speed is quick and the like.

Owner:浙江卫星新材料科技有限公司

Production of cationic microsphere with crosslinked swelling function

InactiveCN101029109AEasy speed controlControllable swelling ratioDrilling compositionCross-linkPersulfate

Production of cationic micro-sphere with cross-linking swelling function is carried out by taking persulfate and sulfite or persulfate and azo-diisobutyl nitrile binary composite or persulfate, sulfite and 2,2'-azo-(2-(2-imidazoline-2-radical)propane)dihydrochloride(VA-044)ternary composite as initiating agent, adding into dispersant and cross-linking agent, initiating DMC monomer and AM monomer in mixed medium of cyclohexane-water or industrial white oil-water or 120#solvent oil-water and reverse suspension polymerizing to obtain the final product. The grain size is 1-50 mu m, it has controllable swelling speed ratio and can be used for third oil-extraction plugging materials.

Owner:JIANGNAN UNIV

Method for preparing acrylic acid series semi-interpenetration network composite high water absorption resin

InactiveCN101240052AEnhance stripping activityEasy to peelAbsorbent padsBandagesWater bathsIce water

A preparation for semi-interpenetrating network complex highly water absorbable resin of acrylic acid series, relates to a preparation of complex resin with high water absorption by reverse suspension polymerization and in-situ polymerization, which includes adding aqueous solution of neutralizer into acrylic acid in ice-water bath, adding acrylamide, acrylic acid-2-hydroxyethyl ester, methanol, aqueous solution of hydrophilic polymer and modified organic silicate in layered form, dispersing by ultrasonic oscillation, adding initiator and cross-linker; dissolving dispersant in organic dispersion medium, then adding it into the mixture, reacting under protection of nitrogen gas; adding mixture of methanol and ethanol, adding organic silicate in layered form after stirring, depositing after adding methanol at room temperature, filtering, scrubbing with methanol, drying in vacuum to obtain final product. The prepared complex highly water absorbable resin has a water absorbency of 200-1800 g / g, brine absorbency of 40-160 g / g, water absorbing rate namely time spent until water absorb degree reaches 80% is 8-60min.

Owner:XIAMEN UNIV

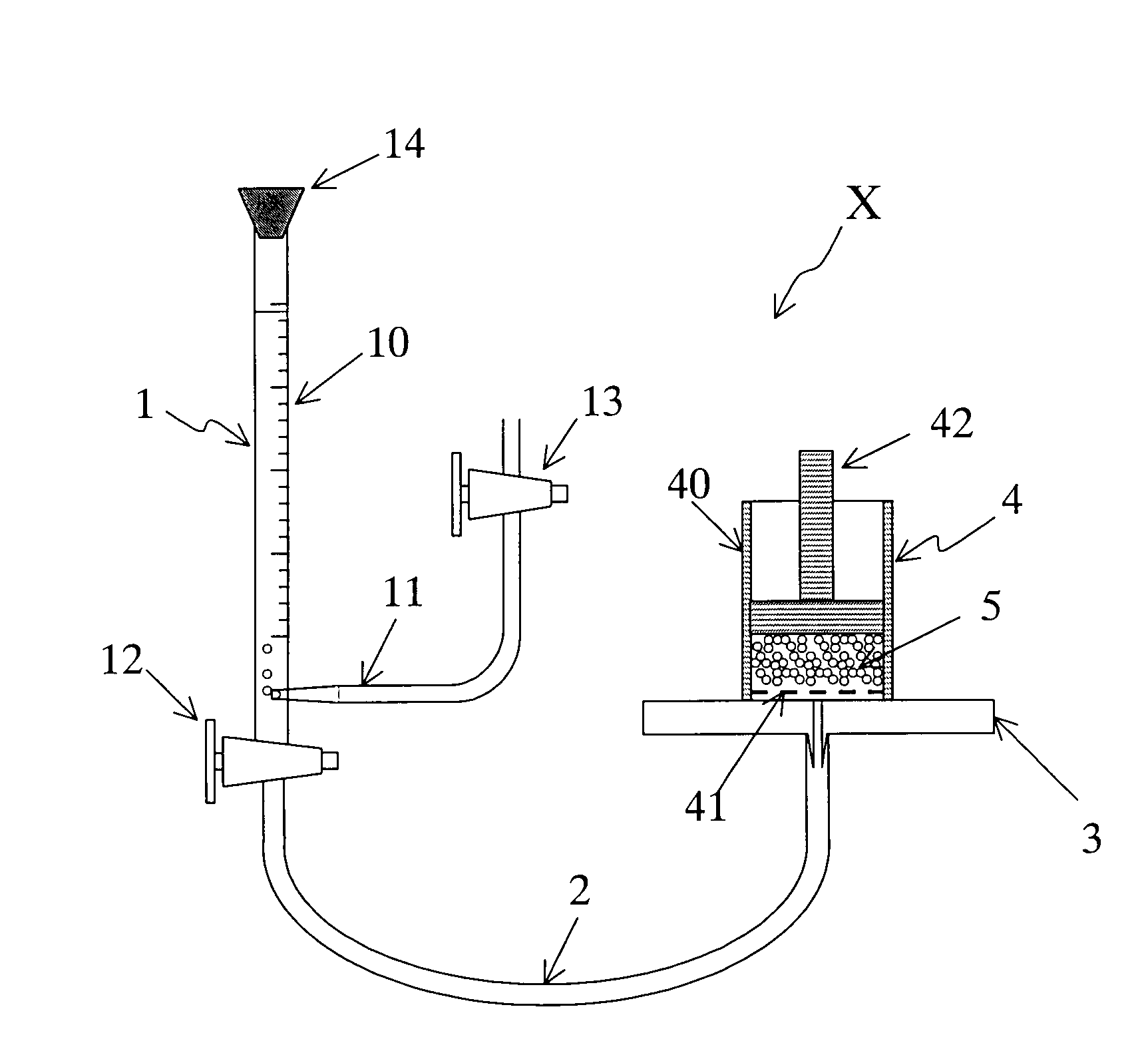

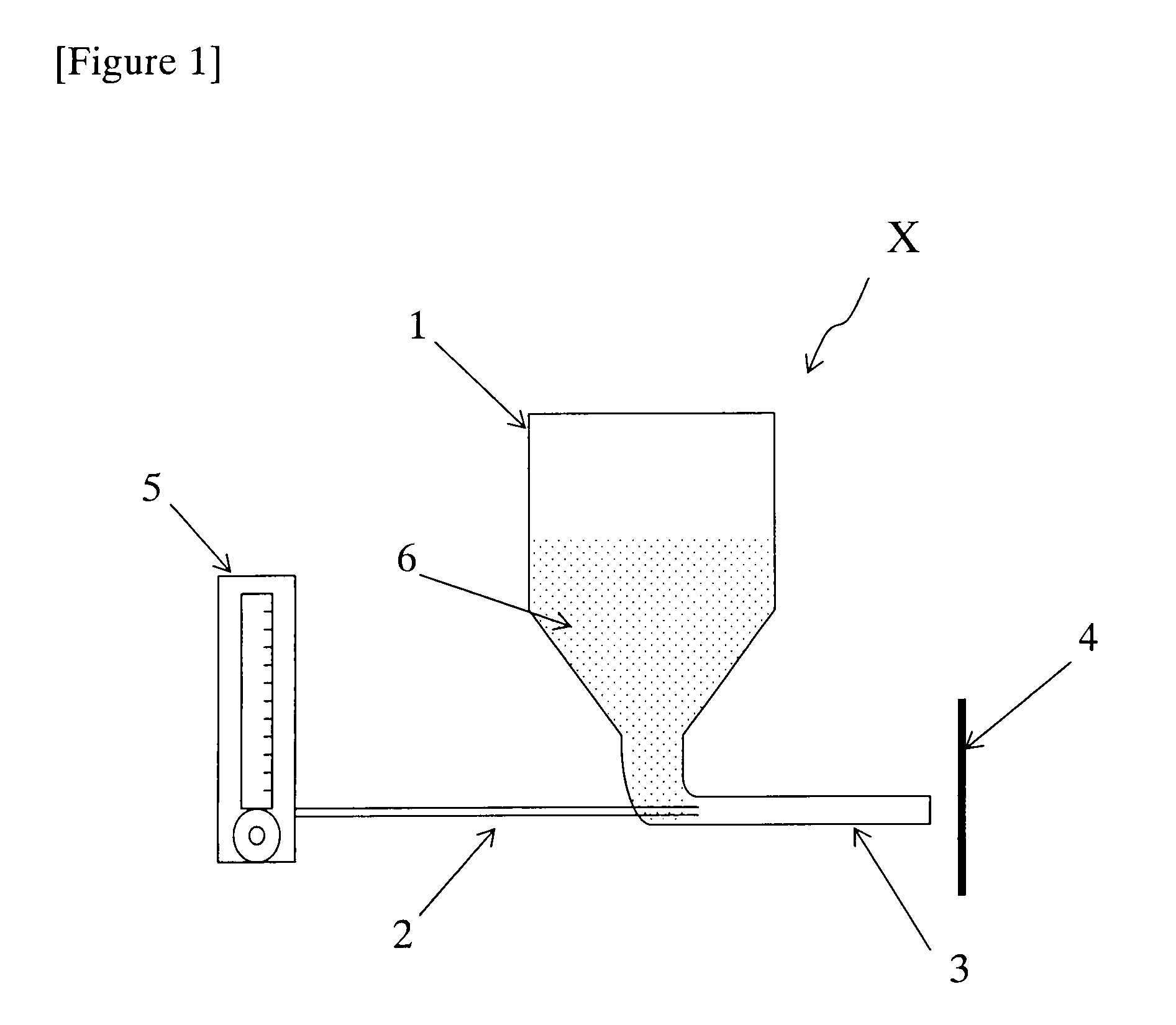

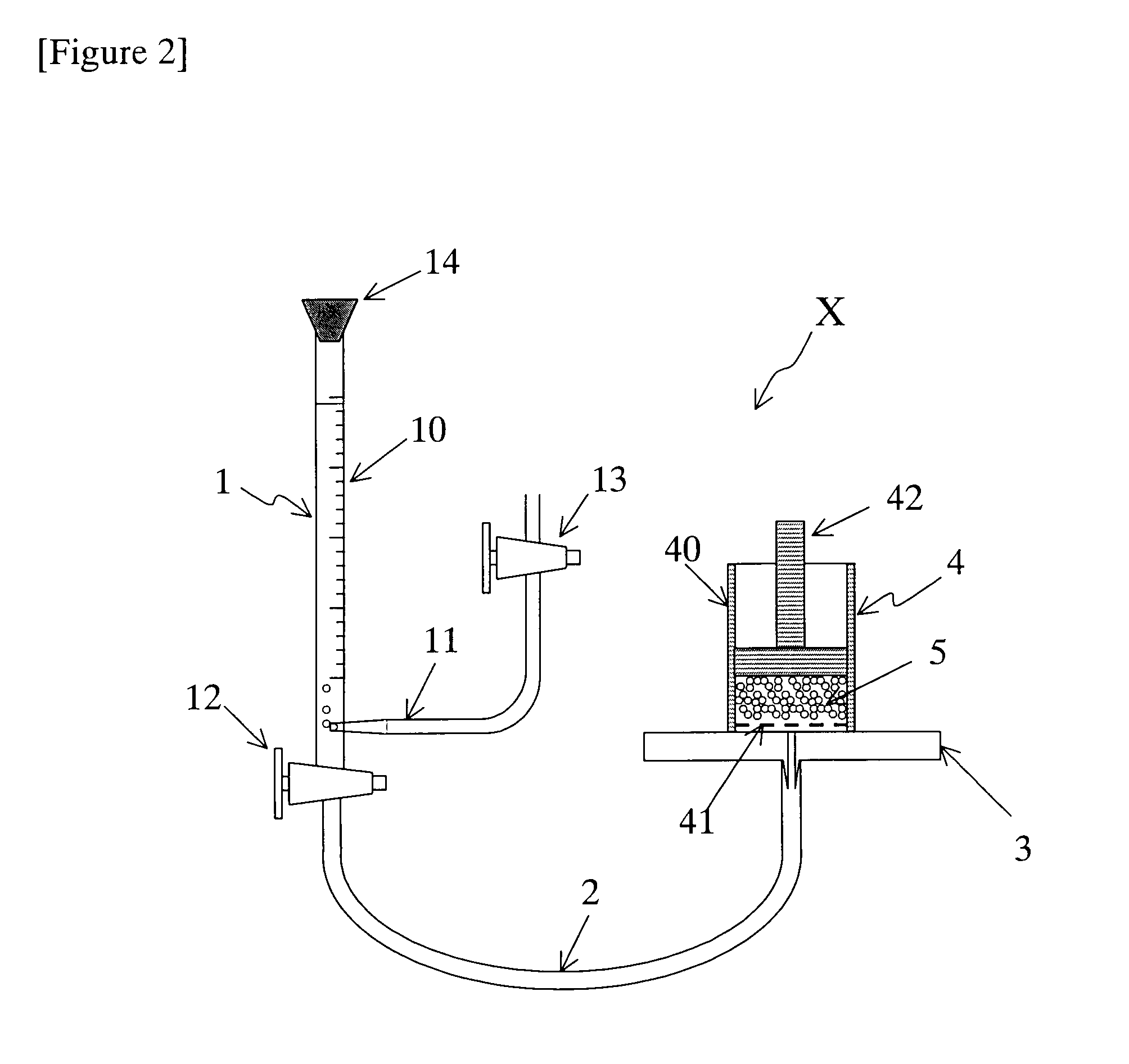

Preparation technology for microspheric embolization agent

ActiveCN101810587AUniform particle sizeGood dispersionPharmaceutical non-active ingredientsGranular deliveryChemical synthesisCross-link

The invention relates to a preparation technology for a microspheric embolization agent. The preparation technology is used for preparing elastic microspheres cross-linked and polymerized by functionalized macromolecules with biocompatibility, wherein the grain range of the microspheres is 1-1500mu m. The preparation technology comprises the following steps that: a cross-linkable micromolecule with a crylic acid structure is connected on a polyvinyl alcohol, polyethylene glycol or polyose macromolecule in form of a covalent bond to form a functionalized macromolecule; and reversed phase suspension polymerization is conducted to the functionalized macromolecule and a 2-acrylamide-2-methylpropanesulfonic acid monomer to prepare cross-linked and polymerized microspheric embolization agent. The embolization agent has the advantages that the flexibility and the elasticity are high, the grain is even and is controllable, the dispersity is good, the raw materials are nontoxic and the biocompatibility and the stability are good. The preparation technology is a pure chemical synthesis technology, no virus pollution is caused to the raw materials and the preparation process, the requirements on international embolization agents are satisfied, and the embolization agent can substitute for all kinds of imported or domestic expensive embolization agent products and can be widely used in surgeries in the field of interventional therapy.

Owner:SUZHOU HENGRUI CALLISYN BIOLOGICAL MEDICINE TECH CO LTD

High molecular weight cationic polyacrylamide preparation method

The invention discloses a high molecular weight cationic polyacrylamide preparation method and the method adopts the inverse suspension polymerization method. The invention is characterized in that the method comprises the following steps: mixing acrylamide, cationic ethyl monomer and composite initiator evenly to form the dispersed phase, adding the dispersed phase in oil-soluble dispersion medium under a certain temperature to disperse to aqueous phase droplets under the action of suspension dispersant and to initiate the polymerization; and after finishing the reaction, obtaining the bead product of high molecular weight cationic polyacrylamide by filtrating and drying the suspension. The invention adopts inverse suspension polymerization method so that the polymerization can be performed steadily at a certain temperature, thus benefiting the chain propagation and providing conditions for the preparation of high molecular weight cationic polyacrylamide; better polymerization effect can be realized by selecting proper composite initiator and using a small amount of initiator so that the high molecular weight product can be obtained and the intrinsic viscosity of the product is not less than 6.0dl / g.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for preparing composite hydrogel through modifying bamboo shoot leftovers and application of composite hydrogel

ActiveCN104086785AImprove adsorption capacityRich sourcesOther chemical processesPaper material treatmentCelluloseSodium chloroacetate

The invention provides a method for preparing composite hydrogel through modifying bamboo shoot leftovers and an application of the composite hydrogel. An adsorption material is prepared by the steps of extracting cellulose from the bamboo shoot leftovers, then modifying by sodium chloroacetate, carrying out epoxy chloropropane cross-linking, followed by carrying out inverse suspension polymerization, and finally carrying out freeze drying. The prepared hydrogel beads are used as a bio-adsorbent, methylene blue is used as a dye model molecule, an adsorption effect on methylene blue is studied, and a theoretical foundation is laid for adsorption and sustained release of the hydrogel. The novel composite hydrogel prepared by utilizing the bamboo shoot processing waste leftovers is rich in raw material sources and low in cost, can achieve waste utilization, and promotes recycling economy; and the prepared hydrogel can be applied to adsorption of dye wastewater and adsorption and sustained release of a model drug, reduces pollution of bamboo shoot leftover arbitrarily discarding on the environment, and can play a certain role in promoting green development of ecological resources.

Owner:SOUTH CHINA UNIV OF TECH

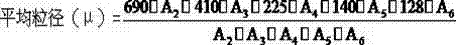

Method for preparing super absorbent resin by inverse suspension polymerization

The invention relates to a method for preparing super absorbent resin by inverse suspension polymerization. With a hydrophobic and lipophilic organic substance as the solvent and a proper compound as the dispersant, the method subjects part of a neutralized acrylic acid solution to an inverse suspension polymerization reaction in the presence of a thickening agent, a cross-linking agent as well as a water-soluble initiator, and then employs a surface cross-linking agent for surface cross-linking treatment. The super absorbent resin prepared by the method of the invention has an average particle size of 100-200 micrometers, a saline water adsorption rate of over 45g / g in 1min, and an imbibition speed of less than 20s.

Owner:浙江卫星新材料科技有限公司

Method for preparing super absorbent resin microspheres

InactiveCN104448102ASolve the problem of poor molding and low yieldSimplify post-processingPolymer scienceResin microsphere

The invention relates to a method for preparing super absorbent resin microspheres, belongs to the technical field of high polymer materials, and solves the problems that a reversed phase suspension polymerization process for preparing super absorbent resin microspheres in the prior art is complex and is high in cost in the production process, the prepared microspheres are poor in molding and low in yield. The method adopts a reversed phase suspension technique and is simple in preparation process, the products can be used without further grinding, the after-processing process of products is simplified, the yield of products is improved, and the production cost of products is reduced.

Owner:CHENGDU JINHUI TECH

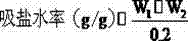

Gelating agent for alkaline cell and alkaline cell

InactiveUS6667133B1Excellent in stringiness of solutionIncrease speedActive material electrodesAlkaline accumulator electrodesCross-linkMeth-

A gelating agent for an alkaline cell is a cross-linked polymer (A) comprising (meth)acrylic acid and / or its alkali metal salt as a main constituent monomer unit and obtained by an aqueous solution polymerization or a reversed phase suspension polymerization and satisfies the following required conditions (1), (2). The gelating agent has good draining property, satisfactorily high speed charging property of the alkaline electrolytic solution and is therefore effective to produce cells with little unevenness of the charging amount of the electrolytic solution and having uniform quality by mass production and an alkaline cell using the gelating agent is provided with durable discharge time and remarkably excellent impact resistance for a long duration. The said required conditions are required condition (1); that the gelating agent contains 50% by weight or more of a particle whose swollen particle size becomes 300 to 4,000 mum when the gelating agent is swollen in an aqueous potassium hydroxide solution of 40% by weight concentration and required condition (2); that the aqueous potassium hydroxide solution of 40% by weight concentration containing 3% by weight of the gelating agent has 0 to 20 mm stringiness.

Owner:SANYO CHEM IND LTD

Process for production of water-absorbent resin

A purpose of the present invention is to reduce odor of a water-absorbent resin during absorption of water. Such the invention is attained by a process for production of a water-absorbent resin by subjecting a water-soluble ethylenically unsaturated monomer to reversed-phase suspension polymerization. The process comprises the following steps (A) to (C): (A) adding an aqueous solution of water-soluble ethylenically unsaturated monomer to a petroleum hydrocarbon dispersion medium to disperse the aqueous solution in the dispersion medium; (B) adding a surfactant to the emulsion to further disperse the emulsion; and (C) performing the reversed-phase suspension polymerization using a water-soluble radical polymerization initiator, optionally in the presence of an internal-crosslinking agent.

Owner:SUMITOMO SEIKA CHEM CO LTD

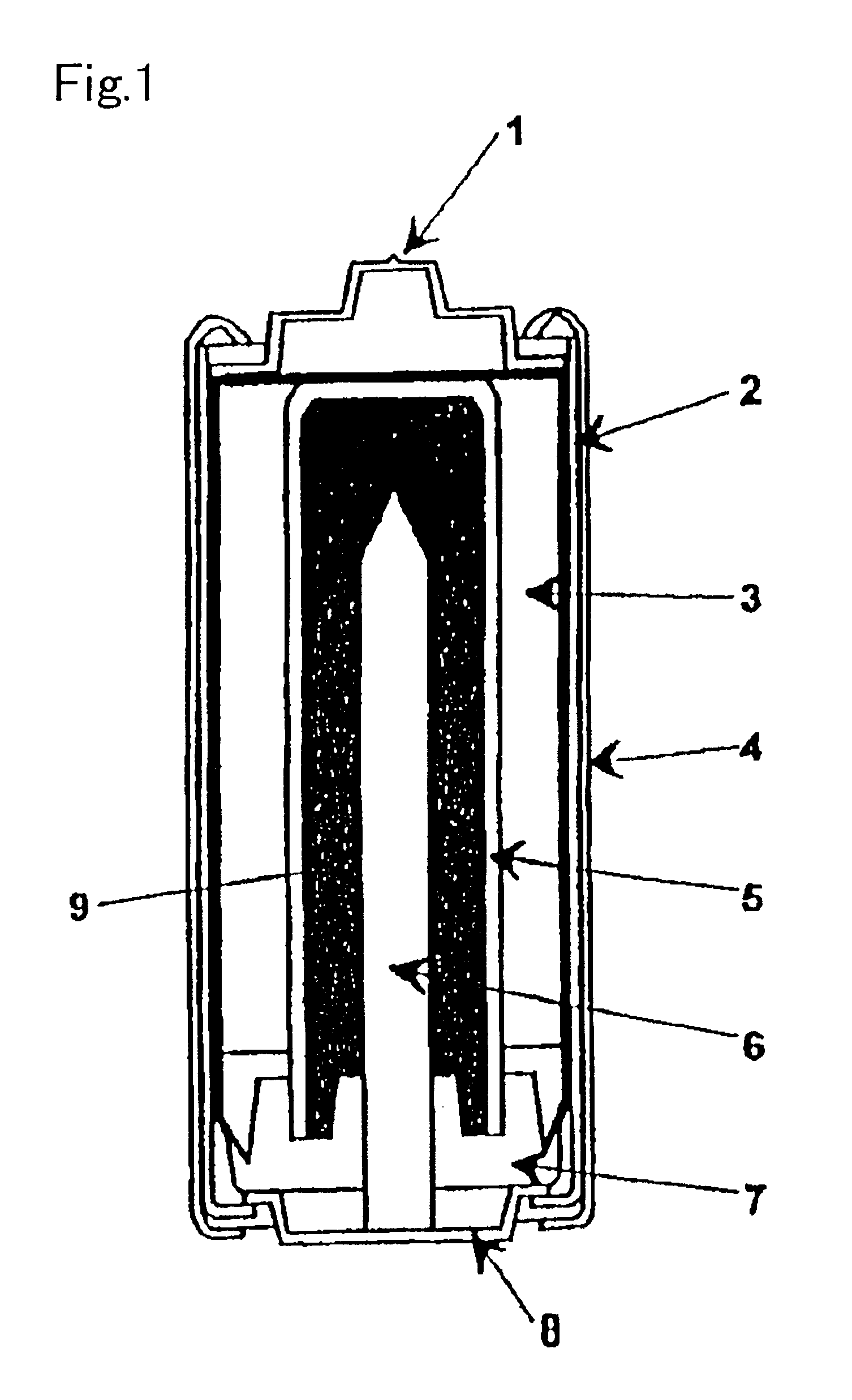

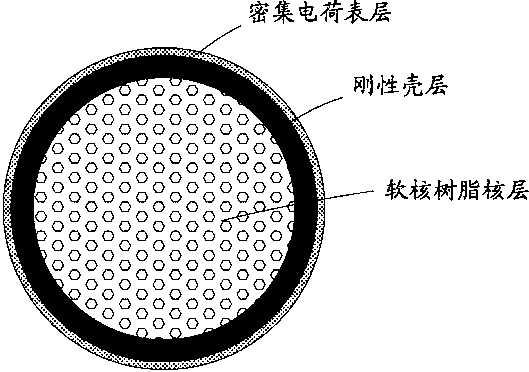

Preparation method of suspension polymerization powdered ink with core-shell structure

ActiveCN103105751AExcellent low temperature fixabilityGood environmental stabilityDevelopersOil phaseSilicon dioxide

The invention provides a preparation method of suspension polymerization powdered ink with a core-shell structure. The preparation method comprises the following steps of: (1) respectively preparing monomer oil phase which contains a certain amount of polar resin and forms into powdered ink soft core resin, and aqueous dispersion liquid; (2) adding the monomer oil phase into the aqueous dispersion liquid, shearing, suspending and pelleting at high speed, transferring into a reactor, and carrying out first warming polymerization reaction to obtain the powdered ink particles with a soft core-hard shell structure; (3) taking the powdered ink with the soft core-hard shell structure as a core layer, adding positive ion monomer components, and carrying out second polymerization reaction by a water-soluble initiator to obtain soft core-hard shell powdered ink particles of which the outer surfaces are evenly distributed with intensive charge surface layers; and (4) cleaning and filtering products, sufficiently drying, and adding silicon dioxide. According to the preparation method, the shell layer which is evenly distributed with the intensive charges can be obtained according to the characteristics of the polar resin and the cation monomer component, so that the electrification evenness of the surface of the powdered ink particles can be improved, and the preparation method is good in low-temperature fixation characteristics and environmental stability.

Owner:SHENZHEN LEPUTAI TECH CO LTD

Process for production of water-absorbable resin particle, and water-absorbable resin particle produced by the process

ActiveUS20090281247A1High particle strengthImprove water absorptionSynthetic resin layered productsCellulosic plastic layered productsHydrocarbon solventsWater soluble

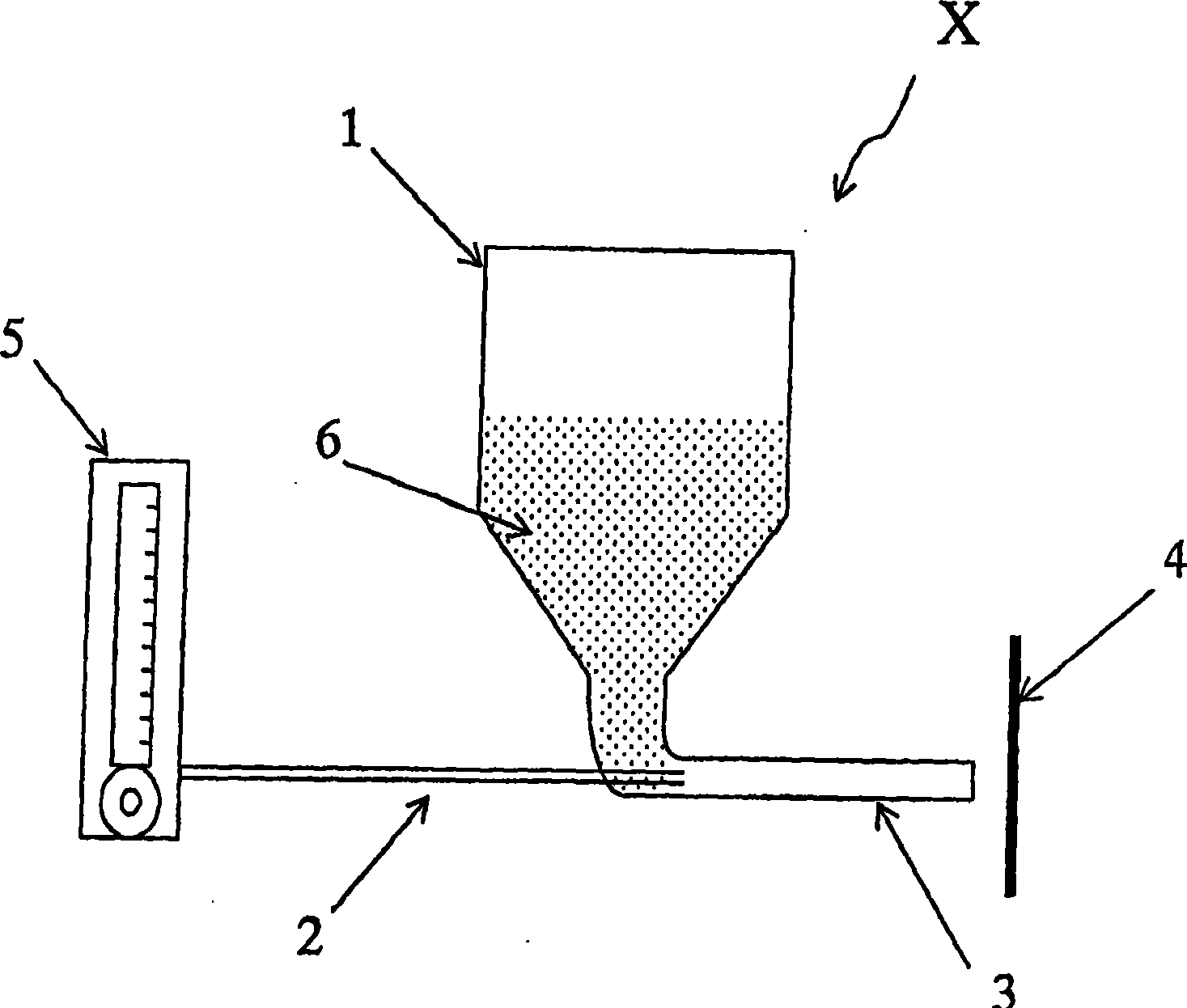

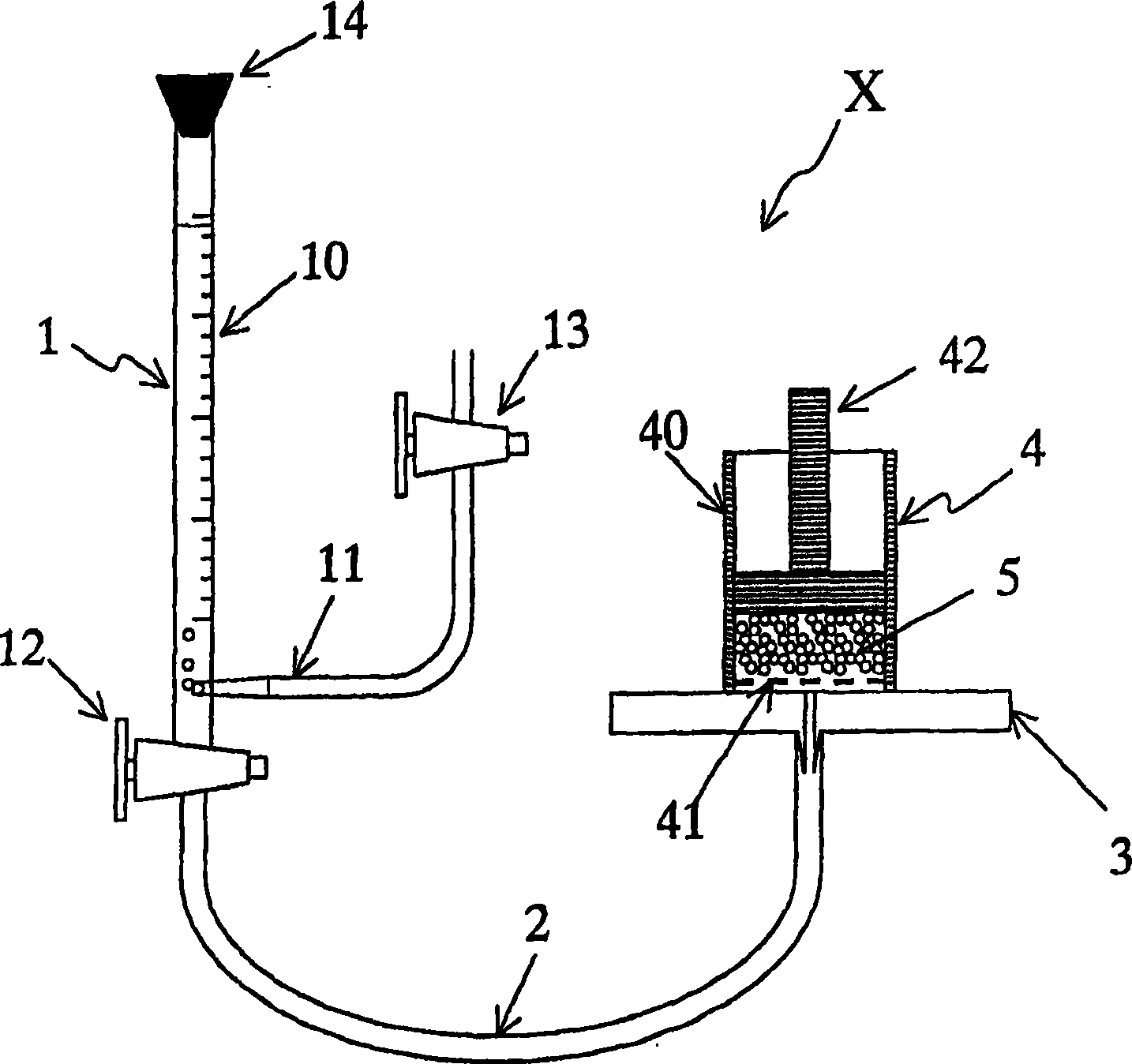

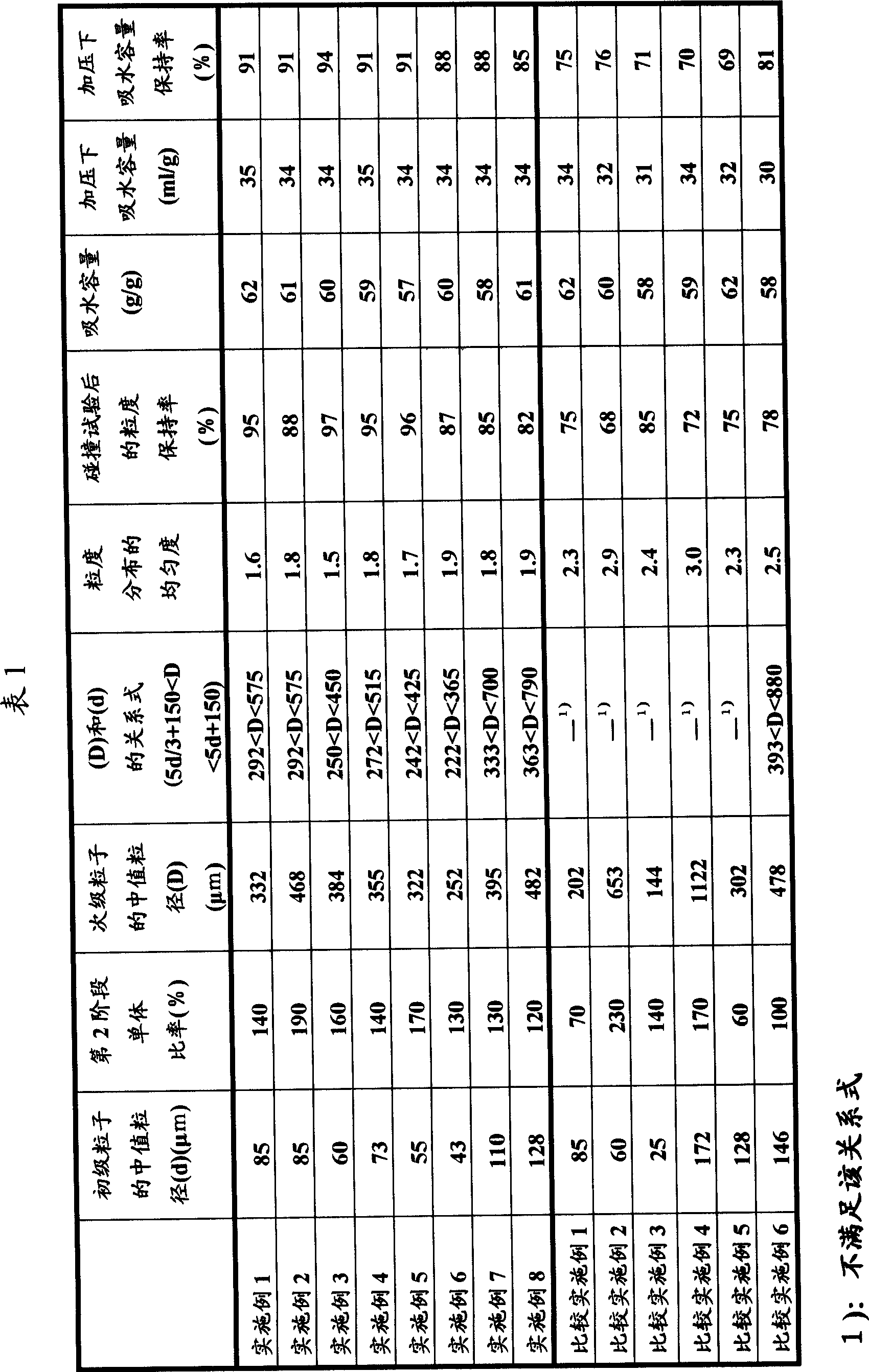

The present invention relates to a method of producing water-absorbent resin particles in which a median particle size of primary particles (d) and a median particle size of secondary particles (D) satisfy the relationship of the formula, 5d / 3+150<D<5d+150, comprising the steps of: (1) subjecting a water-soluble ethylenically unsaturated monomer to a first-step reversed phase suspension polymerization reaction, in a petroleum hydrocarbon solvent, in the presence of a dispersion stabilizer, to give spherical primary particles having a median particle size (d) of from 30 to 130 mum; (2) cooling the polymerization reaction solution, to precipitate the dispersion stabilizer; and (3) carrying out a second-step reversed phase suspension polymerization reaction by adding the water-soluble ethylenically unsaturated monomer for the second step to the polymerization reaction solution to agglomerate the primary particles, to give secondary particles having a median particle size (D) of from 200 to 500 mum.

Owner:SUMITOMO SEIKA CHEM CO LTD

Method of preparing high water absorbing resin by process of reversed phase suspension polymerizing polypropylene

This invention relates to a method to prepare superabsorbent polycrylic acid (or its salt) resin by verse-suspension polymerization, with cyclohexane adopted as solvent, crylic acid as monomers, K2S208 as initiators and N, N'-methylenebisacrylamide as cross-linking reagent. It has the characteristics that the dispersants for verse-suspension in the reaction system can be monoglyceryl ester or octadecyl phosphatide / span-60 complex or octadecyl phosphatide / monogylceryl ester complex and the dispersants weigh 2~20% of crylic acid monomers. The superabsorbent polycrylic acid resin prepared in this invention is white or light yellow visible impurity-free gel solid or solid particles, with sufficient gel strength, a water absorption of over 600ml / g and a salt solution absorption of over 70ml / g.

Owner:ZHEJIANG UNIV

Method for producing water-absorbing resin

A process for preparing a water-absorbent resin comprising carrying out a reverse phase suspension polymerization in multi-steps of at least two steps when the water-absorbent resin is prepared by subjecting a water-soluble ethylenically unsaturated monomer to the reverse phase suspension polymerization in the presence of a crosslinking agent, the process for preparing a water-absorbent resin being characterized by adding a water-soluble chain transfer agent in an amount of 0.000012 to 0.01 mole per 1 mole of the water-soluble ethylenically unsaturated monomer used in a polymerization reaction to at least one step in the second and subsequent steps of the multi-steps, to carry out the polymerization reaction. The water-absorbent resin can be suitably used in hygienic materials such as disposable diaper and sanitary napkin.

Owner:SUMITOMO SEIKA CHEM CO LTD

Gypsum-based composite humidity control material and preparation method thereof

The invention discloses a gypsum-based composite humidity control material which does not contain chlorides and a preparation method thereof. The preparation method comprises the following steps of: firstly, preparing a sepiolite / poly (acrylic acid-acrylamide) composite humidity control ingredient with high humidity containing volume and humidity control capability with a reversed phase suspension method; then, adding the composite humidity control ingredient into building gypsum, lime powder and water; fully stirring and mixing, and extruding the mixture into a sample of the specific shape;and drying to obtain a finished product. The gypsum-based composite humidity control material prepared with the method has the advantages of high humidity containing volume, strong humidity control capability and higher rupture strength and compressive strength, the production requirements of humidity control building materials, such as gypsum building blocks, gypsum plates and the like can be satisfied so as to automatically regulate the humidity of the indoor space of a building after the gypsum-based composite humidity control material is used.

Owner:TIANJIN UNIV

Preparation of high hydroscopic resin by reversed phase microemulsion process

The invention relates to a method for preparing acrylic acid-acrylamide (PAA-AM) high absorbent resin by synthesis with a reversed-phase micro-emulsion polymerization method; the preparation method comprises the following steps of: taking cyclohexane as a continuous phase, water as a dispersed phase, N, N'-methylene double acrylamide as crosslinker, ammonium persulfate (APS) as initiator, using anionic-non-ionic compound surfactant and non-ionic-non-ionic compound surfactant, acrylic acid and acrylamide as a raw material monomer, and the acrylic acid-acrylamide (PAA-AM) high absorbent resin is synthesized with the reversed-phase micro-emulsion polymerization method. Compared with the conventional reversed-phase suspension polymerization and reversed-phase emulsion polymerization, the method for preparing acrylic acid-acrylamide (PAA-AM) high absorbent resin by synthesis with the reversed-phase micro-emulsion polymerization method has the advantages of steady polymerization process, non-flocculation and precipitation-free generation, high reaction rate, and short reaction time, and can greatly improve the production efficiency. The acrylic acid-acrylamide (PAA-AM) high absorbent resin with the reversed-phase micro-emulsion polymerization method which is prepared by the method is a light yellow gel solid or granular solid, has high water and salt absorption rate, high requirement for the water-holding capacity of the soil, and the pH value of not more than 7 of the obtained high absorbent resin, and can be directly used in industries such as agriculture, forestry, and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

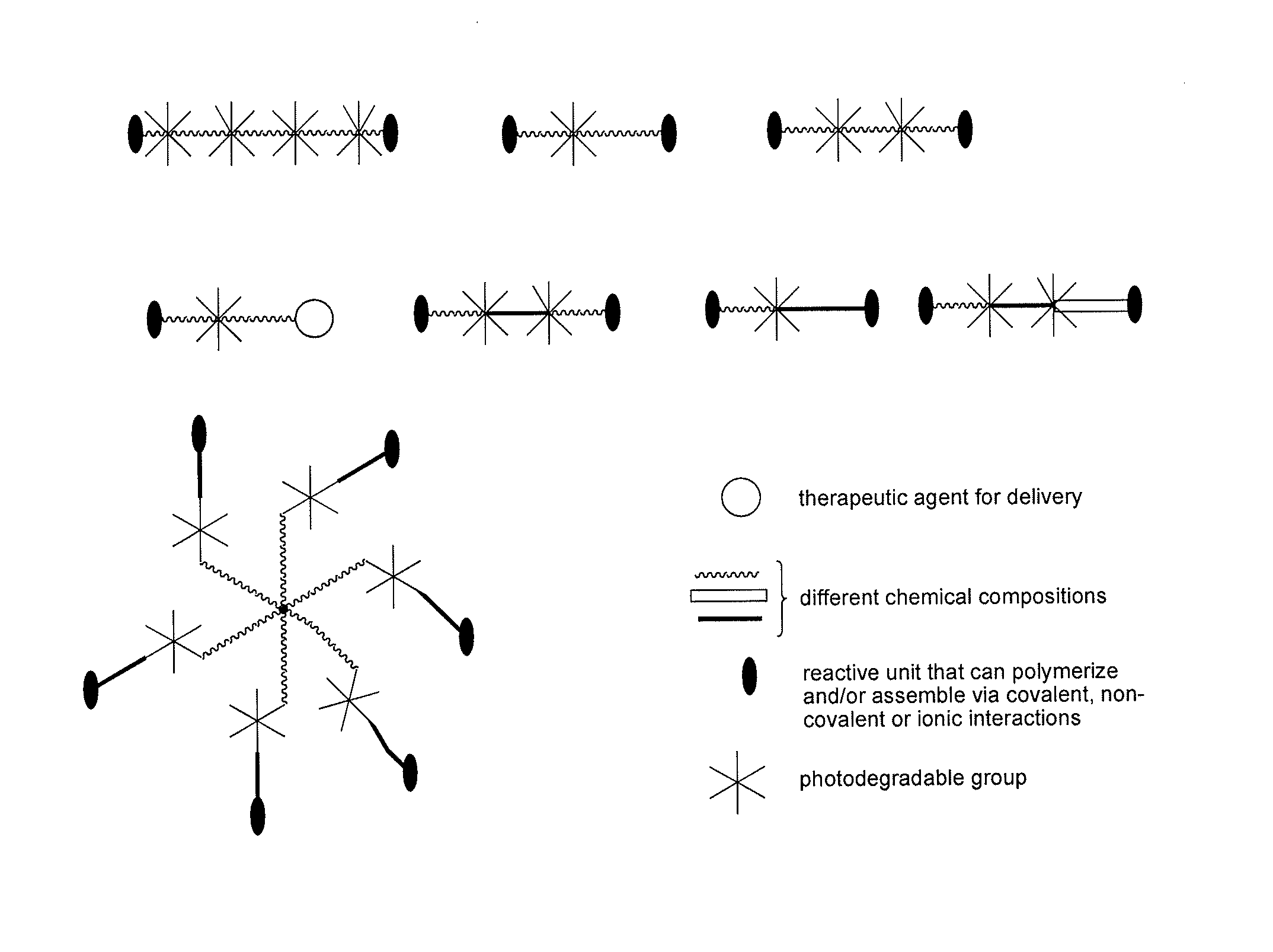

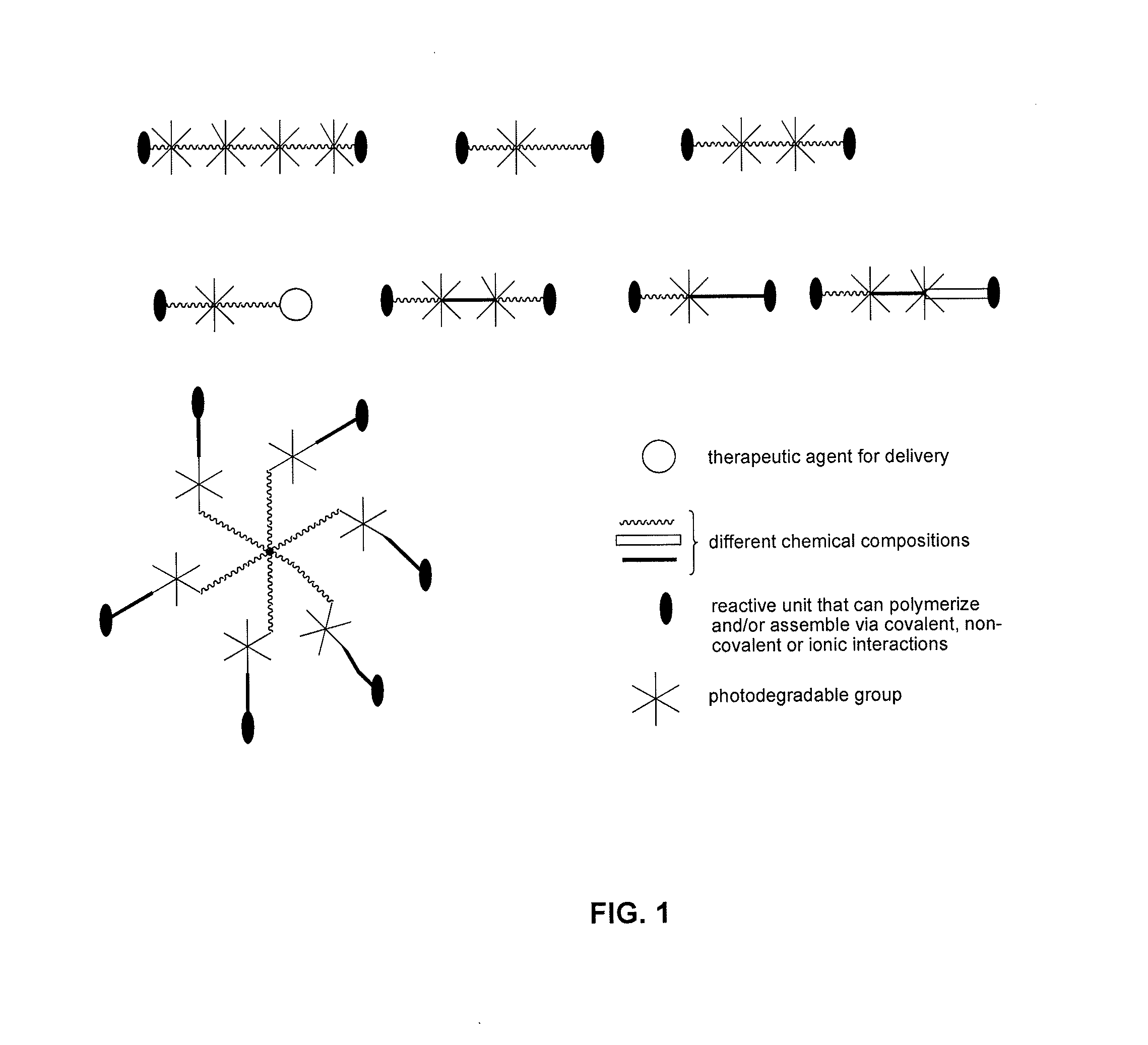

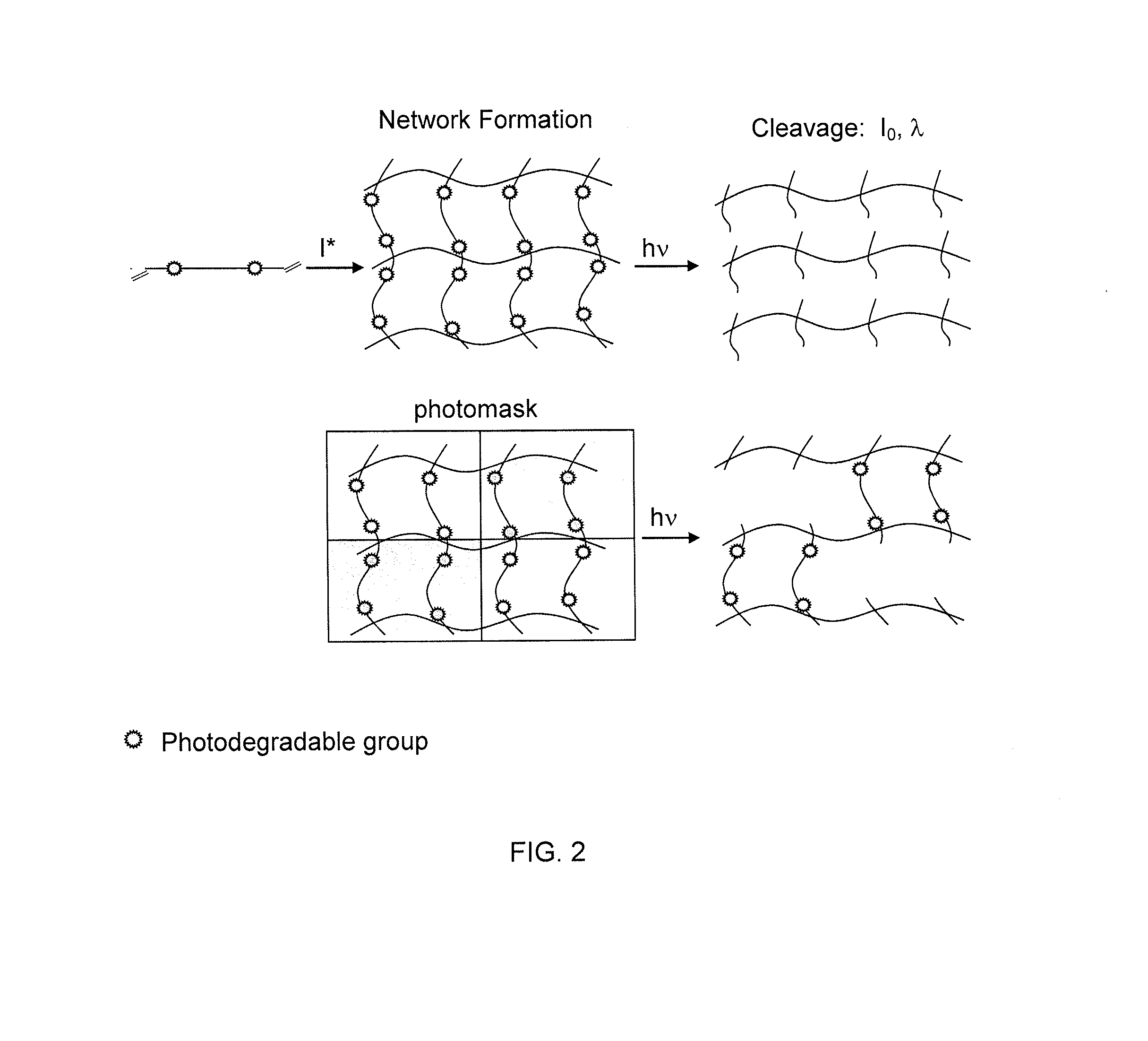

Photodegradable groups for tunable polymeric materials

ActiveUS20140031285A1Sure easyEasy to useDrug photocleavagePeptide/protein ingredientsMean diameterFluorescence

Here, we present a photodegradable microparticle system that can be employed to entrap and deliver bioactive proteins to cells during culture. By using a photosensitive delivery system, experimenters can achieve a wide variety of spatiotemporally regulated release profiles with a single microparticle formulation, thereby enabling one to probe many questions as to how protein presentation can be manipulated to regulate cell function. Photodegradable microparticles were synthesized via inverse suspension polymerization with a mean diameter of 22 μm, and degradation was demonstrated upon exposure to several irradiation conditions. The protein-loaded depots were incorporated into cell cultures and release of bioactive protein was quantified during the photodegradation process. This phototriggered release allowed for the delivery of TGF-β1 to stimulate PE25 cells and for the delivery of fluorescently labeled Annexin V to assay apoptotic 3T3 fibroblasts during culture. By incorporating these photoresponsive protein delivery depots into cell culture, new types of experiments are now possible to test hypotheses about how individual or multiple soluble factors might affect cell function when presented in a uniform, temporally varying, or gradient manner.

Owner:UNIV OF COLORADO THE REGENTS OF

Process for production of water-absorbable resin particle, and water-absorbable resin particle produced by the process

ActiveCN101466740AHigh particle strengthImprove water absorptionOther chemical processesThin material handlingHydrocarbon solventsWater soluble

Owner:SUMITOMO SEIKA CHEM CO LTD

Composite gel for preventing spontaneous combustion of coal

InactiveCN102173722AOvercoming the disadvantage of releasing ammonia gasNo pollutionDust removalFire preventionSodium bicarbonateSpontaneous combustion

The invention discloses a composite gel for preventing spontaneous combustion of coal, which comprises the following ingredients in percentage by weight: 5 to 8 percent of base material, 2 to 5 percent of accelerating agent, 6 to 9 percent of aggregate material, 0.5 to 3 of water-retaining agent and the balance of water. The base material is water glass, the accelerating agent is sodium bicarbonate, the aggregate material is diatomite, and the water-retaining agent is salt-resistant highly-water-absorbent resin. The salt-resistant highly-water-absorbent resin is made by aqueous solution polymerization or reverse-phase suspension polymerization, and has a water absorbency of 1250 to 1355 g<g> and a salt absorbency of 100 to 120 g<g>. The produced gel is excellent in leak stoppage, oxygen insulation, temperature drop and retardancy, has good fluidity and strong moisture-retaining property and can slow water loss. The gel products with different gelling time are made by adjusting the proportions. The gel is convenient and flexible in use, has strong adaptability, and can be widely applied to various high-risk and self-combustible coal areas.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

Method for preparing anti-phase suspension polymeric polyacrylic acid/acrylamide high water absorption resin

The invention relates to a process for preparing a high water absorbing resin of anti-phase suspension polymerization polyacrylic acid / acrylamide, which is characterized in that cyclohexane is dissolvent, alkylating agent and acrylamide are monomers, ammonium peroxodisulfate is initiating agent, N,N'-methylene methylene is cross linker, octadecyl alcohol phosphatides is dispersing agent. polyacrylic acid / acrylamide high water absorbing resin is prepared by adopting an anti-phase suspension polymerization method, and the water absorption ratio of the high water absorbing resin which is prepared by the invention is 298ml / g-346ml / g.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Super absorbent water-retaining agent and preparation method thereof

The invention discloses a super absorbent water-retaining agent and a preparation method thereof. Acrylic acid and acrylamide are used as monomers, potassium persulfate is used as an initiator, N-N' methylene-bisacrylamide is used as a crosslinking agent, polyethylene glycol-2000 and polyethylene glycol-6000 are used as anti-adhesive agents, and bentonite or calcined kaoline is used as an inorganic filler, so that a water phase is formed; and cyclohexane is used as a solvent, glyceryl monostearate is used as a dispersant, and oil phase is mixed with the water phase, so that the super absorbent water-retaining agent is prepared by using an inverted suspension polymerization method. The water absorbency of the prepared poly(acrylic acid / acrylamide / clay) water-retaining agent reaches between1,250 gg<-1> and 1,350 gg<-1>, salt absorbency (0.9 weight percent of NaCl) reaches between 100 gg<-1> and 120 gg<-1>, and water retention rate of a sample can still reach over 50 percent after 13 hours at the temperature of below 70 DEG C; and the super absorbent water-retaining agent can be widely applied to the fields of construction of various water conservancy works, medical treatment and environmental protection.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

Gradient cross-linked high-elasticity embolization microsphere and preparation process thereof

ActiveCN110201215ANo cross-linkingThere will be no mutual restriction of drug loading capacitySurgical adhesivesPharmaceutical delivery mechanismCross-linkMicrosphere

The invention discloses a gradient cross-linked high-elasticity embolization microsphere and a preparation process thereof, which belong to the field of medical instruments. According to the method for preparing the gradient cross-linked high-elasticity embolization microsphere, wherein the embolization microsphere is prepared by an aqueous phase and an oil phase, wherein the volume ratio of the aqueous phase to the oil phase is 1% to 30%, The preparation method comprises the following steps: step 1. preparing a reverse suspension polymerization oil phase; step 2. preparing the aqueous phase of the reverse phase suspension polymerization system; and step 3. performing reverse suspension polymerization. The embolization microsphere has the advantages that the embolization microsphere has excellent compressibility and elasticity, can smoothly pass through the microcavity with an inner diameter being smaller than the size of the microsphere itself, the compressibility is greater than 60%of the diameter of the microsphere, and the microsphere rebounds rapidly to a spherical shape after compression; and the microsphere has strong hydrophilic properties, good expansion capacity, fast adsorption capacity, and high drug loading capacity. The preparation process is simple, and can be completed by one polymerization reaction, and first graft modification and then polymerization cannot be required.

Owner:科睿驰(深圳)医疗科技发展有限公司

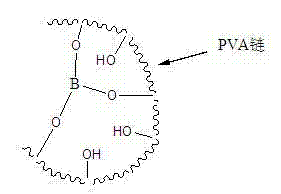

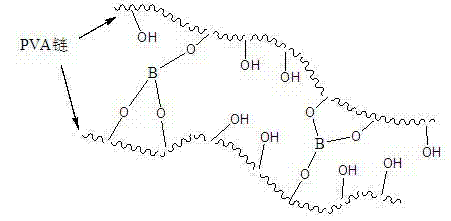

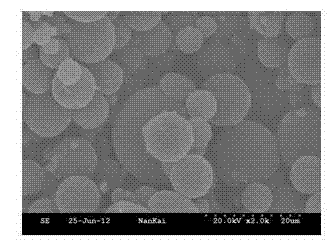

Polyvinyl alcohol-borax microsphere and preparation method thereof

ActiveCN102964612AEasy and efficient to prepareImprove thermal stabilitySodium phosphatesMicrosphere

The invention relates to a polyvinyl alcohol-borax microsphere and a preparation method thereof. In particular, the technical method adopts borax as the crosslinking agent to prepare a polyvinyl alcohol microsphere by means of water-in-oil reversed phase suspension polymerization. The method consists of: taking liquid paraffin-sorbitan monooleate system as the dispersion phase, adopting a polyvinyl alcohol water solution as the polymerization phase, and using borax as the crosslinking agent, subjecting them and polyvinyl alcohol to an esterification crosslinking reaction in an acidic condition, employing sodium phosphate as the pH adjusting agent and the curing agent, and leaving a microsphere to cure, thus obtaining the polyvinyl alcohol-borax microsphere. In the invention, borax is adopted as the crosslinking agent, which is non-toxic and non-simulating to human bodies, thus avoiding using dialdehyde, diacyl chloride and other crosslinking agents having toxicity to human bodies and stimulation to the skin, as well as potential safety hazards. The prepared polyvinyl alcohol microsphere has good thermal stability, no bacterium, no toxicity, no pyrogen, and good biocompatibility.

Owner:IMEIK TECH DEV CO LTD

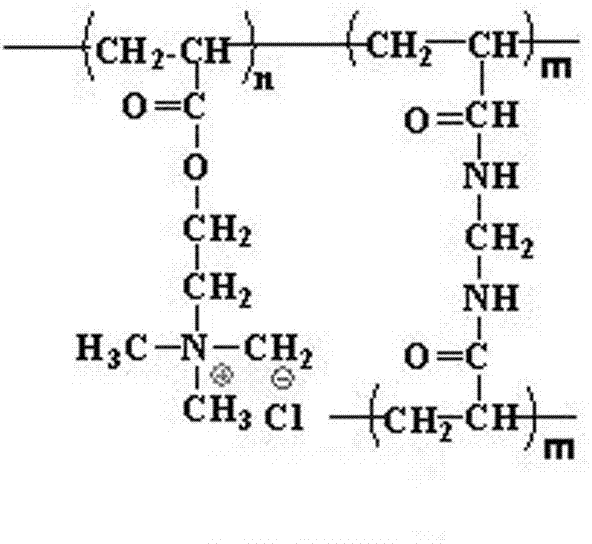

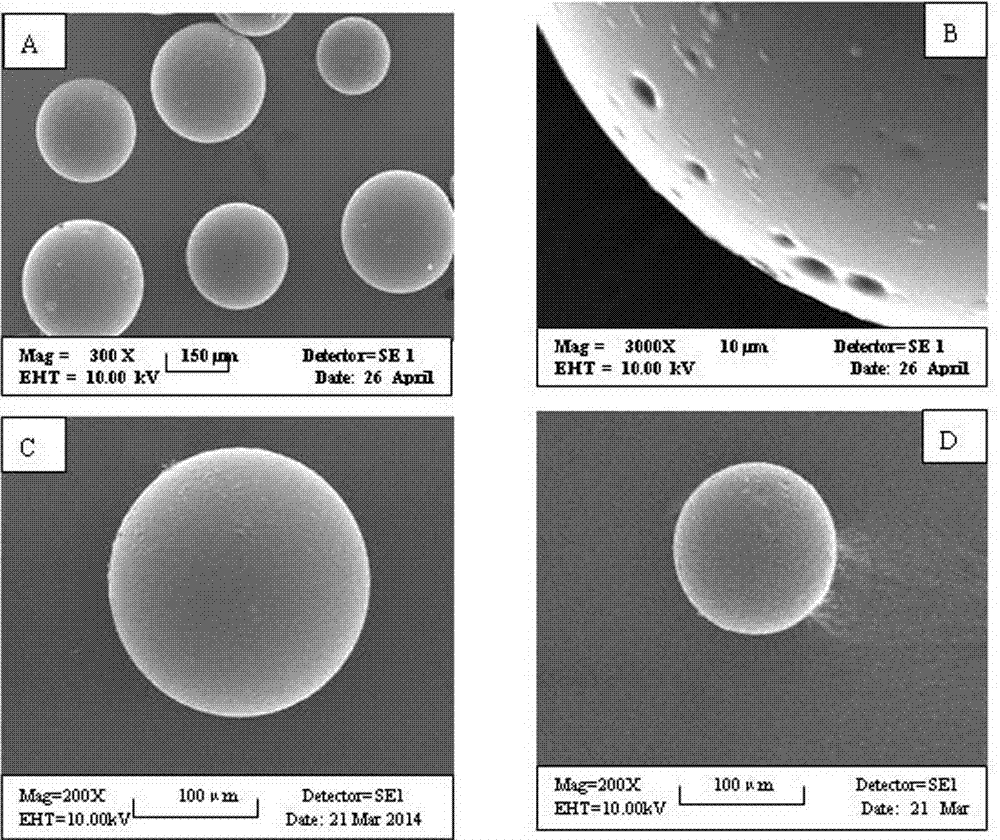

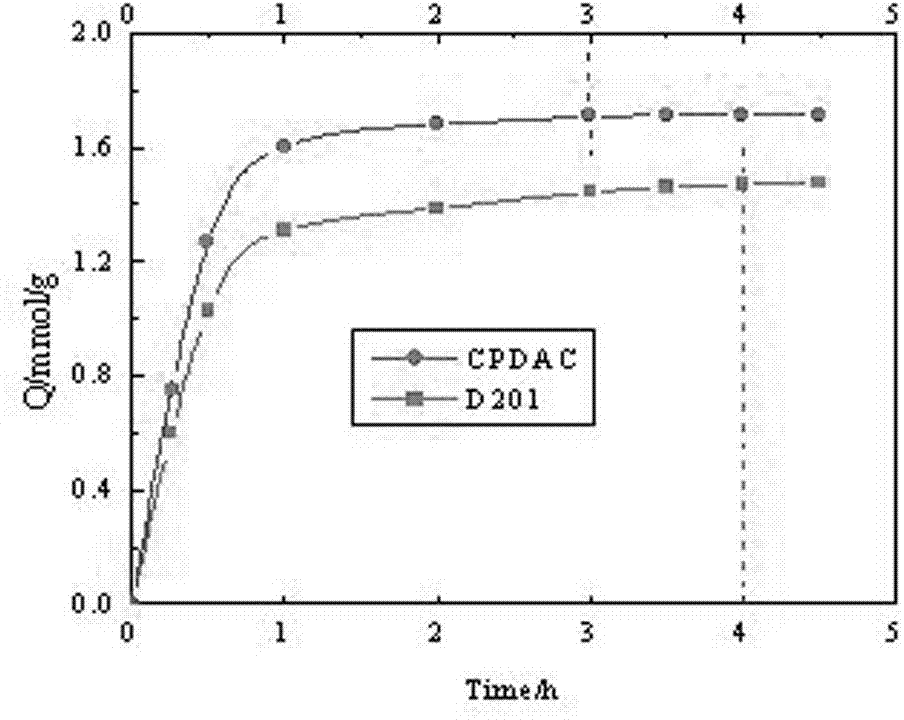

Preparing method of gel microsphere material absorbing molybdate

The invention belongs to the technical fields of material separation and preparation and functional polymer materials and particularly provides a preparing method of a gel microsphere material absorbing molybdate. The method adopts (2-(acryloyloxy)ethyl)trimethylammonium chloride (DAC) as a monomer, adopts a reversed-phase suspension polymerization method and prepares cation gel microspheres CPDAC having a particle size of 200-300 [mu]m. The preparing method is characterized by high stability, mild conditions, simple process, and convenient and controllable operation. The gel microspheres CPDAC adsorb ammonium molybdate, and are high in exchange capacity and high in exchange speed. The gel microspheres CPDAC have a potential application prospect in the field of extraction and separation of anion materials, the field of drug controlled release, and even the field of removing toxic anions from a water environment.

Owner:山西铁居环保科技有限公司

High molecular weight cationic polymers, preparation method and uses thereof

InactiveUS20040030039A1Optimize polymerization conditionOptimize the conditionsDistillationActive matter

This invention relates to a process for preparation of cationic polymers of high molecular weight based on salts of diallyl dialkyl ammonium, in the form of beads, by the method of reverse suspension polymerization. This process makes use of a monomer or mixture of monomers of diallyl dialkyl ammonium in a concentration ranging from 67 to 77 percent, preferably from 68 to 72 percent, by weight of active matter. The process makes it possible to polymerize monomers of this type without development of a specific stabilizing system, without seeded polymerization, even without addition of surfactants to the formulation, without distillation in certain important cases, and avoiding any risk of caking. The invention also relates to the polymers obtained and their applications in industry, particularly in the papermaking industry, water treatment processes, the mining industry, the cosmetics industry, the textile industry, and generally speaking in all industrial coagulation / flocculation methods.

Owner:SNF SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com