Patents

Literature

66results about How to "Prevent riots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of fiber with high water absorption

ActiveCN103160952ASpinning solution stabilityGood physical and mechanical propertiesFilament/thread formingArtificial filament heat treatmentPolyvinyl alcoholAcrylic acid

The invention relates to a preparation method of a fiber with high water absorption, which is a method for preparing the fiber with high water absorption by a post-crosslinking agent. According to the preparation method, the fiber with high water absorption is prepared from acrylic acid (AA) and acrylamide (AM) which are partly neutralized and taken as polymerized monomers through the steps of: blending the polymerized monomers with polyving akohol (PVA), initiating by potassium persulfate (KPS), blending and polymerizing in an aqueous solution, adding a dialdehyde solution to obtain a mixed solution serving as a post-crosslinking agent solution, mixing to be uniform and defoaming to obtain a spinning stock solution; dry-wet spinning the spinning stock solution to form a nascent fiber; and heat-treating the nascent fiber at a certain temperature to generate a crosslinking reaction, thereby forming the three-dimensional net-structured fiber with high water absorption. According to the preparation method, the implosion phenomenon which easily occurs during polymerization of the traditional polymer solution with high water absorption is avoided, the preparation technology is simple and safe, the production cost is reduced, and the production efficiency is increased; and the obtained water-absorbing fiber has high and controllable water adsorption, thermostability, capability of being repeatedly used, and long residual action.

Owner:DONGHUA UNIV

Method of preparing high water absorbing resin by process of reversed phase suspension polymerizing polypropylene

This invention relates to a method to prepare superabsorbent polycrylic acid (or its salt) resin by verse-suspension polymerization, with cyclohexane adopted as solvent, crylic acid as monomers, K2S208 as initiators and N, N'-methylenebisacrylamide as cross-linking reagent. It has the characteristics that the dispersants for verse-suspension in the reaction system can be monoglyceryl ester or octadecyl phosphatide / span-60 complex or octadecyl phosphatide / monogylceryl ester complex and the dispersants weigh 2~20% of crylic acid monomers. The superabsorbent polycrylic acid resin prepared in this invention is white or light yellow visible impurity-free gel solid or solid particles, with sufficient gel strength, a water absorption of over 600ml / g and a salt solution absorption of over 70ml / g.

Owner:ZHEJIANG UNIV

Phyllosilicate modified organic silicon grafted polyether polyurethane elastomer and preparation method and application thereof

Owner:国科广化(南雄)新材料研究院有限公司 +1

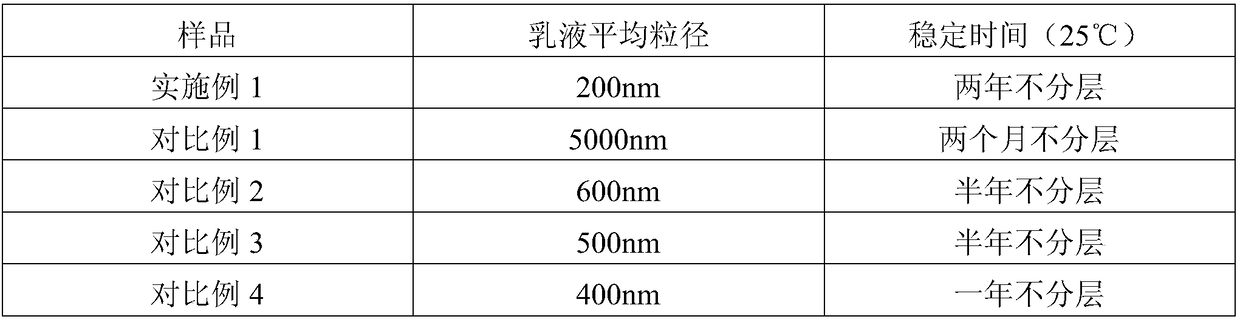

Polymerization method of anion modified polyacrylamide inverse emulsion having high solid content and high molecular weight

ActiveCN103881006APrevent riotsHigh clarityWater/sewage treatment by flocculation/precipitationIonMethacrylamide

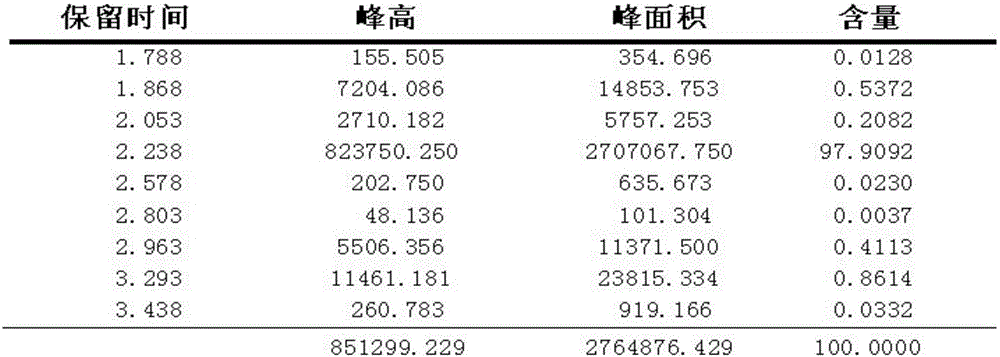

The invention provides a synthesis method of inverse emulsion of a modified polyacrylamide flocculating agent, and in particular relates to a polymerization method of anion modified polyacrylamide inverse emulsion having high solid content and high molecular weight. A method for oxidizing and reducing an initiator from paramisansodium (4-MASANa) and ammonium persulfate-sodium hydrogen sulphite by feeding the third monomer, namely methacrylamide, is adopted; the temperature change in the polymerization reaction is effectively controlled; the high molecular weight of an emulsion product is obtained; furthermore, because of containing a salicylic acid functional group, fine particles and metal ions in suspension can be well absorbed strongly; the flocculating effect and the clarity of the suspension are increased; by means of evaporating and concentrating in vacuum at high pressure in a rotating manner, the solid content of the modified polyacrylamide inverse emulsion products is increased; a compound interface membrane can be generated by compounding the used compound emulsifiers, namely methyl glucoside sesquialter stearate and propylene glycol monostearate, in a certain proportion; and the long-term steady preservation of inverse emulsion under the condition of high solid content can be effectively realized.

Owner:DONGYING BAOMO ENVIRONMENT ENG CO LTD

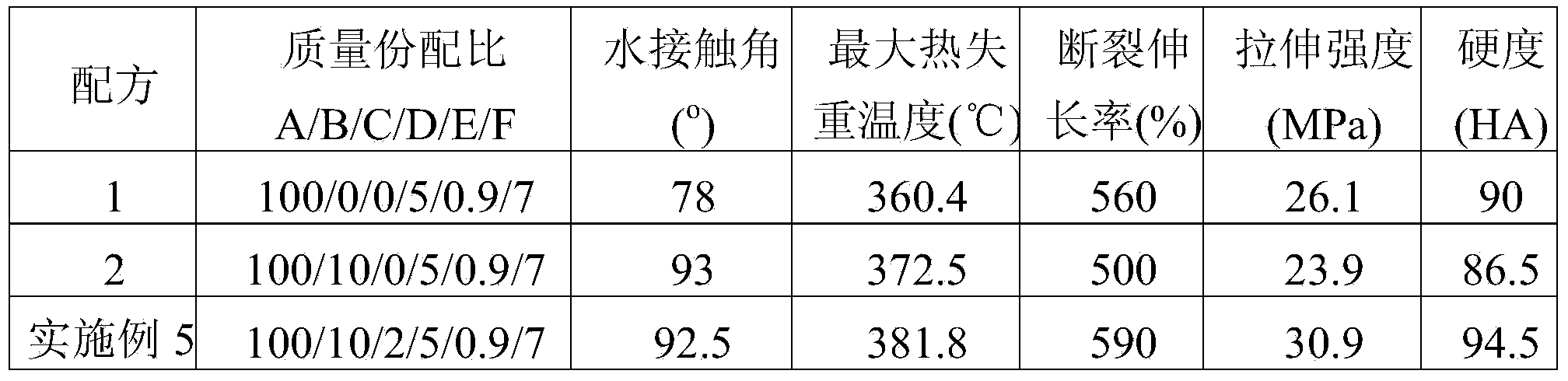

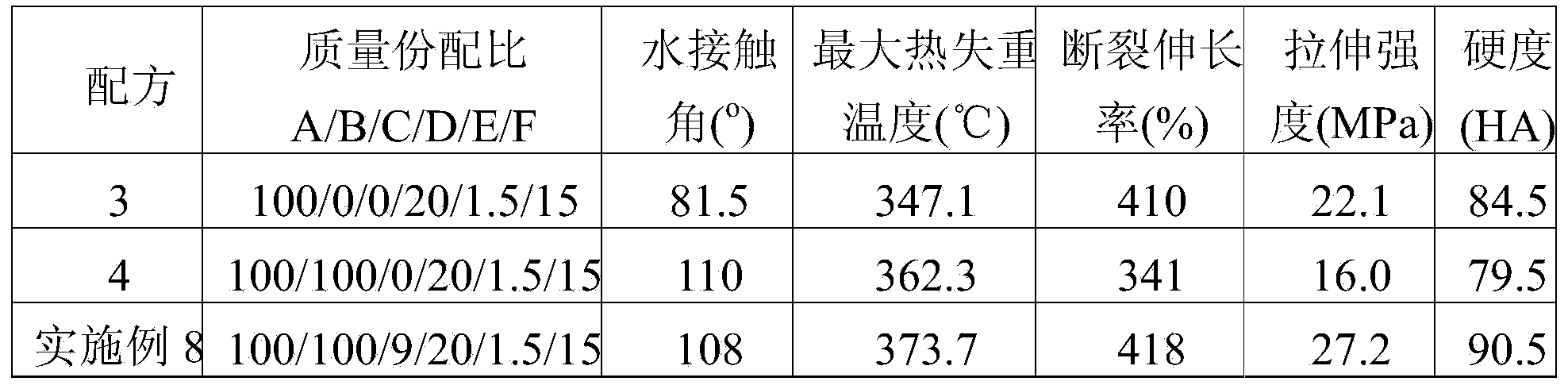

Organic silicon/montmorillonite composite modified polyester-type polyurethane elastomer as well as preparation method and application thereof

ActiveCN104193940AImprove surface propertiesImprove heat resistanceSilicon compoundsPolyesterMechanical property

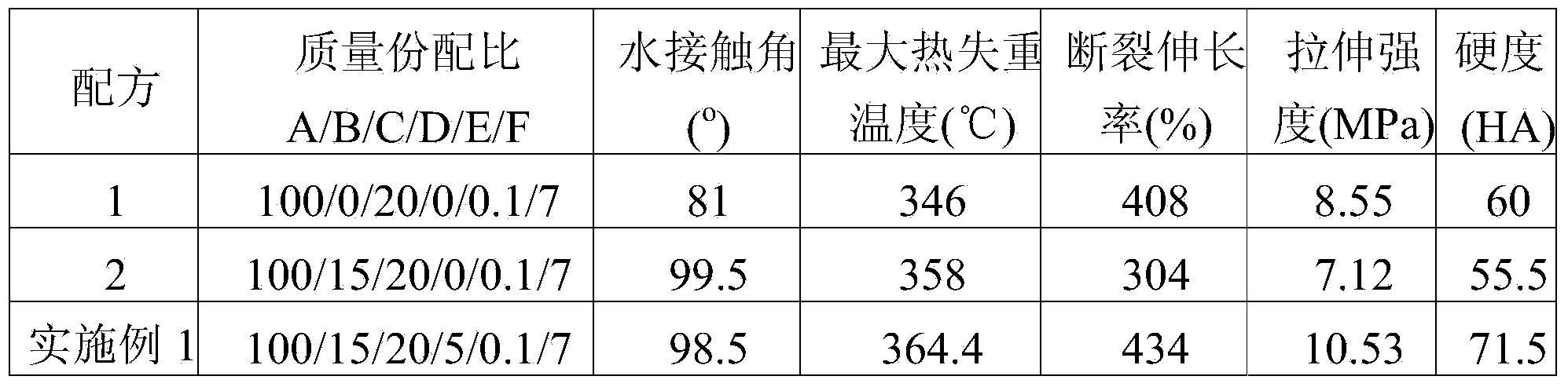

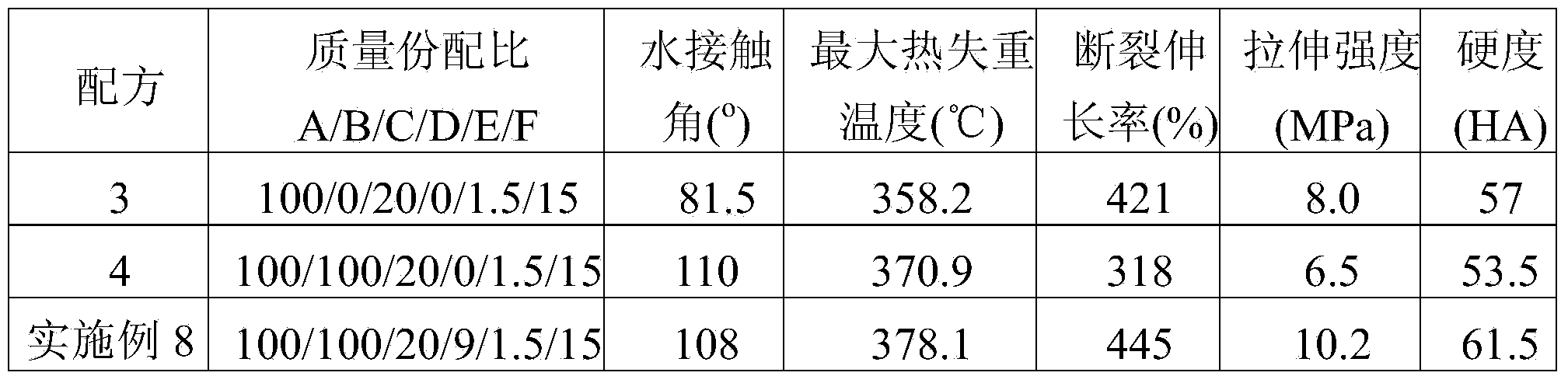

The invention belongs to the field of polymer materials and particularly relates to an organic silicon / montmorillonite composite modified polyester-type polyurethane elastomer as well as a preparation method and an application thereof. The polyurethane elastomer comprises the following components: 100 parts by mass of polyester-type polyurethane prepolymer, 0.5-100 parts by mass of isocyanate-terminated polydimethylsiloxane, 1-40 parts by mass of polyester polyol, 0.5-15 parts by mass of organic montmorillonite, 0.1-1.5 parts by mass of a defoaming agent, 0-5 parts by mass of a chain extender and 2-15 parts by mass of a curing agent. According to the polyurethane elastomer, since the polyurethane is jointly modified by virtue of organic silicon and montmorillonite, the polyurethane elastomer integrates the excellent performances of organic silicon, montmorillonite and polyurethane and thus the material has a plurality of performances, such as excellent surface property, heat resistance and good mechanical properties.

Owner:国科广化(南雄)新材料研究院有限公司 +1

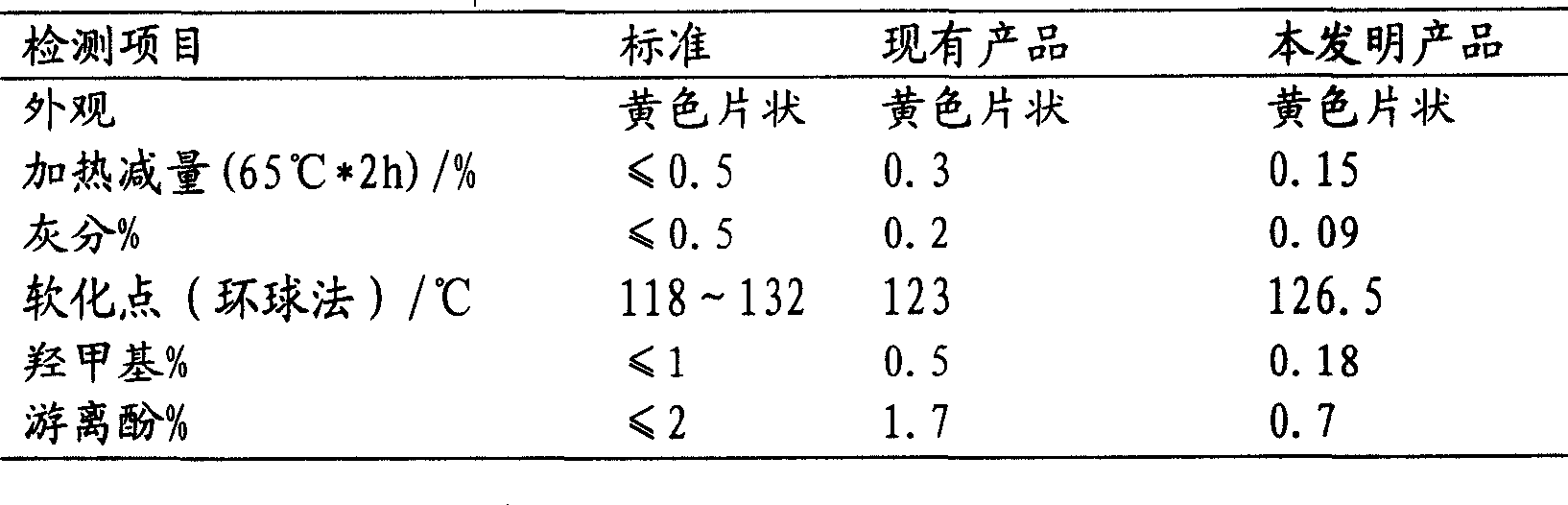

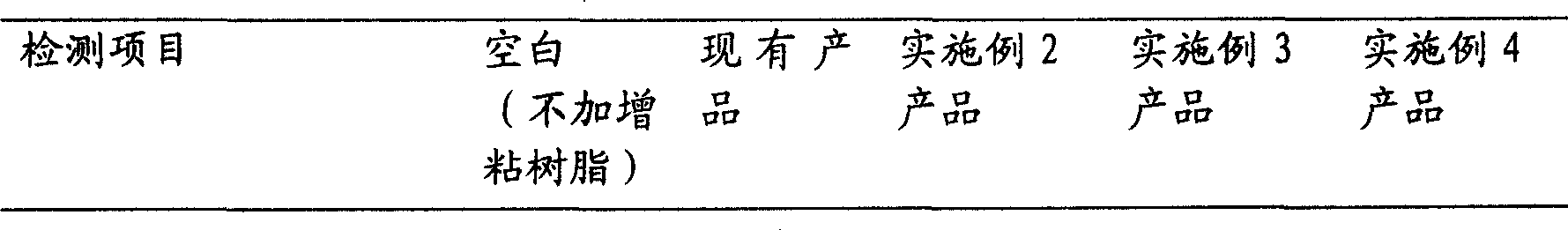

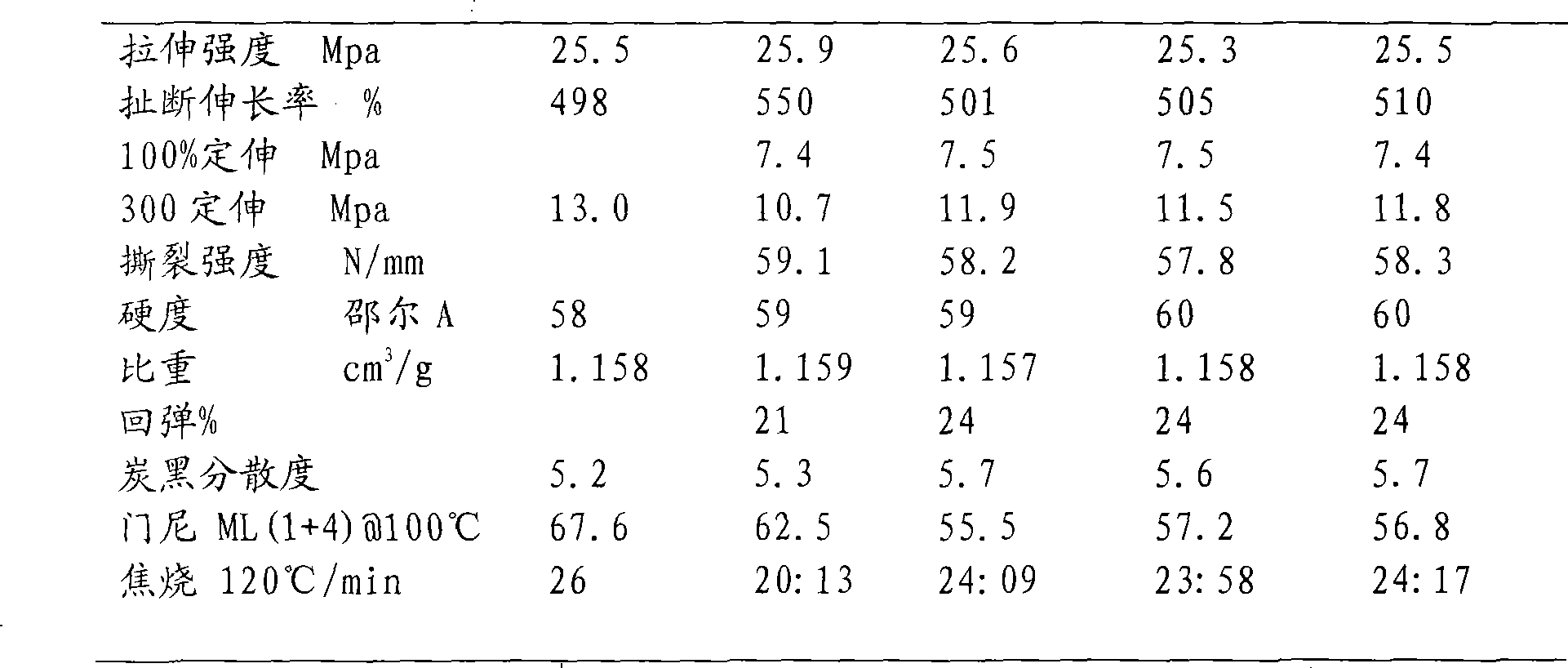

Solvent-free method for preparing tackified p-tert-butyl phenolic resin

A solvent-free method for preparing trackifying para-tertiary butyl phenol phenolic resin comprises the following components and dosage, with the dosage of weight part: 900-1000 parts of para-tertiary butyl phenol, 150-200 parts of 97% formaldehyde, 40-50 parts of 10% hydrochloric acid, 5-10 parts of oxalic acid, and 1.5-3.5 parts of surface-active agent, wherein, 97% formaldehyde and 10% hydrochloric acid are both weight percentage. The method overcomes the shortcoming of the existing method for preparing para-tertiary butyl phenol phenolic resin, which uses solvent; and the method has the advantages of simple synthetic process, low production cost and higher performance than that of the existing product, and avoids sudden gathering in the process of preparation, and the like.

Owner:WUHAN JINGHE CHEM

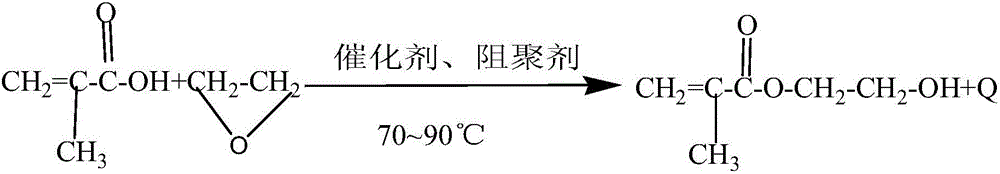

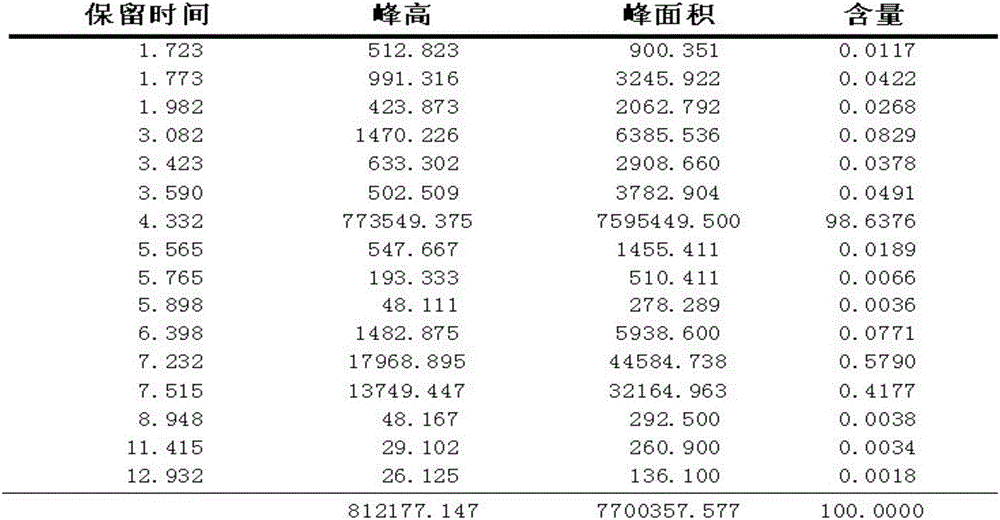

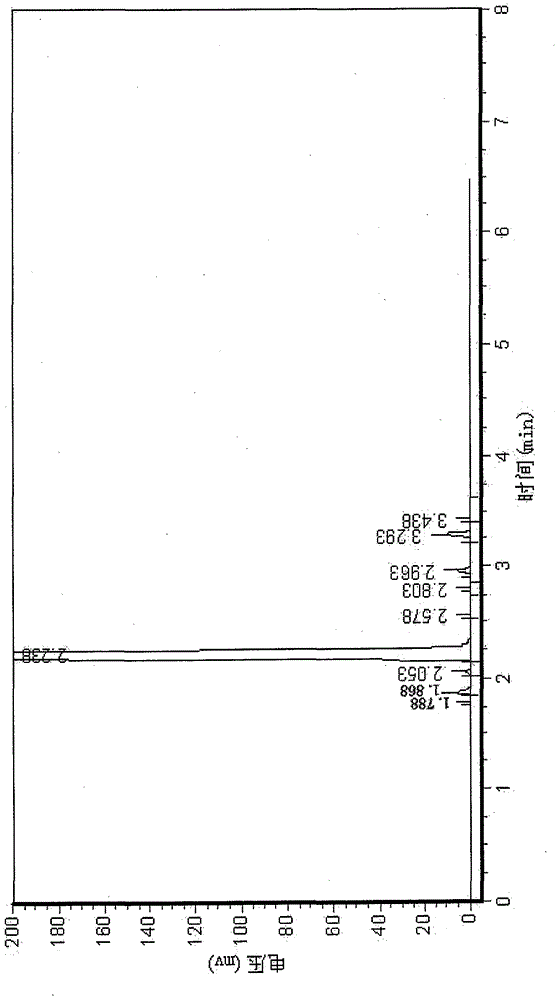

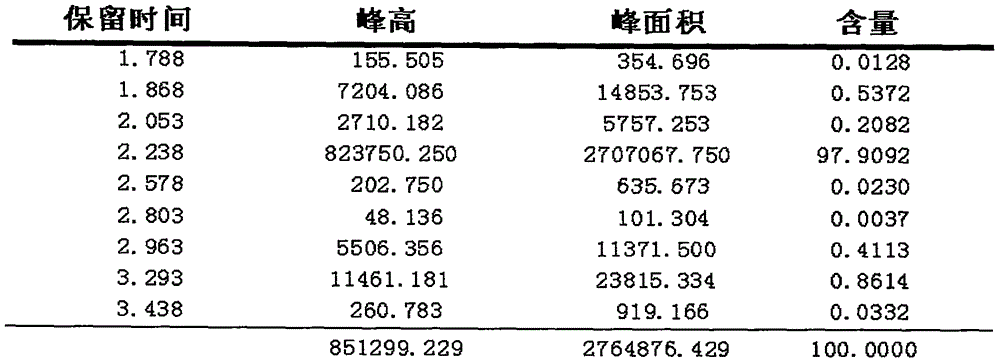

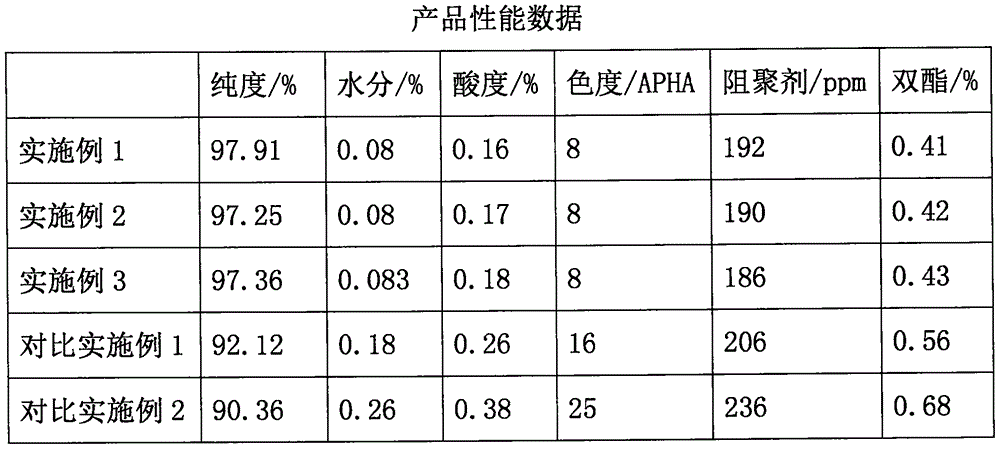

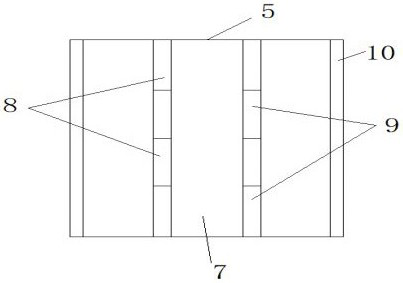

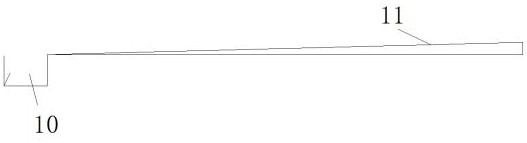

Preparation technique of high-purity hydroxyethyl methacrylate

InactiveCN105968011AImprove dispersionImprove the inhibition effectOrganic compound preparationCarboxylic acid esters preparationChemistry(Hydroxyethyl)methacrylate

The invention provides a preparation technique of high-purity hydroxyethyl methacrylate. A rectification process is added in a purification process; a polymerization inhibitor is replenished through a spraying way in a phase transformation process of the rectification process; meanwhile, the vacuum degree and the working temperature of a tower top are controlled; the flash polymerization, in a rectifying tower, of the hydroxyethyl methacrylate is avoided, so as to achieve the purposes of being stable in operation, being capable of effectively preventing polymerization and improving product quality, thereby improving the purity of a hydroxyethyl methacrylate product.

Owner:CHANGZHOU HICKORY CHEM

Preparation method of fiber with high water absorption

ActiveCN103160952BImprove stabilityPoor spinnabilityFilament/thread formingArtificial filament heat treatmentPotassium persulfateFiber

Owner:DONGHUA UNIV

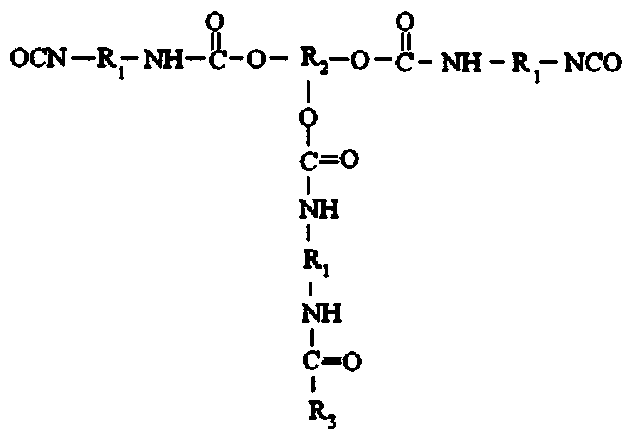

Organosilicone/laminated silicate compound modified polyether polyurethane elastomer as well as preparation method and application thereof

ActiveCN104231225AImprove surface propertiesImprove mechanical propertiesMechanical propertyDefoamer

The invention discloses an organosilicone / laminated silicate compound modified polyether polyurethane elastomer as well as a preparation method and an application thereof. The elastomer is prepared from the following components in parts by mass: 100 parts of a polyether polyurethane prepolymer, 0.5-100 parts of isocyanate group-terminated polydimethylsiloxane, 1-40 parts of polyether polyol, 0.5-15 parts of organically modified laminated silicate, 0.1-1.5 parts of a defoamer, 0-5 parts of a chain extender and 2-15 parts of a curing agent. By adopting the organosilicone / laminated silicate compound modified polyether polyurethane elastomer, excellent performances of organosilicone and laminated silicate can be integrated to supplement the defects on the performance of polyurethane, so that various performances such as surface properties, mechanical properties and heat resistance of the polyurethane elastomer are improved. The polyurethane elastomer disclosed by the invention is simple in preparation method, wide in source of raw materials, low in energy consumption, free from environmental pollution and suitable for industrial production, and the process conditions are easy to control.

Owner:国科广化(南雄)新材料研究院有限公司 +1

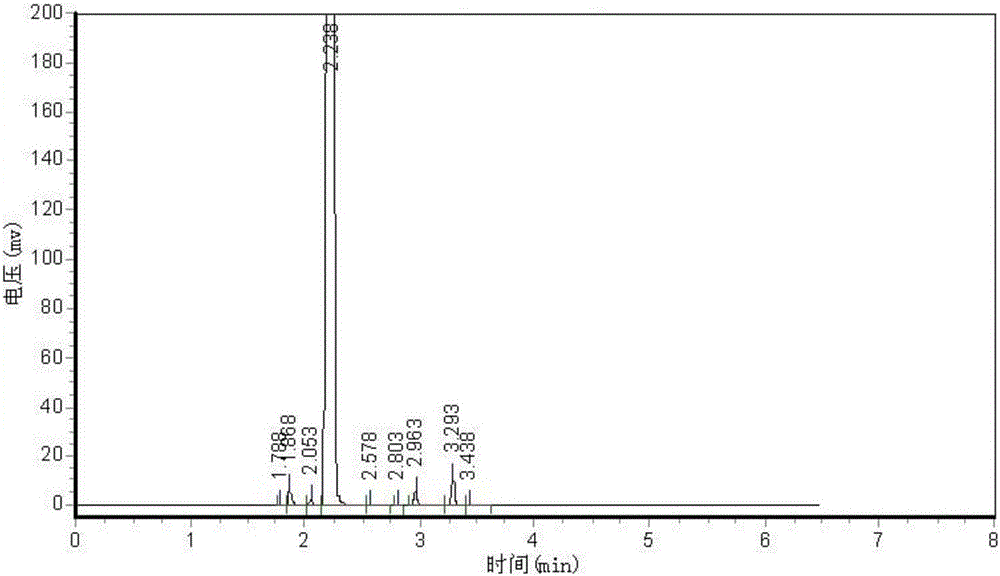

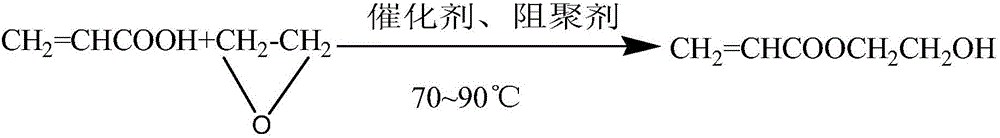

Technology for preparing high-purity 2-hydroxyethyl acrylate

InactiveCN106631790AEfficient recyclingGood dispersionOrganic compound preparationCarboxylic acid esters preparationOperating temperaturePolymerization

The invention discloses a technology for preparing high-purity 2-hydroxyethyl acrylate and relates to the field of 2-hydroxyethyl acrylate preparation technologies. The technology has the advantages that a rectification process is added during purification, a polymerization inhibitor is supplemented through spraying during phase transformation in the rectification process, and the vacuum degree and the operating temperature of a tower top are controlled to eradicate flash polymerization of the 2-hydroxyethyl acrylate in a rectifying tower, so that operation stability is achieved, polymerization can be prevented effectively, the product quality is improved, and the purity of the 2-hydroxyethyl acrylate is enhanced.

Owner:CHANGZHOU HICKORY CHEM

Method for preparing carboxylated NBR latex

The invention relates to a method preparing carboxylic butyronitrile-butadiene, its components comprise deionized water, emulsifying agents, molecular weight regulating agents, PH regulating agents, peroxodisulfate free initiator, butadiene monomers, acrylic nitrile, unsaturated carboxylic acid and unsaturated carboxylic ester, and the process comprises: adding the said components in a percentage by weight of 90-140 % of deionized water, 2.2-3.6 % of emulsifying agents, 0.5-1.5 % molecular weight regulating agents, 0.2-0.5 % of PH regulating agents and 0.3-1.1 % of peroxodisulfate free initiator into a polymeric reactor, then adding the butadiene monomers in a percentage of 52-58 % into the polymeric reactor and stirring to homogeneously mix, increasing the temperature to 40-50 Deg. C, and in the press of 0.3-0.5 MPa, continuously adding the mixture in a percentage of acrylic nitrile of 30-45 %, unsaturated carboxylic acid of 0.5-8 % and unsaturated carboxylic ester of 0.5-7.5 % using a dosage pump, the adding time lasts 6-12 h, and reacting to 2-4 h, then stop, degassing in a degassing tank and second degassing in a degassing column, regulating the latex treated from the degassing column by PH regulating agents to get the completed product.

Owner:DONGYING JIUZHOU AOHUA CHEM

Preparation method of fluorine-containing soap-free emulsion repellent

ActiveCN104861116AOvercome the disadvantages of not being easy to removeEasy to separateCoatingsBulk chemical productionEmulsionNitrogen atmosphere

The invention discloses a preparation method of a fluorine-containing soap-free emulsion repellent, and relates to the technical field of fluorine-containing emulsion repellent preparation, in particular to a preparation method of an environment-friendly fluorine-containing composite emulsion repellent. The preparation method of the fluorine-containing soap-free emulsion repellent comprises the following steps that (1) a fluorine-containing polymer, a water-soluble initiator and a polymer monomer react to form a mixed solution A; and (2) the mixed solution A, the polymer monomer B, an oil-soluble initiator and a polymerization inhibitor are added to a closed reaction kettle with a supercritical carbon dioxide medium for a polymerization reaction under nitrogen atmosphere protection, and supercritical extraction is adopted after reaction completion to form a product. The method overcomes the defect that a solvent is difficultly cleaned up; the obtained product is good in stability; the yield and the purity of the generated fluorine-containing polymer are significantly increased and improved; flash polymerization is avoided; and the production efficiency is improved.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

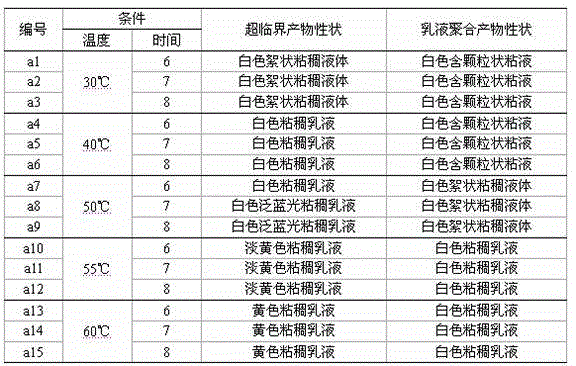

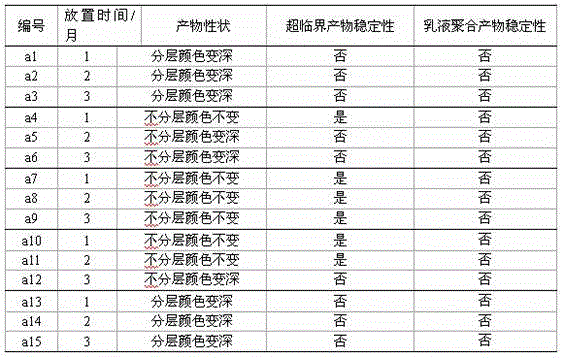

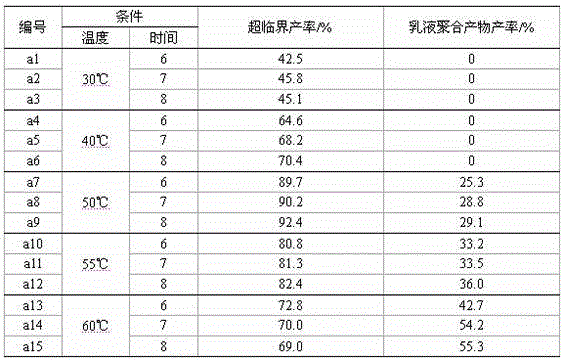

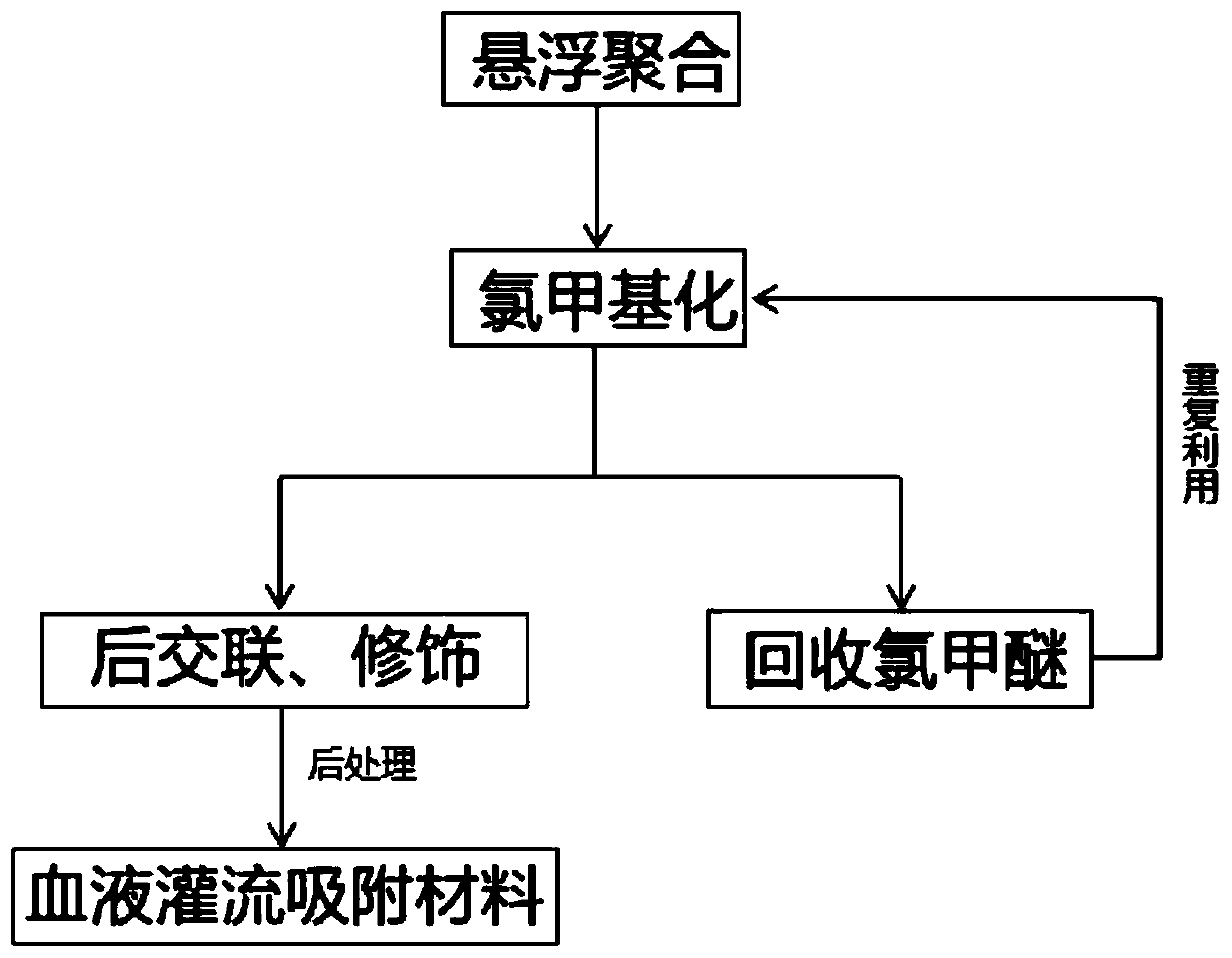

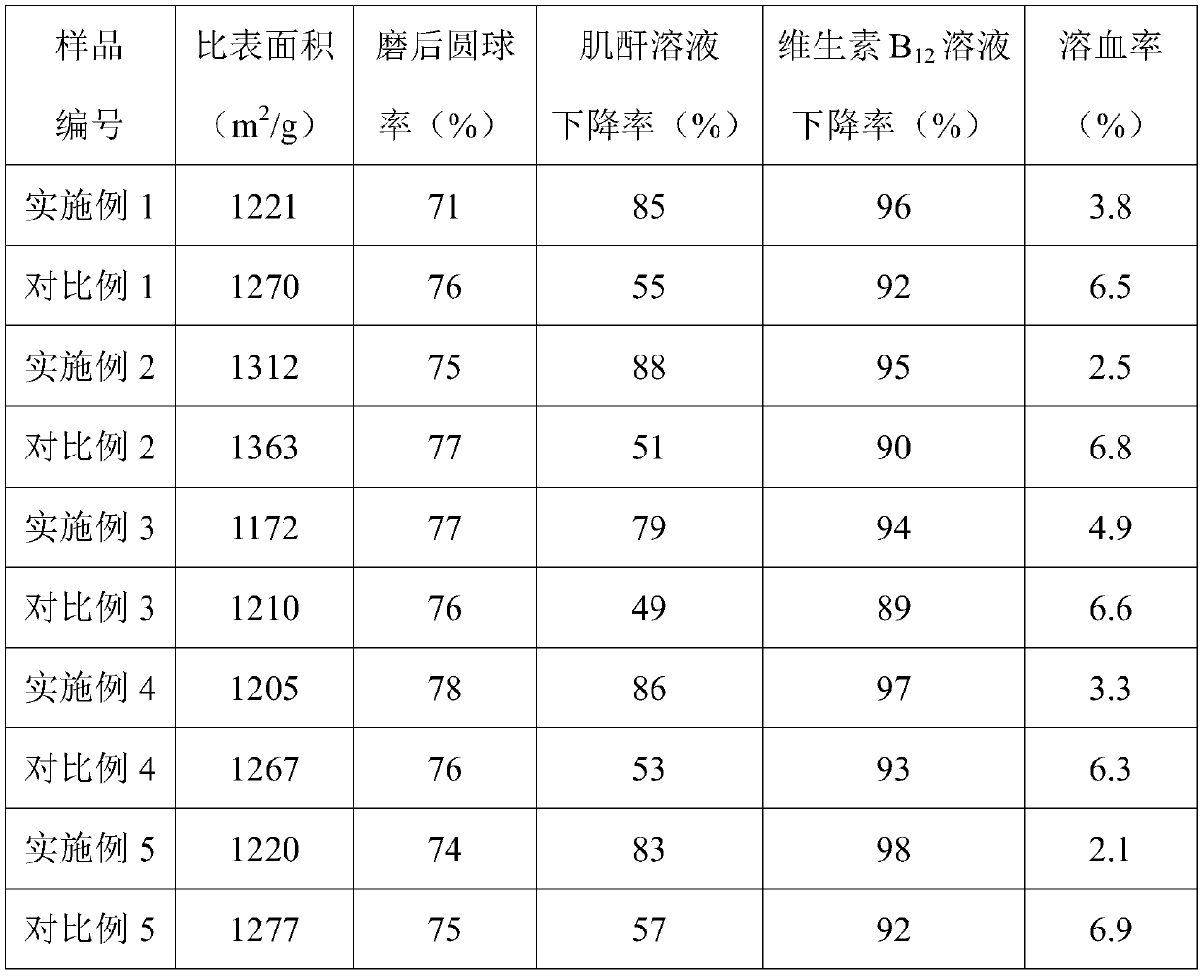

Preparation method of adsorbing material for blood perfusion

ActiveCN111530432AImprove adsorption capacityThe synthetic route is simpleOther blood circulation devicesOther chemical processesChloromethyl EtherOil phase

The invention discloses a preparation method of an adsorption material for blood perfusion. The preparation method comprises the following steps: preparing an oil phase and a water phase, by a suspension polymerization process, preparing a macroporous adsorption resin precursor with the particle size distribution being 0.315-0.8 mm from the the prepared oil phase and water phase, carrying out chloromethylation on the prepared macroporous adsorption resin precursor to prepare a chloromethylated macroporous adsorption resin precursor, carrying out post-crosslinking on the prepared chloromethylated macroporous adsorption resin precursor to prepare macroporous adsorption resin of which the residual chlorine content is less than or equal to 2%, and carrying out post-treatment on the prepared macroporous adsorption resin to prepare the surface functionalized macroporous adsorption resin with adsorption capacity for blood perfusion. According to the invention, recycling of residual chloromethyl ether after the chloromethylation reaction in the synthesis process of the macroporous adsorption resin for blood perfusion is realized, and remarkable economic benefits and environmental protection benefits are brought.

Owner:XIAN LANSHEN NEW MATERIAL TECHNOLOGY CO LTD +1

Polymerization process for fiber-grade polyphenyl thioether production process

InactiveCN101475688AReduce energy consumptionThe process is simple and easy to controlMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a polymerization process during the production of fiber-grade polyphenylene sulfide with simple operation, easily controlled reaction condition, ideal repeatability, short reaction time and reasonable energy consumption. The polymerization process is characterized in that during polymerization reaction of raw materials in a reaction kettle, a continuous heating-up mode is adopted for the reaction kettle and the heating-up speed is controlled between 0.3 and 0.6 DEG C per minute; when the reaction kettle is heated up from a range between 165 and 185 DEG C to another range between 245 and 295 DEG C, the polymerization reaction is finished. PPS products prepared by the method have stable quality and excellent performance and can meet the requirements of fiber-grade PPS resin.

Owner:JIANGSU XINZHONG INVESTMENT

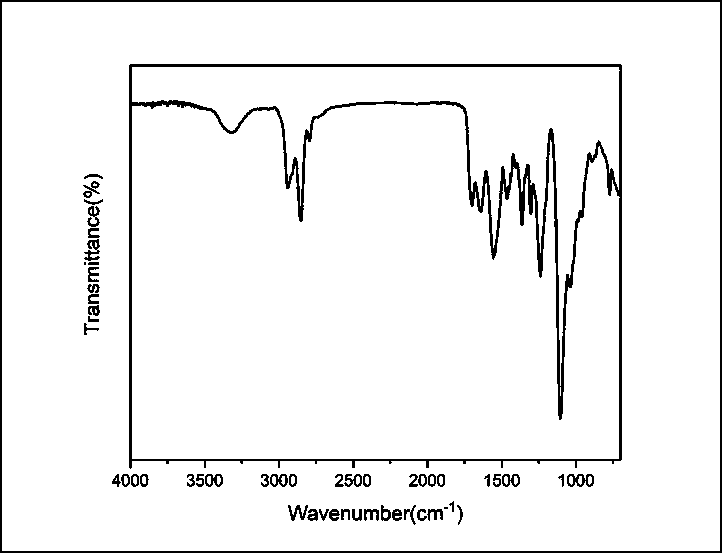

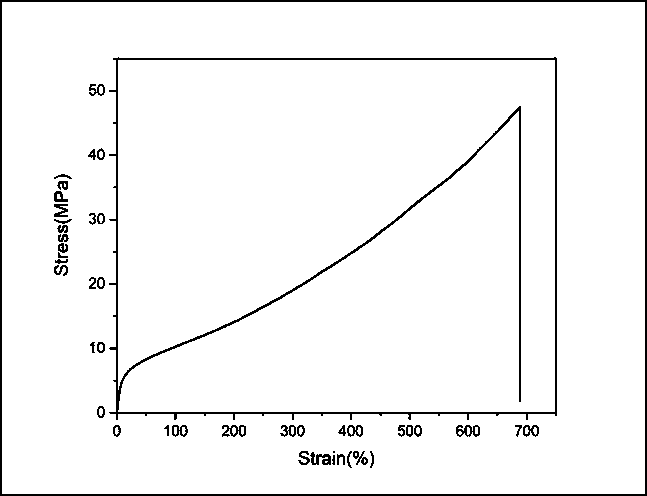

Waterborne polyurethane emulsion with high stretch intensity and preparation method thereof

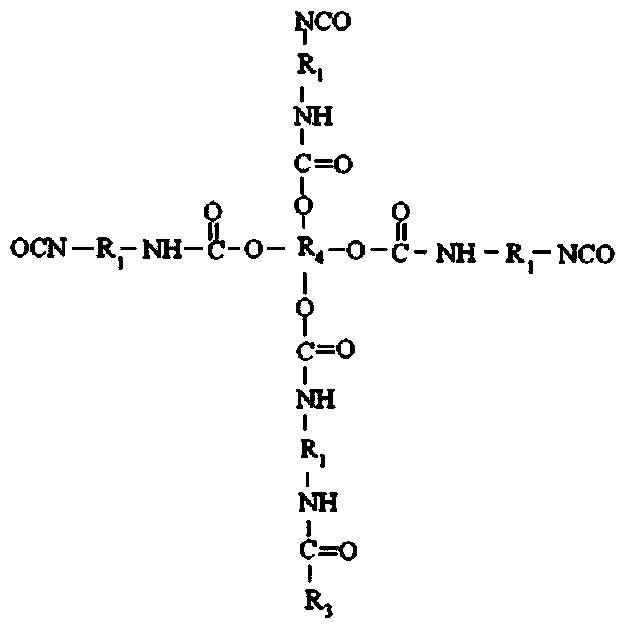

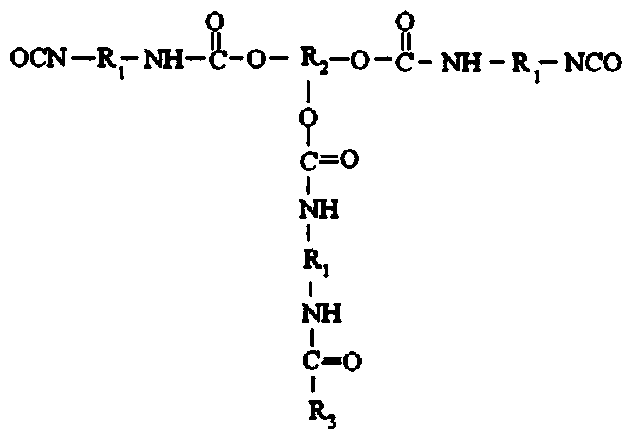

InactiveCN109265646AHigh tensile strengthGood physical propertiesPolyurea/polyurethane coatingsEmulsionPolyol

The invention discloses a waterborne polyurethane emulsion with high stretch intensity and a preparation method thereof, and belongs to the technical field of paint. The waterborne polyurethane emulsion is prepared from the following raw materials in parts by weight: 30 to 90 parts of polyether polyol, 20 to 60 parts of polyisocyanate monomers, 3 to 13 parts of hydrophilic chain-extending agents,2 to 7 parts of salt-forming agents and 2 to 5 parts of quadrol. The invention also discloses a preparation method of the waterborne polyurethane emulsion with high stretch intensity. The method has the advantages that the polyether polyol, polyisocyanate monomers and hydrophilic chain-extending agents are gradually polymerized according to a certain proportion; under the chain expansion effect ofamine chain extenders, the anionic waterborne polyurethane emulsion is synthesized by a self-emulsification method. After the coating deformation film forming by the waterborne polyurethane emulsionwith high stretch intensity, the fracture intensity is higher than or equal to 45 MPa; the stretch resistance performance is good.

Owner:CHANGCHUN UNIV OF TECH

Montmorillonite-modified organic silicon graft polyester type polyurethane elastomer, and preparation method and application thereof

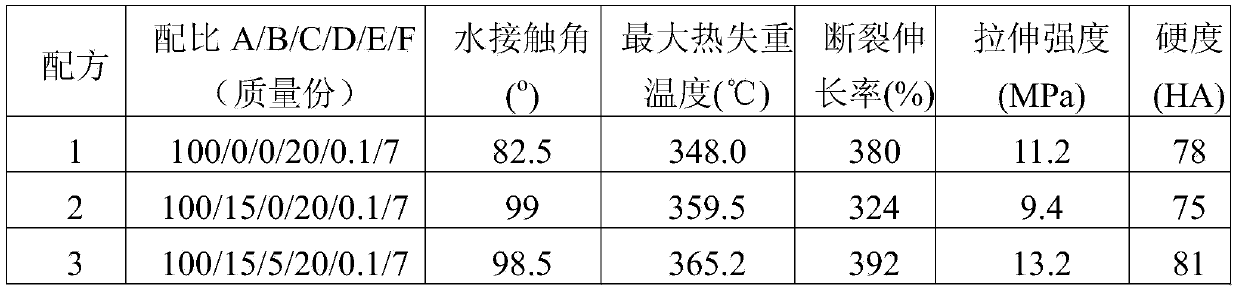

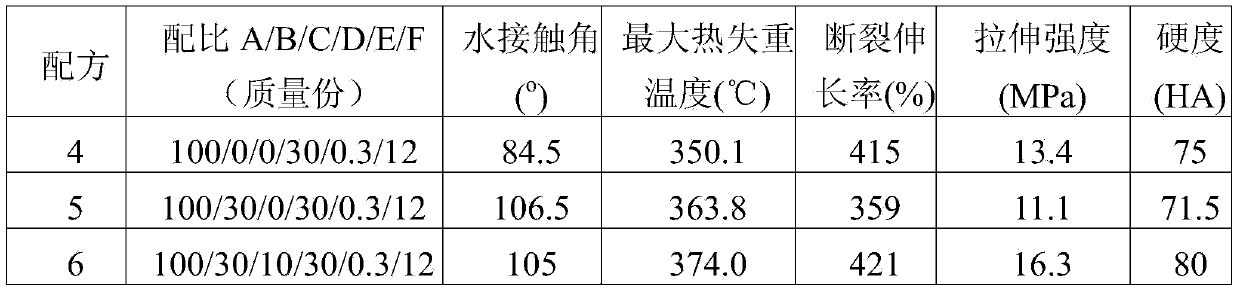

The invention belongs to the field of high polymer materials, and particularly relates to a montmorillonite-modified organic silicon graft polyester type polyurethane elastomer, and a preparation method and application thereof. The montmorillonite-modified organic silicon graft polyester type polyurethane elastomer comprises the following components in parts by mass: 100 parts of polyester type polyurethane prepolymer, 5-100 parts of organic silicon graft polyester type polyurethane prepolymer, 1-40 parts of polyester polyol, 0.5-15 parts of organic montmorillonite, 0-5 parts of chain extender, 0.1-2 parts of defoaming agent and 2-15 parts of curing agent. By using the montmorillonite and organic silicon for modifying the polyurethane, the advantages of the montmorillonite and organic silicon can be utilized to overcome the defects of the properties of the polyurethane, thereby adding excellent surface property, excellent heat resistance and favorable mechanical properties on the premise of keeping the original advantages of polyurethane.

Owner:国科广化(南雄)新材料研究院有限公司 +1

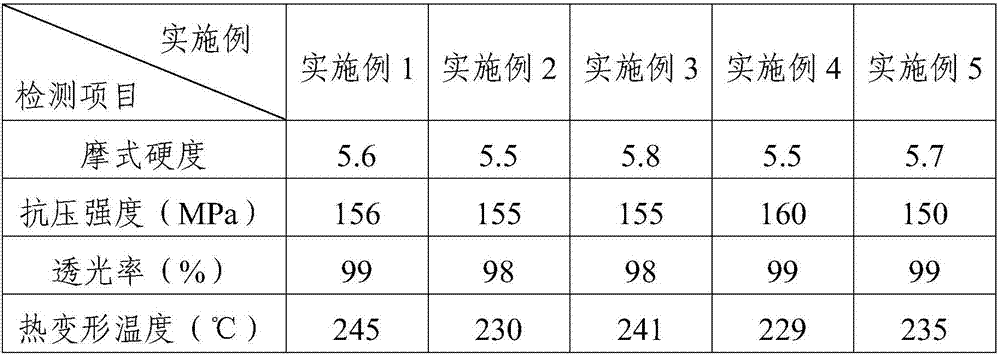

Manufacturing method of high-strength heat-resistant organic glass fruit tray

The invention provides a manufacturing method of a high-strength heat-resistant organic glass fruit tray and relates to the field of glassware manufacturing. The manufacturing method comprises the following steps: weighing raw material and respectively weighing 700 to 800 parts of methyl methacrylate, 100 to 200 parts of methacrylatemethylacrylic polycyclic norborneol ester, 100 to 200 parts of N-substituted maleimide, 100 to 200 parts of methacrylamide, 40 to 60 parts of diethylene glycol dimethacrylateethyleneglycol dimethacrylate, 30 to 50 parts of propylene methacrylatemethylacrylic propylene carbonate, 30 to 50 parts of barium methylacrylate, 30 to 50 parts of montmorillonoid, 10 to 20 parts of dibutyl phthalate and 5 to 10 parts of 2,2'-Azobis(2-methylpropionitrile) for standby application; pre-polymerizing; performing secondarily secondary polymerizing and demoulding to obtain the organic glass fruit tray. The high-strength heat-resistant organic glass fruit tray disclosed by the invention has the advantages of high strength, good heat resistance, high transparency, simple producing and manufacturing technology and suitability for large-scale production.

Owner:安徽晶晶玻璃制品有限公司

Cationic rosin size emulsifier and preparation method thereof

ActiveCN108396589AAdjust molecular weightAvoid interferenceWater-repelling agents additionAcetic acidEmulsion

The invention provides a cationic rosin size emulsifier and a preparation method thereof. The cationic rosin size emulsifier is prepared from dimethylaminoethyl methacrylate, styrene, chitosan, glacial acetic acid, water, acrylic acid, acrylamide, potassium sodium tartrate and an initiator. The obtained emulsifier has a good stability, can be used to directly emulsify rosin, and has the advantagesof small use amount, good effect and low cost, a rosin size emulsion obtained after emulsification has nanoscale particles and a stable quality, and can be stably stored (at -5 to 50 DEG C) for a long time; and the rosin size emulsion obtained after emulsification is applied to sizing, has the advantages of small use amount of other sizing additives, small use amount of a sizing agent, good effect and low cost, and makes sized paper have certain antibacterial and bactericidal effects and good durability.

Owner:辽宁兴东科技有限公司

Human body canal cast filler and preparation method thereof

InactiveCN102391617AEasy to prepareSimple and fast operationDead animal preservationEducational modelsHuman bodyPolymer science

The invention provides a human body canal cast filler and a preparation method of the human body canal cast filler; and the human body canal cast filler is good in physicochemical performance, strong in acid-base resistance, good in flexibility and stronger in support force. The human body canal cast filler is prepared by the components according to the volume ratio: 100ml of cyclodextrin (CYD)-128 type epoxy resin, 20-24ml of liquid-state nitrile rubber, 35-40ml of polypropylene glycol diglycidyl ether, 15ml of 2, 4, 6-tri-(dimethylamino methyl) phenol (DMP-30), 45ml of modified polyether amine epoxy resin curing agent ZY-1784 and 40-45ml of high-performance epoxy resin toughening modifier (RF-400). The human body canal cast filler is easy in preparation as well as simple and convenient in operation, can be completed by once injection without after-teeming, and can be immediately prepared when injection is not sufficient. The invention has the characteristics of being good in fluidity, low in injection resistance, full in molding, fin and attractive, low in contractibility rate, environment-friendly and the like.

Owner:黄海龙

Novel positive ion fixative preparing method

The invention discloses a novel positive ion fixative preparing method. The novel positive ion fixative preparing method comprises the following steps that mixing is conducted by using dimethylamine as the main raw material, using hexamethylenediamine and dimethylamino-ethyl methylacrylate as auxiliary materials and using water as solvent, so that a mixed monomer is formed, wherein the molar ratio of the hexamethylendiamine to the dimethylamine is 0.01-0.5:1; epoxy chloropropane is dripped into the mixed monomer in the first step, so that a pre-polymerized monomer is formed, wherein the molar ratio of the epoxy chloropropane to the mixed monomer is 0.5-4:1, and the reaction temperature is controlled between 10 DEG C and 60 DEG C; after dripping is completed, the temperature is kept between 70 DEG C and 95 DEG C, and water is added and the reaction is ended when the viscosity is increased to 300-1000 cps; inorganic acid and water are added into an obtained product, and the pH value is adjusted to be 3-5. According to the novel positive ion fixative preparing method, the reaction condition is mild, the reaction yield is high, and sudden polymerization caused by direct polymerization is avoided; in addition, the electric charge density is higher than that of similar products in China and foreign counties by 10%, the production cost is low, and the method is suitable for large-scale industrial production.

Owner:TIANHE CHEM SUZHOU CO LTD

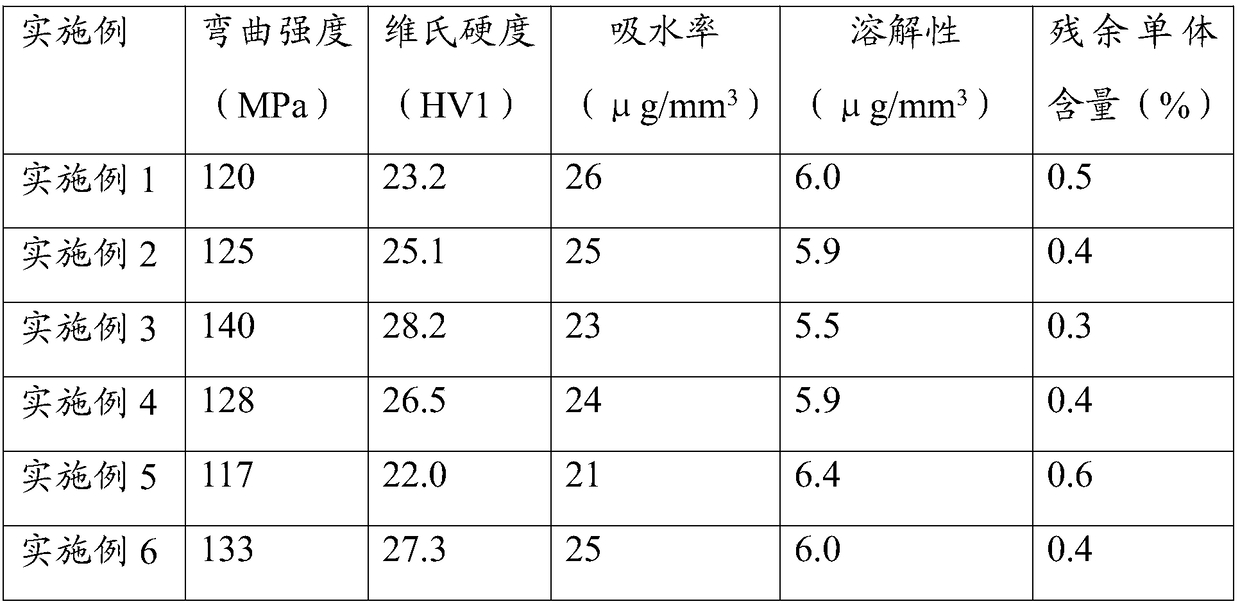

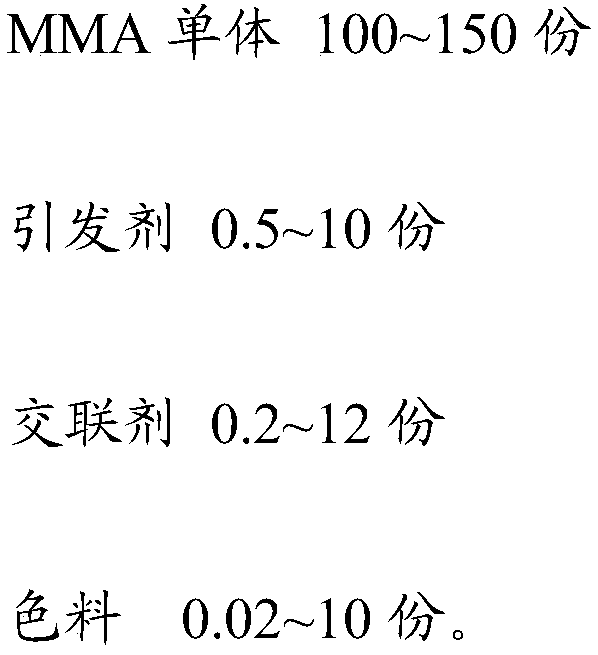

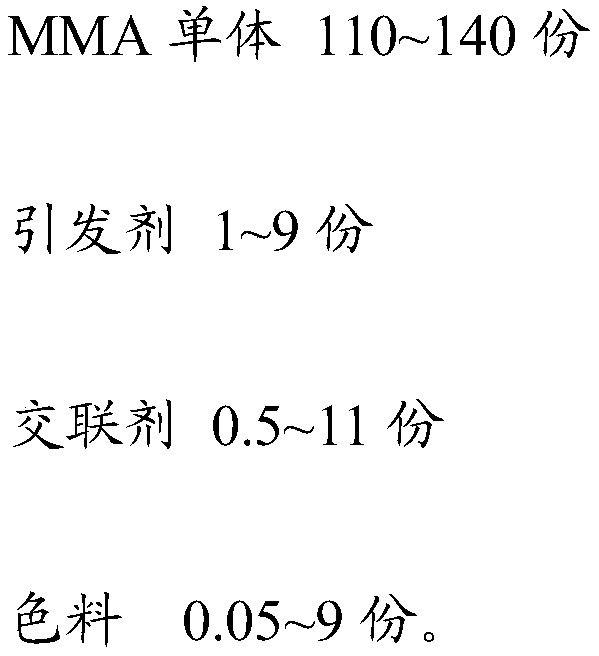

Dental CAD/CAM machinable PMMA and preparation method thereof

The invention discloses a dental CAD / CAM machinable PMMA and a preparation method thereof. Raw materials used are MMA monomers, initiators, cross-linking agents and colorants; the MMA monomers, the initiators and the cross-linking agents are added to a reactor, clockwise stirring of 20-30 turns is conducted, standing is conducted for 10-20 minutes, the MMA monomers, the initiators and the cross-linking agents are put into a water bath at 60-80 DEG C, and pre-polymerization is carried out; the raw materials are taken out after the pre-polymerization is completed, and the raw materials are placed in ice water to be cooled to 20-30 DEG C; the colorants are added to pre-polymerized slurry, then stirred for 30-60 minutes by using a stirrer, and packed into a mold by weight according to the product specifications, a polymerization reaction is carried out, after the completion of the polymerization, the mold is removed, and the PMMA is obtained. A bulk polymerization method has high production efficiency, no waste discharge, simple process, small floor space, low cost and convenient equipment cleaning.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

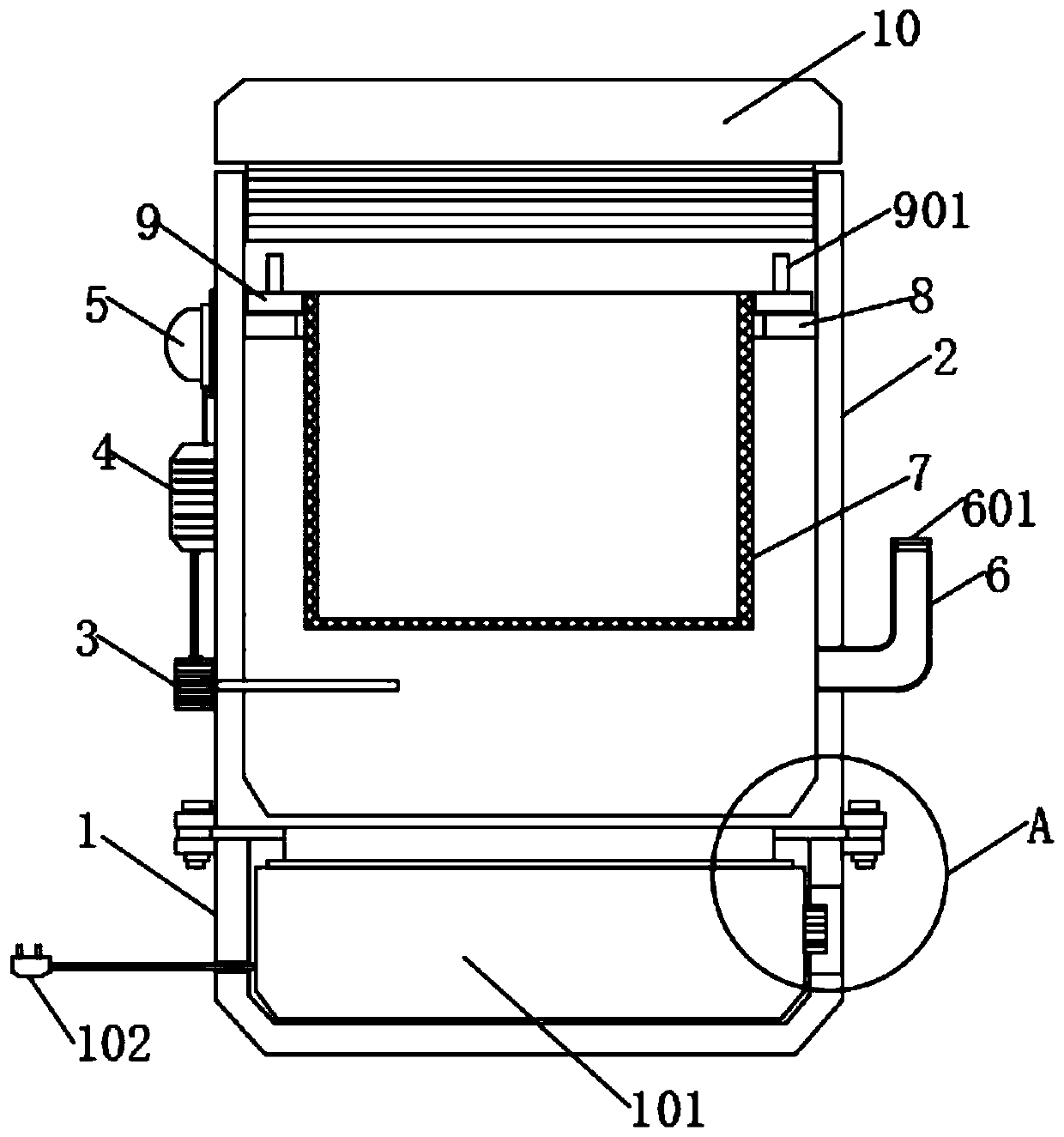

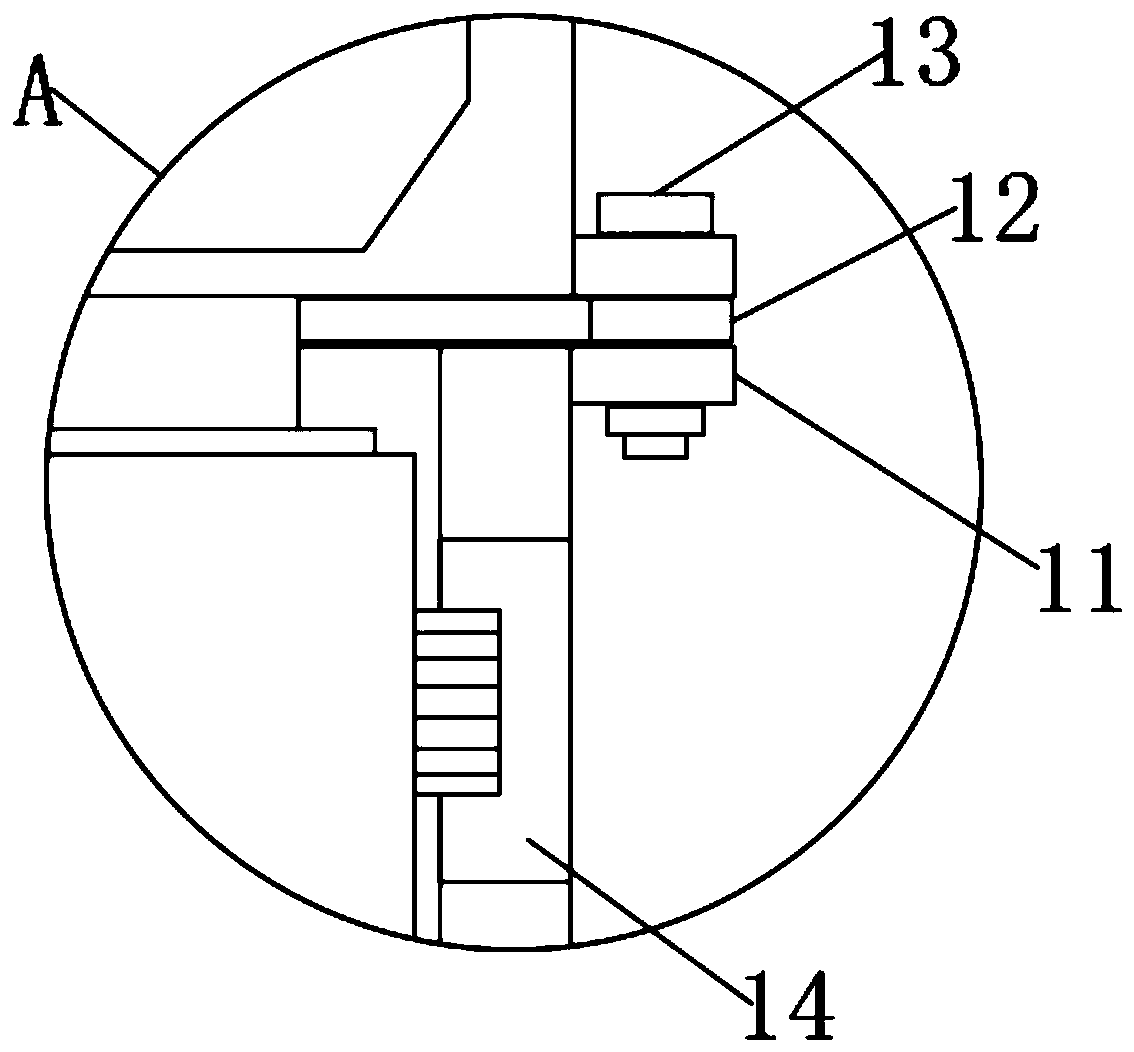

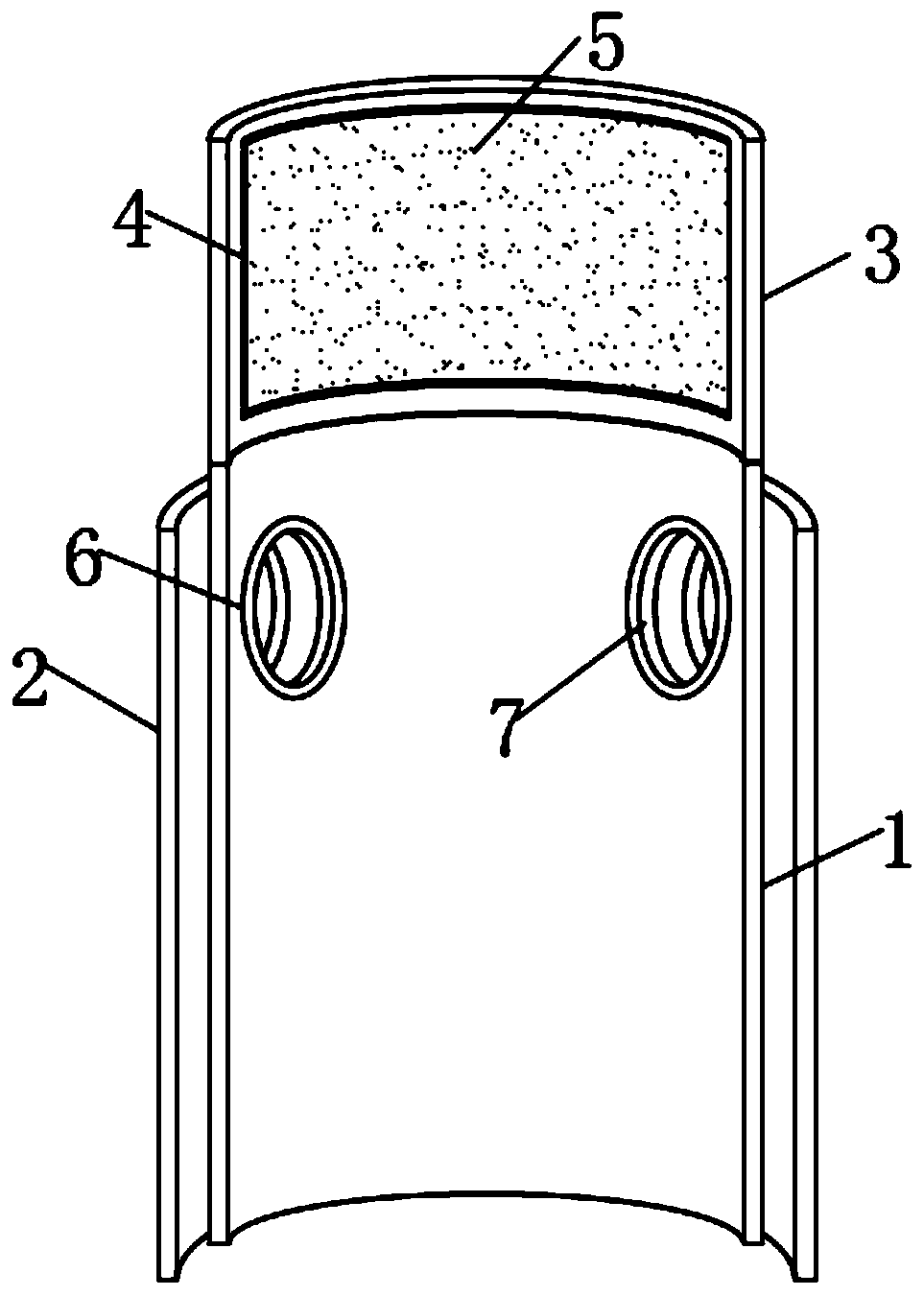

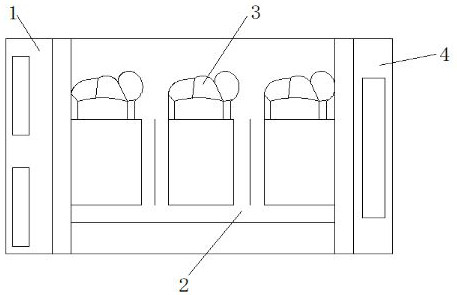

Injection combination tool for use in dairy cattle farm

ActiveCN110833468AQuick pullPrevent kickingInfusion syringesIntravenous devicesMilk cow'sEngineering

The invention discloses an injection combination tool for use in dairy cattle farm, comprising a rapid disinfection device, a safety protection device, a dairy cattle fixing clamp and a push aid; whenan injection is prepared, a syringe is disinfected using the rapid disinfection device; before injection, the safety protection device is used for protecting a human body from injury, and the dairy cattle fixing clamp is used for fixing dairy cattle; a medicine is injected into the body of the dairy cattle via the push aid during injection. The injection combination tool for use in dairy cattle farm helps obtain a clean injector through the rapid disinfection device; the neck and abdomen of the dairy cattle are fixed through the dairy cattle fixing clamp during injection, and a worker is prevented from being kicked during injection; the worker is asked to wear the safety protection device, so that the worker can be protected from body injury during injection; finally, the injection can bequickly, stably and accurately pushed into the body of the dairy cattle by the aid of the push aid, and a needle is quickly pulled out at the time, so that the needle is prevented from being broken in the body of the dairy cattle due to its kicking.

Owner:TARIM UNIV

Healthy ecological cattle breeding method

InactiveCN111685079AGuaranteed uptimePromote healthy growthAnimal watering devicesAnimal feeding devicesCrop livestockSomatotropic hormone

The invention discloses a healthy ecological cattle breeding method, belonging to the technical field of livestock breeding. The invention provides an ecological cattle breeding method with a comfortable growth environment and facilitating healthy growth of cattle, and aims at effectively solving the following problems in the prior art: the cattle are always raised in a cattle house in the growthprocess and are lack of activities, so the taste of produced beef is reduced; meanwhile, the cattle house is poor in air ventilation and poor in sanitary conditions, and diseases or mosquitoes are easily caused, so healthy growth of the cattle is not facilitated; generated cattle manure pollutes the environment; meanwhile, the means like injection of growth hormones and adoption of a chemical additive feed are adopted by a plurality of conventional cattle breeding enterprises to accelerate growth of bred cattle.

Owner:贵州三和福源绿色农业发展有限公司

Preparation technique of high-purity hydroxyethyl acrylate

InactiveCN105968010AEfficient recyclingGood dispersionOrganic compound preparationCarboxylic acid esters preparationWorking temperaturePolymerization

The invention provides a preparation technique of high-purity hydroxyethyl acrylate. A rectification process is added in a purification process; a polymerization inhibitor is replenished through a spraying way in a phase transformation process of the rectification process; meanwhile, the vacuum degree and the working temperature of a tower top are controlled; the flash polymerization, in a rectifying tower, of hydroxyethyl acrylate is avoided, so as to achieve the purposes of being stable in operation, being capable of effectively preventing polymerization and improving product quality, thereby improving the purity of a hydroxyethyl acrylate product.

Owner:CHANGZHOU HICKORY CHEM

Ornamental water body giant acrylic glass installation construction method

ActiveCN103009898ASolve processing problemsSurface smoothingSpecial ornamental structuresSocial benefitsEconomic benefits

The present invention discloses an ornamental water body giant acrylic glass installation construction method, which comprises the following steps: transporting, fitting, splicing, and acrylic glass and structure connection. According to the present invention, a main body casting polymerization method splicing technology is adopted, large scale mechanical equipment is not required, and a treatment surface on a seaming position is smooth; a polymerization reaction gelatification effect tends mild so as to avoid occurrence of flash polymerization phenomenon; and the acrylic glass and structure connection position adopts alum expanding cement and a structure sealant to carry out a treatment, such that seepage resistance and compression resistance of the acrylic glass and structure connection position are ensured with the dual waterproof treatment. With the present invention, a series of effective processes are further adopted, such that a plurality of important and difficult problems during transporting, fitting, splicing and other steps of the giant acrylic glass are effectively solved so as to save cost, shorten a construction time, and create good social benefits and economic benefits for enterprises.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

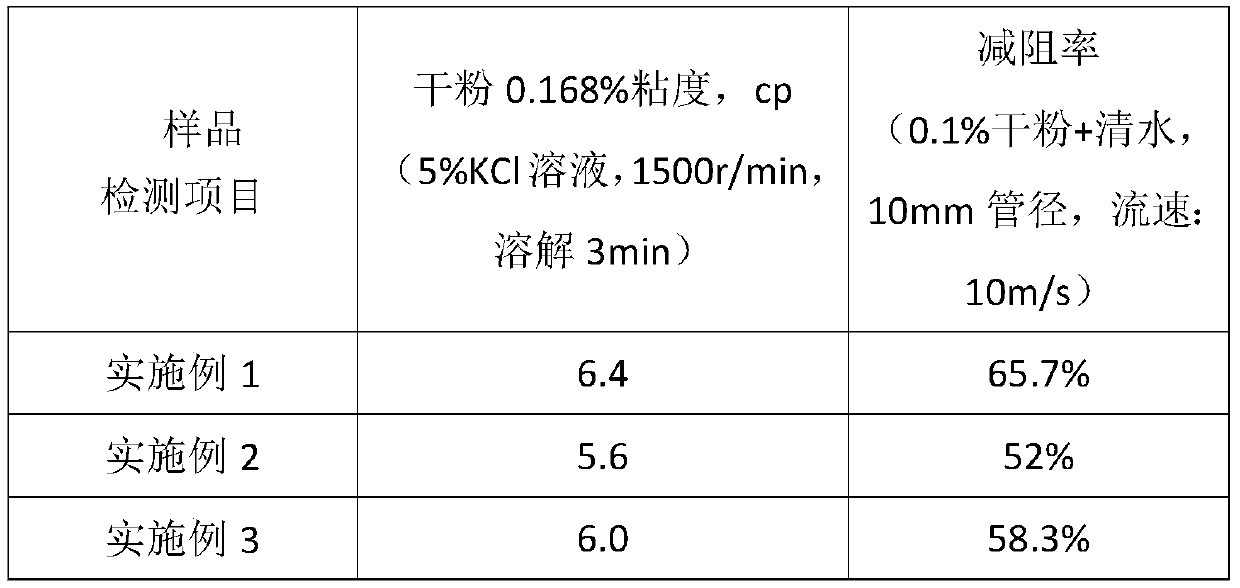

Salt-resistant drag-reduction agent polymer, and synthetic technology thereof

ActiveCN110194816AReduce pollution impactReduce conveying resistanceDrilling compositionSodium bicarbonatePolymer science

The invention discloses a salt-resistant drag-reduction agent polymer, and synthetic technology thereof. The salt-resistant drag-reduction agent polymer comprises, by weight, 320-360 parts of pure water, 0.1-0.3 part of Edta-2Na, 35-45 parts of sodium bicarbonate, 18-22 parts of acrylic acid, 8-12 parts of AMPS, 75-85 parts of acrylamide, and 14-18 parts of urea. The synthetic technology is simplein operation; product quality is stable; and environment pollution influence is extremely low. The salt-resistant drag-reduction agent polymer possesses advantages such as high dissolving speed, temperature resistance, salt resistance, shearing resistance, excellent compatibleness, and high drag reduction rate, is mainly used for reduction of conveying resistance force in shale hydrocarbon reservoir and compact sandstone hydrocarbon reservoir pressing crack construction and other fluid pipelines, enlarging discharge amount, and reducing power consumption.

Owner:江西富诚生态环境科技集团有限公司

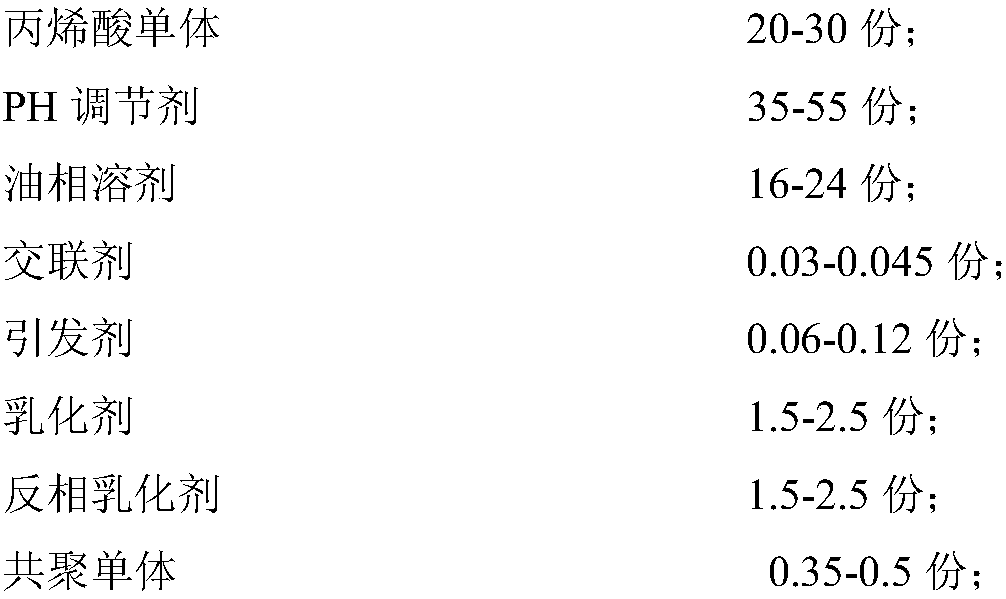

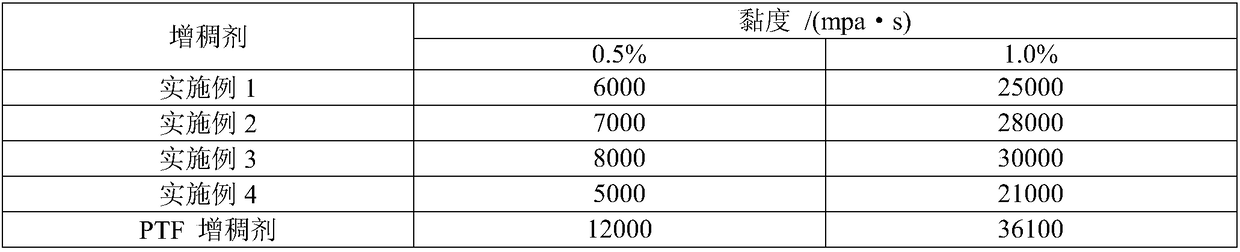

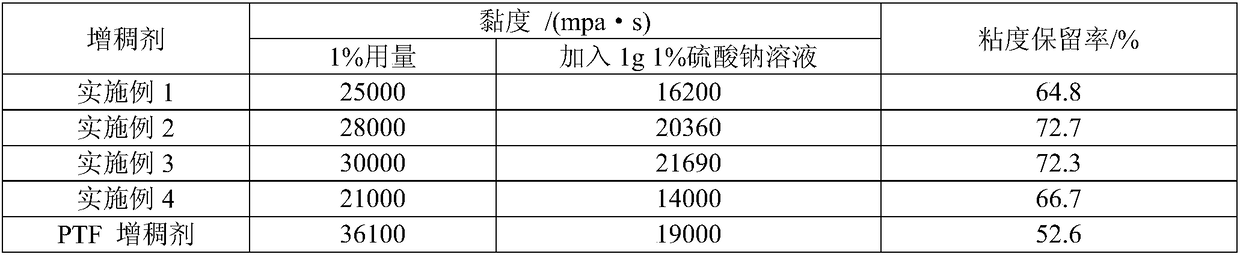

An Electrolyte Resistant Pigment Printing Thickener

ActiveCN106589207BGood thickening effectImprove electrolyte resistanceDyeing processOil phaseSodium bisulfite

The invention discloses an electrolyte-resistant pigment printing thickener, belongs to the technical field of textile dyeing and printing auxiliaries, and aims to solve the problem of poor electrolyte resistance and thickening effect coordination of the conventional printing acrylic acid synthetic thickener. The electrolyte-resistant pigment printing thickener is obtained by neutralizing an acrylic acid monomer with a pH conditioner, adding an initiator ammonium persulfate and a crosslinking agent to prepare an aqueous phase, carrying out pre-emulsification the aqueous phase and an oil phase prepared from an oil-phase solvent, an initiator, an emulsifier and a comonomer, further performing complete emulsification under the action of an initiator sodium bisulfite, finally adding a reversed-phase emulsifier for complete reversed-phase emulsification and performing discharging and drying. The prepared electrolyte-resistant pigment printing thickener has high thickening performance and electrolyte resistance, and is simple in preparation process and easy to be industrially produced.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

Method for preparing polycarboxylate water reducer by normal temperature mixing method

The invention discloses a method for preparing a polycarboxylate water reducing agent by a normal-temperature mixing process. A polyether macromonomer, a redox, acrylic acid, an unsaturated third monomer, a chain transfer agent and water are mixed once at normal temperature to prepare the polycarboxylate water reducing agent. The method disclosed by the invention adopts a one-time mixing mode; in a synthesis process, a pump circulation device only runs in a pre-dissolving macromonomer, and the device is closed after the pre-dissolved reducing agent component is fed. The traditional production method adopts an elevated tank dropping mode to produce the polycarboxylate water reducing agent, and the production is performed in a reaction kettle, so that the equipment cost input is relatively high. In the method disclosed by the invention, a one-time mixing process is adopted creatively, and the method is performed in a normal-temperature way without needing a heat source, so that the production period is short, the energy consumption is low, and the synthesis process does not need a stirring device, a professional for monitoring and an enamel reaction kettle device; the concrete performance of the synthesized polycarboxylate water reducing agent is equivalent to that of the water reducing agent synthesized by the traditional process, a favorable reference basis is provided for workshop-style water reducing agent production, and the polycarboxylate water reducing agent has obvious advantages.

Owner:KZJ NEW MATERIALS GROUP CO LTD

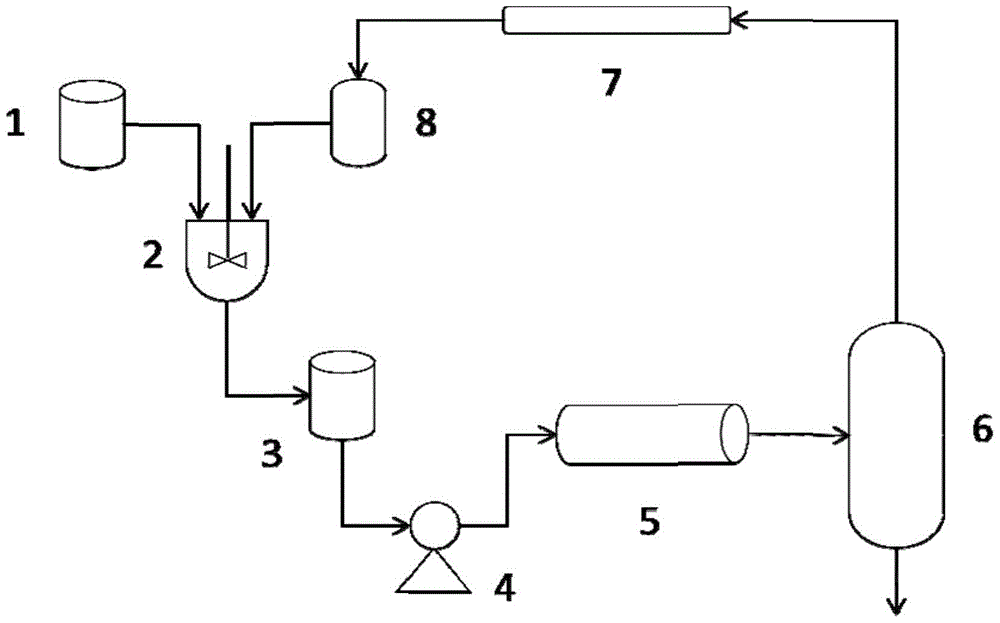

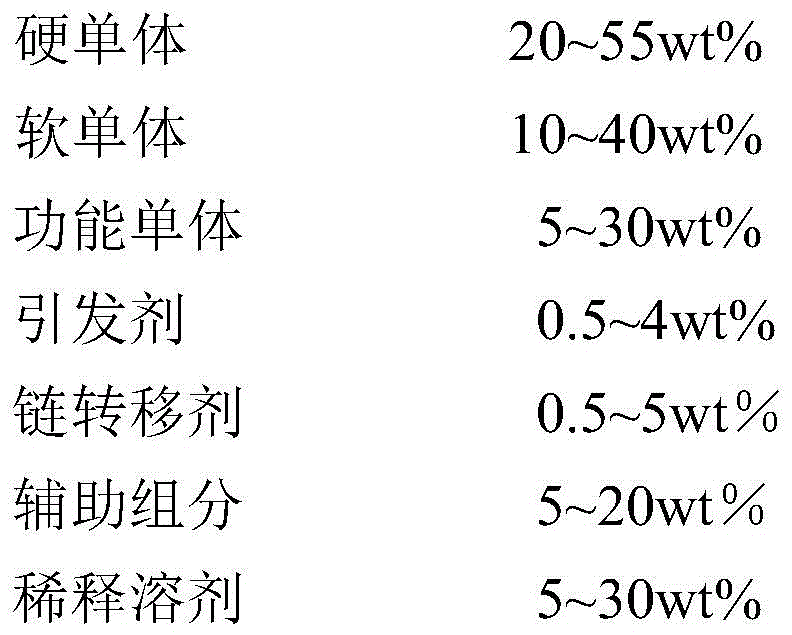

A kind of preparation method of solid acrylic resin

The invention relates to a preparation method of an acrylic resin used in the paint and printing ink industry, in particular to a preparation method of a solid acrylic resin. Add hard monomers, soft monomers, functional monomers, initiators, chain transfer agents and auxiliary components into the reactor for polymerization; when the total conversion rate of the above-mentioned monomers in the reactor is 40-50% When starting to drop the diluted solvent into the reactor gradually to reduce the viscosity until the total conversion rate of the above-mentioned monomers reaches 70-80%, the resulting dilution is discharged from the reactor into the storage tank; then The dilution is continuously poured into the tubular reactor from the storage tank to carry out the polymerization reaction; the reaction product enters the devolatilization tower after coming out of the tubular reactor, and the solid acrylic resin after removing the diluted solvent is discharged from the devolatilization tower. The lower portion was discharged to obtain a solid acrylic resin. The invention overcomes the disadvantages that bulk polymerization is easy to produce detonation phenomenon and the polymerization temperature is difficult to control, and improves the utilization efficiency of equipment.

Owner:INST OF CHEM CHINESE ACAD OF SCI

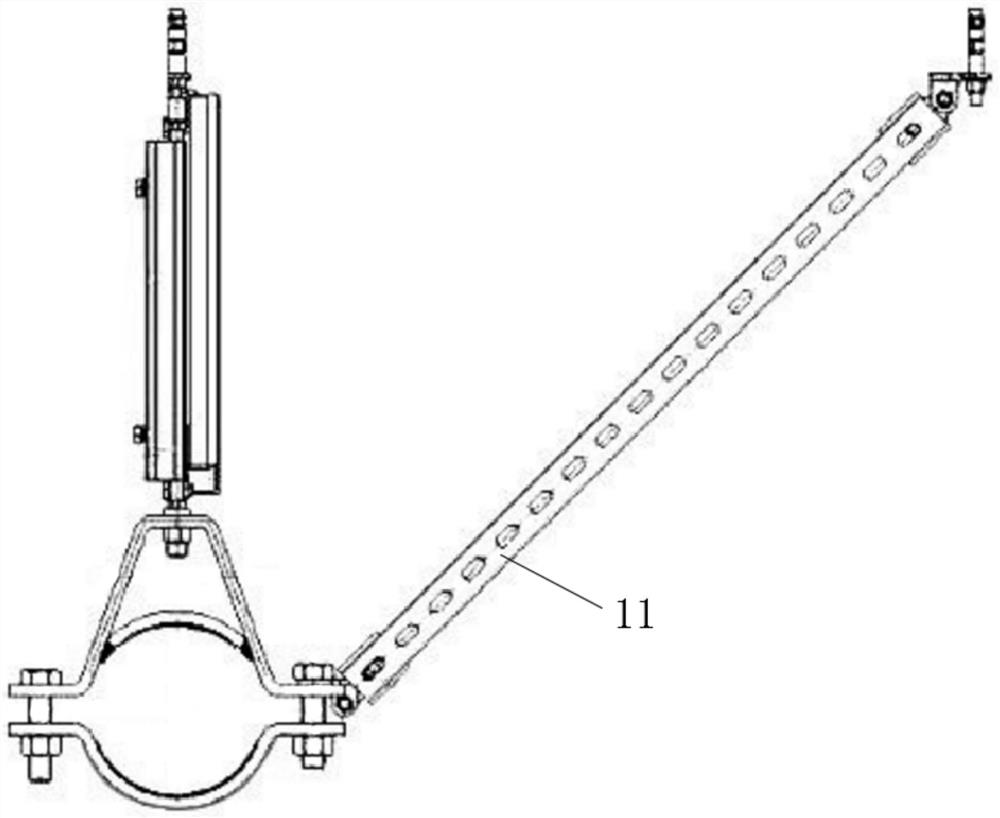

Anti-seismic support special for fire fighting hydropower and detection evacuation alarm system

InactiveCN113593190AGuaranteed accuracyGuarantee the safety of life and propertyPipe supportsAlarmsAlarm messageData acquisition

The invention discloses a fire-fighting hydroelectric special-purpose anti-seismic support and detection evacuation alarm system, which comprises an anti-seismic support body, a detector and a monitoring command center, the detector comprises an emergency lighting module, a first alarm module, a data acquisition module, a first processor, a control module, a first signal transmit-receive module and a first power supply management module. The detection evacuation alarm system can detect and analyze pipeline vibration through the detector installed on the anti-seismic support so as to judge whether an earthquake occurs or not, effective alarm information and escape guidance are rapidly provided for operators, the escape probability is increased, meanwhile, the system adopts comparison analysis of multiple sets of data, and the safety of the operators is improved. Meanwhile, the accuracy of a judgment result is ensured through comparison and analysis of multiple groups of data, so that earthquake misjudgment is reduced, and disturbance is avoided. The anti-seismic requirement of comprehensive fortification in the "Construction project anti-seismic management regulation" is met, the risk of earthquake disasters is greatly reduced, and the life and property safety of people is guaranteed.

Owner:厦门治杰达电力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com