Waterborne polyurethane emulsion with high stretch intensity and preparation method thereof

A technology of water-based polyurethane and high tensile strength, applied in the field of coatings, can solve the problems of poor physical properties, reduce the stability of emulsions, and cannot adapt to the working environment with high physical performance requirements, and achieve good physical properties and high tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a kind of preparation method with the aqueous polyurethane emulsion of high tensile strength, comprises as follows:

[0036] Step 1: Add polyether polyol, isocyanate monomer, hydrophilic chain extender and catalyst into a four-neck flask, and react at 70-90°C for 2-3 hours to obtain a prepolymer;

[0037] Step 2: quickly cool down the system to 30-50° C., add a salt-forming agent to react for 10-20 minutes, then add ethylenediamine and deionized water and stir at high speed for 1-2 hours to obtain an aqueous polyurethane emulsion.

[0038] According to the present invention, first add polyether polyol into the four-necked flask, preferably vacuum dehydrate at 80-120°C for 1-2h, then add isocyanate monomer, hydrophilic chain extender and catalyst, and gradually heat up to 70-90°C ℃ reaction 2 ~ 3h. The catalyst is preferably selected from one or more of stannous octoate, dibutyltin dilaurate, triethanolamine or dimethylethanolamine. ...

Embodiment 1

[0042] Add 40g of polytetrahydrofuran diol (number average molecular weight: 2000) into a four-necked flask equipped with a stirring device, a condensing device, a thermometer and protected by nitrogen gas, dehydrate in vacuum at 90°C for 2 hours, and then add isophorone 20g of diisocyanate, 4.5g of hydrophilic chain extender dimethylolpropionic acid and 0.1g of catalyst dibutyltin dilaurate were reacted for 130min to obtain a prepolymer;

[0043] Cool the system down to 30°C quickly, add 50ml of acetone to reduce the viscosity, wait until the -NCO value of the system reaches the theoretical value, add 2.9g of salt-forming agent triethylamine, continue the reaction for 10min, then add 2.5g of ethylenediamine and deionized water, Adjust the rotation speed of the stirring device to 1000 rad / min, and emulsify at room temperature for 1.5 h to obtain a water-based polyurethane emulsion.

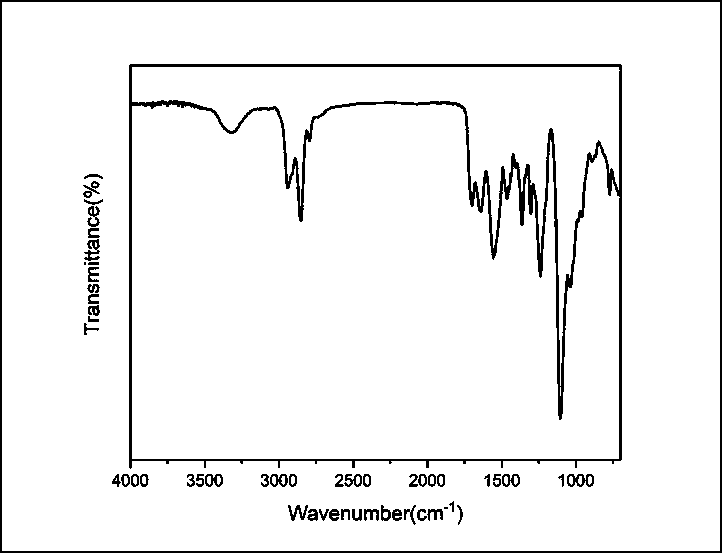

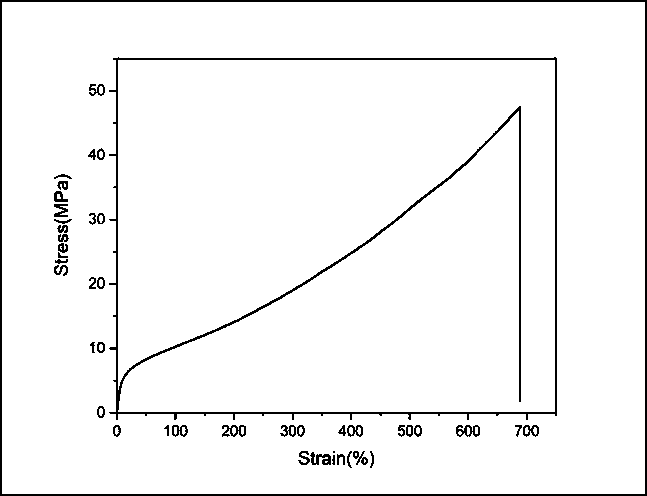

[0044] figure 1 The infrared spectrogram of the film made by a kind of water-based polyuretha...

Embodiment 2

[0047]In a four-necked flask equipped with a stirring device, a condensing device, a thermometer and protected by nitrogen gas, add 35 g of polytetrahydrofuran diol (number average molecular weight: 2000), dehydrate under vacuum at 90 ° C for 1.5 h, and then add isophor Ketone diisocyanate 25g, hydrophilic chain extender dimethylolpropionic acid 4.5g and catalyst dibutyltin dilaurate 0.1g, reacted for 130min to obtain a prepolymer;

[0048] Cool the system down to 30°C quickly, add 50ml of acetone to reduce the viscosity, and when the -NCO value of the system reaches the theoretical value, add 2.9g of salt-forming agent triethylamine, continue the reaction for 10min, then add 2.0g of ethylenediamine and deionized water, Adjust the rotation speed of the stirring device to 1000 rad / min, and emulsify at room temperature for 1 hour to obtain a water-based polyurethane emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com