Patents

Literature

110results about How to "Excellent hot water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-pollution flashover normal-temperature cured fluorocarbon resin coating and preparation method thereof

ActiveCN102010636AImprove hydrophobicityExcellent hydrophobic migrationAntifouling/underwater paintsSynthetic resin layered productsResin coatingDibutyltin dilaurate

The invention discloses a normal-temperature cured fluorocarbon resin coating, which consists of the following components in percentage by weight: 35 to 70 percent of tetrafluorochloroethylene-vinyl ester polymer, 5.5 to 12 percent of curing agent, 2 to 10 percent of coupling agent, 1 to 10 percent of pigment, 1 to 30 percent of hydrophobic particles, 0.03 to 3 percent of aid, 20 to 40 percent ofsolvent and 0.001 to 1 percent of catalyst, wherein the coupling agent is fluorosilane with a -CF3 group and a -CF2 group; the aid is a flatting agent, an antifoaming agent and a dispersing agent; the solvent is butyl acetate and methyl isobutyl ketone; the catalyst is dibutyltin dilaurate; and the curing agent is aliphatic diisocyanate. By adopting a specific coating formula, due to the combinedaction of the fluorosilane coupling agent and the hydrophobic particles, the anti-pollution flashover fluorocarbon resin coating has a static contact angle theta of 120 degrees, is excellent in hydrophobic performance and hydrophobic migration property, high in anti-pollution flashover performance, high in coating leveling property, smooth in surface, and high in self-cleanliness, chemicals resistance and hot-water resistance, and has an adhesive force reaching a zero level.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

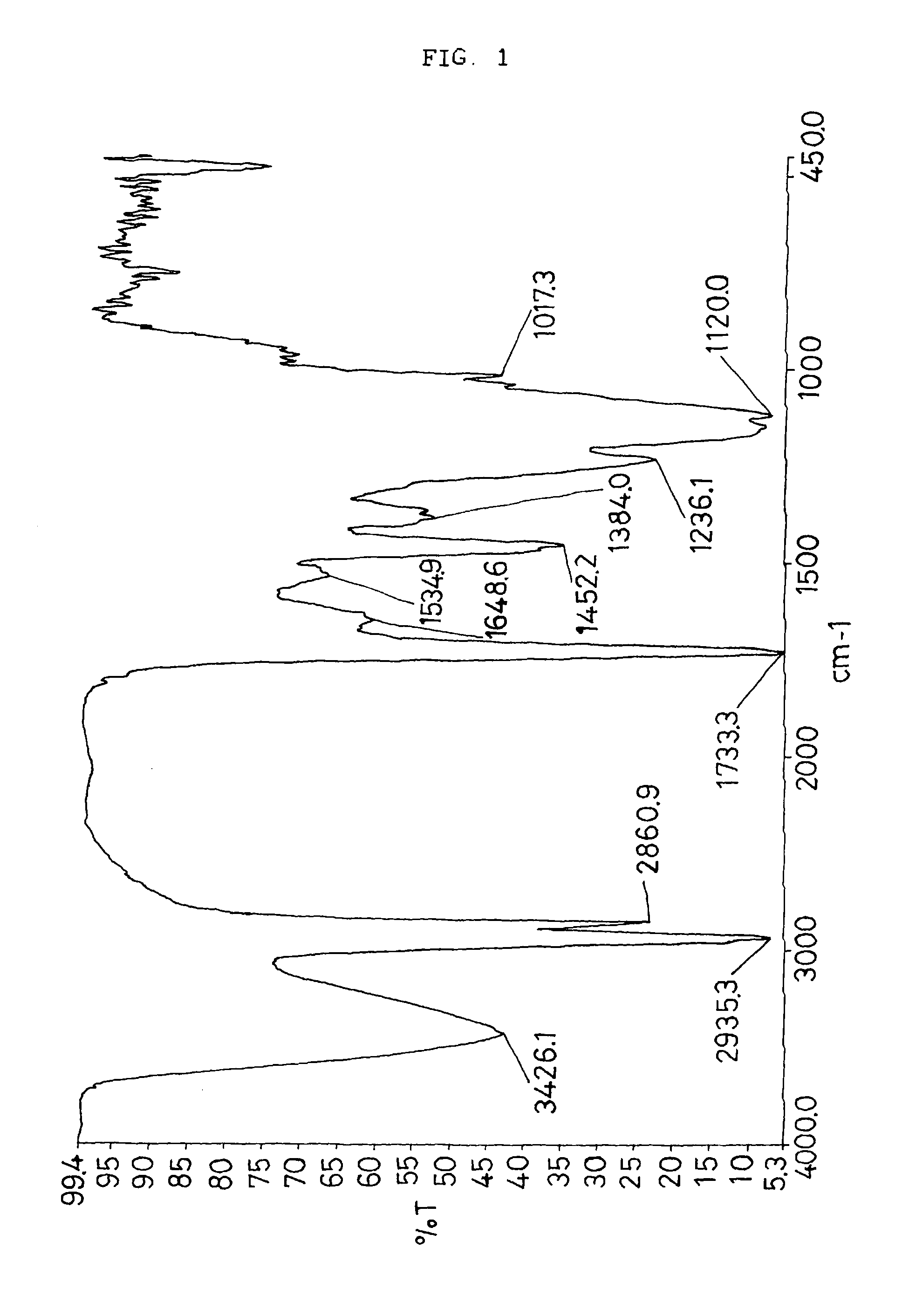

Aqueous resin dispersion composition

InactiveUS6359030B1Excellent hot water resistanceMaintain good propertiesCoatingsKetone solventsMethyl ethyl ketone peroxide

An aqueous-dispersing composition of synthetic resin (A) having an intrinsic viscosity "eta" of from 0.3 to 2.0 measured at 35° C. in a methyl ethyl ketone solvent or a mixture of that aqueous dispersion and an aqueous dispersion of synthetic resin (B) having an intrinsic viscosity "eta" of not less than 0.6 which is larger by 0.3 or more than the intrinsic viscosity "eta" of the synthetic resin (A) when the intrinsic viscosity is measured at 35° C. in a methyl ethyl ketone solvent. The aqueous-dispersing composition and the mixture have improved film forming property and can give a coating film being excellent in chemical resistance, water resistance, mechanical properties and further hot water resistance.

Owner:DAIKIN IND LTD

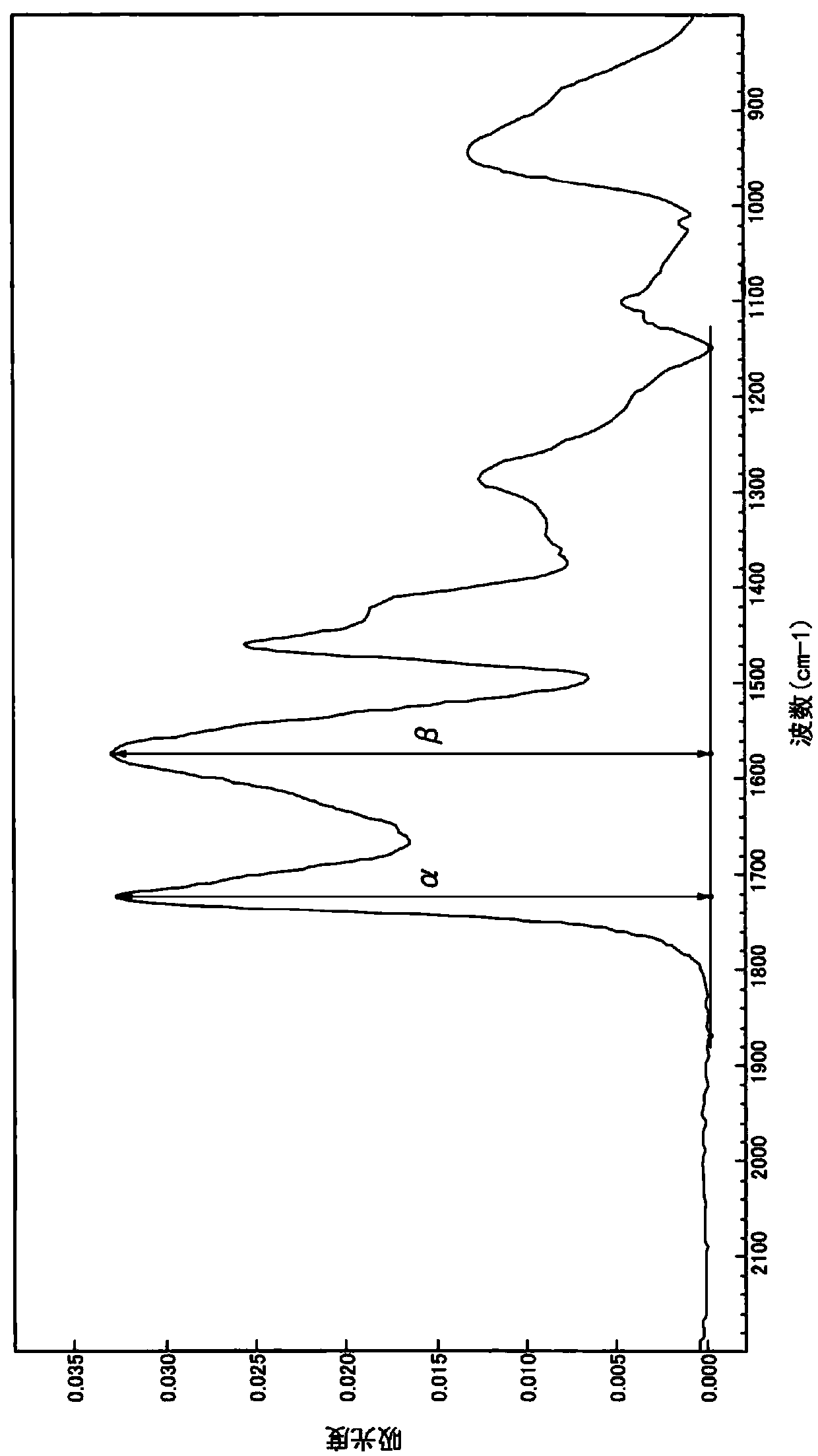

Container for retort packaging, resin composition, and gas-barrier film prepared therefrom

InactiveUS6022913AExcellent oxygen barrier propertiesExcellent not in resistanceCosmetic preparationsWrappersCross-linkChemical structure

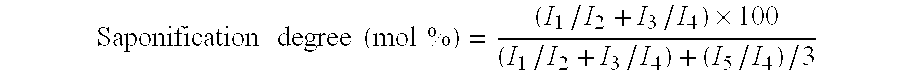

PCT No. PCT / JP97 / 03131 Sec. 371 Date Mar. 19, 1998 Sec. 102(e) Date Mar. 19, 1998 PCT Filed Sep. 5, 1997 PCT Pub. No. WO98 / 09813 PCT Pub. Date Mar. 12, 1998The present invention provides a container for retort packaging comprising a laminated film having an outermost layer comprising a layer formed of a cross-linked structure containing ester bonds between poly(meth)acrylic acid (A) and polyalcoholic polymer (B); a resin composition having at least the chemical structures (X) [poly(meth)acrylic acid (A) residue], (Y) [poly(meth)acrylic acid (A)-polyalcoholic polymer (B) residue] and (Z) [metal cross-linked ionic residues], wherein the degree of esterification defined by the equation: degree of esterification=c / (b+c+d) is from 0.01 to 0.5 and the degree of ionization defined by the equation: degree of ionization=c / (b+c+d) is from 0.01 to 0.9 (wherein b, c and d represent the molar ratios of the carbon-oxygen double bond in the chemical structure of the resin composition; and a gas barrier film comprising the same.

Owner:TOPPAN PRINTING CO LTD

Titanate coupling agent modified pollution-flashover-preventing fluorocarbon paint and preparation method thereof

InactiveCN103242718ASolve the problem of pollution flashoverImprove hydrophobicityCoatingsPolymer sciencePolymer chemistry

The invention discloses titanate coupling agent modified pollution-flashover-preventing fluorocarbon paint which comprises the following components in parts by weight: 30-50 parts of fluorocarbon resin, 10-30 parts of filler, 1-10 parts of pigment, 3.5-10 parts of curing agent, 2-10 parts of coupling agent, 0.03-3 parts of assistant, 35-45 parts of solvent and 0.001-0.1 part of drying agent. The invention also discloses a preparation method of the fluorocarbon resin paint. The static contact angle theta of the fluorocarbon resin paint can be up to 118 degrees; and the fluorocarbon resin paint has favorable hydrophobicity and hydrophobic migration performance and high pollution flashover preventing performance, thus ensuring that the physical / chemical properties and electric properties of a prepared coating can meet pollution flashover preventing conditions. The invention is used for insulator pollution flashover prevention, and solves the problem of insulator pollution flashover of a high-voltage transmission line.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

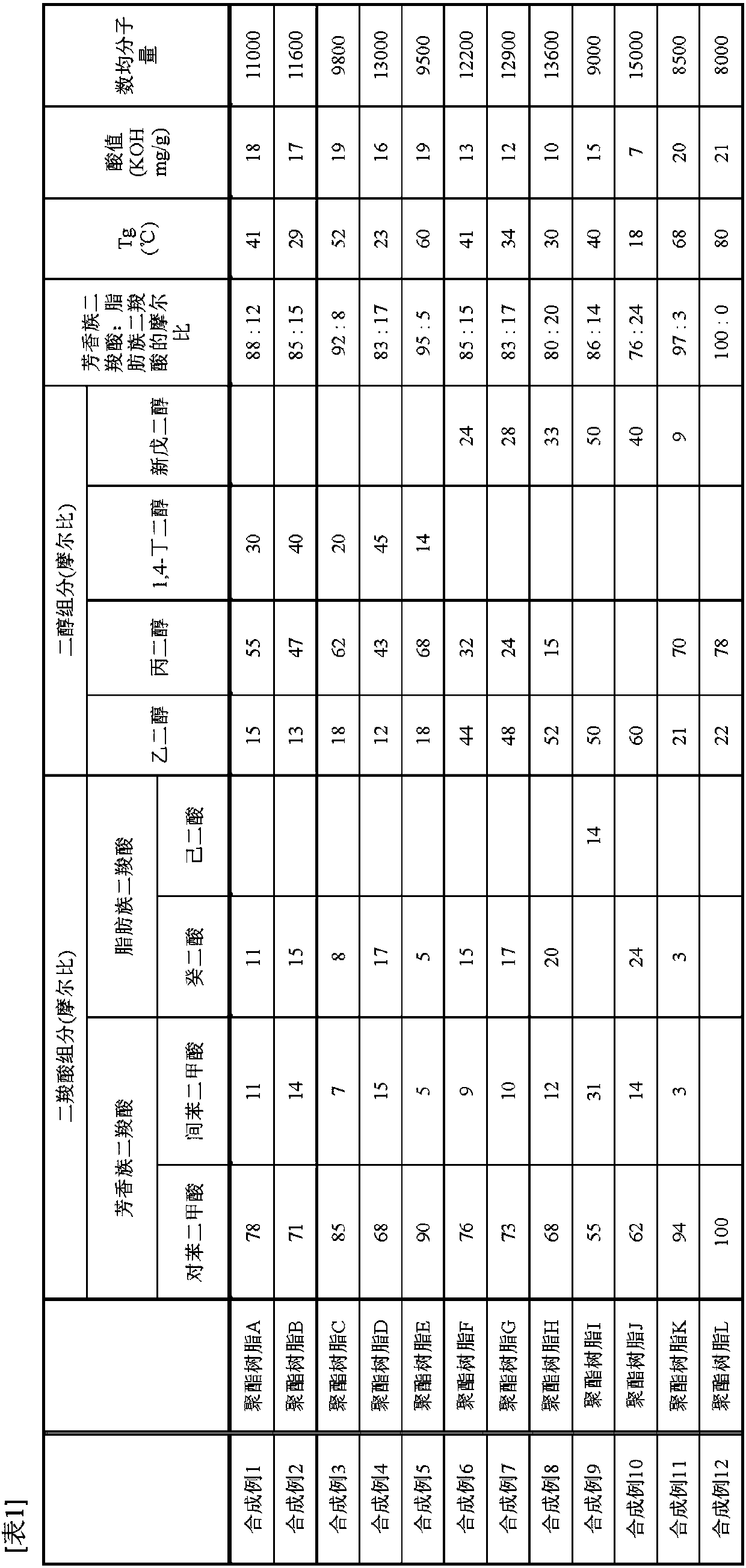

Semi-aromatic polyamide resin

ActiveCN101175791AImprove hot water resistanceGood chemical resistanceSynthetic resin layered productsThin material handlingResidenceAramides

The present invention provides a semi-aromatic polyamide resin having high residence stability, hot water resistance and chemical resistance and also having excellent adhesion property to and compatibility with other resin or the like. [MEANS FOR SOLVING PROBLEMS] The semi-aromatic polyamide resin has dicarboxylate units in which aromatic dicarboxylate units comprise 50 to 100 mol% of the dicarboxylate units and diamine units in which aliphatic diamine units having 9 to 13 carbon atoms comprises 60 to 100 mol% of the diamine units. In the resin, at least 10% of the terminal groups present in the molecular chain are end-capped with an end-capping agent, and the amount of the terminal amino groups present in the molecular chain falls within the range from 60 [mu]-equivalents / g to 120 [mu]-equivalents / g inclusive and satisfies the equation: [NH2] / [COOH]=6 wherein [NH2] ([mu]-equivalent / g) represents the amount of the terminal amino groups and [COOH] ([mu]-equivalent / g) represents the amount of the terminal carboxyl groups.

Owner:KURARAY CO LTD

Gas barrier multilayer film

ActiveUS20090214854A1Excellent gas barrier performanceHigh strengthFlexible coversWrappersPolymer sciencePolyvinyl alcohol

Provided is a film which can be industrially coated easily and exhibits excellent gas barrier performance without being subjected to a high-temperature heat treatment. The film exhibits good gas barrier performance immediately after the production, and maintains the excellent gas barrier performance while exhibiting excellent hot water resistance and printing resistance. More specifically, provided are: a gas barrier laminated film including a resin layer on an inorganic thin film formed on at least one surface of a support film, the resin layer being formed by applying: (1) an aqueous dispersion containing polyvinyl alcohol (a), an ethylene-unsaturated carboxylic acid copolymer (b), and inorganic particles (c); (2) an aqueous dispersion containing an ethylene-unsaturated carboxylic acid copolymer (b), inorganic particles (c), and / or a cross-linking agent (d); or (3) an aqueous dispersion containing polyvinyl alcohol (a), an ethylene-unsaturated carboxylic acid copolymer (b), inorganic particles (c), and a cross-linking agent (d), to the inorganic thin film surface; and a method of producing the gas barrier laminated film.

Owner:MITSUBISHI CHEM CORP

Vitreous antimicrobial agent and antimicrobial product

InactiveUS20060127498A1Exhibit some effectImprove antibacterial propertiesPowder deliveryBiocideMicrobial agentVitreous Bodies

The object is to provide a vitreous antimicrobial agent that can exhibit excellent antimicrobial properties when added to various types of resins, that has excellent discoloration resistance and hot water resistance, and that can easily be produced at a commercial scale. It is also to provide an antimicrobial resin composition and an antimicrobial product including the vitreous antimicrobial agent. The present invention relates to a vitreous antimicrobial agent that includes, relative to 100 mass % of total glass components, 0.1 to 2 mass % of Ag2O, 40.5 to 49 mass % of ZnO, 6 to 9.5 mass % of SiO2, 30.5 to 39.5 mass % of B2O3, 2 to 10 mass % of an alkaline earth metal oxide, and 6 to 7.5 mass % of Na2O; a vitreous antimicrobial agent comprising, in addition to these, 0.01 to 5 mass % of CeO2 as necessary; an antimicrobial resin composition that includes the vitreous antimicrobial agent; and an antimicrobial product that includes the vitreous antimicrobial agent.

Owner:TOAGOSEI CO LTD

Container for retort packaging, resin composition, and gas-barrier film prepared therefrom

InactiveUS6143384AExcellent oxygen barrier propertiesExcellent not in resistanceCosmetic preparationsOrganic detergent compounding agentsCross-linkChemical structure

Owner:TOPPAN PRINTING CO LTD

Flame-retardant polyolefin resin composition and preparation method thereof, and flame-retardant tubular product

The invention discloses a flame-retardant polyolefin resin composition and a preparation method thereof, and a flame-retardant tubular product prepared from the flame-retardant polyolefin resin composition. The flame-retardant polyolefin resin composition disclosed by the invention comprises the following components in parts by weight: 100 parts of polyolefin resin, 30-85 parts of antimony bromine composite flame retardants, 2-20 parts of resin modifiers and 0.3-1.5 parts of processing agents. The tubular product prepared from the flame-retardant polyolefin resin composition disclosed by the invention has the advantages of being high in heat resistance (the vicat softening temperature of the material can be up to over 140 DEG C), high in flame retardant property (the oxygen index is greater than over 32), good in hot water resistance, low temperature resistance and long-term static hydraulic performance, long in service life, free of scaling and the like, the vertical combustion can be up to V0 grade, the smoke density SDR is smaller than 75, the damaged tubular product caused by external force can be connected in a hot melting manner, and the flame-retardant tubular product can be applied to products such as a central air conditioning pipe system, industrial water supply and drainage pipelines and the like.

Owner:应急管理部四川消防研究所

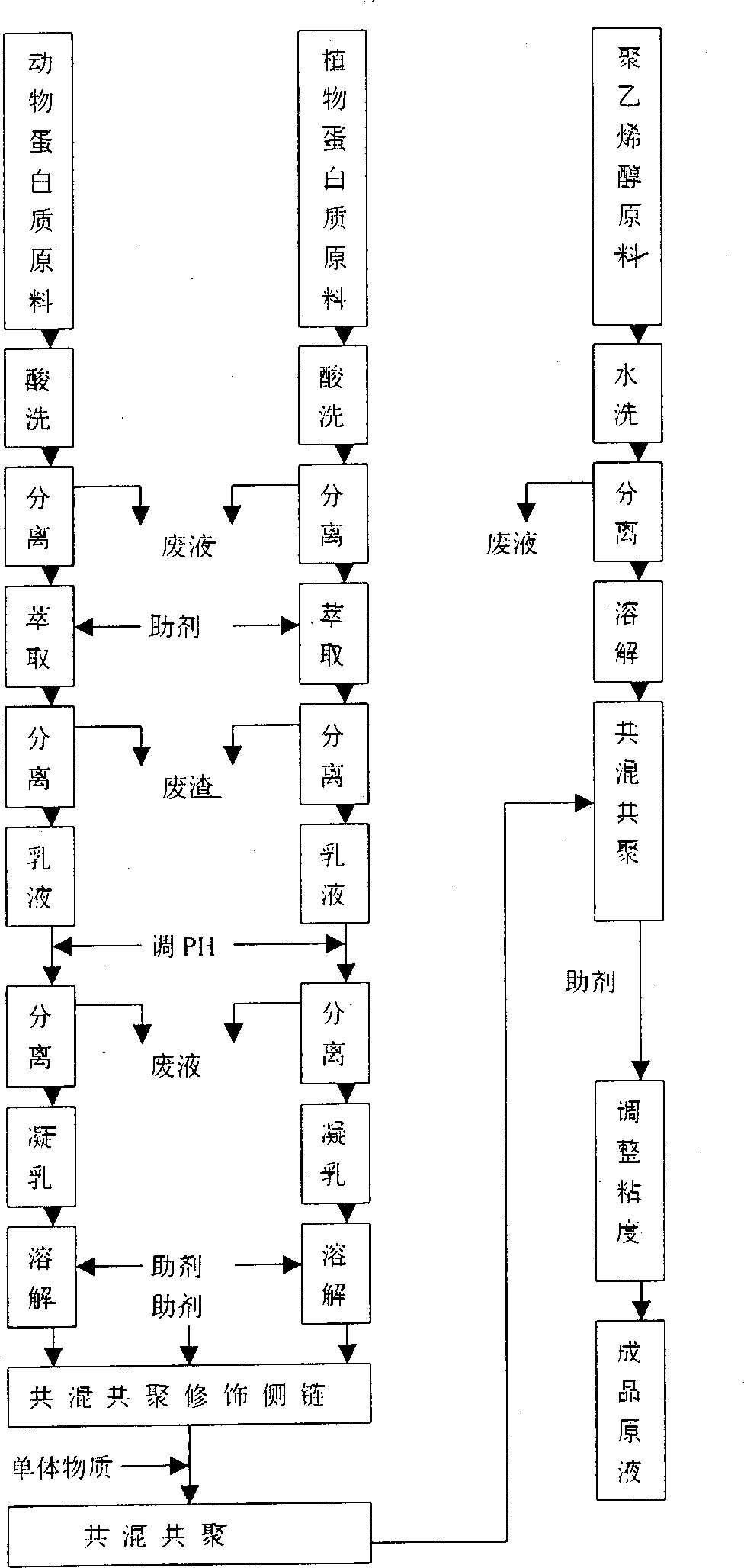

Preparation method of fiber with high water absorption

ActiveCN103160952ASpinning solution stabilityGood physical and mechanical propertiesFilament/thread formingArtificial filament heat treatmentPolyvinyl alcoholAcrylic acid

The invention relates to a preparation method of a fiber with high water absorption, which is a method for preparing the fiber with high water absorption by a post-crosslinking agent. According to the preparation method, the fiber with high water absorption is prepared from acrylic acid (AA) and acrylamide (AM) which are partly neutralized and taken as polymerized monomers through the steps of: blending the polymerized monomers with polyving akohol (PVA), initiating by potassium persulfate (KPS), blending and polymerizing in an aqueous solution, adding a dialdehyde solution to obtain a mixed solution serving as a post-crosslinking agent solution, mixing to be uniform and defoaming to obtain a spinning stock solution; dry-wet spinning the spinning stock solution to form a nascent fiber; and heat-treating the nascent fiber at a certain temperature to generate a crosslinking reaction, thereby forming the three-dimensional net-structured fiber with high water absorption. According to the preparation method, the implosion phenomenon which easily occurs during polymerization of the traditional polymer solution with high water absorption is avoided, the preparation technology is simple and safe, the production cost is reduced, and the production efficiency is increased; and the obtained water-absorbing fiber has high and controllable water adsorption, thermostability, capability of being repeatedly used, and long residual action.

Owner:DONGHUA UNIV

Protein synthetic fibre spinning solution and its producing method

InactiveCN1364948ASkin-friendlyBreathableConjugated cellulose/protein artificial filamentsPolymer scienceAmino acid side chain

The protein fiber spinning solution is produced by using animal and plant material and through the processes of acid pickling, extraction, pH regulation to obtain protein curd, dissolving with cosolvent to form water solution, mixing, modifying side chain of amino acid with modifying agent, copolymerization with coloring monomer, mixing with PVA water solution and addition crosslinking agent to regualte viscosity. It may be used in spinning fiber with the same strengt has chemical fiber, the skin friendship, air penetrability and hygroscopicity the same as natural protein fiber, and improved hot water resistance, shrinkage and color.

Owner:卓宝松 +1

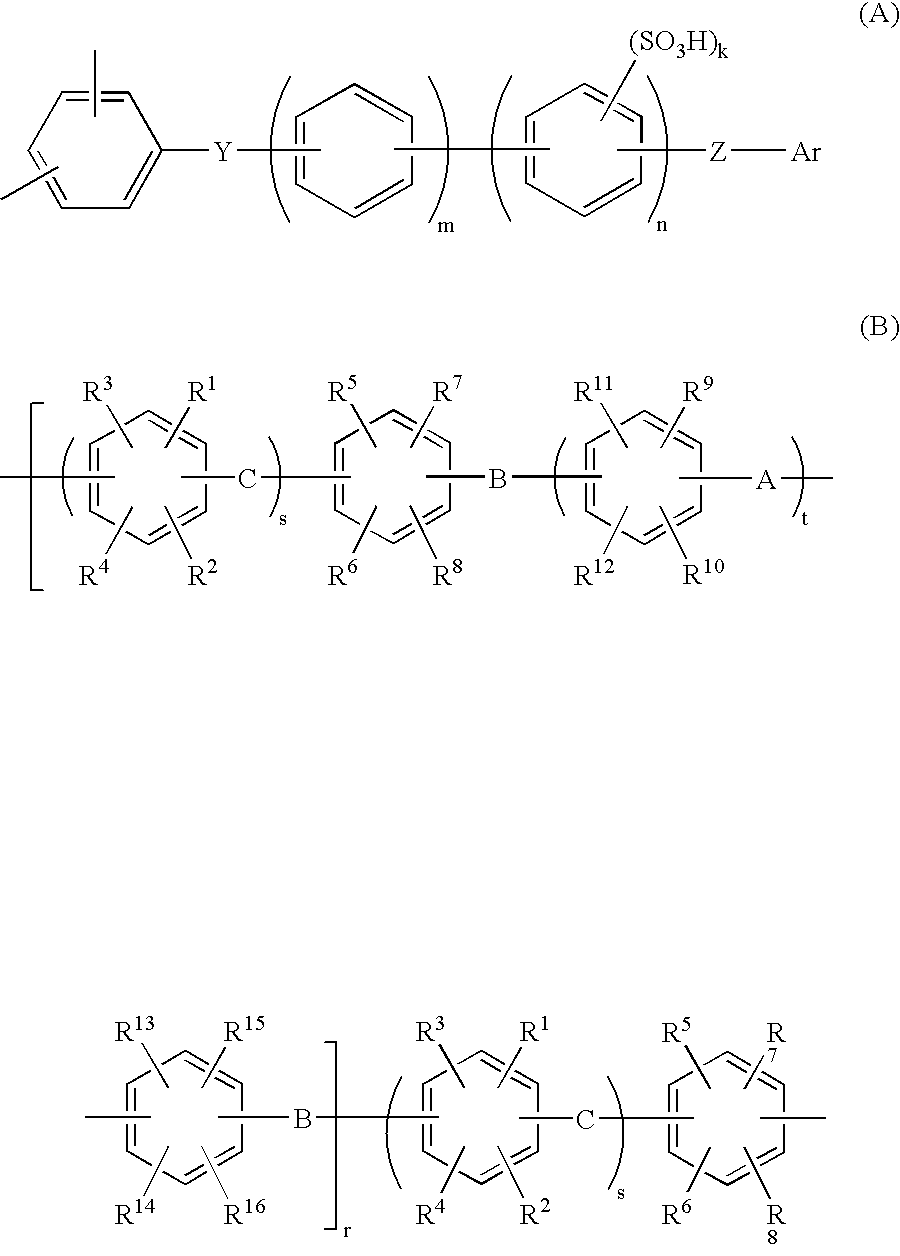

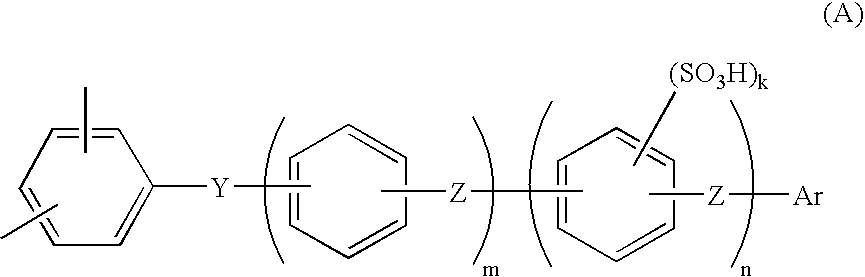

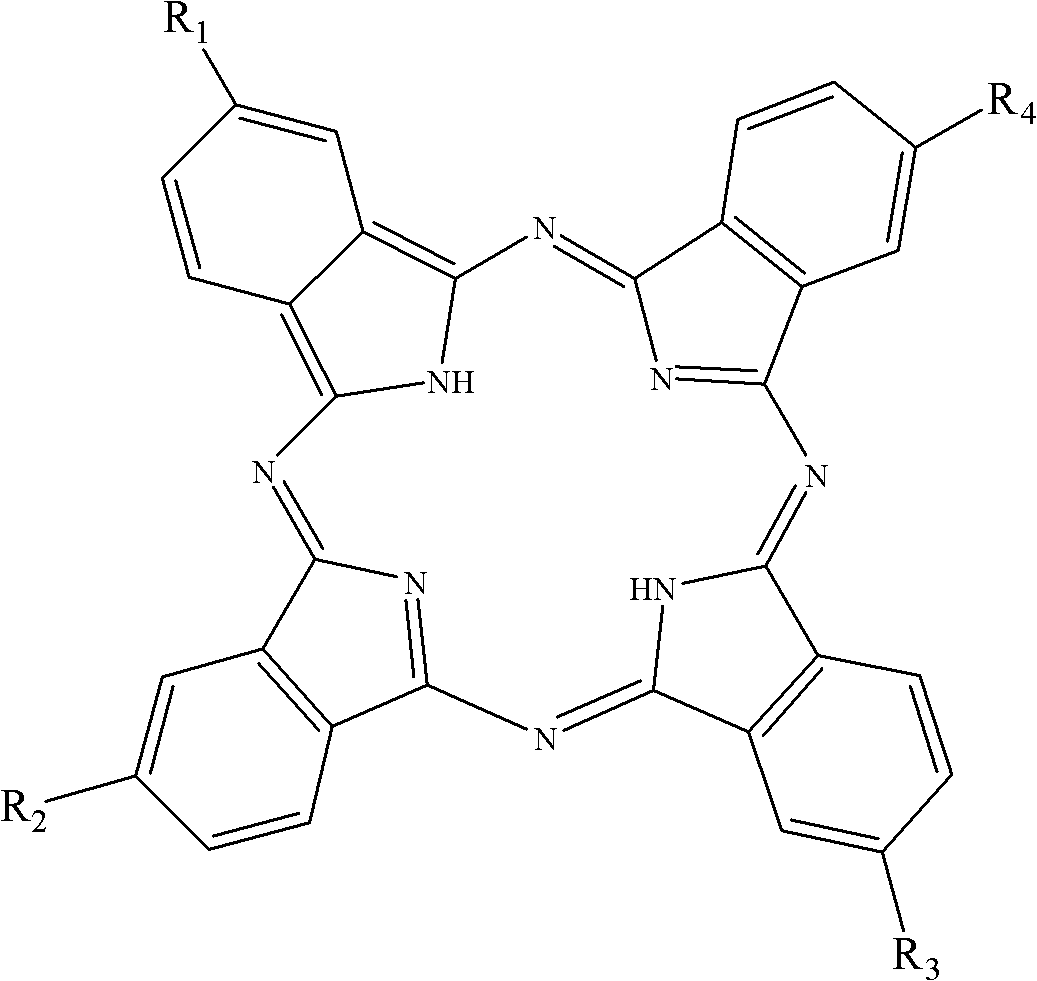

Membrane-electrode assembly for solid polymer electrolyte fuel cell

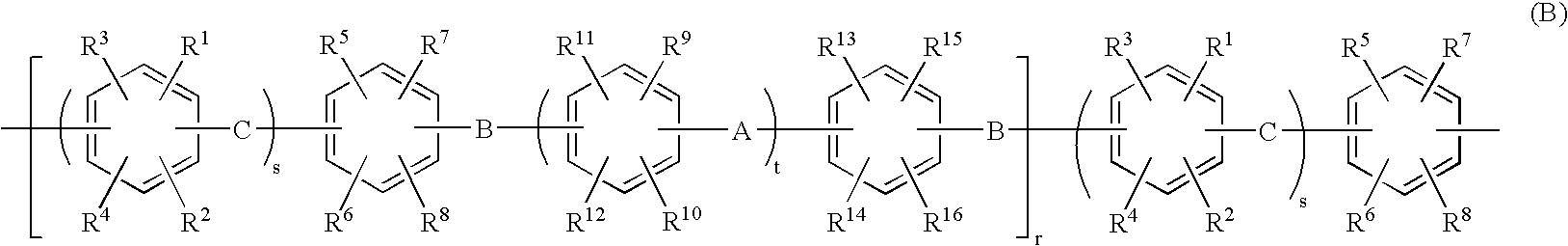

InactiveUS20060280982A1Improve high temperature stabilityImprove stabilitySolid electrolytesCell electrodesPolymer electrolytesArame

A membrane-electrode assembly for solid polymer electrolyte fuel cells is provided that exhibits higher proton conductivity and superior thermal resistance. A polyarylene having a sulfonic acid group and a nitrogen-containing heterocyclic aromatic compound are included in a solid polymer electrolyte membrane that constitutes the membrane-electrode assembly for solid polymer electrolyte fuel cells. Preferably, the polyarylene having sulfonic acid group contains a repeating unit expressed by the general formula (A) and a repeating unit expressed by the general formula (B) shown below.

Owner:HONDA MOTOR CO LTD

Film for reinforcing electrolyte membrane of polymer electrolyte fuel cell

ActiveUS20110020730A1Excellent hot water resistanceSufficient reinforcing effectElectrolyte holding meansMembranesFuel cellsHigh humidity

An object of the present invention is to provide a biaxially oriented film suitable as a reinforcing member for an electrolyte membrane of a polymer electrolyte fuel cell, the film having excellent hot water resistance in a high-temperature and high-humidity use environment and being capable of maintaining the reinforcing effect for a prolonged period of time. The invention resides in a biaxially oriented film for reinforcing an electrolyte membrane of a polymer electrolyte fuel cell, the film being characterized in that the film (i) contains syndiotactic polystyrene as a major component and (ii) has a Young's modulus in at least one of the machine direction and the transverse direction ranging from 4,500 to 8,000 MPa.

Owner:TEIJIN LTD

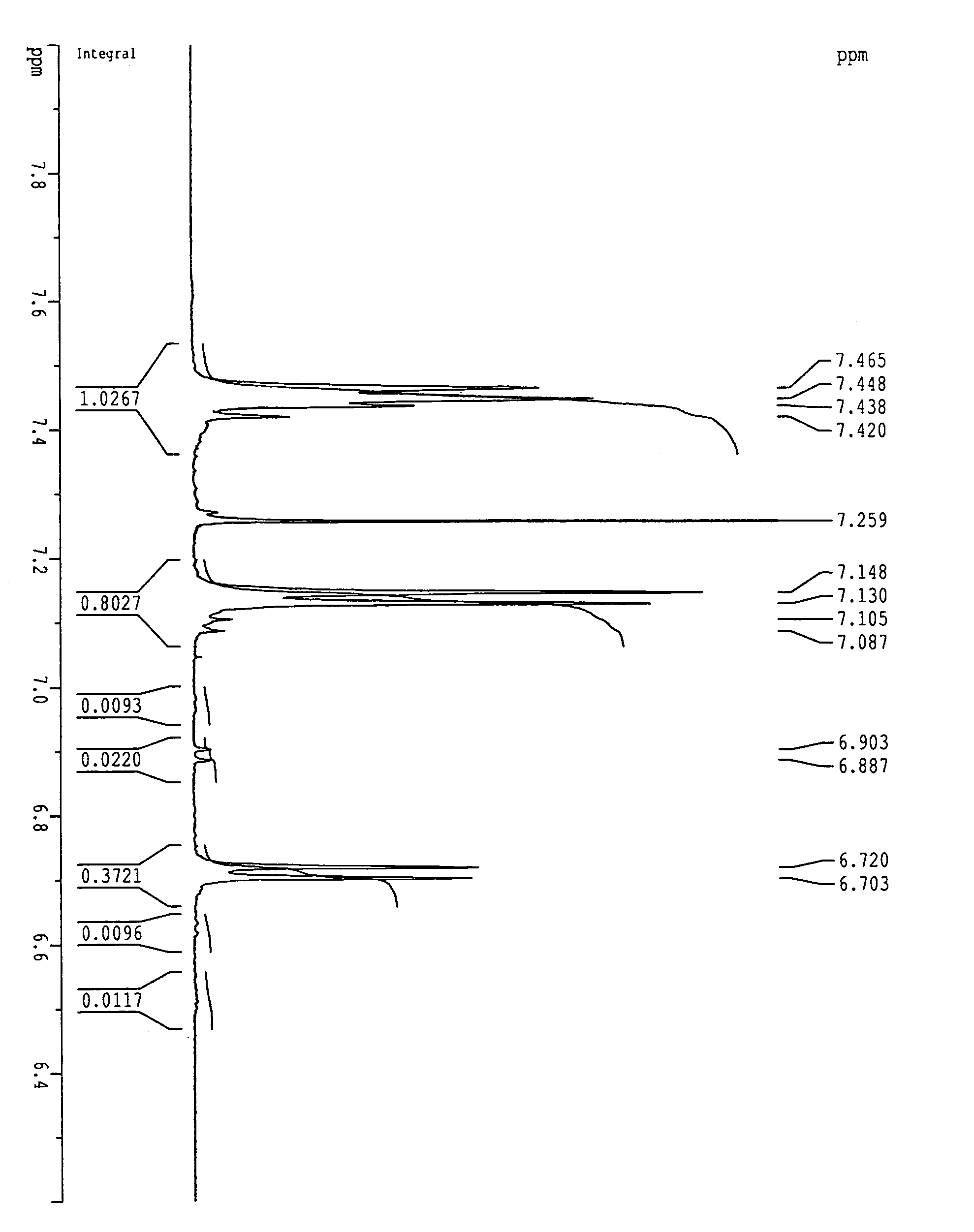

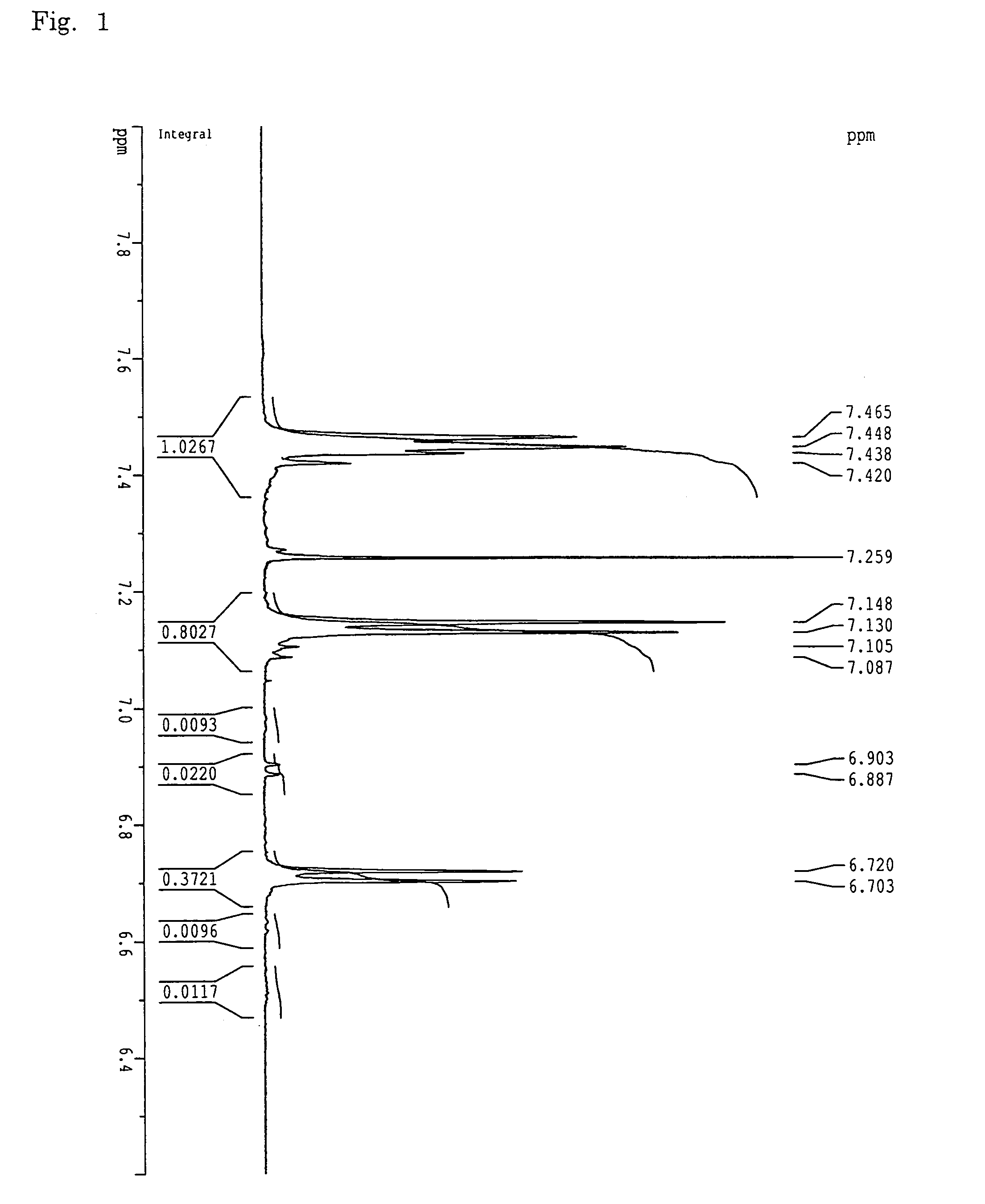

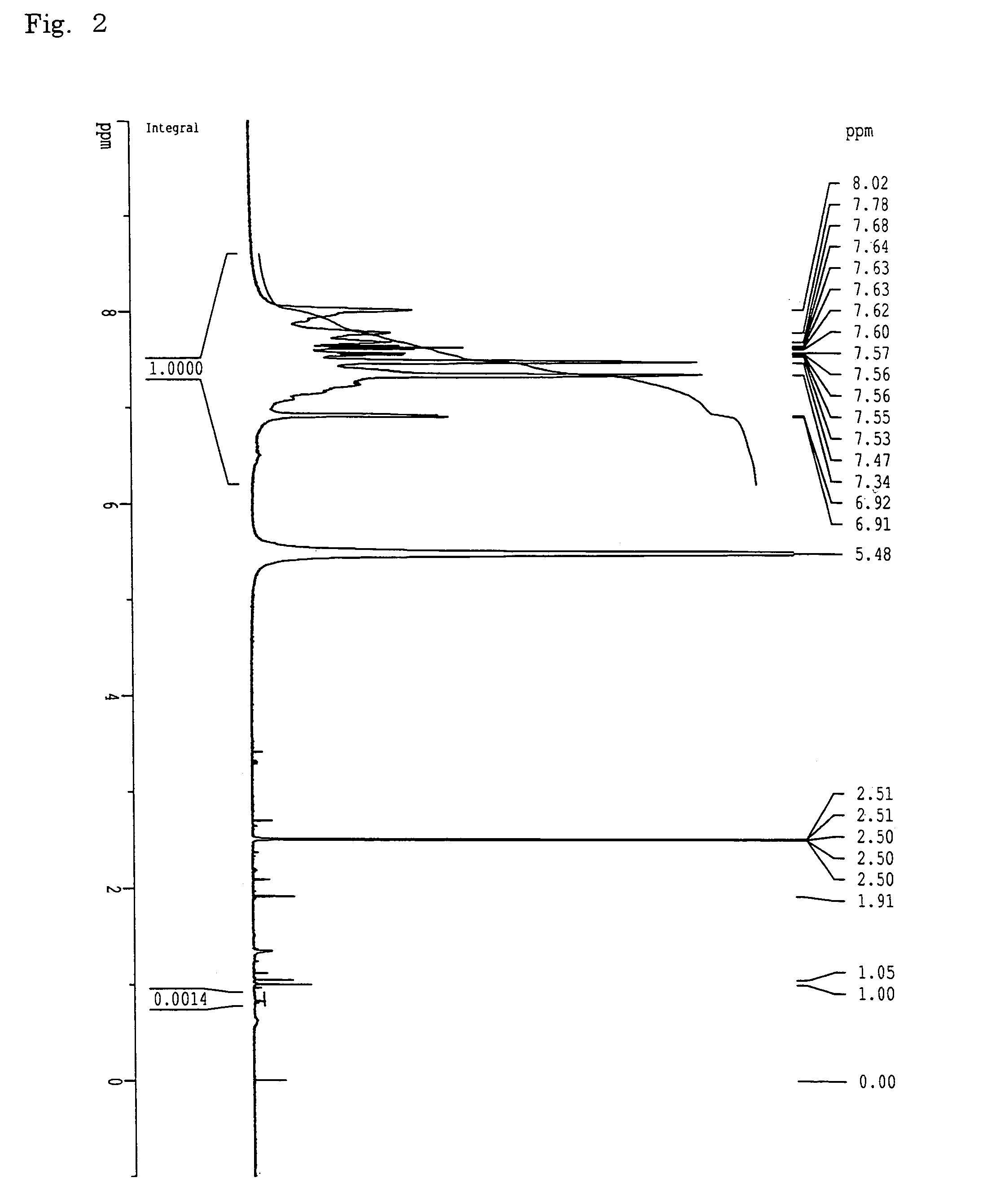

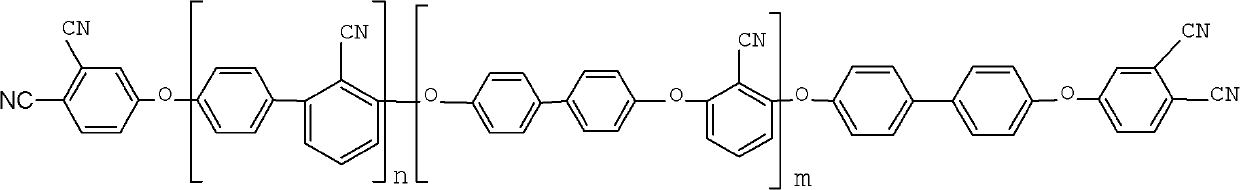

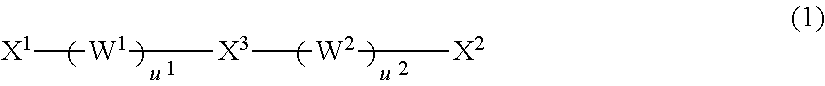

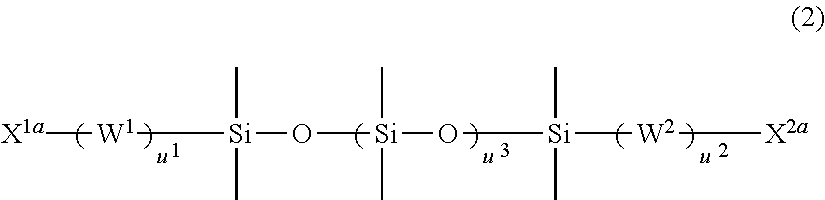

Sulfonated polymer having nitrile-containing hydrophobic block and solid polymer electrolyte

ActiveUS7115699B2Excellent hot water resistanceIncrease acid concentrationNon-metal conductorsSolid electrolytesPolymer electrolytesAryl

Provided are a sulfonated polymer capable of high hot water resistance even if it has an increased amount of the sulfonic groups introduced therein, and a solid polymer electrolyte containing the sulfonated polymer that has high proton conductivity and excellent generating performance.The sulfonated polymer has repeating units represented by the formula (1′):wherein B's are each independently an oxygen or a sulfur atom, R1 to R3 may be the same or different and are selected from a hydrogen atom, a fluorine atom, a nitrile group and an alkyl group, n is an integer of 2 or greater, and Q is a structure represented by the formula (q):wherein A is independently a divalent atom or organic group or a direct bond, and R4 to R11 may be the same or different and are selected from a hydrogen atom, a fluorine atom, an alkyl group and an aromatic group.

Owner:JSR CORPORATIOON

Resin composition and method for producing the same

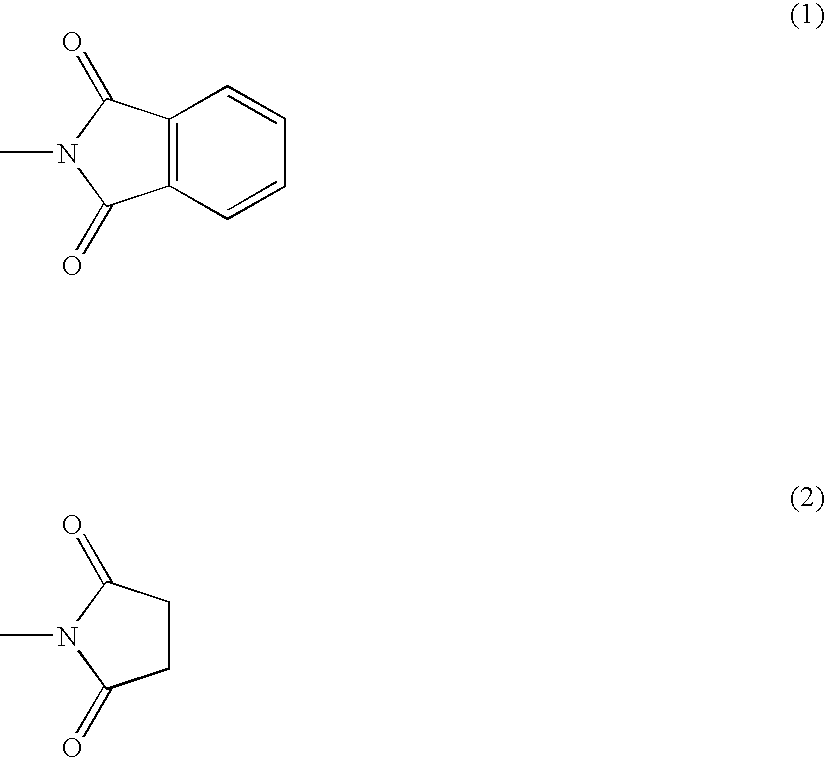

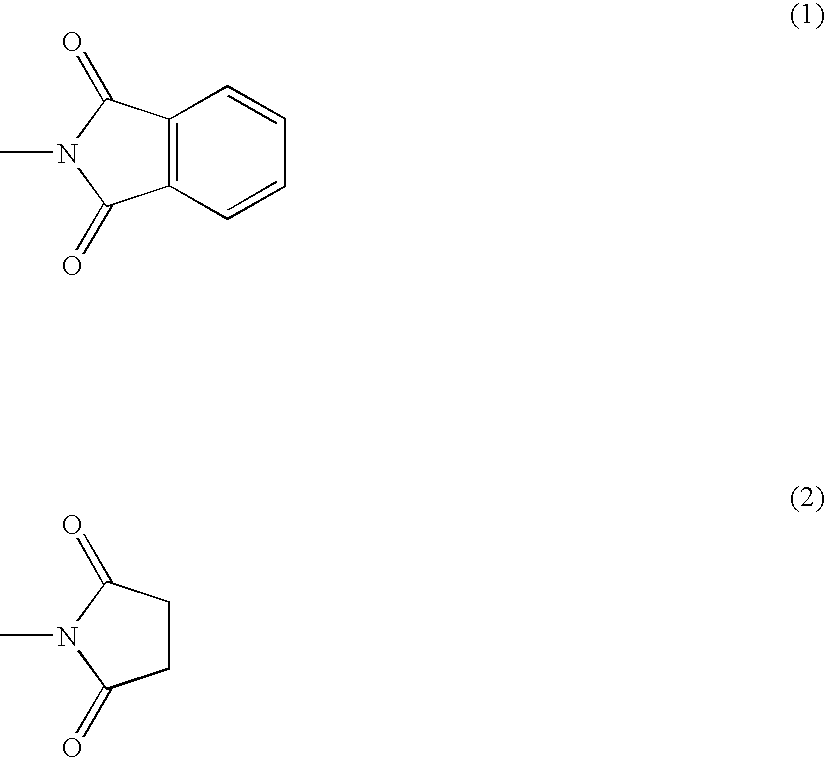

ActiveUS20050009987A1Preventing compositionGreat consequenceBuilding insulationsEthylene vinyl alcohol copolymerWater resistance

The present invention provides a resin composition including an ethylene-vinyl alcohol copolymer (EVOH) and a polyamide resin and having outstanding properties in terms of long-term run stability, appearance, and hot water resistance in melt molding. In this resin composition, 70 mol % or more of all the terminal ends of the polyamide resin are blocked with units including an imide structure. At least a portion of the units containing an imide structure may be units containing a cyclic imide structure.

Owner:KURARAY CO LTD

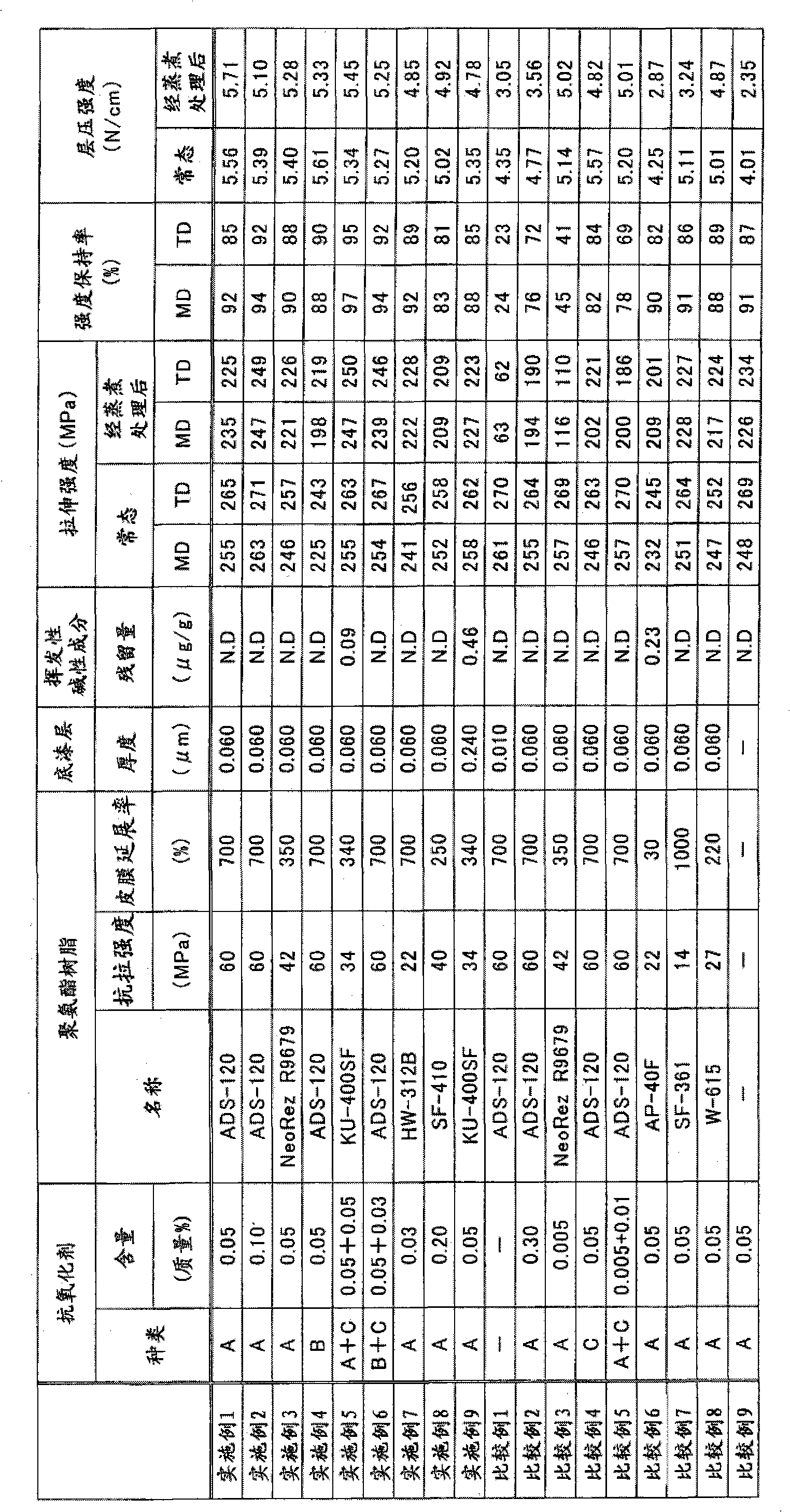

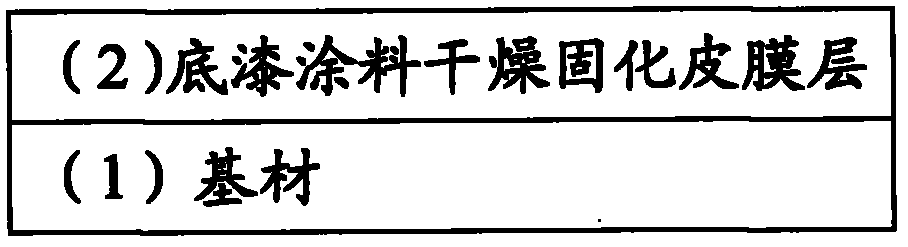

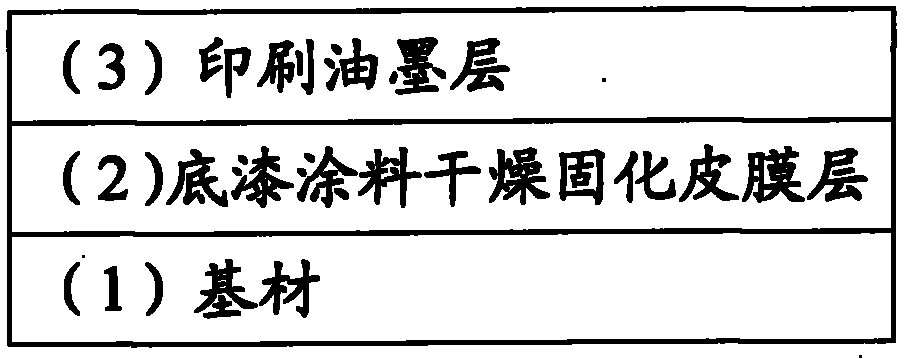

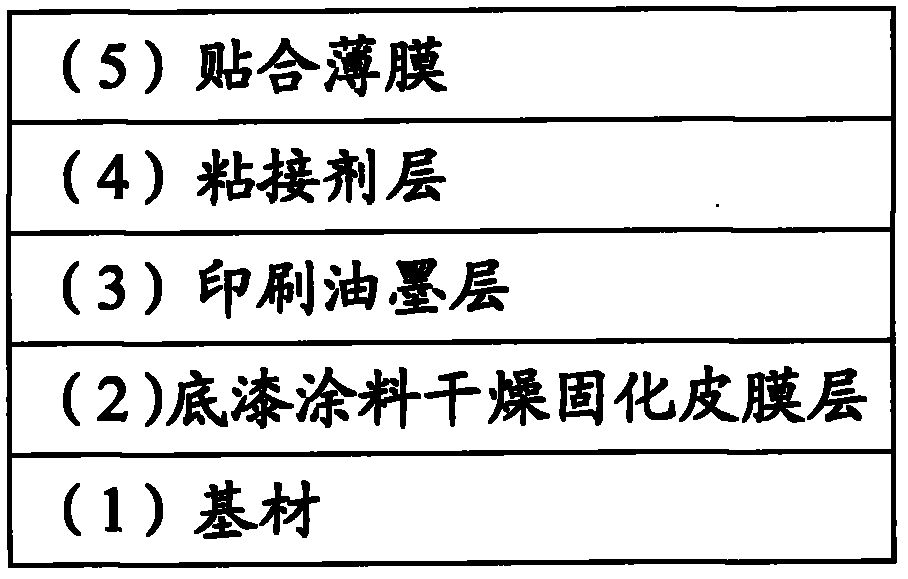

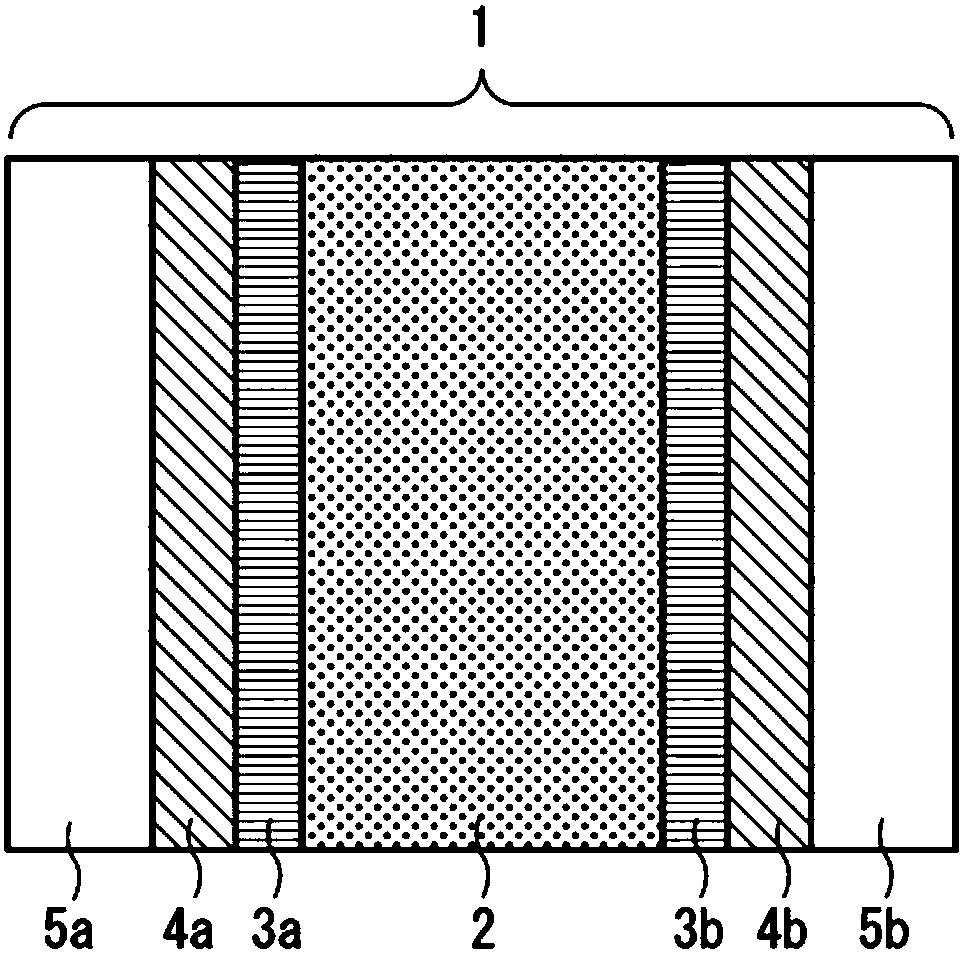

Hot water resistant polyamide thin layer and manufacturing method thereof

InactiveCN102069617AExcellent adhesionExcellent hot water resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsPolyamideChemistry

A hot water resistant polyamide thin layer. An undercoating layer containing polyurethane resin with a film extensional proportion of above 250% and a tensile strength of above 20 MPa is formed on at least one side of a polyamide substrate thin layer containing 0.01-0.2 wt% of hindered phenolic compounds.

Owner:UNITIKA LTD

Cross-linking type polyarylene ether nitrile and preparation method thereof

The invention relates to cross-linking type polyarylene ether nitrile and a preparation method thereof, belonging to the field of special high-polymer materials. The cross-linking type polyarylene ether nitrile is a polyarylene ether nitrile thermo-solid with a phthalocyanine ring as a crosslinking point. The preparation method for the cross-linking type polyarylene ether nitrile comprises the following steps: preparing polyarylene ether nitrile containing a carboxyl group in its side chain and terminated by a hydroxyl group; then reacting the polyarylene ether nitrile with 4-nitrophthalonitrile so as to obtain nitrophthalonitrile-terminated polyarylene ether nitrile containing the carboxyl group in its side chain; then reacting the polyarylene ether nitrile obtained in the previous step with 3-aminophenoxyl phthalonitrile so as to obtain polyarylene ether nitrile containing phthalonitrile groups in its side chain and terminal; and subjecting the polyarylene ether nitrile obtained in the previous step to processing and molding and then to self-crosslinking at high temperature so as to obtain the cross-linking type polyarylene ether nitrile. The cross-linking type polyarylene ether nitrile has good heat resistance, a glass-transition temperature of 300 DEG C or above and an initial decomposition temperature of 500 to 600 DEG C. The cross-linking type polyarylene ether nitrile is applicable as a high-temperature-resistant structural material and a flame-retardation material to the fields of aviation and spaceflight.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

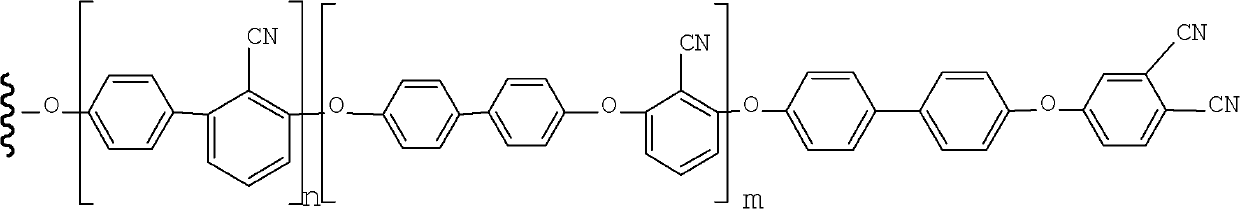

Polyaryl ether nitrile resin, polyaryl ether nitrile film and preparation method thereof

The invention belongs to the field of high polymer materials, and particularly relates to polyaryl ether nitrile resin, a polyaryl ether nitrile film and a preparation method thereof. The structure of the polyaryl ether nitrile resin is represented by formula I: n=40-80, m=10-20. Cross-linking groups are arranged at the chain end of the polyaryl ether nitrile resin, and the polyaryl ether nitrile resin has good curing reaction activity and can be used for preparing a corresponding polyaryl ether nitrile film. The polyaryl ether nitrile film is good in heat-resistant performance, the glass-transition temperature is 200 DEG C to 240 DEG C, the initial decomposition temperature is 560 DEG C to 580 DEG C, and carbon residue rate of thermal decomposition in nitrogen atmosphere at 800 DEG C is more than 69%. The polyaryl ether nitrile film is good in toughness, the elongation at break of the polyaryl ether nitrile film ranges from 8% to 12%, tensile strength is excellent, the tensile strength of the polyaryl ether nitrile film ranges from 80 MPa to 100 MPa.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

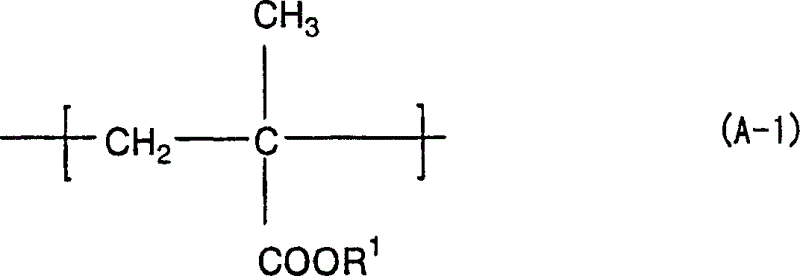

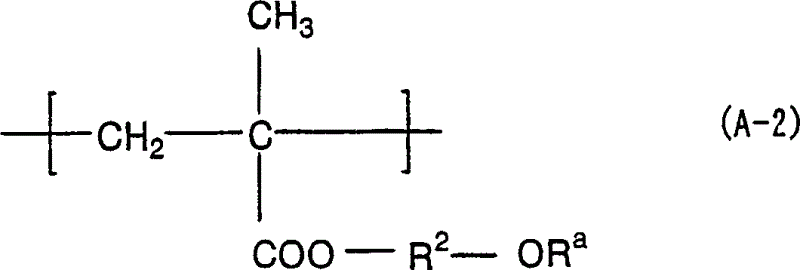

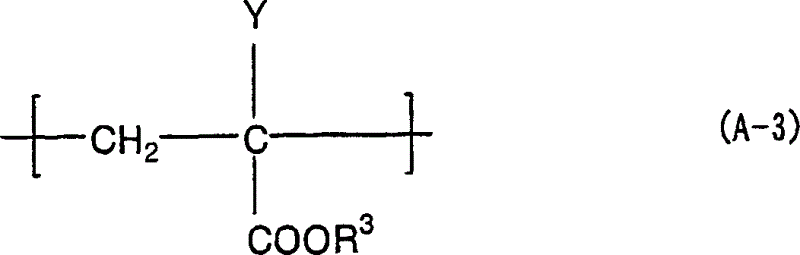

Acrylic resin composition, organosiloxane resin composition and laminate comprising the same

InactiveCN1564742AHigh level of weather resistanceImprove scratch resistanceSynthetic resin layered productsCoatingsColloidal silicaPolymer science

A laminate which is excellent in appearance, adhesion, scratch resistance, abrasion resistance and hot water resistance and has a high level of weatherability and excellent durability, and an acrylic resin composition and an organosiloxane resin composition both of which can be used for the manufacture of the above laminate and have excellent storage stability. The laminate comprises a polycarbonate substrate, a first layer formed on the surface of the polycarbonate substrate, and a second layer formed on the surface of the first layer, wherein the first layer is composed of a crosslinked acrylic copolymer and an ultraviolet light absorber, and the second layer is composed of a crosslinked organosiloxane polymer; and the crosslinked acrylic copolymer comprises specific recurring units and an urethane bond in a specific ratio, and the organosiloxane polymer has a specific structure composed of colloidal silica and alkoxysilanes.

Owner:TEIJIN KASEK KK

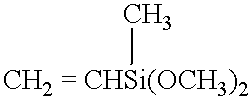

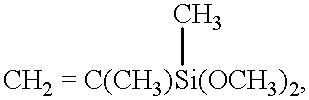

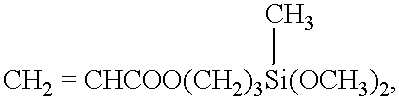

Vinyl-urethane copolymers with intermediary linkage segments having silicon-oxygen bonds and production methods thereof

To provide vinyl-urethane copolymers that can form cured articles having excellent hot-water resistance, water resistance, heat resistance, and weather resistance, and to provide production methods thereof.A vinyl-urethane copolymer contains at least one vinyl polymer chain and at least one urethane polymer chain, in which the vinyl polymer chain is combined with the urethane polymer chain through a linkage segment having a silicon-oxygen bond.A method produces a vinyl-urethane copolymer comprising at least one vinyl polymer chain and at least one urethane polymer chain, in which the vinyl polymer chain is combined with the urethane polymer chain through a linkage segment having a silicon-oxygen bond, by following Steps (X) and (Y): Step (X) of carrying out preparation of an aqueous dispersion or aqueous solution of a urethane polymer (A) having at least one silicon-containing hydrolyzable group; and Step (Y) of, in the aqueous dispersion or aqueous solution of the urethane polymer (A) having at least one silicon-containing hydrolyzable group, carrying out polymerization of an ethylenically unsaturated monomer (B) and carrying out preparation of a vinyl-urethane copolymer using a compound (C) having at least one functional group reactive with a silicon-containing hydrolyzable group and at least one functional group reactive with an ethylenically unsaturated bond-containing group in at least one period selected from before the polymerization reaction, during the polymerization reaction, and after the polymerization reaction.

Owner:KONISHI CO

Method for forming film, and film

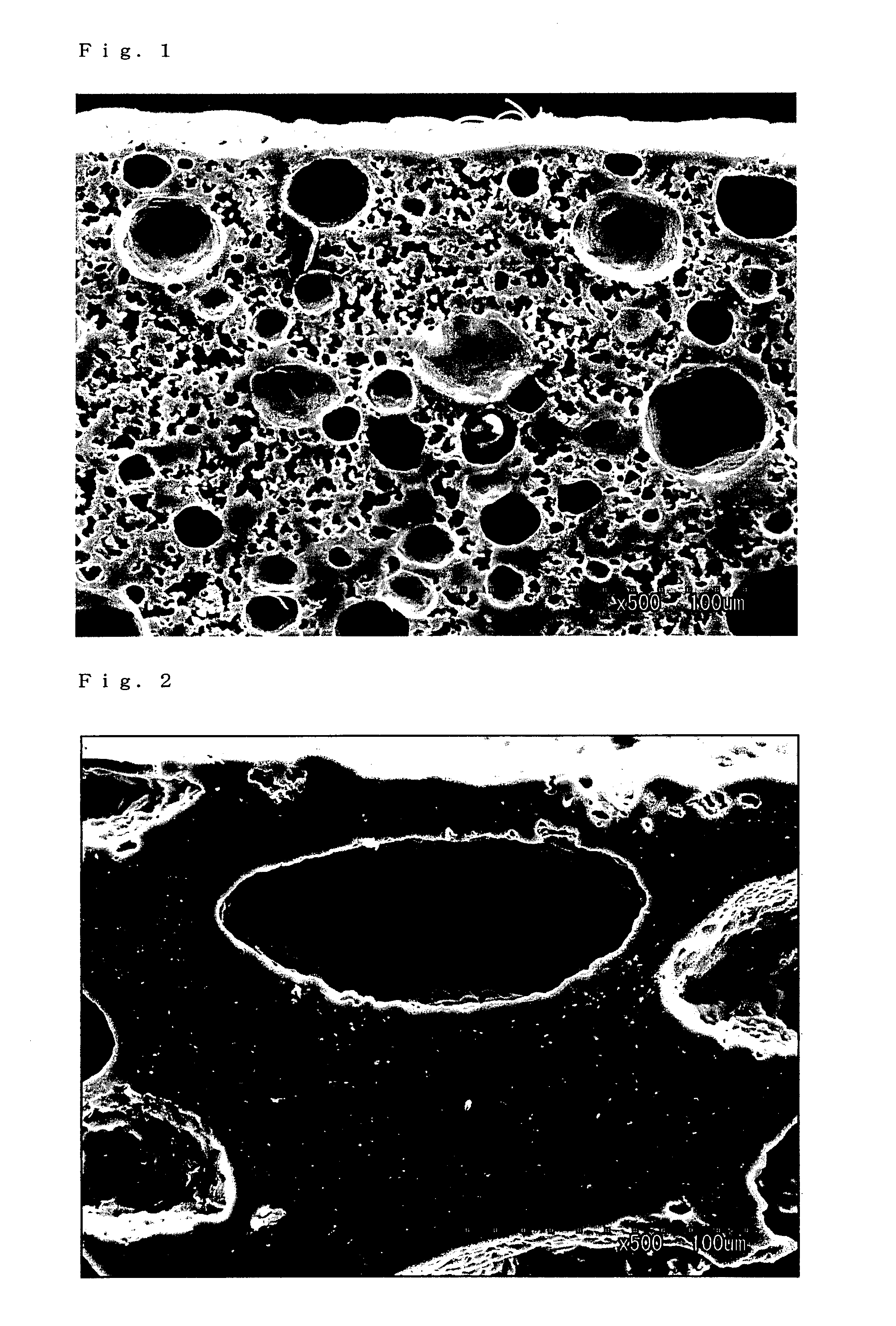

InactiveUS20130183491A1Increase productivityHigh peel strengthLayered productsPretreated surfacesSolid contentAqueous dispersion

A method for forming a film, containing the following steps (1) to (4), and a film obtained by the method for forming a film: step (1): preparing an aqueous dispersion liquid containing (A) a hydrophilic functional group-containing resin, (B) an ammonium salt, and (C) a nonionic thickener, a mixed amount of the component (B) being from 0.25 to 10 parts by mass per 100 parts by mass of a solid content of the component (A); step (2): coating the aqueous dispersion liquid on at least one surface of a substrate to form a coated film; step (3): subjecting the coated film to a thermal gelation treatment to form a gelled film; and step (4): drying and solidifying the gelled film to form a film.

Owner:KURARAY CO LTD

Resin composition and method for producing the same

The present invention provides a resin composition including an ethylene-vinyl alcohol copolymer (EVOH) and a polyamide resin and having outstanding properties in terms of long-term run stability, appearance, and hot water resistance in melt molding. In this resin composition, 70 mol % or more of all the terminal ends of the polyamide resin are blocked with units including an imide structure. At least a portion of the units containing an imide structure may be units containing a cyclic imide structure.

Owner:KURARAY CO LTD

Preparation method of fiber with high water absorption

ActiveCN103160952BImprove stabilityPoor spinnabilityFilament/thread formingArtificial filament heat treatmentPotassium persulfateFiber

Owner:DONGHUA UNIV

Multilayered polyamide film

ActiveCN1914035AImprove oxygen barrier performanceImprove bending resistanceSynthetic resin layered productsHeat resistancePolyamide

Owner:MITSUBISHI CHEM CORP

UV (ultraviolet) polishing and priming-free UV coating and preparation method thereof

InactiveCN103525261AImprove water resistanceExcellent hot water resistanceFireproof paintsPolyether coatingsTetrafluoroborateBound property

An UV polishing and priming-free UV coating is prepared by raw materials in parts by weight as follows: 35-40 parts of epoxy acrylate, 20-25 parts of polyether acrylate, 10-12 parts of trimethylolpropane triacrylate, 5-8 parts of isobornyl acrylate, 1-2 parts of triethanolamine, 3-4 parts of tert-amylphenol, 1-3 parts of tetraethylammonium tetrafluoroborate, 2-4 parts of benzyltriphenylphospho, 1-2 parts of trifluoro acetyl acetone, 4-5 parts of 2,4,6-trimethyl benzoyldiphenyl phosphine oxide, 2-3 parts of benzil dimethyl ketal and 4-5 parts of a dispersing auxiliary. The UV coating has excellent water resistance, hot water resistance, drug resistance, caking property, toughness and flame retardant property, has excellent binding property with printing ink, and has the characteristics of high glossiness, good levelling property, small flavor, good wear resistance and the like; and only one procedure is required when UV gloss oil is adopted for UV polishing, the priming step is omitted, the operation cost is saved, and the work efficiency is improved.

Owner:安徽蓝柯复合材料有限公司

Vitreous antimicrobial agent and antimicrobial product

InactiveUS7514093B2Improve antibacterial propertiesExcellent hot water resistancePowder deliveryBiocideAlkaline earth oxidesAnti-Microbial Agents

A vitreous antimicrobial agent that can exhibit excellent antimicrobial properties when added to various types of resins, that has excellent discoloration resistance and hot water resistance, and that can easily be produced at a commercial scale. The vitreous antimicrobial agent includes, relative to 100 mass % of total glass components, 0.1 to 2 mass % of Ag2O, 40.5 to 49 mass % of ZnO, 6 to 9.5 mass % of SiO2, 30.5 to 39.5 mass % of B2O3, 2 to 10 mass % of an alkaline earth metal oxide, and 6 to 7.5 mass % of Na2O; the vitreous antimicrobial agent comprising, in addition to these, 0.01 to 5 mass % of CeO2 as necessary. An antimicrobial resin composition and an antimicrobial product including the vitreous antimicrobial agent.

Owner:TOAGOSEI CO LTD

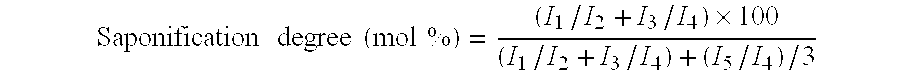

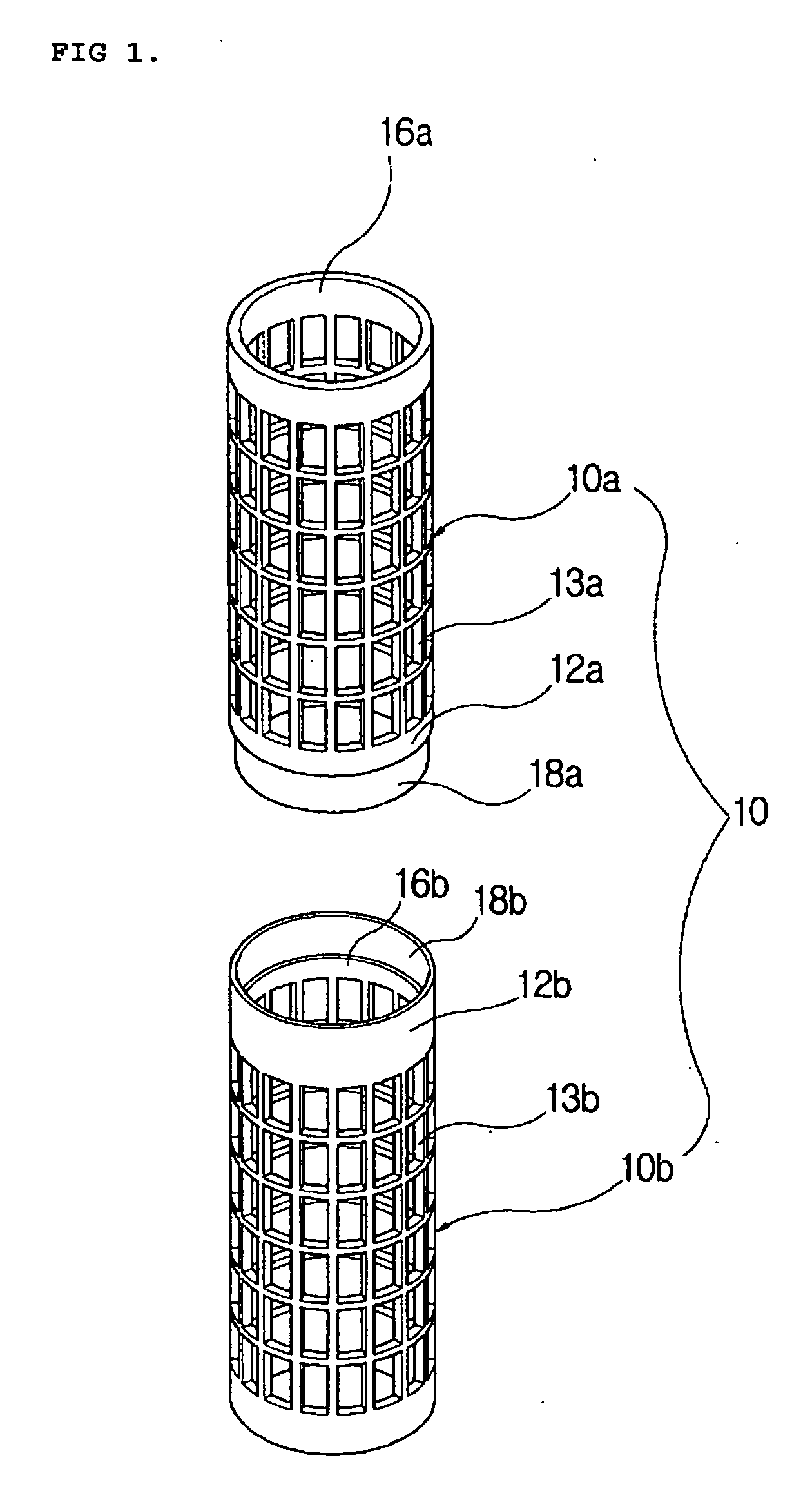

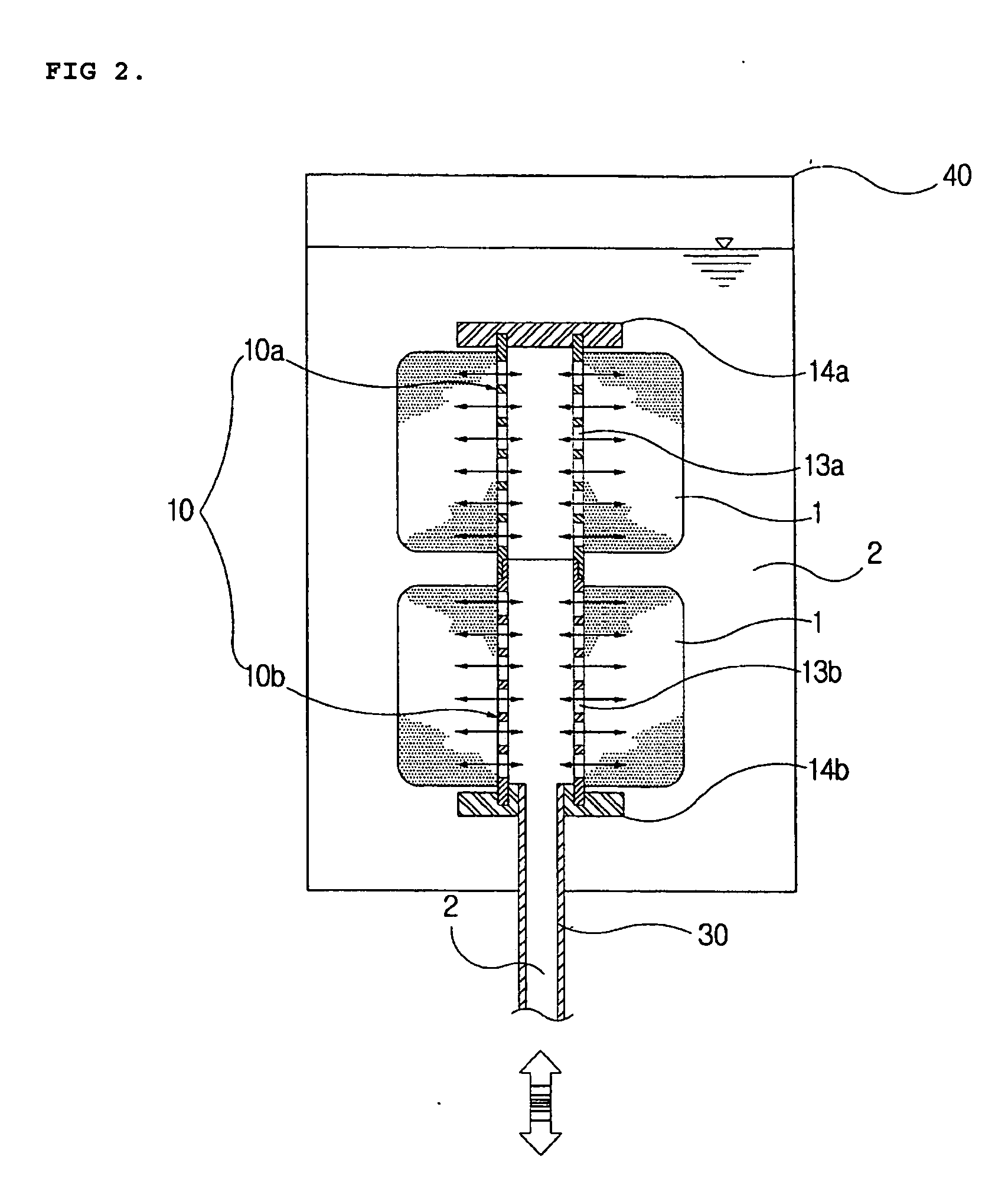

Crosslinked polyvinyl alcohol fiber and method for producing the same

InactiveUS20050118419A1Increase tenacityReduced drawabilityLiquid repellent fibresMonocomponent synthetic polymer artificial filamentCross-linked polyethyleneChemistry

The present invention relates to crosslinked polyvinyl alcohol raw cord and method for producing the same, and more particularly, to crosslinked polyvinyl alcohol fiber, in which PVA resin having a degree of polymerization of more than 1,000 and a degree of saponification of more than 97.0 mol % is dissolved in dimethyl sulfoxide, the solution is subjected to dry and wet gel spinning using methanol as a coagulation solution, drawn and thermally treated, the resulting polyvinyl alcohol drawn yarn with 500-3,000 deniers is twisted to produce a cabling yarn, the cabling yarn is plied into a 2-ply or 3-ply yarn to produce a raw cord, the raw cord is wound on a bobbin for crosslinking and crosslinked in an aqueous crosslinking solution containing an aromatic aldehyde compound and an acid catalyst. Moreover, the present invention relates to a crosslinker-introducing apparatus, which is used in the above method and can effectively induce the crosslinking reaction of the wound raw cord.

Owner:HYOSUNG CORP

Hard Coat Layer-Forming Composition and Optical Lens

ActiveUS20100058955A1High transparencyGood chemical resistanceMaterial nanotechnologyGroup 4/14 element organic compoundsMicroparticleRutile

The hard coat layer-forming composition of this invention includes (A) composite oxide fine particles with a mean particle diameter of 1 to 200 nm, containing titanium, tin and optionally silicon, and with a rutile-type crystal structure, (B) an organosilicon compound represented by the formula R1aR2bSi(OR3)4−(a+b) and / or a hydrolyzate thereof, and (C) a cyanamide derivative compound. A hard coat layer formed from the composition not only is excellent in transparency, scratch resistance, adhesion property, weathering resistance, impact resistance, etc. but also can enjoy no coloration or little coloration, particularly in bluing or yellowing, upon exposure to or irradiation with ultraviolet rays, even if an antireflection film is provided.

Owner:JGC CATALYSTS & CHEM LTD

Primer and laminate including resin film formed from the primer

ActiveCN102137903AGood transferabilityExcellent dot reproducibilitySynthetic resin layered productsPolyurea/polyurethane coatingsPrinting inkHydroxy compound

The present invention provides a primer and a laminate including a layer formed from the primer. The primer improves the tight adhesion between a base layer of wrapping material and a printing ink layer, a coating layer, or an adhesive layer, and thus serves to produce a laminate for wrapping which combines printability including both excellent transfer of printing ink and excellent reproduction of dots, easy adhesion, long-term storability under high humidity, and acid resistance. The primer is characterized by containing (A) a main component consisting of a copolymer prepared from monomers (a) and (b), said monomer(a) being an unsaturated compound having a hydroxyl group and said monomer(b) being at least one unsaturated compound selected from the group consisting of unsaturated carboxylic acid esters, styrene, unsaturated carboxylic acids, unsaturated hydrocarbons, vinyl esters, and vinyl halides, (B) a curing agent consisting of a compound having an isocyanate group, and (C) a compound having two or more carboxyl groups or one or more carboxylic anhydride groups in one molecule.

Owner:DIC CORP

Treated surface metal sheet and treated surface metal sheet coated with organic resin

ActiveCN107849702AGood anti-sag performanceExcellent adhesionPretreated surfacesCans/barrels/drumsChromium freePolymer science

The present invention relates to a treated surface metal sheet in which on at least one surface of a metal sheet, a surface treatment film layer containing a polycarboxylic acid polymer and a zirconium compound is formed, and on said surface treatment film layer, a coating film containing a polyester resin, a phenol resin and an acid catalyst is formed. The treated surface metal sheet is a non-chromium-based treated surface metal sheet that is capable of providing cans and can lids: which have excellent dent resistance with respect to even acidic beverages, etc.; and for which there is no riskof an organic resin covering layer formed on said coating film delaminating even under high temperature / humidity conditions such as in disinfection treatment, and the organic resin covering layer hasexcellent hot water-resistant adhesiveness.

Owner:TOYO SEIKAN GRP HLDG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com