Patents

Literature

186results about How to "Improve oxygen barrier performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

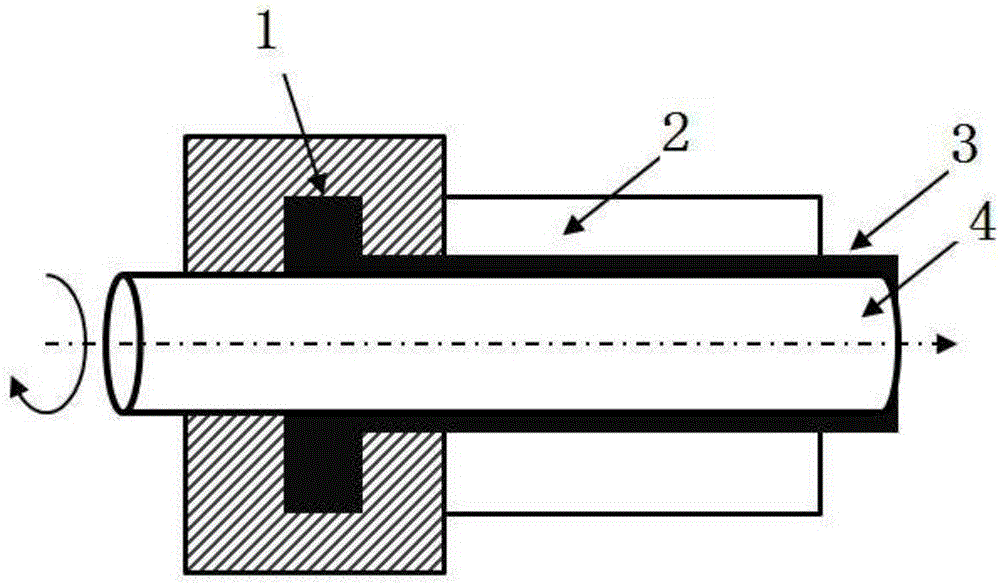

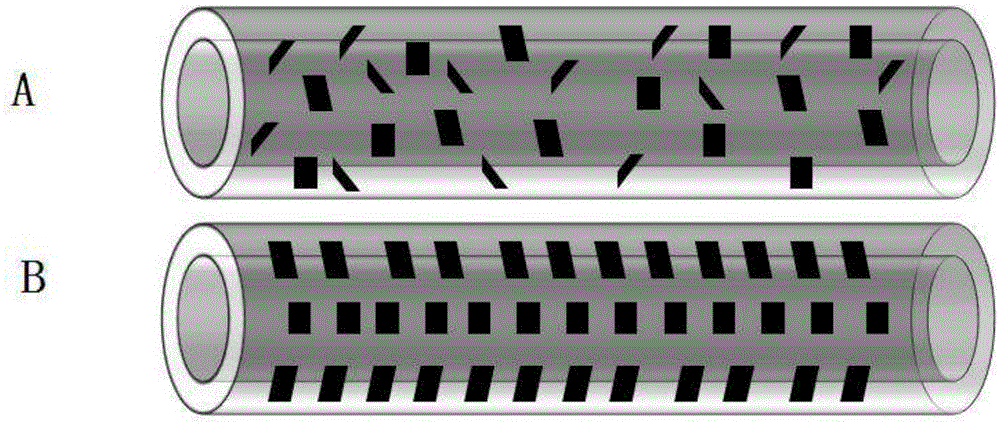

High-oxygen barrier property high-strength polyolefin heat conduction pipe and preparation method thereof

The invention provides a high-oxygen barrier property high-strength polyolefin heat conduction pipe and a preparation method thereof. The high-oxygen resistance high-strength polyolefin heat conduction pipe comprises, by weight, 100 parts of polyolefin resin, 0.1-5 parts of graphene slice layers, 0.1-15 parts of a compatilizer and 0.01-0.2 parts of an anti-oxidant. The graphene slice layers are uniformly distributed in the polyolefin resin in a ring way around a pipe central axis as a center. Through use of the graphene slice layers and a rotary core rod mouth mold, a polyolefin crystallization degree is high, a lot of oriented crystals are formed and pipe mechanical properties, heat conduction and heatproof performances are obviously improved. The graphene slice layers are uniformly distributed in the pipe in a ring way so that graphene slice layer obstruction performances are greatly improved and thus the good oxygen barrier property is kept under the condition of a very small amount of an anti-oxidant.

Owner:TIANJIN KINGFA NEW MATERIAL

Gas barrier laminate and packaged article, and method for producing gas barrier laminate

ActiveUS20070111005A1Improve oxygen barrier performanceHigh strengthSynthetic resin layered productsPretreated surfacesHalogenAlkoxy group

A gas barrier layered product and a method for producing the same are provided. The gas barrier layered product exhibits a high oxygen barrier property regardless of humidity, exhibits a high oxygen barrier property even after being subjected to retort processing, and is excellent in strength and transparency. In order to provide the gas barrier layered product, the gas barrier layered product includes a base material and a layer stacked on at least one surface of the base material. The layer is formed of a composition that includes: a hydrolyzed and condensed product of at least one compound (L) containing a metal atom to which at least one characteristic group selected from a halogen atom and an alkoxy group has been bonded; and a neutralized product of a polymer containing at least one functional group selected from a carboxyl group and a carboxylic anhydride group. At least a part of the —COO— group contained in the at least one functional group has been neutralized with metal ions having a valence of two or more.

Owner:KURARAY CO LTD

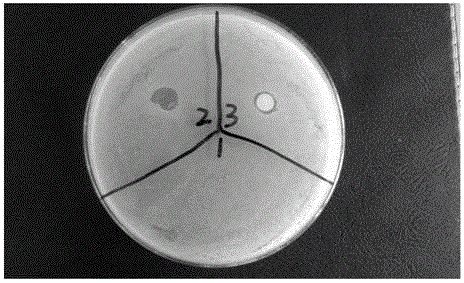

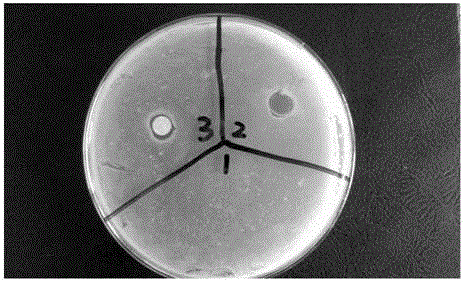

Method for preparing antibacterial edible films

ActiveCN105111477AShort reaction timeReduce the temperatureFlexible coversWrappersReaction timingSolvent

The invention discloses a method for preparing antibacterial edible films. The method includes adding polysaccharide materials and epsilon-polylysine into a stirring ball mill and enabling the polysaccharide materials and the epsilon-polylysine to carry out ball-milling reaction at the temperature of 25-50 DEG C for the reaction time of 5-10min to obtain polysaccharide and epsilon-polylysine compounds; adding water into the polysaccharide and epsilon-polylysine compounds, gelatin and glycerin to prepare film forming liquor; coating the film forming liquor to form the antibacterial edible films. A mass ratio of the polysaccharide materials to the epsilon-polylysine is 5:0.8-2.2. The method has the advantages that other solvents can be omitted in reaction procedures, the reaction time is short, the temperature is low, products have light colors, good film forming effects can be realized, the films obtained by the aid of the method have broad-spectrum antibacterial activity, and the toughness and the oxygen barrier capacity of the edible films can be improved.

Owner:ZHEJIANG UNIV OF TECH

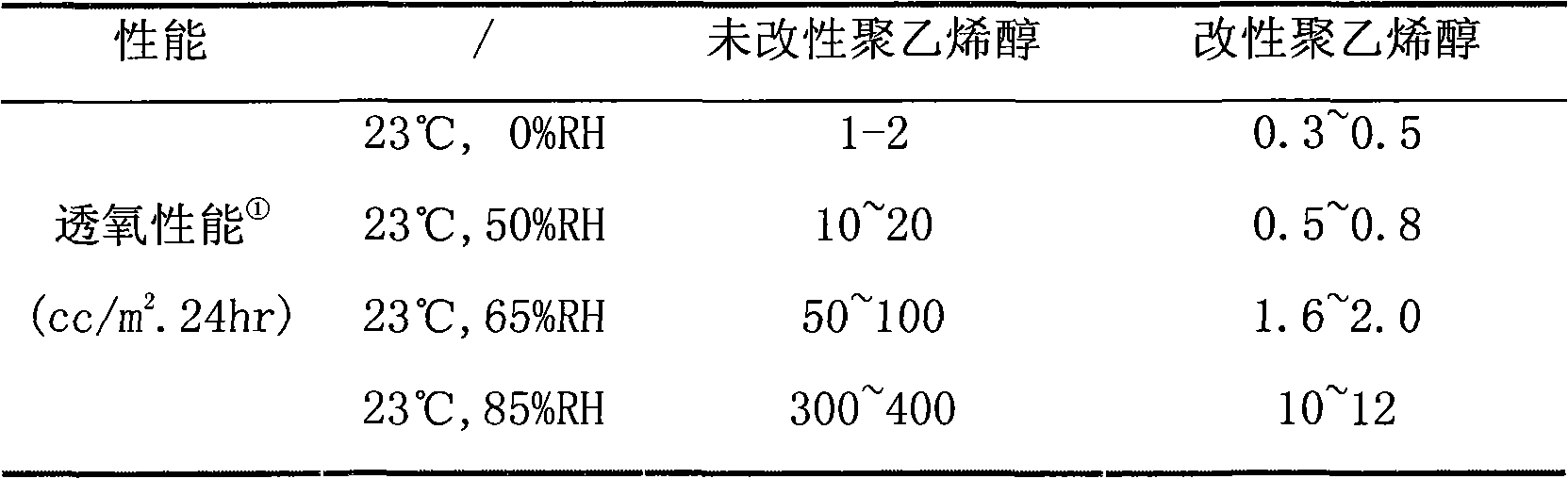

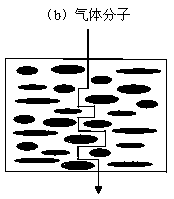

Water-tolerant blocking polyvinyl alcohol coating for coating and preparation method thereof

ActiveCN102304314AImprove sensitivityImprove oxygen barrier performanceCoatingsLayered structureDefoaming Agents

The invention provides a water-tolerant blocking polyvinyl alcohol coating for coating and a preparation method thereof; the coating is prepared from the following raw materials in percentage by weight: 5-7% of polyving akohol, 0.01-0.05% of nanometer montmorillonite, 0.5-1% amino resin, 0.01-0.3% of catalytic agent, 0.01-0.1% of defoaming agent and 91-94% of deionized water; by adding the nanometer montmorillonite in the polyvinyl alcohol coating, after the modified coating is coated, the nanometer montmorillonite is dispersed in a polyving akohol coating in a layered structure so as to block gases such as oxygen and the like from flowing and diffusing so as to further increase the oxygen blocking performance of a polyving akohol coating membrane; and the coating is stable, has good coating adaptability, is simple in process and is suitable for industrial production.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

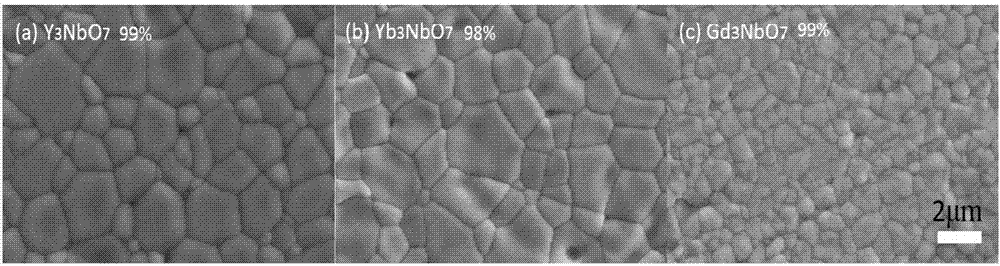

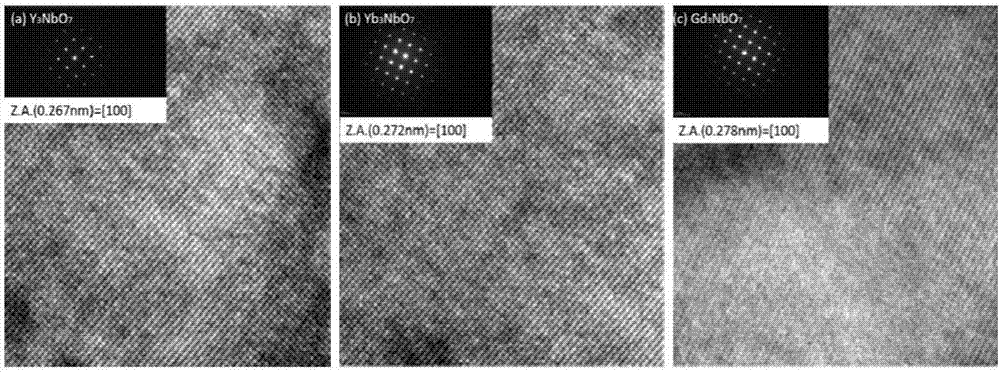

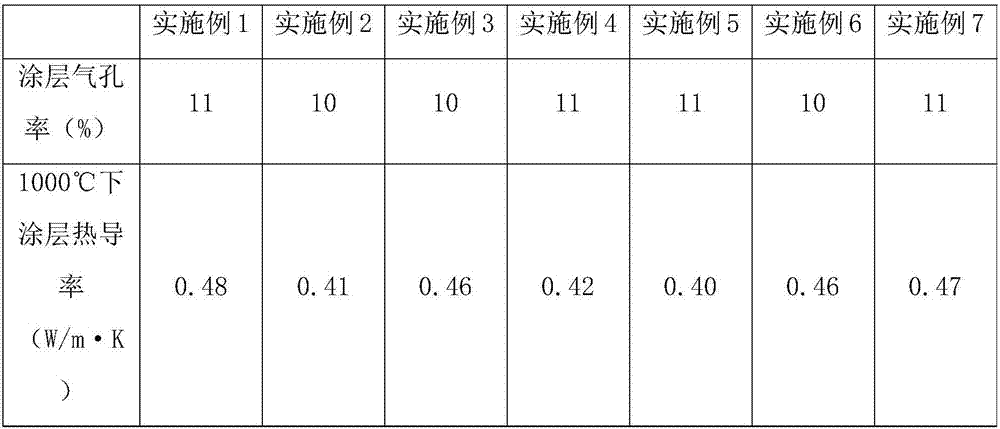

High-temperature thermal barrier coating material

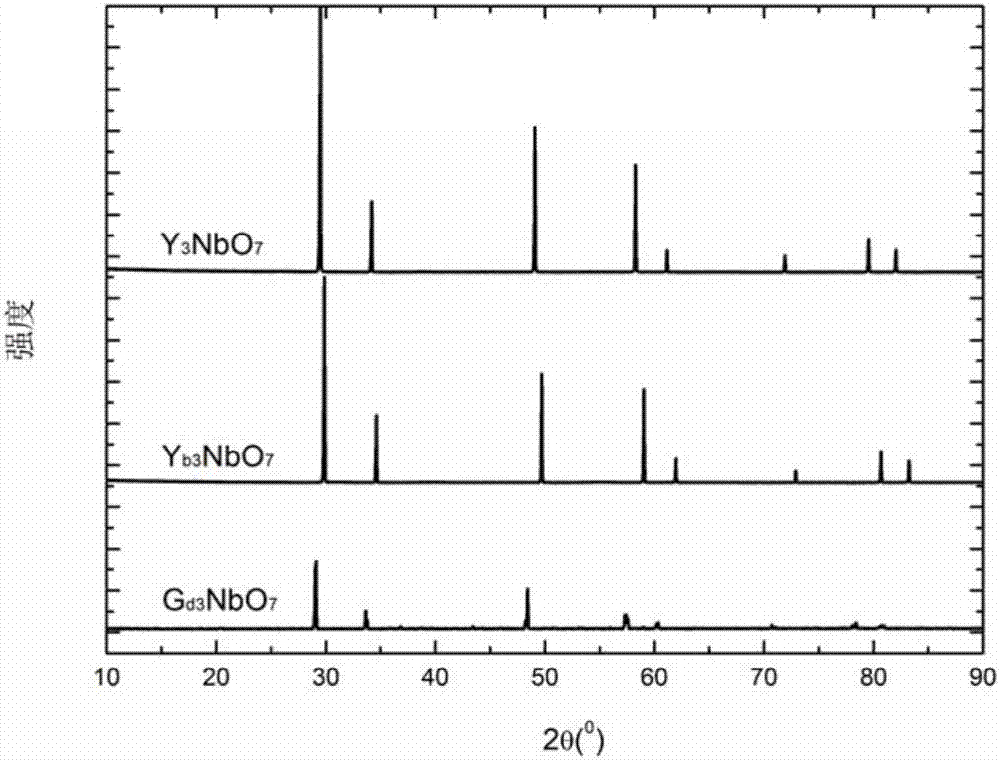

InactiveCN106884132AIncrease scatteringLow thermal conductivityMolten spray coatingVacuum evaporation coatingRare-earth elementYttria-stabilized zirconia

The invention relates to a high-temperature thermal barrier coating material. The high-temperature thermal barrier coating material is rare earth niobate and a solid solution thereof. The chemical constitution of the rare earth niobate is Ln3NbO7, and Ln comprises the rare earth elements of La, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y and Sc. The chemical constitution of the solid solution is Ln3(Nb1-xTax)O7 (x is larger than or equal to 0 and smaller than 1). Ln is a combination of one or more than one of the rare earth elements. The high-temperature thermal barrier coating material is characterized in that the heat conductivity of the material is low, when the temperature is 1000 DEG C, the intrinsic thermal conductivity of a compact block body is 1.1-1.4 W / m.k, compared with a commercial yttria-stabilized zirconia (YSZ) material (the thermal conductivity is about 2.5 W / m.k) with the weight percentage being 7%-8%, the thermal conductivity of the material is reduced by a large margin, and the material keeps phase stability and excellent oxygen-resistance capacity from the indoor temperature to the temperature of 1600 DEG C. The material can be applied to protection of high-temperature metal hot end parts of gas turbines or aero-engines.

Owner:TSINGHUA UNIV

Preserving a hemoglobin blood substitute with a transparent overwrap

InactiveUS20060160724A1High purityExtended shelf lifeWrappersPeptide/protein ingredientsMedicineBlood substitute

The invention relates to a method for preserving the stability of a hemoglobin blood substitute comprising maintaining the hemoglobin blood substitute in an atmosphere substantially free of oxygen. The method for preserving the deoxygenated hemoglobin blood substitute comprises maintaining the deoxygenated blood substitute in an oxygen barrier film overwrap package, wherein at least one face of the overwrap package comprises a transparent laminate material and wherein at least one other face of the overwrap package comprises a foil laminate material. The preserved deoxygenated hemoglobin blood substitute comprises a deoxygenated hemoglobin blood substitute and an oxygen barrier film overwrap package wherein at least one face of the overwrap package comprises a transparent laminate material and wherein at least one other face of the overwrap package comprises a foil laminate material.

Owner:OPK BIOTECH

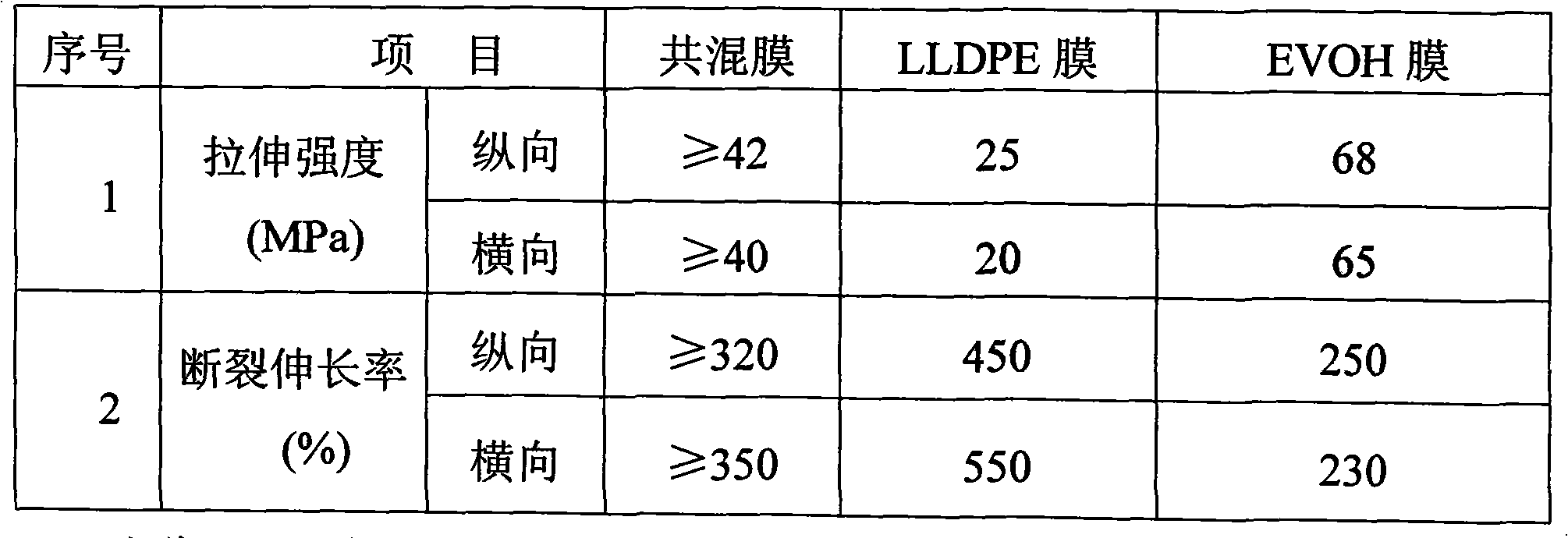

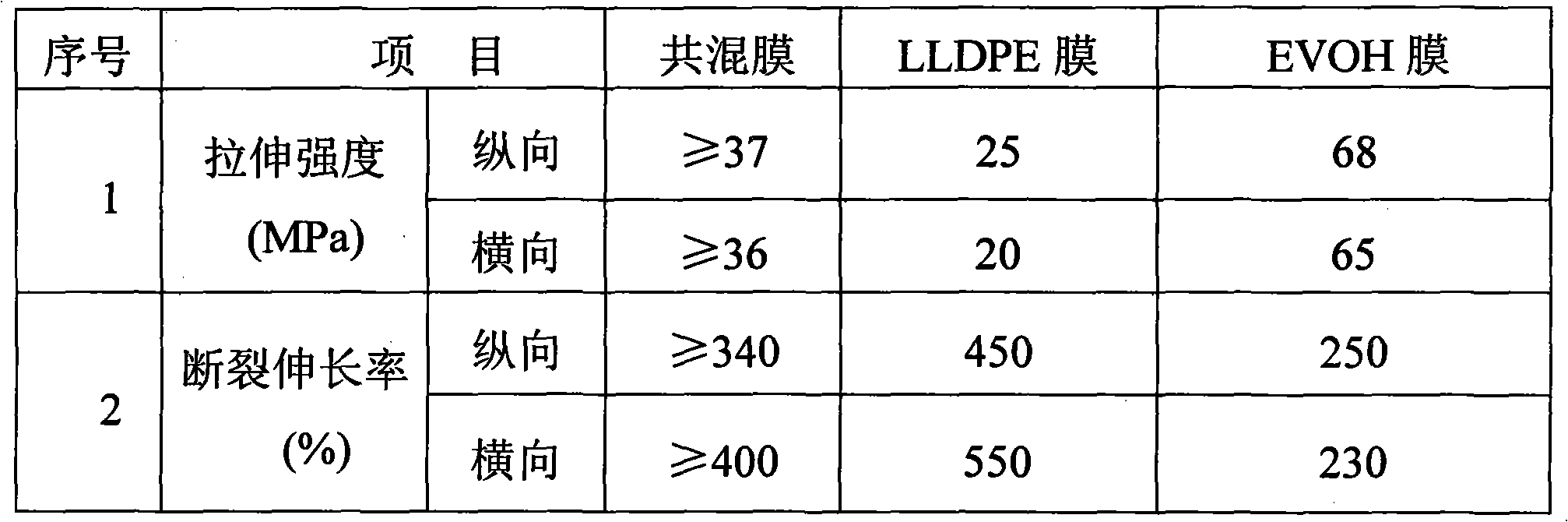

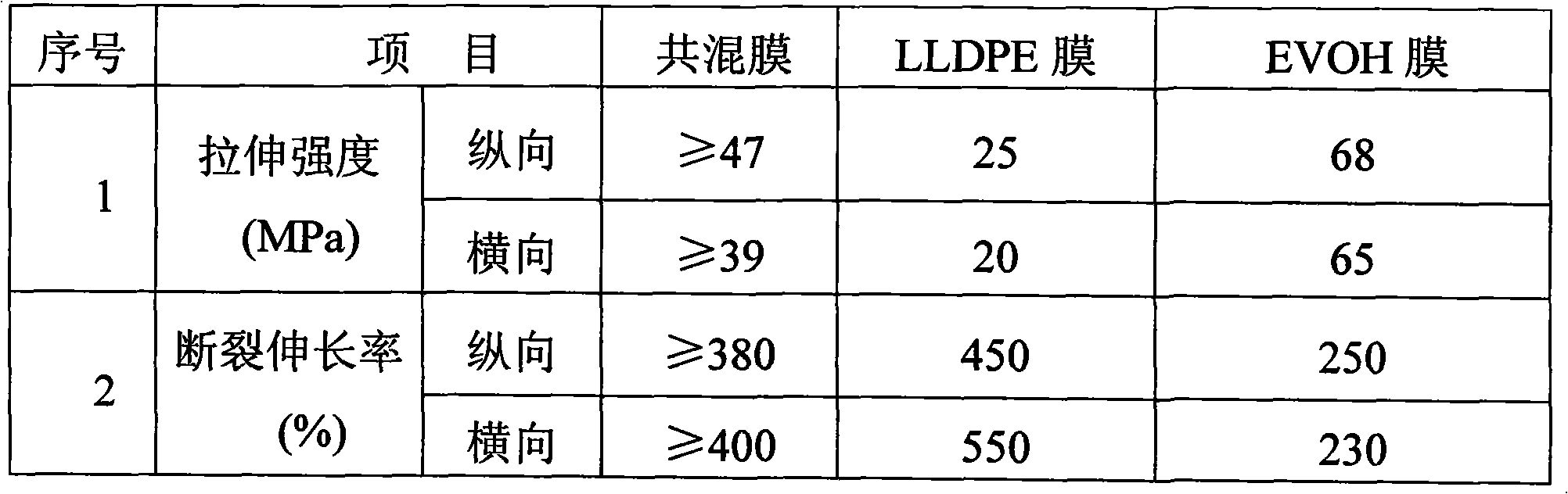

Linear low density blending film of polyethylene and ethylene-ethenol copolymer and method for making the same

InactiveCN101323685ARealize direct blending useImprove adhesionLinear low-density polyethyleneLow density

The invention discloses a blend film of linear low-density polyethylene and ethylene-vinyl alcohol copolymer and a manufacturing method thereof, which relates to a blend film and a making method thereof. The invention solves the problems that LLDPE and EVOH are incompatible and require a bonding layer in the middle when being used together. The blend film of the invention is made by linear low-density polyethylene, ethylene-vinyl alcohol copolymer, calcium carbonate master batches, dicumyl peroxide, dibenzoyl peroxide, dimethylformamide and a maleic anhydride monomer or acrylic acid. The manufacturing method of the invention includes that modified master batches are first prepared to be then used for manufacturing the blend film of the invention. The blend film of the invention can be directly obtained without adding a bonding layer between LLDPE and EVOH when in use of raw materials of LLDPE and EVOH.

Owner:哈尔滨隆华艺达包装制品有限公司

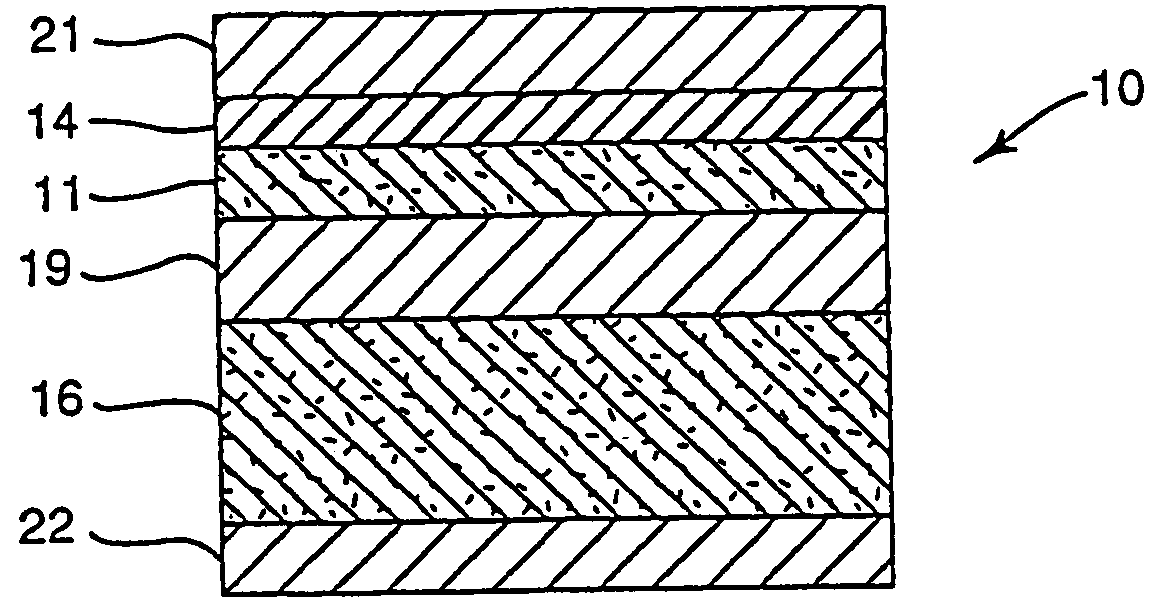

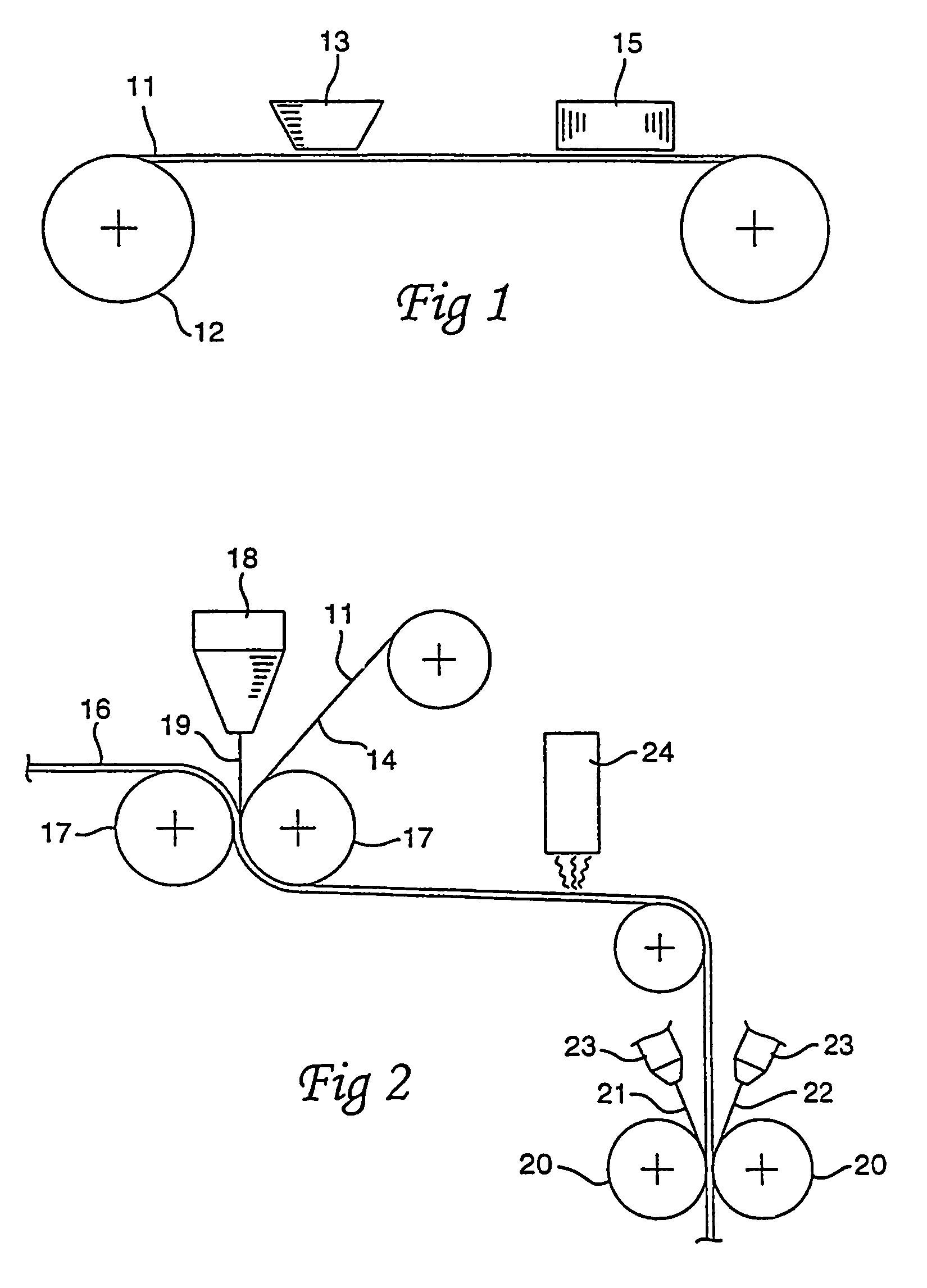

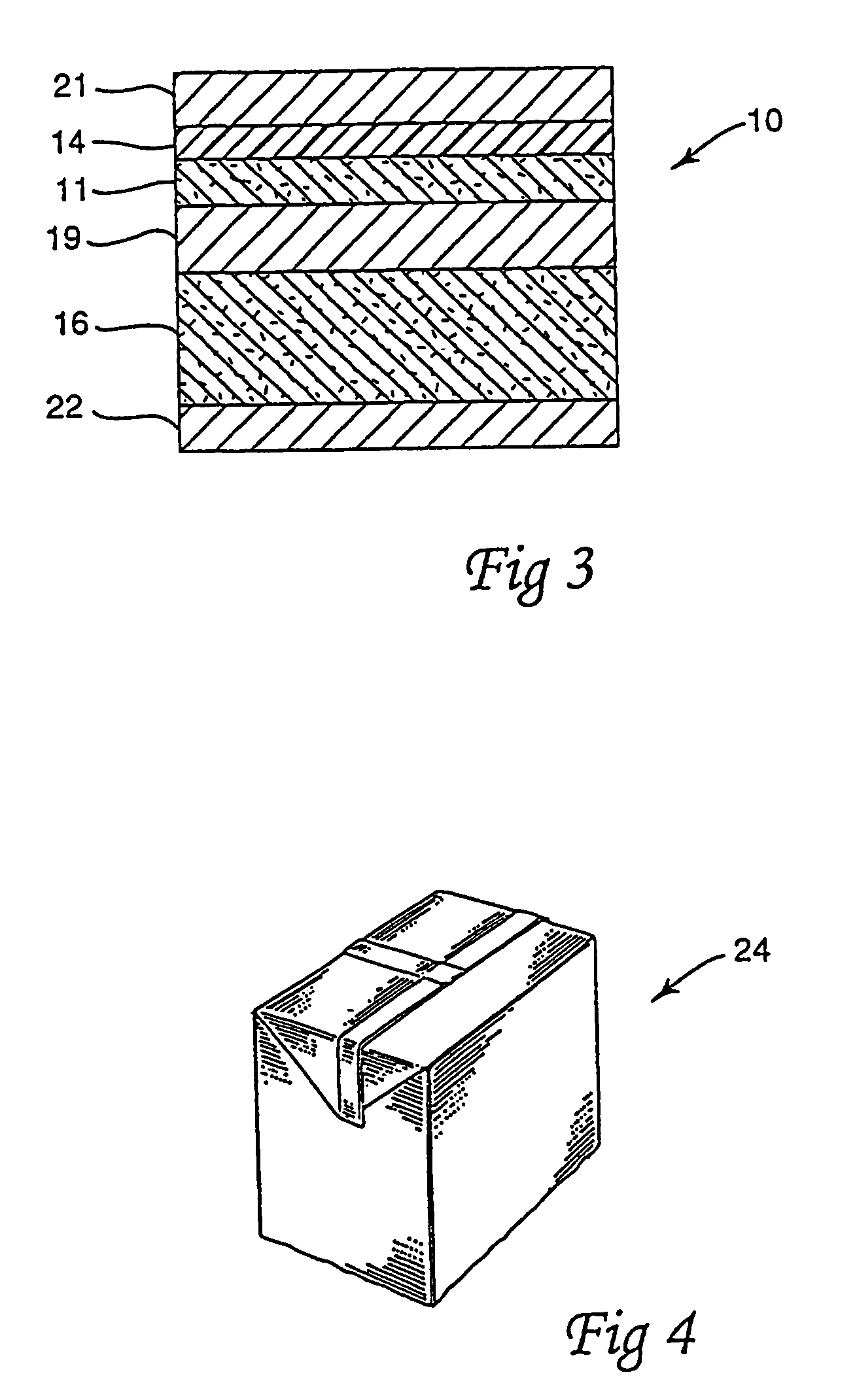

Method of producing a laminated packaging material

InactiveUS7033455B1Less heat energyImprove barrier propertiesWrappersDomestic containersPaper sheetEngineering

The invention relates to a method of producing a laminated packaging material (10) including a core layer (16) of paper or paperboard and a barrier layer (14) applied on one side of the core layer. The invention also relates to a laminated packaging material (10) produced according to the method, as well as a packaging container (50) which is produced from the laminated packaging material (10).

Owner:TETRA LAVAL HLDG & FINANCE SA

Hemicellulose/chitosan based compound membrane with high flexibility and mechanical strength and preparation method thereof

The invention discloses a method for preparing a hemicellulose / chitosan based compound membrane with high flexibility and mechanical strength. The method comprises the following steps: (1) dissolvingchitosan in an acetic acid solution, heating and stirring to prepare a chitosan solution; (2) dissolving hemicellulose in an acetic acid solution, heating and stirring to prepare a hemicellulose solution; (3) mixing the hemicellulose solution and the chitosan solution, and adding a cellulose nano-fiber solution; (4) adding plasticizer into the mixed solution, stirring the mixed solution at room temperature, centrifuging to remove insoluble impurities, performing ultrasonic degassing, and standing to obtain a compound membrane-forming solution; and (5) putting the membrane-forming solution in aculture dish, drying in a vacuum drying tank to form a membrane. The hemicellulose / chitosan based compound membrane has relatively high flexibility, relatively high tensile strength and relatively good oxygen resistance, is antibacterial and antioxidative, and has a relatively good application prospect in food package, oxidation resistance and other aspects.

Owner:BEIJING FORESTRY UNIVERSITY

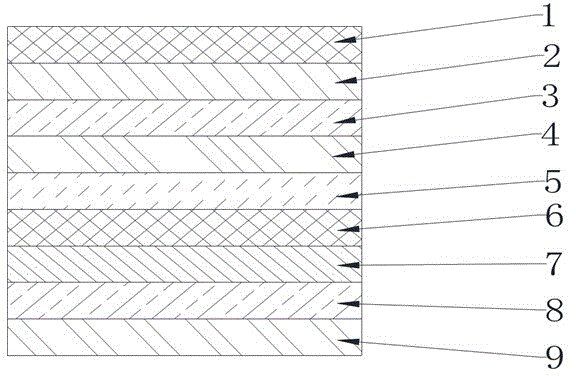

Multilayer co-extrusion high-barrier film and preparation method thereof

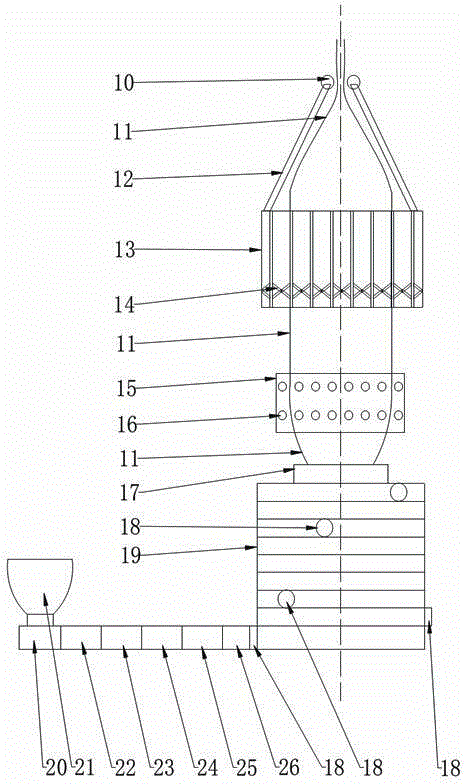

ActiveCN104476753AGood oxygen barrier performanceGood stretchabilitySynthetic resin layered productsMolten stateSolvent free

The invention discloses a multilayer co-extrusion high-barrier film, a preparation method of the film and production equipment used by the preparation method. The multilayer co-extrusion high-barrier film has excellent oxygen barrier properties, tensile strength and high strength, the gradation is distinct, solvent residues are avoided, and the requirements on industrial products and food package can be met. According to the preparation method, a co-extrusion form is adopted, different materials are co-extruded in a molten state by virtue of a die head of a film blowing machine, the barrier film with distinct gradation is prepared, a composite processing technology is reduced, the problems such as solvent residues caused by compounding are solved, and the barrier film has the advantages of high efficiency and high yield. Moreover, the production equipment can be matched with the production method so as to perform high-efficiency production process, so that the barrier film has uniform film thickness, and high production efficiency and product quality are guaranteed.

Owner:朝阳佛瑞达科技有限公司

Technology for producing degradable and edible film by utilizing corn composite modified starch

ActiveCN102311554AGood viscosity stabilityImprove strength propertiesFlexible coversWrappersCarrageenanPhosphate

The invention provides technology for producing a degradable and edible film by utilizing corn composite modified starch, belonging to the technical field of food processing. The technology comprises the following main production processes: firstly gelatinizing the corn hydroxypropyl-phosphate monoester composite modified starch; then adding glycerin, sorbitol, sodium alginate, carrageenan and other components which improve the film performance; carrying out tape casting on the film solution on a copper plate after homogenization and degasification; adopting a copper plate film forming conveyer belt to firstly pass through steam drying pipeline equipment and then pass through cooling pipeline equipment with relative humidity being about 50% to form a film; and finally adopting mechanical film rolling equipment to roll the film, thus producing a degradable and edible film with high strength. The film material has good mechanical performance and oil, moisture and oxygen resistance. The film can be applied to packaging of various materials such as food, health products, drugs, feed and the like.

Owner:活泼

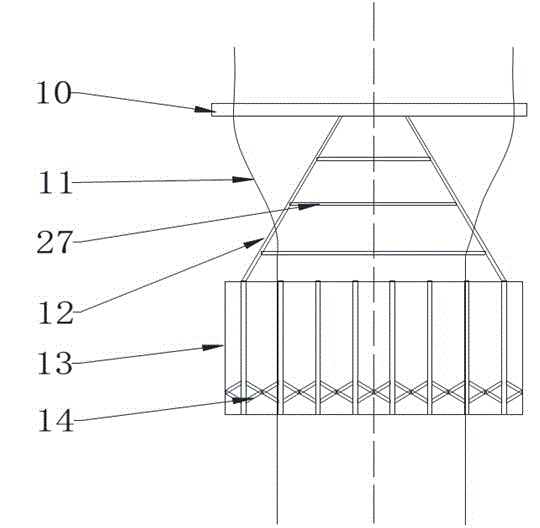

Linseed oil microcapsules and preparation method thereof

InactiveCN108450954AImprove qualityHigh purityFood ingredient as antioxidantFood homogenisationSolubilityLinseed oil

The invention discloses linseed oil microcapsules and a preparation method thereof. The preparation method comprises the following steps of (1) performing hydrolyzing and extracting by an enzyme method to obtain linseed oil; (2) preparing an aqueous phase; (3) preparing an oil phase; (4) performing high-speed cutting emulsifying on a mixture of the aqueous phase and the oil phase by a cutter; (5)performing homogenizing on obtained emulsion by a high pressure homogenizer; and (6) performing spray drying on the obtained emulsion to obtain linseed oil microcapsule granules. The linseed oil microcapsules are high in solubility, good in emulsibility, high in stability, good in film-forming properties and high in packing rate. The linseed oil microcapsules have good mouth feel and flavor, and are safe and reliable in quality; and besides, the preparation technology is simple, mass production is convenient, and the loading quantity of the obtained linseed oil microcapsule granule linseed oilcan achieve 42%, and the microcapsule entrapping rate is 90% or above.

Owner:广州利众生物科技有限公司

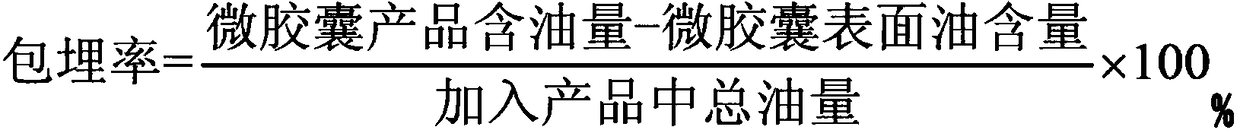

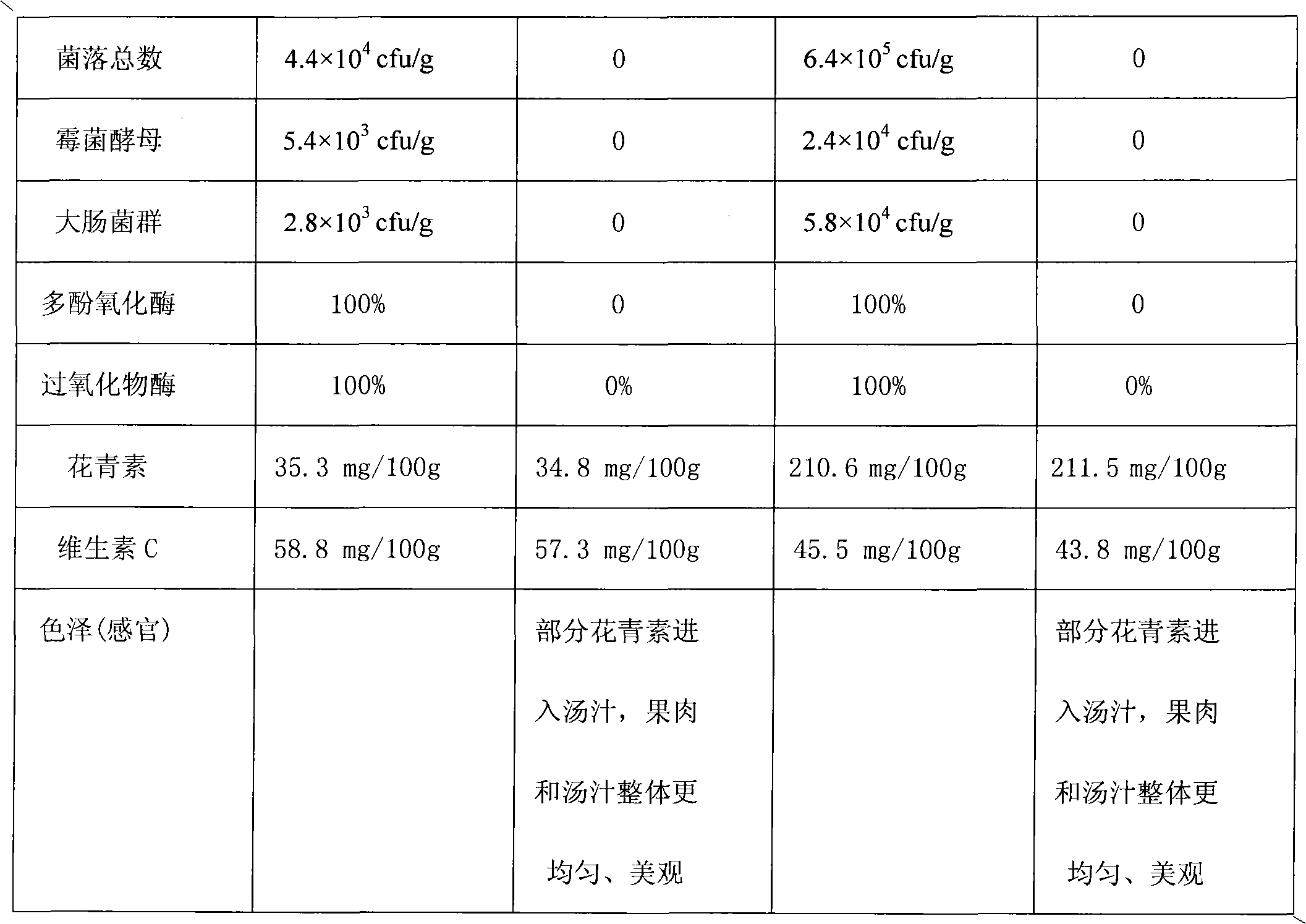

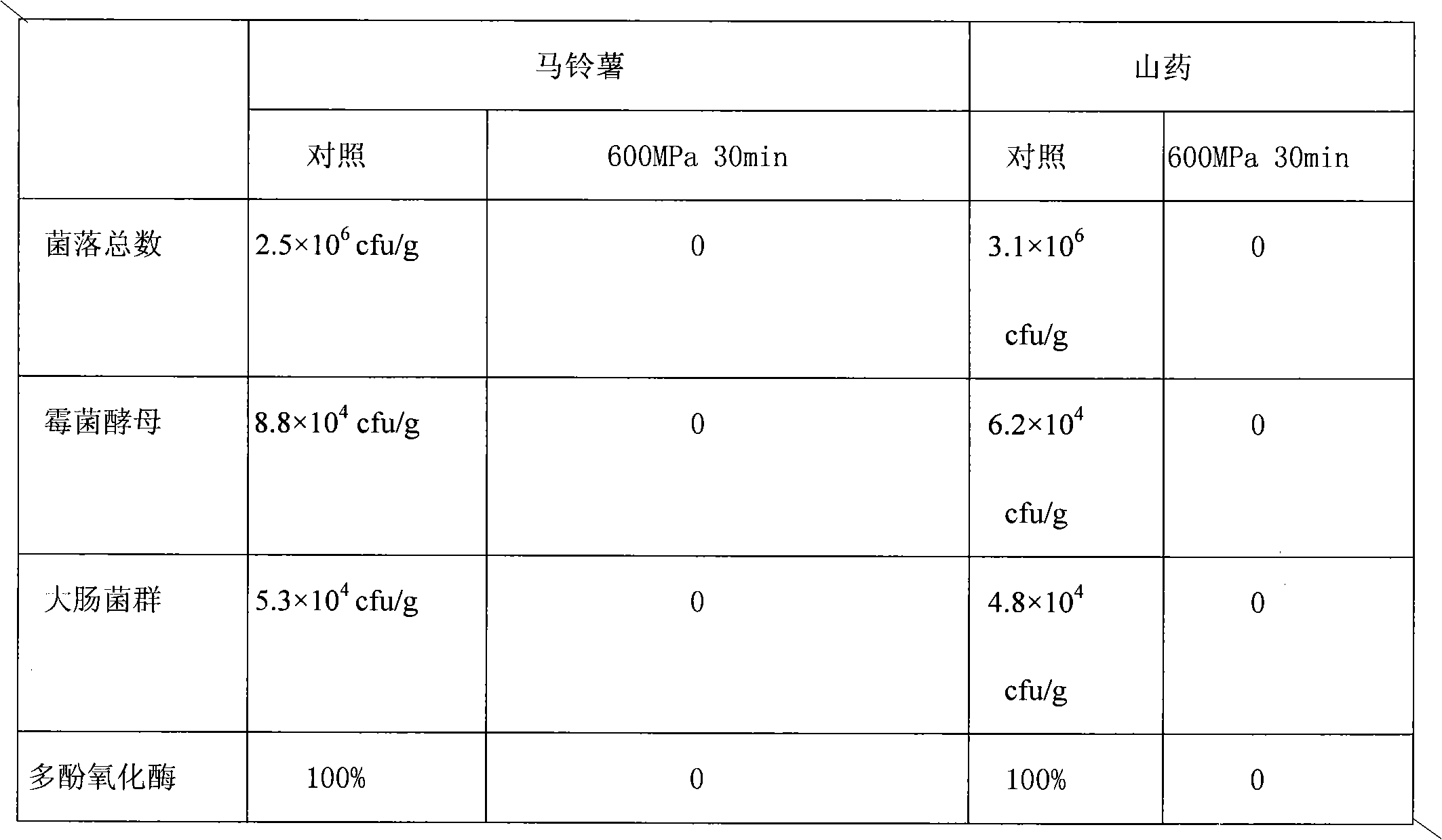

Non-thermal processing method for soft fruit and vegetable cans

InactiveCN101889602AEnsure safetyGreat tasteFruits/vegetable preservation by heatingFruits/vegetable preservation using sugarsMicroorganismPreservative

The invention discloses a non-thermal processing method for soft fruit and vegetable cans, and belongs to the technical field of can processing. The method comprises the following steps of sorting, classification, washing, removal of peels, kernels and seeds, slicing, crisp keeping, blanching, cooling, canning, blending, vacuum seal, high hydrostatical sterilization and the like, wherein the pressure of the high hydrostatical sterilization is 400 to 600 MPa, and the pressure maintaining time is 3 to 30 min. In the method, the blanching is combined with the high hydrostatical sterilization, so that compared with the conventional processing technology for the fruit and vegetable cans, the method has the advantages of killing microorganisms, passivating endogenous enzymes, maintaining organoleptic quality such as color, smell, taste and the like and the nutrient components of the product, ensuring food safety, prolonging storage period under the condition of not adding preservatives, and eliminating the cooking smell of the conventional fruit and vegetable cans; and metal cans and glass bottles are replaced by EVOH / PVPP bottles or bags with high oxygen barrier property, so that the soft fruit and vegetable cans are light and portable, attractive, convenient to open and easy to transport.

Owner:CHINA AGRI UNIV

Water supply pipes and preparation method thereof

The invention discloses water supply pipes and a preparation method thereof. The water supply pipes are formed by combining at least one polyethylene layer and one polyethylene derivative layer closely, wherein the polyethylene derivative layer is the inner layer of the pipes. The preparation method of the water supply pipes comprises the following steps of: extruding the polyethylene layer and the polyethylene derivative layer by using an extruder respectively, heating, extruding by using a die head of a die head area of the same extruder, sizing the combined composite pipes, and cooling twice to form the water supply pipes. The water supply pipes have no toxic or side effect, aging resistance, acid-base resistance, high oxygen resistance, high cost performance, safety and reliability, high strength and toughness, strong impact resistance, low comprehensive cost and strong market competitive power, is easy to machine, convenient to use, difficult to age, crack and permeate, and is the innovation of the pipes. The water supply pipes can solve the problems that anti-aging degree, the using temperature and the oxygen resistance are low, and bacteria are easy to breed and the like inpolyethylene (PE) pipes effectively.

Owner:KANGTAI PLASTIC SCI & TECH GRP

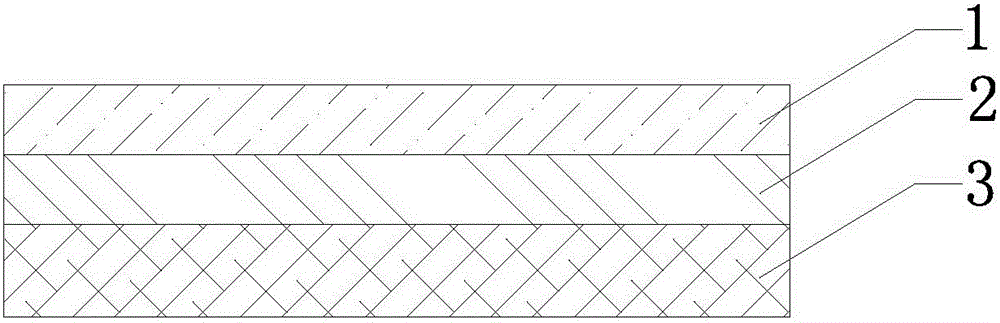

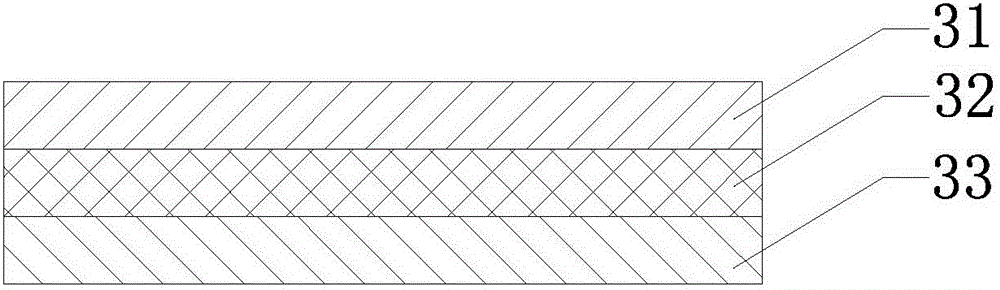

Co-extrusion composite aluminum foil film and preparation method thereof

ActiveCN104999738AImprove water resistanceImprove oxygen barrier performanceSynthetic resin layered productsLaminationSurface layerHeat resistance

The invention relates to the technical field of package, in particular to a co-extrusion composite aluminum foil film and a preparation method thereof. The co-extrusion composite aluminum foil film comprises a surface layer, a middle layer and a substrate layer, arranged in sequence from outside to inside; the upper surface of the middle layer is jointed with the lower surface of the surface layer; the lower surface of the middle layer is jointed with the upper surface of the substrate layer; a PET protection film or a PA protection film is arranged on the surface layer; an aluminum foil film is arranged on the middle layer; a multiple-layer co-extrusion film is arranged on the substrate layer; an antistatic coating is jointed to the outer surface of the surface layer. The co-extrusion composite aluminum foil film can be permanently antistatic, has high block-water capability and oxygen barrier performance, is good in sealing effect, better in tensile strength, heat resistance, cold resistance, photopathy, barrier property and chemical stability, is multiple in function and low in cost, and is a good material for manufacturing electronic component packing bags.

Owner:东莞市博晨塑料科技有限公司

Shining thermal barrier coating system of rare earth niobate based on defective fluorite structure and preparation method of shining thermal barrier coating system

InactiveCN106967953ALow thermal conductivityImprove oxygen barrier performanceMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionGas phase

Owner:乐延伟

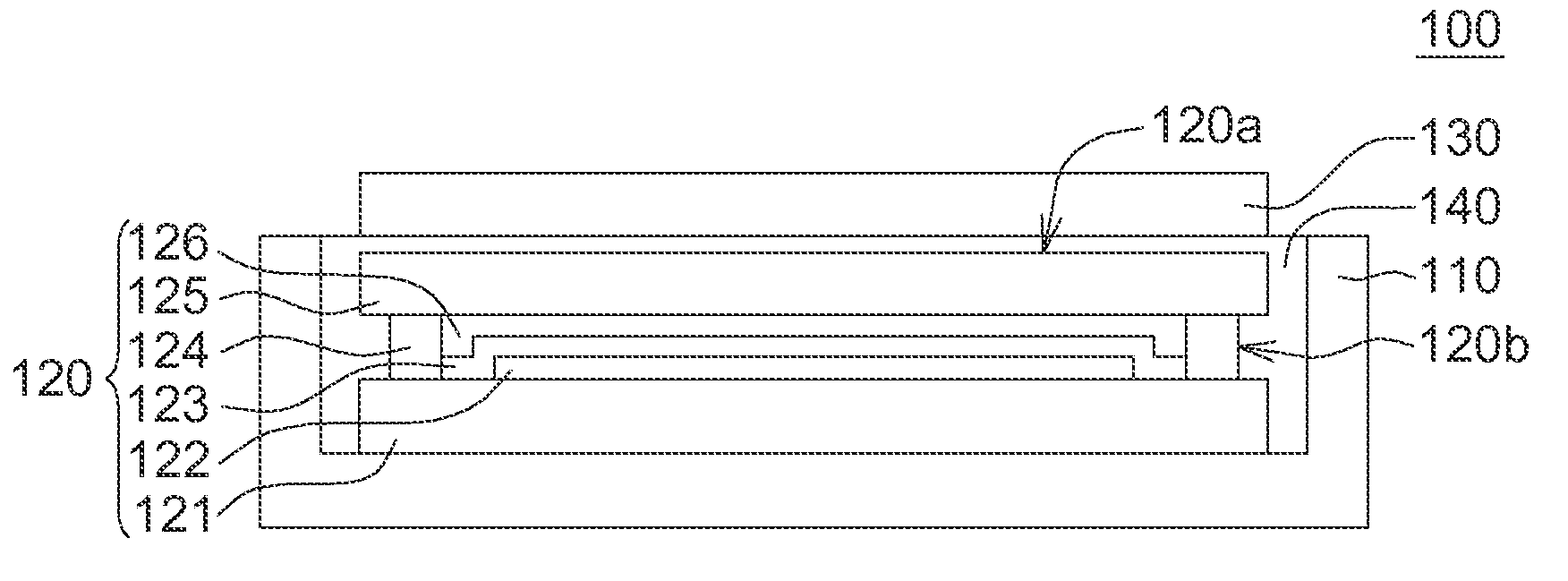

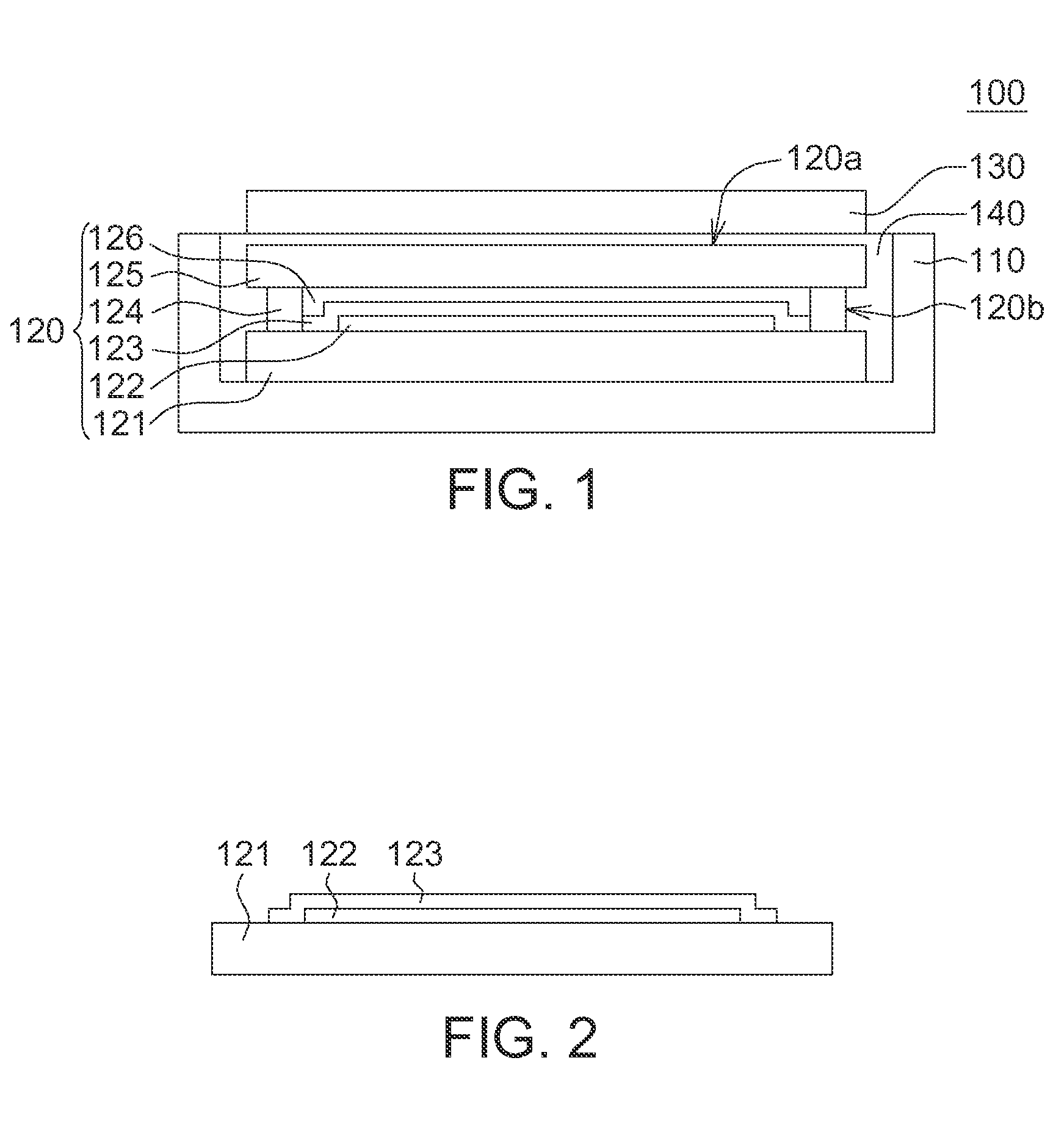

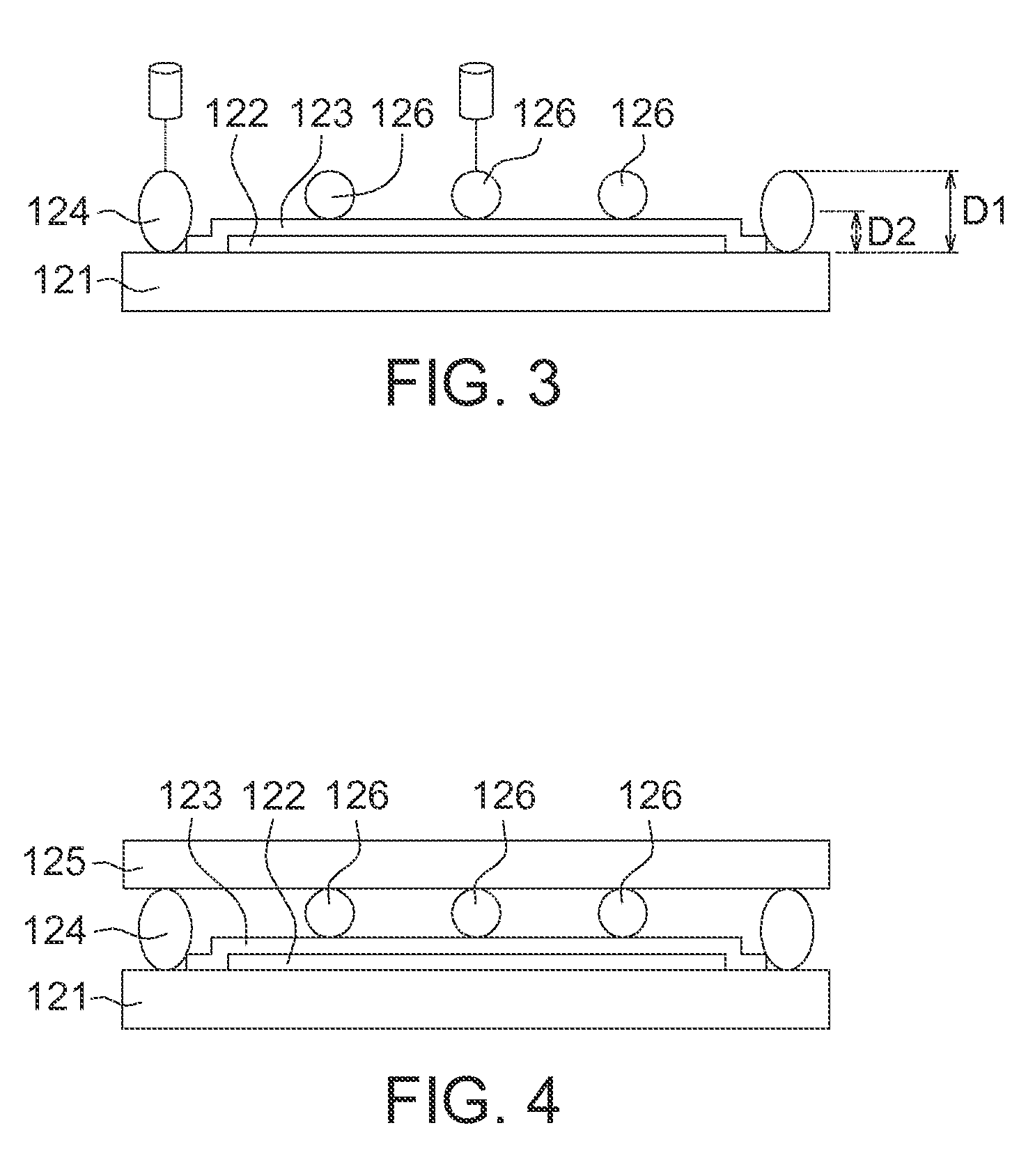

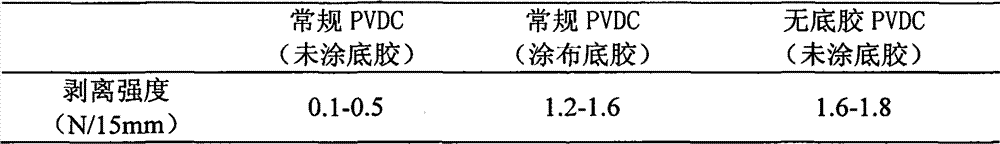

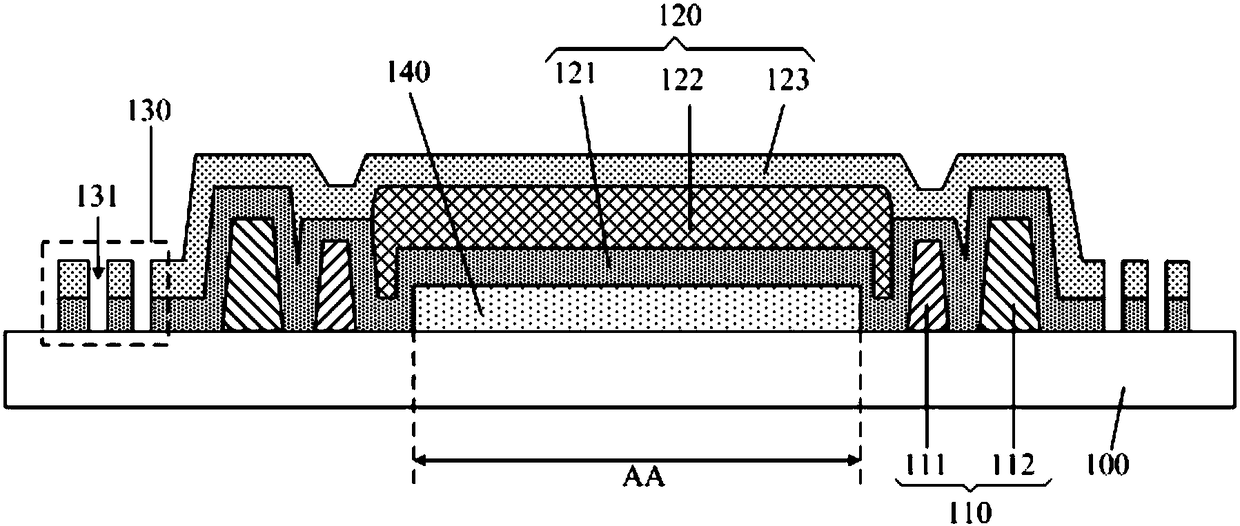

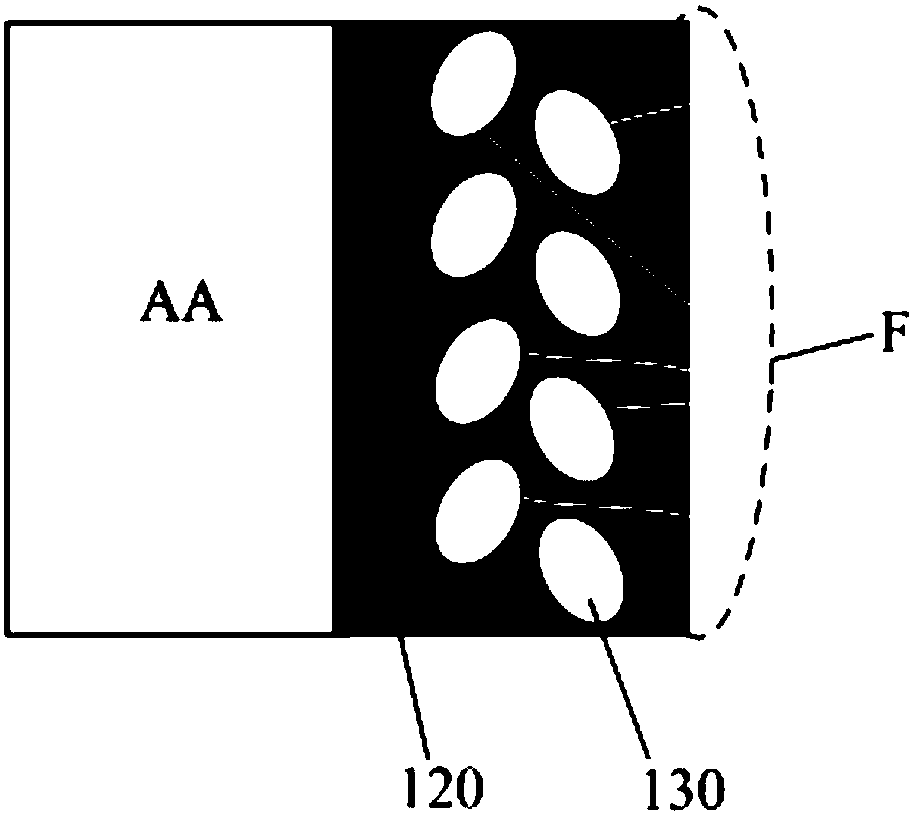

Display and manufacturing method thereof

ActiveUS20130241402A1Improve oxygen barrier performanceImprove processing speedOLED parametersDischarge tube luminescnet screensDisplay deviceAdhesive glue

A display and a manufacturing method thereof are provided. The display includes a frame, an organic light-emitting diode (OLED) panel, a transparent element and a glue. The OLED panel is disposed in the frame. The transparent element is disposed on the OLED panel. The glue is filled between the OLED panel and the transparent element and between the OLED panel and the frame.

Owner:INNOLUX CORP

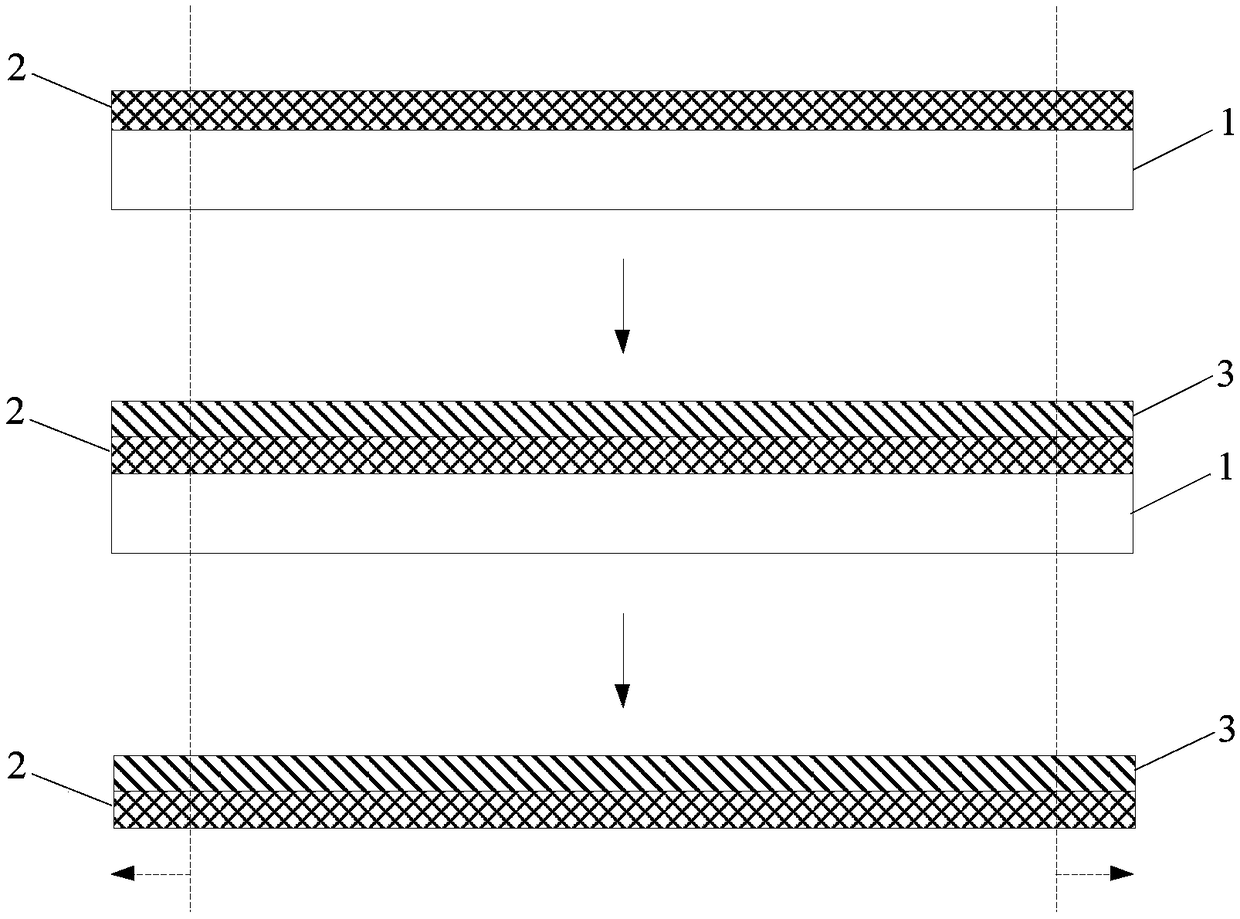

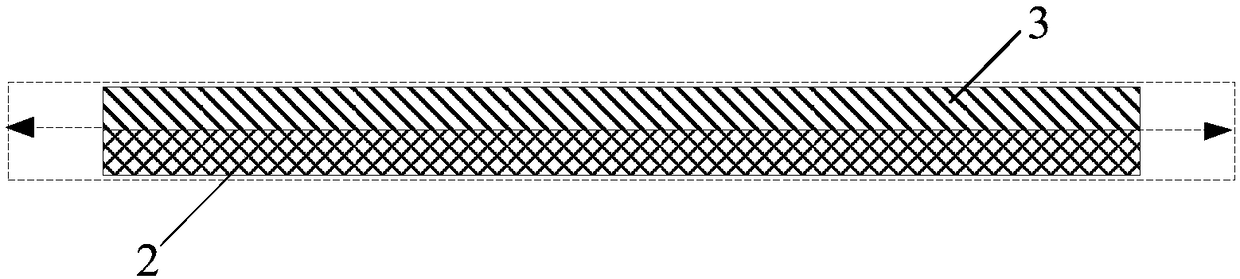

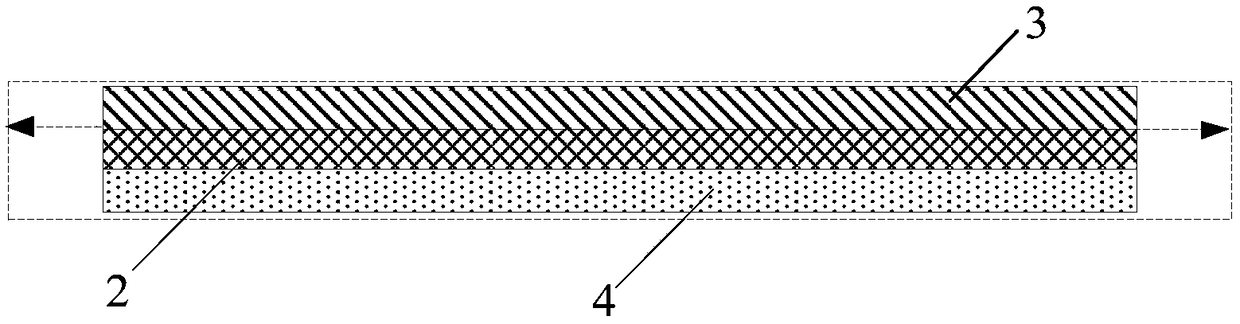

Pre-stretching base and manufacture method thereof and electron device and manufacture method thereof

ActiveCN108597376AUniform thermal expansionGuaranteed uniformityLamination ancillary operationsSolid-state devicesElectronMaterials science

The invention discloses a pre-stretching base and a manufacture method thereof and an electron device and a manufacture method thereof, and relates to the technical field of base pre-stretching. In order to solve the problem that an existing pre-stretching base manufacture method can not form the pre-stretching base with a large area and even pre-stretching quantities, the manufacture method of the pre-stretching base includes the following steps that under the environment with temperature high than preset temperature, at least two layers of films are successively formed on a carrier plate, and thermal expansivity coefficients of the at least two layers of films are different; and the at least two layers of films are separated from the carrier plate, and the pre-stretching base is obtained. The manufacture method of the pre-stretching base is used for manufacturing the pre-stretching base.

Owner:BOE TECH GRP CO LTD

Technology for producing vegetable protein and konjac glucomannan composite degradable and edible film

ActiveCN102311647AAvoid crackingImprove mechanical propertiesFlexible coversWrappersOxygenFilm material

The invention provides technology for producing a vegetable protein and konjac glucomannan composite degradable and edible film, belonging to the technical field of food processing. The technology comprises the following main production processes: mixing and stirring soy protein, glycerin, konjac glucomannan and sodium carboxymethylcellulose; heating the materials to react; then carrying out tape casting on the film solution on a copper plate through homogenization and degasification; adopting a copper plate film forming conveyer belt to firstly pass through steam drying pipeline equipment and then pass through cooling pipeline equipment with relative humidity being about 50% to form a film; and finally adopting mechanical film rolling equipment to roll the film, thus producing a degradable and edible film with high strength. The film material has good mechanical performance and oil, moisture and oxygen resistance. The film can be applied to packaging of various materials such as food, health products, drugs, feed and the like.

Owner:活泼 +1

Process for plasma coating a polypropylene object

InactiveUS20100227119A1Improve barrier propertiesOxygen permeability is inferiorLiquid surface applicatorsLayered productsPolyolefinPolymer science

A process for improving the barrier performance of a plasma coated object comprising a polyolefin is disclosed. The process involves ensuring that the surface of the object to be coated is smooth as characterized by having a root-mean-square surface roughness that varies by less than the thickness of the coating to be applied, typically less than 100 nm. The invention also relates to a process for improving the stain resistance of polyolefin based articles comprising plasma polymerizing an organosilicon compound under conditions to deposit a polyorganosiloxane layer onto the article and / or (b) plasma polymerizing a organosilicon compound under conditions to deposit a silicon oxide layer directly on the article or onto a polyorganosiloxane layer prepared according to step (a).

Owner:BRASKEM AMERICA

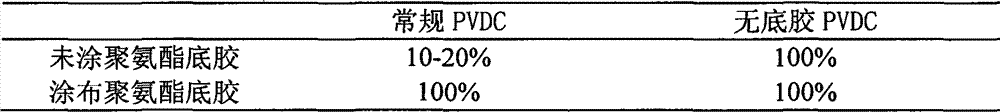

High-oxygen-barrier polyvinylidene chloride coating emulsion and preparation method thereof

InactiveCN102964937AGood dispersionUniform and excellent slip propertiesCoatingsMethacrylateAcrylonitrile

The invention relates to a high-oxygen-barrier polyvinylidene chloride coating emulsion. The emulsion is prepared from the raw materials by weight percent: 65-83% of PVDC (Polyvinyl Dichloride) copolymerization emulsion, 1-6% of adhesion promoter, 2.8-7.5% of nano montmorillonite, 0.2-0.5% of dispersing agent, 2-4% of slip agent, 3-4% of anti-sticking agent and 21-36.5% of deionized water, wherein the PVDC copolymerization emulsion is prepared from the raw materials by weight percent: 43-52% of polyvinyl dichloride, 2-4% of acrylic acid, 3-5% of butyl acrylate, 0.5-3.5% of ethyl methacrylate, 0.4-2.5% of acrylonitrile, 0.2-0.4% of chain initiator, 0.3-0.8% of emulsifying agent, 37-45% of deionized water and 0.1-0.5% of defoaming agent. The emulsion is used for the coating technology, is free from precoating primer, and has higher oxygen barrier performance.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Microfibrillated film

ActiveUS20190234020A1Improve oxygen barrier performanceEasy to handleWrappersCellulose coatingsFiberCellulose

The invention concerns a method of producing an MFC film comprising reinforcement fibers, which film show excellent oxygen barrier properties and is easy to handle. The method of manufacturing the film comprises the steps of: —providing a suspension comprising a first microfibrillated cellulose (MFC) in an amount of at least 50 weight %, reinforcement fibers in an amount of at least 5 weight %, all percentages calculated on the total solid content of said suspension, and a formation aid, —mixing said suspension to form a mixture, —forming a fibrous web from the mixture, and —dewatering and / or drying said fibrous web to form a film having a basis weight of less than 40 g / m2, a specific formation number of below 0.45 g0.5 / m2, and an Oxygen Transmission Rate (OTR) value of below 100 ml / m2 / per 24 hours, preferably of below 50 ml / m2 per 24 hours at 50% relative humidity. The invention further discloses a film and use of the film in food or liquid packaging applications.

Owner:STORA ENSO OYJ

Electroluminescent display panel and packaging method thereof as well as display device

InactiveCN108232033AImprove water resistanceImprove oxygen barrier performanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOxygen

The invention discloses an electroluminescent display panel and a packaging method thereof as well as a display device. A partial area, at the periphery of a retaining wall, of a packaging thin film is arranged into a hollow-out structure, i.e., the edge of the packaging film is subjected to patterned design, and cracks on the edge of the packaging film caused by the subsequent technological preparation or transportation process of the electroluminescent display panel can be blocked off, so that water blocking and oxygen resisting properties are improved.

Owner:BOE TECH GRP CO LTD +1

Transparent oriented polypropylene film with high moisture vapor and oxygen barrier properties

InactiveUS20170015821A1Improve barrier propertiesImprove oxygen barrier performanceSynthetic resin layered productsDomestic containersVapor barrierPolymer science

Described are transparent oriented polypropylene films with improved barrier properties and methods of making these films. The films and methods include a core layer comprising polypropylene, hydrocarbon resin, and polyethylene wax to improve moisture vapor barrier properties, an optional barrier layer comprising polar polymers to improve oxygen barrier properties, and optional skin layers to improve heat sealing, winding, printing, and / or adhesion.

Owner:TORAY PLASTICS AMERICA

Technology for producing degradable and edible film by utilizing pea starch

InactiveCN102311553AAvoid crackingGood viscosity stabilityFlexible coversWrappersGlycerolEngineering

The invention provides technology for producing a degradable and edible film by utilizing pea starch, belonging to the technical field of food processing. The technology comprises the following main production processes: firstly gelatinizing the pea starch; then adding glycerin and sodium alginate which improve the film performance; carrying out tape casting on the film solution on a copper plate after homogenization and degasification; adopting a copper plate film forming conveyer belt to firstly pass through steam drying pipeline equipment and then pass through cooling pipeline equipment with relative humidity being about 50% to form a film; and finally adopting mechanical film rolling equipment to roll the film, thus producing a degradable and edible film with high strength. The film material has good mechanical performance and oil, moisture and oxygen resistance. The film can be applied to packaging of various materials such as food, health products, drugs, feed and the like.

Owner:活泼 +1

Pulullan soft capsule and preparation method thereof

ActiveCN103961335AGood quality and stabilityReduce moisture contentOrganic active ingredientsPharmaceutical non-active ingredientsSoftgelPlasticizer

The invention discloses a Pulullan soft capsule and a preparation method thereof. The Pulullan soft capsule is prepared from the following components in percentage by weight: 20-60% of Pulullan, 0.15-2% of gelatinizer, 15-30% of plasticizer, 0.02-0.8% of emulsifier, 0.03-0.3% of cosolvent and 22-63% of water. The Pulullan soft capsule has the advantages of higher oxygen barrier property, higher shock strength, stable quality, low tendency to crushing, stable disintegration index and low tendency to hydrolysis, and can not easily produce fog or become yellow on the surface after long-time placement. The raw materials are from pure plants, thereby completely avoiding pollutions which can be caused by animal proteins. The capsule has lower water content than the gelatine capsule, is more suitable for filling hydroscopic drugs and aldehyde-containing drugs, and has wide market prospects and practical value.

Owner:SHANDONG MEICHEN ECOLOGY & ENVIRONMENT CO LTD

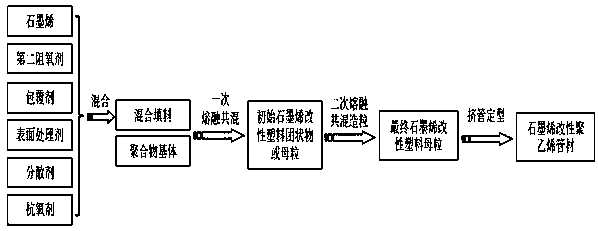

Graphene modified oxygen-resistant polyethylene master batch and preparation method and application thereof

InactiveCN111117041AEvenly dispersedGood oxygen barrierBulk chemical productionPolymer chemistryChemistry

The invention relates to the technical field of functionalization and high performance of plastic pipes, in particular to a graphene modified oxygen-resistant polyethylene master batch and a preparation method and application thereof. The modified plastic master batch is composed of the following components: a polyethylene matrix, graphene, a second oxygen inhibitor, a coating agent, a surface treating agent, a dispersing agent and an antioxidant. According to the three-step production process, the mixing, dispersing and stripping effects of graphene in a polyethylene matrix are improved, thefilling proportion of graphene in the composite material is increased through organic combination of a new material, a new technology and a new method, and formation of a perfect network structure inthe composite material matrix is promoted. The oxygen barrier property of the composite material can be remarkably improved through good construction of a network, so that the application potential ofgraphene in the oxygen barrier pipe is brought into full play, and the pipe filled with the high-barrier graphene nanosheet layer structure is obtained.

Owner:江苏新奥碳纳米材料应用技术研究院有限公司 +1

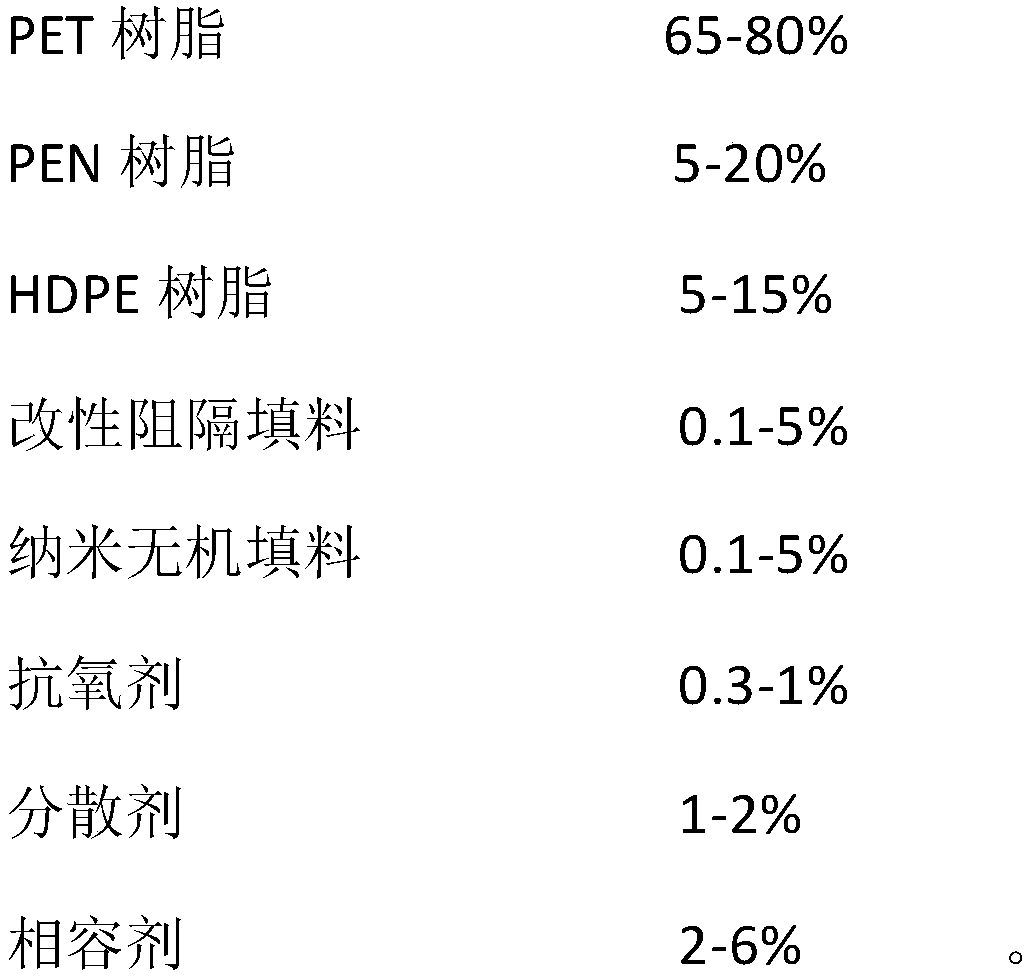

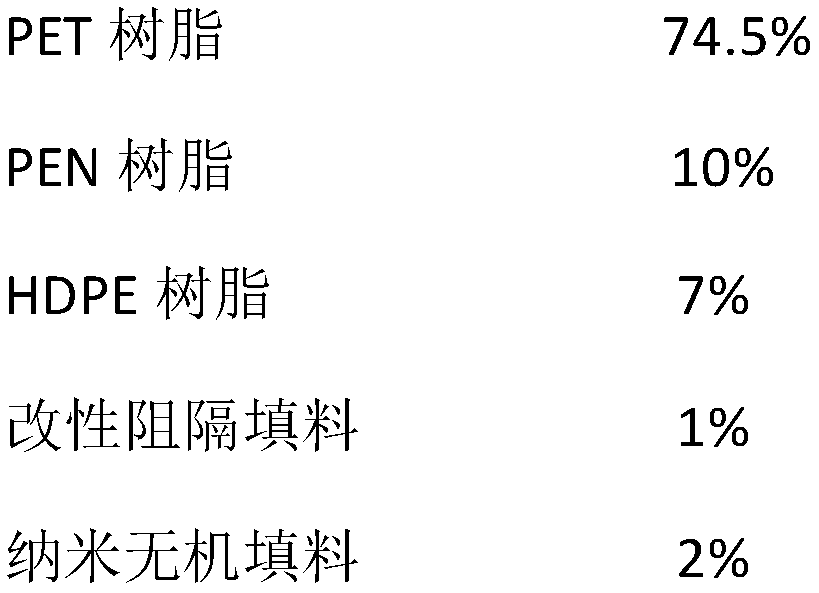

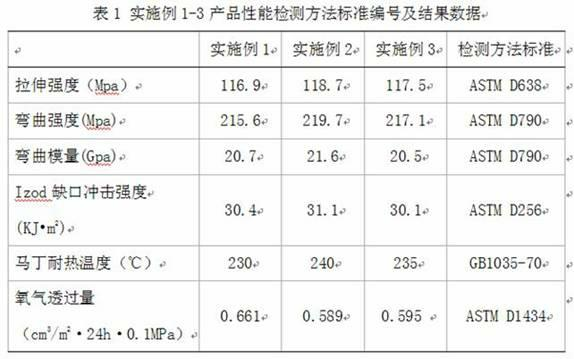

High-barrier PET material and preparation method thereof

InactiveCN109467895AOptimized transmission coefficientImprove barrier propertiesAntioxidantProduct gas

The invention relates to the technical field of polymer materials, in particular to a high-barrier PET material and a preparation method thereof. The high-barrier PET material is prepared from components in percentage by weight as follows: 65%-80% of PET resin, 5%-20% of PEN resin, 5%-15% of HDPE resin, 0.1%-5% of modified barrier filler, 0.1%-5% of nano inorganic filler, 0.3%-1% of an antioxidant, 1%-2% of a dispersant and 2%-6% of a compatilizer. The preparation method comprises the following steps: (1) raw material preparation; (2) mixing; (3) melt extrusion and granulation. The prepared high-barrier PET material gives consideration to balance of barrier property and mechanical property while having better oxygen blocking capacity and gas barrier property, the preparation process is simple and applicable to practical use, and large-scale production is easy.

Owner:CHANGZHOU RUIJIE NEW MATERIAL TECH CO LTD

Calcium sulfate whisker modified polyvinylalcohol composite material and preparation process thereof

The invention relates to a calcium sulfate whisker modified polyvinylalcohol composite material and a preparation process thereof. The composite material is prepared by the following materials according to part by weight: 70 to 90 portions of polyvinyl alcohol, 10 to 20 portions of calcium sulfate whisker with the diameter of 10 to 20 Mum, 1 to 3 portions of surface modifier, 1 to 5 portions of plasticizer, and 0.5 to 1.5 portions of lubricant. The preparation method comprises the following steps: adding the calcium sulfate whisker and the surface modifier to a high-speed mixer to mix for 5 to 15 minutes; then adding the polyvinyl alcohol, the plasticizer and the lubricant to the high-speed mixer to mix for 3 to 7 minutes; extruding the mixture from an equidirectional parallel double-screw extruder for granulation; and then conducting injection molding to the particles in an equidirectional parallel double-screw injection machine. The calcium sulfate whisker modified polyvinylalcohol composite material has high strength, low notch sensitivity, good thermal resistance and oxygen resistance, simple preparation process, and low cost, and is especially suitable for making products such as films and the like.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

Freezing method of Luchuan pork

InactiveCN106879715APrevent the loss of pork nutrientsImprove water resistanceMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingChemistryCentral layer

The invention belongs to the field of fresh keeping of foods, and particularly relates to a freezing method of Luchuan pork. The freezing method comprises the following steps of (1) preparing a film coating agent; (2) performing micro-freezing treatment on pork; (3) performing film coating packaging treatment on the micro-frozen pork; and (4) performing ultrasonic assisted freezing preservation on the packaged pork: conveying the packaged pork into a freezing room, performing freezing until the temperature of the central layer of the pork is reduced to 2-4 DEG C, performing ultrasonic-assisted freezing for 3-6h, when the temperature of the central layer of the pork is reduced to minus 6 to minus 8 DEG C, stopping performing ultrasonic-assisted freezing, and continuing freezing the pork to minus 18 to minus 23 DEG C so as to obtain the frozen pork. The freezing method disclosed by the invention is simple to operate and stable in technology conditions, ice crystals generated during freezing of the pork can be reduced, the pork freezing speed can also be increased, the preservative effect is achieved, bacteria are restrained, the freezing storage time of the pork can be prolonged, the cell activity of frozen fresh meat can be guaranteed, and the phenomenon that juice flows outwards after the frozen pork is unfrozen is reduced.

Owner:广西神龙王农牧食品集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com