Calcium sulfate whisker modified polyvinylalcohol composite material and preparation process thereof

A technology of calcium sulfate whisker and polyvinyl alcohol, which is applied in the field of calcium sulfate whisker modified polyvinyl alcohol composite material and its preparation process, and achieves the effects of simple preparation process, good heat resistance and oxygen barrier, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

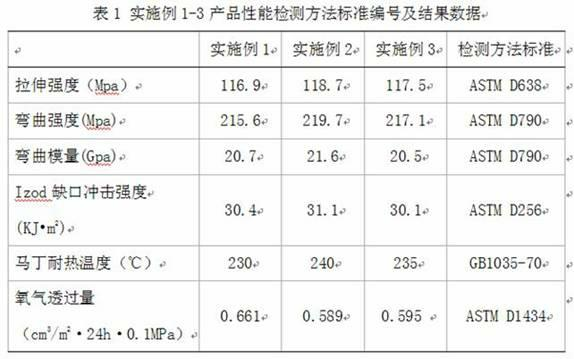

Examples

Embodiment 1

[0019] The calcium sulfate whisker modified polyvinyl alcohol composite material in this embodiment is made of the following raw materials in parts by weight: 83 parts of polyvinyl alcohol, 10 parts of calcium sulfate whisker with a diameter of 10-20 μm, and the surface modifier stearic acid 2 parts, plasticizer DBP 4 parts, lubricant paraffin 1 part.

[0020] Preparation:

[0021] (1) Add calcium sulfate whiskers and surface modifier stearic acid into a high-speed mixer, and mix for 10 minutes to obtain modified calcium sulfate whiskers;

[0022] (2) Add polyvinyl alcohol, plasticizer DBP and lubricant paraffin into a high-speed mixer, and mix for 5 minutes to obtain a mixture of polyvinyl alcohol, plasticizer DBP, lubricant paraffin and modified calcium sulfate whiskers;

[0023] (3) Extrude the mixture obtained in step (2) in a co-rotating parallel twin-screw extruder and granulate. The process parameters are as follows: the temperature in the first zone is 115°C, the temp...

Embodiment 2

[0027] The calcium sulfate whisker modified polyvinyl alcohol composite material in this example is made of the following raw materials in parts by weight: 78 parts of polyvinyl alcohol, 15 parts of calcium sulfate whisker with a diameter of 10-20 μm, and the surface modifier sodium laurate 2 parts, 4 parts of plasticizer DOP, 1 part of lubricant stearic acid.

[0028] Preparation:

[0029] (1) Add calcium sulfate whiskers and surface modifier sodium laurate into a high-speed mixer and mix for 10 minutes to obtain modified calcium sulfate whiskers;

[0030] (2) Add polyvinyl alcohol, plasticizer DOP and lubricant stearic acid into a high-speed mixer and mix for 5 minutes to obtain polyvinyl alcohol, plasticizer DOP, lubricant stearic acid and modified calcium sulfate crystals a mixture of whiskers;

[0031] (3) Extrude the mixture obtained in step (2) in a co-rotating parallel twin-screw extruder and granulate. The process parameters are as follows: the temperature in the fi...

Embodiment 3

[0035] The calcium sulfate whisker-modified polyvinyl alcohol composite material in this example is made of the following raw materials in parts by weight: 73 parts of polyvinyl alcohol, 20 parts of calcium sulfate whiskers with a diameter of 10-20 μm, and the surface modifier stearic acid 2 parts, plasticizer epoxidized soybean oil 4 parts, lubricant butyl stearate 1 part.

[0036] Preparation:

[0037] (1) Add calcium sulfate whiskers and surface modifier stearic acid into a high-speed mixer, and mix for 10 minutes to obtain modified calcium sulfate whiskers;

[0038] (2) Add polyvinyl alcohol, plasticizer epoxy soybean oil and lubricant butyl stearate into a high-speed mixer, and mix for 5 minutes to obtain polyvinyl alcohol, plasticizer epoxy soybean oil, lubricant hard A mixture of butyl fatty acid ester and modified calcium sulfate whiskers;

[0039] (3) Extrude the mixture obtained in step (2) in a co-rotating parallel twin-screw extruder and granulate. The process pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com