Patents

Literature

98results about How to "Low notch sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High cobalt nickel-based high-temperature alloy and preparation method thereof

The invention discloses a high cobalt nickel-based high-temperature alloy used at 650 to 750 DEG C and a preparation method thereof, and belongs to the technical field of high-temperature alloys. Thedifficult problem about improving the comprehensive performance of the nickel-based high-temperature alloy with the consideration of alloy performance and use cost in the prior art is solved by precisely controlling the component range of Co in the high-temperature alloy. The alloy is prepared from the components in percentage by mass: less than or equal to 0.1 percent of C, 12 to 20 percent of Cr, less than or equal to 4.0 percent of Mo, less than or equal to 6 percent of W, 12.01 to 25.00 percent of Co, less than or equal to 14 percent of Fe, 4.0 to 8.0 percent of Nb, 0.6 to 2.6 percent of Al, 0.4 to 1.4 percent of Ti, 0.003 to 0.03 percent of P, 0.003 to 0.015 percent of B, and the balance of Ni; the content of a gamma' phase is 15 to 30 mass percent; the content of eta-Ni3Al0.5Nb0.5 is0.5 to 10.0 mass percent. The preparation method of the nickel-based high-temperature alloy comprises the processes of smelting, forging and cogging, and performing heat treatment. According to the high cobalt nickel-based high-temperature alloy and the preparation method thereof, the high cobalt nickel-based high-temperature alloy can be used at the temperature of 650 to 750 DEG C.

Owner:CENT IRON & STEEL RES INST

Novel high-temperature alloy heat-resistant stainless steel bolt and production process thereof

ActiveCN103014551ADiffusion coefficient is smallImprove reinforcement stabilitySuperalloyUltimate tensile strength

The invention discloses a novel high-temperature alloy heat-resistant stainless steel bolt and a production process thereof. The bolt comprises the components of, by mass, no more than 0.08% of C, no more than 1.00% of Si, no more than 2.00% of Mn, no more than 0.035% of P, no more than 0.030% of S, 24.0-27.0% of Ni, 13.5-16.0% of Cr, 1.90-2.23% of Ti, no more than 0.35% of Al, no more than 0.10-1.50% of Mo, and balance of Fe and unavoidable impurities. The production process comprises that the raw materials are subjected to the steps of solid smelting, cold heading molding, re-crystallization and annealing, stress-removing tempering, hexagon-head cutting and wire rolling, washing, stabilization treatment, and aging treatment. With the process, the bolt has the advantages of high strength, high relaxation-resistance, low notch sensitivity, certain endurance strength, good oxidation resistance, and the like.

Owner:江苏新迅达不锈钢制品有限公司

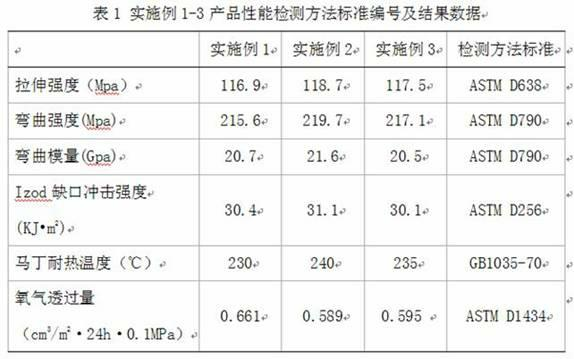

High-content fiberglass-reinforced halogen-free flame-retardant PC (polycarbonate) composite and preparation method thereof

The invention discloses high-content fiberglass-reinforced halogen-free flame-retardant PC (polycarbonate) composite and a preparation method thereof, comprising the following components according to percent by weight: 50-60% of polycarbonate, 34-45% of fiberglass, 2-5% of a toughener, 8-20% of a flame retardant, 1-3% of a flame-retardant synergist, 0.1-1% of a lubricant, and 0.1-1% of an antioxidant; the polycarbonate is a mixture of common polycarbonate and siloxane copolymer. The polymer is formed of PC (polycarbonate) and siloxane, PC is amorphous resin with good performance, and the siloxane copolymer has the advantages of low temperature resistance, chemical corrosion resistance, good dielectric property and the like; the siloxane-PC copolymer has the advantages of both the siloxane copolymer and PC and has reduced stress cracking performance and gap sensitivity, improved low temperature impact performance, and improved weathering resistance.

Owner:DONGGUAN HONOUR E P

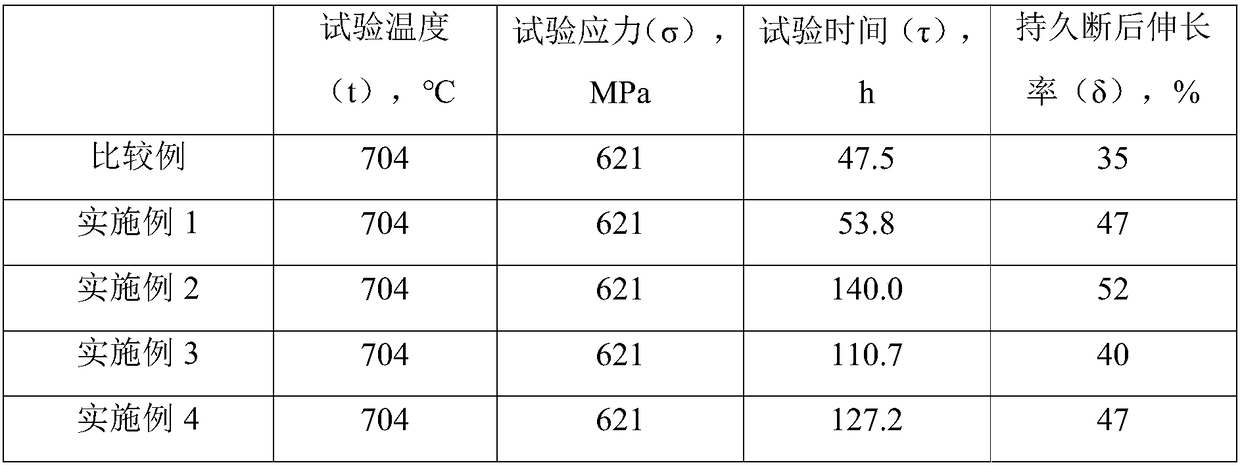

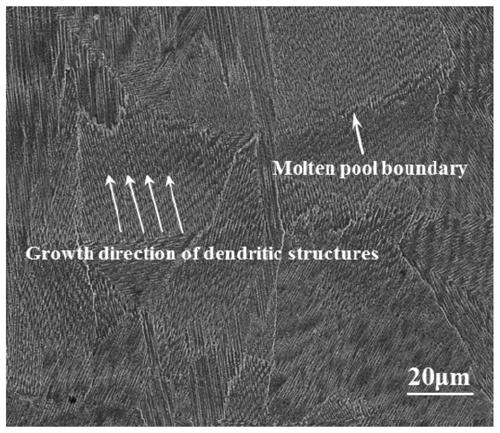

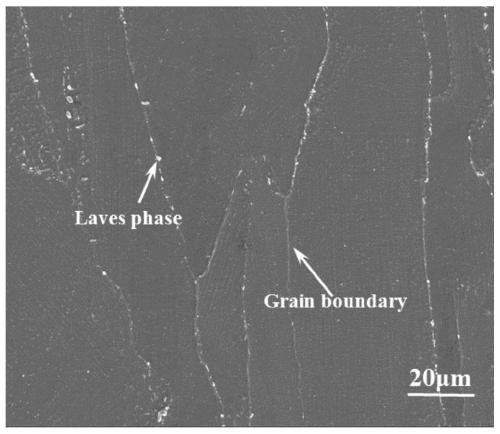

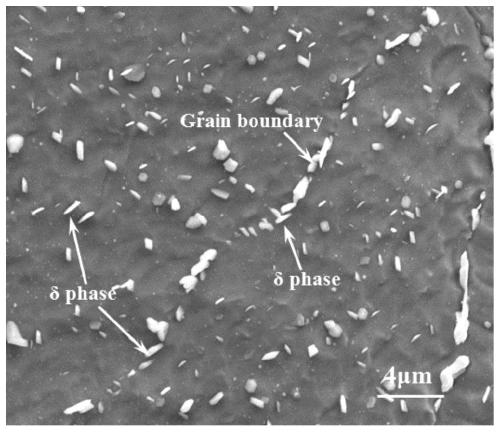

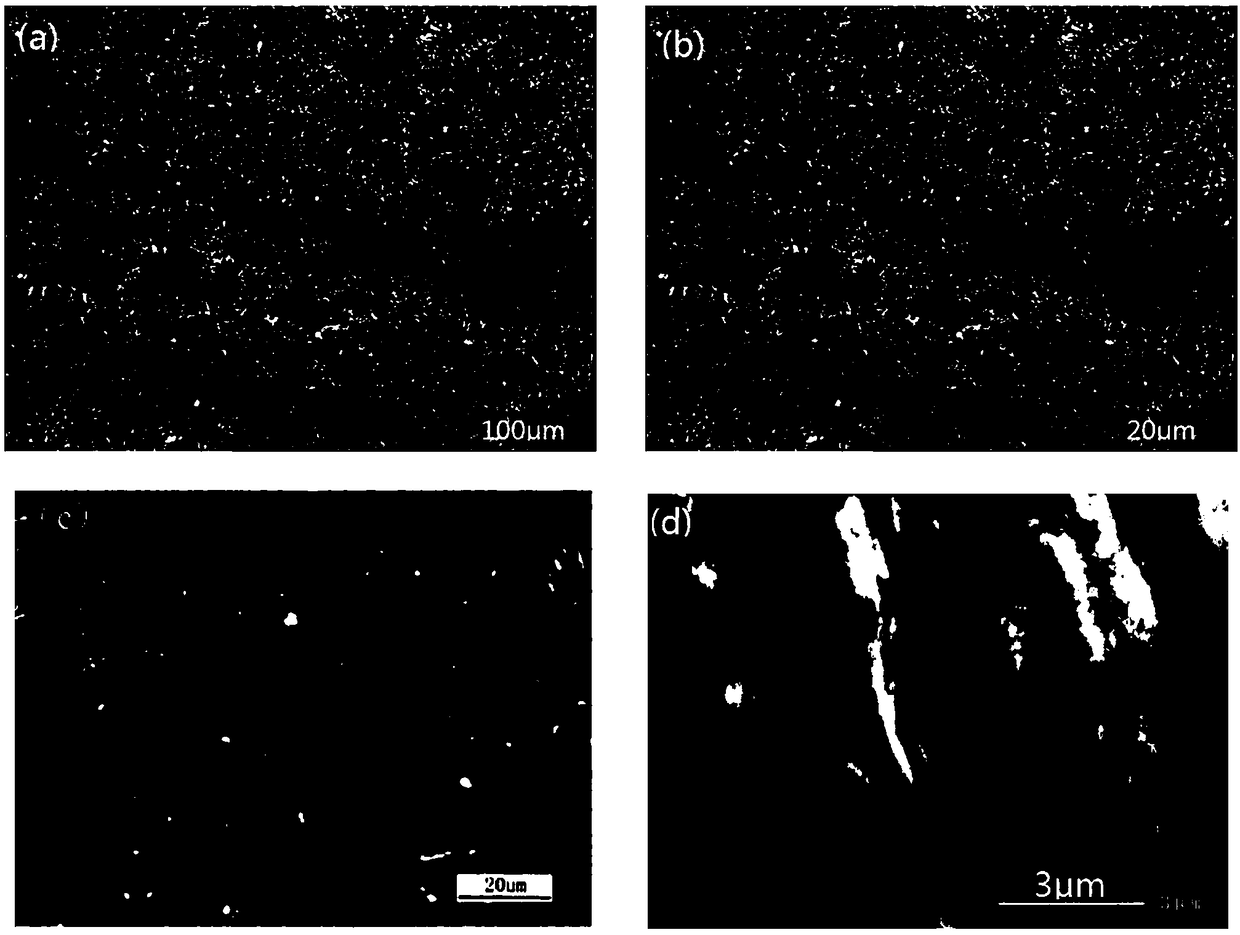

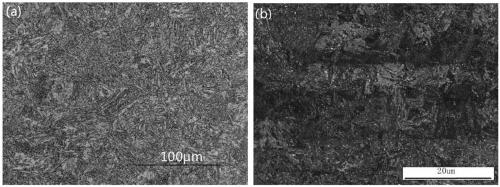

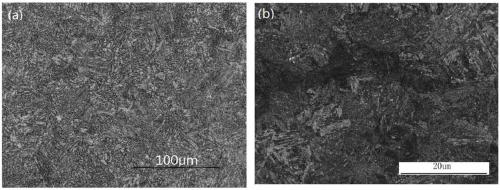

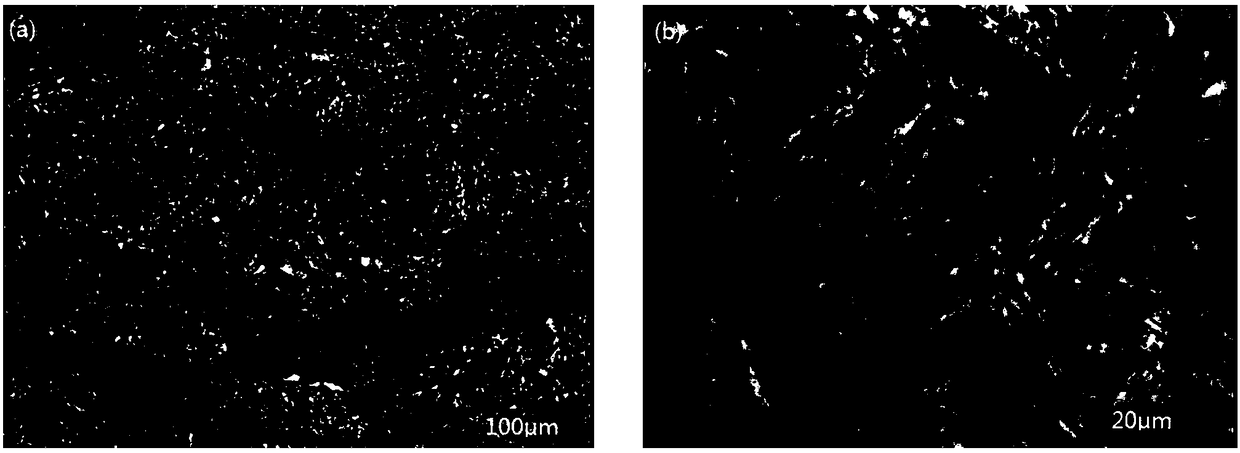

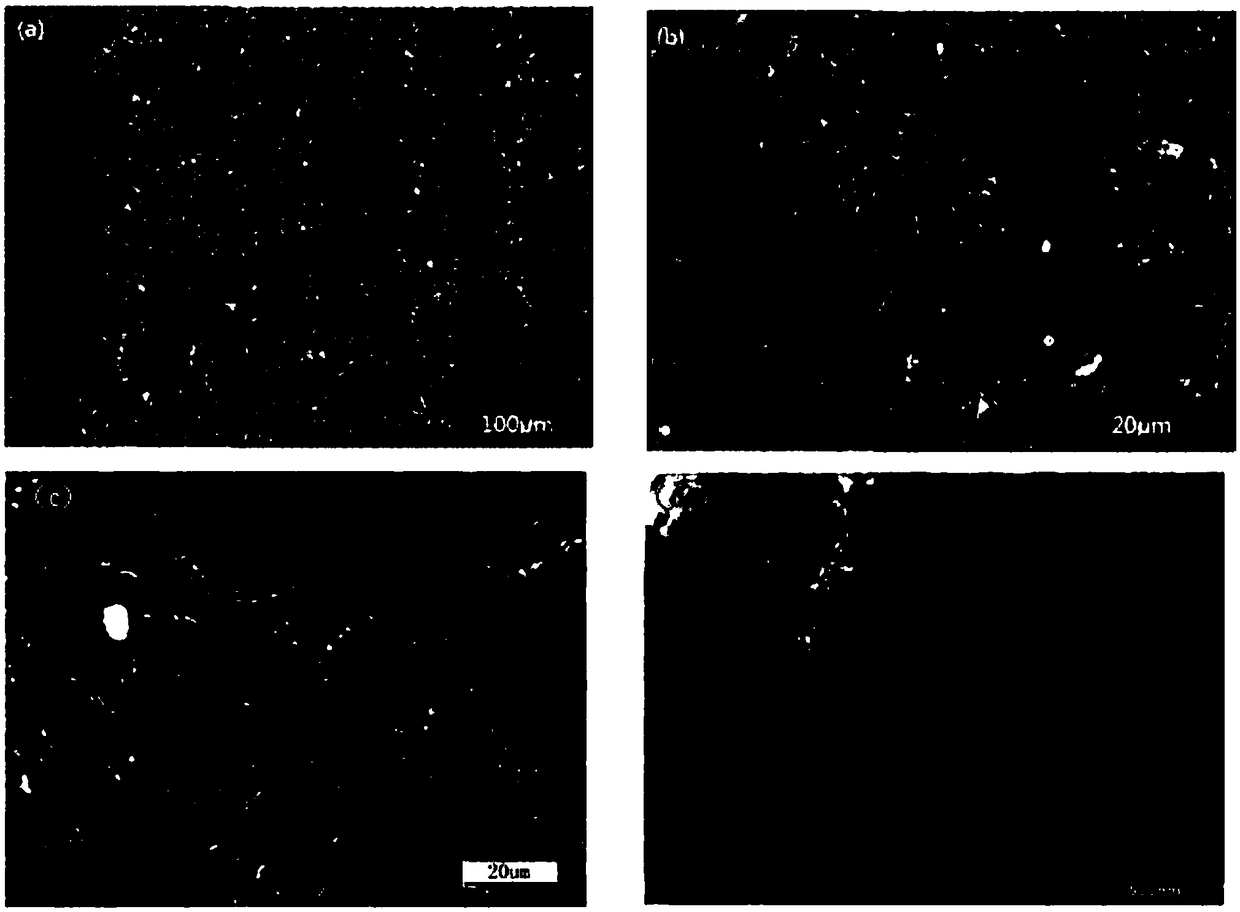

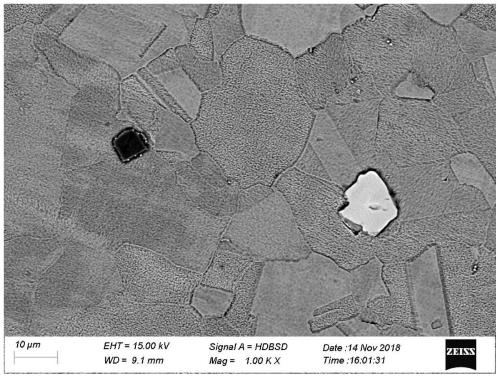

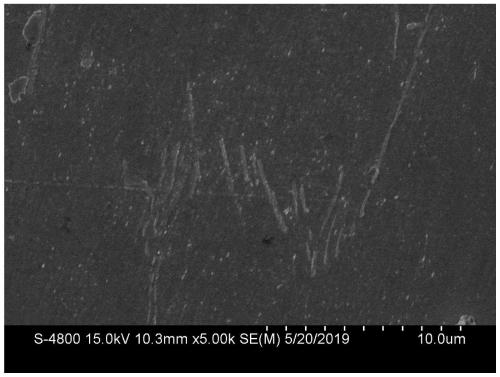

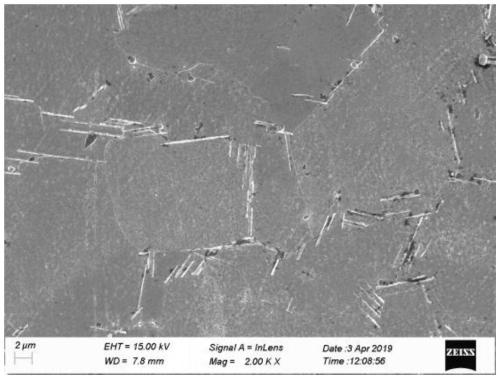

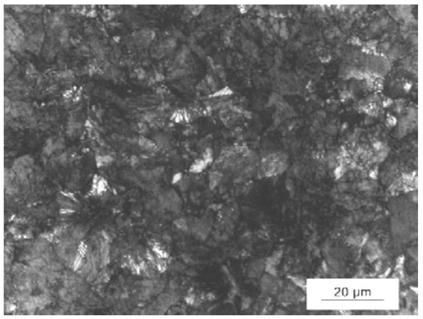

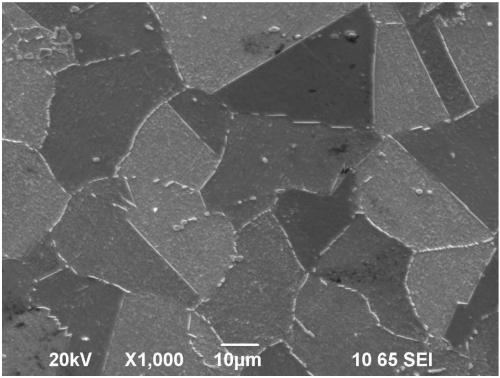

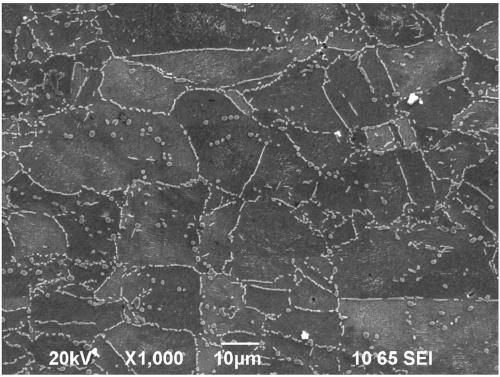

Selective laser melting forming Inconel718 alloy and heat treatment method thereof

InactiveCN111360266AHigh strengthPromote precipitationAdditive manufacturing apparatusIncreasing energy efficiencyHot isostatic pressingHeat conservation

Owner:SOUTH CHINA UNIV OF TECH +1

Polycarbonate composite material with modified calcium sulfate whisker and preparation method thereof

The invention relates to a polycarbonate composite material with modified calcium sulfate whisker and a preparation method thereof. The calcium sulfate whisker-modified polycarbonate composite material comprises the following raw materials by weight parts: 100 parts of polycarbonate, 15 to 20 parts of polystyrene, 15 to 25 parts of calcium sulfate whisker, 0.1 to 0.4 part of antioxidant 1010, 1 to 4 parts of polyfluortetraethylene and 1 to 3 parts of titanic acid ester coupling agent. The preparation method comprises the following steps: calcium sulfate whisker and titanic acid ester coupling agent are activated for 3 to 6 minutes in a high-speed mixer; the rest raw materials are mixed for 6 to 8 minutes with the modified calcium sulfate whisker in the high-speed mixer; and then the obtained mixture is granulated by melting through a double-screw extruder. The polycarbonate composite material with the modified calcium sulfate whisker has good fatigue resistance and low notch sensitivity and is particularly suitable for manufacturing television shells, precise instrument shells, automotive interior trims, instrument structural components and the like.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

Toughened ceramic for insulator and preparation method of toughened ceramic

The invention discloses toughened ceramic for an insulator and a preparation method of the toughened ceramic. The toughened ceramic is prepared from, by weight, 2-3 parts of aluminum borate whiskers, 70-80 parts of silicon carbide micro powder with the proper size, 20-30 parts of aluminum nitride micro powder with the proper size, 1-1.5 parts of calcium fluoride powder, 10-15 parts of carbon powder, 10-15 parts of molybdenum silicide, 6-8 parts of ethyl orthosilicate, 3-5 parts of absolute ethyl alcohol, 3-5 parts of purified water and 1.5-2.5 parts of thermoplastic phenolic resin. By means of the steps of raw material preparation, insulator pre-preparation, insulator sintering and completing, the high-tenacity insulation ceramic with the volume resistivity larger than or equal to 2*1,013 omega-cm, the dielectric strength larger than or equal to 750 kV / cm, the thermal conductivity larger than or equal to 25 W / m.K, the bending strength larger than or equal to 400 Mpa, the Young modulus larger than or equal to 320 Gpa and the breaking tenacity larger than or equal to 25 Mpa is formed. The toughened ceramic is good in economical efficiency, resistant to high temperature oxidation and high in breaking tenacity, and the functions of main materials complement one another.

Owner:宁波高智科技咨询服务有限公司

Preparation method of corrosion-resistant aluminum alloy profile for radiators

InactiveCN103710598AHigh strengthImprove thermal conductivityCorrosion resistantThermal conductivity

The invention discloses a preparation method of a corrosion-resistant aluminum alloy profile for radiators. The aluminum alloy profile comprises the following elements in percentage by mass: 0.6-1.2% of Mg, 0.2-0.4% of Si, 1.4-1.8% of Cu, 0.5-1.0% of Ag, 0.4-0.6% of Fe, 0.05-0.15% of Mn, 0.1-0.2% of Cr, 0.3-0.5% of Zn, 0.1-0.15% of Ti, 0.1-0.2% of Ni, 0.05-0.1% of Ta, 0.04-0.08% of Sb, 0.03-0.05% of Sc, 0.02-0.03% of La, 0.01-0.02% of Ho and the balance of Al. The aluminum alloy profile prepared by the method has the advantages of high strength, favorable thermal conductivity, favorable impact resistance, low notch sensitivity, favorable plasticity and excellent corrosion resistance, can be used in a liquid with the pH of higher than 10 and the temperature of 90 DEG C for a long time, and improves the working reliability and service life of the radiators.

Owner:WUHU WANRUN MACHINERY

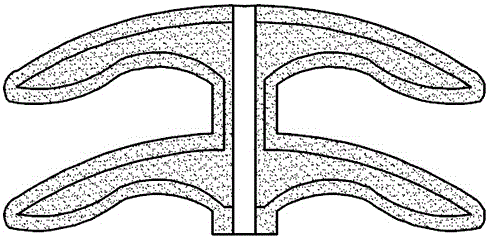

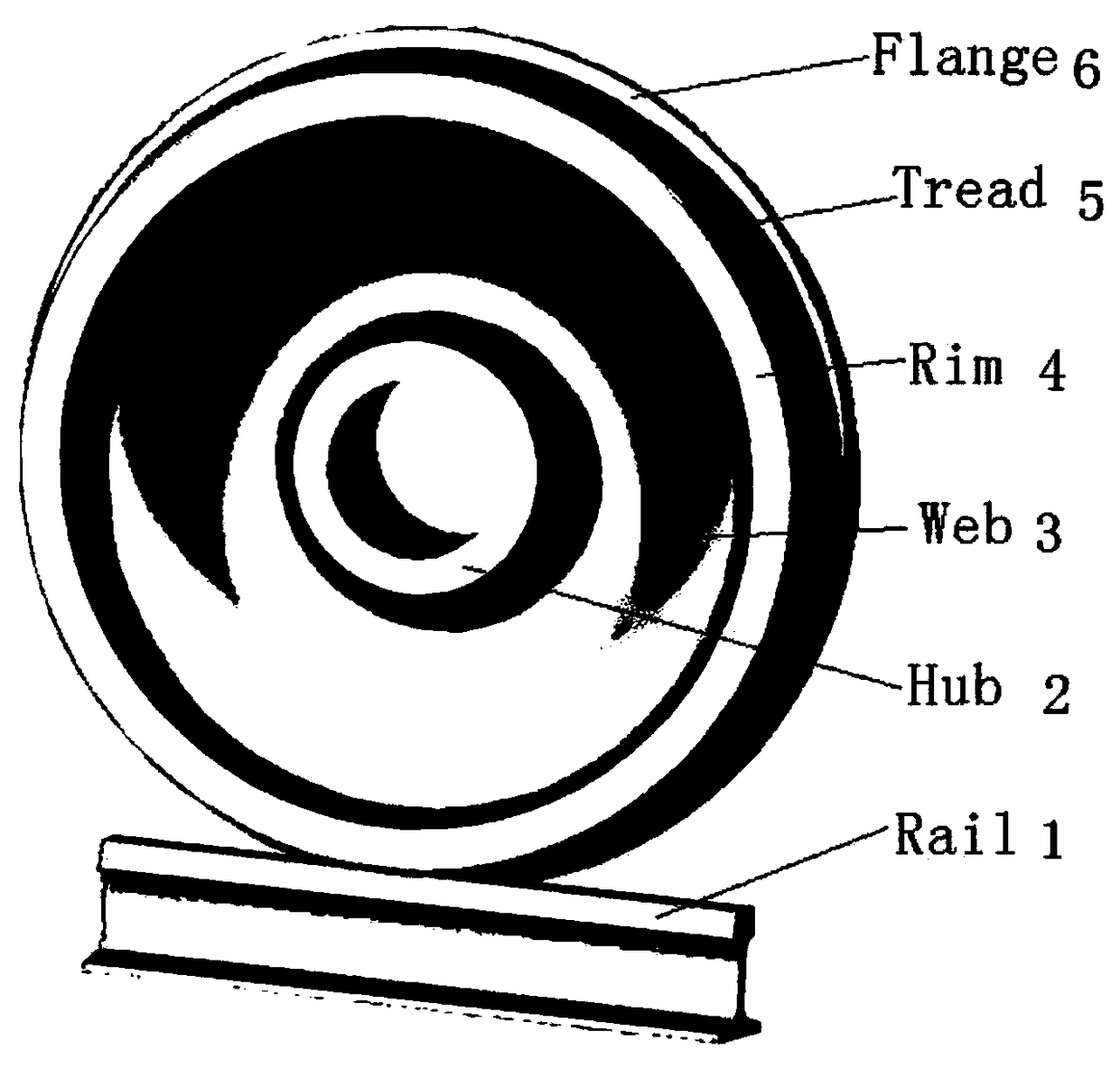

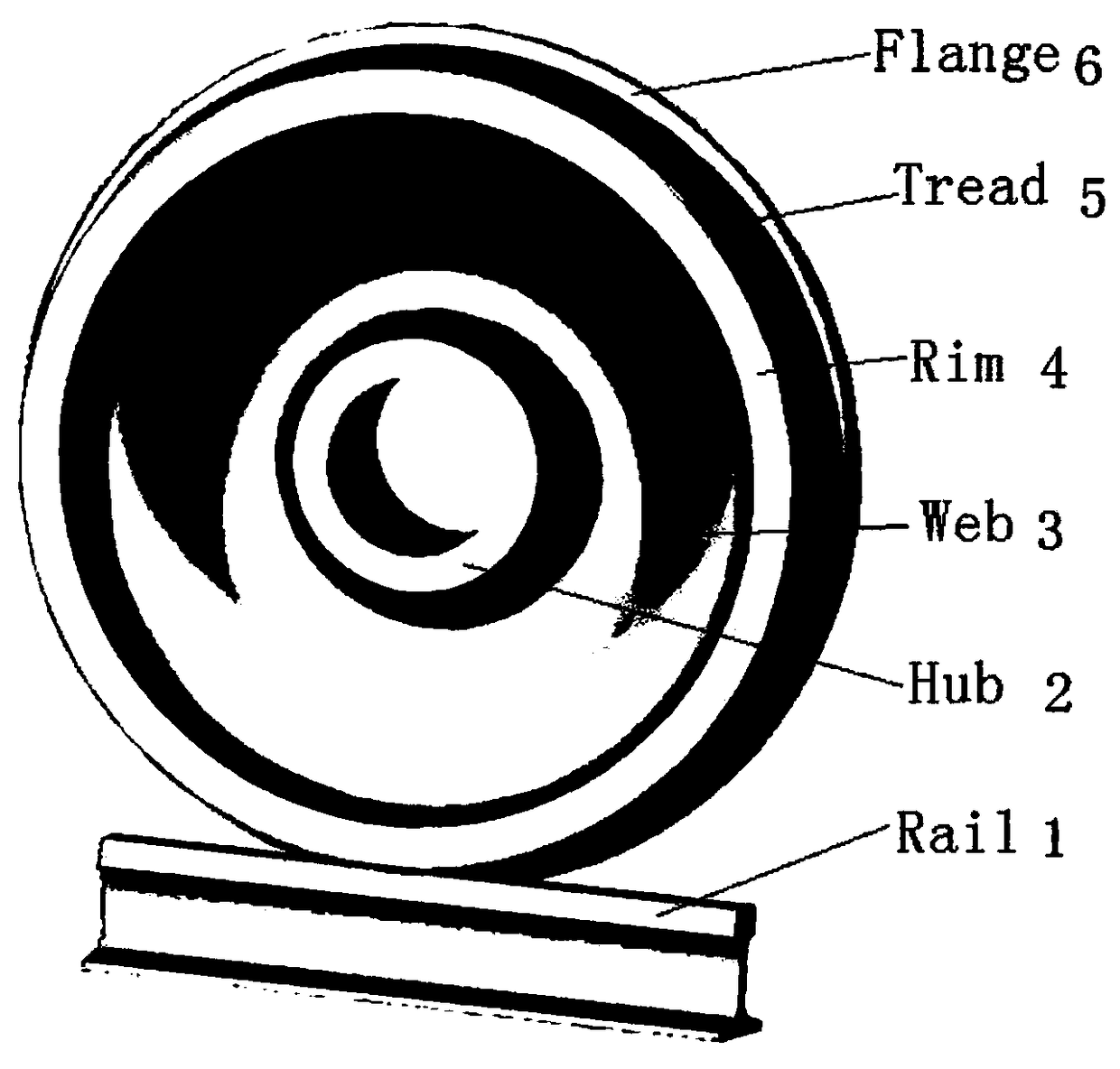

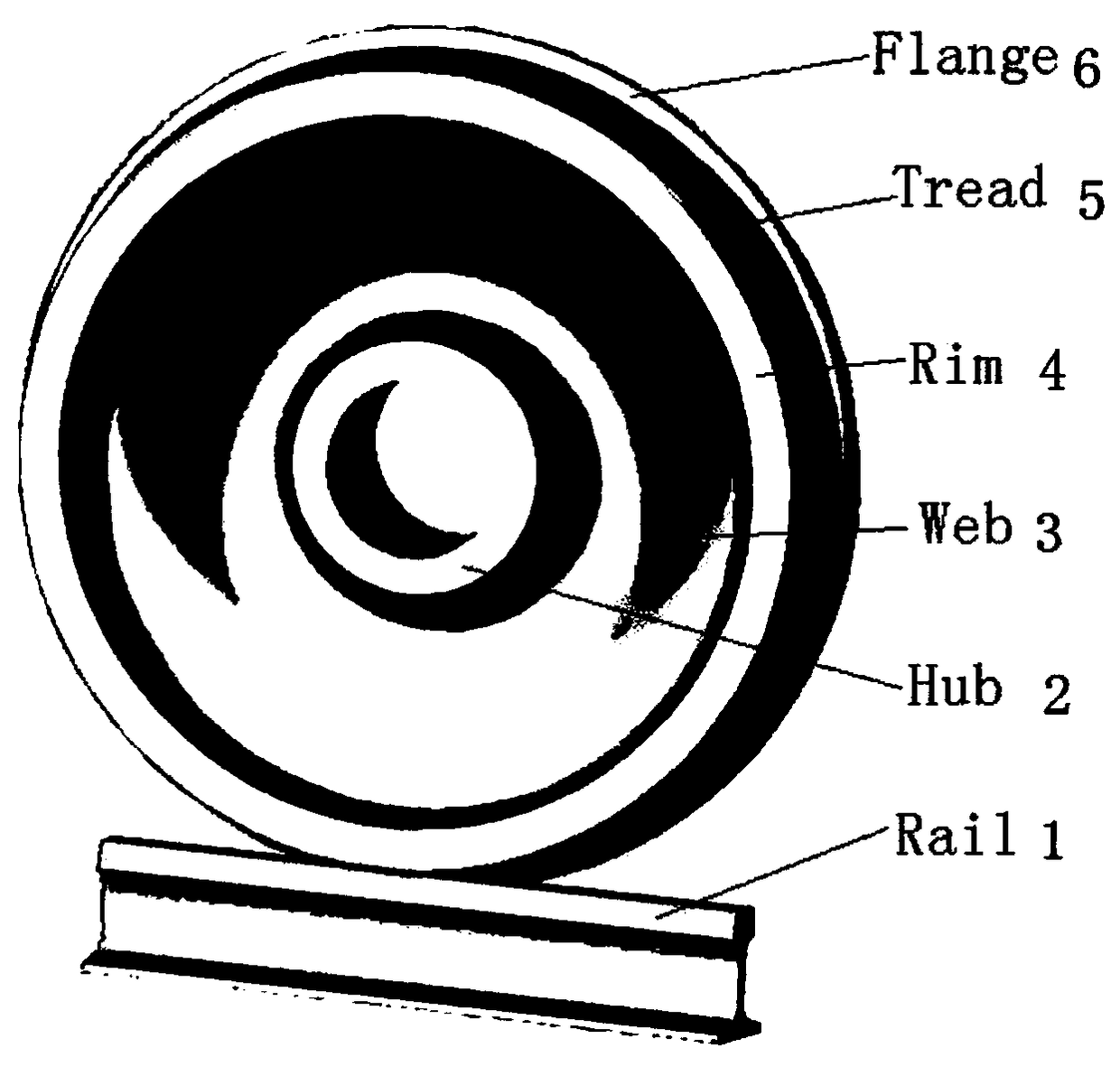

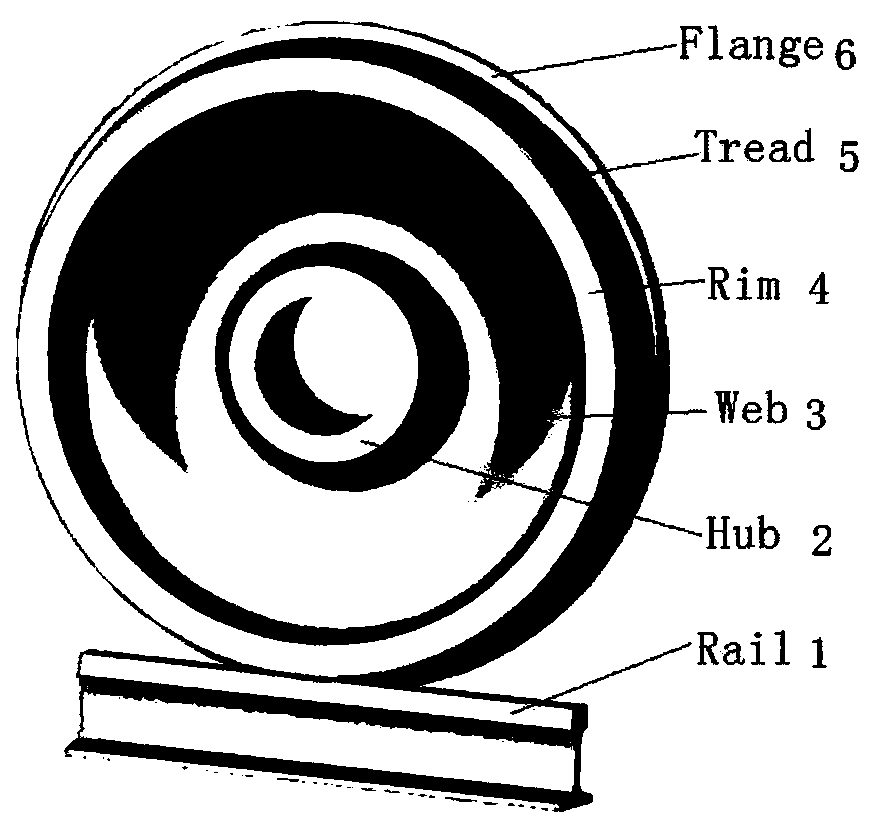

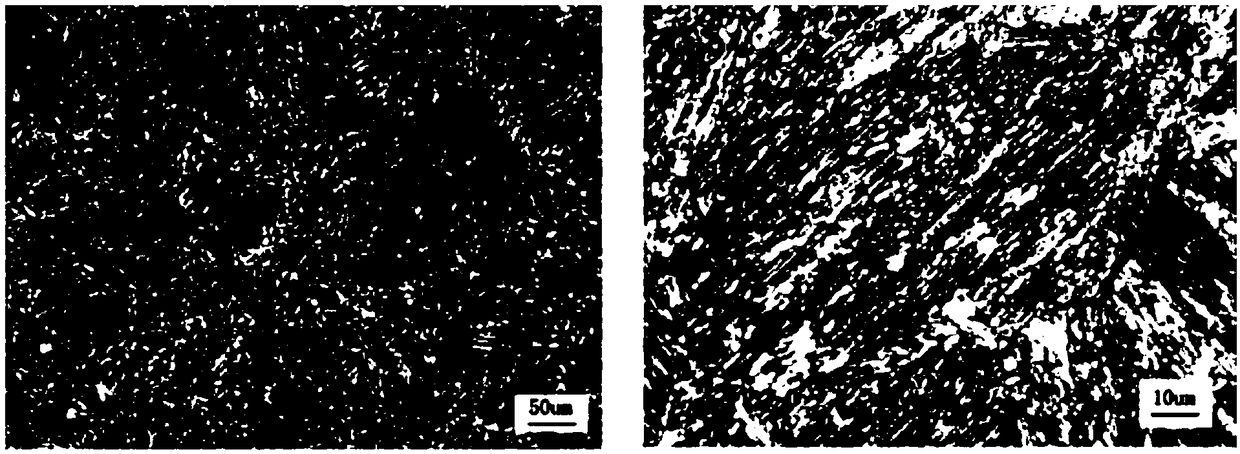

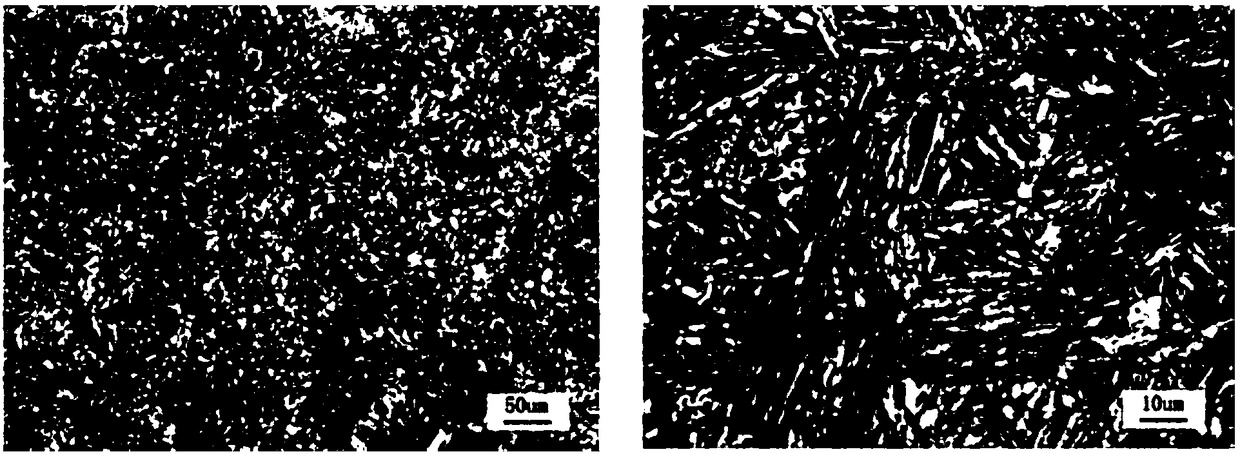

Common rail traffic bainite steel wheel used under cold and rigor service environment and manufacturing method of common rail traffic bainite steel wheel

InactiveCN108707831AHigh yield strengthHigh tensile strengthRail-engaging wheelsFurnace typesChemical compositionCommon rail

The invention discloses a common rail traffic bainite steel wheel used under the cold and rigor service environment and a manufacturing method of the common rail traffic bainite steel wheel. The common rail traffic bainite steel wheel comprises chemical components including 0.05%-0.30% of C, 0.50%-1.50% of Ni, 0.01%-1.20% of Cr, 0.70%-2.10% of Mn, 0.20%-1.00% of Si, 0.01%-1.00% of W, 0.05%-0.60% of Mo, 0.01%-0.80% of Cu, 0.01%-0.20% of V, 0.001%-0.20% of Nb, 0.0001%-0.0350% of B, 0.001%-0.040% of RE, not larger than 0.020% of P, not larger than 0.020% of S and the balance Fe and inevitable residual elements, wherein the sum of Mn and Cr is larger than or equal to 2.0% and smaller than or equal to 3.0%. By adopting a new alloy design system and alloying principle of C-Ni-Mn-Cr-Mo, after thewheel is molded, a rim obtained after advanced heat treatment obtains a carbide-free bainite organization structure, and the wheel has the excellent comprehensive mechanical property, decay resistance and service performance, in particular has the high low-temperature toughness and low-temperature breaking toughness, meets performance and service safety requirement under the low-temperature environment and is suitable for the cold zone under rigor conditions.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Calcium sulfate whisker modified polyvinylalcohol composite material and preparation process thereof

The invention relates to a calcium sulfate whisker modified polyvinylalcohol composite material and a preparation process thereof. The composite material is prepared by the following materials according to part by weight: 70 to 90 portions of polyvinyl alcohol, 10 to 20 portions of calcium sulfate whisker with the diameter of 10 to 20 Mum, 1 to 3 portions of surface modifier, 1 to 5 portions of plasticizer, and 0.5 to 1.5 portions of lubricant. The preparation method comprises the following steps: adding the calcium sulfate whisker and the surface modifier to a high-speed mixer to mix for 5 to 15 minutes; then adding the polyvinyl alcohol, the plasticizer and the lubricant to the high-speed mixer to mix for 3 to 7 minutes; extruding the mixture from an equidirectional parallel double-screw extruder for granulation; and then conducting injection molding to the particles in an equidirectional parallel double-screw injection machine. The calcium sulfate whisker modified polyvinylalcohol composite material has high strength, low notch sensitivity, good thermal resistance and oxygen resistance, simple preparation process, and low cost, and is especially suitable for making products such as films and the like.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

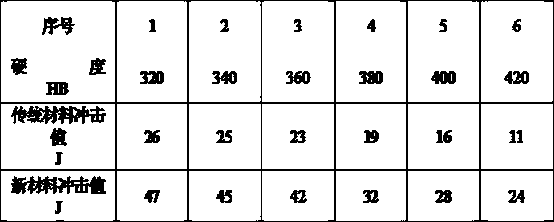

Anti-scratching mandrel material

The invention belongs to the technical field of metal materials, and relates to an anti-scratching mandrel material, in particular to a mandrel material with high impact resistance. The mandrel material consists of the following components in percentage by weight: 0.28 to 0.35 percent of C, 0.4 to 0.8 percent of Si, 0.2 to 0.6 percent of Mn, less than or equal to 0.003 percent of S, less than or equal to 0.012 percent of P, 4 to 5 percent of Cr, 1.1 to 1.3 percent of Mo, 0.6 to 0.8 percent of V, 0.2 to 0.5 percent of Ni and the balance of Fe. According to the mandrel material, the components are regulated in a way that the content of the components capable of reducing the impact toughness is reduced and the content of the components capable of improving the impact toughness is increased, so that the impact resistance of the material is greatly improved; for example, the C content, the Cr content and the V content are reduced, and the Ni content is increased; the components are regulated in such a way, so that the carbide content of steel and the size of formed carbide are reduced, the nick sensitivity of a metal material to impact force is reduced, and an impact toughness index is improved.

Owner:WUXI YOUSIWEIKE PETROLEUM DRILLING TOOLS

Bainitic steel wheel for rail traffic with capability of resisting against damp, hot and corrosive environments and manufacturing method thereof

InactiveCN109182920AHigh yield strengthHigh tensile strengthRail-engaging wheelsFurnace typesCarbideAlloy

The invention discloses a bainitic steel wheel for rail traffic with capability of resisting against damp, hot and corrosive environments and a manufacturing method thereof. The bainitic steel wheel comprises the following chemical components: 0.05-0.40% of C, 0.40-1.50% of Ni, 0.25-1.50% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% ofV, 0.001-0.20% of Nb, 0.0001-0.0350% of B, 0.001-0.040% of RE, less than or equal to 0.020% of P, less than or equal to 0.020% of S and the balance of Fe and inevitable residual elements, wherein Mn+Cr is more than or equal to 2.0% but less than or equal to 3.0%. The new alloy design system of C-Ni-Mn-Cr-Mo-Cu and alloying principle are adopted by the invention; after a wheel is formed, a rim after advanced thermal treatment is endowed with a carbide-free bainite structure; the wheel has excellent comprehensive mechanical property and service performance, especially, atmospheric corrosion resistance; the wheel is capable of resisting against damp, hot and corrosive environments and reducing the harmful influences of stress corrosion and medium corrosion; the service life and running safetyof the wheel can be further promoted.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

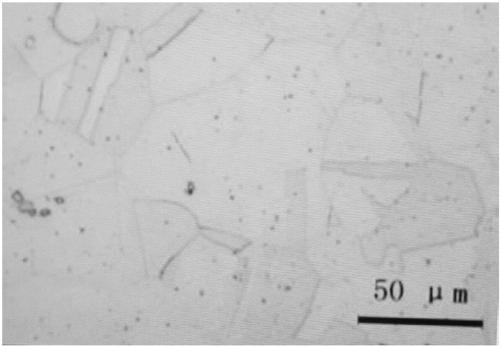

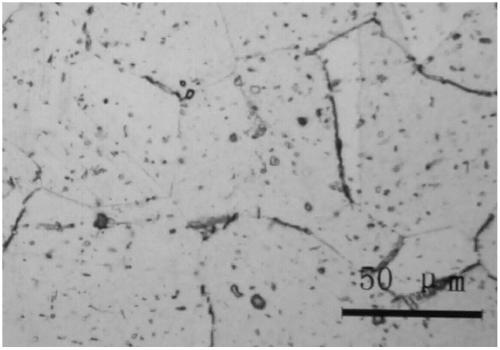

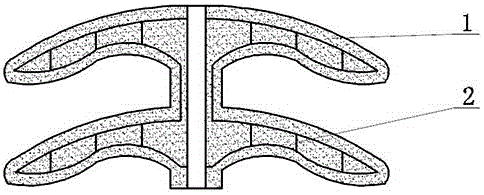

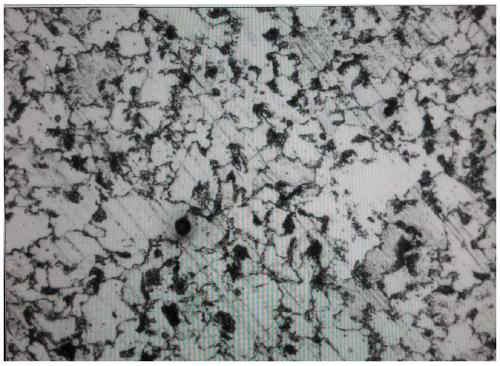

Heat treatment process for recovering endurance property of notch of welding assembly of GH4169 alloy forge piece

For solving the problem that notch sensitivity exists after an existing GH4169 alloy welding assembly is subjected to braze welding and aging treatment, the invention provides an intermediate heat treatment and aging process using a recovery delta phase, namely a process of intermediate heat treatment and aging. The specific intermediate heat treatment technological process comprises the steps ofplacing a GH4169 alloy welding assembly with notch sensitivity in an air furnace, heating to the temperature of 950-980 DEG C, insulating for 0.5-2 h, and cooling to the room temperature within 0.5 h.The aging technological process comprises the steps of placing the GH4169 alloy welding assembly subjected to intermediate heat treatment into the air furnace, heating to the temperature of 700-800 DEG C, insulating for 8 h, cooling to the temperature of 600-700 DEG C at the rate of 50+ / - 10 DEG C / h, insulating for 8 h and cooling in air. The notch sensitivity of the GH4169 alloy forge piece canbe eliminated, and the endurance property of the notch of the GH4169 alloy welding assembly is recovered.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Novel high-temperature alloy heat-resistant stainless steel bolt and production process thereof

Owner:江苏新迅达不锈钢制品有限公司

Bainite steel wheel for rail traffic D-series high-speed train and manufacturing method thereof

PendingCN108796372AHigh yield strengthHigh tensile strengthFoundry mouldsFurnace typesDesign systemsChemical composition

The invention discloses a bainite steel wheel for a rail traffic D-series high-speed train and a manufacturing method thereof. Chemical components of the bainite steel wheel comprise 0.05-0.30% of C,0.10-1.50% of Ni, 0.01-1.20% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% of V, 0.001-0.20% of Nb, 0.0001-0.0350% of B, 0.001-0.040% of RE, smaller than or equal to 0.020% of P, smaller than or equal to 0.020% of S and the balance Fe and inevitable residual elements, and the sum of Mn and Cr is larger than or equal to 2.0% and smaller than or equal to 3.0%. According to the bainite steel wheel, the novel C-Ni-Mn-Cr-Mo alloy design system and the alloying principle are adopted, after the wheel is formed and subjected to advanced heattreatment, a rim obtains a no-carbide bainite structure, and the wheel has excellent comprehensive mechanical performance, anticorrosion performance and service performance, and especially has the beneficial effects of being high in strength, high in hardness, high in toughness, high in low-temperature toughness, high in wheeltrack rolling contact fatigue resisting performance (RCF), high in heatcrack resisting performance and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

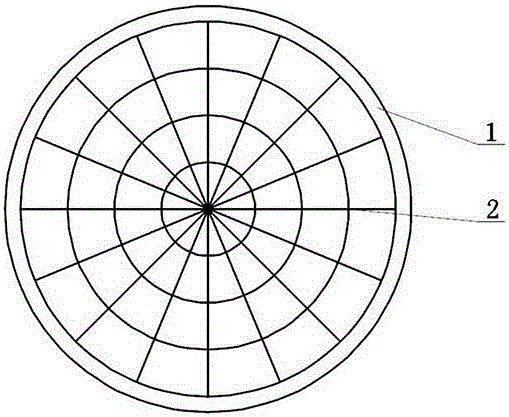

Ceramic insulator with built-in tough frame and manufacturing method thereof

InactiveCN106278340AGood thermal conductivityEvenly heatedFibre chemical featuresTetraethyl orthosilicateDielectric strength

The invention discloses a ceramic insulator with a built-in tough frame and a manufacturing method thereof. The ceramic insulator comprises the following raw materials in parts by weight: 50-60 parts of silicon carbide powder, 10-15 parts of carbon powder, 10-15 parts of silicon dioxide, 6-8 parts of tetraethyl orthosilicate, 3-5 parts of anhydrous ethanol, 3-5 parts of pure water and 1.5-2.5 parts of thermoplastic phenolic resin. A central radial basket-shaped fiber touch frame woven from graphitized carbon fiber is implanted at the center of the ceramic insulator. The ceramic insulator disclosed by the invention has a volume resistivity of not less than 5 *10<12>.cm and a dielectric strength of not less than 650 kv / cm, a thermal conductivity of not less than 45 omega / m .K, a bending strength of not less than 550Mpa, a Young's modulus of not less than 400Gpa, and a fracture toughness of not less than 30Mpa. The ceramic insulator disclosed by the invention has the advantages of good internal thermal conductivity, good frame structure support, and good impact resistance and high temperature oxidation resistance.

Owner:宁波高智科技咨询服务有限公司

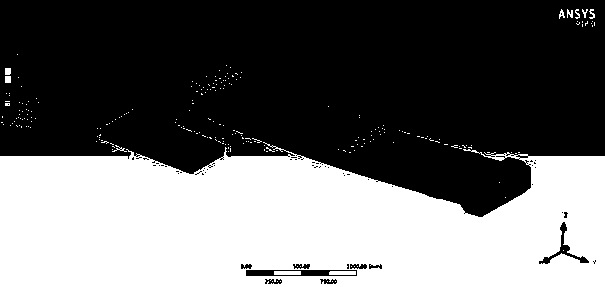

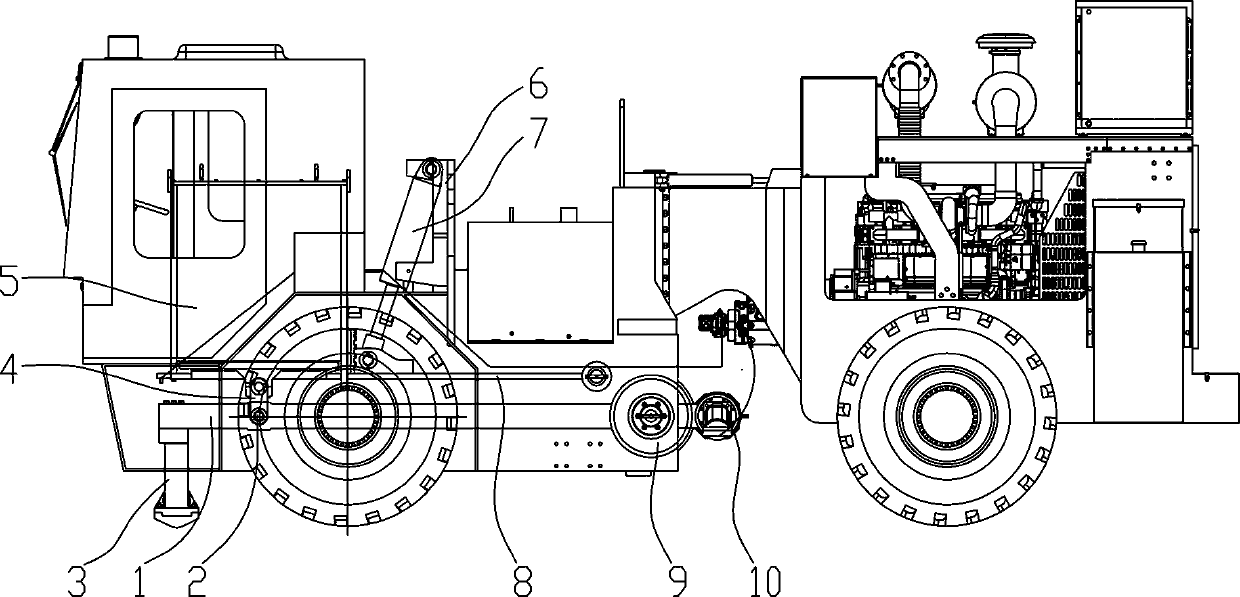

Preparation method of vibration exciting beam of pavement crushing vehicle

ActiveCN110653566AExtended service lifeProtect the surfaceRoads maintainenceSurface roughnessStructural engineering

The invention provides a preparation method of a vibration exciting beam of a pavement crushing vehicle. The preparation method comprises the steps of 1, casting and molding a beam body in a mold cavity; 2, hot forging the beam body; 3, tempering the beam body; 4, finishing the beam body to a preset size, and rounding all broken line positions; and 5, lapping the surface of the beam body to ensurethat the surface roughness is lower than Ra1.6 [mu]m, thereby obtaining the vibration exciting beam of the pavement crushing vehicle through the steps. By adopting the scheme, the service life of thevibration exciting beam under the vibration working condition can be greatly prolonged. The broken line positions of the beam body are all of rounded structures, and micro cracks can be prevented from being generated as fracture source regions. The vibration exciting beam has low surface roughness by adopting a surface lapping process, and the micro cracks under the vibration working condition can be avoided.

Owner:YICHANG JIANGXIA MARINE MACHINERY +1

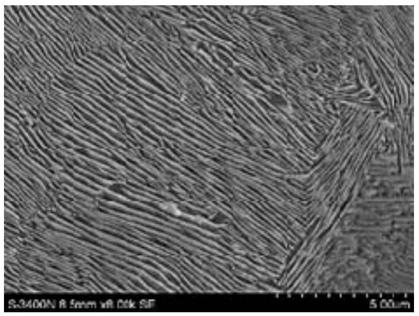

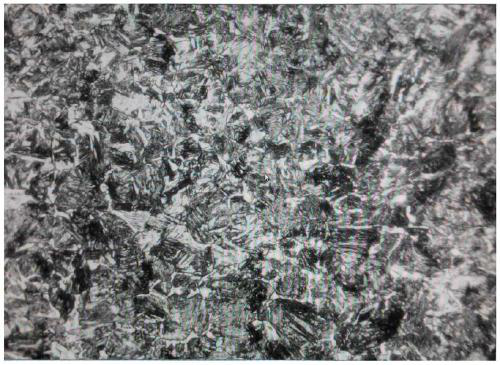

Treatment method for enhancing thermal fatigue property of forged Ni-Cr-Co based alloy

ActiveCN110358991AImprove mechanical propertiesImprove thermal fatigue performanceSolution treatmentThermal fatigue

The invention discloses a treatment method for enhancing the thermal fatigue property of a forged Ni-Cr-Co based alloy. The treatment method comprises the following steps of (1) high temperature homogenization treatment; (2) solid solution pretreatment; (3) predeformation treatment; (4) low-temperature annealing treatment; (5) multi-stage solid solution treatment; and (6) multi-stage ageing treatment. The alloy is subjected to a series of thermal treatment means and stretching treatment, the precipitation behavior and the existence state of two alloy phases are regulated and controlled by introducing defects of voids, dislocation and stacking fault, and the sizes, the distributions, the content and the morphologies of the alloy phases are adjusted by combination with the control to a thermal treatment cooling rate, so that the comprehensive mechanical property of the alloy is improved, the thermal fatigue property of the alloy is further improved, and the alloy is served in a harsher environment and has great application value.

Owner:HEBEI UNIV OF TECH

Bainite steel wheel for rail traffic truck and manufacturing method of bainite steel wheel

InactiveCN108754329AReduce coefficient of frictionReduce wearFurnace typesProcess efficiency improvementCrack resistanceAlloy

The invention discloses a bainite steel wheel for a rail traffic truck and a manufacturing method of the bainite steel wheel. The bainite steel wheel for the rail traffic truck comprises the followingchemical components: 0.10-0.40% of C, 0.10-1.50% of Ni, 0.25-1.50% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% of V, 0.001-0.20% of Nb,0.0001-0.0350% of B, 0.001-0.040% of RE, less than or equal to 0.020% of P, less than or equal to 0.020% of S and the balance of Fe and inevitable residual elements; and moreover, 2.0%< / = Mn+ Cr< / = 3.0%. A novel alloy design system of C-Ni-Mn-Cr-Mo and an alloying principle are adopted, after wheels are formed and subjected to advanced heat treatment, a carbide-free bainite organization structureis obtained, and the wheels have excellent integrated mechanical property, corrosion resistance and service performance, and particularly have the characteristics of high strength, hardness and toughness, high wheel track rolling contact fatigue (RCF) resistance, hot crack resistance and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Technology for machining positioning rings

InactiveCN105983818AHigh surface hardnessExtended service lifeSolid state diffusion coatingFurnace typesEngineeringMachining

The invention discloses a technology for machining positioning rings. The technology is characterized by comprising steps of carrying out technological processes of discharging, forging, annealing, machining, tempering, machining, ion nitriding, inspecting and finished product acquiring and the like. The technology for machining the positioning rings has the advantages that the comprehensive performance of the positioning rings can be improved, and the service lives of the positioning rings can be prolonged.

Owner:重庆沁煌实业有限公司

High-performance alloy steel and manufacturing method thereof

ActiveCN104120350ALow temperature brittle fractureLow delayed fracture performanceProcess efficiency improvementManganeseAnalysis center

The invention discloses high-performance alloy steel which is characterized by being prepared from the following components and the weight ratio: iron:carbon:manganese:molybdenum:silicon:titanium:nickel:phosphorus:sulfur:copper=93.12-96.92:0.10-0.30:1.80-3.20:0.20-0.45:0.90-2.30:0.03-0.30:0.05-0.25:0-0.03:0-0.03:0.01-0.02. The high-performance alloy steel has the product properties: the tensile strength Rm is greater than or equal to 1350 MPa, the yield strength Rel is greater than or equal to 1050 MPa, the elongation rate A (%) is greater than or equal to 10, the cross section shrinking percentage Z (%) is greater than or equal to 50, the room temperature (42 DEG C) impact toughness aku is greater than or equal to 100 J / cm<2>, the low temperature (-40 DEG C) impact toughness aku is greater than or equal to 50 J / cm<2>, and the hardness HRC is 40-50; the product is detected by the national analysis center for iron and steel, and indicators such as non-metallic inclusions and the grain size all accord with national standard high-level requirements.

Owner:SICHUAN YIHENG MACHINERY MFG CO LTD

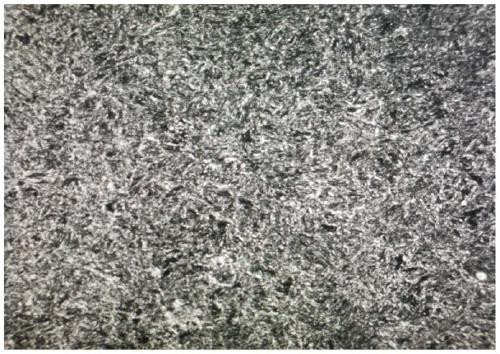

Control method for improving plasticity of hollow steel 95CrMo

ActiveCN109252030AAchieve the effect of low temperature rollingHigh elongationWater coolingContinuous rolling

The invention relates to a control method for improving plasticity of hollow steel 95CrMo and belongs to the technical field of control of steel rolling processes of the hollow steel. The method comprises the steps: during rolling, an incipient rolling temperature is 1,000 DEG C to 1,050 DEG C, a feeding continuous rolling temperature is 930 DEG C to 970 DEG C, and an inlet temperature of finish rolling is 830 DEG C to 860 DEG C; after finish rolling, water cooling-restoring-water cooling-restoring cooling is adopted, an upper cold bed temperature is 700 DEG C to 780 DEG C, and a lower cold bed temperature is above 400 DEG C. The method has the advantages that the plasticity of the hollow steel 95CrMo is improved, the toughness of the hollow steel is improved, and the rock drilling life ofthe hollow steel is prolonged.

Owner:SHOUGANG CORPORATION

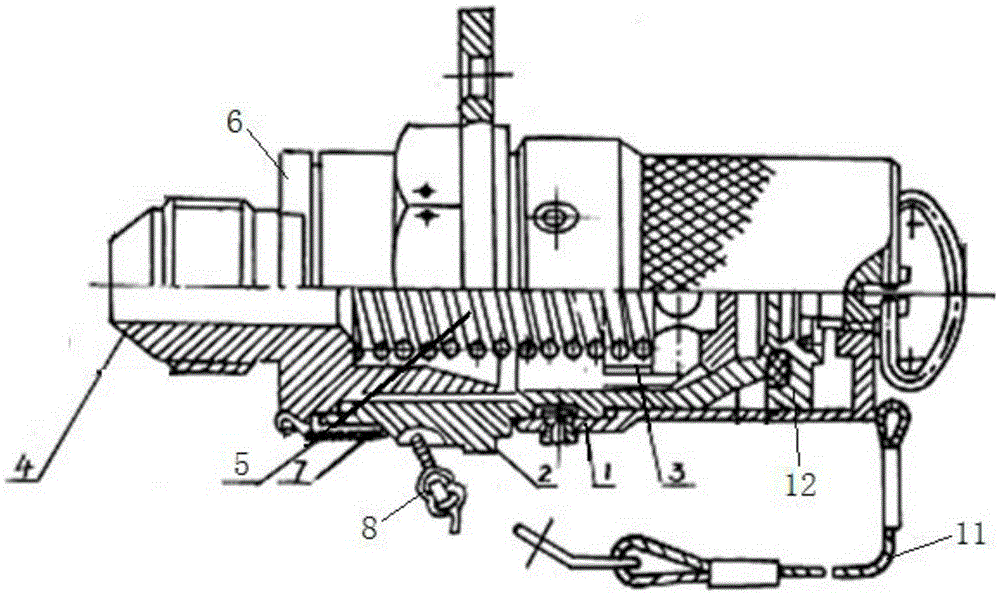

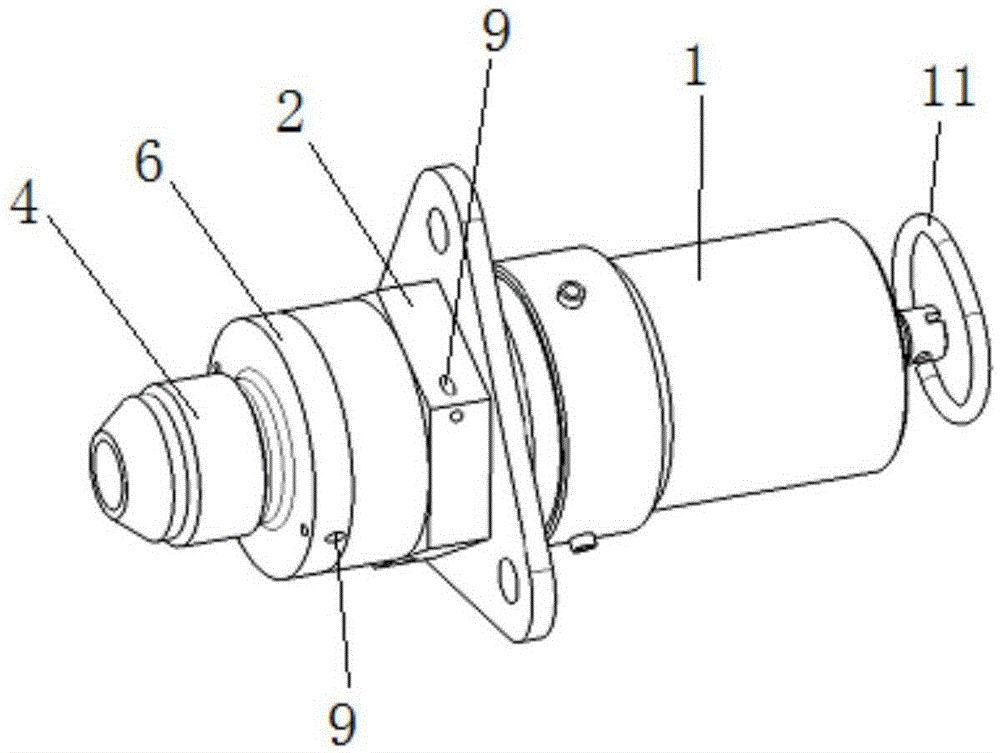

Aviation pressure refueling adapter

InactiveCN105383707AReduce work intensityImprove refueling efficiencyLiquid handling installationsAviationAirplane

The invention discloses an aviation pressure refueling adapter, relating to the technical field of aviation refueling. The aviation pressure refueling adapter comprises a pedestal, a valve, a pipe joint, a spring and a sealing ring, wherein the pedestal is of a hollow structure; one end of the pedestal is fixedly connected with the pipe joint to form an accommodation cavity, and the other end of the pedestal is connected with a ground refueling connection nozzle; one end of the valve is provided with an outer conical surface; the other end of the valve is provided with a groove; through holes are formed longitudinally along the side wall of the groove; the valve and the spring are arranged in the accommodation cavity; one end of the spring is in contact with the pipe joint; the other end of the spring is arranged in the groove at one end of the valve; the outer conical surface of the valve is matched with the pedestal in a sealed manner; and the sealing ring is arranged between the match surfaces of the valve and the pedestal. The aviation pressure refueling adapter has the beneficial effects that after the pressure refueling adapter disclosed by the invention is adopted, the refueling for airplanes can change from traditional gravity refueling to pressure refueling; the refueling efficiency is improved; and light and small refueling equipment can be adopted for ground refueling equipment, so that the cost of the refueling equipment is saved.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

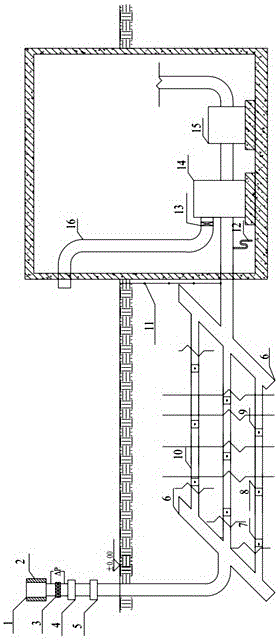

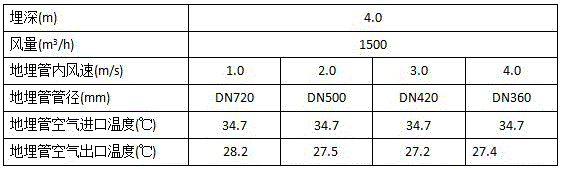

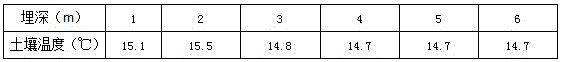

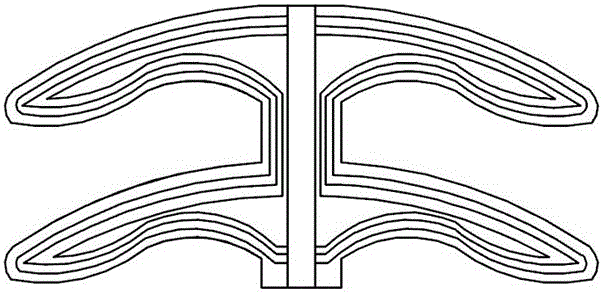

Fresh air pretreatment terrestrial heat exchange system

ActiveCN105737308AReduce indoor pollution sourcesEnsure efficient operationOther heat production devicesGeothermal energy generationVentilation tubeEngineering

The invention relates to a fresh air pretreatment terrestrial heat exchange system. The fresh air pretreatment terrestrial heat exchange system comprises an outdoor fresh air taking part, a terrestrial heat exchange part and an indoor fresh air treatment part, wherein the outdoor fresh air taking part, the terrestrial heat exchange part and the indoor fresh air treatment part are communicated through ventilation pipelines. The fresh air pretreatment terrestrial heat exchange system is characterized in that the outdoor fresh air taking part is arranged on the ground, the outdoor fresh air taking part comprises a fresh air port, a coarse-efficiency filter device, a medium-efficiency filter device, an electrostatic dust collector and a solid dehumidification device which are arranged in sequence from top to bottom and are communicated; the terrestrial heat exchange part comprises buried pipes, temperature measuring points which are formed on the buried pipes, pneumatic cleaning device reserved openings and flow measuring points; the indoor fresh air treatment part comprises a fresh air unit, a drain pipe, a fresh air valve, a plenum chamber and a fresh air pipeline.

Owner:山东省建筑工程质量检验检测中心有限公司 +1

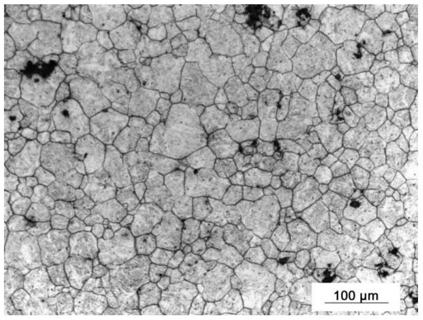

Heat treatment method of low-expansion high-temperature alloy

The invention discloses a heat treatment method of low-expansion high-temperature alloy, and particularly relates to the heat treatment method of the low-expansion high-temperature alloy in the fieldof heat treatment of metal materials. The heat treatment method of the low-expansion high-temperature alloy, provided by the invention, comprises the following steps: A, heating the alloy to 820-920 DEG C, preserving heat for 20 min to 2 h, and then performing air cooling; B, heating the alloy to 960-980 DEG C, preserving heat for 30 min to 2 h, and then performing air cooling; C, heating the alloy to 720-745 DEG C, and preserving heat for 4-8 h; and D, cooling the alloy to 620 DEG C at a cooling speed of 55 DEG C / h, preserving heat for 4 h, and then performing air cooling. By the heat treatment method of the low-expansion high-temperature alloy, the comprehensive performance of the alloy can be improved and the notch sensitivity of the alloy can be eliminated.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Impact-resistant ceramic insulator and manufacturing method thereof

The invention discloses an impact-resistant ceramic insulator and a manufacturing method thereof. The impact-resistant ceramic insulator has impact strength of being not less than 1.5 J / cm<2>, volume resistivity of being not less than 1*10<14>Omega.cm, dielectric strength of being not less than 750 kV / cm, thermal conductivity of being not less than 20 W / m.K, bending strength of being not less than 600 Mpa, Young's modulus of being not less than 450 Gpa and fracture toughness of being not less than 55 Mpa. A one-stage multiple-sintering manner is adopted in every 4-5 mm, so that a finished insulator has a multi-layer buffer and support structure, can withstand multi-angle and high frequency impact energy; a micro-structure is formed on the surface of the insulator, so as to facilitate the use on one hand and also increase the impact resistance on the other hand; and the impact-resistant ceramic insulator provided by the invention has advantages of high economy, high impact resistance, high fracture toughness and high comprehensive mechanical properties.

Owner:郭思源

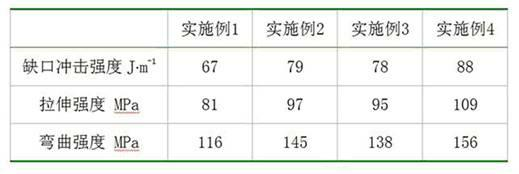

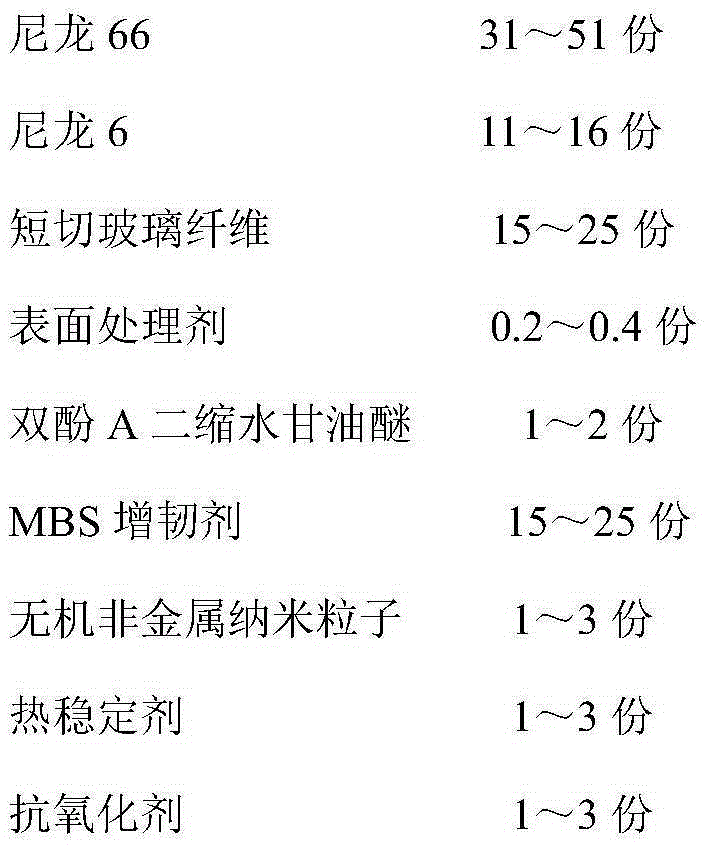

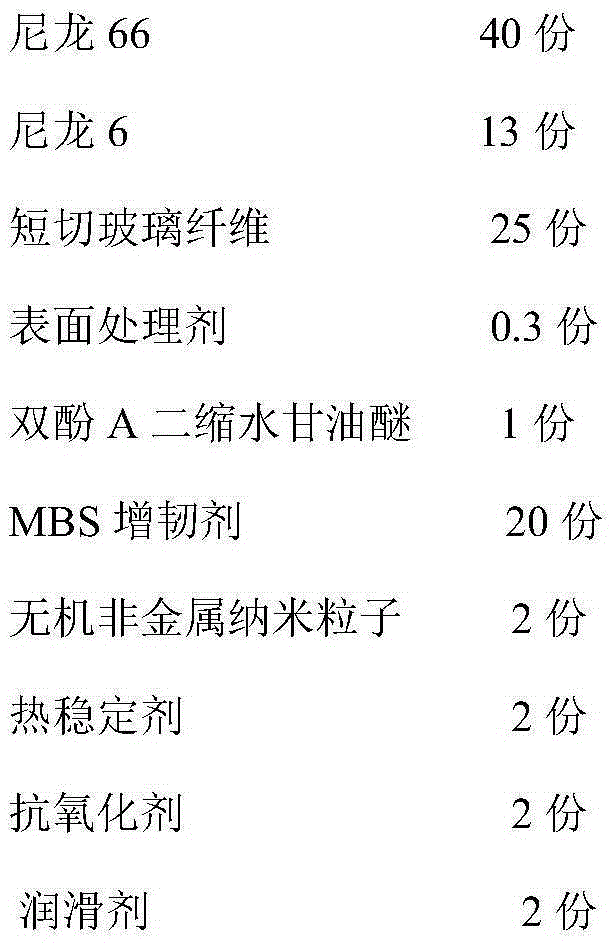

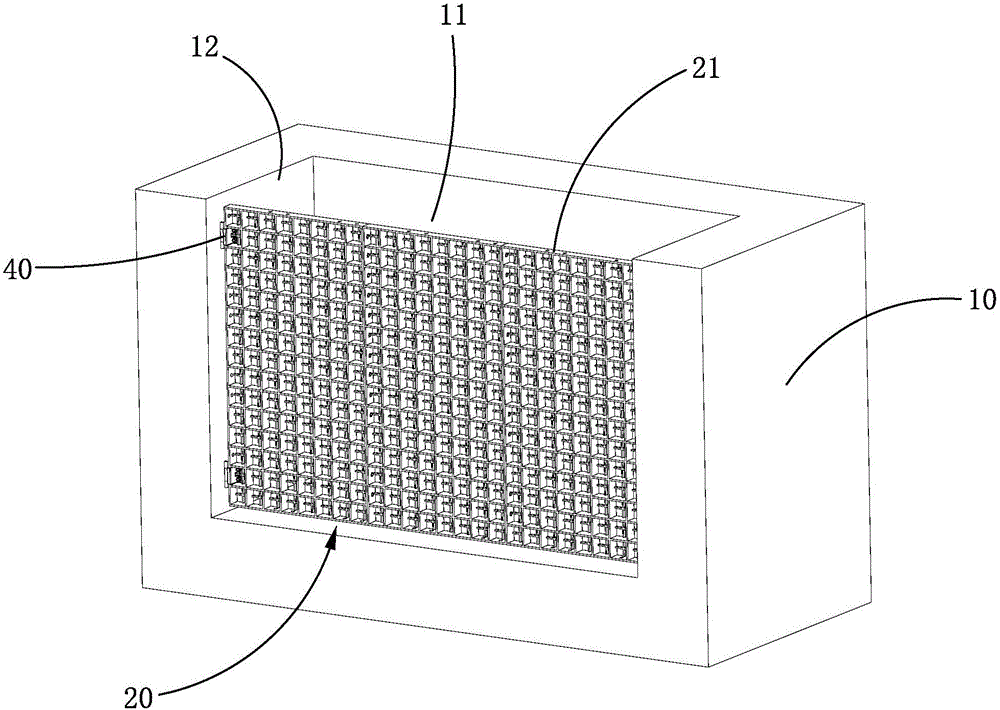

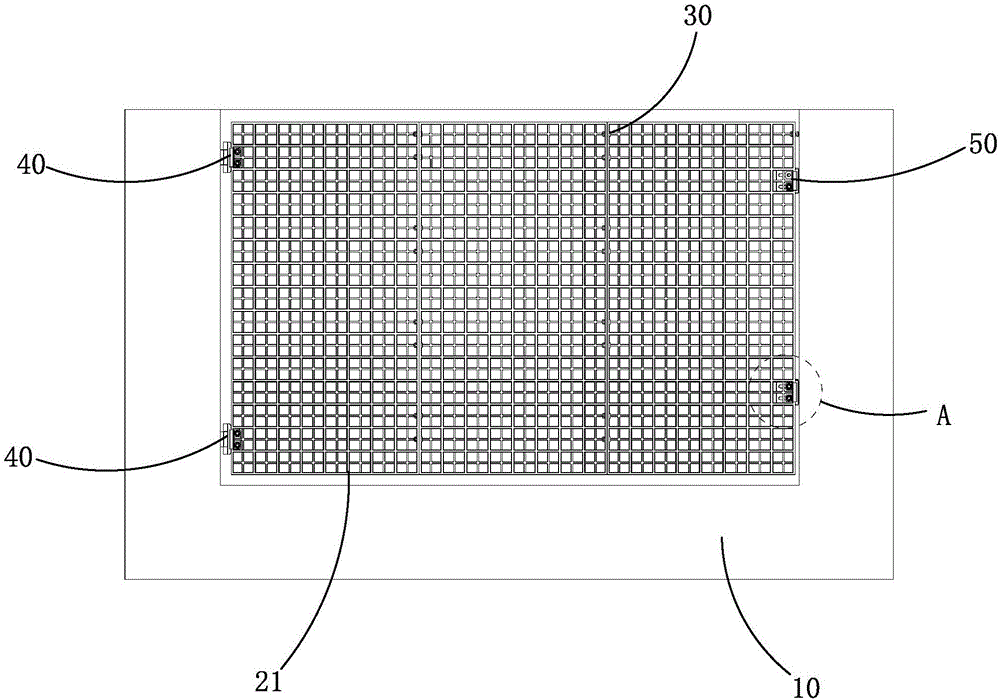

Nylon plastic bearing retainer for draw-bar box and preparation method of nylon plastic bearing retainer

The invention discloses a nylon plastic bearing retainer for a draw-bar box and a preparation method of the nylon plastic bearing retainer. According to the formula of the nylon plastic bearing retainer, nylon 66 and nylon 6 are taken as a compound basic material, through adding materials of short-cut glass fibers, a surface treating agent, bisphenol A diglycidyl ether, an MBS flexibilizer, inorganic nonmetal nano particles, a heat stabilizer, an antioxidant, a lubricating agent and the like, the notch impact strength, the tensile strength and the bending strength of the nylon plastic of the bearing retainer provided by the invention are all higher than those of common nylon plastic, more importantly, the nylon plastic has very high low-temperature-resistant capability, and the lowest using temperature can reach more than subzero 20 DEG C, so the requirements of the nylon plastic bearing retainer for the draw-bar box in a cold region are greatly met.

Owner:XIANGXING FUJIAN BAG ANDLUGGAGE GRP CO LTD

Grating baffle plate

ActiveCN106084712AEasy maintenanceHigh surface finishStairway-like structuresSurface finishGlass fiber

A grating baffle plate comprises a grating main body, the grating main body contains 10-15% of a reinforcing agent, and the reinforcing agent is glass fibers The glass fibers are added to the material of the grating, and the grating baffle plate substitutes traditional metal to make produced products have high surface fineness and excellent appearance. The grafting baffle plate has the characteristics of strong ultraviolet resistance, good shock resistance, high toughness, hydrolysis resistance and strong shock resistance, and greatly improves the performances of the products. Additionally, the grating baffle plate is arranged on the wall through adopting rotating members, and when maintenance of air conditioners or other devices in mounting grooves is needed, the grating main body is opened in a door opening manner without dismounting the whole grating baffle plate, thereby the grating baffle plate has the advantages of convenience for maintaining internal air conditioners, strong practicality, and strong promotion meaning.

Owner:李德雄

Bainite steel wheel for rail traffic passenger car and manufacturing method thereof

PendingCN108728750AReduce coefficient of frictionImprove operational efficiencyRail-engaging wheelsFurnace typesDesign systemsCorrosion

The invention discloses a bainite steel wheel for a rail traffic passenger car and a manufacturing method thereof. The bainite steel wheel comprises the chemical components of 0.08-0.35% of C, 0.10-1.50% of Ni, 0.25-1.50% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% of V, 0.001-0.20% of Nb, 0.0001-0.0350% of B, 0.001-0.040% of RE, 0-0.020% of P, 0-0.020% of S, and the balance Fe and inevitable residual elements, and in addition, the sum of Mn and Cr is larger than or equal to 2.0% and smaller than or equal to 3.0%. According to thebainite steel wheel for the rail traffic passenger car and the manufacturing method thereof, the novel C-Ni-Mn-Cr-Mo alloy design system and the alloying principle are adopted, after the wheel is formed, advanced heat treatment is conducted, then, the carbide-free bainite structure of a rim is obtained, and the wheel has the characteristics of being excellent in comprehensive mechanical property,corrosion resistance and service performance, high in strength, hardness, toughness, wheel rail rolling contact fatigue (RCF) resistance and hot crack resistance, and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Ceramic-metal composite material mixed multilayer material

InactiveCN107225818AImprove toughnessLow notch sensitivityGlass/slag layered productsMetal layered productsMetallic materialsAlloy

The invention discloses a ceramic-metal composite material mixed multilayer material which consists of a C / SiC material, sheet metal and a Glare laminate, and has a laminated structure. The C / SiC material, the sheet metal and the Glare laminate are sequentially arranged from top to bottom. The thickness of the C / SiC material is 1-4 mm; the sheet metal can be Mo, Nb or Ti and one of other alloy materials, and the thickness is 0.3-0.5 mm; and the thickness of the Glare laminate is 2-5 mm. According to a high-temperature hot press molding method, the material disclosed by the invention integrates the advantages of a ceramic-based composite material, the metal material and the Glare plate, so that the toughness of the material is obviously improved, the notch sensitivity is greatly improved, and the strength and toughness of the material are greatly improved.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

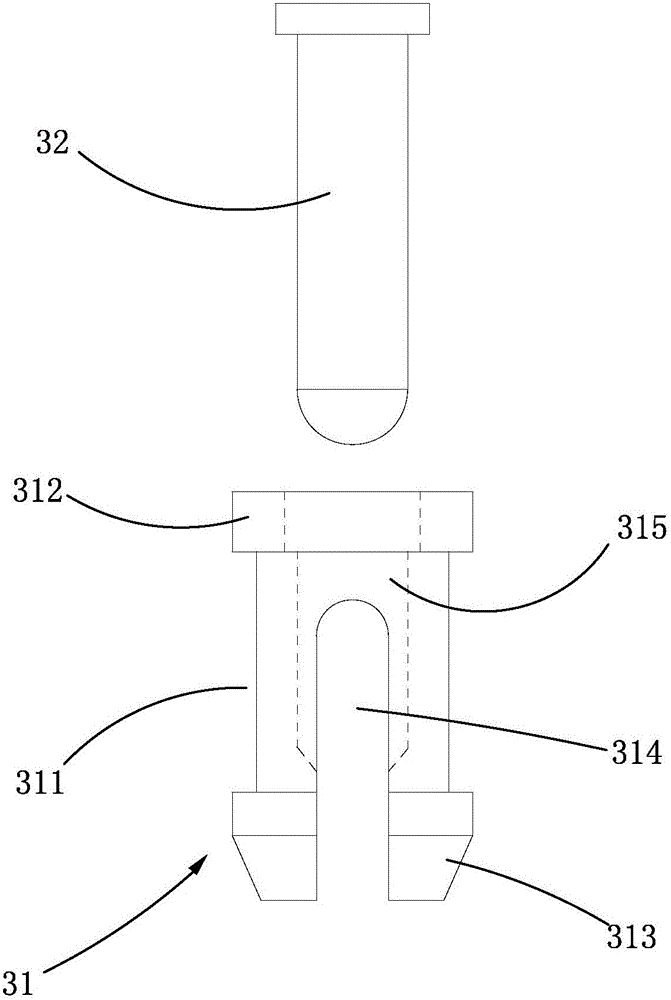

Heat treatment method for check ring for automobile steering gear and clamp thereof

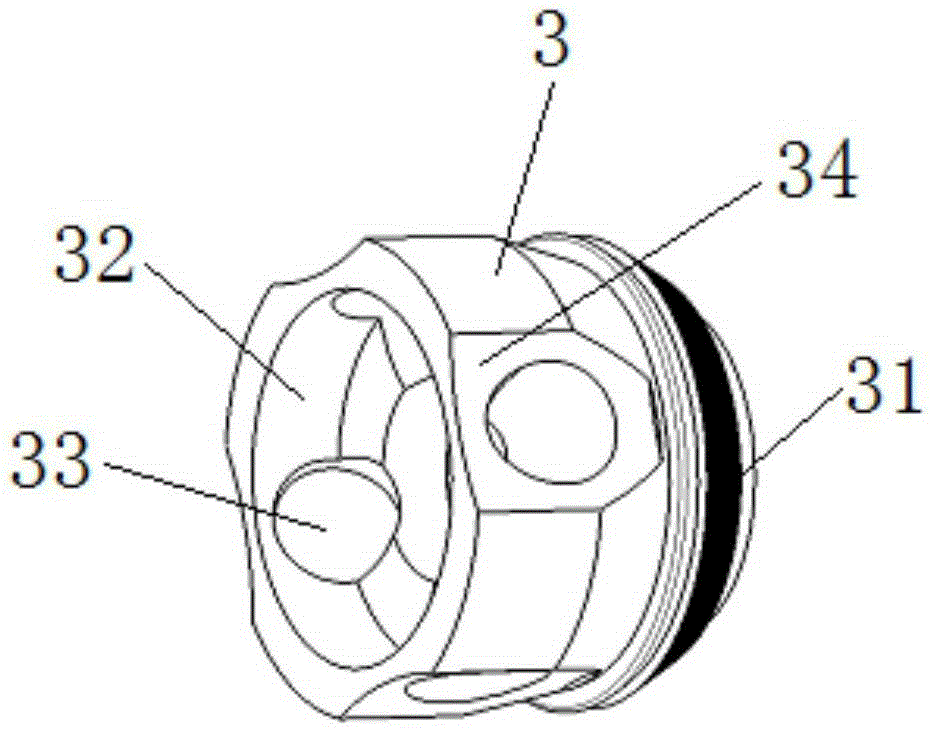

ActiveCN111440937AReduce distortionEasy clampingIncreasing energy efficiencyFurnace typesNumerical controlTempering

The invention discloses a heat treatment method for a check ring for an automobile steering gear and a clamp thereof. The efficiency is high, and the quality is stable and reliable. The clamp comprises a stringing rod, wherein a positioning head is arranged at one end of the stringing rod, threads are arranged at the other end of the stringing rod and matched with a nut in a threaded mode, an upper lining pipe and a lower lining pipe are sleeved between the head of the stringing rod and the nut, a stringing positioning space of the check ring is formed between the upper lining pipe and the lower lining pipe, and the stringing rod, the positioning head, the nut, the upper liner tube and the lower liner tube are made of non-magnetic steel. The heat treatment method comprises the steps that the check ring is clamped through the clamp and installed in a numerical control quenching machine tool; through induction heating, all the check rings on the clamp are subjected to integral water spraying quenching and tempering, and the tempering hardness of the check rings is controlled according to the adjusted electrical parameters and thermal parameters; and in the quenching and tempering process, the numerical control quenching machine tool drives the clamp to rotate, all parts of the check rings are evenly sprayed with water and heated, the numerical control quenching machine tool drives the clamp to do reciprocating motion in the axial direction, and all the check rings are sprayed with water and heated.

Owner:重庆建设传动科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com