Polycarbonate composite material with modified calcium sulfate whisker and preparation method thereof

A technology of calcium sulfate whisker and polycarbonate is applied in the field of calcium sulfate whisker modified polycarbonate composite material and its preparation technology, and achieves the effects of low notch sensitivity and good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

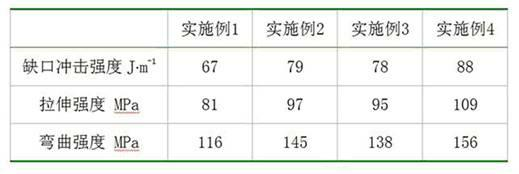

Examples

Embodiment 1

[0015] The present embodiment calcium sulfate whisker modified polycarbonate composite material is made of the raw material of following parts by weight: polycarbonate 100 parts, polystyrene 15 parts, calcium sulfate whisker 15 parts, antioxidant 1010 0.1 part, 3 parts of polytetrafluoroethylene, 1 part of titanate coupling agent.

[0016] Preparation:

[0017] (1) Add calcium sulfate whiskers and titanate coupling agent into a high-speed mixer, and activate for 5 minutes to obtain modified calcium sulfate whiskers; modified calcium sulfate whiskers have an aspect ratio of 15 and a diameter of 2 ;

[0018] (2) Add the polycarbonate, polystyrene, antioxidant 1010, and polytetrafluoroethylene into a high-speed mixer, and mix for 7 minutes to obtain polycarbonate, polystyrene, antioxidant 1010, and polytetrafluoroethylene Mixture with modified calcium sulfate whiskers;

[0019] (3) The mixture obtained in step (2) was melted and granulated through a twin-screw extruder, the b...

Embodiment 2

[0022] The calcium sulfate whisker modified polycarbonate composite material of this embodiment is made of the following raw materials in parts by weight: 100 parts of polycarbonate, 15 parts of polystyrene, 20 parts of calcium sulfate whisker, 0.1 part of antioxidant 1010, 3 parts of polytetrafluoroethylene, 1 part of titanate coupling agent.

[0023] Preparation:

[0024] (1) Add calcium sulfate whiskers and titanate coupling agent into a high-speed mixer, and activate for 5 minutes to obtain modified calcium sulfate whiskers; modified calcium sulfate whiskers have an aspect ratio of 15 and a diameter of 1.8 ;

[0025] (2) Add the polycarbonate, polystyrene, antioxidant 1010, and polytetrafluoroethylene into a high-speed mixer, and mix for 7 minutes to obtain polycarbonate, polystyrene, antioxidant 1010, and polytetrafluoroethylene Mixture with modified calcium sulfate whiskers;

[0026] (3) The mixture obtained in step (2) was melted and granulated through a twin-screw ...

Embodiment 3

[0029] The calcium sulfate whisker modified polycarbonate composite material of this embodiment is made of the following raw materials in parts by weight: 100 parts of polycarbonate, 20 parts of polystyrene, 25 parts of calcium sulfate whisker, 0.1 part of antioxidant 1010, 3 parts of polytetrafluoroethylene, 2 parts of titanate coupling agent.

[0030] Preparation:

[0031] (1) Add calcium sulfate whiskers and titanate coupling agent into a high-speed mixer, and activate for 5 minutes to obtain modified calcium sulfate whiskers; modified calcium sulfate whiskers have an aspect ratio of 20 and a diameter of 2 ;

[0032] (2) Add the polycarbonate, polystyrene, antioxidant 1010, and polytetrafluoroethylene into a high-speed mixer, and mix for 7 minutes to obtain polycarbonate, polystyrene, antioxidant 1010, and polytetrafluoroethylene Mixture with modified calcium sulfate whiskers;

[0033] (3) The mixture obtained in step (2) was melted and granulated through a twin-screw e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com