Rubber material as well as preparation method and application thereof

A rubber material and rubber material technology, applied in the field of functional material preparation, can solve the problems of poor fatigue resistance, lack of shock absorption effect, ineffective fixing of exhaust pipes, etc., and achieves good material strength and tear resistance. , The effect of good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

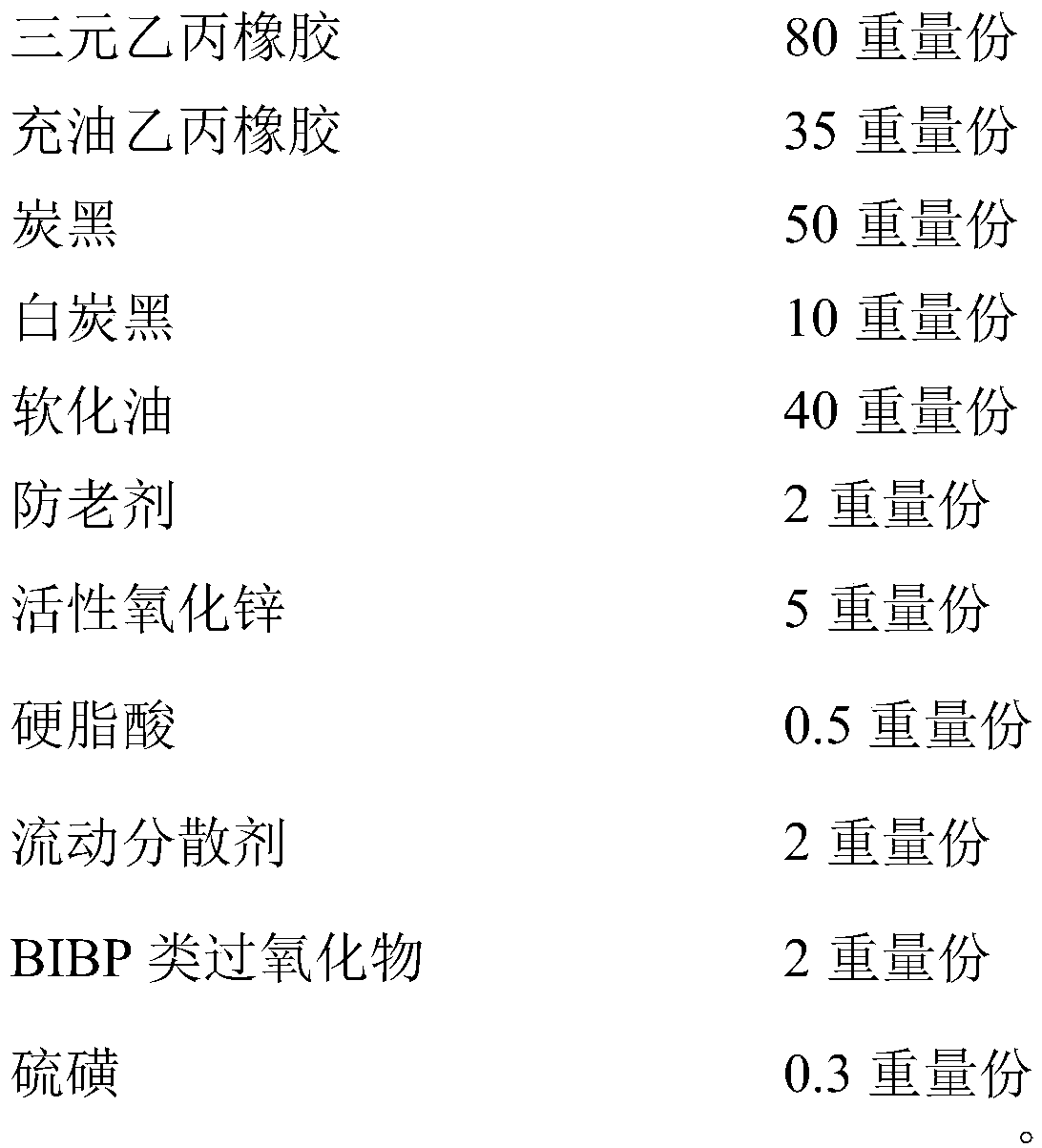

Embodiment 1

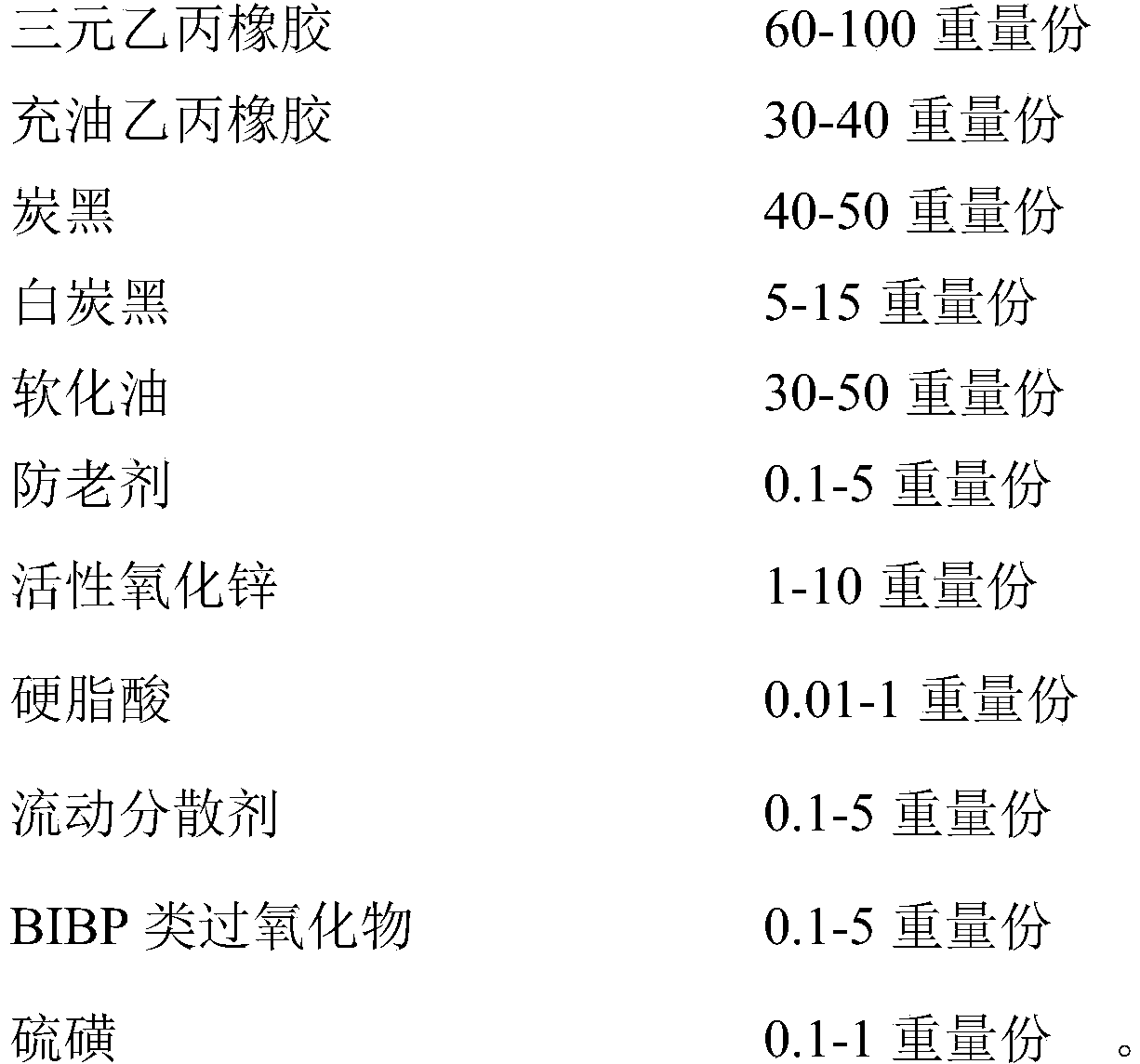

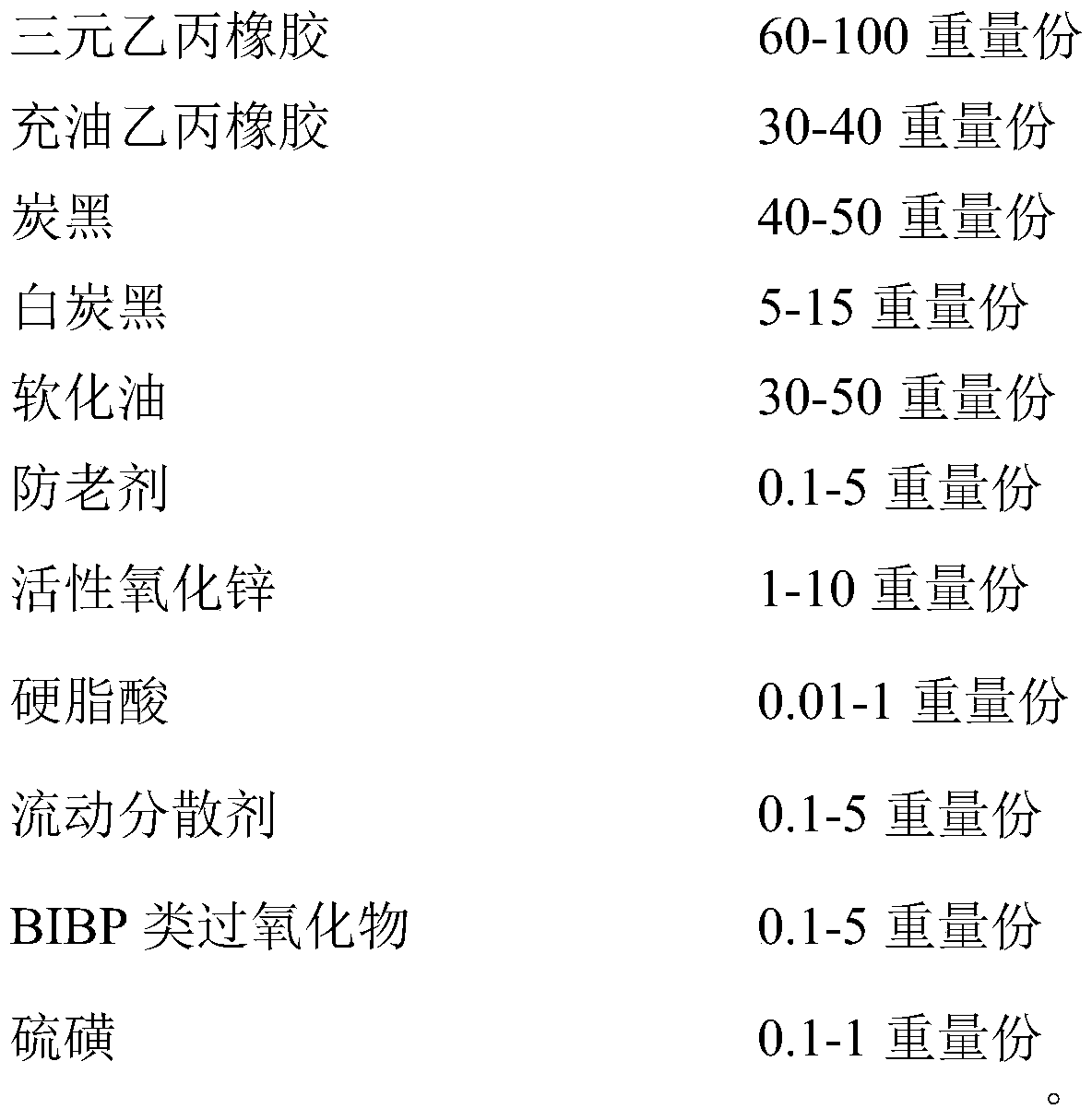

[0057] Prepare rubber material, take raw material according to table 1;

[0058] Mixing: put EPDM rubber and oil-extended ethylene propylene rubber into the internal mixer, masticate for 3 minutes, put in active zinc oxide, stearic acid, carbon black, white carbon black, and flow dispersant and mix for 4 minutes; Then add softener and knead for 4 minutes; when the temperature reaches 115-125°C, finally add BIBP peroxide and sulfur and knead for 0.5 minutes to get a good mixing compound;

[0059] Opening: Put the mixed rubber material into the open mill, the roller distance is 5-6mm, roll twice, adjust the roller distance to 1-1.5mm for thin pass twice, adjust the roller distance to 5-6mm and roll twice After the film, the thickness of the film is 8mm.

[0060] Table 1 raw material consumption table / weight part

[0061]

Embodiment 2

[0063] The rubber material was prepared, and the amount of raw materials was shown in Table 1, and the preparation method was the same as in Example 1.

Embodiment 3

[0065] The rubber material was prepared, and the amount of raw materials was shown in Table 1, and the preparation method was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static stiffness | aaaaa | aaaaa |

| Static stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com