Toughened ceramic for insulator and preparation method of toughened ceramic

A manufacturing method and technology for insulators, which are applied in the field of toughened ceramics for insulators and their manufacturing, can solve the problems of reduced insulation performance, fracture or breakage, and exerting the advantages of comprehensive performance of materials, and achieve the effect of improving fracture toughness and improving insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

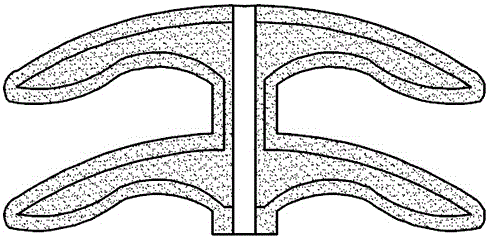

[0026] A toughened ceramic, which is divided into a core part 2 and a surface layer 1, wherein the surface layer 1 includes the following components by weight: 17.5 parts of silicon carbide, 20 parts of aluminum nitride, and 1 part of calcium fluoride; the core part 2 includes the following parts by weight Ingredients: 58 parts of silicon carbide, 2 parts of aluminum borate whiskers, 10 parts of indeterminate compounds of molybdenum;

[0027] A toughened ceramic for an insulator, the manufacturing method comprising the following steps:

[0028] 1) Raw material preparation

[0029] ①Prepare 2 parts by weight of aluminum borate whiskers, 70 parts of silicon carbide micropowder with a particle size of 3 μm-5 μm, 20 parts of aluminum nitride micropowder with a particle size of 3 μm-5 μm, 1 part of calcium fluoride powder, 10 parts of carbon powder, 10 parts of molybdenum silicide, 6 parts of ethyl orthosilicate, 3 parts of absolute ethanol, 3 parts of purified water, 1.5 parts of...

Embodiment 2

[0041] A toughened ceramic, which is divided into a core part 2 and a surface layer 1, wherein the surface layer 1 includes the following components by weight: 32 parts of silicon carbide, 30 parts of aluminum nitride, and 1.5 parts of calcium fluoride; the core part 2 includes the following parts by weight Ingredients: 77.5 parts of silicon carbide, 3 parts of aluminum borate whiskers, 15 parts of indeterminate compounds of molybdenum;

[0042] A toughened ceramic for an insulator, the manufacturing method comprising the following steps:

[0043] 1) Raw material preparation

[0044] ①Prepare 3 parts by weight of aluminum borate whiskers, 80 parts of silicon carbide micropowder with a particle size of 3 μm-5 μm, 30 parts of aluminum nitride micropowder with a particle size of 3 μm-5 μm, 1.5 parts of calcium fluoride powder, 15 parts of carbon powder, 15 parts of molybdenum silicide, 8 parts of ethyl orthosilicate, 5 parts of absolute ethanol, 5 parts of purified water, 2.5 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com