Patents

Literature

226 results about "Aluminum borate whiskers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

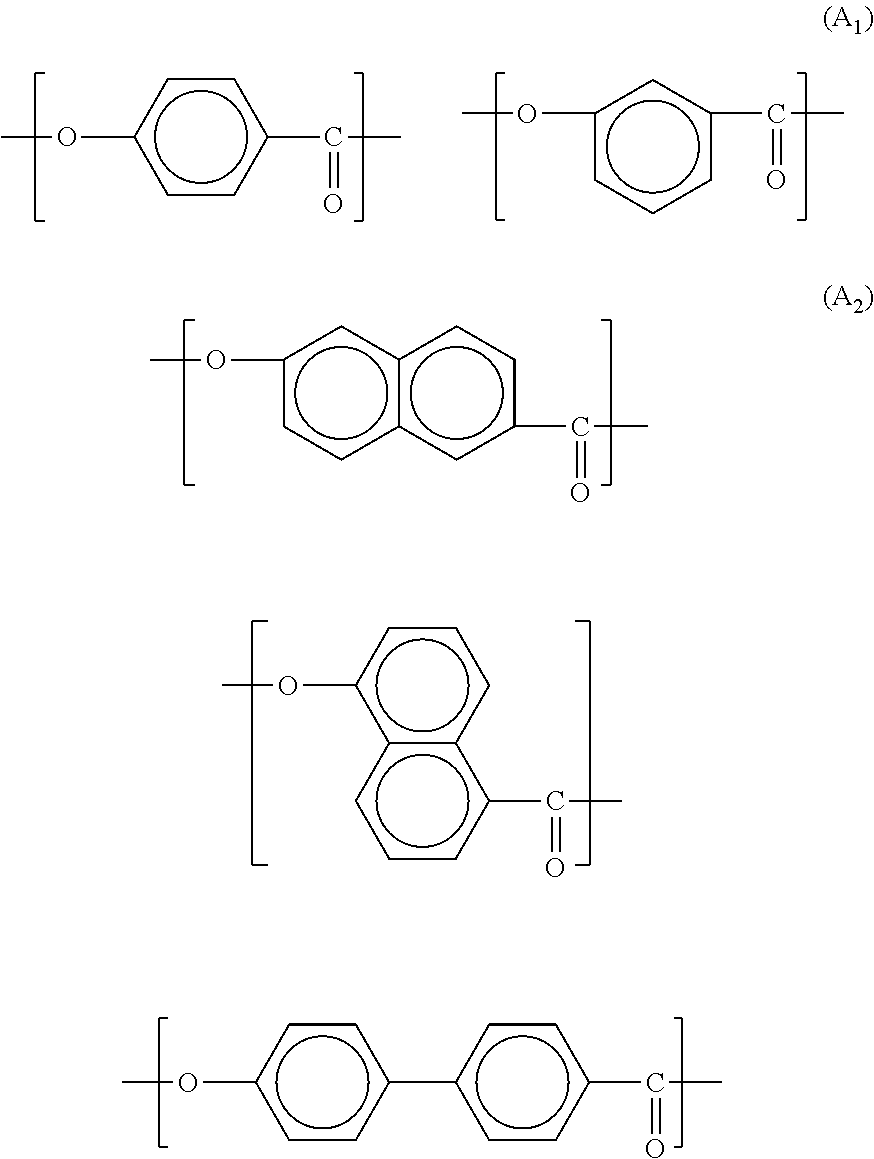

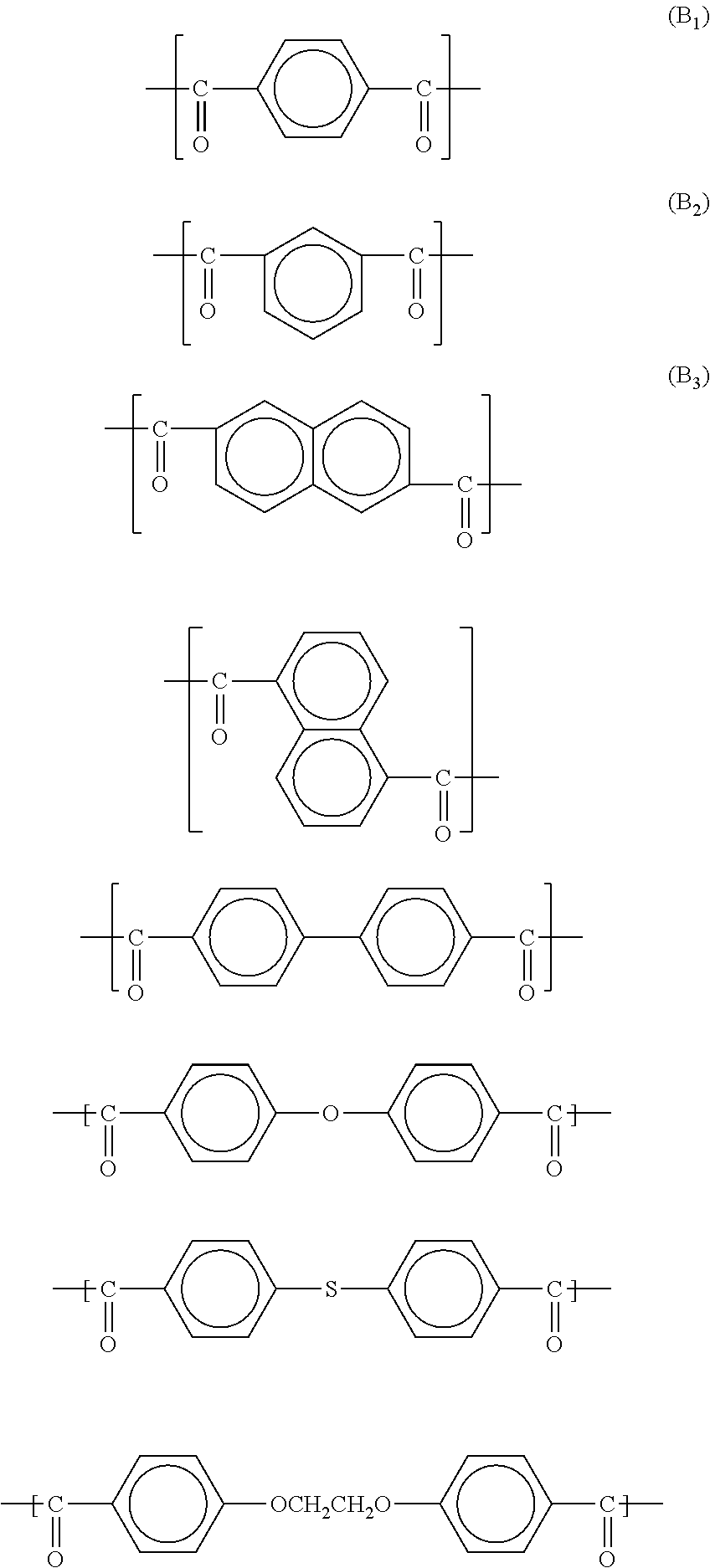

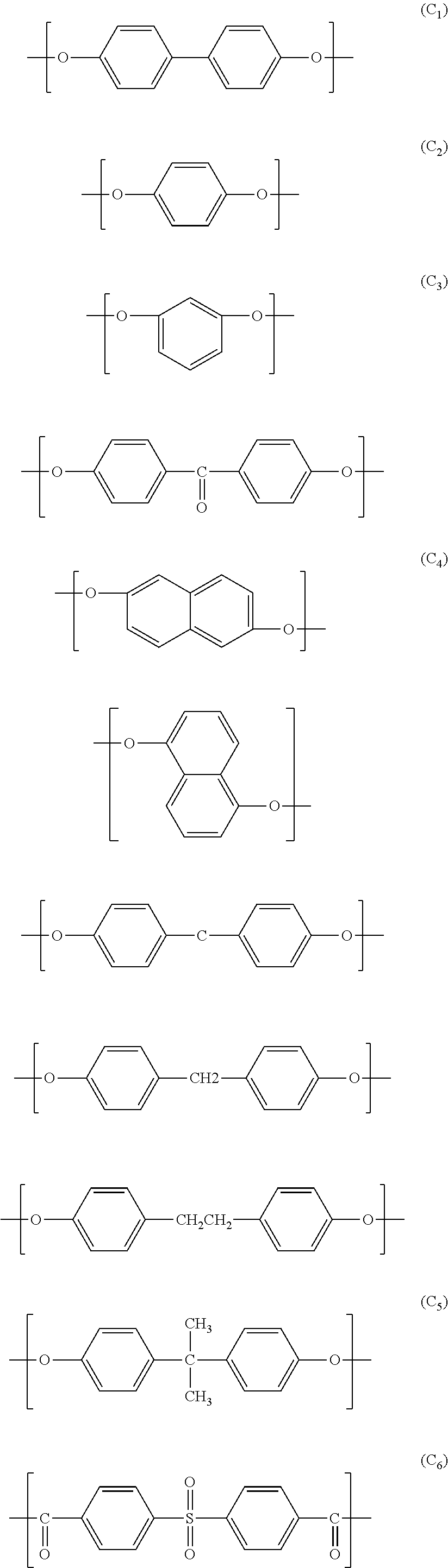

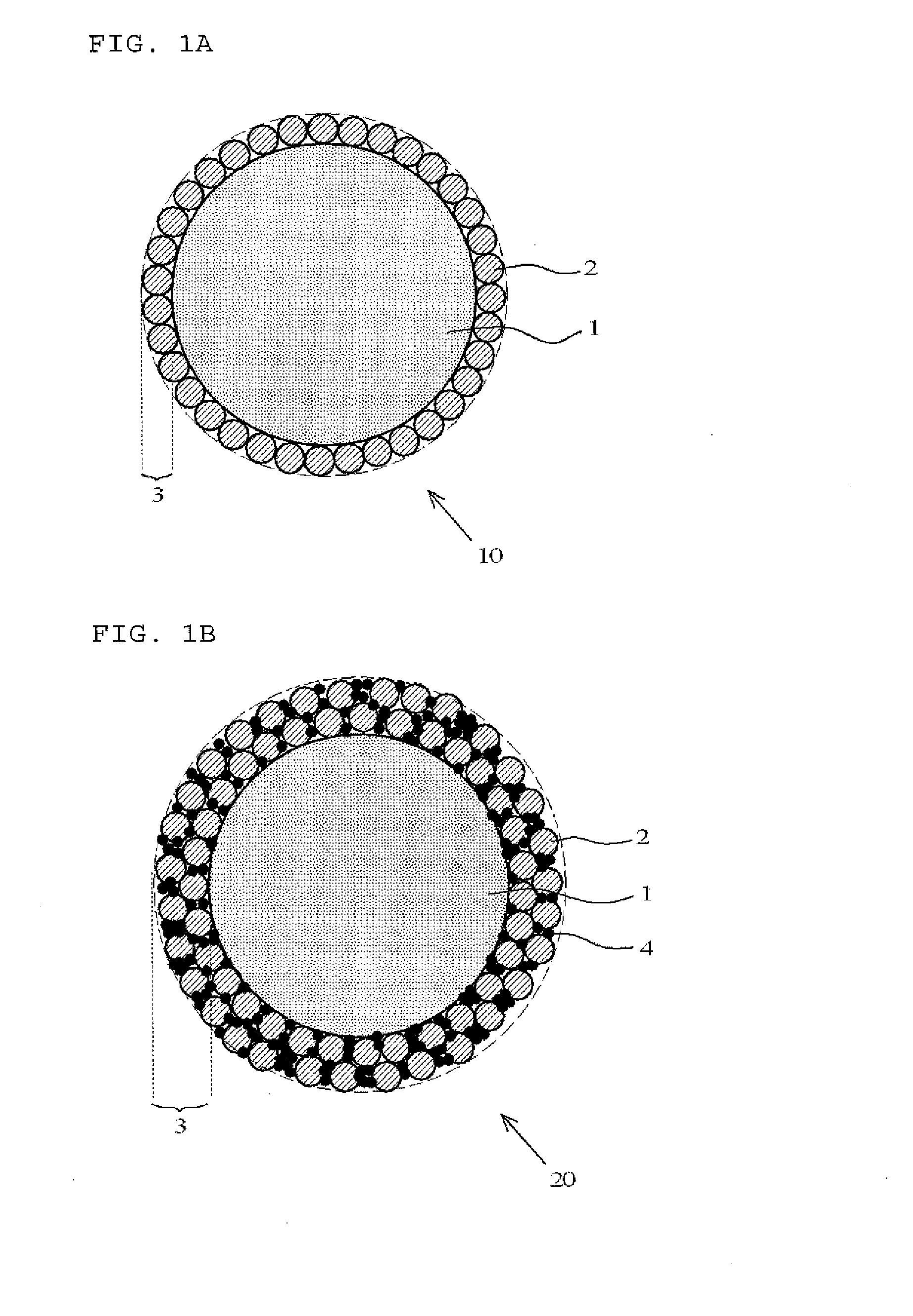

Liquid-crystal polyester resin composition

InactiveUS7985351B2Improve mechanical propertiesLiquid crystal compositionsConductive materialLiquid crystallinePolyester resin

A liquid crystalline polyester resin composition comprising 100 parts by weight of a liquid crystalline polyester; 50 to 150 parts by weight of at least one whisker selected from aluminum borate whisker and titanium oxide whisker; and 1 to 30 parts by weight of carbon black having a specific surface area of at least 200 m2 / g. This liquid crystalline polyester resin composition has excellent mechanical properties and provides an insulator which is hardly charged.

Owner:SUMITOMO CHEM CO LTD +1

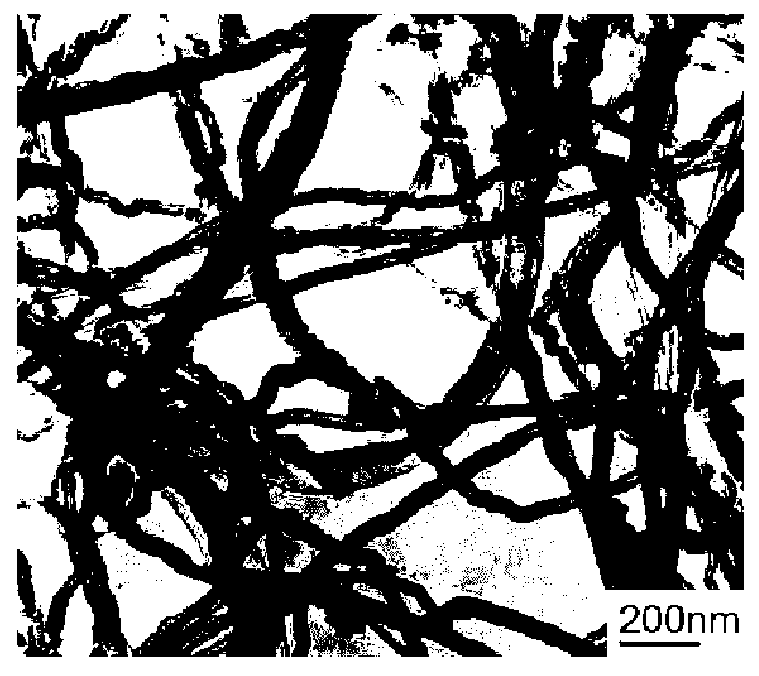

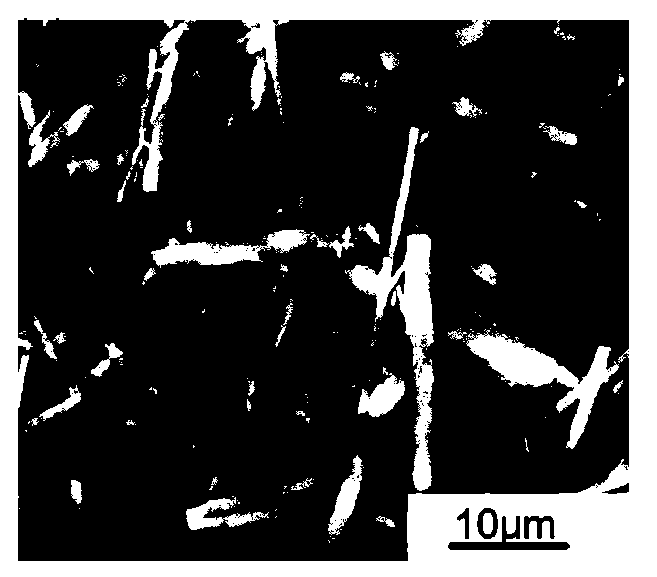

Method for preparing carbon nanotube and aluminum borate whisker hybrid reinforced aluminum-matrix composite material

The invention relates to a method for preparing a carbon nanotube and aluminum borate whisker hybrid reinforced aluminum-matrix composite material, which relates to a method for preparing an aluminum-matrix composite material which is simultaneously reinforced by microfibers and nanofibers. The method solves the problem that the aluminum-matrix composite material prepared by the conventional method for preparing aluminum-matrix composite materials has poor performance, low interface bonding and difficult uniform distribution of two wild phases of carbon nanotubes and whiskers. The method comprises the following steps of: 1, mixing raw materials by a wet process; 2, preparing a prefabricated block; 3, drying the prefabricated block; 4, sintering the prefabricated block; and 5, casting molten aluminum alloy into a mould provided with the prefabricated block and applying pressure on the mould to obtain the carbon nanotube and aluminum borate whisker hybrid reinforced aluminum-matrix composite material. In the method, the two wide phases of the carbon nanotubes and the whiskers are uniformly distributed, and the carbon nanotube and aluminum borate whisker hybrid reinforced aluminum-matrix composite material prepared by the method has high performance and high interface bonding.

Owner:HARBIN INST OF TECH

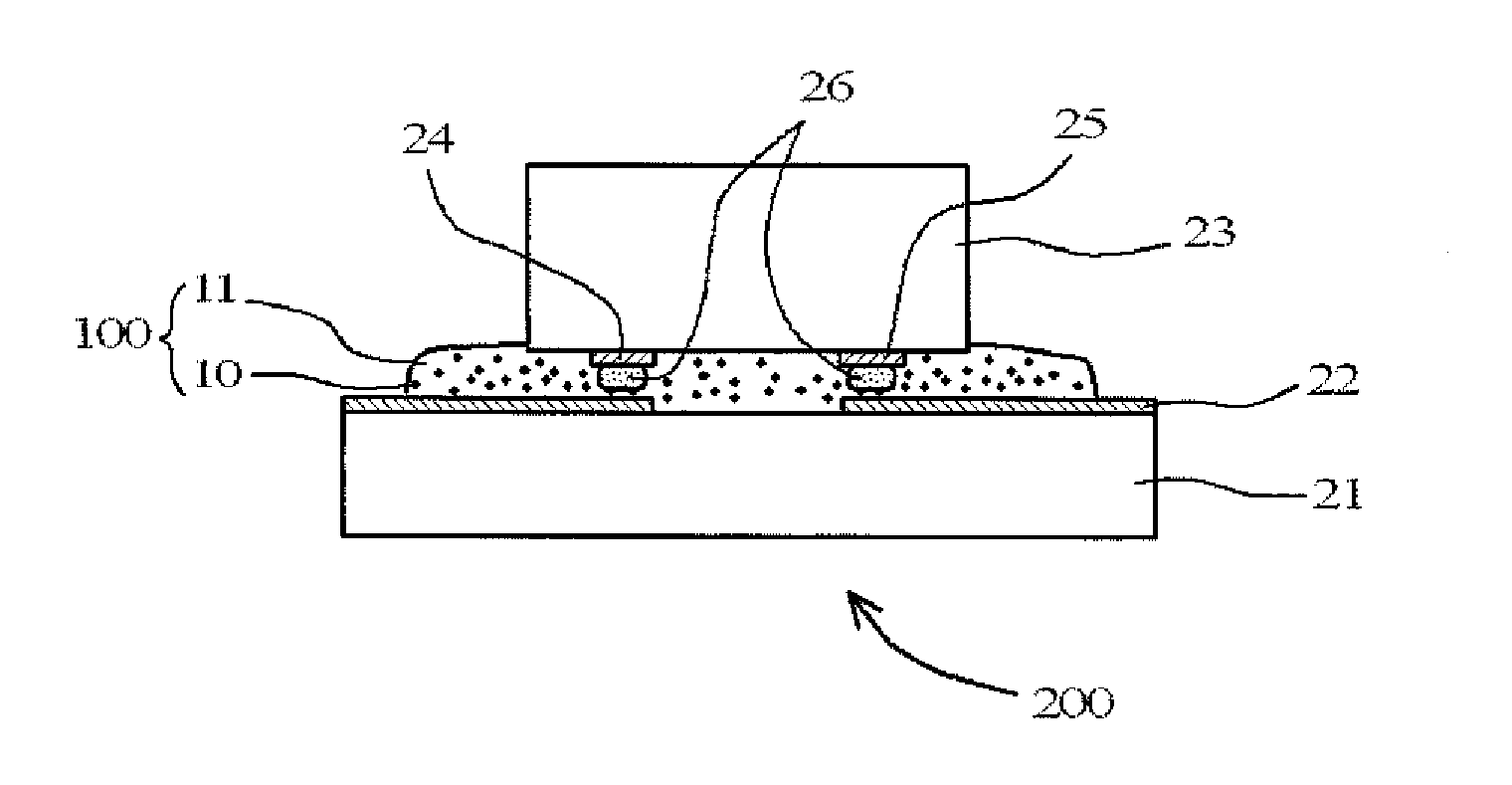

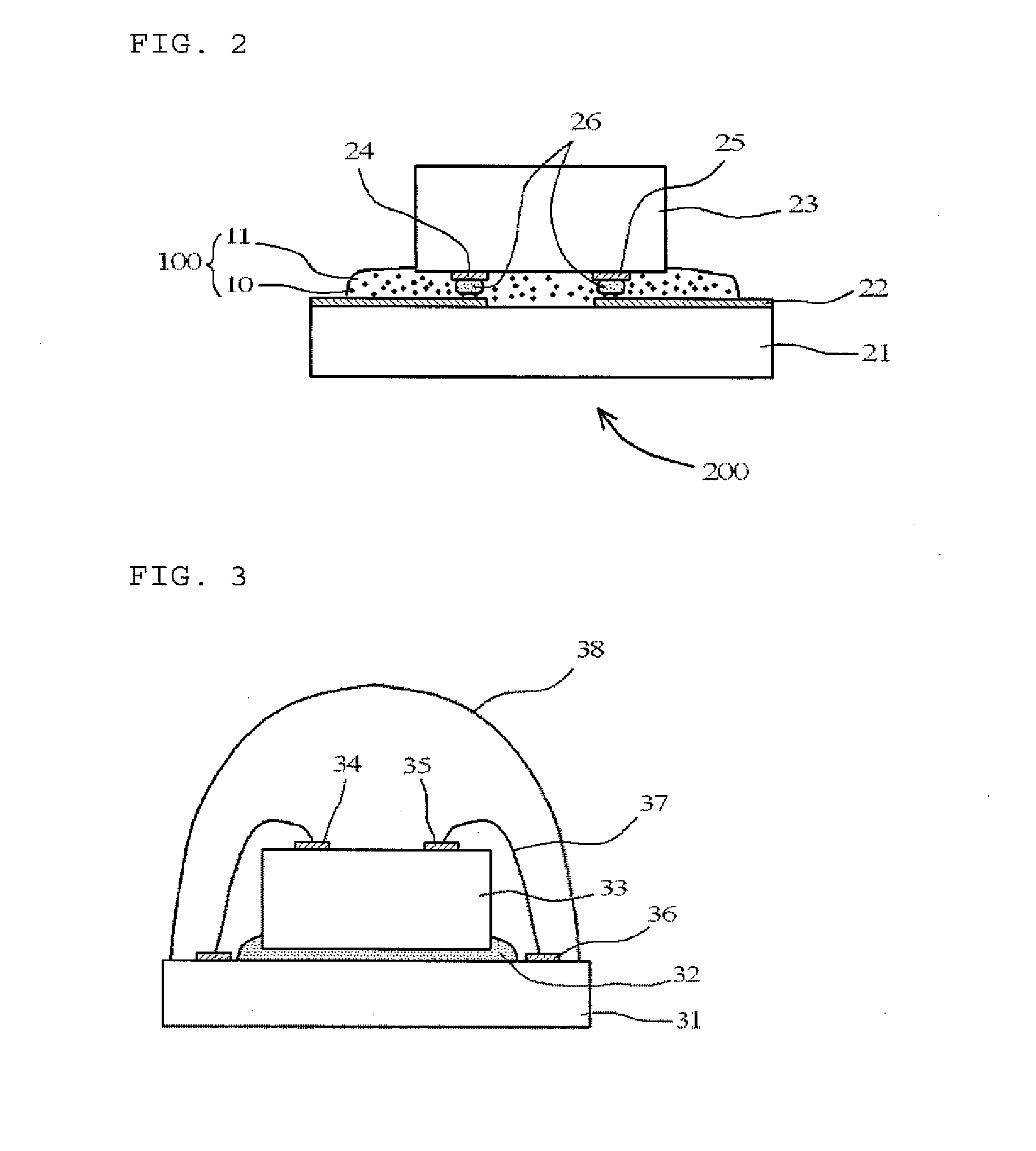

Light-reflective anisotropic conductive adhesive and light-emitting device

InactiveUS20130264602A1Increase production costLowering of conducting reliabilityConductive materialSolid-state devicesAnisotropic conductive adhesiveZinc

A light-reflective anisotropic conductive adhesive used for anisotropic conductive connection of a light-emitting element to a wiring board contains a thermosetting resin composition, conductive particles, light-reflective needle-shaped insulating particles, and light-reflective spherical insulating particles. Each of the amount of the light-reflective needle-shaped insulating particles and the amount of the light-reflective spherical insulating particles in the thermosetting resin composition is 1 to 50 percent by volume based on the volume of the thermosetting resin composition, and the mixing ratio (V / V) of the light-reflective spherical insulating particles to the light-reflective needle-shaped insulating particles is 1:1 to 10. The light-reflective needle-shaped insulating particles are titanium oxide whiskers, zinc oxide whiskers, titanate whiskers, aluminum borate whiskers, or wollastonite.

Owner:DEXERIALS CORP

Alumina ceramic low temperature brazing connection method

ActiveCN105418131ALow softening temperatureReduce residual internal stressThermal expansionSolder paste

The invention relates to an alumina ceramic low temperature brazing connection method and aims at solving the problems that existing brazing alumina ceramics are high in soldering temperature and low in connection strength of obtained joints. The brazing connection method comprises the following steps: 1, mixing Bi2O3, B2O3, ZnO and SiO2, and obtaining low-melting-point bismuthate glass powder; 2, conducting mechanical grinding on an alumina ceramic, conducting ultrasonic cleaning, and obtaining a pre-treated alumina ceramic; 3, preparing an alumina ceramic where aluminum borate whiskers grow; 4, applying glass soldering paste to the surface of the alumina ceramic where the aluminum borate whiskers grow; 5, making two alumina ceramic parts to be soldered be in contact and aligned with each other; 6, conducting brazing connection at the temperature of 480-650 DEG C. By means of the alumina ceramic low temperature brazing connection method, connection of the alumina ceramic is achieved at the low temperature, the thermal expansion coefficient of the adopted glass brazing material is matched with the alumina ceramic, the shearing strength of an obtained soldered joint can reach 60-100 MPa, and reliability of alumina connection is guaranteed.

Owner:HARBIN INST OF TECH

Friction material for brake block of heavy-duty automobile

InactiveCN106147124AImprove stress resistanceImprove impact resistanceOther chemical processesFriction liningAcrylic rubberHeat stability

The invention discloses a friction material for a brake block of a heavy-duty automobile. The friction material is prepared from, by weight, 20-35 parts of phenolic resin, 2-5 parts of acrylic rubber, 3-8 parts of amph-POSS, 2-8 parts of quartz fibers, 10-20 parts of high silica fibers, 3-10 parts of silica fibers, 3-12 parts of aluminum borate whiskers, 3-10 parts of basic magnesium sulfate whiskers, 20-35 parts of nano-palygorskite, 15-35 parts of barium carbonate, 3-10 parts of aluminum powder, 3-10 parts of nano powdered carbon, 5-15 parts of boron nitride, 3-12 parts of emery powder, 2-6 parts of vermiculite, 0.5-5 parts of mica, 3-5 parts of molybdenum trioxide, 2-6 parts of natural graphite, 2-10 parts of micron zirconia balls and 2-8 parts of graphene oxide. The friction material for the brake block of the heavy-duty automobile has excellent high temperature resistance, wear resistance and heat stability and is used for the brake block of the heavy-duty automobile, and is good in braking performance and long in service life.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

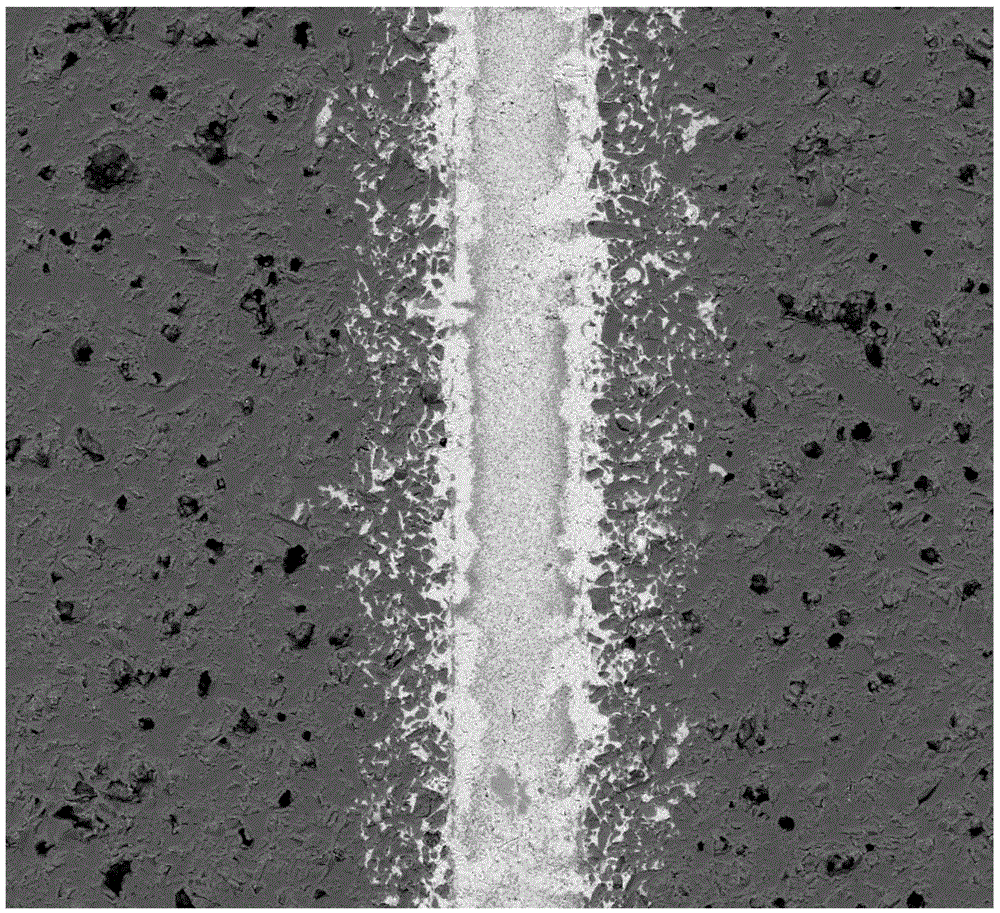

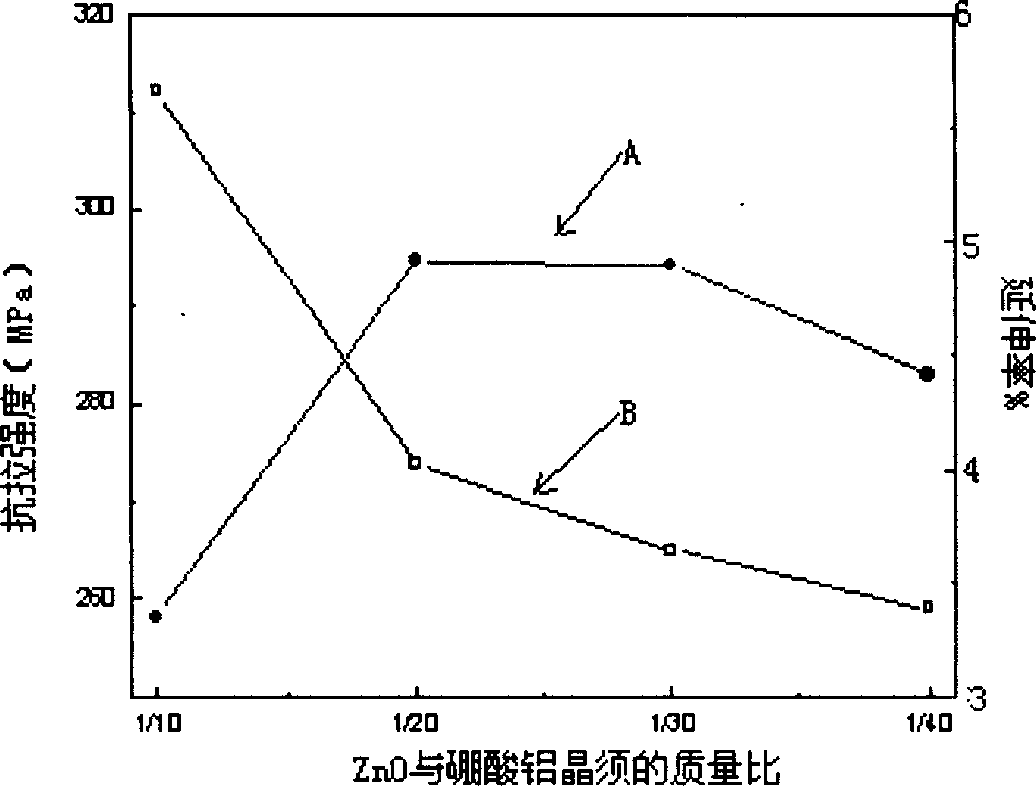

ZnAl2O4 coated aluminium borate whister reinforced aluminium base or magnesium base composite meterial and its preparation method

InactiveCN1786250AImprove wettabilityImprove mechanical propertiesMagnesium matrix compositeBoric acid

The invention relates to ZnAl2O4 covering aluminium borate crystal whisker strengthening aluminium base or magnesium base composite and its manufacturing method. It solves the current problems that aluminium borate crystal whisker and basal body wet ability is bad and their bonding strength is not high. And it can effectively obstruct interface reaction. The composite is made up of ZnO, aluminium borate crystal whisker, and aluminium base or magnesium base. The preparing steps as the following: adding aluminium borate crystal whisker into ZnO sol to make ZnO coating aluminium borate crystal whisker; preparing ZnAl2O4 covering aluminium borate crystal whisker precast block; extrusion casting to gain the composite. The superficial reacted by ZnO and aluminium borate can improve aluminium borate crystal whisker and basal body wet ability and interface bonding strength to obviously improve composite mechanical property.

Owner:HARBIN INST OF TECH

Heat insulation spray coating

The invention relates to a heat insulation spray coating, belonging to the field of fireproof materials. The heat insulation spray coating comprises the following components in parts by weight: 38-58 parts of waste lightweight clay bricks, 3-9 parts of raw perlite, 10-20 parts of cement, 20-30 parts of flint clay powder, 5-8 parts of Guangxi mud, 1-3 parts of talc powder and 0.5-2 parts of additional aluminum borate whiskers. The heat insulation spray coating disclosed by the invention can be used for rapid construction in use, is practical, does not need special maintenance, has good acid resistance and reduction resistance, is good in service performance, and is suitable for occasions requiring heat insulation or occasions with strong reducing properties.

Owner:浙江科明电子有限公司

Heat-resistant anti-impact grinding wheel material

The invention discloses a heat-resistant anti-impact grinding wheel material. The heat-resistant anti-impact grinding wheel material is prepared from diamond, silicon carbide whiskers, aluminum borate whiskers, potassium titanate whiskers, aluminum oxide whiskers, yttrium oxide, cerium oxide, feldspar, fluorite, modified phenolic resin, polyurethane resin, polyethylene wax emulsion, calcium lignosulphonate, slag, glass fibers, carbon fibers, a pore forming agent and alloy powder. The heat-resistant anti-impact grinding wheel material is reasonable in composition. An obtained grinding wheel is excellent in bending strength, microhardness, impact toughness, wear resistance, heat dissipation performance and heat resistance, not likely to burst apart and high in safety coefficient and meanwhile has the beneficial effects of being high in grinding efficiency and grinding ratio, good in grinding quality, long in service life and the like. Good economic benefits are achieved.

Owner:安徽昌悌进出口贸易有限公司

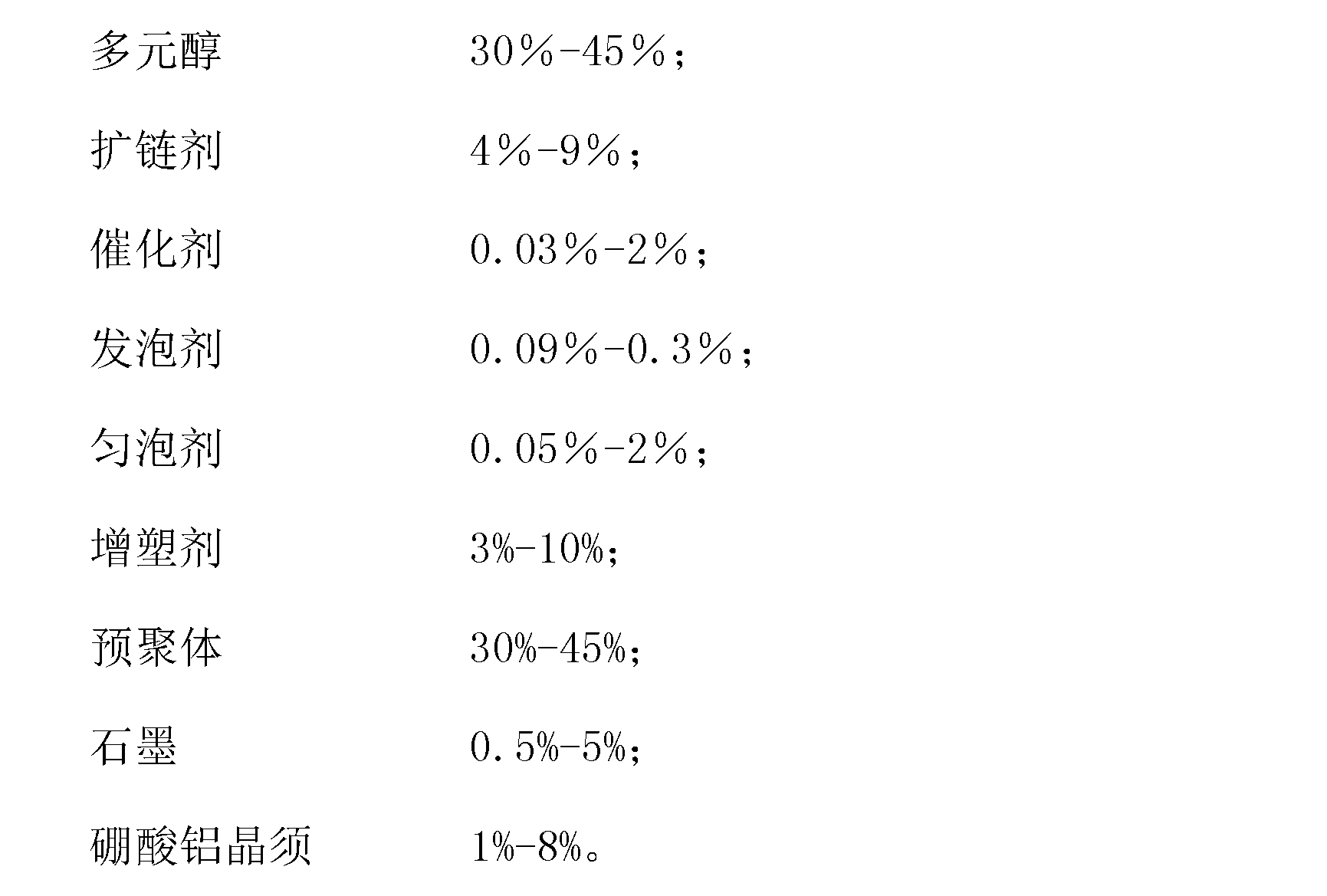

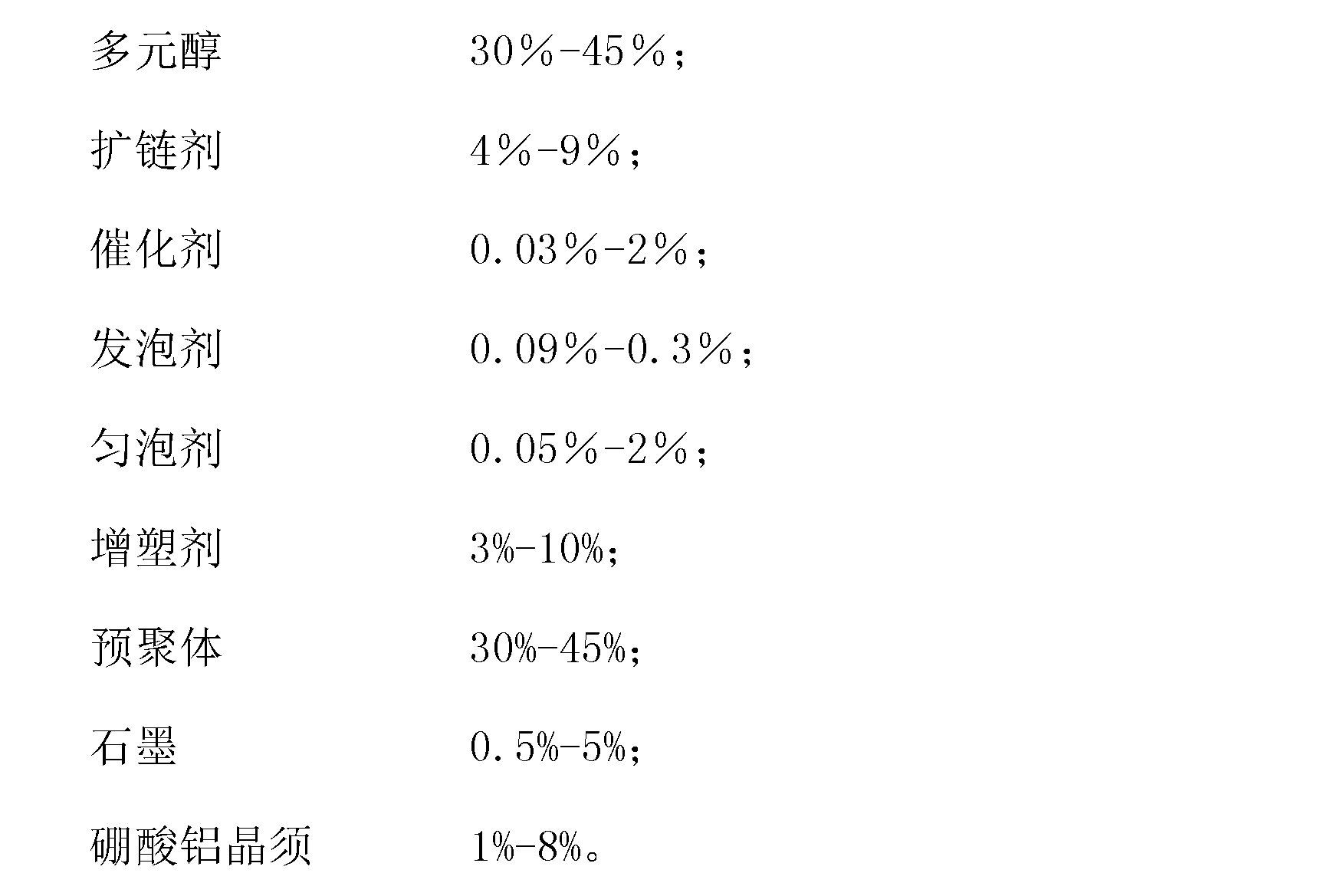

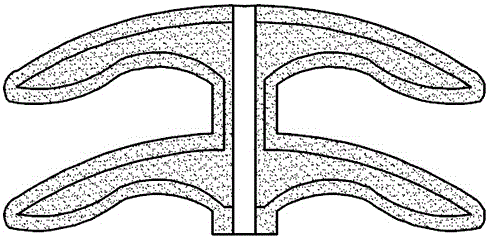

Conductive polyurethane sole material

The invention discloses a conductive polyurethane sole material which comprises the following components in percentage by weight: 30-45% of polyhydric alcohol, 4-9% of a chain extender, 0.03-2% of a catalyst, 0.09-0.3% of a foamer, 0.05-2% of a foam stabilizer, 3-10% of plasticizer, 30-45% of prepolymer, 0.5-5% of graphite and 1-8% of aluminum borate crystal whiskers. The conductive performance of the polyurethane shoe material can be extremely improved by adding graphite and aluminum borate crystal whiskers. The affinity of graphite and aluminum borate crystal whiskers to the polymer is improved by surface pretreatment for graphite and aluminum borate crystal whiskers through a coupler. The toughness of the polyurethane material is not reduced to a great extent due to the addition of the inorganic conductive component by adding the plasticizer. In addition, the conductive polyurethane sole material disclosed by the invention is simple in process and environment-friendly.

Owner:SUZHOU JINGRO TECH

Toughened ceramic for insulator and preparation method of toughened ceramic

The invention discloses toughened ceramic for an insulator and a preparation method of the toughened ceramic. The toughened ceramic is prepared from, by weight, 2-3 parts of aluminum borate whiskers, 70-80 parts of silicon carbide micro powder with the proper size, 20-30 parts of aluminum nitride micro powder with the proper size, 1-1.5 parts of calcium fluoride powder, 10-15 parts of carbon powder, 10-15 parts of molybdenum silicide, 6-8 parts of ethyl orthosilicate, 3-5 parts of absolute ethyl alcohol, 3-5 parts of purified water and 1.5-2.5 parts of thermoplastic phenolic resin. By means of the steps of raw material preparation, insulator pre-preparation, insulator sintering and completing, the high-tenacity insulation ceramic with the volume resistivity larger than or equal to 2*1,013 omega-cm, the dielectric strength larger than or equal to 750 kV / cm, the thermal conductivity larger than or equal to 25 W / m.K, the bending strength larger than or equal to 400 Mpa, the Young modulus larger than or equal to 320 Gpa and the breaking tenacity larger than or equal to 25 Mpa is formed. The toughened ceramic is good in economical efficiency, resistant to high temperature oxidation and high in breaking tenacity, and the functions of main materials complement one another.

Owner:宁波高智科技咨询服务有限公司

ZnO coating aluminum boric acid crystal whisker reinforcing aluminum base composite material and method for producing the same

InactiveCN101195885AImprove wettabilitySimple interfaceLiquid/solution decomposition chemical coatingSemi solidBoric acid

The invention discloses ZnO coating aluminum borate whisker reinforced aluminum matrix composite material and the preparation method thereof, which relates to composite material and the preparation method thereof. The invention solves the problems that the wettability of the aluminum borate whisker and the matrix in the composite material is poor, the interface reaction is generated between the aluminum borate whisker and elements of the matrix, the process of preparing aluminum borate reinforced aluminum matrix composite material is complex, the cost is high, and the material tissues are not uniform. In the method of the invention, ZnO coating aluminum borate whisker is prepared, then alloy is smelted, the preheating ZnO coating aluminum borate whisker is added into the alloy in the semi-solid state, semi-solid state mechanical stirring is performed to obtain semi-solid state pulp material, and the ZnO coating aluminum borate whisker reinforced aluminum matrix composite material is obtained through semi-solid state extrusion forming. In the invention, the wettability of the aluminum borate whisker and the matrix in the composite material is enhanced, the interface reaction in the elements of the matrix is prevented, the process of preparing aluminum borate reinforced aluminum matrix composite material is simple, the cost is low, and the material tissues are uniform.

Owner:HARBIN INST OF TECH

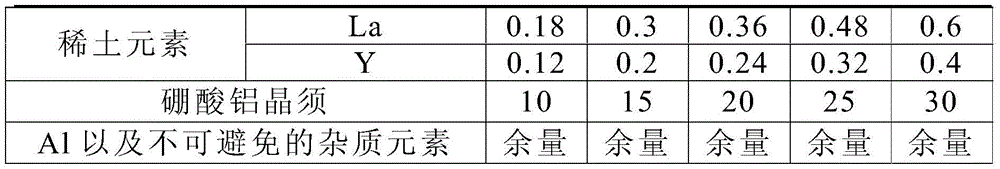

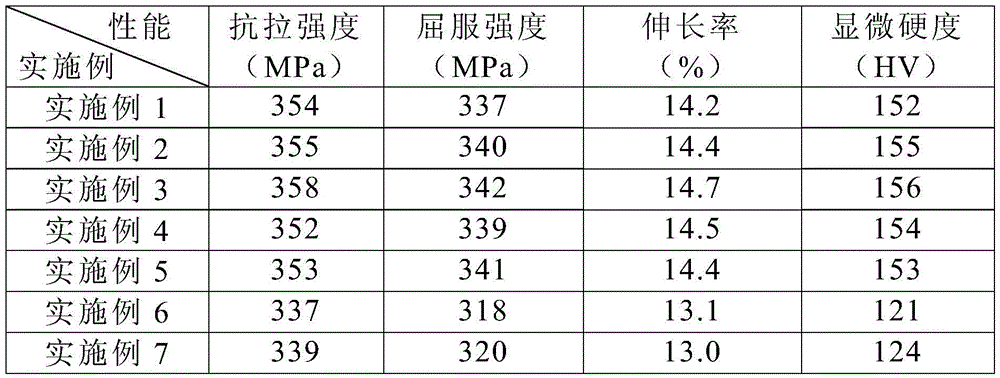

Aluminum alloy sliding valve

InactiveCN105463271AEasy to processImprove corrosion resistanceRare-earth elementAluminum borate whiskers

The invention relates to an aluminum alloy sliding valve which comprises a valve body and a valve element. The valve body and the valve element are made of aluminum alloy materials. Aluminum alloy comprises, by mass percent, 1.0-1.5% of Mg, 0.6-1.0% of Si, 0.3-0.5% of Cu, 0.1-0.3% of Zn, 0.1-0.3% of Mn, 0.05-0.2% of Cr, 0.05-0.1% of Ti, 0.3-0.6% of Fe, 0.15-0.5% of Zr, 0.05-0.3% of Nb, 0.5-0.8% of Bi, 0.3-1% of rare earth element, 10-30% of aluminum borate whisker and the balance Al and inevitable impurity elements. The valve body and the valve element of the sliding valve are made of aluminum alloy materials, and the beneficial effects of being low in weight, high in strength, resistant to corrosion and the like are achieved.

Owner:NINGBO HONGBO MACHINERY MFG

Aluminum borate crystal whisker reinforced low-temperature unleaded composite soldering paste and preparation method thereof

ActiveCN102240866AImproved solder joint shear strengthIncreased shear strengthWelding/cutting media/materialsSoldering mediaHydroxystearic AcidStearic acid

The invention provides an aluminum borate crystal whisker reinforced low-temperature unleaded composite soldering paste and a preparation method thereof, relating to a soldering paste and a preparation method thereof, which solve the problem that extremely serious coarsing of tissues and an intermetallic compound after high-temperature aging exists in the traditional low-temperature unleaded solder. The aluminum borate crystal whisker reinforced low-temperature unleaded composite soldering paste is prepared from aluminum borate crystal whiskers, Sn-58Bi powder and rosin type scaling powder. The method comprises the steps of: weighing raw materials, filtering and drying the aluminum borate crystal whiskers after stirring, putting the aluminum borate crystal whiskers together with the Sn-58Bi powder, 12-hydroxystearic acid and ZrO2 grinding balls into a ball milling jar for ball milling to obtain composite solder powder; and stirring the composite solder powder and the rosin type scaling powder to obtain the soldering paste. According to the invention, the tissues are obviously refined, the tensile strength of the prepared soldering paste is 59.4-62.0 MPa, the 0.2% yield strength ofthe prepared soldering paste is 51.9-55.2 MPa, the percentage elongation of the prepared soldering paste is 33.1-56.5%, and the shear strength of a BGA (Ball Grid Array) soldering point is increased by 14-29.3%.

Owner:HARBIN INST OF TECH

Preparation method of anti-aging polypropylene fiber

ActiveCN106120020AConjugated synthetic polymer artificial filamentsArtifical filament manufactureSodium bicarbonatePolymer science

The invention relates to a preparation method of anti-aging polypropylene fiber, and belongs to the technical field of functional fiber preparation. According to the method, wollastonite raphioid fiber, aluminum borate whisker, concave-convex rod crystals, sodium bicarbonate water solution and nano-montmorillonite are mixed and stirred; then, the materials are soaked into a sulfamic acid solution for heating, stirring and dispersing; suspended solids are taken to be subjected to ultrasonic treatment; then, upper layer suspended solids are taken to be filtered, washed and dried; obtained materials are mixed with the aluminum borate whisker, PP-g-MAH, silane coupling agents, ultraviolet absorbents, light stabilizers and antioxidants; the obtained mixture is stirred and dried; isotatic polypropylene is added; the mixture is stirred; fusion compounding is performed to prepare the anti-aging polypropylene fiber. The preparation method has the advantages that the defects in the prior art are overcome; the aluminum borate whisker, the PP-g-MAH, the wollastonite raphioid fiber, the ultraviolet absorbents, the light stabilizers and the antioxidants are added in the isotactic polypropylene; the blending fusion is performed with the isotactic polypropylene to prepare the sheath core type anti-aging polypropylene fiber using the anti-aging polypropylene as a sheath layer.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

Preparation method of high-barrier and high density polyethylene plastic

The invention relates to a preparation method of high-barrier and high density polyethylene (HDPE) plastic, and belongs to the technical field of preparation of plastic products. The preparation method comprises the following steps: mixing and stirring aluminum borate whiskers, attapulgite crystals, isinglass, a sodium hydrogen carbonate solution and talcum powder to obtain a mixture, performing microwave radiation, soaking the mixture into a sulfamic acid solution for heating and dispersion, performing ultrasonic treatment on suspensions, filtering, washing and drying the suspensions on the upper layer, mixing and stirring an obtained material with silicon dioxide, polyisobutylene colloidal particles, stearic acid, organic montmorillonite, HDPE-g-MAH and a silane coupling agent, drying, then adding HDPE plastic powder, performing blending and extrusion through two screw rods to obtain high-barrier HDPE plastic particles, and melting the particles to obtain the high-barrier HDPE plastic. Compared with the prior art, barrier materials such as the isinglass are added into the HDPE, so that the prepared HDPE has the characteristics of high barrier and high intensity, and can be used for high-barrier packaging of thin films, bottled and canned foods, medicines, daily necessities and the like.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

Anti-aging and wear-resistant rubber material for tire

The invention discloses an anti-aging and wear-resistant rubber material for a tire. The anti-aging and wear-resistant rubber material for the tire is prepared from, by weight, 15-35 parts of natural rubber, 25-35 parts of 320 type chloroprene rubber, 25-35 parts of neoprene, 20-50 parts of modified kaolinite, 0.5-1.5 parts of 616 antiager, 0.2-0.8 part of phosphite, 0.5-1.2 parts of tetramethyl thiuram disulfide, 0.5-1.5 parts of zinc oxide, 1-3 parts of magnesium oxide, 5-15 parts of pumice, 10-18 parts of zinc borate, 1-2 parts of aluminum borate whiskers, 12-18 parts of sodium antimonite, 5-15 parts of aluminum phosphate, 10-20 parts of carbon black, 0.2-0.8 part of polyepoxy soybean oil, 0.1-0.9 part of hydroxyl silicone oil, 1-2 parts of white oil, 1-3 parts of pine tar, 0.2-0.8 part of fatty acid, 0.5-1.5 part of stearic acid and 1-2 parts of 3-aminopropyltrimethoxysilane. The anti-aging and wear-resistant rubber material for the tire is good in wear-resistant and anti-tear performance and excellent in anti-aging performance.

Owner:DELUN RUBBER

Zirconia-doped alumina ceramic and preparation method thereof

The invention relates to the field of ceramic materials, and provides zirconia-doped alumina ceramic and a preparation method thereof. The alumina ceramic is prepared from the following raw materials in parts by weight: 75-95 parts of alumina powder, 5-15 parts of zirconia, 2-6 parts of aluminum borate whiskers, 6-12 parts of a sintering aid, 0.8-2 parts of a dispersing agent, 2.1-8.4 parts of a binder and 18-36 parts of a solvent, wherein the sintering aid is a mixture of titanium dioxide and alkali-free aluminosilicate glass. The problem that the requirement of a high-quality ceramic material cannot be met by adopting a single toughening mode in the prior art is solved.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

Anti-cracking self-lubricating metal ceramic bearing and preparation method thereof

The invention discloses an anti-cracking self-lubricating metal ceramic bearing. The anti-cracking self-lubricating metal ceramic bearing is prepared from, by weight, 2.3-2.4 parts of ferric citrate, 3.1-3.5 parts of basic nickel carbonate, 0.2-0.3 part of flaky niobium pentoxide, 0.3-0.4 part of dimolybdate boride, 25-30 parts of water, an appropriate amount of ammonium hydroxide, 2.9-3 parts of TiH2, 12-12.5 parts TiC, 2-2.3 parts of aluminum borate whisker, 1.6-1.8 parts of tantalum-doped tungsten bronze powder, 0.7-0.9 part of lubricant, 1-1.1 parts of C, 8.6-9 parts of W, 6.1-6.3 parts of Mo, 3.1-3.3 parts of V and 65-66 parts of Fe. By means of flaky niobium pentoxide, dimolybdate boride, aluminum borate whisker and tantalum-doped tungsten bronze powder, the lubricating performance in the pressing process is improved, and the toughness and cracking resistance are improved after sintering.

Owner:ANHUI SILVER BALL BEARING

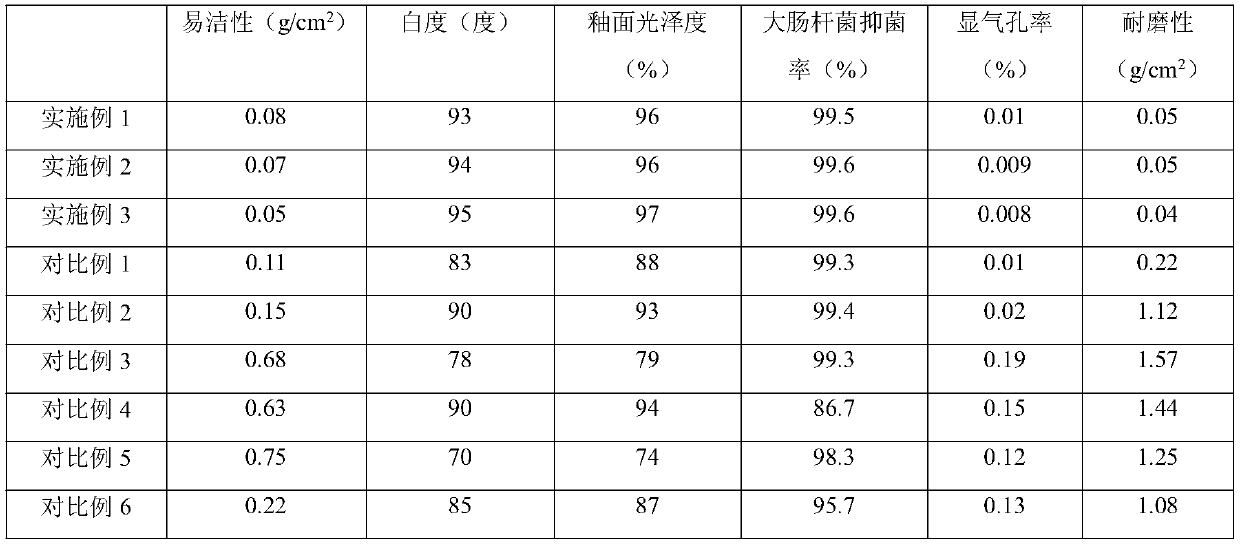

Porcelain formula and manufacturing process thereof

The invention provides a porcelain formula and a manufacturing process thereof. Soft kaolin, flint clay, potassium feldspar and large ball mud are used as raw materials to prepare a matrix material; silicon dioxide, potassium fluoroaluminate, cerium dioxide, yttrium oxide, aluminum borate whiskers, nano-zinc oxide, cerium-graphene nano-particles and large ball mud superfine powder are used as rawmaterials to prepare glaze, the raw materials of the glaze are properly matched in thickness, the compactness of a glaze layer is improved, the apparent porosity is low, contamination is not likely tohappen, the wear resistance is good, and the bactericidal effect is achieved. The matrix material and the glaze material generate light interaction, so that the porcelain has relatively high whiteness and glossiness, and the attractiveness is greatly improved.

Owner:贺俊威

Method for improving mechanical property of aluminum borate whisker enhanced aluminum matrix composite materials

The invention relates to a method for improving the mechanical property of aluminum matrix composite materials, in particular to a method for improving the mechanical property of aluminum borate whisker enhanced aluminum matrix composite materials. The technical problem that the mechanical property of existing aluminum borate whisker enhanced aluminum matrix composite materials is poor is solved. The method comprises the first step of adding of matrix alloy elements, the second step of preparing of aluminum magnesium alloy cast ingots, the third step of preparing of aluminum borate whisker prefabricated members and the fourth step of squeeze casting. Alloying element zinc or magnesium is added into pure aluminum, and a formed binary alloy is adopted as a matrix of the composite materials. In the preparing process of the composite materials, by means of the change and the content change of the matrix alloy elements, the interface structure and state of the composite materials are changed, and interfacial wettability is improved; and interface bonding of whiskers and the matrix is improved, and the mechanical property of the composite materials is remarkably improved. The method is applied to preparing of the aluminum matrix composite materials.

Owner:HARBIN INST OF TECH

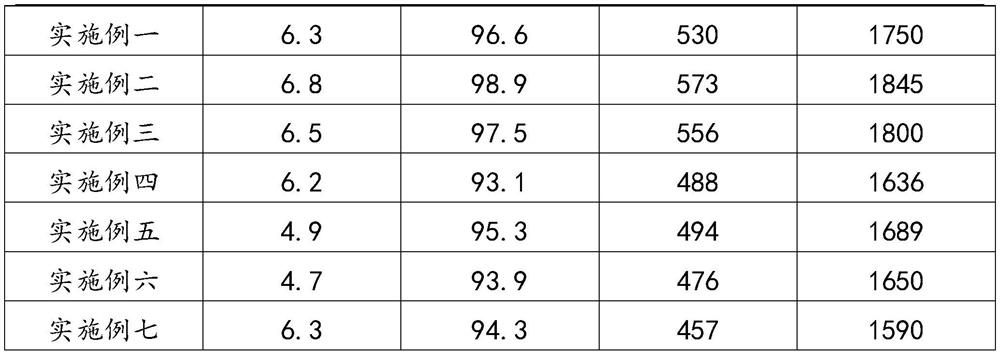

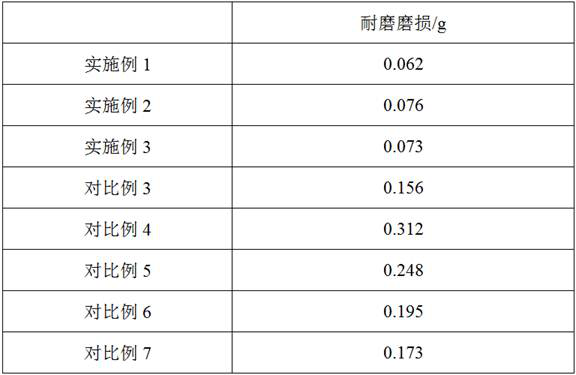

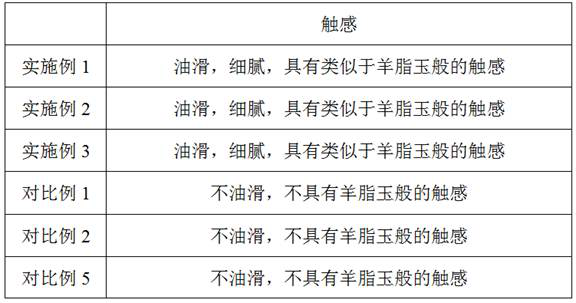

Rock plate with mutton fat jade touch feeling and preparation method thereof

The invention belongs to the technical field of rock plates, and particularly discloses a rock plate with a mutton fat jade touch feeling , the rock plate comprises a green body layer and a glaze layer from bottom to top, and the glaze layer is formed by sintering mutton fat jade glaze on the green body layer; and the mutton fat jade glaze is prepared from the following raw materials in parts by weight: 28-40 parts of potassium-containing minerals, 20-30 parts of kaolin, 15-20 parts of quartz sand, 6-11 parts of modified aluminum borate whiskers, 4-8 parts of spodumene, 3-7 parts of a lubricant and 1-4 parts of calcium silicate. The rock plate disclosed by the invention is oily, smooth and fine in touch feeling, has the touch feeling similar to that of mutton fat jade, and has a good wear-resistant effect. Under the formula system taking the potassium-containing minerals and the kaolin as the main materials, the lubricant is added, so that the rock plate which is oily, smooth and fine in touch feeling and has the touch feeling similar to that of mutton fat jade can be obtained.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

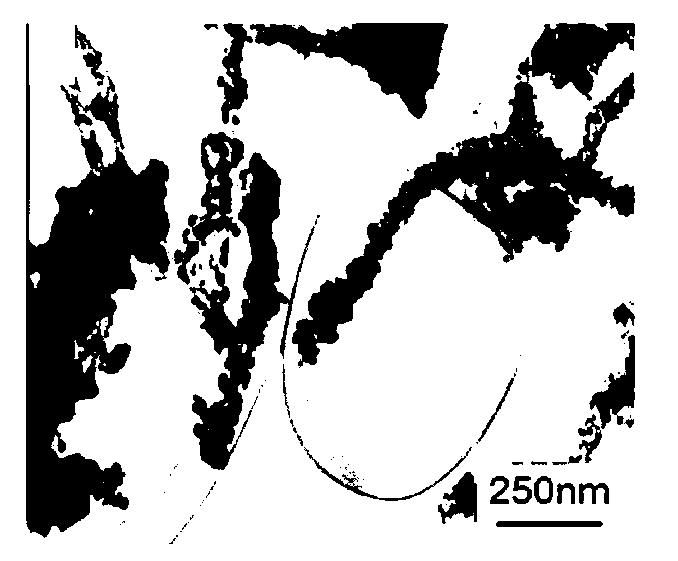

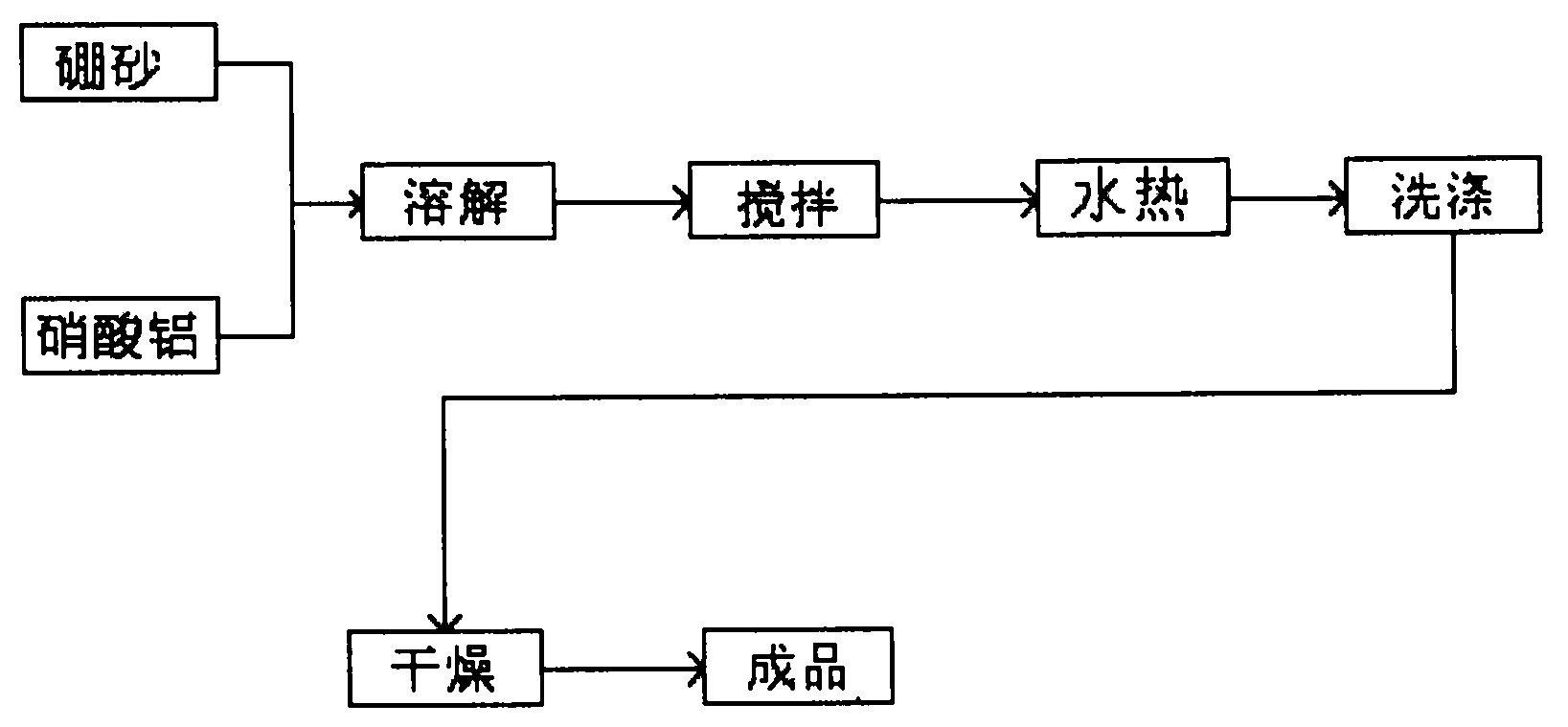

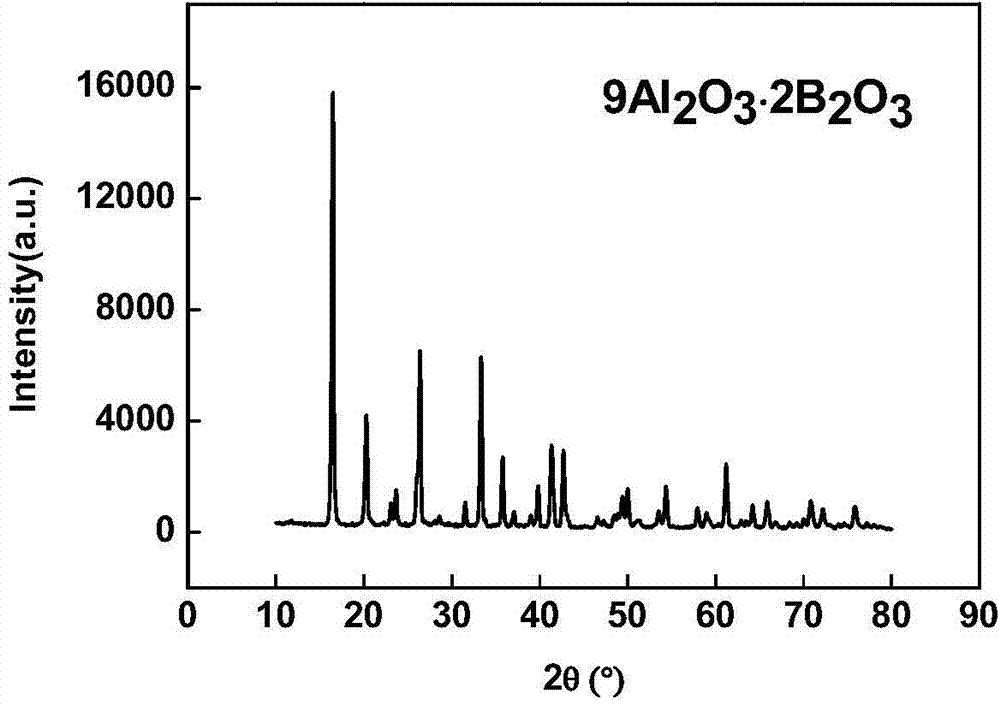

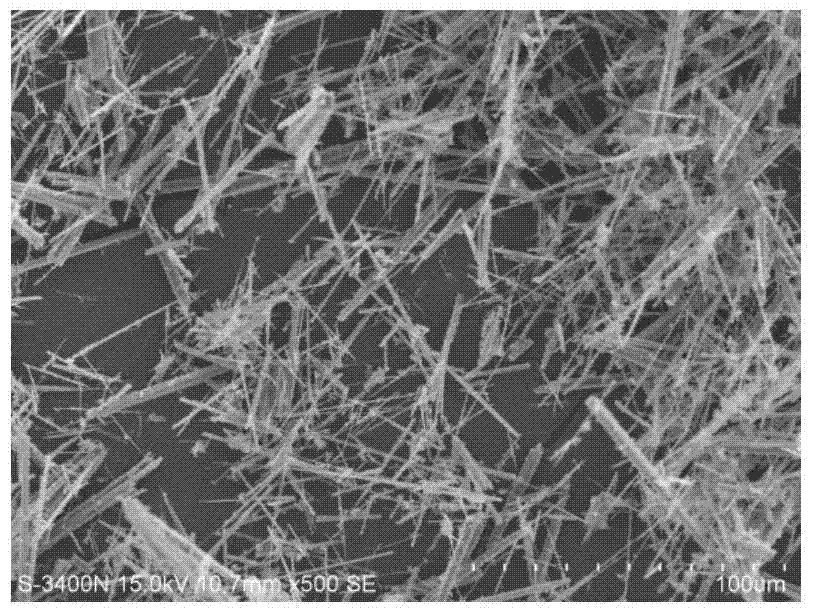

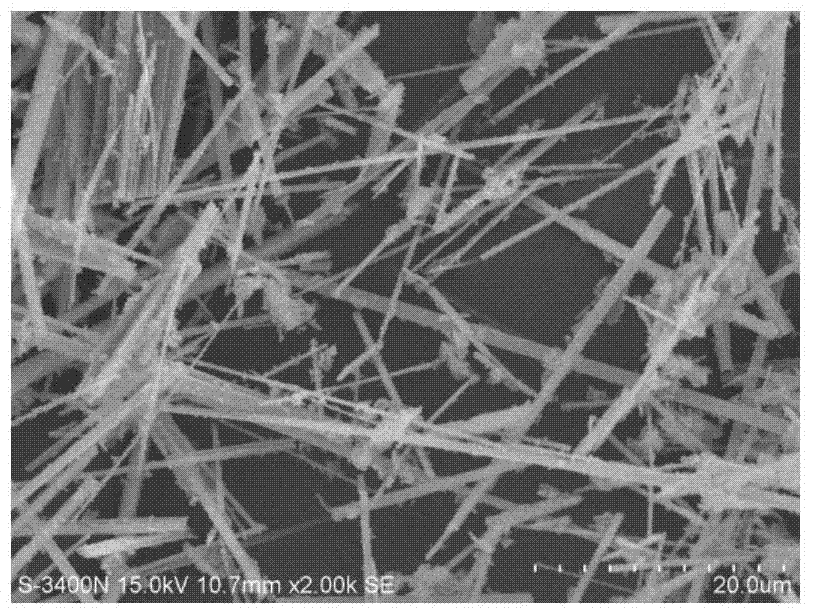

Method for preparing nano slabby aluminium borate whisker by hydrothermal method

InactiveCN101892513ASimple and fast operationImprove product qualityPolycrystalline material growthFrom normal temperature solutionsFiberBorax

The invention provides a method for preparing nano slabby aluminium borate whisker by hydrothermal method, relating to a borax preparation technology. The method includes the following steps: firstly aluminium nitrate solution is mixed with borax solution, then surfactant is added, pH value of solution is regulated, reaction is carried out, solution is moved into a hydrothermal kettle, reaction is carried out again under pressure and temperature conditions, and cooling, filtering, washing and drying are carried out, thus obtaining the slabby aluminium borate whisker. The nano slabby (band) aluminium borate whisker with high elastic modulus, good mechanical strength, heat resistance, chemical resistance, acid resistance, electric insulativity, neutron absorption performance and covalency with metal can be prepared. The whisker not only can be applied to heat-insulating, heat-resistant and corrosion-resistant materials but also can be applied to thermoplastic resin, thermosetting resin, cement, ceramic and metal reinforcing agent. The whisker also can be applied to reinforced metal base (aluminium base and magnesium base), ceramic base, plastic, glass, fiber and paint.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

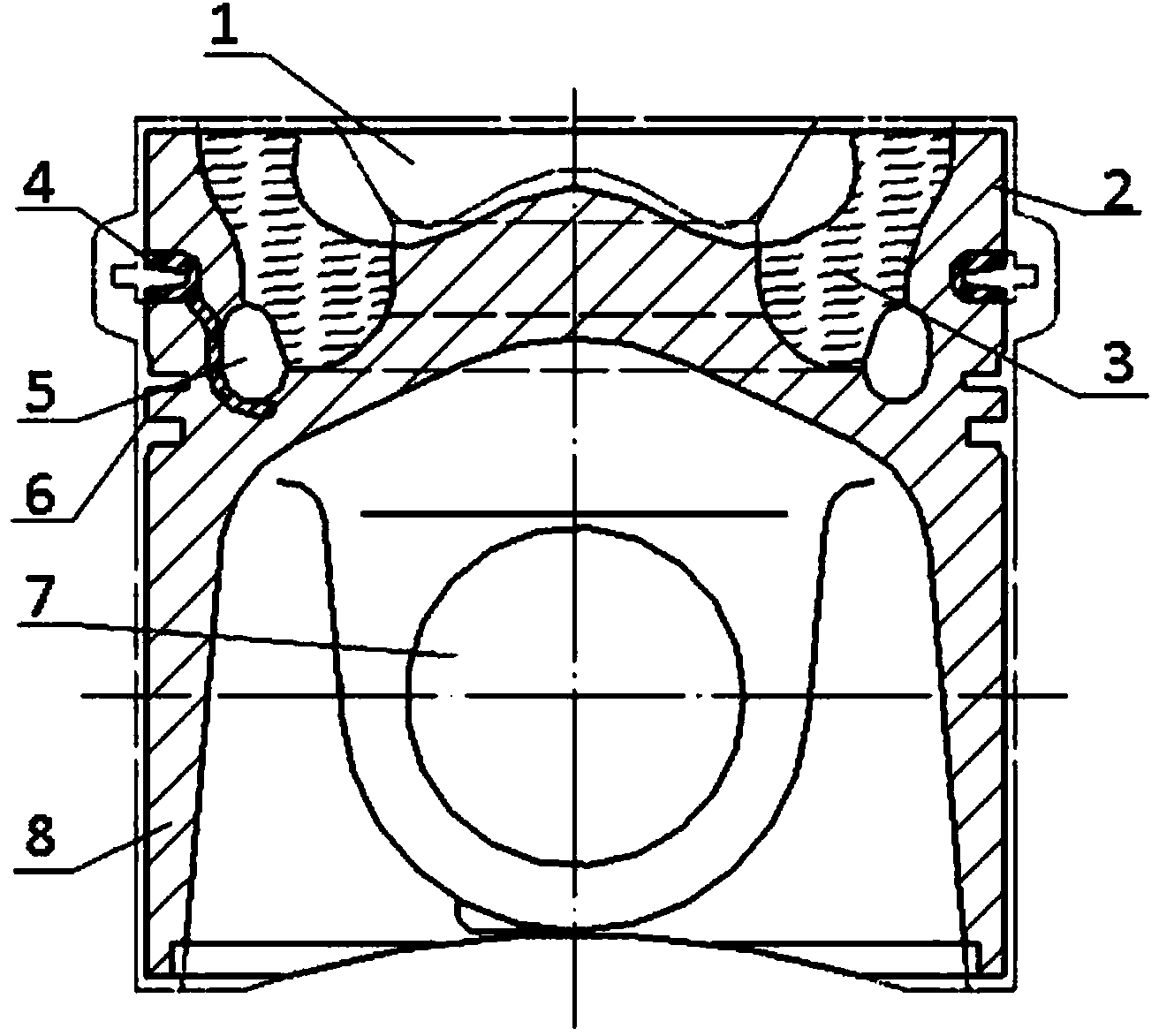

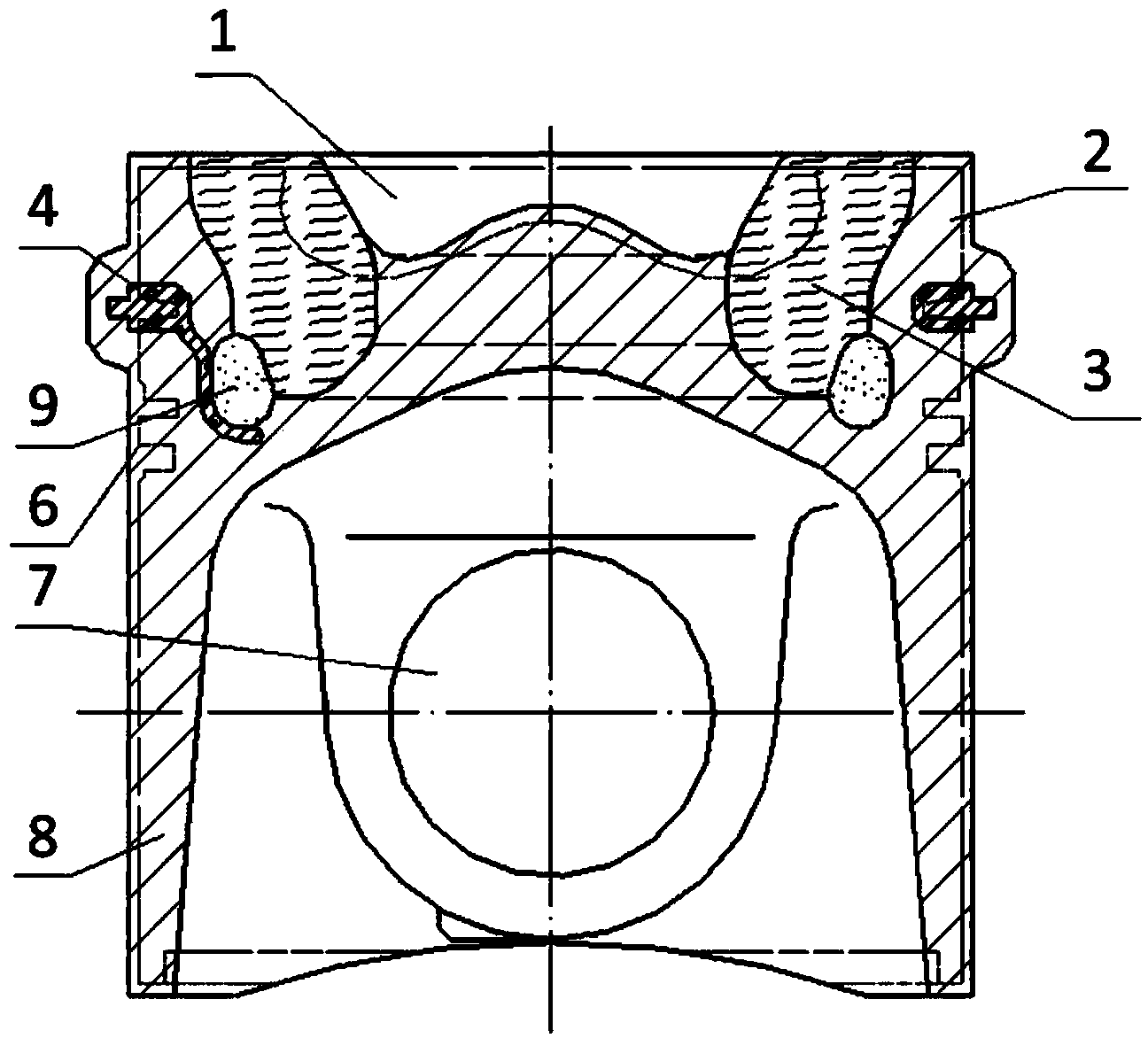

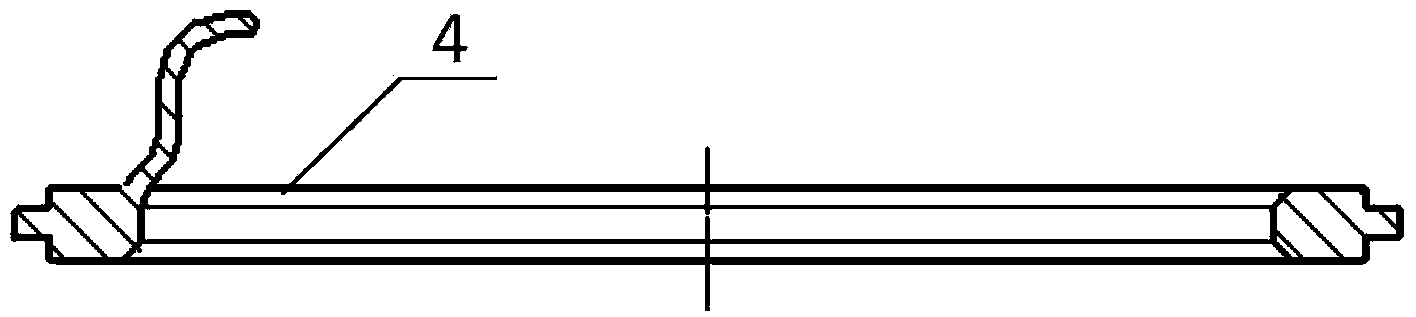

Method for manufacturing aluminum borate crystal whisker enhancement combustor throat embedded ring inner-cooling aluminum piston

The invention discloses a method for manufacturing an aluminum borate crystal whisker enhancement combustor throat embedded ring inner-cooling aluminum piston. The method comprises the steps that firstly, an aluminum borate crystal whisker prefabricated piece blank is manufactured with the in-situ growth method, the shape of the blank is close to the final shape, and only one to three millimeters of working allowance is reserved; secondly, the aluminum borate crystal whisker prefabricated piece blank is manufactured into a finished product; thirdly, a ceramic salt core is manufactured; fourthly, the aluminum borate crystal whisker prefabricated piece is preheated; fifthly, after the soluble core is preheated, the aluminum borate crystal whisker prefabricated piece is taken out, and the soluble core is placed into the aluminum borate crystal whisker prefabricated piece and placed into a casting die rapidly; sixthly, an alumetized abrasion resistant cast iron embedded ring is placed into the casting die to be fixed; seventhly, an aluminum alloy solution is poured into the casting die to be pressed and formed; eighthly, a piston blank is heated and machined into a finished product. Crystal whiskers in the aluminum borate crystal whisker prefabricated piece blank formed in an in-situ growth mode are in isotropy, a formed composite material is in isotropy, and the circumferential-direction fatigue crack, caused by isotropy, of original alumina fiber composite materials is avoided.

Owner:BINZHOU BOHAI PISTON CO LTD

Nano-aluminum-oxide-based metal ceramic mold material and preparation method thereof

The invention discloses a nano-aluminum-oxide-based metal ceramic mold material and a preparation method thereof. The metal ceramic mold material is prepared from, by weight, nano aluminum oxide, boron nitride, samarium powder, slag powder, titanium hydride, lithium vanadate, aluminum borate whiskers, gallium oxide, nano calcium carbonate, titanium diboride, iodide europium, niobium carbide, yttrium oxide, erucyl amide, tantalum carbide, molybdenum disulfide and dichloromethylvinylsilane. The metal ceramic mold material is good in bending strength and breaking tenacity and ling in service life, and the defects that a traditional metal ceramic mold material is prone to cracking, poor in tenacity and accordingly short in service life are overcome. Meanwhile, according to the prepared mold, in the actual using process, demolding is easy, the abrasion resistance is high, the quality of finished products is good, and the yield is high.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

Preparation method of ceramic mold material

The invention discloses a preparation method of a ceramic mold material, and belongs to the field of ceramic mold materials. The preparation method comprises the following steps: uniformly mixing a powder for the ceramic mold material with deionized water to prepare a mixed slurry, placing the mixed slurry in a mold, standing, drying, demolding to obtain a ceramic mold material green body, and carrying out high-temperature sintering to obtain the ceramic mold material. The preparation method of the powder for the ceramic mold material comprises the step of uniformly grinding alpha-aluminum oxide powder, aluminum borate whiskers, tin oxide powder, zirconium oxide bead powder and polyurethane / asbestos nano composite material powder under the action of mechanical grinding to obtain the powderfor the ceramic mold material. The powder for the ceramic mold material used in the preparation method is good in dispersity and uniform in particle, and the ceramic mold material which is good in fracture toughness and abrasion resistance, high in strength and high in hardness can be obtained.

Owner:嘉兴市爵拓科技有限公司

High-temperature-resistant ceramic material and preparation method thereof

The invention discloses a high-temperature-resistant ceramic material and a preparation method thereof. The high-temperature-resistant ceramic material is prepared from, by weight, 208-233 parts of nanometer zirconium, 25-36 parts of wolfram carbide powder, 20-22 parts of mica powder, 18-20 parts of iron oxide powder, 10-14 parts of tetrapod-like zinc oxide whiskers, 50-53 parts of aluminum nitride powder, 2-6 parts of scandium oxide powder, 30-70 parts of cobalt powder, 10-15 parts of molybdenum carbide powder, 22-28 parts of silicon carbide whiskers, 6-10 parts of aluminum borate whiskers, 3-6 parts of nano-iridium and 3-8 parts of yttrium oxide powder. The high-temperature-resistant ceramic material has good heat dissipation performance.

Owner:严克飞

Heat-resistant high-toughness polystyrene resin expanded plastic

The invention provides heat-resistant high-toughness polystyrene resin expanded plastic, which is prepared from the following raw materials in parts by mass: 40 to 60 parts of polystyrene resin, 20 to 25 parts of polyimide resin, 16 to 22 parts of polysulfone, 6 to 10 parts of nanometer hydrotalcite, 2 to 7 parts of PBO fiber, 1 to 3 parts of glycerin monostearate, 7 to 10 parts of chlorinated paraffin, 6 to 14 parts of nano-montmorillonite, 2 to 6 parts of rutile powder, 4 to 6 parts of aluminum borate whisker and 2 to 6 parts of coupling agent. The heat-resistant high-toughness polystyrene resin expanded plastic provided by the invention has excellent high / low temperature resistant performance and mechanical property, the fire resistance is good, and the strength and toughness are both obviously improved.

Owner:揭阳市越兴塑胶制品有限公司

Thermal insulation material and preparation method thereof

The invention provides a thermal insulation material and a preparation method thereof, and relates to the technical field of building materials. The thermal insulation material comprises the followingraw materials: pitchstone glass beads, light magnesium oxide, sodium fluosilicate, aluminium dihydrogen phosphate, polyvinyl alcohol, kaolin, pulverized fuel ash, attapulgite, sepiolite fiber, sodiumsulfosuccinate, cement, floating beads, boron carbide, aluminum borate whiskers, glass fiber, aerogel, a fire retardant, a water reducing agent, a retarder, an air entraining agent, a foaming agent and water. The preparation method comprises the following steps: (1) weighing the raw materials; (2) stirring; and (3) putting the raw materials in a mold and curing. The thermal insulation material prepared according to the preparation method has the advantages of being high in strength, high in flame retardance and high in thermal insulation performance.

Owner:桐城市景瑞建筑装饰工程有限公司

Preparation method of aluminum borate whisker

InactiveCN104328496AHigh densityImprove fullyPolycrystalline material growthFrom melt solutionsBoric acidPotassium alum

The invention relates to a preparation method of aluminum borate whisker, and particularly relates to a preparation method of the aluminum borate whisker. The preparation method of the aluminum borate whisker comprises the following steps of (1) pretreating alumen: calcining the alumen for 2-6 hours at a temperature of 250-350 DEG C, grinding or ball-milling and screening with a 120-mesh sieve; (2) mixing auxiliary materials: mixing pretreated alumen with boric acid and a fluxing agent by fully grinding or ball-milling, wherein a molar ratio of the pretreated alumen to boric acid is (1-4.5):1 and a molar ratio of the pretreated alumen and boric acid to the fluxing agent is 1:(0.5-2); and (3) tabletting the auxiliary materials: putting the mixed auxiliary materials in a mold with a diameter of 10-30 mm, regulating a pressure to 20-80 kN, tabletting the auxiliary materials to obtain a cylindrical auxiliary material; and sintering, leaching and drying the cylindrical auxiliary material to obtain the aluminum borate whisker. The preparation method is simple in process; the produced aluminum borate whisker has excellent qualities; an alum mineral product of alumen and boron resource in Qarhan salt lake are fully utilized; production cost is reduced; and the preparation method has wide industrialization prospects.

Owner:JIANGXI FENGZHU NEW MATERIAL TECH

Preparation method for phenolic aldehyde plate thermal insulation material for building exterior wall

InactiveCN108690321AImprove impact resistanceImprove fire insulation performanceThermal insulationFireproofing

The invention discloses a preparation method for a phenolic aldehyde plate thermal insulation material for a building exterior wall, and relates to the technical field of building materials. The preparation method comprises the following steps that expanded perlite and inorganic mineral powder are mixed, the surface is sprayed with water, placing and drying are carried out, the surface of a mixture is sprayed by using an ethanol solution of thermosetting dodecyltrimethoxysilane modified phenolic resin, and curing and drying are carried out so as to obtain a material a; the phenolic resin and carboxyl nitrile rubber are mixed so as to obtain a material b; glass fibers, aluminum borate whiskers, mica powder, sepiolite powder, a silane coupling agent and ethanol are mixed and stirred, then the material b, silicon dioxide aerogel and castor oil polyoxyethylene ether are added, mixing and stirring are carried out, then dichloromethane, lauryl sodium sulfate, a curing agent and the materiala are added, and stirring is carried out so as to obtain a material c; and the material c is poured into a mold, hot-press molding is carried out, and pressure maintaining and cooling are carried outso as to obtain the phenolic aldehyde plate thermal insulation material. The phenolic aldehyde plate thermal insulation material is good in thermal insulation performance and high in strength, powderfalling and scaling-off are not liable to occur, and the fireproofing grade can reach A1 grade.

Owner:安徽润晟建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com