ZnO coating aluminum boric acid crystal whisker reinforcing aluminum base composite material and method for producing the same

A technology for coating aluminum borate and aluminum borate whiskers, which is applied in metal material coating process, liquid chemical plating, coating, etc. Poor wetness and other problems, to achieve low deformation resistance, improve floating, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

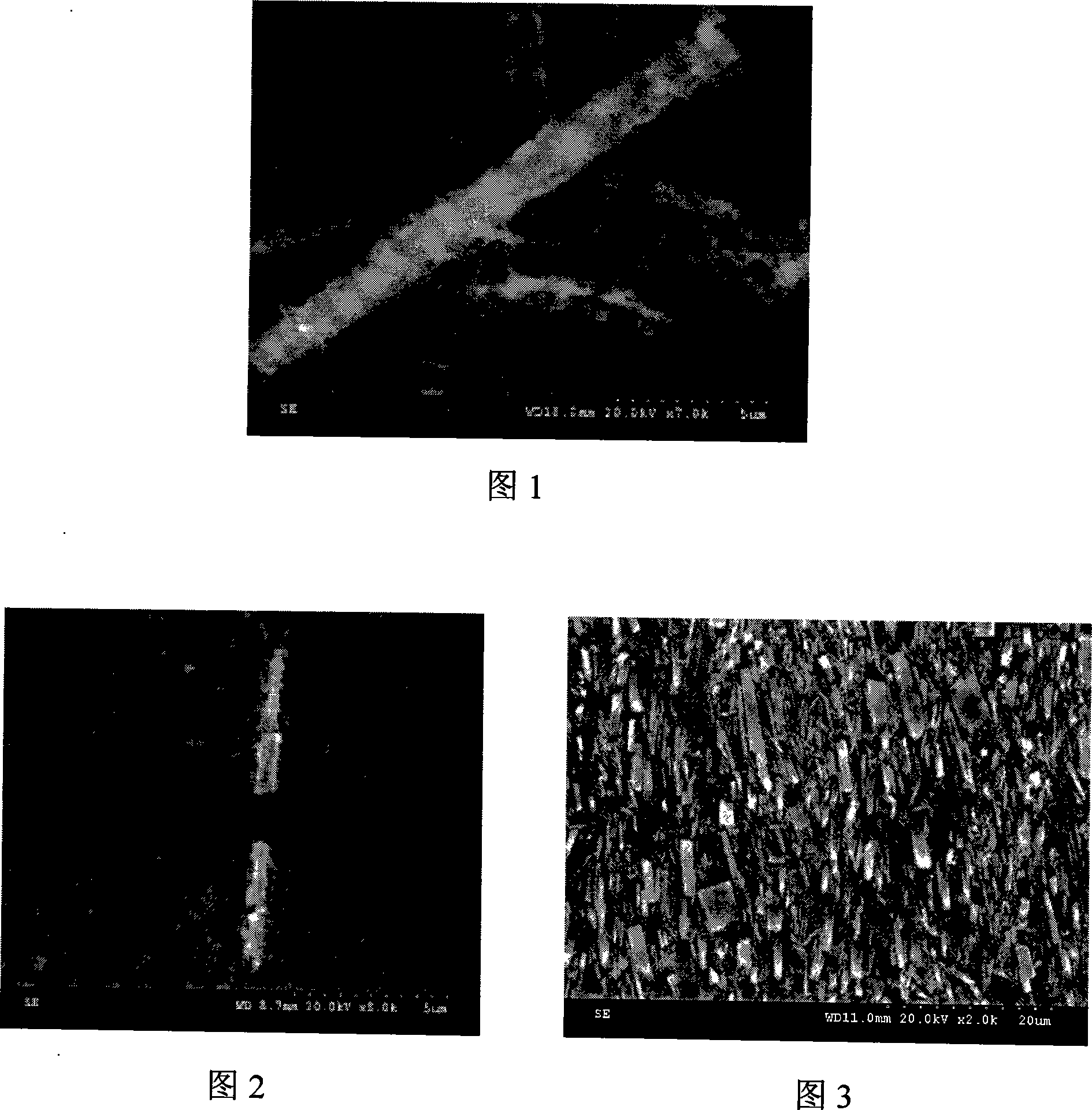

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment 1: In this embodiment, the ZnO-coated aluminum borate whisker-reinforced aluminum-based composite material is synthesized by processing ZnO-coated aluminum borate whiskers and an aluminum alloy matrix, wherein the ZnO-coated aluminum borate whiskers account for 1% of the total volume of the composite material. ~15%.

specific Embodiment approach 2

[0009] Embodiment 2: The difference between this embodiment and Embodiment 1 is that ZnO-coated aluminum borate whiskers account for 8% of the total volume of the composite material. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific embodiment three: the method for preparing ZnO-coated aluminum borate whisker reinforced aluminum matrix composite material is realized by the following steps: one, the concentration is that the aluminum borate whisker of 100g / L and the concentration are the hydrofluoric acid of 70% by 1: Mix at a molar ratio of 480 to 520, let stand for 5 to 7 hours, wash the precipitate with distilled water to make the pH value 6 to 8, and then dry to obtain pure aluminum borate whiskers; 2. Mix 1 mole of pure aluminum borate Whiskers, 27,600-28,000 moles of distilled water and 45-55 moles of zinc chloride are mixed and stirred, ultrasonically dispersed for 30-60 minutes, filtered and dried, then put into a heating furnace, and heated to 480-520°C at a rate of 20°C / min and calcined for 1-3 hours, and then taken out with furnace cooling; 3. Add distilled water to the calcined product, stir and ultrasonically disperse for 25-35 minutes, then dry, grind and disperse to obtain ZnO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com