Patents

Literature

111 results about "Materials tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano mesoporous and mesoporous-macroporous composite biological glass and its preparing method

InactiveCN1554607AMild reaction conditionsEasy to operateProsthesisSurface-active agentsNanotechnology

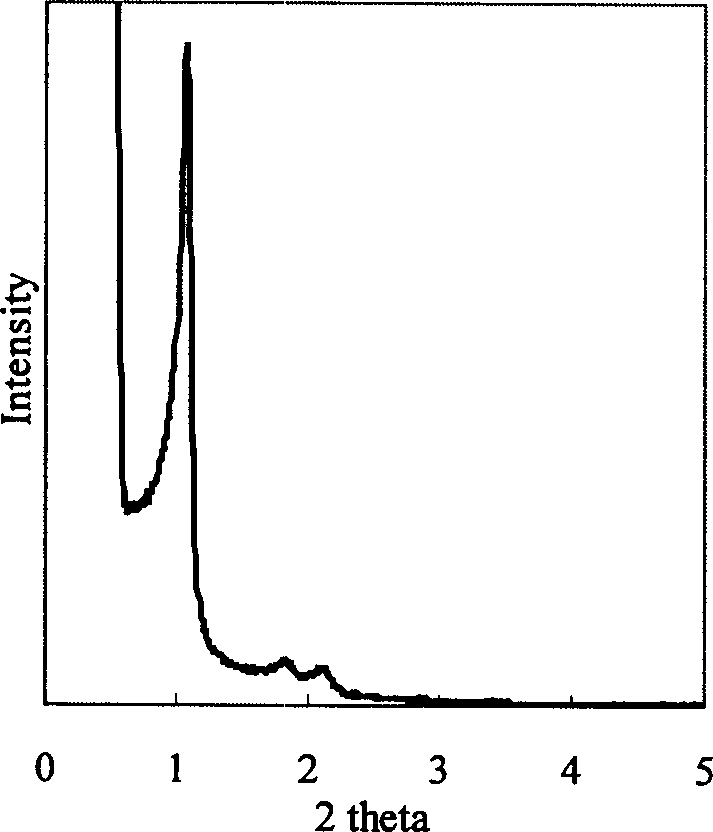

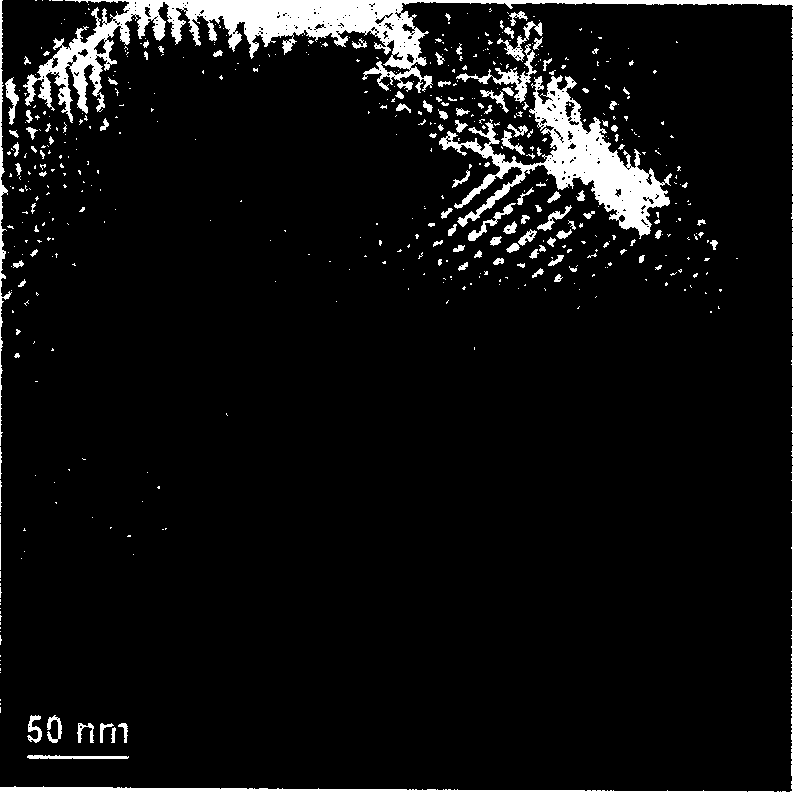

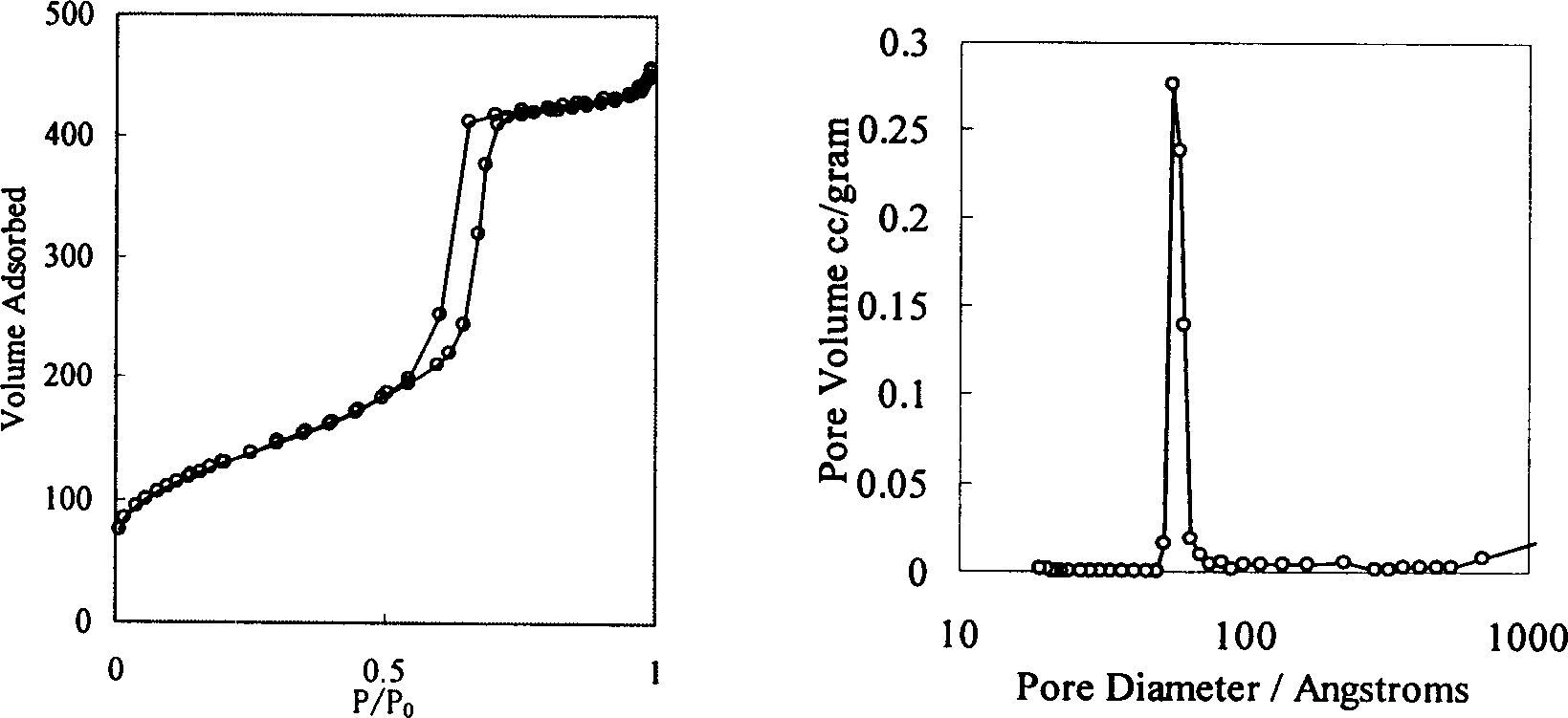

The present invention relates to nano mesoporous and mesoporous-macroporous biological glass produced and through surfactant self-assembling and sol-gel process under mild reaction condition and possessing excellent bioactivity. The new type of biological glass has controllable mesoporous structure, homogeneous and adjustable mesopore distribution, relatively great specific surface area and porosity, macropores with adjustable size and porosity, and controllable shape. The present invention may be used as bone repairing material, dental material and rack material in tissue engineering and for medicine embedding and controlling releasing, etc.

Owner:FUDAN UNIV

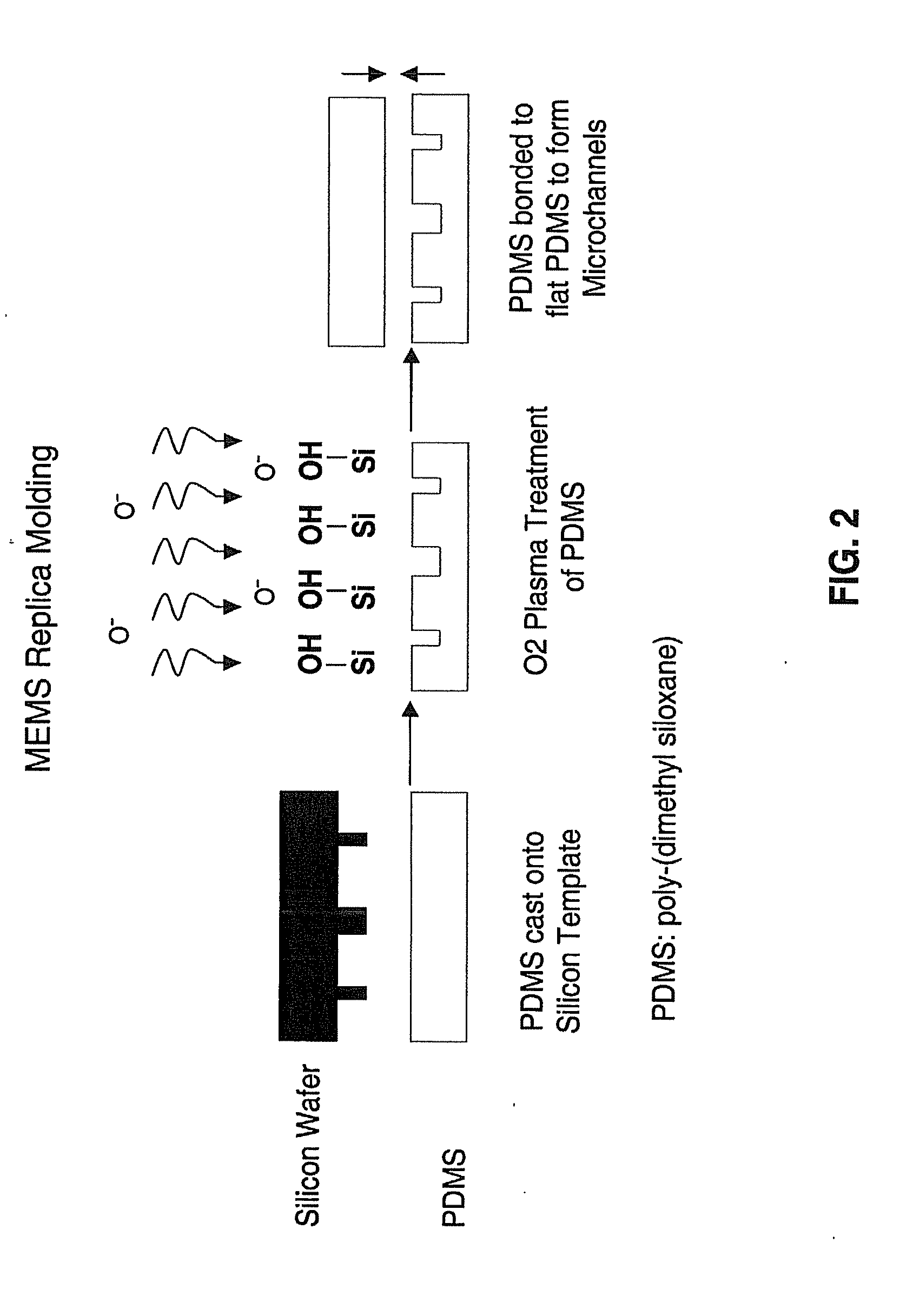

Fabrication of vascularized tissue using microfabricated two-dimensional molds

InactiveUS20100267136A1Bioreactor/fermenter combinationsBiological substance pretreatmentsVascularizesLiver tissue

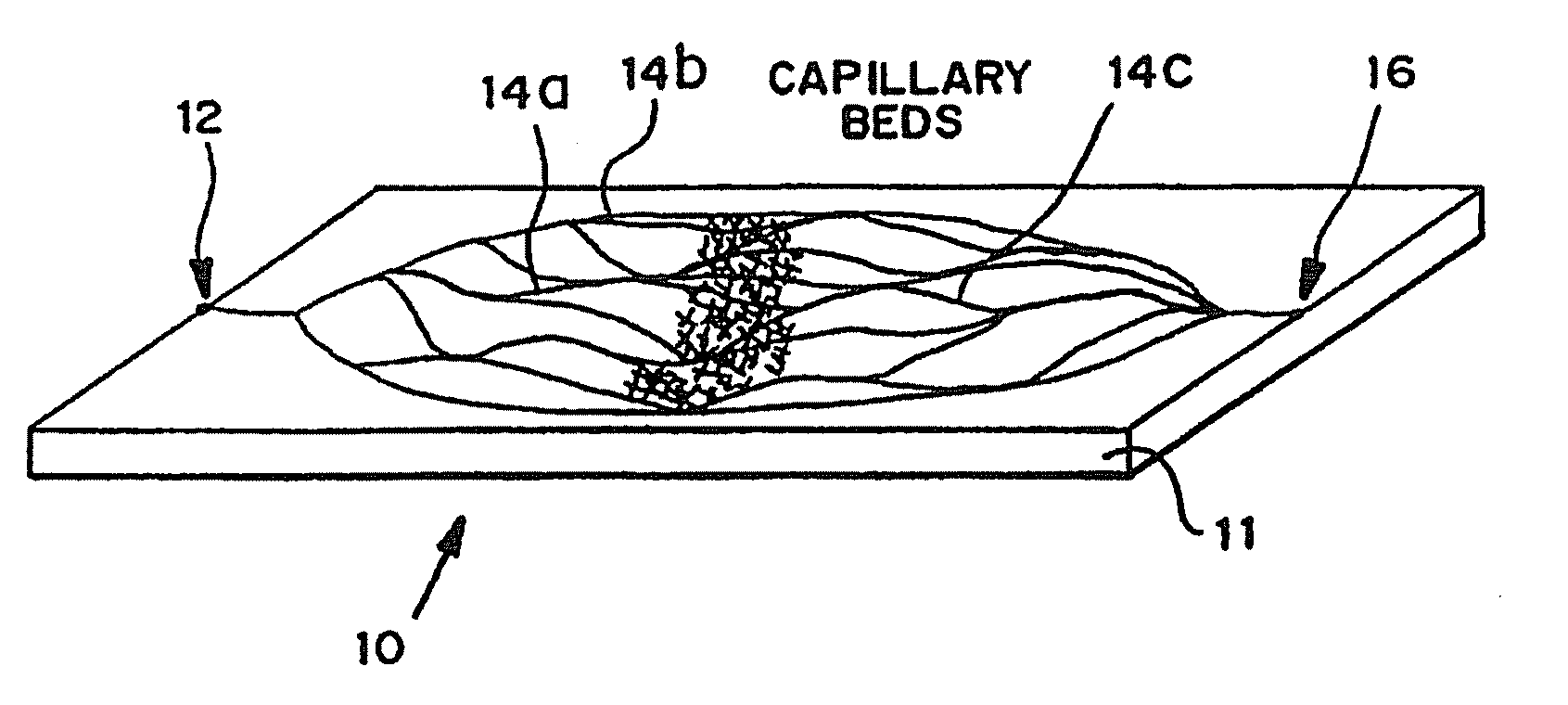

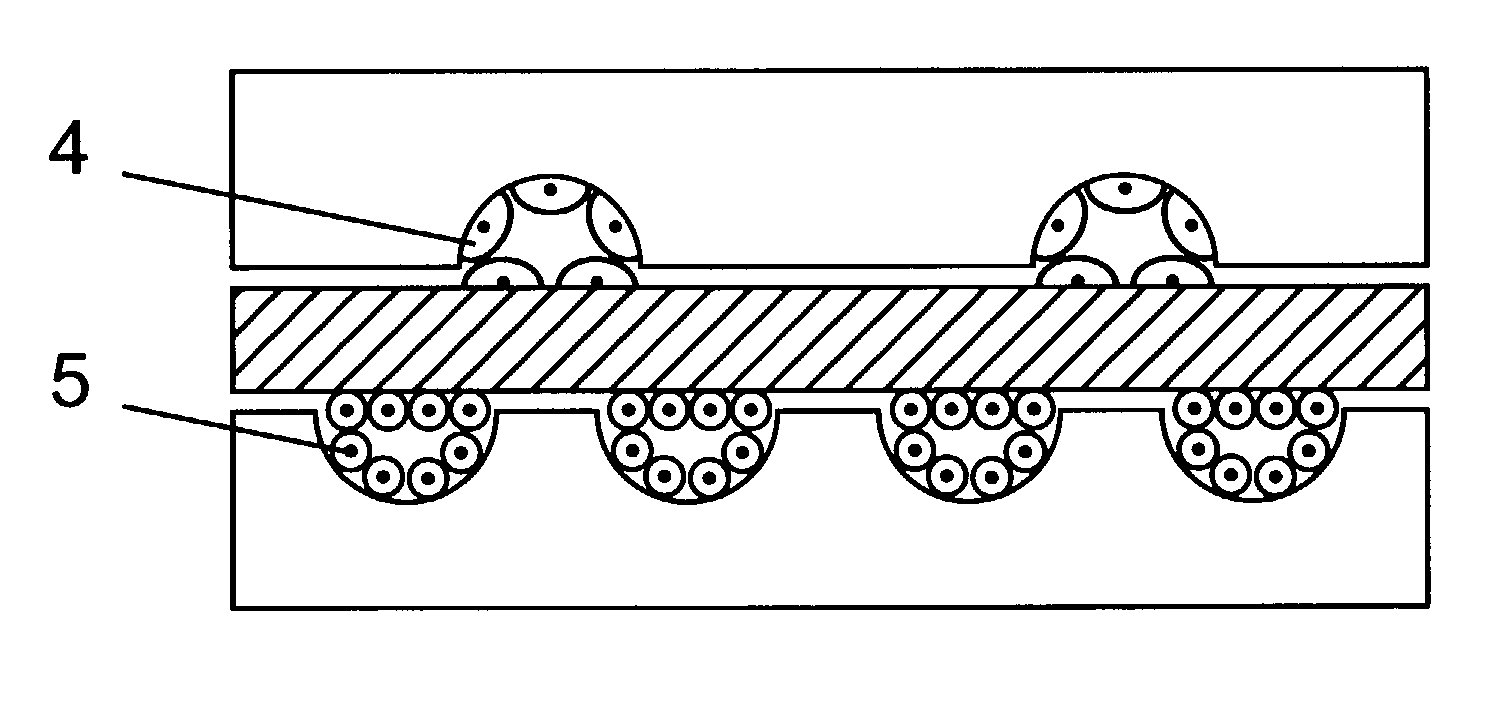

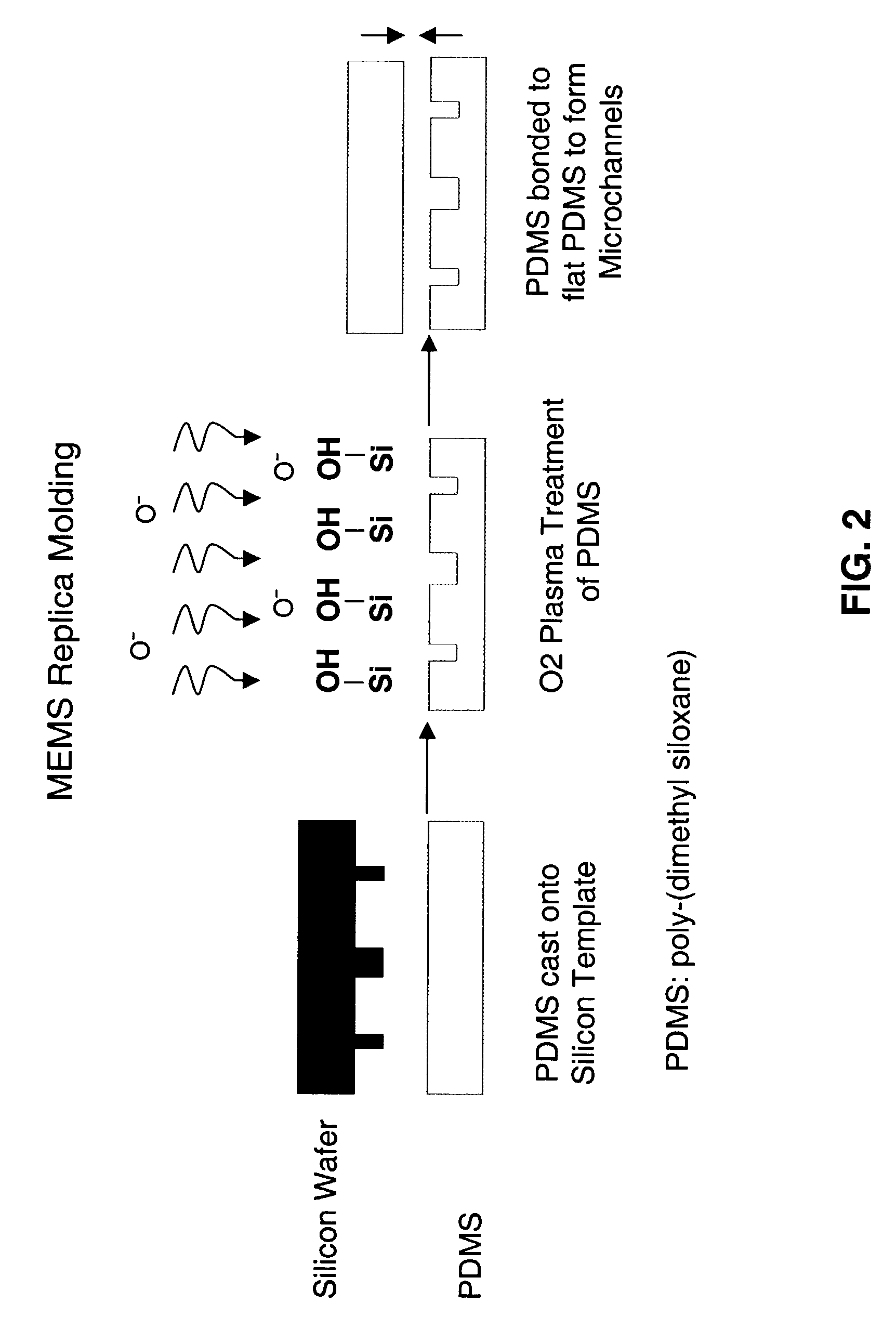

Methods and materials for making complex, living, vascularized tissues for organ and tissue replacement, especially complex and / or thick structures, such as liver tissue is provided. Tissue lamina is made in a system comprising an apparatus having (a) a first mold or polymer scaffold, a semi-permeable membrane, and a second mold or polymer scaffold, wherein the semi-permeable membrane is disposed between the first and second molds or polymer scaffolds, wherein the first and second molds or polymer scaffolds have means defining microchannels positioned toward the semi-permeable membrane, wherein the first and second molds or polymer scaffolds are fastened together; and (b) animal cells. Methods for producing complex, three-dimensional tissues or organs from tissue lamina are also provided.

Owner:THE GENERAL HOSPITAL CORP +1

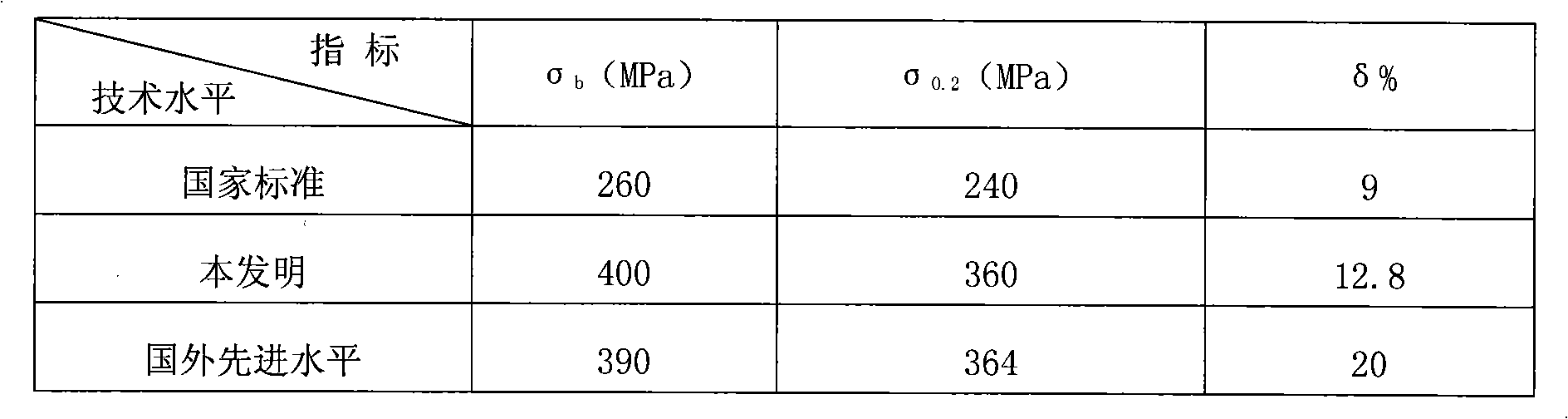

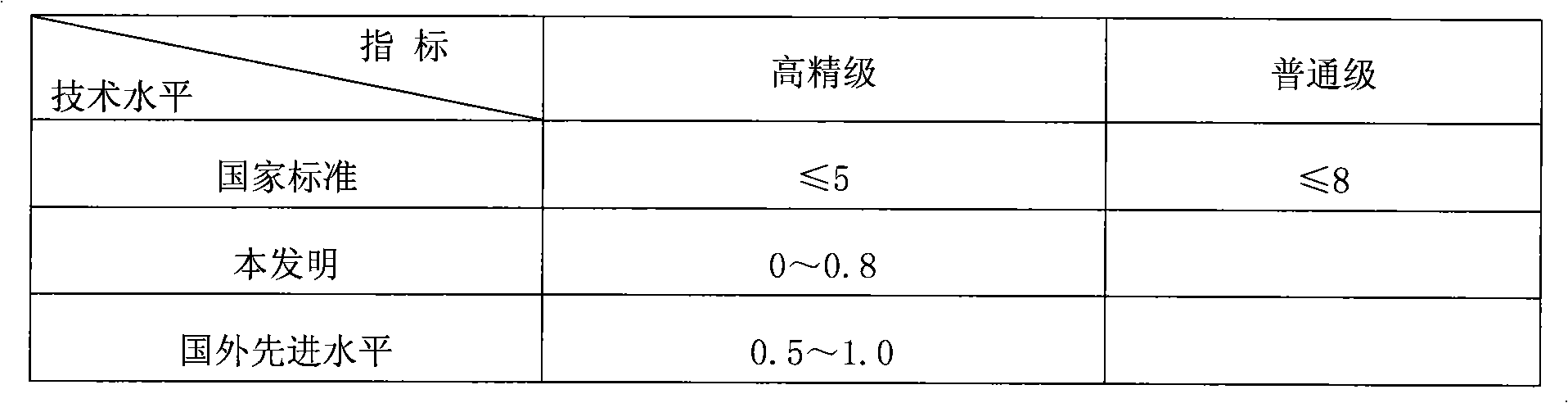

Production process of ABS valve body material for cars

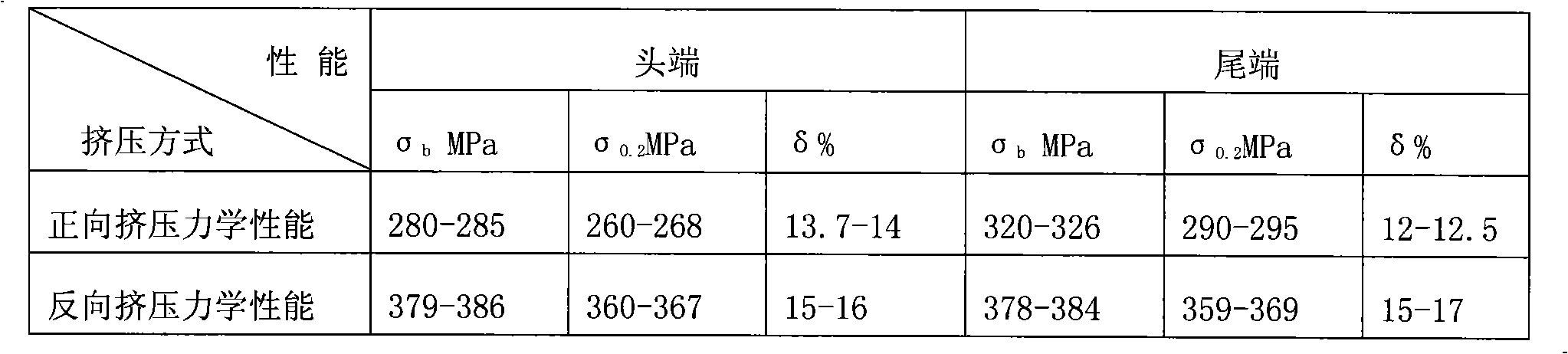

The invention provides a production process of the automobile ABS valve body material, which includes the following steps: preparing raw materials, melting, refining and standing, filtering and casting, homogenizing, ingot processing, ingot heating, indirect extruding, on-line water quenching, stretch rolling, artificial aging and finished product inspecting. By adopting the optimized alloy component in combination with indirect extrusion technology and on-line heat treatment technology, particularly the indirect extrusion technology, the inventive production process achieves the high uniformity of material structure, head-and-tail measures and mechanical property, thereby solving the problems of 6061 alloy coarse grain zone and mechanical property, increasing the production yield index, reducing the energy consumption of unit product, obtaining the material of which the mechanical property, metallographic structure, dimensional precision and the surface quality reach the advanced level of foreign similar products, achieving the import substitution of the material and laying the foundation of automobile localization.

Owner:西北铝业有限责任公司

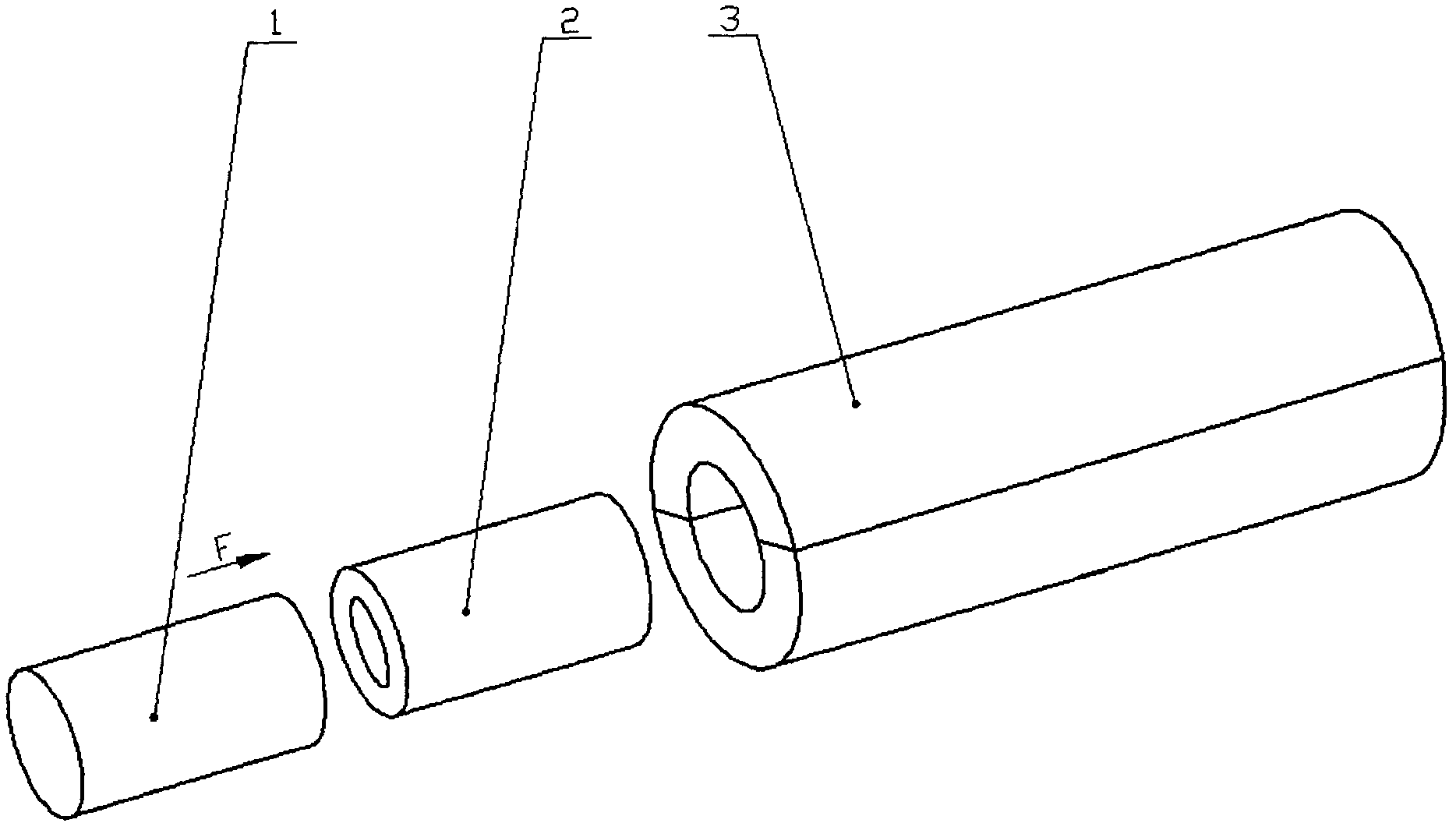

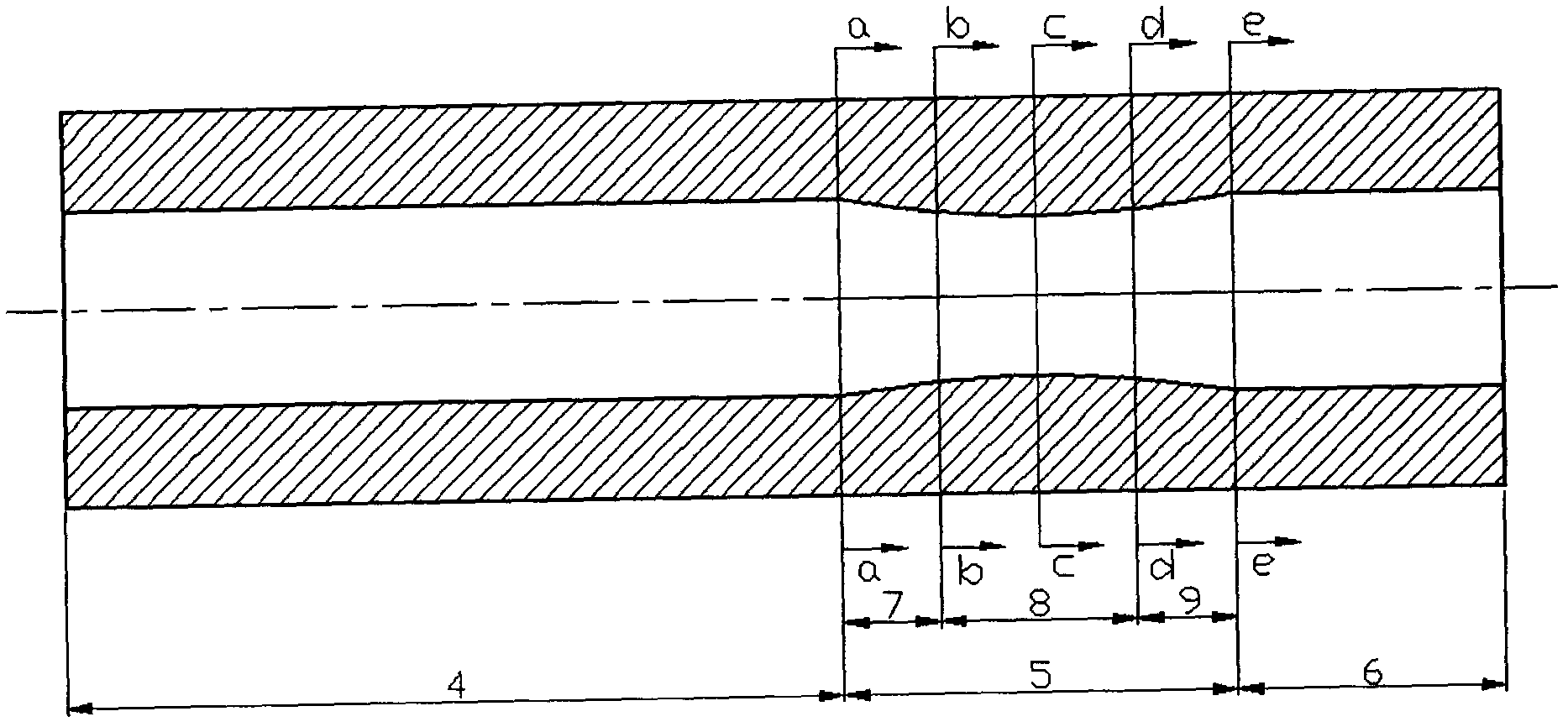

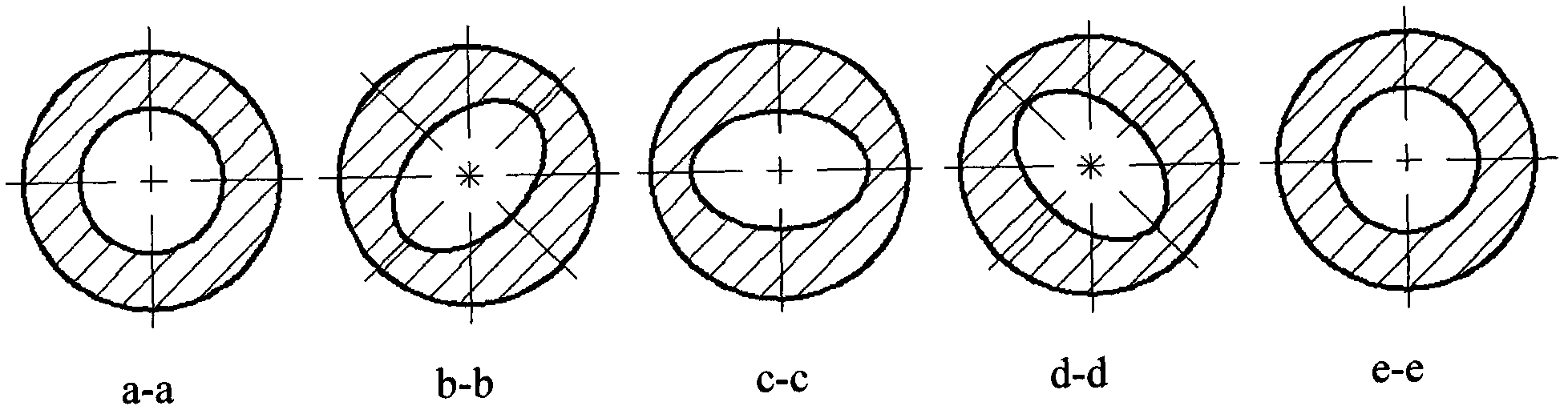

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fabrication of tissue lamina using microfabricated two-dimensional molds

Owner:THE GENERAL HOSPITAL CORP +1

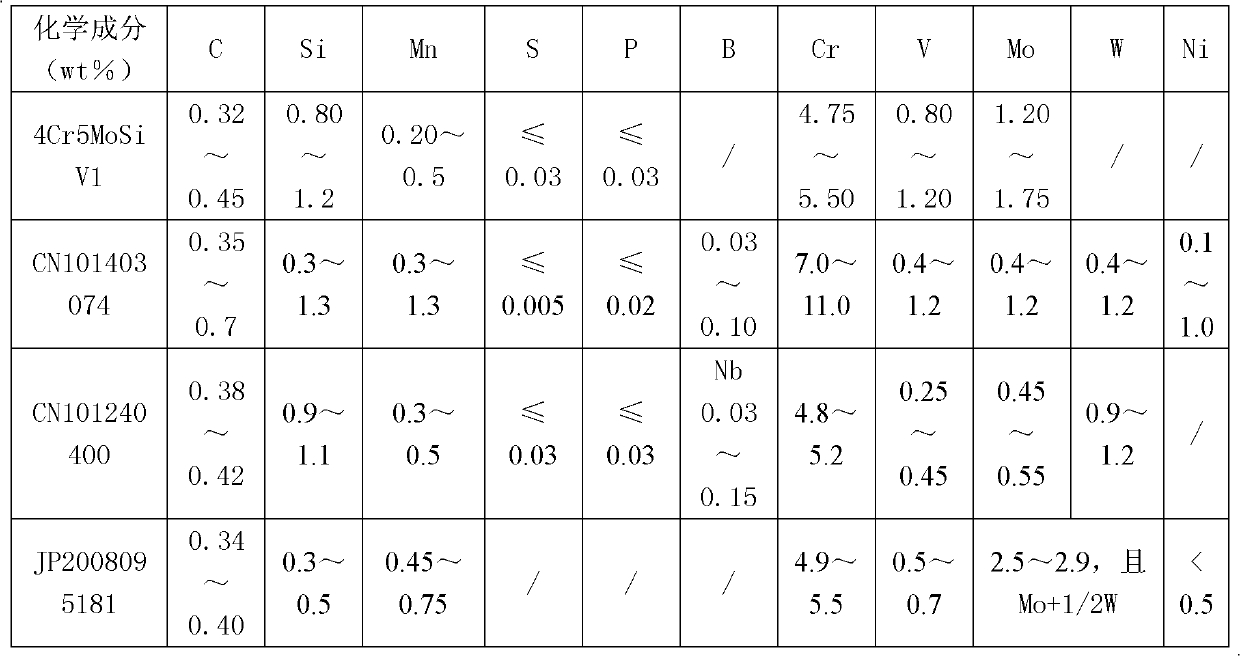

Hot stamping mould steel and method for manufacturing same

The invention discloses a hot stamping mould steel which comprises the following chemical elements in percent by weight: 0.43-0.48% of C, 0.3-0.5% Si, 0.5-0.8% of Mn, 2.3-2.7% of Cr, 1.9-2.4% of Mo, 0.7-1.0% of V, 0.03% of P or less, 0.03% of S or less and the balance of Fe and other inevitable impurities. In addition, the invention further discloses a method for manufacturing the hot stamping mould steel, which adopts the electroslag remelting process and the high-temperature homogenization and ultrafining heat-treatment process to control the material tissue so as to strengthen the material and improve the performance index of the material. Compared with the prior material, the thermal conductivity coefficient of the hot stamping mould steel is improved by more than 29.5%, the tempering hardness is improved by more than 7.5%, and impact toughness is improved by more than 16.7%. In addition, the hot stamping mould steel has the advantages of low-cost and high comprehensive performance.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

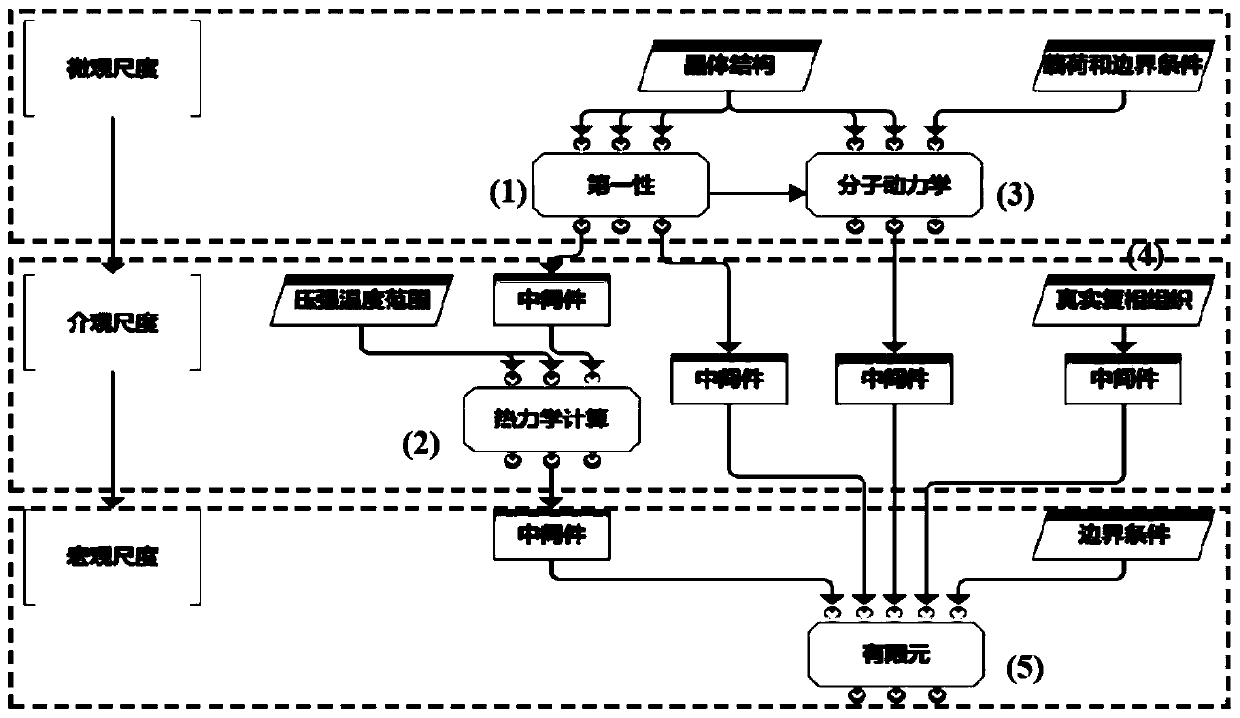

Multi-scale simulation method for mechanical behaviors of multi-phase composite material

ActiveCN110210103AImprove continuityRealize simulationChemical property predictionDesign optimisation/simulationMacroscopic scaleFirst principle

Owner:BEIJING UNIV OF TECH

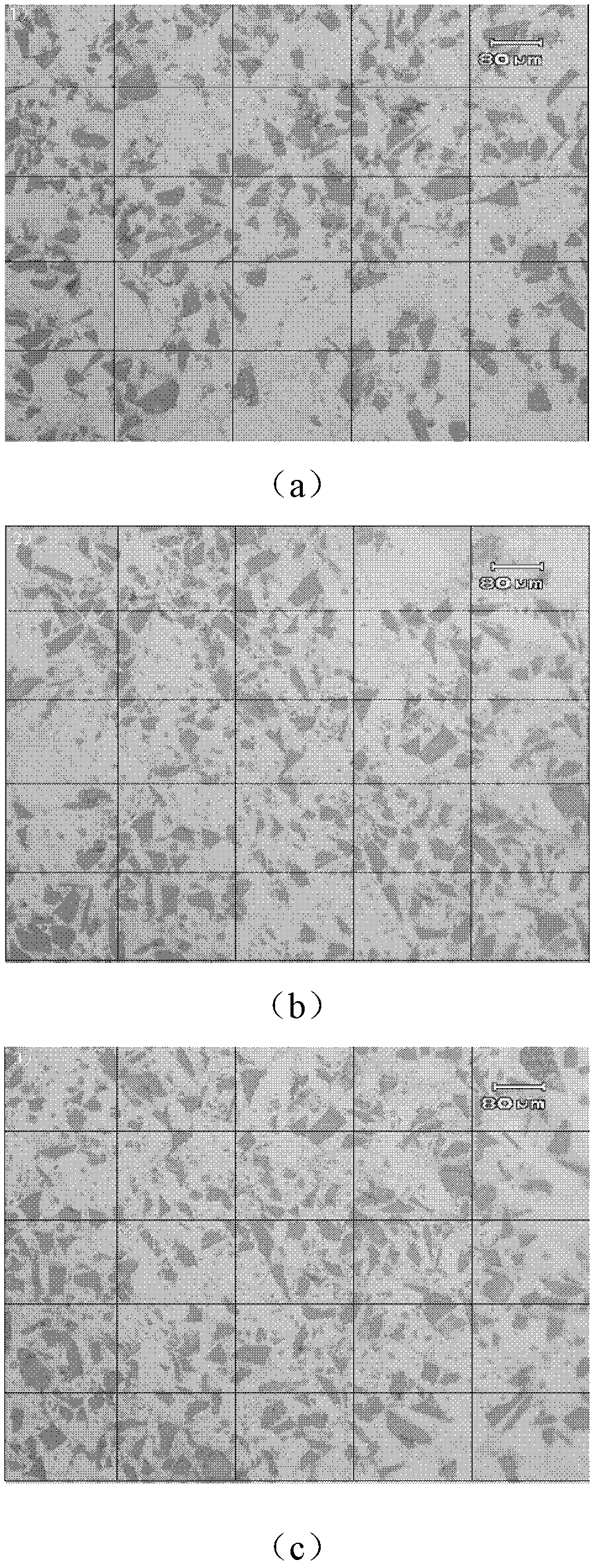

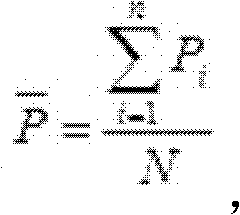

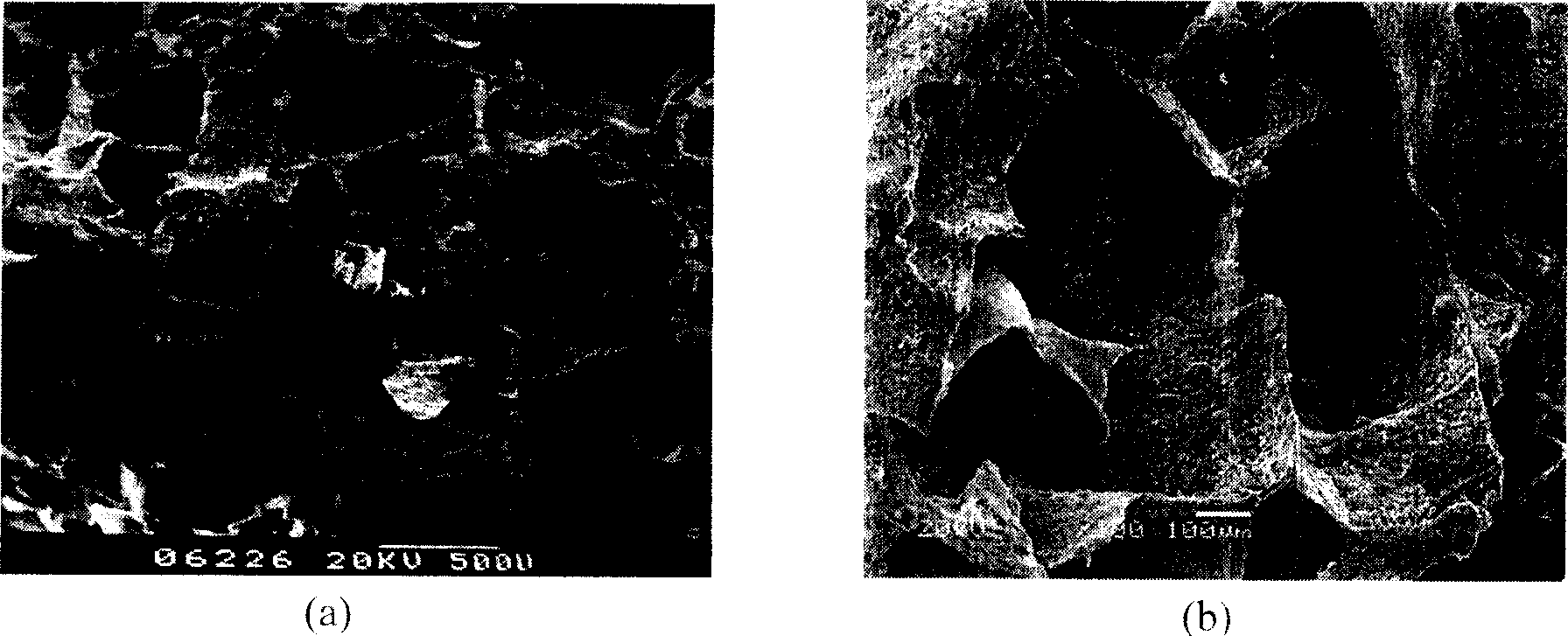

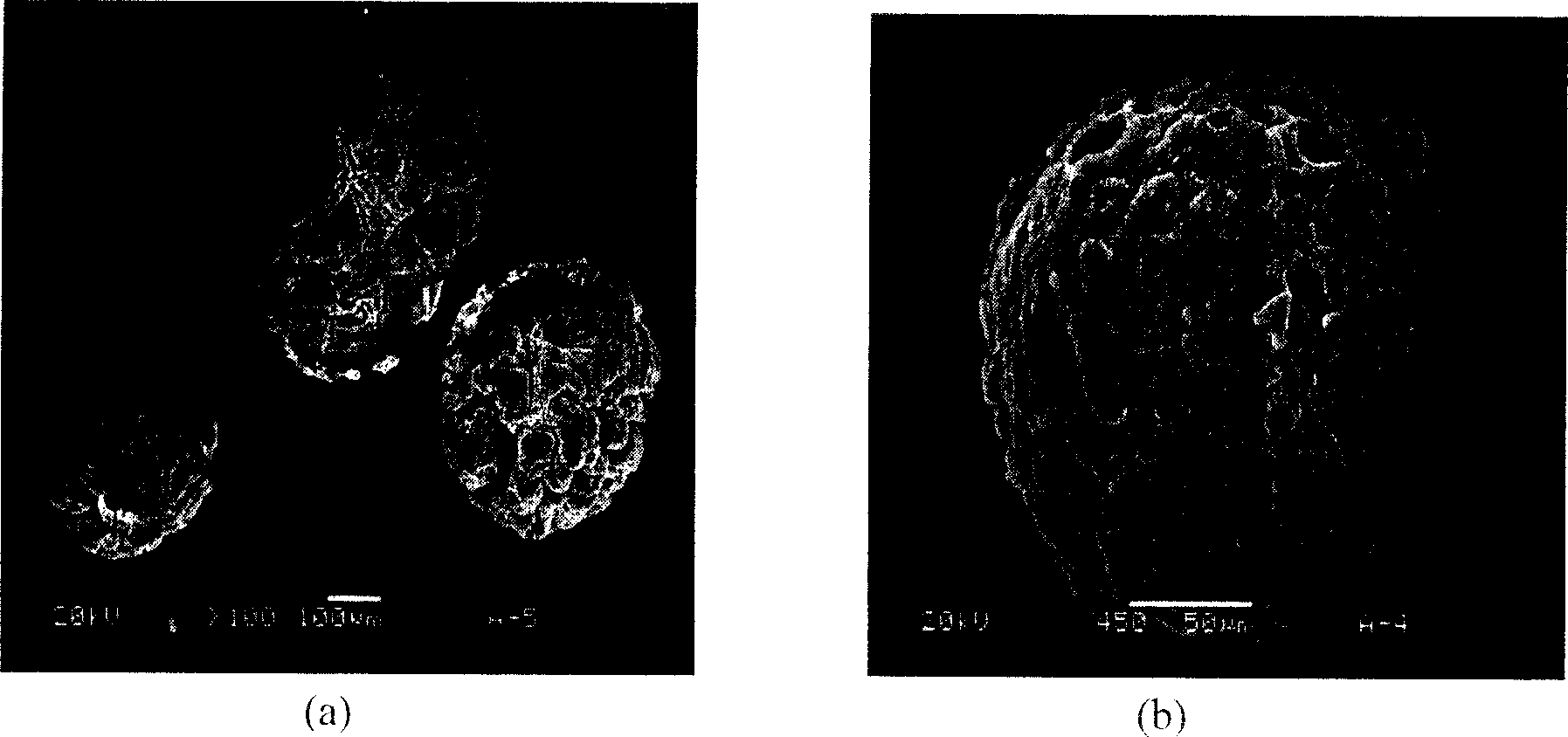

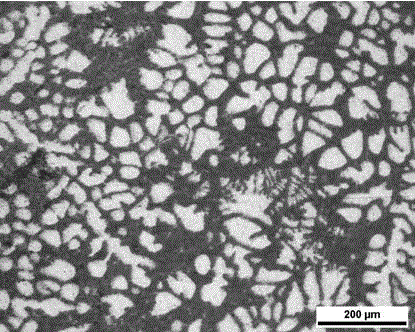

Method for evaluating tissue uniformity of particles reinforced aluminum composite material

The invention discloses a method for evaluating tissue uniformity of a particles reinforced aluminum composite material, base on basic theory of stereoscopy and statistics decision, by combing an image analysis technology and aiming at the particles reinforced aluminum composite material, mathematical statistics is carried out on the ideal particles uniform distribution in a microstructure, a calculating method of the particle distribution uniformity coefficient in the particles reinforced aluminum composite material is established. The uniformity coefficient of the particles distribution state in the particles reinforced aluminum composite material tissue under a practical state can be corrected. A test analysis is carried out according to the method, the tissue uniformity of the particles reinforced aluminum composite material with volume fraction of 2%-8%, the result can show that uniform degree of the particle distribution in the particles reinforced aluminum composite material. So that the evaluation method is used for objectively and scientifically evaluating the particle distribution state in the microstructure of the particles reinforced aluminum composite material with different volume fractions.

Owner:CSIC NO 12 RES INST

Composite nanometer hydroxy apatitel medical polymer material tissue engineering stent material and preparation method

A tissue-engineered scaffold material for medical purpose is composed of nano-class hydroxy apatite and the medical high-molecular material, and has the pores communicated with each other. It features that the dispersed microporous microballs are proportionally contained by it. Its preparing process includes such steps as proportionally mixing said microballs, nano-class hydroxy apatite, medical high-molecular slurry and the salt able to thermally generate gas, heating, and freeze-drying at -20 deg.C for at least 24 hr.

Owner:SICHUAN UNIV

Preparation method of double-scale crystalline grain Ti-6Al-4V material

InactiveCN102703756AProportional precision controlOvercome the defect that the ratio is difficult to control preciselyHigh energyTi 6al 4v

The invention discloses a preparation method of a double-scale crystalline grain Ti-6Al-4V material. The preparation method adopts a forming way combining a high energy ball milling process with a spark plasma sintering process, and comprises the following steps of: firstly, taking powder in a segmentation manner in the whole high energy ball milling process to obtain powder with different refining degrees, wherein the grain size distribution range of the ultrafine crystal powder is controlled to be between 100nm and 1 mu m, and the grain size distribution range of the nanocrystalline powder is controlled to be between 10nm and 100nm; then, compounding and uniformly mixing one of the powder serving as the raw material and the ultrafine crystal powder with the nanocrystalline powder according to any mass ratio; and finally, optimizing the spark plasma sintering process. By controlling the mixing proportion of the two powder, the proportion of a rough crystal zone and a fine crystal area in a double-scale crystalline grain Ti-6Al-4V material tissue can be accurately controlled, and the defect that the proportion of rough and fine crystals are difficult to be accurately controlled is overcome; and meanwhile, by optimizing the sintering parameters of the spark plasma sintering process, the material has an excellent comprehensive mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

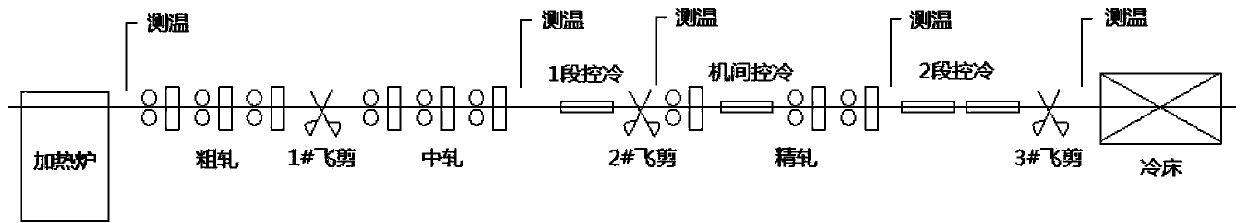

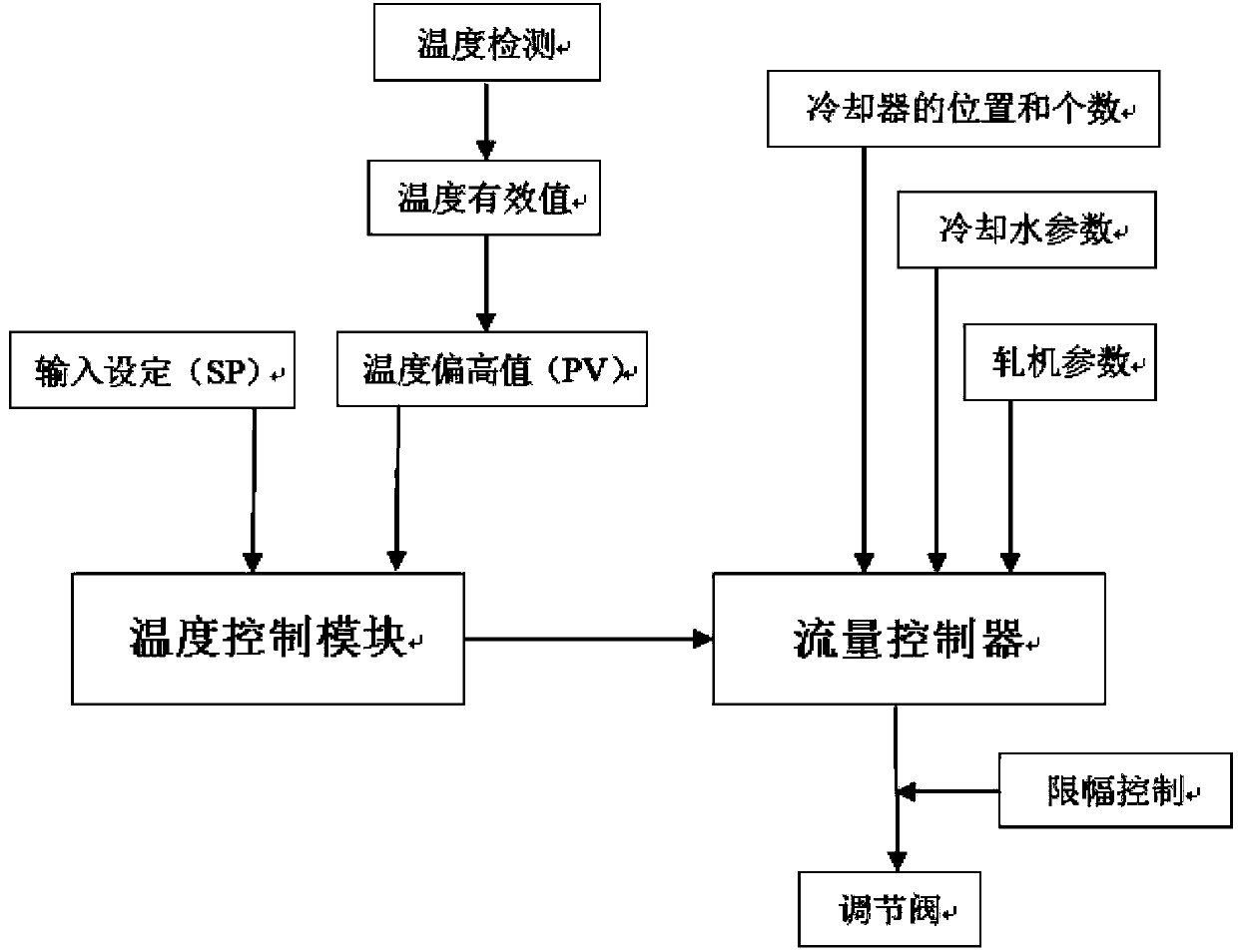

Automatic temperature control method for rod material cold control system

ActiveCN103464474ARealize fully automatic controlHigh precisionTemperature control deviceAutomatic controlEngineering

The invention provides an automatic temperature control method for a rod material cold control system, and belongs to the technical field of rod material heat treatment. The method comprises the following control steps including temperature detection treatment: the effective value of actual temperature detection equipment is judged, and the actual detection value is corrected; automatic temperature regulation: the automatic temperature regulation is realized on the temperature after the pre-cooling section before the rod material fine rolling, and the automatic temperature regulation is realized on the cold bed inlet temperature of the rod materials. The problems of temperature control precision and stability of the rod materials are effectively solved. The method has the advantages that all cold control equipment realizes the automatic operation, and the distribution of the core part temperature and the surface temperature of the rod materials after the cold control automatic control is stable, so the intensity and the toughness of steel materials are improved, the steel material tissue is improved, and in addition, electric energy sources and water energy sources are saved through automatically controlling a cooling water pump and a valve group.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Method for preparing glucoraphanin from broccoli

ActiveCN103709211ARich sourcesImprove extraction efficiencySugar derivativesSugar derivatives preparationGlucoraphaninSlag

The invention discloses a method for preparing glucoraphanin from broccoli, which comprises the following steps: cleaning the raw material, chopping, adding into an extraction tank set host, and sufficiently contacting solid-phase and liquid-phase substances in the extraction tank set in a reverse motion process, thereby extracting effective components from the medicinal material. The medicine slag are forcedly pushed to a slag outlet to be discharged by a discharge conveyer, and a special squeezing machine extrudes the medicine slag to obtain medicinal material tissues from the residual liquor in the medicine slag, thereby reducing the residual liquor content in the medicine slag. The method has the advantages of higher extraction efficiency and more complete extraction. By adopting the macroporous adsorbent resin combined with silica gel column chromatography for purification, the separating effect is better. The method can be used for preparing the glucoraphanin finished product of which the maximum yield is 1% and the content is higher than 95%.

Owner:HEILONGJIANG DINGHENGSHENG PHARM CO LTD

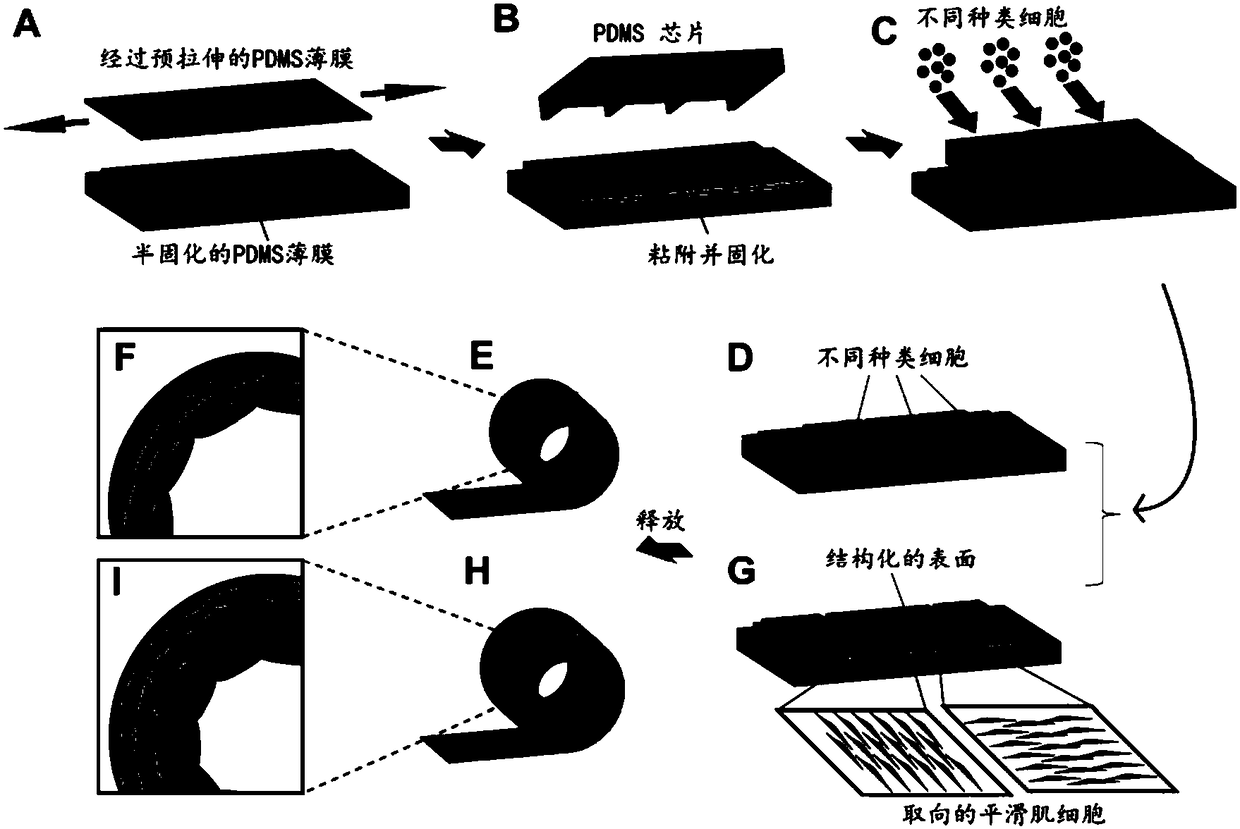

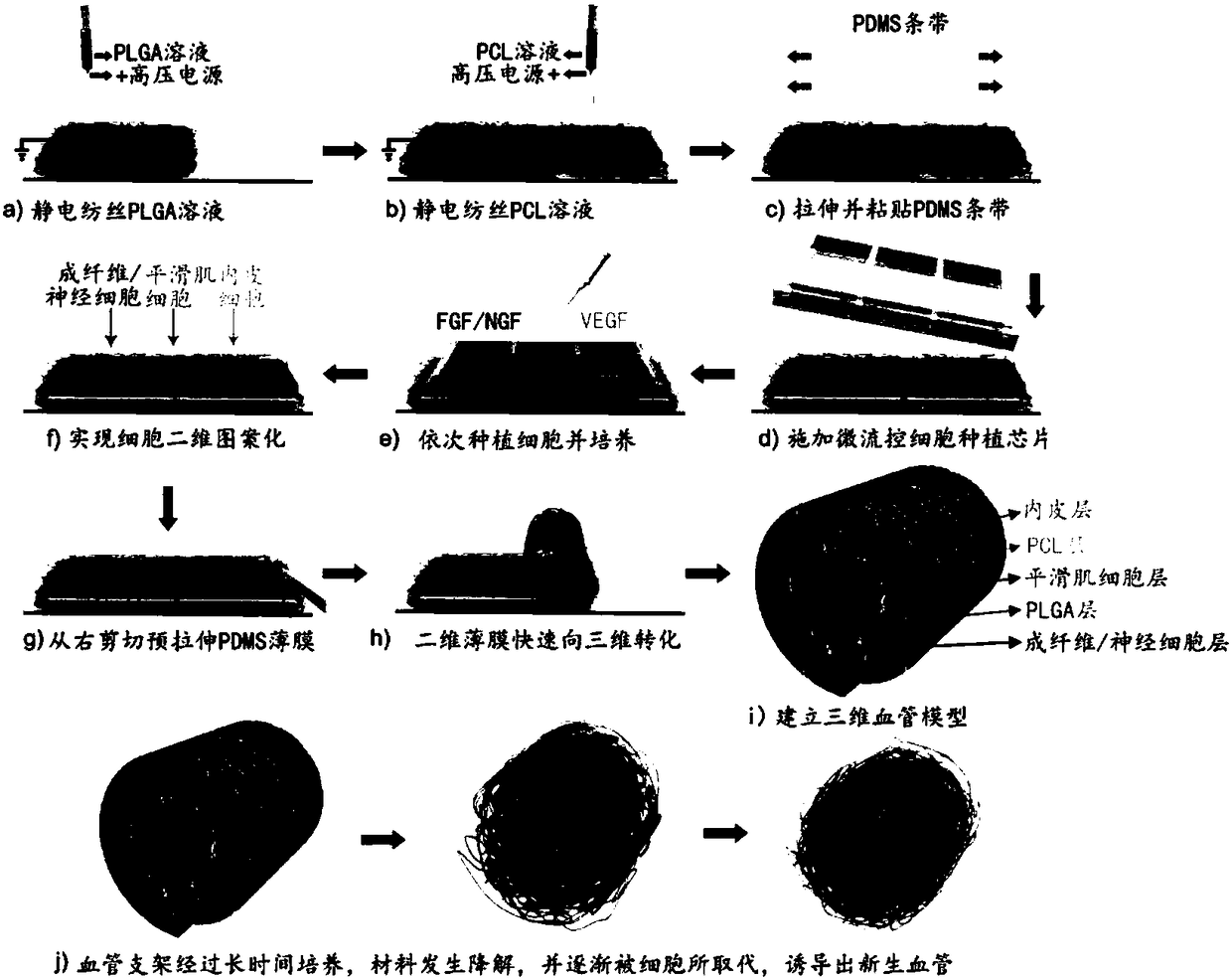

Three-dimensional coiled structure with function of automatically adjusting structure, as well as preparation method and applications of three-dimensional coiled structure

ActiveCN108653815AStabilizes vascular structuresIncrease the number of layersSynthetic resin layered productsMedical devicesVascular structureCoil structure

The invention provides a three-dimensional coiled structure with the function of automatically adjusting the structure, as well as a preparation method and applications of the three-dimensional coiledstructure. The three-dimensional multi-layer coiled structure has the function of automatically adjusting the self structure aiming at the external environment, and can be taken as the tissue engineering blood vessel similar to the real vascular structure to be applied to the fields including medical materials, tissue engineering and the like.

Owner:柔脉医疗(深圳)有限公司

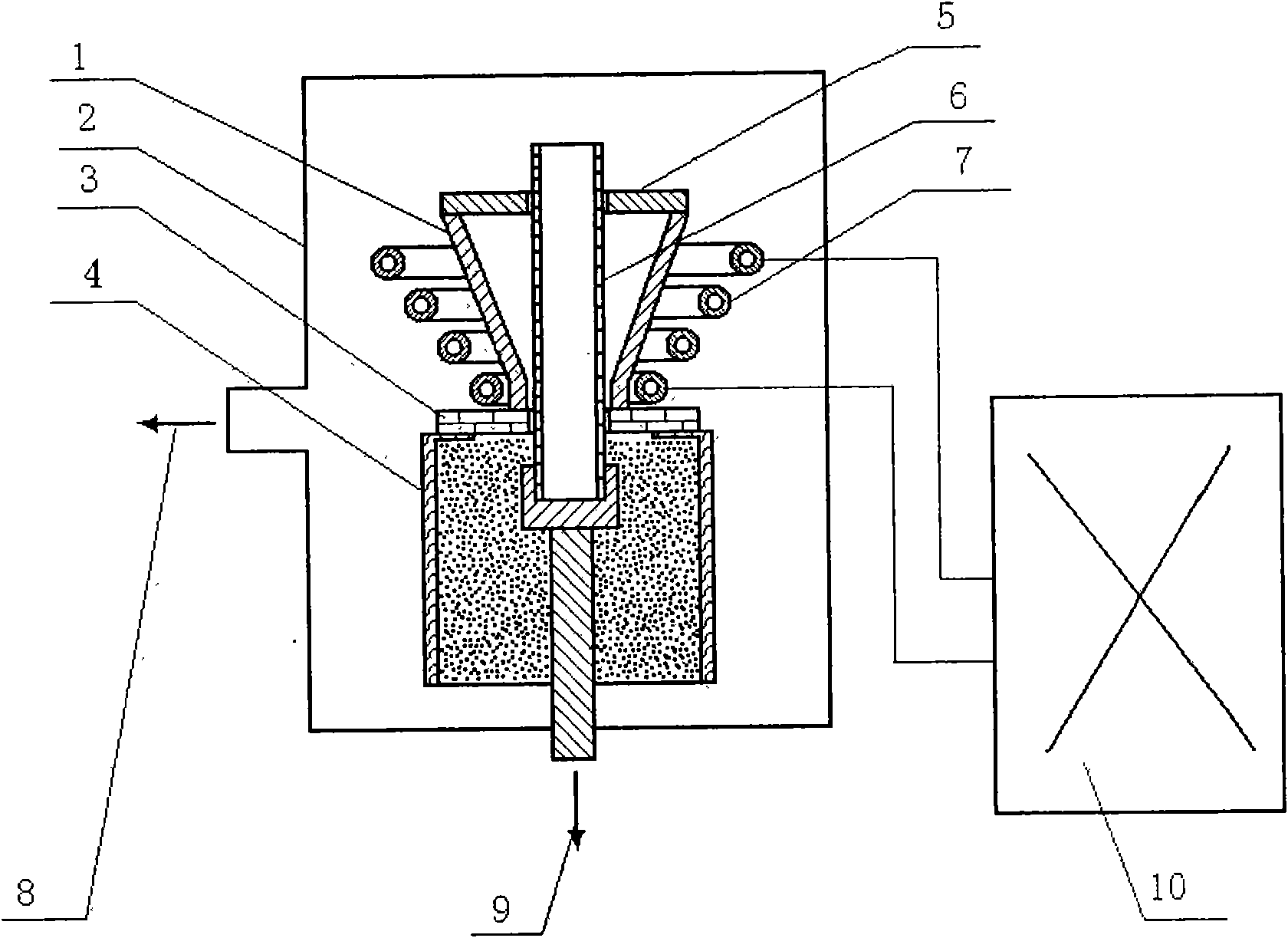

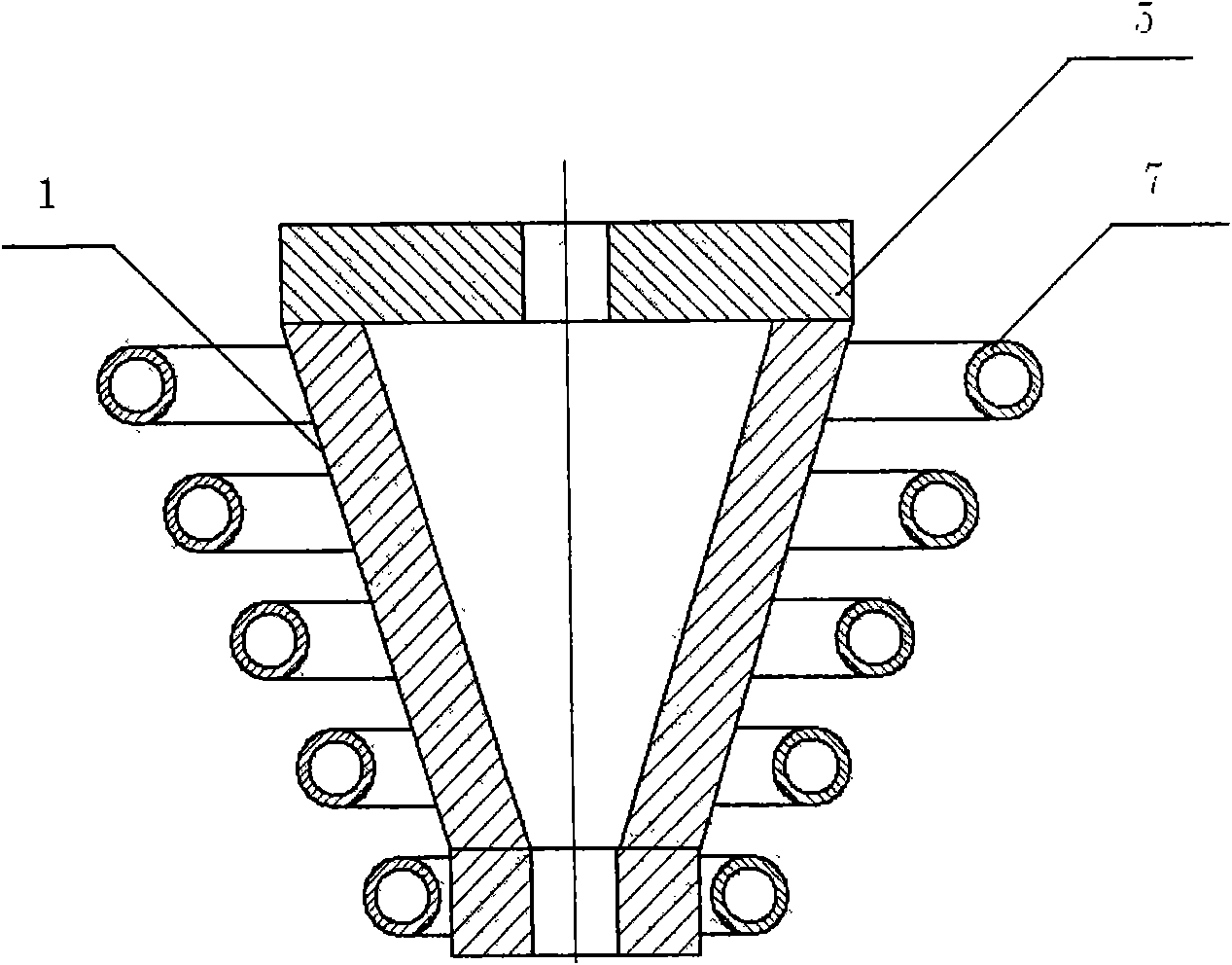

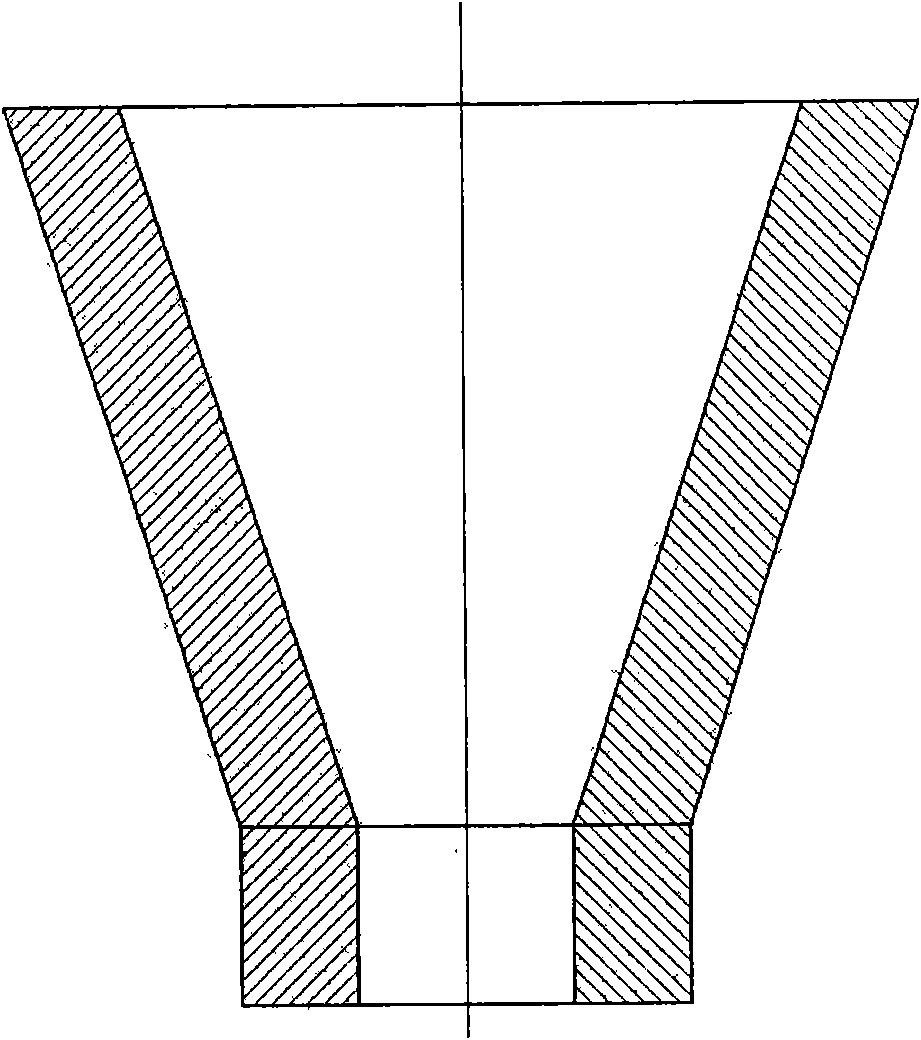

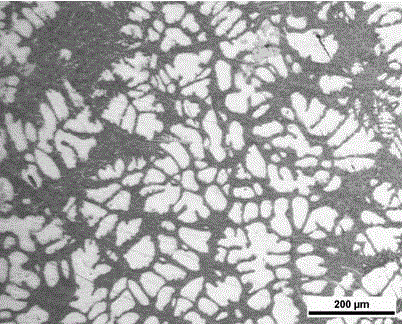

High-temperature gradient directional solidification conical graphite induction heater

InactiveCN101562920ASo as not to damageReduce distanceFurnaces without endless coreCoil arrangementsFront edgeMaterials science

The invention relates to a high-temperature gradient directional solidification conical graphite induction heater which comprises a conical high-frequency induction coil (7) and a conical heating body (1). A straight cylinder is arranged at the small diameter end of the heating body (1), and the small diameter end of the heating body (1) is arranged on a radiation baffle (3); one end of a crucible (6) penetrates through a middle hole of the radiation baffle (3) to be connected with a pulling system (9), and the other end is arranged in the heating body (1); and the high-frequency induction coil (7) is sleeved outside the heating body (1) to be connected with a high-frequency induction power supply (10). The high-temperature gradient directional solidification conical graphite induction heater uses the small diameter end of the heating body to intensively and emphatically heat a melting interface of a sample and limits overheating within a small area at the front edge of the interface so as to prevent the corundum crucible in the directional solidification process from being damaged due to durable overheating, shorten the distance between the highest temperature area and the solidifying interface and improve the temperature grads of the front edge of the solid / liquid interface, thereby improving the material texture and the comprehensive performance of the material and being suitable for large-size directional solidification samples.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

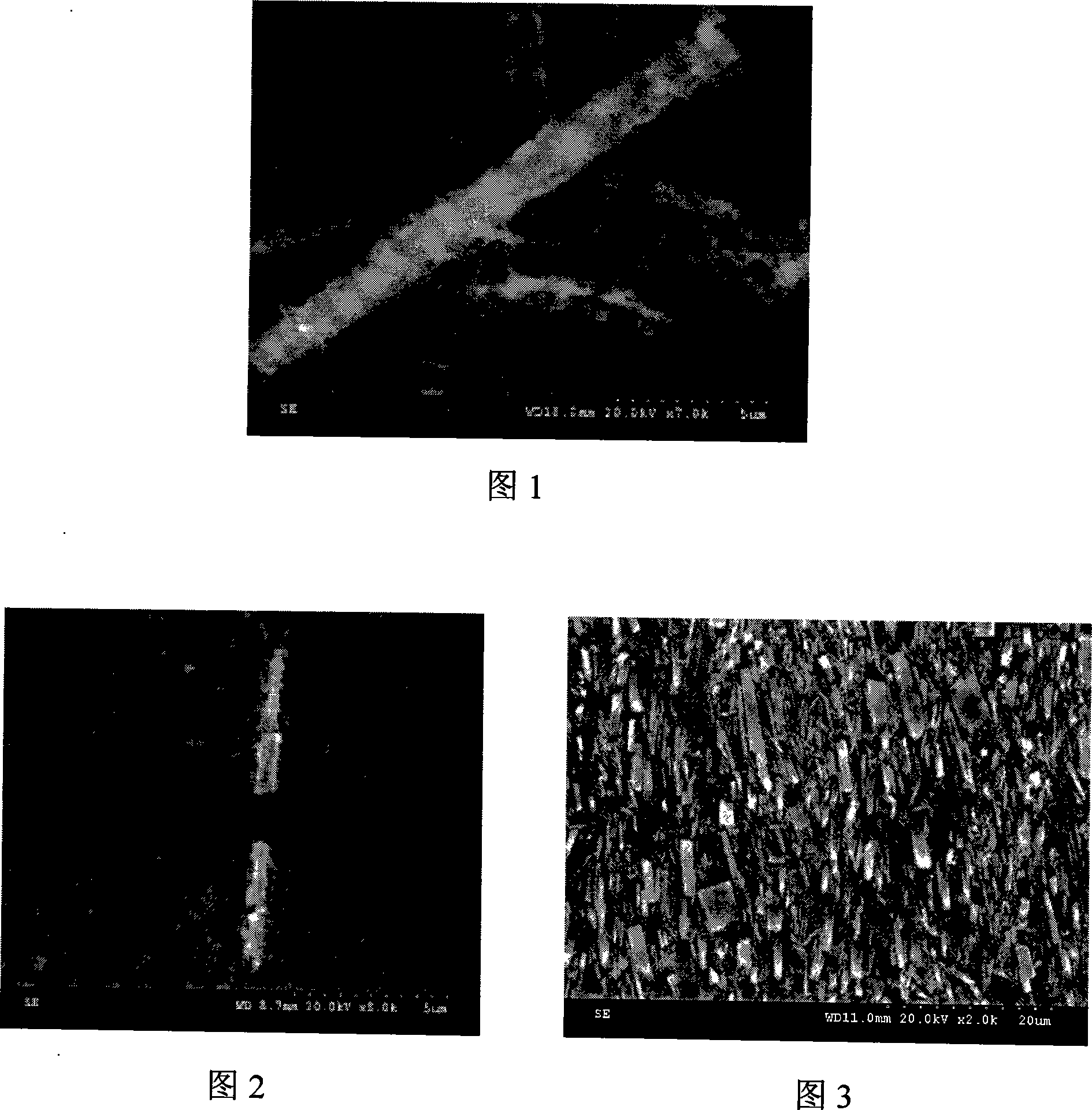

ZnO coating aluminum boric acid crystal whisker reinforcing aluminum base composite material and method for producing the same

InactiveCN101195885AImprove wettabilitySimple interfaceLiquid/solution decomposition chemical coatingSemi solidBoric acid

The invention discloses ZnO coating aluminum borate whisker reinforced aluminum matrix composite material and the preparation method thereof, which relates to composite material and the preparation method thereof. The invention solves the problems that the wettability of the aluminum borate whisker and the matrix in the composite material is poor, the interface reaction is generated between the aluminum borate whisker and elements of the matrix, the process of preparing aluminum borate reinforced aluminum matrix composite material is complex, the cost is high, and the material tissues are not uniform. In the method of the invention, ZnO coating aluminum borate whisker is prepared, then alloy is smelted, the preheating ZnO coating aluminum borate whisker is added into the alloy in the semi-solid state, semi-solid state mechanical stirring is performed to obtain semi-solid state pulp material, and the ZnO coating aluminum borate whisker reinforced aluminum matrix composite material is obtained through semi-solid state extrusion forming. In the invention, the wettability of the aluminum borate whisker and the matrix in the composite material is enhanced, the interface reaction in the elements of the matrix is prevented, the process of preparing aluminum borate reinforced aluminum matrix composite material is simple, the cost is low, and the material tissues are uniform.

Owner:HARBIN INST OF TECH

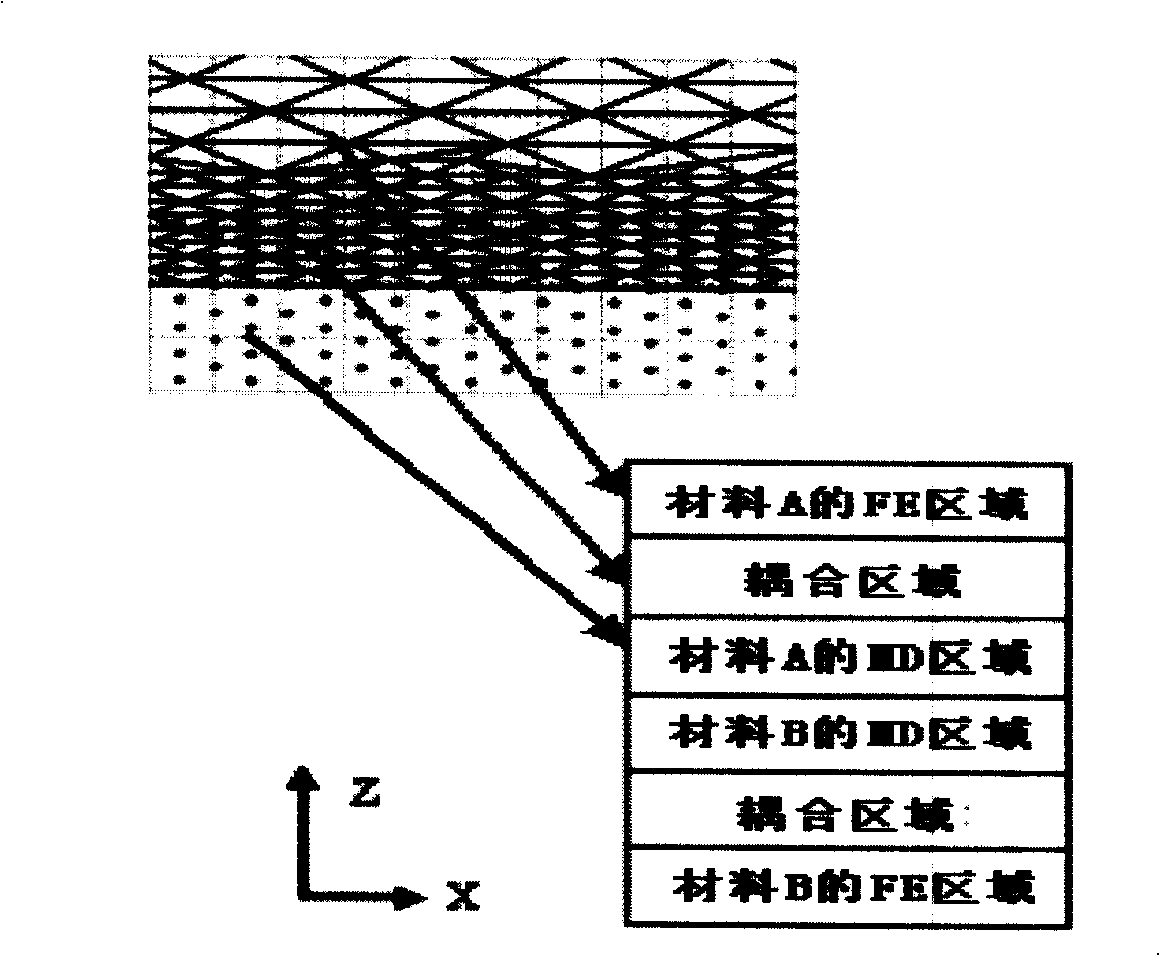

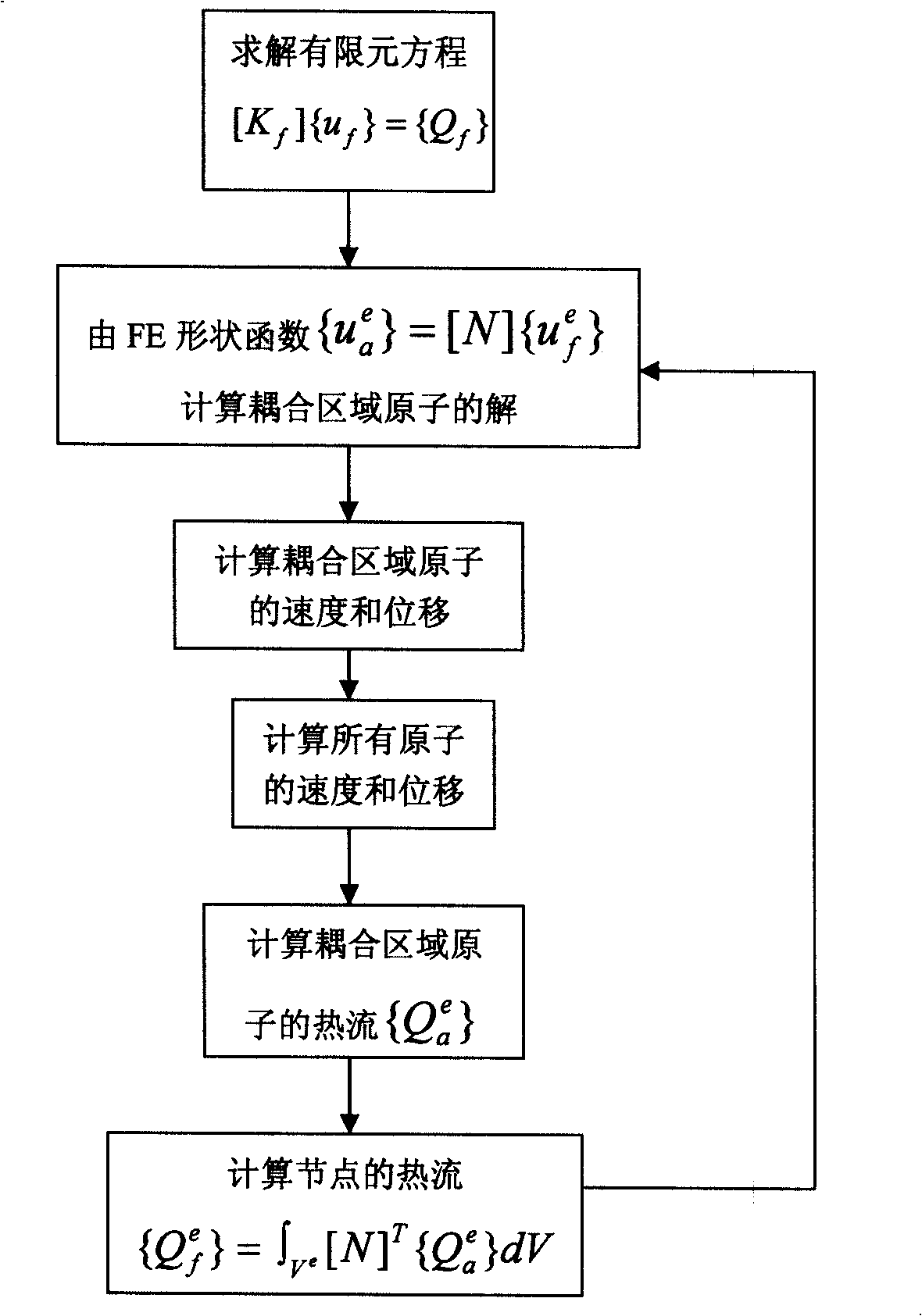

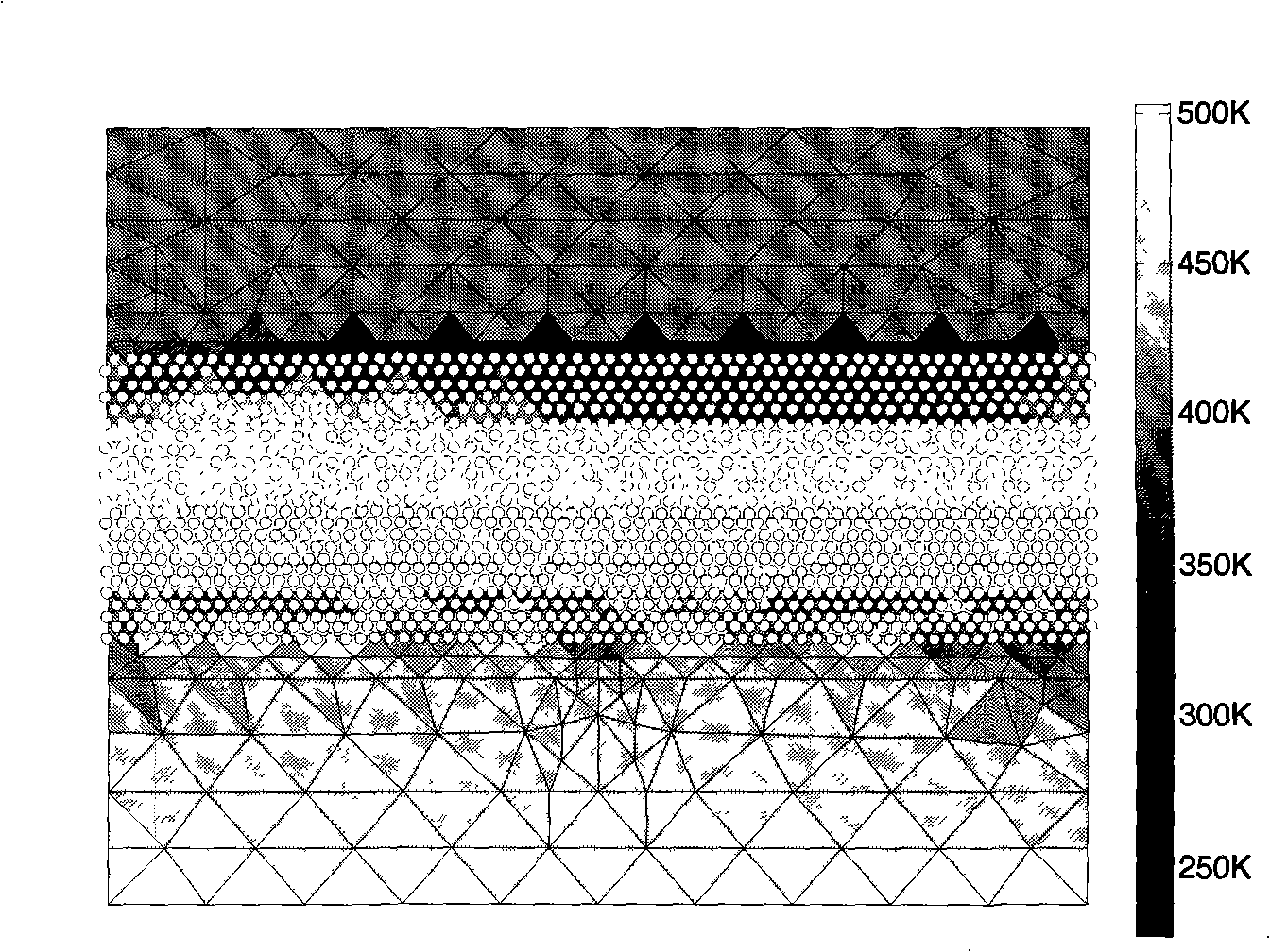

Multi-physical field interface multi-scale design method of structure of micro-nano electronic device

InactiveCN101515307APackage Design EfficientLow costSpecial data processing applicationsMaterial defectMicro nano

The invention discloses a multi-physical field interface multi-scale design method of structure of a micro-nano electronic device. A coupling system is firstly described, and the molecular dynamics is used for describing the interface tissue evolution and the material defect characteristics; finite elements are used for providing boundary conditions of thermal cycling, bending and stretching actions to a molecular dynamics model; finally, the mathematical simulation of the characteristics of the interface multi-physical field is carried out. The multi-physical field interface multi-scale design method of the structure of the micro-nano electronic device is formed in view of the characteristics of the multi-physical field interface, especially mask interface of the structure of the micro-nano electronic device for researching a framework of a multi-scale model and also in view of influences of the evolution of micro-interface scale material tissues, the production mechanism of thermal defects and material defects consisting holes, cracks, and the like on the physical characteristics of the micro-structure. Both the calculation efficiency and the scientific accuracy are considered. The macroscopical and microcosmic and nanoscopic simulation of whole performance characteristics of the multi-physical field interface of the structure of the micro-nano electronic device is realized. The hard multi-physical field interface multi-scale design problem of the structure of the micro-nano electronic device is solved.

Owner:JIANGSU UNIV

Boron carbide base ceramic sand jet material

InactiveCN1800096AHigh degree of densificationReduce energy consumptionBlast gunsBoron carbideTitanium carbide

The invention relates to a ceramic sand blowing nozzle material, which takes boron carbide as basal body, titanium carbide as reinforced phase, at the same time, we add metal binding phase molybdenum and nickel to enhance the bond of material tissue. The degree of compactness of sand blowing nozzle produced by said material is high, whose strength and tenacity is greatly enhanced compared with pure boron carbide, burning temperature is deduced to less than 1900 Deg C from 2200 Deg C of pure boron carbide, and the burning time is greatly decreased, said material has excellent anti-scouring wear ability with long life duration.

Owner:SHANDONG UNIV

Valve body forging technology

InactiveCN106825376ASolve the problem of easy crackingAvoid damageMetal-working apparatusSolid state diffusion coatingThermal treatmentMaterials science

The invention discloses a valve body forging technology. The valve body forging technology includes the steps of A, blanking, B, heating, C, free forging, D, rough die forging, E, precision die forging, F, trimming, G, character pressing, H, thermal treatment and I, shot blasting. The valve body forging technology has the advantages that through adoption of a valve body lengthening end integrated forging technology, the problem that a welded position is prone to stress cracking during split forging is solved, and damage to material tissues due to forging squeezing in an integrated flange forging process is avoided.

Owner:浙江电泰阀业有限公司

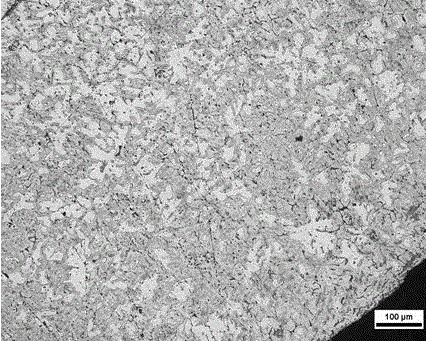

Method for preparing nano-aluminum-nitride reinforced aluminum-based composite semi-solid slurry based on ultrasonic and mechanical vibration combination

The invention relates to a method for preparing nano-aluminum-nitride reinforced aluminum-based composite semi-solid slurry based on ultrasonic and mechanical vibration combination. The method comprises the steps: firstly, mixing nano aluminum nitride particles and aluminum powder according to the mass ratio of (1: 1) to (2: 3), and carrying out ball milling for 50-60 hours at the revolving speed of 60-70rpm so as to obtain mixed powder; putting the mixed powder into a crucible, and heating to the temperature of 660-670 DEG C; cooling with air, crushing and sieving; melting aluminum alloy in the crucible so as to obtain aluminum alloy melt, adding the sieved mixed powder into the aluminum alloy melt at the temperature of 700-750 DEG C in 5-10 minutes in accordance with that the addition amount of the nano aluminum nitride particles is 1-4wt.% of the amount of the aluminum alloy melt, meanwhile, introducing high-energy ultrasonic sound of 20KHz and 1-3KW, and then, continuing to carry out ultrasonic treatment for 5-10 minutes; cooling the melt to an alloy semi-solid temperature range at the cooling speed of 5-15 DEG C / min, and applying mechanical vibration treatment at the power of 1.5KW, the frequency of 400-600Hz and the amplitude of vibration of 0.5-1.5mm. According to aluminum-based nano composite material tissue prepared by the method, a newborn alpha-Al phase is fine and is uniform in distribution, nano aluminum nitride particles are uniform in distribution and are free from an agglomeration phenomenon, and the method is low in process cost and convenient in operation and is simple, safe and reliable.

Owner:DE RUISEN NANTONG COMPOSITE MATERIAL CO LTD

Production technology for extracting usnic acid from usnea longissima

InactiveCN103044372AReduce contentImprove extraction efficiencyOrganic chemistryUsnea longissimaEngineering

The invention discloses a production technology for extracting usnic acid from usnea longissima. The technology comprises the steps that a raw material is subjected to coarse grinding, and fed in from a feeding hopper; an extraction tank unit host rotates to slowly push the material from the front end of a unit backwards; an extraction solvent enters an extraction tank from a liquid inlet tube at the tail end of the unit, passes through the moving material from the back end of the tank, and flows towards the front end; and solid and liquid substances are contacted fully in an inverse motion, so that effective components in the medicinal material are extracted. Dregs are forcibly pushed to a dreg discharge port by a discharge transport and then discharged; a special juice squeezer squeezes the dregs; residual medicine liquor in the dregs is squeezed out of a medicinal material tissue; and the content of the residual medicine liquor in the dregs is reduced. The extraction efficiency is higher, and the extraction is more complete. The method adopts a continuous extraction tank unit for extraction, and is combined with a silica gel column chromatography for purification, so that a separating effect is better. Finished usnic acid with a maximum yield of 1% and the content above 95% can be obtained.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

Method for preparing nano-alumina reinforced aluminum-based composite semi-solid slurry

The invention relates to a method for preparing nano-alumina reinforced aluminum-based composite semi-solid slurry. The method comprises the steps: firstly, carrying out ultrasonic treatment on nano alumina for 20-25 minutes in anhydrous ethanol, removing anhydrous ethanol, drying, calcining for 3-4 hours at the temperature of 550-600 DEG C, adding magnesium powder according to the mass ratio of (1: 7) to (5: 3), and carrying out ball milling for 30-60 minutes at the revolving speed of 100-150rpm so as to obtain mixed powder; melting aluminum alloy in a clay crucible so as to obtain aluminum alloy melt, adding the mixed powder into the aluminum alloy melt at the speed of 0.2-0.3g / min at the temperature of 700-800 DEG C in accordance with that the addition amount of the nano alumina is 0.5-2.5wt.% of the amount of the aluminum alloy melt, meanwhile, treating with high-energy ultrasonic sound of 5-10KHz and 1,000W, and then, continuing to treat with ultrasonic sound of 20KHz and 800-1,000W for 5-20 minutes; pouring the melt in the crucible of 600-650 DEG C, controlling the temperature to 700-720 DEG C, treating by applying ultrasonic sound of 20KHz and 600-1,000W, and cooling the alloy melt to a semi-solid temperature range at the cooling speed of 5-15 DEG C / min. According to aluminum-based nano composite material tissue prepared by the method, a newborn alpha-Al phase is fine and is uniform in distribution, nano alumina particles are uniform in distribution and are free from an agglomeration phenomenon, and the method is low in process cost and convenient in operation and is simple, safe and reliable.

Owner:NANCHANG UNIV

Application of allograft acellular dermal matrix in oral diseases

The invention relates to application of an allograft acellular dermal matrix in oral diseases, in particular to application of the allograft acellular dermal matrix in the repairing of cleft lip and / or alveolar cleft, cleft palate and oral mucous membrane defect, the repairing of periodontal defect and gingival recession, the repairing of nasal mucosa, tooth implantation, the repairing of furcation involvement and the prevention of complications such as dry socket after impacted tooth extraction, and belongs to the technical field of biological medical material tissue engineering. The allograft acellular dermal matrix is a product improved by a process, the mechanical performance of the product is suitable for surgery, and the sewing strength of the product is 16-18N; the allograft acellular dermal matrix is free of immunological rejection, capable of fast inducing tissue regeneration, soft in texture after implantation, free of contour feeling and good in in-vivo compatibility and hasa stable stent and template effect.

Owner:BEIJING JAYYALIFE BIOTECH CO LTD

Method for preparing nano-alumina reinforced aluminum-based composite semi-solid slurry based on composite vibration technology

The invention relates to a method for preparing nano-alumina reinforced aluminum-based composite semi-solid slurry based on a composite vibration technology. The method comprises the steps: mixing nano alumina and aluminum powder according to the mass ratio of (1: 1) to (1: 2), carrying out ball milling for 45-50 hours at the revolving speed of 50-60rpm, then, adding magnesium powder, and carrying out ball milling for 20-25 hours so as to obtain mixed powder, wherein the mass ratio of nano alumina to aluminum powder to magnesium powder is (4: 4: 3) to (4: 8: 3); melting aluminum alloy in a clay crucible so as to obtain aluminum alloy melt, and carrying out heat preservation for 10-15 minutes at the temperature of 720-750 DEG C; cooling the aluminum alloy melt to a semi-solid temperature range, adding the mixed powder into the aluminum alloy slurry at the speed of 1-1.5g / min in accordance with that the addition amount of the nano alumina is 1-5wt.% of the amount of the aluminum alloy slurry, meanwhile, carrying out mechanical stirring at the revolving speed of 300-400rpm, and then, re-stirring for 15-20 minutes; heating the slurry to the temperature of 680-700 DEG C, treating with ultrasonic sound of 20KHz and 1,000W for 5-10 minutes, then, cooling the melt to the semi-solid temperature range at the cooling speed of 5-15 DEG C / min, and treating with ultrasonic sound of 20KHz and 600-1,000W. According to aluminum-based nano composite material tissue prepared by the method, a newborn alpha-Al phase is fine and is uniform in distribution, nano alumina particles are uniform in distribution and are free from an agglomeration phenomenon, and the method is low in process cost and convenient in operation and is safe and reliable.

Owner:NANCHANG UNIV

Alloy ball iron guide disc for precision tube grimper

The invention discloses a new-typed alloy ball-iron guide disc of fine rolling machine, which comprises the following parts: 3.0-3.6% C, 1.5-2.2% Si, 0.4-0.8% Mn, not more than 0.04% P, not more than 0.04% S, 0.1-0.3%Cr, 2.0-3.5% Ni, 0.5-1.0% Mo, not less than 0.04% Mg and Fe and inevitable impurity. The material tissue uniforms interior and exterior to improve abrasion resistance and flexibility, which improves manufacturing efficiency obviously.

Owner:SHANDONG SIFANG STEEL PIPE EQUIP MFG

On-site high magnification inspection method applicable to tower material tissue

InactiveCN103439169ARealize material analysisAchieve lifePreparing sample for investigationTransmission towerHigh magnification

The invention relates to an on-site high magnification inspection method which is applicable to a tower material tissue, and comprises the steps that (1), an inspected surface is ground; (2), polishing is performed by a chemical polishing method; (3), erosion is performed by a nitric acid and alcohol mixture; and (4), high magnification inspection is performed, and the inspected surface is observed or a laminated film is taken to a laboratory for careful analysis. According to the on-site high magnification inspection method, on-site high magnification inspection of an in-service power iron transmission tower and a lightning rod iron tower is achieved very well; grinding, the polishing, the erosion, and on-site high magnification observation photographing or metallographic film laminating are achieved; and material analysis and life assessment of the in-service power transmission iron tower and the lightning rod iron tower are achieved.

Owner:STATE GRID CORP OF CHINA +1

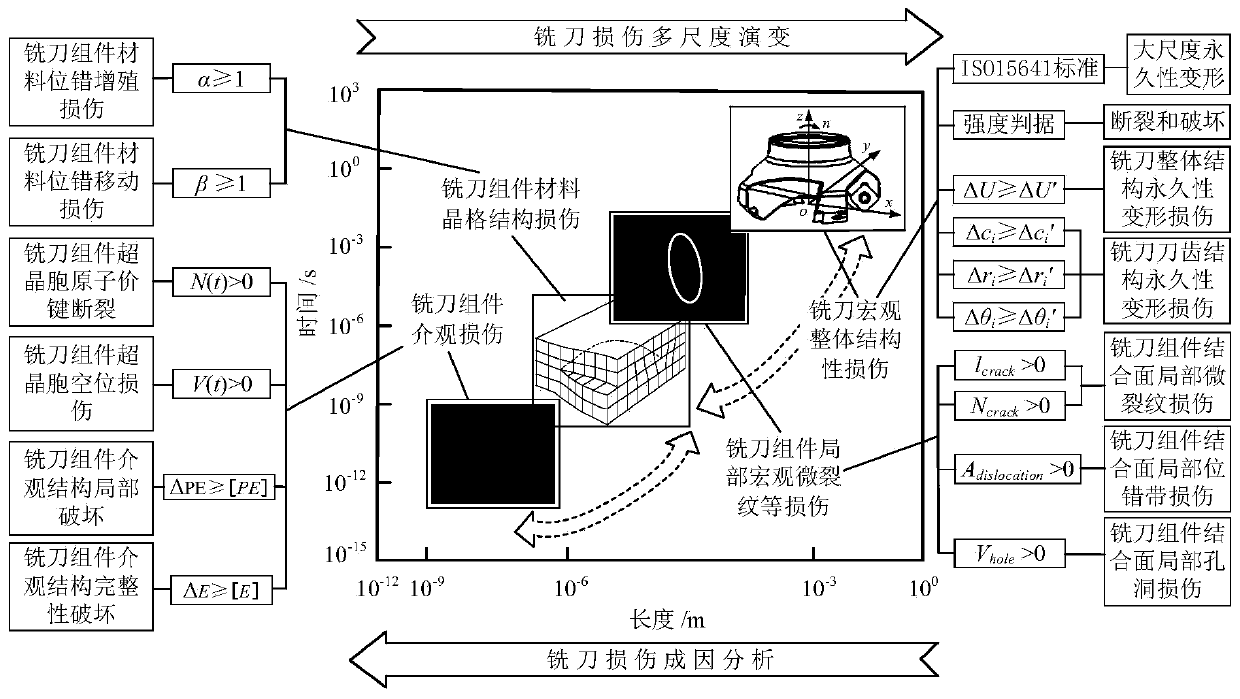

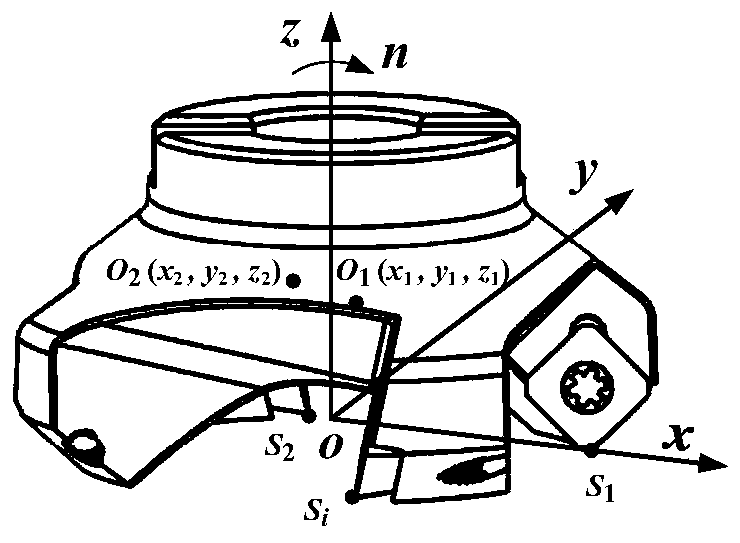

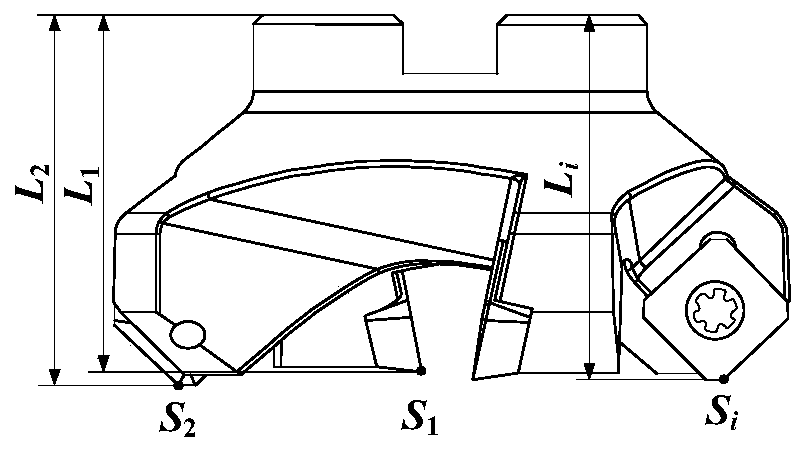

Efficient multi-scale recognizing method for milling tool injuries

ActiveCN109940459AOvercome limitationsEnsure safetyMeasurement/indication equipmentsMacroscopic scaleAlgorithm

The invention discloses an efficient multi-scale recognizing method for milling tool injuries and belongs to the technical field of milling tools. The objective of the invention is to solve the problem that the existing milling tool injury recognizing method does not carry out multi-scale considering on the milling tool injuries but focuses on micrometer and above macroscales. The method comprisesthe following steps: step a, carrying out scale division on the recognizing data of the milling tool injuries; step b, establishing milling tool structures and working load feature models; step c, carrying out measurement and recognition on the permanent deformation of milling tools; step d, analyzing the stress fields of the milling tools and recognizing partial injuries; step e, recognizing thematerial organization structural injuries of milling tool components; step f, recognizing the mesoscopic injury forming of the milling tool components; and step g, carrying out multi-scale recognition and experimental verification on the milling tool injuries. The efficient multi-scale recognizing method for the milling tool injuries can effectively recognize the milling tool injuries from multiple layers and overcomes the limitation of the existing macroscopic scale recognition for milling tool injuries.

Owner:HARBIN UNIV OF SCI & TECH

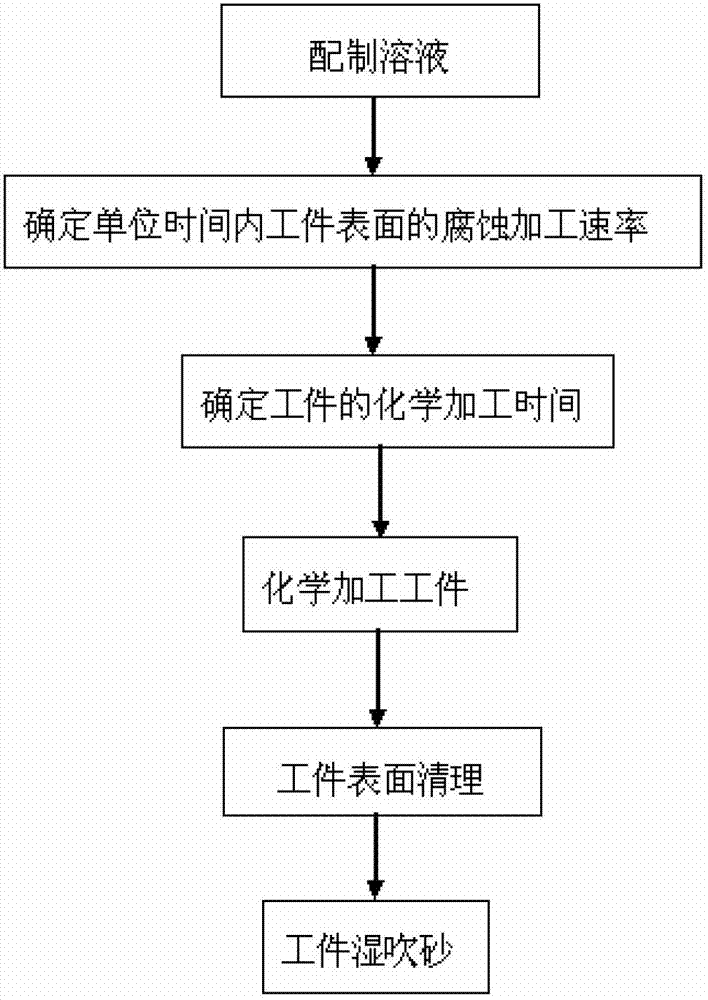

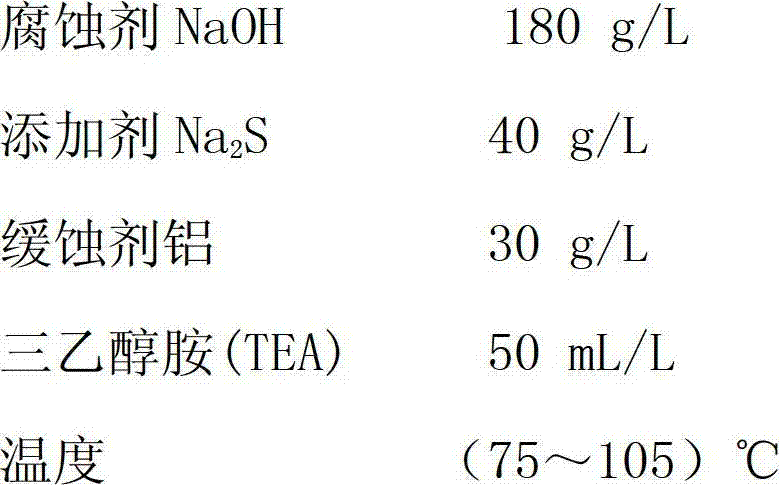

Solution and method for chemical machining of ei768 stainless steel workpiece

The invention discloses a solution and a method for the chemical machining of a ei768 stainless steel workpiece. The solution comprises hydrochloric acid with a volume ratio of 132 ml / L to 142 ml / L, nitric acid with a volume ratio of 115 ml / L to 125 ml / L, ferric trichloride with a weight-to-volume ratio of 445 g / L to 453 g / L, and the balance of water. In a machining process, a corrosion machining speed on the surface of the workpiece within a unit time is first determined through a sample, and the chemical machining time of the workpiece is determined according to the obtained chemical machining speed of the sample and the surface removal amount of the workpiece to be machined. The dimensional accuracy and the surface roughness of the workpiece machined through the solution and the method both can reach an ideal level; moreover, cutting stress cannot be generated; and the deformation does not exist. Through metallographic inspection, the solution and the method cannot cause intercrystalline corrosion to ei768 stainless steel, and the abnormality of a material tissue is not discovered.

Owner:AECC AVIATION POWER CO LTD

High-hardness impact-resistant cold rolled steel working roll and processing technique thereof

ActiveCN103173688AImprove hardenabilityImprove stabilityFurnace typesRollsWork rollChemical composition

The invention discloses a high-hardness impact-resistant cold rolled steel working roll. The working roll adopts low-alloy high-strength steel, and the low-alloy high-strength steel comprises chemical components (C, Si, Mn, Cr, Mo, V, Ti, S and P) and the balance of Fe and inevitable impurities. The processing technique of the cold rolled steel working roll comprises the following steps of: teeming, forging forming, heat treatment after forging, machining for forming, ultrasonic flaw detection, modulating treatment, preheating, line-frequency induction treatment, tempering, finish machining, ultrasonic flaw detection, coarse grinding of grinding machine, finish machining for modifying R, ultrasonic surface flaw detection, hardness detection of finished product, and packaging and storing. In the chemical component proportion of the cold rolled steel working roll, Si and Mn with lower price are selected to improve the hardenability of the material and change the bainite in material tissues, the form distributed tissues has higher stability, tenacity, crack initiation resistance capability, as well as high crack propagation resistance capability.

Owner:JIANGYIN RUNYUAN MACHINERY

Method for preparing saikoside from bupleurum longiradiatum

InactiveCN103040887ARich sourcesImprove extraction efficiencyAntipyreticAnalgesicsBupleurum longiradiatumEngineering

The invention discloses a method for preparing saikoside from bupleurum longiradiatum. The method comprises the steps that a raw material is subjected to coarse grinding, and fed in from a feeding hopper; an extraction tank unit host rotates to slowly push the material from the front end of a unit backwards; an extraction solvent enters an extraction tank from a liquid inlet tube at the tail end of the unit, passes through the moving material from the back end of the tank, and flows towards the front end; and solid and liquid substances are contacted fully in an inverse motion, so that effective components in the medicinal material are extracted. Dregs are forcibly pushed to a dreg discharge port by a discharge transport and then discharged; a special juice squeezer squeezes the dregs; residual liquor in the dregs is squeezed out of a medicinal material tissue; and the content of the residual liquor in the dregs is reduced. The extraction efficiency is higher, and the extraction is more complete. The method adopts a continuous extraction tank unit for extraction, and is combined with a silica gel column chromatography for purification, so that a separating effect is better. Finished saikoside with a maximum yield of 4% and the content above 95% can be obtained.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

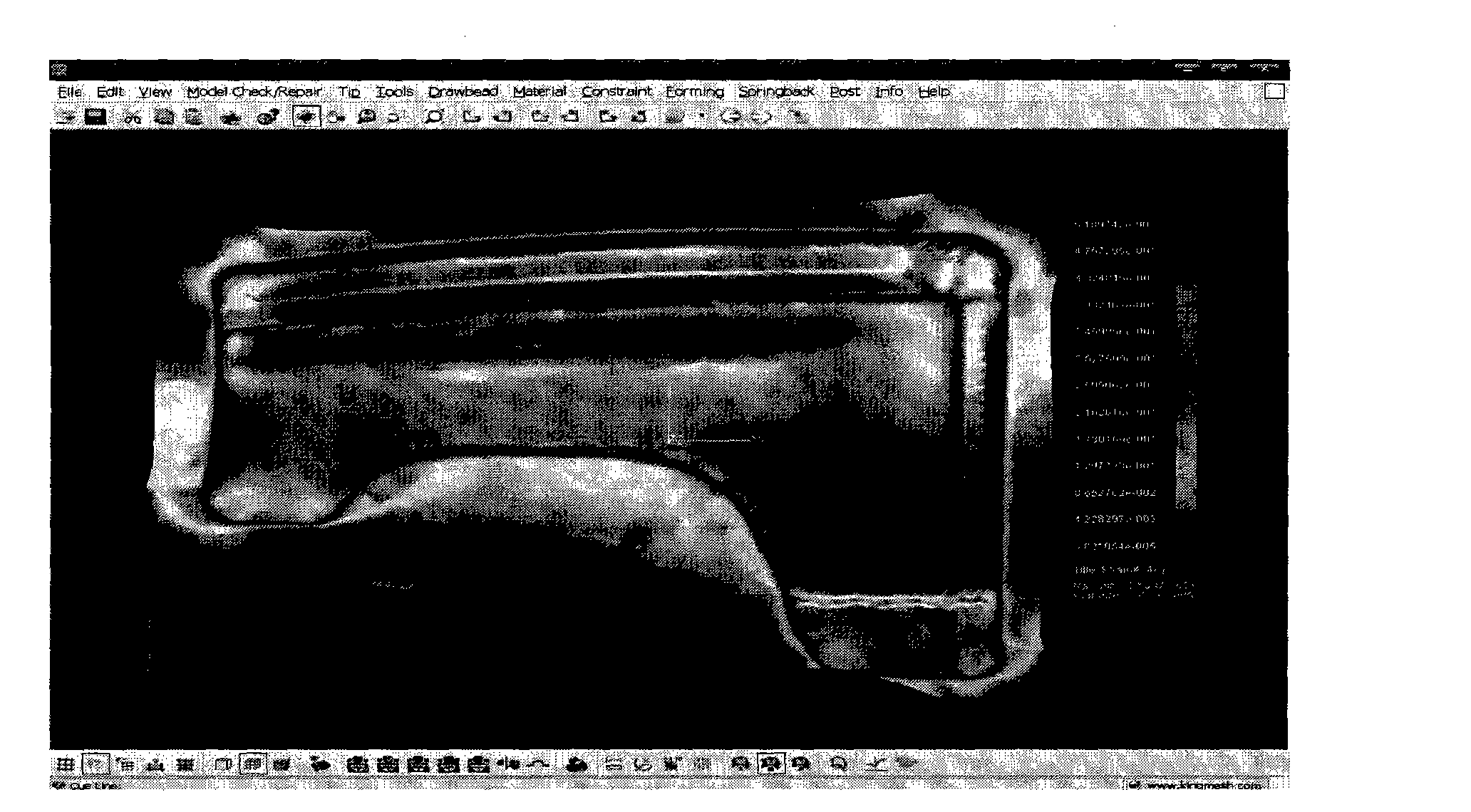

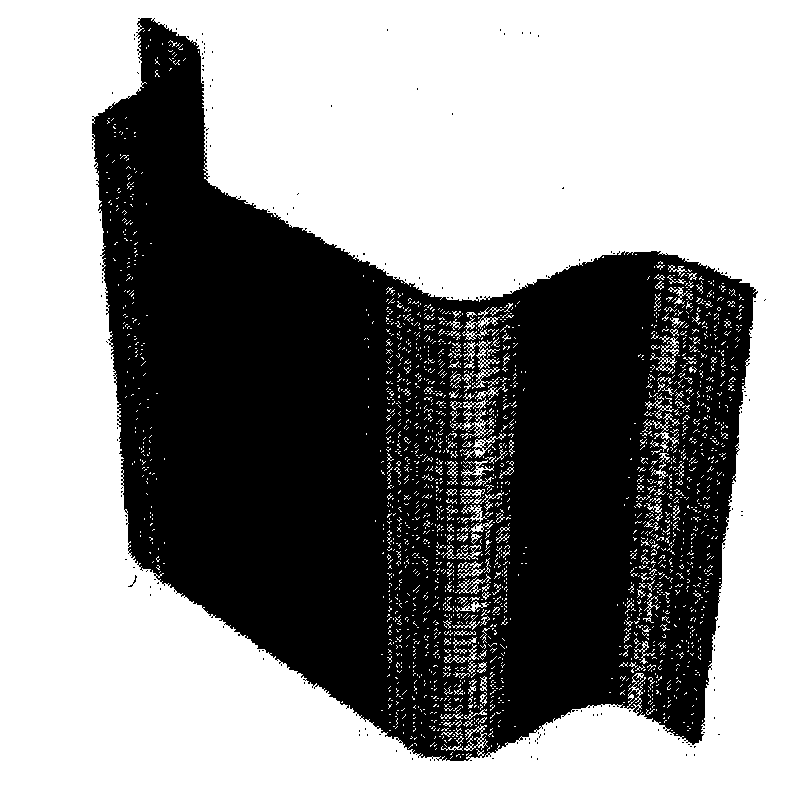

Software for simulation and optimum design of warm-hot formation

The invention provides software for simulation and optimum design of warm-hot formation of high-strength steel plate, automobile and aviation aluminum-magnesium alloy and composite materials used in an automobile. The software introduces a multi-scale constitutive model and considers the rate dependence and the temperature dependence of the materials, simultaneously the software also considers the contact property of the plate and the die during the heat conduction, deformation and high temperature of the die in the warm-hot forming process, the warm-hot forming simulation is carried out by introducing multi-field coupling factors such as temperature, mechanics, phase change and the like and non-linear problems such as geometry, physics and the like, and the simulation results show temperature distribution, thickness distribution, strain stress distribution, hardness distribution, material tissue percentage, material forming limit diagram and the like in the whole process of the warm-hot formation of the materials. By the optimum design of the warm-hot formation based on the warm-hot simulation, the optimal process parameters and die design schemes can be obtained.

Owner:CHANGCHUN WEIFUTE AUTOMOBILE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com