Patents

Literature

63results about How to "Solve the problem of easy cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

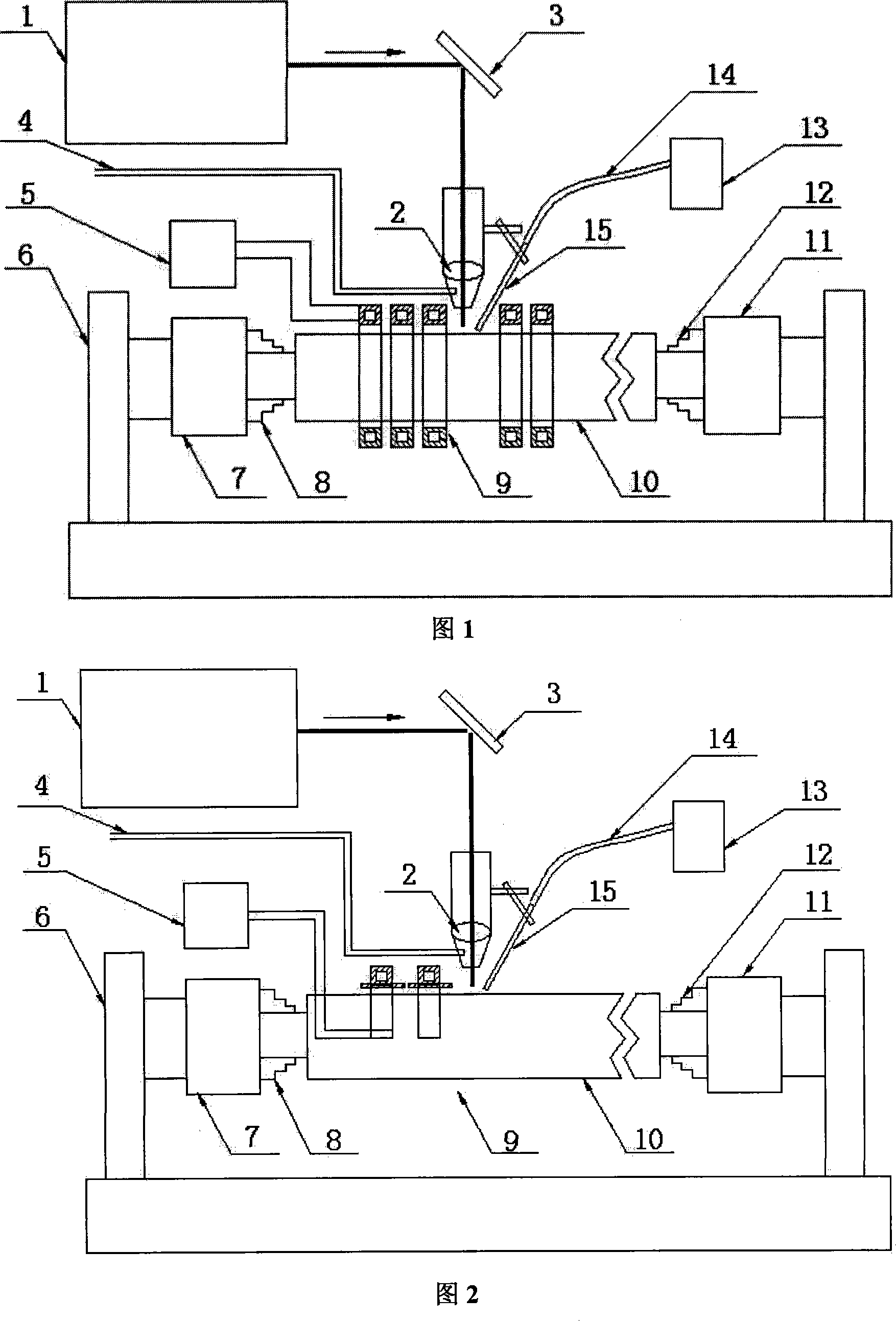

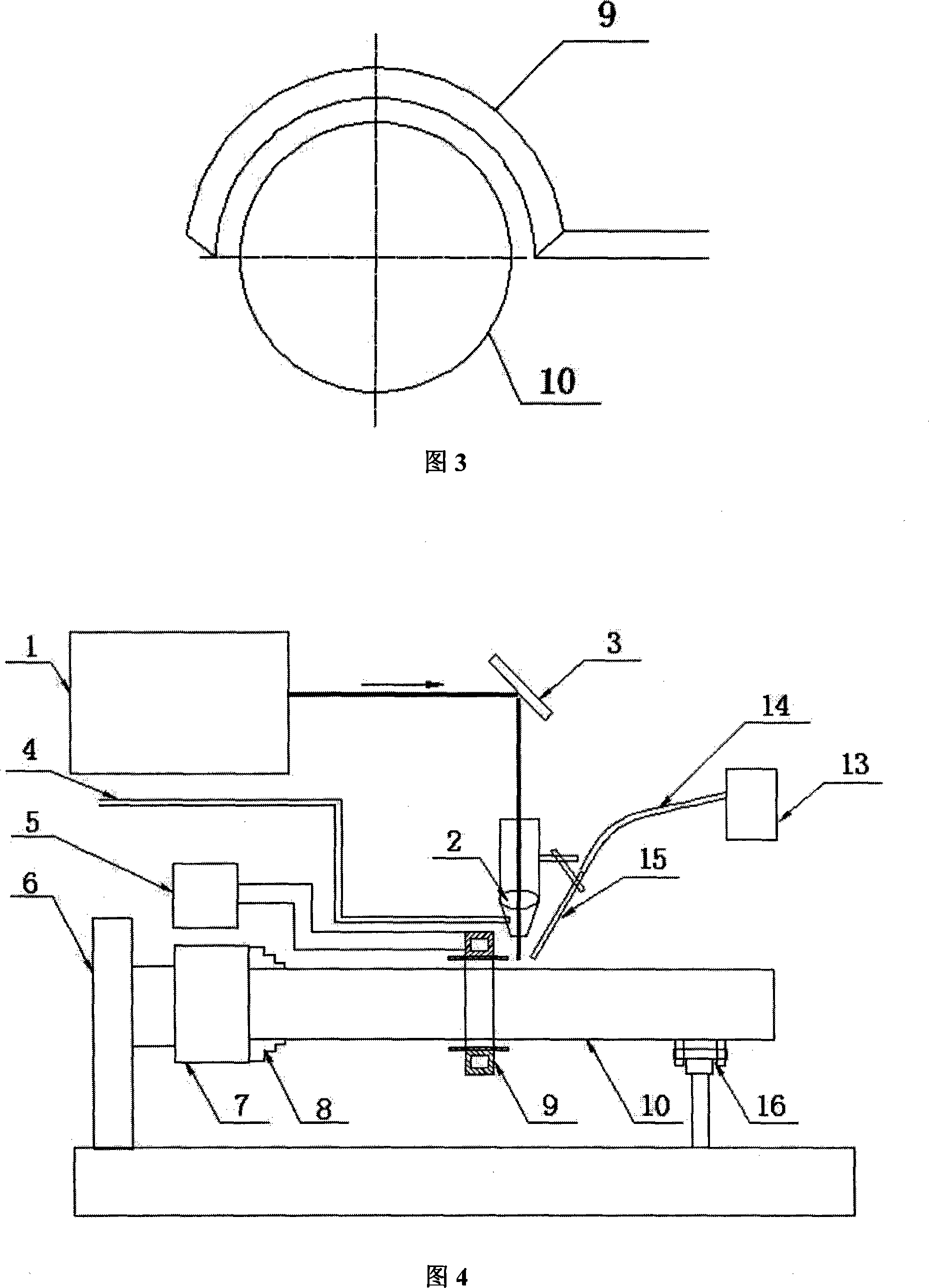

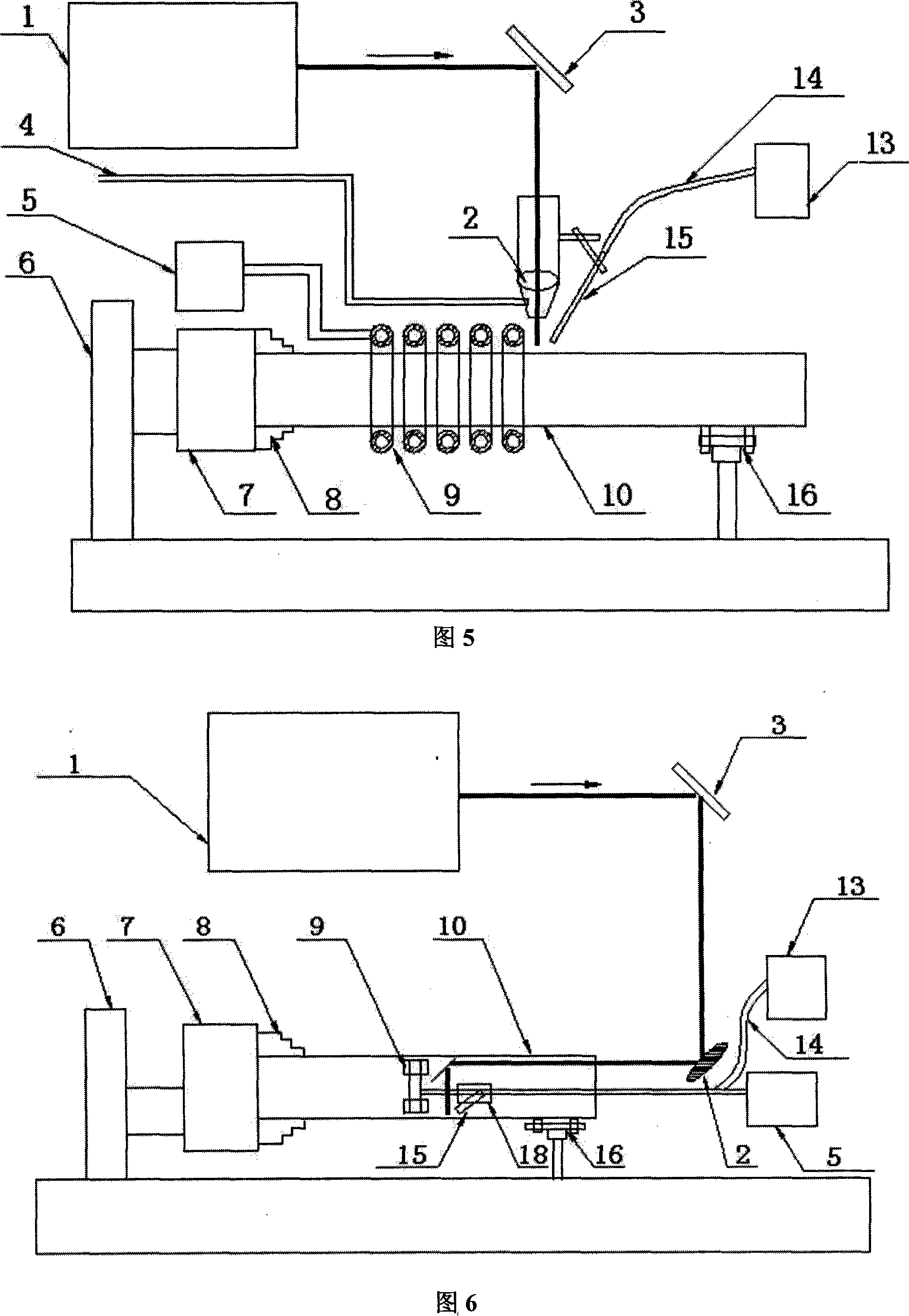

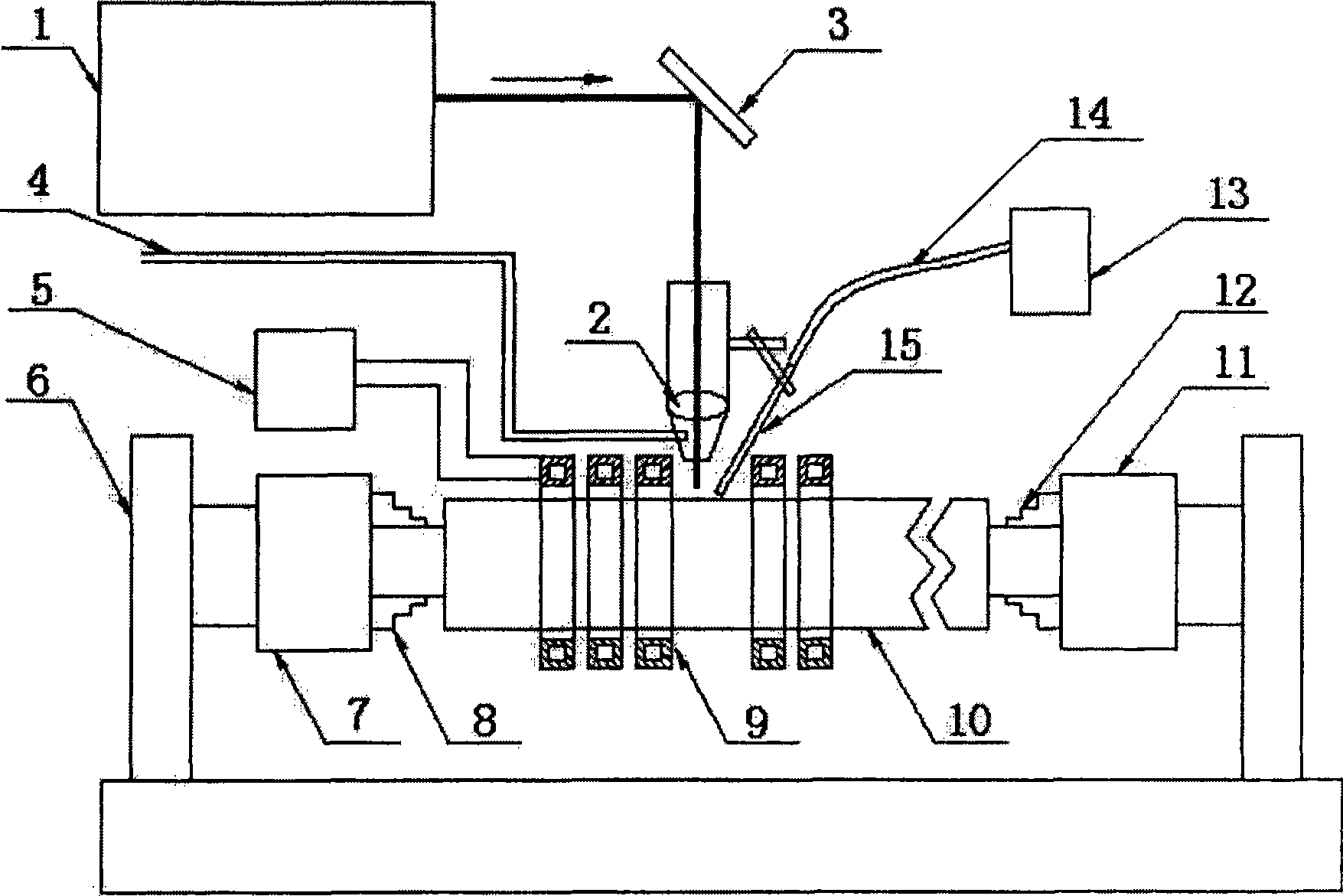

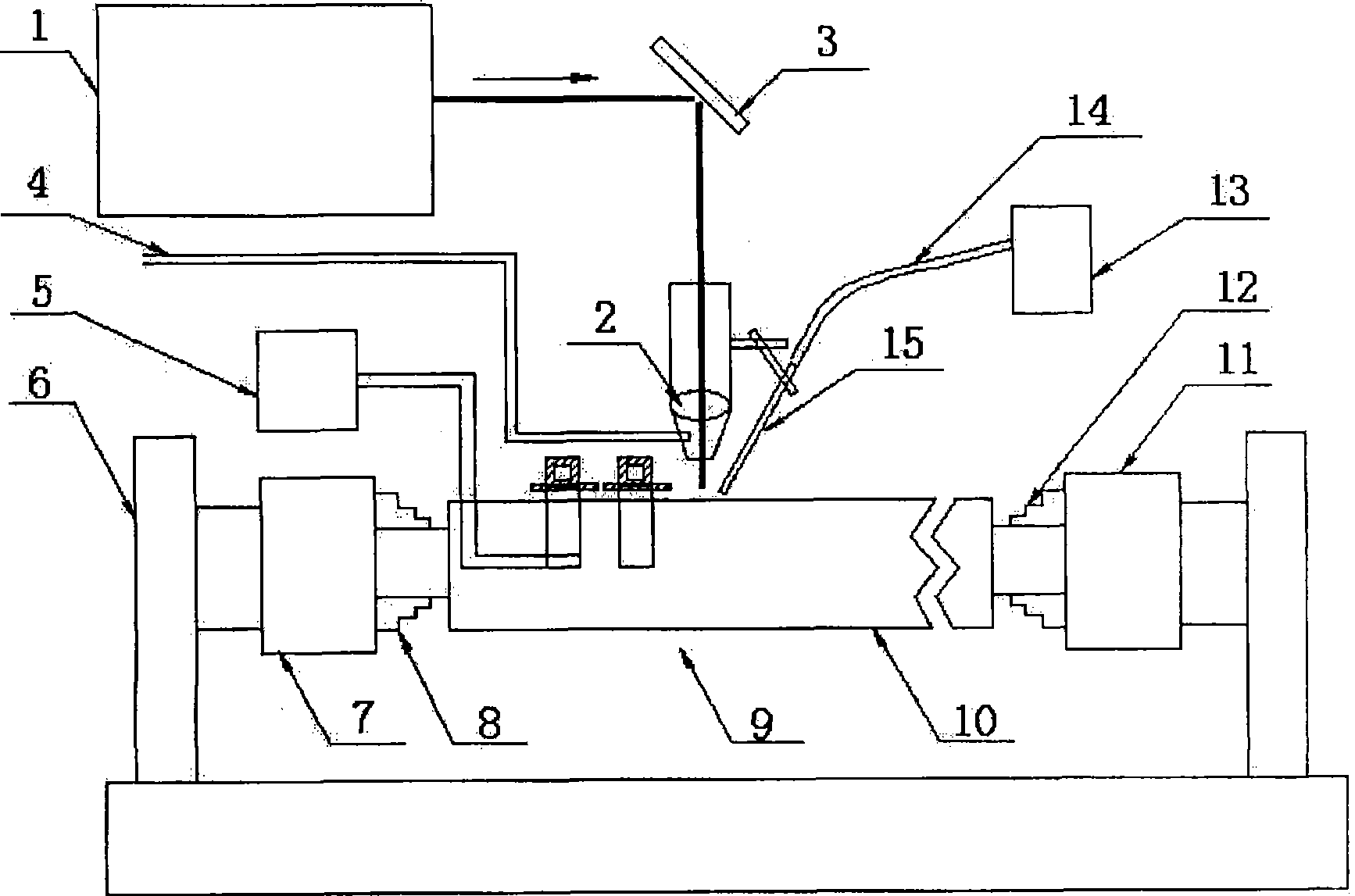

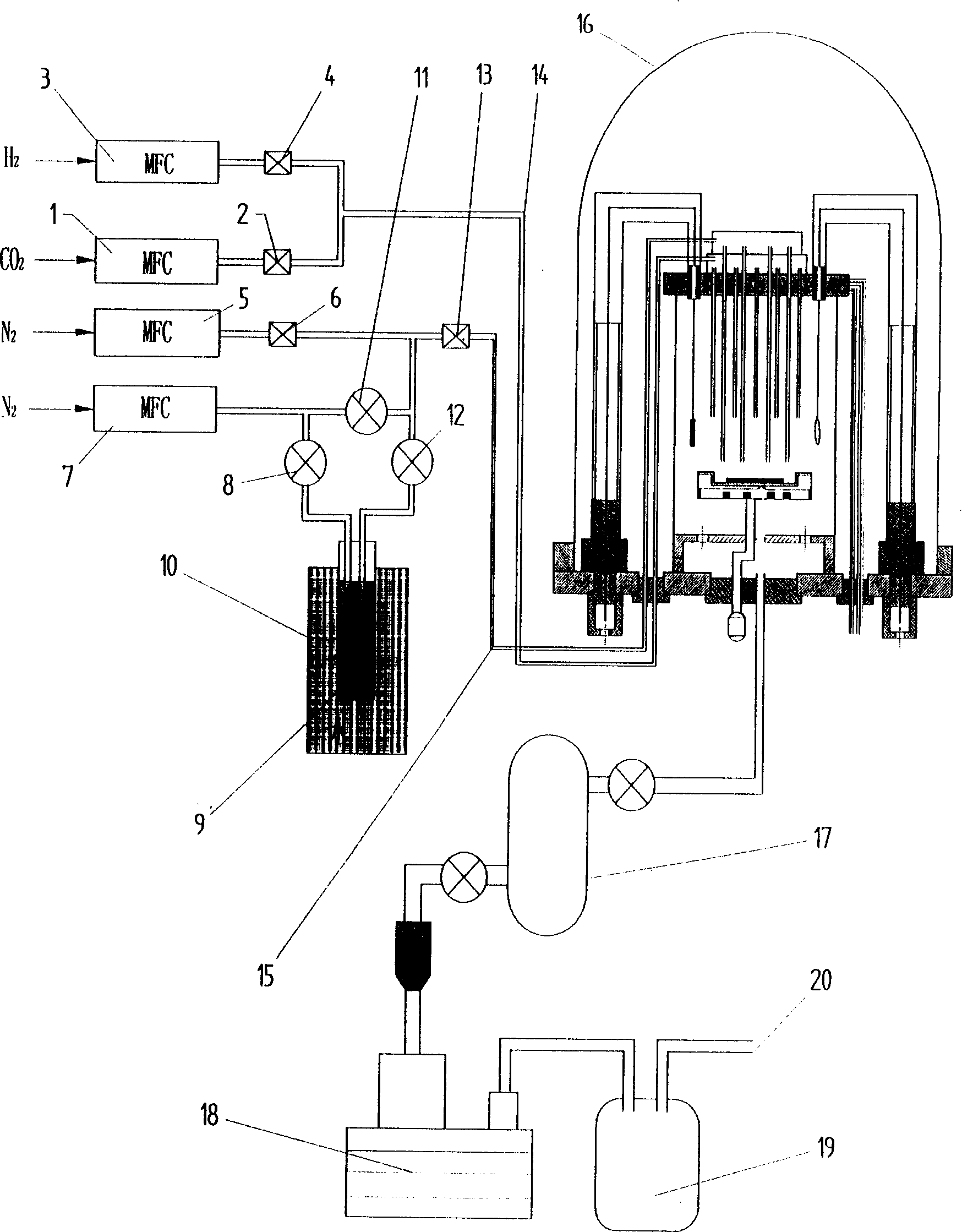

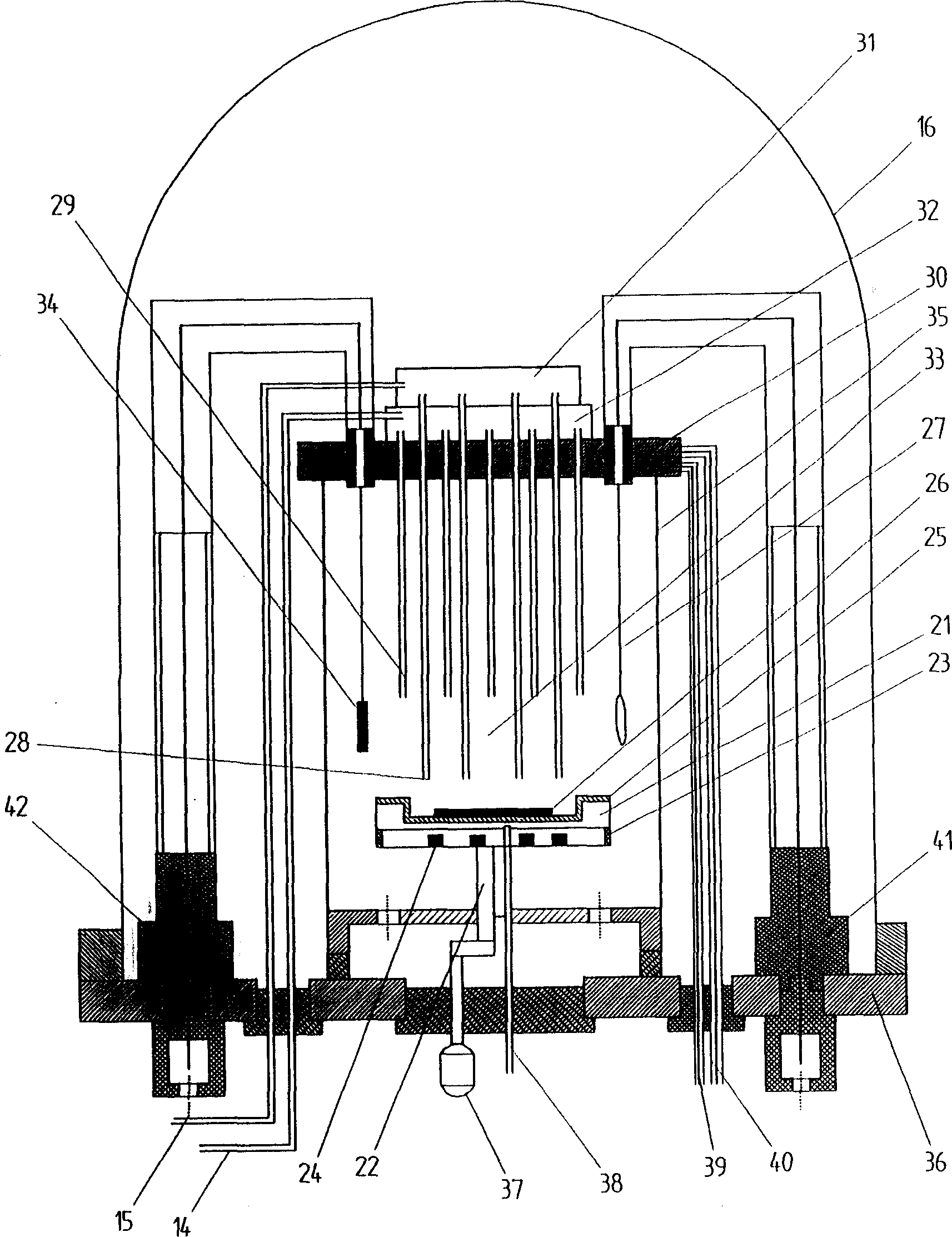

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

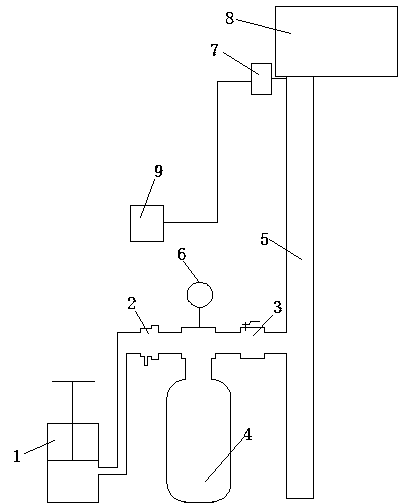

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

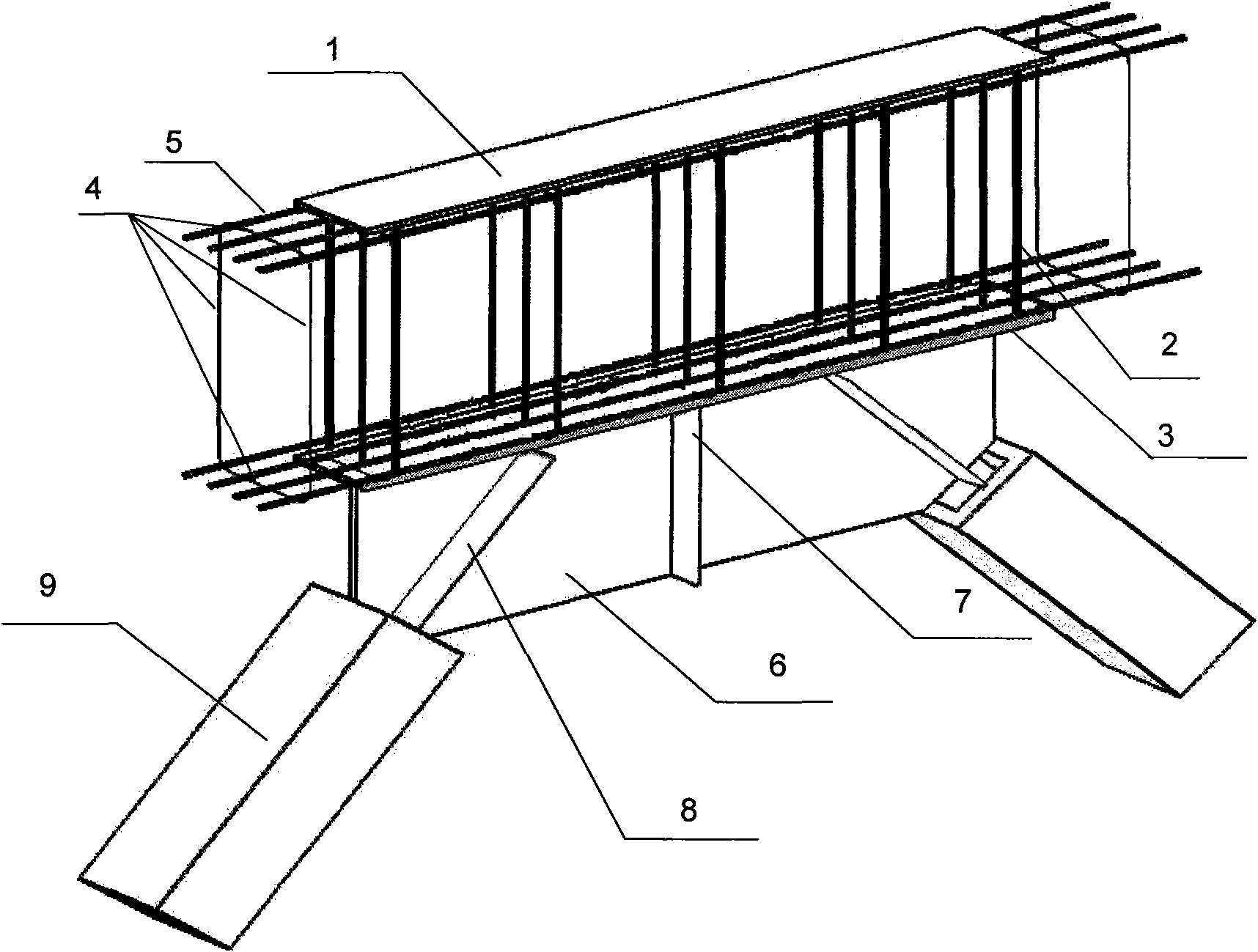

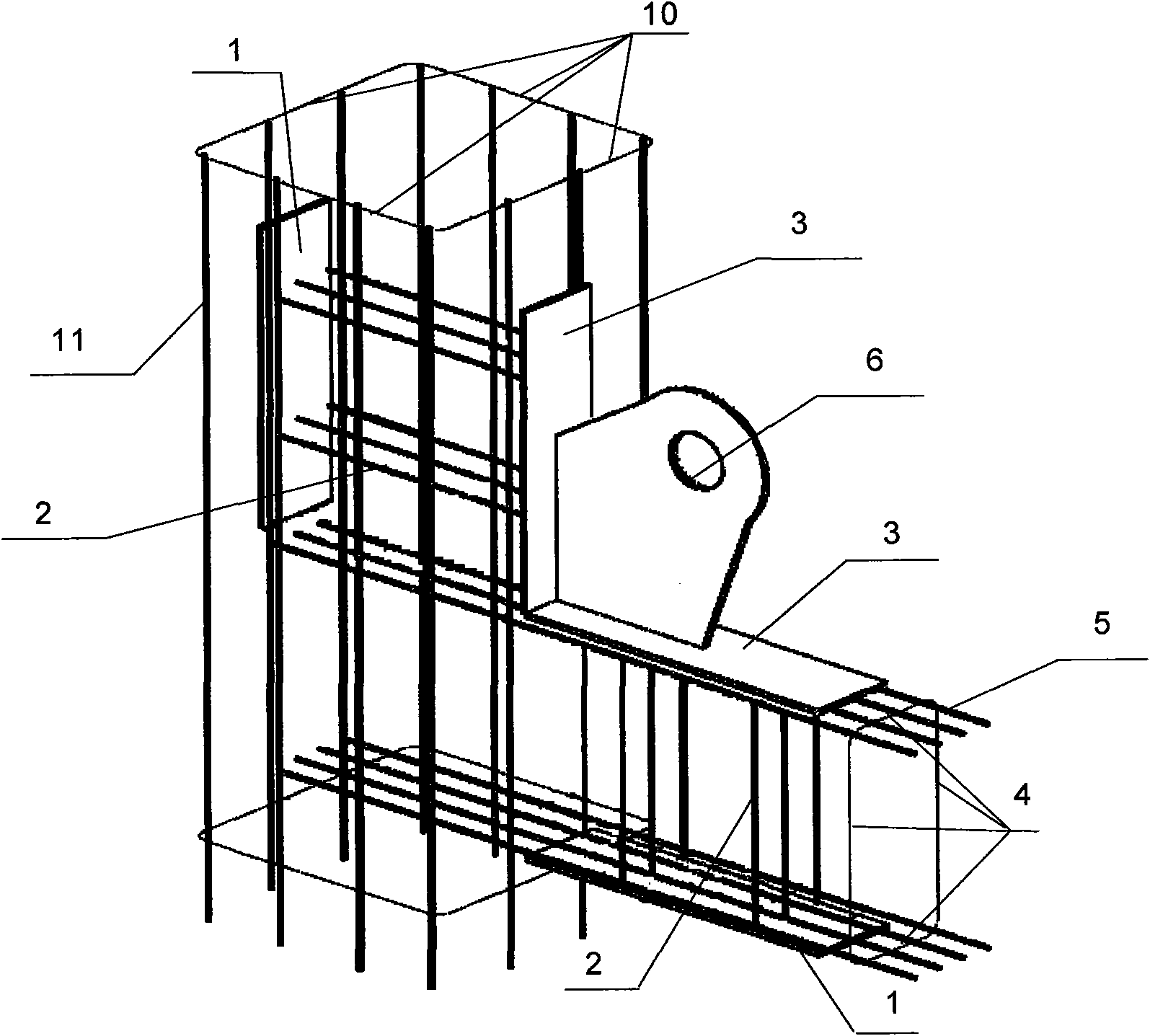

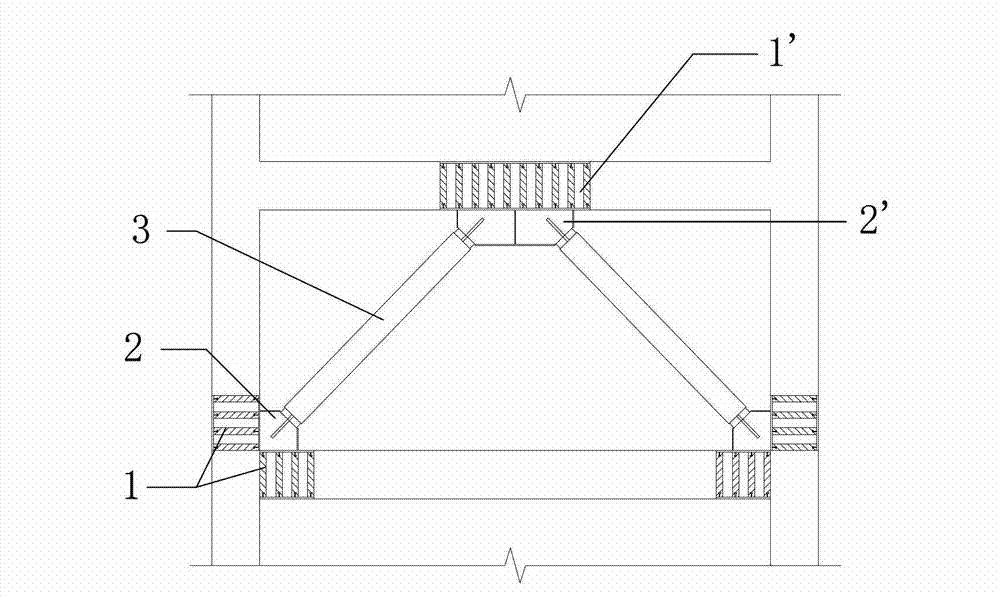

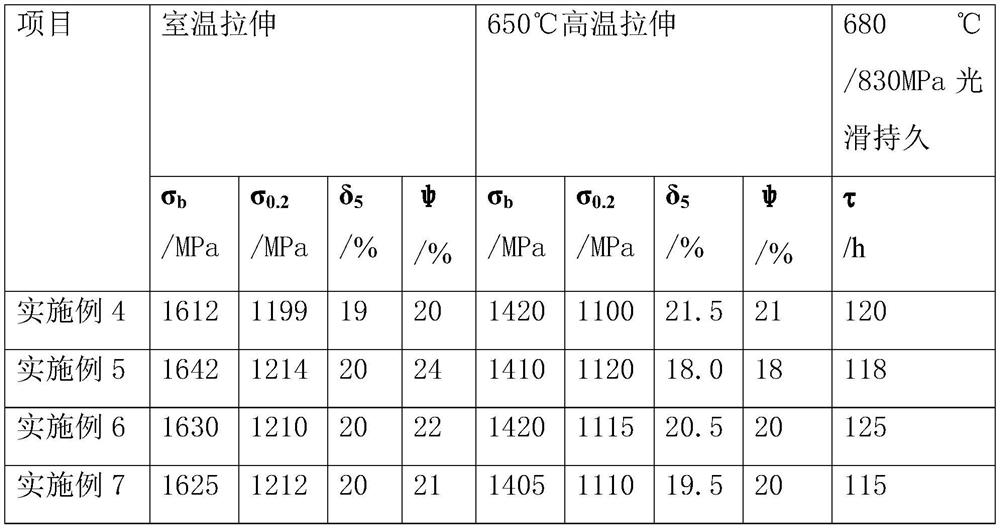

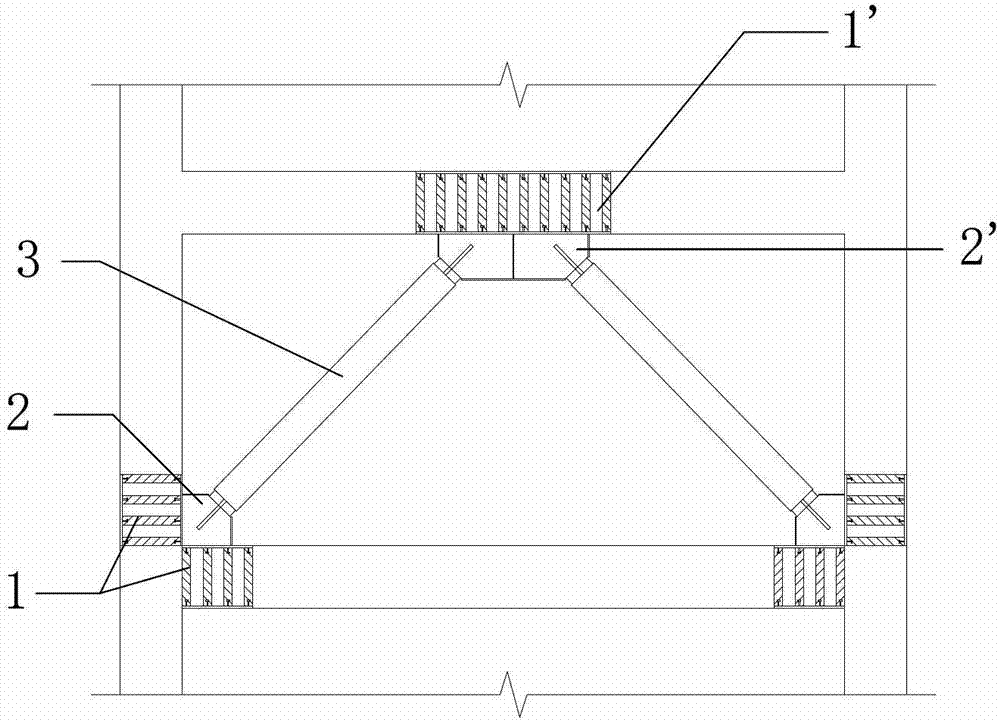

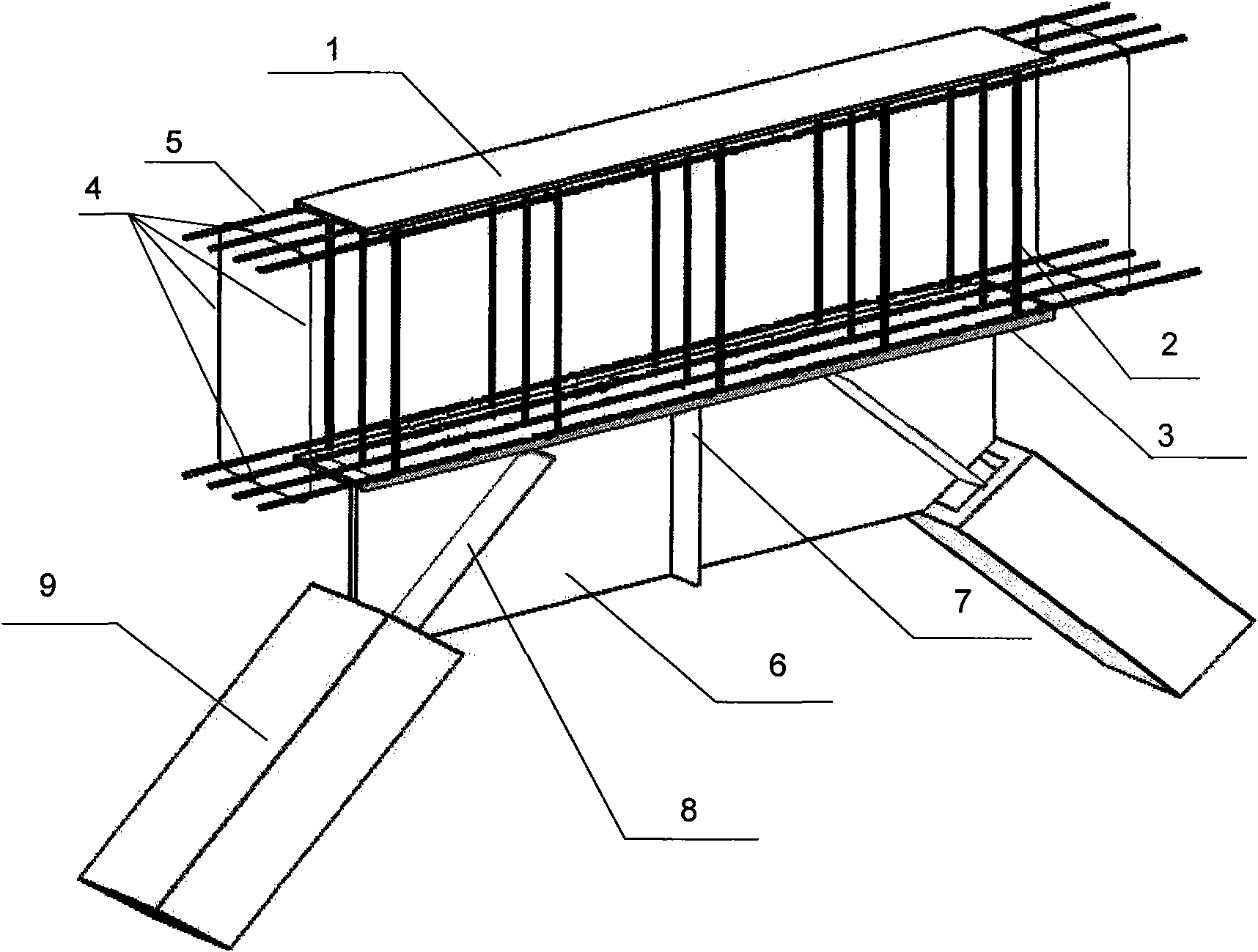

Vertical reinforced concrete component-connection node of buckling-restrained brace

ActiveCN101672071ASimple connection structureSimplify spatial relationshipsBuilding constructionsPunchingBuckling-restrained brace

The invention belongs to the technical field of node connection of architectural structure, in particular to a vertical reinforced concrete component, that is, a connection node of a buckling-restrained brace (BRB), which consists of steel plates, internal-thread steel bars for embedded parts, internal stirrups for concrete beams, internal longitudinal bars for concrete beams, support connection node plates, support node stiffening plates, buckling-restrained supports, internal stirrups for concrete columns and internal longitudinal bars for concrete columns, wherein, two steel plates are connected by the internal-thread steel bars for embedded parts; plug welding holes are formed on the steel plates; steel bars are welded with a first steel plate and a second steel plate at the plug welding holes; a first support connection node plate is located at the upper part of the first steel plate or at the lower part of the second steel plate; a second support connection node plate is connected with the first support connection node plate; one end of the second support connection node plate is fixed at the upper part of the first steel plate or the lower part of the second steel plate, andthe other end thereof is connected with the buckling-restrained brace; and the support node stiffening plates are fixed at one side of the first support connection node plate. The invention solves the problems that steel support connection nodes are difficult to be mounted in a concrete frame, structural steel needs punching when being embedded in a concrete component, and stirrups and longitudinal bars are arranged with difficulties; and the invention has the advantages that the construction is convenient, the stress performance of connection is good, and steel materials can be saved, therefore, the invention has wide application prospect.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

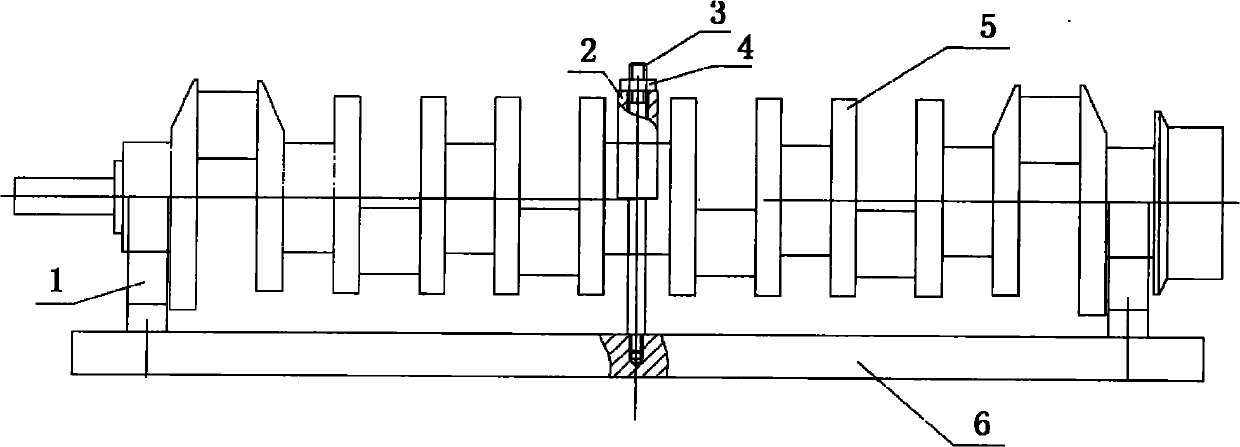

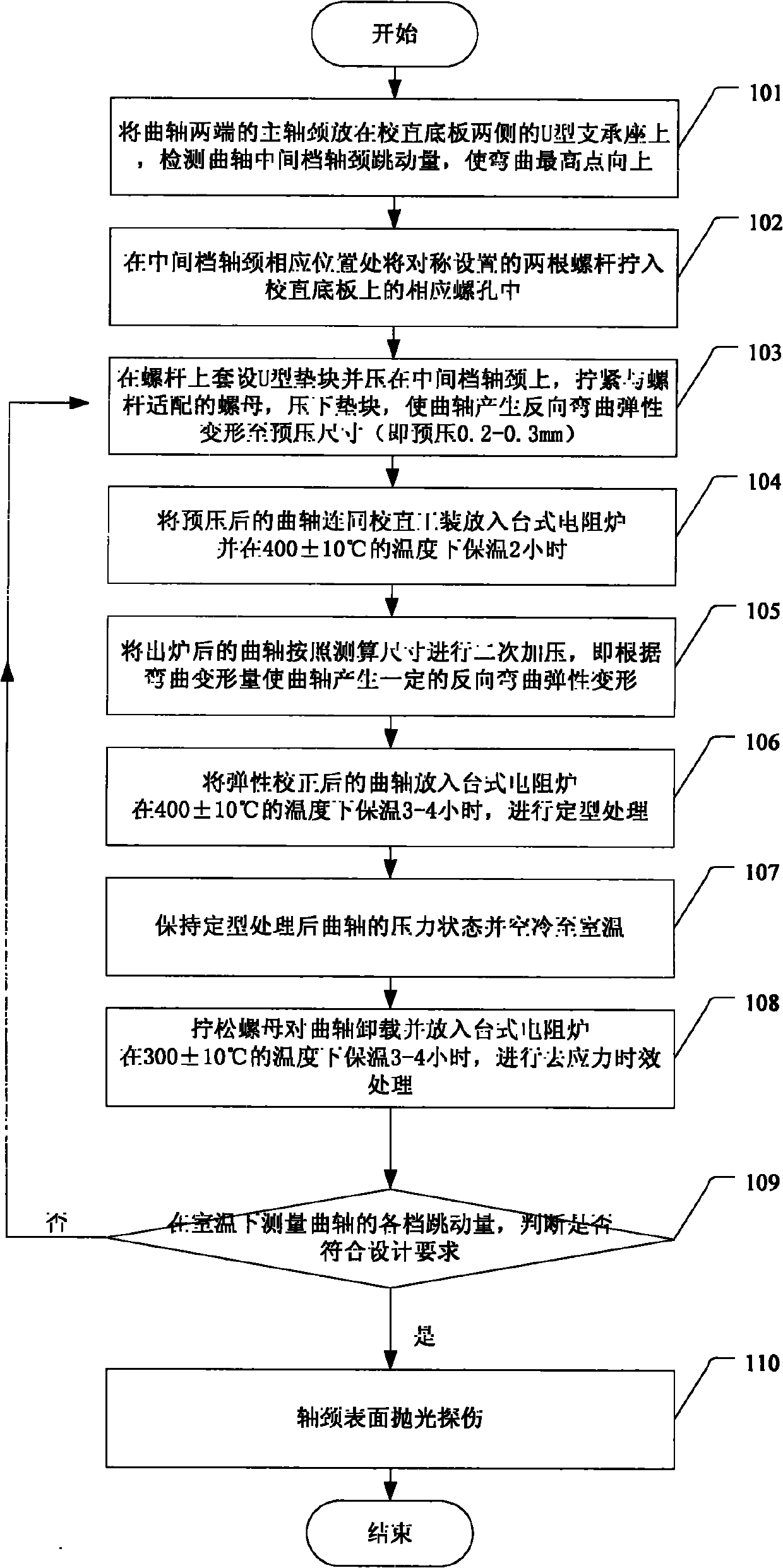

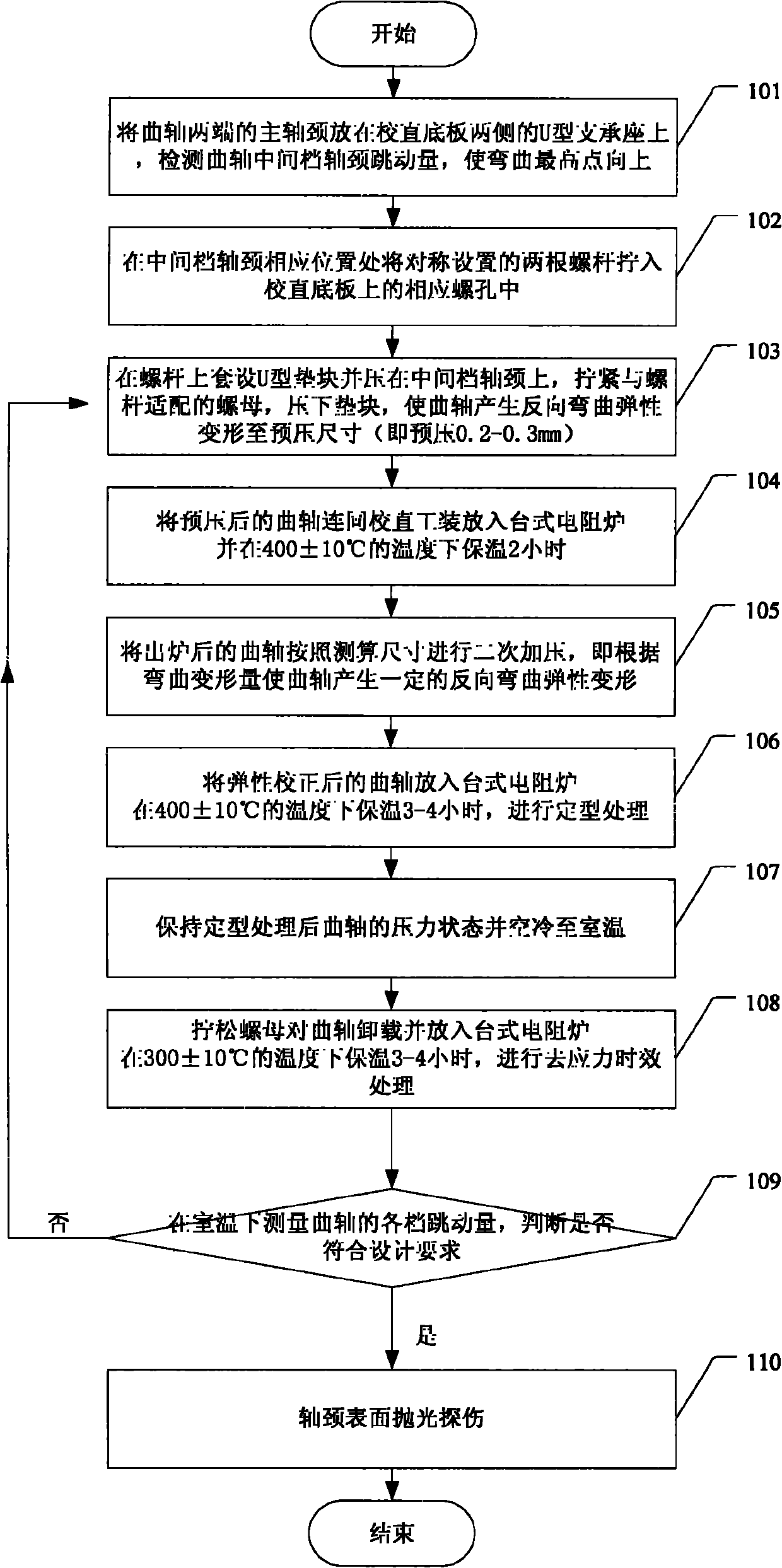

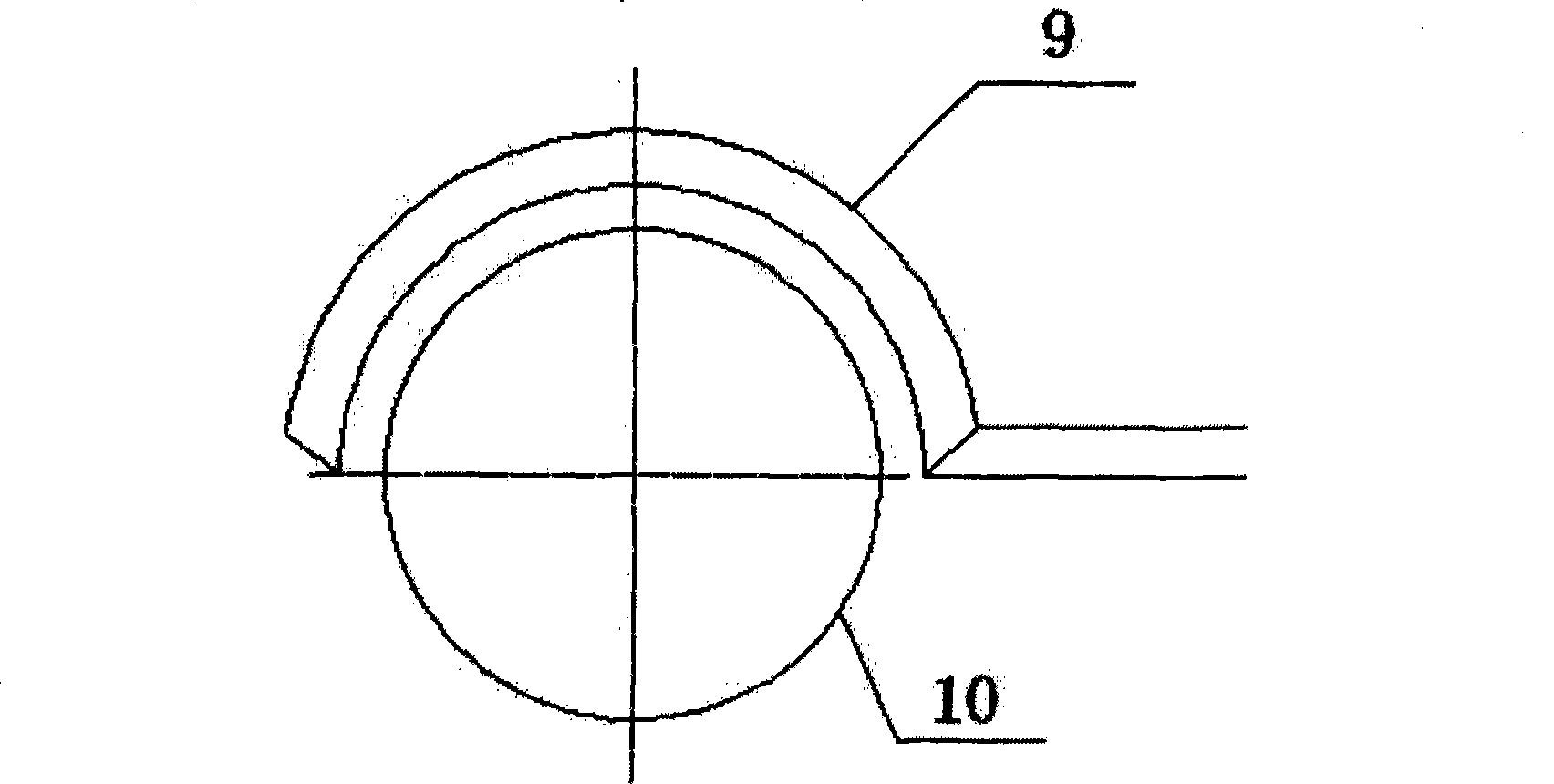

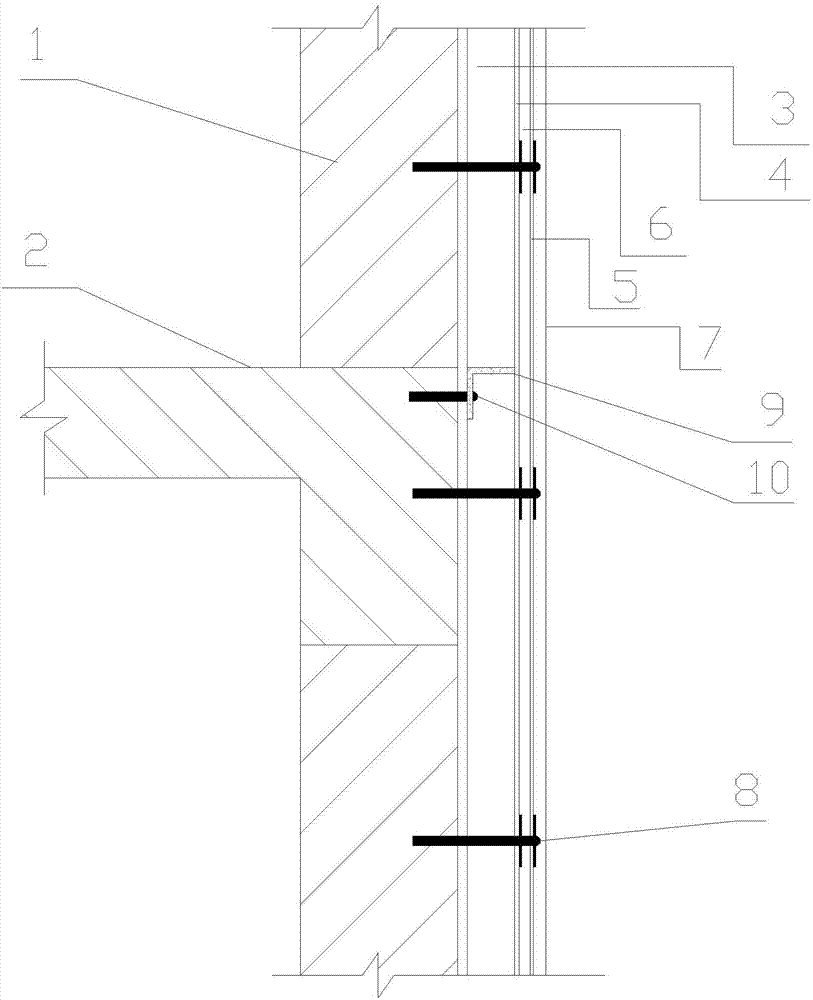

Method and tool for straightening bending deformation of crankshaft

ActiveCN102198457ASolve difficult straighteningSolve the problem of easy crackingRoom temperatureEngineering

The invention discloses a method for straightening bending deformation of a crankshaft. The method comprises the following steps of: performing elastic correction on the bent deformed crankshaft by using a straightening tool in a hot state, namely making the crankshaft generate certain reverse bending elastic deformation according to the bending deformation; performing setting treatment on the elastically corrected crankshaft at the temperature of 400+ / -10 DEG C; keeping the pressure state of the set crankshaft, and cooling the crankshaft to room temperature by air; and unloading the crankshaft, and performing stress removal aging treatment on the unloaded crankshaft at the temperature of 300+ / -10 DEG C. The invention also discloses a tool for straightening bending deformation of the crankshaft. The crankshaft is elastically corrected through the special straightening tool, the problems that the large crankshaft is difficult to straighten and easy to crack in the prior art are solved,and the straightening process is simple, convenient, safe and reliable.

Owner:GUANGXI YUCHAI MASCH CO LTD

High-performance polyurethane external thermal insulation anti-crack leveling mortar and construction method thereof

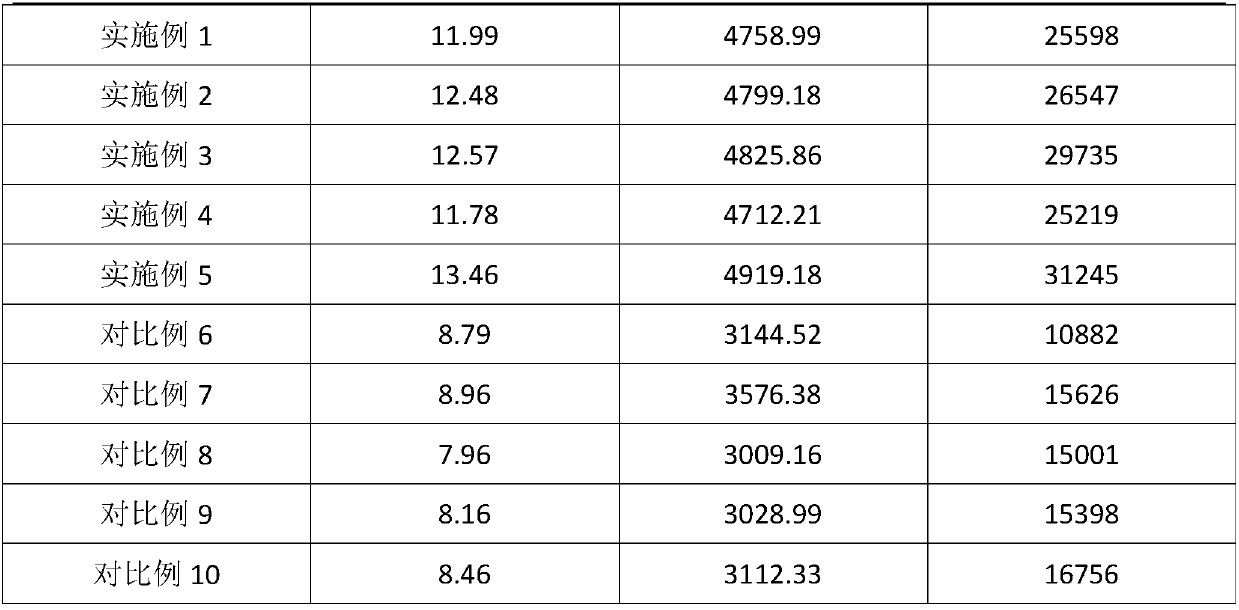

The invention discloses a high-performance two-component polyurethane external thermal insulation anti-crack leveling mortar which is prepared by mixing a component A and a component B, wherein the component A comprises the following compositions in percentage by weight: 60 to 80 percent of gelled materials, 20 to 30 percent of aggregates and 0 to 10 percent of functional admixtures; and the component B is water repellents. The construction method of the mortar comprises the following steps: mixing the component A and the component B; adding an appropriate amount of water in the obtained mixture; and uniformly stirring the obtained object until the obtained object reaches the consistence suitable for mechanical spraying or manual construction, namely, the obtained object can be subject to mechanical spraying or manual construction. The external thermal insulation anti-crack leveling mortar of the invention has the advantages of low water absorption rate, low modular ratio, high caking property and stable performance; and the interface processing carried out on a polyurethane insulation coating can be omitted, and the quality problems that a polyurethane external thermal insulation system is easy to produce crazes and hollowing, and the like can be solved.

Owner:JIANGSU NIGAO SCI & TECH +1

Method for producing ladle joint material by utilizing waste corundum bricks

The invention discloses a method for producing a ladle joint material by utilizing waste corundum bricks. The method comprises the following steps of: conveying 35 parts of 1-8 mm waste corundum brick granules, 35 parts of 0.1-8 mm white fused alumina granules, 10 parts of powder materials, 10 parts of alumina powder, 3 parts of fused magnesia powder, 1 part of silica powder and 6 parts of calcium aluminate cement into a stirrer, and fully stirring to obtain the ladle joint material finished product. The obtained ladle joint material finished product has the physical and chemical indexes as follows: after the ladle joint material is dried at the temperature of 110 DEG C for 24 hours, the compressive strength is more than 40MPa, and the flexural strength is more than 5MPa; and after the ladle joint material is sintered at the temperature of 1550 DEG C for 24 hours, the bulk density is not less than 3.0 g / cm<3>, the flexural strength is more than 12MPa, and the linear change rate is + / -0.5%. In the method disclosed by the invention, 1 / 3 of waste corundum brick granules are used as aggregates, thus the cost of the ladle joint material and the cost of per ton of steel are greatly lowered; and calcium aluminate cement is used for binding, and alumina, fused magnesia and silica are used as media, thus the problem that the recovered waste corundum brick granules are easy to crack when used in high-grade pouring materials is solved, and the requirements for safety and durability of the ladle are achieved.

Owner:ZHENGZHOU ZHENDONG TECH

Crack control and forming method for large and medium-sized GH141 alloy annular forged piece

InactiveCN106694791ASolve the problem of easy crackingImprove controlEngine componentsTemperature controlAlloy

The invention relates to a crack control and forming method for a large and medium-sized GH141 alloy annular forged piece. The method includes the following specific steps that first, feeding control is performed, a blank is required to be a turning material, the degree of finish is Ra3.2-Ra6.3, the end face chamfer is R5-R10, the blank is subjected to surface inspection, and crack hidden danger is eliminated; second, tool control is conducted; third, heating control is carried out, and the blank is covered with silicate or quartz sand; fourth, discharging transfer control is performed; fifth, the forging process is controlled; sixth, the final forging temperature is controlled, and the terminal temperature is higher than or equal to 950 DEG C and is controlled above a recrystallization temperature; and seventh, cooling control is conducted, and wind sheltering air cooling is performed. According to the crack control and forming method, by refining the control requirements of all stages in the forging process, control capacity is enhanced, and the problem that the large and medium-sized GH141 alloy annular forged piece is prone to cracking is solved.

Owner:SHAANXI HONGYUAN AVIATION FORGING

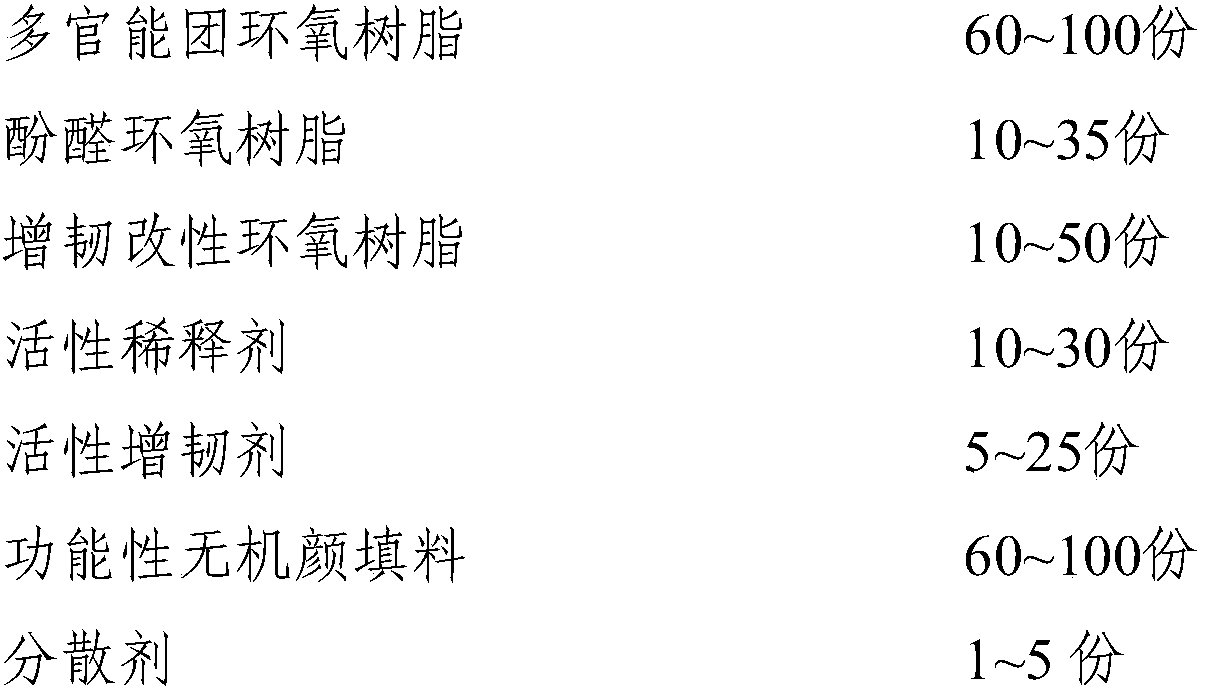

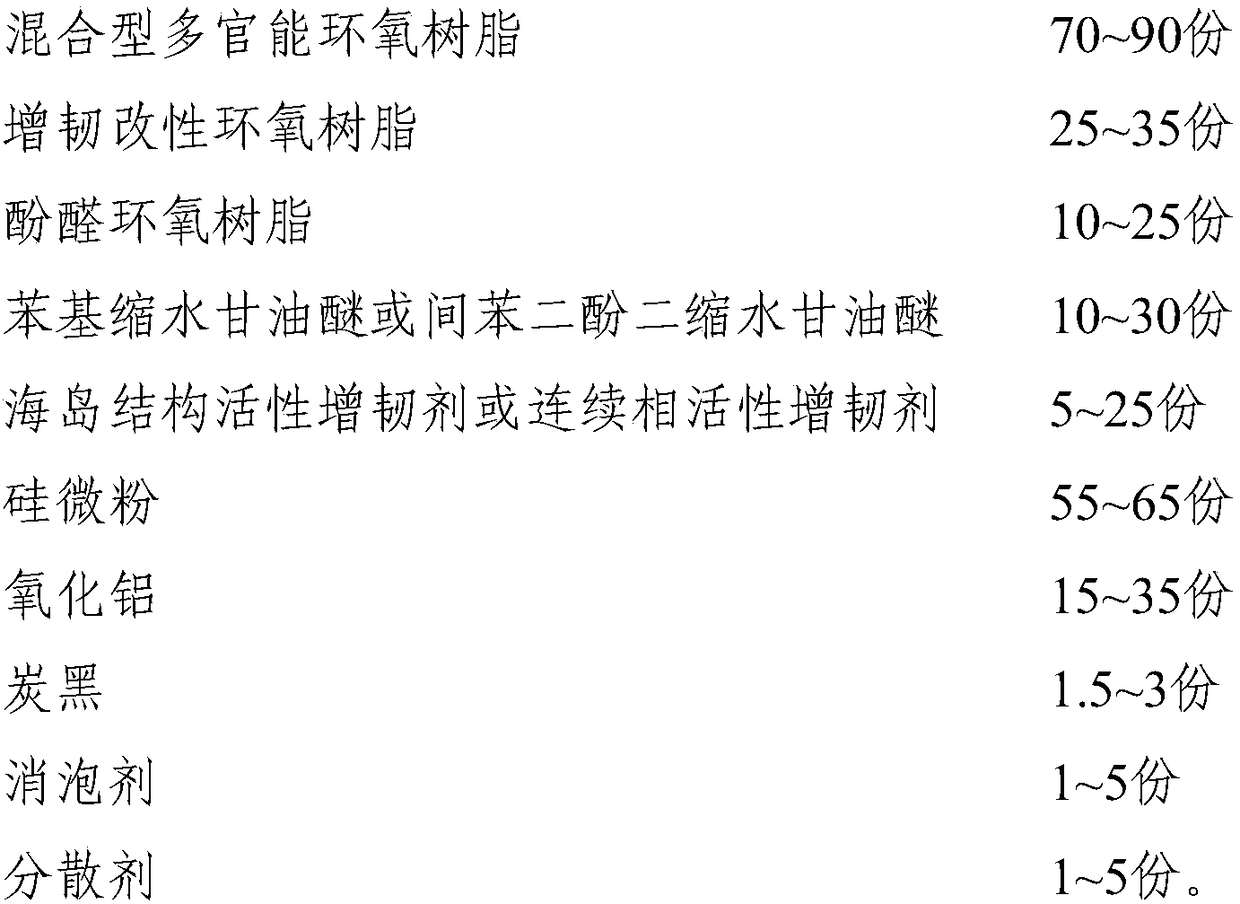

Epoxy pouring sealant as well as preparation method and application thereof to nuclear power equipment

InactiveCN108165220ASolve the problem of easy crackingImprove thermal stabilityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyGamma irradiation

The invention relates to an epoxy pouring sealant as well as a preparation method and application thereof to nuclear power equipment. The epoxy pouring sealant comprises a main agent and a curing agent with a weight ratio of 1:(0.5-2); the main agent comprises the following raw materials in parts by weight: 60-100 parts of poly-functional epoxy resin, 10-35 parts of phenolic epoxy resin, 10-50 parts of toughened and modified epoxy resin, 10-30 parts of an active diluent, 5-25 parts of an active toughening agent, 60-100 parts of functional inorganic pigments and fillers and 1-10 parts of an auxiliary; the curing agent comprises the following raw materials in parts by weight: 100-200 parts by weight of an anhydride curing agent, 0.1-3 parts of a promoting agent, 100-200 parts of functional inorganic fillers, 5-40 parts of a flame retardant and 1-10 parts by of an auxiliary. The epoxy pouring sealant provided by the invention has the advantages of gamma irradiation resistance, high and low temperature impact resistance, good air tightness, insulation properties and mechanical properties, low shrinkage rate, long service life and the like. The epoxy pouring sealant can meet a special application environment in a nuclear power plant.

Owner:BEIJING GUANGKEBOYE SCI & TECH

Automatic powder feeding laser induction composite coating method and device

ActiveCN100503130CImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingNumerical controlSolid component

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

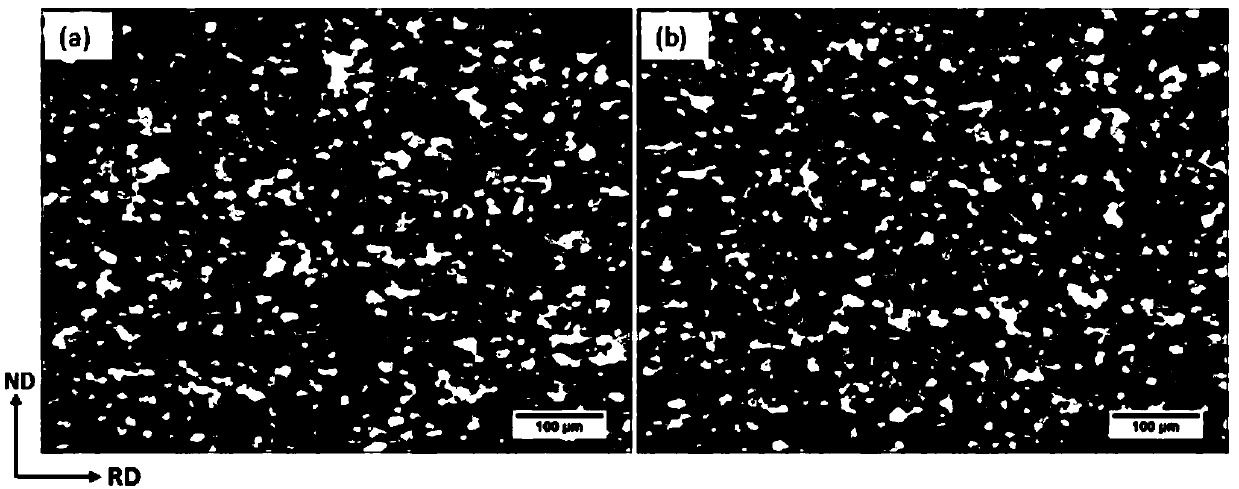

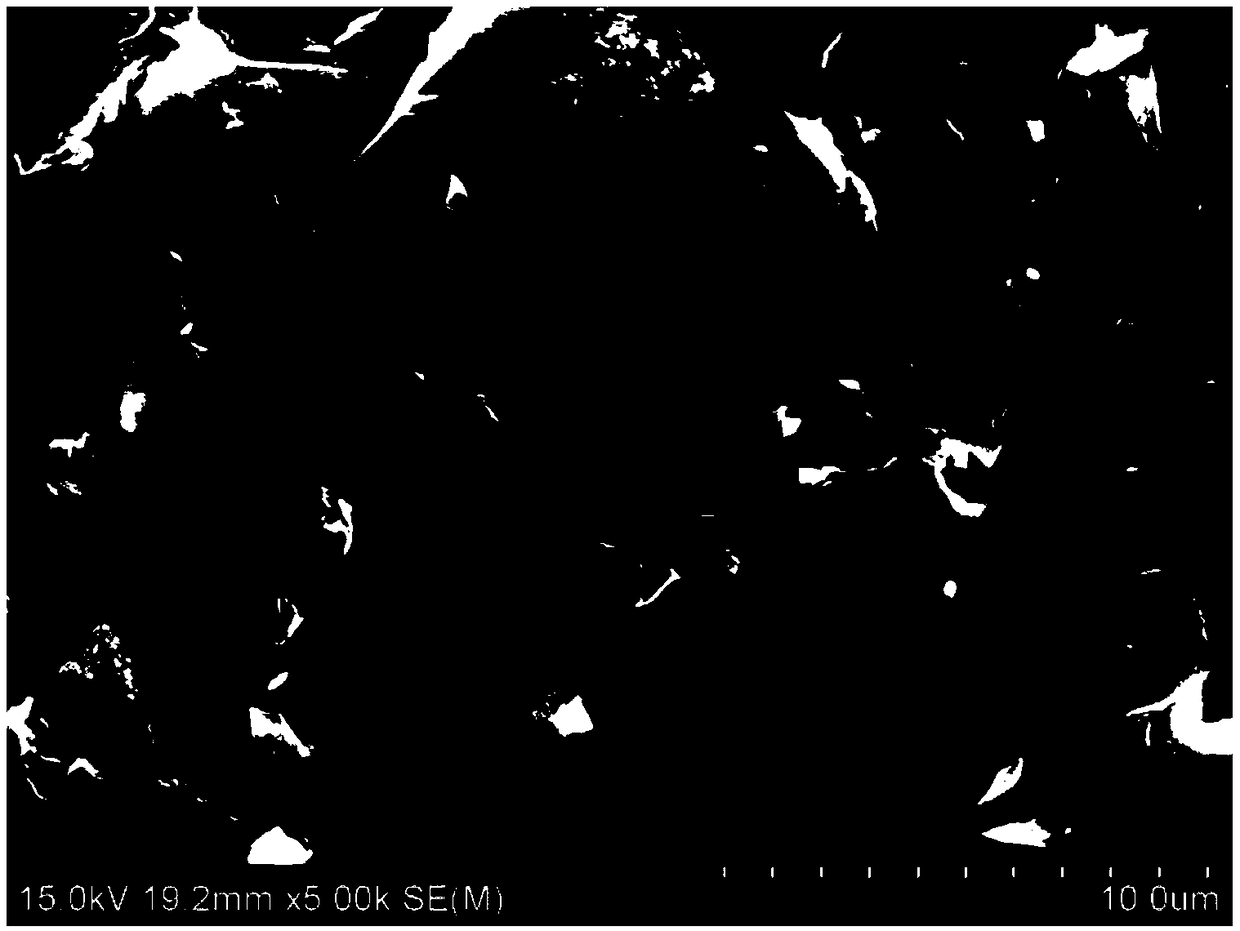

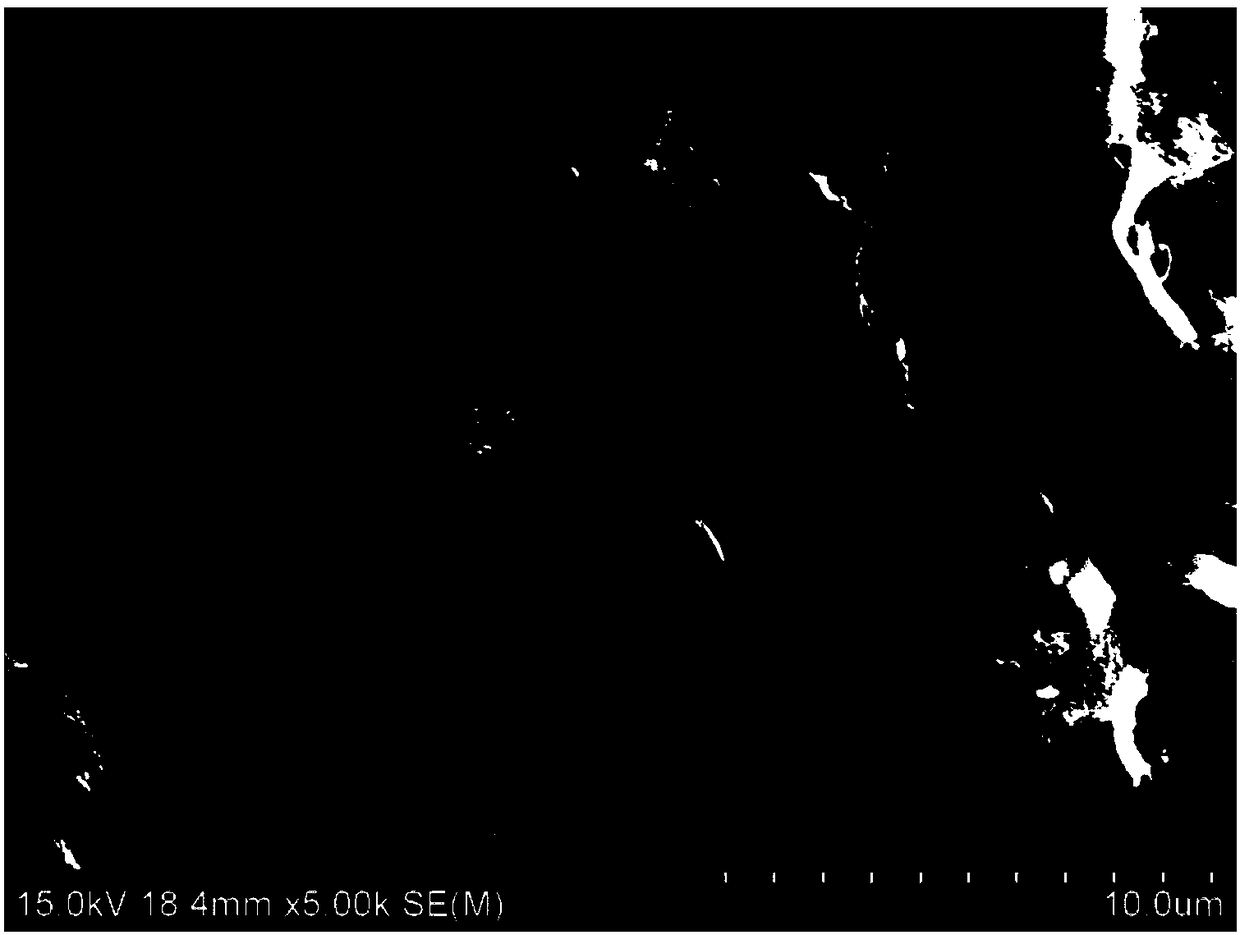

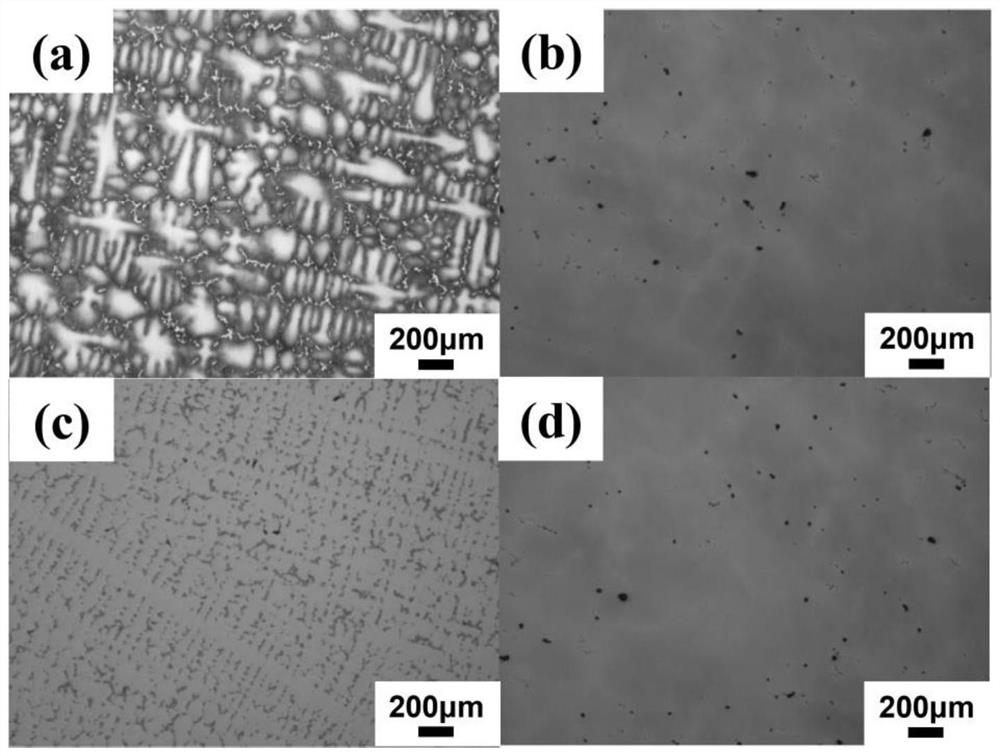

Preparation method of 2050 aluminium-lithium alloy fine-grain plate

The invention discloses a preparation method of a 2050 aluminium-lithium alloy fine-grain plate. The preparation method comprises the steps: firstly carrying out solid solution and water quenching atthe temperature of 450-550 DEG C; then carrying out rolling predeformation under room temperature, wherein the total predeformation amount is 35-55%; then carrying out overaging treatment for 24-60 hours at the temperature of 350-450 DEG C; then after preserving heat for 1-3 hours at the temperature of 150-250 DEG C, carrying out rolling deformation on the plate, wherein the total deformation amount is 80-96% and the pass deformation amount is 10-30%; finally, carrying out recrystallization and annealing in a salt bathing furnace for 1-60 minutes at the temperature of 450-550 DEG C. The preparation method disclosed by the invention has the beneficial effects that rolling predeformation with large deformation amount is adopted, and overaging and intermediate annealing are combined, so that92% low-temperature rolling deformation is realized in aluminium alloy with poor low-temperature plasticity, the deformation energy storage of the alloy is fully preserved, simultaneously the crackingof the plate is effectively inhibited, the grain refinement is realized, and the 2050 alloy plate with the grain size being 8-10mu m and without cracking is prepared.

Owner:CENT SOUTH UNIV

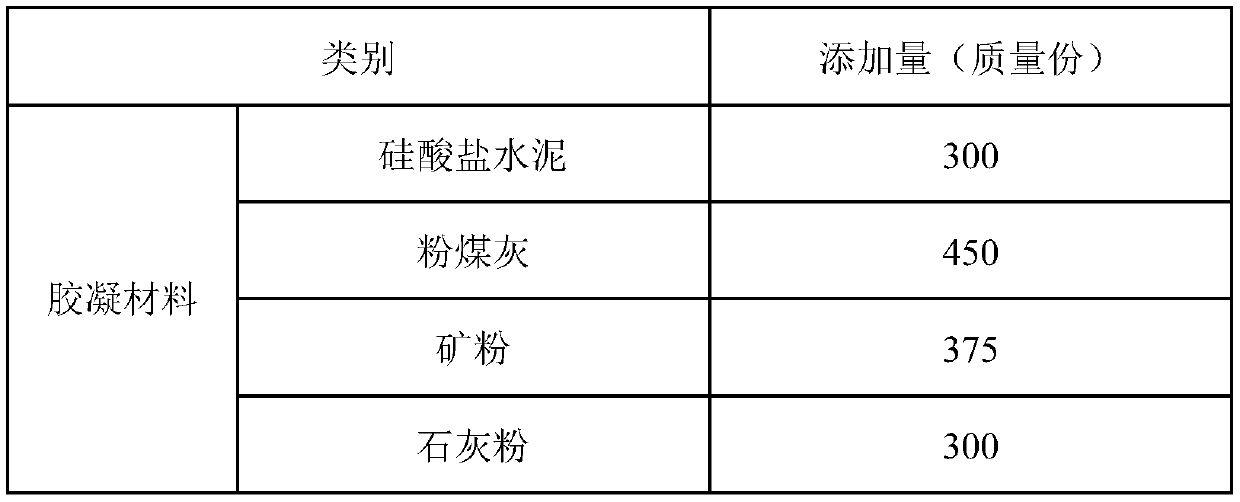

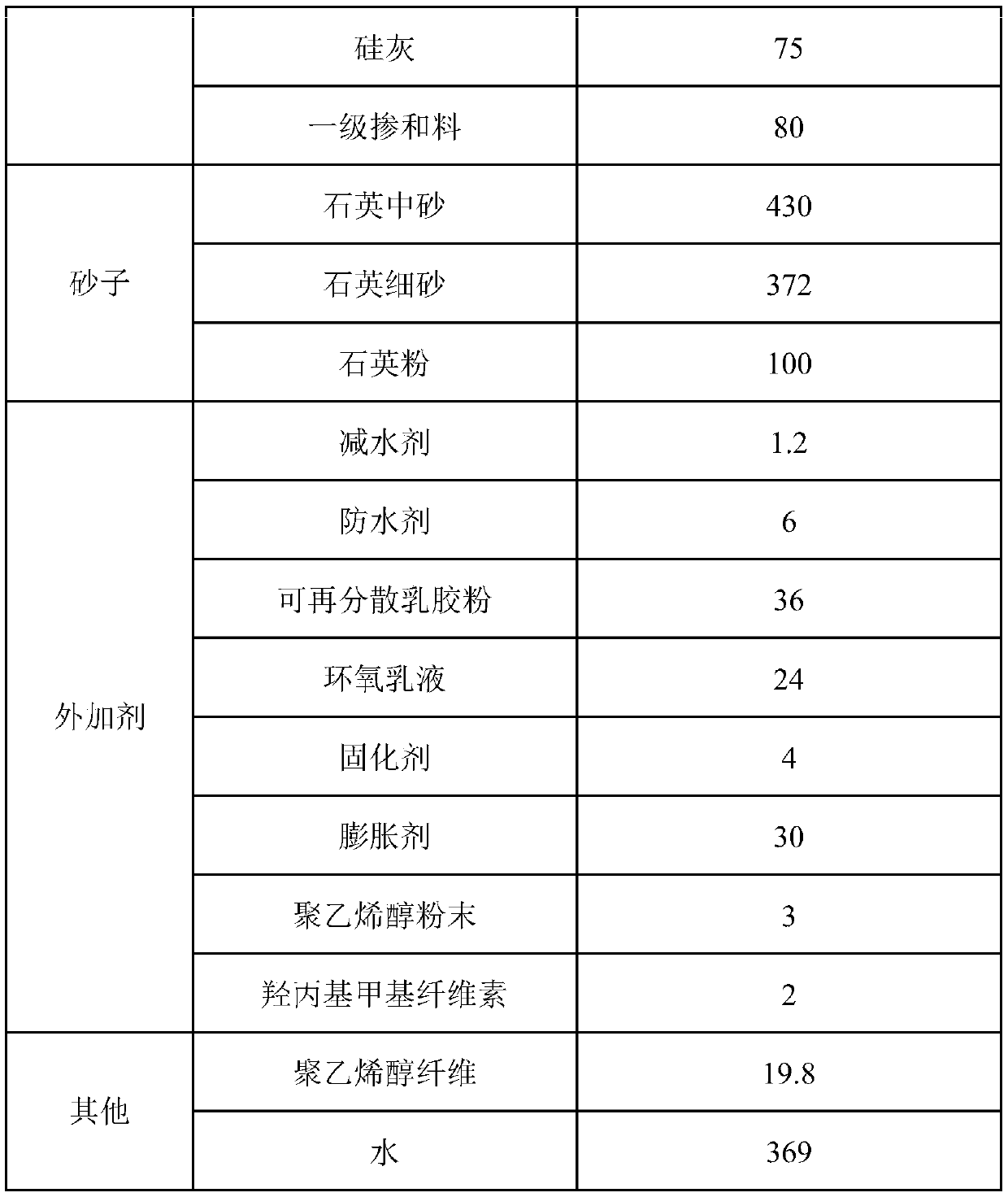

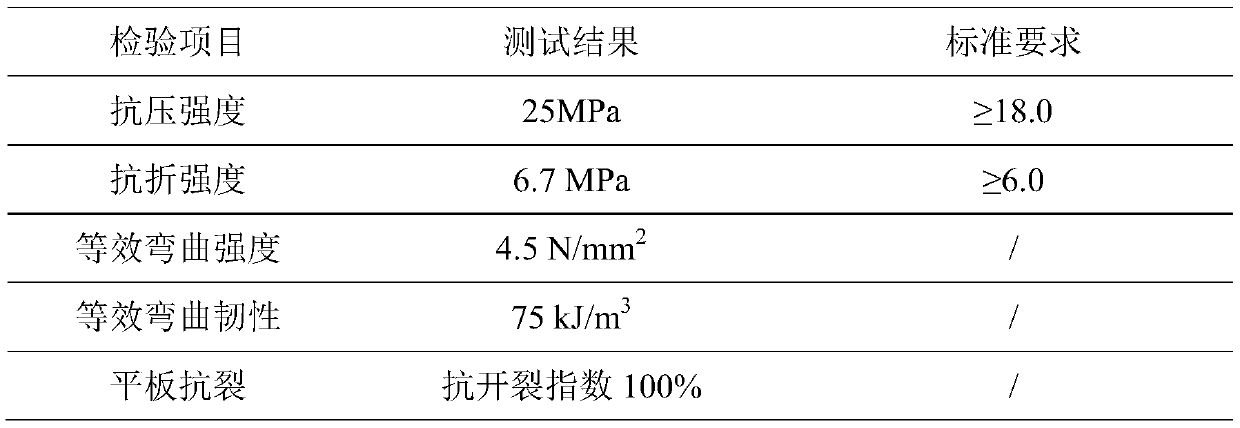

High-ductility waterproof anti-crack composite mortar as well as mixing method and construction process thereof

ActiveCN111003980AImprove compactnessHigh strengthCovering/liningsHydroxypropylmethyl celluloseSilica fume

The invention discloses high-ductility waterproof anti-crack composite mortar and a mixing method and a construction method thereof. The mortar is prepared from cement, fly ash, mineral powder, lime powder, silica fume, a primary admixture, quartz sand, redispersible latex powder, a waterproof agent, polyvinyl alcohol powder, a water reducing agent, an epoxy emulsion, a curing agent, hydroxypropylmethyl cellulose, an expanding agent and polyvinyl alcohol fibers. According to the disclosed mixing method, a reasonable feeding sequence is adopted to obtain a uniform mortar material. The construction method provided by the invention adopts construction steps suitable for the mortar provided by the invention for different building environments. The composite mortar prepared by the invention has the advantages of water resistance, crack resistance, high ductility, high cohesiveness, seepage resistance, harmful ion erosion resistance, no shrinkage, simplicity and convenience in constructionand the like; can be used for rigid waterproof and anti-cracking engineering of building outer walls and toilets, rigid waterproof and anti-cracking engineering of places such as elevator shafts, roofs and basements, and hydrological engineering such as ports and wharfs which need to be waterproof, anti-cracking and corrosion-resistant.

Owner:西安五和新材料科技集团股份有限公司

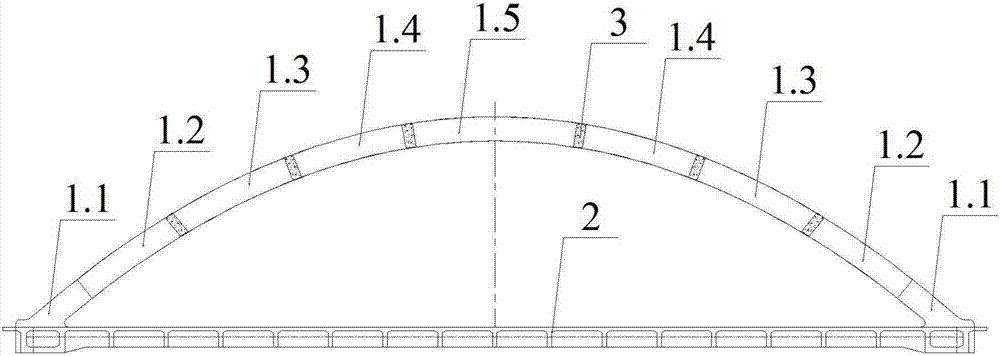

Concrete arc rib construction method

InactiveCN107237262ASolve the deformationWarranty requirementsBridge erection/assemblyBridge deckStress relief

The invention relates to the technical field of bridge construction, in particular to a concrete arch rib construction method. Divide the arch rib to be constructed into multiple sections arranged at intervals, build formwork on the bridge deck, pour the sections in sequence based on the formwork and reserve separation grooves between adjacent sections, and after all the sections are poured, the Concrete is filled in the separation groove to connect all the segments as a whole to form arch ribs. The present invention minimizes the stress generated during the pouring construction of the arch ribs through segmental construction, avoids the deformation of the arch ribs caused by stress release, ensures the requirements of the arch rib line shape, and at the same time, the arch ribs are reasonably segmented The construction efficiency is improved, the construction period is saved, and the difficult problem that the arch foot concrete is easy to crack is solved.

Owner:CCCC SECOND HARBOR ENG

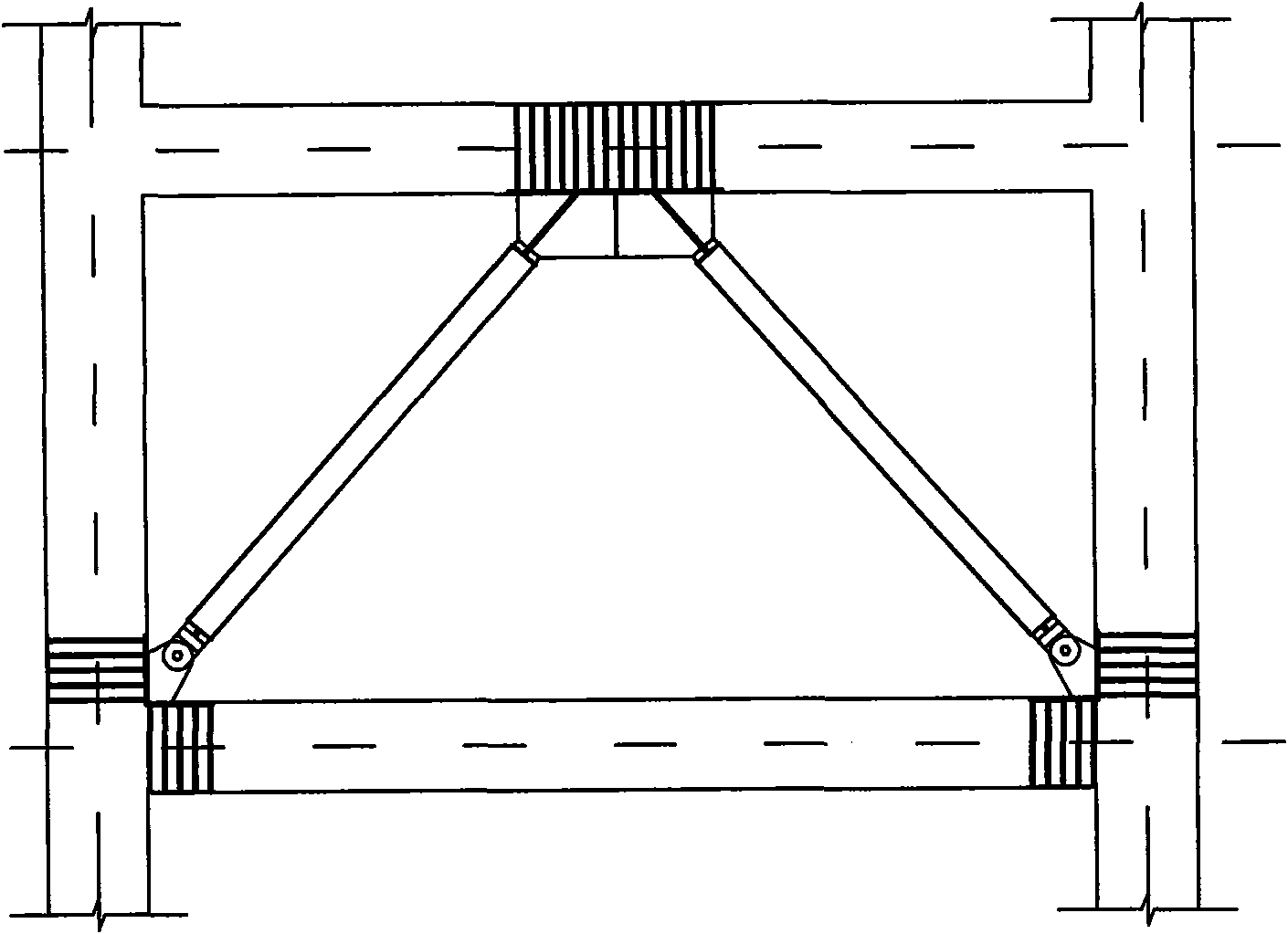

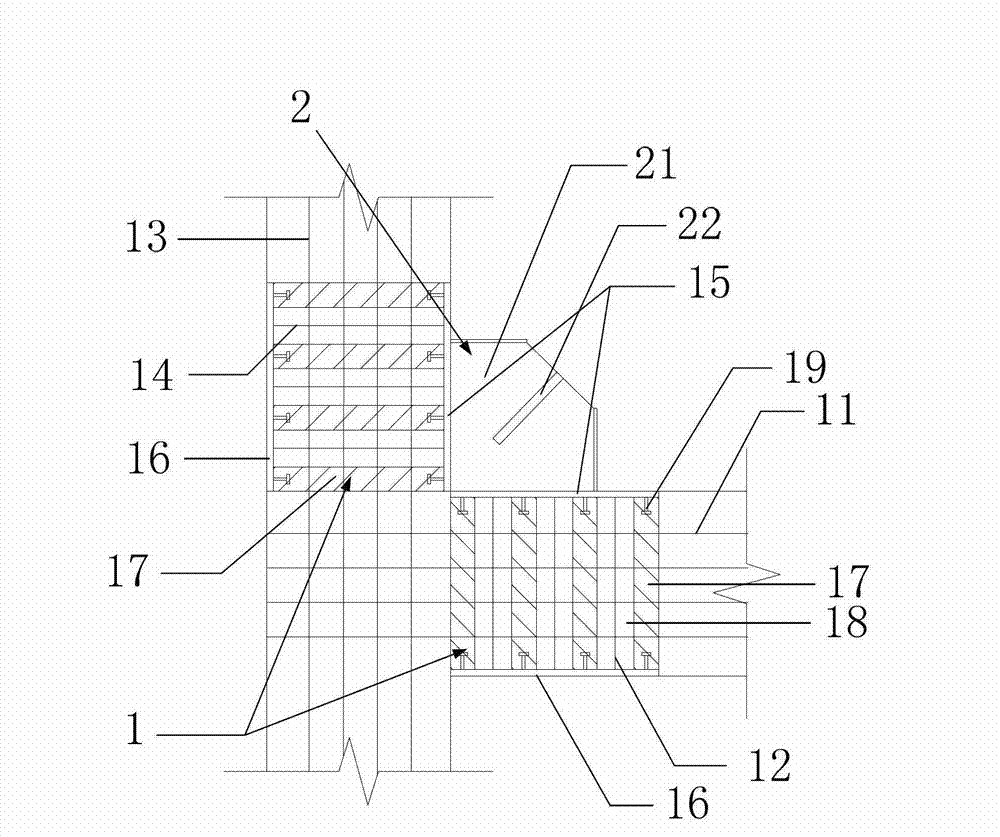

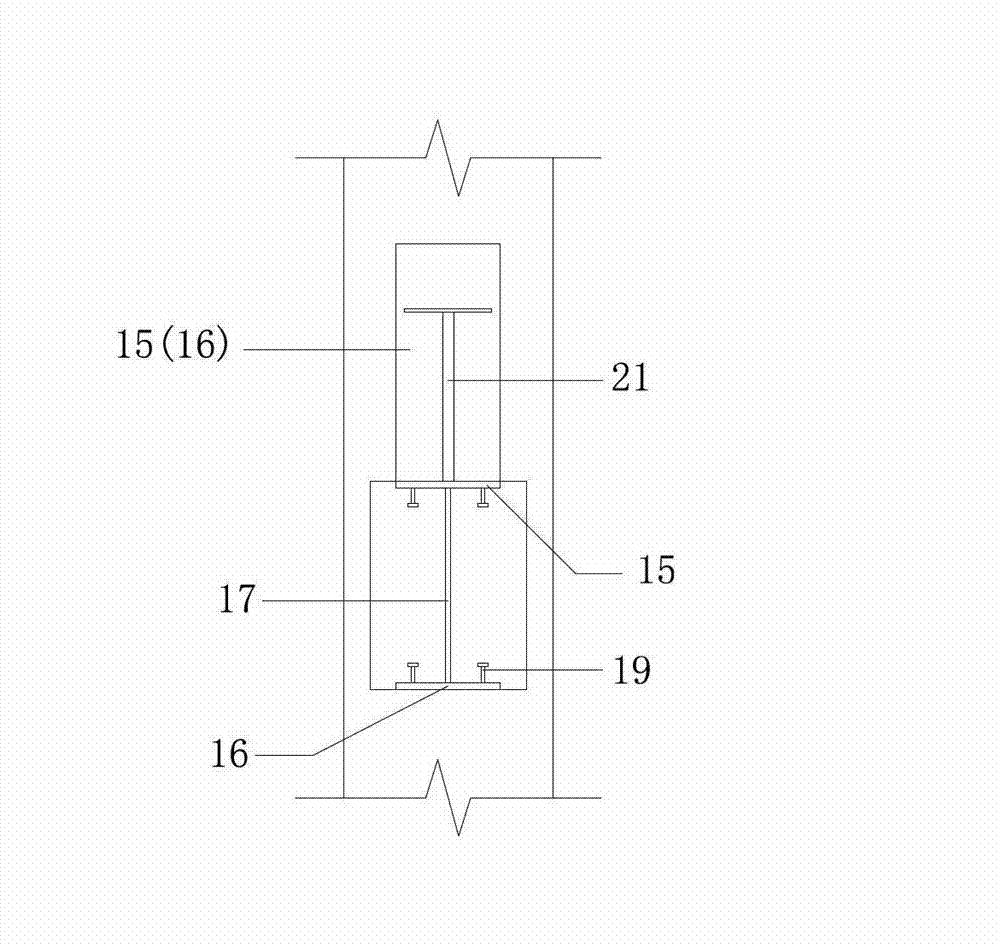

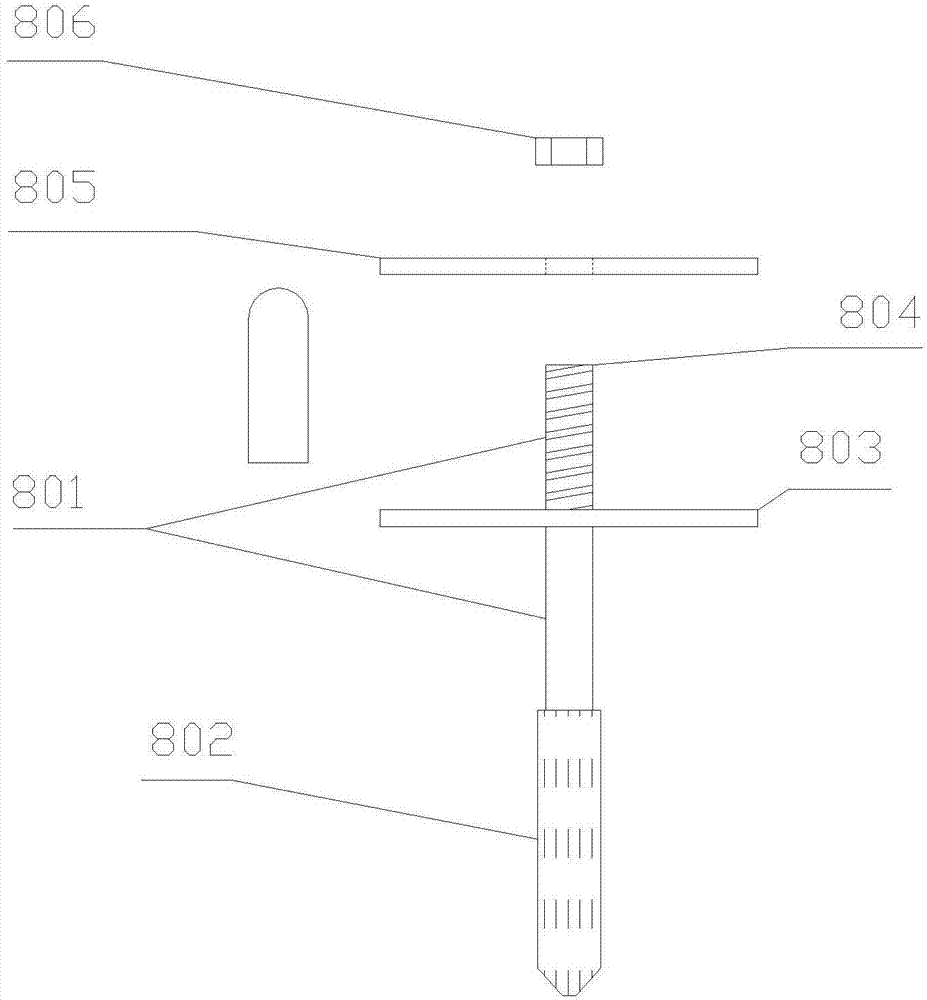

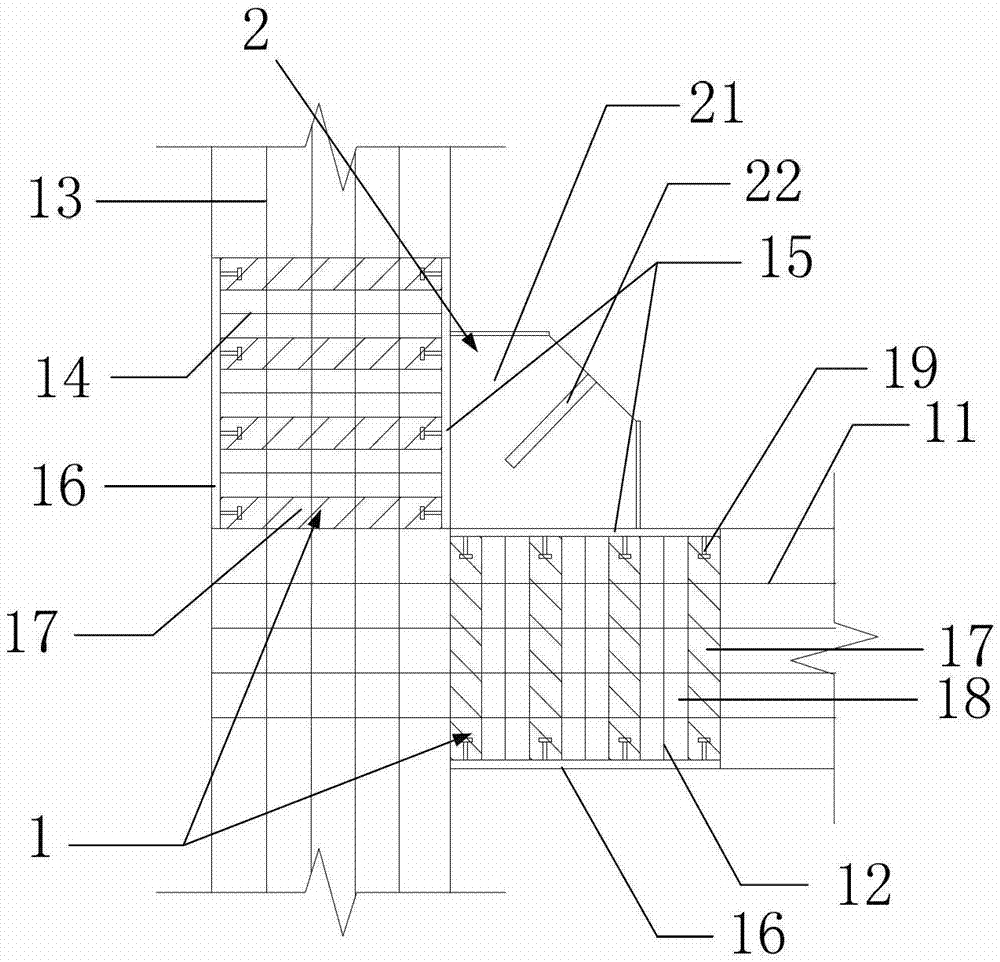

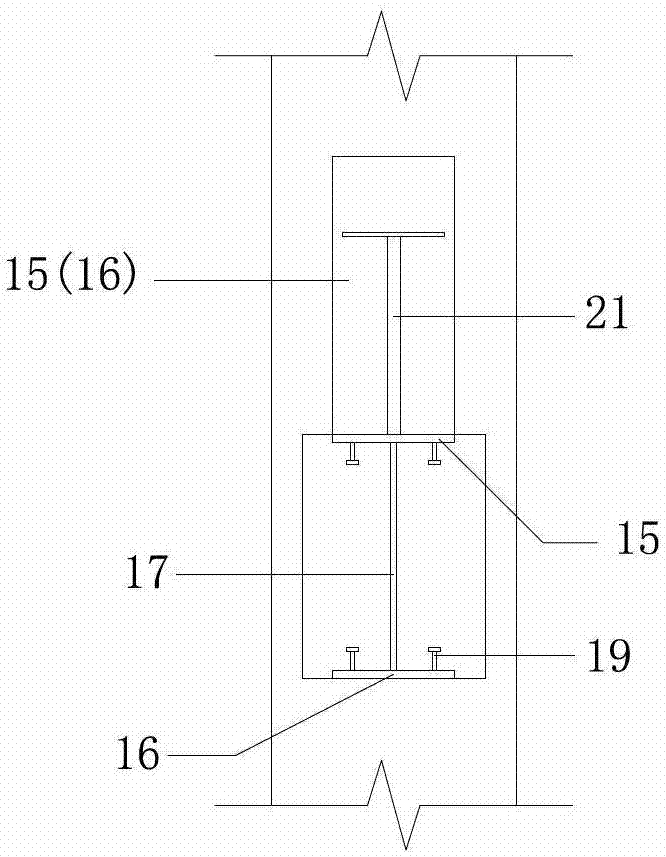

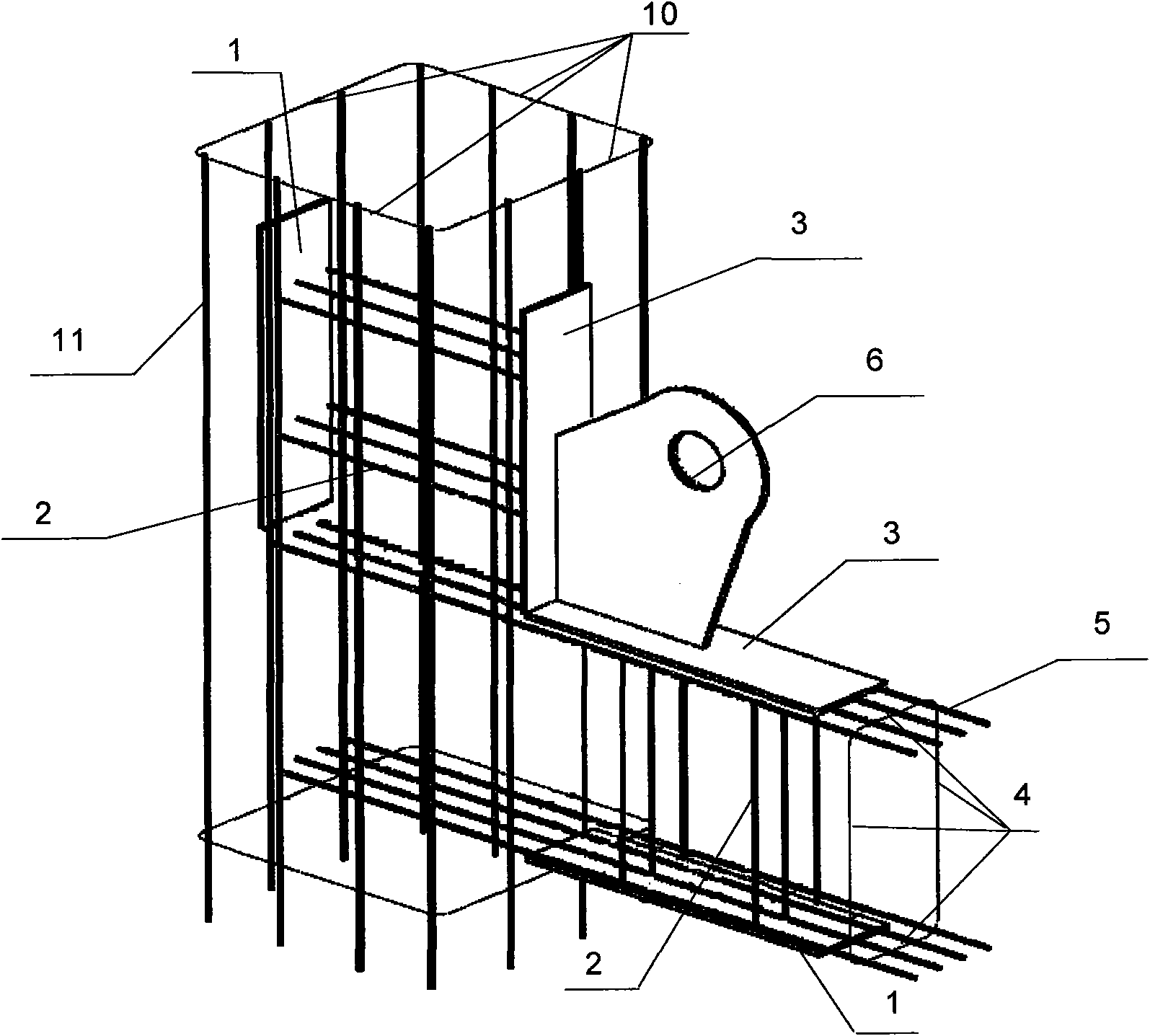

Concrete member and steel support H-shaped embedded connection joint

ActiveCN102966182ASimple connection structureReduce steel consumptionBuilding constructionsSteel platesStructural engineering

The invention provides a concrete member and steel support H-shaped embedded connection joint. The concrete member and steel support H-shaped embedded connection joint is arranged between beams and columns of a house. The concrete member and steel support H-shaped embedded connection joint comprises concrete member parts and connection joint parts, wherein each concrete member part comprises concrete beam inner longitudinal bars, concrete beam inner stirrups, concrete column inner longitudinal bars, concrete column inner stirrups, a first steel plate and a second steel plate; each connection joint part comprises a first support connection joint plate, a second support connection joint plate and steel supports; and both ends of each support steel are respectively and mutually connected with the connection joint parts. The concrete member and steel support H-shaped embedded connection joint is characterized in that the corresponding concrete member part also comprises third steel plates. The third steel plates are located between the first steel plate and the second steel plate; one ends of the third steel plates are connected with the first steel plate; and the other ends of the third steel plates are connected with the second steel plate.

Owner:SHANGHAI LANKE STEEL STRUCTURE TECH DEV

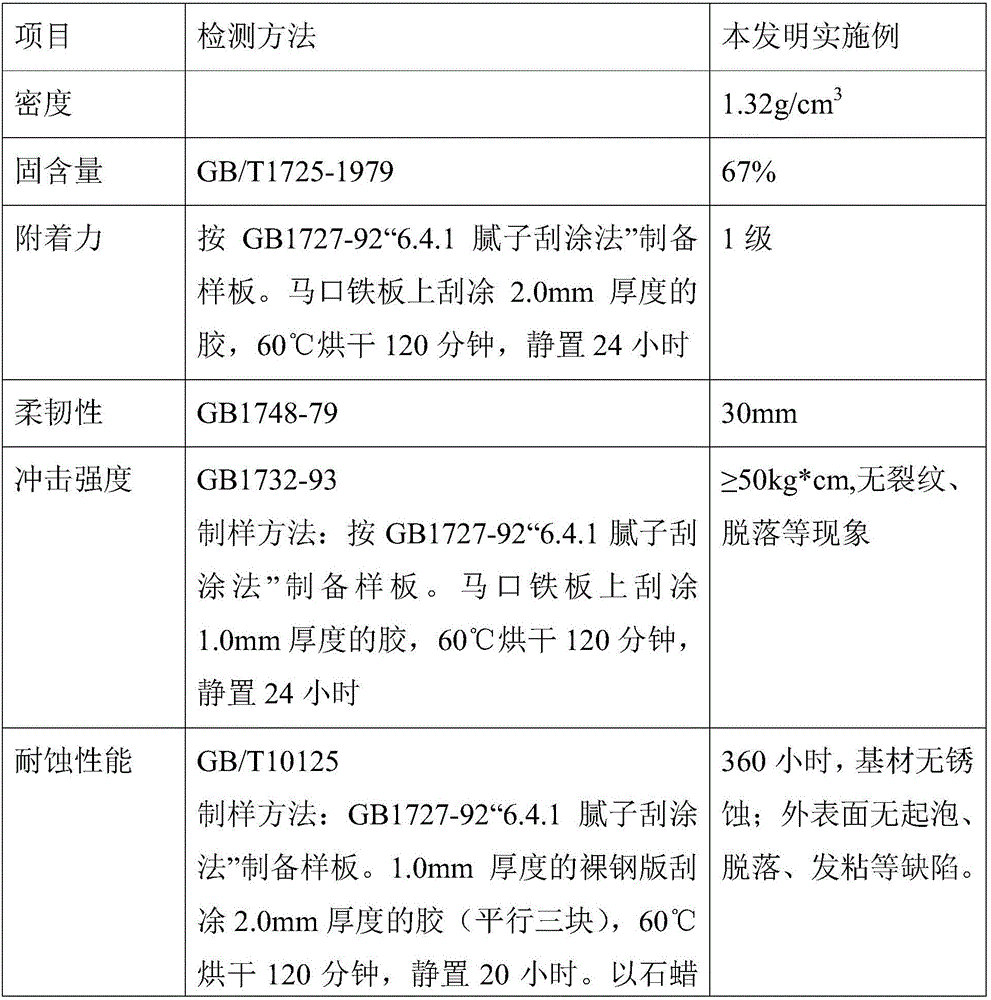

High-crack-resistance damping coating

ActiveCN106433350ASolve the problem of easy crackingWide temperature rangeAnti-corrosive paintsHigh resistanceEmulsion

The invention provides a high-crack-resistance damping coating. The high-crack-resistance damping coating comprises the following raw materials in parts by weight: 290 to 310 parts of an acrylic acid waterproof emulsion, 95 t 105 parts of an anti-rust emulsion, 45 to 55 parts of a plasticized acrylic acid emulsion, 13 to 17 parts of a film-forming aid, 90 to 110 parts of functional fillers and 45 to 55 parts of corrosion-resistant fillers. The damping coating has high flexibility, impact resistance and high stone crash resistance, and solves the problem that the profile 90-degree transitional coating is susceptible to cracking.

Owner:郑州安邦达水性材料有限公司

Large-section U-shaped earth pressure balance shield tunnel construction method based on U-shaped shield tunneling machine

InactiveCN108661655AReal-time pressure controlLow costUnderground chambersTunnel liningForce structureShield tunneling

The invention discloses a large-section U-shaped earth pressure balance shield tunnel construction method based on a U-shaped shield tunneling machine. The large-section U-shaped earth pressure balance shield tunnel construction method comprises the following steps that 1, an opencut tunnel counter-force structure shield launching device is arranged, and the end is reinforced through a large pipeshed in the tunnel entering direction; 2, a launching base is arranged on a bottom plate structure, three first guide rails are arranged on the launching base to serve as a shield tunneling machine guiding rail, three second guide rails are laid in a tunnel portal pilot tunnel, the first guide rails and the second guide rails are connected and located at the connecting position of the shield tailof the shield tunneling machine and a medium shield, and a shield tail welding groove is formed in the launching base; and 3, an opencut tunnel reinforcing section structure is arranged to provide counterforce for the shield tunneling machine. On the basis of the U-shaped shield tunneling machine, a complete set of technologies, including the opencut tunnel counter-force structure shield launchingtechnology, the shield tunneling parameter control technology, the large-section U-shaped shield segment splicing technology and the muck improvement technology, of large-section U-shaped shield construction is formed.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +2

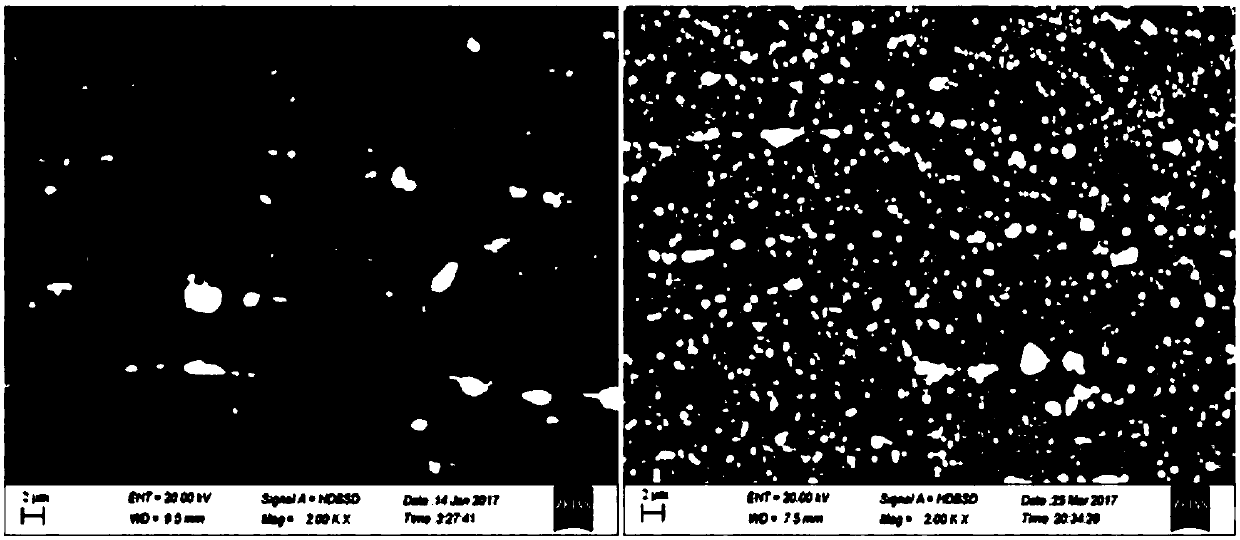

Preparation method of graphene composite silicon-carbon-nitrogen precursor ceramics

The invention relates to a preparation method of graphene composite silicon-carbon-nitrogen precursor ceramics, wherein the preparation method includes the following steps: (1) stirring polysilazane (PSZ) and graphene evenly in an N2 atmosphere to obtain a mixed solution; (2) rising the temperature of the mixed solution obtained by the step (1) with the heating rate of 3-5 DEG C / min from room temperature to 300-800 DEG C, and solidifying for 1-8 h; (3) carrying out crushing ball milling of the material solidified in the step (2) in a vibrating ball mill, and allowing the powder to pass througha 100-200 mesh sieve; (4) carrying out press molding of the powder obtained in the step (3) under the pressure of 5 MPa-15 MPa, carrying out cold isostatic pressing, and under the pressure of 150-250MPa, maintaining the pressure for 200-400 s to obtain a green body; and (5) carrying out heat treatment of the green body obtained in the step (4) under N2 atmosphere protection at the temperature of1000 DEG C-1300 DEG C, carrying out heat preservation for 2 h-6 h, and thus obtaining the product. The graphene material is introduced in the preparation process of a precursor, a real part and a virtual part of the relative complex dielectric constant of the ceramic material obtained by heat treatment are increased, the loss factor is increased and the reflection loss of the material is improved.

Owner:SHANDONG UNIV

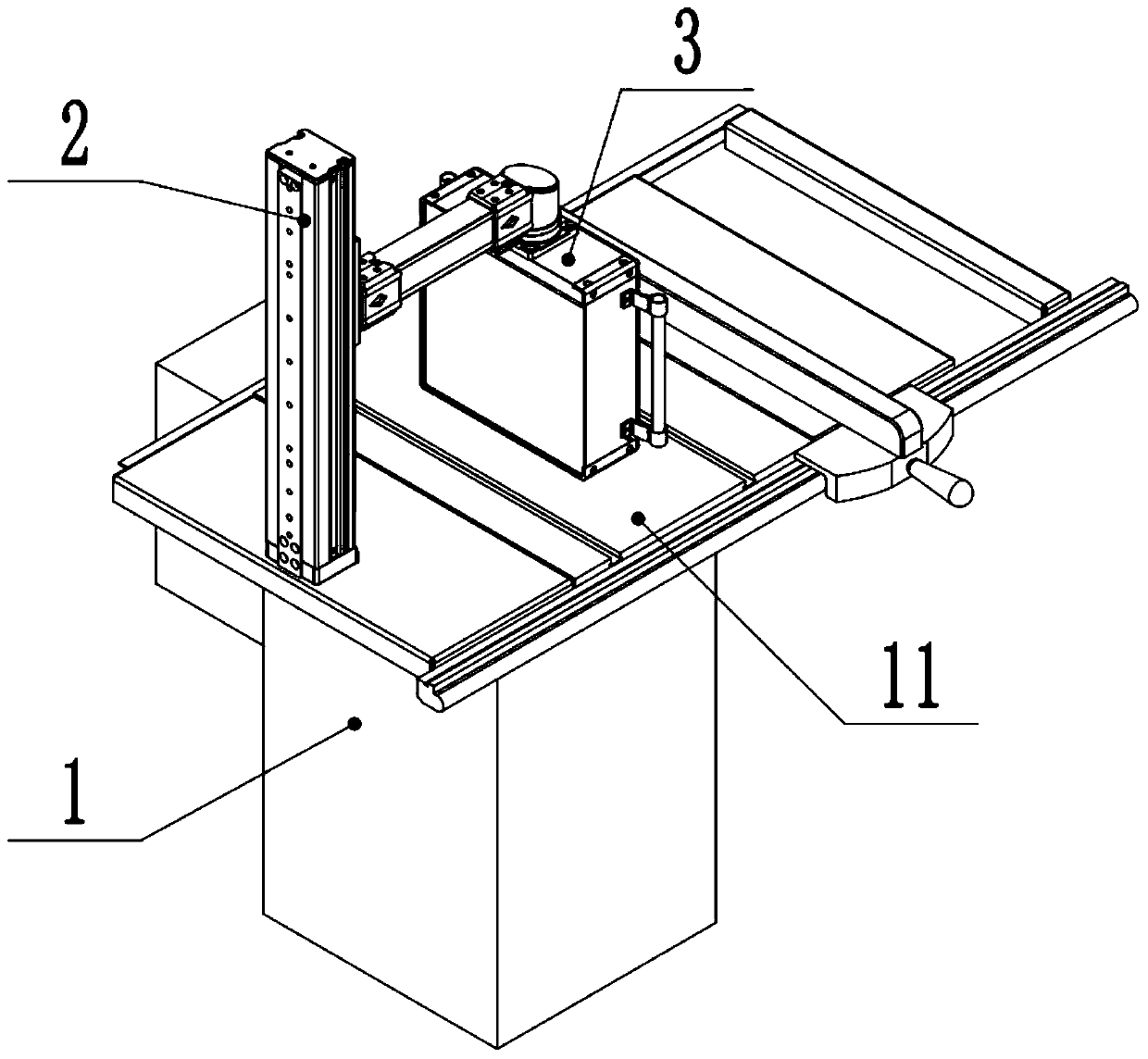

Safe-to-use sliding table saw and safety use method

PendingCN111113565ACause some damagesPrevent mildewCleaning using gasesCircular sawsWoodworking machineryStructural engineering

The invention discloses a safe-to-use sliding table saw and a safety use method, and belongs to the field of woodworking machinery. The safe-to-use sliding table saw comprises a sliding table saw body, a lifting assembly and a saw blade shield, wherein the sliding table saw body comprises a processing table for placing wood, a rotary saw blade fixedly connected with the processing table and a sawdust collecting assembly fixedly arranged at one end of the rotary saw blade; the lifting assembly performs up-and-down linear motion on one side of the rotary saw blade; the saw blade shield comprisesa shield body, an elastic assembly and a rolling assembly; the shield body is fixedly connected with the lifting assembly through the elastic assembly; the shield body abuts against timber through the rolling assembly; and a humidifying assembly is arranged in the shield body. According to the safe-to-use sliding table saw and the safety use method, an existing sawdust recycling function is reserved, the resistance generated when the shield body abuts against the timber is reduced through the rolling assembly, the abutting between the shield body and the timber is achieved, the safety of workers in misoperation is improved, and the probability of fire is reduced by humidifying the timber and the rotary saw blade through the humidifying assembly.

Owner:南京天悦家具有限公司

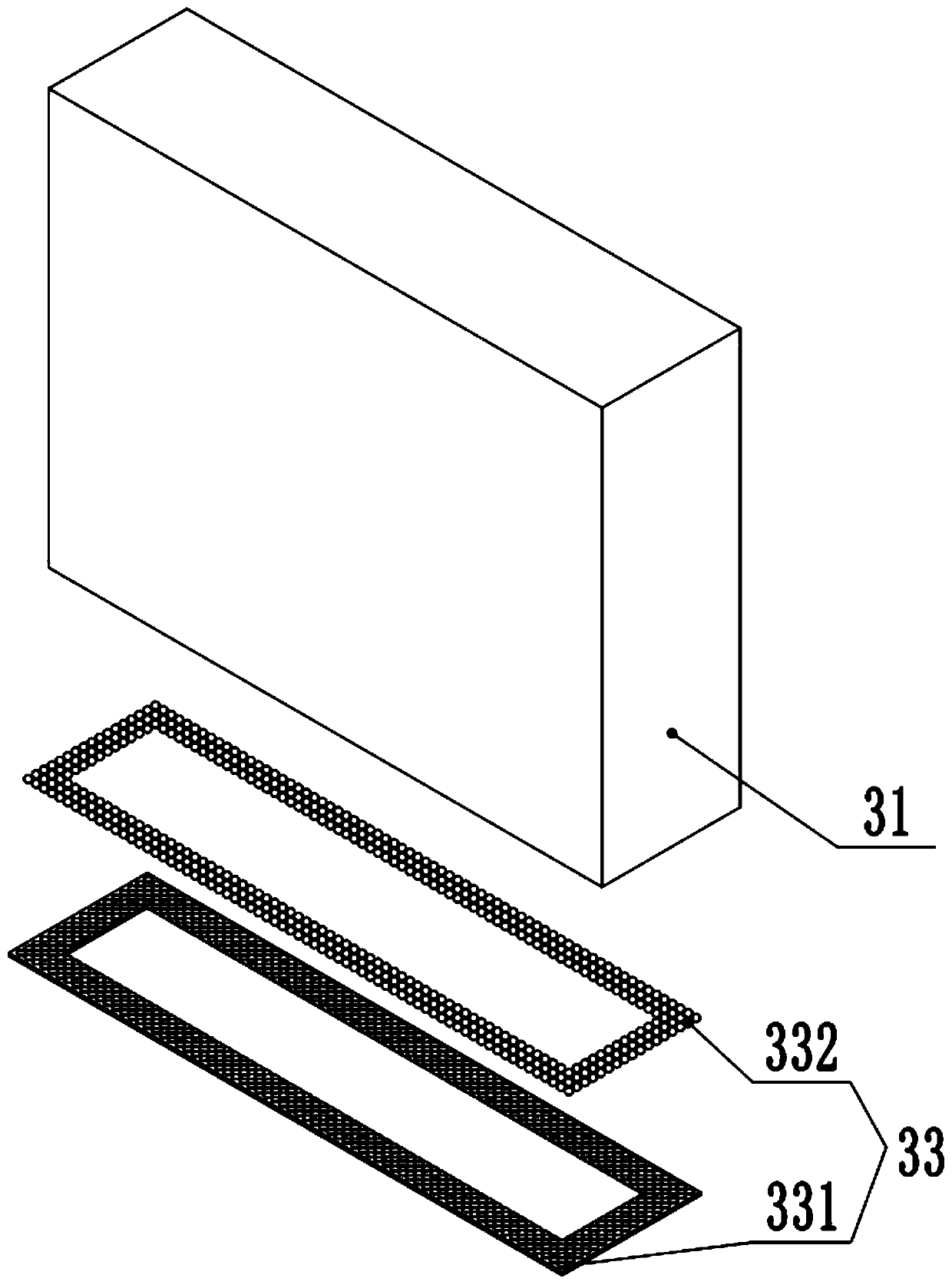

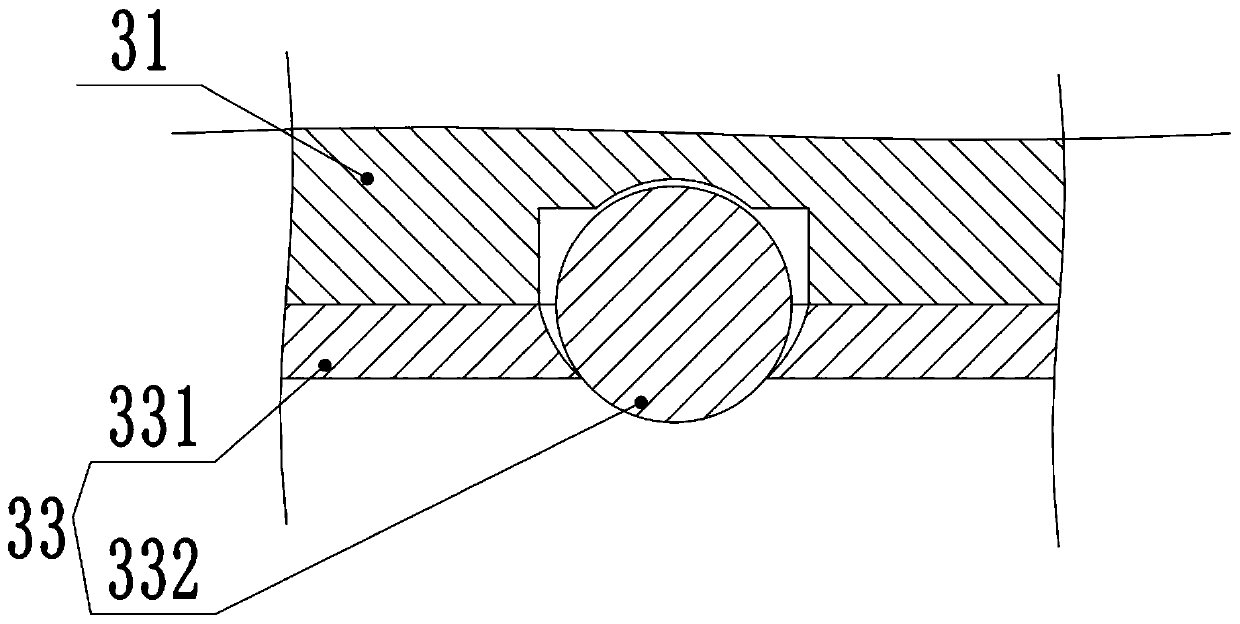

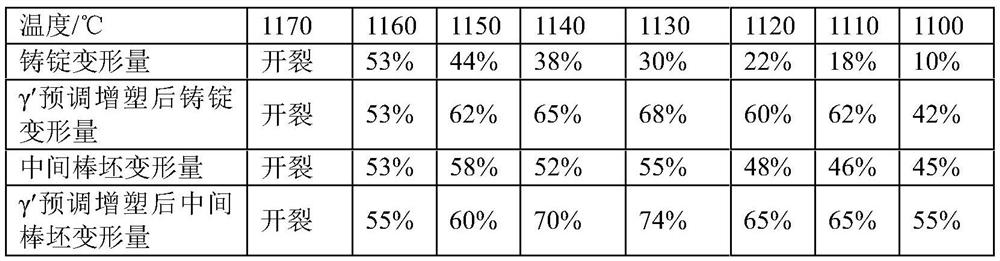

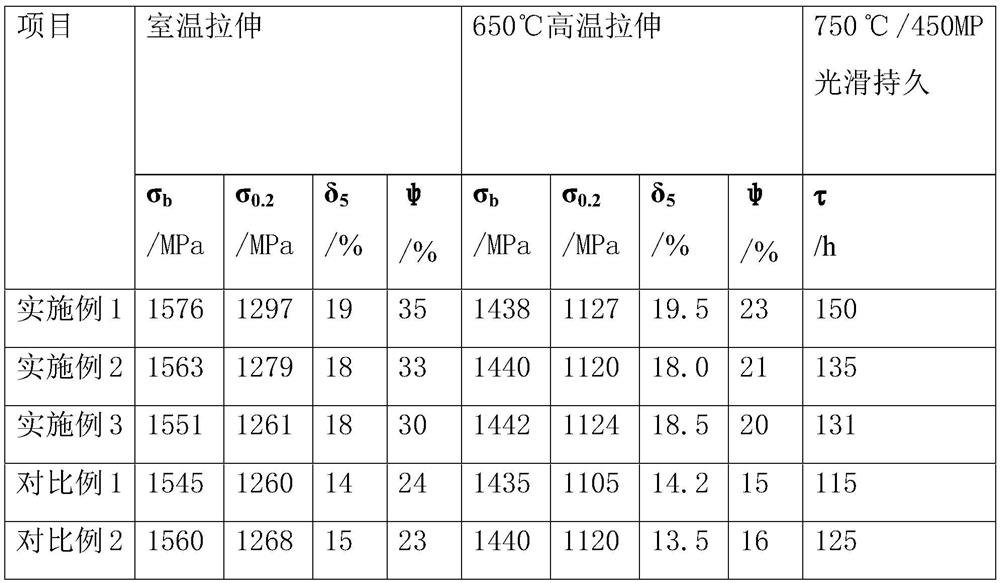

Gamma'phase pre-adjusting plasticizing production process of high-performance high-temperature alloy

ActiveCN112746231AImprove high temperature plasticityReduce deformation resistanceMetal-working apparatusIngotHeat conservation

The invention discloses a gamma'phase pre-adjusting plasticizing production process of a high-performance high-temperature alloy, and belongs to the technical field of material processing. The gamma 'phase pre-adjusting plasticizing production process comprises the following preparation steps: 1, smelting is performed to prepare a cast ingot to form a fine-grain homogeneous bar after multi-heating forging; 2, before the bar is forged in a two-phase region, when the heating number forging deformation is higher than the critical cracking deformation, the bar is treated through the gamma'phase pre-adjusting plasticizing technology so as to improve the critical cracking deformation, gamma 'phase pre-adjusting plasticizing adjusts the temperature of the bar subjected to two-phase region forging to be the forging temperature Td, heat preservation is conducted for 2-12 h, then the temperature is reduced to 800-1000 DEG C at the speed of 5-50 DEG C / min, and heat preservation is conducted for 3-12 hours; and 3, the cast ingot or the bar billet obtained in the second step is heated to the forging temperature Td again, heat preservation is conducted, the cast ingot or the bar billet is taken out of a furnace and forged, and a homogeneous bar billet is obtained after multiple times of forging. The hot working high-temperature plasticity of the high-temperature alloy is improved.

Owner:BEIJING CISRI GAONA TECH +1

Wall structure for external thermal-insulating rock wool wall and construction method thereof

InactiveCN107012971ASolve the problem of easy crackingAvoid deformationWallsHeat proofingGlass fiberWire gauze

The invention relates to a building component and specifically relates to a wall structure for an external thermal-insulating rock wool wall. The wall structure comprises a base wall, wherein a reinforced concrete slab is arranged at the center of the base wall; a rock wool board structure is arranged above the base wall; a steel wire gauze structure for preventing the rock wool board structure from deforming is arranged above the rock wool board structure; a middle ash structure which is made from anti-cracking cement pulp is arranged between a steel wire gauze structure and an alkali-resistant glass fiber mesh cloth; a surface ash structure which is made from anti-cracking cement pulp is arranged on the outer side of the alkali-resistant glass fiber mesh cloth; the base wall, the rock wool board structure, the steel wire gauze structure, the middle ash structure and the alkali-resistant glass fiber mesh cloth are fixed into an integrated structure through a double-layer anchoring structure. The invention has the beneficial effects that the wall structure is free from the phenomenon of easiness in bulging caused by high dead load of the external thermal-insulating rock wool wall and the durability and fireproof property of the external thermal-insulating rock wool wall are promoted.

Owner:GANSU BUILDING RES INST +1

An H-shaped embedded connection node between a concrete member and a steel support

ActiveCN102966182BSimple connection structureSimplify spatial relationshipsBuilding constructionsConcrete beamsStructural engineering

The invention provides a concrete member and steel support H-shaped embedded connection joint. The concrete member and steel support H-shaped embedded connection joint is arranged between beams and columns of a house. The concrete member and steel support H-shaped embedded connection joint comprises concrete member parts and connection joint parts, wherein each concrete member part comprises concrete beam inner longitudinal bars, concrete beam inner stirrups, concrete column inner longitudinal bars, concrete column inner stirrups, a first steel plate and a second steel plate; each connection joint part comprises a first support connection joint plate, a second support connection joint plate and steel supports; and both ends of each support steel are respectively and mutually connected with the connection joint parts. The concrete member and steel support H-shaped embedded connection joint is characterized in that the corresponding concrete member part also comprises third steel plates. The third steel plates are located between the first steel plate and the second steel plate; one ends of the third steel plates are connected with the first steel plate; and the other ends of the third steel plates are connected with the second steel plate.

Owner:SHANGHAI LANKE STEEL STRUCTURE TECH DEV

Preparation method of large-size sintered silicon carbide wear-resistant pipeline

PendingCN111908933APromote formationSolve the problem of easy crackingMouldsCeramic shaping coresCarbide siliconProduction drawing

The invention discloses a preparation method of a large-size sintered silicon carbide wear-resistant pipeline, which comprises the following steps: earlier-stage molding, slurry mixing and slip casting, later-stage sintering and earlier-stage molding. The method specifically comprises the following steps that (1) a production drawing is processed, (2) an outer bottom die is manufactured, (3) an inner bottom die is manufactured, (4) the outer bottom die is used for manufacturing the production outer die, (5) a production inner die is manufactured, and (6) the production inner die is used for manufacturing the inner die. After the sizes of the production units are obtained after a drawing is analyzed, production is conducted according to the production units, then splicing is conducted, andthe large-size sintered silicon carbide abrasion-resistant pipeline can be obtained. The method is simple in overall process, the content of the dispersing agent and the content of the binding agent are increased in the slurry, blank forming can be promoted, and therefore the problem that a large-size pipeline is prone to cracking is solved. According to the technology, a traditional production process is completely changed, a two-mold-opening structure is adopted, and a positioning assembly and a sliding block assembly structure are additionally arranged on the mold, so that green body forming and demolding can be assisted, and use is convenient.

Owner:山东中鹏特种陶瓷有限公司

Recycled asphalt concrete and preparation method thereof

ActiveCN109608093ASolve the problem of easy crackingImprove performanceSolid waste managementRoad surfaceMaterials science

The invention discloses recycled asphalt concrete. The recycled asphalt concrete comprises the following components in parts by weight: 38-42 parts of coarse aggregates, 45-55 parts of an old asphaltmixture, 3-5 parts of iron ore powder, 1.2-2.5 parts of asphalt and 2-3.5 parts of a regenerating agent. The invention further provides a preparation method of the recycled asphalt concrete. The preparation method comprises the following steps: (1) preparing a recycling agent; (2) preparing a recycled asphalt mixture; and (3) sequentially adding the coarse aggregates and the iron ore powder into the recycled asphalt mixture prepared in the step (2), and carrying out heating and stirring to obtain the recycled asphalt concrete. According to the recycled asphalt concrete provided by the invention, the problem that a regenerated asphalt mixture cracks easily is effectively solved while the utilization rate of the highly old asphalt mixture is considered, so that the recycled asphalt concreteprovided by the invention can be applied to paving high-grade pavements such as fast roads, main trunk roads and the like.

Owner:湖南莲城机械化工程有限责任公司

Preparation method of rare earth ion doped ITO target material

PendingCN114032517ASolve densitySolve the problem of easy crackingVacuum evaporation coatingSputtering coatingGrindingIndium

The invention provides a preparation method of a rare earth ion doped ITO target material, and belongs to the field of ITO target materials. The powder of the ITO target material is prepared through the steps of powder vacuum feeding, powder coarse grinding, powder accurate grinding, powder nanoscale sanding, slurry glue preparation, spray granulation and mixing and sieving, then dry pressing and cold isostatic pressing forming, biscuit turning, sintering, machining and binding detection are conducted, and the rare earth oxide powder is added, so that the problems that the high-indium-tin-ratio ITO target material is not high in density and easy to crack are solved, the carrier mobility of the film is improved, and the material can be better applied to the solar cell industry.

Owner:WUHU YINGRI TECH CO LTD

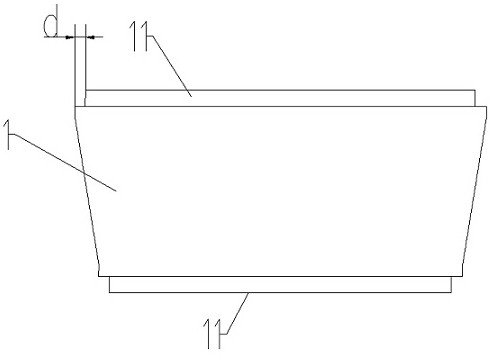

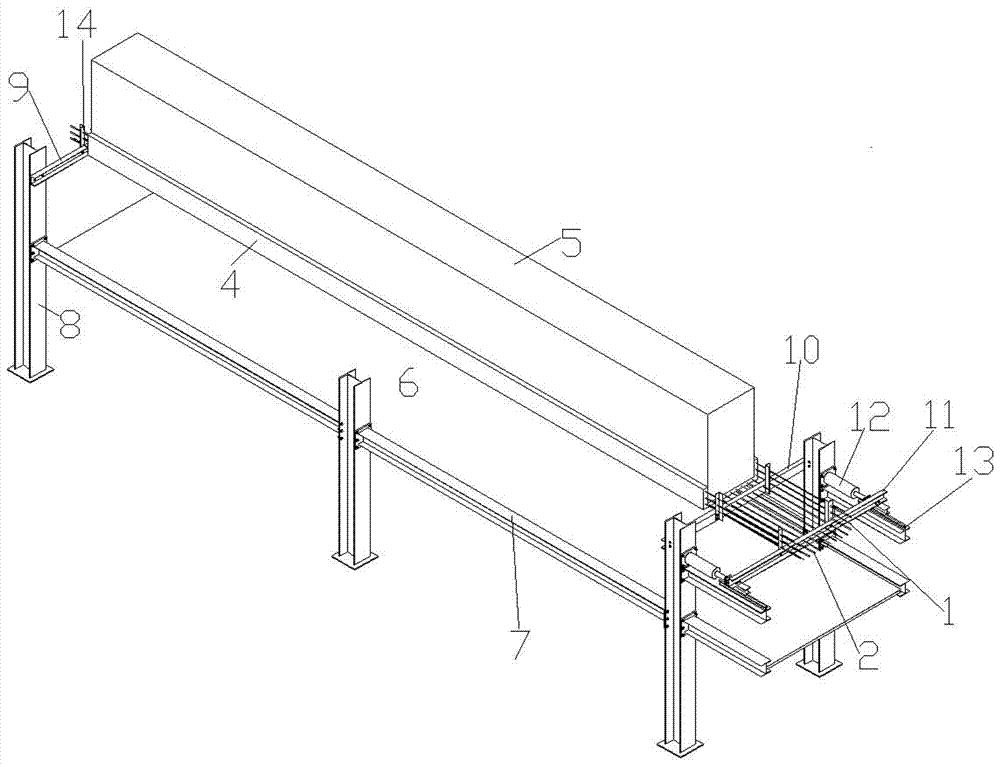

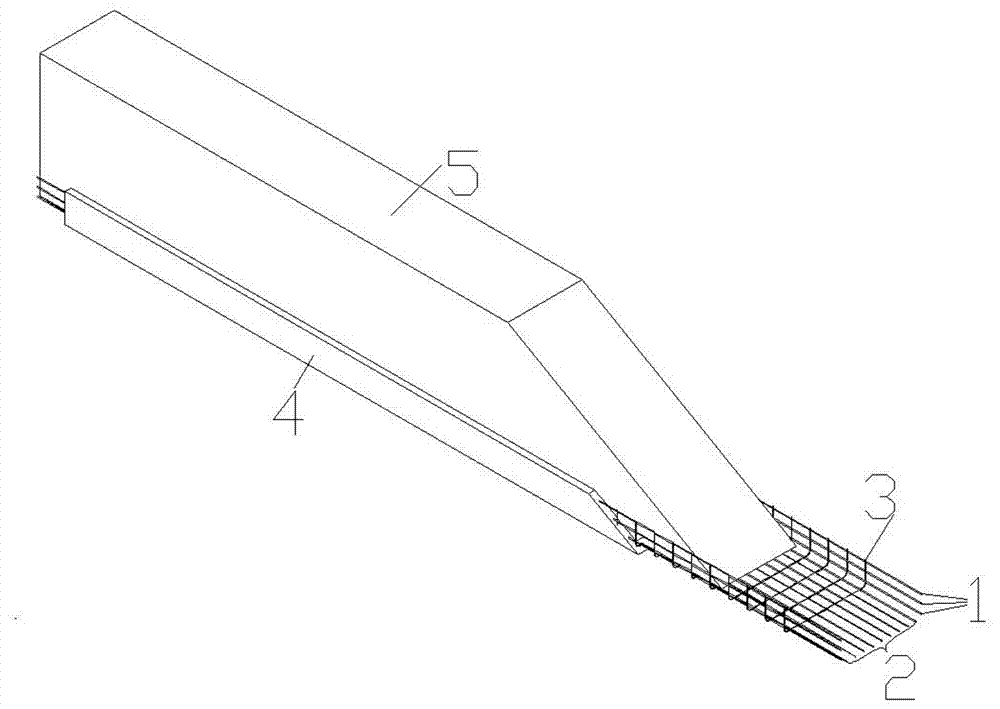

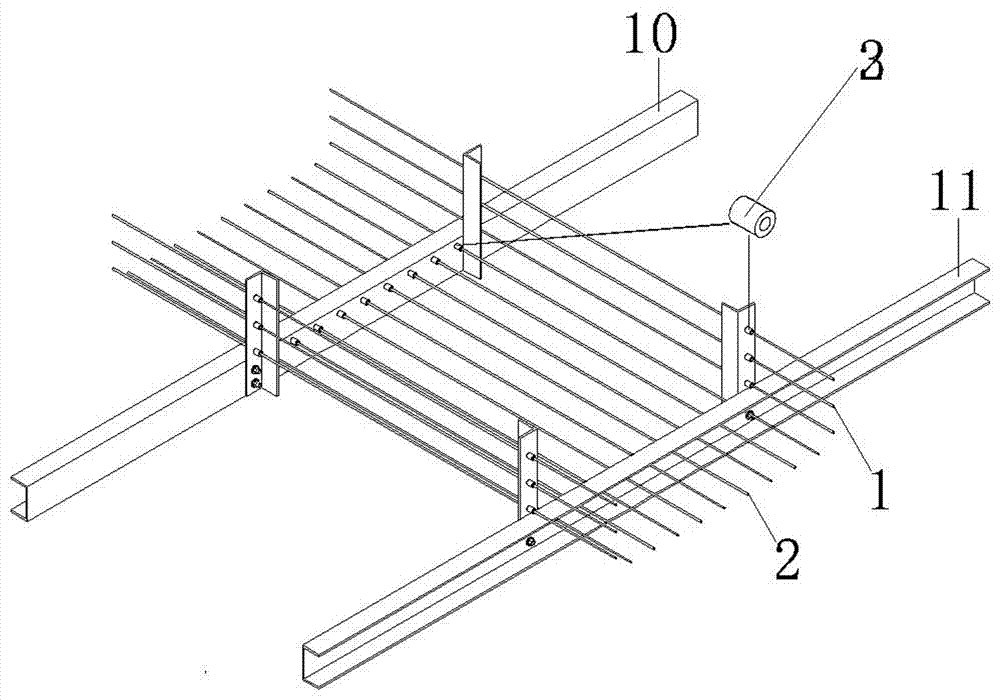

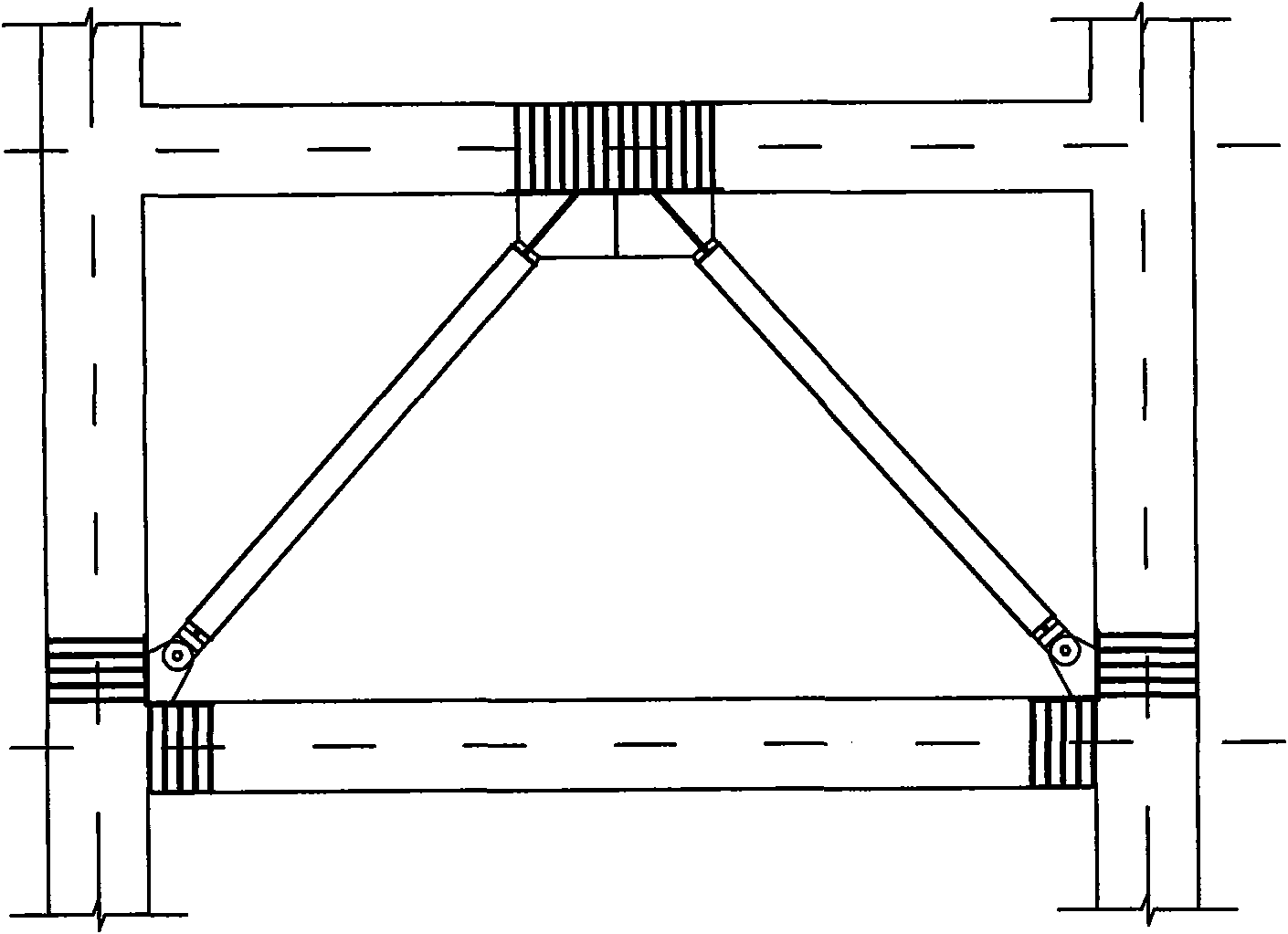

Anchoring-device-free prestress high-strength steel stand mesh U-shaped concrete member reinforcing method

InactiveCN106906753AEasy constructionImprove construction efficiencyBuilding repairsBridge erection/assemblySteel barPre stress

The invention discloses an anchoringdevice-free prestress high-strength steel stand mesh U-shaped concrete member reinforcing method. The method comprises the following steps that (1) a stretching bed is erected; (2) prestress steel strands are installed; (3) the prestress steel strands are stretched; (4) holes are punched in the bottom of a beam for steel bar planting; (5) U-shaped steel strands are installed; (6) polymer mortar is sprayed to the outer layer; and (7) the ends of the prestress steel strands on the fixed cross beam at the stretching end are cut off, the stretching bed is detached, and reinforcing is completed. No anchoring device is arranged in the stretching bed, the thickness of a reinforcing layer is small, the dead weight is low, the reinforcing layer is good in bonding performance, convenient and fast to construct, excellent in reinforcing effect and high in adaptability, and corner areas are not prone to cracking after reinforment.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Vertical reinforced concrete component-connection node for buckling-restrained brace

ActiveCN101672071BSimple connection structureSimplify spatial relationshipsBuilding constructionsPunchingBuckling-restrained brace

The invention belongs to the technical field of node connection of architectural structure, in particular to a vertical reinforced concrete component, that is, a connection node of a buckling-restrained brace (BRB), which consists of steel plates, internal-thread steel bars for embedded parts, internal stirrups for concrete beams, internal longitudinal bars for concrete beams, support connection node plates, support node stiffening plates, buckling-restrained supports, internal stirrups for concrete columns and internal longitudinal bars for concrete columns, wherein, two steel plates are connected by the internal-thread steel bars for embedded parts; plug welding holes are formed on the steel plates; steel bars are welded with a first steel plate and a second steel plate at the plug welding holes; a first support connection node plate is located at the upper part of the first steel plate or at the lower part of the second steel plate; a second support connection node plate is connected with the first support connection node plate; one end of the second support connection node plate is fixed at the upper part of the first steel plate or the lower part of the second steel plate, and the other end thereof is connected with the buckling-restrained brace; and the support node stiffening plates are fixed at one side of the first support connection node plate. The invention solves the problems that steel support connection nodes are difficult to be mounted in a concrete frame, structural steel needs punching when being embedded in a concrete component, and stirrups and longitudinal bars are arranged with difficulties; and the invention has the advantages that the construction is convenient, the stress performance of connection is good, and steel materials can be saved, therefore, the invention has wide application prospect.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

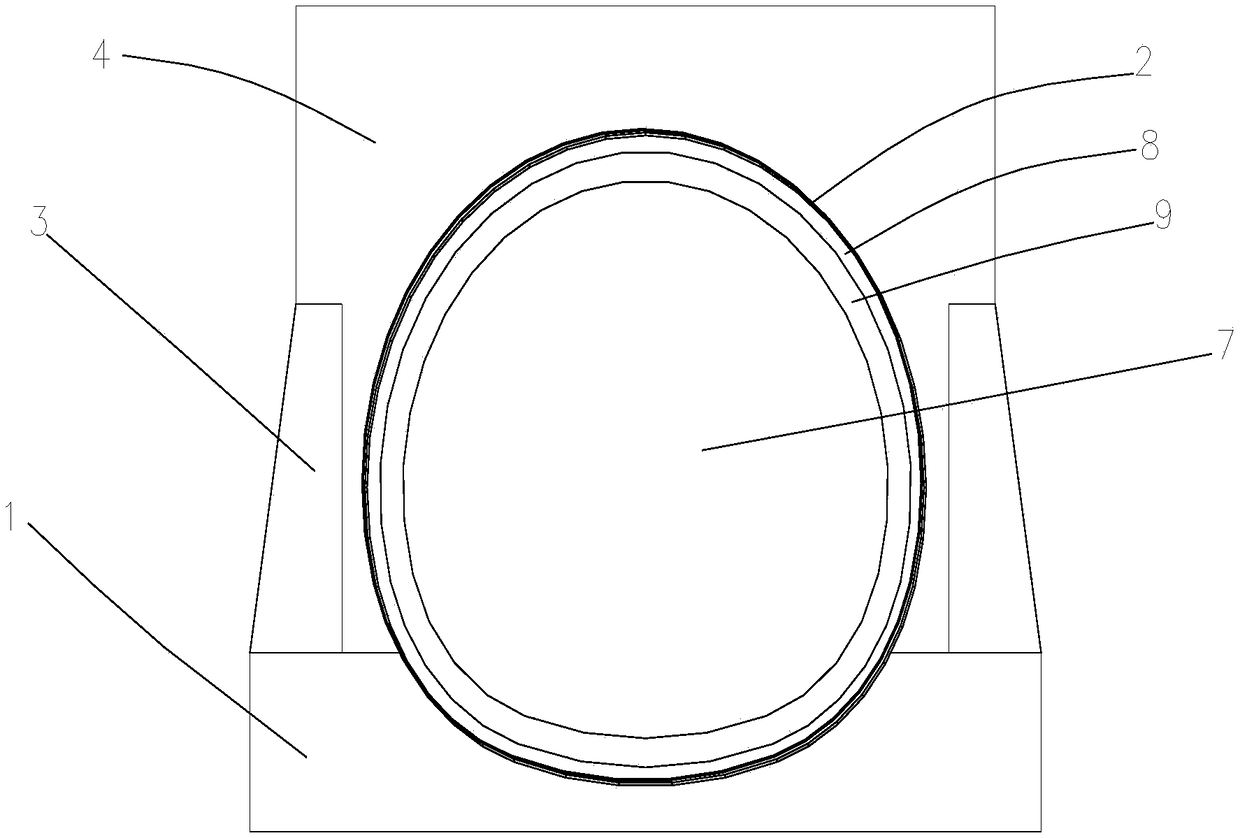

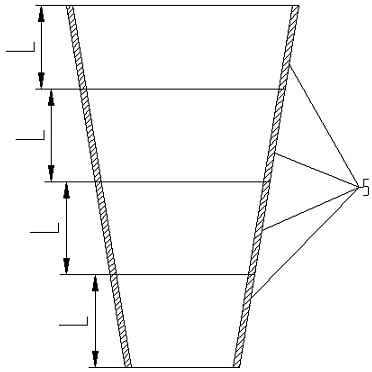

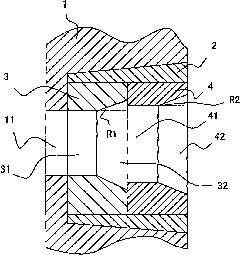

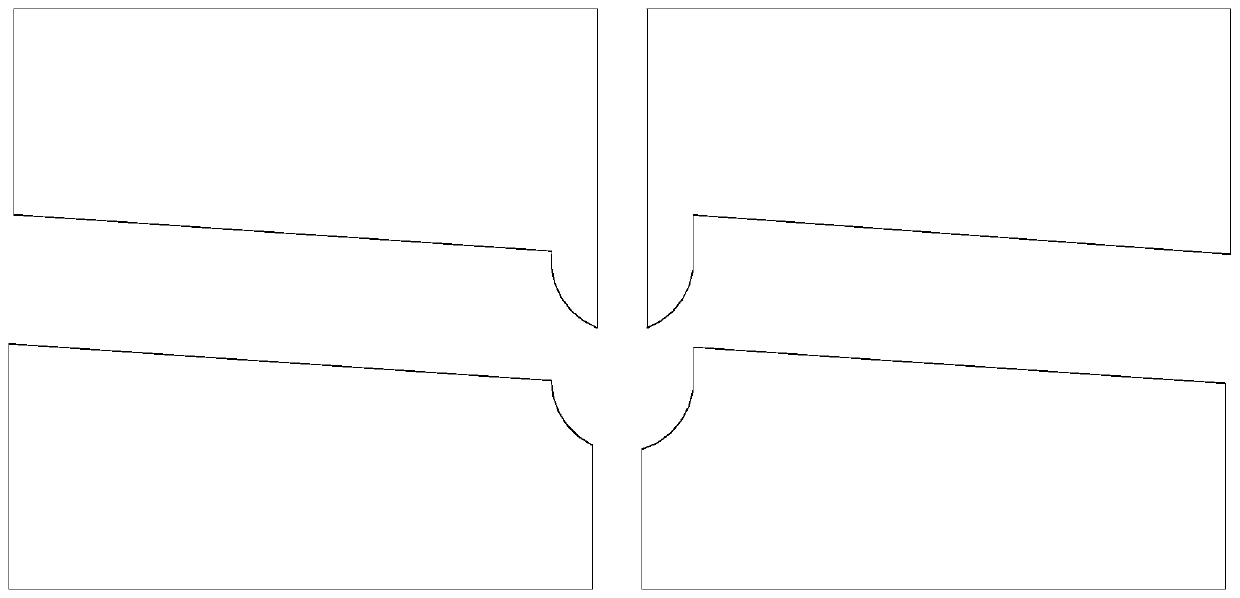

External mould assembly for cold-drawing pipes

InactiveCN101823083AEliminates sharp diameter reductionsSolve the problem of easy crackingDrawing diesSteel tubeSizing

The invention relates to an external mould assembly for cold-drawing pipes, comprising a mould seat, the middle part of the mould seat is provided with an axial external mould containing cavity, the front of the external mould containing cavity is the exit of the mould seat; wherein the external moulding containing cavity is internally provided with a front mould and a rear mould, aperture of a rear mould sizing region is larger than the aperture of a front mould sizing region, and a rear mould transition angle of a rear mould transition region is greater than the a front mould transition angle of a front mould transition region. The invention adopts double external mould structure to carry out steel tube empty sinking operation, not only dimensional change of inner hole and wall thickness of target steel tube can be controlled by the external mould, but also the phenomenon that the diameter of the original pipe is sharply reduced can be eliminated, the problem that the target pipe is easy to crack and has high flexibility when in cold-drawing pipe process reinforcement is effectively solved, and the invention has the advantage that structure improvement is simple while mould cost is not increased.

Owner:浙江伦宝管业股份有限公司

System for CD glow plasma CVD zin oxide film and preparing process

InactiveCN1752280ASolve the problem of easy crackingImprove performanceChemical vapor deposition coatingCooling chamberGraphite

A system and process for preparing zinc oxide film by DC glow plasma CVD is disclosed. Said system is composed of vaccuum reaction chamber, upper and lower gas inlet tubes, insulating base, cooling chamber, upper and lower gas cavities, and upper and lower gas outlet tubes. Its process includes such steps as vacuumizing reaction chamber, heating substrate on the Ta sheet, filling the gas of diethyl (or dimethyl) zinc via upper gas inlet tube, filling CO2 and H2 via lower gas inlet tube, reacting and thermocracking of diethyl (or dimethyl) zinc to deposit zinc oxide film.

Owner:NANCHANG HANGKONG UNIVERSITY

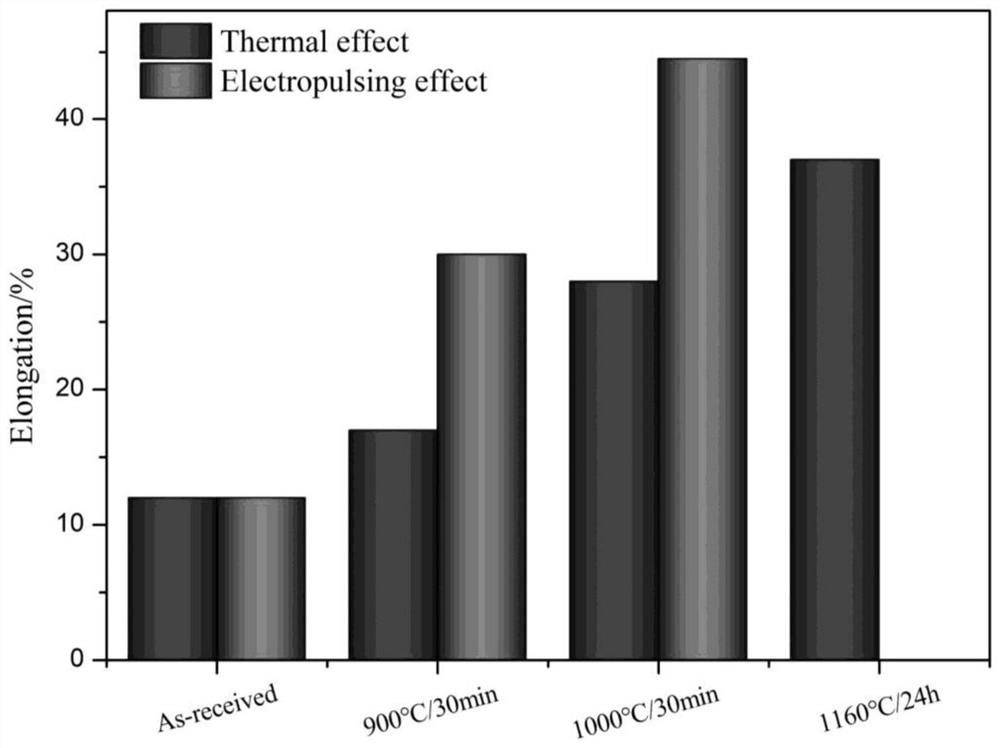

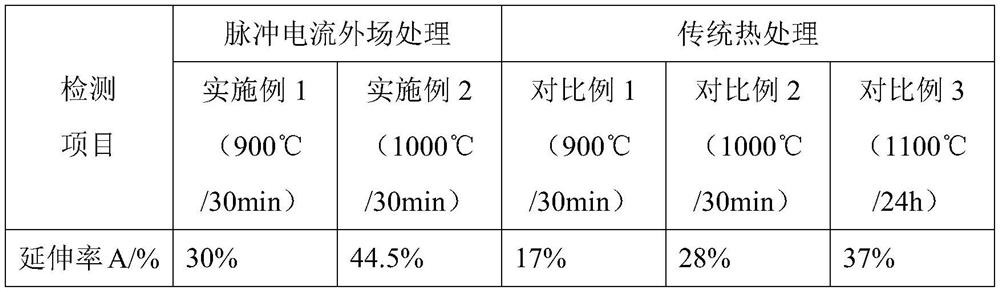

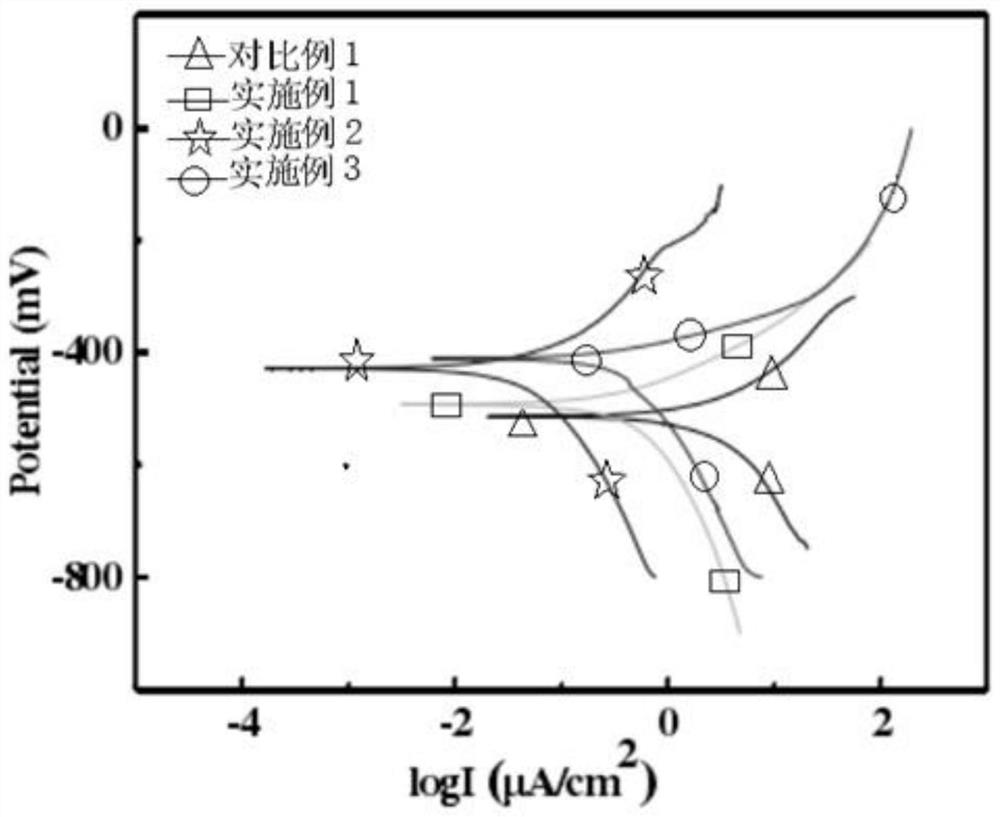

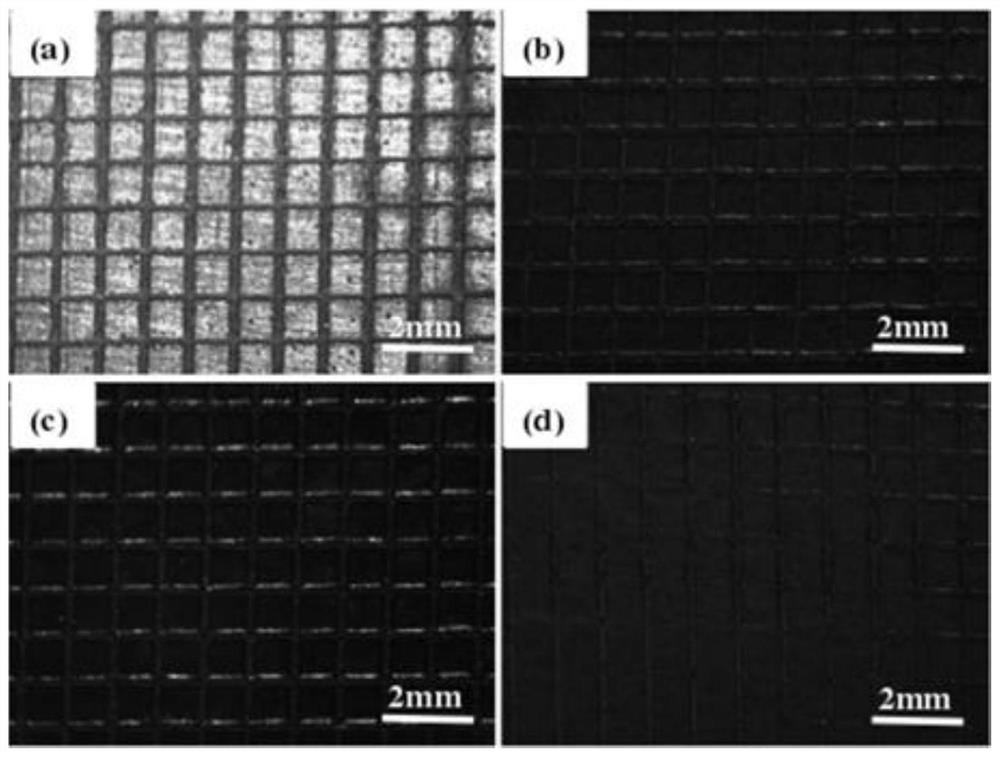

Method for rapidly dissolving Laves phase in deformed high-temperature alloy ingot by pulse current

The invention discloses a method for rapidly dissolving Laves phase in a deformed high-temperature alloy ingot by pulse current. The method comprises the following steps of carrying out pulse currentexternal field treatment on the deformed high-temperature alloy ingot under the following treatment parameters that the pulse frequency is 25000-35000 Hz, the current density is 1A / mm<2> - 100A / mm<2>.The method has the advantages that the Laves phase in the material can be completely dissolved at a relatively low temperature within an extremely short time, the time is short, the temperature is low, the operation is simple, the energy consumption can be greatly reduced, and the requirements of current industrial green development planning are met; and in addition, the plasticity of the alloy can be improved, the alloy is used for deformed high-temperature alloy treatment, subsequent cogging and forging processes are facilitated, and a new method is provided for preparation of a high-temperature alloy turbine disc.

Owner:BEIJING CISRI GAONA TECH +1

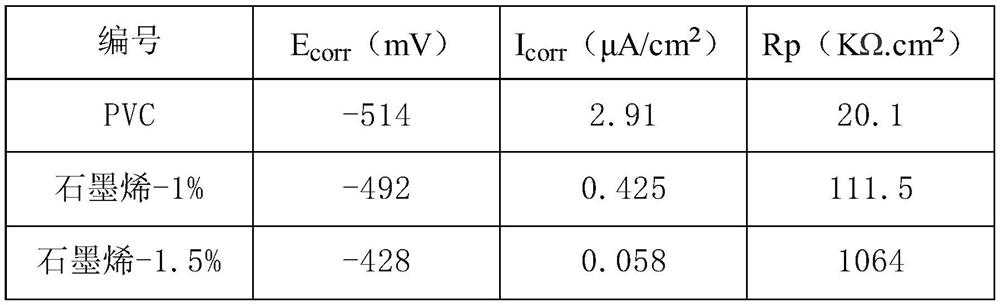

Preparation method of graphene/polyvinyl chloride composite material

The invention discloses a preparation method of a graphene / polyvinyl chloride composite material. The preparation method comprises the following steps of 1, preparing modified graphene, 2, preparing awater-based emulsion, 3, preparing modified polyvinyl chloride resin, and 4, preparing the graphene / polyvinyl chloride composite material. The method disclosed by the invention is low in cost, simpleto prepare and easy for industrial batch production, solves the problem that the traditional waterproof material is easy to crack, and utilizes the graphene to be uniformly dispersed in the polyvinylchloride resin to prepare the waterproof corrosion-resistant composite material under the synergistic effect of the graphene and the polyvinyl chloride resin.

Owner:JIANGSU UNIV OF TECH

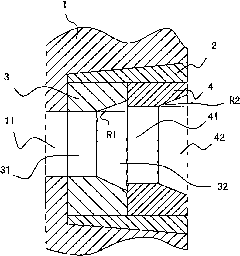

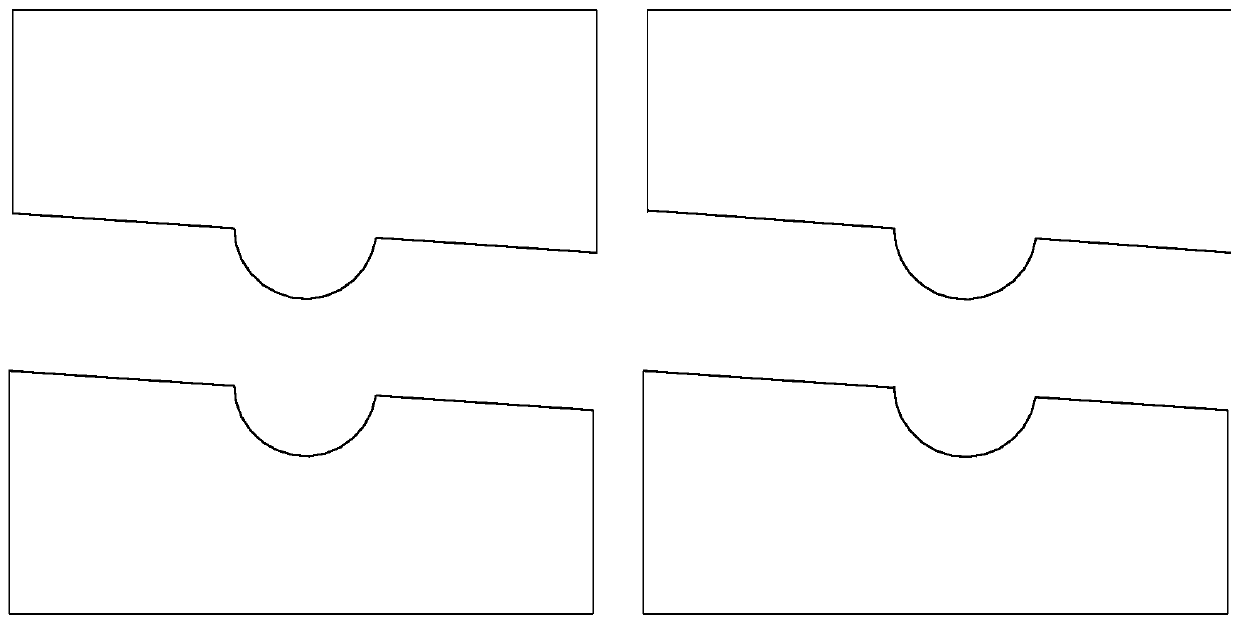

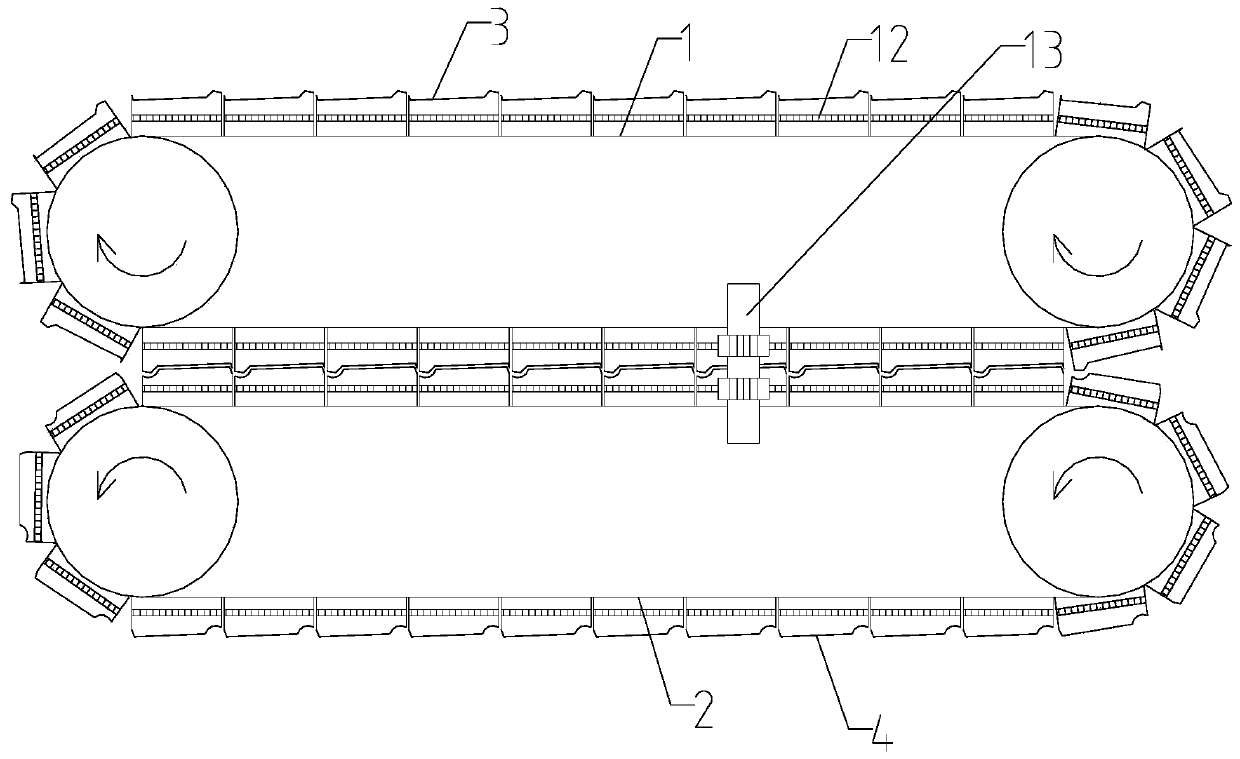

Tile forming machine and tile manufacturing method

The invention relates to a tile forming machine. The tile forming machine comprises an upper caterpillar band, a lower caterpillar band and a power device, wherein the upper caterpillar band and the lower caterpillar band are arranged oppositely; the power device drives the upper caterpillar band and the lower caterpillar band to rotate; a plurality of upper molds are arranged on the upper caterpillar band; a plurality of lower molds are arranged on the lower caterpillar band; the rotation direction of the upper caterpillar band is opposite to the rotation direction of the lower caterpillar band, so that the upper molds and the lower molds move synchronously towards the same direction after being pressed and combined; gaps exist among the adjacent upper molds, gaps also exist among the adjacent lower molds, and the gaps are the same; each upper mold is provided with an arc-shaped protrusion with the radius R1, and each lower mold is provided with an arc-shaped groove matched with the corresponding arc-shaped protrusion; after each arc-shaped protrusion and the corresponding arc-shaped groove are pressed and combined, a joint between the corresponding adjacent tiles is formed, eachgap deviates from the center of the corresponding arc-shaped protrusion, the distance between the edge, which is closest to the center of the corresponding arc-shaped protrusion, of each gap and the center of the corresponding arc-shaped protrusion is L1, and the width of each gap is L2, wherein L1 is greater than or equal to 0 and less than or equal to (R1-L2). The problem about flaws that jointscannot be formed or protrusions are formed on tiles is solved.

Owner:南城颖鼎户外家俱树脂制品厂

Frost crack prevention solar water heater water inlet-outlet pipe

InactiveCN103591715APrevent frost crackingAvoid wastingSolar heat devicesSolar thermal energy generationFrost crackWater storage tank

The invention discloses a frost crack prevention solar water heater water inlet-outlet pipe which comprises a water inlet-outlet pipe body connected with a water storage tank of a solar water heater, an inflation device, an air cylinder, pressure measurement devices and a display window. An air inlet of the air cylinder is connected with the inflation device through a pipeline, an air outlet of the air cylinder is connected with the water inlet-outlet pipe body of the solar water heater, a pressure limit valve is arranged between the air cylinder and the inflation device, and a control valve is arranged between the air cylinder and the water inlet-outlet pipe body of the solar water heater. One pressure measurement device is arranged on the air cylinder. The other pressure measurement device is arranged at the top end of the water inlet-outlet pipe body, the display device is arranged in a user house, the pressure measurement device at the top end of the water inlet-outlet pipe body is connected with the display device through a guide wire, and when the pressure value on the display device in the user house is equal to the pressure value of the pressure measurement device on the air cylinder, the water inlet-outlet pipe body is filled with air. The frost crack prevention solar water heater water inlet-outlet pipe is ingenious in concept and simple in structure, saves energy, is environmentally friendly and low in production cost, solves the problem that frost crack easily occurs to the solar water heater water inlet (outlet) pipe, and eradicates water waste.

Owner:张杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com