Epoxy pouring sealant as well as preparation method and application thereof to nuclear power equipment

A technology of potting glue and epoxy, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc. It can solve the problems of fast curing speed, air bubbles, brittle products, poor fluidity and castability, etc., and achieve insulation and Good mechanical properties, low shrinkage and water absorption, good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment provides an epoxy potting glue, comprising a main agent and a curing agent with a weight ratio of 1:1.2;

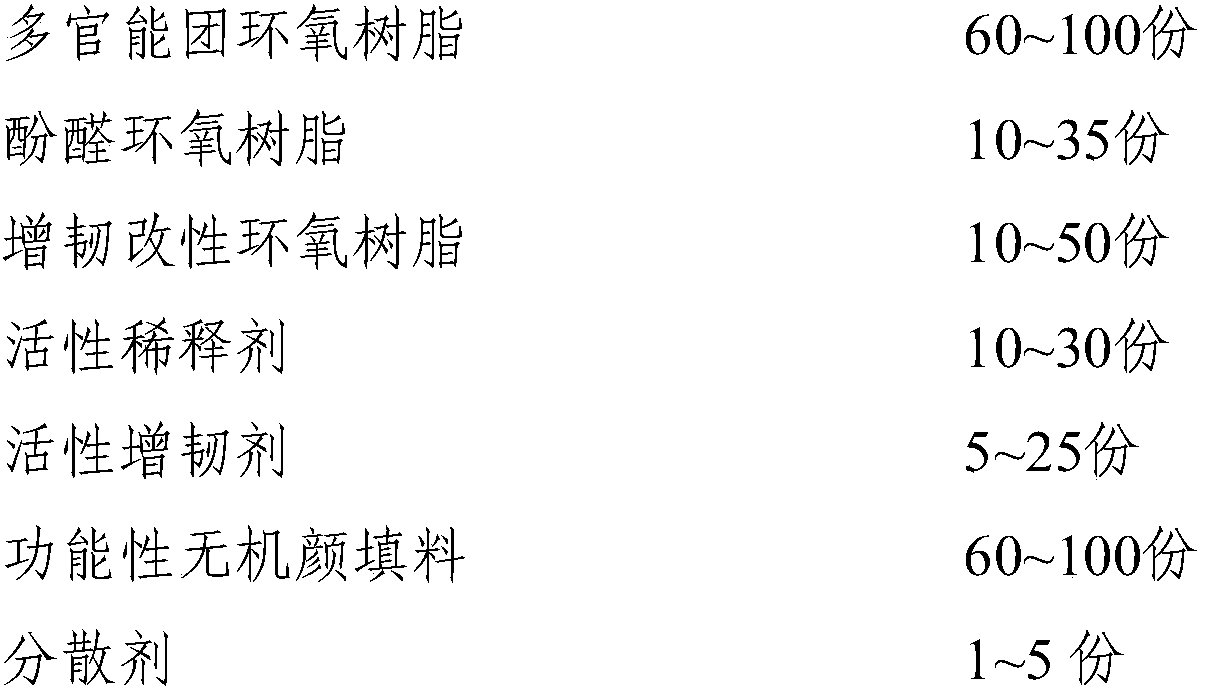

[0069] The main ingredient is composed of the following raw materials in parts by mass:

[0070]

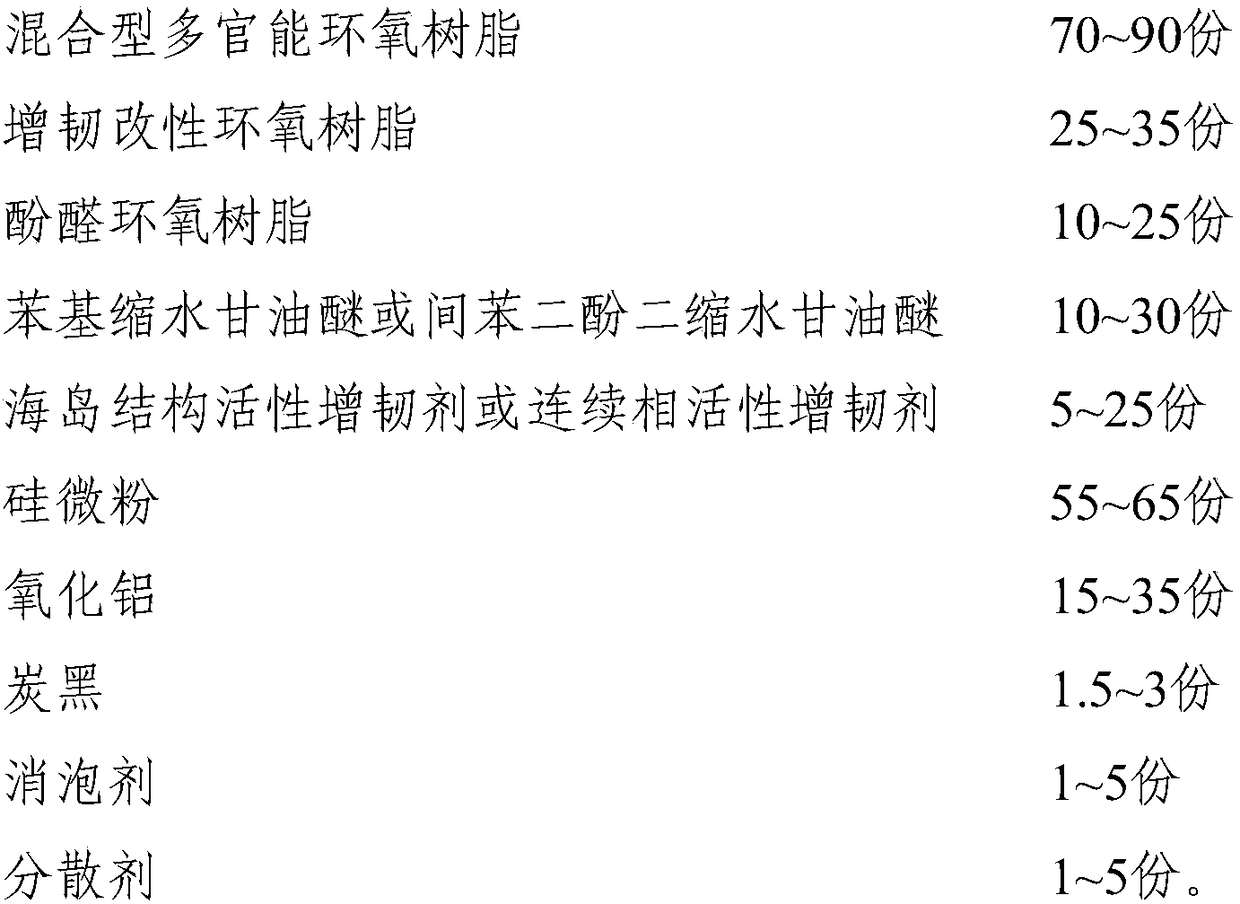

[0071] Described curing agent is made up of the raw material of following mass parts:

[0072]

[0073]

Embodiment 2

[0075] This embodiment provides an epoxy potting glue, including main agent A and curing agent B with a weight ratio of 1:1.4;

[0076] The main ingredient A is composed of the following raw materials in parts by mass:

[0077]

[0078] The curing agent B consists of the following raw materials in parts by mass:

[0079]

Embodiment 3

[0081] This embodiment provides an epoxy potting glue, including main agent A and curing agent B with a weight ratio of 1:0.8;

[0082] The main ingredient A is composed of the following raw materials in parts by mass:

[0083]

[0084] The curing agent B consists of the following raw materials in parts by mass:

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com