Patents

Literature

139 results about "Force structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A force structure is the combat-capable part of a military organisation which describes how military personnel, and their weapons and equipment, are organised for the operations, missions and tasks expected from them by the particular doctrine of the service or demanded by the environment of the conflict.

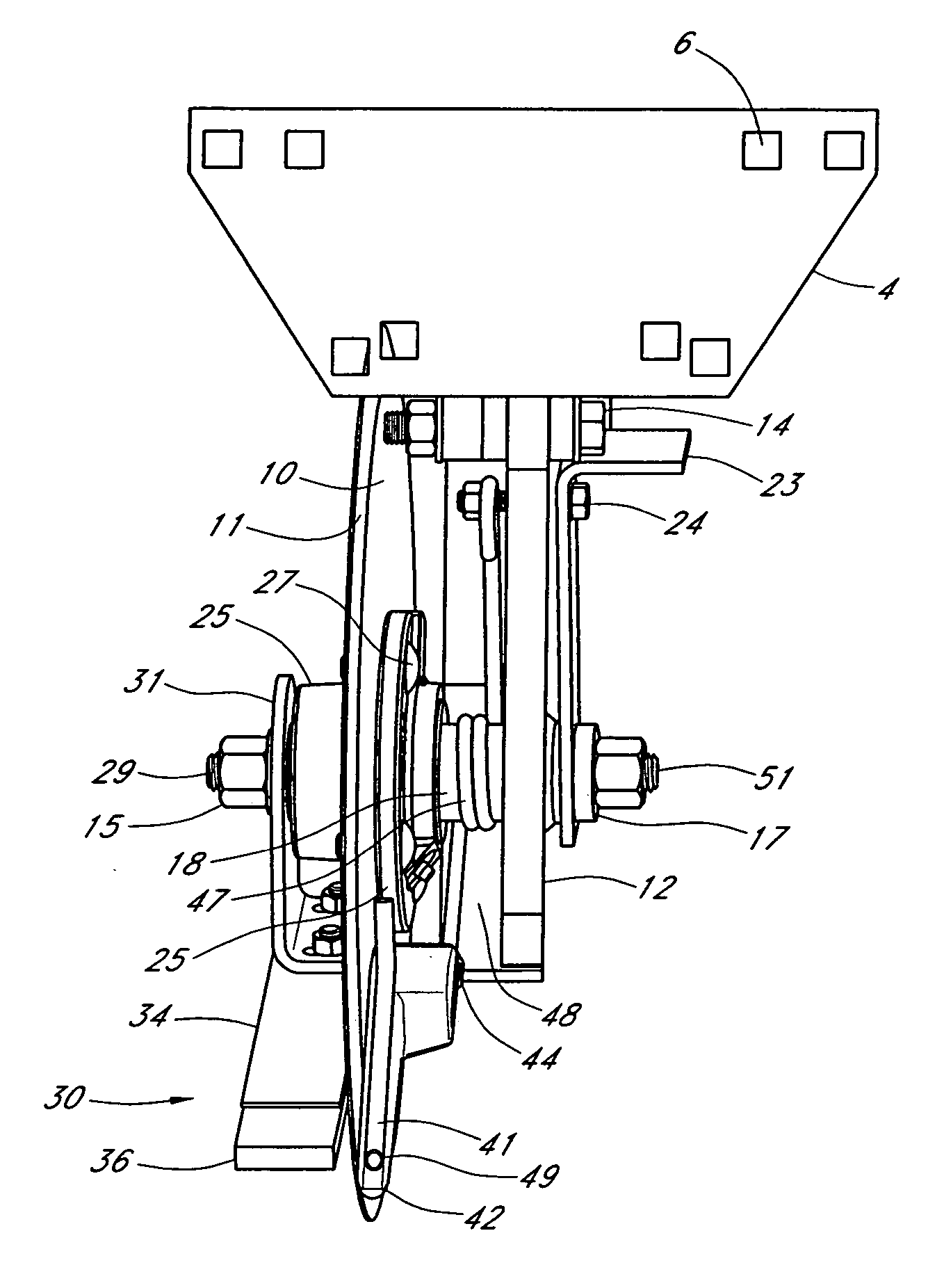

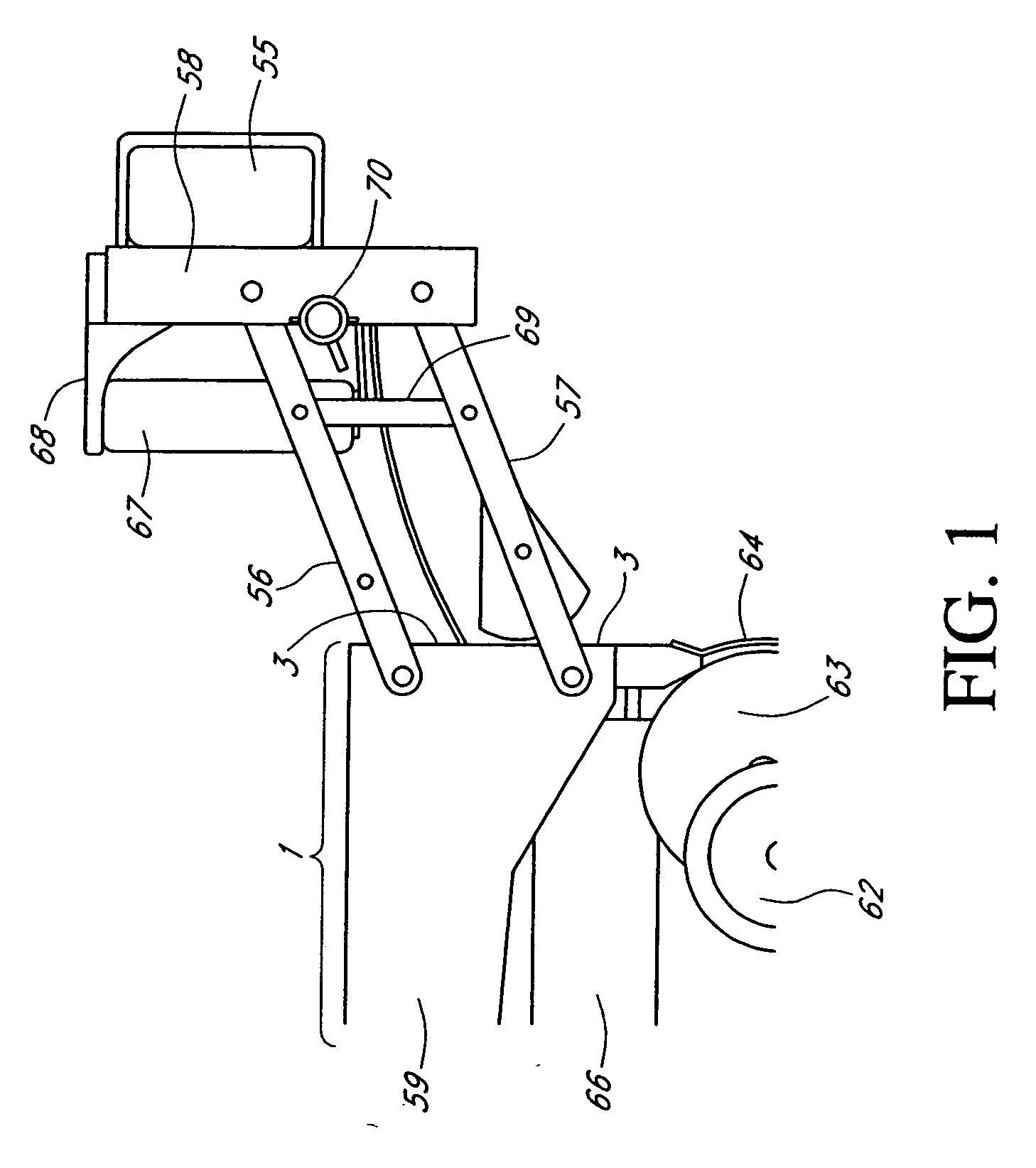

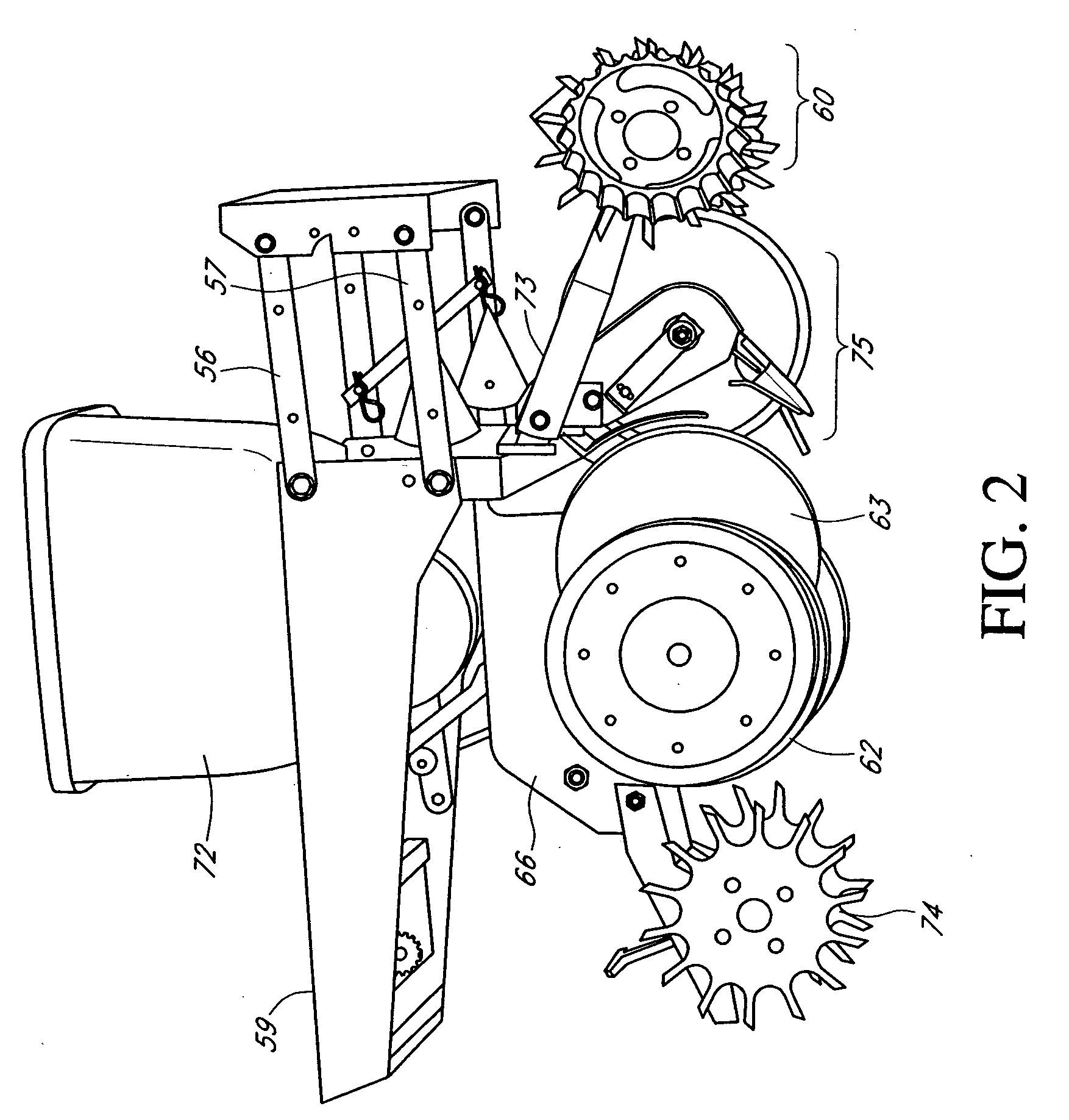

Single disc liquid fertilizer opener

ActiveUS20070044694A1Minimize opportunityEliminate premature mechanical failureTill seedingPlantingForce structureCircular disc

A method and apparatus to be mounted upon a planter row unit for delivering liquid fertilizer to the bottom of a trench without contacting the seed to be planted is disclosed and claimed. The system as claimed and described is adapted for mounting to substantially all modern row units employing floating row units. The method and apparatus as described does not interfere with existing down pressure or seed placement systems as found on modern row crop planters. As described and implemented, the method and apparatus is more compact and lighter in weight than the prior art. The attached assembly for a seed planting unit works in combination with a seed trench opener to form a trench for the deposit of liquid fertilizer offset from and parallel to the later formed seed trench. The apparatus allows directed liquid fertilizer delivery in close proximity to the seed trench with minimal disruption of said seed trench. The attachment includes a single disk blade disposed forward of the seed trench forming unit. The single disk blade is disposed at an angle of four degrees or less from the line defining the direction of travel of the seed planting implement in combination with a furrow strap. The attachment includes a selectively adjustable down force structure and a selectively adjustable depth control mechanism.

Owner:MARTIN HOWARD D

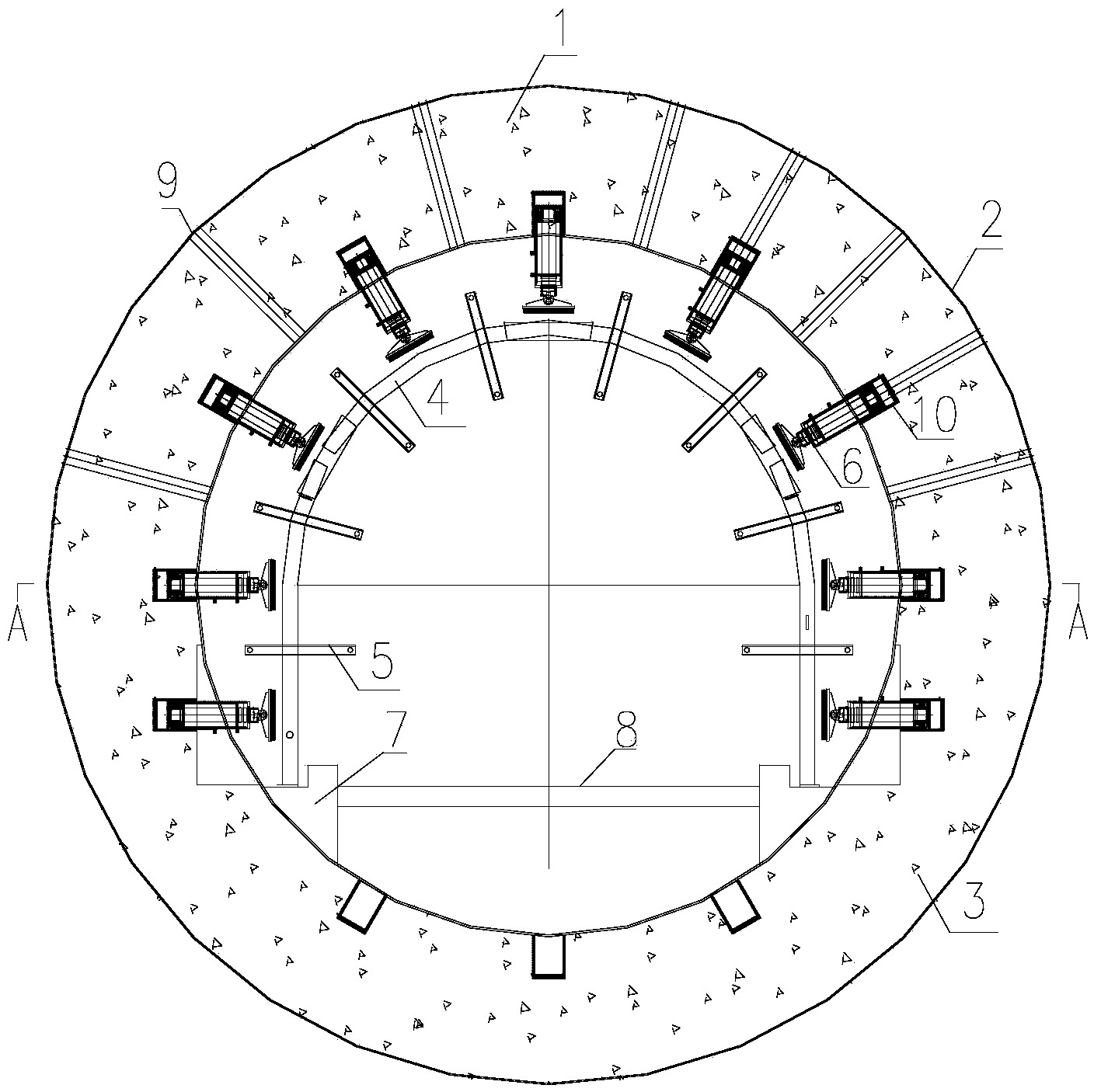

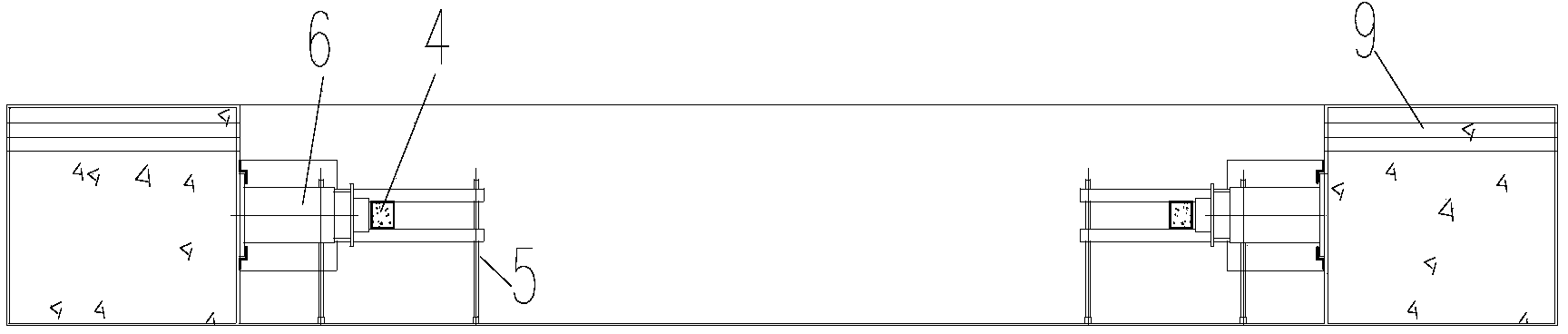

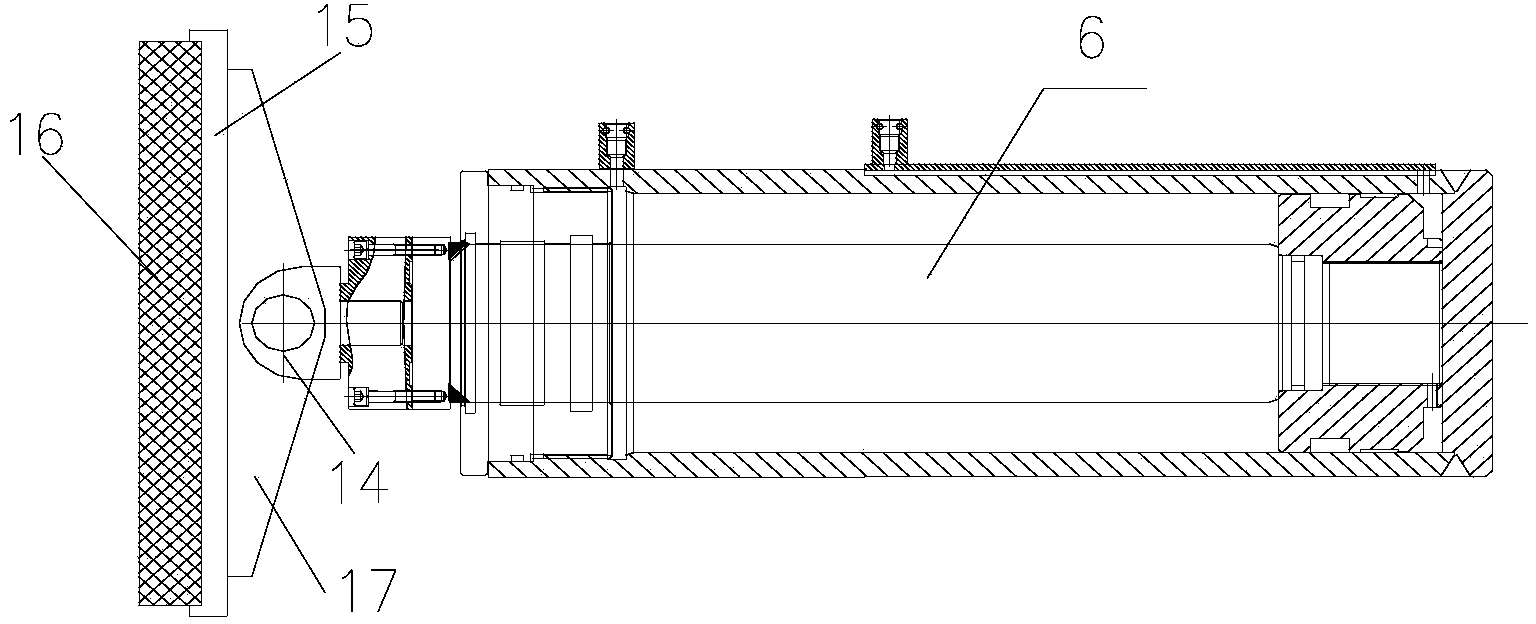

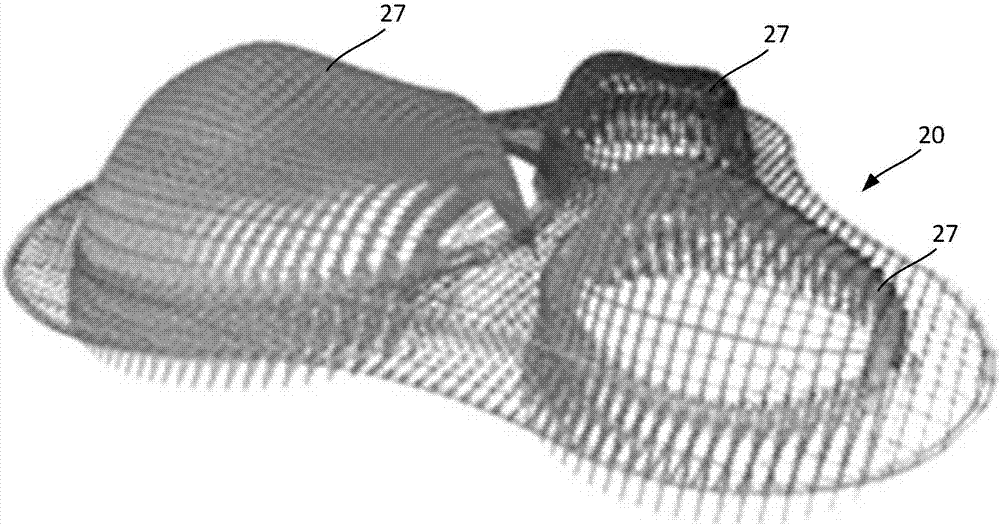

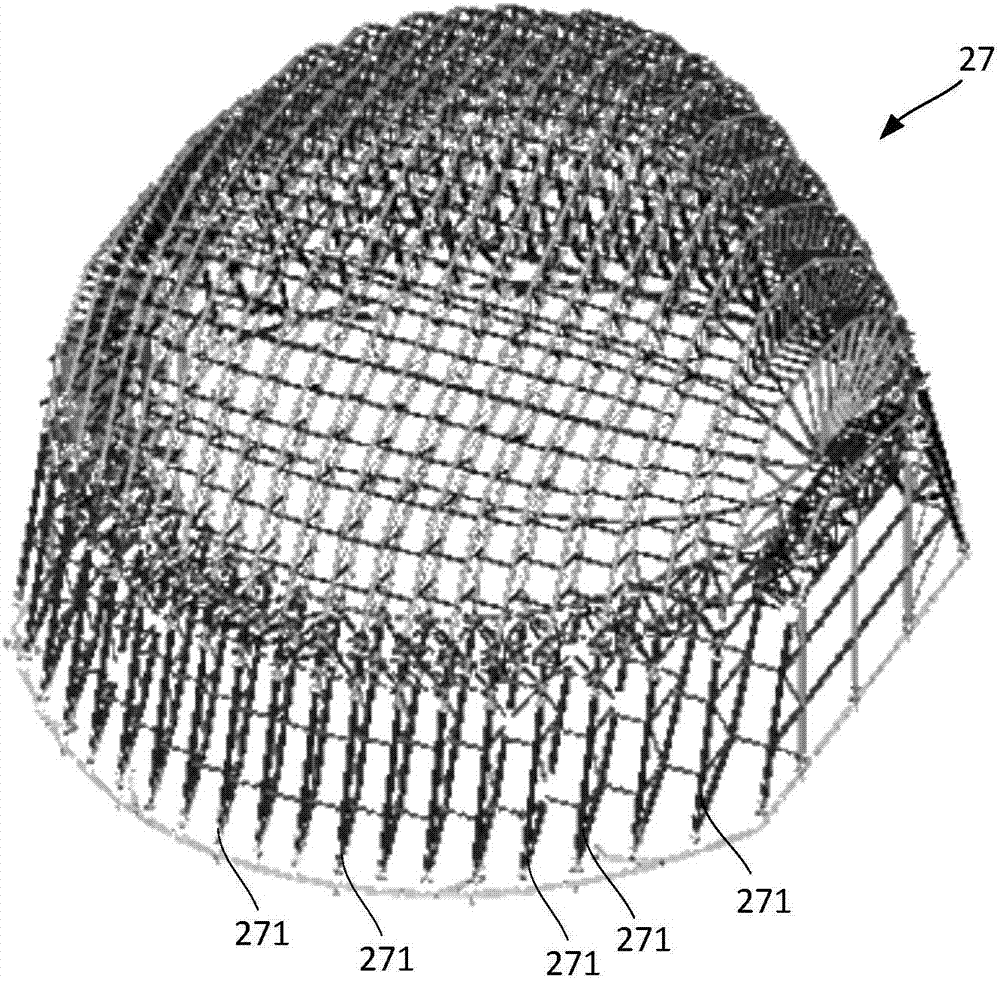

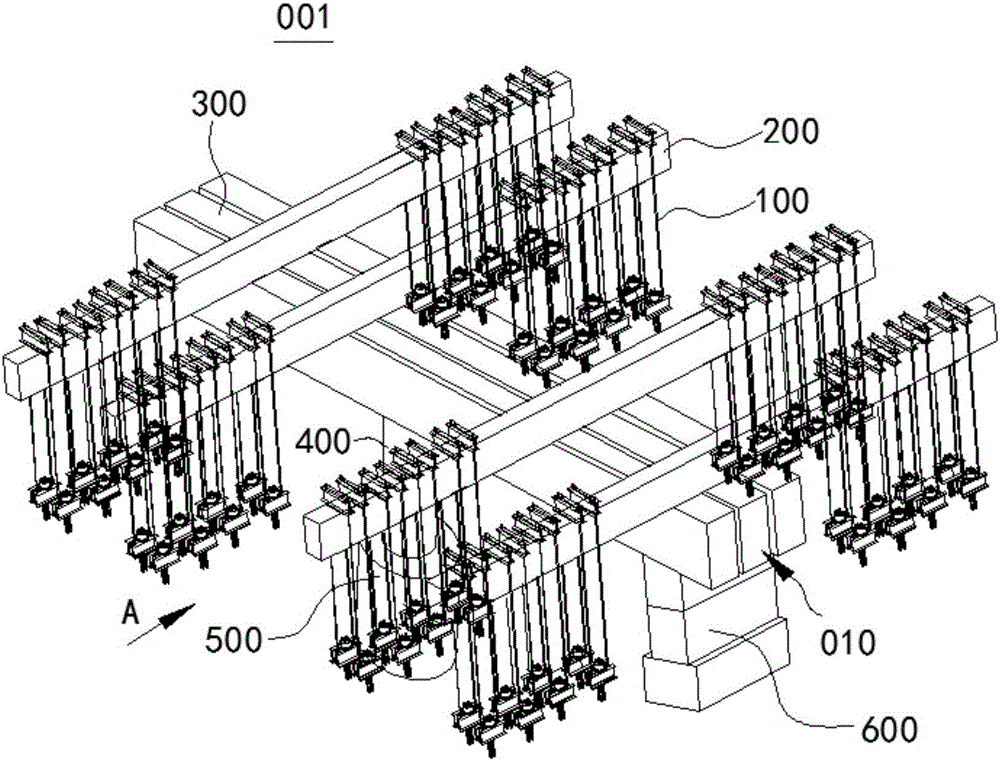

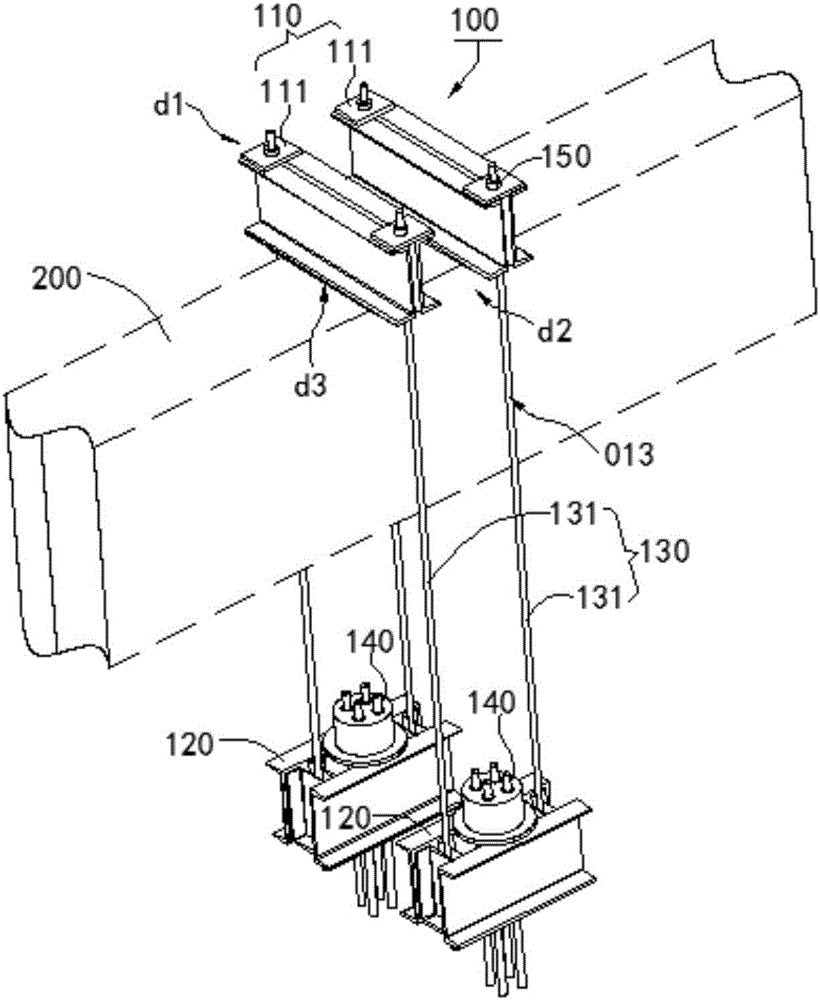

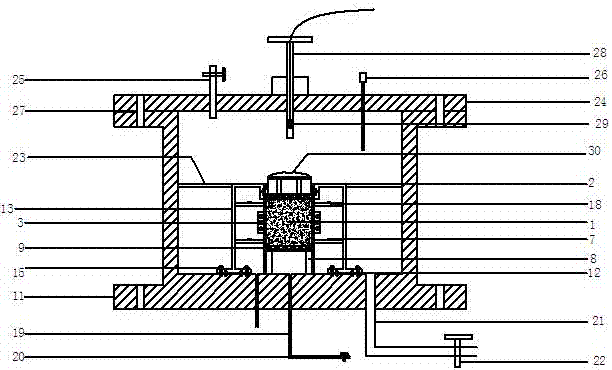

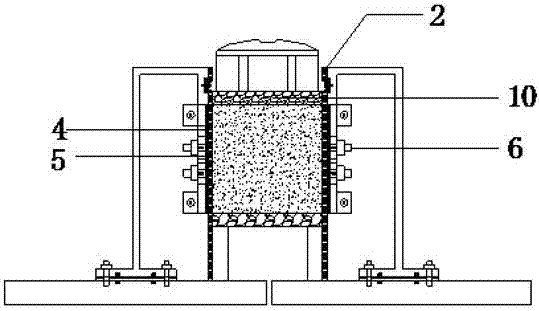

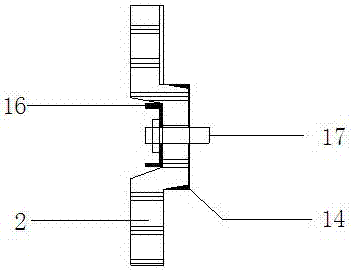

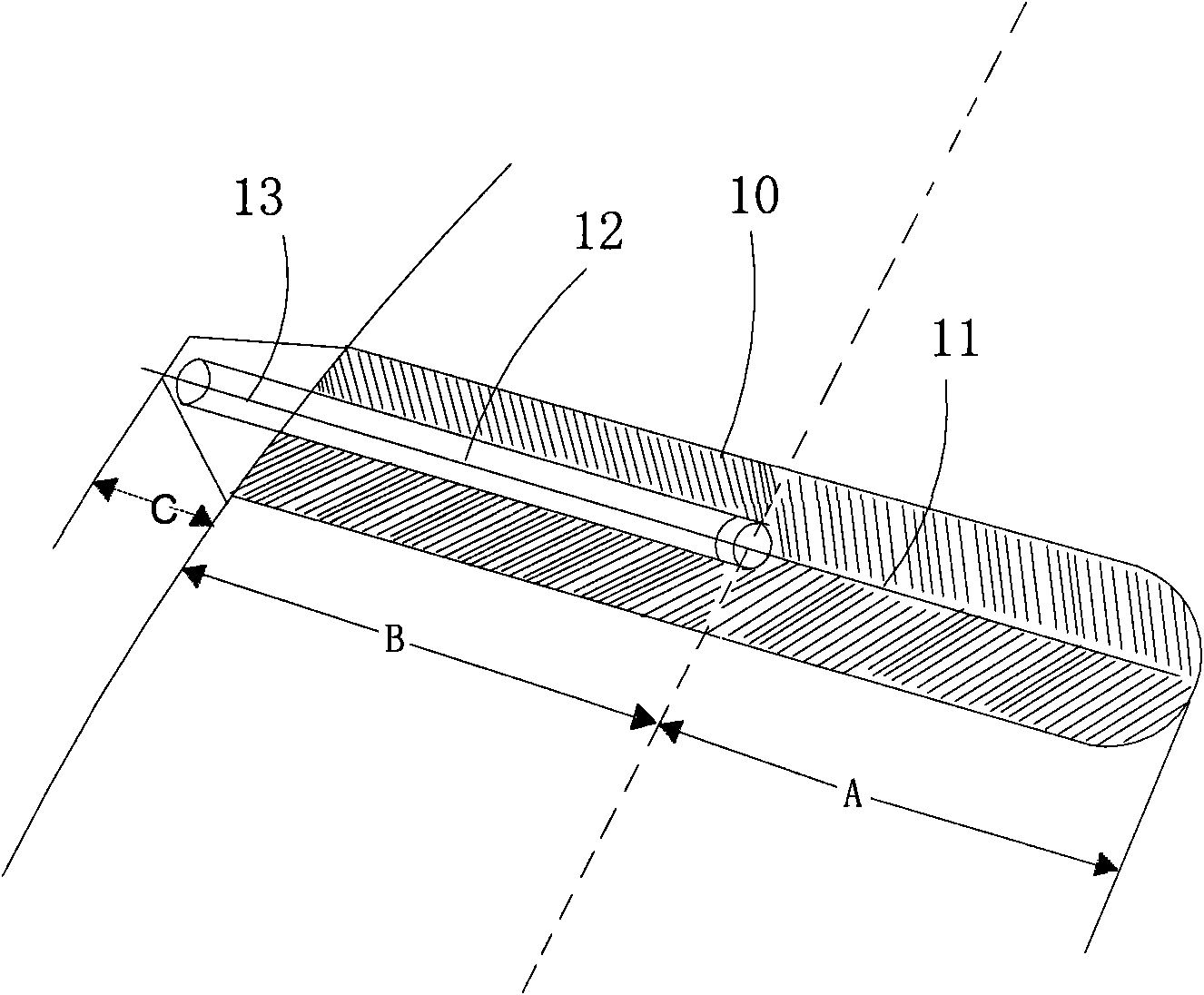

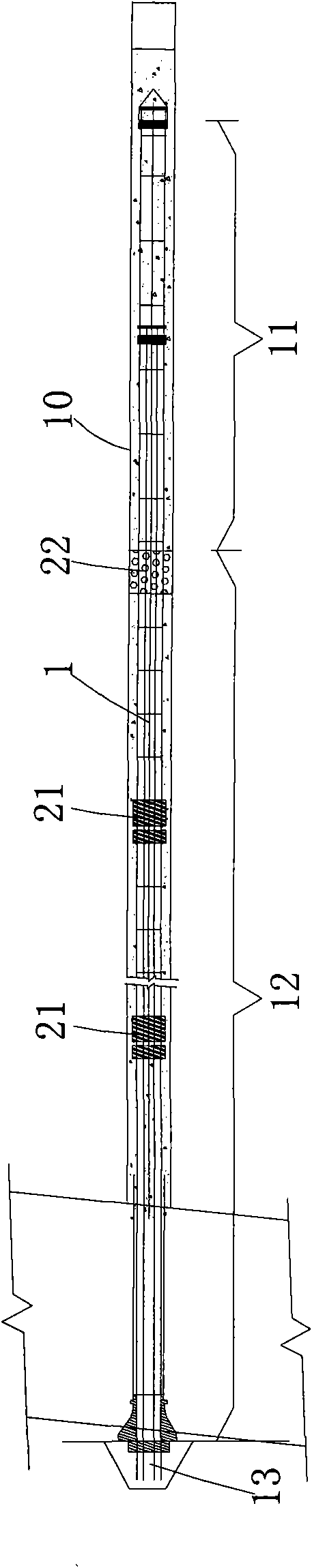

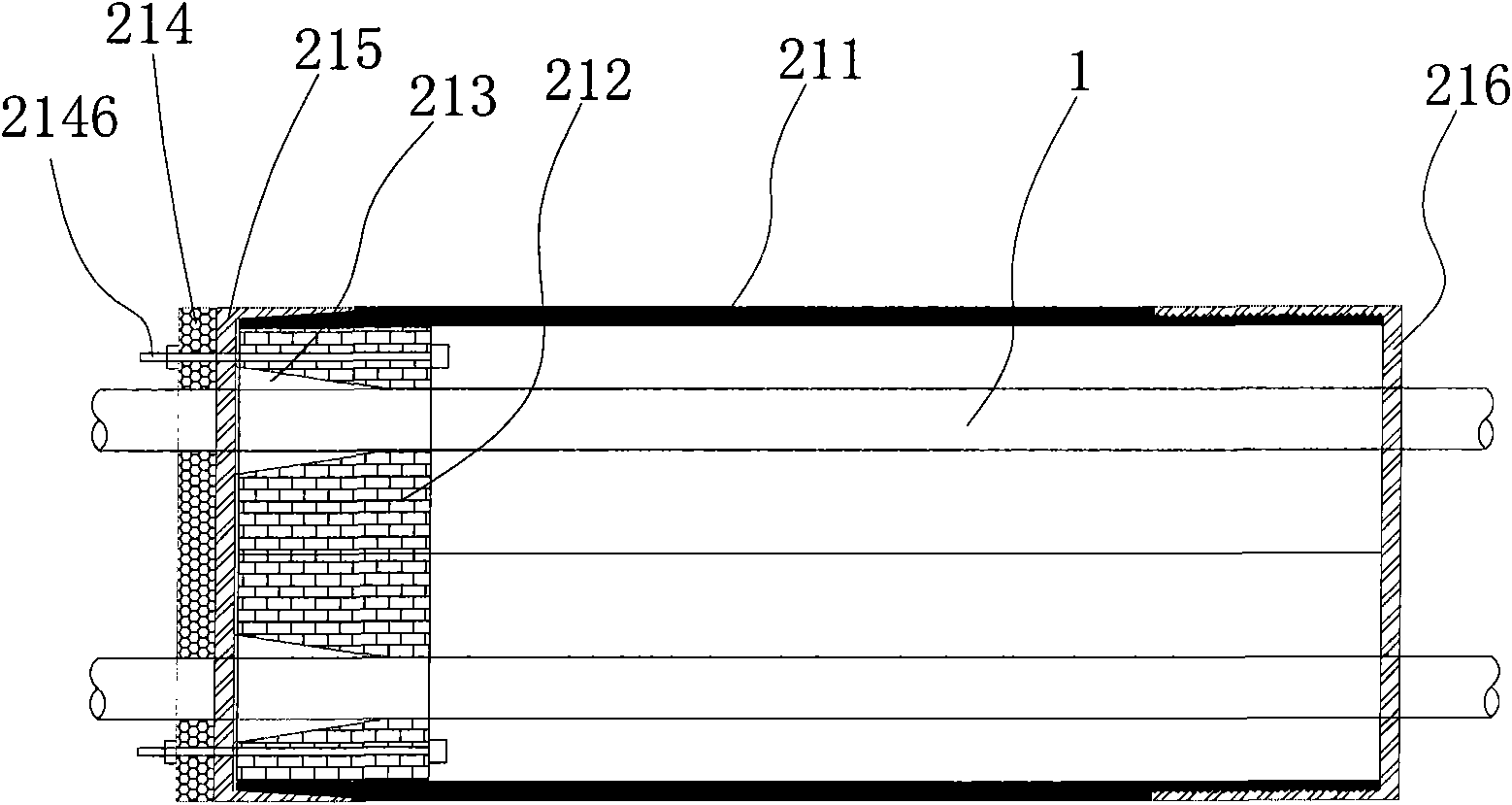

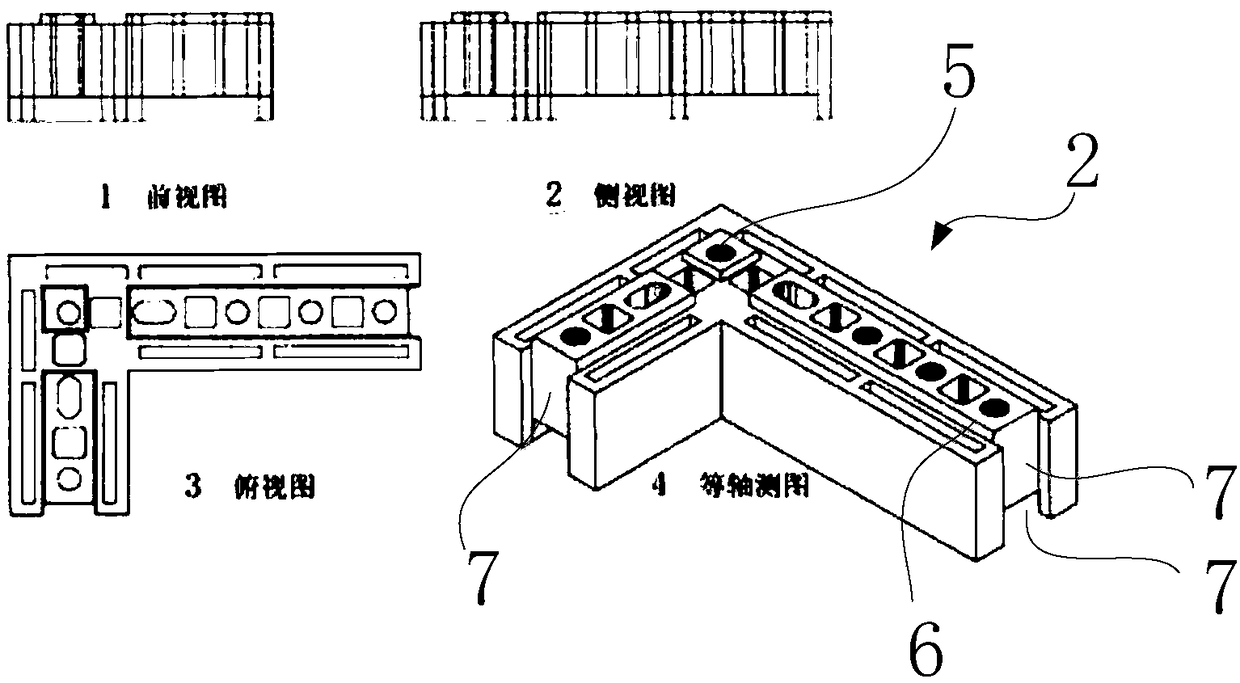

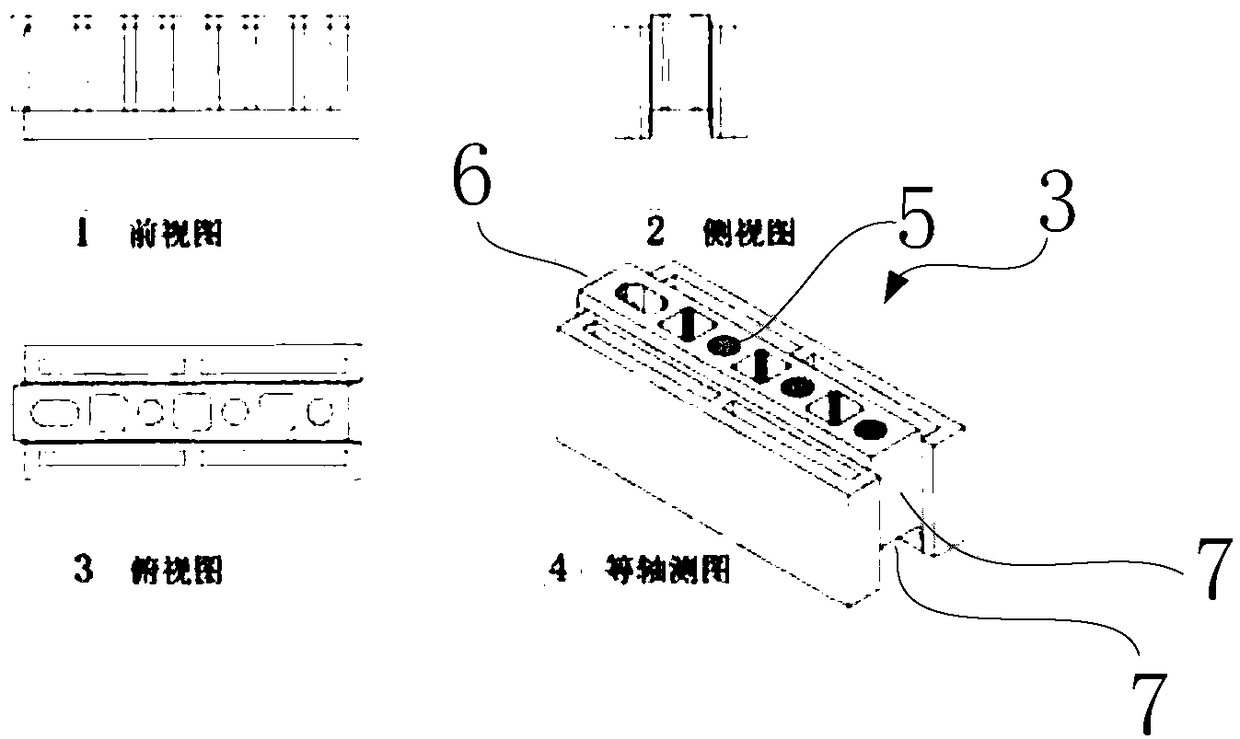

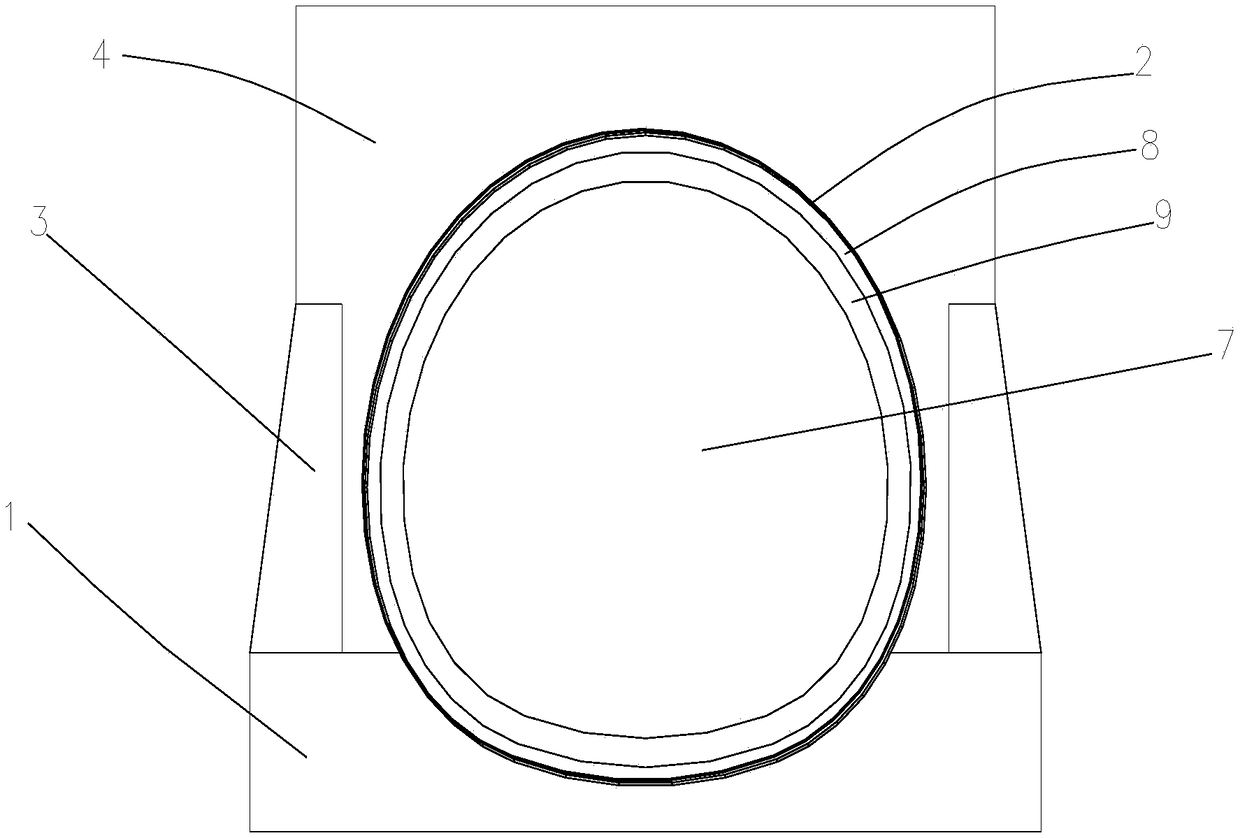

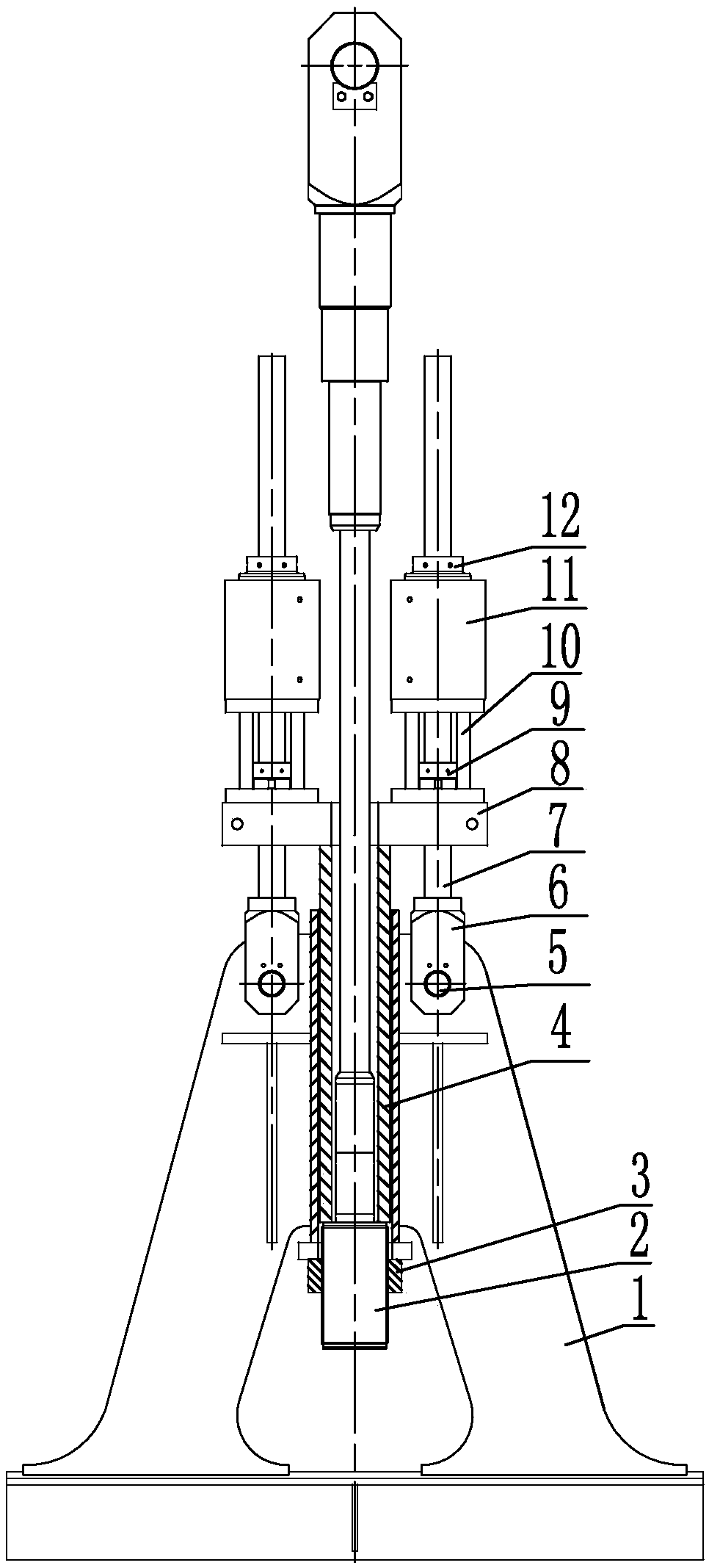

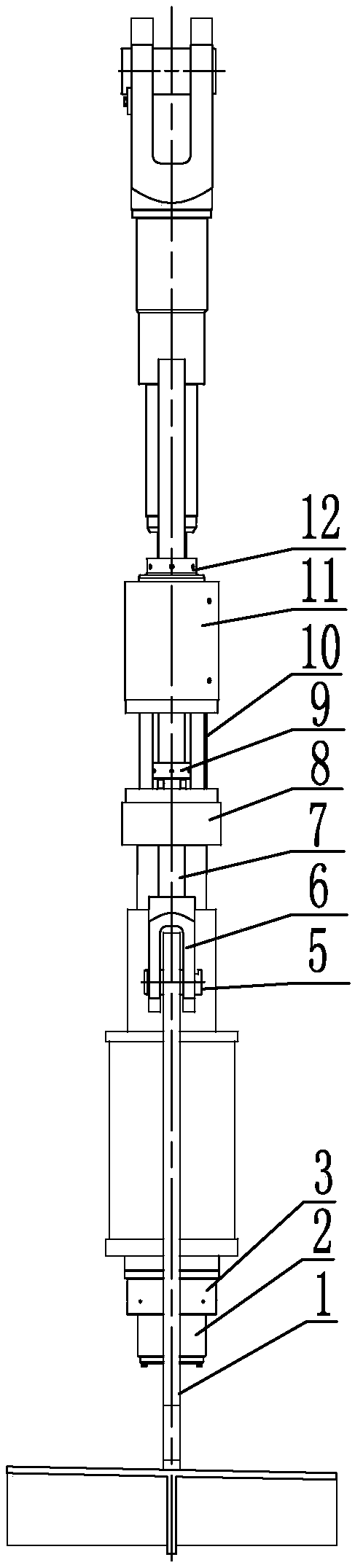

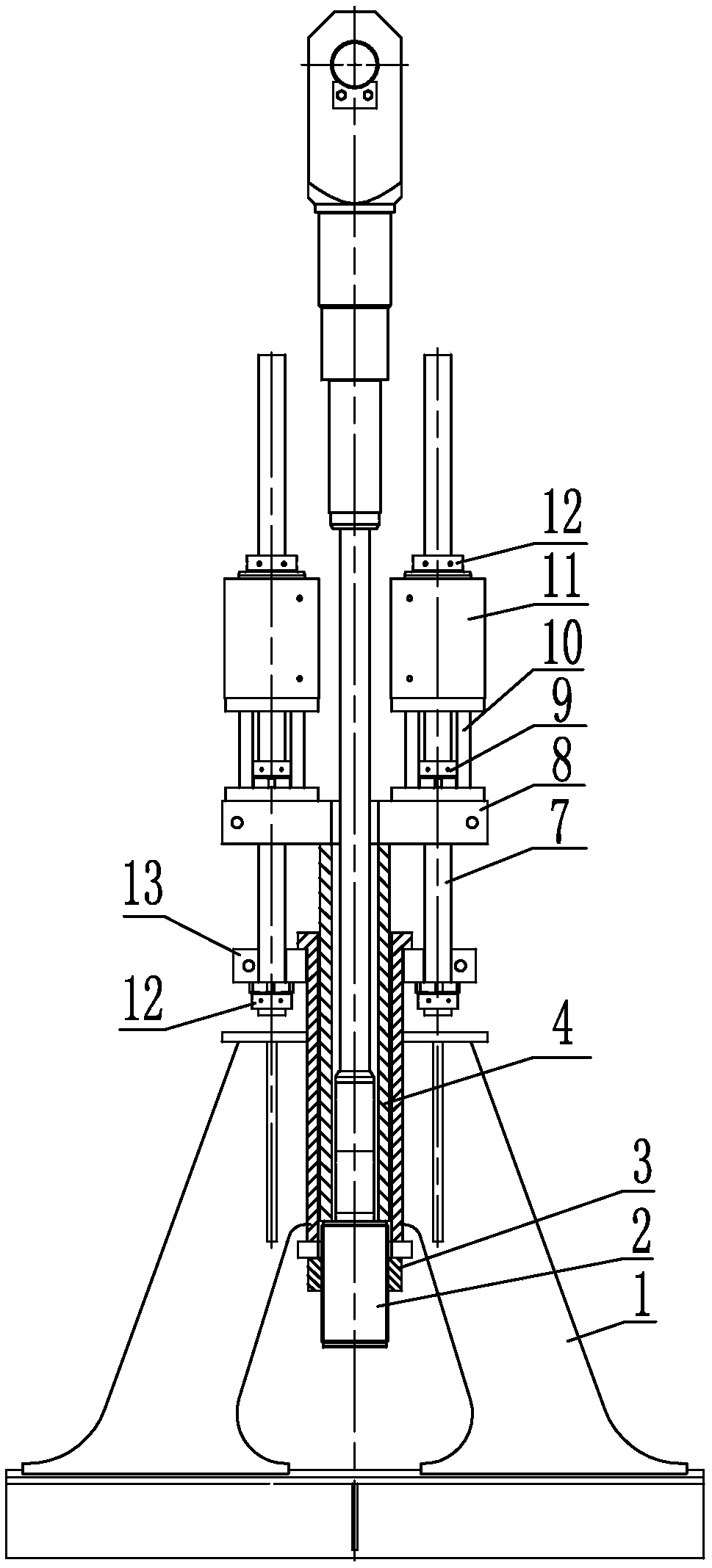

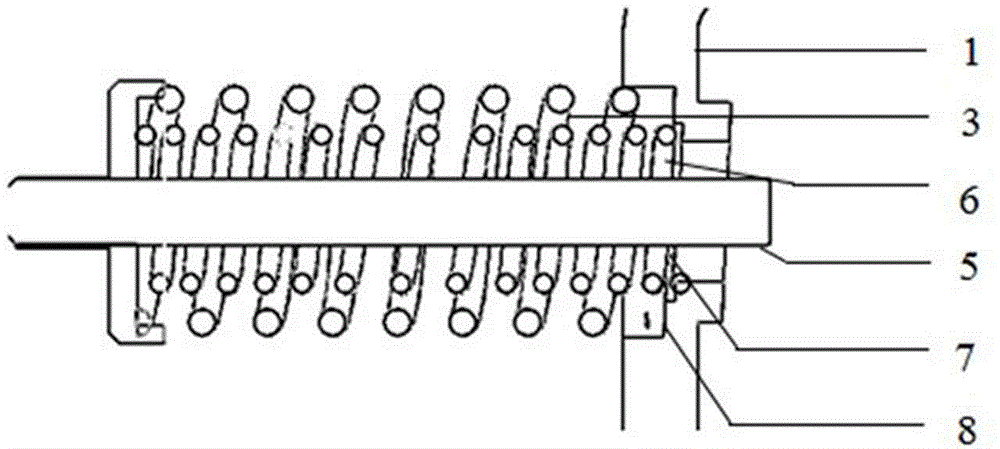

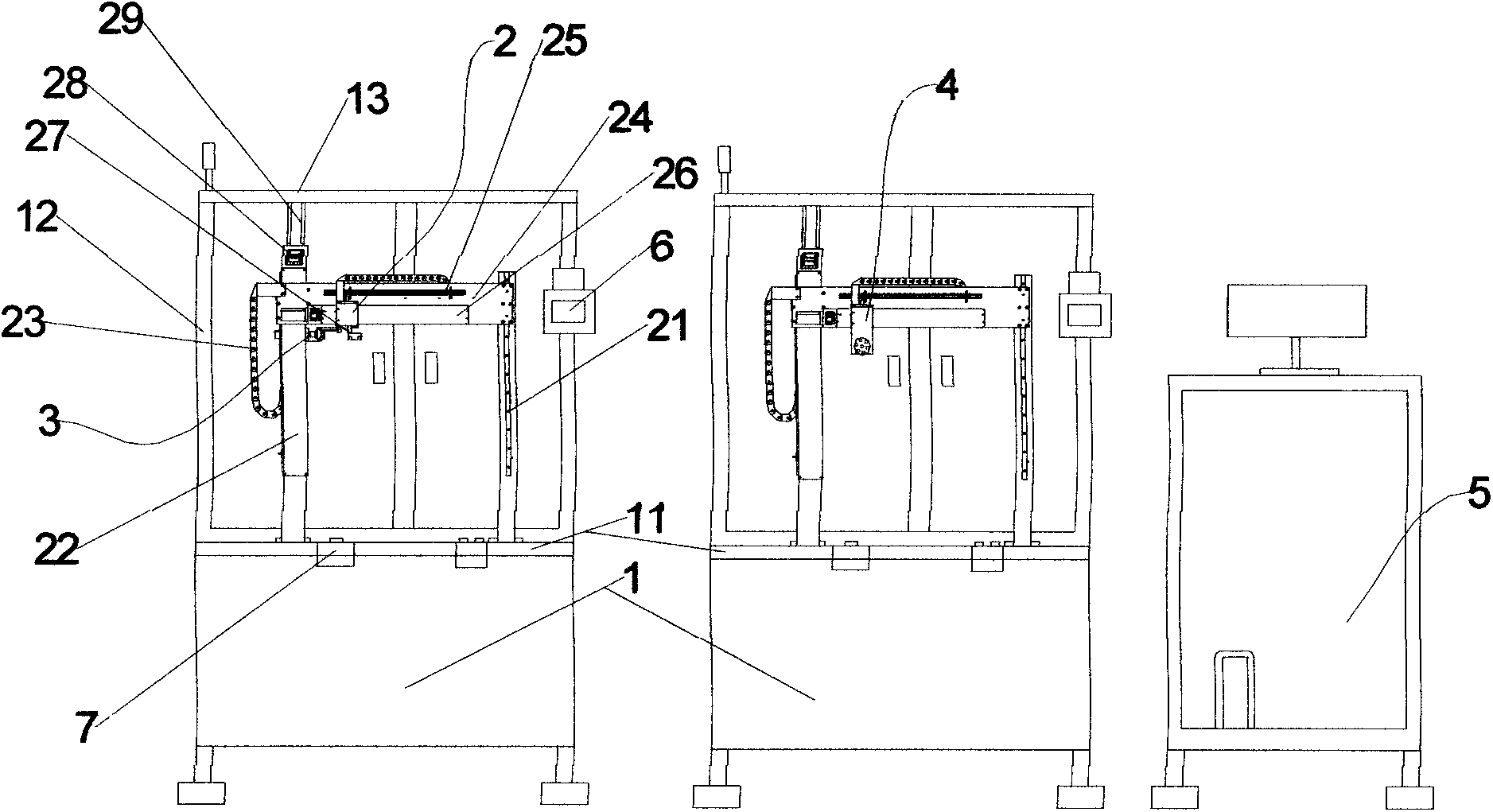

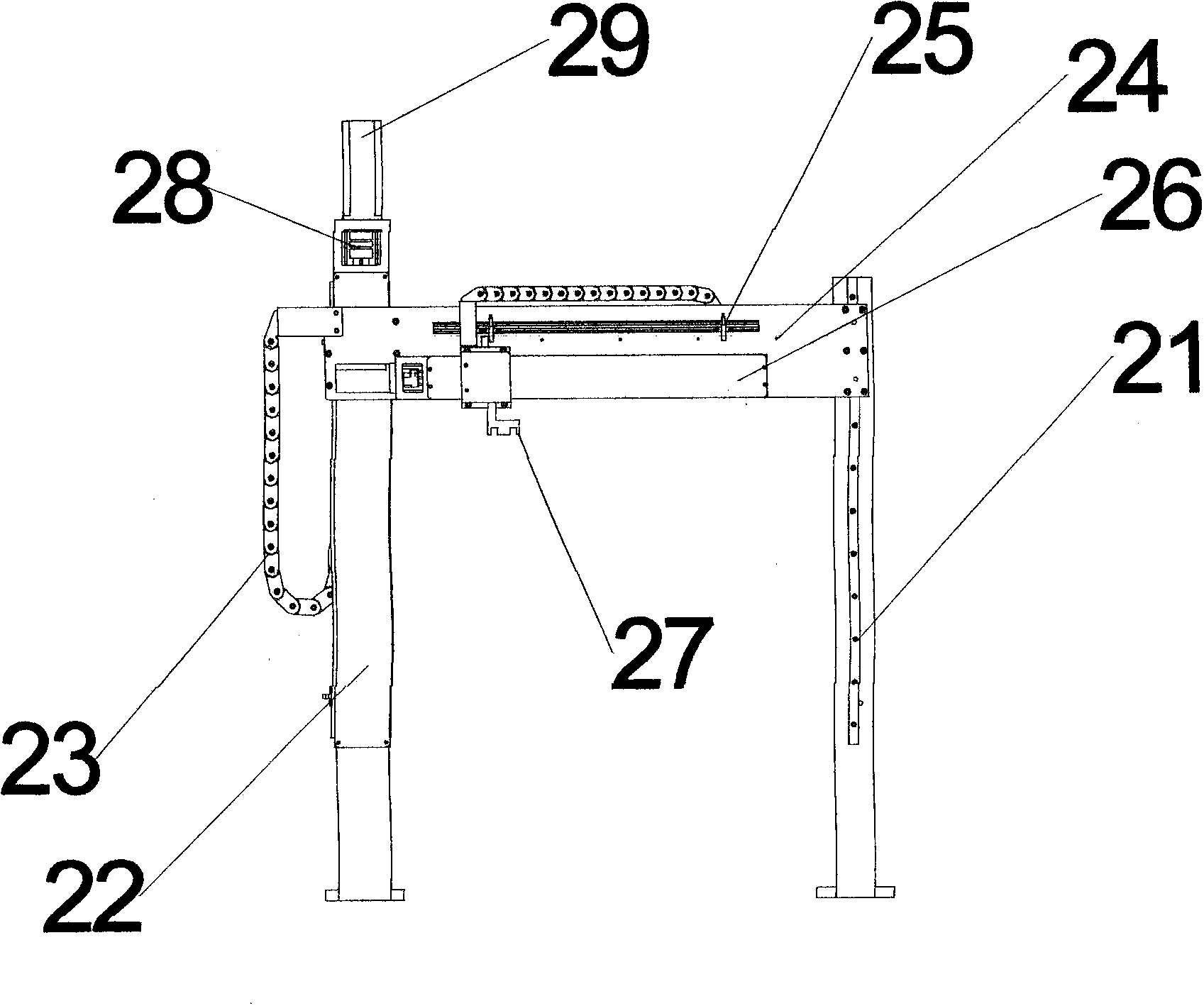

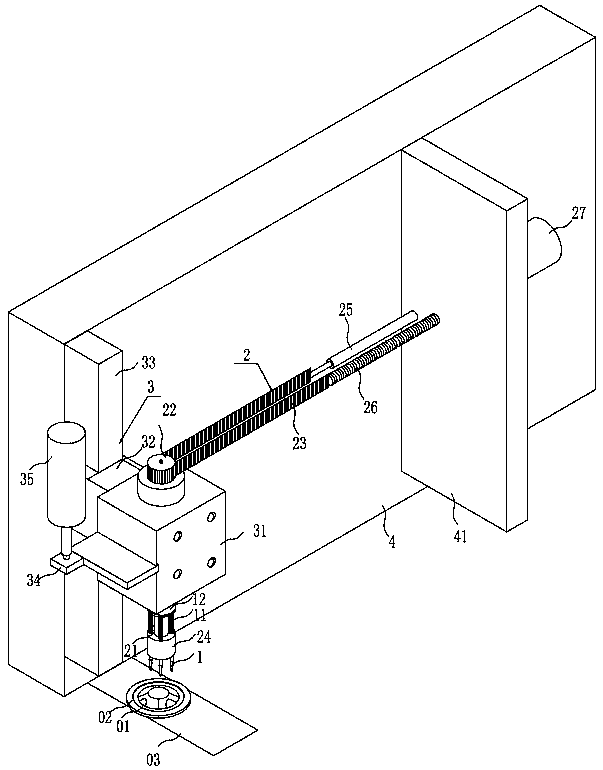

Large mechanical test system for combined adjustable constraint concrete arch frame

ActiveCN103883333AEfficient detection of acoustic emission response behaviorRealize mechanical testUnderground chambersTunnel liningForce structureHydraulic cylinder

The invention relates to a large mechanical test system for a combined adjustable constraint concrete arch frame. The system comprises a monitoring system, a hollow cylindrical counter force structure, a hydraulic loading device and an auxiliary loading device, wherein the monitoring system is used for monitoring and collecting arch frame parameters and data. The inner cylindrical surface of the counter force structure is provided with multiple oil cylinder positioning holes, the hydraulic loading device is disposed in the oil cylinder positioning holes, the hydraulic loading device comprises a hydraulic oil cylinder arranged in the oil cylinder positioning holes, a force transmission dispersion device connected with the hydraulic oil cylinder and a control system, and the hydraulic oil cylinder achieves loading through contact of the force transmission dispersion device and an arch frame to be tested. By means of the system, a 1:1 mechanical test can be carried out on the constraint concrete arch frame and other conventional arch frames, and tests of arch frames of different sizes and shapes can be achieved.

Owner:SHANDONG UNIV +1

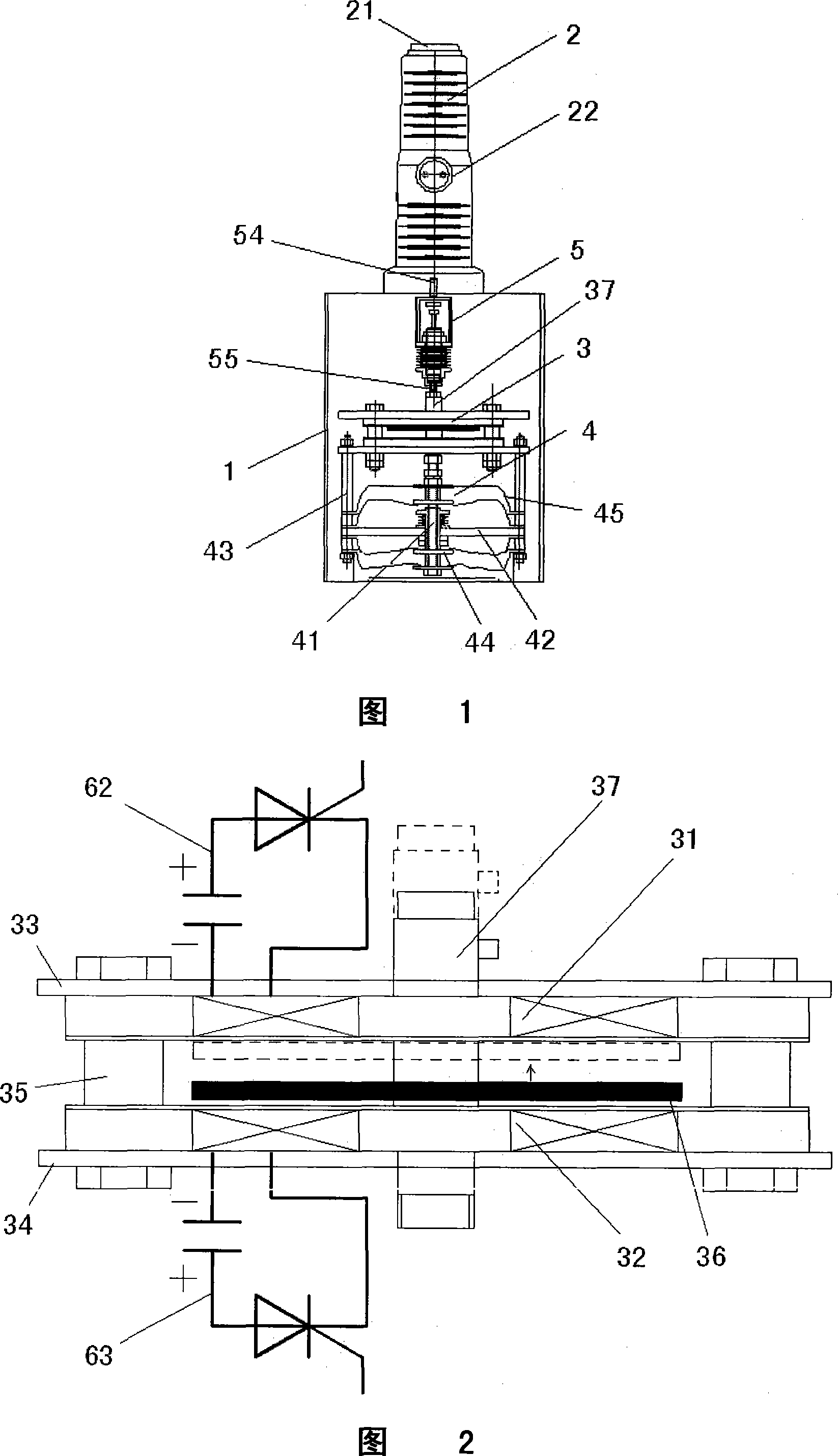

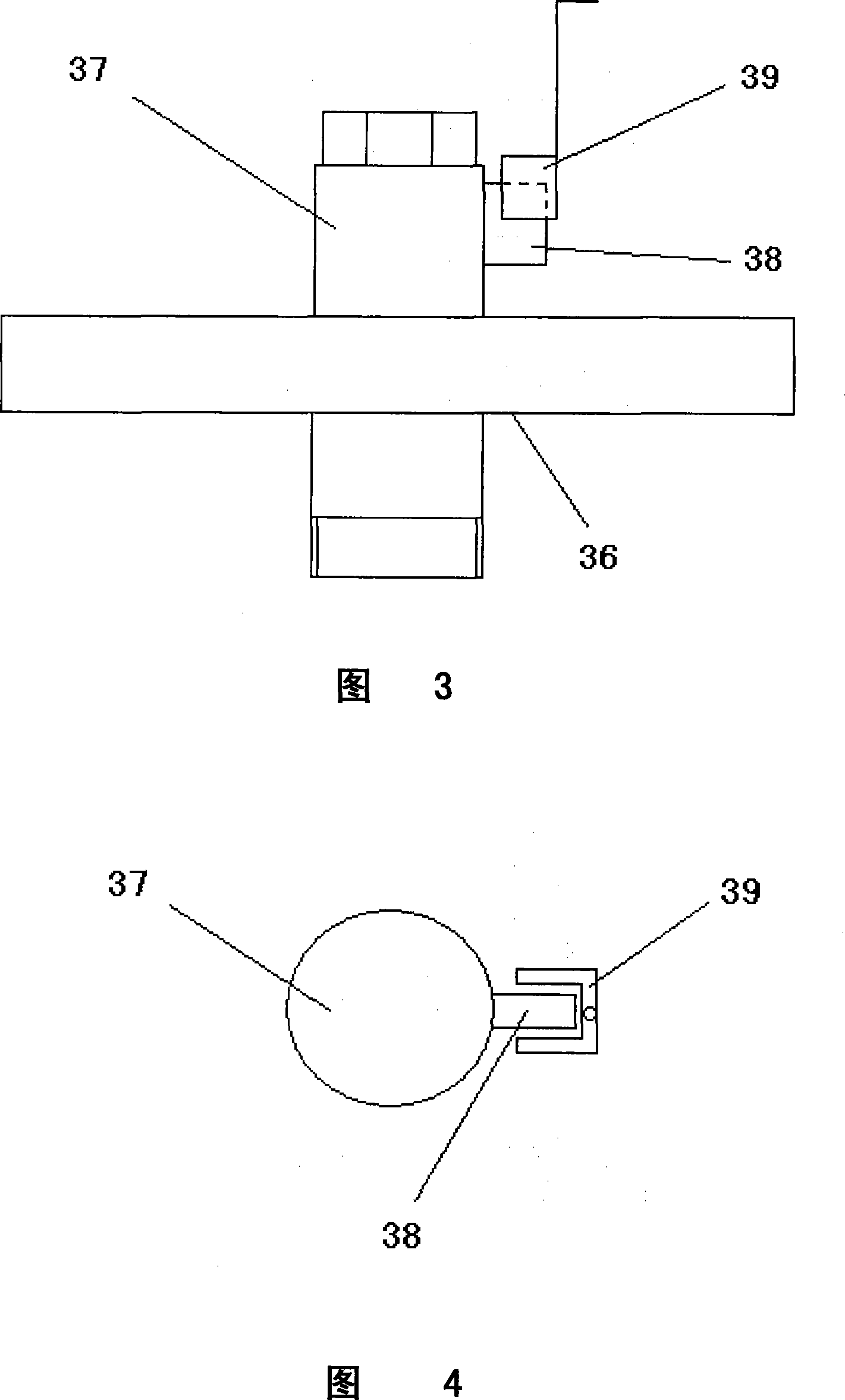

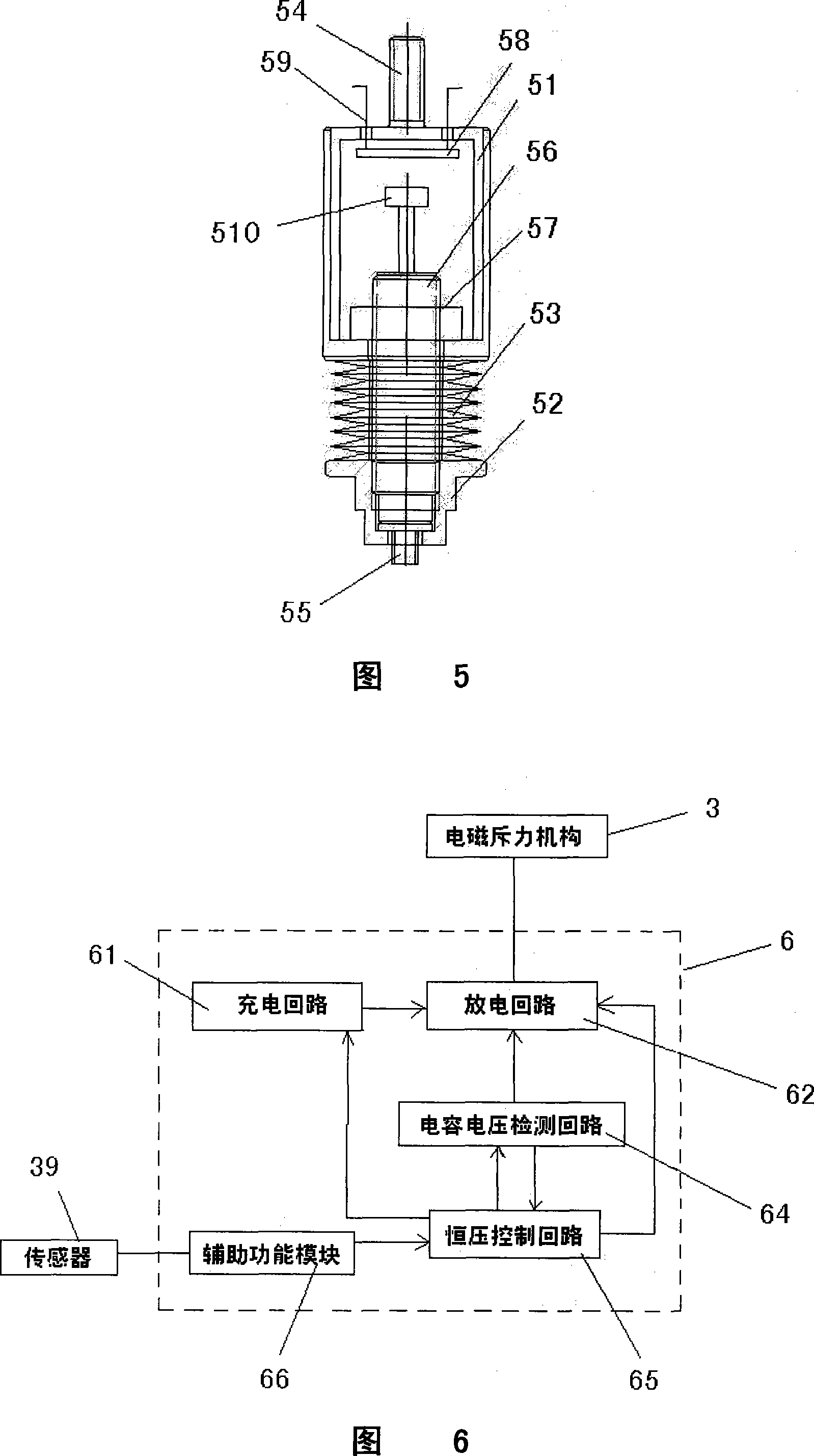

AC high voltage vacuum breaker

ActiveCN101226847AUndisturbedMove quicklyHigh-tension/heavy-dress switchesAir-break switchesForce structureFault current limiter

The invention relates to an alternating current high-voltage vacuum circuit breaker, which is characterized in that the invention comprises a case body, a vacuum arc extinguish chamber is seated and connected to the case body, an electromagnetic repulsive force mechanism is disposed in the case body, the mechanism comprises an open coil and a close coil which form a fixed gap, a repulsion disk arranged in the gap, a repulsion rod which is fixedly penetrated by the equipped repulsion disk, a retention capacity rod of a composite disc spring retention force structure connected with the lower end of the repulsion rod, a catch spring fixed on the retention force rod and at least two pieces of disc springs top-arranged on the catch spring. The upper end of the electromagnetic repulsive force is connected with a closing buffer gear which comprises a spring frame structure and a hydraulic cylinder, further, the closing buffer gear comprises an intelligent pulse generator. Because the invention employs the electromagnetic repulsive force mechanism, employs bi-stable composite disc springs to retain, employs the closing hydraulic pressure buffer gear to inhibit closing bouncing, and employs a photoelectric sensor to realize position returning, thereby belonging to the advanced design at home and abroad, therefore, the invention can be widely applied to the field of fault current limiters, phase selection switches, solid change-over switches and the like.

Owner:CHINA ELECTRIC POWER RES INST +1

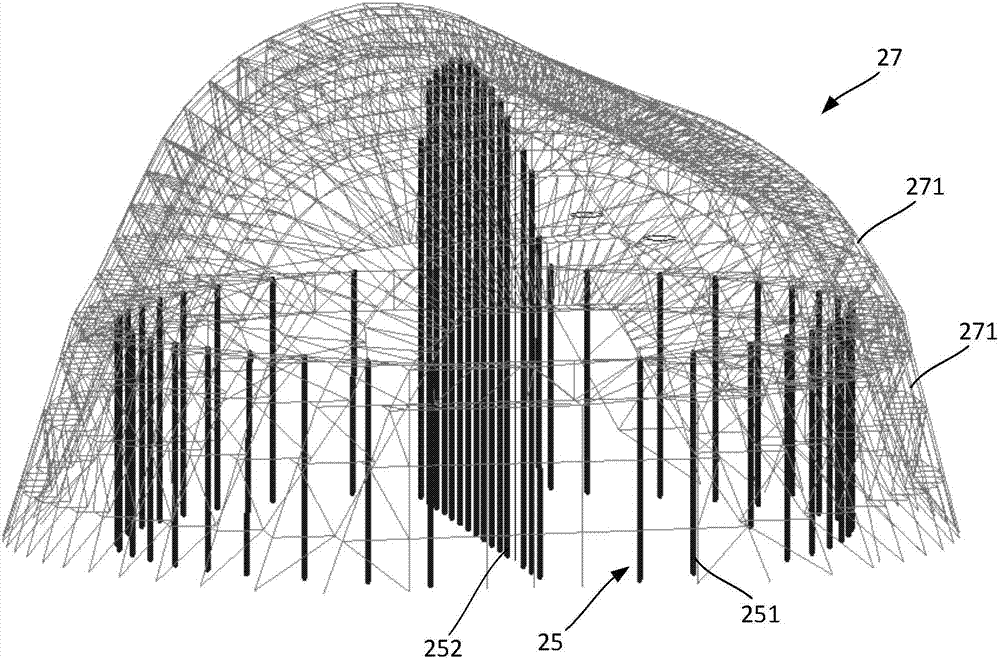

Construction method of large-span thin wall planar arch truss based on stiffened ring beam

ActiveCN107090932AAvoid uniformityAvoid concentrated stressBuilding roofsGirdersForce structureStress concentration

The invention relates to a construction method of a large-span thin wall planar arch truss based on a stiffened ring beam. The construction method comprises the steps: constructing an annularly closed ring beam foundation at the top of a main body structure; mounting a support seat on the ring beam foundation; arranging a support system at the top of the main body structure; arranging a single arch truss with an irregularly shape in the local area subsidence; forming multi-section truss units by segmenting the single arch truss; mounting the truss units two-symmetrically from bottom to top; connecting the adjacent two single arch trusses together through a connecting rod to form a roof cover structure; unloading the support system. By adopting the way of two- two symmetrically installation, the load of the installed truss unit on the support system is balanced; the truss unit is connected into a whole by the connecting rod to form a stable whole force structure, thus the problems of the unevenness of the force of the arch truss with the irregularly shape and concentrated stress are avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

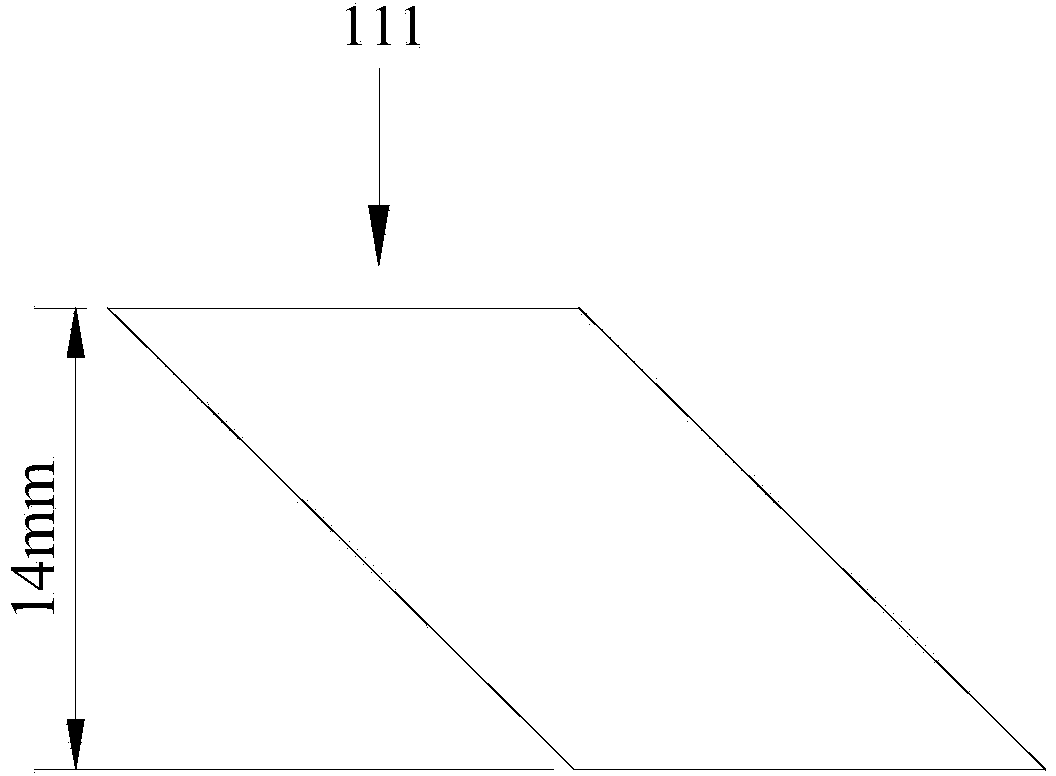

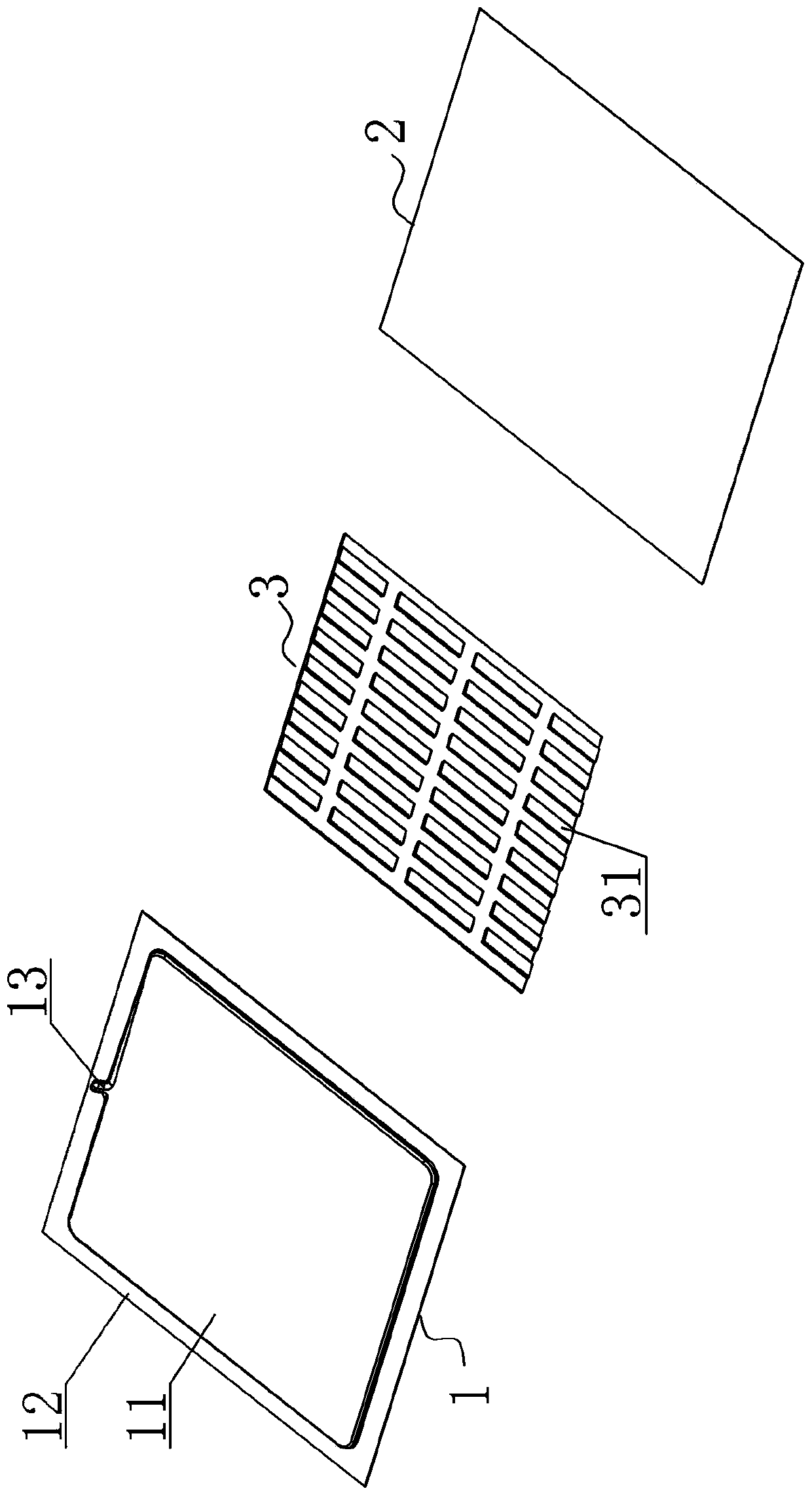

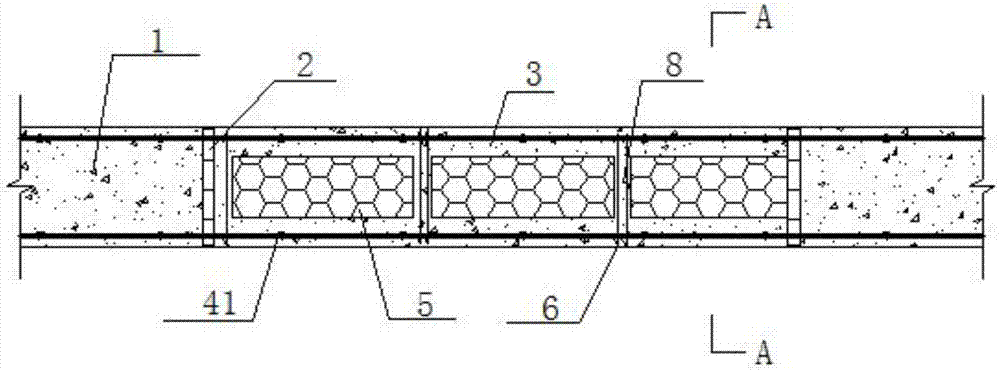

Structural slab and slab core and machining method of slab core

ActiveCN104070567ADecompose the external forceDecompose external forceWood veneer joiningForce structureTransverse pressure

The invention discloses a slab core of a structural slab. The slab core is provided with multiple structure units, the structure units are sequentially stacked and attached in an adhesive mode in the length direction of the structural slab, each structure unit comprises a substrates and a shearing force body inclined relative to the substrate, the substrates are stacked in the length direction of the structural slab to form a frame shearing force structure, each substrate is provided with a continuous transverse pressure-bearing body and a vertical pressure-bearing body extending in the thickness direction of the structural slab, each shearing force body at least comprises two layers of shearing force layers and a plurality of shearing force piece strips arranged at intervals, and one shearing force piece strip and the shearing force piece strips corresponding to the adjacent shearing force layers in position are crossed and stacked. By means of the arrangement, the frame shearing force structure can be formed, the strength of the structural slab is effectively improved, the bearing capacity of the structural slab is improved, consumption of wood resources is reduced, energy is saved and environment protection is achieved. On the basis of the slab core, the invention further provides the structural slab with the slab core and a machining method of the slab core of the structural slab.

Owner:ZHENJIANG SUNSIER DENDRO TECH CO LTD

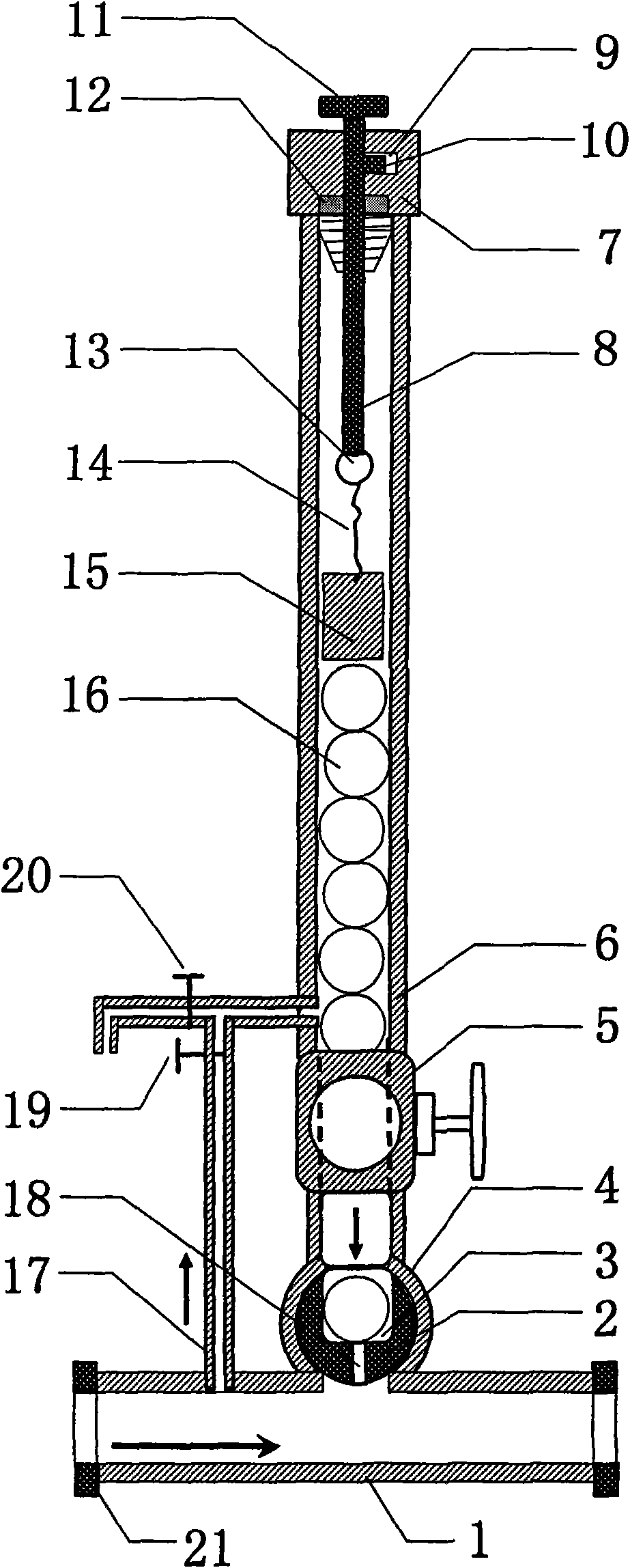

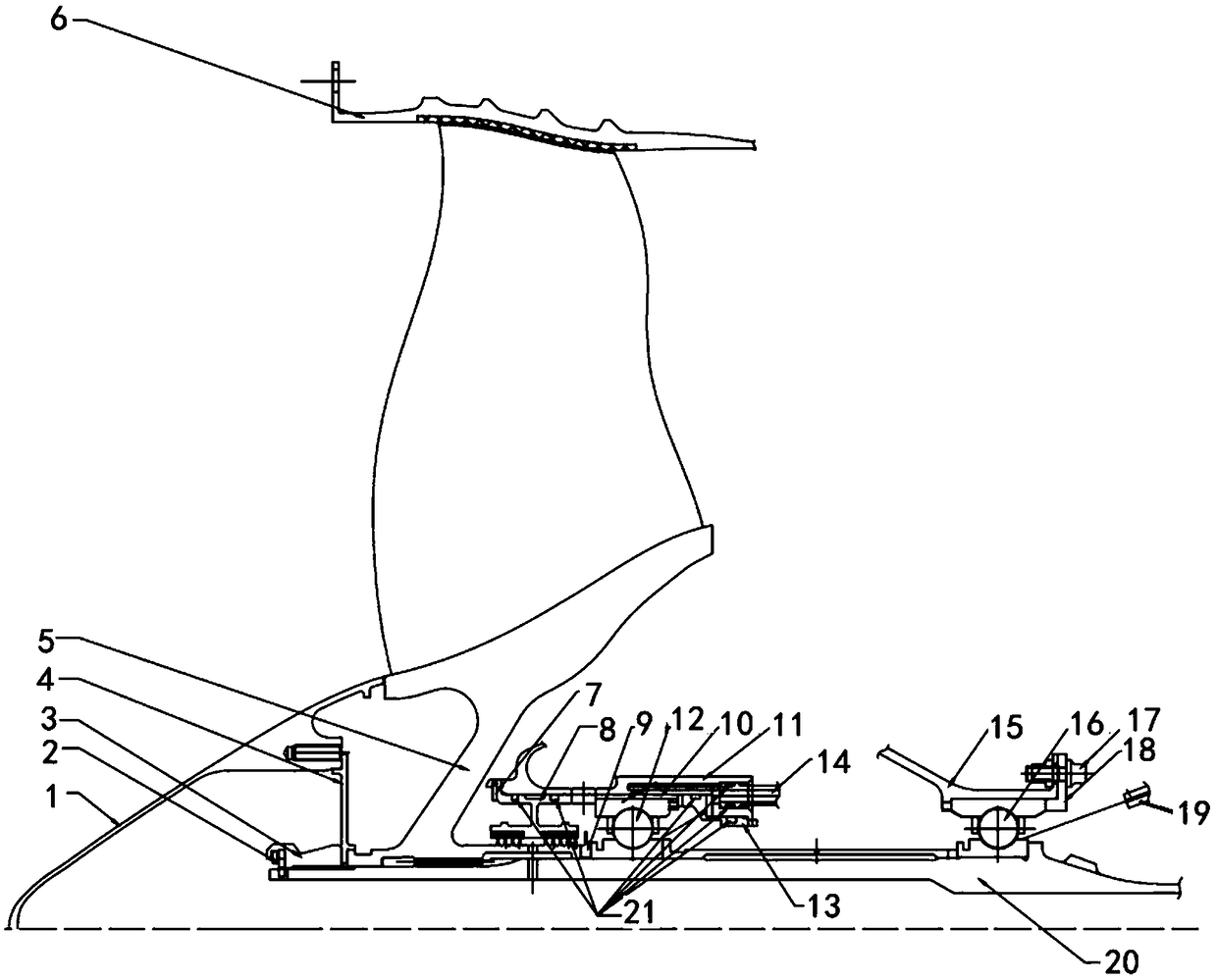

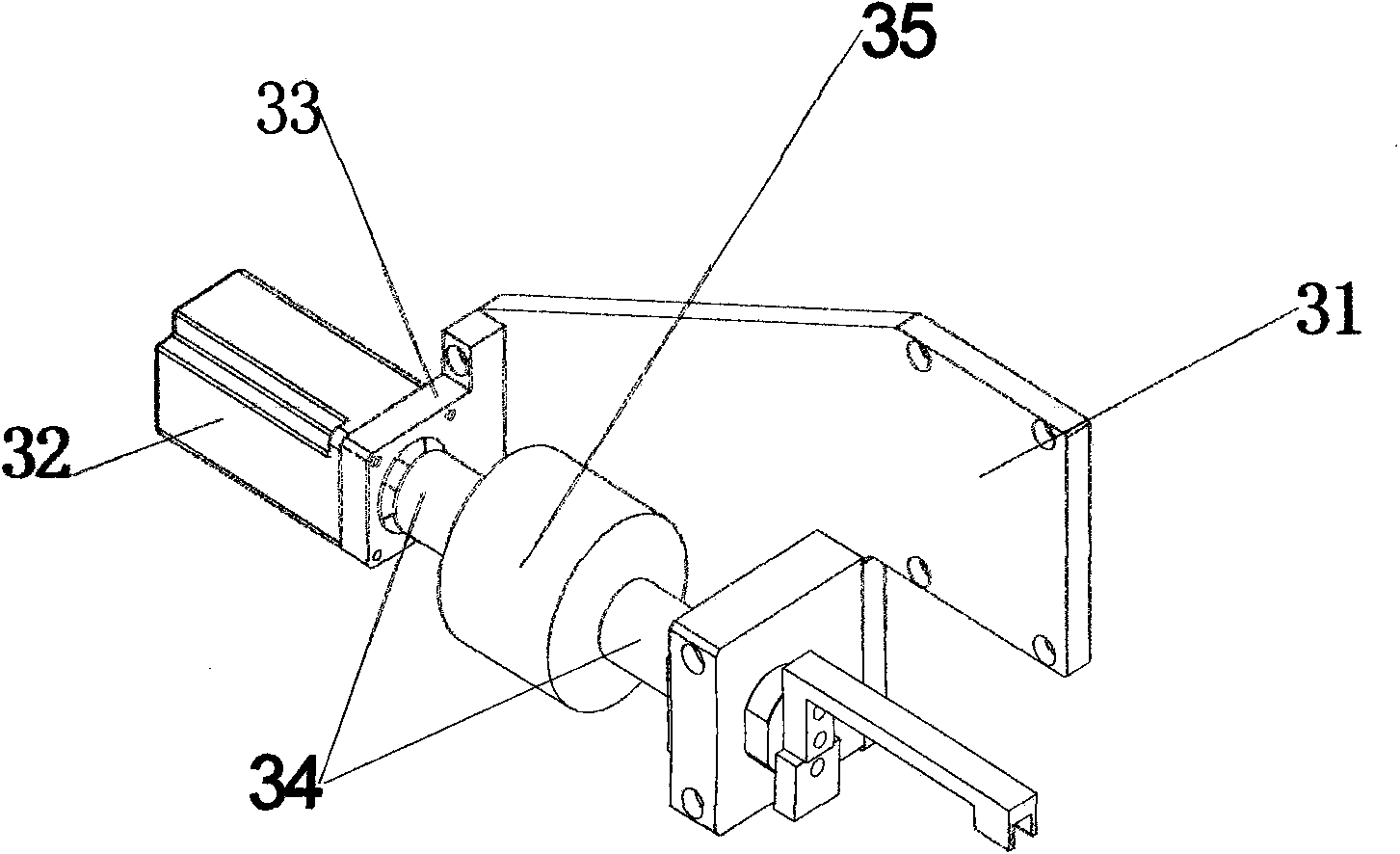

Ball taking and casting device, paraffin removal ball casting machine for oil transmission pipeline and ball casting method

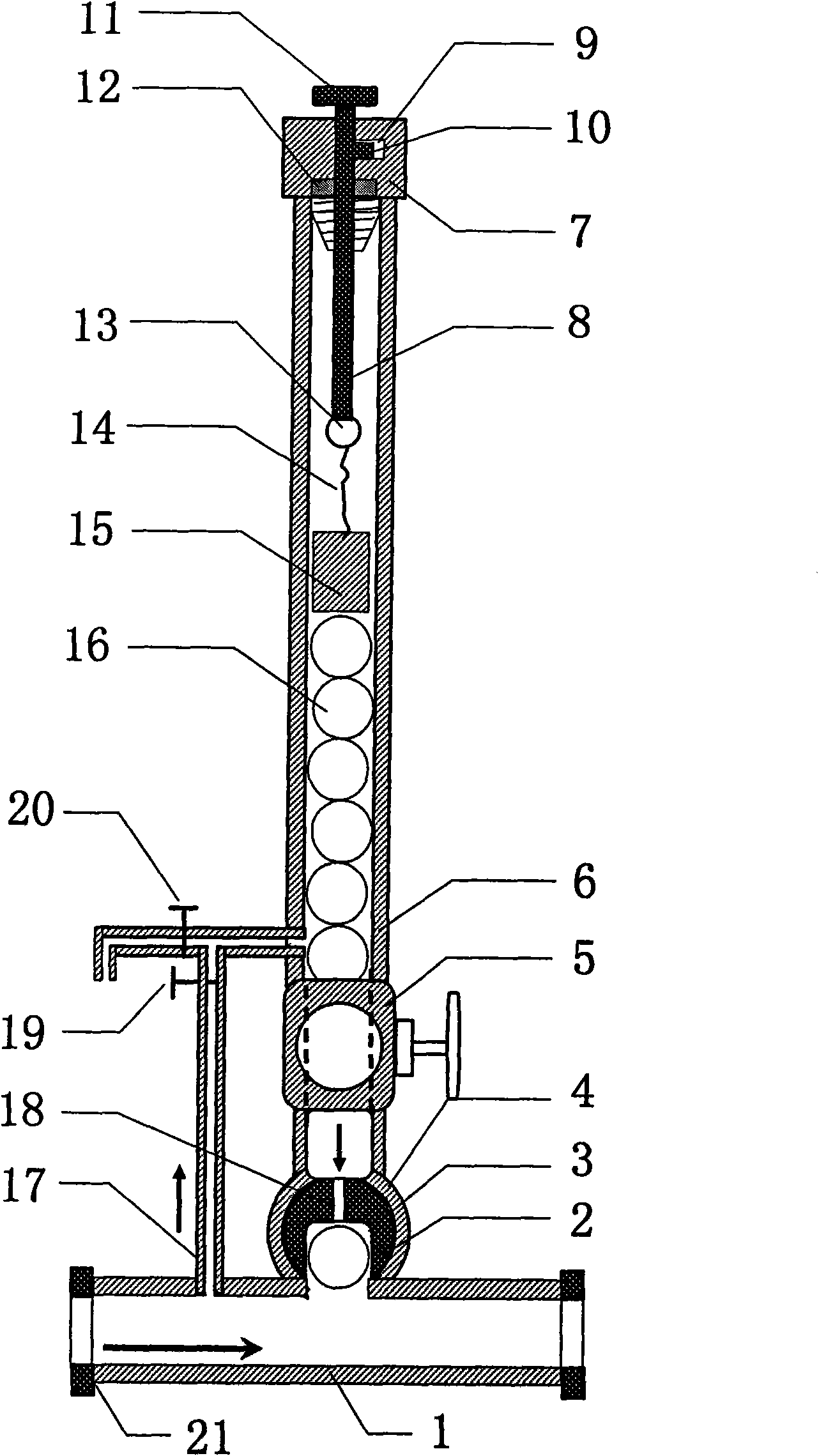

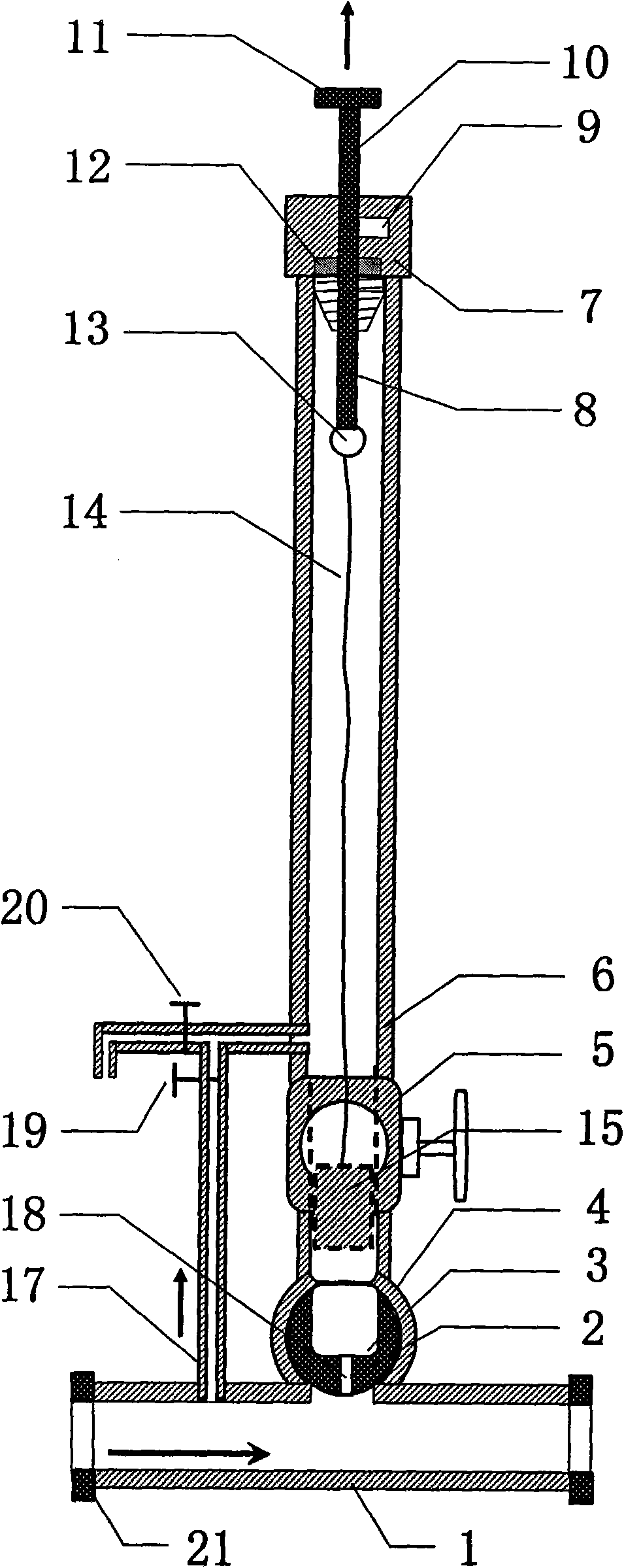

ActiveCN101648195ALame pressure will not occurPitching does not affectHollow article cleaningForce structureWax

The invention relates to a ball taking and casting device, a paraffin removal ball casting machine for an oil transmission pipeline and a ball casting method. The ball taking and casting device is communicated with the oil transmission pipeline and comprises a ball storage barrel, a ball taking and casting rotor shell and a ball taking and casting rotor which rotates in the ball taking and castingrotor shell, wherein the top end of the ball storage barrel is sealed and the bottom end is fixedly connected and communicated with the upper end of the ball taking and casting rotor shell; the ballstorage barrel has a pushing force structure for pushing a paraffin removal ball to the bottom end; the lower end of the ball taking and casting rotor shell is fixedly connected and communicated withthe oil transmission pipeline; the ball taking and casting rotor comprises a rotor main body, a ball taking and casting chamber, a pressure balance hole and a rotor rotating shaft; the ball taking andcasting chamber has a space for containing the paraffin removal ball, the diameter of a space opening is slightly larger than that of the paraffin removal ball, and the pressure balance hole penetrates through the rotor main body from the back of the ball taking and casting chamber and is communicated with the ball taking and casting chamber. The ball taking and casting device automatically caststhe ball with pressure without pressuring out or depending on other valves and bypasses and has the advantages of simple structure and easy operation.

Owner:北京众博达石油科技有限公司 +1

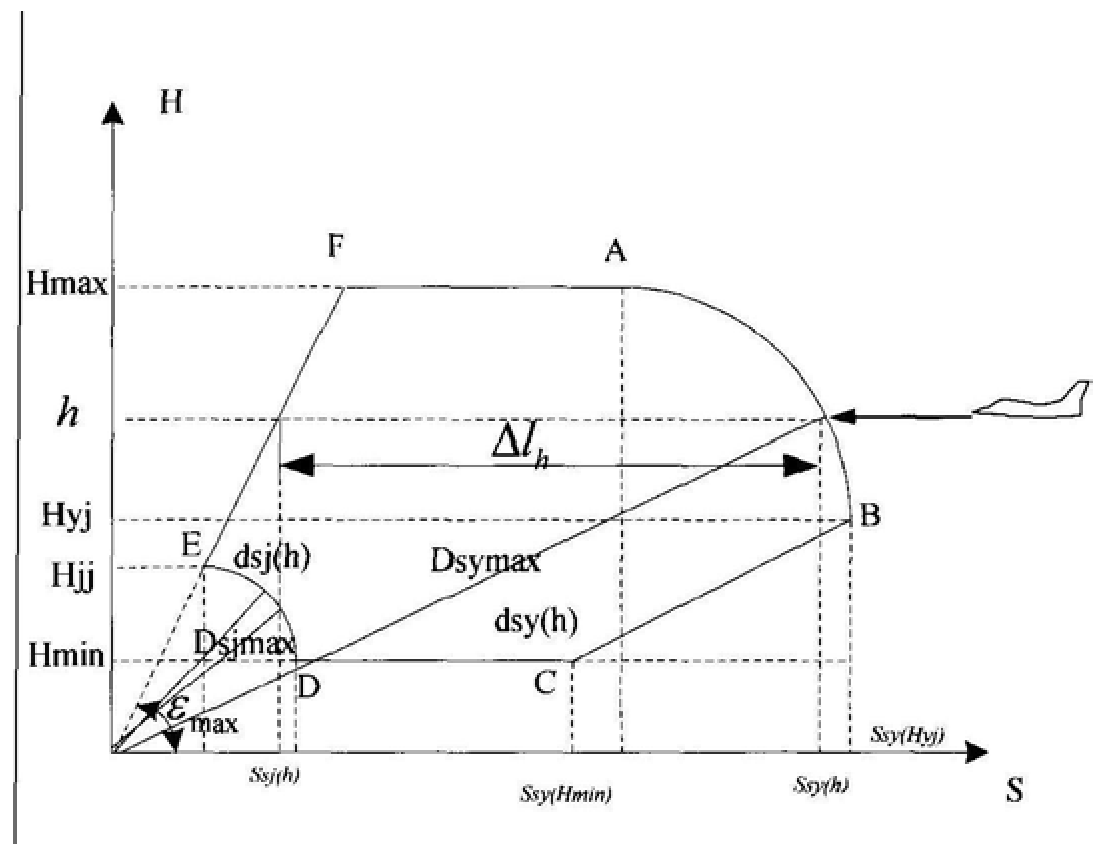

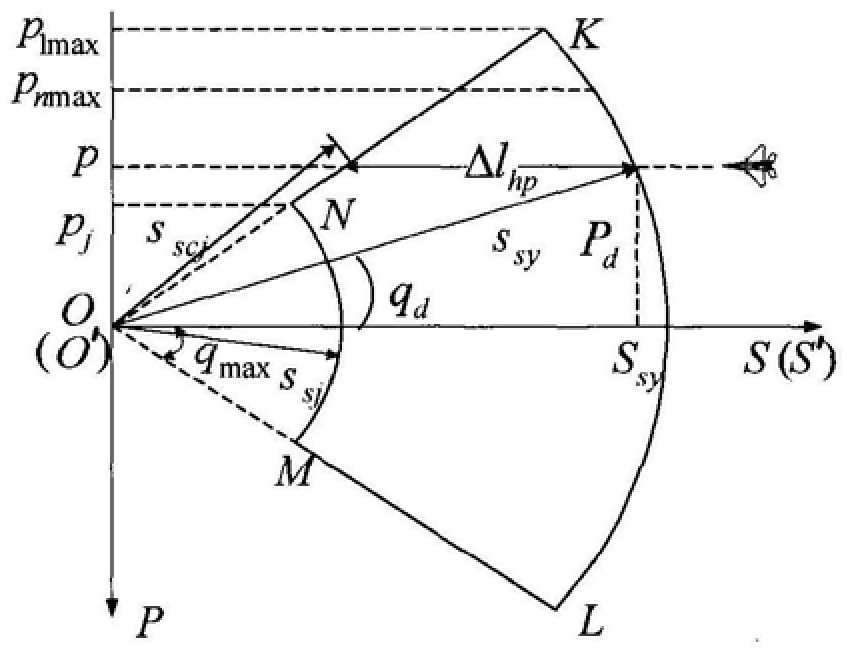

A Method for Analyzing Force Scale Requirements of Ground Air Defense Weapons

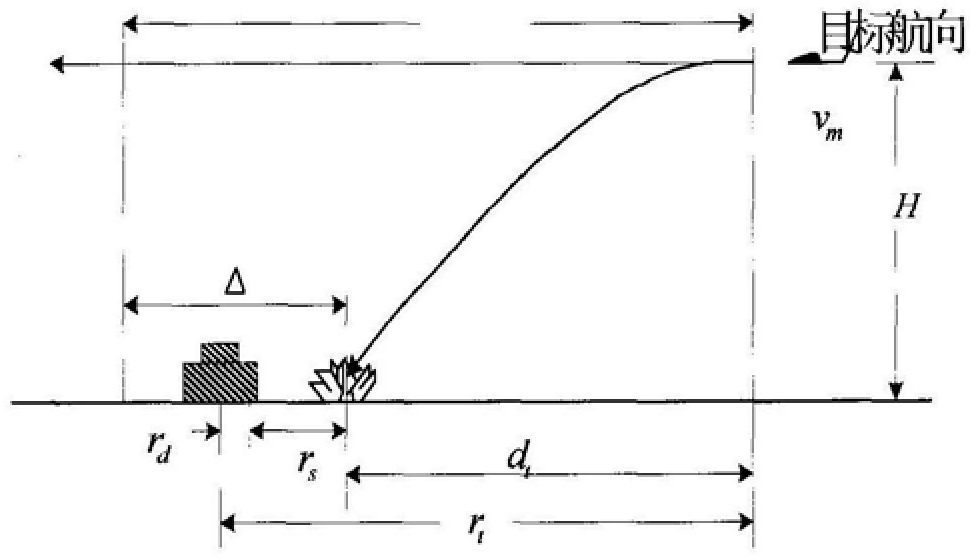

InactiveCN106508044BImprove collaboration efficiencyImprove the combat effectiveness of comprehensive defenseData processing applicationsSpecial data processing applicationsForce structureMissile defense

The invention belongs to the field of force utilization of air defense and anti-missile weapons and equipment, and in particular relates to a method for analyzing the force scale demand of ground air defense weapons. The present invention takes the air defense confrontation between the enemy and the enemy as the background, and comprehensively considers factors such as the enemy's attack direction, the tactical and technical indicators of the enemy's weapons, the combat use mode, the characteristics of different defensive locations or areas, different firepower connection conditions, and different firepower density requirements. , analyze and calculate the force scale and structure requirements of ground air defense weapons in three basic combat deployment styles of ring, sector and linear for different defense areas, and construct the analysis and calculation model of ground air defense force scale structure, which is aimed at single type and multiple types respectively Mixed ground air defense weapons calculate the force scale requirements, and obtain a reasonable number of troops and equipment structure required for ground air defense weapons to defend a specific target, effectively improving the coordination efficiency of the ground air defense firepower network and the effectiveness of comprehensive defense operations.

Owner:GROUND TO AIR DEFENSE EQUIP INST OF AIRFORCE EQUIP INST OF THE PLA

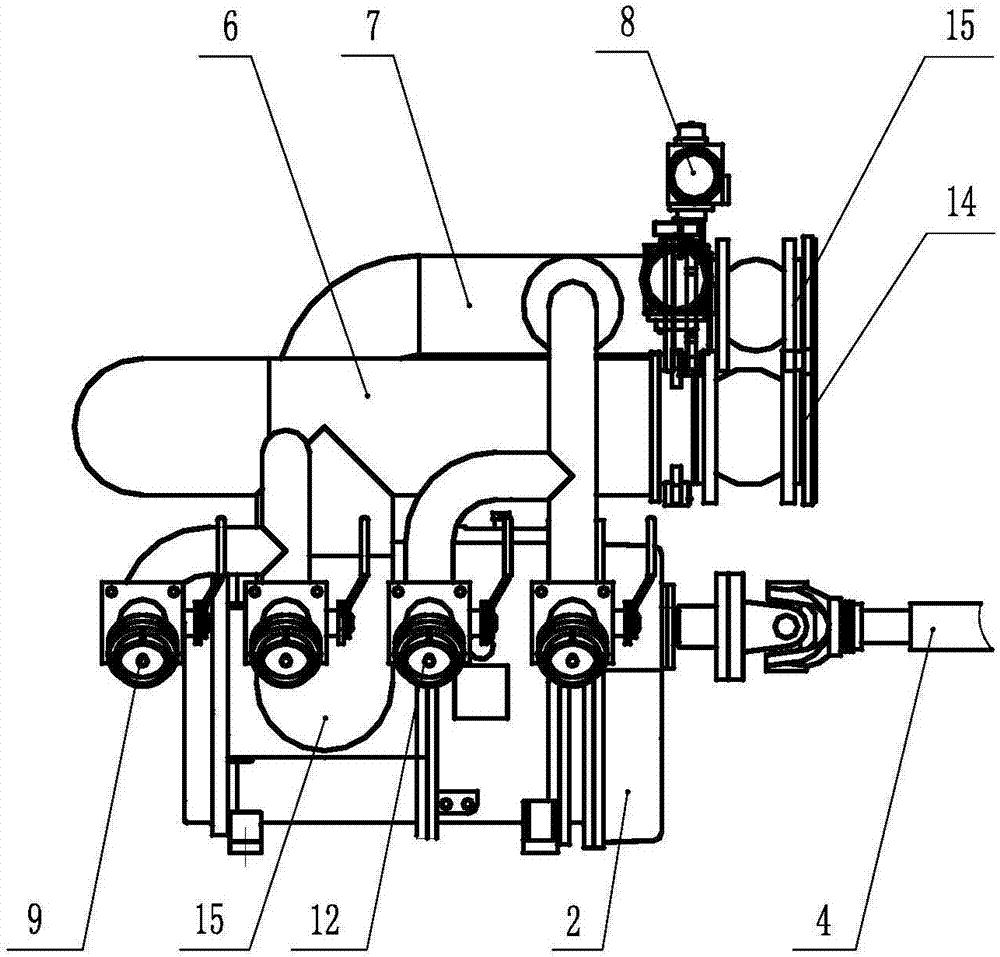

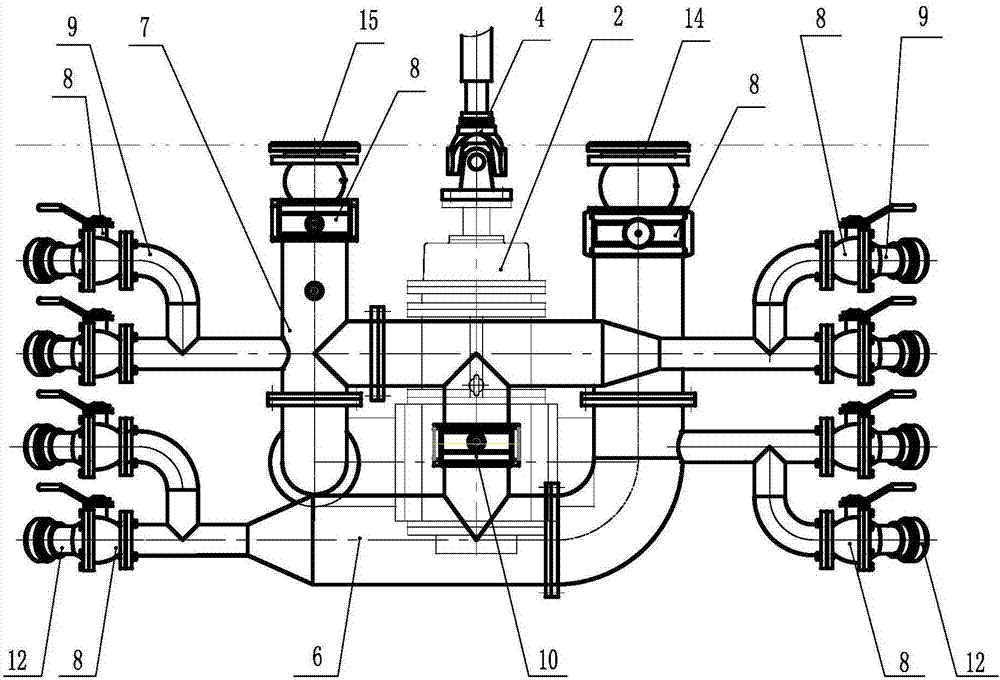

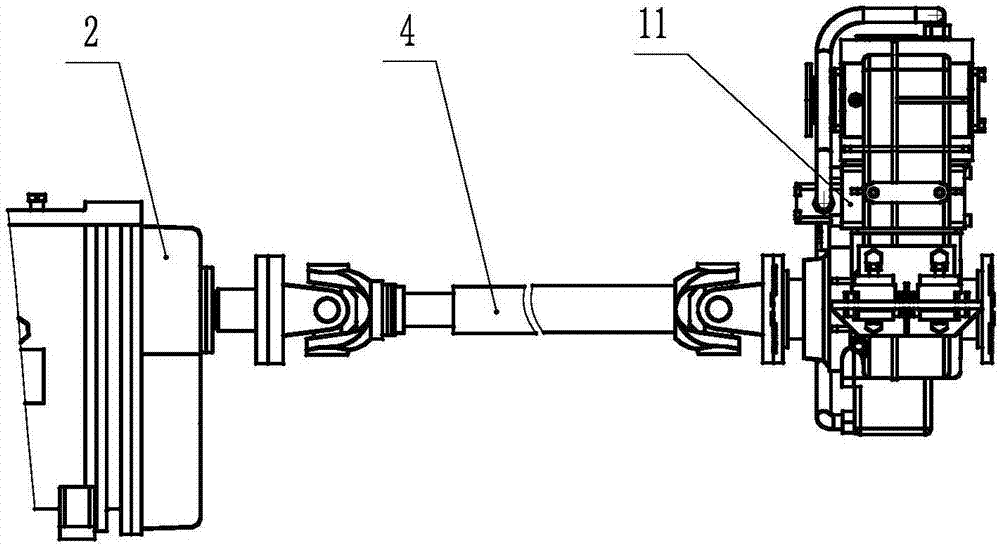

Novel foam fire truck and foam supplying and conveying device

ActiveCN107007958AImprove supply capacityTake advantage ofFire rescueForce structureOperational capabilities

The invention discloses a novel foam fire truck and a foam supplying and conveying device. The foam supplying and conveying device comprises a foam pump, a foam liquid inlet pipeline and a foam liquid outlet pipeline, wherein the foam liquid inlet pipeline communicates with a liquid sucking opening of the foam pump; the foam liquid outlet pipeline communicates with a liquid outlet of the foam pump; the foam liquid inlet pipeline comprises a first foam tank communicating opening and a plurality of foam liquid inlet interfaces; the foam liquid outlet pipeline comprises a second foam tank communicating opening and a plurality of foam liquid outlet interfaces; and valves are separately arranged on each foam liquid inlet interface, each foam liquid outlet interface, the first foam tank communicating opening and the second foam tank communicating opening. According to the novel foam fire truck and the foam supplying and conveying device disclosed by the invention, the own extinguishing property of the foam fire truck is effectively improved, and the joint operational capability of the foam fire truck with an force-structure fire truck is also greatly improved; and the utilization rate and the extinguishing efficiency of stored foam liquid in an accident scene are greatly improved.

Owner:MINGGUANG HAOMIAO SECURITY PROTECTION TECH

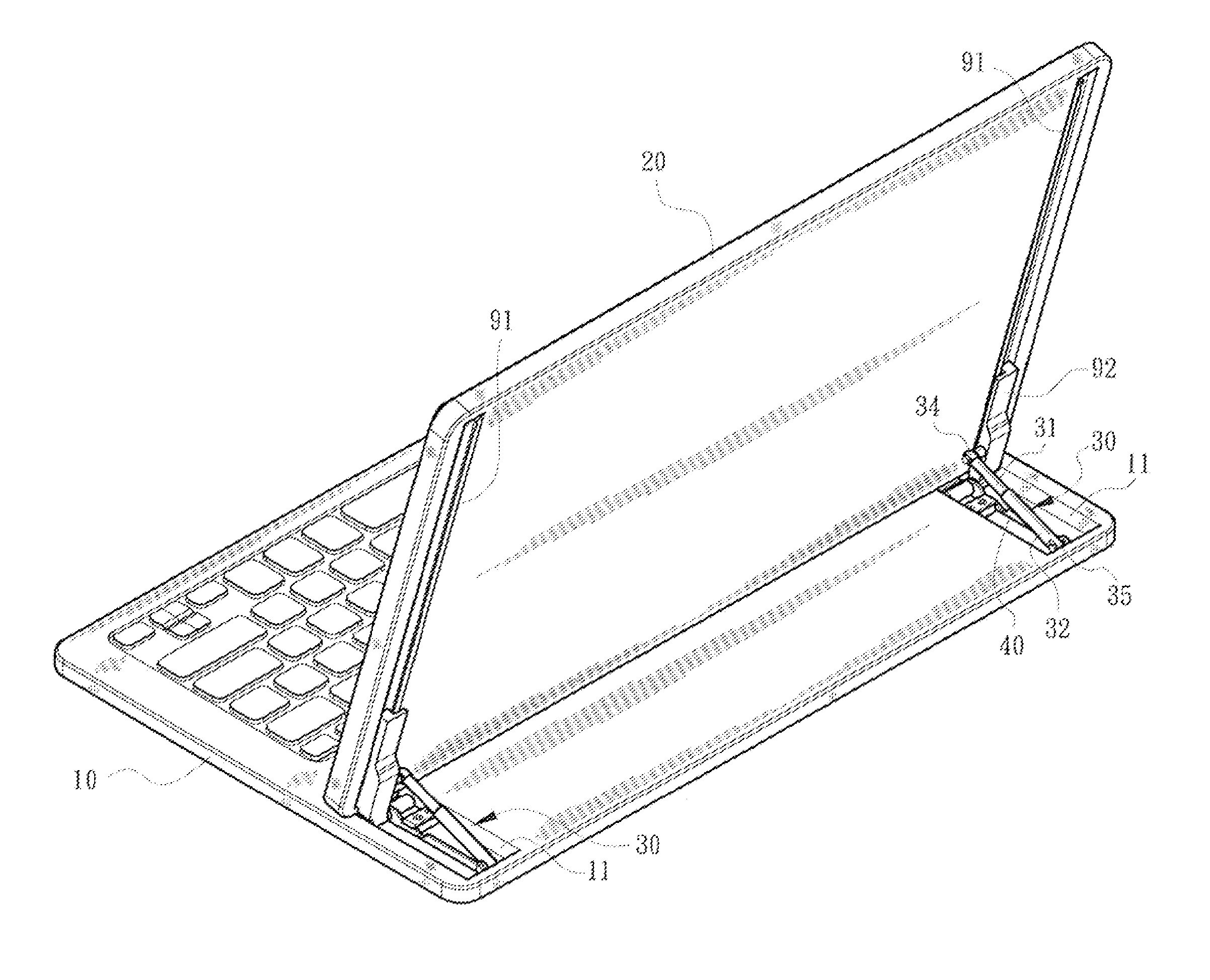

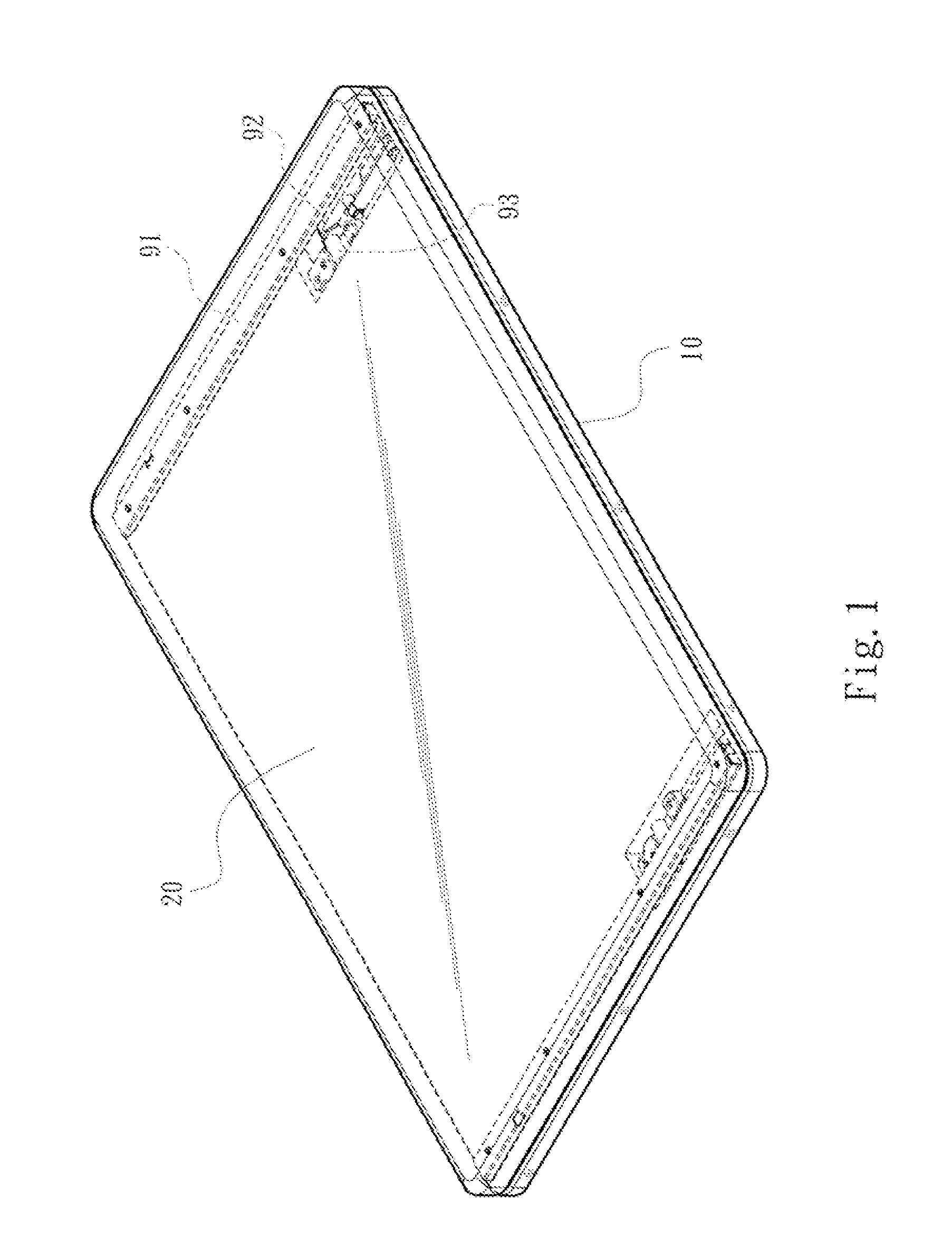

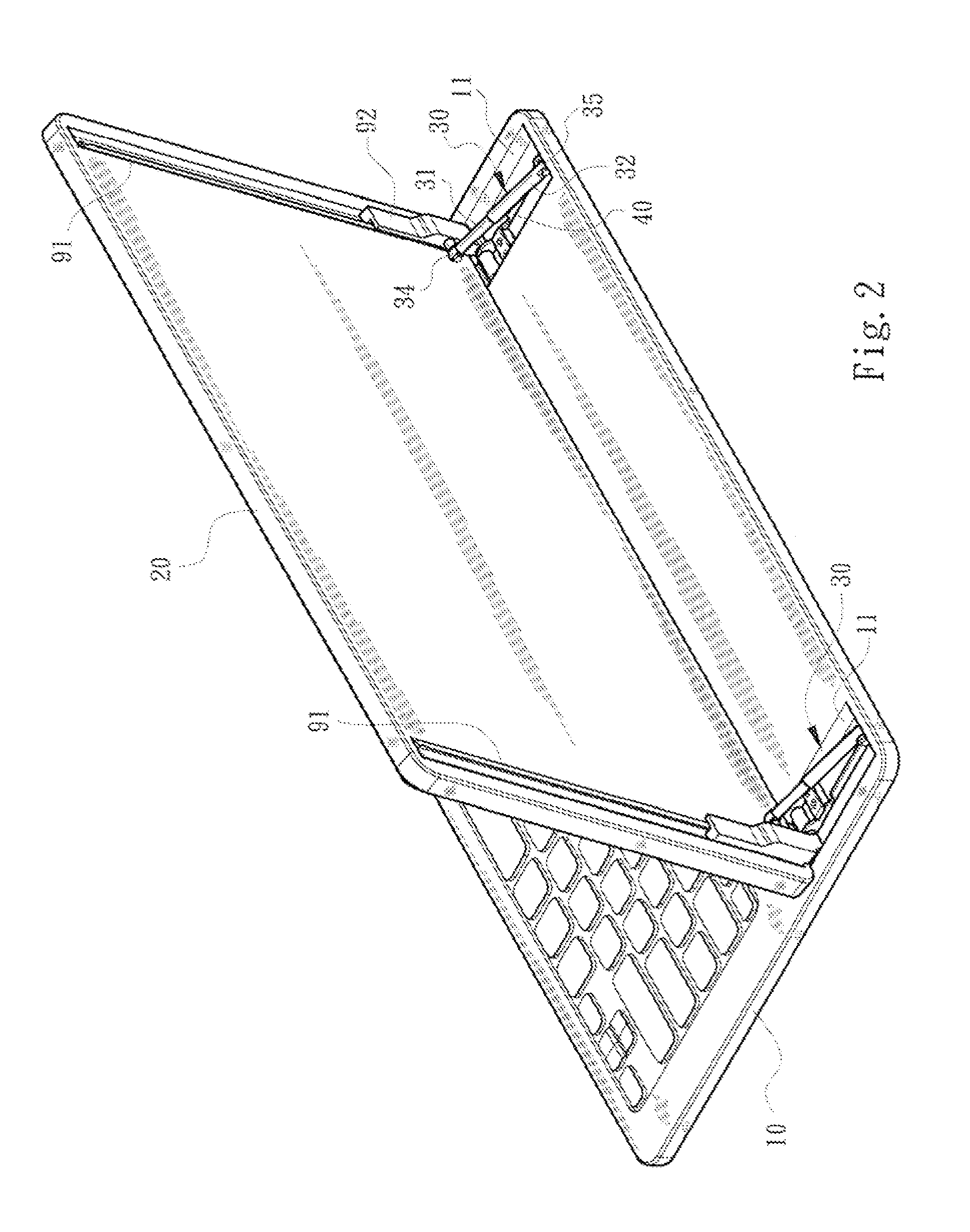

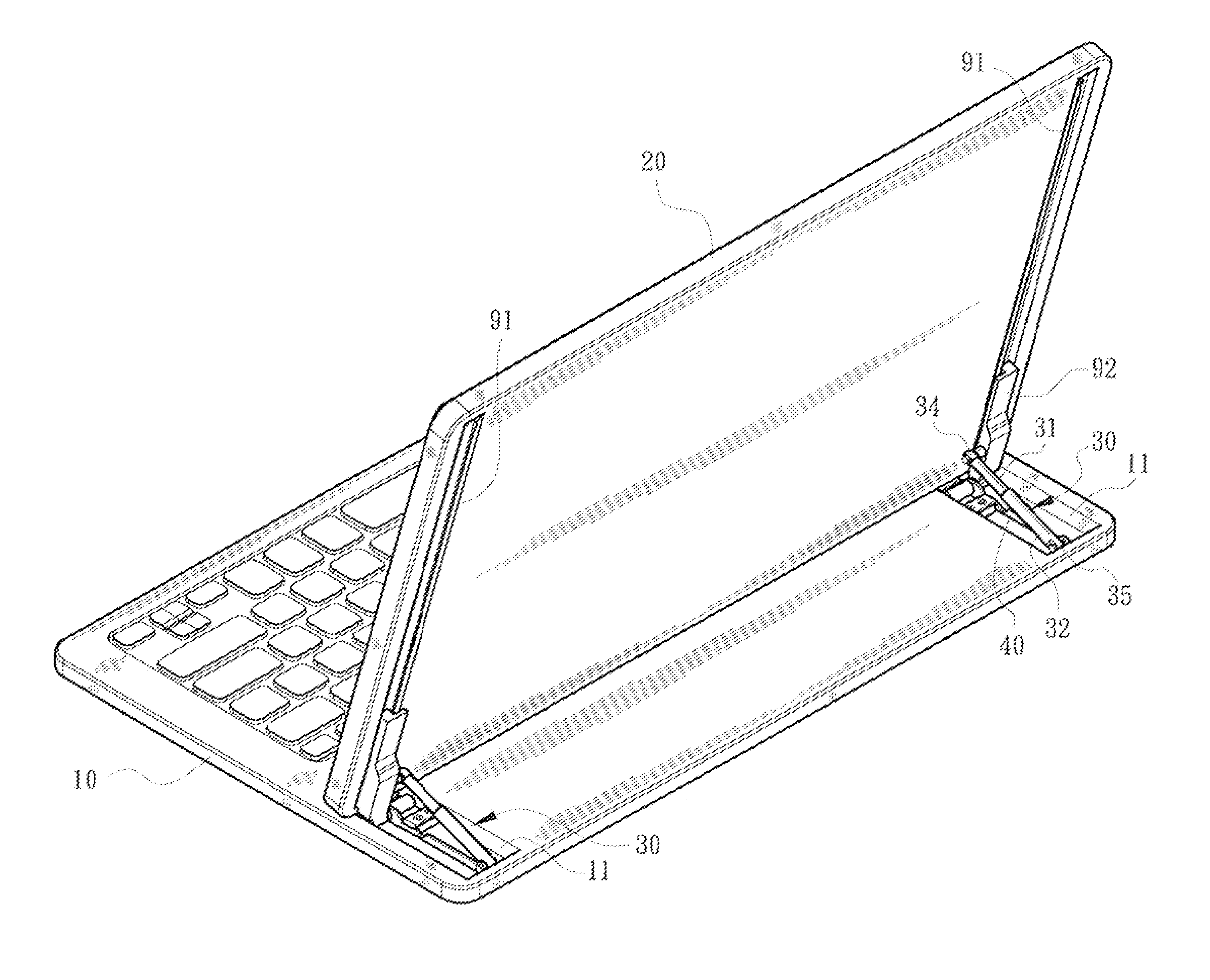

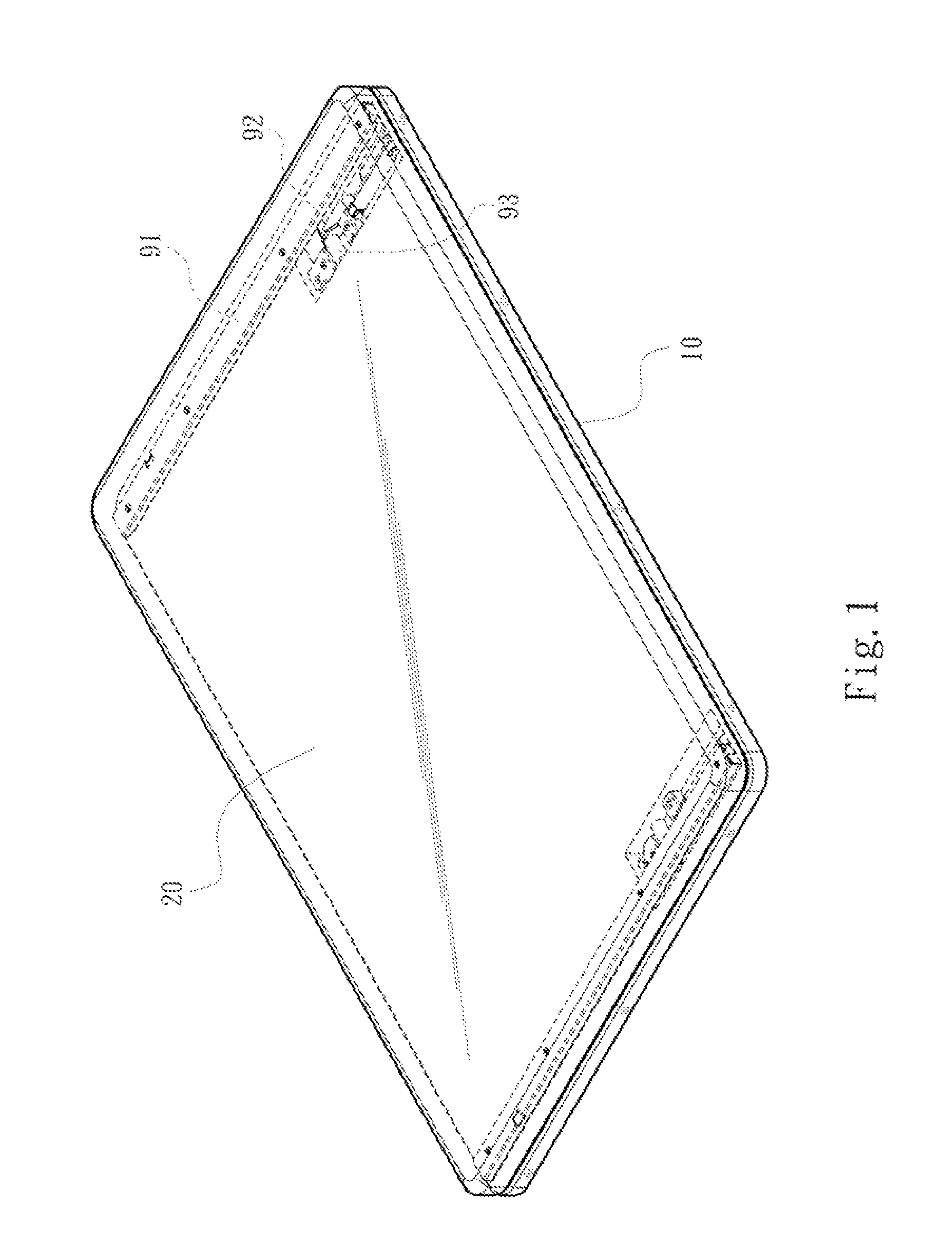

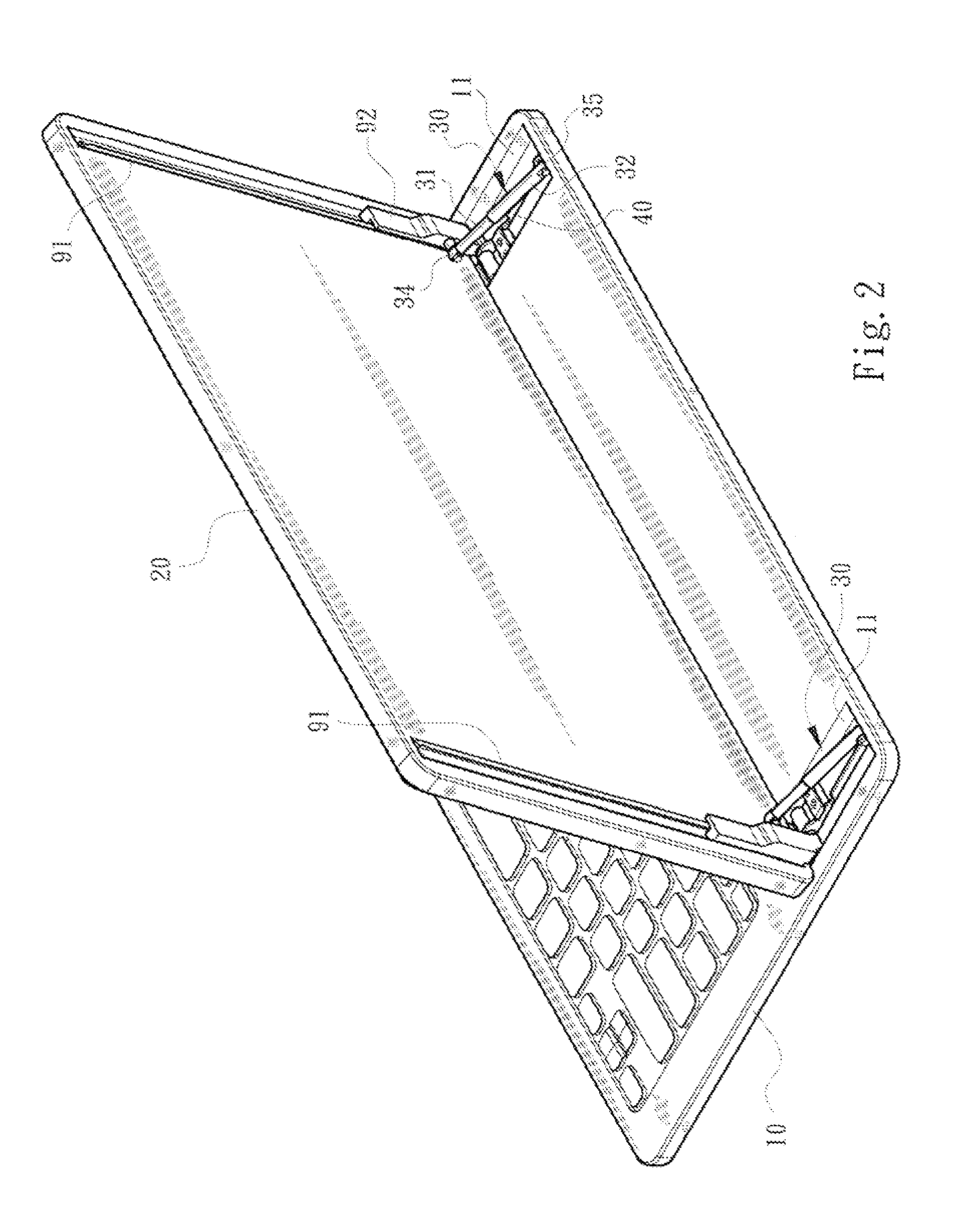

Sliding-type electronic apparatus with strengthening force structure

ActiveUS8947867B2Simple structureAvoid resistanceDigital data processing detailsElectrical apparatus contructional detailsForce structureOperational stability

A sliding-type electronic apparatus with a strengthening force structure includes a body served as a system terminal and an upper cover disposed on the body and having a surface configured with a touch screen. A sliding and cover-lifting member constituted by a sliding rail, a sliding member and a pivot shaft device is at least disposed between the body and the upper cover. In a normal state, a supporting device, together with the sliding and cover-lifting member, is horizontally and supportively placed in a preset concave chamber space of the body. The auxiliary supporting devices can be formed as an inclined auxiliary support structure on the rear surface of the upper cover when the upper cover is lifted, thereby effectively increasing the screen touch resistance to inhibit screen wobble in an operation process and to promote the support effect and operation stability of the screen.

Owner:FIRST DOME

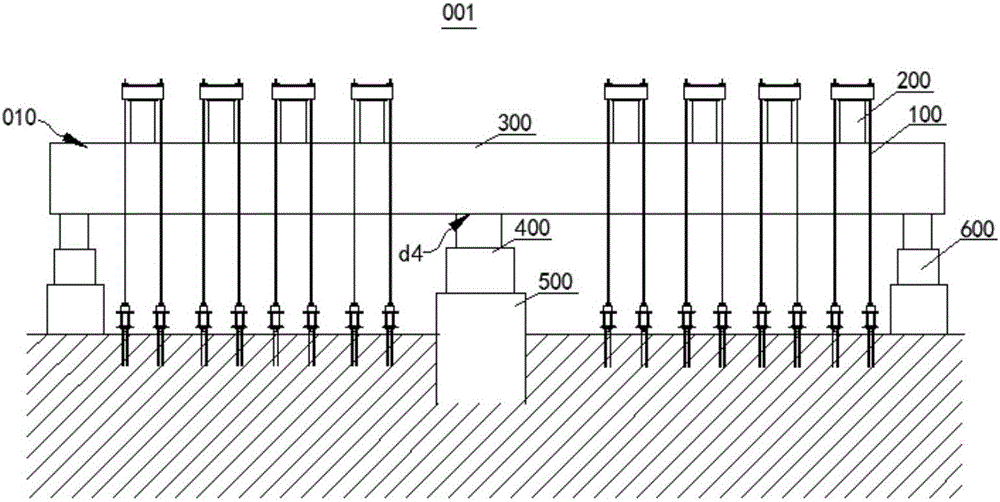

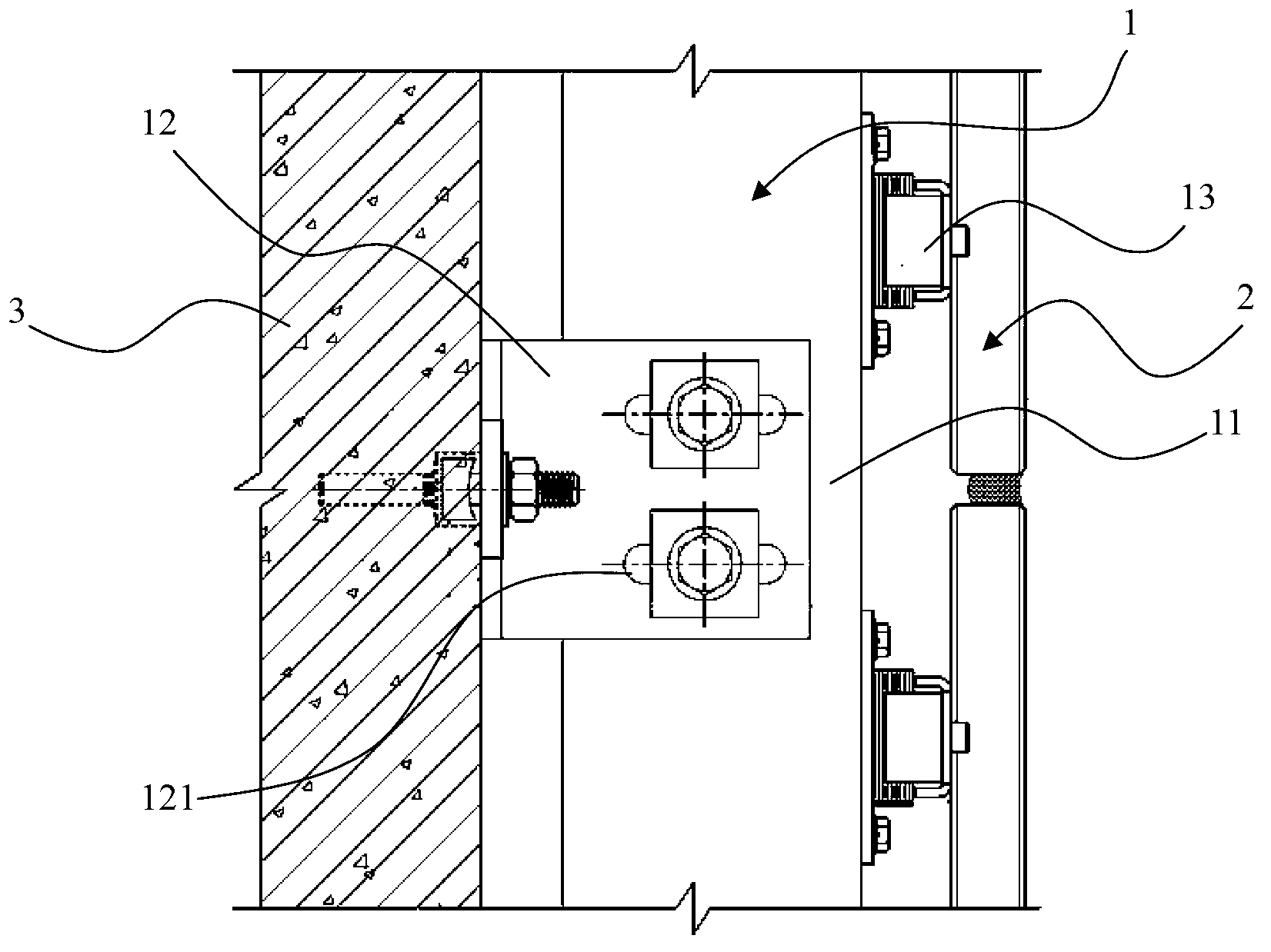

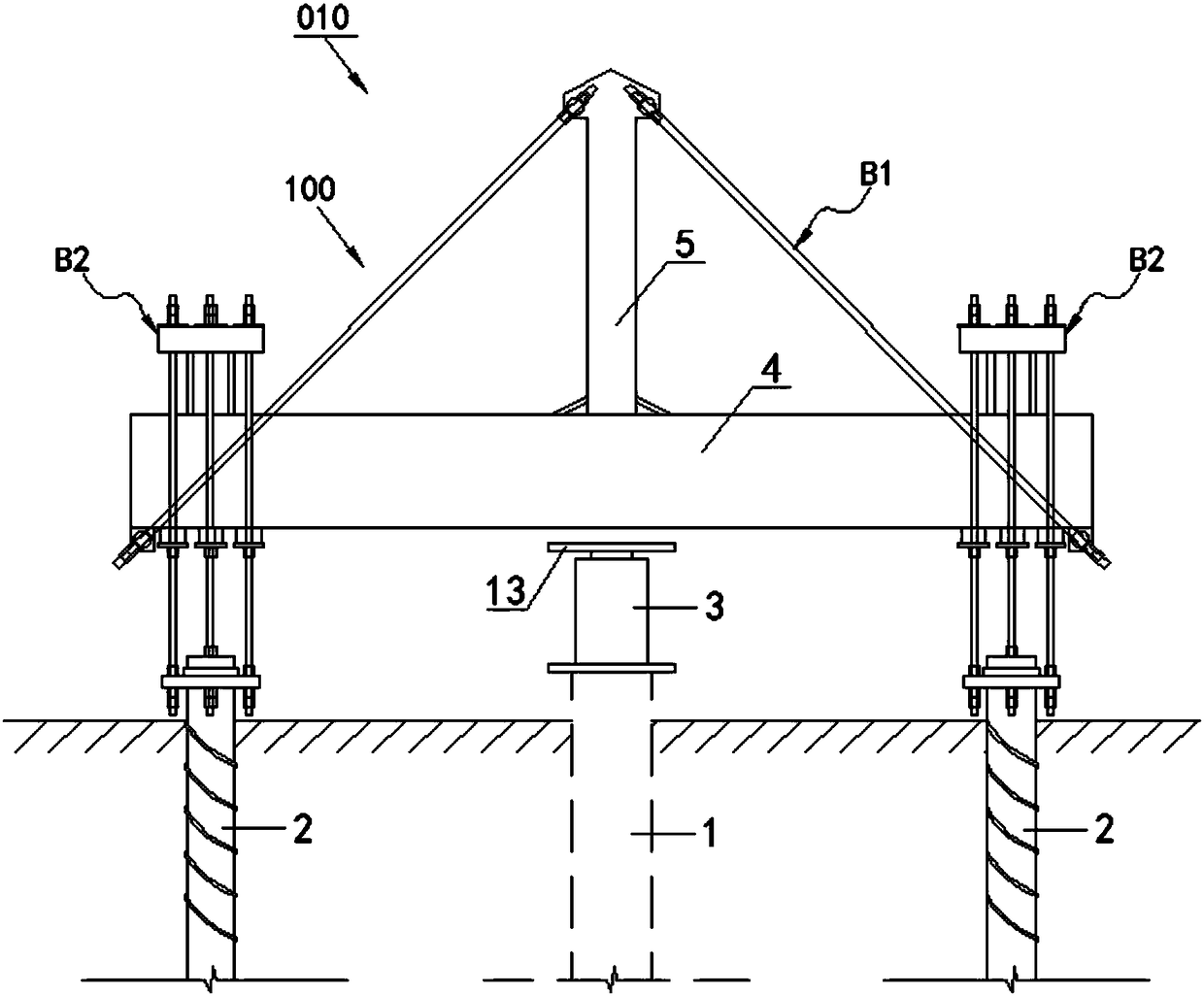

Counter-force structure of static load test and static load test system

The invention relates to the field of constructional engineering, aims to solve the problem that in the prior art, a counter-force structure of a static load test is not suitable or is poor in safety in the mounting process, and provides a counter-force structure of the static load test and a static load test system provided with the counter-force structure of the static load test. The counter-force structure of the static load test comprises a jack, a primary beam which is supported at the upper end of the jack, a plurality of secondary beams which separately press the two ends of the upper end surface of the primary beam and a plurality of anchor rod connecting structures which are separately distributed along the length directions of the secondary beams and are located on two sides of the primary beam. The upper ends of the anchor rod connecting structures are connected to the secondary beams, and the lower ends of the anchor rod connecting structures are fixedly arranged for limiting upward displacement of the secondary beams. The jack is supported in a supporting position between the two ends of the lower end surface of the primary beam, and the secondary beams on two sides are separately located on two sides of the supporting device. The counter-force structure of the static load test provided by the invention has the beneficial effects that the counter-force structure of the static load test is flexibly arranged, can be suitable for different pile base design forms and provide different counter-forces, and is convenient in mounting process and good in safety.

Owner:中冶沈勘工程技术有限公司

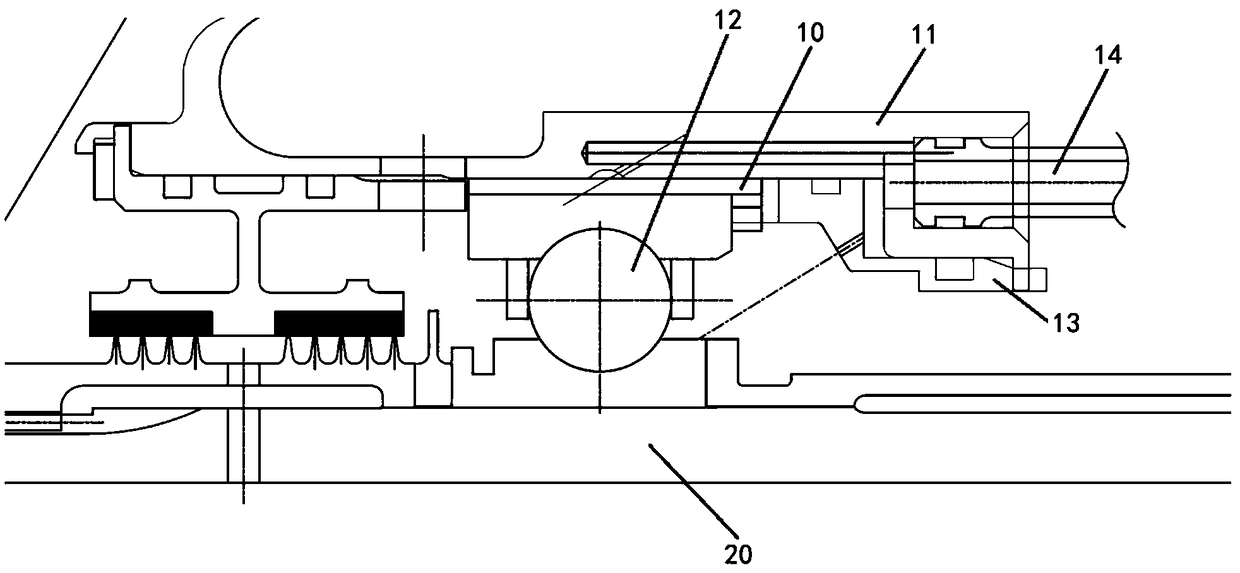

Inorganic reinforced fiberglass pipe jacking and molding process

InactiveCN101097035AHeat resistantAnti-agingLayered productsPipe connection arrangementsForce structureFiber

The invention discloses an inorganic reinforced fiberglass top pipe and forming craft, which is characterized by the following: choosing fiberglass reinforced organic resin composite material as seepage control and preserve lining; using fiberglass reinforced modified inorganic material as middle forced structure layer; using fiberglass fiber reinforced organic resin as covering layer; adopting top advanced construction method; adopting metal collar and plug with rubber ring to bell and spigot joint. The inner pressure of this pipe is 1.0MPa.

Owner:贺建军

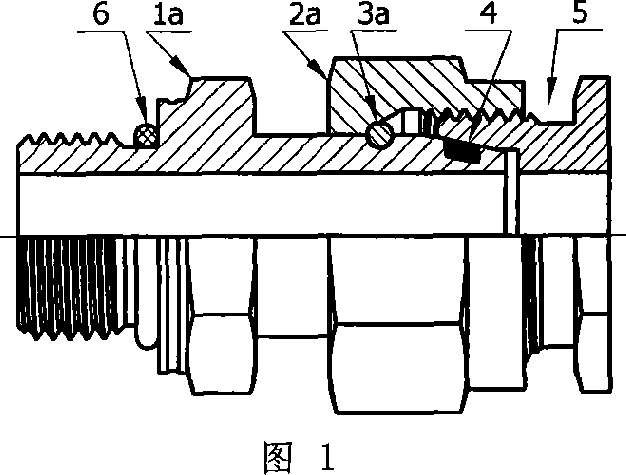

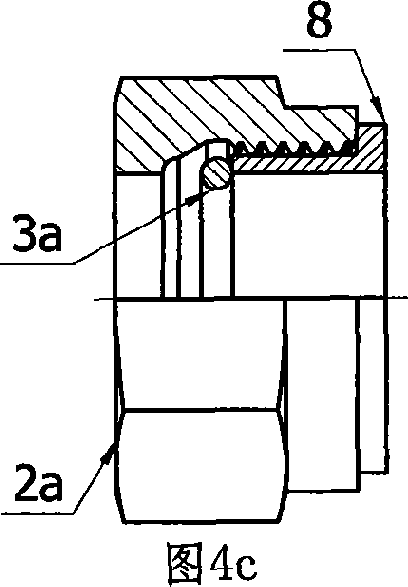

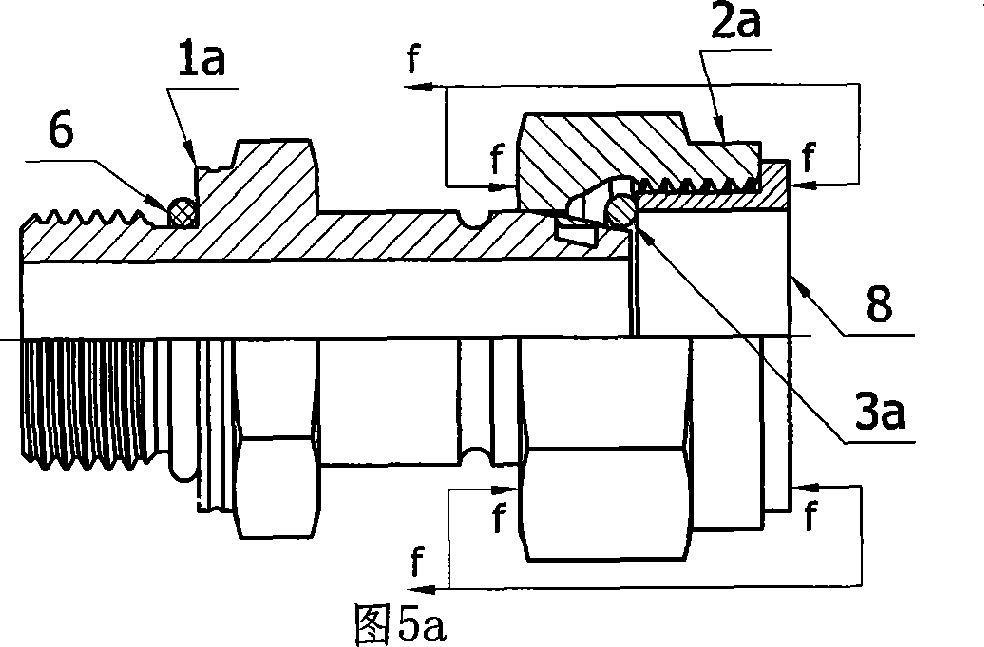

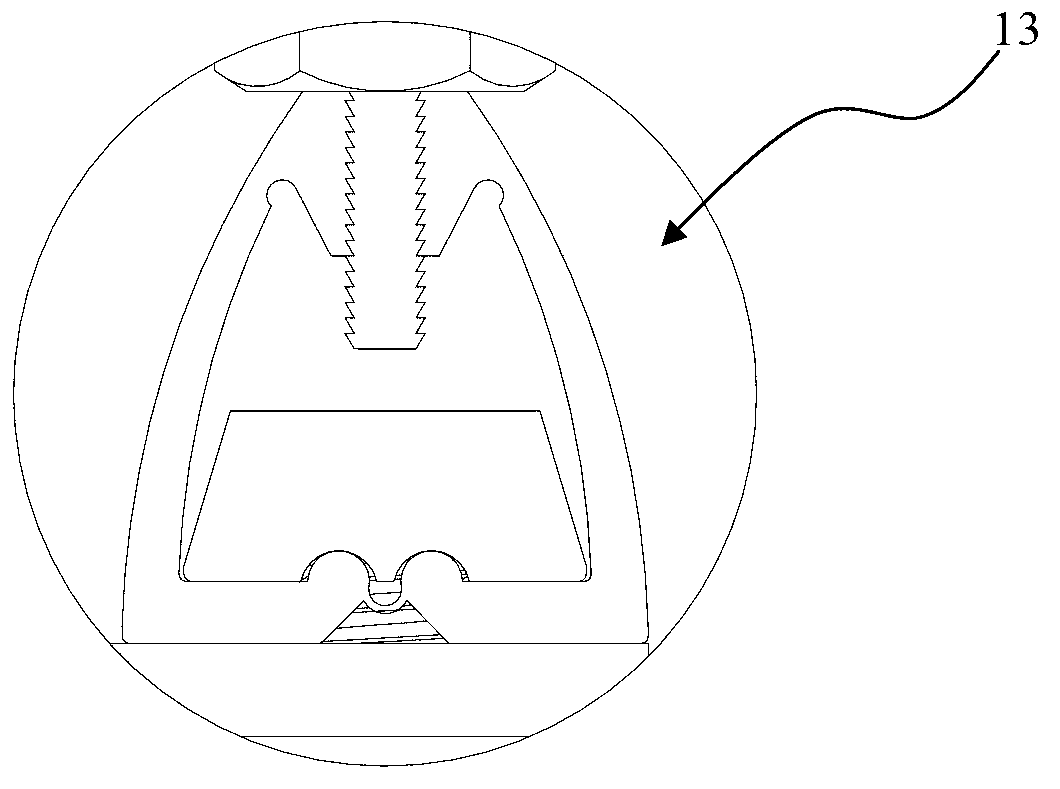

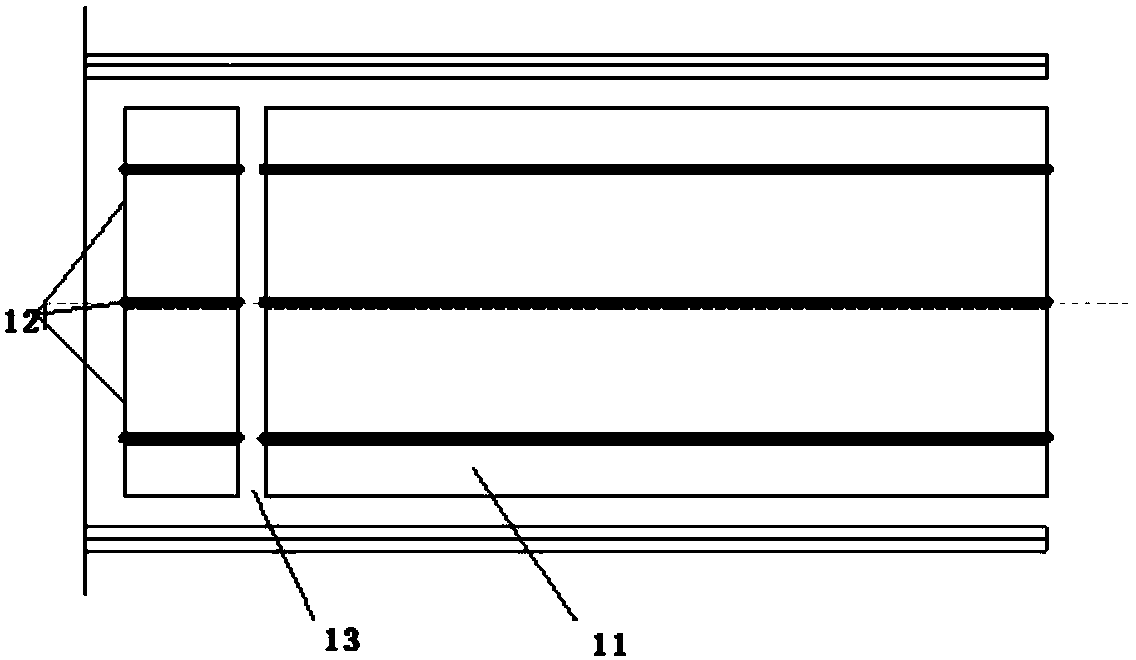

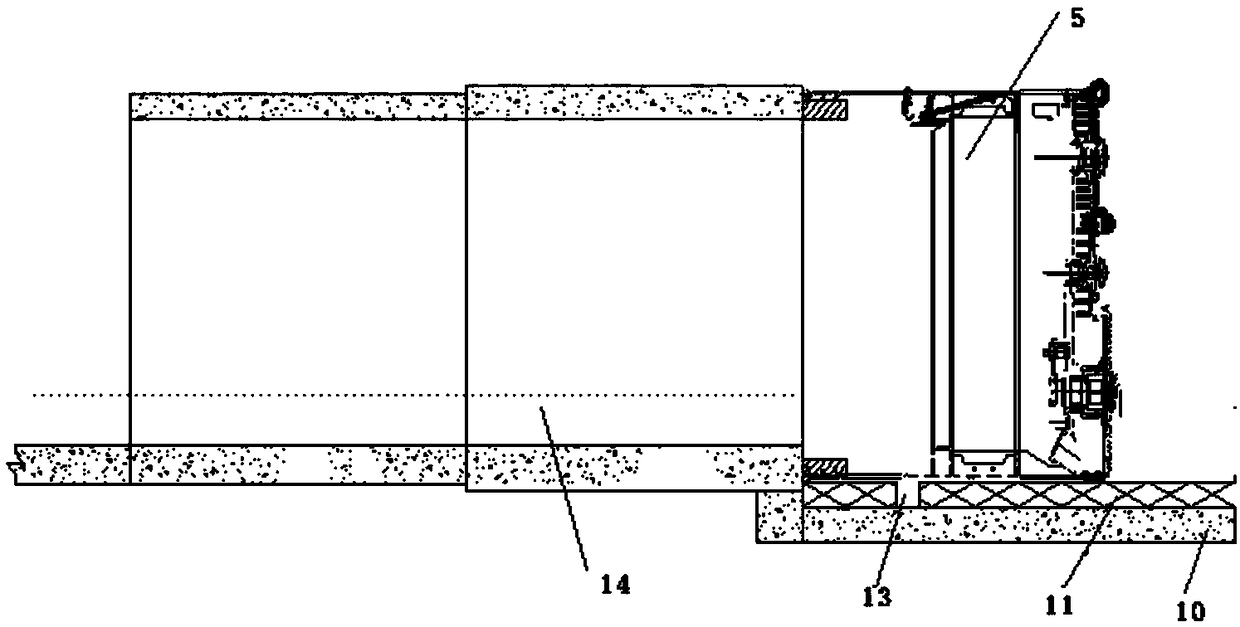

Pipe union fastening structure and its assembling process

InactiveCN101046267AAvoid unreliableOvercome installation difficultiesJoints with sealing surfacesForce structureSteel ball

The pipe union fastening structure consists of one screw nut capable of rotating on the pipe union and one screw nut meshed and operated thrust force structure. The thrust force structure is used to push the conic mouth, conic head or spherical head of the union to the pipe end with corresponding structure to realize the pipeline connection. The thrust force structure has prefabricated step in the screw nut as the pushing step and the prefabricated open-mouthed steel wire or steel ball embedded in the slot on the connected pipe as the pushed step.

Owner:ZHEJIANG HUAXIA VALVE

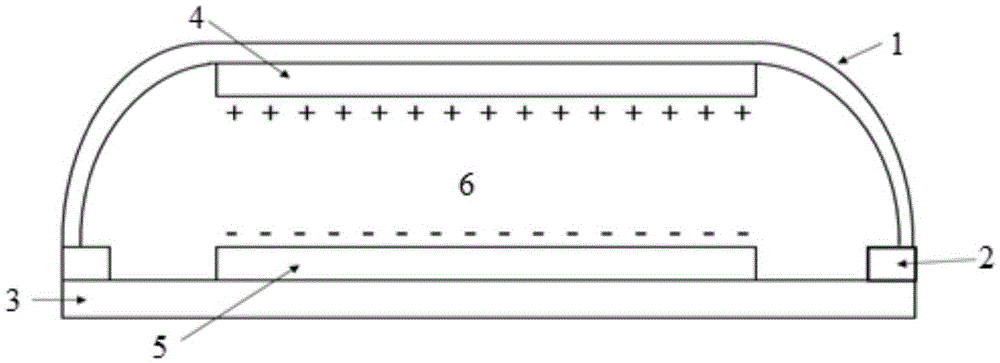

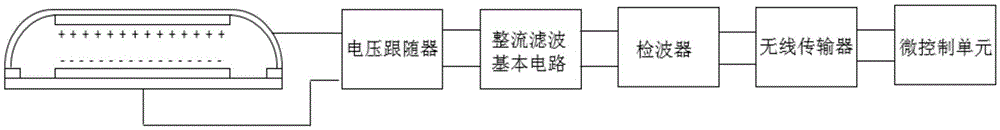

Passive highly-sensitive impact sensor based on piezoelectrets and testing method thereof

ActiveCN105547553AHigh sensitivityImprove mechanical propertiesApparatus for force/torque/work measurementForce/torque/work measurement apparatus calibration/testingForce structureElectricity

The present invention discloses a passive highly-sensitive impact sensor based on piezoelectrets and a testing method thereof. Electret layers are arranged on a back electrode and a spring electrode, a cavity is formed between a spring electrode electret layer and a back electrode electret layer, and a pair of piezoelectrets is formed. The surfaces of the piezoelectrets have opposite polarization charges, and a macroscopic dipole is between the spring electrode electret layer and the back electrode electret layer. Under an external force, a macroscopic dipole distance is changed, an impact type voltage spike signal is formed, and the external force is obtained through measuring voltage. According to the sensor and the method, a special impact force structure mode is used to provide impact voltage, the sensitivity can reach 80V / 1MPa, and the sensor has the characteristics of high impact, high load, high sensitivity and the like. An external power supply is not needed, the sensor is self-powered and without paranoid voltage, the passive operation is achieved, and the sensor has the characteristics of low consumption and high efficiency and ultra high sensitivity in the current impact sensor power generation technology.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

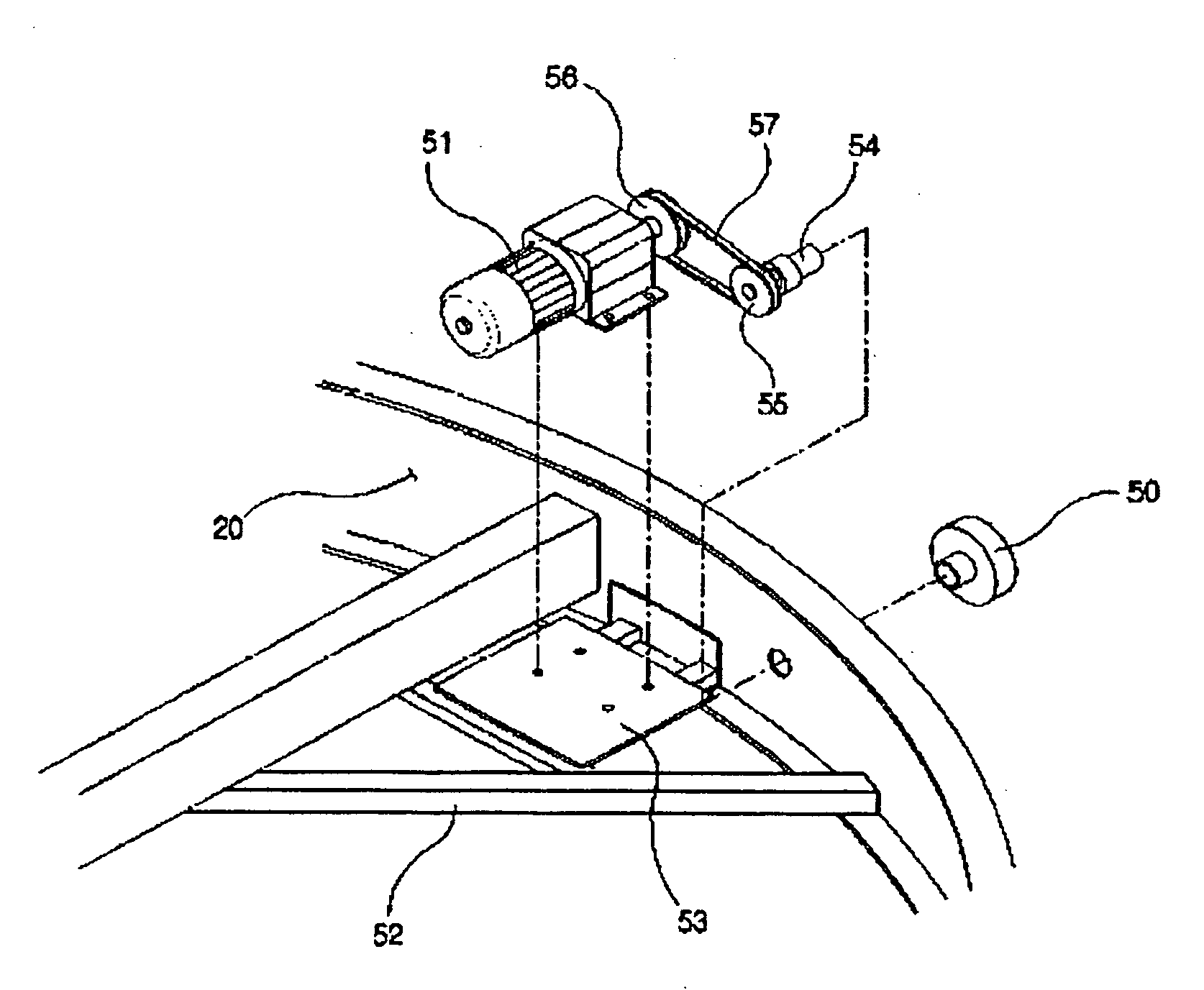

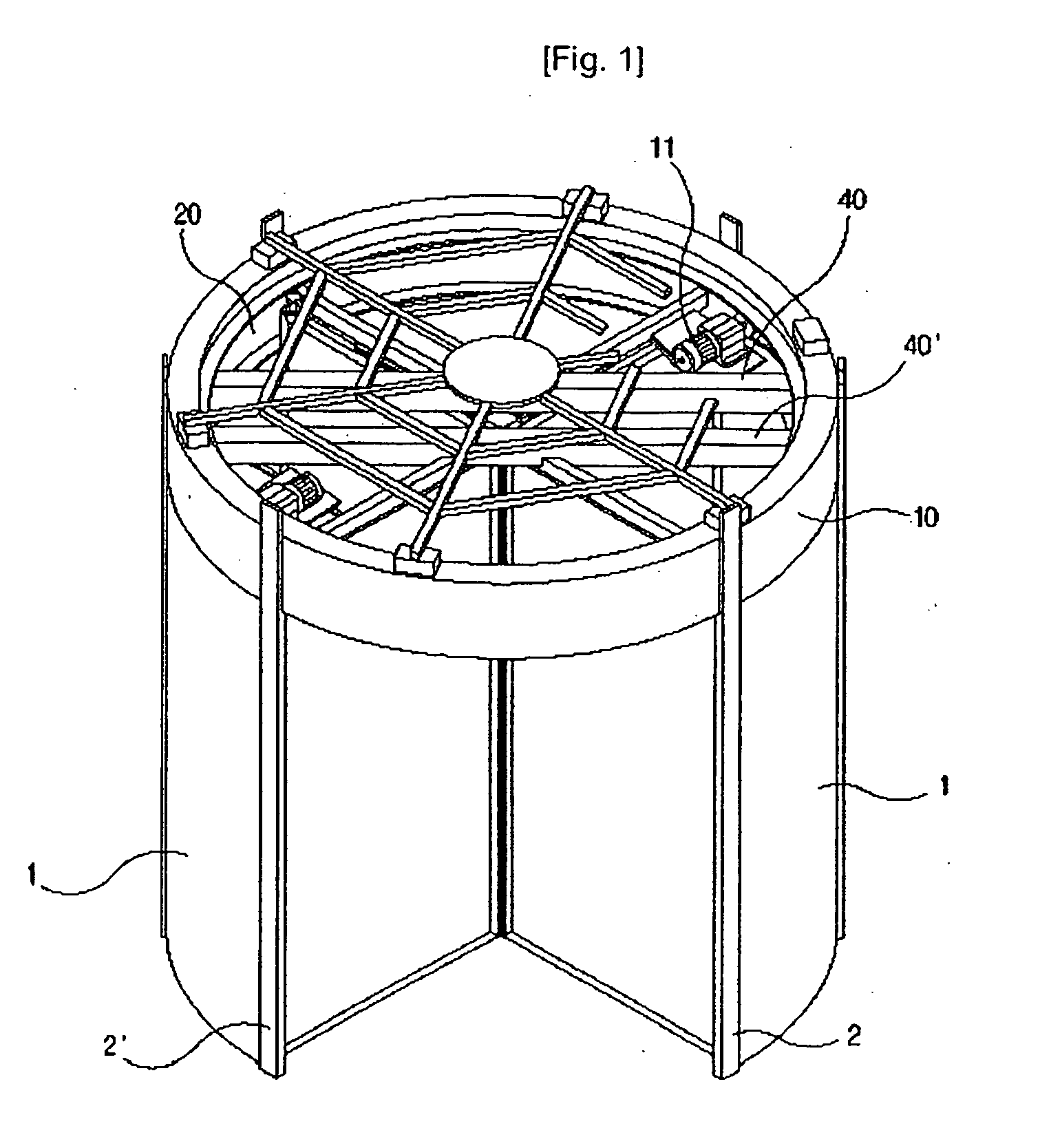

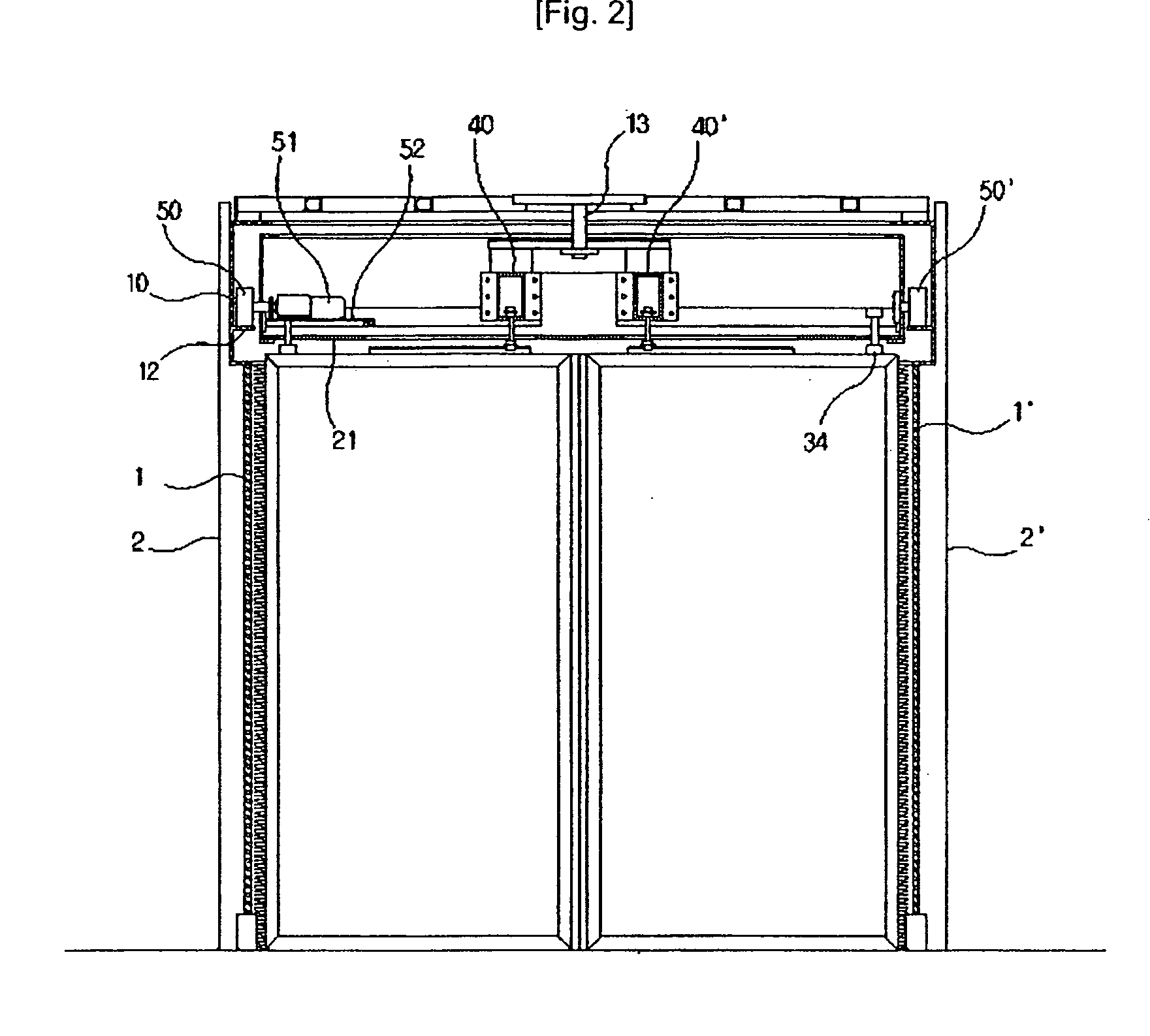

Power transmitting system for rotary wings of automatic revolving door

InactiveUS20090119996A1Avoid security issuesImprove structural stabilityPower-operated mechanismWing suspension devicesForce structureEngineering

A revolving driving force structure of a revolving wing for an automatic revolving door is provided, in which a revolving door of an automatic revolving door having an inner body with a revolving door at an inner side of an outer body provided at a front end of a transparent wall member is generated based on a rotation roller protruded from the inner body and by an operation motor which rotates the rotation door, and the rotation roller is supported on an inner support protrusion, and it is possible to prevent any safety accident based on a stable rotation of the inner body and the revolving wing and a constant gap during the rotation of the revolving wing, and a simple structure can be obtained, and a durability and life span increase without any load.

Owner:WANG BOK KWON

Three-way tensile pressure-high hydraulic gradient action concrete corrosion test device and method

ActiveCN107228805AConvenient corrosion degradation testSmall footprintWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesForce structureSheet steel

The invention discloses a three-way tensile pressure-high hydraulic gradient action concrete corrosion test device and method. The method comprises applying constant compressive stress to a specimen through forward preload, applying reverse preload to a tensile steel plate bonded to the surface of the specimen and tensile bolts through a seal chamber steel plate in the tension side as a reverse force structure to realize constant tensile stress loading, applying axial compressive stress to a loading bar with a protection shell along a longitudinal direction, monitoring the stress state of the specimen in the corrosion process through tension and pressure sensors and supplying preload and axial pressure in good time. Through combination of sealing of the specimen tension side with the structure glue and a high elastic rubber tube, the pressure solution flows into the specimen from the top and flows out of the specimen from the bottom so that hydraulic gradient action is formed, and a water pressure sensor monitors corrosion solution pressure in the solution chamber in the corrosion process and supplies the solution in good time to keep stable pressure. In the solution chamber, one or more osmotic corrosion environments such as sulfate and chloride environments are provided. The device has a string structure and can carry out three groups of tests simultaneously.

Owner:HOHAI UNIV

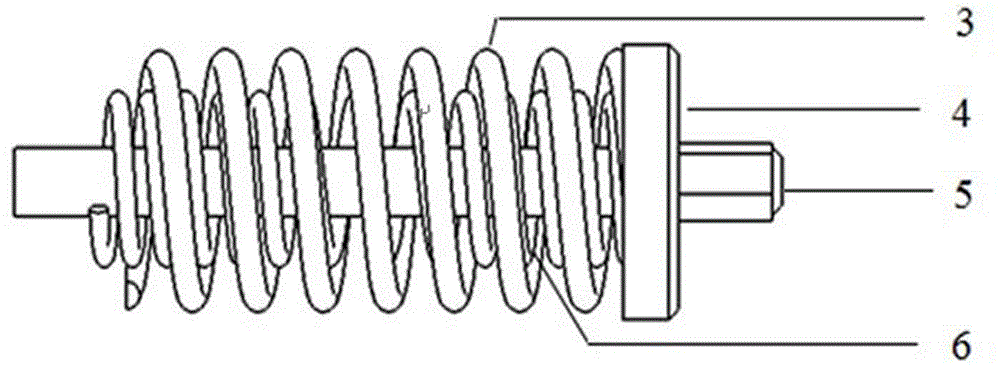

Self-locking device and self-locking type pre-stress anchor wire having the same

InactiveCN101768963AReduce load lossUniform pressureExcavationsAnchoring boltsForce structurePre stress

The invention discloses a self-locking device and a self-locking type pre-stress anchor wire having the same. The self-locking device comprises a load bearing steel plate and a limiting steel plate, wherein the load bearing steel plate is a cylinder which is provided with a plurality of conical anchor holes; the anchor holes have a same diameter, are used for locking the anchor wire and for the anchor wire passing through and are symmetrically distributed; the anchor holes have gradually contracted conical degrees in the direction opposite to a stretching direction of the anchor wire; a clamping piece which is used for clamping the anchor wire and is matched with the anchor holes structure is arranged in the anchor holes; the limiting steel plate is of a round plate shape and is fixed on one side of the load bearing steel plate close to a big opening of the conical holes by a bolt; and a round hole which allows the anchor wire to pass through is arranged in the limiting steel plate. Based on a normal anchor wire structure, the anchor wire is locked by arranging the self-clocking device on a free section, the energy field of the free section is fully utilized and the anchor stress field distribution is improved, thereby, the self-locking type pre-stress anchor wire has the advantages of uniform load distribution, decreased counter-force structure scale, convenient construction, saved manufacturing cost, environmental protection, and the like.

Owner:中铁西北科学研究院有限公司深圳南方分院

Axial force pre-loading structure of deep groove ball bearing in engine rotor fulcrum

ActiveCN109281944ALarge technology scalabilityGreat application potentialBearing componentsForce structureImpeller

The invention relates to an axial force pre-loading structure of a deep groove ball bearing in an engine rotor fulcrum. An engine is a gas turbine or a turbojet engine, the inner ring of the deep groove ball bearing is fixedly arranged on an engine rotor shaft in a sleeved mode and is arranged close to a rotor impeller disc in the axial direction, the outer ring of the deep groove ball bearing isfixedly supported in a bearing block, a closed oil collecting ring structure is additionally arranged on the outer ring of the deep groove ball bearing, a proper axial force load is formed on the annular end face of the oil collecting ring by utilizing the high-pressure lubricating oil, the oil supply pressure of the lubricating oil and the annular action area of the oil collecting ring are utilized, a proper axial pre-tightening load can be provided for the outer ring of the bearing, and the traditional bearing pre-tightening force structure is simplified. The axial force pre-loading structure has important engineering application significance in the field of ground gas turbines or aero-engines.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

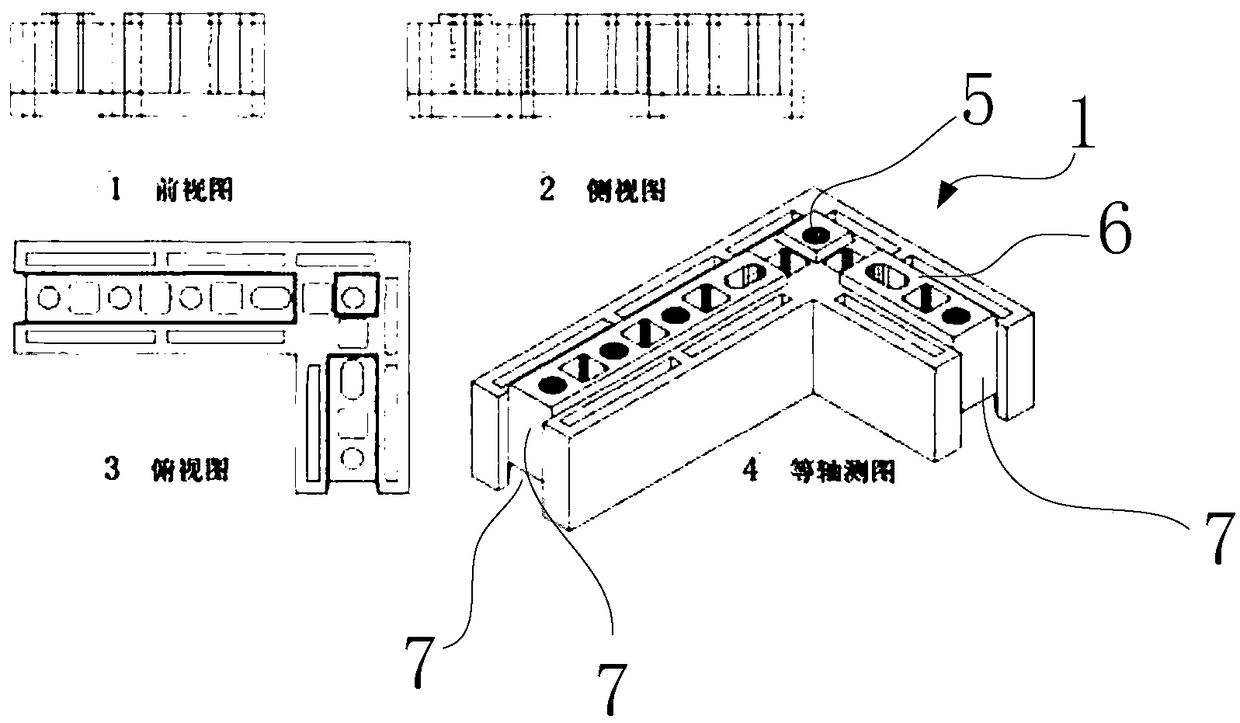

Wall, column and beam integrated assembly construction method

InactiveCN109083302ARealize large-scale standardized productionArbitrary assembly and constructionWallsForce structureMortise and tenon

The invention provides a wall, column and beam integrated assembly construction method. The construction method comprises the steps that walls are built on a flat foundation and / or floor plate, the walls are formed by splicing standard building blocks, the adjacent standard building blocks on the same layer and the standard building blocks on the upper layer and the lower layer are connected through mortises and tenons, and through holes are formed in the standard building blocks. The through holes in the walls built through the standard building blocks are vertically through to form verticallocking holes, and locking rods matched with the space of the locking holes are inserted into the locking holes to lock the walls. By means of the tenon-mortise structure principle, load bearing structural parts and light non-load-bearing structural parts are ingeniously combined, and columns, beams and the walls of a building are integrated to form a load-bearing and anti-seismic lateral force structure. The standard building blocks are adopted, large-scale standardized production is achieved, the standard building blocks can be personalized and flexibly assembled for use, and a right-angle wall or a T-wall wall or a cross wall can be easily achieved.

Owner:SHENZHEN XINTIANNENG TECH DEV

Structure for mounting stone and method for mounting stone

ActiveCN103306453AStable prestressed fasteningEffective prestressed fasteningCovering/liningsGeneration processForce structure

The method discloses a structure for mounting a stone, which comprises a building main body, the stone mounted on the building main body, and as well as a mounting baseplate, wherein the stone is adjusted to a designed position to be fastened through the mounting baseplate; and the position of the stone is not changed in the process of fastening. Through the adoption of the structure, the motivation and the controlling for a dynamic generating process of prestressing force of elastic material are provided, a stable prestressing force structure is formed, a three-dimensional adjustment is conducted in the process of mounting to greatly improve the mounting accuracy of the stone, and the characteristics of excellent firmness, accuracy, safety, convenience, and changeable are adopted.

Owner:深圳市湛艺建设集团有限公司

Large-section U-shaped earth pressure balance shield tunnel construction method based on U-shaped shield tunneling machine

InactiveCN108661655AReal-time pressure controlLow costUnderground chambersTunnel liningForce structureShield tunneling

The invention discloses a large-section U-shaped earth pressure balance shield tunnel construction method based on a U-shaped shield tunneling machine. The large-section U-shaped earth pressure balance shield tunnel construction method comprises the following steps that 1, an opencut tunnel counter-force structure shield launching device is arranged, and the end is reinforced through a large pipeshed in the tunnel entering direction; 2, a launching base is arranged on a bottom plate structure, three first guide rails are arranged on the launching base to serve as a shield tunneling machine guiding rail, three second guide rails are laid in a tunnel portal pilot tunnel, the first guide rails and the second guide rails are connected and located at the connecting position of the shield tailof the shield tunneling machine and a medium shield, and a shield tail welding groove is formed in the launching base; and 3, an opencut tunnel reinforcing section structure is arranged to provide counterforce for the shield tunneling machine. On the basis of the U-shaped shield tunneling machine, a complete set of technologies, including the opencut tunnel counter-force structure shield launchingtechnology, the shield tunneling parameter control technology, the large-section U-shaped shield segment splicing technology and the muck improvement technology, of large-section U-shaped shield construction is formed.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +2

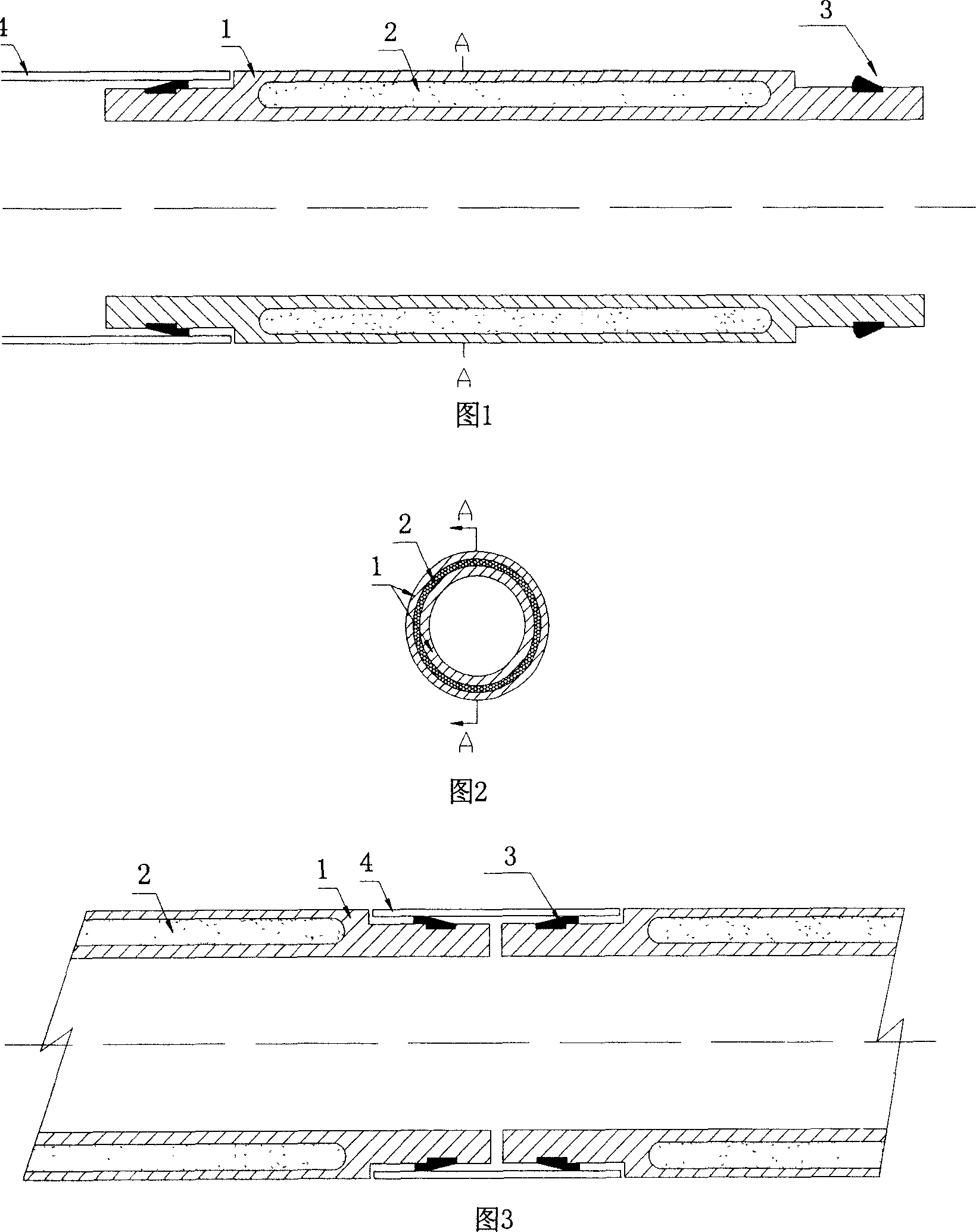

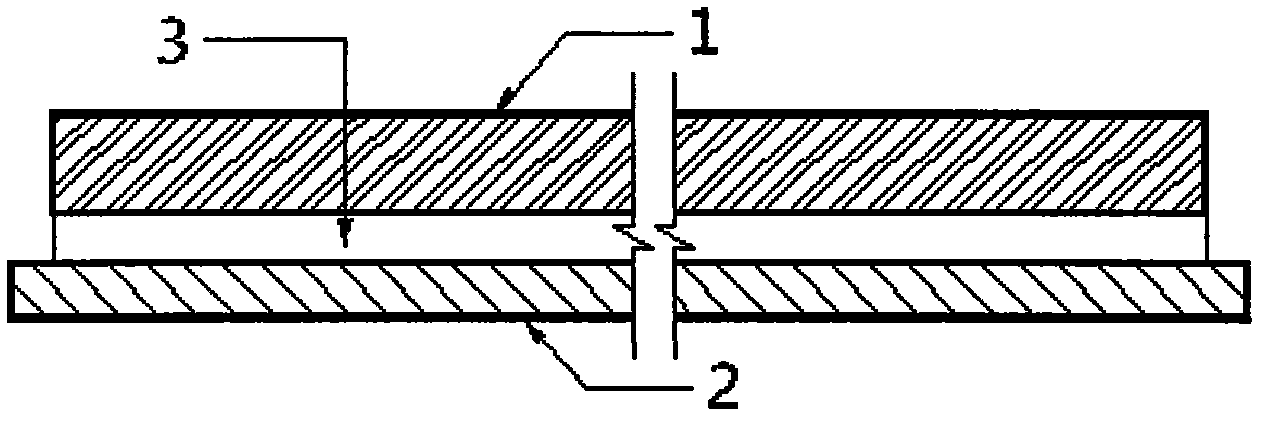

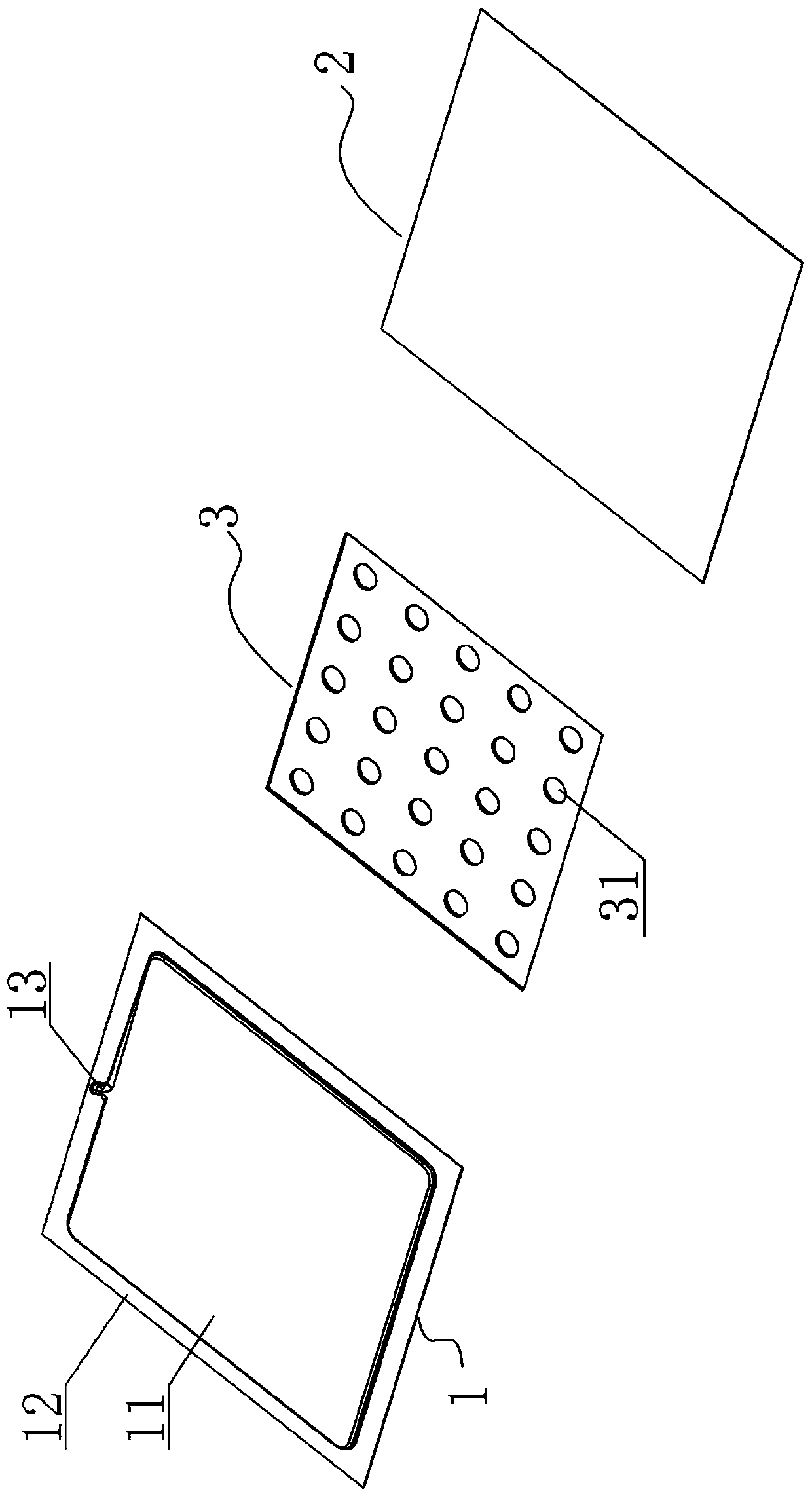

Pre-stress composite glass plate and manufacturing process thereof

InactiveCN102862340AImprove cracking strengthGlass/slag layered productsMetal layered productsCompound aForce structure

The invention relates to a decorative material and a manufacturing process thereof. The decorative material is applied to the field of buildings, furniture and the like, and the invention particularly relates to a pre-stress composite glass plate which takes a glass material as a surface layer, and a manufacturing process thereof. The pre-stress composite glass plate is formed by compounding a glass thin-plate layer (1) and a pre-stress layer (2) by a locking force structure (3); the glass thin-plate layer (1) is a thin-plate layer which is made of fragile glass materials including a glass plate, a toughened glass plate, a micro-crystalline glass plate and the like; the original state of the thin-sheet layer is in a sheet shape and the thin-sheet layer is formed by arraying one or more pieces; the pre-stress layer (2) is a sheet-shaped tensile structure layer; and the structure layer and the glass thin-plate layer (1) are placed in parallel. The manufacturing process of the pre-stress composite glass plate can adopt a thermal solidification method, comprising the following steps of: checking the appearance and the size; washing the material; drying; combining the sheet and heating; cooling; checking a product; and packaging.

Owner:吕孟龙

Drive wheel identification device

ActiveCN106652476AEliminate forceEffective monitoring of horizontal frictionRoad vehicles traffic controlForce structureDrive wheel

The invention relates to the technical field of vehicle identification systems and particularly to a drive wheel identification device comprising a base and a quartz-sensitive unit mounted in the base. The base is provided with a clamping portion for clamping the quartz-sensitive unit including two oppositely-arranged clamping surfaces. In operation, an intersection angle is formed between the clamping surfaces and the driving direction of the vehicle. The base is provided with a component force structure for eliminating the component force of the gravity of the vehicle in the horizontal direction. The quartz-sensitive unit arranged in the device is capable of monitoring the magnitude and the direction of horizontal frictional force so as to identify a wheel type and determine single-axle driving or multi-axle driving by means of the monitored magnitude and direction of the frictional force. The drive wheel identification device solve a problem that it is low in identification efficiency and poor in identification effectiveness in the prior art to identify a drive axle by means of manual observation or monitoring equipment, and is high in identification efficiency and identification precision.

Owner:成都皆为科技有限公司

Anchor tension plate type anchoring structure cable and tensioning construction method thereof

PendingCN109295852AImprove integrityDirect and reliable force transmissionBridge structural detailsBridge erection/assemblyForce structureBridge deck

An anchor tension plate type anchoring structure cable comprises an anchor tension plate with a counter-force structure, a cable anchorage device, an anchoring nut and a tensioning mechanism. The anchor tension plate comprises a bridge deck, anchor tension plate main plates, an anchor backing plate, steel ducts and an anchor tension plate upper sealing plate. The anchor tension plate main plates are symmetrically fixed on the bridge deck to form an invert "V" shape, the steel ducts are positioned between the two anchor tension plate main plates to fixedly connect the two anchor tension plate main plates into a whole, and the anchor tension plate upper sealing plate is positioned at the middles or the tops of the anchor tension plate main plates; the anchor backing plate is fixed at the bottoms of the steel ducts, and the steel ducts protrude out of the anchor tension plate upper sealing plate; the counter-force structure is a counter-force structure lug plate located on the upper partsof the anchor tension plate main plates or an integral counter-force step structure arranged on the steel ducts of the anchor tension plate. In the installation state, the bridge deck at the lower end of the anchor tension plate is fixed on a deck, and the lower end of the cable penetrates into the steel ducts of the anchor tension plate; the tensioning mechanism is installed on the counter-forcestructure arranged on the upper part of the anchor tension plate. By using the structure cable and the tensioning construction method, the tensioning construction of the cable can be carried out on the deck.

Owner:LIUZHOU OVM MASCH CO LTD

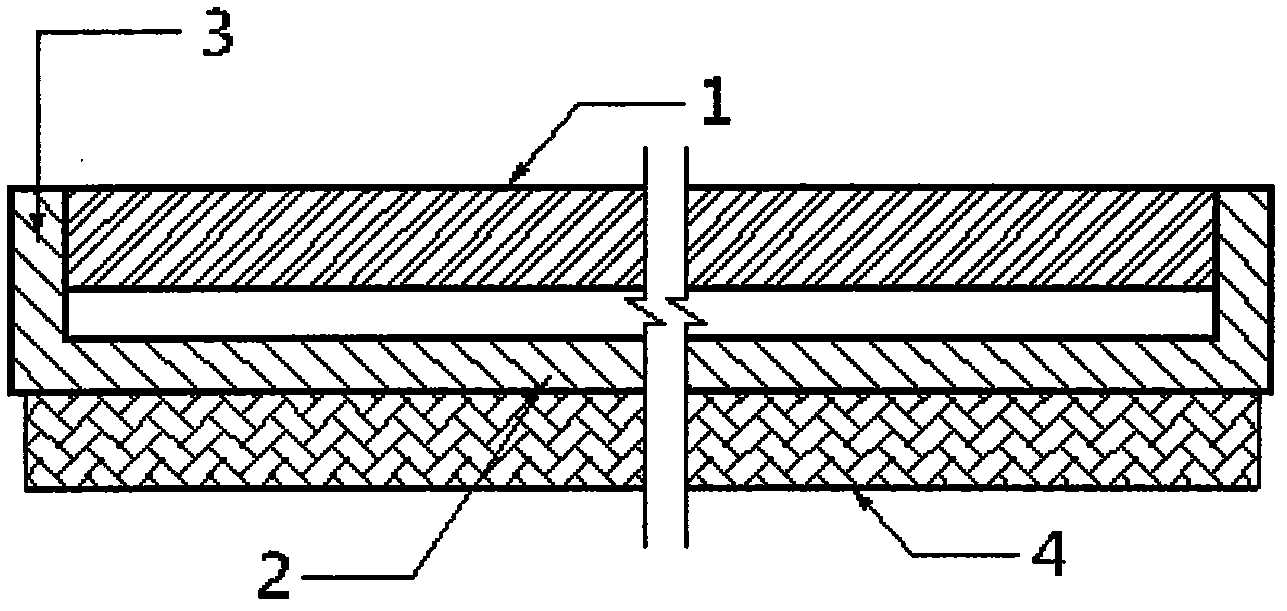

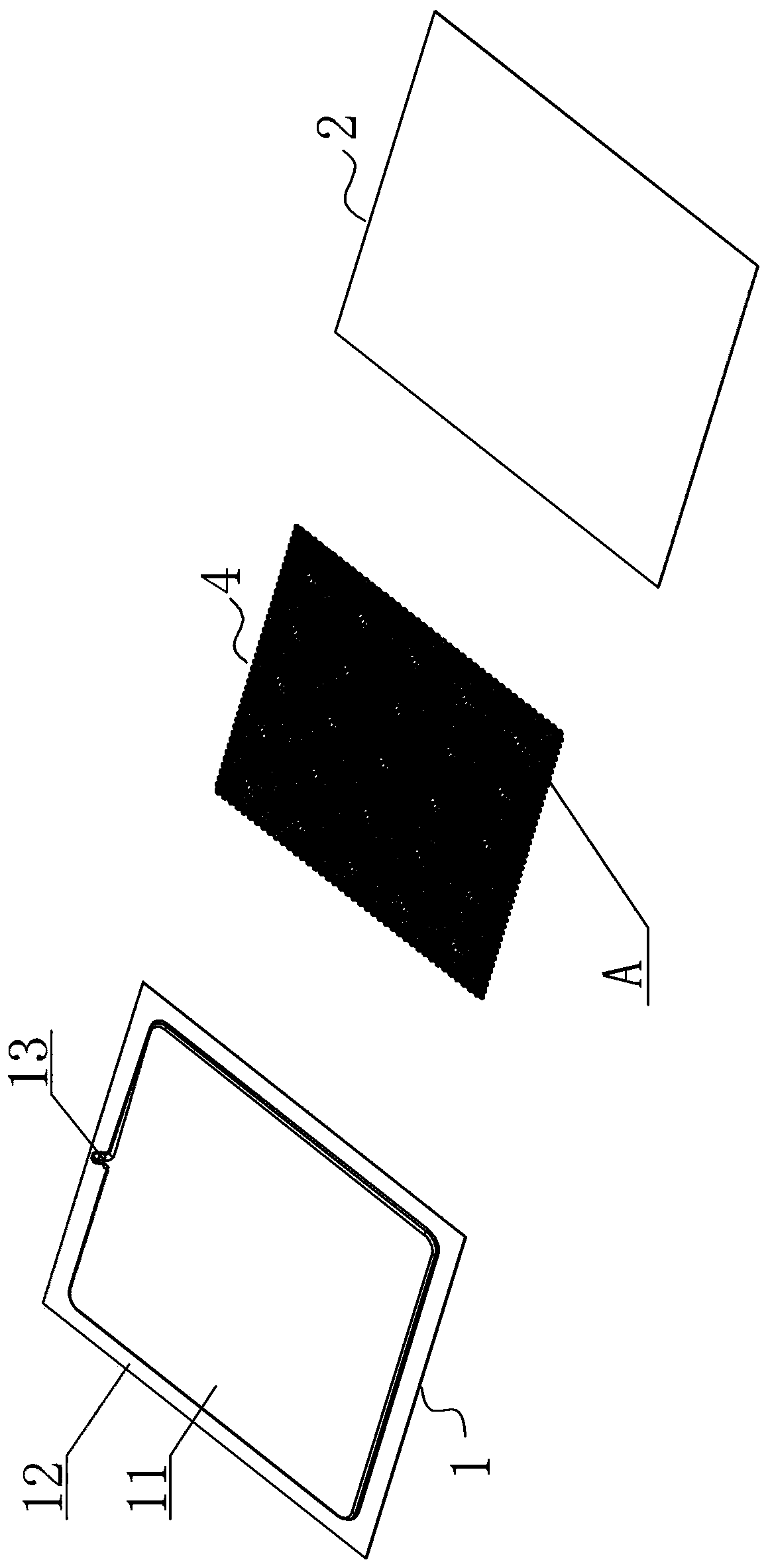

Thin capillary structure supporting uniform temperature plate

The invention provides a thin capillary structure supporting uniform temperature plate. A capillary structure in an inner cavity of the uniform temperature plate has the function of supporting a forcestructure while serving as a phase change medium capillary force structure of the uniform temperature plate. The heat conduction capacity and the heat dissipation efficiency of the uniform temperature plate are improved. The thin capillary structure supporting uniform temperature plate comprises a first cover plate and a second cover plate. The center area of the first cover plate is provided with an upward convex cavity. The second cover plate is of a flat plate structure. The periphery area of the second cover plate is covered with an outer frame of the first cover plate. The uniform temperature plate further comprises a capillary supporting structure. One surface of the overall plane area of the capillary supporting structure is provided with a plurality of outward convex supporting components. The capillary supporting structure is located in the upward convex cavity. The plane surface of the overall plane area of the capillary supporting structure is attached to the inner surfaceof the upward convex cavity. Outward convex points of the supporting components form an equivalent plane and are attached to the inner surface of the second cover plate.

Owner:KUNSHAN LEMTECH ELECTRONICS TECH CO LTD

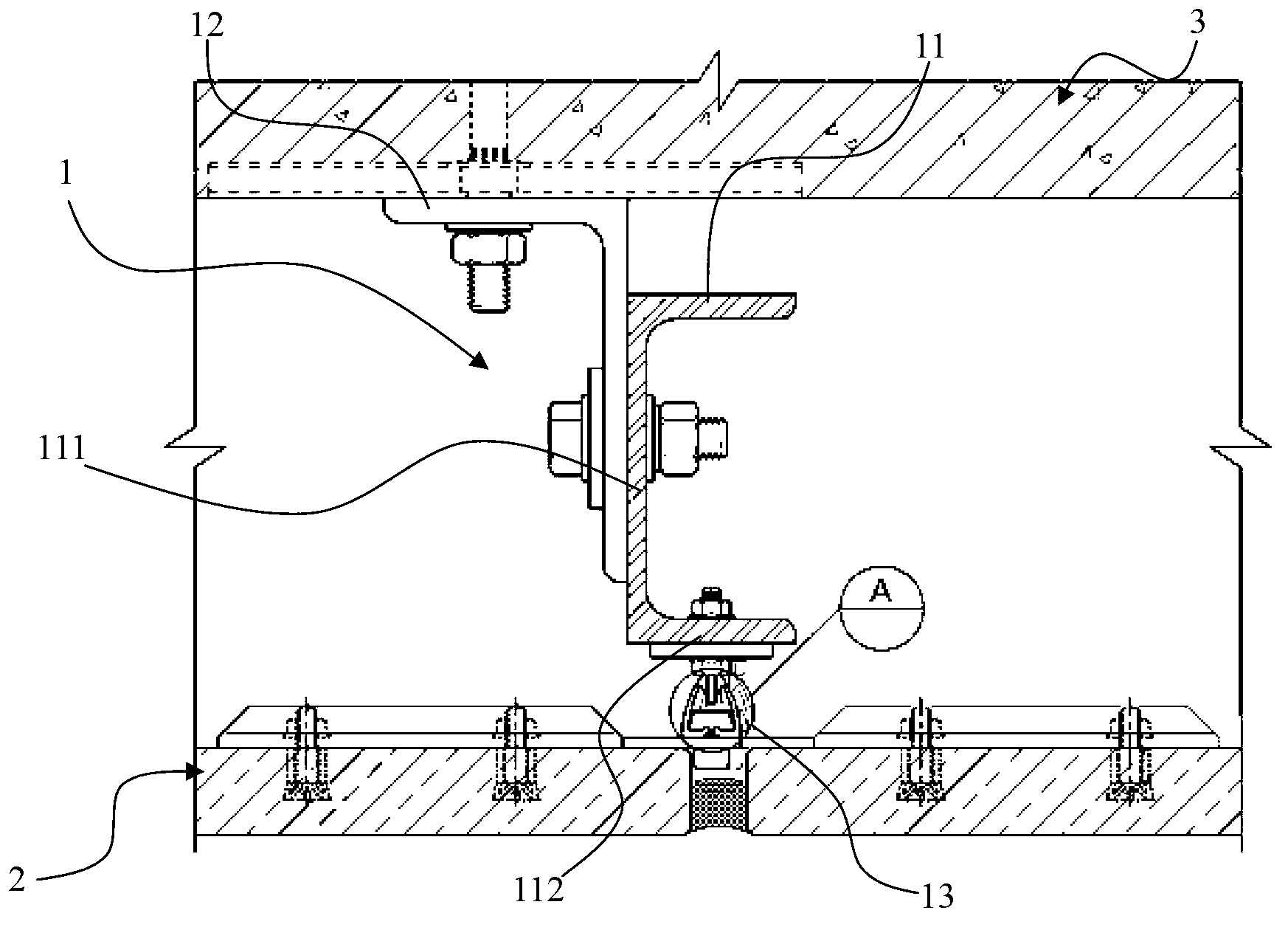

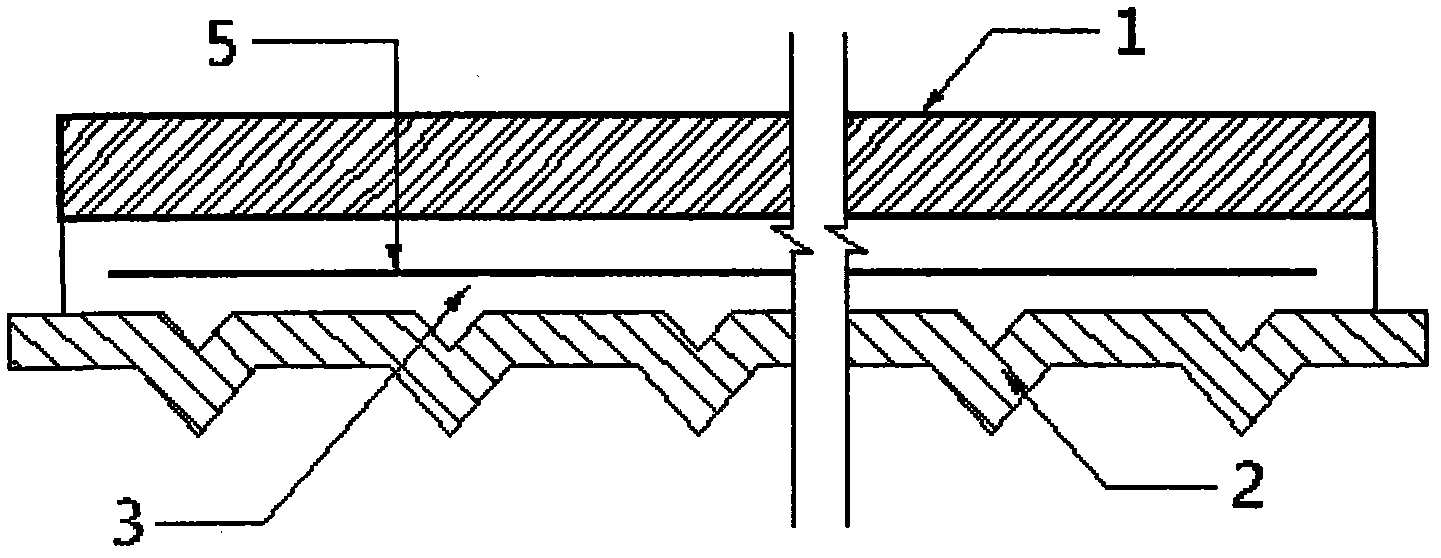

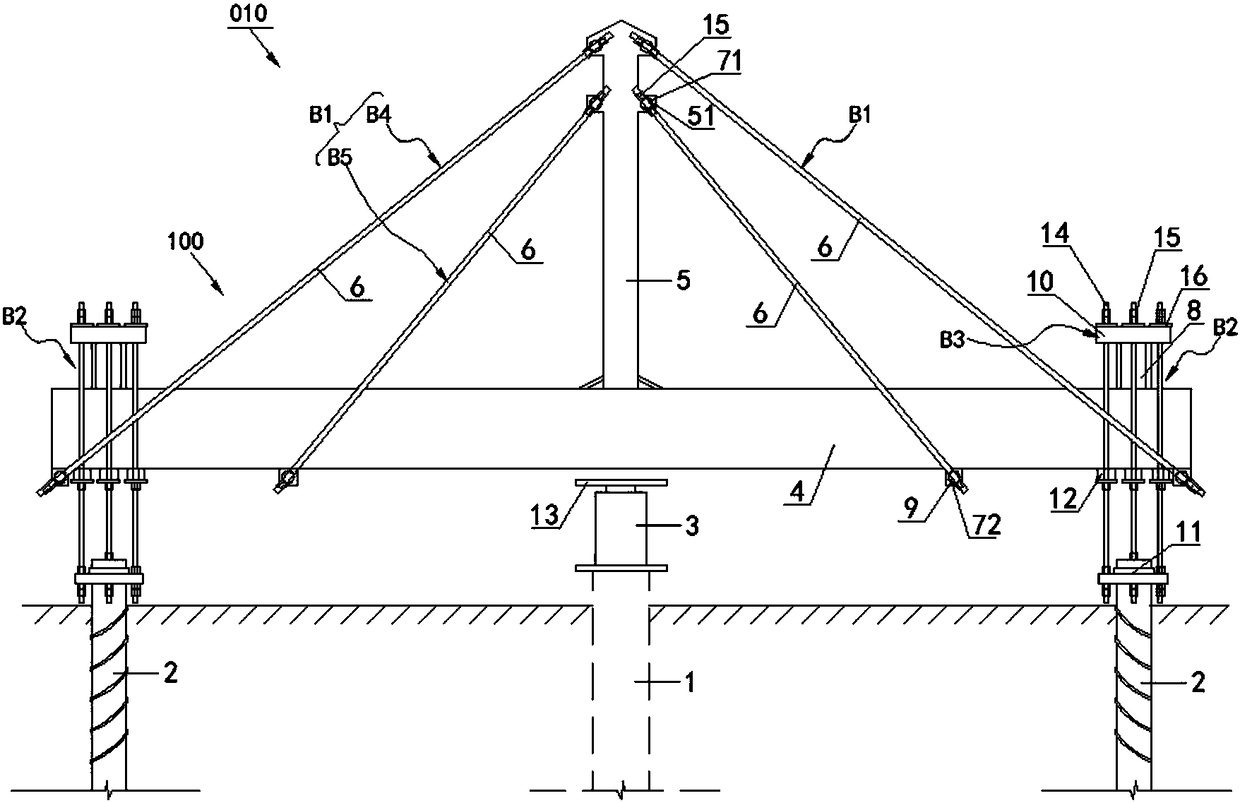

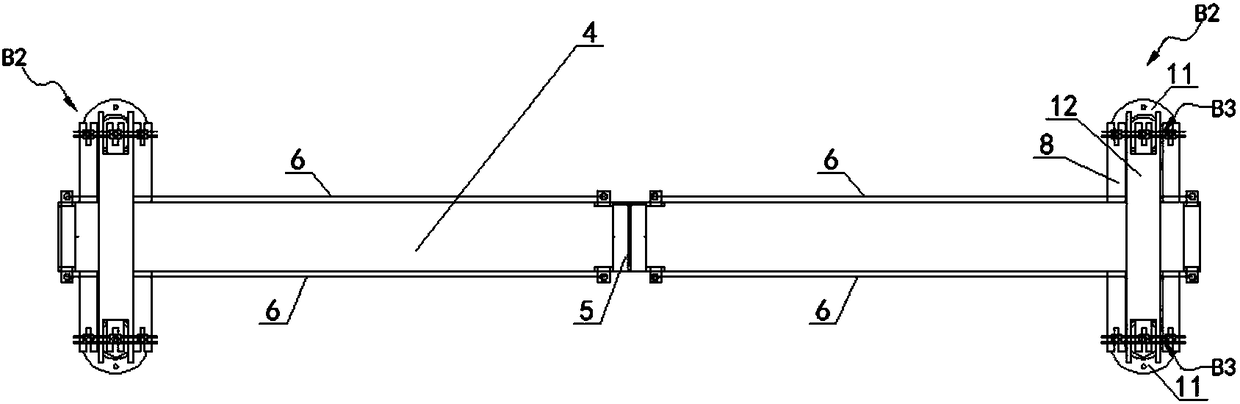

Large-tonnage static-load test counter-force structure and static-load test device

PendingCN108487341AImprove flexural strengthGreat reactionFoundation testingForce structureUpward displacement

The invention relates to the field of buildings, aims to solve the problem that measured results are great in deviation as a test device in the prior art performs test on a large-tonnage foundation pile, and provides a large-tonnage static-load test counter-force structure and a static-load test device. The large-tonnage static-load test counter-force structure comprises a main beam, a stand column and inclined pulling structures, wherein the stand column is perpendicularly arranged on the mid-span position of the upper surface of the main beam in the vertical direction; the portions, at the two sides of the stand column, of the main beam are tensioned at the upper end of the stand column through the inclined pulling structures separately; and the inclined pulling structures at the two sides are symmetrical with respect to the stand column. Anti-pulling structures which are anchored on a foundation are separately arranged on positions near the two ends in the length direction of the main beam; the lower ends of the anti-pulling structures are anchored; and the upper ends of the anti-pulling structures are configured to match with corresponding ends of the main beam, and can limit upward displacement, in the vertical direction, of the main beam. The large-tonnage static-load test counter-force structure has the beneficial effects that the structure can be integrally suitable forthe foundation pile static-load test with larger tonnage, and can obtain higher measuring precision.

Owner:广州市汇富盈投资有限公司

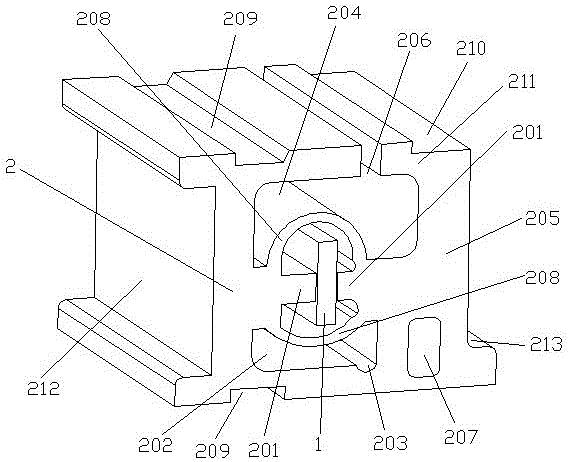

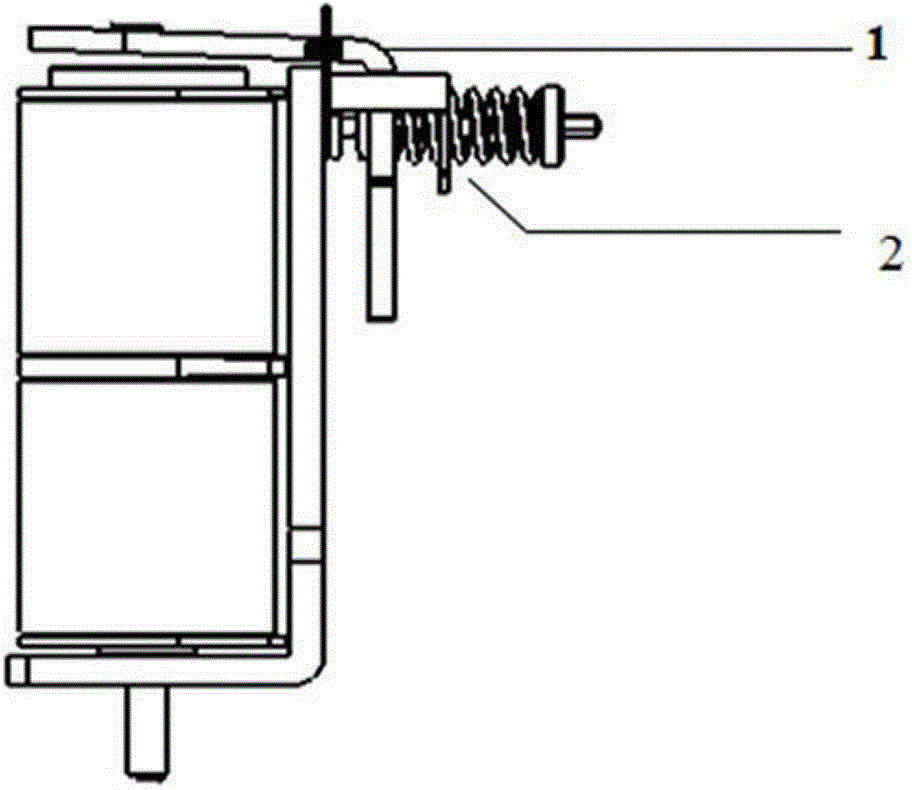

Dual-spring counter-force structure of railway signal relay

ActiveCN104701094AGuaranteed operating characteristicsReduce bouncingElectromagnetic relay detailsForce structureEngineering

The invention discloses a dual-spring counter-force structure of a railway signal relay, which comprises a spring counter-force structure formed by a spring, a spring fixing cover (4), a square-head screw rod (5), a nut, and a keeper (1), and is characterized in that the spring is formed by an outer spring and an inner spring (6) with different stiffness arranged on the square-head screw rod; and at the beginning stage, the inner spring (6) provides a counter force, and in the case of movement to a certain displacement, the outer spring (3) and the inner spring (6) together provide the counter force. The defect that adjustability of counter-force features of a single-spring counter-force structure is not high can be solved, improvement of anti-vibration performance of the relay is facilitated, movement features of the keeper can be well ensured, and the dual-spring counter-force structure of railway signal relay has the advantages of reasonable and compact structure, good reliability and simplicity.

Owner:华珑(沈阳)数字科技有限公司

Sliding-type electronic apparatus with strengthening force structure

ActiveUS20140055938A1Avoid resistanceSimple structureDigital data processing detailsElectrical apparatus contructional detailsForce structureOperational stability

A sliding-type electronic apparatus with a strengthening force structure includes a body served as a system terminal and an upper cover disposed on the body and having a surface configured with a touch screen. A sliding and cover-lifting member constituted by a sliding rail, a sliding member and a pivot shaft device is at least disposed between the body and the upper cover. In a normal state, a supporting device, together with the sliding and cover-lifting member, is horizontally and supportively placed in a preset concave chamber space of the body. The auxiliary supporting devices can be formed as an inclined auxiliary support structure on the rear surface of the upper cover when the upper cover is lifted, thereby effectively increasing the screen touch resistance to inhibit screen wobble in an operation process and to promote the support effect and operation stability of the screen.

Owner:FIRST DOME

Full server automobile air outlet force measuring machine

ActiveCN103884511ARealize multi-station measurementHigh degree of automationVehicle testingWork measurementForce structurePull force

The invention discloses a full server automobile air outlet force measuring machine, comprising a support and an industrial personal computer and a rotation torsion structure, a forward-and-back torsion structure and a left-right pushing force structure for detecting the push-pull force of a sliding block which are arranged on the support for detecting torque of a hand wheel. The rotation torsion structure, the forward-and-back torsion structure and the left-right pushing force structure are respectively connected to the industrial personal computer. The full server automobile air outlet force measuring machine has advantages that the device can automatically measure, analyze data and draws force value curve graphs, and has high automation degree. The full server automobile air outlet force measuring machine improves working efficiency, greatly reduces time of the testing people and provides convenience to usage.

Owner:NINGBO CHANGSHENG ELECTRONICS TECH

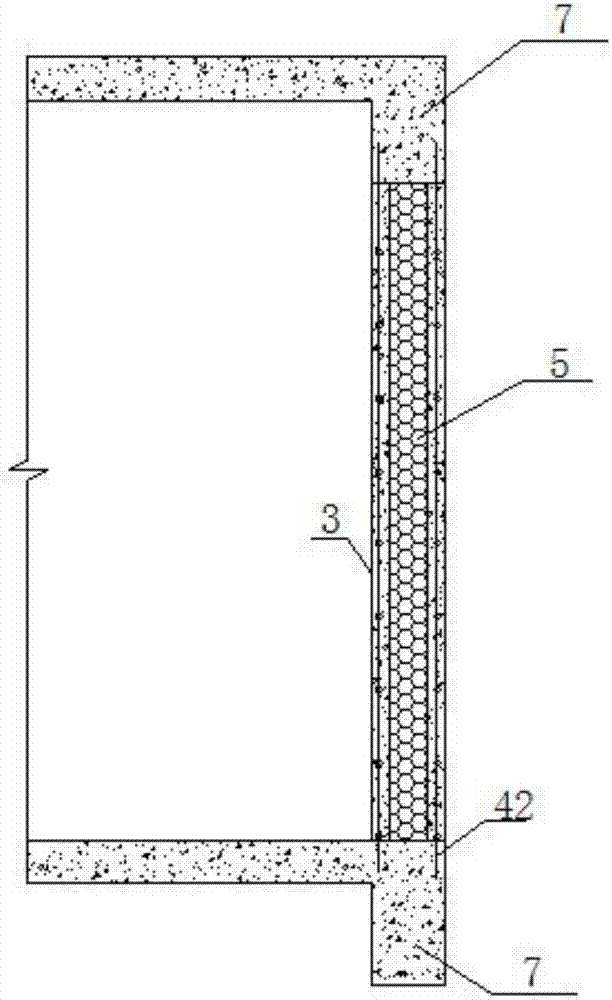

Cast-in-place hollow reinforced concrete filled wall and its construction technology

The invention discloses a cast-in-place hollow reinforced concrete filled wall and its construction technology. The cast-in-place hollow reinforced concrete filled wall includes a single-piece thin wall, deformation partition plates, non-dismantling light filling material layers, a connection wall and a fixing hook; the deformation partition plates are arranged between the filled wall and a forced structure; two layers of single-piece thin walls opposite to each other are arranged between the deformation partition plates, horizontal reinforced bars and longitudinal reinforced bars are embedded in the single-piece thin walls, the horizontal reinforced bars pass through the deformation partition plates and are anchored in the forced structure, the longitudinal reinforced bars are anchored in a beam body, the non-dismantling light filling material layers are arranged between the single-piece thin walls, and a connection wall is arranged between the every two adjacent non-dismantling light filling material layers. According to the wall and its construction technology, the forced structure of a main body is integrally formed with the filled wall so that the outer wall can be fully coated with concrete, at the same time, the forced structure of the main body is integrally formed with the filled wall so that the materials of the forced structure and the filled wall can be same in property, the permeation prevention and cracking prevention of the wall body is facilitated, the construction process is simplified, the construction period is largely shortened, and an effective premise is provided for alternate construction.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Automatic deviation adjusting mechanism for welding position of lithium battery cap

PendingCN107824969AReduce security risksAvoid the problem of falling into the roof holeLaser beam welding apparatusForce structureElectrical battery

The invention discloses an automatic deviation adjusting mechanism for welding positions of a lithium battery cap. The deviation adjusting mechanism comprises at least two positioning probes, the positioning probes are connected with a deviation adjusting power structure, and the deviation adjusting power structure can drive the positioning probes to rotate so that the positioning probes can be inserted into the top cover holes. According to the automatic deviation adjusting mechanism for the welding positions of the lithium battery cap, the top cover holes of a top cover of the battery cap are adjusted to positions matched with the positioning probes in advance, then the battery cap is conveyed to the position below the positioning probes through a rail, if the positioning probes are inserted into the holes, adjustment of the deviation adjusting power structure is not needed, laser welding is directly carried out, and the hole positions of the top cover is avoided; when the positionsare offset, the positioning probes touch other parts of the top cover, the deviation adjusting power structure rapidly reacts, the positioning probes are adjusted into the top cover hole through fineadjustment driving of the deviation adjusting power structure, so that the top cover is fixed during welding, and welding slag is shielded to be prevented from splashing into the top cover holes.

Owner:安徽镭腾能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com