Drive wheel identification device

A recognition device and driving wheel technology, applied in the field of vehicle recognition systems, can solve the problems of poor recognition effectiveness, high recognition efficiency, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

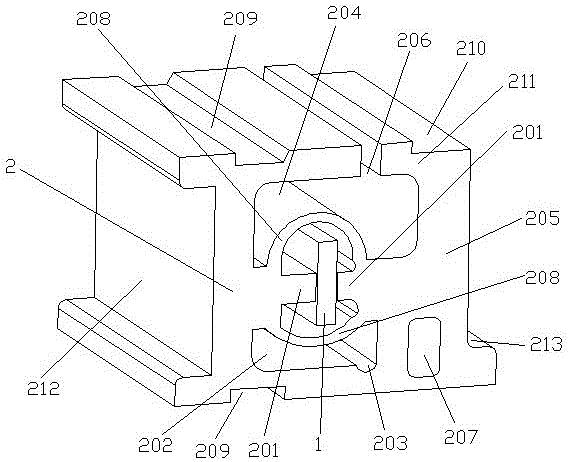

[0035] Such as figure 1 As shown, the driving wheel identification device includes a base 2 and a quartz sensitive unit 1 installed in the base 2. The base 2 is provided with a clamping portion 201 for clamping the quartz sensitive unit 1, and includes two oppositely arranged clamping planes. , when working, the clamping plane forms an angle with the driving direction of the vehicle, and the base 2 is provided with a force component structure that eliminates the force component of the vehicle's gravity in the horizontal direction.

[0036] The base 2 is installed under the road surface in an inlaid manner. When a cargo transport vehicle passes the base 2, the base 2 is subjected to the large gravity of the vehicle in the vertical direction and the horizontal force of the transport vehicle at the same time. The clamping part 201, when the driving wheel identification device is working, the two clamping planes of the clamping part 201 are arranged opposite in the horizontal dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com