Patents

Literature

33results about How to "Achieve collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

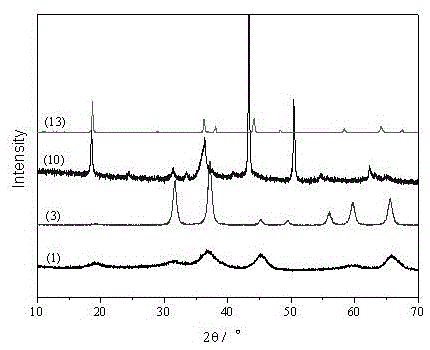

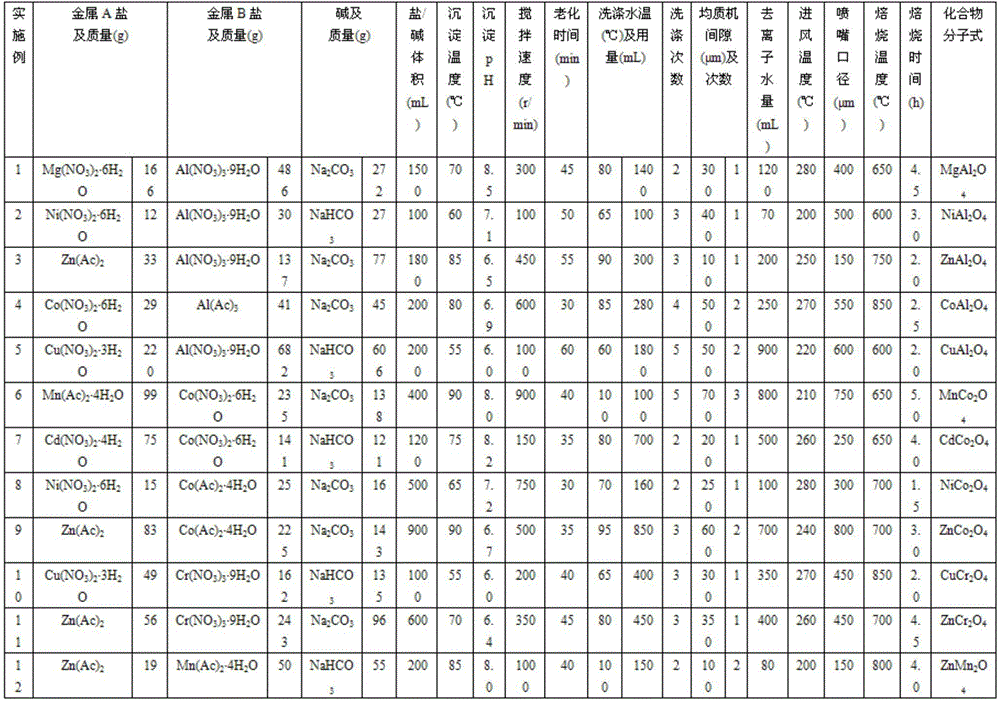

Method for preparing spinel-type complex oxide through co-precipitation, homogenization and spray drying

ActiveCN105417570AGuaranteed uniformityImprove purityZinc oxides/hydroxidesGallium/indium/thallium compoundsMetal nitrateNitrate

The invention belongs to the field of chemical engineering and relates to a preparation method of a spinel type material, in particular to a method for preparing a spinel-type complex oxide through co-precipitation, homogenization and spray drying. According to the method, a mixed solution of two metallic nitrates and an alkaline solution are combined and added to a precipitation tank for a reaction, an obtained material is washed by deionized water, filtered, subjected to beating and refined by a homogenizer and then is sent to a spray drying machine, the dried material is subjected to calcination, and the spinel-type complex oxide powder is obtained. The method has the advantages of low calcination temperature, short time and low energy consumption, and a product has low loss, high purity and small particle size.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

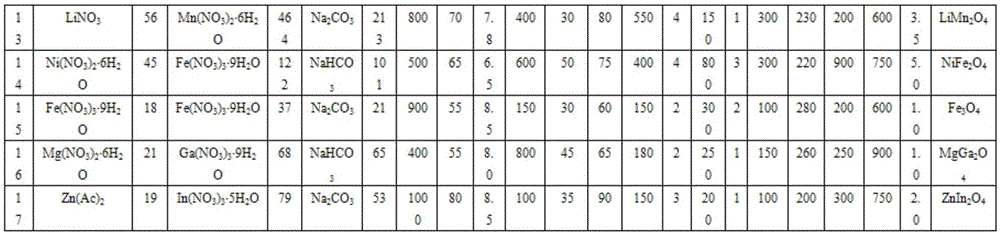

Pulper low in power consumption and noise

The invention provides a pulper low in power consumption and noise. The pulper mainly comprises a cylinder wall, a motor, a reducer, a seal device, a spindle, a spiral blade rotor, upper vortex board grooves, lower vortex board grooves and vortex boards. The pulper is characterized in the motor provides power, and the power is transmitted to the spiral blade rotor sequentially through the reducer and the spindle. By the inner and outer crescent arc transitions of the upper and lower vortex board grooves and the crescent cylindrical four-side arc structures at the inner edges of the vortex boards, flows can stably generate four vortexes at the four-side arcs of the vortex boards, vortex kinetic energy pulping is achieved, and low power consumption is achieved. Due to the fact that the hollow holes in two sides of the upper and lower vortex board groove retaining plates and in the middle portions of the vortex boards can be filled with damping and sound absorbing materials, fluid exciting force and solid noises can be absorbed, and low noise is achieved.

Owner:UNIV OF JINAN

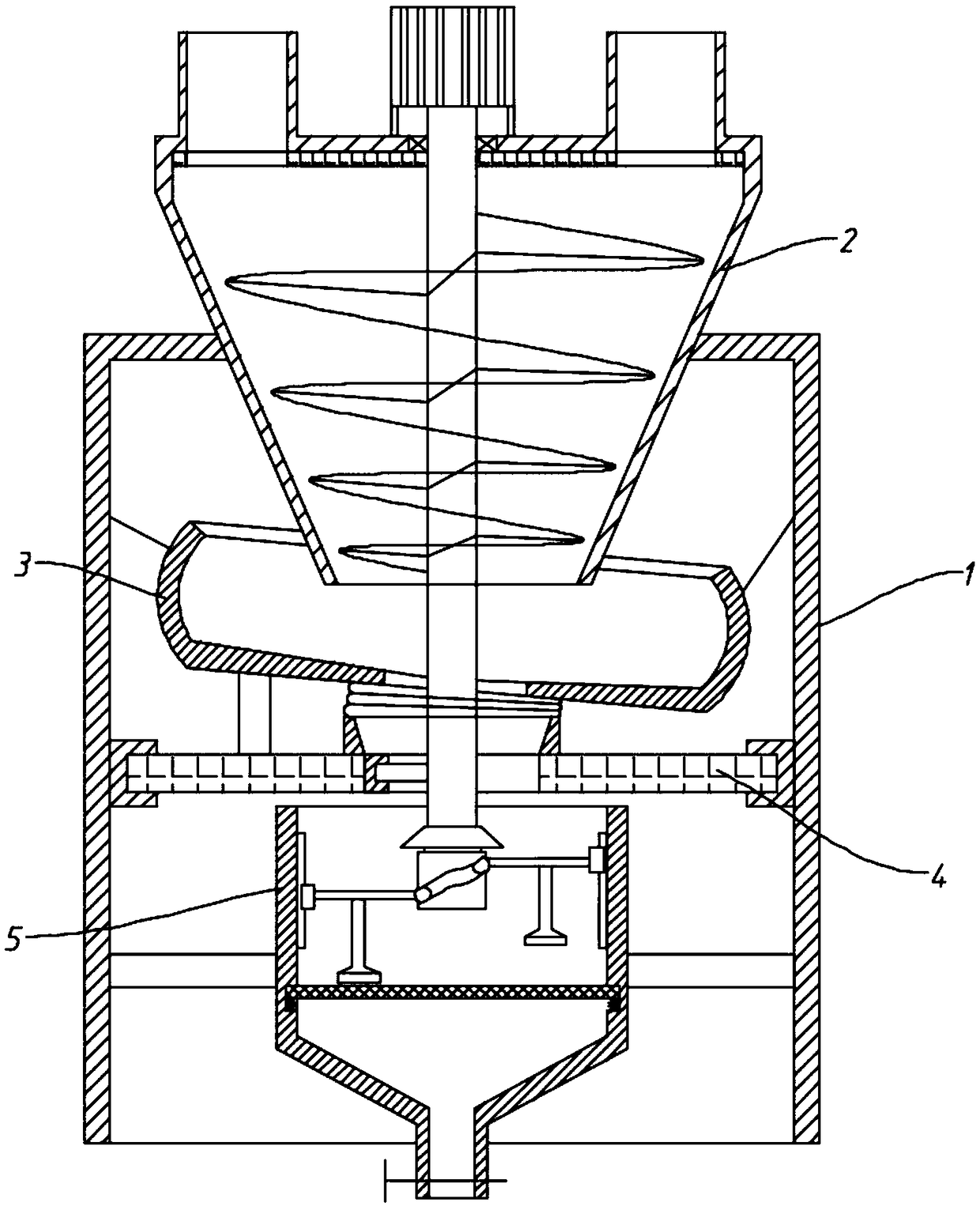

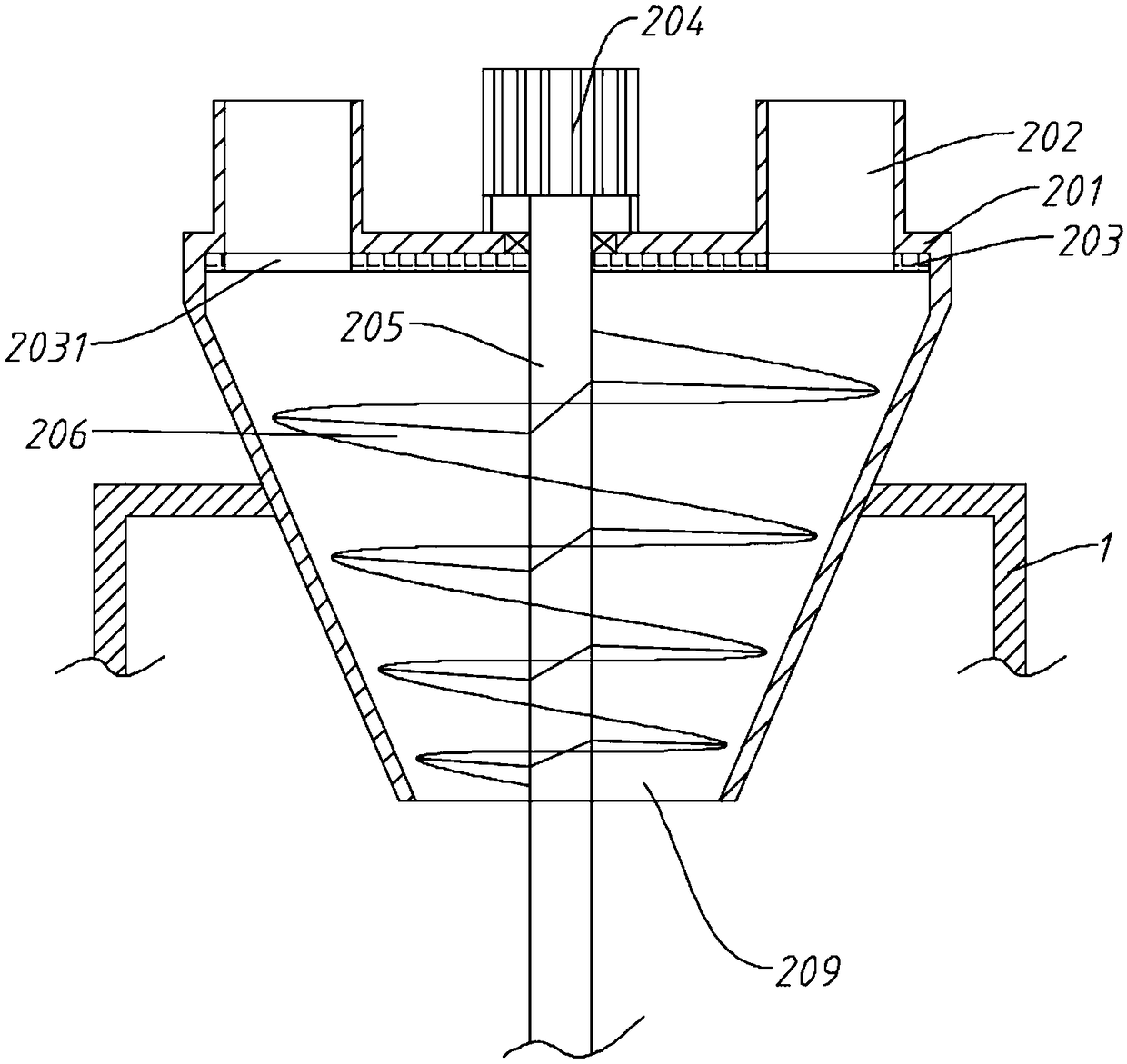

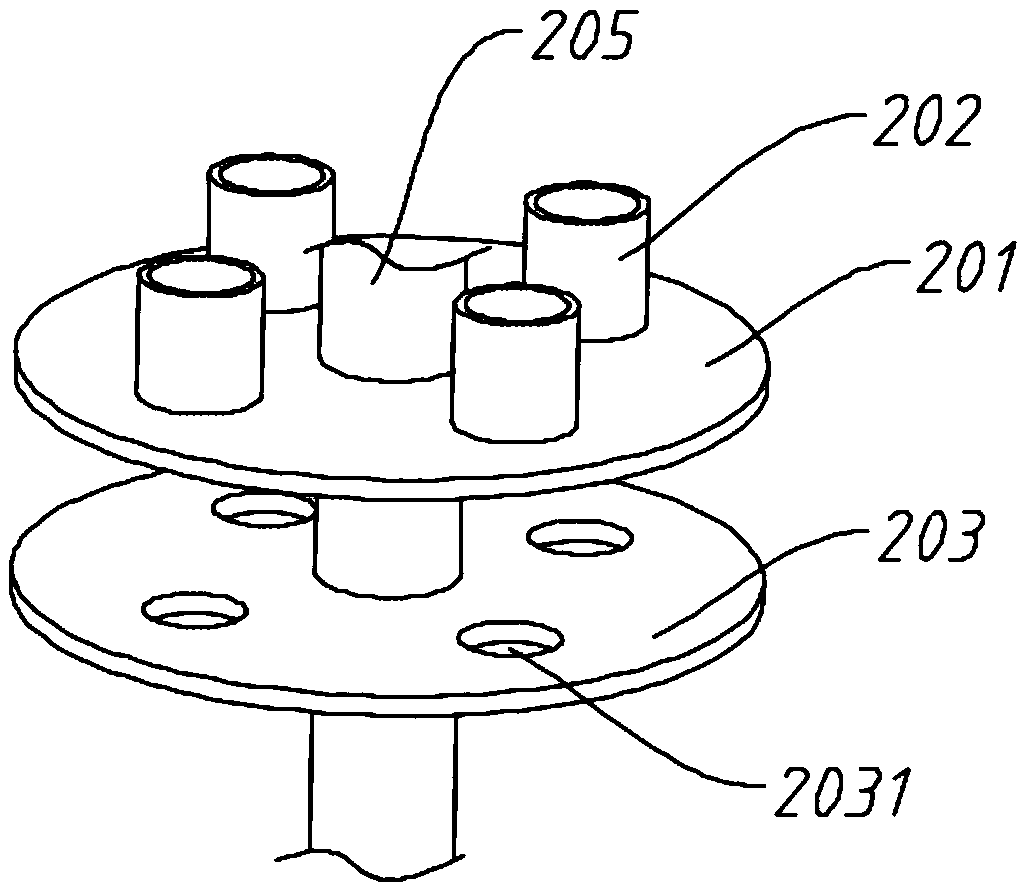

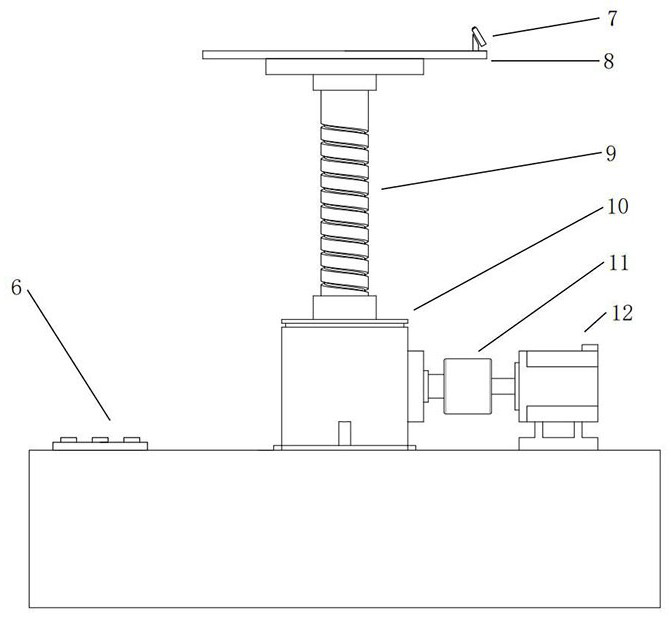

Pulping device repulping based on rotating lifting type rotor

PendingCN106948205AAvoid cloggingAvoid unevennessRaw material divisionPaper recyclingEngineeringSlurry

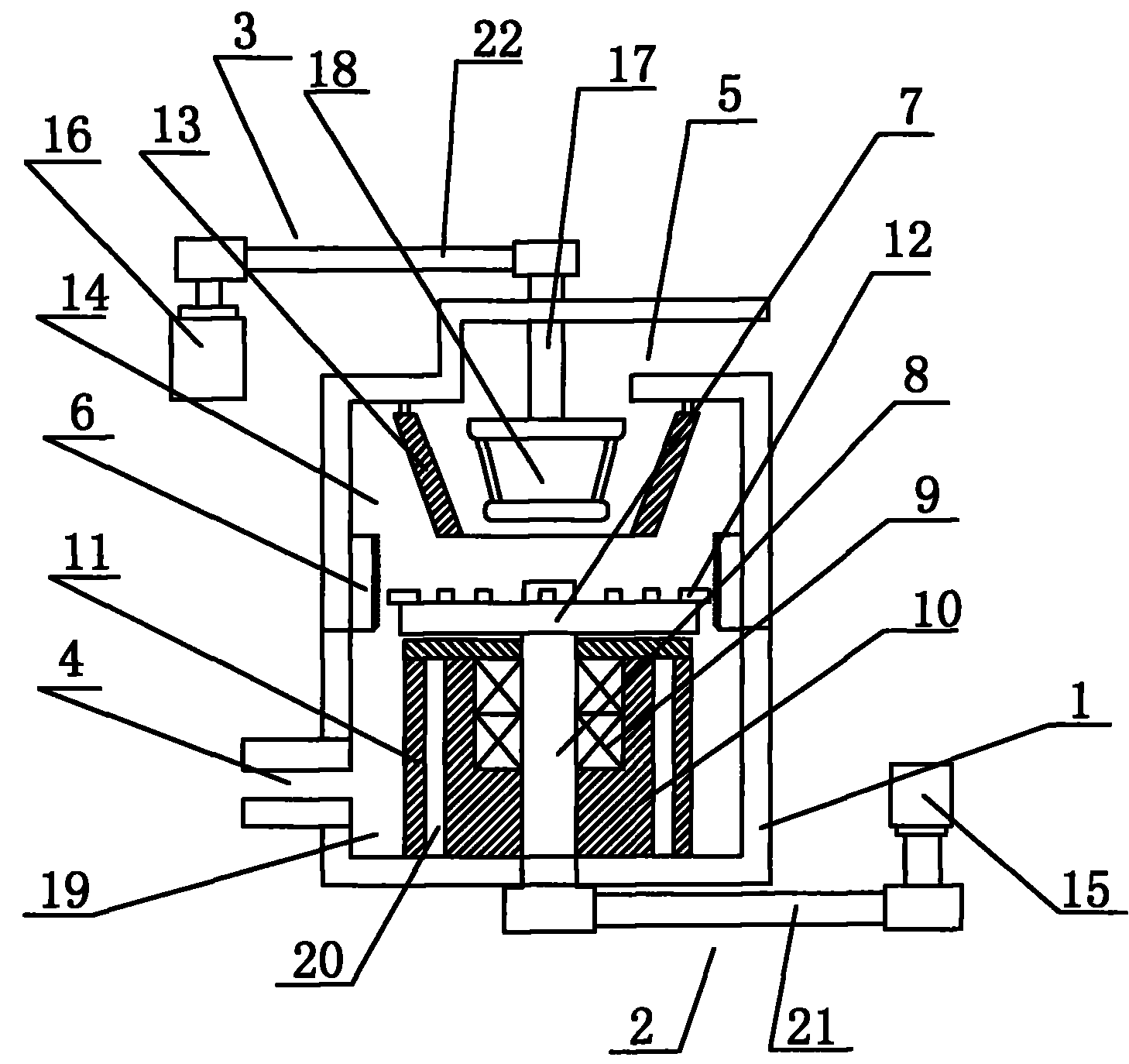

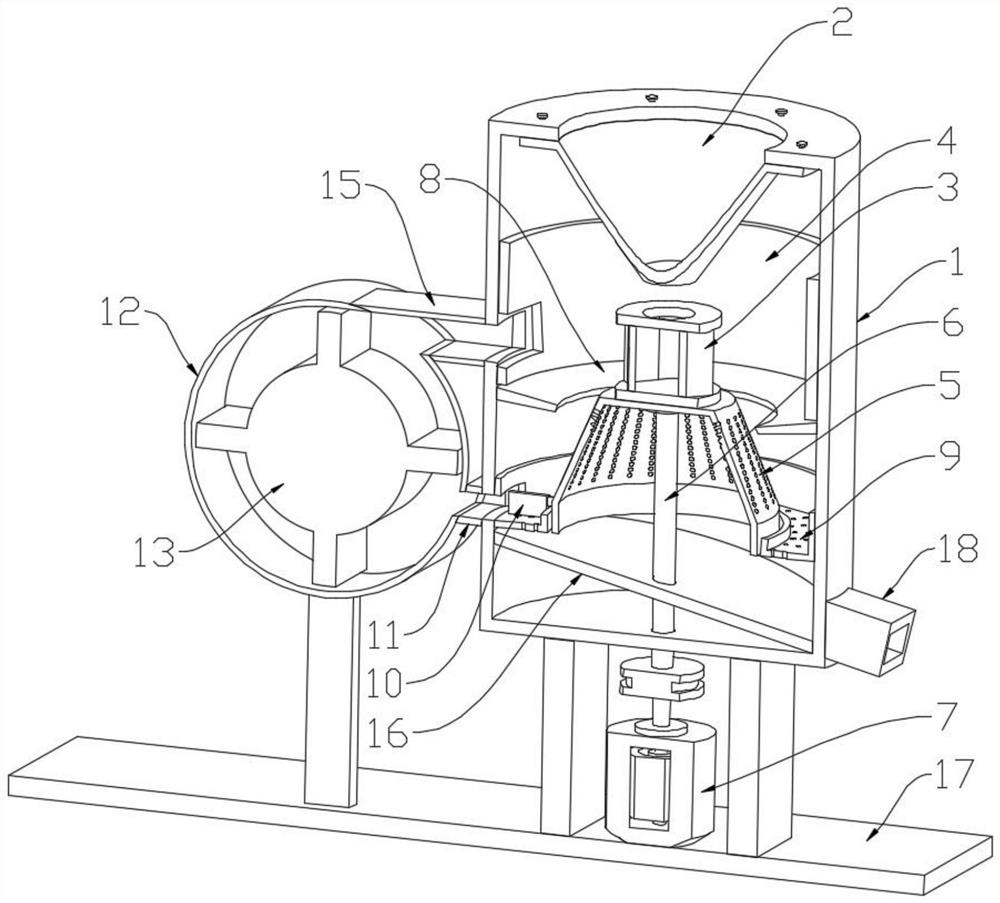

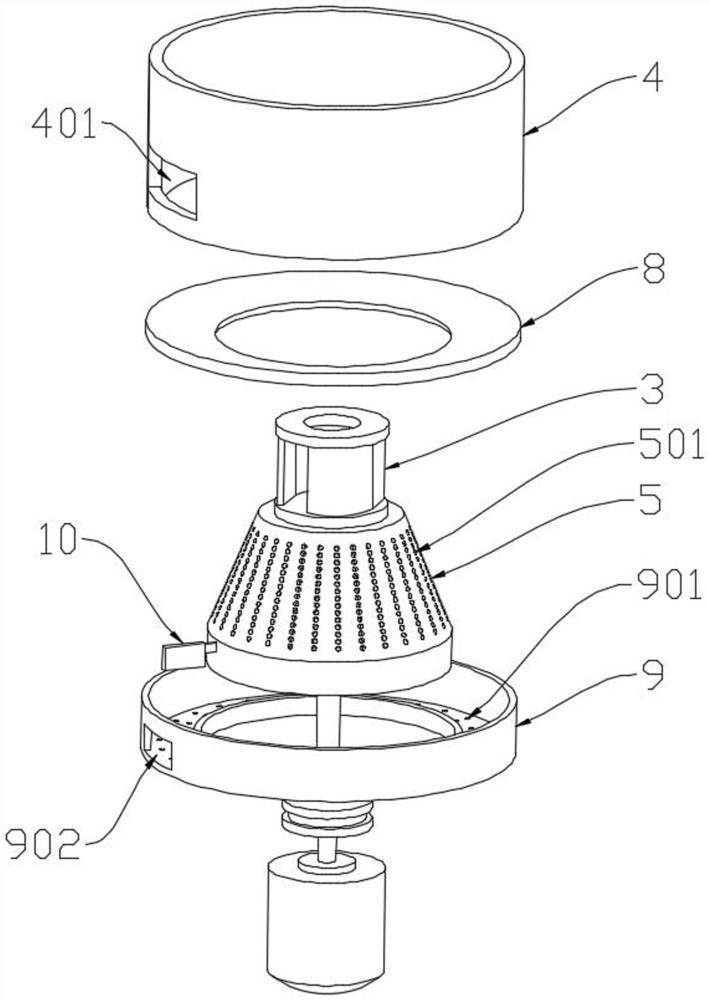

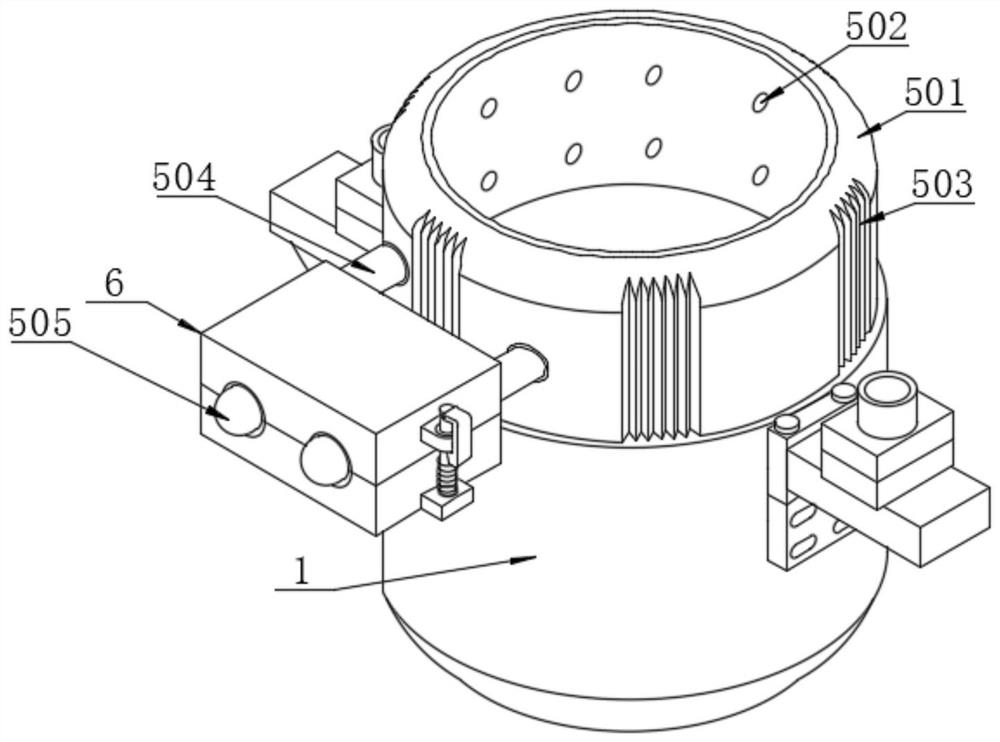

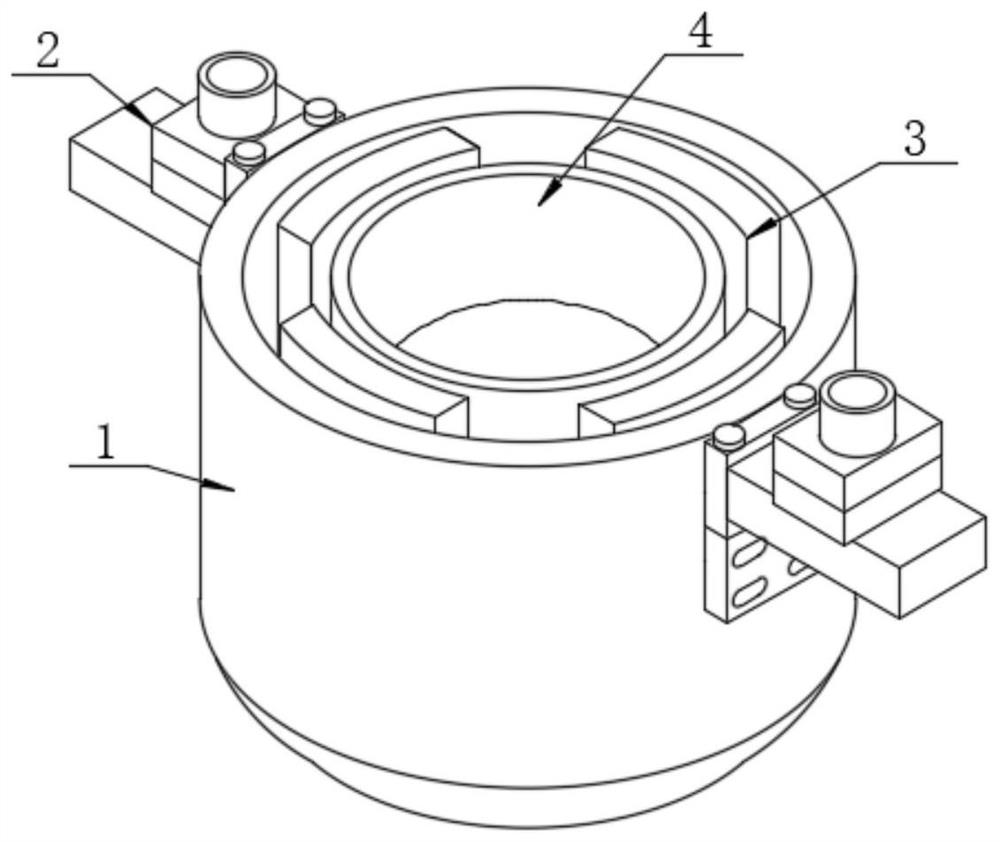

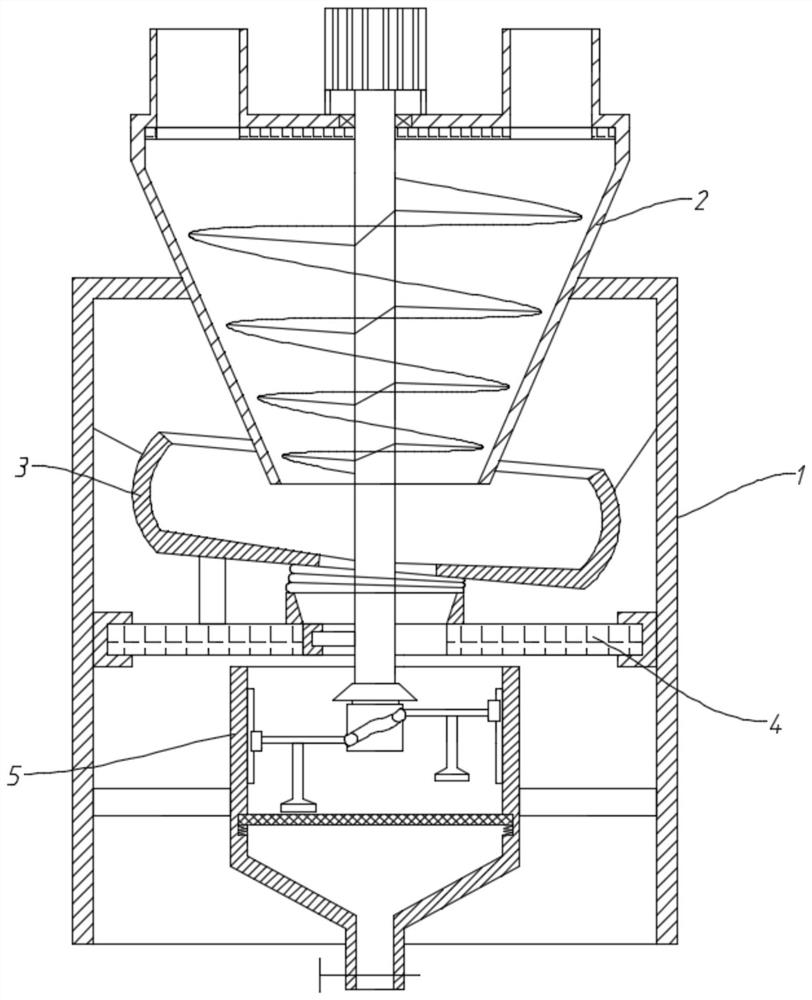

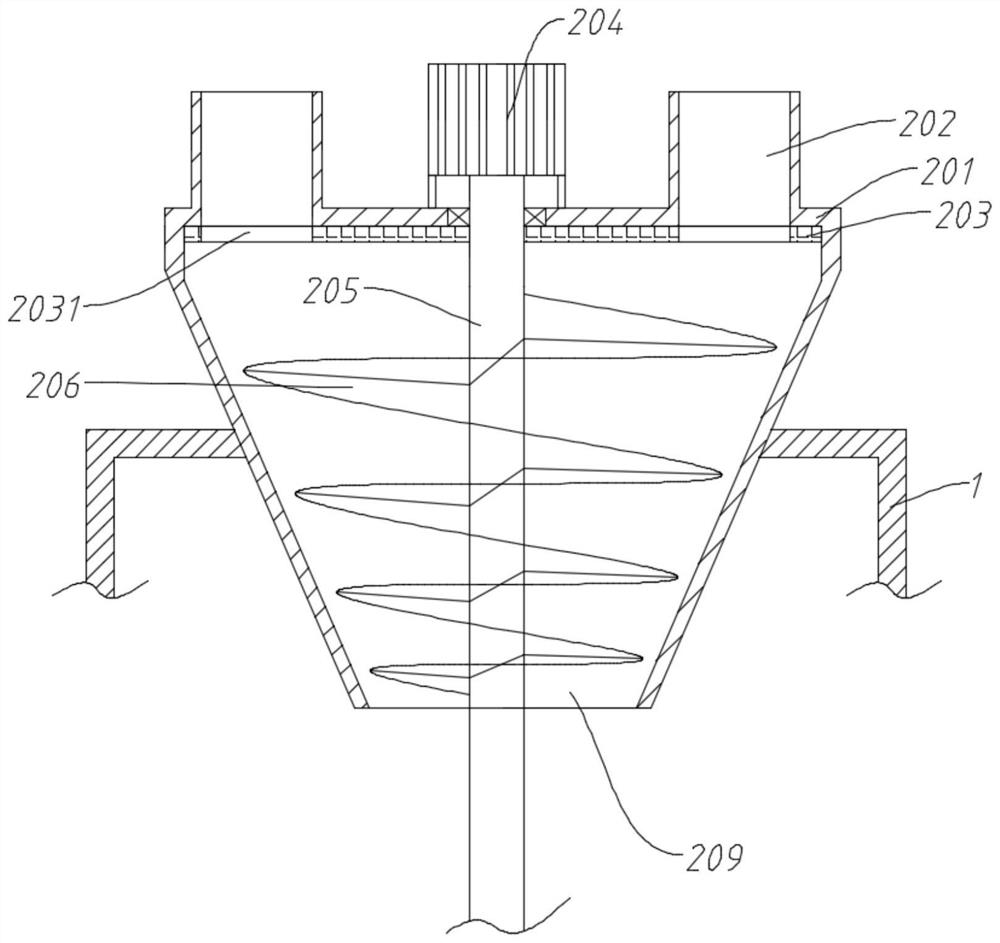

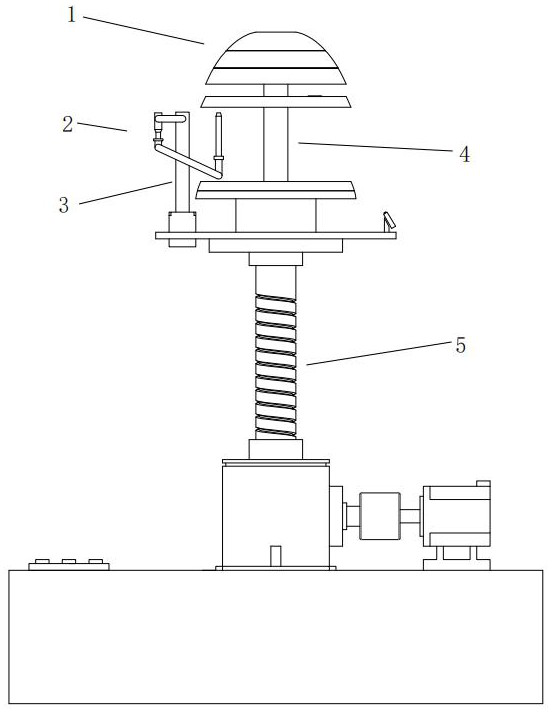

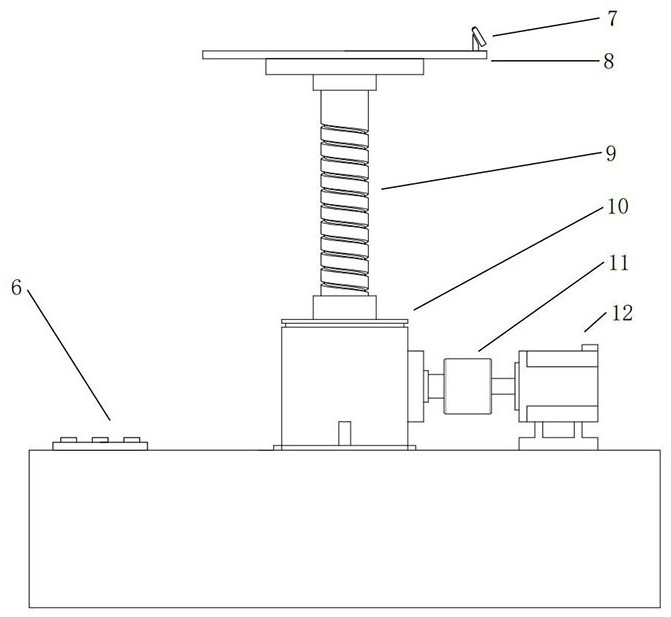

The invention provides a pulping device repulping based on a rotating lifting type rotor. The device mainly comprises an electromagnetic lifting device, a rotating mixing device, a buffer device, and a slurry generating device. The device is characterized in that the rotor is reciprocating and lifts while rotating, stirring, crushing, and decomposing to pulp. Through the electromagnetic lifting device, a lifting function of the rotating mixing device is realized, through a thread shaft, a rotating function of the rotating mixing device is realized, through the rotating mixing device, high-efficiency stirring, crushing, and decomposing of crushed aggregates are realized, and through the buffer device, buffer protection of the rotating mixing device is realized, and through filter holes on a filter plate, homogeneous control of decomposed crushed aggregates is realized.

Owner:UNIV OF JINAN

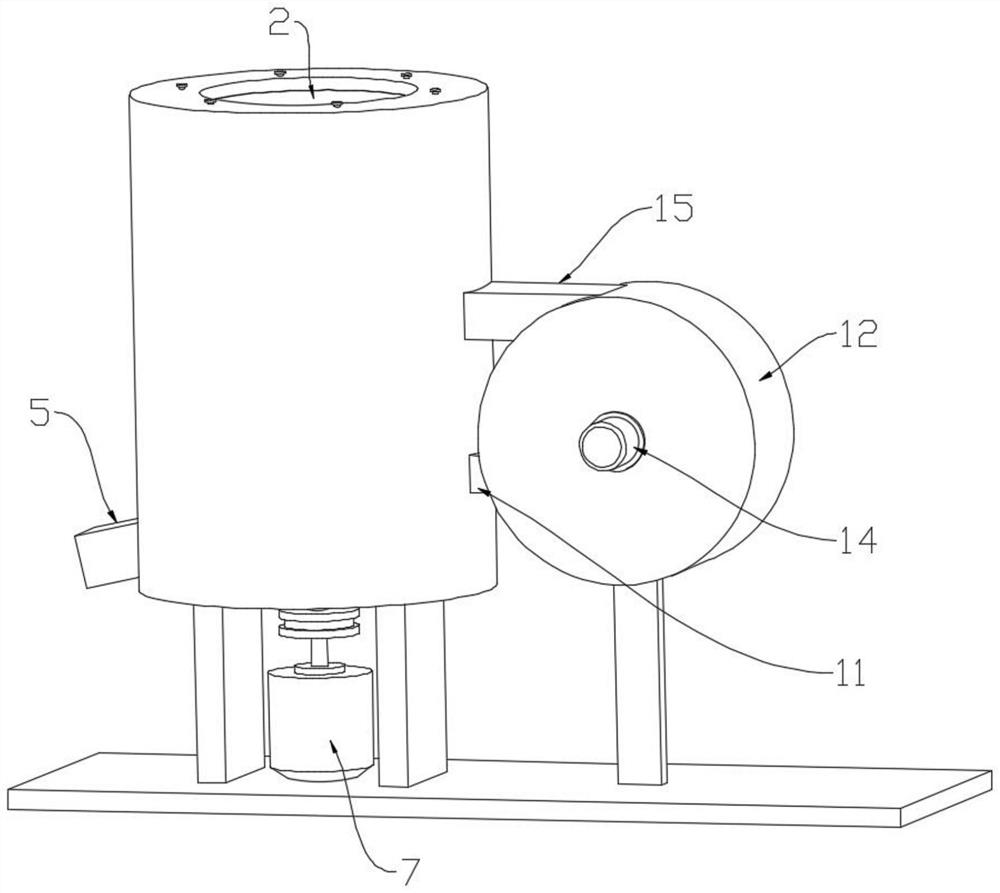

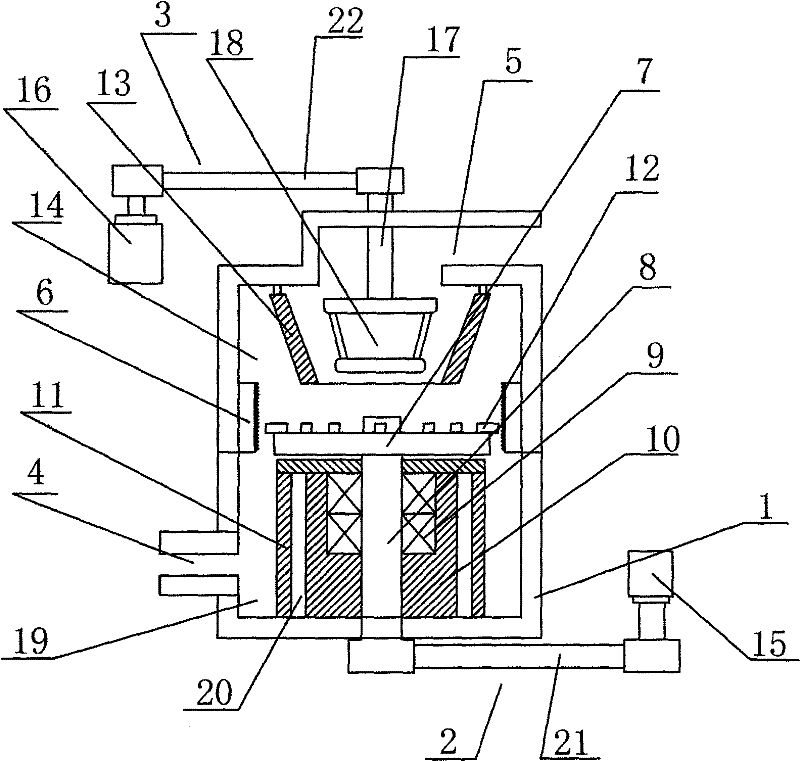

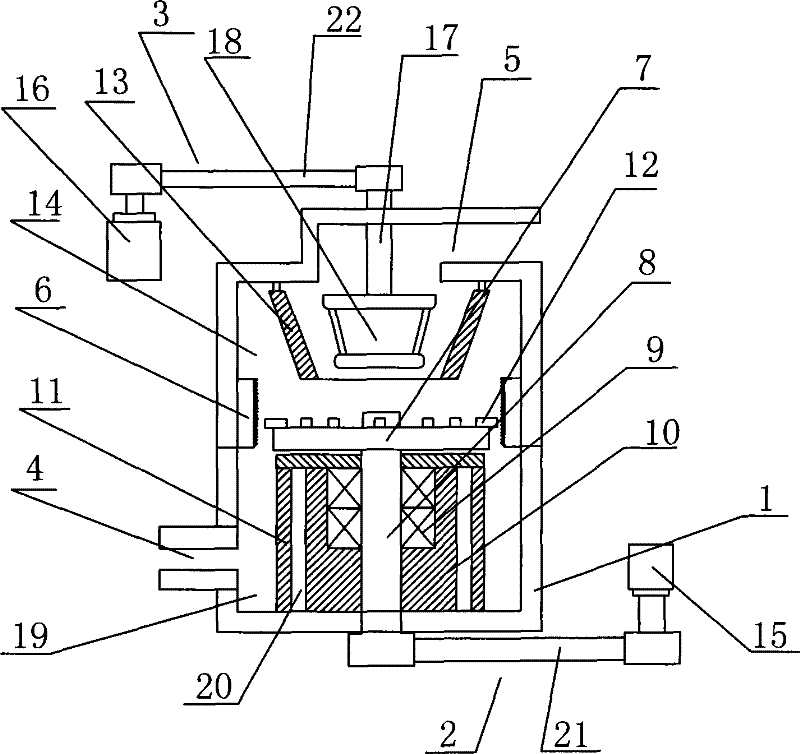

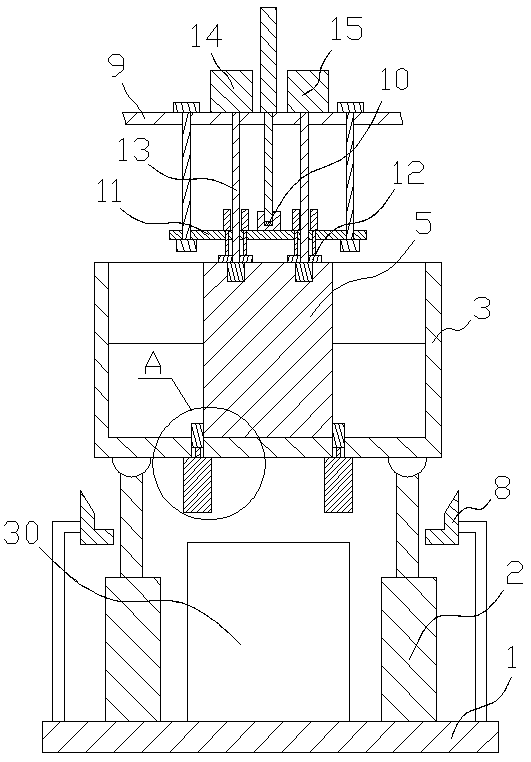

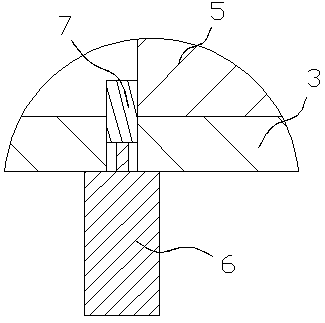

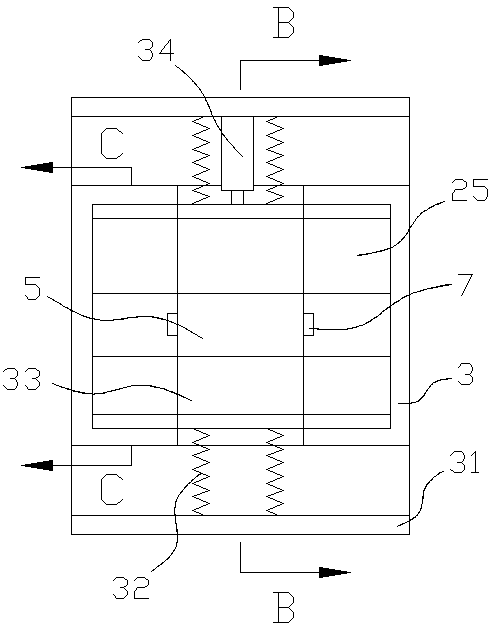

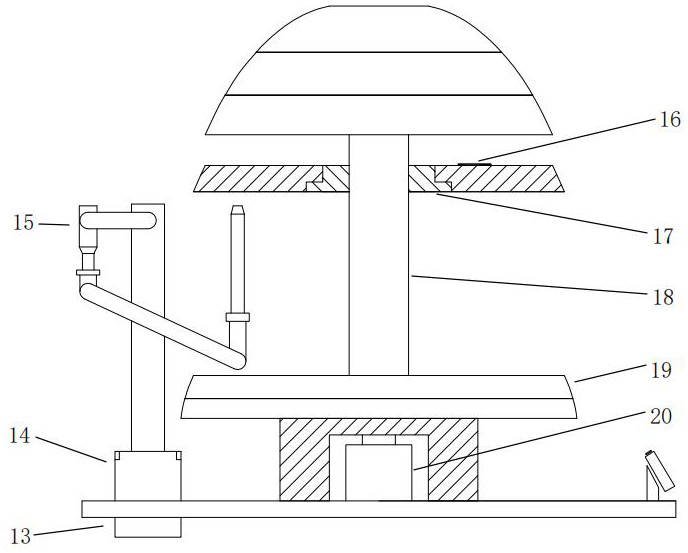

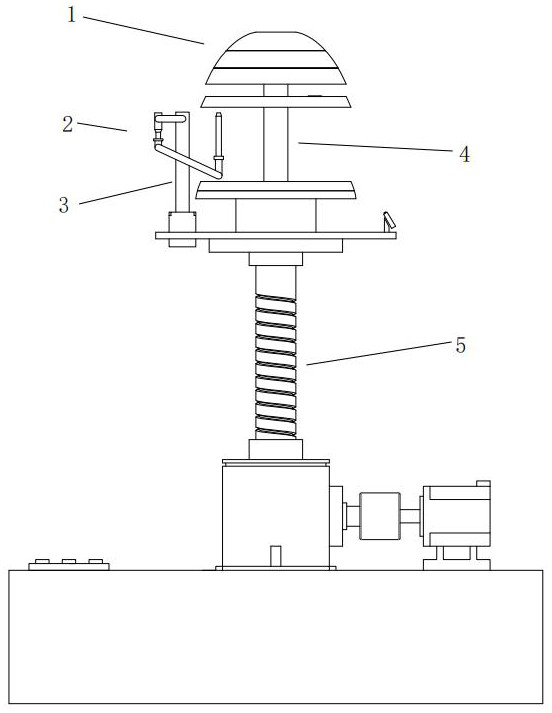

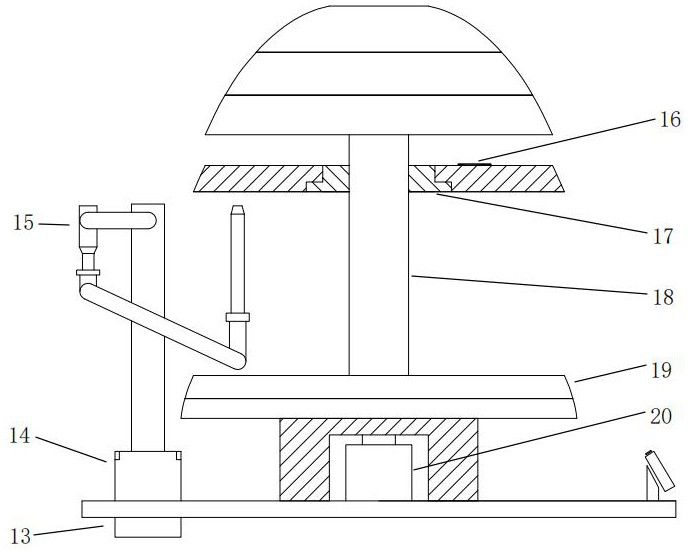

Method and apparatus for measuring dynamic thermal stability of solid particles

ActiveCN103196801AAchieve mutual frictionAchieve collisionMaterial analysisActivated carbonSolid mass

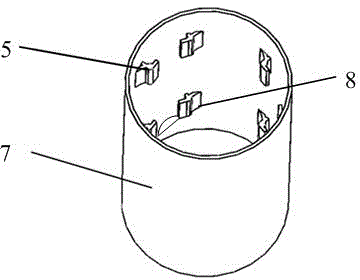

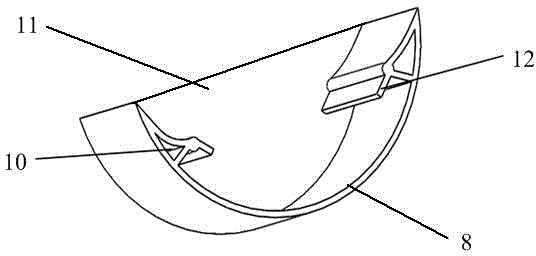

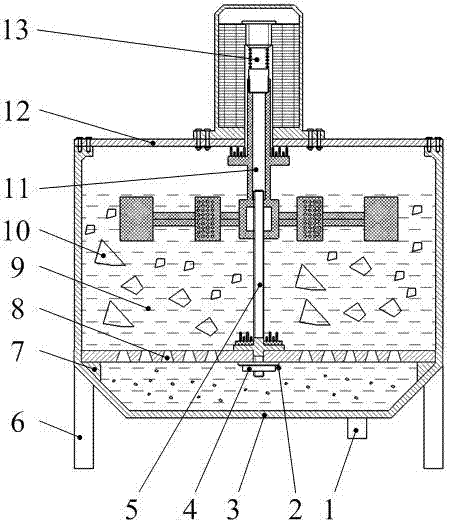

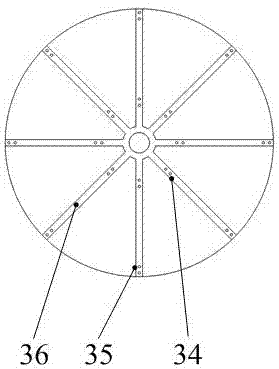

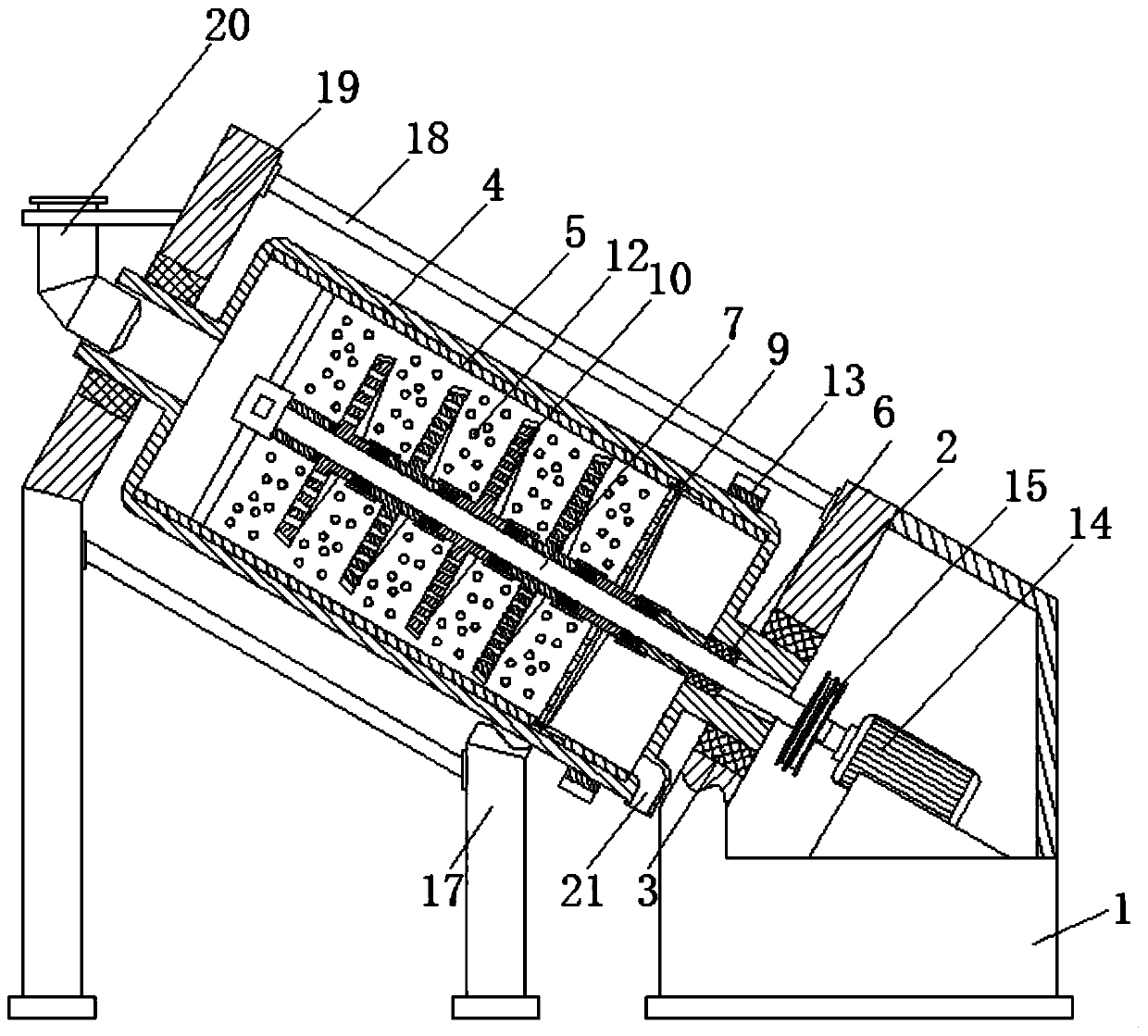

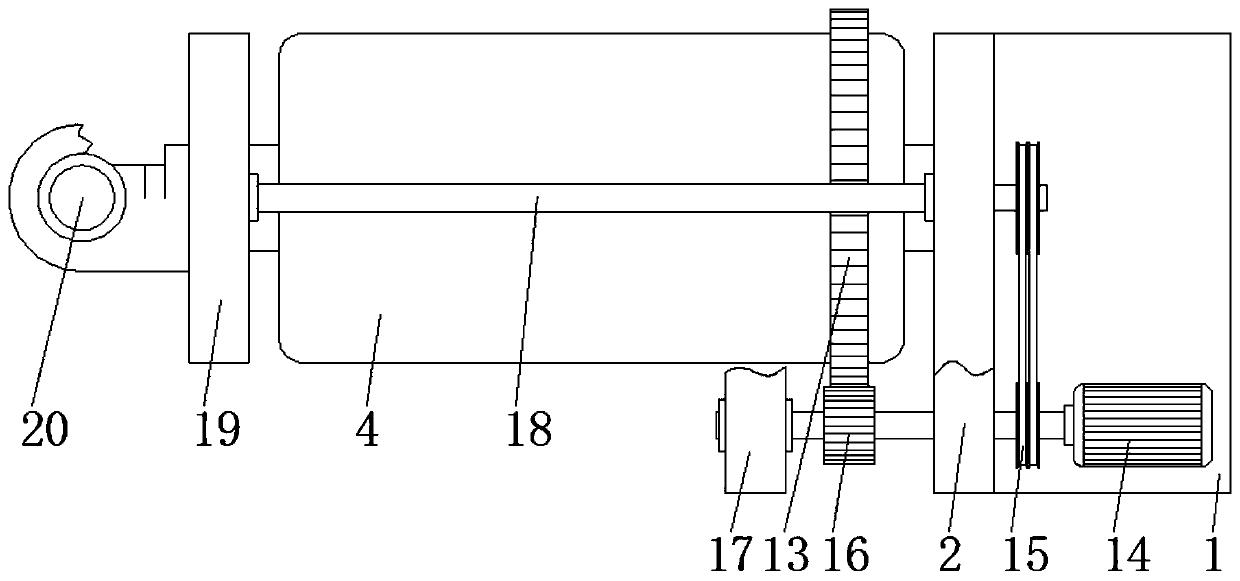

The invention discloses a method and an apparatus for measuring dynamic thermal stability of solid particles. The method, while heating the solid particles, enables the solid particles to move so as to realize mutual friction and collision among the solid particles. The apparatus comprises an actuating mechanism, a motion mechanism and a heating mechanism for heating the solid particles, wherein the solid particles are put into a rotating cylinder used as the motion mechanism, and the rotating cylinder is driven by the actuating mechanism to rotate. According to the invention, dynamic thermal stability of coal, semi-coke, activated carbon, coke, briquette and other solid particle samples can be stimulated under conditions of different temperature, heating ways, heating rates, environment atmospheres and rotating speeds of the rotating cylinder, that is, crushing and pulverization of the solid particle samples subjected to thermal stress, mechanical wear and particle collision in the rotating cylinder can be obtained through tests, thereby truly reflecting a crushing and pulverization degree of the solid particles during a practical industrial utilization process, and thus building a determination standard which is about dynamic thermal stability of the solid particles and is relatively close to the reality.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

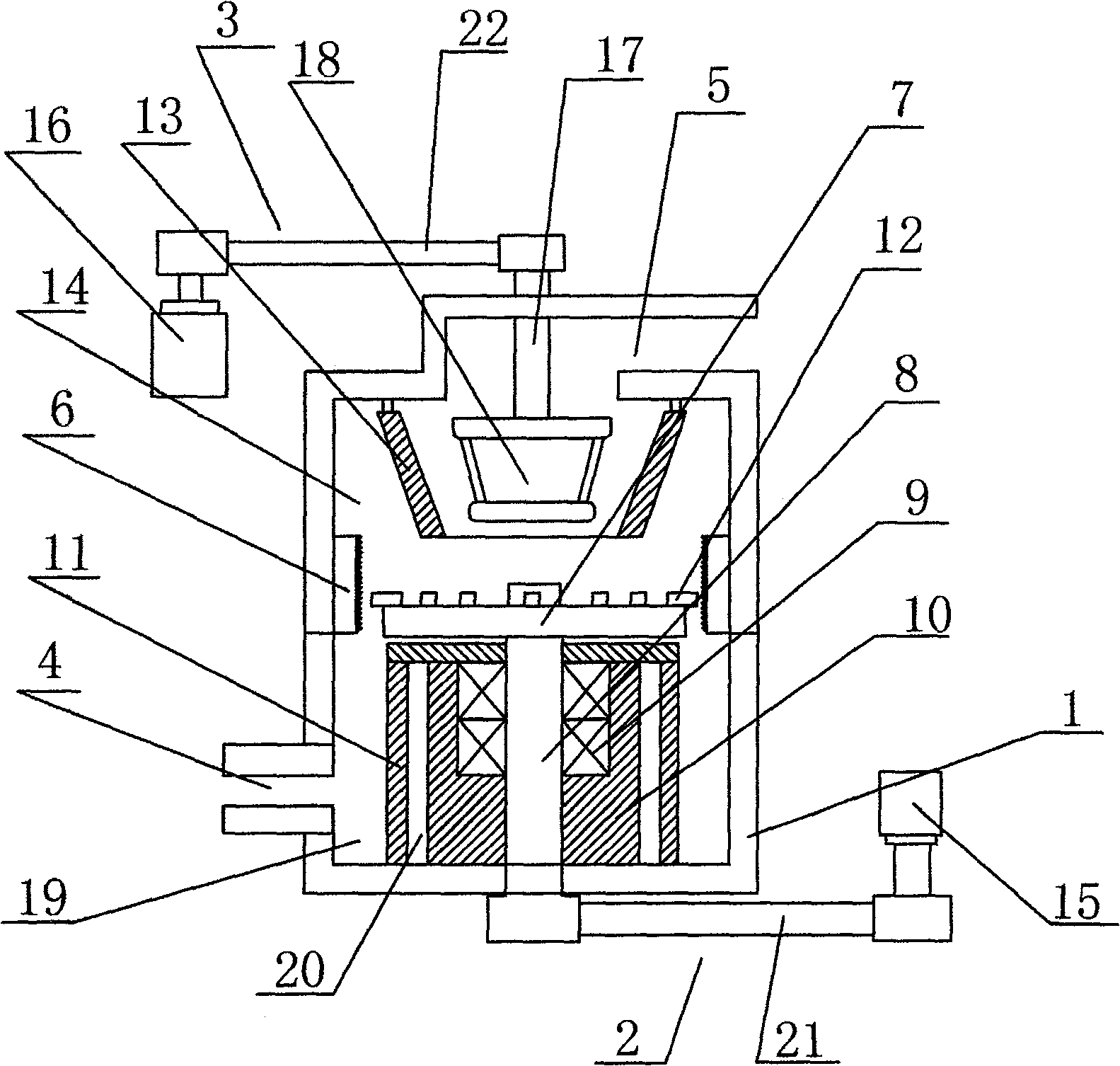

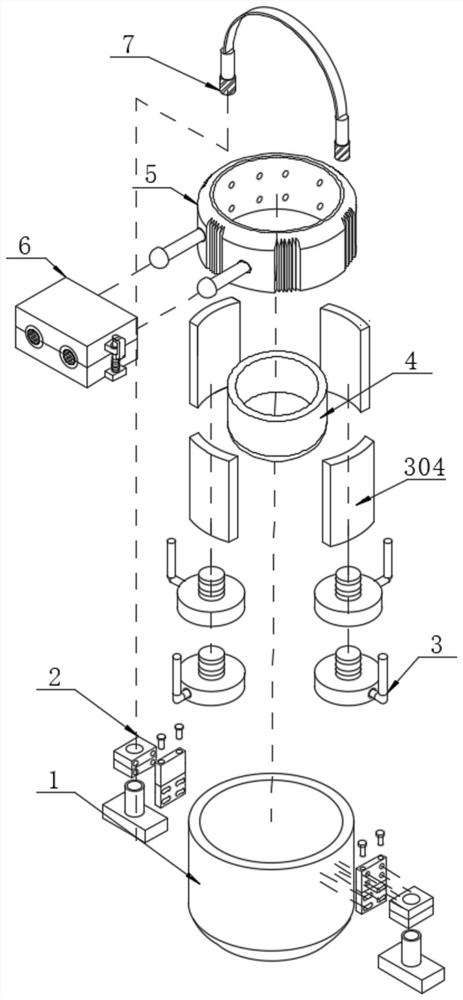

Uniform feeding type proportioning equipment for aquaculture

ActiveCN109351261ARealize multi-stage mixingEasy to controlShaking/oscillating/vibrating mixersFeeding-stuffMechanical engineeringAquaculture

The invention relates to the technical field of aquaculture proportioning, in particular to uniform feeding type proportioning equipment for aquaculture. A plurality of discharging cylinders are uniformly arranged on the top of a mixing cylinder in the circumferential direction and used for storing different kinds of raw materials; since first-level discharge ports of a discharge tray correspond to the outlets of the discharge cylinders, under the action of a servo motor, the discharge tray rotates along with a rotating shaft, and therefore the first-level discharge ports are overlapped with or staggered with the outlets of the discharge cylinders to achieve uniform and intermittent discharge of the raw materials; meanwhile, the rotating shaft drives a spiral auger to mix the raw materialsfalling into the mixing cylinder to complete preliminary mixing; raw material particles discharged by the mixing cylinder fall into a mixing basket; meanwhile, under the action of a clamping rod anda clamping groove, the rotation force of the rotating shaft is utilized to drive a turntable to rotate, a protrusive block is correspondingly driven to rotate, and therefore the mixing basket is shaken periodically; during shaking of the mixing basket, the raw materials are further mixed on the one hand and moved on the other hand; the raw materials fall from a third-level discharge port and thenfall from a fourth discharge port, and correspondingly the turntable rotates.

Owner:临沂高新文旅发展有限公司

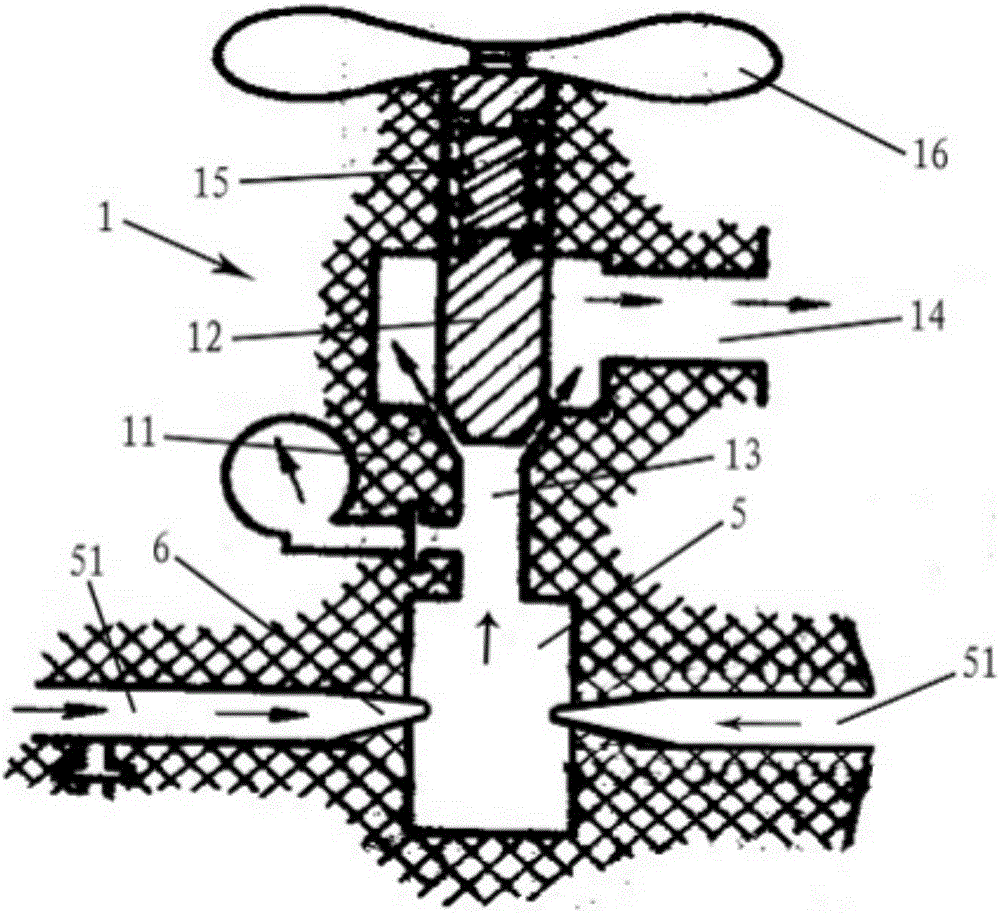

Air-flow vortex balling machine for producing spherical graphite

The invention discloses an air-flow vortex balling machine for producing spherical graphite, which consists of a machine body, a balling drive device and an internal classification machine drive device, wherein an internal classification machine, a powder balling module and a cooling system are arranged in the machine body. In the invention, an internal balling module and a classification module are rationally arranged, and thus, the air-flow vortex balling machine for producing the spherical graphite is provided. The air-flow vortex balling machine can ensure that the graphite powder undergoes the physical processes of thinning, shearing, collision, friction, coiling, uniting and densification in an air-flow vortex balling room or can realize the combination of a physical balling process and a mechanical powder thinning process to prepare the spherical product. The indexes, such as sphericity, grain fineness distribution, tap density, apparent density, actual density and special surface area, of the spherical graphite powder can be controlled in the range of pre-determined values; the quality is stable; the yield can be improved by over three times; and over 50 percent of energy consumption can be reduced.

Owner:LUOYANG GUANQI INDAL & TRADE

Ball mill for grinding soft magnetic core

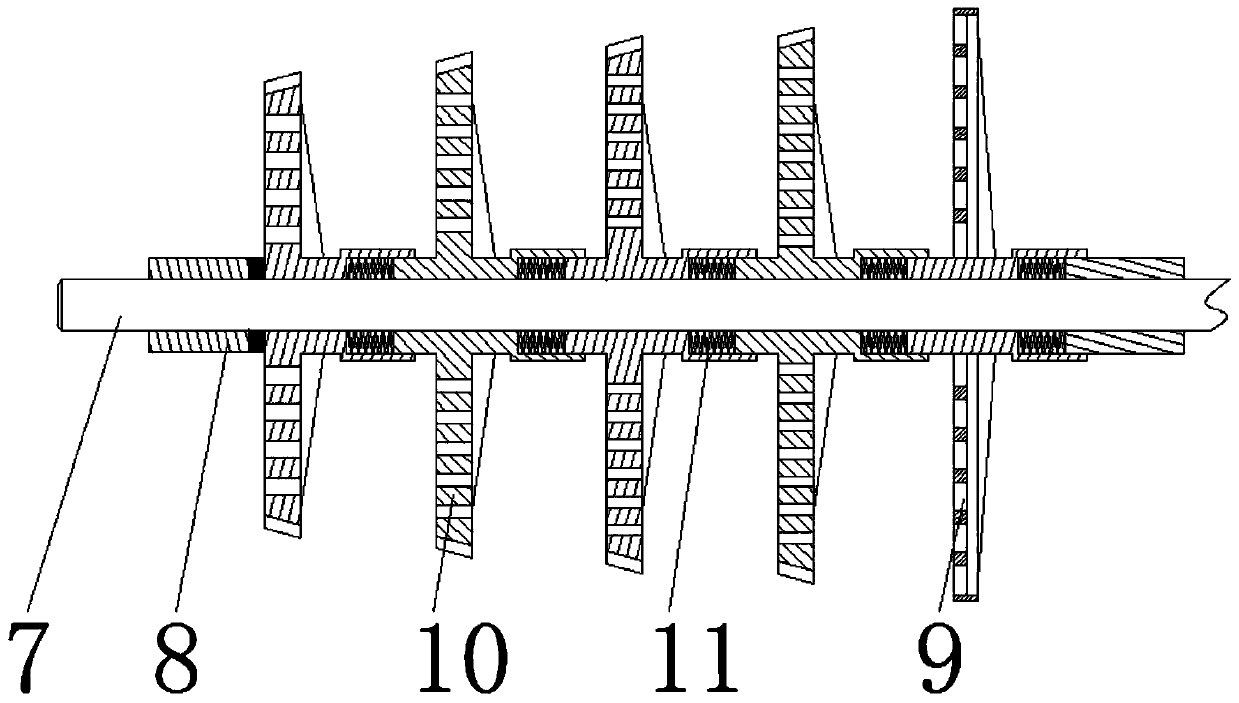

ActiveCN111420759AImprove impact efficiencyExtend the trajectoryGrain treatmentsGear wheelIndustrial equipment

The invention relates to the technical field of industrial equipment, and discloses a ball mill for grinding a soft magnetic core. The ball mill comprises a fixing box, a rotating cylinder, a lining,grinding steel balls, an outer gear and a key, wherein the lining is fixedly arranged on the inner wall of the rotating cylinder, the outer gear is fixedly arranged at the bottom of the rotating cylinder in a sleeving mode, the grinding steel balls are movably arranged inside the lining, a bottom support seat is fixedly arranged on the fixing box, and a large thrust bearing is fixedly arranged inside the bottom support seat. Due to the arrangement of the rotating cylinder and a partitioning device, the space inside the rotating cylinder is equally divided, the effective grinding space is further compressed, the impact efficiency between the grinding steel balls and a material is improved, the grinding effect in the area is improved, and the grinding efficiency is improved; and the rotatingcylinder and the partitioning device are rotated in different directions, so that the movement track and the movement speed of the grinding steel balls are increased, the impact times among the grinding steel balls and between the grinding steel balls and the material are increased, and the grinding effect on the material is further improved.

Owner:LOUDI CITY LITONG MAGNETOELECTRICITY SCI & TECH

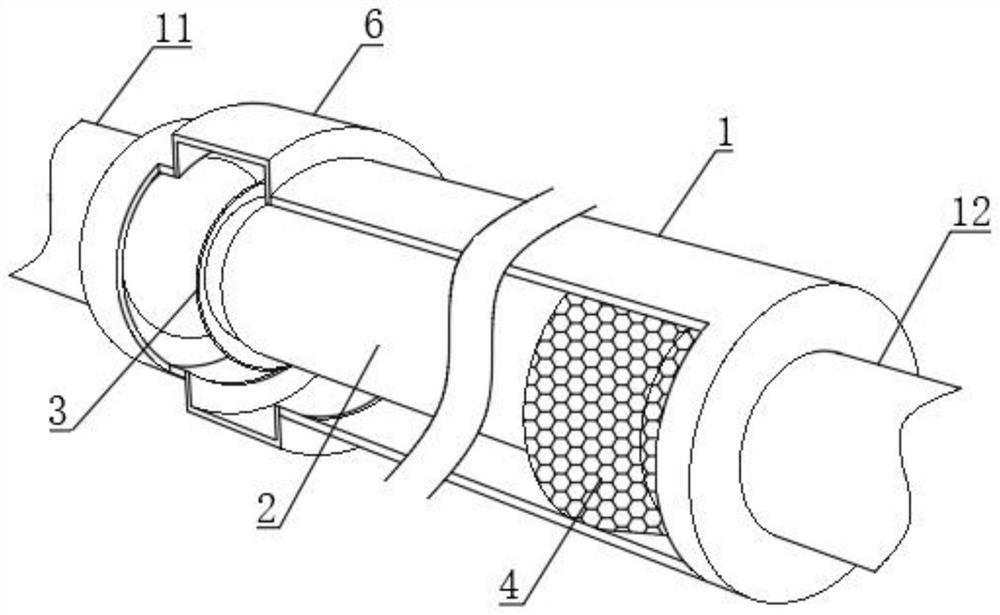

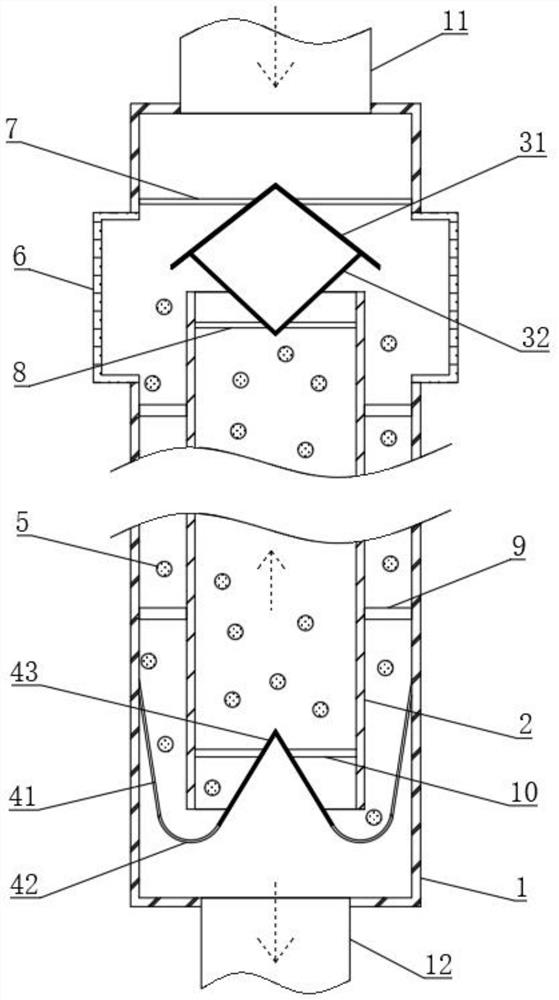

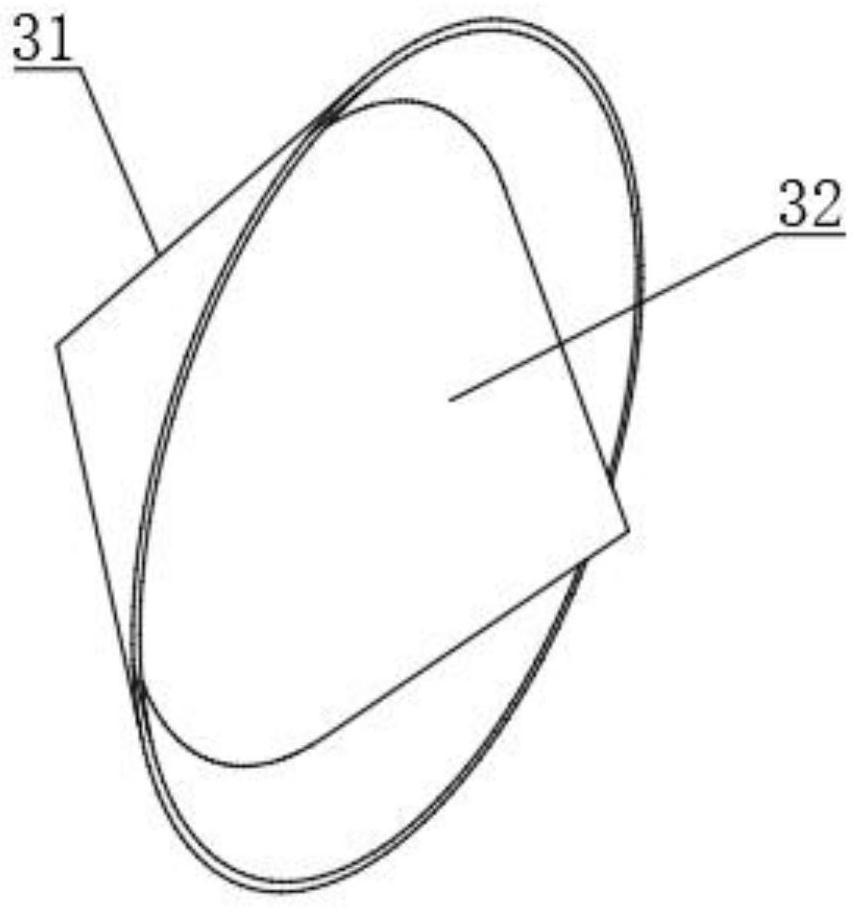

Backflow elastic striking type self-cleaning flue gas heat exchange tube

InactiveCN113048827AImprove heat transfer efficiencyReduce the influence of heat transfer effectRecuperative heat exchangersVibration cleaningEngineeringFlue gas

The invention discloses a backflow elastic striking type self-cleaning flue gas heat exchange tube, and belongs to the field of heat exchange tubes. According to the heat exchange tube, flue gas passes through the space between a heat exchange tube body and a backflow inner tube, so that the flue gas flows in an annular mode, on one hand, the heat exchange area between the flue gas and an external medium is enlarged through the heat exchange tube body, and the heat exchange efficiency is greatly improved; and on the other hand, before flue gas flows out of the heat exchange tube body, part of the flue gas is guided into the backflow inner tube through a backflow introducer, the flue gas gradually flows back along the backflow inner tube, and finally the flue gas is guided into the heat exchange tube body again by a double-cone extractor and is converged with the introduced flue gas, so that the flue gas is jointly guided by the double-cone extractor and the backflow introducer, part of flue gas continuously flows back in the space between the heat exchange tube body and the backflow inner tube, a magnetic ball is driven to do loop movement, the inner wall of the heat exchange tube body is continuously impacted, cleaning of the inner wall of the heat exchange tube body is achieved, and the influence of impurity accumulation on the heat exchange effect of the heat exchange tube body is effectively reduced.

Owner:温州捷合郸科技有限公司

Crushing and screening all-in-one machine for processing high-purity quartz sand

The invention relates to the field of quartz sand processing, in particular to a high-purity quartz sand processing crushing and screening all-in-one machine which comprises a processing cylinder and a feeding cylinder. The rotor is installed in the processing cylinder and located under the feeding cylinder, the screening cylinder is fixedly connected with the lower end of the rotor, and the discharging groove plate is rotationally connected to the edge of the lower end of the screening cylinder in a sleeving mode and fixedly connected with the inner wall of the processing cylinder. The blanking groove plate is provided with an annular plate with an annular groove, and a scraping plate is embedded in the annular groove. Through the arrangement of the rotor, the impact plate, the conical cylindrical screen drum, the annular blanking groove plate and the scraper, quartz sand particles are thrown to the impact plate through high-speed rotation of the rotor to be impacted and crushed, and the crushed quartz sand particles are screened through the screen drum; intercepted large particles are borne by the blanking groove plate and are centrifugally discharged through the scraping plate rotating along with the screen drum, so that centralized treatment of crushing and screening is realized, raw materials do not need to be transferred among different devices, and the processing flow is simplified.

Owner:新沂市紫金硅业有限公司

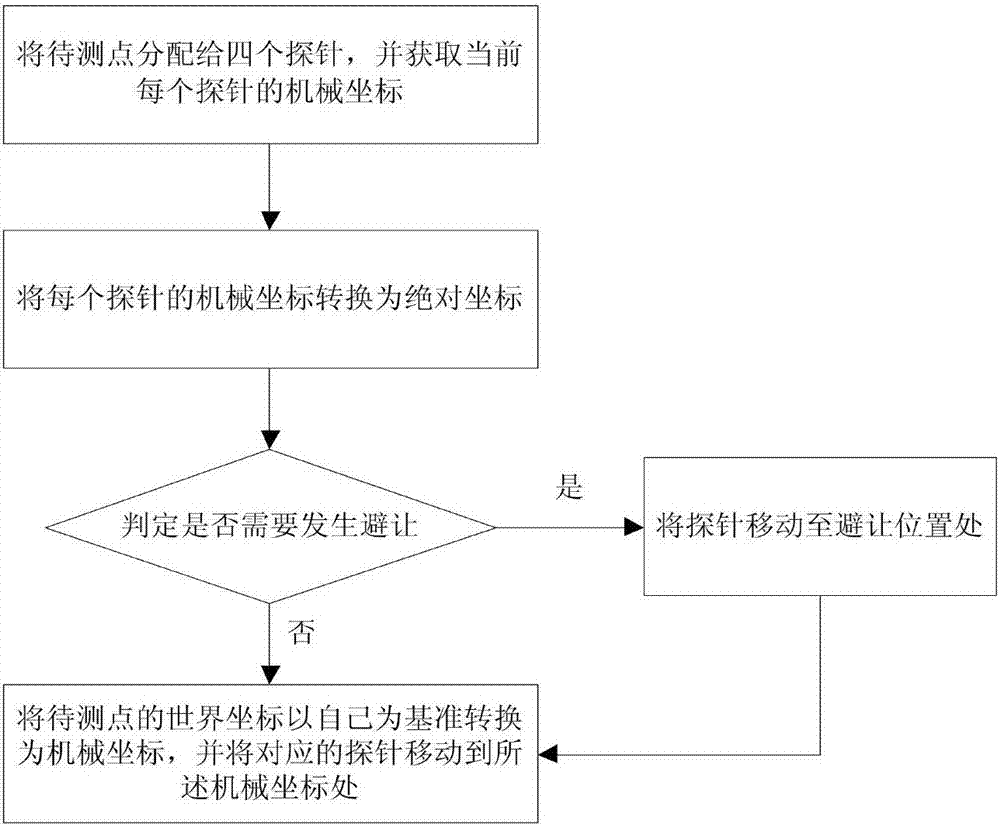

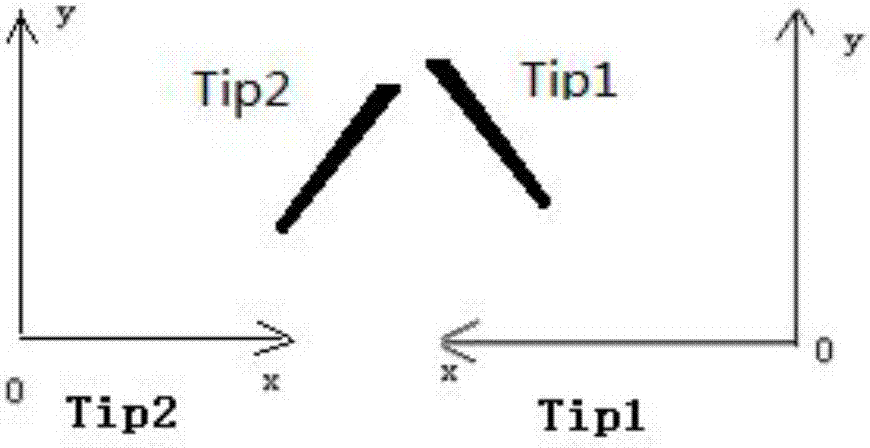

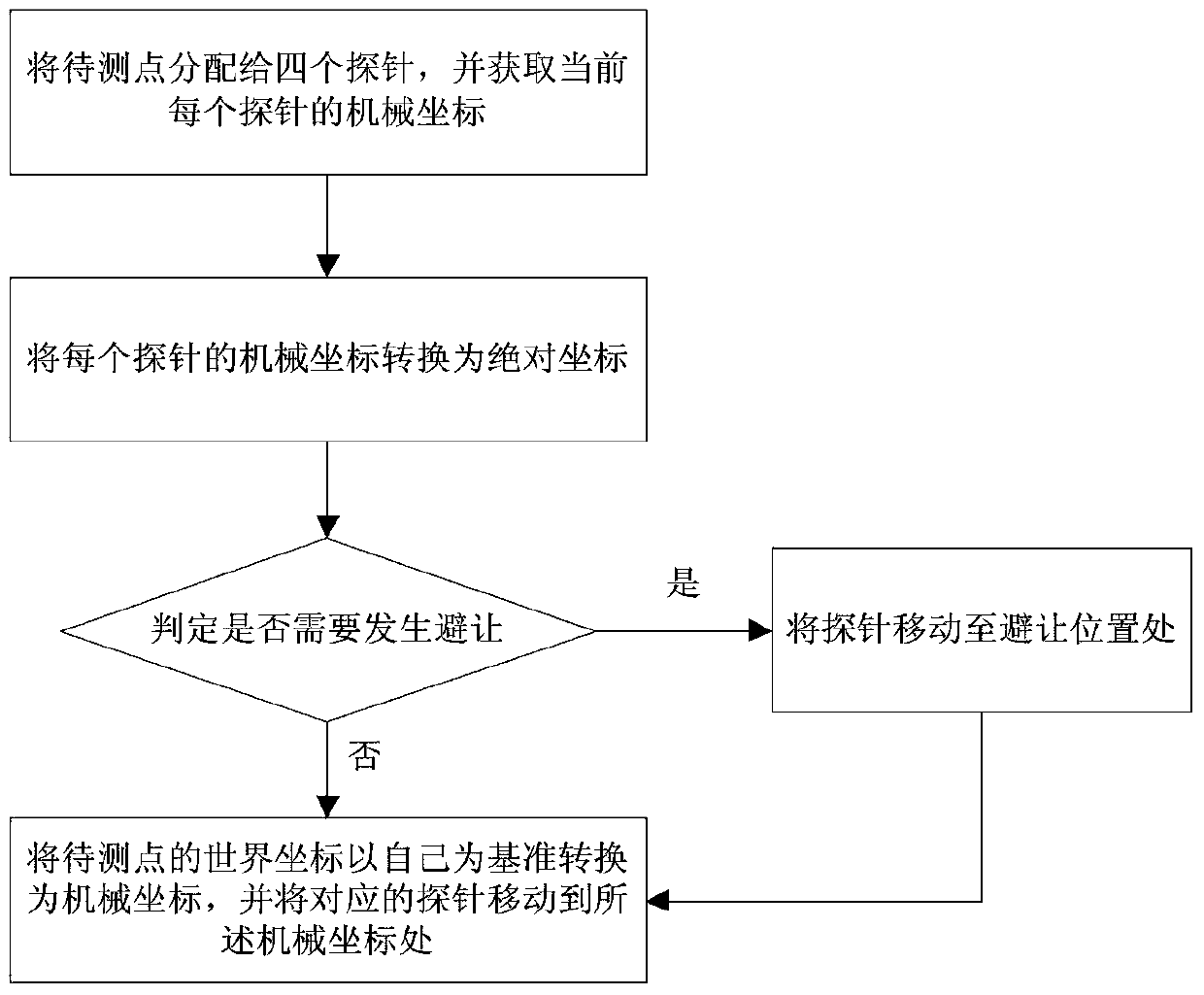

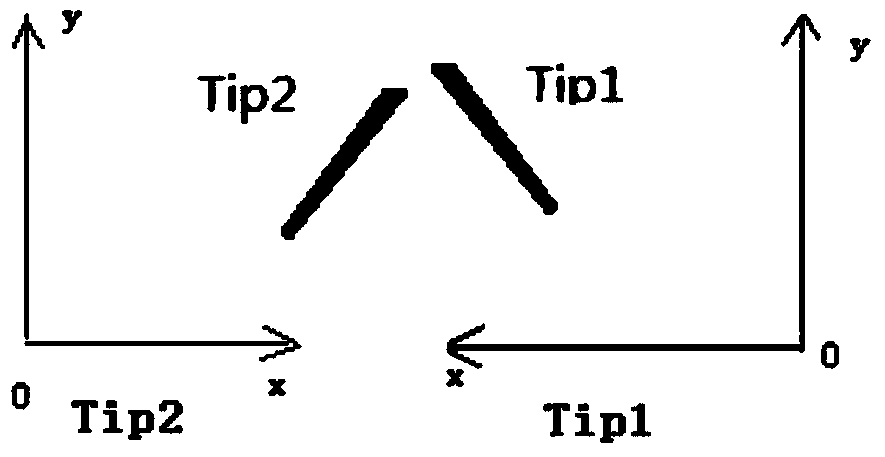

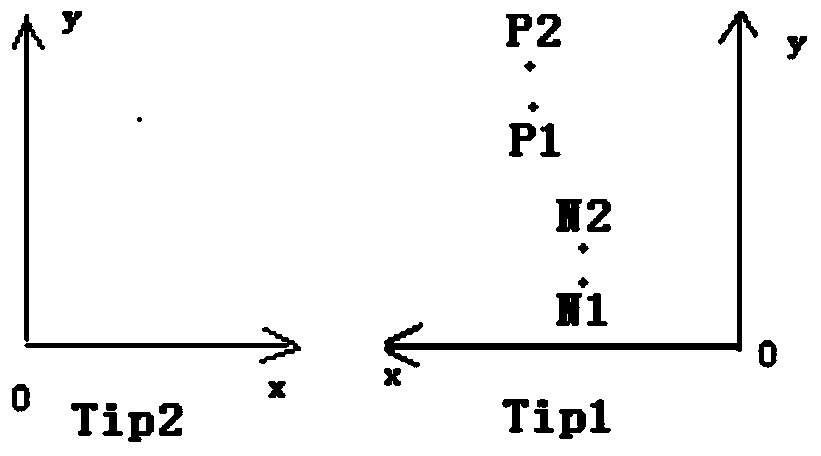

Flying probe tester test shaft automatic avoidance method

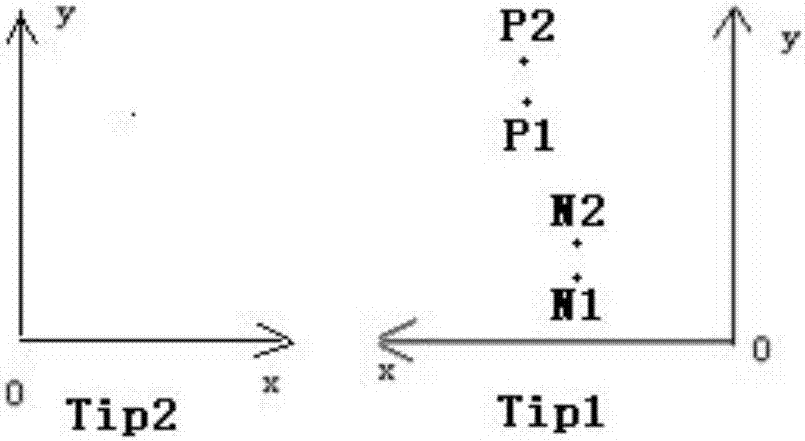

ActiveCN107102249ARealize automatic avoidanceAchieve collisionElectronic circuit testingMeasurement pointFlying probe

The invention relates to the technical field of circuit board test equipment, and discloses a flying probe tester test shaft automatic avoidance method. The front surface of a flying probe tester is provided with probes Tip 1 and Tip 2 and the reverse surface is provided with probes Tip 3 and Tip 4. According to the automatic avoidance method, firstly points to be tested are allocated to the four probes Tip 1, Tip 2, Tip 3 and Tip 4 and the current mechanical coordinates of each probe are acquired; the mechanical coordinates of each probe are transformed into absolute coordinates, wherein the probes Tip 1 and Tip 2 are based on the probe Tip 1 in the transformation process, and the probes Tip 3 and Tip 4 are based on the probe Tip 3; avoidance is judged through the position relation of the world coordinates of the current measurement points corresponding to the two probes of the same side and the points to be tested, and one of the probes is moved to the avoidance position if avoidance is required; and if avoidance is not required, the world coordinates of the points to be tested are directly transformed into the mechanical coordinates based on themselves and the corresponding probes are moved to the positions of the mechanical coordinates. The method is simple, reliable and easy to implement.

Owner:HANS CNC SCI & TECH

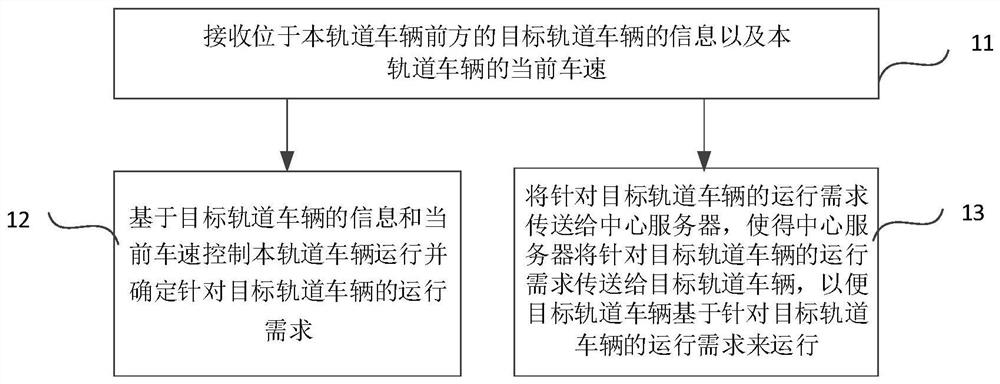

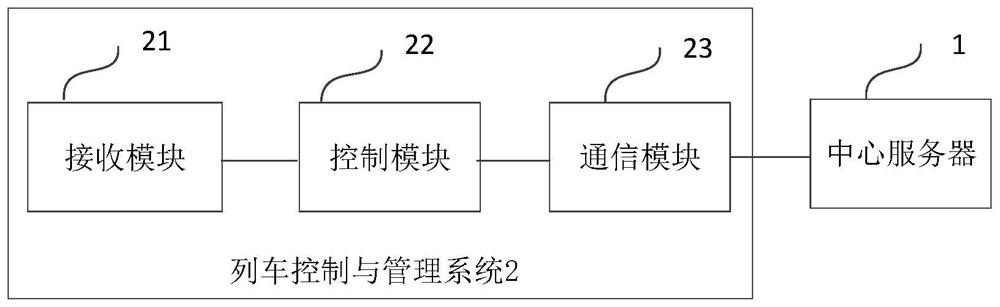

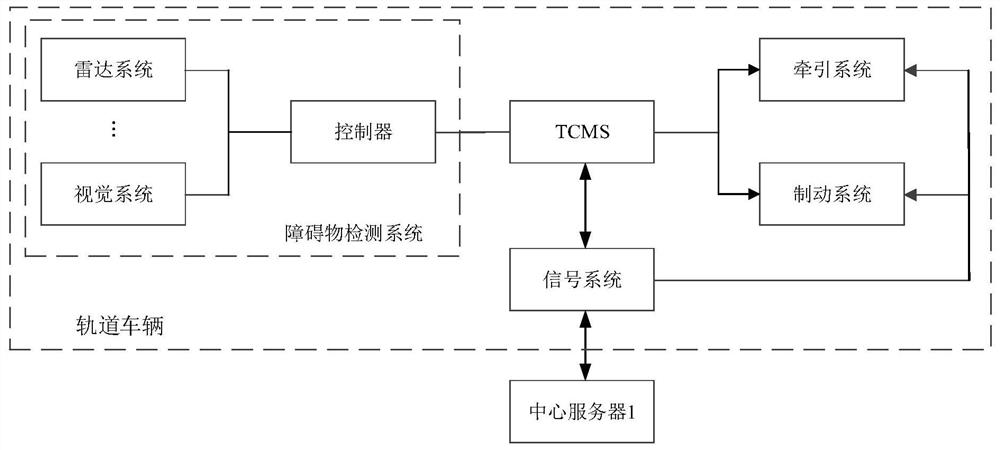

Railway vehicle, control method and system thereof and train control and management system

PendingCN112441086ARealize linkage controlControl actionSignalling indicators on vehicleRailway traffic control systemsControl engineeringManagement system

The invention relates to a railway vehicle, a control method and system thereof and a train control and management system. Operation control over the whole railway vehicle can be achieved. The controlmethod of the railway vehicle comprises the steps of receiving information of a target railway vehicle located in front of the railway vehicle and the current vehicle speed of the railway vehicle; based on the information of the target railway vehicle and the current vehicle speed, controlling the railway vehicle to operate, and determining the operation requirement for the target railway vehicle; and transmitting the operation requirement for the target railway vehicle to a center server so as to enable the center server to transmit the operation requirement for the target railway vehicle tothe target railway vehicle and facilitate the target railway vehicle to operate based on the operation requirement for the target railway vehicle.

Owner:BYD CO LTD

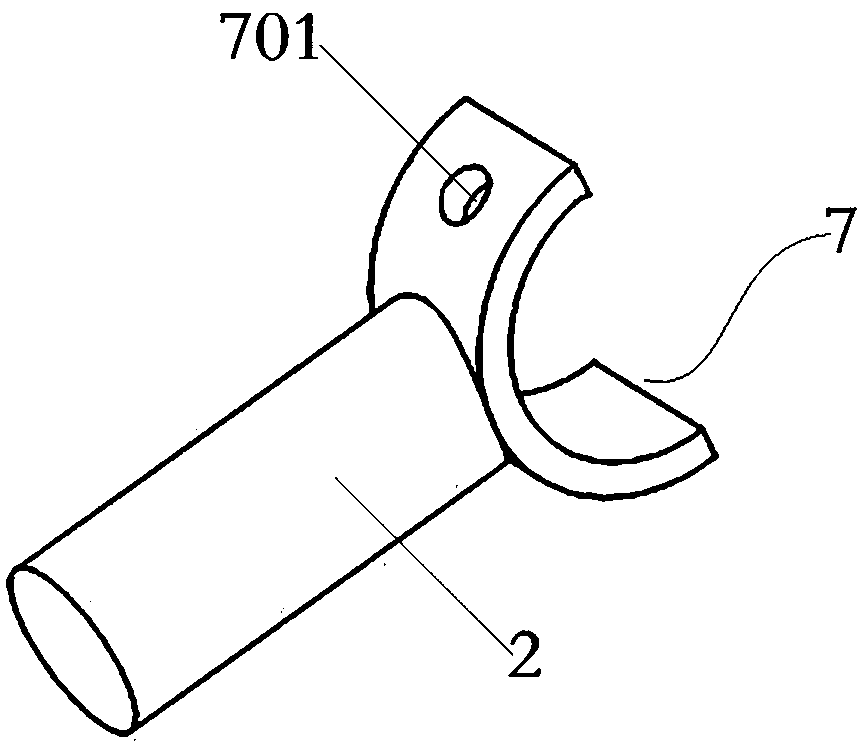

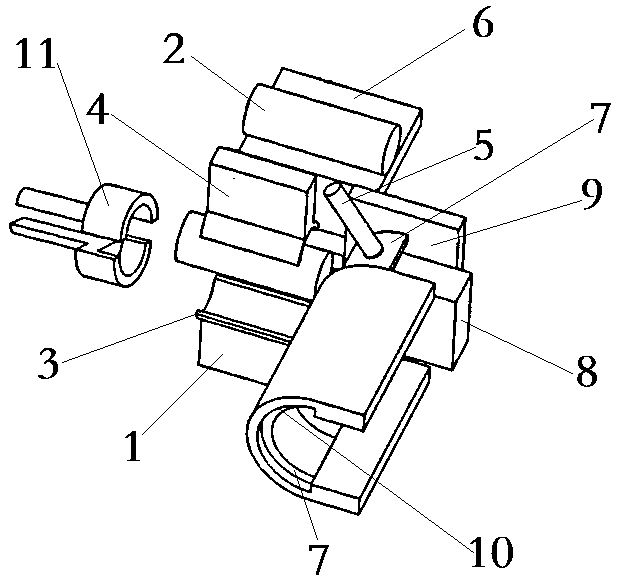

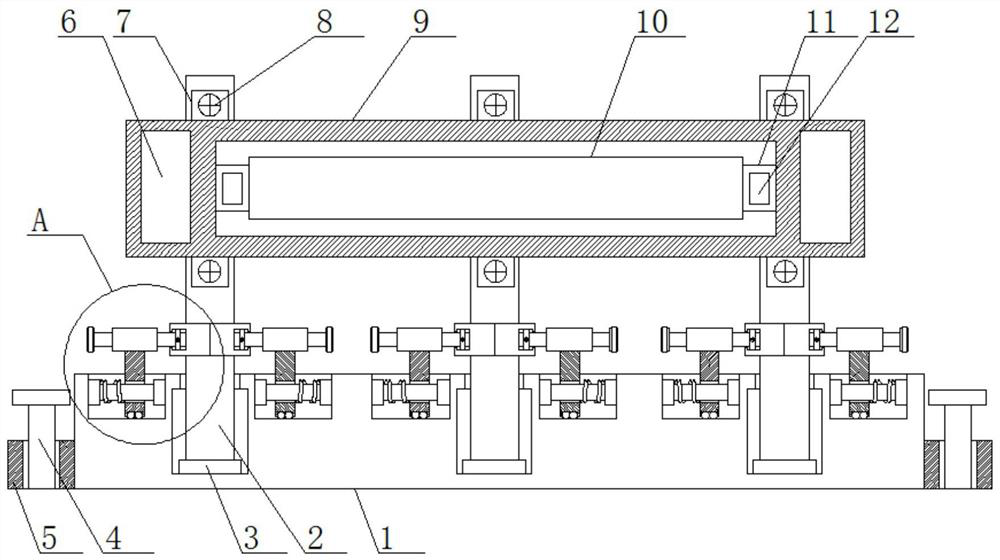

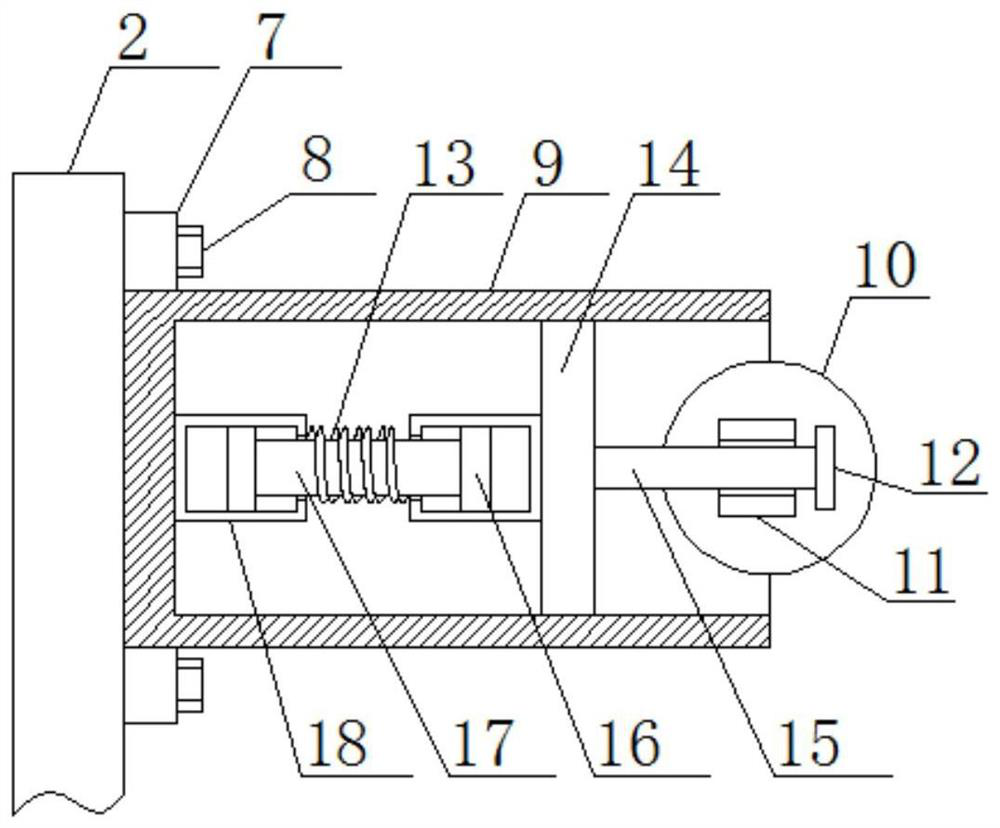

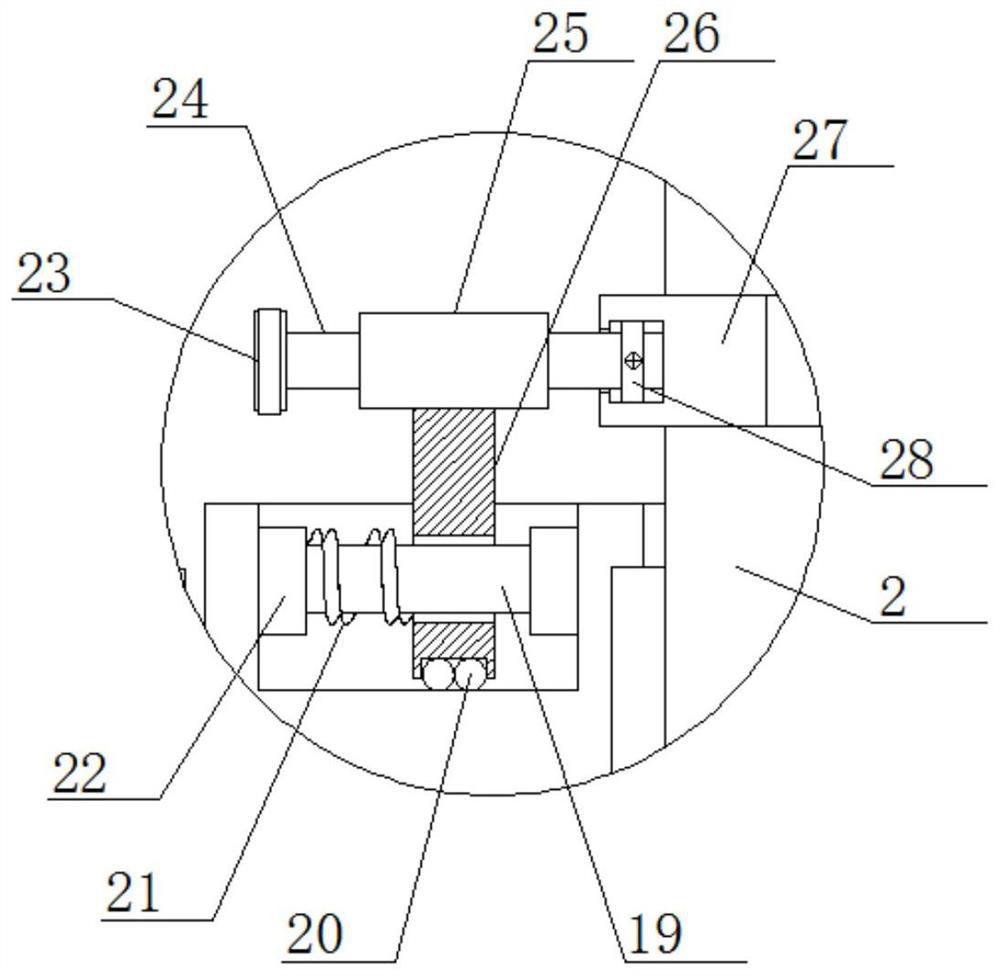

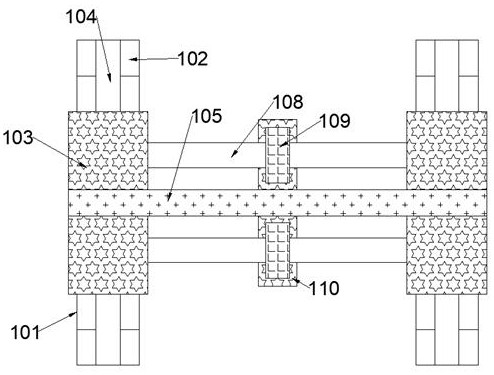

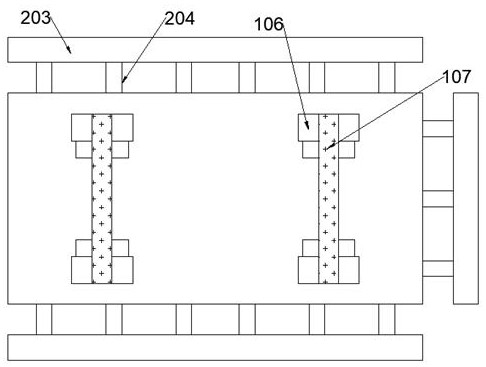

Agricultural machine transverse transmission rod limiting support welding device and welding positioning device thereof

ActiveCN109732190AImprove the limit effectEasy to controlWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to an agricultural machine transverse transmission rod limiting support welding device and a welding positioning device thereof. The agricultural machine transverse transmissionrod limiting support welding positioning device comprises a machine frame, a shaft part positioning seat is arranged on the machine frame, and a shaft part positioning structure is arranged on the shaft part positioning seat; an arc part positioning seat is further arranged on the machine frame, and a positioning piece and a stop positioning structure are arranged on the arc part positioning seat;and the welding positioning device further comprises a pressure contact driving mechanism, a shaft part feeding mechanism and an arc part feeding mechanism, wherein the shaft part feeding mechanism and the arc part feeding mechanism are arranged on the machine frame, and an in-place controller is arranged on the arc part feeding mechanism. The shaft part and the arc part are accurately conveyed to the shaft part positioning seat and the arc part positioning seat correspondingly, the shaft part positioning structure is used for positioning the shaft part, a positioning pin and the positioningpiece are used for positioning the arc part, the pressure contact driving mechanism applies acting force on the shaft part and / or the arc part to enable the shaft part and the arc part to be close toeach other, and finally, the arc part and the shaft part are welded through a welding mechanism. In this way, the positioning precision of the shaft part and the arc part is greatly improved, and thewelding efficiency is also improved.

Owner:HENAN UNIV OF SCI & TECH

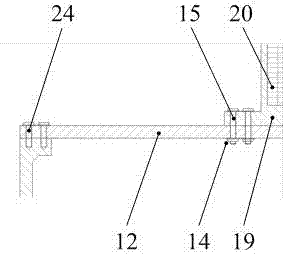

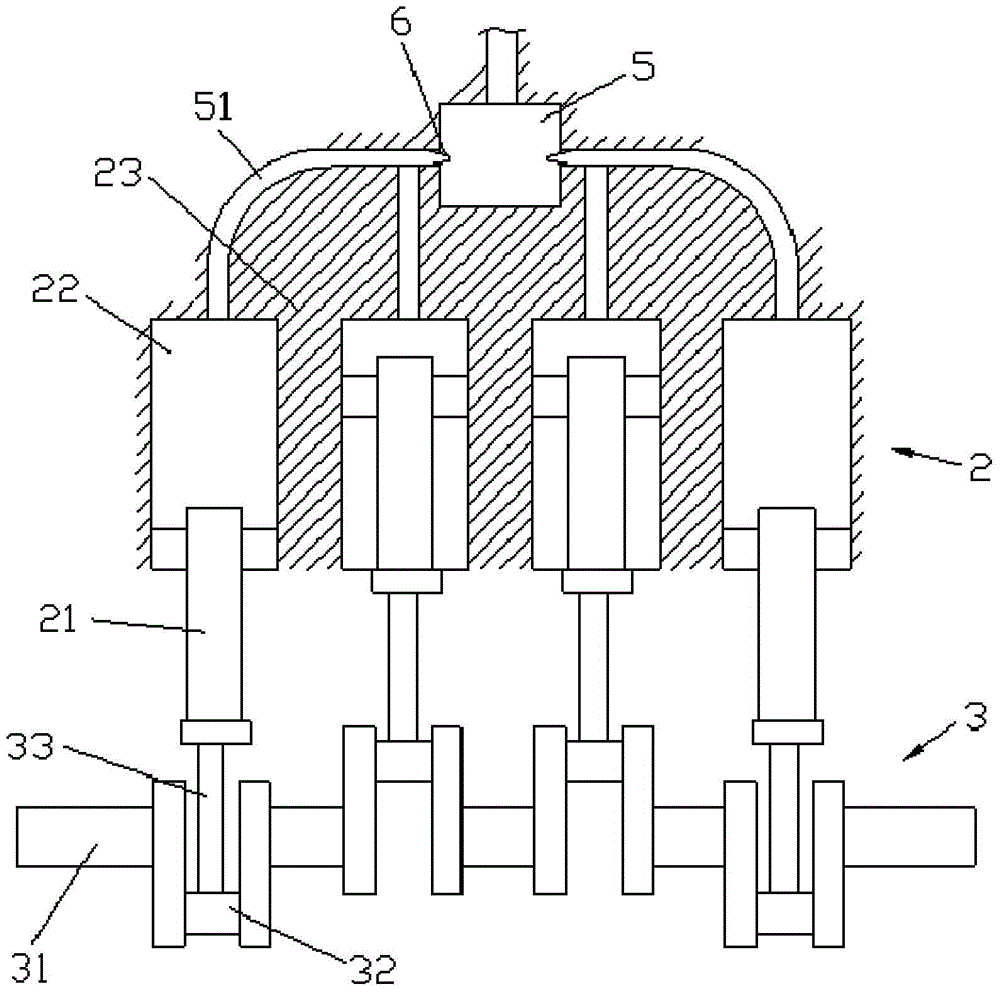

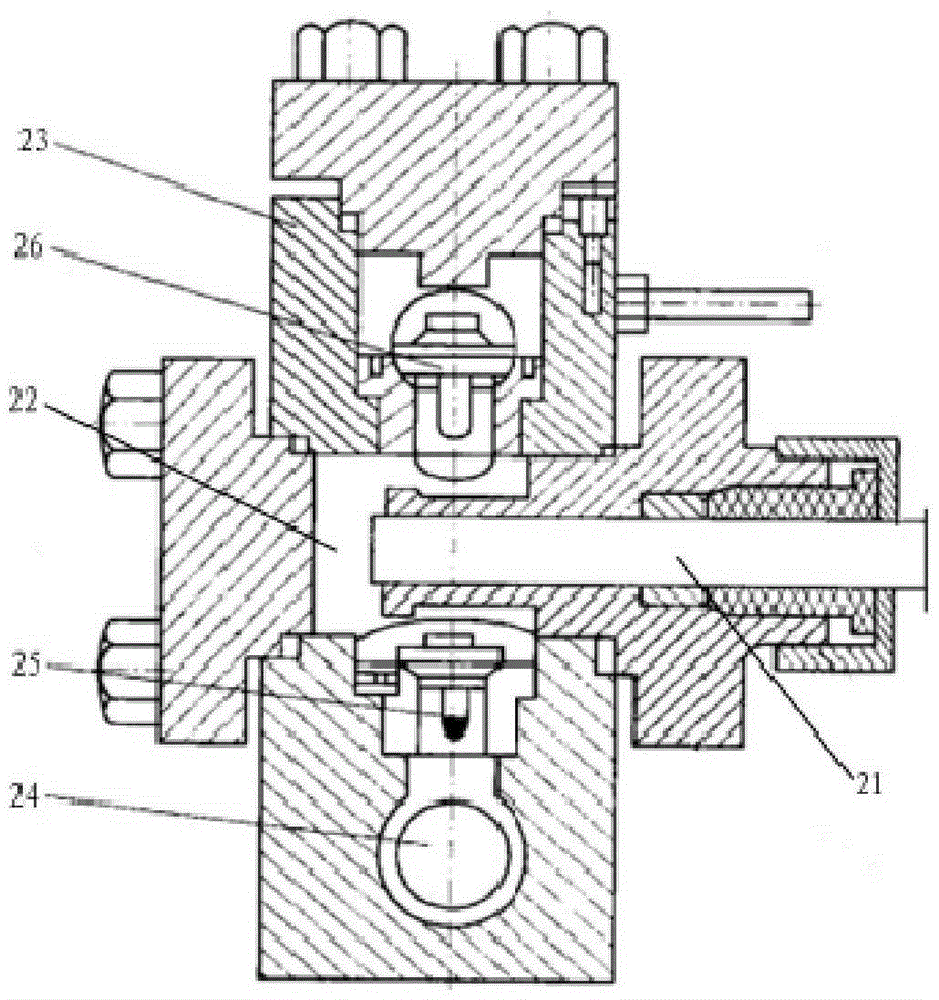

A high-pressure nano homogenizer

The invention relates to material refining equipment, and in particular relates to a high-pressure nano homogenizer comprising a homogenizing valve and a high pressure pump for pumping materials, wherein the high pressure pump comprises at least one pair of plungers driven by a transmission mechanism; each plunger is arranged in a pump cavity; through each pair of the plungers, materials in two corresponding pump cavities are simultaneously delivered to a collision cavity to be collided, and the collided materials are gathered and flow to the homogenizing valve. According to the high-pressure nano homogenizer, the jetted materials are collided through paired nozzles and then are delivered to the homogenizing valve to be refined; compared with existing two-stage homogenization, the high-pressure nano homogenizer is not only relatively simple in structure but also obvious in refining effect to achieve nanoscale; furthermore, super-pressure pumps of the two pairs of plungers are used for pumping materials, so that the materials are continuously sucked and discharged, so that the production efficiency is improved.

Owner:PUHLER GUANGDONG SMART NANO TECH CO LTD

Air-flow vortex balling machine for producing spherical graphite

The invention discloses an air-flow vortex balling machine for producing spherical graphite, which consists of a machine body, a balling drive device and an internal classification machine drive device, wherein an internal classification machine, a powder balling module and a cooling system are arranged in the machine body. In the invention, an internal balling module and a classification module are rationally arranged, and thus, the air-flow vortex balling machine for producing the spherical graphite is provided. The air-flow vortex balling machine can ensure that the graphite powder undergoes the physical processes of thinning, shearing, collision, friction, coiling, uniting and densification in an air-flow vortex balling room or can realize the combination of a physical balling processand a mechanical powder thinning process to prepare the spherical product. The indexes, such as sphericity, grain fineness distribution, tap density, apparent density, actual density and special surface area, of the spherical graphite powder can be controlled in the range of pre-determined values; the quality is stable; the yield can be improved by over three times; and over 50 percent of energy consumption can be reduced.

Owner:LUOYANG GUANQI INDAL & TRADE

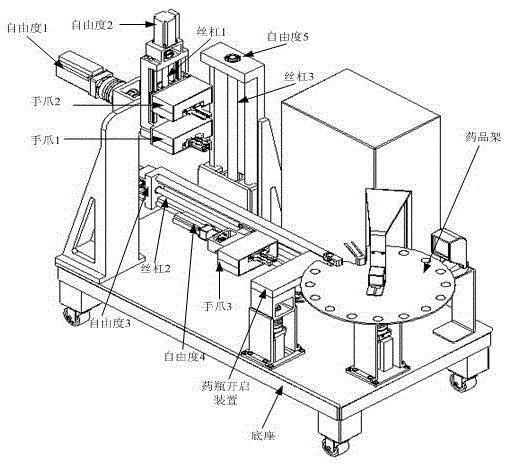

Implementation method of a zero-return control system for a dispensing robot

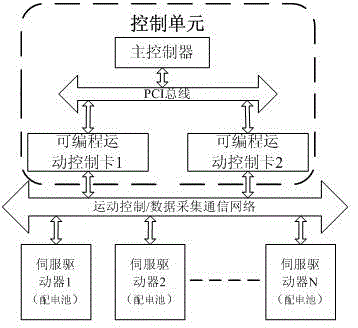

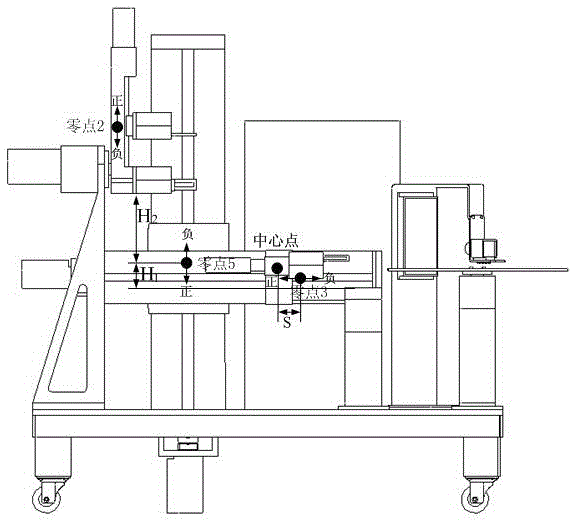

ActiveCN103543677BResolve Motion InterferenceShorten return to zero timeProgramme controlComputer controlProgrammable read-only memoryControl system

The invention discloses a dosage robot resetting control system and an implementation method thereof. A main controller sets each freedom degree control mode as an absolute position control mode according to a user command; in the absolute position control mode, a servo driver stores current position data of freedom degree in an EEP-ROM (electrically-erasable programmable read-only memory) of the servo driver through zero setting to serve as a zero position; experiments show that a dosage robot can be automatically reset under various working conditions and collision is avoided, the problem of motion interference of the dosage robot during resetting is solved well, resetting time of the robot is shortened, working efficiency of the robot is improved, and needs for cooperative work of robot arms are met well.

Owner:深圳市博为医疗机器人有限公司

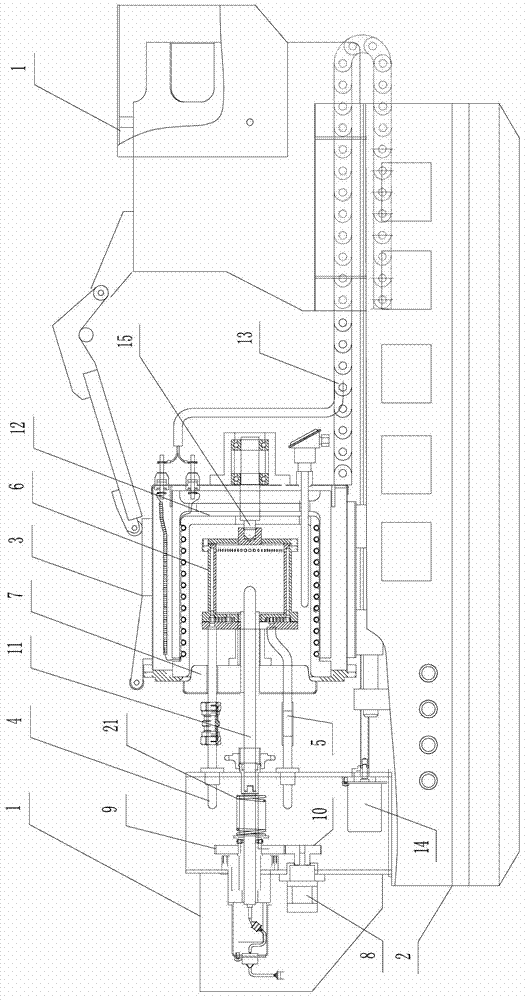

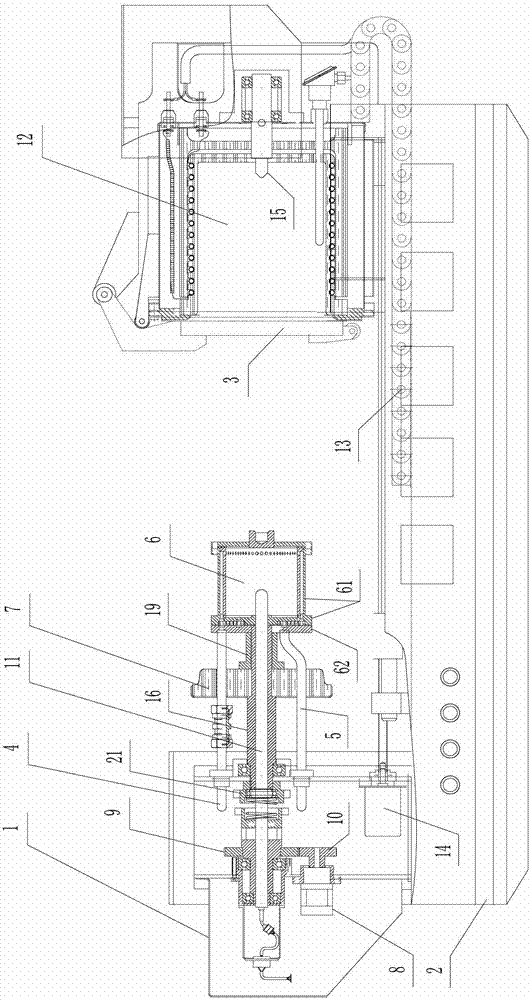

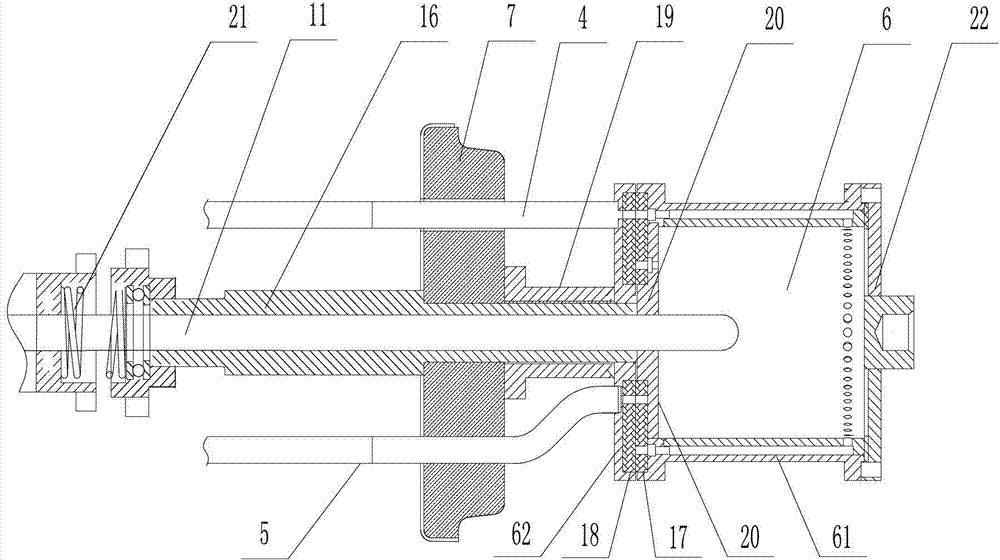

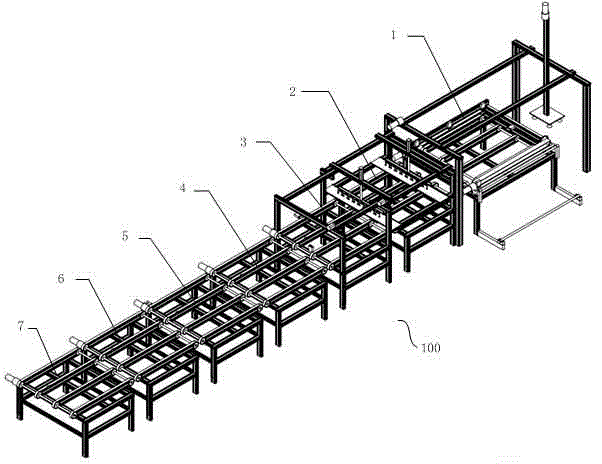

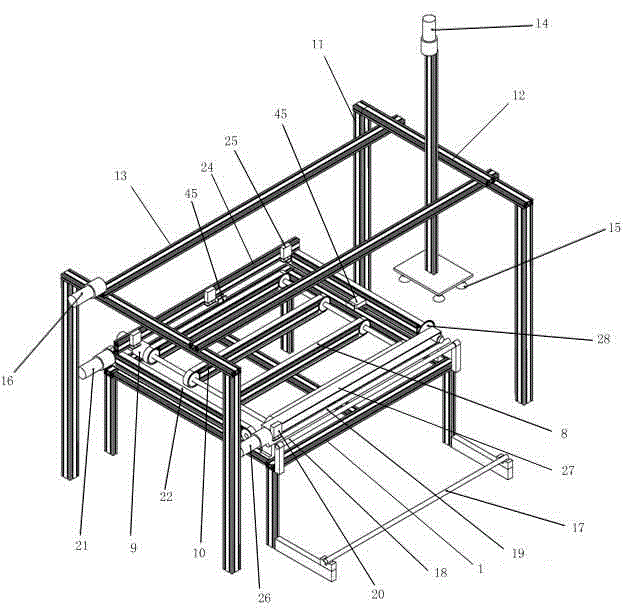

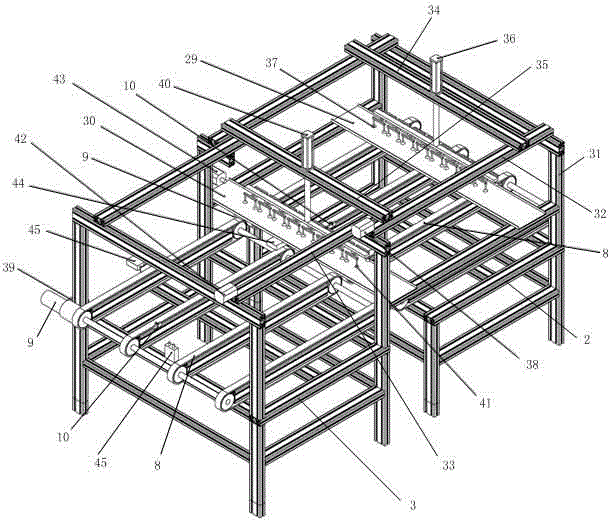

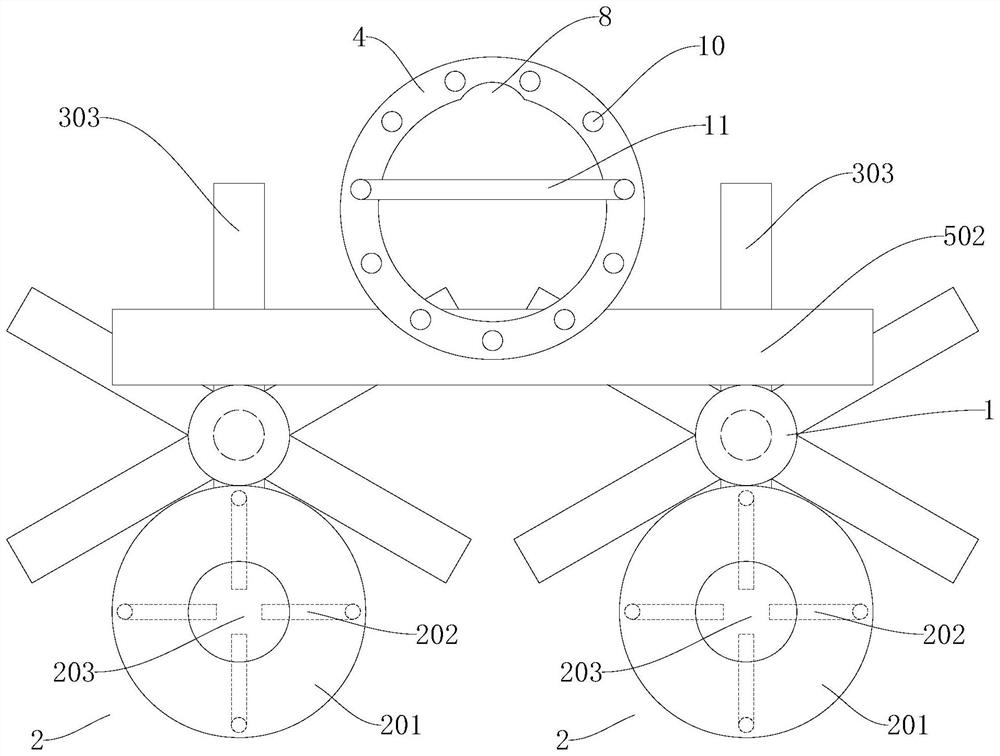

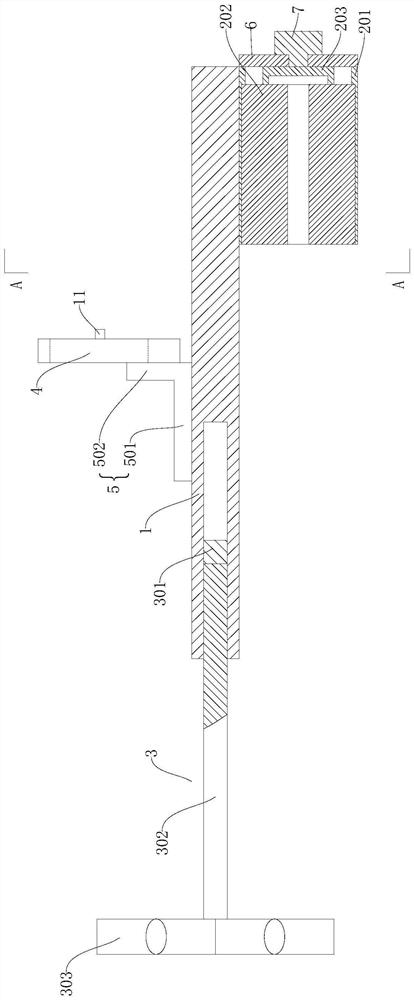

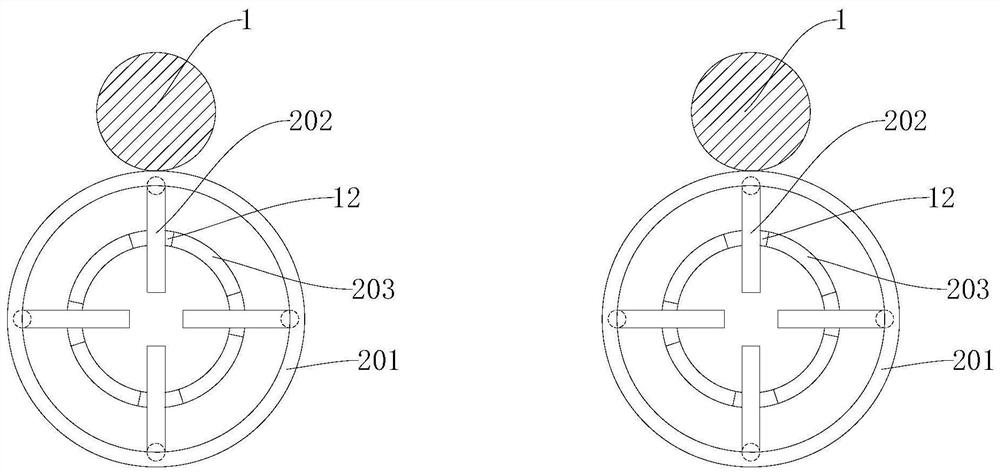

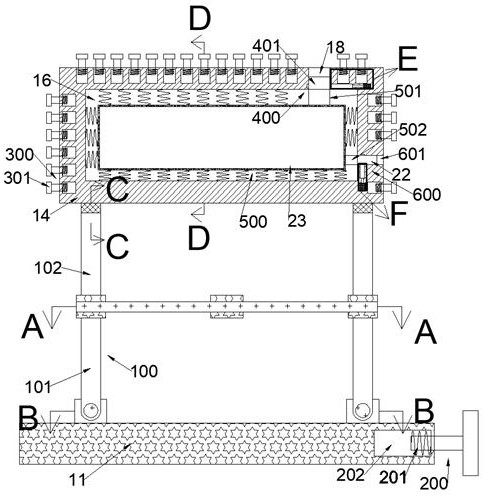

A fully automatic photovoltaic module lamination equipment

ActiveCN103531668BAchieve collisionAvoid collisionFinal product manufacturePhotovoltaic energy generationHorizontal transmissionEngineering

The invention is applicable to photovoltaic module manufacturing equipment and provides a piece of full-automatic photovoltaic module laminating equipment. The laminating equipment comprises EVA material laying devices respectively arranged on multiple laminating working tables, a battery string type-setting machine, a battery string bus bar welding machine, an EVA and TPT material composited laying machine and an automatic inspection device, wherein the EVA material laying devices are arranged on a first laminating working table, the laminating equipment further comprises an automatic tempered glass feed mechanism arranged close to the first laminating working table, a horizontal gear conveyor belt, a horizontal transmission motor for driving the horizontal gear conveyor belt and a stroke control switch for starting and stopping the horizontal transmission motor are arranged on each of the plurality of laminating working tables, and a glass substrate of a photovoltaic module is conveyed between the plurality of laminating working tables through the horizontal gear conveyor belts. Therefore, according to the full-automatic photovoltaic module laminating equipment, the manufacturing of the photovoltaic module is automated, the production efficiency is improved, and the product quality is improved.

Owner:深圳市索阳新能源科技有限公司

Axle box hoisting tool

ActiveCN112520564AAchieve fixationAchieve clampingLoad-engaging elementsStructural engineeringMechanical engineering

The invention provides an axle box hoisting tool, which belongs to the technical field of tools. The axle box hoisting tool comprises a connecting rod, a sleeve, a fixing assembly and a hoisting ring,the sleeve is arranged at the front end of the connecting rod and is used for sleeving a convex block on an axle box, the fixing assembly is telescopically arranged at the rear end of the connectingrod in the axial direction of the connecting rod and is used for being matched with the sleeve to clamp the axle box, and the hoisting ring is arranged at the top of the connecting rod and is used forbeing connected to a lifting hook of a crown block in a hung mode. According to the axle box hoisting tool, in the axle box hoisting process, the axle box is hoisted through the hoisting ring, so that the hoisting hook of the crown block does not make direct contact with the axle box, and abrasion of the outer surface of the axle box is reduced; and the axle box is fixed and clamped through the fixing assembly and the sleeve, so that the hoisting stability of the axle box is improved, the axle box is prevented from shaking in the hoisting process, the occurrence of the falling safety accidents are effectively reduced, collision of the axle box to a bearing inner ring is also reduced, the normal production takt is guaranteed, and the production efficiency is improved.

Owner:CRRC SHIJIAZHUANG CO LTD

A special warning guardrail for viaduct emergency lane and its application method

ActiveCN108999081BRealize fixed installationAchieve collisionBridge structural detailsTraffic signalsStructural engineeringMechanical engineering

The invention discloses a viaduct emergency lane special warning fence and a use method thereof. The viaduct emergency lane special warning fence includes a mounting seat, the upper end of the mounting seat is uniformly provided with a plurality of mounting grooves, a guard rail is arranged above the mounting seat, the lower end of the guard rail penetrates the mounting seat and extends into the mounting groove, the upper end of the mounting seat is provided with a plurality of limiting grooves, the mounting groove is positioned between two limit grooves, A limit position block is fixed on that oppose side walls in the limiting groove, A limit bar is fixed between that two limit blocks, a support block is sleeved on the outer side of the limit bar, a fixing ring is fixedly connected with the upper end of the support block, a hollow slot is arranged in the fixing ring, an internal thread is arranged on the inner side wall of the hollow slot, a fixing bar is arranged in the hollow slot,and one end of the fixing bar is fixedly connected with a rotating handle. The warning fence of the invention is convenient to install, improves work efficiency, has good cushioning effect and improves safety.

Owner:广州国伟建筑工程有限公司

Material flexible freight bag of semicircular special engineering plastic processing equipment

InactiveCN113306894AAffect cleanlinessAchieving tightened closure protectionLarge containersEngineering plasticStructural engineering

The invention discloses a material flexible freight bag of semicircular special engineering plastic processing equipment, and belongs to the technical field of flexible freight bags. The material flexible freight bags comprises an outer bag main body, hanging mechanisms are arranged on both sides of the outer bag main body, a buffer mechanism is arranged at the bottom of an inner cavity of the outer bag main body, an inner bag main body is attached to the top of the buffer mechanism, and the top of the inner bag main body is fixedly connected to a sealing mechanism. According to the material flexible freight bag, a buckle on one side is pressed to drive a bottom connecting block and a connecting plate to move upwards to drive a bottom limiting sleeve and teeth to extrude and fix a twisted rope, the situation that an elastic cover body is unfolded through the elasticity of an elastic cover body is avoided, therefore tightening and sealing protection of internal materials can be achieved by sealing the elastic cover body, the material flexible freight bag has higher limiting occlusion capacity, prevents external rainwater or dust impurities from settling in the inner bag main body to affect the cleanliness of raw materials of special engineering plastic, and can be quickly reset and unfolded through the elastic cover body to meet the requirement for quick loading and unloading of the materials.

Owner:天津新龙桥工程塑料有限公司

A kind of uniform feeding type batching equipment for aquaculture

ActiveCN109351261BEvenly mixedAchieve collisionShaking/oscillating/vibrating mixersFeeding-stuffAnimal scienceEngineering

Owner:临沂高新文旅发展有限公司

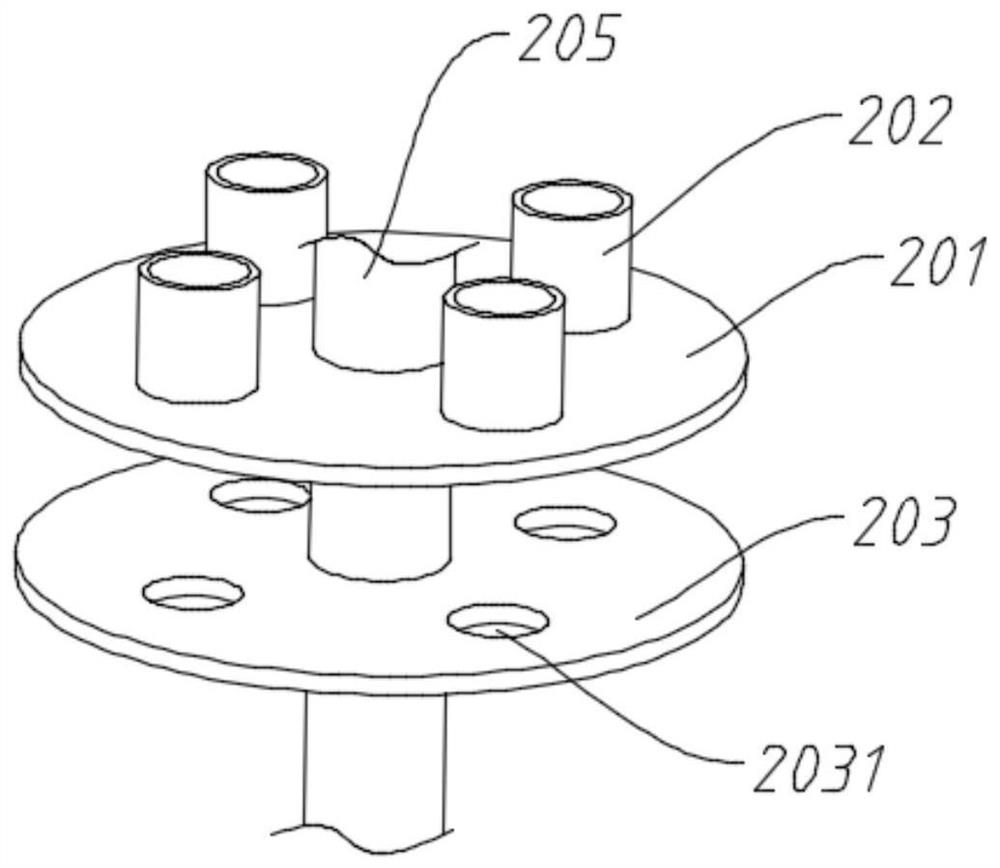

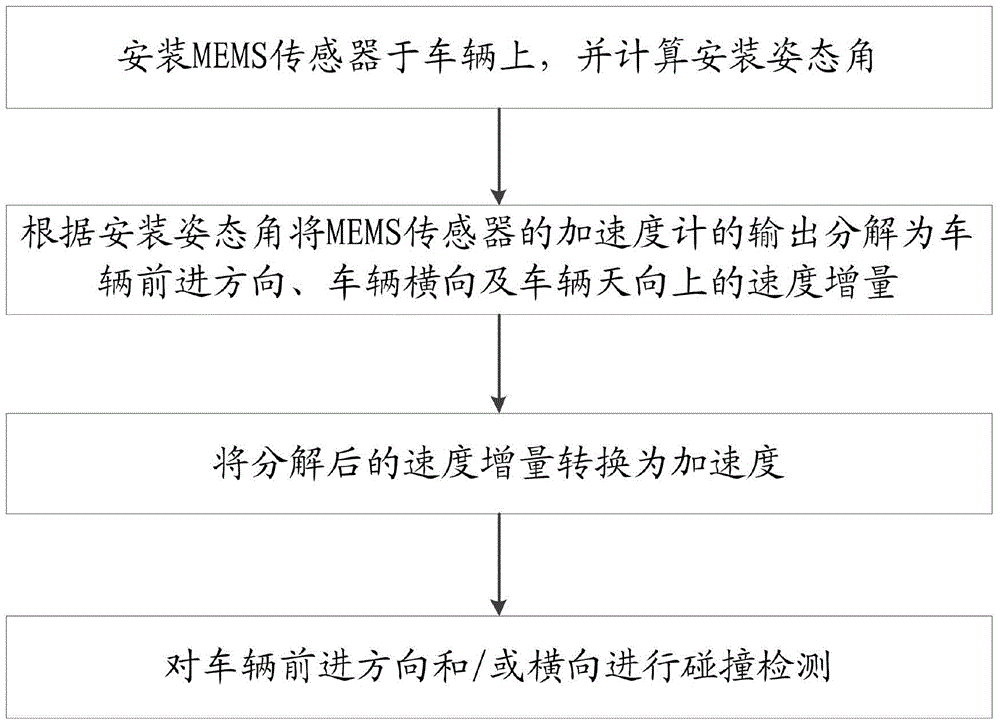

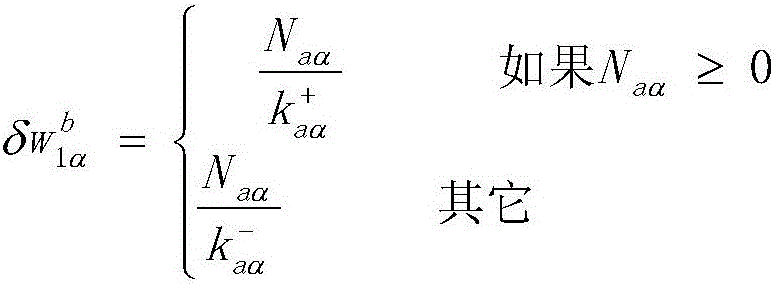

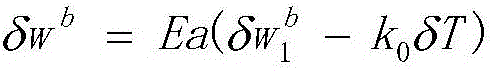

Vehicle collision detection method based on non-horizontal installation of mems sensors

ActiveCN104748974BAchieve collisionRealize identificationVehicle testingCollision detectionEngineering

The invention discloses a vehicle collision detection method based on the non-horizontal installation of an MEMS (Micro Electro Mechanical Systems) sensor. The method comprises the following steps: S1, installing an MEMS sensor on a vehicle, and calculating an installation attitude angle; S2, decomposing the output of an accelerator of the MEMS into the velocity increment of a vehicle forward direction, a vehicle transverse direction and a vehicle upward direction according to the installation attitude angle; S3, converting the decomposed velocity increment into an acceleration; S4, carrying out collision detection to the vehicle forward direction and / or the transverse direction. According to the detection method provided by the invention, the effective detection on the vehicle collision can be realized.

Owner:DALIAN ROILAND SCI & TECH CO LTD

Mobile power supply collision, charge and discharge detection integrated machine

InactiveCN108593239APrecise positioningAchieve collisionElectrical testingShock testingCylinder headEngineering

The invention relates to a mobile power supply collision, charge and discharge detection integrated machine, comprising a lower support and an upper support. Two loading frame lift cylinders are arranged side by side on the left and right of the lower support, and cylinder heads of the two loading frame lift cylinders are both hinged to the lower side of a loading frame which is matched with one mobile power supply. The distance between the inner sides of a left side plate and a right side plate of the loading frame is 2-4 times of the distance between the left end and the right end of the mobile power supply. Two mobile power supply clamping devices capable of inserting the loading frame are arranged on the lower portion of the loading frame, and the distance between the two mobile powersupply clamping devices is equal to the distance between the left end and the right end of the mobile power supply. An electric detection device which is matched with the mobile power supply between the two mobile power supply clamping devices is arranged on the upper support. With the structural design of the loading frame and the connection mode of the loading frame lift cylinders, collision between the mobile power supply and the loading frame can be achieved, while the mobile power supply in the loading frame can be positioned accurately after collision, and thus, the mobile power supply can be matched with the electric detection device accurately and collision and charge and discharge detection can be carried out integrally.

Owner:DONGGUAN UNIV OF TECH

Equipment special for anti-collision protection of oil tank truck

InactiveCN113002407ARealize the shock absorption effectAchieve protectionTank vehiclesItem transportation vehiclesTank truckOil transportation

The invention relates to the technical field of oil tank truck equipment, in particular to equipment special for anti-collision protection of an oil tank truck. The equipment comprises a mounting plate; a lifting device is fixedly mounted on the end wall of one side, far away from the ground, of the mounting plate; the lifting device is used for lifting protection of a protection cylinder, and collision can be detected by utilizing a collision detection device; the lifting device can be used for driving the oil tank to quickly lift, so that collision of the oil tank is avoided; the oil tank can be damped when the oil tank truck is overturned, and the oil tank can be protected by inert protective gas to prevent deformation of the oil tank; the oil outlet and the oil inlet can be sealed when the oil tank truck is overturned, so that safety accidents caused by oil leakage are prevented; the safety of the oil tank truck in the oil transportation process is improved, and the occurrence frequency of safety accidents is reduced.

Owner:深圳市旺久鑫科技有限公司

A three-dimensional braiding machine discretization mandrel system based on variable-curvature special-shaped rotators

The invention discloses a three-dimensional braiding machine discretized core mold system based on a variable-curvature special-shaped rotary body, comprising: a core mold assembly unit, a core mold lifting unit, and a PLC, and the core mold assembly unit is connected with the core mold lifting unit. , the PLC is respectively connected with the core mold assembly unit and the core mold lifting unit; the core mold assembly unit includes: a discrete core mold layer unit, a core mold interlayer locking mechanism, and a core mold layer unit lifting mechanism. The discretized core model layer unit is composed of variable curvature core model layer slices, the discrete core model layer unit is arranged on the core model layer unit raising mechanism, the core model layer unit rising mechanism and the core model layer interlayer locking mechanism Both are fixedly connected with the core mold lifting unit. The discrete mandrel system of the three-dimensional braiding machine of the invention avoids the interference between the mandrel and the yarn, and ensures the three-dimensional weaving of the variable-curvature special-shaped revolving body with constant weaving fell height.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

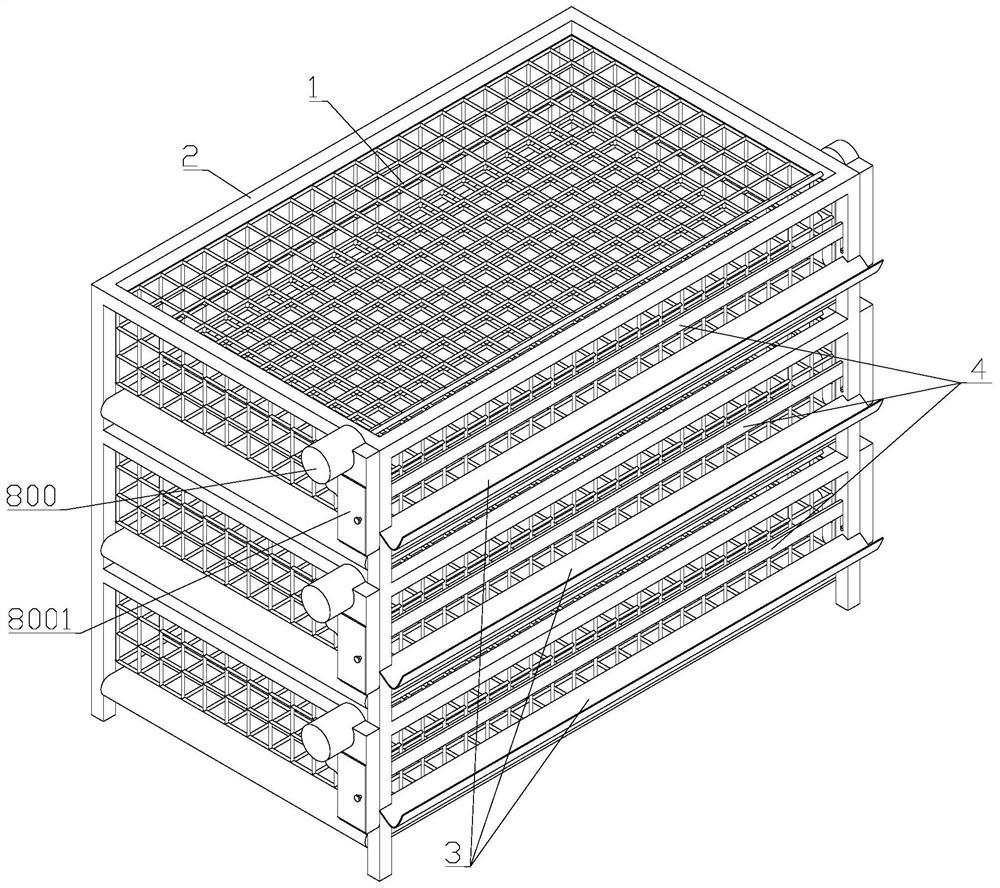

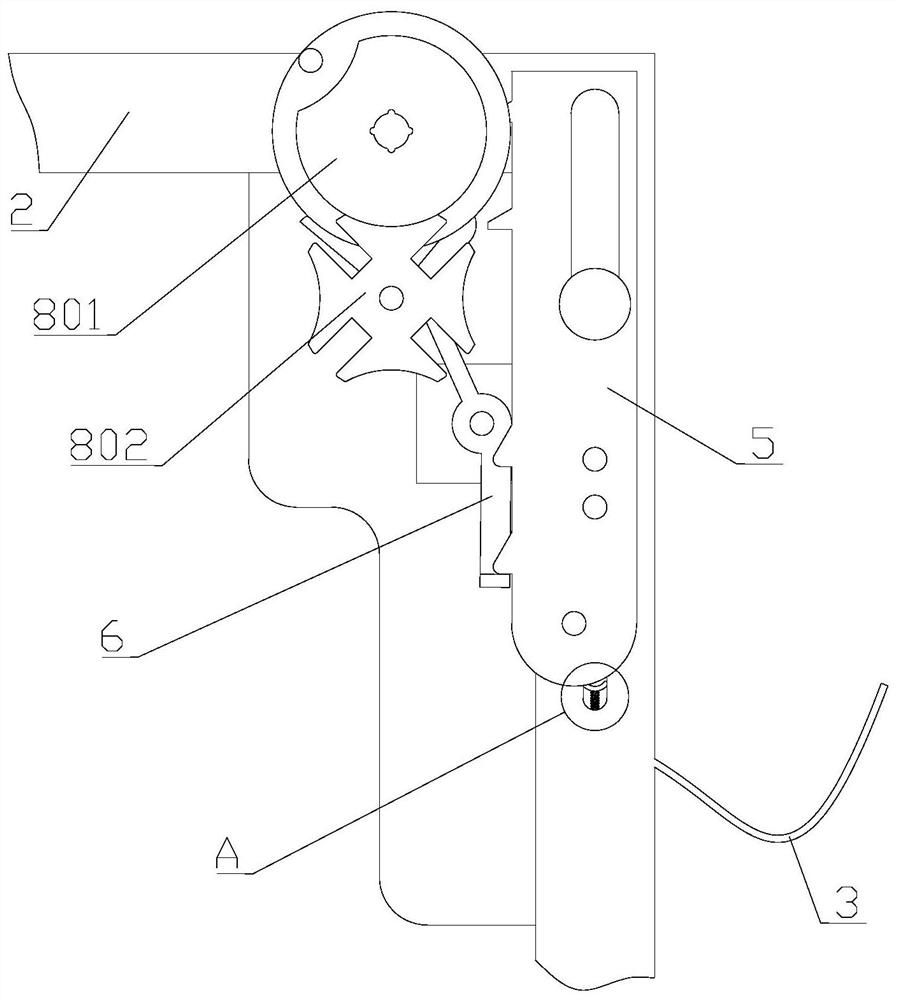

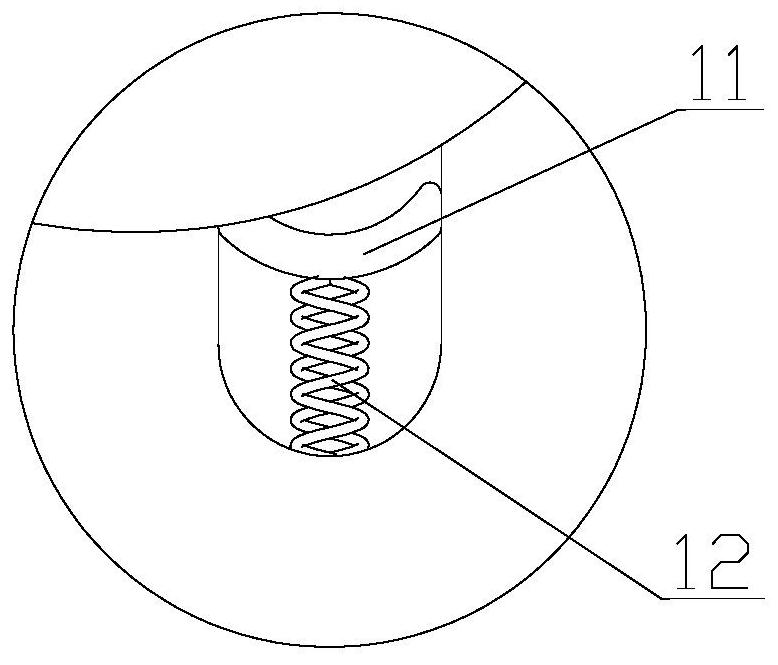

A meat duck breeding cage with adjustable feeding height

ActiveCN110881419BImpact dropRealize fully automatic controlBird housingsAnimal scienceDomestic bird

Owner:馆陶六和食品有限公司 +1

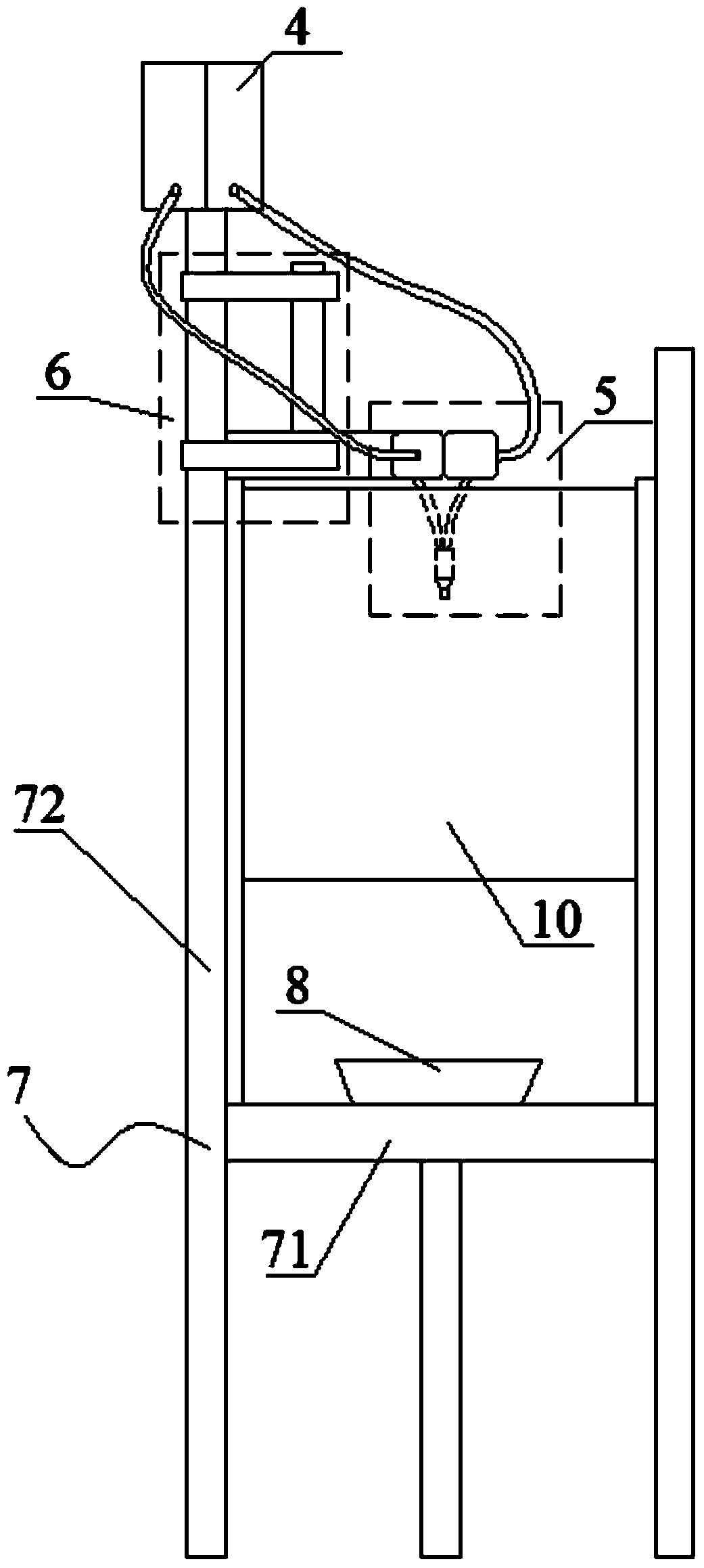

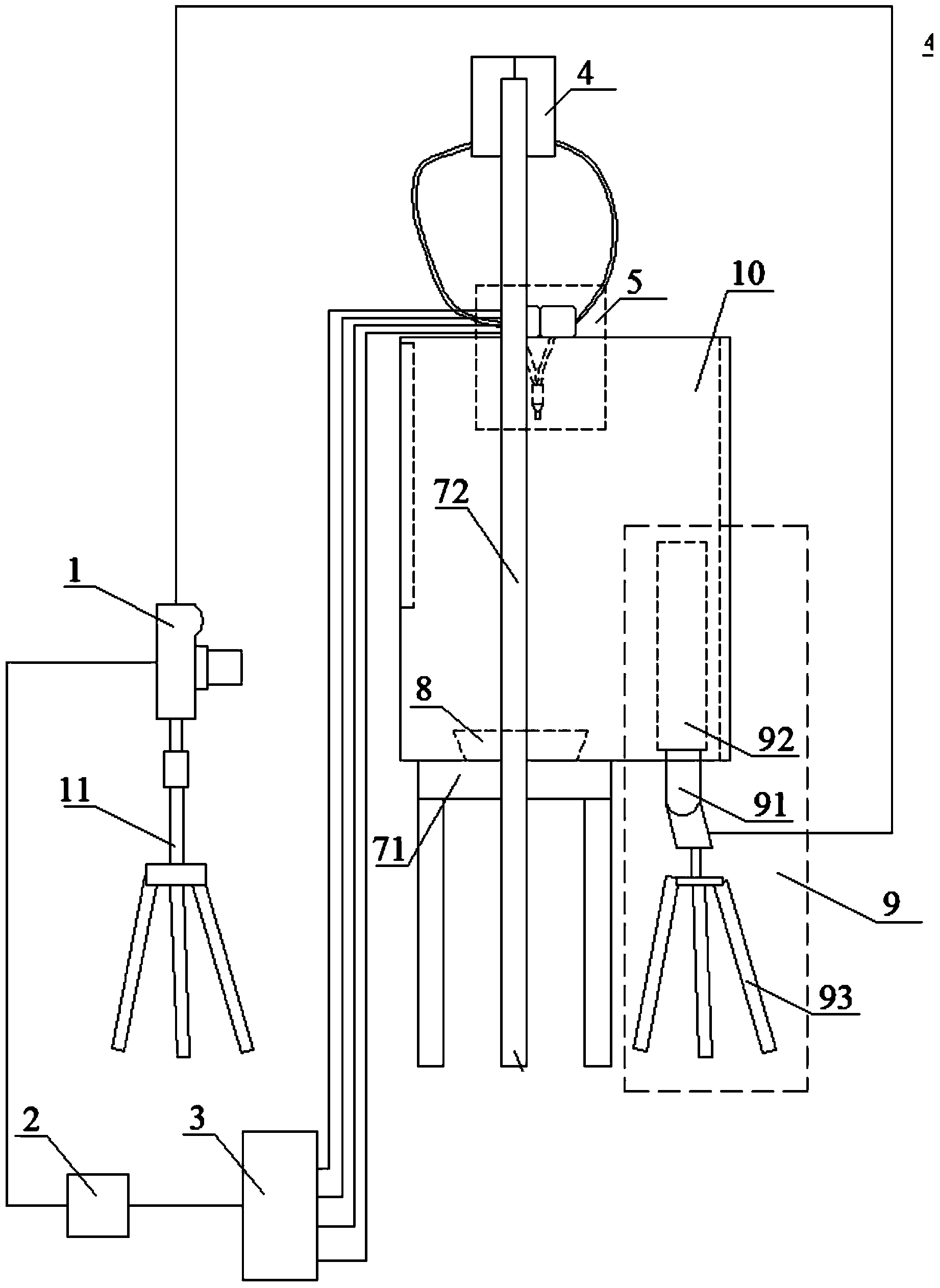

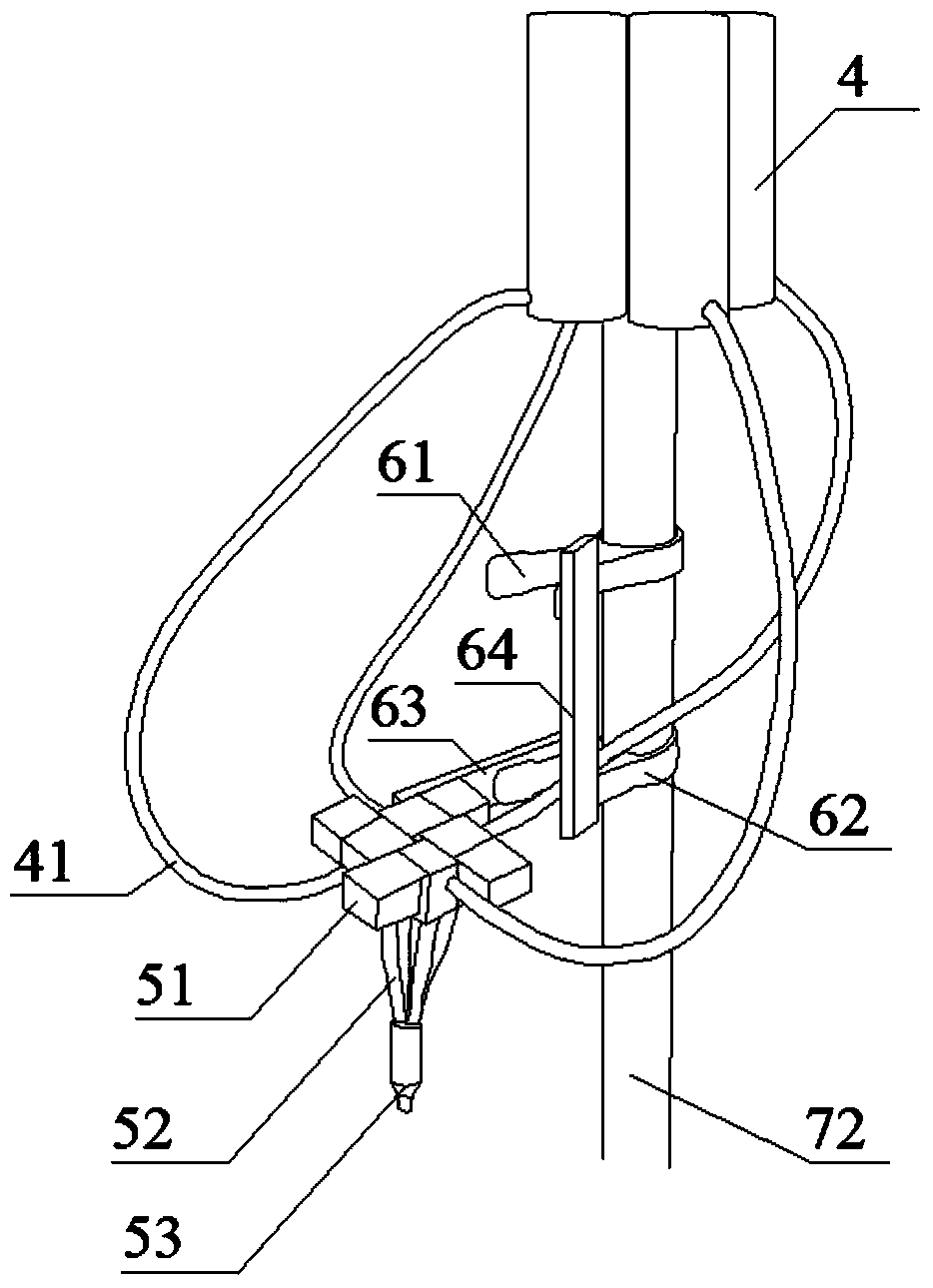

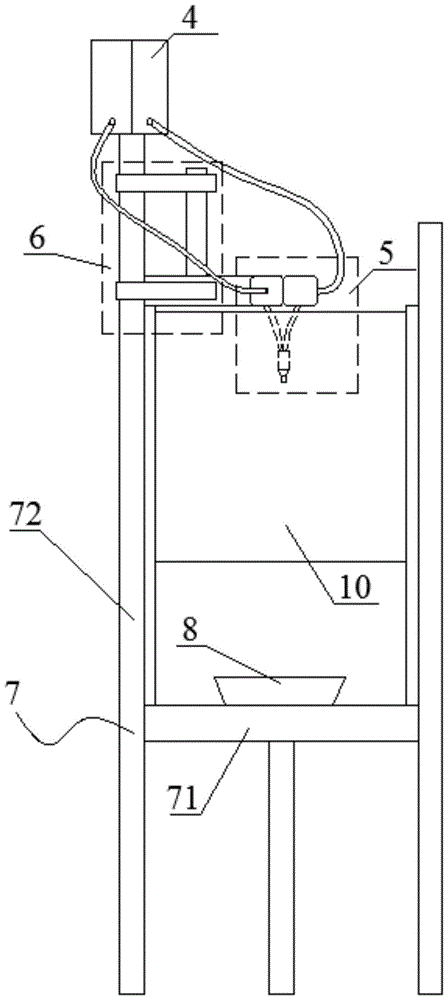

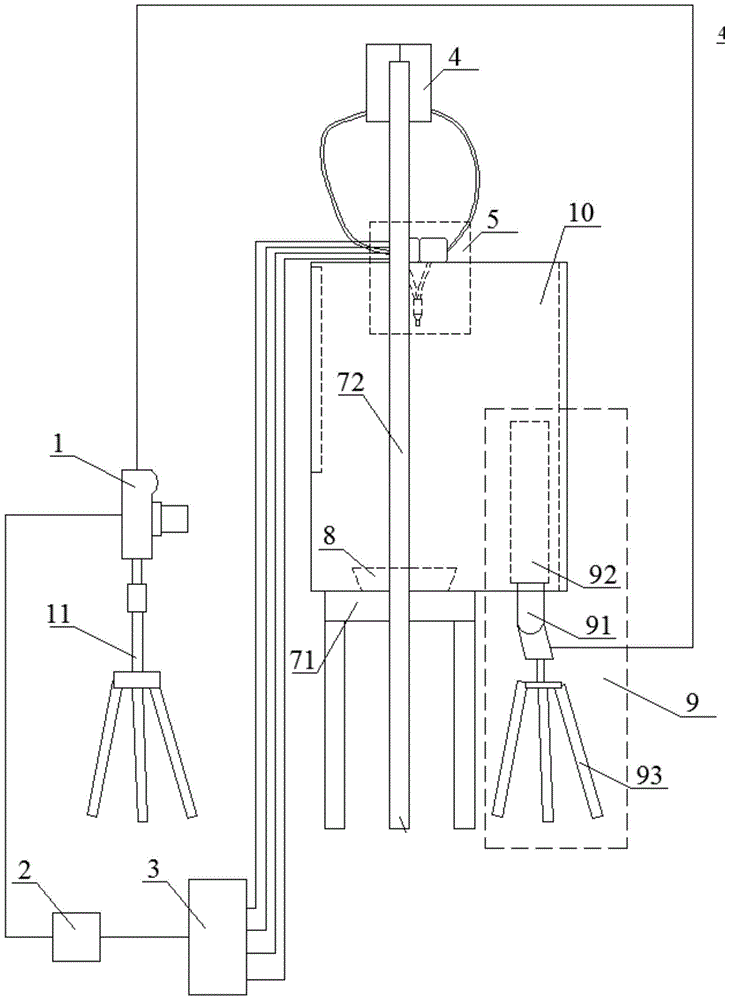

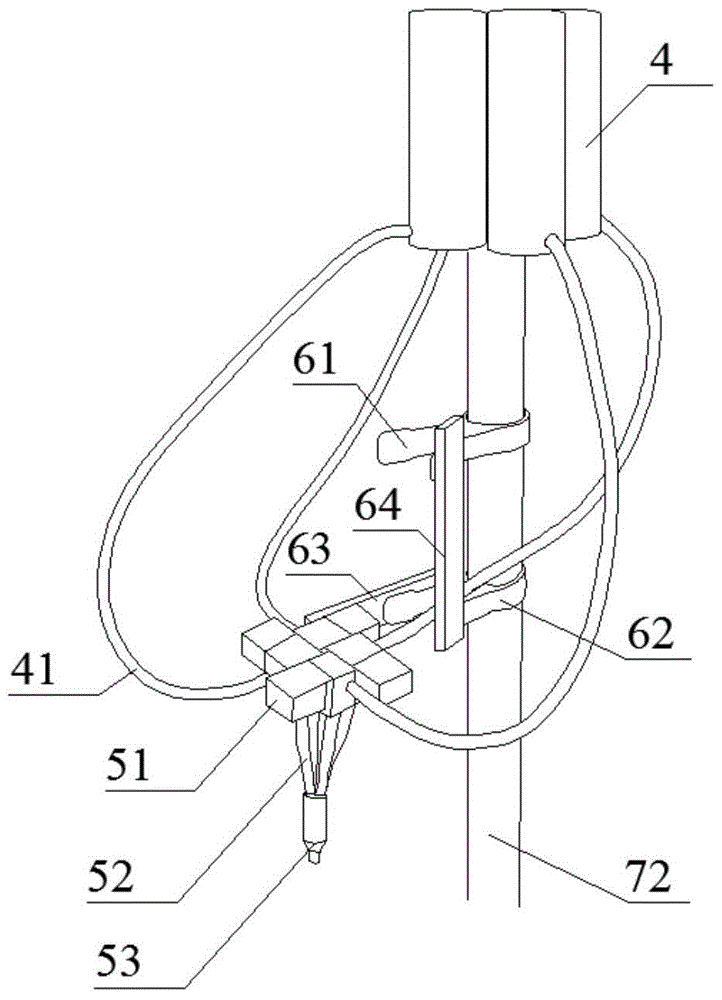

Water drip collision automatic photo taking device

InactiveCN103529638ARealize automatic shootingAchieve collisionTelevision system detailsColor television detailsWater storageCamera lens

The invention provides a water drip collision automatic photo taking device, which comprises a camera, an electromagnetic valve triggering switch, an electromagnetic valve controller, a water storage component, a water dripping component, a clamping component and a fixing table, wherein the camera is connected with the electromagnetic valve controller through a conducting wire, the electromagnetic valve triggering switch is arranged on the conducting wire arranged between the camera and the electromagnetic valve controller, the fixing table comprises a platform and support rods, the support rods are vertically arranged at the two sides of the platform, the water storage component is arranged at the upper part of the support rods and is connected with the water dripping component through a connecting pipe, the clamping component is arranged on the support rod, the water dripping component is fixedly arranged on the clamping component and is connected with the electromagnetic valve controller through a conducting wire, and the fixing component is positioned right in front of a camera lens. The water drip collision automatic photo taking device has the advantage of simple and ingenious structure and has the beneficial effects that an electromagnetic valve and the camera are controlled through the electromagnetic valve controller, and the automatic shooting of collision effects of several water drips with different colors in various types can be realized.

Owner:SHAOGUAN CITY INST OF TECHNICIAN

Three-dimensional braiding machine discretization core mold system based on variable-curvature special-shaped revolving body

The invention discloses a three-dimensional braiding machine discretization core mold system based on a variable-curvature special-shaped revolving body, which comprises a core mold assembly unit, a core mold lifting unit and a PLC, wherein the core mold assembly unit is connected with the core mold lifting unit, and the PLC is connected with the core mold assembly unit and the core mold lifting unit; the core mold assembly unit comprises a discretization core mold layer unit, a core mold interlayer locking mechanism and a core mold layer unit ascending mechanism, wherein the discretization core mold layer unit is composed of variable-curvature core mold layer slices, and the discretization core mold layer unit is arranged on the core mold layer unit ascending mechanism; and the core mold layer unit ascending mechanism and the core mold interlayer locking mechanism are fixedly connected with the core mold ascending unit. According to the three-dimensional braiding machine discretization core mold system based on the variable-curvature special-shaped revolving body, interference between the core mold and a yarn is avoided, and three-dimensional braiding of a variable-curvature special-shaped revolving body with cloth fell height being constant is guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

An automatic avoidance method for the testing axis of a flying probe testing machine

ActiveCN107102249BRealize automatic avoidanceAchieve collisionElectronic circuit testingEngineeringMechanical engineering

The invention relates to the technical field of circuit board test equipment, and discloses a flying probe tester test shaft automatic avoidance method. The front surface of a flying probe tester is provided with probes Tip 1 and Tip 2 and the reverse surface is provided with probes Tip 3 and Tip 4. According to the automatic avoidance method, firstly points to be tested are allocated to the four probes Tip 1, Tip 2, Tip 3 and Tip 4 and the current mechanical coordinates of each probe are acquired; the mechanical coordinates of each probe are transformed into absolute coordinates, wherein the probes Tip 1 and Tip 2 are based on the probe Tip 1 in the transformation process, and the probes Tip 3 and Tip 4 are based on the probe Tip 3; avoidance is judged through the position relation of the world coordinates of the current measurement points corresponding to the two probes of the same side and the points to be tested, and one of the probes is moved to the avoidance position if avoidance is required; and if avoidance is not required, the world coordinates of the points to be tested are directly transformed into the mechanical coordinates based on themselves and the corresponding probes are moved to the positions of the mechanical coordinates. The method is simple, reliable and easy to implement.

Owner:HANS CNC SCI & TECH

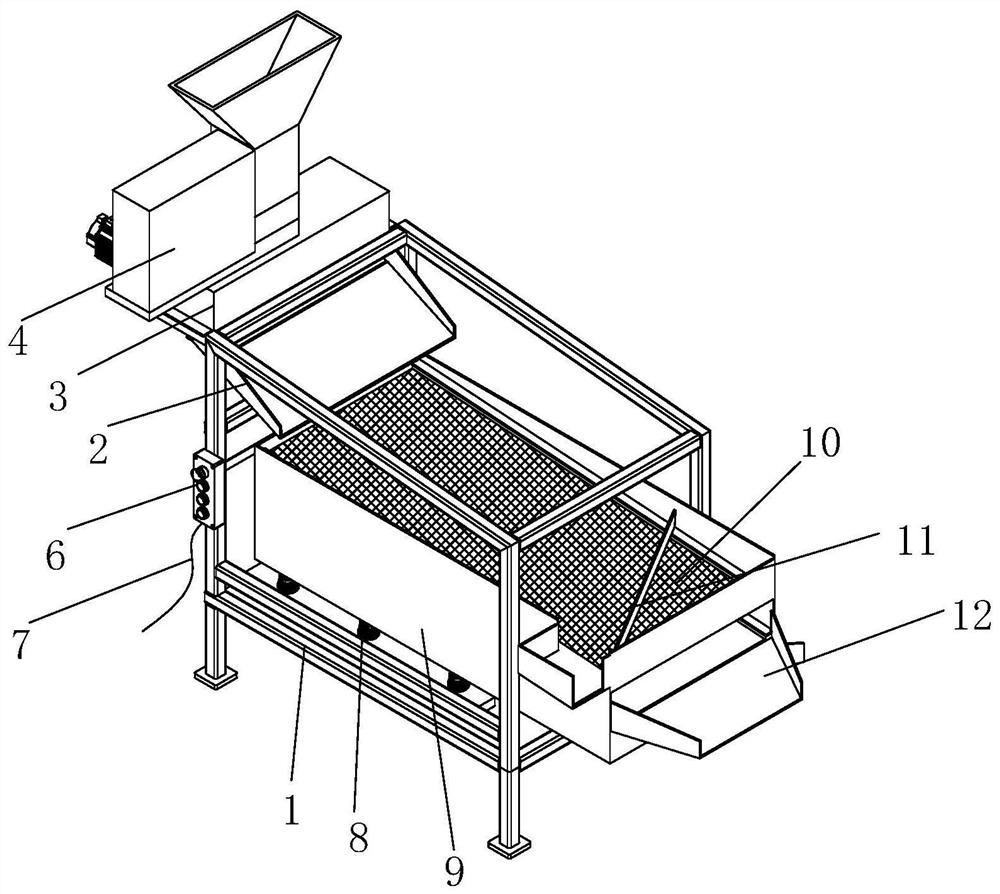

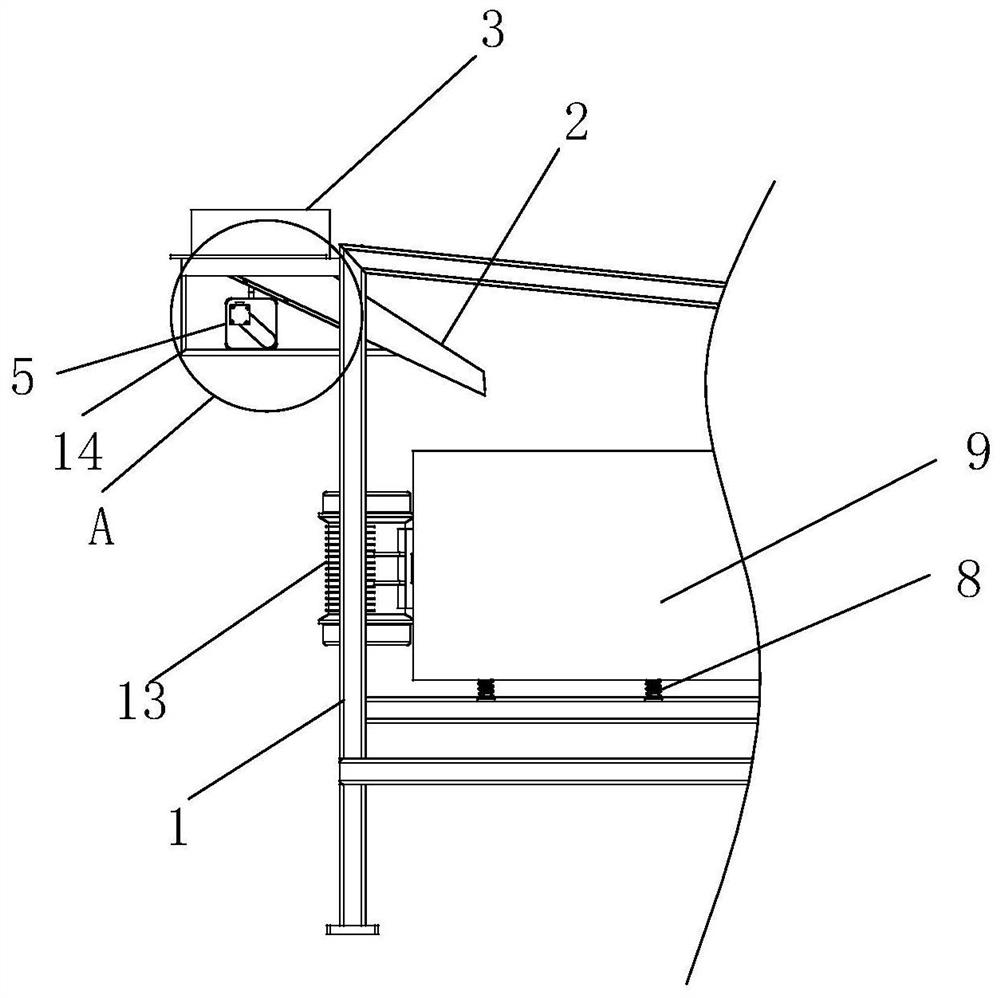

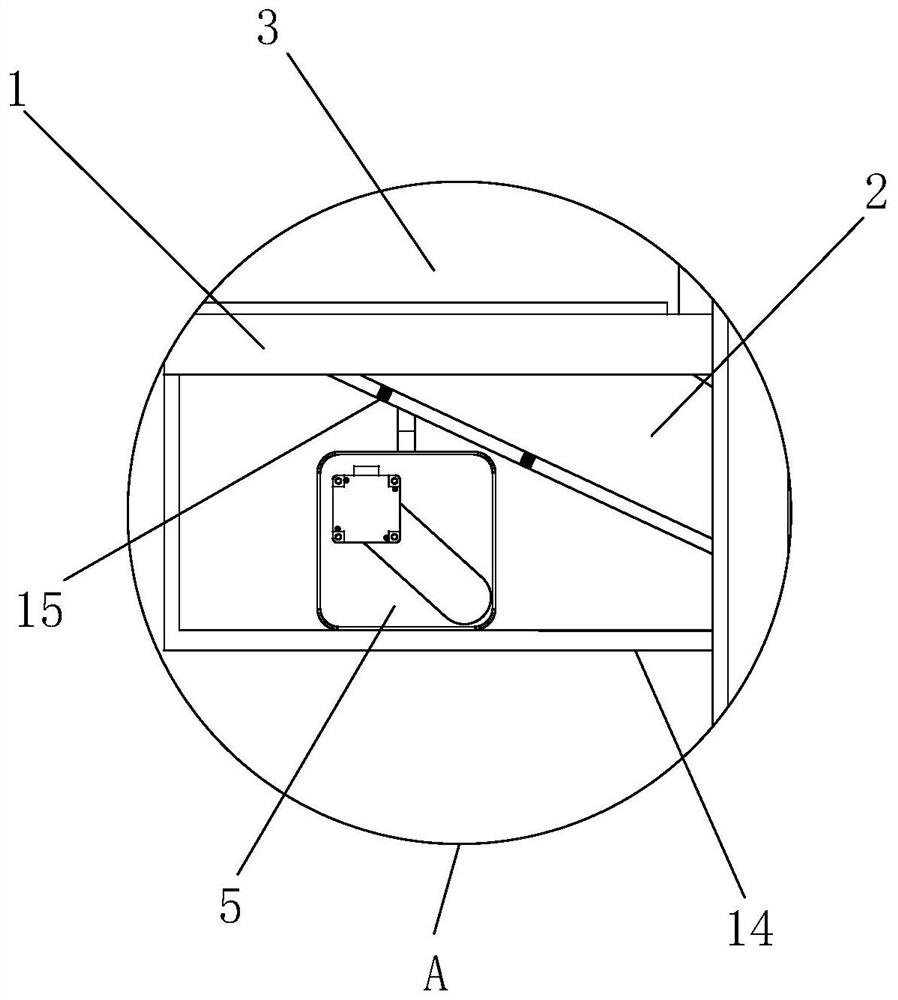

Grading device for traditional chinese medicinal material chipping recycling

InactiveCN111672751AReduce manual operationsImprove work efficiencySievingScreeningGear driveGear wheel

The invention discloses a grading device for traditional chinese medicinal material chipping recycling. The device comprises a bracket, a feeding hopper, a feeding box, an auxiliary grading device, adispersing device, a grading bin, a lifting frame and rubber blocks. According to the device, the auxiliary grading device is arranged at the left end of the top of the feeding box, and when materialsenter the auxiliary grading device, a reciprocating collision mechanism arranged inside is driven by a motor, then a rotating piece moves through gear transmission to drive a push rod to enable an impact head to impact the falling materials to scatter the agglomerated and caked materials, the manual operation is reduced, and the working efficiency is improved; and the dispersing device is arranged at the top of the lifting frame, an independent motor is arranged in the dispersing device, the motor controls a transmission mechanism to move, and then a reciprocating jacking mechanism can jack up a jacking block at the top in a reciprocating mode, so that the collision to the left end of the bottom of the feeding hopper is achieved, the materials passing through the feeding hopper can be conveniently dispersed, and the materials are effectively and uniformly fed into the grading bin to be treated.

Owner:林闽华

A water drop collision automatic photography device

InactiveCN103529638BRealize automatic shootingAchieve collisionTelevision system detailsColor television detailsCamera lensSolenoid valve

An automatic photography device for water drop collision, comprising a camera, a solenoid valve trigger switch, a solenoid valve controller, a water storage part, a dripping part, a clamping part and a fixing table, the camera is connected to the solenoid valve controller through a wire, and the camera is connected to the solenoid valve The wires between the valve controllers are provided with electromagnetic valve trigger switches. The fixed platform includes a platform and support rods. The support rods are installed vertically on both sides of the platform. The pipe is connected with the dripping part, and the clamping part is arranged on the support rod, and the dripping part is fixed on the clamping part, and is connected with the solenoid valve controller through a wire, and the fixed part is located directly in front of the camera lens. The present invention has a simple and ingenious structure, and its beneficial effect is that by using the solenoid valve controller to control the solenoid valve and the camera, it can realize the automatic shooting of the collision effect of multiple drops of different colors in various patterns.

Owner:SHAOGUAN CITY INST OF TECHNICIAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com