Patents

Literature

49results about How to "Improve impact efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

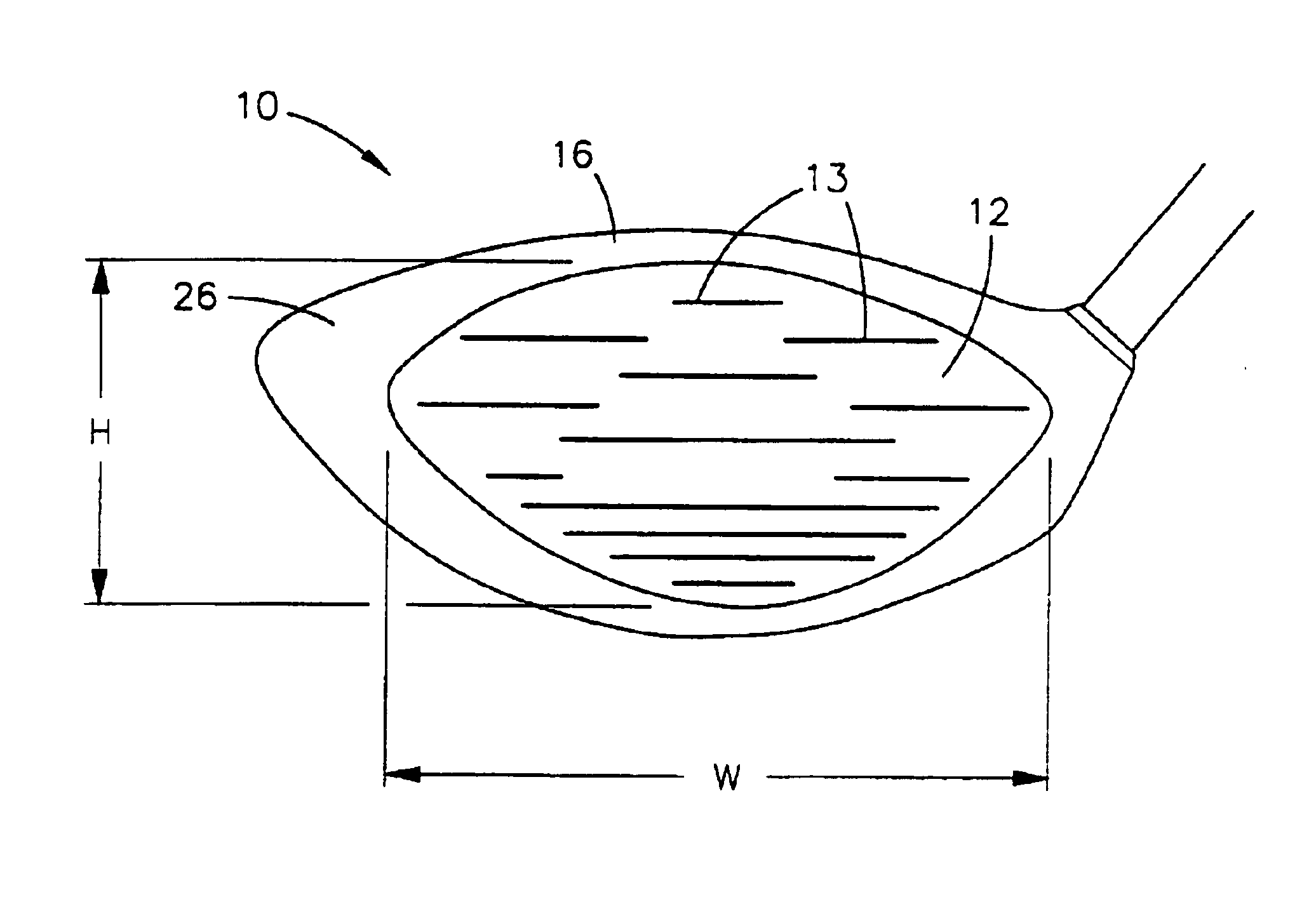

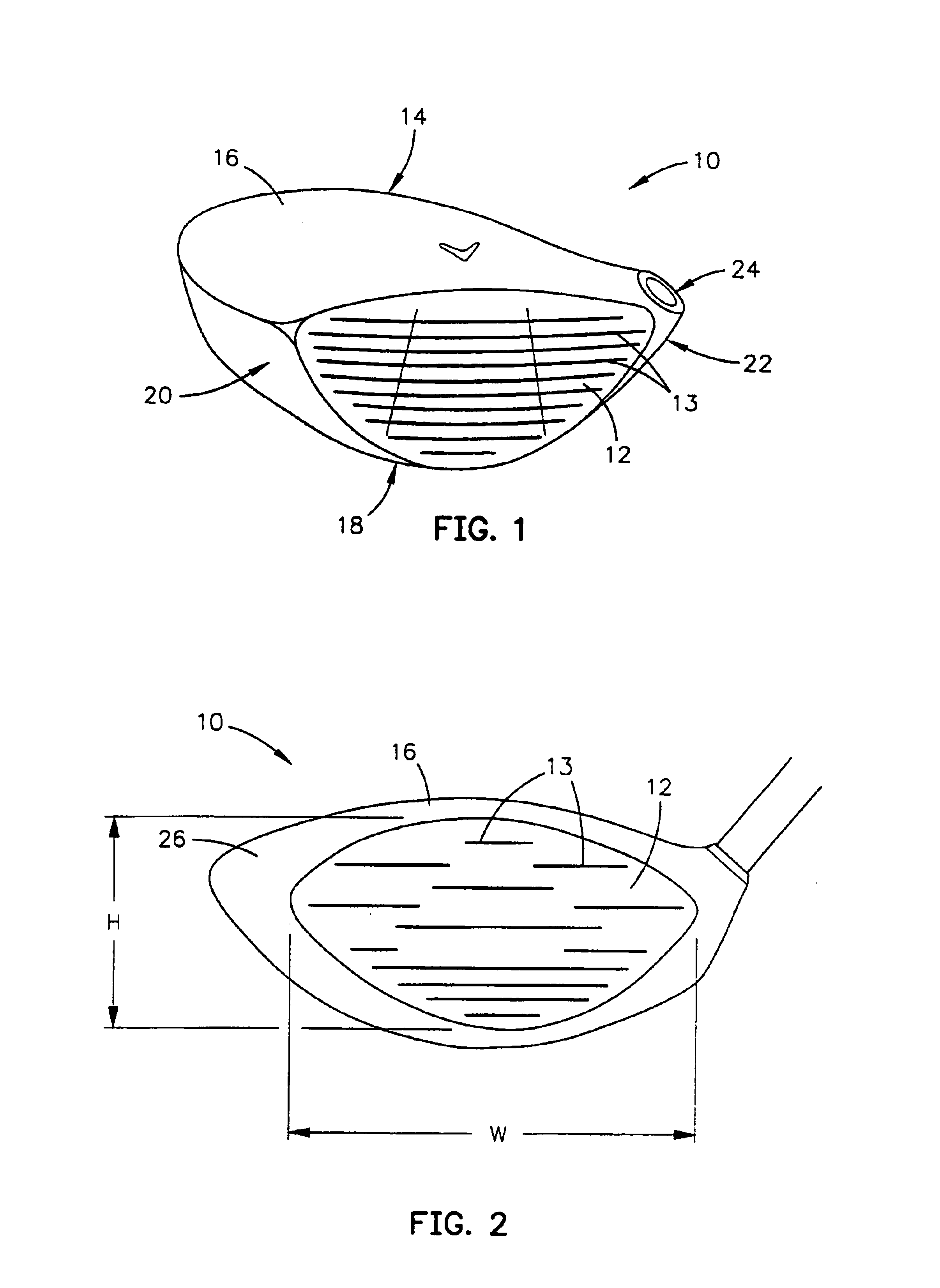

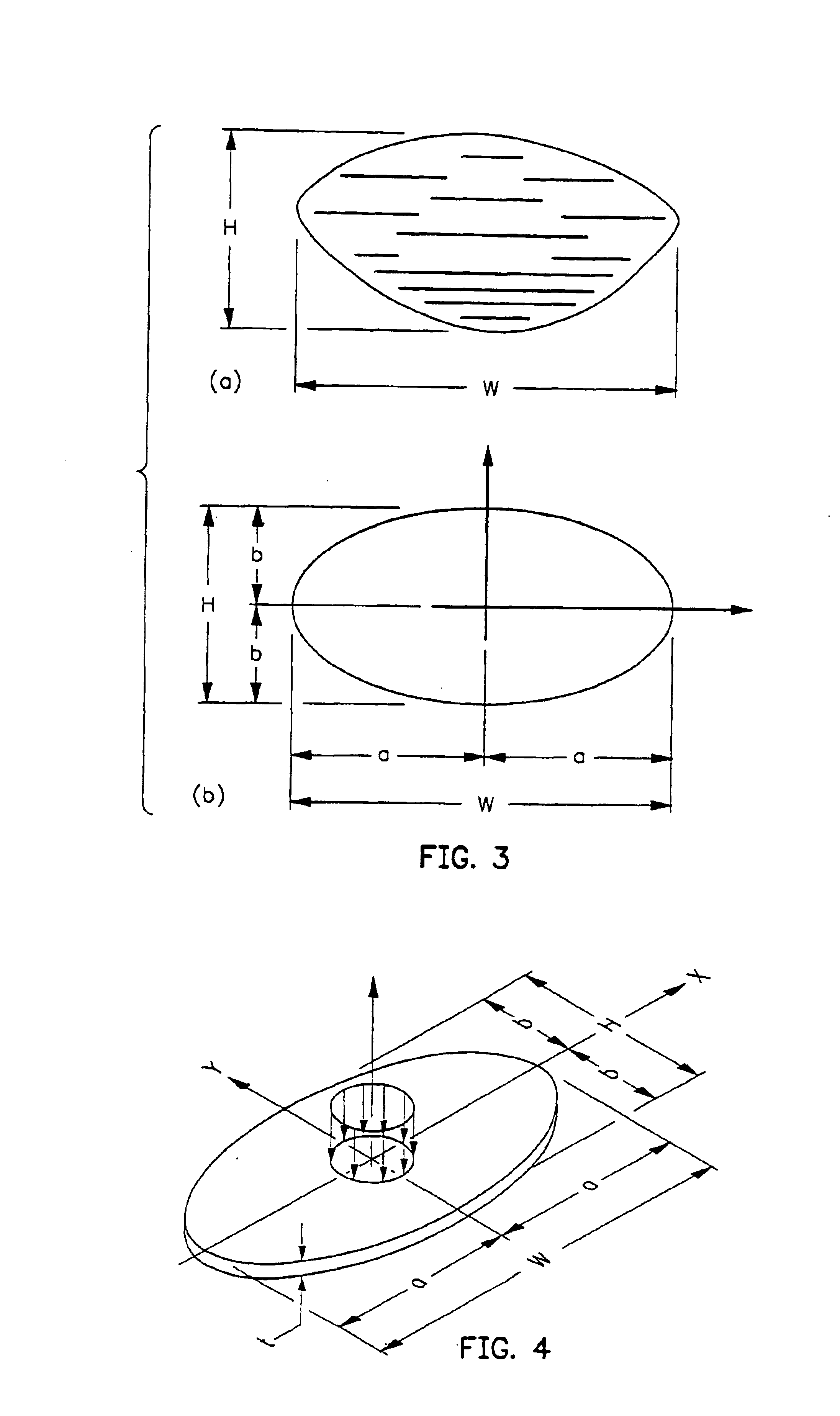

Golf club head having a striking face with improved impact efficiency

InactiveUS6949032B2Improve energy efficiencyReduced magnitudeGolf clubsRacket sportsStrain rateEnergy loss

A compliant golf club head permits a more efficient impact between a golf ball and the golf club head. Material and geometry constraints of a striking plate of the golf club head can reduce energy losses caused by large strain and strain rate values of the golf ball, these constraints on the striking plate yield a measure of the impact efficiency of the golf club head. Designating a required natural frequency range of the striking plate provides improved impact efficiency between the golf ball the golf club head.

Owner:CALLAWAY GOLF CO

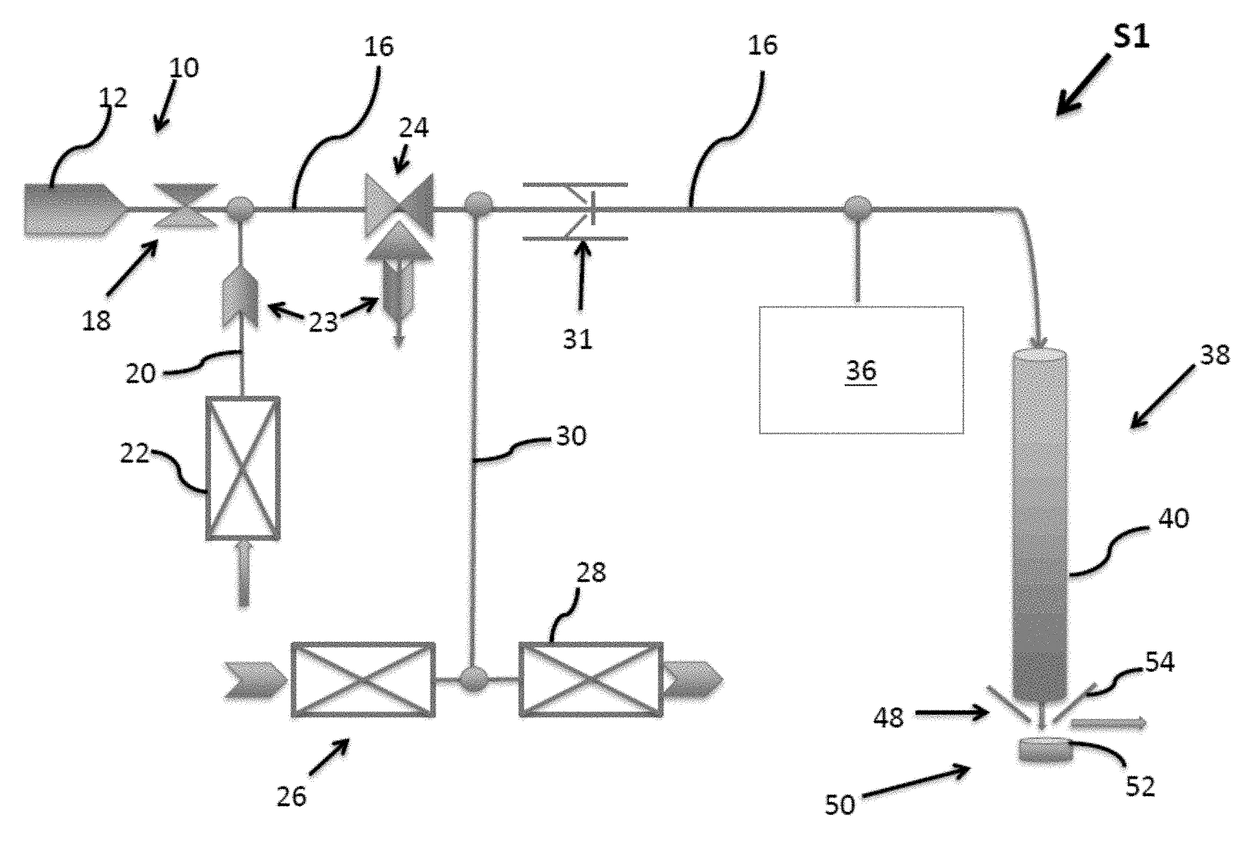

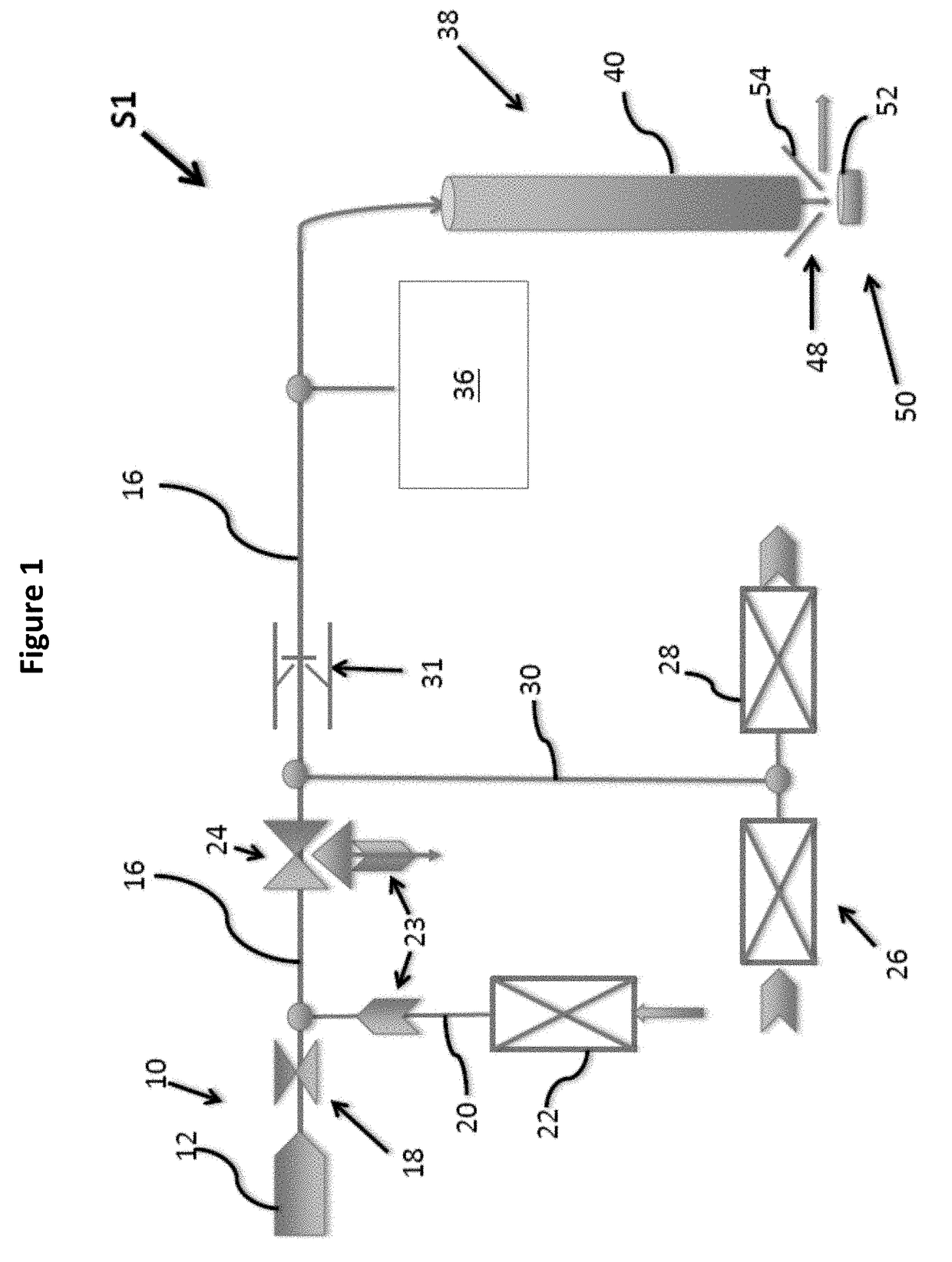

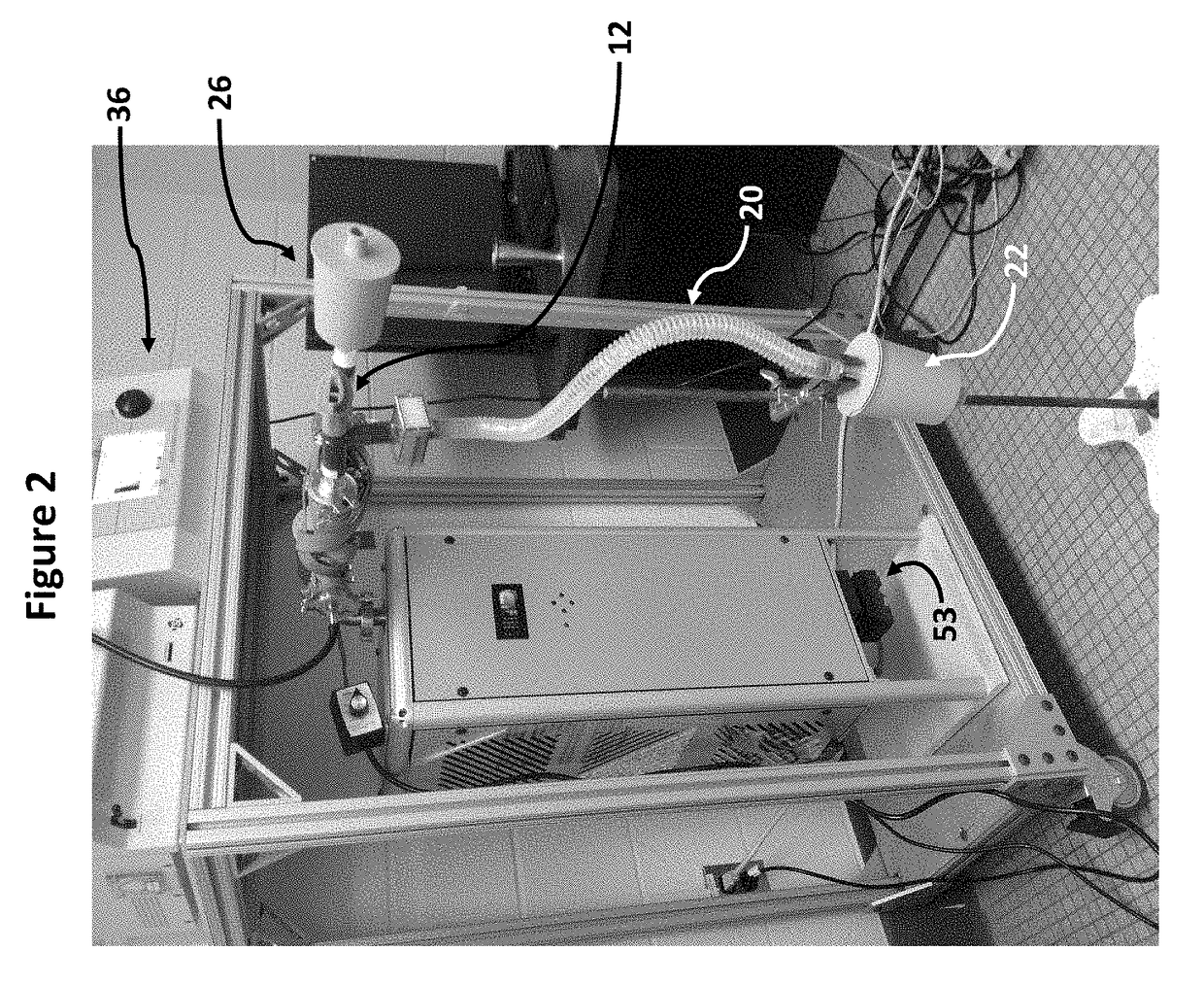

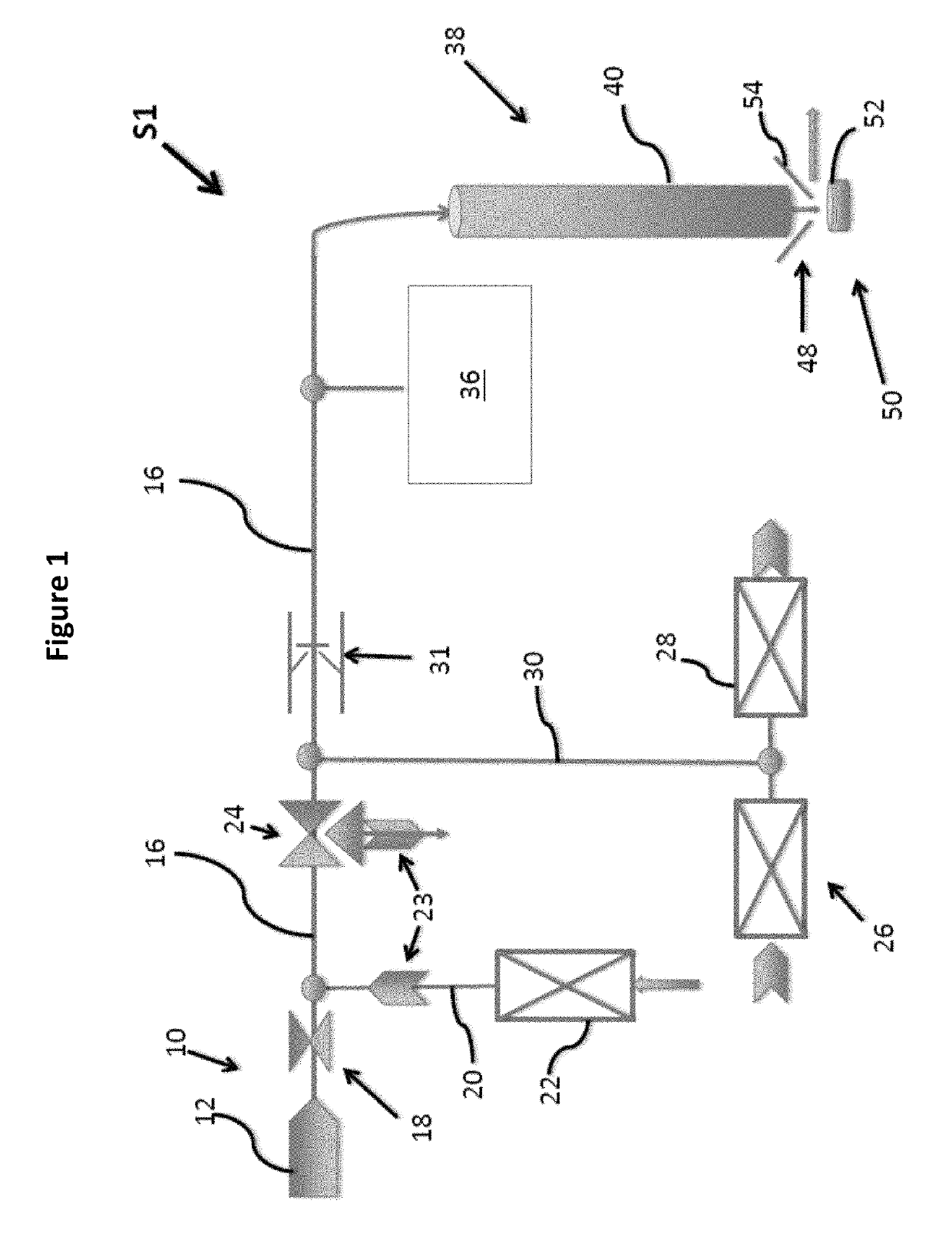

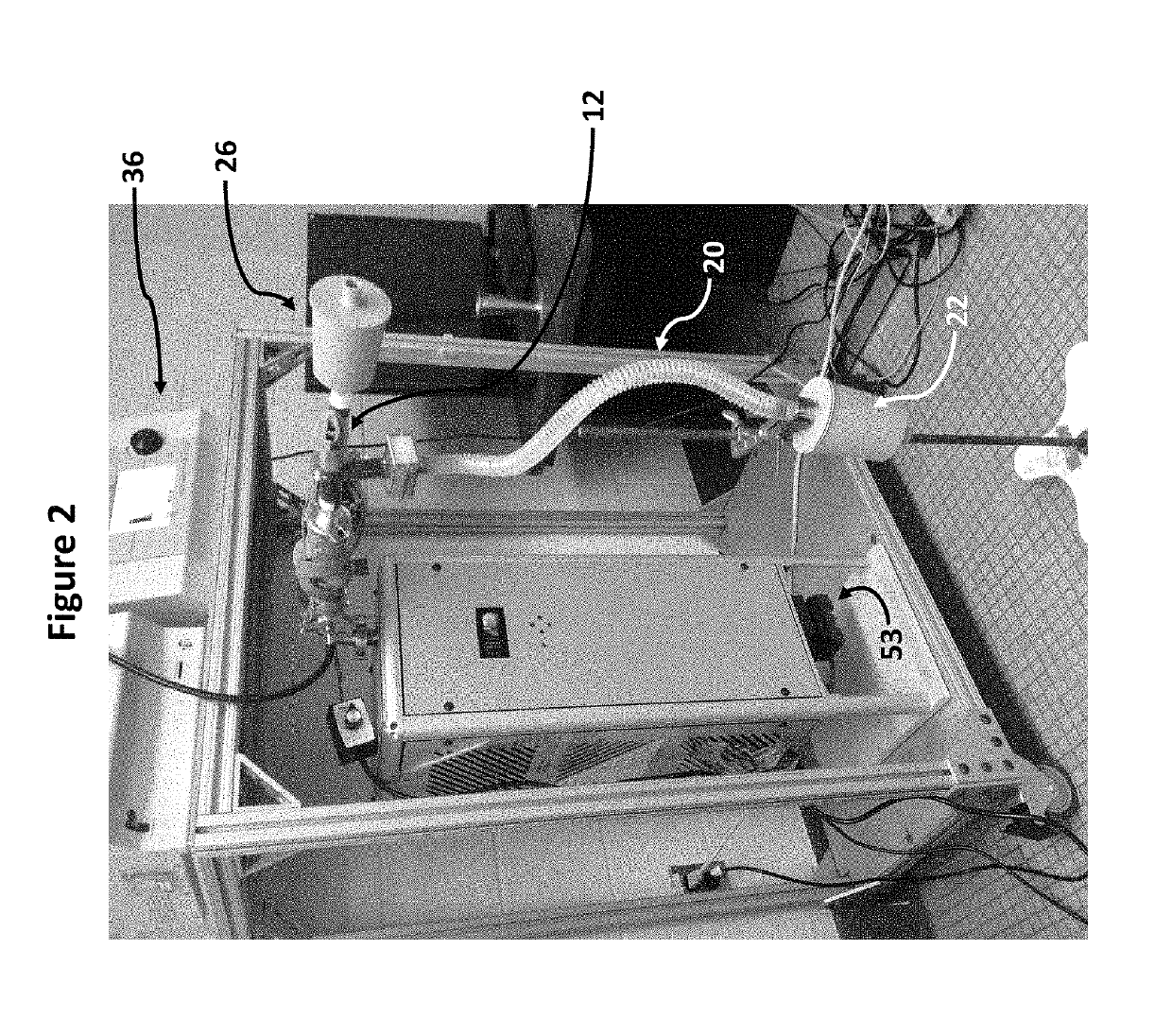

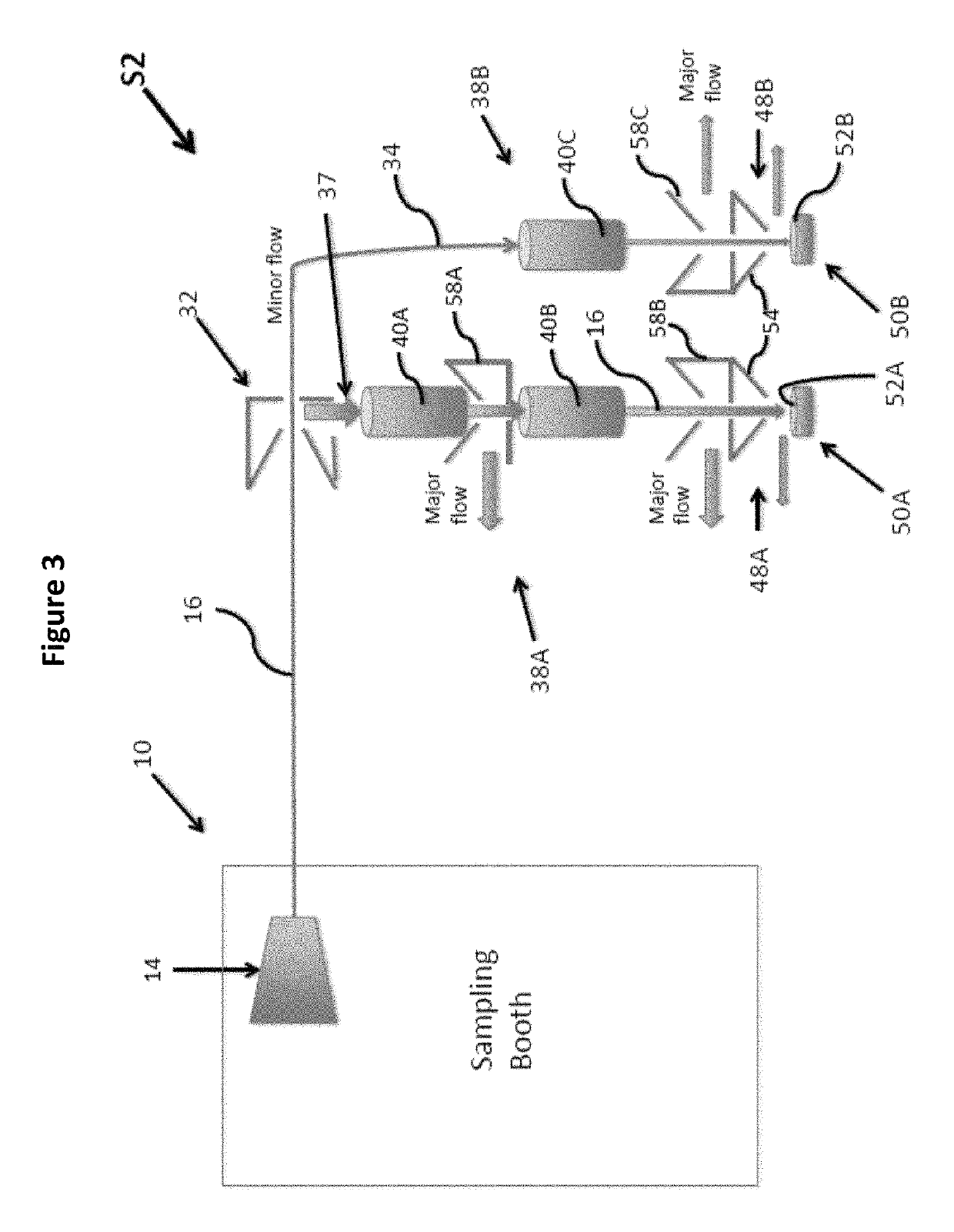

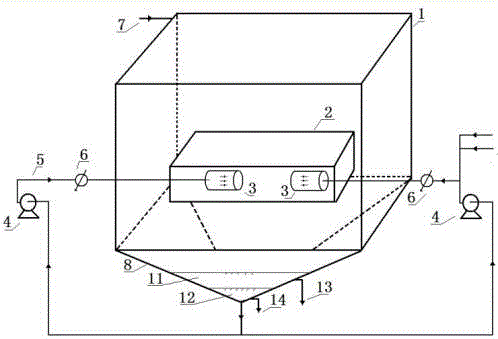

Aerosol Collection System and Method

ActiveUS20170299477A1Improve impact efficiencyIncrease analyte concentrationLiquid dispersion analysisWithdrawing sample devicesWater vaporMedicine

The present invention relates to systems and methods for collecting and analyzing bioaerosols, including exhaled breath aerosol from a subject. The collection system comprises an inlet portion configured to receive a gaseous fluid containing water vapor and aerosol particles. A primary passage for gaseous fluid flow is in fluid communication with the inlet portion and configured to channel the gaseous fluid flow therethrough. An outlet portion is in fluid communication with the primary passage. A sample collection region is provided, which is configured to receive from the outlet portion aerosol particles from the gaseous fluid, wherein the aerosol particles are impacted onto a layer of ice.

Owner:AEROSOL DYNAMICS INC +1

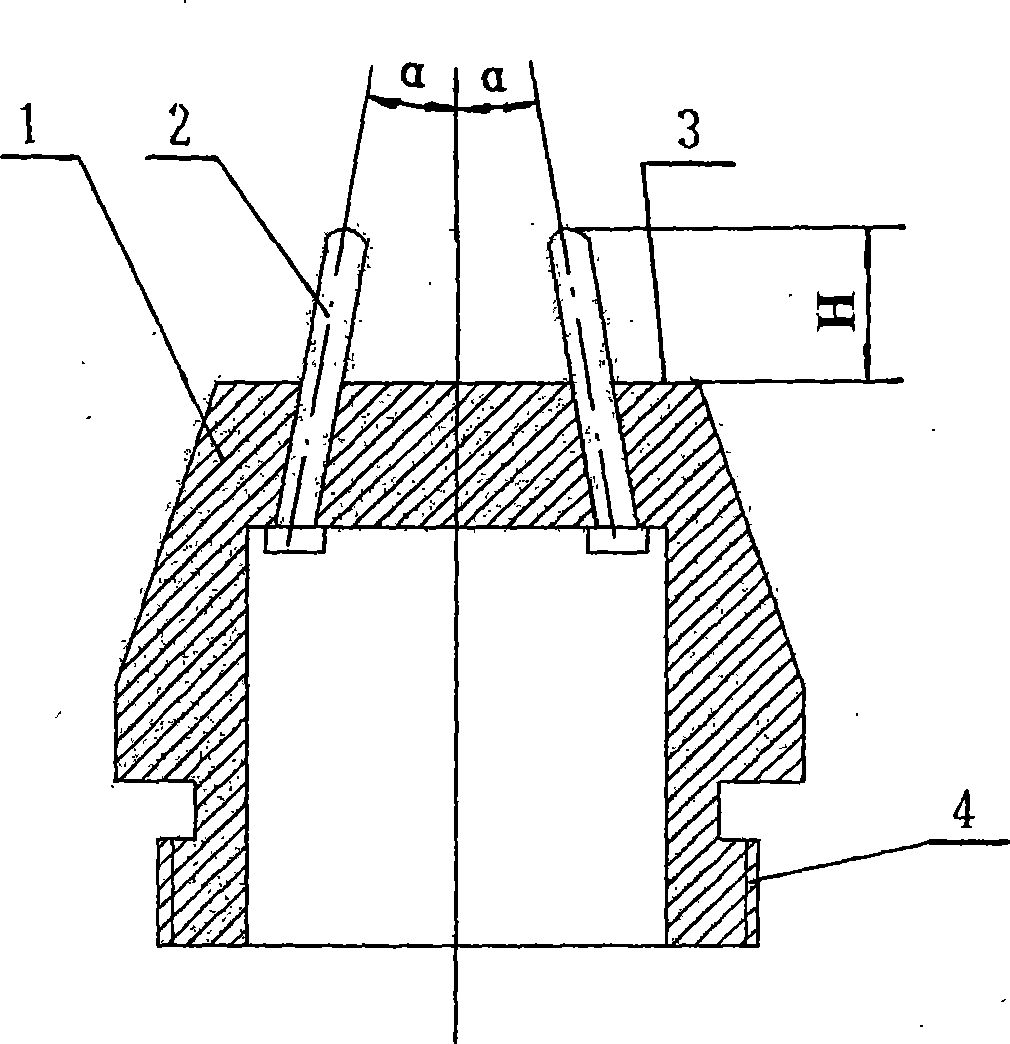

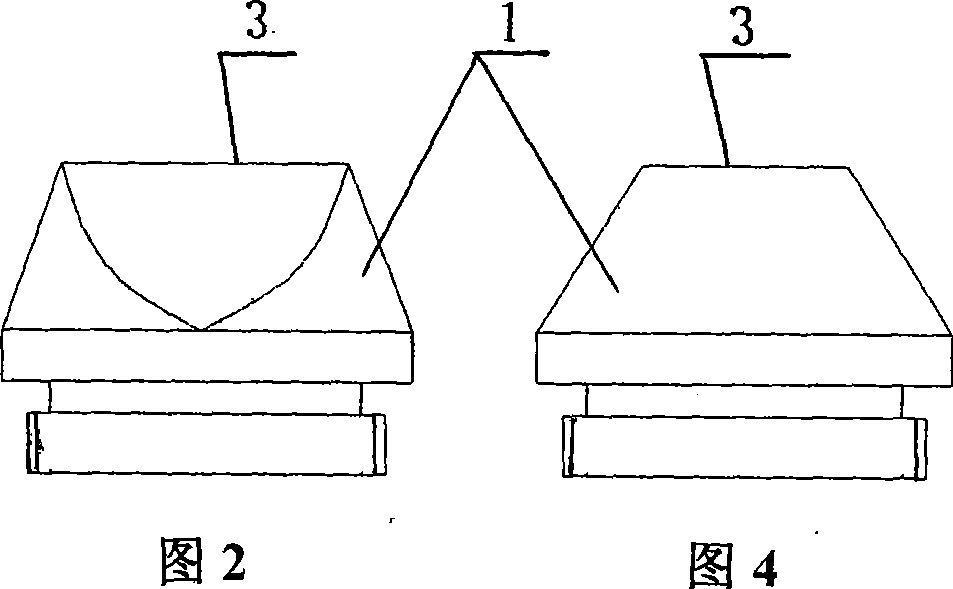

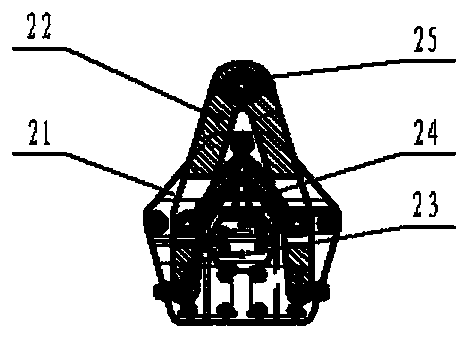

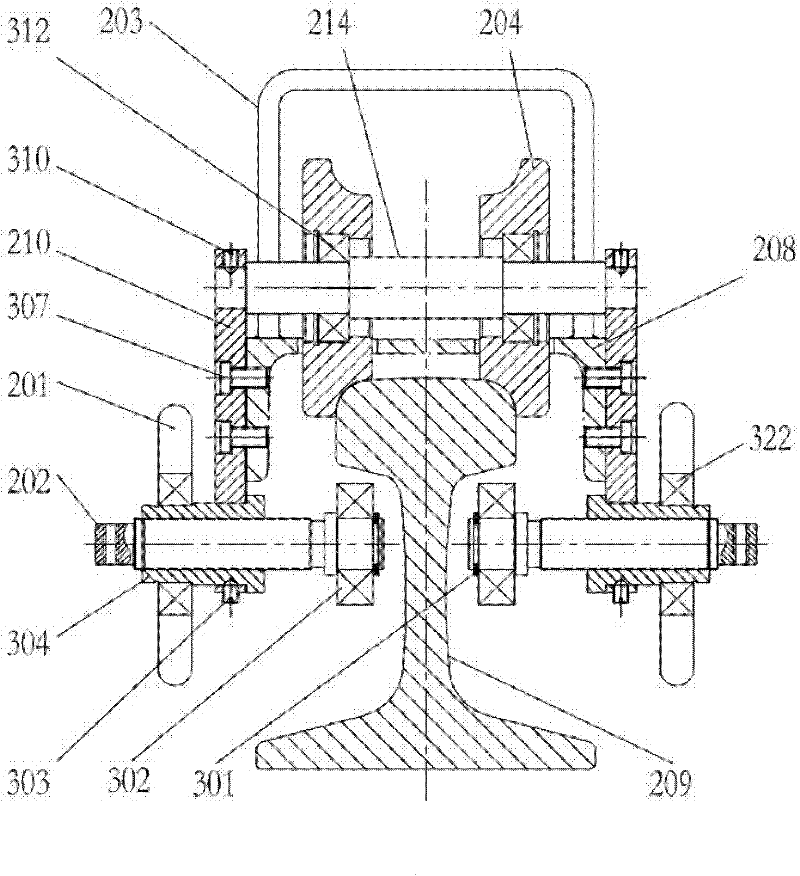

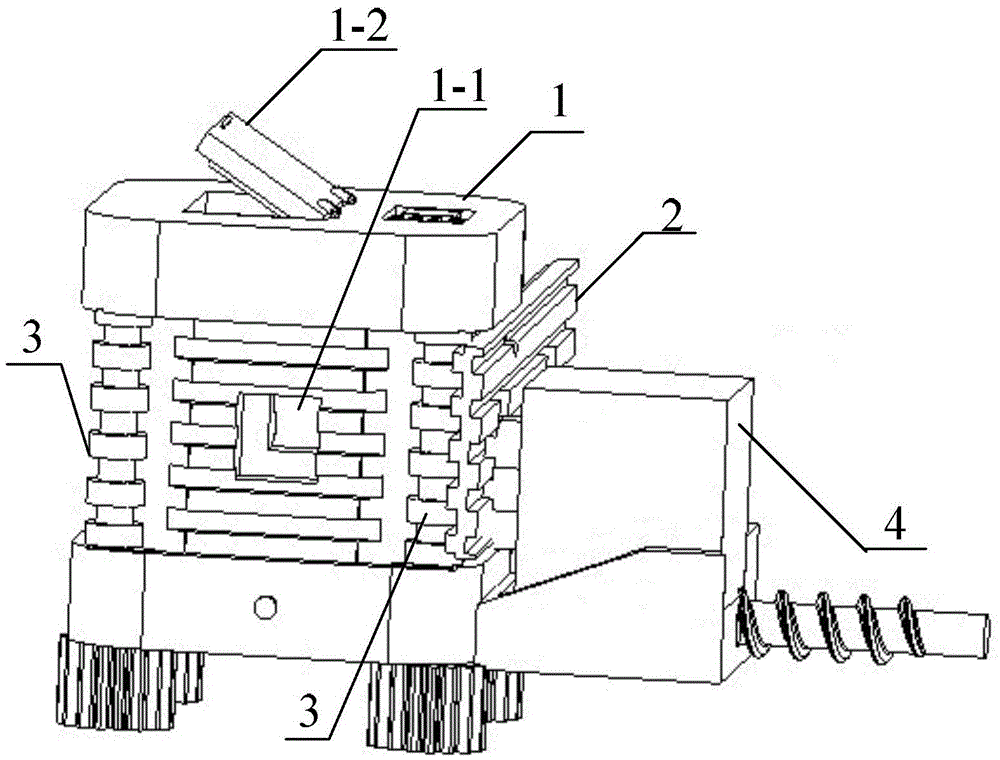

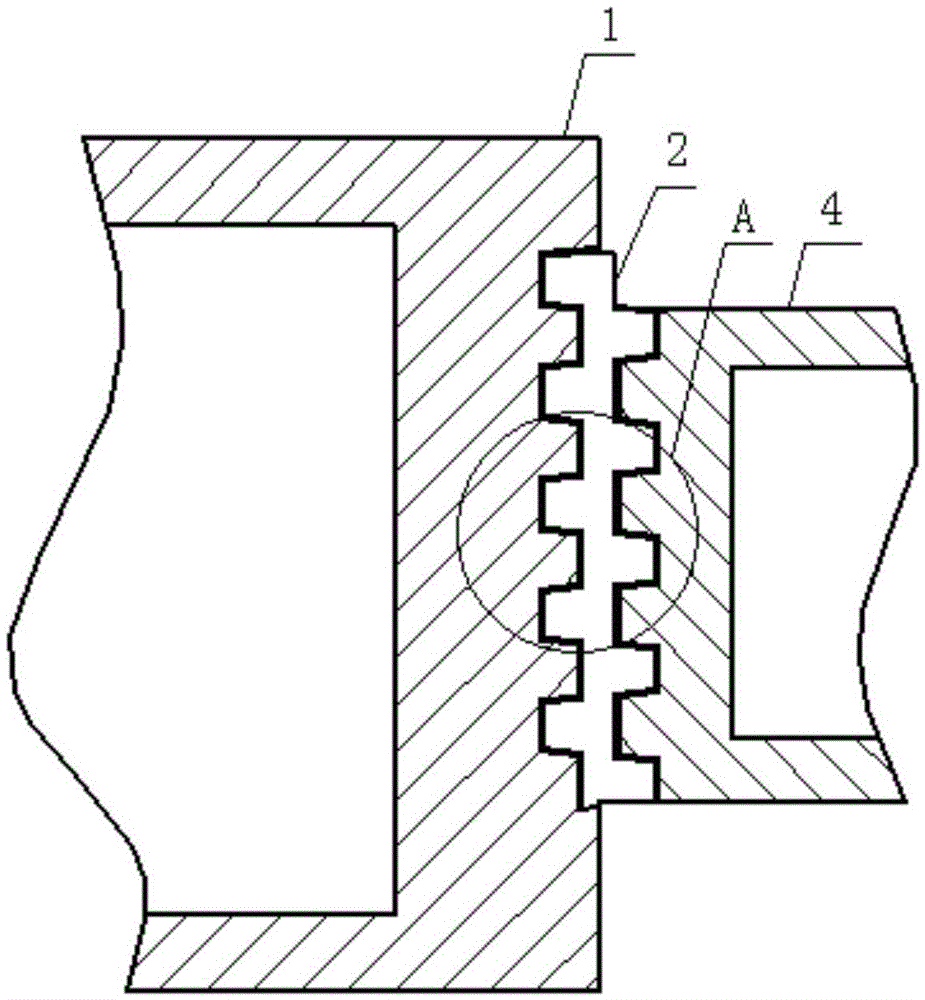

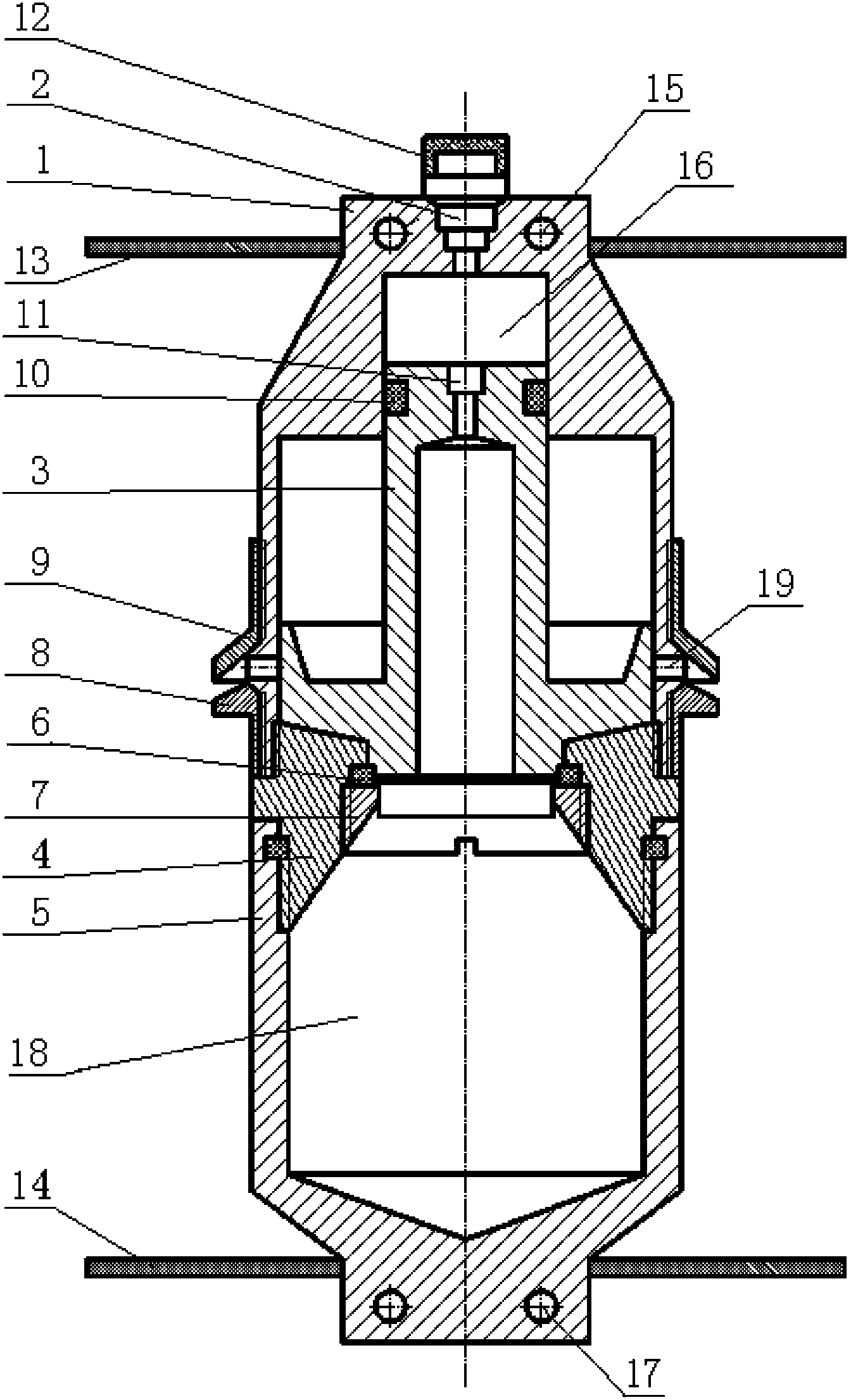

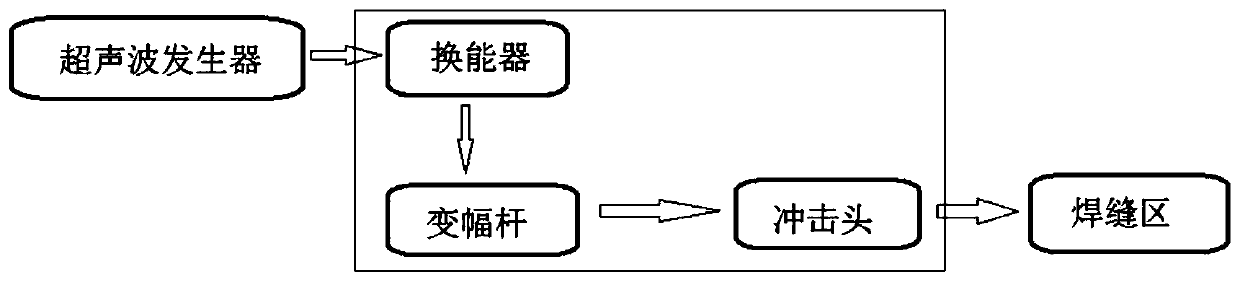

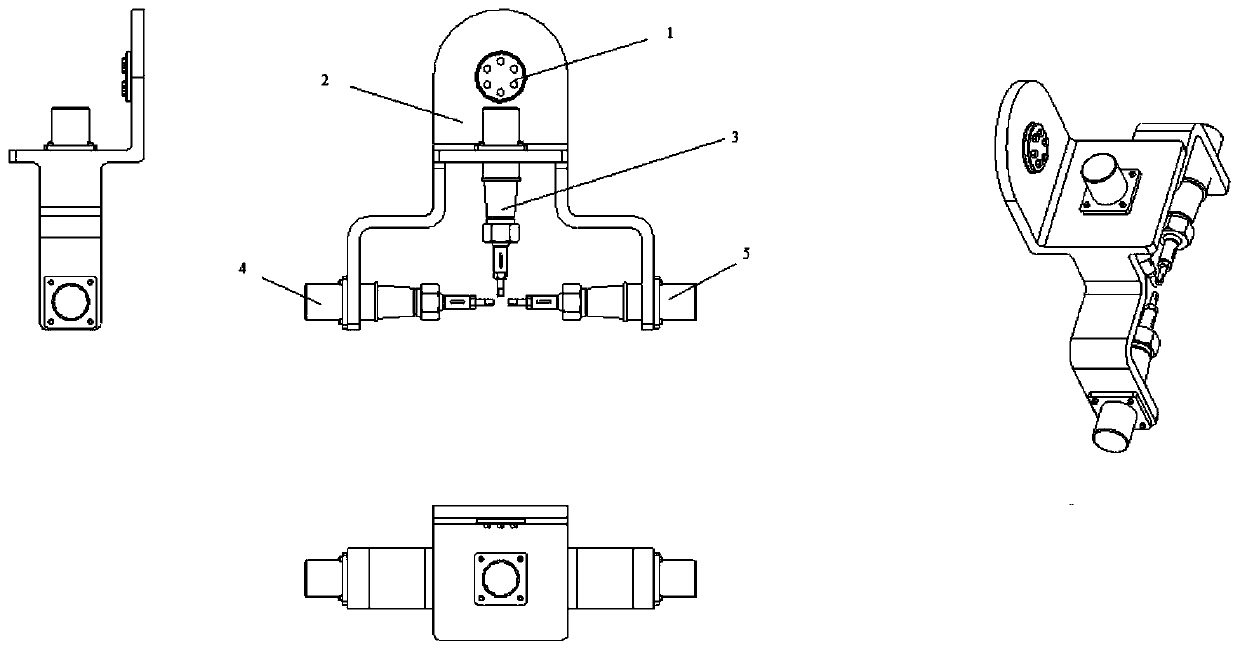

High-efficiency ultrasonic impact head for soldering joint stress release

InactiveCN101429588AImprove impact efficiencyIncrease impactNon-electric welding apparatusFatigue IntensityEconomic benefits

The invention relates to a high-efficient ultrasonic impact head for removing welding stress. The impact head comprises an impact head body and impact pins movably assembled in impact pinholes of the impact head body; two impact pins are symmetrically distributed on two side of a central axis, take the central axis as criteria and incline inwards to form an oblique angle alpha of between 2 and 5 degrees; each impact pin is of a cylindrical ball head shape; the diameter of each impact pin is between 5 and 8 mm; the length of each impact pin is between 30 and 35 mm; after each impact pin is arranged in the impact pin body, the length of the exposed part is required between 15 and 20 mm; and the lower part of the impact pin body is connected with an impact gun through screw thread. The impact head adopts two symmetric impact pins to simultaneously treat welding toes of two side of a weld joint, can remarkably improve the impact efficiency by 20 to 50 percent compared with a multi-pin impact head, improve the degree of the impact force, the impact strength, the removal of welding stress and the improvement of fatigue strength by more than 5 to 10 percent compared with the multi-pin impact head, has good impact effect, greatly improve the impact efficiency and stability in the treatment of a long aluminum alloy welding joint and has good economic benefit.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

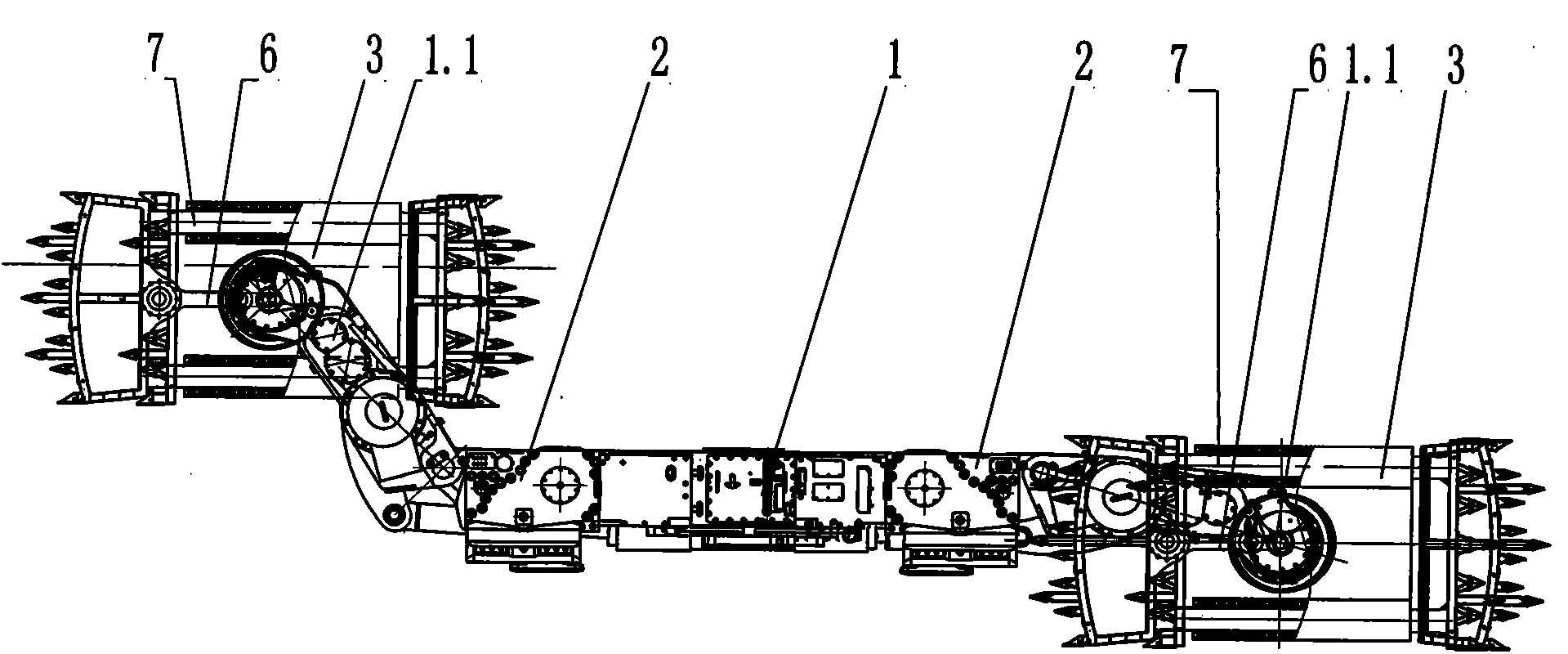

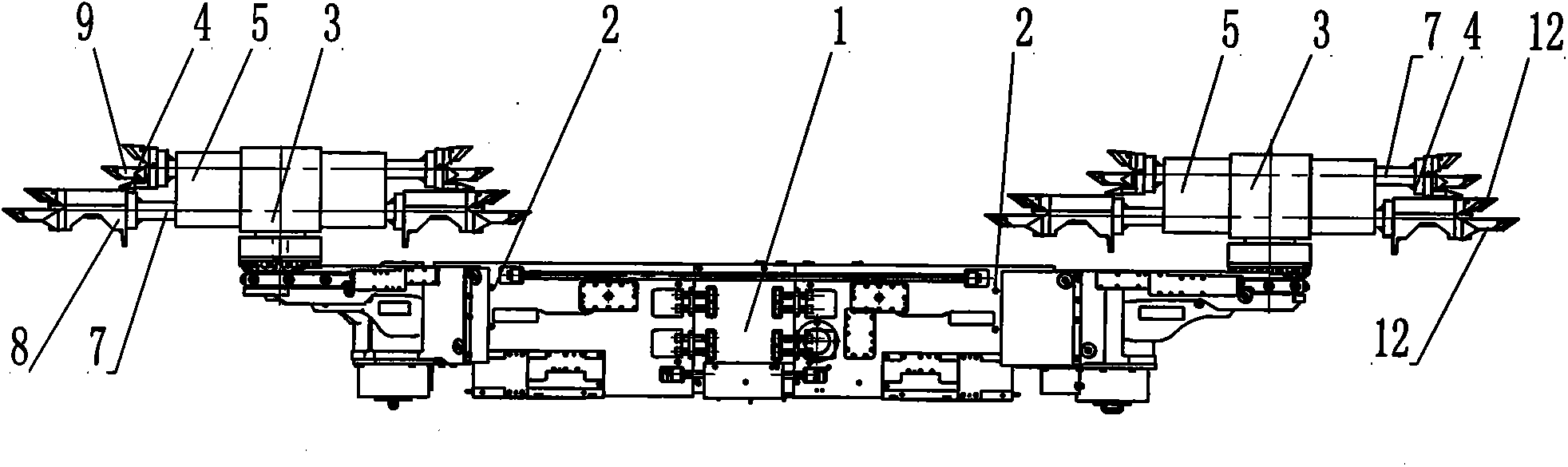

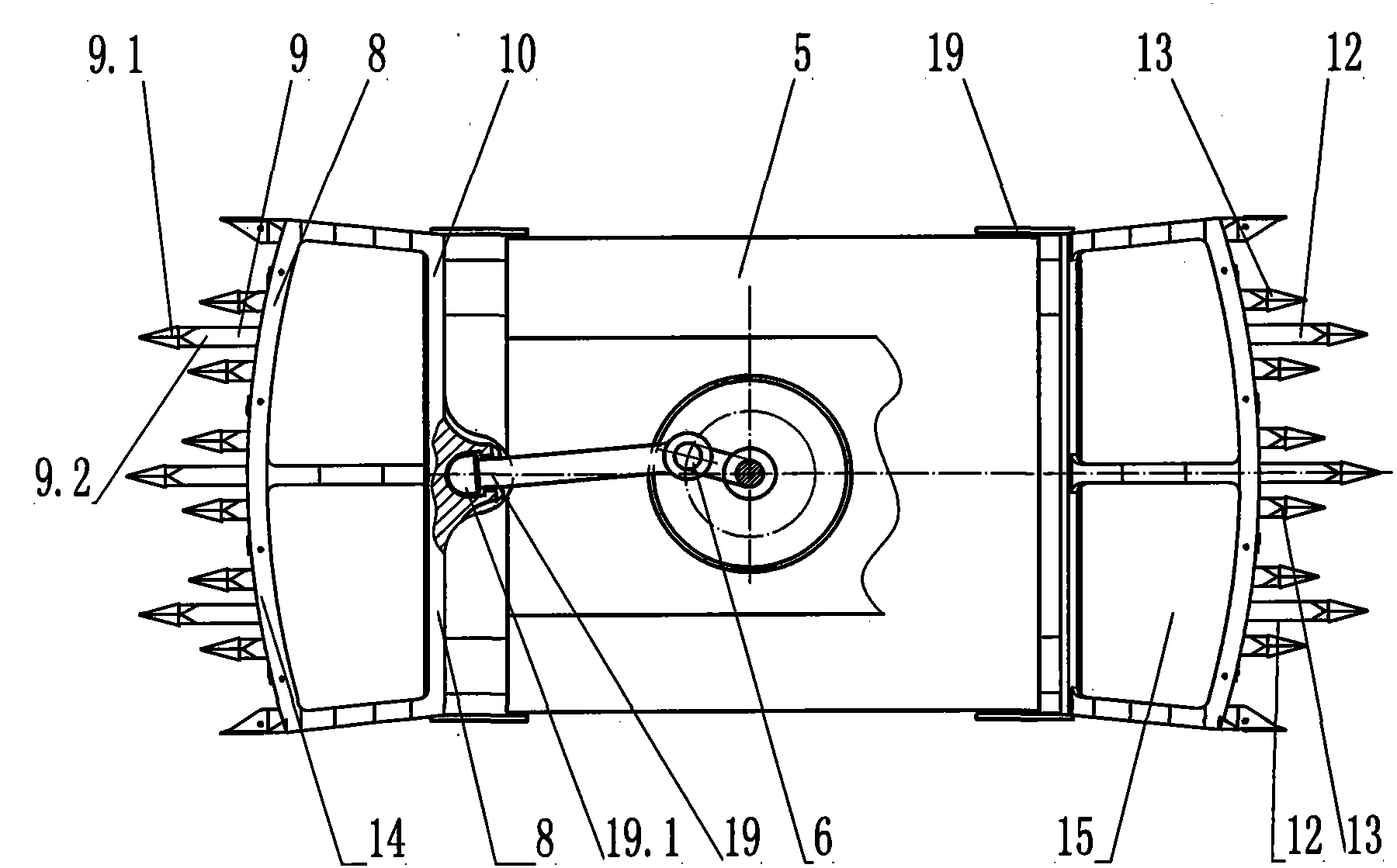

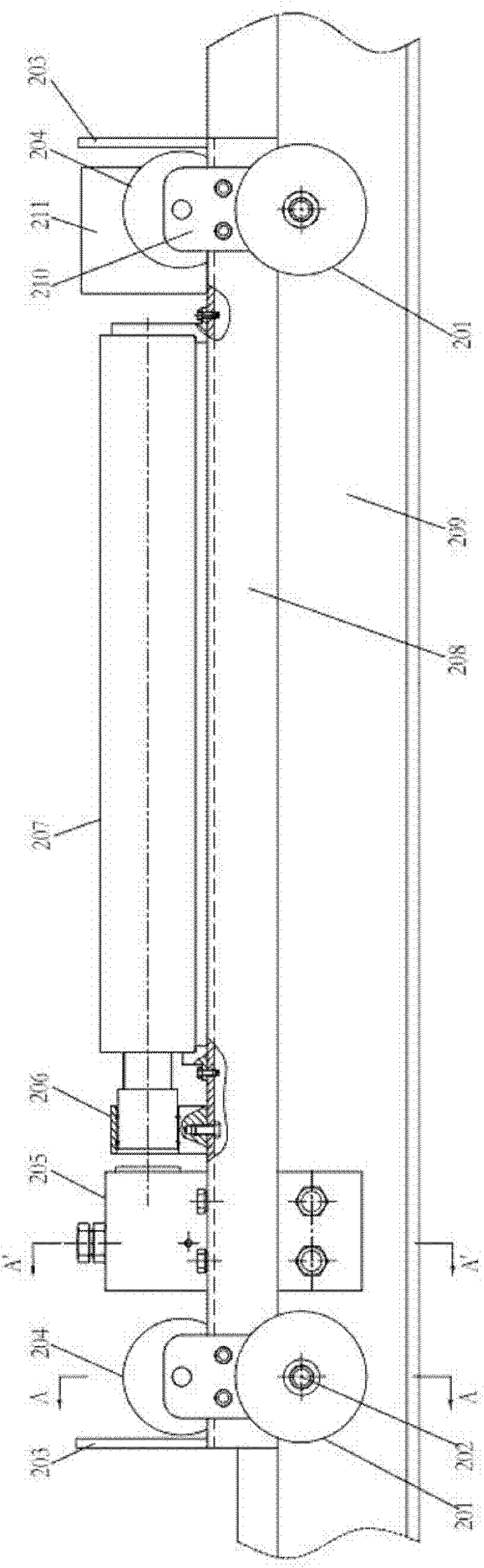

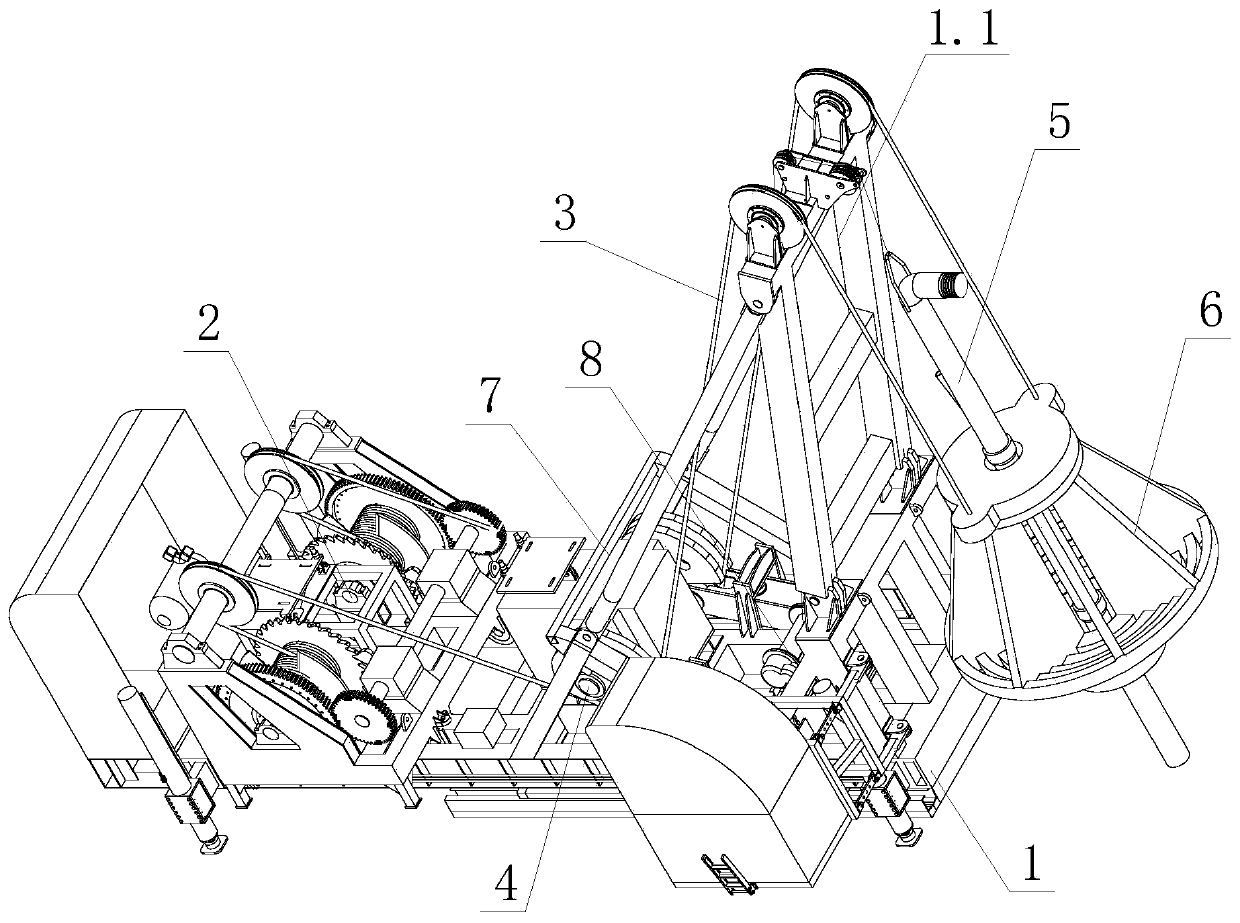

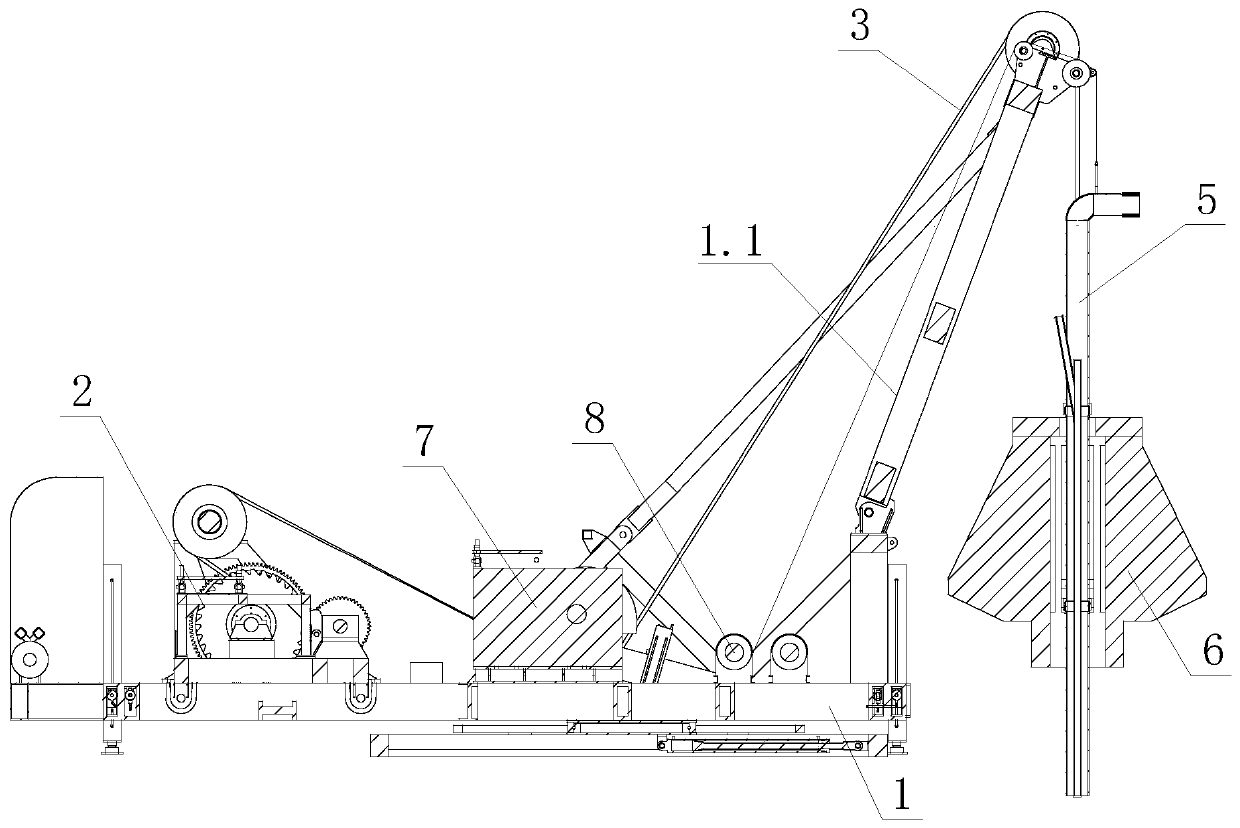

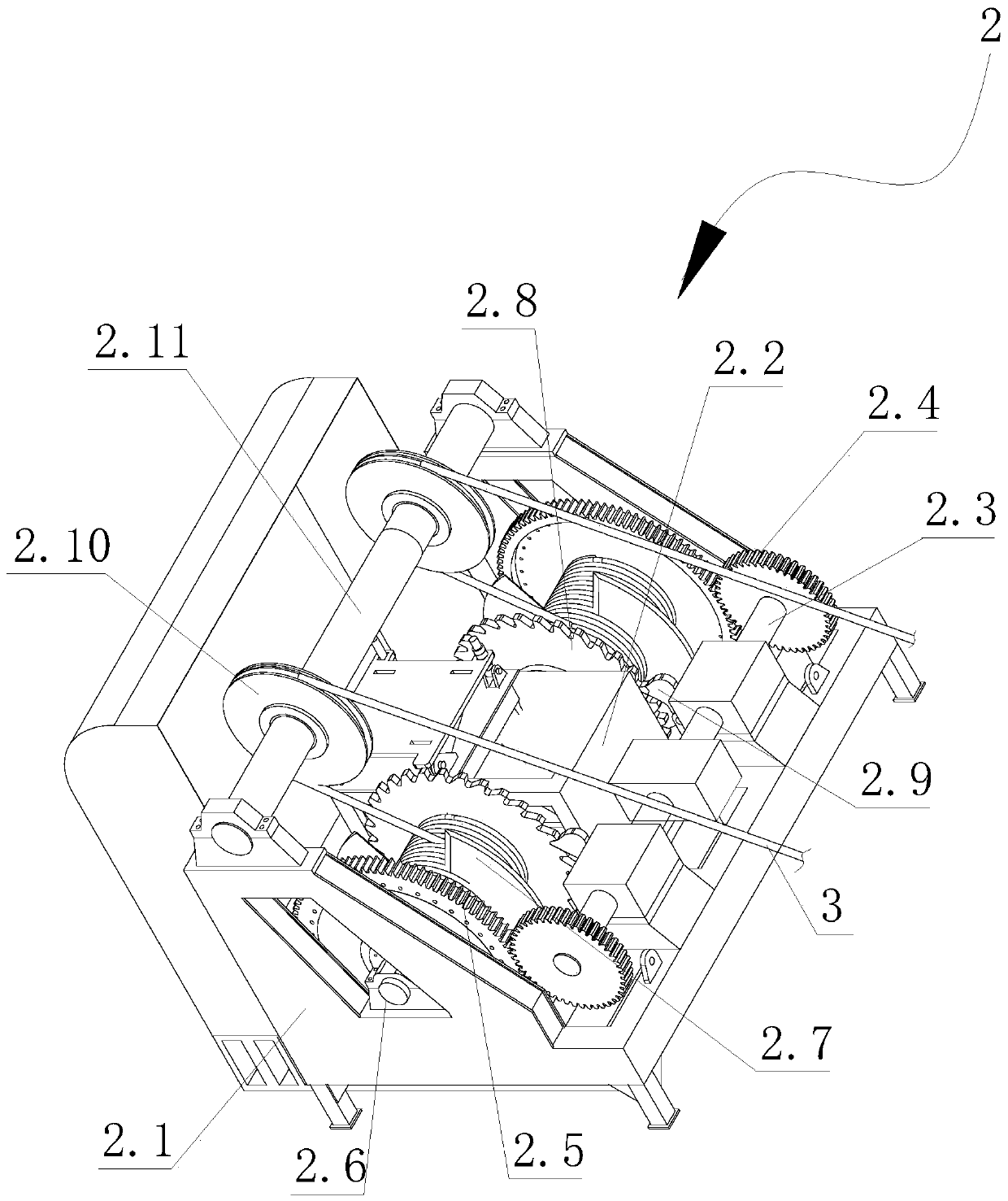

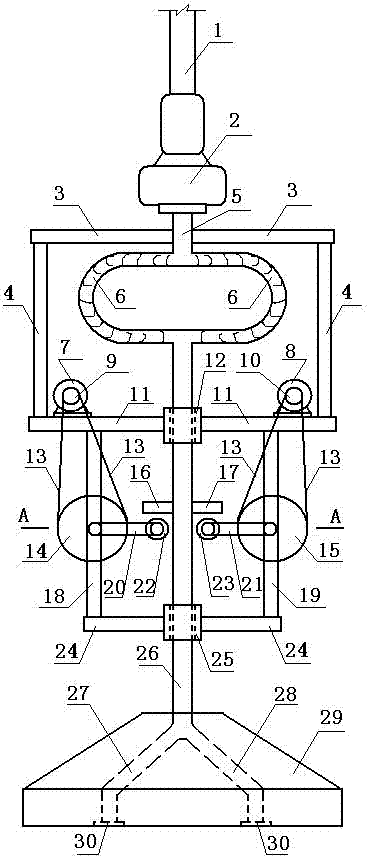

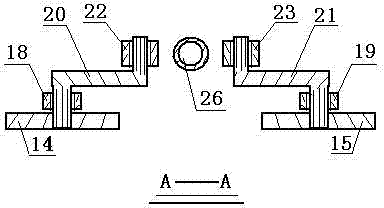

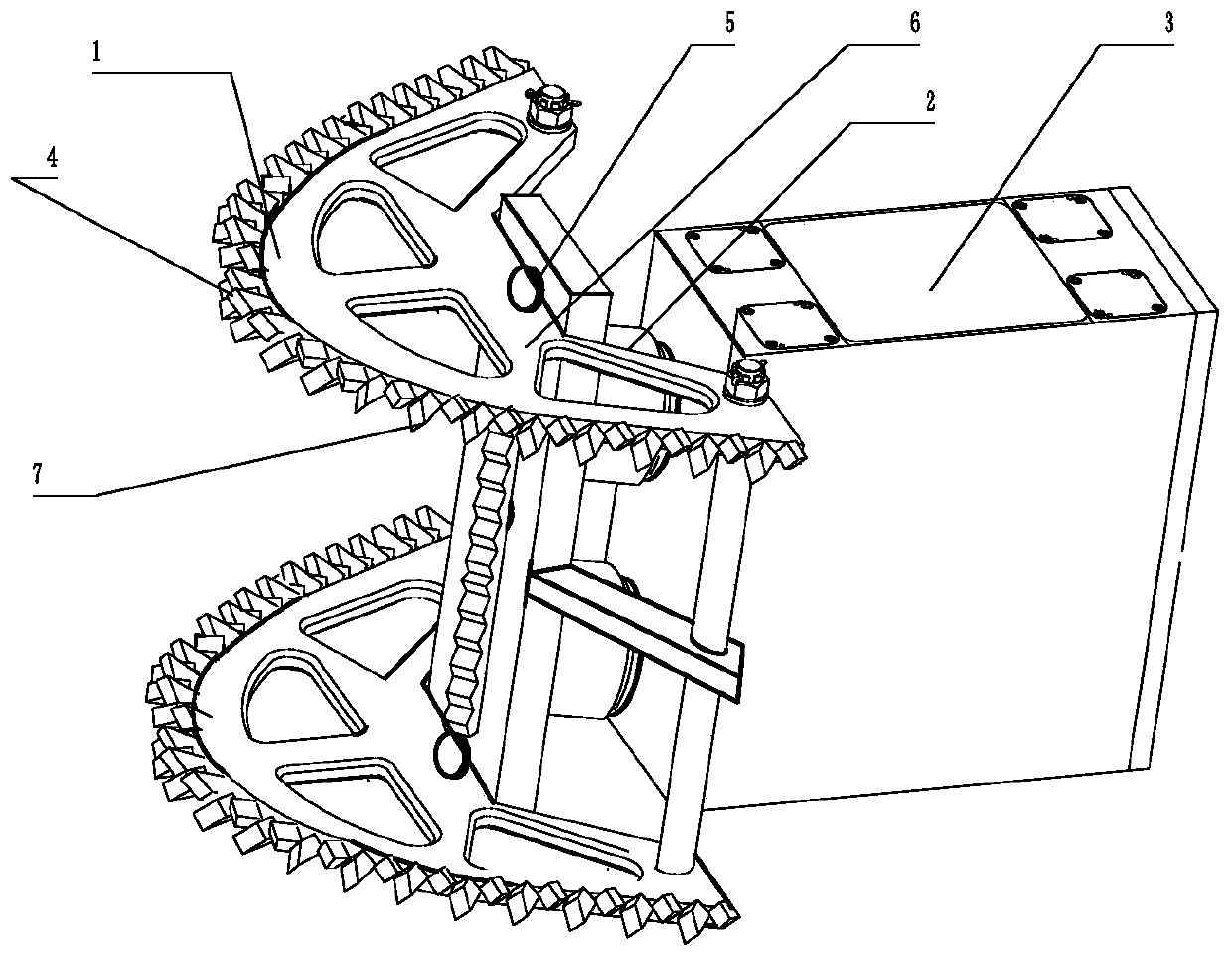

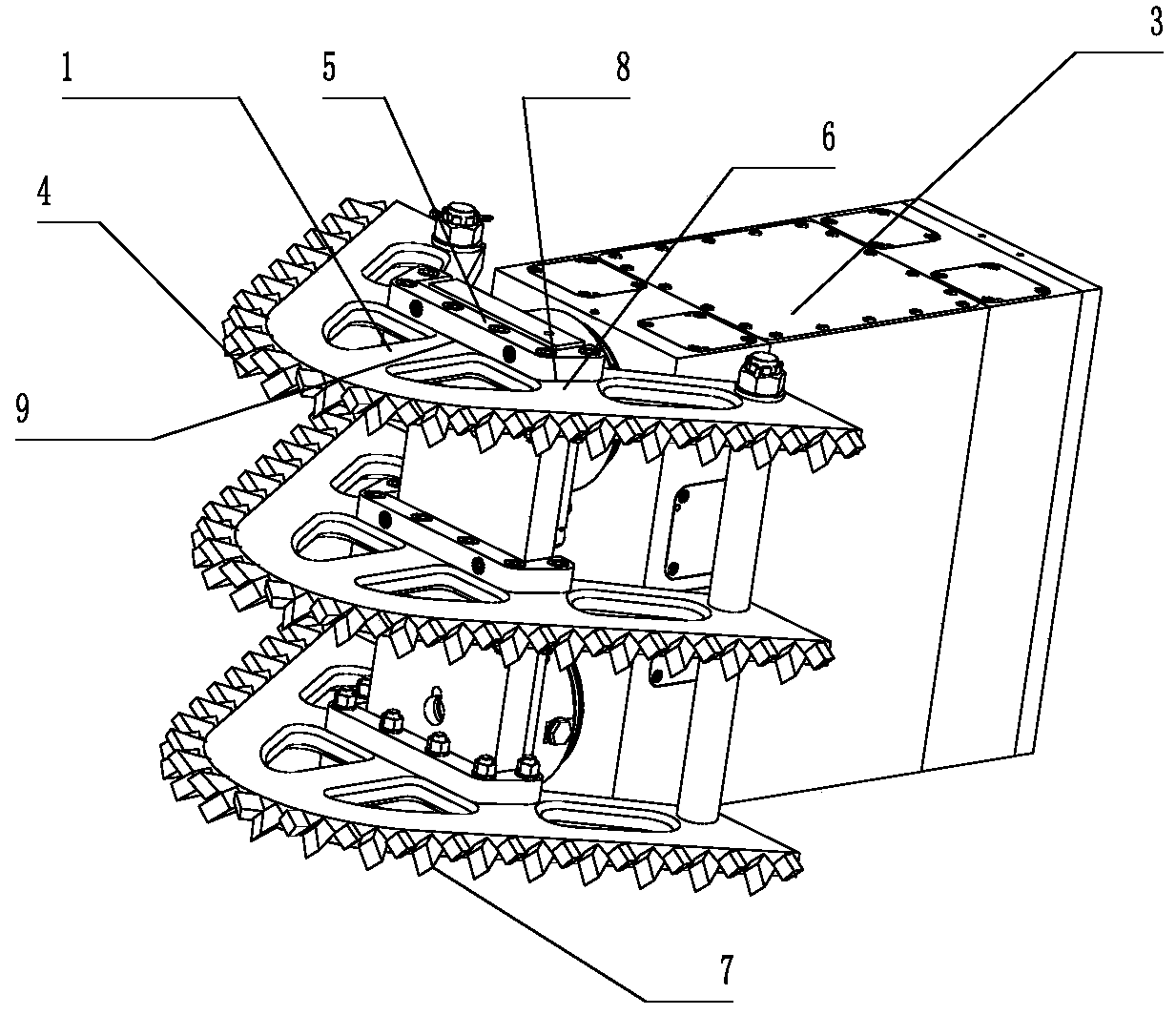

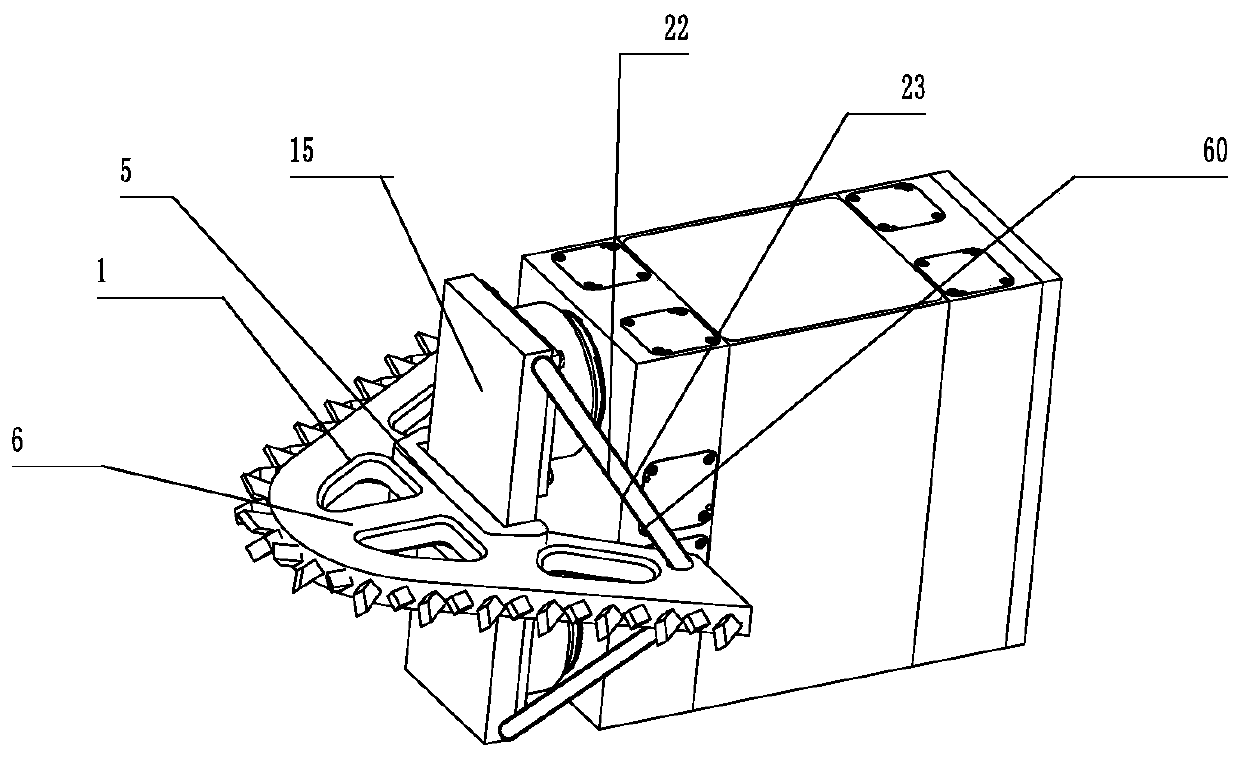

Step-tooth excavating method of reciprocating impact excavators, and step-tooth reciprocating impact excavator used for realizing step-tooth excavating method

ActiveCN103510953AReduce compressive stressReduce intensitySlitting machinesCutting machinesImpact toothEngineering

The invention belongs to the field of machinery, is especially suitable for the field of excavating, and specifically relates to a step-tooth excavating method of reciprocating impact excavators, and a step-tooth reciprocating impact excavator used for realizing the step-tooth excavating method. The step-tooth reciprocating impact excavator comprises a machine body, a travelling mechanism, an impact blanking mechanism and the like; the impact blanking mechanism is arranged on the machine body; and the travelling mechanism is arranged on the lower part of the machine body. The impact blanking mechanism comprises a step-tooth impact-cutting device, an impact power box, a power impact part, an impact guiding element and the like; step teeth are formed by adjacent impact teeth arranged on the step-tooth impact-cutting device. The step-tooth impact-cutting device is driven by the power impact part, material to be excavated is impacted to be step shaped so as to obtain two or more opposite free faces, and pressure stress and / or structural strength relative to original material is reduced greatly. When the impact teeth is used for excavating for another time, the two or the more opposite free faces are used for reducing impact resistance greatly; generation of oversized material blocks, which fall because of excavating, is avoided; impaction efficiency is increased, and equipment depreciation is reduced.

Owner:刘素华

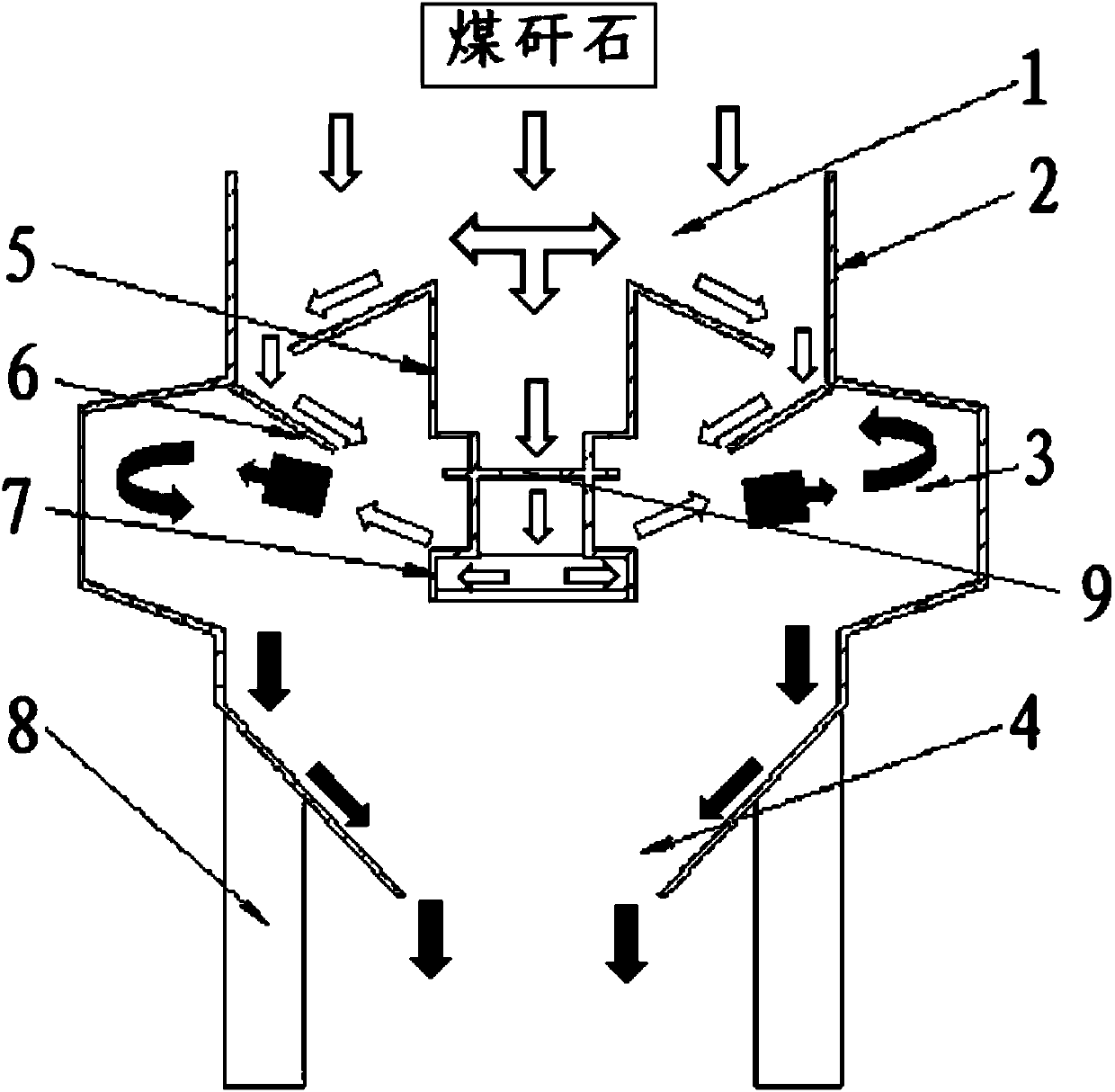

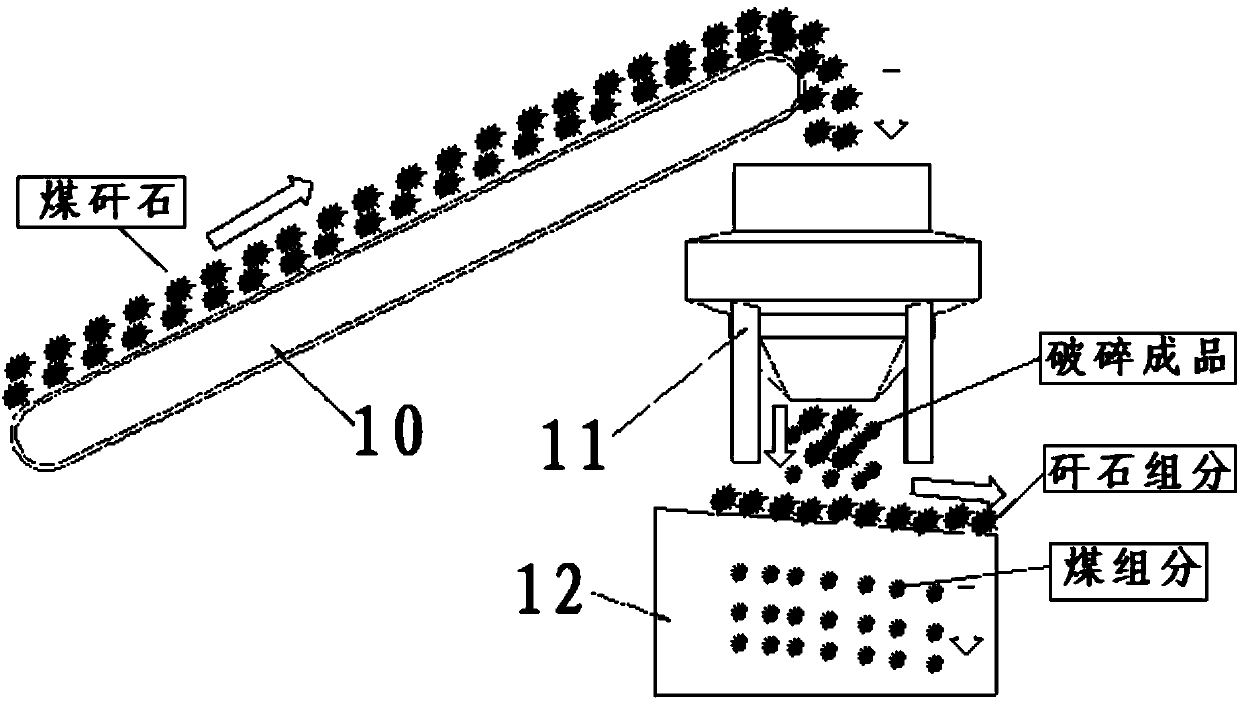

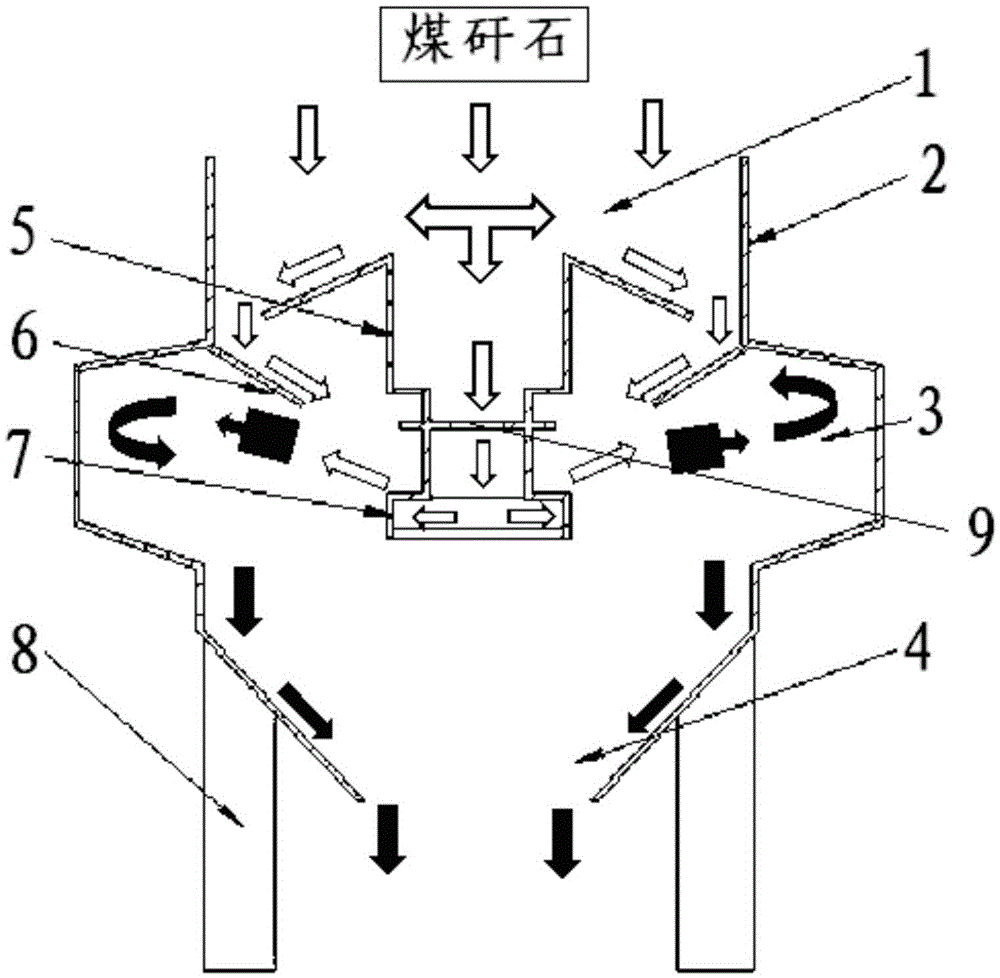

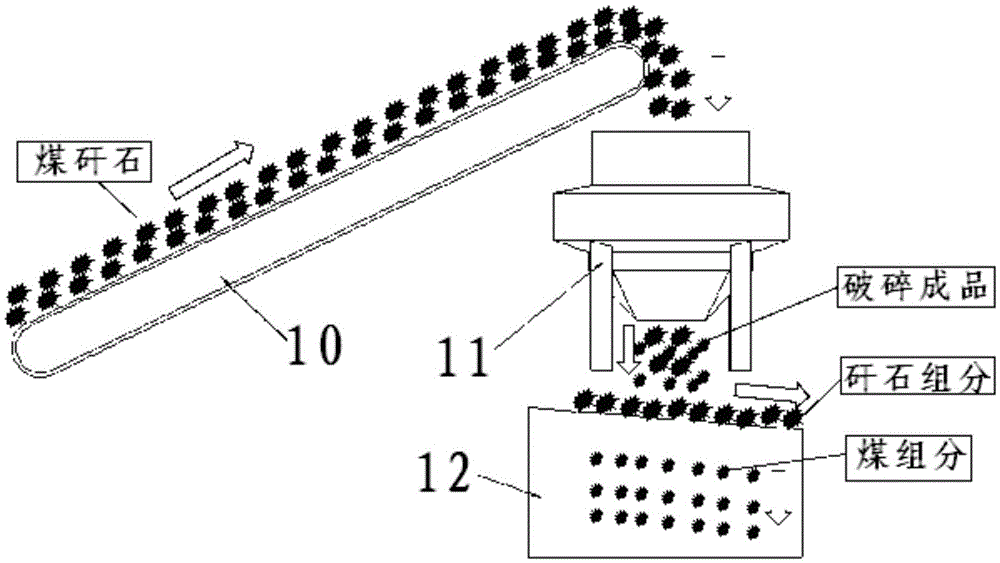

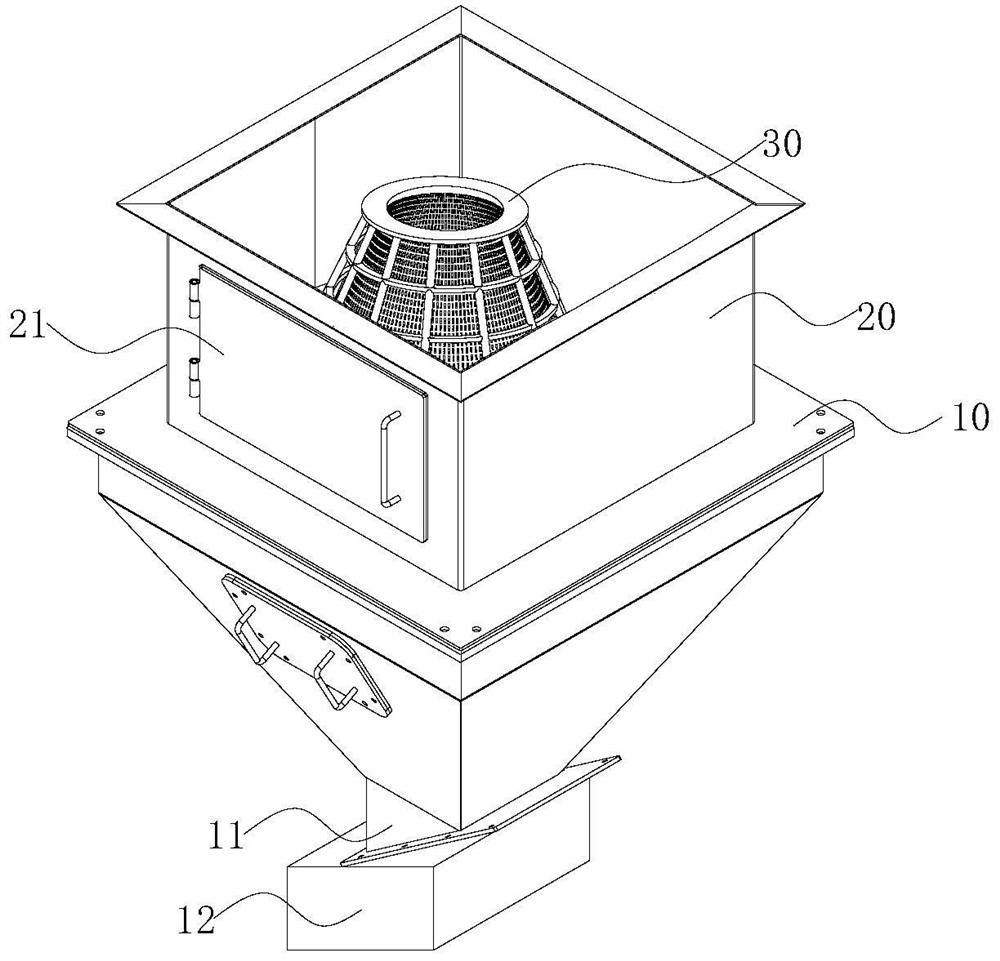

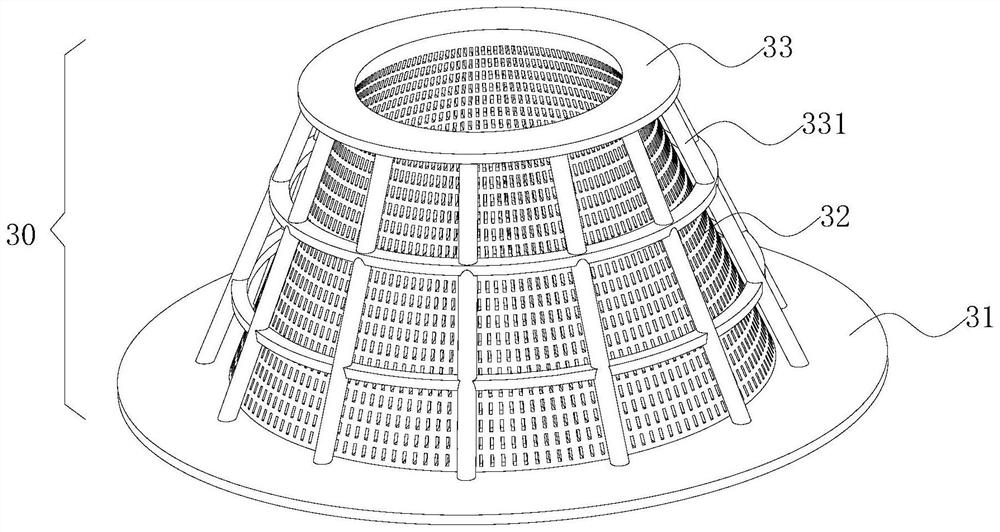

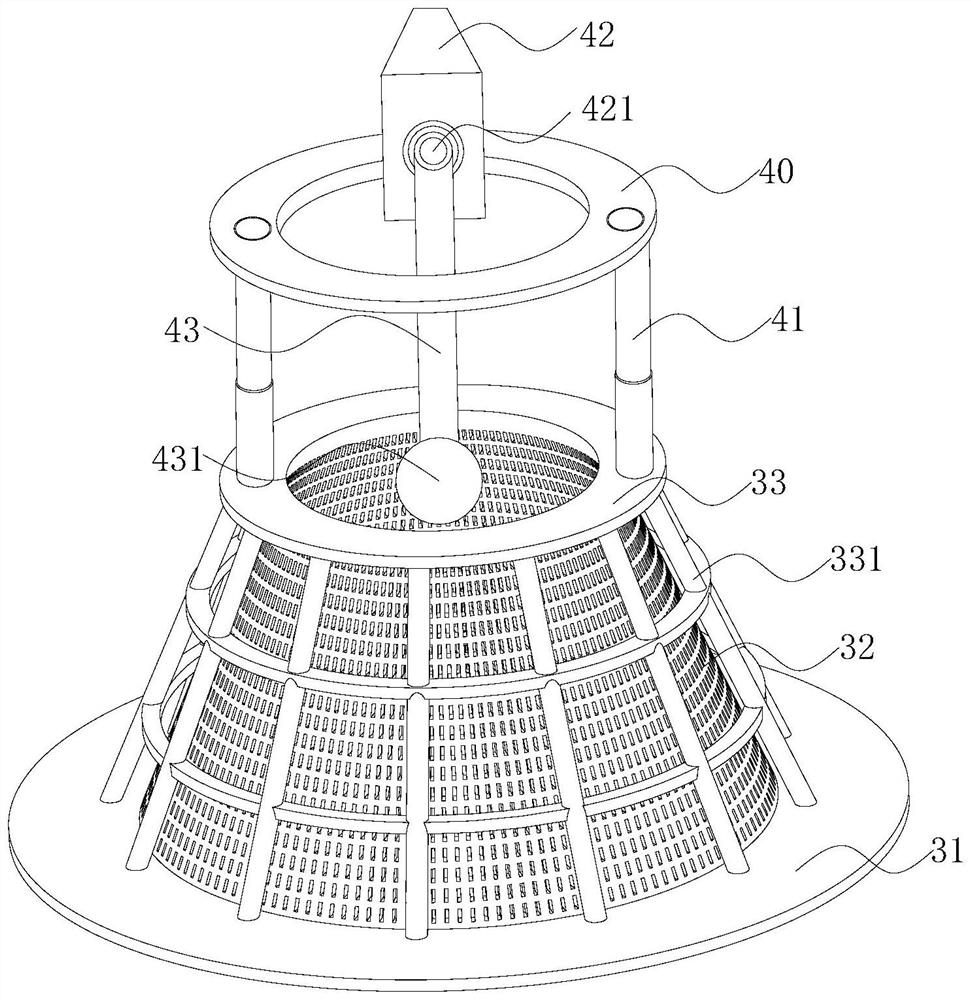

Crushing device for coal gangue separation

ActiveCN103433106AImprove impact efficiencySimple crushing workGrain treatmentsEngineeringCoal gangue

The invention relates to a crushing device for coal gangue separation. The crushing device comprises an outer cover, a material separating device, a plurality of guide plates, a material throwing tray and a bracket, wherein the outer cover is fixed on the bracket; a feeding hole is formed in the top of the outer cover; the bottom of the outer cover is provided with a discharge hole; a vortex bin is arranged in the middle of the outer cover; the material separating device is arranged in the feeding hole and the vortex bin; the upper part of the material separating device has an umbrella-shaped structure; a feed opening is formed in the top of the material separating device; a coal gangue storage bin is arranged in the middle of the material separating device; the material throwing tray is arranged under the material separating device; the plurality of guide plates are respectively arranged under the umbrella-shaped structure of the material separating device and fixed on the outer cover. The crushing device can be used for selectively crushing coal components in the coal gangue while maintaining the integrity of the gangue component, thus meeting the requirement of separation.

Owner:长治市武理工工程技术研究院

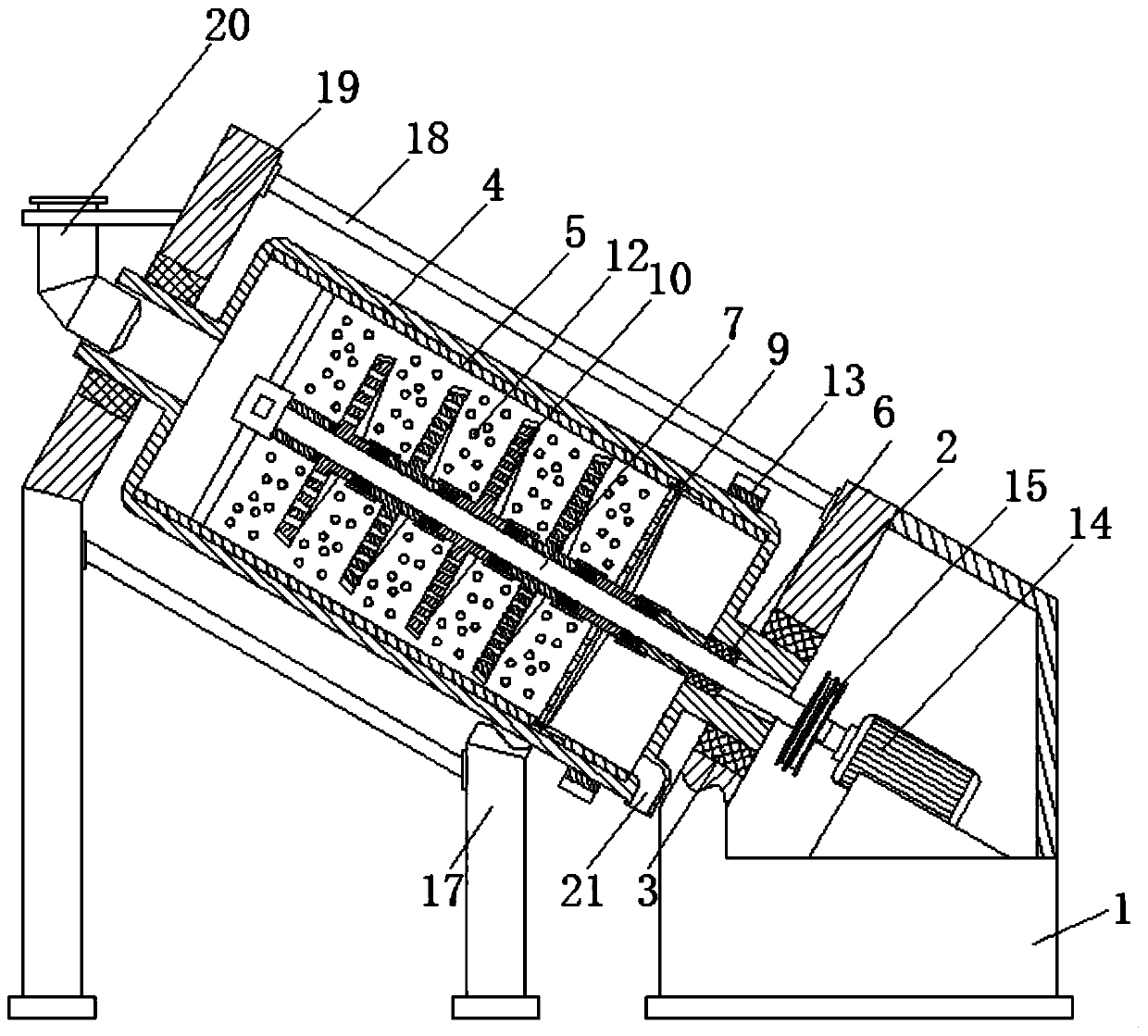

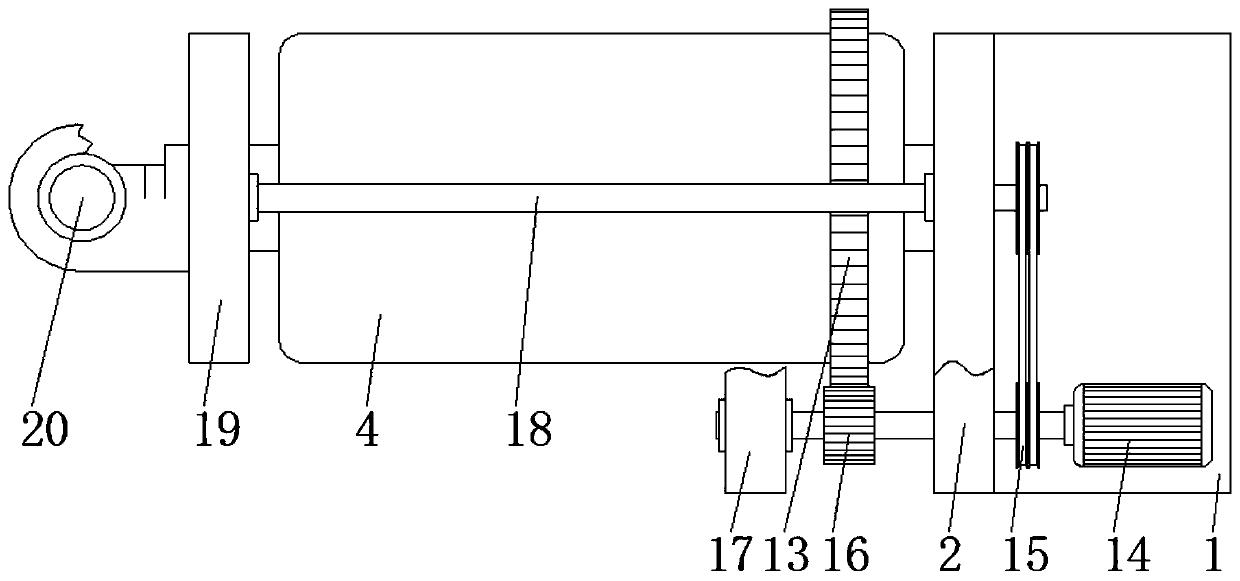

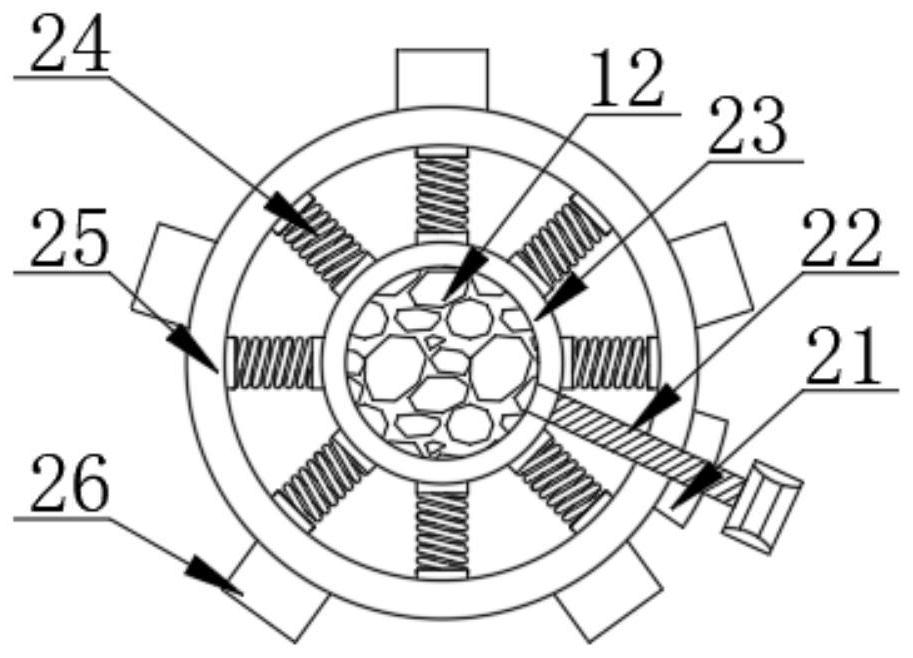

Ball mill for grinding soft magnetic core

ActiveCN111420759AImprove impact efficiencyExtend the trajectoryGrain treatmentsGear wheelIndustrial equipment

The invention relates to the technical field of industrial equipment, and discloses a ball mill for grinding a soft magnetic core. The ball mill comprises a fixing box, a rotating cylinder, a lining,grinding steel balls, an outer gear and a key, wherein the lining is fixedly arranged on the inner wall of the rotating cylinder, the outer gear is fixedly arranged at the bottom of the rotating cylinder in a sleeving mode, the grinding steel balls are movably arranged inside the lining, a bottom support seat is fixedly arranged on the fixing box, and a large thrust bearing is fixedly arranged inside the bottom support seat. Due to the arrangement of the rotating cylinder and a partitioning device, the space inside the rotating cylinder is equally divided, the effective grinding space is further compressed, the impact efficiency between the grinding steel balls and a material is improved, the grinding effect in the area is improved, and the grinding efficiency is improved; and the rotatingcylinder and the partitioning device are rotated in different directions, so that the movement track and the movement speed of the grinding steel balls are increased, the impact times among the grinding steel balls and between the grinding steel balls and the material are increased, and the grinding effect on the material is further improved.

Owner:LOUDI CITY LITONG MAGNETOELECTRICITY SCI & TECH

Compression resistance detection device for automobile part production and processing

InactiveCN112014246AEasy clampingHit fullMachine part testingMaterial strength using tensile/compressive forcesElectric machineGear wheel

The invention discloses a compression resistance detection device for automobile part production and processing. The device comprises a mounting rack, u-shaped plates, metering lines, rotary drums, L-shaped guide rods, guide columns, placement seats, striking hammers, adjusting plates, limiting grooves, electric push rods, telescopic columns, fixed pulleys, pull ropes, first stepping motors, winding wheels, driven bevel gears, electromagnets, clamping plates, driving bevel gears, mounting frames, small worms, large worms, second stepping motors, shaft rods, driving gears, sliding rods, U-shaped guide rods and driven gears. According to the device, spare and accessory parts can be better clamped; the position deviation of spare and accessory parts during impact is avoided; the striking hammers can strike the spare and accessory parts more sufficiently, the striking efficiency is greatly improved, different striking forces are better applied to the spare and accessory parts for strikingdetection, the detection efficiency is greatly improved, the detection result is also greatly improved, and meanwhile, the practicability is also enhanced.

Owner:芜湖肯昌机电有限公司

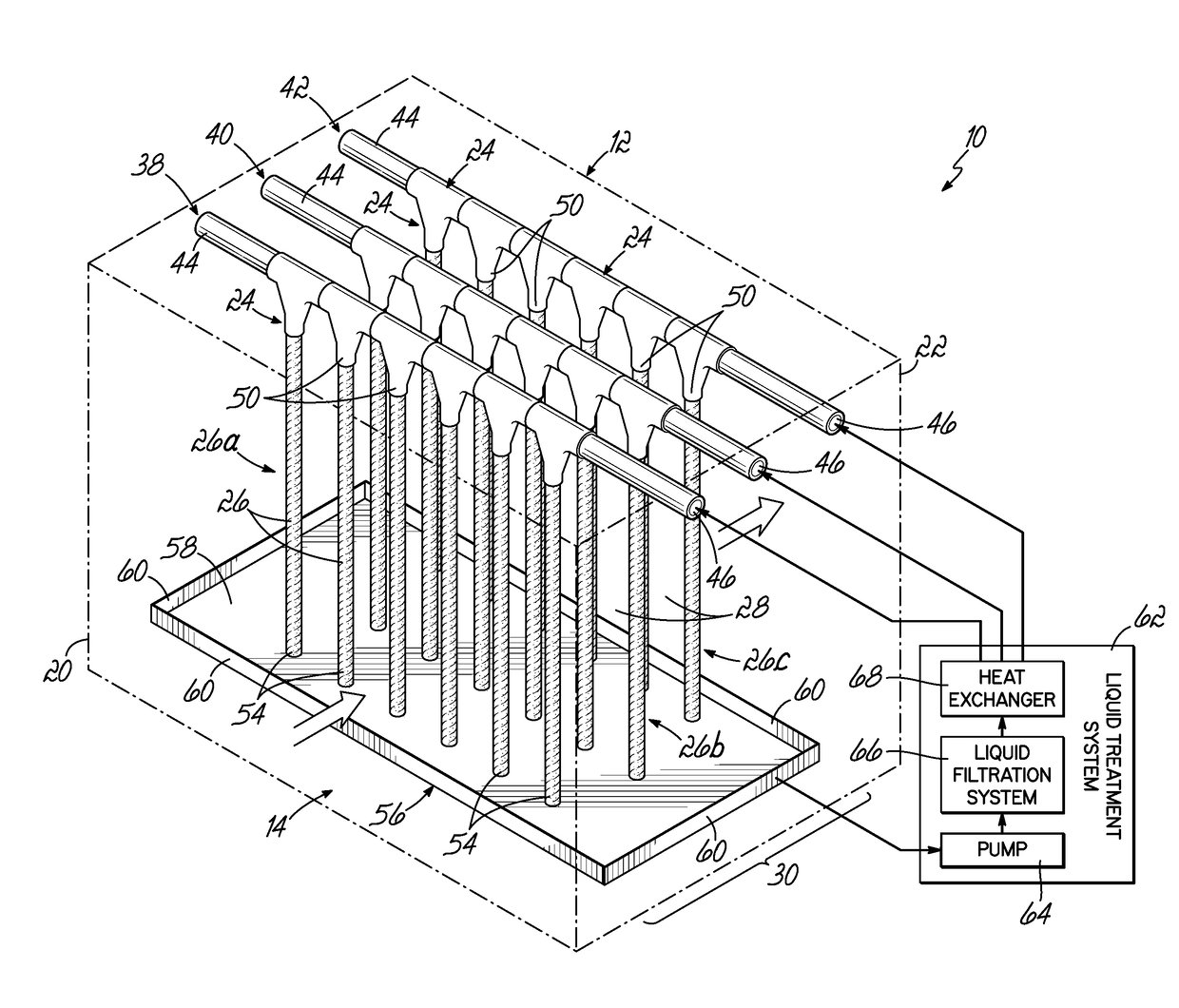

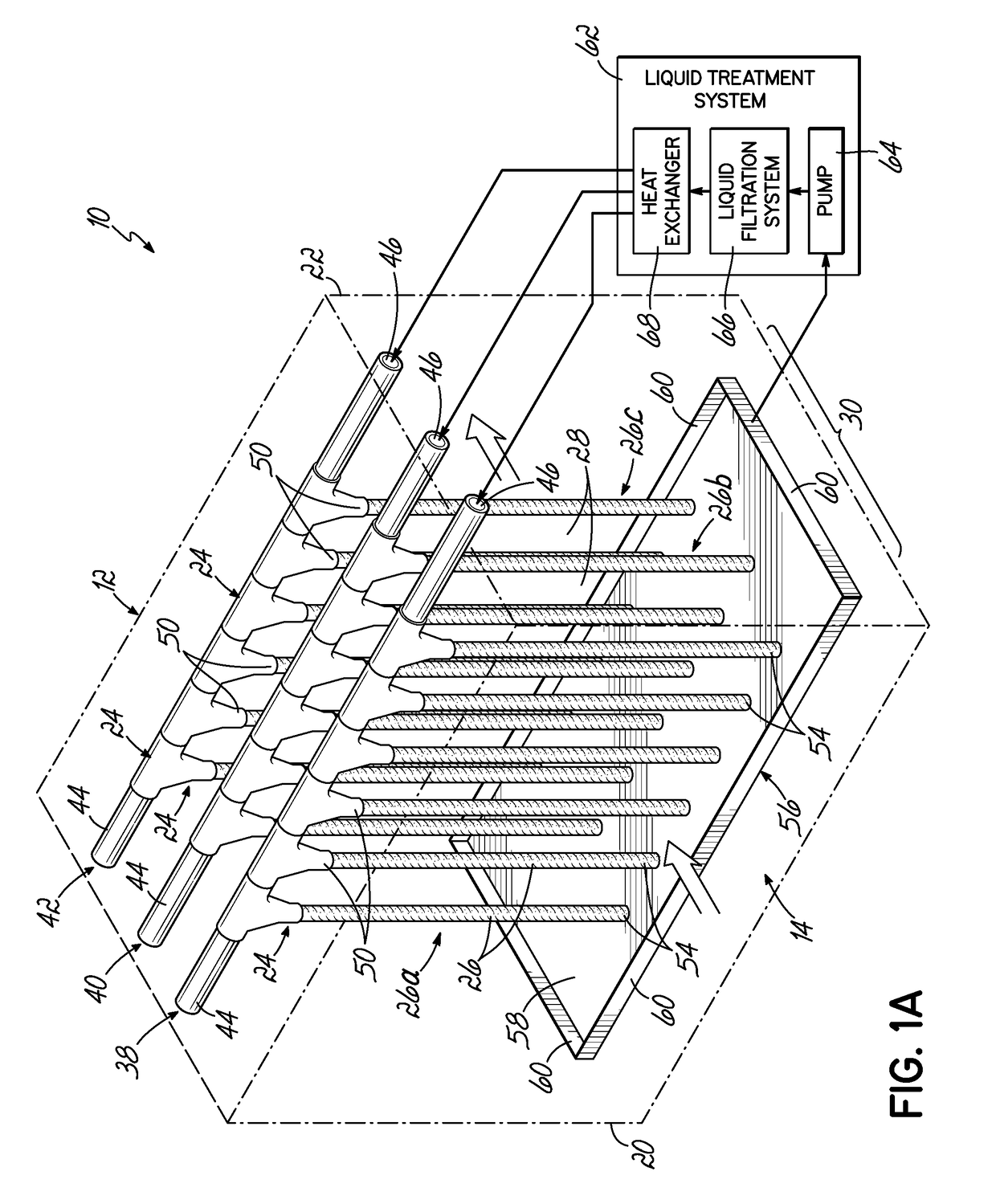

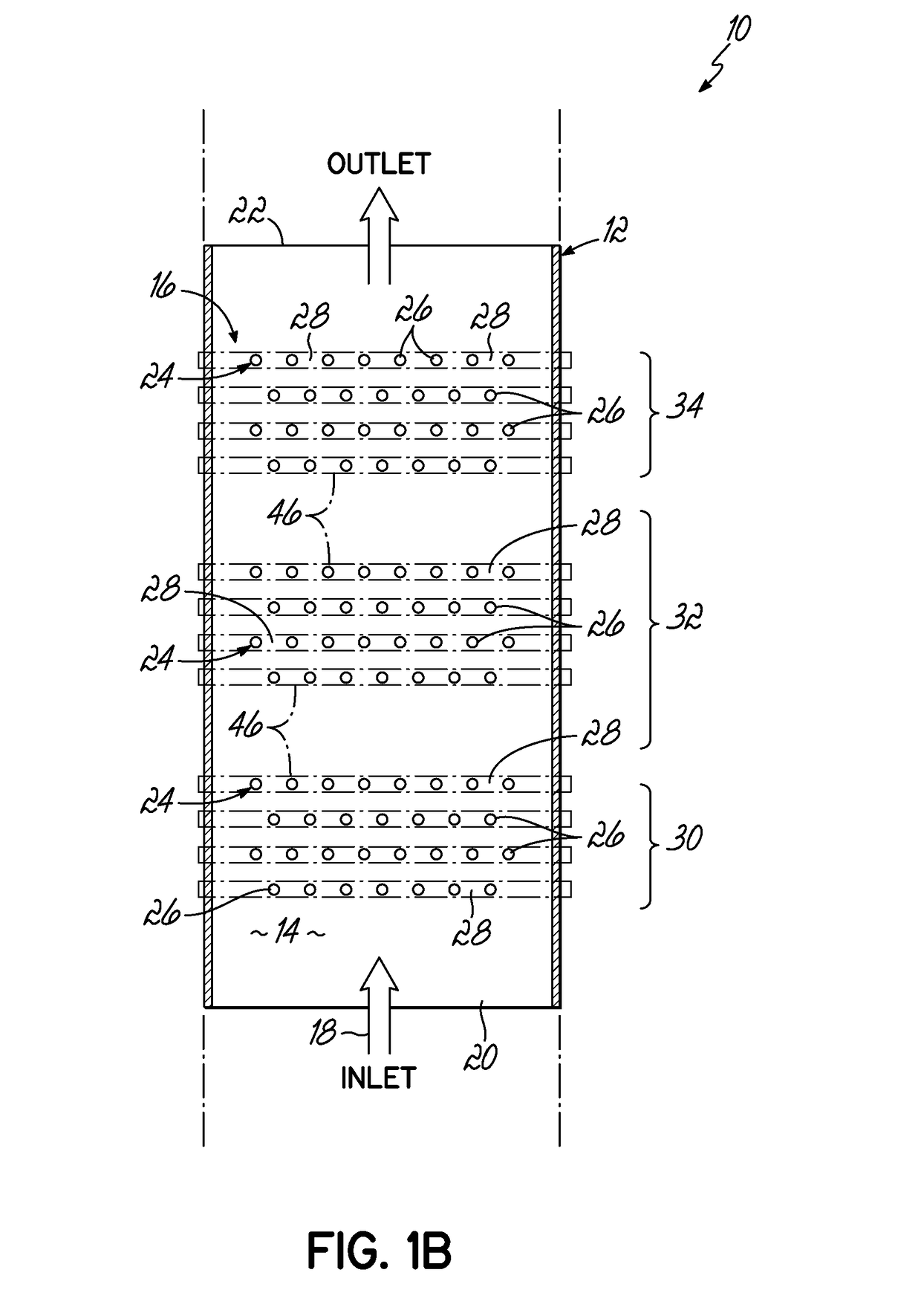

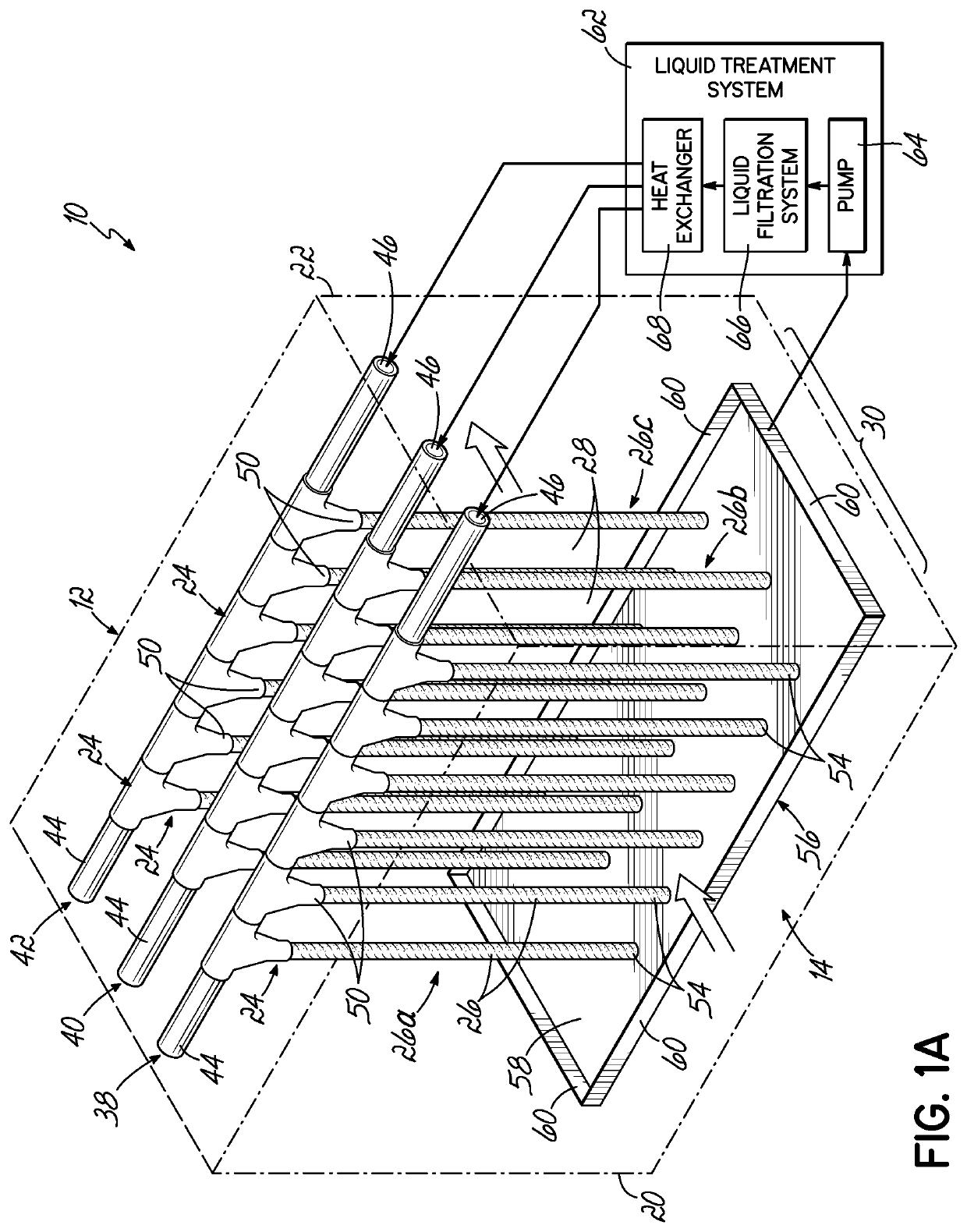

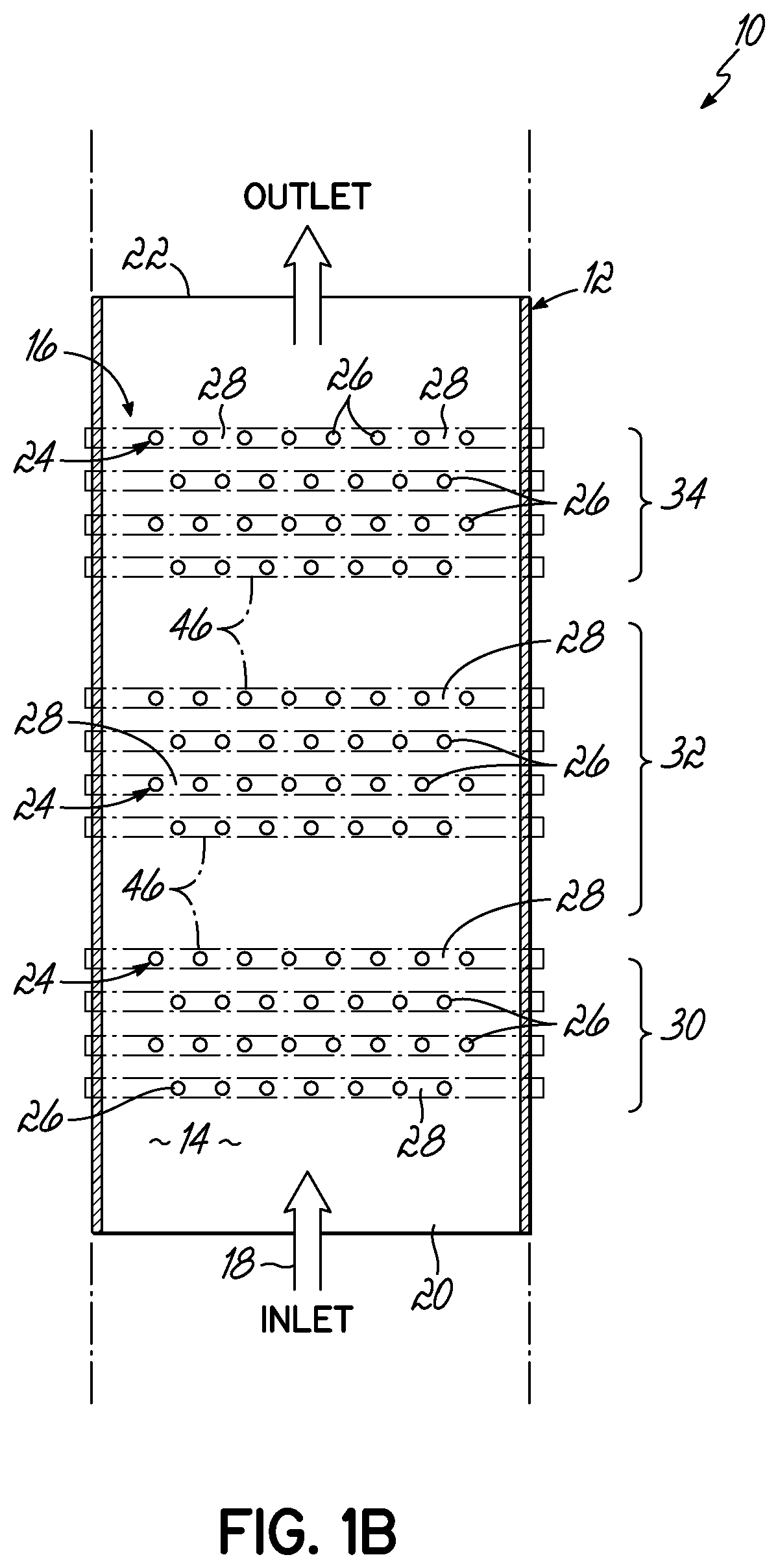

Sieve array and precipitator device and method of treating exhaust

ActiveUS20180117519A1Efficient energy recoveryHigh speedDispersed particle filtrationUsing liquid separation agentParticulatesHeat transfer efficiency

A vibrating wet precipitator is designed to remove particulates from particulate-laden hot gas. The precipitator includes an array of vertical wet cords stretched within a duct. The cords are tuned to vibrate due to the gas flow by controlling key parameters such as gas flow, velocity, cord length and diameter so that particulate collection and heat transfer efficiency are maximized. The cords are part of sieves. A plurality of these sieves are arranged to define a plurality of gaps, through which the exhaust flows. The sieves and thus the cords are space so that a vortex from a first cord affects an adjacent cord and subsequently cord. The particles are then absorbed in liquid, which can be passed through a heat exchanger filtered and subsequently reused. Preferably the cord arrangement is designed to allow the cords to vibrate at high frequencies, typically 10 to 100 Hz, to maximize particulate collection.

Owner:OHIO UNIV

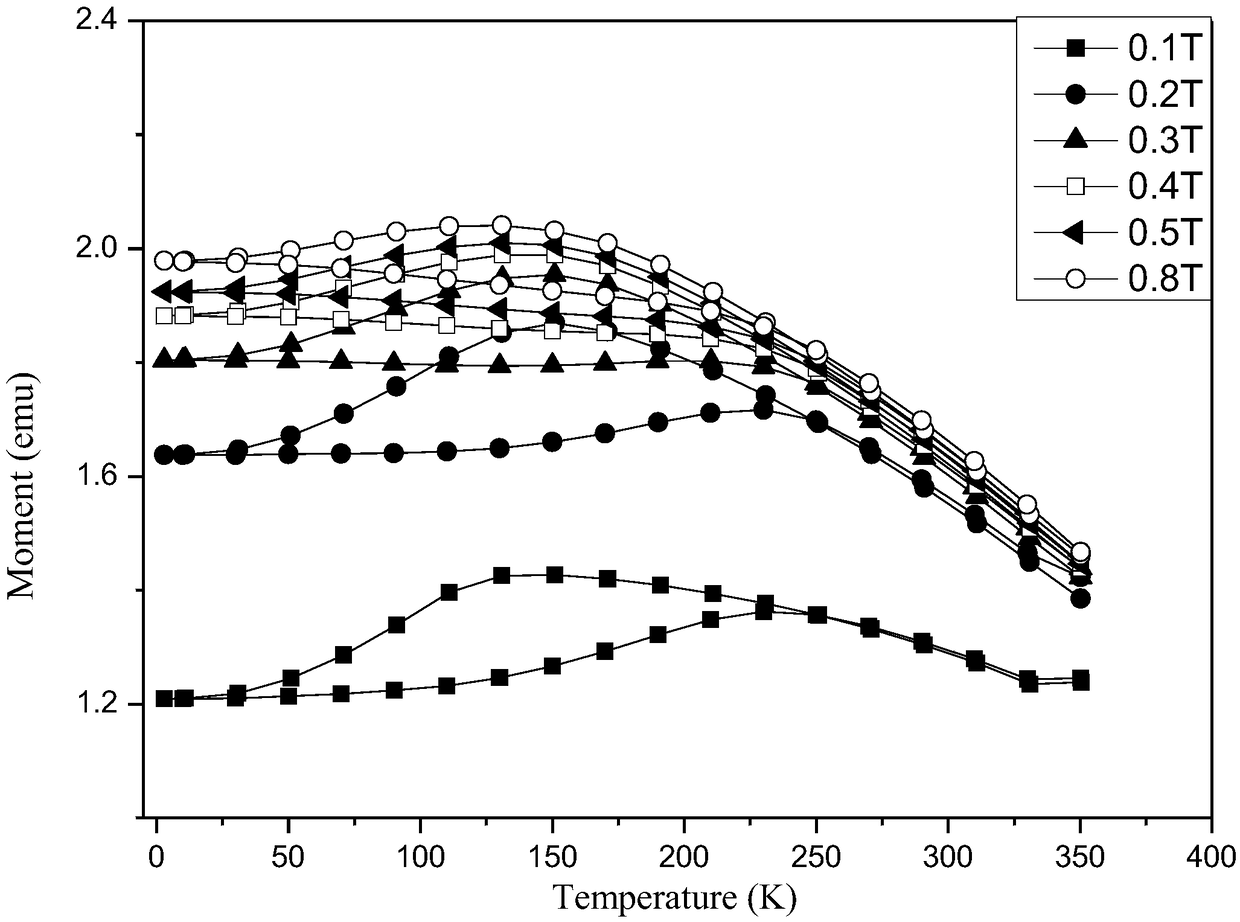

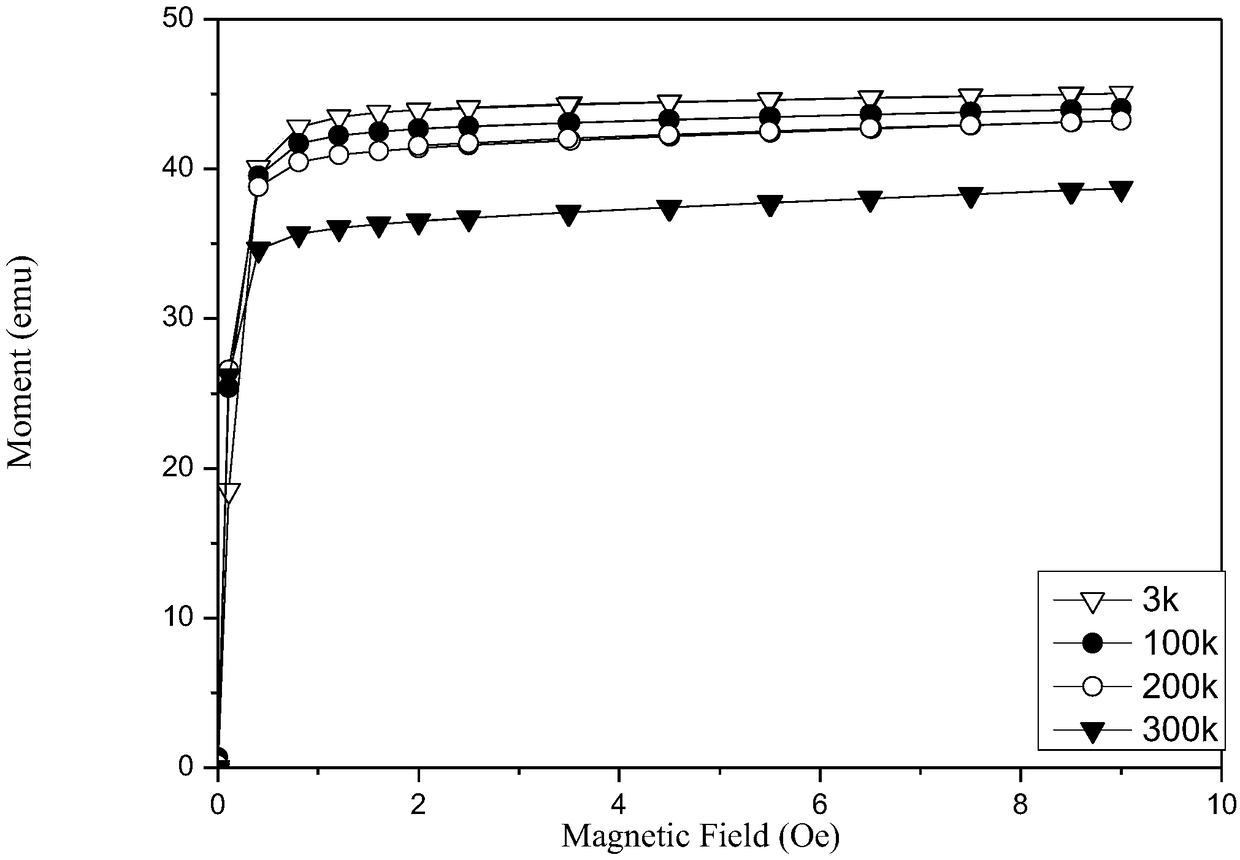

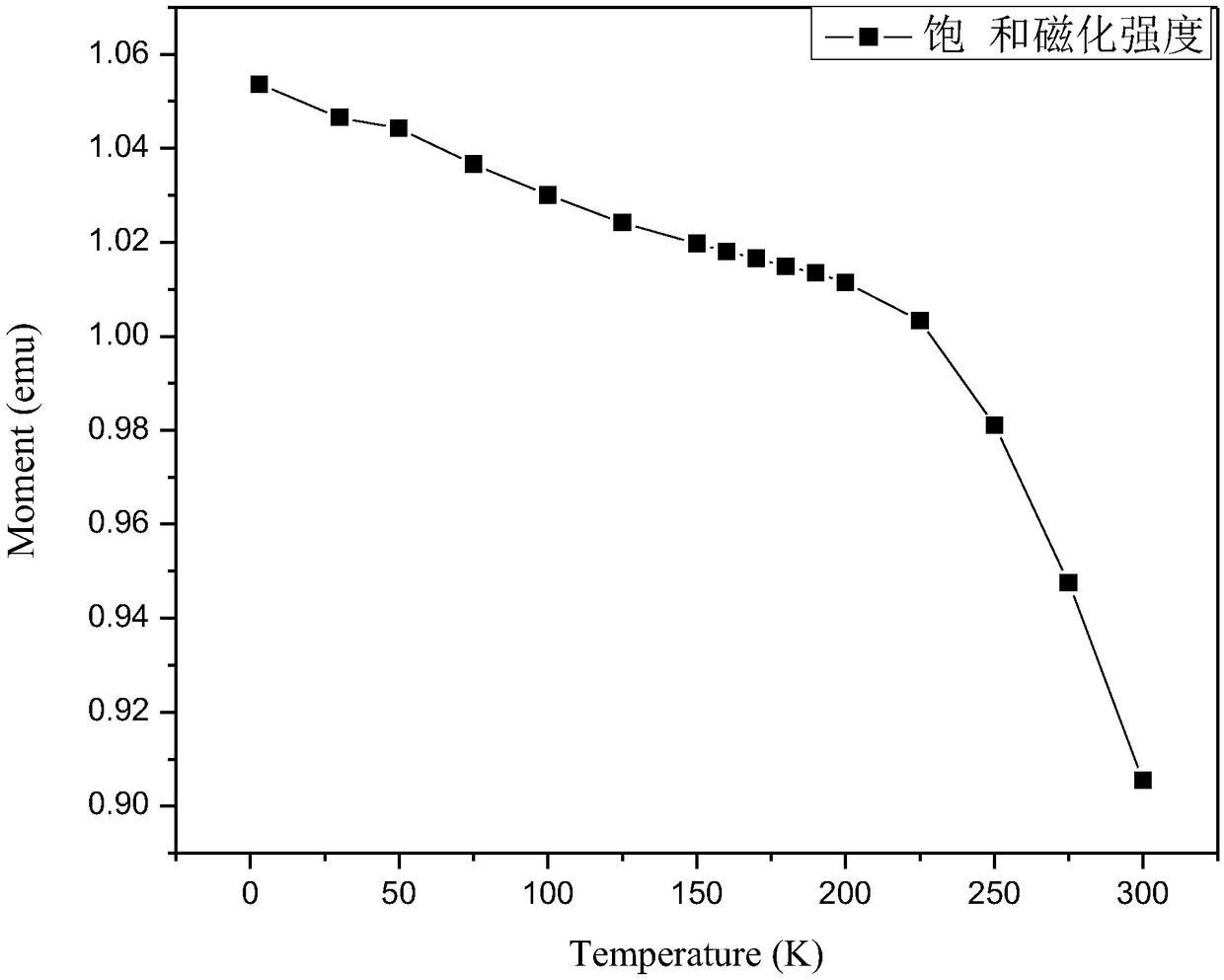

Preparation method for composite material with magnetic field regulating martensitic transformation

The invention relates to a preparation method for a composite material with magnetic field regulation martensitic transformation. According to the method, two materials of Tb0.27Dy0.73Fe1.9 and Mn48Co4Ni28Ga20 are used, the granularity is uniformly mixed according to different proportions, different sintering temperatures are set, and a plasma sintering method is adopted; and under an external magnetic field, magnetostriction of a rare earth giant magnetostrictive material is taken as stress to induce appreciable martensitic transformation or martensitic variant rearrangement of a ferromagnetic shape memory alloy material. The material prepared by the method can work in a low magnetic field and work when distributed in a 0-380 K temperature region, and the magnetic field has the maximum effect efficiency of 41 K / T on the phase transition temperature.

Owner:HEBEI UNIV OF TECH

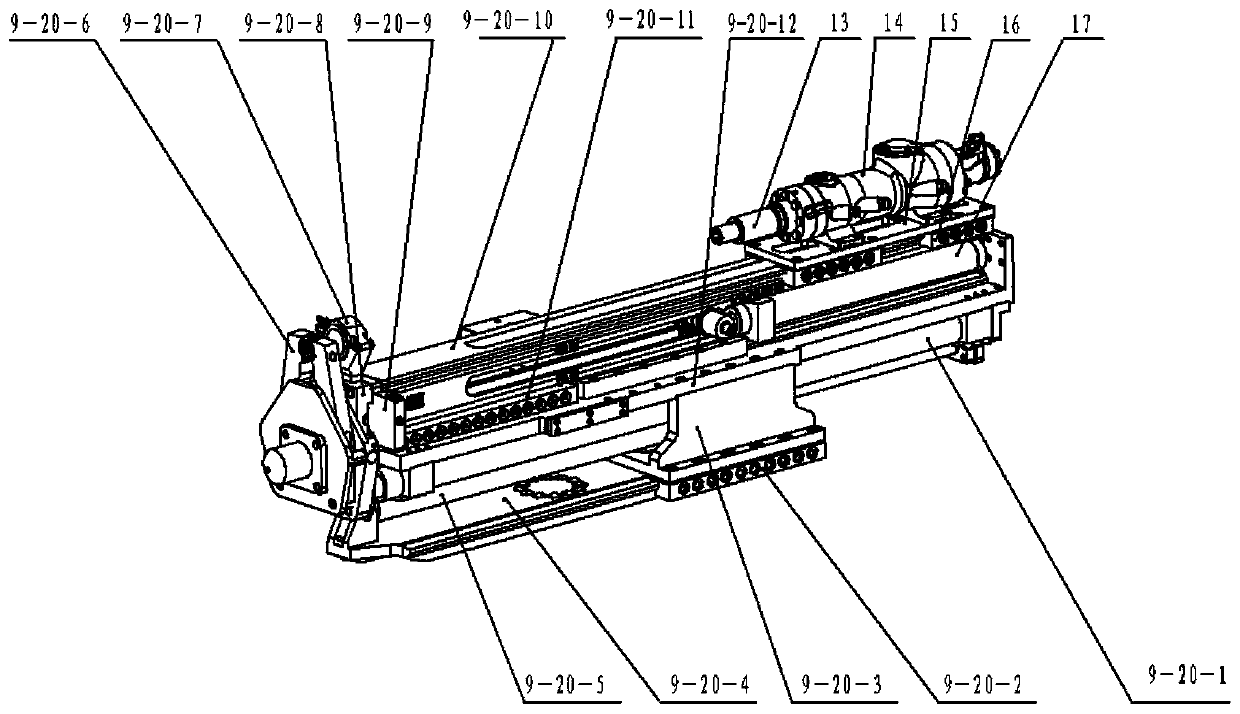

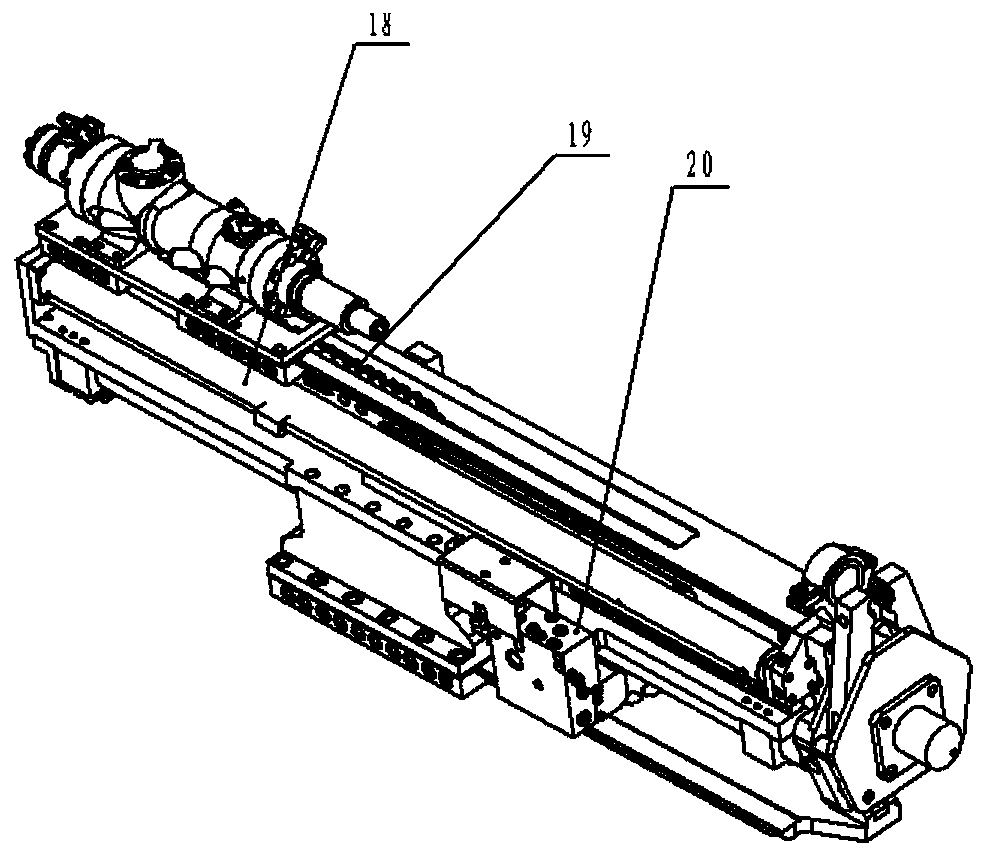

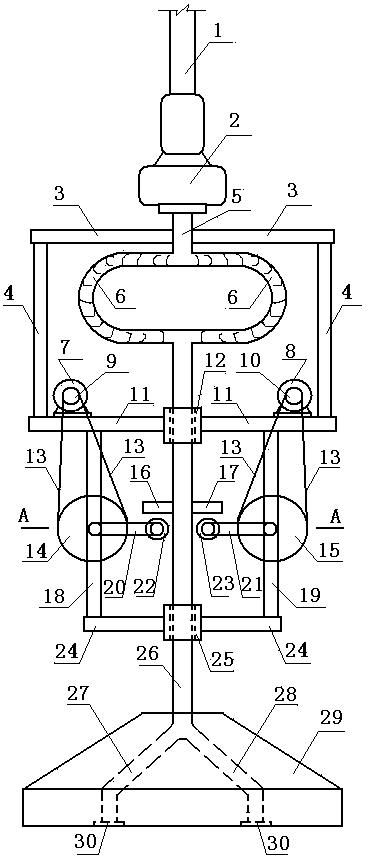

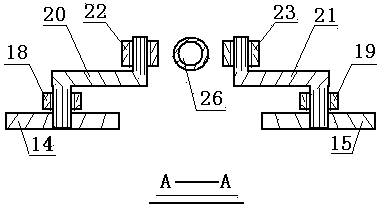

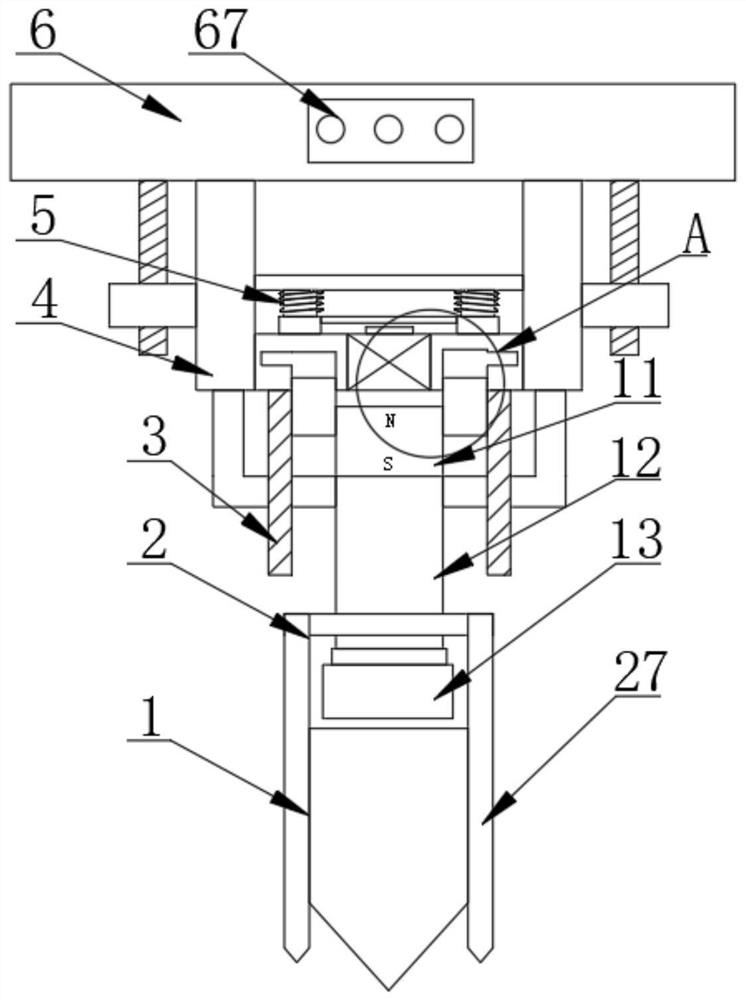

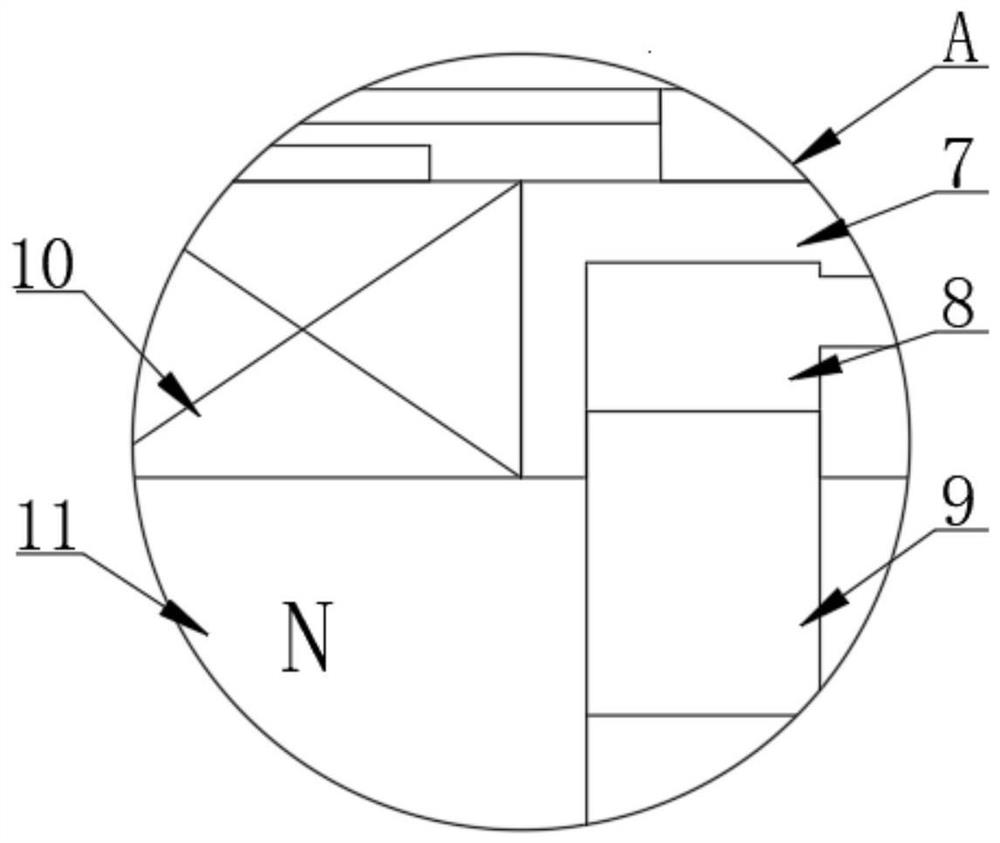

Impact type multifunctional airborne drilling rig

PendingCN110273643AIncrease drilling speedImprove impact efficiencyDrilling rodsConstructionsTorque transmissionPropeller

The invention belongs to the technical field of coal mine development machinery, is used for blasting drilling holes of a hard-rock rock roadway in an underground coal mine in construction and various drilling holes in the support work of anchor rods and anchor ropes, and provides an impact type multifunctional airborne drilling rig. According to the technical scheme, the impact type multifunctional airborne drilling rig comprises a positioning oil cylinder, a propulsion slide way pressing block, a slide way seat, a propulsion slide way, a propulsion cylinder, a clamp holder, a drill rod support, a drill rod support seat, a slide way top plate, a slide way, a slide way pressing block, a slide way bottom plate, a forward and reverse large torque transmission device, an impact type rock-drilling drilling rig, a rock-drilling drilling rig fixing plate, a fixing plate slide way pressing block, a first stage oil cylinder, a secondary oil cylinder, a chain assembly and an integrated valve group. The impact type multifunctional airborne drilling rig has the advantages that the rock drilling speed is fast, the impact efficiency is high, the noise is low, drilling tools are not prone to being stuck, good appearance is achieved, collision is avoided flexibly and effectively, a propeller is protected, the number of exposed oil pipes is greatly reduced, the occurrence of oil pipe extrusion is avoided, and the overall performance of the drilling rig is improved.

Owner:SHANXI TIAN JU HEAVY IND

Cone frustum hammer pore-forming machine

ActiveCN103410438AImprove impact efficiencyReduce power consumptionBorehole drivesEngineeringFrustum

Disclosed is a cone frustum hammer pore-forming machine. The lower end of a drill rod is connected with a slurry pump, the lower end of the slurry pump is connected with a suction pipe, the suction pipe is fixed in the middle of a transverse arm A, the transverse arm A, a transverse arm B, a transverse arm C, two longitudinal arms A, a longitudinal arm B and a longitudinal arm C are welded to form a stable steel structure, the lower end of the suction pipe is connected to the upper end of a suction pipe B through two bent corrugated pipes, the suction pipe B penetrates a sleeve A and a sleeve B, the lower end of the suction pipe B is connected with a suction pipe C and a suction pipe D and also fixed to a cone frustum hammer, a crank arm A is arranged in the middle of the longitudinal arm B, a driven belt pulley A is fixed to a shaft end on one side of the crank arm A, a wheel A is sleeved at a shaft end on the other side of the crank arm A, the upper portion of the wheel A is provided with a handle lever A, the handle lever A is fixed to the left of the suction pipe B, a crank arm B is arranged in the middle of the longitudinal arm C, a driven belt pulley B is fixed to a shaft end on one side of the crank arm B, a wheel B is sleeved at a shaft end on the other side of the crank arm B, the upper portion of the wheel B is provided with a handle lever B, and the handle lever B is fixed to the right of the suction pipe B.

Owner:歌玛磨具南通有限公司

Aerosol collection system and method

ActiveUS10502665B2Improve impact efficiencyIncrease concentrationLiquid dispersion analysisWithdrawing sample devicesMedicineCollection system

The present invention relates to systems and methods for collecting and analyzing bioaerosols, including exhaled breath aerosol from a subject. The collection system comprises an inlet portion configured to receive a gaseous fluid containing water vapor and aerosol particles. A primary passage for gaseous fluid flow is in fluid communication with the inlet portion and configured to channel the gaseous fluid flow therethrough. An outlet portion is in fluid communication with the primary passage. A sample collection region is provided, which is configured to receive from the outlet portion aerosol particles from the gaseous fluid, wherein the aerosol particles are impacted onto a layer of ice.

Owner:AEROSOL DYNAMICS INC +1

A crushing device for coal gangue sorting

ActiveCN103433106BImprove impact efficiencySimple crushing workGrain treatmentsEngineeringCoal gangue

The invention relates to a crushing device for coal gangue separation. The crushing device comprises an outer cover, a material separating device, a plurality of guide plates, a material throwing tray and a bracket, wherein the outer cover is fixed on the bracket; a feeding hole is formed in the top of the outer cover; the bottom of the outer cover is provided with a discharge hole; a vortex bin is arranged in the middle of the outer cover; the material separating device is arranged in the feeding hole and the vortex bin; the upper part of the material separating device has an umbrella-shaped structure; a feed opening is formed in the top of the material separating device; a coal gangue storage bin is arranged in the middle of the material separating device; the material throwing tray is arranged under the material separating device; the plurality of guide plates are respectively arranged under the umbrella-shaped structure of the material separating device and fixed on the outer cover. The crushing device can be used for selectively crushing coal components in the coal gangue while maintaining the integrity of the gangue component, thus meeting the requirement of separation.

Owner:长治市武理工工程技术研究院

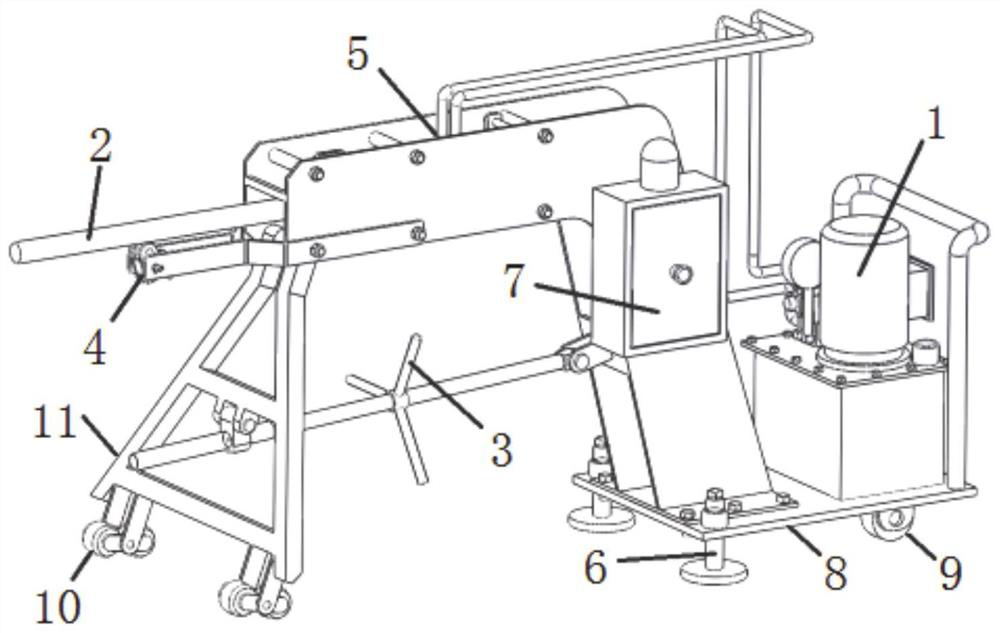

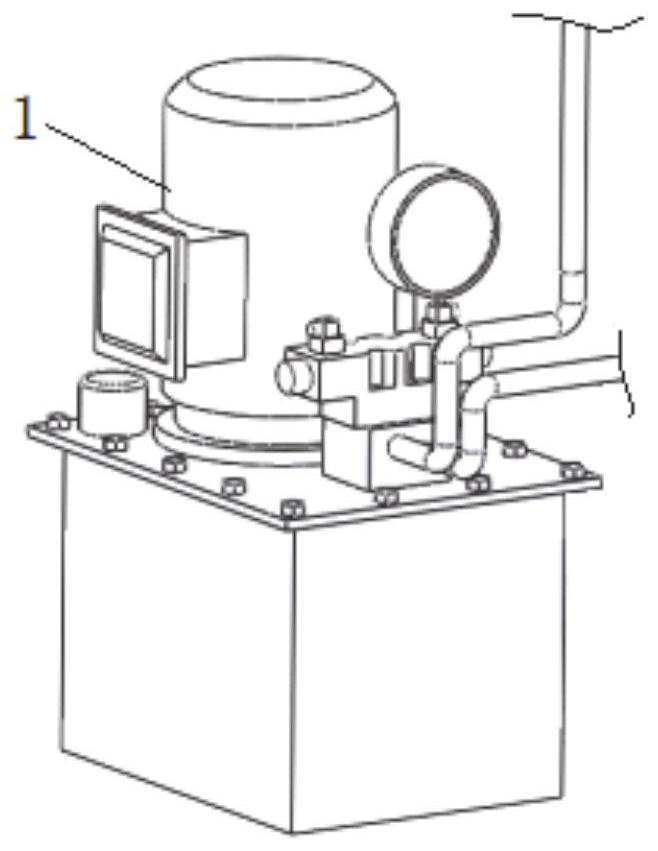

Stress-relieving device for seamless rails by using excitation method, and the relieving method

InactiveCN102226326BEasy to carryBalance overturning momentRailway track constructionElectricityStress relieving

The invention discloses a stress-relieving device for seamless rails by using a vibration method and a stress-relieving method, and is implemented by carrying out field detection on the stress-relieving effect of rails mainly by using a device for realizing the stress homogenization of rails in a periodic-vibration gas-liquid pressurized mode and supplementarily by using a stress sensor, and then carrying out stress-relieving operation in a machine-liquid-electricity integrated automatic mode. The whole stress-relieving device disclosed by the invention is light in weight, and provided with an anti-overturn device for ensuring a trolley is not overturned to the side during the operation of the trolley, thereby reducing the labor intensity and improving the operating efficiency and quality.

Owner:HUBEI UNIV OF TECH

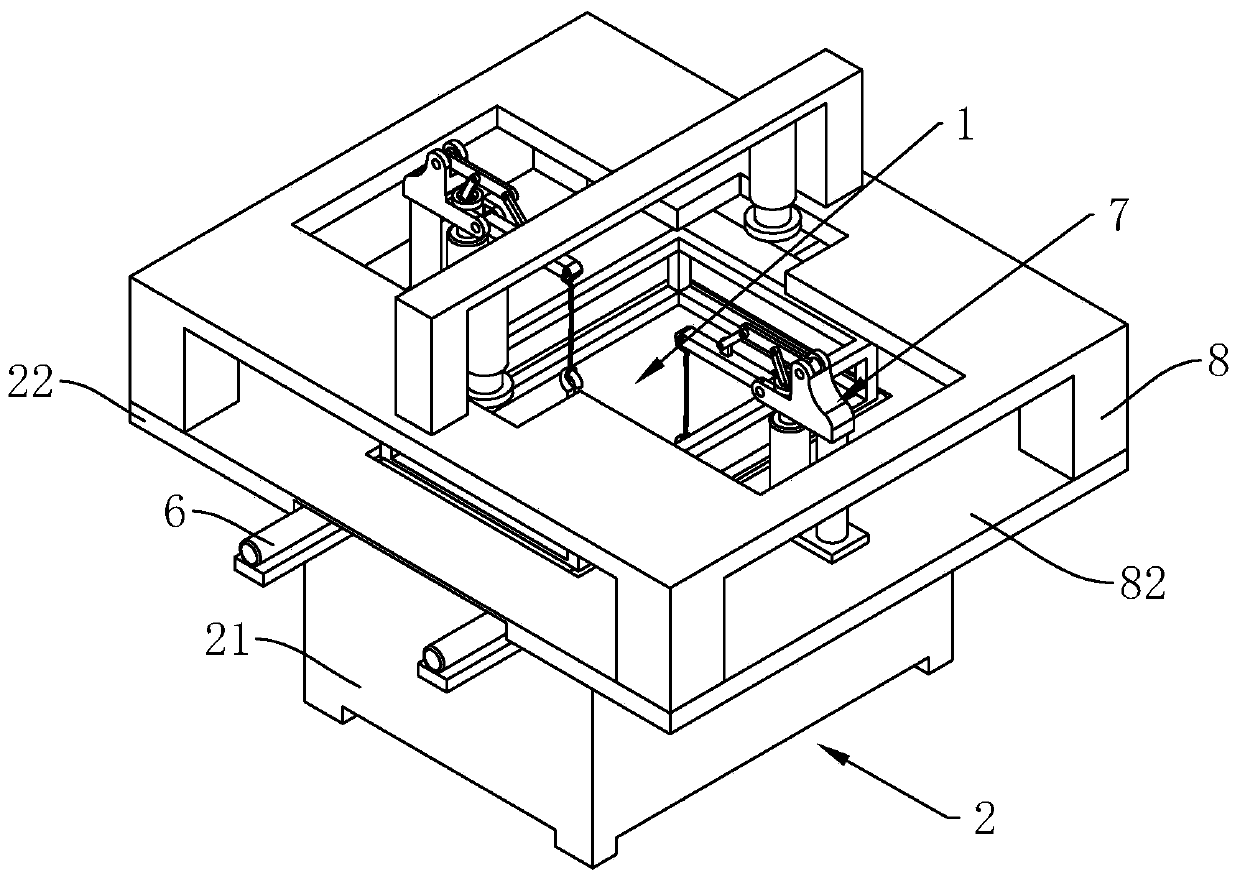

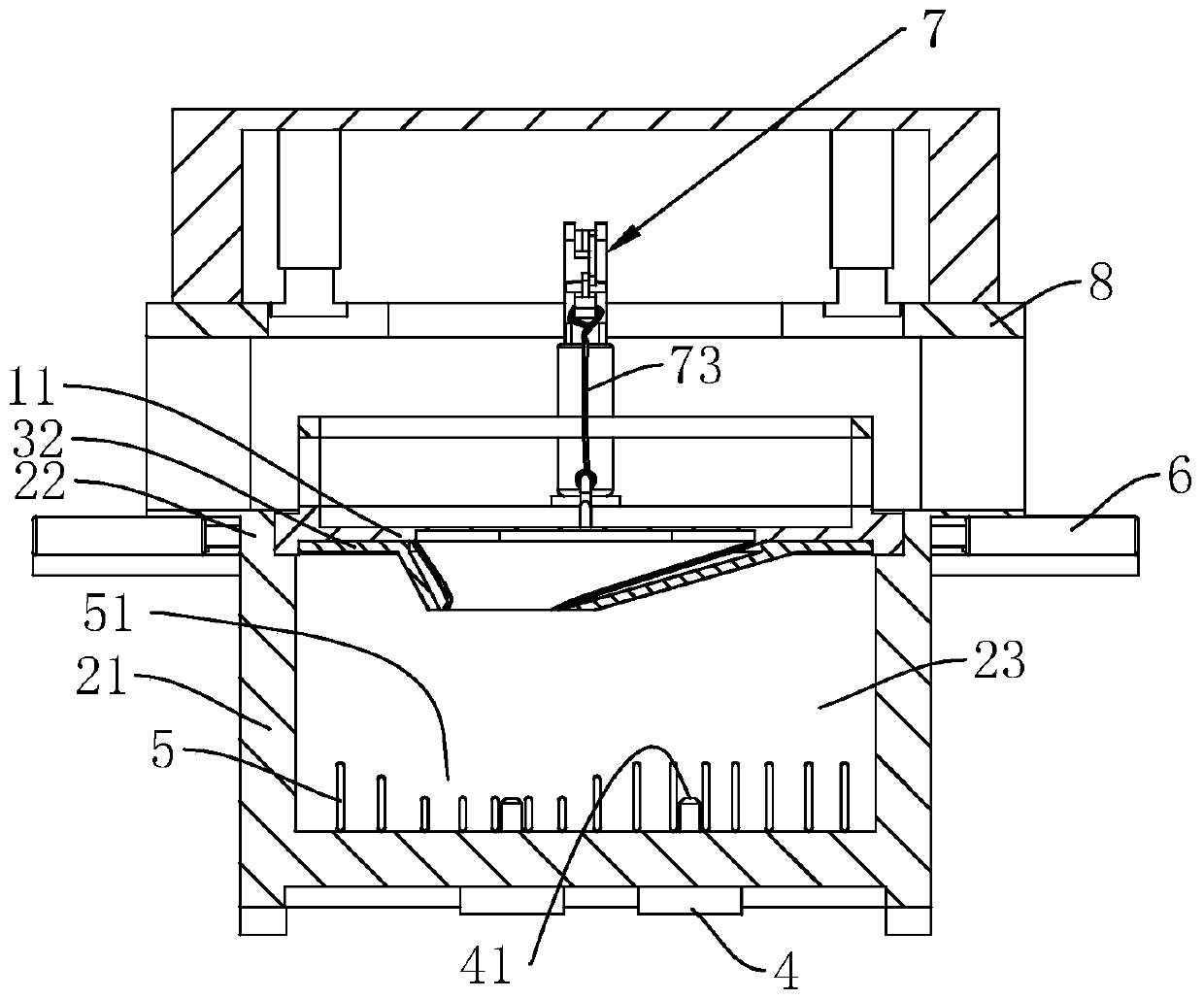

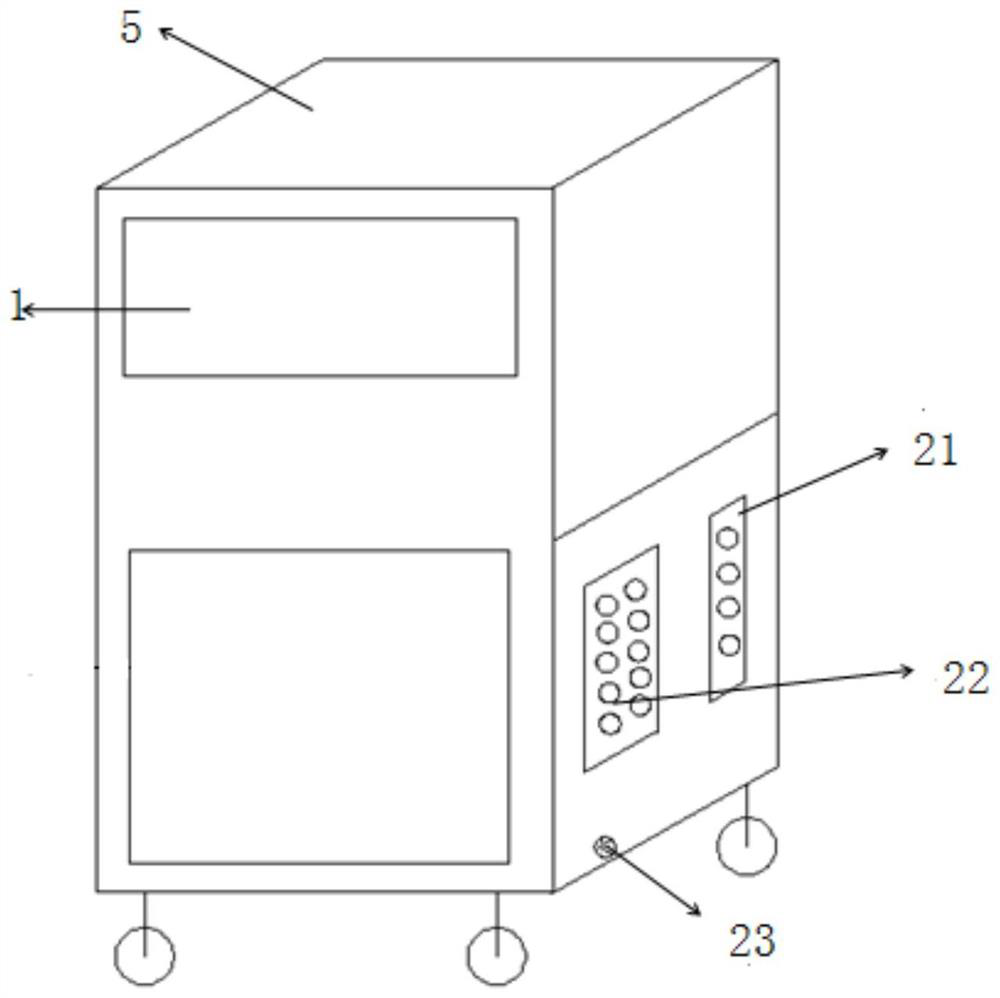

A sealed belt cold and hot shock box

The invention relates to thermal shock chambers, in particular to a thermal shock chamber with sealing belts and aims to solve the problems of proneness to collision or displacement of samples, poor airtightness, poor shock effects, low control precision and the like in a shock process in the prior art. The outer surfaces of four side walls of a sample case, the inner and outer sides of the sealing belts, the outer surfaces of two heat storage tanks and two cold storage tanks and the lateral sides of four rotating shafts are provided with a plurality of projections and grooves in alternate array, and consequently excellent sealing effects are achieved. After photoelectric receivers receive optical signals, a controller controls a motor to stop, and refrigeration or heating is started in order to realize thermal shock. The thermal shock chamber with the sealing belts has the advantages that the samples are less prone to displacement, adverse factors such as collision, displacement and the like are avoided, accuracy in control is achieved due to adoption of the controller, low cost, structural simplicity, convenience in operation, high shock efficiency and effectiveness in sealing are realized, and service life of the thermal shock chamber is greatly prolonged. Furthermore, the thermal shock chamber is applicable to thermal shock test of devices.

Owner:HARBIN UNIV OF SCI & TECH

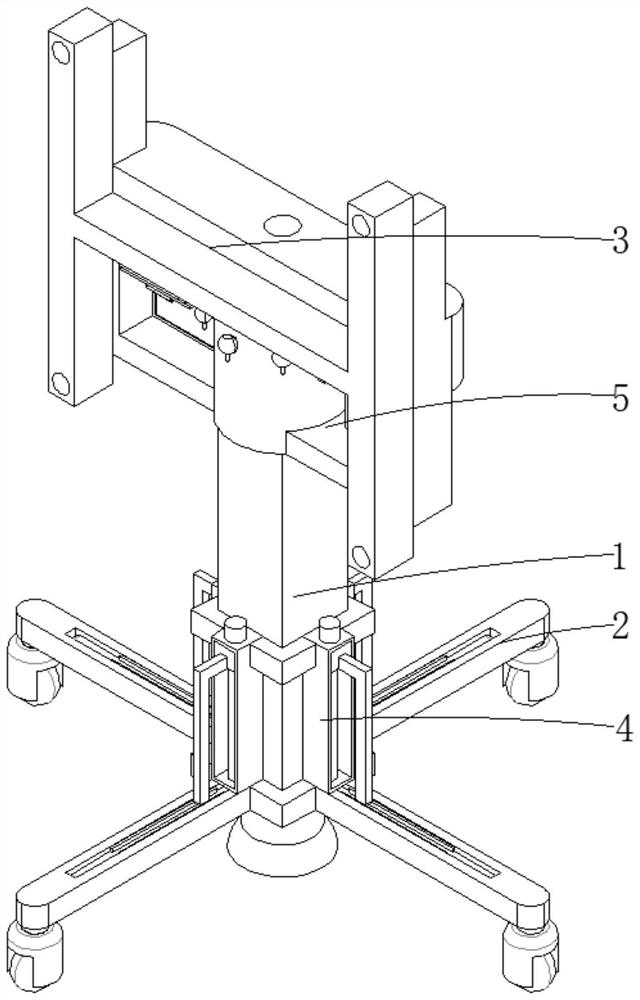

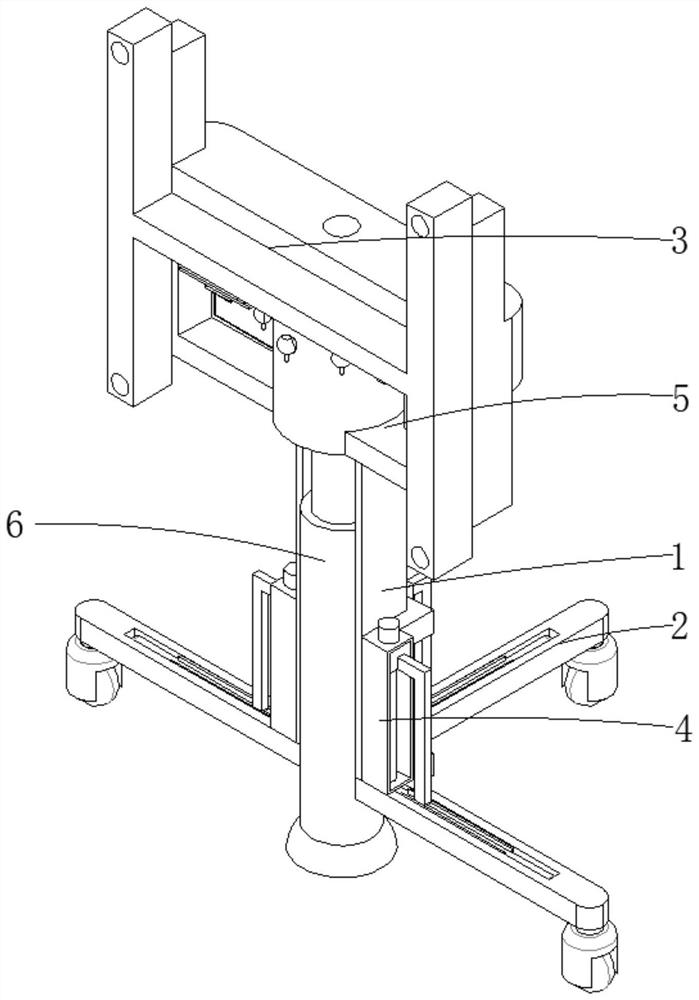

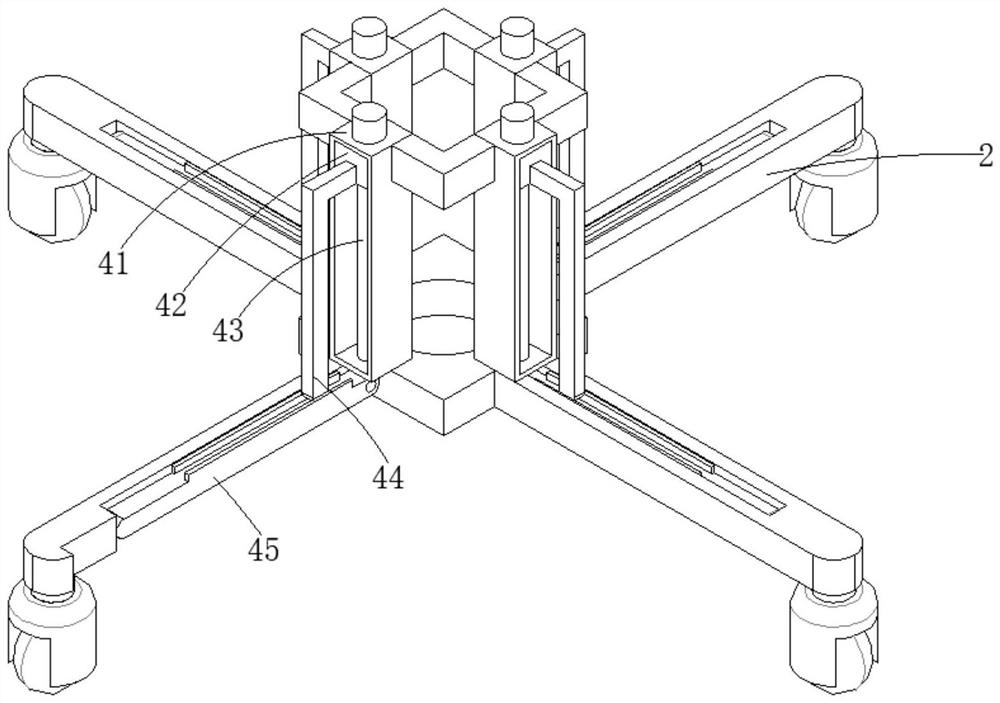

Television floor stand capable of being used on bumpy ground

InactiveCN114542920AAvoid the problem of easy shakingAvoid shakingTelevision system detailsColor television detailsStructural engineeringMechanical engineering

The invention discloses a television floor stand capable of being used for a bumpy ground, and relates to the technical field of television floor stands. The device comprises a support rod, a moving frame is fixed to the bottom of the support rod, a through groove is formed in the top of the moving frame, an adapting device is arranged above the moving frame, a mounting frame is rotationally mounted at the top of the support rod, a protection device is arranged on the back face of the mounting frame, and a fixing device is arranged in the support rod. The adapting device comprises a fixing shell, and the fixing shell is fixedly installed on the outer side of the support rod. Through cooperation of the threaded rod and the threaded block, the threaded rod drives the L-shaped rod to move downwards through the threaded block, and under cooperation of the L-shaped rod and the supporting rod, the L-shaped rod abuts against the supporting rod and turns downwards, so that the supporting rod makes contact with the ground, the television floor frame adapts to the bumpy ground, and the use stability of the floor frame is improved.

Owner:唐广明

Sieve array and precipitator device and method of treating exhaust

ActiveUS10625197B2Effective recoveryHigh speedDispersed particle filtrationUsing liquid separation agentParticulatesHeat transfer efficiency

A vibrating wet precipitator is designed to remove particulates from particulate-laden hot gas. The precipitator includes an array of vertical wet cords stretched within a duct. The cords are tuned to vibrate due to the gas flow by controlling key parameters such as gas flow, velocity, cord length and diameter so that particulate collection and heat transfer efficiency are maximized. The cords are part of sieves. A plurality of these sieves are arranged to define a plurality of gaps, through which the exhaust flows. The sieves and thus the cords are space so that a vortex from a first cord affects an adjacent cord and subsequently cord. The particles are then absorbed in liquid, which can be passed through a heat exchanger filtered and subsequently reused. Preferably the cord arrangement is designed to allow the cords to vibrate at high frequencies, typically 10 to 100 Hz, to maximize particulate collection.

Owner:OHIO UNIV

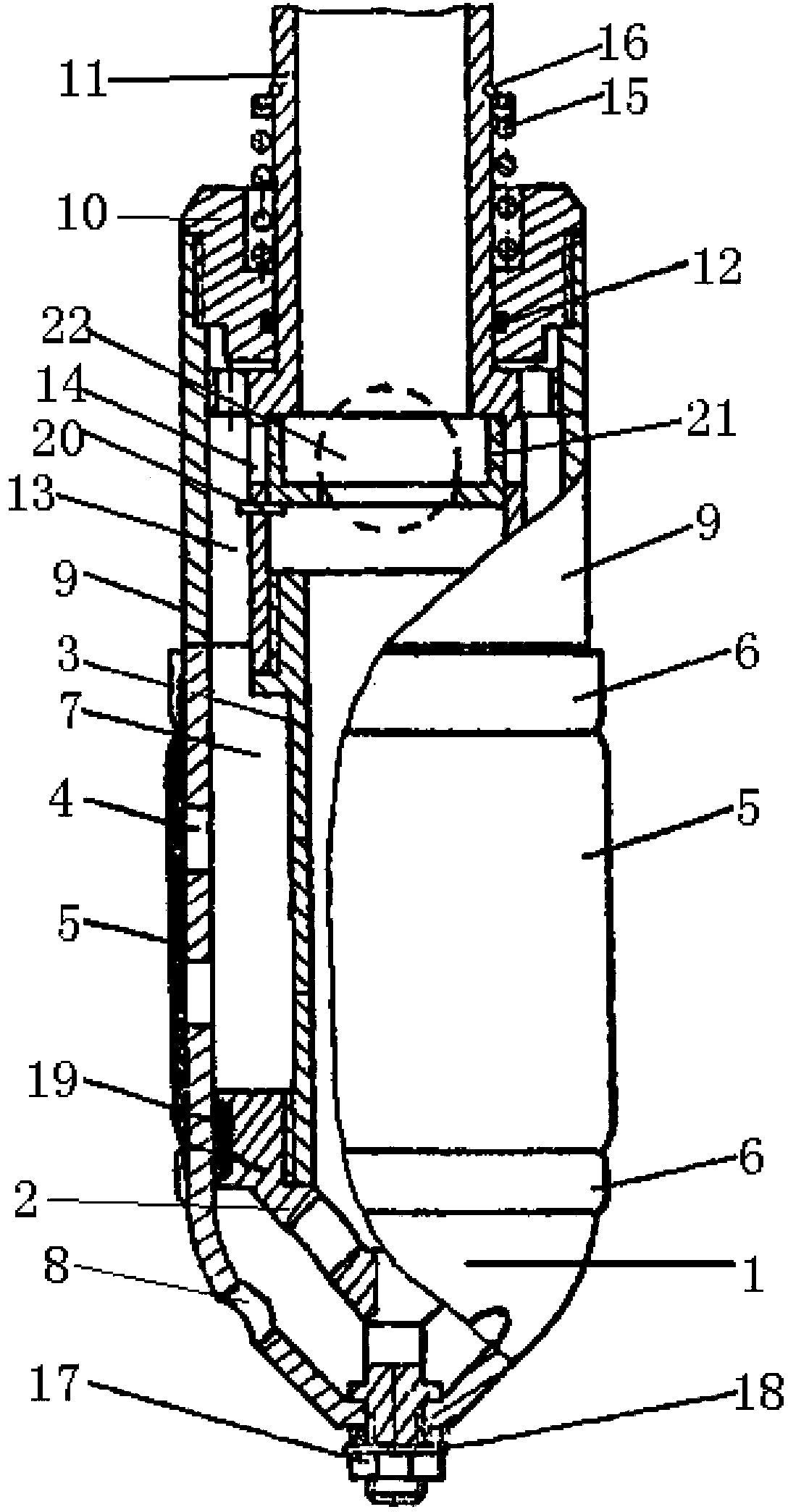

Downhole pneumatic shock wave generator

InactiveCN103437732AExtended service lifeImprove impact efficiencyBorehole/well accessoriesShock waveEngineering

The invention provides a downhole pneumatic shock wave generator, which at least comprises a generator body, a top shock wave reflector and a bottom shock wave reflector, which are elastic parts, are respectively arranged on the top and bottom of the generator body, and moreover, the top shock wave reflector and the bottom shock wave reflector are arranged on the left side and right side of the generator body, and are used for isolating the generator body from the well wall; the generator body at least comprises a housing, a duct, a nipple, a support and a piston, a movable ring A and a movable ring B are also sleeved on the outer wall of the housing, wherein the movable ring A is located under vent holes, and the movable ring B is located over the vent holes. The structure of the pneumatic shock wave generator is simple, the service life is long, and the defects of the background art are solved. The service life of the pneumatic shock wave generator can be prolonged, and moreover, the generated air shock wave is concentrated.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

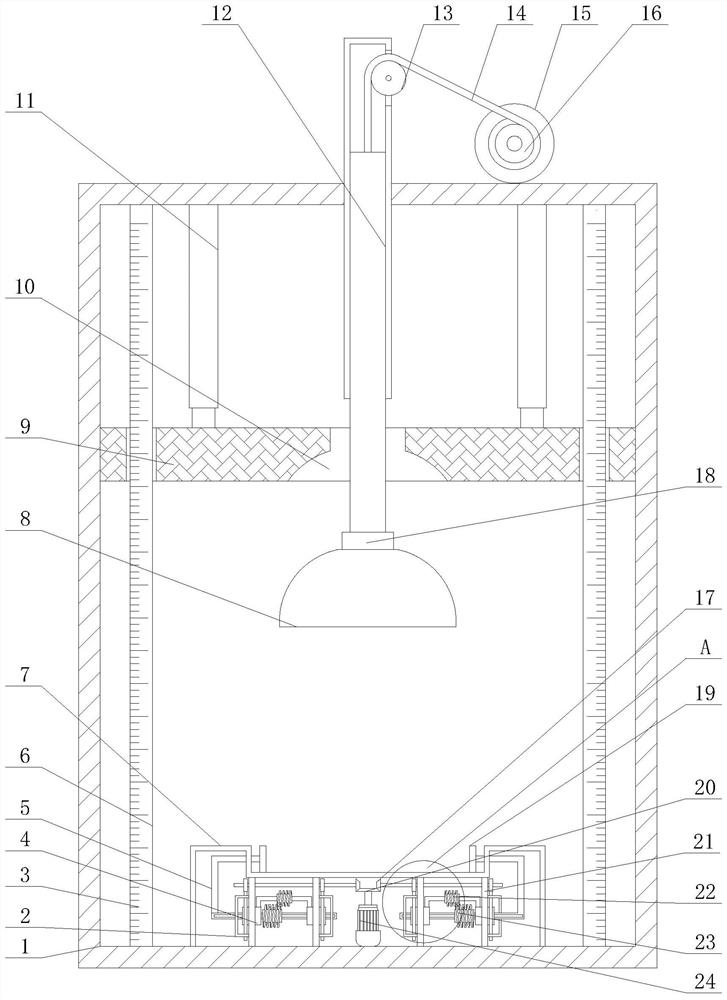

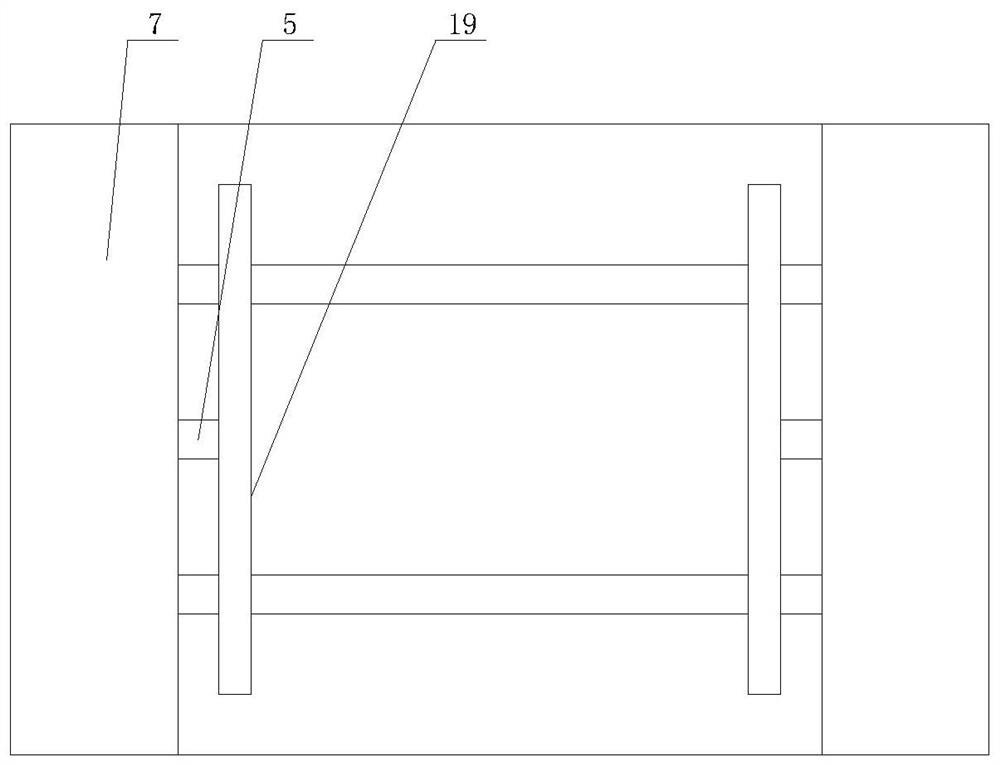

Fence vertical pile fixing device for livestock breeding

InactiveCN112438210ARealize frequent impactImprove impact efficiencyPasturing equipmentAnimal scienceCrop livestock

The invention discloses a fence vertical pile fixing device for livestock breeding, and particularly relates to the field of livestock. The fence vertical pile fixing device comprises a height settingmechanism, a connecting sleeve is slidably connected to the bottom end of the height setting mechanism, a control mechanism is slidably connected with the side end of the connecting sleeve, a fixingblock is fixedly connected with the bottom end of the control mechanism, an electromagnet is fixedly installed in the center of the fixing block, a springback damping mechanism is fixedly installed onthe inner side of the fixing block, a vertical guide rod is fixedly connected to the bottom end of the fixing block, and a magnet connecting block is slidably connected to the side end of the vertical guide rod. According to the scheme of the fence vertical pile fixing device for livestock breeding, the electromagnet is mutually matched with the vertical guide rod, the controller controls the electromagnet to be started, a permanent magnet is pushed to move downwards, a connecting column is pushed to move downwards, then a hammering hammer head is pushed to hit fixed vertical piles downwards,the connecting column moves to indirectly drive a same-direction bottom plate to abut against a control button, the electromagnetic direction is changed to attract the permanent magnet upwards, the frequent impact effect on the fixed vertical piles is achieved, and the impact efficiency is improved.

Owner:合肥初升信息科技有限公司

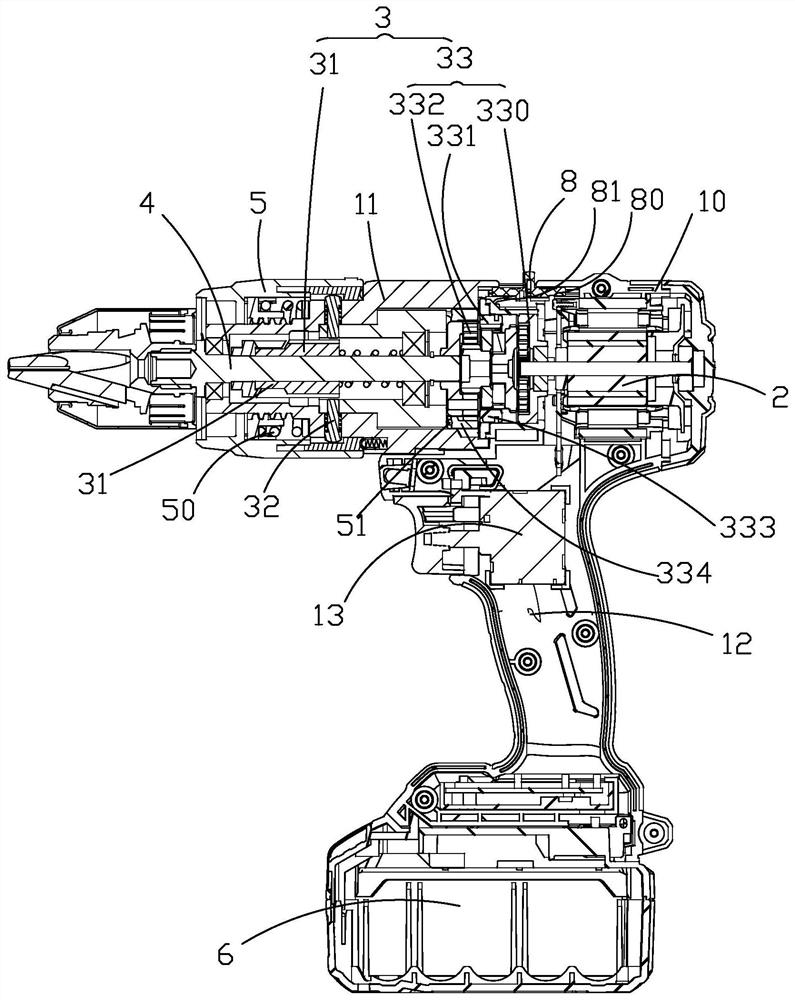

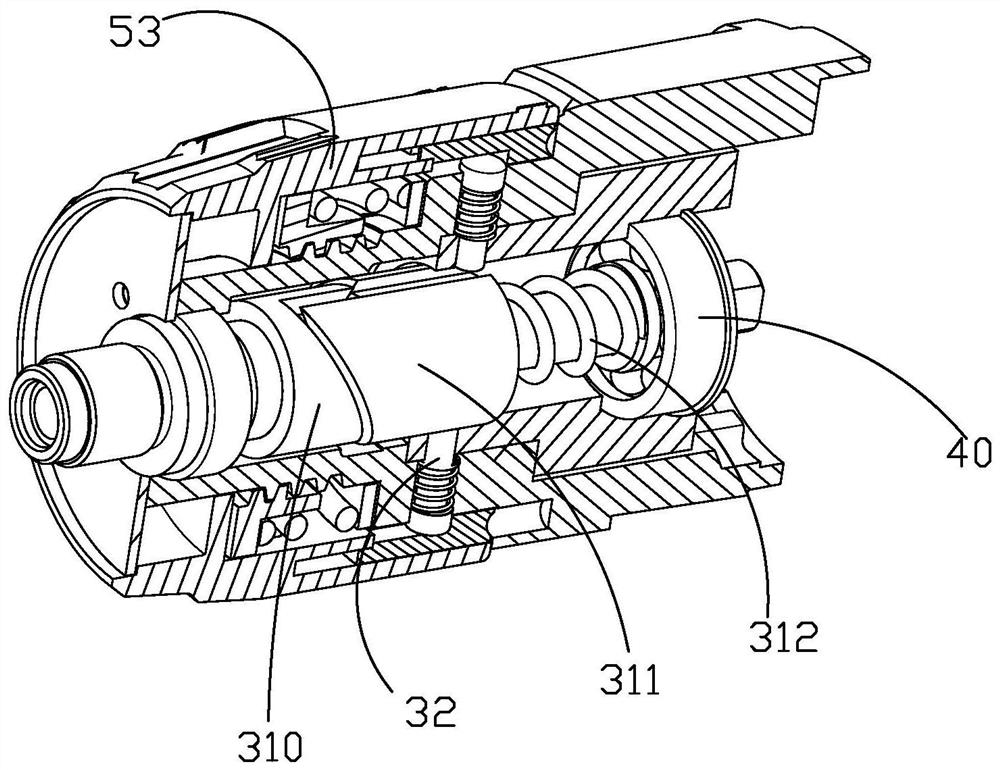

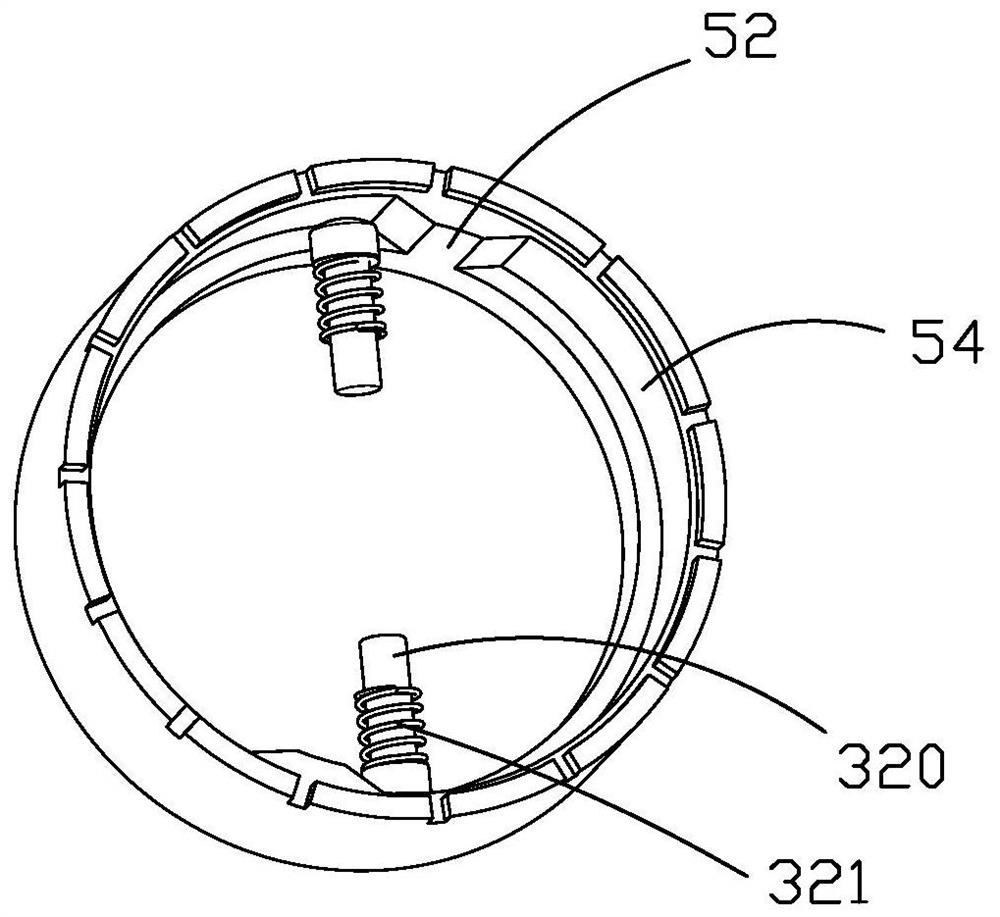

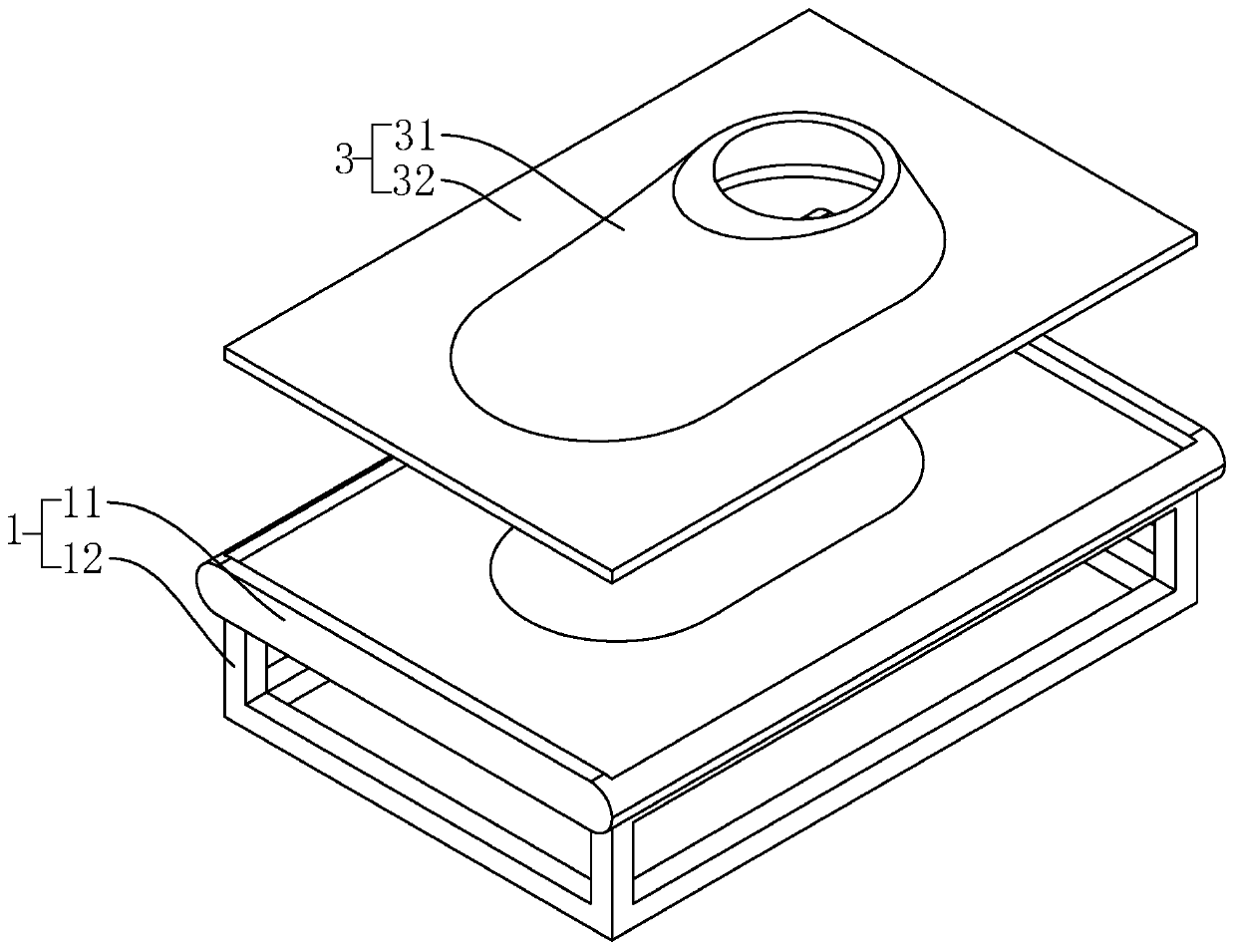

Impact tool

PendingCN113814941ARealize the impact functionImprove impact efficiencyPortable percussive toolsPortable power-driven toolsRatchetElectric machine

The invention discloses an impact tool. The impact tool comprises a rack, a motor contained in the rack, a transmission mechanism, an output shaft and an adjusting cup installed on the outer side of the rack, and the motor drives the transmission mechanism to rotate and drives the output shaft to do rotary output motion. The impact tool is provided with an impact mechanism and a rotation stopping part, the impact mechanism is provided with a movable ratchet fixedly held with the output shaft, an impact hammer axially sliding on the output shaft and an elastic piece sleeving the output shaft, and the movable ratchet and the impact hammer are provided with mutually coupled inclined planes; in an impact mode, the rotation stopping part abuts against the impact hammer, then the impact hammer can only move axially but cannot rotate, the impact hammer moves on the inclined plane, and an impact function is achieved under the release of the capacity of the elastic piece; and when only an electric drill mode is needed, a rotation stopping pin is separated from the impact hammer, the impact hammer and the movable ratchet rotate together, an impact mode with higher impact efficiency is achieved, and the working efficiency is improved.

Owner:JIANGSU DONGCHENG TOOLS TECH CO LTD

A demoulding machine for bathroom products and a demoulding process using the demoulding machine

Owner:FUYANG BEAUTIFUL SANITARY WARE

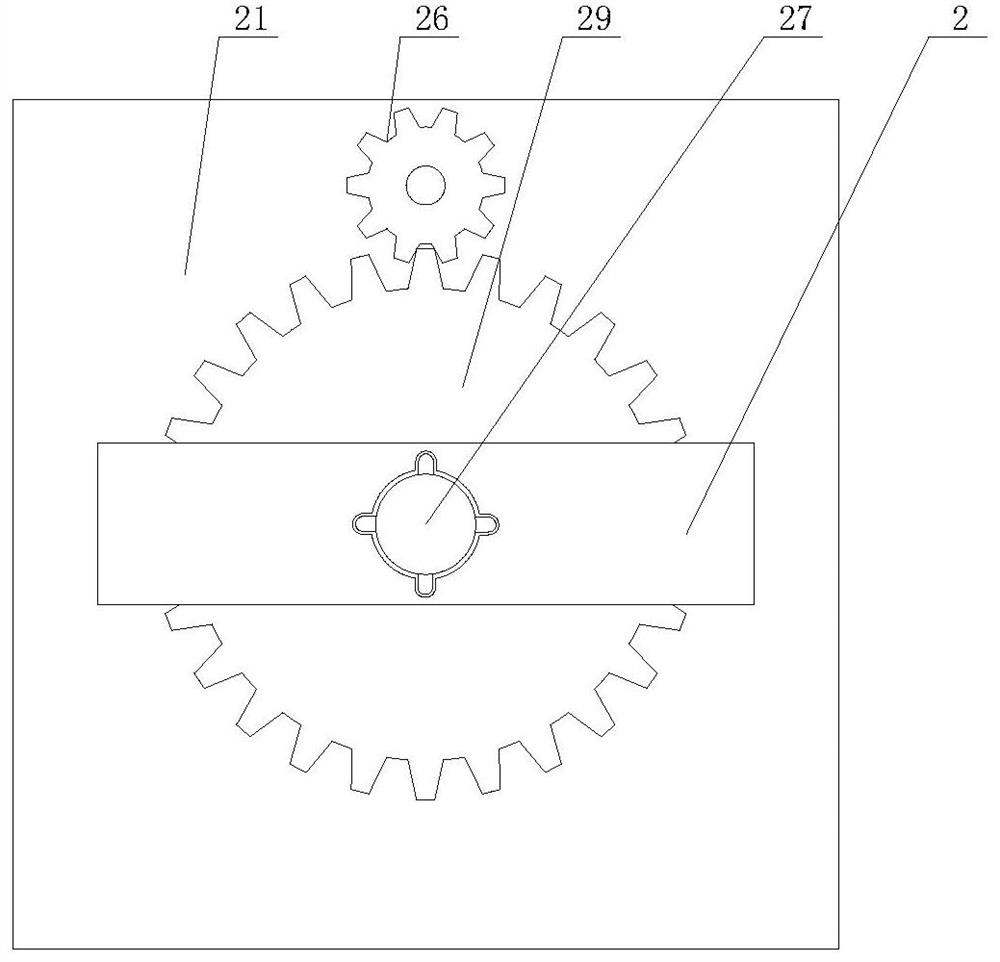

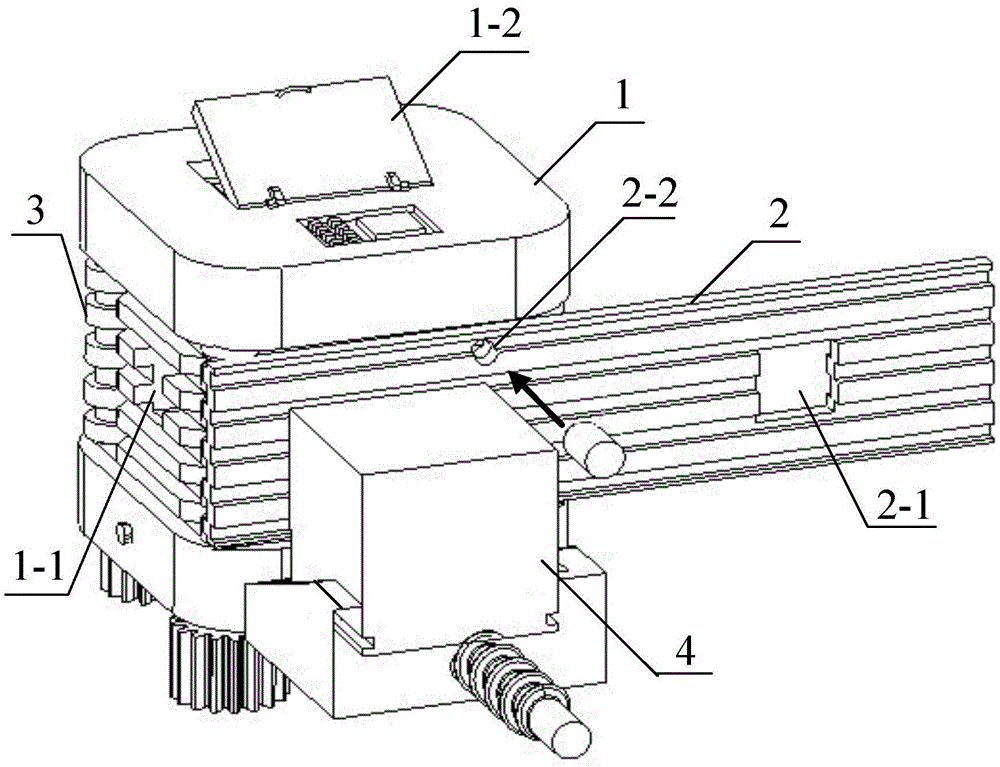

Novel efficient impact drilling machine

PendingCN111305746ACompact structureSolve efficiency problemsReciprocating drilling machinesConstructionsGear wheelMachine

The invention relates to the technical field of impact drilling machine equipment, and provides a novel efficient impact drilling machine which comprises a machine frame. A driving rear axle is connected to the rear side wall of the machine frame. The novel efficient impact drilling machine is characterized in that the driving rear axle is provided with two steel wire ropes, and the two steel wireropes pass through a stand column and are connected to a same drill bit. The defects in the prior art are overcome, the design is reasonable, the structure is compact, and the problems of low impactefficiency, poor effect and no sand discharge of an existing impact drilling machine are solved. Through the simple structural combination, by adopting the two steel wire ropes to be connected with the dill bit, the stability of the drill bit is improved, meanwhile, a mode that a smaller gear is meshed with a large gear is adopted to improve output power, the drill bit with the large weight can bedriven to work, the work efficiency is improved, strong airflow produced by an air compressor is used for discharging sand, and therefore the effect of quickly discharging the sand is realized.

Owner:南京尚泰工程机械制造有限公司

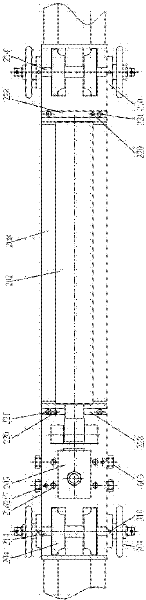

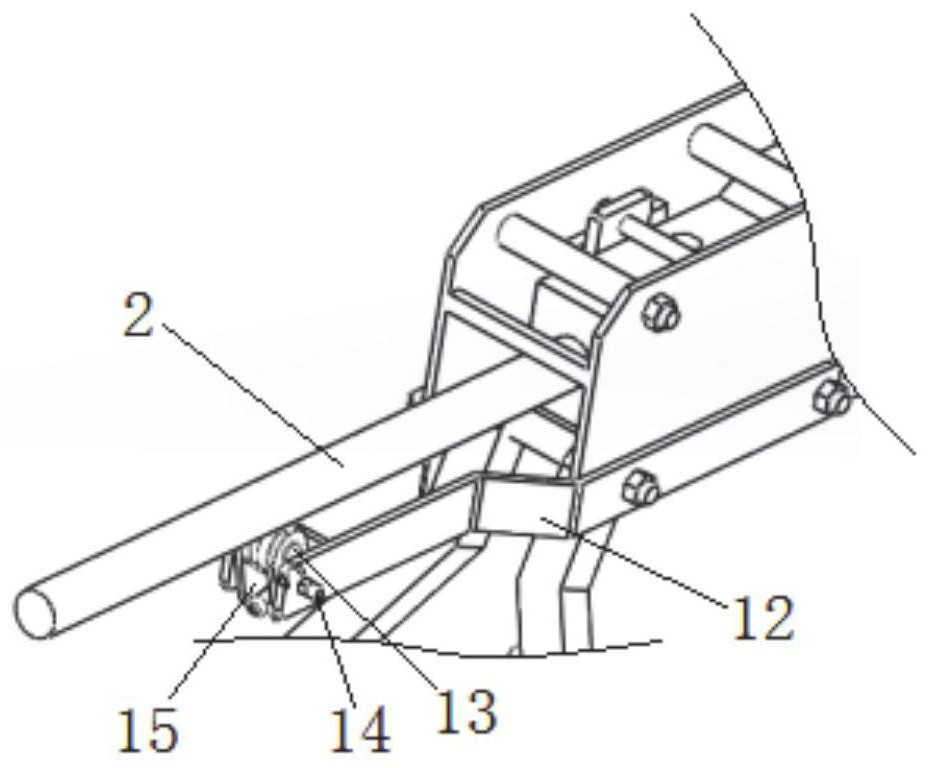

Movable impact type large pin shaft replacement device and method

The invention discloses a movable impact type large pin shaft replacement device and method. According to the technical scheme, the movable impact type large pin shaft replacement device comprises an impact device body, a fine adjustment mechanism, an adjustment mechanism and a movable supporting assembly. The impact device body comprises an impact drill rod and an impact moving mechanism, and the impact moving mechanism can provide circulating reciprocating power for the impact drill rod. The fine adjustment mechanism comprises a pulley making contact with the bottom of the impact drill rod, and the pulley is connected with the impact moving mechanism through a connecting support. The adjustment mechanism is located below the impact drill rod and comprises a lead screw rotationally connected with the impact moving mechanism, and the lead screw is provided with a manual pull rod. The movable supporting assembly is used for supporting the impact device body and installed at the bottom of the impact moving mechanism. The safety of maintenance operation can be improved, the working efficiency is improved, and the resource utilization rate is increased.

Owner:HUOLINHE OPENCUT COAL IND CORP LTD OF INNER MOGOLIA

Round Table Hammer Hole Making Machine

ActiveCN103410438BImprove impact efficiencyReduce power consumptionBorehole drivesRound tableEngineering

Disclosed is a cone frustum hammer pore-forming machine. The lower end of a drill rod is connected with a slurry pump, the lower end of the slurry pump is connected with a suction pipe, the suction pipe is fixed in the middle of a transverse arm A, the transverse arm A, a transverse arm B, a transverse arm C, two longitudinal arms A, a longitudinal arm B and a longitudinal arm C are welded to form a stable steel structure, the lower end of the suction pipe is connected to the upper end of a suction pipe B through two bent corrugated pipes, the suction pipe B penetrates a sleeve A and a sleeve B, the lower end of the suction pipe B is connected with a suction pipe C and a suction pipe D and also fixed to a cone frustum hammer, a crank arm A is arranged in the middle of the longitudinal arm B, a driven belt pulley A is fixed to a shaft end on one side of the crank arm A, a wheel A is sleeved at a shaft end on the other side of the crank arm A, the upper portion of the wheel A is provided with a handle lever A, the handle lever A is fixed to the left of the suction pipe B, a crank arm B is arranged in the middle of the longitudinal arm C, a driven belt pulley B is fixed to a shaft end on one side of the crank arm B, a wheel B is sleeved at a shaft end on the other side of the crank arm B, the upper portion of the wheel B is provided with a handle lever B, and the handle lever B is fixed to the right of the suction pipe B.

Owner:歌玛磨具南通有限公司

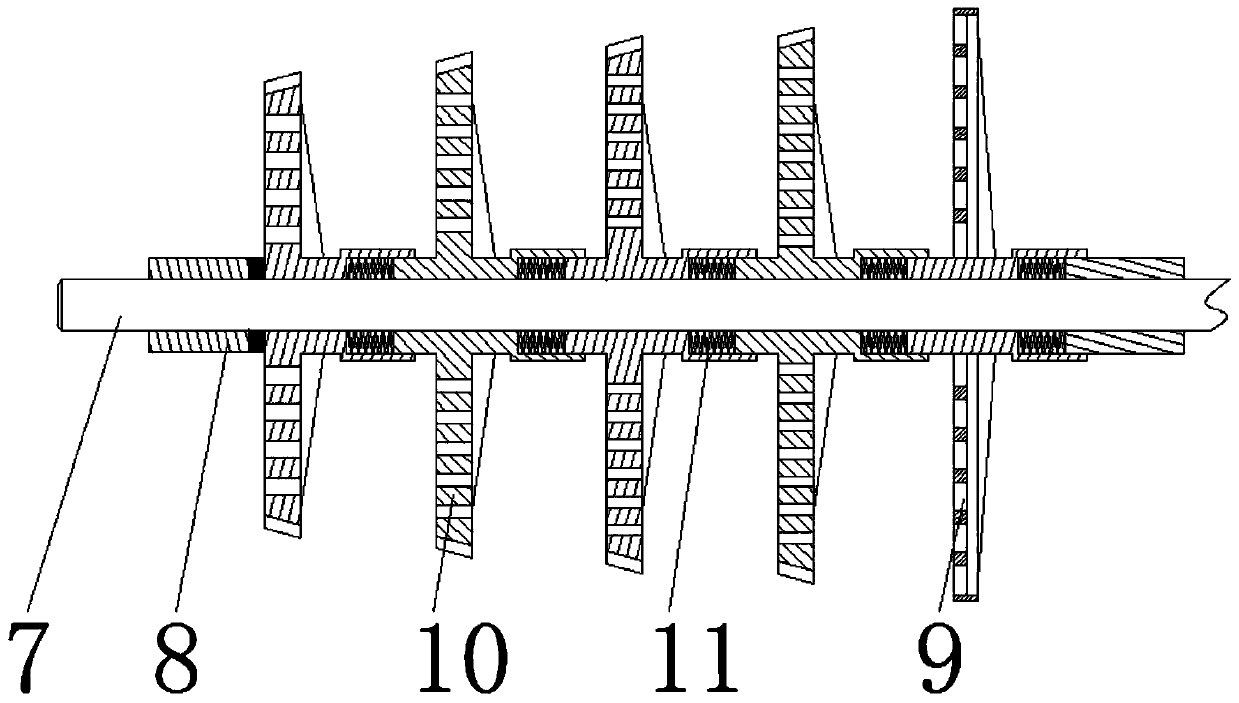

Reciprocating impact oblique tooth discharging shovel of reciprocating impact mining machine

The invention relates to the field of mining machinery, in particular to a reciprocating impact oblique tooth discharging shovel of a reciprocating impact mining machine. The reciprocating impact oblique tooth discharging shovel of the reciprocating impact mining machine comprises a reciprocating impact box and a reciprocating impact oblique tooth discharging shovel body. The reciprocating impactbox comprises a reciprocating impact box body, a reciprocating impact power part and a reciprocating impact guiding part, the reciprocating impact guiding part is disposed in the reciprocating impactbox body, the reciprocating impact power part is supported by the reciprocating impact box body to drive the reciprocating impact guiding part, and one end or both ends of the reciprocating impact guiding part extend out of the reciprocating impact box body. The reciprocating impact oblique tooth discharging shovel body comprises a main tooth seat, a main punching tooth, a side discharging tooth wing plate and side discharging oblique teeth, and the main tooth seat is arranged on the end part of the reciprocating impact guiding part extending out of the reciprocating impact box body, the mainpunching tooth is arranged at the top end of the main tooth seat, the thickness of the side discharging tooth wing plate is smaller than that of the main tooth seat to reduce the height of the discharging surface of the reciprocating impact oblique tooth discharging shovel body, the side discharging oblique teeth are staggered or symmetrically arranged or arranged front and back on the side discharging tooth wing plate, and the tooth top ends of the side discharge oblique teeth protrude from the side plane of the side discharging tooth wing plate. Impacted sweeping materials are enabled to conveniently flow out from the gap, higher than the side discharging tooth wing plate, of the side discharging oblique teeth, and the resistance of the materials to the reciprocating impact oblique toothdischarging shovel is reduced.

Owner:刘素华

A kind of impinging flow reactor and its application

ActiveCN103861544BRelieve pressureSmall temperature fluctuationsChemical/physical/physico-chemical stationary reactorsHydrocarbon oils refiningProcess engineeringOil phase

The invention discloses an impinging stream reactor, which comprises a reactor housing, a reaction impinging tank, and a liquid transfer pump. The reaction impinging tank is arranged in the reactor housing, the impinging tank is openmouthed, the guide cylinders are symmetrically arranged in the impinging tank, the guide cylinder is passed through a liquid feed line of the reactor housing and is connected to the liquid transfer pump, an air intake is arranged on a top cover of the reactor housing, a lower cover is a liquid holding tank with a taper structure, and an extraction port is arranged on the holding tank. In the impinging stream reactor, an oil phase extraction port, a water phase extraction port and a circulation solution extraction port are arranged on the holding tank, and are respectively arranged at an oil phase zone of the holding tank, a water phase zone and a tone top position of the holding tank. The temperature and pressure in the impinging stream reactor is easy to be controlled, the shocking of the reactor due to impinging reaction is reduced, and the impinging stream reactor is suitable for oil product oxidation desulphurization reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

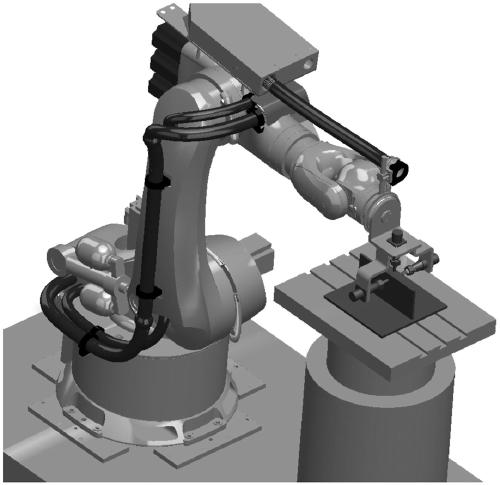

Ultrasonic multi-head impact device and method for manufacturing materials such as robots

ActiveCN108517479BIncrease contact areaSimple structureWelding accessoriesRobot handWelding residual stress

The invention relates to a robot equal material manufacturing and multi-head ultrasonic peening device and method. In order to conform to a manufacturing pattern based on addition in recent years, theequal material ultrasonic peening device and an installation method thereof in additive equal and subtractive material integrated compound manufacturing conducted on a thin-wall part with a complex shape are provided. By combining ultrasonic peening and additive and subtractive material manufacturing, welding residual stress can be eliminated, surface nanocrystallines are obtained, and damaged part repair is achieved, and the internal structure is changed to achieve performance optimization. The device is connected with an industrial robot tail end arm, a robot hand is controlled through programming to run according to a preconceived track, and meanwhile, through an ultrasonic peening gun, the different side surfaces of a part after material addition are peened simultaneously, so that a hammer forging peening equal mateirla shape controlling technology process of the top surface and the bilateral side surfaces of the thin-wall wall part is completed at once. The device and the methodare simple, convenient and lower in cost, for a processed component, residual stress can be eliminated, and surface crystalline grains can be refined.

Owner:BEIJING UNIV OF TECH

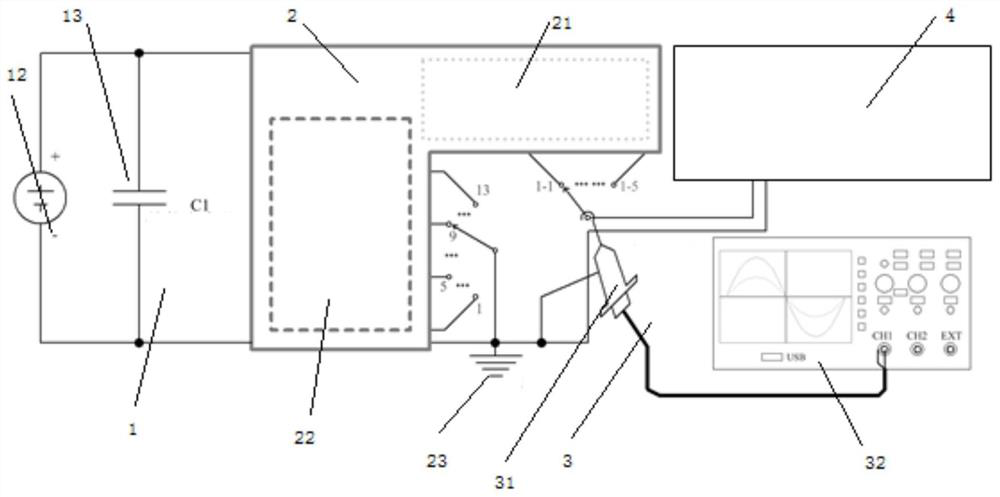

Photoelectric material and device impulse voltage testing device and method

PendingCN113009289AImprove impact efficiencyEasy to adjustTesting dielectric strengthCapacitanceEngineering

The invention discloses a photoelectric material and device impulse voltage testing device and method. The photoelectric material and device impulse voltage testing device comprises a charging assembly, an adjusting output assembly, a monitoring assembly and a to-be-tested carrier. The charging assembly is connected with the adjusting output assembly, the adjusting output assembly is connected with a to-be-detected carrier, the monitoring assembly is connected with the to-be-detected carrier, and the to-be-detected assembly is used for monitoring the voltage condition at the two ends of the to-be-detected carrier; the charging assembly is used for being connected with an external power source and conducting energy charging. The charging assembly comprises a control panel, a controller, a charging power source and an energy storage capacitor. The charging power supply is connected with the energy storage capacitor, and the control panel is connected with the controller. According to the invention, the standard waveform of the to-be-tested carrier can be rapidly obtained, adjustment can be rapidly and conveniently carried out, the impact efficiency of the photoelectric materials and devices is improved, the device can be matched with the output waveform requirements of various types of photoelectric materials and devices, adjustment is carried out according to different to-be-tested carrier materials, and the test efficiency is improved. The operation difficulty is greatly reduced, and the working efficiency is improved.

Owner:成都市产品质量监督检验研究院

Screening device for petroleum-contaminated soil treatment

InactiveCN114210536AReduce the probability of cloggingImprove impactSievingScreeningSoil treatmentElectric machinery

A screening device for petroleum contaminated soil treatment belongs to the technical field of contaminated soil treatment and comprises a limiting frame, a screening mechanism is mounted in the limiting frame and comprises a base, a mesh screen, a plurality of mounting plates and a plurality of first connecting rods, and the mounting plates and the first connecting rods form a rotating frame. The rotating frame is connected to the outer surface of the mesh screen in a sleeving mode, a plurality of screen holes are evenly distributed in the mesh screen, a rotating ring is rotationally connected to the base, the rotating frame is rotationally connected with the base through the rotating ring, and through arrangement of the screening mechanism, an impact block is arranged on the screening mechanism, and a first driving motor is used for controlling a first rotating rod to rotate; the first rotating rod is driven to rotate to drive an impact block fixedly connected to the first rotating rod in a sleeving mode to shake, in the shaking process of the impact block, the inner side wall of the mesh screen can be knocked, an acting force opposite to the screening direction is provided for the mesh screen, and therefore the permeability of the mesh screen in the screening process can be improved, and certain progressive significance is achieved.

Owner:YANGTZE NORMAL UNIVERSITY

Multipurpose water pulse device used in well

InactiveCN103422826AReduce the chance of explosionExtended service lifeBorehole/well accessoriesEngineeringUltimate tensile strength

The invention provides a multipurpose water pulse device used in a well. The multipurpose water pulse device used in the well at least comprises a head portion and a tail portion, wherein the head portion at least comprises a shell, a flange disc and a short pipe, a through hole A is formed in the shell, an elastic sleeve is arranged at the position of the through hole A, the elastic sleeve is installed on the outer wall of the shell through a clamp, the flange disc is located on the bottom of the interior of the shell, the short pipe is installed in the shell, the tail portion at least comprises an outer cover and a connecting piece, the outer cover is cylindrical, the connecting piece is fixed to the top of the outer cover, an inner pipe is arranged in the outer cover and in the connecting piece, and the outer cover and the connecting piece are arranged on the inner pipe in a sleeved mode and can slide on the inner pipe. Compared with the prior art, the multipurpose water pulse device used in the well has the advantages that water impact and water pulse can be generated to have effect on a filter pipe column and a producing zone, and then siltation is damaged; meanwhile, connecting strength of the siltation is reduced by a treating agent sent into the well, and therefore impacting efficiency is improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com